Bonded copper wire and preparation method thereof

A copper wire and bonding technology, which is applied in the field of bonded copper wire and its preparation, can solve the problems of uneven mechanical properties of products, affecting the mechanical properties of products, and affecting the service life of finished products, so as to improve surface oxidation resistance and improve molding Stability and quality, and the effect of improving ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

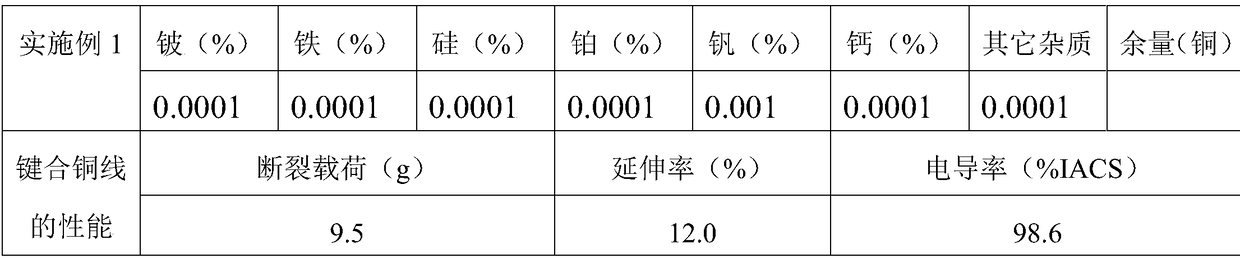

[0028] Example 1 (based on the preparation of a bonding copper wire with a diameter of 20 μm):

[0029] The mass percentage content of each component of the bonding copper wire is as follows: beryllium 0.0001%, iron 0.0001%, silicon 0.0001%, platinum 0.0001%, vanadium 0.001%, calcium 0.0001%, the total amount of other unavoidable impurity elements 0.0001%, and the balance is copper.

