Patents

Literature

39results about How to "Outstanding appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

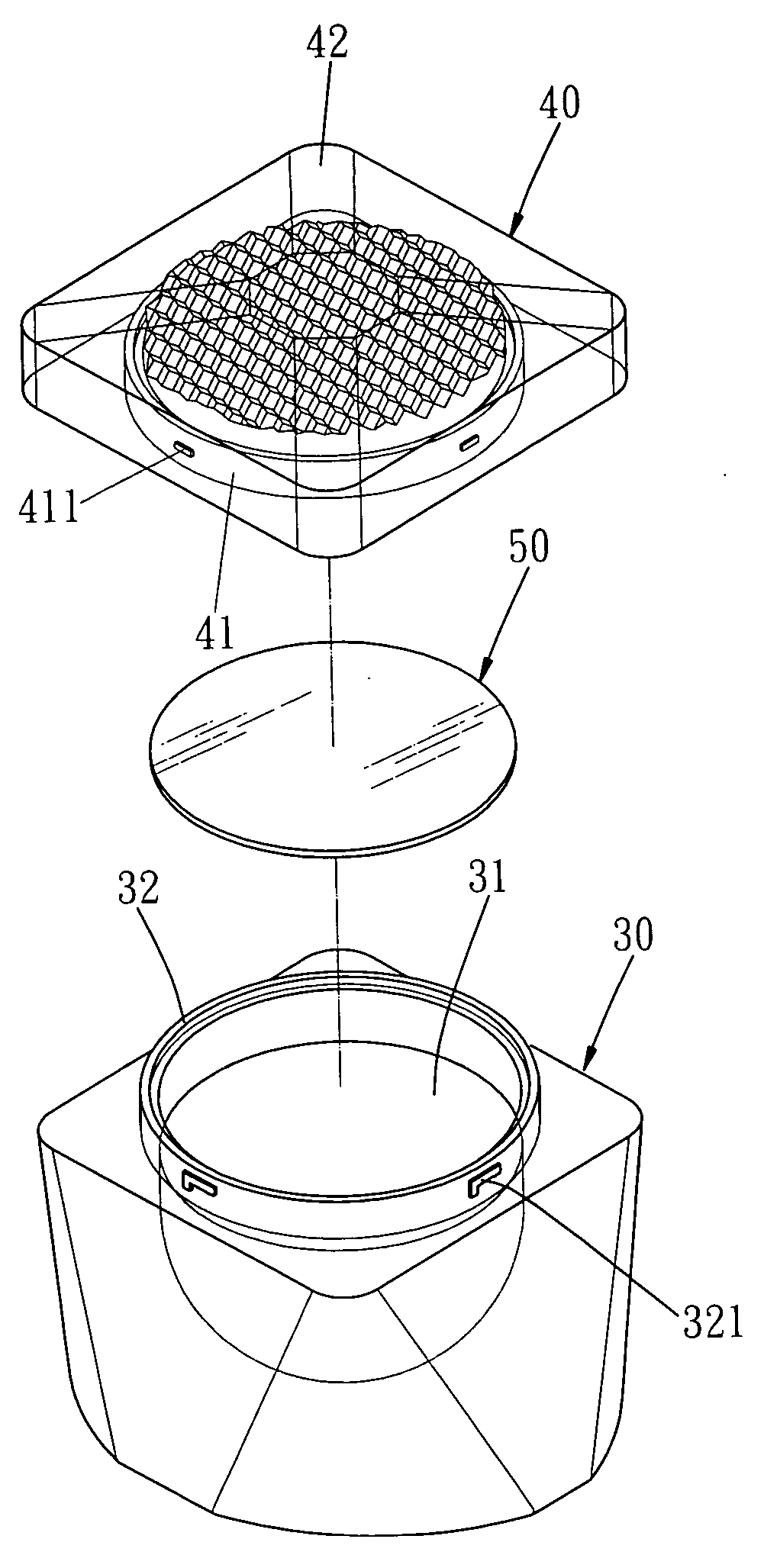

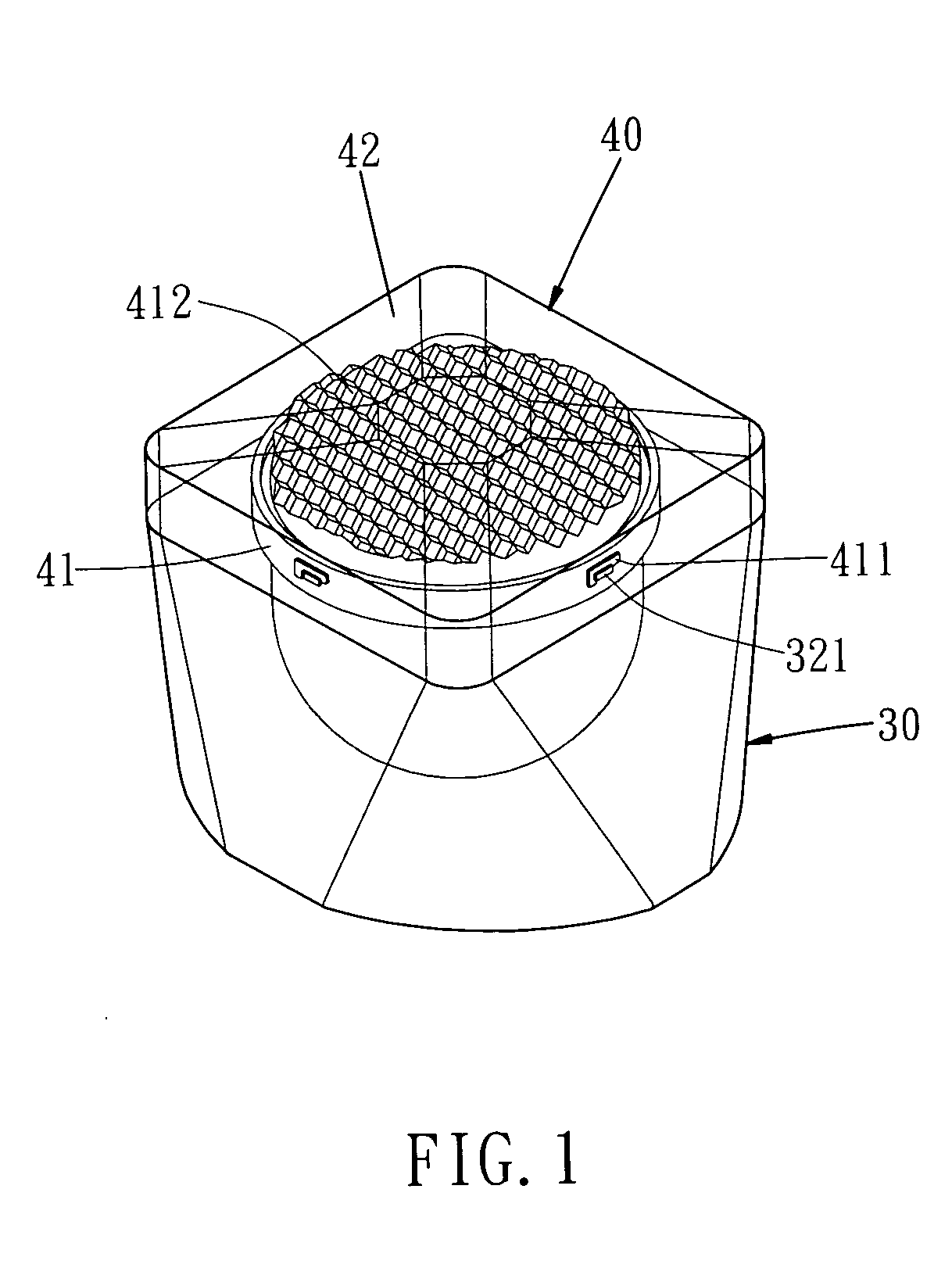

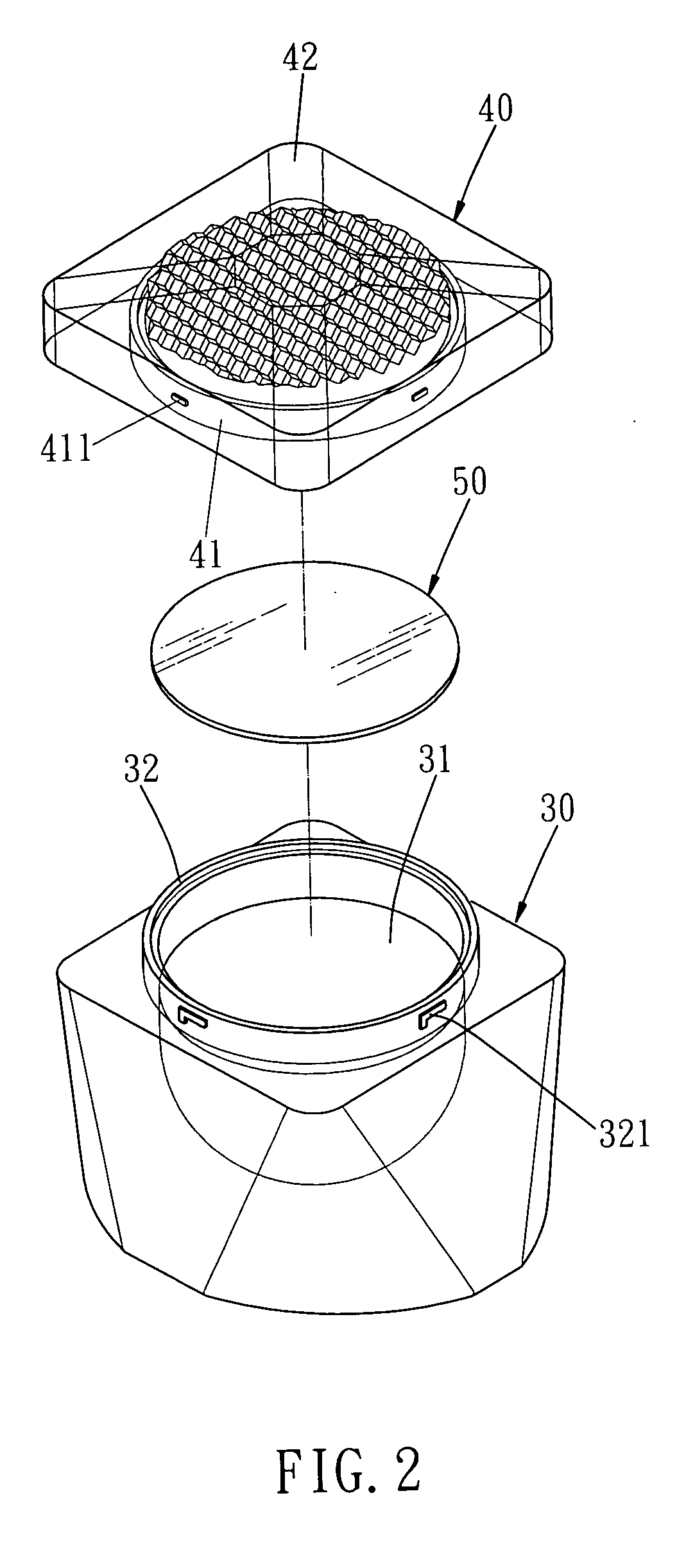

Cosmetics container having outstanding appearance

InactiveUS20050011895A1Outstanding appearanceImprove appearance qualityCapsClosure capsCosmetic appearanceColored light

A cosmetics container includes a main body, a top cover, and a colored plate. Thus, the reflective face of the top cover co-operates with the colored plate to produce a colorful optical reflective effect, and the refractive face of the top cover produces a refractive effect, thereby enhancing the aesthetic quality of the cosmetics container so that the cosmetics container has an outstanding appearance.

Owner:LIN YI HUNG

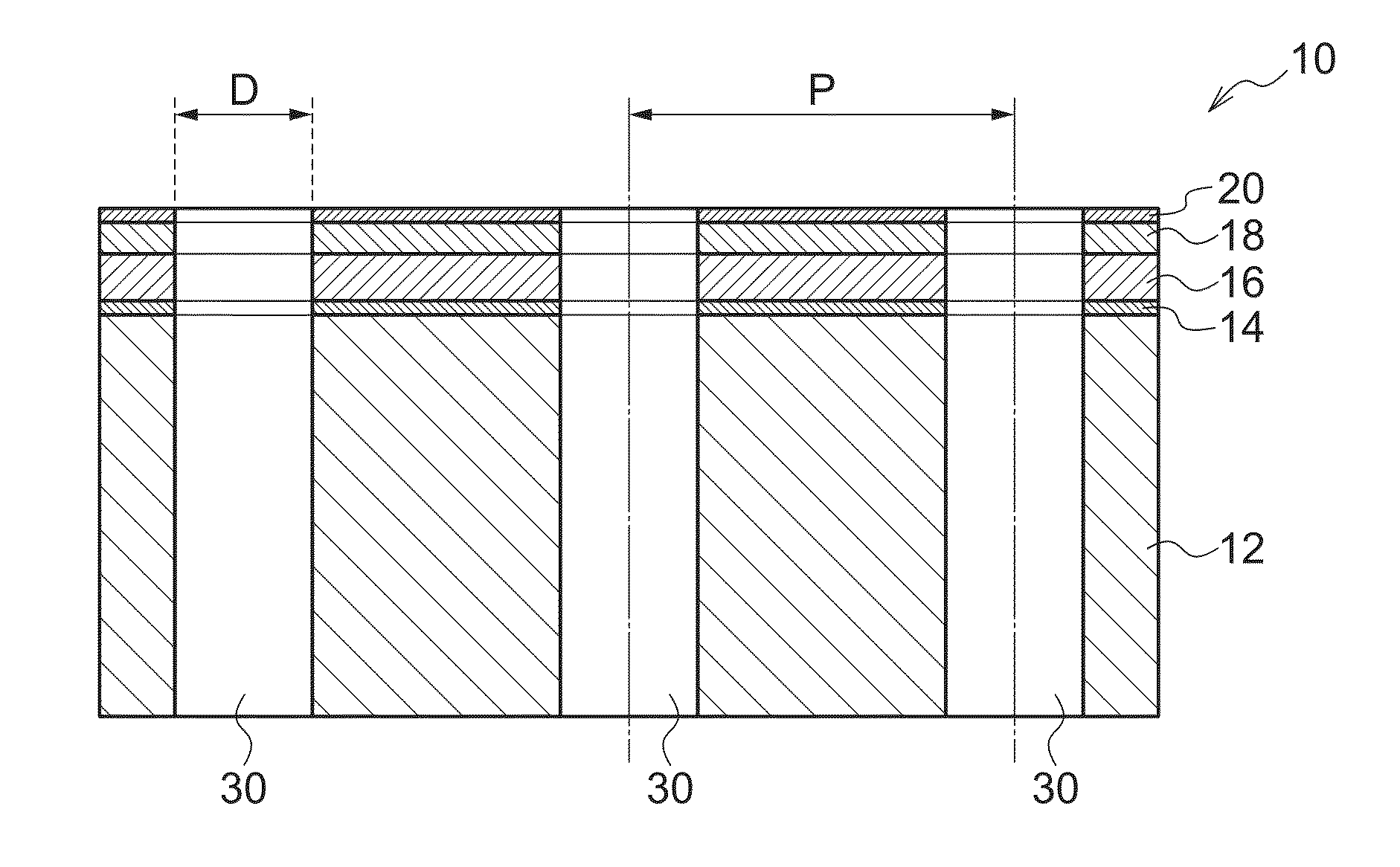

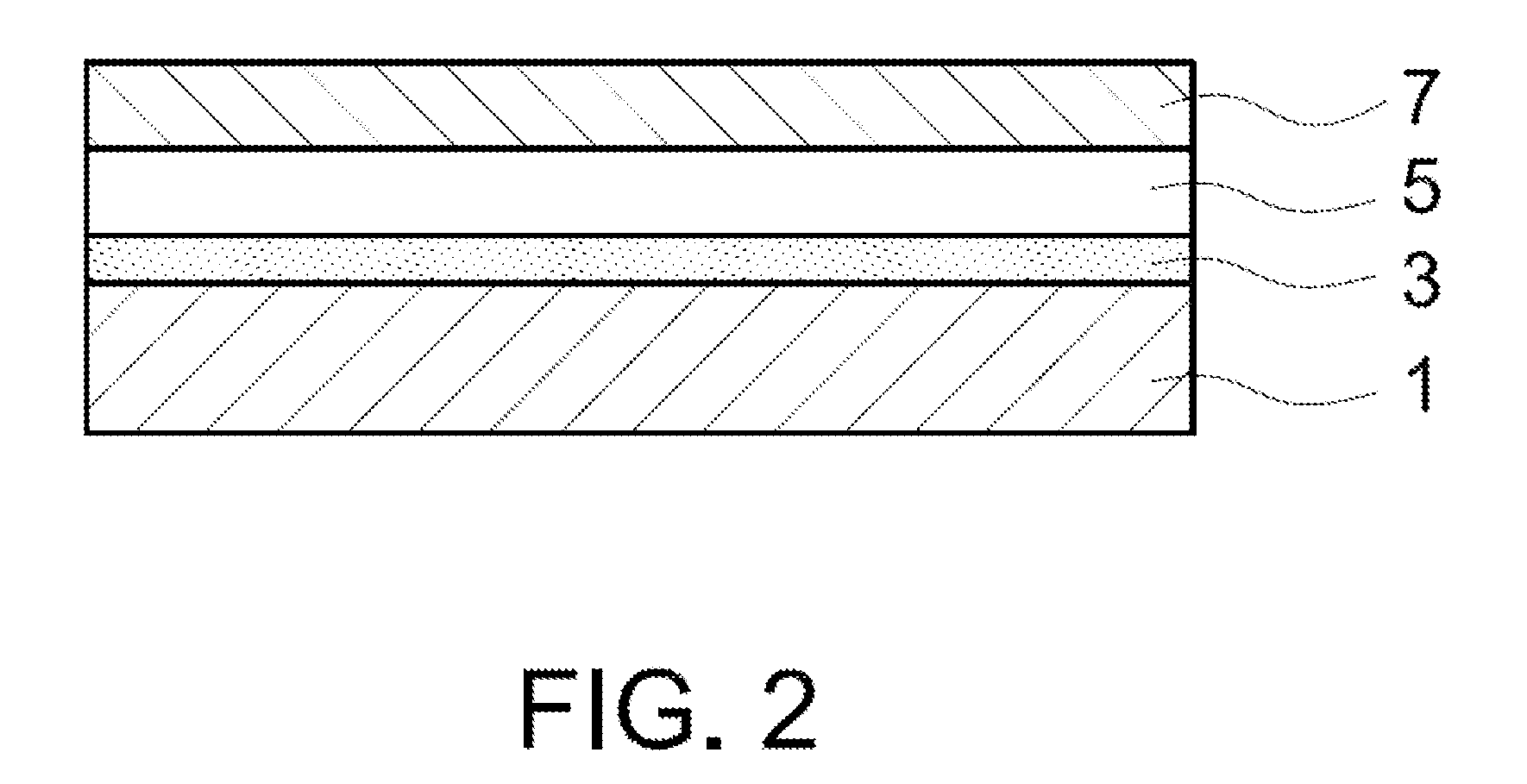

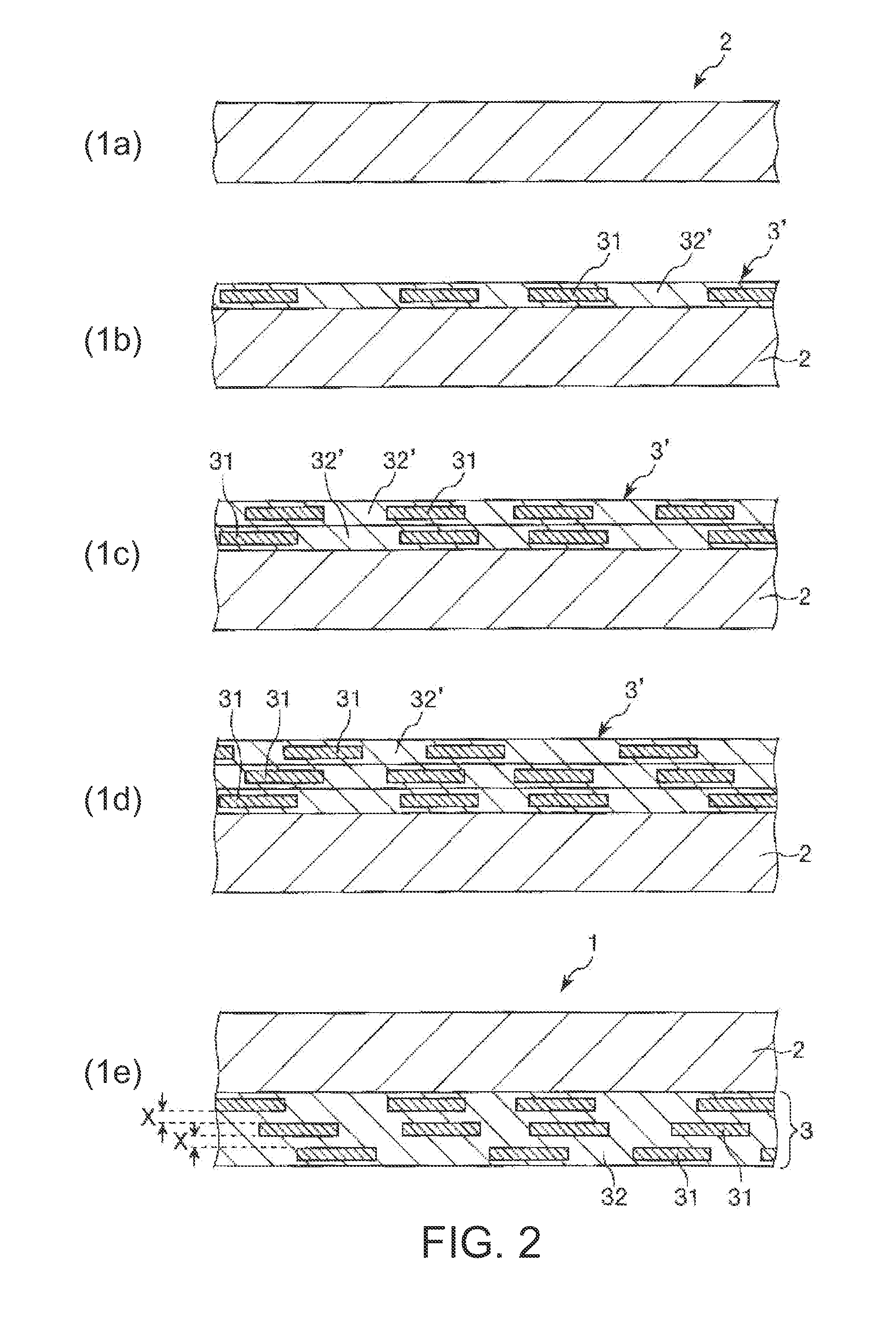

Laminated sheet and method of manufacturing the same

ActiveUS20150299944A1DistortionOutstanding appearanceDomestic upholsteryHeat resistant fibresEngineeringUltimate tensile strength

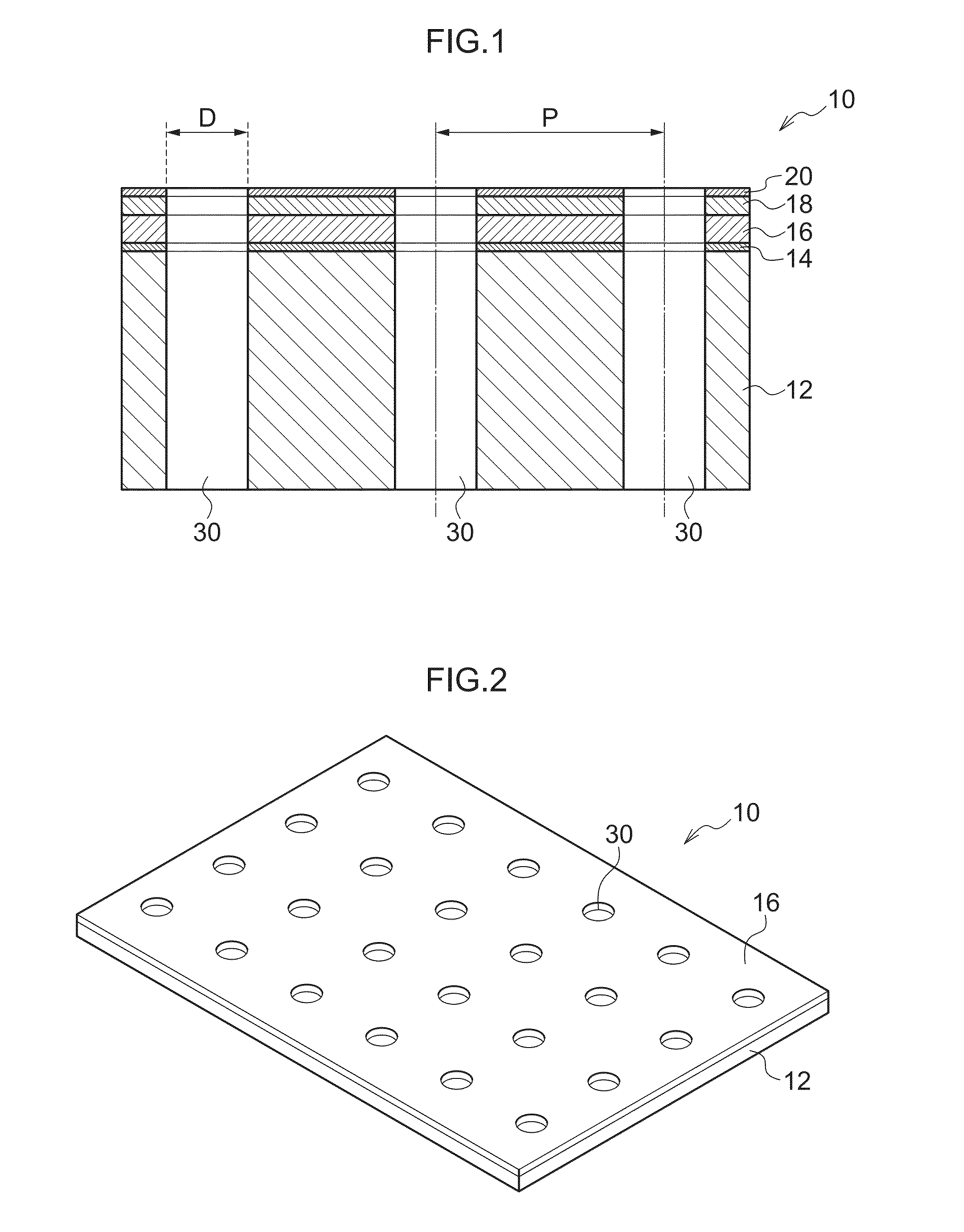

A laminated sheet includes a base cloth layer having a porous structure obtained by impregnating a woven fabric, which has a tear strength by a trapezoid method of 150 N or more in the longitudinal direction and 100 N or more in the lateral direction, with a resin composition containing a polyurethane resin and an organic flame retardant, and a skin layer layered on the base cloth layer, and has plural air holes penetrating in the thickness direction.

Owner:KYOWA LEATHER CLOTH CO LTD +1

Decorative product and timepiece

InactiveUS20070217293A1High hardnessAttractive appearanceSolid state diffusion coatingClockwork casesNitrogenEngineering

A decorative product having a base member composed of primarily an Fe—Cr alloy, and an austenite layer that is austenitized by adding nitrogen atoms near the surface of the base member.

