Patents

Literature

1569results about How to "High surface gloss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

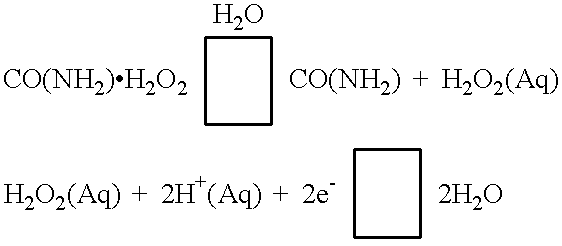

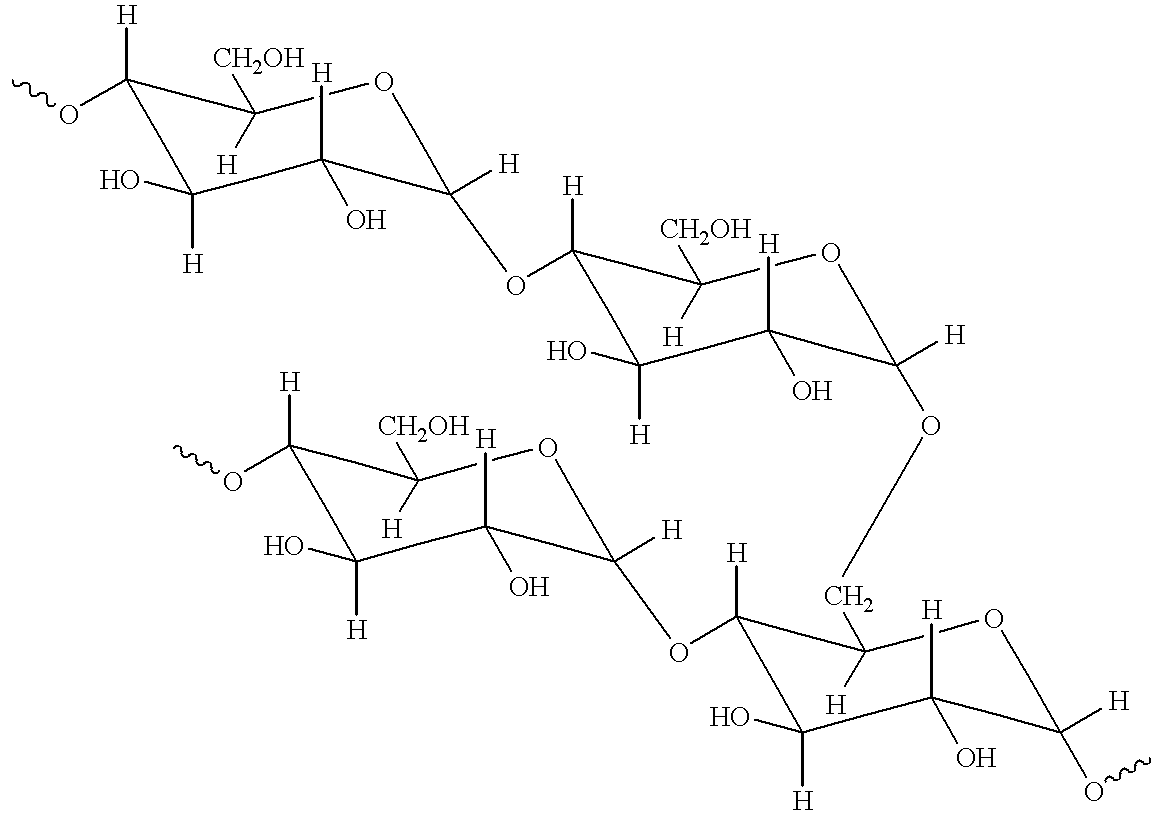

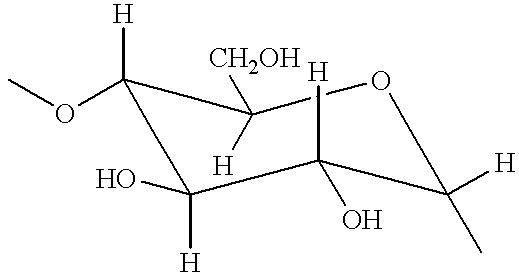

Dentifrice gel/paste compositions

InactiveUS6331291B1Reduce the amount requiredSpeed upCosmetic preparationsTeeth fillingHomopolysaccharideSolid particle

A thixotropic, smooth-flowing liquid, bulk-water-free dentifrice gel / paste that contains a stable mixture of at least one of amylopectin containing discrete solid particles and modified amylopectin containing discrete solid particles, uniformly suspended in and wetted by an inert essentially anhydrous organic hydroxylated liquid matrix material, and which dentifrice gel / paste is characterized by a high surface sheen. Preferably, the modified homopolysaccharide discrete particles contain esterified amylopectin and / or esterified amylose. The dentifrice gel / paste can be used as a toothpaste, a bleaching gel and a brushing gel.

