Patents

Literature

856results about "Cellulose coatings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose dispersion

InactiveUS6541627B1Good dispersionImprove stabilitySugar derivativesCellulose coatingsCelluloseDispersion stability

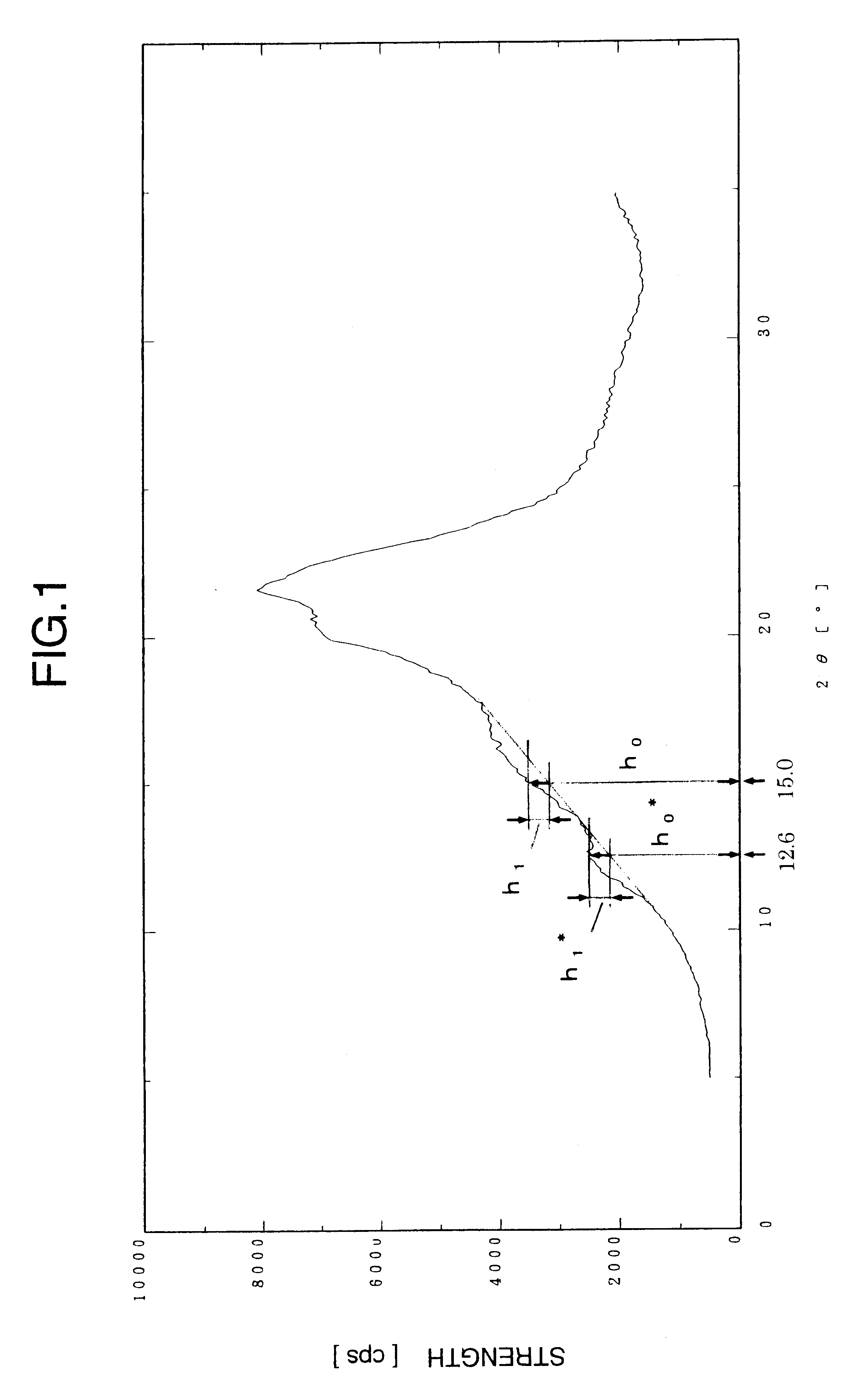

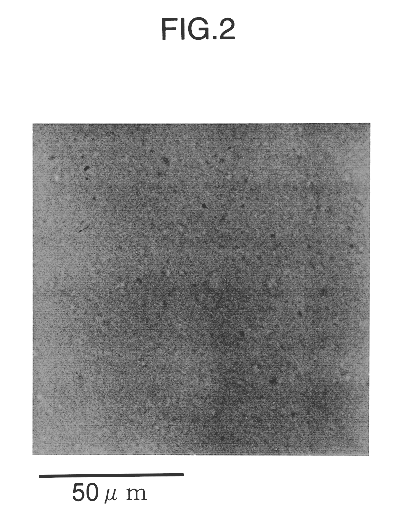

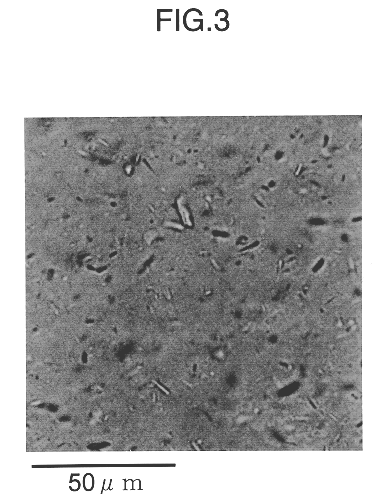

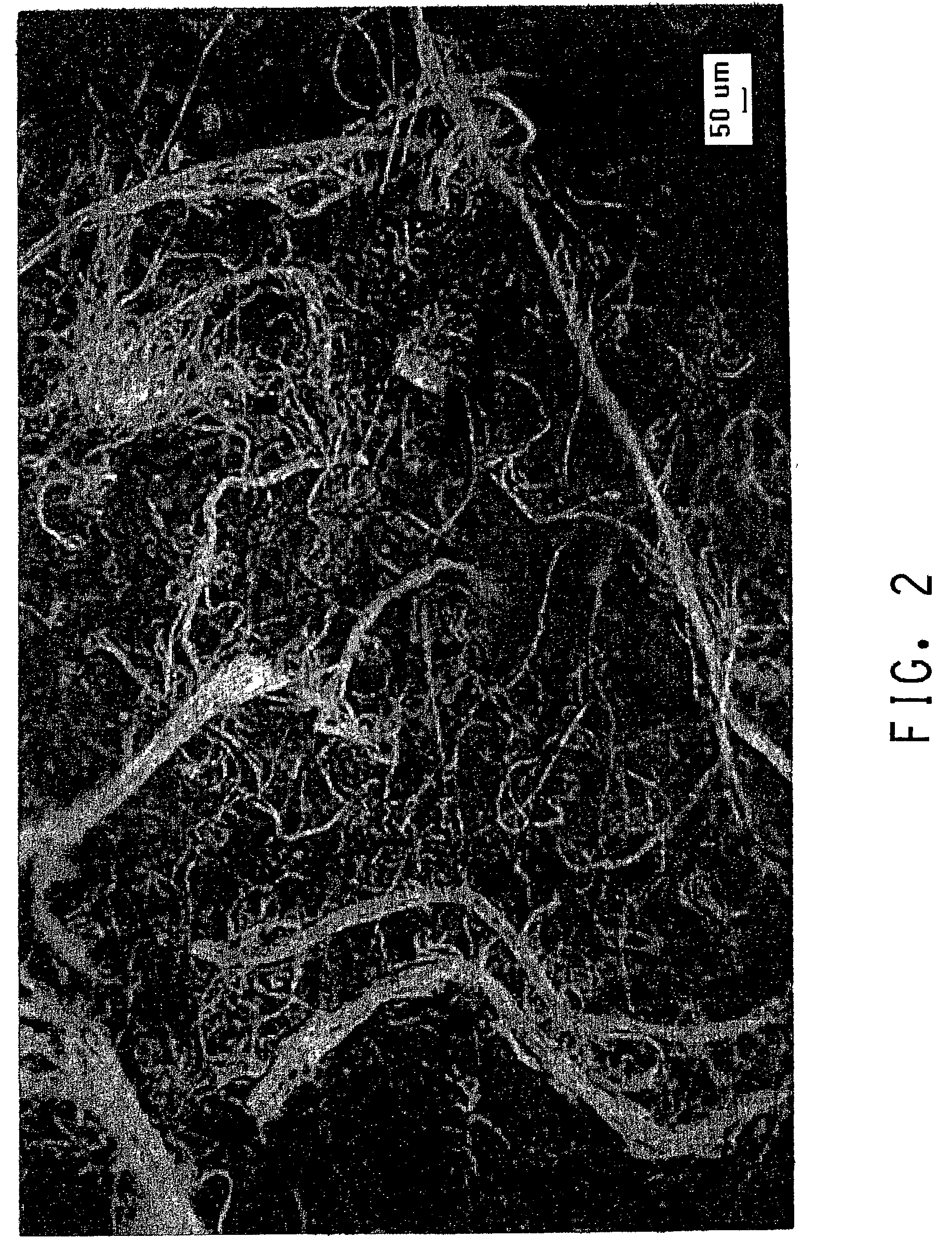

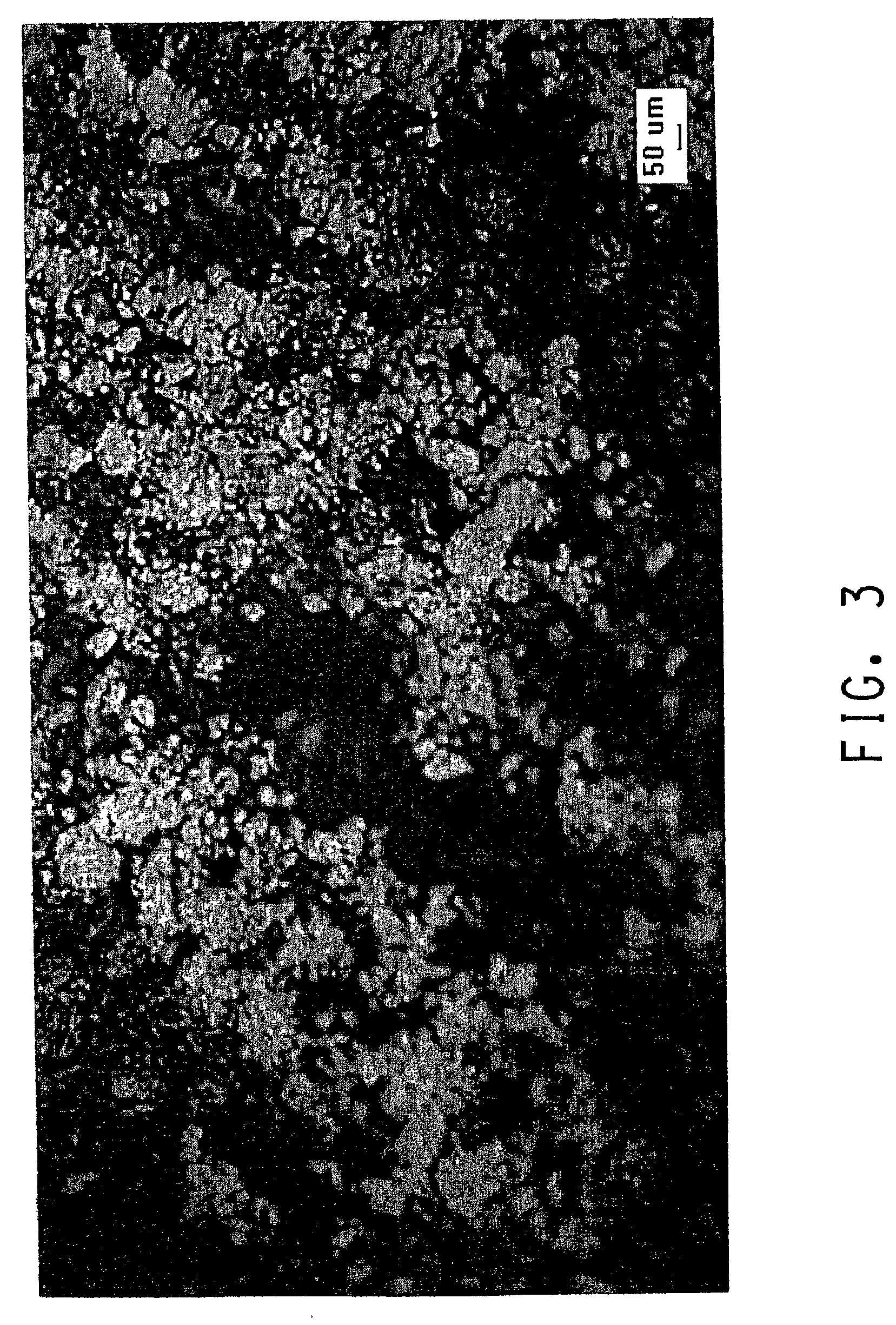

A cellulose dispersion which is a dispersion comprising a dispersing medium and a cellulose having a fraction of cellulose I type crystal component of not more than 0.1 and a fraction of cellulose II type crystal component of not more than 0.4 and in which the average particle diameter of the constitutive cellulose is not more than 5 mum. A cellulose particulate and a cellulose composite particulate which have an average particle diameter of 0.2 to 20 mum, a ratio of long diameter (L) to short diameter (D) observed through a scanning electron microscope (L / D) of not more than 1.2 and a coefficient of aggregation of 1.0 to 3.0. The present invention provides a cellulose dispersion which has an excellent effect such as dispersion stability or the like and is high in transparency. Moreover, it provides a cellulose particulate and a cellulose composite particulate which have such performances as no rough feel, excellent rolling properties, high dispersibility and the like.

Owner:ASAHI KASEI KK

Method of producing micropulp and micropulp made therefrom

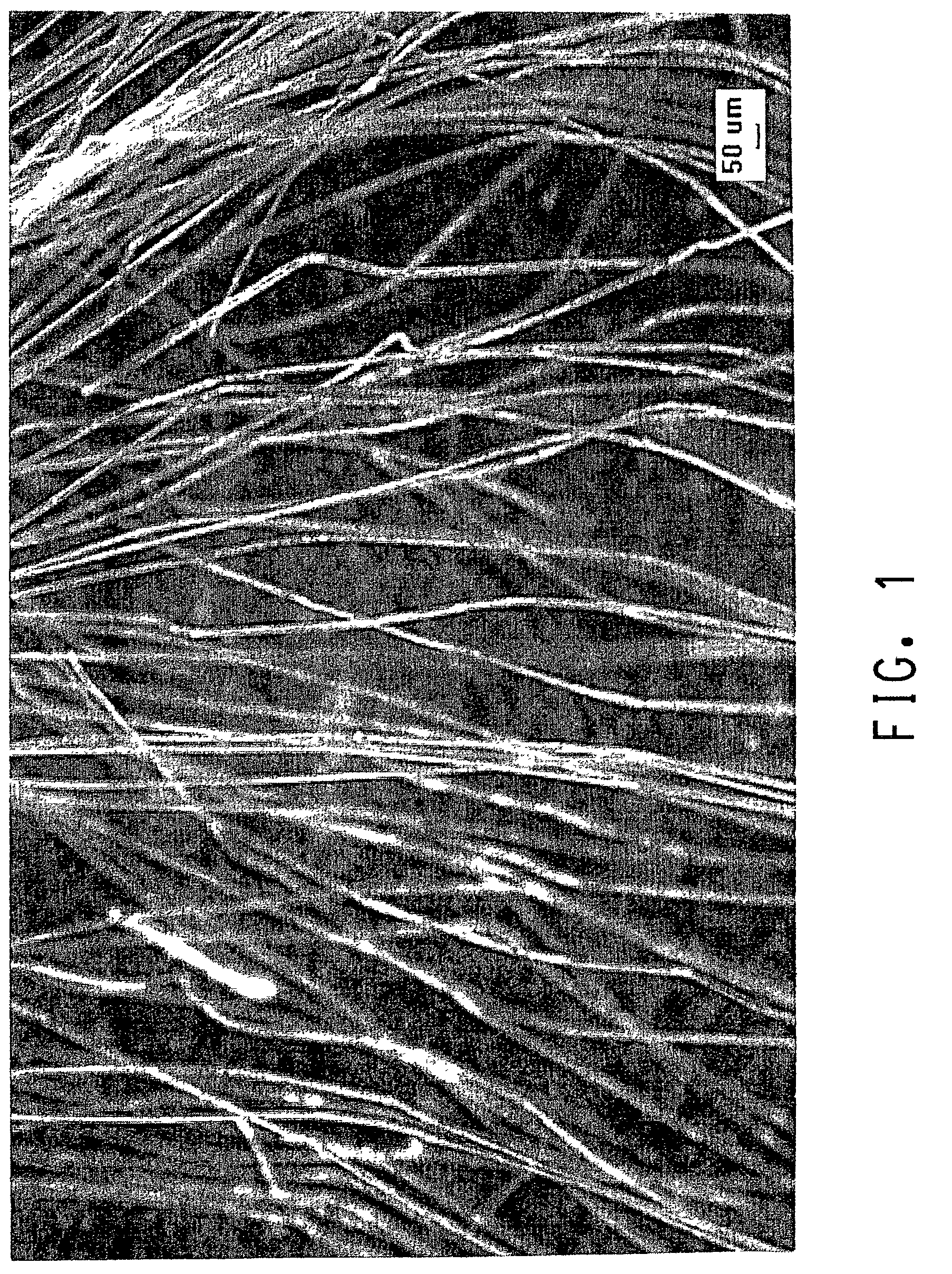

InactiveUS20030114641A1More cost-effectivelySmall sizeCellulose coatingsPaper/cardboardFiberSolid component

The present invention is directed to a process for producing micropulp. The process includes contacting organic fibers with a medium comprising a liquid component and a solid component, agitating the medium and the organic fibers to transform the organic fibers into the micropulp dispersed in the medium. If desired, the slurry of the micropulp in the liquid component can be used or the micropulp can be separated from the medium. The micropulp can be readily incorporated into coating compositions such as those used in automotive OEM or refinish applications. The micropulp can also be incorporated into powder coating applications or as a thixotrope or reinforcement in polymer formulations.

