Patents

Literature

1602results about How to "Guaranteed display effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

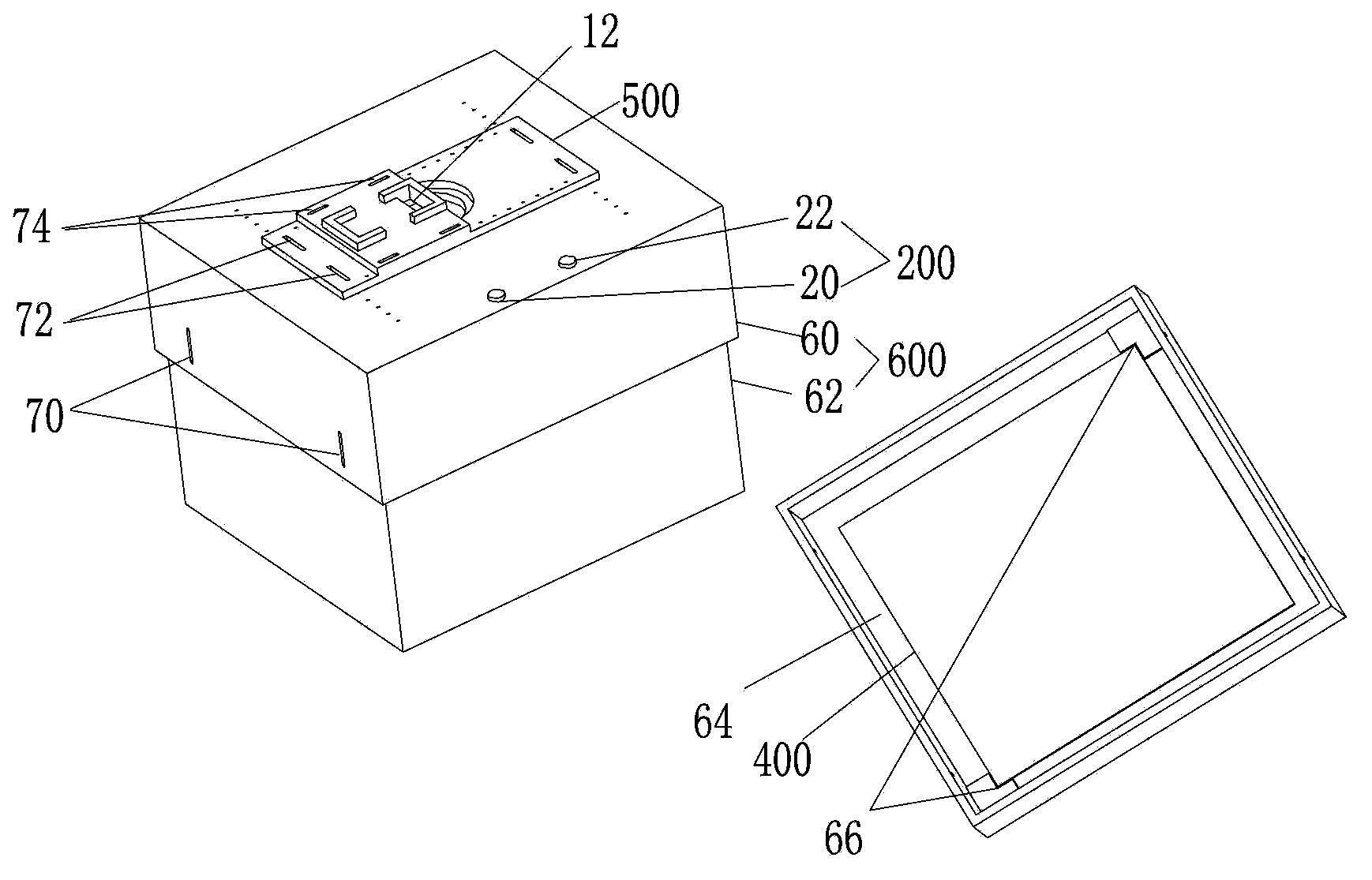

Automatic adjusting type display device and adjusting method thereof

InactiveCN103645749AGuaranteed display effectImprove user experienceInput/output for user-computer interactionControl using feedbackDistance sensorsMotor drive

