Patents

Literature

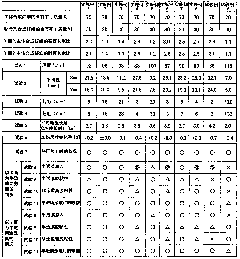

493 results about "Longest Diameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The longest possible length of a straight line passing through the center of a circular or spheroid object that connects two points on the circumference.

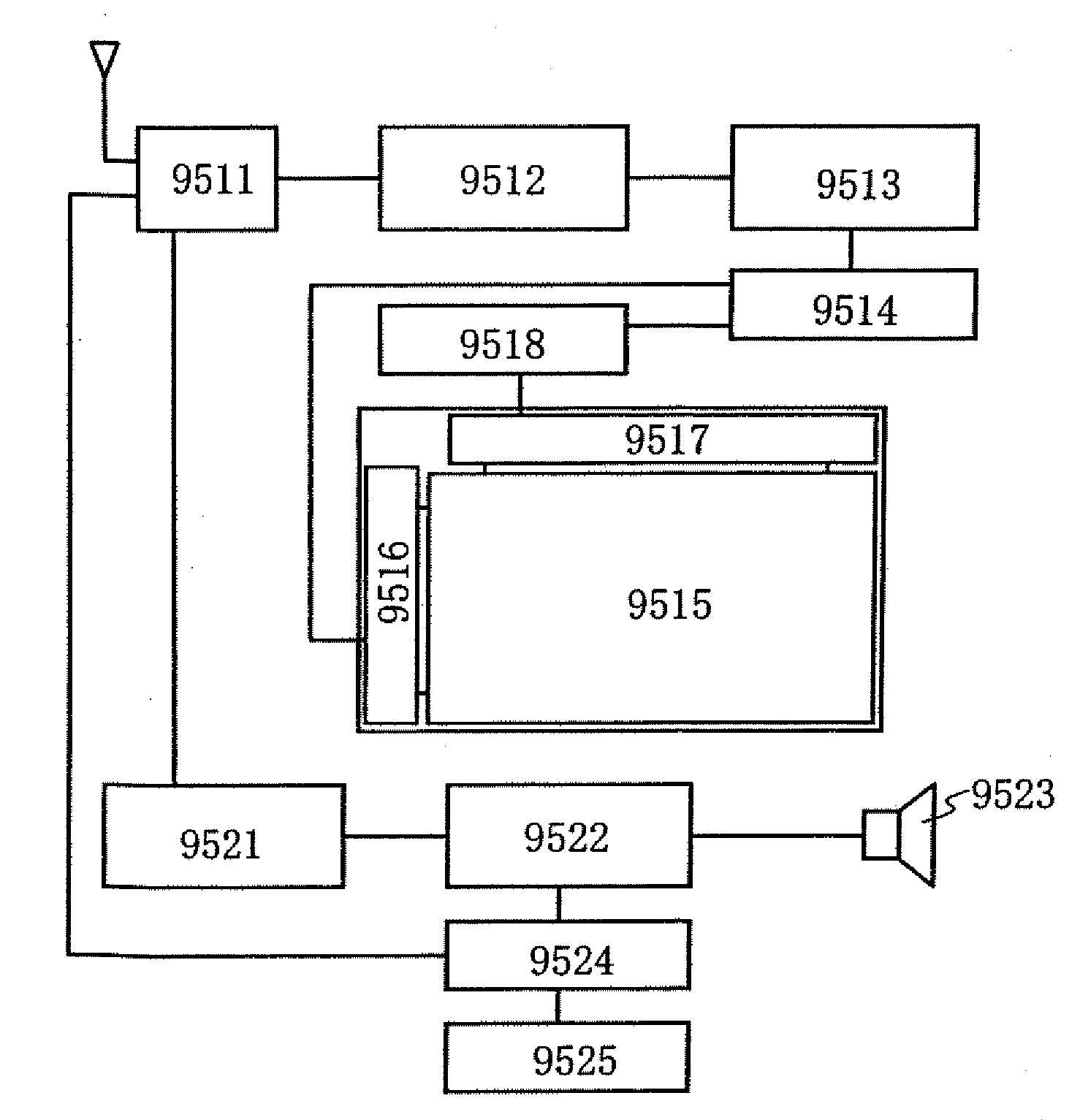

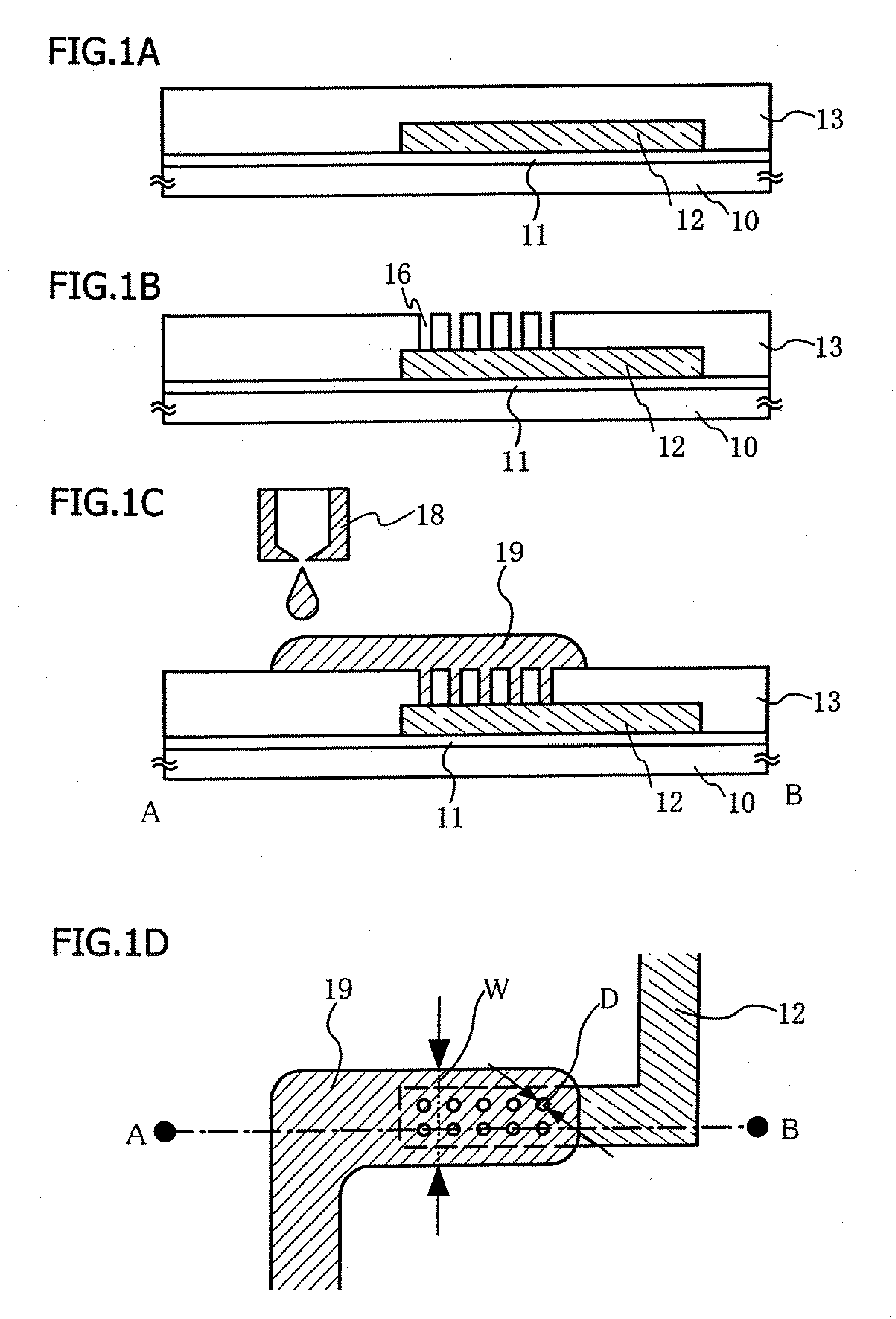

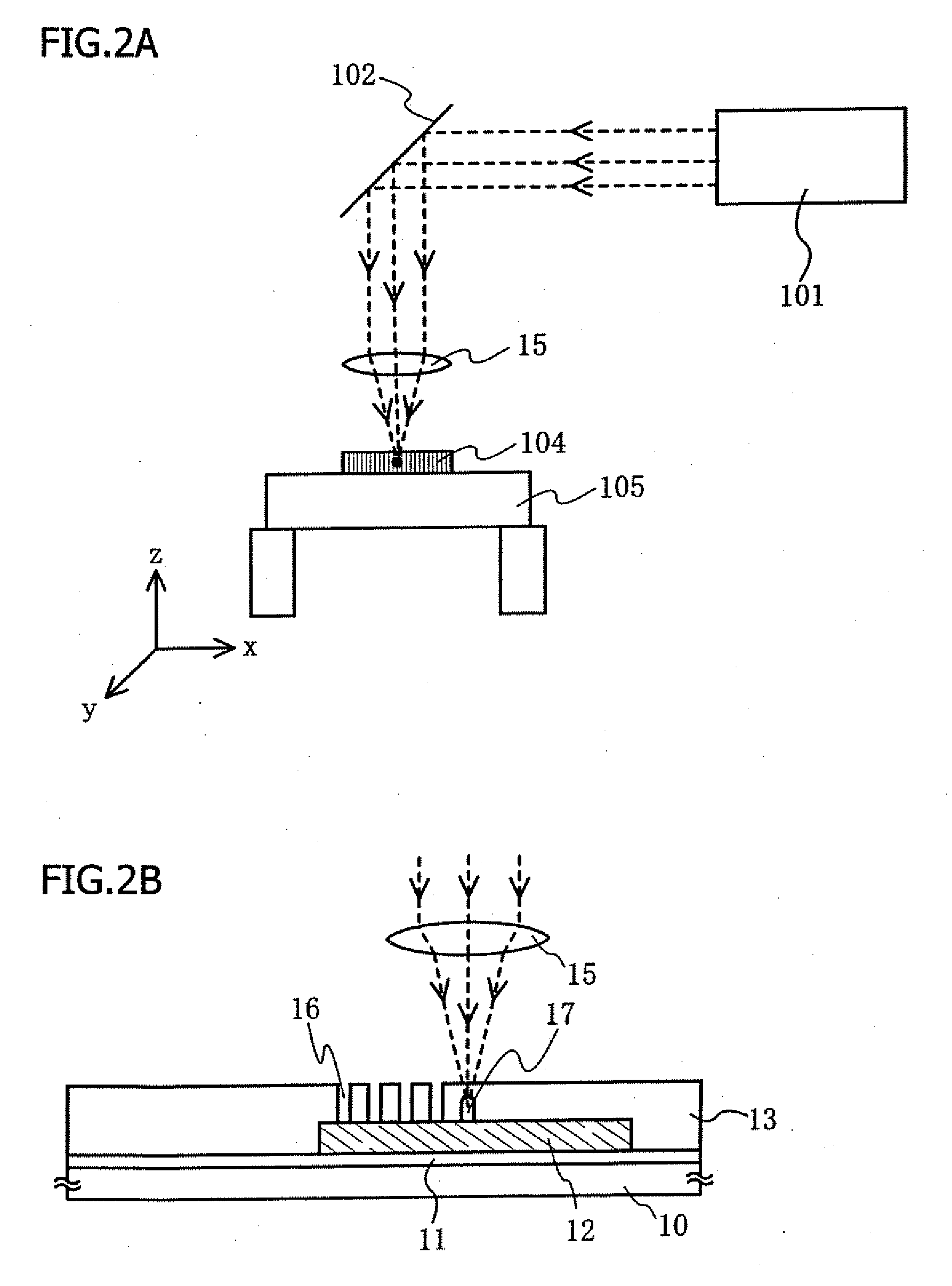

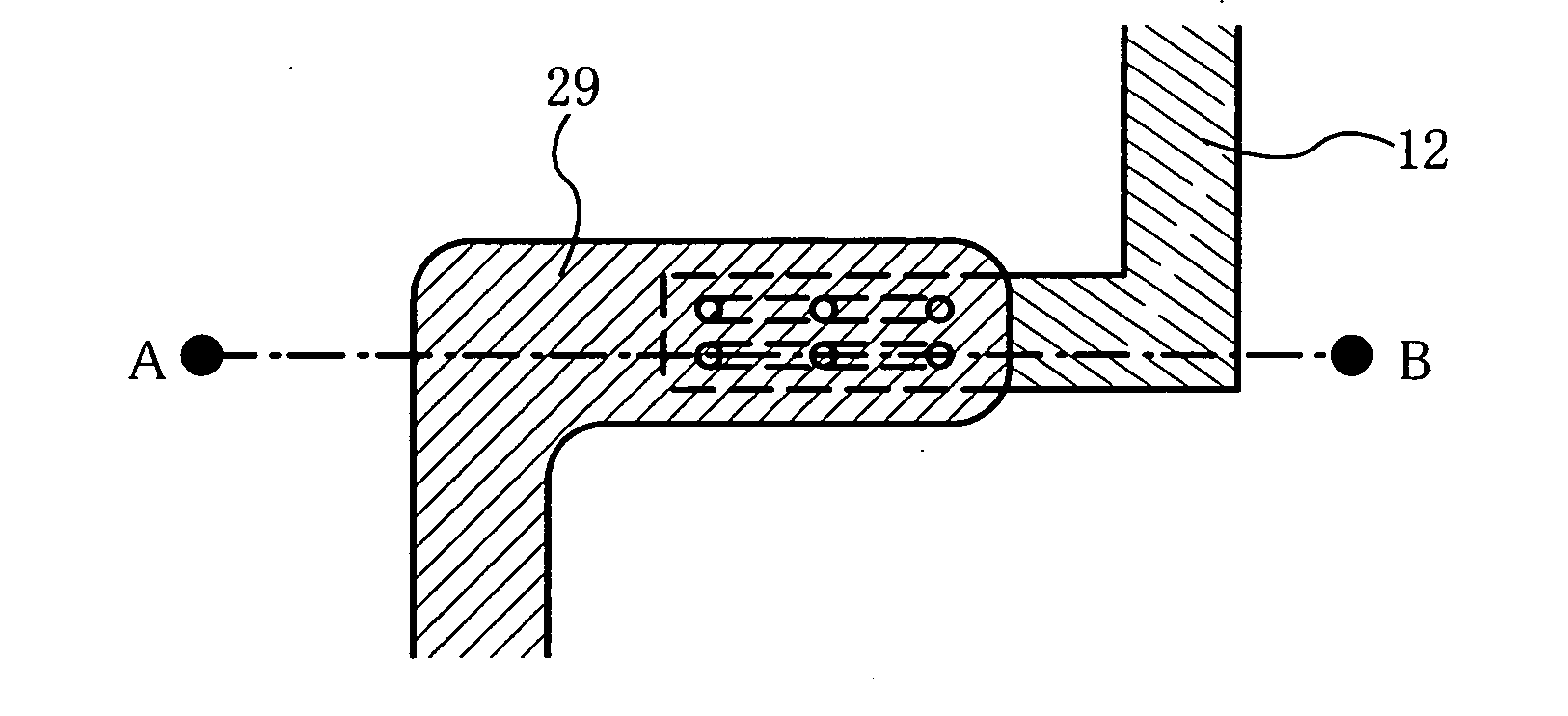

Semiconductor device and method for manufacturing the same, and electric device

InactiveUS20090073325A1Simple stepsHighly integratedTransistorTelevision system detailsElectrical resistance and conductanceLongest Diameter

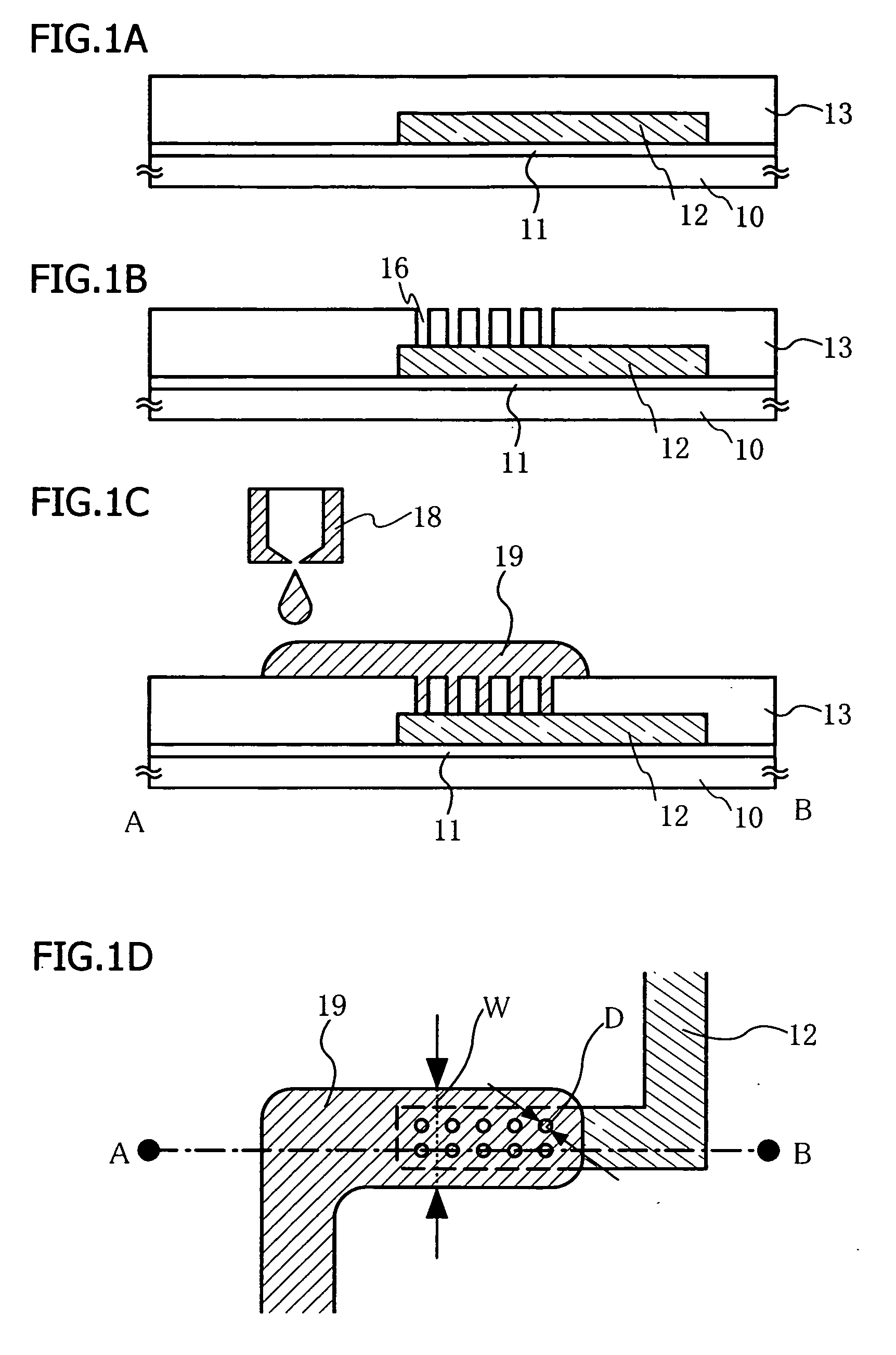

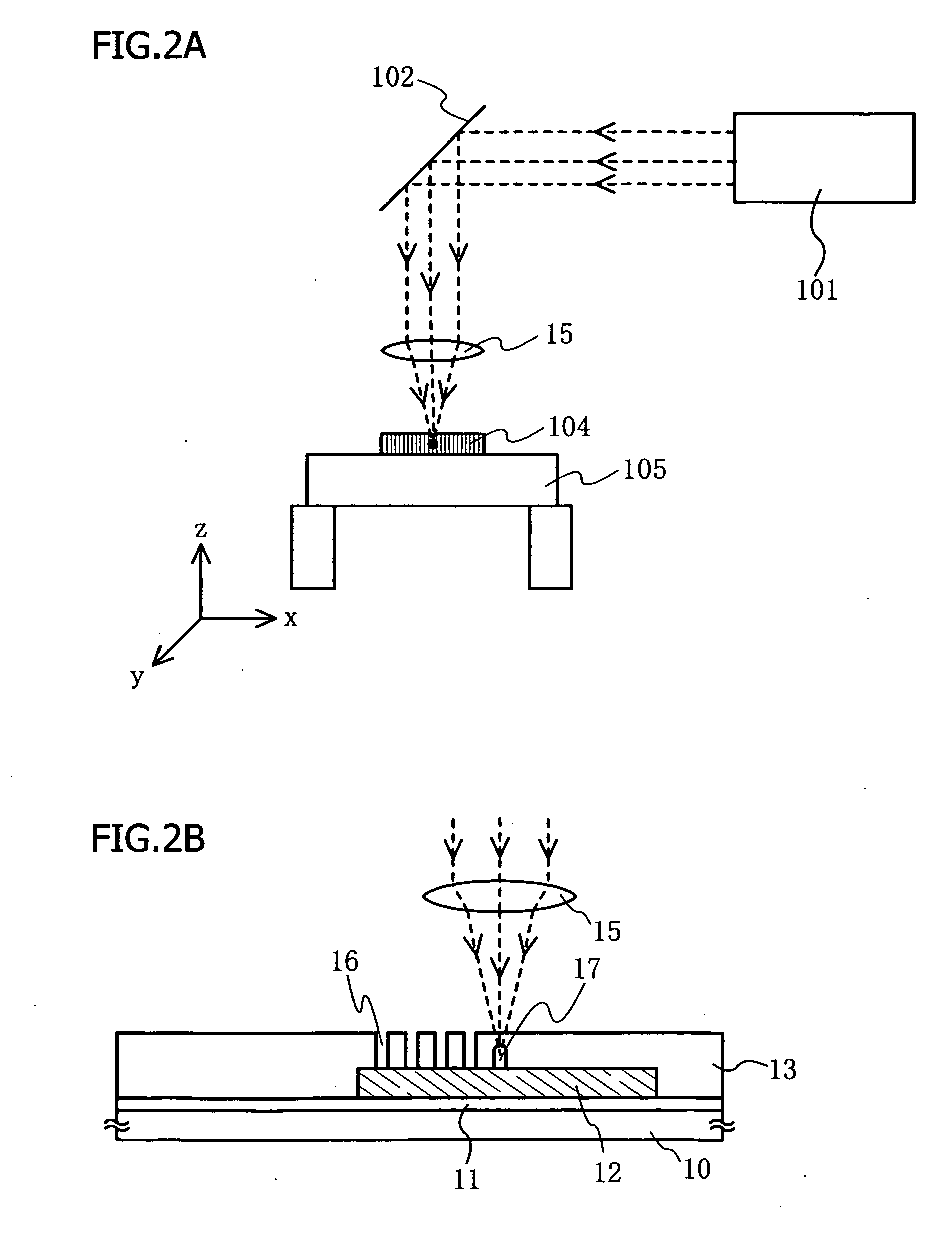

It is an object of the present invention to simplify steps needed to process a wiring in forming a multilayer wiring. In addition, when a droplet discharging technique or a nanoimprint technique is used to form a wiring in a contact hole having a comparatively long diameter, the wiring in accordance with the shape of the contact hole is formed, and the wiring portion of the contact hole is likely to have a depression compared with other portions. A penetrating opening is formed by irradiating a light-transmitting insulating film with laser light having high intensity and a pulse high in repetition frequency. A plurality of openings having a minute contact area is provided instead of forming one penetrating opening having a large contact area to have an even thickness of a wiring by reducing a partial depression and also to ensure contact resistance.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method for manufacturing the same, and electric device

InactiveUS20060163743A1Simple stepsHighly integratedSemiconductor/solid-state device detailsElectroluminescent light sourcesElectrical resistance and conductanceLongest Diameter

It is an object of the present invention to simplify steps needed to process a wiring in forming a multilayer wiring. In addition, when a droplet discharging technique or a nanoimprint technique is used to form a wiring in a contact hole having a comparatively long diameter, the wiring in accordance with the shape of the contact hole is formed, and the wiring portion of the contact hole is likely to have a depression compared with other portions. A penetrating opening is formed by irradiating a light-transmitting insulating film with laser light having high intensity and a pulse high in repetition frequency. A plurality of openings having a minute contact area is provided instead of forming one penetrating opening having a large contact area to have an even thickness of a wiring by reducing a partial depression and also to ensure contact resistance.

Owner:SEMICON ENERGY LAB CO LTD

Cellulose dispersion

InactiveUS6541627B1Good dispersionImprove stabilitySugar derivativesCellulose coatingsCelluloseDispersion stability

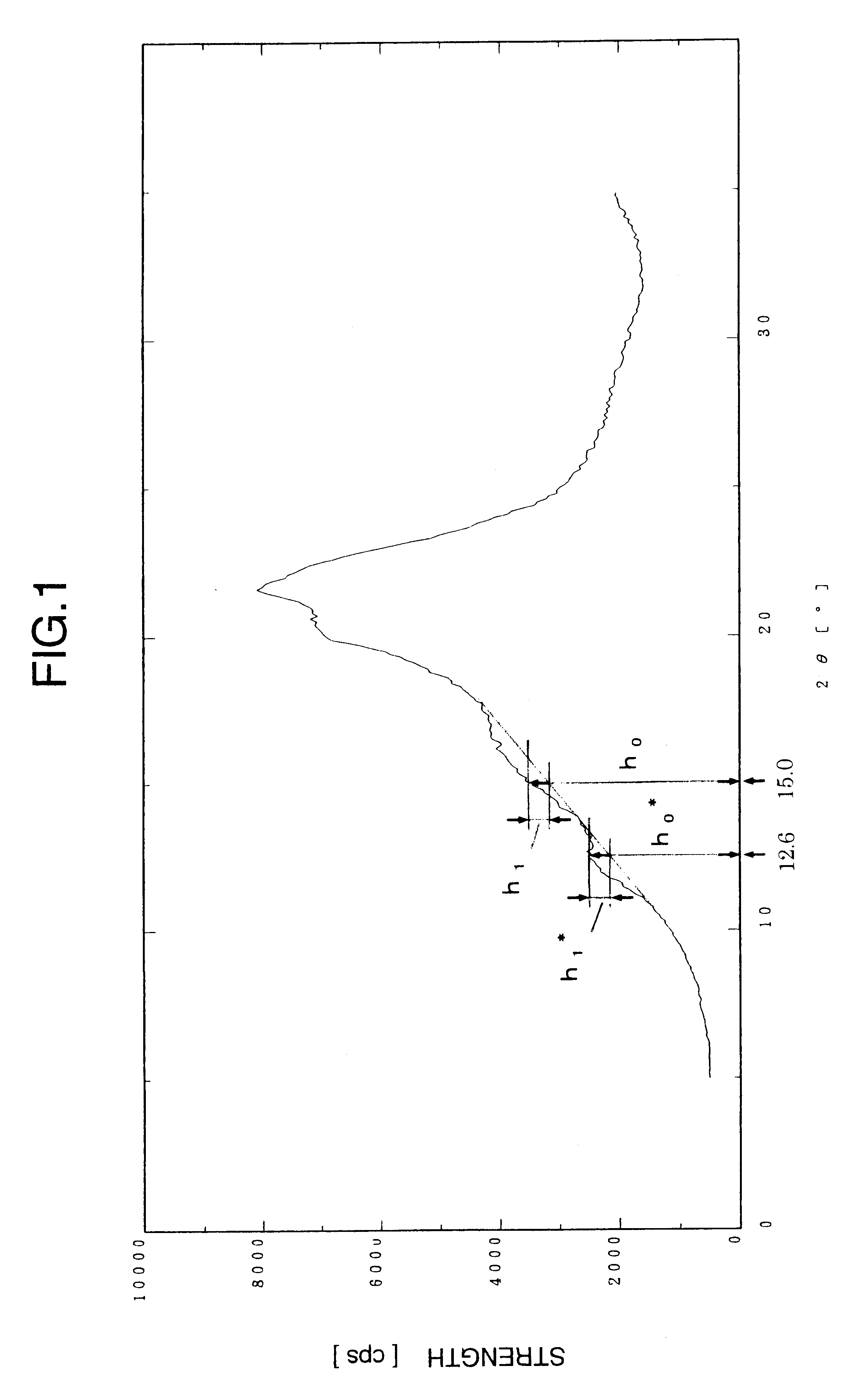

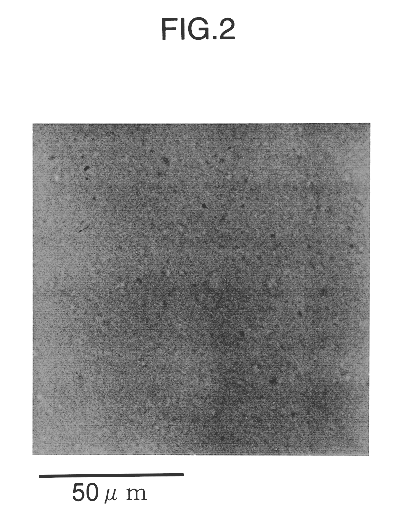

A cellulose dispersion which is a dispersion comprising a dispersing medium and a cellulose having a fraction of cellulose I type crystal component of not more than 0.1 and a fraction of cellulose II type crystal component of not more than 0.4 and in which the average particle diameter of the constitutive cellulose is not more than 5 mum. A cellulose particulate and a cellulose composite particulate which have an average particle diameter of 0.2 to 20 mum, a ratio of long diameter (L) to short diameter (D) observed through a scanning electron microscope (L / D) of not more than 1.2 and a coefficient of aggregation of 1.0 to 3.0. The present invention provides a cellulose dispersion which has an excellent effect such as dispersion stability or the like and is high in transparency. Moreover, it provides a cellulose particulate and a cellulose composite particulate which have such performances as no rough feel, excellent rolling properties, high dispersibility and the like.