Owner:EI DU PONT DE NEMOURS & CO

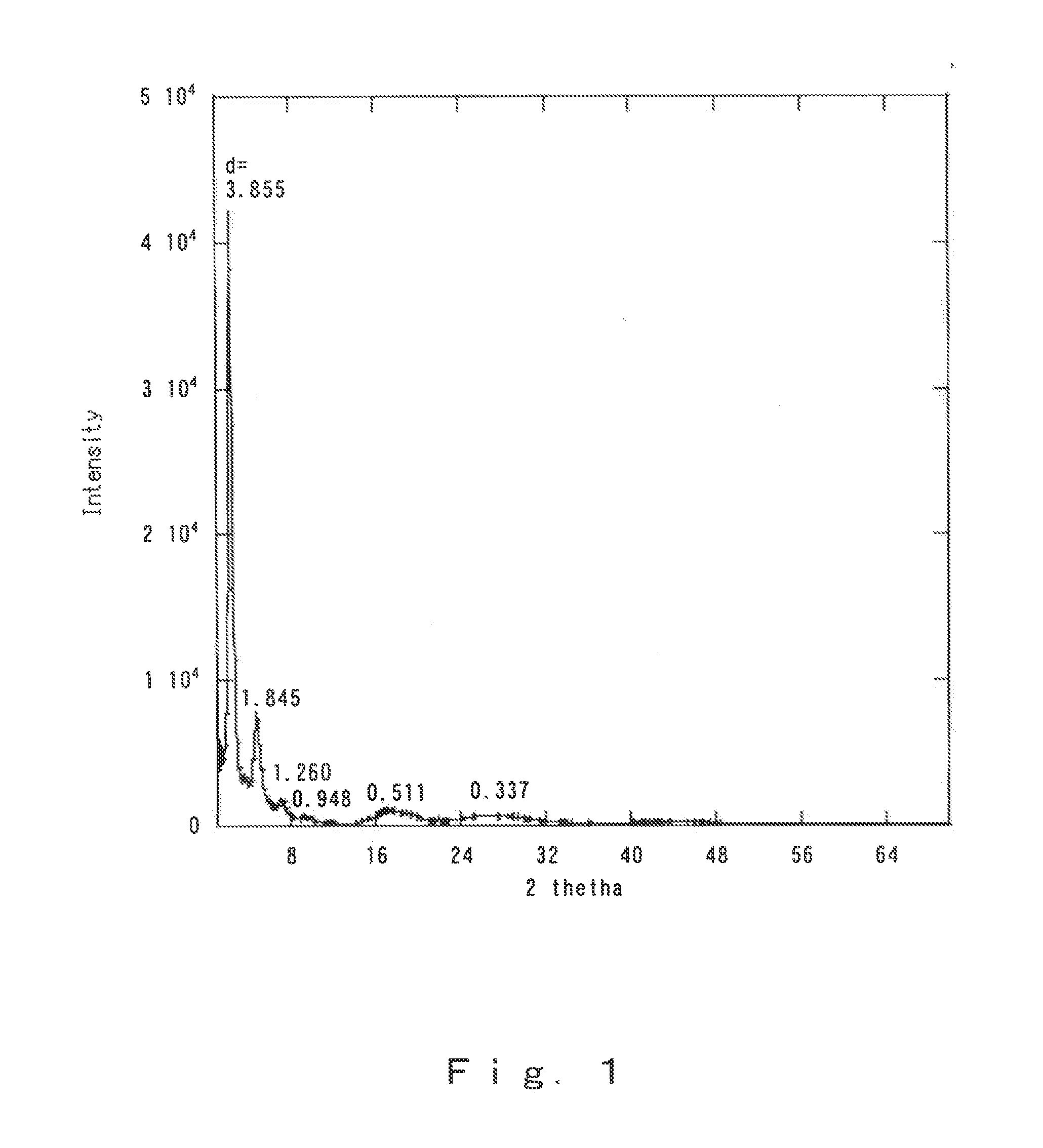

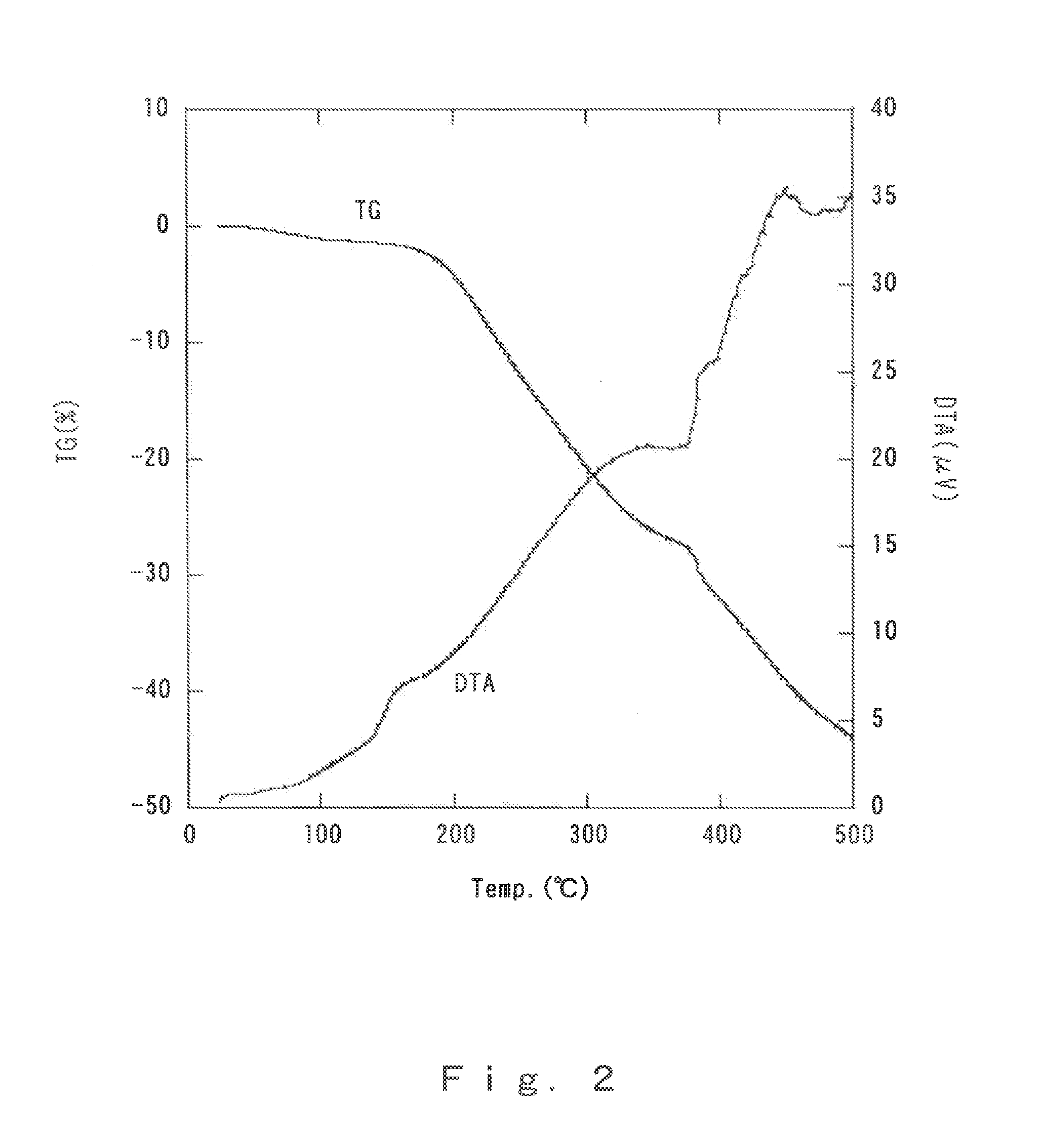

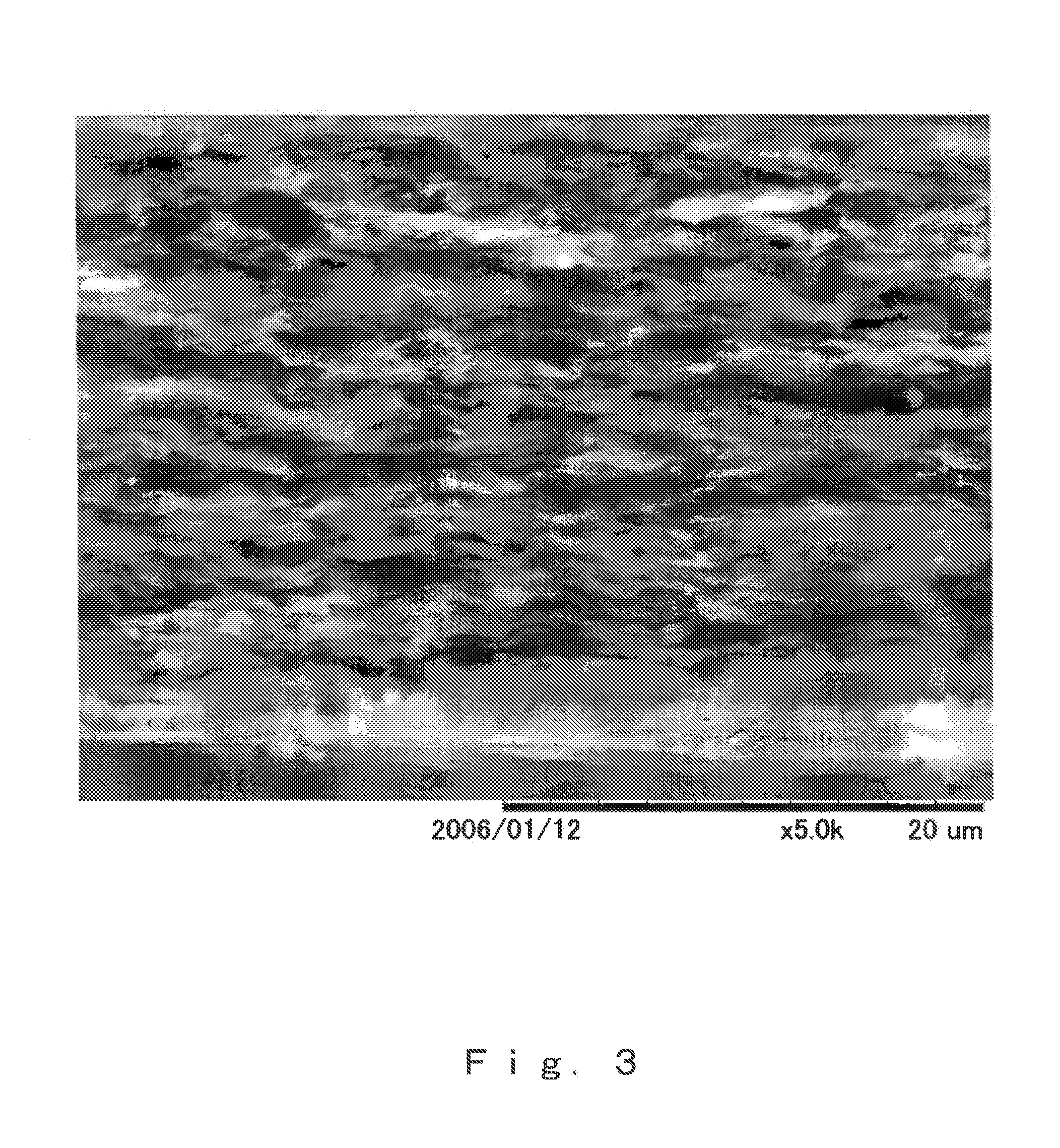

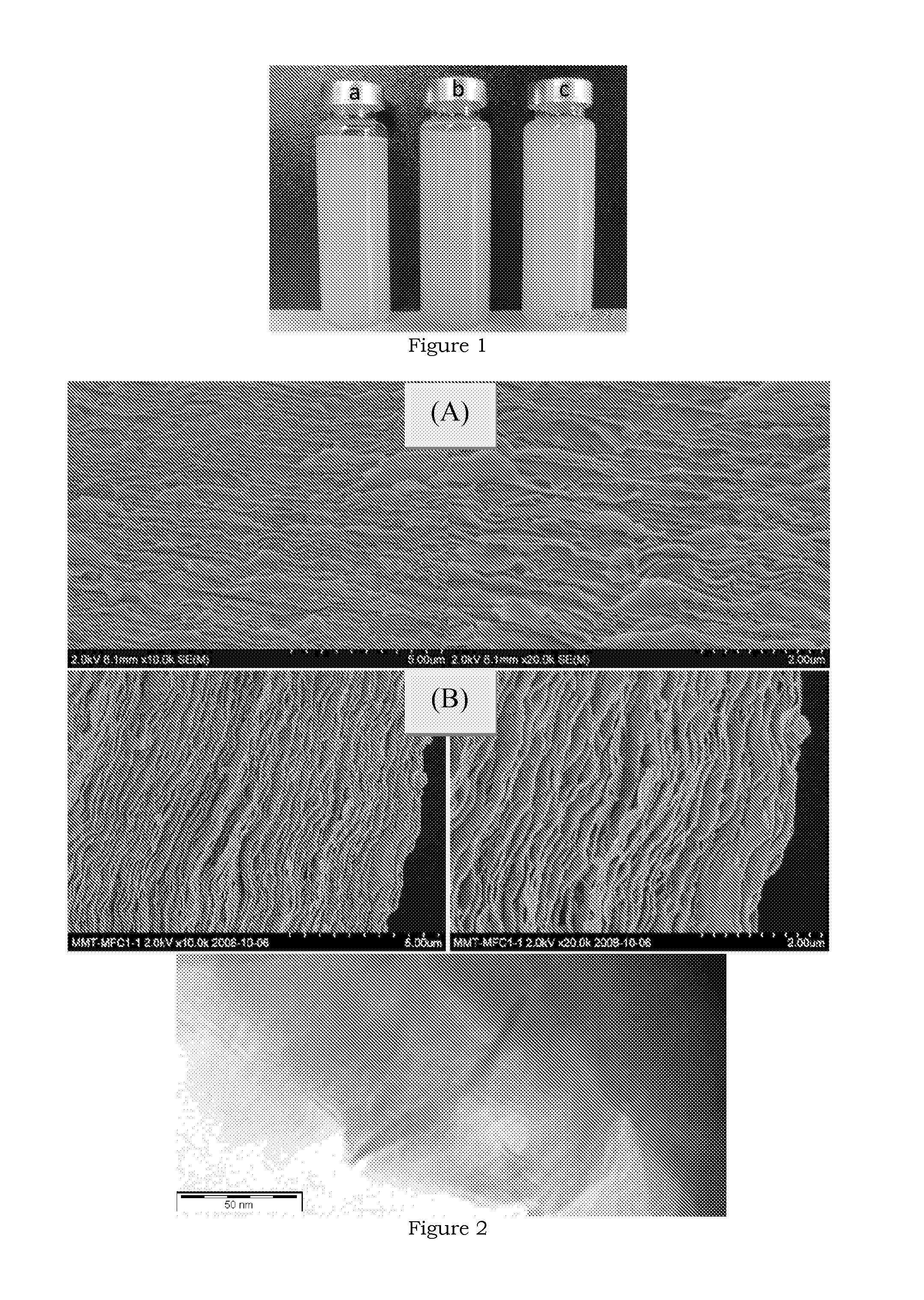

Nanocomposites of cellulose and clay

InactiveUS20050051054A1Improve thermal stabilityIncreased degradation temperatureMaterial nanotechnologyFibre treatmentCelluloseNanometre

This invention relates to a process of forming a nanocomposite of cellulose with a clay material that is used as the nanofiller material. The nanocomposites show significant improvements in thermal properties when compared to unbleached cotton and cotton processed under conditions for nanocomposite preparation. The degradation temperature of these nanocomposites is significantly increased over that of unbleached cotton.

