Patents

Literature

201 results about "Heat pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

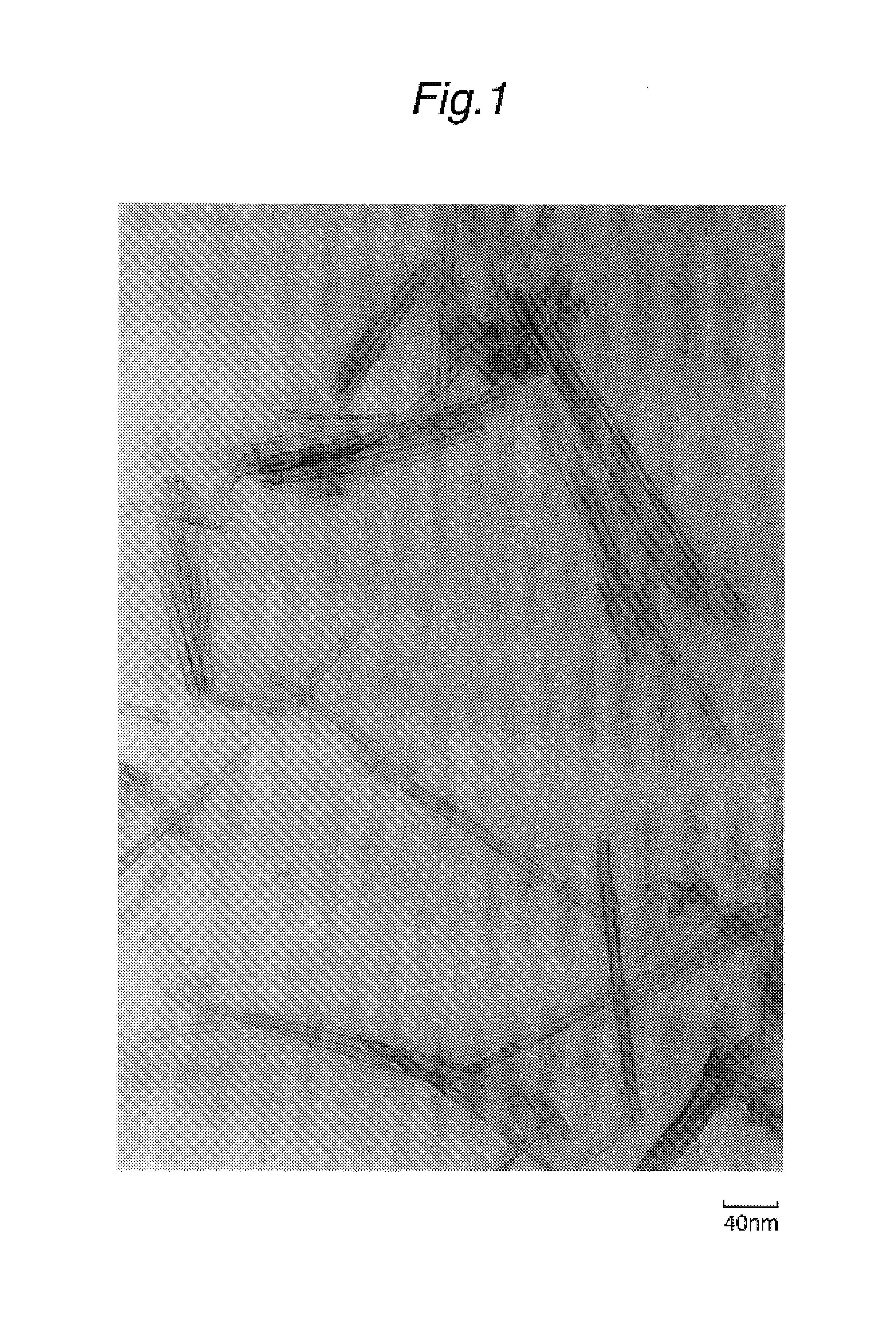

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

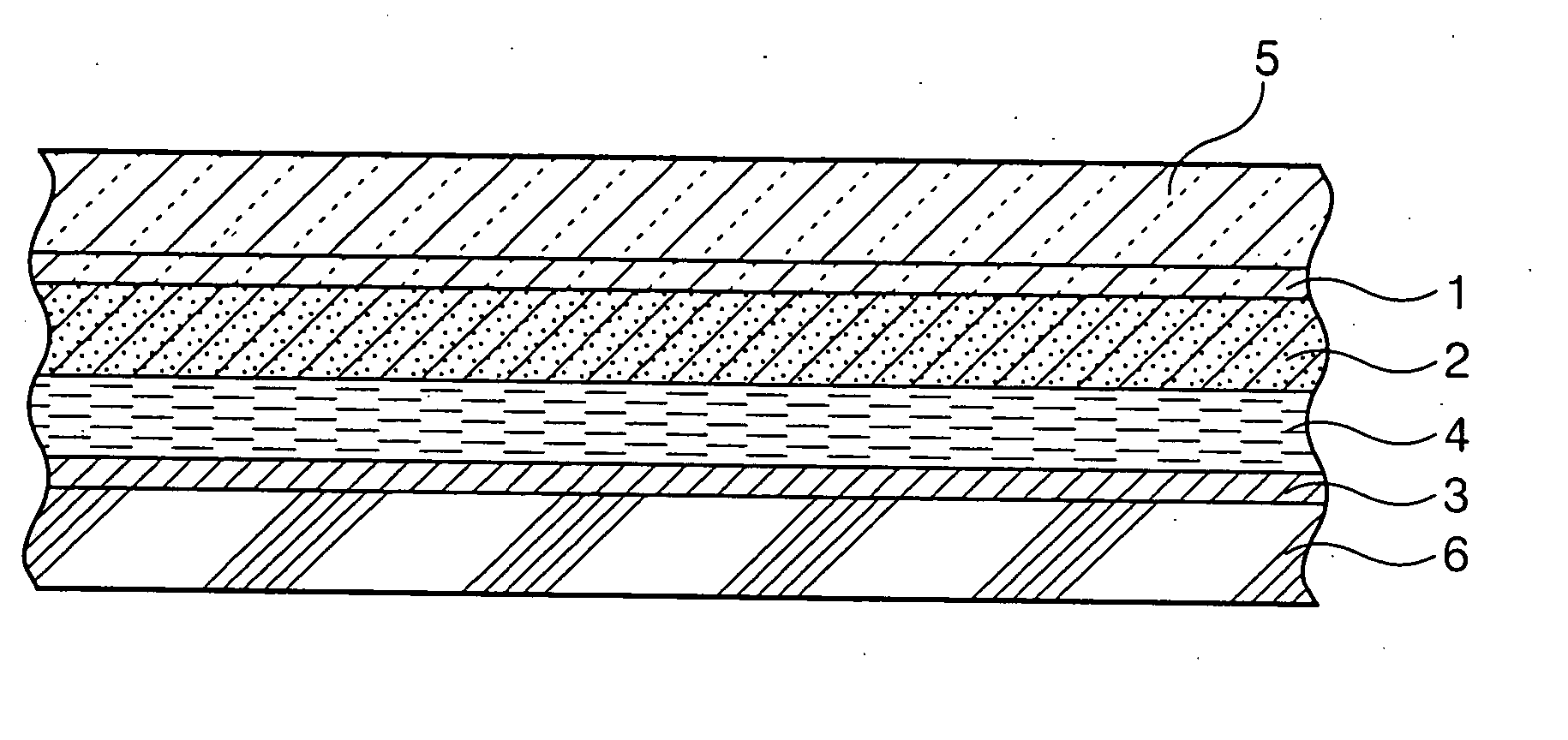

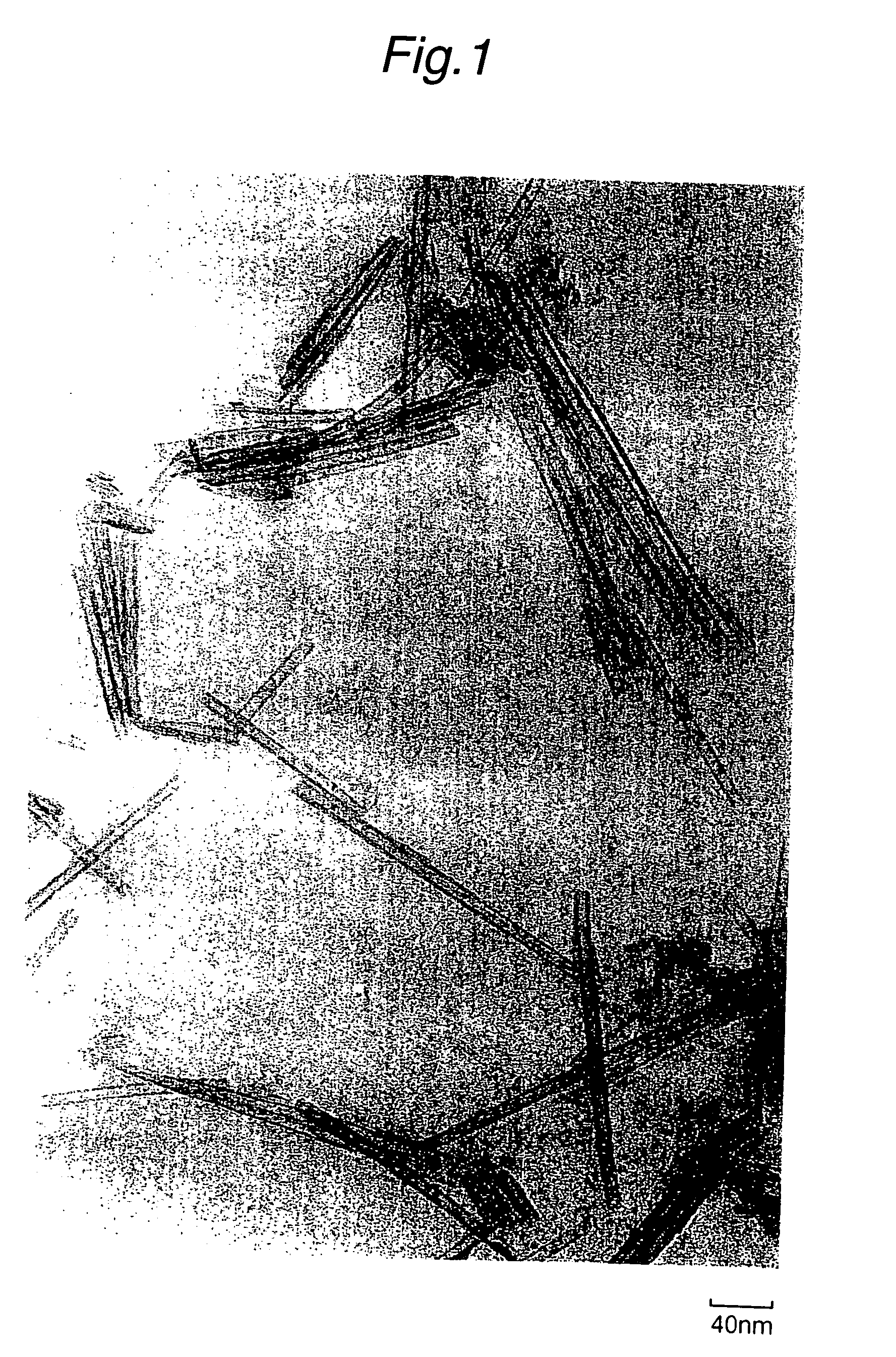

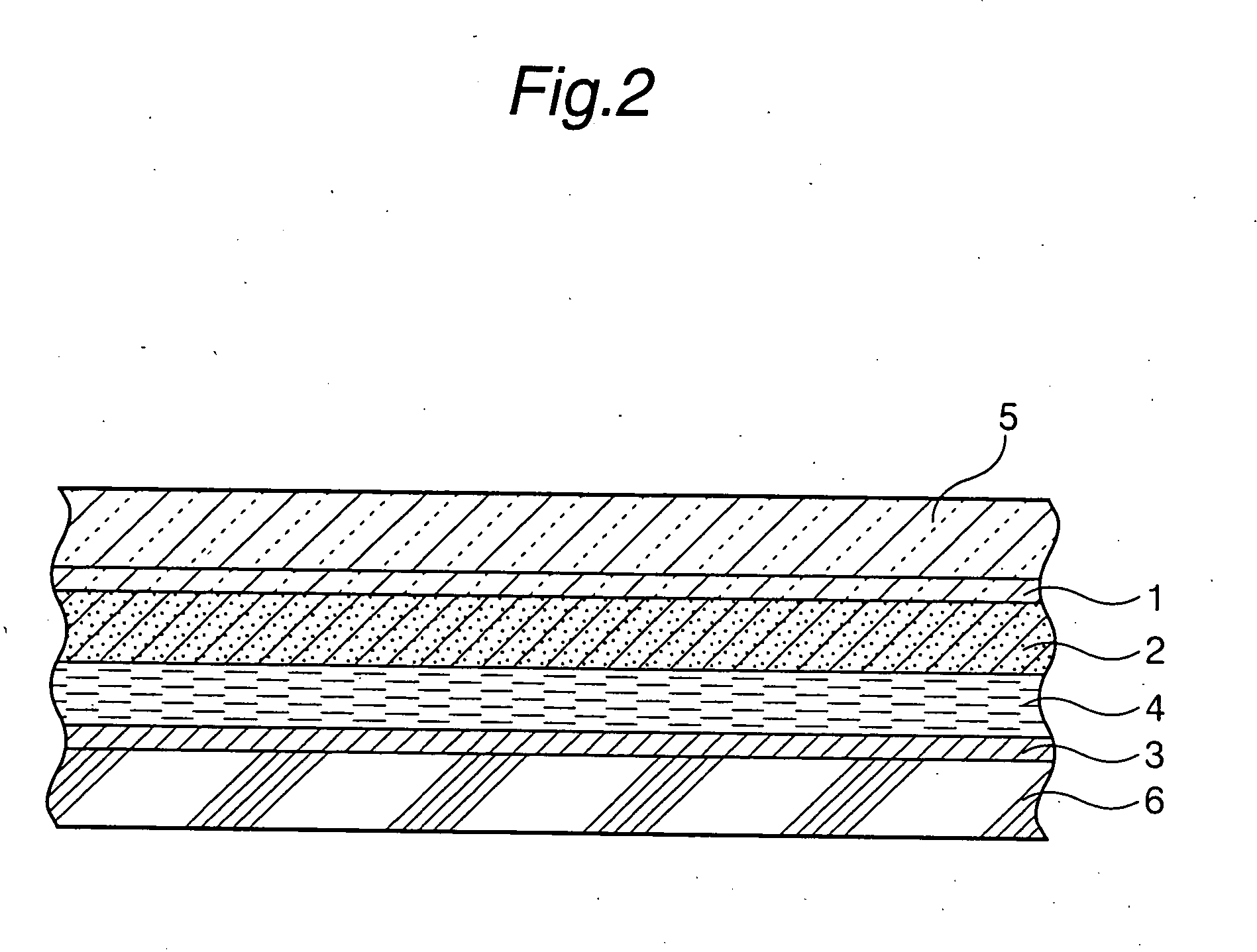

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

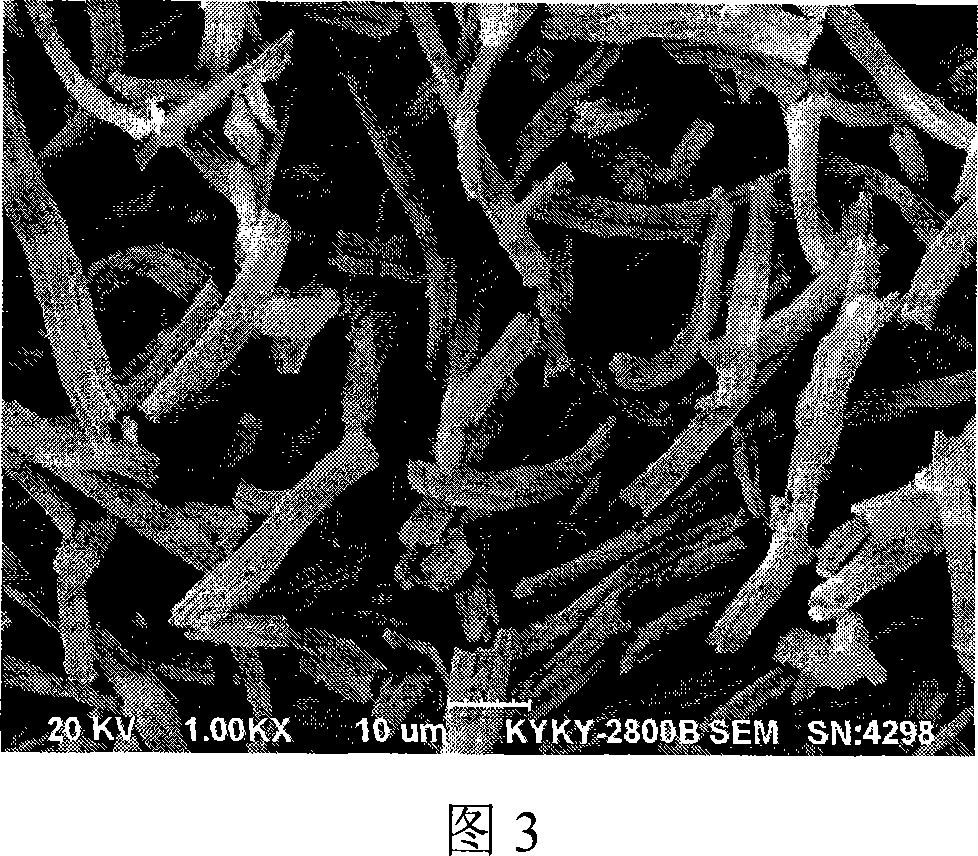

Zirconium oxide fabrics prepared from organic polyzirconium fore spinning solution by silk process

InactiveCN1584155AGood effectRaw materials are cheap and easy to getInorganic material artificial filamentsFuranSolvent

The manufacture method of a kind of zirconia fibre cotton relates to the field of resistance of fire fibre material. We compose van-style acetamide acetone zirconium polymer according to chloridze zirconia, acetamide acetone and three-ethylamine. We use methanol as the dilute impregnant, we mix round them to let hloridize zirconia, acetamide acetone and three-ethylamine react at 40-20 deg.C, and we can receive poly-acetamide acetone zirconium van-substance. Four-hydrogen furan filtrate and remove the outgrowth hydrochloric three-ethylamine. The offspring dissolve in the filature liquid made of methanol. After centrifugal swing, we can receive van-substance fibre. After we do special hear treatment, the zirconia fibre cotton we receive has the characteristic of good filature ability, high content of zirconium, equality andclarity and jarles capability. It can be used as industrial stove, roomage fusion stove, atomic energy reactor and the high temperature heat insulation material used in aviation and military. The material of the invention cost low, the method is easy, the impregnant can be recycled, the preparation of fibre cost low.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

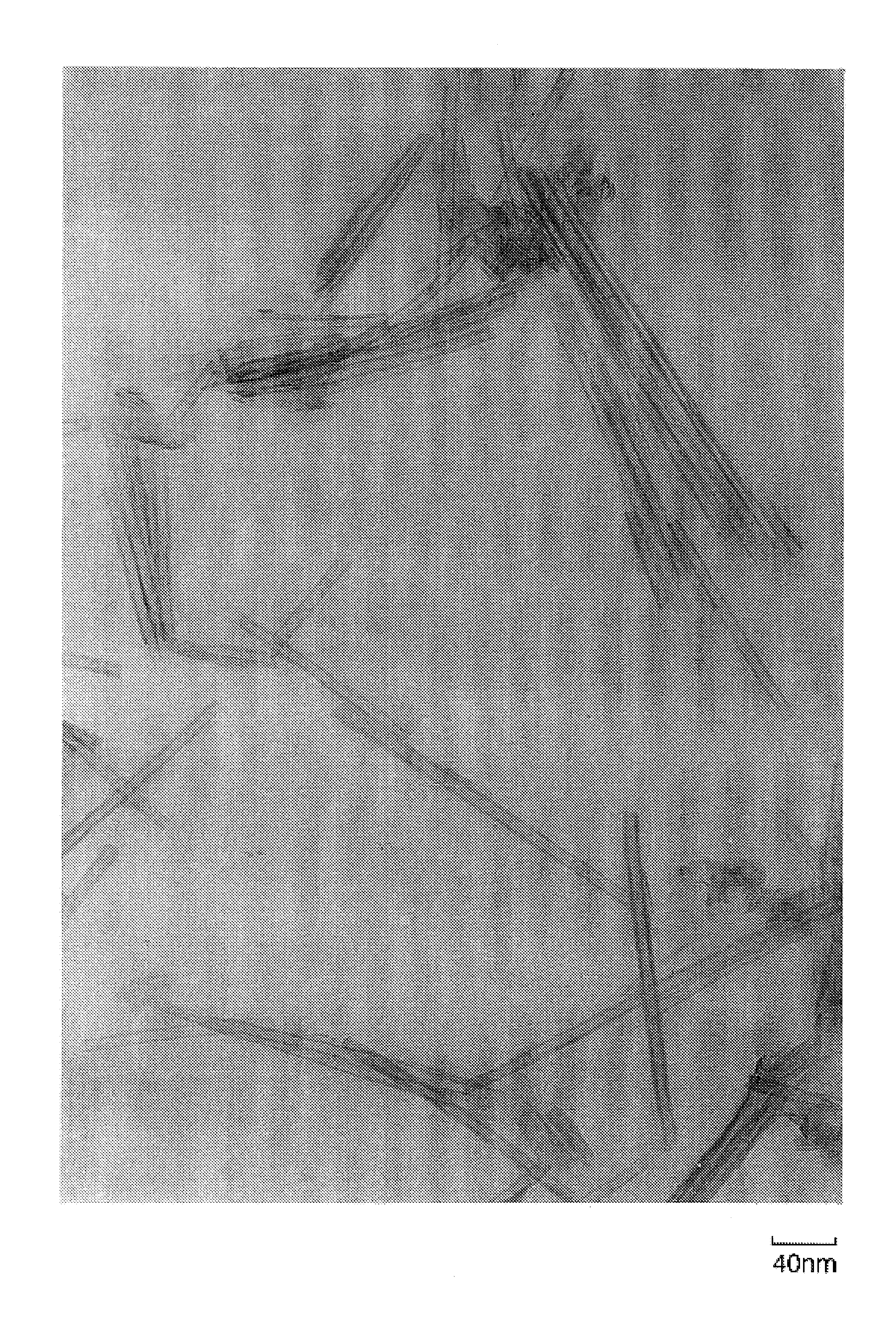

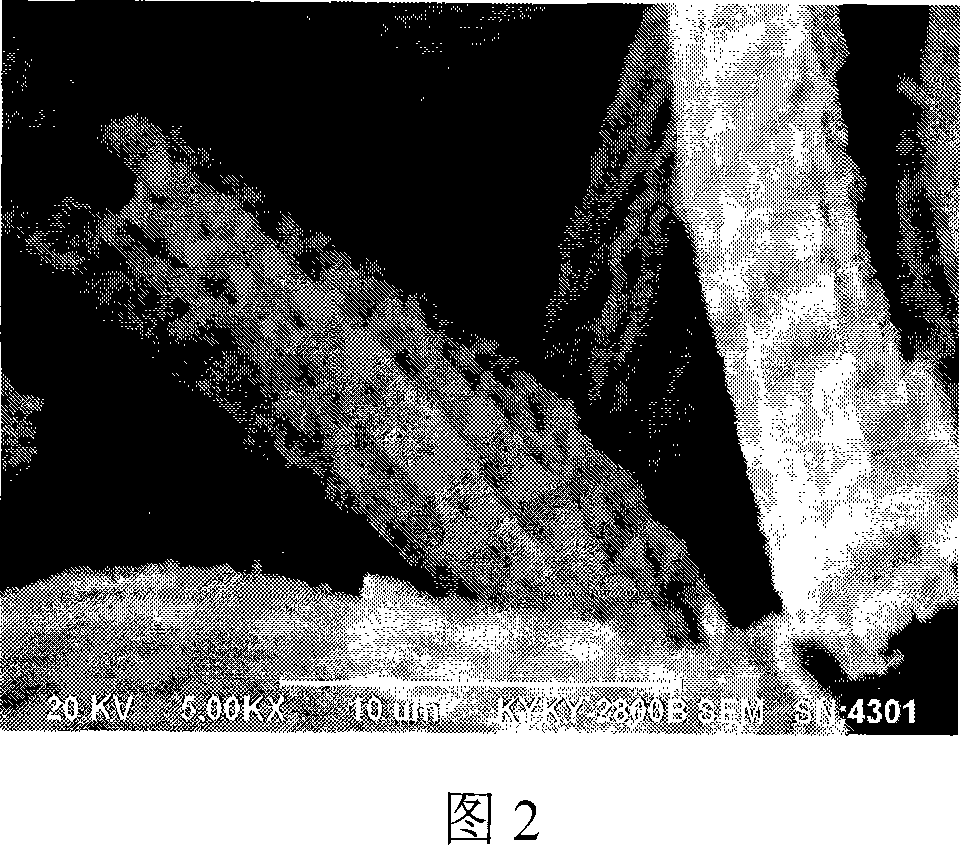

Tubular titanium oxide particles and process for preparing same

InactiveUS7431903B2Uniform particle shapeReduce contentMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

