Patents

Literature

45results about How to "Improve surface oxidation resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

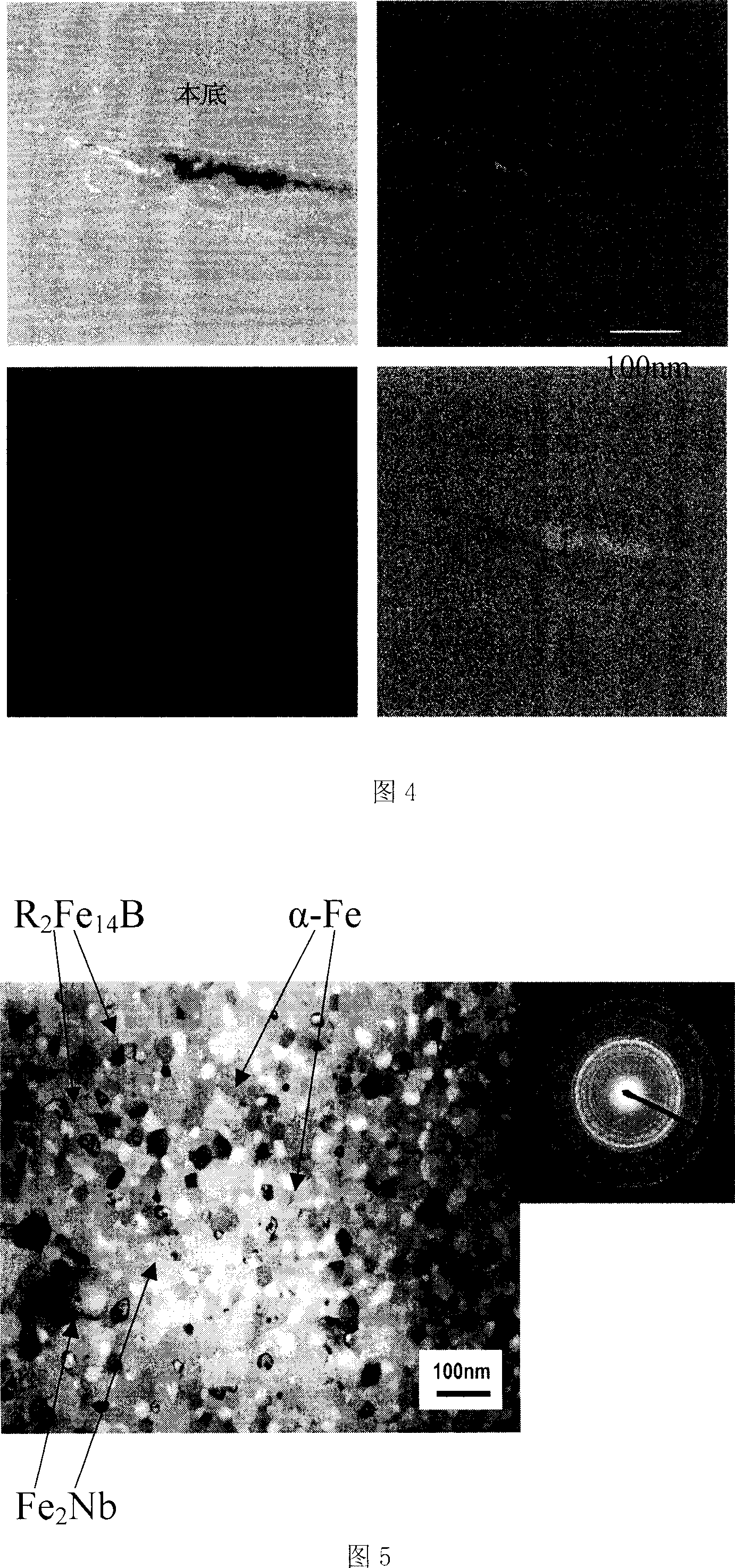

High stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder

The high stability and high magnetism quenched R-Fe-B base permanent magnetic alloy powder has the basic expression of RxFe100-x-y-z-vMzCovBy, where R is light RE element(s) Nd, Pr and La, and M is element(s) of Nb, Zr, Ti, etc; and consists of main R2Fe14B phase and small amount of superfine auxiliary Fe-alpha-M-beta phase. Adding Nb and other transition elements to form small amount of superfine auxiliary Fe-alpha-M-beta phase during fast solidification can inhibit over nucleation and growth of Nd2Fe14B crystal grain, improve the performance of the quenched material, fine the Nd2Fe14B crystal grain and raise the temperature stability and antioxidant process of the material. In addition, the permanent magnetic alloy powder has obviously raised intrinsic coercive force, high saturated magnetization, high residual magnetism and other advantages.

Owner:DONGFANG MICRON & NANOMETER SCI TECH

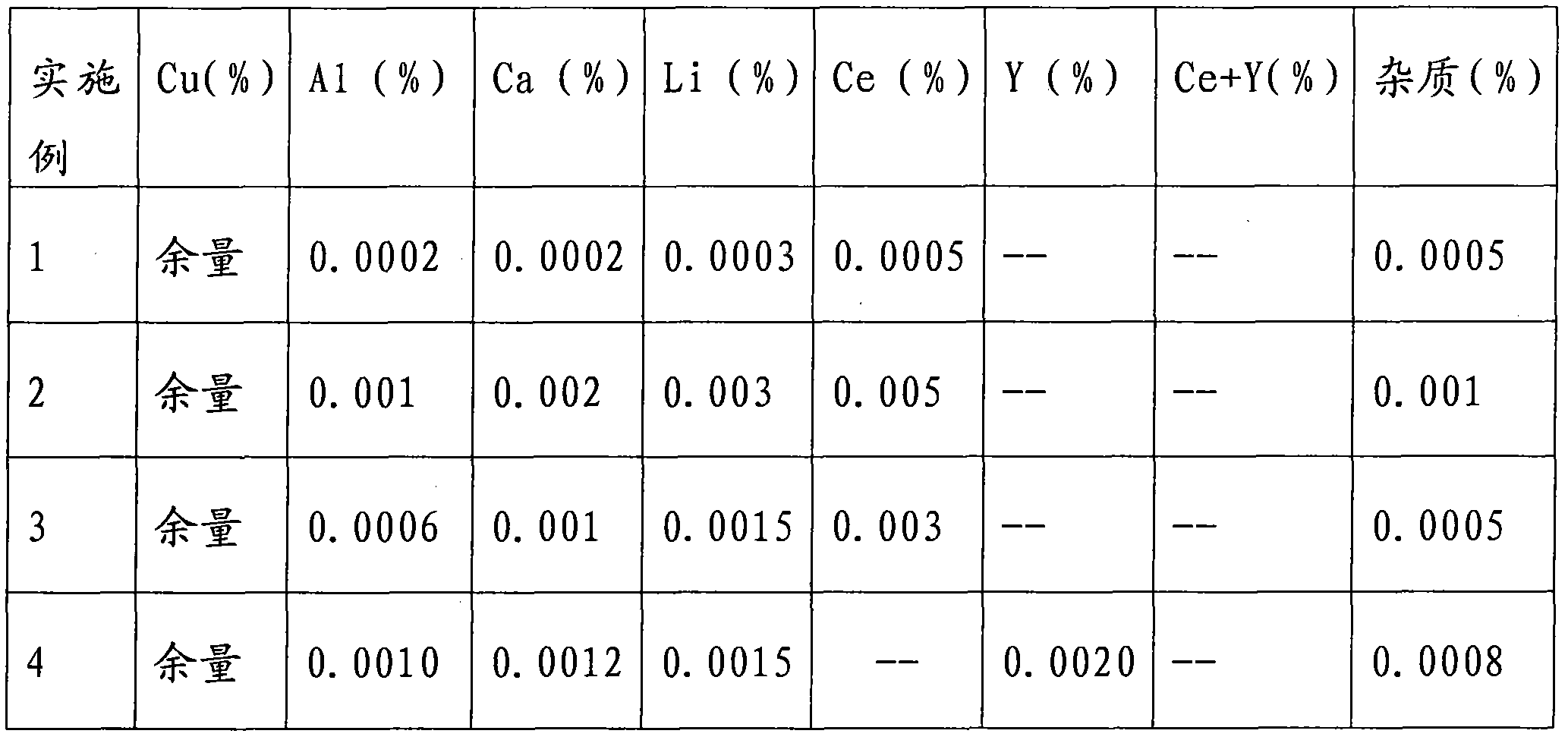

Bonding copper wire and preparation method thereof

InactiveCN101979689AImprove surface oxidation resistanceImprove performanceSingle bars/rods/wires/strips conductorsSolid-state devicesCopper wireCerium

