Patents

Literature

881 results about "Tio2 particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

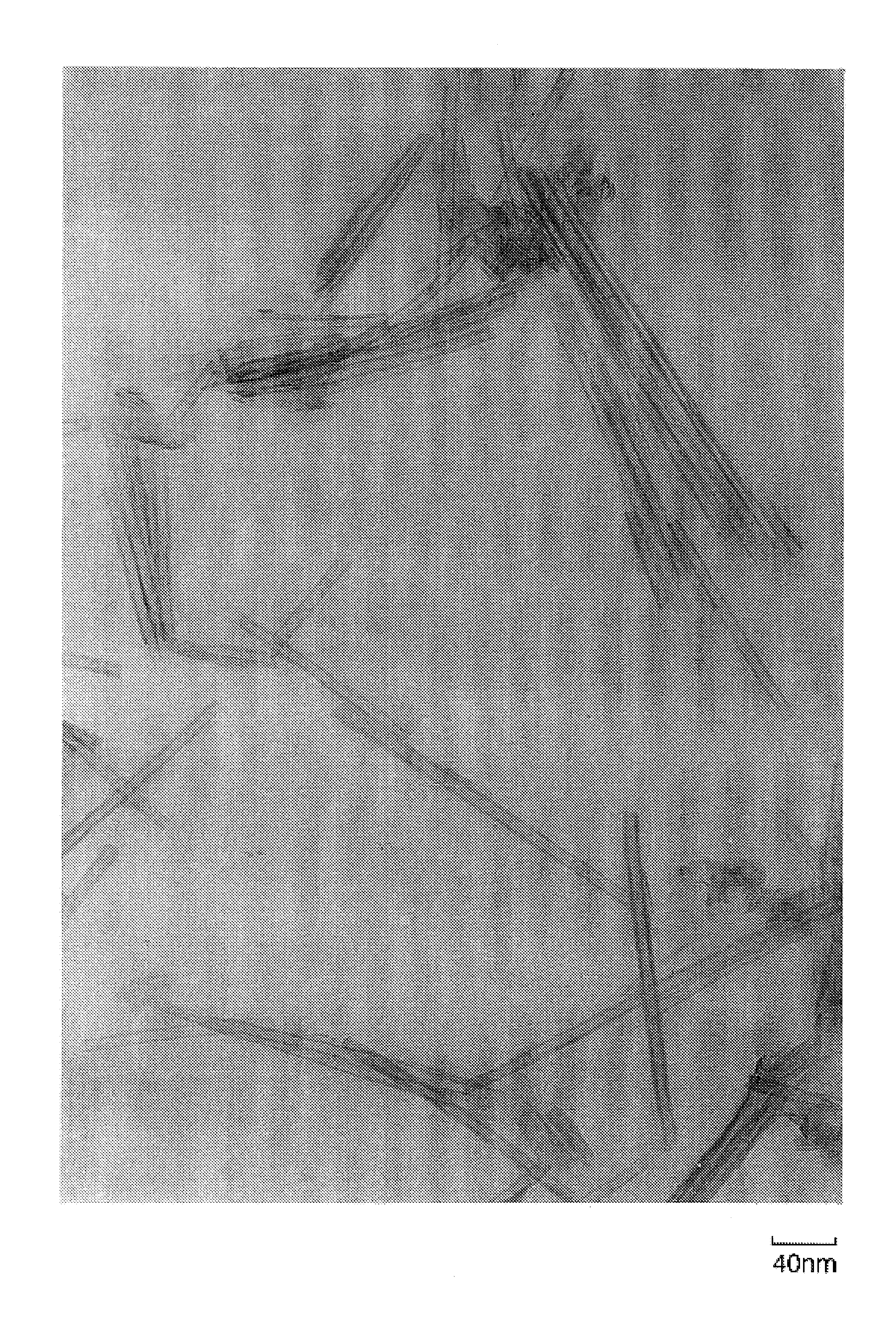

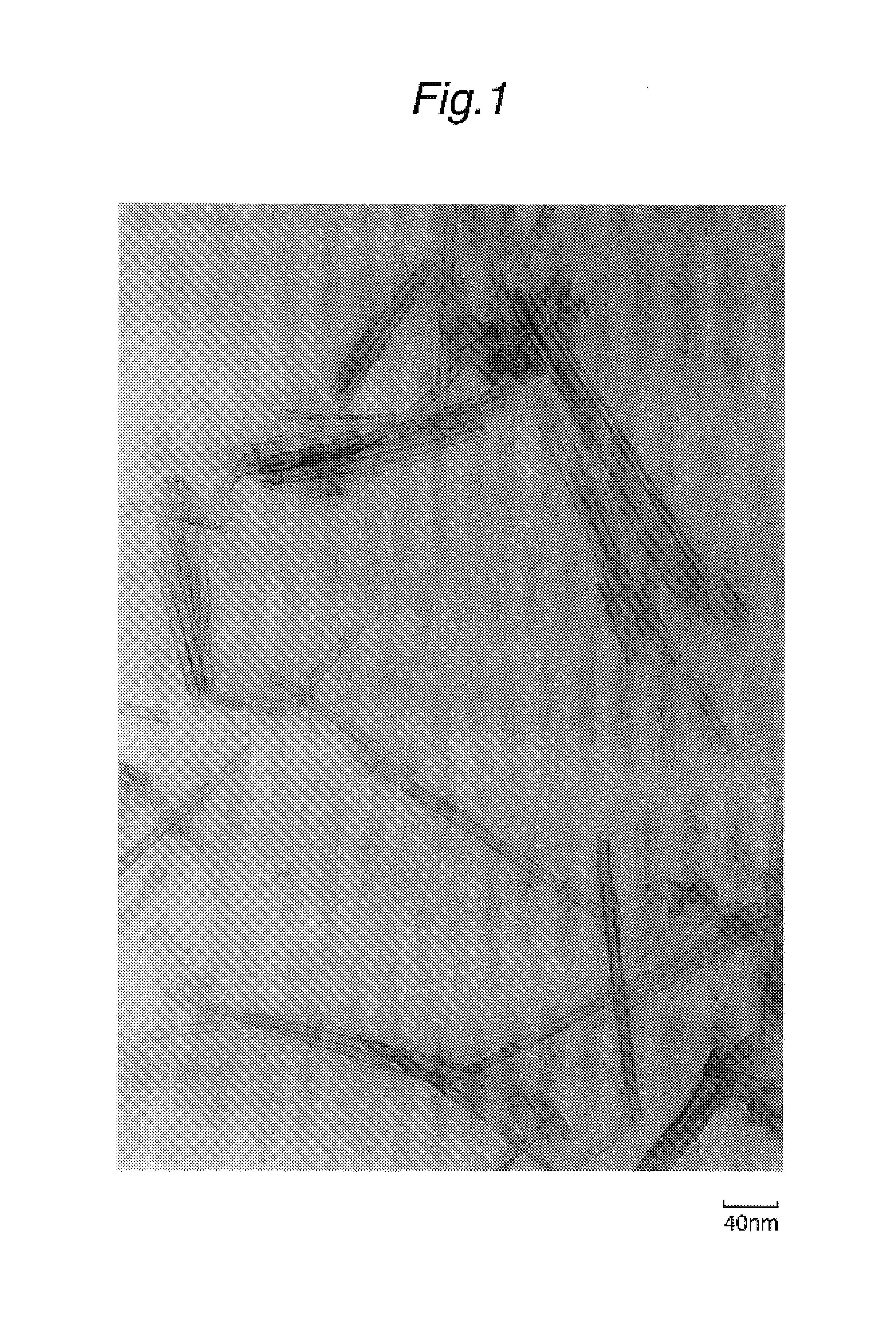

Tubular titanium oxide particles, method for preparing the same, and use of the same

InactiveUS20040265587A1Large specific surface areaImprove detection accuracyMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