Owner:SEIKO EPSON CORP

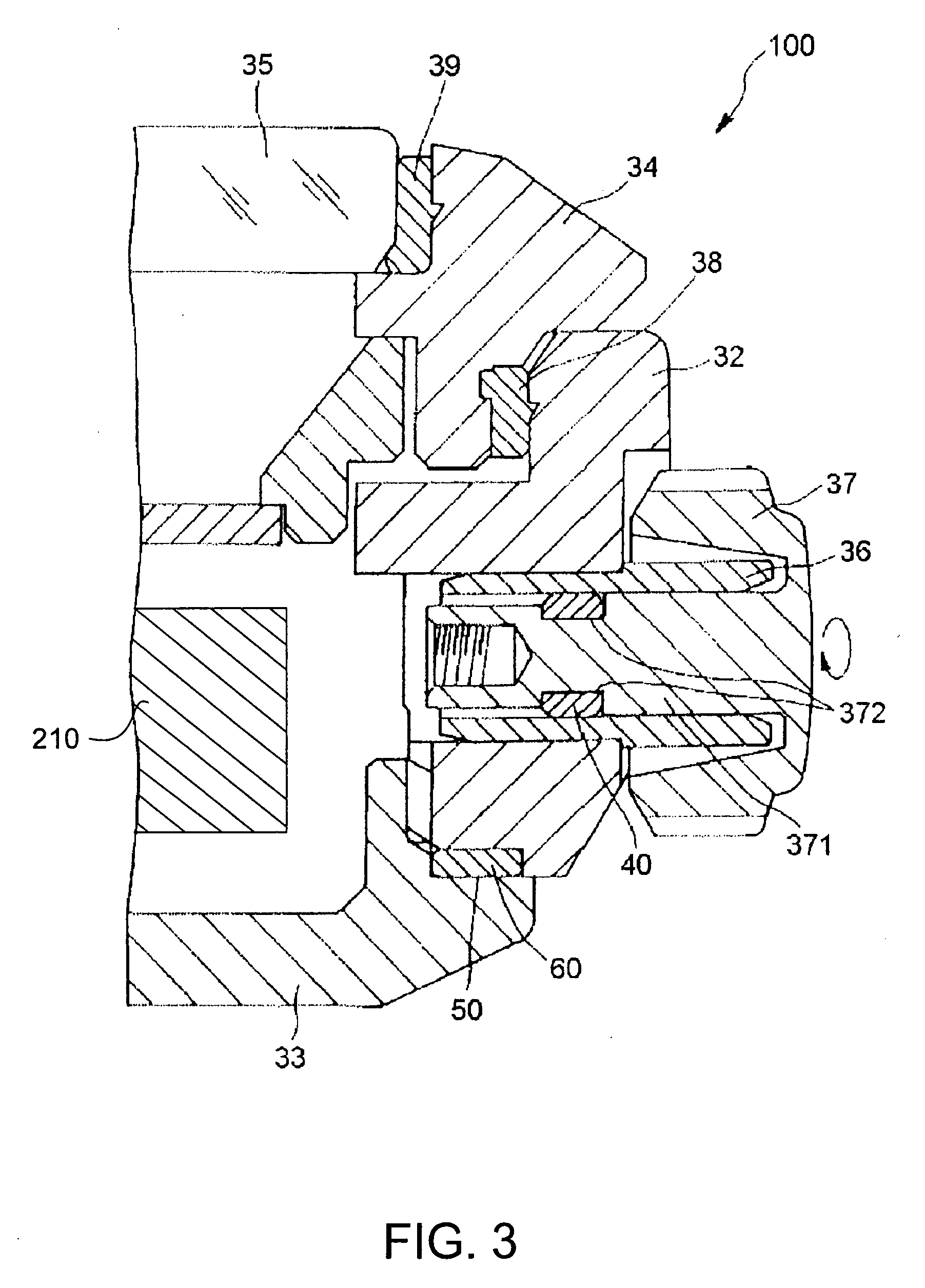

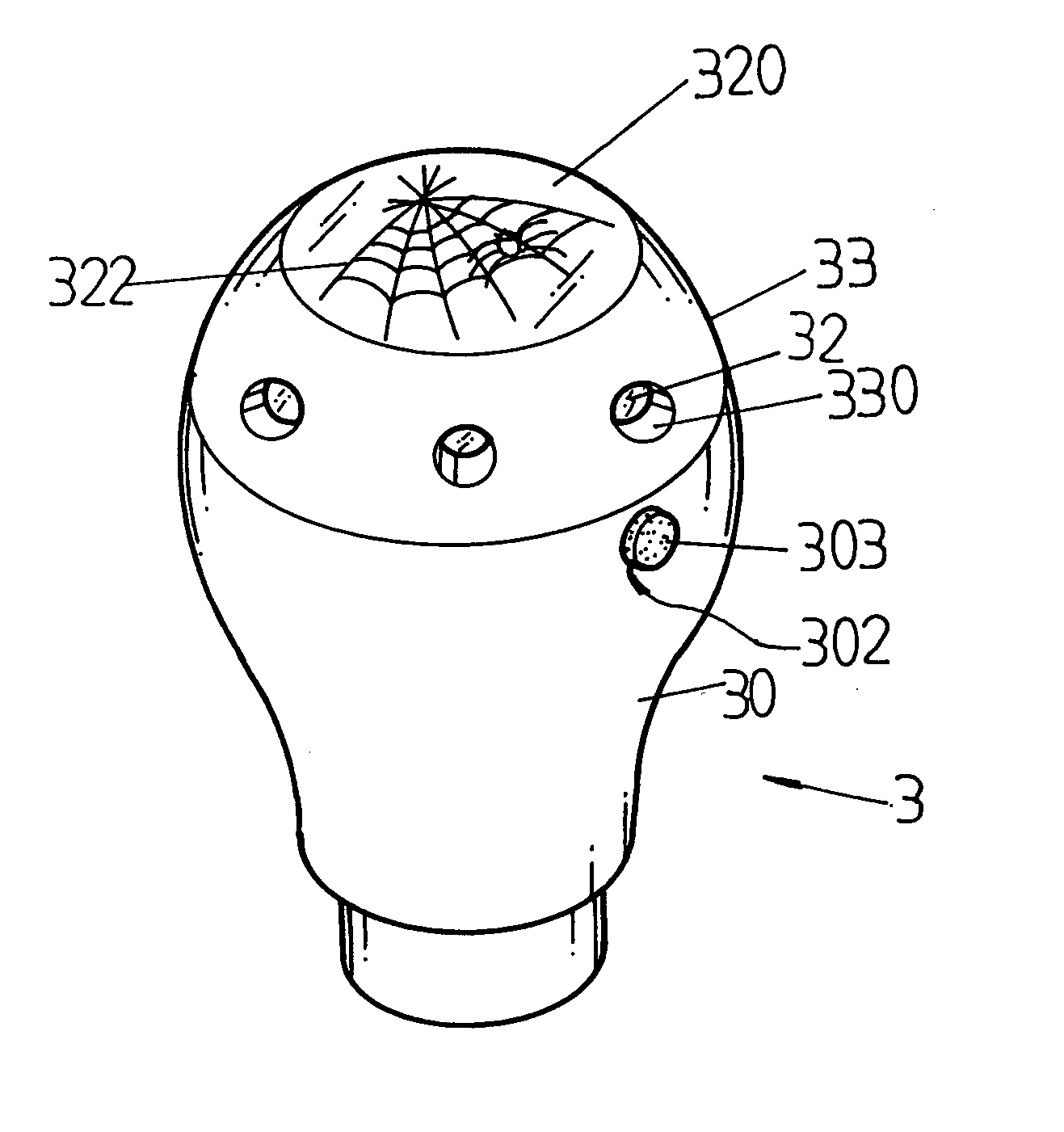

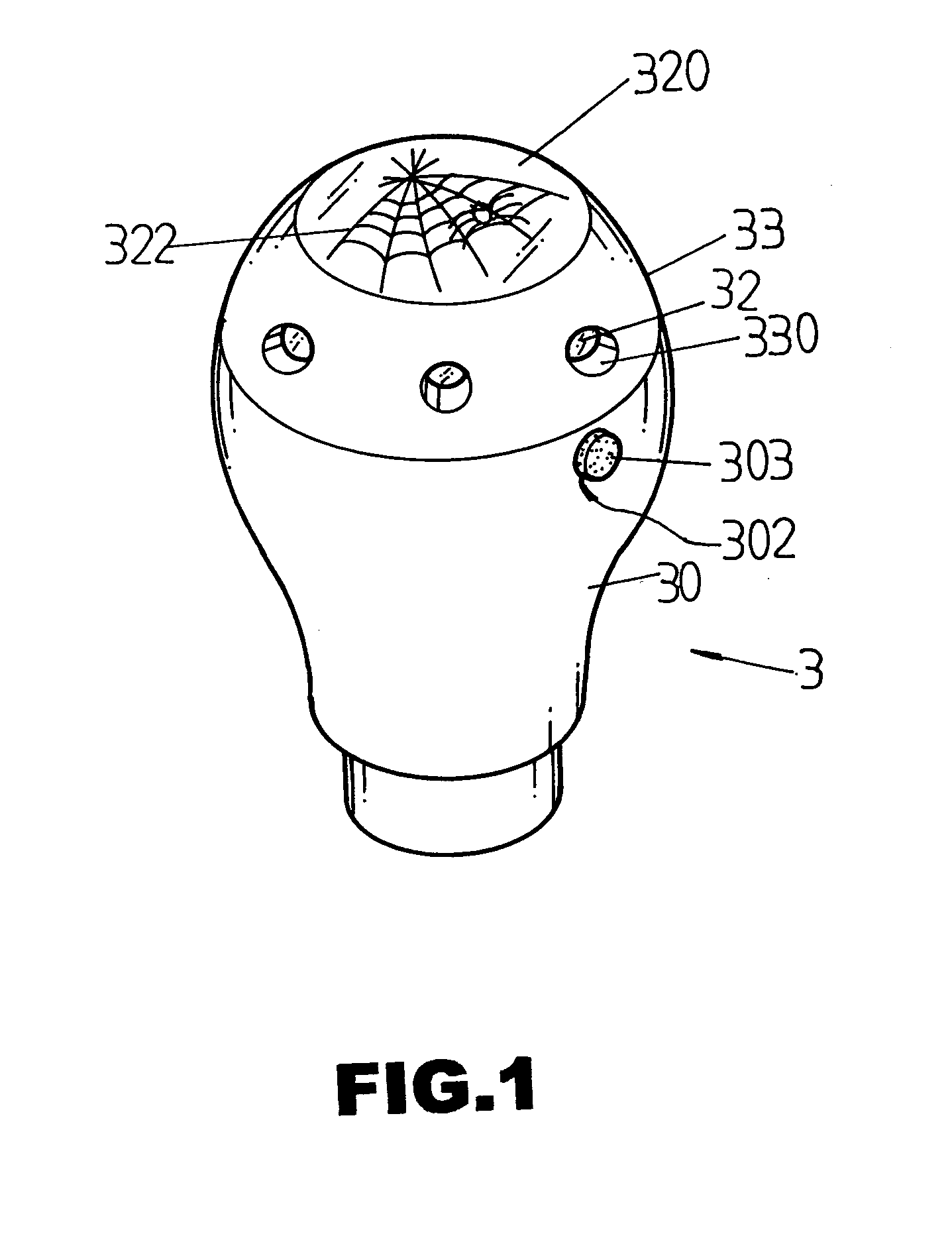

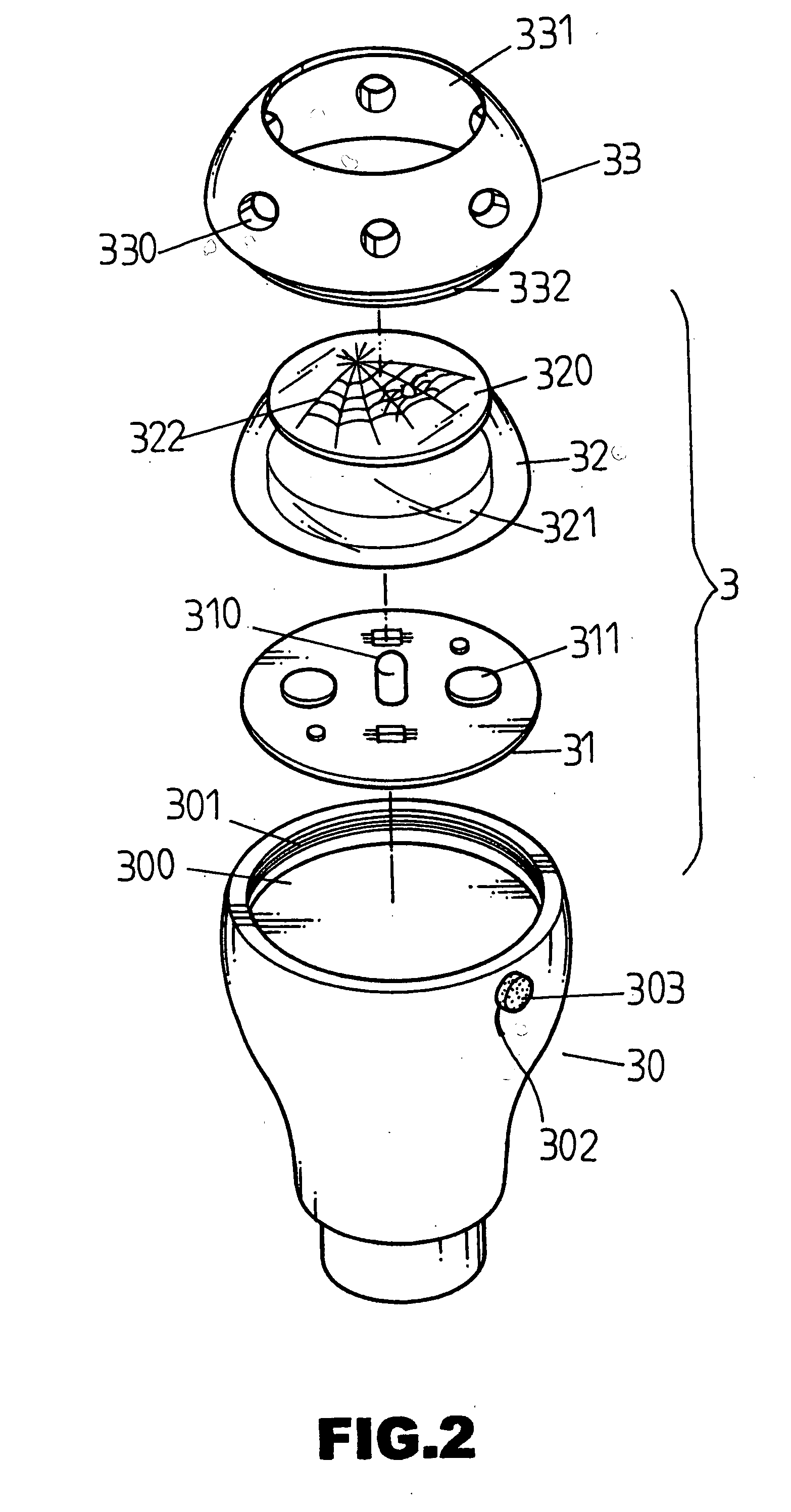

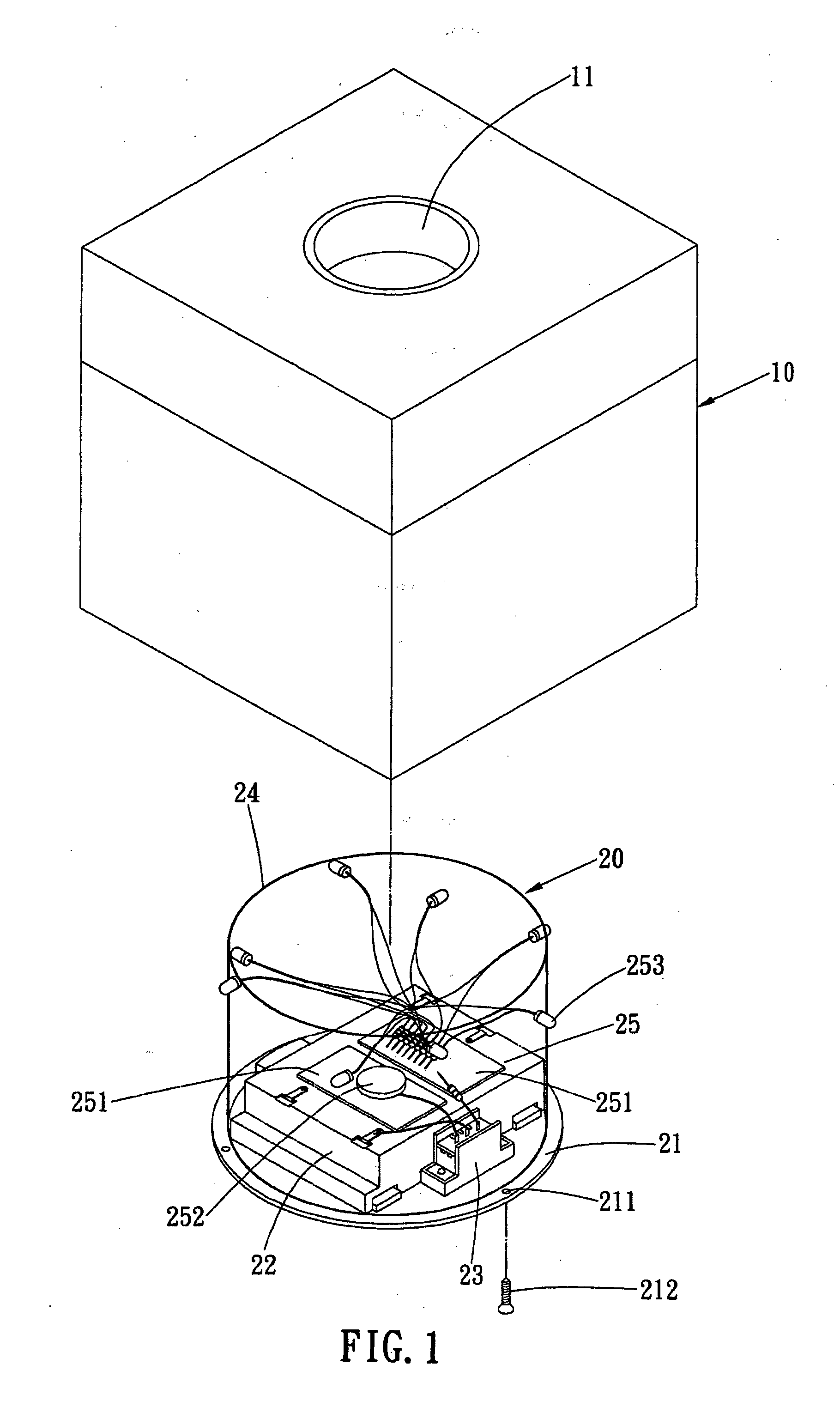

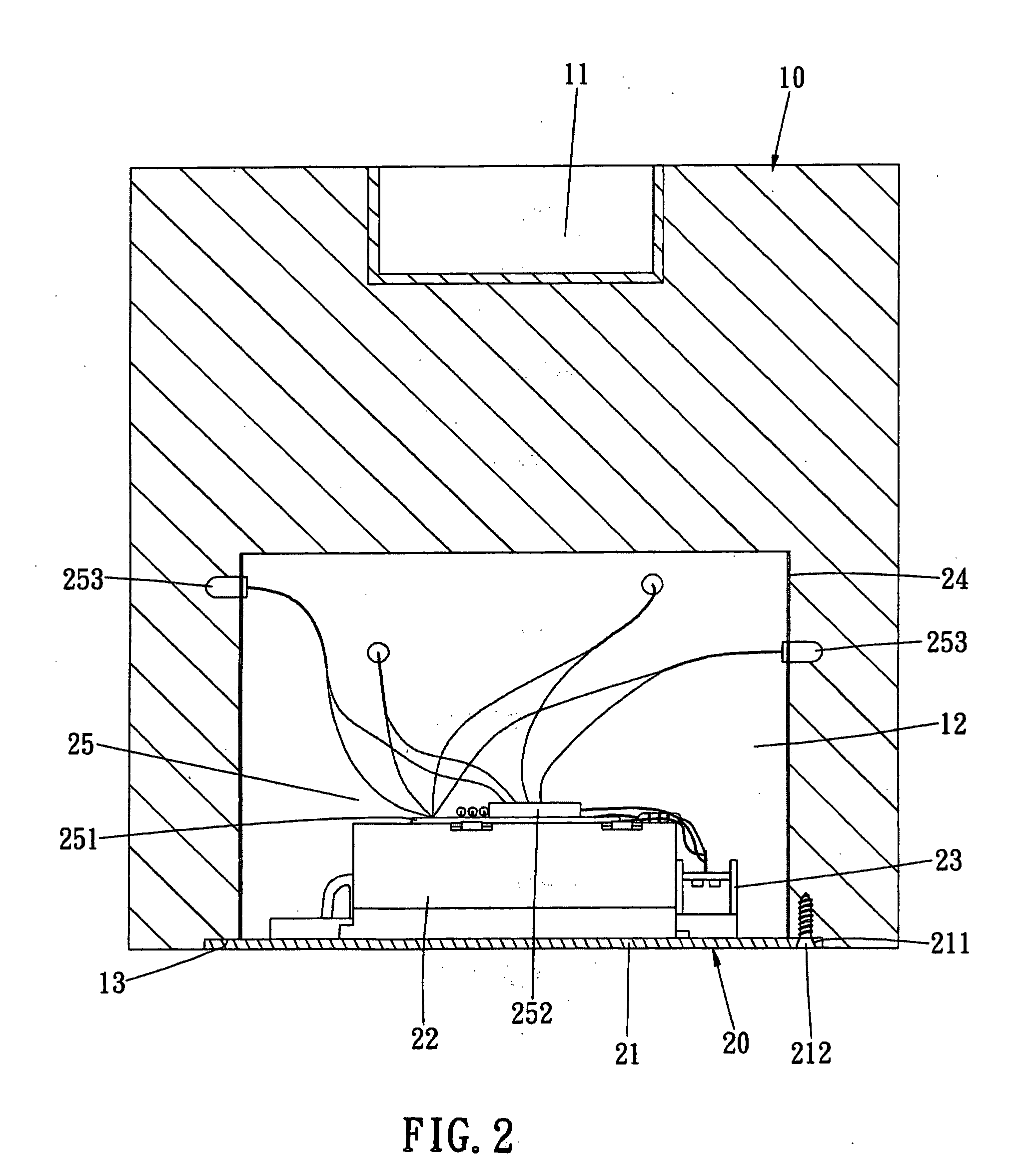

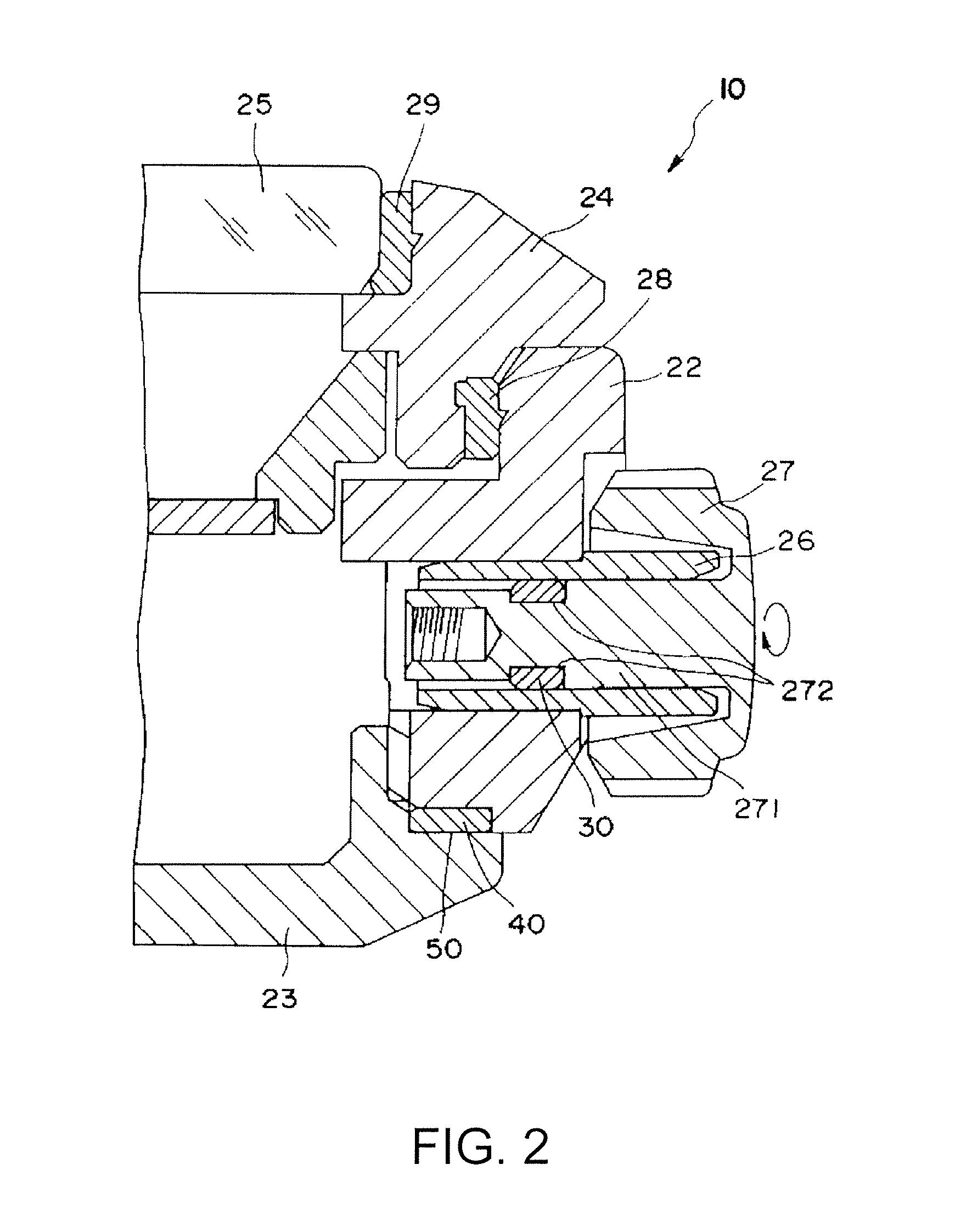

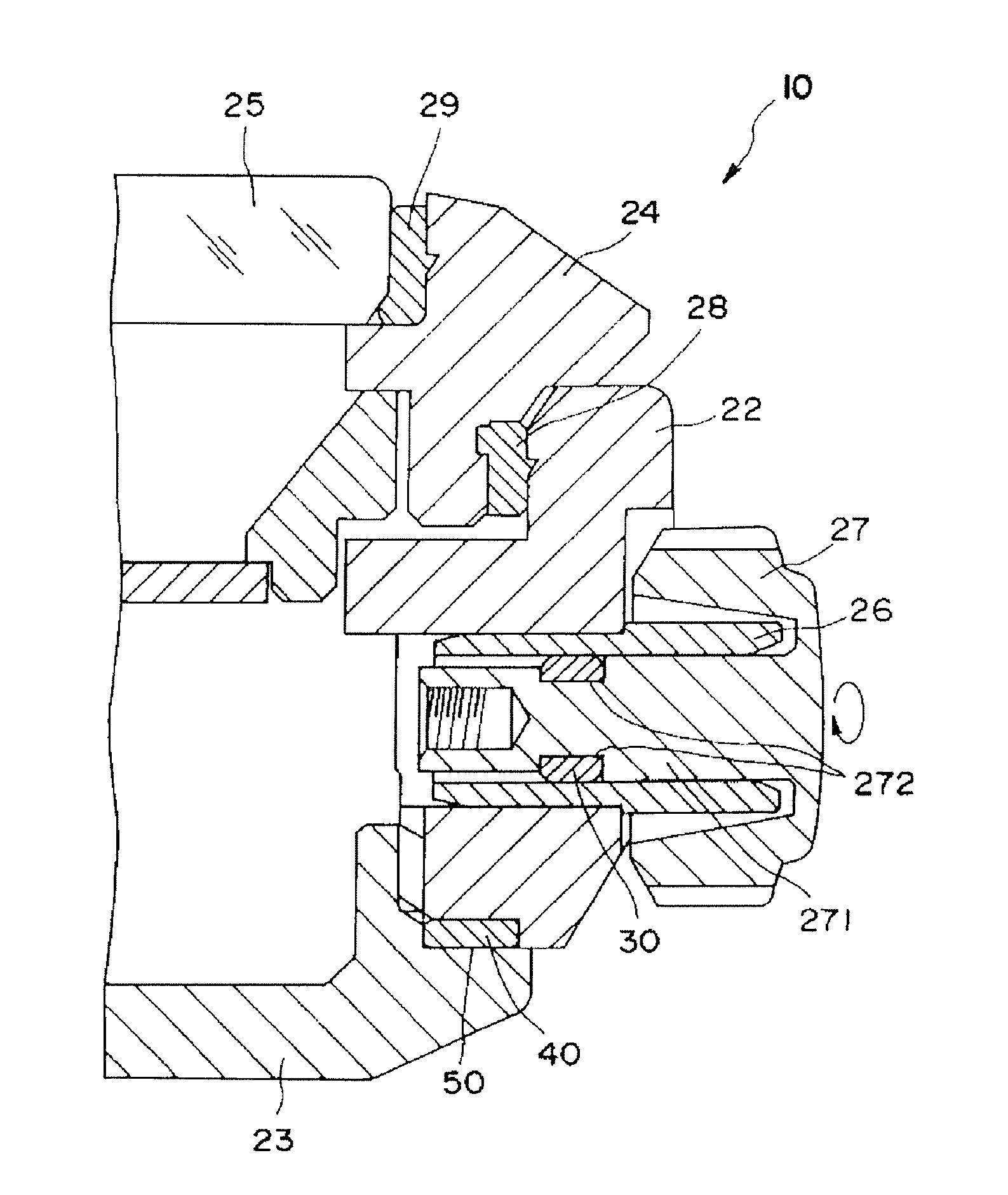

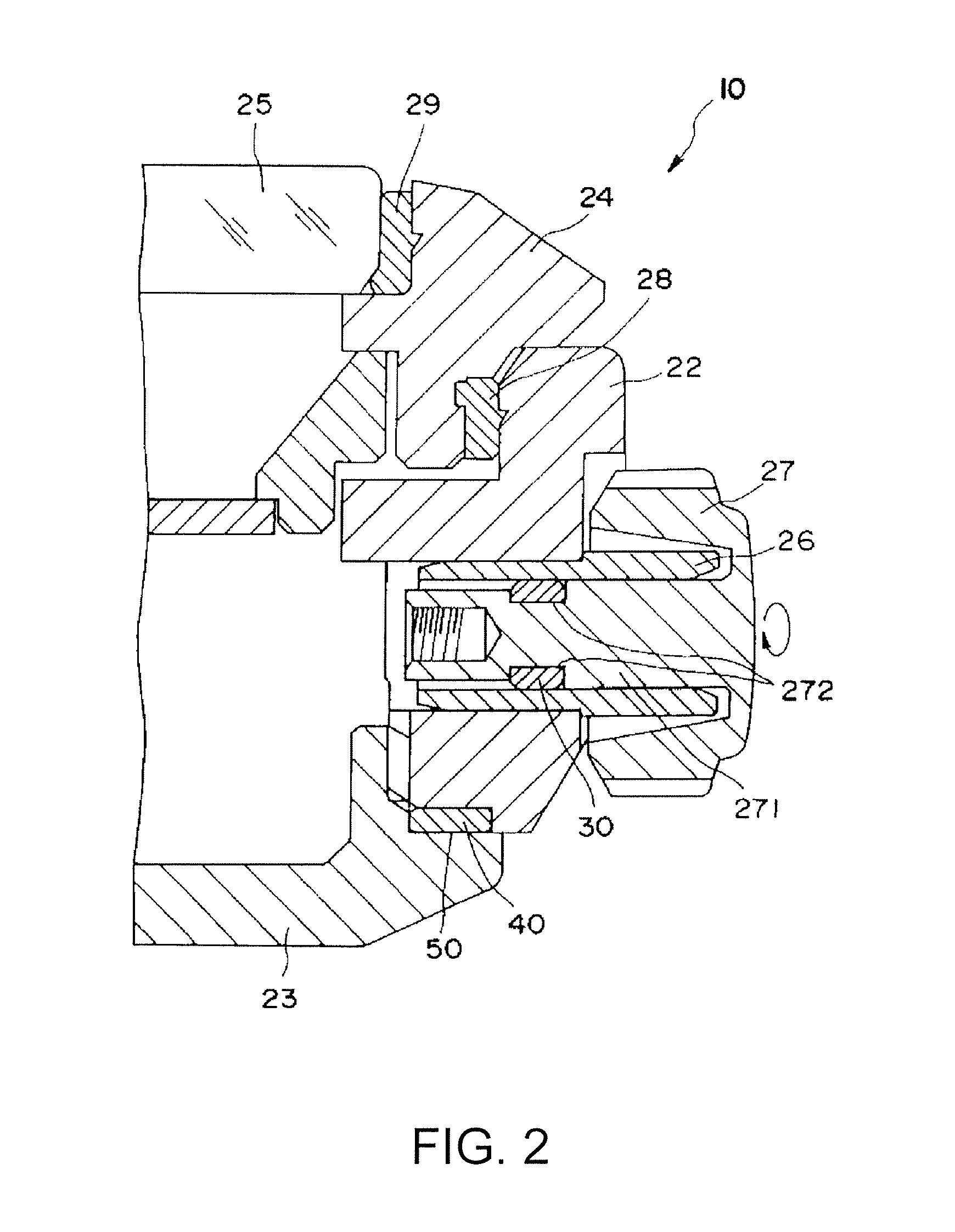

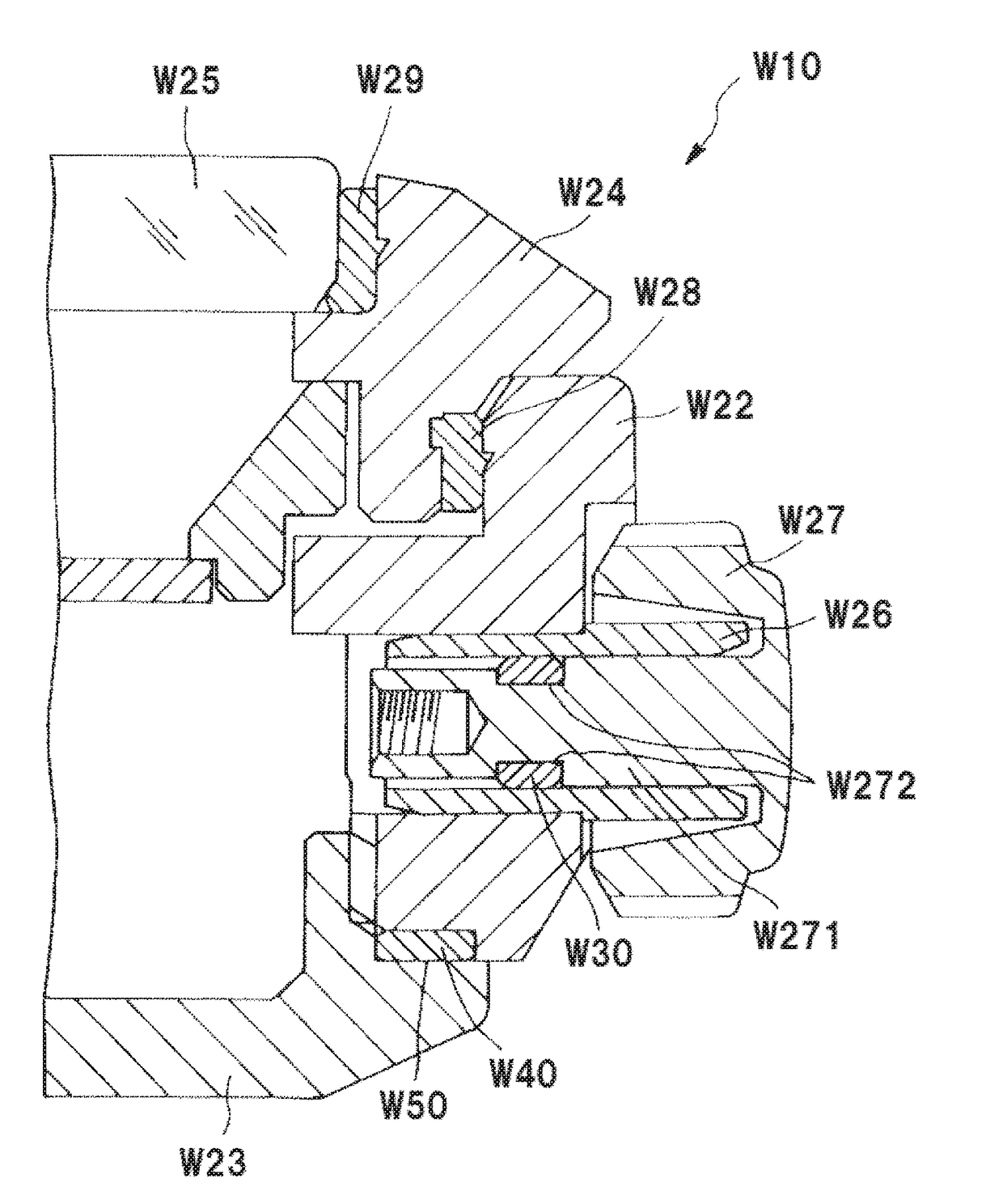

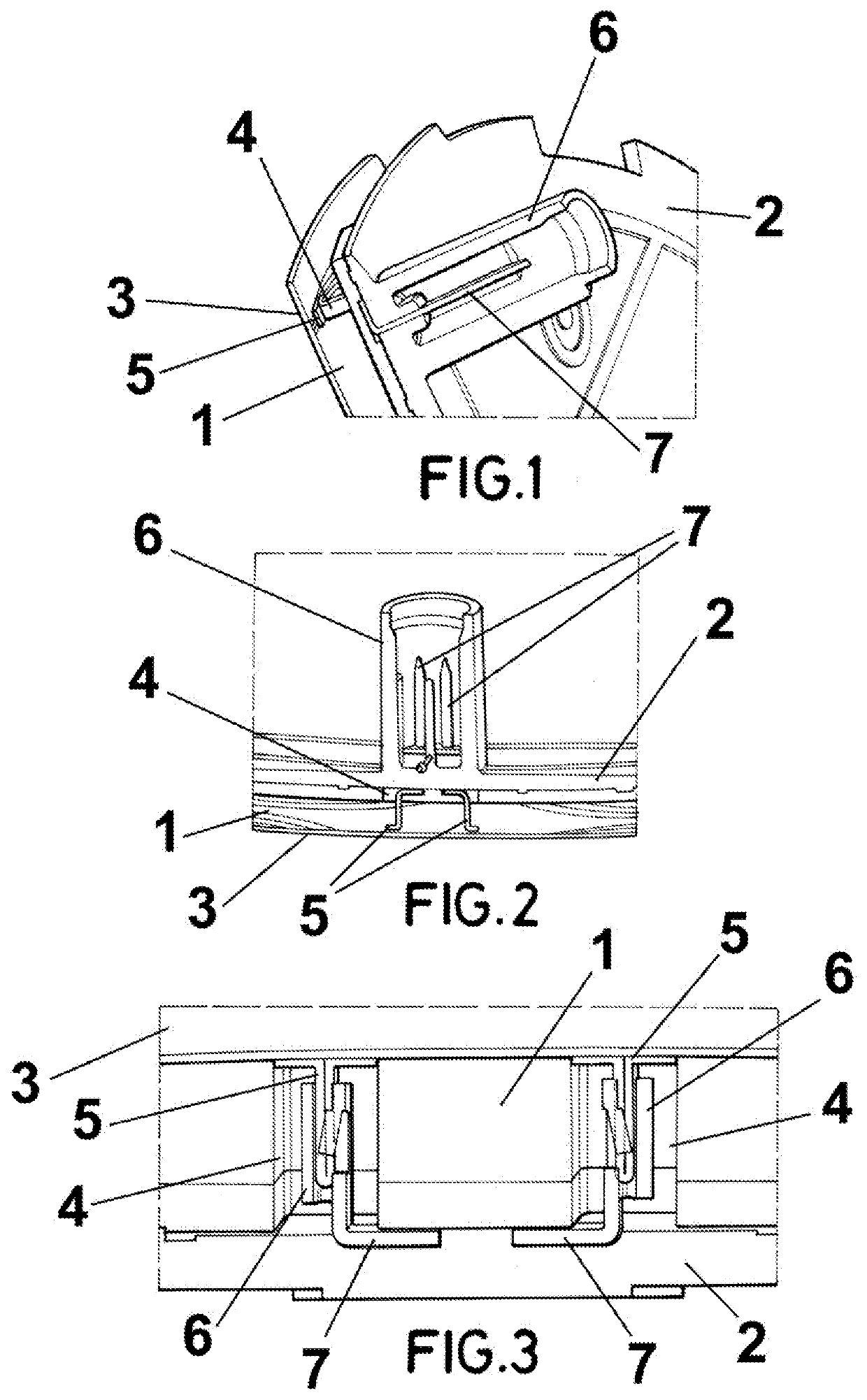

Gear lever having a light emitting effect

InactiveUS20060096406A1Enhancing outstanding appearanceEasy to replaceControlling membersGearing controlEngineeringTop cap

A gear lever for a car gear lever includes a main body, a top cover mounted on the main body, a light-gathering member mounted between the main body and the top cover, and a circuit board mounted between the main body and the light-gathering member and provided with a light emitting member directed toward the light-gathering member. Thus, the light rays emitted from the light emitting member are gathered in the light-gathering member and are emitted outward from the transparent flange of the light-gathering member and the through holes of the top cover, thereby enhancing the outstanding appearance of the gear lever.

Owner:LIU YAO HUANG

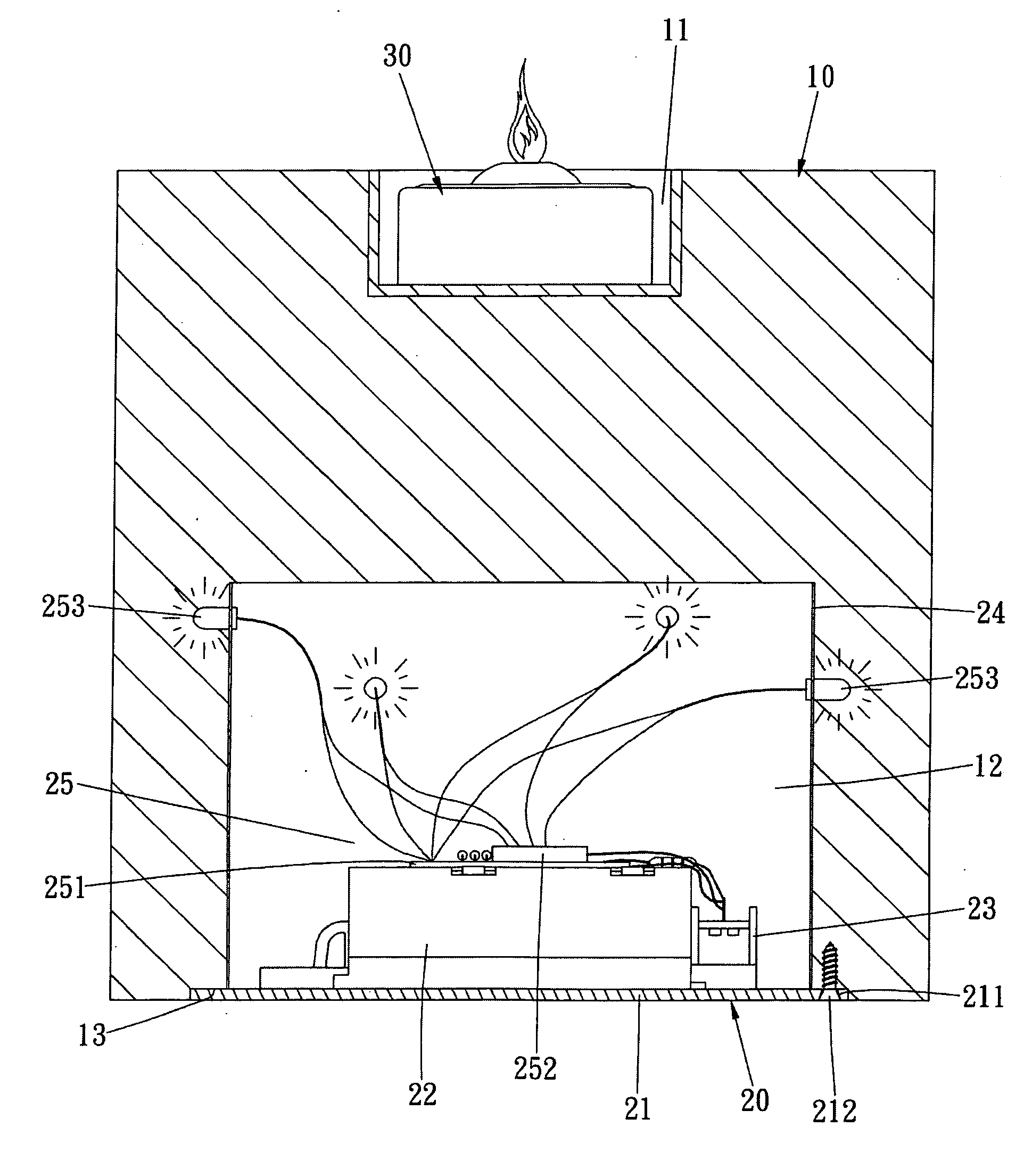

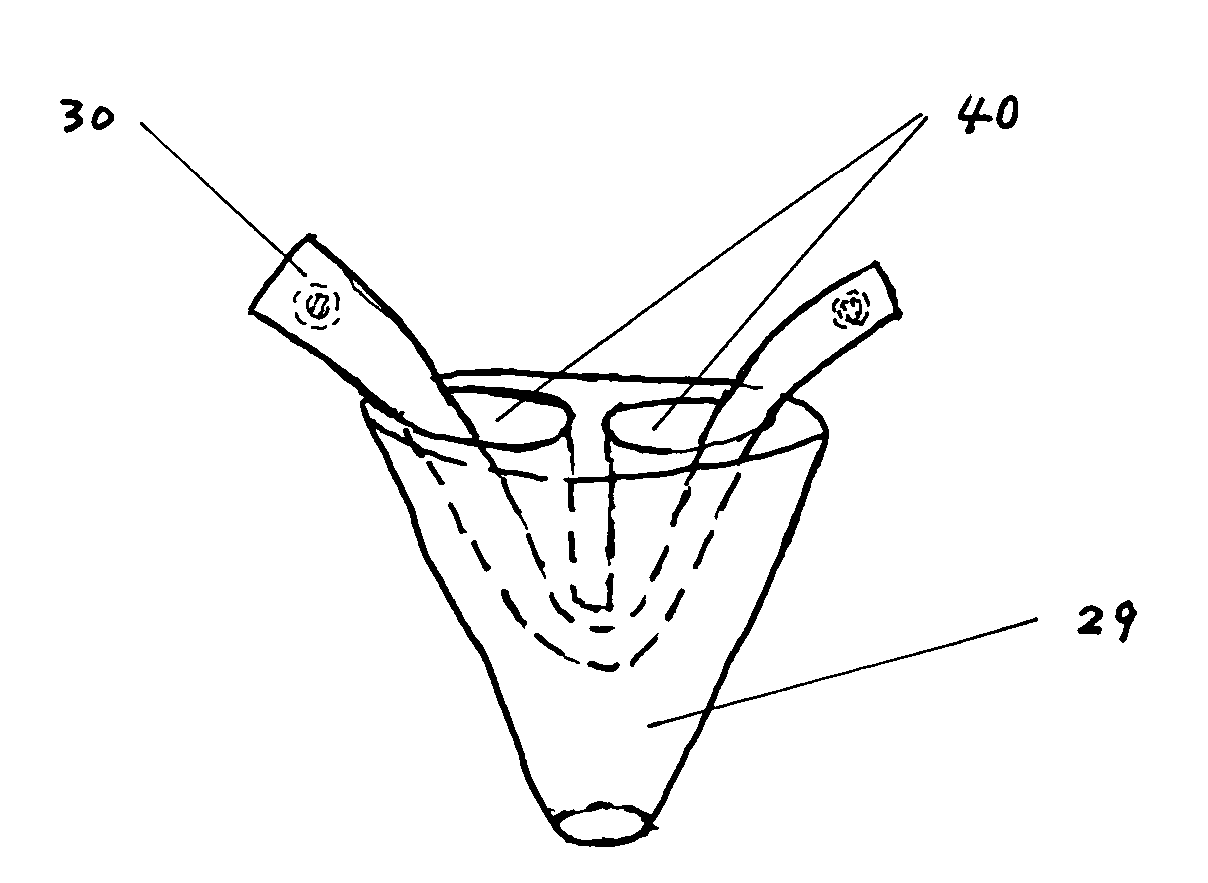

Led candle holder