Owner:ASAHI KASEI KK

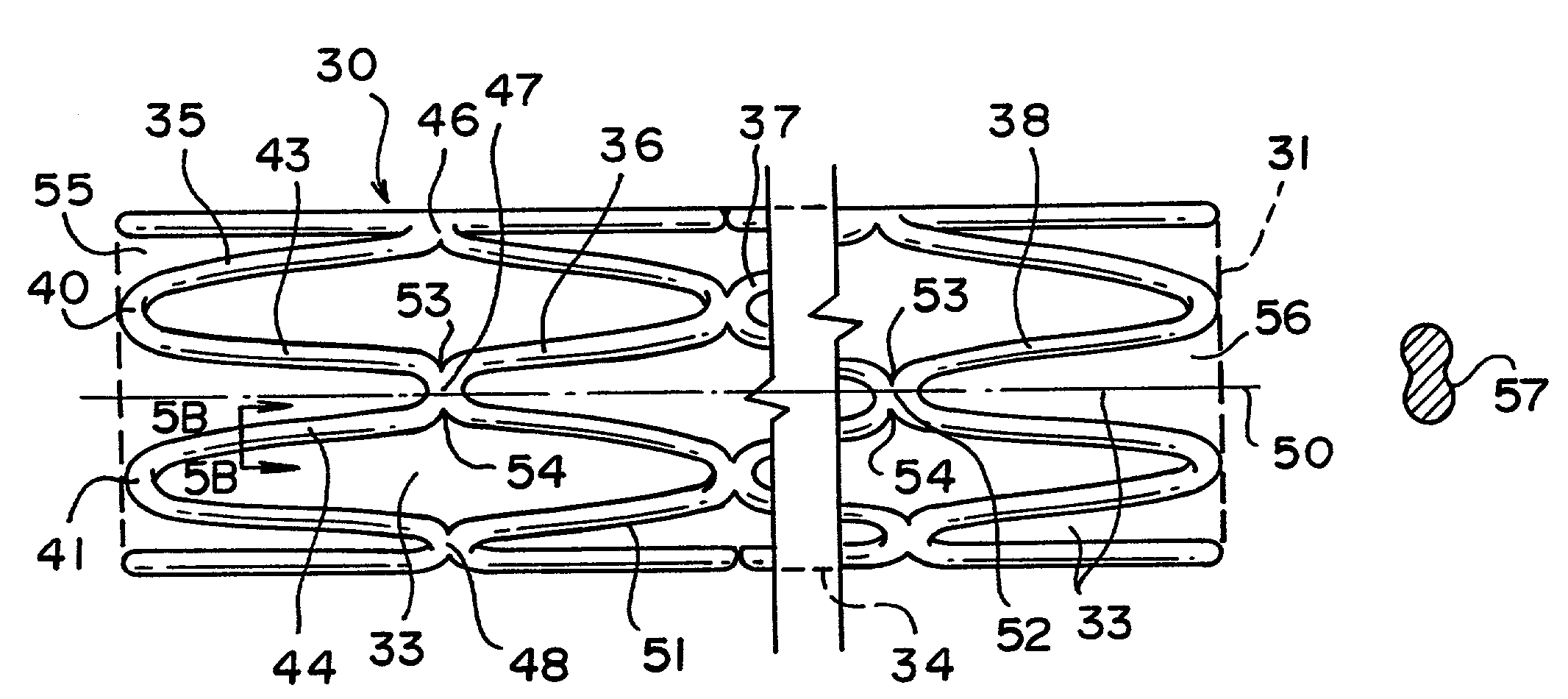

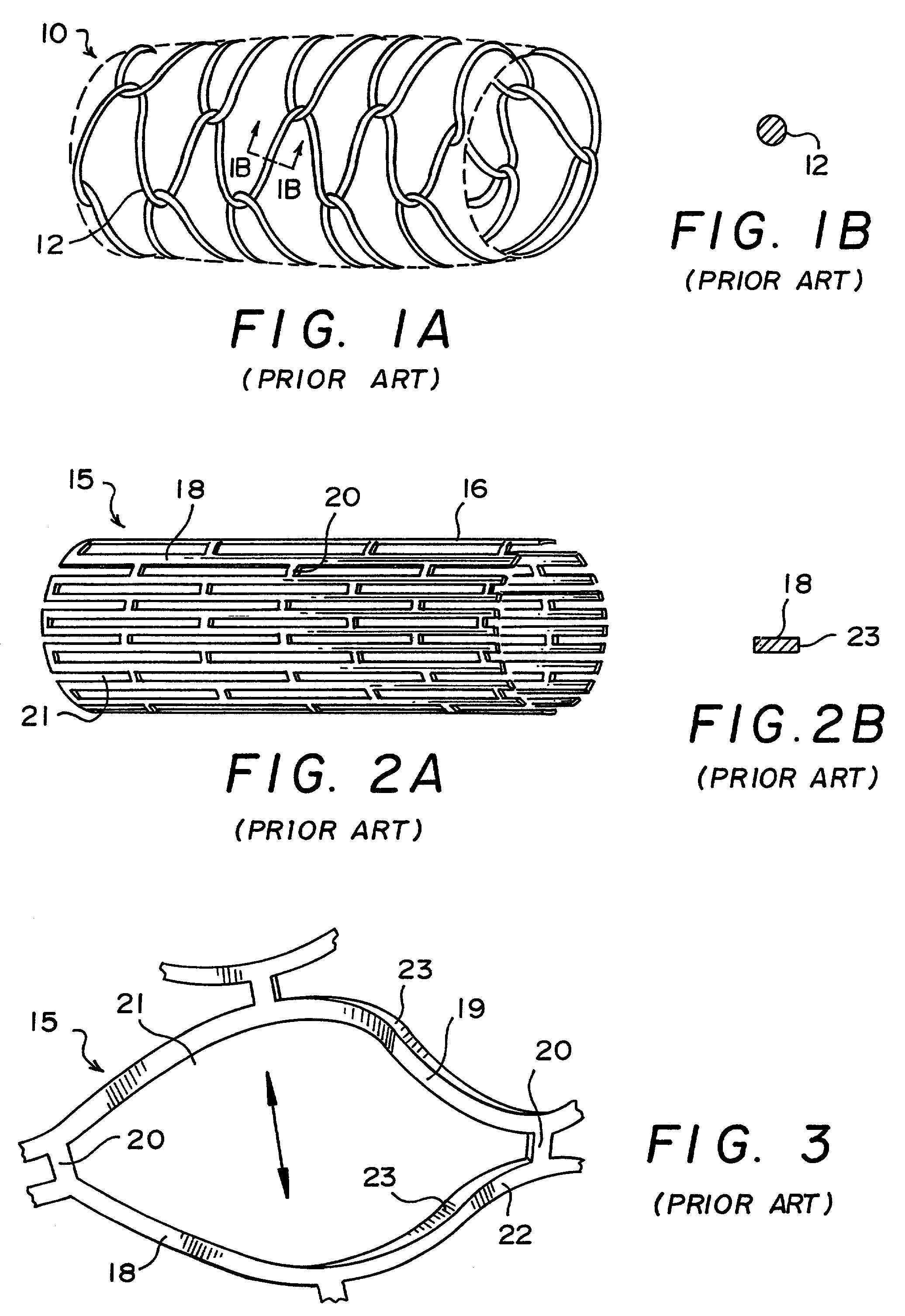

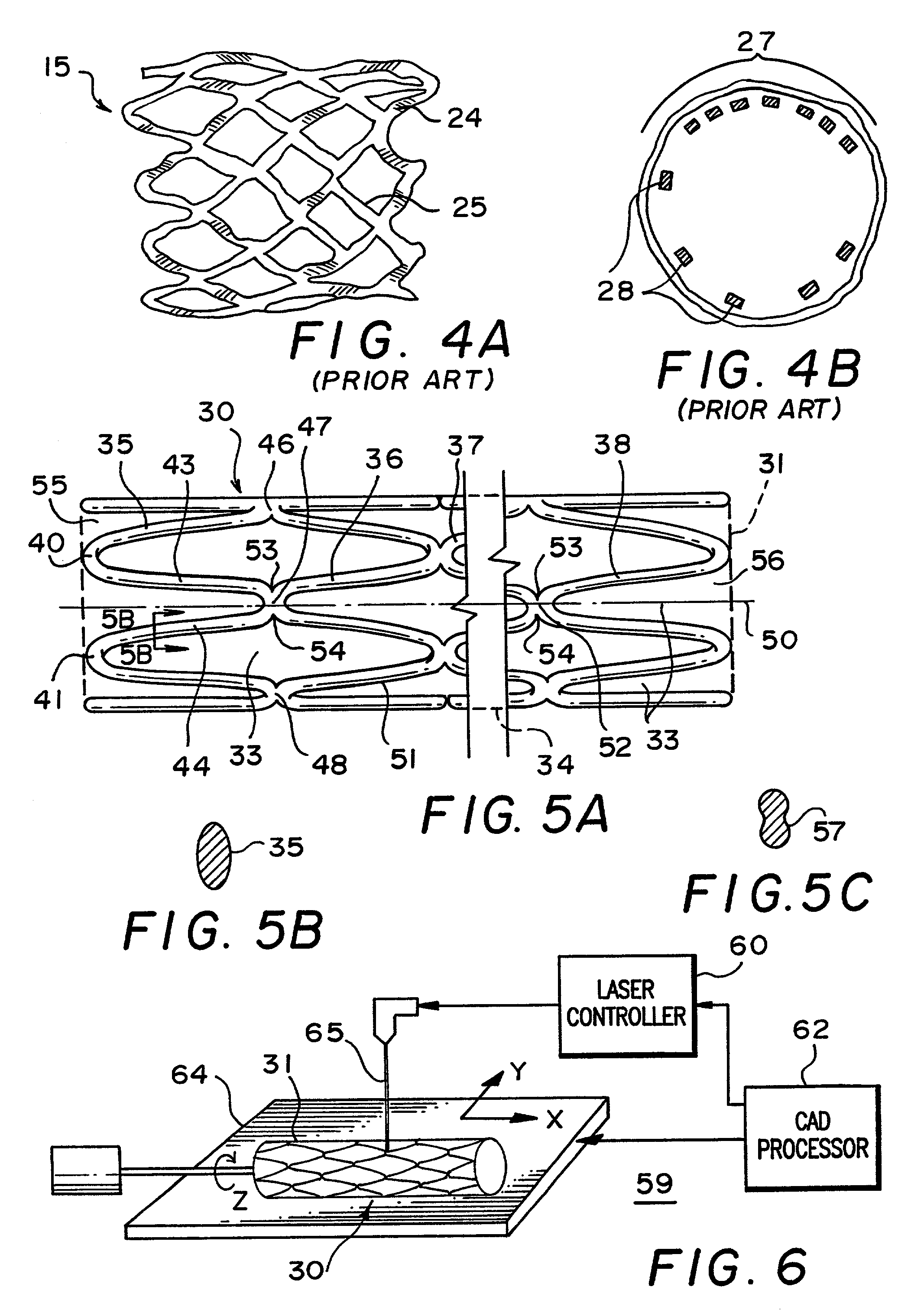

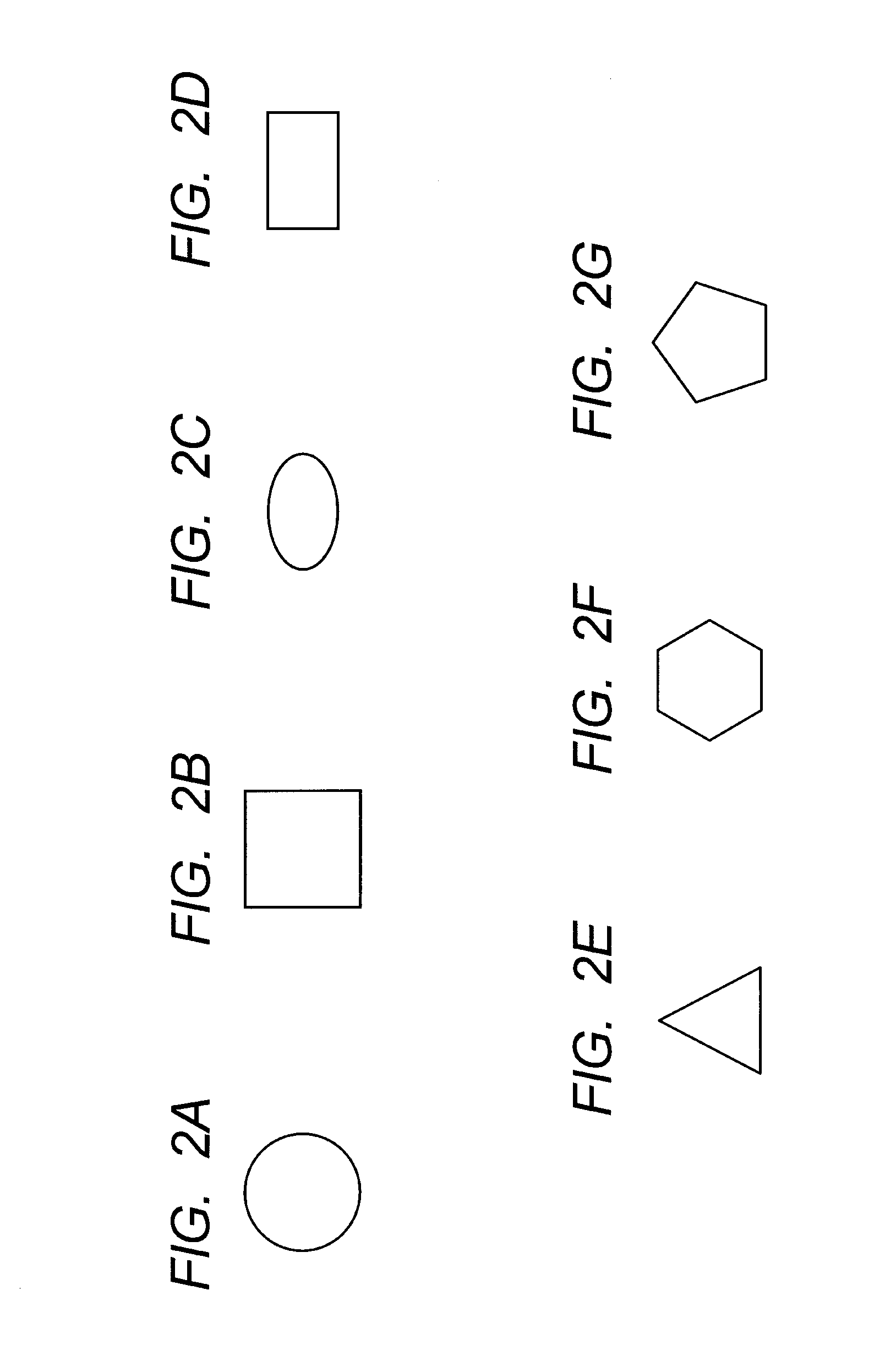

Tubular stent with oval struts

InactiveUS7153322B2Enhance crimping and symmetric expansion of stentLength of tubeStentsBlood vesselsLongest DiameterEndoluminal stent

A vascular or endoluminal stent is adapted for deployment in a vessel or tract of a patient to maintain an open lumen. The stent constitutes a scaffold formed from a single open-ended tube having a multiplicity of through-holes in its wall. The through-holes are defined by a plurality of struts that bound the holes. Each of the struts has an optimized cross-section of oval shape with a long diameter generally aligned with the length or circumference of the tube wall and a short diameter generally aligned with the thickness of the tube wall. The oval shape of the struts provide several advantages including enhancing flexibility of the stent, easing advancement of the stent through a lumen of the vessel or tract for deployment at a target site therein, protecting the balloon of a balloon catheter on which the stent is tightly crimped, and enhancing expansion of the stent during deployment while maintaining its capability to withstand compression in response to recoil of the vessel or tract following deployment.

Owner:BOSTON SCI SCIMED INC

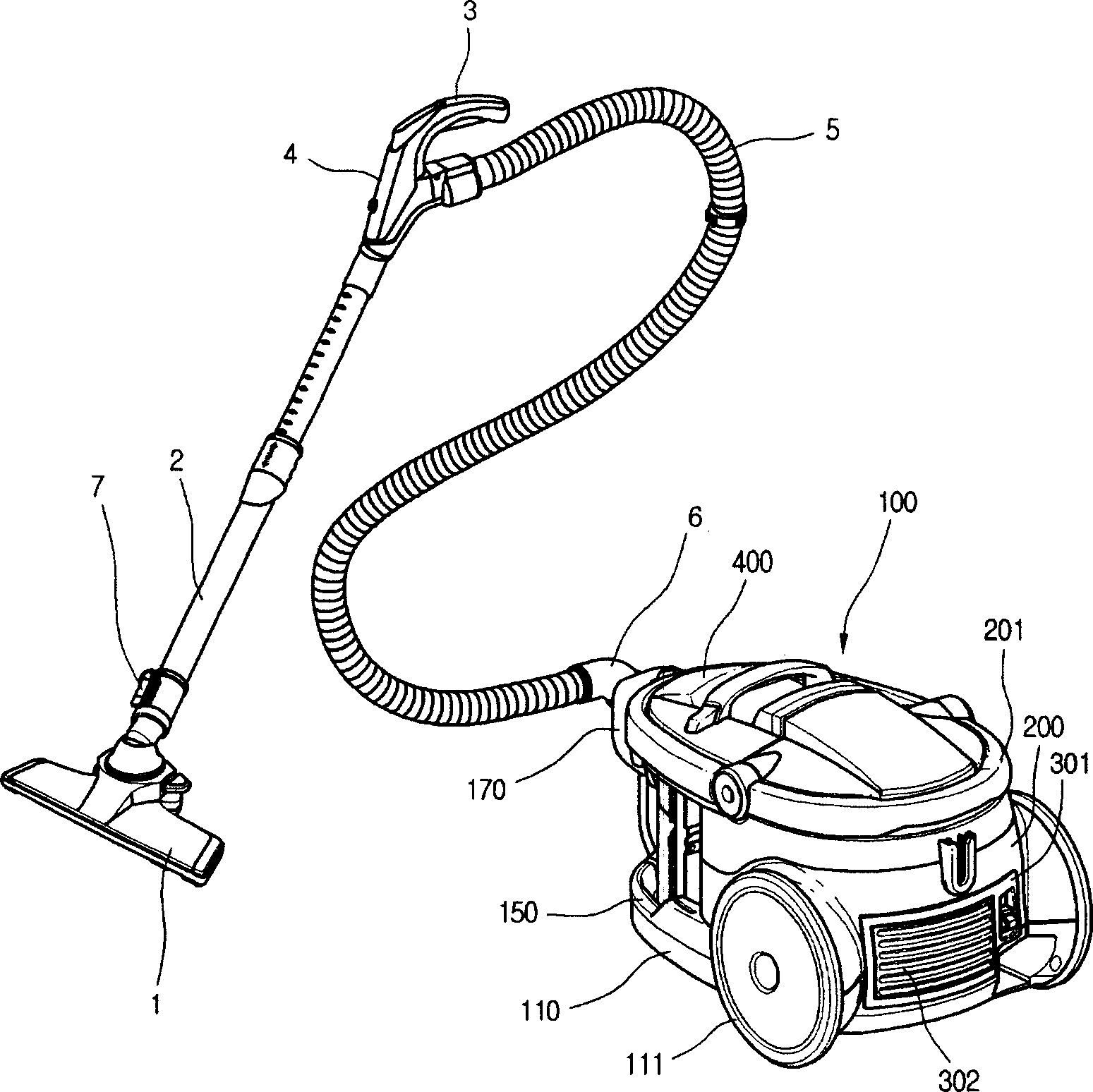

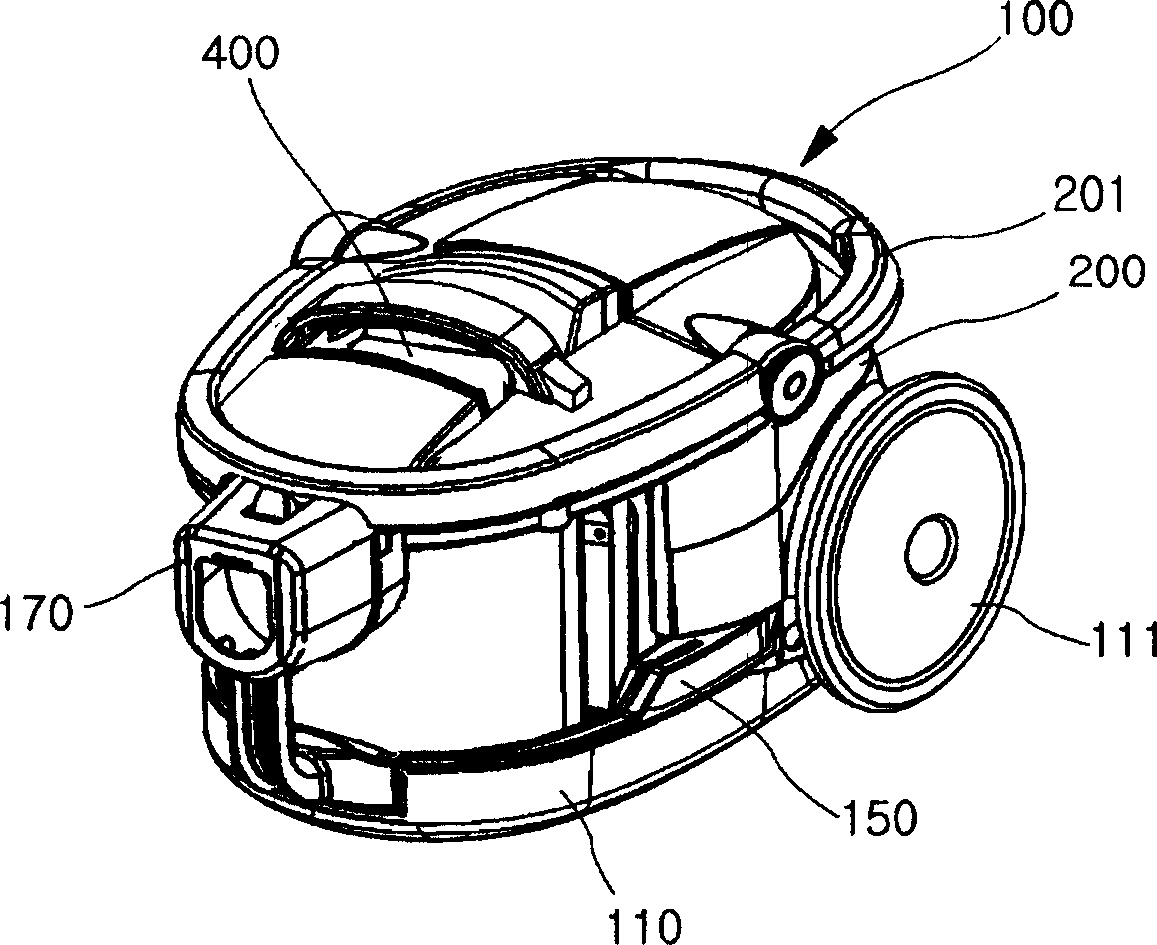

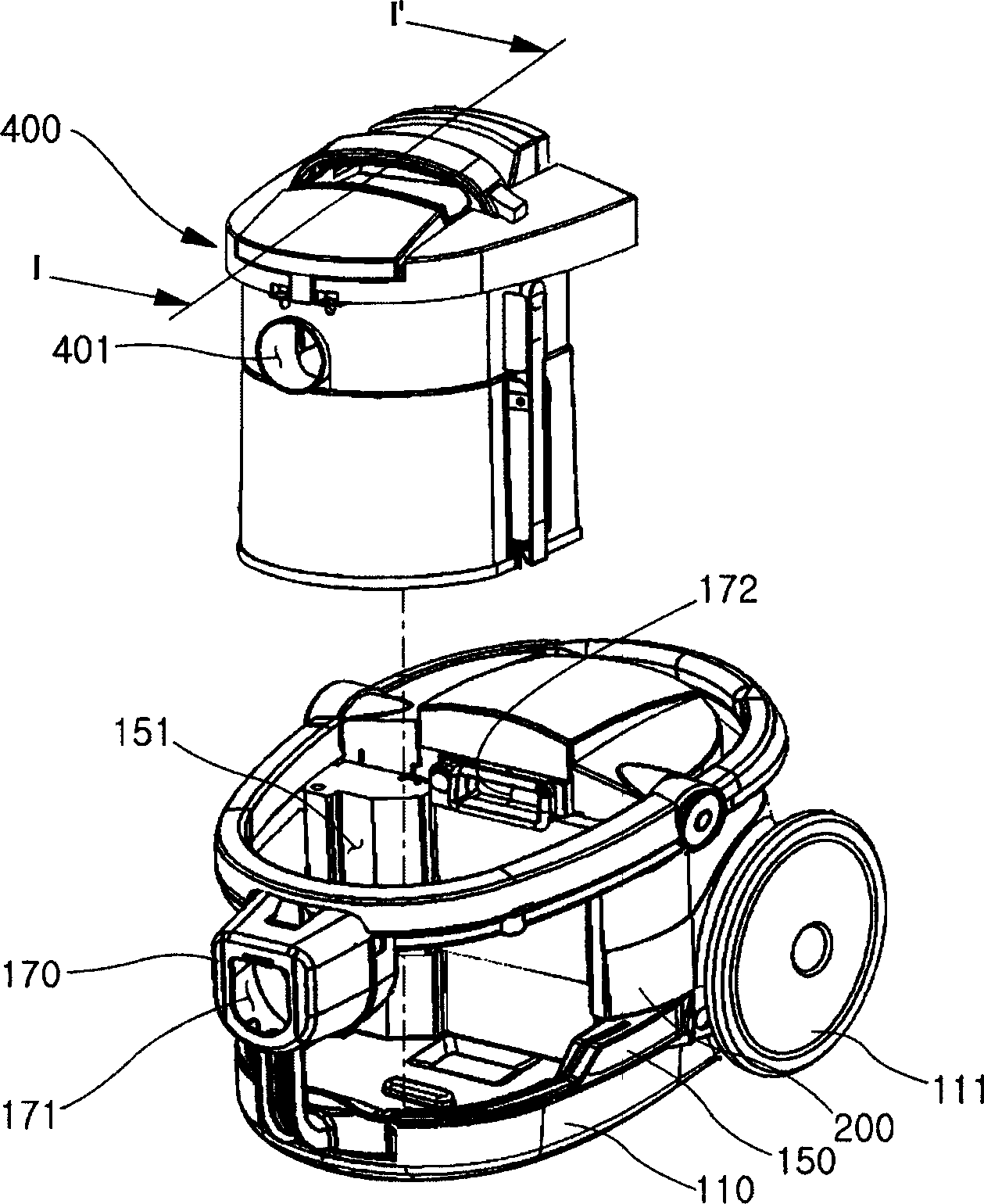

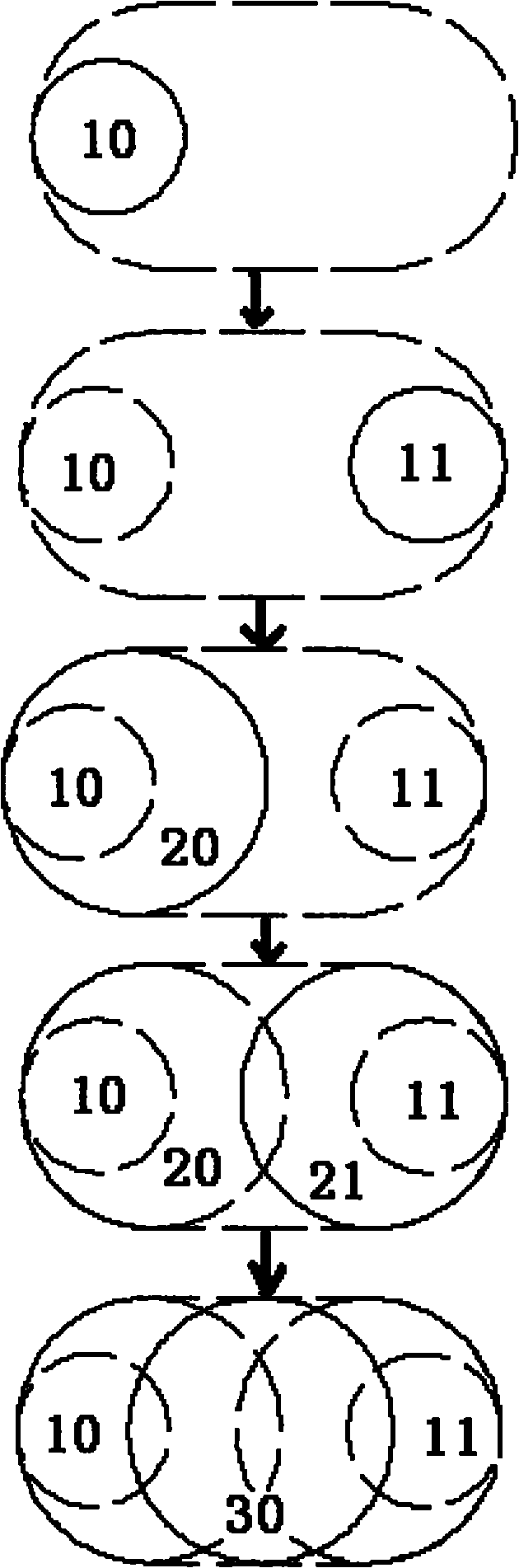

Dust collection unit of vacuum cleaner

The invention discloses a dust collecting device of vacuum cleaner, which comprises the following parts: first separating box with long diameter, second separating box with short diameter to separate the foreign body from the first separating box, commutating part to form at the vent side of second separating box to communicate air flow. The invention can reduce noise in the working course, which improves satisfaction of multi-cyclone flow typed dust collecting device for user.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

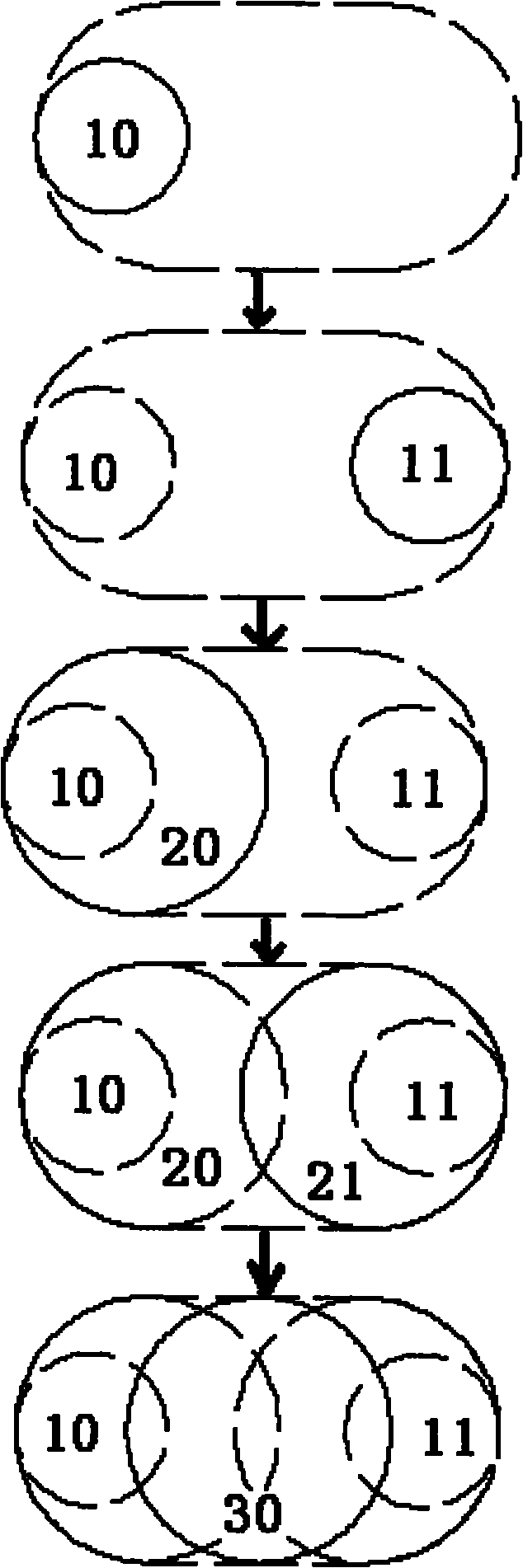

Method for manufacturing PCB short slot

InactiveCN102009198AReduce scrapReduce manufacturing costPrinted circuit manufactureLongest DiameterMachining process

The invention relates to the field of printed circuit board (PCB) manufacture, in particular to a method for manufacturing a PCB slot. The method comprises the following steps of: (1) manufacturing a slot graph on a PCB; (2) drilling a guide hole in two edges of the length direction of the slot graph respectively; and (3) performing superposition drilling based on the guide holes by adopting a drill bit, the diameter of which is equal to the short diameter of the slot, wherein the diameter of the guide holes is less than half of the long diameter of the slot. The method can effectively avoid the quality problems of deformation, large slots, small slots and the like in the short slot processing process, reduces unnecessary rejection of the PCB, reduces the production cost of enterprises and greatly improves the production efficiency.

