Preparation method of graphene/titanium dioxide composite photocatalyst

A technology of titanium dioxide and composite light, which is applied in the field of photocatalysis to achieve excellent photocatalytic activity, avoid agglomeration, and prevent heavy accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 30 mg of graphite oxide to 30 mL of isopropanol, and sonicate for 1 hour to obtain a graphene oxide dispersion. Then 5 mL of n-butyl titanate was added and stirred for 30 minutes, followed by the addition of 1 mL of deionized water and continued stirring for 30 minutes to obtain a beige gel. The gel was transferred to a hydrothermal reactor and reacted at 180°C for 8 hours. The hydrothermal product was washed several times by centrifugation with ethanol and deionized water respectively, placed in a vacuum oven, and dried at 60° C. for 12 hours to obtain a graphene / titanium dioxide composite photocatalyst.

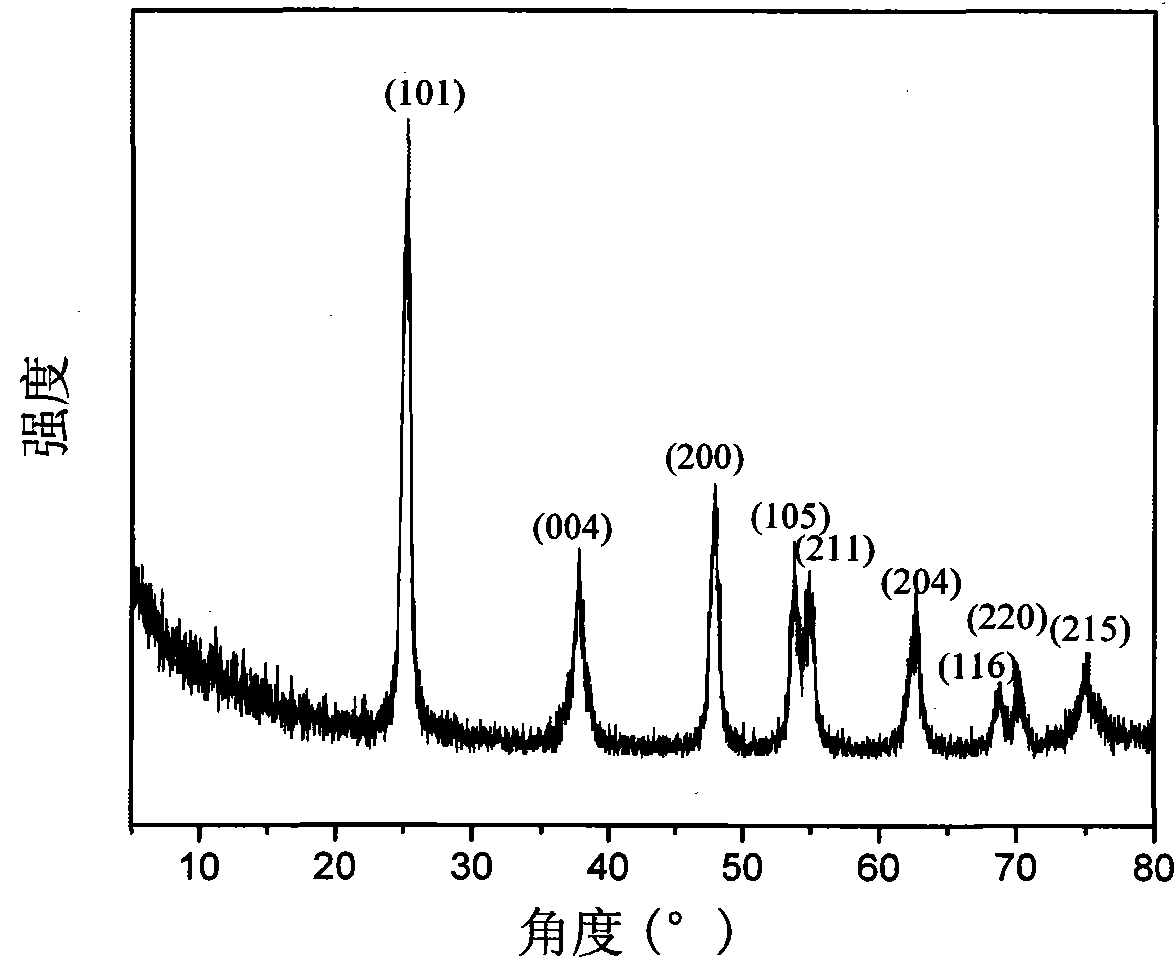

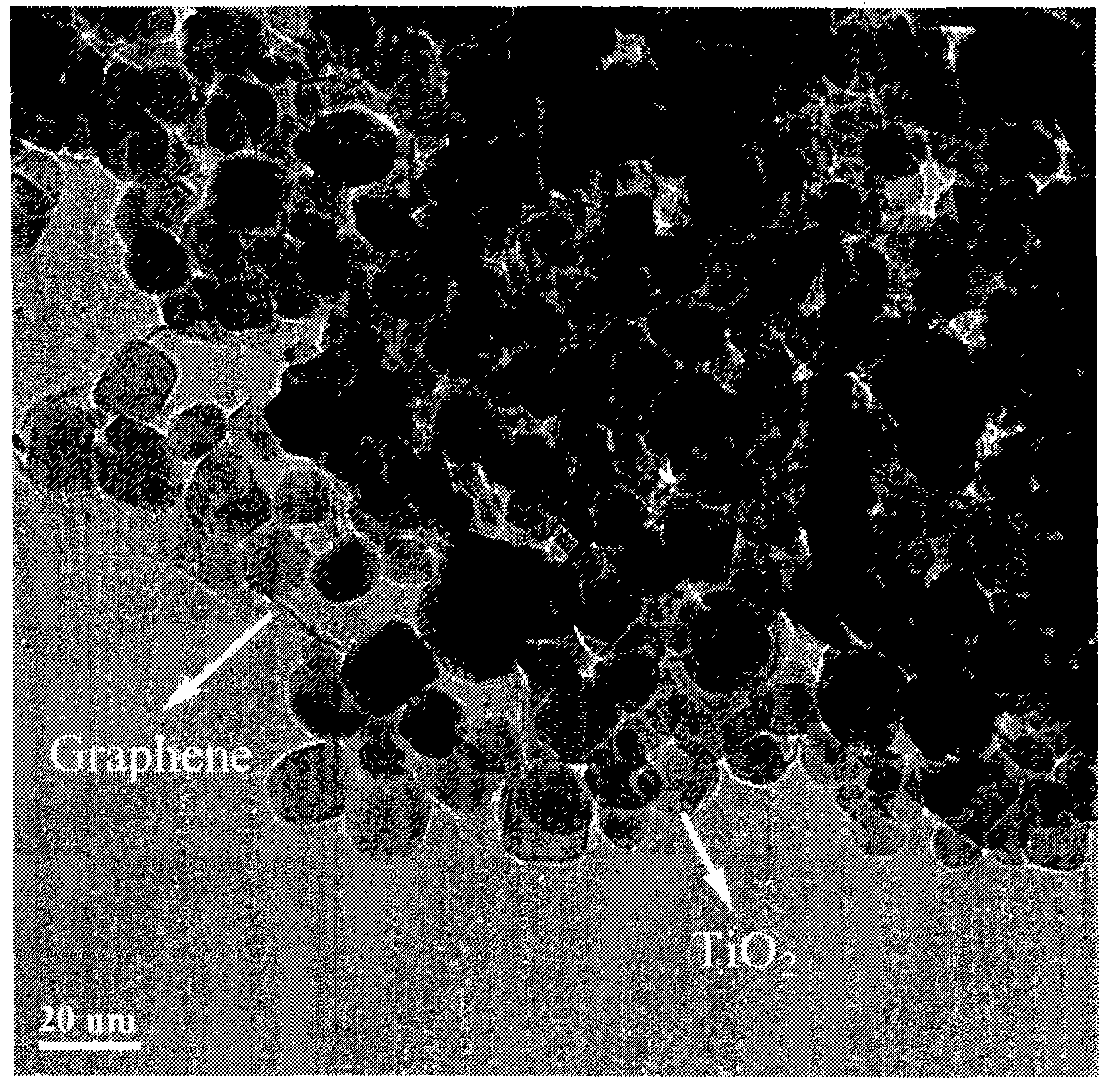

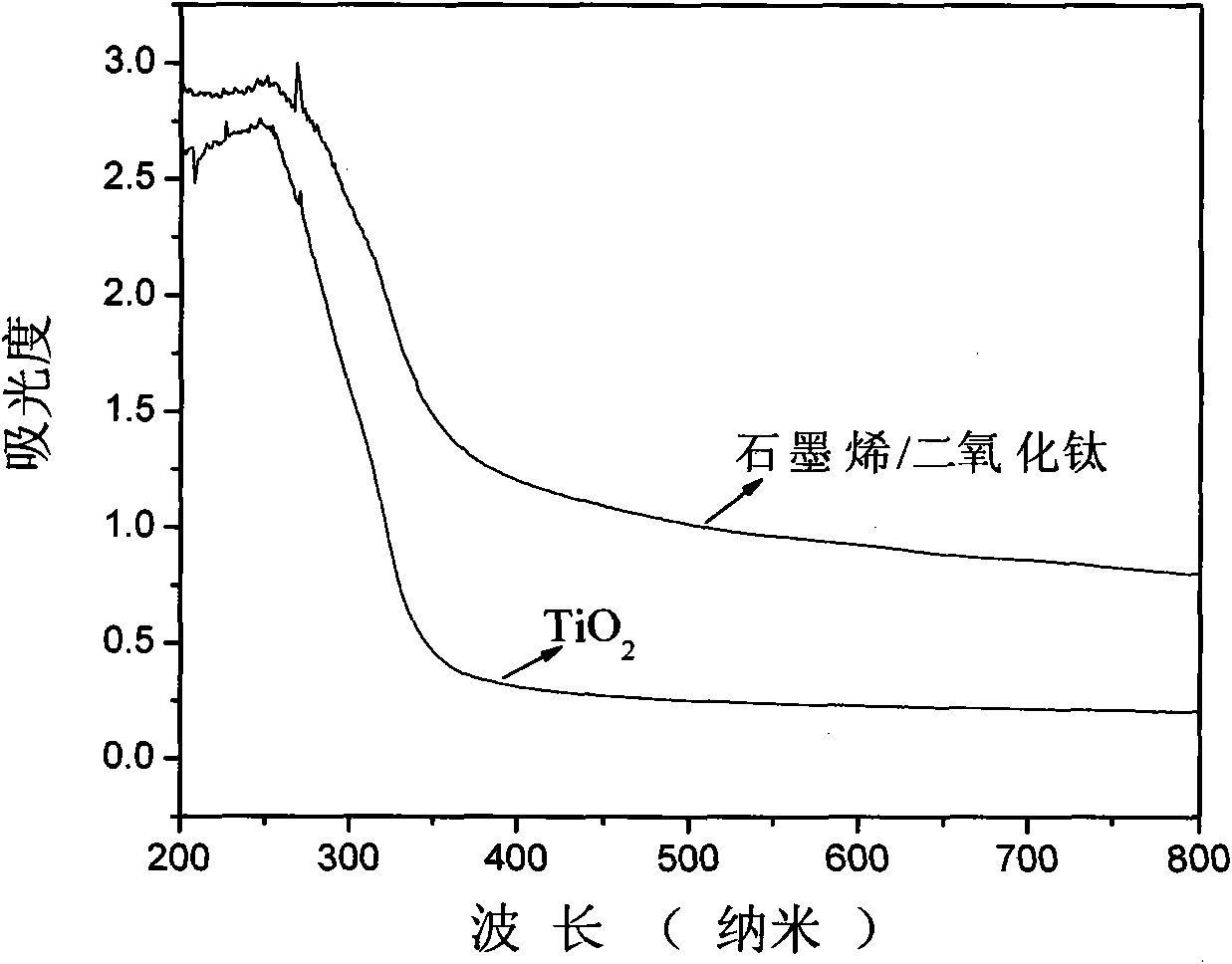

[0020] figure 1 The XRD figure of the graphene / titanium dioxide composite material that is made in this embodiment. All the diffraction peaks in the figure correspond to TiO 2 In the anatase phase, the characteristic diffraction peak of graphite oxide at 2θ=10.7° disappeared, indicating that the hydrothermal reaction effectively reduced graphite oxide to graph...

Embodiment 2

[0022] Add 10 mg of graphite oxide to 30 mL of isopropanol, and sonicate for 40 minutes to obtain a graphene oxide dispersion. Then 5 mL of n-butyl titanate was added and stirred for 30 minutes, followed by the addition of 1 mL of deionized water and continued stirring for 20 minutes to obtain a beige gel. The gel was transferred to a hydrothermal reactor and reacted at 140°C for 12 hours. The hydrothermal product was washed several times by centrifugation with ethanol and deionized water respectively, placed in a vacuum oven, and dried at 50° C. for 18 hours to obtain a graphene / titanium dioxide composite photocatalyst.

Embodiment 3

[0024] Add 50 mg of graphite oxide to 30 mL of ethanol, and ultrasonicate for 1 hour to obtain a graphene oxide dispersion. Then 5 mL of n-butyl titanate was added and stirred for 30 minutes, followed by the addition of 1 mL of deionized water and continued stirring for 30 minutes to obtain a beige gel. The gel was transferred to a hydrothermal reactor and reacted at 200°C for 6 hours. The hydrothermal product was washed several times by centrifugation with ethanol and deionized water respectively, placed in a vacuum oven, and dried at 70° C. for 10 hours to obtain a graphene / titanium dioxide composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com