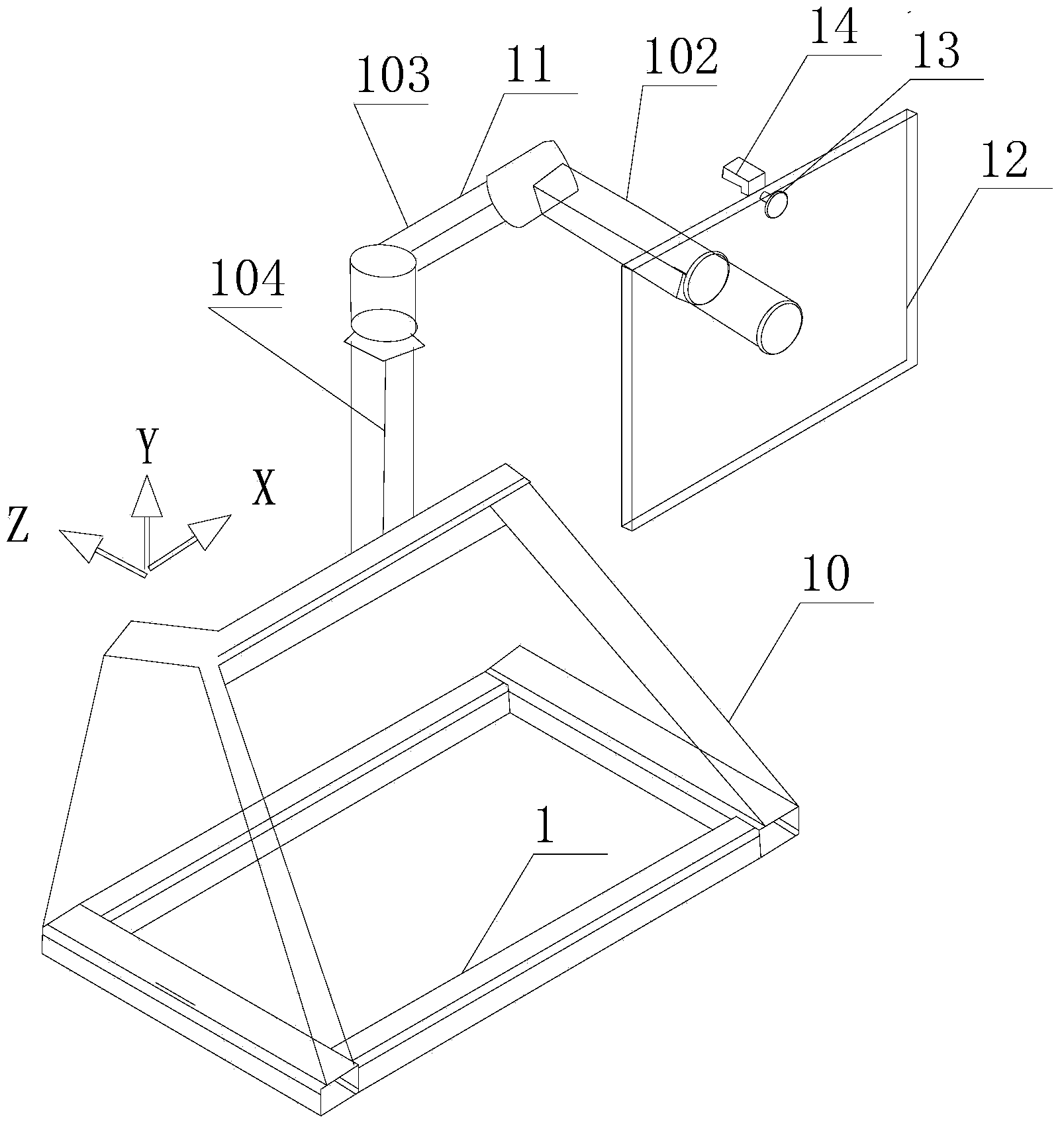

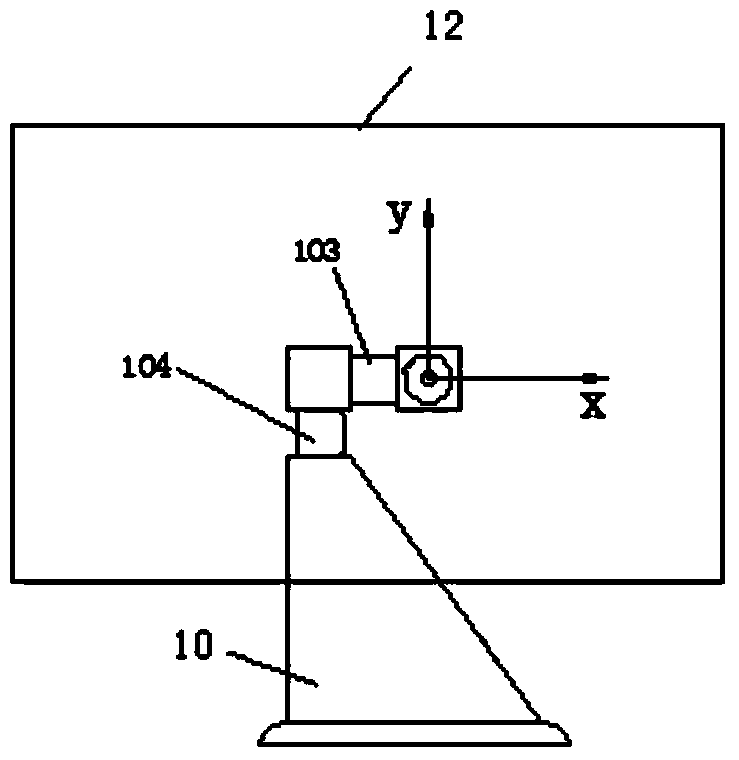

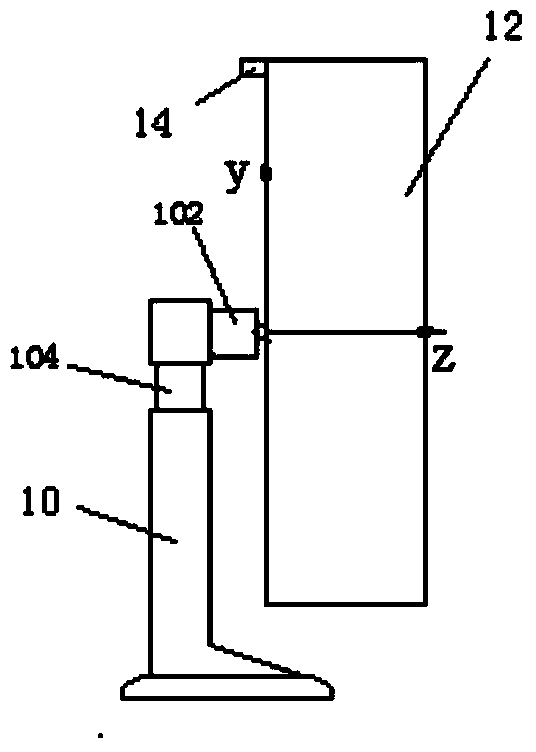

The invention discloses an automatic adjusting type display device and an adjusting method thereof. The adjusting method comprises the steps of: obtaining and identifying a facial image of a user at the current spatial position by a receiving camera and determining the coordinate of the facial image of the user at the current spatial position in a spatial coordinate system; calculating a rotation angle of a displayer needed to be adjusted, with respect to the face, based on the coordinate of the spatial coordinate system, and controlling a motor driving device to drive the displayer to rotate respectively around X-axis, Y-axis and Z-axis of a space rectangular coordinate system by utilizing rotation angle feedback; receiving a distance from