Patents

Literature

287results about How to "Does not affect conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

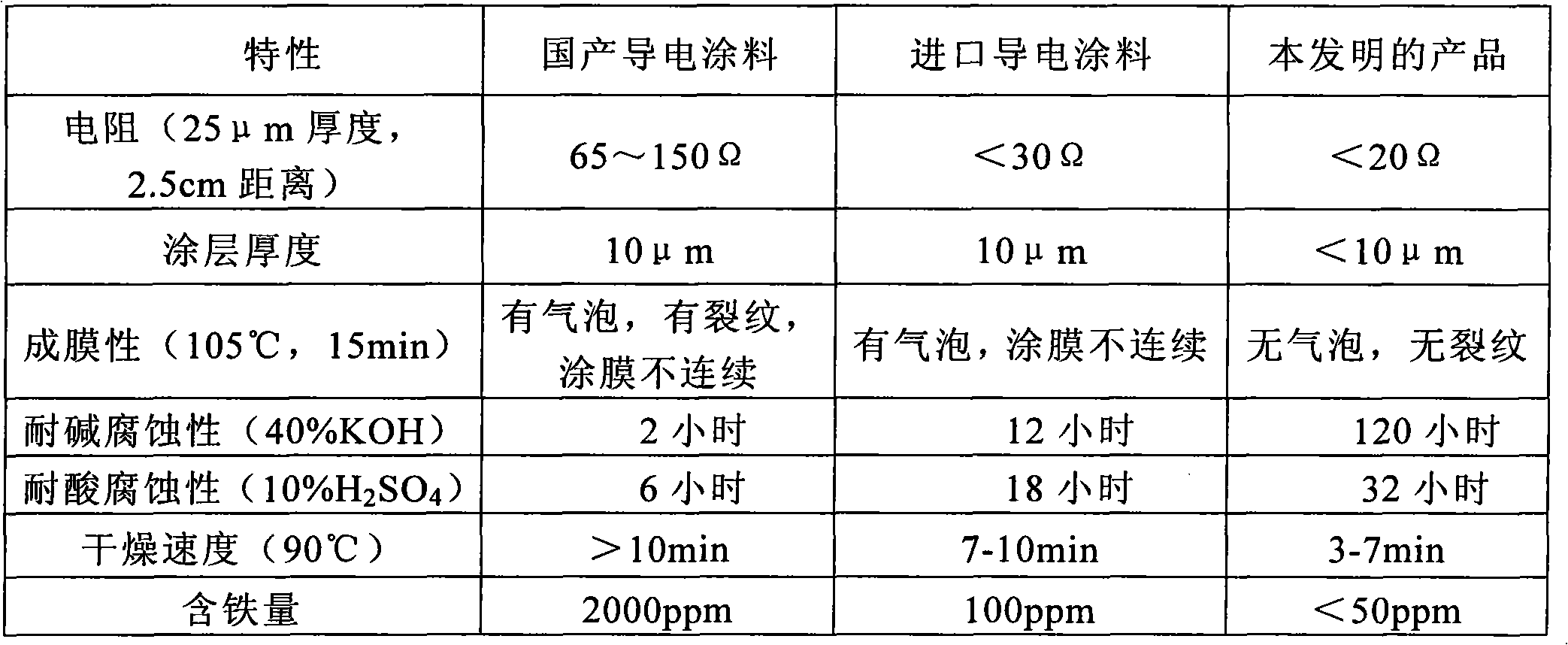

Supercapacitor electrode corrosion-resistant conductive coating

ActiveCN101899233AImprove conductivityReduce volumeAlkali metal silicate coatingsElectrolytic capacitorsConductive coatingSupercapacitor

The invention discloses a supercapacitor electrode corrosion-resistant conductive coating, which comprises the following components in percentage by weight: 10 to 35 percent of conductive agent, 0.1 to 3.5 percent of dispersing agent, 2.0 to 15 percent of binder, 0.1 to 8.0 percent of pH regulator, and 50 to 70 percent of pure water. The supercapacitor electrode corrosion-resistant conductive coating is prepared by the following steps of: fully mixing and uniformly stirring the components, adding the components into a ball mill for peptizing and dispersing, and discharging to obtain the supercapacitor electrode corrosion-resistant conductive coating. Compared with the conventional like products at home and abroad, the supercapacitor electrode corrosion-resistant conductive coating has the advantages of greatly improving the acid and alkali corrosion resistance, having no bubbles, falling off, corrosion and other phenomena after being soaked in alkaline solution for 120 hours and in acid solution for 32 hours, and improving the conductivity, adhesiveness and drying speed. The product can be diluted and adjusted according to need during use.

Owner:SHANGHAI HANBO ENTERPRISE +1

Conductive graphite cream and preparation method thereof

ActiveCN102618107AReduce carbon additionDoes not affect conductivityCellulose coatingsConjugated diene hydrocarbon coatingsConductive polymerGraphite

The invention discloses conductive graphite cream and a preparation method thereof, which solve the technical problem of improving dispersibility of graphite cream. The conductive graphite cream comprises materials including, in weight percent, 10-30% of conductive graphite, 1-30% of matrix resin, 0.1-5% of conductive polymer auxiliaries, 0.1-5% of dispersing auxiliaries and the balance solvents. The preparation method includes the steps: adding the conductive polymer auxiliaries into the solvents to obtain solution 1; adding the matrix resin into the solvents to obtain solution 2; adding the conductive graphite into the solution 2; adding the dispersing auxiliaries into the solution 2 for ball-milling; adding the solution 1 into solution 3; and performing ultrasonic oscillation, high-pressure dispersion and stirring to obtain the conductive graphite cream. Compared with the prior art, the conductive graphite cream and the preparation method have the advantages that nano carbon materials are added, ball-milling, ultrasonic oscillation and high-pressure dispersion are performed for assisting so that the conductive graphite cream is uniformly dispersed, and the preparation method is simple and low-cost.

Owner:BTR NEW MATERIAL GRP CO LTD

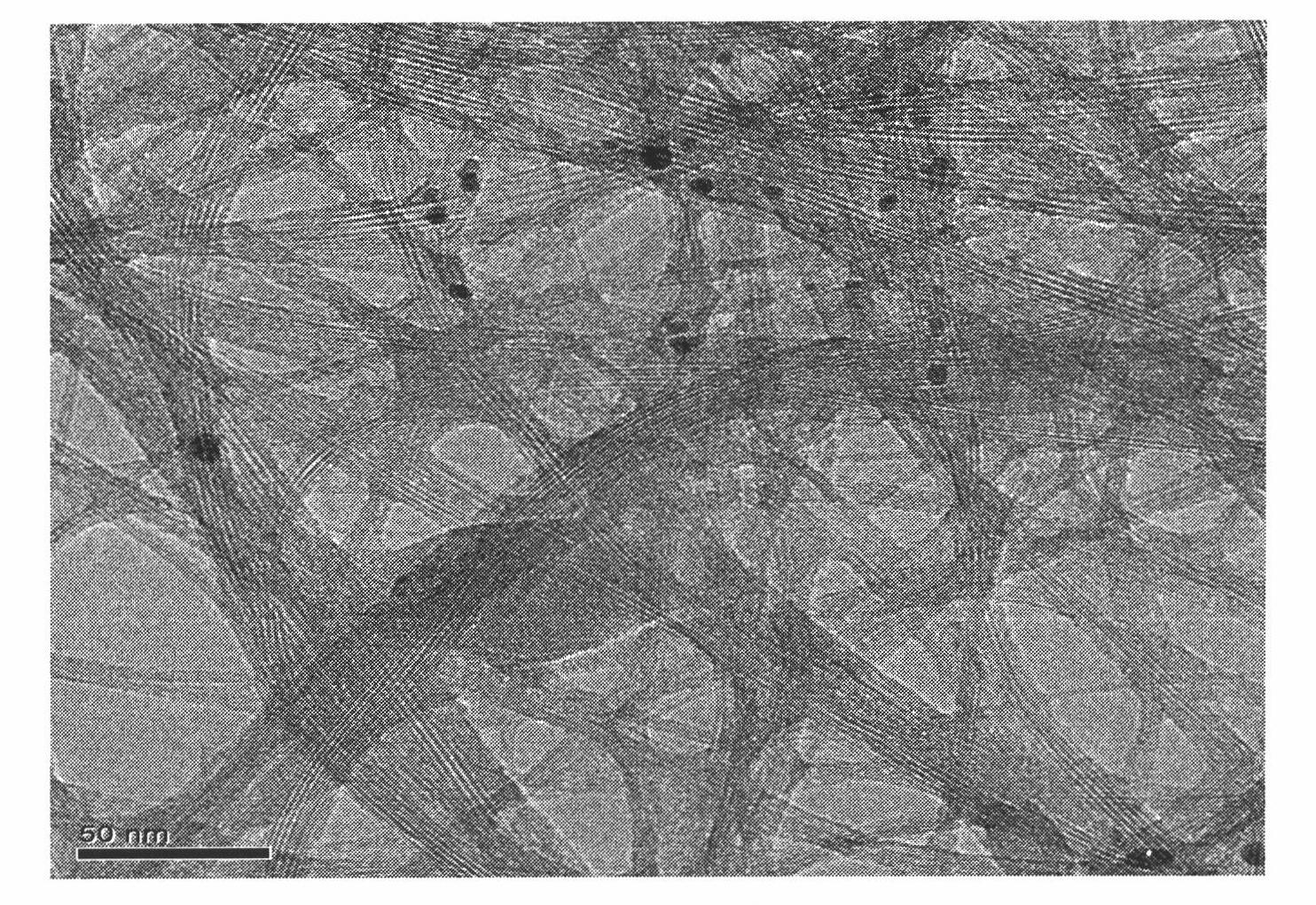

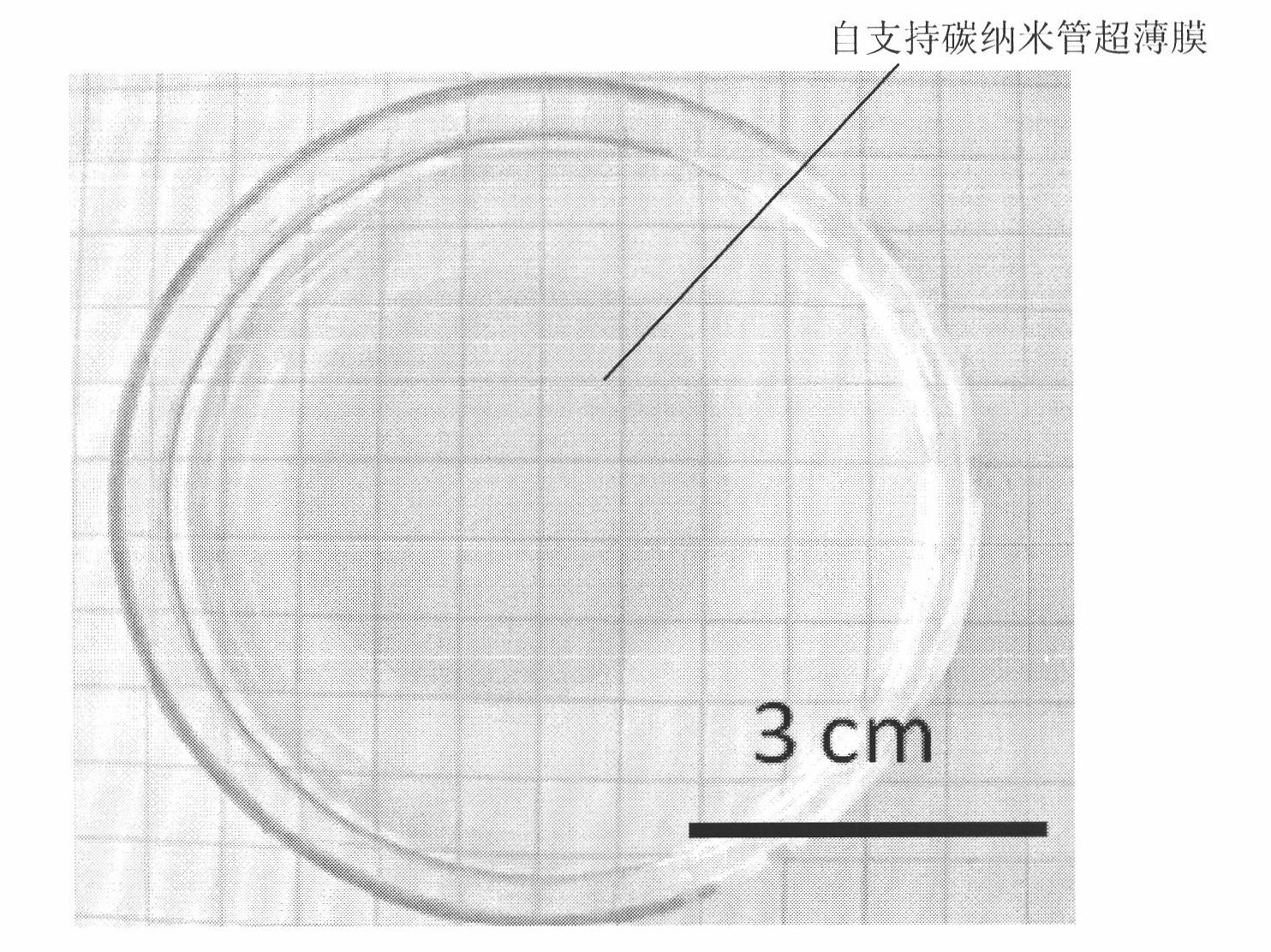

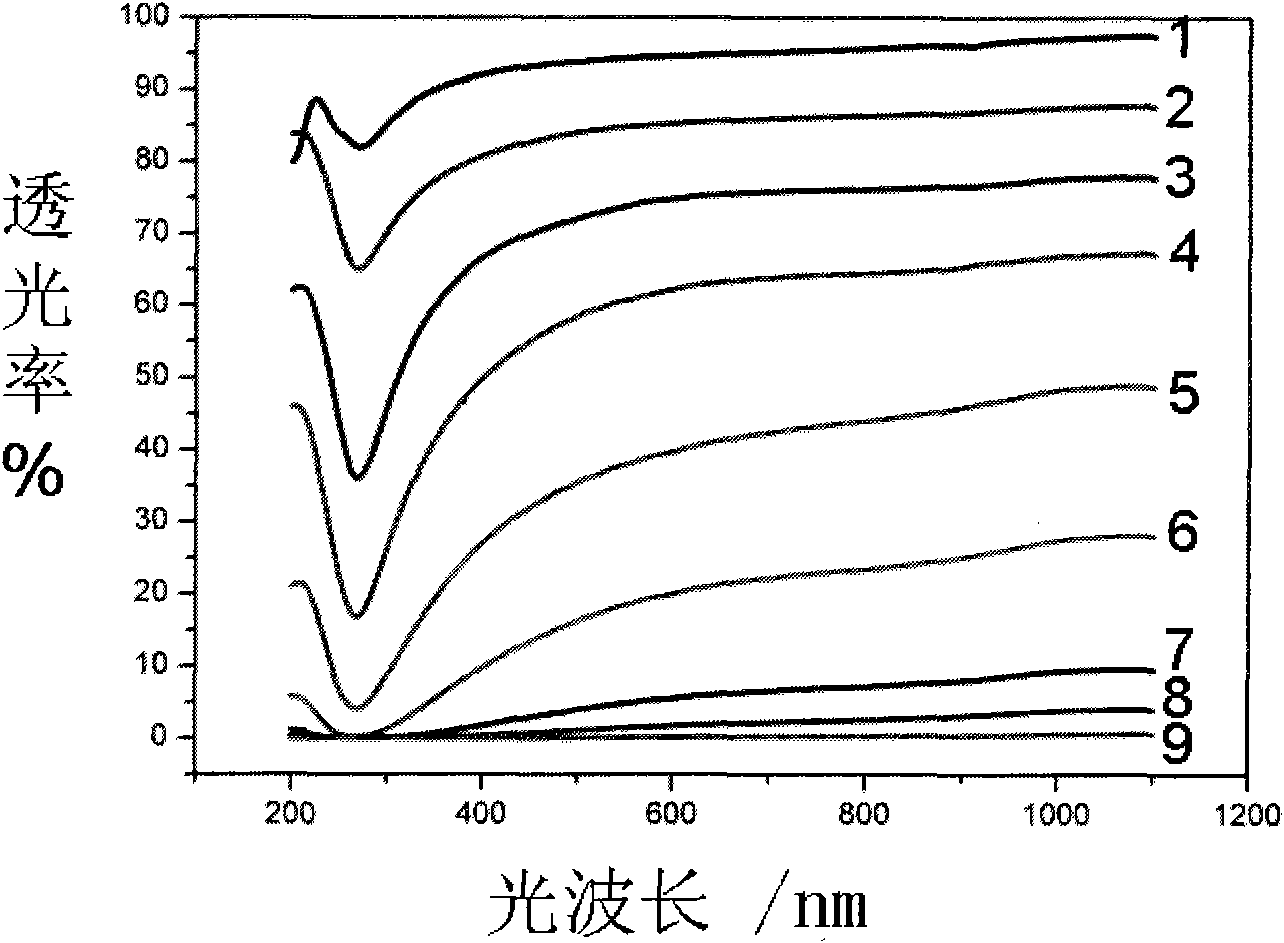

Ultrathin film of transparent high-strength and high-conductivity electrical self-supporting carbon nano-tube and preparation method thereof

InactiveCN102110489AKeep the lengthMaintain structureNon-insulated conductorsCarbon-silicon compound conductorsDouble wallControllability

