Patents

Literature

199results about How to "Good slipperiness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organosilicon modified aqueous polyurethane resin and preparation thereof

An organosilicon modified aqueous polyurethane resin comprises the following raw materials in percentage by weight: 10 to 20 percent of isocyanate, 20 to 40 percent of polyester polyol, 0.1 to 5 percent of organic silicon oil, 2 to 5 percent of a hydrophilic chain extender, 2 to 5 percent of a polyol chain extender, 1 to 3 percent of a polybasic amine chain extender, 0.01 to 1 percent of a catalyst, 1 to 4 percent of a salifying agent, 5 to 8 percent of a solvent and the rest of water. The emulsion made by the organosilicon modified aqueous polyurethane resin is obviously better than the emulsion made by a non-modified aqueous polyurethane resin regarding adhesion force, abrasion resistance, heat tolerance, smoothness, etc. The polyurethane emulsion made by the organosilicon modified aqueous polyurethane resin can be applied to the surface of a product through spray coating, brush coating, roller coating and dip coating. At present, the polyurethane emulsion is mainly used for the coating of the surfaces of gloves, condoms, medical ducts, etc.

Owner:SHANDONG INOV POLYURETHANE

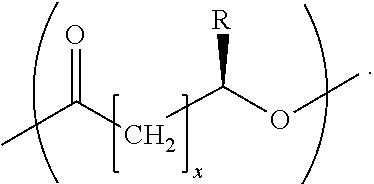

Composition comprising biodegradable polymers for use in a cosmetic composition

ActiveUS20110287105A1Good slipperinessImprove textureCosmetic preparationsHair cosmeticsPersonal careMedicine

The present invention relates to certain novel polymer powder compositions suitable for personal care and cosmetic compositions. The present invention also relates to cosmetic compositions comprising such novel polymer powders. The present invention also relates to processes for manufacturing the polymer powders, methods of making cosmetic and personal care compositions and the use of such cosmetic compositions in topical applications.

Owner:MICROPOWDERS

Display screen protection film and polarization plate

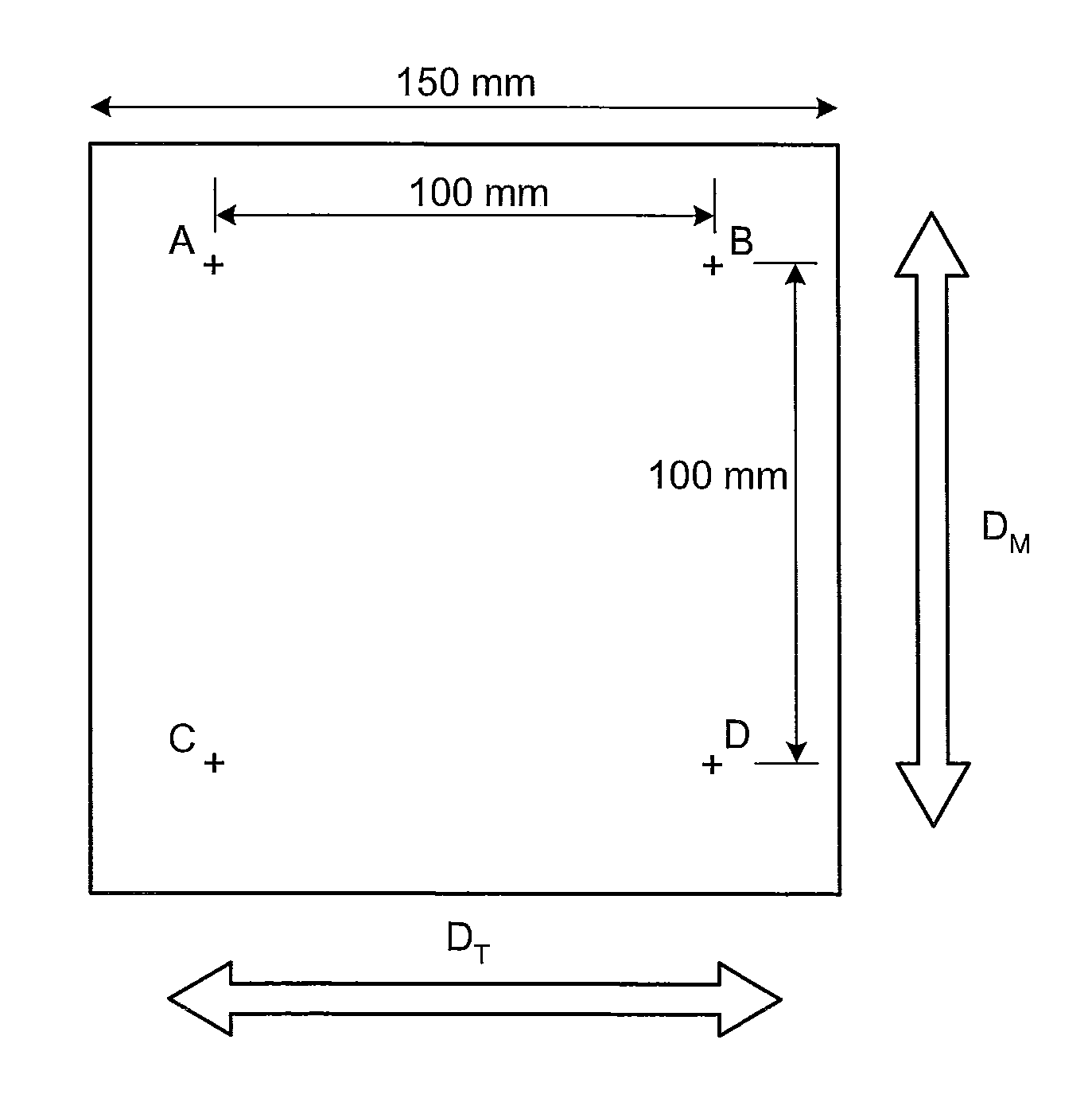

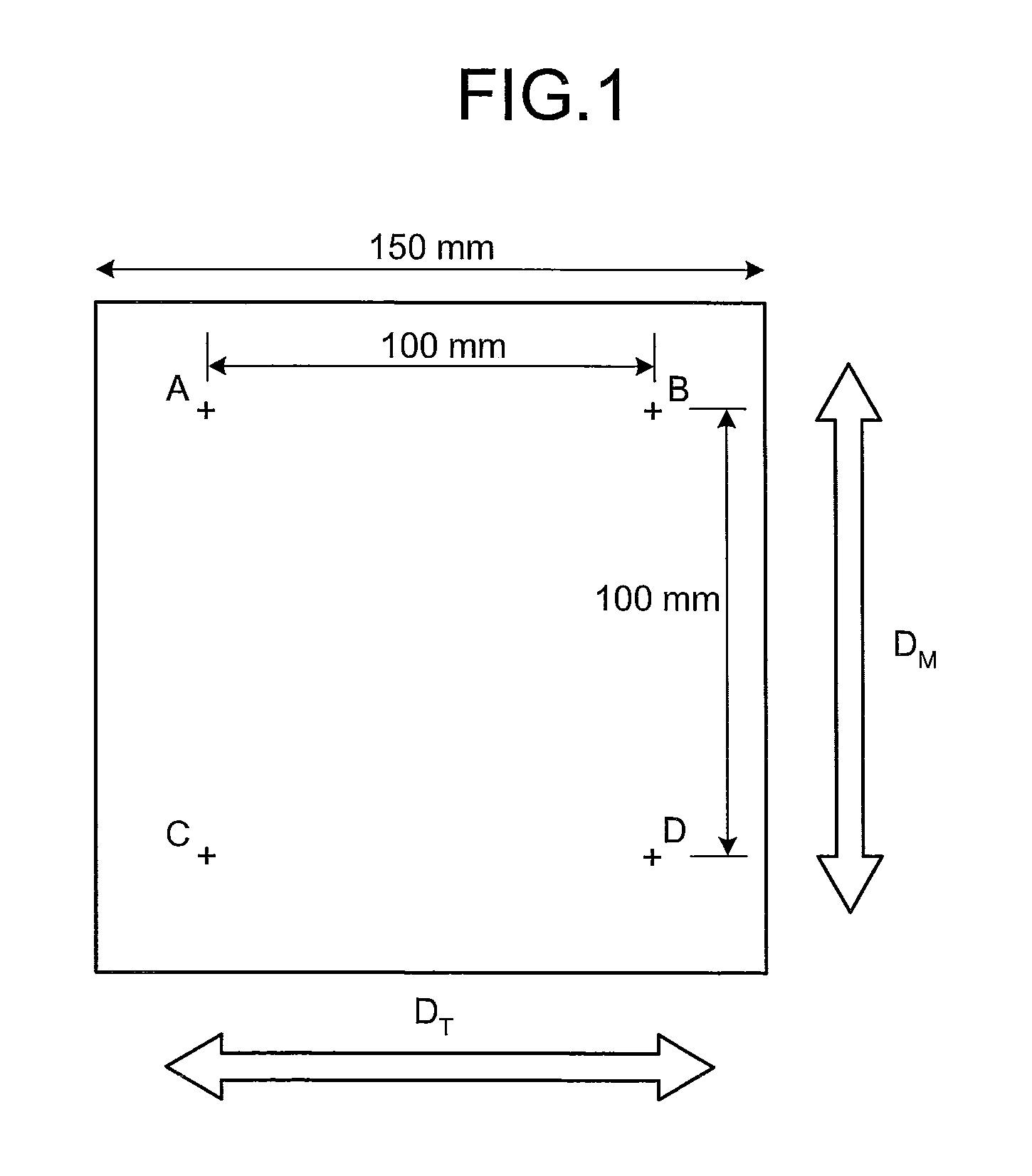

InactiveUS20100134879A1Increase flexibilityImprove heat resistanceOptical filtersSynthetic resin layered productsOptical propertyAcrylic resin

The present invention is to provide a display screen protection film that exhibits uniform in-plane ultraviolet absorption property, excellent mechanical strength, flexibility, heat resistance and optical property, and to provide a polarization plate wherein the display screen protection film is used as a polarization plate protection film. The display screen protection film obtained by stretching 1.2 to 6 times a film having a thickness of 20 to 300 μm wherein an acrylic resin layer (B1) containing no ultraviolet light absorbing agent is disposed on one surface of an acrylic resin layer (A) containing the ultraviolet light absorbing agent, and an acrylic resin layer (B2) containing no ultraviolet light absorbing agent is disposed on another surface thereof.

Owner:ZEON CORP

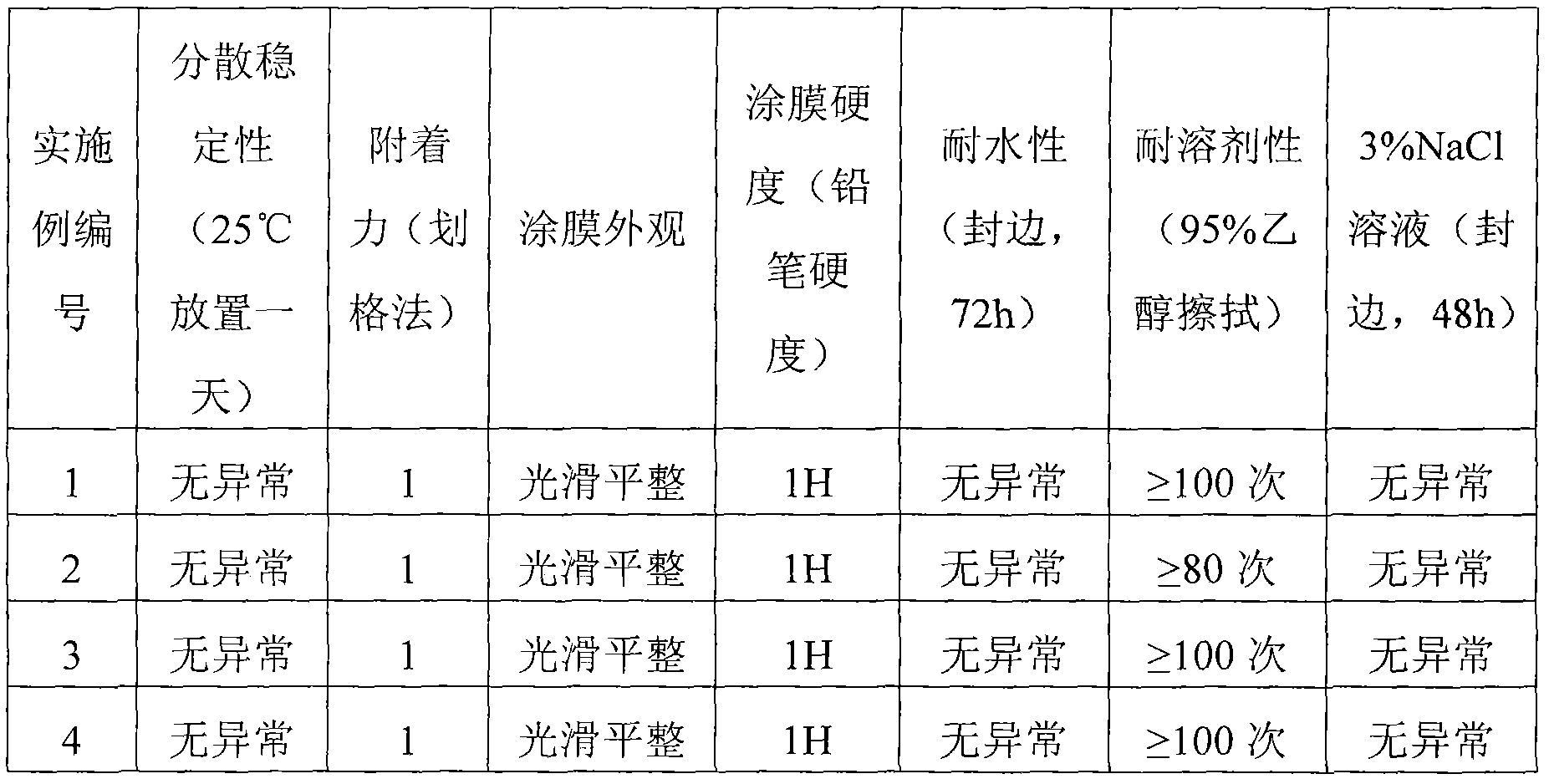

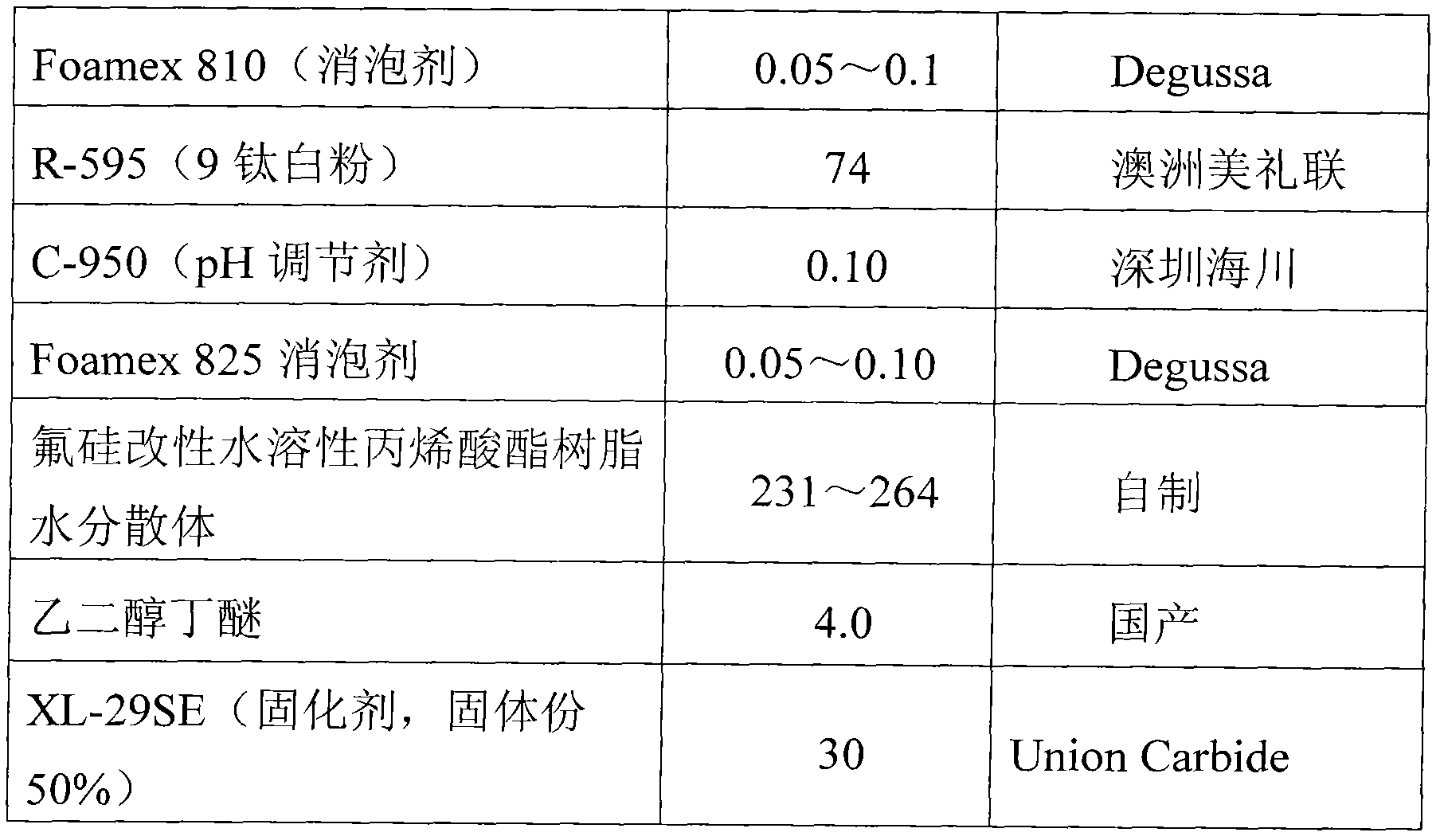

Fluosilicic modification water-soluble acrylic resin dispersion and application thereof

The invention provides a fluosilicic modification water-soluble acrylic resin dispersion and an application thereof. The dispersion is prepared from 20-50% of non-functional (methyl) acrylic ester, 5-35% of fluorinated acrylic ester monomer, 5-15% of carboxyl group-containing alkene monomer, less than or equal to 15% of vinyl monomer, 2-20% of (methyl) hydroxyl acrylate, 1-5% of organic silicon modified monomer, 15-30% of low carbon alcohol, 0.5-4% of inhibitor and 0.1-1.8% of molecular regulator according to a radical solution polymerization method. Based on solid parts, the acidic value of the dispersion is 20-100 mg KOH / g; the glass-transition temperature is 5-40 DEG C; the dispersion has a good appearance and dispersion stability as well as good water diluent property; a film obtained by cross-linking and curing a polycarbodiimide cross-linking agent and the dispersion has excellent water tolerance, solvent tolerance, high temperature tolerance, smooth property, stain tolerance and humidity resistance; the adhesion and hardness are improved; and the dispersion has strong practicable value and can be used for substrates such as wooden wares, metals, plastics and the like.