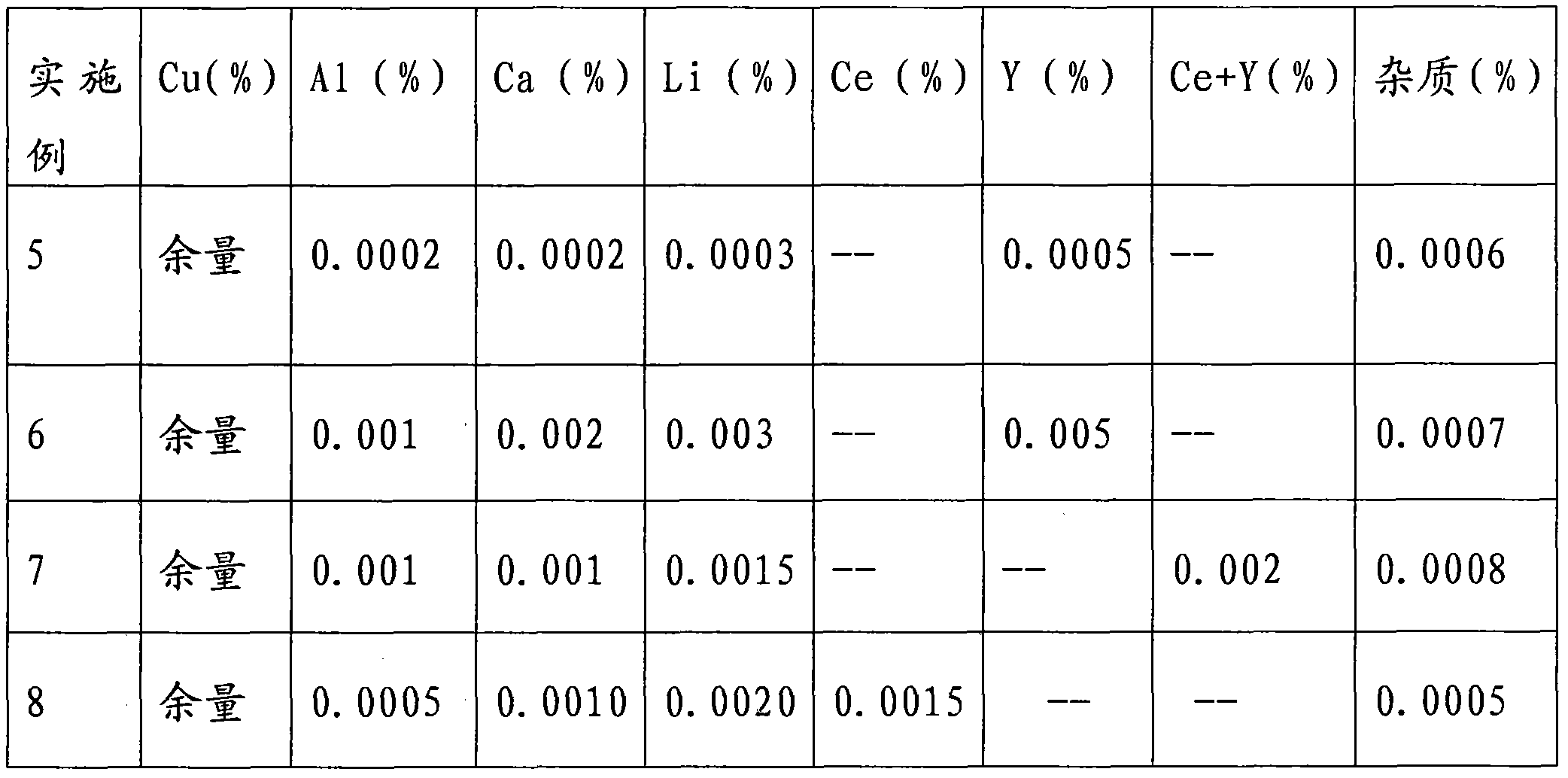

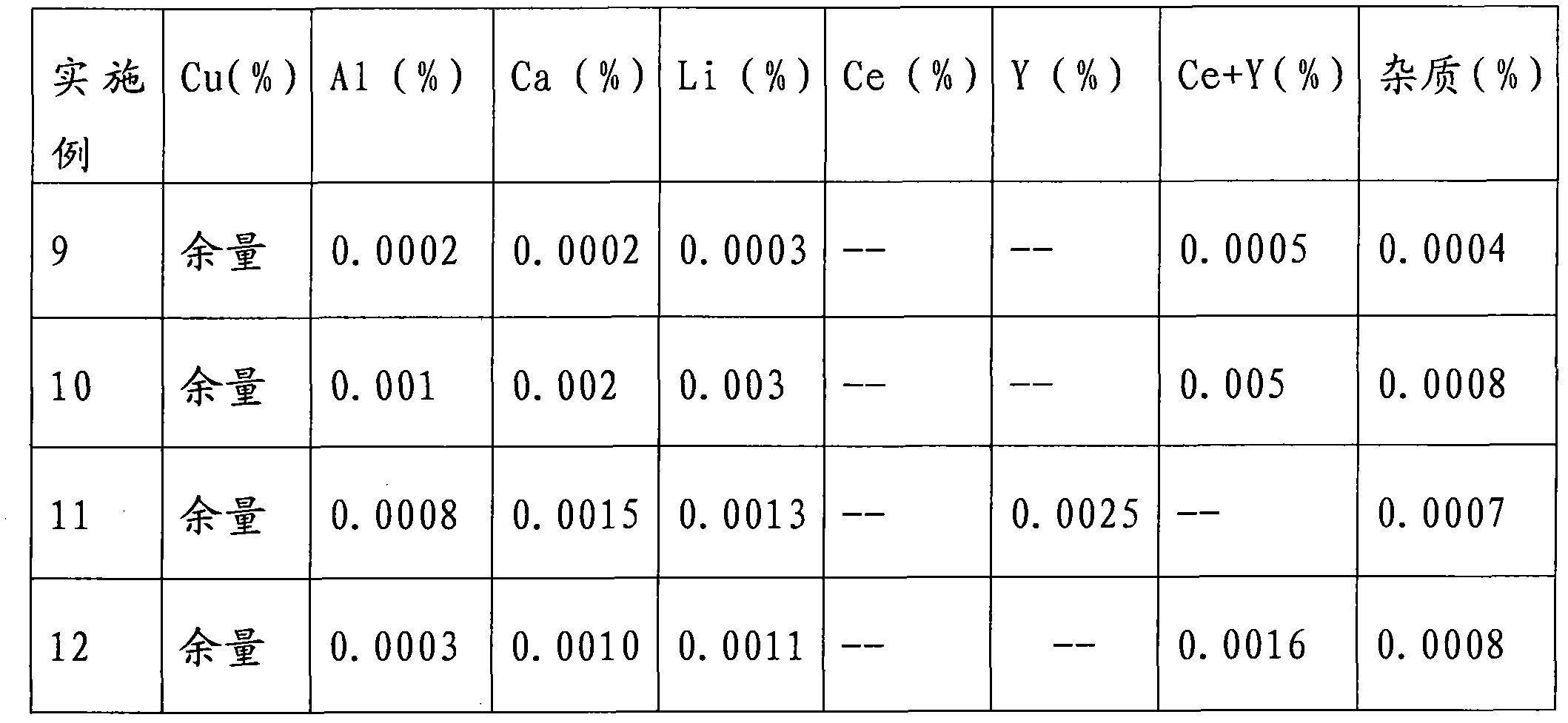

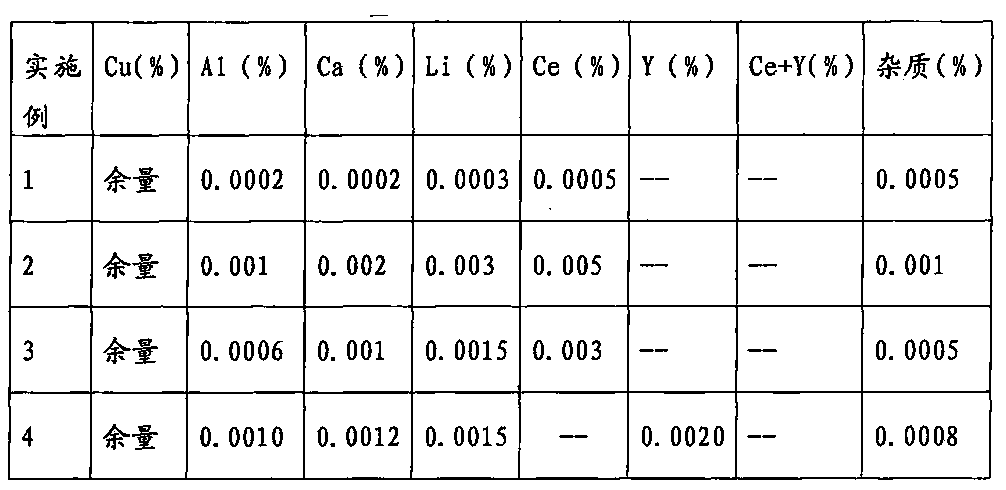

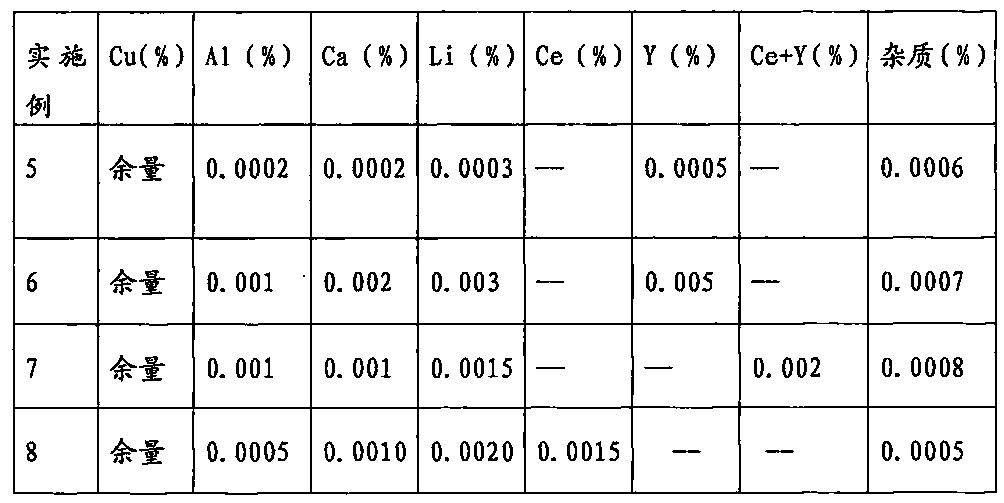

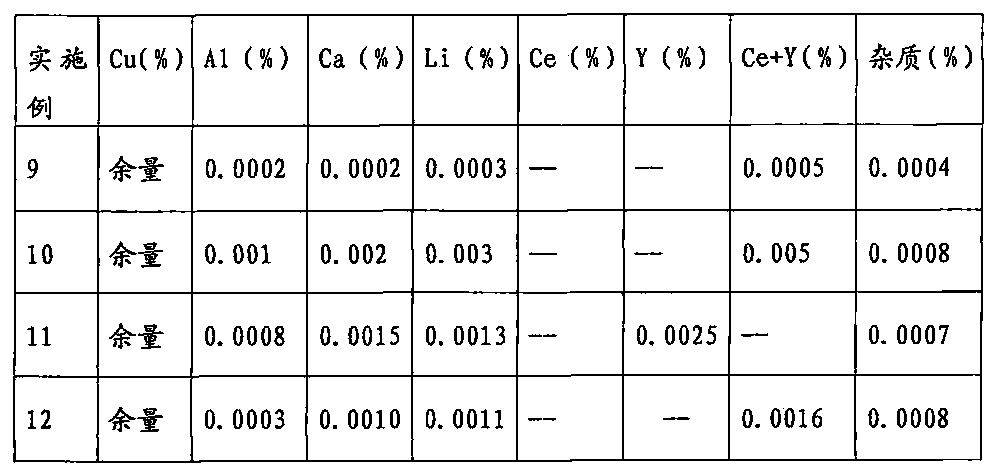

The invention relates to a bonding copper wire and a preparation method thereof. The bonding copper wire comprises the following components in percentage by mass: 0.0003 percent to 0.003 percent of lithium, 0.0002 percent to 0.002 percent of calcium, 0.0002 percent to 0.001 percent of aluminium, 0.0005 percent to 0.005 percent of cerium and / or yttrium, 0.0001 percent to 0.001 percent of other inevitable impurity elements and the balance of copper. The preparation method of the bonding copper wire comprises the following steps of: preparing a middle alloy, preparing an alloy cast ingot, annealing uniformly, heat extrusion, stress relief annealing, drawing, final annealing, winding for multiple coils, packaging, and final protective packaging, wherein in a drawing process, middle stress relief annealing can be performed according to practical needs. The bonding copper wire has better inoxidizability while keeping better conduction and radiation properties; in the preparation process of the bonding copper wire, the uniform annealing is added and the middle stress relief annealing is performed, so that the mechanical property of the prepared bonding copper wire is better.

Owner:蔡元华

Alpha+beta type titanium alloy

The invention discloses an alpha plus beta type titanium alloy. The titanium alloy comprises the following components in percentage by weight: 7 to 8.5 percent of aluminum, 0.5 to 1.5 percent of vanadium, 1 to 3 percent of molybdenum, 1 to 3 percent of chromium, 0.3 to 1 percent of iron, 0.05 to 0.1 percent of rare earth element, the balance being titanium and inevitable impurities. The titanium alloy can be manufactured by common manufacturing methods for the titanium alloy such as the fusion casting pressure processing method and the powder metallurgic method. The total weight percentage of carbon, hydrogen, oxygen and nitrogen in the impurities is no more than 0.25 percent, and the vanadium is added in the form of aluminum-vanadium intermediate alloy, the molybdenum is added in the form of aluminum-molybdenum intermediate alloy, and the rare earth is added in the form of lanthanum-cerium mixed rare earth. Compared with Ti-6Al-4V, the room-temperature tensile strength and yield strength of the titanium alloy are improved by more than 30 percent, the high-temperature strength is also obviously enhanced, and the density and the cost are slightly lowered, so that the titanium alloy has more desirable performance-to-price ratio and wider market prospect.

Owner:李世琼

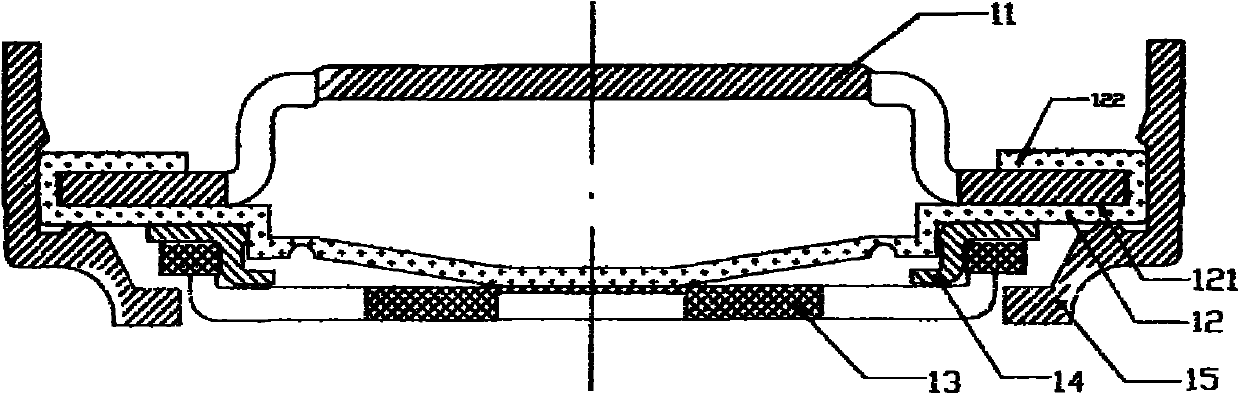

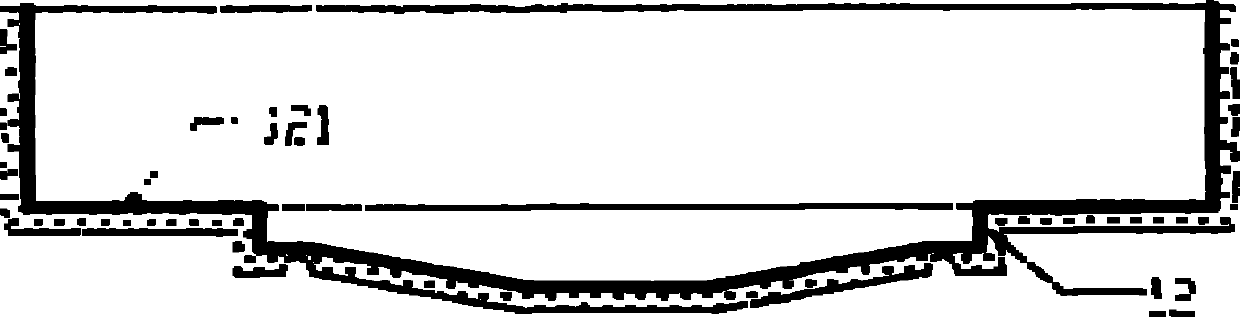

Explosion-proof combined cap of high-power battery

InactiveCN102005549AIncrease security protection functionExtended service lifeCell component detailsEngineeringSoldering

The invention relates to an explosion-proof combined cap of a high-power battery, which is composed of a steel cap (11), an explosion-proof plate (12), a connecting plate (13), a spacing ring (14) and sealing rings (15), wherein the outer circumferences of the steel cap (11), the explosion-proof plate (12), the connecting plate (13) and the spacing ring (14) are covered with the sealing rings (15); and the surface of the explosion-proof plate (12) is provided with a nickel plating layer (121), and the steel cap (11) and the explosion-proof plate (12) are welded by way of tin soldering. The explosion-proof combined cap of the invention can guarantee the low resistivity / consumption and high-power through-current capabilities of the battery when the battery runs normally; and when the battery runs exceptionally, the inner part of the battery can be disconnected reliably, therefore, the security protection function of the explosion-proof combined cap is played more effectively.