Non-molybdenum non-nickel middle chrome wear resistant steel casting and heat treatment method thereof

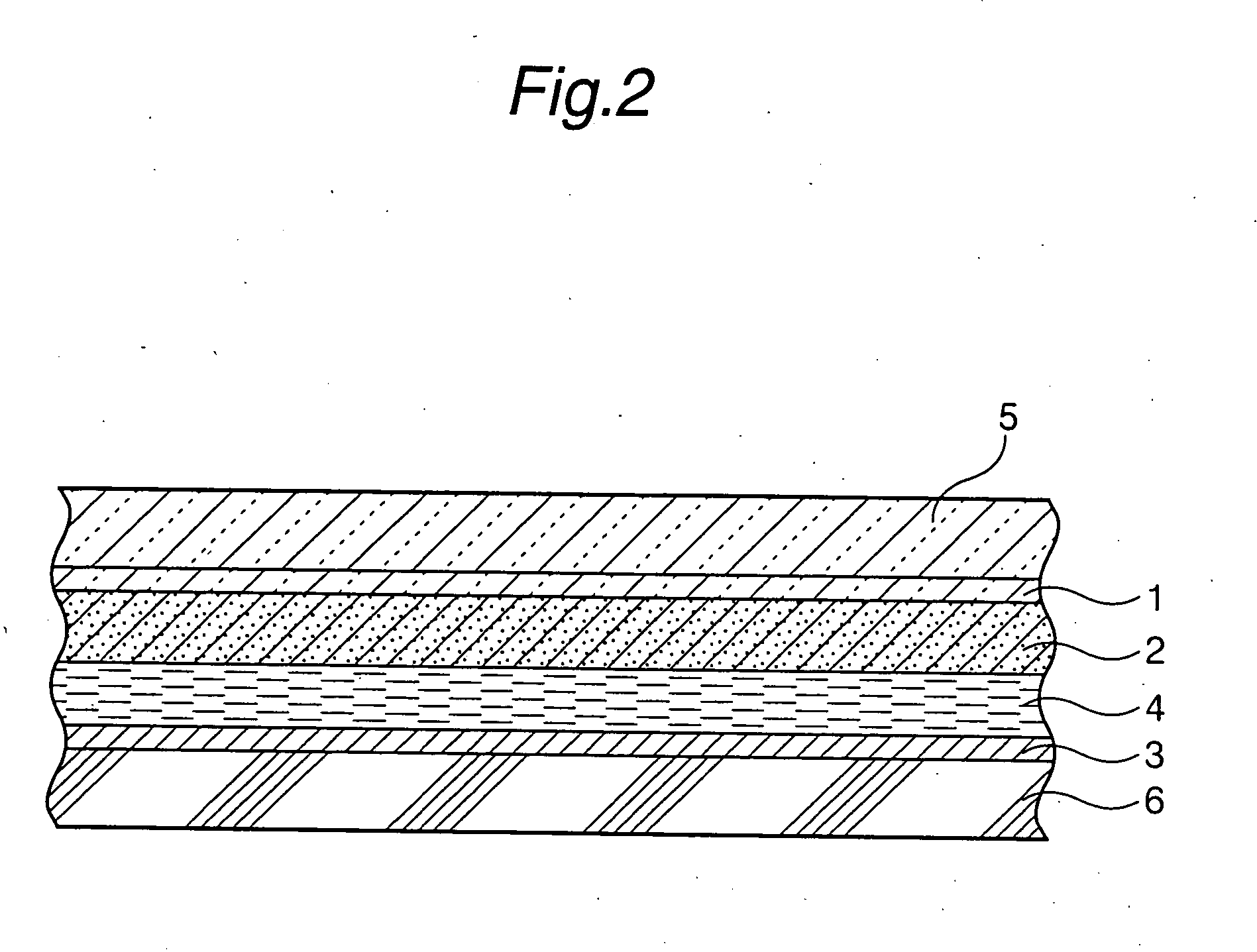

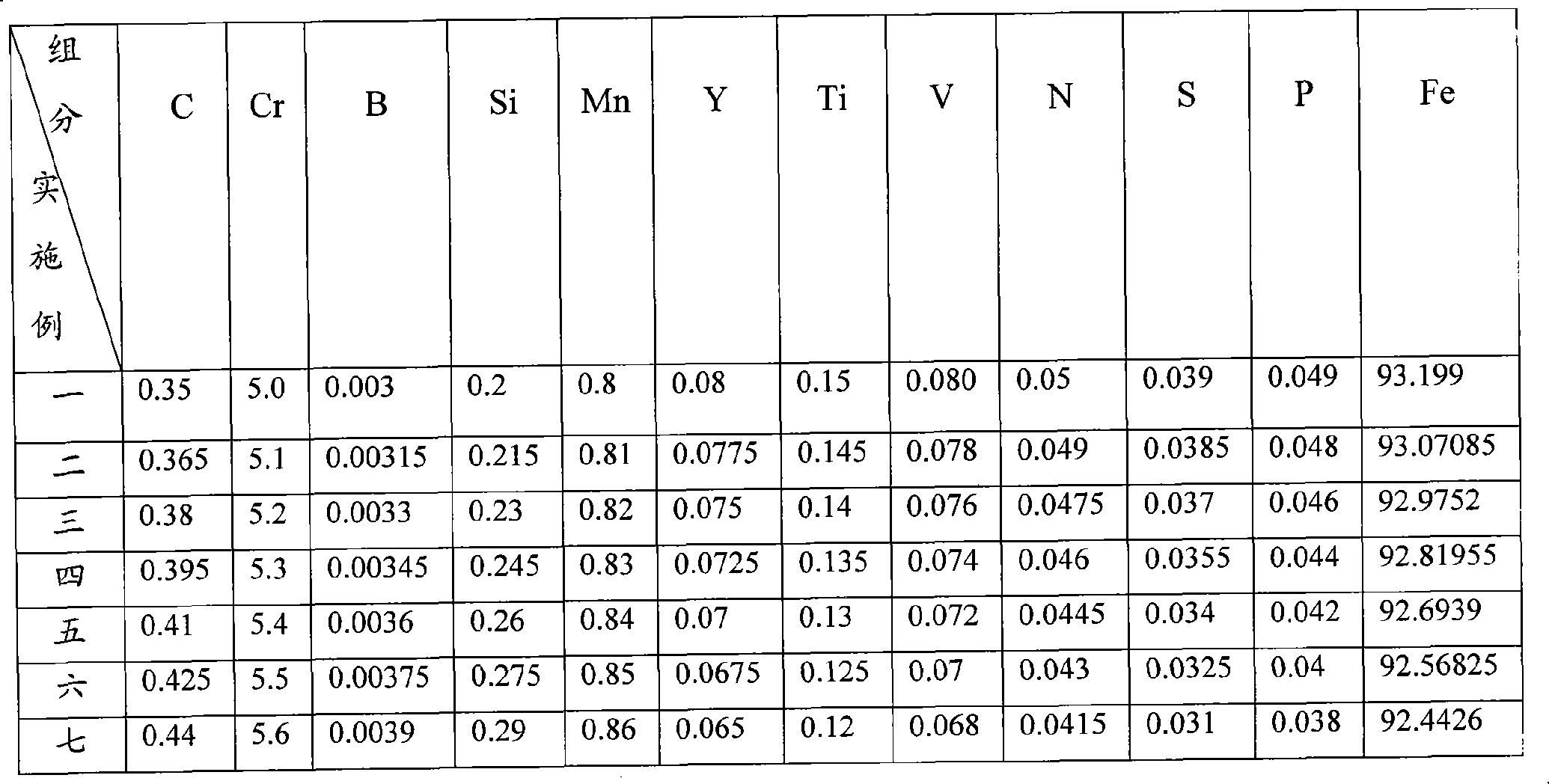

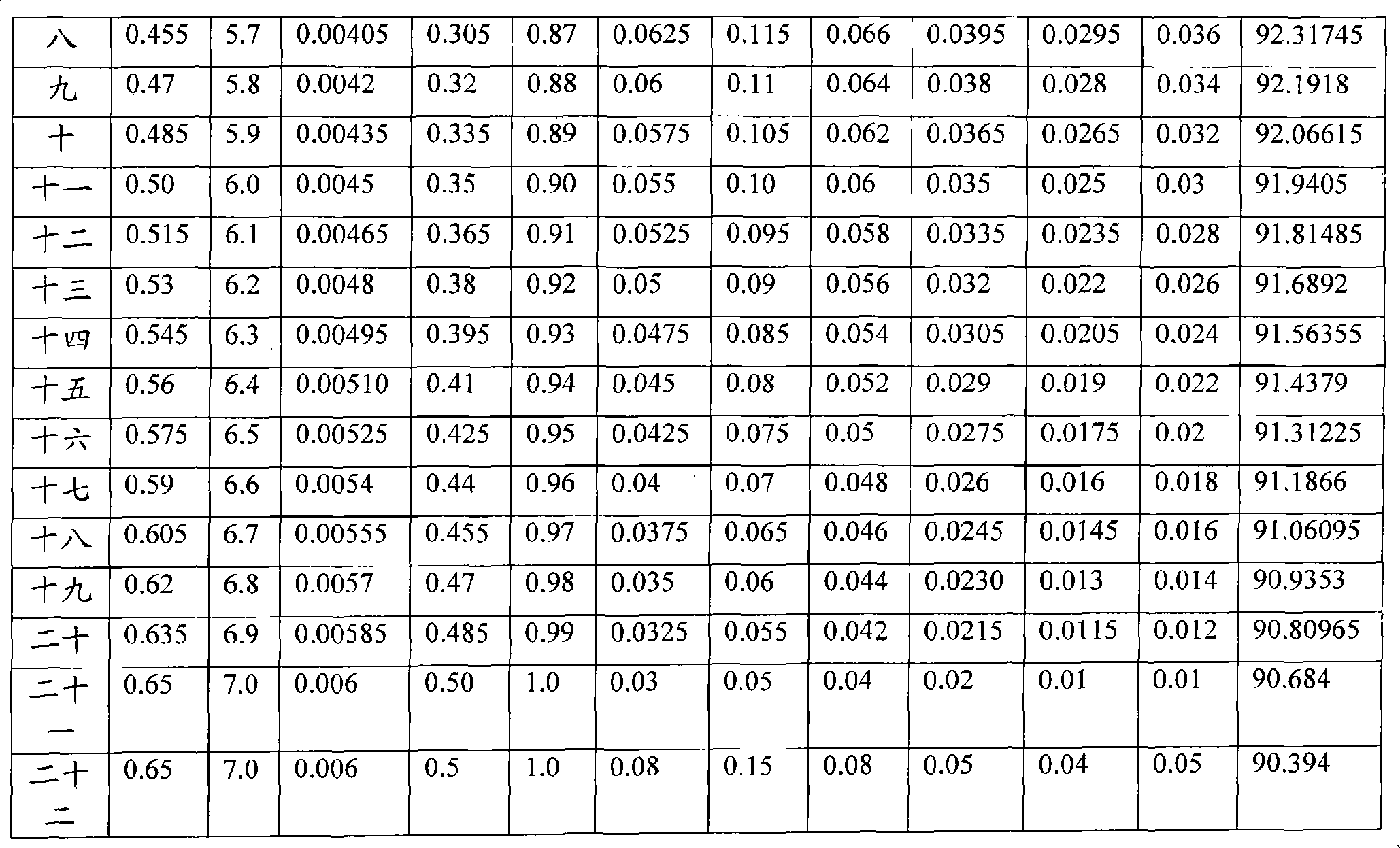

The invention belongs to the technical field of metal wear-resistant materials and particularly relates to a wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium and a heat treatment method thereof. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium comprises the components of the following mass percentages: 0.35 to 0.65 wt percent of C, 5.0 to 7.0 wt percent of Cr, 0.003 to 0.006 wt percent of B, 0.2 to 0.5 wt percent of Si, 0.8 to 1.0 wt percent of Mn, 0.03 to 0.08 wt percent of Y, 0.05 to 0.15 wt percent of Ti, 0.04 to 0.08 wt percent of V, 0.02 to 0.05 wt percent of N, less than 0.04 wt percent of S, less than 0.05 wt percent of P and the balance of ferrite. The wear-resistant casting steel part which is free of molybdenum-nickel and medium-chromium can be manufactured by an electric furnace using a sand casting. The invention carries out step quenching by using two types of quenching oils with different temperatures, thus leading to depth of more than 60mm of the quenching full hardening layer of the cast steel, high hardness, good uniformity of the hardness, and no cracks in the heat treatment. The casting steel is free of expensive alloying elements such as molybdenum or nickel, raw materials resource is rich, the manufacture cost is low and economic benefit is good.

Owner:SHENZHEN UNIV

Method of preparing titanium dioxide, stannum dioxide and doping composite fiber material thereof

InactiveCN101033082AGood lookingSimple structureNanostructure manufactureTitanium dioxideTin dioxideNitrogen gas

This invention relates to a method for preparing fiber TiO2, SnO2 and its doped compound material characterizing in utilizing a fiber material as a template, taking TBT, titanium tetrahalide, tin tetrachloride or a mixture as a precursor, which is carried by nitrogen or argon and enters into a reactor with a gas containing ammonia for chemical gaseous phase deposition, in which, the gas flow, deposition temperature and the sinter atmosphere and temperature are controlled, the inert gas is heated to get load-type fiber material to be sintered under the atmosphere of oxidation and reaction to remove the fiber template and form an oxide fiber material, and utilize the active carbon fiber template and ignition process to form porous fiber or tubular fiber material.

Owner:DALIAN UNIV OF TECH

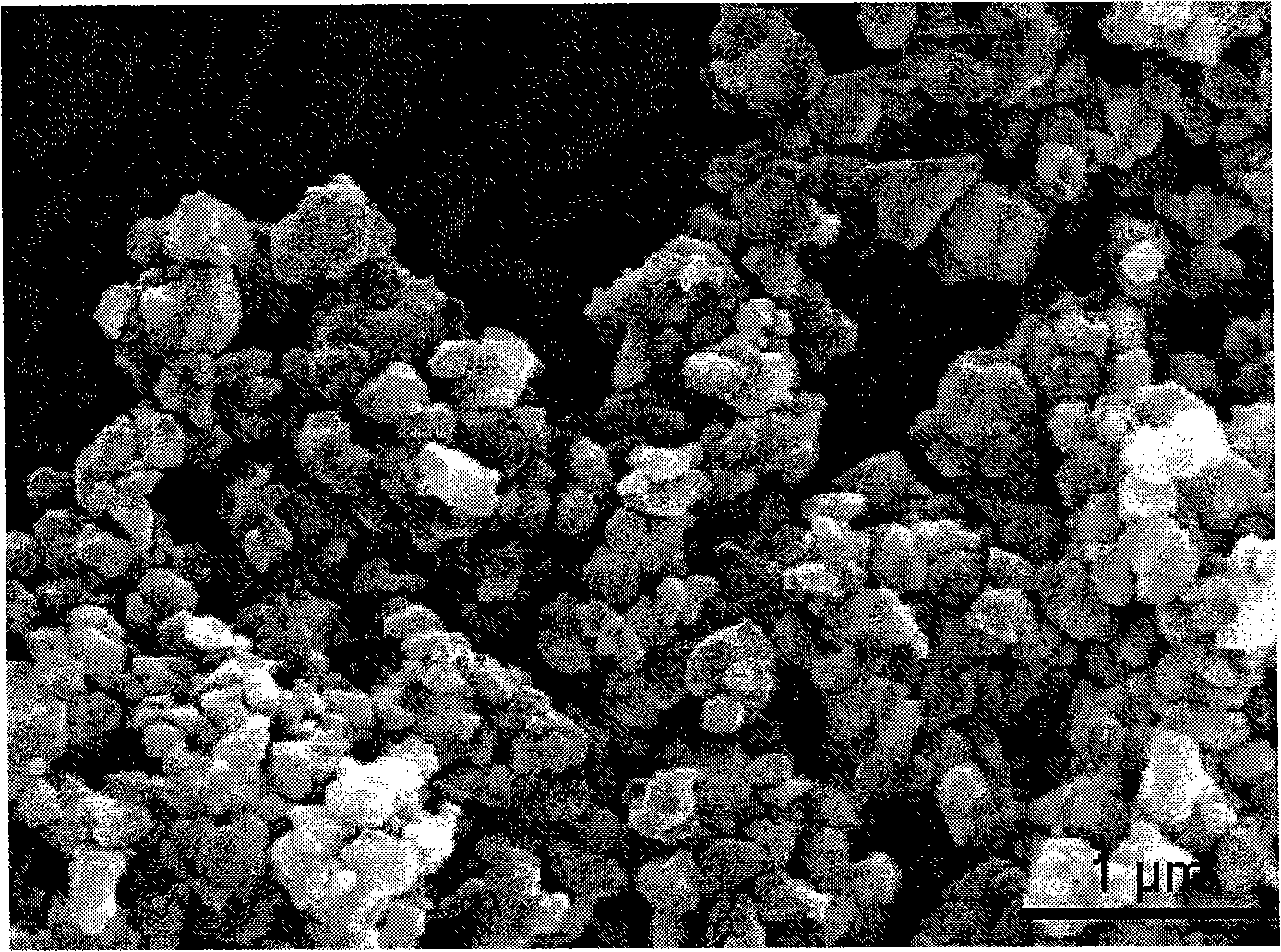

Preparation of nano-ferriferrous oxide

InactiveCN101323466ASimple processSave raw materialsFerroso-ferric oxidesDispersityHeat pretreatment

The invention discloses a chemical processing method, in particular to a preparation method for utilizing a solvothermal method to synthesize nano iron oxide. The invention adopts a certain amount of ferric chloride and dissolves the ferric chloride into a certain amount of methanol, ethanol or glycol and then a certain amount of sodium hydroxide is added, and later ultrasonic sound is adopted to equally disperse the mixture, and then the prepared mixture is transferred into a hydro-thermal reactor for a hydro-thermal processing under the temperature of 140 to 200 DEG C, and de-ethanol and / or deionized water for reaction liquid are adopted to wash reactants, and a centrifuge is adopted to remove the glycol solution and spare sodium hydroxide; the reactant is dried to obtain the iron oxide powder. The invention has the advantages that the method is simple, safe and reliable; the material is cheap; the output is high; the dispersity is better and the grain distribution is narrow, etc. The invention can be widely used by iron oxide manufacturers.

