High-gloss antibacterial flame-retardant AS/MS composite material used for bathrooms and preparation method of composite material

A composite material and high-gloss technology, which is applied in the field of bathroom material modification, can solve the problems of poor gloss performance of alloy products, no flame-retardant and anti-bacterial effects of alloys, etc., and achieve excellent yellowing resistance, outstanding flame retardancy, The effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

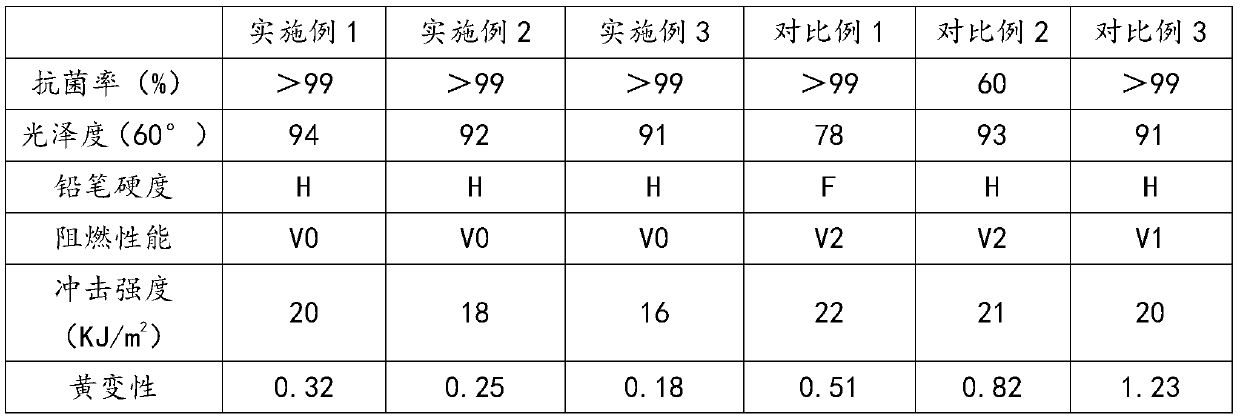

Examples

Embodiment 1、2

[0036] Embodiment 1,2, the antibacterial agent in comparative example 1,2 is nano-silver ion, the antibacterial agent in comparative example 2 is not through ultrasonic treatment; Among the embodiment 3 comparative example 3, antibacterial agent is nano-zinc ion;

[0037] Above-mentioned embodiment and comparative example are prepared according to the following method, and obtain corresponding sample:

[0038] Step a, weighing the AS resin and MS resin and stirring at a low speed for 60 seconds for mixing;

[0039] Step b, adding flame retardant to the mixed material in step a and stirring for 120 seconds;

[0040] Step c, adding lubricant, toughening agent, antibacterial agent and stabilizer to the mixed material in step b by weight percentage and fully stirring for 200 seconds;

[0041] Step d, putting the mixed material in step c into the hopper of the twin-screw extruder, extruding through melting, and granulating;

[0042] Among them, the processing technology is as fol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com