Patents

Literature

163 results about "Shock treatments" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface strengthening method for metal component by vibration-assisted laser shock treatment

ActiveCN108660307AImprove mechanical propertiesImprove fatigue lifeVibration exciterMechanical property

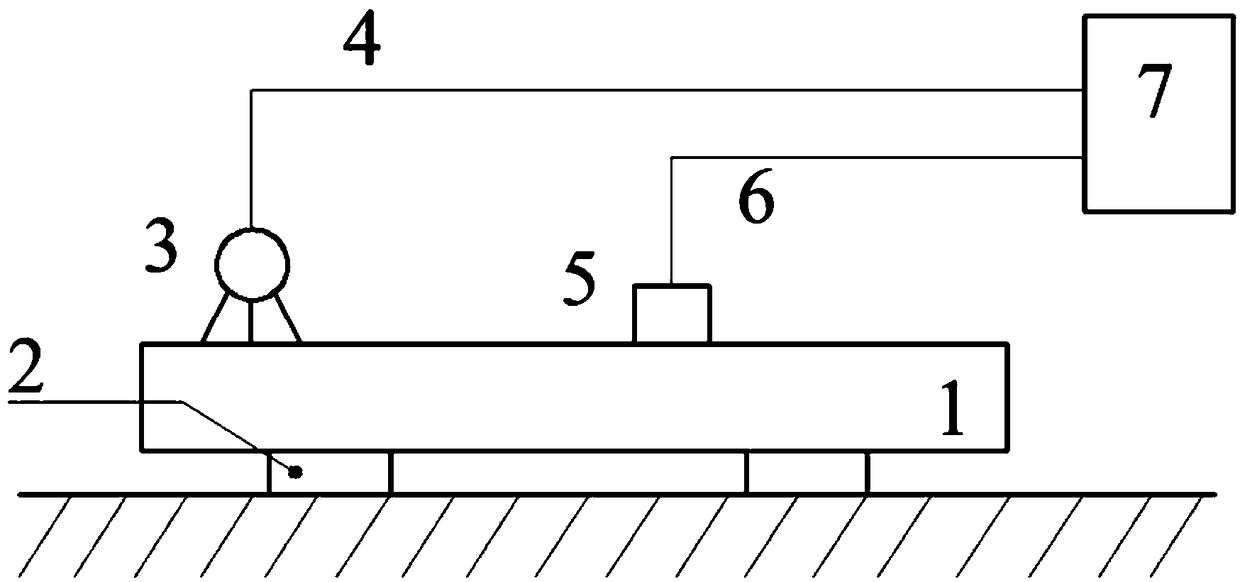

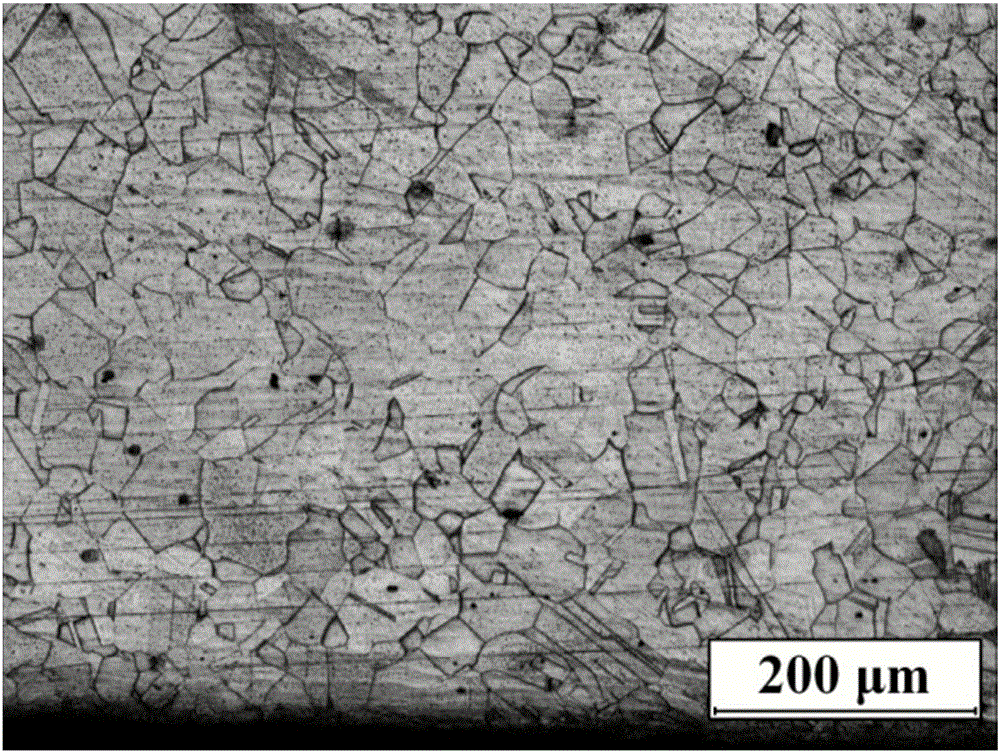

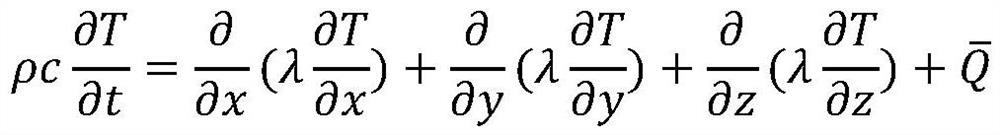

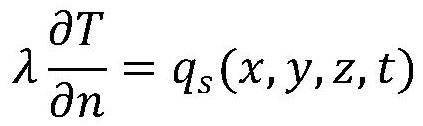

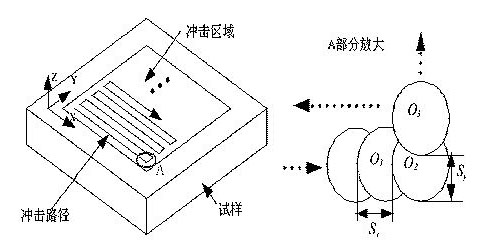

The invention relates to the field of new techniques of laser processing and vibration aging, in particular to a surface strengthening method for a metal component by vibration-assisted laser shock treatment. According to the method, by combining laser shock strengthening technology with vibration aging treatment, a vibration exciter is used to excite vibration, a sensor picks up vibration, the vibration frequency is controlled to keep the amplitude value within a specified range, laser lap impact strengthening treatment is carried out with the aid of vibration aging treatment so that more serious plastic deformation can be generated on the surface of the metal component, and high-amplitude residual compressive stress is induced in an impact area; meanwhile under the condition that laser beam irradiates the metal surface, vibration further refines or even nanocrystallizes the surface grain, and under the action of the temperature field, vibration reduces the thermal stress field gradient, and thus the residual stress inside the material is uniformized; and the mechanical properties of the metal component are remarkably improved, and the metal surface is strengthened, so that the fatigue life of the metal component is prolonged effectively, and initiation and expansion of fatigue cracks are prevented.

Owner:JIANGSU UNIV

Laser shock peening method and device using high-pressure gas as constrained layer

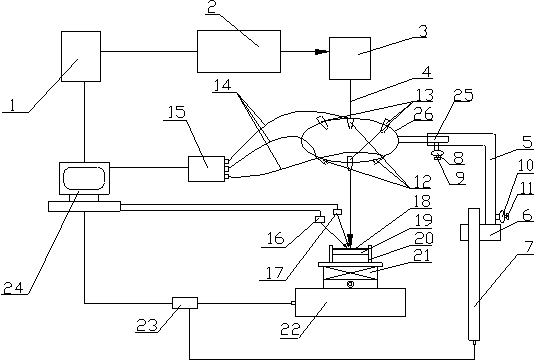

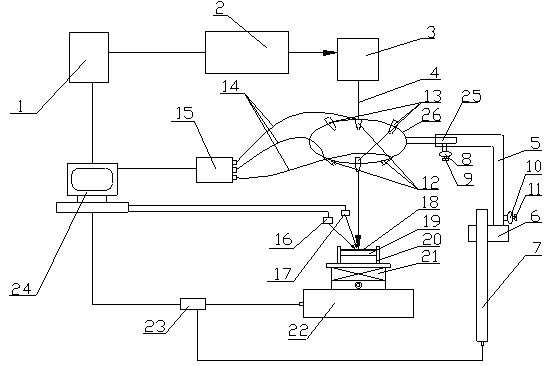

InactiveCN102560079AGuaranteed coincidenceReliable constraintsLaser beam welding apparatusLaser processingTest sample

The invention relates to the field of laser processing, in particular to a laser shock peening method and a laser shock peening device using high-pressure gas as a constrained layer. The high-pressure gas serves as the constrained layer; the pressure of the high-pressure gas can be set and adjusted according to the test requirement; the pressure in the whole shocking process is controlled to be unchanged; and the position of a nozzle can be adjusted in real time, so that the jet center of the high-pressure gas, the spot center of laser and the pre-shock treatment position of a workpiece are overlapped, and single-point multi-time shock and multi-point continuous shock on a test sample are realized.

Owner:JIANGSU UNIV

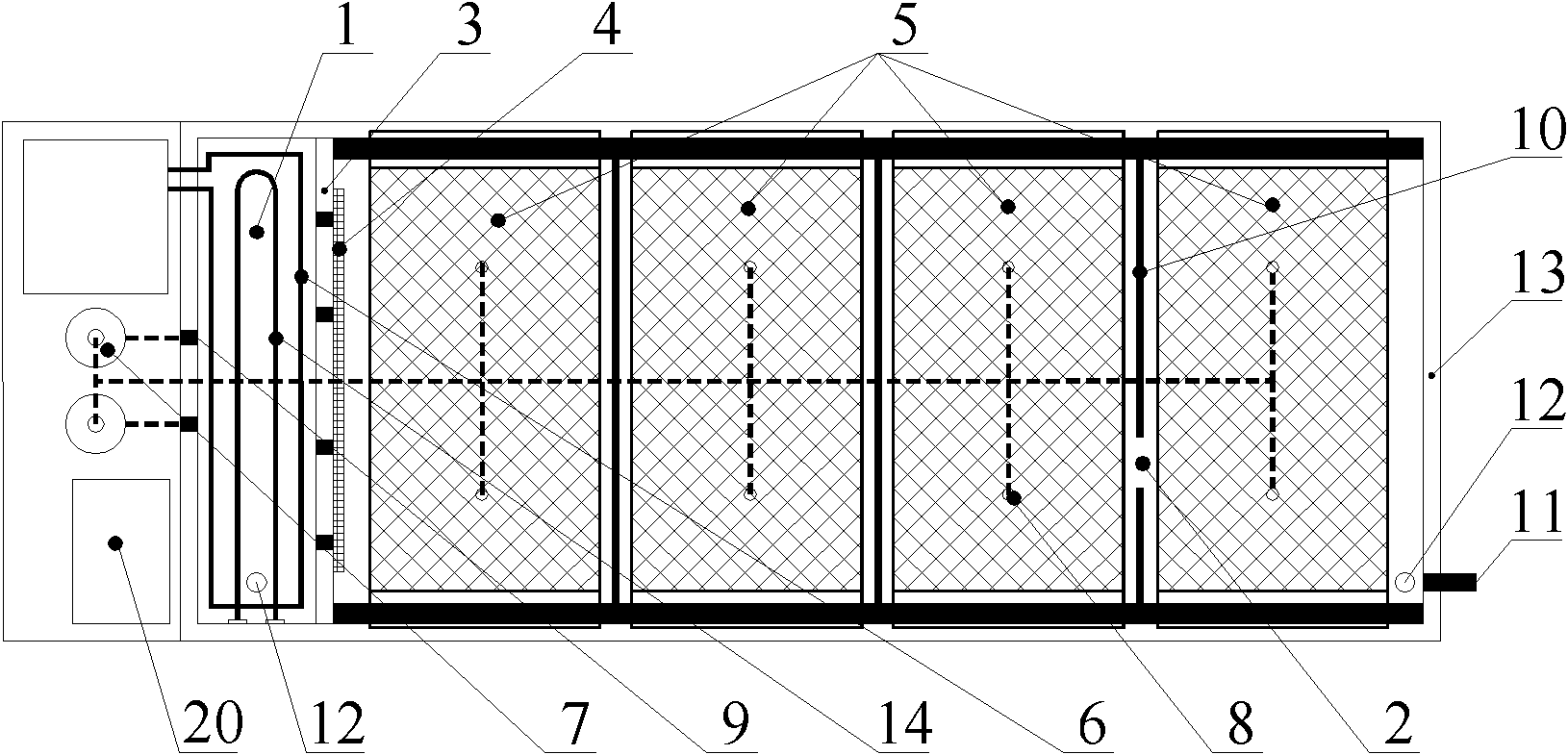

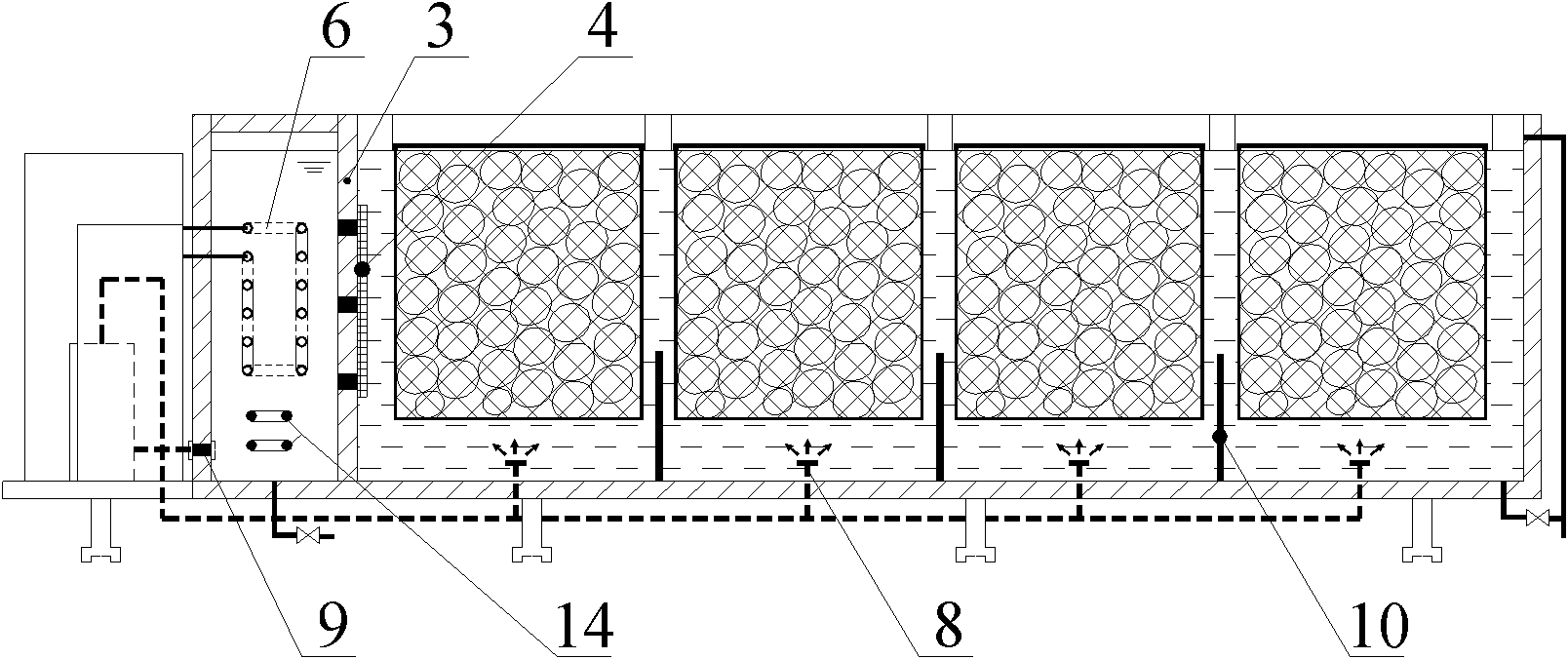

Energy-saving multifunctional cold-heat pretreatment device for fruits and vegetables before storage