Owner:HANGZHOU NORMAL UNIVERSITY

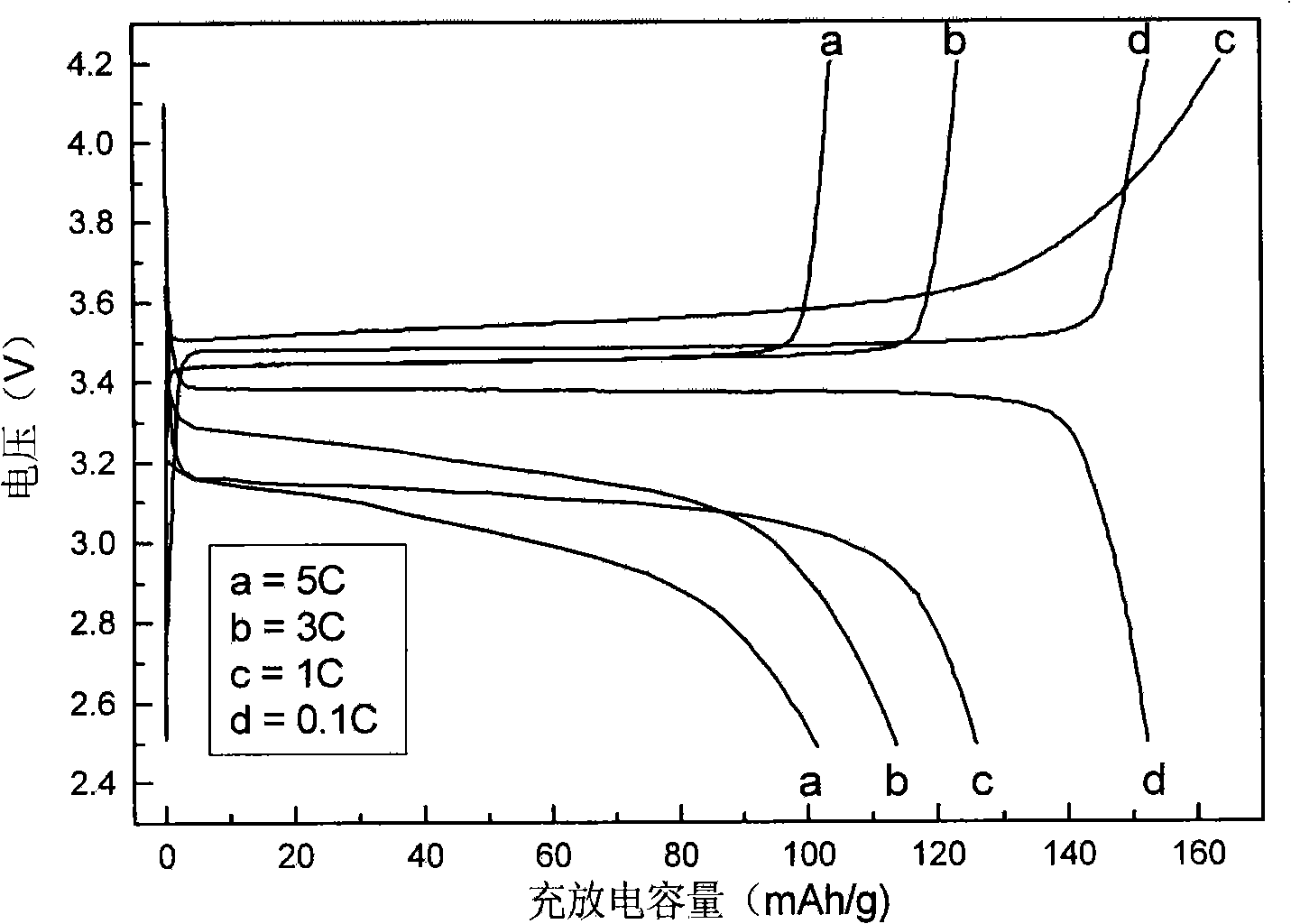

Low-temperature hydro-thermal synthesis for nano-lithium iron phosphate

InactiveCN101279727ANo pollution in the processEasy to controlCell electrodesPhosphorus compoundsPhosphate ionFerrous salts

The invention relates to a low temperature hydrothermal synthesis method for nano lithium ferrous iron phosphate and pertains to the technical field of production process of inorganic compound energy materials. In the method, aqueous solutions of ferrous salt and aqueous solutions of phosphate are mixed, proper amount of complexing agent is added, water-soluble lithium salt or lithium salt which is soluble in a weak acid environment is added, the ratio of lithium ion, ferrous ion and phosphate ion is 1-2:1:1 and the total concentration of the reaction system is 0.1-3.0mol / L; proper amount of pH regulator is added, resultant obtained after heating reaction in a high pressure reaction kettle is carried out washing, separating, drying and heat treatment to obtain nano lithium ferrous iron phosphate material. The method of the invention has simply controllable process, high yield of materials, no heavy metal pollution during the process, even particle of the materials and excellent electrochemical performance, which can be applied to electrode material of lithium-ion battery.

Owner:SHANGHAI UNIV

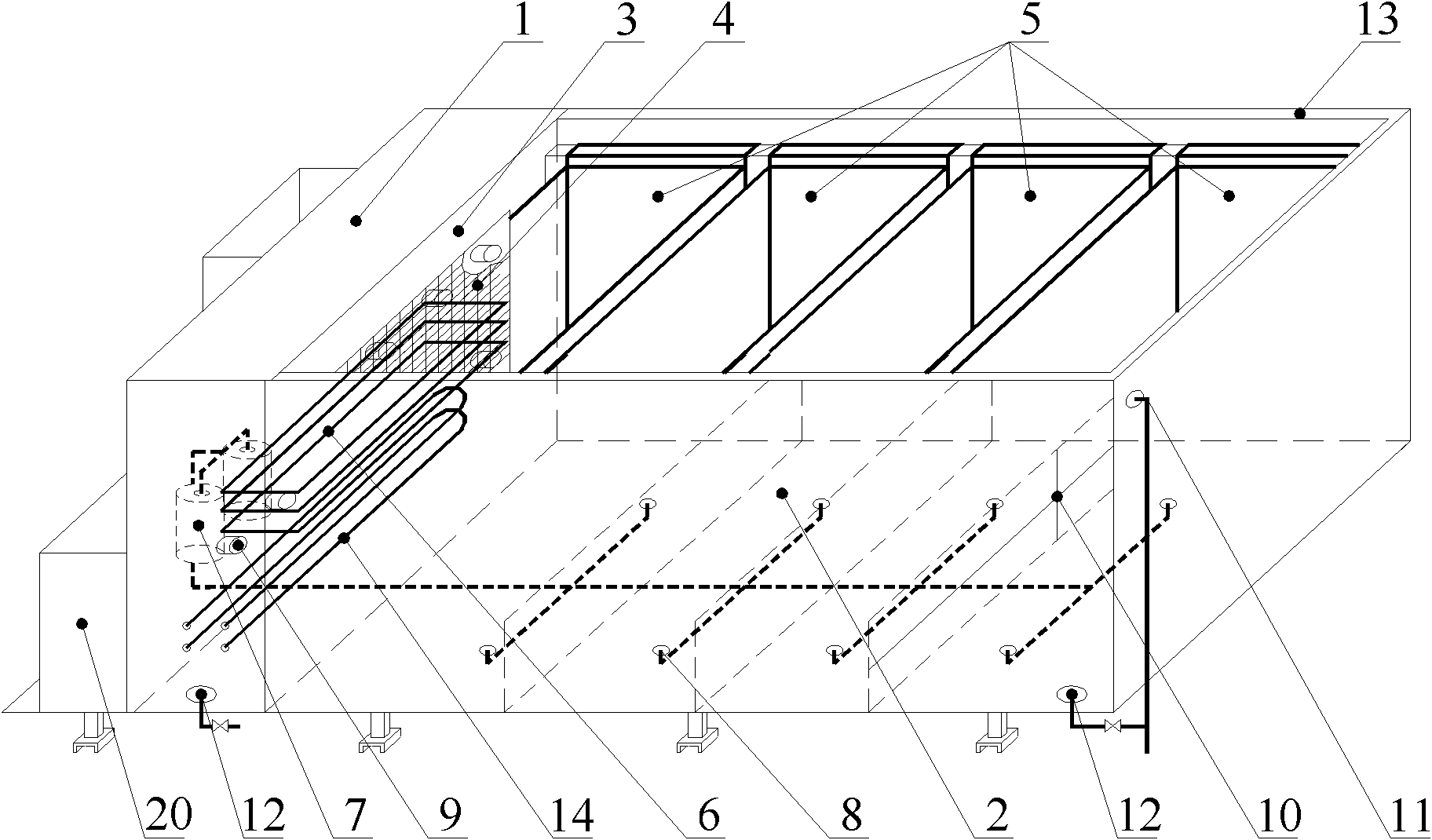

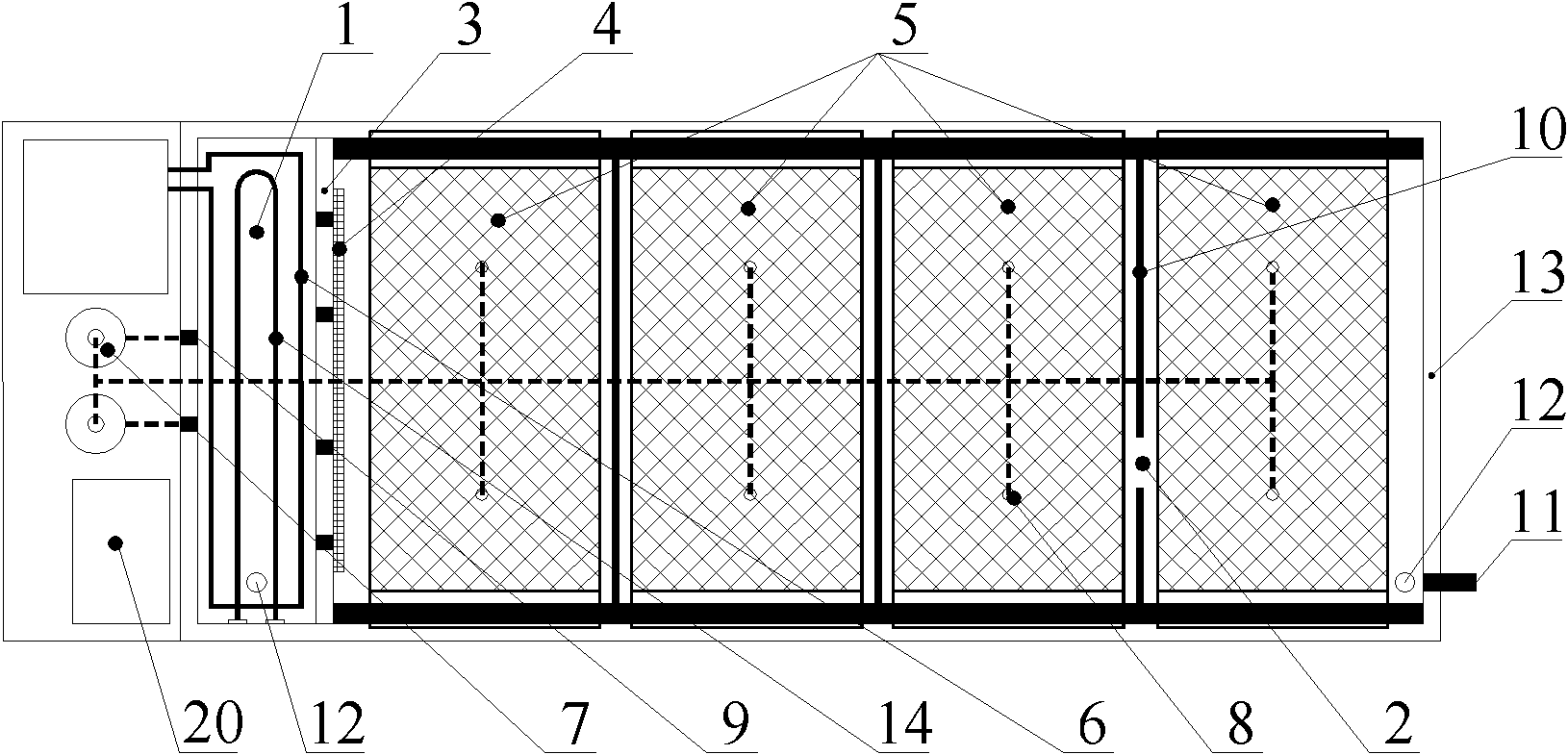

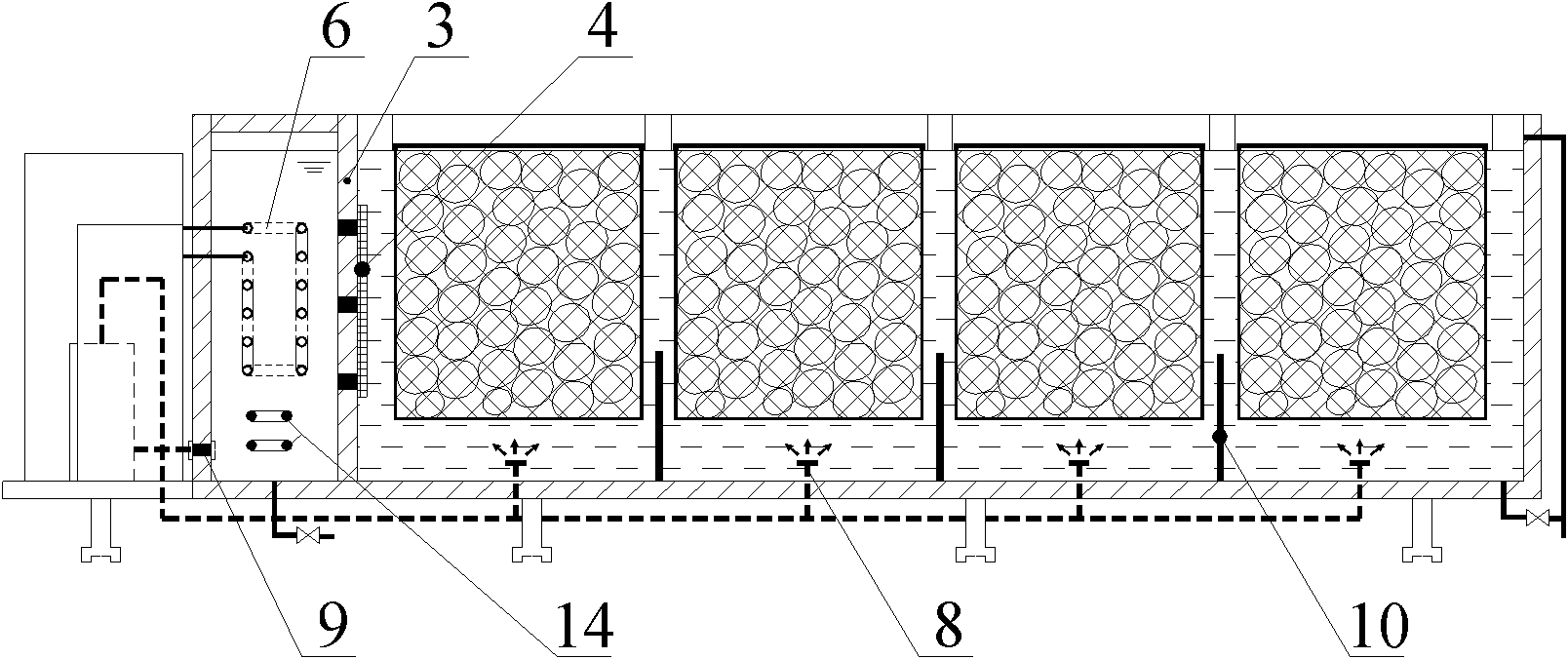

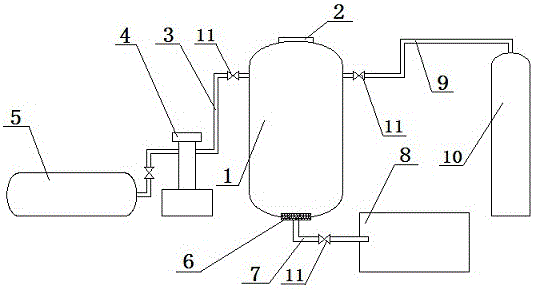

Energy-saving multifunctional cold-heat pretreatment device for fruits and vegetables before storage

InactiveCN101843276AInhibit dry consumptionHas a cleaning effectFood processingFruits/vegetable preservation by heatingEngineeringCold injury

The invention discloses an energy-saving multifunctional cold-heat pretreatment device for fruits and vegetables before storage. A water temperature treatment chamber is connected with a fruit and vegetable pretreatment chamber to form an integral water tank, and a partition board with through holes and a filter screen are arranged between the two chambers. A fruit and vegetable basket is placed in the pretreatment chamber, a spiral tubular heat exchanger is placed in the water temperature treatment chamber, and circulating cold water or hot water enters the fruit and vegetable pretreatment chamber from the lower part in a parallel mode through a water pump. The return water is subjected to heat re-exchange through the filter screen, the partition board and the spiral tubular heat exchanger and then returns to the water pump. The device integrates pre-cooling, cold shock and hot shock treatment of the fruits and the vegetables, and saves running energy consumption when the treatment of the fruits and the vegetables is finished; and compared with air, the water serving as a treatment medium has high heat exchange efficiency, can inhibit drying loss during the pretreatment of the fruits and the vegetables, and has cleaning effects on the fruits and the vegetables. A control system can timely adjust the running parameters of the system according to the change of working conditions so as to avoid cold injury of the fruits and the vegetables caused by over-low water temperature and hot injury of the fruits and the vegetables caused by over-high water temperature.

Owner:TIANJIN UNIV

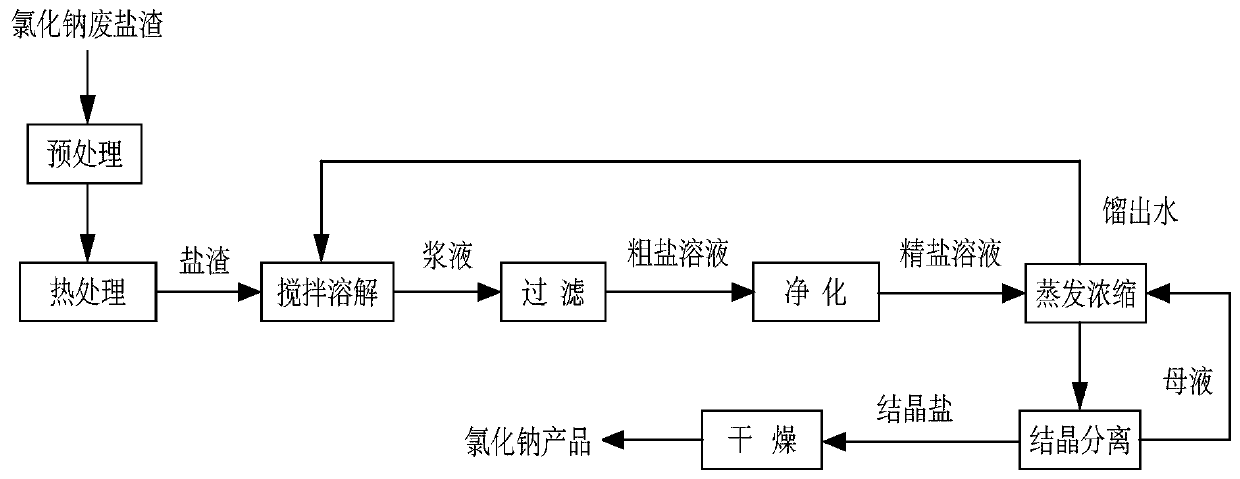

Refining method of industrial sodium chloride waste salt residues

InactiveCN109867296AImprove applicabilityGuaranteed qualityAlkali metal chloridesAlkali metal halide purificationSocial benefitsDistilled water

The invention discloses a refining method of industrial sodium chloride waste salt residues. The method comprises the following steps: firstly, carrying out pretreatment such as crushing and the likeon sodium chloride waste salt residues, carrying out heat treatment to remove organic matter, then adding hot water, carrying out stirring to completely dissolve soluble salt, then carrying out filtering, carrying out purification treatment on the obtained crude sodium chloride solution, and carrying out evaporative concentration, cooling crystallization and drying to obtain a sodium chloride product, wherein the evaporated distilled water is completely recycled for dissolving the salt residues after heat treatment. According to the method, the sodium chloride recovery rate reaches 98% or above, the sodium chloride content in the obtained sodium chloride product is up to 99% (wt%) or above, the impurity content is extremely low, and the obtained sodium chloride product reaches the first-grade standard or above of industrial dry salt and can be directly sold as a raw material in chlor-alkali and other industries. According to the method, harmless and resourceful treatment of the sodiumchloride waste salt residues is realized, remarkable economic benefits, environmental benefits and social benefits are achieved, and the purposes of completely recycling the sodium chloride salt resources, saving energy and protecting the environment are achieved, so that the method is an environment-friendly technology.