the face of the user located at the current spatial position and acquired by a distance sensor to the displayer, adjusting a cambered surface bending deformation amount of a substrate made of an electro-active polymer and located on the displayer based on the distance feedback so as to adaptively drive a soft screen attached on the surface of the substrate to bend. As the rotation angle and the bending cambered surface of the displayer is driven to be adjusted, the display device is guaranteed to be adjusted to adapt to spatial position change of the user in a movement process, and the display effect is guaranteed.

Owner:张志增

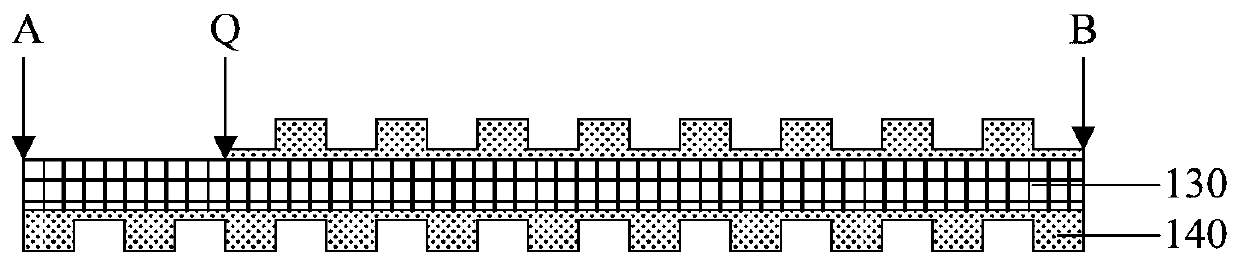

Flexible back plate for flexible display

ActiveCN103177656AGuaranteed display effectDo not collide with each otherSynthetic resin layered productsIdentification meansCentral planeGlass transition