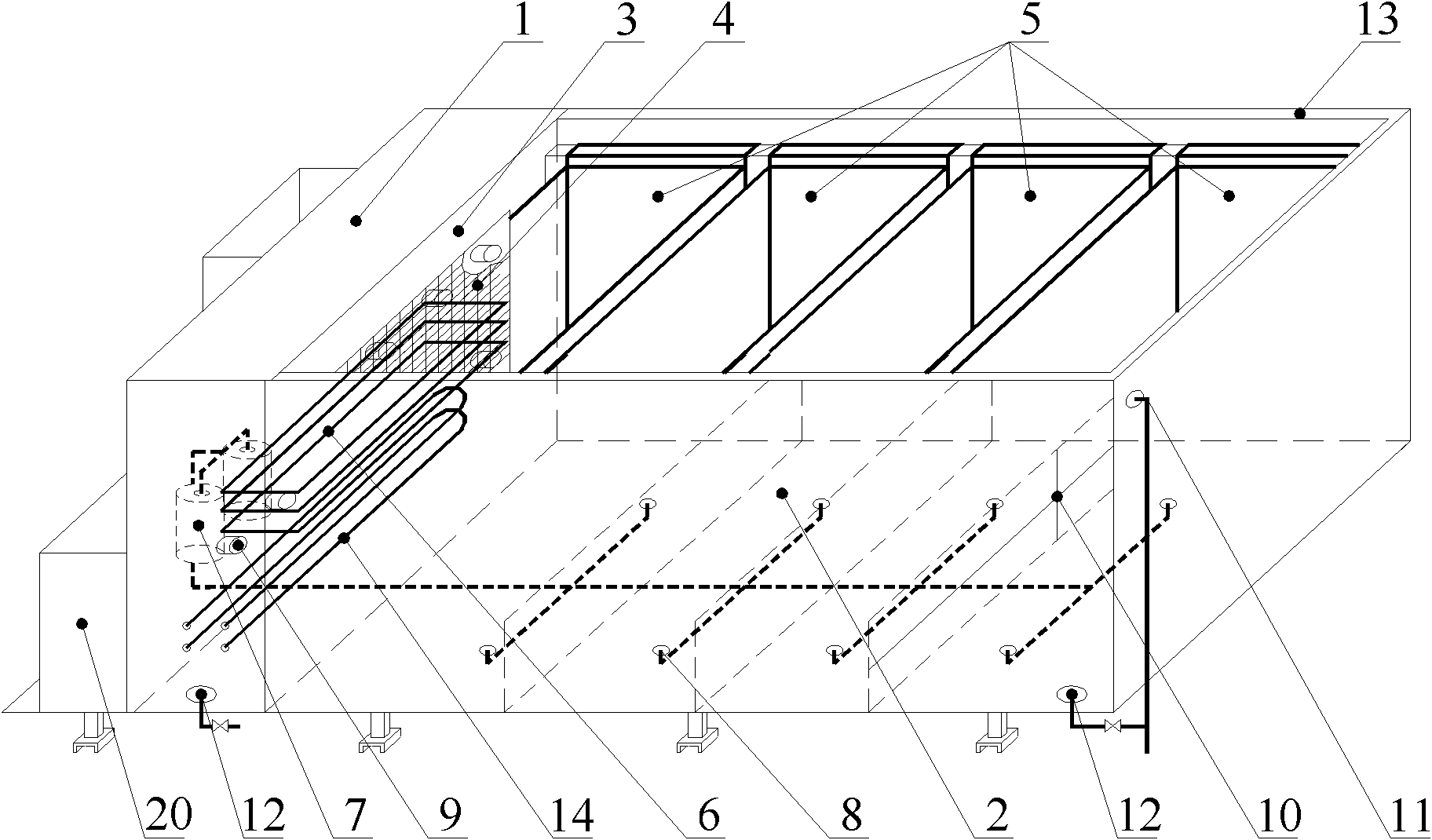

InactiveCN101843276AInhibit dry consumptionHas a cleaning effectFood processingFruits/vegetable preservation by heatingEngineeringCold injury

The invention discloses an energy-saving multifunctional cold-heat pretreatment device for fruits and vegetables before storage. A water temperature treatment chamber is connected with a fruit and vegetable pretreatment chamber to form an integral water tank, and a partition board with through holes and a filter screen are arranged between the two chambers. A fruit and vegetable basket is placed in the pretreatment chamber, a spiral tubular heat exchanger is placed in the water temperature treatment chamber, and circulating cold water or hot water enters the fruit and vegetable pretreatment chamber from the lower part in a parallel mode through a water pump. The return water is subjected to heat re-exchange through the filter screen, the partition board and the spiral tubular heat exchanger and then returns to the water pump. The device integrates pre-cooling, cold shock and hot shock treatment of the fruits and the vegetables, and saves running energy consumption when the treatment of the fruits and the vegetables is finished; and compared with air, the water serving as a treatment medium has high heat exchange efficiency, can inhibit drying loss during the pretreatment of the fruits and the vegetables, and has cleaning effects on the fruits and the vegetables. A control system can timely adjust the running parameters of the system according to the change of working conditions so as to avoid cold injury of the fruits and the vegetables caused by over-low water temperature and hot injury of the fruits and the vegetables caused by over-high water temperature.