The invention relates to an ultrathin film of a transparent high-strength and high-conductivity electrical self-supporting carbon nano-tube and a preparation method thereof. The ultrathin film mainly comprises a network consisting of interweaved carbon nano-tubes, and the application amount of the carbon nano-tubes is 0.01-0.7 mg / cm<2>; and the thickness of the film is more than 10nm, the light transmittance of the film is 50-97%, the electrical conductivity of the film is 30-500 MS / m, the tensile strength of the film can be as high as 2000MPa, and the ultrathin film has a larger area. The ultrathin film is prepared from single-walled and / or double-walled and / or multi-walled carbon nano-tubes through the steps of filtering, printing, coating and the like so as to form films, and then stripping from the formed films so as to from self-supporting films. The ultrathin film of the self-supporting carbon nano-tube provided by the invention has ultrahigh mechanical properties and excellent electronic and optical properties, therefore, the ultrathin film can be widely applied to the technical field of photoelectricity; and meanwhile, the ultrathin film is simple in process, easy to operate, good in controllability, safe and environmental-friendly, and can be prepared by using merchant carbon nano-tubes as raw materials, therefore, the ultrathin film is wide in material source and low in cost and is suitable for the industrial production on large-batch and large-area ultrathin film preparation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

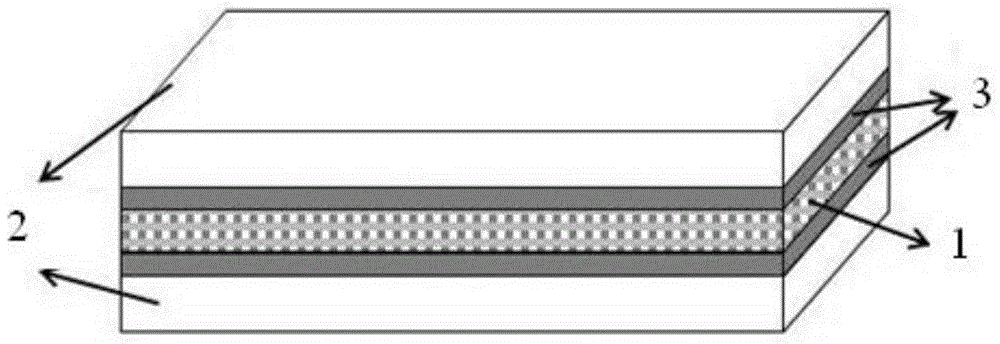

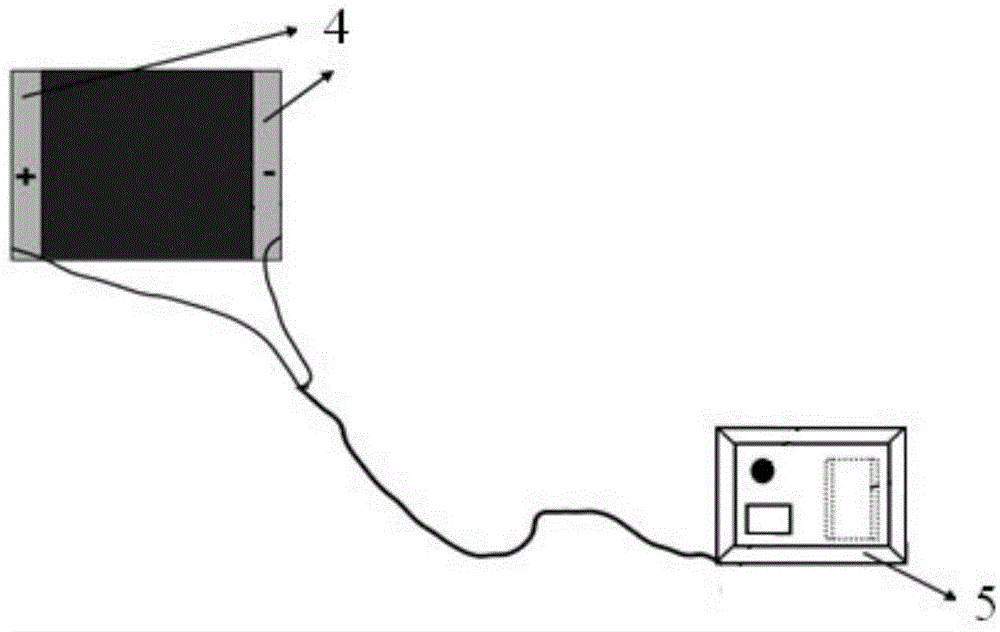

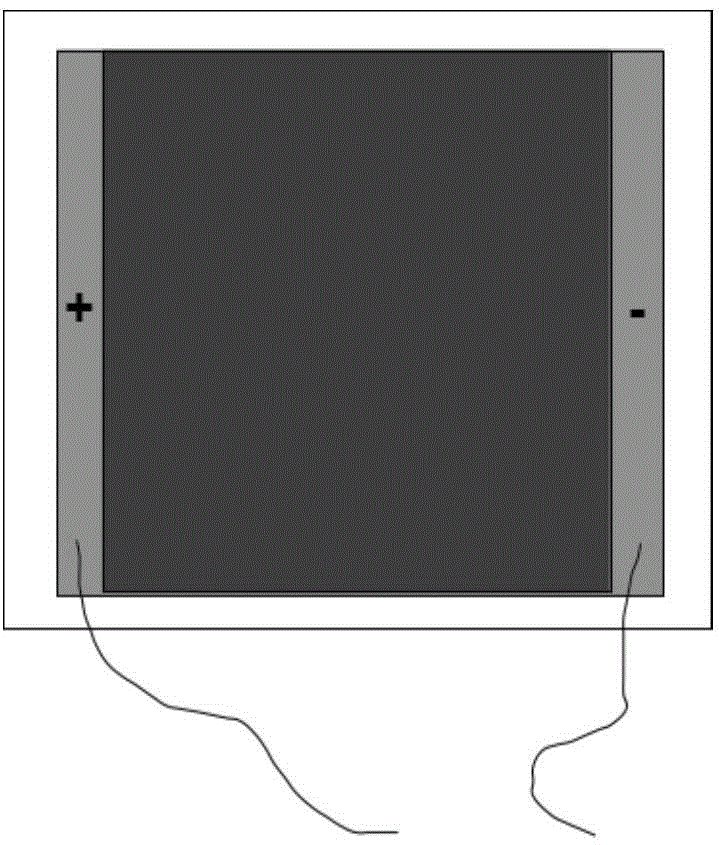

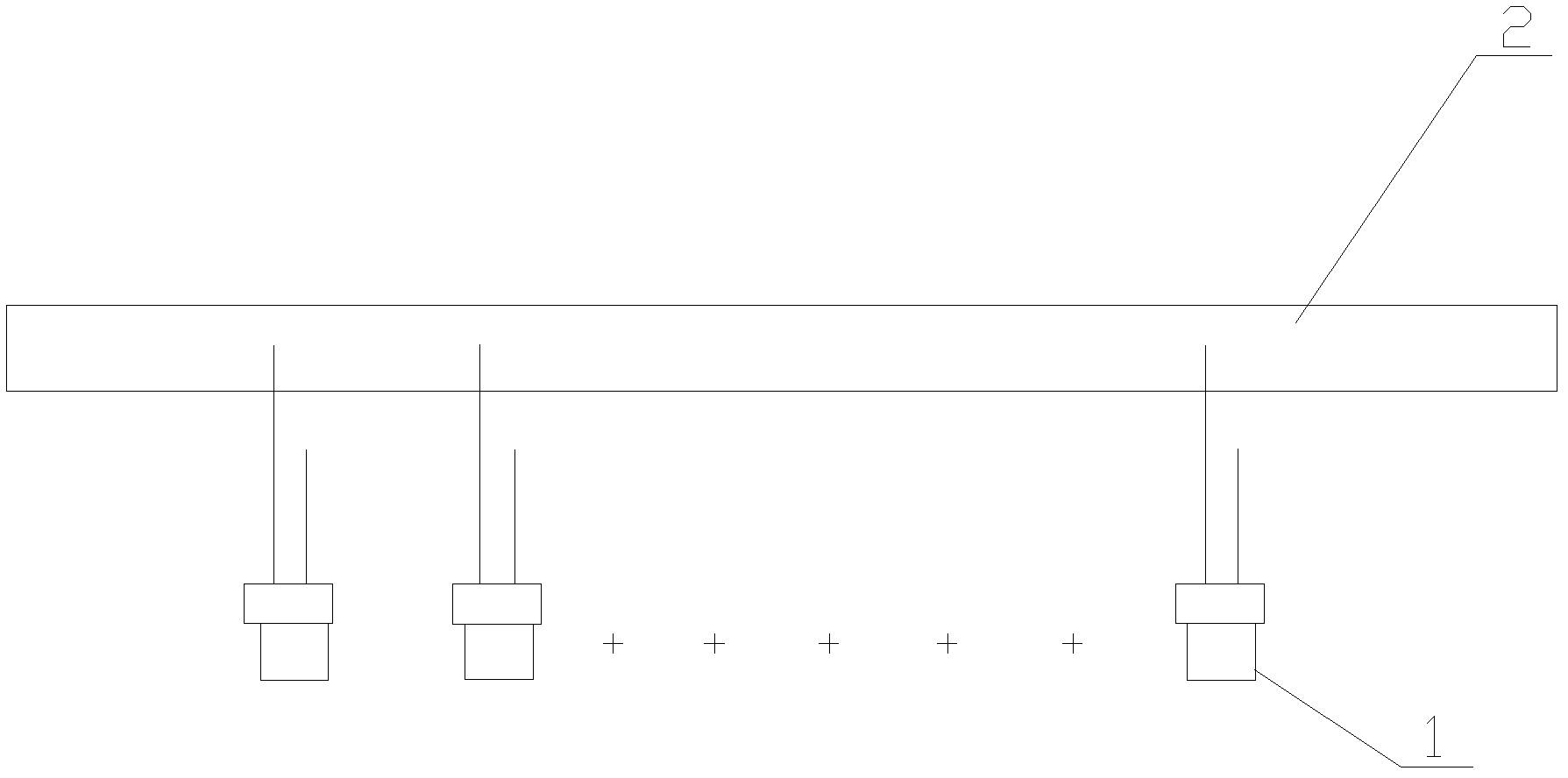

Electric heating textile based on carbon nano tubular membrane

InactiveCN104589714AHigh insulation requirementsThin and flexibleLayered productsOhmic-resistance heatingCarbon nanotubeEngineering

The invention relates to an electric heating textile based on a carbon nano tubular membrane. The electric heating textile based on the carbon nano tubular membrane comprises a heating layer, textile protection layers and bonding layers, wherein the upper and lower surfaces of the heating layer are stuck with the textile protection layers by the bonding layers; and the heating layer is the carbon nano tubular membrane. The electric heating textile has the characteristics of stability of heating, uniform temperature, safety, comfort, lightness, portability and the like.

Owner:DONGHUA UNIV

Improved method for manufacturing solid electrolyte/aluminum electrolytic capacitor

ActiveCN102592848AReduce dosageGood temperature resistanceSolid electrolytic capacitorsAluminium foilAluminium

The invention relates to an improved method for manufacturing a solid electrolyte / aluminum electrolytic capacitor. The method comprises the following steps: 1, electrolytic papers between an anode formation aluminium foil and a cathode foil are reeled to form core bags, wherein the cathode foil faces outwards and wraps the electrolytic papers, a high-temperature rubber belt is used for clinging and fixing both in a ring manner, and sealing rubber covers are mounted on the core bags; 2, the core bags are immersed into formation liquid to be subjected to repair processing, and the repaired core bags are subjected to carbonization processing, wherein the step 2 is repeated about 2-10 times; 3; the core bags are immersed into the formation liquid again to be subjected to formation and repair processing; 4, the carbonized core bags are immersed into an oxide-film protection liquid and then are dried at the temperature of 50-150 DEG C; and 5, firstly, the core bags are respectively placed into monomers and oxidant for immersion and heating convergence, then the processed core bags are mounted in an aluminum shell and a sealing procedure is performed, and lastly, the produced products are subjected to ageing processing.

Owner:ZHAOQING BERYL ELECTRONICS TECH

Preparation method of high-conductivity aluminum alloy

InactiveCN103276261AHigh affinityPlay the role of hydrogen absorption and hydrogen fixationRare-earth elementElectrical conductor

The invention relates to a preparation method of high-conductivity aluminum alloy and belongs to the field of nonferrous metal materials. The preparation method comprises the following steps of: preparing an aluminum ingot comprising the following alloy elements in percentage by weight: 4.5 to 13.5 percent of Si (silicon), 0.1 to 1.5 percent of Mg (magnesium) and not more than 0.1 percent of impurity elements, smelting the aluminum ingot in a furnace, adding 0.1 to 0.3 percent of zirconium which serves as additive for the alloying treatment, uniformly mixing, then adding 0.1 to 1.35 percent of rare-earth element for degeneration, purifying, degassing and deslagging, and covering the surface of aluminum liquid with a solid covering agent; casting to prepare the aluminum alloy conductor material; and carrying out the first-stage aging treatment and the second-stage aging treatment on the aluminum alloy conductor material, discharging and cooling with air. The manufactured aluminum-silicon alloy can meet the requirements on the aluminum alloy material conductivity and the mechanical property; and moreover, the preparation process is simple, the cost is low, and the mass production is easy to realize.

Owner:JIANGSU UNIV

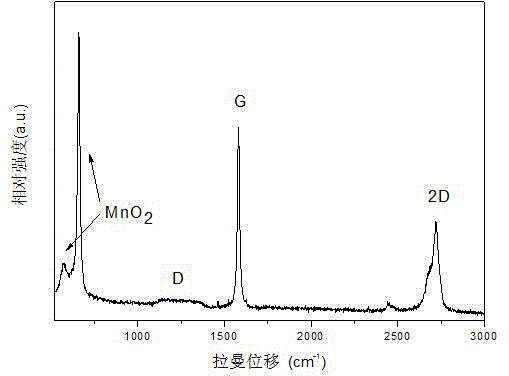

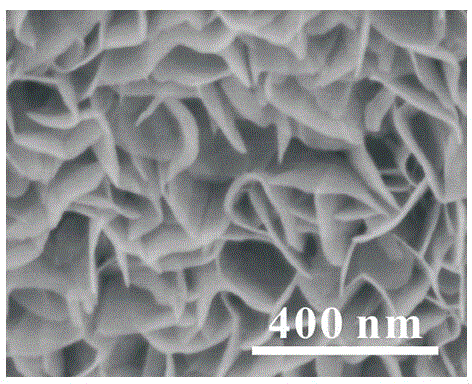

Manganese dioxide/graphene lithium ion battery cathode material and preparation method thereof

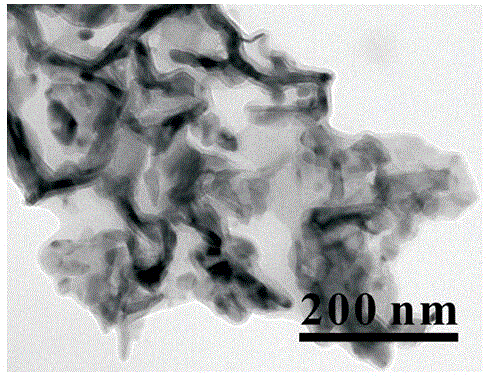

InactiveCN104900864ASave time and costEasy to prepareCell electrodesSecondary cellsCvd graphenePotassium permanganate

The invention discloses a manganese dioxide / graphene lithium ion battery cathode material and a preparation method thereof, which belongs to the new energy and material fields. The preparation method comprises the following steps: 1)preparing three-dimensional graphene bubble; 2)adding potassium permanganate and manganese sulfate monohydrate in ultrapure water and uniformly stirring to obtain a mixing solution; 3)adding the three-dimensional graphene bubble and the mixing solution in an inner container of a high temperature-resistance enclosed stainless steel reaction vessel, tightly screwing the stainless steel reaction vessel and placing in a program control baking oven for heating treatment, separating to obtain a compound; and 4)washing, drying under vacuum and annealing under constant temperature to obtain the manganese dioxide / graphene lithium ion battery cathode material. According to the invention, the method has no damage on graphene, excellent conductivity of graphene can be influenced; the product can be directly used for assembling a battery, no extra current collector is required, and no binder and conductive agent is added; the preparation process is simple, and operationality is strong.