Owner:杨学新

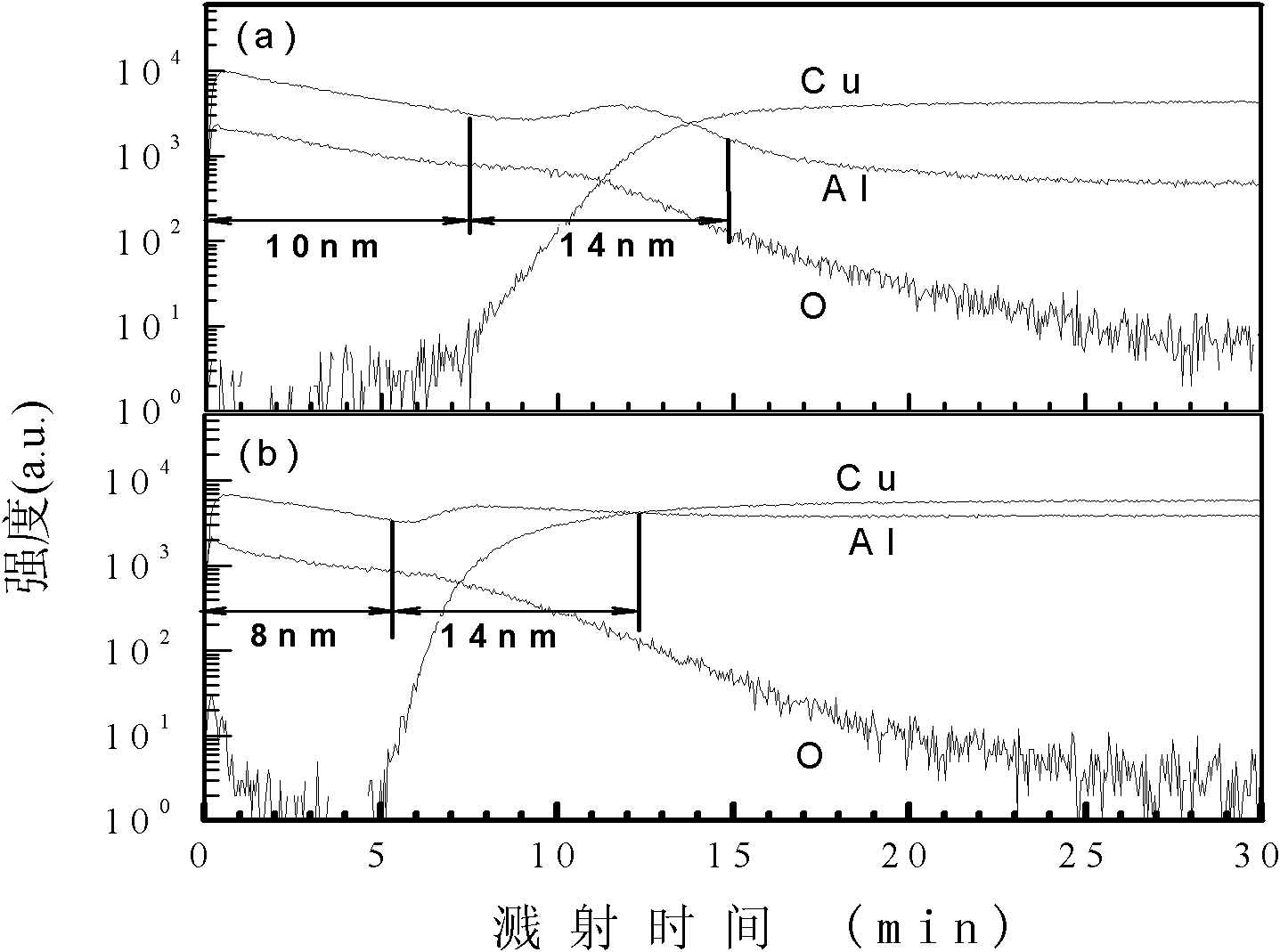

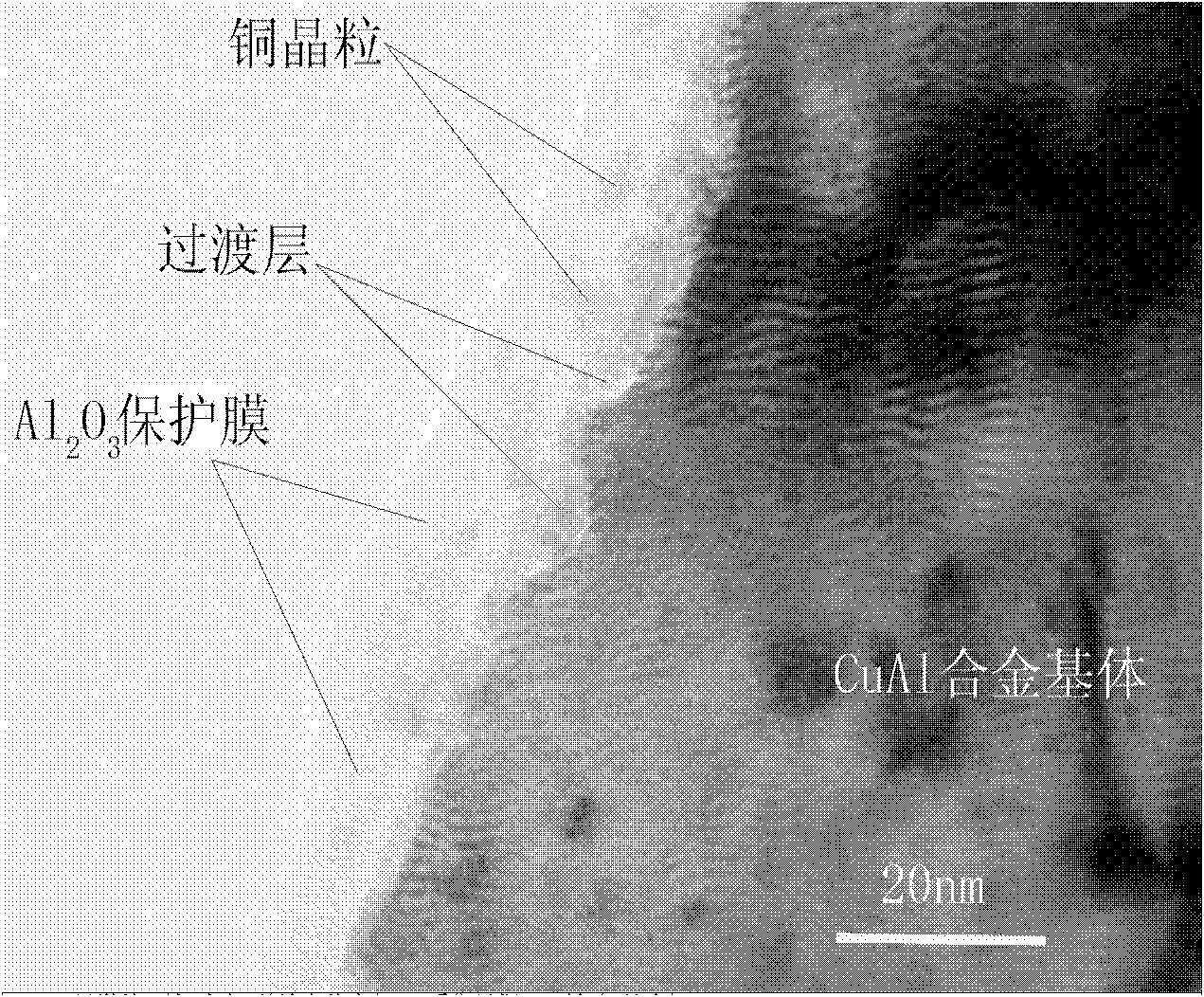

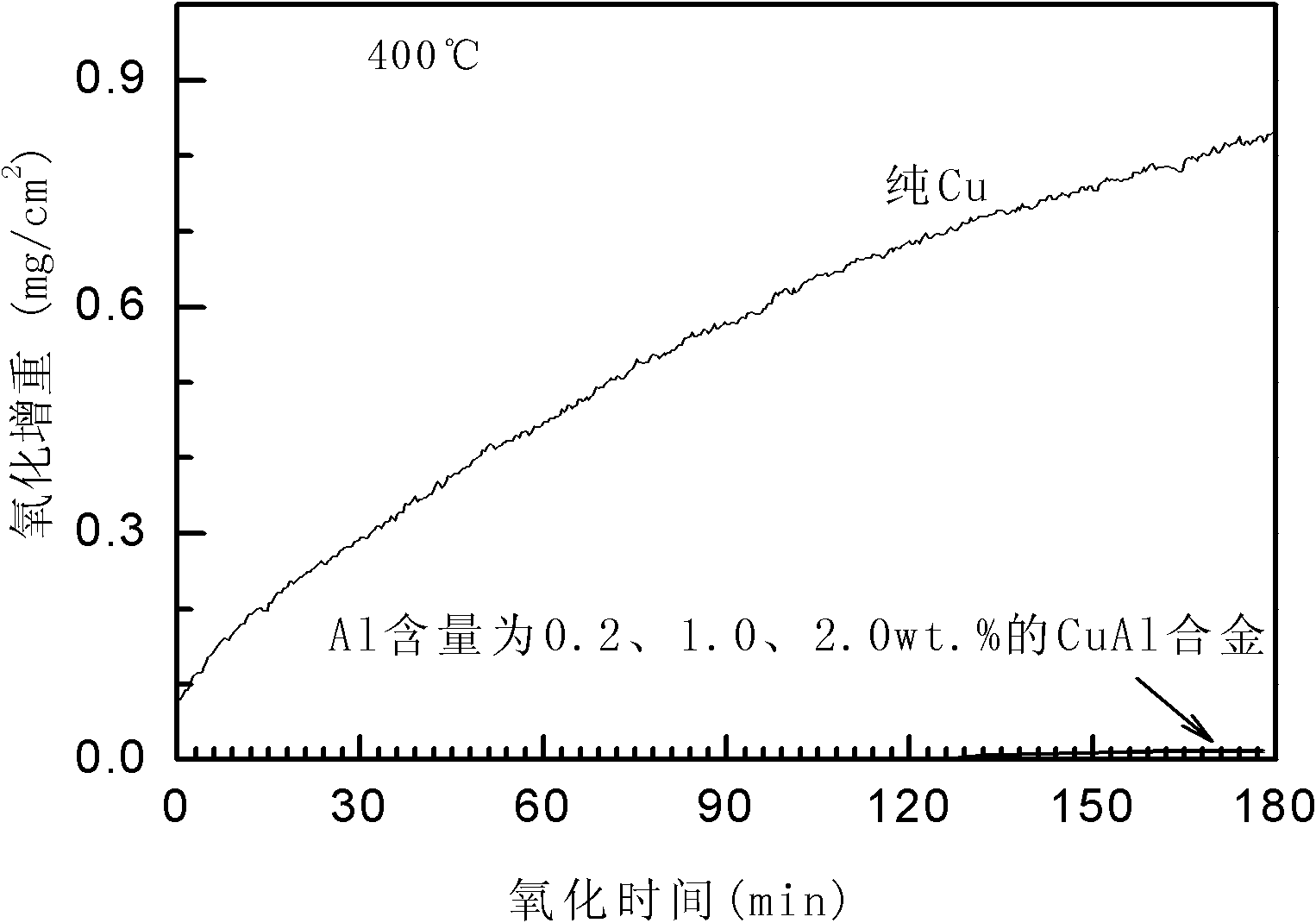

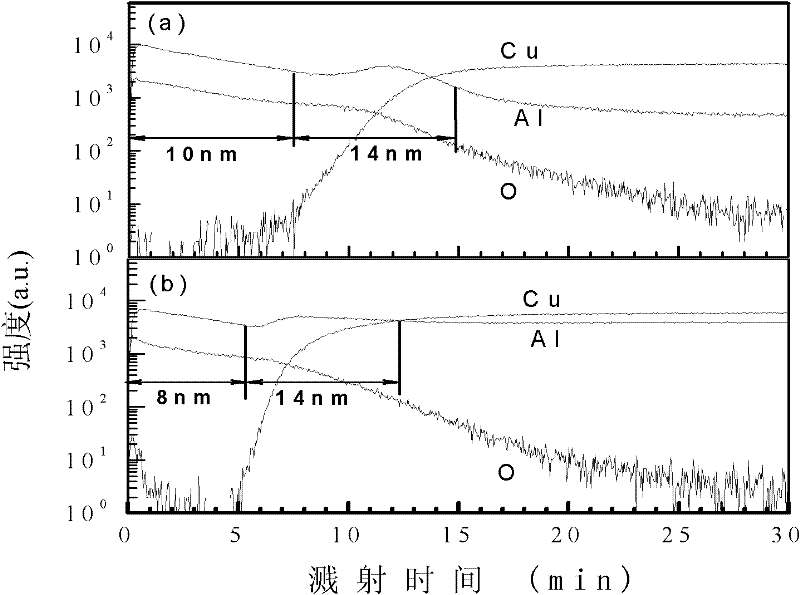

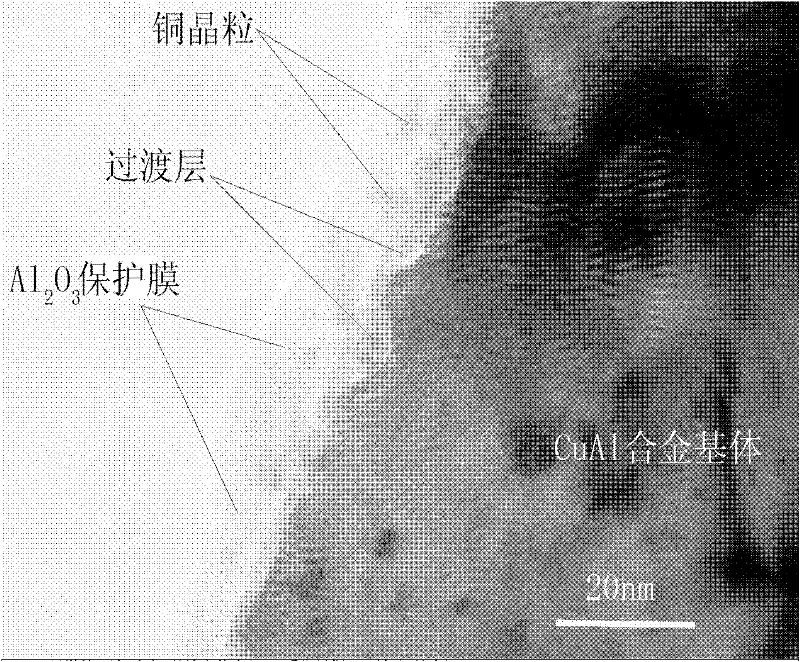

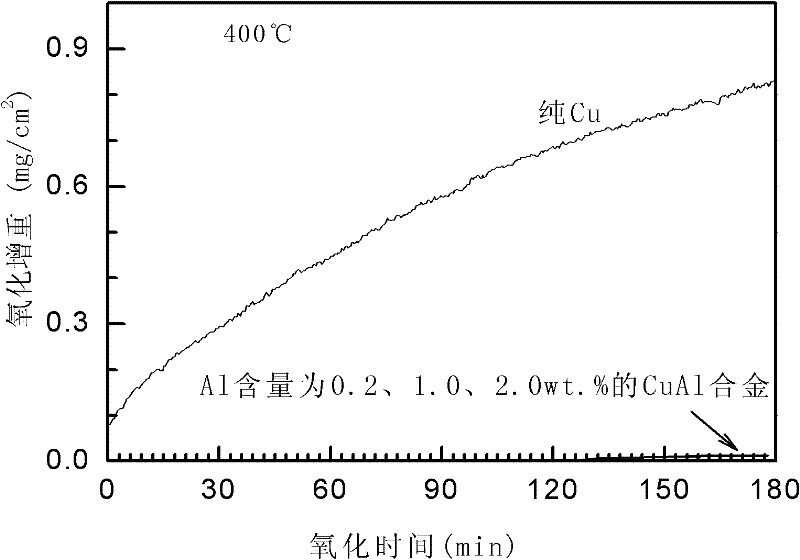

Method for preparing composite membrane for improving oxidation resistance of copper lead of integrated circuit

InactiveCN101831566AImprove antioxidant capacityInhibit further oxidationOxidation resistantIntegrated circuit

The invention relates to a method for preparing a composite membrane for improving oxidation resistance of a copper lead of an integrated circuit. The method comprises the following steps of: mixing a little amount of Al and Cu, and repeatedly smelting the mixture in an electric arc furnace to form CuAl alloy; and annealing the CuAl alloy in a heating furnace under hydrogen atmosphere, preserving the heat for certain time, and cooling the annealed product to room temperature to form anti-oxidation copper. After Al element is added, the alloy is annealed in the hydrogen, the Al in the alloy is segregated to the surface of Cu through segregation action and reacts with the rest O in the annealing atmosphere to generate Al2O3 on the surface of the alloy, and a Cu-Al2O3 composite attached membrane with good mechanical property is formed on the surface of the Cu so as to block further oxidation of the Cu and well solve the problem of oxidation of a connecting wire in the copper. The encapsulation temperature of an encapsulation material in the conventional integrated circuit is below 400 DEG C, and the Cu-Al2O3 composite attached membrane formed on the surface of the integrated circuit by using the CuAl alloy as a lead frame material improves the anti-oxidation capability of the lead material and reduces the encapsulation cost.