Owner:TIANJIN UNIV

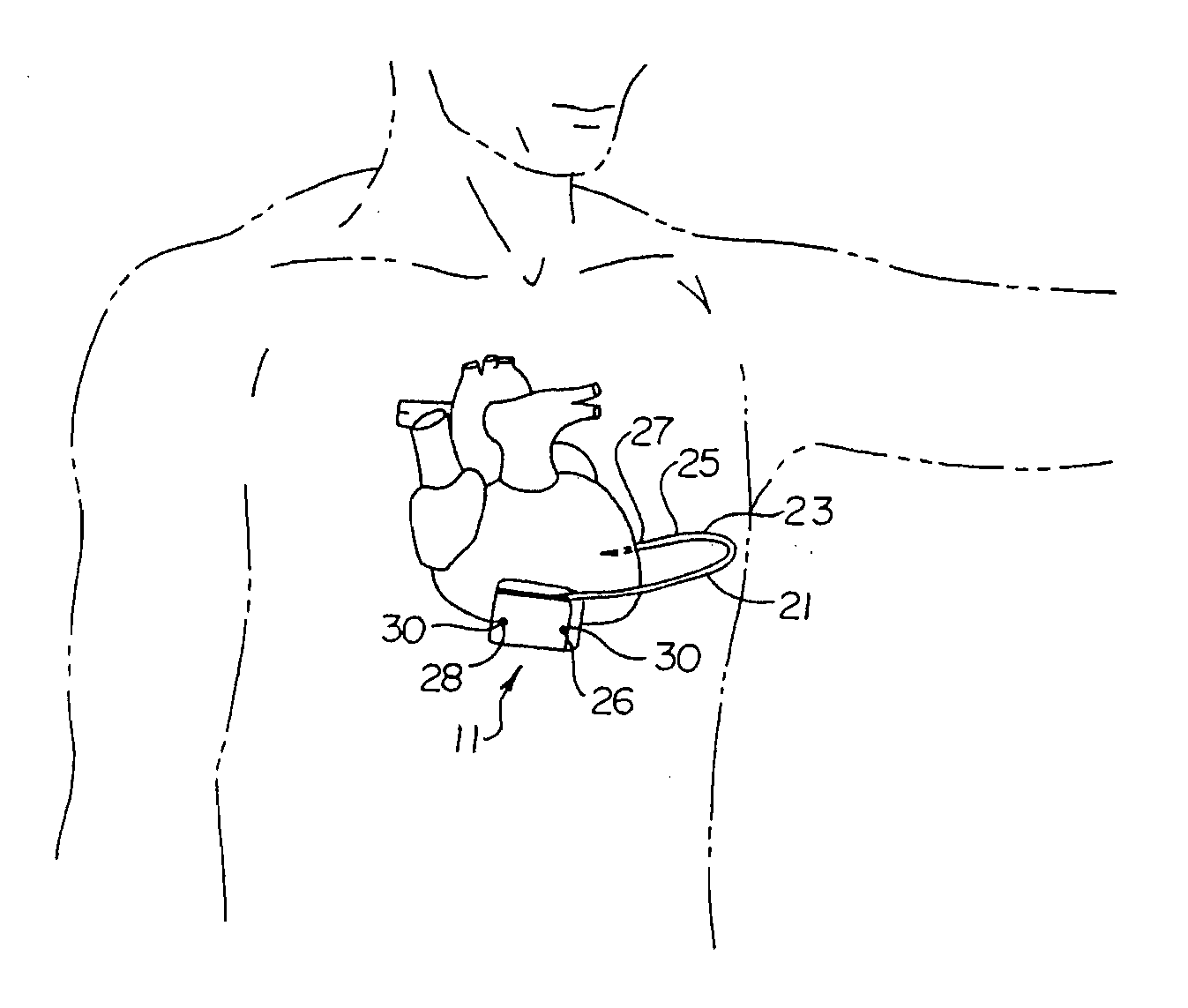

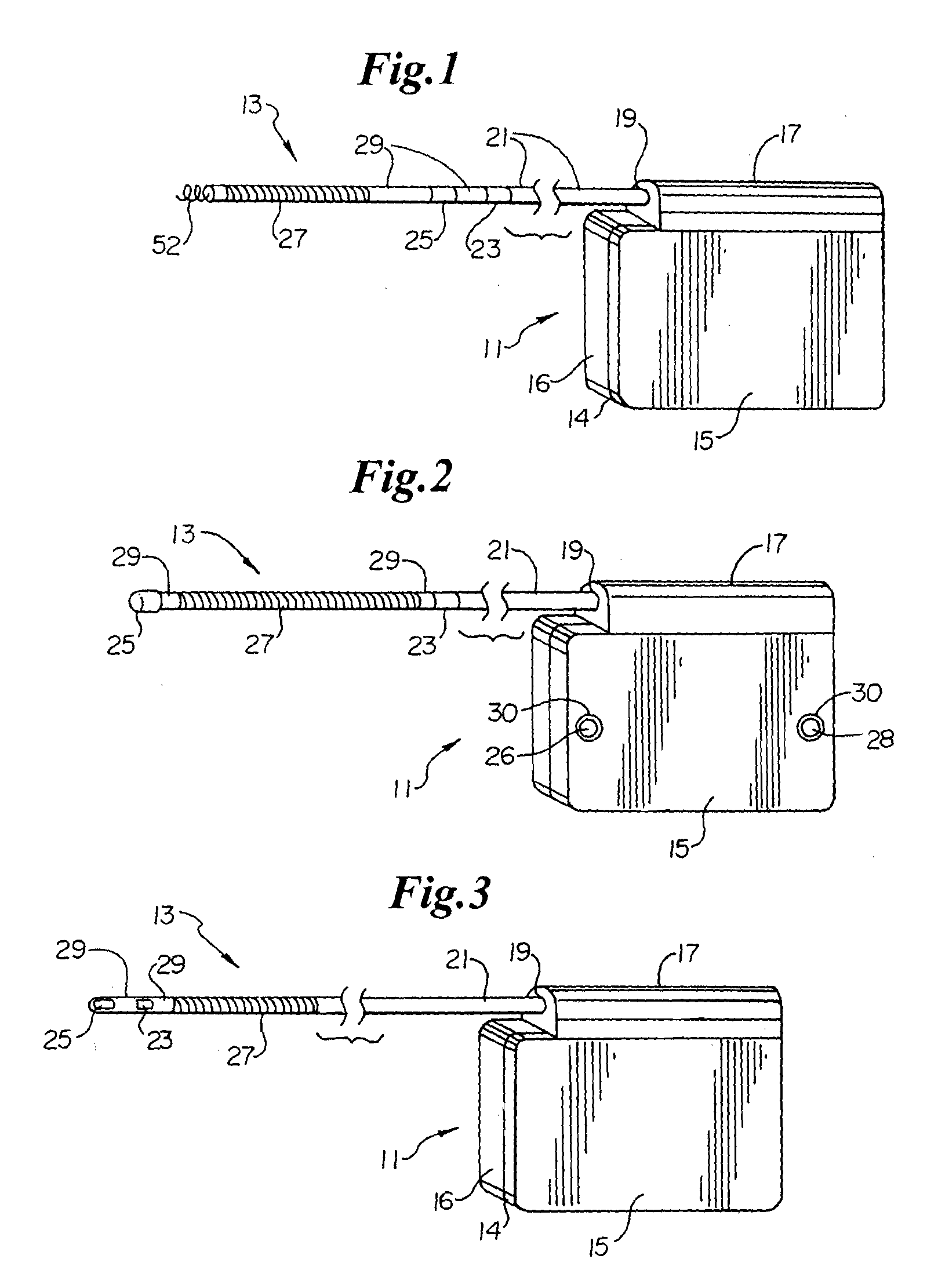

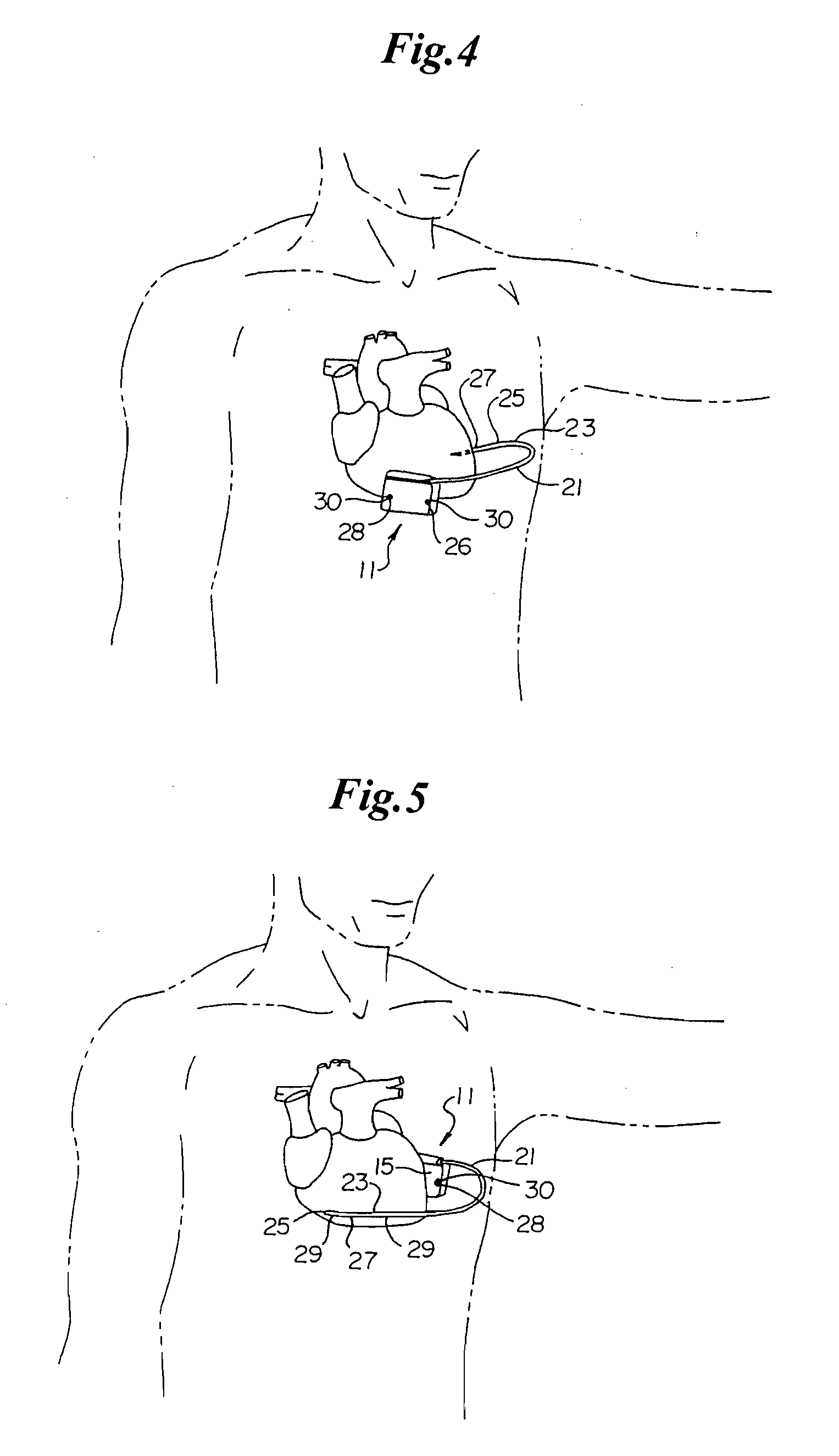

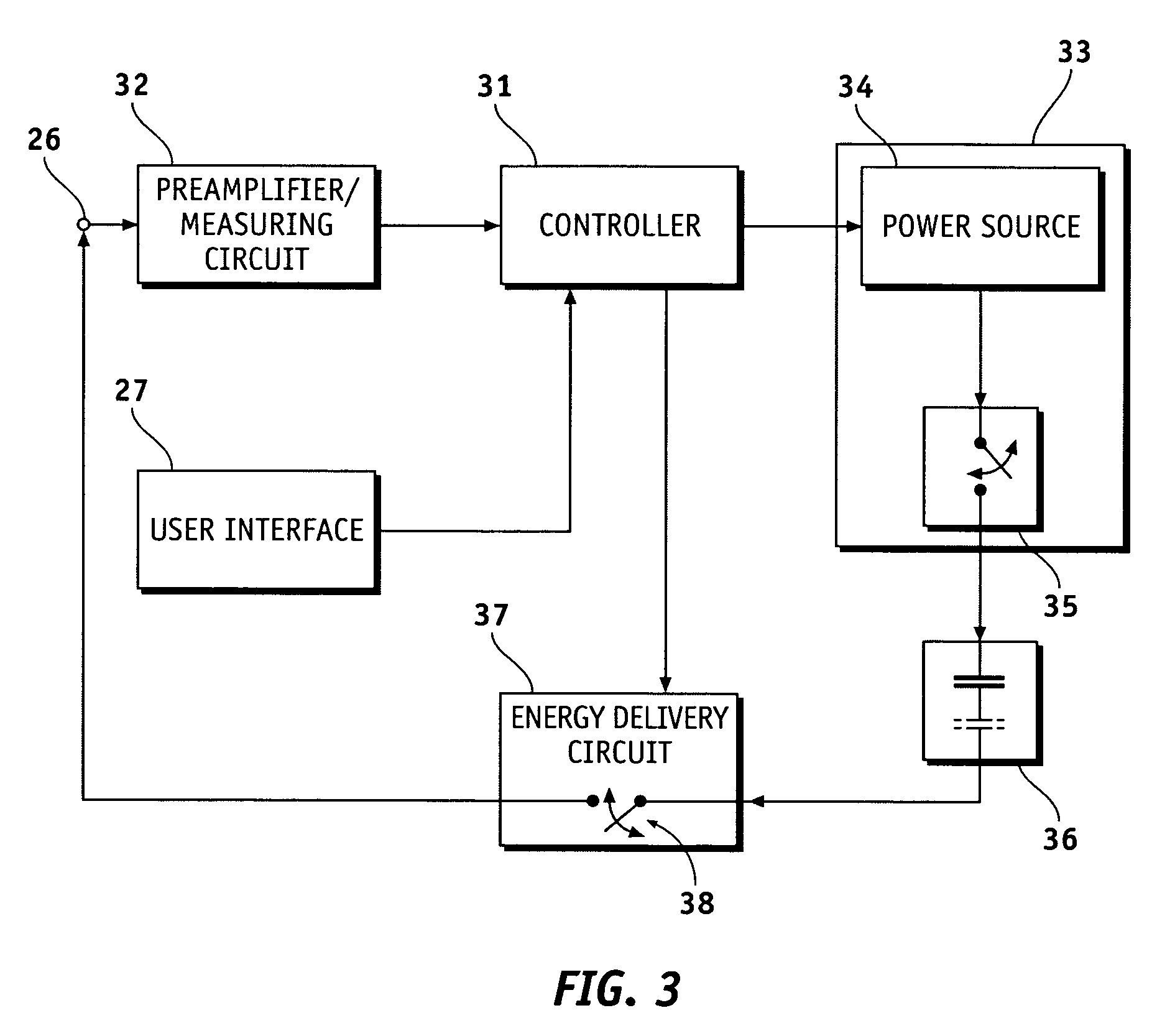

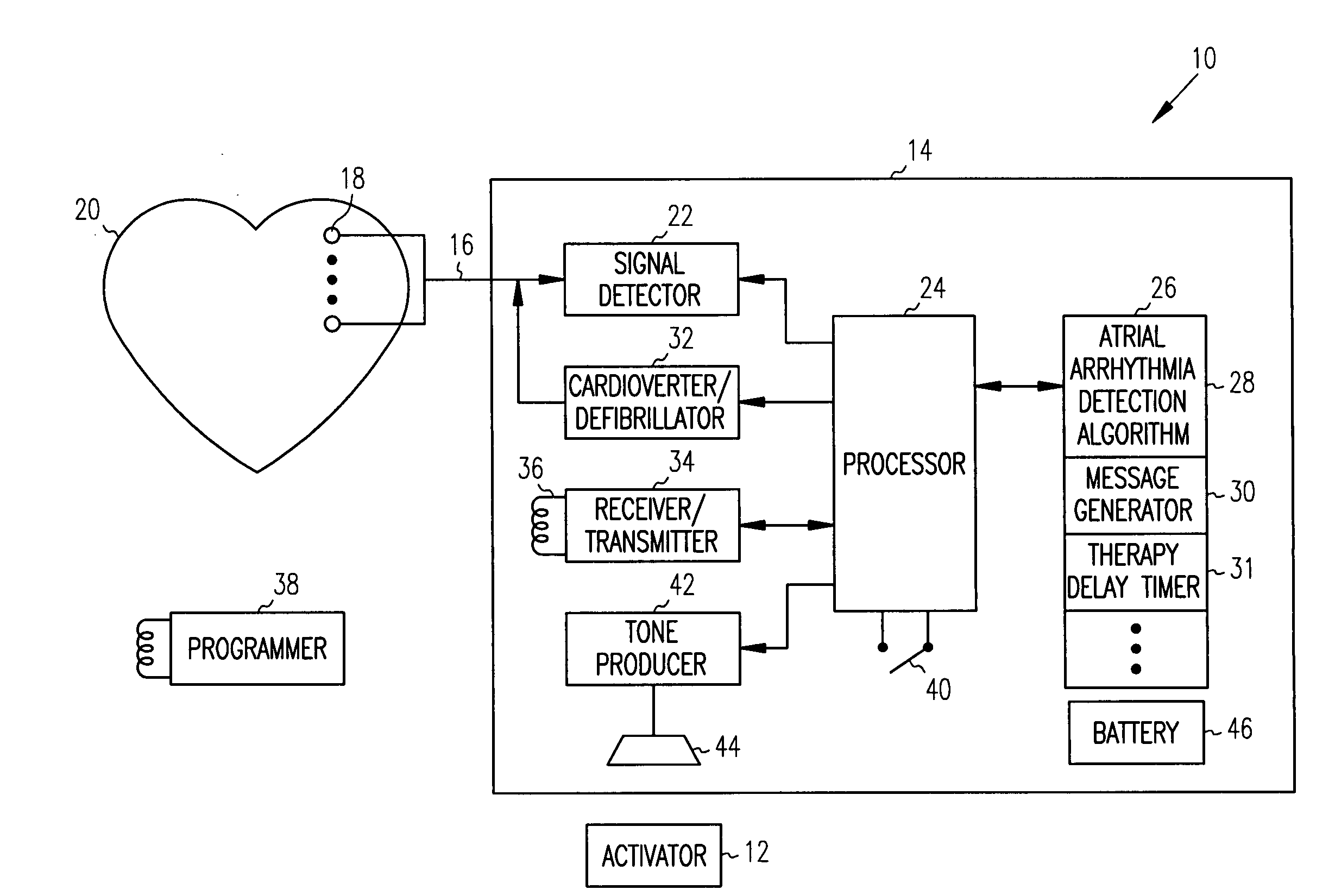

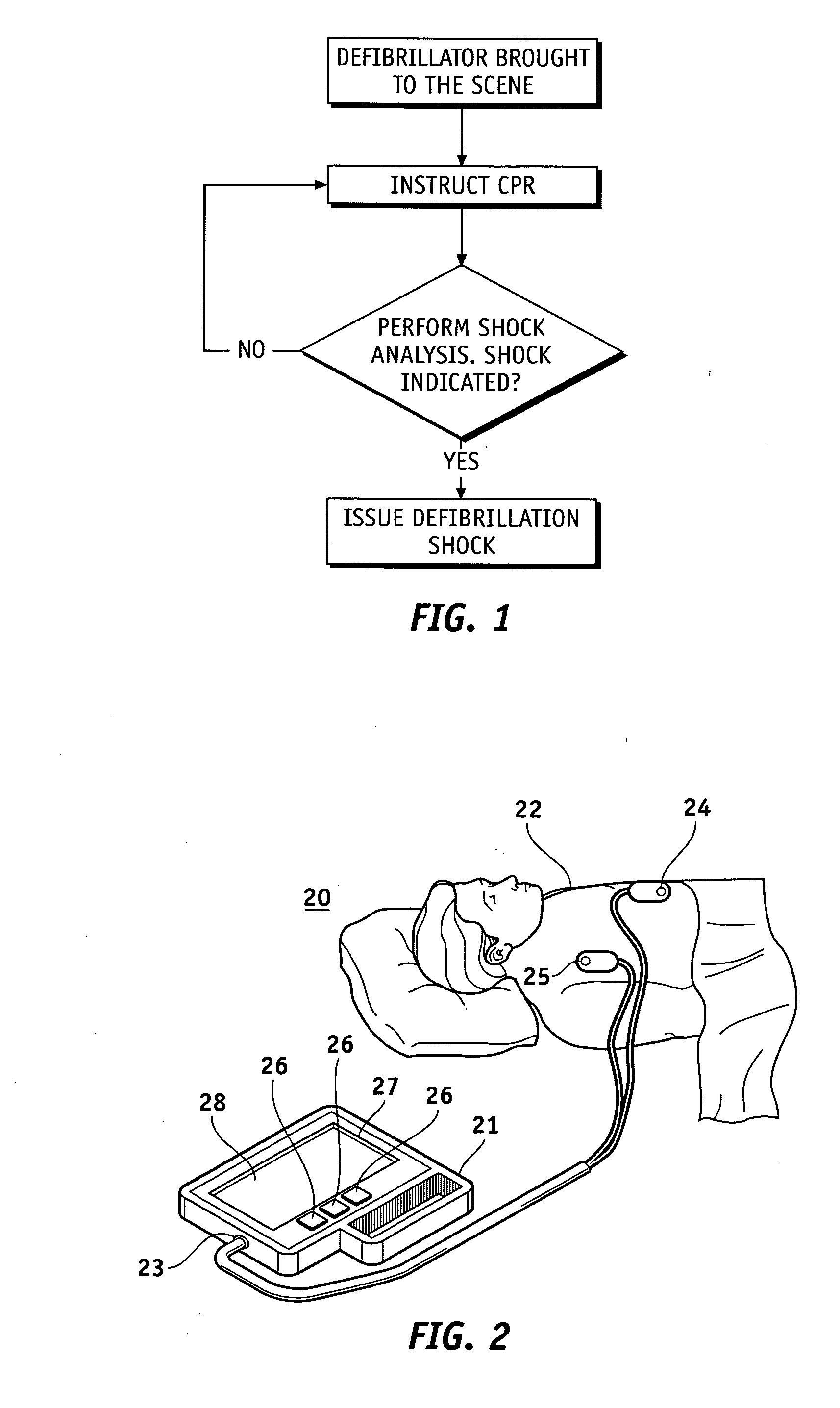

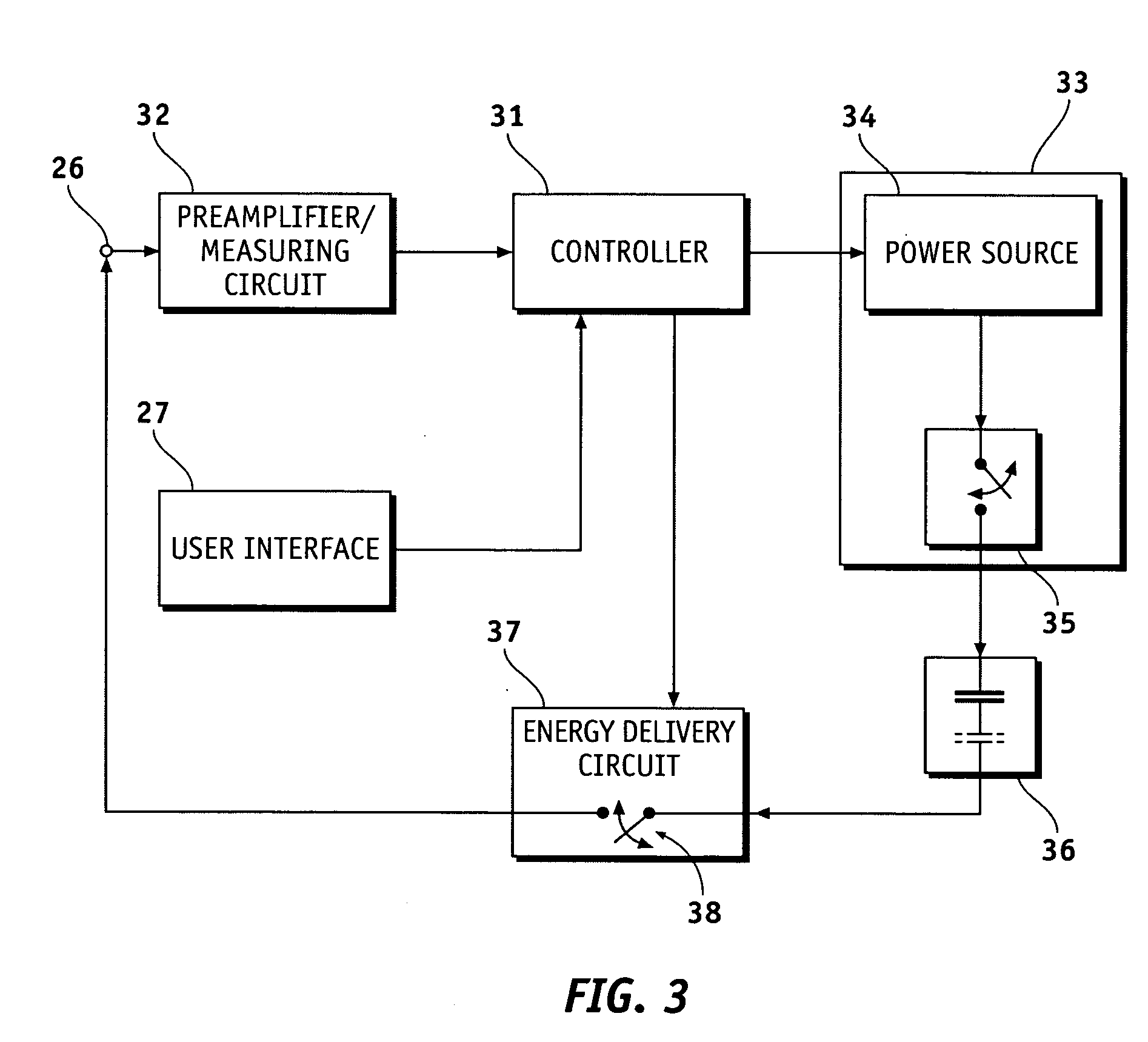

Post-shock treatment in a subcutaneous device

A power supply for an implantable cardioverter-defibrillator for subcutaneous positioning between the third rib and the twelfth rib and using a lead system that does not directly contact a patient's heart or reside in the intrathoracic blood vessels and for providing anti-bradycardia pacing energy to the heart, comprising a capacitor subsystem for storing the anti-bradycardia pacing energy for delivery to the patient's heart; and a battery subsystem electrically coupled to the capacitor subsystem for providing the anti-bradycardia pacing energy to the capacitor subsystem.

Owner:CAMERON HEALTH

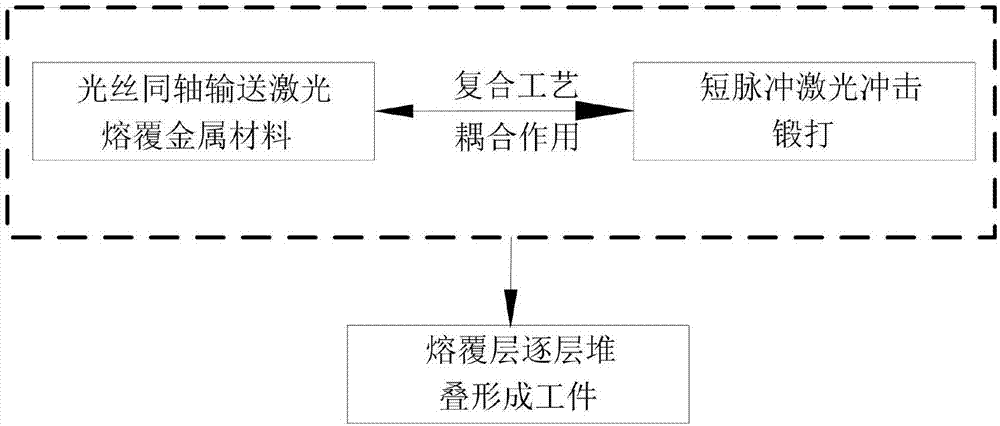

Metal part inside-laser wire-feeding cladding laser shocked and forged composite additional material manufacturing method

ActiveCN107335805AQuality improvementEfficient qualityAdditive manufacturing apparatusIncreasing energy efficiencyShock wavePulse energy

The invention discloses a metal part inside-laser wire-feeding cladding laser shocked and forged composite additional material manufacturing method. The metal part inside-laser wire-feeding cladding laser shocked and forged composite additional material manufacturing method is based on a composite manufacturing process of the laser thermal effect and the shock wave mechanical effect, a cladding zone is subjected to laser shock treatment synchronously while metal wires are fused by a heat source to form the cladding zone, forming and reinforcement processes are completed in a one-step manufacturing procedure, the remarkable characteristics of high efficiency and high quality are achieved, the defects of secondary heating, heat stress and lowered efficiency caused by a secondary reinforcement process are overcome, lots of time is saved, the production cost is greatly lowered, and parameters such as laser beam diameter and shape, pulse width, pulse energy and repetition frequency can be accurately adjusted and controlled so that the method can adapt to high-quality forming of various material and complex structural parts; and meanwhile, laser-wire coaxial conveying cladding forming is adopted based on continuous laser, and high-quality cladding layers can be formed by efficiently using the metal wires.