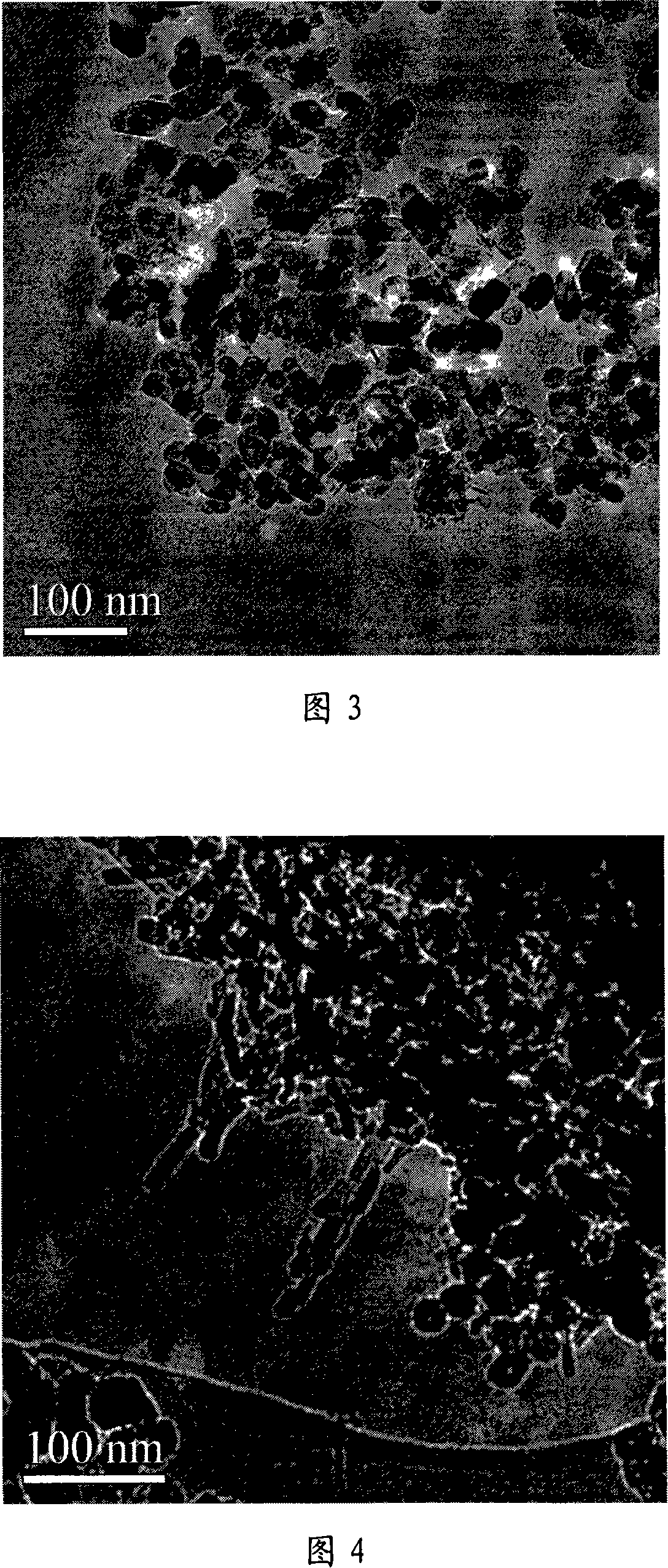

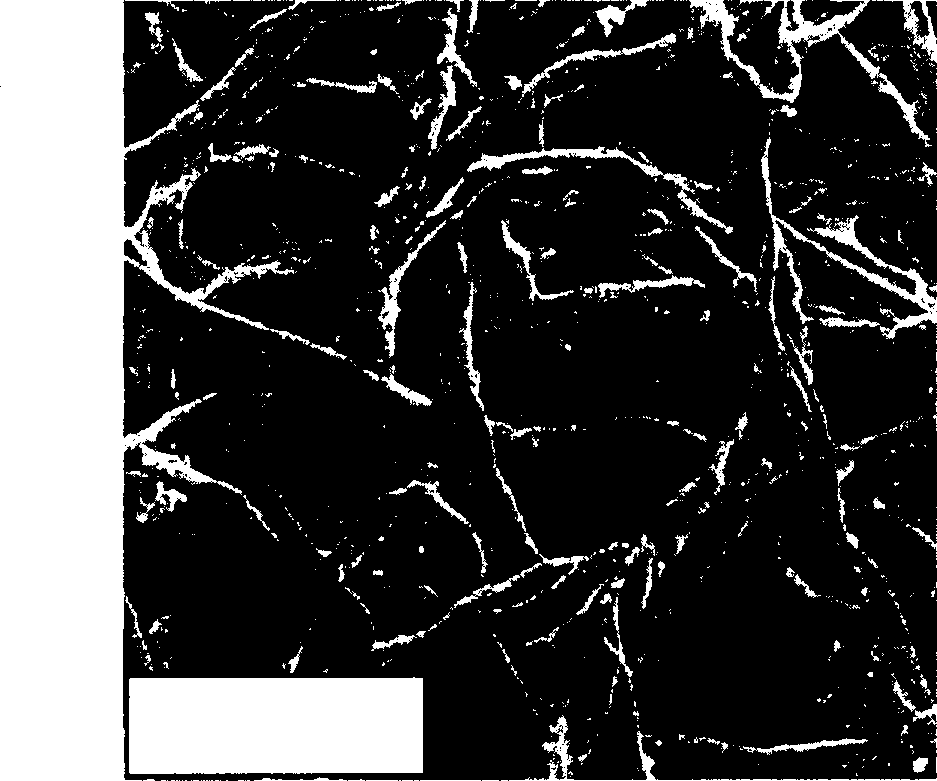

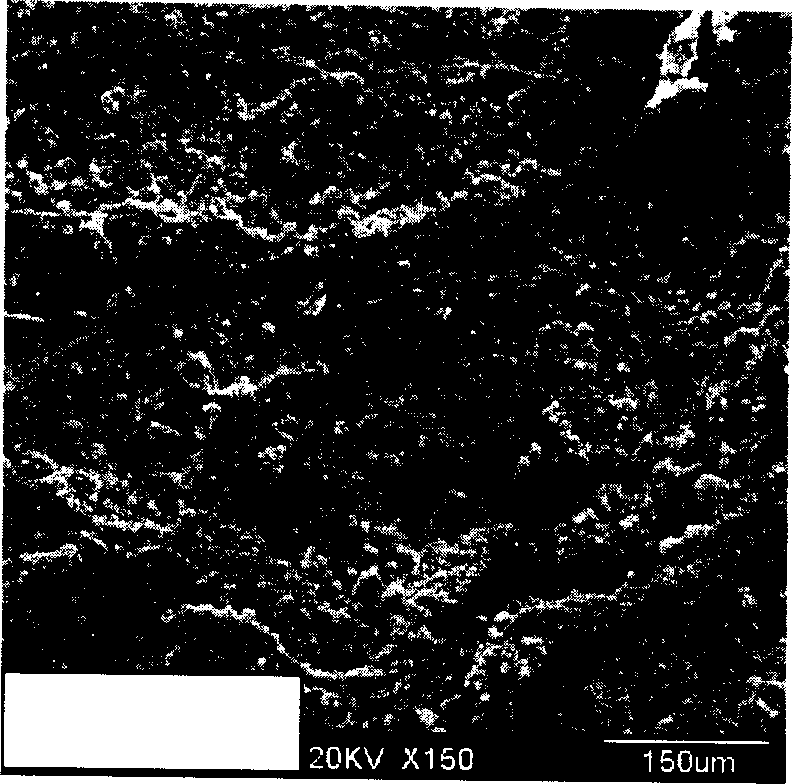

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

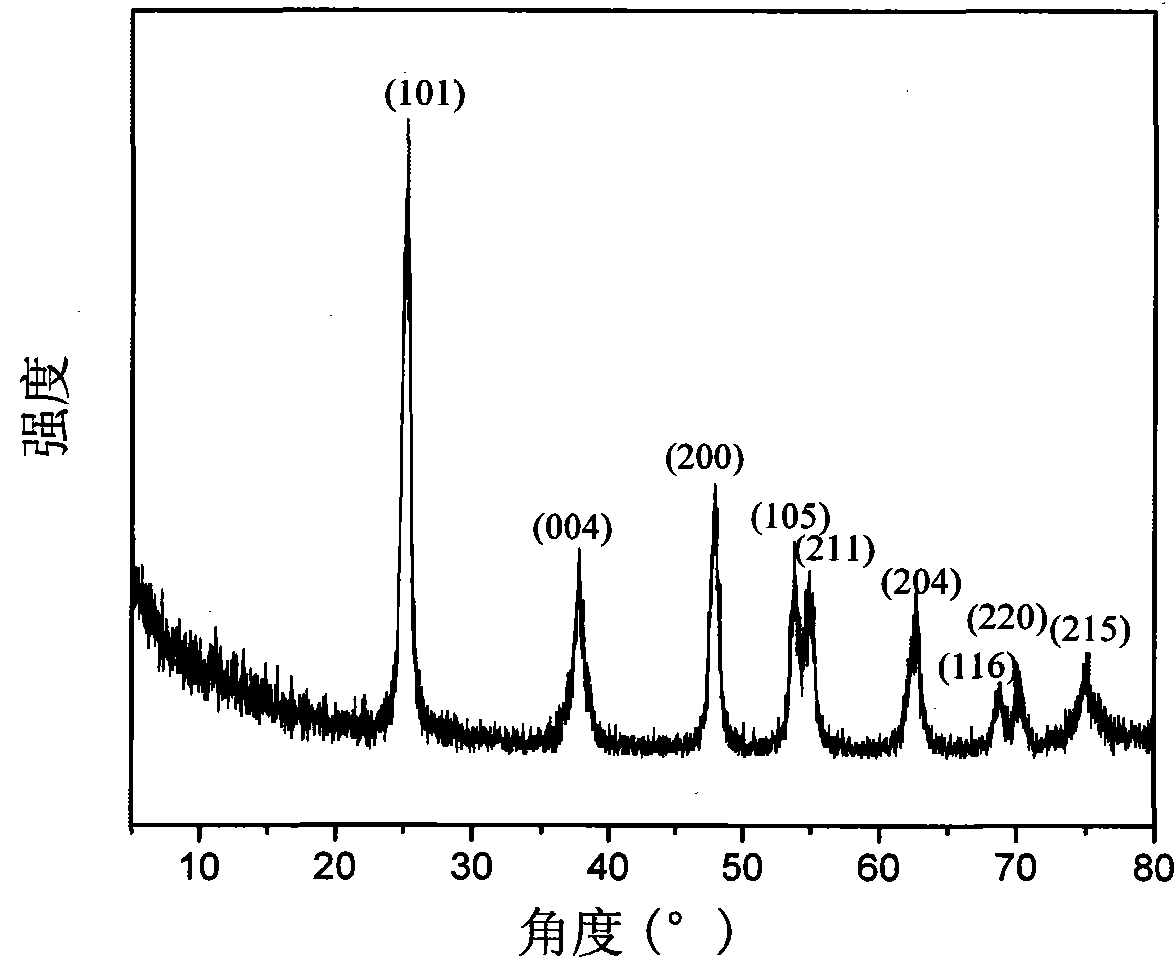

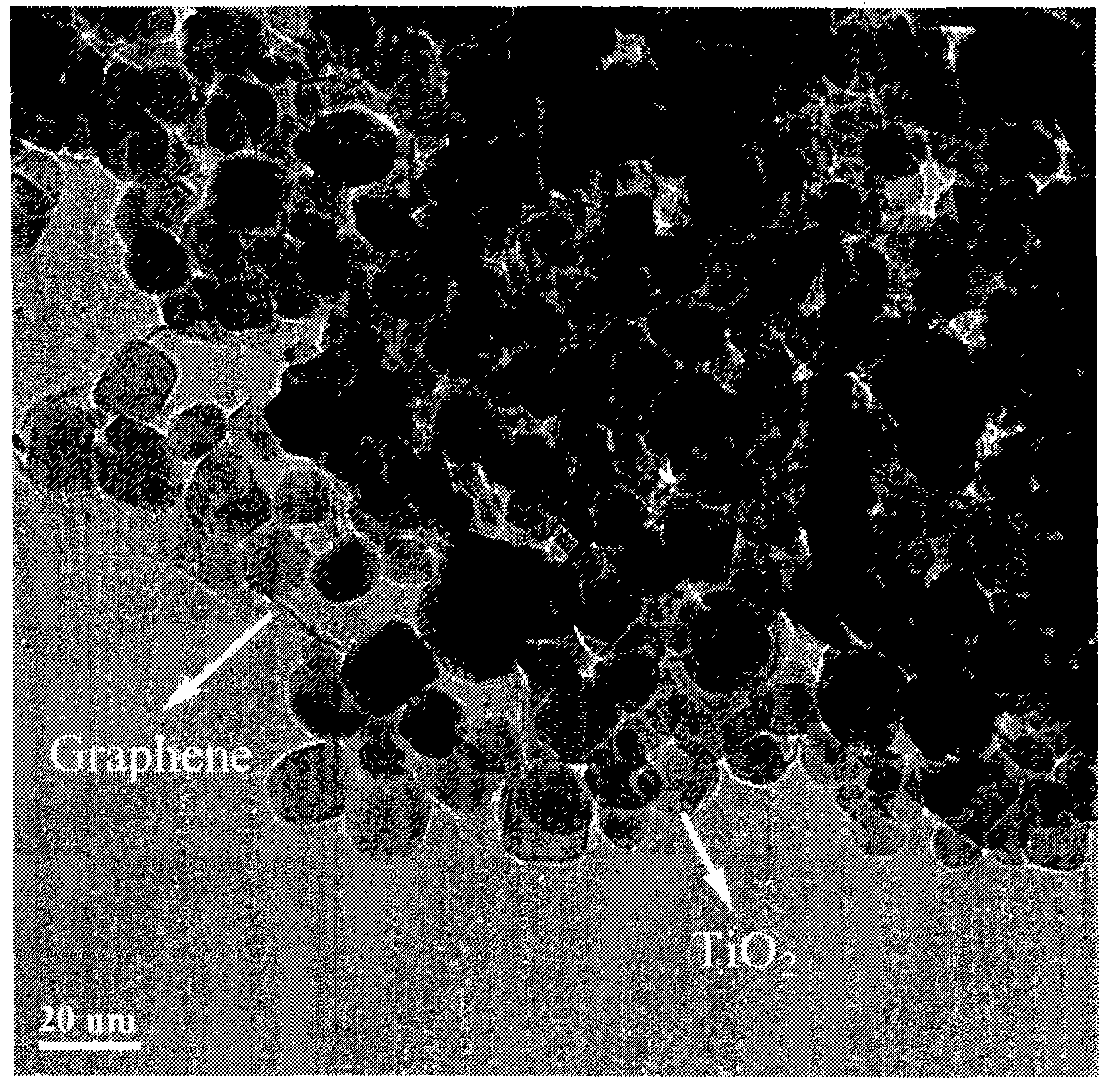

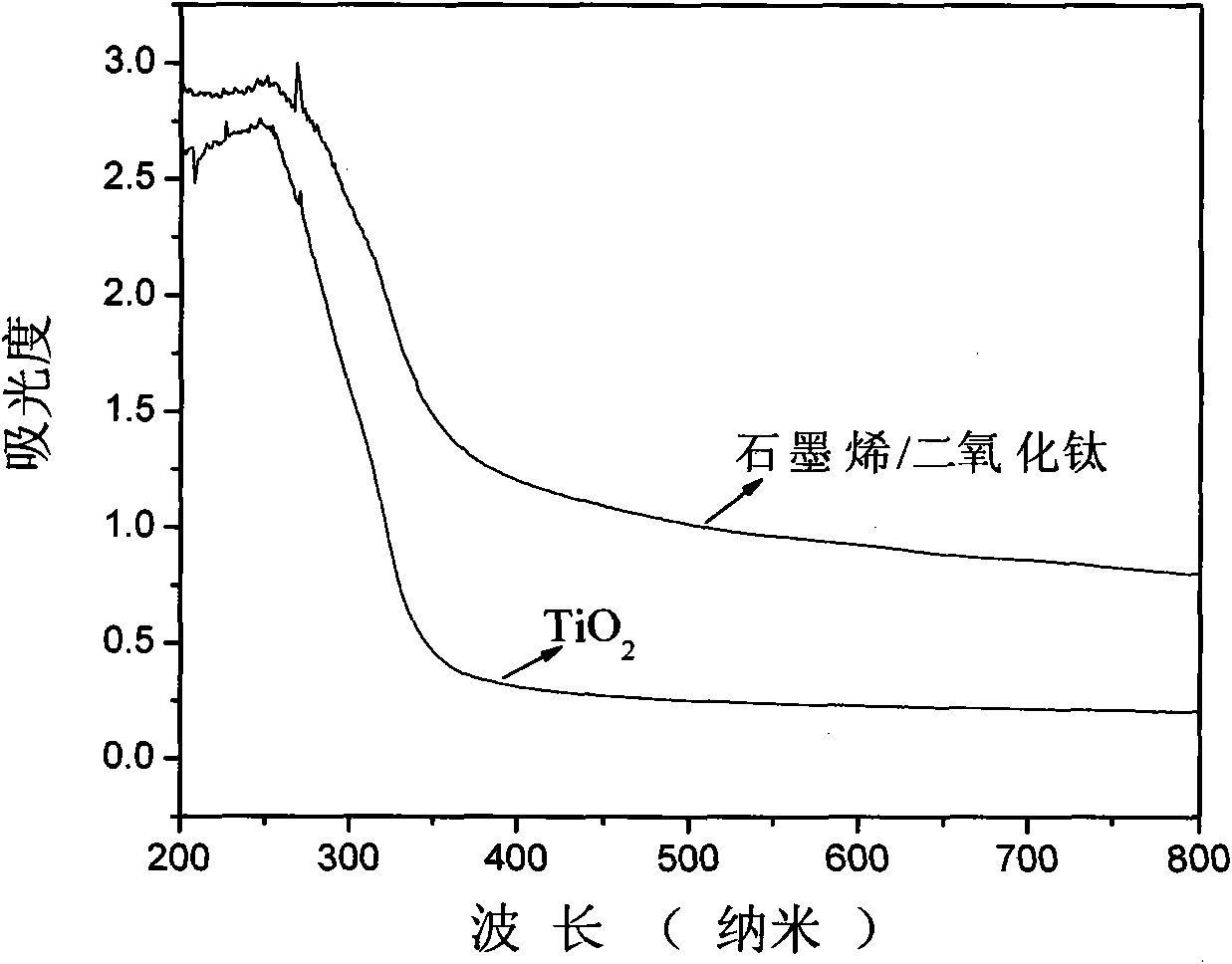

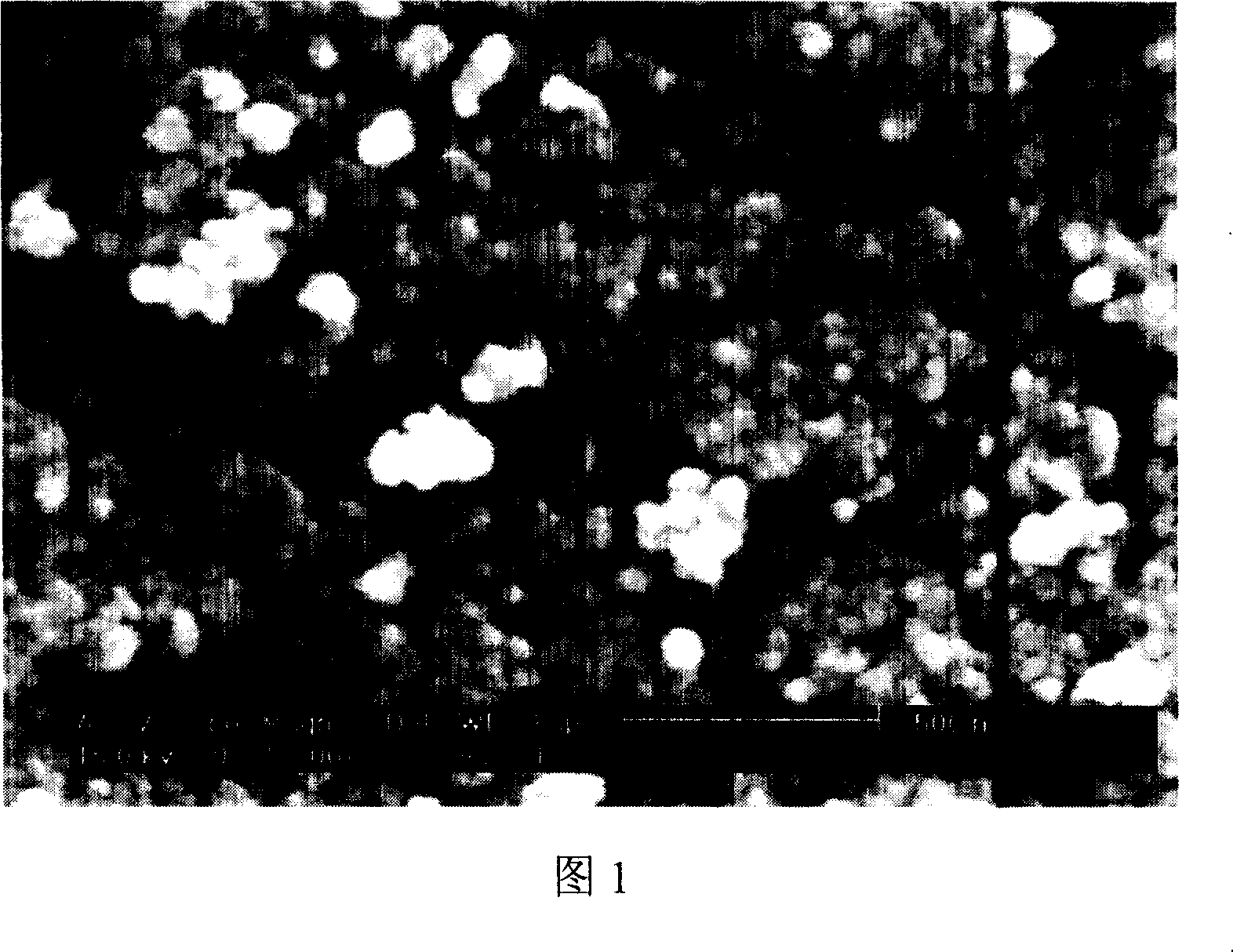

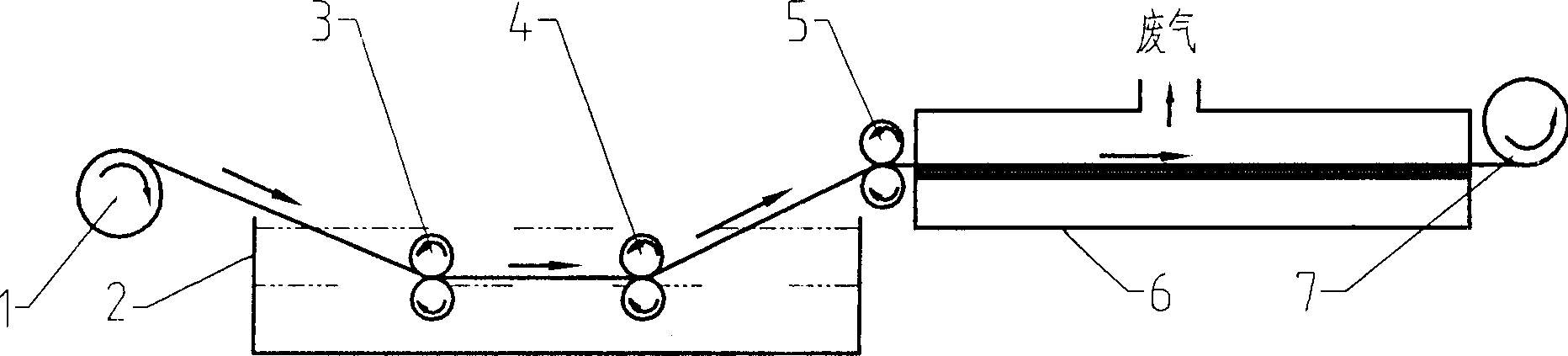

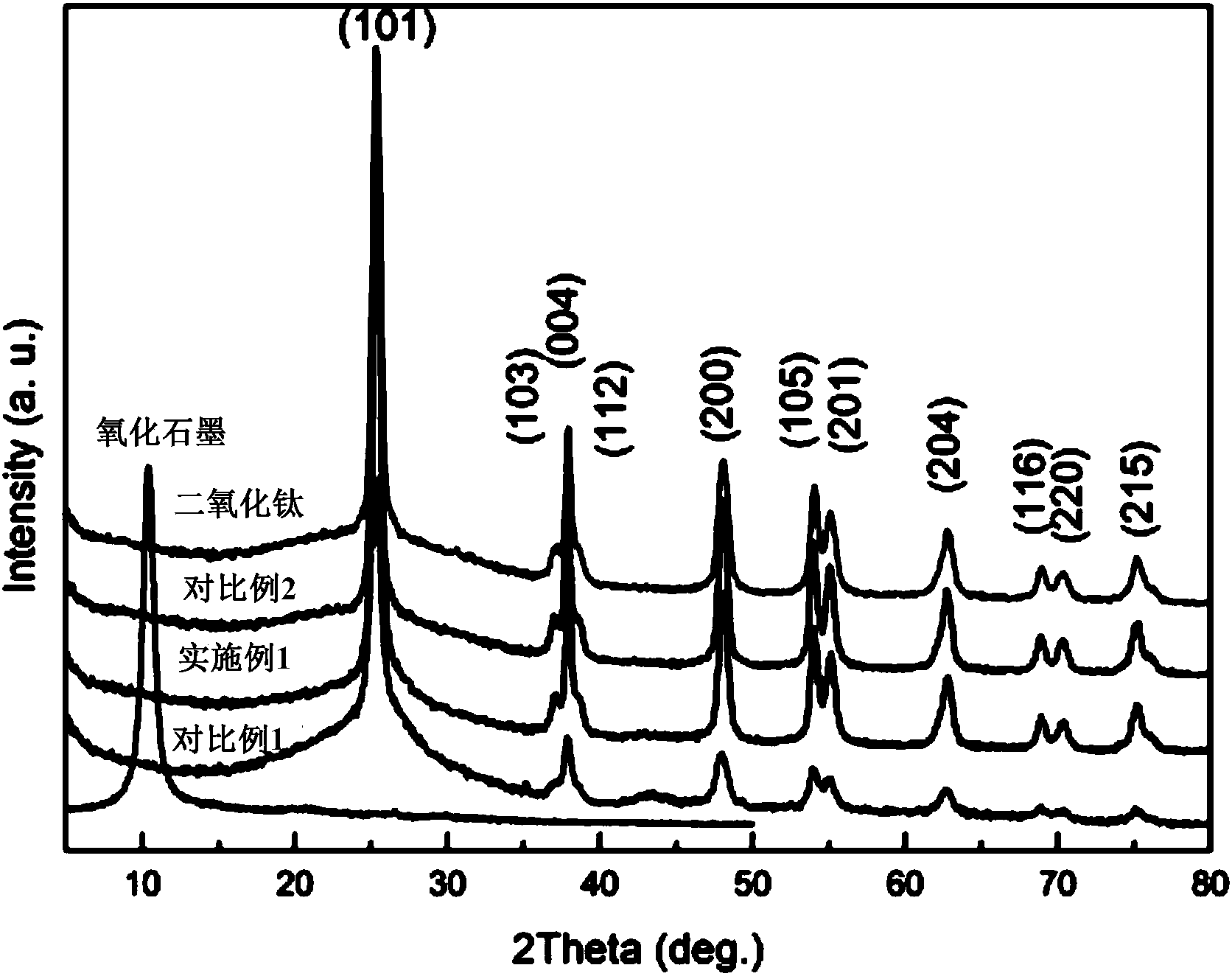

Preparation method of graphene/titanium dioxide composite photocatalyst

The invention relates to a preparation method of a graphene / titanium dioxide composite photocatalyst, which comprises the following steps: dissolving oxidized graphite in an organic solvent and obtaining oxidized graphene dispersion by ultrasonic processing; adding titanium salt precursor to the oxidized graphene dispersion and stirring evenly; transferring the mixed dispersion into a hydrothermal reaction kettle and reacting at 120-200 DEG C for 4-20 hours; respectively cleaning the product of the reaction by absolute ethyl alcohol and de-ionized water; and drying in vacuum at 40-80 DEG C for 8-24 hours to obtain the graphene / titanium dioxide composite photocatalyst. The invention has the advantages of common and easily obtained raw material, low cost and simple and safe preparation process, and in the obtained product, TiO2 particles can be evenly dispersed on the surface of the graphene, and stronger acting force is formed between the TiO2 particles and the surface of the graphene, thereby avoiding aggregation of the particles and effectively preventing restacking of graphene laminas. The graphene / titanium dioxide composite photocatalyst has good photocatalysis activity due to structural advantages and has potential application value in the fields of environment protection and solar cells.

Owner:EAST CHINA UNIV OF SCI & TECH

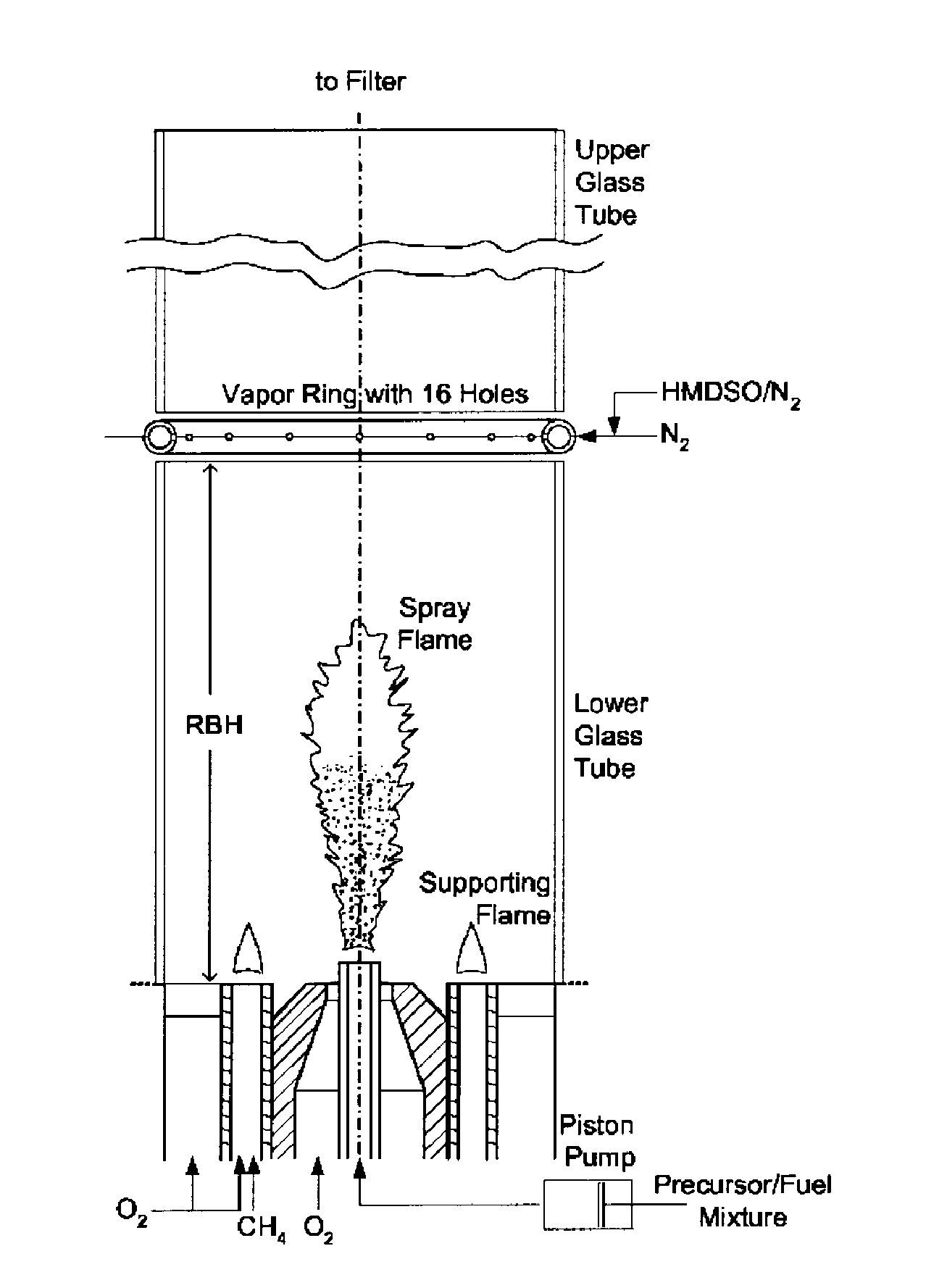

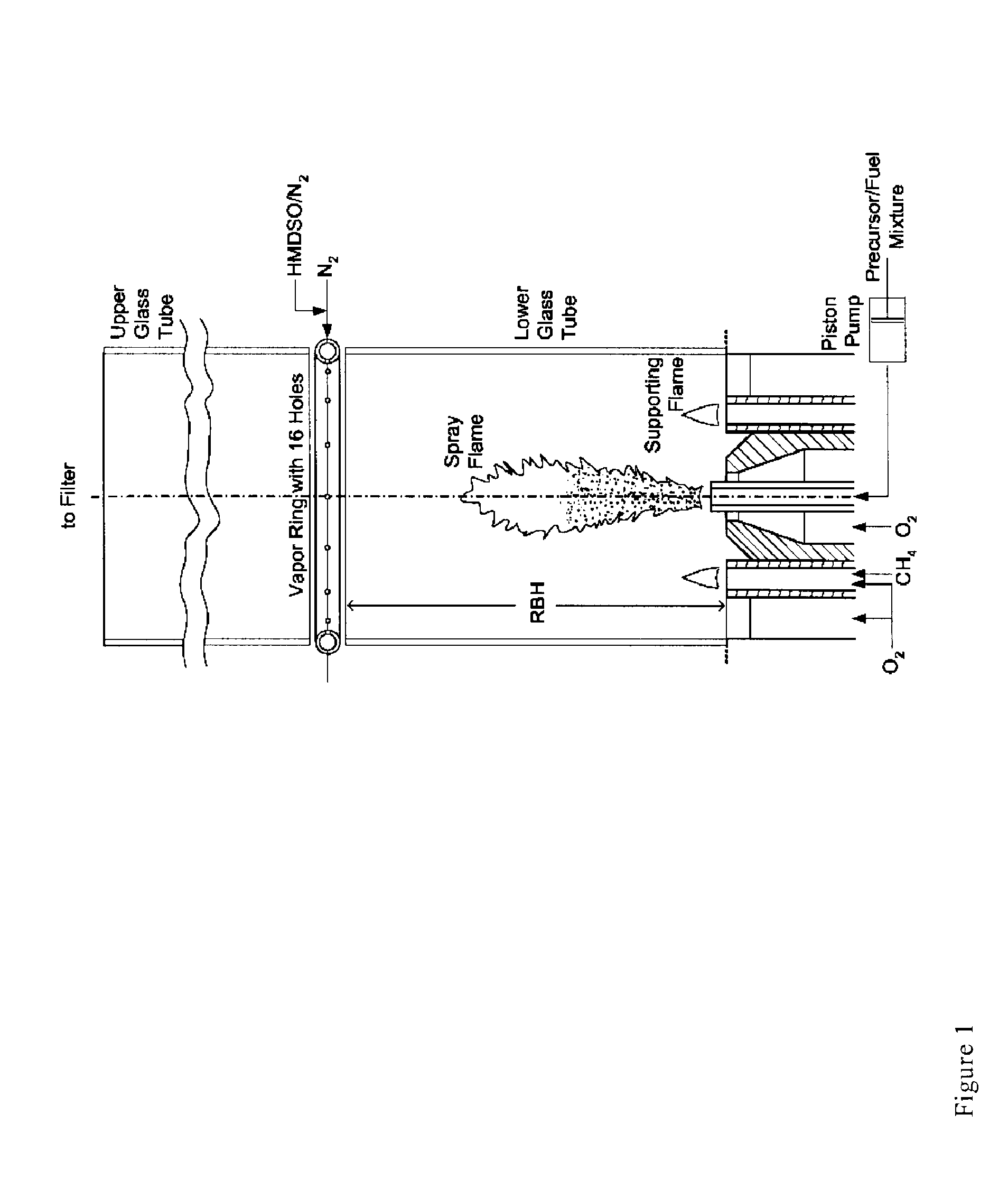

Gas phase production of coated titania

InactiveUS20090126604A1Not to wasteDesired characteristicPigmenting treatmentMaterial nanotechnologyGas phaseSpray pyrolysis

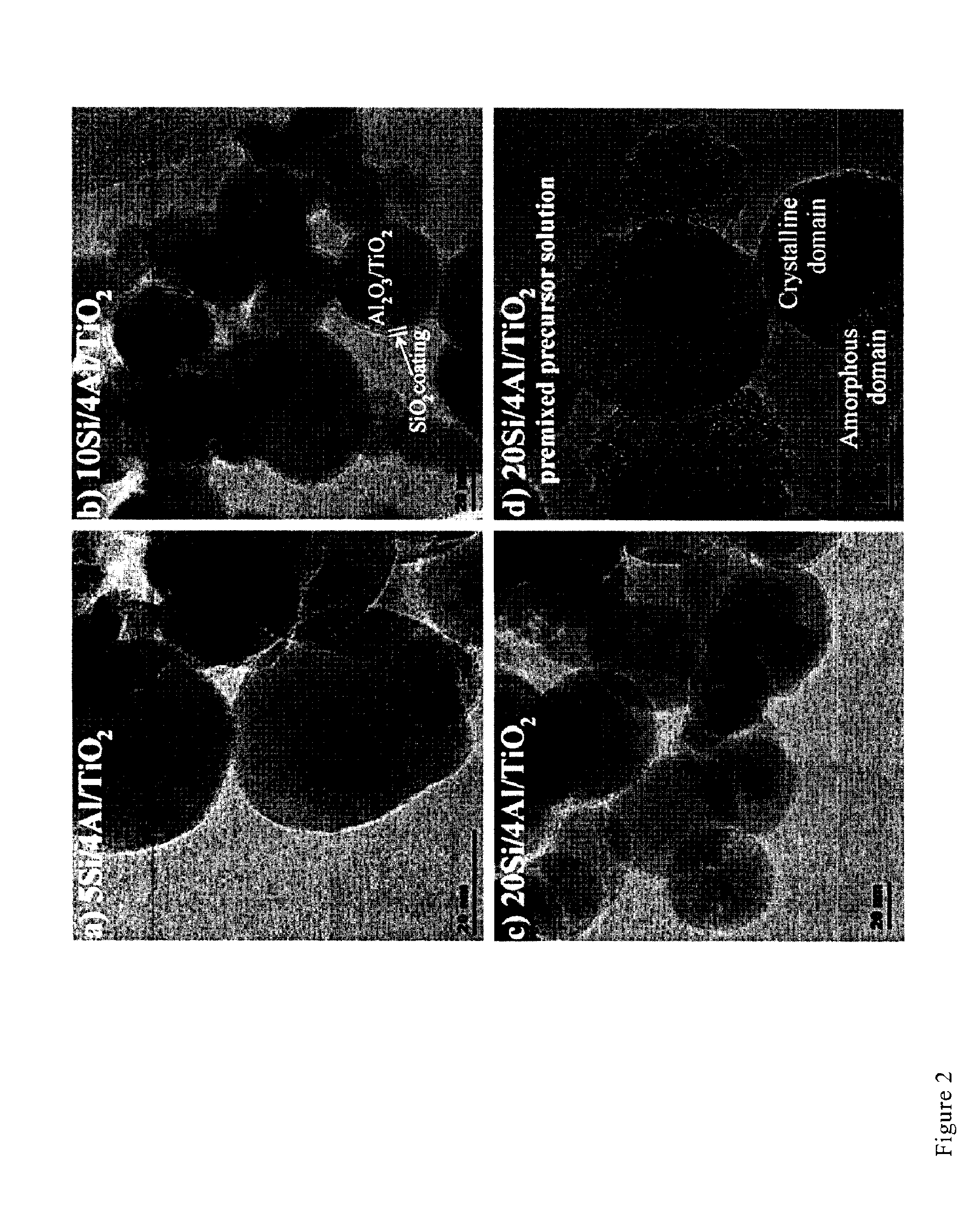

A flame spray pyrolysis process for the preparation of ultrafine titania particles coated with a smooth, homogeneous coating of one or more metal oxides is provided. The metal oxide coating is achieved by contacting the titania particles with a metal oxide precursor downstream of the titania formation zone, after the titania particles have formed. The process provides titania particles with a high rutile content and a smooth and homogeneous coating of a metal oxide.

Owner:TRONOX LLC

Active carbon fiber containing nano titanium dioxide particles and its preparation method and uses

This invention relates to a method for preparing an activated carbon fiber of Titania particle having nanometer and its usage. The fiber is formed from the activated carbon fiber material loaded with the Titania particles, wherein the mass ratio of the Titania particles is 5~25%. The preparing method uses the sol-gel processing: a) hydrolyzing organic titanium compounds of the TiO2 to the TiO2 collosol, and depositing on the activated carbon fiber, b) drying the colloslo and getting the jel, c) annealing, and transforming to nanometer TiO2 particles compounded in the surface of the fiber, then getting the fiber. The fiber not only maintains the poriness but also enhances the optical catalytic activity of the Titania particle, and can be used for removing the volatile organic contaminant with low concentration, wherein its absorbance can reach to 500mg / g and its optical catalytic dissolution rate can reach to 36%.

Owner:SUN YAT SEN UNIV

Timepiece dial and timepiece

InactiveUS20080159083A1Outstanding appearanceOutstanding durabilityVisual indicationElectric windingMetallurgySilicon oxide

A timepiece dial has a base member made of primarily polycarbonate, a titanium oxide particle dispersion layer having titanium oxide particles made of titanium oxide dispersed in a dispersion medium, and a silicon oxide particle dispersion layer having silicon oxide particles made of silicon oxide dispersed in a dispersion medium. In this timepiece dial, the titanium oxide particle dispersion layer is disposed on one side of the base member, and the silicon oxide particle dispersion layer is disposed on the other side.

Owner:SEIKO EPSON CORP

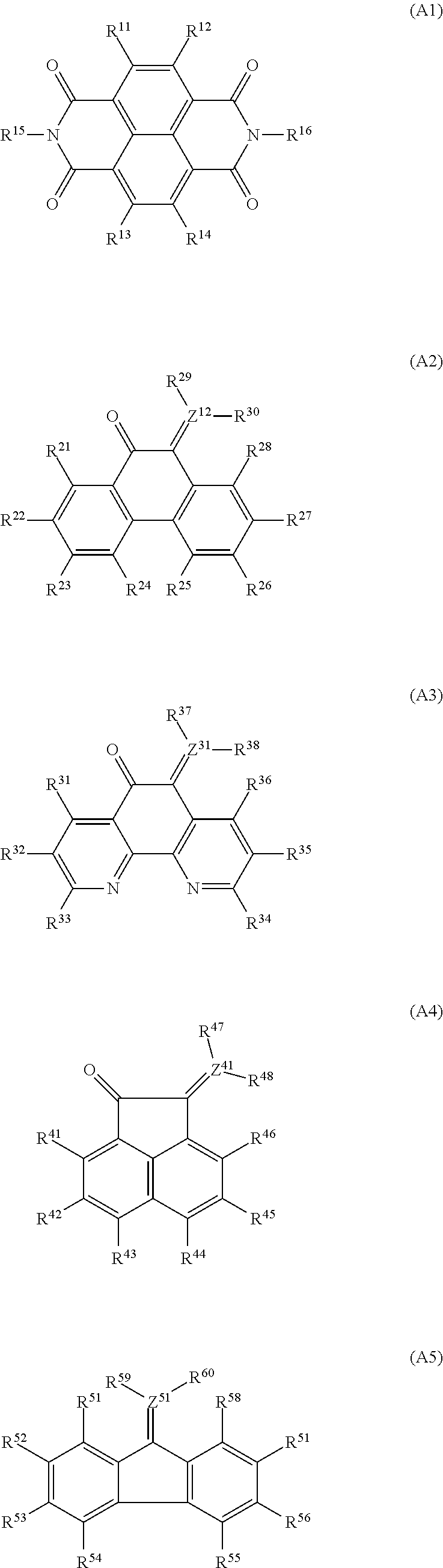

Toner

The present invention provides a toner improved in dispersibility of a colorant in the toner particles and excellent in the color reproducibility including color mixability and transparency. The toner is also excellent in the stability in long-term of the chargeability and capable of forming images maintaining high image quality. The present invention provides a toner for forming a full-color image which includes at least toner particles containing a binder resin, a colorant and a wax, and inorganic fine particles, wherein the binder resin comprises a resin having polyester units which is synthesized by use of an aromatic carboxylic acid titanium compound as a catalyst, and the inorganic fine particles comprise fine titanium oxide particles.