Owner:JIANGSU BLUESTAR GREEN TECH

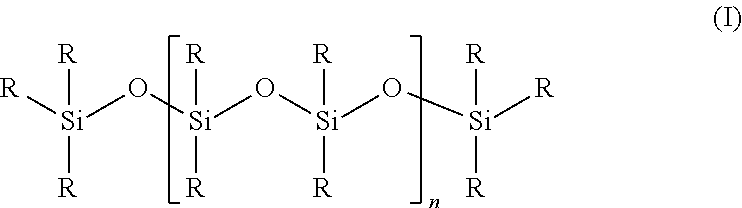

Non-aqueous liquid composition having ultraviolet-absorbing capability

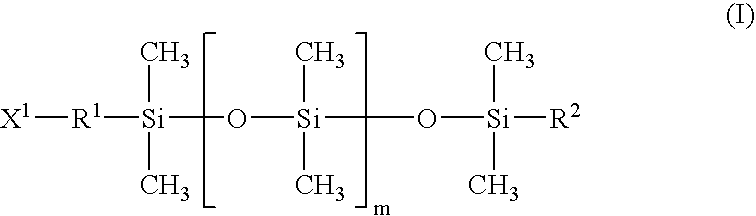

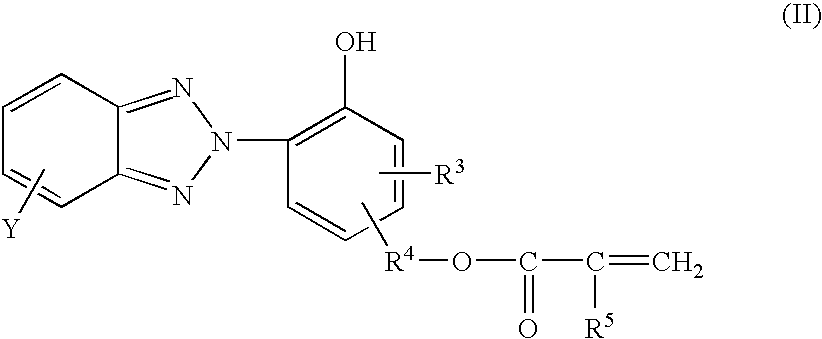

InactiveUS20070098653A1Good slipperinessTransparent appearanceCosmetic preparationsHair cosmeticsPolymer scienceSilicone fluid

The present invention provides a non-aqueous liquid composition from which the coated film on the skin is transparent and slippery, does not cause stickiness and uncomfortable feeling such as creaky feeling and stretch feeling, but causes fresh feeling of use, and keeps the capability of protecting the skin from ultraviolet rays for a desired period of time even under the presence of sweat or sebum, and which is suitable for sunscreen cosmetics, a skin external preparation or a bandage preparation. The non-aqueous liquid composition comprises particles composed of at least a copolymer derived from a silicone macromer (A) and an ultraviolet-absorbing compound and silicone oil in which the particles are dispersed, wherein the silicone macromer (A) exists in the copolymer within 1 to 20 wt % of all components of the particles and orients toward the outer surface of the particle, and wherein, the ultraviolet-absorbing compound is incorporated in the polymer particle as an independent component or a part of the copolymer.

Owner:TAISEI FINE CHEM

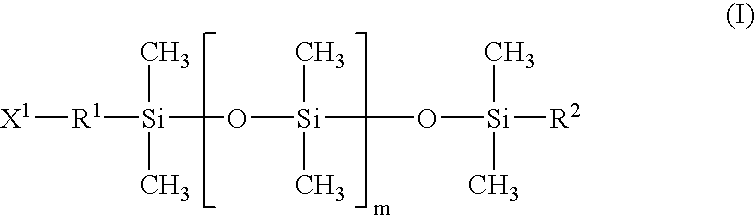

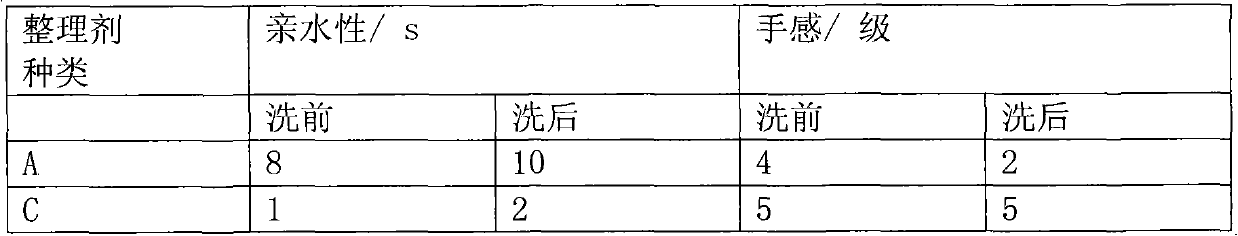

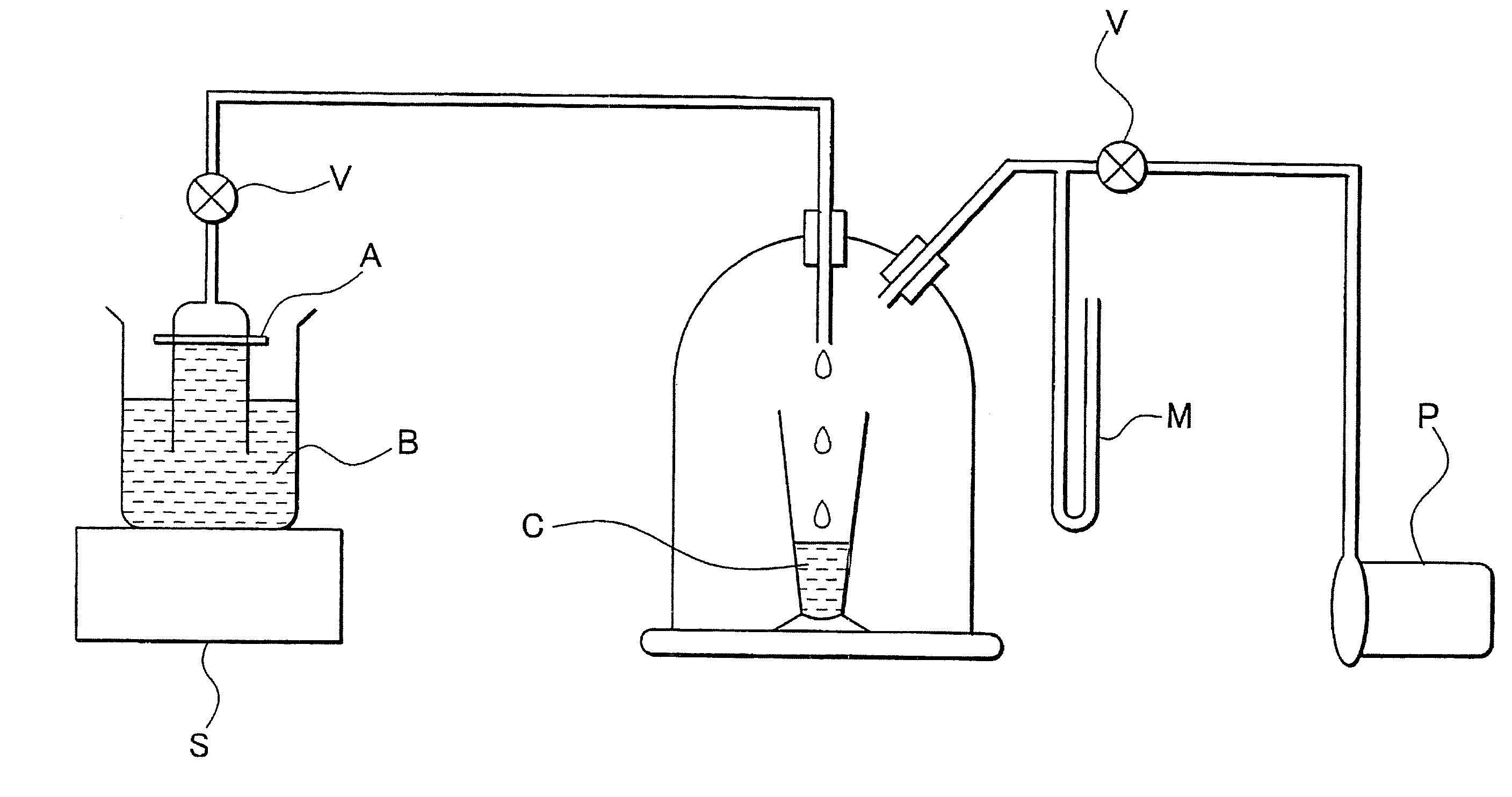

Preparation method of hydrophilic amino silicone oil

The invention discloses a preparation method of hydrophilic amino silicone oil. The invention is characterized in that the preparation method comprises the following steps: A. the preparation of low-hydrogen silicone oil: siloxane ring body, high-hydrogen silicone oil, blocking agent and acid are mixed for reaction and are cooled, and the pH is adjusted; B. the preparation of epoxy silicone oil: the prepared low-hydrogen silicone oil, alkenyl epoxy compound and catalyst are mixed for reaction and are cooled; and C. the preparation of hydrophilic amino silicone oil: the prepared epoxy silicone oil, organic amine and solvent are mixed for reaction, and the solvent is distilled. The bonding is firmer in the form of a chemical bond when the hydrophilic amino silicone oil prepared by the method reacts with the fabric, and the hydrophilic amino silicone oil is washable, has soft effect of the common amino silicone oil, no yellowing and good smoothness and antistatic property, and can be widely used in fabric finishing.

Owner:HUBEI COLOR ROOT TECH CO LTD

Method for preparing ceramic tile antifouling agent

InactiveCN102174290AReduce surface tensionGood oil resistanceAntifouling/underwater paintsPaints with biocidesHydrogenMetallurgy

The invention discloses a method for preparing a ceramic tile antifouling agent. The method for preparing the ceramic tile antifouling agent comprises the following steps of: mixing methyl hydrogen-containing silicone oil, fluoro silicone oil, amino silicone oil and a solvent at the temperature of 10-60 DEG C under a stirring action; adding an adjusting agent to adjust pH value of a system to be between 3 and 8; and continuously stirring for 10-60 minutes to obtain the ceramic tile antifouling agent. After being uniformly coated on the surface of a ceramic tile, the ceramic tile antifouling agent can infiltrate into the surface of the ceramic tile and form a stable chemical bonding action so as to form an organosilicon enhanced protection layer with hydrophobic and oleophobic properties, so that long-acting, high-luminosity and wash-resistant antifouling performance is realized. The ceramic tile antifouling agent prepared by the invention has the advantages of superior performance, wide application range and convenience for production, and is an ideal antifouling nursing agent for modern ceramic tiles.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Water soluble acrylic resin and its prepn

The present invention relates to one kind of water soluble acrylic resin for ink, polish oil and paint and its preparation process. The organic silicone oil modified acrylic resin is prepared with acrylic acid monomer 15-57 wt%, organic silicone oil with double bond 1-15 wt%, organic solvent 20-60 wt% and initiator 0.1-10 wt%, and through free radical solution polymerization at 60-160 deg.c to obtain organic silicone oil modified acrylic resin, adding neutralizing agent and water through stirring, distilling to eliminate organic solvent, further adding neutralizing agent and water to reach solid content of 20-60 wt%. The organic silicone oil modified acrylic resin has high vitrification point, low filming temperature, high water tolerance and other advantages.

Owner:JIANGSU SANMU GROUP CORPORATION

Lightweight joint compound containing stable air pockets

InactiveUS20040182287A1Low densityEnhances slip and ease of spreadingOther chemical processesCeramicwareJoint compoundTalc

Low density joint compounds, and methods for their use are disclosed. Joint compounds comprising water, calcium carbonate, a foaming agent, and a rheology modification agent contain a plurality of stable air bubbles. Joint compounds can have densities of about 4 pounds per gallon to about 8 pounds per gallon. A presently prepared composition has a density of about 4.8 pounds per gallon. A presently preferred foaming agent is a polyether siloxane copolymer. A presently preferred rheology modification agent is poly(ethylene oxide). The joint compounds can comprise additional components such as perlite, mica, talc, preservatives, and latex.

Owner:PROFORM FINISHING PROD LLC

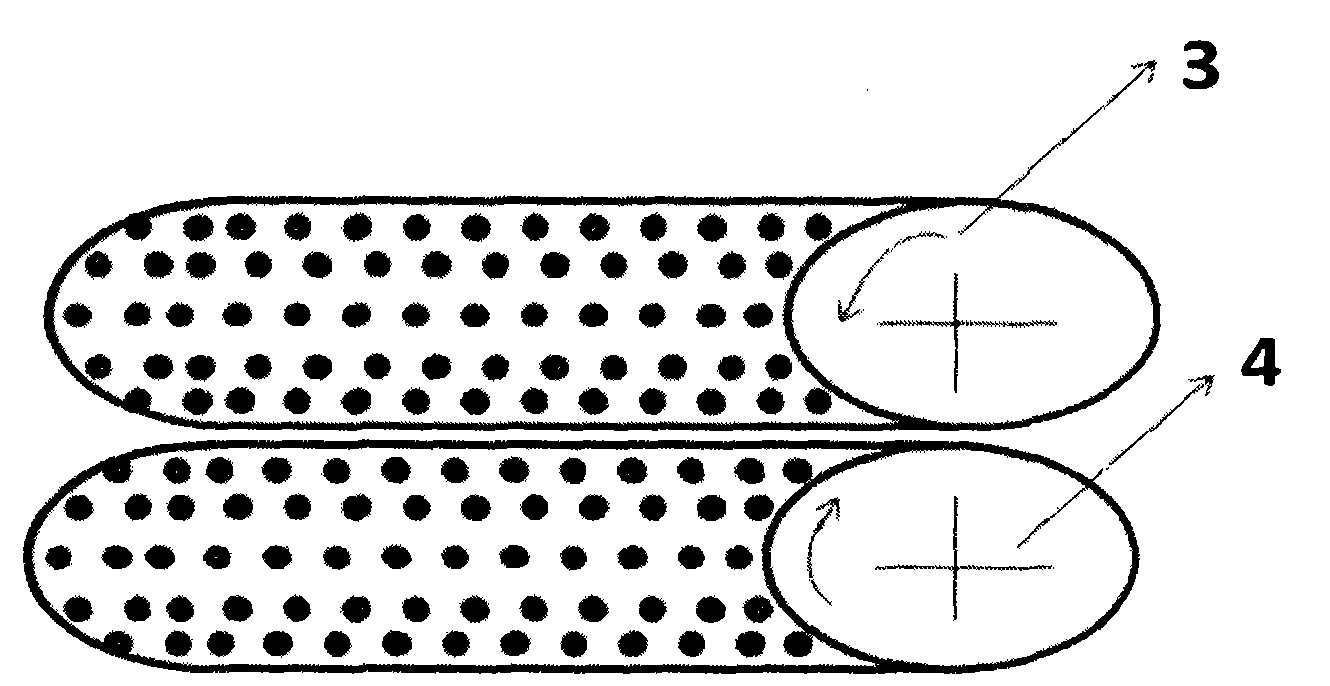

Multilayer shrink film for high speed packaging lines

ActiveUS7179521B2Superior hot slip propertyGood low temperatureWrappersContainer/bottle contructionSingle siteLow-density polyethylene

A multilayer shrink film and methods of making same comprising high speed polyethylenic outer layers along with one or more cyclic-olefin copolymer (COC) containing inner layers. The multilayer shrink films of the invention are produced using film biaxial orienting means, have haze values of 5 or less and Young's modulus of 50,000 psi or greater and superior hot slip properties. In order to achieve the desired modulus, films of the present invention comprise from 10% to 30% COC and from 2% to 25% softening olefin copolymer. Preferably the film comprises large proportion of linear low density polyethylene (LLDPE). Suitable COCs for use in the invention are limited to single site catalyzed COC.