Owner:JILIN UNIV

Chopped fiber carbon fiber composite material and preparation method thereof

The invention relates to a chopped fiber carbon fiber composite material and a preparation method thereof, and belongs to the technical field of carbon fiber composite material preparation. The preparation method comprises the following steps: 1, grinding a carbon fiber raw material; 2, carrying out short fiber deposition molding; 3, carrying out resin impregnation; 4, forming a mold and injectingliquid, namely putting the resin-infiltrated fiber blank into the mold for forming the mold, and injecting a potential mesophase pitch liquid at the same time; 5, performing high-pressure forming heat treatment: subjecting the infiltrated fiber blank containing the asphalt liquid to heat treatment under high pressure and then condensing the fiber blank to obtain a cured blank; 6, carbonization heat treatment: demolding the cured blank body and then carbonizing to obtain a carbonized blank body; and 7, high-temperature graphitization: carrying out high-temperature graphitization treatment on the carbonized blank to obtain the finished product carbon fiber composite material. The chopped fiber carbon fiber composite material prepared by the invention has high purity and greatly improved compression strength and bending strength, solves the problem of corner solid waste, realizes recycling of the material and generates good economic benefits.

Owner:江苏米格新材料股份有限公司

Copper bonding wire and preparation method thereof

The invention relates to a copper bonding wire and a preparation method thereof. The copper bonding wire comprises, by mass, 0.0003-0.003% of lithium, 0.0002-0.002% of calcium, 0.0002-0.001% of aluminum, 0.0005-0.005% of cerium or yttrium, 0.0001-0.001% of other inevitable impurity elements and the balance copper. The preparation method of the copper bonding wire comprises the steps of manufacturing of intermediate alloy, manufacturing of alloy ingots, homogenizing annealing, hot extrusion, stress relief annealing, drawing, final annealing, multiple winding subpackaging and final protective packaging, and intermediate stress relief annealing can further be conducted in the drawing process according to the actual demands. The copper bonding wire has better oxidation resistance while maintaining the good conducting and radiating properties, and the prepared copper bonding wire is better in mechanical performance due to the facts that homogenizing annealing is additionally conducted and the intermediate stress relief annealing technique can be conducted according to demands in the preparation process of the copper bonding wire.

Owner:上海铭沣科技股份有限公司

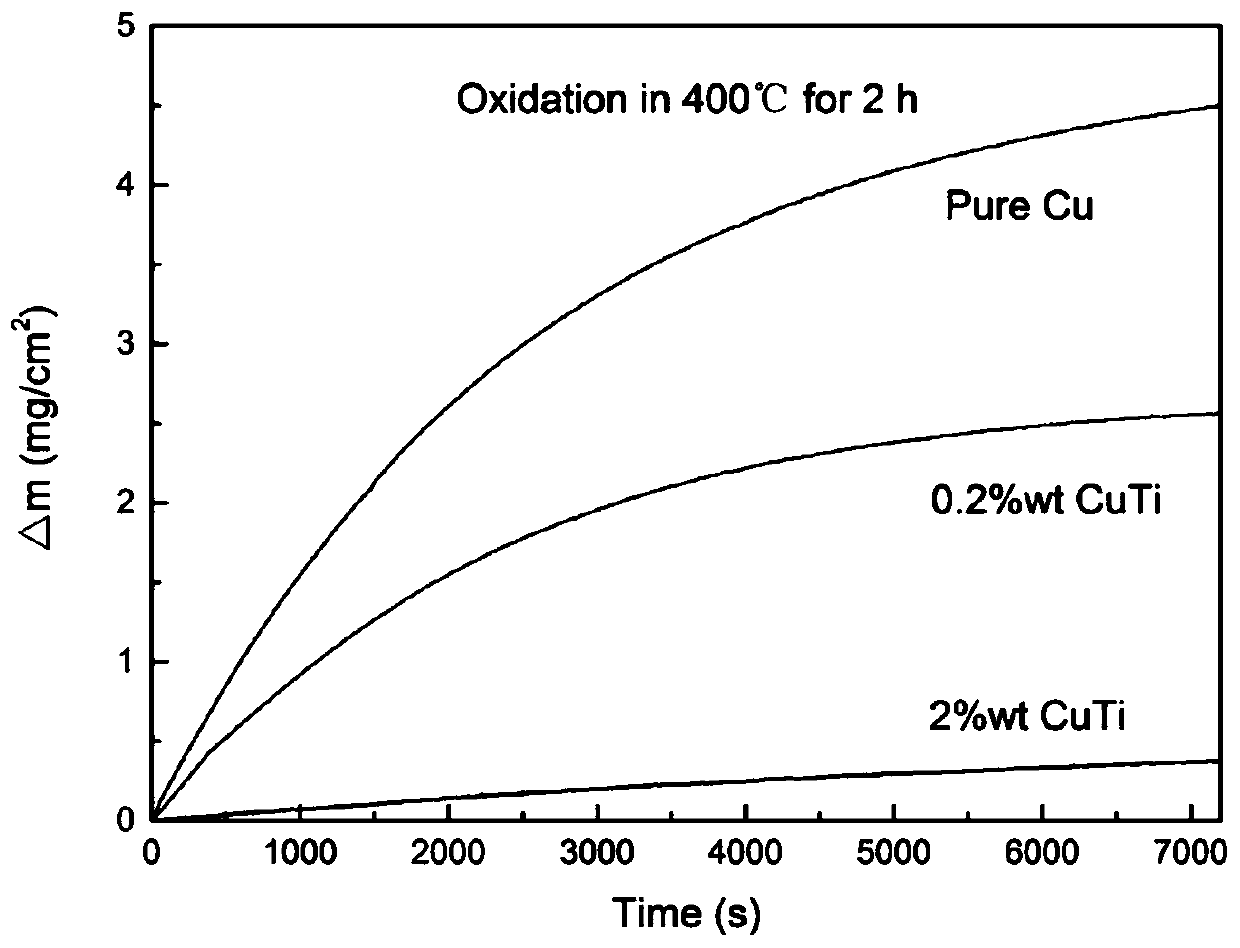

Copper alloy and copper alloy plate and preparation method and application thereof

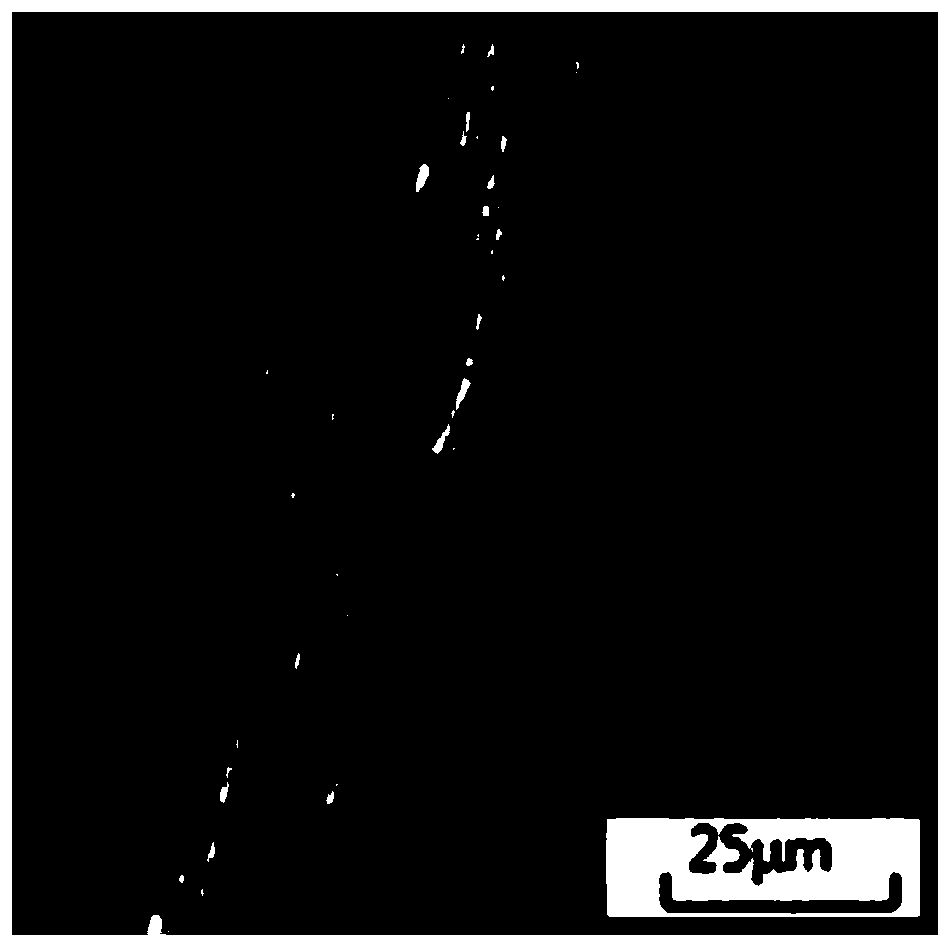

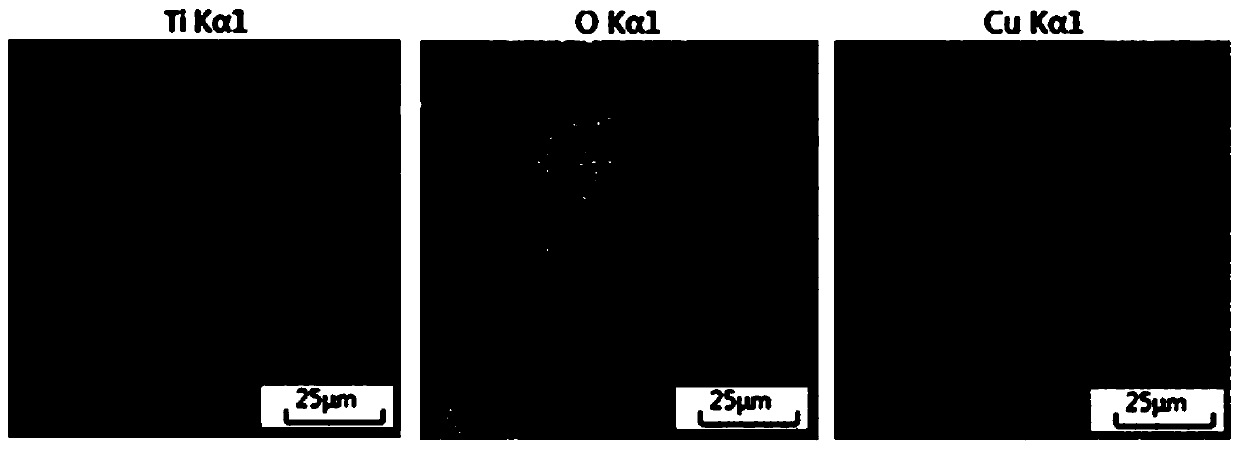

ActiveCN110592421AImprove corrosion resistanceImprove surface oxidation resistanceComposite filmWater vapor

The invention relates to the field of metal materials, and particularly discloses a copper alloy and a copper alloy plate and a preparation method and application thereof. The copper alloy has good corrosion resistance, the trace titanium element and the metal copper are melted into an alloy, Ti is segregated to the surface of the alloy by a heat treatment process and annealing in a mixed gas composed of argon and hydrogen, so that the surface of the metal copper is attached to TiO2 composite films, therefore, the internal metal copper can be well protected from reacting with surrounding oxygen, water vapor and the like, so that the surface oxidation resistances of automobile parts with copper as main raw materials can be improved, corrosion prevention is not needed by using an electroplating method, the performance is excellent, and the technical problem of environmental pollution caused by the fact that existing copper products are corroded by adopting electroplating is solved.

Owner:JILIN UNIV

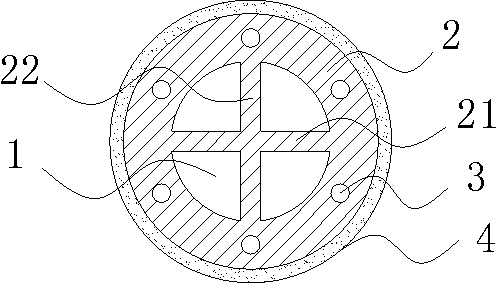

Anti-spattering soldering tin wire structure

InactiveCN103433640AReduce internal pressurePrevent splashWelding/cutting media/materialsSoldering mediaInternal pressureOxidation resistant

The invention relates to an anti-spattering soldering tin wire structure which comprises a soldering-aid layer, a tin layer and an anti-oxidation layer. The tin layer wraps the surface of the soldering-aid layer, and the anti-oxidation layer evenly coats the surface of the tin layer. The tin layer comprises a transverse tin layer body and a longitudinal tin layer body which are arranged in the soldering-aid layer, the soldering-aid layer is divided into four arc soldering-aid layer bodies by the transverse tin layer body and the longitudinal tin layer body, and at least one through hole is formed in the tin layer. By the arrangement of the through hole, internal pressure is effectively relieved, and the spattering phenomenon is avoided; by the arrangement of the transverse tin layer body and the longitudinal tin layer body, a soldering flux does not need to be additionally added in the soldering process, and the surface anti-oxidation performance is improved.