Owner:CANON KK

White color reflecting material and process for production thereof

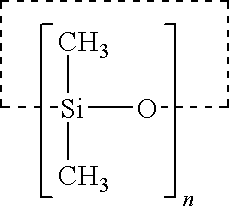

ActiveUS20120138997A1Improve heat resistanceImprove light resistanceDiffusing elementsSolid-state devicesUltravioletRutile

A general-use white color reflecting material, and a process for production thereof are provided. The white color reflecting material, without troublesome surface treatment such as formation of a reflective layer by plating, is capable of reflecting a near-ultraviolet ray of a wavelength region of 380 nm or longer or a near-infrared ray sufficiently without light leakage; does not become yellow even when exposed to near-ultraviolet rays; has excellent lightfastness, heat resistance, and weatherability; has high mechanical strength and chemical stability; is capable of maintaining a high degree of whiteness; and is easily moldable at a low cost. Further a white color reflecting material used as an ink composition for producing the white color reflecting material in a film shape is also provided. The white color reflecting material comprises; a silicone resin or silicone rubber formed from titanium oxide-containing silicone composition, in which anatase-type or rutile-type titanium oxide particles are dispersed.

Owner:ASAHI RUBBER

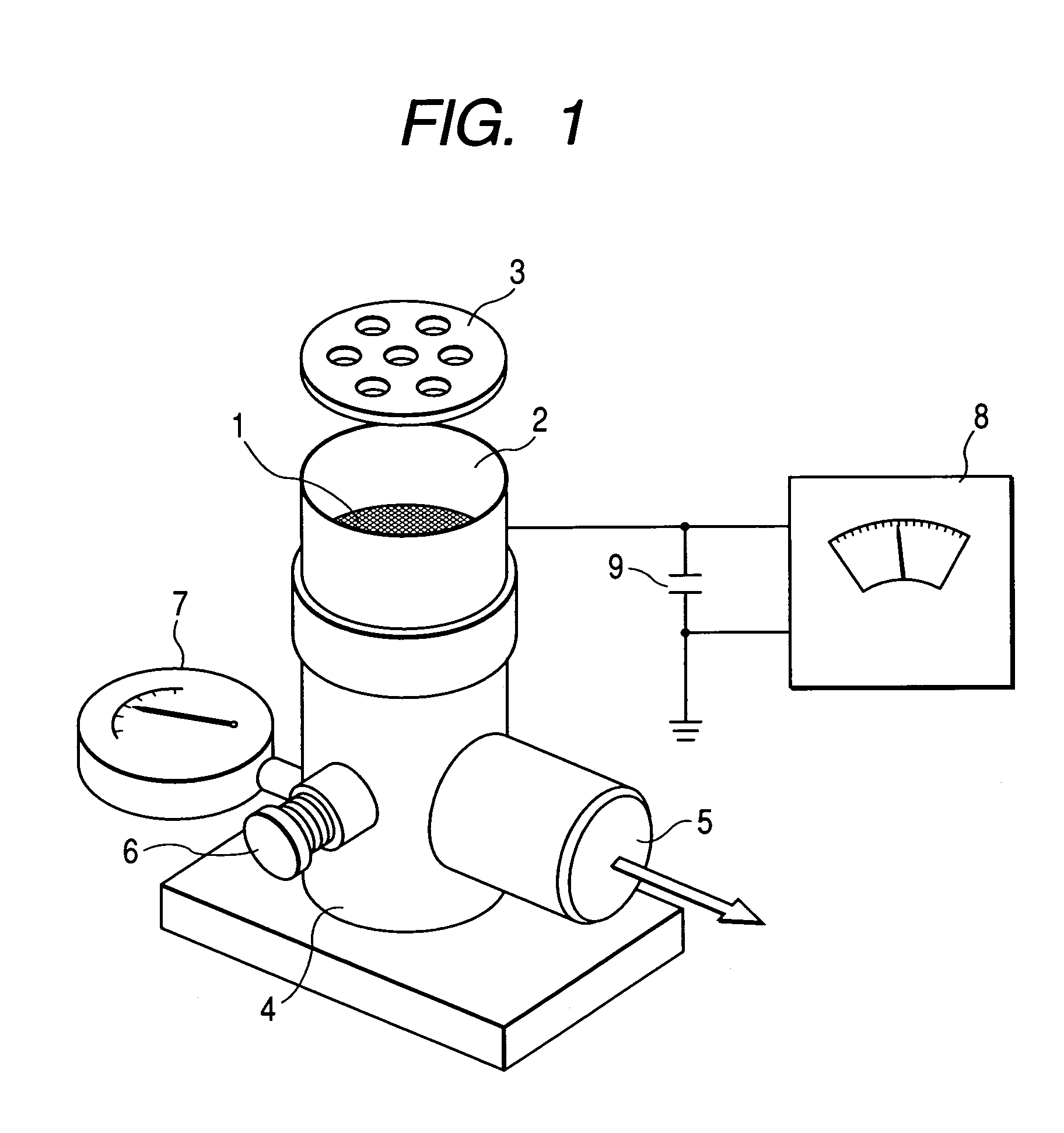

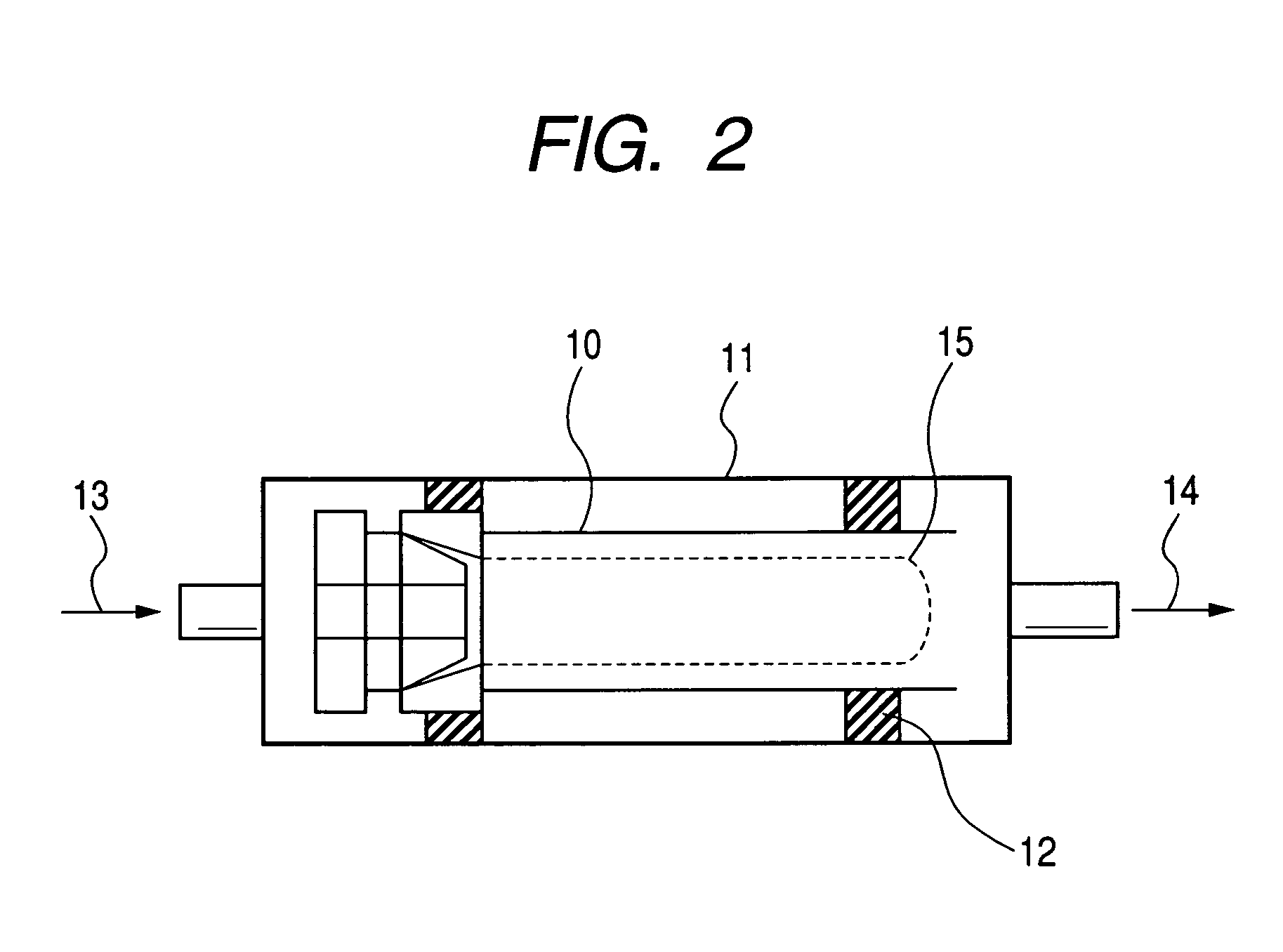

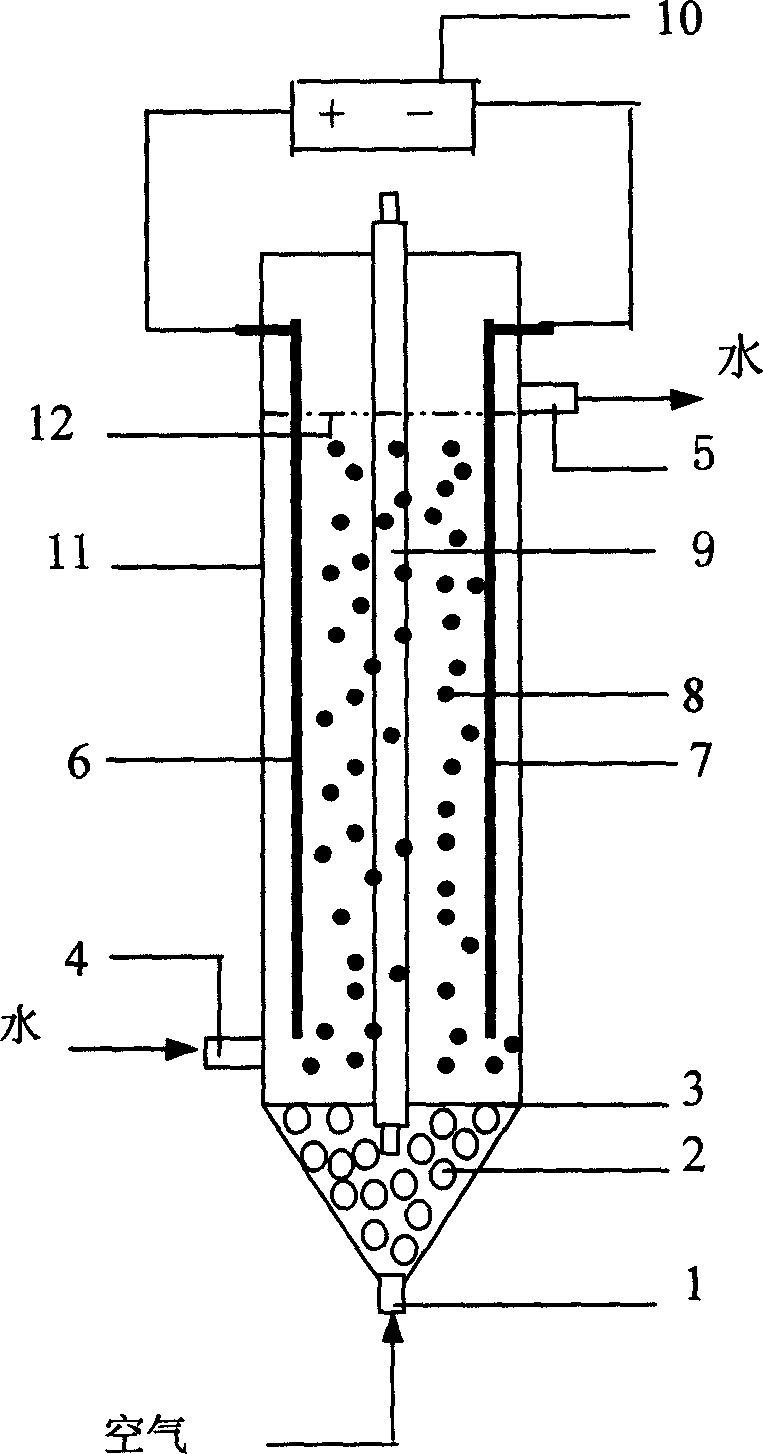

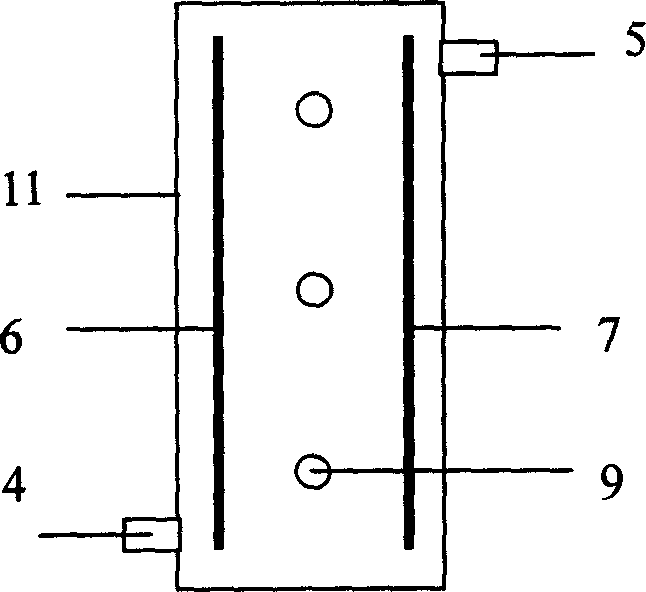

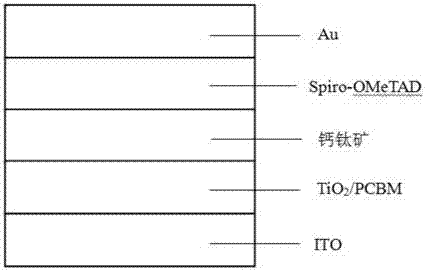

Photoelectrocatalysis and oxidation device for treating organic substance in water

InactiveCN1562795ACompact and reasonable structureMass transfer coordinationPhysical/chemical process catalystsWater/sewage treatment by irradiationUltraviolet lightsVolumetric Mass Density

Fluid-bed photo-electro catalytic organic water processing device consists of titanium-base oxide positive electrode, negative oxygen electrode, TiO2 / C sulfide particle, ultraviolet light source, constant potentiometer DC power source, air distribution board and casing. Not only oxidizing action of positive electrode and reducting action of negative oxygen electrode are used, but also active perssad OH, H2O2, OH- and light, photocatalysis are used, to go deep into bed layer by strong stirring of fluidized particle to increase OH density of the system and to be uniform, TiO2 on surface of fluidized particle produces OH by lighting continuously, and surface of TiO2 particle is renewed continuously.

Owner:TAIYUAN UNIV OF TECH

Weather-resistant rust-proof water paint and preparing method thereof

InactiveCN101012351AReduced photodecomposition functionWide choiceAnti-corrosive paintsEmulsion paintsAdjuvantUltraviolet

The invention discloses a weather resistant anti-rust aqueous paint and preparing method, which comprises the following steps: allocating raw material with 10-40% deionized water, 30-70% waterthinnable resin emulsion, 1-10% titanium oxide particle and fitful paint adjuvant; making the even grain size of titanium oxide particle less than 1um; packing inorganic silica on the surface; dispersing deionized water, waterthinnable resin emulsion, titanium oxide particle and fitful paint adjuvant evenly to obtain the product.

Owner:SOUTH CHINA UNIV OF TECH +2

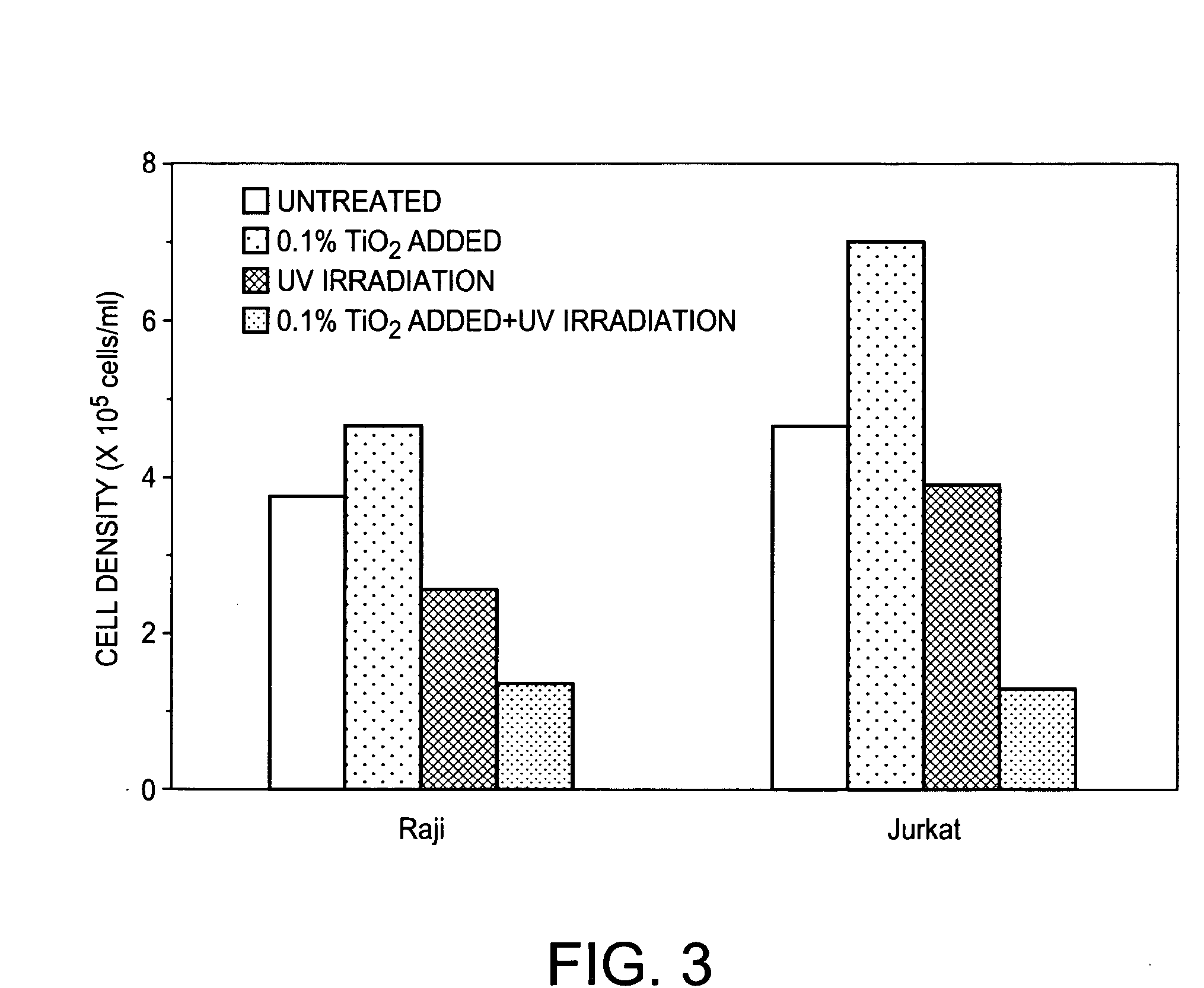

Surface-modified titanium dioxide fine particles and dispersion comprising the same, and method for producing the same

InactiveUS20060264520A1Good dispersionGood dispersibilityAntibacterial agentsHeavy metal active ingredientsWater solubleMicroparticle

Surface-modified titanium dioxide particles which have a surface chemically modified with a hydrophilic polymer, wherein a carboxyl group of the hydrophilic polymer and titanium dioxide are bound through an ester bonding; and a method for producing the surface-modified titanium dioxide fine particles, which comprises mixing a dispersion comprising titanium dioxide fine particles having a particle size of 2 to 200 nm and a solution of a water-soluble polymer, heating the resultant mixture to a temperature of 80 to 220° C., to thereby bind both the components through an ester bonding, and removing an unbound water-soluble polymer, to purify the resuultant particles. The surface-modified titanium dioxide fine particles exhibit excellent dispersibility and stability in an aqueous solvent over a wide pH region including a neutral range.

Owner:STARBOARD TECH +1

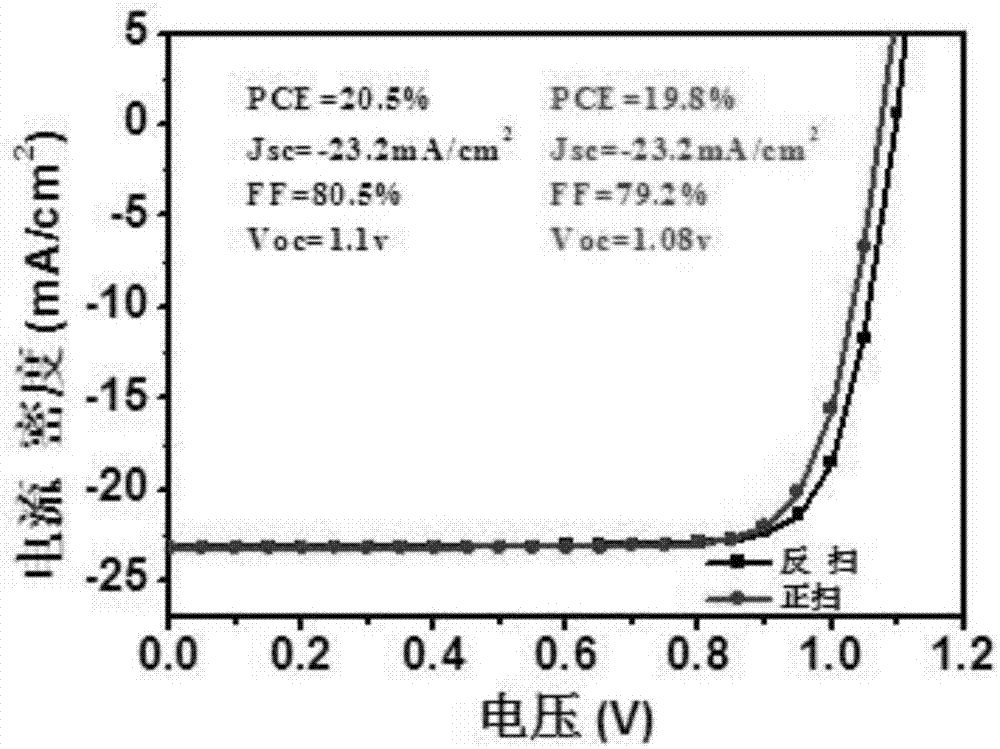

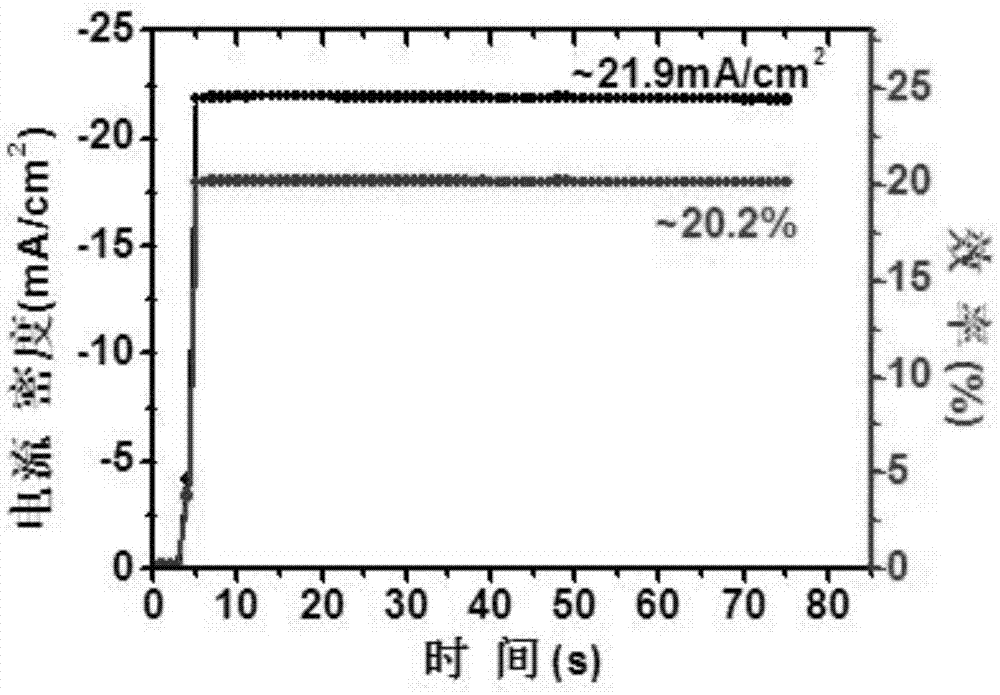

Perovskite solar cell and preparation method thereof

InactiveCN107316942AGood dispersionSpeed up extractionSolid-state devicesSemiconductor/solid-state device manufacturingHysteresisHole transport layer

The invention belongs to the field of a solar cell, and discloses a perovskite solar cell. The perovskite solar cell sequentially comprises a transparent conductive substrate, an electron transmission layer, an interface modification layer, a modified perovskite active layer, a hole transmission layer and a positive electrode, wherein the electron transmission layer is a nanometer TiO2 particle layer, and the interface modification layer is a fullerene derivative layer. A sol-gel method is employed, high-crystallization TiO2 nanoparticles are synthesized by taking titanium tetrachloride is used as a precursor, the TiO2 nanoparticles are applied to the perovskite solar cell by employing a low-temperature annealing process, a fullerene derivative is directly spin-coated on a surface of the obtained nanometer TiO2 particle layer for modification, the defects in TiO2 and perovskite are passivated, a novel perovskite synthesis path is employed, the obtained perovskite solar cell has high efficiency and does not have hysteresis effect under a low-temperature preparation process, and the device can be used for stable transmission; and moreover, the related preparation method is simple, is low in energy consumption and is suitable for promotion and application.