InactiveUS20060172239A1Outstanding appearanceEnhancing decorative amusement effectLighting applicationsCandle holdersCandelabrumEngineering

A candle holder includes a decorative candle, and a photo-audio control device mounted in the decorative candle. Thus, the photo-audio control device emits light and sound to provide photo-audio effect, thereby enhancing the amusement effect of the candle holder. In addition, the decorative candle has an outstanding appearance, thereby enhancing the aesthetic effect of the candle holder.

Owner:HSINN INN ENTERPRISE

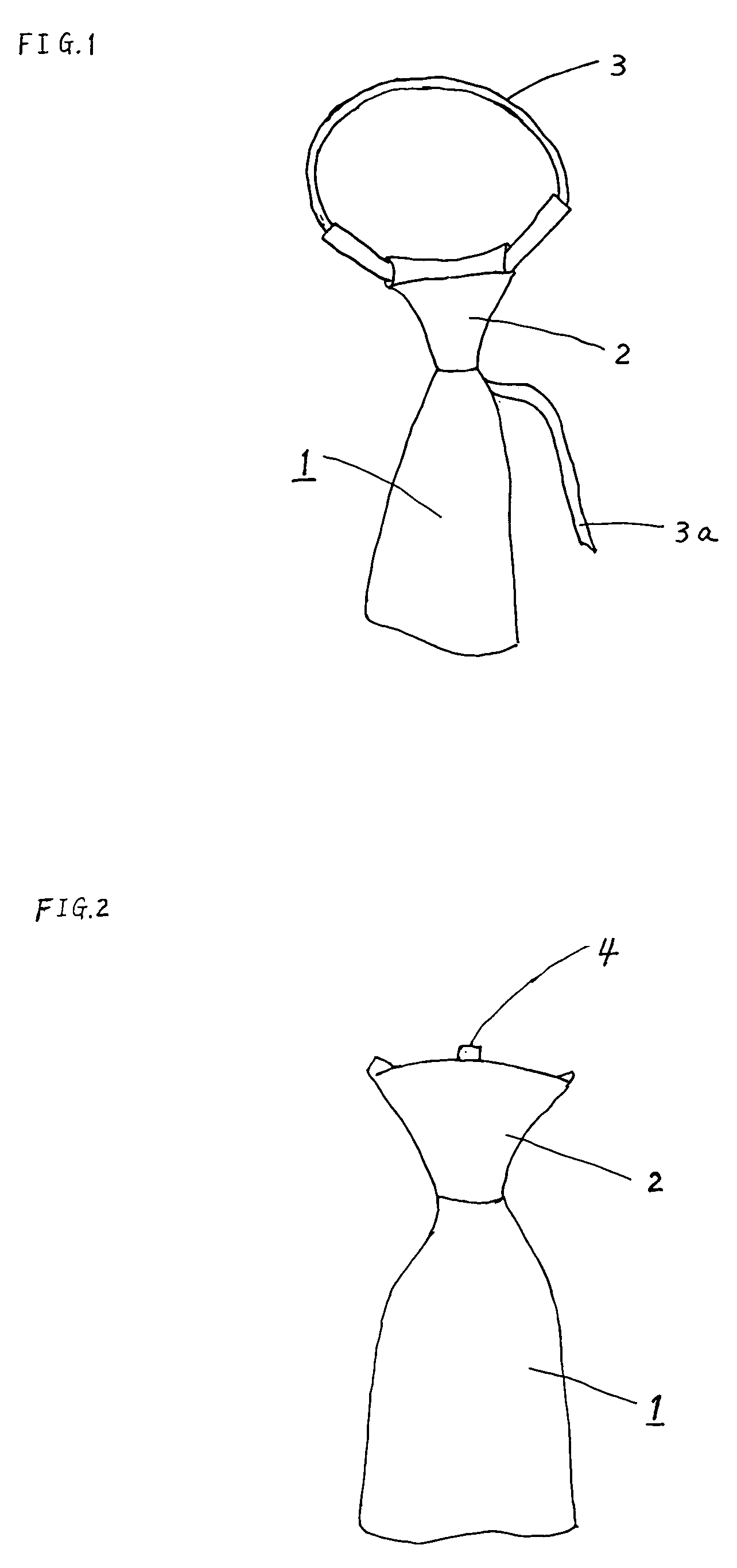

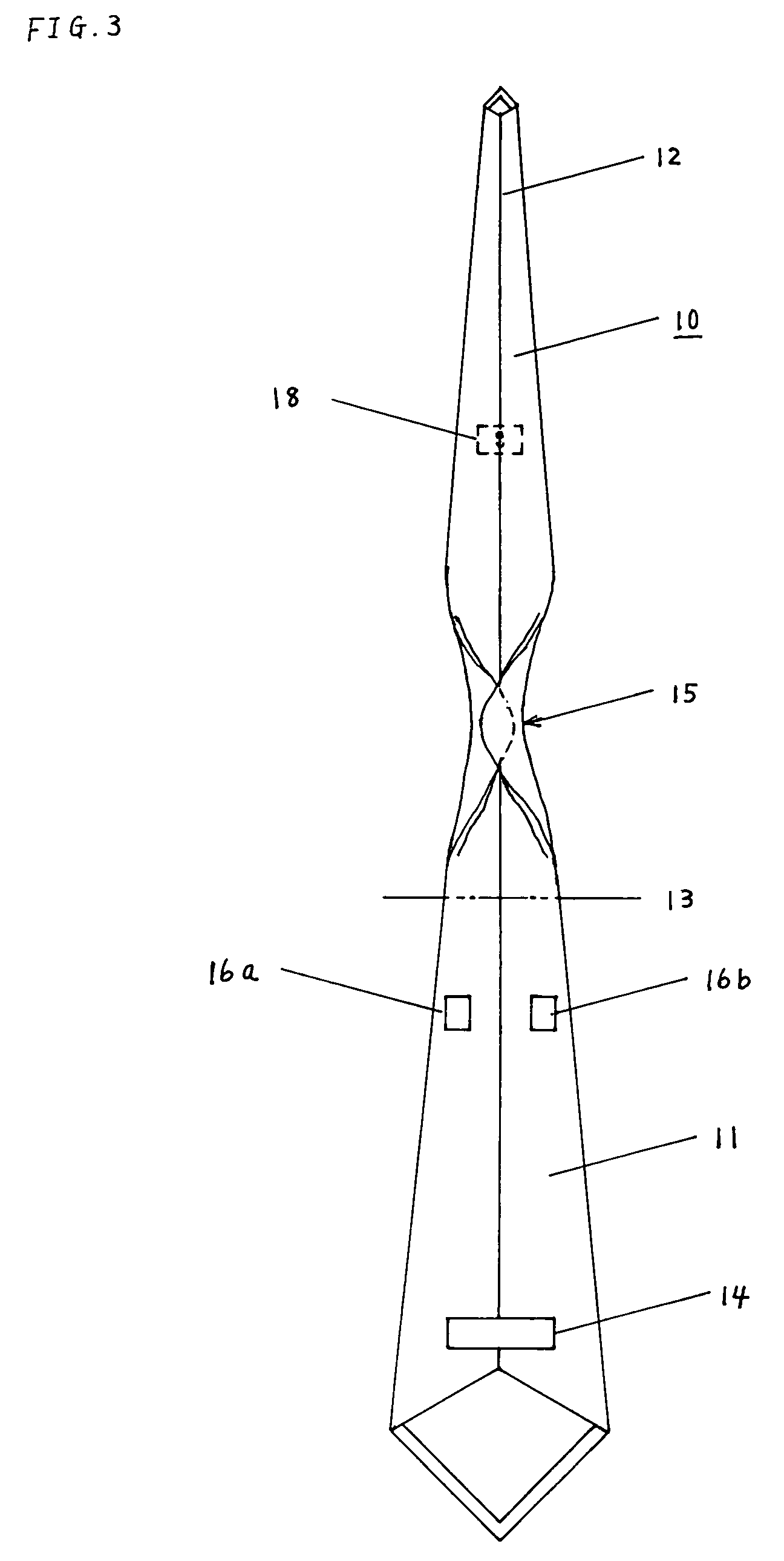

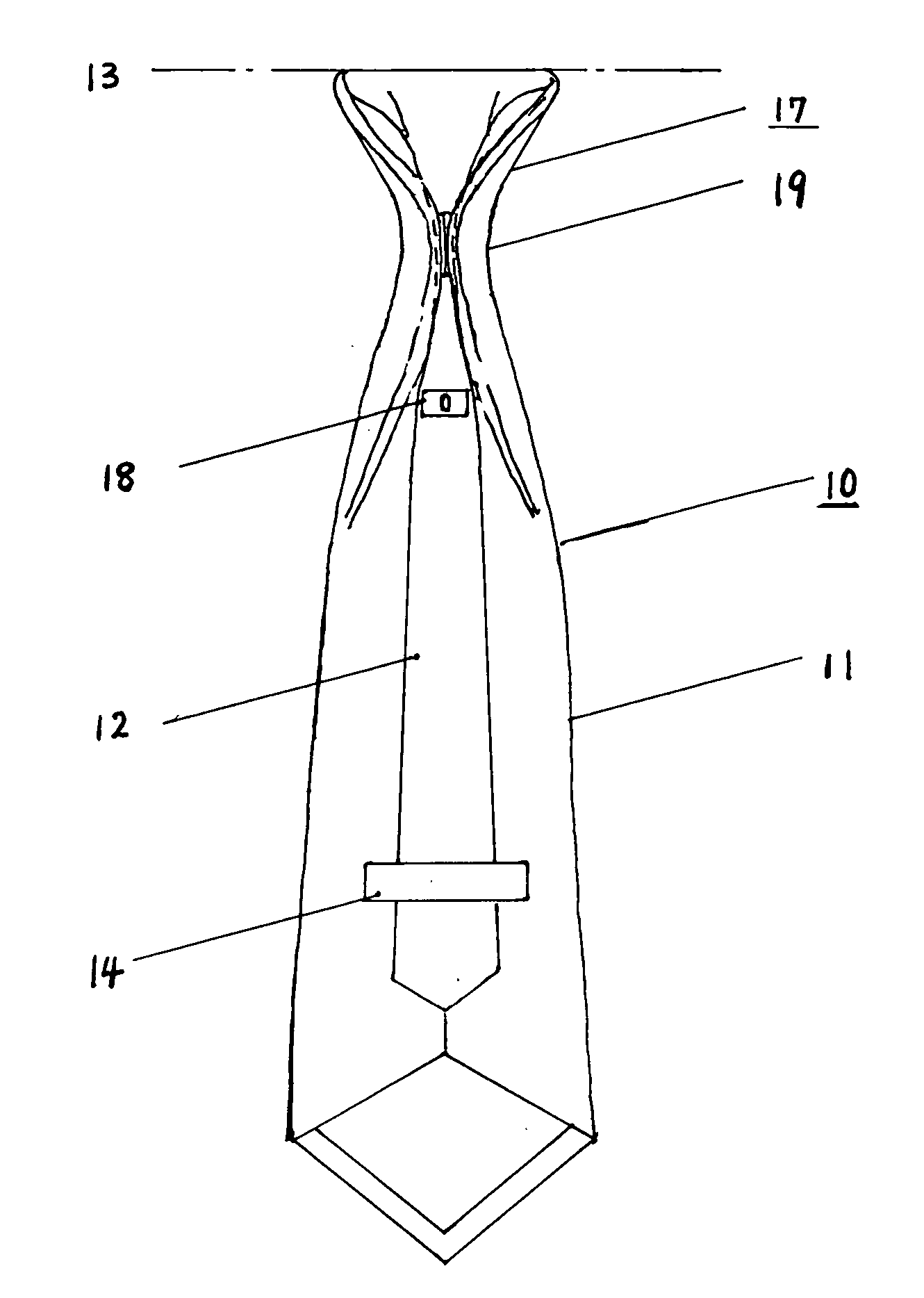

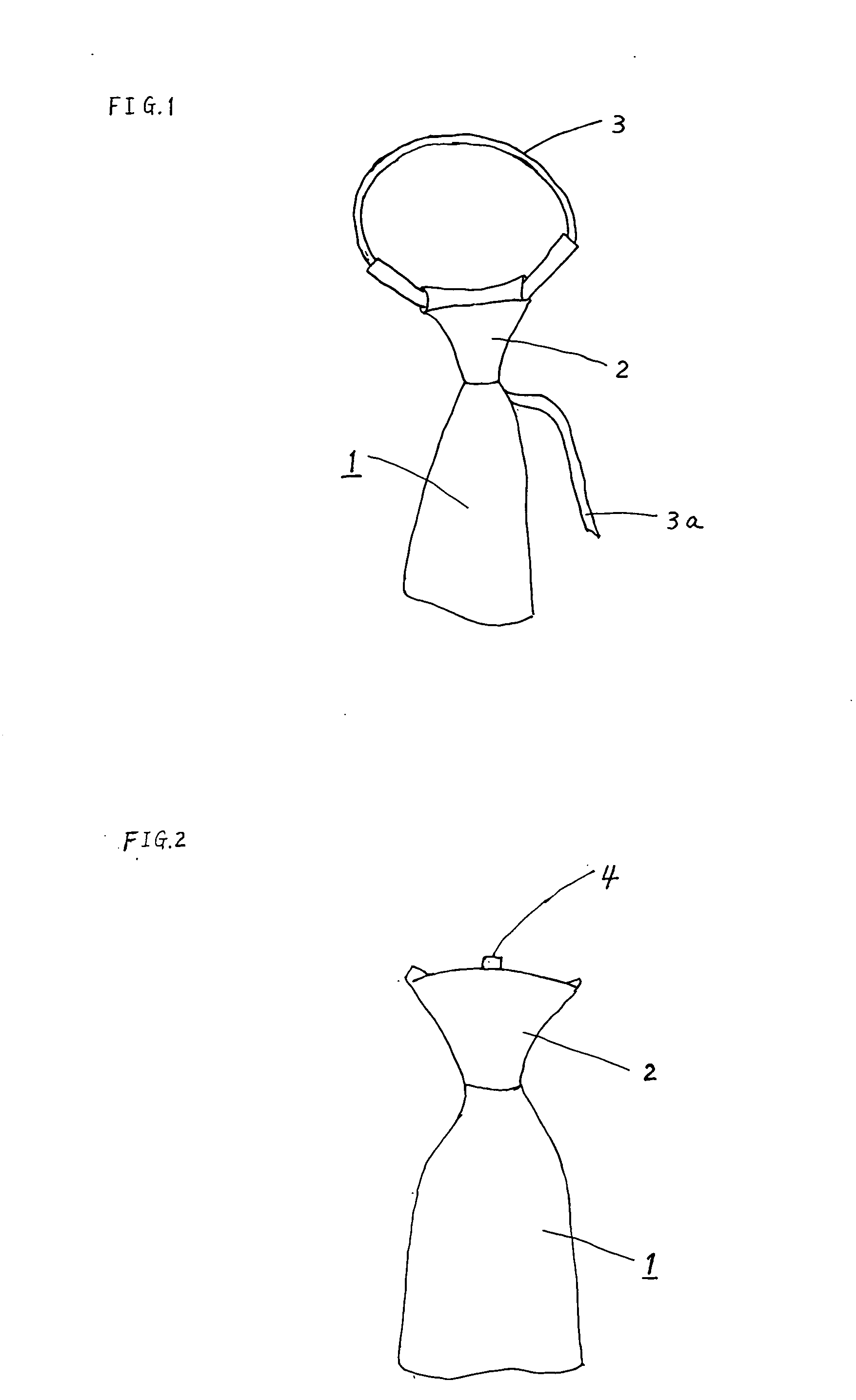

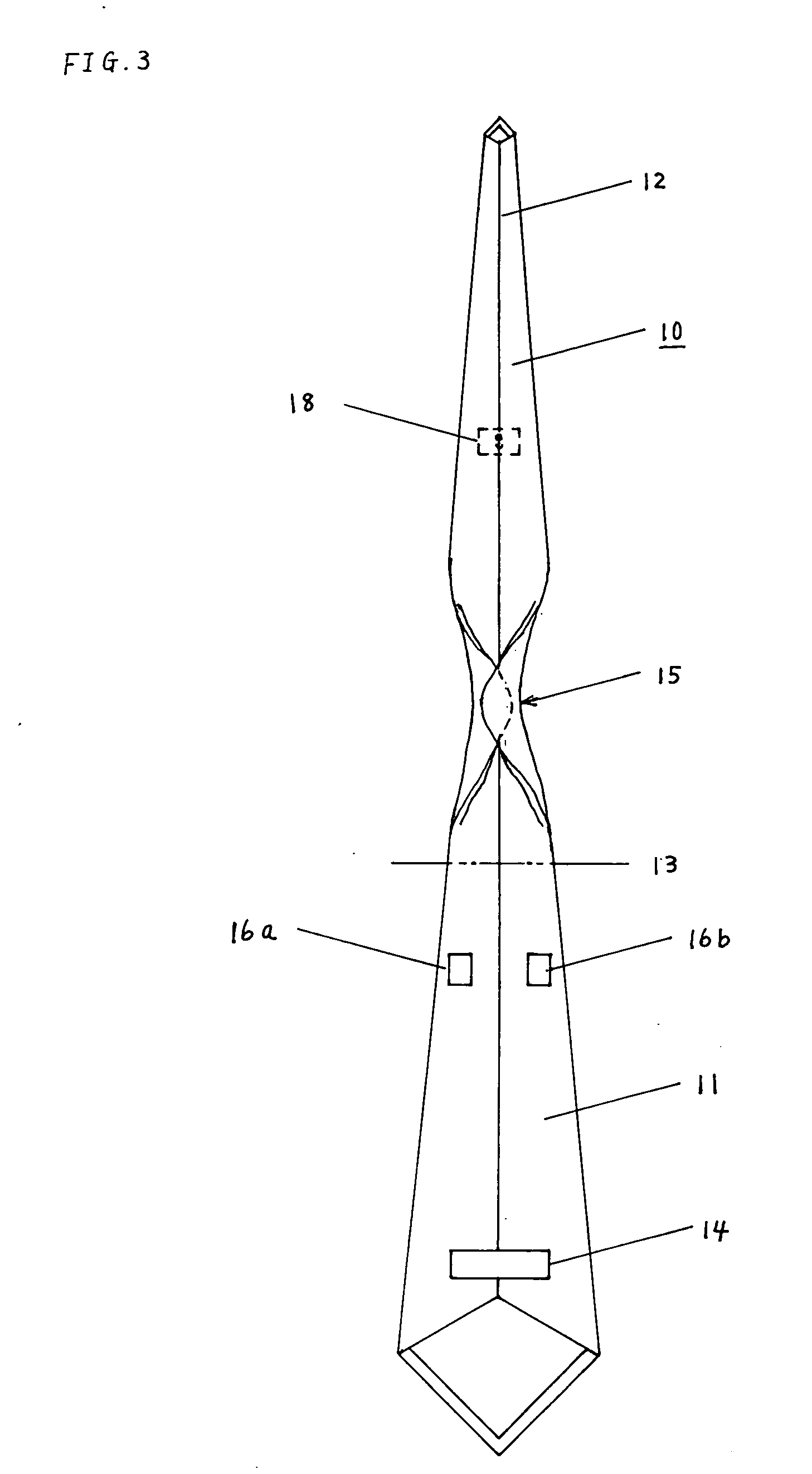

Necktie

A necktie is preformed with a knot or knot like section which is adapted to be attached to the collar of a shirt by a fastening means that can be separated from the necktie body and can be attached to the shirt collar to cause the necktie to be suspended. Such an entirely new type of necktie can be used by one irrespective of age and sex.Use of the fastening means makes fitting easy and makes nil the sense of oppression around the neck area. Only a minor change made to an ordinary necktie allows this new necktie to be manufactured inexpensively and to be washed while retaining its shape. A necktie is thus provided that can be returned easily to the state of an ordinary necktie and that is not different in appearance from an ordinary necktie.