Owner:INTERTAPE POLYMER CORP

Scratch-resistant UV-finishing coat

InactiveCN101555382AStructural ToughGood slipperinessPolyurea/polyurethane coatingsEpoxy resin coatingsLacquerMonomer

Owner:JIANGSU HIMONIA TECH

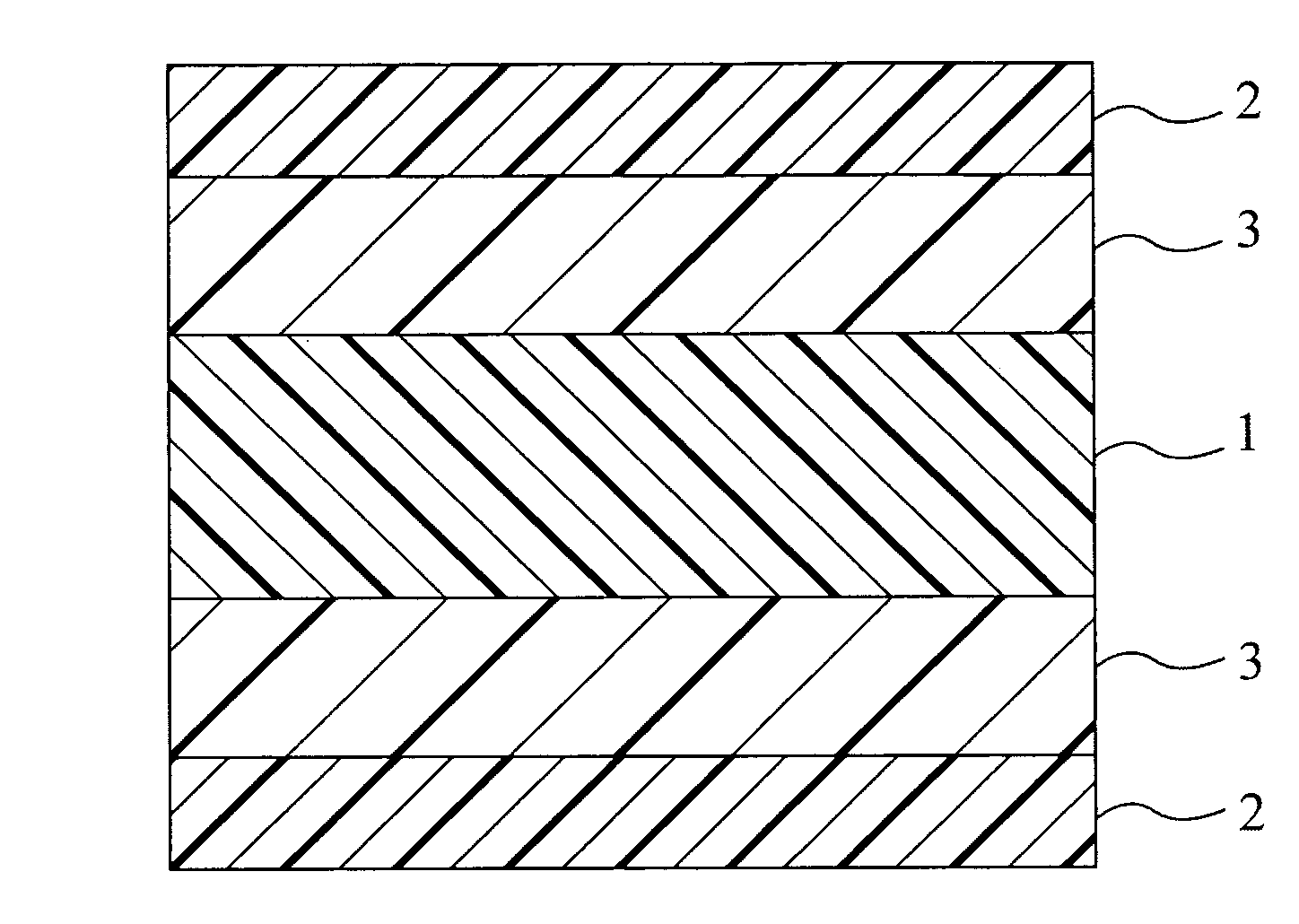

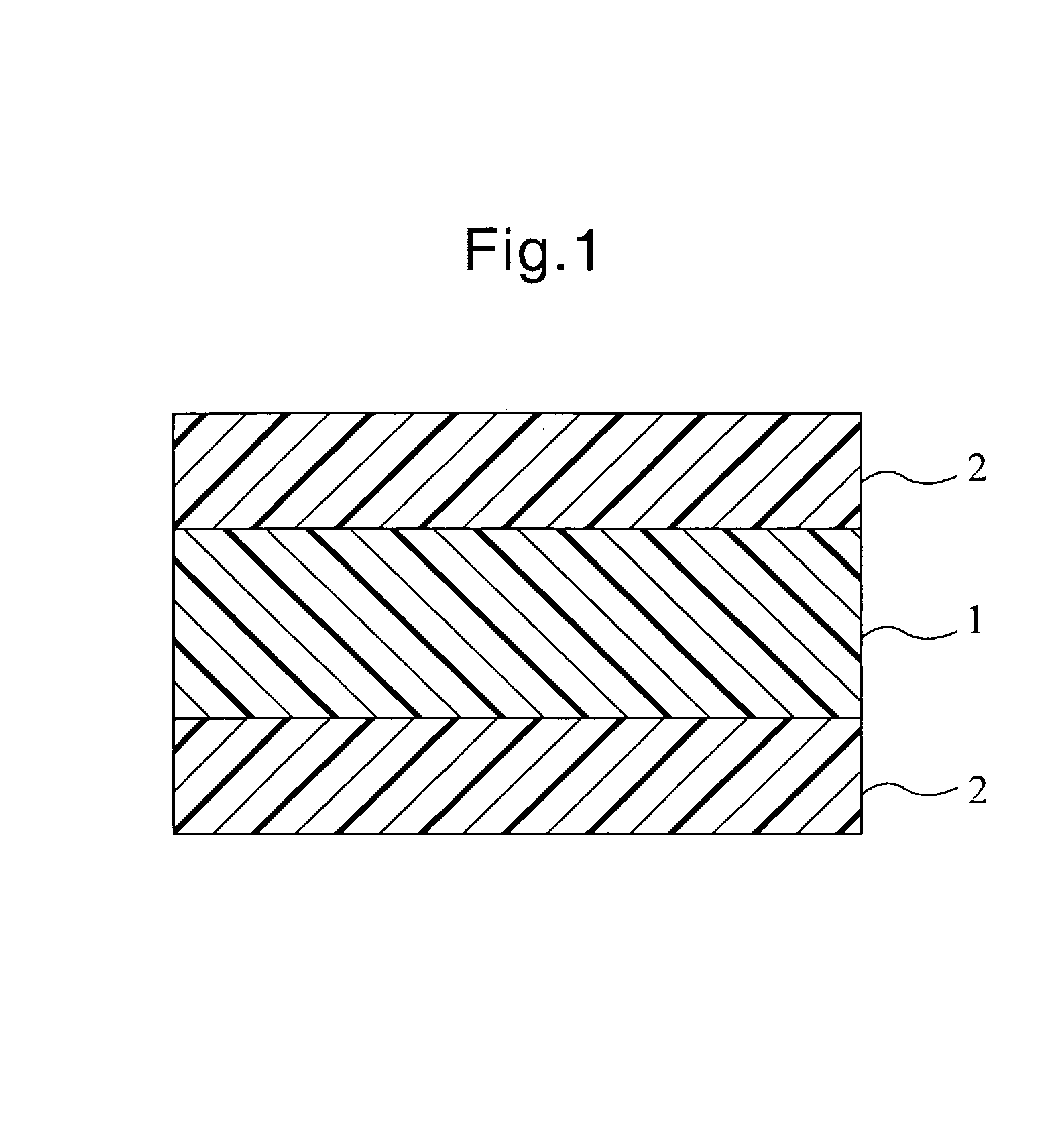

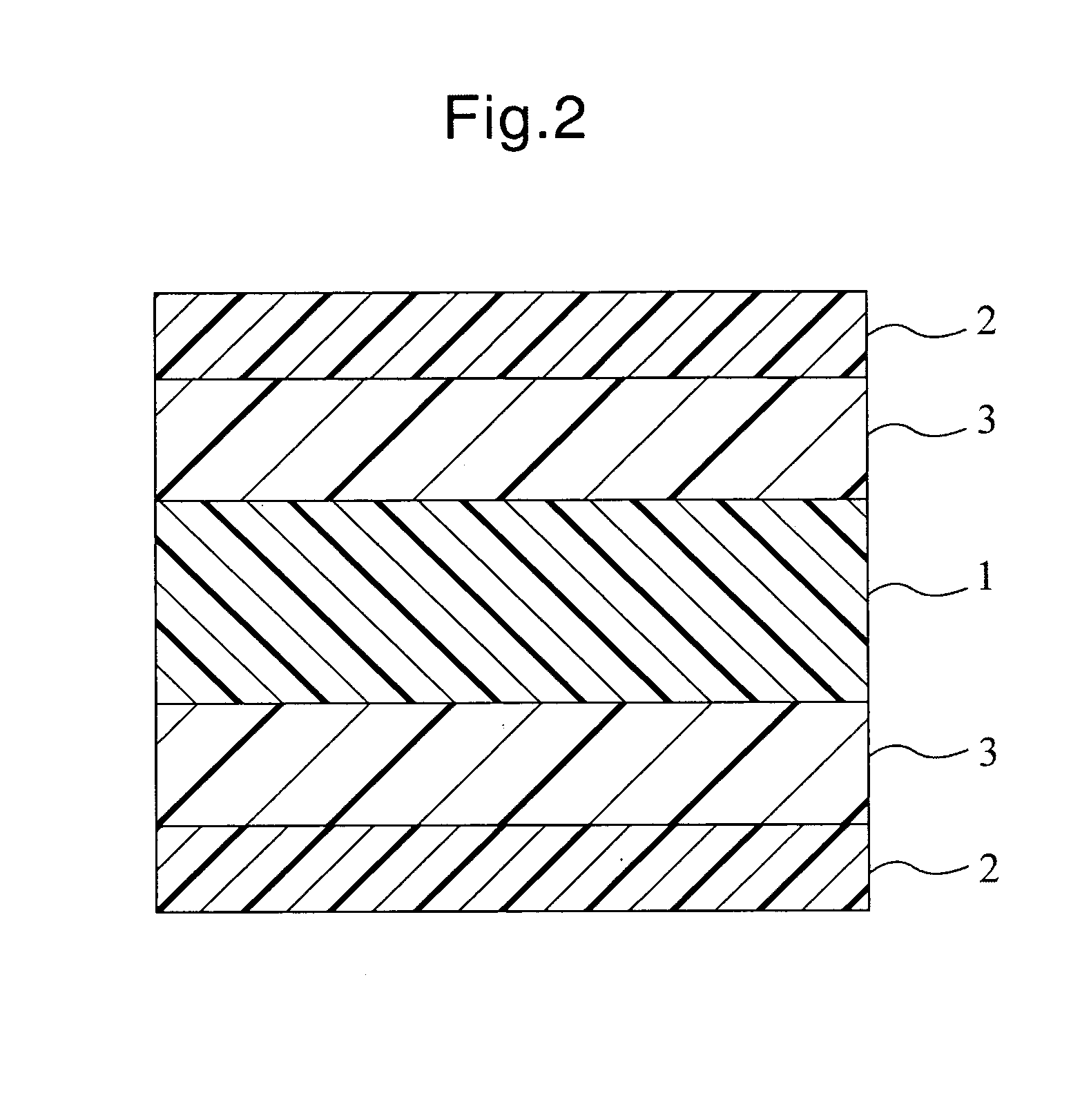

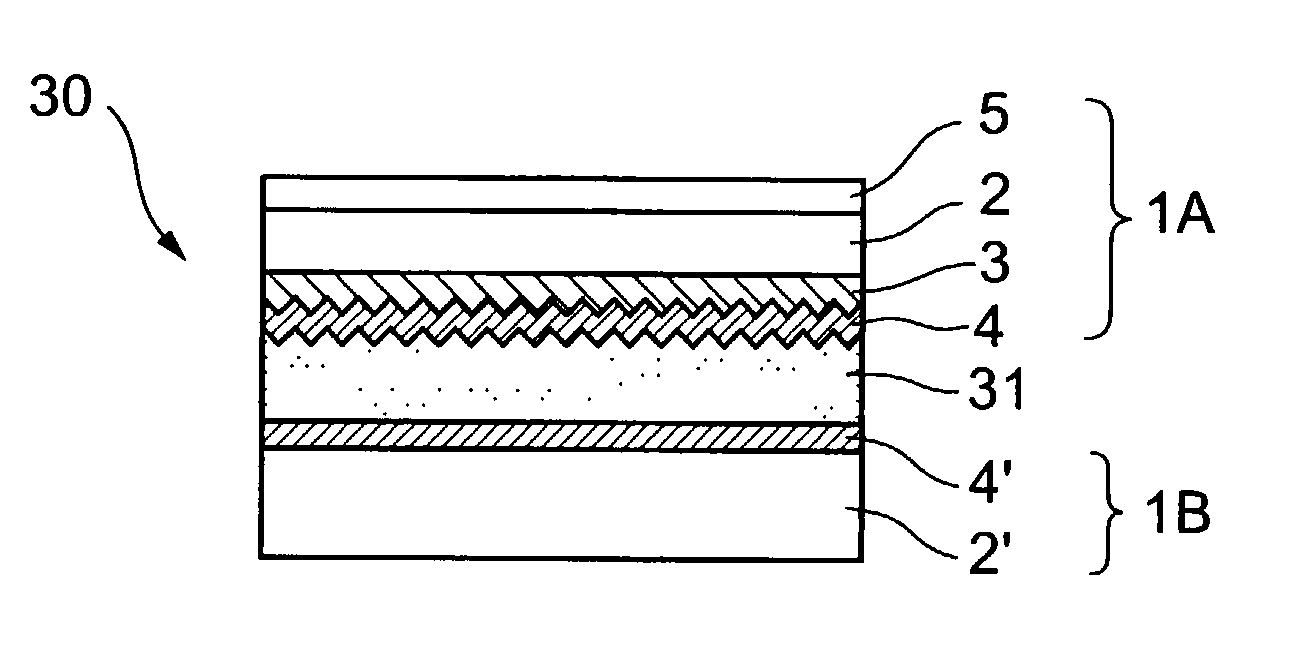

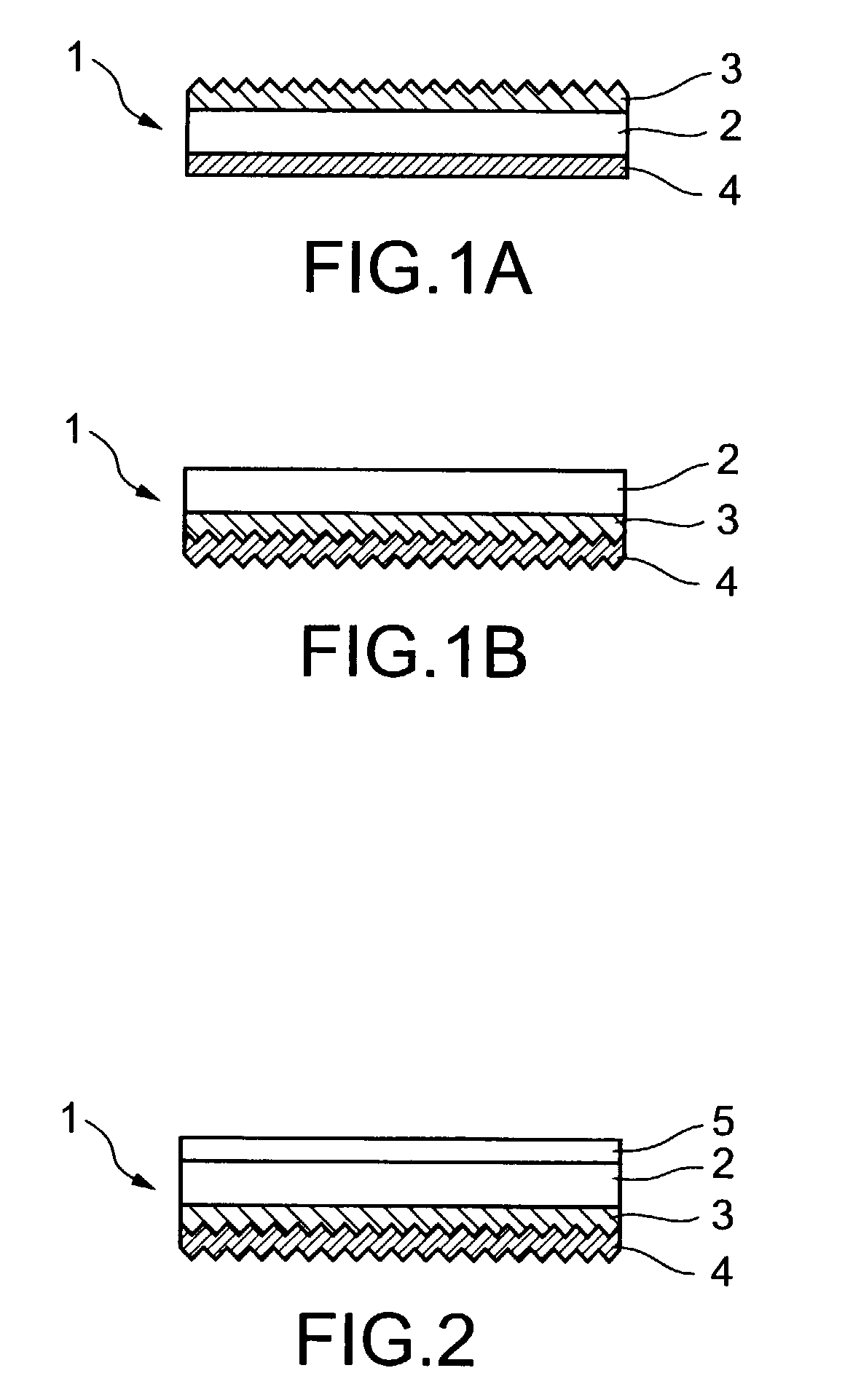

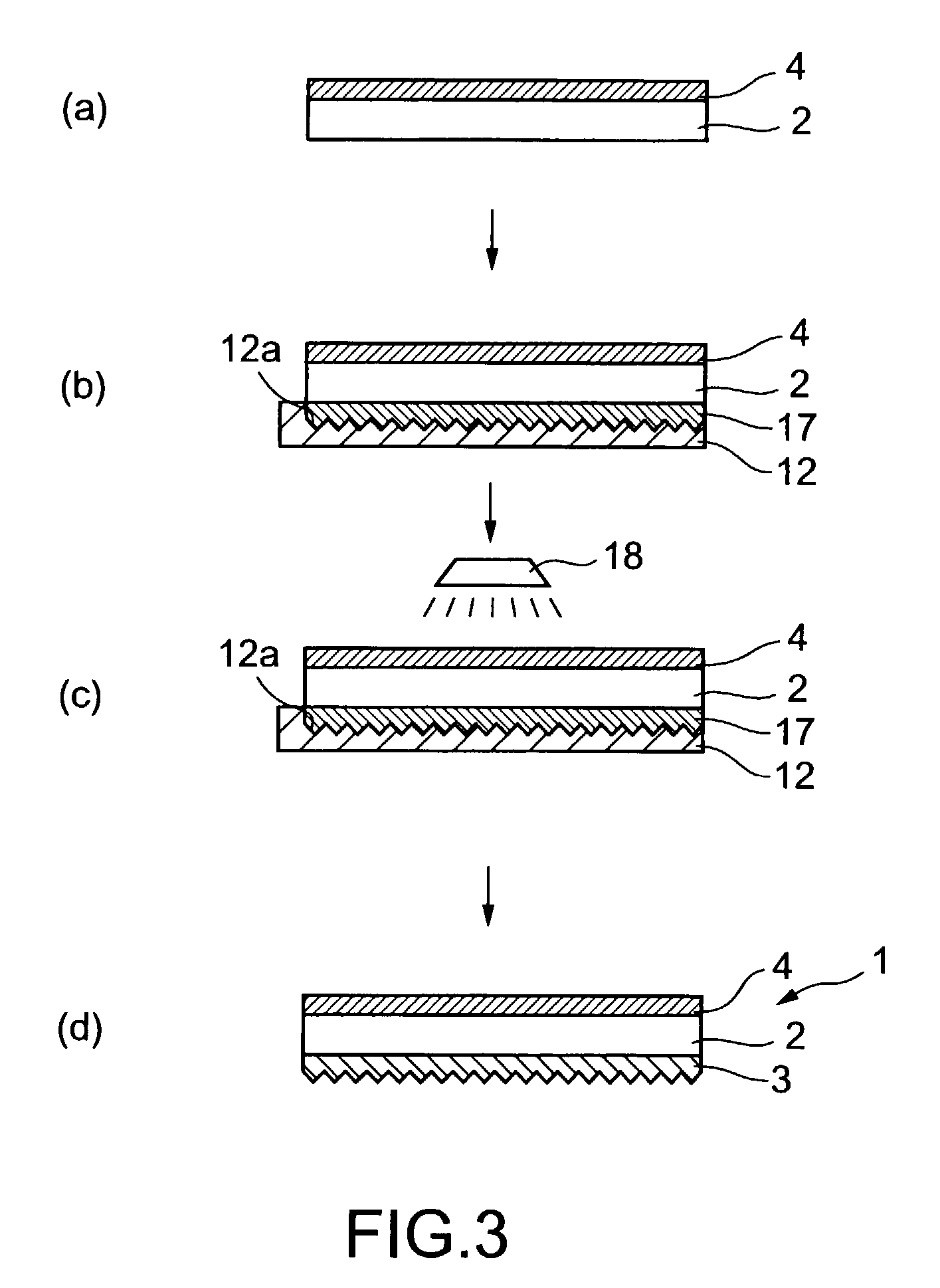

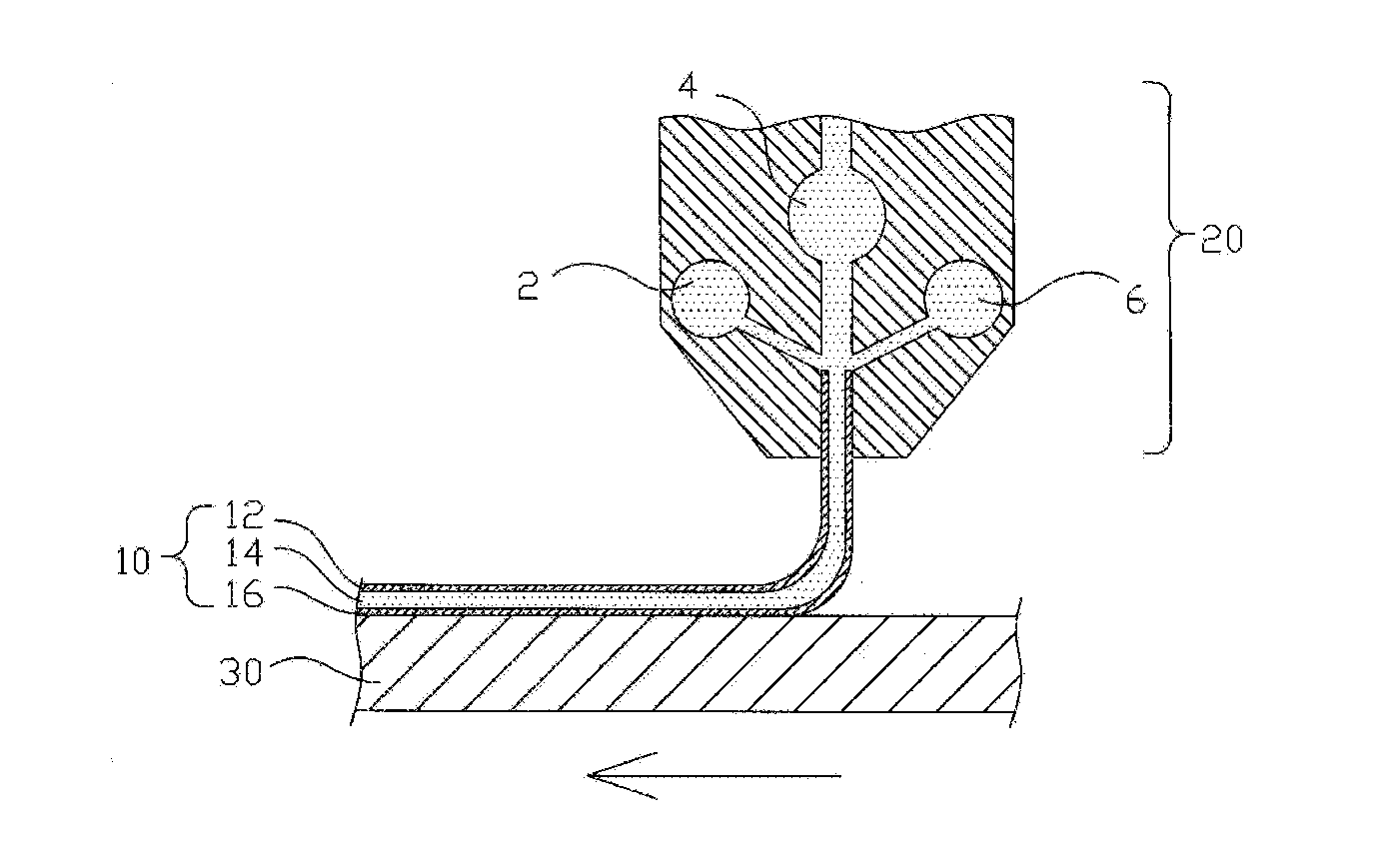

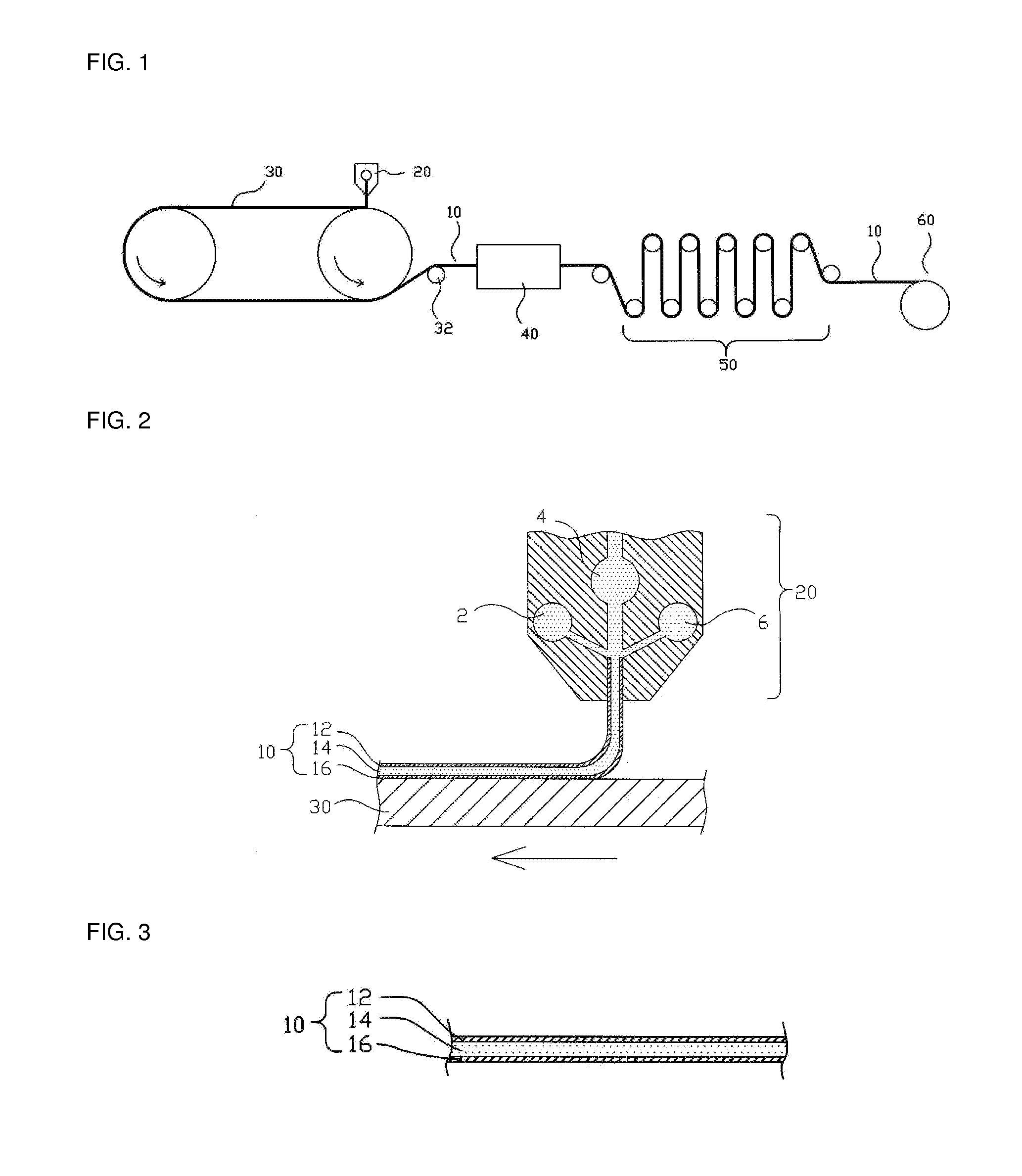

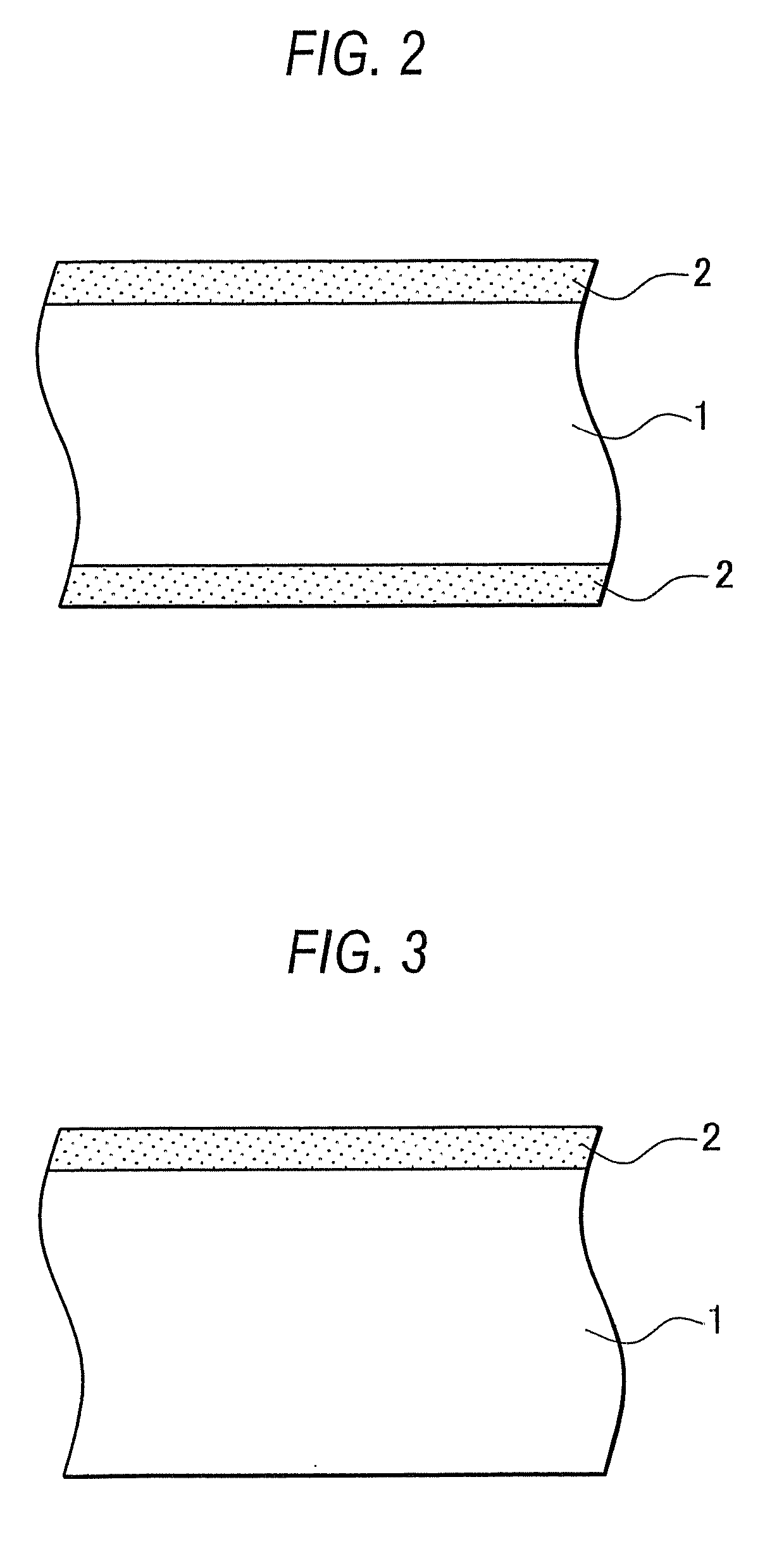

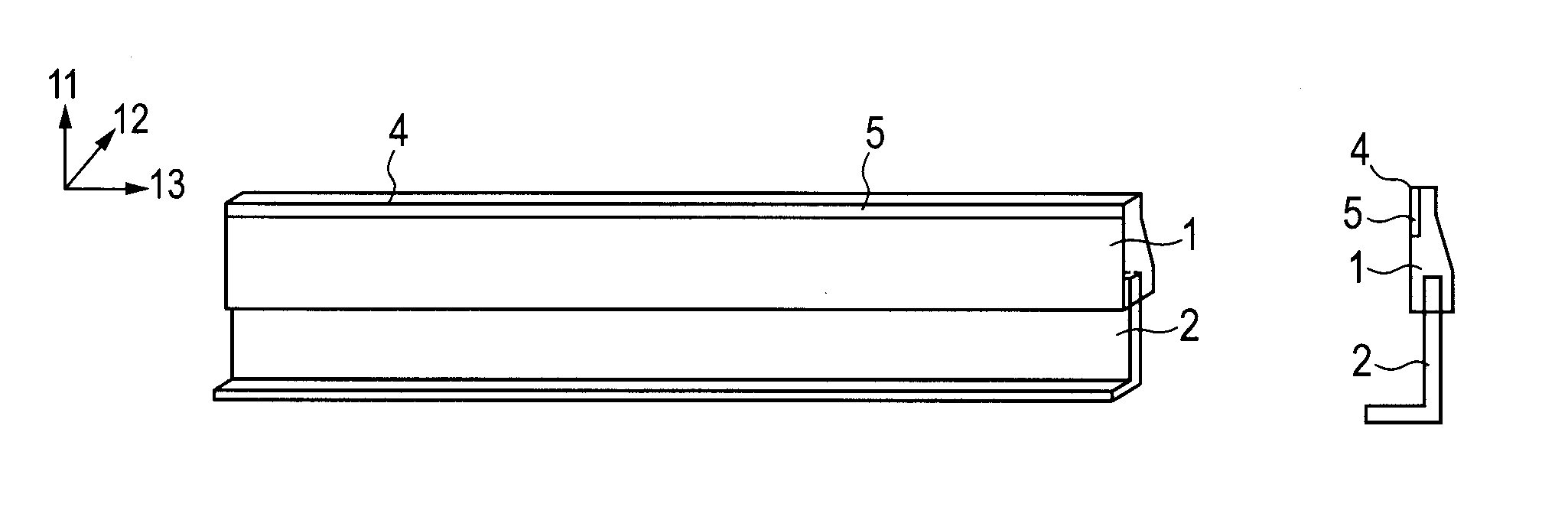

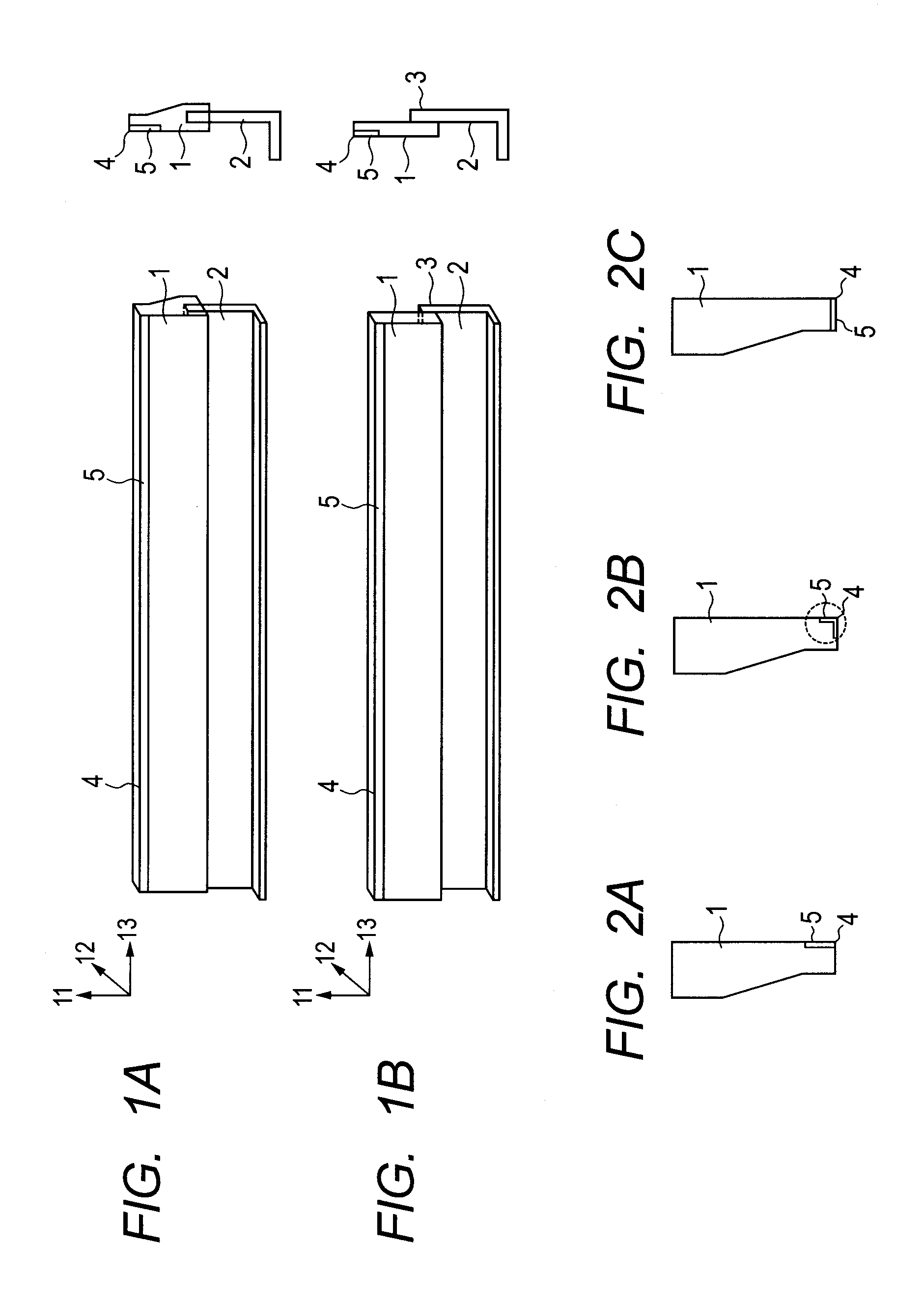

Transparent conductive film

InactiveUS6987354B2Good slipperinessEasy to produceConductive layers on insulating-supportsDischarge tube luminescnet screensTransparent conducting filmEngineering

A transparent conductive film 1 comprises a transparent plastic film 2 and a transparent conductive layer 4 laminated to at least one surface of the transparent plastic film 2. The transparent conductive film 1, as a whole, has a haze value of 8 or less; and at least one of the two surfaces of the transparent plastic film 2, that is, the surface to which the transparent conductive film 4 is laminated and the other surface, is provided with fine irregularities having a maximum height (Rmax) of 0.5 to 2.0 μm. These fine irregularities preferably have a ten-point mean roughness (Rz) of 0.35 to 1.5 μm. The fine irregularities maybe provided as the surface structure of a fine irregularity layer 3 laminated to one surface of the transparent