Owner:WUHAN UNIV

Film bulk acoustic resonator and manufacturing method thereof

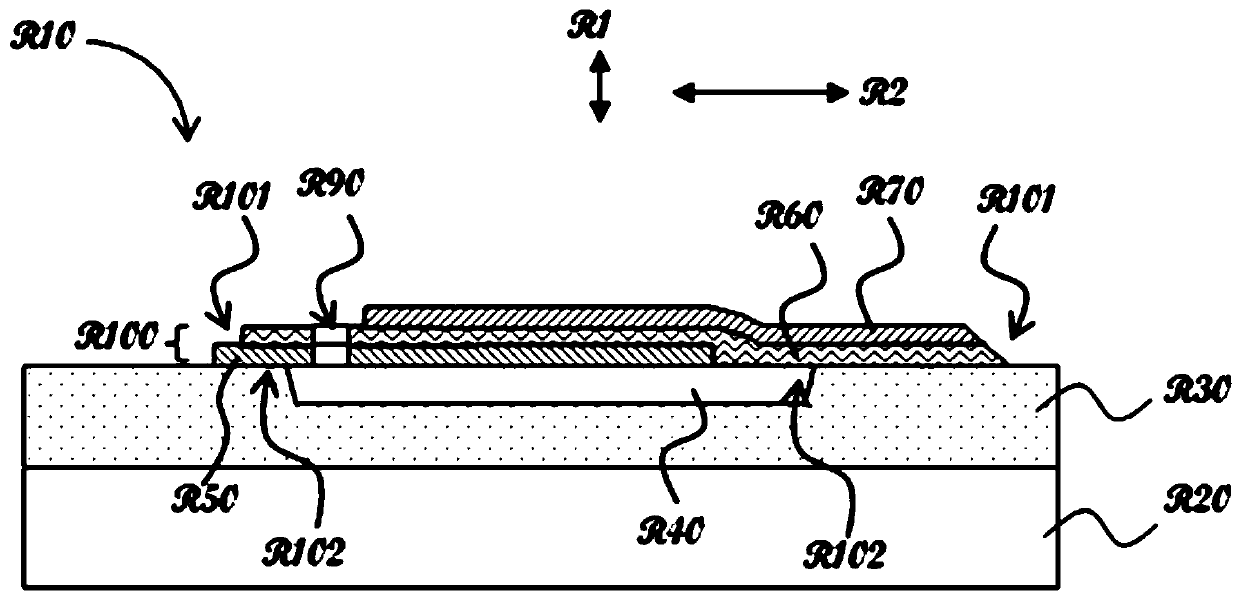

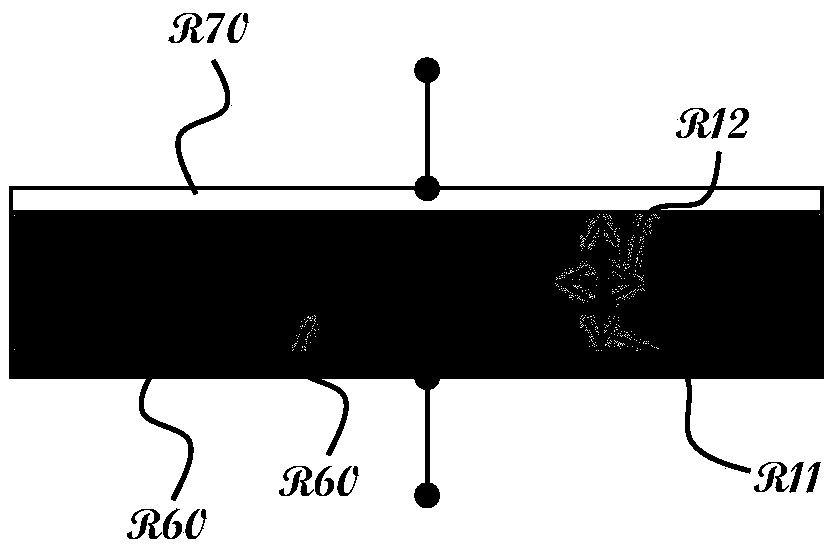

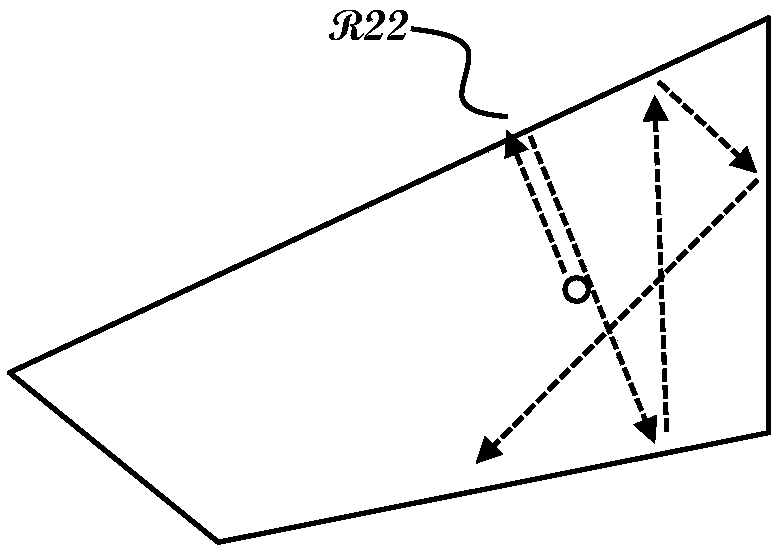

ActiveCN110829997AReduce intensityReduce stiffnessImpedence networksThin-film bulk acoustic resonatorReflected waves

The invention discloses a film bulk acoustic resonator and a manufacturing method thereof. The film bulk acoustic resonator is characterized in that out of a cavity overlapping region and outside an electrode overlapping region, a first electrode plate body and a second electrode plate body respectively comprise a first vibration buffer strip and a second vibration buffer strip, so that the rigidity in the horizontal direction can be effectively reduced (the flexibility is enhanced) while the rigidity in the vertical direction is less influenced, and a buffering effect is achieved for horizontal elastic waves propagating along the electrode plate in the horizontal direction, so that the strength of elastic reflection waves is reduced. Besides, a piezoelectric induction oscillation plate clamped between the first electrode plate body and the second electrode plate body is integrally arranged in the cavity overlapping area, and the boundary of the piezoelectric induction oscillation plate is a polygon without any parallel opposite sides; and additional standing wave oscillation which becomes clutter in the horizontal direction is eliminated, and meanwhile energy consumed by transverse parasitic waves is reduced to the maximum extent. A corresponding manufacturing method is also disclosed.

Owner:芯知微(上海)电子科技有限公司

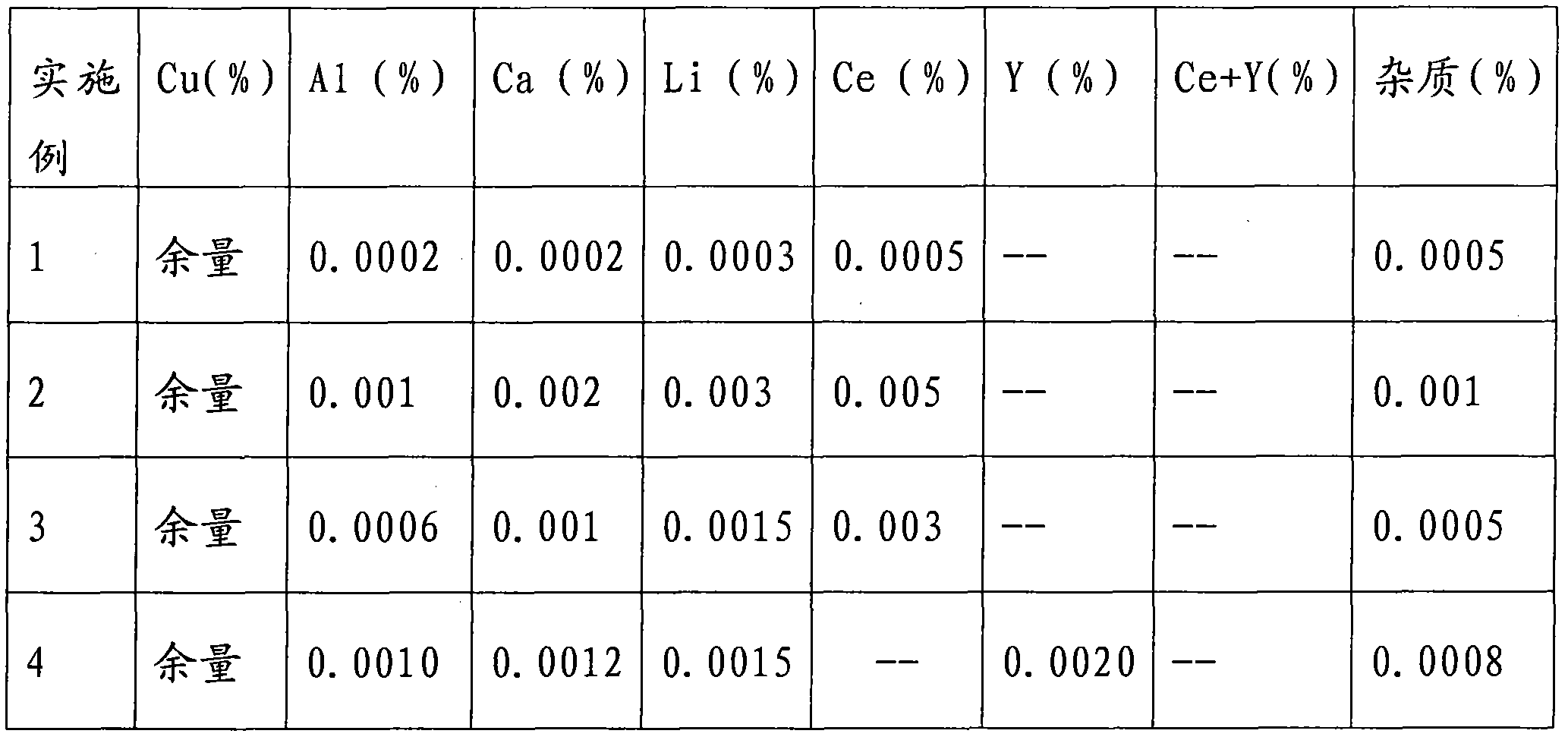

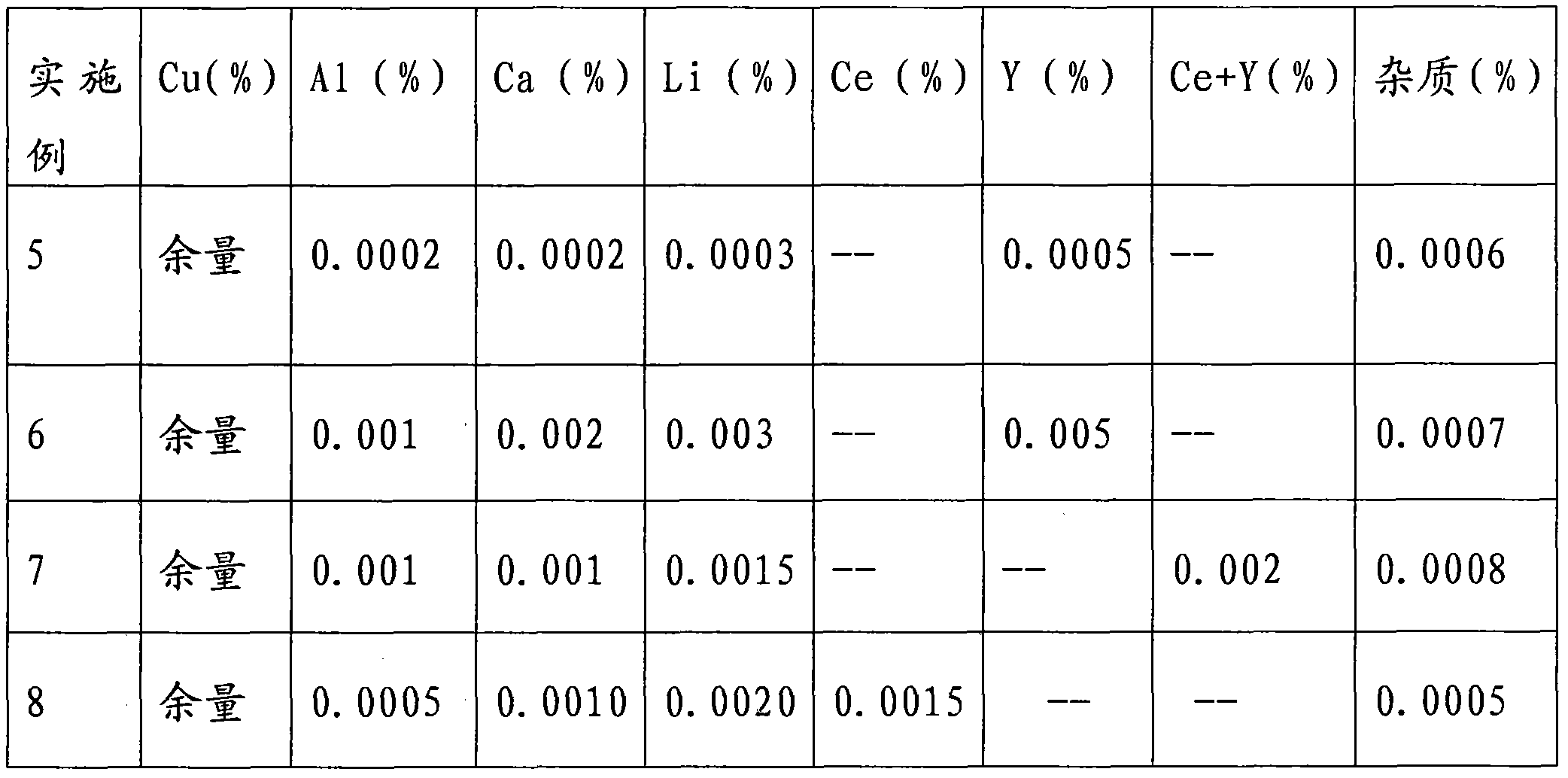

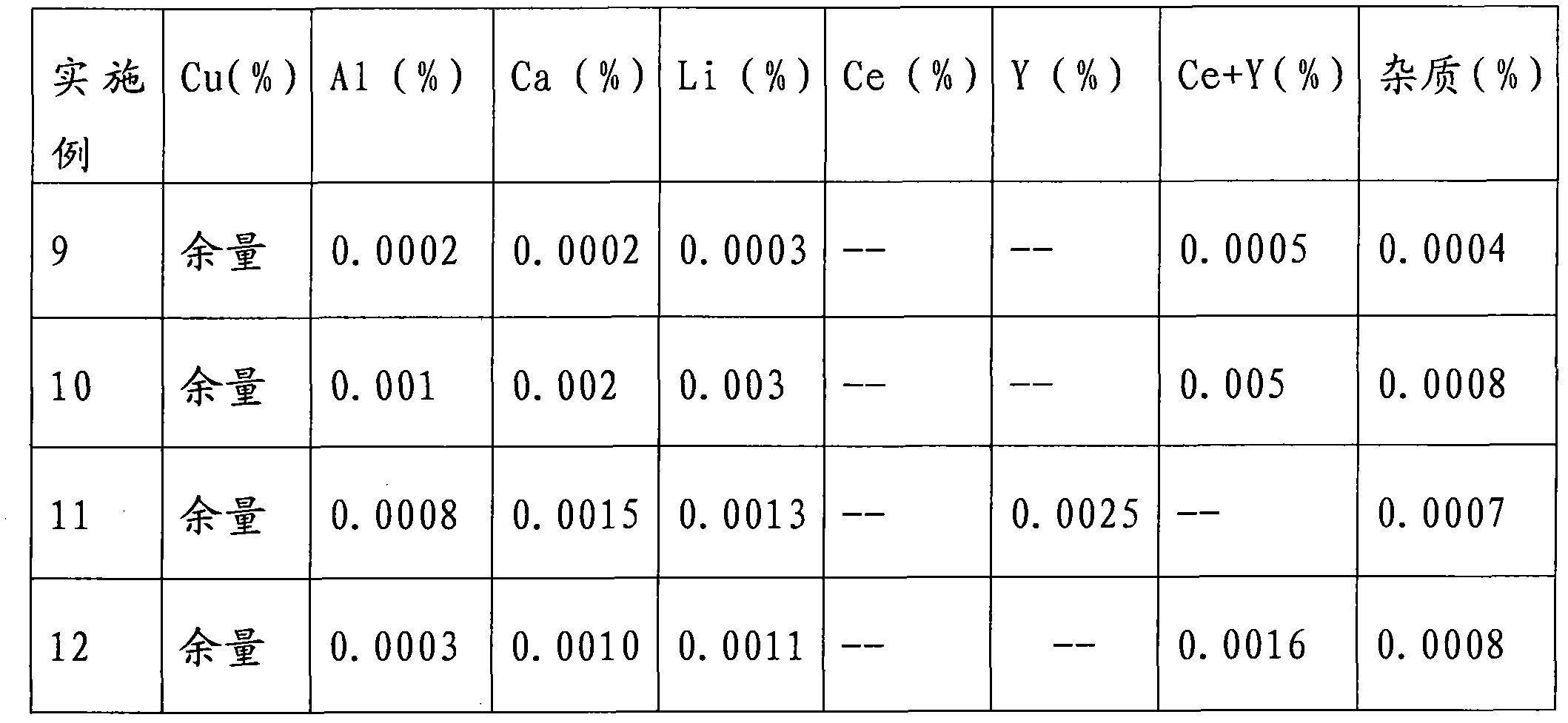

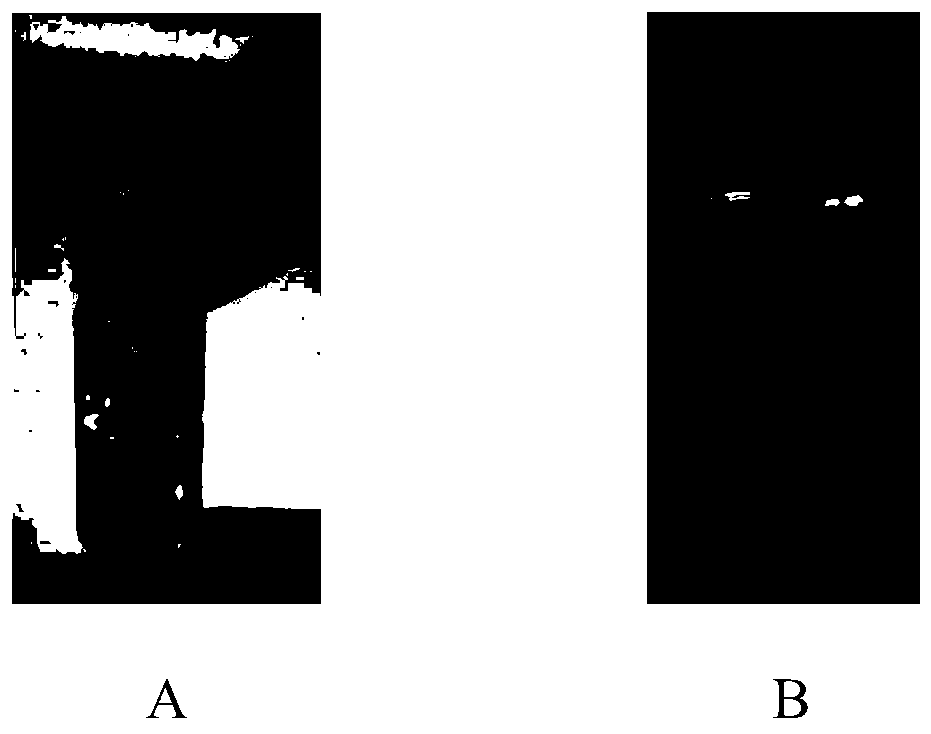

Bonding copper wire and preparation method thereof

InactiveCN101979689AImprove surface oxidation resistanceImprove performanceSingle bars/rods/wires/strips conductorsSolid-state devicesCopper wireCerium

The invention relates to a bonding copper wire and a preparation method thereof. The bonding copper wire comprises the following components in percentage by mass: 0.0003 percent to 0.003 percent of lithium, 0.0002 percent to 0.002 percent of calcium, 0.0002 percent to 0.001 percent of aluminium, 0.0005 percent to 0.005 percent of cerium and / or yttrium, 0.0001 percent to 0.001 percent of other inevitable impurity elements and the balance of copper. The preparation method of the bonding copper wire comprises the following steps of: preparing a middle alloy, preparing an alloy cast ingot, annealing uniformly, heat extrusion, stress relief annealing, drawing, final annealing, winding for multiple coils, packaging, and final protective packaging, wherein in a drawing process, middle stress relief annealing can be performed according to practical needs. The bonding copper wire has better inoxidizability while keeping better conduction and radiation properties; in the preparation process of the bonding copper wire, the uniform annealing is added and the middle stress relief annealing is performed, so that the mechanical property of the prepared bonding copper wire is better.