Owner:MCNEIL PPC INC

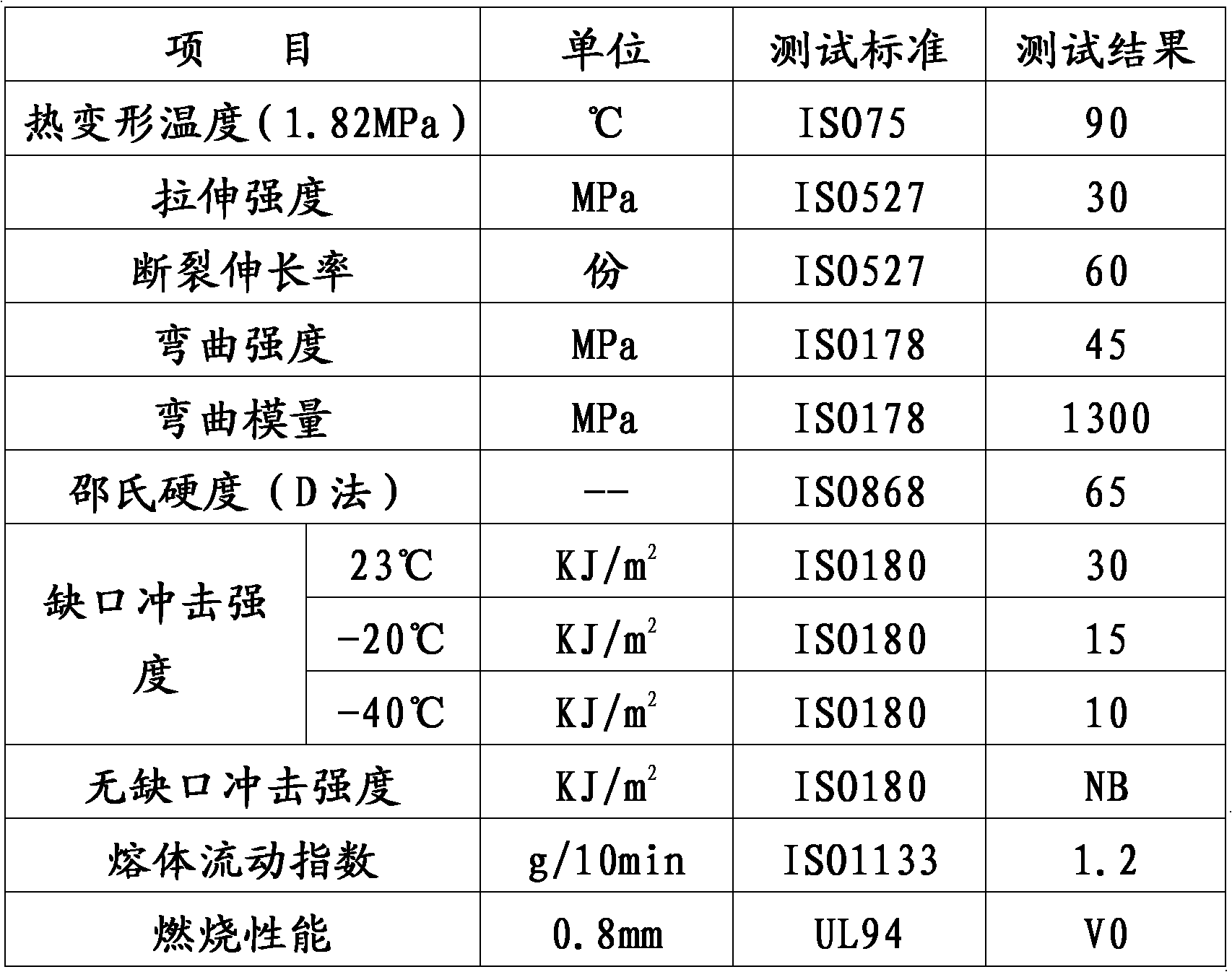

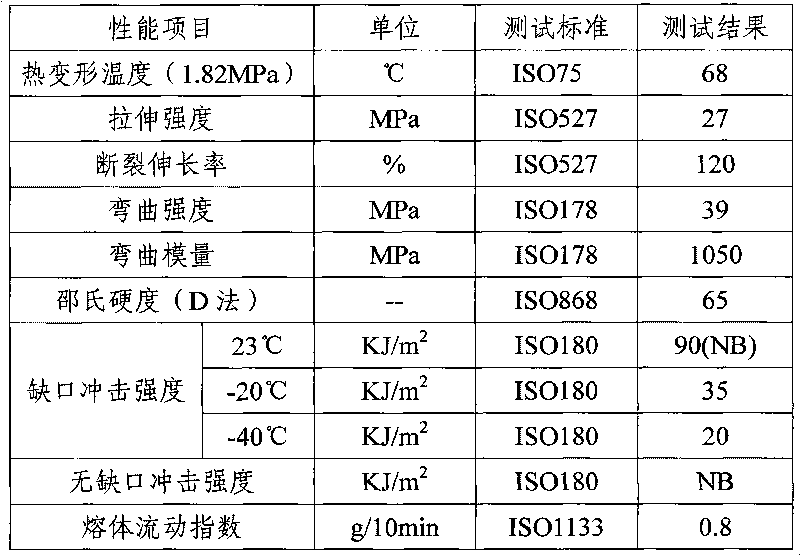

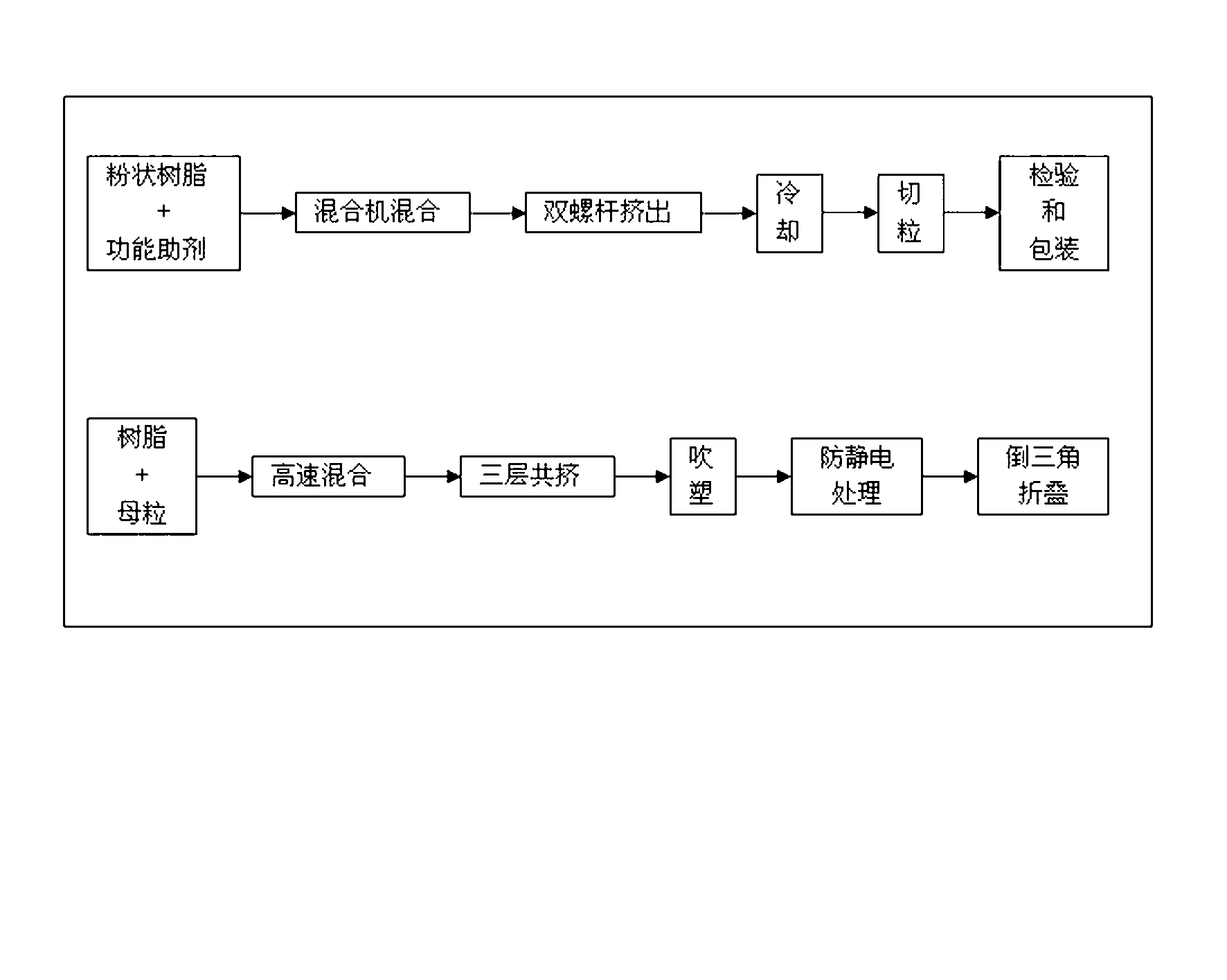

Low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof

The invention relates to a low warping high surface gloss glass fiber reinforced polyester composite material and preparation method thereof. The composite material comprises the following components (wt%): 10-35% of polycarbonate, 20-45% of polybutylece terephthalate, 1-10% of flexibilizer, 3-10% of kaolin and 15-38% of glass fiber; 0.1-1% of antioxidant, 0.1-0.5% of ester exchange inhibiting agent and 0.1-3% of processing agent are prepared, silane coupling agent is utilized to process kaolin, then raw materials are placed into a mixing machine to be mixed for 2-5min, then mixture is placed into a screw machine for extrusion granulation, and meanwhile side charging is carried out on the glass fiber, the rotating speed of screw machine is 180-600rpm, and temperature is 240-280 DEG C, thus obtaining the product. The invention can obtain products with high surface gloss, excellent comprehensive mechanical properties and dimensional stability and especially ensures low warping property of product when being produced into injection moulding product.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

Flame-retardant PP/nylon corrugated tube composite material and preparation method thereof

ActiveCN102050993AImprove flame retardant performanceImprove high temperature resistanceProcedure AgentsManufacturing technology

The invention relates to a corrugated tube material and particularly discloses a flame-retardant PP (Polypropylene) / nylon corrugated tube composite material and a preparation method thereof, aiming to overcome the shortcomings in the prior art that the mechanical property of the PP corrugated tube is bad, the nylon corrugated tube is not flame-retardant, the stability is bad, and the service lifeis short. The material disclosed by the invention comprises the following substances by weight percentage: 47-75 of PP, 3-40 of nylon, 5-30 of flame retardant, 5-20 of compatilizer, 1-40 of flexibilizer, 0-10 of filling master batches, 0.2-1.5 of heat stabilizer, and 0.2-1.5 of processing agent. The preparation method comprises the steps as follows: the filling master batches are firstly preparedand then added into a twin-screw extruder to melt and mix with other materials, and pelletings are extruded out to prepare the flame-retardant PP / nylon composite material. The invention has the advantages of favorable flame-retardant property, excellent high-temperature resistance, friction resistance, chemical corrosion resistance, long service life, high surface glossiness, high electrical insulativity, simple manufacturing technology, and low cost.