Owner:ZHEJIANG SHENLIAN ENVIRONMENTAL PROTECTION GRP CO LTD

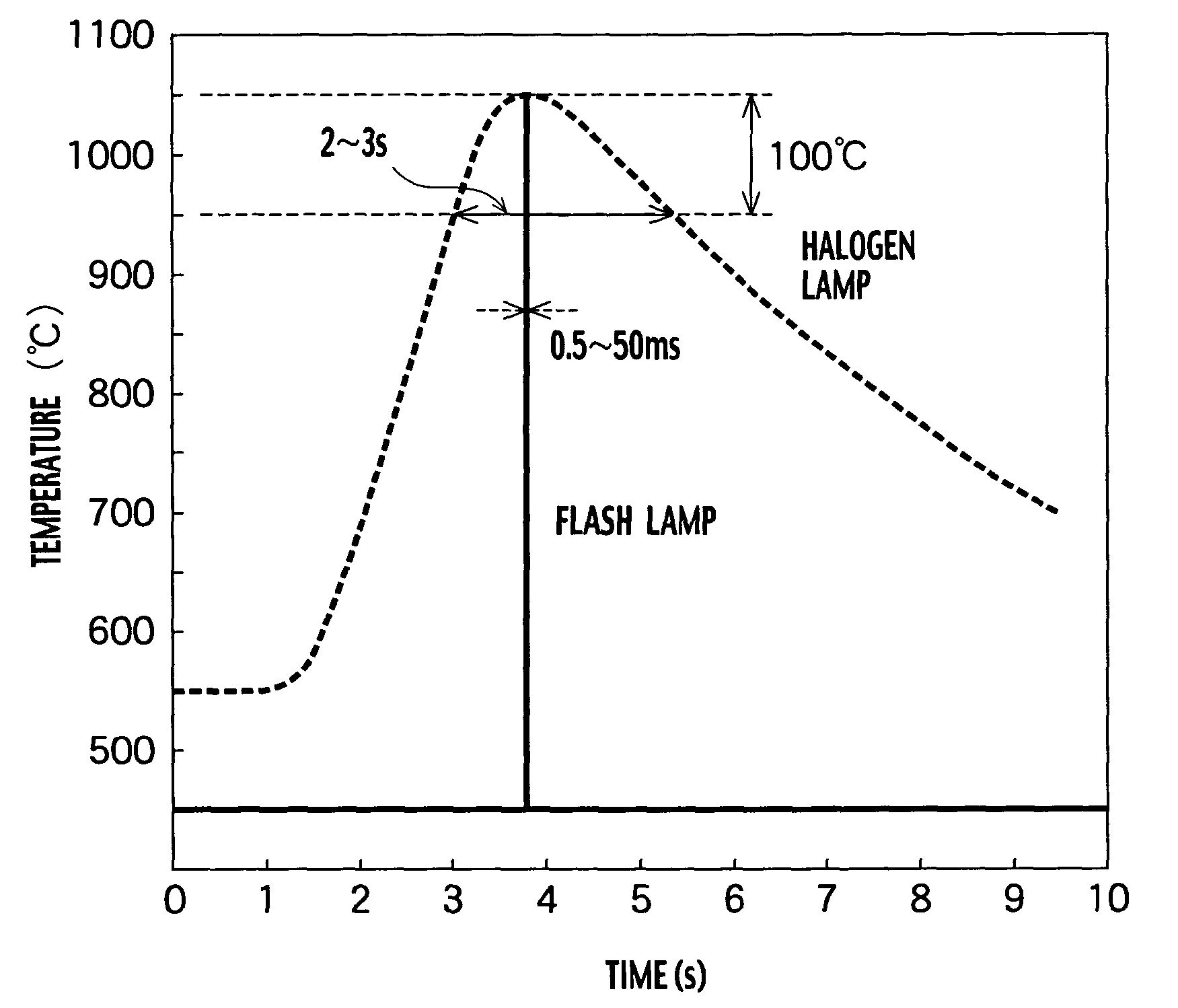

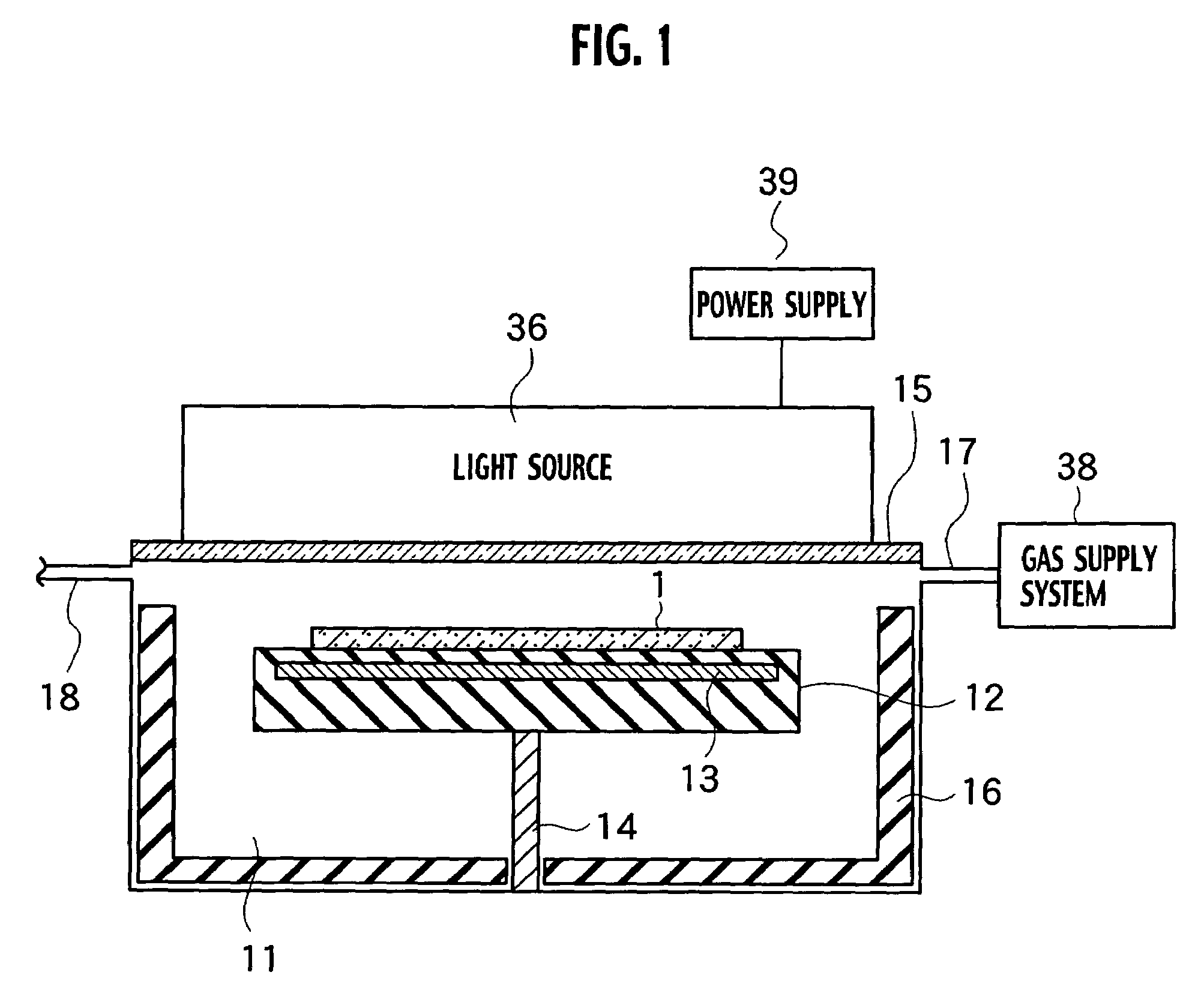

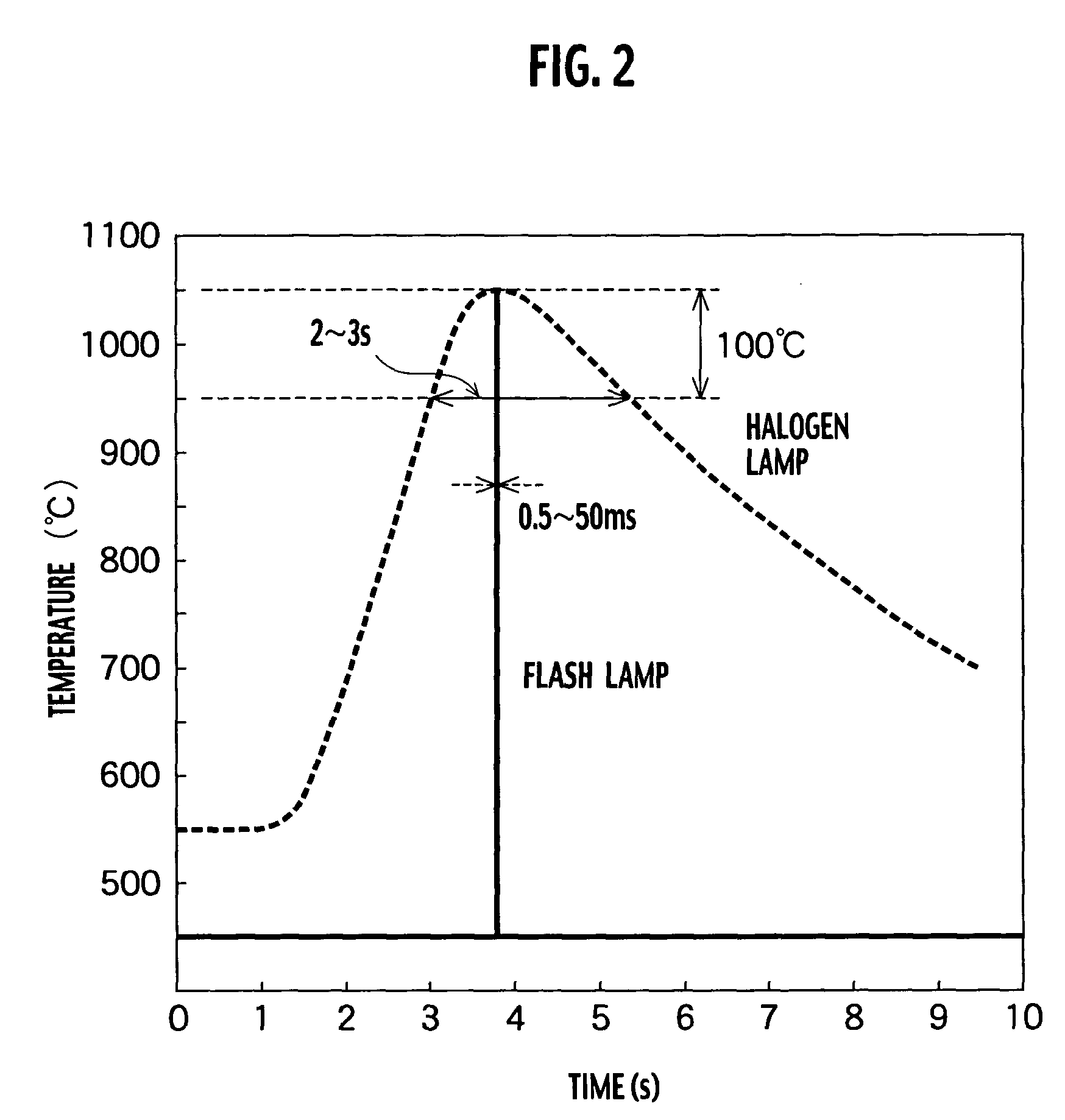

Annealing furnace, manufacturing apparatus, annealing method and manufacturing method of electronic device

InactiveUS7084068B2TransistorSemiconductor/solid-state device manufacturingSusceptorManufactured apparatus

An annealing furnace, includes a processing chamber configured to store a substrate; a susceptor located in the processing chamber so as to load the substrate and having an auxiliary heater for heating the substrate at 650° C. or less, the susceptor having a surface being made of quartz; a gas supply system configured to supply a gas required for a thermal processing on the substrate in parallel to a surface of the substrate; a transparent window located on an upper part of the processing chamber facing the susceptor; and a main heater configured to irradiate a pulsed light on the surface of the substrate to heat the substrate from the transparent window, the pulsed light having a pulse duration of approximately 0.1 ms to 200 ms and having a plurality of emission wavelengths.

Owner:KK TOSHIBA

Preparation of mesoporous zircite

The invention discloses a preparation method of mesoporous ZrO2 which is characterized by dissolving a template and zirconium salt with water and stirring the mixture; dropping a NaOH solution into the mixture and continuously stirring and aging the mixture to obtain a suspension solution; transferring the obtained suspension solution into a reactor and taking out the mixture after heat treatment at 100-140 DEG C; washing, drying and calcining the precipitate in the reactor with water and hot alcohol to obtain a ZrO2 mesoporous material; the template is binary star type Gemini surfactants or cetyl trimethyl ammonium bromide or the mixture of one of Gemino surfactants and cetyl trimethyl ammonium bromide. The obtained mesoporous ZrO2 solid solution is an important material in the catalytic field with a specific surface area more than 160m<2> / g.

Owner:CENT SOUTH UNIV

Semi-high speed steel break-down (BD) roller and manufacturing method thereof

ActiveCN105695873AHigh hardnessHigh hardness is controlled at HSD50~70, wear resistanceFurnace typesRollsManufacturing technologyAlloy

The invention discloses a semi-high speed steel break-down (BD) roller and a manufacturing method thereof, particularly relates to a roller applied to a profile steel rail beam BD rolling mill and belongs to the technical field of roller manufacturing. The whole roller is made of semi-high speed steel. The alloy components of the roller comprise, by weight, 0.3-1.5% of C, 0.2-1.4% of Si, 0.2-1.0% of Mn, 1.5-5.0% of Cr, 0-1.0% of Ni, 0.5-2% of Mo, 0.5-1.5% of W, 0-1.5% of V, and the balance Fe and inevitable impurities. The manufacturing method comprises the steps of raw material smelting, integral casting, heat preservation and demolding, heat pretreatment and heat treatment. According to the heat treatment, the high-temperature quenching technique and the high-temperature tempering technique are adopted. According to the structure of the roller, 3% or less of granular carbides are distributed on tempered sorbite, the macro-hardness of the roller is controlled to be HSD50-70, the abrasion resistance is high, the tensile strength is equal to or higher than 800 MPa, the crack extension resistance is high, and the roller is good in roller surface quality under the off-machine condition and small in abrasion under the on-machine condition; and the requirements of rail beam rolling can be well met, and especially the requirements for high strength, high abrasion resistance, high impact resistance and high hot cracking resistance of the roller in the rail beam rolling process can be well met.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

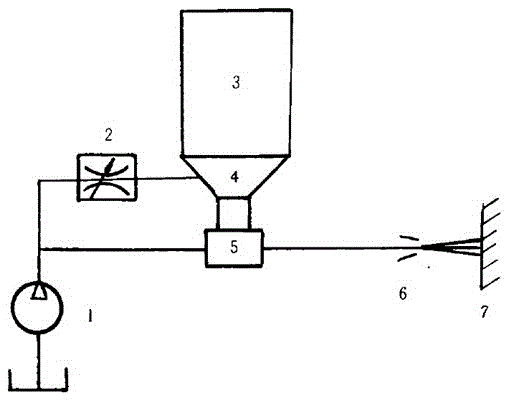

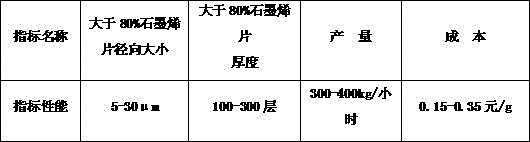

Method for preparing graphene microchip material with high-pressure water jet pulverizer

InactiveCN105621405AFacilitate the promotion of large-scale applicationEvenly distributed layersGrapheneGraphiteHigh pressure water

The invention relates to the field of graphene materials, in particular to a method for preparing a graphene microchip material with a high-pressure water jet pulverizer. The method includes the steps that graphite powder is heated, pretreated and dispersed uniformly, the graphite powder collides with a target material through nozzles, with a certain diameter, of the high-pressure water jet pulverizer to be smashed, the uniformly-dispersed graphene microchip material with the layer number of 100-300 is obtained, and the graphene microchip material with the uniform layer number can be produced continuously on a large scale. The method is high in yield, low in cost and free of pollution, and the layer number meets the use requirements in the fields of rubber reinforcement, plastic reinforcement, paint corrosion prevention, lubrication and sewage treatment, which is beneficial for promoting large-scale application of graphene.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

Wood dyeing method of pretreatment using microwave

InactiveCN101229646AWon't breakSmall investmentWood treatment detailsMicrowave irradiationMaterials science

The invention discloses a timber dyeing method with microwave pretreatment. The method comprises the following steps: the timber is dried with a conventional drying method to the extent that the moisture content is 20 percent to 40 percent; the microwave is used for heating pretreatment of timber, with the power density of microwave radiation controlled at 0.1-5 w / cm<3>, the radiation temperature at 80-120 DEG C, and the radiation time lasting for 30 to 480 seconds; the timber after heating pretreatment by the microwave is quickly immersed in properly prepared dye liquor in the normal temperature with the immersion time controlled at 30 to 240 minutes; finally, the dyed timber is washed with water and then piled in a drying kiln for post treatment of drying. The method of the invention has the advantages of low investment in equipment, simple technique, good effect of treatment, etc.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

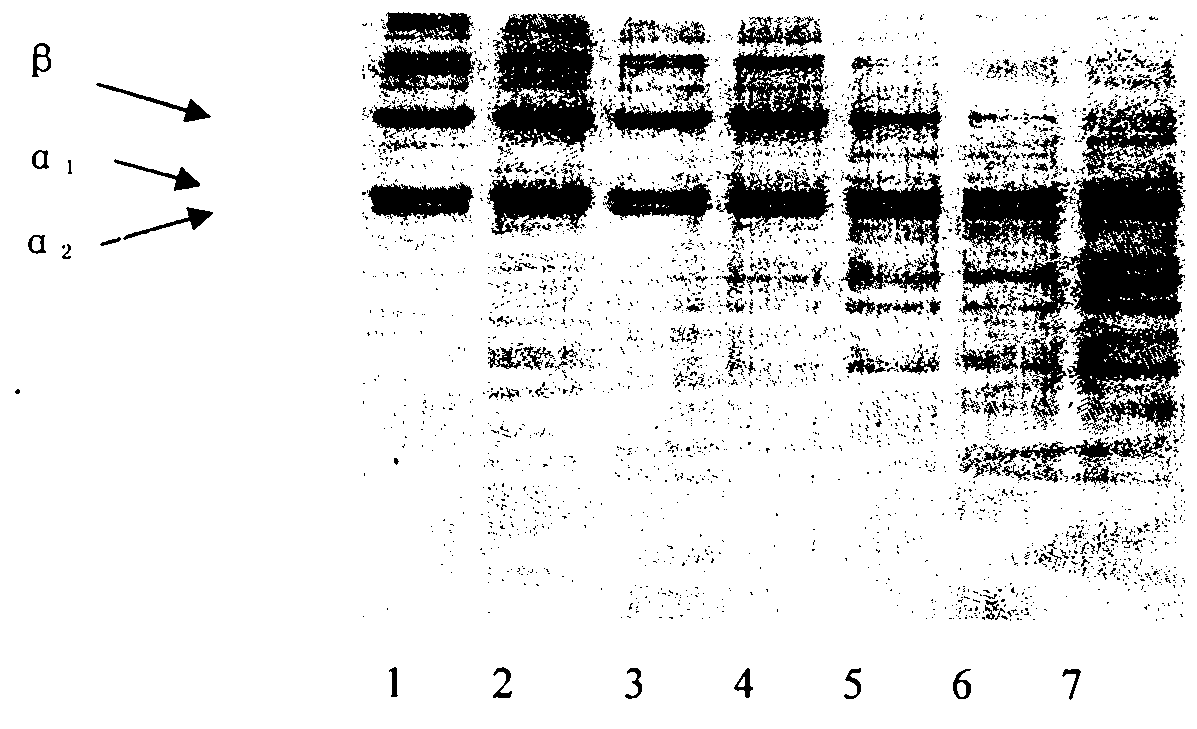

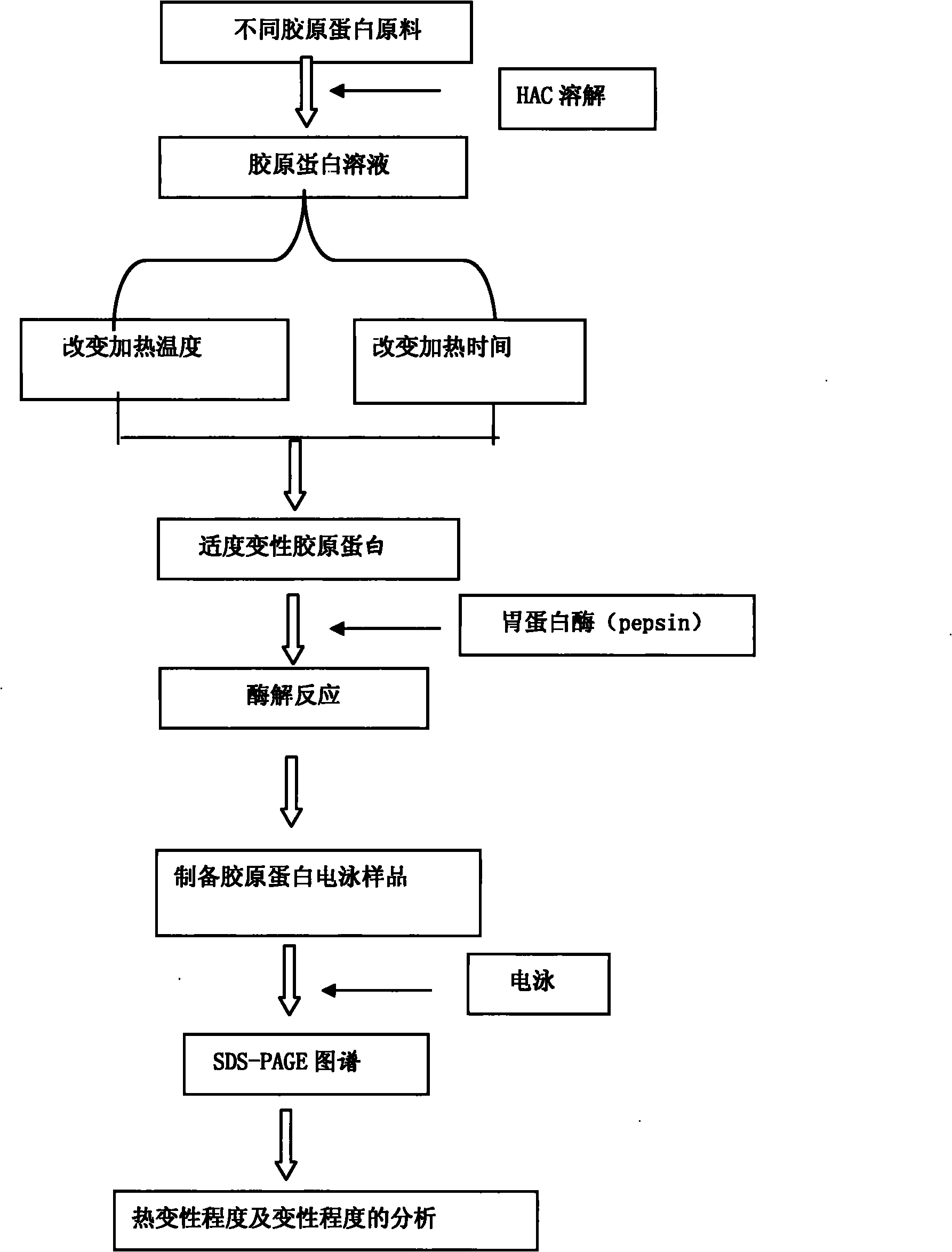

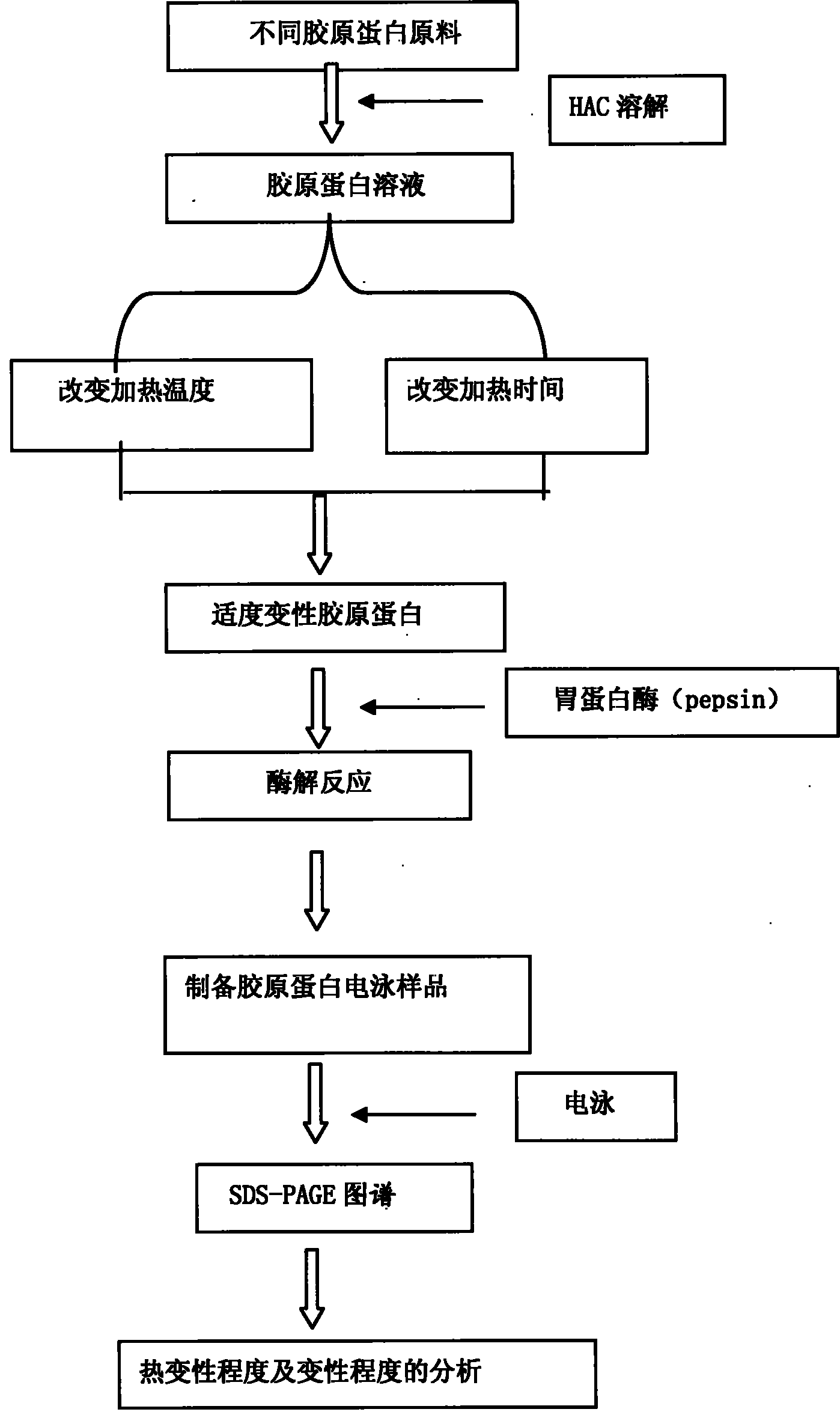

Evaluation method for degree of thermal denaturation of macromolecular collagen by using pepsin process