Owner:WUHAN UNIV OF TECH

Silver phosphate antibacterial modified titanium dioxide composite particle and its preparation method and use

An antibacterial composite TiO2 particle modified by silver phosphate for paint, ceramics, rubber, etc. is prepared from nanometre-class or submicron-class TiO2 particle as kernel through coating SiO2 layer, alumina layer, or SiO2-alumina layer, and coating silver phosphate layer. Its advantages are high purity dispersity and sure antibacterial action.

Owner:中山市华铿喷涂有限公司 +1

Preparation method of titanium pigment used in ship paint

ActiveCN102226043AGood dispersionGood weather resistancePigment treatment with organosilicon compoundsSilicon oxideSlurry

The invention discloses a preparation method of titanium pigment used in ship paint. The method comprises the following steps that: a. metatitanic acid is calcined, such that a titanium pigment crude product is obtained, the titanium pigment crude product is prepared into TiO2 slurry, and sodium hexametaphosphate is added to the slurry; b. the slurry is heated, a silicon-containing compound is added to the slurry, and the slurry is homogenized; c. the pH value of the TiO2 slurry is regulated to 0.8 to 4; d. after the slurry is slaked, an organic dispersant is added to the slurry, an aluminum-containing compound is added to the slurry, and the mixture is homogenized; e. the pH value of the TiO2 slurry is regulated to 4 to 8; f. the TiO2 slurry is slaked; g. the TiO2 slurry is filtered, such that the resistivity of the filter cake is greater than or equal to 100 [omega]M; and the filter cake is dried and heat treated; h. an organic surface conditioning agent is added to the filter cake, and the filter cake is crushed, such that the finished product is obtained. According to the present invention, nano-sized silicon oxide sol and alumina sol are prepared sequentially. Through physical adsorption and chemical absorption, a compact coating layer is formed on the surface of the TiO2 particles. Then, the coating layer is firmly attached to the surface of the TiO2 particles through chemical deposition. With the coating layer, the product provided by the present invention possesses good dispersibility, weatherability and corrosion resistance. Meanwhile, according to the method provided by the present invention, the raw materials are easy to obtain, the processes are smooth and are easy to control.

Owner:NINGBO XINFU TITANIUM DIOXIDE

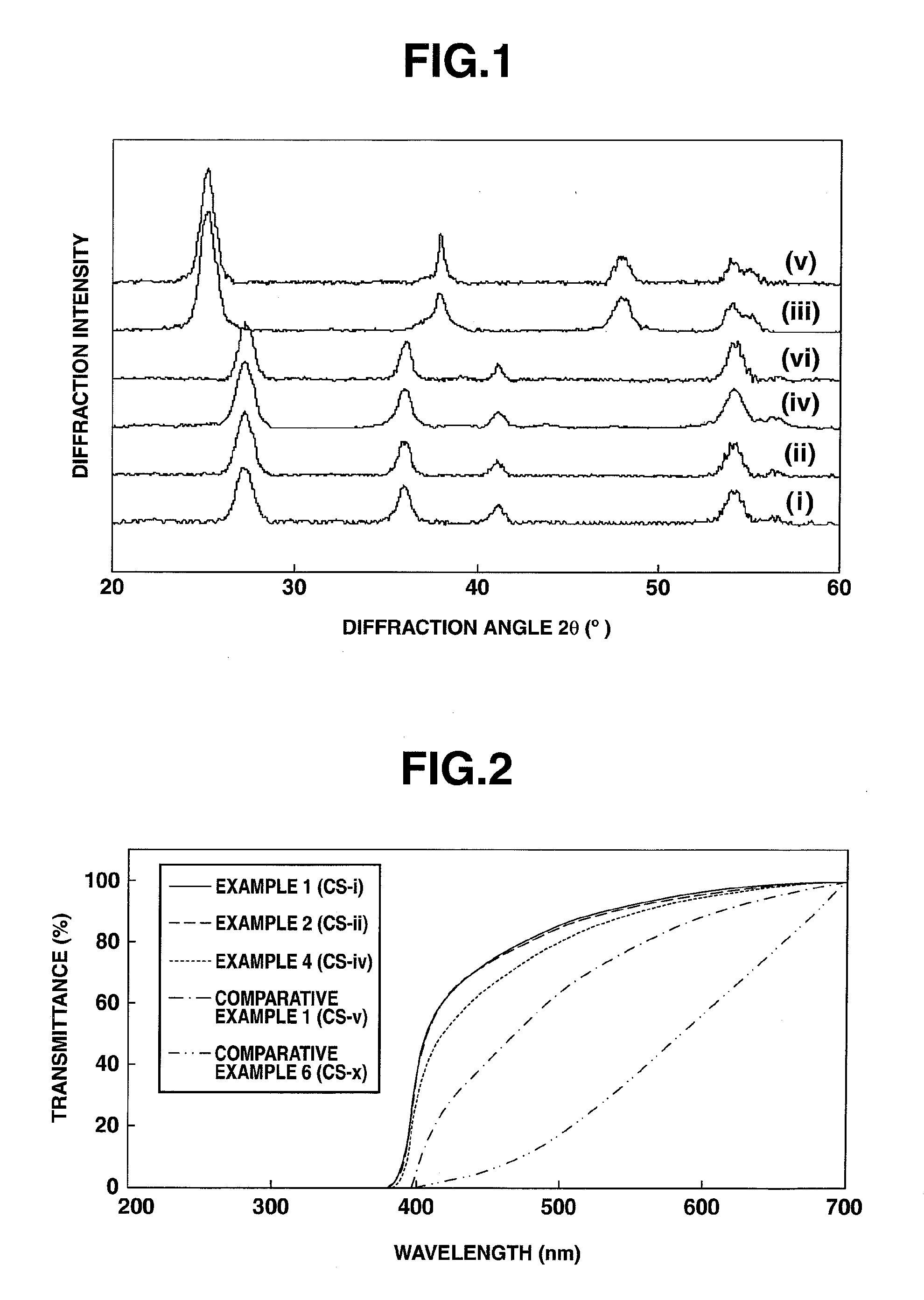

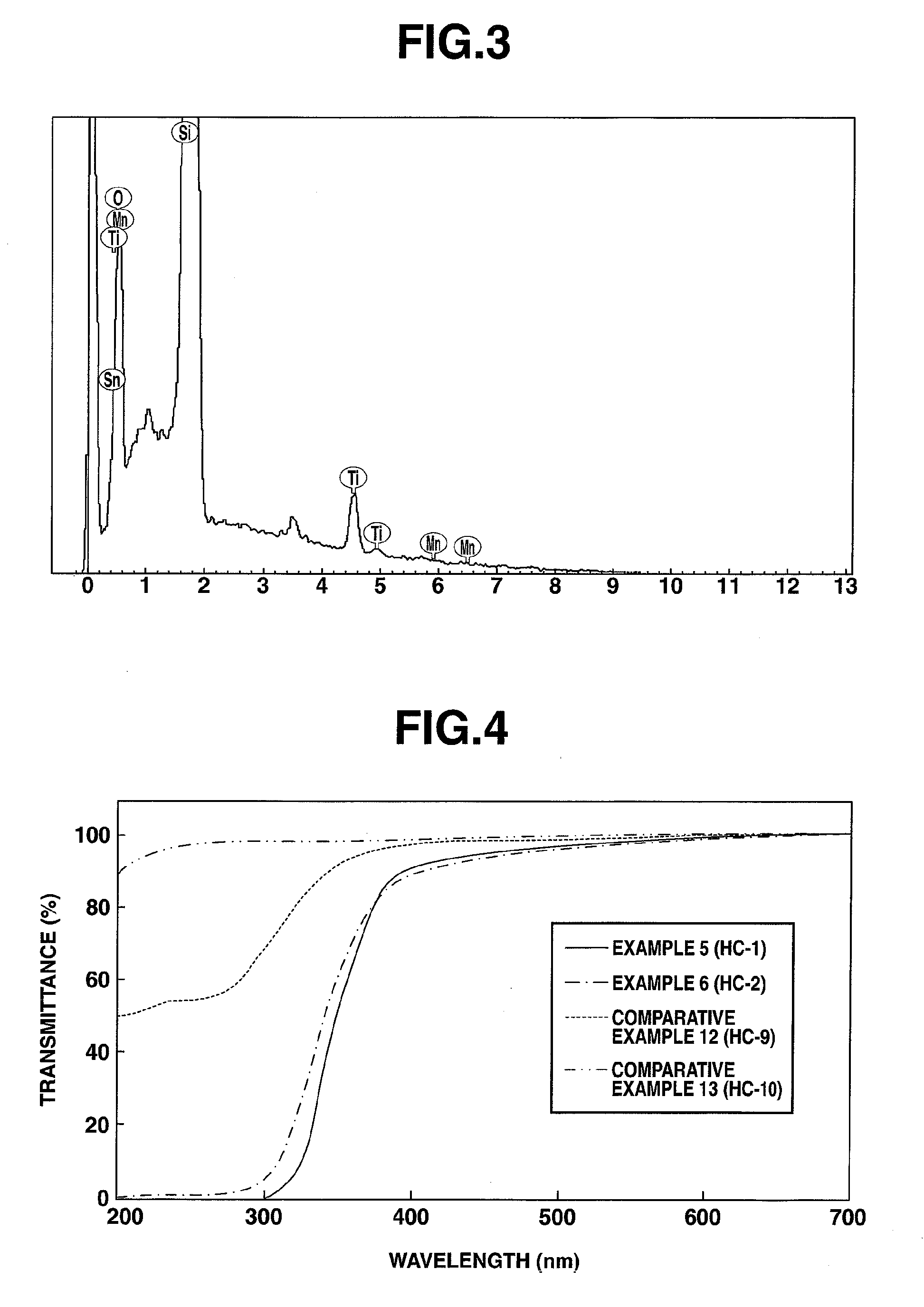

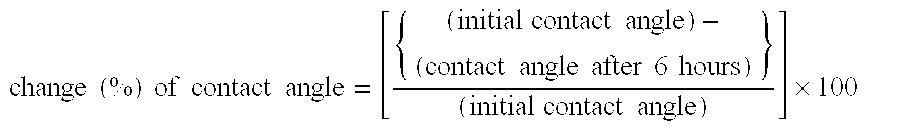

Core/shell type tetragonal titanium oxide particle water dispersion, making method, uv-shielding silicone coating composition and coated article

Core / shell type tetragonal titanium oxide particles consisting of a nanosized core of tetragonal titanium oxide having tin and manganese incorporated in solid solution and a shell of silicon oxide around the core are dispersed in an aqueous dispersing medium. The cores and the core / shell type titanium oxide particles have an average particle size of ≦30 nm and ≦50 nm, respectively. The amount of tin or manganese in solid solution is to provide a molar ratio Ti / Sn or Ti / Mn between 10 and 1,000.

Owner:SHIN ETSU CHEM IND CO LTD

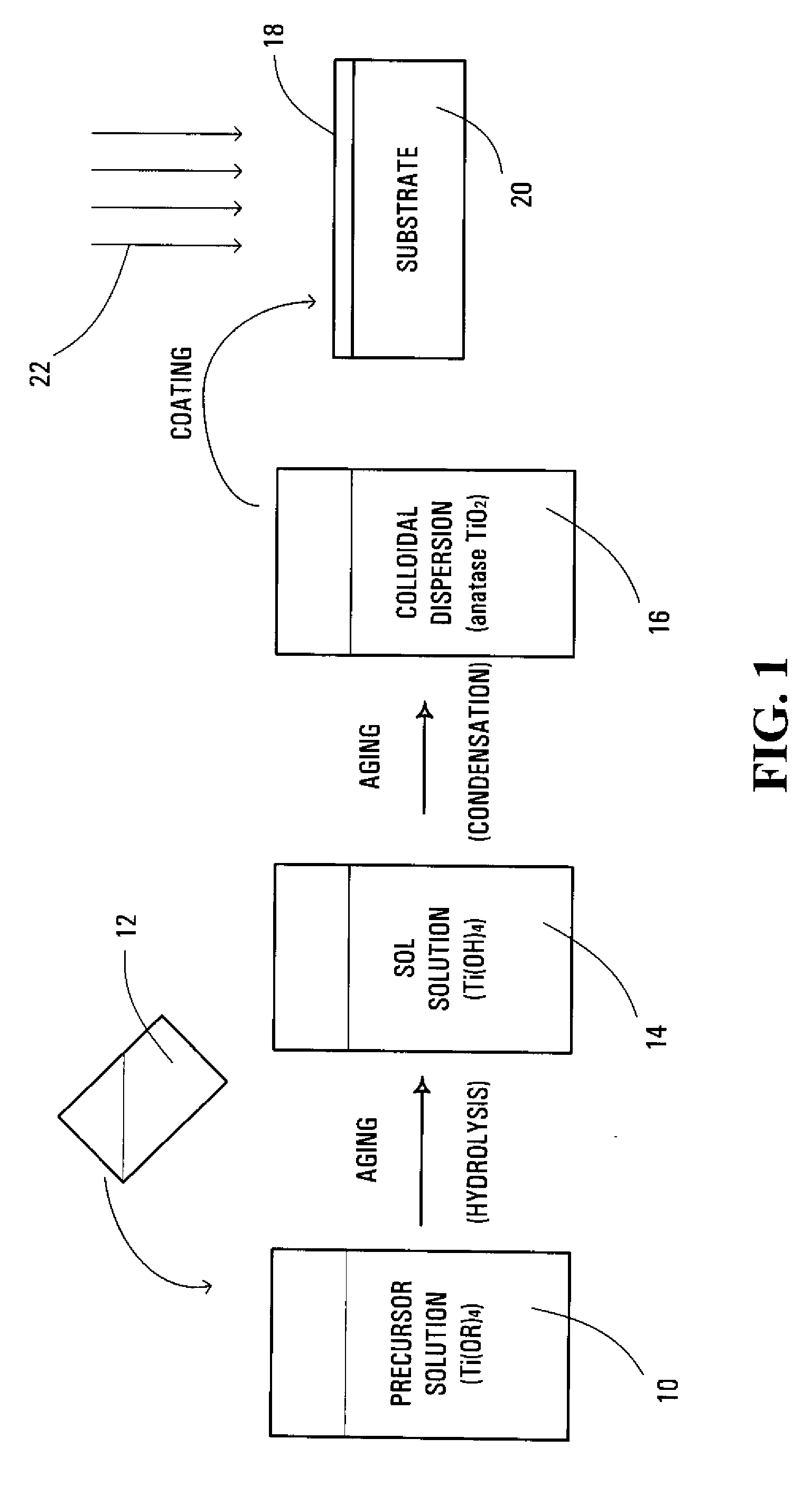

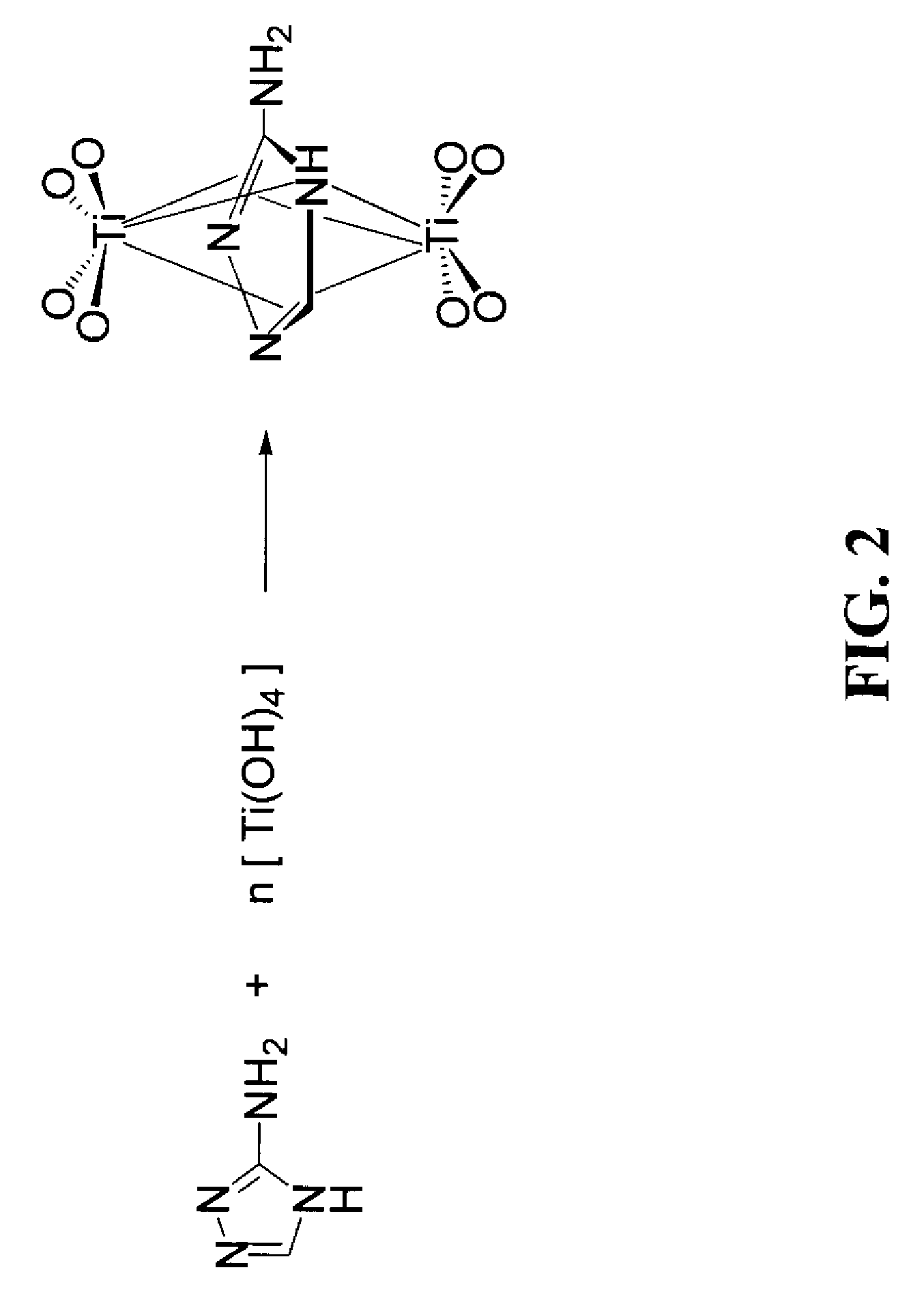

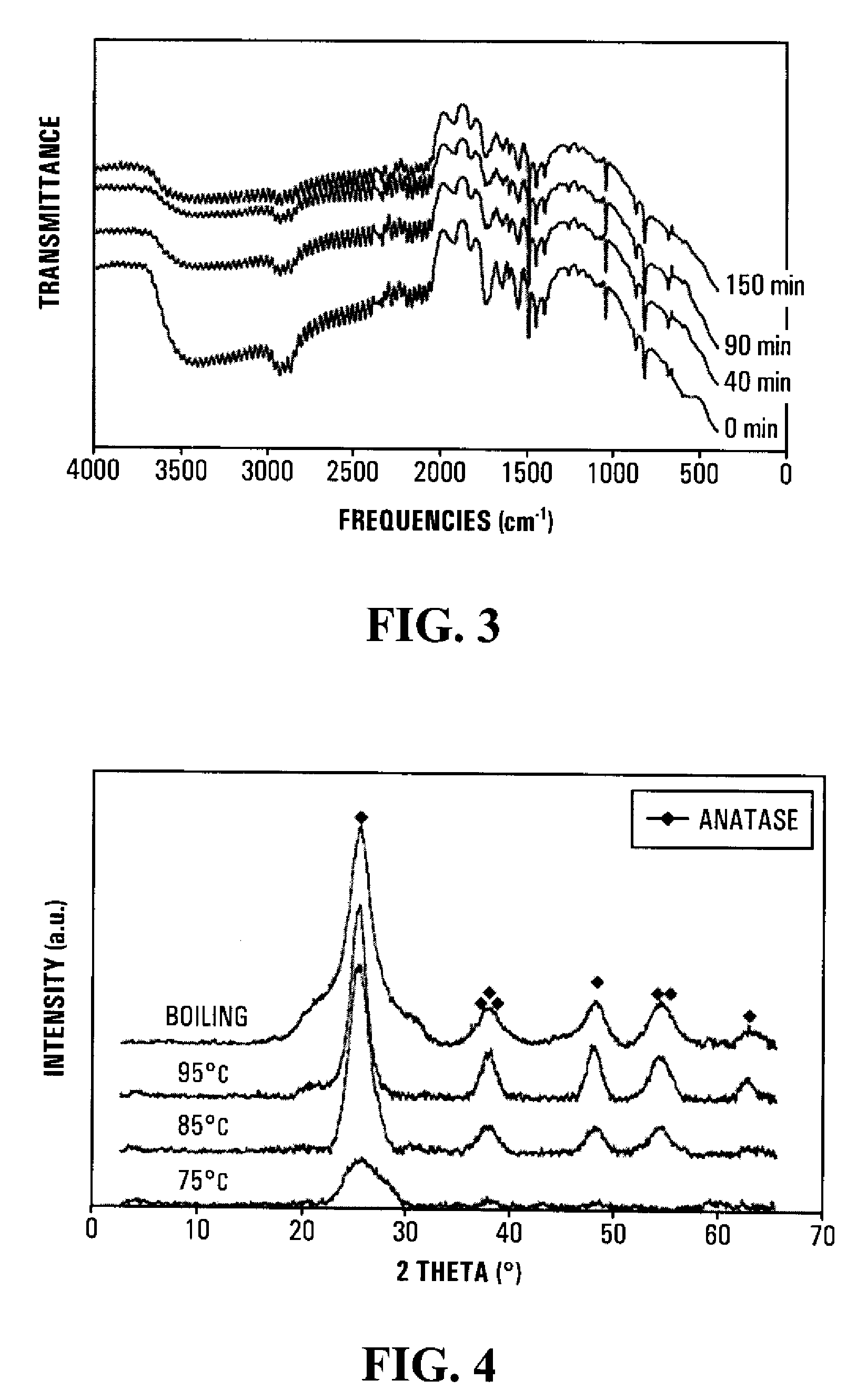

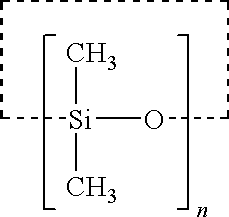

Method and solution for forming anatase titanium dioxide, and titanium dioxide particles, colloidal dispersion and film

InactiveUS20060254461A1Accelerated agingImprove propertiesPigmenting treatmentOther chemical processesTitanium chlorideTetrazole

A sol solution containing poly(titanic acid) and a planar heterocyclic ligand is provided. Titanium dioxide (TiO2) particles are formed by aging the sol solution at a temperature below about 140° C. The particles have metallocene-like Ti-complexes comprising the heterocyclic ligand and can be substantially in the anatase phase. The heterocyclic ligands can be triazole, tetrazole, or thiadiazole. The sol solution may be prepared by aging a precursor solution. The precursor solution may contain the heterocyclic ligands and a precursor for poly(titanic acid). The precursor may be titanium alkoxide or titanium chloride. The sol solution may also contain at least one of an organic acid, a base, and a surfactant. The aged sol solution may form a colloidal dispersion of the TiO2 particles. A photo-catalytic and transparent film may be formed from the TiO2 particles by depositing a layer of the colloidal dispersion on a support.

Owner:AGENCY FOR SCI TECH & RES

Cosmetic Composition

InactiveUS20100003205A1Increase coverageMinimizing reflectanceBiocideHeavy metal active ingredientsSkin appearanceMedicine

Cosmetic composition providing a high coverage of skin while retaining a natural skin appearance comprising iron oxide particles having an average primary particle size of less than or equal to 100 nm, iron-containing titanium dioxide particles having an average primary particle size of at least 105 nm and comprising from 1% to 15% iron by weight of the titanium dioxide, and a cosmetically acceptable carrier and its use as a foundation and / or as a composition to correct skin discoloration surrounding the eye.