Owner:GUANGDONG UNIV OF TECH

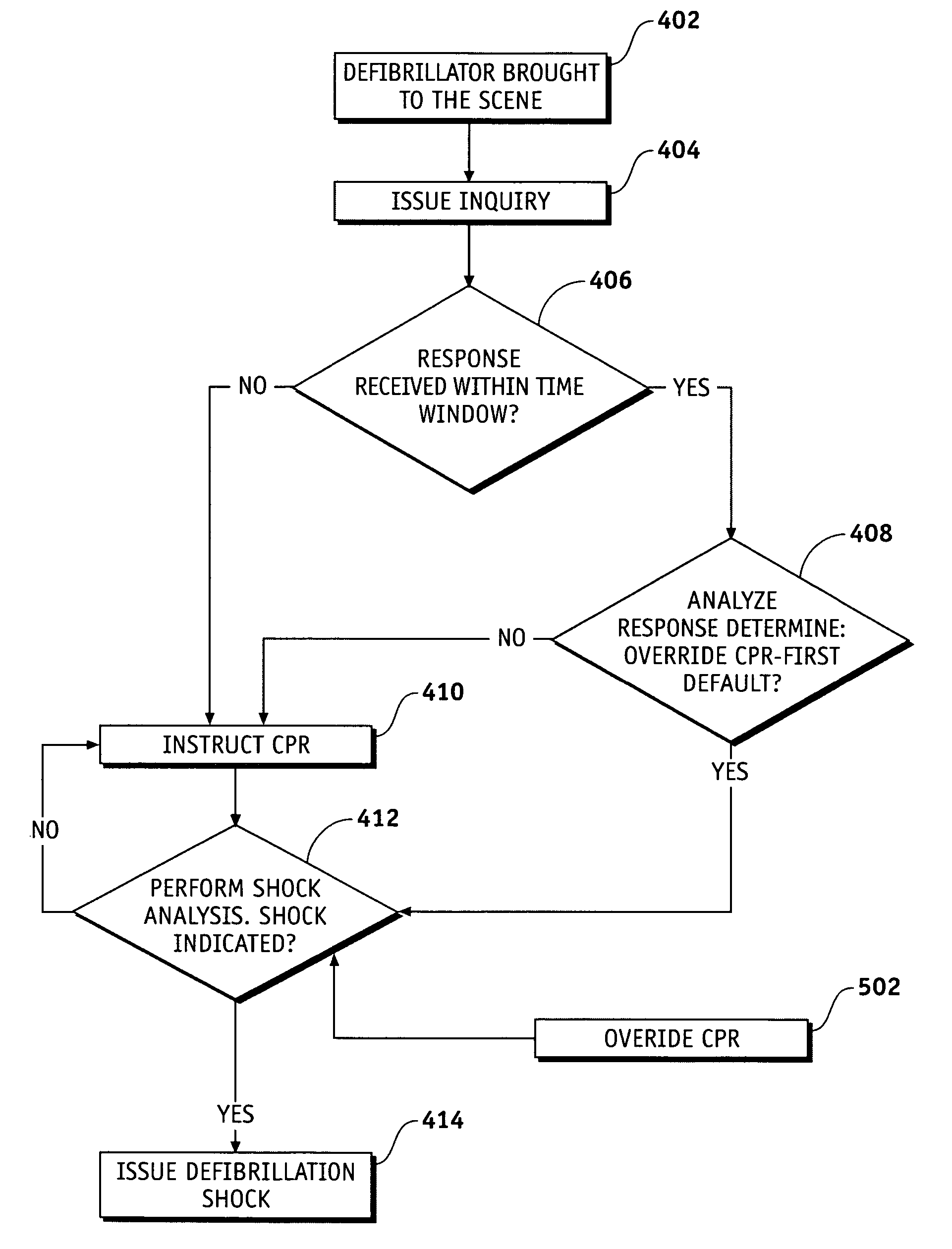

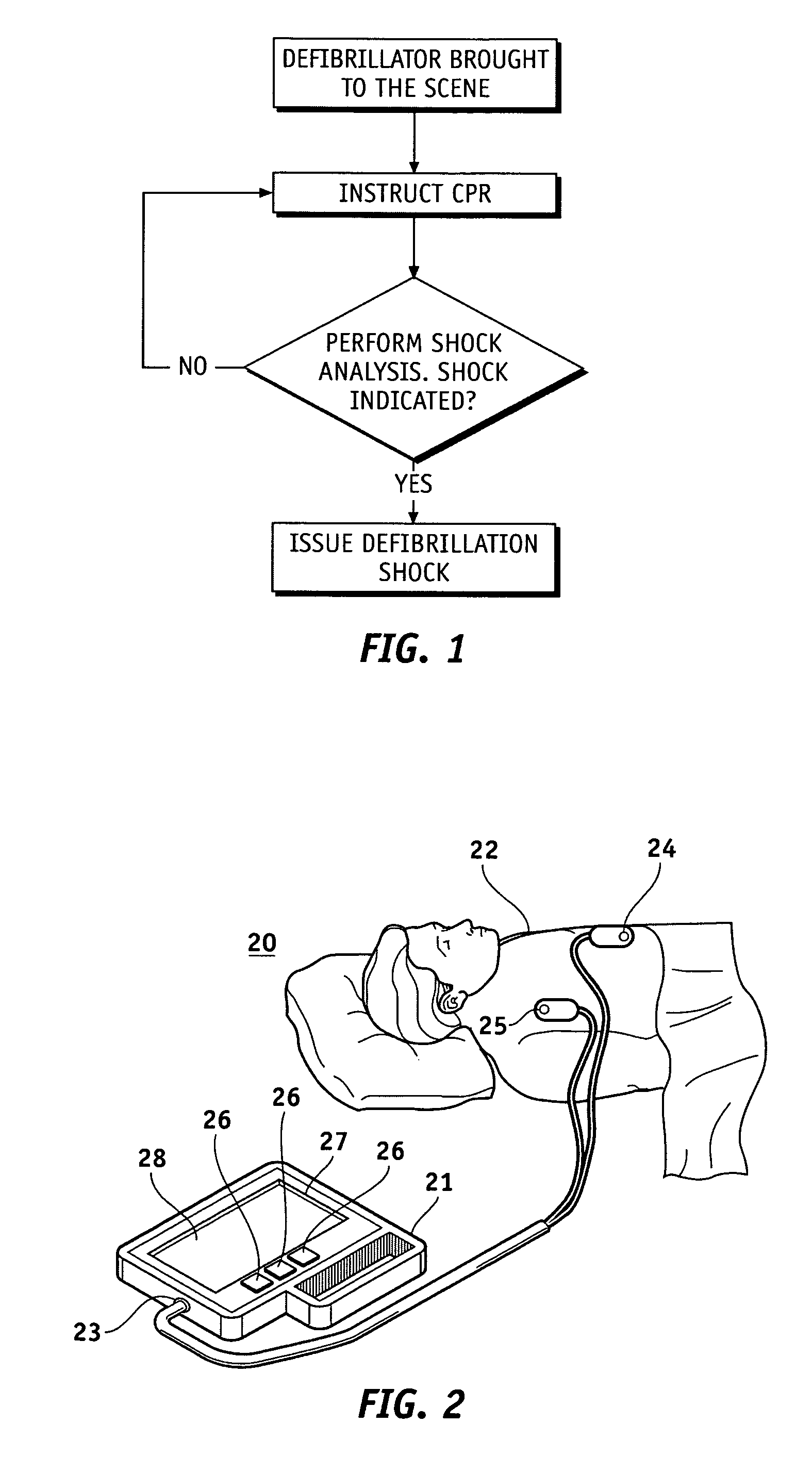

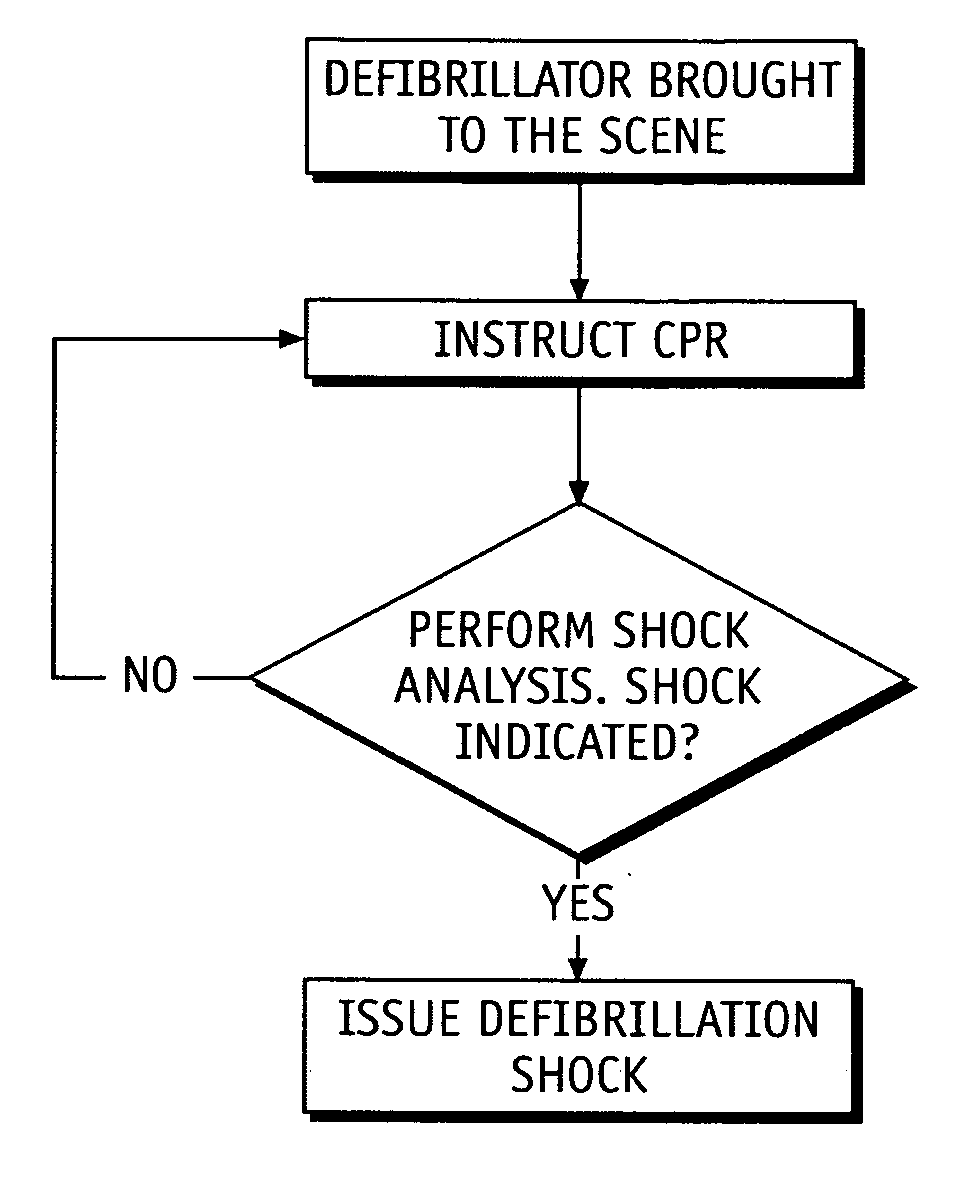

Defibrillator with overridable CPR-first protocol

Owner:PHYSIO CONTROL INC

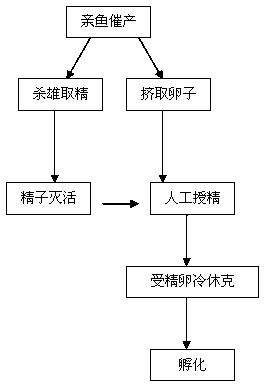

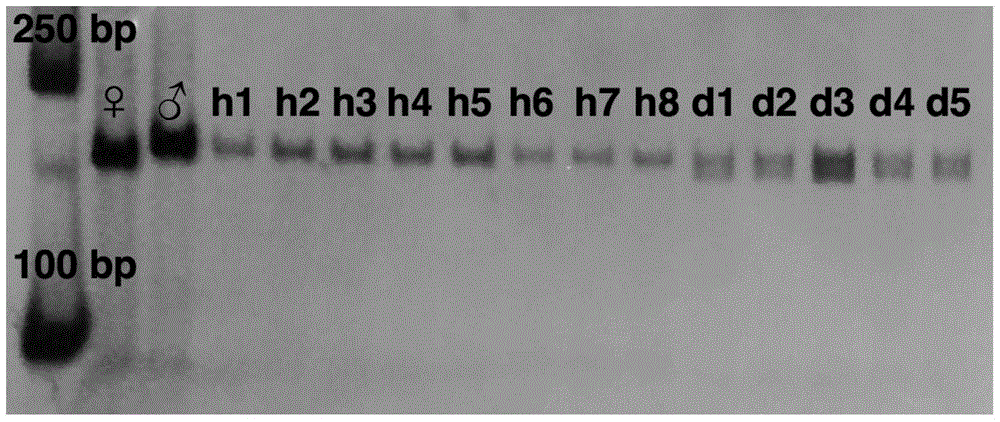

Method for inducing gynogenesis of cyprinus carpio L. by using megalobrama amblycephala sperms

InactiveCN102919185ABreed fastAccelerated homozygosityClimate change adaptationPisciculture and aquariaCyprinusEmbryo

The invention discloses a method for inducing gynogenesis of cyprinus carpio L. by using megalobrama amblycephala sperms. The method comprises the following steps of: firstly, selecting a female gynogenesis of cyprinus carpio L. and a male megalobrama amblycephala as parent fishes, secondly, performing artificial induced spawning to obtain megalobrama amblycephala sperms and cyprinus carpio L. spawns; and finally, uniformly mixing ultraviolet-inactivated megalobrama amblycephala seminal sperms and the cyprinus carpio L. spawns, scattering the mixture on a mesh which is flatly paved in water, after 5 minutes, placing activated spawns in cold water of 5 DEG C to perform cold shock treatment for 18 to 25 minutes, and incubating embryos after the cold shock treatment at 21 to 23 DEG C in water to obtain diploid gynogenesis cyprinus carpio L. According to the method, the measures of activating the gynogenesis of the cyprinus carpio L. spawns by using the inactivated megalobrama amblycephala seminal sperms and doubling genomes are used, so that the induced descendants only contain genes of female parents, the homozygosis of genes can be accelerated, and the method has important biological significance in the aspects of color inheritance law study and genetic breeding of the cyprinus carpio L.

Owner:BEIJING FISHERIES RES INST

Treating method for improving g strength and toughness of magnesium alloy materials

The invention discloses a treating method for improving strength and toughness of magnesium alloy materials. The treating method for improving the strength and the toughness of the magnesium alloy materials comprises solution treatment and aging treatment, and further comprises subzero treatment after the aging treatment and ultrasonic filed shock treatment in the process of the subzero treatment. The process of the subzero treatment comprises the steps of cooling the magnesium alloy materials to ultralow temperature at minus 196DEG C from the starting room temperature at the cooling speed 1-10DEG C / min, and holding the temperature for 12-30 hours. Preferably, the ultrasonic filed shock treatment is carried out at the late period of the subzero treatment, the intensity of an ultrasonic field is 1-50Kw / m2, the frequency of the ultrasonic field is 10-40KHz, and the treating time in the ultrasonic field is 60-200 seconds. The magnesium alloy materials after the subzero treatment and the ultrasonic field shock treatment are put into an oven which is 170DEG C at temperature, the holding time is 2-6 hours, and then the magnesium alloy materials in the oven are put in air to recover to the room temperature naturally. The treating method for improving the strength and the toughness of the magnesium alloy materials enables the magnesium alloy materials to be compact in structure and high in hardness and roughness.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