Owner:SATO

Aqueous coating material, its preparation and use

ActiveUS20090270548A1Easy to prepareOutstanding performance propertyFilm/foil adhesivesPolyurea/polyurethane coatingsSulfolaneGlycerol

Disclosed herein is an aqueous coating material comprising (A) at least one polyurethane which is ionically stabilized, nonionically stabilized, or a combination thereof, and which is saturated, unsaturated, grafted with olefinically unsaturated compounds, or a combination thereof, (B) at least one wetting agent or dispersant; and (C) at least one organic solvent selected from the group consisting of dimethyl sulfoxide, sulfolane, 2-methyl-1-butanol, 3-methyl-1-butanol, 2-methyl-1-pentanol, hexyl glycol, 1,6-hexanediol, diethylene glycol, triethylene glycol, glycerol, solutions of trimethylolpropane, solutions of pentaerythritol, solutions of sorbitol, reactive polyether polyols with a number-average molecular weight of 110 to 6000 daltons and a hydroxyl number of 25 to 1000 mg KOH / g, propylene glycol monobutyl ether, dipropylene glycol dimethyl ether, glycerol ethoxylate, ethyl 3-ethoxypropionate, gamma-butyrolactone, N-(2-hydroxyethyl)piperidine, N-methylmorpholine, N-(2-hydroxyethyl)morpholine, N-acetylmorpholine, N-cyclohexylpyrrolidone, N-octyl-2-pyrrolidone, and a combination thereof. Also disclosed is a process for preparing the foregoing aqueous coating material.

Owner:BASF COATINGS GMBH

Method of manufacturing a decorative article, a decorative article, and a timepiece

ActiveUS20110123815A1Outstanding appearanceAvoid color changesAdditive manufacturing apparatusMechanical clocksSolid solutionHeat treated

A method of manufacturing a decorative article, including a first coating formation step of forming a first coating of primarily TiN on a substrate; a second coating formation step of forming a second coating on the first coating by means of a dry plating method using a target containing 70.0 wt %≦85.0 wt % Au and 15.0 wt %≦30.0 wt % Cu; a heat treatment step of promoting formation of a solid solution of the constituents of the second coating by applying a heating process that heats the substrate on which the first coating and the second coating are disposed to 300° C.≦395° C. and then applying a cooling process; and an acid treatment step that, of the constituents of the second coating to which the heating process was applied, removes the constituents not forming a solid solution by applying an acid treatment.

Owner:SEIKO EPSON CORP

Necktie, shirt, button and napkin

A necktie is preformed with a knot or knot like section which is adapted to be attached to the collar of a shirt by a fastening means that can be separated from the necktie body and can be attached to the shirt collar to cause the necktie to be suspended. Such an entirely new type of necktie can be used by one irrespective of age and sex. Use of the fastening means makes fitting easy and makes nil the sense of oppression around the neck area. Only a minor change made to an ordinary necktie allows this new necktie to be manufactured inexpensively and to be washed while retaining its shape. A necktie is thus provided that can be returned easily to the state of an ordinary necktie and that is not different in appearance from an ordinary necktie.

Owner:SATO

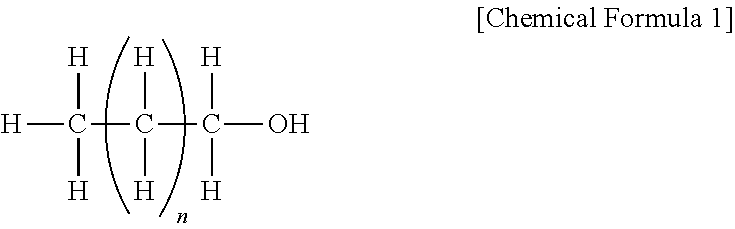

Hair care compositions comprising polyalkylene glycol styling agents

InactiveCN1446073AOutstanding appearanceHighlight the feelingCosmetic preparationsHair cosmeticsPolymer dissolutionWater soluble

The present invention provides a hair care composition comprising: a water-soluble polyalkylene glycol having a number average molecular weight of from about 200 to about 900 and having from about 4 to about 18 repeating oxyalkylene groups, wherein Each repeating oxyalkylene group has 2 to 6 carbon atoms; a film-forming polymer, wherein the film-forming polymer is dissolved in the polyalkylene glycol and the weight ratio of the polyalkylene glycol to the film-forming polymer From about 5:1 to about 50:1; and a liquid carrier. The hair care composition optionally further includes a non-volatile silicone having a molecular weight greater than about 40,000 daltons.

Owner:THE PROCTER & GAMBLE COMPANY

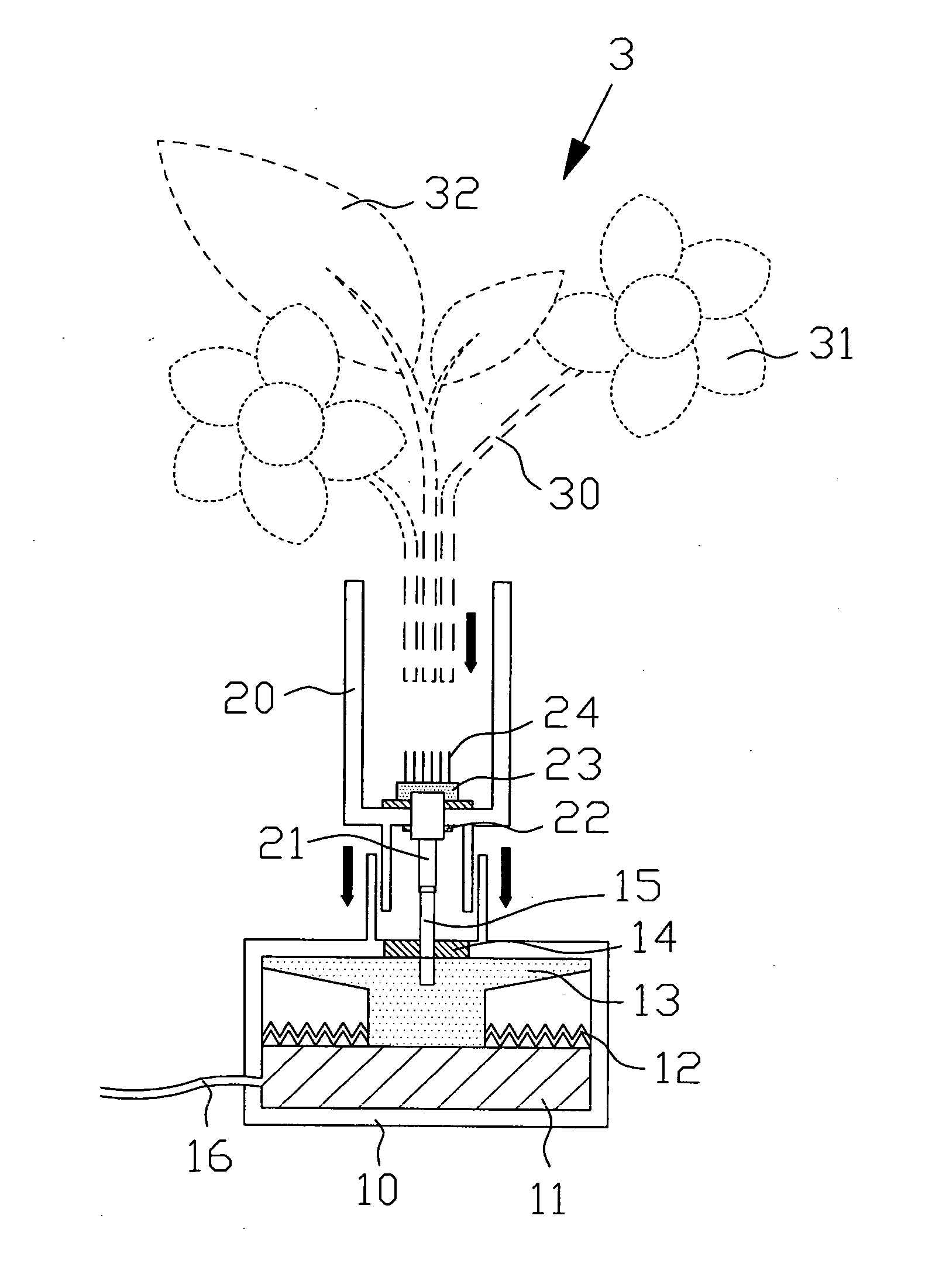

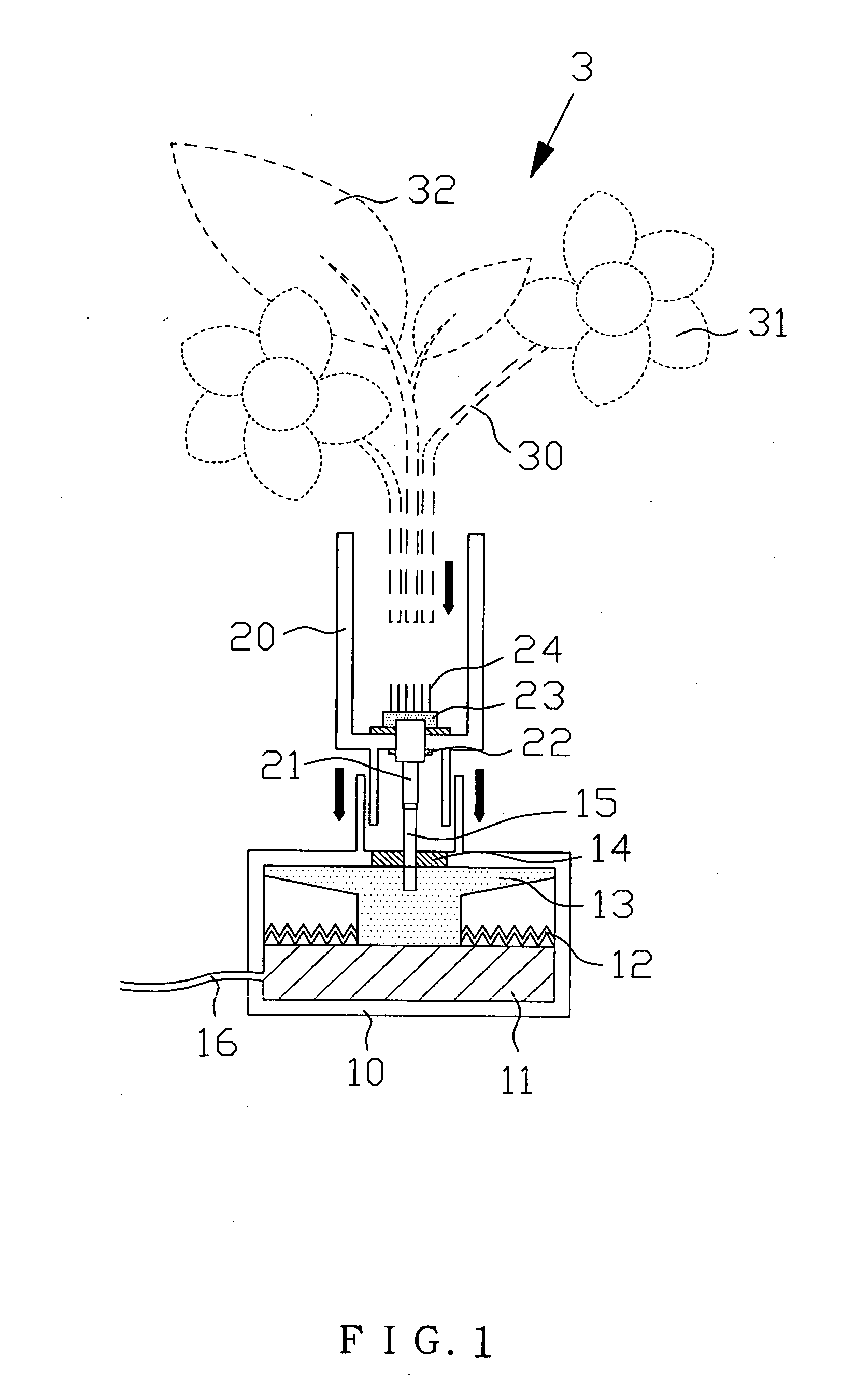

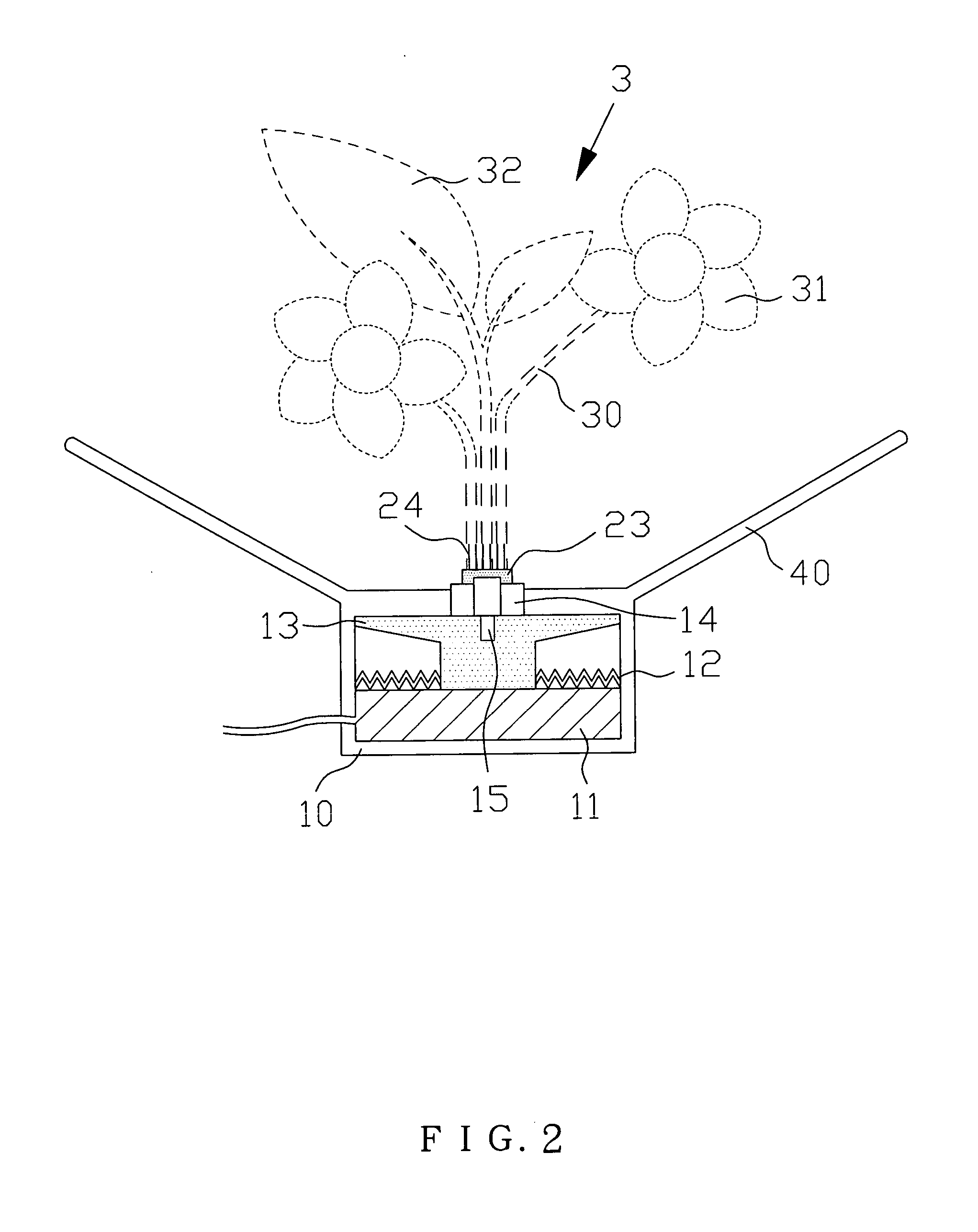

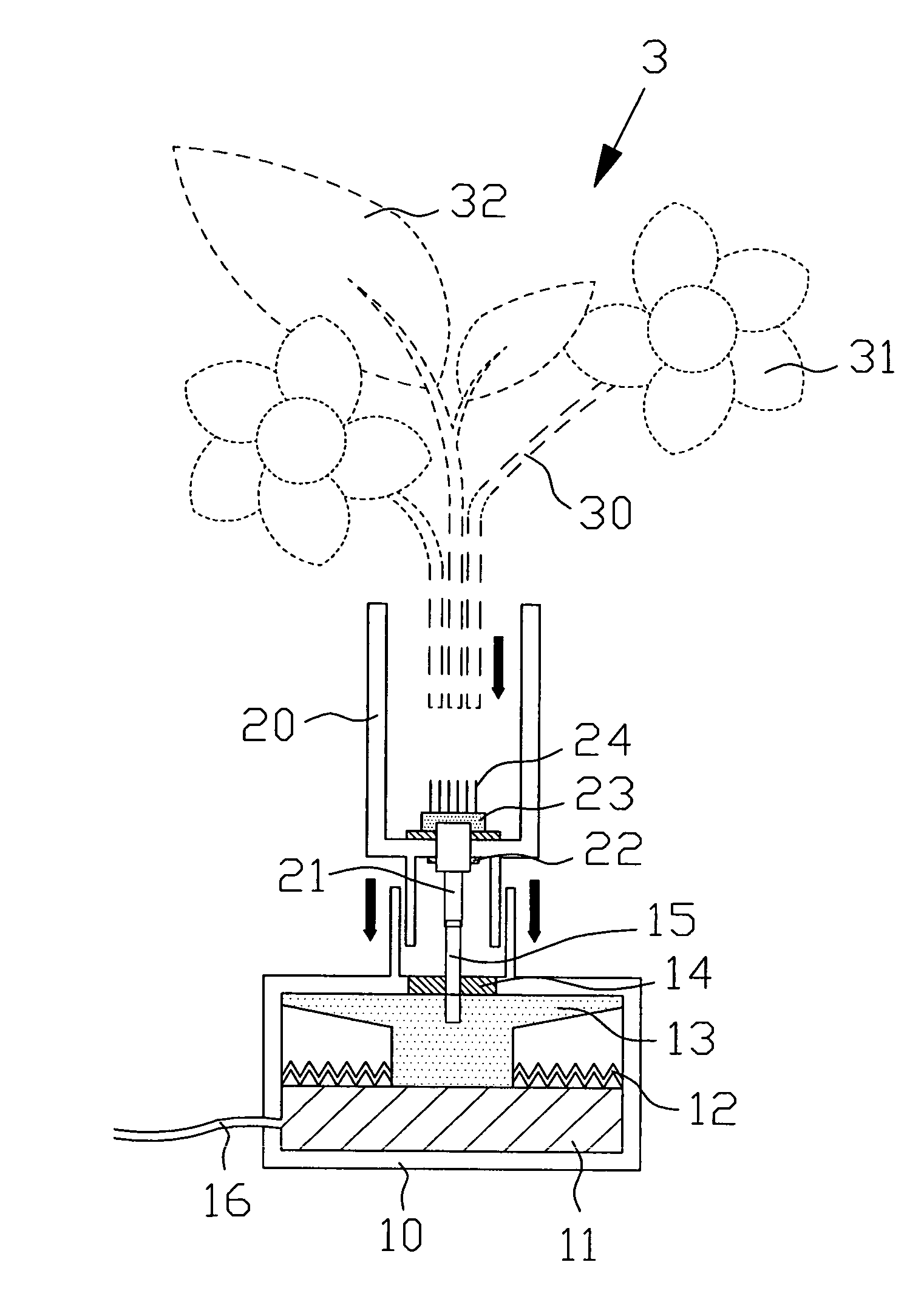

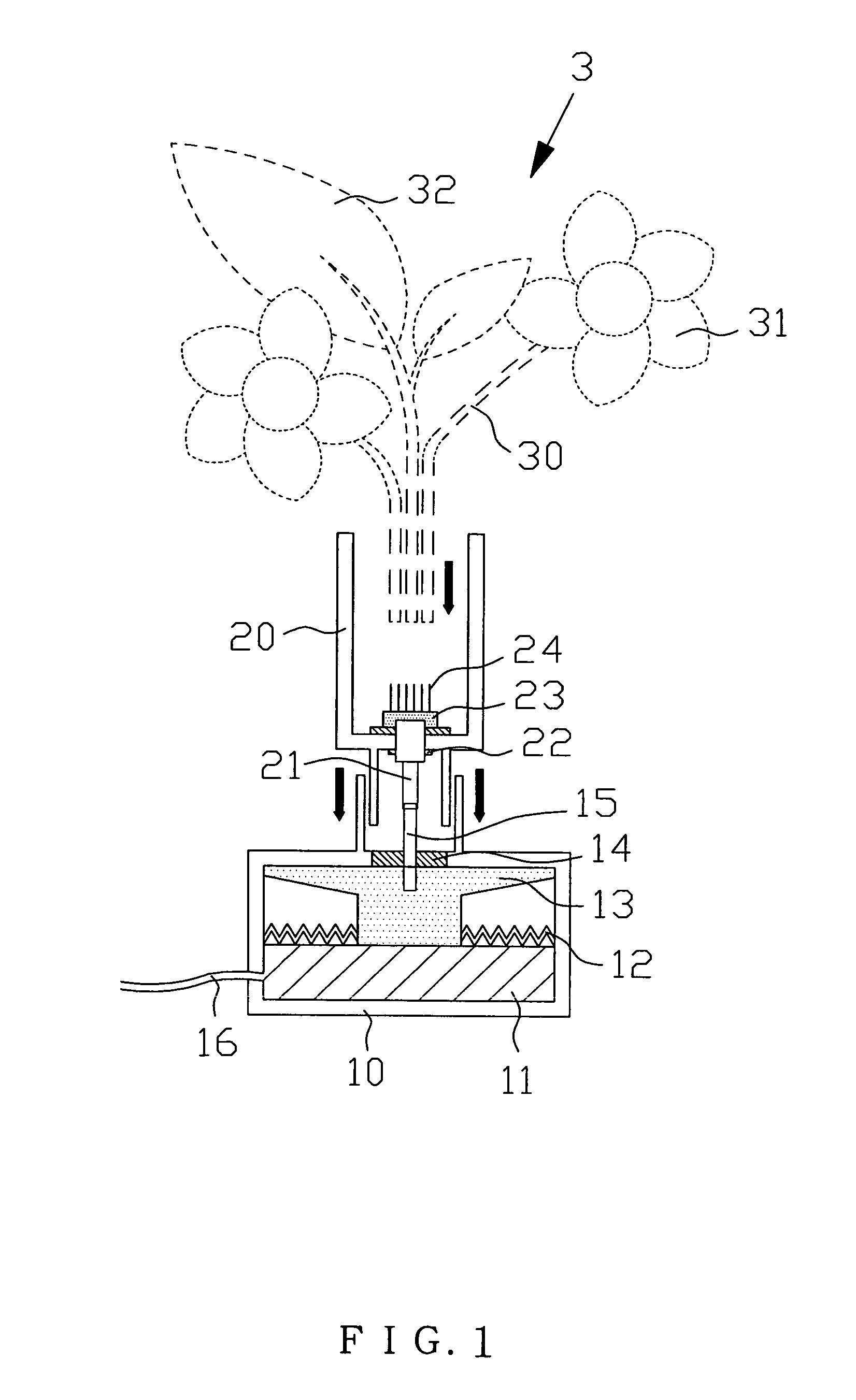

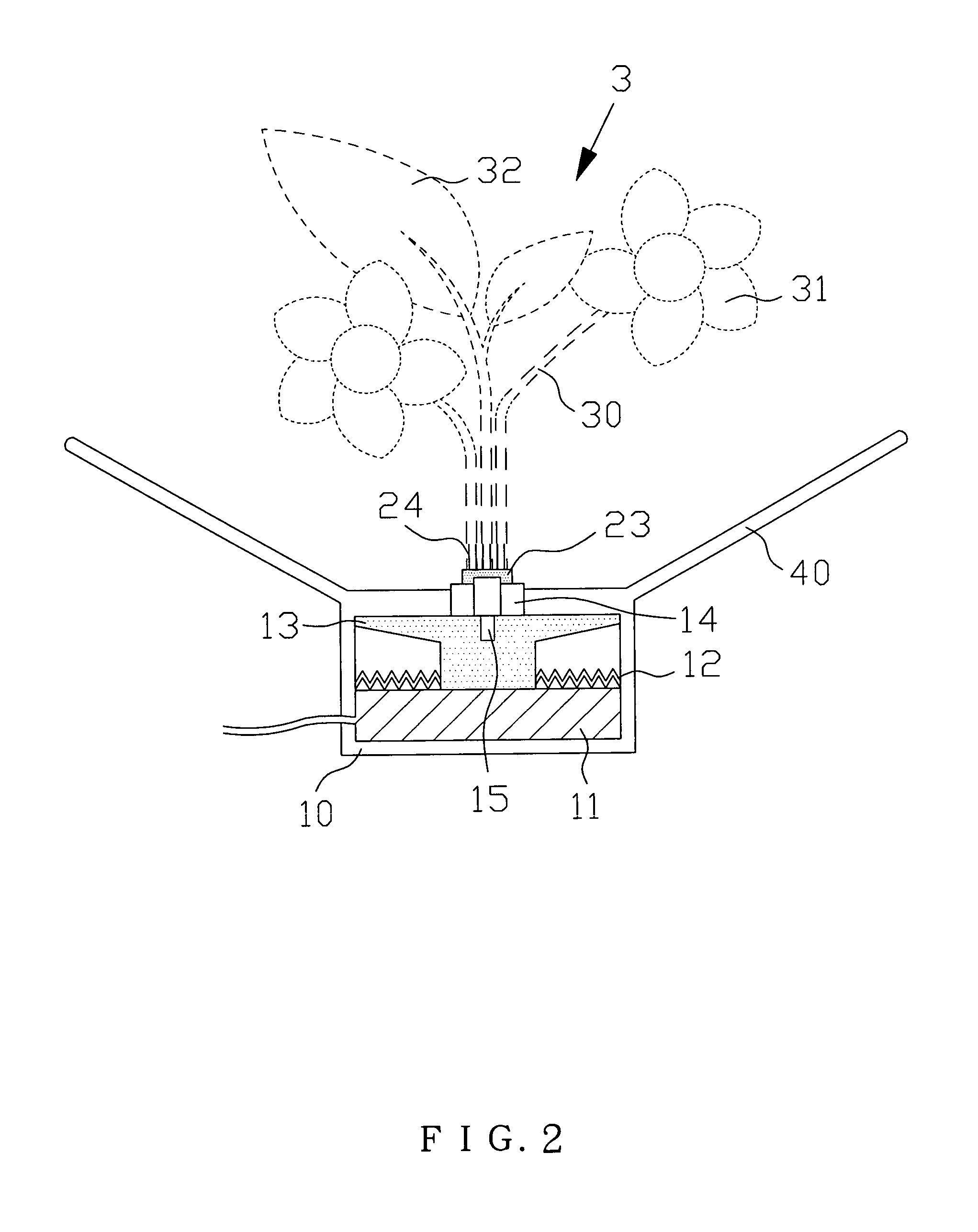

Plant potting having a sounding effect

InactiveUS20080271372A1Improve soundOutstanding appearanceFloral handlingFlower holdersAcoustic transmissionEngineering

A plant potting includes a base, a magnet mounted in the base and connected to an electric cord, a damper mounted on the magnet, a vibration absorber mounted in the base and located above the damper, a vibrator protruding outwardly from the base and connected to the vibration absorber, a vibration receiver having a lower end connected to the vibrator, a pin holder mounted on an upper end of the vibration receiver, and a plant mounted on the pin holder. Thus, the stems, the flowers and the leaves of the plant function as a medium to transmit the sound wave from the sound so as to output a sound wave in a different sound transmitting way, thereby enhancing the sounding effect of the sound.