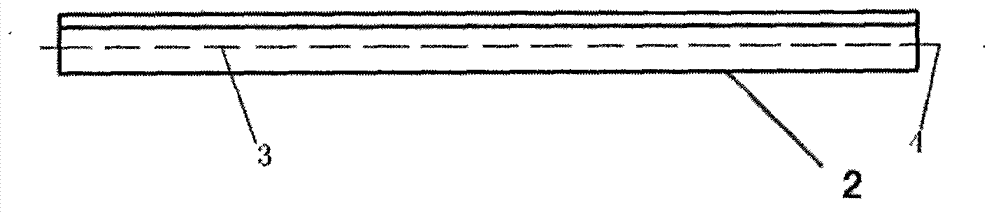

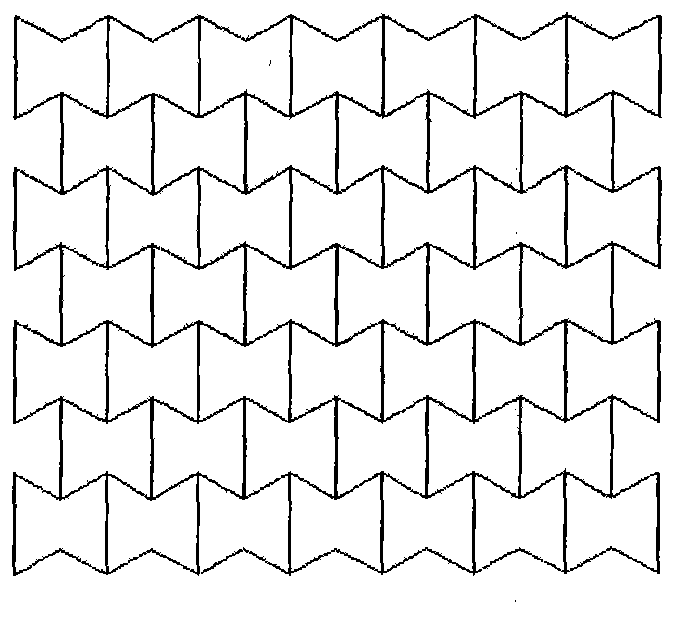

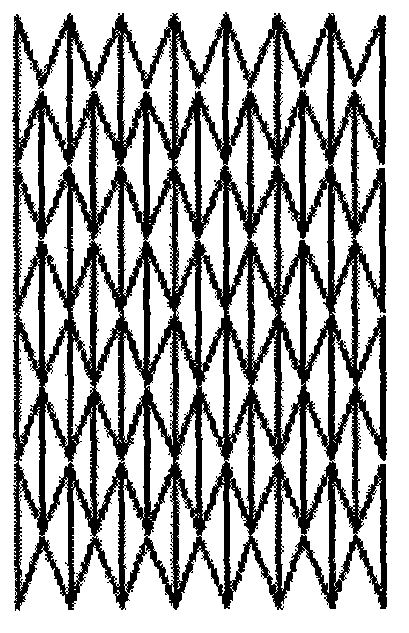

The invention relates to a flexible back plate for a flexible display. The flexible back plate comprises a structure layer and a laying layer, wherein the structure layer is of a honeycomb structure with negative Poisson ratio; the laying layer is evenly laid in the central plane of the structure layer; the structure layer is made of shape memory polymers or composite materials; the laying layer is made of carbon fibers; the laying layer is provided with an leading-out terminal provided with two electrodes; when the two electrodes are electrified, the laying layer generates heat to heat the structure layer to enable the structure layer to reach the glass-transition temperature of the material of the structure layer, and exerts an external force to the honeycomb structure to achieve the purpose of deforming the honeycomb, the shape of the honeycomb can be fixed after the heating is stopped, the size is increased in two directions, in this way, the size of the back plate is increased; when the honeycomb structure is in an unidirectional compression, the size is decreased in a plane, in this way, the size of the back plate is decreased; and the honeycomb structure with negative Poisson ratio has double-curvature characteristic. The flexible back plate has the following characteristics of being bendable, having double curvature, impact resistance and anti-shock performance, being capable of being driven intelligently, and being light and beautiful.