Owner:SHANGHAI KINGFA SCI & TECH +1

Low-diffusion modified polypropylene composite material and preparation method thereof

ActiveCN101817953AHigh surface glossImprove impact resistancePolypropylene compositesMolecular sieve

The invention belongs to the field of modified polypropylene composite materials and relates to a low-odor and low-diffusion modified polypropylene composite material suitable for manufacturing interior decorative parts of automobiles. The composite material comprises the following components in part by weight: 60 to 90 parts of polypropylene, 0 to 40 parts of mineral filler, 1 to 5 parts of odor adsorbent and 0.1 to 1 part of assistant, wherein the odor adsorbent is a mixture of three types of clay, bentonite, porous silicon dioxide, activated aluminum oxide or molecular sieve. The prepared modified polypropylene composite material has the characteristics of high surface glossiness, high shock resistance and intensity, melt flowing property and mechanical property; due to the adoption of various gas adsorbents, the product has low odor diffusion property and a total carbon value of between 13.7 and 24.5 mu gC / g; simultaneously, needed raw materials have wide sources and are readily available.

Owner:SUZHOU SUNWAY POLYMER

PP/PA composite material used for corrugated pipe and preparation method thereof

InactiveCN101724197ASolve heat resistanceSettle the priceFlexible pipesProcedure AgentsHeat resistance

The invention discloses a PP / PA composite material used for a corrugated pipe, which is prepared by processing polypropylene, nylon, compatilizer, toughening agent, filling master batch, light stabilizer, heat stabilizer and processing aid. The PP / PA composite material is prepared by feeding the components into mixing equipment according to a proportion, and melting, mixing, scattering, extruding and granulating the components at the temperature of between 210 and 280 DEG C. The PP / PA composite material not only has higher toughness, excellent high impact resistance and bending property and extremely good high temperature resistance, but also are excellent in the aspects of surface gloss, abrasion resistance, chemical corrosion resistance, electric insulation and the like, and solves the defect problems of insufficient heat resistance of the conventional PP corrugated pipe, over-high price of the PA corrugated pipe; and in addition, a preparation method for the PP / PA composite material is simple and meets the requirement of industrialized production.

Owner:SHANGHAI KINGFA SCI & TECH +1

High-impact-resistance less-fiber-floating long glass fiber reinforced polypropylene material

The invention discloses a high-impact-resistance less-fiber-floating long glass fiber reinforced polypropylene material which is prepared from the following components in parts by weight: 10-80% of long glass fiber reinforced polypropylene master batch and 20-90% of high-impact-resistance less-fiber-floating master batch. The long glass fiber reinforced polypropylene master batch is prepared from 8-80% of polypropylene copolymer, 0-80% of polypropylene homopolymer, 10-60% of glass fiber, 1-10% of grafted polypropylene, 0.1-2% of antioxidant and 0.2-2% of processing aid. The high-impact-resistance less-fiber-floating master batch is prepared from 20-80% of polypropylene copolymer, 0-50% of glass fiber, 0-30% of elastomer, 0-30% of grafted elastomer, 0-10% of low-viscosity polyamide resin, 0.1-2% of antioxidant and 0.2-5% of processing aid. The polypropylene material disclosed by the invention has the advantages of high glossiness and less fiber floatings; and the finished product made of the polypropylene material has the advantages of good drop resistance and processability, and can be used for replacing the parts made of engineering plastics.

Owner:WUHAN JINFA TECH CO LTD

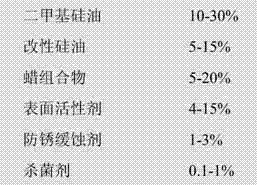

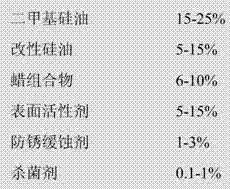

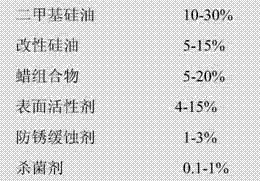

Water-based release agent for aluminum alloy die casting and preparation method thereof

The invention discloses a water-based release agent for aluminum alloy die casting and a preparation method thereof. The release agent comprises, by mass, 10 to 30% of dimethicone, 5 to 15% of modified silicone oil, 5 to 20% of a wax composition, 4 to 15% of a surfactant, 1 to 3% of an anti-rust corrosion inhibitor and 0.1 to 1% of a bactericide, with the balance being deionized water. The preparation method comprises the following steps: heating dimethicone, modified silicone oil, the wax composition and the surfactant to a temperature of 70 to 80 DEG C and carrying out uniform mixing with stirring; slowly adding deionized water accounting for 30 to 40% of the total weight of the release agent with stirring in batches so as to prepare an oil-in-water O / W pre-emulsion; and carrying out grinding by using a colloid mill and adding the anti-rust corrosion inhibitor, the bactericide and residual deionized water so as to obtain the water-based release agent with an emulsion particle size of 0.1 to 0.4 mu m. According to the invention, modified silicone oil is used as main base oil, so emulsification difficulty is lowered down, heat resistance is improved, and good high temperature stability is obtained; the wax composition has excellent lubrication capability and a good film forming effect. The release agent has excellent heat resistance, excellent lubricity and a good film forming effect.

Owner:上海福岛新材料科技有限公司

Moulding-grade wood-plastic composite and processing process

InactiveCN101024709AImprove high temperature fluidityExcellent formabilityCoatingsMoulding gradeStearic acid

The invention relates to an injection moulding wood plastic compound material and the process technology. It is made up from recycled P or HDPE or PVC 100 portions, wood flour 80-130 portions, chlorinated polyethylene 5-10 portions, polyethylene wax 0.5-5.0 portions, geoceric acid or stearate 1.0-5.0 portions, nanometer reinforcing agent 4.0-8.0 portions, organic esters flexibilizer 5.0-15.0 portions, and PE grafted by maleic anhydride 5.0-20 portions. Mixing the materials at low speed (300-600round / min), high speed (1500-2500 round / min), low speed (300-600 round / min) for 5-10min, 25-40min, and 5-10min, the premixed material would be gained. After being extruded from extruder, the moulding wood plastic compound material would be gained. It could be widely used in producing complex shaped products.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

