Patents

Literature

188 results about "Muscovite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Muscovite (also known as common mica, isinglass, or potash mica) is a hydrated phyllosilicate mineral of aluminium and potassium with formula KAl₂(AlSi₃O₁₀)(FOH)₂, or (KF)₂(Al₂O₃)₃(SiO₂)₆(H₂O). It has a highly perfect basal cleavage yielding remarkably thin laminae (sheets) which are often highly elastic. Sheets of muscovite 5 meters × 3 meters (16.5 feet × 10 feet) have been found in Nellore, India.

Liquid-crystalline polyester resin composition and connector using the same

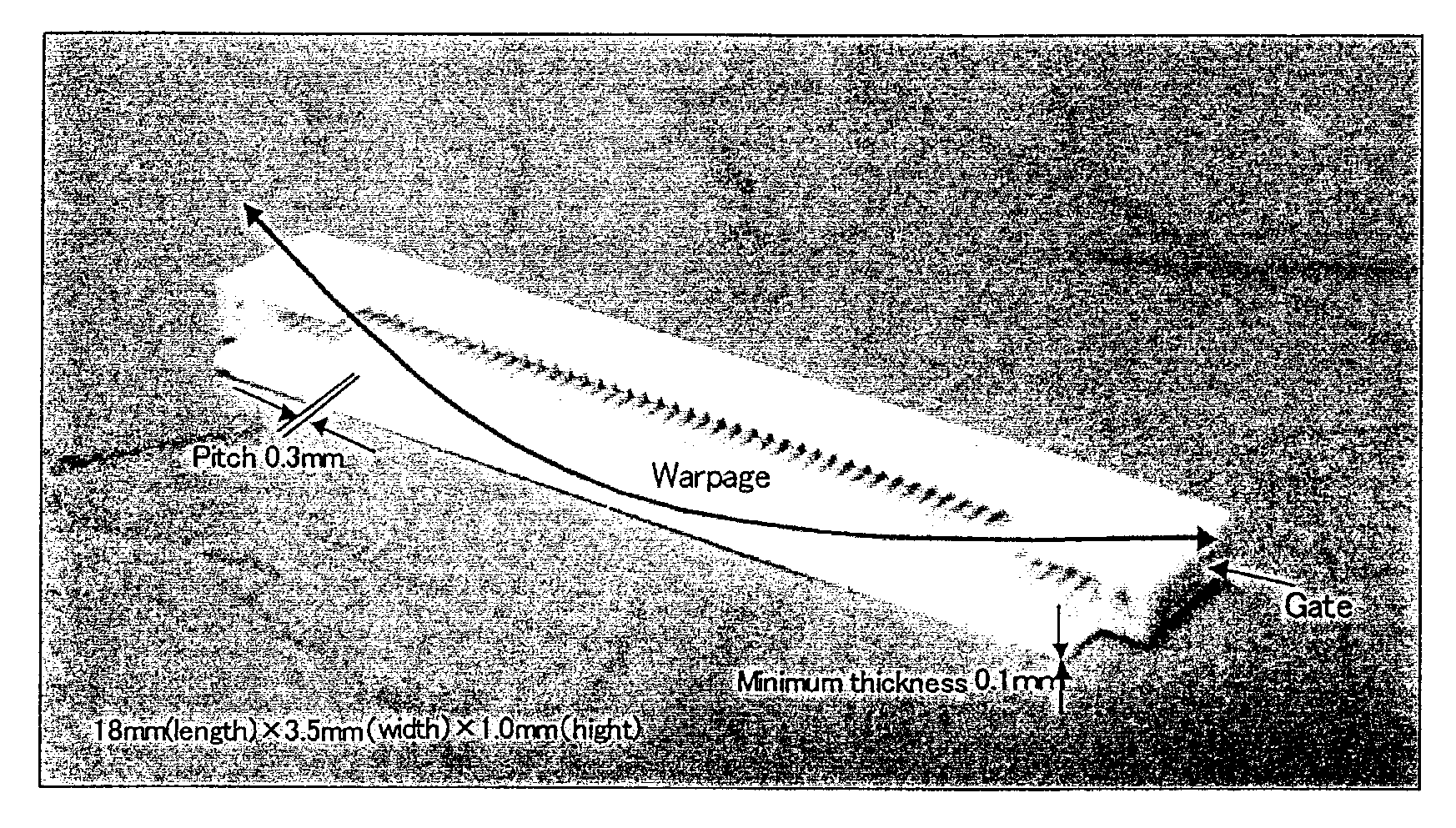

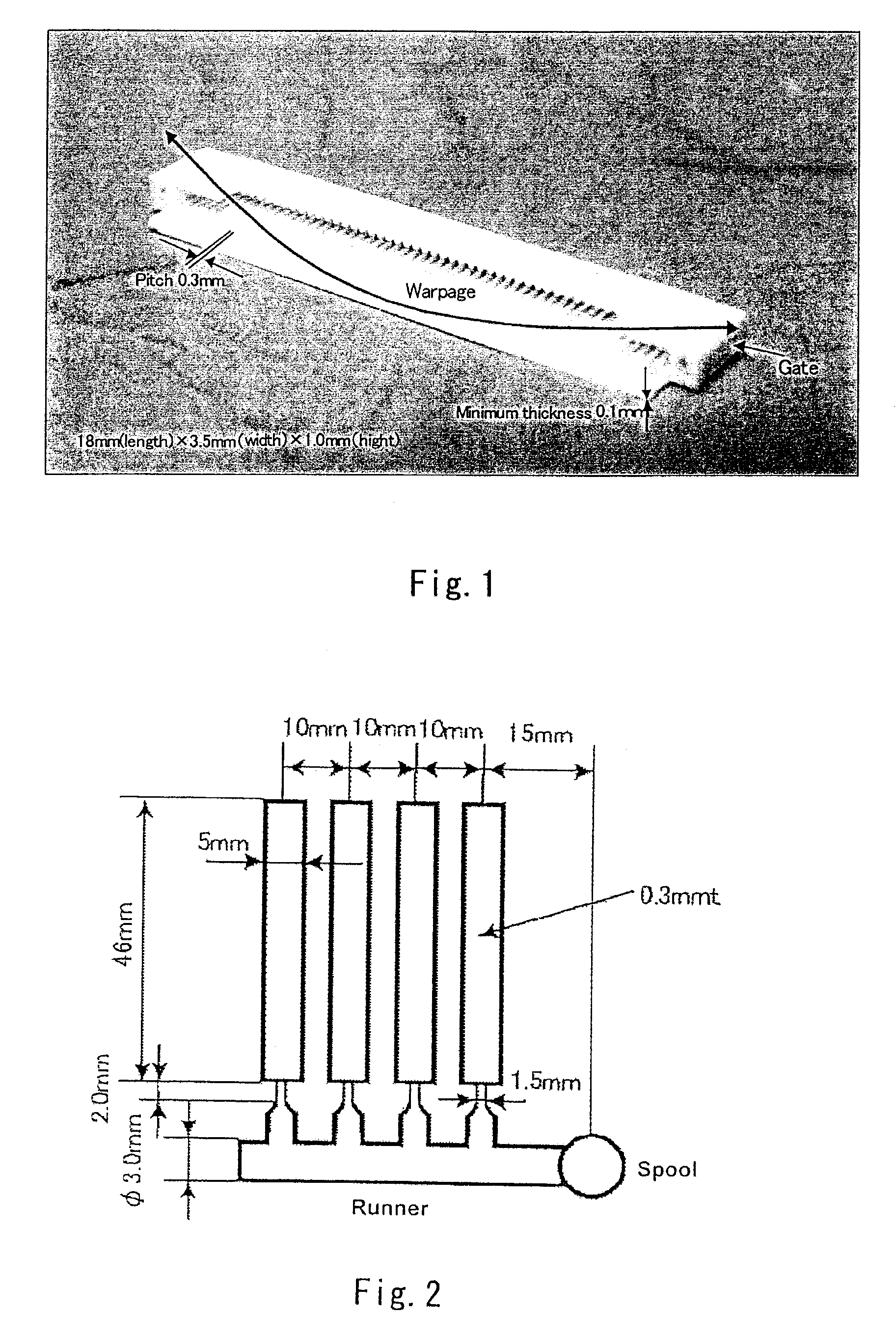

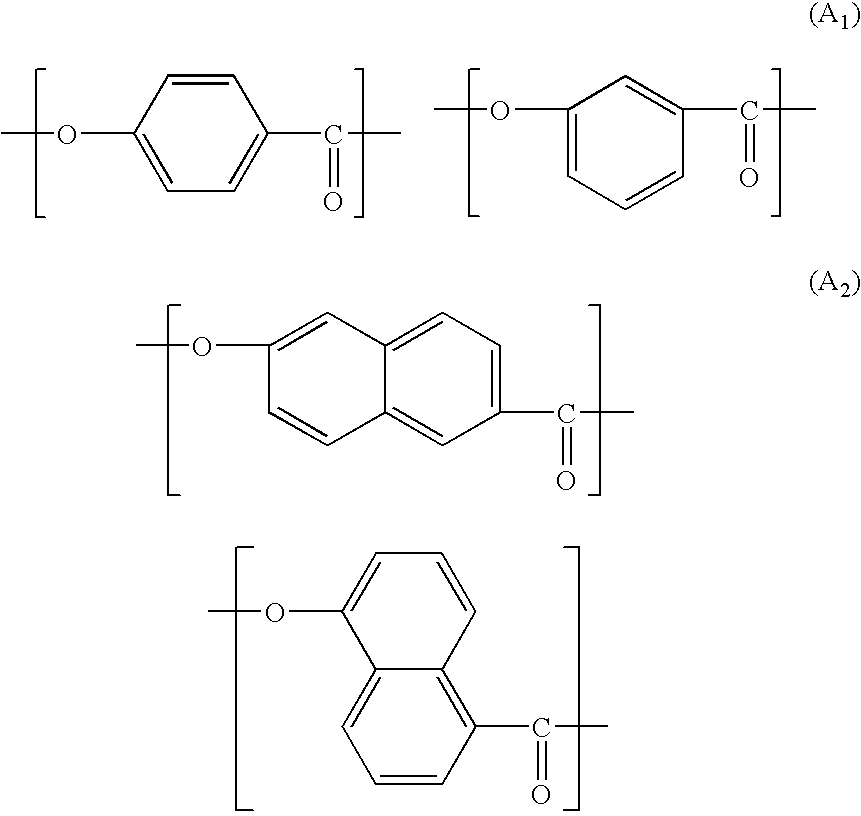

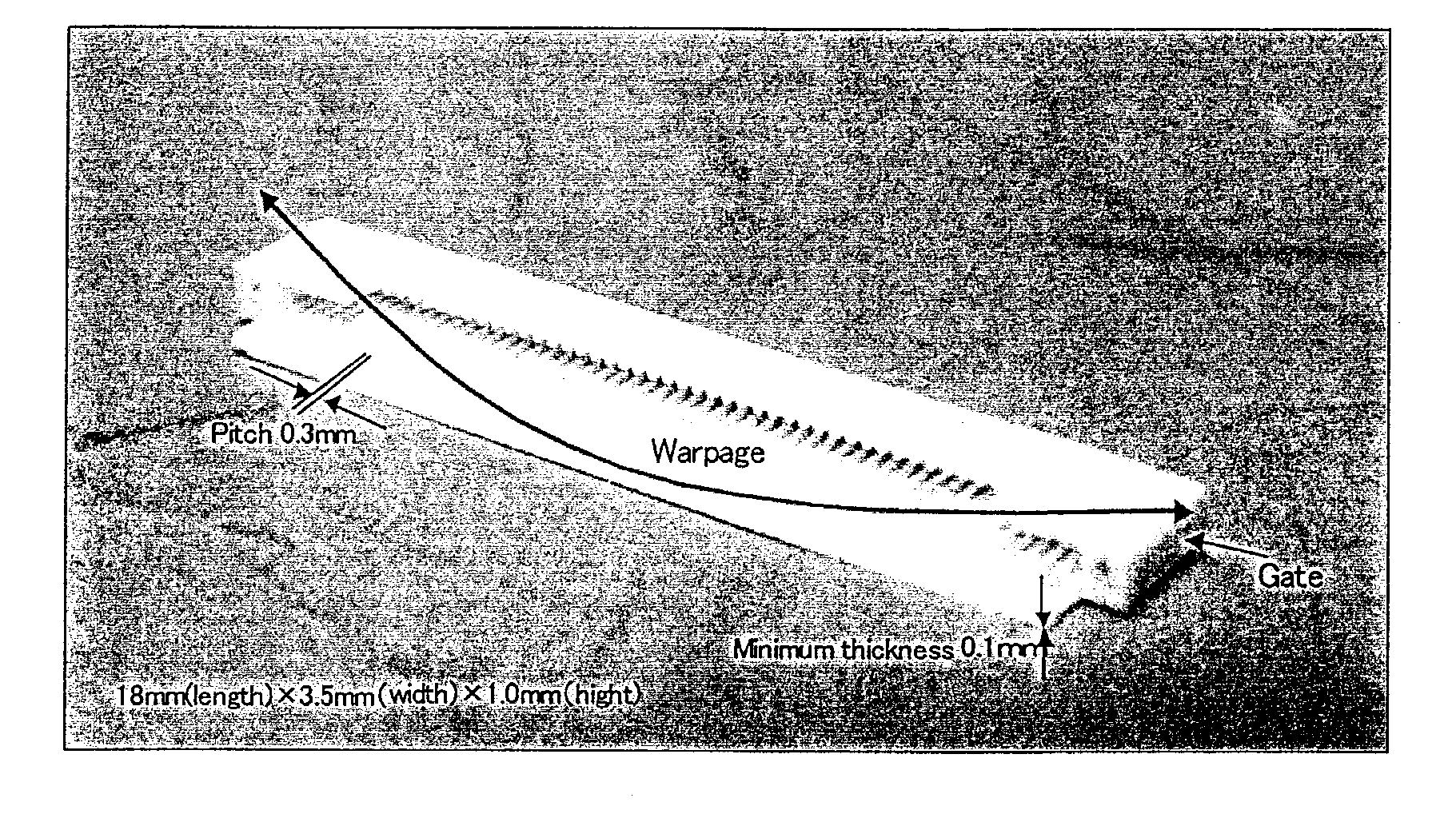

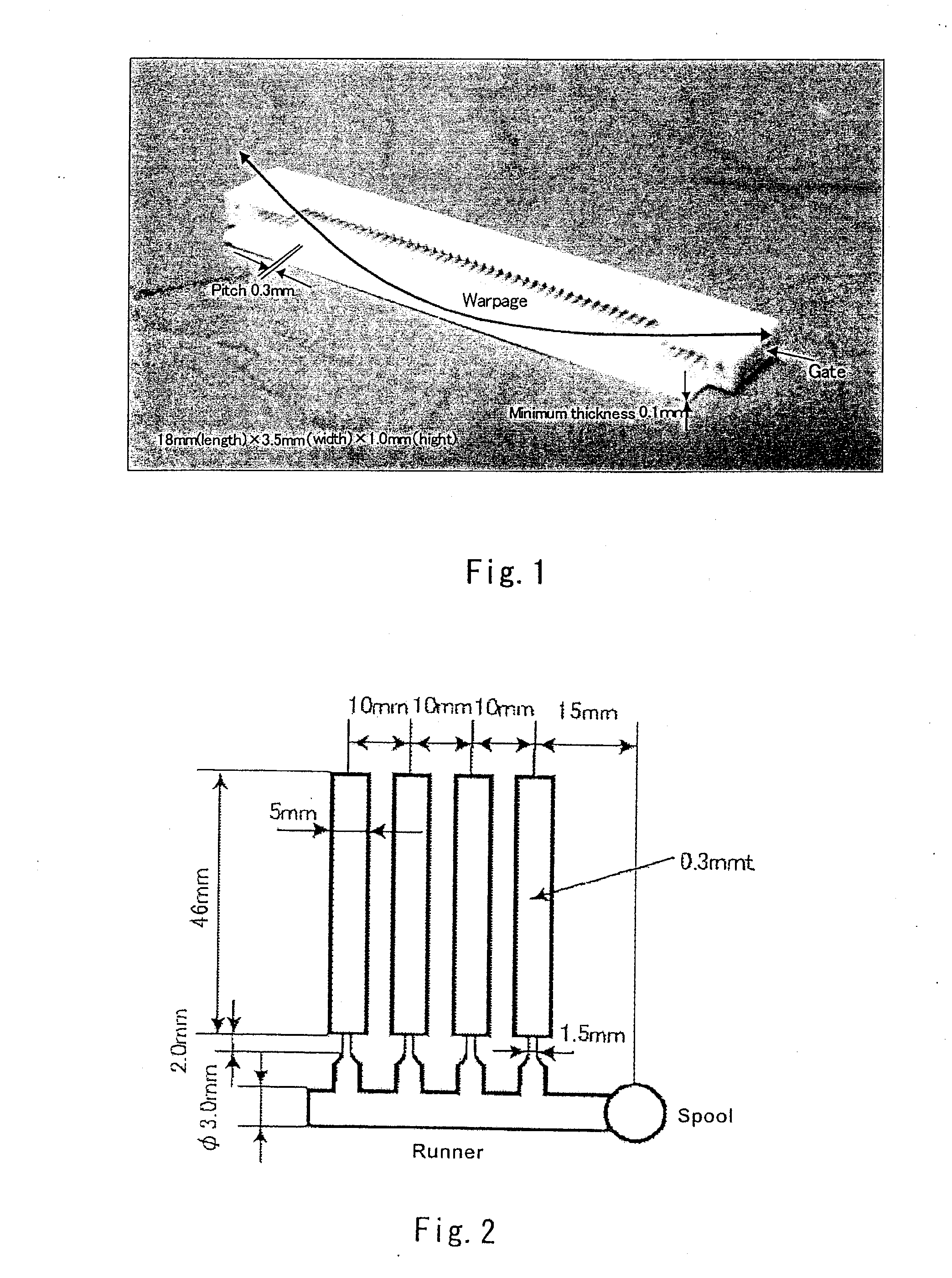

ActiveUS8202448B2Sufficient soldering resistanceSufficiently suppressed warpLiquid crystal compositionsMicaLiquid crystallinePolyester resin

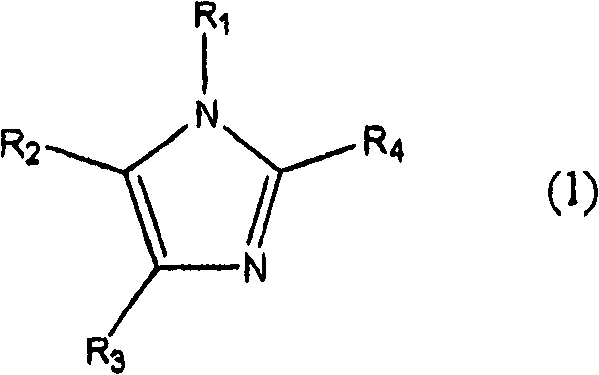

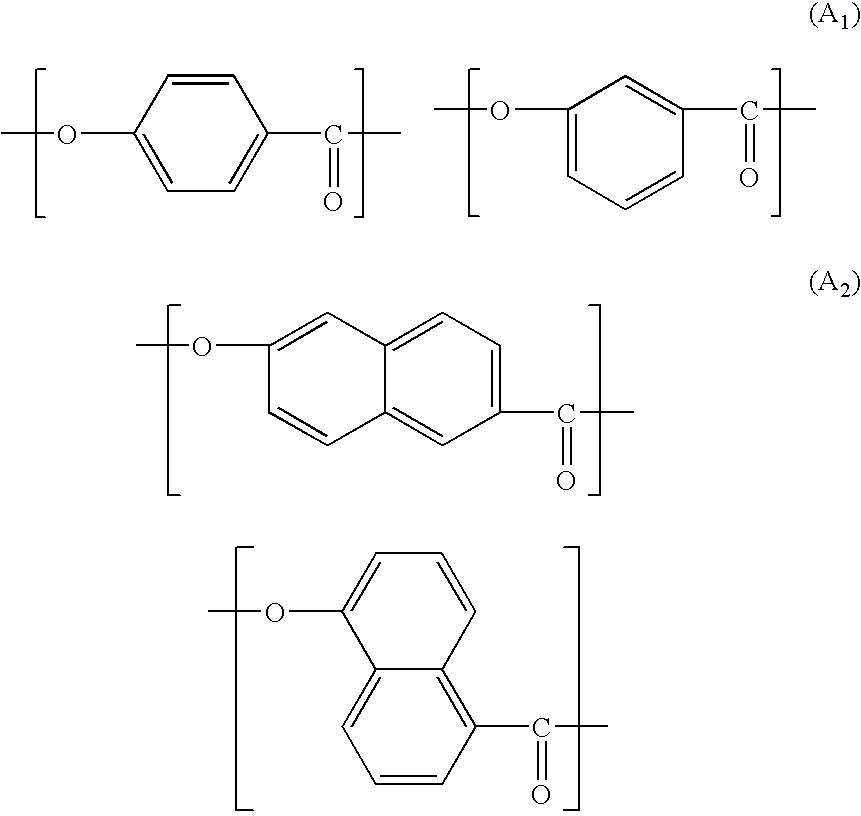

A liquid-crystalline polyester resin composition is provided including a liquid-crystalline polyester obtained by polymerizing monomers of an aromatic hydroxycarboxylic acid in the presence of an imidazole compound. The composition also includes a mica which is a muscovite and has a volume average particle diameter of 40 μm or less and a specific surface area of 6 m2 / g or less, the amount of the mica being 15 to 100 parts by weight based on 100 parts by weight of the liquid-crystalline polyester. The liquid-crystalline polyester resin composition has melt fluidity sufficient to be molded into a connector having an ultra-thin wall thickness portion. The resulting connector has sufficiently suppressed warp and sufficient soldering resistance.

Owner:SUMITOMO CHEM CO LTD

Liquid-crystalline polyester resin composition and connector using the same

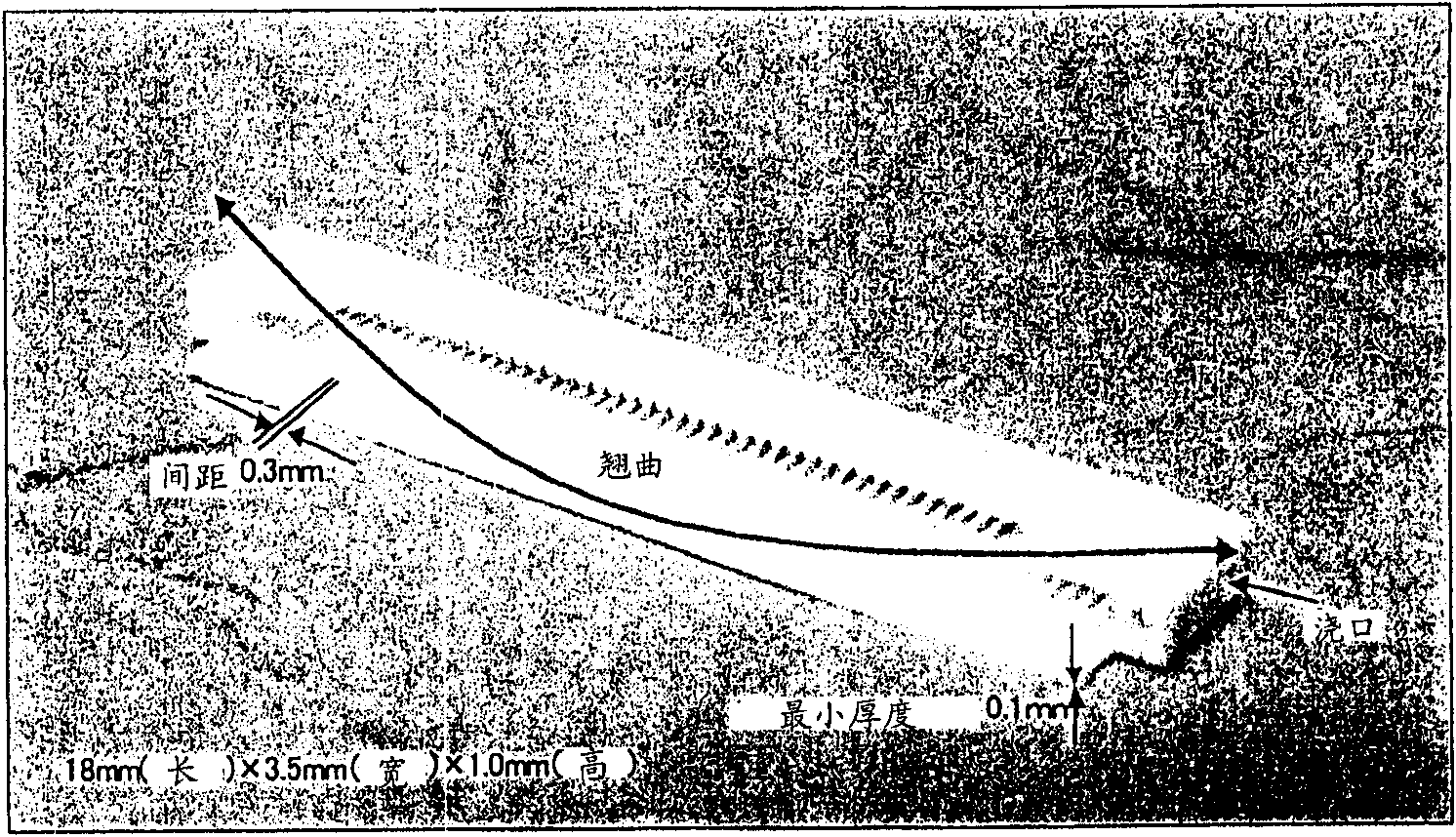

ActiveCN101875762AAdequate solder resistanceWarpage suppressionLiquid crystal compositionsCouplings bases/casesLiquid crystallineVolume average

A liquid-crystalline polyester resin composition is provided including a liquid-crystalline polyester obtained by polymerizing monomers of an aromatic hydroxycarboxylic acid in the presence of an imidazole compound. The composition also includes a mica which is a muscovite and has a volume average particle diameter of 40 [mu]m or less and a specific surface area of 6 m2 / g or less, the amount of the mica being 15 to 100 parts by weight based on 100 parts by weight of the liquid-crystalline polyester. The liquid-crystalline polyester resin composition has melt fluidity sufficient to be molded into a connector having an ultra-thin wall thickness portion. The resulting connector has sufficiently suppressed warp and sufficient soldering resistance.

Owner:SUMITOMO CHEM CO LTD