Owner:HARBIN INST OF TECH

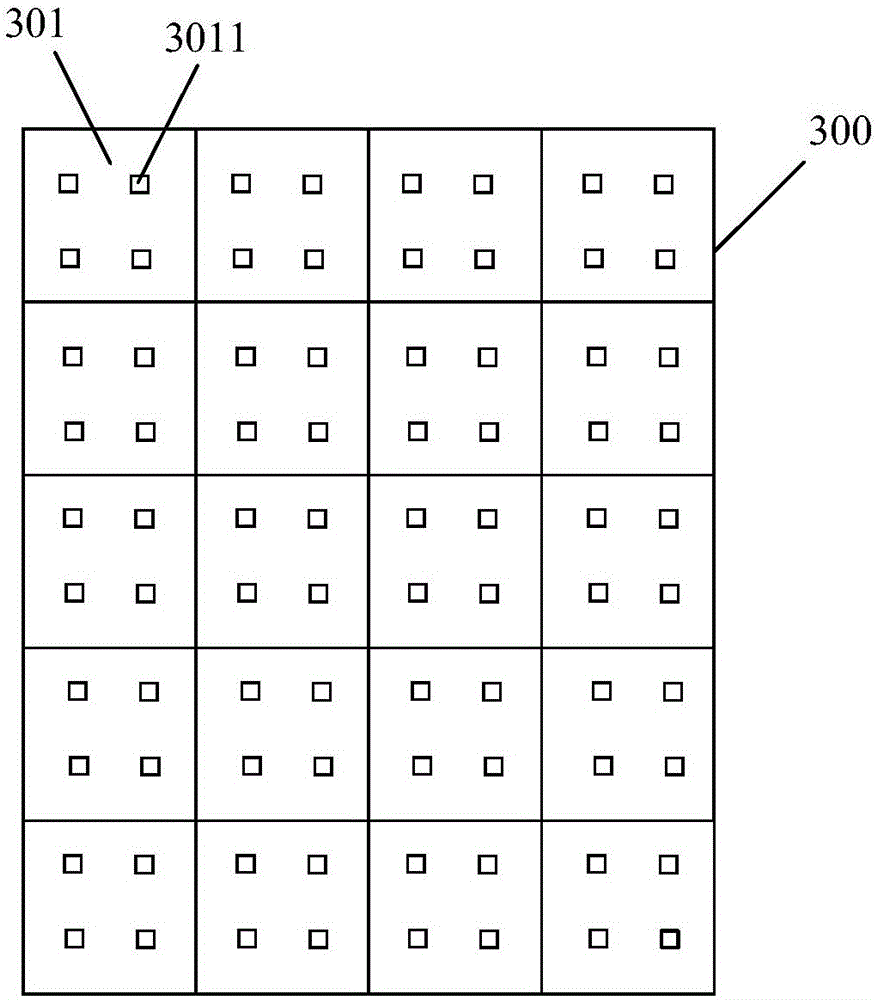

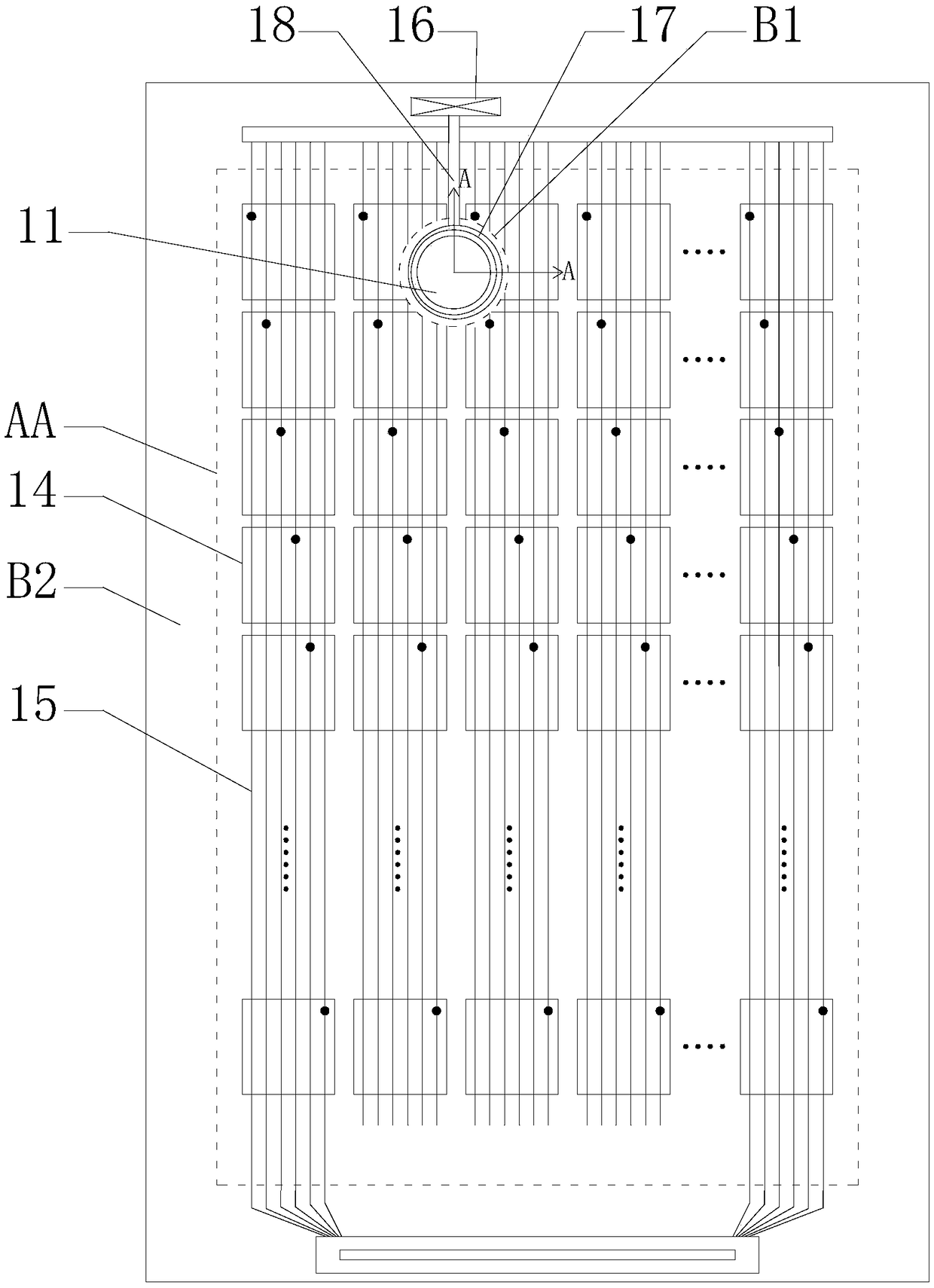

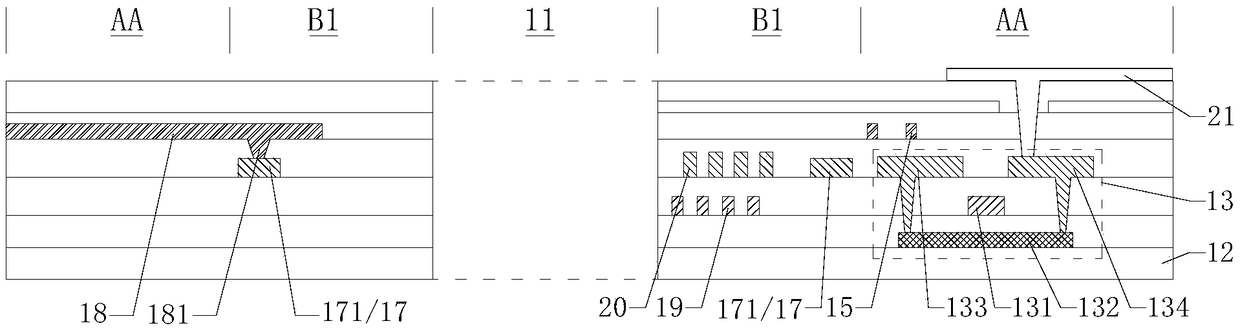

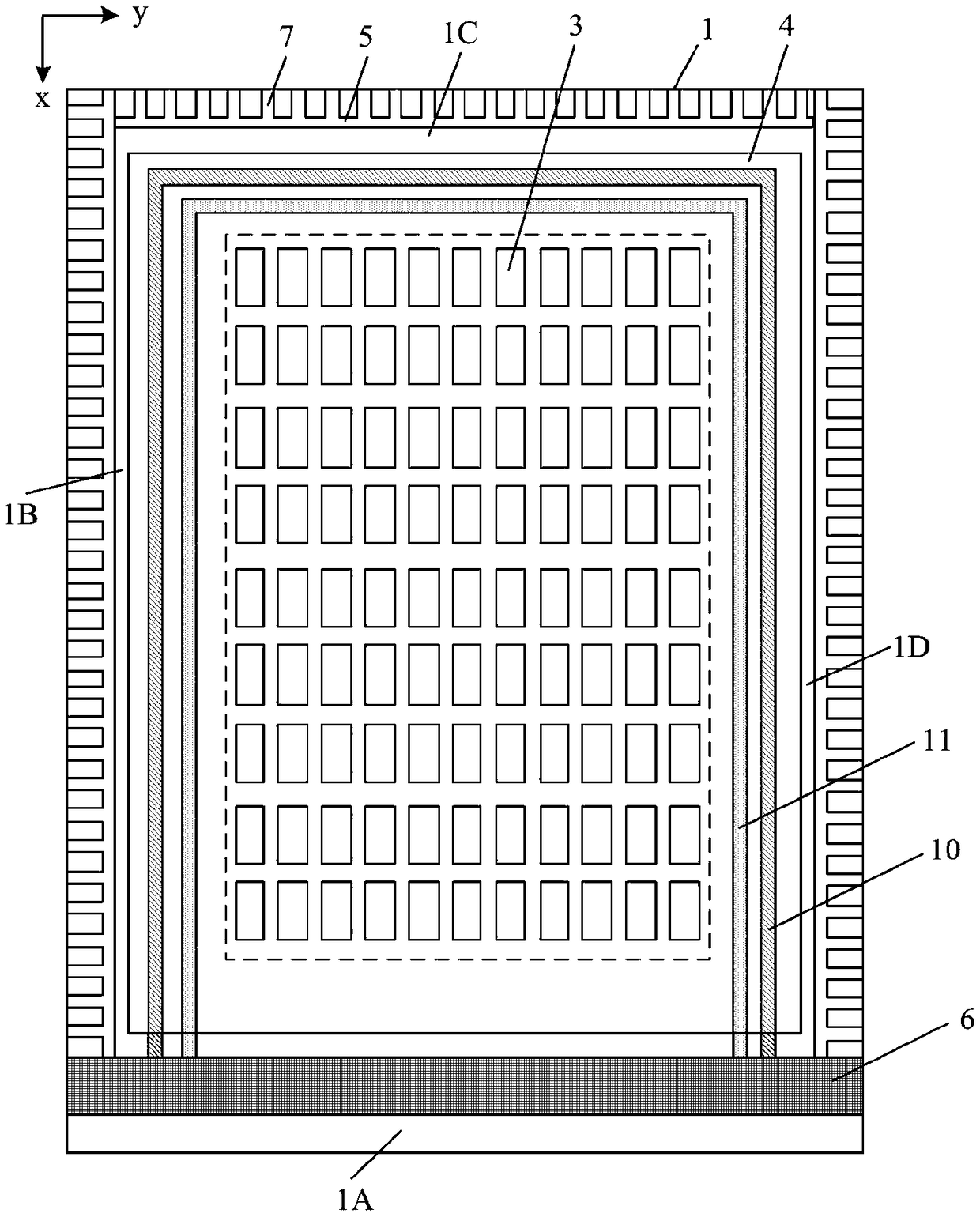