Owner:惠州中京电子科技股份有限公司

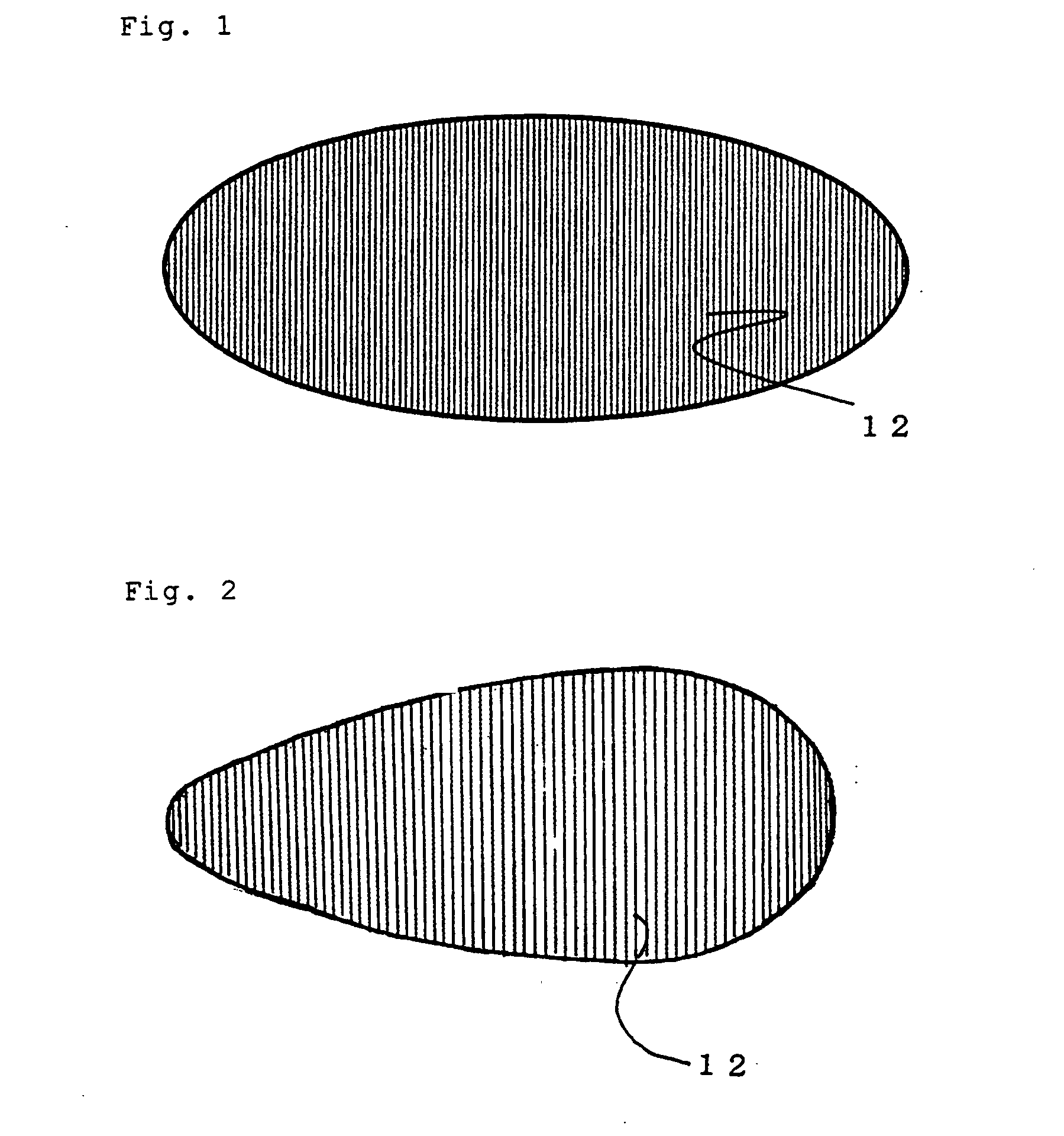

Chemical mechanical polishing pad, manufacturing process thereof and chemical mechanical polishing method for semiconductor wafers

InactiveUS20050245171A1Improve polishing efficiencySemiconductor/solid-state device manufacturingLapping machinesLongest DiameterCompound (substance)

There is provided a chemical mechanical polishing pad containing a polishing substrate having a polishing surface and a light-transmitting member fused to the polishing substrate. The sectional form of the light-transmitting member when it is cut with a plane parallel to the polishing surface is elliptic with a value obtained by dividing its long diameter by its short diameter of more than 1. The pad is capable of transmitting end-point detection light without reducing its polishing efficiency in polishing a semiconductor wafer.

Owner:JSR CORPORATIOON

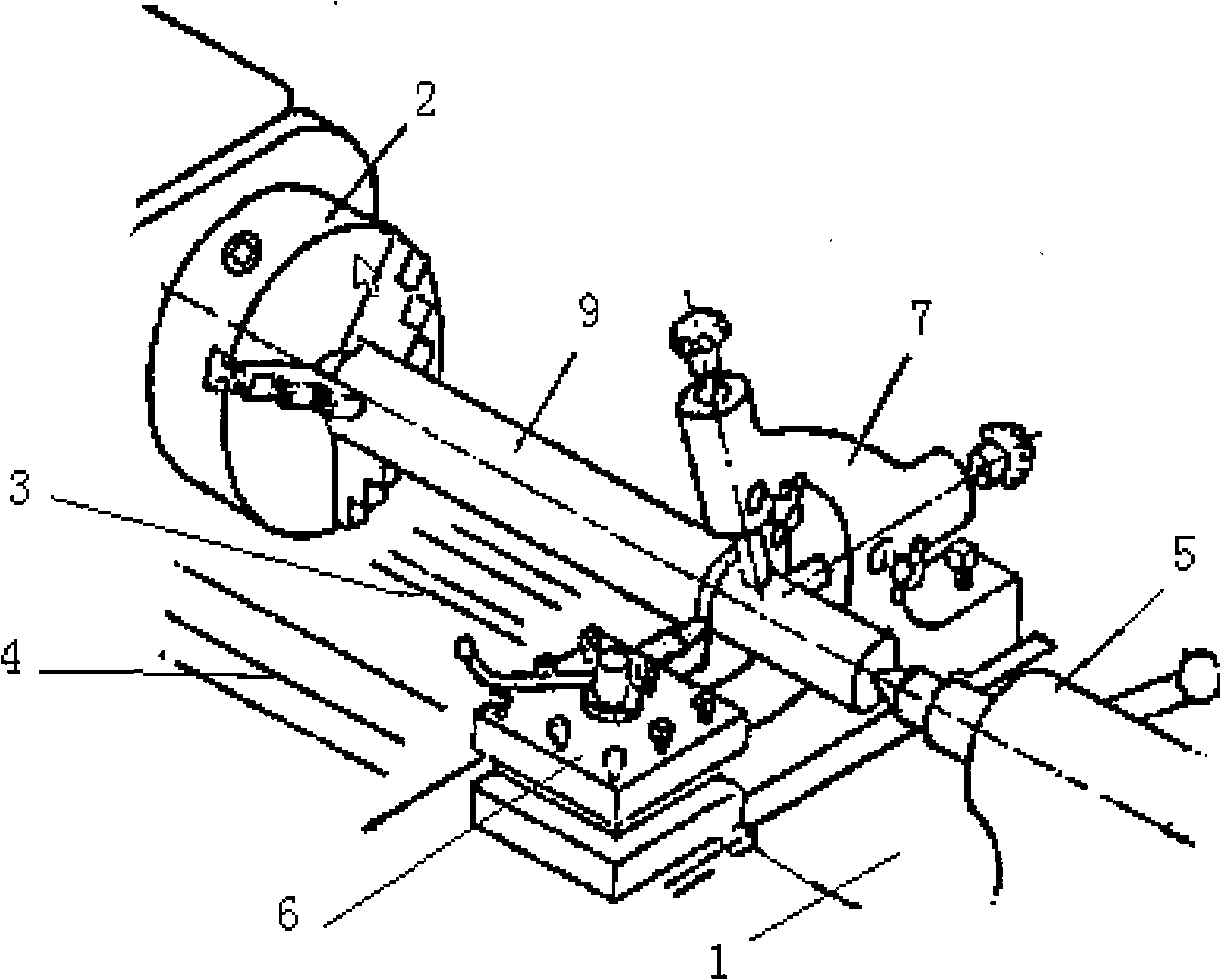

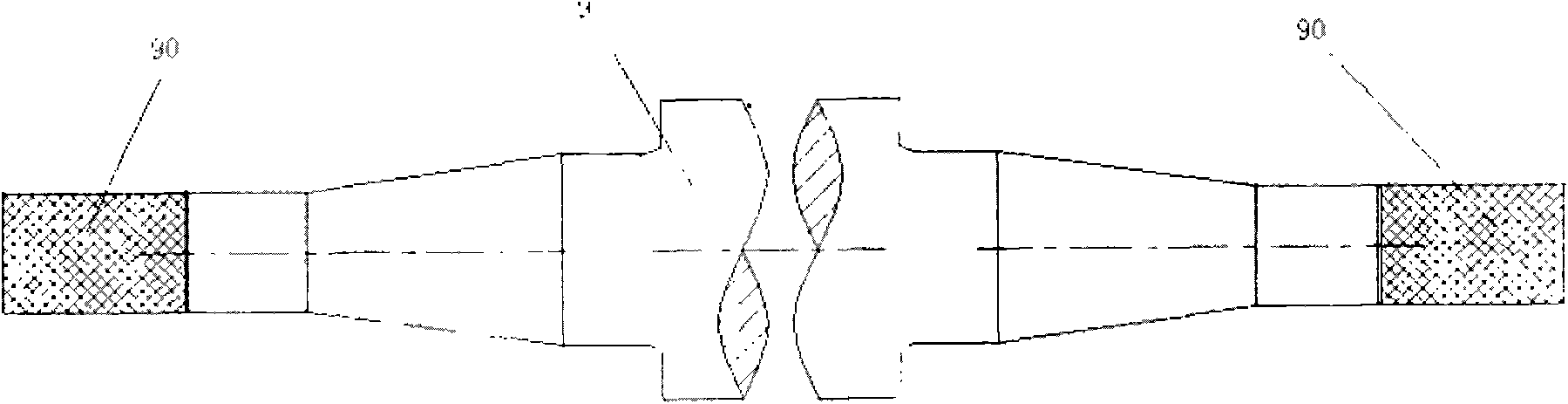

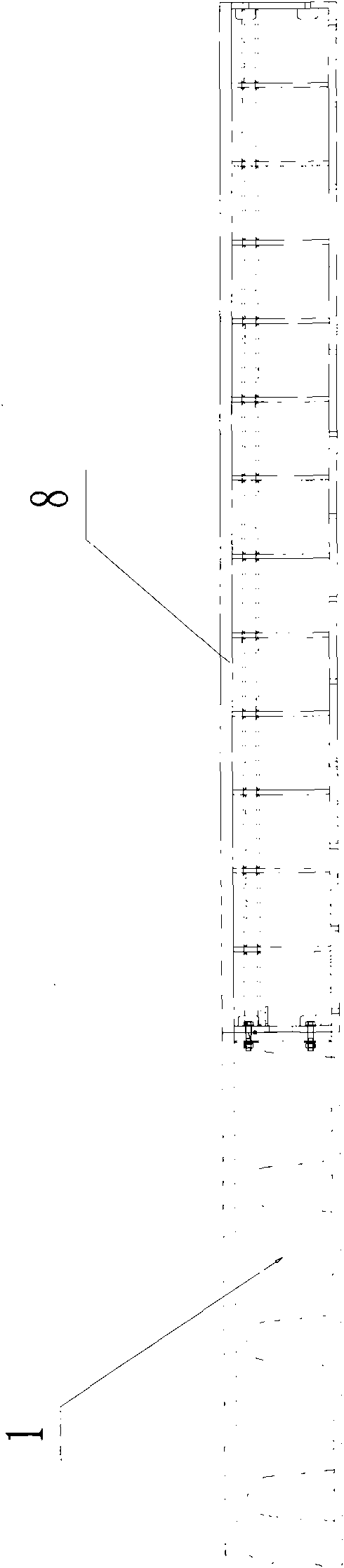

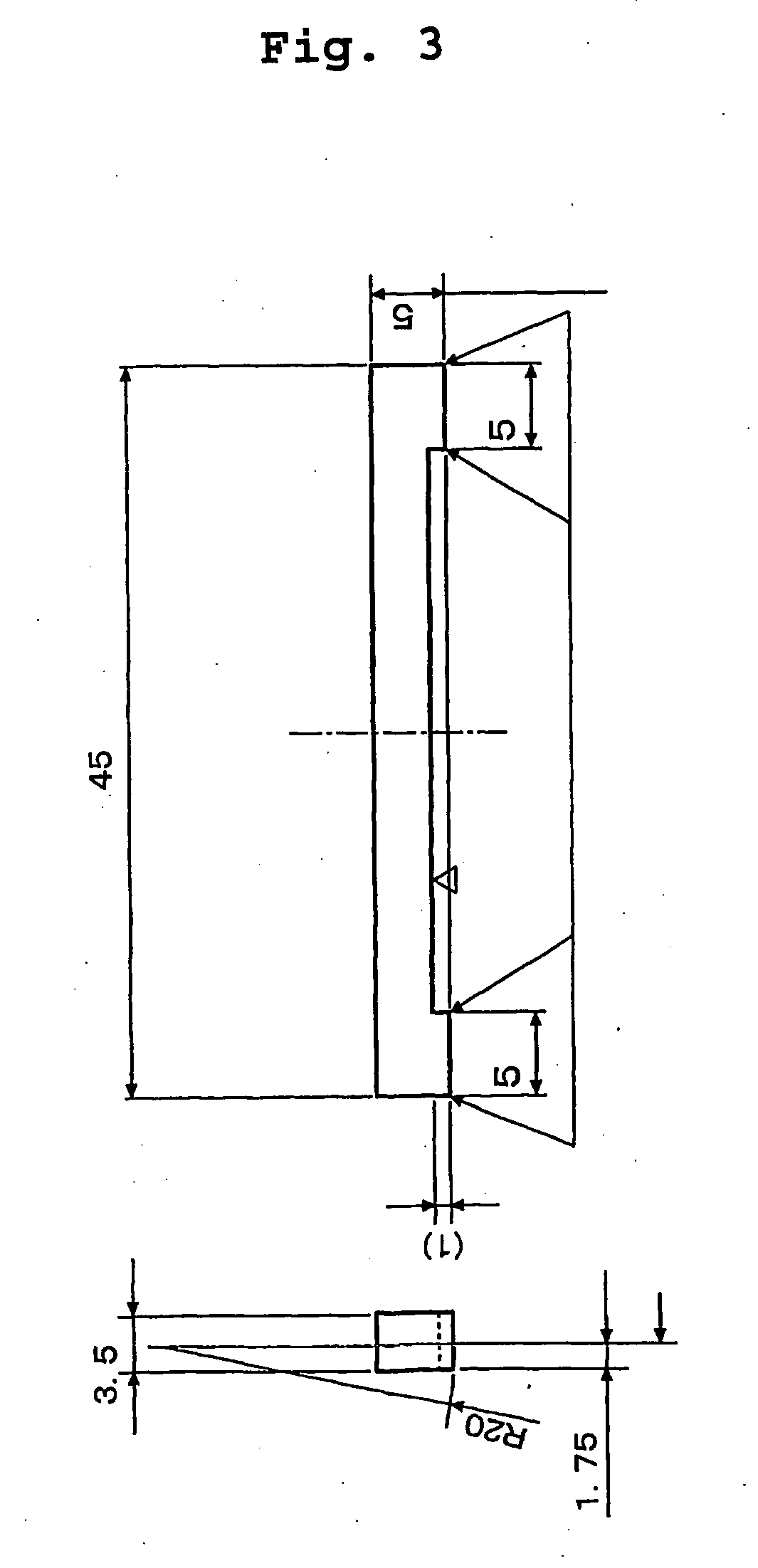

Machine tool and method for machining over-long diameter ratio shaft exceeding machine tool standard

InactiveCN101574743AIncrease profitIncrease travelLarge fixed membersTurning machinesFinialLongest Diameter

The invention discloses a machine tool and a method for machining an over-long diameter ratio shaft exceeding the machine tool standard. The method comprises the following steps: firstly, leaving a section of chuck dock with an effective length respectively at two ends of a workpiece in advance, and drilling central holes on two end surfaces of the workpiece; secondly clamping one end of the workpiece on a chuck of a headstock, and supporting the other end by a finial on a tailstock; thirdly, coarsely turning the excircle of each section of the workpiece, and reversing the workpiece for turning when a knife rest feeds to the tail end of a knife rest lead rail; fourthly, finely turning the excircle of each section of the workpiece, and reversing and clamping the workpiece for turning when the knife rest feeds to the tail end of the knife rest lead rail; and finally, milling the chuck docks at the two ends and the chamfer angle on a boring lathe, a milling machine or other machine tools. The machine tool and the method for machining an over-long diameter ratio shaft exceeding the machine tool standard achieve the purpose of machining long-shaft parts over 15 m on a common machine tool for machining long shaft parts, thereby reducing the production cost.

