Method for modifying mechanical surface of sintered nd-fe-b magnet based on plastic constraint

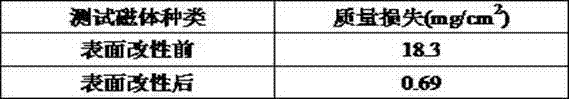

A surface modification, NdFeB technology, applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of increasing the cost of magnets, damaging the magnetic properties of magnets, etc., reducing impact brittleness and improving corrosion resistance. , the effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) The sintered NdFeB magnet Nd 12 Dy 1 Fe 79.4 co 2 B 5.5 Zr 0.1 Grinding, polishing, cleaning and drying of the surface to be processed;

[0025] 2) Coating black paint on the surface of the sintered NdFeB magnet to be processed as an absorbing layer, and then fixing glass on it as a constraining layer;

[0026] 3) Cover the non-processed surface of the sintered NdFeB magnet with metal aluminum;

[0027] 4) The surface of the wrapped sintered NdFeB magnet to be processed is subjected to low-energy laser shock treatment with a nanosecond pulse laser, the laser pulse energy is 5J, the laser pulse width is 40ns, the spot diameter is 5mm, and the overlap rate is 20%;

[0028] 5) Clean the surface of the sintered NdFeB magnet after impact treatment, and use continuous CO 2 The laser is used for laser surface heat treatment, the laser power is 100W, the scanning speed is 10mm / s, the spot diameter is 0.5mm, and the overlap rate is 40%;

[0029] 6) Repeat steps 2)-5) ...

Embodiment 2

[0033] 1) The sintered NdFeB magnet Nd 11 PR 4 Dy 1 Fe 72 Ni 2 B 8 Cu 1.5 Ga 0.5 Grinding, polishing, cleaning and drying of the surface to be processed;

[0034] 2) Paste aluminum foil on the surface of the sintered NdFeB magnet to be processed as the absorbing layer, and then fix glass on it as the constraining layer;

[0035] 3) Cover the non-processed surface of the sintered NdFeB magnet with metallic copper;

[0036] 4) The surface of the wrapped sintered NdFeB magnet to be processed is subjected to low-energy laser shock treatment with a nanosecond pulse laser, the laser pulse energy is 1J, the laser pulse width is 20ns, the spot diameter is 2mm, and the overlap rate is 50%;

[0037] 5) Clean the surface of the sintered NdFeB magnet after impact treatment, and use continuous CO 2 The laser is used for laser surface heat treatment, the laser power is 500W, the scanning speed is 5mm / s, the spot diameter is 2mm, and the overlap rate is 30%;

[0038] 6) Repeat steps ...

Embodiment 3

[0042] 1) The sintered NdFeB magnet Nd 12 Ho 2 Fe 79 B 6 Al 0.5 sn 0.5 Grinding, polishing, cleaning and drying of the surface to be processed;

[0043] 2) Paste aluminum foil on the surface of the sintered NdFeB magnet to be processed as the absorbing layer, and then set flowing water on it as the constraining layer;

[0044] 3) Cover the non-processed surface of the sintered NdFeB magnet with low carbon steel;

[0045] 4) The surface of the wrapped sintered NdFeB magnet to be processed is subjected to low-energy laser shock treatment with a nanosecond pulse laser, the laser pulse energy is 2J, the laser pulse width is 30ns, the spot diameter is 3mm, and the overlap rate is 80%;

[0046] 5) Clean the surface of the sintered NdFeB magnet after impact treatment, and use continuous CO 2 The laser is used for laser surface heat treatment, the laser power is 400W, the scanning speed is 8mm / s, the spot diameter is 1mm, and the overlap rate is 60%;

[0047] 6) Repeat steps 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| laser pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com