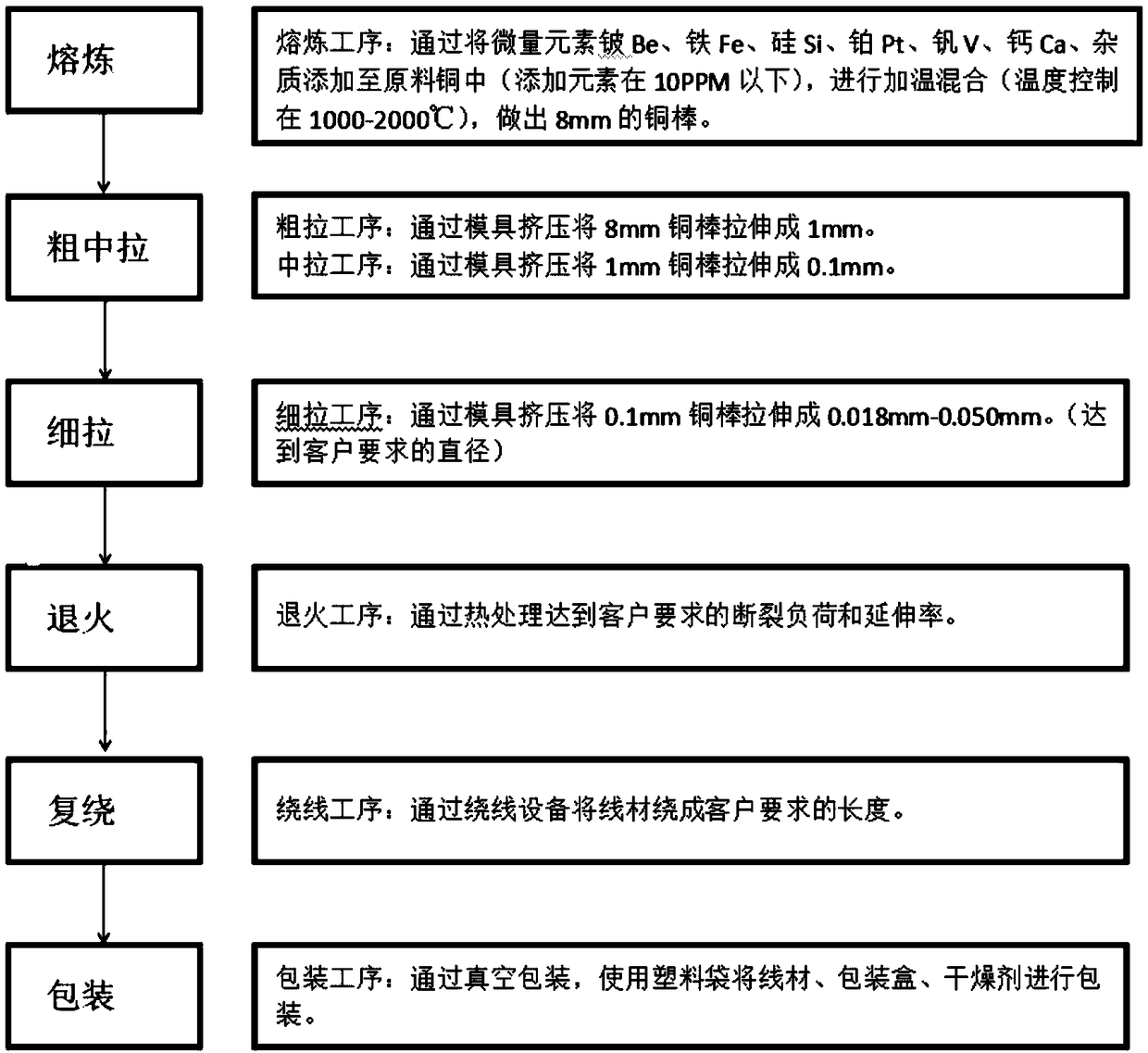

[0030] The preparation process is as follows: Step (1) smelting: Weigh each trace element, add trace elements beryllium Be, iron Fe, silicon Si, platinum Pt, vanadium V, calcium Ca, and other unavoidable impurity elements to the raw material copper ( The added element is below 10PPM), placed in a vacuum furnace melting crucible, vacuumed to 10ˉ3Pa, backfilled with argon to a slight positive pressure in the vacuum furnace, and heated and mixed (the temperature for heating and mixing is controlled at 1000-2000 ℃), the obtained copper liquid is poured into the mould, and a copper rod of 8 mm is mad...

Embodiment 2

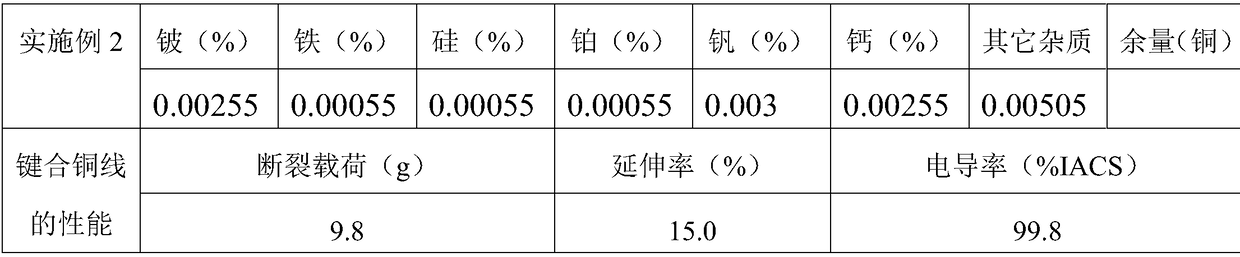

[0036] Embodiment 2 (based on preparing a bonding copper wire with a diameter of 20 μm):

[0037] The mass percentage content of each component of the bonding copper wire is as follows: beryllium 0.00255%, iron 0.00055%, silicon 0.00055%, platinum 0.00055%, vanadium 0.003%, calcium 0.00255%, the total amount of other unavoidable impurity elements 0.00505%, and the balance is copper.

[0038] The preparation process is as follows: Step (1) smelting: Weigh each trace element, add trace elements beryllium Be, iron Fe, silicon Si, platinum Pt, vanadium V, calcium Ca, and other unavoidable impurity elements to the raw material copper ( The added element is less than 10PPM), put it into the melting crucible of the vacuum furnace, evacuate to 10-3Pa, and then backfill argon to the slight positive pressure in the vacuum furnace, and carry out heating and mixing (the temperature for heating and mixing is controlled at 1000 -2000°C), the obtained copper liquid is poured into the mold t...

Embodiment 3

[0044] Embodiment 3 (based on preparing a bonding copper wire with a diameter of 20 μm):

[0045] The mass percentage content of each component of the bonding copper wire is as follows: beryllium 0.0050%, iron 0.0010%, silicon 0.001%, platinum 0.0010%, vanadium 0.0050%, calcium 0.0050%, the total amount of other unavoidable impurity elements 0.01%, and the balance is copper.

[0046] The preparation process is as follows: Step (1) smelting: Weigh each trace element, add trace elements beryllium Be, iron Fe, silicon Si, platinum Pt, vanadium V, calcium Ca, and other unavoidable impurity elements to the raw material copper ( The added element is below 10PPM), placed in a vacuum furnace melting crucible, vacuumed to 10ˉ3Pa, backfilled with argon to a slight positive pressure in the vacuum furnace, and heated and mixed (the temperature for heating and mixing is controlled at 1000-2000 ℃), the obtained copper liquid is poured into the mould, and a copper rod of 8 mm is made; step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com