Owner:SHANGHAI HEAVY MACHINERY PLANT

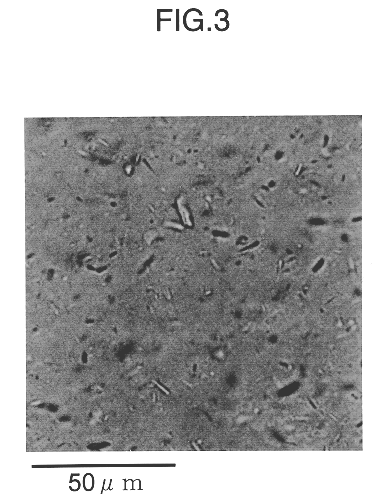

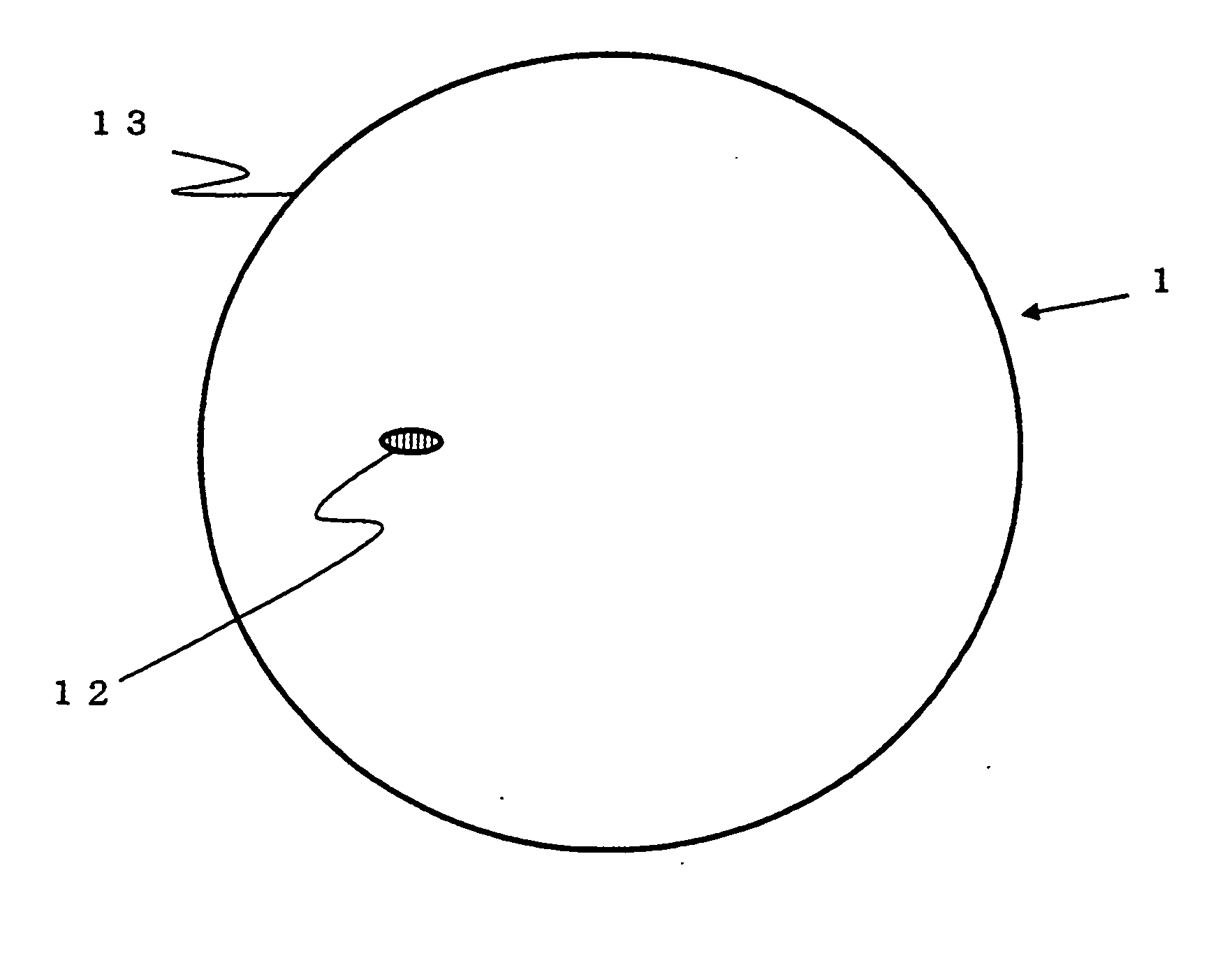

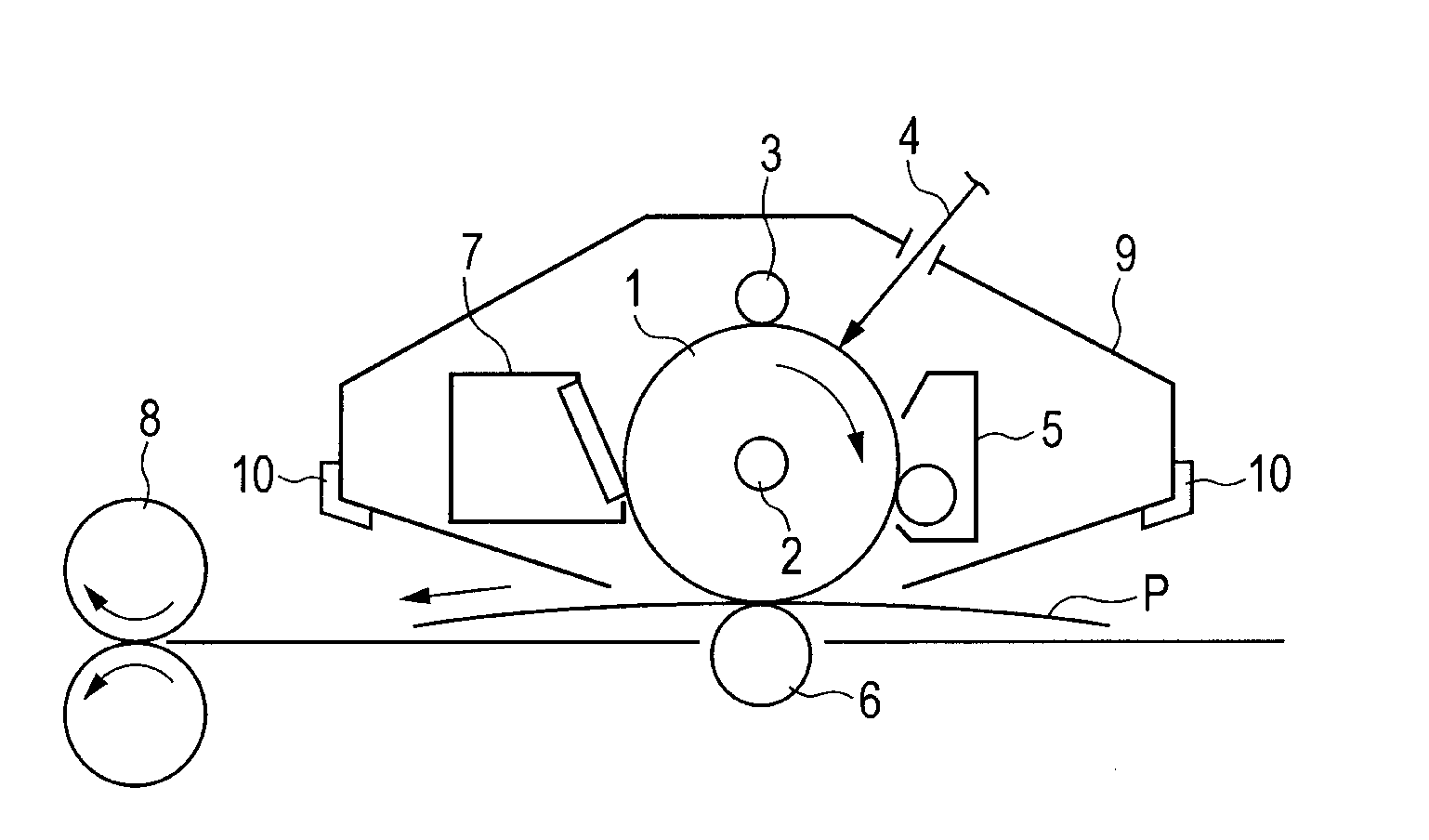

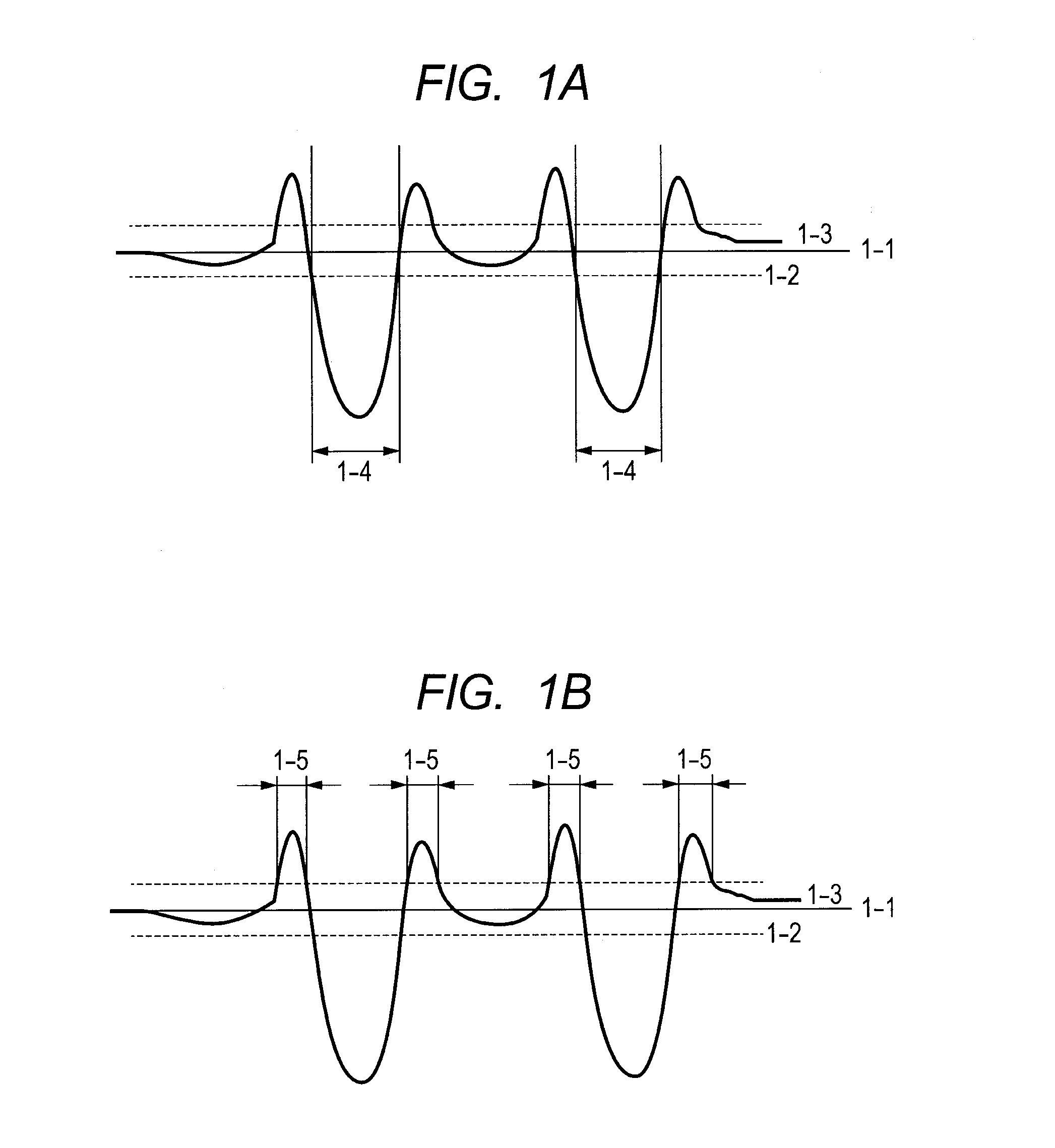

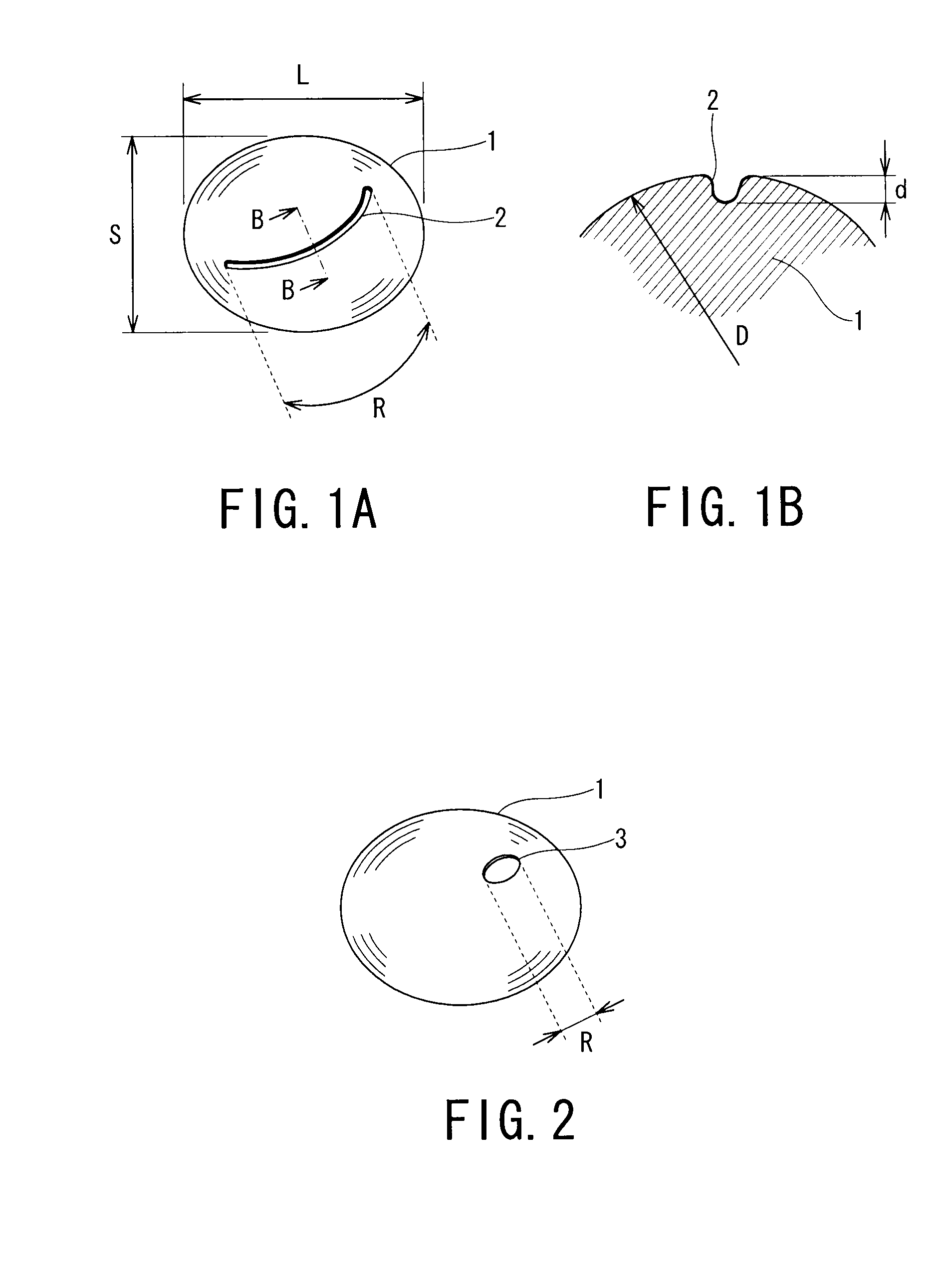

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

An electrophotographic photosensitive member in which image deletion is hardly produced, and a process cartridge and electrophotographic apparatus having the electrophotographic photosensitive member are provided. For this, a surface of the electrophotographic photosensitive member includes a plurality of depressed portions and a portion other than the depressed portions, each of the depressed portions having a depth of 0.5 to 5 μm and an opening longest diameter of 20 to 80 μm; when a 500 μm×500 μm square region is disposed in an arbitrary position of the surface of the electrophotographic photosensitive member, the area of the depressed portions in the 500 μm×500 μm square region is from 10000 to 90000 μm2, and the area of a flat part contained in the portion other than the depressed portions is from 80000 to 240000 μm2.

Owner:CANON KK

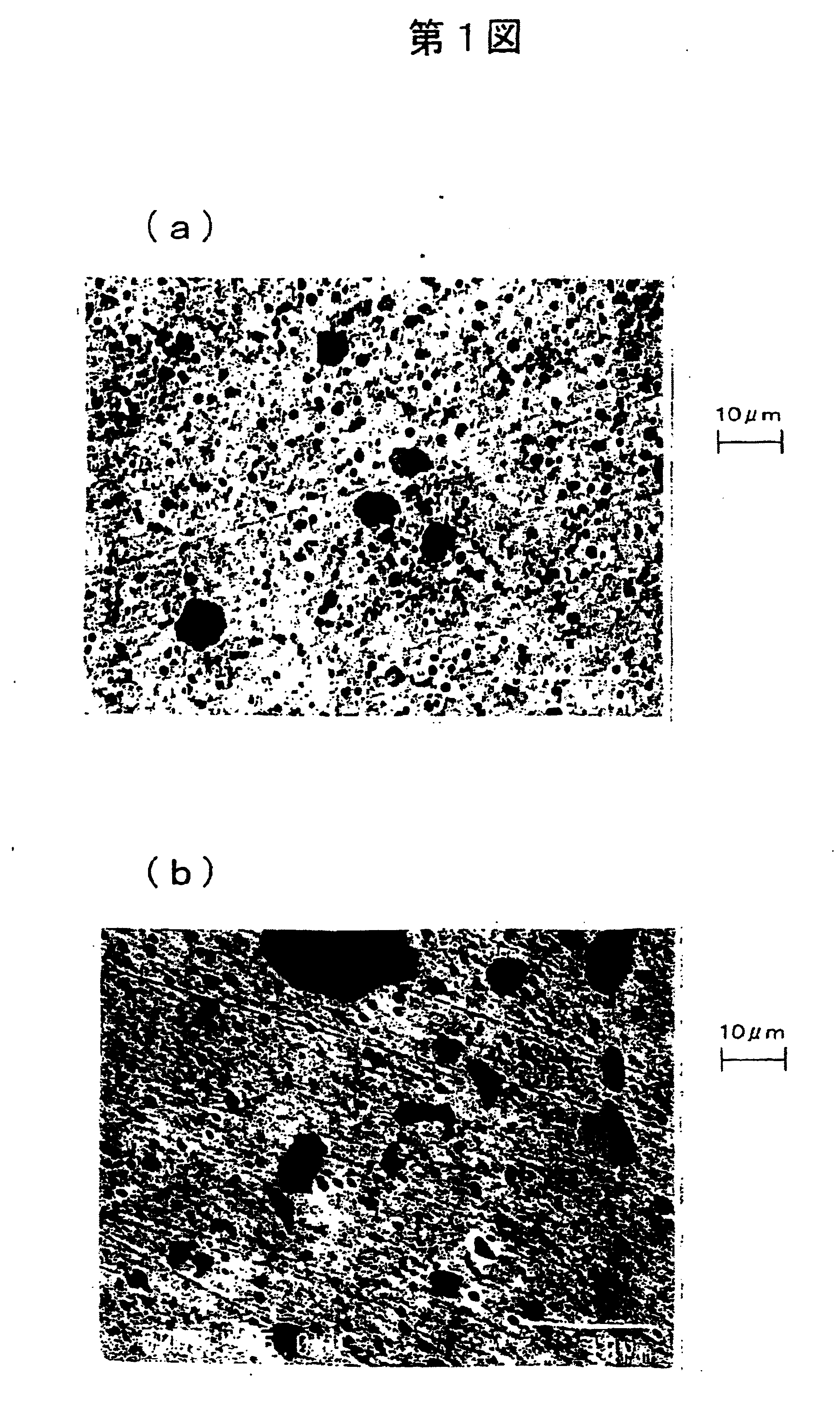

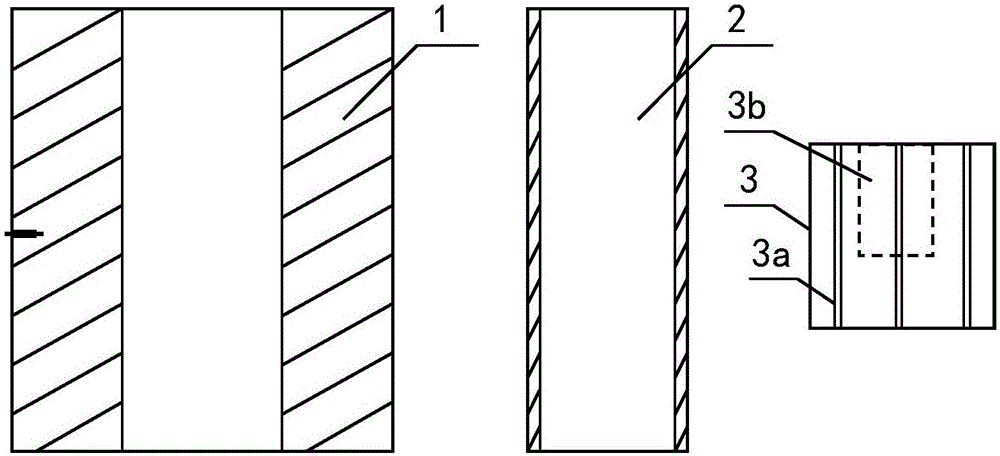

Semipermeable membrane supporting body and manufacturing method thereof

A task of the invention is to provide a semipermeable membrane supporting body which has excellent smoothness on a semipermeable membrane coating surface and can not be permeated by the semipermeable membrane solution. The semipermeable membrane supporting body is characterized in that the semipermeable membrane supporting body is composed of non-woven fabric which comprises more than two main synthetic fiber and adhesive synthetic fiber with different fiber diameters and is provided with the semipermeable membrane coating surface and a semipermeable membrane non-coating surface. In a thickness direction when observed from a cross section SEM of the non-woven fabric, a cross section aspect ratio (long diameter / short diameter of the cross section of the fiber) of the main synthetic fiber in a range between a surface and 1 / 3 part of the semipermeable membrane coating surface and / or a cross section aspect ratio (long diameter / short diameter of the cross section of the fiber) of the main synthetic fiber in a range between a surface and 1 / 3 part of the semipermeable membrane non-coating surface are 1.2-3.0.

Owner:MITSUBISHI PAPER MILLS LTD

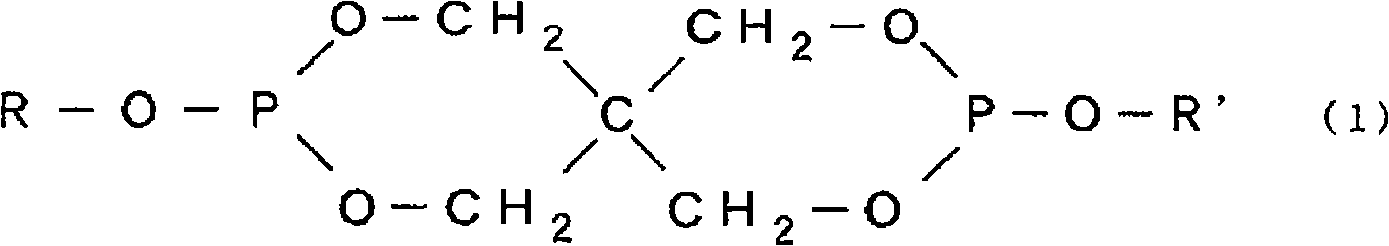

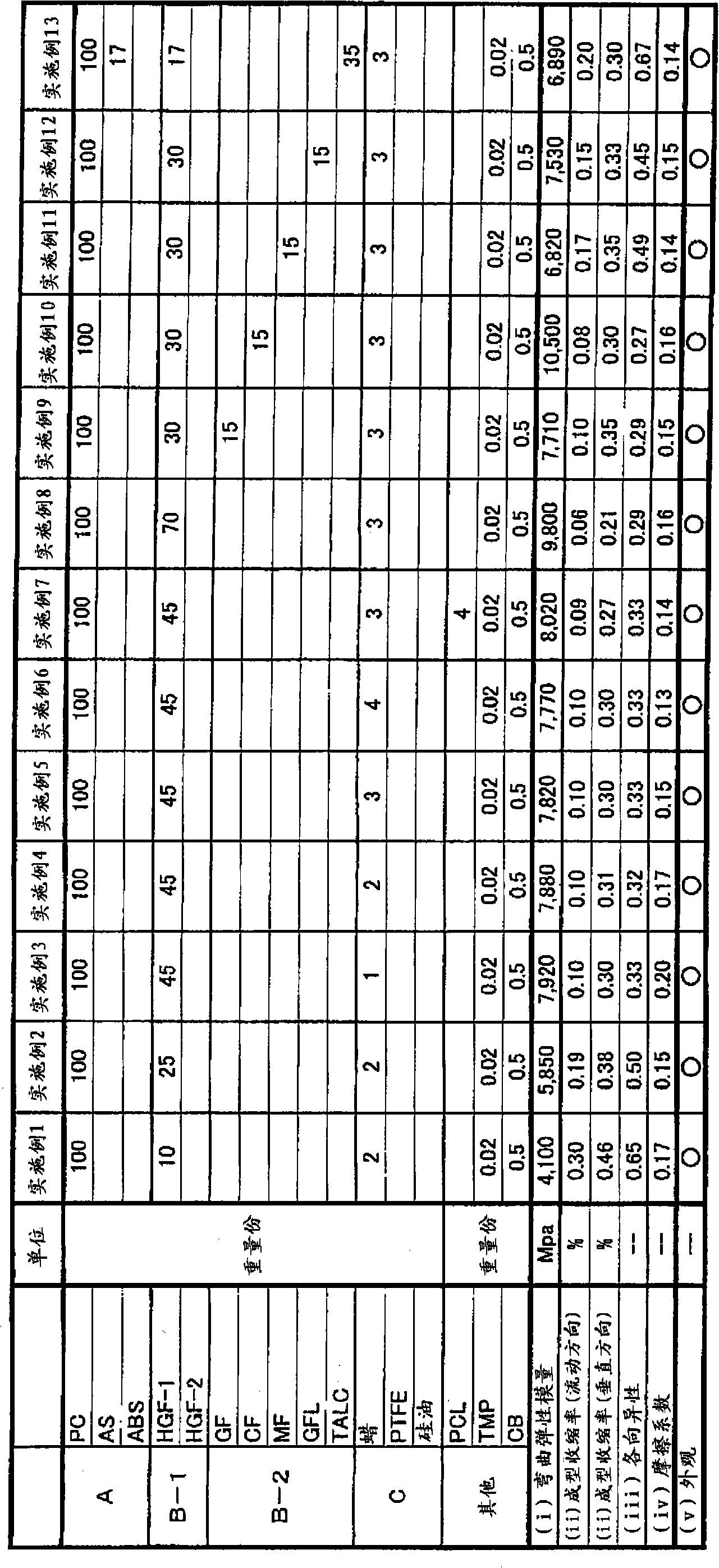

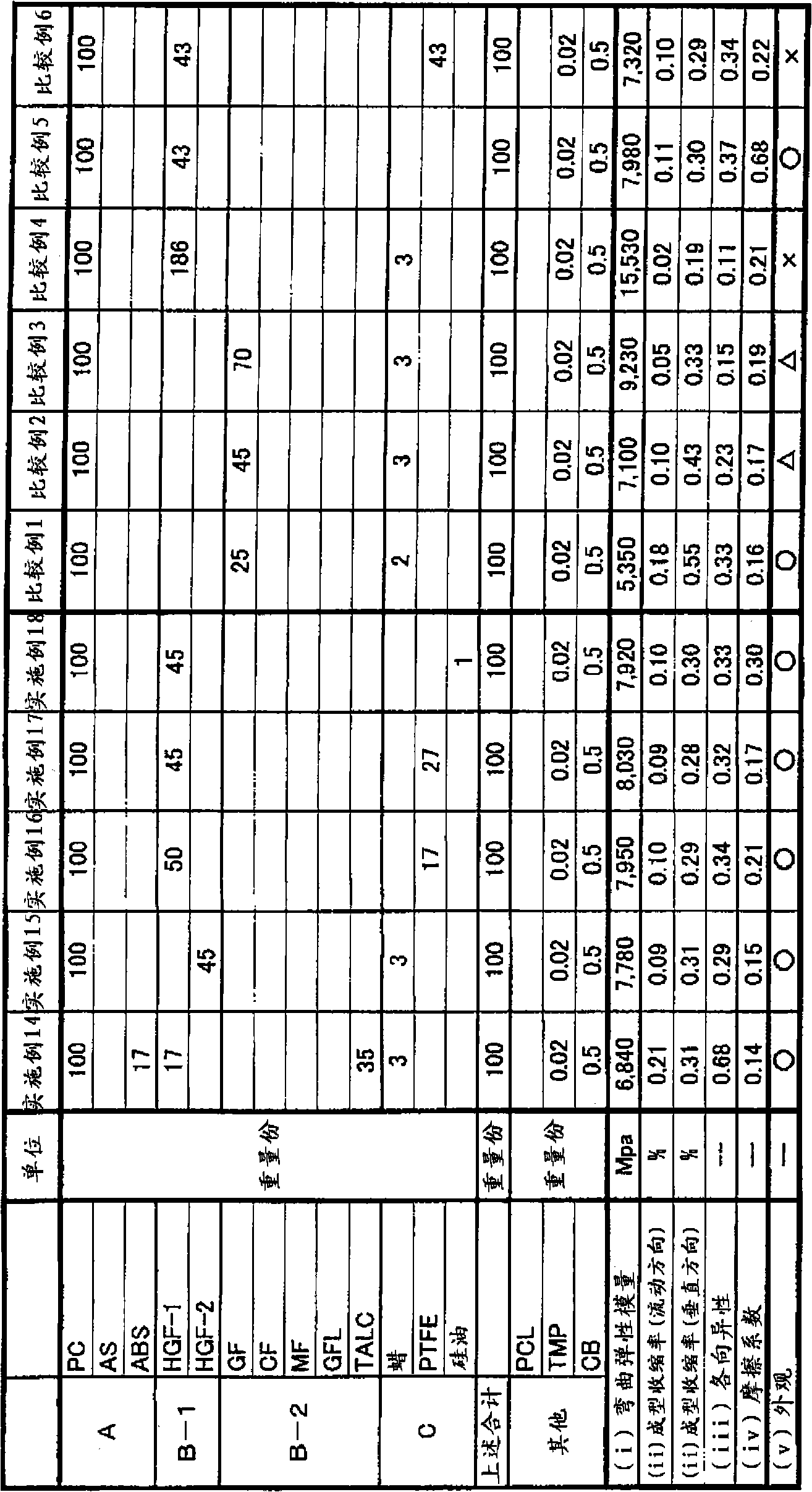

Glass fiber reinforced resin composition

The present invention relates to a glass fiber reinforced resin composition. The objective is to provide a resin composition based on flat cross section glass fiber reinforced thermoplastic resin and having excellent mechanical strength, small aeolotropism of mold shrinkage, good appearance and sliding characteristic. The resin composition contains (A) thermoplastic resin (component A) containing aromatic polycarbonate resin (component A-1); (B) flat cross section glass fibre (component B-1) that an average value of long diameters of the fibre cross section is 10-15[Mu]m, an average value of ratios of the long diameters and short diameters is 1.5-8, and filler material (component B-2), and (C) slide endowing agent (component C), wherein relative to 100 parts of component A by weight, the resin composition contains 1-150 parts of B-1 by weight, 0-150 parts of B-2 by weight, and 0.1-30 parts of C by weight.