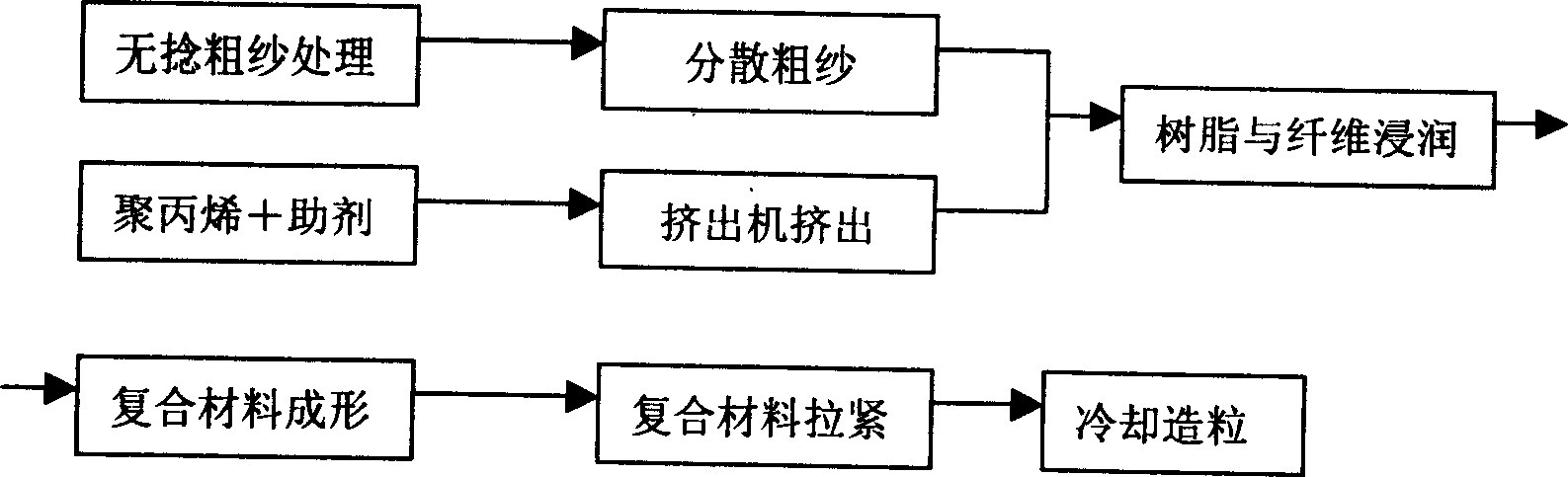

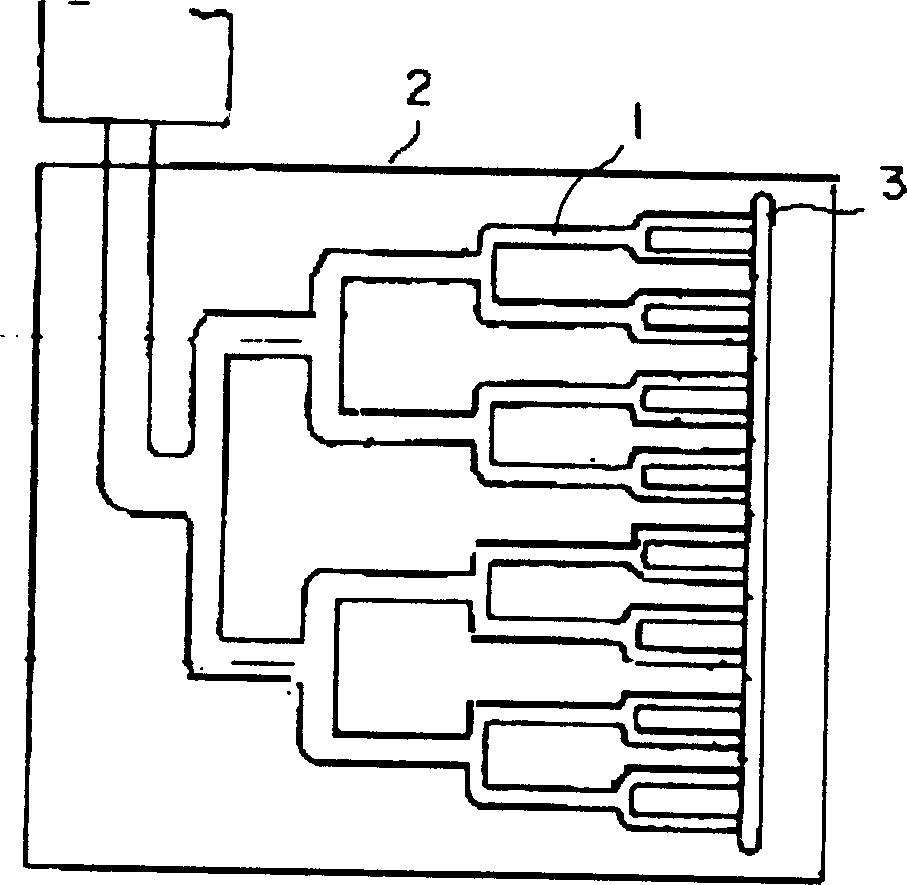

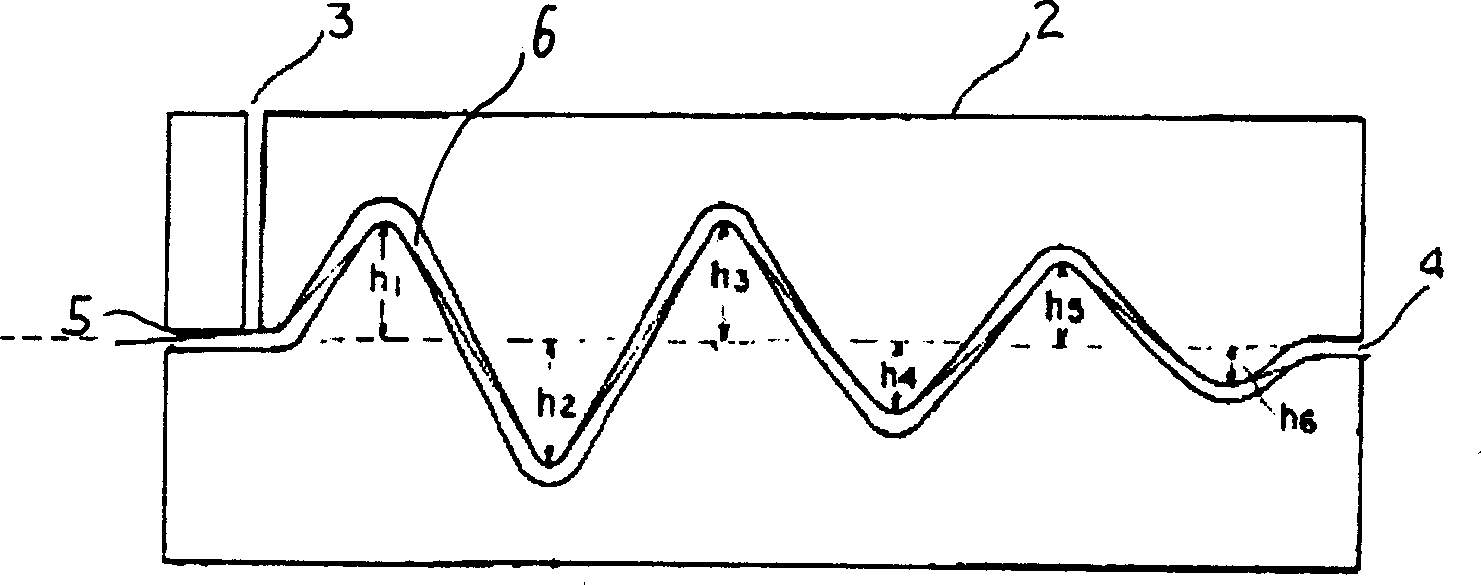

Continuous fiber reinforced composite materials, its production method and special equipment therefor

The invention relates to a glass fiberreinforced thermoplastic composite and a continuous fiber-reinforced composite, which are prepared with the following raw materials percentagewise by weight: 35-60 % of resin, 35-60 % of dip treated glass fiber and 0.5-5 % of auxiliary agent. The invention adopts resin and dip treated glass fiber as main raw materials, mixtures of antioxidant, ultraviolet absorbent and light-stability agent as main auxiliary agents, with logical formulations, eliminates the damage to glass fibrous surface caused by twin-screw with continuous fiber-reinforced composite producted by this manufacturing technique, improves product lustrous surface, binding properties between fiberglass and resins by a treatment for glass fibrous surface and mechanical properties of products, protects the materials for long periods from destruction because of addition of various stabilizing agents, and solves the limitation that general materials can not be used for a long time in extreme conditions such as high temperature, high humidity, radiation and so on.

Owner:JIANGSU QIYI TECH

Preparation method of 3D printing inorganic powder molding material

InactiveCN103936392ASmall median diameterStable in natureClaywaresMaterials preparationPolyvinyl alcohol

The invention discloses a preparation method of a 3D printing inorganic powder molding material. The method is characterized in that the method comprises the following steps: 1, powder material pretreatment: mixing 10-30% of acetone with 62-85% of a powdery material and 2-10% of gamma-(2,3-epoxypropoxy)propyltrimethoxysilicane, and grinding the obtained mixture at a rotating speed of 500-1000rpm for 1-2h to obtain a pretreated powdery material; and 2, molding material preparation: adding 40-65% by mass of acetone, adding 2-8% of polyvinyl formal, stirring for dissolving, adding 30-55% of the pretreated powdery material, stirring for uniform mixing, putting the obtained solution in a grinder, carrying out normal temperature mixing grinding at a rotating speed of 500-1000rpm for 6-9h, and carrying out spray drying to obtain the 3D printing inorganic powder molding material. The 3D printing inorganic powder molding material can be directly molded at a temperature of 190-210DEG C under a pressure of 1-10MPa without sprinkling a binder, and has the advantages of simple preparation technology, easy condition control, low production cost and easy industrialized production.