Owner:蔡元华

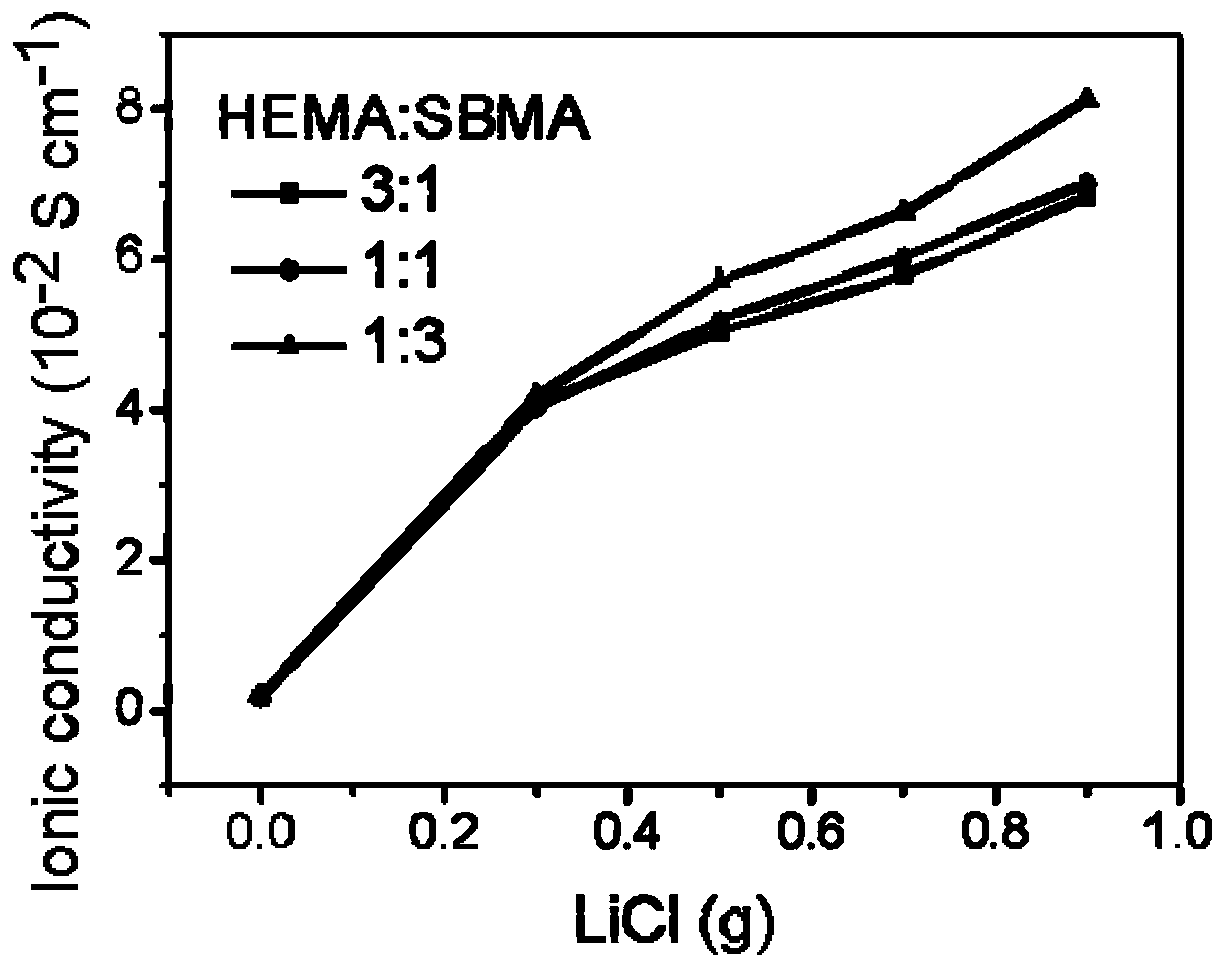

High-conductivity, stretchable, compressible and repairable zwitterionic gel polymer electrolyte as well as preparation and application thereof

ActiveCN111019041AImprove mechanical propertiesDoes not affect conductivityHybrid capacitor electrolytesPolymer electrolytesPolymer science

The invention relates to a high-conductivity, stretchable, compressible and repairable zwitterionic gel polymer electrolyte as well as preparation and application thereof. Zwitterionic SBMA, and monomers HEMA and LiCl which can enhance mechanical properties and do not affect electric conductivity are utilized, and the gel polymer electrolyte with good performance is prepared through an in-situ polymerization reaction. The P(HEMA-SBMA) electrolyte has good tensile compression performance, and the strain and stress can be adjusted by regulating the monomer ratio and the content of LiCl, so thatthe desired electrolyte with super-tensile strength or high strength is obtained. 50% compression cycle tests can be carried out for 50 times. The good adhesion provides the capability of maintainingthe shape of equipment when the assembled energy storage equipment bears deformation, and the electric conductivity is responsive during stretching and compression.

Owner:QILU UNIV OF TECH

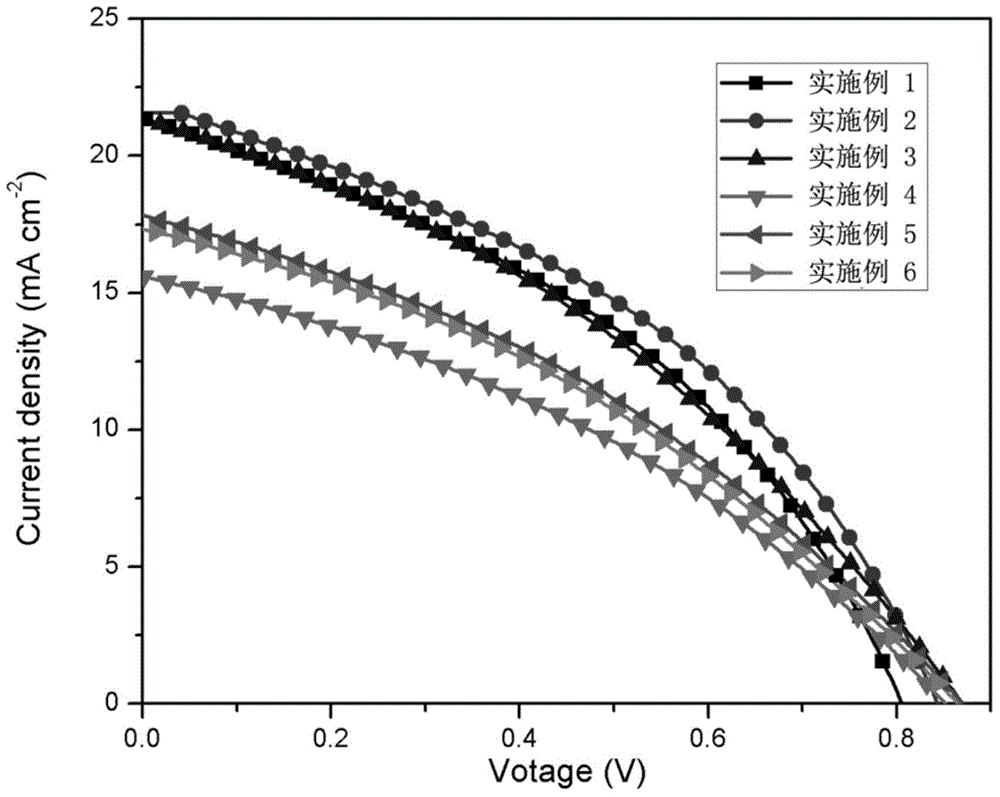

Perovskite solar cell conductive carbon paste, carbon counter electrode, cell and method of manufacturing the conductive carbon paste

InactiveCN104966548ABlocking compositeIncrease photocurrentSolid-state devicesSemiconductor/solid-state device manufacturingScreen printingOrganic solvent

The invention discloses perovskite solar cell conductive carbon paste which comprises organic solvents, binders and conductive filling materials. The conductive carbon paste further comprises inorganic additives. The inorganic additives are ZrO2 or NiO powder. By mass percent, the conductive carbon paste comprises 6%-15% of binders, 14%-20% of conductive filling materials and 3%-5% of inorganic additives. The invention further discloses a carbon counter electrode for a perovskite solar cell. The carbon counter electrode is prepared and acquired by adopting the above-mentioned conductive carbon paste in a screen printing means. The invention further discloses the perovskite solar cell comprising the above-mentioned carbon counter electrode. A method of preparing the conductive carbon paste is further disclosed. The conductive carbon paste which does not make a perovskite film corroded further increases the photoelectric conversion efficiency.

Owner:HUAZHONG UNIV OF SCI & TECH

Electroencephalogram signal wireless collecting system

ActiveCN105769182ASimple structureLow priceDiagnostic recording/measuringSensorsPower flowAudio power amplifier

The invention discloses an electroencephalogram signal wireless collecting system which comprises a control module, a wireless electrode cap module and an electroencephalogram processing module.The control module, the wireless electrode cap module and the electroencephalogram processing module are each provided with a wireless signal transmission module.The wireless electrode cap module further comprises a microcurrent stimulator, a dry electrode and an electroencephalogram resistance detecting device.The microcurrent stimulator receives a control instruction wirelessly sent by the control module and simulates the electrode to output simulation current to act on scalp.The dry electrode collects an electroencephalogram signal fed back by the scalp and sends the signal to the electroencephalogram resistance detecting device, and the signal is processed and then transmitted to an amplifier through the corresponding wireless signal transmission module to be amplified.The dry electrode structure in the electroencephalogram signal wireless collecting system is improved, the dry electrode can make tighter contact with scalp, and the signal to noise ratio is higher.

Owner:WUHAN ZHIPU TIANCHUANG TECH CO LTD

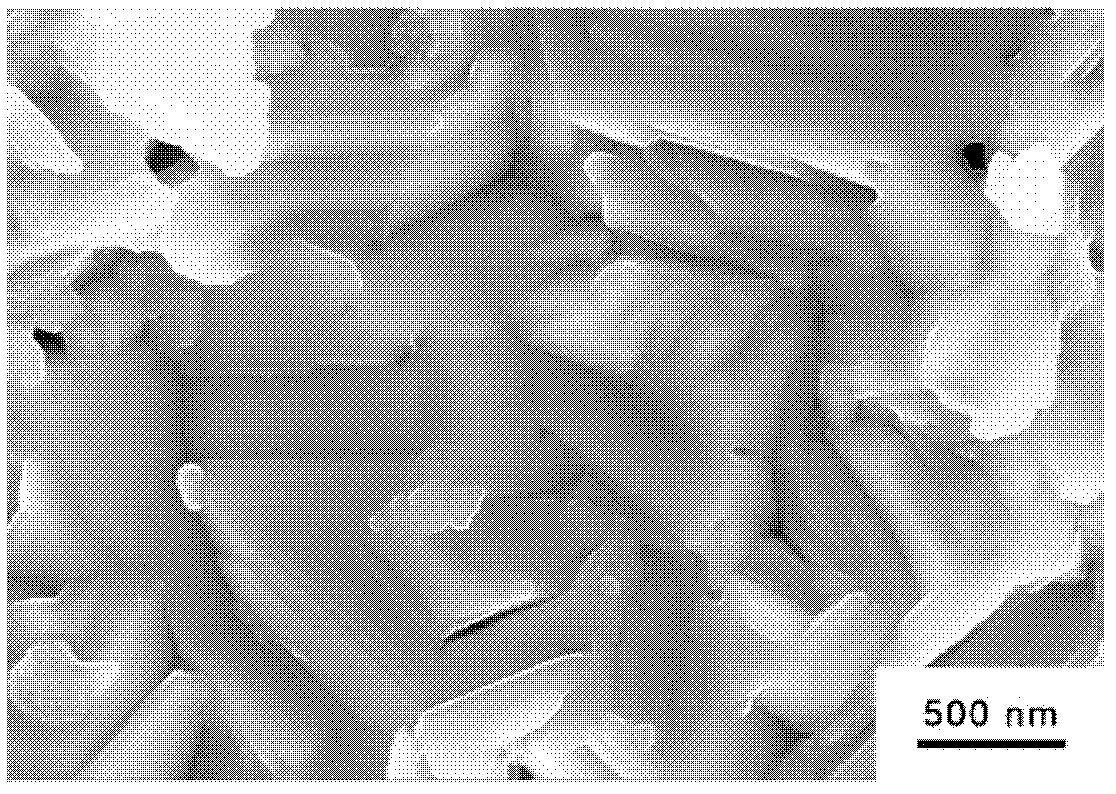

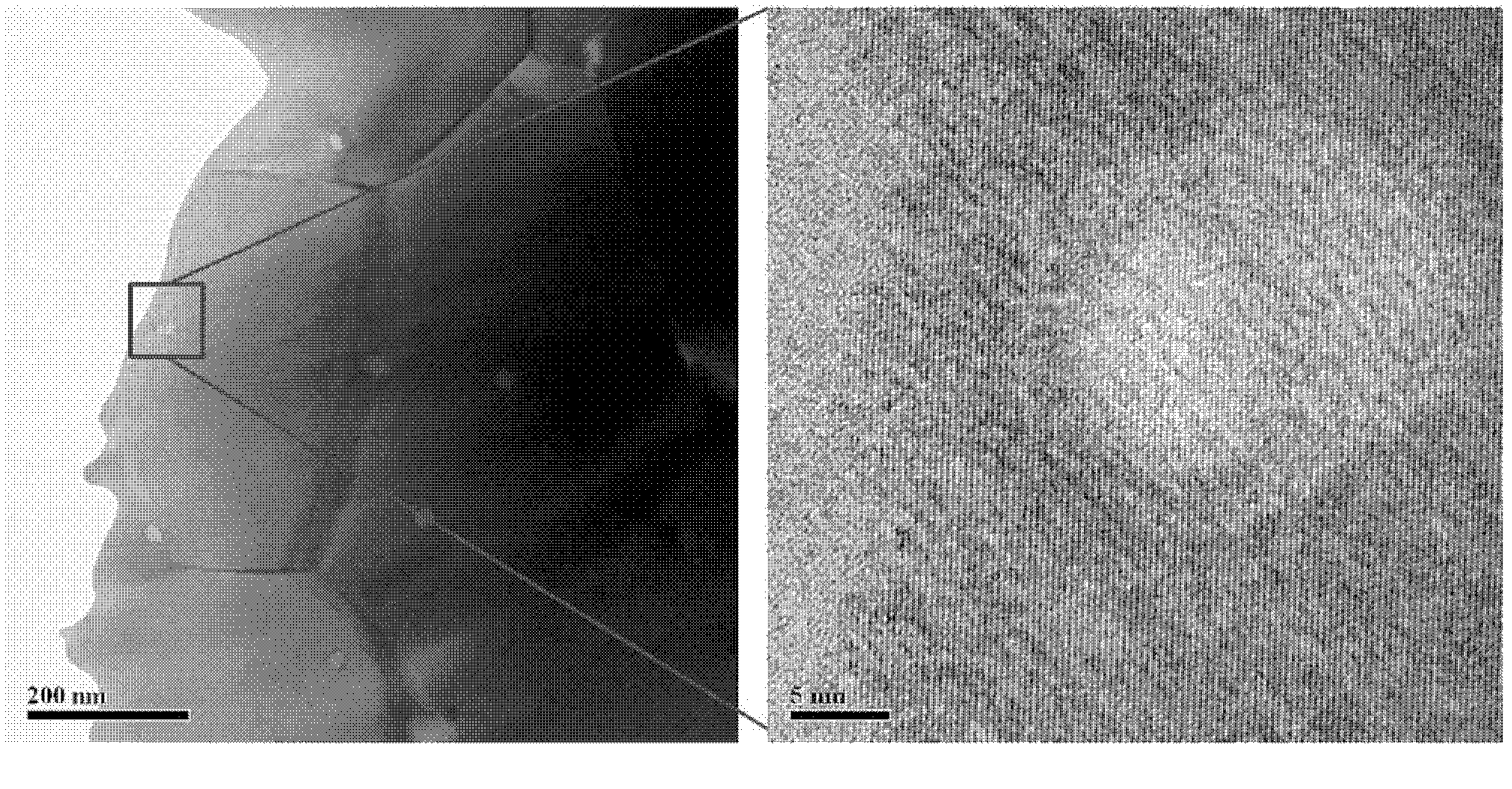

A Trace Cu-doped Bi2S3-Based Thermoelectric Material

InactiveCN102280570AControl stoichiometric ratioPrecise control of stoichiometric ratioThermoelectric device junction materialsMetallurgyElectric properties

The invention belongs to the technical field of energy materials and in particular relates to a trace Cu-doped Bi2S3-based thermoelectric material. In the thermoelectric material, metal simple substance Bi and Cu powder with the purity of 99.99 percent and simple substance S powder serve as raw materials, the thermoelectric material is prepared according to a chemical general formula of CuxBi2-xS3, wherein x is mole fraction of a Cu component and x is more than or equal to 0.001 and less than or equal to 0.05, and the thermoelectric material is prepared into a block material by combining a discharge plasma sintering technology and a mechanical alloying method. By the method, the trace Cu-doped Bi2S3-based block thermoelectric material can be easy and convenient to prepare, trace Cu is introduced into a Bi2S3 lattice, the carrier concentration of a sample is improved, a power factor is optimized, a Cu-S nano deposition coherent with a substrate structure is formed, and the thermal conductivity is greatly reduced; therefore, the thermoelectric performance of the Bi2S3-based block material can be greatly improved.

