Array substrate, manufacturing method of array substrate, and display device

An array substrate and pixel electrode technology, which is applied in the fields of semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of reducing the display effect of the display device, affecting the shading effect of the drain, etc., so as to improve the display effect, reduce the reflection effect, The effect of reducing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

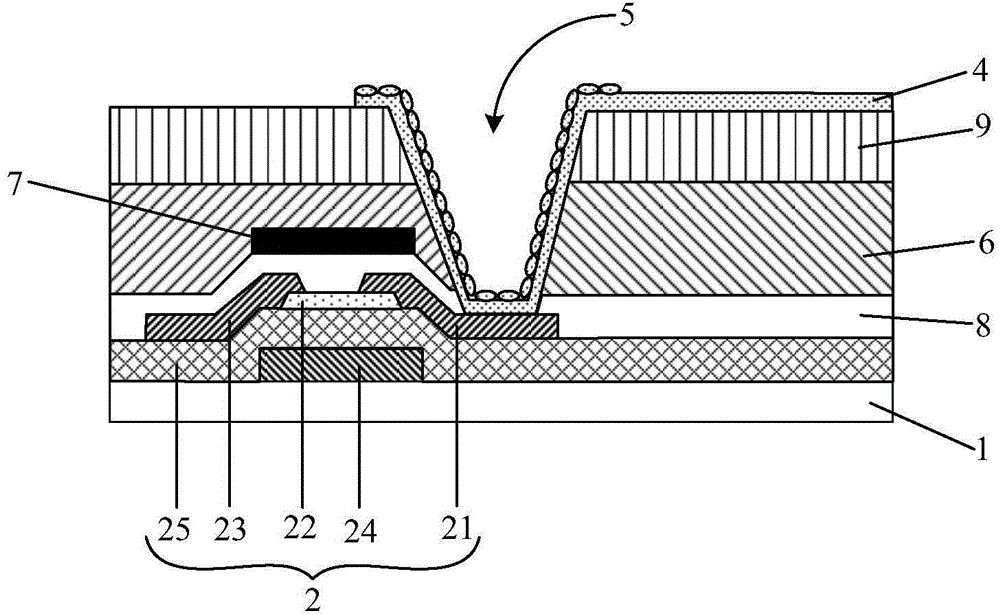

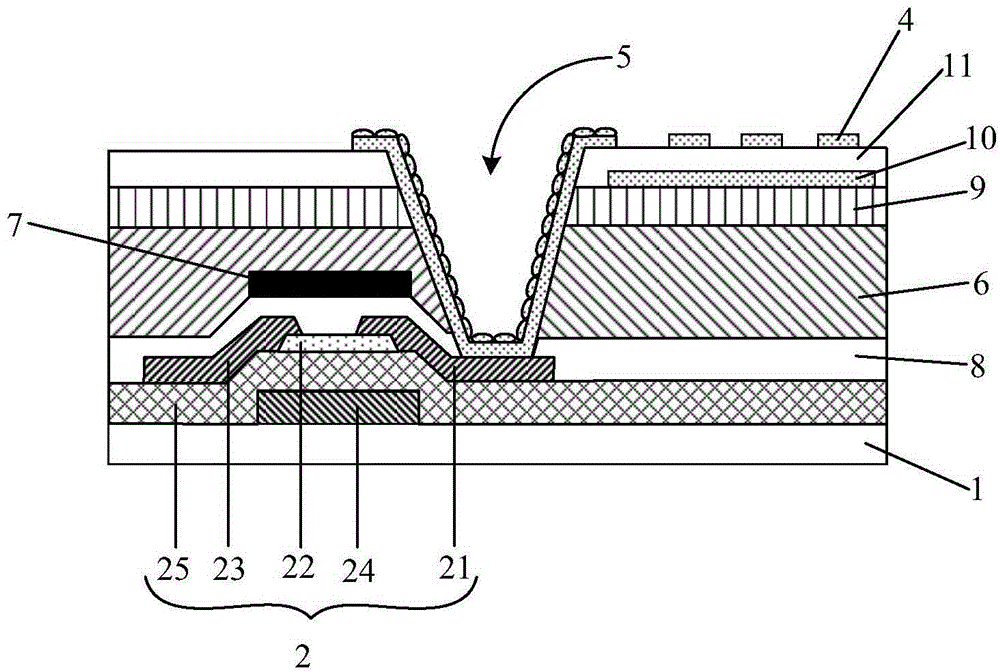

[0037] An embodiment of the present invention provides an array substrate, such as figure 1 As shown, the array substrate includes:

[0038] The drain 21, the insulating layer 3 and the pixel electrode 4 of the thin film transistor unit 2 located on the base substrate 1, the insulating layer 3 is located between the drain 21 and the pixel electrode 4, the insulating layer 3 A via hole 5 is formed through which the drain electrode 21 and the pixel electrode 4 are connected; wherein, the surface of the pixel electrode 4 at the via hole 5 is a rough surface.

[0039] In the embodiment of the present invention, the COA technology is adopted, and the color filter 6 , the black matrix 7 and the TFT unit 2 are all formed on the same base substrate 1 . Since the thin film transistor unit 2 mainly forms a conductive channel in the active layer 22 , the transmission of electric signals can be realized between the source 23 and the drain 21 . The light will affect the ability of the co...

Embodiment 2

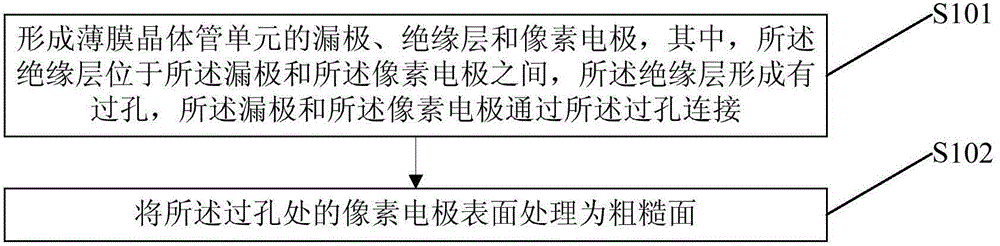

[0053] An embodiment of the present invention provides a method for preparing an array substrate, such as image 3 As shown, the preparation method of the array substrate includes:

[0054] Step S101, forming a drain, an insulating layer, and a pixel electrode of a TFT unit, wherein the insulating layer is located between the drain and the pixel electrode, the insulating layer is formed with a via hole, and the drain and The pixel electrodes are connected through the via holes;

[0055] Step S102 , processing the surface of the pixel electrode at the via hole to a rough surface.

[0056] Wherein, step S102 includes: treating the pixel electrode at the via hole with plasma, so that the surface of the pixel electrode at the via hole is a rough surface.

[0057] Specifically, when processing the surface of the pixel electrode 4 at the via hole 5, it is necessary to use a photoresist to form a protective layer to protect the pixel electrode that does not need to be processed, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com