Owner:US SEC AGRI

Dry powder type shell powder interior wall coating material and preparation method thereof

ActiveCN103627261AHave production costsNice decorationAntifouling/underwater paintsCellulose coatingsCobalt-60High energy

The invention relates to a dry powder type shell powder interior wall coating material which has the functions of adsorbing and decomposing harmful gas and peculiar smell, restraining bacteria, sterilizing and resisting static electricity and using shell powder, nanometer inorganic filler and high molecular powder materials as main components. The invention solves the defects of high cost, high energy consumption, pollution and incapability of purifying indoor harmful gas in the existing interior wall coating materials. The coating material uses natural or manually cultivated shell powder as basic materials; meanwhile, a certain quantity of nanometer titanium dioxide and nanometer electric stone powder radiated by cobalt-60 gamma ray and the high molecular powder materials are added; the weight percentages of all components are as follows: 30-60% of shell powder, 10-20% of calcined kaolin, 10-20% of heavy calcium, 10-20% of talcum powder, 1-5% of nanometer titanium dioxide, 1-5% of nanometer electric stone powder, and 5-20% of high molecular powder materials; the particle size of the shell powder is 200-1250 meshes.

Owner:JILIN RIHE TECH DEV

Anti-fog coating composition, anti-fog thin film and product

The invention provides an anti-fog coating composition which comprises at least one hydrophilic polymer; at least one anionic surfactant which accounts for 0.5% by weight-25% by weight calculated by taking the weight of the polymer as 100% by weight; inorganic oxide particles which account for 0% by weight-60% by weight calculated by taking the weight of the polymer as 100% by weight; and a solvent, wherein the polymer is at least one selected from cellulose, polyvinylpyrrolidone, polyacrylic acid, polypropylene amide and polyvinyl alcohol. The invention further provides an anti-fog thin film, which comprises a substrate and a coating which is positioned on one part of the surface of at least one surface of the substrate and produced by the composition. The invention also provides a product comprising the anti-fog thin film, such as masks and glasses for medical operations, mine masks, food packaging boxes, food packaging bags and the like.

Owner:3M INNOVATIVE PROPERTIES CO

Coated substrate, a process for production of a coated substrate, a package and a dispersion coating

InactiveUS20130017349A1High strengthEasy to recycleMaterial nanotechnologyStarch dervative coatingsFiberCellulose

The present invention relates to a coated fiber based substrate comprising a dispersion coating wherein said dispersion coating comprises microfibrillated cellulose and colloidal particles of a polymer. The invention further relates to a package formed from said substrate, a dispersion coating and process for the production of mentioned substrate.

Owner:STORA ENSO OYJ

Metal nanowire inks for the formation of transparent conductive films with fused networks

Fusing nanowire inks are described that can also comprise a hydrophilic polymer binder, such as a cellulose based binder. The fusing nanowire inks can be deposited onto a substrate surface and dried to drive the fusing process. Transparent conductive films can be formed with desirable properties.

Owner:C3 NANO INC

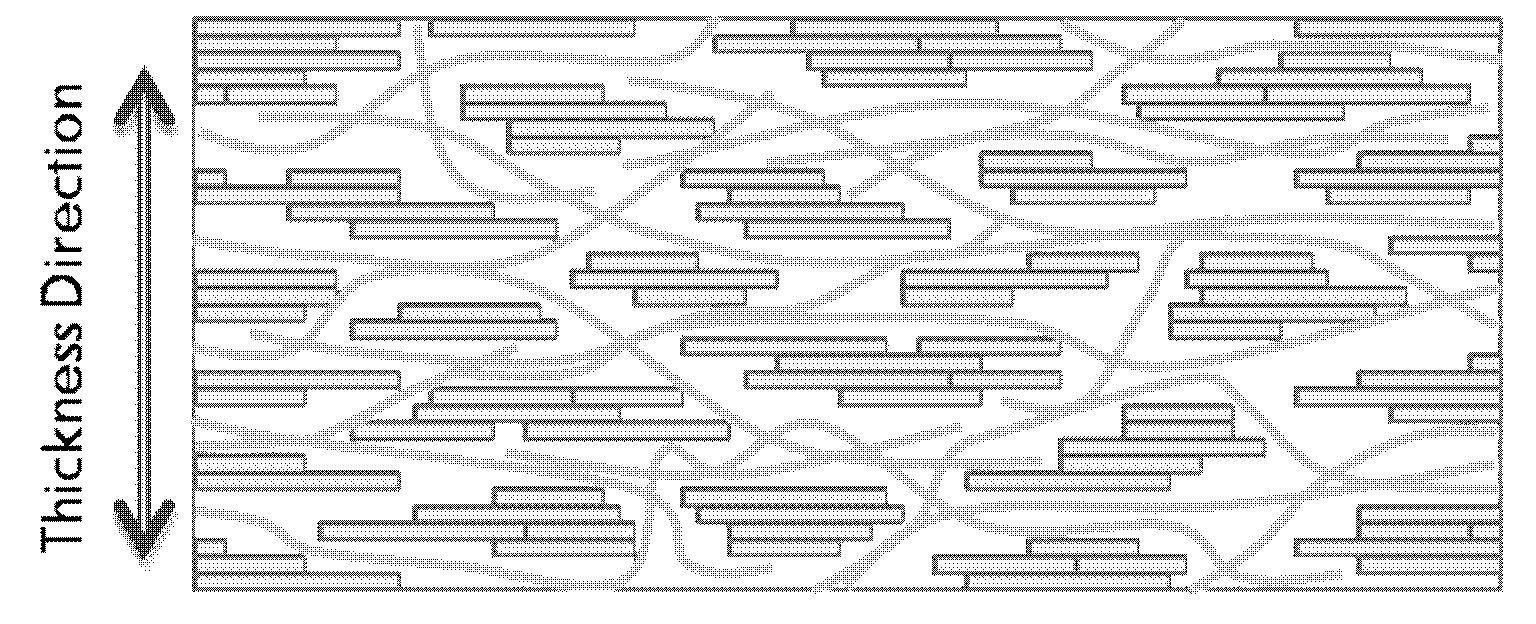

Film made from denatured clay

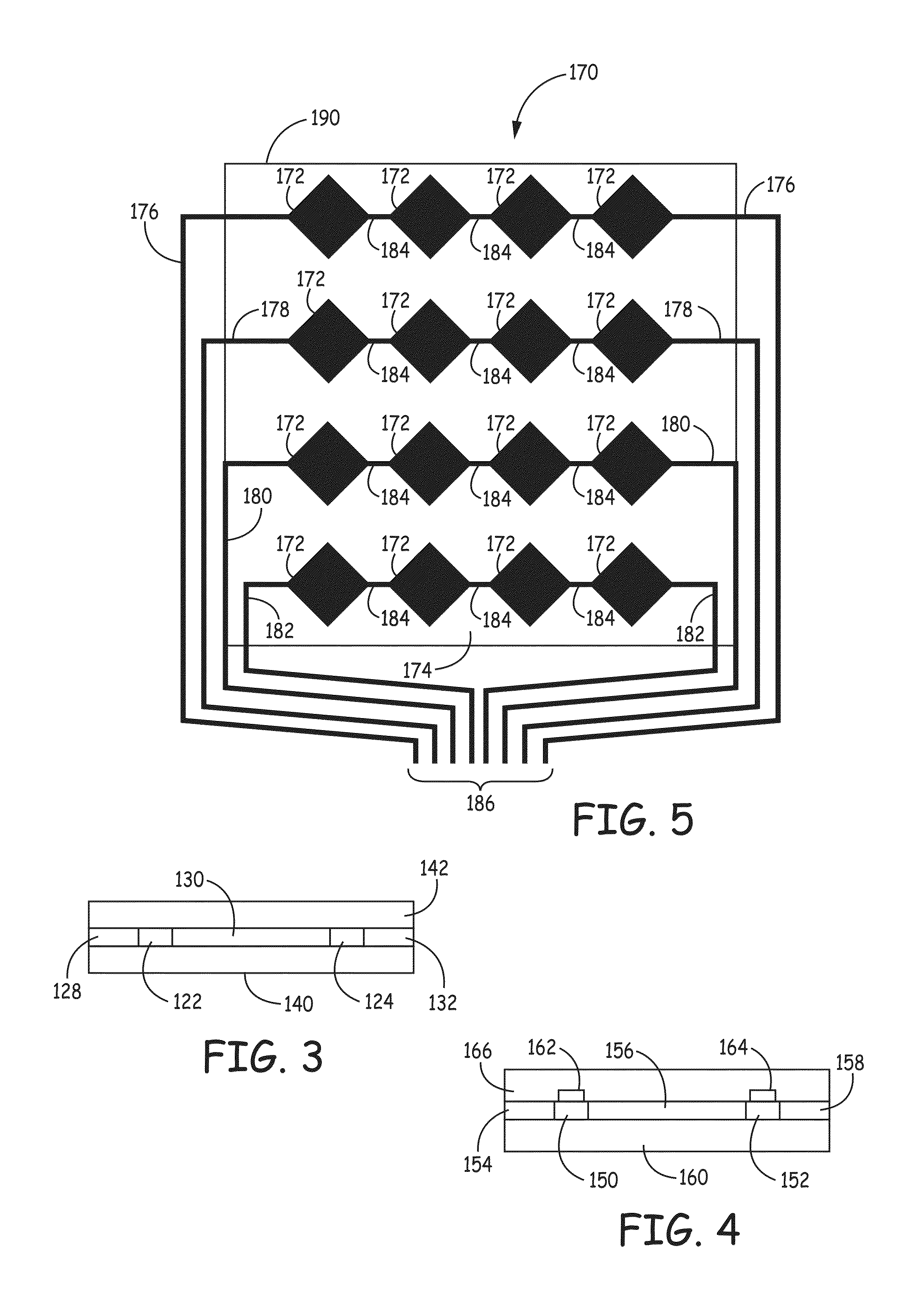

ActiveUS20090202806A1High mechanical strengthGood flexibilityAlkali metal silicate coatingsCellulose coatingsHeat resistanceWater vapor

The present invention provides a novel technology and a novel material having excellent pliability, gas barrier properties and water resistance, for the technical fields of packaging materials, sealing materials, electric insulating materials and the like, the present invention relates to a film of a material having a denatured clay as a main constituent thereof, wherein (1) the film comprises a denatured clay and an additive, (2) the weight ratio of the denatured clay is not less than 70% relative to total solids, (3) the film has gas barrier properties and water-vapor barrier properties, (4) the film has heat resistance, (5) the film has water resistance, (6) the film has sufficient mechanical strength to be used as a self-supporting film, and (7) the film can be formed on the surface of metals, plastics, rubber, paper and the like, and the present invention can provide a material comprising the denatured clay film in which denatured clay particles are highly oriented and which has excellent heat resistance, excellent pliability, excellent gas barrier properties, excellent water-vapor barrier properties, and high water resistance.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Coating composition, a method for coating a substrate, a coated substrate, a packaging material and a liquid package

InactiveUS20140251856A1Improving gas barrier functionExcellent gas barrier propertiesLiquid surface applicatorsWrappersAlcoholPolyvinyl alcohol

The present invention relates to a curtain coatable gas barrier coating composition comprising a polymer and a surfactant, wherein the polymer is selected from a group consisting of polyvinyl alcohol and polysaccharides, or mixtures thereof, wherein said polysaccharides are soluble or dispersable or suspendable in water and the surfactant is a water soluble non-ionic ethoxylated alcohol. The present invention also relates to a method for providing a substrate with a gas barrier layer by means of the coating composition, and a coated substrate having at least one gas barrier layer obtained by coating the substrate with the coating composition. Further, the invention relates to a packaging material comprising a coated paperboard coated with the coating composition, and a liquid package comprising such a packaging material.