Owner:UNIV OF JINAN

Three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film

ActiveCN103264563AGood colorEasy to processClimate change adaptationSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a nano fog-dissipation multifunctional greenhouse agricultural film, and in particular relates to a three-layer co-extruded EVA (ethylene-vinyl acetate copolymer) long-life fog-dissipation environment-friendly multifunctional greenhouse film, belonging to the field of agricultural mulching films. The raw material formula of an outer layer comprises the following components in percentage by weight: 20-50% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE), 10-20% of metallocene polyethylene (mPE) and 5-10% of double-prevention masterbatch; the raw material formula of a middle layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 20-40% of linear low-density polyethylene (LLDPE), 20-40% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; the raw material formula of an inner layer comprises the following components in percentage by weight: 30-40% of ethylene-vinyl acetate copolymer (EVA), 10-20% of linear low-density polyethylene (LLDPE), 20-50% of low-density polyethylene (LDPE) and 5-10% of three-prevention masterbatch; and the formulas of the outer layer, the middle layer and the inner layer are uniformly mixed respectively, master batches are prepared by using a double-head thread screw double-screw extruding machine, a three-layer film is formed through a co-extrusion die head and is extruded out to prepare the multifunctional agricultural greenhouse film. Every quality technical index of the film reaches or exceeds a national standard, and a small part of the indexes is more than 2 times better than the national standard, so that the film is excellent in antiaging performance and cannot generate fog drops, and the service life of the film reaches more than 3 years.

Owner:HENAN YINFENG PLASTIC

Modified polylactic acid composite material suitable for 3D printing and preparation method of composite material

The invention relates to a modified polylactic acid composite material suitable for 3D printing and a preparation method of the composite material. The modified polylactic acid composite material suitable for 3D printing is prepared from the following raw materials in percentage by weight: 80-90% of polylactic acid, 6-10% of a flexibilizer, 1-2% of a nucleating agent, 1-3% of a dispersing agent, 1-2% of a chain extender and 1-3% of a compatilizer. The preparation method of the modified polylactic acid composite material suitable for 3D printing comprises the following steps: mixing the raw materials by virtue of a high-speed mixer, and extruding and drawing by using a single-screw extruder. Compared with the prior art, the composite material prepared by the method is good in flexibility; meanwhile, the impact strength, the heat resistance and the breakage elongation can be greatly improved; the printing is smooth when the composite material is used for 3D printing; the finished product has the advantages of smooth surface, beautiful and shapely appearance and stable size.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

High heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified material and preparation method thereof

ActiveCN103059465AImprove wear resistance and heat resistanceImprove surface gloss and surface smoothnessPelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to high heat resisting and high abrasion resistant polyvinyl chloride (PVC) modified materials and a preparation method of the high heat resisting and high abrasion resistant PVC modified materials. The modified materials comprise the following raw materials, by weight, 80-120 parts of PVC resin, 25-60 parts of stuffing bulking agents, 21-60 parts of plasticizer, 1-10 parts of chlorinated polyvinyl chloride, 1-10 parts of fire retardant, 1-10 parts of stabilizer, 1-10 parts of impact modifier and 0.2-2 parts of lubricating agents. The raw materials are weighed according to parts by weight and are blended. After being blended, the raw materials are extruded out to be granulated through a double-screw extruder to produce the modified materials. The modified materials are good in heat resisting property and abrasion resistant property, environment-friendly, high in strength, good in flame retardant effect, strong in compressing property and toughness, good in processing property and good in comprehensive property. The preparation method is simple in craft, convenient to operate and control, stable in quality and high in production efficiency, and can be produced in a large scale industrialization mode.

Owner:广东祺龙科技有限公司

Plant fiber-reinforced polylactic acid foam material and preparation method thereof

The invention discloses a plant fiber-reinforced polylactic acid foam material, which is prepared from the following components: 20 to 95 percent of polylactic acid, 1 to 60 percent of plant fiber powder, 1 to 5 percent of foaming agent, 1 to 5 percent of nucleating agent, 1 to 5 percent of antioxidant and 1 to 5 percent of bulking agent. The invention also discloses a preparation method for the material. The foam material has the advantages of low apparent density, biodegradability, no environmental pollution, capacity of replacing polyolefin foam materials, wide application in the fields of heat insulation, buffer and packaging, simple preparation process and high production efficiency.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

ActiveCN103059468AGood flexibility and electrical insulation propertiesImprove low temperature resistancePelletizingPlasticizer

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 20-45 parts of filling agent, 41-80 parts of plasticizer, 1-10 parts of cold-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed, after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The low temperature resistant performance of the modified material manufactured by the preparing method is fine; the minimum usage temperature can reach below 65 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in technology, convenient to control and operate, stable in quality, high in production efficiency. In addition, the preparation method of the low temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large scale industrial production.

Owner:广东祺龙科技有限公司

Low-emanation automobile inner fitting special-purpose material and preparation thereof

The invention relates to a kind of low emission type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, organic expellent of low molecule 1.0-3.0 parts, antioxidant 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and organic expellent of low molecule, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 3) three-stage vacuum extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

Two-component epoxy resin adhesive for stone skin patching and preparation thereof

ActiveCN101314704AHigh surface glossGood yellowing resistanceEpoxy resin adhesivesAdhesive cementPolymer science

The invention relates to a double-component epoxy resin adhesive for repairing stone surface and the preparation method thereof. The double epoxy resin adhesive is composed of a component A consisting of epoxy resin and diluting agent, and a component B consisting of curing agent, optical stabilizer and UV absorber. The double-component epoxy resin adhesive is used for repairing microcrack on stone surface and ant road, and has the advantages of moderate curing speed, good yellowing-resistant performance, good permeability, high glossiness after cured and polished, easily-obtained environment-friendly material, simple process, etc.

Owner:HUNAN SHENLI IND

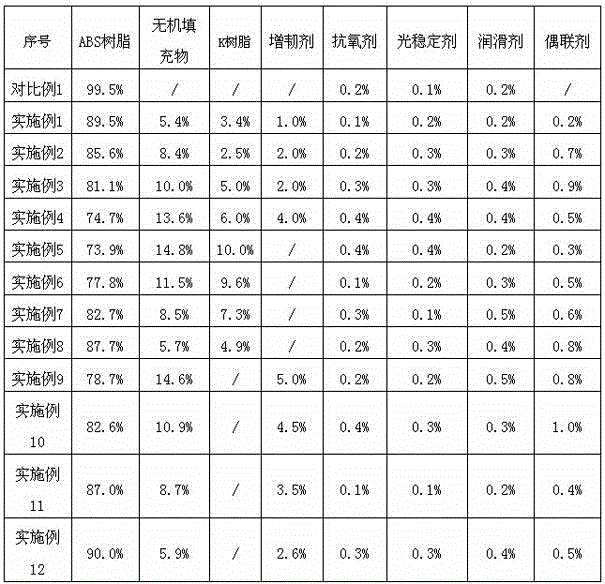

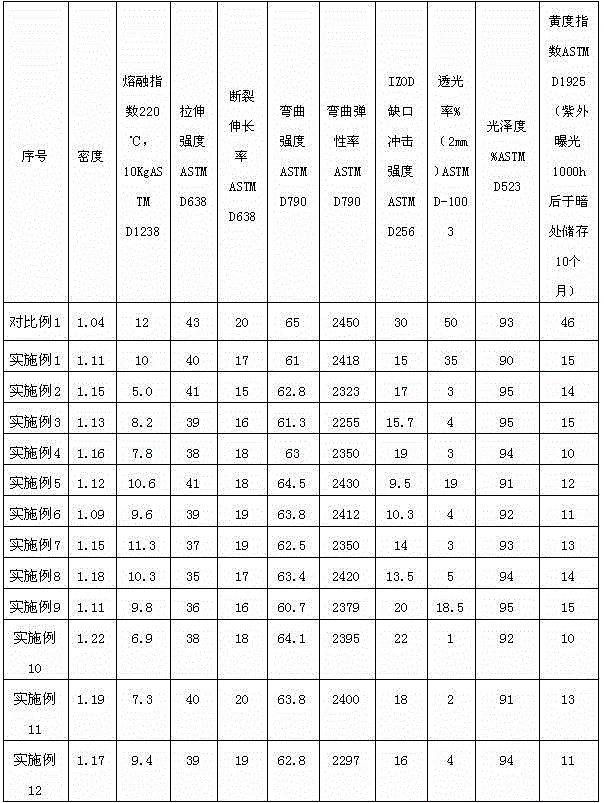

High-light-shading acrylonitrile butadiene styrene (ABS) composite material and preparation method thereof

The invention relates to the technical field of modification of acrylonitrile butadiene styrene (ABS) materials and in particular relates to a high-light-shading ABS composite material and a preparation process thereof. The ABS composite material consists of the following raw materials in percentage by weight: 70 to 90 percent of ABS resin, 5 to 15 percent of an inorganic filler, 0 to 15 (0 to 10) percent of a styrene-butadiene copolymer, 0 to 10 (0 to 5) percent of a flexibilizer, 0.1 to 0.5 percent of an antioxidant, 0.1 to 0.5 percent of a light stabilizer, 0.1 to 0.5 percent of a lubricating agent and 0.2 to 1.0 percent of a coupling agent. The high-light-shading ABS composite material has white appearance and high light-shading performance, meets the requirements of shells of IT equipment and lampshades of lighting lamps on high light-shading performance and light aging resistance, and has high surface gloss.