Owner:THE PROCTER & GAMBLE COMPANY

Cosmetic Composition

InactiveUS20100074928A1Increase coverageMinimizing reflectanceHeavy metal active ingredientsCosmetic preparationsSkin appearanceTio2 particle

Cosmetic composition providing a high coverage of skin while retaining a natural skin appearance comprising iron oxide particles having an average surface area from 30 m2 / g to 150 m2 / g, iron-containing titanium dioxide particles having an average surface area from 1 m2 / g to 30 m2 / g and comprising from 1% to 15% iron by weight of the titanium dioxide, and a cosmetically acceptable carrier and its use as a foundation and / or as a composition to correct skin discoloration surrounding the eye.

Owner:NOXELL CORP

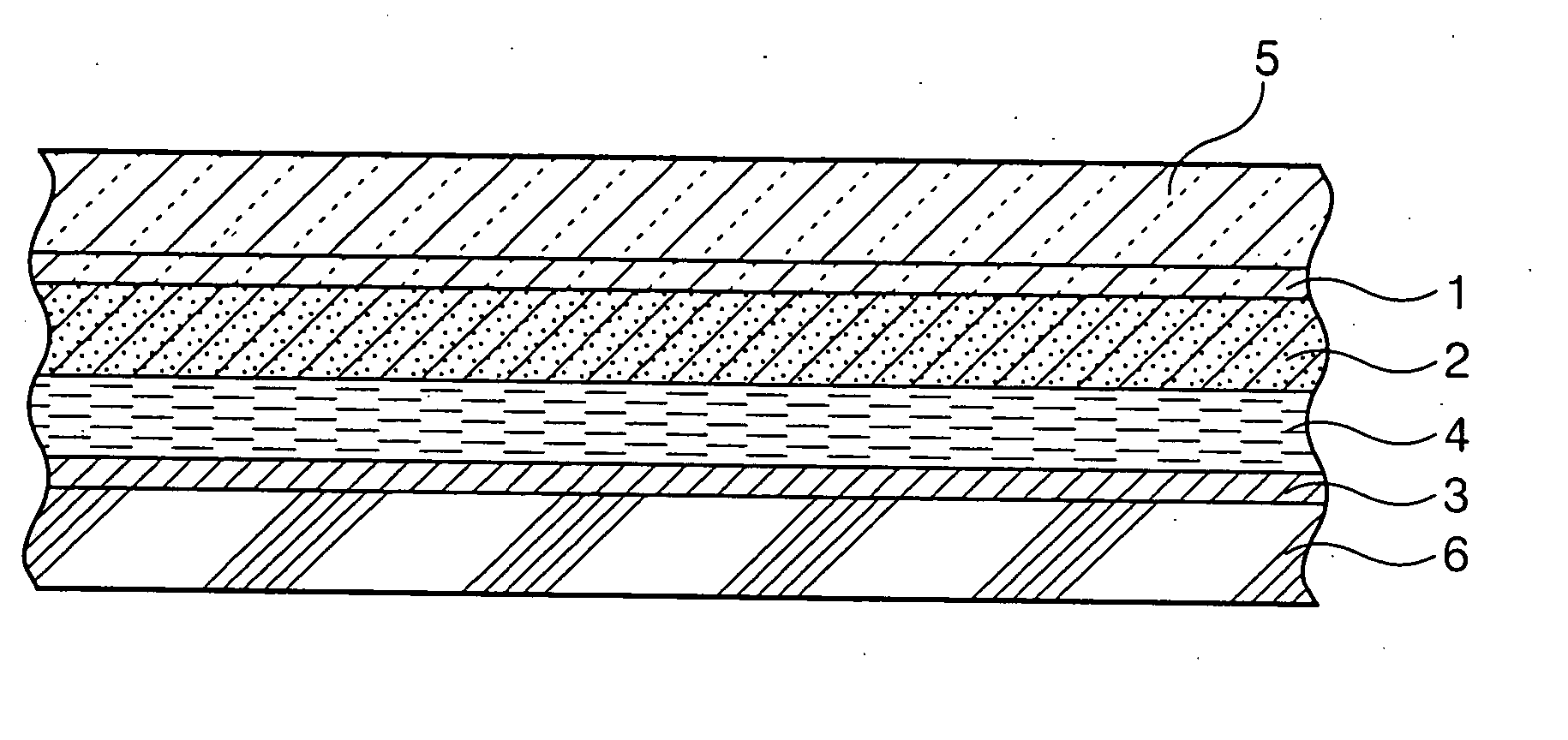

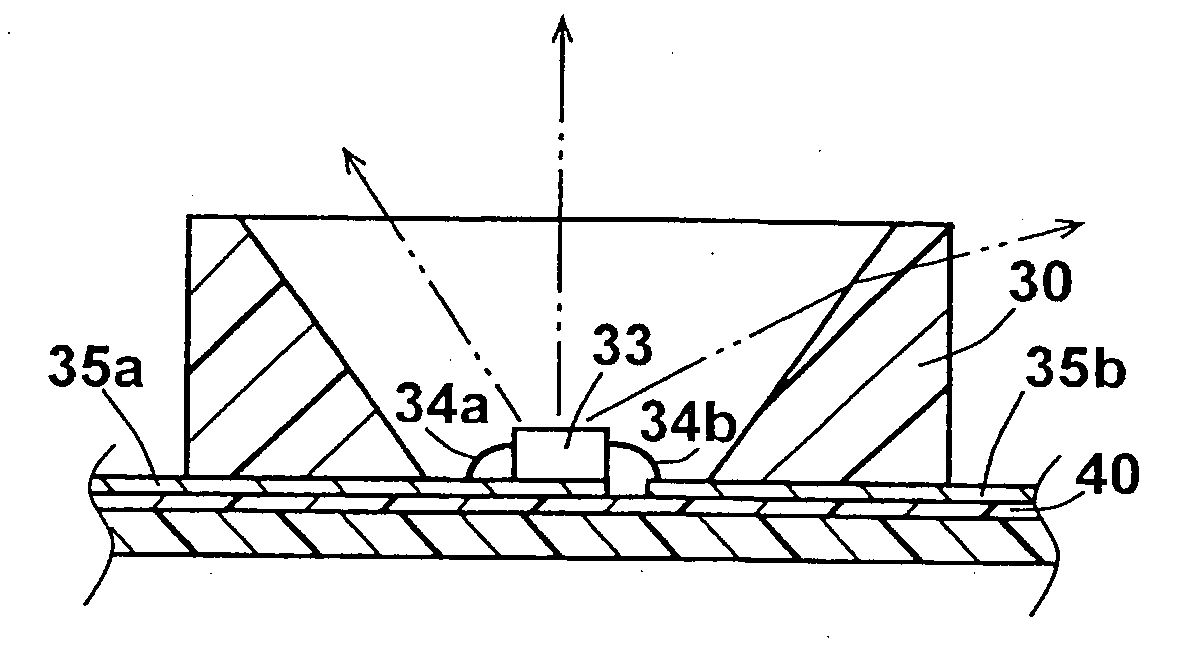

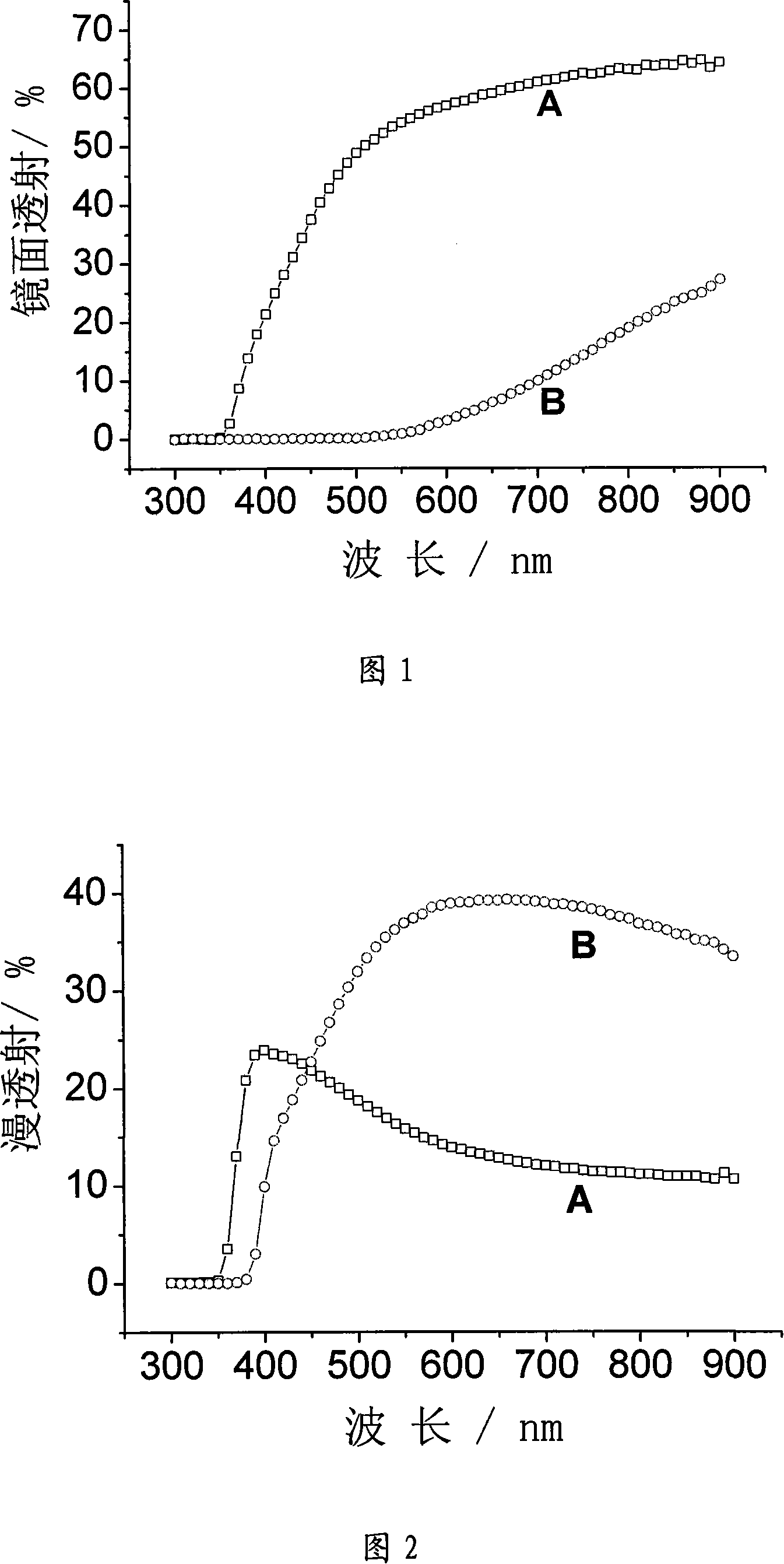

Dye sensitization solar cell based on titanic oxide nano bar light scattering thin film electric pole and its preparing method

ActiveCN101140957AImprove light scattering performanceEasy to prepareLight-sensitive devicesFinal product manufactureMicroparticleOptoelectronics

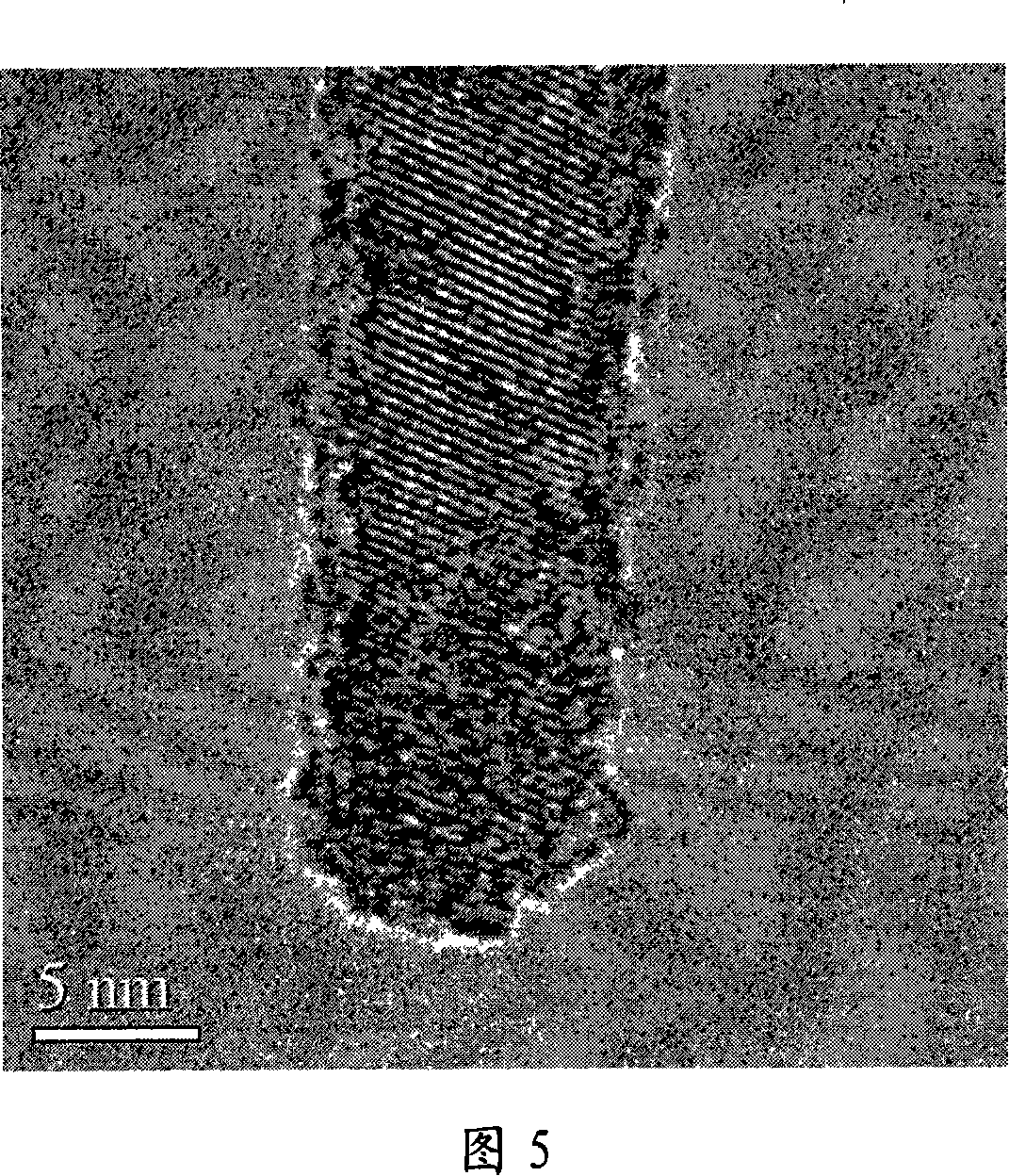

A dye sensitize solar battery based on the light scattering membrane electrode of the titanium dioxide Nano Rods is provided, which belongs to technical field of solar battery manufacturing. The invention comprises light anode, electrolyte solution and counter electrode, which is characterized in that the said light anode includes in turn the first layer closely connected with the conducting fundus and the second layer contacted with the first layer. The first layer is a dense TiO2 thin membrane formed by the TiO2 particles of 2 to 5 nm in grain diameter, while the second layer is a Nano Rods thin membrane formed by the TiO2 tiny particles of 5 to 60 nm in grain diameter and Nano Rods with diameter of 6 to 11 nm and length of 90 to 450. The mirror face diascoptic lighting intensity is obviously weakened while the diffuse transmission light intensity is increased in the infrared band and near infrared band of 600 to 900. The first layer is 50 to 15 nm in thickness while the second layer is 2 to 12 micron in thickness. The dye sensitize solar battery is characterized in high light scattering property, simple preparation method and easy operation.

Owner:TSINGHUA UNIV +1

Modified liquid for filter paper of filter and its preparation method and use

InactiveCN1831243AParty economyLong-lasting functionSpecial paperNon-macromolecular organic additionSolventChemistry

The invention relates to a filter paper modified liquid for a filter and the preparing method and use thereof, comprising phenylpropyl latex or organic silicone acrylic acid 4-20 weight shares, melamine 1-4 weight shares, and solvent 24-78.9 weight shares, where the solvent is any one of the water, deionized water, alcohol and isopropanol; also comprising Teflon latex 15-35 weight shares; further able to comprise micrometer or nanometer titanium dioxide particles 1-10 weight shares, and NP-13 0.1-2 weight shares; and able to the filtering performance and service life of the filter paper of the filter. And the making method is the traditional mixing method. and the use: adopting traditional methods spraying and dipping to form a film layer on each side of the filter paper, then keeping temperature at 110-130DEG C for 1.5-2min, thus able to obtain two layers of modified films on the filter paper, which can help improve filtering efficiency and service life of the filter.

Owner:BENGBU HAOYE FILTER

Grading three-dimensional porous graphene/titanium dioxide photocatalyst and preparation method thereof

InactiveCN104069844AHigh specific surface areaImprove adsorption capacityPhysical/chemical process catalystsPorous grapheneMicrosphere

The invention provides a grading three-dimensional porous graphene / titanium dioxide photocatalyst and preparation method thereof. The photocatalyst is composed by a three-dimensional grapheme framework and nano titanium dioxide particles; the grahene is provided with a macroporous structure; titanium dioxide is mesoporous titanium dioxide; the macropores and the mesopores are communicated; the nano titanium dioxide particles are scattered on a grapheme nano sheet; the surfaces of nano titanium dioxide microspheres are wrapped with graphene nano sheets; the macropores of the graphene are filled with the nano titanium dioxide microspheres. The photocatalyst with a three-dimensional structure can not only prevent the graphene sheet layers from stacking, but also scatter titanium dioxide particles excellently, and is high in specific surface area; besides, samples can be used for photocatalysis degradation of methylene blue, and the methylene blue can be fully degraded in 25 minutes. The preparation method provides a new thought for preparation of the photocatalyst, and has a potential application value in the fields of energy sources and environment.

Owner:WUHAN UNIV OF TECH

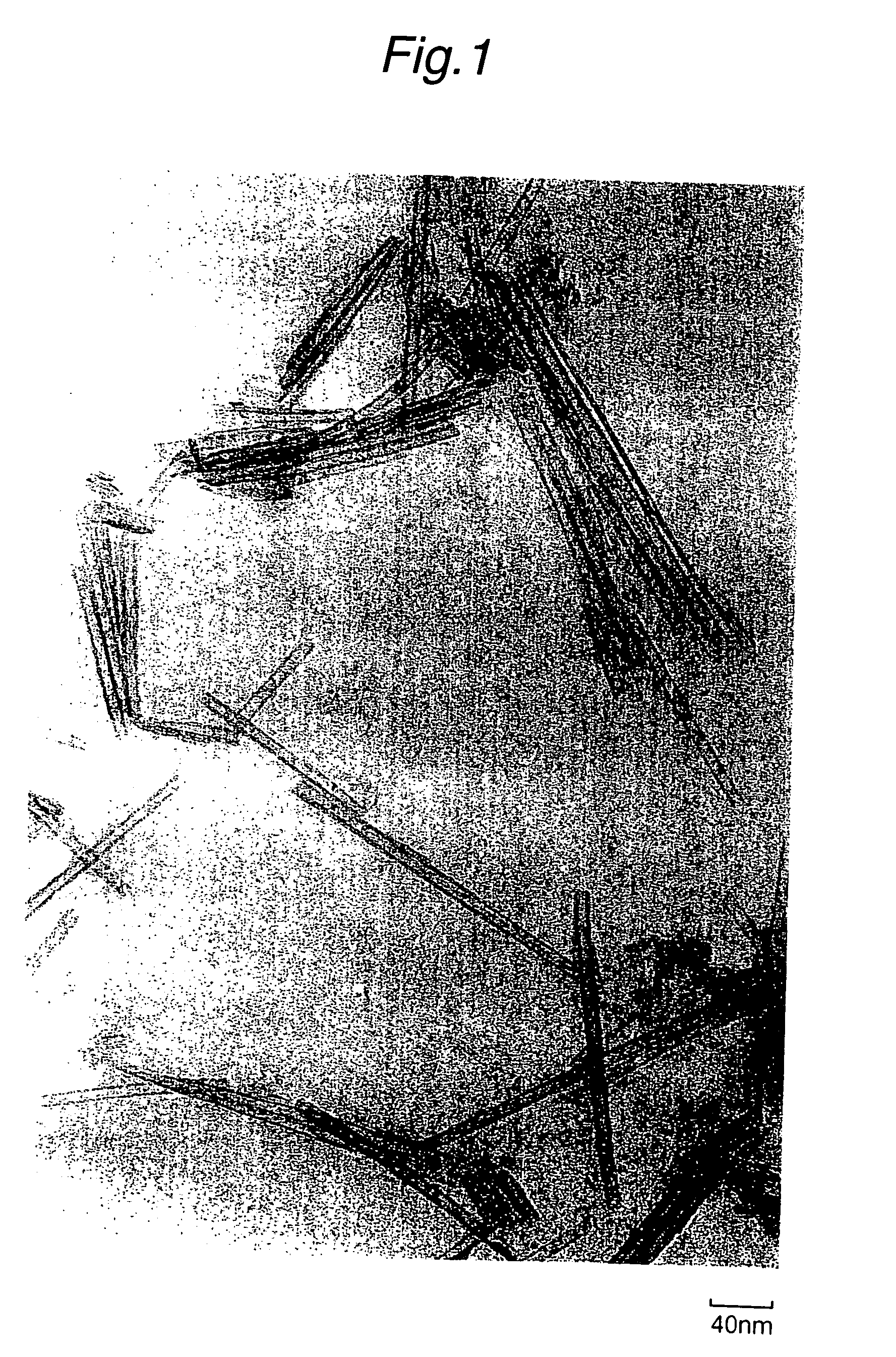

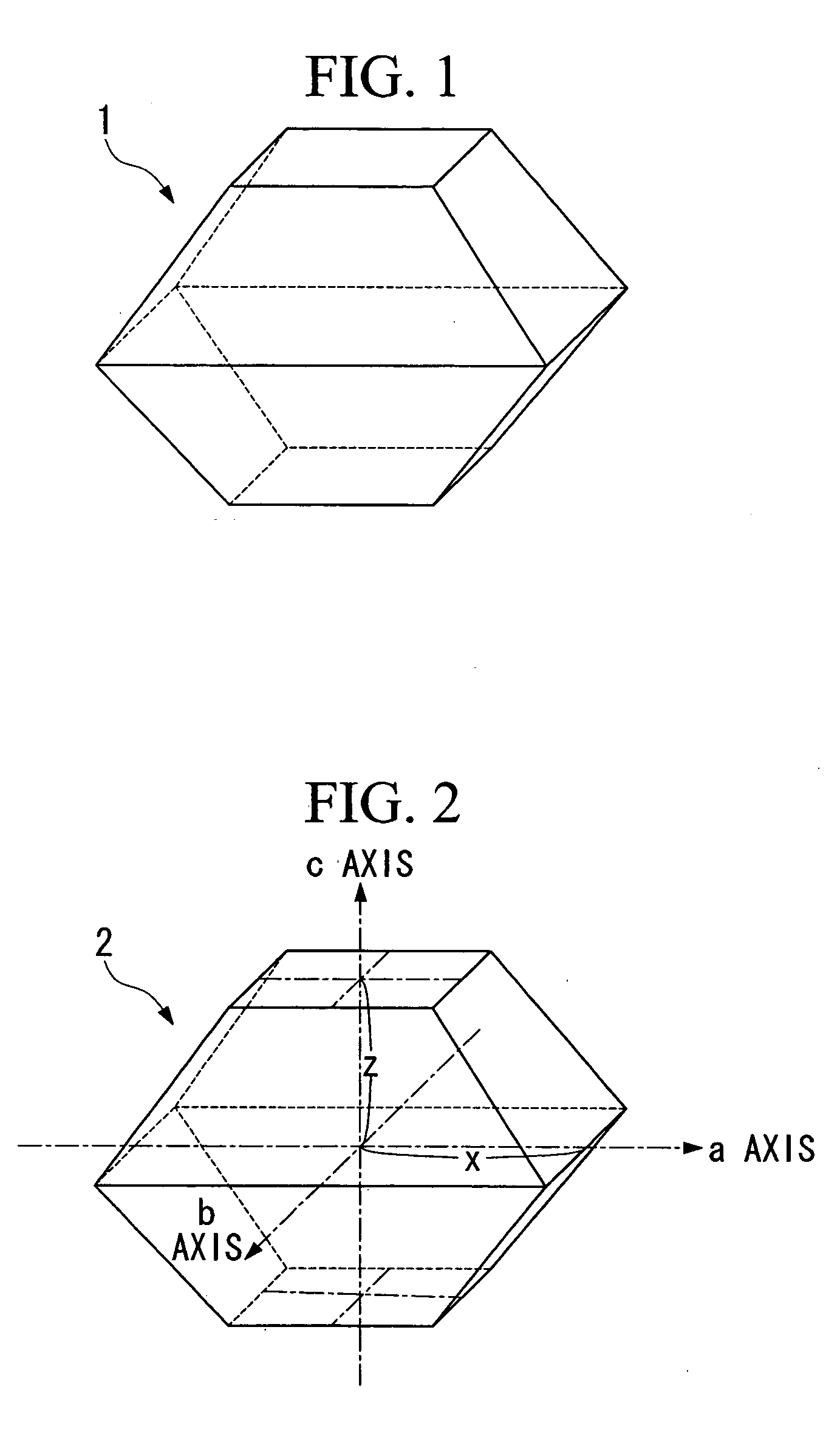

Tubular titanium oxide particles and process for preparing same

InactiveUS7431903B2Uniform particle shapeReduce contentMaterial nanotechnologyLight-sensitive devicesReduction treatmentSorbent

The process for preparing tubular titanium oxide particles comprises subjecting a water dispersion sol, which is obtained by dispersing (i) titanium oxide particles and / or (ii) titanium oxide type composite oxide particles comprising titanium oxide and an oxide other than titanium oxide in water, said particles having an average particle diameter of 2 to 100 nm, to hydrothermal treatment in the presence of an alkali metal hydroxide. After the hydrothermal treatment, reduction treatment (including nitriding treatment) may be carried out. The tubular titanium oxide particles obtained in this process are useful as catalysts, catalyst carriers, adsorbents, photocatalysts, decorative materials, optical materials and photoelectric conversion materials. Especially when the particles are used for semiconductor films for photovoltaic cells or photocatalysts, prominently excellent effects are exhibited.