Owner:KUNSHAN HONGJIA SOLDER MFG

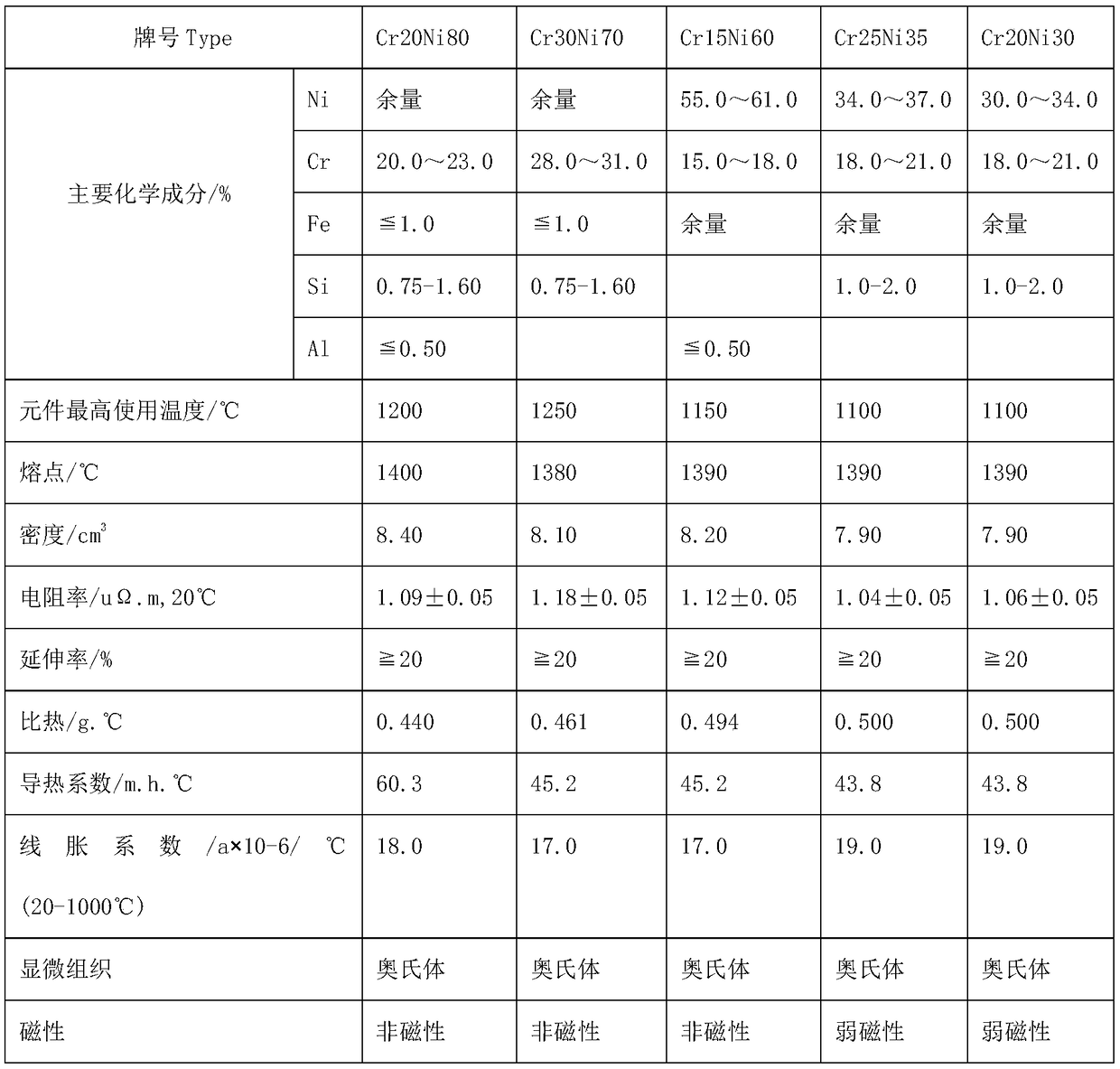

Nickel-chromium high-resistance electrothermal alloy wire

InactiveCN108901088AHigh resistivityHigh temperature levelHeating element materialsHigh resistanceSurface oxidation

The invention relates to the technical field of nickel-chromium high-resistance electrothermal alloy wires, and particularly relates to a nickel-chromium high-resistance electrothermal alloy wire. Thenickel-chromium high-resistance electrothermal alloy wire is divided into five different alloy wires according to weight percent: Cr20Ni80, Cr30Ni70, Cr15Ni60, Cr25Ni35 and Cr20Ni30, wherein the Cr20Ni80 is prepared from the main chemical components: 20.0-23.0% of Cr, less than or equal to 1.0% of Fe, 0.75-1.60% of Si, less than or equal to 0.50% of Al and the balance of Ni and inevitable impurities; an element maximum service temperature is 1200 DEG C; a melting point is 1400 DEG C; the density is 8.40 cm<3>; the specific resistance at 20 DEG C is 1.09+ / -0.05 mu ohm.m; the ductility is higher than or equal to 20%; specific heat is 0.440 g.DEG C; a heat conductivity coefficient is 60.3 KJ / m.h.DEG C; a linear expansion coefficient is a*10<-6> / DEG C (20 to 1000 DEG C): 18.0; a microscopic structure of the nickel-chromium high-resistance electrothermal alloy wire is austenite and is nonmagnetic. The nickel-chromium high-resistance electrothermal alloy wire has high specific resistance, the surface oxidation resistance is good, a temperature class is high, and the nickel-chromium high-resistance electrothermal alloy wire has high strength at high temperatures.

Owner:丹阳市亚力电热合金有限公司

Nano silicon material with low cost and high yield and preparation method thereof

InactiveCN110783555AWide variety of sourcesImprove conductivityMaterial nanotechnologySiliconNano siliconCarbon coating

The invention discloses a nano silicon material with low cost and high yield in the technical field of nano silicon material preparation. Nano-SiO2 with rod-like morphology is directly prepared by using natural attapulgite which is cheap and easily available, and then the nano-SiO2 is reduced by magnesium to acquire single crystal silicon nanoparticles with an average particle diameter of 20 nm. Carbon coating is carried out on the single crystal silicon nanoparticles to acquire the carbon-coated composite nano silicon material which has low cost and is conducive to improving production capacity. A carbon material as a grinding medium is added in ganister sand paste. On the one hand, finer particle grinding can be promoted. On the other hand, traditional dispersants are replaced with the carbon material, which effectively avoids the occurrence of agglomeration between nano-silicon particles. The addition of the carbon material can effectively improve the conductivity of the material, can promote the passivation of the surface of the silicon material, and improves the surface oxidation resistance of the silicon material. The conductivity of the silicon material after carbon coatingtreatment is greatly improved.