InactiveCN102621213AReflect comprehensive and intuitivePreparing sample for investigationMaterial analysis by electric/magnetic meansEthylic acidPepsin

The invention discloses an evaluation method for the degree of thermal denaturation of macromolecular collagen by using a pepsin process. The method is characterized by comprising the following steps: (1) selection of a raw material: a step of selecting leftovers of aquatic product processing-fishskin as the raw material; (2) immersion and dissolving: a step of adding acetic acid with a concentration of 0.01 to 1.0 mol / L into the raw material to obtain a collagen solution; (3) heat pretreatment: a step of heating the collagen solution, shaking the solution every five minutes during heating and carrying out rapid cooling after heating is finished; (4) enzymatic hydrolysis: a step of adding pepsin into the collagen solution, carrying out a heat reaction and adding phenylmethylsulfonyl fluoride after the heat reaction is finished so as to terminate the reaction; and (5) preparation of an electrophoresis sample and electrophoresis. The invention has the following advantages: used equipment is simple; more comprehensive and visual reflection of the denaturation state of protein is realized.

Owner:HUAIHAI INST OF TECH +1

Method for preparing nano metal oxide powder

InactiveCN108557770AEfficient preparationNarrow particle size distributionMaterial nanotechnologyOxygen/ozone/oxide/hydroxideDoped oxideNitrogen gas

The invention discloses a method for preparing nano metal oxide powder. The method comprises the following steps: taking nitrogen gas or inert gas as protection gas or carrier gas; after atomizing high-purity metal liquid which is melted at high temperature, carrying out electric arc heating and then rapidly gasifying to form highly-dispersed plasma metal atomized airflow; then introducing the airflow into a low-temperature reactor containing high-purity air and carrying out oxidization reaction on the airflow and oxygen gas. The temperature of the whole airflow is suddenly reduced after the airflow enters the reactor, and the oxidization reaction is rapidly stopped; crystallization and growth of generated solid-phase oxide are prevented so that nanoparticles with a narrow granularity range are formed. After the nanoparticles are precipitated and collected through gravity, nano oxide powder with the purity greater than 99.9 percent can be obtained through heat temperature at specific temperature. The method disclosed by the invention not only can be used for preparing single metal oxide, but also can be used for preparing doped oxide. Furthermore, the method disclosed by the invention has the advantages of simple equipment technology, low cost and zero pollution and can be completely applied to industrialized large-batch production.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY +1

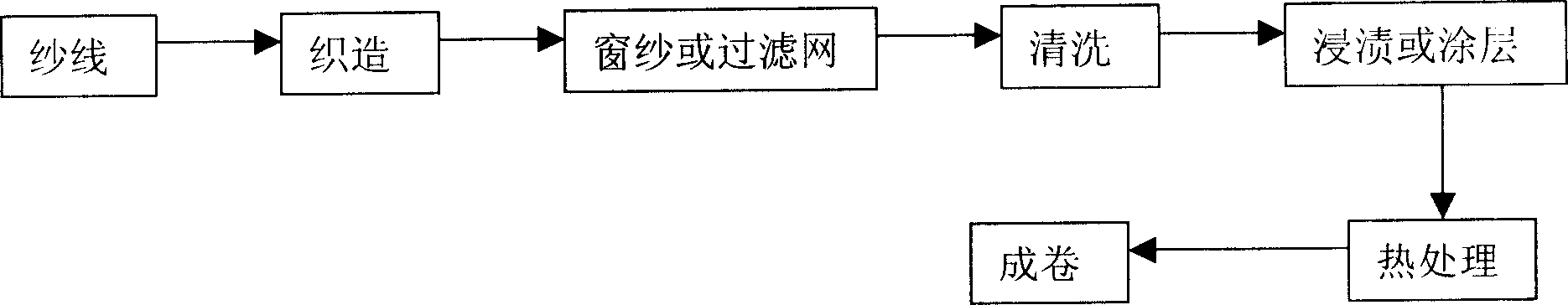

Hydrophobic window screening and filtering net preparation method

InactiveCN1884653ADurable Hydrophobic FunctionOpen work fabricsLiquid/gas/vapor textile treatmentFiberHeat pretreatment

The invention discloses a hydrophobic curtain and screen preparing method, which is characterized by the following: utilizing textile machinery to weave fiber material into 18-1000 order curtain or screen; washing curtain or screen through detergent and clean water; adopting immersing method or coating method to proceed hydrophobic disposal; soaking curtain or screen in the hydrophobic agent for 5 s to 5 h through soaking method; coating the hydrophobic agent on the curtain or screen fiber surface through coating method; drying curtain or screen at 80-350 deg.c for 5s to 60 min; coiling the product; fitting hotel, house, writing building and each professional solid-liquid separating technology.

Owner:孙熙

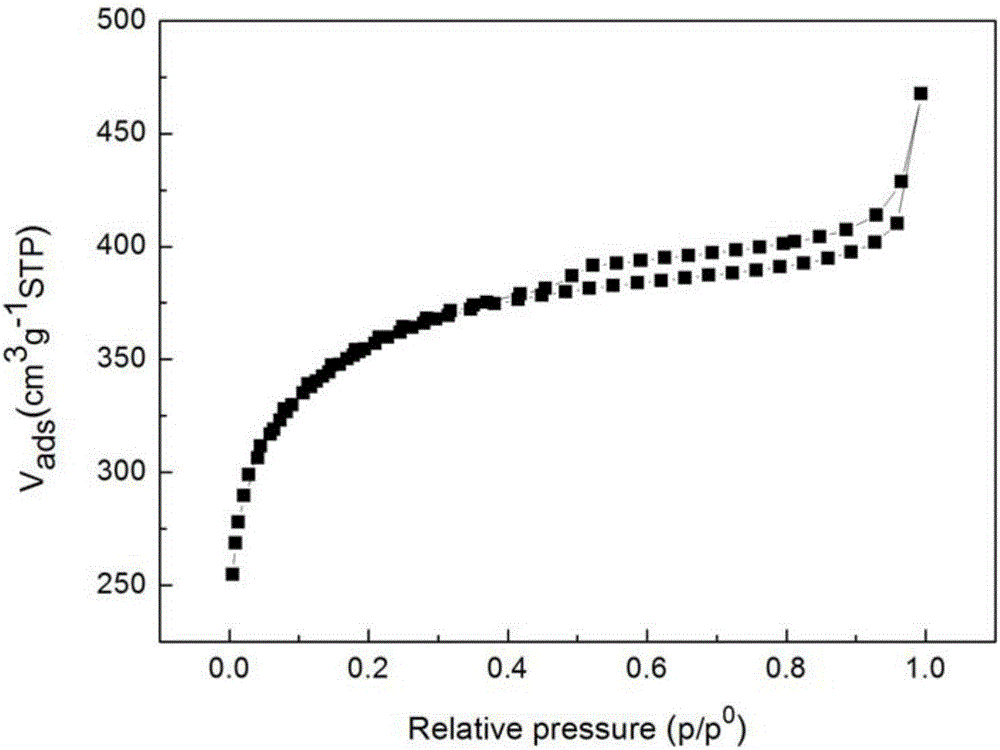

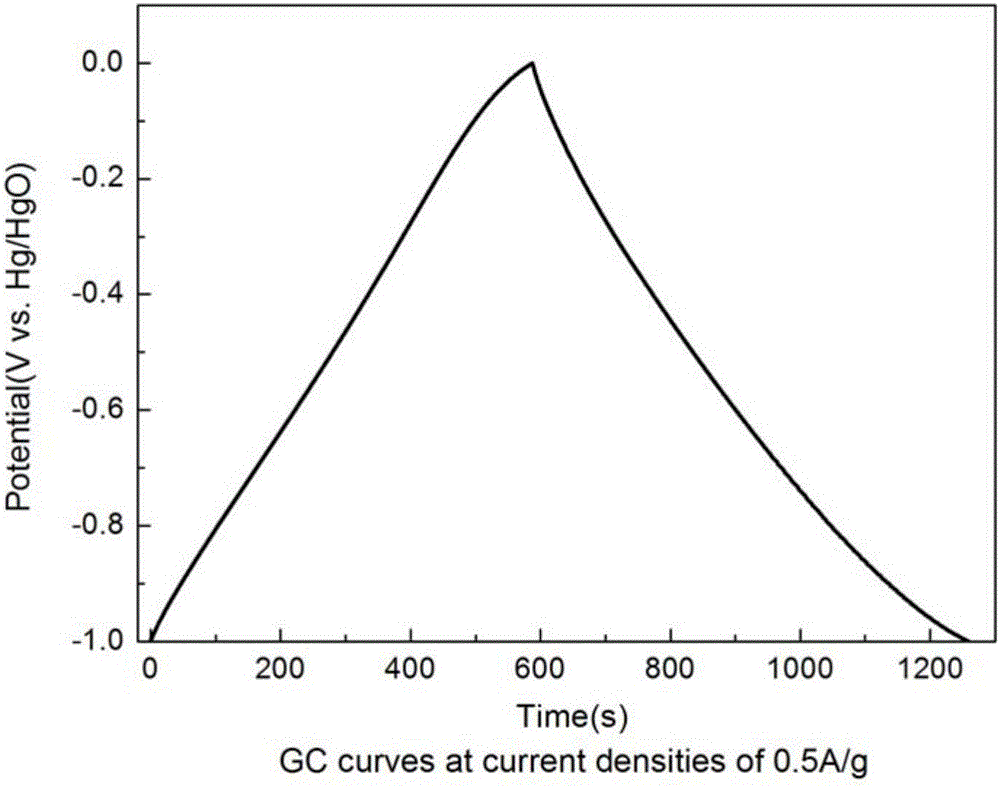

Juncus effuses biochar with loose porous structures, and preparation method thereof

The invention discloses a juncus effuses biochar with loose porous structures. The juncus effuses biochar is a porous carbon material prepared by taking juncus effuses as a raw materials via high-temperature pyrolysis (carbonization). A preparation method comprises following steps: juncus effuses is washed, and is subjected to heating pretreatment in an alkaline liquor, is subjected to high temperature high pressure alkali boiling at 130 DEG C, and is subjected to high temperature carbonization under gas protection so as to obtain the juncus effuses biochar. The juncus effuses biochar is large in specific surface area; raw materials are easily available; the preparation method is simple; the juncus effuses biochar possesses excellent capacitive performance and cycling stability when the juncus effuses biochar is taken as an electrode material of supercapacitors; juncus effuses possesses potential in the field of energy; and application value is increased.

Owner:XIANGTAN UNIV

Method for recovering highly pure potassium chloride from fluorination reaction byproduct

ActiveCN106006679ASimple processConducive to downstream utilizationAlkali metal halide purificationPotassium fluoridePotassium

The invention provides a method for recovering highly pure potassium chloride from a fluorination reaction byproduct. The method comprises the following steps: 1, preprocessing: carrying out heat treatment on the fluorination reaction byproduct to remove adhered organic matter wastes; 2, dissolving and separating: placing a preprocessed solid mixture in a separation device, introducing liquid ammonia to dissolve potassium fluoride in the preprocessed solid mixture to form a mixed solution, filtering the mixed solution to obtain a filter cake which is crude primary potassium chloride and a filtrate which is a liquid ammonia solution of potassium chloride, squeezing the filtrate, introducing the squeezed filtrate to a pressure reducing chamber, and reducing the pressure to normal pressure to gasify the liquid ammonia in the filtrate in order to obtain a pure potassium fluoride solid; 3, washing: adding a mixed solvent A to the crude primary potassium chloride, washing the crude primary potassium chloride to remove residual trace impurities, and filtering the washed crude primary potassium chloride to obtain crude secondary potassium chloride; and 4, purifying: adding deionized water to the crude secondary potassium chloride, heating the deionized water to dissolve the crude secondary potassium chloride in order to prepare a saturated solution, cooling the saturated solution to room temperature, adding a solvent B to carry out re-crystallization, filtering the obtained solution, washing obtained crystals with the solvent b, and drying the washed crystals to obtain highly pure potassium chloride.

Owner:RONGCHENG QINGMU CHEM MATERIALS

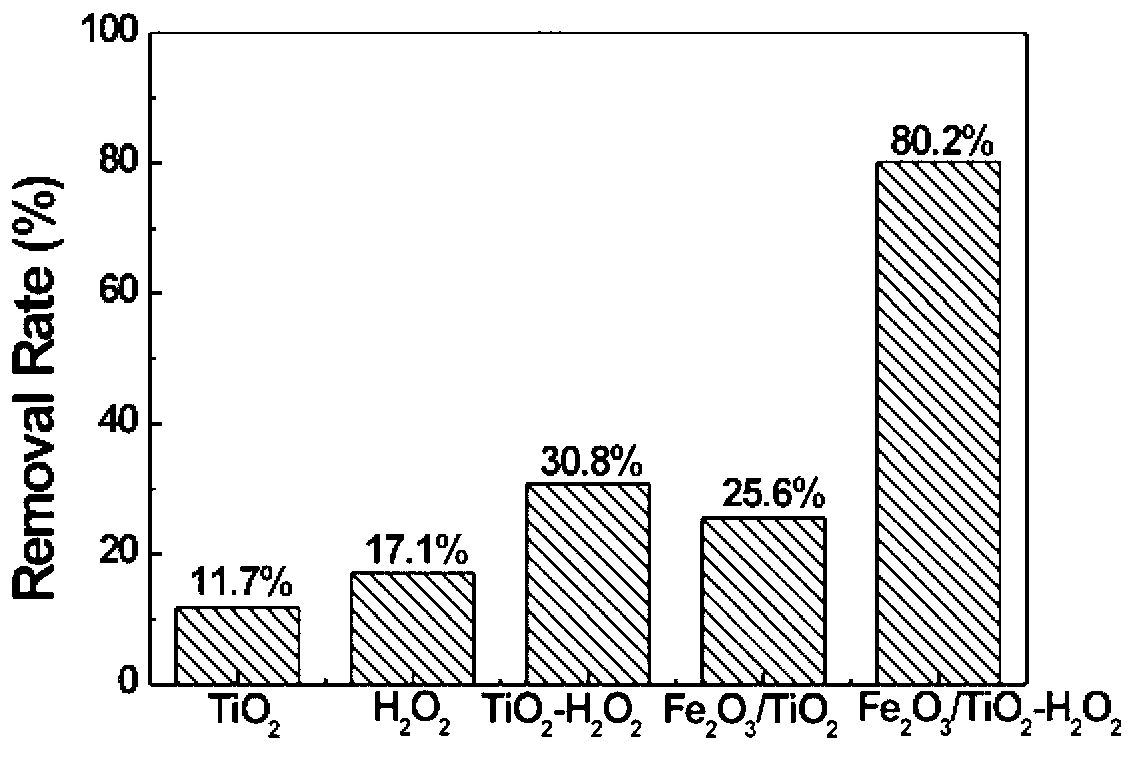

Method for processing dye wastewater by applying nanocomposite photocatalyst combination-Fenton

ActiveCN102701315AImprove photocatalytic treatment efficiencyReduce processing costsWater/sewage treatment by irradiationWaste water treatment from textile industryWater bathsTio2 nanotube

The invention discloses a method for processing dye wastewater by applying nanocomposite photocatalyst combination-Fenton, relating a method for processing the dye wastewater. The method comprises the following steps of: pre-processing the surface of a Ti plate; preparing a solution containing fluoride ions; oxidizing an anode to obtain a Ti-based TiO2 nanotube array photocatalyst on the surface of the Ti plate, wherein the Ti plate serves as the anode, and a platinum sheet serves as a counter electrode; preparing Fe (NO3)3 aqueous solution; preserving constant temperature in water bath until the solution is turned from slight yellow into red brown; immersing the Ti-based TiO2 nanotube array photocatalyst into the Fe (NO3)3 aqueous solution for ultrasound; drying and heating to obtain a Ti-based Fe2O3 / TiO2 nanotube array composite photocatalyst; placing in a reactor loaded with the dye wastewater; adding H2O2; regulating pH of the solution to be between 2 and 10; taking a spherical mercury lamp as a light source; performing photocatalysis to degrade the dye wastewater in the condition of oxygen; and taking out the Ti-based Fe2O3 / TiO2 nanotube array composite photocatalyst and cleaning.