plastic film 2. The transparent conductive layer 4 may be laminated to the surface of the fine irregularity layer 3 formed on the transparent plastic film 2, or to the surface of the transparent plastic film 2 to which the fine irregularity layer 3 is not laminated.

Owner:DAI NIPPON PRINTING CO LTD

Heat shrinking polyester film

InactiveUS20060063008A1Good printabilityHigh transparencySynthetic resin layered productsFlat articlesPolyesterEngineering

A heat-shrinkable polyester type film has a dynamic friction coefficient of at least one face with one face of another film of μd≦0.27 and range R≦0.05 and a weight loss of less than 0.24 g / m2 after 10 reciprocation times with 400 g load using a color fastness rubbing tester comprising a friction element bearing a sand paper with #1000 particle diameter.

Owner:TOYOBO CO LTD

Process for knitting towel

The invention discloses a process for knitting a towel, which comprises the procedures of warping, kitting and grey cloth post-processing. The process for knitting a towel is characterized by adopting yarn made from zein fiber and cotton fiber, and after the procedures of the warping, the kitting and the grey cloth post-processing, the yarn is prepared into a finished towel product. The towel prepared by the process has little filoplume, good appearance transparence, soft texture, textural quality, good resiliency, is easy to degrade, has good stability for solvents, such as a dry cleaning agent and can resist the dirt, the sunlight and the weather. The process for knitting a towel can reduce the environmental pollution and prolong the service life of the towel. The towel with the zein fiber feels good on skin and has good permeability, smoothness, better gloss and wash-and-wear effect, thereby being a new generation green product.