Owner:安徽若水化工有限公司

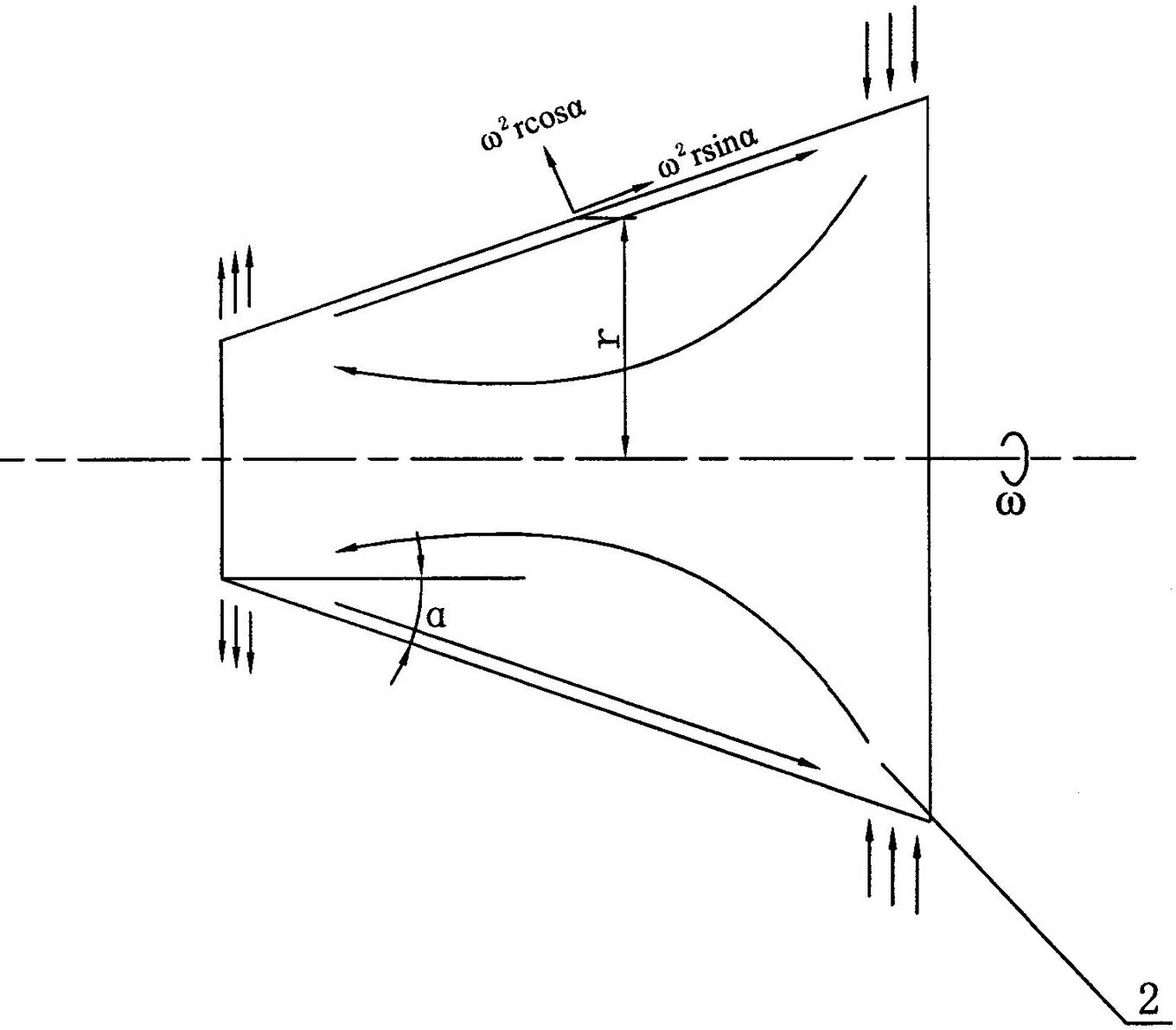

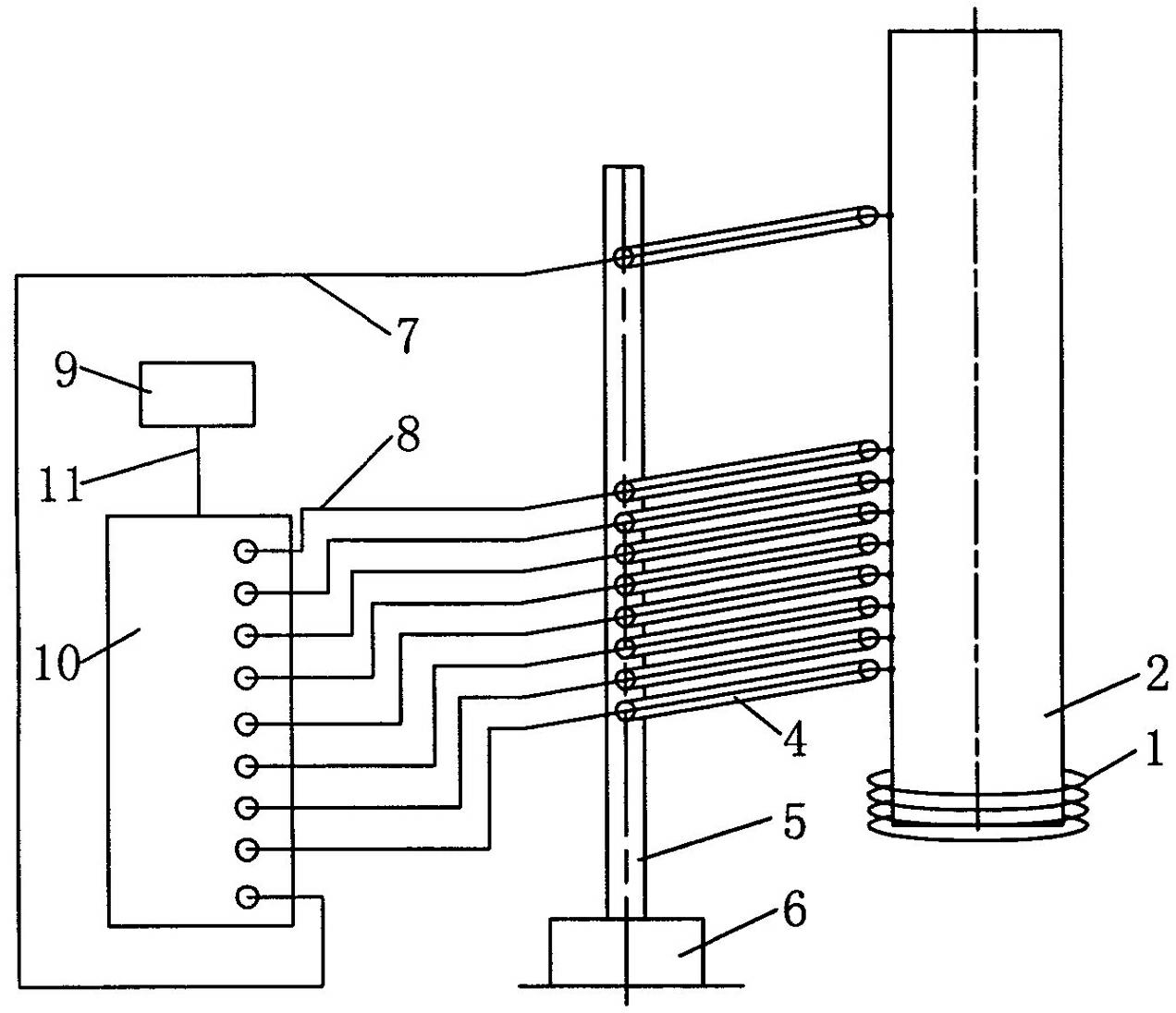

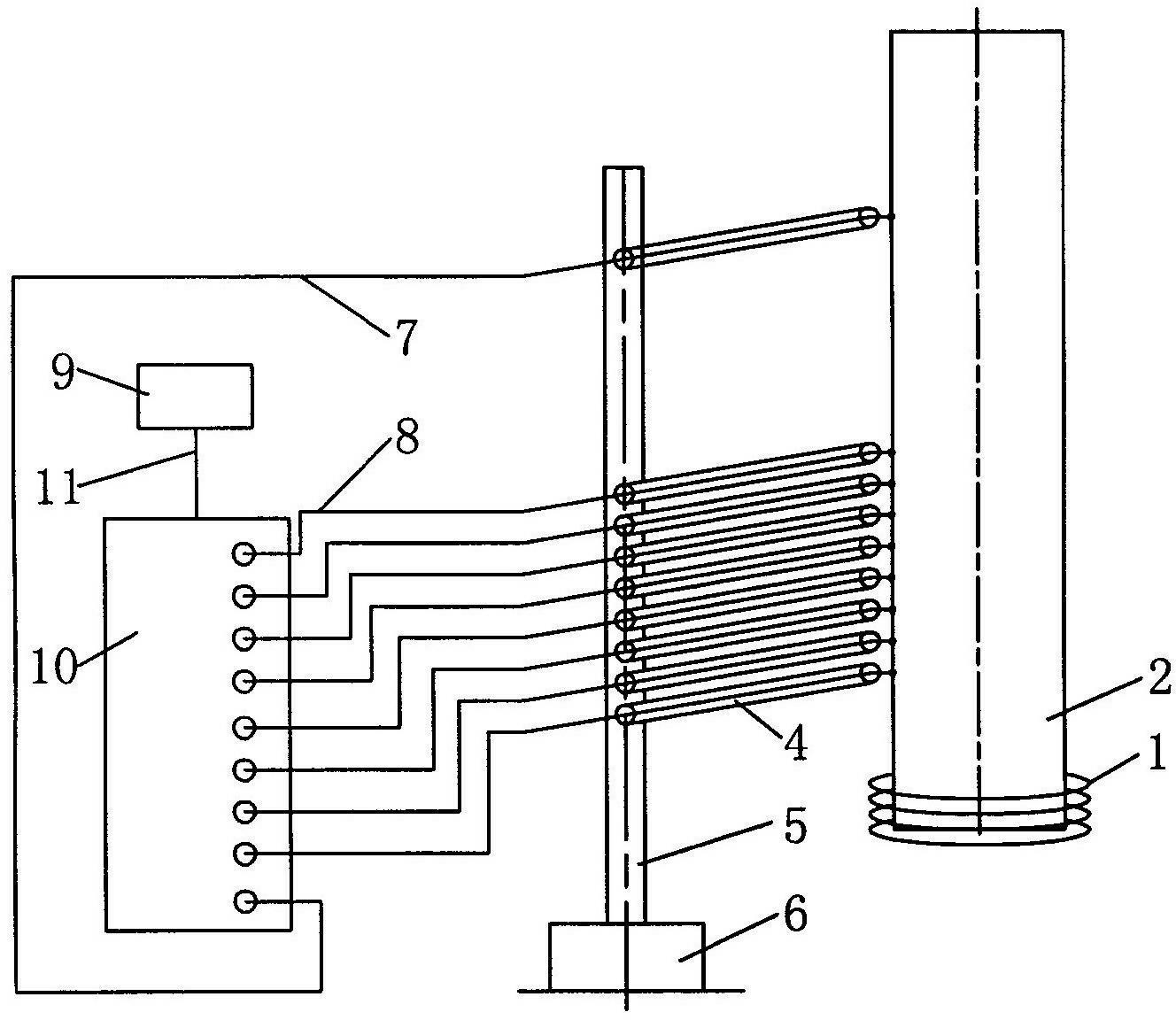

Device for detecting properties of rotating heat pipe

InactiveCN102661973AImprove heat transfer performanceHigh resistivityMaterial heat developmentEngineeringCopper

The invention discloses a device for detecting properties of a rotating heat pipe. The device comprises a computer, a signal collecting card, a copper lead wire, and a plurality of heating wires, wherein the copper lead wire and the heating wires are axially and uniformly distributed along the rotating heat pipe and can be in contact with a pipe shell of the rotating heat pipe. The computer is connected with the signal collecting card through a data line; a loop is formed by each heating wire and the copper lead wire through the pipe shell of the rotating heat pipe; a supporting device is fixedly arranged at one ends of the heating wires and the copper lead wire, which are in contact with the pipe shell of the rotating heat pipe; and the other ends of the copper lead wire and the heating wires are respectively connected with the signal collecting card. The device provided by the invention has a simple structure and can rapidly, simply and conveniently detect the heat conduction properties of the rotating heat pipe at a high-speed rotation state.

Owner:HOHAI UNIV CHANGZHOU

Tin-plated copper alloy conductor production process and tin-plated structure

PendingCN114178782AEasy to press downEasy to installHot-dipping/immersion processesTinningElectrical conductor

The invention discloses a tinned copper alloy conductor production process and a tinned structure, and relates to the technical field of conductors, the tinned copper alloy conductor production process specifically comprises the following steps: step 1, removing surface oxides of a copper-aluminum-rare earth alloy blank by a polisher to obtain a copper-aluminum-rare earth alloy ingot; secondly, the aluminum alloy cast ingot is stretched through a water tank type drawing machine, drawing oil is sprayed synchronously during stretching, the drawing speed is 400 m / min, a bus is obtained, and the diameter of the bus is 2.05 mm; 3, a wire drawing machine carries out wire drawing treatment on the bus to obtain a wire rod, and the wire diameter of the wire rod is 0.8 mm; through the mode, the copper-aluminum rare earth alloy is replaced by the copper alloy wire, under the corrosion resistance of the copper element in the copper-aluminum rare earth alloy and the synergistic effect of the copper element and the aluminum element, the conductivity is not reduced while the surface oxidation resistance is improved, the weldability and the signal transmission of the wire are ensured, and meanwhile, the copper alloy wire has the advantages of being simple in structure and low in cost. And the soft wire can be conveniently mounted in the tinning structure during tinning.

Owner:常熟市普华电工材料有限公司

Manufacturing method of metal valve

The invention discloses a manufacturing method of a metal valve. The metal valve has the beneficial effects of being resistant to corrosion, low in cost, high in thermal fatigue property and thermal stability and excellent in overall property through the material matching and the manufacturing process of metal materials. The metal valve has high surface oxidation resistance and is long in service life.

