A method for preparing lithium strips by continuous electrodeposition

A technology of electrodeposition and lithium strips, which is applied in the field of continuous electrodeposition to prepare lithium strips, can solve problems such as the inability to continuously prepare ultra-thin lithium strips, and achieve the effects of easy storage and transportation, uniform film layers, and simple methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

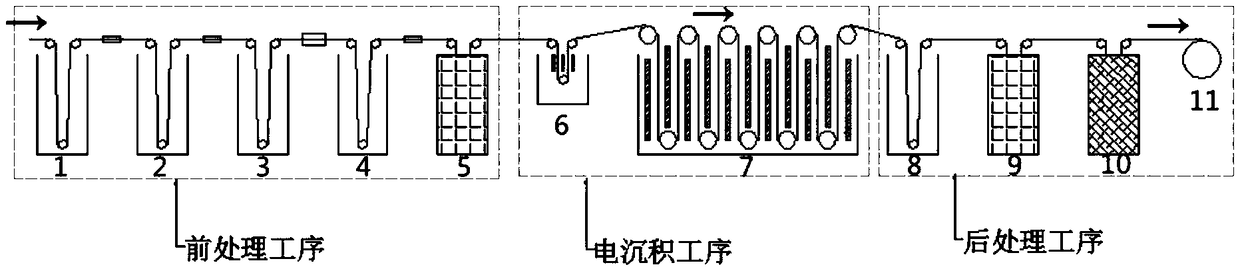

Method used

Image

Examples

Embodiment 1

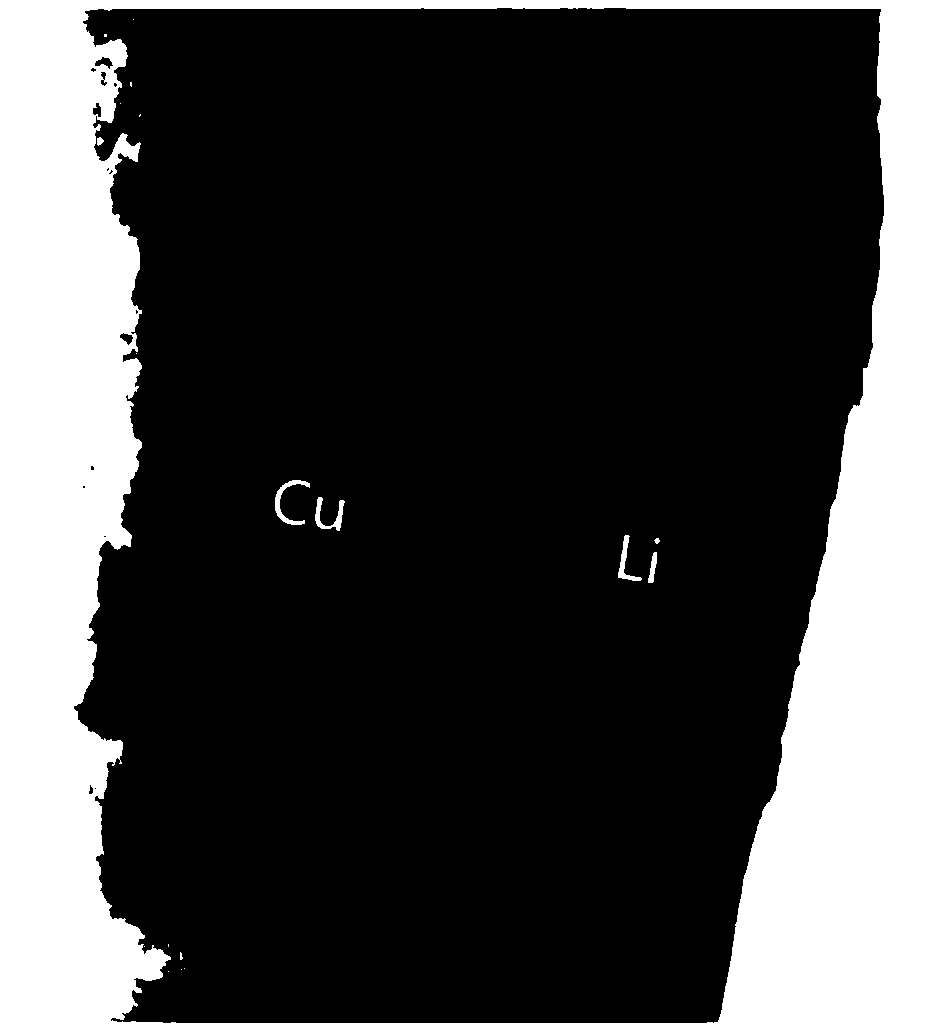

[0044] A high-purity copper foil strip with a thickness of 10 μm is used as the deposition base strip, and the surface is uniformly coated with a metal lithium layer with a thickness of about 15 μm through pre-treatment, electrodeposition, and post-treatment processes, and finally an ultra-thin lithium strip (such as figure 2shown). The pre-treatment conditions are: 1M sodium hydroxide solution for degreasing, 0.05M dilute nitric acid solution for second immersion activation, the activation here is actually a coarsening process, and the above-mentioned each treatment is washed with high-purity water and quickly dried at 80°C . Electrodeposition conditions are: use 10mA cm -2 The high-current deposition of 5s allows a small amount of lithium to deposit everywhere on the surface of the copper foil substrate, and then enters the 0.1mA·cm -2 The low current lithium electrodeposition, the low current lithium deposition time is 5h, the electrolyte formula is EC, PC, DMC, lithium ...

Embodiment 2

[0046] A high-purity copper foil tape with a thickness of 10 μm is used as the deposition base tape, and the surface is uniformly covered with a metal lithium layer with a thickness of about 8 μm through pretreatment, electrodeposition, and post-treatment processes, and finally an ultra-thin lithium strip (lithium layer) is obtained. thickness is 8 μm). The pre-treatment conditions are: 1M sodium hydroxide solution for degreasing, 0.05M dilute nitric acid solution for second immersion activation, the activation here is actually a coarsening process, and the above-mentioned each treatment is washed with high-purity water and quickly dried at 80°C . Electrodeposition conditions are: use 5.0mA·cm -2 The high-current deposition of 10s allows a small amount of lithium to deposit everywhere on the surface of the copper foil substrate, and then enters the 0.02mA·cm -2 The low-current lithium electrodeposition, the low-current lithium deposition time is 10h, and the electrolyte form...

Embodiment 3

[0048] A high-purity copper foil tape with a thickness of 10 μm is used as the deposition base tape, and the surface is uniformly covered with a metal lithium layer with a thickness of about 28 μm through pre-treatment, electrodeposition, and post-treatment processes, and finally an ultra-thin lithium tape (lithium layer) is obtained. thickness is 28 μm). The pre-treatment conditions are: 1M sodium hydroxide solution for degreasing, 0.05M dilute nitric acid solution for second immersion activation, the activation here is actually a coarsening process, and the above-mentioned each treatment is washed with high-purity water and quickly dried at 80°C . The electrodeposition condition is: use 50mA·cm -2 The high-current deposition of 0.5s allows a small amount of lithium to deposit everywhere on the surface of the copper foil substrate, and then enters the 1mA·cm -2 The low-current lithium electrodeposition, the low-current lithium deposition time is 1h, and the electrolyte form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com