Owner:SUNVIM GROUP

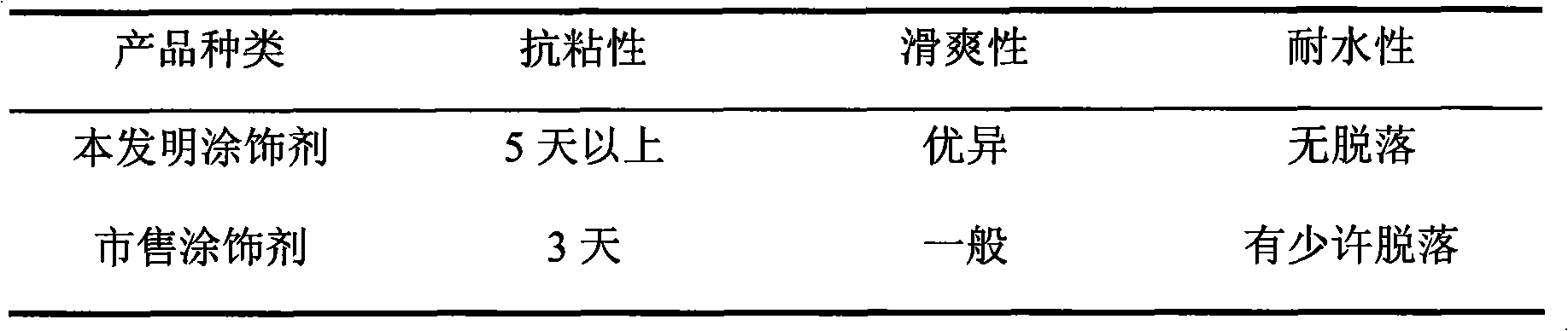

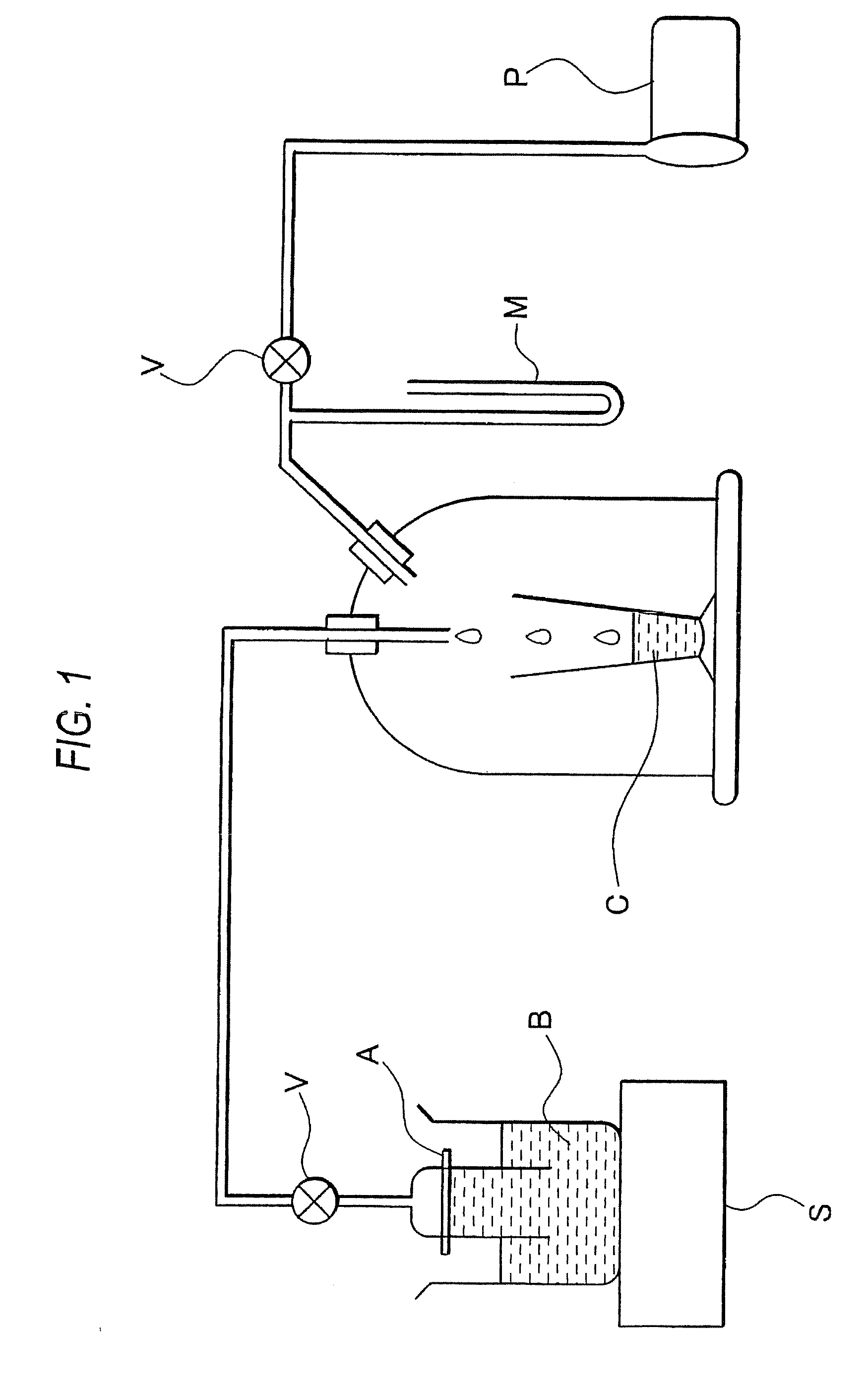

Organosilicon-modified acrylate emulsion and preparation method of coating agent for powder-free gloves

InactiveCN101575398ALow costImprove unevennessAntifouling/underwater paintsPaints with biocidesEmulsionSolid content

The invention relates to an organosilicon-modified acrylate emulsion and a preparation method of a coating agent for powder-free gloves. The preparation method comprises the following steps of: preparing the organosilicone-modified acrylate emulsion; adding the organosilicon-modified acrylate emulsion into a stirred tank; adding a wetting agent for base materials, a germicide and deionized water under constant mixing; then adding a foam killer, a thickening agent, a pH value conditioner after evenly mixing; and discharging after evenly mixing. The solid content of the coating agent of the organosilicon-modified acrylate emulsion is between 10% and 30%; the surface tension is not more than 35mN / m; and the viscosity is between 100 mPa.s and 1000mPa.s; and the pH value is between 7 and 9. The coating agent is diluted with the deionized water according to a rate of 1:19, is leached by a hand model coated with a disposable glove and then is dried at the temperature between 100 DEG C and 150 DEG C. Finally the powder-free gloves processed by the coating agent are formed after demolding.