Owner:GUANGDONG SILVER AGE SCI & TECH CO LTD

Low-diffusion modified polypropylene composite material and preparation method thereof

ActiveCN101817953BHigh surface glossImprove impact resistancePolypropylene compositesMolecular sieve

Owner:SUZHOU SUNWAY POLYMER

Phenyl organic silicon modified polyurethane resin, preparation method and application thereof

ActiveCN104387546AImprove surface propertiesSmall water absorptionPolyethylene glycolMethyl phenyl polysiloxane

The invention discloses a phenyl organic silicon modified polyurethane resin, a preparation method and application thereof, and belongs to the field of polyurethane resin. The structural formula of the phenyl organic silicon modified polyurethane resin is as shown in the description; the preparation method of the phenyl organic silicon modified polyurethane resin comprises the following steps: dissolving phenylsilanediol into an organic solvent, taking a reaction with chlorosilane (R<2>SiCH3Cl2) to prepare hydroxyl-terminated methyphenyl polysiloxane, under the action of a catalyst, mixing the hydroxyl-terminated methyphenyl polysiloxane with a silane compound to obtain amino or imino terminated methyphenyl polysiloxane, then in the atmosphere of argon, mixing diisocyanate, amino or imino terminated methyphenyl polysiloxane, polyethylene glycol or polyol with a mixed solvent, and taking a reaction to obtain the phenyl organic silicon modified polyurethane resin. The phenyl organic silicon modified polyurethane resin has the advantages of being capable of reducing the water absorption, improving the hydrophobicity, and improving the compatibility of organic silicon and polyurethane, and can be prepared to thin film with good properties; the preparation method is simple and feasible.

Owner:WUHAN UNIV

Anticorrosive coating containing rron oxide red

InactiveCN103173102AGood metal adhesionStructural pores are smallAnti-corrosive paintsEpoxy resin coatingsChemistryDibutyl tin dilaurate

The invention discloses an anticorrosive coating containing iron oxide red, which comprises two components A and B, wherein the component A comprises the following raw materials in parts by weight: 68-77 parts of epoxy resin E44, 20-25 parts of high chlorinated polyethylene resin, 5-7 parts of titanium dioxide, 5-7 parts of zinc borate, 2-3 parts of catechol, 1-2 parts of iron oxide red, 2-4 parts of sodium hexametaphosphate, 2-4 parts of dibutyltin dilaurate, 3-6 parts of propylene glycol, 2-4 parts of poly (butyl acrylate), 3-5 parts of stearic acid, 2-3 parts of polyacrylamide, 2-3 parts of diphenylamine, 2-5 parts of diethylene glycol dibenzoate, 3-4 parts of zinc stearate, 1-2 parts of hexamethylene tetramine, 10-25 parts of compound modifier, 25-30 parts of dimethylbenzene, 8-10 parts of n-butyl alcohol, 0.8-1 part of 3-(methacryloxy) propyl trimethoxy silane and 0.5-1 part of simethicone. The coating disclosed by the invention has the advantages of good metal adhesive force, small structural pore, compact structure, excellent adhesive force, good flexibility, high impact strength and good corrosion resistance and is capable of playing an efficient protection role to base metal.

Owner:ANHUI MINGZHU PIGMENT TECH

High temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and preparing method thereof

The invention relates to the technical field of polyvinyl chloride composite materials, in particular to a high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material and a preparing method thereof. The modified material comprises by weight, 80-120 parts of PVC resin, 30-70 parts of filling agent, 31-70 parts of plasticizer, 1-10 parts of hot-resistant modifying agent, 1-10 parts of fire retardant, 1-10 parts of stabilizing agent, 5-15 parts of impact modifier and 0.2-2 parts of lubricating agent. Each raw material is weighed by weight and mixed after being stirred; the raw material is squeezed out of prilling through a double-screw extruder and the modified material is available. The hot temperature resistant performance of the modified material manufactured by the preparing method is fine; the maximum usage temperature can reach up to 135 DEG C. The modified material is environment-friendly and has the advantages of high intensity, good flame retardant effects, strong compression performance and toughness, excellent processing performance and better comprehensive performance. The preparing method of the high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material has the advantages of being simple in process, convenient to control and operate, stable in quality, and high in production efficiency. In addition, the preparation method of the high temperature resistant environment-friendly polyvinyl chloride (PVC) modified material can be used for a large-scale industrial production.

Owner:广东祺龙科技有限公司

Scraping-resistant automobile inner fitting special-purpose material and preparation thereof

ActiveCN101255253AExcellent surface scratch resistanceLow costUltimate tensile strengthPolypropylene

The invention relates to a kind of scraping tolerance type special material for ornament in motor and preparation method, comprising(by weight parts): polypropylene 80-90 parts, superfine talcum powder 10-20 parts, lubricant 0.5-3.0 parts, antioxidant1010 1.0-2.0 parts. The method comprises: 1) stirring and mixing the polypropylene and lubricant, antioxidant at rotate speed of 300-500 rpm for 3-5 minutes; 2) adding superfine talcum powder and stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes; 3) stirring and mixing at rotate speed of 1500-2000 rpm for 10-15 minutes; 4) stirring and mixing at rotate speed of 300-500 rpm for 5-10 minutes to obtain premix material; 5) extruding the premix material by extruder to pelletizen finally the finished product being obtained. The invention has features: low odor emission, low cost, high surfaceness, better impact resistance, intension and toughness and good melt flowing, widely used in production of ornament in motor.