Owner:BILLERUDKORSNES SKOG & IND AB

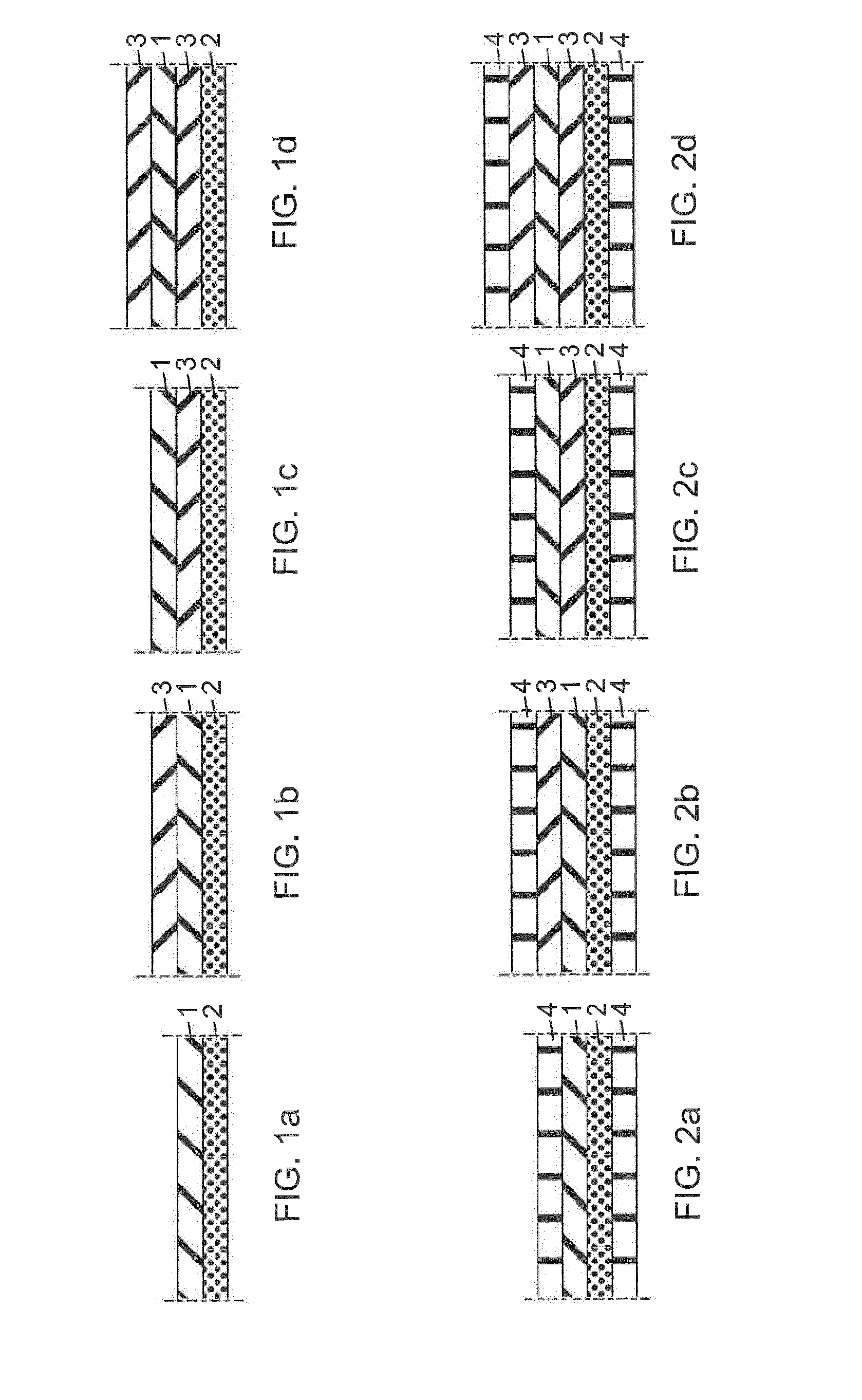

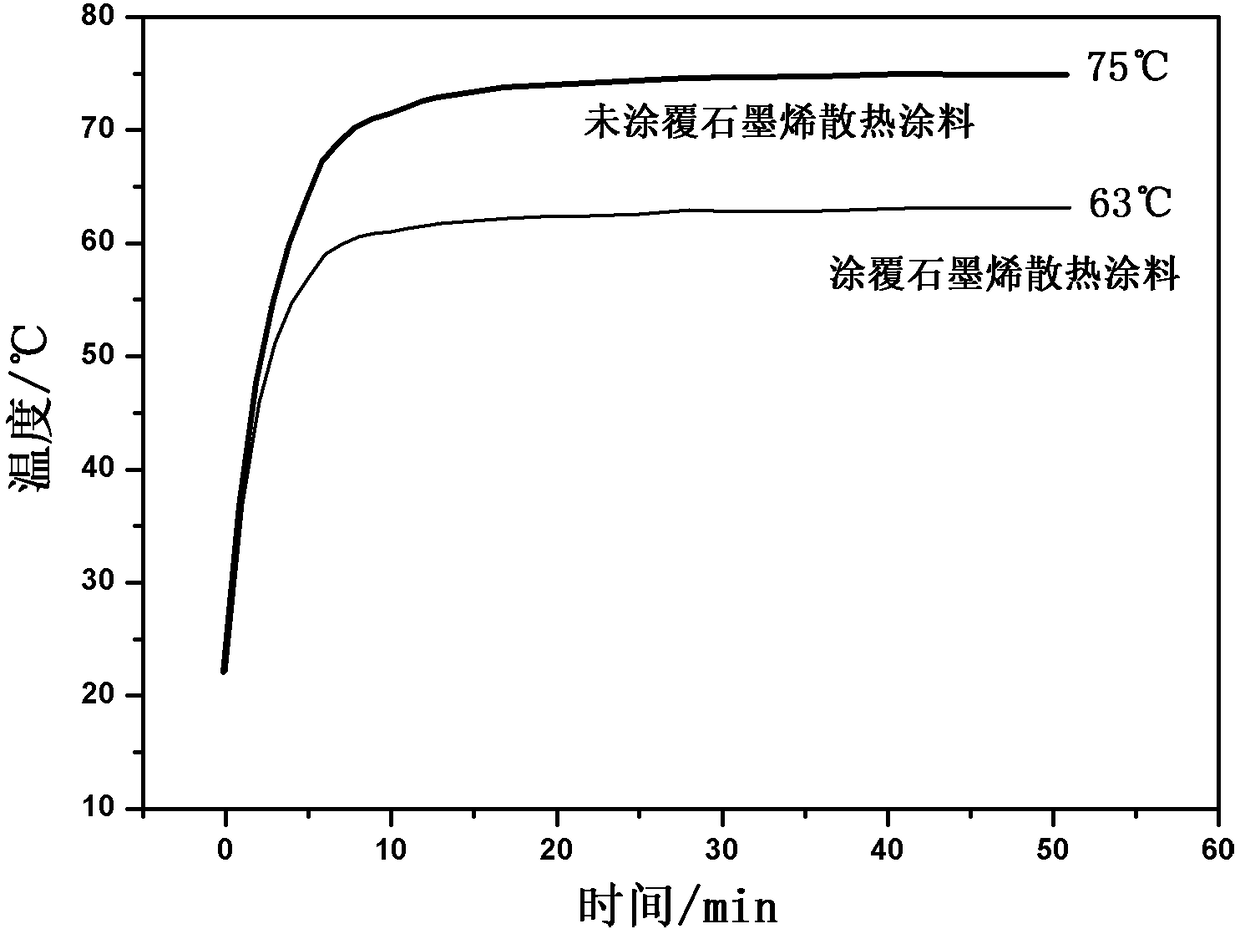

Graphene heat-dissipation coating material, preparation method and applications thereof

ActiveCN108690454ACoating film quality is lightHigh film strengthCellulose coatingsAnti-corrosive paintsSolventCvd graphene

The invention relates to the field of heat dissipation coating materials, particularly to a graphene heat-dissipation coating material, a preparation method and applications thereof, wherein the graphene heat-dissipation coating material mainly comprises, by weight, 5-20 parts of a graphene material, 10-30 parts of a filler, 50-150 parts of a polymer binder, 20-50 parts of a solvent, and 5-10 parts of a coating material aid, wherein the graphene material exists in the heat-dissipation coating material mainly in the two forms, the graphene material having a particle size of not more than 5 [mu]m is mainly combined with the filler in an adsorption manner, and the graphene material having a particle size of 5-15 [mu]m exists in the heat-dissipation coating material mainly in a dispersed manner. According to the present invention, the cost of the graphene heat-dissipation coating material is low; and the graphene material exists in the heat-dissipation coating material mainly in the two forms, such that the dispersion is uniform and stable, the intrinsic characteristics of the graphene are easily achieved, and the heat dissipating effect of the obtained coating material is obvious.

Owner:SHANDONG SHENGQUAN NEW MATERIALS CO LTD

Process for the production of a composition comprising fibrillated cellulose and a composition

ActiveUS8728273B2Produced in advanceImprove propertiesCellulosic pulp after-treatmentNon-fibrous pulp additionCellulose fiberPre treatment

The present invention relates to a process for the production of a composition wherein the process comprises pre-treating cellulosic fibers by mechanical, chemical and / or enzymatic treatment, mixing the pre-treated cellulosic fibers with pigments forming a dispersion and dispersing the dispersion of pre-treated cellulosic fibers and pigments whereby a composition comprising microfibrillated cellulose is formed. The invention further relates to a composition produced according to the process.

Owner:STORA ENSO OYJ

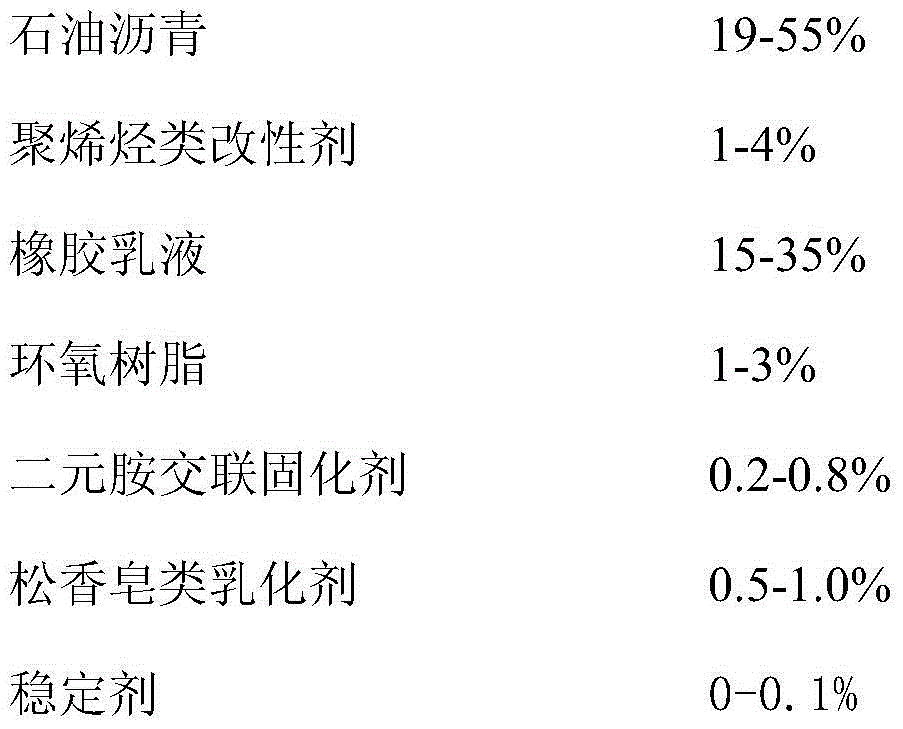

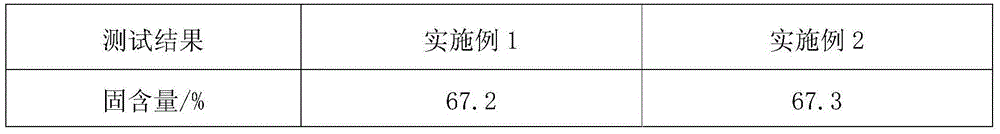

High-polymer modified water-emulsion asphalt-based thick waterproof paint and preparation method thereof

ActiveCN103555204AImprove low temperature performanceIncrease elasticityCellulose coatingsConjugated diene hydrocarbon coatingsHigh concentrationEpoxy

The invention discloses a high-polymer modified water-emulsion asphalt-based thick waterproof paint and a preparation method thereof. The paint is prepared by taking high-concentration ultrafine suspension microemulsion anion modified emulsified asphalt, a polyolefins modifier, rubber emulsions such as chloroprene rubber or butadiene styrene rubber or the like, multiple synthetic high-molecular polymers such as epoxy resin and the like, inorganic powders such as SiO2 and bentonite and the like as raw materials and mixing by employing a special production technology. Tests show that after a film is formed from the paint, no embrittlement happens at a low temperature of -20 DEG C, no flow happens at a high temperature of 120 DEG C, the elasticity recovery rate reaches up to 90%, and the paint can be stored stably for one year or more.

Owner:ZHEJIANG YUXI CORROSION CONTROL CORP

Process for the production of a composition comprising fibrillated cellulose and a composition

ActiveUS20130053454A1High dry contentIncrease productionCosmetic preparationsBiocideCellulose fiberPre treatment

The present invention relates to a process for the production of a composition wherein the process comprises pre-treating cellulosic fibers by mechanical, chemical and / or enzymatic treatment, mixing the pre-treated cellulosic fibers with pigments forming a dispersion and dispersing the dispersion of pre-treated cellulosic fibers and pigments whereby a composition comprising microfibrillated cellulose is formed. The invention further relates to a composition produced according to the process.

Owner:STORA ENSO OYJ

Strong Nanopaper

The present invention refers to a nanopaper comprising clay and microfibrillated cellulose nanofibres wherein the MFC nanofibres and the layered clay are orientated substantially parallel to the paper surface. The invention further relates to a method of making the nanopaper and the use of the nanopaper.

Owner:TETRA LAVAL HLDG & FINANCE SA

Transparent conductive film

ActiveUS20160293288A1Material nanotechnologyConductive layers on insulating-supportsElectricityMetal nanowires

Metal nanowires with uniform noble metal coatings are described. Two methods, galvanic exchange and direct deposition, are disclosed for the successful formation of the uniform noble metal coatings. Both the galvanic exchange reaction and the direct deposition method benefit from the inclusion of appropriately strong binding ligands to control or mediate the coating process to provide for the formation of a uniform coating. The noble metal coated nanowires are effective for the production of stable transparent conductive films, which may comprise a fused metal nanostructured network.