Owner:UNIV OF SCI & TECH BEIJING

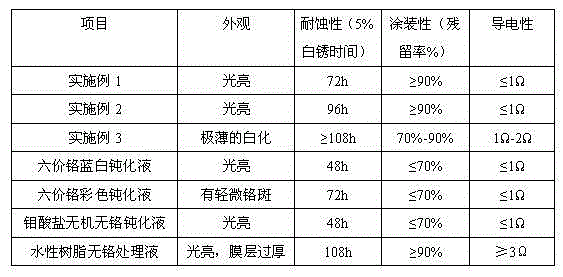

Water-based composite passivation solution for galvanized steel plate and preparation method of water-based composite passivation solution

InactiveCN104451641AImprove corrosion resistanceQuality improvementMetallic material coating processesWater basedChromium free

The invention relates to a water-based composite chromium-free passivation solution for a galvanized steel plate. The passivation solution contains 10-30g / L of sodium molybdate, 0-10g / L of sodium phosphate, 5-10g / L of organic phosphoric acid, 1-10g / L of fluotitanic acid, 5-15g / L of a silane coupling agent, 5-20g / L of sodium metasilicate, 0.1-1% of a wetting dispersant and the balance of deionized water. The passivation solution provided by the invention consists of an organic phosphoric acid-molybdate system in match with the modified hydrolysis type silane coupling agent and a nano-inorganic filler, does not contain a chromate and is in line with ROHS requirements; the passivation and drying curing time is short, the degree of stability is high, the quality of a film layer is good, the white rust area in a 72h salt fog test does not exceed 5%, the cost is relatively low, a passivation process device does not need to be changed, and continuous passivation can be realized by using a hexavalent chromium passivation device in early period.

Owner:北京蓝星清洗有限公司

Lithium battery electrolyte

InactiveCN106229548AGood chemical stabilityImprove thermal stabilitySecondary cells servicing/maintenanceOrganic electrolytesPhysical chemistryNitrogen

The invention discloses lithium battery electrolyte. The electrolyte comprises solvent, lithium salt and flame retardant additive. The dosage of the lithium salt is 0.1-2.5mol / L. The dosage of the flame retardant additive is 0.1-30% of the total mass of the electrolyte. The flame retardant additive comprises polymerized phosphorus-nitrogen compounds. The lithium battery electrolyte provided by the invention is characterized in flame retardance, high chemical stability, high thermal stability and a high capacity retention ratio.

Owner:恺时浦(上海)检测技术有限公司

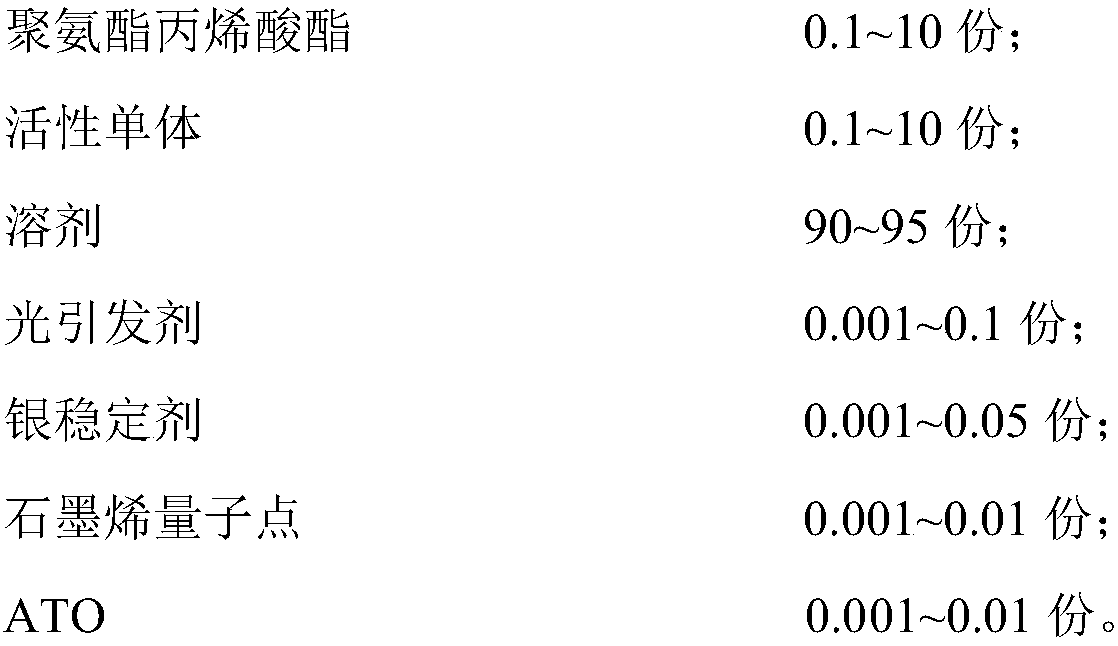

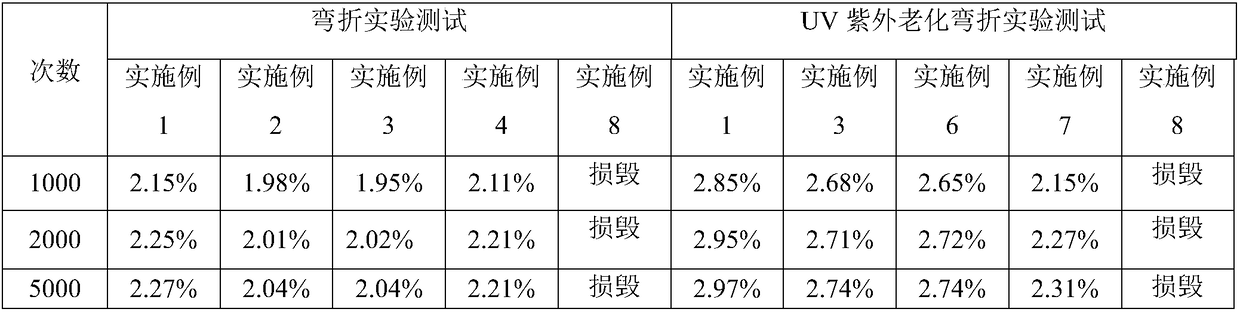

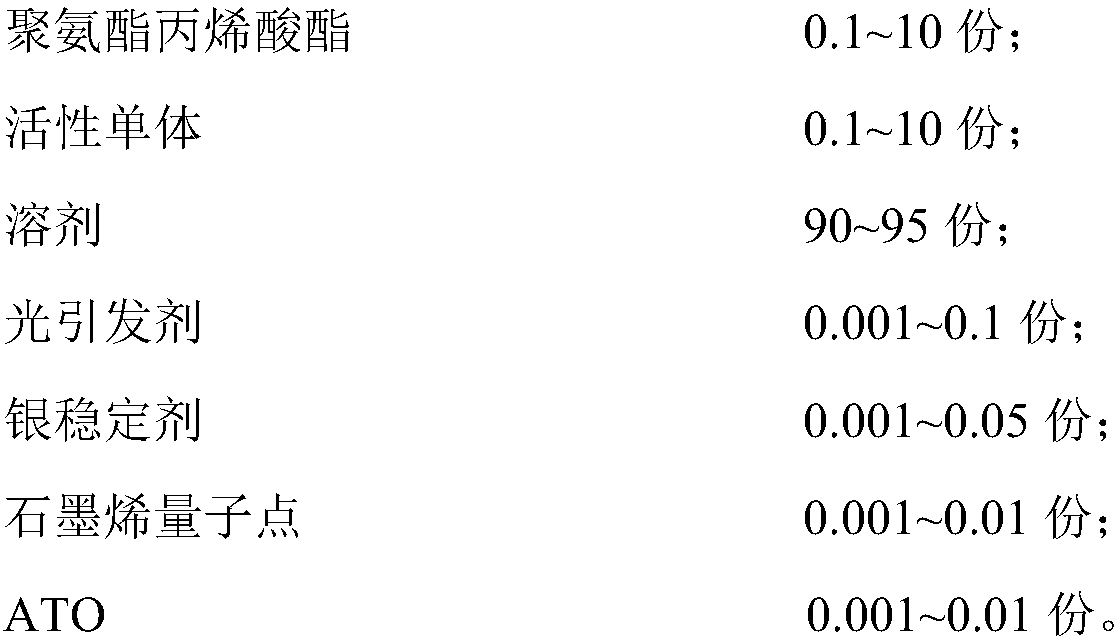

UV light-cured resin applied to silver nanowire conductive film and preparation method of UV light-cured resin

ActiveCN108384439AHigh hardnessGuaranteed hardnessPolyurea/polyurethane coatingsUrethane acrylateSolvent

The invention discloses UV light-cured resin applied to a silver nanowire conductive film and a preparation method of the UV light-cured resin. The UV light-cured resin is prepared from the raw materials: polyurethane acrylate, active monomers, a solvent, a light initiator, a silver stabilizer, graphene quantum dots and ATO. Compared with the existing polyurethane acrylate UV light-cured resin, the UV light-cured resin provided by the invention is greatly improved in the aspects of water resistance, bending resistance, surface hardness and solvent resistance, and is more suitable for the silver nanowire conductive film.

Owner:合肥微晶材料科技有限公司

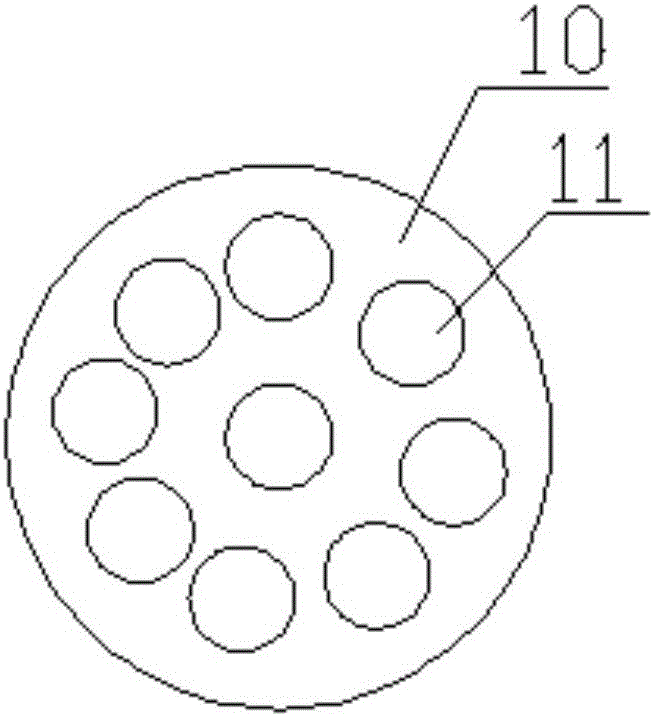

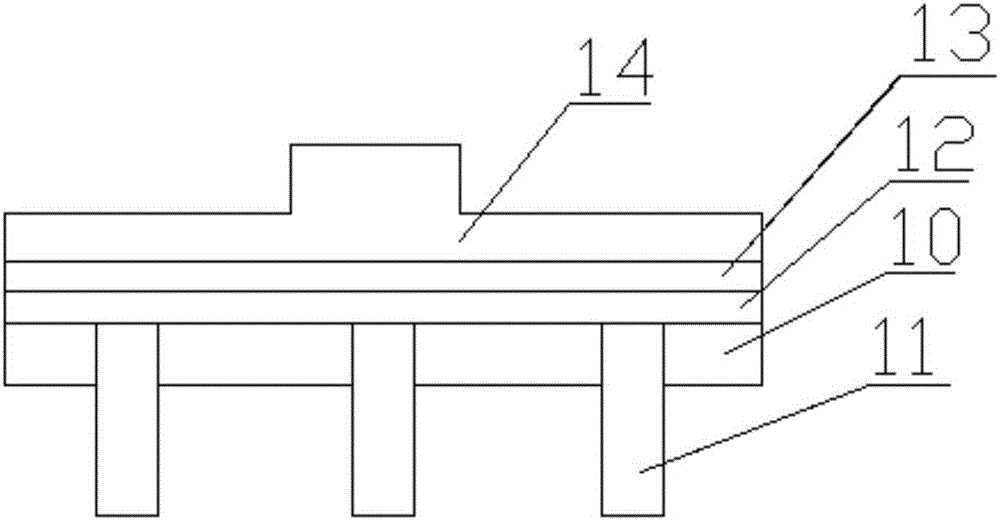

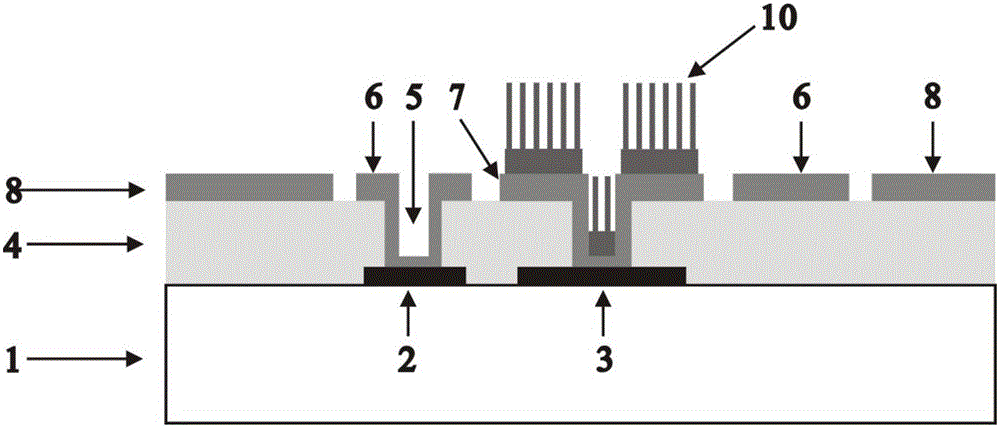

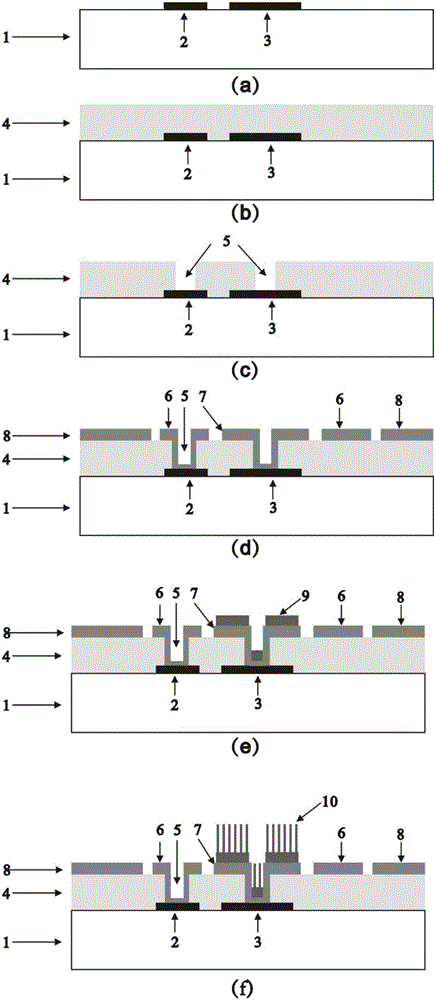

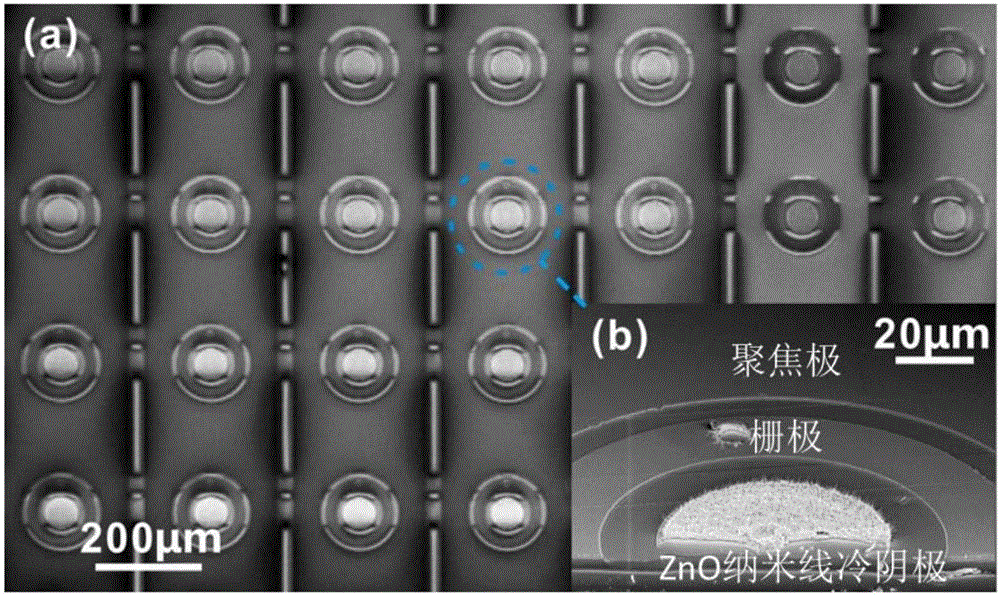

Nanowire cold cathode electron source array with self-aligned focusing structure and manufacturing method thereof

ActiveCN106158551ADoes not affect conductivityFix layout issuesDischarge tube/lamp detailsCold cathode manufactureNanowireElectron source

The invention discloses a nanowire cold cathode electron source array with a self-aligned focusing structure and a manufacturing method thereof. The electron source array structure comprises a substrate, a bottom cathode electrode strip, a bottom gate electrode strip, an insulating layer configured to cover the above electrode strips, an annular top gate electrode, a top cathode electrode, a focusing electrode, and a circular nanowire cold cathode array. The bottom cathode electrode strip and the bottom gate electrode strip are arranged on the substrate and are positioned in parallel with each other. The annular top gate electrode, the top cathode electrode and the focusing electrode are manufactured above the insulating layer and are connected with the bottom corresponding electrode strips through etching through holes in the insulating layer. The circular nanowire cold cathode array is manufactured on the top cathode electrode. The invention further discloses a manufacturing method of the nanowire cold cathode electron source array. According to the technical scheme of the invention, the nanowire cold cathode electron source array is provided with the self-aligned focusing structure, so that the row-by-row addressing function can be realized. The manufacturing method is simple, and the prepared nanowire cold cathode electron source array is good in capability of regulating and controlling electron emission and focusing electron beams. Therefore, the nanowire cold cathode electron source array and the manufacturing method thereof have an important application prospect in the aspect of flat plate X-ray sources.