Light blue jun porcelain and firing method thereof

ActiveCN106045563ADoes not affect strengthHelp to combineCeramic materials productionCeramicwareTin dioxidePotassium

Owner:JIAXIAN HONGDA PORCELAIN CO LTD

Nanometer deodorant for purifying air and preparing method thereof

A nano-class deodoring agent for cleaning air is prepared from TiO2 nanoparticles, tourmalinite nanoparticles, muscovite nanoparticles, sodium silicate, sodium benzoate, sodium chloride, polyacrylamide, hydroxyethylene cellulose and propanetriol through ball grinding and baking. Its advantages are high effect to remove benzene, ammonia and formaldehyde by 60-80%, and short time (24hr).

Owner:万意群

Flocculating agent for treating sewage in Chinese patent medicine production enterprises and preparation method thereof

ActiveCN102887581ANot easy to recycleBiodegradableOther chemical processesWater/sewage treatment by flocculation/precipitationMedicinePhytic acid

The invention discloses a flocculating agent for treating sewage in Chinese patent medicine production enterprises, wherein the flocculating agent comprises the following compositions: 30-45% of carapace crushed materials, 3-12% of modified chitosan, 0.05-0.5% of nanometer titanium dioxide, 0.1-0.5% of phytic acid, and 45-55% of zeolite; in order to optimize the effect, the flocculating agent is also added with 1-5% of white mica and 1-5% of active carbon. The flocculating agent provided by the invention is utilized to treat the sewage; the flocculating agent provided by the invention has very high efficiencies of removing COD (chemical oxygen demand) and BOD (biochemical oxygen demand); and the flocculating agent provided by the invention is efficient and economical.

Owner:JIANGSU SHANGDA WATER AFFAIR

Modified tourmaline powder for ceramic glaze, anion ceramic glaze and preparation method

The invention relates to modified tourmaline powder for ceramic glaze, anion ceramic glaze and a preparation method, belonging to the technical field of ceramics. The anion ceramic glaze comprises the following raw materials in parts by mass: 20-30 parts of nepheline syenite, 5-8 parts of kaolin, 6.8-9.5 parts of muscovite, 6.2-7.8 parts of modified tourmaline powder, 3-6 parts of zinc oxide, 8-12 parts of light calcium carbonate, 4.6-5.7 parts of aluminum oxide, 1-4 parts of magnesium oxide, 2.5-4.8 parts of potassium oxide and 0.1-0.3 part of rubidium oxide. According to the invention, through the modification of tourmaline powder, the anion release amount of the tourmaline powder is effectively increased, and the surface polarity of the modified tourmaline is relatively low; and due to the stable dispersing performance of the tourmaline powder, the agglomeration phenomenon is avoided in the preparation of glaze slurry, and the ceramic products get a good anion function.