Owner:TEIJIN KASEK KK

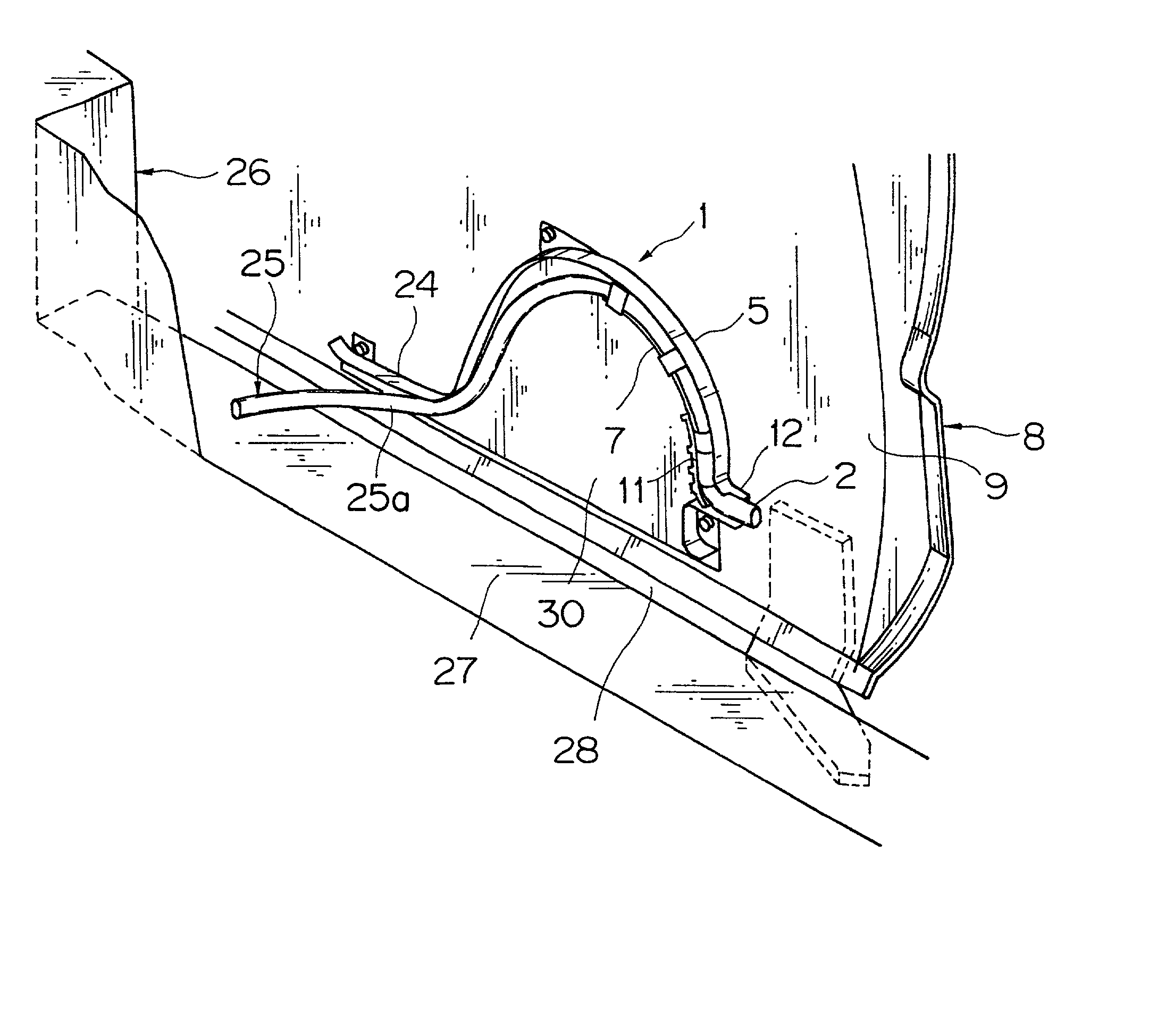

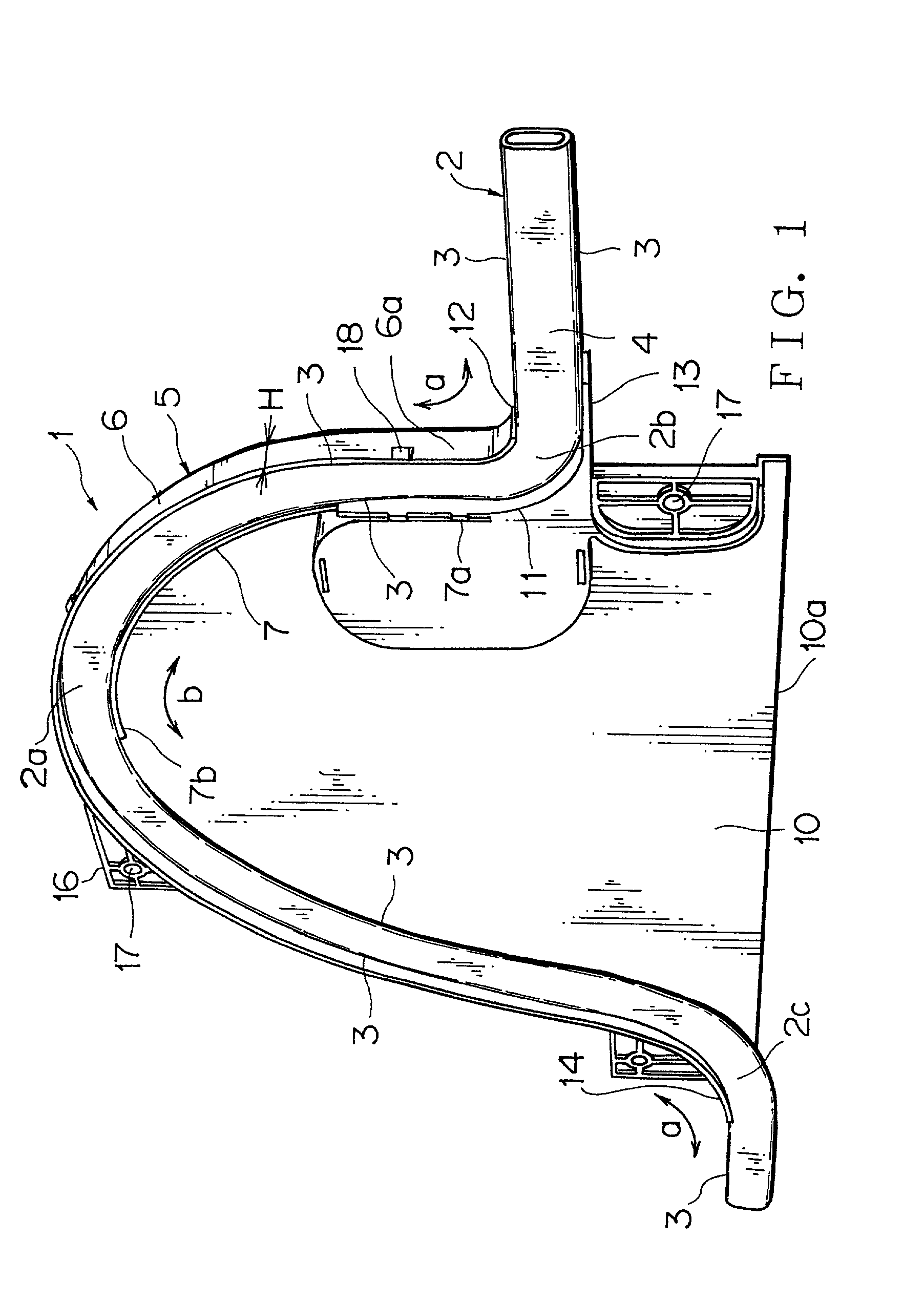

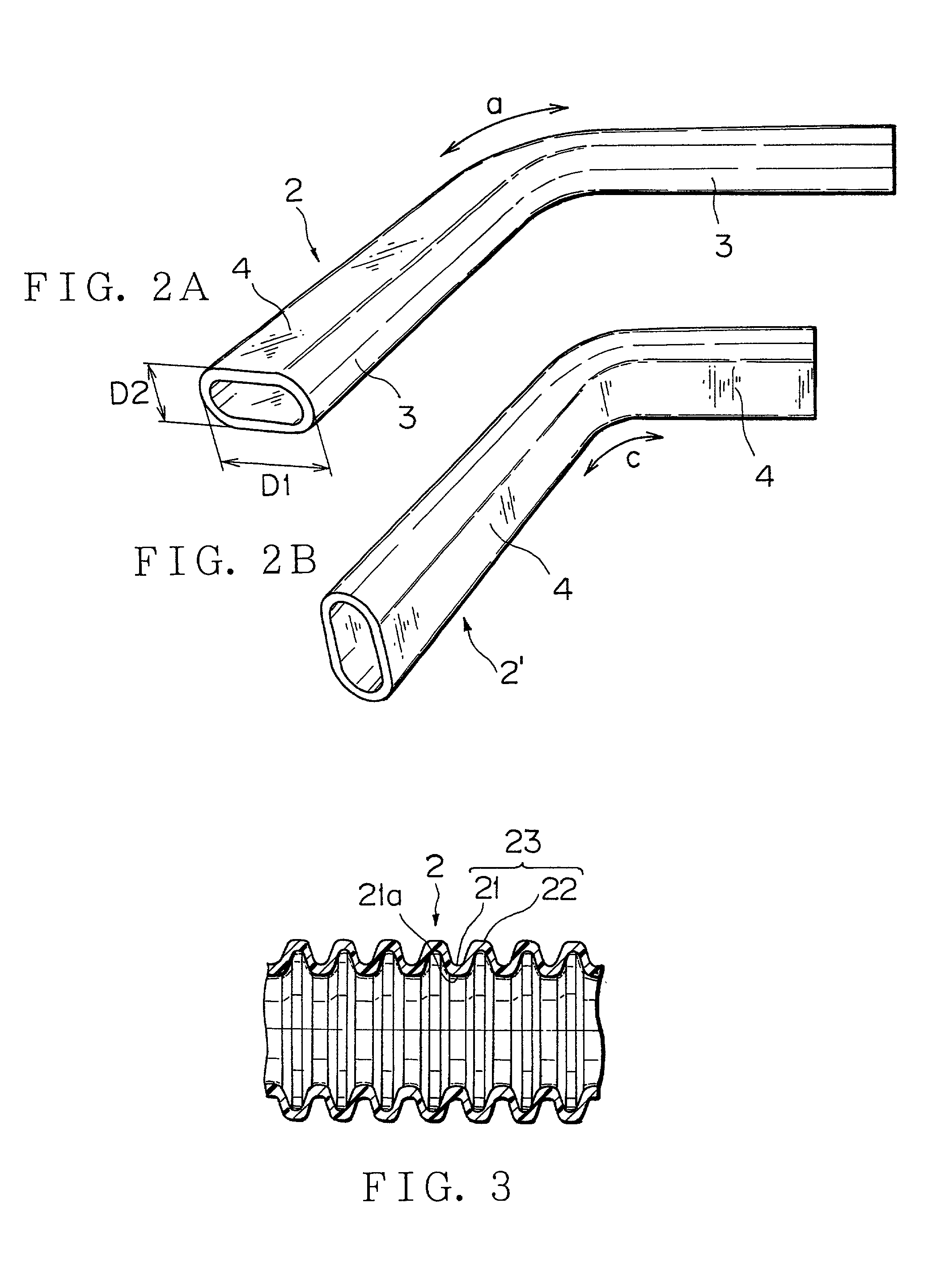

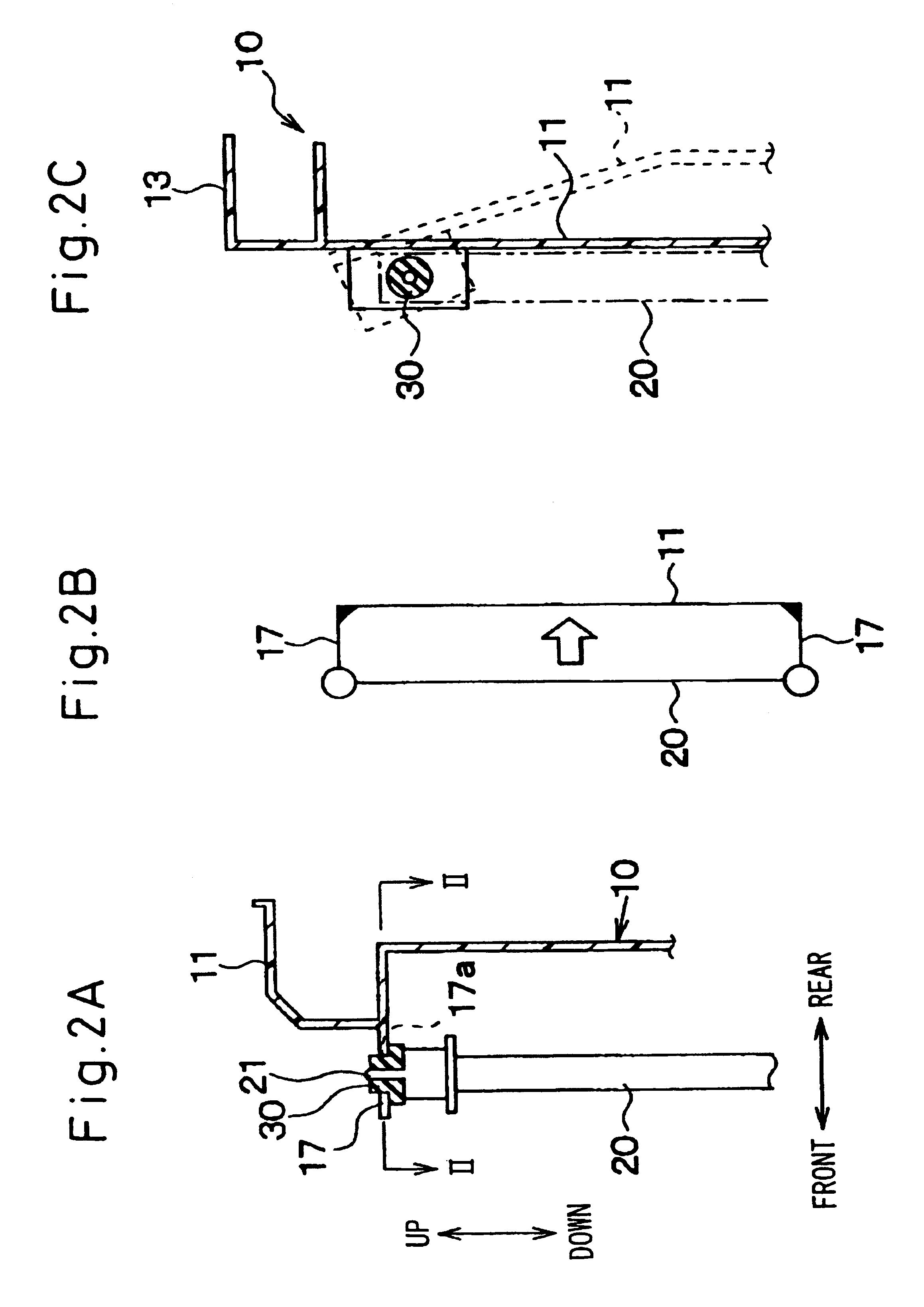

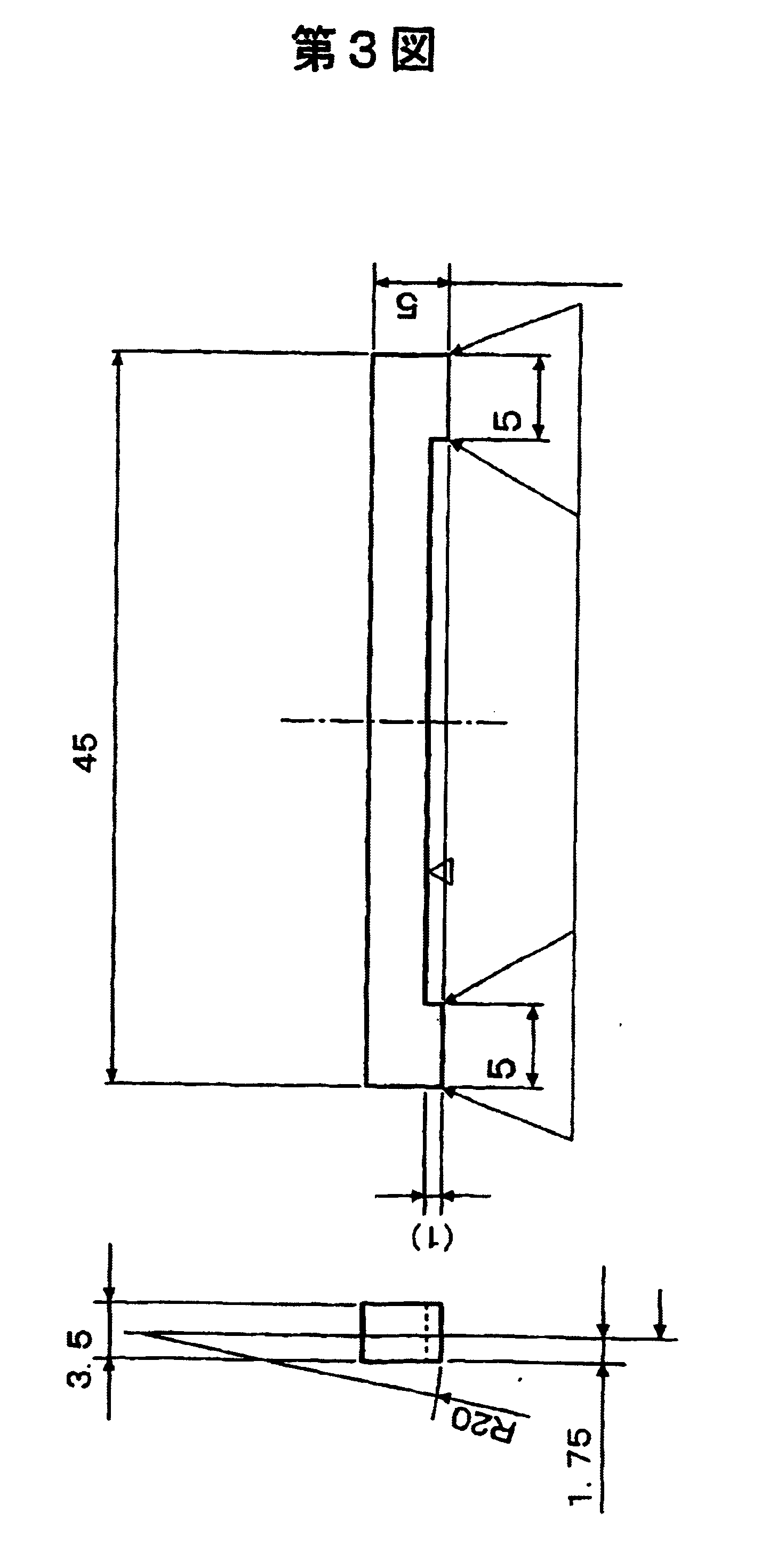

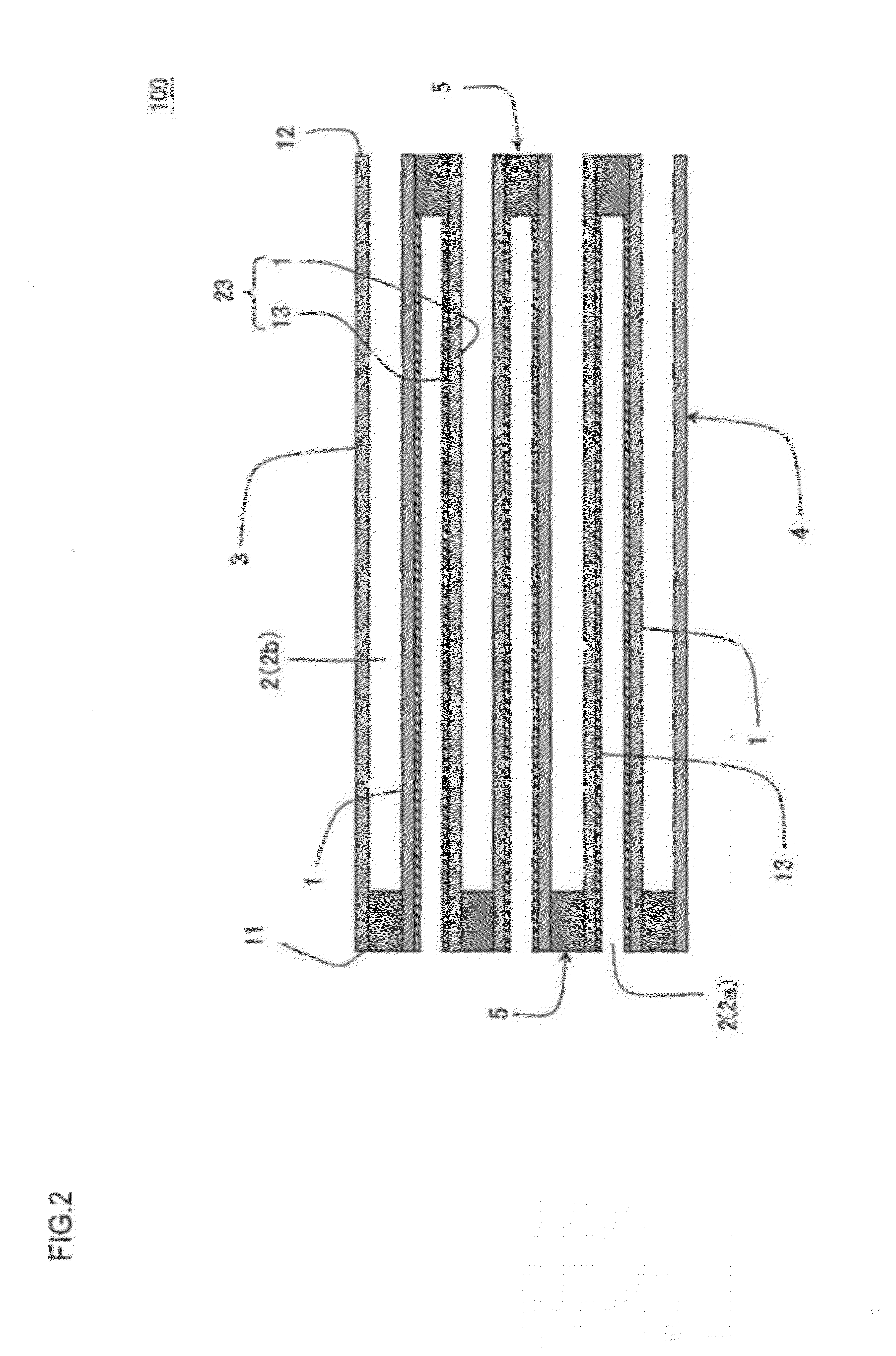

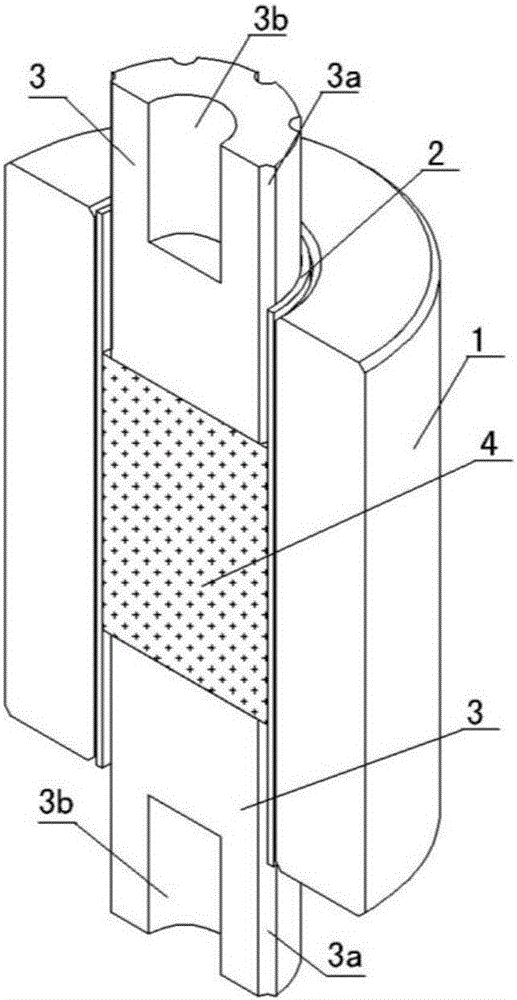

Structure of installing wire harness for sliding door

InactiveUS20020014348A1Electrically conductive connectionsExtensible conductorsLongest DiameterElectric wire

A structure of installing a wire harness for a sliding door includes a harness protective tube 2 in which electric wires are contained to compose the wire harness. The harness protective tube 2 is curved at the sliding door side and installed at a vehicle body side. The harness protective tube 2 has an oval shape in cross section, and is curved in a direction of its longer diameter portions 3 at the sliding door side so that the longer diameter portions are positioned in a vertical direction, whereby harness slack absorbing function is imparted to the harness protective tube. The longer diameter portions 3 are supported by a support part 11 at the sliding door side, and the harness protective tube 2 is curved in a direction of the longer diameter portions extending from the support part to the vehicle body side. There is provided a protector 5 in which the support part 11 is positioned, and the harness protective tube 2 is contained in a curved state in a direction of the longer diameter portions 3. The longer diameter portions 3 in a curved section 2a of the harness protective tube 2 are urged upward by an elastic member 7.

Owner:YAZAKI CORP

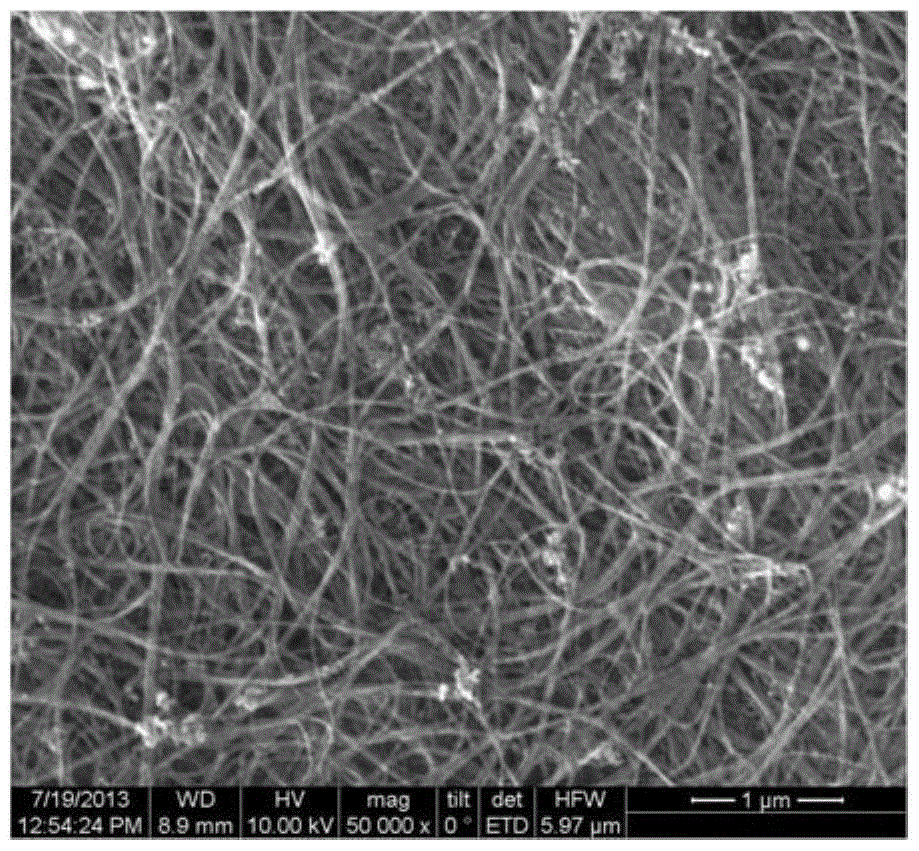

Flexible heating film assembly and preparing method thereof

ActiveCN105208692AGuaranteed softnessGuaranteed comfortHeating element materialsLongest DiameterFlexural strength

The invention discloses a flexible heating film assembly and a preparing method thereof. The flexible heating film assembly comprises a flexible heating layer. The flexible heating layer is formed by connecting five to one thousand heating film layers in a stacked mode. Loose and porous structures are formed between every two layers. A circuit system is connected to the flexible heating layer. At least one of the upper side and the lower side of the flexible heating layer is provided with a protecting layer. The multiple heating film layers of the flexible heating layer are connected in a stacked mode, the loose and porous structures are formed between every two layers, and by means of unique nanometer holes, the large long-diameter ratio and the large specific area, the flexible heating layer has large elasticity modulus and high bending strength, macroscopic flexibility and hand feeling comfort of the flexible heating film assembly are ensured; in addition, the flexible heating film assembly has ultra-thin thickness and high flexibility, is easy to process and form and resistant to detergent, and is an excellent insulating and heat preserving material.

Owner:J NOVA WORKS CO LTD

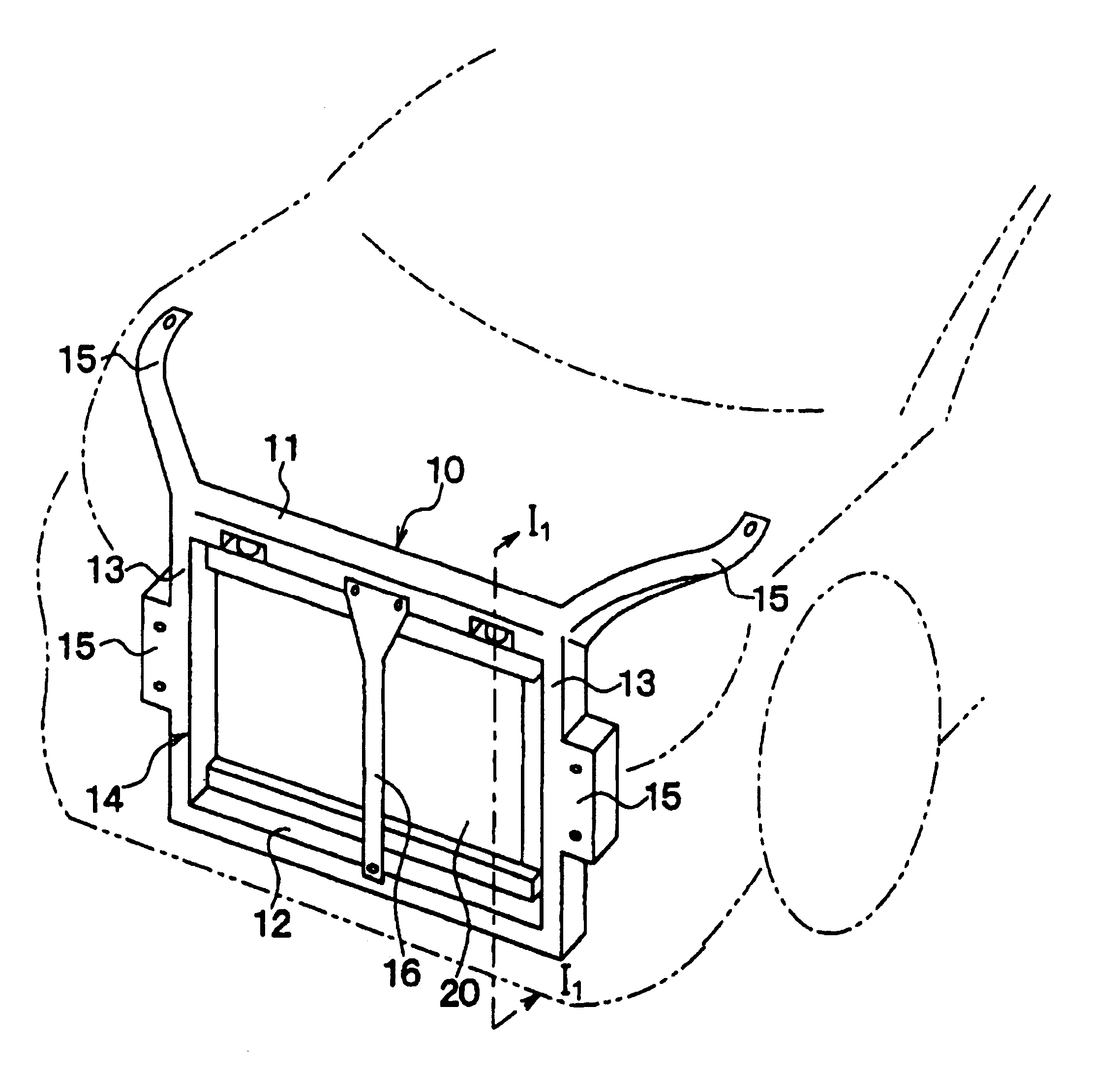

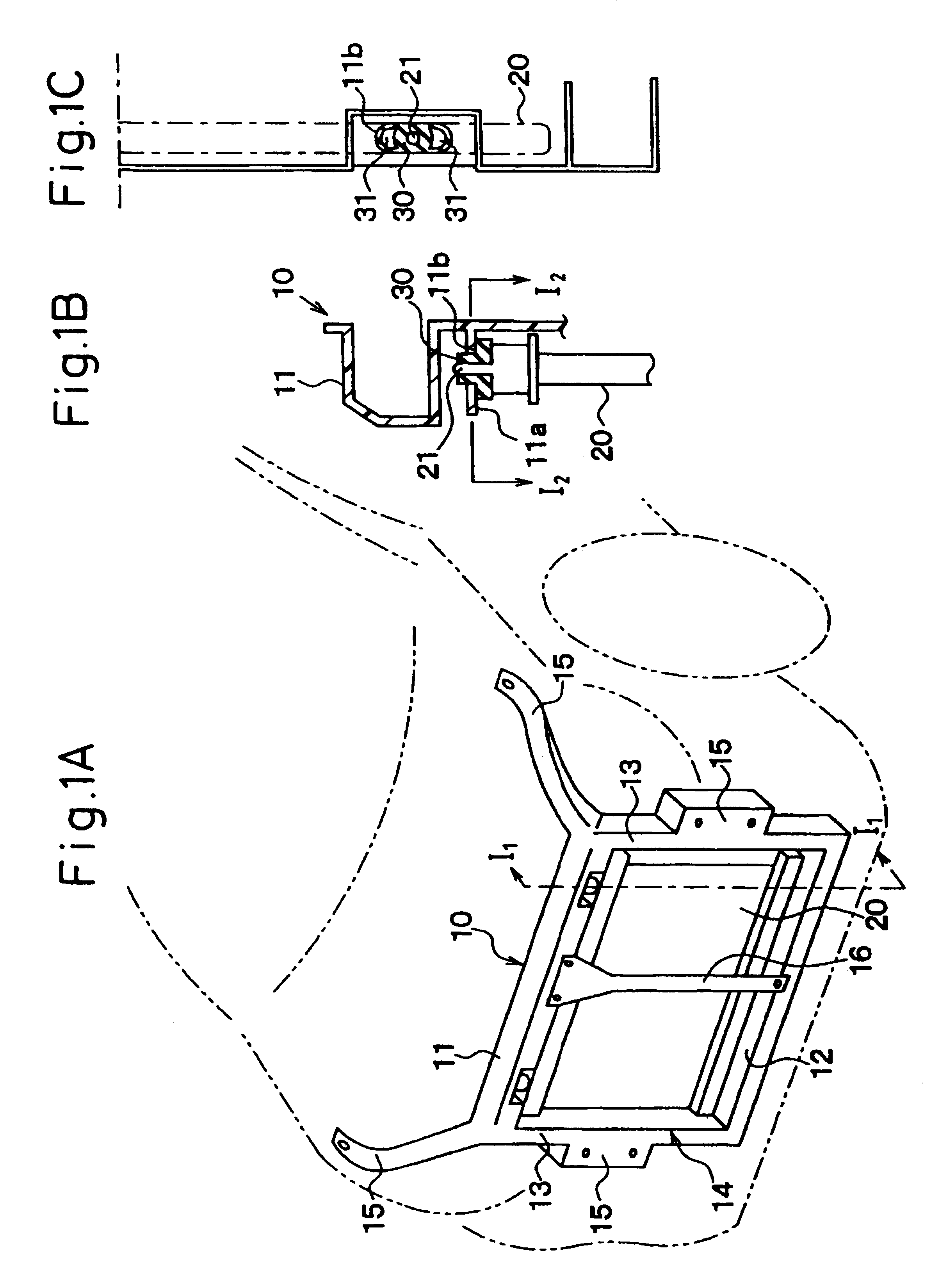

Front-end structure of vehicle

InactiveUS7331413B2Improve pedestrian protectionVehicle seatsPedestrian/occupant safety arrangementLongest DiameterEngineering

An attachment portion between an upper member (11) and a radiator (20) is constructed so as to be displaced in a longitudinal direction of the upper member (11) when an impact force is applied to the upper member (11) by constructing a mount cushion (30) so as to be deformed easily in a longer diameter direction thereof. By this structure, when an impact force is applied to the upper member (11) from a front side of a vehicle, as it is not that the radiator (20) and the upper member (11) are deformed together but that the upper member (11) is deformed prior to the radiator (20), a bending rigidity to an impact force becomes smaller than a conventional case. Consequently, since the upper member is allowed to be deformed easily at the time of collision without largely reducing the mechanical strength of the upper member (11), compatibility between the requirements of protection of pedestrians and sufficient strength of the upper member (11) can be ensured.