Owner:SUN YAT SEN UNIV

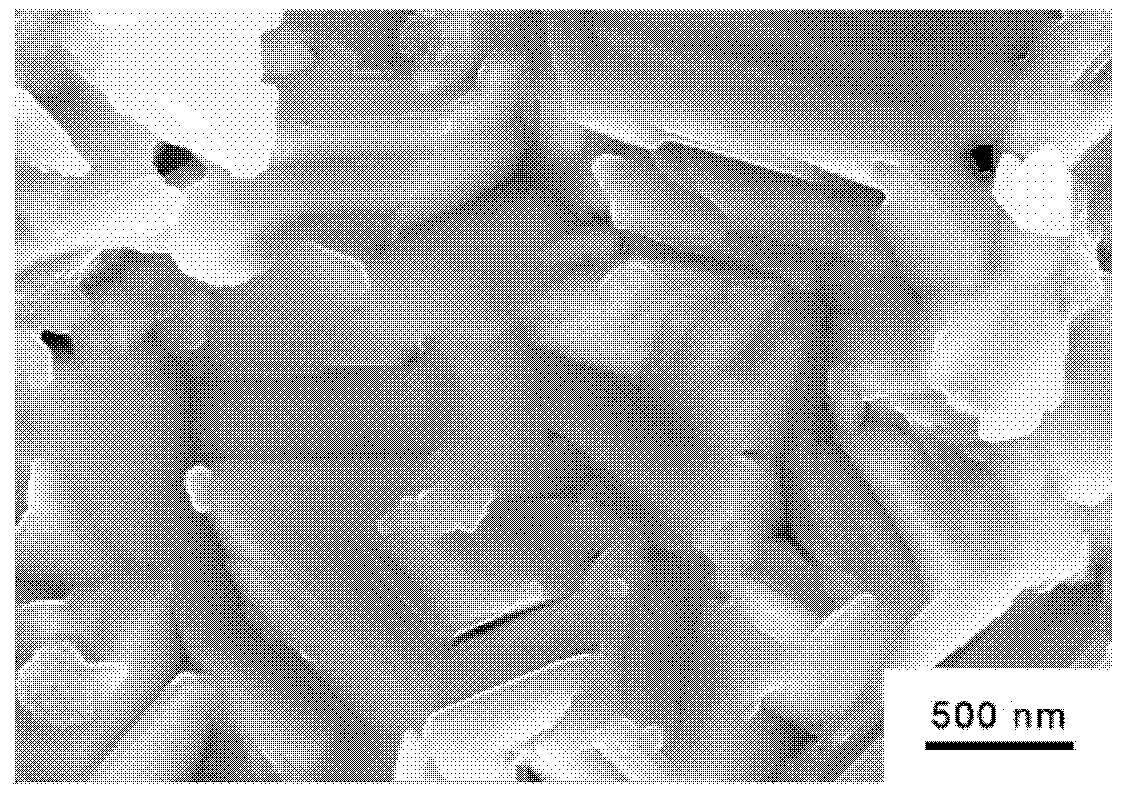

Orderly heterogeneous nano-wire flexible conductive film and preparation method thereof

InactiveCN103011070AThe method steps are simpleImprove conductivityMaterial nanotechnologyNanostructure manufacturePolyethylene terephthalate glycolNanowire

The invention discloses a preparation method for an orderly heterogeneous nano-wire assembling body. The preparation method comprises the following steps of: first, tellurium nano-wires are prepared by a hydrothermal method; then, obtaining a tellurium nano-wire assembling body by an LB assembling method; and finally, generating a tellurium-aurum heterogeneous nano-wire assembling body by taking the tellurium nano-wire assembling body as a template and reacting with a chloroauric acid solution. By the orderly heterogeneous nano-wire flexible conductive film, the flexible conductive film can be obtained by taking polyethylene terephthalate (PET) as a substrate. Compared with the prior art, the method provided by the invention is simple in steps, has the characteristics of economy and rapidness, and is applicable to the macroscopic preparation of a plurality of nano-wire material assembling bodies.

Owner:UNIV OF SCI & TECH OF CHINA

Lithium ion cathode material with high security and lithium ion battery employing same

InactiveCN103022458ADoes not affect conductivitySelf-resistance increasesCell electrodesSecondary cellsAluminium-ion batteryLithium-ion battery

The invention discloses a lithium ion cathode material with high security and a lithium ion battery employing the same. The lithium ion cathode material with high security comprises primary particles of a lithium ion metal oxide and a PTC high-molecular polymer having good conductivity. Secondary ions uniformly doped by the lithium ion metal oxide and the PTC high-molecular polymer by pretreatment of the lithium ion metal oxide and the PTC high-molecular polymer. The PTC high-molecular polymer of the lithium ion cathode material with high security is uniformly distributed in the positive electrode lithium ion metal oxide, has no influence on the conductivity of the positive electrode at a normal temperature. However, when the temperature of the battery raises to 80 DEG C or higher, the size of the doped PTC high-molecular polymer expands to cut off connection between the positive electrode particles, and at the same time, self-resistance of the doped PTC high-molecular polymer increases rapidly to cut off current, so that the security of the lithium ion battery can be effectively guaranteed.

Owner:TIANJIN ENERGIES

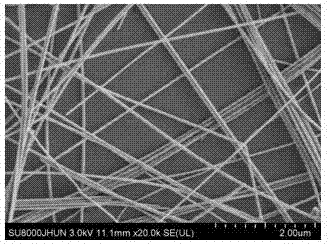

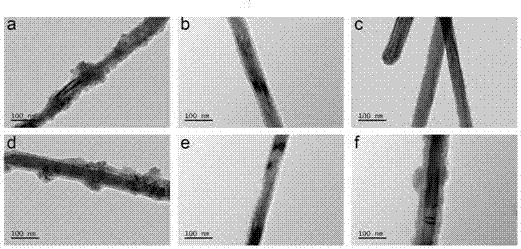

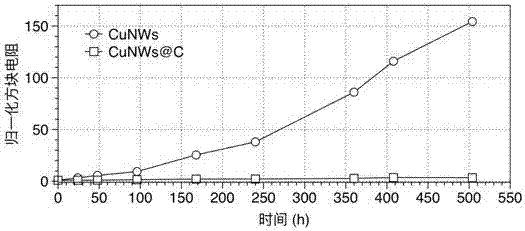

Method of preparing carbon-coated metal nanowire conductive thin film

InactiveCN106971771AEasy to operateCarbon film thickness controllableNon-conductive material with dispersed conductive materialSemiconductor devicesMetal nanowireElectrically conductive

The invention discloses a method of preparing a carbon-coated metal nanowire conductive thin film. A certain amount of metal nanowires is dispersed in a glucose solution, and a hydro-thermal reaction is carried out in a condition of 160 to 200 DEG C for 1 to 5 hours. The metal nanowire is a gold, silver, copper and the like metal nanowire or an alloy and a mixture. The metal nanowire transparent conductive thin film can be prepared through spraying or a thin film transfer method. The method is simple and easy to operate, and the metal nanowire conductive thin film stability can be improved obviously, and the method can promote application of the metal nanowire transparent conductive thin film in the field of an optoelectronic device such as a solar cell.

Owner:JIANGHAN UNIVERSITY

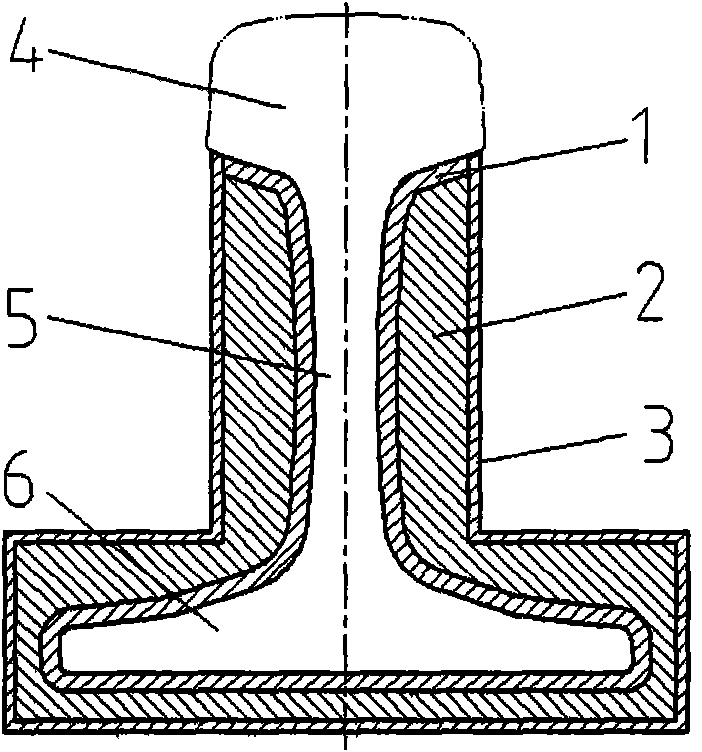

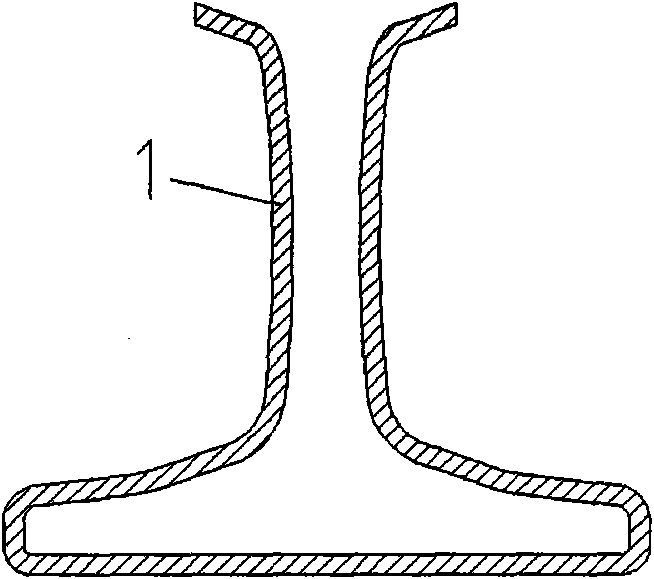

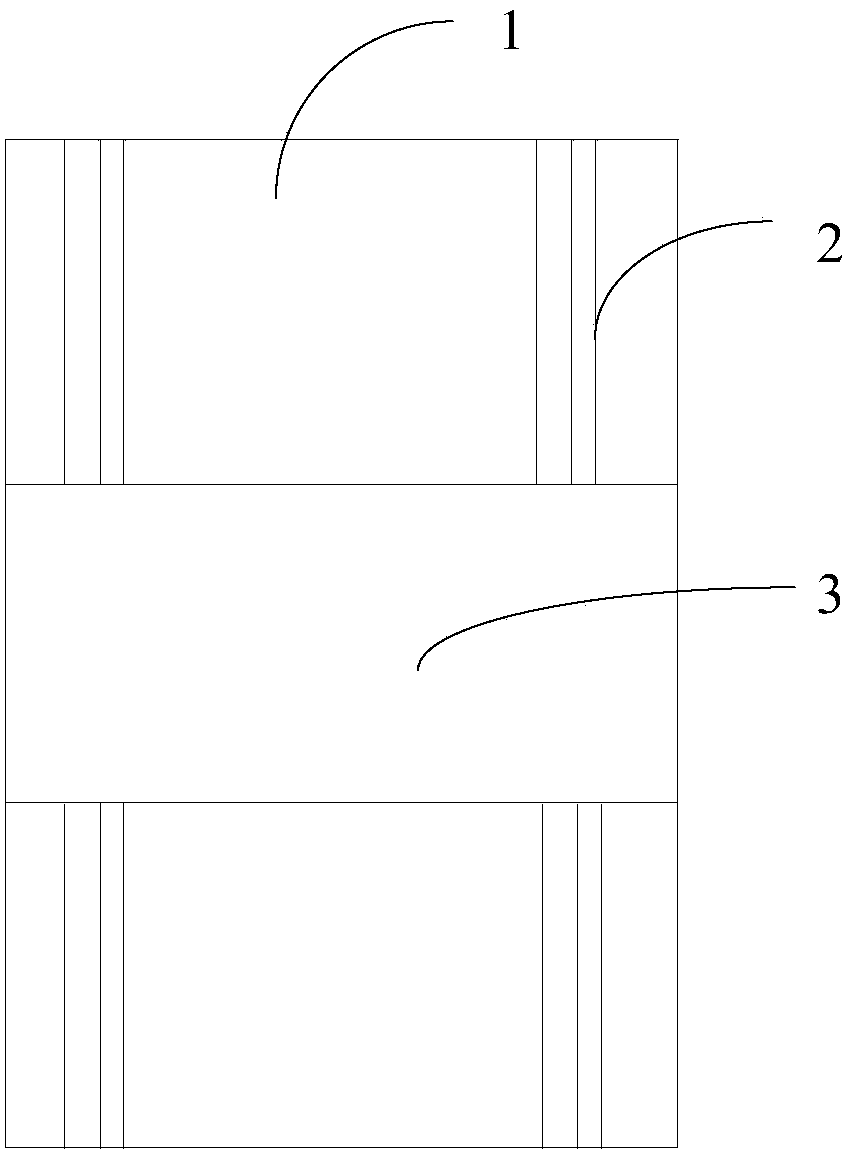

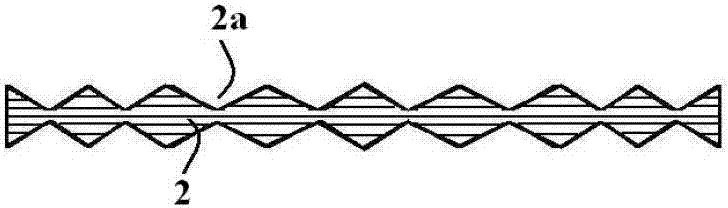

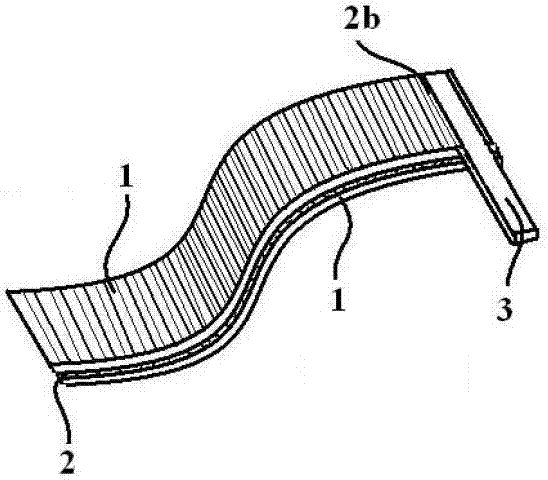

Vibration-damping and noise-reducing jacket for railway steel rail

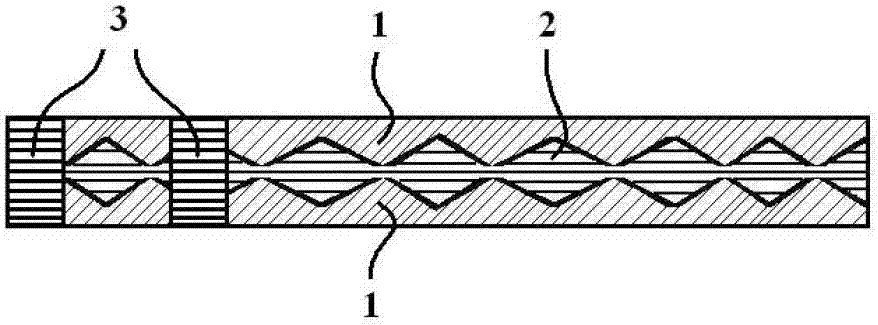

The invention relates to a vibration-damping and noise-reducing jacket for a railway steel rail, belonging to the field of vibration-damping and noise-reducing technology in rail traffic. The vibration-damping and noise-reducing jacket is characterized by comprising a band groove expanding layer, an inverted T-shaped restricting layer and a damping layer, wherein the band groove expanding layer is symmetrically coated on the steel rail bottom and the rail waist along the central line of the steel rail; the inverted T-shaped restricting layer is arranged outside the band groove expanding layer; and the damping layer is bonded between the band groove expanding layer and the restricting layer. The vibration-damping and noise-reducing jacket has the advantages of inhibiting wheel rail vibration and noise radiation from sound source and obviously reducing vibration and noise. The vibration-damping and noise-reducing jacket is simple to manufacture and convenient for field assembly and disassembly without influencing the primary function of steel rail, and is suitable for the areas with requirements on noise of railway, subway and urban light rail in urban district.