Owner:FUJIAN WILL CERAMIC CO LTD

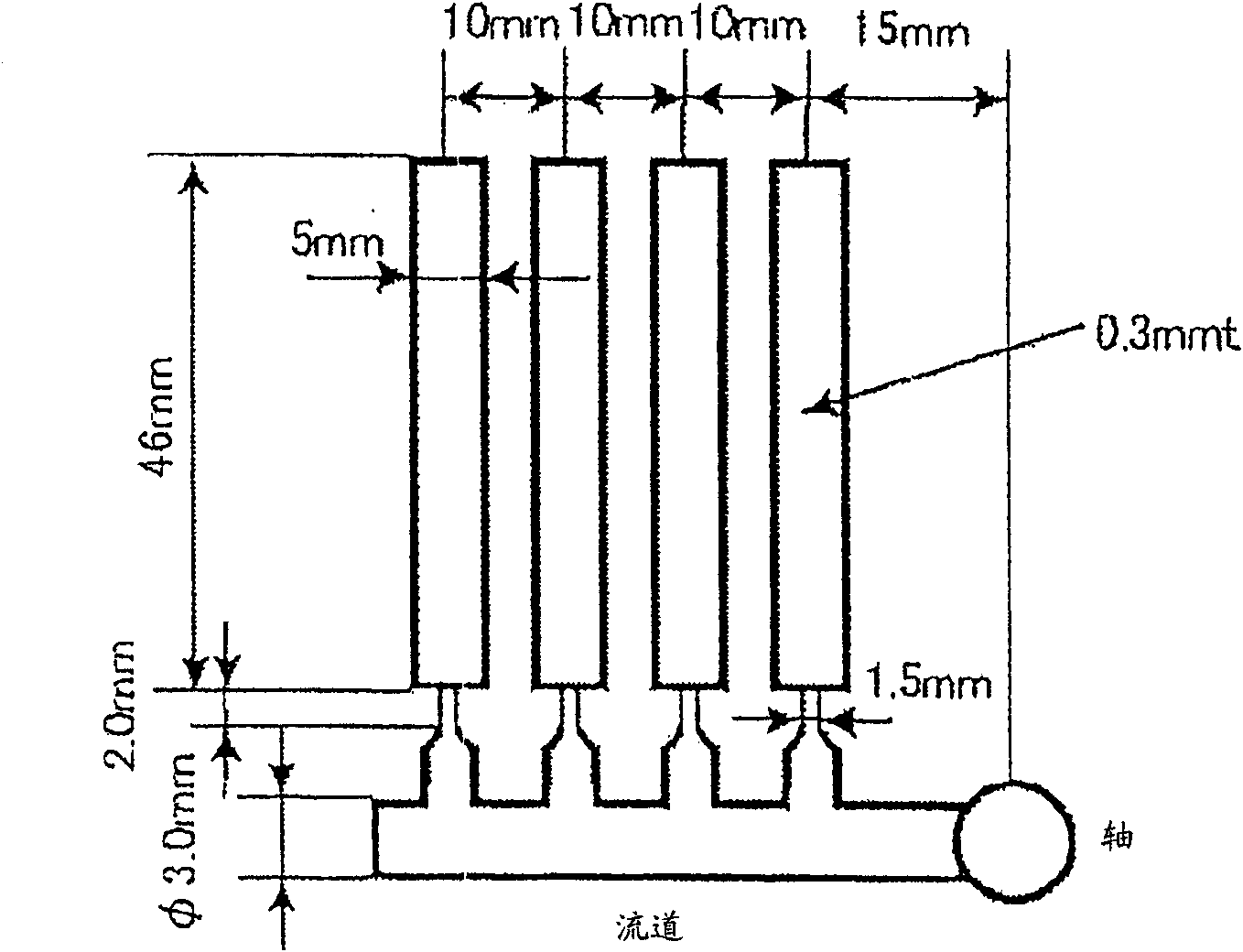

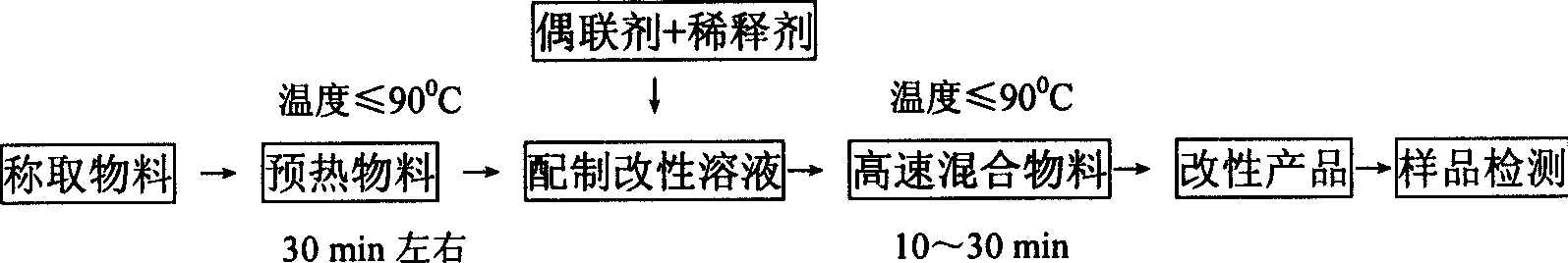

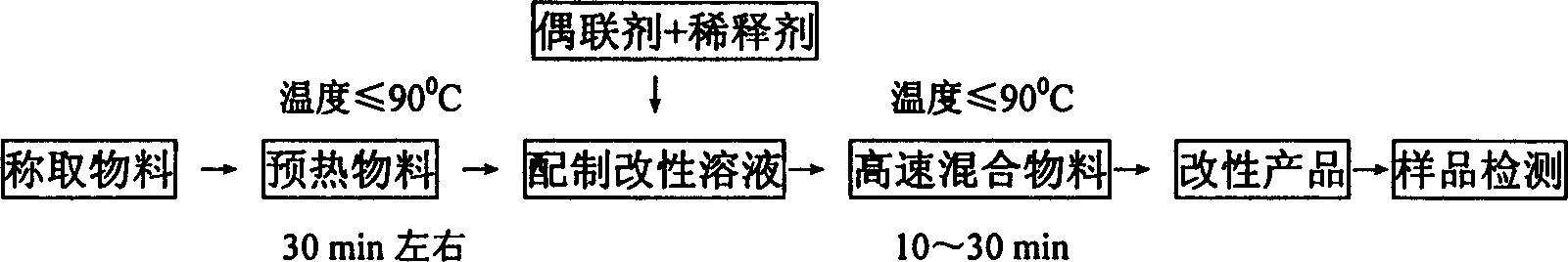

Titanate KR-38S surface modified micro-crystal white mica active filler preparing method

The invention discloses a kind of preparation method of the titanate KR-38S surface modified minicrystal muscovite active fille and chooses muscovite as raw material. The technics is as follows: weigh minicrystal muscovite and then put it into high-speed mizer; heat the material, whisk it in the high-speed mixer for 30 minutes and adjust the temperature no higher than 90deg.C; weigh the thinner of titanate, acetone, in amounts of weight, titanate:acetone=1:1-3; weigh titanate KR-38S, material: titanate=100:0.4-3.9; confect the titanate surface modified solution, put the titanate into the container with thinner of acetone and whisk it until being well-proportioned; mix the material in high gear, put the titanate surface modified solution into the high-speed mixer and whisk it for between 10min and 30min and control the temperature no more than 90deg.C. It is featured by abundant resource, low cost, convenient technics, wide use and obvious economic and social effects.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

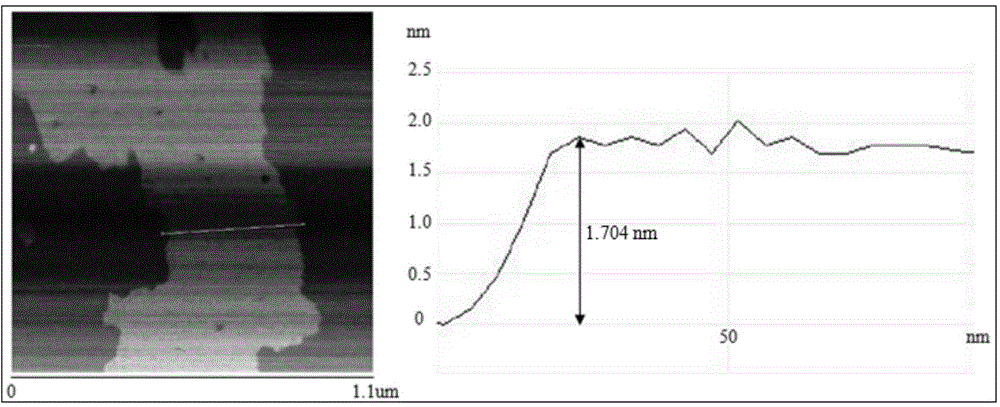

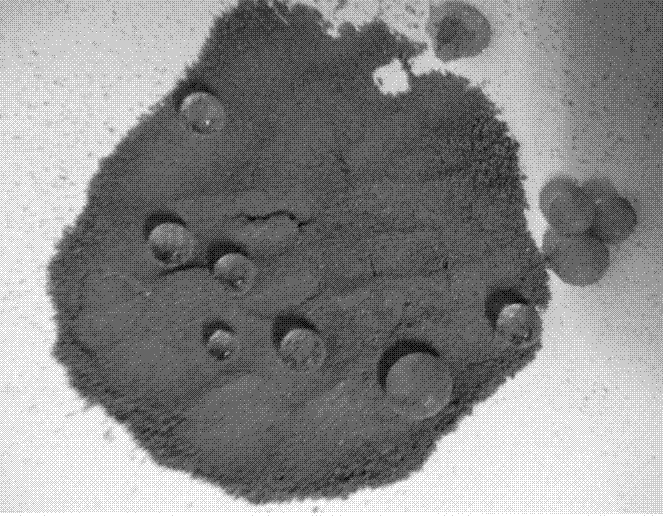

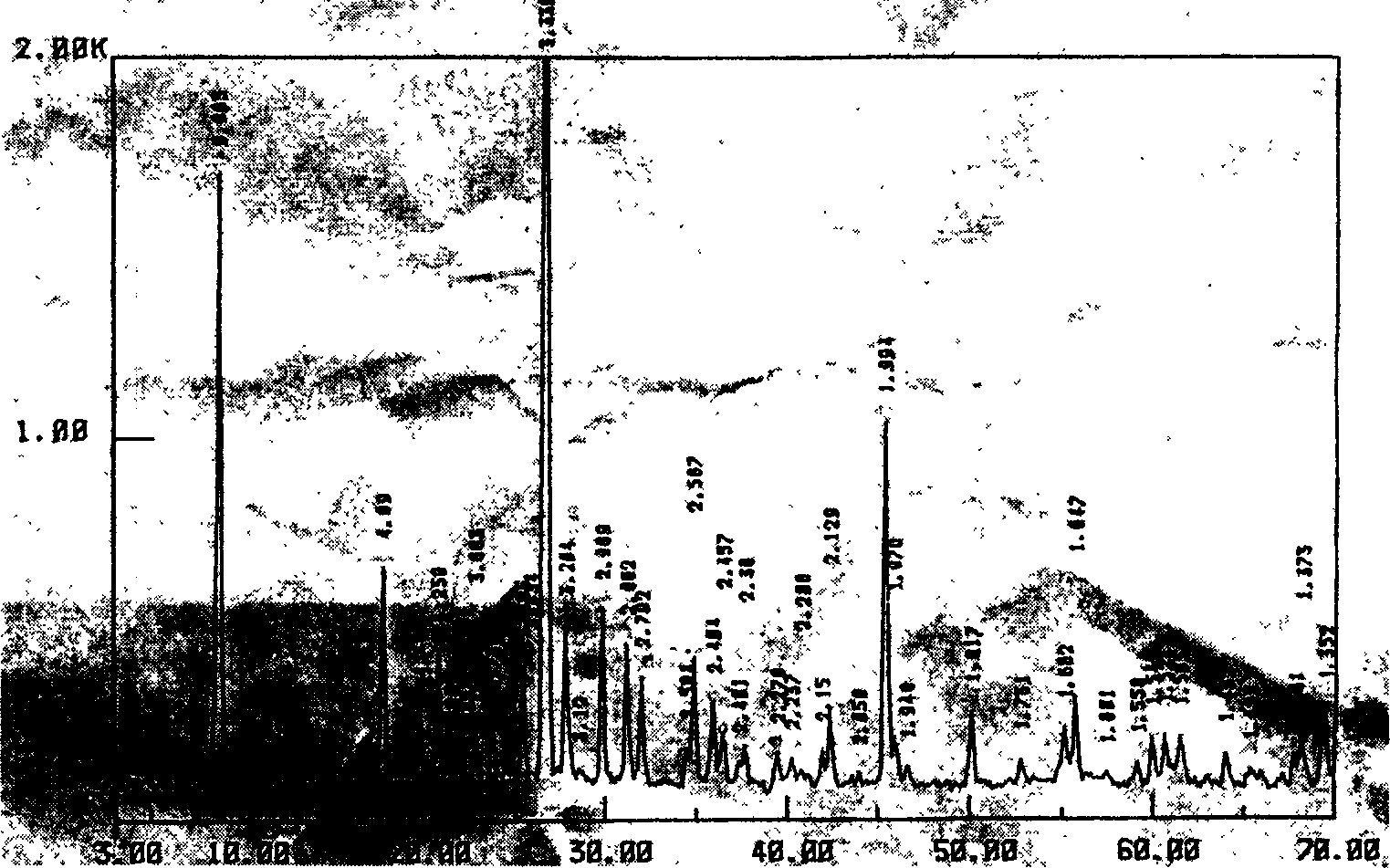

Preparation method of two-dimensional nano muscovite

ActiveCN104445235AIncrease spacingLow costMaterial nanotechnologyAluminium silicatesFreeze-dryingIon exchange

The invention relates to a method for preparing two-dimensional nano muscovite. The method comprises the following steps: heating muscovite powder in a roasting furnace to 650-750 DEG C at 5-50 DEG C / min, calcining for 2-5h, naturally cooling, exchanging all potassium ions among the lamellas of the calcined muscovite by virtue of positive ions, washing and freeze-drying, and processing the muscovite by virtue of a mechanical process for 20min-5h so as to obtain the two-dimensional nano muscovite. The preparation method disclosed by the invention has the beneficial effects that by virtue of calcining and ion exchange, the inter-lamellar spacing of the muscovite is increased and the inter-lamellar force is weakened, and the inter-lamellar force is destructed by virtue of the mechanical process, so that the muscovite exists in the form of a single lamella or a few of lamellas and therefore, the two-dimension nano muscovite is prepared. The preparation method is low in cost, rapid and effective. The method is good in stripping effect, and the thickness of the prepared two-dimension nano muscovite can reach atomic grade. A tearing method by the viscosity of an adhesive tape and a hand-tearing method are suitable for preparing the two-dimension nano muscovite with controllable thickness in a small quantity, and a grinding method and an ultrasonic method are suitable for preparing the two-dimension nano muscovite on a large scale.