Owner:DENSO CORP

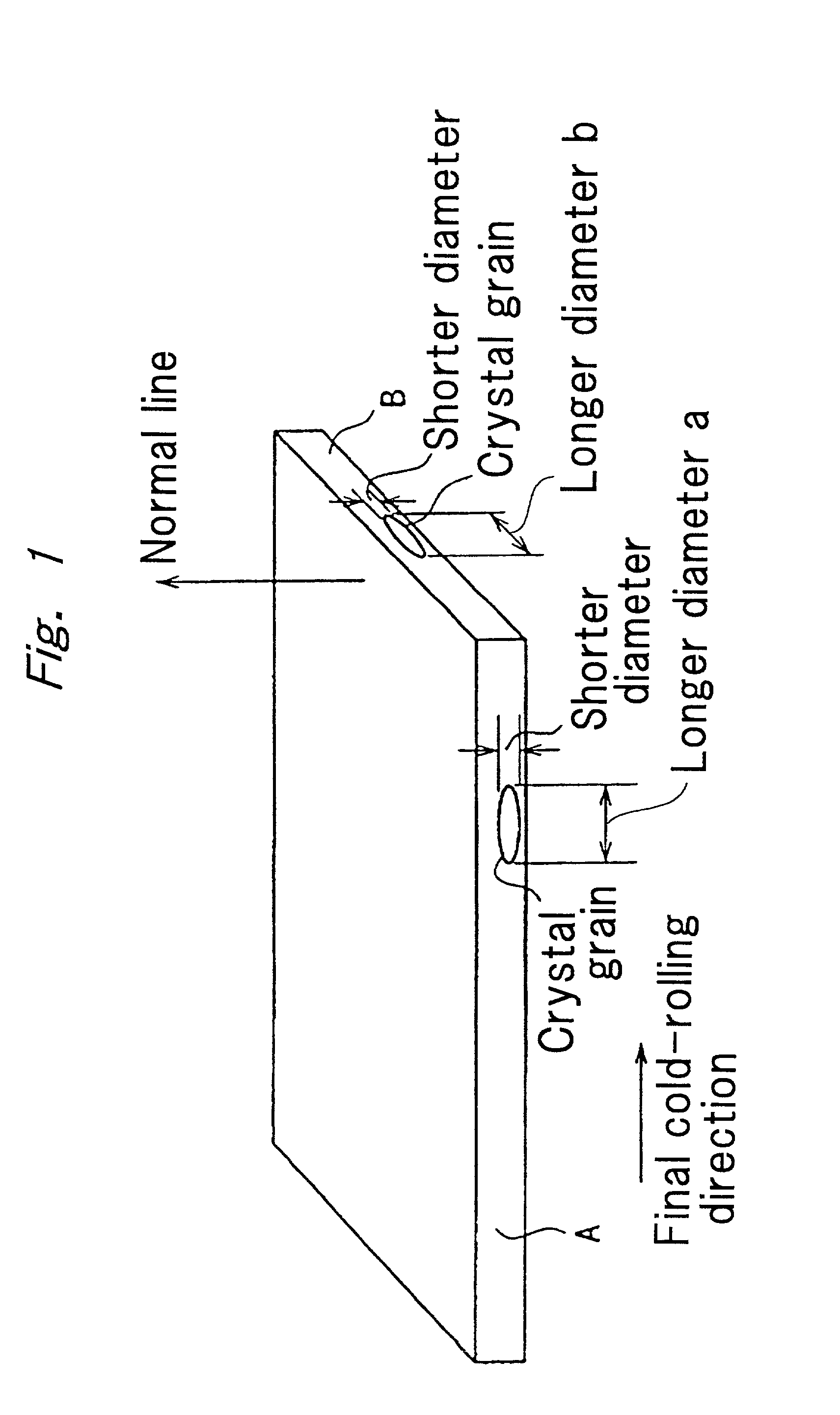

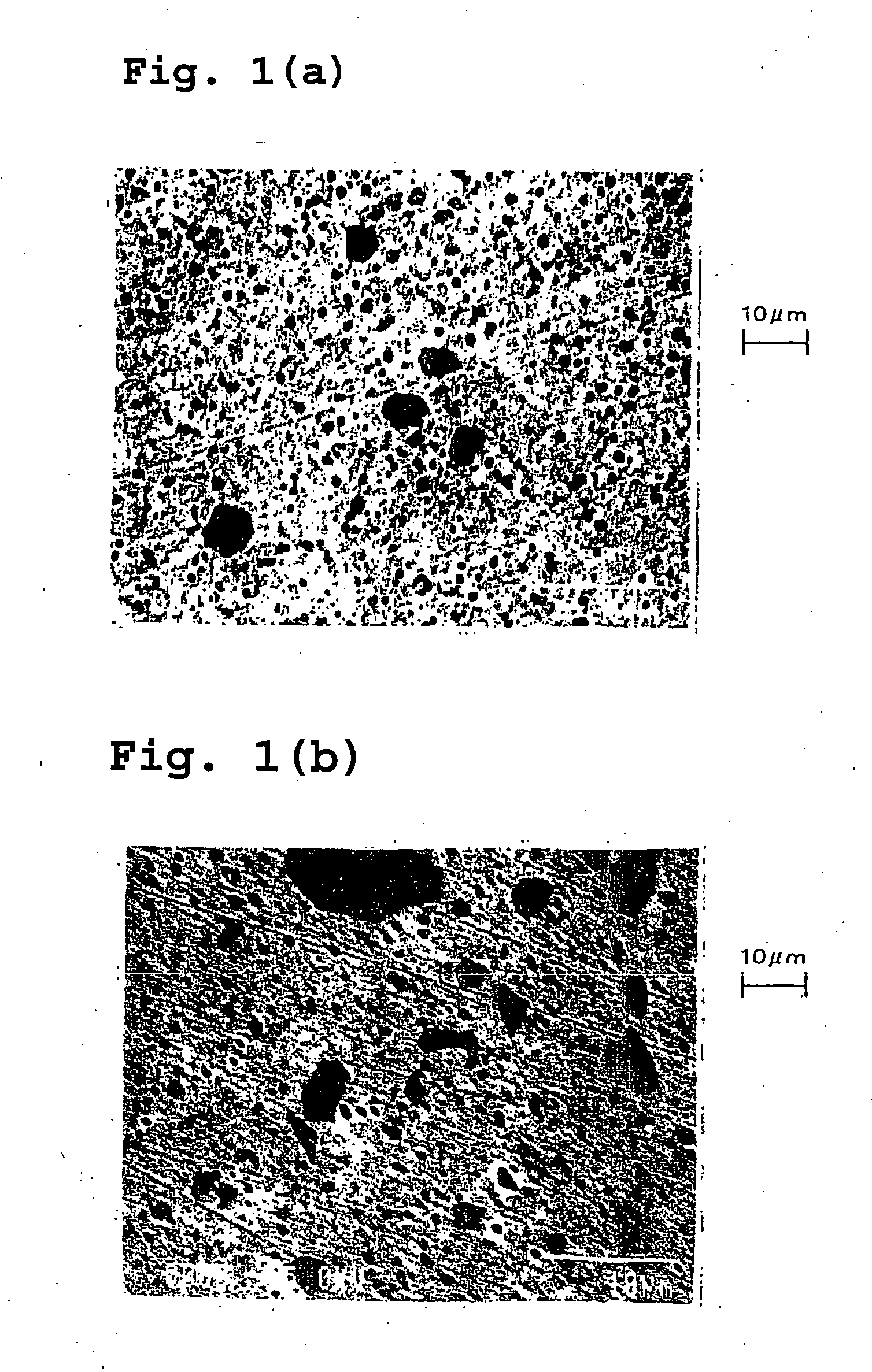

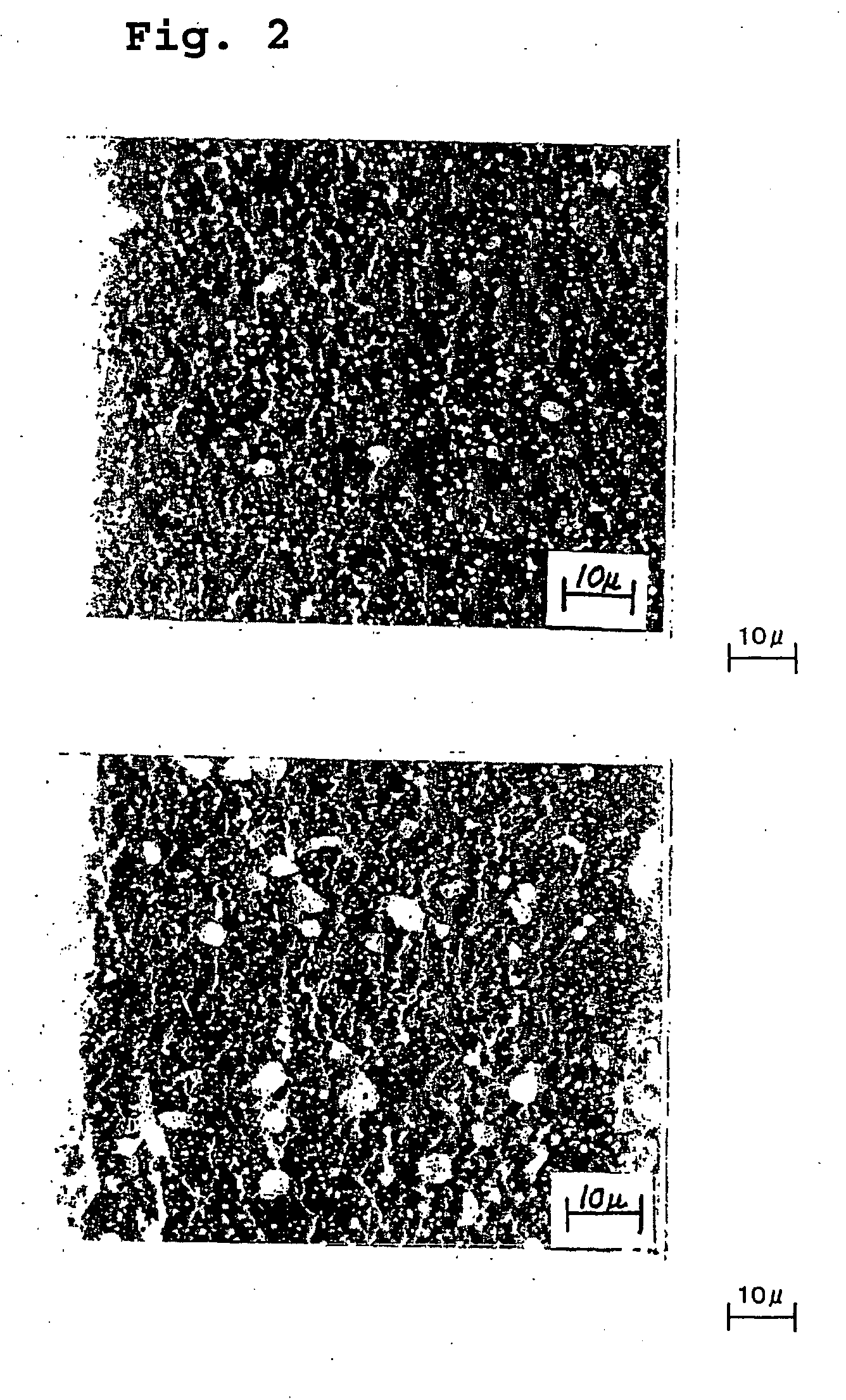

Copper alloy material for parts of electronic and electric machinery and tools

InactiveUS20020127133A1Improved in bending property and stress relaxation propertyExcellent in essential characteristicCoupling contact membersThin material handlingLongest DiameterSurface roughness

A copper alloy material for parts of electronic and electric machinery and tools contains 1.0 to 3.0 mass % of Ni, 0.2 to 0.7 mass % of Si, 0.01 to 0.2 mass % of Mg, 0.05 to 1.5 mass % of Sn, 0.2 to 1.5 mass % of Zn, and less than 0.005 mass % (including 0 mass %) of S, with the balance being Cu and inevitable impurities, wherein the copper alloy material has: (1) a specific crystal grain diameter, and a specific ratio between the longer diameters of a crystal grain on a cross section parallel or perpendicular to a direction of final plastic working; and / or (2) a specific surface roughness after the final plastic working.

Owner:FURUKAWA ELECTRIC CO LTD

Full-degradation natural fibre/polylactic acid composite material and preparation method thereof

The present invention belongs to the technological field of the polymer material, provides and relates to a wholly degradable natural fiber and polylactic composite material and the preparation method. The composite material consists of the surface modified natural fiber and the polylactic acid. The specific preparation steps are: first the natural fiber of a certain long diameter is taken and the natural fiber is soaked in the aqueous solution of the coupling agent for 1 to 100 minutes; then the natural fiber is taken out and dried; thus the surface modified natural fiber can be got. Then the polylactic acid is molded and refined in the two-roller smelting machine at a temperature between 100 and 160 Celsius system; after 1 to 20 minutes, the surface modified natural fiber is added to mix and refine. The mixed products are putinto the mold; the mixed products are compressed and molded in the flat vulcanization machine to make the natural fiber and polylactic composite material. Compared with the pure polylactic acid, the mechanical and thermal performances of the composite material are improved; the composite material can be used in the preparation of the engineering plastics with the demanding conditions. The composite material of the present invention can be wholly degraded in the natural environment after being used and wasted, and the composite material belongs to the environmentally friendly material.

Owner:TONGJI UNIV

Ferritic stainless steel sheet with excellent thermal fatigue properties, and automotive exhaust-gas path member

InactiveUS20080279712A1Reasonable component designIncreased durabilityThermal fatigueLongest Diameter

Disclosed is a ferritic stainless steel sheet with excellent thermal fatigue properties, including, by mass %, 0.03% or less of C, 1.0% or less of Si, 1.5% or less of Mn, 0.6% or less of Ni, 10˜20% of Cr, 0.05˜0.30% of Ti, 0.51˜0.65% of Nb, 0˜less than 0.10% of Mo, 0.8˜2.0% of Cu, 0˜0.10% of Al, 0.0005˜0.02% of B, 0˜0.20% of V, and 0.03% or less of N, with the balance being Fe and inevitable impurities, having a composition satisfying the following equations (1) and (2) and having a structure in which ε-Cu phase grains each having a long diameter of 0.5 μm or more are present in a density of 10 or less per 25 μm2: Nb−8(C+N)≧0 . . . (1), 10 Si+20 Mo+30 Cu+20(Ti+V)+160 Nb−(Mn+Ni)≧100 . . . (2). The ferritic stainless steel sheet, having a relatively inexpensive component composition, has excellent thermal fatigue properties, and is suitable for use in an automotive exhaust-gas path member, including an exhaust manifold, a catalyst converter, a front pipe, or a center pipe.

Owner:NISSHIN STEEL CO LTD +1

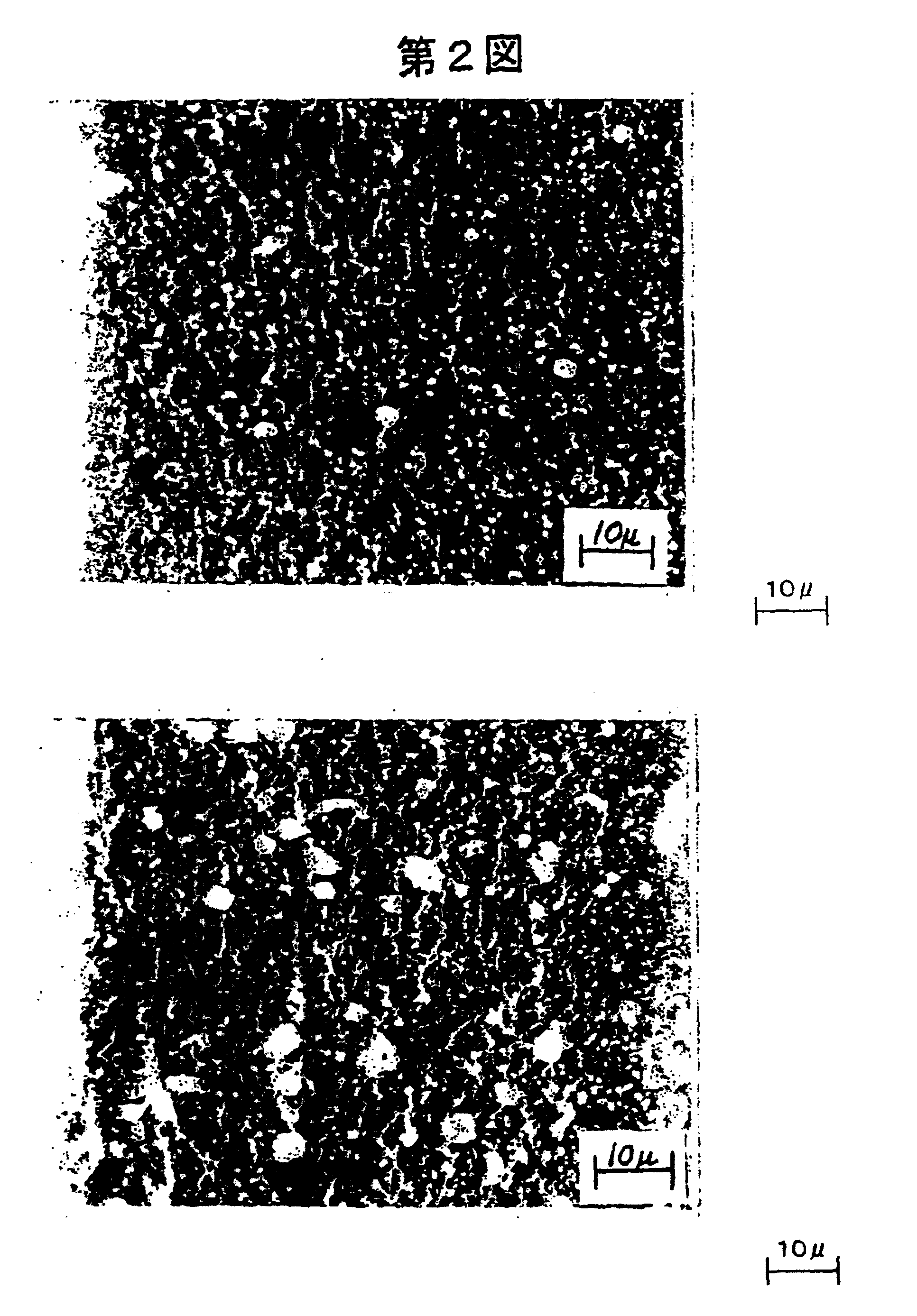

Piston ring having improved scuffing, cracking and fatigue resistances, and its production method, as well as combination of piston ring and cylinder block

InactiveUS20070187002A1Contact pressureScuffing canPiston ringsSolid state diffusion coatingCrack resistanceLongest Diameter

A piston ring having improved scuffing resistance, cracking resistance and fatigue resistance, consists of a high-chromium martensitic stainless steel and a sliding nitriding layer formed on the surface of said steel. The stainless steel consists of C: 0.3 to 1.0%; Cr: 14.0 to 21.0%, N: 0.05 to 0.50%, at least one of Mo, V, W and Nb: 0.03 to 3.0% in total, Si: 0.1 to 1.0%, Mn 0.1 to 1.0%, P: 0.05% or less, S: 0.05% or less, the balance being Fe and unavoidable impurities. The sliding nitriding layer comprises on its surface hard particles mainly consisting of nitrides in a range of from 0.2 to 2.0 μm of average particle size, 7 μm or less of the longest diameter, and from 5 to 30% in area ratio.

Owner:TAKAHASHI JUNYA +3

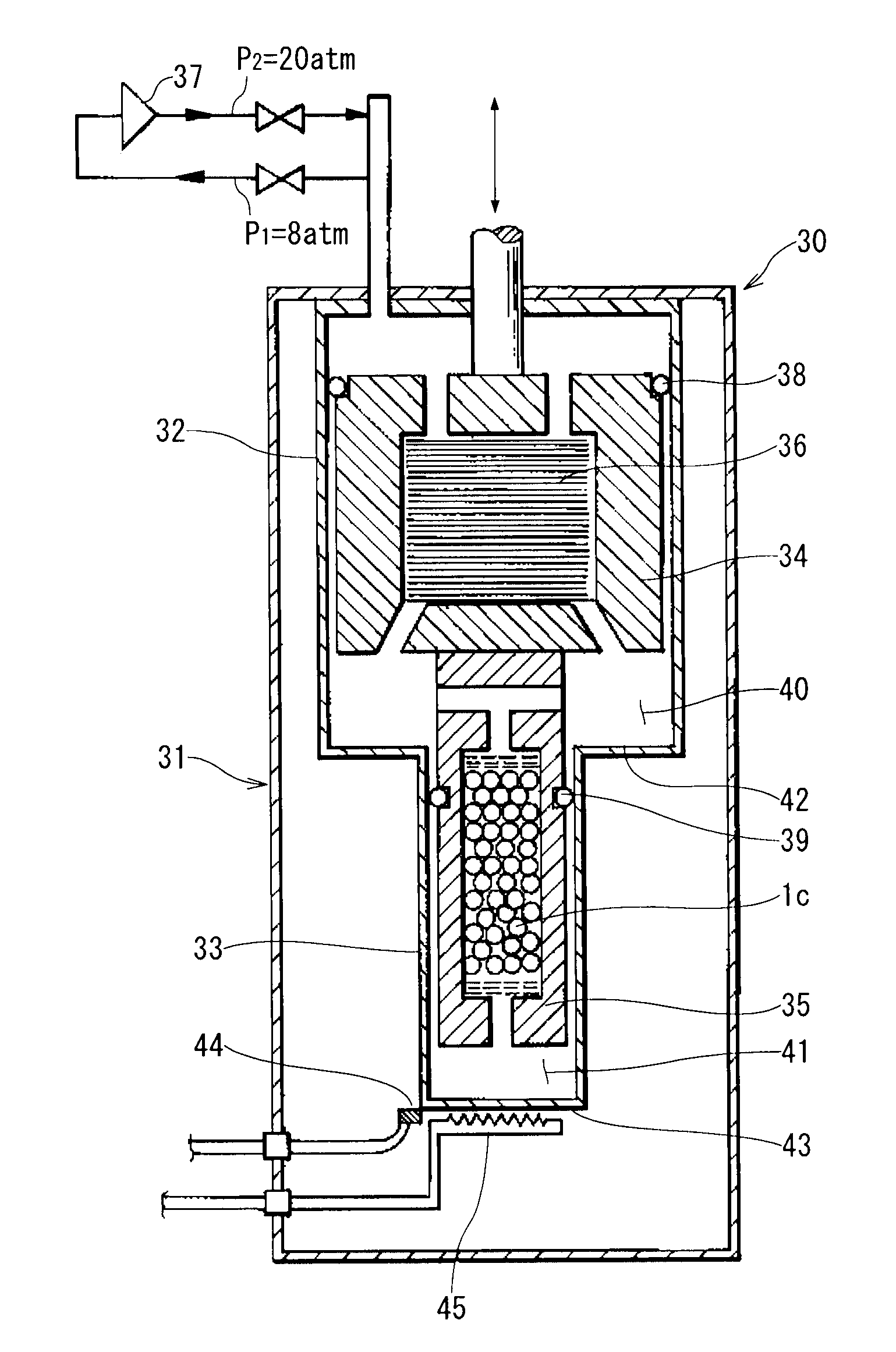

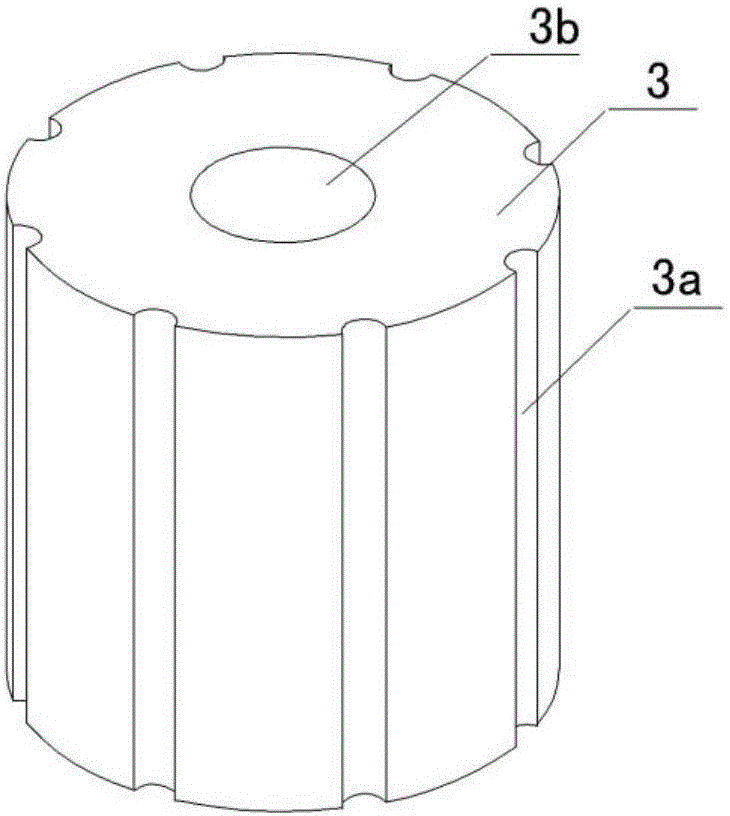

Rare-earth regenerator material particles, and group of rare-earth regenerator material particles, refrigerator and measuring apparatus using the same, and method for manufacturing the same

ActiveUS20120157320A1Avoid smallImprove featuresLayered productsHeat-exchange elementsLongest DiameterRare earth

Provided is a group of rare-earth regenerator material particles having an average particle size of 0.01 to 3 mm, wherein the proportion of particles having a ratio of a long diameter to a short diameter of 2 or less is 90% or more by number, and the proportion of particles having a depressed portion having a length of 1 / 10 to ½ of a circumferential length on a particle surface is 30% or more by number. By forming the depressed portion on the surface of the regenerator material particles, it is possible to increase permeability of an operating medium gas and a contact surface area with the operating medium gas.

