Method for preparing ohm contact electrode made from temperature sensing ceramics

A technology of ohmic contact electrodes and heat-sensitive ceramics, applied in the direction of resistors with positive temperature coefficients, etc., can solve problems such as poor oxidation resistance and thermal fatigue resistance, easy oxidation of metal elements, and affect the quality of electrodes, etc., to achieve uniform coating thickness Densification, easy operation, and quality-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The material of the ohmic contact electrode is -500 mesh Al powder with a purity of 99%, and the substrate is a 20×15×2mm PTC ceramic chip. The specific steps are as follows:

[0020] (1) Substrate pretreatment: surface alcohol cleaning;

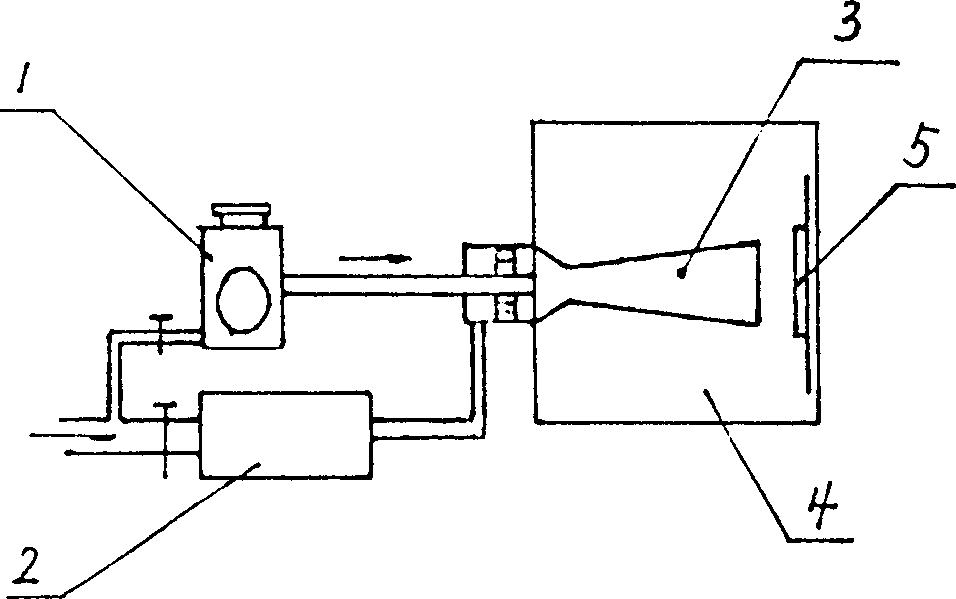

[0021] (2) Clamp the substrate in the spray booth of the air-conditioning power spray system;

[0022] (3) Spraying: adopt the method of cold air power spraying, use compressed gas to carry aluminum powder to spray on the surface of heat-sensitive ceramics at supersonic speed, and form heat-sensitive ceramic ohmic contact electrodes. The process parameters are as follows:

[0023] Spraying Al electrode process: spraying distance 10mm, gas pressure 1.8MPa, gas temperature 210°C, gas flow rate 18g / s, time 5 minutes;

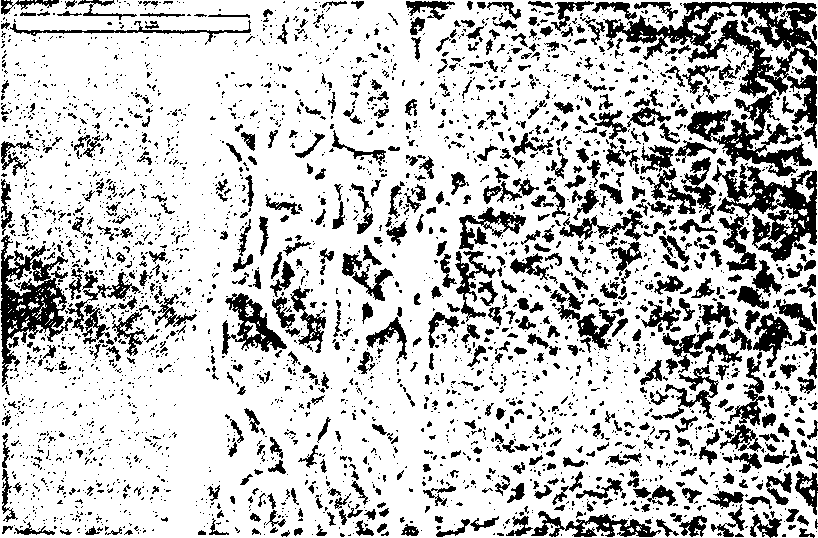

[0024] (4) Electrode inspection: The ceramic chip after spraying the Al electrode is checked for resistance, the resistance value is 814Ω, and the thickness of the Al coating on the surface of the PTC ceramic is 50 μm;

...

Embodiment 2

[0044] The difference from Example 1 is:

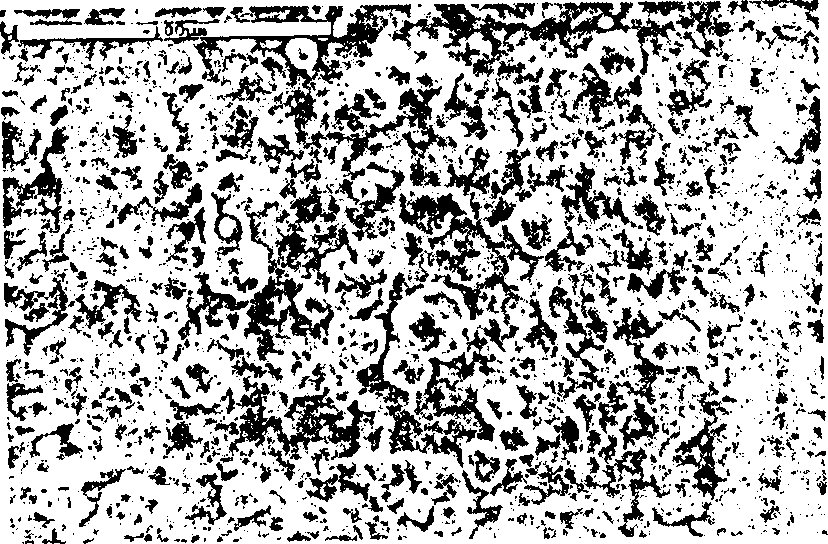

[0045] Spray zinc powder on the surface of PTC ceramics, the powder particle size is 300 mesh, and the process parameters are as follows:

[0046] Spraying Zn electrode process: spraying distance 5mm, gas pressure 2.0MPa, gas temperature 240°C, gas flow rate 28g / s, time 2 minutes to form a heat-sensitive ceramic ohmic contact electrode, and the thickness of the zinc coating on the PTC ceramic surface is 30μm.

[0047] In addition, in order to obtain supersonic speed for the powder in the present invention, the supersonic nozzle in the spraying system can be replaced by a Laval nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com