Owner:广东碧之江环保能源股份有限公司

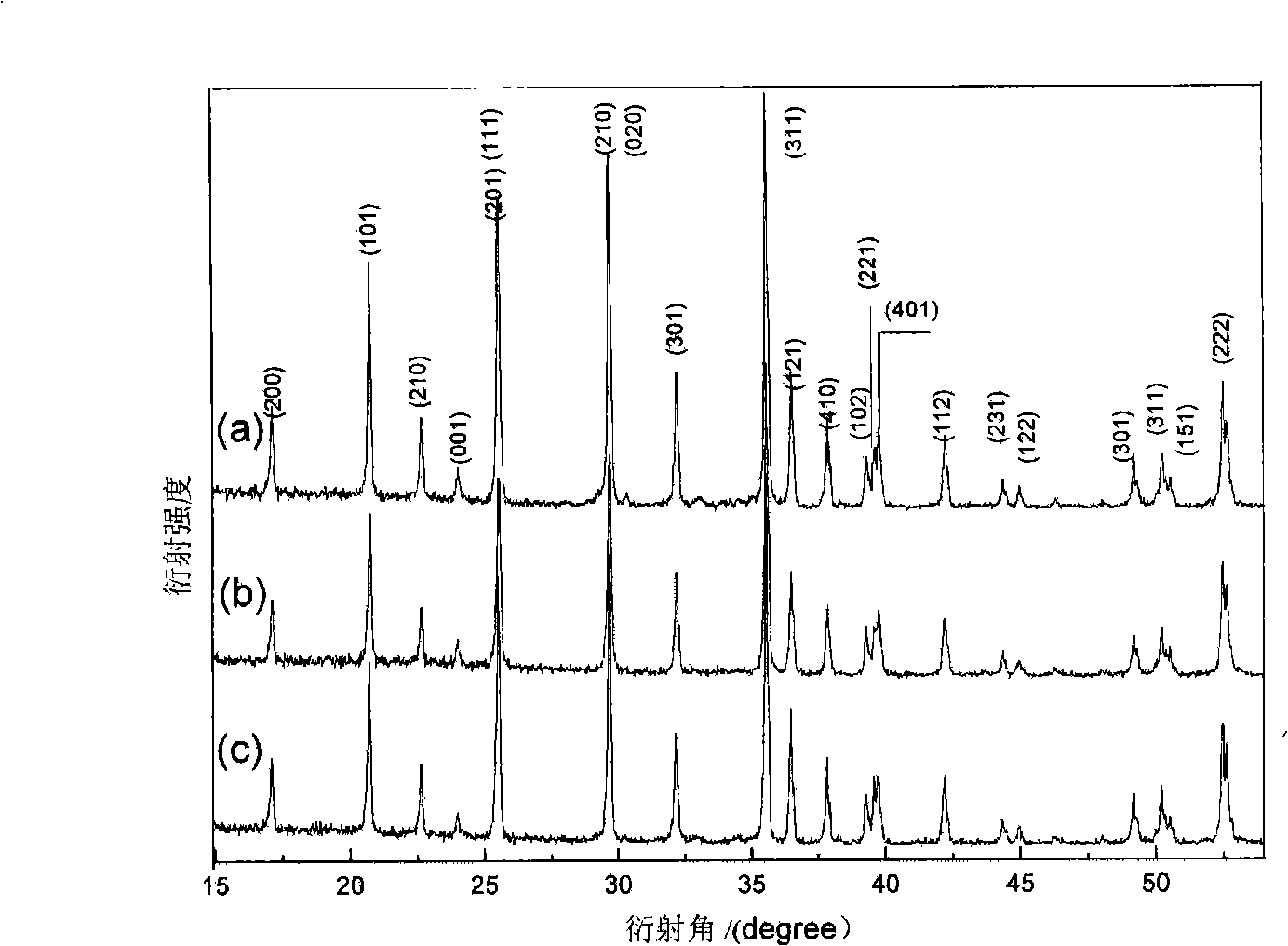

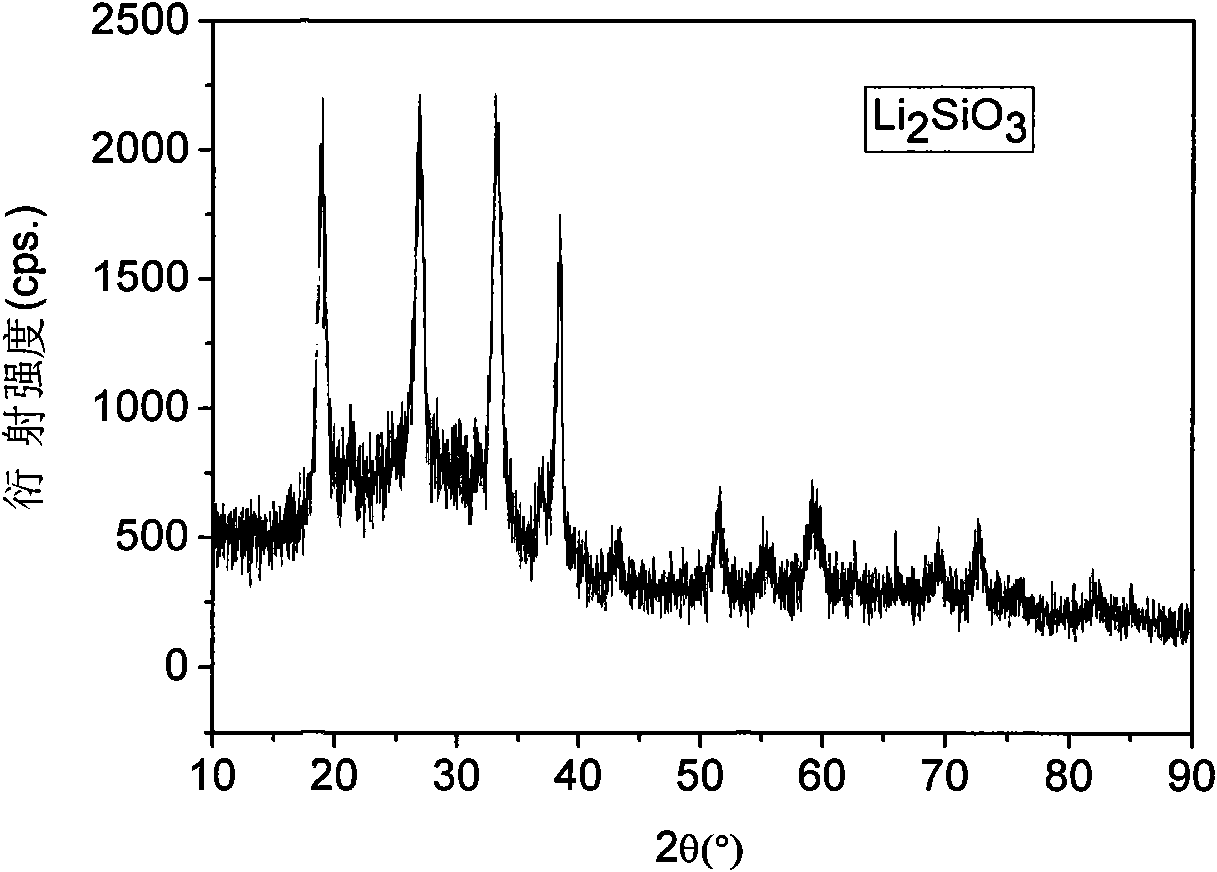

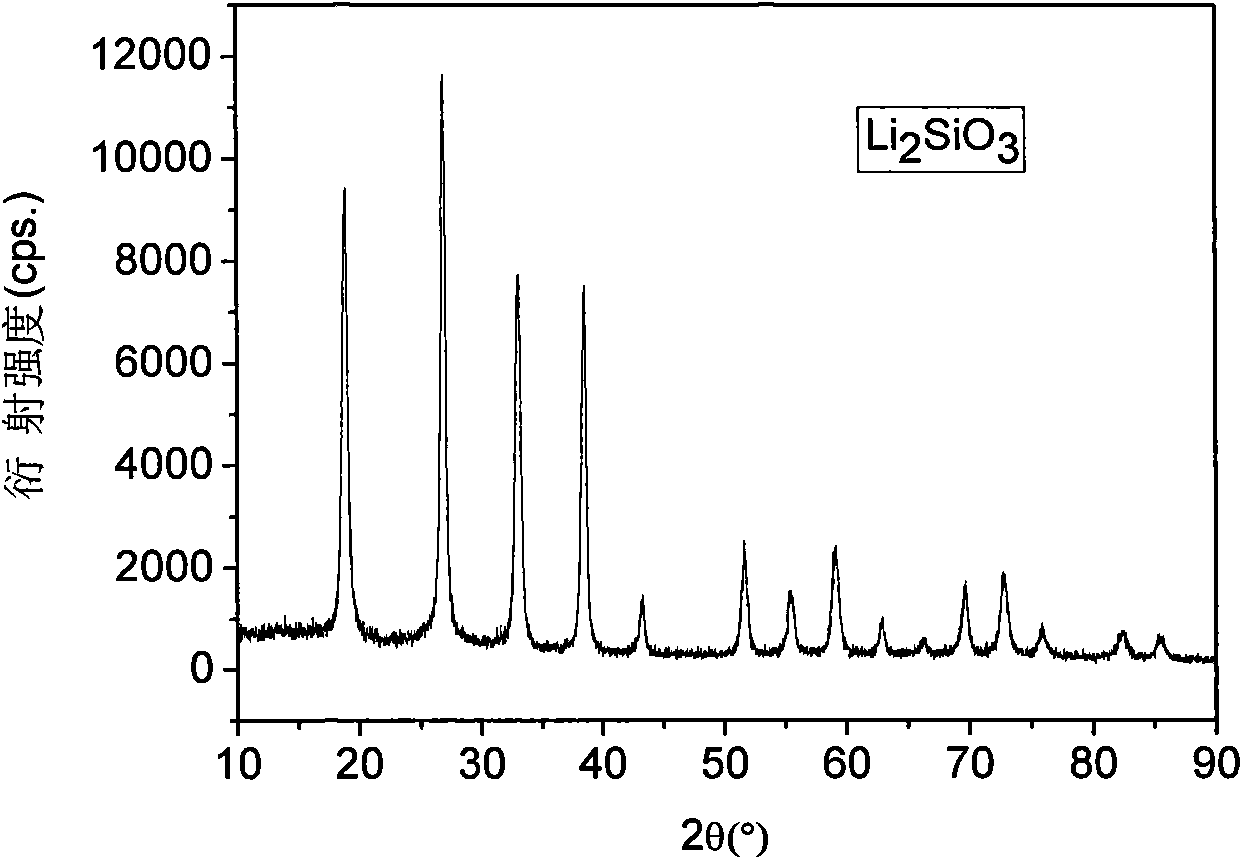

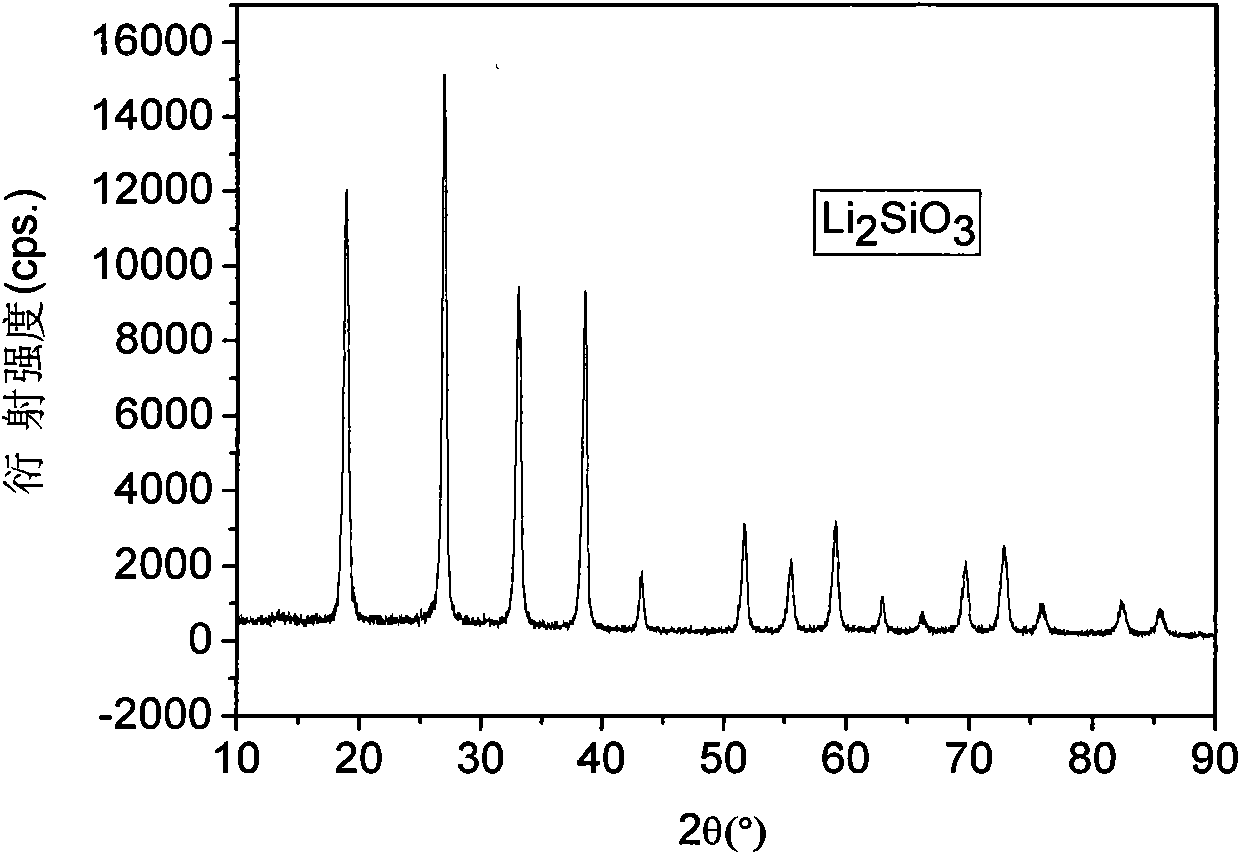

Preparation method of lithium silicate material with high purity

InactiveCN101913616AHigh purityControllable particle sizeAlkali metal silicatesCrystallinityImpurity

The invention provides a preparation method of a lithium silicate material with high purity, which comprises the steps of: firstly, mixing absolute ethyl alcohol and ammonia water into a mixed solution with pH of 8-11, adding tetraethoxysilane into the mixed solution of the ammonia water and the absolute ethyl alcohol step by step according to the proportion of the tetraethoxysilane to the absolute ethyl alcohol of 1:15-1:60 in volume ratio, and stirring to obtain liquid A; then weighing a lithium source according to the mol ratio of Li:Si of 2:1, dissolving into the absolute ethyl alcohol, adding a prepared lithium salt mixed solution into the mixed solution A to generate a suspension solution B; and drying the suspension solution B and then placing into a high temperature furnace for heat treatment, and cooling the dried suspension solution B to the room temperature with the furnace to obtain the lithium silicate material with high purity. The method has the advantages of simple process, low synthesis temperature and low cost; and the synthesized lithium silicate powder has uniform and thin powder particle, better crystallinity and no impurity phase and is a higher-purity lithium silicate material. The lithium silicate (LiSiO3) material can be used for the fields of a coating material, a lithium battery raw material, a breeder reactor material, and the like.

Owner:UNIV OF SCI & TECH BEIJING

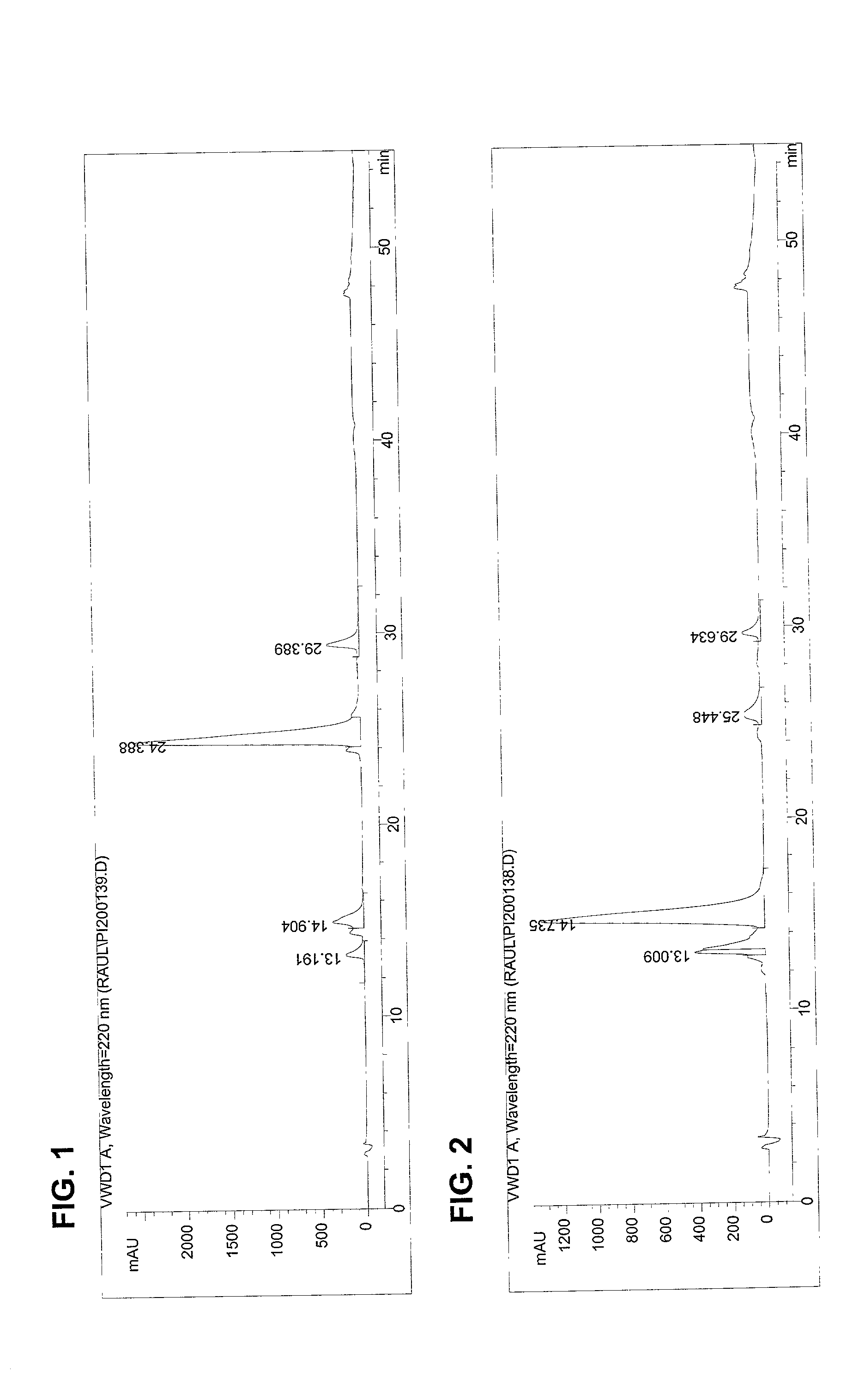

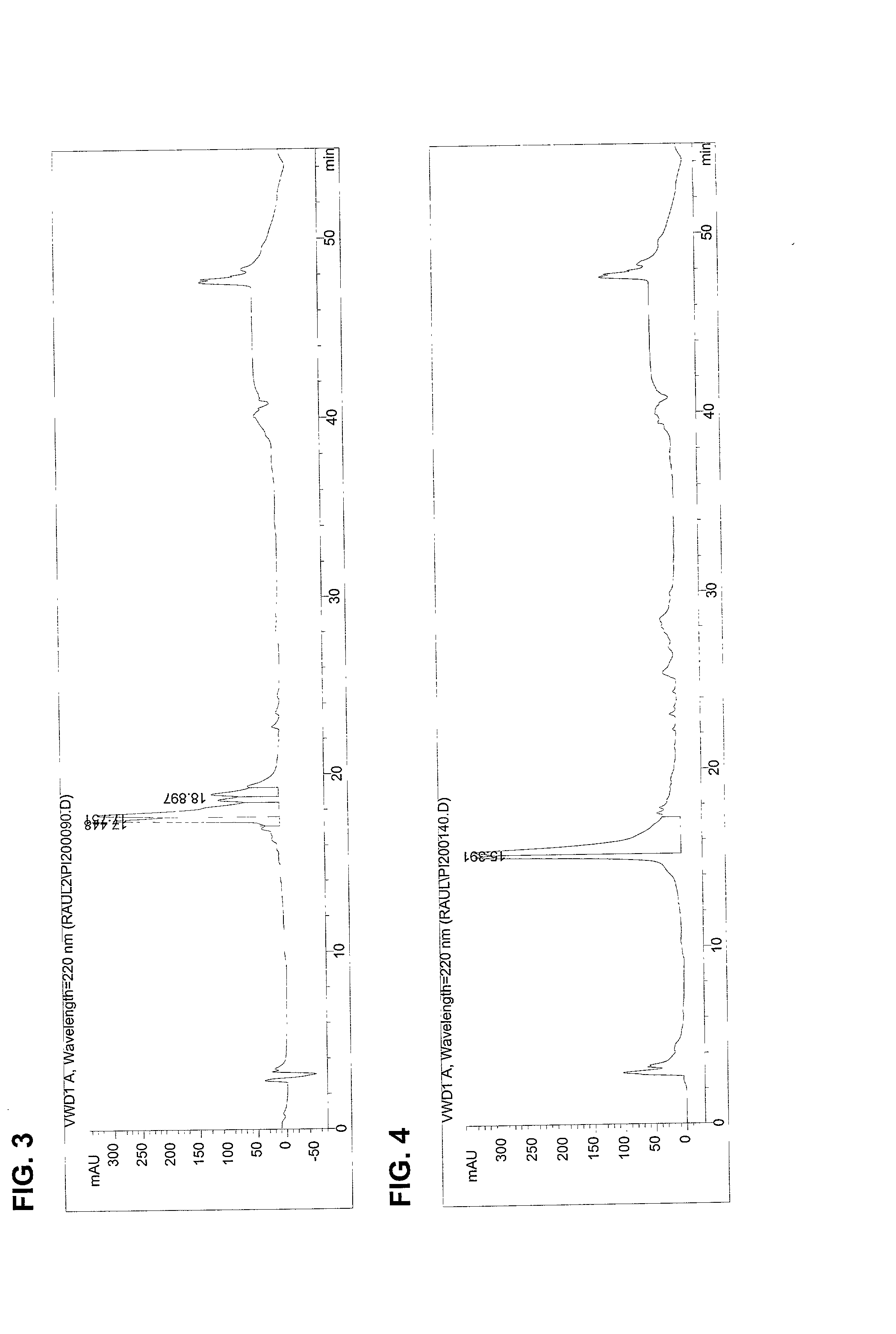

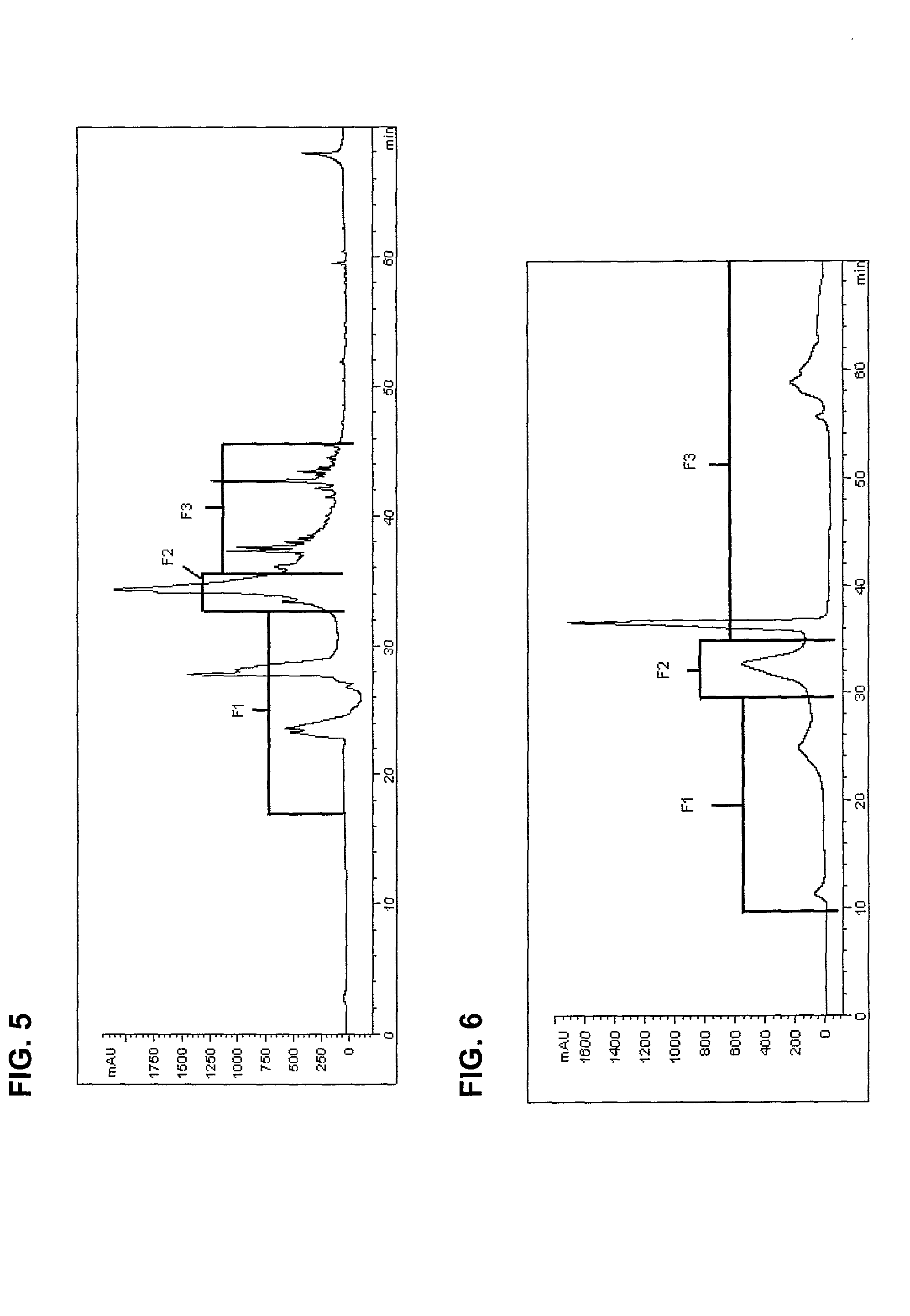

Method for the elimination of kunitz and bowman-birk trypsin inhibitors and carboxypeptidase inhibitor from potato proteins

A method for removing protein impurities from extracts of protease inhibitor-containing plant material. Plant materials containing protease inhibitors, such a potato tubers that contain protease inhibitor II, are extracted using an alcohol-free solvent. The proteins present in the extract include impurities other than the protease inhibitor, specifically Kunitz, Bowman-Birk and carboxypeptidase inhibitors. The extract is subjected to heat treatment to denature and precipitate the unstable protein impurities followed by centrifugation to remove the precipitate. Ultrafiltration in the presence of a buffer removes the Bowman-Birk and carboxypeptidase inhibitors. The resulting purified protease inhibitor has applicability in the control of obesity and diabetes.