Owner:KK TOSHIBA +1

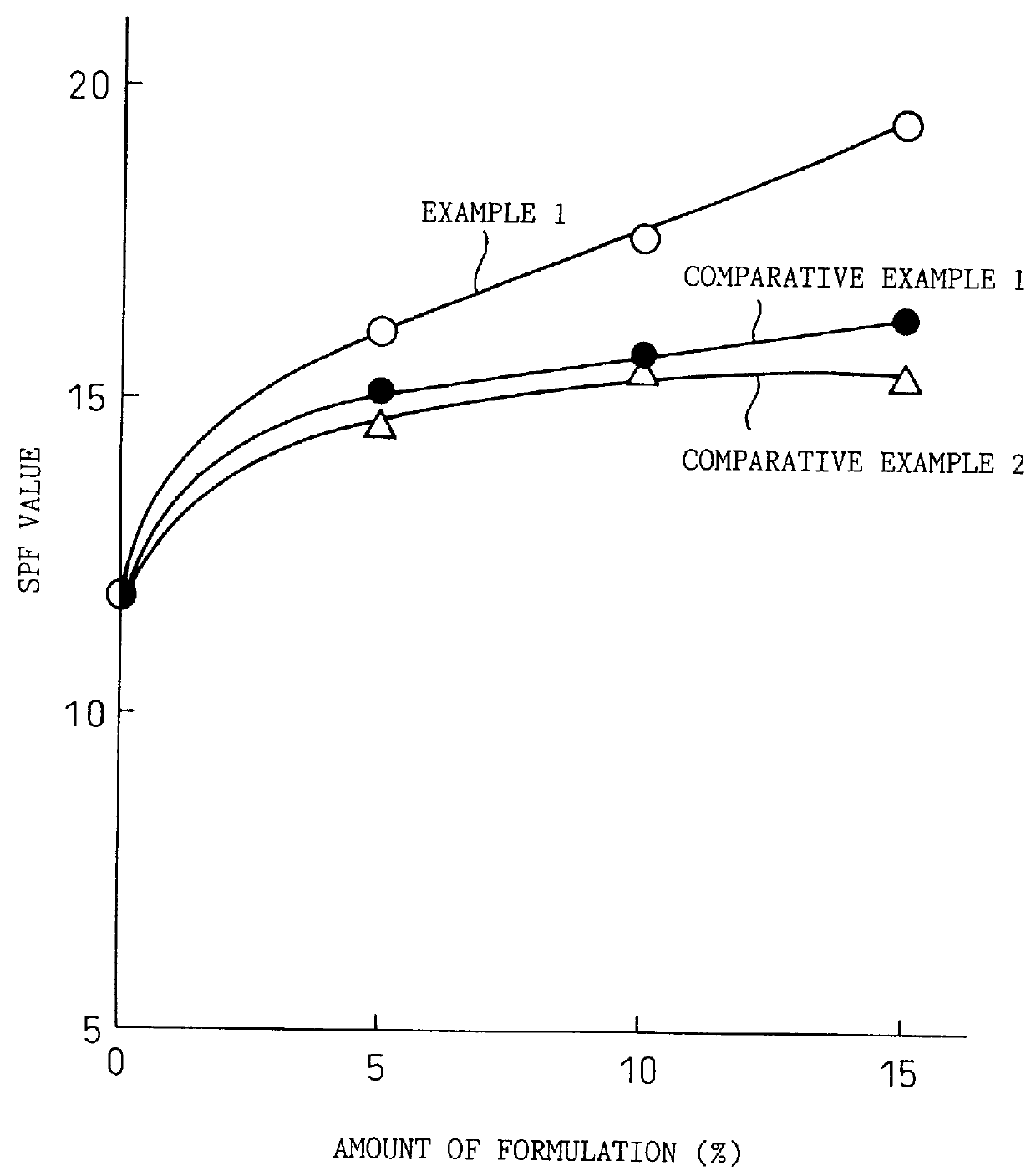

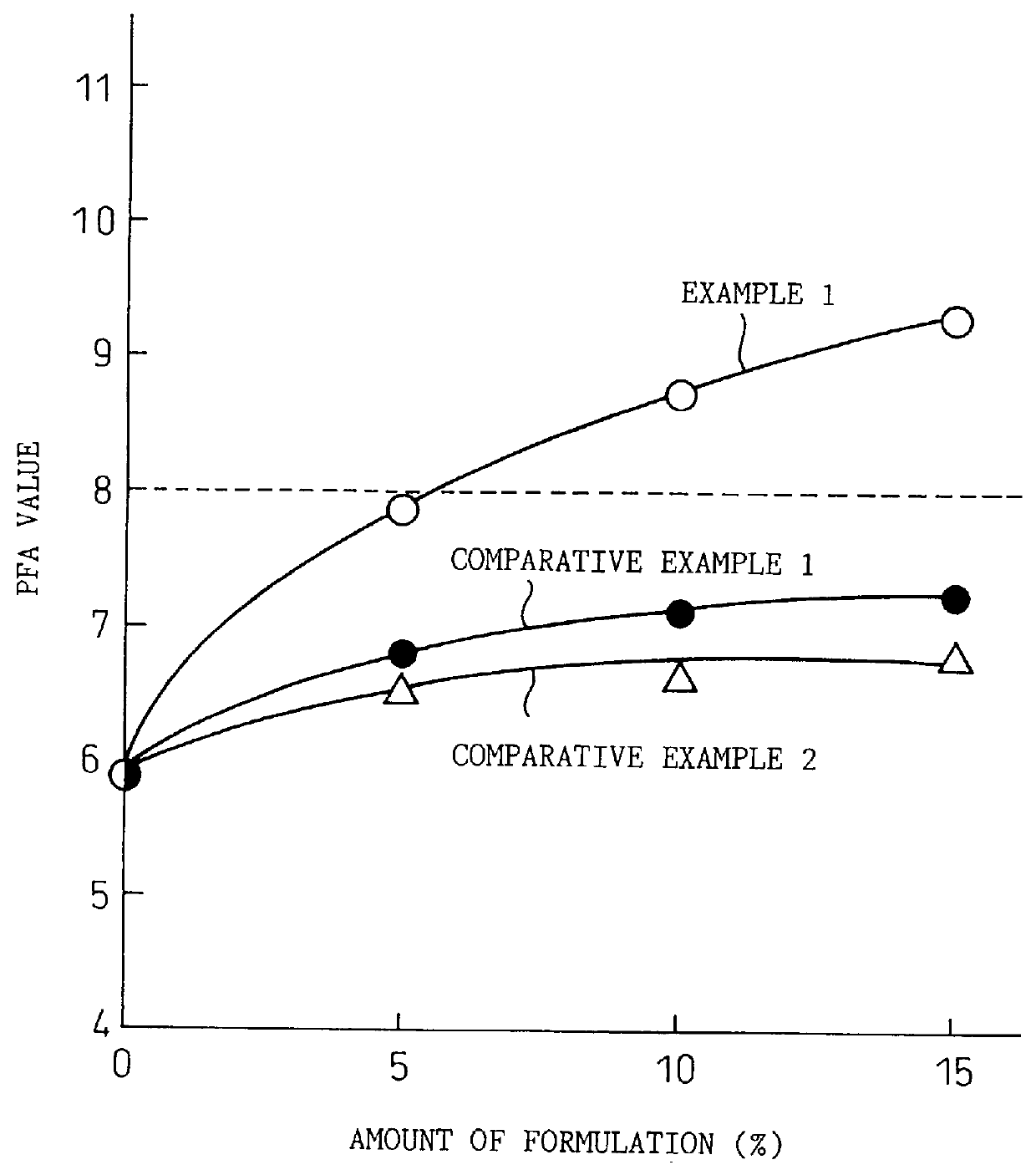

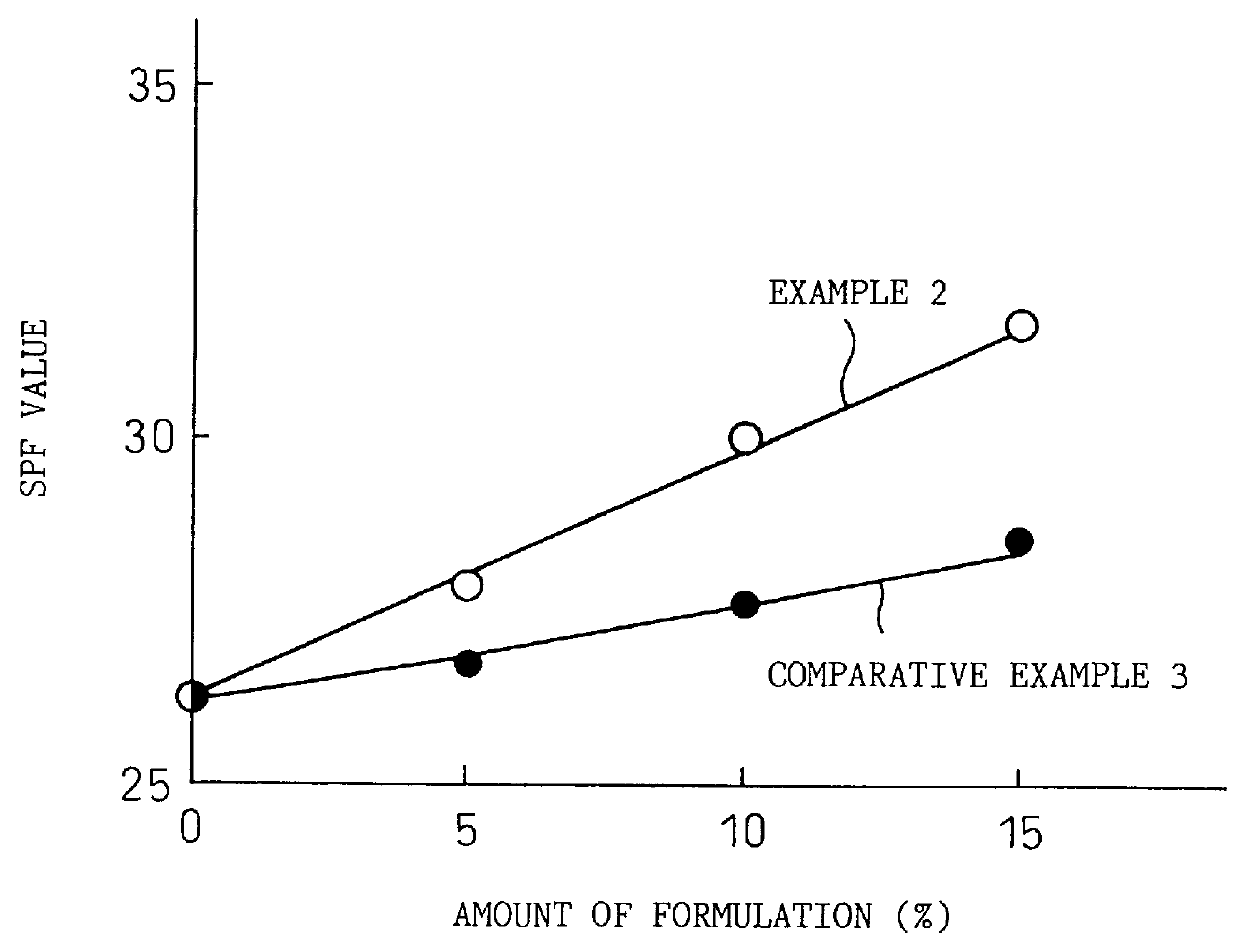

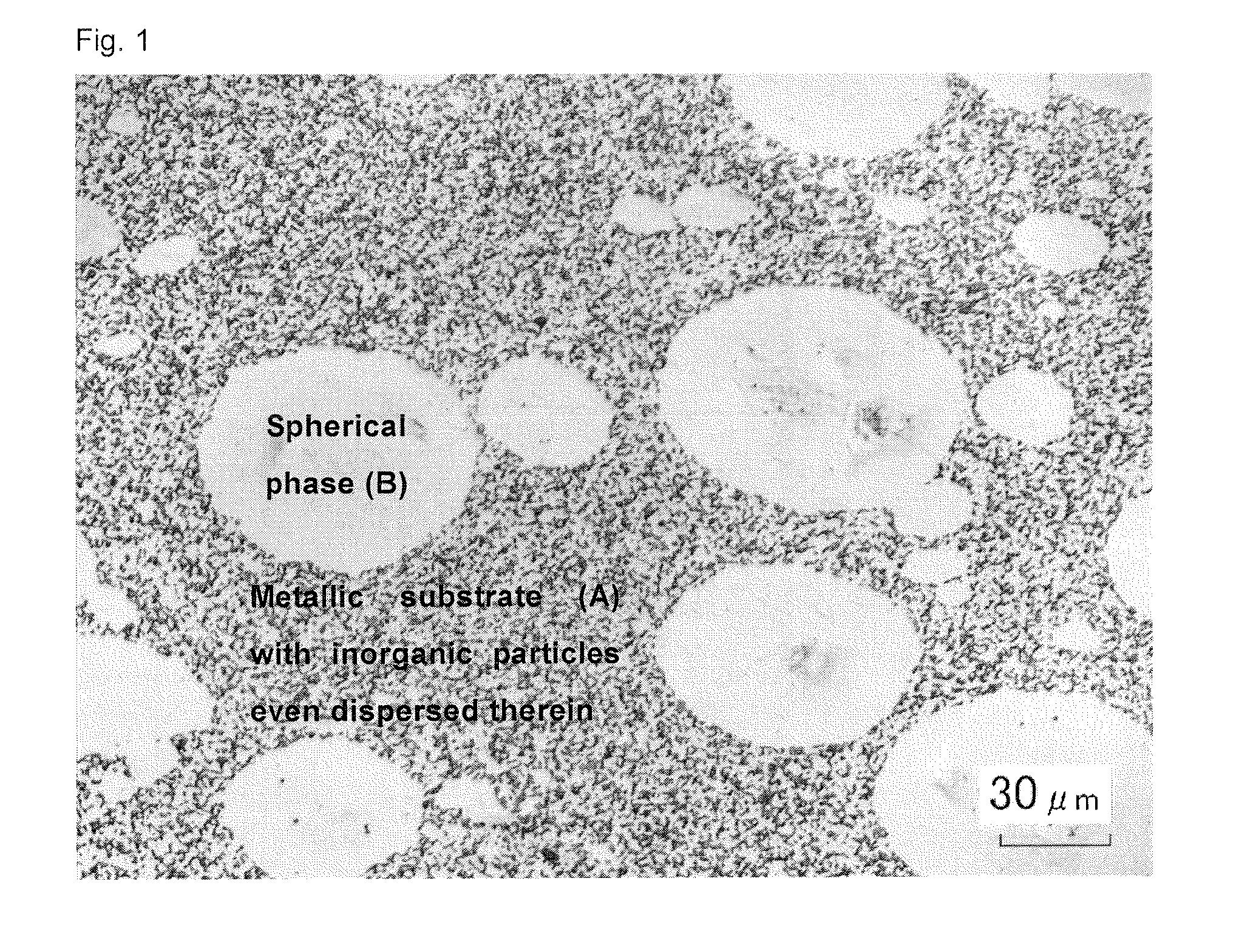

Cosmetic composition containing spindle shaped fine particles of titanium dioxide

InactiveUS6123927AFine granularityGood dispersionCosmetic preparationsBody powdersLongest DiameterUv blocking

Owner:SHISEIDO CO LTD +1

Particulate alumina, method for producing particulate alumina and composition containing particulate alumina

InactiveUS20050182172A1Reduce crushing efficiencyDegree of improvementPigmenting treatmentSemiconductor/solid-state device detailsParticulatesLongest Diameter

Particulate alumina has a mean particle size corresponding to a volume-cumulative 50% mean particle size (D50) falling within a range of 3 to 6 μm, has a ratio of D90 to D10 that is 2.5 or less, contains particles that have a particle size of at least 12 μm in an amount of 0.5 mass % or less, particles that have a particle size of 20 μm or more in an amount of 0.01 mass % or less and particles that have a particle size of 1.5 μm or less in an amount of 0.2 mass % or less, and contains an α-phase as a predominant phase. In addition, the particulate alumina has a ratio of longer diameter (DL) to shorter diameter (DS) that is 2 or less and a ratio of D50 to mean primary particle size (DP) that is 3 or less. With these features, the particulate alumina has a narrow particle size distribution profile, causes little wear and exhibits excellent flow characteristics.

Owner:SHOWA DENKO KK

Embedded shaping articles

The present invention provided an insert molded product excellent in high and low temperature impact characteristics and reduced in the occurring amount of a mold deposit at the time of molding. This insert molded product is constituted by the insert molding of a resin composition, which is obtained by compounding 5-200 pts.wt. of a fibrous reinforcing material (B) having a flat cross-sectional shape wherein the ratio of the long diameter (the longest straight line distance of a cross section) and short diameter (the longest straight line distance in the direction right-angled to the long diameter) of a cross section right-angled to a length direction is 1.3-10 and 1-25 pts.wt. of a thermoplastic elastomer (C) with 100 pts.wt. of a polyarylene sulfide resin (A), and a metal or an inorganic solid.

Owner:POLYPLASTICS CO LTD

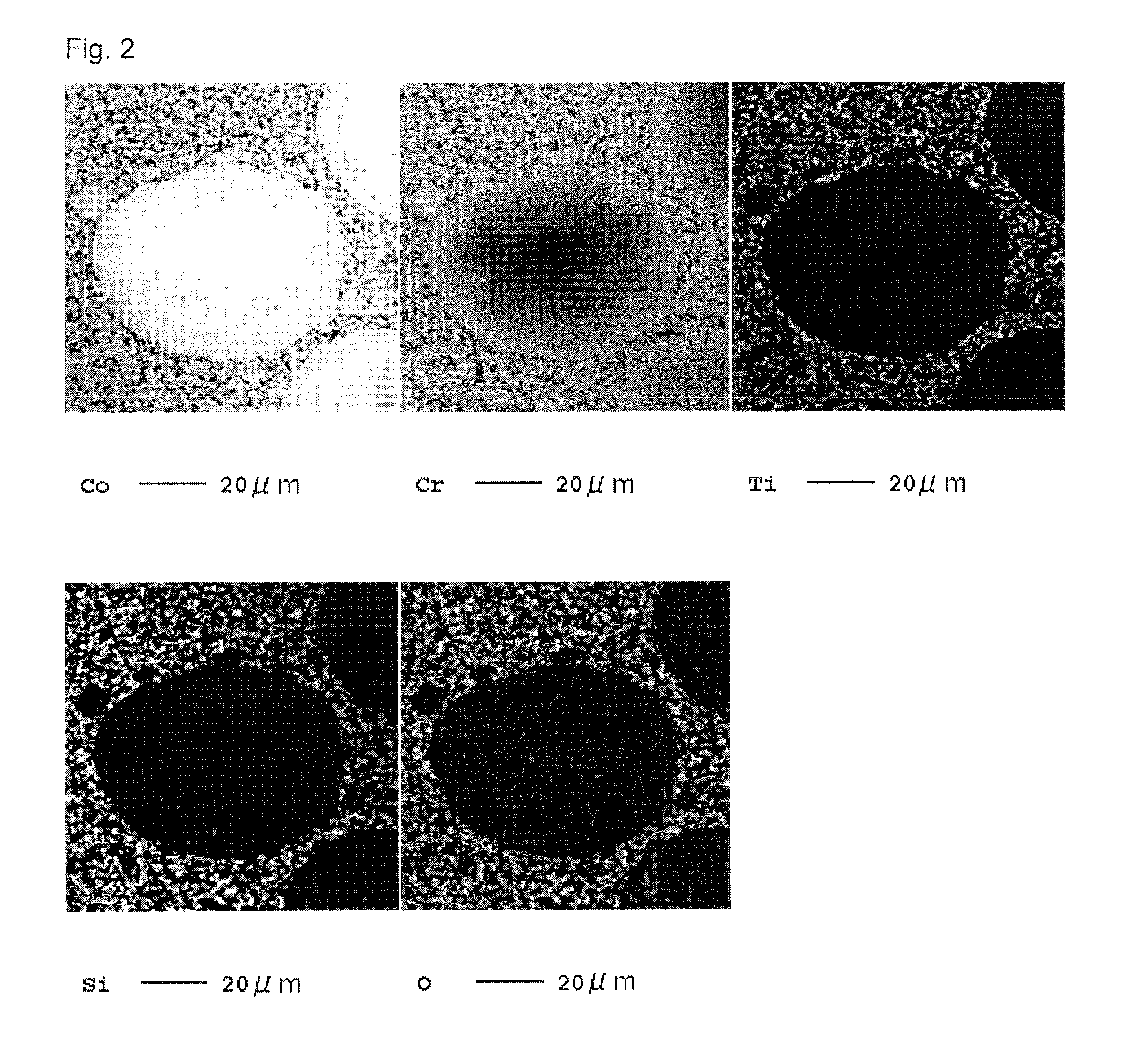

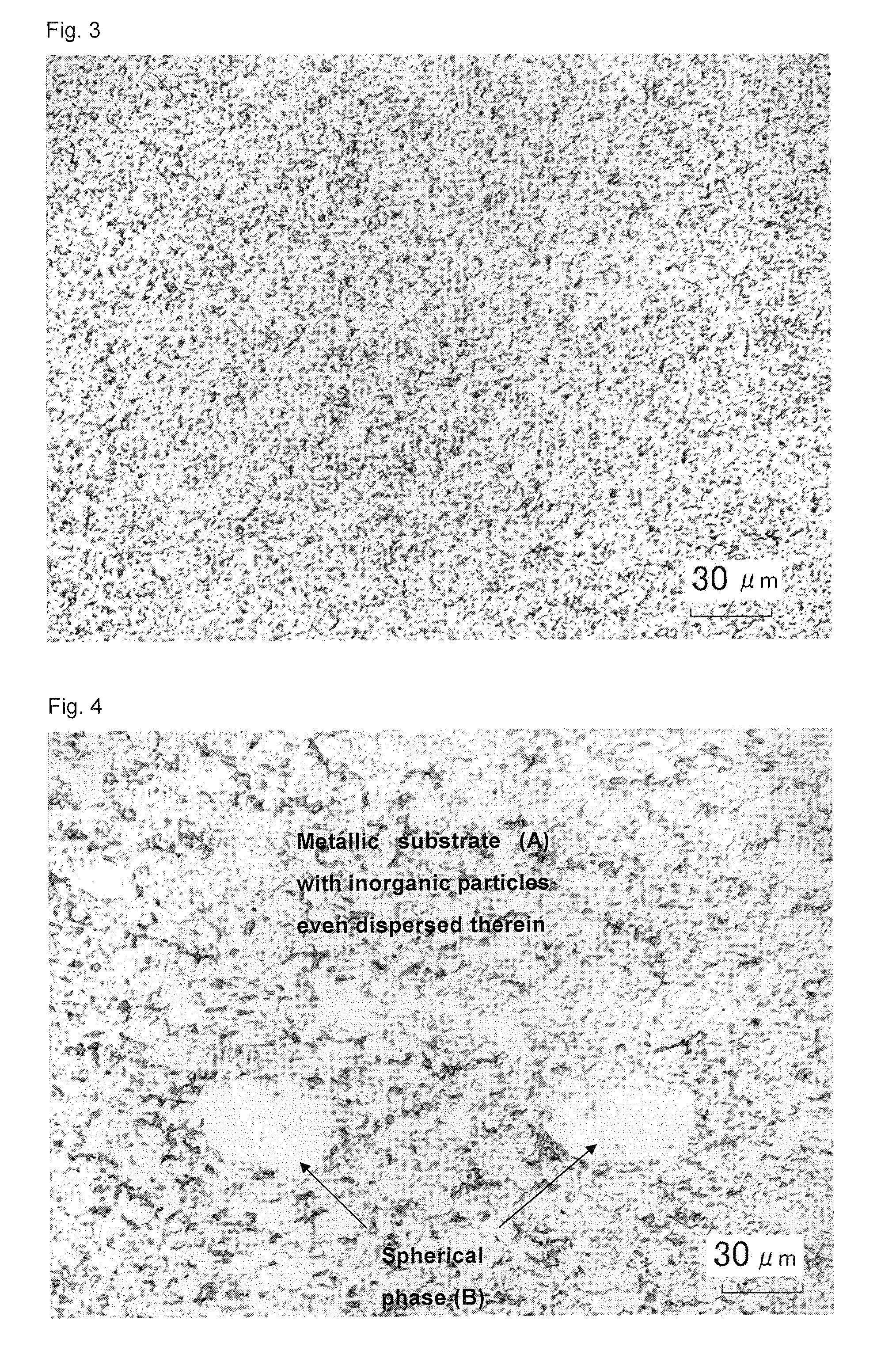

Ferromagnetic Material Sputtering Target

ActiveUS20120118734A1Improve featuresIncrease target densityCellsVacuum evaporation coatingSputteringLongest Diameter

Owner:JX NIPPON MINING& METALS CORP

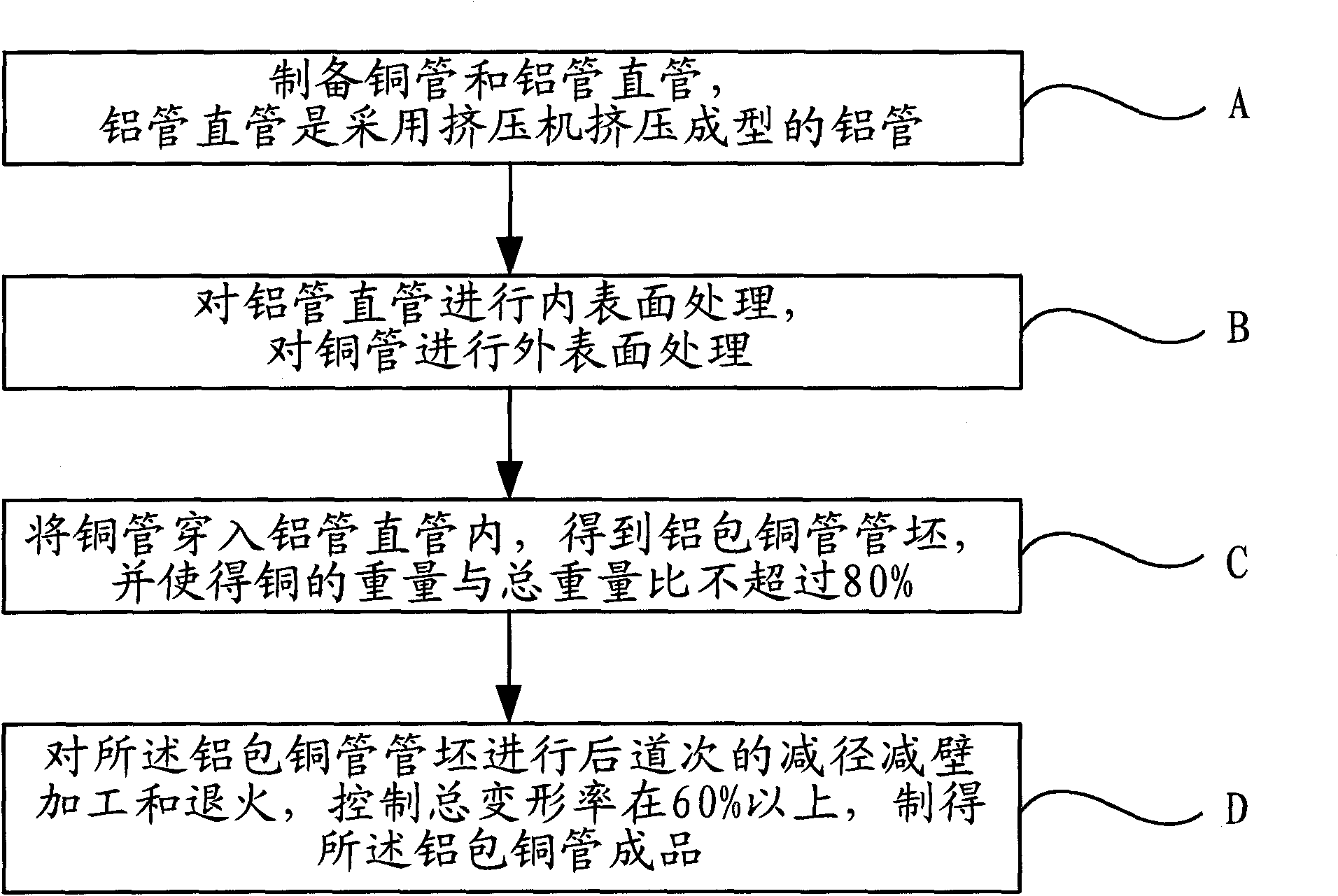

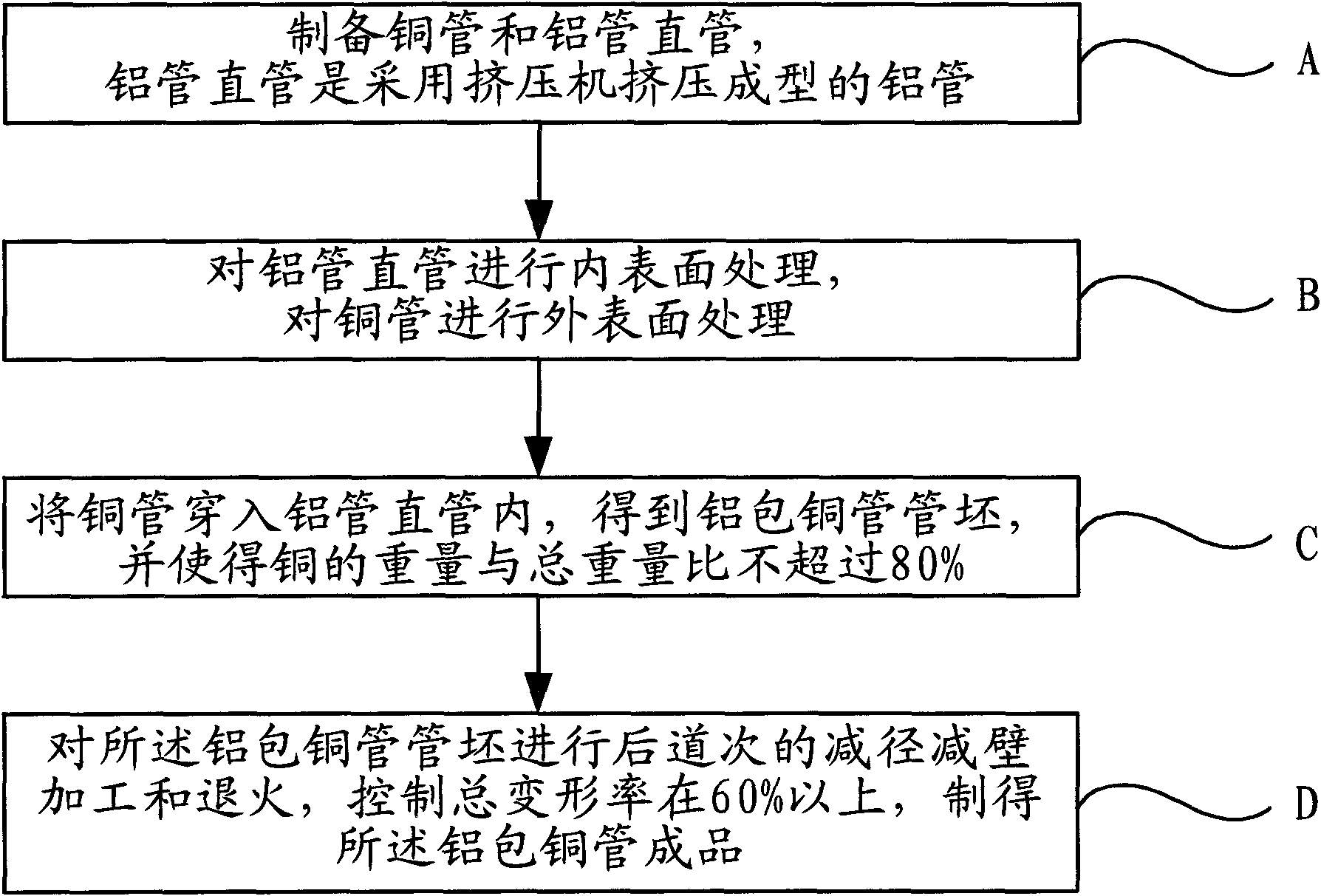

Method of making aluminum clad copper tube with metallurgical bonding

InactiveCN102284549AManufacturing Method AdvantagesImprove product qualityLongest DiameterMolding machine

The invention provides a method for manufacturing an aluminum-clad copper tube with metallurgical bonding, comprising: A, preparing a copper tube and an aluminum tube straight tube, and the aluminum tube straight tube is an aluminum tube extruded by an extrusion machine; B, The inner surface of the straight aluminum tube is treated, and the outer surface of the copper tube is treated; C, the copper tube is penetrated into the straight aluminum tube to obtain an aluminum-clad copper tube blank, and the copper-to-total weight ratio does not exceed 80%; D, The aluminum-clad copper tube billet is processed and annealed for diameter reduction and wall reduction in the subsequent pass, and the total deformation rate is controlled to be above 60%, so as to obtain a finished product of the aluminum-clad copper tube. The manufacturing method of the aluminum-clad copper pipe provided by the present invention adopts an extrusion machine to manufacture straight aluminum pipes without welded pipe welds, and can withstand mechanical processing without cracking. Straight tubes can manufacture large and heavy aluminum-clad copper tubes, and because of the post-pass diameter reduction and wall reduction processing and annealing and control of deformation rate, the copper-aluminum interface metallurgical bonding is stable, the process flow is stable, and it is suitable for mass production.