Owner:WUHAN UNIV OF TECH

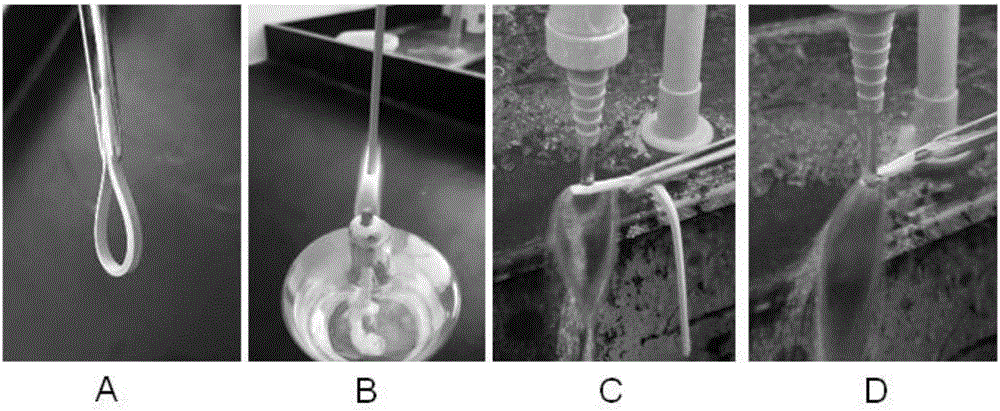

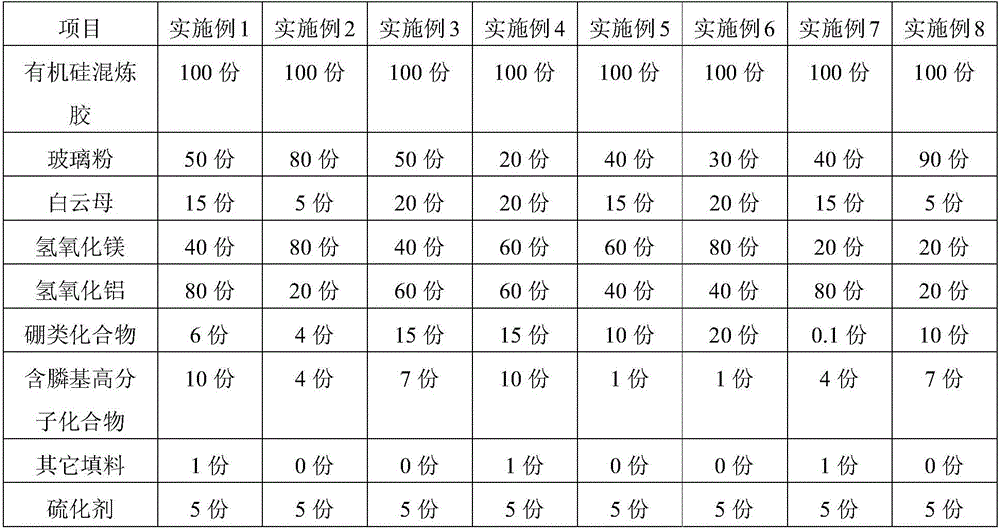

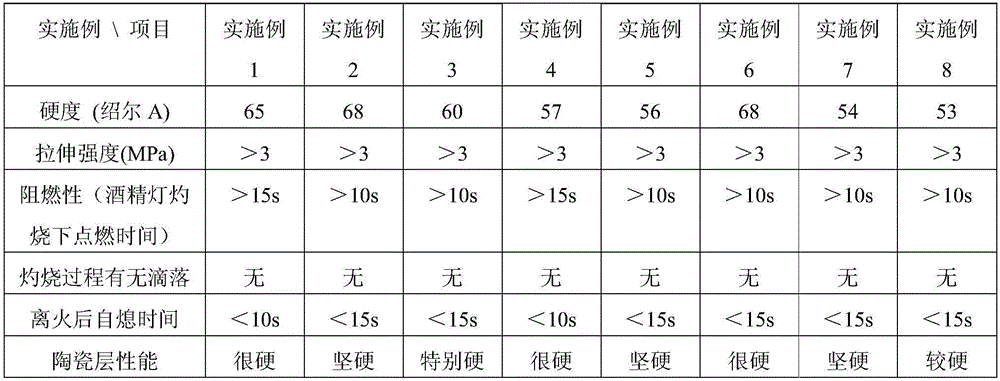

Flame-retardant and drippage-free ceramization silicon rubber and preparation method thereof

ActiveCN105884267AGood physical and mechanical propertiesThe process is simple and easy to controlAluminium hydroxideEconomic benefits

The invention relates to flame-retardant and drippage-free ceramization silicon rubber and a preparation method thereof. The silicon rubber is prepared from components in parts by weight as follows: 100 parts of organic silicon rubber compounds, 1 part to 10 parts of a vulcanizing agent, 100 parts to 150 parts of ceramization powder and 0 to 100 parts of other filler or auxiliaries, wherein the ceramization powder is prepared from raw materials in parts by weight as follows: 1 part to 120 parts of glass powder, 1 part to 20 parts of muscovite, 1 part to 200 parts of magnesium hydroxide, 1 part to 200 parts of aluminum hydroxide, 0.1 parts to 50 parts of boron compounds and 0.1 parts to 20 parts of phosphono-containing polymer compounds. The ceramization silicon rubber prepared with the method has advantages of good flame retardance and self-extinguishment performance; a ceramic layer formed after firing has good compactness and insulativity, external force resistance and the like. The preparation process is simple, raw materials are cheap, and accordingly the silicon rubber is expected to be applied to fields such as wires and cables, the electronic and electrical technology, aerospace engineering and the like and has quite good economic benefits and popularization value.

Owner:SHANDONG UNIV

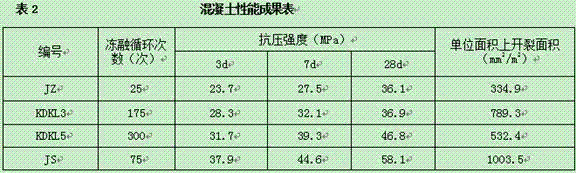

Concrete anti-freezing and anti-cracking agent

The invention discloses a concrete anti-freezing and anti-cracking agent. The concrete anti-freezing and anti-cracking agent is formed by mixing 95 parts by weight of hydrophobic modified mica powder with 5 parts of nano silicon dioxide. Hydrophobic modified mica is prepared by a method comprising the following steps: first step, drying white mica or bronze mica; step two, pulverizing the white mica or the bronze mica into flaky micro-powder of which the granularity is 80 mu m, the screen residues are 15% or below and the thickness is 2.5 mu m; and third step, after mixing a silane coupling agent, methylsilicone oil and white mica powder or bronze mica powder which is prepared in the second step according to a formula, carrying out modification treatment on the mixture at the temperature of 150 DEG C, and the pulverizing the mixture to obtain the finished hydrophobic modified mica powder. The shrinkage of the concrete added with the anti-freezing and anti-cracking agent is greatly reduced, and the anti-cracking property is greatly improved.

Owner:YELLOW RIVER ENG CONSULTING +1

Liquid-crystalline polyester resin composition and connector using the same

ActiveUS20100163796A1Sufficient soldering resistanceSufficiently suppressed warpLiquid crystal compositionsMicaLiquid crystallineShell molding

A liquid-crystalline polyester resin composition is provided including a liquid-crystalline polyester obtained by polymerizing monomers of an aromatic hydroxycarboxylic acid in the presence of an imidazole compound. The composition also includes a mica which is a muscovite and has a volume average particle diameter of 40 μm or less and a specific surface area of 6 m2 / g or less, the amount of the mica being 15 to 100 parts by weight based on 100 parts by weight of the liquid-crystalline polyester. The liquid-crystalline polyester resin composition has melt fluidity sufficient to be molded into a connector having an ultra-thin wall thickness portion. The resulting connector has sufficiently suppressed warp and sufficient soldering resistance.

Owner:SUMITOMO CHEM CO LTD

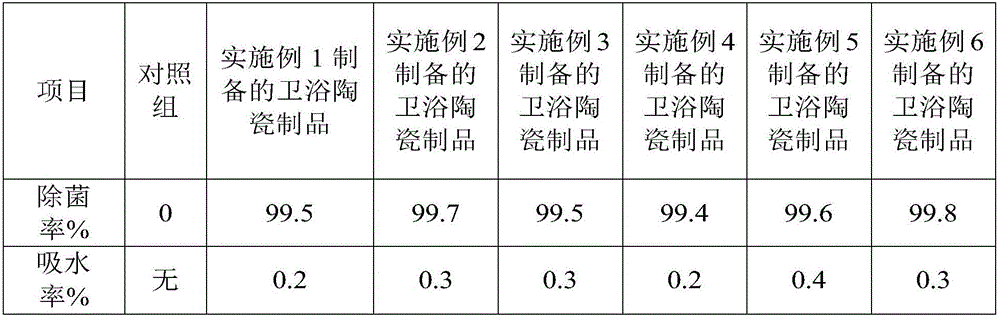

Antibacterial bathroom ceramic article and preparation method thereof

The invention discloses an antibacterial bathroom ceramic article and a preparation method thereof. The antibacterial bathroom ceramic article comprises a billet and glaze, wherein the billet is prepared from talcum, kaolin, anorthite, bauxite, muscovite, ilmenite, wollastonite, chlorite and silicon nitride; and the glaze is prepared from talcum, anorthite, borax, zirconium silicate, titanium dioxide, zinc oxide and nano silver. The preparation method comprises the following steps: pulverizing the raw materials of the billet, and screening to obtain the billet raw material; carrying out wet-process ball milling on the billet raw material, aging by standing, carrying out injection molding, demolding, drying, and carrying out bisque firing to obtain the billet; mixing and pulverizing the talcum, anorthite and borax, adding the nano silver and dilute nitric acid, drying, and adding the zirconium silicate, titanium dioxide and zinc oxide to obtain a glaze material; carrying out wet-process ball milling on the glaze material, aging by standing, spraying on the billet surface to obtain an article to be fired; and carrying out glaze firing on the article to be fired, thereby obtaining the antibacterial bathroom ceramic article. The antibacterial bathroom ceramic article has the advantages of favorable weather resistance, favorable antibacterial property and low water absorptivity.

Owner:张海淼

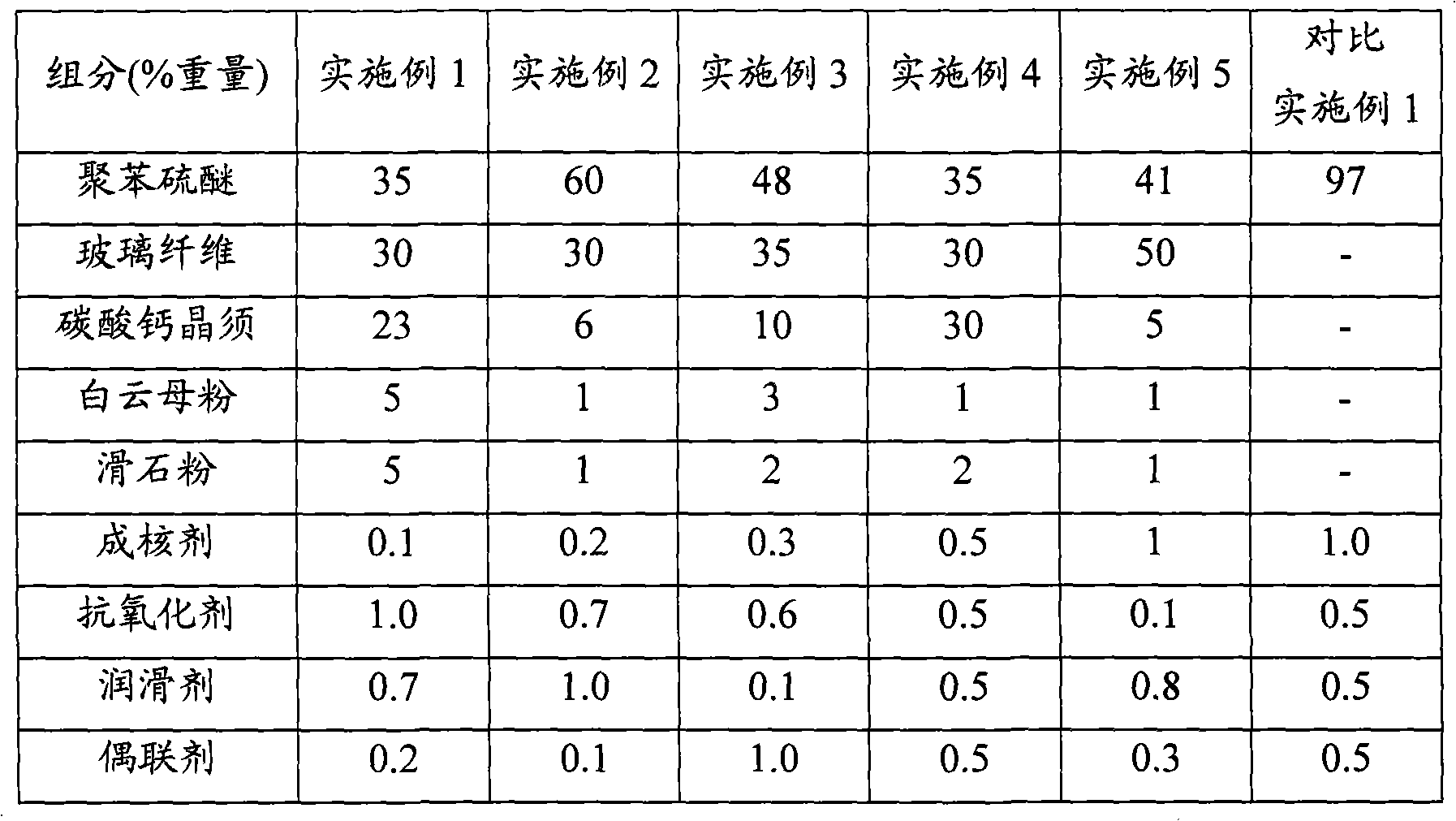

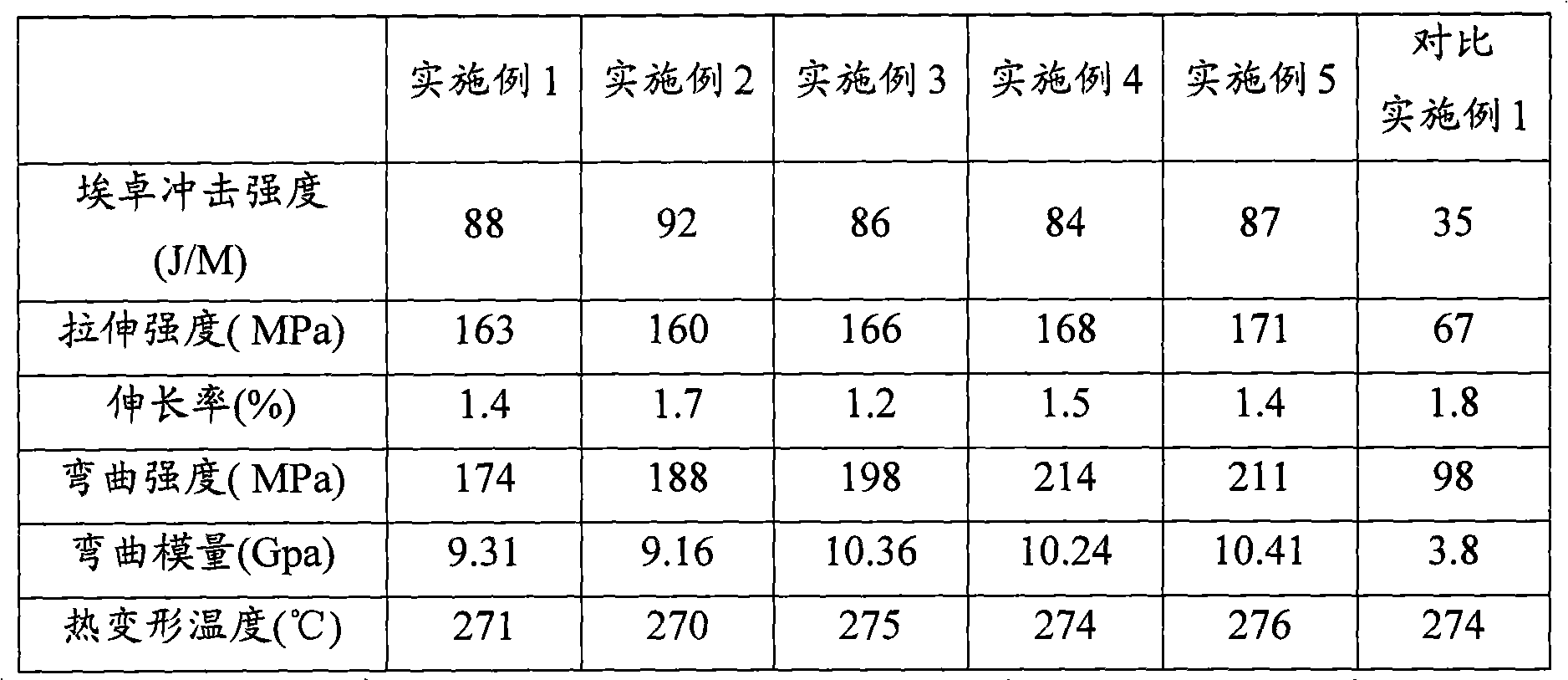

Composite polyphenylene sulfide resin and preparation method thereof

The invention provides a composite polyphenylene sulfide resin which is prepared from the following raw materials in weight percent: 35-60% of polyphenylene sulfide, 30-50% of glass fiber, 5-30% of calcium carbonate whisker, 1-5% of muscovite powder, 1-5% of talc powder, 0.1-1% of nucleating agent, 0.1-1% of antioxidant, 0.1-1% of lubricant and 0.1-1% of coupling agent. The preparation method of the composite polyphenylene sulfide resin comprises the following steps: a. premixing the raw materials apart from the glass fiber in a mixer; b. extruding the premixed raw materials by a double-screw extruder; c. after the premixed raw materials are extruded from an extruder head, adding the glass fiber to the raw materials from a glass fiber opening; and d. cooling and palletizing. The composite polyphenylene sulfide resin of the invention has excellent mechanical property, simple preparation method and low cost.