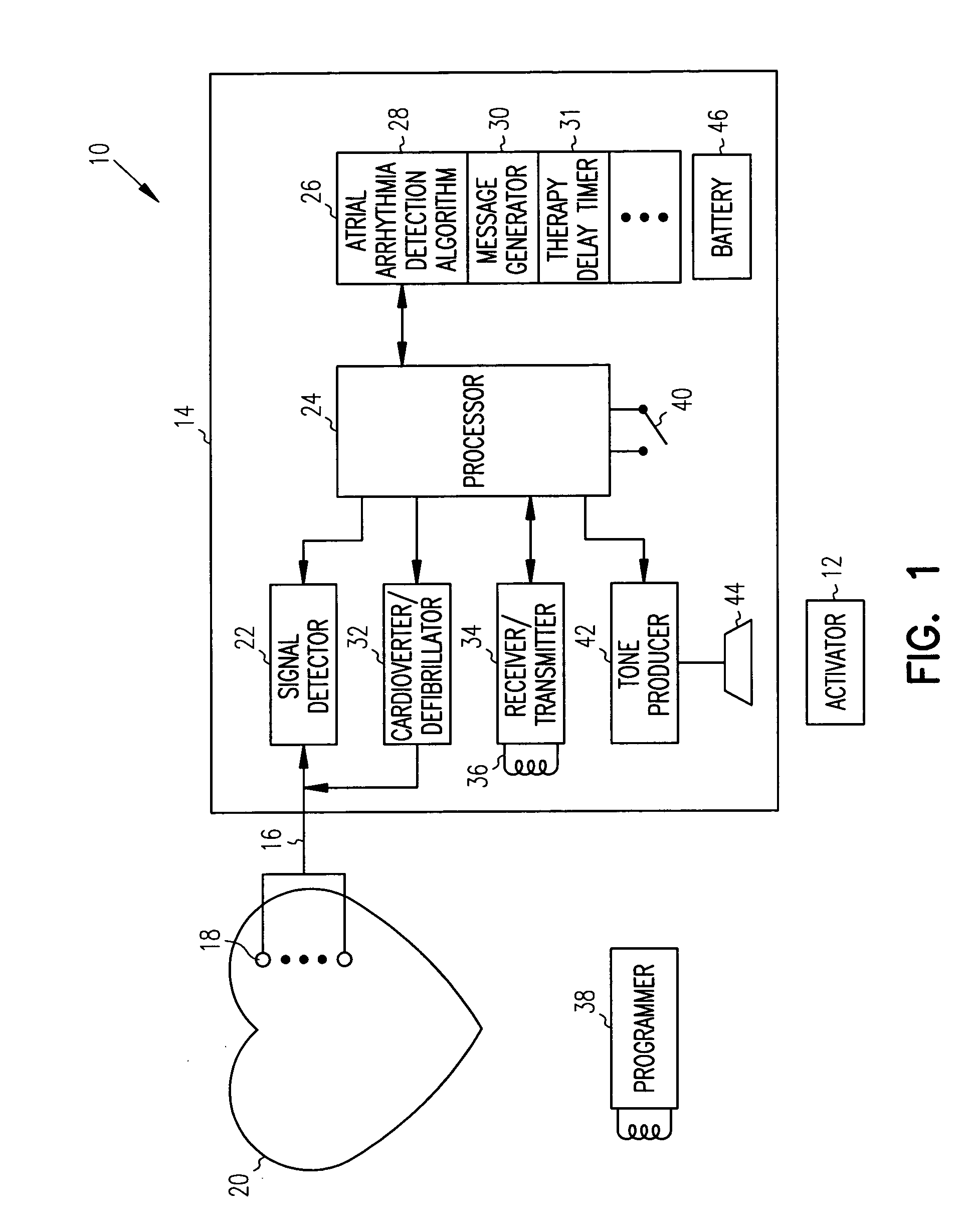

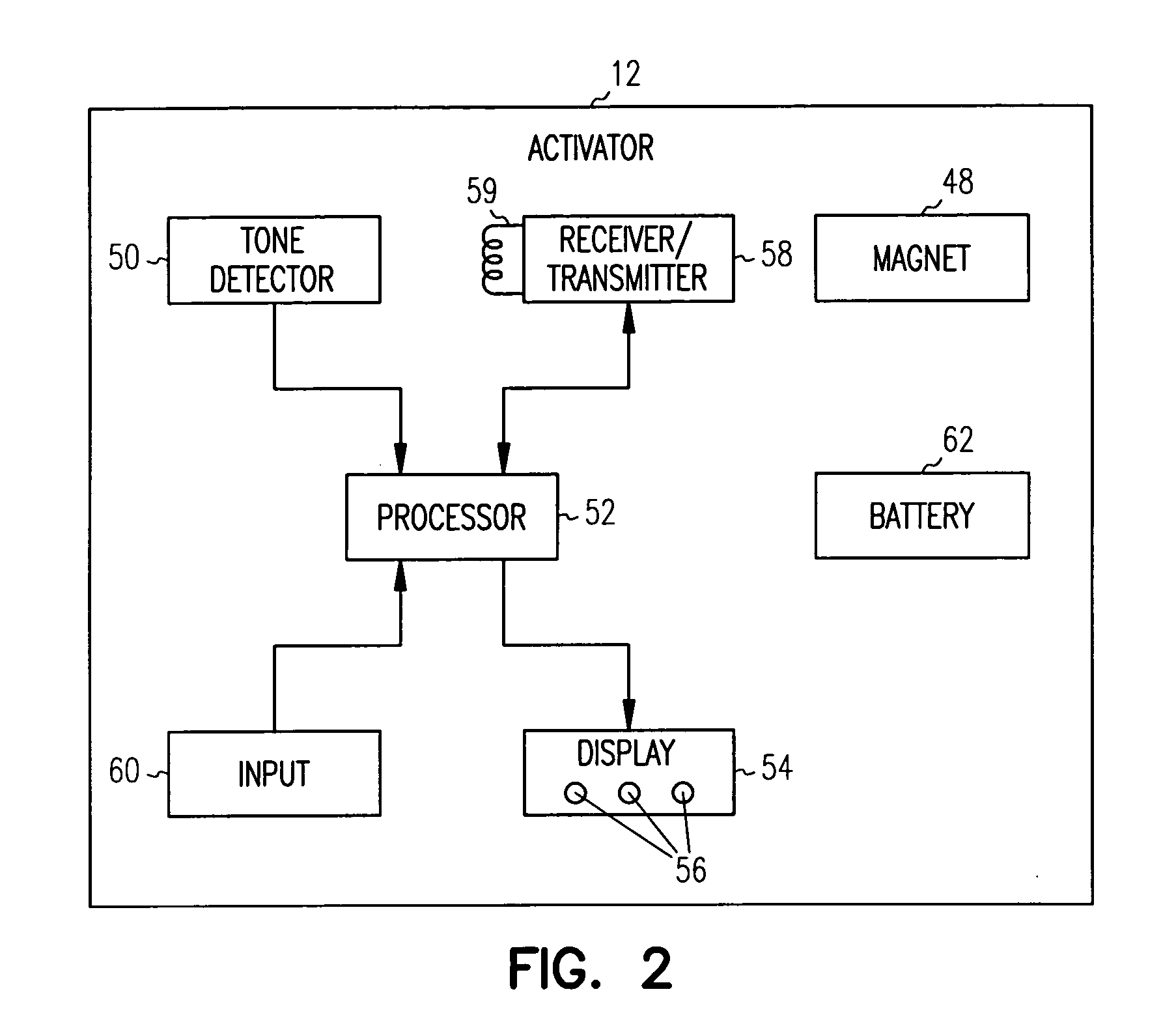

Delay to therapy following patient controlled atrial shock therapy request

InactiveUS20060079939A1Provide slackOptimization mechanismHeart defibrillatorsImplanted devicePhysical therapy

An implantable cardiac device detects a patient therapy request originating from external to the implantable device. A shock therapy delay period is timed in response to the detection of the patient therapy request. Atrial shock therapy is provided to the patient after expiration of the shock therapy delay period (if the presence of an ongoing atrial arrhythmia is detected). The patient therapy request may be provided by a patient activator including a magnet for operating a reed switch in the implanted device to provide the request. A patient activator including an input and receiver / transmitter circuitry may be employed to request the immediate providing of atrial shock therapy, and / or to set the duration the shock therapy delay period. By allowing specific delays to therapy after a therapy request, a patient can prepare for the requested therapy and thereby mitigate therapy discomfort.

Owner:CARDIAC PACEMAKERS INC

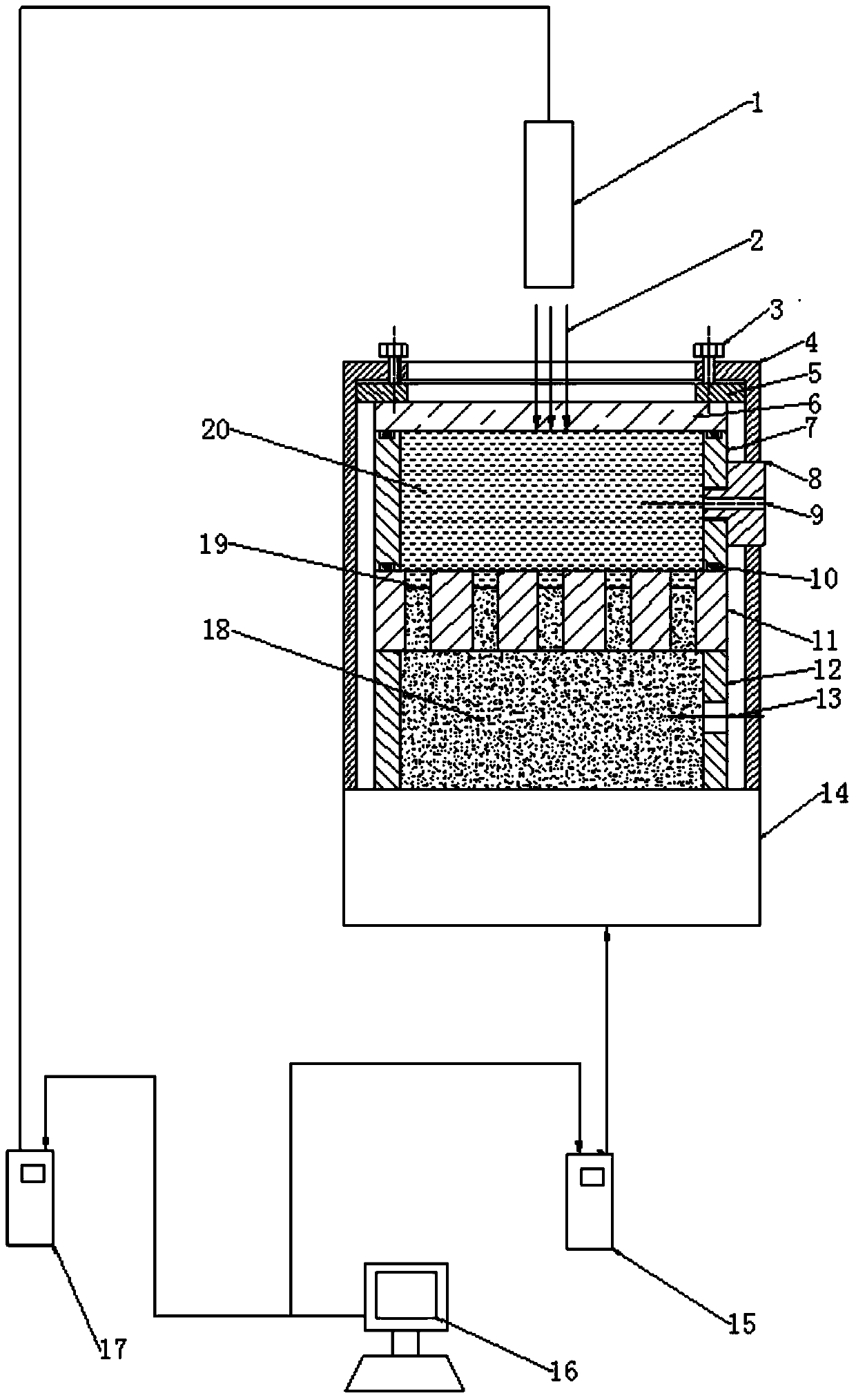

Laser shock treatment device taking flowable liquid as energy absorption layer

ActiveCN103143836AConsistent absorption efficiencyThe impact effect is stableLaser beam welding apparatusControl flowHigh density

The invention discloses a laser shock treatment device taking flowable liquid as an energy absorption layer, and belongs to the technical field of laser processing. According to the laser shock treatment device, the laser shock energy absorption layer and a restraint layer are the flowable liquid; an absorption layer pump and a restraint layer pump inject the absorption layer and the restraint layer to the surface of a workpiece through a dual-channel pipeline, and continue to work to allow the absorption layer and the restraint layer to be in flowing states all the time; a control system controls flow velocities of the restraint layer and the absorption layer that flow through the surface of the workpiece through controlling flow rates of the two pumps, and allows the flow velocities of the two pumps to be the same; the flow velocities are less than a critical flow velocity maintaining the restraint layer and the absorption layer to be in laminar states; and the flowing restraint layer and the flowing absorption layer that are distinct in gradation, and stable in state and are in the laminar states are obtained. Serving as a convenient on-line updating method of the absorption layer, the laser shock treatment device can ensure that the energy absorption efficiency of each laser pulse is the same, is stable in shock effect, and is particularly applicable to same-point multiple continuous laser shock and high-density continuous laser shock courses.

Owner:JIANGSU UNIV

Defibrillator with overridable CPR-first protocol

Methods and apparatus are provided for determining a defibrillation treatment protocol in an external defibrillator whereby a user may override a CPR-first default protocol. The method includes following steps configured in a defibrillator controller of issuing an inquiry; waiting for a response to the inquiry for a set time; ordering a CPR treatment protocol if no response is received within the set time; analyzing a response; ordering a CPR treatment protocol upon receiving a non-affirmative response to the inquiry; and ordering a shock treatment protocol upon receiving an affirmative response to the inquiry. Upon selecting a shock treatment protocol, the defibrillator performs a shock analysis under the shock treatment protocol, and either orders a CPR treatment protocol if shock treatment is not indicated by the shock analysis or provides a defibrillation shock if shock treatment is indicated by the shock analysis. Queries may be presented to a user in visual, audible, or both visual and audible format.

