Organosilicon-modified acrylate emulsion and preparation method of coating agent for powder-free gloves

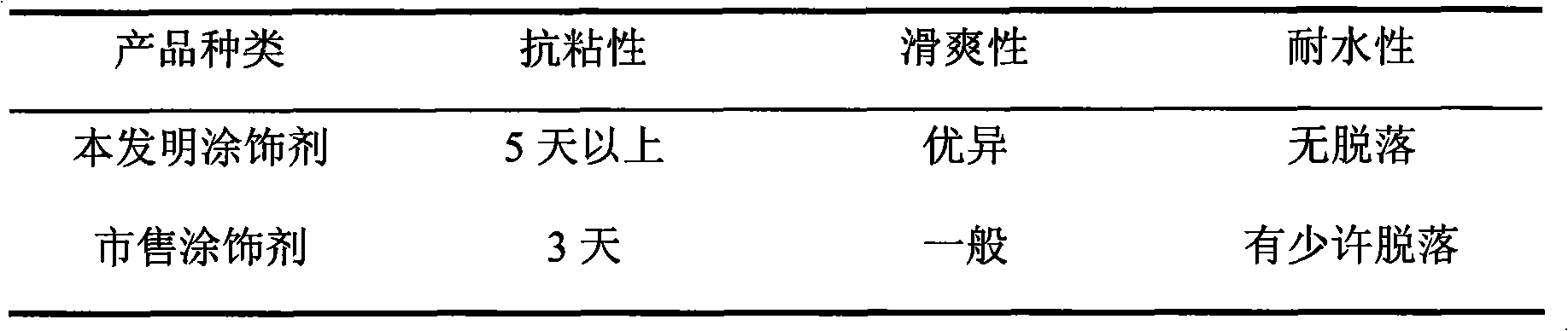

A technology of acrylate and silicone modification, which is applied to biocide-containing paints, coatings, antifouling/underwater coatings, etc. It can solve the problems of reducing the cost of finishing agents, uneven coating, poor water resistance, etc., and achieves Improve coating unevenness, reduce cost, and achieve excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of Silicone Modified Acrylic Emulsion

[0048] The specific raw materials used and the ratio of parts by mass are as follows:

[0049] Methyl methacrylate 42 parts

[0050] 25 parts ethyl acrylate

[0051] Butyl acrylate 10 parts

[0052] 4 parts of 2-hydroxyethyl acrylate

[0053] Acrylonitrile 10 parts

[0054] Acrylic 4 parts

[0055] Diethylene glycol diacrylate 2 parts

[0056] Vinyltrimethoxysilane 3 parts

[0057] Nonylphenol polyoxyethylene (10) ether 1 part

[0058] Sodium Lauryl Sulfate 0.5 parts

[0059] Ammonium persulfate 0.2 parts

[0060] Sodium bicarbonate 0.5 parts

[0061] 80 parts of deionized water

[0062] (1) Preparation of nuclear layer

[0063] Weigh 0.6 parts of nonylphenol polyoxyethylene ether, 0.3 parts of sodium lauryl sulfate and 0.5 parts of sodium bicarbonate, dissolve them in 35 parts of deionized water and place them in a reaction kettle. Under continuous stirring, 25 parts of methyl Methyl acrylate, 17 parts o...

Embodiment 2

[0077] 1. Preparation of Silicone Modified Acrylic Emulsion

[0078] The specific raw materials used and the ratio of parts by mass are as follows:

[0079] 50 parts of methyl methacrylate

[0080] 10 parts ethyl methacrylate

[0081] Ethyl acrylate 20 parts

[0082] 2.5 parts of 2-hydroxypropyl acrylate

[0083] Acrylic 2 parts

[0084] Diethylene glycol diacrylate 0.5 parts

[0085] Vinyltriethoxysilane 15 parts

[0086] Nonylphenol polyoxyethylene (10) ether 1.5 parts

[0087] Sodium dodecylbenzenesulfonate 1.5 parts

[0088] Potassium persulfate 1 part

[0089] 3 parts sodium bicarbonate

[0090] 150 parts of deionized water

[0091] (1) Preparation of nuclear layer

[0092] Weigh 0.6 parts of nonylphenol polyoxyethylene ether, 0.6 parts of sodium dodecylbenzene sulfonate and 3 parts of sodium bicarbonate dissolved in 65 parts of deionized water and place in the reaction kettle, under continuous stirring, 24 parts A mixed monomer composed of methyl methacrylate...

Embodiment 3

[0106] 1. Preparation of Silicone Modified Acrylic Emulsion

[0107] The specific raw materials used and the ratio of parts by mass are as follows:

[0108] 52 parts of methyl methacrylate

[0109] 10 parts methyl acrylate

[0110] 30 parts ethyl acrylate

[0111] 2 parts of 2-hydroxyethyl acrylate

[0112] 2 parts methacrylic acid

[0113] 1 part methylenebisacrylamide

[0114] γ-methacryloxypropyltrimethoxysilane 3 parts

[0115] Polyoxyethylene (20) sorbitan monooleate 4.5 parts

[0116] Sodium dodecylbenzenesulfonate 1.5 parts

[0117] 2 parts sodium persulfate

[0118] Sodium bicarbonate 1 part

[0119] 200 parts of deionized water

[0120] (1) Preparation of nuclear layer

[0121]Take by weighing 2.3 parts of polyoxyethylene (20) sorbitan monooleate, 0.8 part of sodium dodecylbenzene sulfonate and 1 part of sodium bicarbonate and be dissolved in 90 parts of deionized water and placed in a reaction kettle, Under continuous stirring, 27 parts of methyl methacry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com