Owner:JGC CATALYSTS & CHEM LTD

Titanium dioxide pigment, process for producing the same, and resin composition containing the same

InactiveUS6576052B1Good light fastnessMinimized change in colorPigmenting treatmentALUMINUM PHOSPHATEWear resistance

The titanium dioxide pigment of the present invention comprises titanium dioxide particles, the coating layer containing the aluminum phosphate compound and the coating layer containing the hydrolyzate of the organosilane compound, on the surface of the particles, in which a difference in water content between 100° C. and 300° C., determined by the Karl Fischer method, is not greater than 1500 ppm, and is thus excellent in light fastness, hydrophobicity and dispersibility. In particular, the titanium dioxide pigment of the invention is extremely advantageous as a colorant for plastics, which requires light fastness (resistance to discoloration) lacing resistance and dispersibility, to a high degree.

Owner:ISHIHARA SANGYO KAISHA LTD

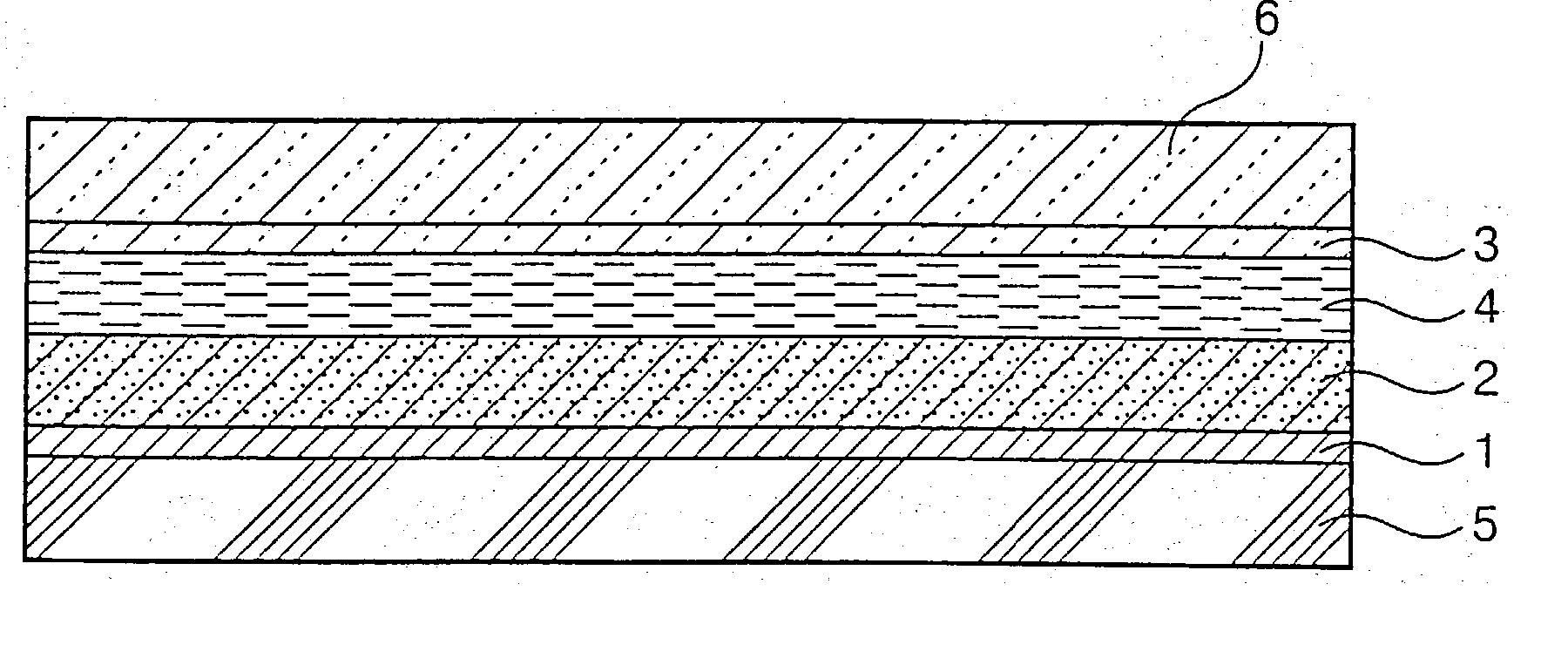

Preparation method of super-hydrophobic coating layer on aluminum surface

ActiveCN105521934AImprove hydrophobicityGood anti-fogPretreated surfacesLiquid/solution decomposition chemical coatingAcid etchingSilanes

The invention discloses a preparation method of a super-hydrophobic coating layer on an aluminum surface. The preparation method mainly comprises the following steps: (1) an aluminum piece is polished by an abrasive paper, is ultrasonically cleaned for 10 minutes by acetone and ethanol, is washed by distilled water to remove oil stains on the surface, and is dried in an oven; (2) the aluminum piece is dip in an acid etching agent for etching to obtain the aluminum surface with a micron rough structure; (3) the micron rough aluminum piece is dip in nanometer TiO2 particle solution, and is treated at high temperature to obtain the aluminum surface with a micron-nanometer composite rough structure; and (4) the aluminum surface with the micron-nanometer composite rough structure is treated by fluorine silane with low surface energy to obtain the aluminum surface with super-hydrophobic performance. The prepared super-hydrophobic aluminum piece is excellent in self-cleaning performance, fog resistance and ice covering resistance, and can be applied to field of ice covering prevention.