Owner:PHYSIO CONTROL INC

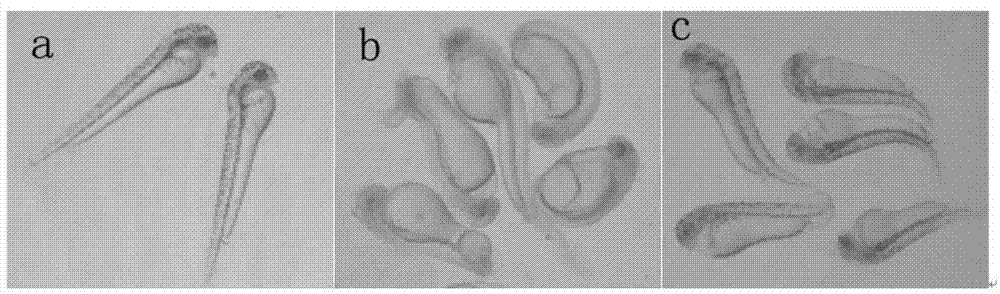

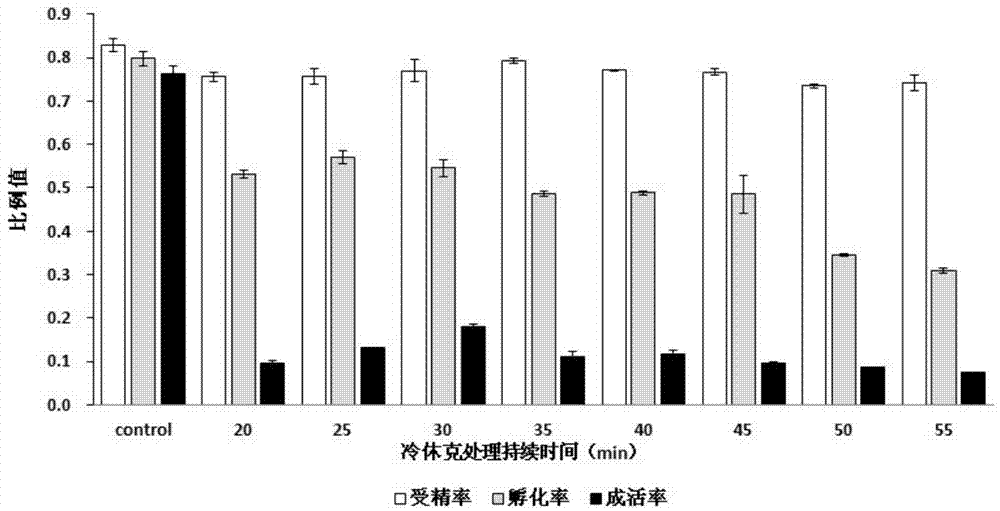

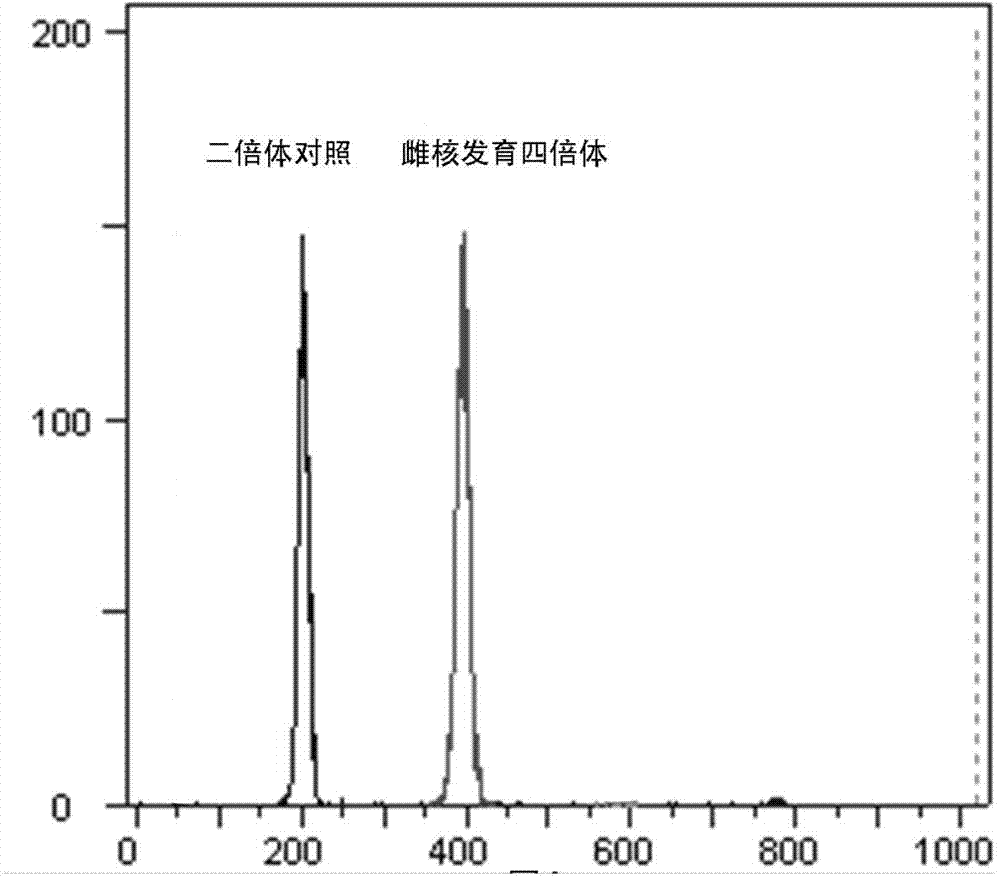

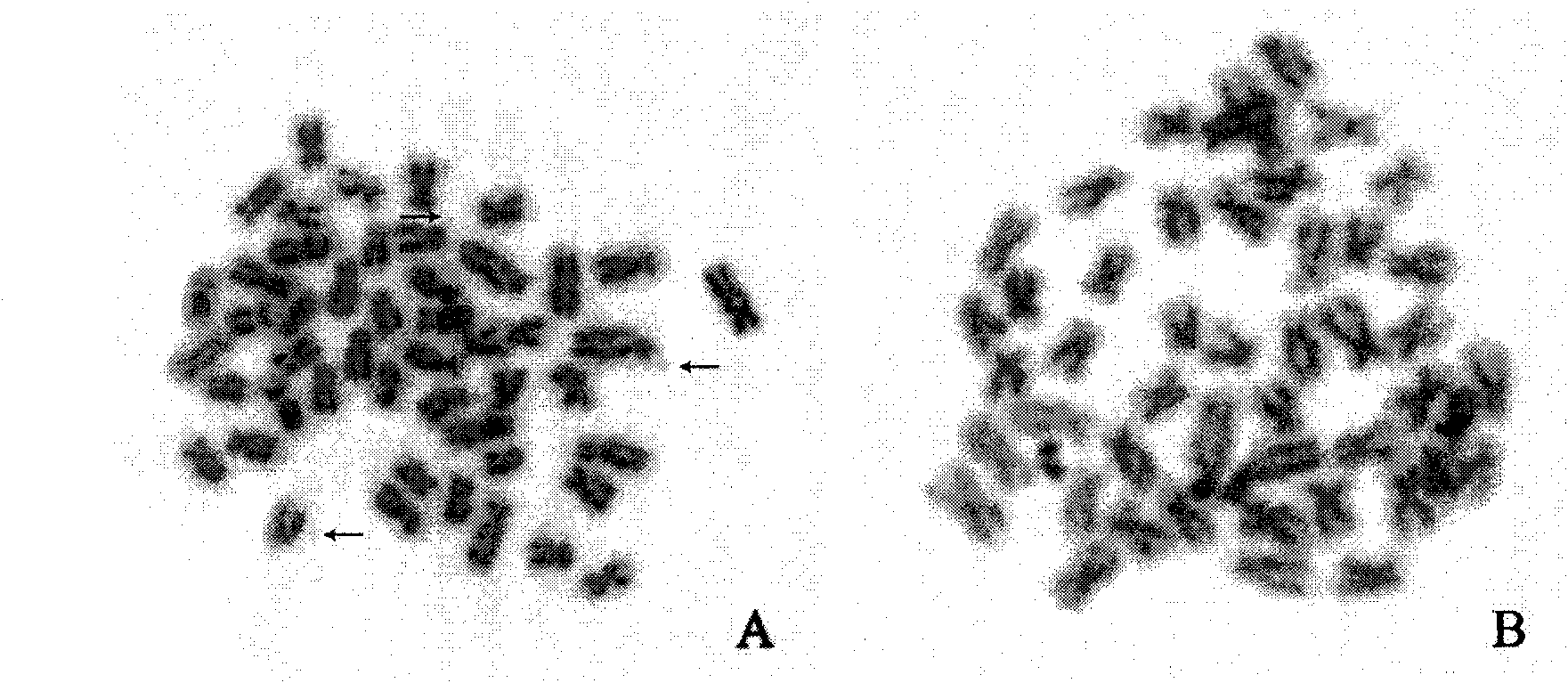

Method for inducing misgurnus anguillicaudatus gynogenesis tetraploid fries by using heterogenenos sperms

ActiveCN103478054ASimplify the identification problemAdvanced technologyClimate change adaptationPisciculture and aquariaWeatherfishHigh fertility

The invention discloses a method for inducing misgurnus anguillicaudatus gynogenesis tetraploid fries by using heterogenenos sperms. The method comprises the following steps: selecting parents, performing genetic inactivation on sperms, inducing gynogenesis tetraploid fries, and performing cold shock treatment to obtain gynogenesis tetraploid fries. The highest fertility rate, hatching rate and survival rate of the gynogenesis tetraploid misgurnus anguillicaudatus can reach 76.99+ / -2.51%, 54.54+ / -1.87% and 17.9+ / -0.65% respectively. The method disclosed by the invention has the characteristics of advancement, high efficiency, practicability and reliability, and has an important application value and a wide application prospect in the breeding of misgurnus anguillicaudatus.

Owner:HUAZHONG AGRI UNIV

Coating natto and production method thereof

The invention discloses a coating natto which is obtained by inoculating the cooked soybean with bacillus natto to obtain a natto, coating the surface of the pre-frozen natto by a coating agent and vacuum freeze drying. The production method comprises the following steps of: cleaning the soybean; soaking, cooking and cooling with water at room temperature; under the aseptic condition, spraying a bacillus natto fermenting agent on the surface of the soybean; cultivating to obtain the natto; carrying out cold shock treatment and pre-freezing treatment on the natto at low temperature; under the aseptic and low-temperature conditions, coating the surface of the natto by the coating agent; feeding the natto in vacuum freeze drying equipment for freeze drying; and the vacuum packaging the driedcoating natto to obtain a finished product. The viable count of the bacillus natto contained in the coating natto can reach 88*10<8> / g; the relative enzyme activity of the natto kinase can reach 8750IU / g; and the coating natto has diversified flavors and long shelf life and is convenient to carry and eat.

Owner:NANJING SHENGNUO BIO TECH IND

Method for improving freeze-drying survival rate of Lactobacillus acidophilus

InactiveCN102329759AImprove freeze-drying survival rateImprove the immunityBacteriaMicroorganism based processesFreeze-dryingSludge

The invention aims to provide a method for improving the freeze-drying survival rate of Lactobacillus acidophilus. The method comprises the following steps of: culturing the Lactobacillus acidophilus for 18h at the temperature of 37 DEG C, performing sublethal treatment on the Lactobacillus acidophilus, centrifuging for 10 to 15min at the temperature of 4 DEG C at the rotating speed of 7,000rpm, adding skimmed milk and a phosphate buffer solution into bacterial sludge of the Lactobacillus acidophilus, pre-freezing for 8 to 12h at the temperature of -40 DEG C, and putting into a freeze dryer and freeze-drying for 18 to 24h at the temperature of between -50 and -60 DEG C under the vacuum degree of between 4 and 6Pa to obtain bacterial powder of the Lactobacillus acidophilus. In the method for improving the freeze-drying survival rate of the Lactobacillus acidophilus, a Lactobacillus acidophilus culture solution is subjected to cold shock, heat shock or acid shock treatment first so as to ensure that the Lactobacillus acidophilus induces to synthesize cold shock protein and heat shock protein under adverse circumstances or changes the composition of fatty acid of cell membranes, so that the resistance of the Lactobacillus acidophilus in the subsequent freeze-drying process is improved, and the freeze-drying survival rate and the viable count of the bacterial powder are improved.

Owner:SHAANXI RES INST OF AGRI PRODS PROCESSING TECH +1

Treating method for improving strength and toughness of aluminum alloy materials

The invention discloses a treating method for improving strength and toughness of aluminum alloy materials. The treating method for improving the strength and the toughness of the aluminum alloy materials comprises solution treatment and aging treatment, and further comprises subzero treatment after the aging treatment and ultrasonic filed shock treatment in the process of the subzero treatment. The process of the subzero treatment comprises the steps of cooling the aluminum alloy materials to ultralow temperature at minus 196DEG C from the starting room temperature at the cooling speed 1-10DEG C / min, and holding the temperature for 12-30 hours. Preferably, the ultrasonic filed shock treatment is carried out at the late period of the subzero treatment, the intensity of an ultrasonic field is 1-50Kw / m2, the frequency of the ultrasonic field is 10-40KHZ, and the treating time in the ultrasonic field is 60-200 seconds. The aluminum alloy materials after the subzero treatment and the ultrasonic field shock treatment are put into an oven which is 110DEG C in temperature, the holding time is 2-6 hours, and then the aluminum alloy materials in the oven are put in air to recover to the room temperature naturally. According to the treating method for improving the strength and the toughness of the aluminum alloy materials, the aluminum alloy materials are made to be compact in structure and small in residual stress, and the roughness is synchronously improved to a large extent.

Owner:CHANGZHOU RUNYUAN WARP KNITTING MACHINERY

Gynogenesis method of grass carp and application thereof

ActiveCN101669449AImprove hatchabilityHigh activityClimate change adaptationPisciculture and aquariaOosporeShock treatments

The invention discloses a gynogenesis method of grass carp and application thereof. The method comprises the following steps: taking the diploid sperms of a properly inactivated allotetraploid cruciancarp as a stimulus to stimulate mature eggs of the grass carp, after activating for 2-3 min or fertilizing for 20-22 min, carrying out the water-cooling shock treatment for 10-12 min at 4-6 DEG C, and hatching and controlling the temperature by to obtain the gynogenesis grass carp restraining the discharge of a second polar body or the first cleavage. The method greatly improves the hatching rateand the survival rate of the gynogenesis diploid grass carp, simplifies the preparation process, and can prepare a gynogenesis grass carp colony with good characters and stable heredity.

Owner:HUNAN NORMAL UNIVERSITY

Method for inducing gynogenetic diploid of grouper

InactiveCN101926300AAccelerated homozygosityExcellent genetic traitsClimate change adaptationPisciculture and aquariaOosporeSemen

The invention discloses a method for inducing gynogenetic diploid of grouper, which comprises the following steps of: diluting semen of the grouper, and radiating the semen by using ultraviolet rays to make the heritability of the semen deactivated; mixing with mature eggs of the grouper; after the eggs are fertilized, transferring to seawater for cold shock treatment to double genomes and generate the gynogenetic diploid; and transferring to seawater, and managing according to common grouper fry to obtain the gynogenetic diploid of the grouper. The offspring generated by induction only contains the gene of the female parent, the homozygosis of good genes can be quickened, and good hereditary features are quickly fixed; and the method can be applied to genetic analysis of the grouper, and has wide application prospect in the aspects of culture and breeding of the grouper.

Owner:SUN YAT SEN UNIV

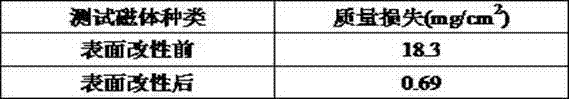

Method for modifying mechanical surface of sintered nd-fe-b magnet based on plastic constraint

ActiveCN103646776AImprove corrosion resistanceReduce impact brittlenessInductances/transformers/magnets manufactureGrain boundaryAbsorption layer

The invention discloses a method for modifying a mechanical surface of a sintered nd-fe-b magnet based on plastic constraint, and relates to surface modification technologies of permanent magnet materials. The method mainly comprises the steps that 1) the surface, to be processed, of the sintered nd-fe-b magnet is pretreated; 2) an absorption layer and a restraint layer are arranged on the surface, to be processed, of the sintered nd-fe-b magnet; 3) the unprocessed surface of the sintered nd-fe-b magnet is covered with plastic tough metal; 4) low-energy laser shock treatment is carried out on the covered surface, to be processed, of the sintered nd-fe-b magnet; 5) laser surface heat treatment is carried out on the cleaned surface of the sintered nd-fe-b magnet after the shock treatment; 6) the steps 2)-5) are repeated, the low-energy laser shock treatment and the laser surface heat treatment are carried out many times, and the sintered nd-fe-b magnet with the modified surface is obtained. The surface crystalline grains of the sintered nd-fe-b magnet can be effectively refined, surface layer grain boundary rich neodymium phase distribution can be homogenized, and the corrosion resisting performance of the sintered nd-fe-b magnet can be improved obviously. The method is simple in process, easy to operate, and suitable for large-scale and mass production.

