Method for producing continuous casting crystalli-zing roll

A continuous casting crystallization and manufacturing method technology, applied in the fields of metal continuous casting, iron and steel metallurgy, and machinery manufacturing, to achieve the effects of simple and reliable manufacturing methods, elimination of adsorbed oxygen layers, and firm interface bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

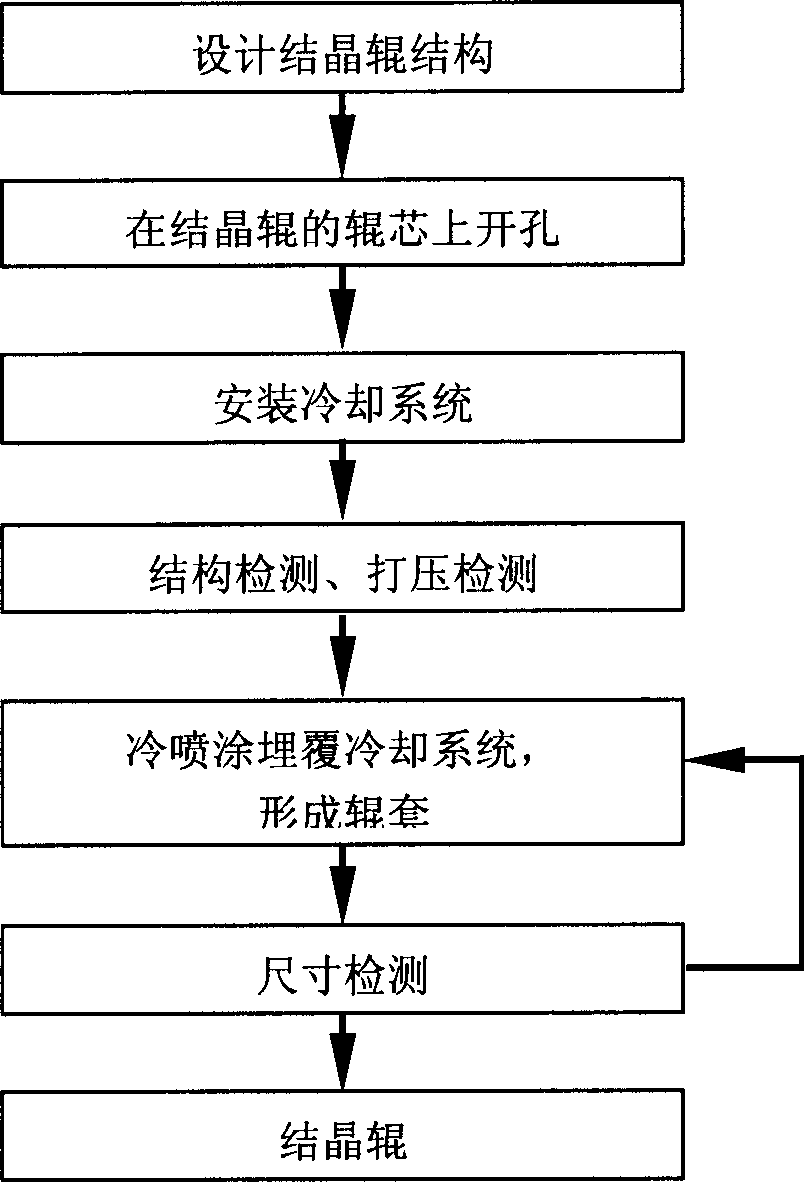

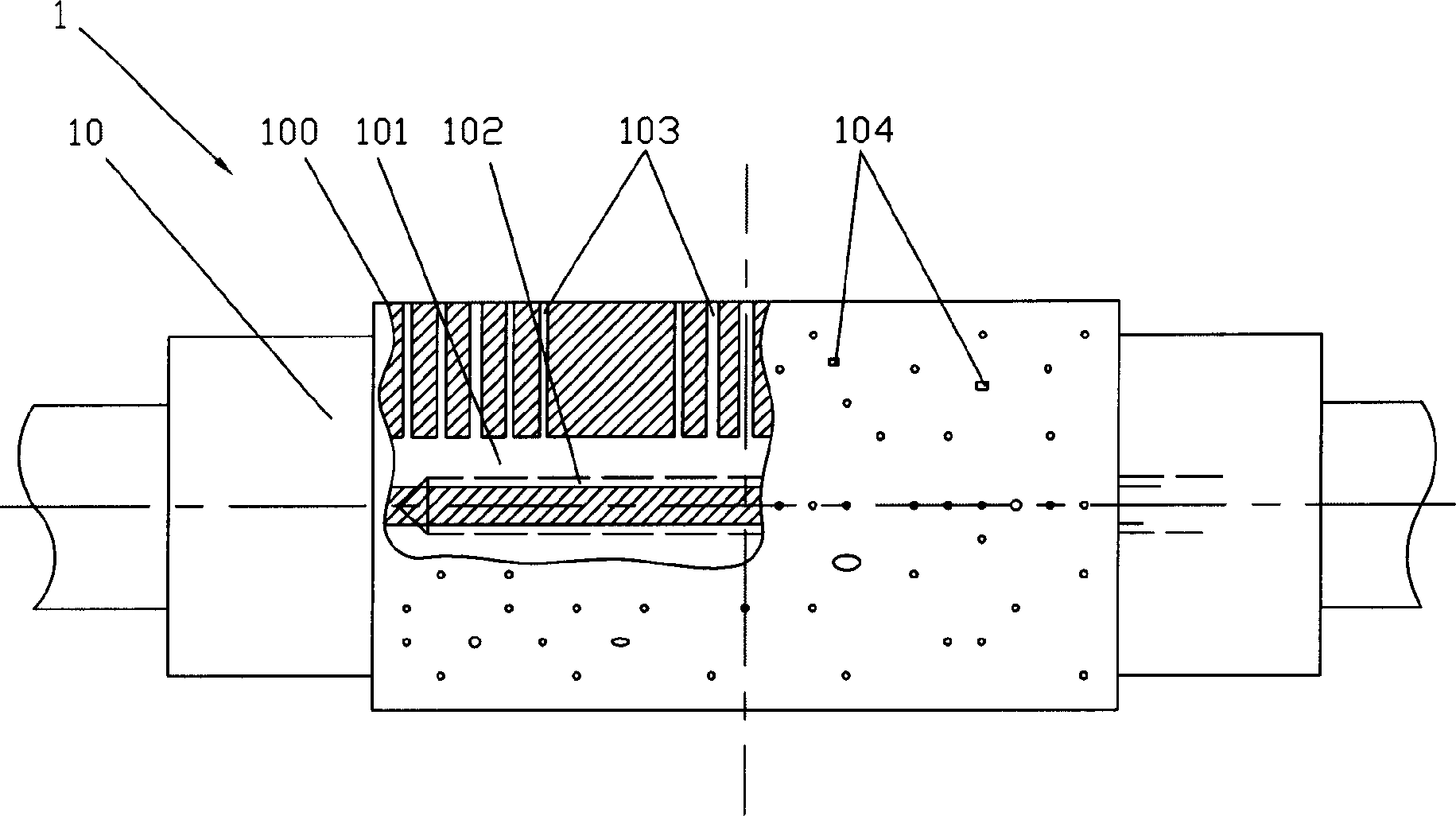

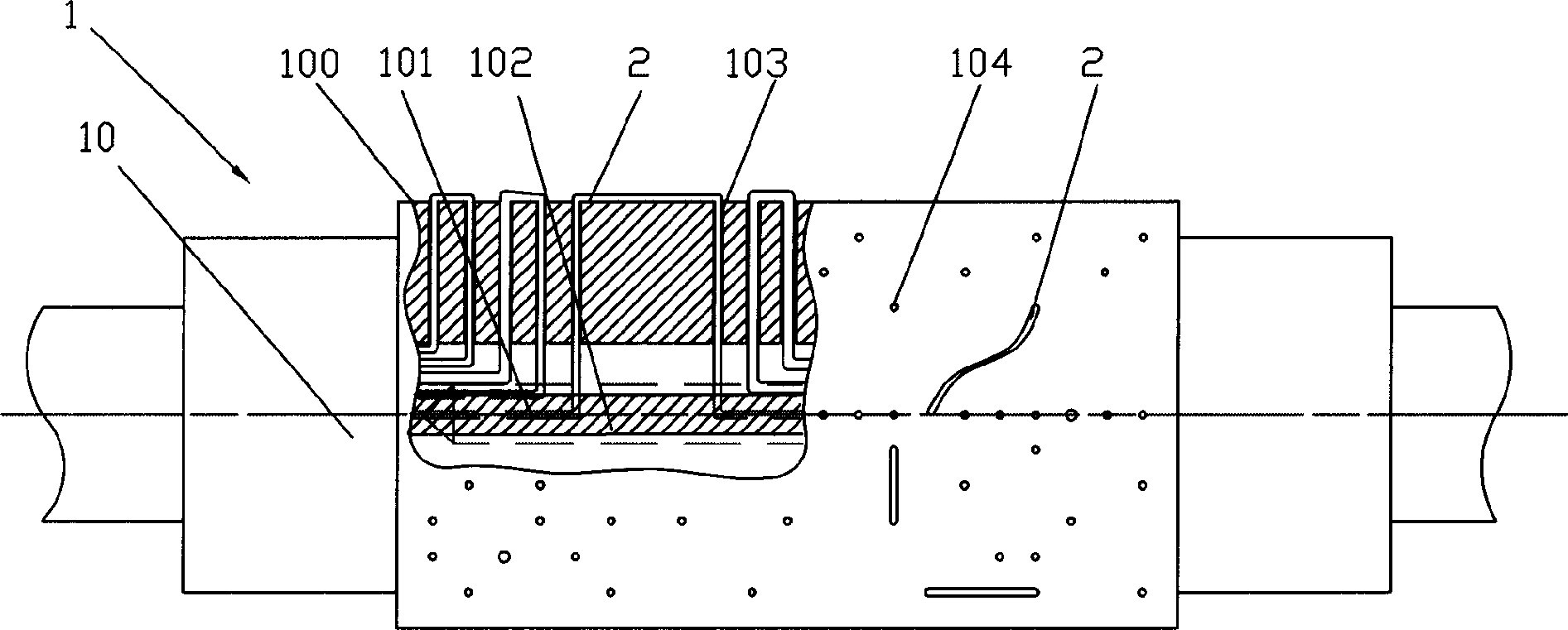

[0032] see Figure 1 to Figure 5 , continuous casting crystallization roll manufacturing method of the present invention, at first on the roll core 10 of crystallization roll 1 along the roll core 10 axially open water inlet hole 101, water outlet hole 102, on the roll core 10 wall, have water guide hole 103, 104, respectively connected to the water inlet hole 101, the water outlet hole 102 and the outer surface 100 of the roller core 10; the metal pipe 2 is installed on the outer surface 100 of the roller core 10 of the crystallization roller 1, and passes through the water guide holes 103, 104 on the roller core wall respectively It is connected with the water inlet hole 101 and the water outlet hole 102 to form a plurality of cooling circuits, forming a crystallization roller cooling system; using cold air power spraying, driving the tiny metal particles 3 to be sprayed through the nozzle 4 at a high speed with a pressure greater than 1.0MPa. The metal particles 3 collide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com