Owner:天津碧海蓝天水性高分子材料有限公司

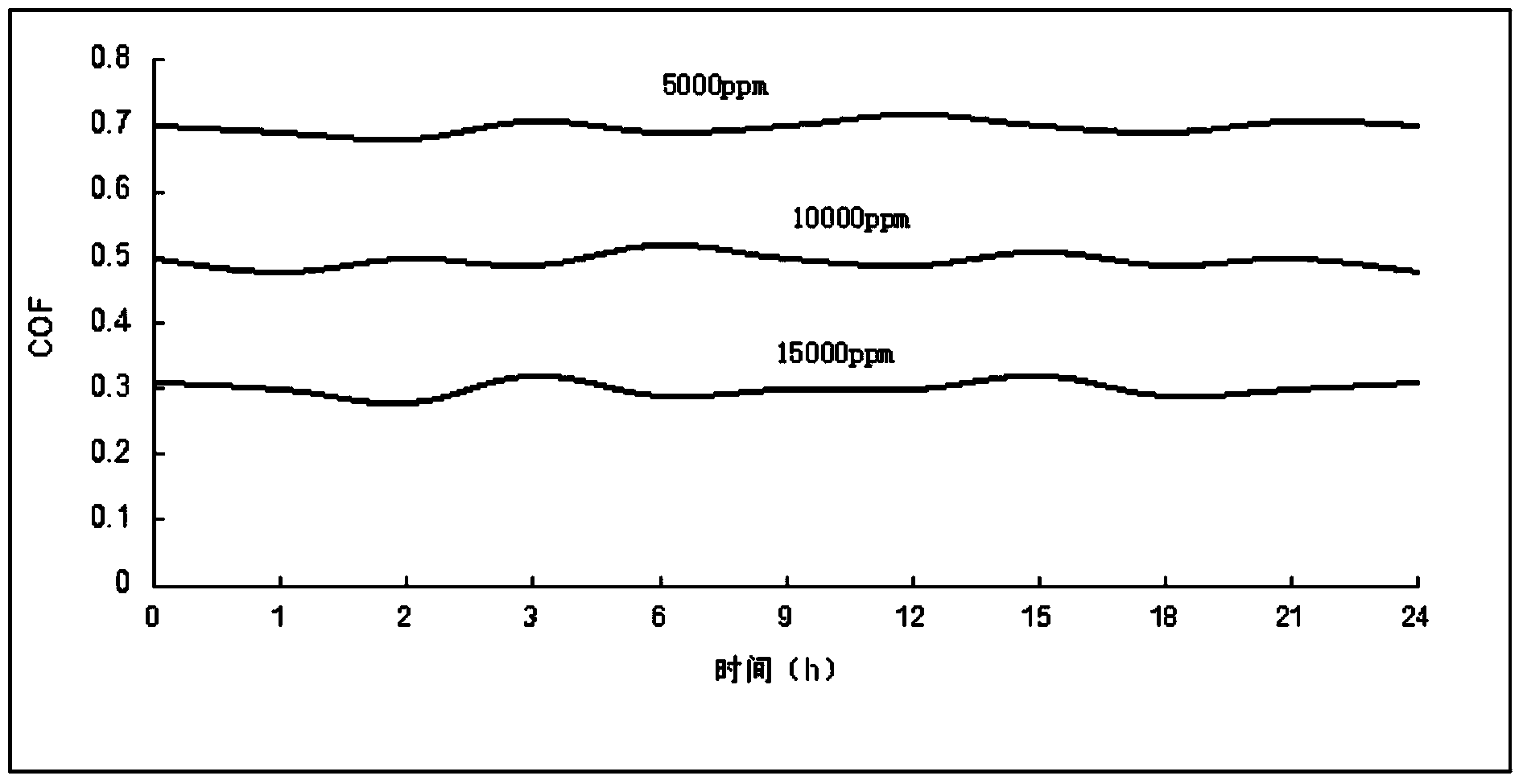

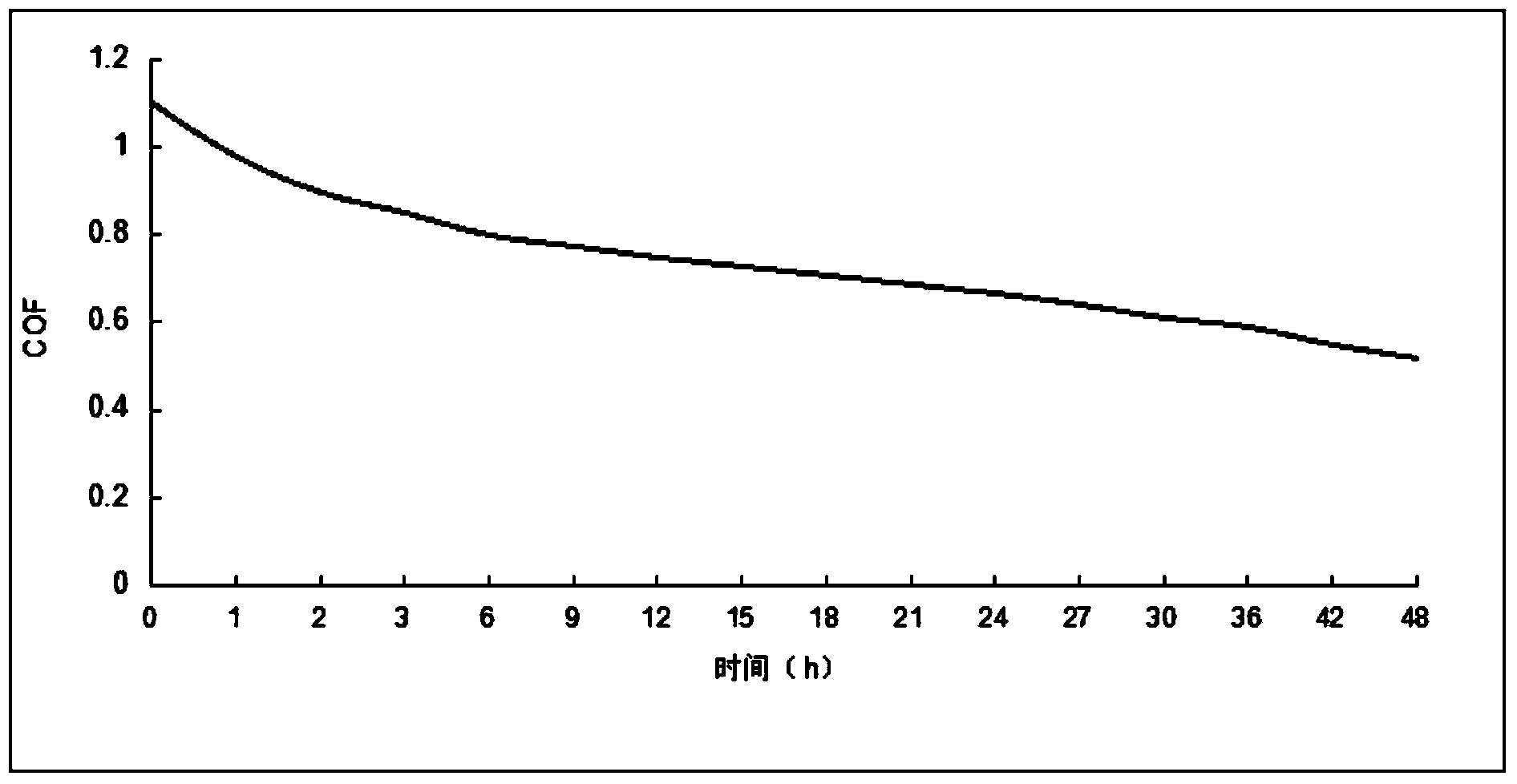

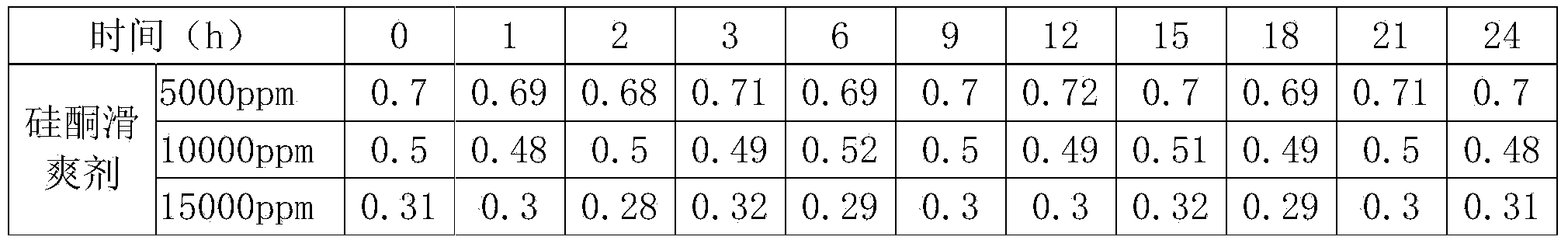

Casting polypropylene film with controllable friction coefficient and preparation method thereof

InactiveCN104015448AHigh in active ingredientsGood compatibilityFlexible coversWrappersPolymer sciencePolypropylene

The invention discloses a casting polypropylene film with a controllable friction coefficient and a preparation method thereof, belonging to the technical field of packaging materials. The casting polypropylene film sequentially comprises a corona layer, a middle layer and a heat-seal layer with a thickness ratio of (20-30) to (50-65) to (15-20). The corona layer is made from homo-polypropylene or polypropylene random copolymer, the middle layer is made from isotactic homo-polypropylene, and the heat-seal layer comprises 90wt%-98wt% of propylene copolymer, 1wt%-3wt% of adhesion resisting agent and 1wt%-7wt% of macromolecule slip agent, namely silicone master batch. The preparation method sequentially comprises the following steps: mixing materials, extruding to form a film, cooling for shaping, measuring thickness, aureoling, trimming, reeling, performing aging treatment, and slitting. The heat-seal layer is uniformly dispersed in main body resin by the macromolecule slip agent, and the slip agent is well compatible with the main body resin due to high molecular weight, and thus a film surface friction coefficient is prevented from being changed by migration of the macromolecule slip agent due to temperature of a storage or usage environment.

Owner:永新股份(黄山)包装有限公司

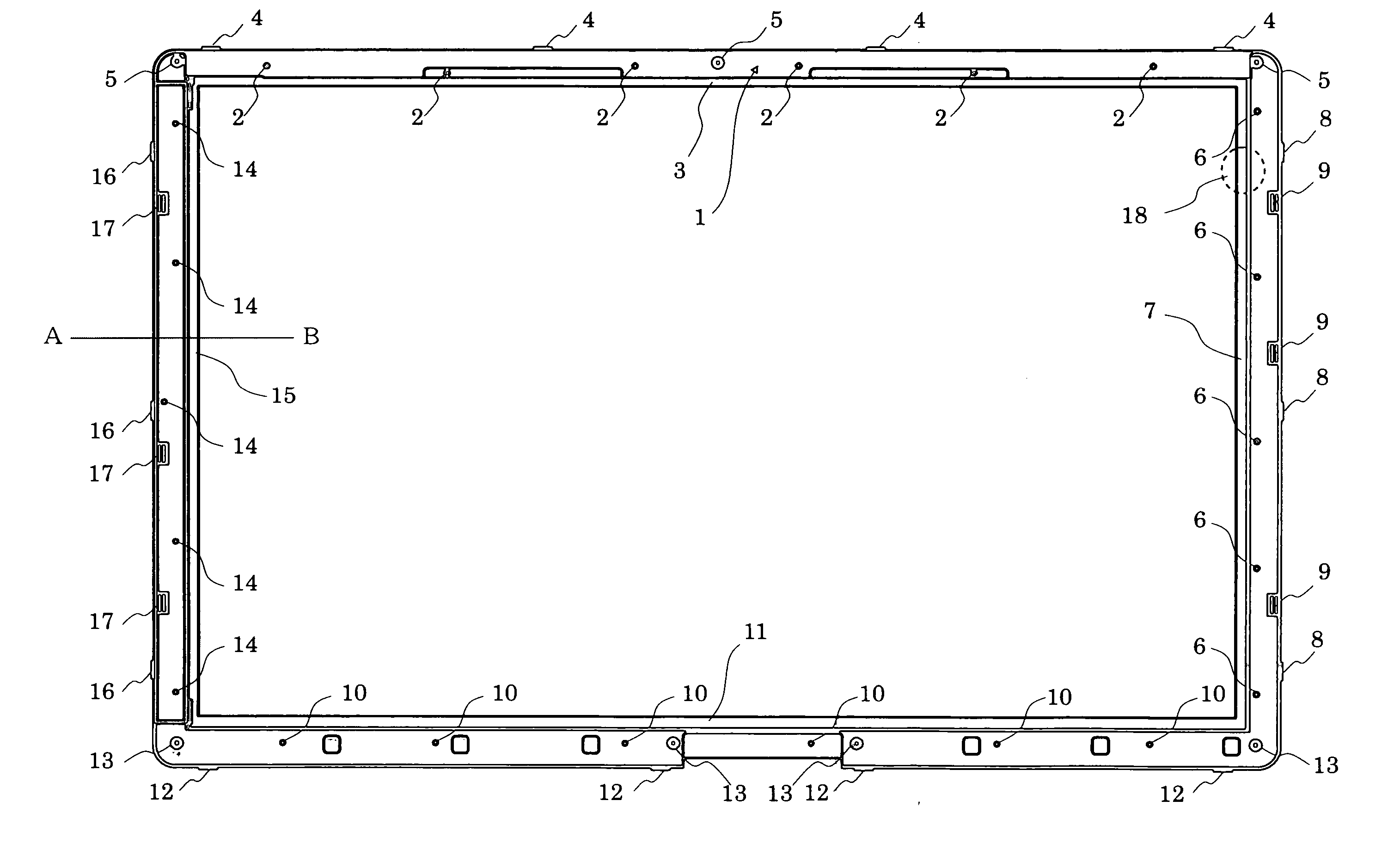

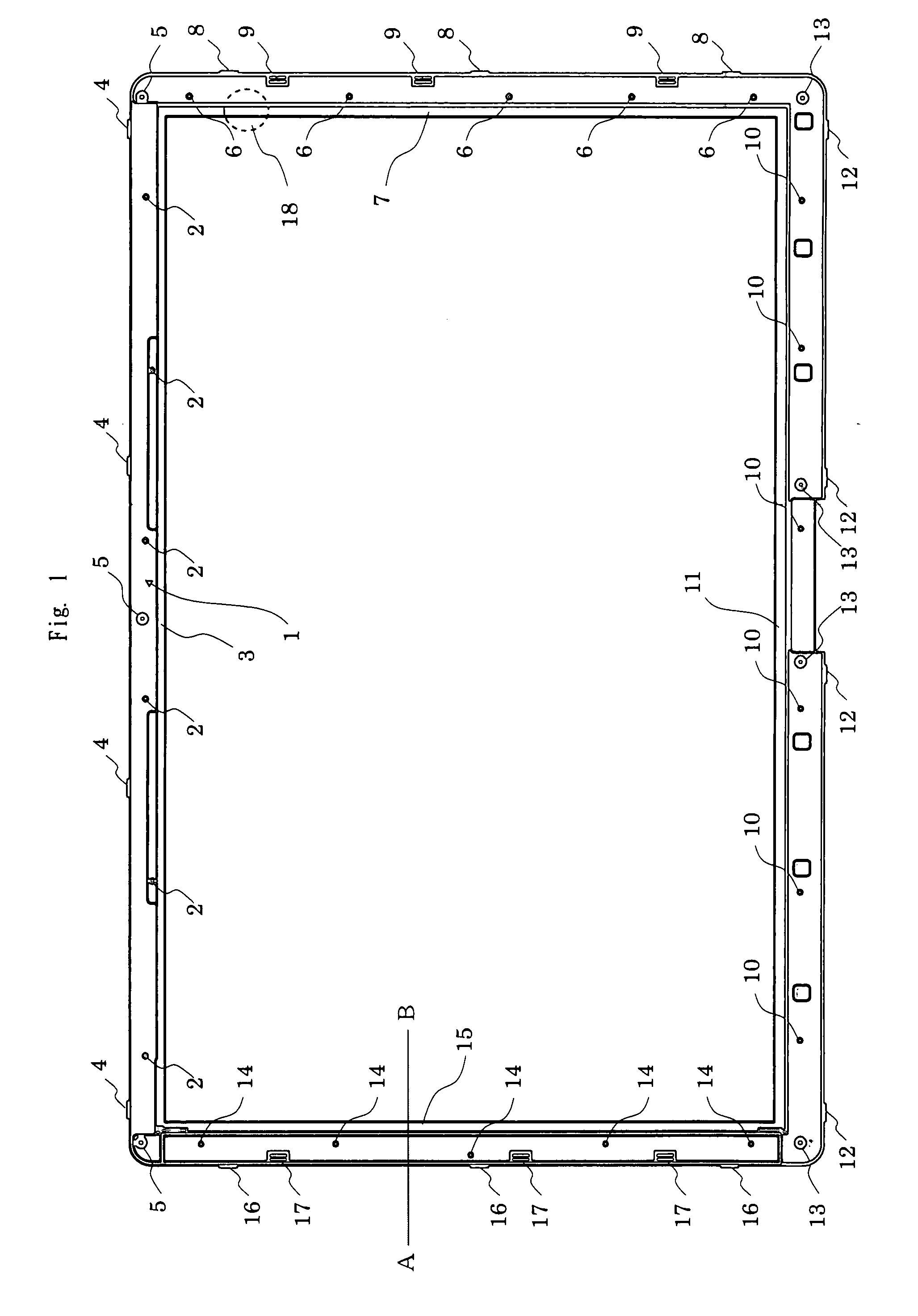

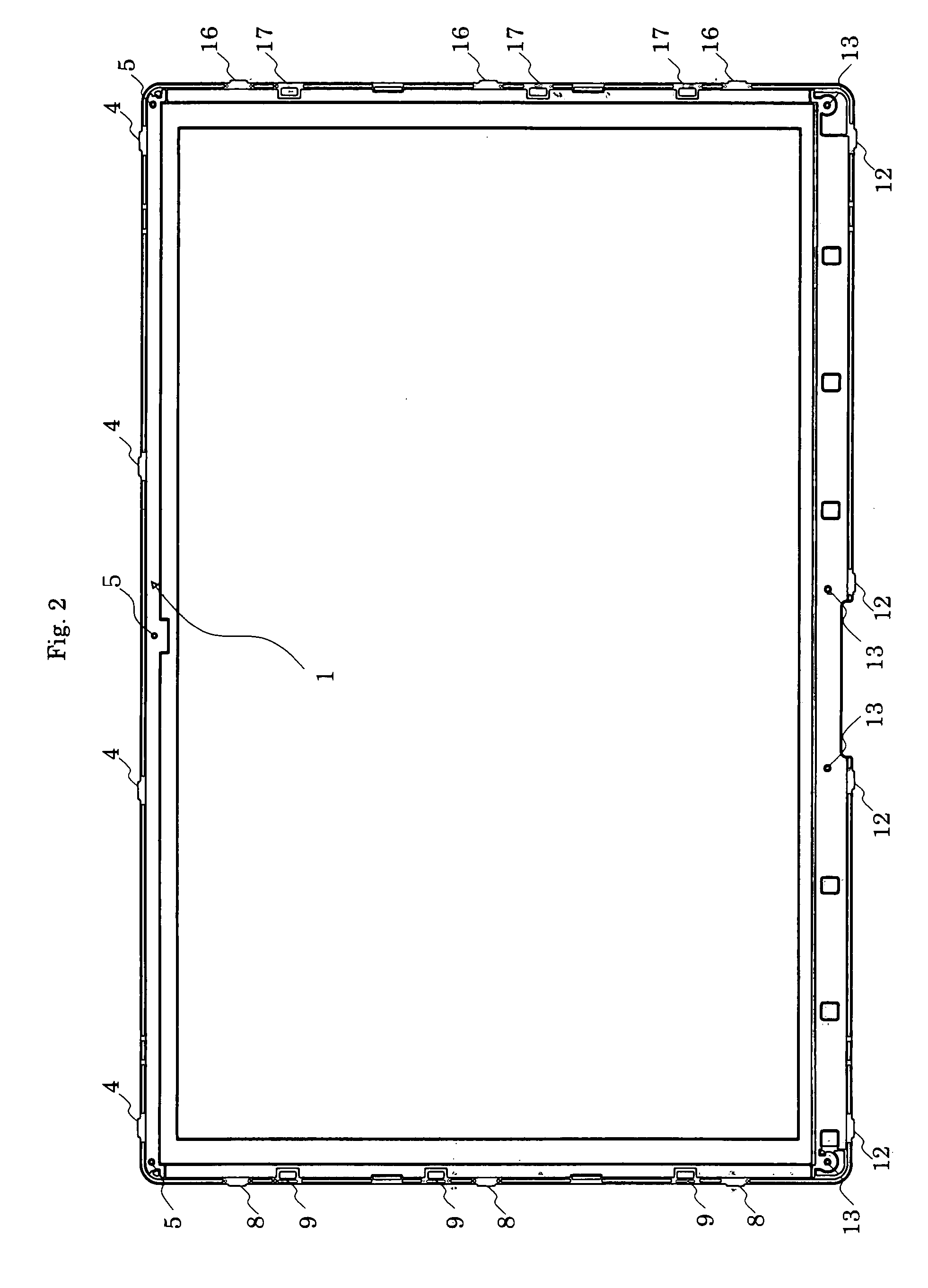

Resin Composition and Flat Panel Display Fixing Frame

InactiveUS20070257401A1Increase fraction defectiveIncrease probabilitySpecial tyresWater/sewage treatment by flocculation/precipitationFlat panel displayMuscovite

The object of the present invention are to provide a resin composition suitable for use in a flat panel display fixing frame having a snap fit structure, which comprises a filler and has stiffness and flame retardancy and a flat panel display fixing frame. There are provided the resin composition comprising (i) an aromatic polycarbonate resin (component A), (ii) at least one lamellar silicate mineral (component B) selected from the group consisting of talc having an average particle diameter of 0.5 to 9 μm (component B-1) and muscovite mica having an average particle diameter of 0.5 to 50 μm (component B-2), (iii) a fluorine-containing dripping preventing agent (component C), and (iv) an organic sulfonic acid alkali (earth) metal salt (component D) in a specific ratio, and is used in a flat panel display fixing frame having at least one snap-fit projection, hole or groove, and a flat panel display fixing frame comprising the composition in the present invention.

Owner:TEIJIN CHEM LTD

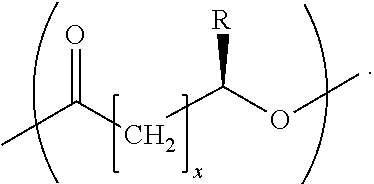

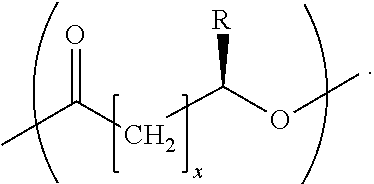

Ultrafine Polyhydroxyalkanoates

InactiveUS20200268637A1Good slipperinessImprove textureCosmetic preparationsBody powdersPolymer sciencePersonal Care Product

A powder for use in cosmetic and personal care products containing ultrafine polyhydroxyalkanoate (PHA), ultrafine polyhydroxybutyrate (PHB), or ultrafine polyhydroxybutyrate-co-hydroxyvalerate (PHBV).