Owner:SHENZHEN HALCYON NEW MATERIALS

Heat-insulating coating for outer walls

The invention discloses a heat-insulating coating for outer walls. The heat-insulating coating is prepared from raw materials in parts by weight as follows: 15-30 parts of hollow ceramic microspheres, 10-20 parts of diatomite, 10-25 parts of coarse whiting, 8-18 parts of talc powder, 15-30 parts of muscovite, 5-12 parts of titanium dioxide, 3-10 parts of zinc oxide, 2-10 parts of an elastic acrylic emulsion, 1-8 parts of hydroxyl cellulose, 1-5 parts of an aid and 80-150 parts of water. The prepared coating can effectively reduce temperatures of surfaces of the outer walls of buildings and indoor temperatures, has the good heat-insulating effect, is high in bonding strength to wall bodies, greatly improves heat-insulating, waterproof and corrosion-resistant functions of the wall bodies, and prolongs service lives of the wall bodies.

Owner:韦棋

Nanometer composite material of polyester and abio-silicate and preparing method thereof

InactiveCN1504509AHigh molecular weightIncreased overall crystallization rateChemical LinkagePolytetramethylene terephthalate

The invention provides a polyester and inorganic silicate nano composite material and method for making it, wherein the inorganic silicate metallic oxide prepared by porcelain clay and muscovite is first pre-processed for reaction, then is placed in polymerization reaction device along with polytetramethylene terephthalate (PET) for condensation copolymerization, thus obtaining the high-performance polyethylene glycol terephthalate alcohol and inorganic salt nano composite material integrating inorganic silicate and polyester base through chemical bonds dispersed evenly in nano scale.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Silicon rubber-based heat-resistant composite material and preparation method thereof

ActiveCN106977925ALower melting temperatureImprove performance during ablation resistanceFiberModified carbon

The invention relates to a silicon rubber-based heat-resistant composite material and a preparation method thereof. The silicon rubber-based heat-resistant composite material is a silicon rubber-based heat-resistant porcelainized composite material, and is prepared from the following components in parts by weight: 100 parts of raw methyl vinyl silicone rubber, 20 to 30 parts of fumed silica, 5 to 10 parts of modified carbon fiber, 30 to 40 parts of muscovite, 10 to 15 parts of zirconium dioxide, 15 to 20 parts of fluxing agent and 1 to 2 parts of vulcanizing agent. The preparation method comprises the following steps of uniformly blending in a open mill or a closed mill; after uniformly blending, performing primary vulcanizing and forming in a flat plate vulcanizing machine; performing secondary vulcanizing and forming in an air blowing drying box, so as to obtain the silicon rubber-based heat-resistant composite material. The silicon rubber-based heat-resistant porcelainized composite material prepared by the method has the advantages that by using the modified carbon fiber, the zirconium dioxide and the muscovite as the heat-resistant ceramic forming material, the heat-resistant property of the composite material is effectively improved, and the strength of a pyrolysis product is improved; the technology is simple, the production efficiency is high, and the industrialized batched production is easily realized.

Owner:WUHAN UNIV OF TECH

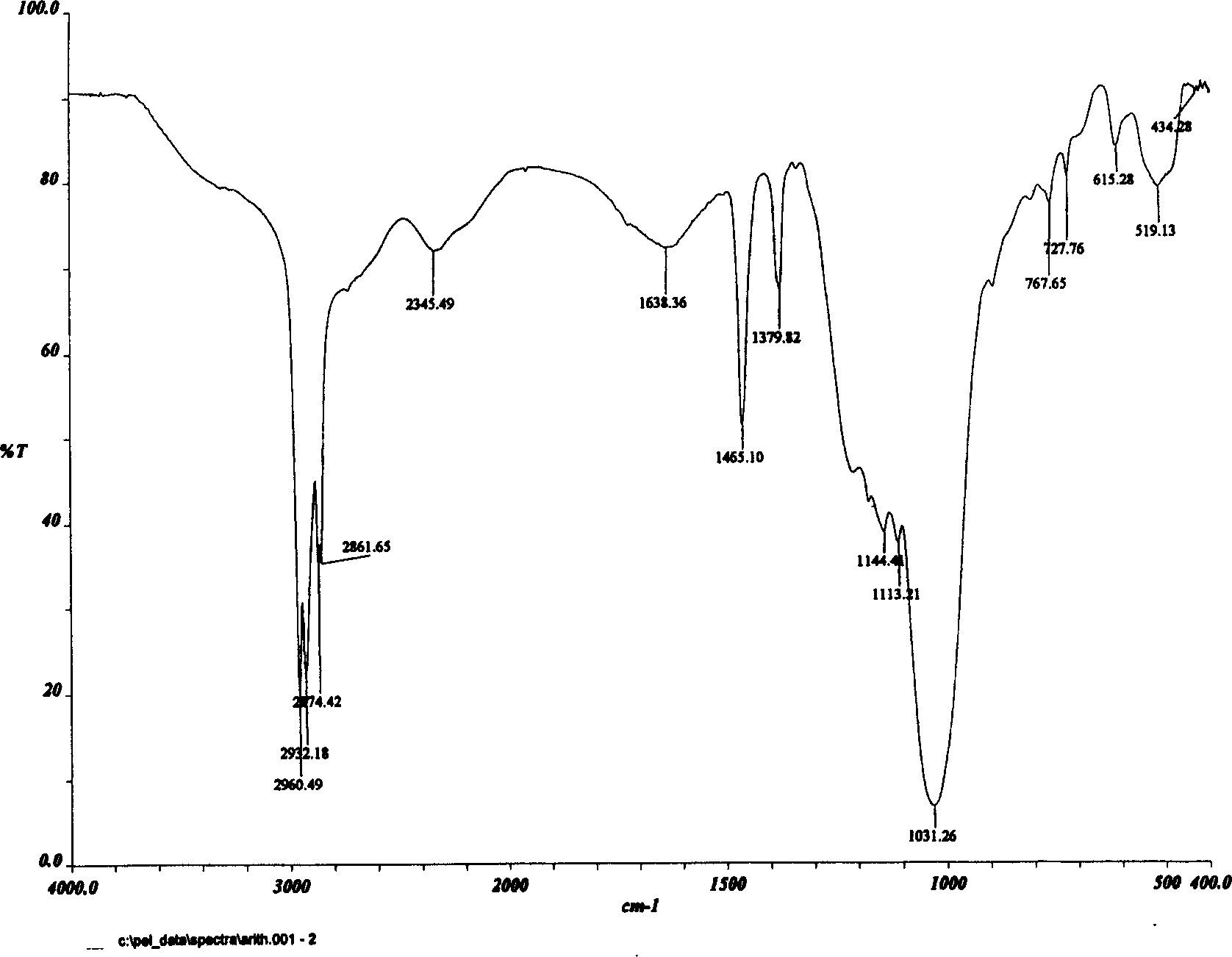

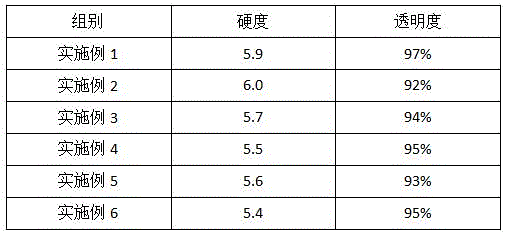

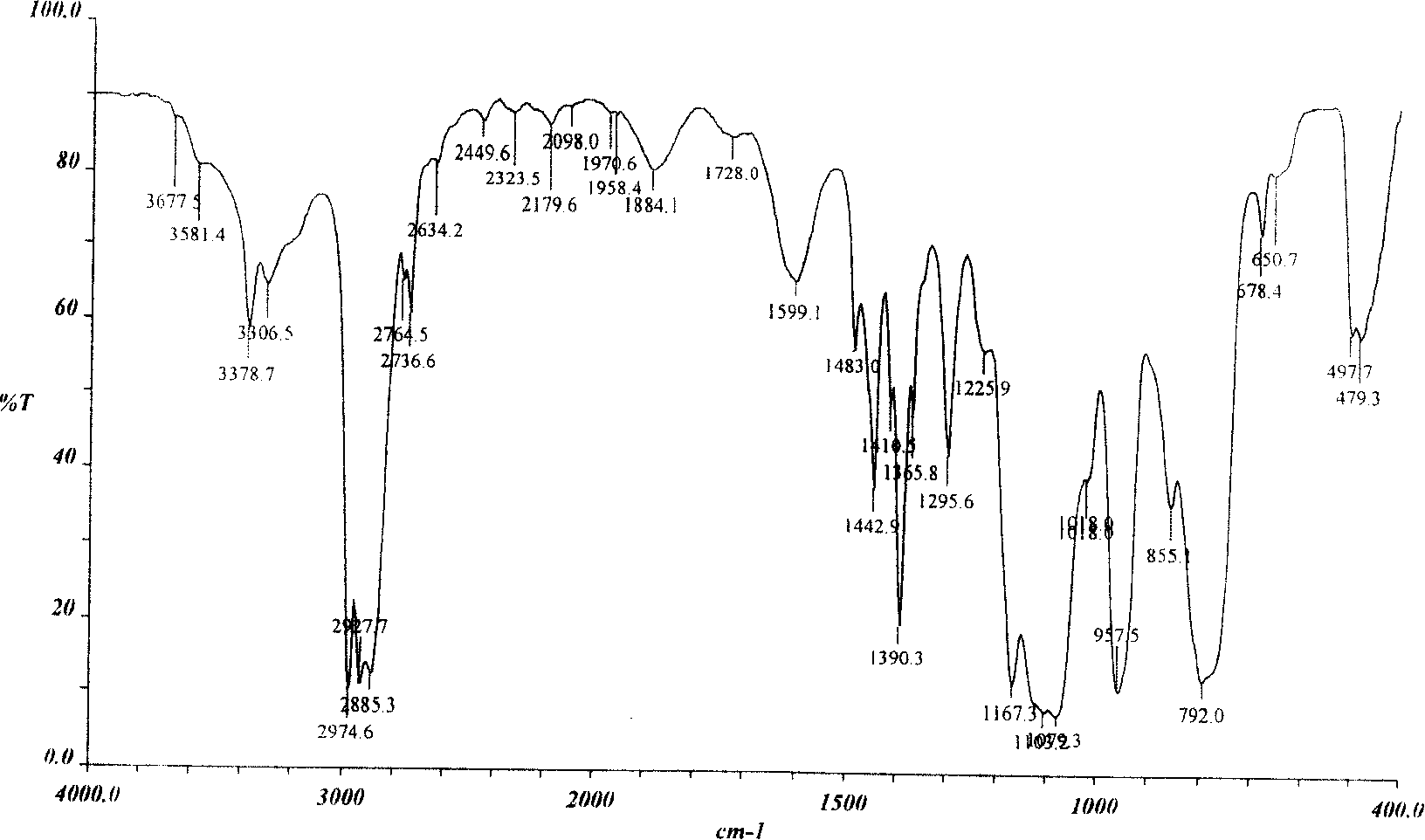

Method for composite modification of microcrystalline antonite powder using methacryloxypropyl silane and aluminate

InactiveCN101323716AGood dispersionImprove liquidityPigment treatment with organosilicon compoundsAluminateBiological activation