Owner:ZHEJIANG UNIV

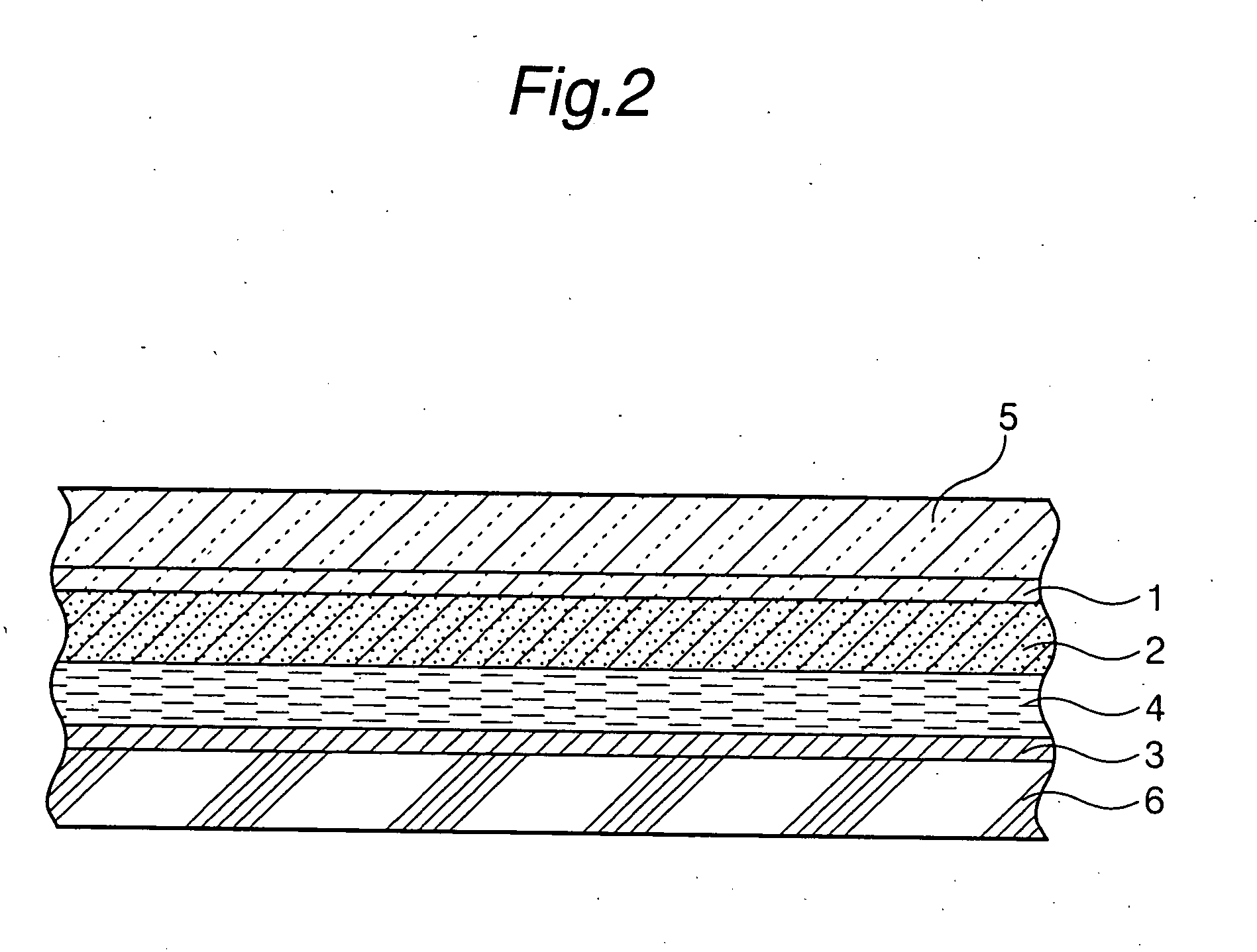

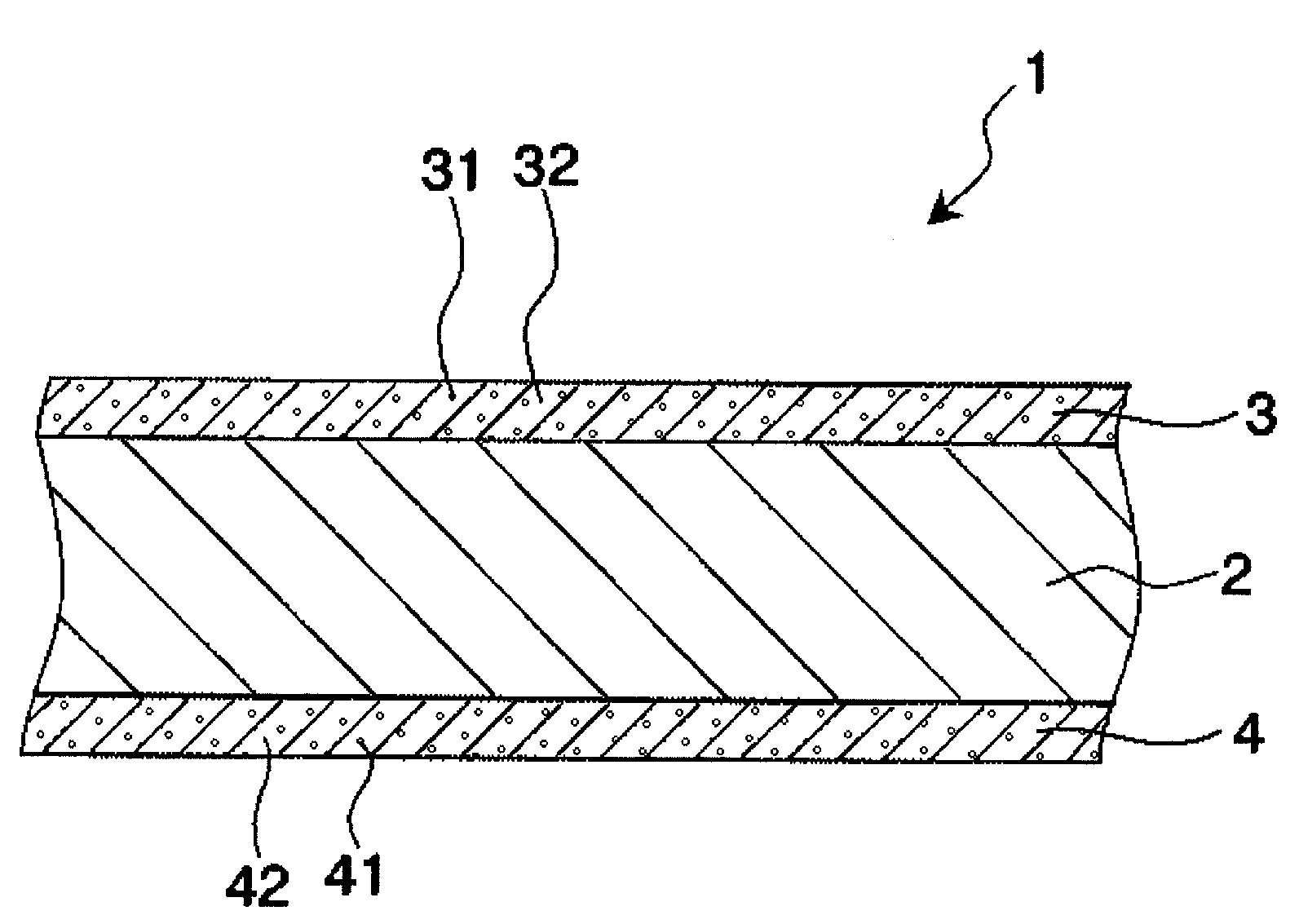

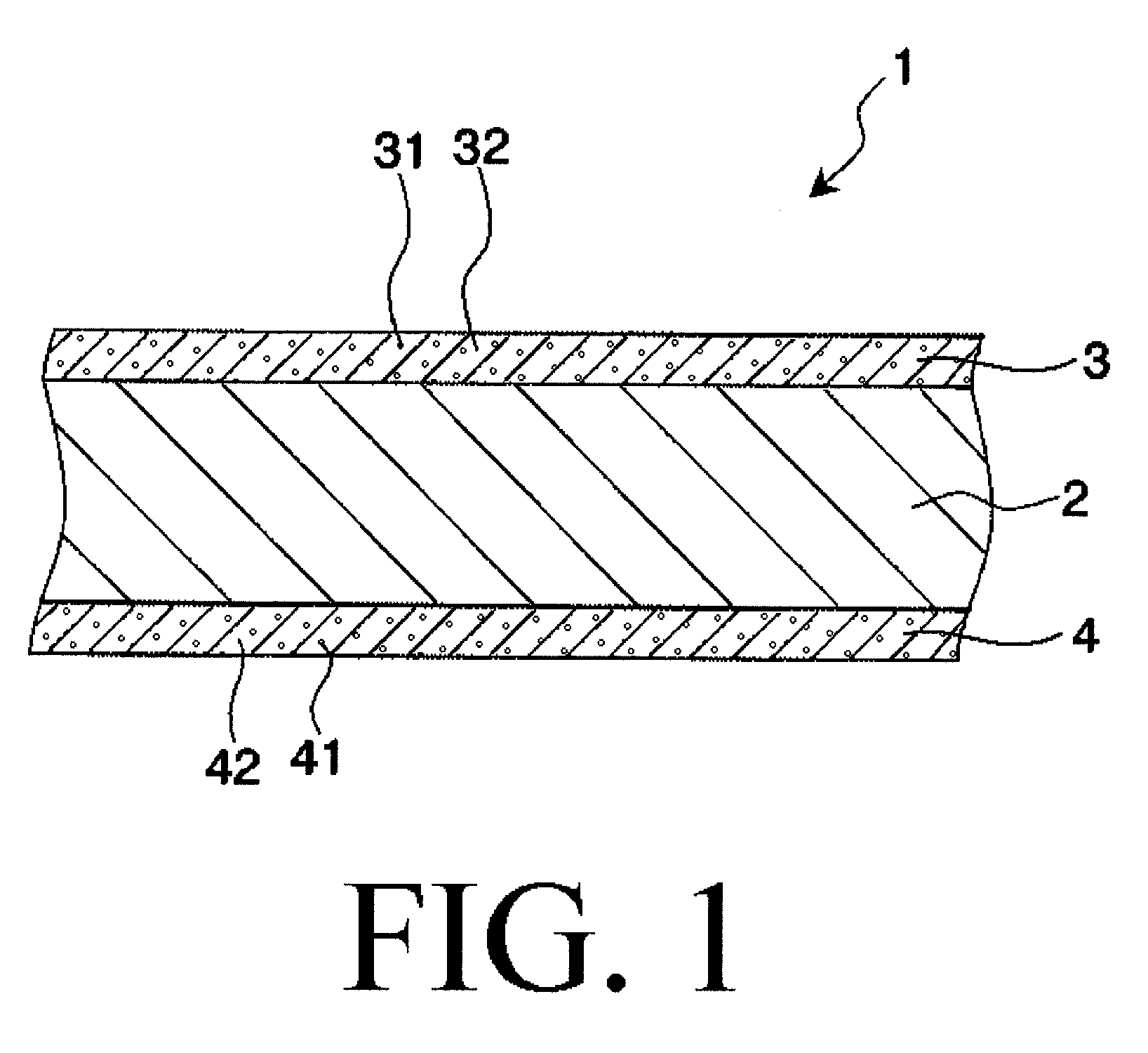

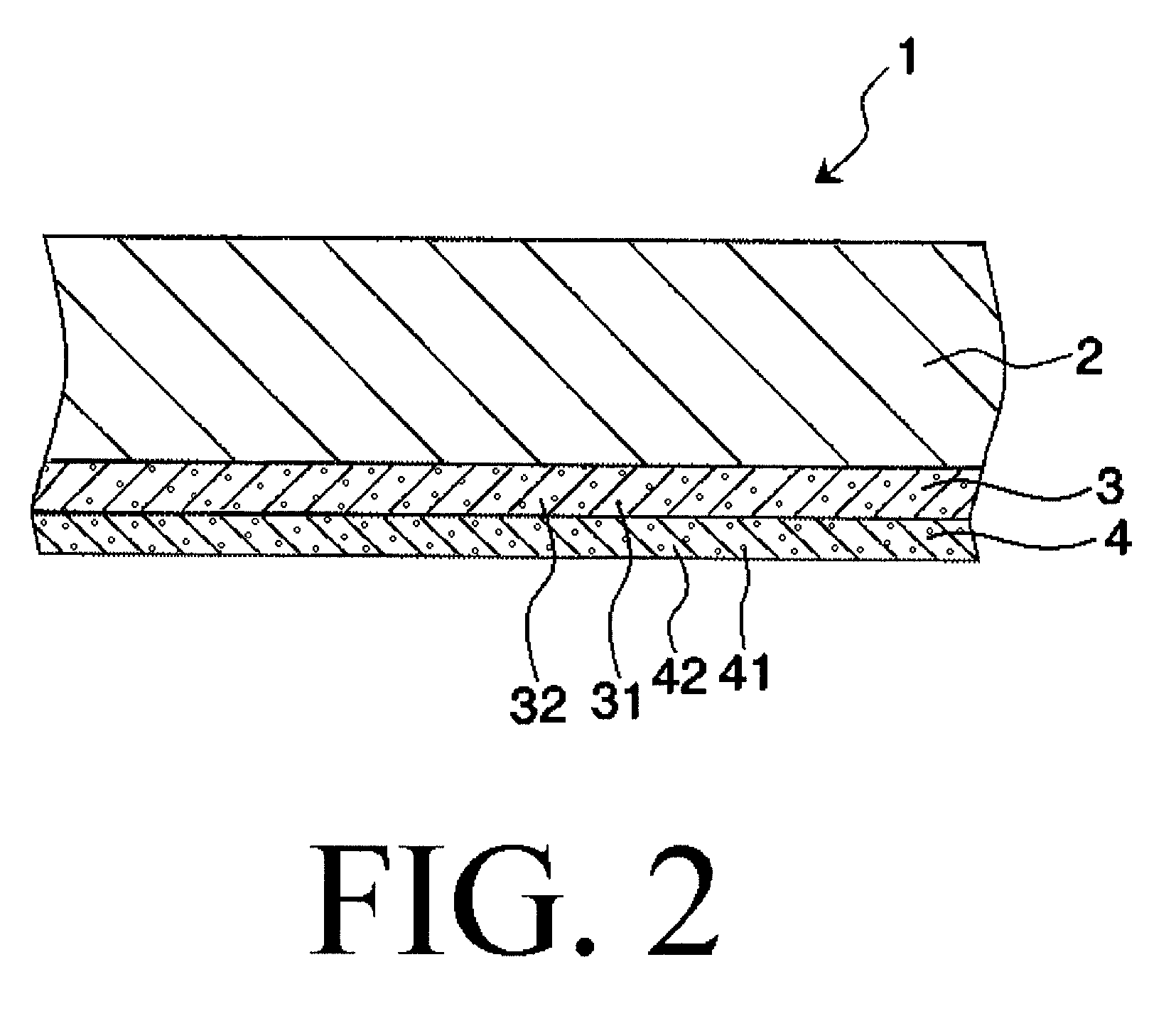

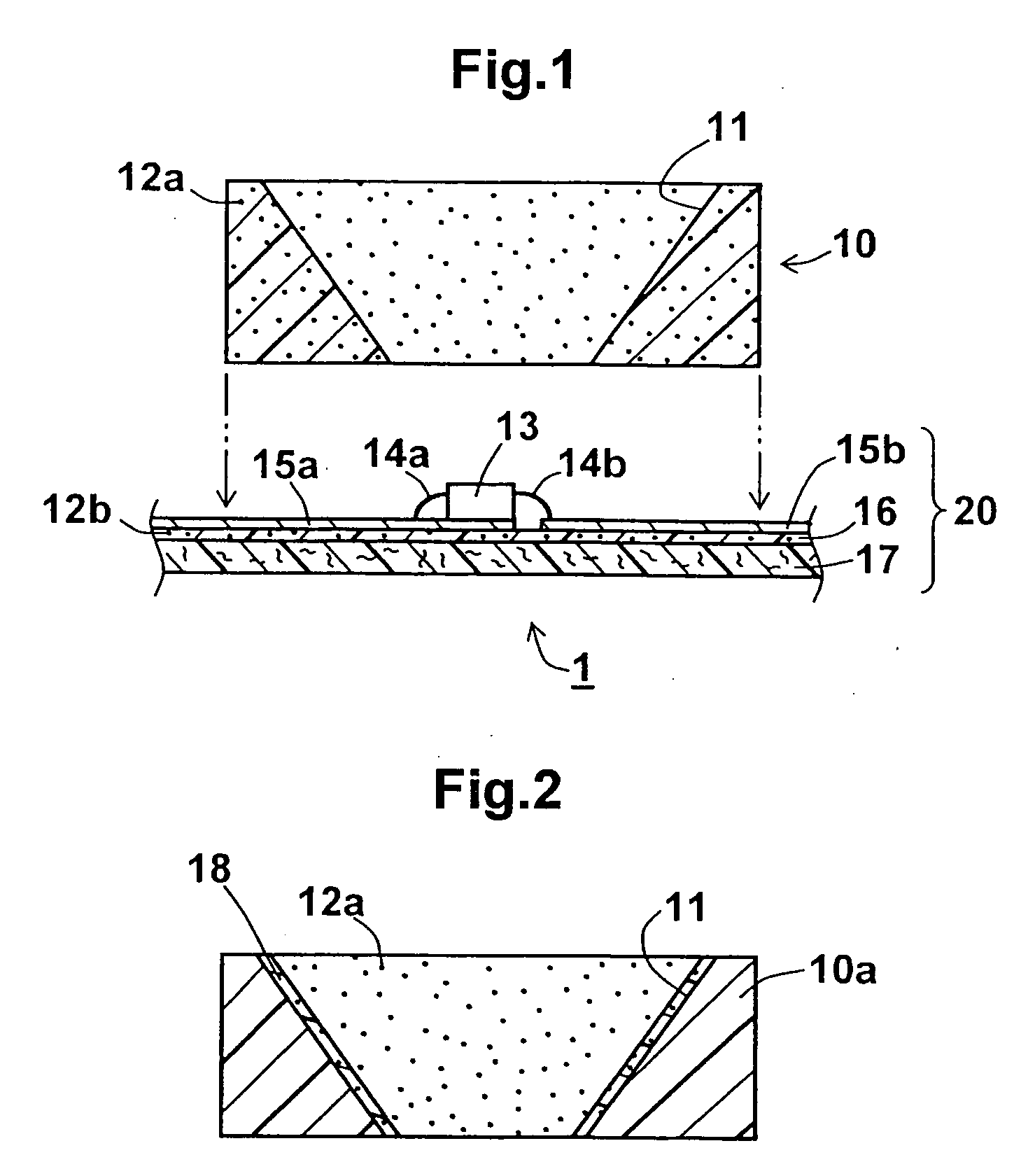

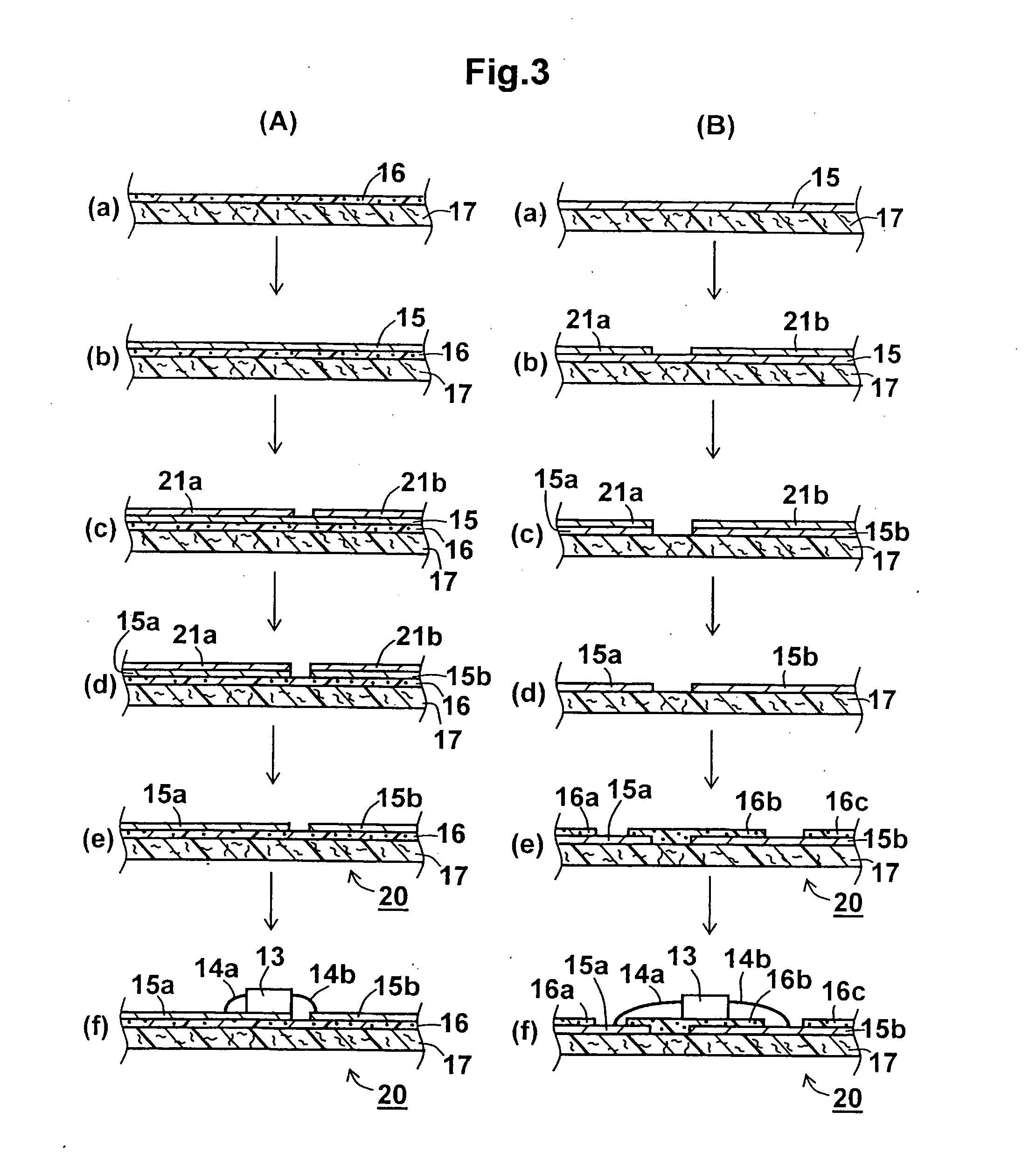

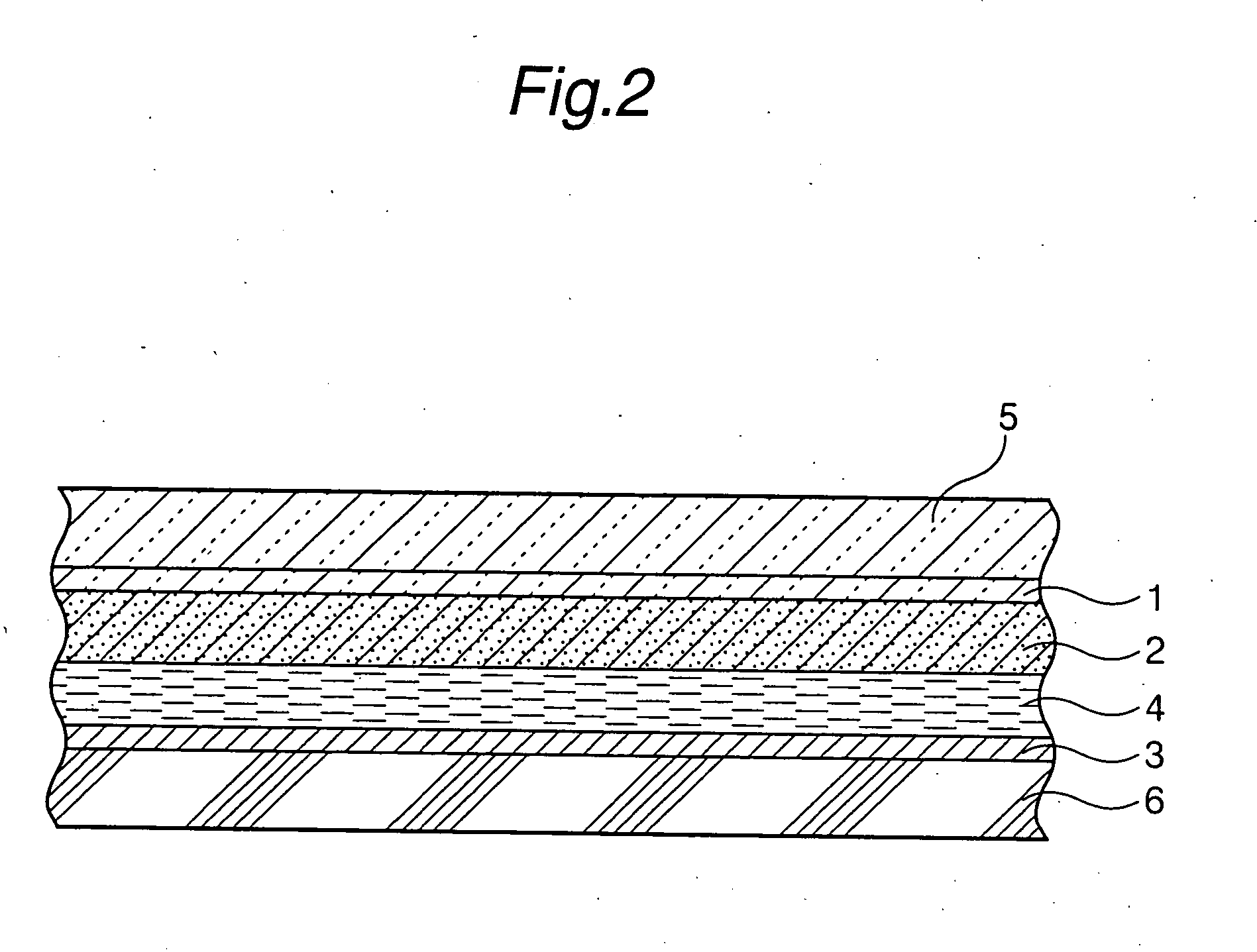

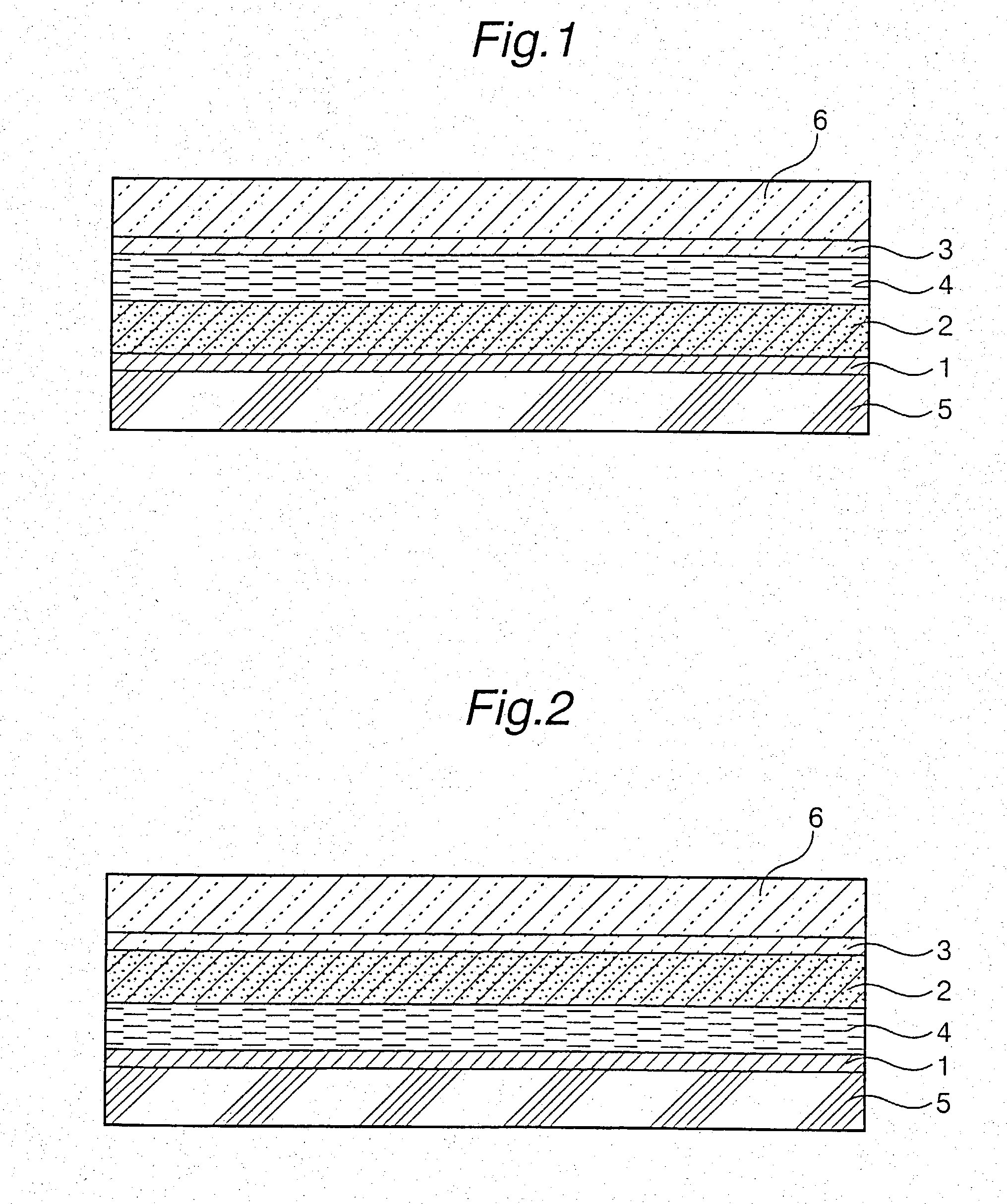

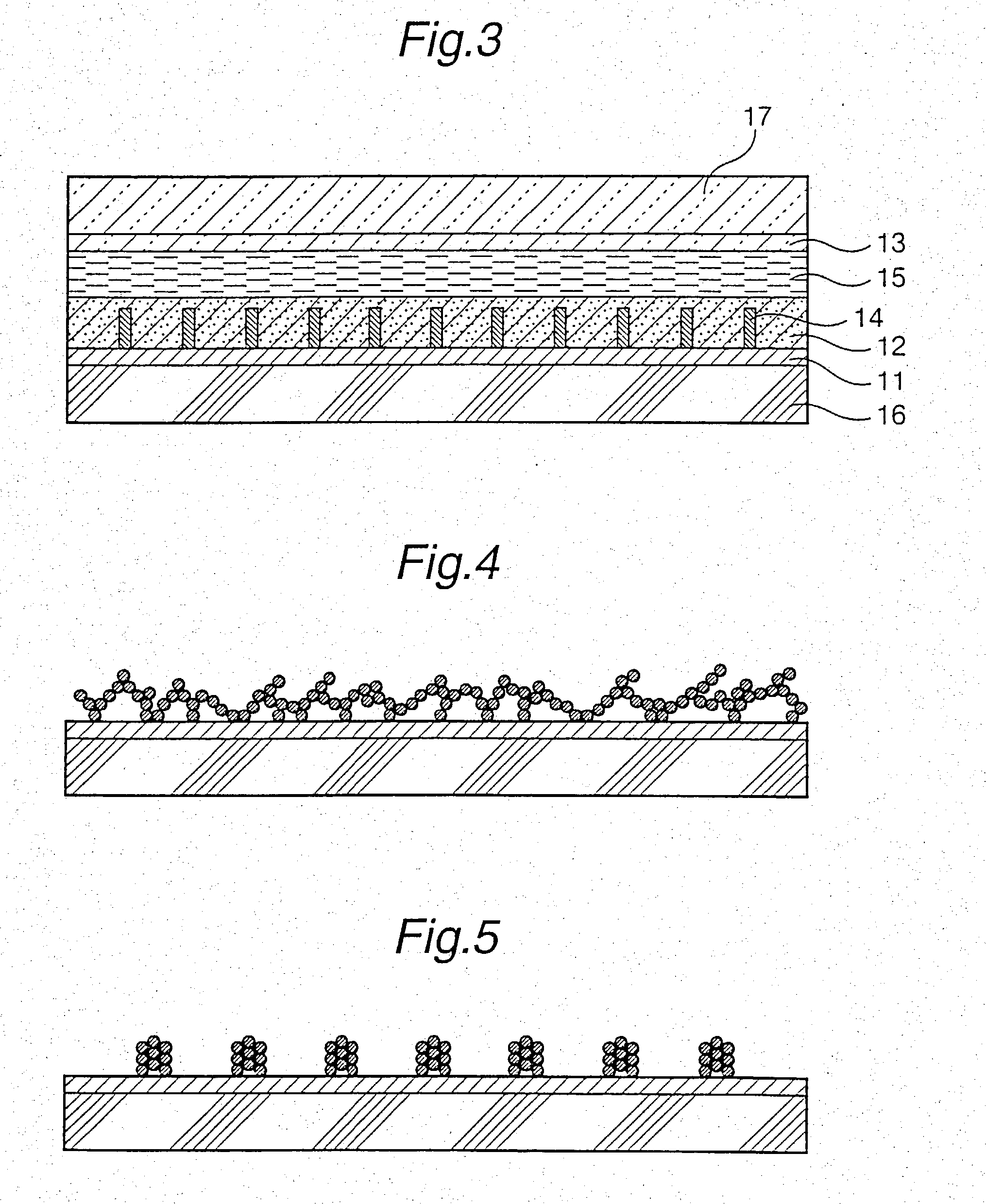

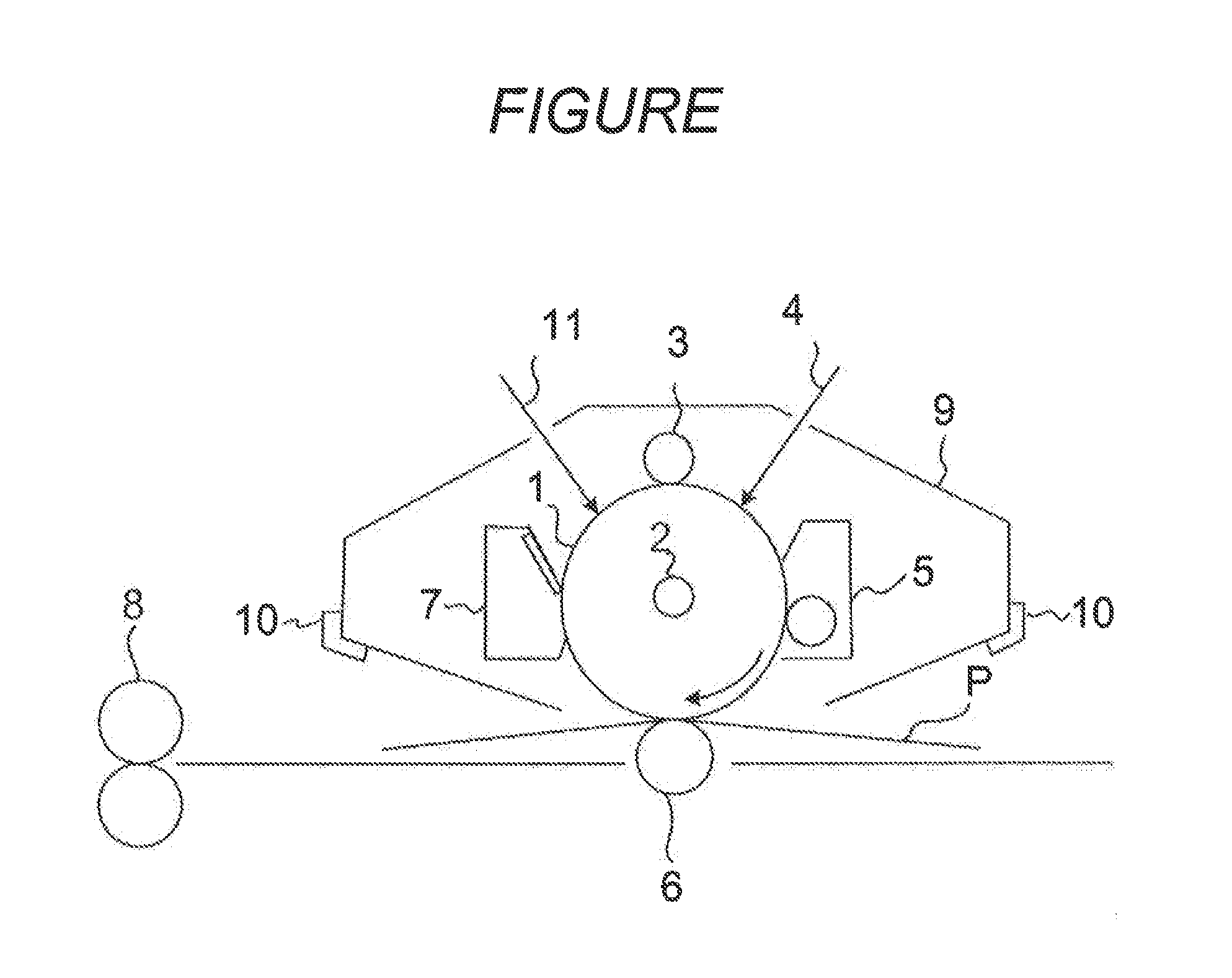

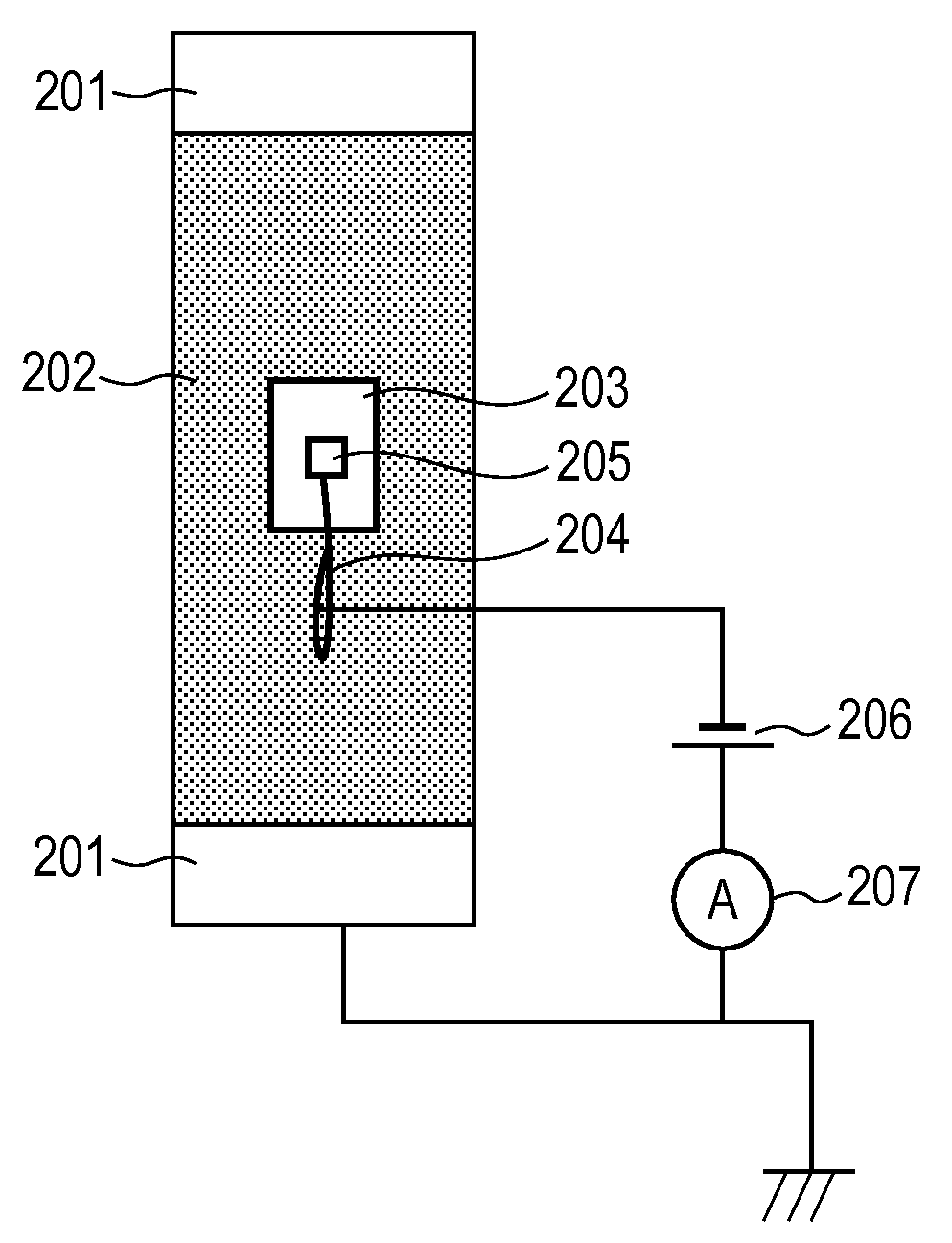

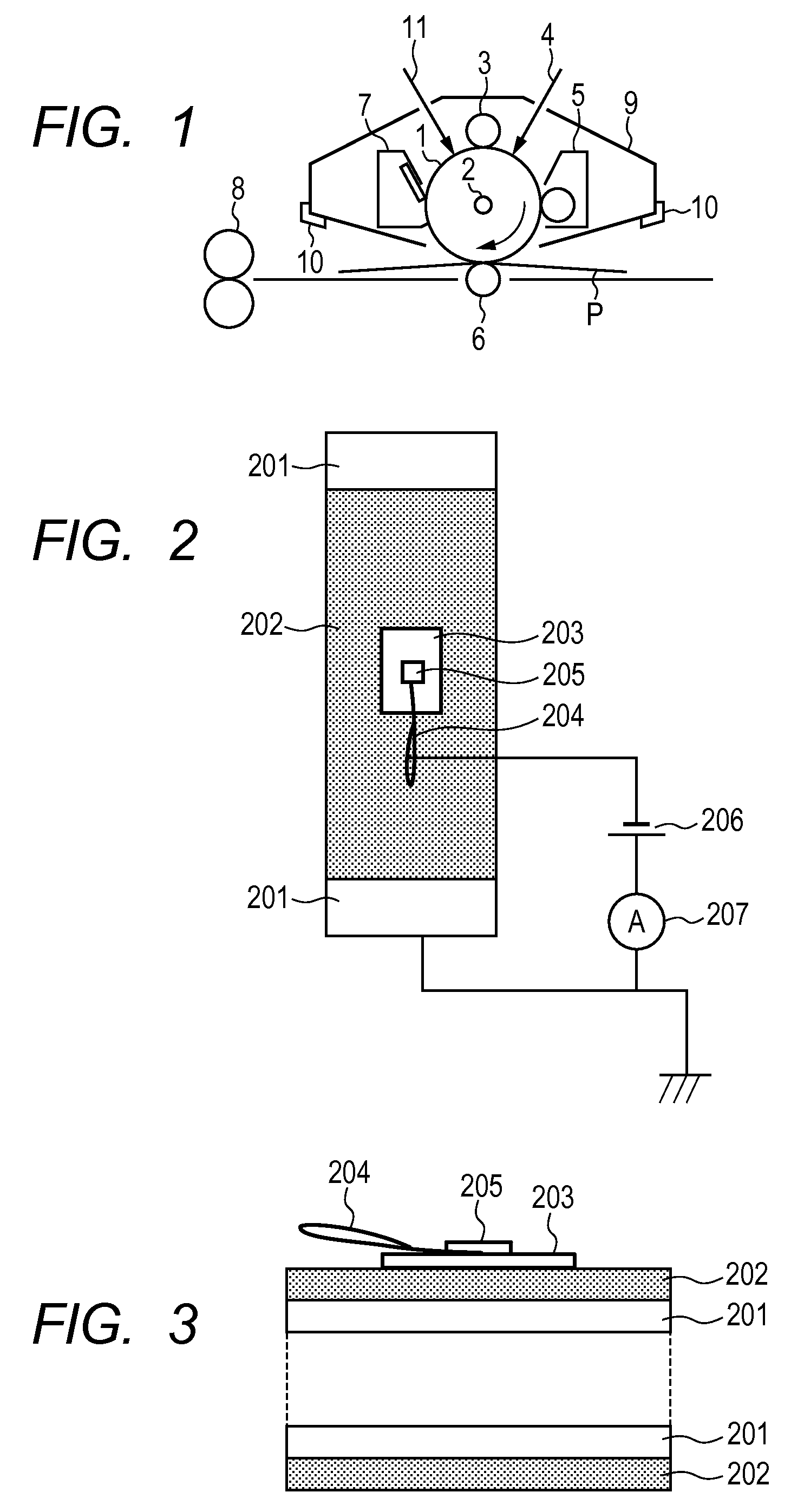

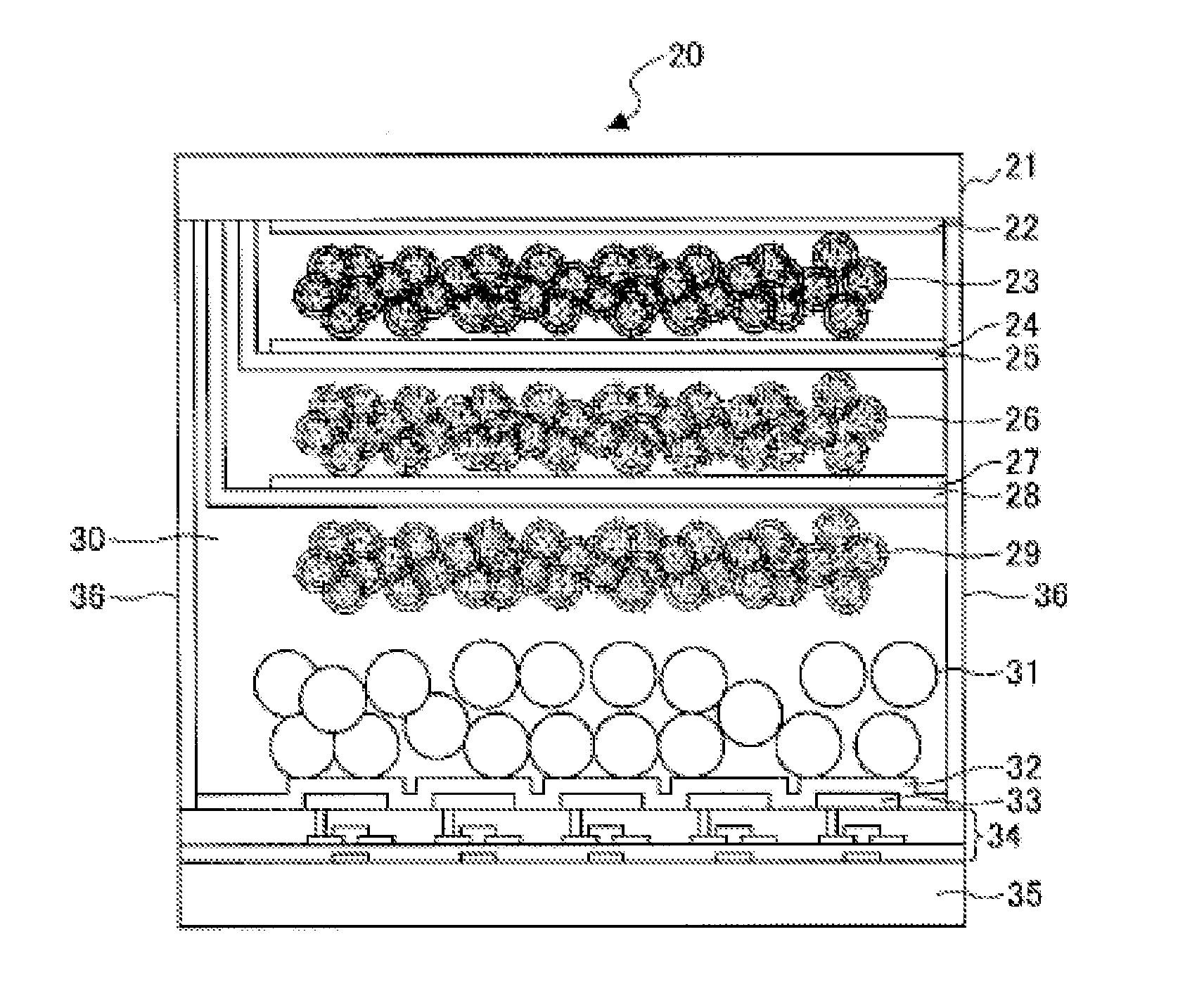

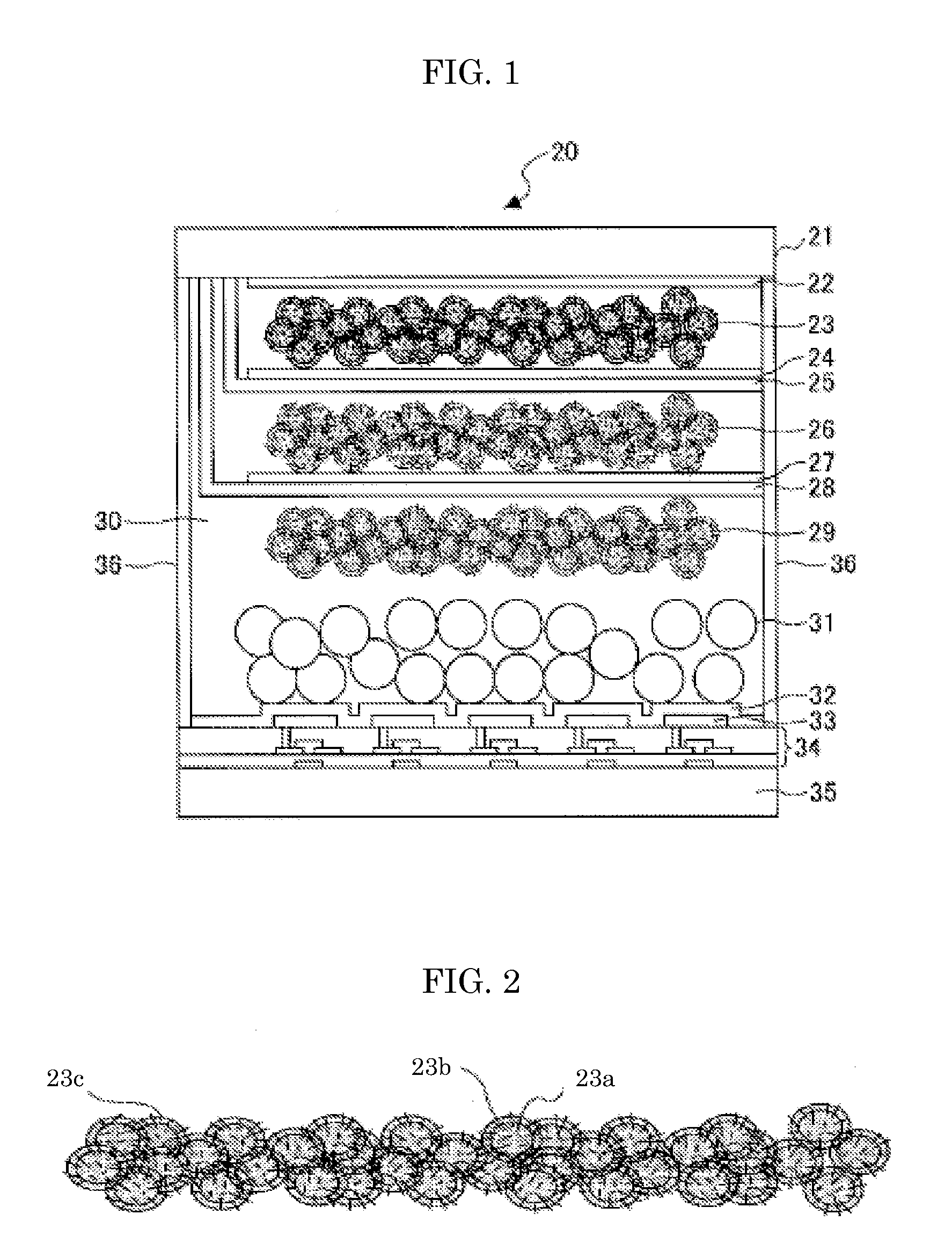

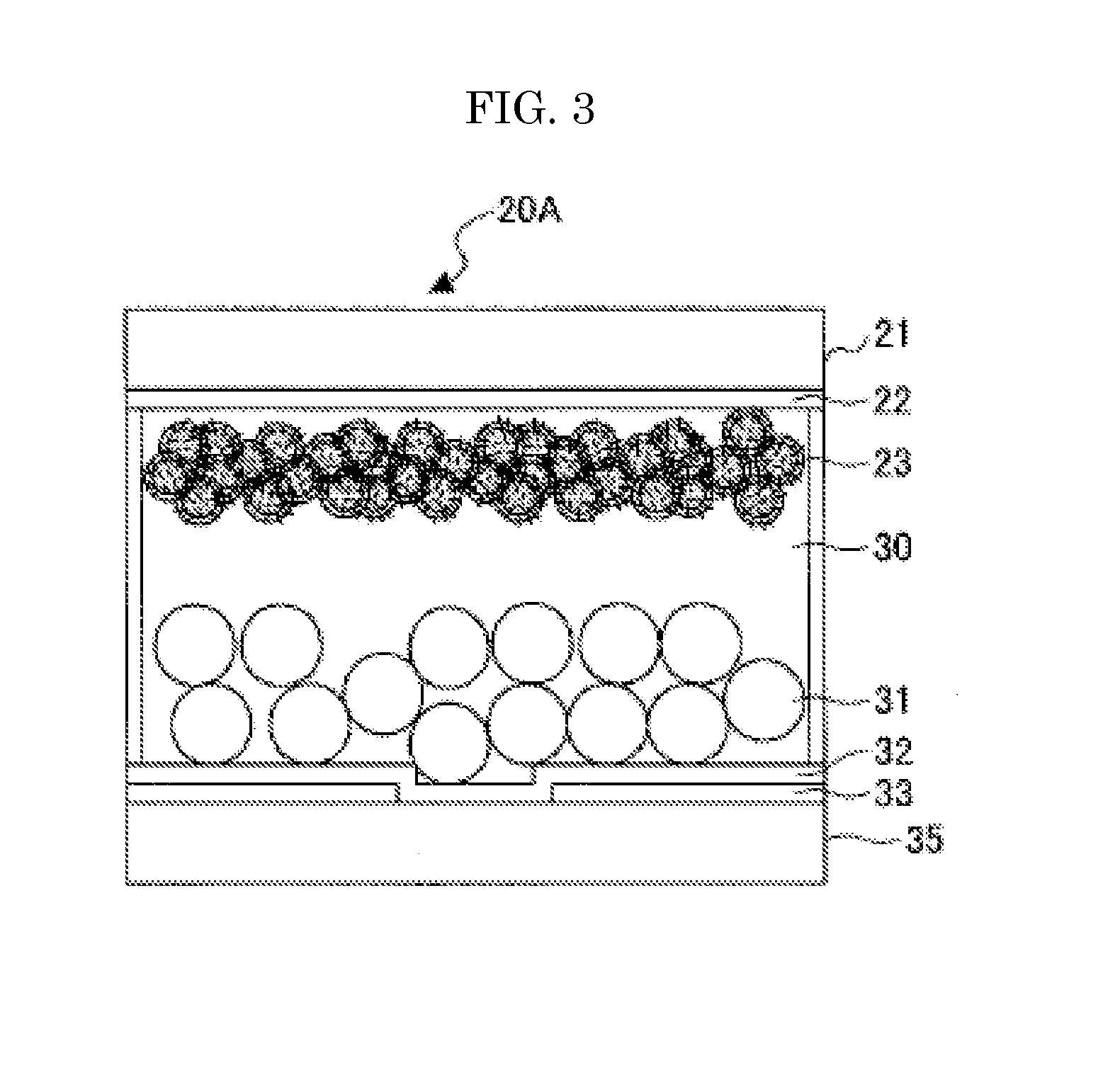

Photoelectric cell and process for producing metal oxide semiconductor film for use in photoelectric cell

InactiveUS20030150485A1High photoelectric transfer efficiencyExcellent in photoelectric transfer efficiencyPigmenting treatmentMaterial nanotechnologyTitanium oxideElectron

The first photoelectric cell of the present invention comprises: an insulating base having on its surface an electrode layer (1), the electrode layer (1) having on its surface a metal oxide semiconductor film (2) on which a photosensitizer is adsorbed; an insulating base having on its surface an electrode layer (3), the electrode layer (1) and the electrode layer (3) arranged opposite to each other; and an electrolyte sealed between the metal oxide semiconductor film (2) and the electrode layer (3), wherein at least one of the electrode-having insulating bases is transparent; and the metal oxide semiconductor film (2) comprises anatase titanium oxide particles. This first photoelectric cell includes a semiconductor film comprising anatase titanium oxide particles, having a high proportion of photosensitizer adsorbed, so that the electron mobility in the semiconductor film is high to thereby realize excellent photoelectric transfer efficiency. The second photoelectric cell of the present invention comprises: an insulating base having on its surface an electrode layer (1), the electrode layer (1) having on its surface a metal oxide semiconductor layer (2) on which a photosensitizer is adsorbed; an insulating base having on its surface an electrode layer (3), the electrode layer (1) and the electrode layer (3) arranged opposite to each other; and an electrolyte sealed between the metal oxide semiconductor layer (2) and the electrode layer (3), wherein conductive protrusions (4) jutting from the surface of the electrode layer (1) exist, the metal oxide semiconductor layer (2) formed so as to cover the conductive protrusions (4) and the electrode layer (1), and at least one of the electrode-layer-having insulating bases is transparent. In this second photoelectric cell, conductive protrusions are provided on the electrode surface, so that generated electrons not only can rapidly move toward the electrode but also are free from recombining with the photosensitizer. Moreover, in this photoelectric cell, not only is the adsorption proportion of photosensitizer high but also the moving of generated electrons is smooth. Therefore, the second photoelectric cell exhibits excellent photoelectric transfer efficiency.

Owner:CATALYSTS & CHEM

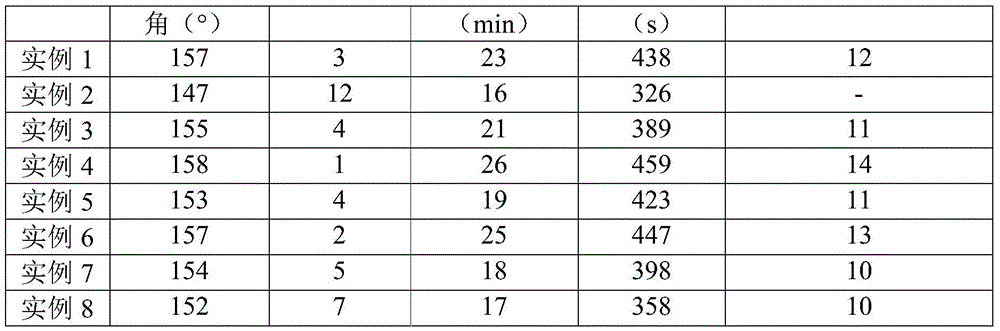

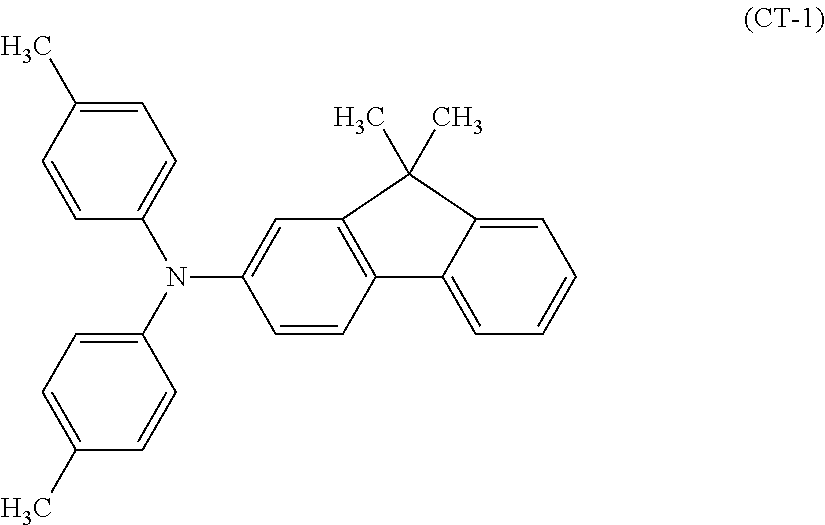

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS20150185634A1Reduce fluctuation in potentialReduce volatilityElectrographic process apparatusCorona dischargeInter layerHole transport layer

An electrophotographic photosensitive member including a support, a first intermediate layer formed on the support, a second intermediate layer formed directly on the first intermediate layer, a charge generating layer formed directly on the second intermediate layer, and a hole transporting layer formed on the charge generating layer, wherein the first intermediate layer contains a binder resin and a titanium oxide particle, and the second intermediate layer contains a polymerized product of a composition including an electron transporting substance having a polymerizable functional group and a crosslinking agent.