Owner:MICROPOWDERS

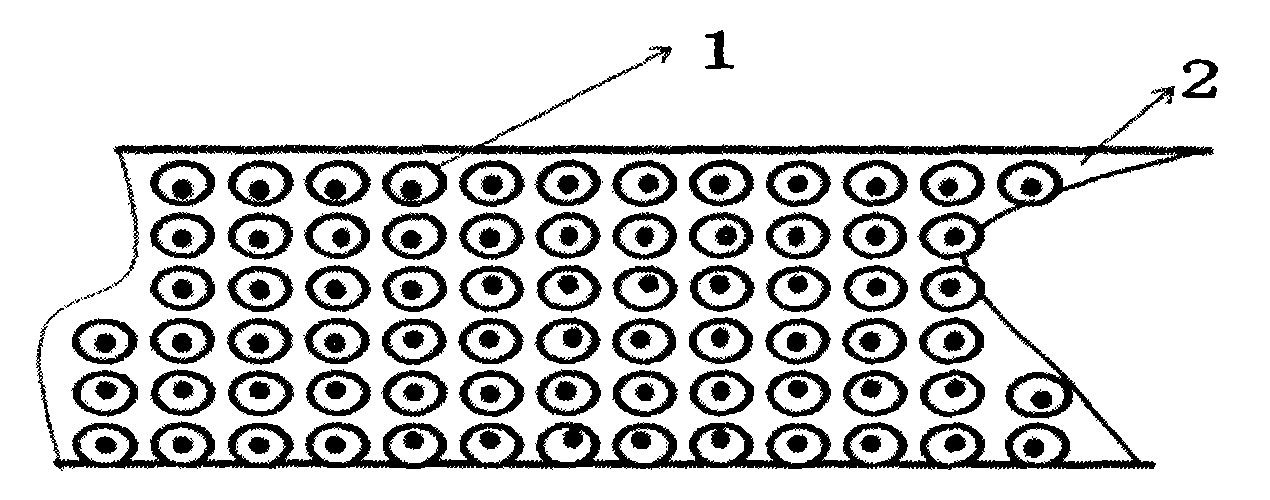

Polyethylene compounds having non-migratory slip properties

ActiveUS20150203643A1Reduced slip propertyLimited long-term stabilitySynthetic resin layered productsGlass/slag layered productsStatic friction coefficientMasterbatch

A masterbatch having functionalized silicone with an epoxy group or a secondary amine group as a slip additive, the polyethylene compound that the silicone-containing masterbatch has been let down into, and the plastic articles and films from such compounds having improved slip properties are disclosed. The improved slip properties are evidenced by essentially no migration of the slip additive 12 weeks after manufacturing and a dynamic coefficient of friction value of less than 0.4 and a static coefficient of friction 0.5 or less as measured within the first day of manufacturing according to the ASTM D1894-01 method.

Owner:AVIENT CORP

Cellulose film and method for producing the same

InactiveUS20110151224A1Good dimensional stabilityInhibition formationSynthetic resin layered productsCellulosic plastic layered productsPhosphoric Acid EstersCellulose

A cellulose film for protecting a polarizing plate of a Liquid Crystal Display Device, and a method for producing the same are disclosed. The cellulose film comprises a front layer which includes a non-phosphoric acid ester type plasticizer; an inner layer which includes a plasticizer and a UV absorbent, and a rear layer which includes a non-phosphoric acid ester type plasticizer and fine particles. Preferably, the front layer further includes fine particles, and the plasticizer in the inner layer includes at least two kinds of plasticizers, and at least one of plasticizer in the inner layer is phosphoric acid ester type plasticizer.

Owner:HYOSUNG CORP

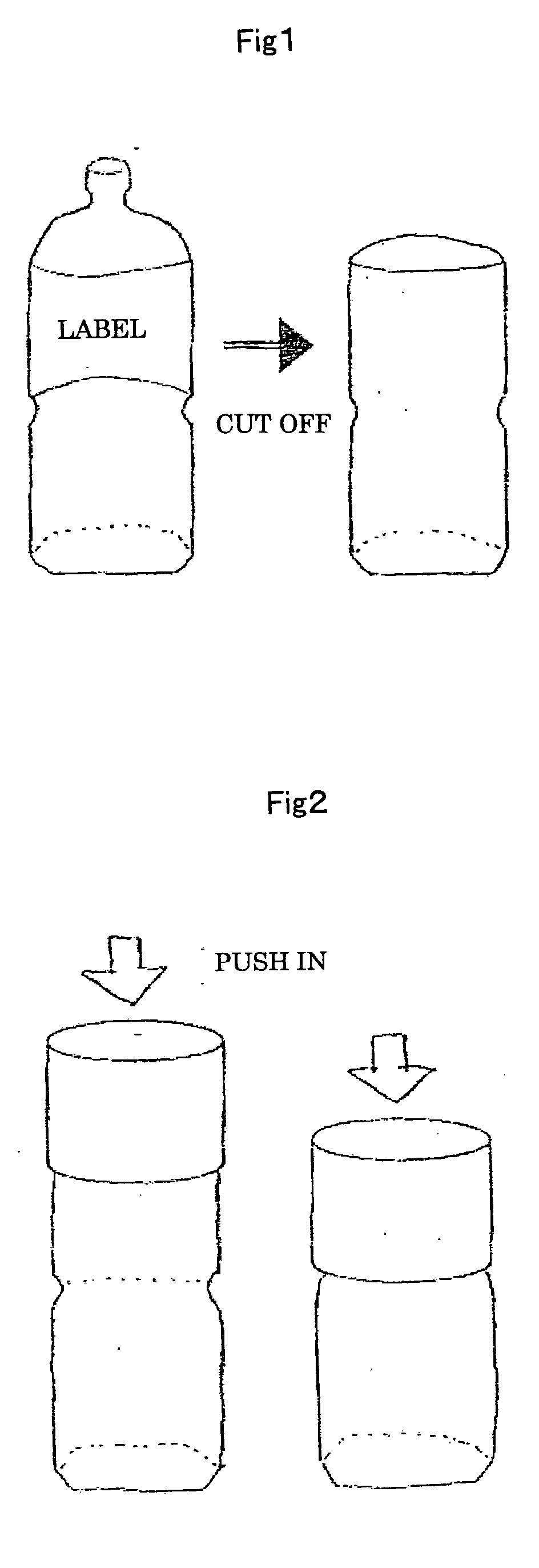

Heat shrinkable film

InactiveUS20070071967A1Outstanding processing suitabilityHigh transparencySynthetic resin layered productsCoatingsPolyesterEngineering

[PROBLEMS]To provide a heat shrinkable film that, when used as a label of beverage container, enhances the smoothness of external surface side to thereby prevent merchandise jamming in an automatic vending machine of beverage and that is fully satisfactory in solvent bonding capability and excels in processability. [MEANS FOR SOLVING PROBLEMS]There is provided a heat shrinkable polyester film characterized in that (A) at least one major surface thereof is overlaid with 0.002 to 0.5 g / m2, in terms of solid content coating amount of a silicone containing easily slipping layer, (B) a friction coefficient between one and the same easily-slipping layer satisfies a relationship of μd≦0.27, and that (C) the heat shrinkable polyester film exhibits a heat shrinkage percentage of not less than 50% in a maximum shrinkage direction, after immersion in hot water at 95° C. for 10 seconds. Thus, there is provided the heat shrinkable film that when used as a label of beverage container, enhances the smoothness of external surface side to thereby prevent merchandise jamming in an automatic vending machine of beverage and that is fully satisfactory in solvent bonding capability and excels in processability.

Owner:TOYOBO CO LTD

Aqueous buffing oil with shell/core structure

InactiveCN1632022AStrong adhesionImprove wear resistanceSpecial paperPaper/cardboardWaxSocial benefits

Disclosed is a hydrophilic buffing oil with core-shell structure,with its component and mass content: base materials 48-5%, latex 1-3%,water 43-48%, thickener 2-4% and assistant 0.1-0.5%. Coat the hydrophilic buffing oil on printed matter,then buffing it under rolling of 150kg in 80-100deg.C, making the wear resistance and ornamental higher,with protection to water and increased additional value;meanwhile, it uses latex polymerization method,inwhich there is no solvent,remarkably advancing productive condition,it has notably social benefit.

Owner:广州电器科学研究院

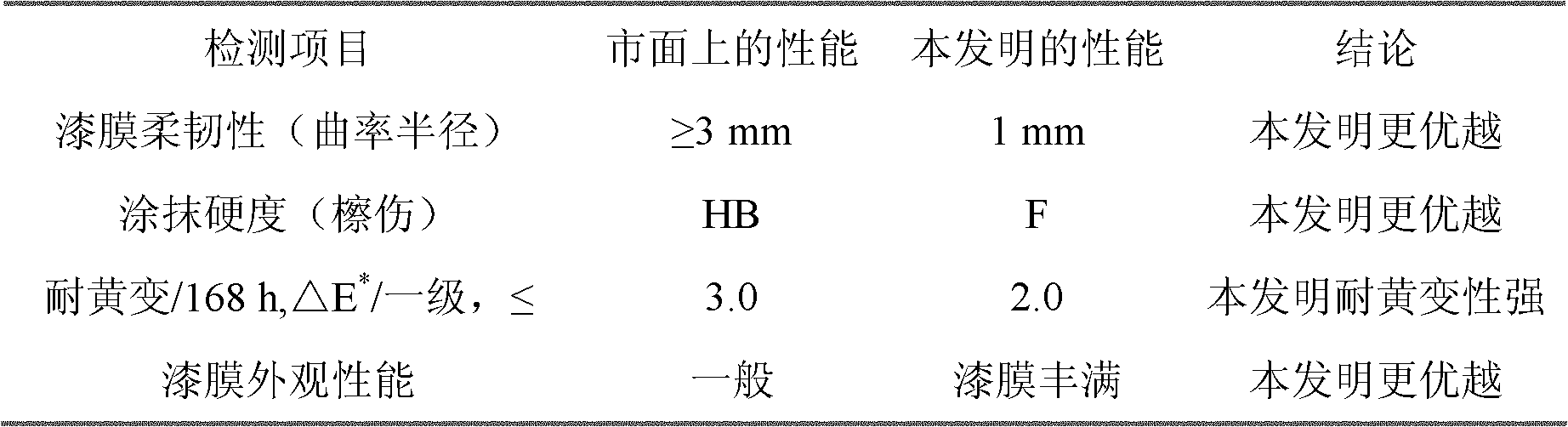

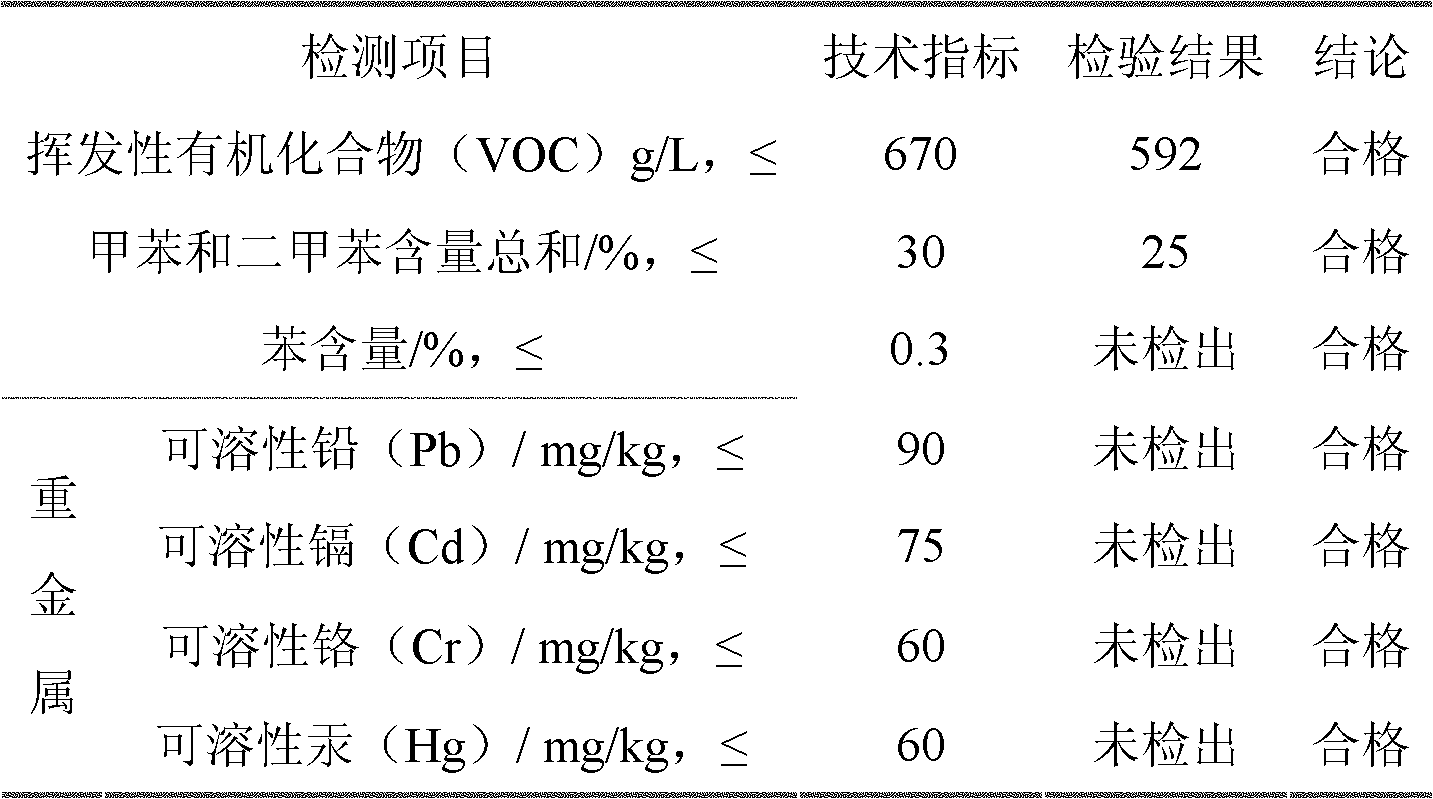

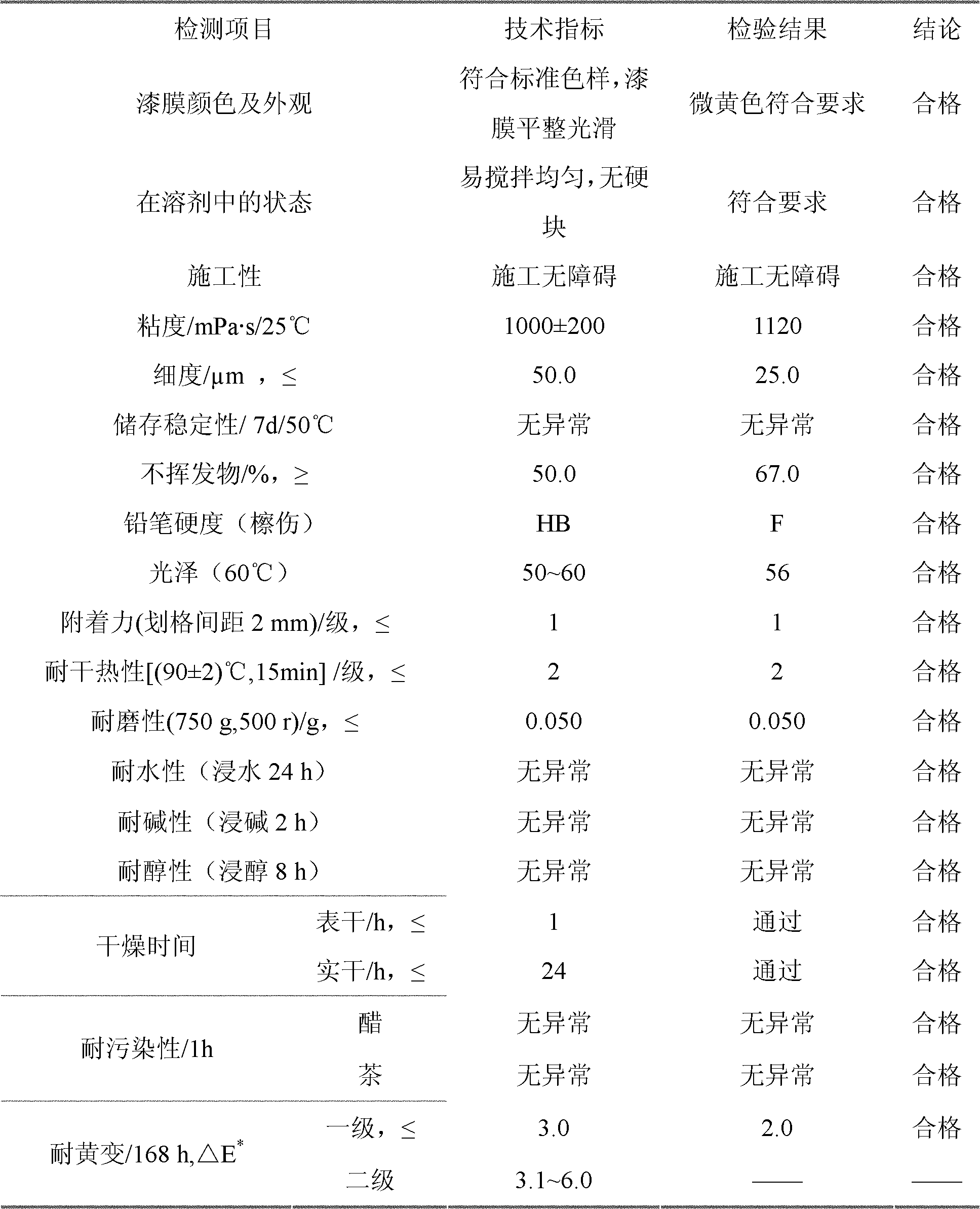

Novel polyurethane semi-matte white finish for woodware protection

InactiveCN101967340AHigh glass transition temperatureSmall steric hindrancePolyurea/polyurethane coatingsWaxDeodorant

The invention discloses novel polyurethane semi-matte white finish for woodware protection. The finish is prepared by mixing the following components: stearic acid modified alkyd resin, polyketone resin solution, an antifoaming agent, an anti-settling agent, a dispersing agent, white slurry, handfeel wax powder, aerosol extinction powder, 20 percent hydroxyl modified vinyl acetate (VAGH) resin, a leveling agent, an anti-yellowing auxiliary agent, a deodorant and butyl ester. A film prepared from the novel polyurethane semi-matte white finish has the advantages of fullness, moderate hardness, high flexibility, high water resistance, yellowing resistance and environmental protection; and the semi-matte white finish has high comprehensive performance.