Owner:WANG CHIEN JEN

Black glass and solar cell assembly using the same

InactiveUS20150144188A1Improve thermal conductivityImprove performanceGlass/slag layered productsCoatingsWeather resistanceAdhesive

The subject invention is related to a black glass and a solar cell assembly comprising the same. The subject invention provides a black glass comprising a glass substrate; and a black coating formed on the glass substrate, wherein the black coating comprises an inorganic film-forming material, a black pigment and an adhesive. The subject invention also provides a solar cell assembly comprising: a front glass substrate; the aforementioned black glass; and a photovoltaic cell sealed between the front glass substrate and the black glass. The black glass of the subject invention has a good thermal conductivity, waterproof performance, mechanical properties and weather resistance such that the black glass is not only aesthetically pleasing but also useful as a backside protection material of a solar cell assembly for long-term outdoor use.

Owner:CHANGZHOU ALMADEN

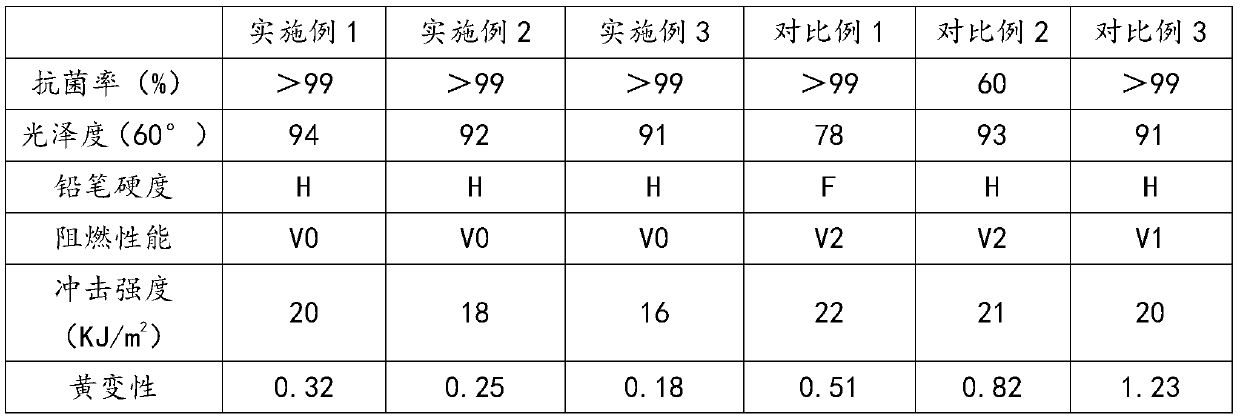

High-gloss antibacterial flame-retardant AS/MS composite material used for bathrooms and preparation method of composite material

InactiveCN109721922AImprove flame retardant performanceOutstanding antibacterial propertiesAntioxidantApplication areas

The invention relates to the technical field of bathroom material modification, and in particular relates to a high-gloss antibacterial flame-retardant AS / MS composite material used for bathrooms anda preparation method of the composite material. The composite material comprises the following components: 40-60 parts of AS resin, 10-30 parts of MS resin, 8-12 parts of ABS high rubber powder, 0.5-1part of an antibacterial agent, 15-20 parts of a flame retardant, 0.5-2 parts of a lubricant, 0.1-0.4 part of a high-efficiency composite antioxidant, 0.1-0.4 part of a light stabilizing agent, and 1part of titanium dioxide. According to the composite material and method provided by the invention, the AS resin, the MS resin and the related auxiliary agent are reasonably used to prepare the high-gloss antibacterial flame-retardant AS / MS composite material, and the composite material has outstanding flame retardancy, antibacterial properties and appearance; the MS resin is added, so that the surface gloss of the material is significantly improved, the gloss can be up to 90% (60 degrees) or more, and the scratch resistance is improved; and the application field of the bathroom product is expanded, and the composite material has important practical application value.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Method of manufacturing a decorative article, a decorative article, and a timepiece

ActiveUS8343584B2Easily subject to external impactBeautiful appearanceAdditive manufacturing apparatusMechanical clocksSolid solutionHeat treating

A method of manufacturing a decorative article, including a first coating formation step of forming a first coating of primarily TiN on a substrate; a second coating formation step of forming a second coating on the first coating by means of a dry plating method using a target containing 70.0 wt %≦85.0 wt % Au and 15.0 wt %≦30.0 wt % Cu; a heat treatment step of promoting formation of a solid solution of the constituents of the second coating by applying a heating process that heats the substrate on which the first coating and the second coating are disposed to 300° C.≦395° C. and then applying a cooling process; and an acid treatment step that, of the constituents of the second coating to which the heating process was applied, removes the constituents not forming a solid solution by applying an acid treatment.

Owner:SEIKO EPSON CORP

Colored glass and solar cell assembly using the same

InactiveUS20150207001A1Improve thermal conductivityImprove performanceCoatingsPhotovoltaic energy generationWeather resistanceAdhesive

The subject invention is related to a colored glass and a solar cell assembly comprising the same. The subject invention provides a colored glass comprising a glass substrate; and a colored coating formed on the glass substrate, wherein the colored coating comprises an inorganic film-forming material, a pigment and an adhesive. The subject invention also provides a solar cell assembly comprising: a front glass substrate; the aforementioned colored glass; and a photovoltaic cell sealed between the front glass substrate and the colored glass. The colored glass of the subject invention has a good thermal conductivity, improved waterproof performance, mechanical properties and weather resistance such that the colored glass is not only aesthetically pleasing but also useful as a backside protection material of a solar cell assembly for long-term outdoor use.

Owner:CHANGZHOU ALMADEN

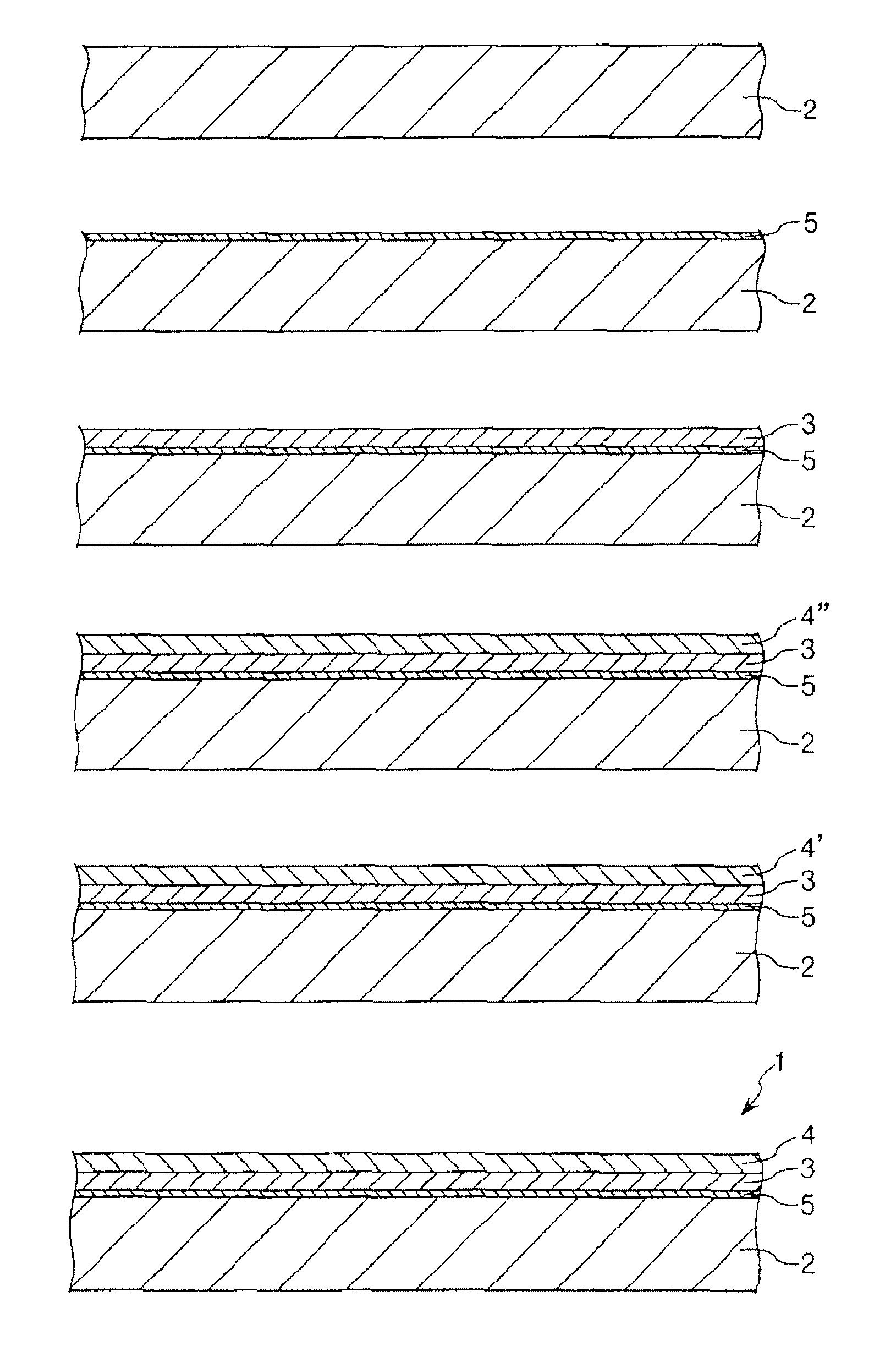

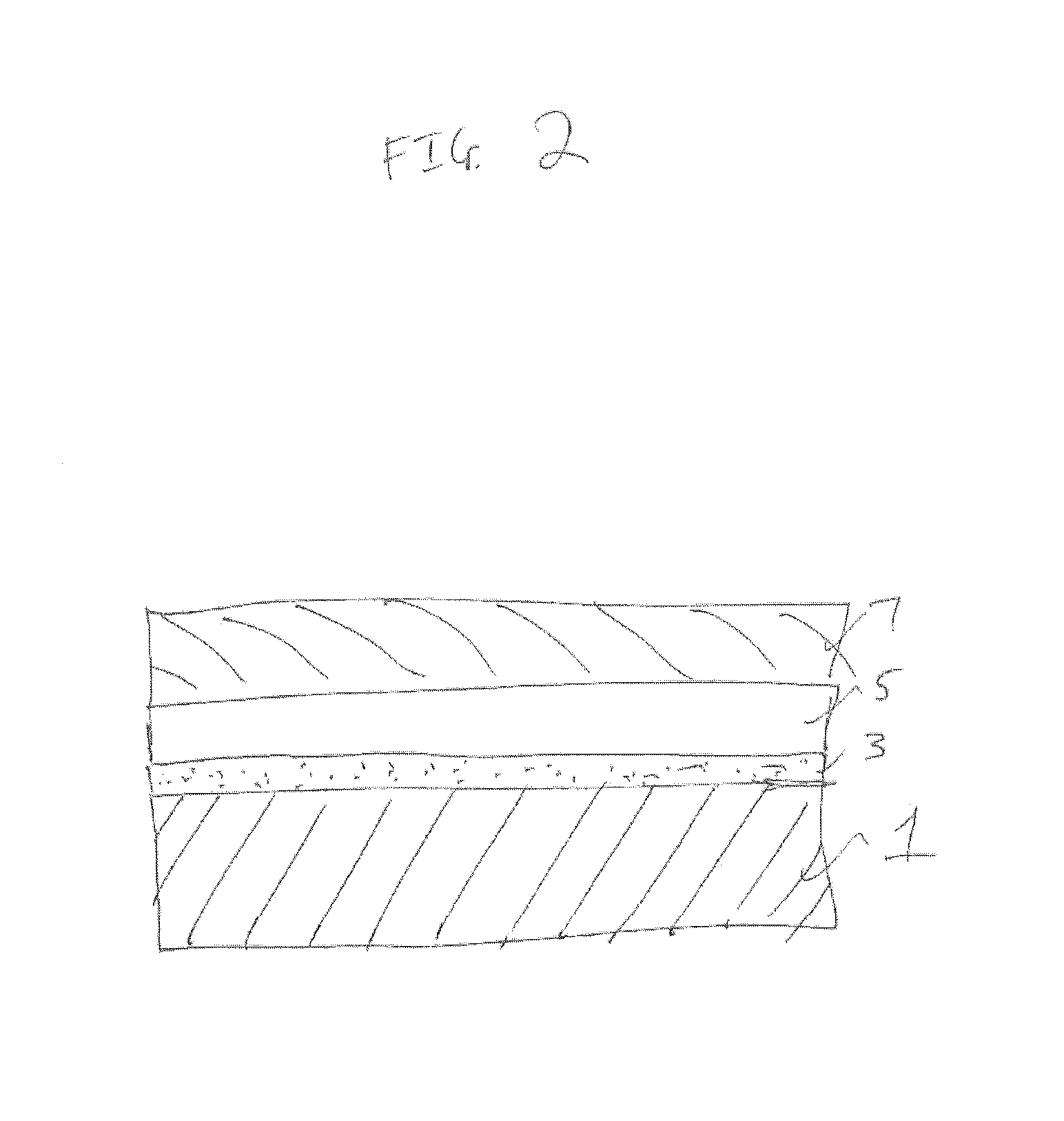

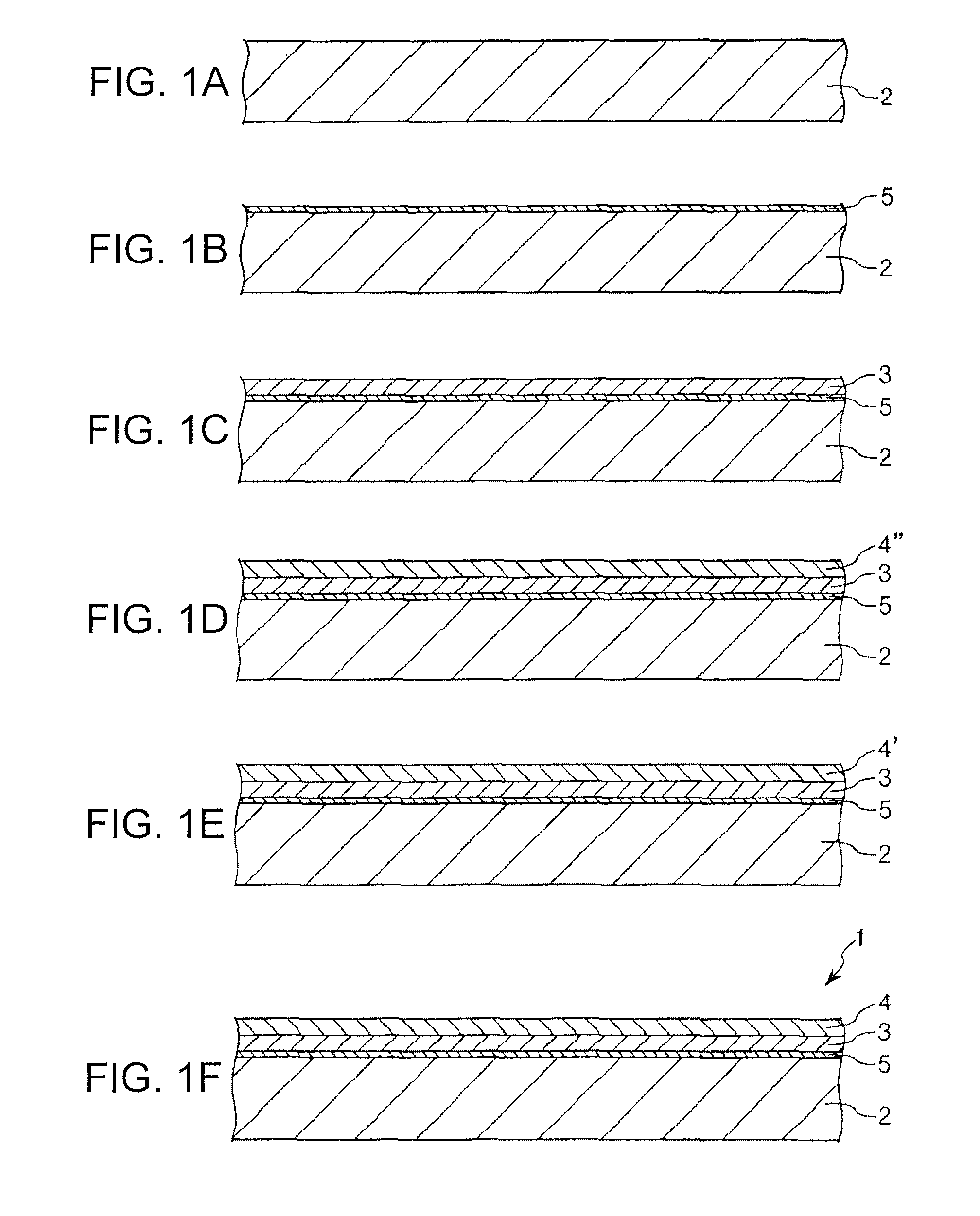

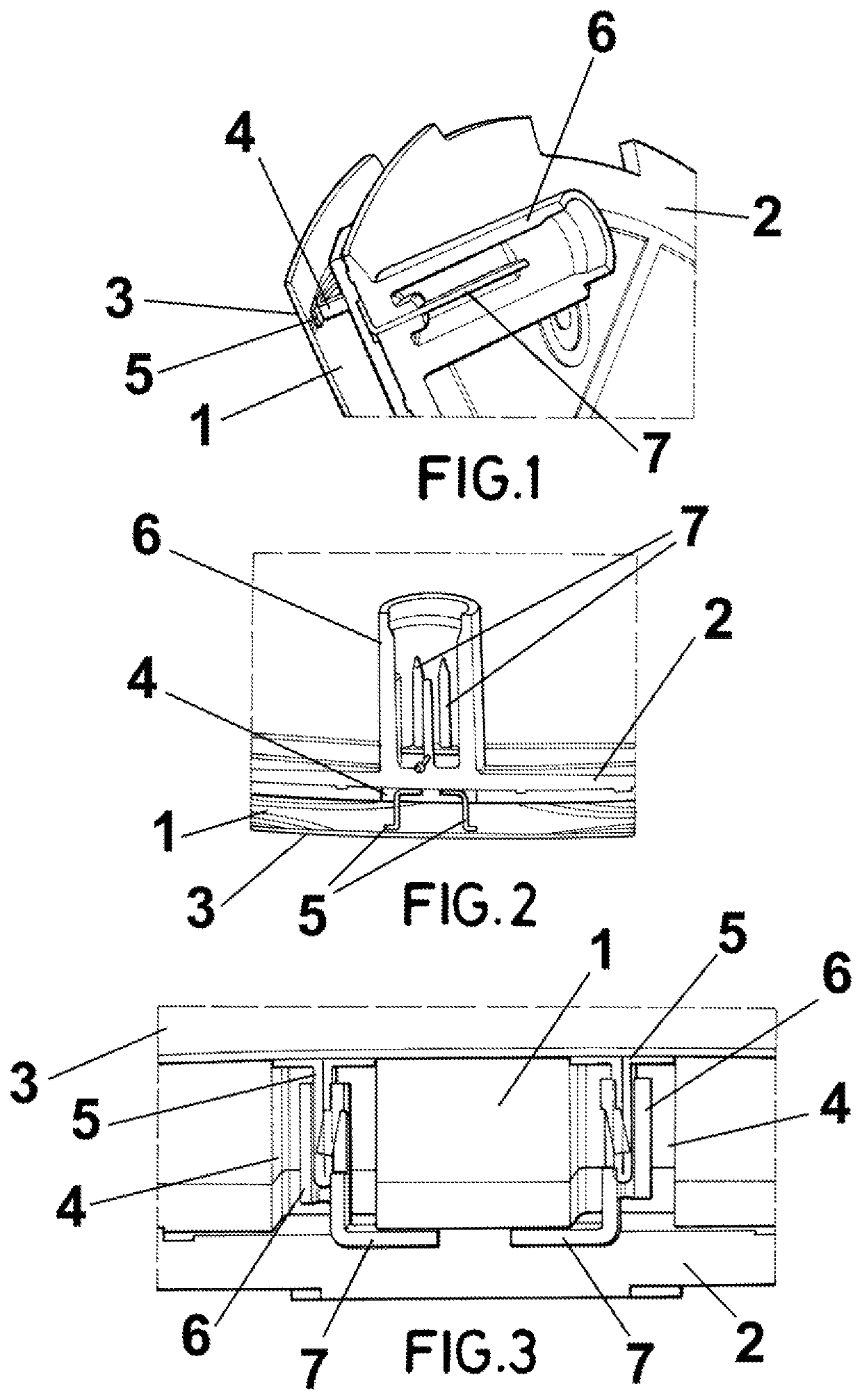

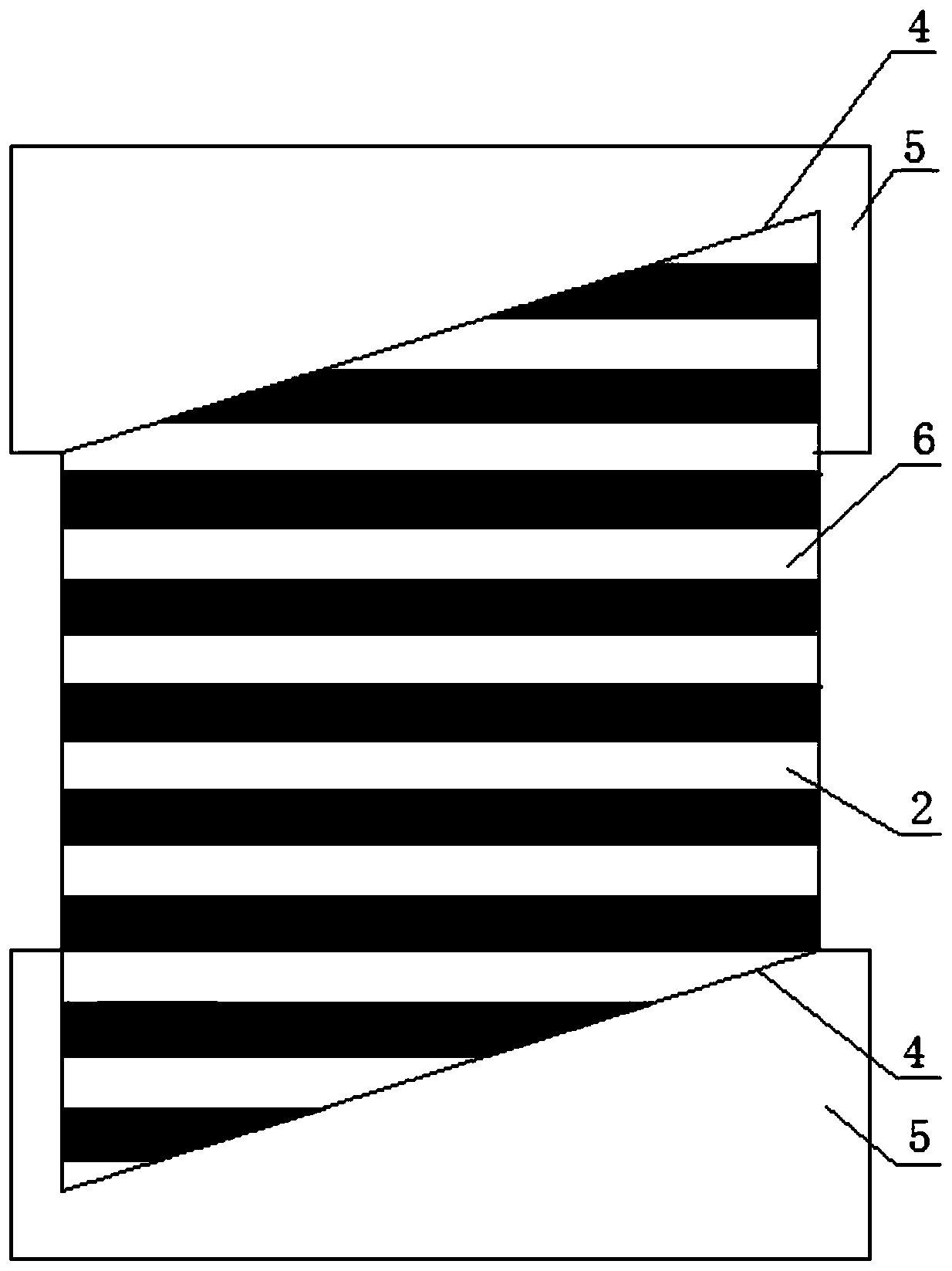

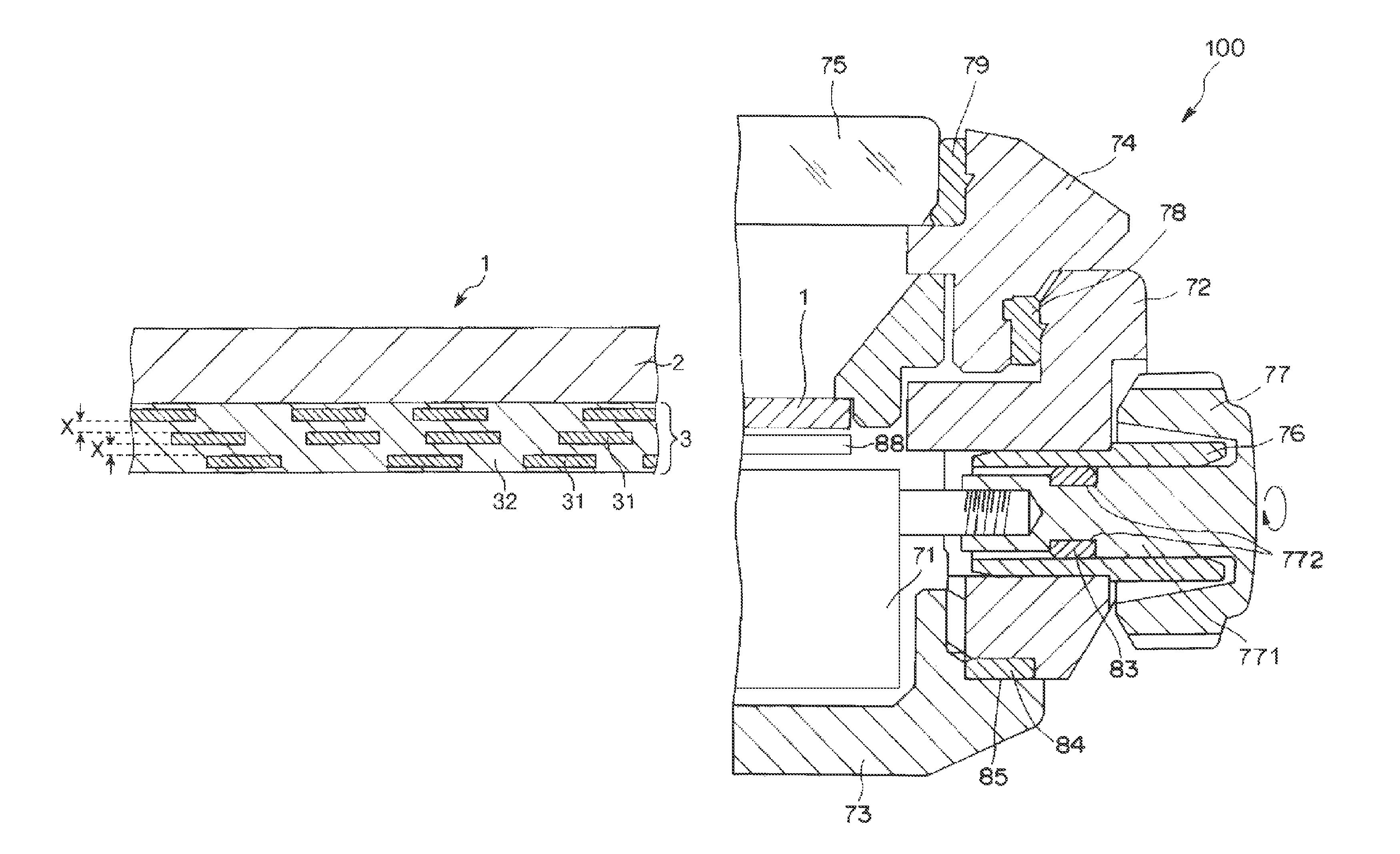

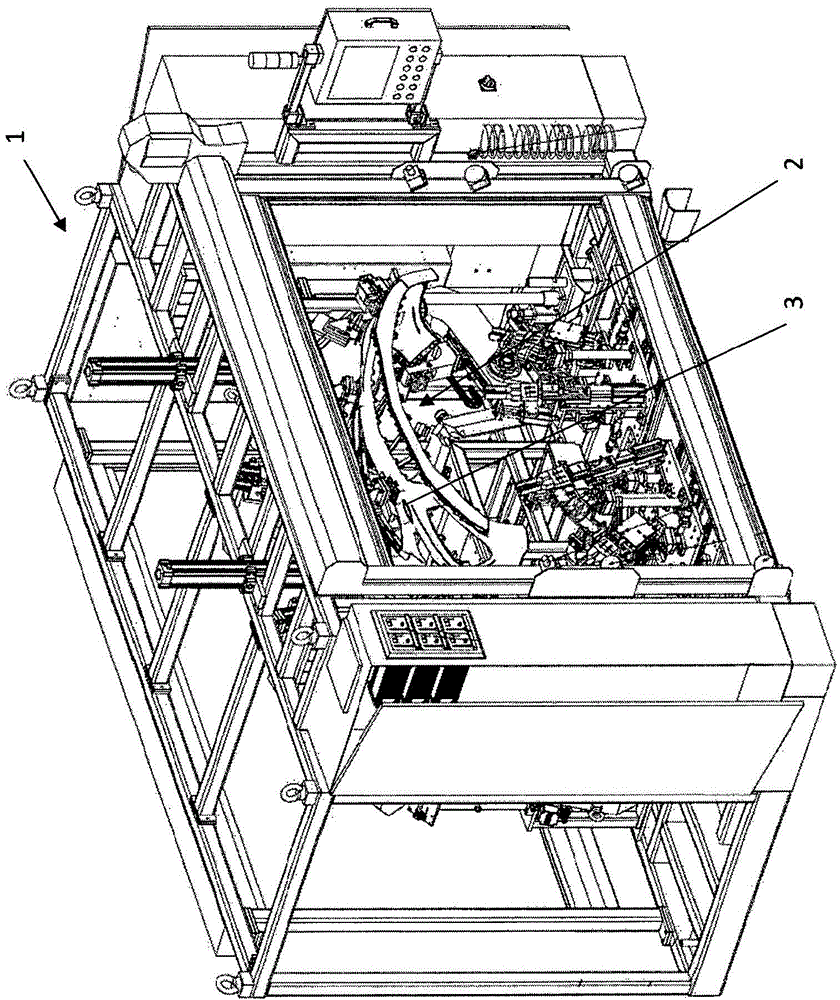

Radome for vehicles and method for manufacturing said radome

ActiveUS11005151B2Simple processOutstanding appearanceAntenna adaptation in movable bodiesRadiating element housingsThermoplastic materialsElectrically conductive

The radome for vehicles includes a frontal layer (1) and a rear layer (2), both made from thermoplastic material, and it also includes a heating element (3) placed on the frontal layer (1), on its face opposed to the rear layer (2). The method for manufacturing the radome includes forming the frontal layer (1) with the heating element (3) placed on a face of the frontal layer (1); placing the conductive element(s) (5) in the heating element (3) ; forming the rear layer (2); assembling the frontal and rear layers (1, 2), so that the heating element (3) is on the face of the frontal layer (1) opposite to the rear layer (2). Some embodiments provide a radome with a heating function and an outstanding appearance.