Owner:KEMIN FOODS L C

Process for preparing nano chromium carbide powder

InactiveCN100357187CSimple processUniform particle size distributionChromium compoundsHydrazine compoundPhenol

The invention provides a Method for preparation of nanochromium carbide powder, belonging to nanometal carbide powder preparation technical realm. Using ammonium dichromate, hydrazine hydrate, nanocarbon black and formaldehyde-phenol resin as raw material, first deoxidizing ammonium dichromate in aqueous solution by hydrazine hydrate and getting the amorphous nanoCr2O3, and then mixing nanoCr2O3, nanocarbon black and formaldehyde-phenol resin, getting nanoCr2O3 after 800-1100 Deg C heat treatment in vacuum furnace. The advantages of this invention are lies in: realizing the granularity of chromium carbide powder can controlled, the technics and equipment is simple and is the same with industrialization production.

Owner:UNIV OF SCI & TECH BEIJING

Method for the elimination of Kunitz and Bowman-Birk trypsin inhibitors and carboxypeptidase inhibitor from potato proteins

A method for removing protein impurities from extracts of protease inhibitor-containing plant material. Plant materials containing protease inhibitors, such a potato tubers that contain protease inhibitor II, are extracted using an alcohol-free solvent. The proteins present in the extract include impurities other than the protease inhibitor, specifically Kunitz, Bowman-Birk and carboxypeptidase inhibitors. The extract is subjected to heat treatment to denature and precipitate the unstable protein impurities followed by centrifugation to remove the precipitate. Ultrafiltration in the presence of a buffer removes the Bowman-Birk and carboxypeptidase inhibitors. The resulting purified protease inhibitor has applicability in the control of obesity and diabetes.

Owner:KEMIN FOODS L C

Solid base catalyst and preparation method and application of solid base catalyst

ActiveCN102909040AHigh activityHigh selectivityPhysical/chemical process catalystsEther preparation from oxiranesOrganic synthesisPotassium fluoride

The invention relates to the field of catalysts and organic synthesis, and discloses a solid base catalyst, namely zinc magnesium aluminum composite oxide, for catalytically preparing propylene glycol ether compound. The preparation method comprises the steps of preparing and roasting zinc magnesium aluminum volknerite, conducting hydrothermal treatment on roasted products, impregnating the roasted products to load a right amount of potassium fluoride, and conducting drying and activation. The solid base catalyst comprises the following components by weight percent: 65%-75% of zinc magnesium aluminum composite oxide and 25%-35% of potassium fluoride, wherein the mole ratio of magnesium to aluminum is 2.8-3.2, the mass ratio of zinc, magnesium and aluminum to total zinc is 9%-12%. The solid base catalyst is used for catalytically preparing the propylene glycol ether, the conversion rate of PO (Propylene oxide) is above 95%, the selectivity is above 95:5, and the yield is above 85%.

Owner:上海泰坦科技股份有限公司

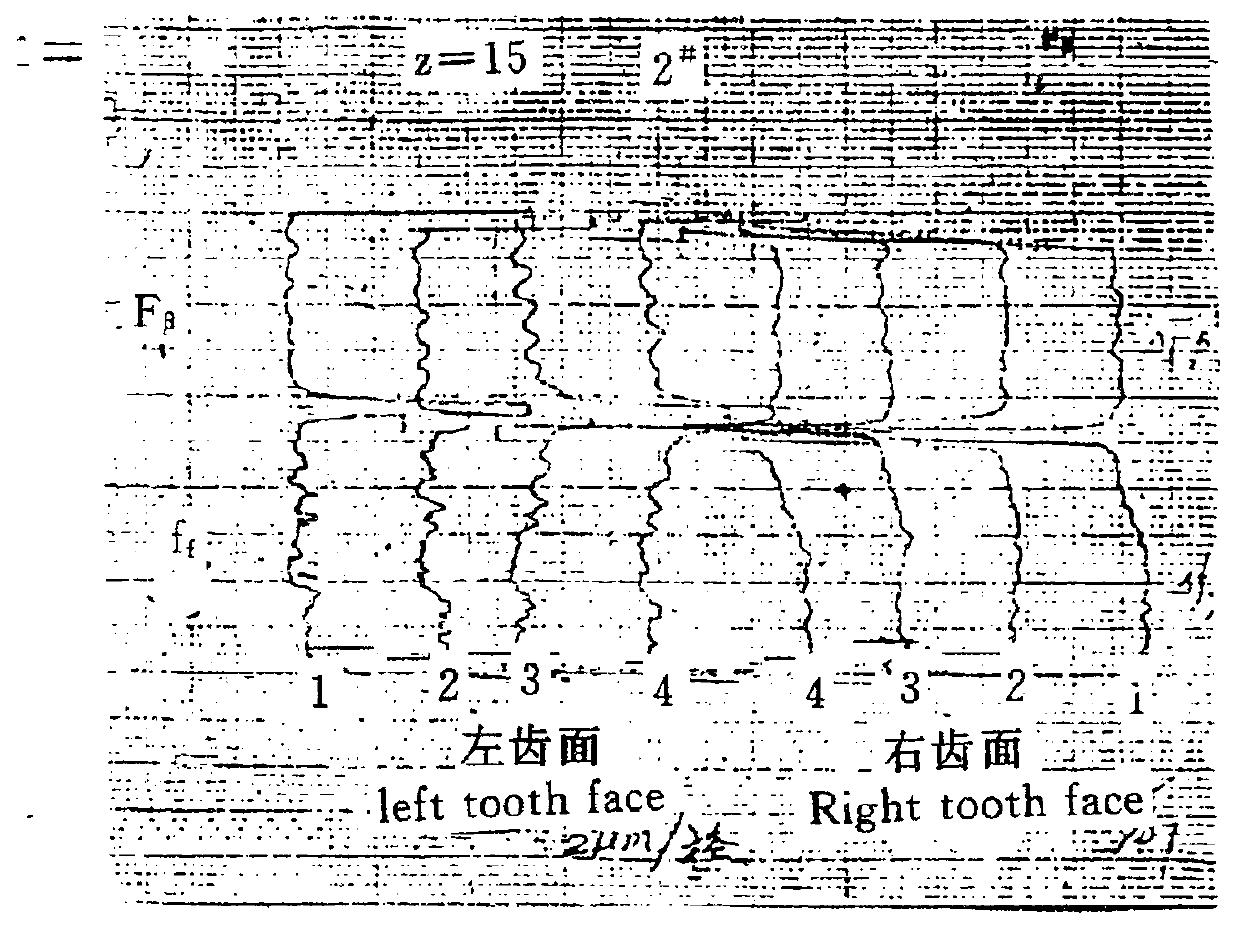

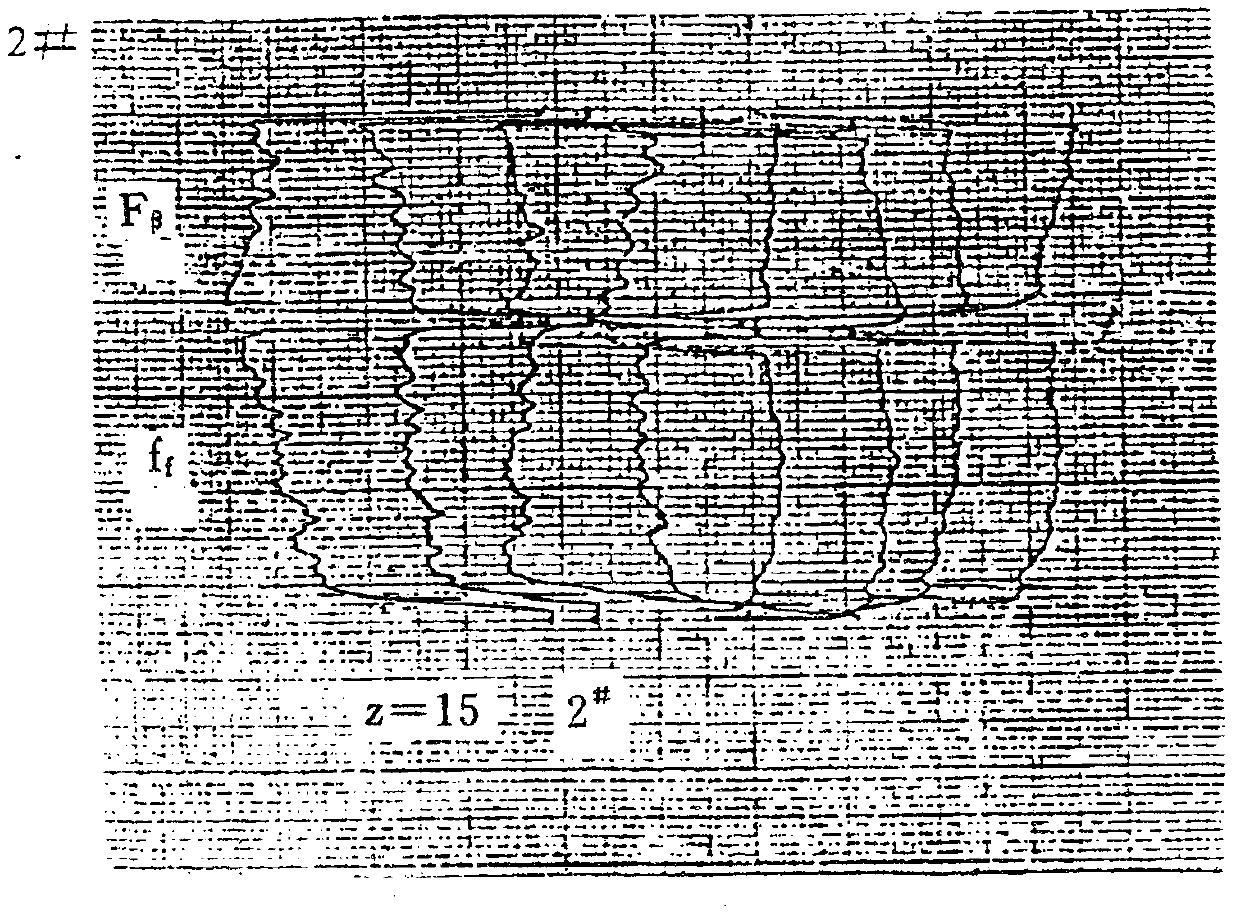

Anti-fatigue manufacturing method of car transmission gear

ActiveCN103302464AEasy to adjustImprove fatigue lifeSolid state diffusion coatingFurnace typesCarrying capacityHobbing

An anti-fatigue manufacturing method of a car transmission gear comprises the steps that forging blanking, heat pretreatment (isothermal normal fire), gear blank processing, gear hobbing, gear strengthening and toughening treatment (the gear part is subject to two times of induction heating and circulatory quenching), modification of criteria to the drawing demand, gear hobbing, gear shaving and gas nitrizing process are carried out in sequence. By adopting the method, 6-grade or more than 6-grade precise car gears can be efficiently produced in batch at low price, and the produced car gears has the bearing / carrying capacity almost as well as that of alloy cemented steel. The car transmission gear manufactured by adopting the method can replace the carburized and quenched gear in the prior art.

Owner:天津市天瑞硬化工程有限公司

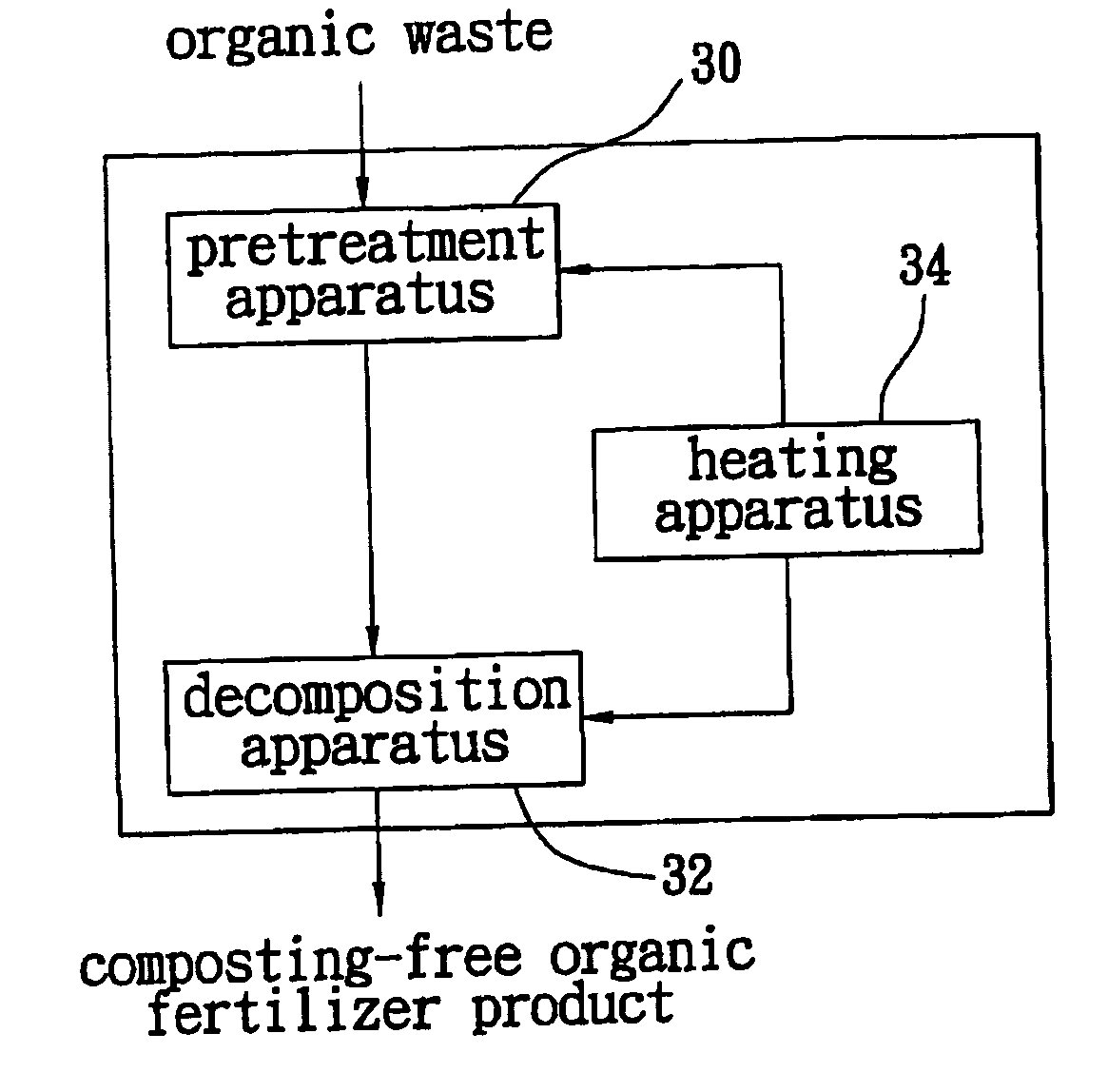

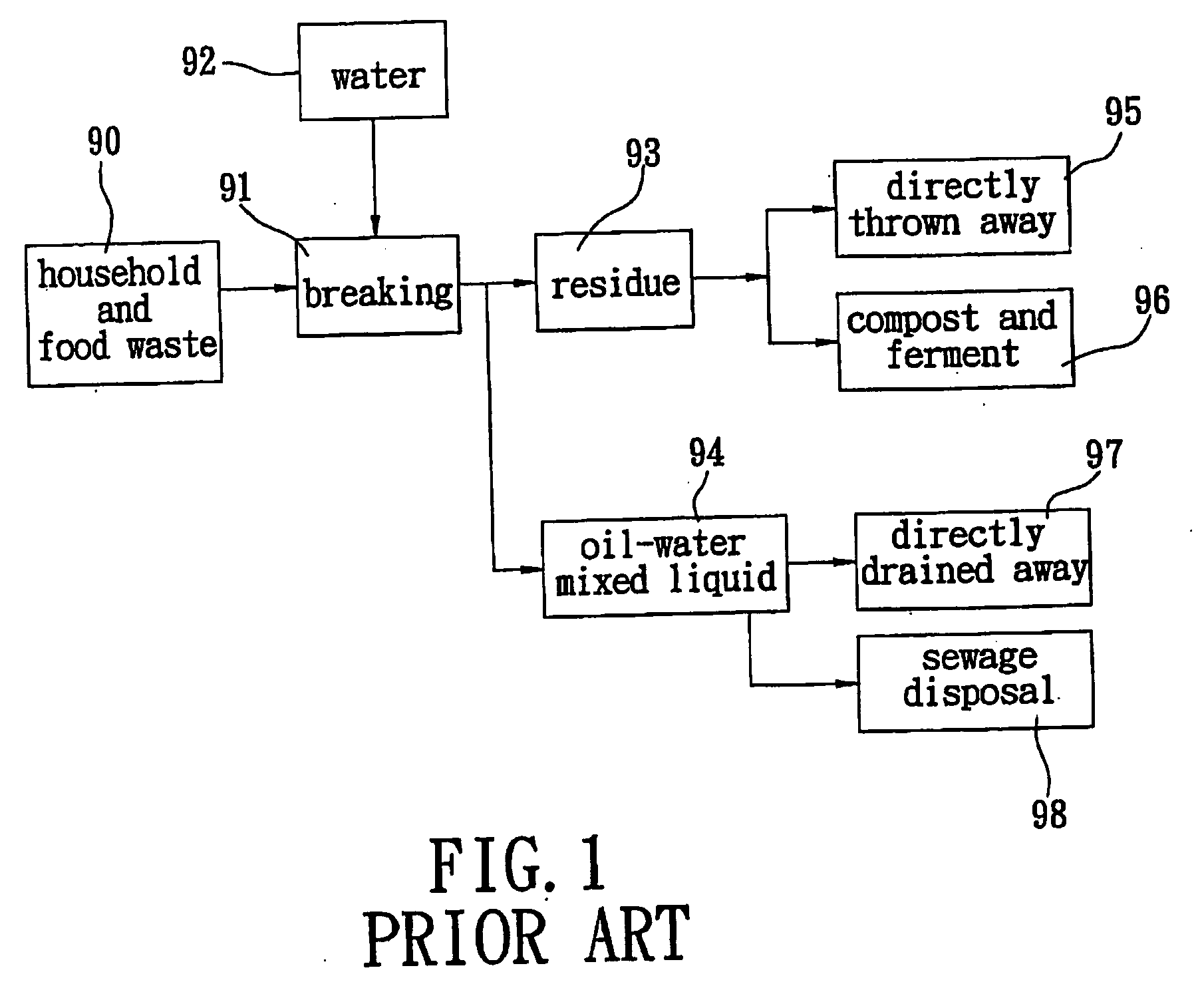

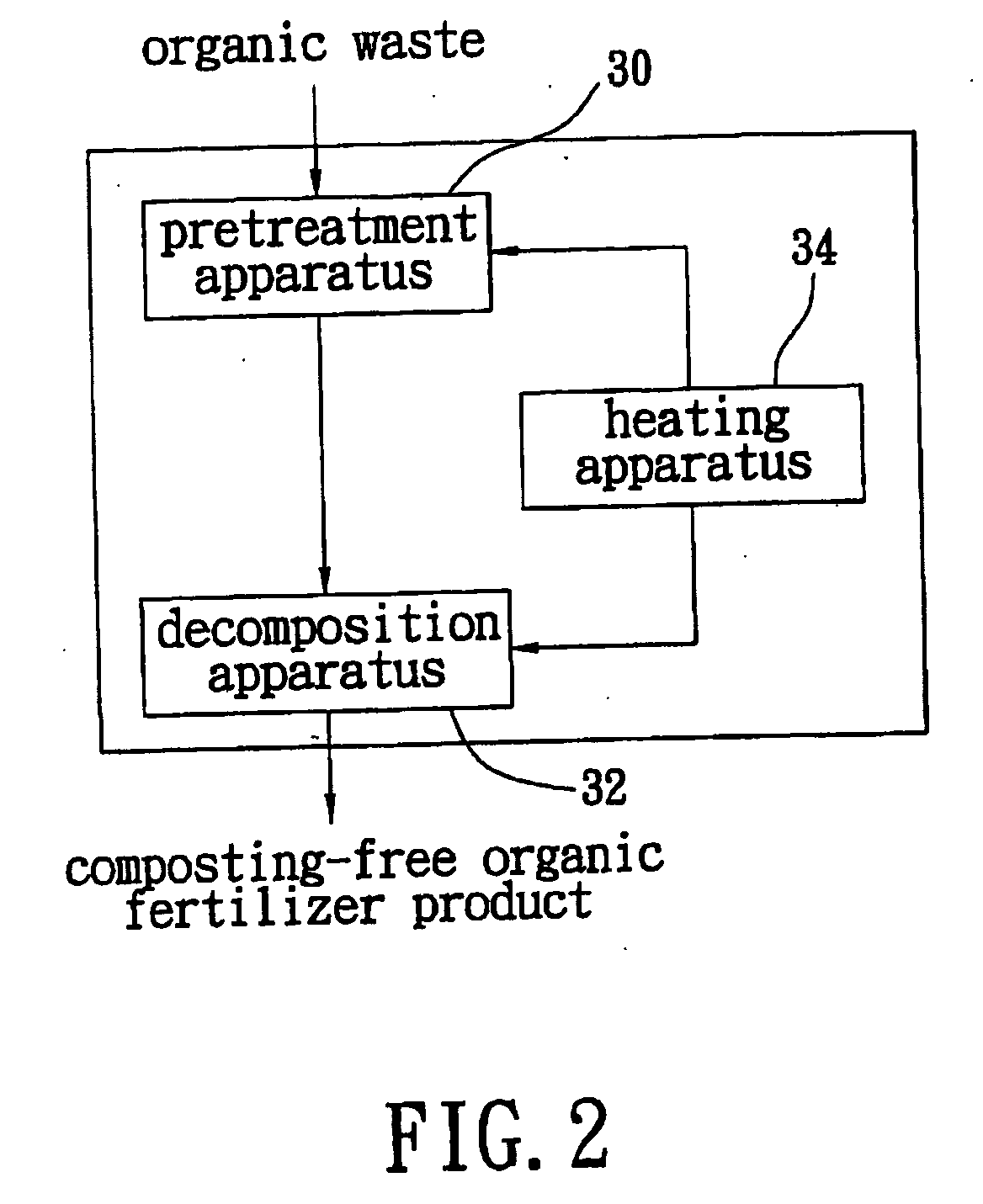

System and method for composting-free disposal of organic wastes

ActiveUS20050252261A1Improve efficiencyLess spaceBiocideSolid waste disposalDecompositionMicrobial enzymes

A system for composting-free disposal of organic waste and method thereof included a heating apparatus, a pretreatment apparatus, and a decomposition apparatus. The heating apparatus heats the pretreatment apparatus and the decomposition apparatus. The organic waste is separated into a slurry and a surface oil-water mixed liquid by the pretreatment apparatus. Microbial enzymes and raw material are added into the slurry to become a mixture. The mixture is then decomposed and sterilized by the decomposition apparatus to become a composting-free organic fertilizer product. All these procedures can be carried out within 3 to 24 hours. The system and the method thereof provides an efficiently fast, space-saving way to deal with organic waste and achieve environmental protection and sanitation.