Owner:JIANGSU XINGRONG HI TECH

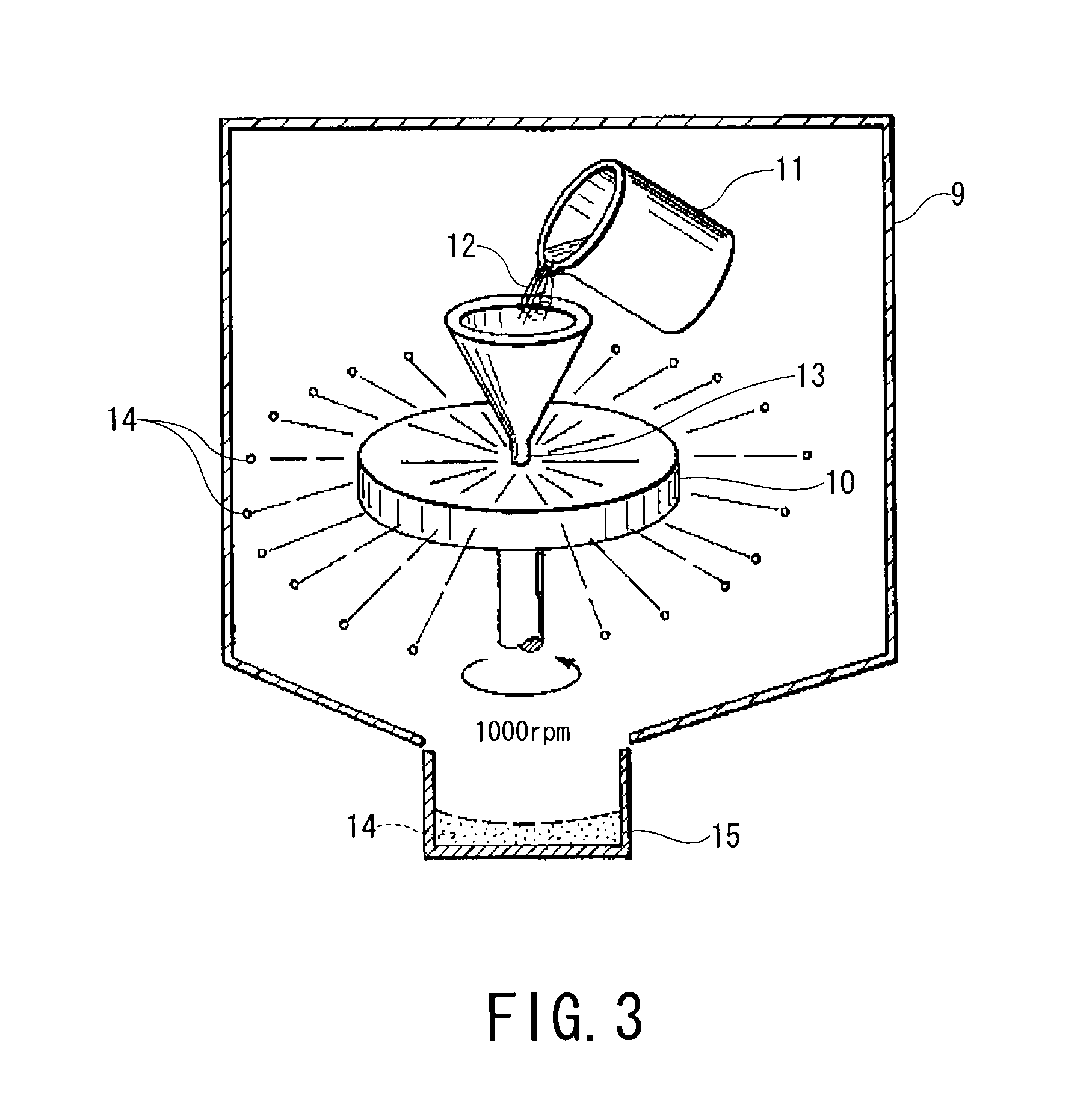

Method for manufacturing polyisophthaloyl metaphenylene diamide pulp-shaped fibre

ActiveCN101250833ASynthetic cellulose/non-cellulose material pulp/paperApparent viscosityLongest Diameter

The invention relates to a method for preparing polyisophthaloyl metaphenylene diamide pulp-shaped fiber belonging to the special synthesis fiber preparation technique field, which is characterized in that the polyisophthaloyl metaphenylene diamide solution is mixed with a precipitant in a shaping equipment which rotates at certain speed, the polyisophthaloyl metaphenylene diamide solution dissolves out the pulp-shaped fiber in the shearing condition through the precipitant directly. The component of the precipitant contains organic solvent which is provided with high-apparent viscosity for adjusting the apparent viscosity of the precipitant, thereby the pulp-shaped fiber of different long diameter ratio is obtained to satisfy different application need of the product. The viscosity ratio of the precipitant and the pulp is enlarged and the force between the pulp and the precipitant is strengthened due to increasing the apparent viscosity of the precipitant, thereby the superior property pulp-shaped fiber can be obtained in the relatively low stirring rotary speed condition of the shaping equipment.

Owner:X FIPER NEW MATERIAL CO LTD

Powder metallurgy preparation method of valve clack of membrane valve

InactiveCN103028730AReasonable formulaHigh hardnessTurbinesOther manufacturing equipments/toolsWaxAl powder

The invention discloses a powder metallurgy preparation method of a valve clack of a membrane valve. The preparation method comprises the following steps that iron-based mixed powder is prepared so that the iron-based mixed powder comprises the following ingredients in percentage by mass: 0.5 to 1.2 percent of Mo, 0.1 to 0.25 percent of Mn as prealloy and the balance of iron and impurities, in addition, 0.6 to 4.2 percent of Al powder, 0.6 to 1.2 percent of Cu powder, 0.5 to 1.5 percent of Ni powder, 0.5 to 1.2 percent of graphite powder and 0.21 to 4.9 percent of polyamide wax flake powder are added into the iron-based mixed powder, the average grain diameter of the long diameter of the polyamide wax flake powder is less than 200mum, the thickness is less than 30mum, and valve plate workpieces are obtained through pressing and sintering. The powder metallurgy preparation method has the advantages that the manufacture process has higher production continuity, in addition, the material utilization rate is high, the preparation method is suitable for mass production, and the cost is reduced.

Owner:ANHUI HECHENG MACHINERY

Piston ring excellent in resistance to scuffing, cracking and fatigue and method for producing the same, and combination of piston ring and cylinder block

InactiveUS20040040631A1Easy to wearEnhances scuffing resistancePiston ringsSolid state diffusion coatingCrack resistanceLongest Diameter

A piston ring having improved scuffing resistance, cracking resistance and fatigue resistance, consists of a high-chromium martensitic stainless steel and a sliding nitriding layer formed on the surface of said steel. The stainless steel consists of C: 0.3 to 1.0%; Cr: 14.0 to 21.0%, N: 0.05 to 0.50%, at least one of Mo, V, W and Nb: 0.03 to 3.0% in total, Si: 0.1 to 1.0%, Mn 0.1 to 1.0%, P: 0.05% or less, S: 0.05% or less, the balance being Fe and unavoidable impurities. The sliding nitriding layer comprises on its surface hard particles mainly consisting of nitrides in a range of from 0.2 to 2.0 mum of average particle size, 7 mum or less of the longest diameter, and from 5 to 30% in area ratio.

Owner:RIKEN CO LTD +1

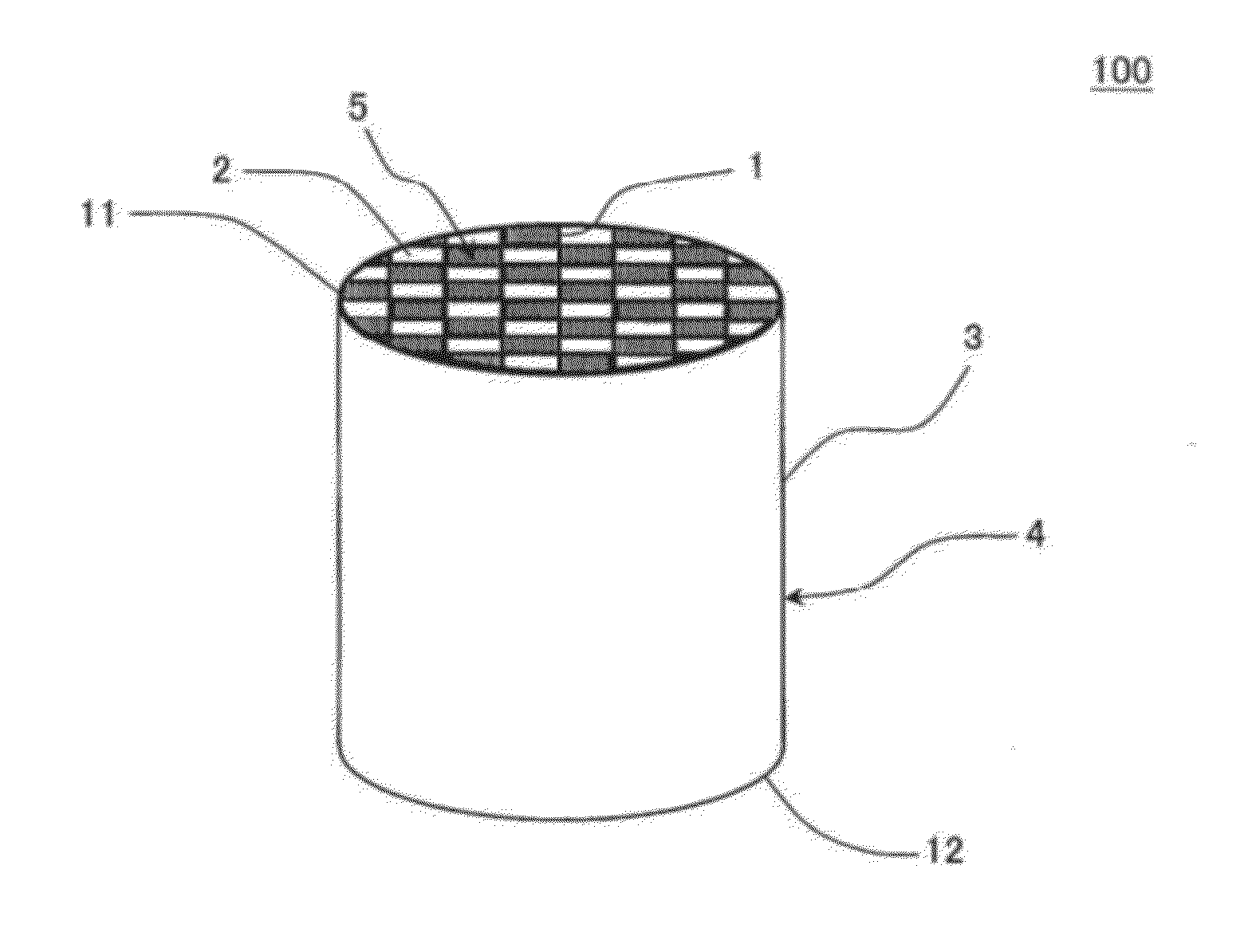

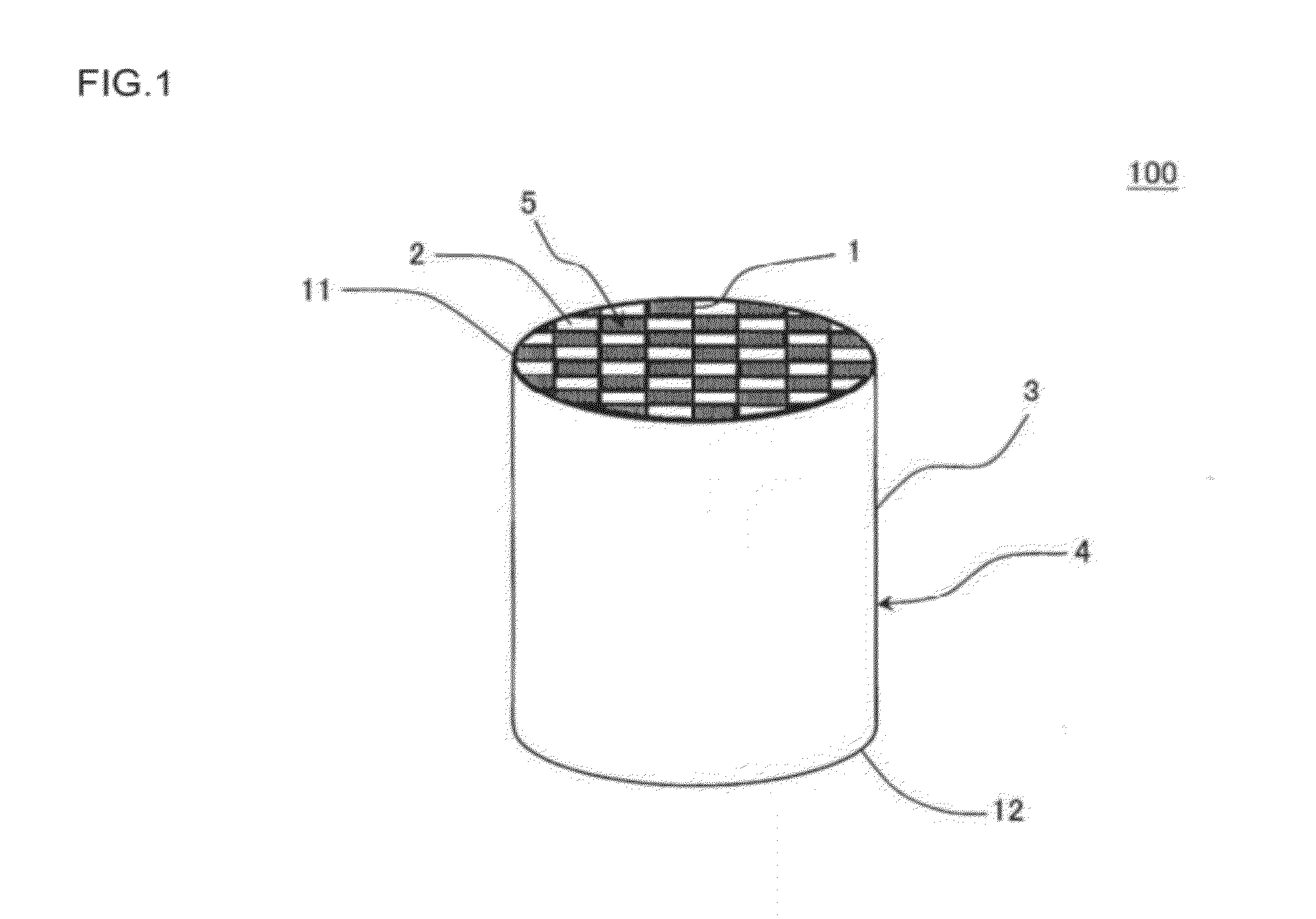

Honeycomb filter and manufacturing method of the same

ActiveUS20120240538A1Suppress increase of initial pressure lossReduce total pressure lossCombination devicesDispersed particle filtrationLongest DiameterHoneycomb

There is provided a honeycomb filter including: a honeycomb base material; plugged portions; and a porous collecting layer disposed on the surface of the partition wall parent material in at least the remaining cells. The collecting layer has a constitution in which a plurality of particles combine or intertwine with one another, and the collecting layer includes flat plate-like particles as the plurality of particles. The plurality of particles are particles in which an average long diameter is 0.2 μm or larger and smaller than 10 μm, an average value of ratios (long diameters / short diameters) of the long diameters to the short diameters of the respective particles is smaller than 3, and an average value of ratios (the long diameters / thicknesses) of the long diameters to thicknesses of the respective particles is 3 or larger. An open area ratio of the surface of the collecting layer is 10% or larger.

Owner:NGK INSULATORS LTD

Manufacturing method for large-size high-density high-uniformity CuCr alloy

The invention discloses a manufacturing method for a large-size high-density high-uniformity CuCr alloy. The manufacturing method is characterized in that CuCr mixed powder is solidified and formed through discharge plasma sintering, by optimizing a sintering die structure, the temperature is increased to 800 DEG C to 880 DEG C through a step heating manner at 10 DEG C / min to 50 DEG C / min and then kept for 2 minutes to 8 minutes while axial mechanical pressure is applied, and a sintered cylinder ingot with the diameter not smaller than 50 mm, the long diameter ratio of 0.04-1.0, the density larger than 99.0%, axial and radial fluctuation less than 1% and an uniform component structure can be obtained. According to the manufacturing method, different sintering conditions can be selected according to the size demand of the CuCr alloy, the process is simple, the period is short, the production efficiency is high, and the obtained CuCr alloy can be made into a finished product through a small amount of subsequent machining and then used as a part of a vacuum circuit breaker in large-power transmission and transformation equipment.

Owner:HEFEI UNIV OF TECH +1

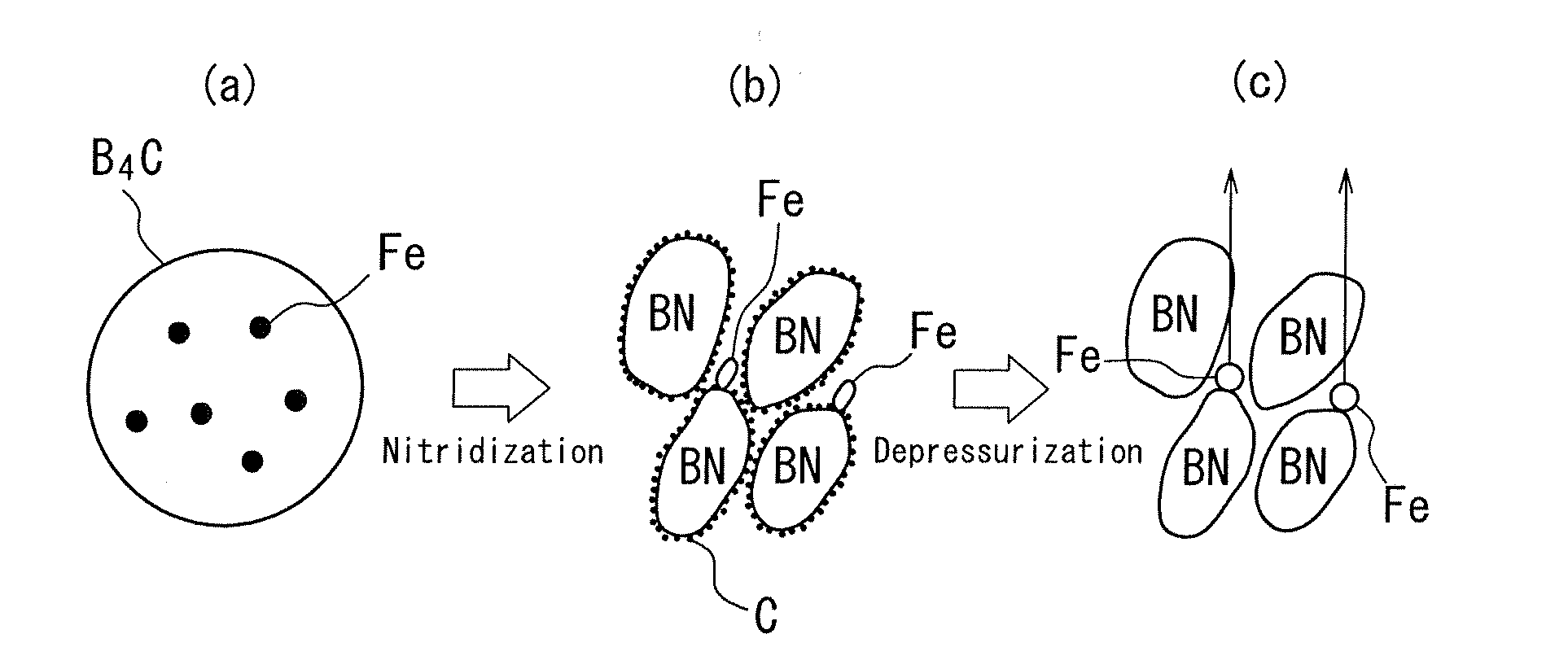

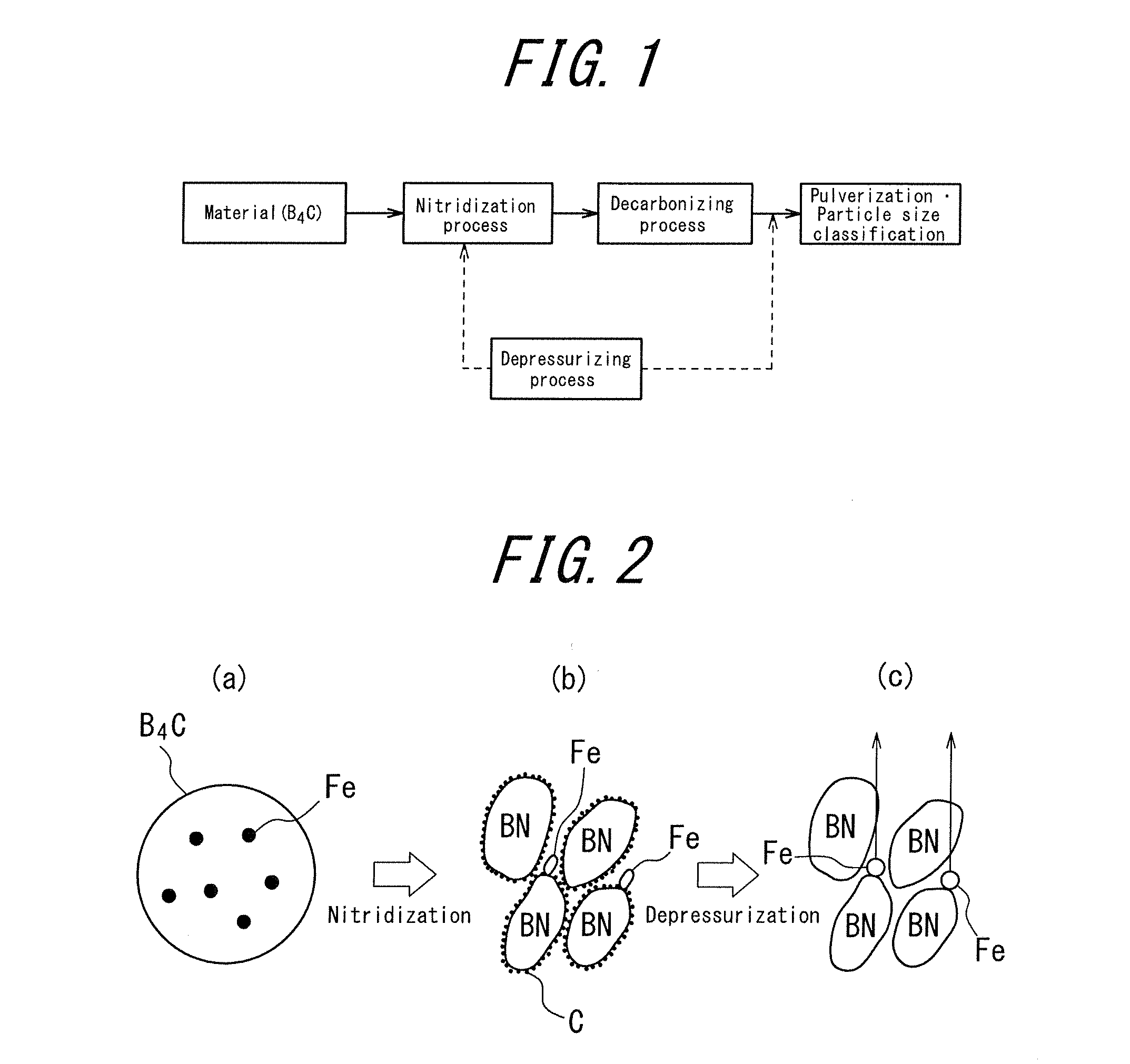

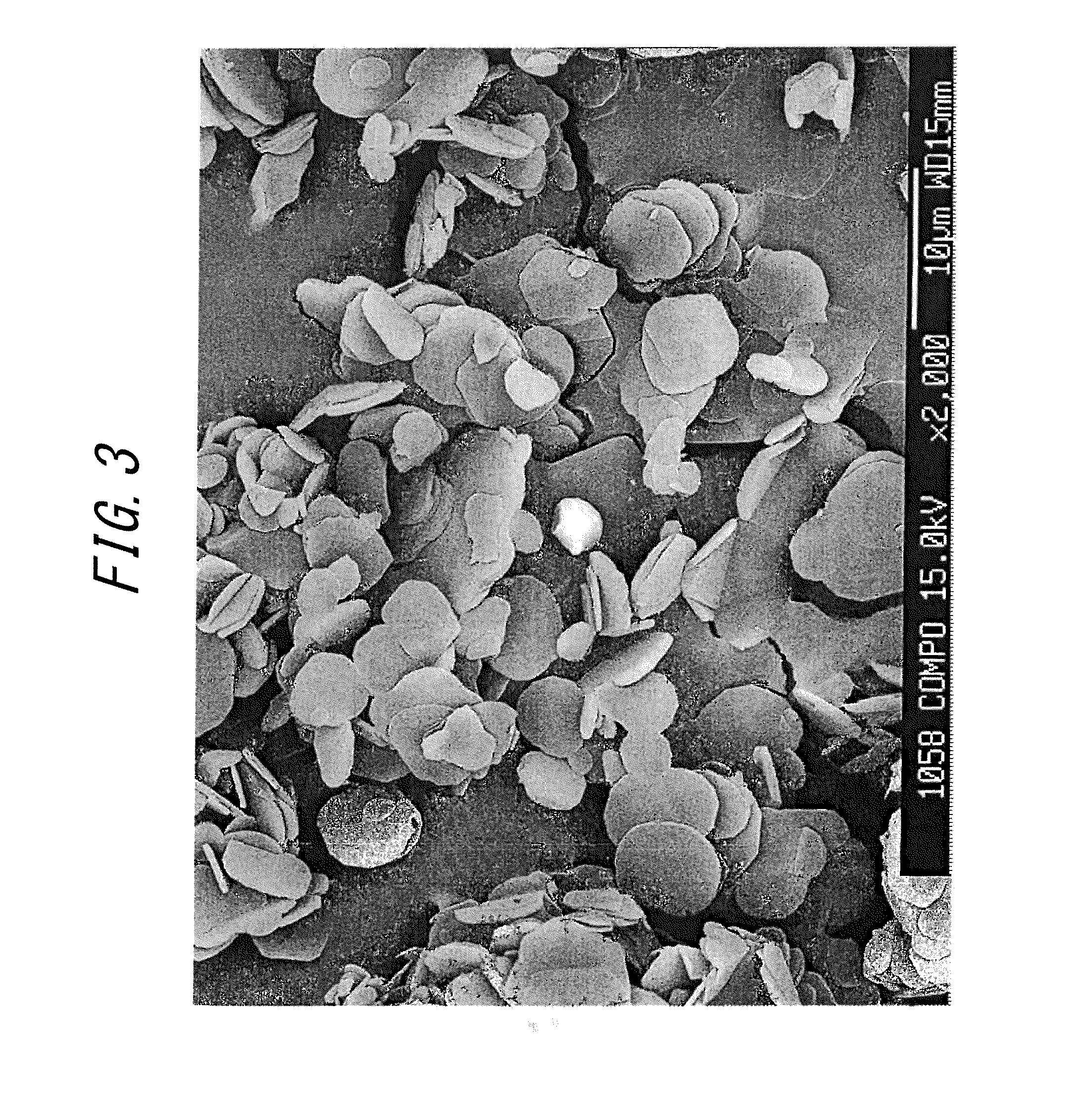

Hexagonal boron nitride powder and method for producing same

ActiveUS20120196128A1Made denserHigh strengthNitrogen compoundsSynthetic resin layered productsLongest DiameterHexagonal boron nitride

A hexagonal boron nitride (h-BN) powder is disclosed in which primary particles of the powder exhibit a ratio (D / d) of long diameter (D) to thickness (d) in a range of 5 to 10. Agglomerated particle bodies made of the primary particles have an average particle diameter (D50) in a range of 2 μm to 200 μm, inclusive, and the powder has a bulk density in a range of 0.5 g / cm3 to 1.0 g / cm3. In an exemplary method for producing the h-BN, boron carbide is nitridizated in a nitrogen partial pressure of at least 5 kPa at 1800° C. to 2200° C., inclusive. B2O3 (or precursor thereof) is added to the nitridization product to produce a mixture. The mixture is decarbonized in a non-oxidizing atmosphere at a 1500° C. to 2200° C., inclusive. The decarbonization product is pulverized and subject to particle-size classification, yielding H-BN powder. The method includes a depressurizing step, performed at 100 kPa or less either during nitridization or after decarbonization.

Owner:MIZUSHIMA FERROALLOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com