Owner:朱颖 +8

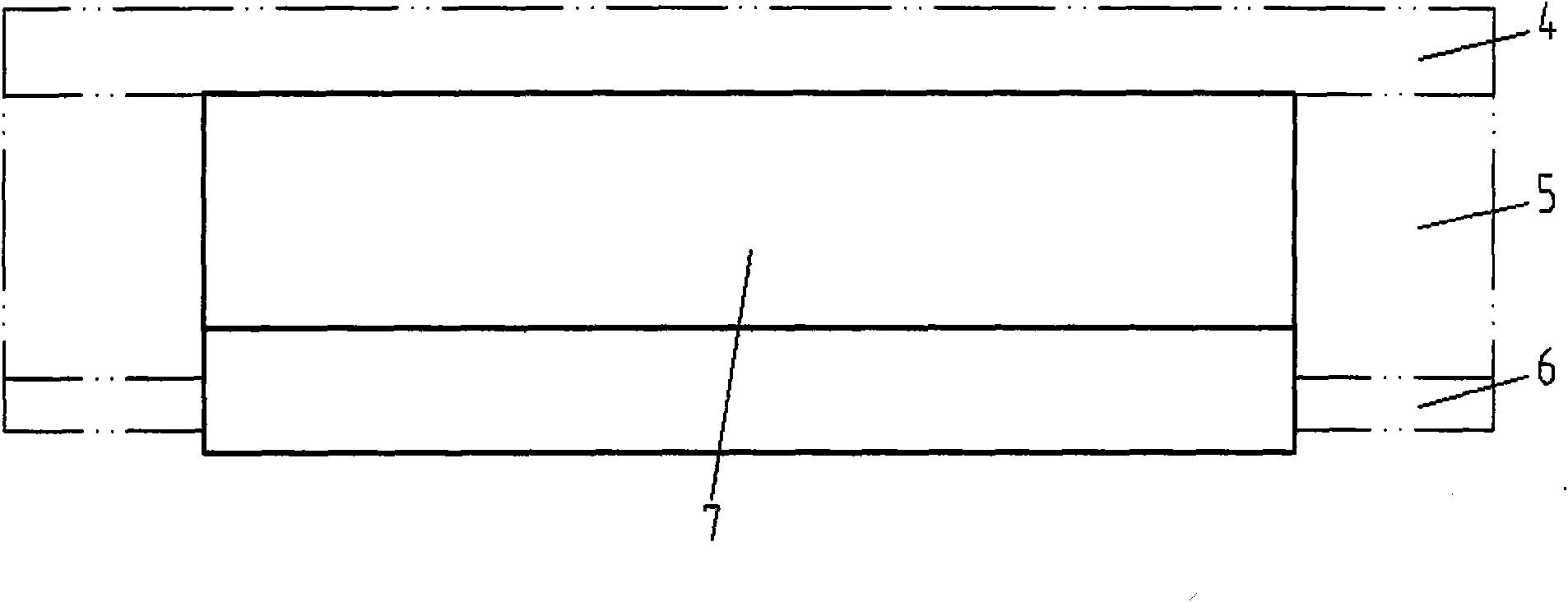

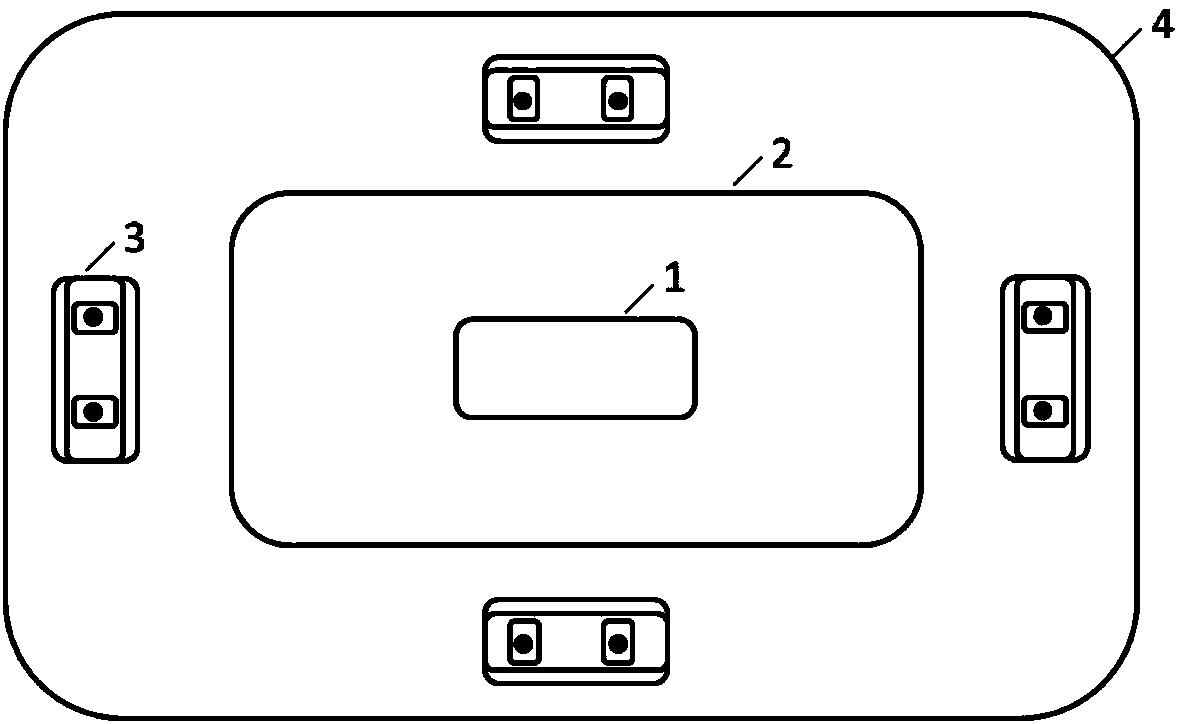

Far-infrared carbon fiber composite heating film

The invention relates to a far-infrared carbon fiber composite heating film, which comprises an upper base layer, a lower base layer, a carbon fiber composite heating layer, an upper insulated flame-retardant and heat-resistant waterproof layer and a lower insulated flame-retardant and heat-resistant waterproof layer, wherein the carbon fiber composite heating layer is located between the upper base layer and the lower base layer; and the upper insulated flame-retardant and heat-resistant waterproof layer and the lower insulated flame-retardant and heat-resistant waterproof layer coat the outer sides of the upper base layer and the lower base layer, wherein the far-infrared carbon fiber composite heating film is preferably carbon fiber cloth or carbon fiber composite paper. The far-infrared carbon fiber composite heating film is simple in structure, has good flexibility and can be freely cut and folded; the flexibility is not affected in a low-temperature condition; the load resistance deviation does not exceed 8% after a single side is folded for 1,000 times at a speed of 30times / min; the security and the stability are significantly improved; the service life is long; and furthermore, the far-infrared carbon fiber composite heating film has high external insulativity, high-temperature resistance, open fire resistance and waterproofness, the internal conductivity and the heating property are good and the security is high.

Owner:石家庄邦迪高分子材料有限公司

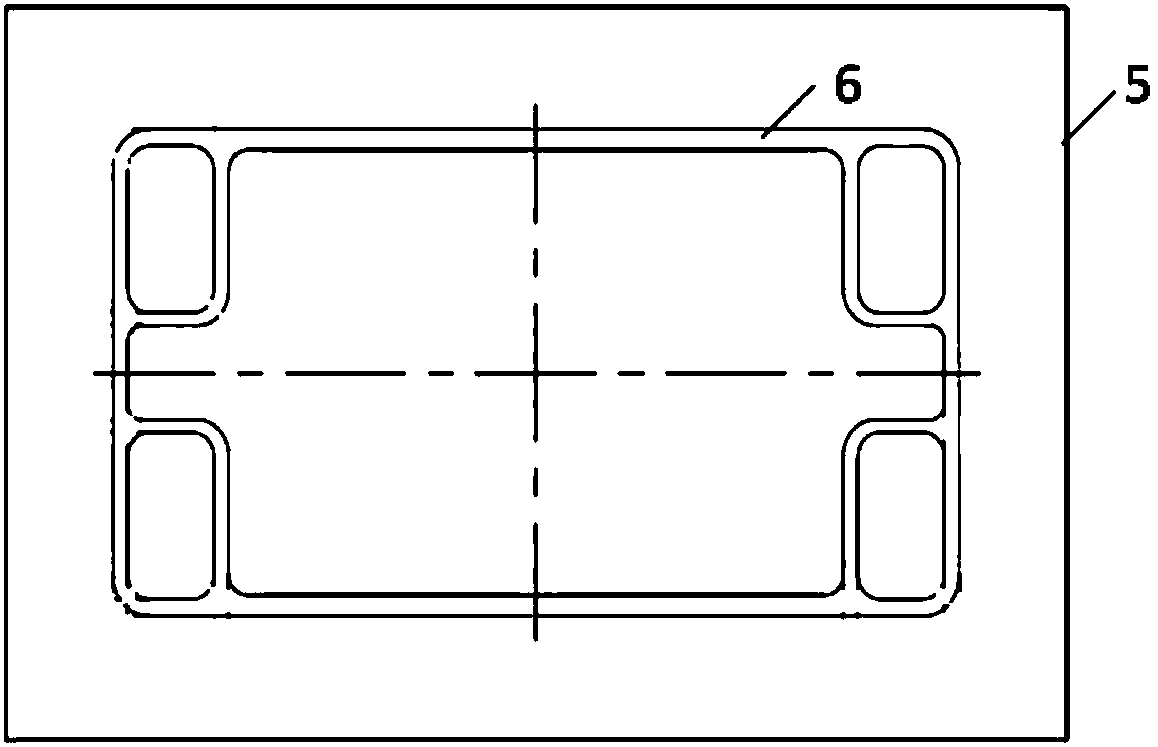

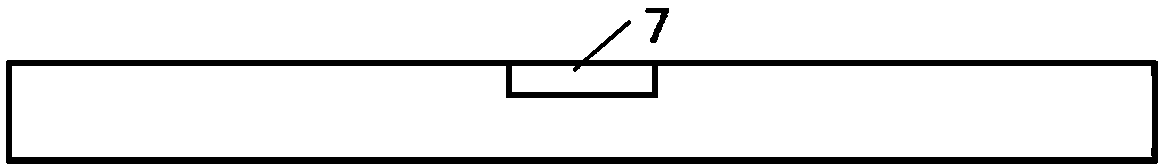

Bipolar plate for a high-temperature fuel cell, and manufacturing method thereof

InactiveCN108172859ADoes not affect conductivityConductivity does not decreaseFinal product manufactureSealing/support meansScreen printingFuel cells

The invention provides a bipolar plate for a high-temperature fuel cell, and a manufacturing method thereof. In the prior art, the fuel cell stack bipolar plate needs to meet the circulation requirements of fuels, oxidants and cooling mediums. According to the bipolar plate, based on the problem in the prior art, the circumferential surface of a cathode plate is coated with an adhesive material through a screen printing technology and positioning design in a scraping coating manner, wherein the adhesive material meets fuel cell working environment requirements; the cathode plate is precisely aligned to an anode plate through a positioning groove, and standing curing is performed to obtain a bipolar plate; the bipolar plate comprises an anode plate, a cooling channel and a cathode plate, wherein both sides of the cathode plate are respectively provided with a flowing channel, the single surface of the anode plate is provided with a flowing channel, and the cathode plate surface with thecooling medium flowing channel is adhered to the anode plate surface with no flowing channel to form the bipolar plate, and the cooling medium flowing channel is formed between the two plates, such that the cooling medium flowing channel is additionally arranged without the increasing of the thickness; and the adhesive liquid distribution and the thickness can be precisely controlled through thescreen printing technology, such that the two plates can be integrally adhered within a certain adhesive liquid thickness range while the conductivity of the bipolar plate is not affected.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