Owner:李文霞

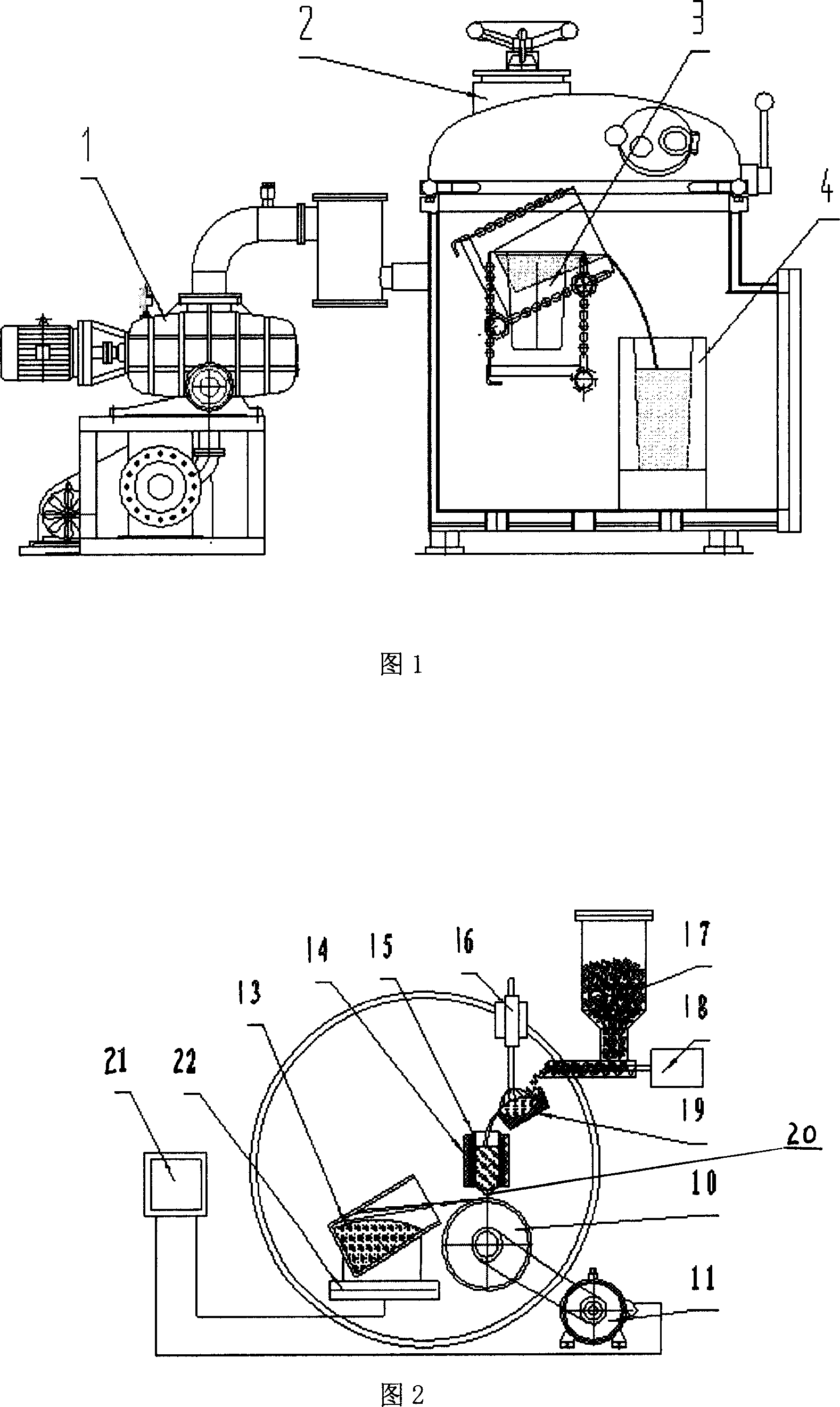

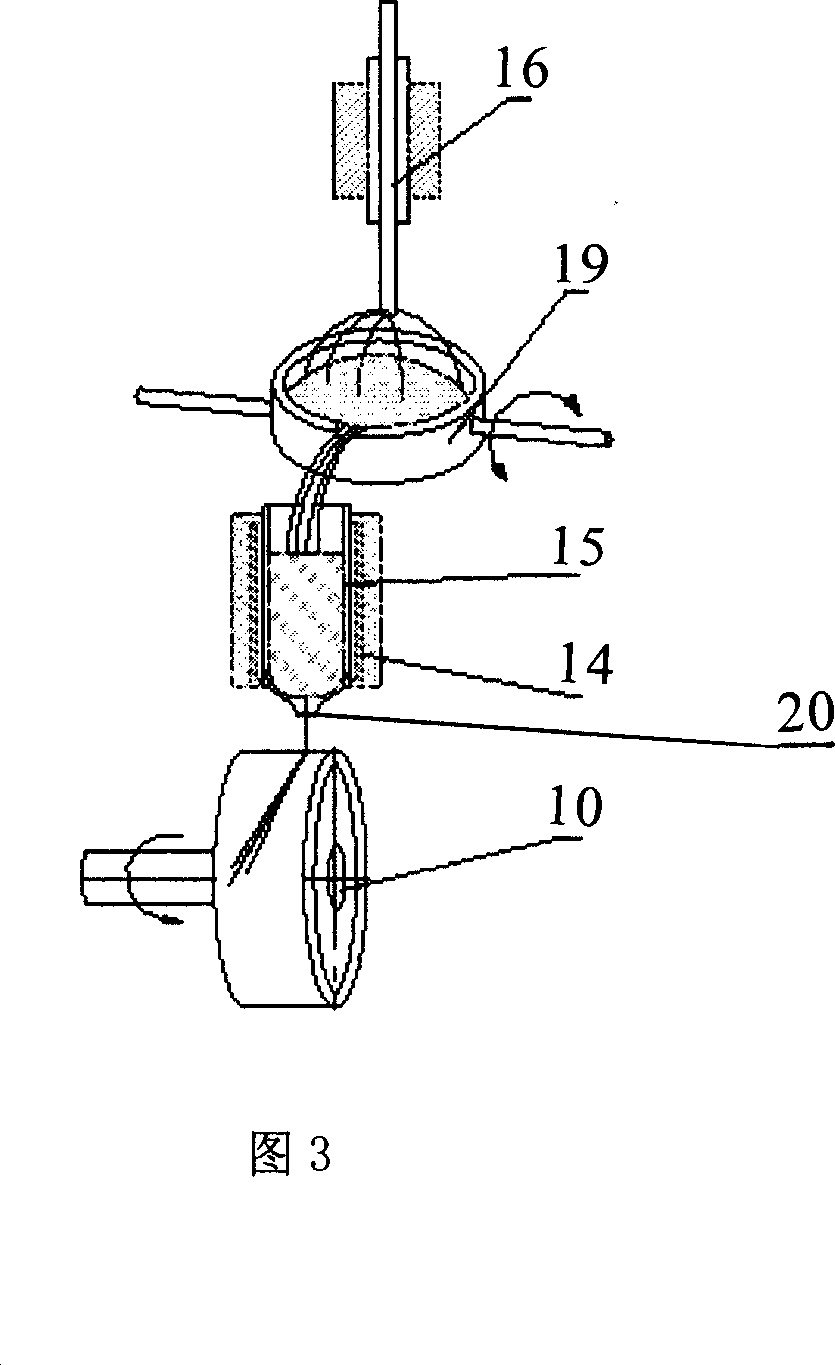

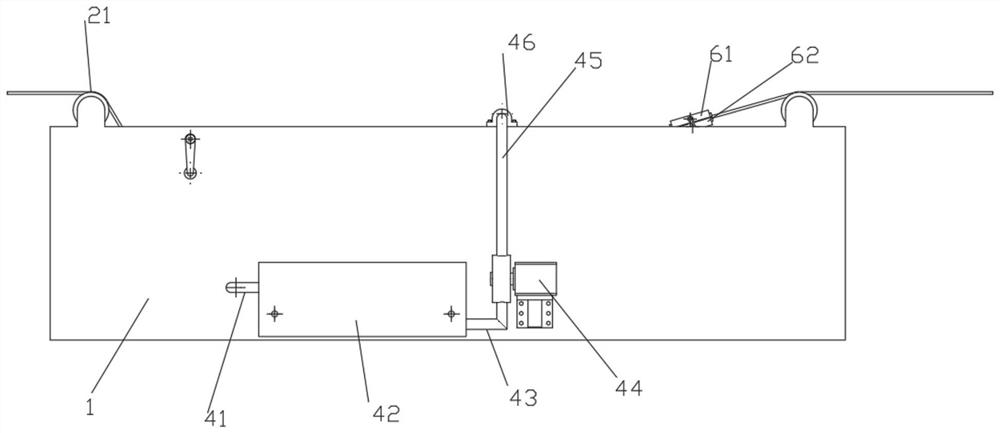

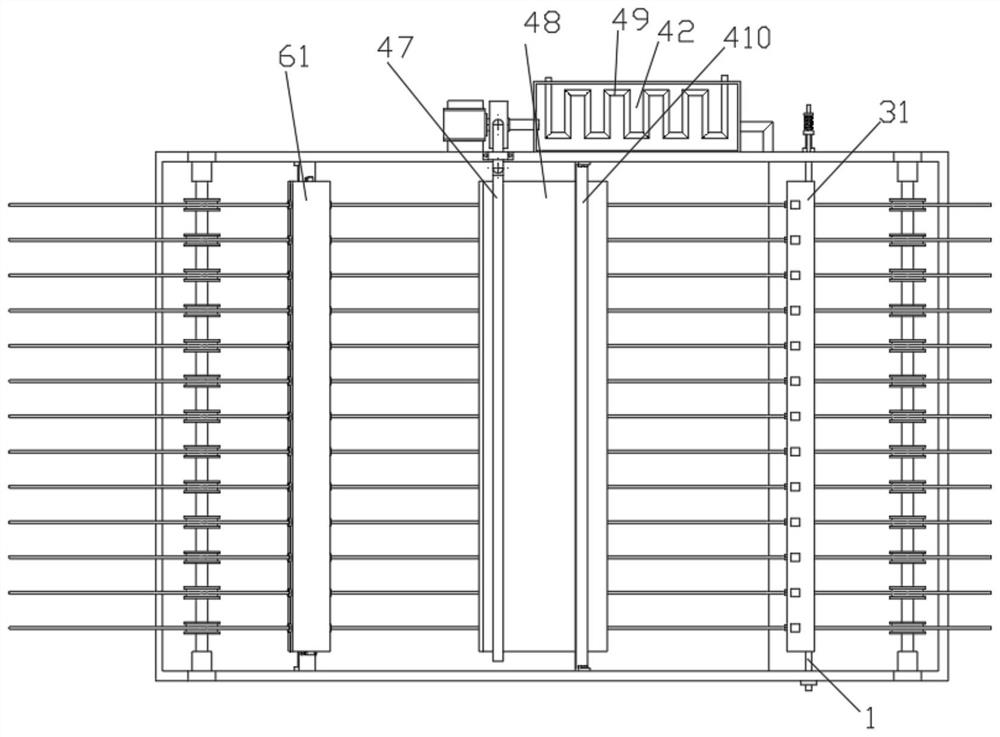

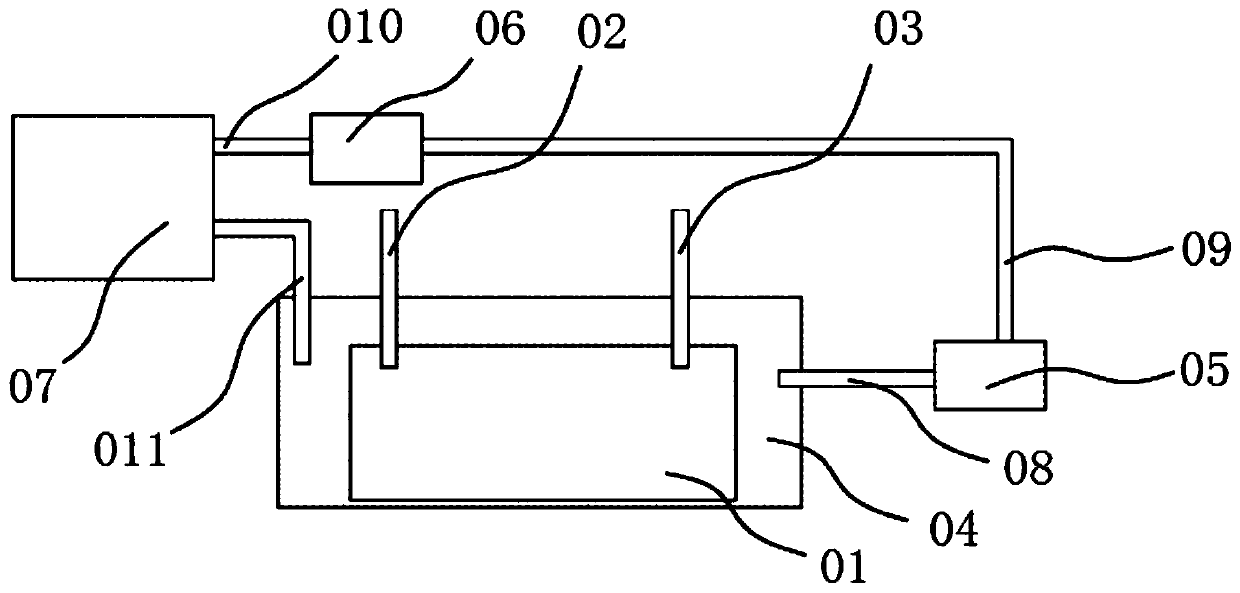

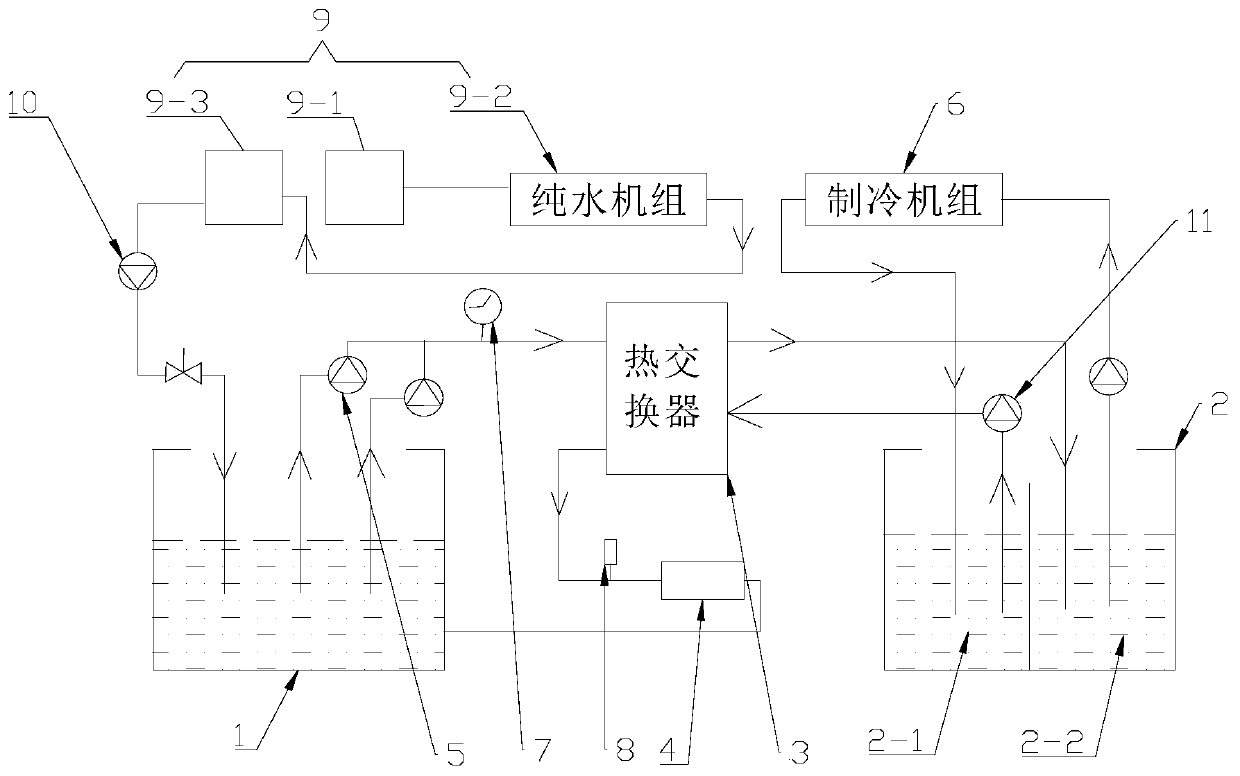

Constant-temperature and constant-pressure circulation supply system for copper wire drawing oil

PendingCN110814071AImprove surface oxidation resistanceConstant water temperatureCopper wireCopper-wiring

The invention discloses a constant-temperature and constant-pressure circulation supply system for copper wire drawing oil. The constant-temperature and constant-pressure circulation supply system comprises a wire drawing oil tank, a cooling water tank and a heat exchanger; the wire drawing oil tank and the cooling water tank are connected with the heat exchanger through pipelines; the wire drawing oil in the wire drawing oil tank is cooled by the heat exchanger, enters a wire drawing machine and then is circulated by the wire drawing machine to return into the wire drawing oil tank; the constant-temperature and constant-pressure circulation supply system is characterized in that the wire drawing oil in the wire drawing oil tank is pumped into the wire drawing machine under the constant pressure by the aid of a first variable-frequency pump; the cooling water tank comprises a cold water zone and a hot water zone which are separated from each other; a refrigerating unit is connected onto the cold water zone and the hot water zone; water in the cold water zone flows back to the hot water zone after passing through the heat exchanger; and water in the hot water zone returns to the cold water zone after being refrigerated by the refrigerating unit. By the aid of the system, the surface oxidation resistance of wire-drawing products can be improved effectively.

Owner:佛山市祥盈盛金属实业有限公司

Electrothermal Ni-Cr alloy wire with high resistance

InactiveCN105349845AHigh resistivityImprove surface oxidation resistanceHigh resistanceElectrical resistance and conductance

The invention discloses an electrothermal Ni-Cr alloy wire with high resistance. The electrothermal Ni-Cr alloy wire is made of an alloy material, and the alloy material comprises components as follows: 1%-2% of Te, 0.2% of Si, 0.7% of At, 0.4% of Os, 0.2% of Nd, 28.7% of Cr and the balance of Ni and inevitable impurities. The electrothermal Ni-Cr alloy wire with high resistance has higher electrical resistivity, good surface oxidation resistance, high temperature level and higher strength at the high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

Nickel chrome wire

InactiveCN105624471AHigh resistivityImprove surface oxidation resistanceSurface oxidationPressure casting

The invention discloses a nickel chrome wire. The nickel chrome wire is made of an alloy material, and the alloy material comprises 1% to 2% of P, 1.5% of Si, 2.2% of Cu, 0.8% of Mn, 0.9% of In, 14.5% of Cr and the balance Ni and inevitable impurities. The alloy material is prepared through the following steps: firstly, Ni, P, an Ni-Si alloy and an Ni-Cu alloy are molten under the protective atmosphere; secondly, the temperature is adjusted to 900 DEG C, an Ni-Mn alloy, an Ni-In alloy and an Ni-Cr alloy are added into a melt and are evenly stirred, and the melt is subject to heat preservation and standing for 25 minutes; and thirdly, argon is led, the melt is subject to standing and is cooled to 600 DEG C, and pressure casting is carried out, so that the alloy material is obtained. The nickel chrome wire has the higher specific resistance, is good in surface oxidation resistance and high in temperature level and has the higher strength at the high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

Nickel-chromium alloy wire

The invention discloses a nickel-chromium alloy wire. The nickel-chromium alloy wire is made from an alloy material, and the alloy material comprises the following ingredients: 1-2% of P, 0.9% of Te, 1.1% of Be, 0.7% of Sr, 0.3% of Nb, 19.5% of Cr, and the balance Ni and inevitable impurities; and the alloy material is prepared through the following steps: 1) melting Ni, P, Ni-Te alloy and Ni-Be alloy under a protective atmosphere; 2) adjusting a temperature to 975 DEG C, adding Ni-Sr alloy, Ni-Nb alloy and Ni-Cr alloy into a melt, uniformly stirring, and insulating heat and standing for 33 minutes; and 3) charging argon, and standing and cooling the melt to 675 DEG C, and carrying out die-casting to obtain the alloy material. The nickel-chromium alloy wire disclosed by the invention has a high electrical resistivity, high surface oxidation resistance, a high temperature class, and a high strength under a high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