Owner:南京金杉合成材料有限公司

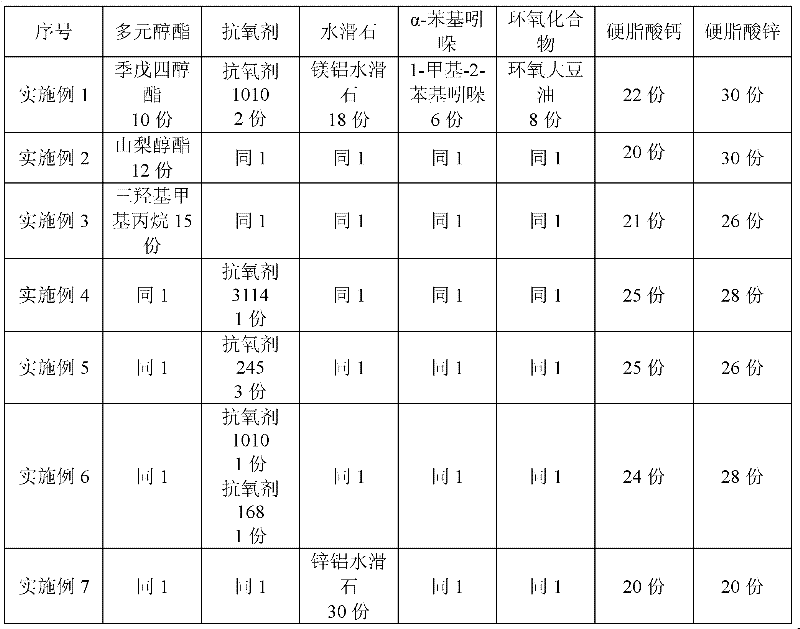

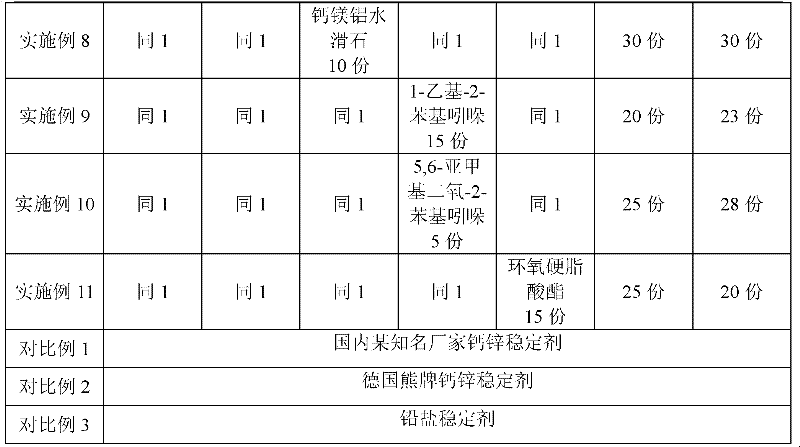

High-efficiency environment-friendly stabilizing agent used for PVC section bars

The invention relates to a high-efficiency environment-friendly stabilizing agent used for PVC section bars, which belongs to the technical field of PVC processing aids. The stabilizing agent comprises the following raw materials by weight: 20 to 30 of calcium stearate, 20 to 30 of zinc stearate, 10 to 15 of polyol ester, 1 to 3 of an anti-oxidant, 0.5 of an ultraviolet ray absorber, 10 to 30 of hydrotalcite, 3.5 of beta-diketone, 5 to 15 of alpha-phenylindole and 8 to 15 of epoxy compounds. The invention enables the problem of thermal decomposition of PVC section bars during processing to beovercome and the problem of discoloring because of long-term illumination and exposure in air during daily usage of PVC section bars to be solved, meeting developmental needs of section bars in China.

Owner:SHANDONG RUIFENG CHEM

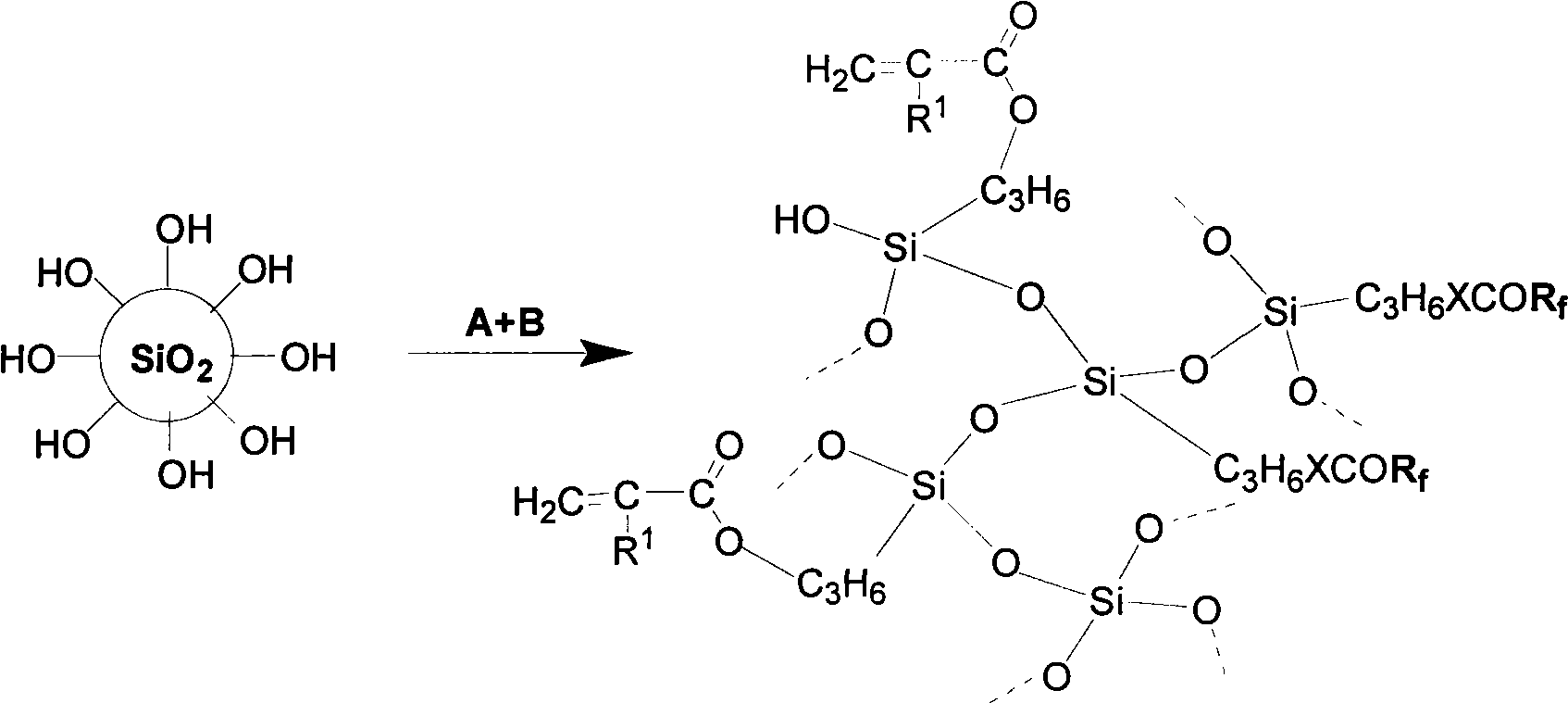

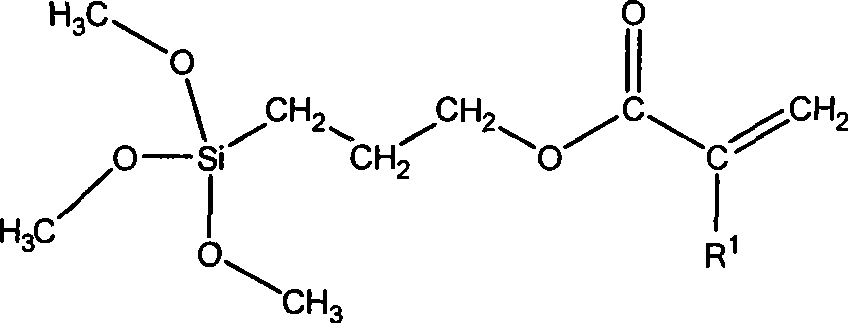

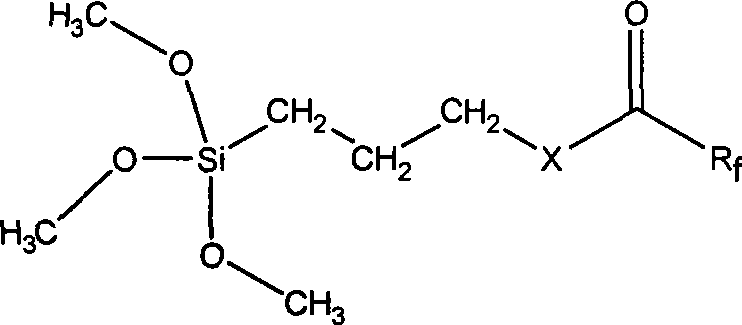

Surface modified nano silicon dioxide and acrylic resin coating containing the same

InactiveCN101497749AGood water and oil resistanceImprove stain resistanceCoatingsPigment treatment with non-polymer organic compoundsPolymer scienceWeather resistance

The invention discloses a nano-silicon dioxide which is functionalized by acrylic ester and modified on surface by perfluoro alkoxy, a method for preparing the nano-silicon dioxide, and an acrylic resin coating containing the nano-silicon dioxide. The acrylic resin coating containing the nano-silicon dioxide also contains single-functional acrylic ester, acrylic ester containing at least two acrylic ester groups, alcoholic solvent and evocating agent. The acrylic resin coating containing fluorine and silicon can be quickly solidified, and the coating film hereby formed has excellent oil resistance, water resistance, weather resistance, pollution resistance, surface hardness and surface gloss.