Owner:东台城东科技创业园管理有限公司

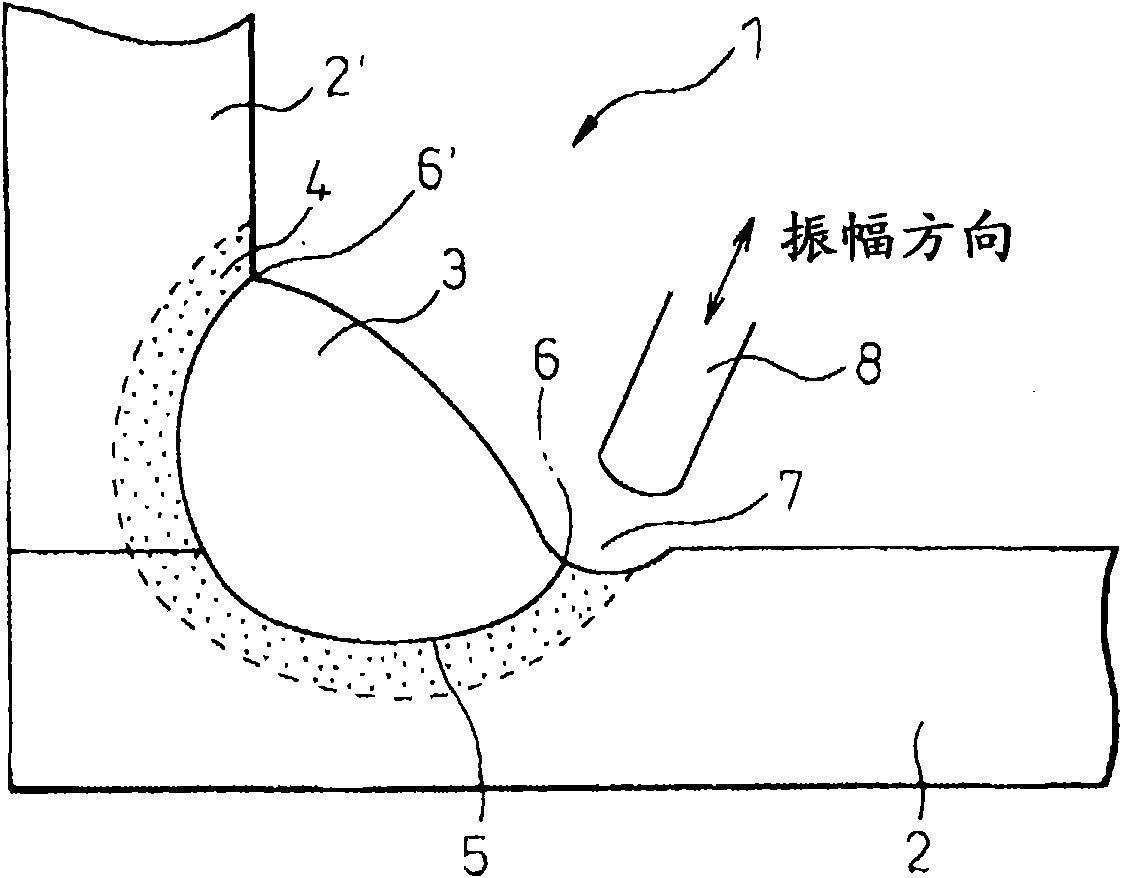

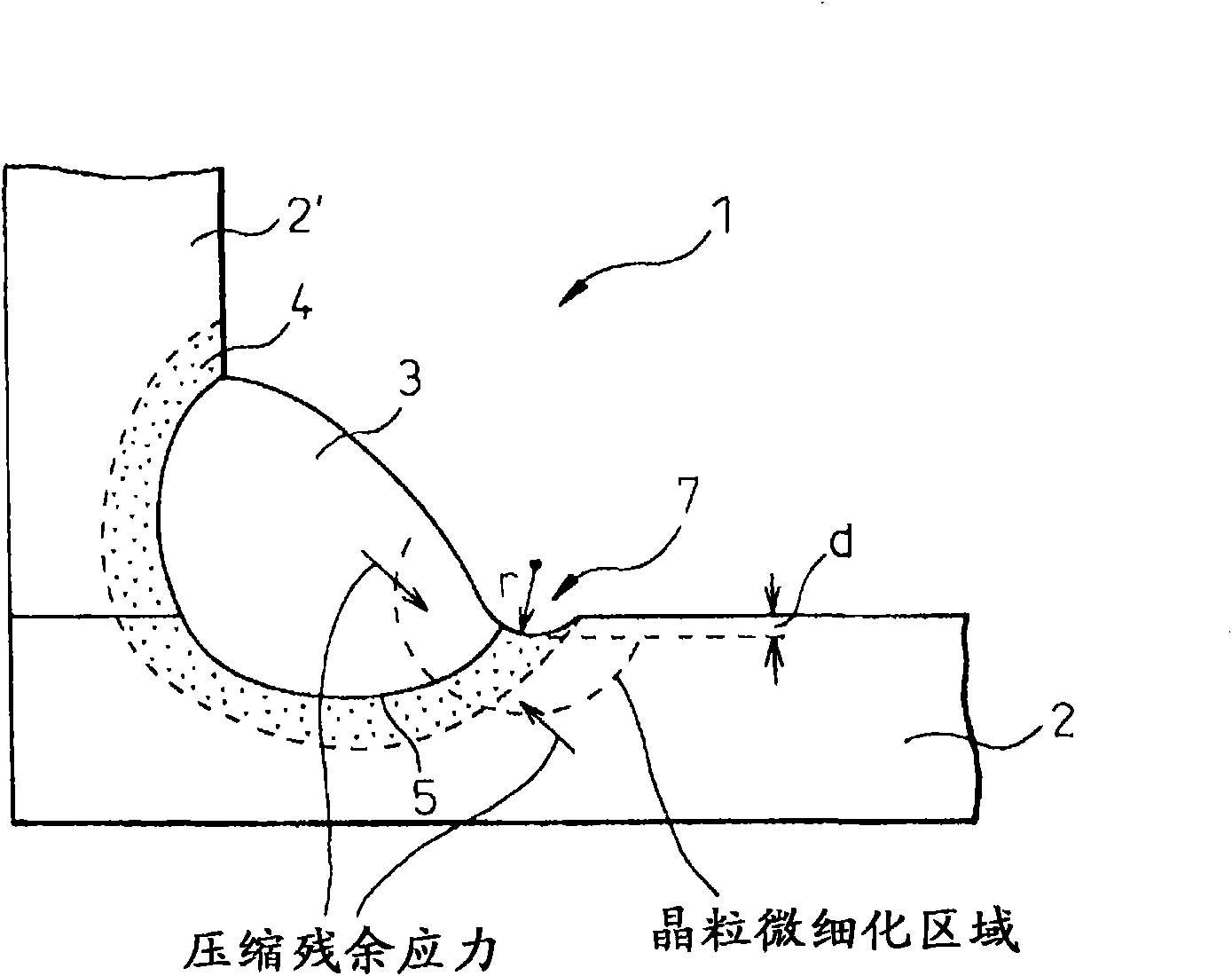

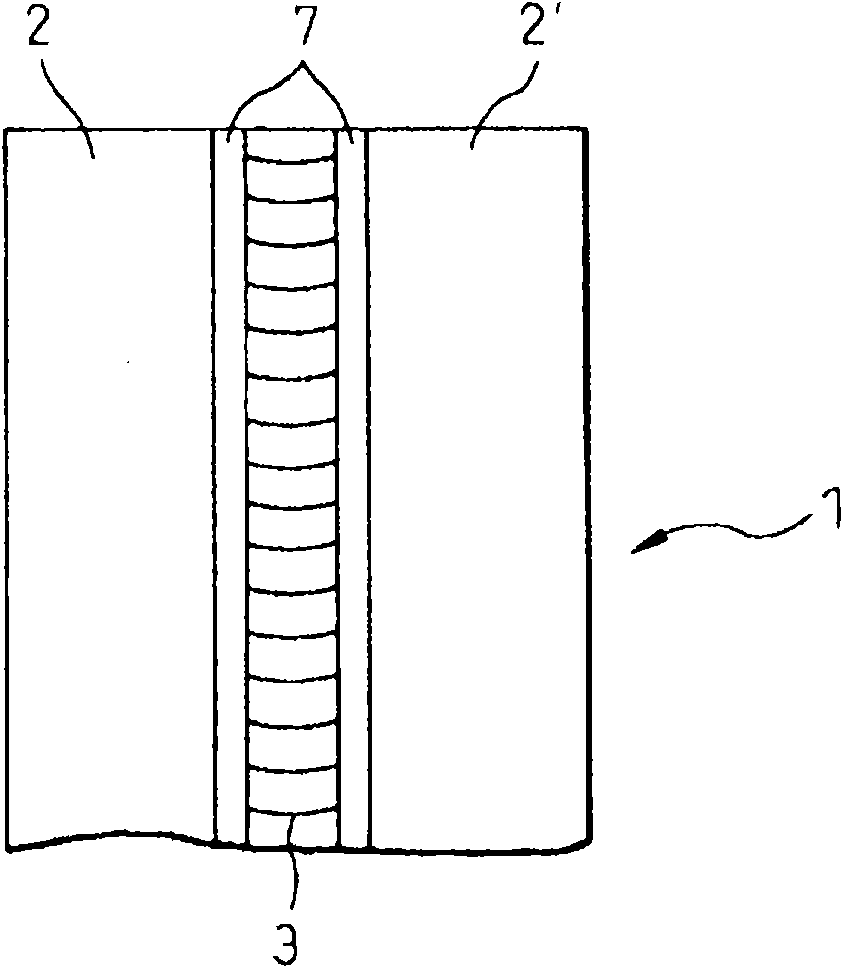

Welded joint with excellent fatigue-resistance characteristics, and method for producing same

ActiveCN101678511AImprove fatigue strengthInhibition of fatigue cracksArc welding apparatusWelding/cutting media/materialsHeat-affected zoneMetallurgy

Provided are: a welded joint that exhibits the effect of ultrasonic shock treatment more efficiently, and has improved fatigue-resistance characteristics; and a method for producing the joint. In thisjoint, the average hardness of the weld zone and of the heat-affected zone is 15% to 50% higher than that of the steel stock, and at the weld toe, an ultrasonic shock scar is formed which has a radius of curvature r of 1.0 to 10.0 mm at the cross-section perpendicular to the weld-line, and a thickness d of 1.0 mm or less from the surface of the steel stock.

Owner:NIPPON STEEL CORP

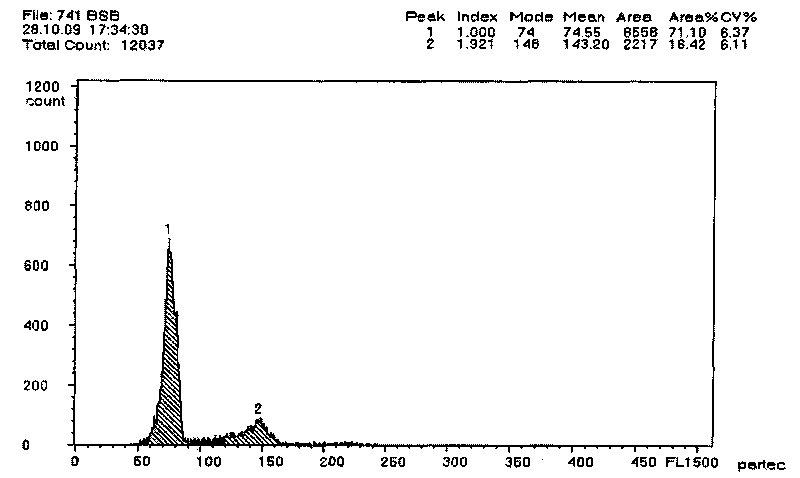

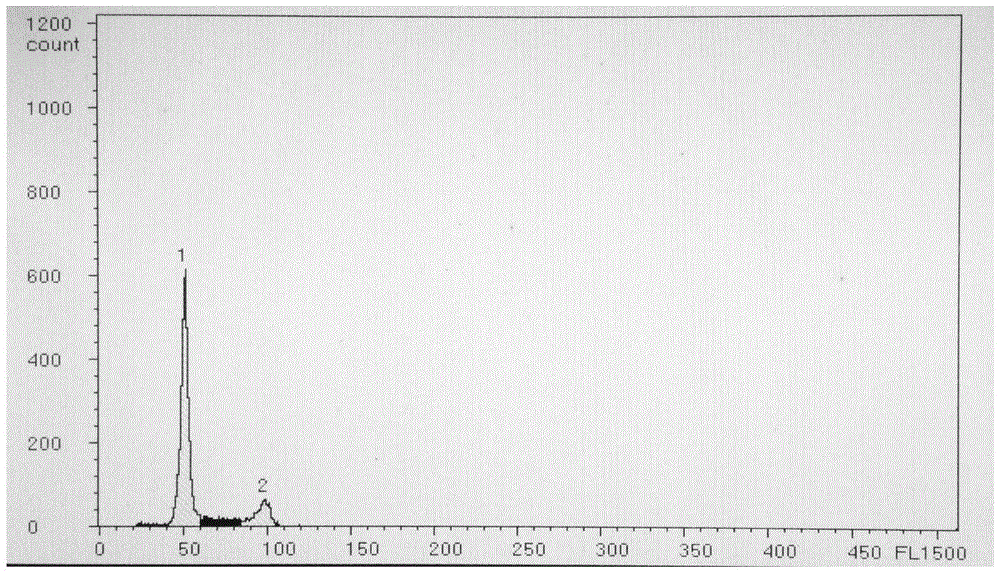

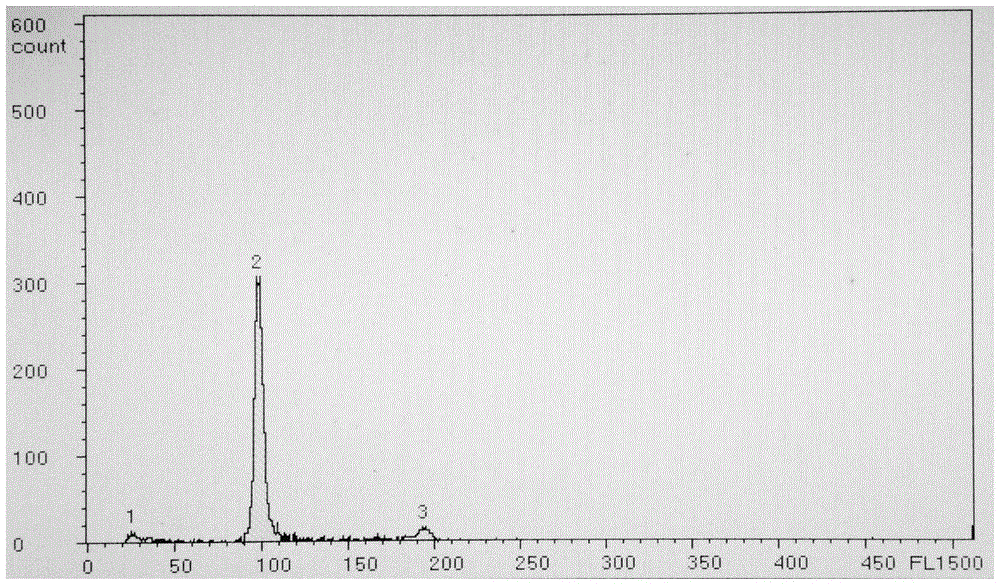

Cultivation method of gynogenesis megalobrama amblycephala

ActiveCN101720697AFacilitates genetic researchShorten breeding timeClimate change adaptationPisciculture and aquariaEmbryoPloidy

The invention discloses a cultivation method of a gynogenesis megalobrama amblycephala, which comprises the following steps of: firstly selecting and breeding a female megalobrama amblycephala and a male erythroculter ilishaeformis bleeker as parent fishes; then carrying out artificial induced spawning to obtain the sperms of the erythroculter ilishaeformis bleeker and the ripe ovums of the megalobrama amblycephala; mixing the erythroculter ilishaeformis bleeker sperms inactivated by ultraviolet rays with the ripe ovums of the megalobrama amblycephala; 3-4 minutes later, placing the ovums activated at 0-4 DEG C for cold shock treatment for 20-30 minutes; and after incubating embryos treated by cold shock at 23-24 DEG C, obtaining diploid gynogenesis megalobrama amblycephalas through a flow type cell DNA content determination method and a chromosome ploidy detection method of peripheral blood cell culturing. The cultivation method of the gynogenesis megalobrama amblycephala has the advantages of short cultivation time, fast growth speed, high incubation rate, excellent offspring property, and the like, and has great importance on aspects of fish inheritance breeding and biological evolution researches.

Owner:HUNAN NORMAL UNIVERSITY

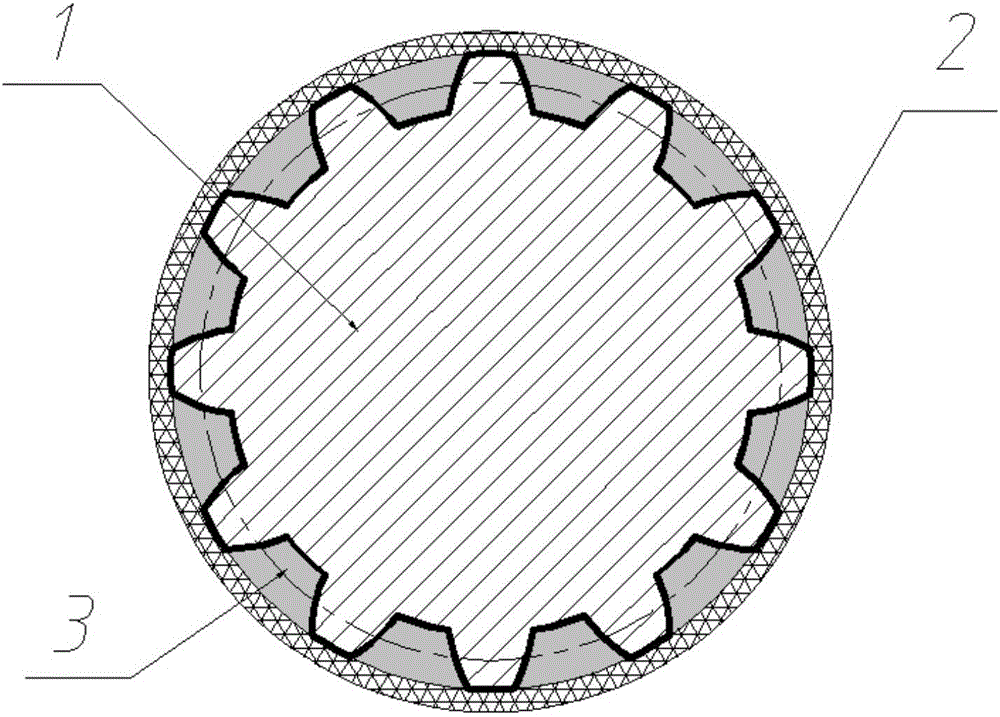

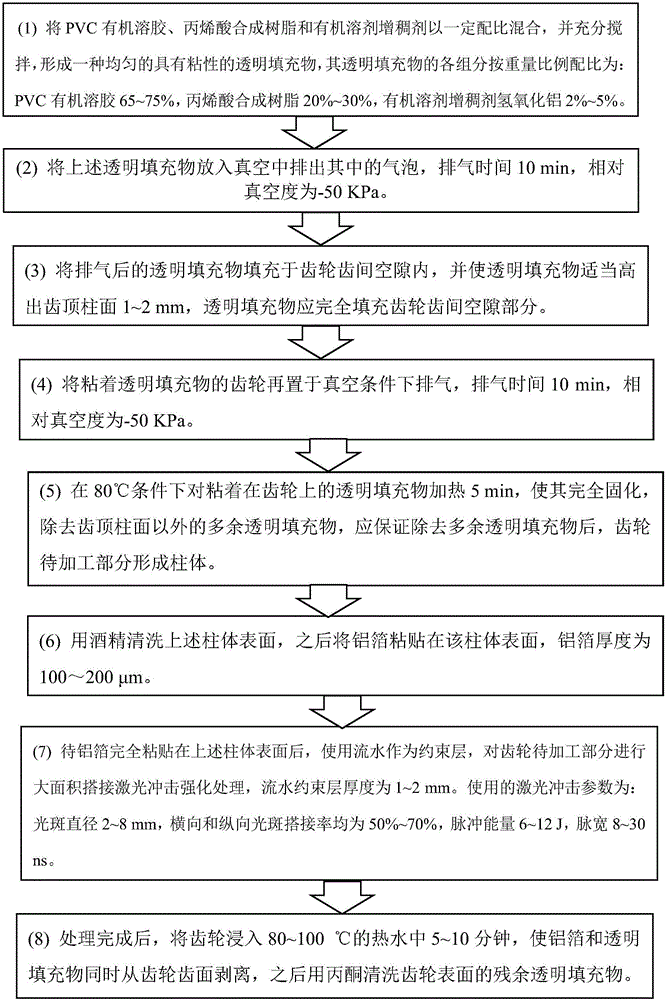

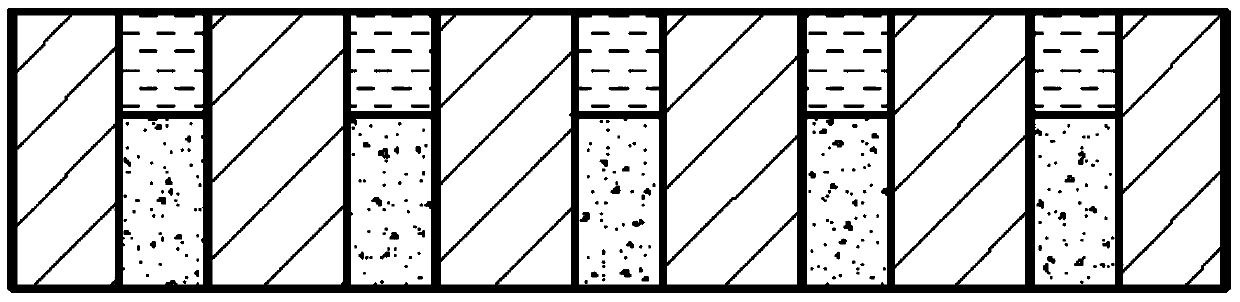

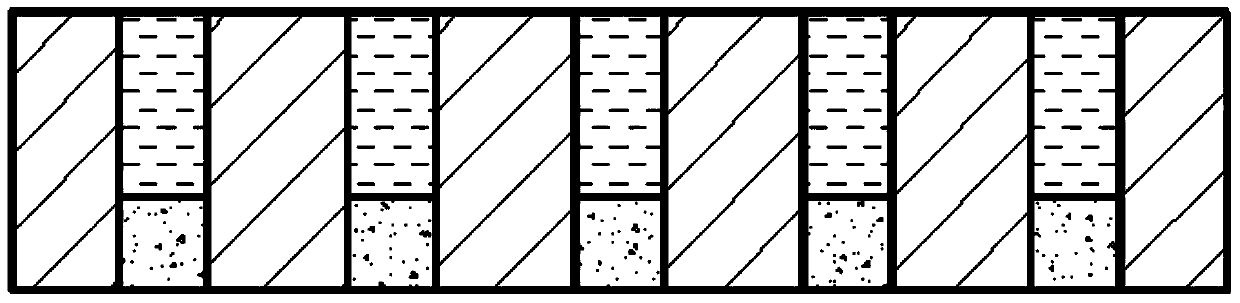

Laser shock strengthening method for small-pitch gear surface

InactiveCN105936974AEasy to cleanFacilitate large-area overlapping laser shock treatmentFurnace typesHeat treatment furnacesShock treatmentsGear tooth

The invention relates to a laser surface shock strengthening technology, and in particular to a laser shock strengthening method for a small-pitch gear surface. The method can be expanded into surface strengthening of a small-pitch spline male die and a fine-pitch thread. The method is characterized in that clearances among teeth of a gear are filled with transparent fillers prepared by mixing materials in ratio, and the clearances are full of the transparent fillers in order to form a column body by the gear and the transparent fillers; then an aluminum foil is adhered to the column surface to be used as an energy absorbing layer; the gear surface can be subjected to large-area overlapping laser shock treatment under the condition that running water is used as a limiting layer. The method has the advantages that the clearances among the teeth of the gear are fully filled with the transparent fillers, and the tops of the teeth of the gear and the transparent fillers can form a smooth column surface, thus the large-area overlapping laser shock treatment can be conveniently carried out for the gear, and as a result, the laser shock strengthening effect can be greatly improved; and after the shock treatment, the transparent fillers in the clearances among the teeth of the gear can be easily removed, so that the demand of mass production can be met.