Owner:ZANINI AUTO GRUP

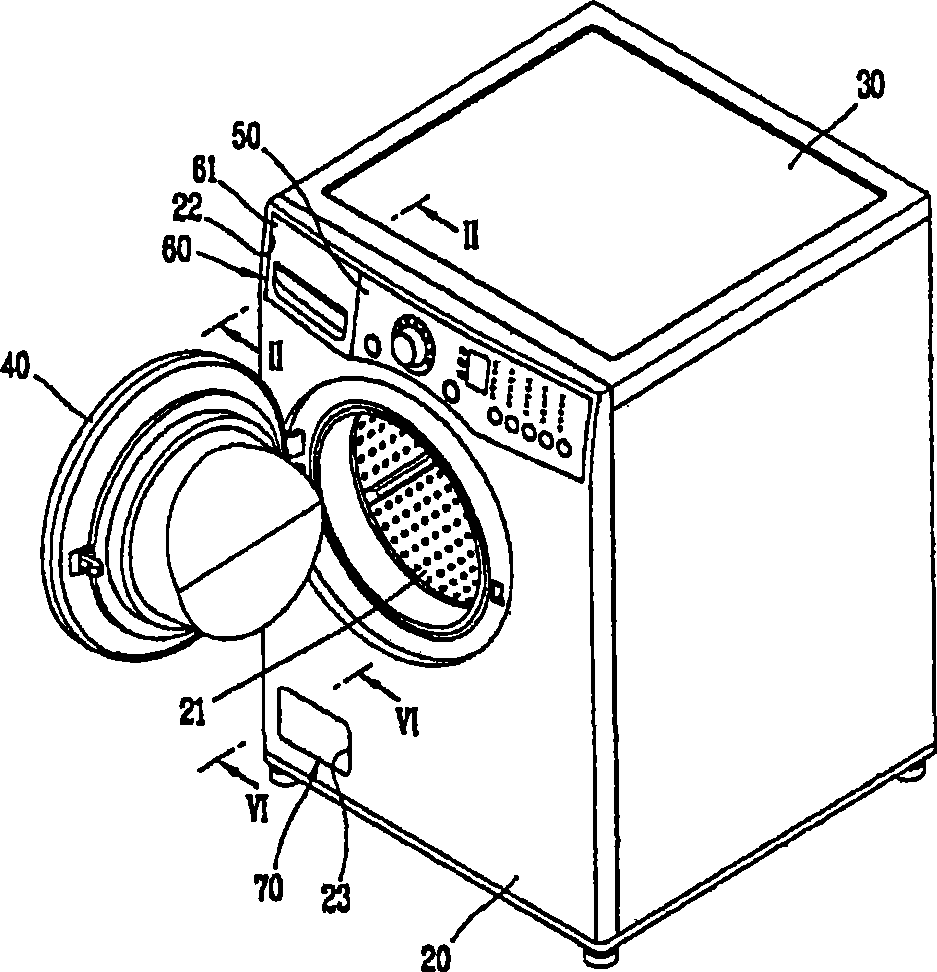

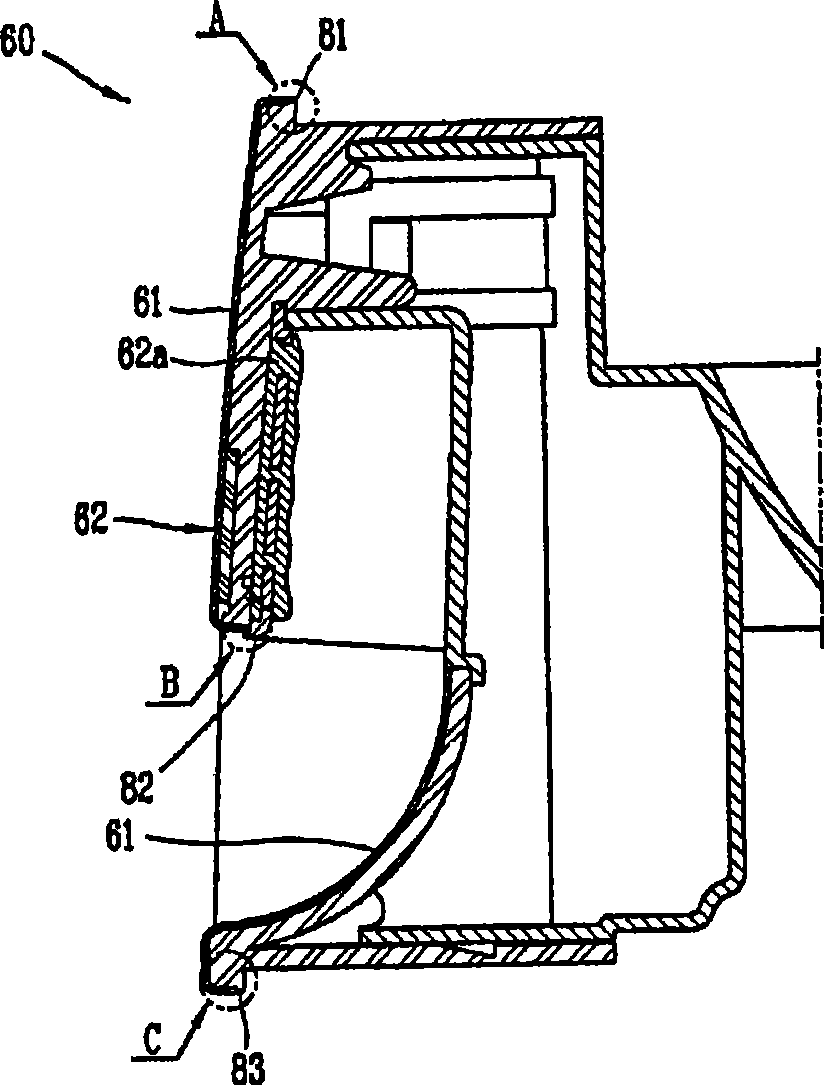

Washing machine

InactiveCN101387066AAvoid damageAvoid harmOther washing machinesTextiles and paperPulp and paper industry

The invention discloses a washing machine which includes a stainless steel cover for forming appearance and a burr protection part for protecting burr on the cover. Because the washing machine is equipped with the stainless steel cover, the washing machine has superior appearance; and because the washing machine is equipped with the burr protection part for protecting burr on the cover, the washing machine can protecting users form hurt by the burr.

Owner:LG ELECTRONICS INC

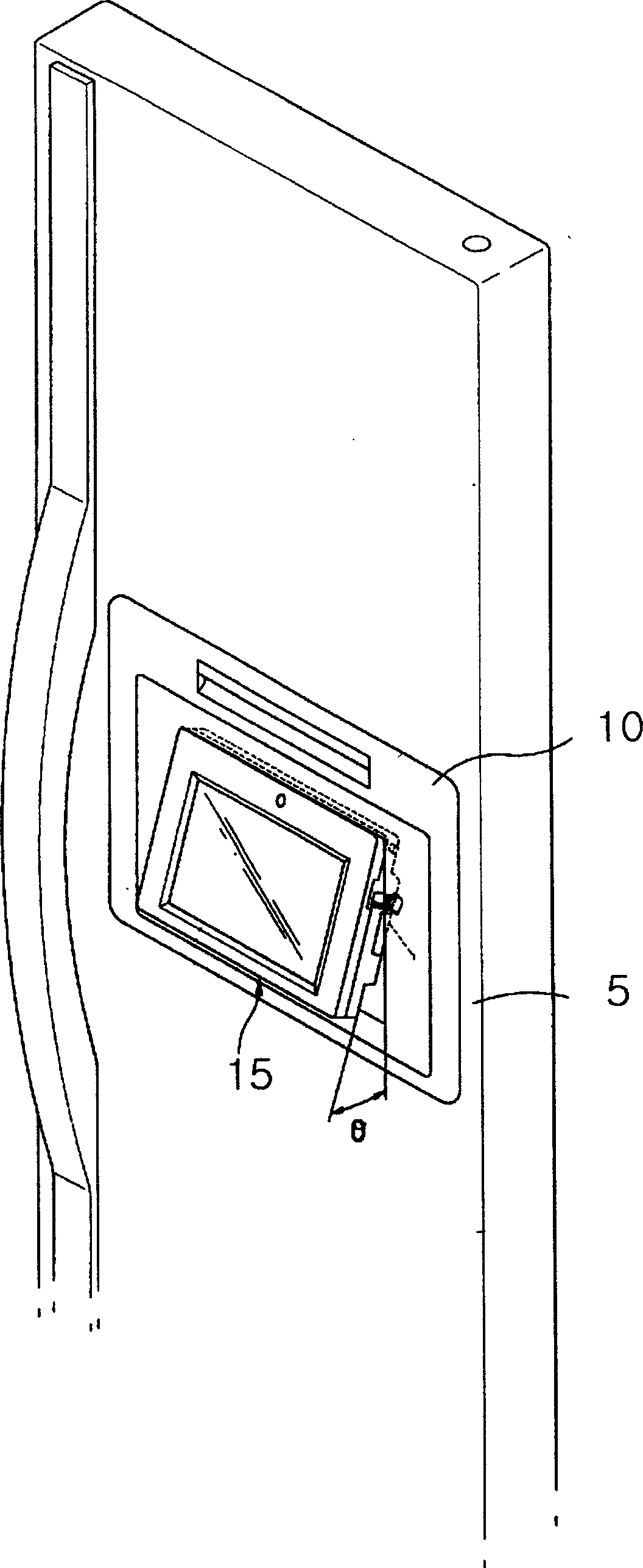

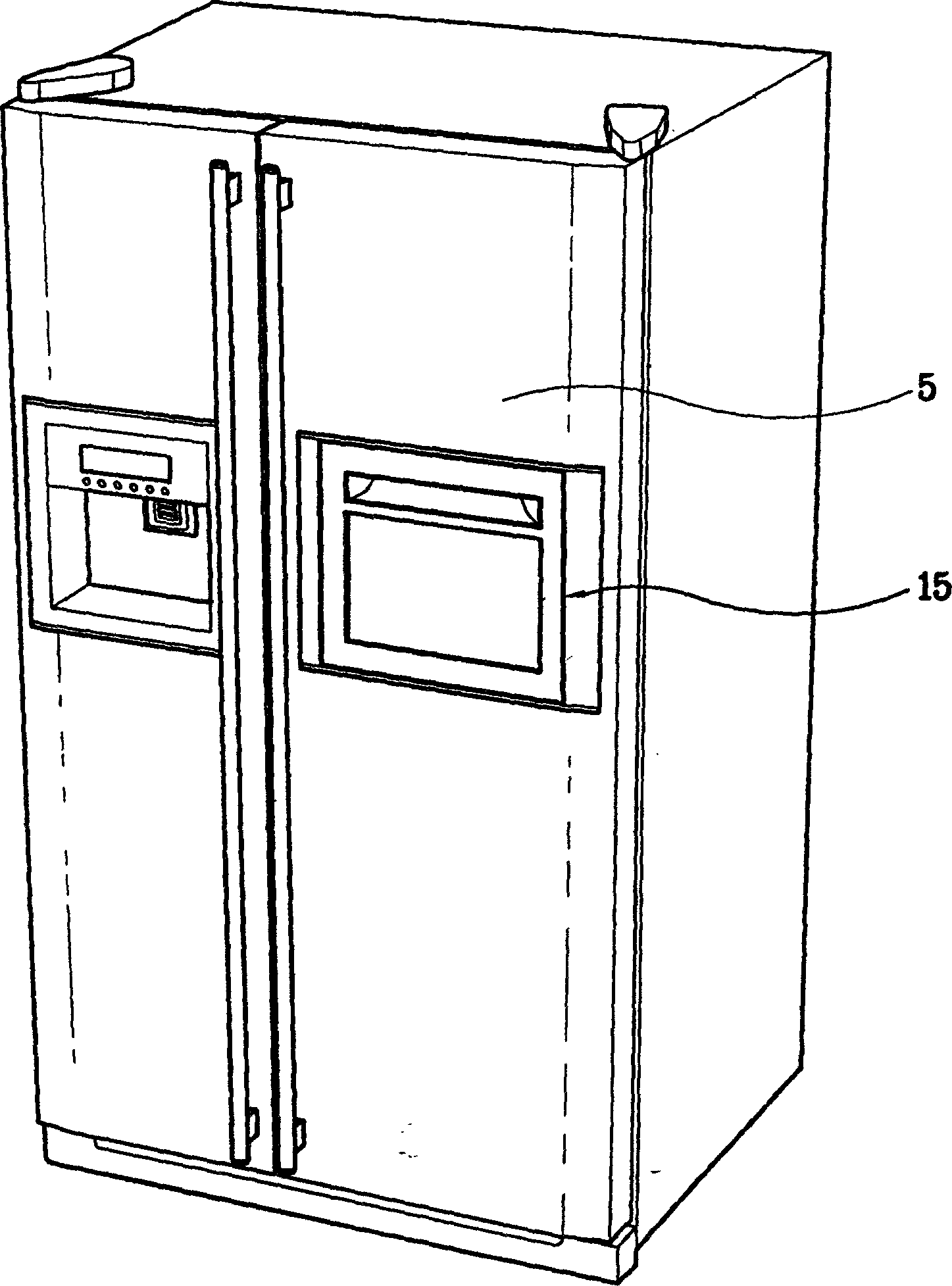

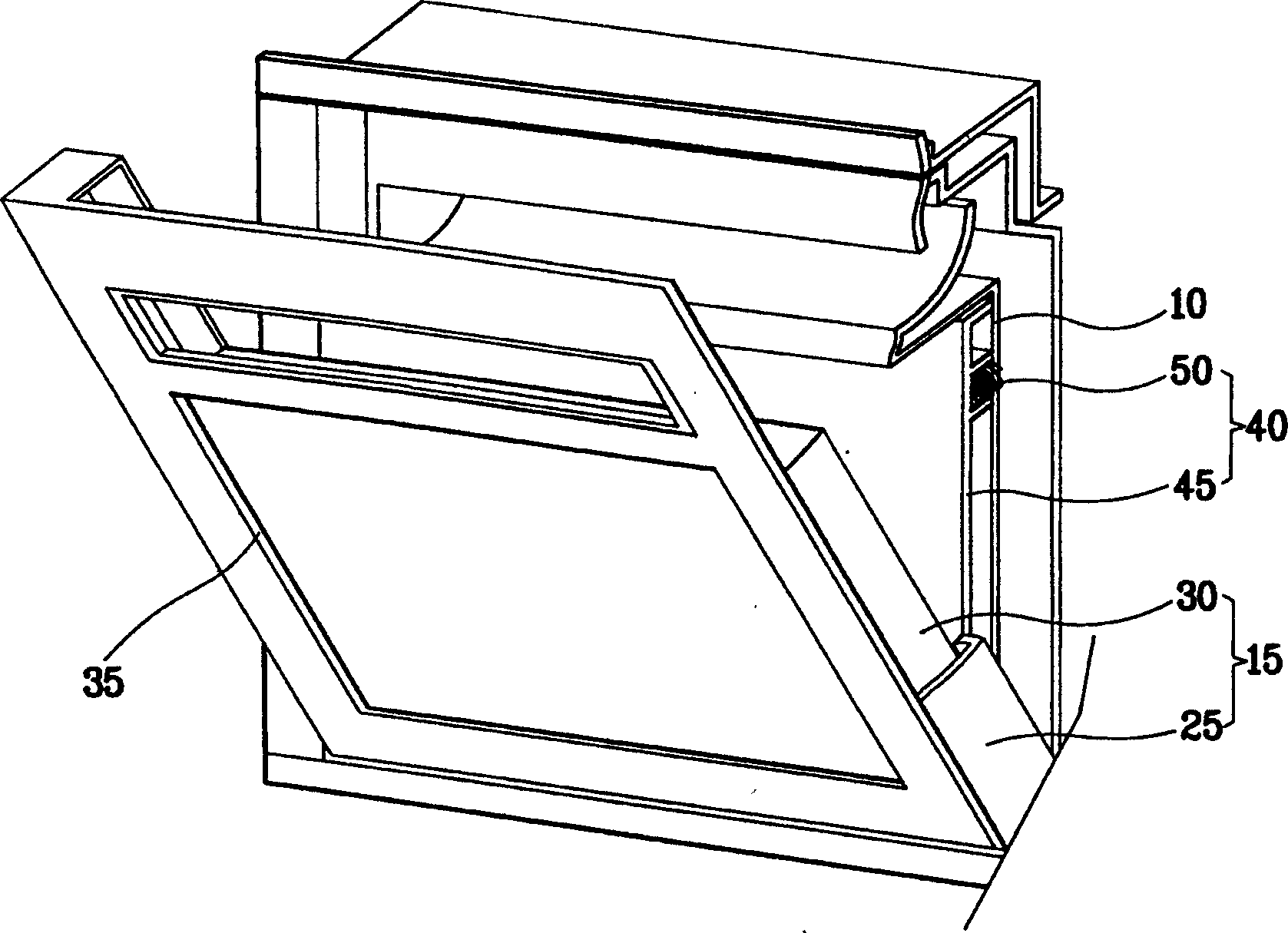

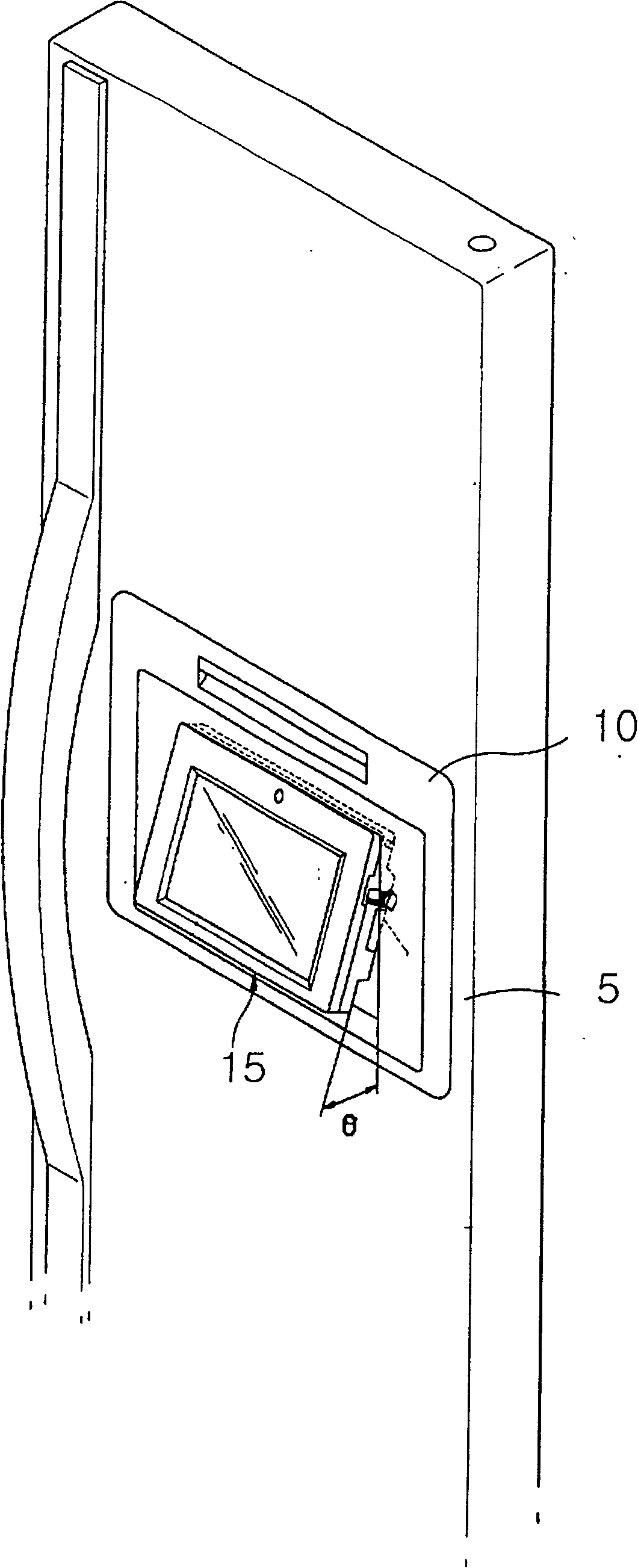

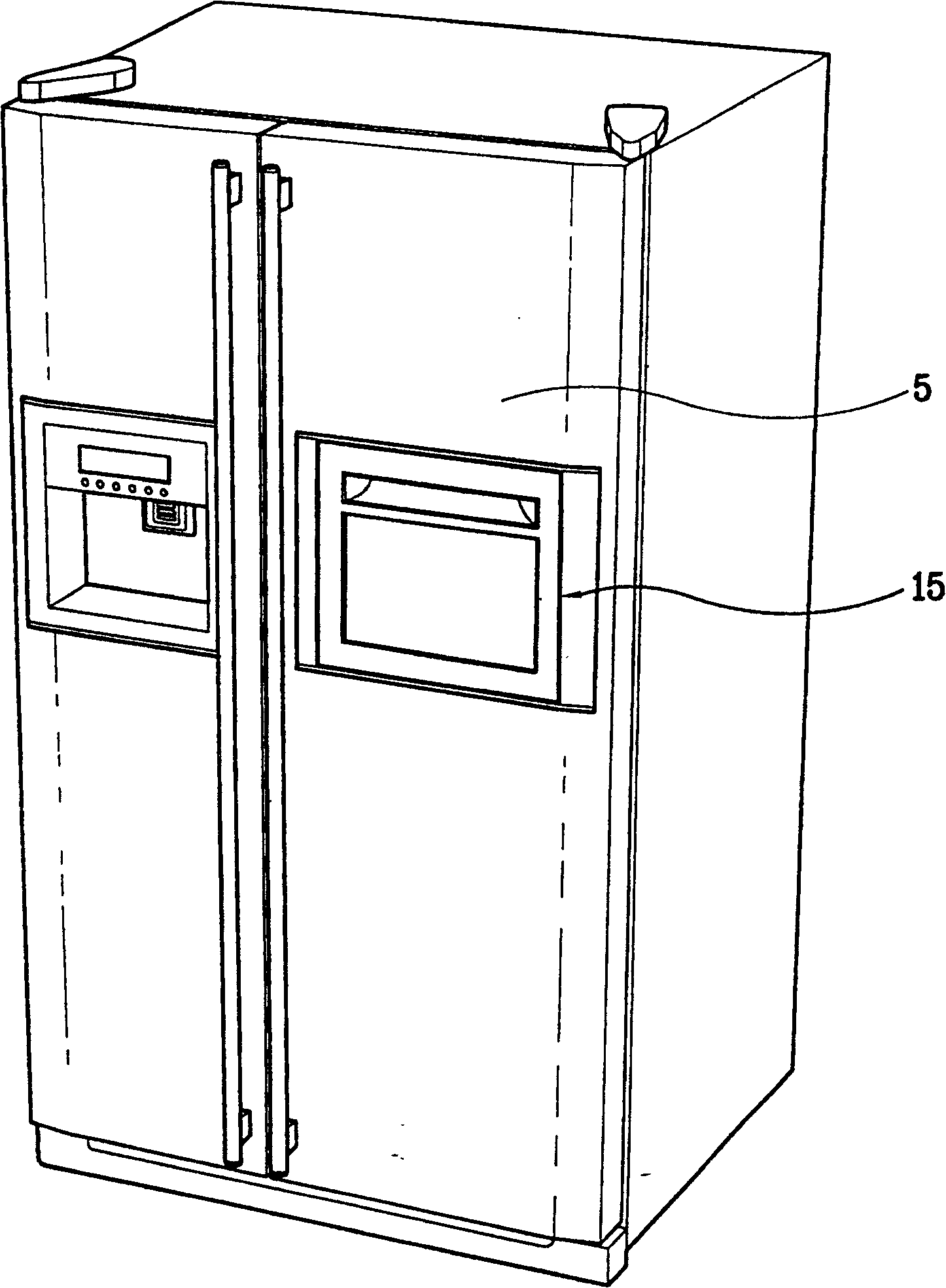

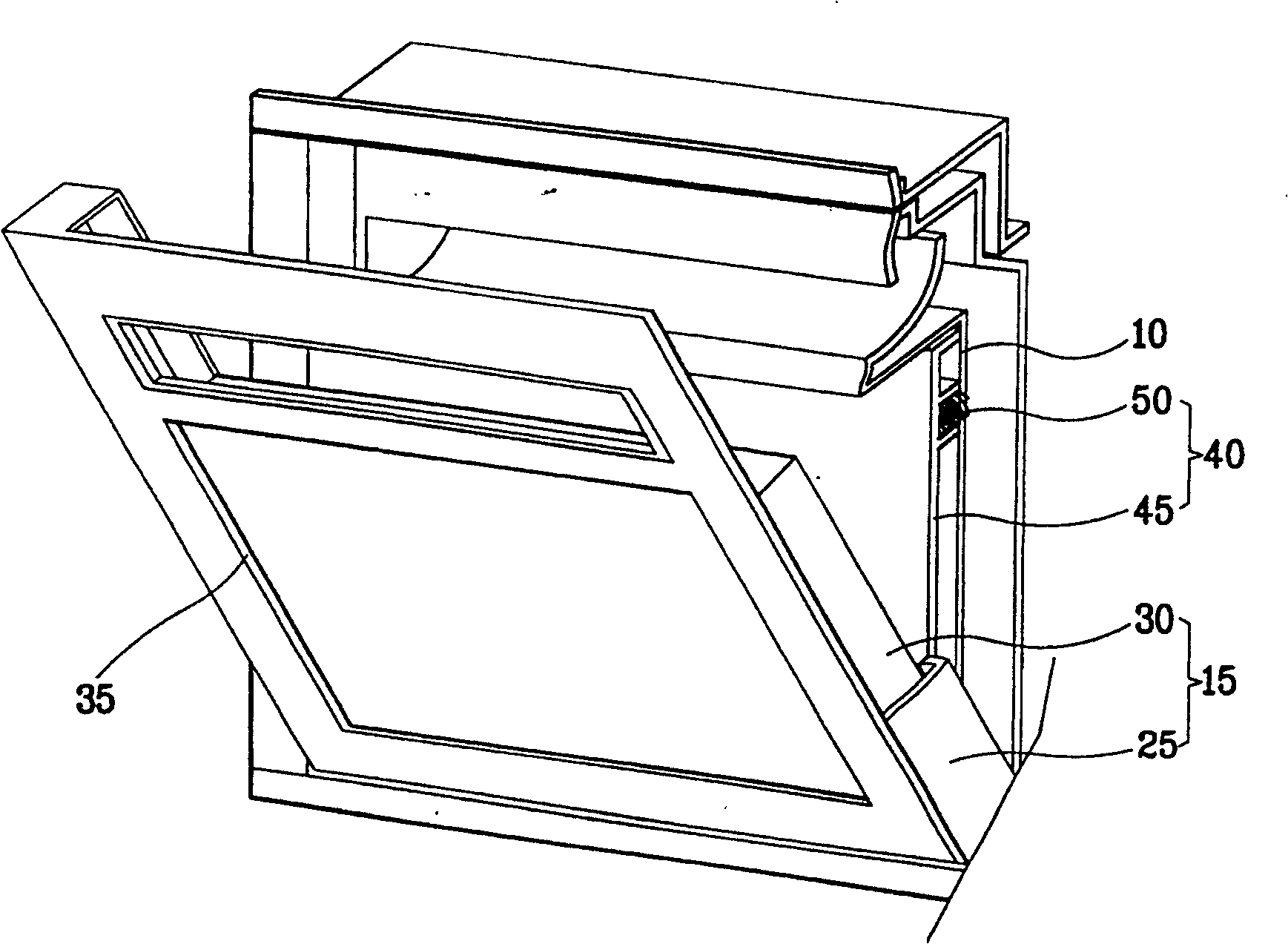

Refrigerator with display part

InactiveCN1683858APrevent intrusionImprove satisfactionLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The refrigerator display includes refrigerator door, display and covering unit. The refrigerator door has display and display holder, and the display includes openable casing on the display holder and detachable display panel. The covering unit includes movable cover and elastic unit to cover the residual space after the display panel is separated from the casing and to provide the cover with elastic force. The present invention covers the residual space to avoid dust from invading and to make the refrigerator beautiful.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Timepiece part and timepiece

InactiveUS20180143592A1High glossLuxurious appearanceVacuum evaporation coatingSputtering coatingMetallurgyCoating

A timepiece part has a substrate; and a first coating made from a material containing Co and including greater than or equal to 26 wt % and less than or equal to 30 wt % Cr, and greater than or equal to 5 wt % and less than or equal to 7 wt % Mo. The substrate is preferably made from a material including at least one of stainless steel and Ti. A second coating made of a material including at least one of TiC and TiCN is preferably disposed between the substrate and first coating.