Owner:JIANGSU CHAMPION TECHNOLOGY GROUP CO LTD

Method of Producing Cyclic Polyolefin Film, Cyclic Polyolefin Film Produced by the Production Method, Method of Preparing Liquid Dispersion of Fine Particles, Liquid Dispersion of Fine Particles and Method of Preparing Dope

InactiveUS20090081387A1Good slipperinessReduced frictional injury damageLiquid crystal compositionsSynthetic resin layered productsOrganic solventPolymer science

A method of producing a cyclic polyolefin film comprising: dissolving or dispersing a cyclic polyolefin resin and at least one compound selected from a higher fatty acid and a derivative of the higher fatty acid in a solvent; a casting step; a drying step; and a taking-up step; and a method of preparing a liquid dispersion of fine particles, which comprises: subjecting fine particles, an organic solvent and a dispersant to a dispersing treatment, wherein the dispersant contains a cyclic olefin resin.

Owner:FUJIFILM CORP

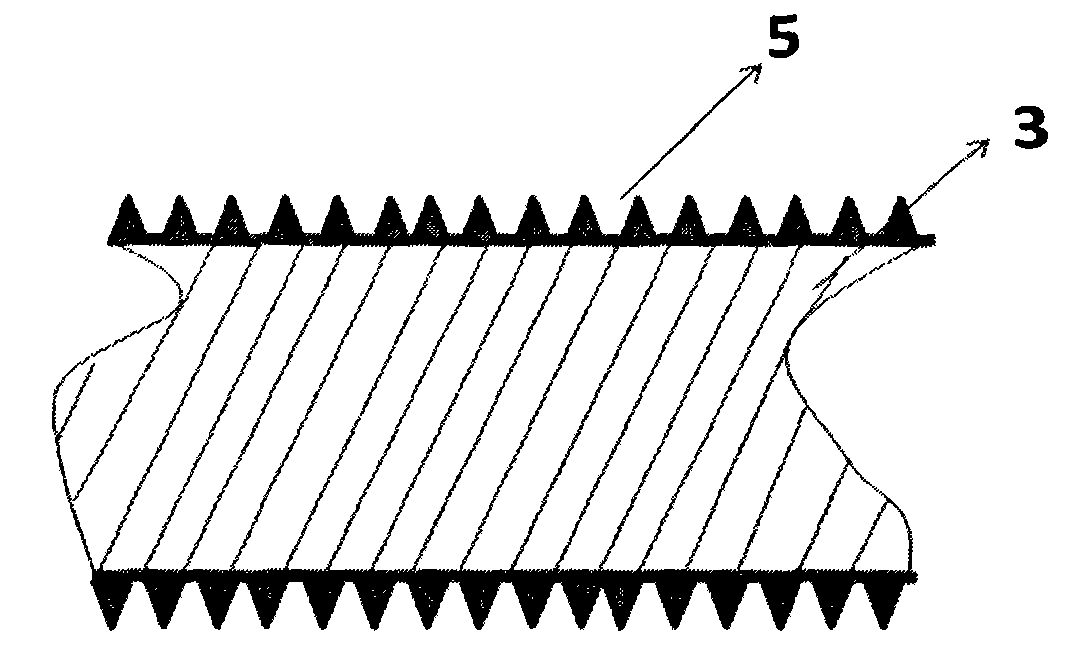

Bubble type flexible non-woven cloth and manufacturing method thereof

The invention discloses a piece of bubble type flexible non-woven cloth and a manufacturing method of the bubble type flexible non-woven cloth. Raw materials, namely, polylactic acid high polymers, are solidified into the cloth through melt spinning net laying and twice hot rolling. Annular nips are formed through the first time of hot rolling, point nips are formed through the second time of hot rolling, and finally the bubble type non-woven cloth is formed. Due to the fact that the nip area is small and the three-dimensional structure is obvious, the non-woven cloth is excellent in flexibility, small in contact area when making contact with the skin, fresh and cool, can not be attached to the human body, enables a user to feel nice and cool, and can be widely applied to disposal medical treatment and public health products such as sanitary towels, paper diapers, adult incontinence trousers, surgical gowns and operation cushions through combination with the advantages of polylactic acid fibers. Meanwhile, the polylactic acid raw materials have the advantages that the polylactic acid raw materials can be completely and naturally circulated and can be decomposed in a biological mode, energy consumption is lowered, and the environment protection role is played.

Owner:HAINING WEITAI BIOTECH CO LTD

Bone meal nutritious fresh wet noodle and making method thereof

InactiveCN102028146AIncrease elasticityImprove extensibilityDough treatmentFood preparationChemistryFineness

The invention relates to a bone meal nutritious fresh wet noodle. According to the formula, the noodle comprises the following components in part by weight: 100 parts of flour, 32 to 38 parts of water, 0.8 to 1.5 parts of table salt, 0.15 to 0.3 part of dietary alkali, 1.2 parts of bone meal, 0.5 part of soya bean lecithin and 3 parts of potato starch, wherein the fineness of the bone meal is between 120 and 200 meshes. The bone meal nutritious fresh wet noodle is produced by the following steps of: mixing raw materials and auxiliary materials according to the formula; kneading dough; performing secondary curing and tabletting; and finally shredding. The invention has the characteristics that: the bone meal is added into the flour; and the bone meal nutritious fresh wet noodle which has high tensile property and bright color and can difficultly thicken soup can be produced by optimizing the formula of an additive and improving a making process.

Owner:HEFEI UNIV OF TECH

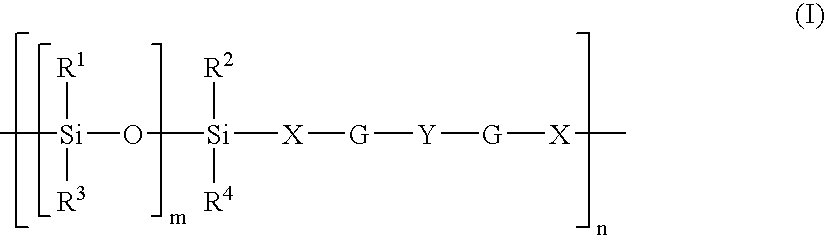

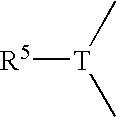

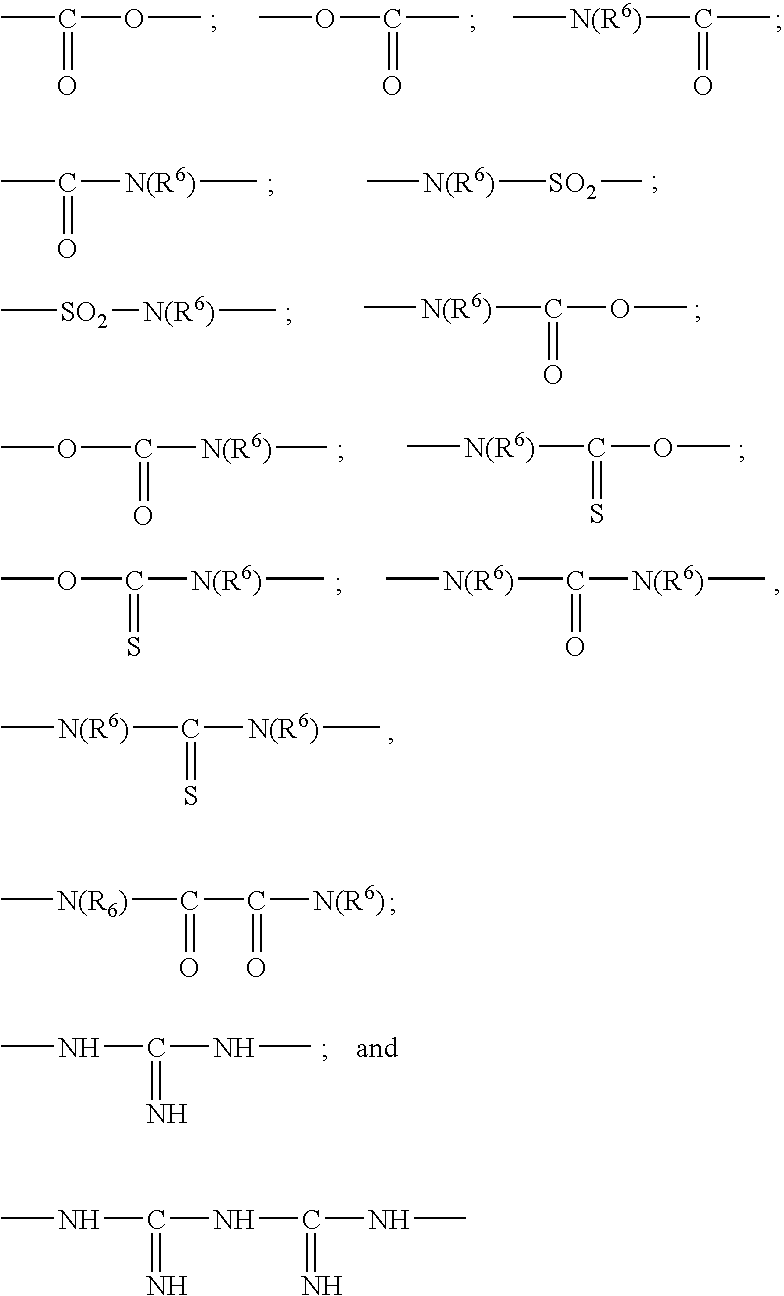

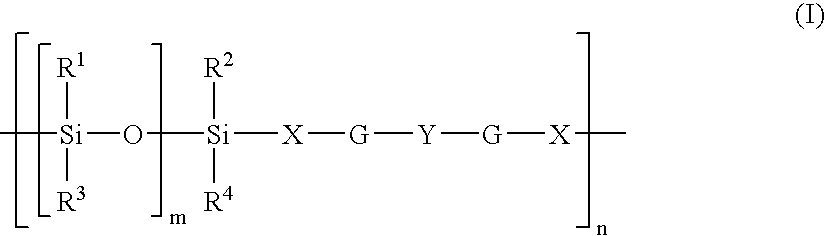

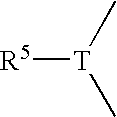

Care and/or make-up cosmetic composition structured with silicone polymers

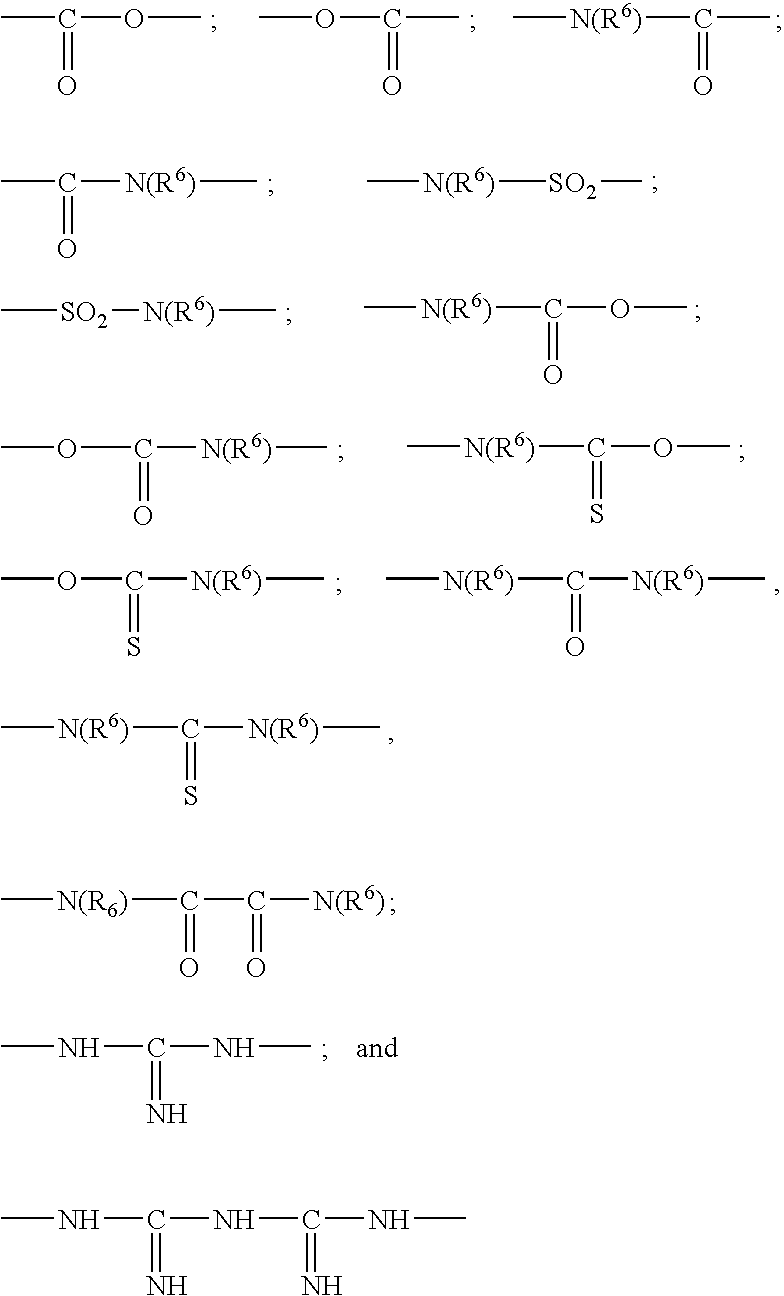

InactiveUS7887786B2Efficient use ofFew or no effectsCosmetic preparationsMake-upThiocarbamateCarbamate

Care and / or make-up cosmetic composition comprising: a liquid continuous fatty Phase structured with at least one structuring polymer (homopolymer or copolymer) having a weight-average molecular mass ranging from 500 to 500 000, containing at least one moiety comprising: at least one polyorganosiloxane group consisting of 1 to 1 000 organosiloxane units in the chain of the moiety or in the form of a graft, and at least two groups capable of establishing hydrogen interactions, Chosen from ester, amide, sulphonamide, carbamate, thiocarbamate, urea, urethane, thiourea, oxamido, guanidino and biguanidino groups, and combinations thereof, the polymer being solid at room temperature and soluble in the liquid fatty Phase at a temperature of 25 to 250° C., the Said liquid fatty Phase comprising at least one compound capable of reducing the enthalpy of fusion of the structuring polymer, and then the liquid fatty Phase, the structuring polymer and the compound capable of reducing the enthalpy of fusion of the structuring polymer forming a physiologically acceptable medium.

Owner:LOREAL SA

Technique for producing UV plate

InactiveCN101322966AImprove smoothnessImprove toughnessOther plywood/veneer working apparatusPretreated surfacesWear resistanceUV coating

The invention discloses and provides a process for producing a UV panel, which belongs to a process for manufacturing a UV coating. The invention comprises the specific process flows of substrate sanding and dedusting, roll-coating of primer, infrared drying, sanding and dedusting, roll-coating of primer, UV light curing, sanding and dedusting, roll-coating of UV top coat, UV light curing, infrared drying, roll-coating of UV top coat and UV light curing; by the process flows, finished products can be obtained. The products produced by the process have good smoothness, tenacity, wear resistance and skidding property with the attrition value less than or equal to 0.05 percent and a worn-out revolution more than or equal to 1000r and are eco-friendly. The process has the advantages of short production period, low labor intensity of workers and lower production cost.

Owner:韩勇

Cleaning blade for electrophotographic apparatus, and method for producing the same

ActiveUS20120163890A1High hardnessGood slipperinessSynthetic resin layered productsElectrography/magnetographyPolyurethane elastomerNitrogen

A cleaning blade for an electrophotographic apparatus including a thermosetting polyurethane elastomer blade member, in which in the blade member, a concentration of nitrogen is gradually increased from an inside of a contact region to contact the image bearing member toward the surface of the contact region; and a relationship between an amount of the concentration of nitrogen to be changed Δ1=N0−N5 and an amount of the concentration of nitrogen to be changed Δ2=N5−Ne is Δ1>Δ2 wherein a concentration of nitrogen in the surface N0 is not less than 1.5 wt % and not more than 20.0 wt %, a concentration of nitrogen Ne at a depth in which the concentration of nitrogen is no longer changed is not less than 0.7 wt % and not more than 10 wt %, and N5 is a concentration of nitrogen at a depth of 5 μm.

Owner:CANON KK

Care and /or Make-Up Cosmetic Composition Structured with Silicone Polymers

ActiveUS20060204470A1Efficient use ofGood disintegrationCosmetic preparationsHair cosmeticsThiocarbamateCarbamate

Care and / or make-up cosmetic composition comprising: a liquid continuous fatty Phase structured with at least one structuring polymer (homopolymer or copolymer) having a weight-average molecular mass ranging from 500 to 500 000, containing at least one moiety comprising: at least one polyorganosiloxane group consisting of I to 1 000 organosiloxane units in the chain of the moiety or in the form of a graft, and at least two groups capable of establishing hydrogen interactions, Chosen from ester, amide, sulphonamide, carbamate, thiocarbamate, urea, urethane, thiourea, oxamido, guanidino and biguanidino groups, and combinations thereof, the polymer being solid at room temperature and soluble in the liquid fatty Phase at a temperature of 25 to 250° C., the Said liquid fatty Phase comprising at least one compound capable of reducing the enthalpy of fusion of the structuring polymer, and then the liquid fatty Phase, the structuring polymer and the compound capable of reducing the enthalpy of fusion of the structuring polymer forming a physiologically acceptable medium.

Owner:LOREAL SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com