Owner:C3 NANO INC

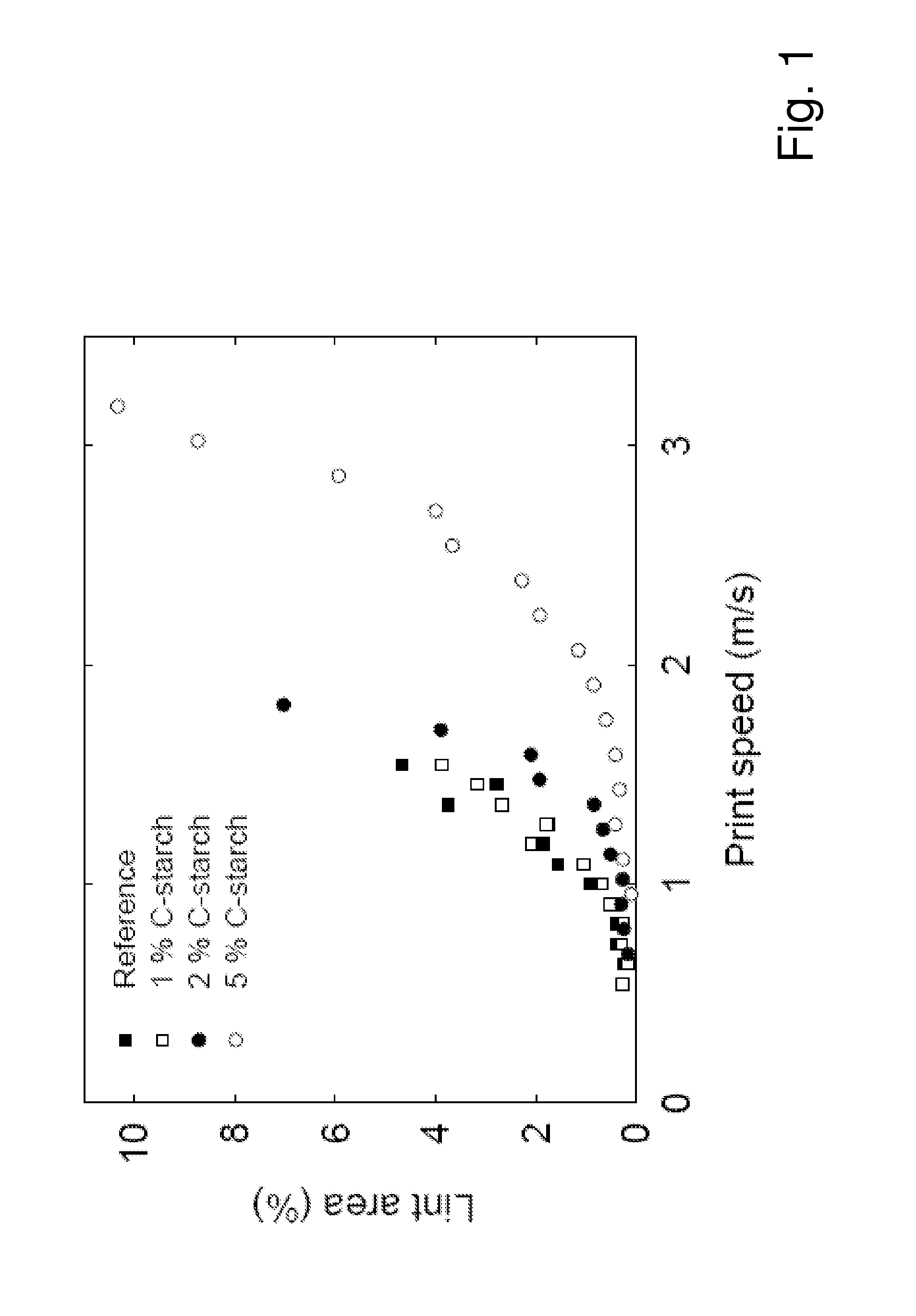

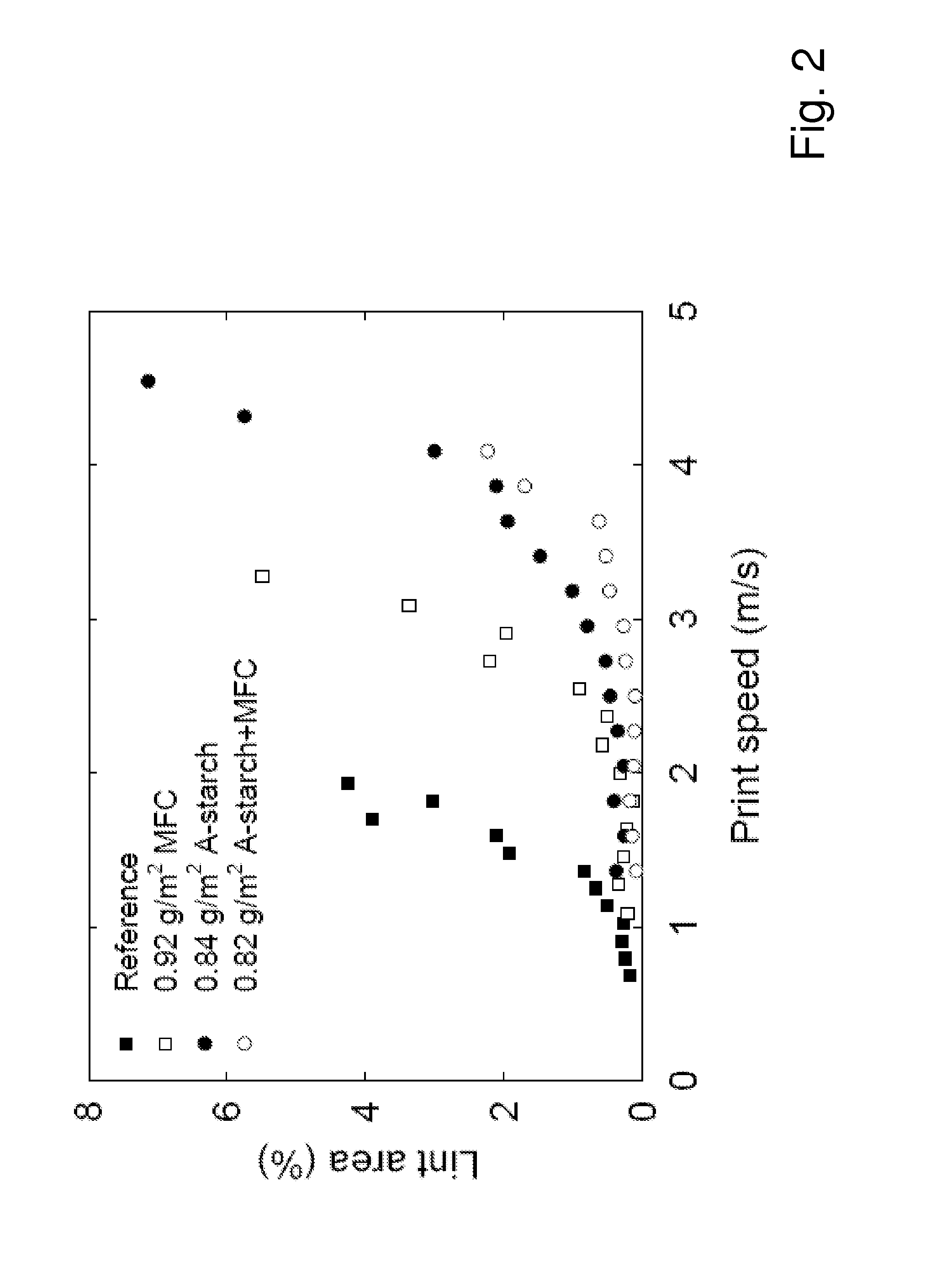

Composition for coating of printing paper

ActiveUS20110081554A1Reduced linting propensitySimple interfaceStarch dervative coatingsSpecial paperCelluloseColloid

The invention relates to compositions for coating of printing paper, said compositions comprising microfibrillated cellulose (MFC) and one or more polysaccharide hydrocolloids, and use of said compositions. Further, the invention relates to coated paper, comprising a first layer of polysaccharide hydrocolloid(s) and a second layer of MFC, and use of said paper. A method for reducing the linting and / or dusting of a paper is also disclosed.

Owner:INNVENTIA

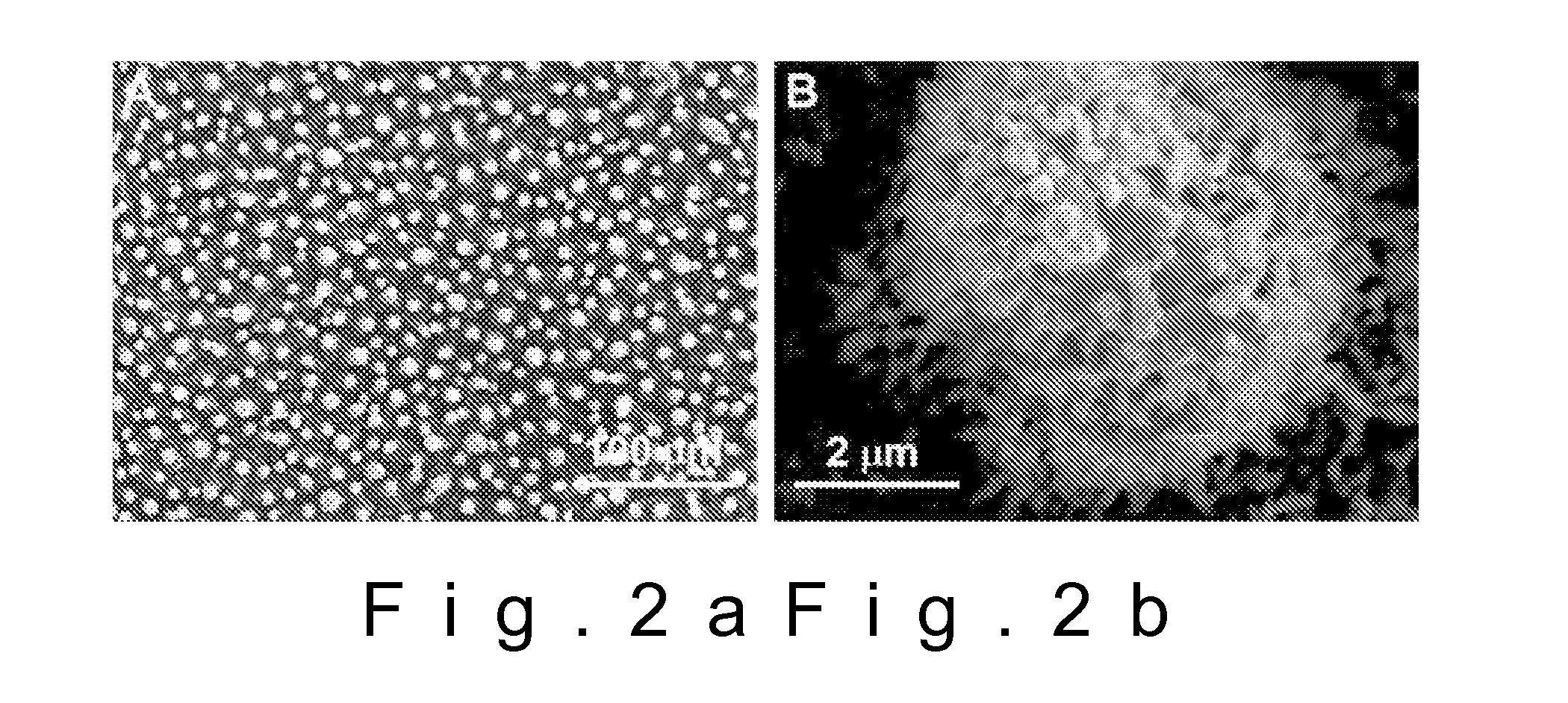

Coating layers of a nanocomposite comprising a nano-cellulose material and nanoparticles

InactiveUS20150017432A1Good effectImprove efficiencyMaterial nanotechnologyOptical filtersNanoparticleNanocomposite

The invention provides articles and methods for making such articles including a substrate coated on at least one region thereof with a layer of nanocomposites nano-cellulose materials and nanoparticles.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

Self-associating low adhesion backsize material

A low adhesion backsize (LAB) material made by mixing together materials, which self-associate. The mixtures can be waterbased and have high solids levels. The release is provided by functional groups such as silicones, fluorocarbons or long chain hydrocarbons. Release level can be tailored with release levels as low as the 0.5 gram / cm range to microsphere adhesives.

Owner:3M INNOVATIVE PROPERTIES CO

Metal nanowire inks for the formation of transparent conductive films with fused networks

Fusing nanowire inks are described that can also comprise a hydrophilic polymer binder, such as a cellulose based binder. The fusing nanowire inks can be deposited onto a substrate surface and dried to drive the fusing process. Transparent conductive films can be formed with desirable properties.

Owner:C3 NANO INC

Nanotube dispersants and dispersant free nanotube films therefrom

ActiveUS20140083752A1Diminishes little of apparent transparencyImprove conductivityMaterial nanotechnologyCarbon compoundsBackbone chainDip-coating

A degradable polymeric nanotube (NT) dispersant comprises a multiplicity of NT associative groups that are connected to a polymer backbone by a linking group where there are cleavable groups within the polymer backbone and / or the linking groups such that on a directed change of conditions, bond breaking of the cleavable groups results in residues from the degradable polymeric NT dispersant in a manner where the associative groups are uncoupled from other associative groups, rendering the associative groups monomelic in nature. The degradable polymeric nanotube (NT) dispersant can be combined with carbon NTs to form a NT dispersion that can be deposited to form a NT film, or other structure, by air brushing, electrostatic spraying, ultrasonic spraying, ink-jet printing, roll-to-roll coating, or dip coating. The deposition can render a NT film that is of a uniform thickness or is patterned with various thicknesses. Upon deposition of the film, the degradable polymeric nanotube (NT) dispersant can be cleaved and the cleavage residues removed from the film to yield a film where contact between NTs is unencumbered by dispersants, resulting in highly conductive NT films.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

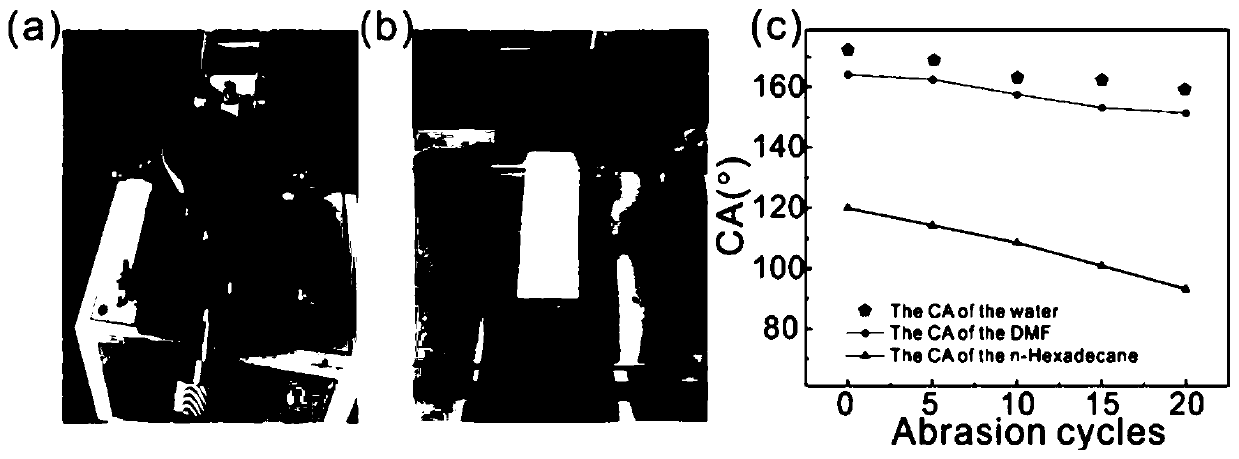

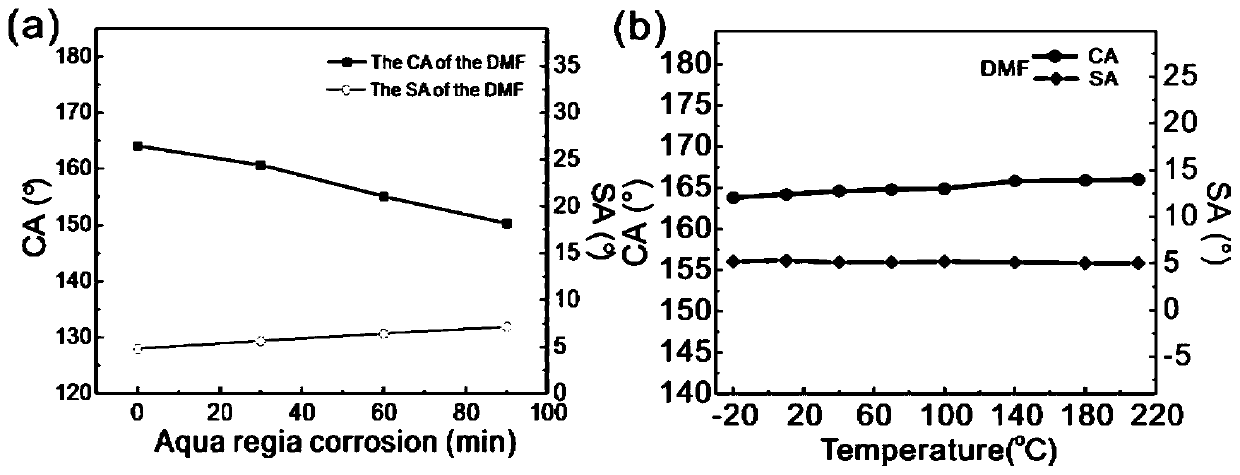

Preparation and application of super-hydrophobic/oleophobic coating layer with excellent performance

The invention relates to preparation and application of a super-hydrophobic / oleophobic coating layer with excellent performance, wherein the preparation comprises the steps: dispersing nanoparticles and cellulose in an alkaline substance-containing alcoholic solution, and adding tetraethyl orthosilicate and fluorine-containing organosilane for hydrolytic coating to form a solution A; dispersing epoxy resin in an alcoholic solution to form a solution B; uniformly mixing the solution A and the solution B, and then adding tetraethyl orthosilicate and fluorine-containing organosilane to react to generate polysiloxane, to obtain a solution C; dissolving a fluorine-containing amine compound in an alcoholic solution to obtain a solution D; and uniformly mixing the solution C and the solution D, spraying the mixture on a substrate, and curing to obtain the product. A multi-stage micro-nano hierarchical structure is constructed; the super-hydrophobic / oleophobic coating layer has good chemical stability, can achieve a complete repelling effect on N,N-dimethylformamide liquid drops (34.4 mN / m), has a contact angle of 120 degrees on n-hexadecane (27.1 mN / m), is simple in preparation method, can be sprayed on a large scale, and paves a road for industrialization of the super-hydrophobic / oleophobic coating layer.

