High-light-shading acrylonitrile butadiene styrene (ABS) composite material and preparation method thereof

A composite material, high shading technology, applied in the field of ABS material modification, can solve the problems of no material shading performance, reduced light transmittance, high processing cost, improve interface bonding performance and dispersion, reduce resin melt viscosity, Enhance the effect of UV aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

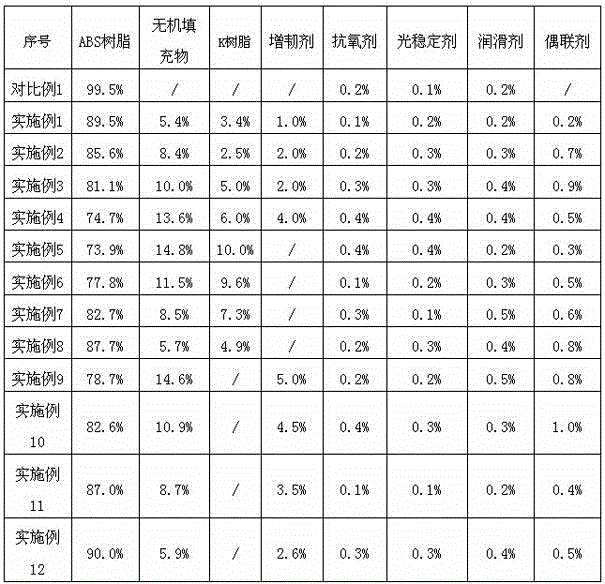

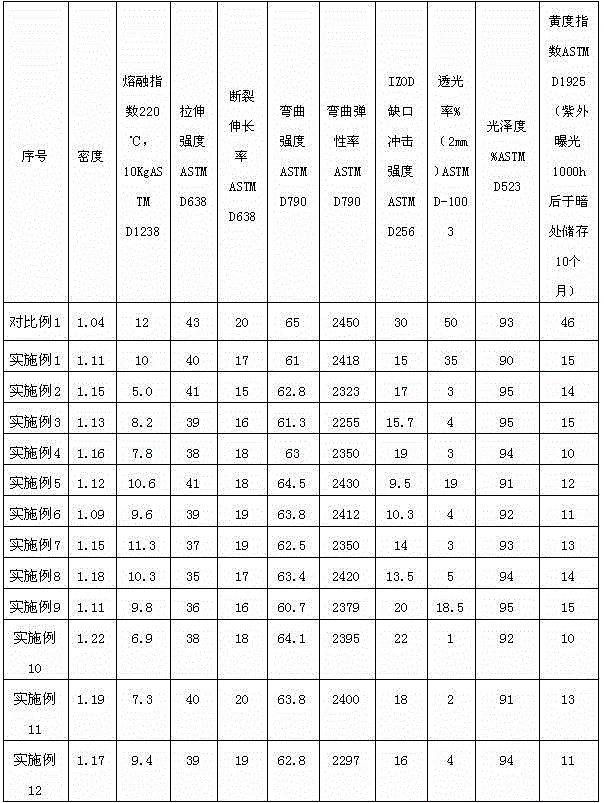

Embodiment 1

[0085] A high light-shielding ABS composite material, which is composed of the following raw materials in weight percentage: ABS resin 89.5%, inorganic filler 5.4%, styrene-butadiene copolymer 3.4%, toughening agent 1%, antioxidant 0.1%, Light stabilizer 0.2%, lubricant 0.2%, coupling agent 0.2%.

[0086] Wherein, the ABS resin is BASF ABS GP22;

[0087] Wherein, the inorganic filler is barium sulfate;

[0088] Wherein, the toughening agent polybutadiene grafted acrylonitrile styrene copolymer (ABS high rubber powder);

[0089] Wherein, the antioxidant is a compounded mixture of antioxidant 168 and antioxidant 1010 in a mass ratio of 1:1;

[0090] Wherein, the light stabilizer is 2-(-2H-benzotriazol-2-yl)-p-cresol;

[0091] Wherein, the lubricant is magnesium stearate;

[0092] Wherein, the coupling agent is silane coupling agent KH560.

[0093] The preparation method of the high shading ABS composite material of the present embodiment compr...

Embodiment 2

[0098] A high light-shielding ABS composite material, which is composed of the following raw materials in weight percentage: ABS resin 85.6%, inorganic filler 8.4%, styrene-butadiene copolymer 2.5%, toughening agent 2%, antioxidant 0.2%, Light stabilizer 0.3%, lubricant 0.3%, coupling agent 0.7%.

[0099] Wherein, the ABS resin is Chimei ABS747;

[0100] Wherein, the inorganic filler is titanium dioxide;

[0101] Wherein, the toughening agent is polybutadiene grafted methacrylate styrene copolymer (MBS);

[0102] Wherein, the antioxidant is a compounded mixture of antioxidant 168 and antioxidant 1076 in a mass ratio of 1:1;

[0103] Wherein, the light stabilizer is bis(2,2,6,6-tetramethyl-4-piperidinyl) sebacate;

[0104] Wherein, the lubricant is ethylene bis stearamide;

[0105] Wherein, the coupling agent is silane coupling agent KH560.

[0106] The preparation method of the high shading ABS composite material of the present embodiment c...

Embodiment 3

[0111] A high light-shielding ABS composite material, which is composed of the following raw materials in weight percentage: ABS resin 81.1%, inorganic filler 10%, styrene-butadiene copolymer 5%, toughening agent 2%, antioxidant 0.3%, Light stabilizer 0.3%, lubricant 0.4%, coupling agent 0.9%.

[0112] Wherein, the ABS resin is a mixture of BASF ABS GP22 and Chimei ABS747 in a mass ratio of 1:1;

[0113] Wherein, the inorganic filler is a mixture of barium sulfate and titanium dioxide in a weight ratio of 3:2;

[0114] Wherein, the toughening agent is polybutadiene grafted acrylonitrile styrene copolymer (ABS high rubber powder);

[0115] Wherein, the antioxidant is a compounded mixture of antioxidant 1010 and antioxidant 1076 in a mass ratio of 1:1;

[0116] Wherein, the light stabilizer is 2-(-2H-benzotriazol-2-yl)-p-cresol and bis(2,2,6,6-tetramethyl-4-piperidinyl)decanedi A mixture of acid esters compounded at a mass ratio of 1:1;

[0117] Where...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com