Owner:SEIKO EPSON CORP

Plant potting having a sounding effect

InactiveUS7631457B2Improve soundOutstanding appearanceFloral handlingFlower holdersEngineeringAcoustic wave

Owner:WANG CHIEN JEN

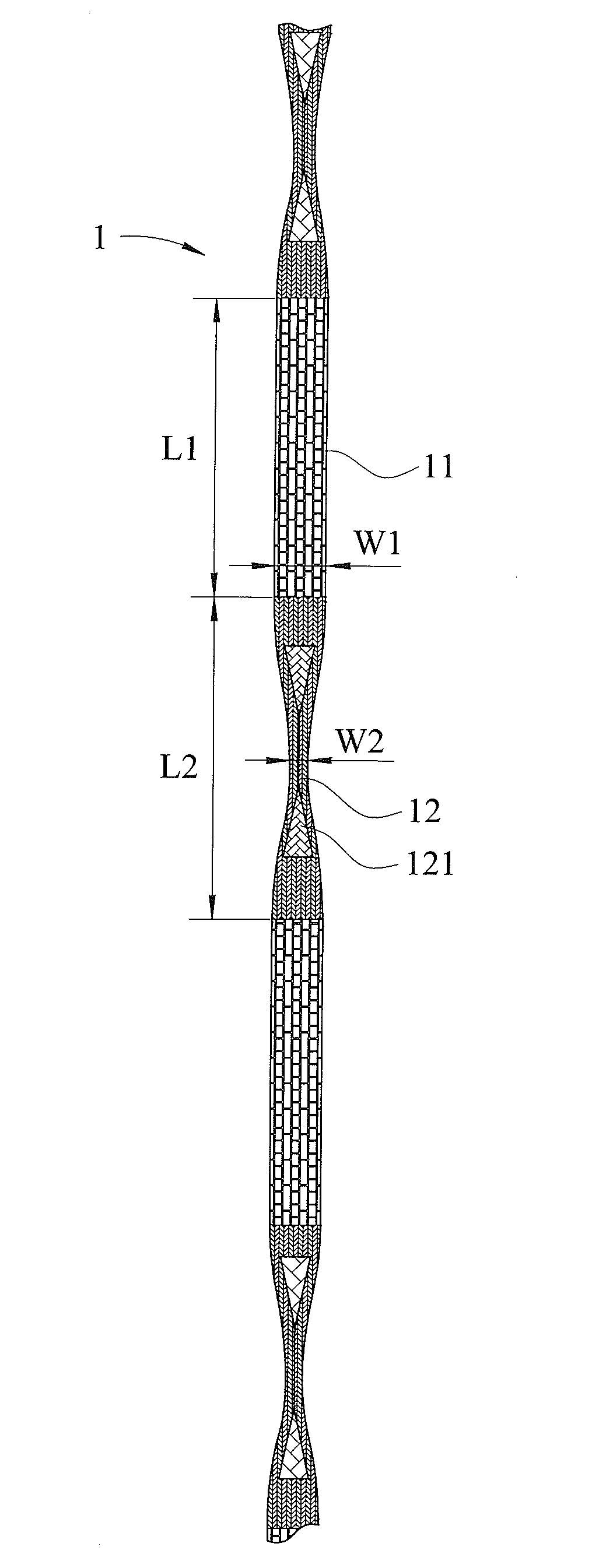

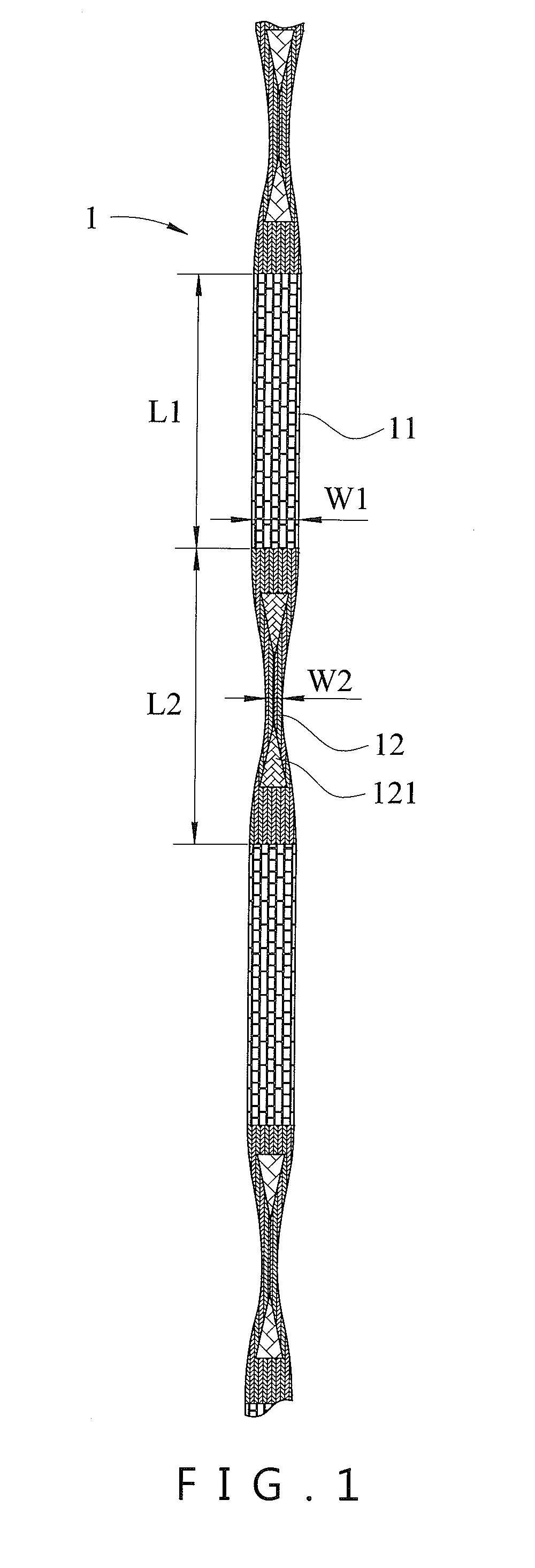

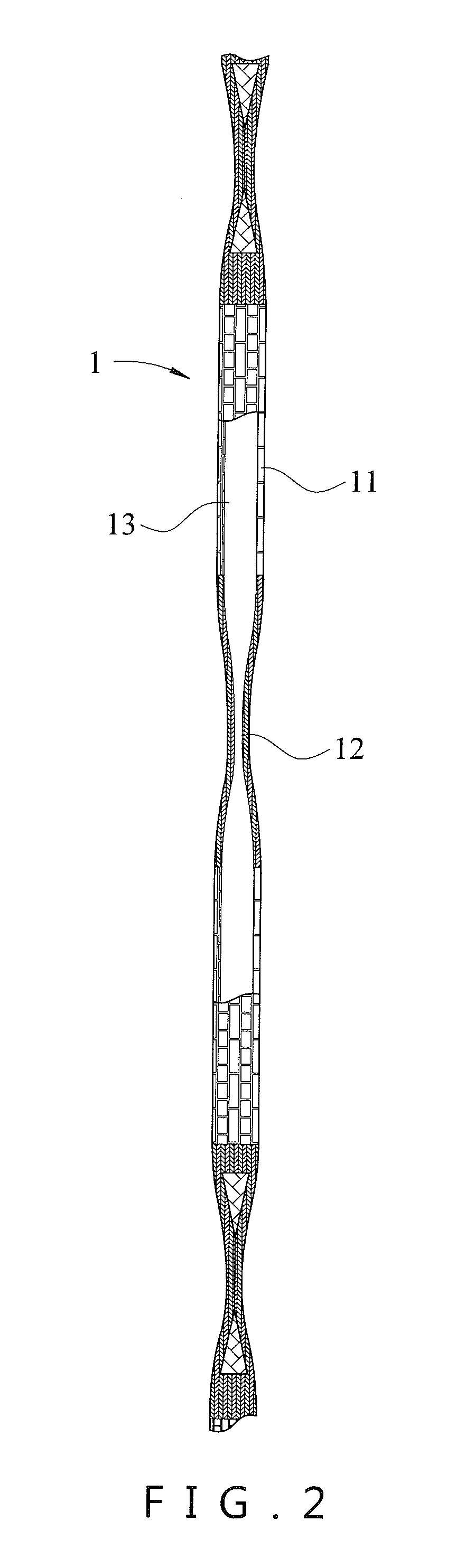

Lace Structure

A lace structure includes a plurality of weaving threads and a plurality of resilient threads which are interlaced in a lengthwise direction to form an elongate lace which defines a plurality of first sections and a plurality of second sections arranged in an alternating manner. Each of the second sections of the lace has a weaving density greater than and a width smaller than that of each of the first sections. In such a manner, each of the first sections of the lace has a wide face with a low density, and each of the second sections of the lace has a narrow face with a high density. Thus, each of the first sections of the lace has an elasticity greater than that of each of the second sections, so that the lace has a stepwise elastic function.

Owner:KAE SHENG IND

Nutritive feed capable of promoting chicken feathers to be glossy and bright and preparation method of nutritive feed

InactiveCN105876147AColorful feathersBright feathersFood processingAnimal feeding stuffBiotechnologyDracocephalum moldavica

The invention discloses a nutritive feed capable of promoting chicken feathers to be glossy and bright and a preparation method of the nutritive feed. The nutritive feed is prepared from the following raw materials in parts by weight: 500-600 parts of grape seed dregs, 2-3 parts of a yeast extract, 8-10 parts of papaya protein powder, 18-21 parts of calabash gourd leaves, 34-36 parts of dracocephalum moldavica, 25-27 parts of gynura bicolor herb, stems or leaves, 124-148 parts of linseed dregs, 13-15 parts of Chinese wolfberry fruit paste, 45-48 parts of towel gourd seed dregs, 53-56 parts of locust bean residues, 3-4 parts of fumaric acid, 35-37 parts of hibiscus flowers, 14-15 parts of potato powder, 4-7 parts of loquat fruit powder, 0.4-0.6 part of active lactic acid bacteria, 8-10 parts of streaky pork, 0.5-0.6 part of curry powder, 18-22 parts of rice flour, 18-20 parts of wall-broken yeast powder, 5-7 parts of white fungus powder and 2-4 parts of emulsified fat. After the feed disclosed by the invention is fed to chickens, the color of the chicken feathers can be gorgeous and bright, the appearance characteristics of the chickens are outstanding, the appearances are good, the dung shaping property is good, and the ornamental value is increased.

Owner:MAANSHAN WUGU POULTRY IND SPECIALIZED COOP

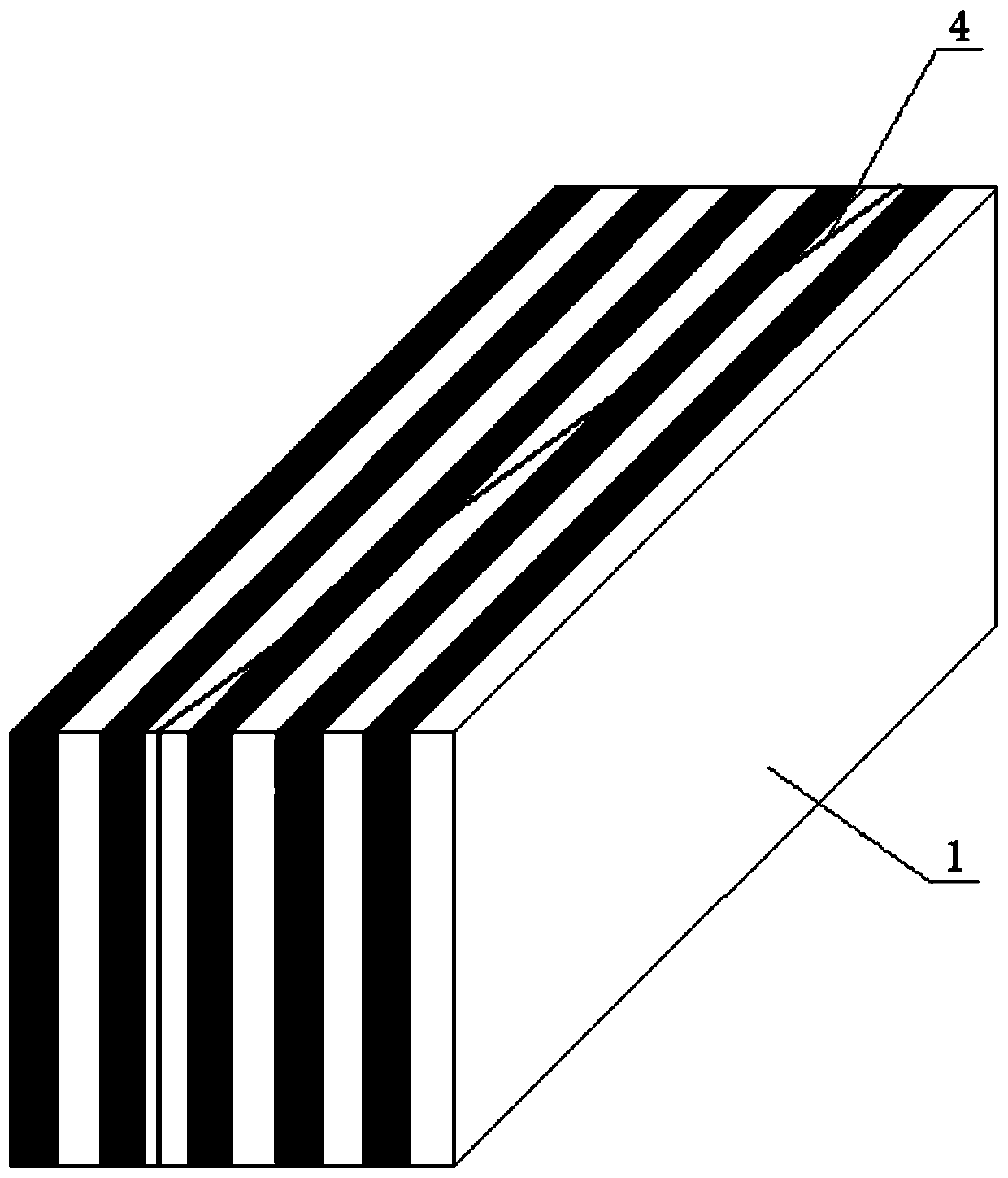

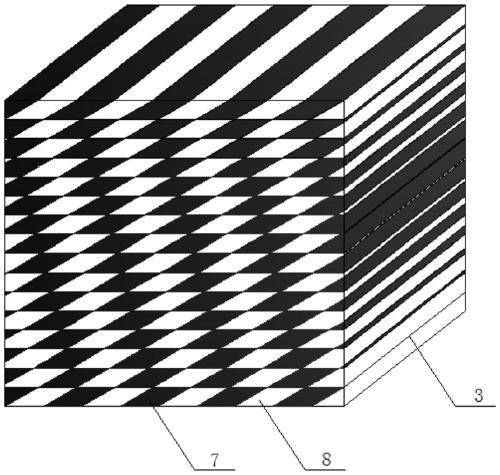

Manufacturing method of recombined decorative veneer with rhombus interweaving pattern

ActiveCN107718182BDifferent decorative effectsThe decorative effect appearsOther plywood/veneer working apparatusWood veneer joiningSingle plateEngineering

The invention belongs to the field of reconstituted veneer manufacturing, and particularly relates to a manufacturing method of a rhombus interwoven pattern reconstituted decorative veneer. Accordingto the manufacturing method, through multi-times permutation and combination of multiple procedures of same-color and multicolor blank assembling, overturning blank assembling, sawing according to angles, slicing according to the angles, special-shape gluing and the like, a whole set of manufacturing method is formed; according to the trend and need of the decoration market, by adjusting technicalparameters such as the blank assembling thickness, a blank assembling mode, the sawing angles and the sawing thickness, rhombus interwoven geometrical patterns of different colors are manufactured, and the rhombus interwoven geometrical patterns are different from natural texture patterns such as imitation wood grains; the color of the rhombus interwoven patterns manufactured by the method is more complex and changeable, and the characteristics of modern fashion and man-made design are highlighted; and the manufacturing method is simple in manufacturing procedure, easy to operate, firm in bonding between veneers and high in yield, and the finished decorative veneer obtained is not prone to being bent, deformed and dry-shrunk and dry-cracked.

Owner:黑龙江省木材科学研究所

Surface modifier for rubber composition, and rubber composition containing same

The present invention provides a surface modifier for a rubber composition that can enhance appearance without decreasing ozone resistance of the rubber composition. The surface modifier for a rubber composition of the present invention includes a hydrocarbon-based anti-aging wax for rubber (B) and an appearance-improving agent (C), in which: the content of a linear monovalent primary alcohol is more than 1.5 parts by weight and less than 35 parts by weight per 100 parts by weight of the surface modifier for a rubber composition; per 100 parts by weight of the primary alcohol, the content of a component having 30 to 38 carbon atoms is more than 35 parts by weight; the content of a component having 12 to 26 carbon atoms is less than 25 parts by weight; and the content of a component having 42 to 68 carbon atoms is less than 25 parts by weight.

Owner:NIPPON SEIRO

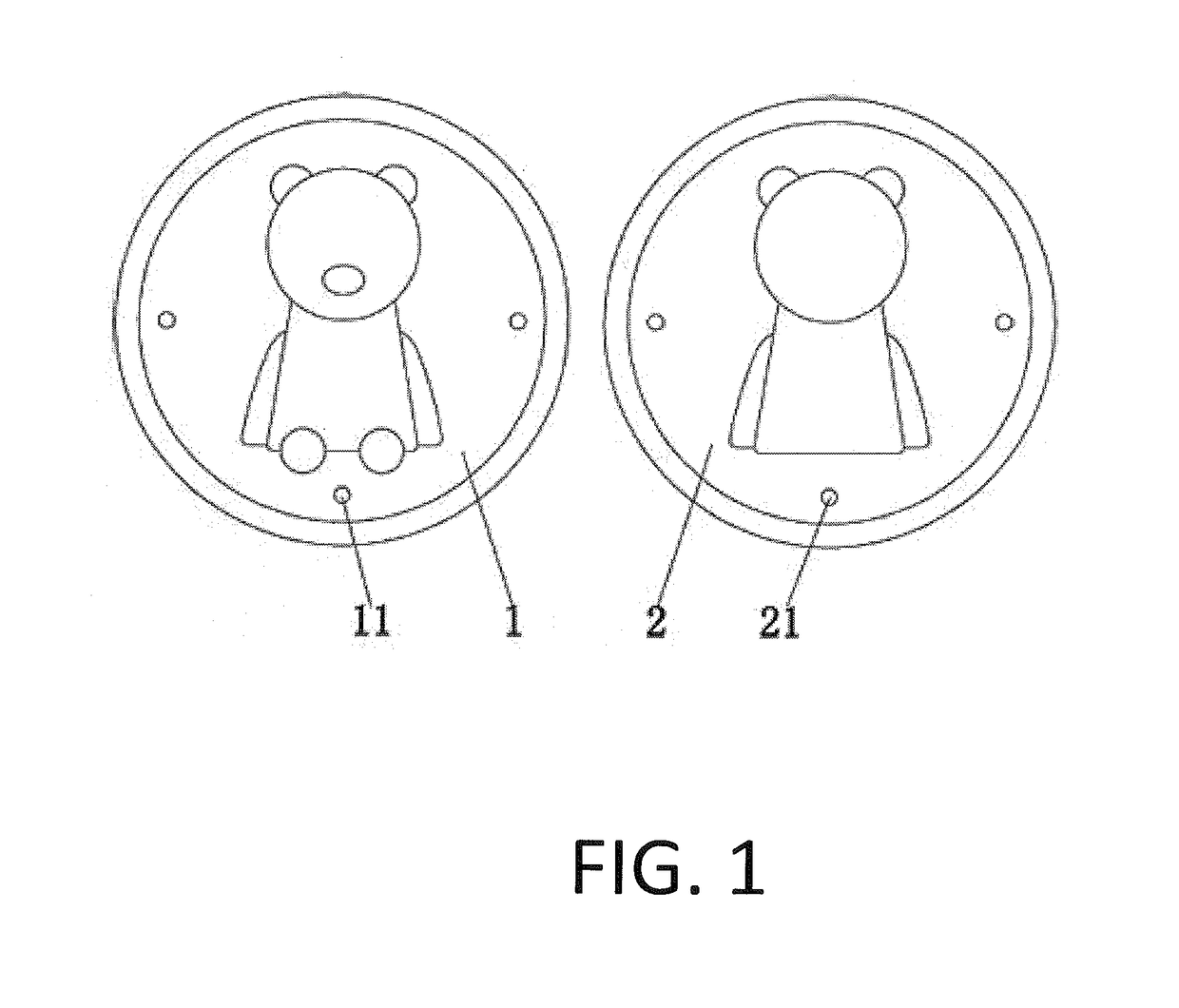

Method for Molding Three-Dimensional Toy

InactiveUS20180370085A1Fast curing featureMolded quicklyDomestic articlesCoatingsElectrical and Electronics engineering

A method for molding a three-dimensional toy includes selecting an upper die and a lower die each having a three-dimensional molding cavity, spreading a photosensitive molding glue on the inner wall of the molding cavity of each of the upper die and the lower die, closing the upper die and the lower die, placing the upper die and the lower die in an ultraviolet lamp box or irradiating the upper die and the lower die under the sun to solidify the photosensitive molding glue so as to mold a three-dimensional toy, and opening the upper die and the lower die to remove the three-dimensional toy from the upper die and the lower die.

Owner:XIELE ELECTRONICS & PLASTIC LTD

Refrigerator with display part

InactiveCN100458321CPrevent intrusionImprove satisfactionLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

The refrigerator display includes refrigerator door, display and covering unit. The refrigerator door has display and display holder, and the display includes openable casing on the display holder and detachable display panel. The covering unit includes movable cover and elastic unit to cover the residual space after the display panel is separated from the casing and to provide the cover with elastic force. The present invention covers the residual space to avoid dust from invading and to make the refrigerator beautiful.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

Radome for vehicles and method for manufacturing said radome

ActiveUS20200072970A1Simple processOutstanding appearanceAntenna adaptation in movable bodiesRadiating element housingsThermoplastic materialsElectrically conductive

The radome for vehicles comprises a frontal layer (1) and a rear layer (2), both made from thermoplastic material, and it also comprises a heating element (3) placed on the frontal layer (1), on its face opposed to the rear layer (2).The method for manufacturing the radome comprises: forming the frontal layer (1) with the heating element (3) placed on a face of the frontal layer (1); placing the conductive element(s) (5) in the heating element (3); forming the rear layer (2); assembling the frontal and rear layers (1, 2), so that the heating element (3) is on the face of the frontal layer (1) opposite to the rear layer (2).It permits to provide a radome with a heating function and an outstanding appearance.