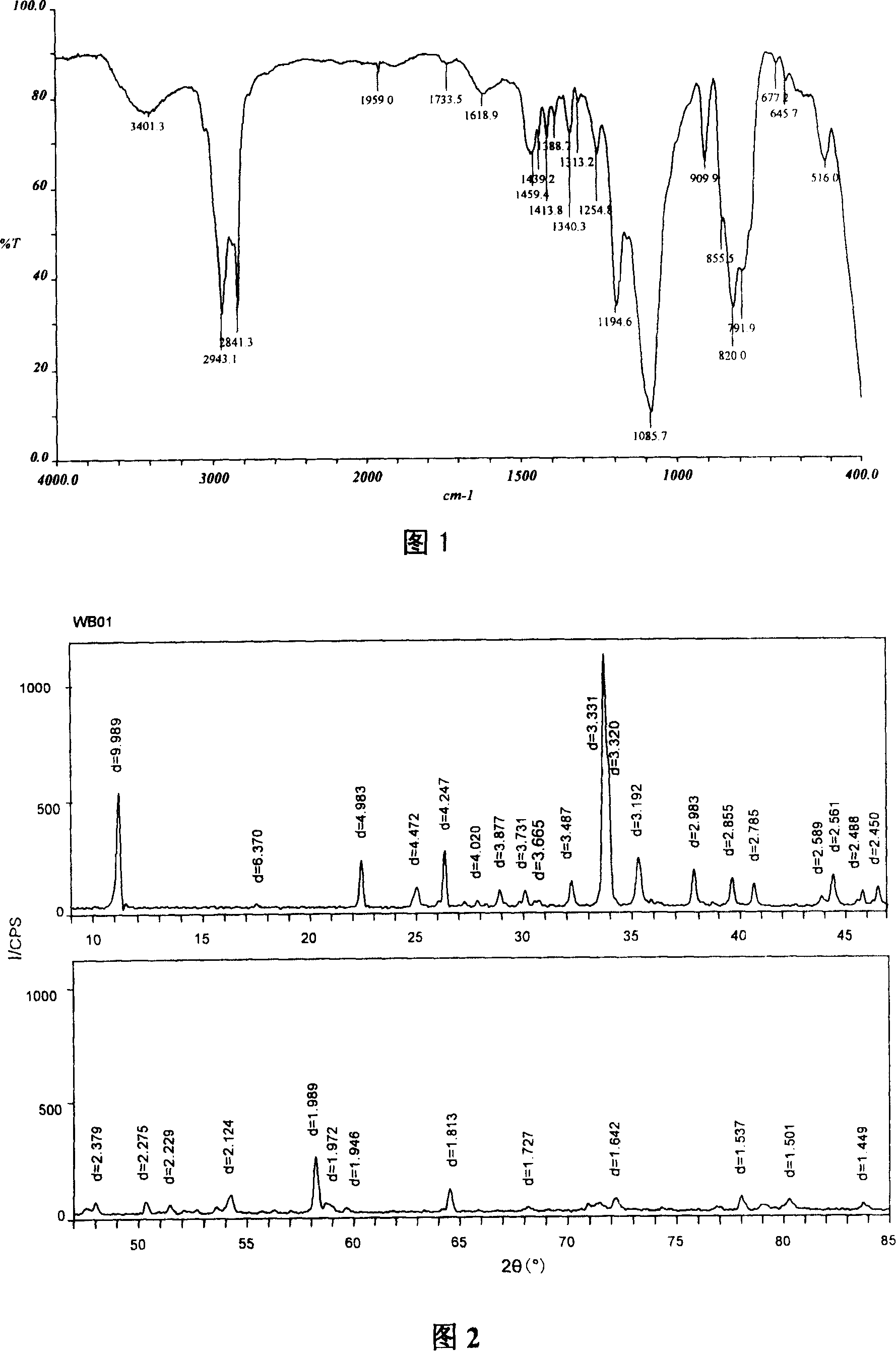

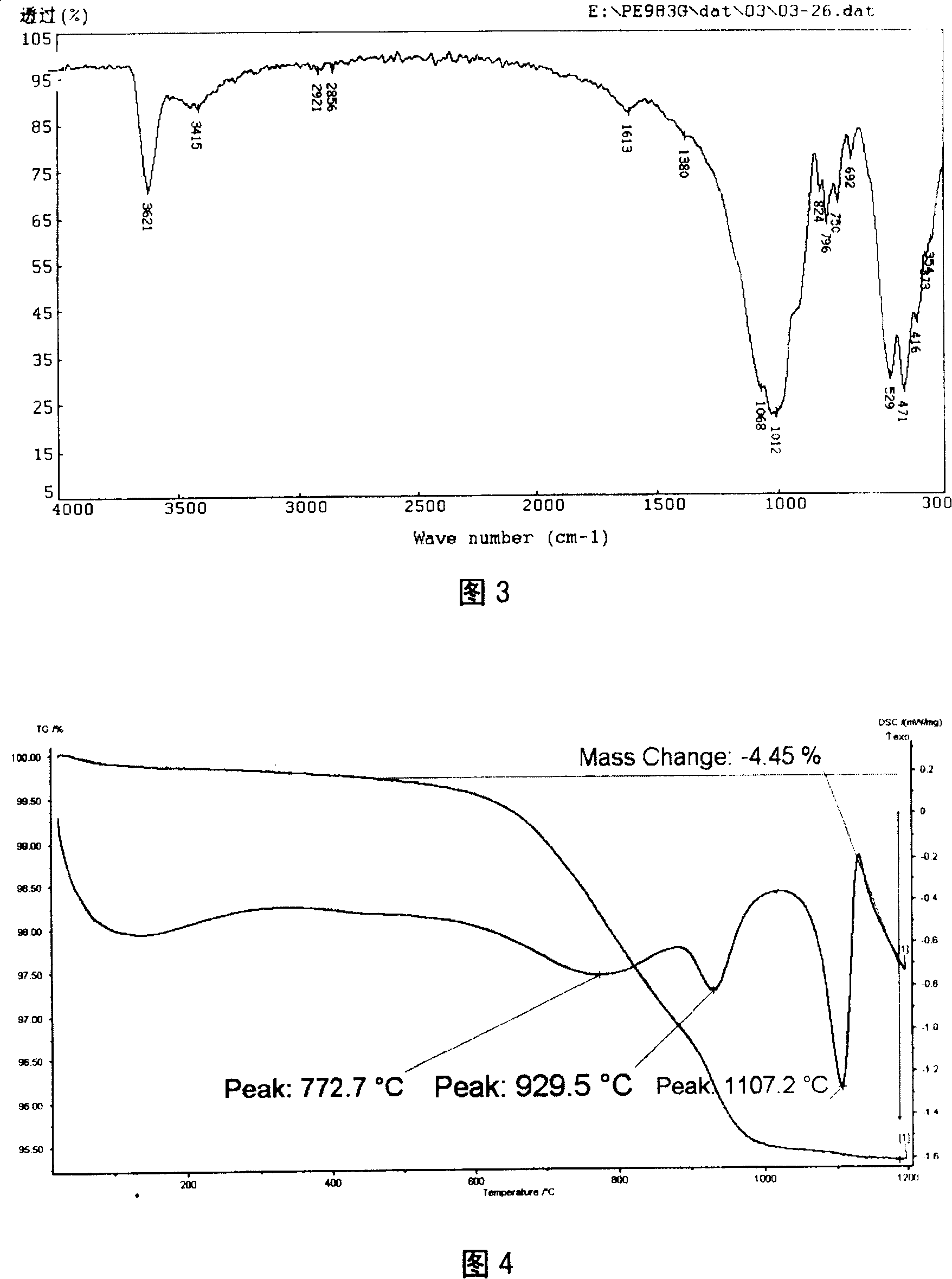

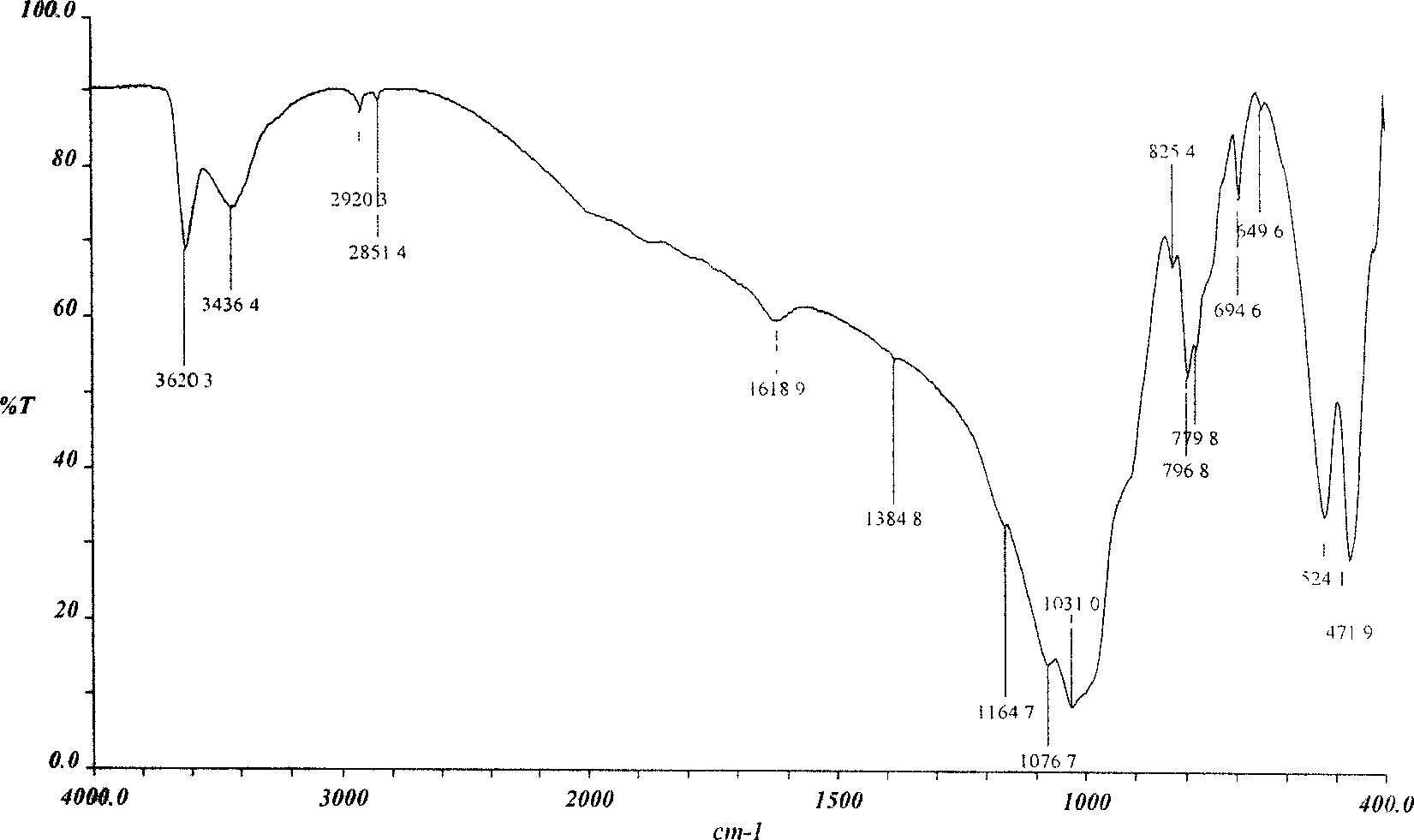

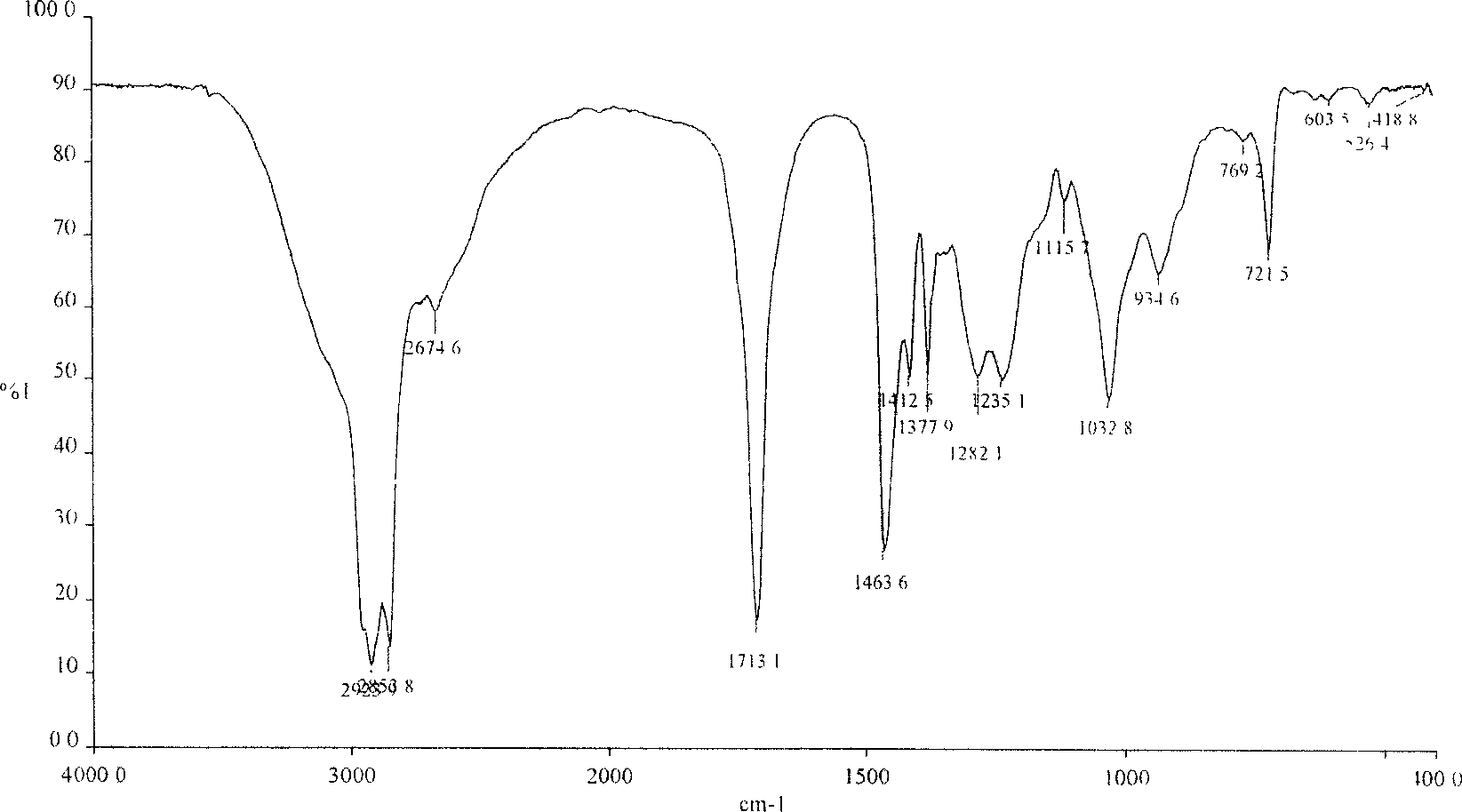

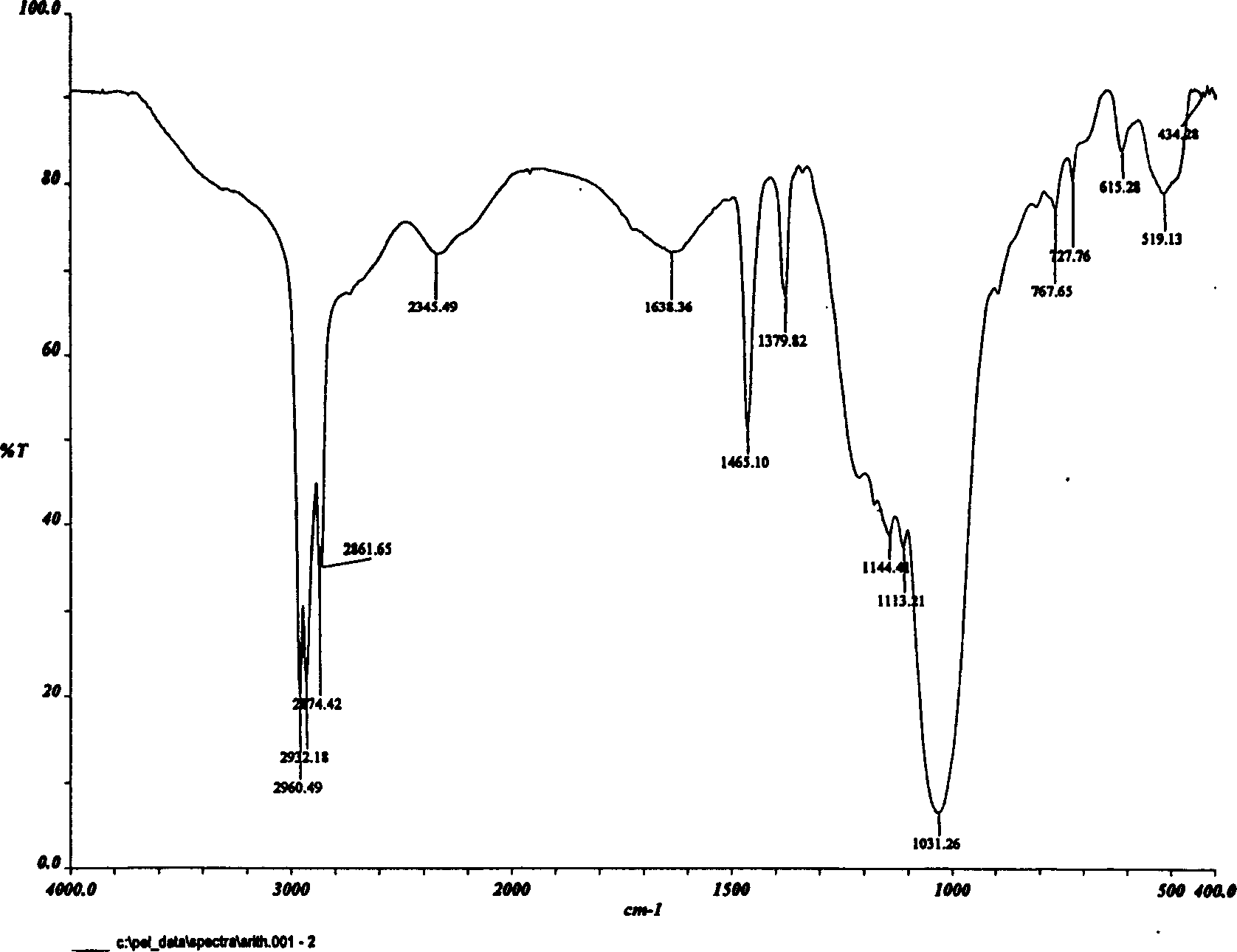

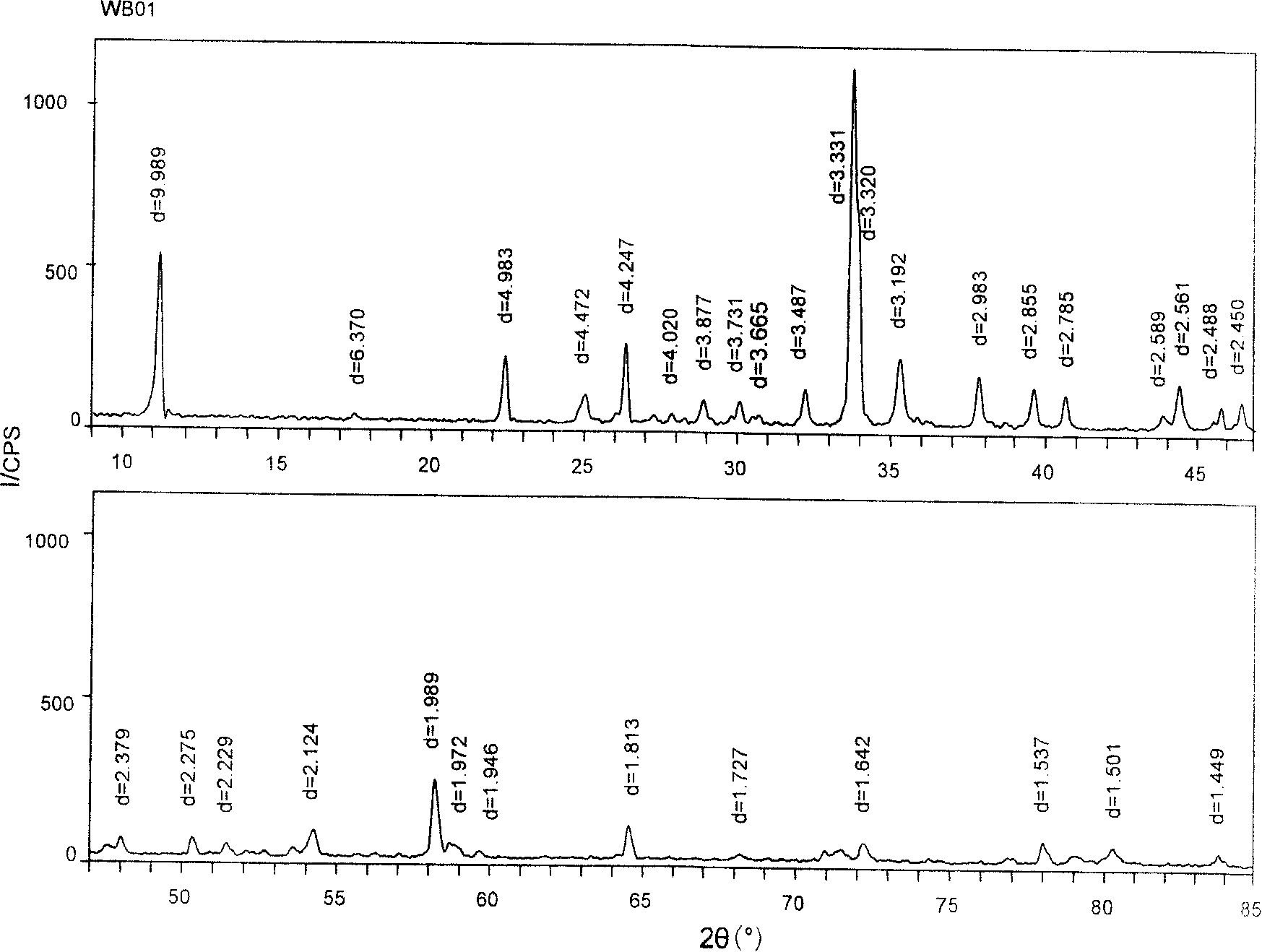

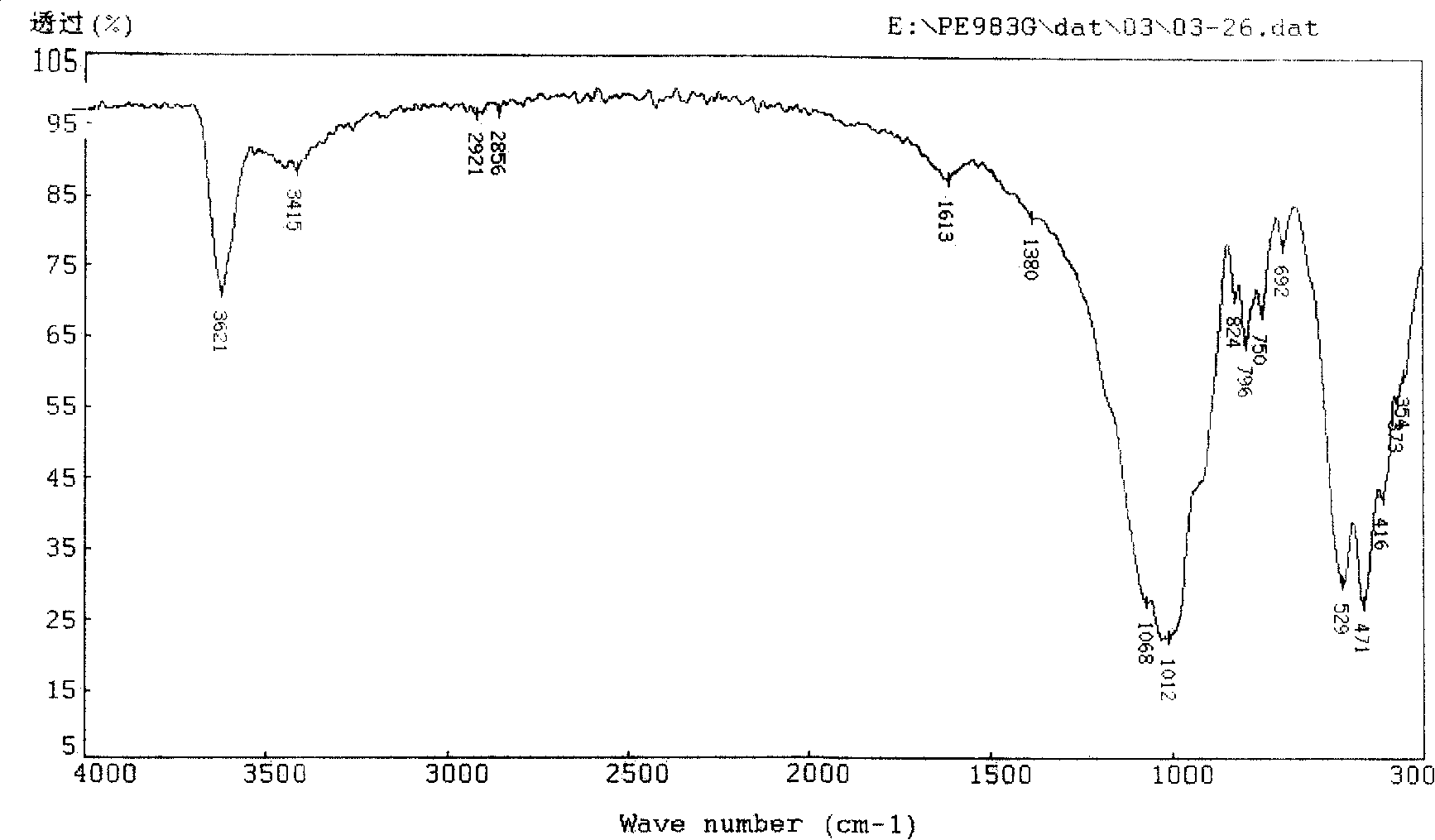

The invention relates to a technical method for complexly modifying micro-crystal muscovite powder by adopting a gamma-methyl propylene acyloxy propyl trimethoxy silicane coupling agent and an aluminate coupling agent. The method of the invention takes the micro-crystal muscovite powder as raw material, and the gamma-methyl propylene acyloxy propyl trimethoxy silicane coupling agent and the aluminate coupling agent as modifiers, and utilizes a mechanochemical modification method to complexly modify the micro-crystal muscovite powder by the mutual winding and crosslinking functions of the gamma-methyl propylene acyloxy propyl trimethoxy silicane coupling agent and the aluminate coupling agent. Compared with the micro-crystal muscovite powder modified by the single gamma-methyl propylene acyloxy propyl trimethoxy silicane coupling agent or the single aluminate coupling agent, the modified micro-crystal muscovite powder complexly has obviously improved compatibility with organic polymers, processing flow property and decentrality. Meanwhile, the infrared absorption spectroscopy of the modified micro-crystal muscovite products shows that the gamma-methyl propylene acyloxy propyl trimethoxy silicane coupling agent and the aluminate coupling agent are coated on the surface of the micro-crystal muscovite powder and carry out coupling activation with the micro-crystal muscovite powder materials in a certain way.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