Owner:CANON KK

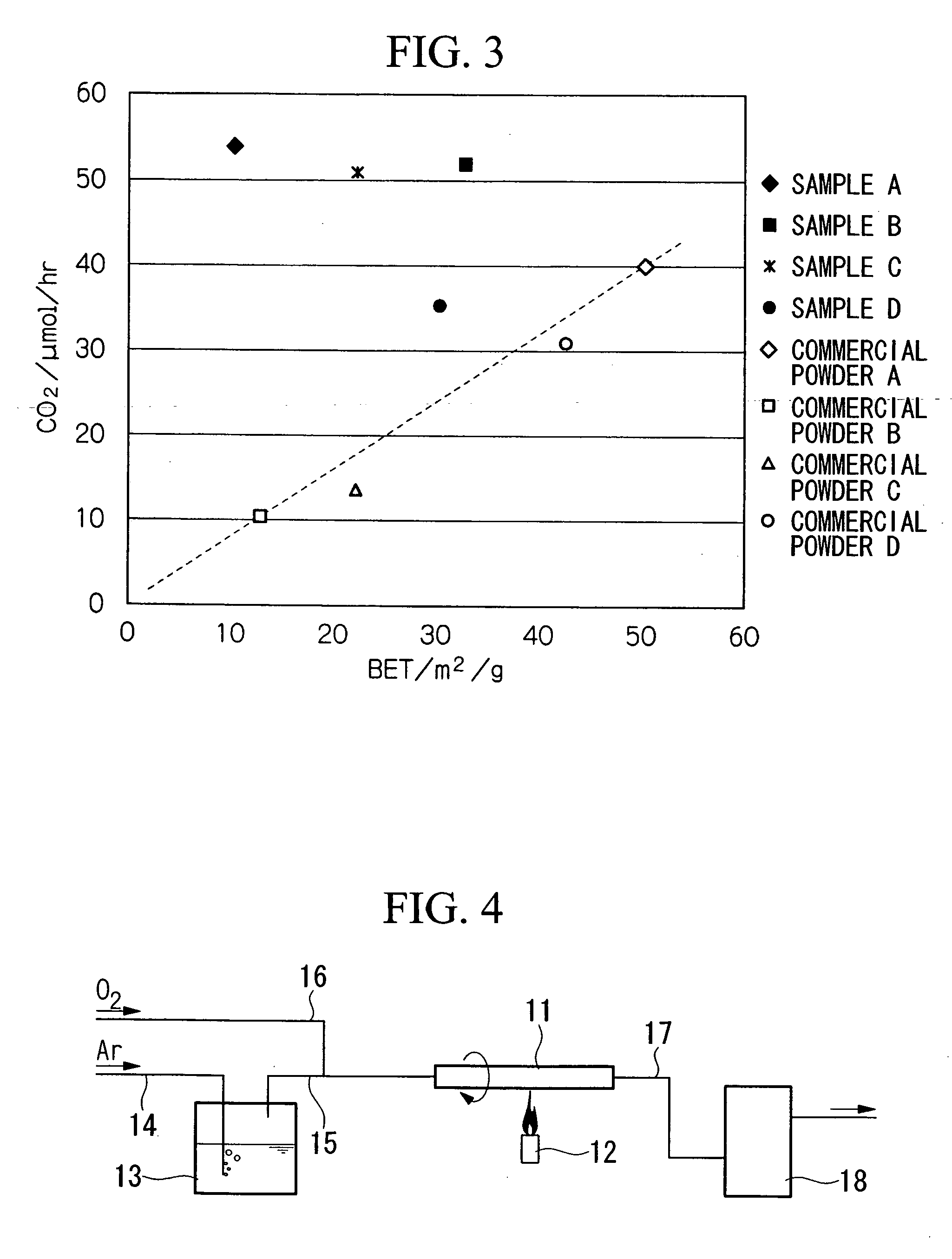

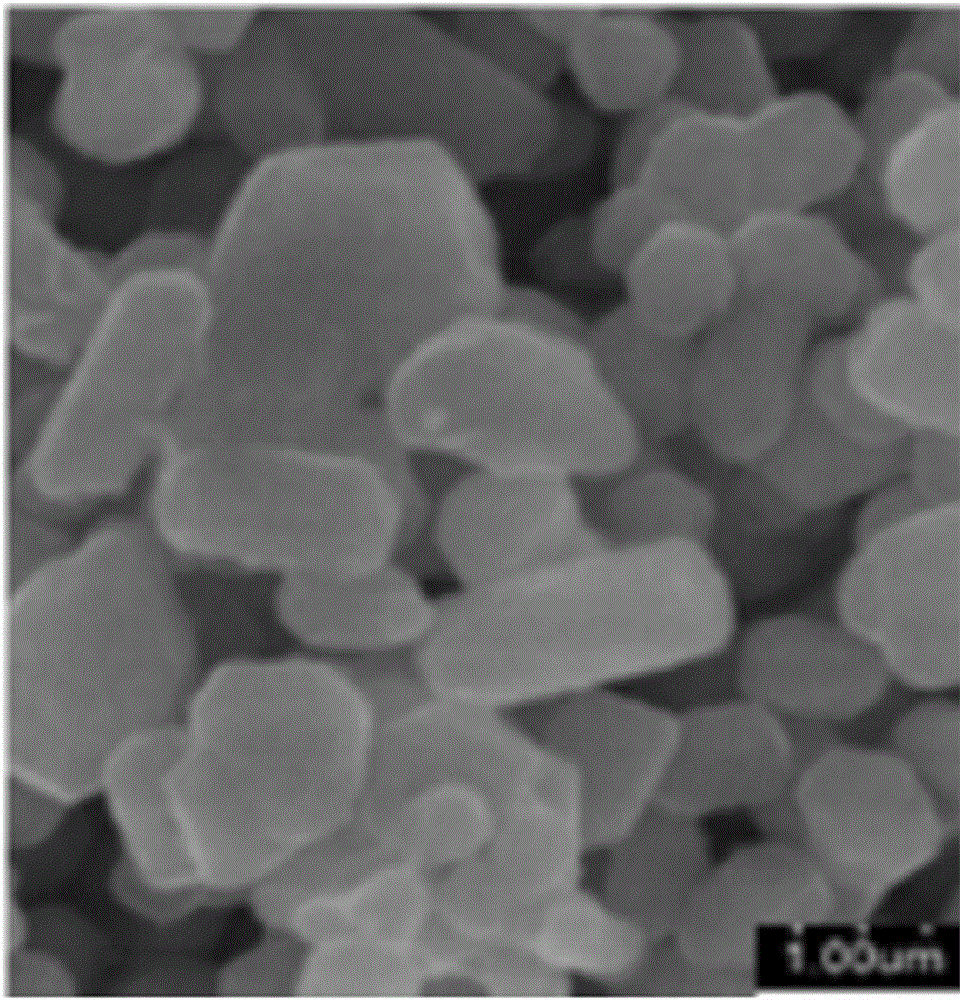

Particulate titanium oxide, method and apparatus for manufacturing the same, and treatment methods using such titanium oxide

InactiveUS20050271578A1No decline in photocatalytic activityReduce probabilityPolycrystalline material growthFrom normal temperature solutionsParticulatesSingle crystal

A particulate titanium oxide is obtained which has a large specific surface area and a high crystallinity with few internal defects, and thus a high photocatalytic activity as a photocatalyst is expected. Particulate titanium oxide in which the particles are box-shaped polyhedra is used as the photocatalyst. The particles are each a box-shaped polyhedron composed of one or more titanium oxide single crystalline polyhedron. When this single crystalline polyhedron has a flatness ratio of 0.33 to 3.0, the crystallinity is even higher. The particulate titanium oxide typically has a rutile transition ratio R(700-24) of not more than 7.5% and a rutile transition ratio R(500-24) of not more than 2.0%. Titanium oxide particles of these shapes are manufactured by feeding titanium tetrachloride vapor and oxygen into a reaction tube made of silica glass and applying heat from outside the tube to effect thermal oxidation.

Owner:THE FUJIKURA CABLE WORKS LTD

Preparation method of titanium dioxide for color masterbatch

InactiveCN105419404AHigh whitenessGood dispersionPigment treatment with organosilicon compoundsPigment physical treatmentDispersityHigh concentration

The invention relates to a preparation method of titanium dioxide for a color masterbatch. The preparation method comprises the following steps: a) preparing TiO2 slurry; b) silicon coating: diluting the TiO2 slurry obtained in step a to 300g / L to 450g / L, regulating pH of the slurry to 8 to 11, adding dispersing agent, feeding steam to heat to 60 to 90 DEG C, adding a silicon-containing compound under agitation, maintaining the pH of the slurry to be 8 to 10 to enable the surfaces of TiO2 particles to be coated with silicon oxide layers; c) aluminum coating: adding an aluminum oxide compound into the slurry obtained in step b, performing hydrolysis to form water-containing aluminum oxide layers on the surfaces of the silicon oxide layers, and maintaining the pH of the slurry to be 4 to 10 and temperature to be 40 to 60 DEG C; d) drying; e) crushing. The whiteness of the titanium dioxide obtained by adopting the preparation method provided by the invention is high, the dispersity is good, the newly formed interfacial surface energy is reduced through coating treatment, the titanium dioxide is prevented from being coagulated again during processing of the color masterbatch, especially high-concentration masterbatch, and thus not only can the amount of the used titanium dioxide be reduced, but also the rheological property of the color masterbatch can be improved.

Owner:NINGBO XINFU TITANIUM DIOXIDE

Electrochromic display element, display device, information system, and electrochromic dimming lens

ActiveUS20150331295A1Good light fastnessMaintain good propertiesNon-linear opticsCharge retentionDisplay device

To provide an electrochromic display element, which contains: a display substrate; a display electrode; an electrochromic layer provided in contact with the display electrode; a counter substrate provided to face the display substrate; a counter electrode; a charge retention layer provided in contact with the counter electrode; and an electrolyte layer filling between the display substrate and the counter substrate, wherein the electrochromic layer contains titanium oxide particles, and metal hydroxide is dispersed on surfaces and in inner parts of the titanium oxide particles.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com