Coating layers of a nanocomposite comprising a nano-cellulose material and nanoparticles

a technology of nano-cellulose and nanoparticles, which is applied in the field of multi-layers of cellulose nanomaterials, can solve the problems of material or article with optoelectronic properties that have so far been proved unsuccessful, and achieve the effect of increasing the efficiency of a greenhouse and enhancing the plasmonic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Results

Preparation of Ordered NCC Films With or Without NPs

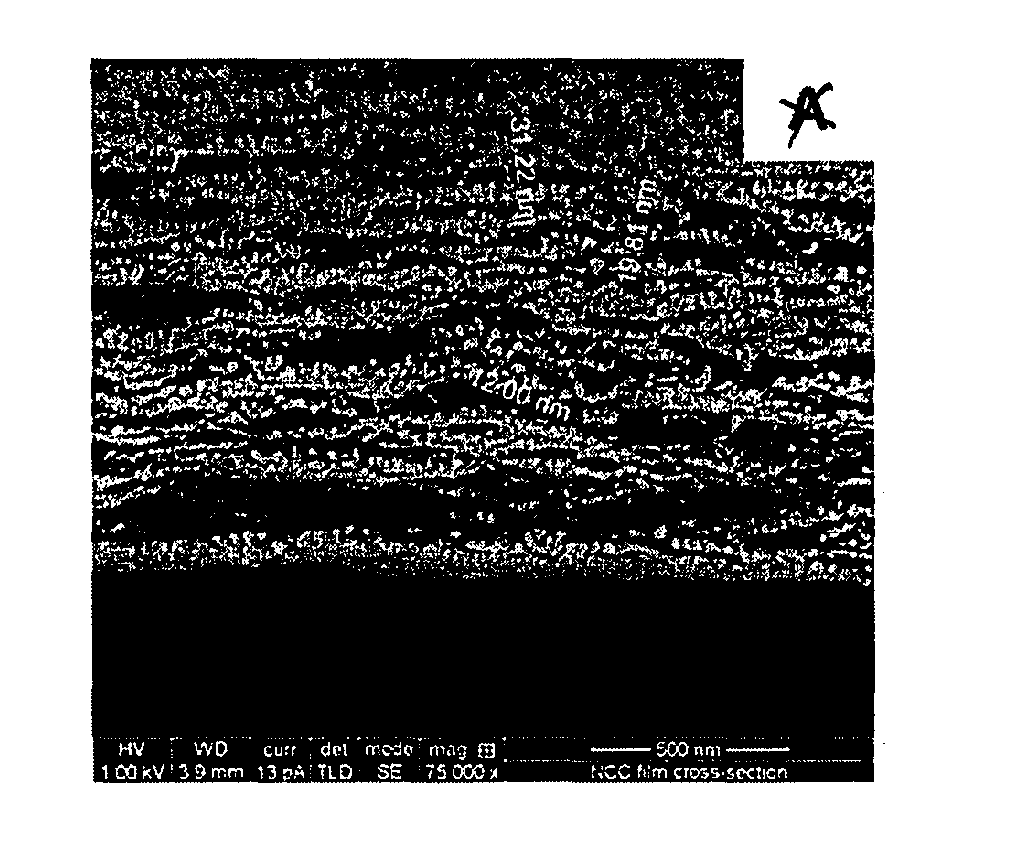

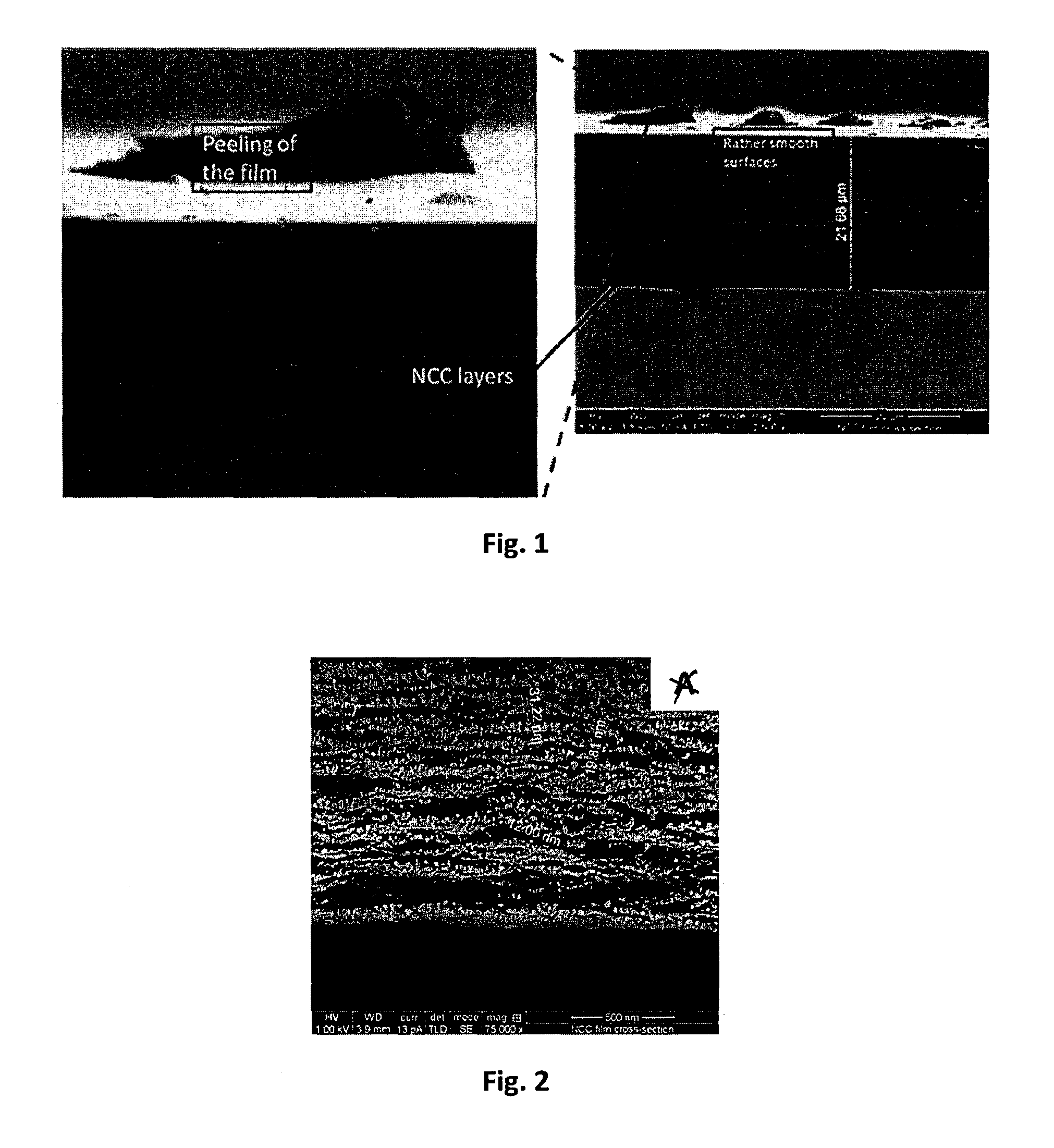

[0134]NCC solutions with or without nanoparticles (NPs) were dried in an oven at 37° C. The resulting films were analyzed using Magellan™ XHR scanning microscope. The NCC film displayed formation of highly ordered NCC layers having a thickness in the range of 5-20 nm (FIG. 1).

[0135]In addition, the hybrid NCC / NP film demonstrated the same ordered layers formation, but with nanoparticles trapped between the layers (FIG. 2).