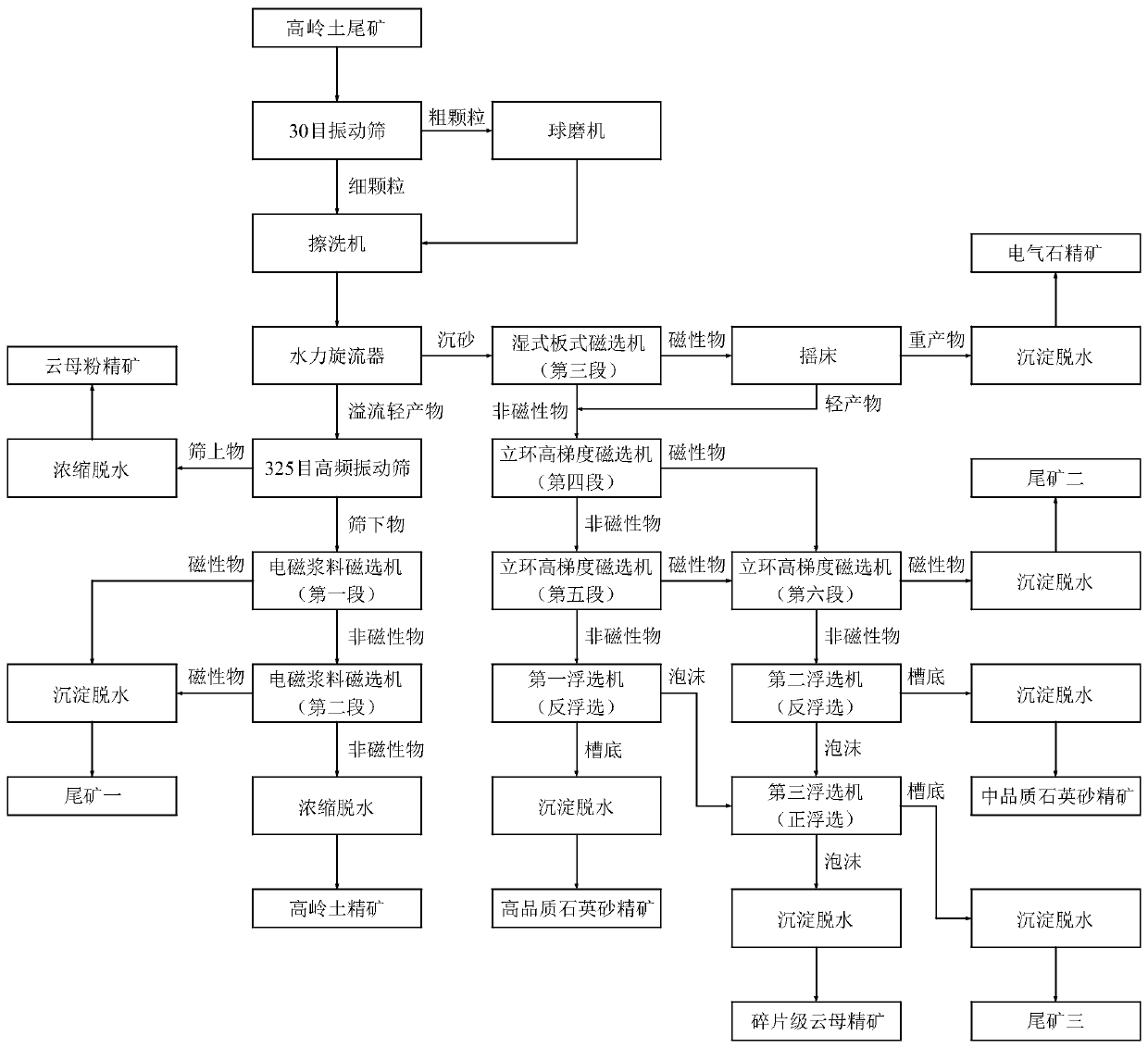

Comprehensive utilization method of sandy kaolin tailings containing tourmaline, muscovite and quartz sand

ActiveCN110201791AEffective control of granularityImprove recycling ratesSolid separationMechanical material recoveryKaolin claySlurry

The invention discloses a comprehensive utilization method of sandy kaolin tailings containing tourmaline, mica and quartz sand. The method comprises the following steps that after the sandy kaolin tailings are subjected to screening operation, various products such as mica powder, kaolin, the tourmaline, fragment-grade mica, quartz sand, and magnetic tailings are separated through grinding of coarse products, stirring and rinsing of fine products, hydrocyclone classification, high-frequency vibrating screen screening, and magnetic separation, gravity separation and flotation combined beneficiation process flows by using an electromagnetic slurry magnetic separator, a wet-type plate magnetic separator, a vertical-ring high-gradient magnetic separator, a shaking table, a flotation machine and like. According to the method, the magnetic separation, the gravity separation and the flotation combined beneficiation process is adopted, concentrate products such as the high-quality quartz sand, the tourmaline, and the mica are obtained, meanwhile, the residual kaolin products are recovered; and magnetically separated ferric silicate minerals can be used as building materials or cement rawmaterials, the comprehensive recovery utilization rate of secondary resources of the kaolin tailings is improved to the greatest extent, zero discharge of the tailings is achieved, and high economicaland social benefits are achieved as well.