Owner:JIANGSU UNIV

Preparation method of hemp stalk activated carbon

ActiveCN108706585AEffective dissolutionWill not remainCarbon compoundsTetramethylammonium hydroxideActivated carbon

The invention discloses a preparation method of hemp stalk activated carbon, belonging to the technical field of the preparation of activated carbon. The preparation method comprises the following steps: roasting hemp stalks under the protection of a nitrogen atmosphere, cooling to room temperature so as to obtain hemp stalk carbon, and grinding the hemp stalk carbon to a particle size below 300 meshes; mixing granulated hemp stalk carbon with tetramethylammonium hydroxide, and heating and stirring to realize pretreatment, so as to obtain pretreated hemp stalk carbon; mixing the pretreated hemp stalk carbon with sodium ethoxide, adding water, stirring, carrying out shock treatment under an ultrasonic wave condition, roasting the obtained hemp stalk carbon under the protection of the nitrogen atmosphere, and naturally cooling to room temperature; and activating, soaking the hemp stalks into a cationic guar gum solution, washing by virtue of distilled water until the hemp stalks are neutral, drying, grinding, and sieving by virtue of a 80-200-mesh sieve, so as to obtain the hemp stalk activated carbon. The hemp stalk activated carbon prepared by virtue of the preparation method has relatively high adsorptive property.

Owner:KUNMING UNIV OF SCI & TECH

Electric arc additive manufacturing method with adjustable laser shock

PendingCN112329161AReduce residual stressOptimum Laser Shock Working ParametersGeometric CADDesign optimisation/simulationEngineeringShock treatments

The invention belongs to the field of electric arc additive manufacturing, and particularly relates to a laser shock adjustable electric arc additive manufacturing method. The method comprises the following steps: (1) obtaining a machining path of an electric arc additive; (2) setting a temperature threshold; (3) obtaining the stress field distribution of the electric arc additive manufacturing component in real time by adopting a numerical simulation method; (4) setting a laser impact path and setting laser beam parameters; (5) setting technological parameters of arc additive manufacturing, and carrying out layer-by-layer wire arc manufacturing; (6) repeating the steps (3) and (4), and carrying out laser shock treatment on the weld bead to eliminate residual stress; and (7) repeating thestep (5) and the step (6) until the electric arc additive manufacturing component is machined. Numerical simulation and laser shock are combined and applied to electric arc additive manufacturing, sothat residual stress conditions of different areas correspond to laser shock parameters, the optimal laser shock working parameters are adjusted and maintained in real time, and the forming precisionis effectively controlled.

Owner:NANJING UNIV OF SCI & TECH

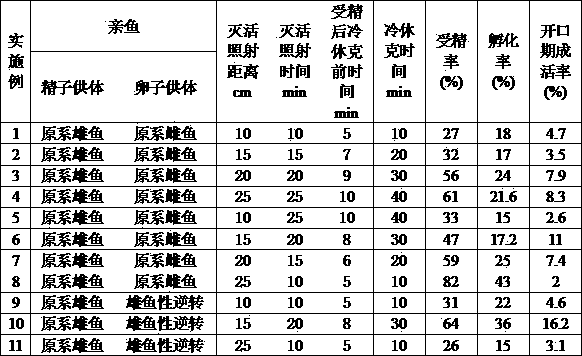

Artificially induced gynogenesis method for Pseudobagrus ussuriensis

ActiveCN103404461AAvoid toxic effectsIrradiation equipment is simple and easy to operateClimate change adaptationPisciculture and aquariaPlant Germ CellsHigh survival rate

The invention discloses an artificially induced gynogenesis method for Pseudobagrus ussuriensis, comprising the steps of heredity inactivation of sperms, cold shock treatment of germ cells, and hatching; the best time for inactivating the sperms of the Pseudobagrus ussuriensis is found out by regulating the irradiation distance and the irradiation time of ultraviolet; the cold shocks with different time spans are carried out at different time starts after fertilization, the treatment time for a highest survival rate is determined to be the proper time span of the cold shock, and thus the optimal condition suitable for artificially induced gynogenesis of the Pseudobagrus ussuriensis is screened out. According to the technical route of milter sex reversal-artificial gynogenesis-super-milter cultivating-complete milter cultivating, the invention provides a technological base for cultivating the super-milter of the Pseudobagrus ussuriensis and cultivating the monotropic complete milter, so that the cultivation scale is exoanded and the yield is greatly increased, so that the income of farmers is greatly increased, and therefore, the method has a broad industrialized cultivation prospect.

Owner:HUAIYIN TEACHERS COLLEGE

Induction and detection method for androgenesis dihaploid of Paralichthys olivaceus

ActiveCN105230533AEasy to operateEliminate useClimate change adaptationPisciculture and aquariaGenetic MaterialsIrradiation

The invention relates to an induction and detection method for androgenesis dihaploid of Paralichthys olivaceus. The induction and detection method provided by the invention has the beneficial effects that nuclear genetic materials in eggs can be deactivated by only carrying out cold-shock treatment on the fertilized eggs for a certain time, the effect the same as that achieved by ray irradiation deactivation in the traditional androgenesis induction techniques is achieved; and hydrostatic treatment is adopted, the androgenesis dihaploid of the Paralichthys olivaceus can be rapidly prepared.

Owner:中国水产科学研究院北戴河中心实验站

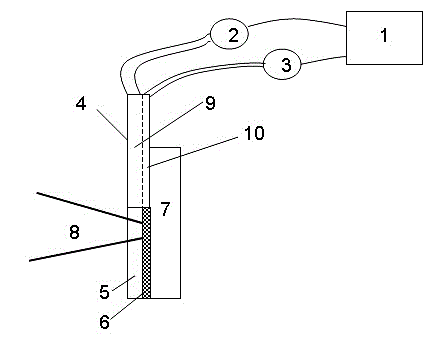

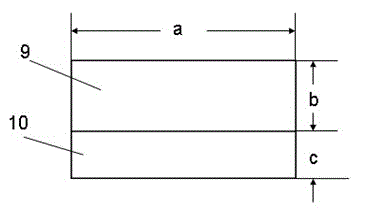

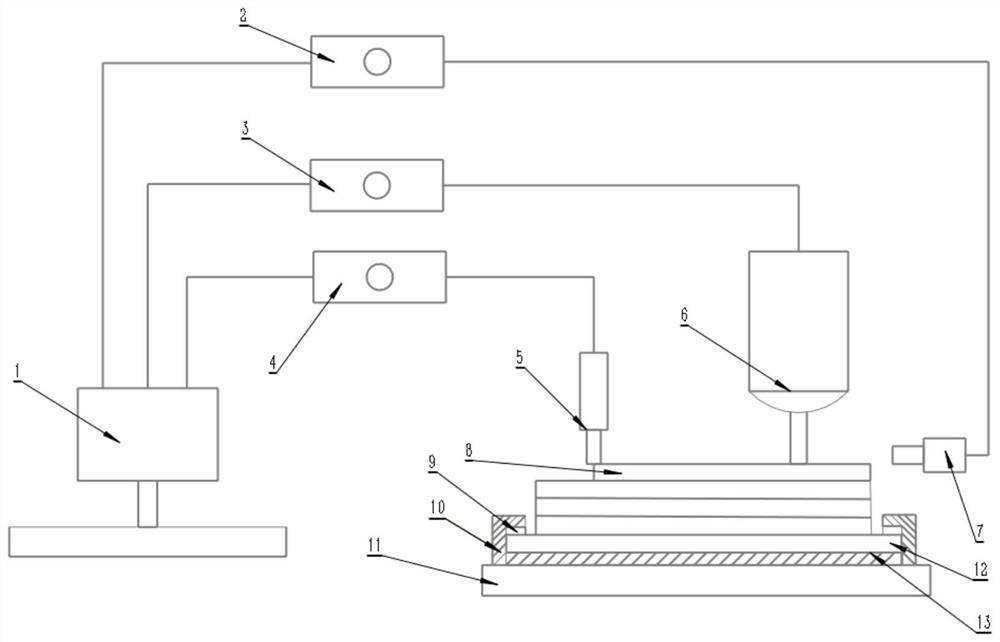

Laser shock treatment method and device of porous plate

The invention relates to a laser shock treatment method of a porous plate. By using a transparent liquid and glass as a composite restraint layer and a viscoelastic fluid material as an absorption layer, the position of the viscoelastic fluid in pores is changed through the pressure of the transparent liquid, so that all the pore walls are treated. The device is composed of a laser generator, a compression screw, a clamp, a pressure plate, glass, a water tank, an upper cylinder, a water inlet pipe, a seal ring, a workpiece, a lower cylinder, a worktable, a worktable control unit. a computer, a laser generator control unit, a viscoelastic fluid and a transparent liquid. When the porous plate is subjected to laser shock treatment, since the laser penetration depth of the viscoelastic fluid is small, the energy is concentrated on the upper surface of the viscoelastic fluid, and thus, the shock strength is obviously enhanced as compared with the liquid absorption layer. Besides, the flowability of the viscoelastic fluid is poor, and the attenuation of shock waves penetrating through the viscoelastic fluid is small, so the glass is utilized to restrict the splash of the transparent liquid, thereby further enhancing the laser shock effect.

Owner:JIANGSU UNIV

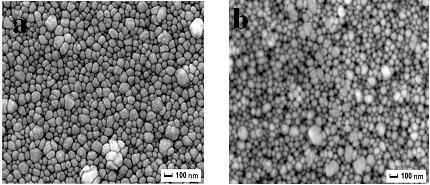

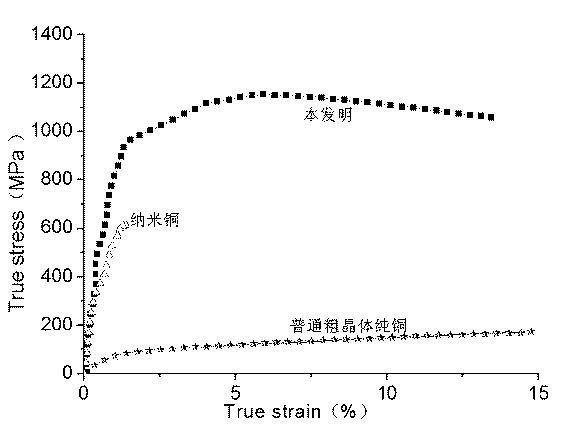

High-strength high-conductivity nanocrystal copper material and preparation method thereof

ActiveCN102031490AHigh purityHigh densityMaterial nanotechnologyVacuum evaporation coatingImpulse frequencyMechanical property

The invention relates to nanocrystal metal materials, in particular to a high-strength high-conductivity nanocrystal copper material and a preparation method thereof. An electrodeposited nano metal copper material is subjected to laser shock treatment at room temperature, wherein laser shock parameters are that: the impulse frequency is 5ns, the shock power is 60-80mJ, the spot size is 2mm, the wavelength is 1,064nm, the selected coating is an aluminum foil with the thickness of 15 mu m, and a restraint layer is made of K9 glass; and an overlapping shock treatment method is adopted, the overlapping rate is 33 percent and the strain rate is 1*10<-6>-1*10<-7> / s. For the nanocrystal copper material prepared by the method, the hardness is improved by 36 to 55 percent, the elastic modulus is improved by 60 to 207 percent, the comprehensive mechanical properties are greatly improved, and the resistivity rho is reduced from 1.52-1.58 to 1.34-1.38 correspondingly, and the nanocrystal copper material can simultaneously meet the requirements on high strength and high conductivity.

Owner:JIANGSU UNIV

High-efficient induction method of tetraploid cynoglossus semilaevis fish fries

InactiveCN102090360AImprove induction efficiencyInduction efficiency is stableClimate change adaptationPisciculture and aquariaFisheryCynoglossus semilaevis

The invention relates to a high-efficient induction method of tetraploid cynoglossus semilaevis fish fries, and the method comprises the steps of induction of the tetraploid cynoglossus semilaevis fish fries and identification of the tetraploid cynoglossus semilaevis fish fries, and is characterized by performing pressure shock treatment for 3.5-6 minutes under hydrostatic pressure of 38-44MPa within 19-28 minutes after fertilization; and transferring fertilized eggs into seawater at the temperature of 19-23 DEG C for culture and incubation after completing the shock treatment. According to the invention, a technical method which can be used for effectively inducing the fertilized eggs of cynoglossus semilaevis to produce tetraploid fish fries in a doubled manner is established, and a technical parameter for inhibiting the first cleavage of the eggs of the cynoglossus semilaevis is firstly determined. The method is simple to operate, strong in practicality, easy to implement, safe and reliable; and the induction efficiency of the tetraploid fish fries is high. By adopting the method, a new technical approach is provided for the sex control and polyploid breeding of the cynoglossus semilaevis.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Preparation method for triploid grouper

ActiveCN103004653ASpeed up the processFast growthClimate change adaptationPisciculture and aquariaEcological environmentPlant Germ Cells

The invention discloses a preparation method for a triploid grouper, which comprises the following steps: selecting different types of triploid groupers with the genetic relationship of 0.140 to 0.145 genetic distances as parent fishes; adopting a dry method to perform artificial fertilization and distant hybridization; transferring germ cells into seawater after fertilization to perform cold shock treatment; and catching and domesticating for culture of seedlings and identifying the triploid groupers. The preparation method has the advantages of short period for breeding, fast growth speed and no influence on the marine ecological environment.

Owner:SUN YAT SEN UNIV

Method of improving quality of room temperature cooked food prefabricated packed meal after reheating

ActiveCN106721870AReduce the intensity of high temperature and high pressure sterilizationImprove reheat qualityFood preservationRoom temperatureEngineering

The present invention discloses a method of improving quality of room temperature cooked food prefabricated packed meal after reheating and belongs to the technical field of prepared food processing. Radiofrequency sterilization, cold shock treatment and radiofrequency reheating are combined to reduce high temperature and high pressure sterilization strength of the prefabricated packed meal, and the method replaces conventional reheating and improves the quality of the prefabricated packed meal after the reheating. The method mainly comprises the following steps: raw material selecting, frying, oil-frying, cooking and stir-frying until half-cooked, cooked rice matching, vacuum sealing, radio-frequency sterilizing, cold shock treating, low temperature storing at 0-5 DEG C, radiofrequency reheating, reheating, and quality sense assessing. The main advantages are as follows: the radiofrequency sterilization is combined with the cold shock treatment and radiofrequency reheating, and the method meets the sterilization conditions, reduces the high temperature and high pressure sterilization strength, uses radiofrequency reheating to replace the conventional reheating, and reduces the destroy to the packed meal, especially nutrients and texture structures of the food. After the food is preheated, the sense assessment is conducted and the sense quality score of the product is not very different from that of the food just taken out from a pot.

Owner:JIANGNAN UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com