Owner:浙江池河科技有限公司

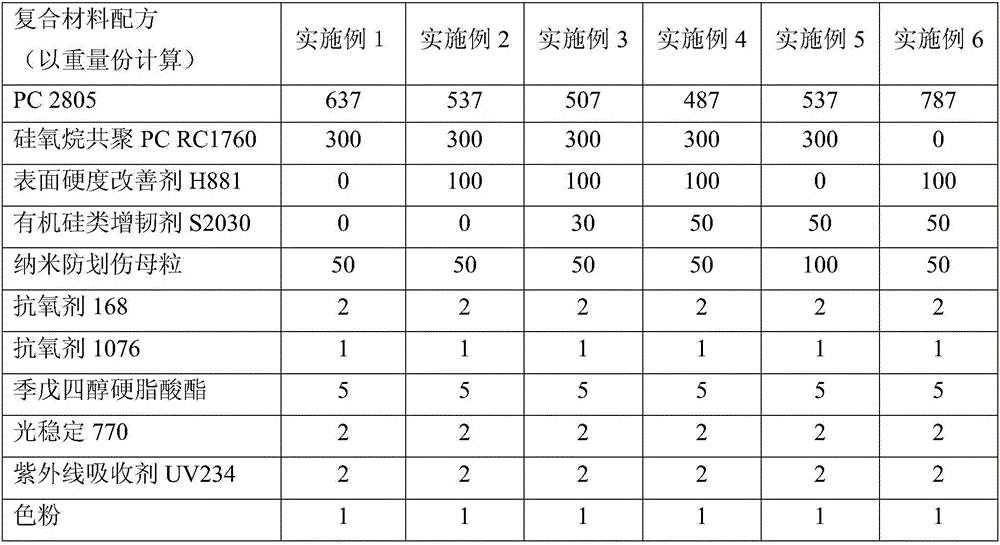

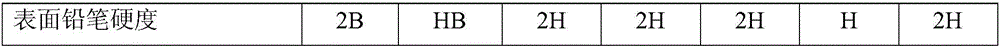

Transparent low-temperature-resistant scuffing-resistant polycarbonate composite material

The invention relates to the field of polymer composite materials, in particular to a transparent low-temperature-resistant scuffing-resistant polycarbonate composite material. The polycarbonate composite material is prepared from, by weight, 300-800 parts of bisphenol A polycarbonate resin, 100-500 parts of siloxane copolymerized PC resin, 10-50 parts of organosilicone flexibilizer, 50-200 parts of surface hardness improving agent, 10-100 parts of nanometer scuffing-resistant master batch and 5-15 parts of additive. The siloxane copolymerized PC, the surface hardness improving agent and the nanometer scuffing-resistant master batch are composited for use, on the basis that the luminousness and the basic mechanical properties of PC are uninfluenced, the surface hardness and the low-temperature properties of the material are improved, the surface hardness can be increased to 2 H, the abrasion resistance of the surface of a product is obviously improved, and the surface glossiness and the weather resistance are also improved. Moreover, the surface tension of the product can be increased, and the product is easier to clean; the composite material is good in mechanical property, high temperature impact property and low temperature impact property.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

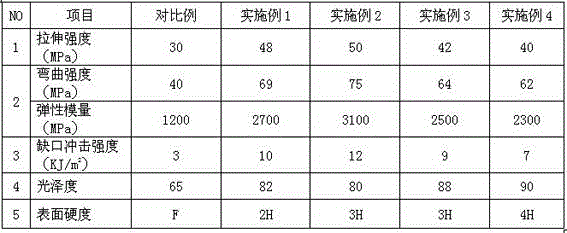

High-hardness scratch-resistant high-gloss modified polypropylene (PP) material

The invention discloses a high-hardness scratch-resistant high-gloss modified polypropylene (PP) material, belonging to the technical field of high polymer materials. The high-hardness scratch-resistant high-gloss modified PP material is prepared from the following raw materials in parts by weight: 40-80 parts of homopolymerized or copolymerized PP, 5-30 parts of polymethyl methacrylate (PMMA), 15-20 parts of barium sulfate, 5-10 parts of glass fiber, 0.5-10 parts of modifier, 5-20 parts of compatilizer and 0.2-0.8 part of coupling agent. PP is compatible with PMMA to ensure that the mechanical strength of the material is improved, meanwhile, the surface hardness and corrosion resistance of the product are improved, and the surface gloss of the product is increased; inorganic fillers of glass fiber and barium sulfate are filled into the modified PP material disclosed by the invention to ensure that the mechanical performance of the product is further improved, and meanwhile, the glossiness of the product is improved; various antioxidants, weather resistance agents, antistatic agents and anti-freezing agents are added into the modified PP material disclosed by the invention to ensure the service life of the product, prevent the product from aging, and ensure that the product can adapt to various environments and can be normally used under rigorous conditions.

Owner:杭州金州高分子科技有限公司

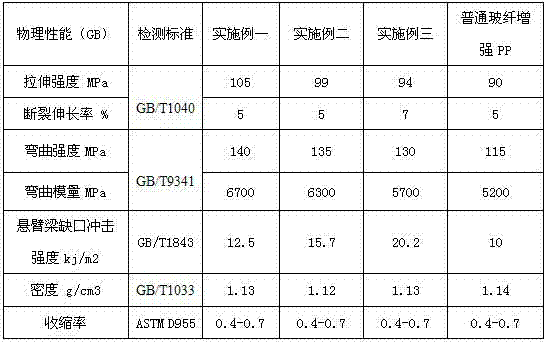

Reinforced polypropylene composite material and preparation method thereof

InactiveCN103589058ARaw materials are easy to getSolving Recycling ProblemsPolypropylene compositesGlass fiber

Owner:ORINKO NEW MATERIAL CO LTD

Normal-temperature sealer for anodic oxide film of aluminum and aluminum alloy and sealing method thereof

InactiveCN101665970AQuick sealImprove sealing efficiencySurface reaction electrolytic coatingTetramineDodecylsulfonic acid

The invention provides a normal-temperature sealer for an anodic oxide film of aluminum and aluminum alloy. The sealer is characterized by comprising the following components in concentration (g / L): Ni<2+>0.8-1.3, F<-> 0.4-0.8, triethanolamine 0.1-5.0, hexamethylene tetramine 0.1-1.0, sodium dodecanesulphonate0.001-0.1, bloom inhibitor 0.01-2.0 and the balance of water. The invention also discloses a sealing method for the sealer. Compared with the prior art, the sealer has the advantages of low cost, easy preparation, easy operation, and great improvement on the surface anti-pollution ability, the anti-corrosion property and the electric insulativity of the anodic oxide film of the aluminum alloy.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

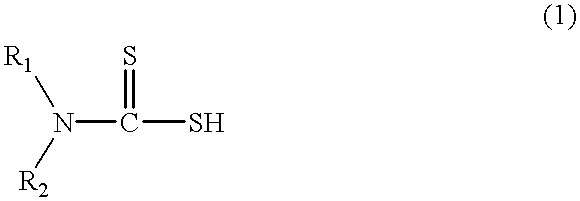

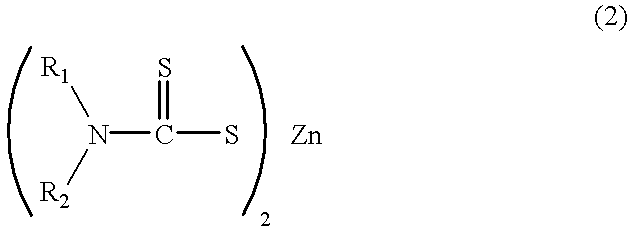

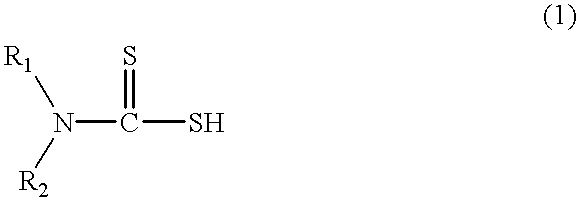

Dipping latex composition and rubber articles made therefrom by dipping

InactiveUS6187857B1High surface glossMaintain good propertiesGroup 4/14 element organic compoundsCatheterNitrosamineConjugated diene

A vulcanizable dip-forming rubber latex composition comprising an unsaturated nitrile-conjugated diene copolymer rubber latex, a sulfur-containing vulcanizer, and a vulcanization accelerator comprising at least one compound selected from (i) dithiocarbamic acid compounds of the formula:and (ii) zinc dithiocarbamate compounds of the formula:wherein R1 and R2 are hydrocarbon groups having at least 6 carbon atoms which may be the same or different, and an optional thiazole compound. A rubber article dip-formed from the rubber latex composition has no crack occurrence, good surface luster and good vulcanization properties, and does not contain a nitrosamine, and therefore, is suitable for medical use.

Owner:ZEON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com