Owner:QILU UNIV OF TECH

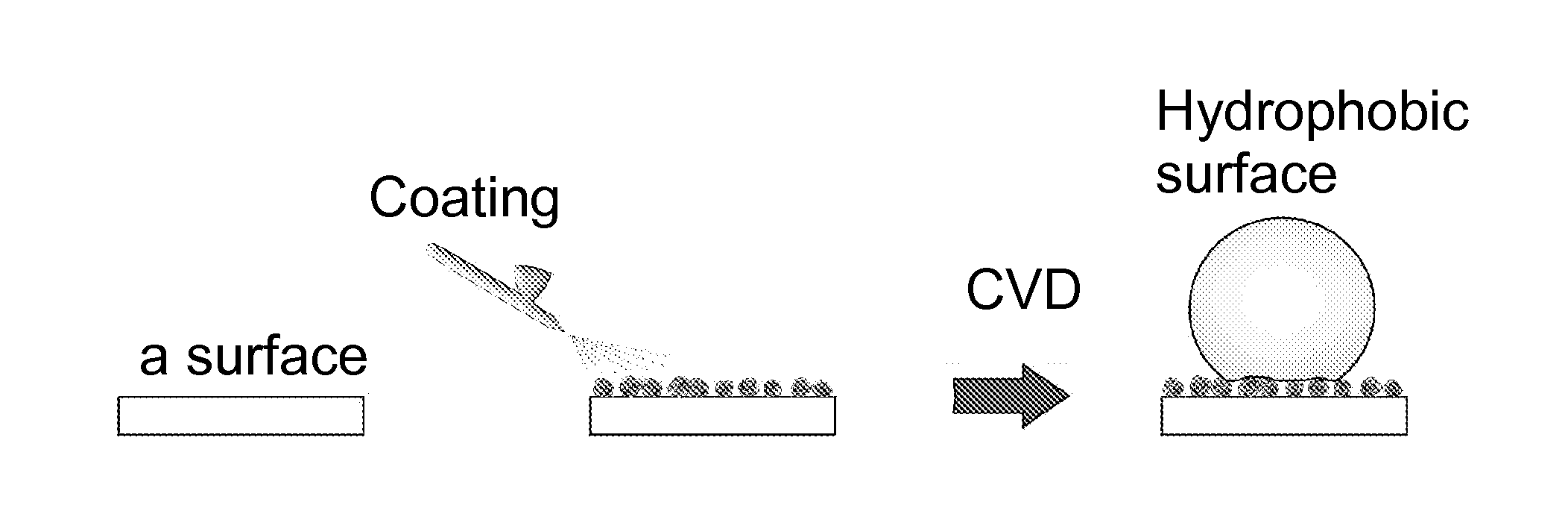

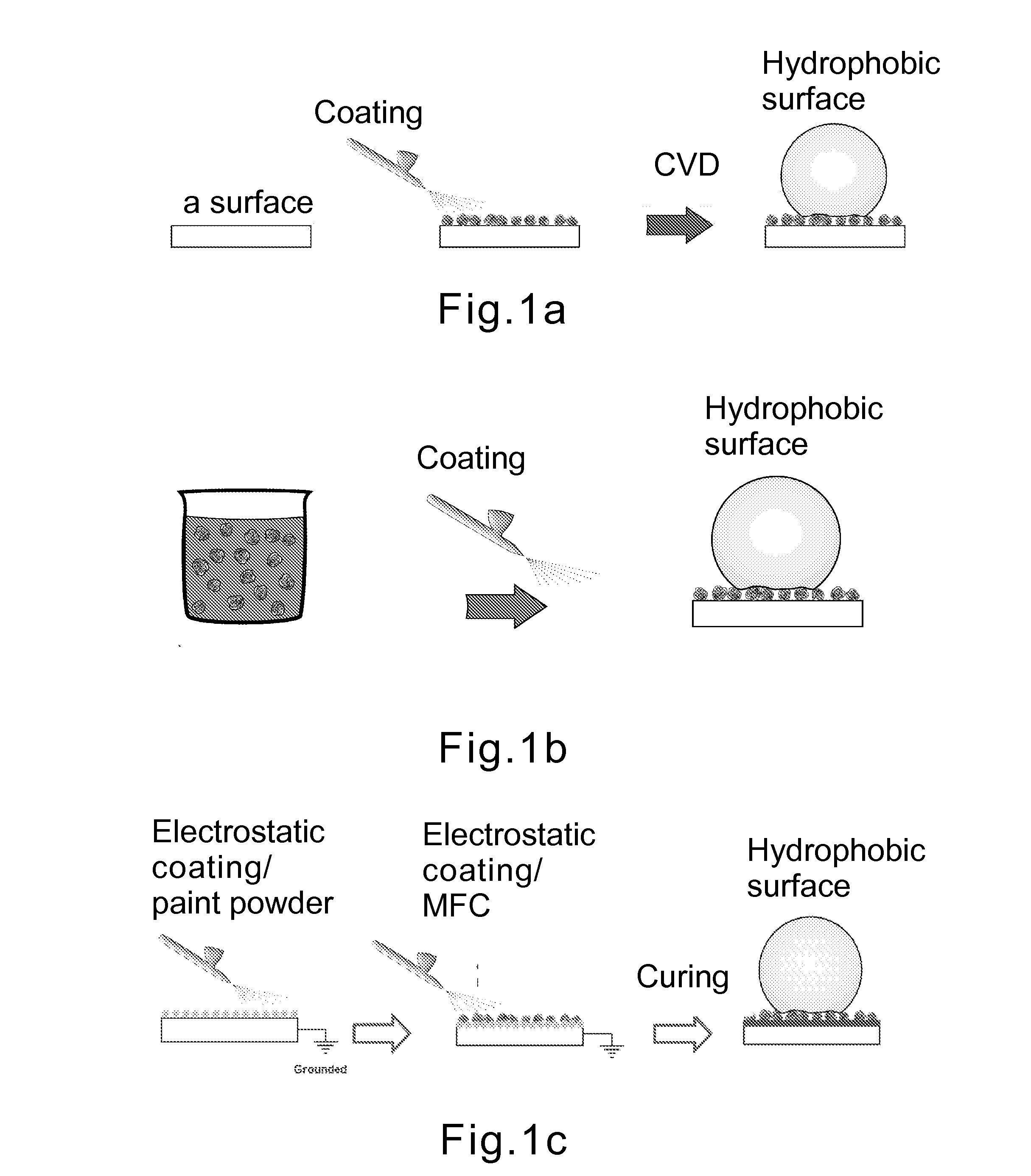

Hydrophobic coating and a method for producing hydrophobic surface

InactiveUS20140130710A1Similar in sizeIncrease contact angleElectric shock equipmentsWater-repelling agents additionPolymer chemistryHydrophobic surfaces

A method for producing a superhydrophobic surface, which includes cellulosic material. The cellulosic material includes nanocellulose particles and the method includes adding the nanocellulose particles to a surface and hydrophobizing the nanocellulose particles with a modifier before, during and / or after the addition of the particles. The invention further relates to a hydrophobic coating.

Owner:UPM-KYMMENE OYJ

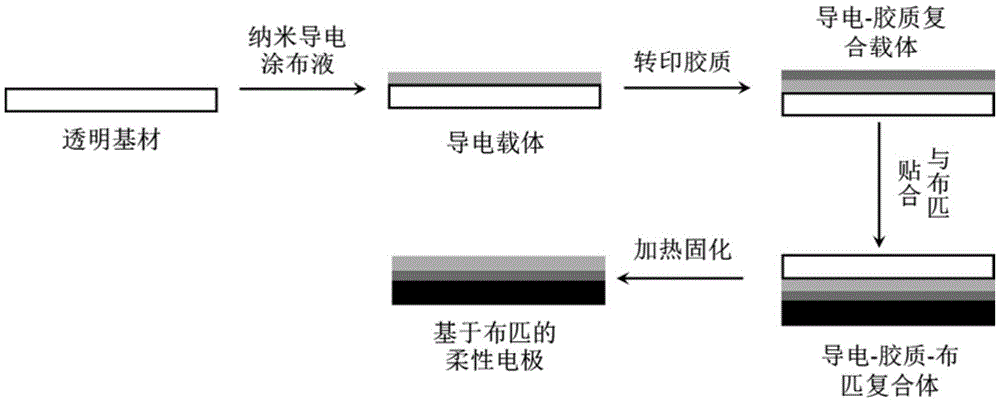

Flexible wearable dry electrode and preparation method thereof

ActiveCN105455804AImprove conductivityMaintain structural propertiesAdhesive processesLayered productsAdhesiveEngineering

The invention provides a flexible wearable dry electrode and a preparation method thereof. The flexible wearable dry electrode comprises a basic cloth material, a transfer print gelatinous layer and a nanometer electric conduction layer which are sequentially attached. The transfer print gelatinous layer is prepared from, by weight, 50-90% of elastic resin, 5-15% of curing agent and 5-35% of filler. The nanometer electric conduction layer is prepared from, by weight, 0.1-20 parts of electric conduction nanometer materials, 0.1-30 parts of dispersing agent and 0.01-5 parts of adhesives. The preparation method includes the steps of preparing electric conduction coating liquid and transfer print gelatine, sequentially arranging the electric conduction coating liquid and the transfer print gelatine on a flexible release film through transfer print, pressing the flexible release film on the basic cloth material, conducting resolidification, and tearing off the release film. The flexible wearable dry electrode has the advantages of high conductivity, high flexibility, high environment tolerance, long-time stability, washing resistance, kneading resistance and the like, can be freely cut according to garment requirements, and is high in universality.

Owner:西大(常熟)研究院有限公司

Conductive graphite cream and preparation method thereof

ActiveCN102618107AReduce carbon additionDoes not affect conductivityCellulose coatingsConjugated diene hydrocarbon coatingsConductive polymerGraphite

The invention discloses conductive graphite cream and a preparation method thereof, which solve the technical problem of improving dispersibility of graphite cream. The conductive graphite cream comprises materials including, in weight percent, 10-30% of conductive graphite, 1-30% of matrix resin, 0.1-5% of conductive polymer auxiliaries, 0.1-5% of dispersing auxiliaries and the balance solvents. The preparation method includes the steps: adding the conductive polymer auxiliaries into the solvents to obtain solution 1; adding the matrix resin into the solvents to obtain solution 2; adding the conductive graphite into the solution 2; adding the dispersing auxiliaries into the solution 2 for ball-milling; adding the solution 1 into solution 3; and performing ultrasonic oscillation, high-pressure dispersion and stirring to obtain the conductive graphite cream. Compared with the prior art, the conductive graphite cream and the preparation method have the advantages that nano carbon materials are added, ball-milling, ultrasonic oscillation and high-pressure dispersion are performed for assisting so that the conductive graphite cream is uniformly dispersed, and the preparation method is simple and low-cost.

Owner:BTR NEW MATERIAL GRP CO LTD

Nanocellulose compositions and processes to produce same

A composition comprising nanocellulose is disclosed, wherein the nanocellulose contains very low or essentially no sulfur content. The nanocellulose may be in the form of cellulose nanocrystals, cellulose nanofibrils, or both. The nanocellulose is characterized by a crystallinity of at least 80%, an onset of thermal decomposition of 300° F. or higher, and a low light transmittance over the range 400-700 nm. Other variations provide a composition comprising lignin-coated hydrophobic nanocellulose, wherein the nanocellulose contains very low or essentially no sulfur content. Some variations provide a composition comprising nanocellulose, wherein the nanocellulose contains about 0.1 wt % equivalent sulfur content, or less, as SO4 groups chemically or physically bound to the nanocellulose. In some embodiments, the nanocellulose contains essentially no hydrogen atoms (apart from hydrogen structurally contained in nanocellulose itself) bound to the nanocellulose. Various compositions, materials, and products may incorporate the nanocellulose compositions disclosed herein.