Owner:SHANDONG HUATE MAGNET TECH

Method for composite modification of microcrystalline antonite powder using epoxy silane and aluminate

InactiveCN101323715AGood dispersionImprove liquidityPigment treatment with organosilicon compoundsBiological activationAbsorption spectroscopy

The invention relates to a technical method for complexly modifying micro-crystal muscovite powder by adopting a gamma-(2, 3-epoxy propoxy) propyl trimethoxy silicane coupling agent and an aluminate coupling agent. The method of the invention takes the micro-crystal muscovite powder as raw material, and the gamma-(2, 3-epoxy propoxy) propyl trimethoxy silicane coupling agent and the aluminate coupling agent as modifiers, and utilizes a mechanochemical modification method to complexly modify the micro-crystal muscovite powder by the mutual winding and crosslinking functions of the gamma-(2, 3-epoxy propoxy) propyl trimethoxy silicane coupling agent and the aluminate coupling agent. Compared with the micro-crystal muscovite powder modified by the single gamma-(2, 3-epoxy propoxy) propyl trimethoxy silicane coupling agent or the single aluminate coupling agent, the modified micro-crystal muscovite powder complexly has obviously improved compatibility with organic polymers, processing flow property and decentrality. Meanwhile, the infrared absorption spectroscopy of the modified micro-crystal muscovite products shows that the gamma-(2, 3-epoxy propoxy) propyl trimethoxy silicane coupling agent and the aluminate coupling agent are coated on the surface of the micro-crystal muscovite powder and carry out coupling activation with the micro-crystal muscovite powder materials in a certain way.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Multifunctional environment-friendly woodware waterborne putty coating

InactiveCN103952081AHas acid and alkali resistanceCorrosion resistantCoatingsAdhesion forceWollastonite

The invention belongs to multifunctional environment-friendly woodware waterborne putty coating. The multifunctional environment-friendly woodware waterborne putty coating is characterized by consisting of the following materials in parts by weight: 15 parts of modified waterborne resin, 0.5 part of thickening anti-settling agent, 0.5 part of wetting dispersant, 0.5 part of base material wetting agent, 3.0 part of anti-settling agent, 26 parts of coalescing agent, 3.5 parts of powder anti-settling agent, 7.5 parts of kaolin, 12 parts of muscovite, 12 parts of wollastonite in powder and 18 parts of edible starch. The multifunctional environment-friendly woodware waterborne putty coating disclosed by the invention has better wood conduit filling performance and wide range of application, is good in bidirectional compatibility, easy to color, uniform in color, free of chromatic aberration and spot and free of any pollution, and is a pure environment-friendly material; moreover, the multifunctional environment-friendly woodware waterborne putty coating is not broken and strong in adhesion force.

Owner:大连佳秀百隆新材料股份有限公司

Master batch used for preparing high heat-resisting polypropylene plastic as well as preparation method and application thereof

The invention discloses a master batch used for preparing high heat-resisting polypropylene plastic as well as a preparation method and an application thereof. The master batch is prepared by polypropylene and pulverized fodder with the proportion by weight of 100:30-45; the pulverized fodder is prepared by the following components according to parts by weight of: 11-30 parts of laminal filter, 1-3 parts of nano filter and 0.1-0.3 parts of polypropylene nucleating agent; the laminal filter is white mica or sericite. The preparation method of the master batch used for preparing high heat-resisting polypropylene plastic comprises the following steps: mixing the laminal filter and the nano filter; dissolving the nucleating agent by acetone and then evenly spraying into the mixed filter; mixing evenly and drying; mixing the dried pulverized fodder with the polypropylene fusion to prepare the master batch used for preparing high heat-resisting polypropylene plastic. The application of the master batch used for preparing high heat-resisting polypropylene plastic is as follows: 5-10 parts by weight of master batch are shattered, and are then extruded with 50-100 parts of polypropylene fusion to prepare high heat-resisting polypropylene plastic. The invention improves the heat resistance of polypropylene by the synergy of each component, and has wide market prospect.

Owner:中山市瑞邦红利塑料工业有限公司

Epoxy silane surface modified microcrystal muscovite active filler and its preparation method

InactiveCN100374513CQuality improvementEasy to modifyPigment treatment with organosilicon compoundsAcetic acidEpoxy

A process for preparing the active filler from the microcrystalline muscovite through modifying its surface by epoxy silane includes such steps as baking the microcrystalline muscovite, loading it in a mixer, using glacial acetic acid for regulating the pH value of alcohol to 3-7 to obtain deluent, proportionally mixing it with epoxy silane as coupling agent to obtain surface modifier, spraying it onto the microcrystalline muscovite in mixer, high-speed mixing and drying.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Aluminate surface modified microcrystal white mica active filler and its preparation method

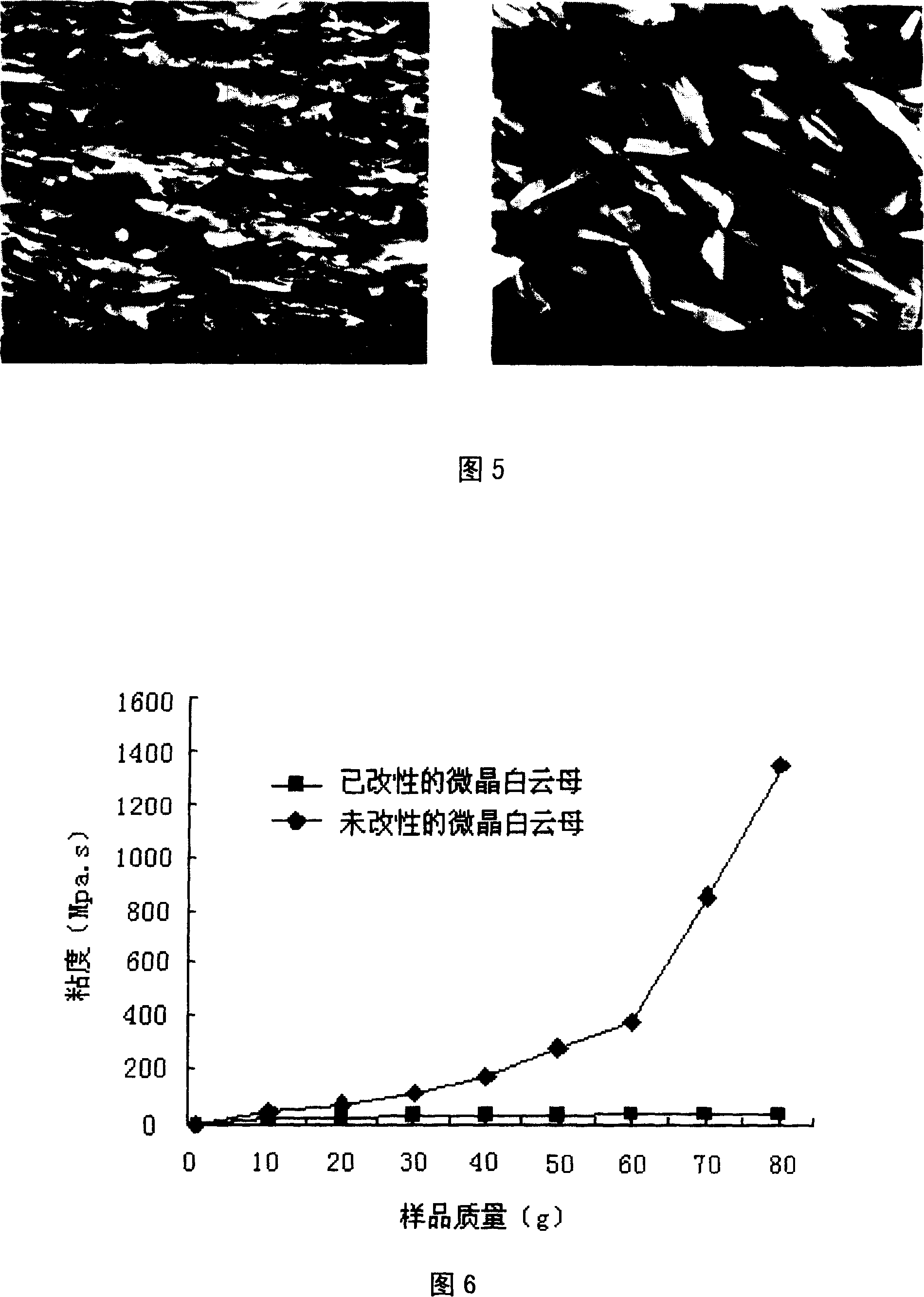

InactiveCN1255486CEasy to modifyLow costPigment treatment with non-polymer organic compoundsSocial benefitsViscosity

The invention discloses a microcrystalline muscovite active powder filler modified on the surface of an aluminate coupling agent and a preparation method thereof. The microcrystalline muscovite powder is used as a raw material. The muscovite powder material is dried at about 110 °C to remove all adsorbed moisture; melt the aluminate (for wax-like solids), and melt the aluminate at a temperature slightly higher than the melting point of 70 to 73 °C; Dry the material and put it into a high-speed mixer; preheat the material, make the material stir at a high speed in the high-speed mixer for about 30 minutes, and control the temperature to be ≤73°C; weigh the aluminate, and the weight is based on material: aluminate = 100:0.5 ~3.9; high-speed mixing of materials, slowly and evenly pour the aluminate into the high-speed mixer, high-speed mixing for about 20 minutes, and control the temperature to be ≤90 °C; modification effect testing, using viscosity testing and other methods to test and evaluate the modification effect. Evaluation. It has abundant resources, convenient modification process, low cost, good effect, wide application and obvious economic and social benefits.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Titanate KR-38S surface modified micro-crystal white mica active filler preparing method

InactiveCN1264932CEasy to modifyLow costPigment treatment with non-polymer organic compoundsSocial effectsHigh velocity

The invention discloses a kind of preparation method of the titanate KR-38S surface modified minicrystal muscovite active fille and chooses muscovite as raw material. The technics is as follows: weigh minicrystal muscovite and then put it into high-speed mizer; heat the material, whisk it in the high-speed mixer for 30 minutes and adjust the temperature no higher than 90deg.C; weigh the thinner of titanate, acetone, in amounts of weight, titanate:acetone=1:1-3; weigh titanate KR-38S, material: titanate=100:0.4-3.9; confect the titanate surface modified solution, put the titanate into the container with thinner of acetone and whisk it until being well-proportioned; mix the material in high gear, put the titanate surface modified solution into the high-speed mixer and whisk it for between 10min and 30min and control the temperature no more than 90deg.C. It is featured by abundant resource, low cost, convenient technics, wide use and obvious economic and social effects.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Refractory material used for glass kilns

InactiveCN107162615AAvoid crackingPrevents the effects of sinteringGlass furnace apparatusGlass productionBoron carbideSilicon dioxide

The invention relates to the technical field of refractory materials, and discloses a refractory material used for glass kilns. The refractory material used for glass kilns comprises, by weight, 10-15 parts of silica, 1-3 parts of ferriferrous oxide, 1-8 parts of alumina, 1-2 parts of propylene glycol, 3-7 parts of acrylamide, 1-2 parts of aluminum nitride powder, 1-2 parts of yttrium oxide powder, 2-7 parts of barium sulfate, 1-1.5 parts of boron carbide, 0.5-1.5 parts of cerium oxide powder, 10-12 parts of phenolic resin, 6-8 parts of muscovite powder, 1-2 parts of sericite powder, 10-15 parts of polycarbosilane, 2-6 parts of zirconium oxide and 5-6 parts of magnesium oxide. The invention also provides a preparation method of the refractory material for glass kilns. The preparation method comprises the following steps: fully mixing the raw materials of all above components, ageing the raw materials, placing the aged raw materials in an electric furnace, heating the aged raw materials, cooling the heated raw materials, pouring the cooled raw materials into a precast mold, and cooling and annealing the raw materials. The refractory material used for glass kilns has the advantages of high thermal shock resistance, high strength, high toughness, good corrosion resistance and high wear resistance.

Owner:长兴华悦耐火材料厂

A fully-glazed frit and a preparing method thereof

Owner:江西宏瑞新材料有限公司

Novel coating having electromagnetic radiation resistance and anti-static function

A novel coating having electromagnetic radiation resistance and an anti-static function is characterized by comprising 85% of environment-friendly coating, 10% of carbon nano-tube, 1.5% of polypeptide molecules and 3.5% of conductive mica powder. Wet method muscovite serves as a substrate for the conductive mica powder, a nanotechnology is adopted, and a conductive oxide layer is formed on the surface of the substrate through surface treatment and semiconductor doping treatment. The long diameter of the carbon nano-tube is not larger than 150 nm. The problem that a coating manufactured according to a conventional preparation process does not have dual effects of static resistance and radiation resistance is solved, so that the construction becomes simple and convenient. The use range of the carbon nano-tube is expanded, the damage to the lung of the human body and the skin caused by the carbon nano-tube is reduced, the coexistence of people and the environment is harmonized while the energy saving and environmental protection are achieved, and the novel coating can well be used for oil tanks, gas stations, factories, homes and intensive radiation region environments near high-tension cables or substations and the like and the environment where the static requirements are high.

Owner:CHUZHOU JINQIAO TEXAS NEW MATERIALS CO LTD

Amine silane surface modified micro crystal isinglass active filler and its preparation method

InactiveCN100393821CImprove mechanical propertiesGood electrical propertiesPigment treatment with organosilicon compoundsAcetic acidAlcohol

A process for preparing the active filler from the microcrystalline muscovite through modifying its surface by aminosilane includes such steps as baking said microcrystalline muscovite, loading it in a mixer, using glacial acetic acid to regulate pH value of alcohol to 3-7 to obtain deluent, proportionally mixing the aminosilane as coupling agent with said deluent to obtain surface modifier, spraying it onto the microcrystalline mascovite in mixer, high-speed mixing, and drying.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Preparation method of antimicrobial moldproof MDI (methylenediphenyl diisocyanate) polyurethane foam

ActiveCN102675576AGive full play to antibacterial propertiesGood compatibilityDisinfectantsAfter treatment8-Hydroxyquinoline

The invention discloses a preparation method of antimicrobial moldproof MDI (methylenediphenyl diisocyanate) polyurethane foam, which comprises the following steps: 1) impregnating muscovite powder in oxydol, and treating to obtain expanded muscovite powder; 2) adding the expanded muscovite powder obtained in the step 1 into the trisodium phosphate solution, and treating to obtain a solid product; 3) adding the solid product obtained in the step 2) into an AgNO3 solution, stirring and carrying out after-treatment to obtain immobilized silver muscovite antimicrobial powder; 4) adding the product obtained in the step 3) into a diluter-coupling agent mixed solution, mixing and stirring to obtain a plastic antimicrobial agent; and 5) adding the plastic antimicrobial agent and a mold preventive into a butter PPG reaction kettle, dissolving by stirring, adding auxiliary materials and MDI, stirring at high speed, pouring into a reaction tank, and naturally aging to obtain the product. By using the immobilized silver muscovite powder and the 8-hydroxyquinoline copper mold preventive, the product prepared by the method has antimicrobial performance and moldproof effect.

Owner:FUJIAN YUETE NEW MATERIAL TECH

Feed additive for promoting livestock growth and preparation method thereof

InactiveCN101637221APromote growthImprove immunityAnimal feeding stuffAccessory food factorsAntibiotic YOxygen

The invention relates to a feed additive for promoting livestock growth, comprising the following raw materials in parts by weight: 5-15 parts of polar mineral tourmaline micro powder, 4 to 10 parts of photocatalysis semiconductor material micro powder, 2 to 5 parts of nanometer zinc oxide micro powder, 2 to 5 parts of biotite micro powder, 2 to 5 parts of muscovite micro powder, 2 to 5 parts of feldspar micro powder, 8 to 12 parts of diatomite micro powder, 8 to 13 parts of vermiculite micro powder, and 30 to 67 parts of light clay micro powder. A preparation method for the feed additive comprises the following steps: coarse grinding, fine grinding and precision grinding. The invention has the advantages that the feed additive does not contain antibiotics, is safe to promote the livestock growth with high efficiency, resists bacterium and improves the dissolved oxygen.

Owner:平湖市畜牧兽医局 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com