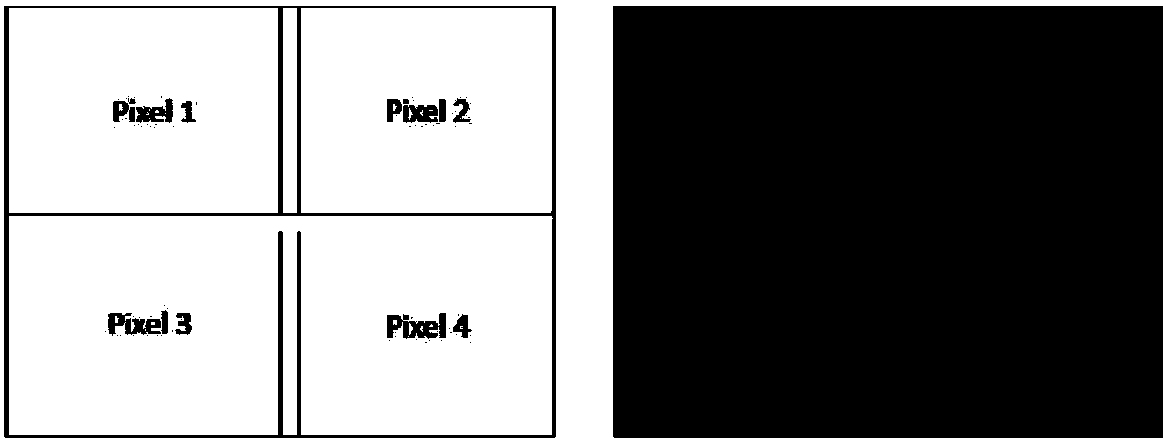

Display panel

InactiveCN106295611ARealize the fingerprint recognition functionGuaranteed display effectDigital data processing detailsPrint image acquisitionComputer scienceFingerprint