Owner:GRANBIO INTELLECTUAL PROPERTY HOLDINGS LLC

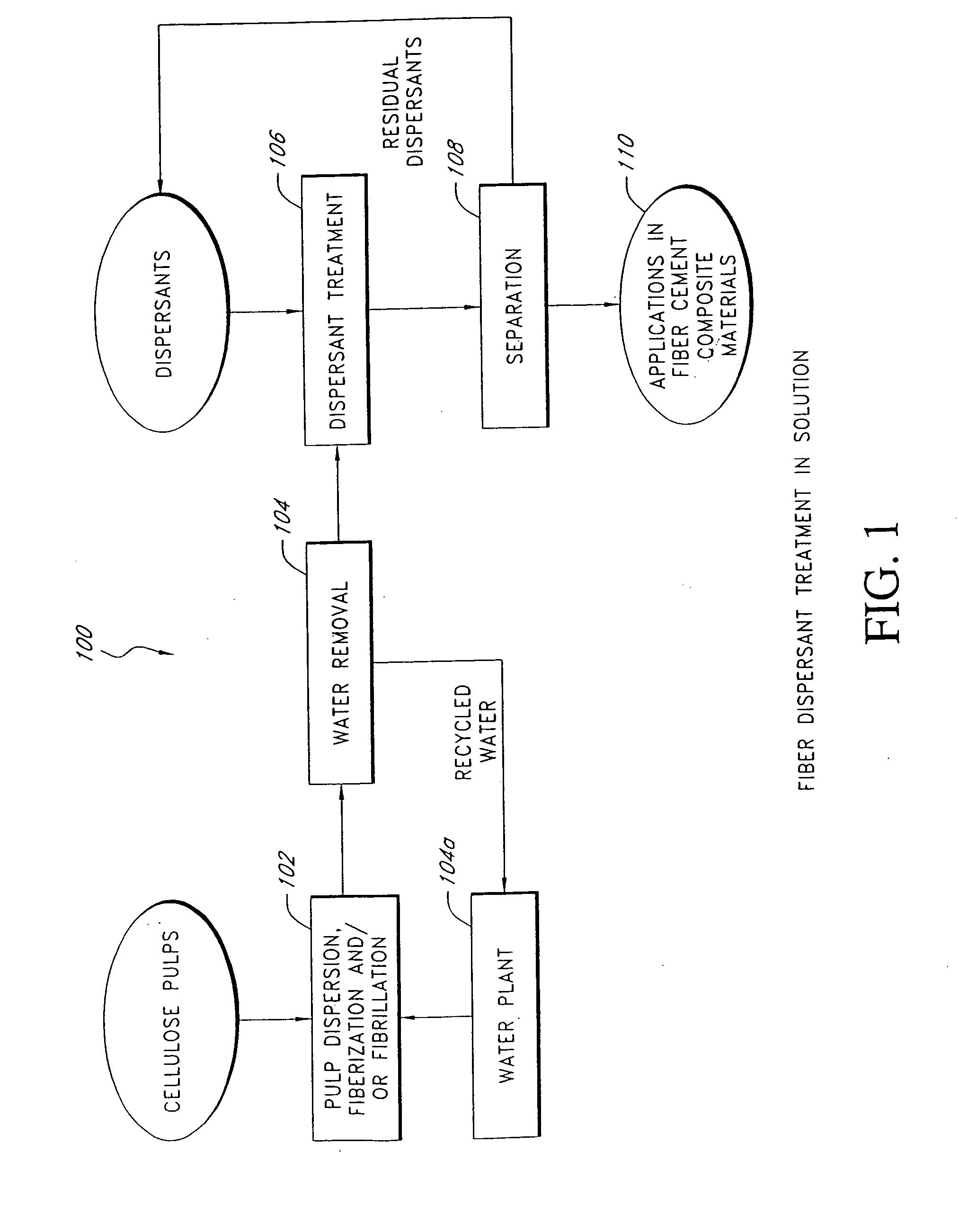

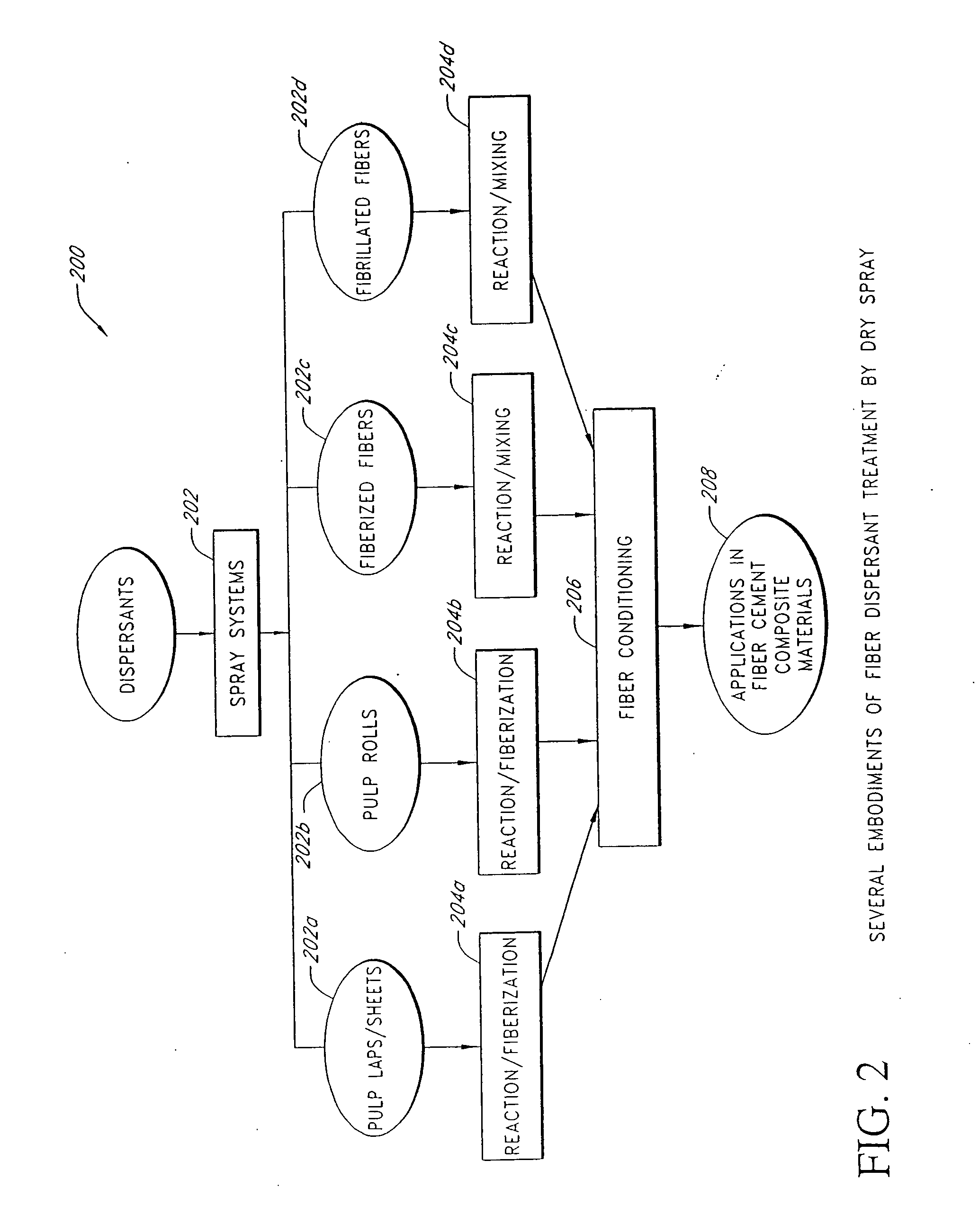

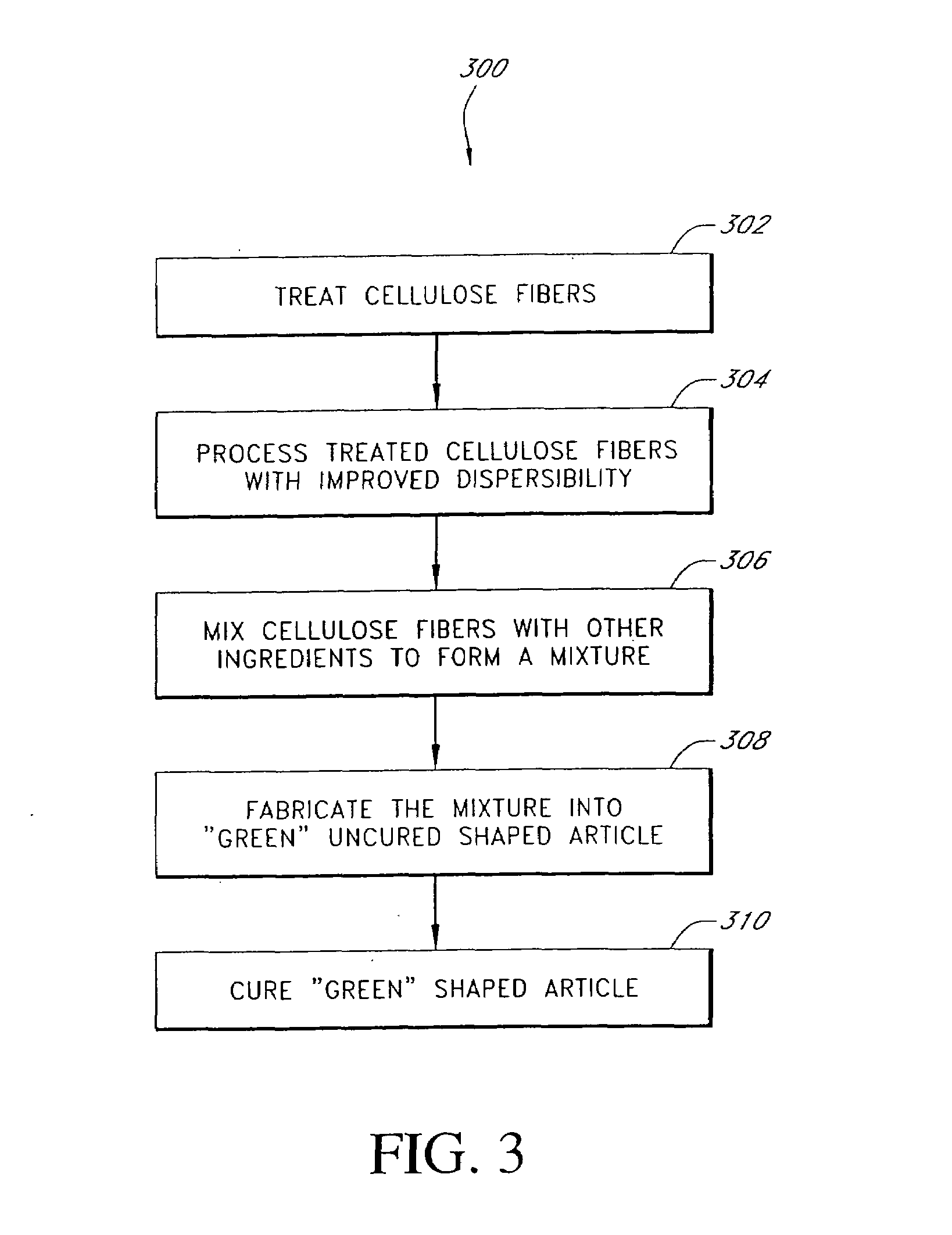

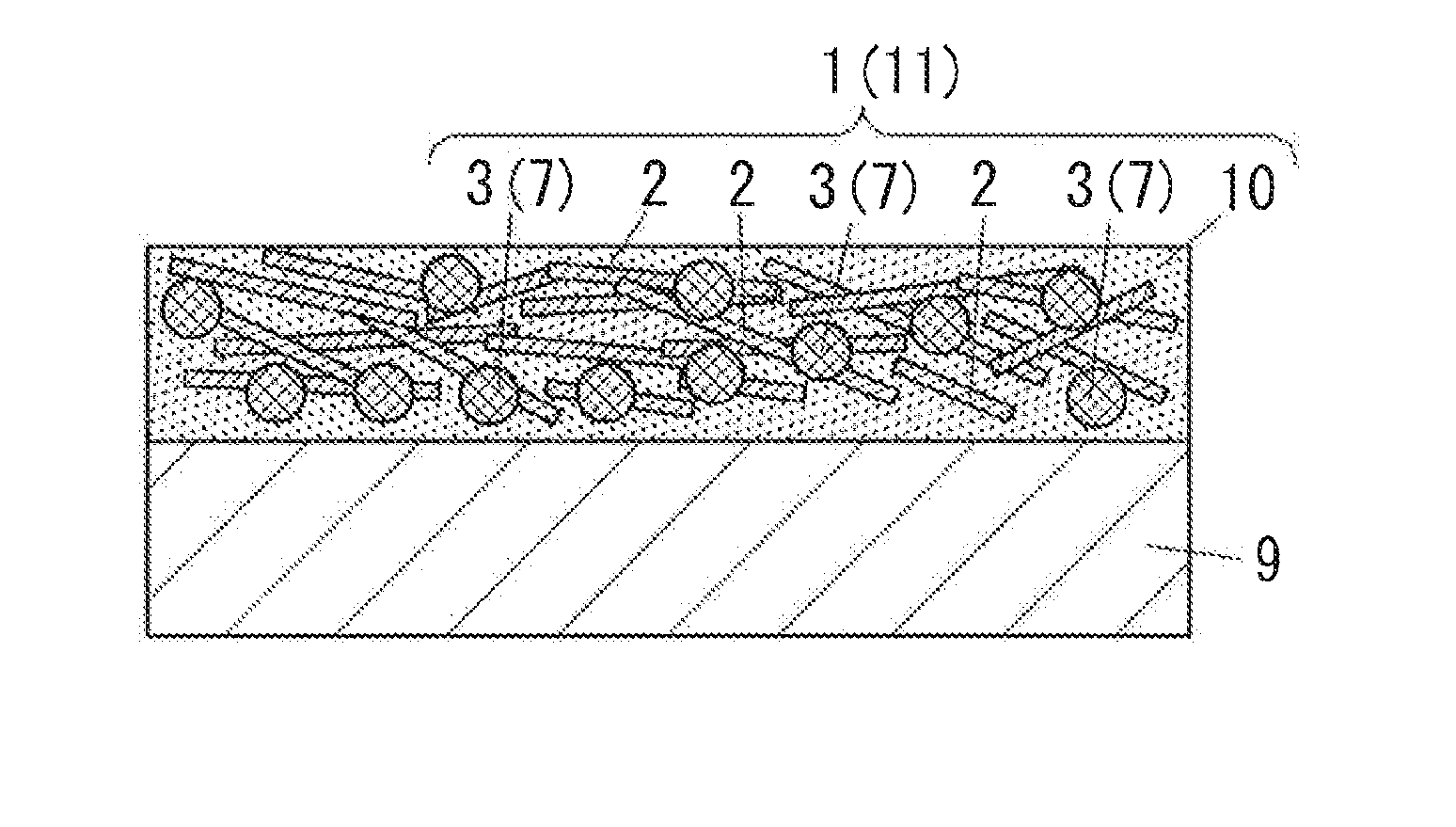

Fiber reinforced cement composite materials using chemically treated fibers with improved dispersibility

InactiveUS20080148999A1Good dispersionAvoid bondingPulp properties modificationSolid waste managementChemical treatmentSurface finish

A fiber-reinforced building material in one embodiment incorporates cellulose fibers that are chemically treated with a dispersant to impart improved dispersibility to the fibers. The fibers are treated with a dispersant which deactivates the hydroxyl sites of the fiber surfaces and in some cases, making the fiber surface more hydrophobic. The dispersant inhibits the hydroxyl groups on the cellulose fiber surface from bonding with hydroxyl groups of other fibers and from bonding with hydroxyl groups of the same fiber, thereby significantly reducing inter-fiber and intra-fiber hydrogen bonding. The treated fibers can be readily dispersed and uniformly distributed throughout a mixture without re-clustering or reclumping once the mechanical mixing action stops. The chemically treated fibers with improved dispersibility improve the fiber distribution and reinforcing efficiency, which in turn improves key physical and mechanical properties of the material such as the modulus of rupture, z-direction tensile strength, and toughness, and surface finishes. With improved fiber reinforcing efficiency, less dosage of fiber is needed to achieve the required physical and mechanical properties.

Owner:JAMES HARDIE TECH LTD

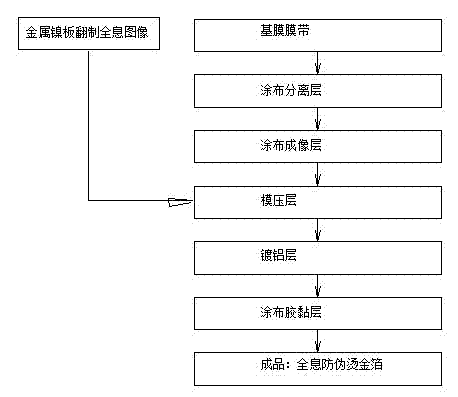

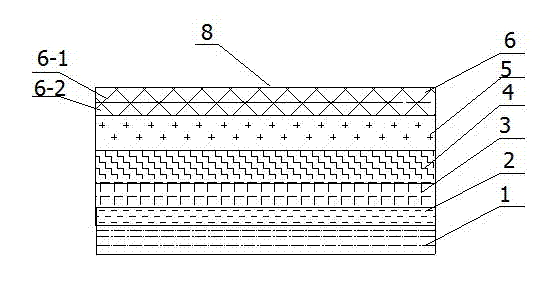

Preparation method for laser hot stamping foil of metal coin and prepared product

ActiveCN103072393ATo achieve the purpose of printingImprove curing speedDuplicating/marking methodsCellulose coatingsHot stampingWeather resistance

The invention relates to the technology of laser holography anti-counterfeiting hot stamping, in particular to a preparation method for laser hot stamping foil of a metal coin and prepared laser hot stamping foil by using the method, and provides a preparation method for laser hot stamping foil of a metal coin and prepared laser hot stamping foil by using the method, which can adapt to gold stamping on the surface of the metal coin, enrich patterns on the surface of the metal coin, has an anti-counterfeiting function and is suitable for printing after stamping. The preparation method comprises the steps that a metallic nickel plate is manufactured, and a release layer, an imaging layer, a mold pressing layer, an aluminum coated layer and an adhesive layer are coated on a basement membrane strip, so that the metal coin has a brand-new effect, the operation process is simple and rapid, reproducibility of texts is good, large-scale production and durability are realized, the cost is reduced, the adhesion of the laser hot stamping foil is high, after being fastened on the surface of a metal product, the hot stamping foil does not easily fall off and has a smooth surface, through changing the formula of the adhesive layer and coating the adhesive layer for multiple times, a multi-layer bonding layer is formed, so that texts are firmly adhered on the surface of the metal, and wear resistance and weather fastness are realized.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

Composition comprising microfibrillated cellulose and a process for the production of a composition

ActiveUS20130047893A1Easy to moveIncrease dry contentPigmenting treatmentCoatings with pigmentsCellulose fiberViscosity

The present invention relates to a composition comprising microfibrillated cellulose, mono-, di- or oligo-saccharides and a pigment in order to achieve a composition with improved rheological properties such as a low viscosity even at high dry content. The present invention further relates to process for the production of said composition. The microfibrillated cellulose is produced by at least partly enzymatic treatment of cellulosic fibers such that even mono-, di- or oligo-saccharide is formed.