Owner:YES SUN ENVIRONMENTAL BIOTECH

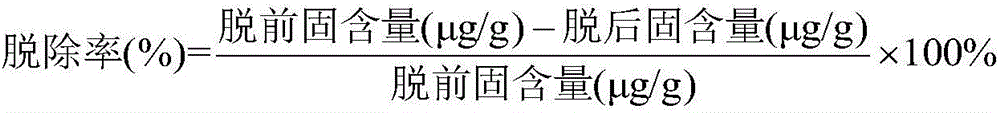

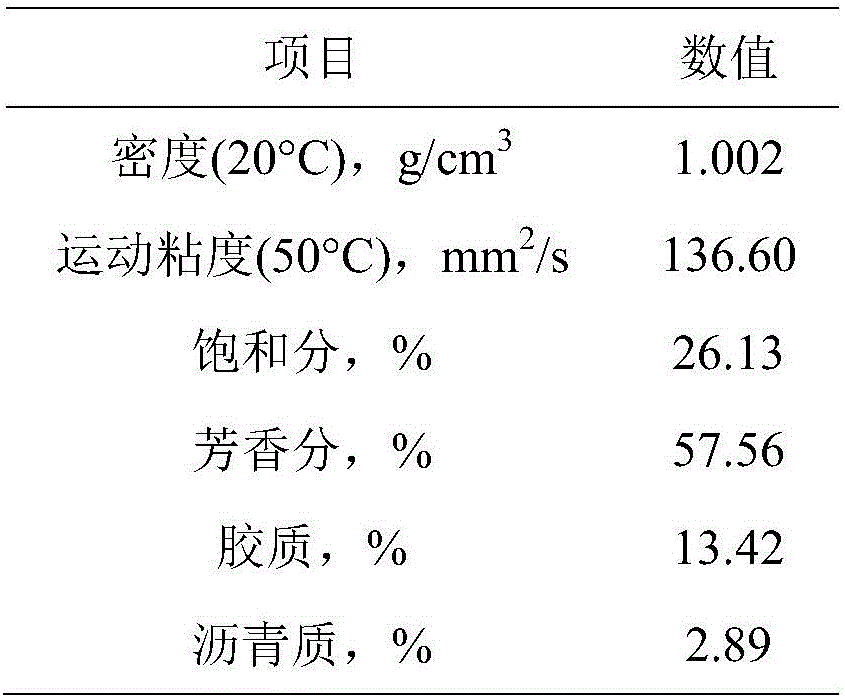

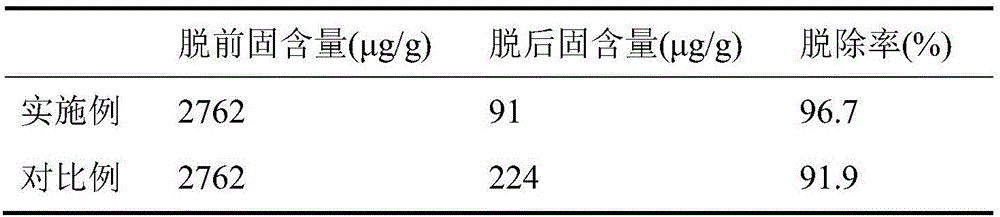

Catalytic cracking slurry oil solid content removal method

InactiveCN105802657ALow solid contentAdaptableHydrocarbon distillation control/regulationHydrocarbon oils treatmentHeat pretreatmentSolid particle

The invention discloses a catalytic cracking slurry oil solid content removal method.The method comprises the following steps that 1, heat pretreatment is conducted on catalytic cracking slurry oil; 2, vacuum distillation is conducted on the catalytic cracking slurry oil subjected to heat pretreatment, and solid removal slurry oil distillate oil is obtained.According to the catalytic cracking slurry oil solid content removal method, heat pretreatment is conducted on the slurry oil before distillation is conducted so as to enable micron or submicron solid particles in the slurry oil to aggregate and grow up, and the solid particles can stay in distillation residues more easily, so that the solid content in the slurry oil distillate oil is reduced, and the solid content of the slurry oil distillate oil is further reduced on the basis of simple distillation operation.The catalytic cracking slurry oil solid content removal method is easy to operate and high in removal efficiency, adaptability to raw materials is high, influence factors are few, the cost is low, and industrialization is easy.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Motorcycle clutch iron base friction sheet, preparation process and pairing sheet thereof

The invention provides an iron base friction plate for a motorcycle clutch which is sintered by an iron-base powder metallurgical material. The formula comprises the following compositions of the iron base friction plate in percentage by weight: 1.0 to 6.0 percent of manganese, 0.2 to 1.5 percent of carbon, 1.0 to 5.5 percent of copper, respectively more than 0 but less than 10.0 percent of one or a plurality of compositions of silicon, molybdenum, chromium, nickel, lead, ferric sulfide, tungsten, silicon dioxide, calcium sulfide and asbestos, and the balance being iron, with a density range of the friction plate of between 6.2 and 7.2g / cm<3>. The friction plate uses iron as a base with low cost, which is only one sixth to one tenth of the cost of a copper base material; with the adoption of a powder metallurgy technology, the manufacturing process of the iron base friction plate is simpler than that of the copper base friction plate. A dual disc matched with the friction plate is made of a mild steel disc, and is subject to nitridizing heat treatment or soft nitriding heat treatment on the surface, with a thickness of a nitration case of the dual disc more than or equal to 0.005mm and hardness of the dual disc more than or equal to 350HV0.1. The friction plate can be used under a wet condition, not only has a higher friction coefficient (0.09 to 0.13), but also has excellent wearing resistance, and can be used in the motorcycle clutch.

Owner:重庆市璧山区三泰粉末冶金有限公司 +1

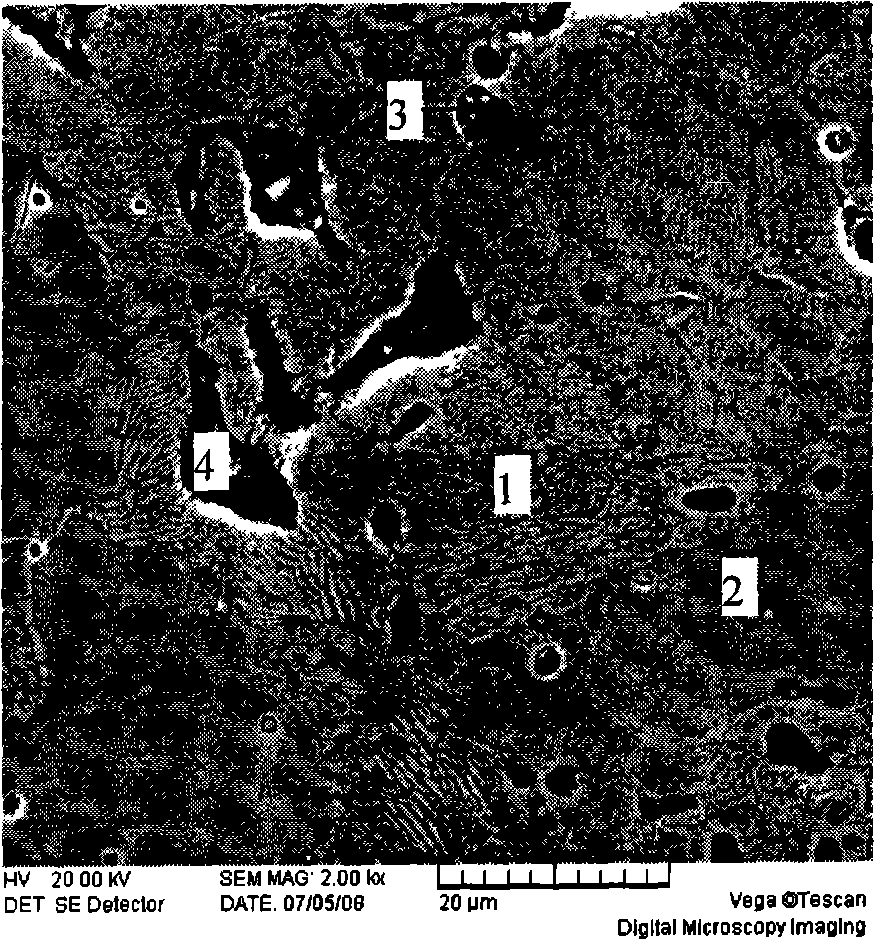

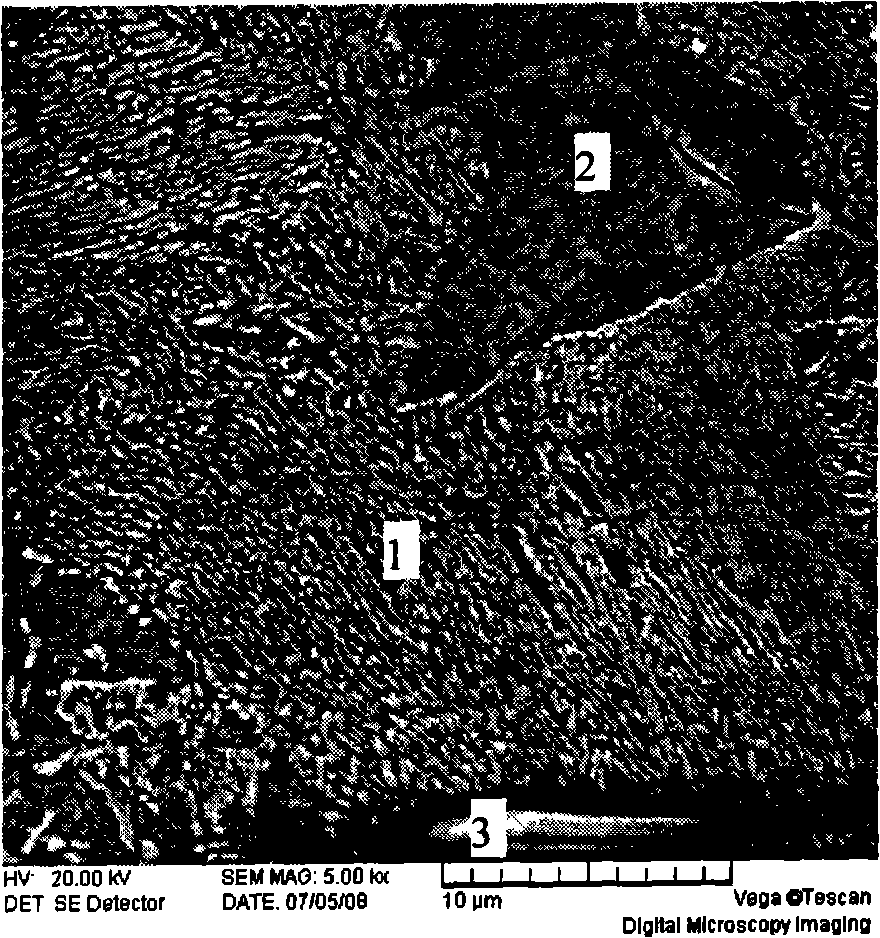

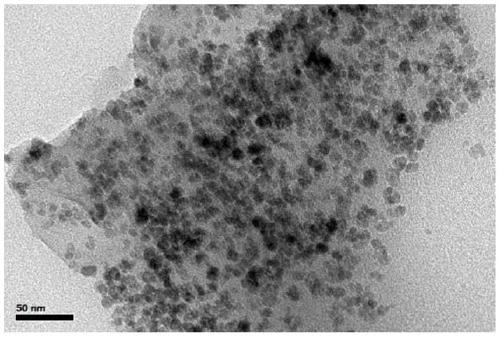

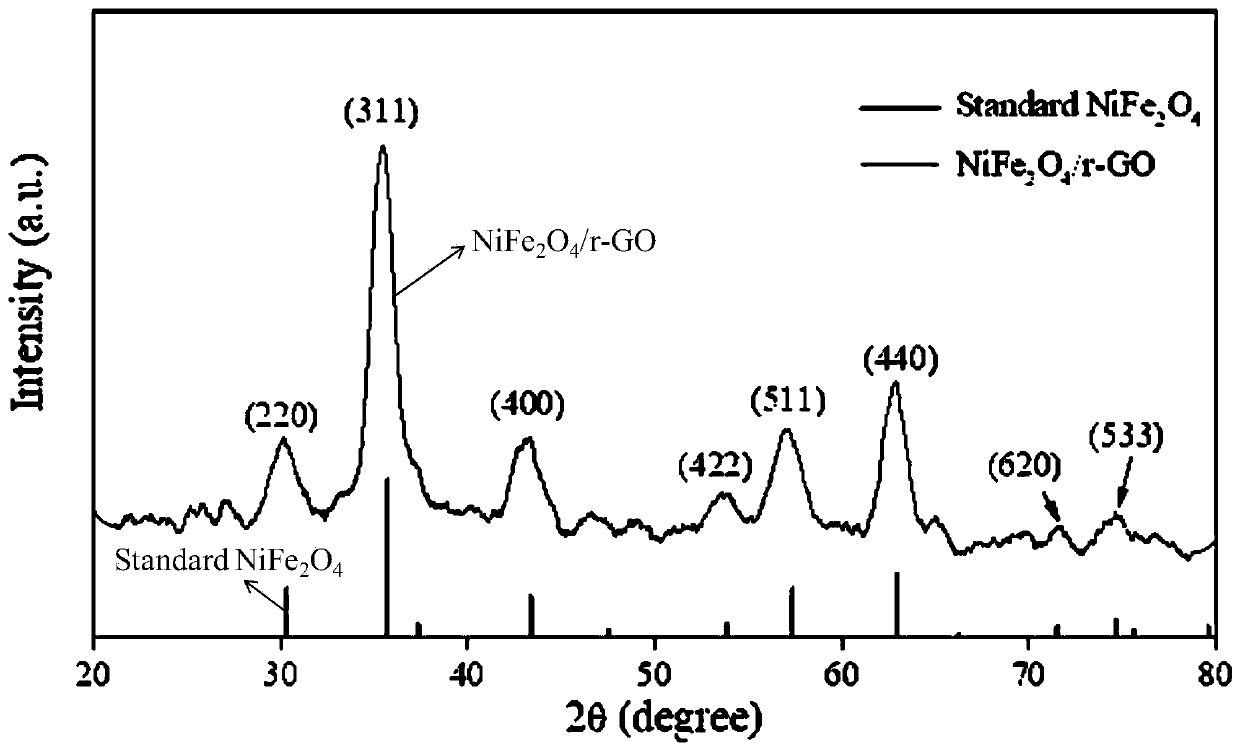

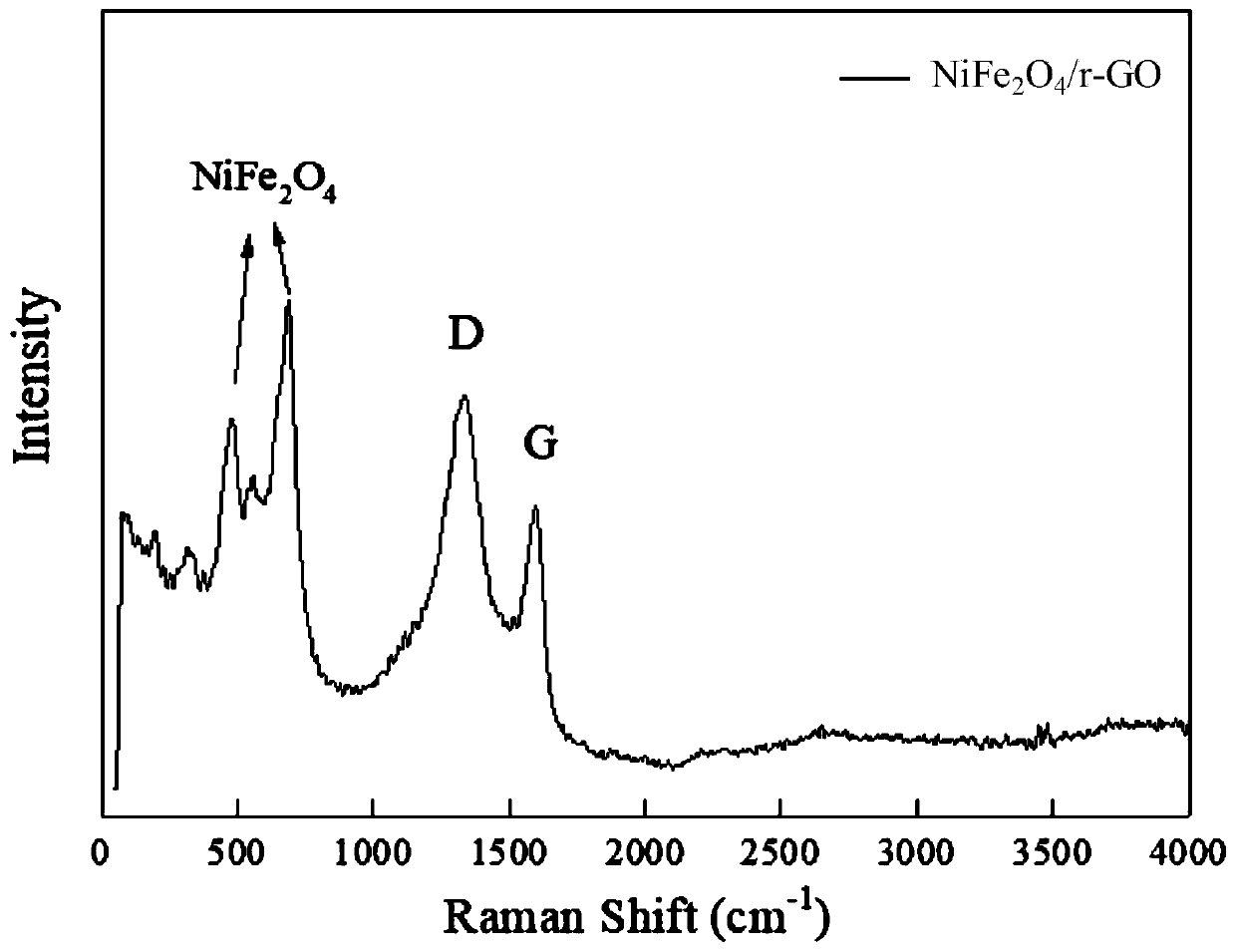

Magnetic reduction graphene oxide nano composite material and preparation method and application thereof

InactiveCN109896520AImprove microwave absorption performanceSolve reunionMagnetic/electric field screeningGrapheneNickel saltIron salts

The invention relates to a magnetic reduction graphene oxide nano composite material and a preparation method and application thereof. The nano composite material comprises reduced graphene oxide andmagnetic nickel ferrite nanocrystalline with the average particle diameter of 6-12 nm uniformly deposited on the surface of the reduced graphene oxide. The method comprises the following steps: uniformly dispersing graphene oxide with deionized water to obtain graphene oxide dispersion liquid; adding divalent nickel salt and trivalent iron salt into the graphene oxide dispersion liquid, and uniformly stirring to obtain a first mixed solution; adding ammonia water into the first mixed solution to adjust the first mixed solution to be alkaline to obtain a second mixed solution; and carrying outhydrothermal treatment on the second mixed solution to obtain the nano composite material. The nano composite material has strong absorption strength, wide absorption bandwidth and double-band microwave absorption performance. The process is simple and convenient, the agglomeration problem of reduced graphene oxide and magnetic small-size nanocrystals can be avoided, and the microwave absorption performance and the effective absorption bandwidth of the composite material are improved.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com