Owner:ZANINI AUTO GRUP

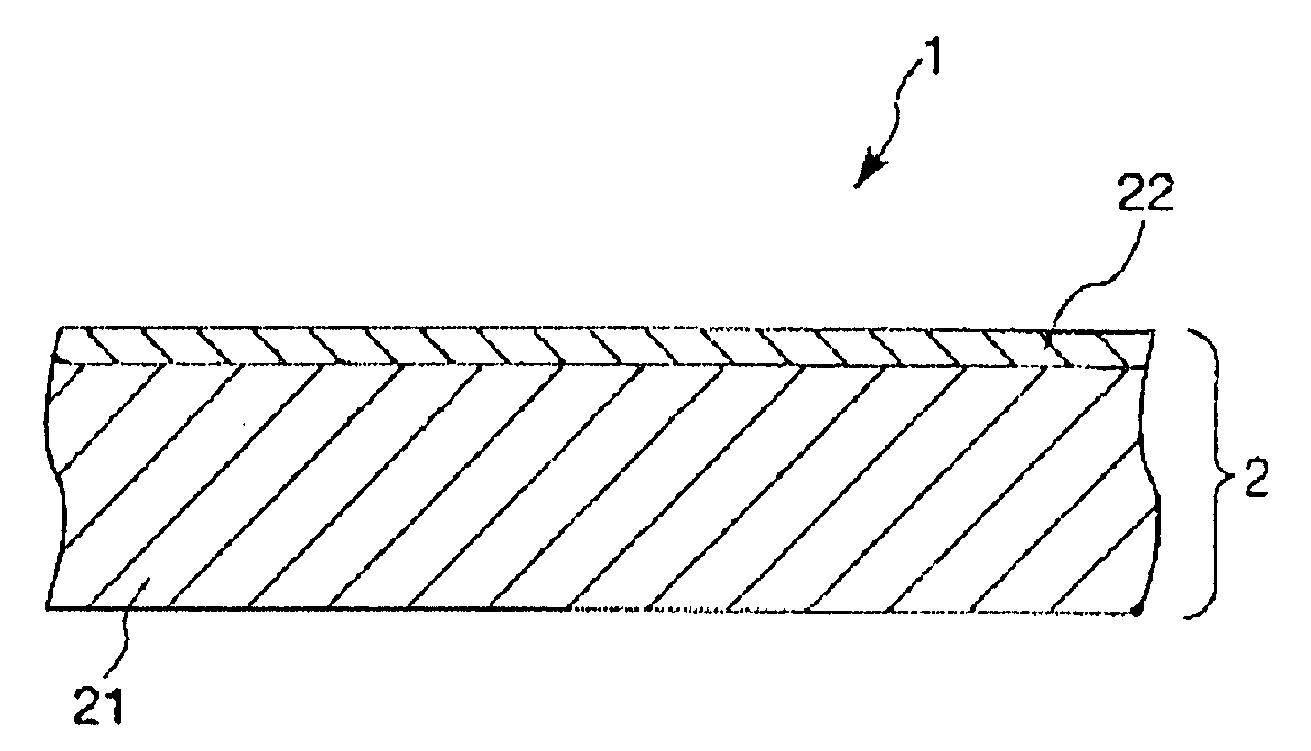

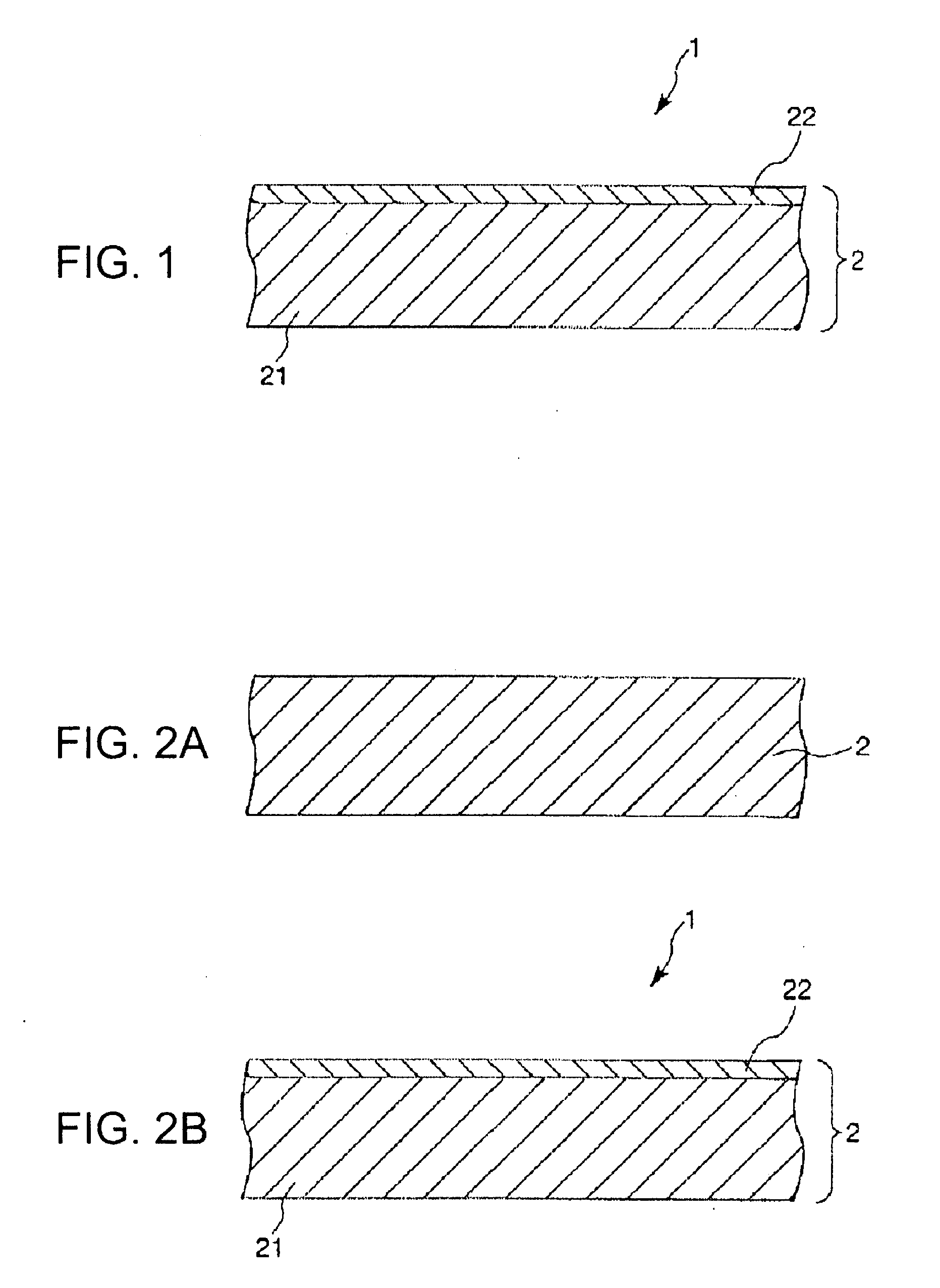

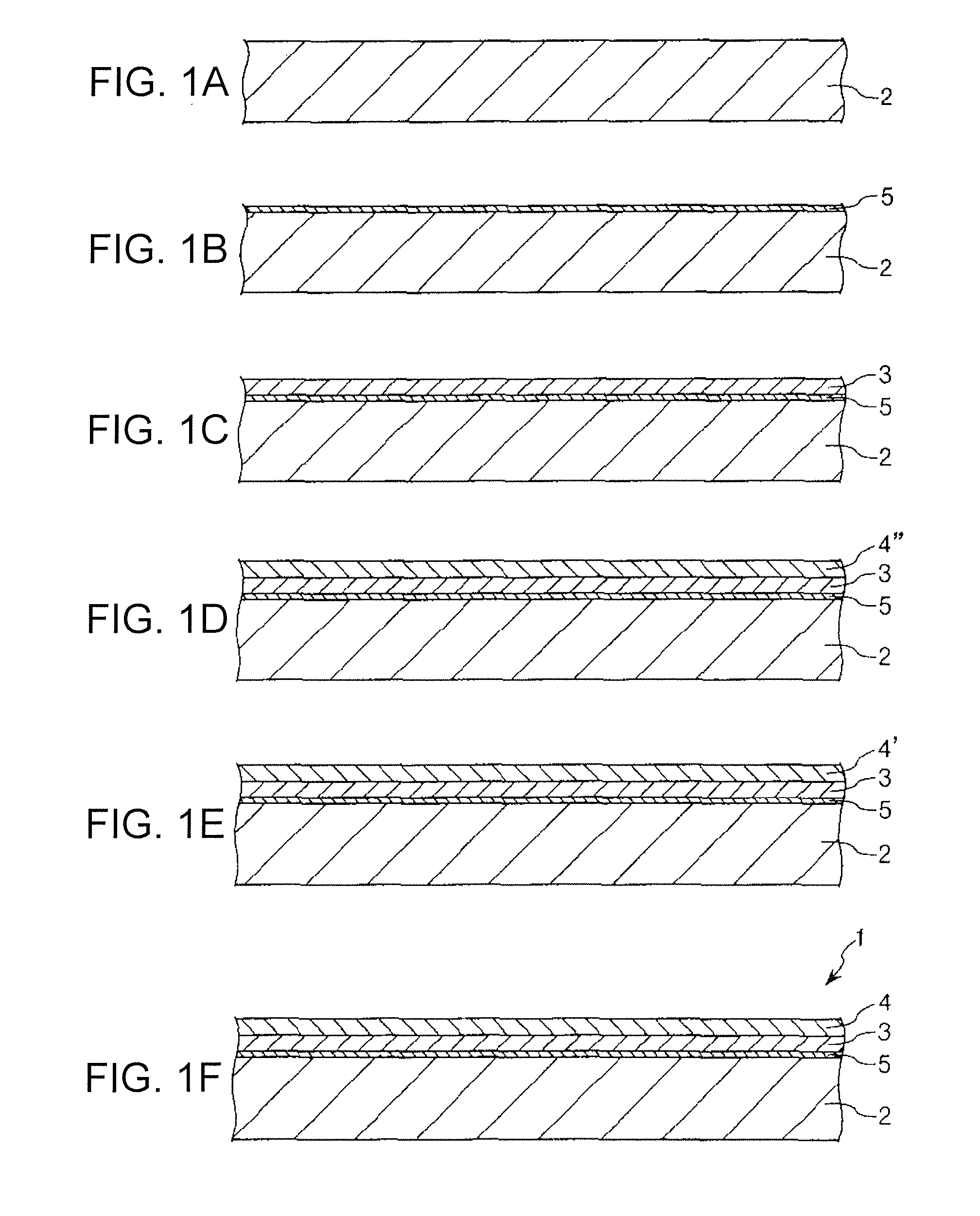

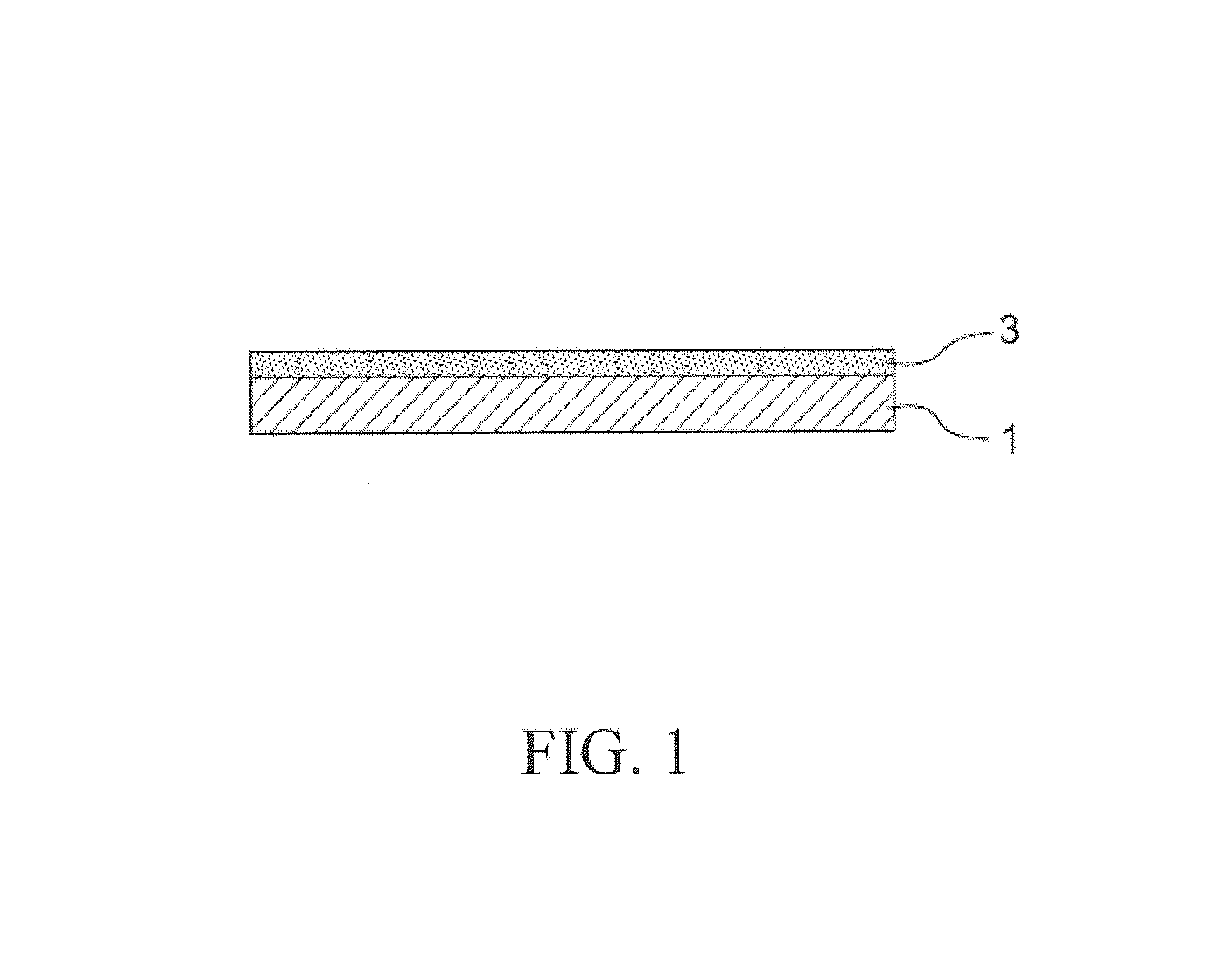

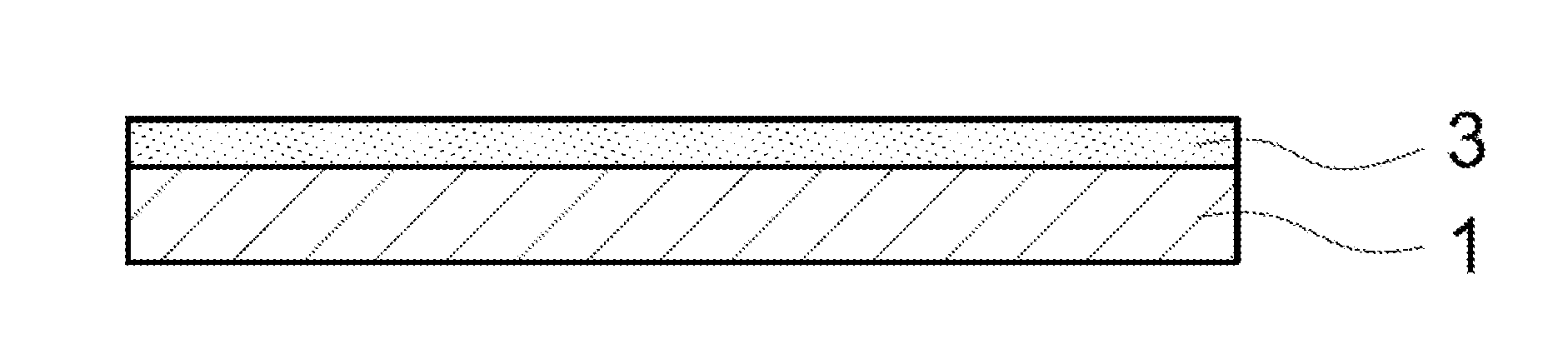

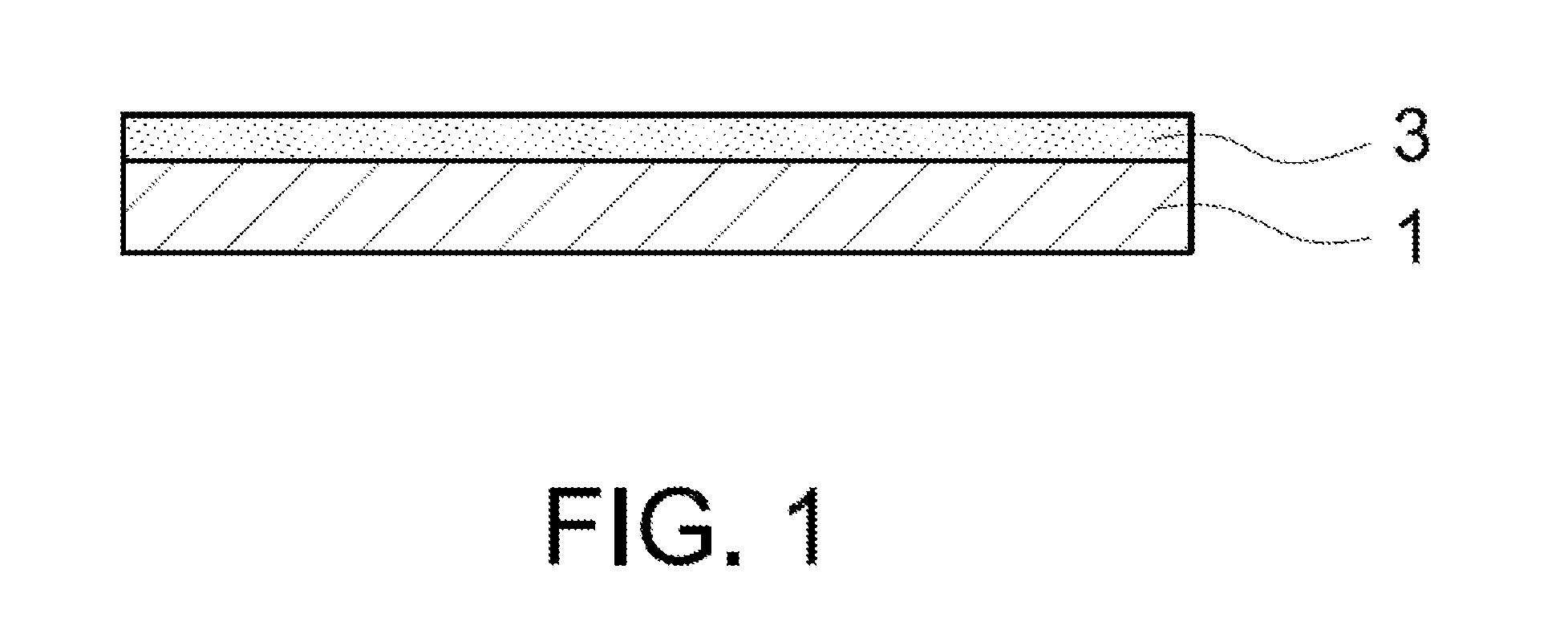

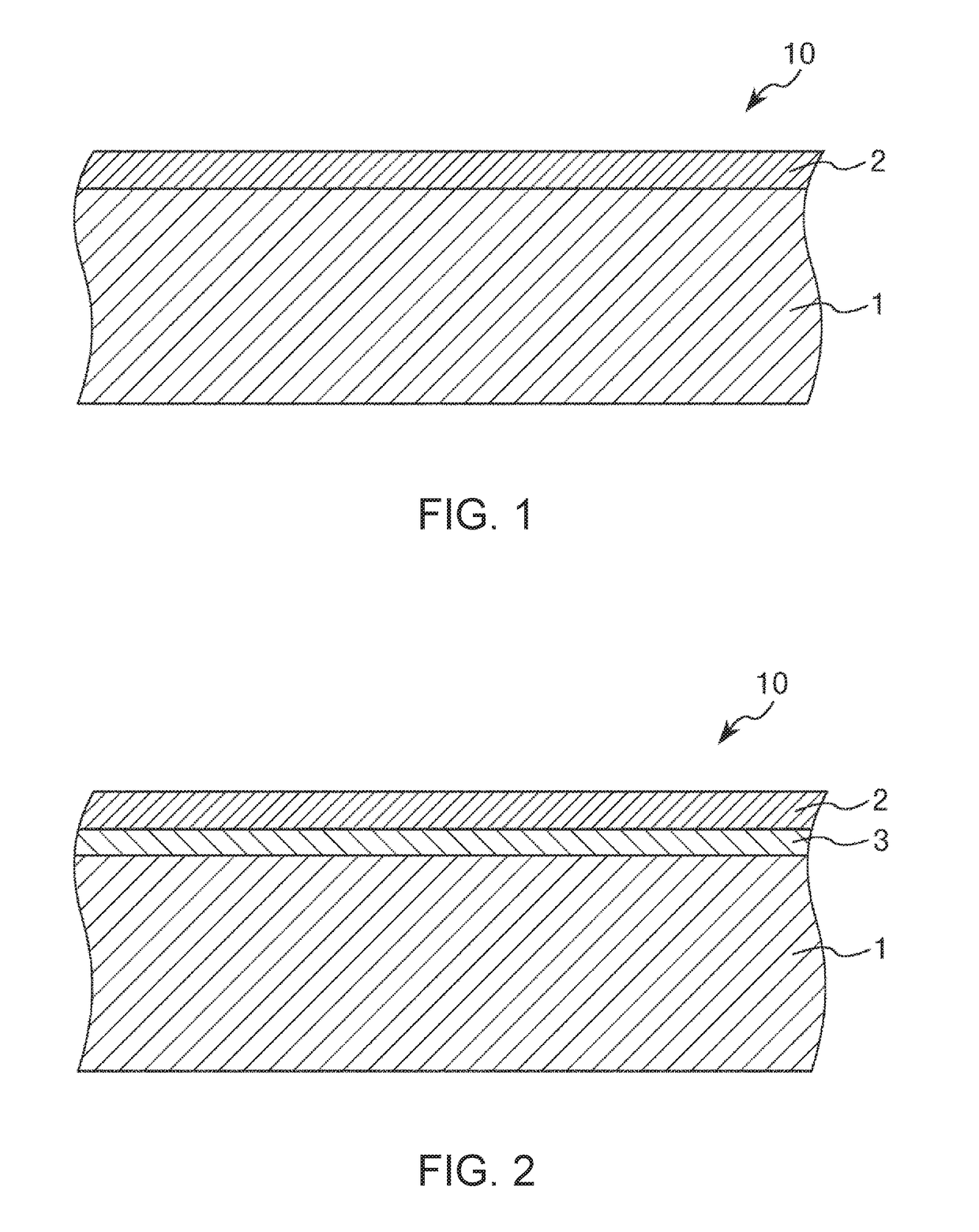

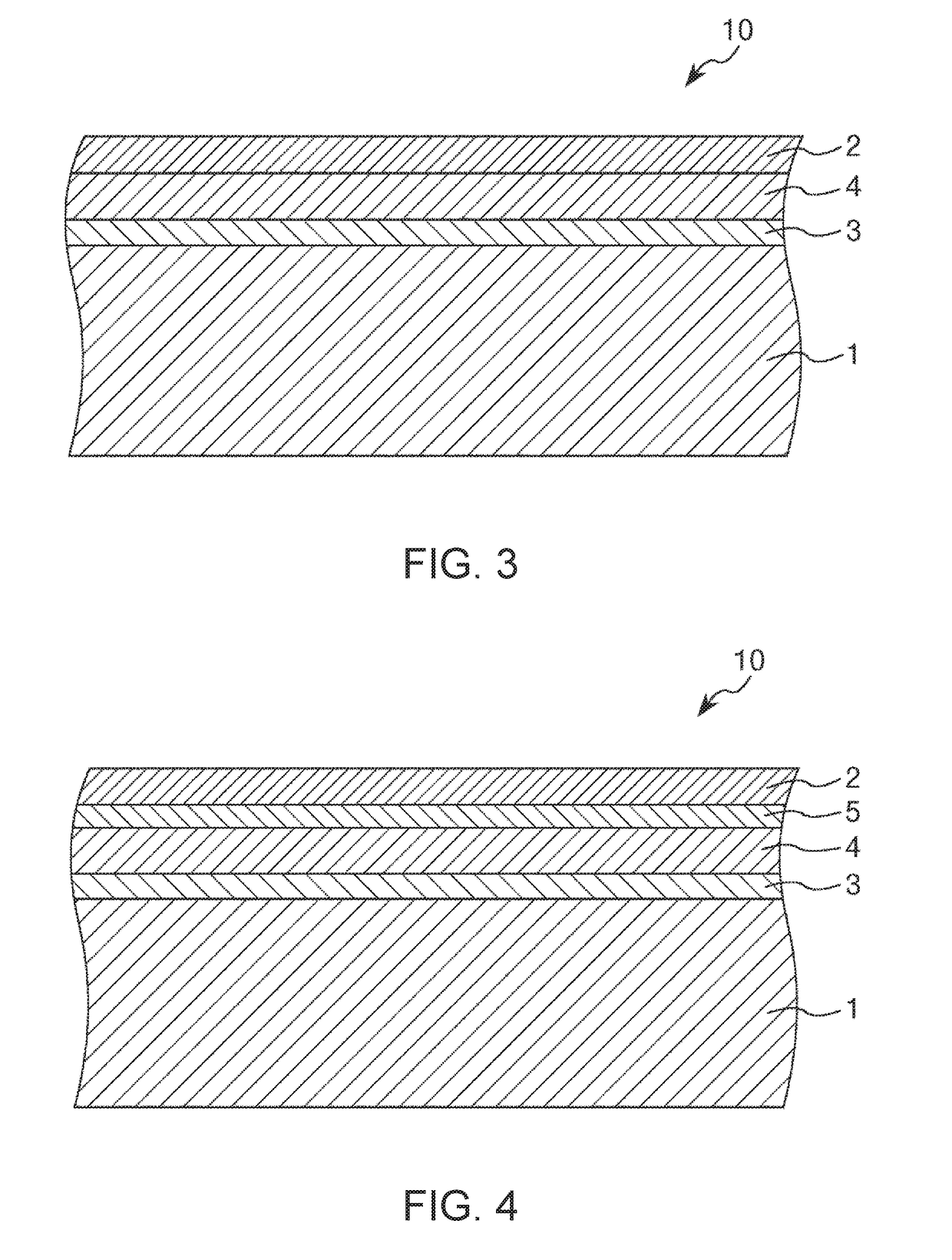

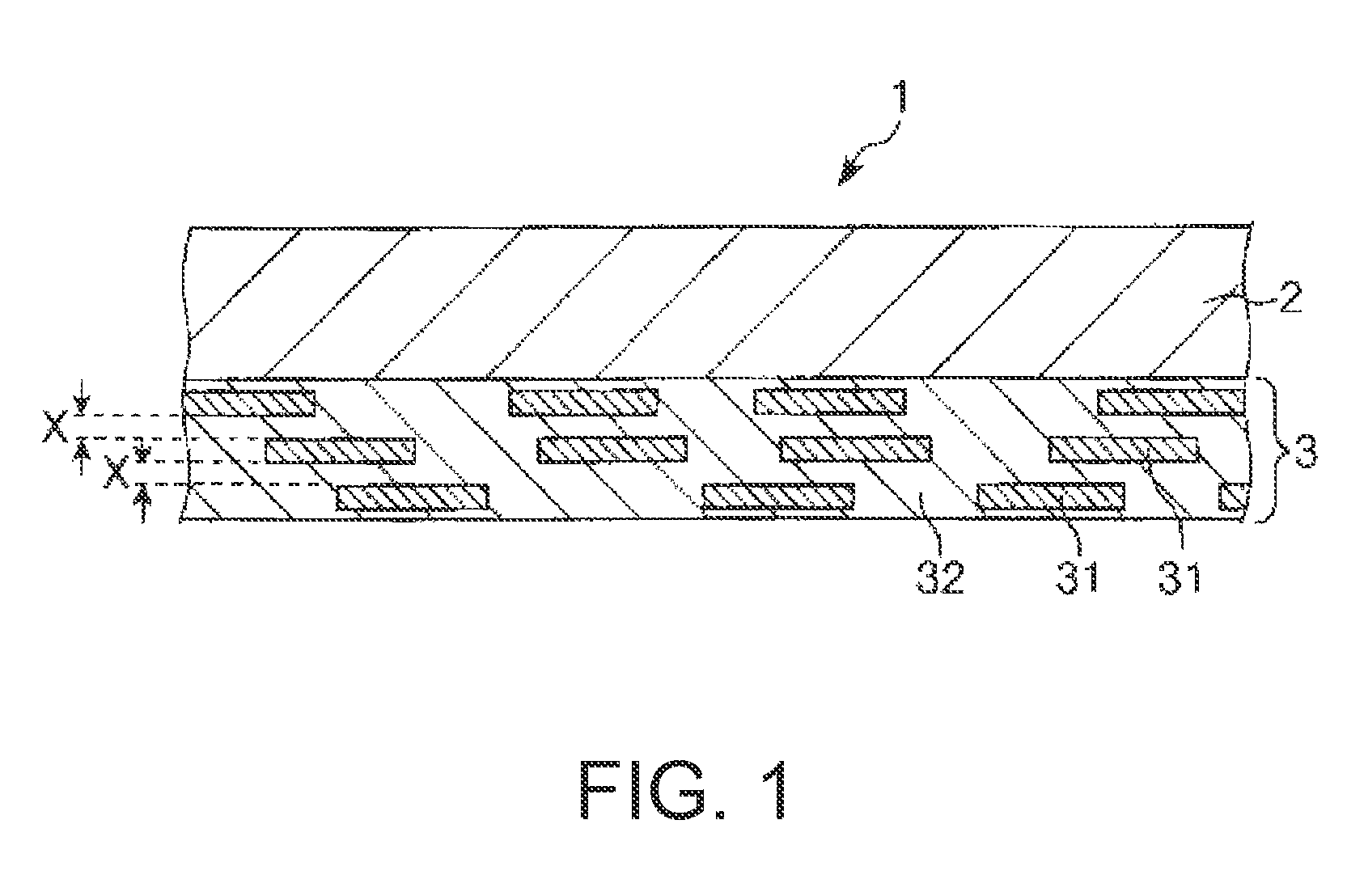

Timepiece dial, method of manufacturing a timepiece dial, and a timepiece

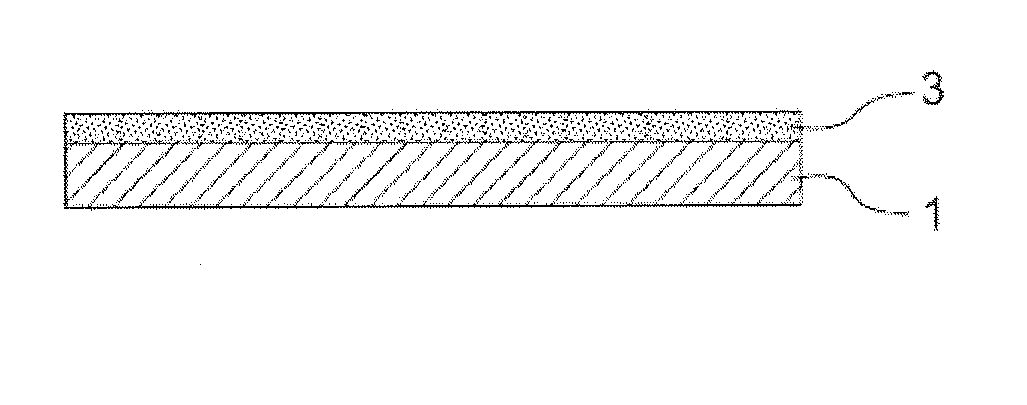

ActiveUS8427909B2Sufficiently pleasing appearanceAppropriate useVisual indicationElectric windingEngineering

A timepiece dial has excellent transparency to electromagnetic waves (radio and light), and an excellent appearance, a timepiece dial manufacturing method enables manufacturing the timepiece dial, and a timepiece has the timepiece dial. The timepiece dial 1 has a substrate 2 that is electromagnetically transparent, and a dispersion film 3 containing a dispersion of metal powder 31 with an average particle diameter of 5 μm≦20 μm and an average particle thickness of 30 nm≦50 nm. The average thickness of the dispersion film 3 is 0.5 μm≦3.0 μm. The metal powder 31 is disposed with a specific gap therebetween in the through-thickness direction of the dispersion film 3.

Owner:SEIKO EPSON CORP

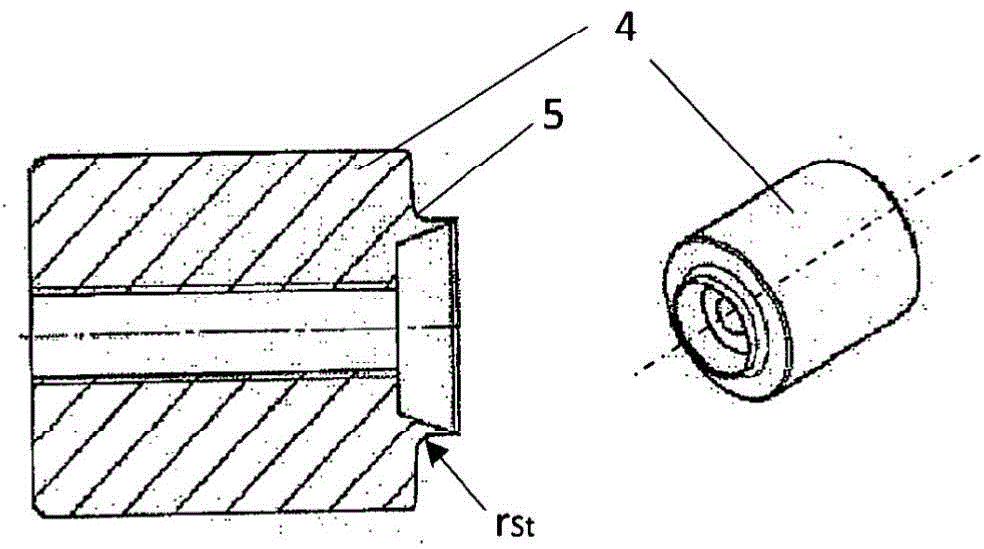

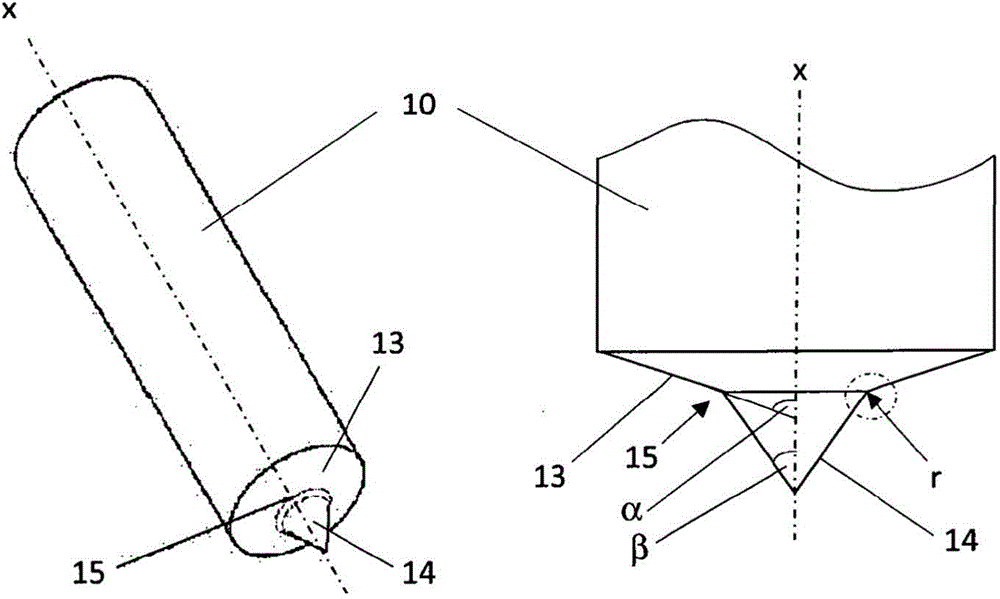

Method for producing polymer motor vehicle component

ActiveCN104936765AIncrease flexibilityLow costWorkpiecesVehicle componentsEngineeringMechanical engineering

The invention relates to a method for producing a polymer motor vehicle component (2), in particular an outer add‑on part in the form of a bumper, spoiler, sill, mud guard or the like. First of all, a polymer body shell part (6) is produced, preferably by means of an injection‑moulding method, wherein, then, at least one aperture (3) is produced in the body shell part (6), optionally by means of a first automated method step, the aperture then defining an inner border (7) of the body shell part (6), and wherein, then, in a separate, second automated method step, a stamped formation (R) of a radius onto the peripheral edge (9) formed by the outer body shell‑part surface (8) and inner border (7) and / or onto an outer edge formed by the outer border of the body shell part (6) takes place by a stamping tool (10) having a contour corresponding to the desired radius (r) of the stamped formation (R) being pressed along the inner border (7) against the peripheral edge (9) and / or along the outer border of the body shell part (6) against the outer edge.

Owner:レーアウオートモーティヴソシエタスヨーロピアウントコンパニーコマンディートゲゼルシャフト

Rosin-fatty acid ester vinylic polymers

This invention relates to novel rosin-alkyl ester of unsaturated fatty acid vinylic polymer and emulsion compositions and the processes for preparing them. In particular, the invention relates to novel rosin-alkyl ester of unsaturated fatty acid vinylic polymer and emulsion compositions which the polymer exhibit properties that make them useful as support resins for industrial coatings, ink and overprint formulations and as additives for formulating various coating compositions; and the emulsion which exhibits properties that make them useful as water-borne vehicles for coatings on various substrates.

Owner:MEADWESTVACO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com