Antioxidant heat plate liquid-suction core and preparation method thereof

An anti-oxidation and liquid-absorbing core technology, applied in the direction of using liquid cooling for modification, cooling/ventilation/heating transformation, etc., can solve the problems of capillary capacity decline, oxidation, etc., to improve the binding force, improve the surface oxidation resistance, and ensure The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

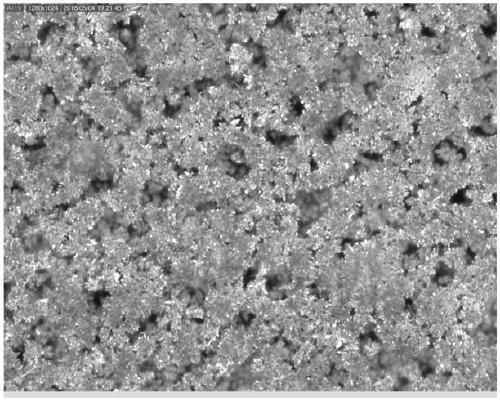

Image

Examples

Embodiment 1

[0022] A preparation method for an anti-oxidation hot plate liquid-absorbent core, comprising the steps of:

[0023] (1) Prepare electroplating bath solution I. The composition of electroplating bath solution I is copper sulfate 50g / L, concentrated sulfuric acid 100ml / L, bath temperature 20-30 ℃;

[0024] (2) Preparation of electroplating bath II. The composition of electroplating bath II is copper sulfate 250g / L, sulfuric acid 75ml / L, bath temperature 20-30°C;

[0025] (3) Preparation of electroplating bath III: the composition of electroplating bath III is nickel sulfate 250g / L, nickel chloride 20g / L, boric acid 40g / L, bath temperature 20-30°C;

[0026] (4) Copper plating:

[0027] For the first copper plating, phosphor copper is used as the anode, the workpiece is used as the cathode, the electroplating process parameters are current density 2A / dm2, and the electroplating time is 5min;

[0028] For the second copper plating, take out the workpiece that has been copper-p...

Embodiment 2

[0034] A preparation method for an anti-oxidation hot plate liquid-absorbent core, comprising the steps of:

[0035] (1) Preparation of electroplating bath I: the composition of electroplating bath I is copper sulfate 50g / L, concentrated sulfuric acid 200ml / L, bath temperature 50-60°C;

[0036] (2) Preparation of electroplating bath II: the composition of electroplating bath II is copper sulfate 300g / L, sulfuric acid 100ml / L, bath temperature 50--60°C;

[0037] (3) Preparation of electroplating bath III: the composition of electroplating bath III is nickel sulfate 300g / L, nickel chloride 10g / L, boric acid 25g / L, bath temperature 30-40°C;

[0038] (4) Copper plating:

[0039] For the first copper plating, phosphor copper is used as the anode, and the workpiece is used as the cathode. The electroplating process parameters are current density 4A / dm2 and electroplating time 5min;

[0040] For the second copper plating, take out the workpiece that has been copper-plated for the f...

Embodiment 3

[0046] A preparation method for an anti-oxidation hot plate liquid-absorbent core, comprising the steps of:

[0047] (1) Prepare electroplating bath solution I: the composition of electroplating bath solution I is copper sulfate 20g / L, concentrated sulfuric acid 300ml / L, bath temperature 20-30 ℃;

[0048] (2) Preparation of electroplating bath II: the composition of electroplating bath II is copper sulfate 300g / L, sulfuric acid 120ml / L, bath temperature 20-30°C;

[0049] (3) Preparation of electroplating bath III: the composition of electroplating bath III is nickel sulfamate 250g / L, nickel chloride 10g / L, boric acid 40g / L, bath temperature 55-60°C;

[0050] (4) Copper plating:

[0051] For the first copper plating, phosphor copper is used as the anode, and the workpiece is used as the cathode. The electroplating process parameters are current density 1A / dm2 and electroplating time 10min;

[0052] For the second copper plating, take out the workpiece that has been copper-pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com