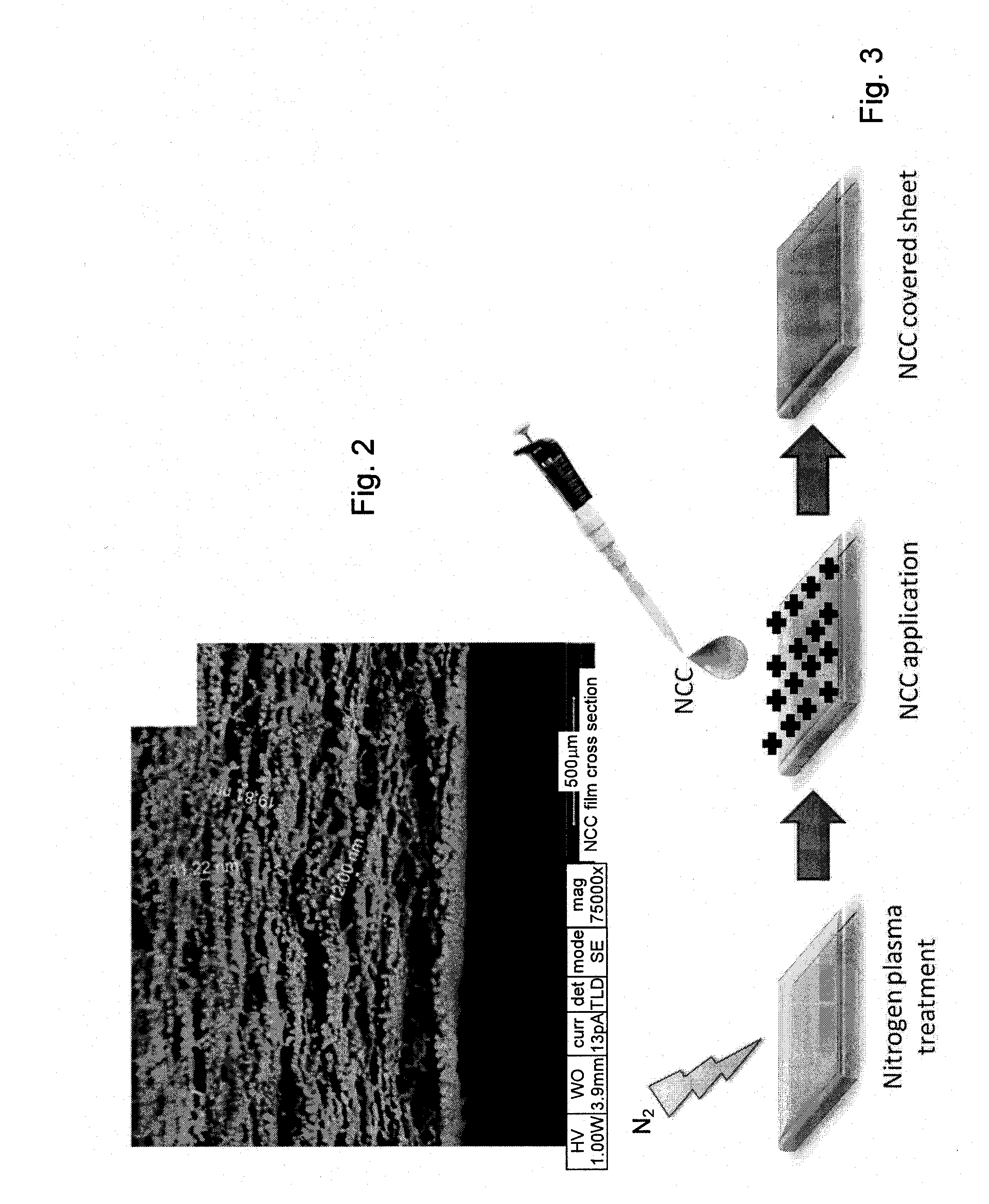

Preparation of Hybrid Nanomaterials Made of Polyethylene (PE) and NCC

[0136]NCC coating on PE sheets was performed using N2 plasma jet treatment (50% power, 150 W for 5 min, as depicted in FIG. 3). Subsequently, the NCC was spread over the pre-treated PE sheet to form a thin layer. Finally, the PE / NCC sheet was dried in an oven at 37° C. The resulting hybrid sheet displayed uniform NCC coating on the PE sheet, unlike the untreated PE sample, from which the NCC coating was observed to peel off (FIG. 4).

Prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com