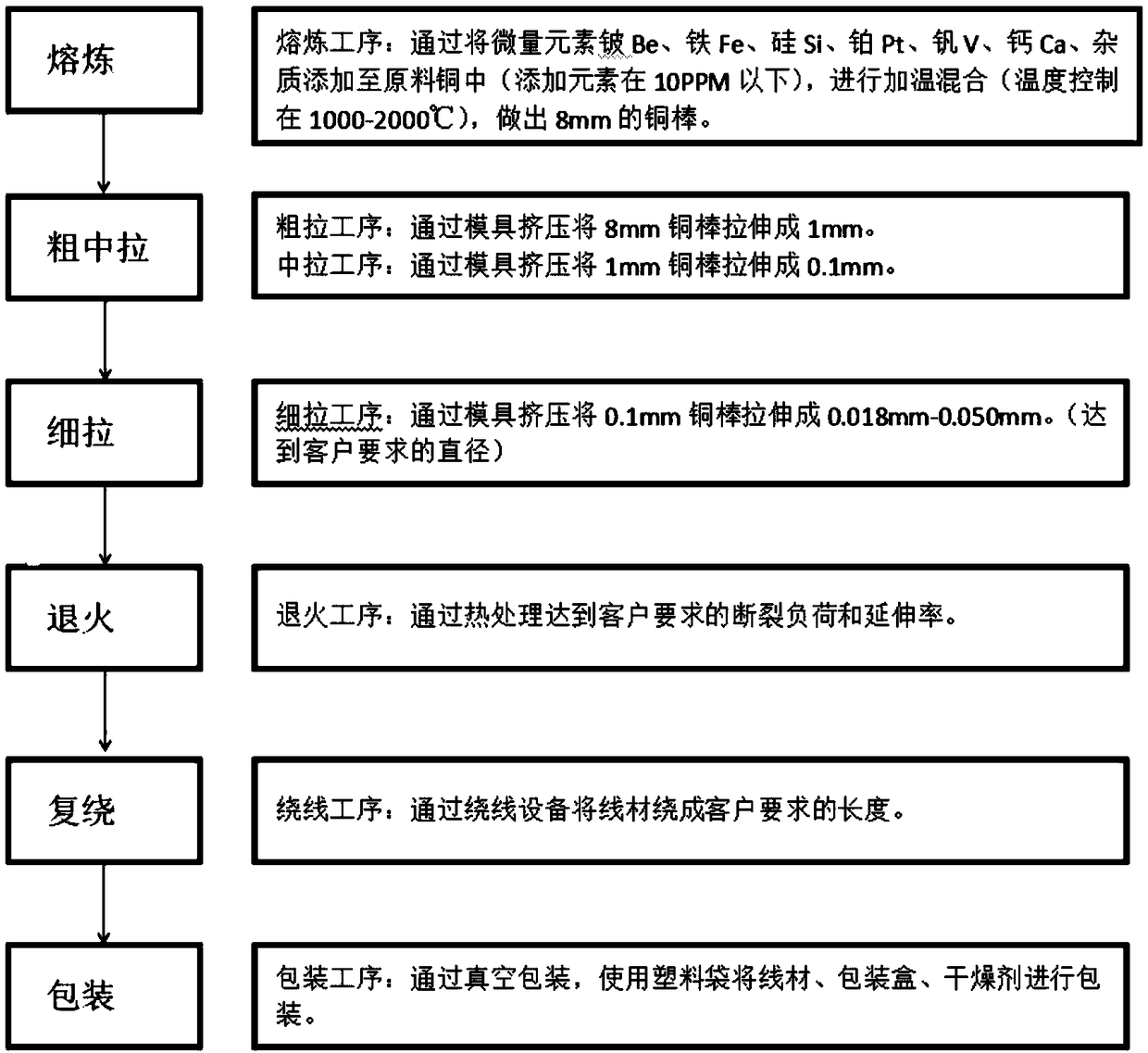

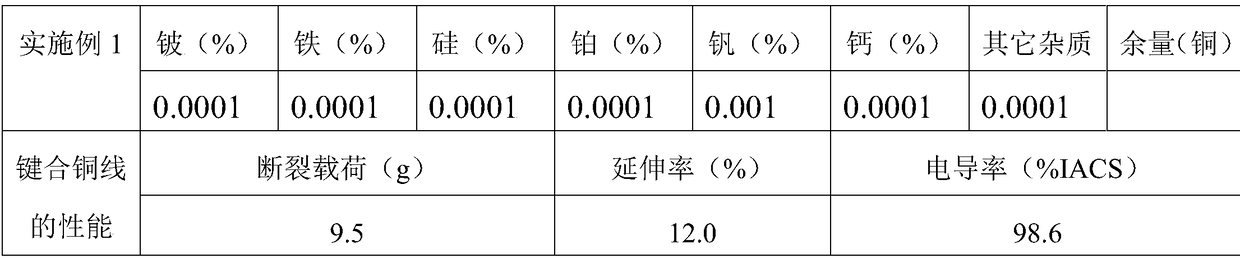

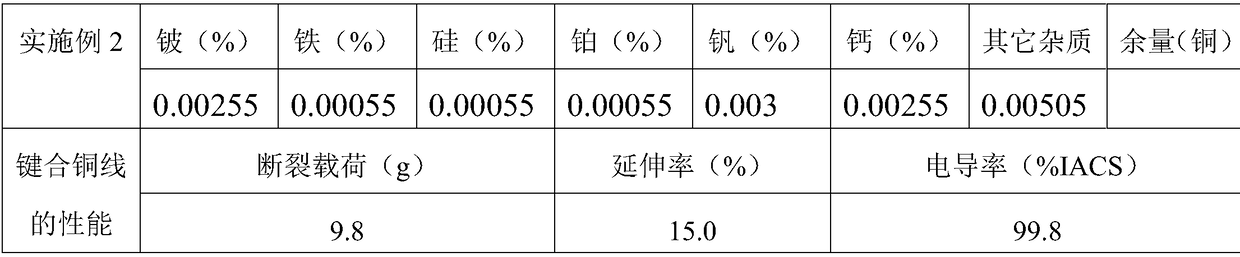

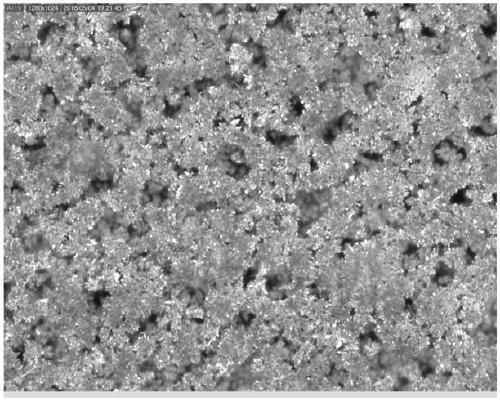

Bonded copper wire and preparation method thereof

The invention discloses a bonded copper wire. The bonded copper wire is prepared from the following components in percentage by mass: 0.0001%-0.0050% of beryllium, 0.0001-0.0010% of iron, 0.0001%-0.001% of silicon, 0.0001%-0.0010% of platinum, 0.001%-0.0050% of vanadium, 0.0001%-0.0050% of calcium, 0.0001%-0.01% of inevitable other impurity elements, and the balance of copper. A preparation methodfor the bonded copper wire comprises the following steps: (1) smelting; (2) rough-medium pulling; (3) fine pulling; (4) annealing; (5) re-winding; and (6) packaging. The preparation method can meet mechanical properties of a bonding material, and can provide the bonded copper wire with better surface oxidization resistance. Moreover, the preparation method is simple and convenient to operate, enables the processing material to obtain excellent mechanical properties, and meets practical using requirements.

Owner:上海万生合金材料有限公司

Nickel-chromium high-resistance electrothermal alloy

The invention discloses a nickel-chromium high-resistance electrothermal alloy. The nickel-chromium high-resistance electrothermal alloy is made from an alloy material, and the alloy material comprises the following ingredients: 1-2% of P, 1.1% of S, 0.9% of V, 1.3% of Co, 0.8% of Cd, 15.5% of Cr, and the balance Ni and inevitable impurities; and the alloy material is prepared through the following steps: 1) melting Ni, P, Ni-S alloy and Ni-V alloy under a protective atmosphere; 2) adjusting a temperature to 905 DEG C, adding Ni-Co alloy, Ni-Cd alloy and Ni-Cr alloy into a melt, uniformly stirring, and insulating heat and standing for 26 minutes; and 3) charging argon, and standing and cooling the melt to 605 DEG C, and carrying out die-casting to obtain the alloy material. The nickel-chromium high-resistance electrothermal alloy disclosed by the invention has a high electrical resistivity, high surface oxidation resistance, a high temperature class, and a high strength under a high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

Watch dial embellishing and flash sand pressing treatment method

PendingCN113211328AImprove antioxidant capacityImprove ornamental and corrosion resistanceElectrophoretic coatingsCleaning using liquidsCorrosion resistantManufacturing engineering

The invention discloses a watch dial embellishing and flash sand pressing treatment method, and belongs to the technical field of watch dial embellishing and flash sand pressing treatment. The method comprises the steps of flash sand preparation, watch dial preparation, sand pressing pretreatment on a watch dial, arc-shaped sand treatment and electrophoretic coating treatment, the watch dial is stamped and formed into a required shape, and then mirror polishing is conducted on the stamped watch dial to achieve a bright mirror effect. By conducting heat treatment on a workpiece at different temperature and different time, the workpiece presents different colors on the basis of different lines, so that the ornamental value and the corrosion resistance are improved; and flash sand is pressed on the dial by utilizing an arc-shaped sand process, and the dial is subjected to electrophoretic coating, so that the product has metal luster, the dial has both a sand surface effect and the mirror effect, and the corrosion resistance is also improved.

Owner:东莞市百兴精密五金有限公司

High-resistance electrothermal alloy material

The invention discloses a high-resistance electrothermal alloy material made of an alloy material. The alloy material comprises the components: 1-2% of P, 1.3% of At, 0.9% of Na, 0.4% of Rb, 0.5% of Mo, 29.5% of Cr, and the balance of Ni and unavoidable impurities; the alloy material is prepared through the following steps: 1), melting Ni, P, Ni-At alloy and Ni-Na alloy in an protective atmosphere; 2), adjusting the temperature to 965 DEG C, adding Ni-Rb alloy, Ni-Mo alloy and Ni-Cr alloy into melt, stirring well, and holding the temperature and standing for 32 min; 3), introducing argon, standing and cooling the melt to 665 DEG C, and pressure casting to the alloy material. The high-resistance electrothermal alloy material has high resistivity, good surface oxidation resistance, high temperature level and high strength at high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

Nickel-chromium flat wire

The invention discloses a nickel-chromium flat wire. The nickel-chromium flat wire is made from an alloy material, and the alloy material comprises the following ingredients: 1-2% of P, 0.9% of Ti, 1.2% of Li, 0.2% of Y, 0.4% of Zr, 18.5% of Cr, and the balance Ni and inevitable impurities; and the alloy material is prepared through the following steps: 1) melting Ni, P, Ni-Ti alloy and Ni-Li alloy under a protective atmosphere; 2) adjusting a temperature to 985 DEG C, adding Ni-Y alloy, Ni-Zr alloy and Ni-Cr alloy into a melt, uniformly stirring, and insulating heat and standing for 34 minutes; and 3) charging argon, and standing and cooling the melt to 685 DEG C, and carrying out die-casting to obtain the alloy material. The nickel-chromium flat wire disclosed by the invention has a high electrical resistivity, high surface oxidation resistance, a high temperature class, and a high strength under a high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

Manufacture method of corrosion-resistant metal valve

InactiveCN108866288ACorrosion resistanceLow costFurnace typesHeat treatment furnacesThermal fatigueMetallic materials

The invention discloses a manufacture method of a corrosion-resistant metal valve. Based on the material ratio and the manufacturing process of a metal material, the metal valve has the characteristics of corrosion resistance, low cost, high thermal fatigue performance, high thermal stability and excellent comprehensive performance, and also has high surface oxidation resistance and long service life.

Owner:南通鑫农阀门科技有限公司

Magnesium-aluminum electrothermal alloy material

The invention discloses a magnesium-aluminum electrothermal alloy material. The magnesium-aluminum electrothermal alloy material is made of an alloy material body, wherein the alloy material body is prepared from the components of 2-3% of Si, 0.3% of B, 0.5% of C, 0.2% of Mn, 0.5% of Na, 21.8% of Mg and the balance of Al and inevitable impurities. The magnesium-aluminum electrothermal alloy material has the advantages of being relatively high in electrical resistivity, good in surface oxidation resistance, high in temperature grade and relatively high in strength at a high temperature.

Owner:王海龙

Flake zinc and zinc-aluminium alloy powder wet method producing process

InactiveCN1186153CImprove surface oxidation resistanceLarge diameter-to-thickness ratioGranularitySolvent

Owner:肖骁

High-resistance chromium-nickel electrothermal alloy material

The invention discloses a high-resistance chromium-nickel electrothermal alloy material. The high-resistance chromium-nickel electrothermal alloy material is made of an alloy material, and the alloy material comprises the following components: 1-2% of P, 1.3% of Se, 0.8% of Mg, 0.4% of Ge, 0.9% of Tc, 28.5% of Cr, and the balance of Ni and inevitable impurities. The alloy material is prepared by the following steps: (1) melting Ni, P, Ni-Se alloy and Ni-Mg alloy under a protective atmosphere; (2) adjusting the temperature to 955 DEG C, adding Ni-Ge alloy, Ni-Tc alloy and Ni-Cr alloy in melt, evenly stirring, insulating and standing for 31 minutes; and (3) feeding argon, standing and cooling the melt to 655 DEG C, and carrying out die casting to obtain the alloy material. The high-resistance chromium-nickel electrothermal alloy material has relatively high resistivity, is good in surface oxidation resistance and high in temperature grade, and has relatively high strength at high temperature.

Owner:CHANGSHU MEILI ALLOY MATERIAL CO LTD

Antioxidant heat plate liquid-suction core and preparation method thereof

InactiveCN109295484AGuaranteed thermal conductivityImprove bindingModifications using liquid coolingAntioxidant capacityOxidation resistant

The invention relates to an antioxidant heat plate liquid-suction core. The antioxidant heat plate liquid-suction core comprises a workpiece, a copper layer which covers the surface of the workpiece and a nickel layer which covers the surface of the copper layer; the copper layer covers the workpiece through an electroplating process; and the nickel layer covers the copper layer through the electroplating process. The surface of the workpiece of the liquid-suction core is covered with the copper layer, the surface of the copper layer is covered with the nickel layer, the heat conductivity of the liquid-suction core can be guaranteed, and furthermore the surface antioxidant capacity can be improved; and firstly, the particle copper layer with a rich capillary structure is electroplated on the workpiece, then the nickel layer is electroplated on the surface of the particle copper layer, thus the function of fixing the particle copper layer can be achieved, the binding force of the particle copper layer and the workpiece is improved, and the surface antioxidant capacity can be improved as well.

Owner:江西华度电子新材料有限公司

Method for preparing composite membrane for improving oxidation resistance of copper lead of integrated circuit

Owner:JILIN UNIV

Wear-resistant alloy material

InactiveCN109811208AImprove wear resistanceGood surface oxidation resistanceSurface oxidationWear resistant

The invention discloses a wear-resistant alloy material. The wear-resistant alloy material is made of an alloy material, wherein the alloy material comprises 2-3% of Si, 0.3% of ZR, 0.5% of C, 0.2% ofMn, 0.5% of Cr, 21.8% of Mg and the balance Al and inevitable impurities. The wear-resistant alloy material has the advantages of being high in wear resistance, good in surface oxidation resistance,high in temperature grade and high in strength at a high temperature.

Owner:王海龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com