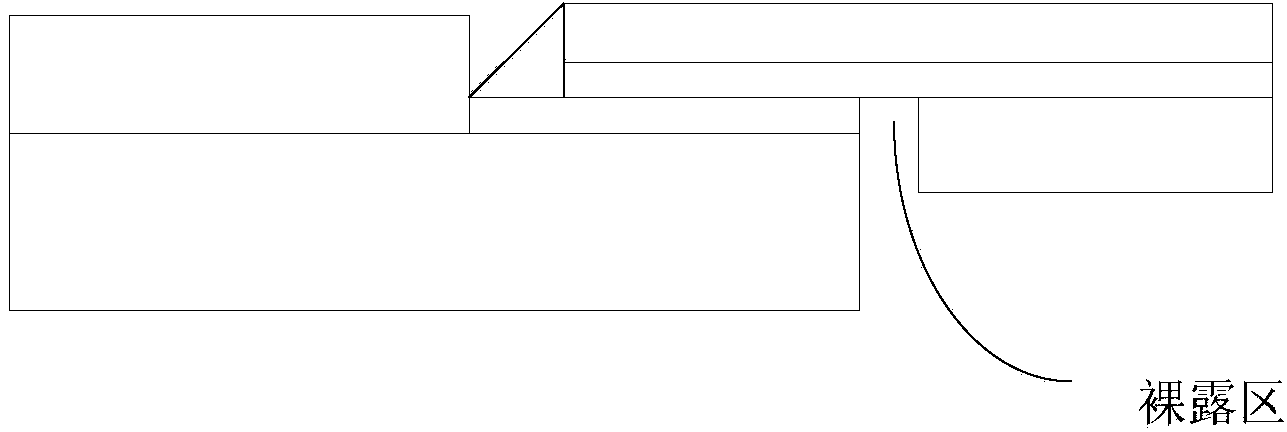

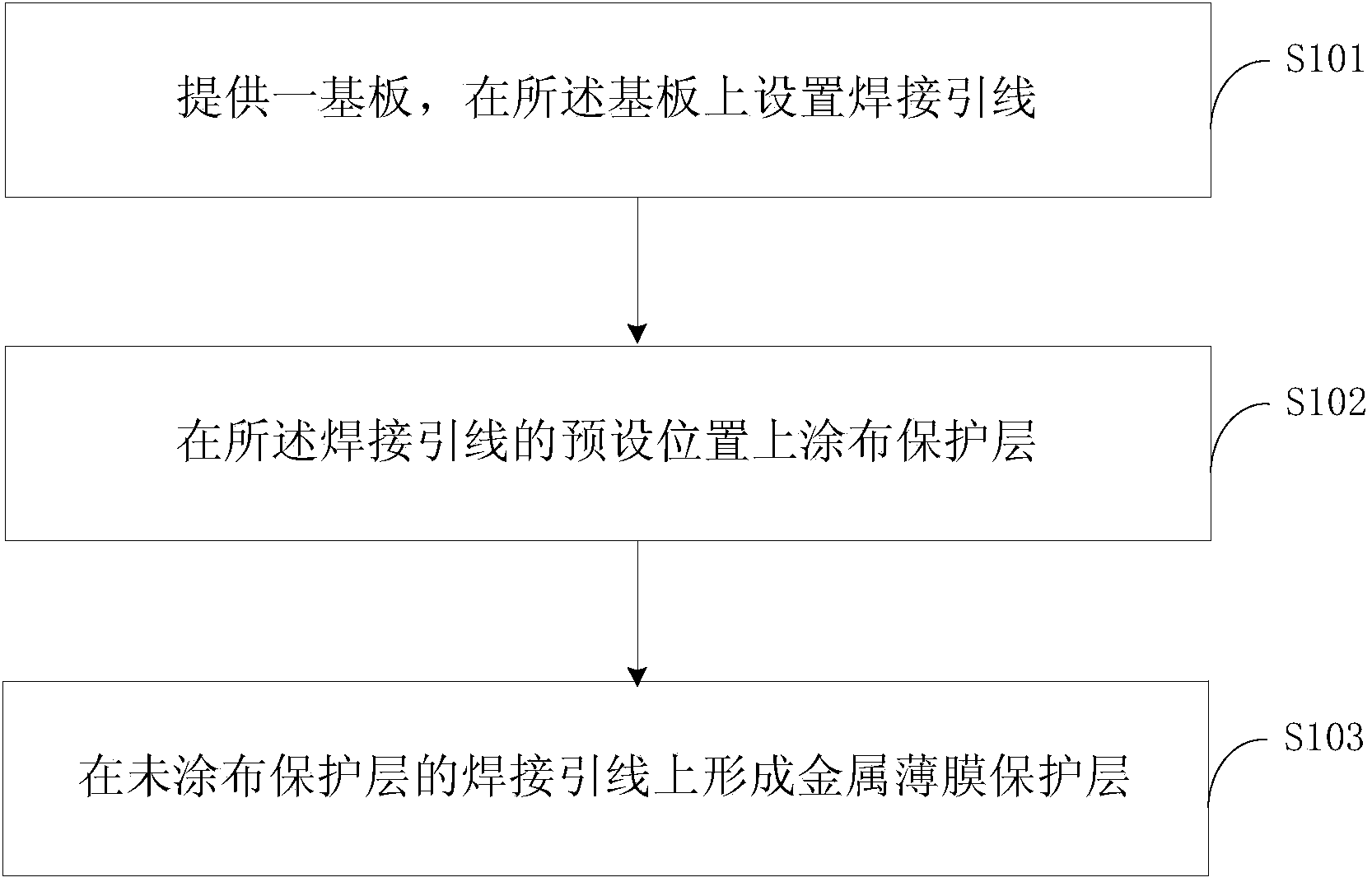

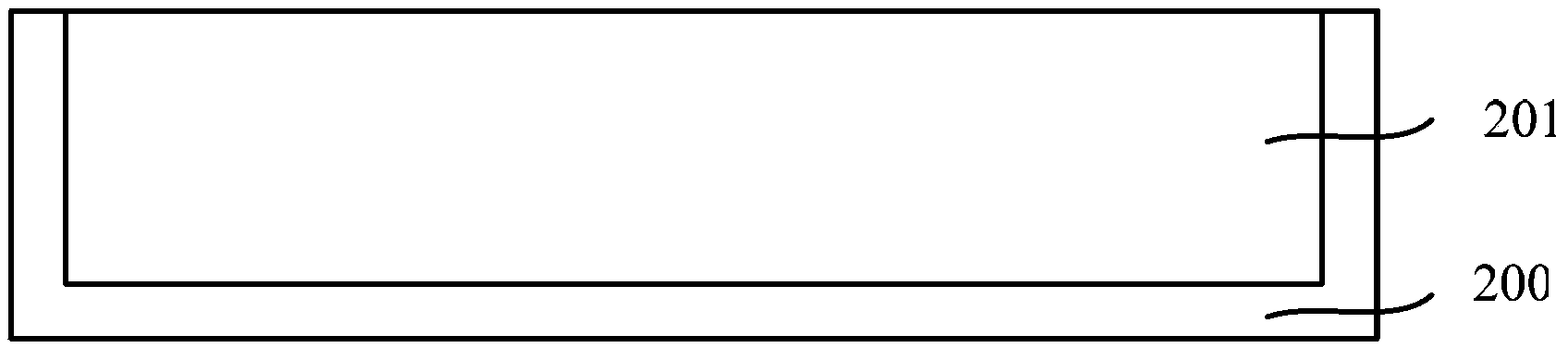

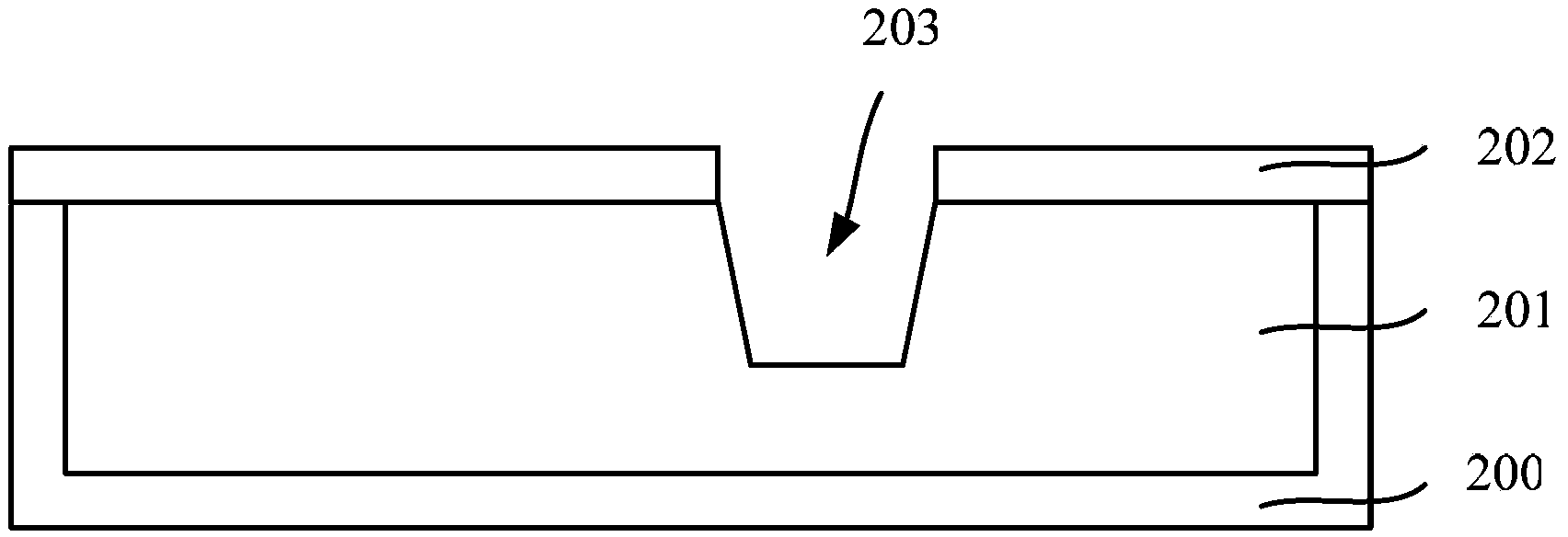

Chip on film (COF) substrate and manufacturing method thereof and display panel

InactiveCN104049393AReduce time to corrodeReduced risk of corrosion fracturesPrinted circuit assemblingNon-linear opticsChip on filmDisplay device

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Carbon nanotube paper and preparation method thereof

ActiveCN108385450AStrong mechanical propertiesStable structureNon-fibrous pulp additionPaper/cardboardFiberAlcohol

The invention belongs to the technical field of carbon nano materials, and particularly to carbon nanotube paper. The carbon nanotube paper comprises carbon nanotubes and chemical fibers. The invention also relates to a preparation method of the carbon nanotube paper, and the preparation method comprises the following steps: step one, placing the carbon nanotubes in an alcohol solvent, conductingultrasonic dispersion, placing the chemical fibers in an alcohol solvent, and conducting high-speed dispersion; step two, mixing the chemical fiber dispersion liquid with the carbon nanotube dispersion liquid to obtain a uniform mixed solution; step three, placing the uniform mixed solution in a corresponding filter device, conducting filtering, and forming carbon nanotube wet paper with uniform thickness on a filter membrane; step four, placing the carbon nanotube wet paper and the filter membrane into a drying oven together, and carrying out baking; and step five, stripping dried carbon nanotube paper from the filter membrane, and carrying out roll pressing by using a roller press. The carbon nanotube paper provided by the invention is low in cost, high in purity, and convenient in transfer; and the preparation method has few preparation processes, and is suitable for large-scale production.

Owner:柔电(武汉)科技有限公司

Coating for copper-plating-free welding wire and application thereof

InactiveCN107322192AImprove rust resistanceImprove bindingWelding/cutting media/materialsSoldering mediaCopper platingEmulsion

The invention provides coating for a copper-plating-free welding wire and application thereof and belongs to the field of copper-plating-free welding wires. The coating comprises the following raw materials of, by weight, 30-40 parts of acrylic resin emulsion, 5-10 parts of grapheme, 10-20 parts of nano titanium dioxide, 2-5 parts of calcium stearate, 2-3 parts of a dispersing agent, 1-2 parts of a wetting agent, 1-2 parts of a defoaming agent and 25-40 parts of water. According to the coating for the copper-plating-free welding wire, a coated layer can be formed on the surface of the welding wire, and according to the prepared welding wire, abrasion of an existing copper-plating-free welding wire to a current contact nozzle can be greatly reduced, and the wire feeding performance of the welding wire in the using process can be improved. A uniform and thickness-controllable protective film can be formed on the surface of the copper-plating-free welding wire, the surface of the welding wire is smooth, and the problems of unsmooth wire feeding, harsh electric arc sound, splashing, lots of air holes and the like are prevented.

Owner:KUNSHAN MCC BAOSTEEL WELDING CONSUMABLES +1

Preparation method of negative electrode plate of nickel-metal hydride battery

ActiveCN102779981AHigh current charge and discharge effect is improvedHigh current charging and discharging effect is goodAlkaline accumulator electrodesCarbon nanotubeSlurry

The invention discloses a preparation method of negative electrode plate of a nickel-metal hydride battery. The preparation method comprises: (1) mixing nano metal hydride alloy, carbon nanotubes and nanographite with a particle size of 5 to 100 nm, and an active substance mixture with a particle size of 5 to 35nm according to a mass ratio of 3:1:1 to 3:0.5:0.5 to obtain a mixture, and preparing a slurry from the mixture, polytetrafluoroethylene (emulsion), and distilled water, wherein polytetrafluoroethylene (emulsion) and distilled water respectively account for 1.5% to 3% and 15% to 30% the mass of the mixture of nano metal hydride alloy, carbon nanotubes and nanographite; and (2) coating the slurry prepared in step (1) on a negative current collector, oven-drying, pressing by a roll crusher, so that the active substance slurry forms an electrode active substance coating on the current collector, cutting, and ultrasonic or laser welding 1 to 5 negative electrode lugs at the reserved blank positions of the current collector. The battery provided by the invention has the advantages of high cycling capacity, long service life and storage life, good large-current discharge effect, and high safety performance.

Owner:广州云通锂电池股份有限公司

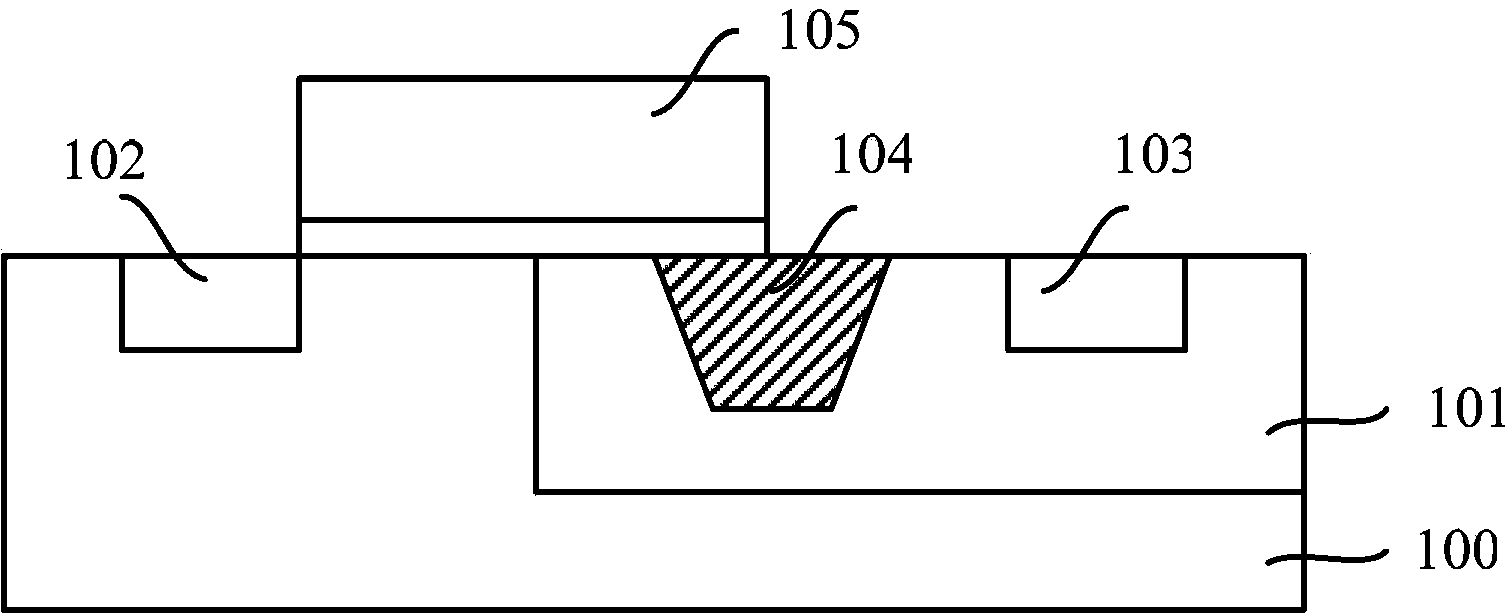

LDMOS device and forming method thereof

InactiveCN104282563ASmall driving currentIncrease drive currentSemiconductor/solid-state device manufacturingSemiconductor devicesDriving currentLDMOS

The invention discloses an LDMOS device and a forming method thereof. The LDMOS device comprises a semiconductor substrate, a drift region, a shallow trench isolation structure, a doping layer, a gate structure, a source region and a drain region. A well region is located in the semiconductor substrate. The drift region is located in the well region, and the doping type of the drift region is opposite to the doping type of the well region. The shallow trench isolation structure is placed in the drift region, and the depth of the shallow trench isolation structure is smaller than the depth of the drift region. The doping layer is placed at the bottom of the shallow trench isolation structure, and the doping type of the doping layer is opposite to the doping type of the drift region. The gate structure is placed on the semiconductor substrate, one end of the gate structure extends to the position above the well region, and the other end of the gate structure extends to the position above the shallow trench isolation structure. The source region is located in the well region on one side of the gate structure, and the drain region is located in the drift region on the other side of the gate structure. The breakdown voltage of the LDMOS device is kept unchanged, and meanwhile drive currents are increased.

Owner:SEMICON MFG INT (SHANGHAI) CORP

High barrier and high tolerance composite proton exchange membrane and preparation method thereof

InactiveCN108232262AGood barrier and mechanical resistanceHigh elastic modulusFuel cellsIon exchangeKetone

The invention relates to a high barrier and high tolerance composite proton exchange membrane and a preparation method thereof, belonging to the technical field of proton exchange membranes. The composite proton exchange membrane is prepared from 95-99.5wt% of ion exchange resin and 0.5-5wt% of an orientation layer, wherein the ion exchange resin is one of perfluorosulfonic acid resin, sulfonatedpolyarylether, sulfonated polyaryletherketone, sulfonated polythioether ketone or sulfonated polyarylether sulfone ketone; the orientation layer component is one of reduced graphene oxide, single-walled carbon nanotubes or a modified montmorillonite. The composite proton exchange membrane prepared by the method has efficient proton conduction ability, high mechanical tolerance and high barrier property. The invention also provides the preparation method of the composite proton exchange membrane; the method comprises four steps, and is scientific and reasonable, simple and easy to implement, low in cost, safe and environmentally-friendly.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

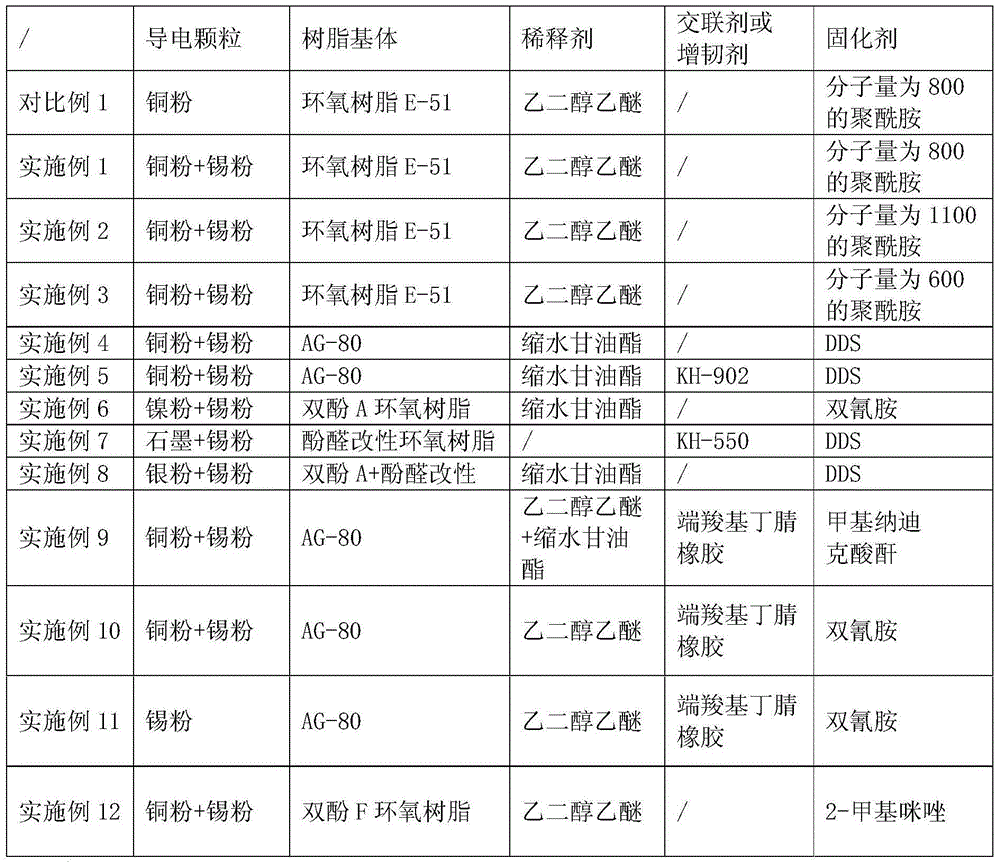

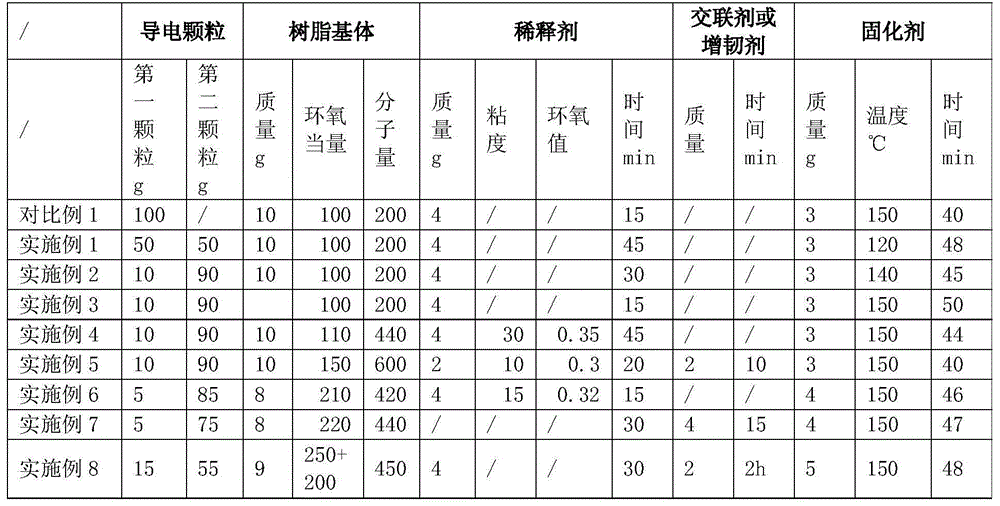

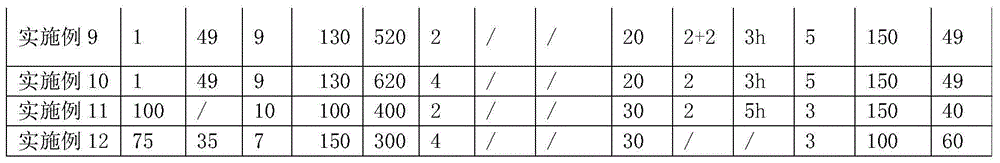

Conductive glue, preparation method thereof and circuit board

ActiveCN104629643AImprove solderabilityDoes not affect conductivityEpoxynovolac adhesivesElectrical connection printed elementsTinNanotechnology

The invention discloses conductive glue, a preparation method thereof and a circuit board. The conductive glue comprises a resin base body as well as conductive particles mixed in the resin base body, wherein the conductive particles comprise first conductive particles which are tin powder particles. The conductive glue disclosed by the invention substitutes noble metals by tin powder, so that the production cost is reduced on the premise of not affecting the conductive performances. Meanwhile, tin powder is added to substitute noble metals to effectively improve weldability of a printed circuit, so that the conductive glue is more suitable for welding production.

Owner:LANGFANG GAOCI NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com