Owner:STORA ENSO OYJ

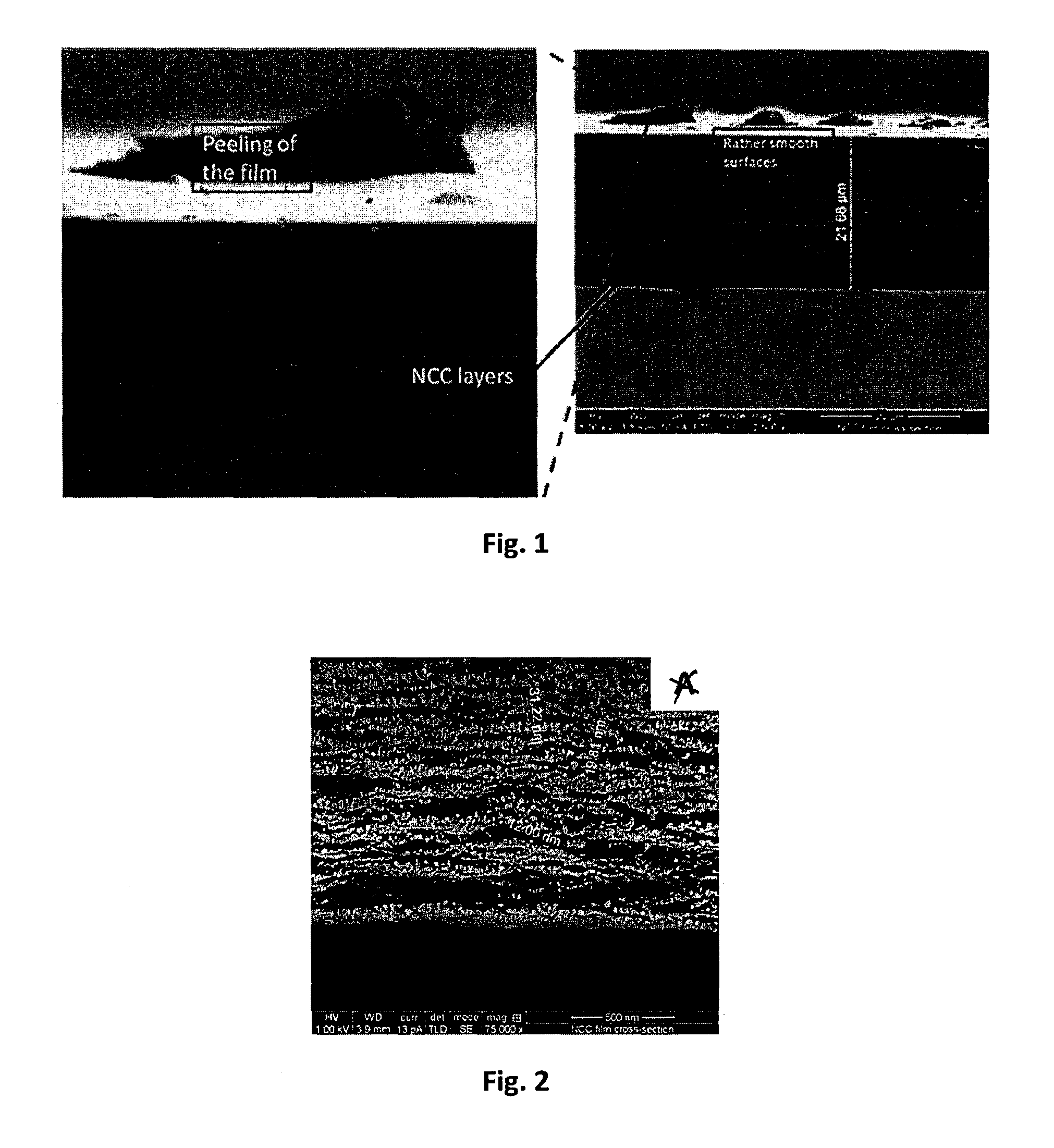

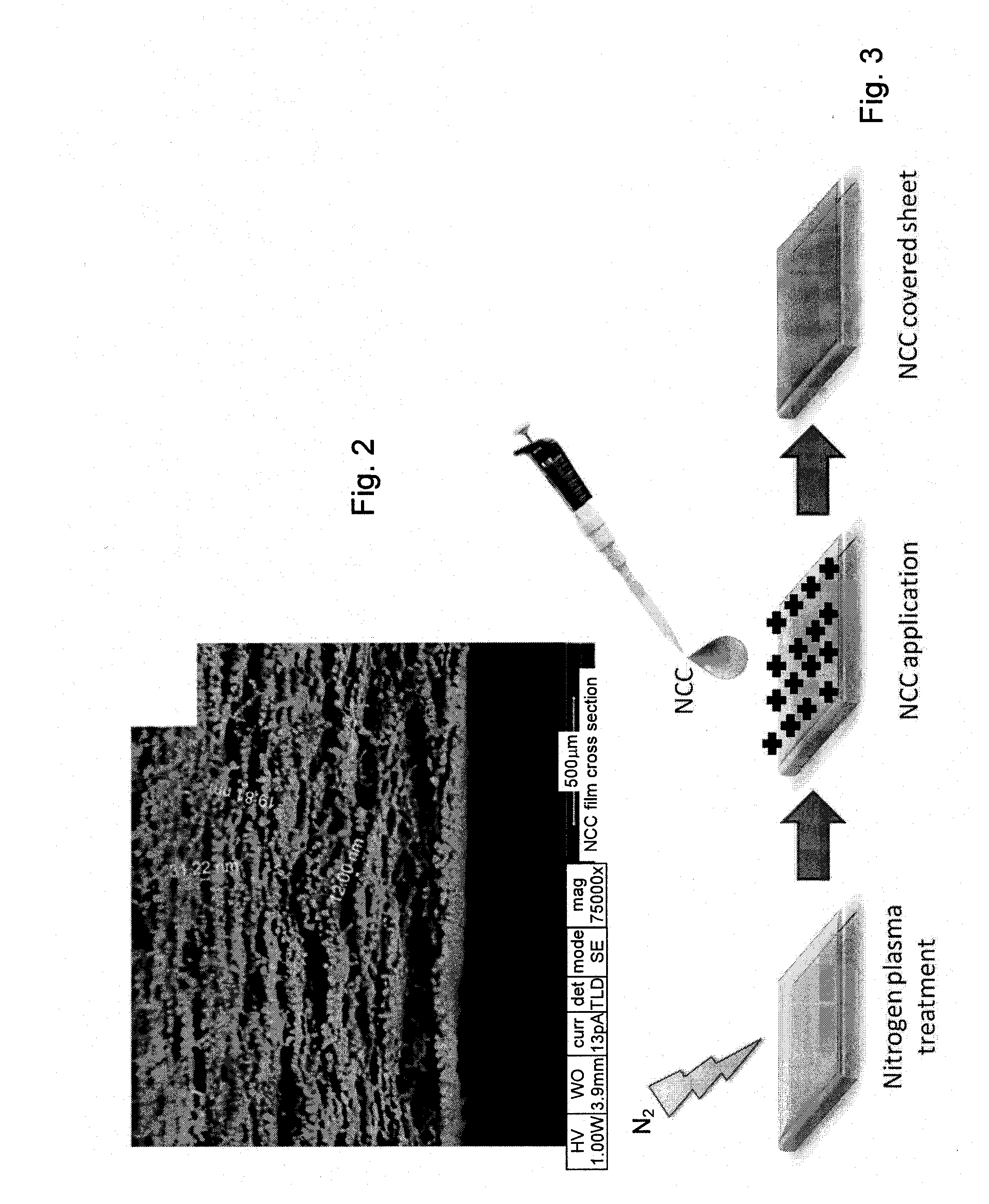

Method for the preparation of NFC films on supports

InactiveUS20140255688A1Excellent oxygen barrier propertiesReduce porosityCellulose coatingsCellulosic plastic layered productsCellulosePolymer science

The present invention concerns a method of preparing a film of nanofibrillated cellulose (NFC) on at least one surface of a support material, wherein the film is applied and spread directly onto a surface of the plastic support material in the form of a suspension of nanofibrillated cellulose, whereby the nanofibrillated cellulose forms a film. Further, the invention concerns a structure containing or consisting of a film of nanofibrillated cellulose prepared using said method.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

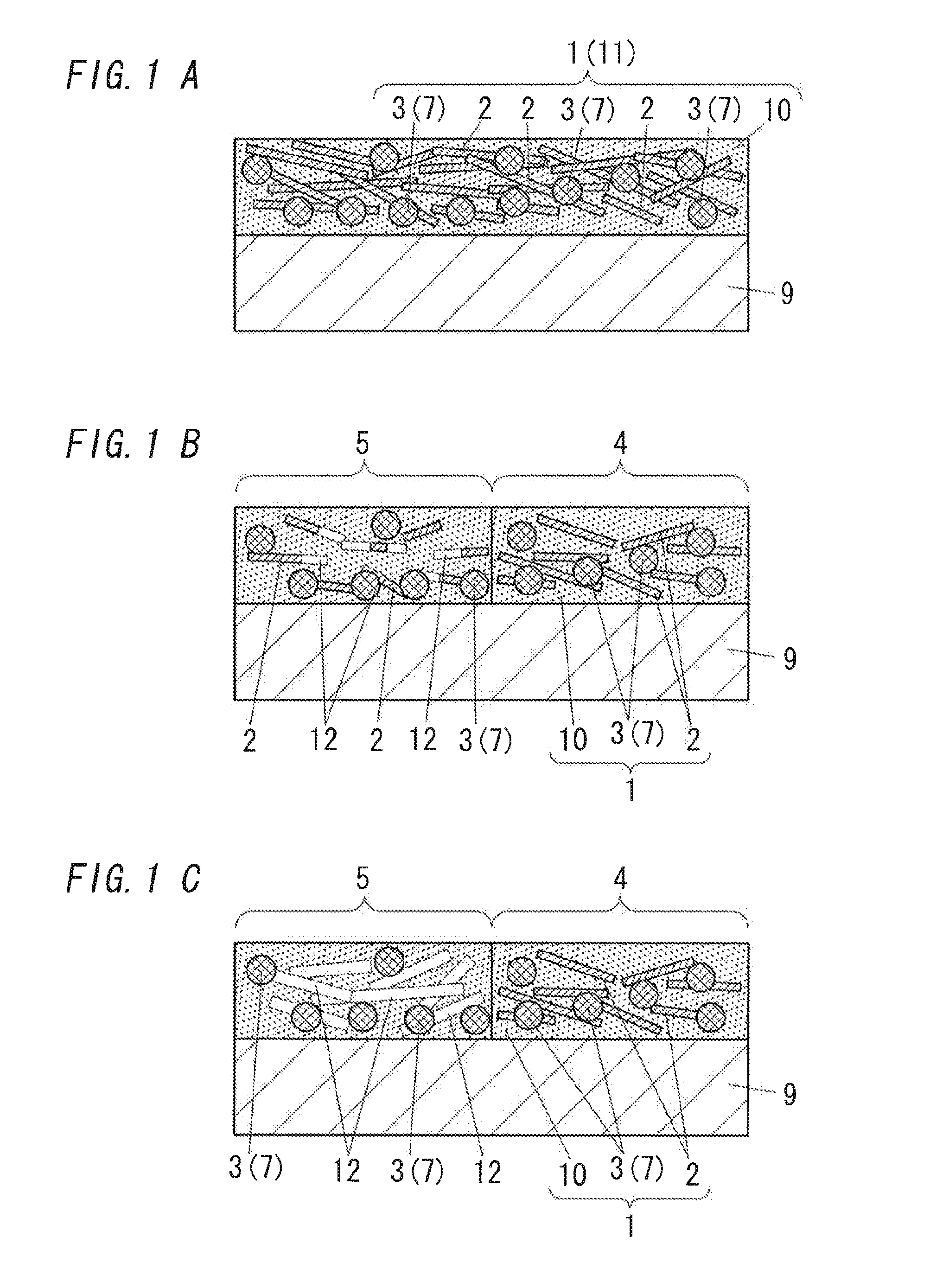

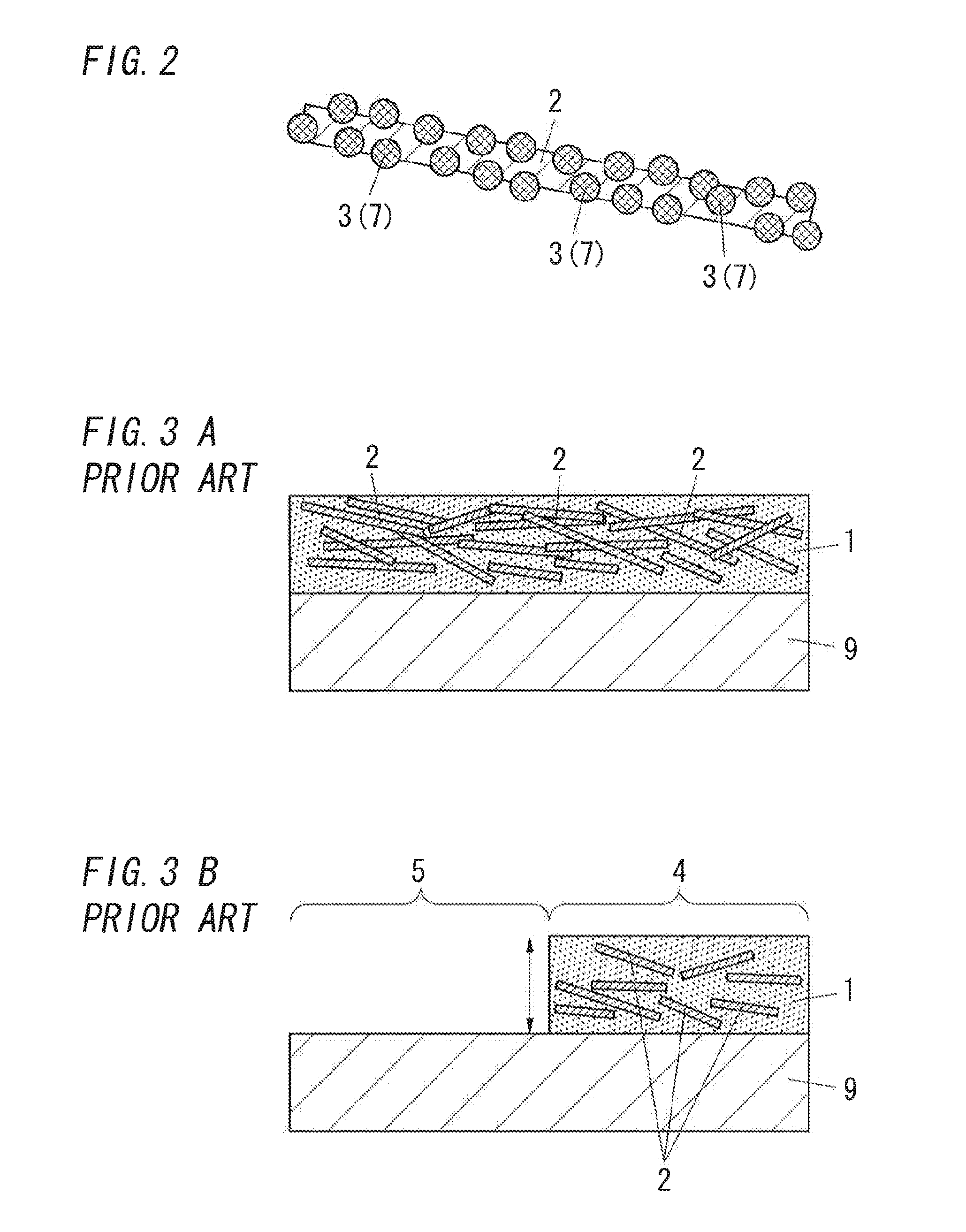

Transparent conductive film, substrate carrying transparent conductive film, and production method thereof

InactiveUS20150027755A1Reduce in quantityReduce level differenceMaterial nanotechnologyRadiation applicationsTransparent conducting filmMaterials science

Provided is a transparent conductive film wherein an electrically conductive region is converted to an electrically insulating region more readily and rapidly than traditional conductive films and the level difference between the electrically conductive region and the electrically insulating region is smaller. The transparent conductive film has an electrically conductive region 4 and an electrically insulating region 5. The electrically conductive region 4 contains a resin component 10, a metal nanowire 2 and an insulation-promoting component 3. The insulation-promoting component 3 has a light absorption higher than that of the metal nanowire 2. The electrically insulating region 5 is defined by a region which contains a resin component 10 but not the metal nanowire 2 or a region which contains a resin component 10 and additionally a metal nanowire 2 having an aspect ratio of smaller than that of the metal nanowire 2.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Popular searches

Paper coating Cellulose adhesives Sugar derivatives preparation Chemical/physical/physico-chemical stationary reactors Pulp beating/refining methods Cellulose pulp after-treatment modification Monocomponent polyamides artificial filament Monocomponent cellulose artificial filament Organic non-macromolecular adhesive Inorganic adhesives

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com