Bidirectional-stretching online-coating optical base film and its making method

A biaxial stretching and coating technology, applied in the field of optical films, can solve the problems of uneven dispersion of inorganic particles, increased haze, lack of affinity, etc. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] By mass percentage: polyurethane polymer 30%, nano-sized colloidal silica 0.8%, micron-sized silica 0.4%, ethylene glycol monobutyl ether 1%, surfactant 0.03%, curing agent 9.4%, a small amount of acid The balance of alkali conditioning agent is pure water. Prepared as a coating solution for use.

[0023] Film preparation:

[0024] 1. Dry the core layer and surface layer PET raw materials (intrinsic viscosity is 0.68, chromaticity b value +1) at 170°C for 3.5 hours. Since polyester is prone to hydrolysis reaction at high temperature, it must be dried before use. The water content should be ≤45ppm (determination of trace moisture by differential pressure method);

[0025] 2. Send the core layer PET raw material into the twin-screw extruder for melting, and at the same time, send the surface layer PET raw material into another twin-screw extruder for melting, and the core layer melt and the surface layer melt are melted in the two extruders Extrusion, through the melt ...

Embodiment 2

[0031] By mass percentage: polyurethane polymer 30%, nano-sized colloidal silica 0.80%, micron-sized silica 0.20%, ethylene glycol monobutyl ether 1%, surfactant 0.03%, curing agent 9.4%, a small amount of acid The balance of alkali conditioning agent is pure water. Prepared as a coating solution for use.

[0032] The film preparation process is the same as in Example 1.

Embodiment 3

[0034] By mass percentage: polyurethane polymer 30%, nano-sized colloidal silica 1.00%, micron-sized silica 0.10%, ethylene glycol monobutyl ether 1%, surfactant 0.03%, curing agent 9.4%, a small amount of acid The balance of alkali conditioning agent is pure water. Prepared as a coating solution for use.

[0035] The film preparation process is the same as in Example 1.

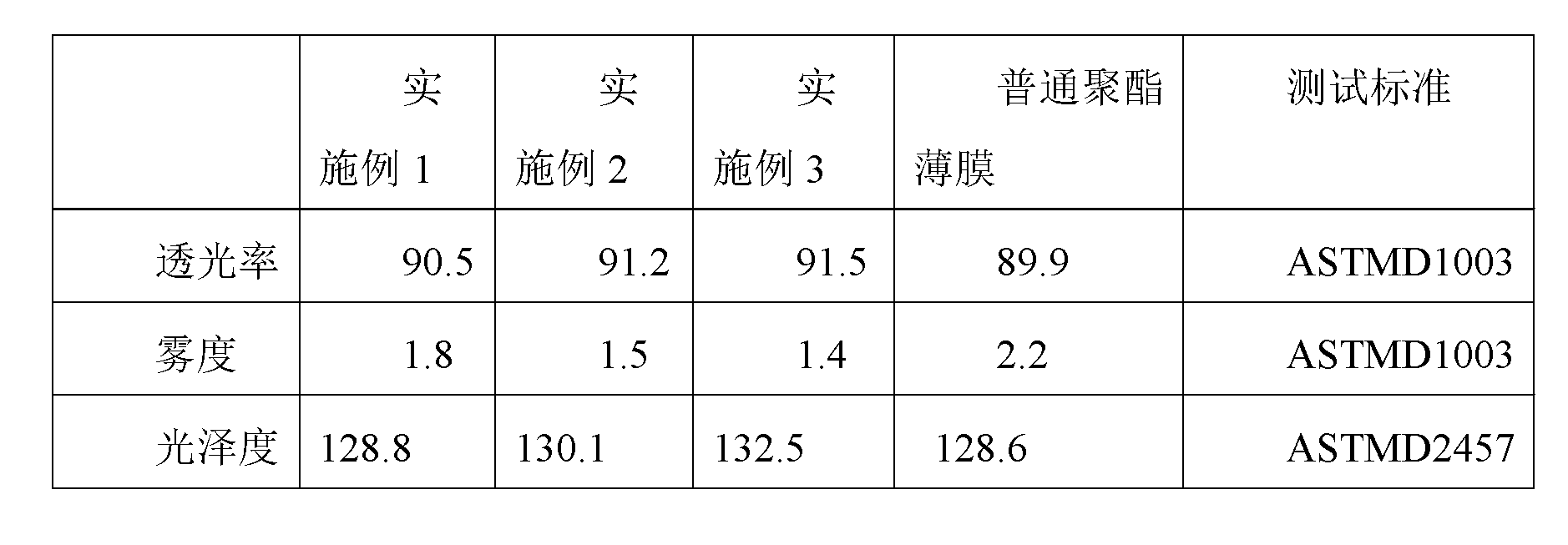

[0036] Performance comparison:

[0037] The above example is compared with a film with a common thickness of 188 μm

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com