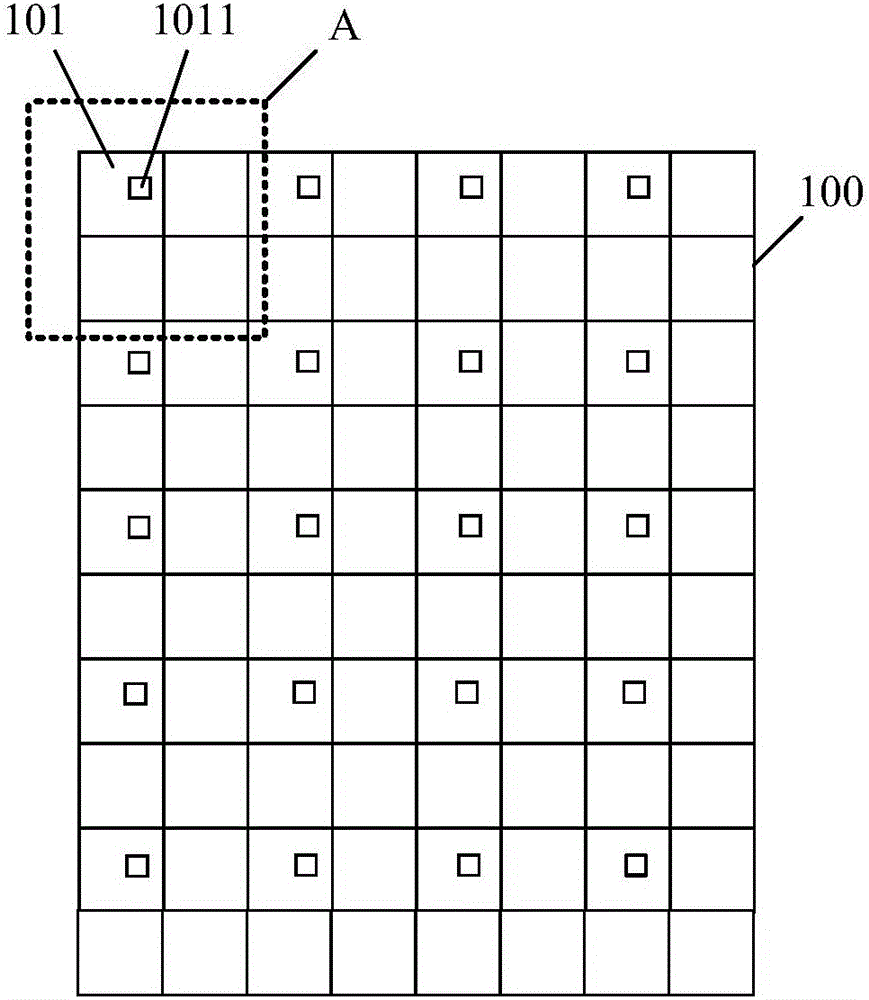

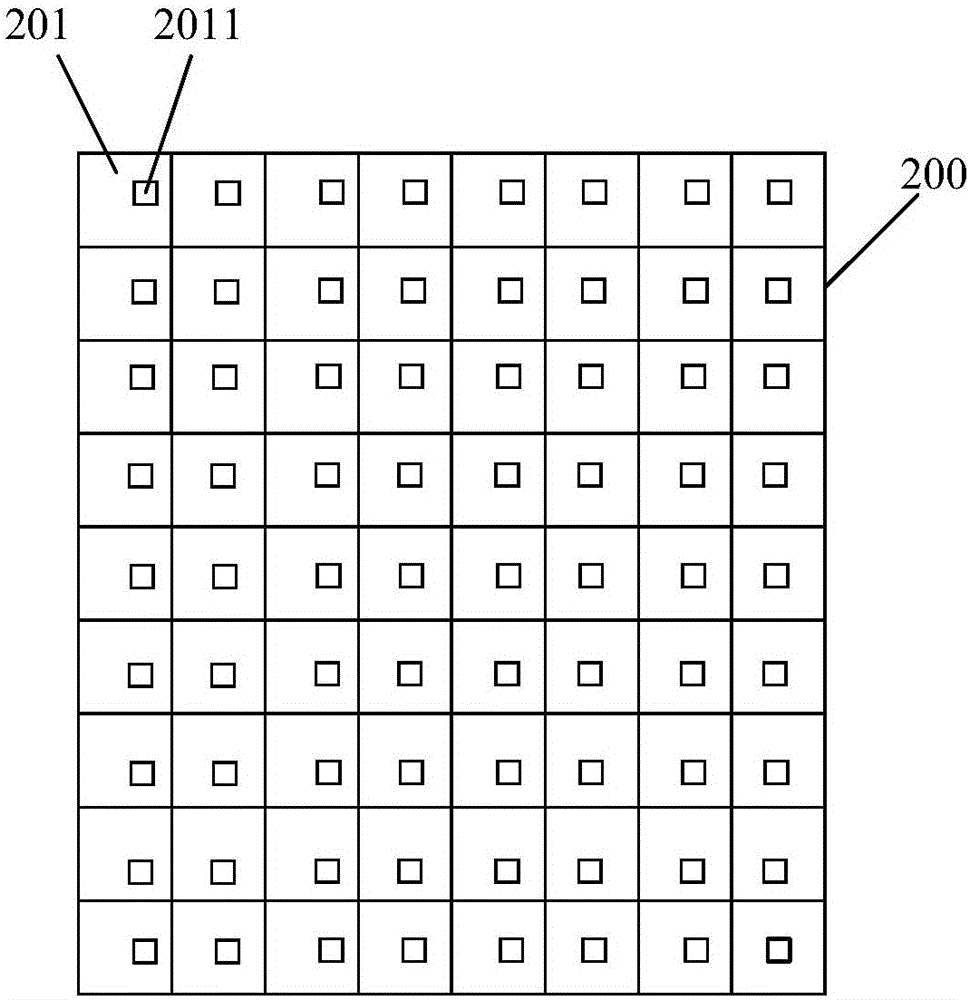

The invention discloses a display panel, and the display panel comprises a display region. The display region is provided with a plurality of self-luminous display pixels which are arranged in an array. The display region comprises one or more optical fingerprint sensing areas. In each optical fingerprint sensing area, each of k self-luminous display pixels of m*n self-luminous display pixels is provided with at least one optical fingerprint sensing element, wherein m and n are random integers greater than one, and k is any integer which is in the section from 1 to m*n. The performances of all functions are higher while the function of the display panel is improved.

Owner:SHANGHAI OXI TECH

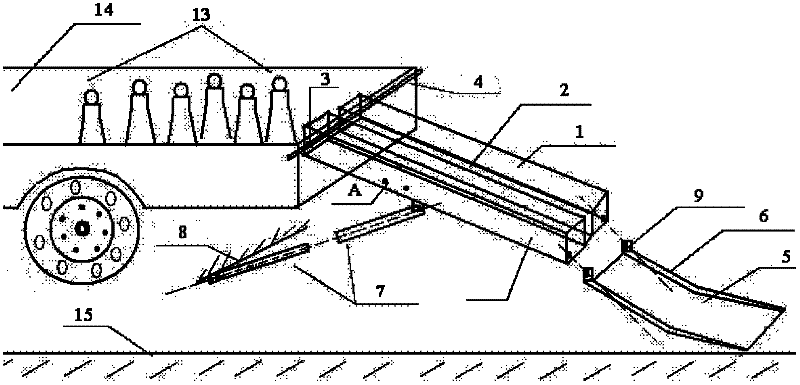

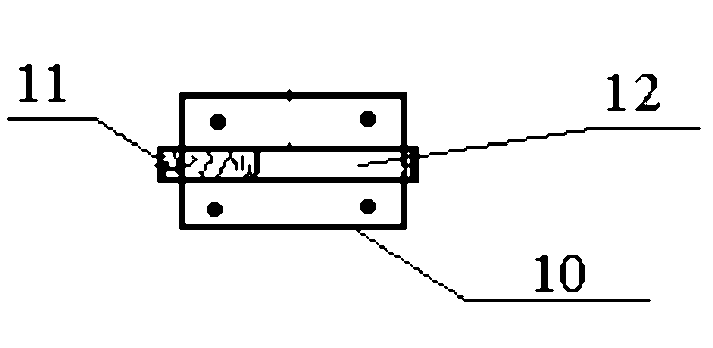

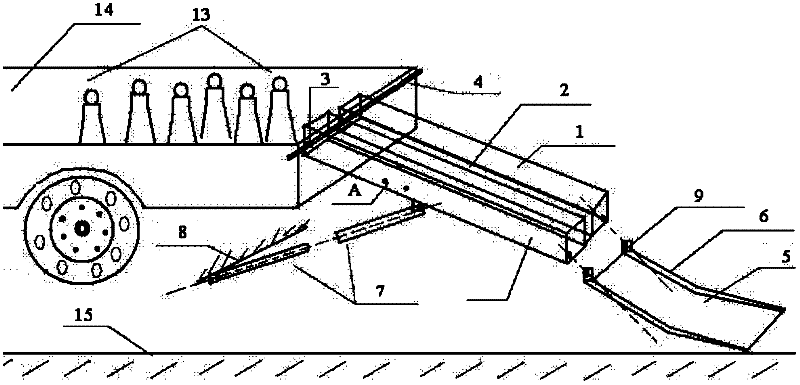

Automatic traffic cone putting device

InactiveCN102400444AIncrease placement speedEnsure safetyTraffic signalsRoad signsMonitoring systemSimulation

The invention relates to an automatic traffic cone putting device, which belongs to the field of traffic machinery, and comprises a cone putting device, a suspension device, a guiding device and a supporting device, wherein the suspension device and the guiding device are arranged at the two ends of the cone putting device, and the supporting device is arranged at the bottom of the cone putting device. Compared with the prior art, the automatic traffic cone putting device provided by the invention has a novel structure and a reasonable design, is simple and convenient to install and maintain, is easy to operate, is flexible to move, and is convenient to regulate and control, a large number of labor can be saved, the speed for putting traffic cones can be obviously improved, the safety of workers can be effectively guaranteed, simultaneously, the putting effect is ensured, stable and accurate putting of the traffic cones can be realized, the consistency in putting intervals of the traffic cones is ensured, the putting intervals can be regulated according to the need, an operator can know running conditions of devices constantly through a monitoring system, the construction safety is fully ensured, and the automatic traffic cone putting device is suitable to be promoted and applied in traffic-related engineer operation requiring putting the traffic cones and similar facilities.

Owner:北京公联洁达公路养护工程有限公司

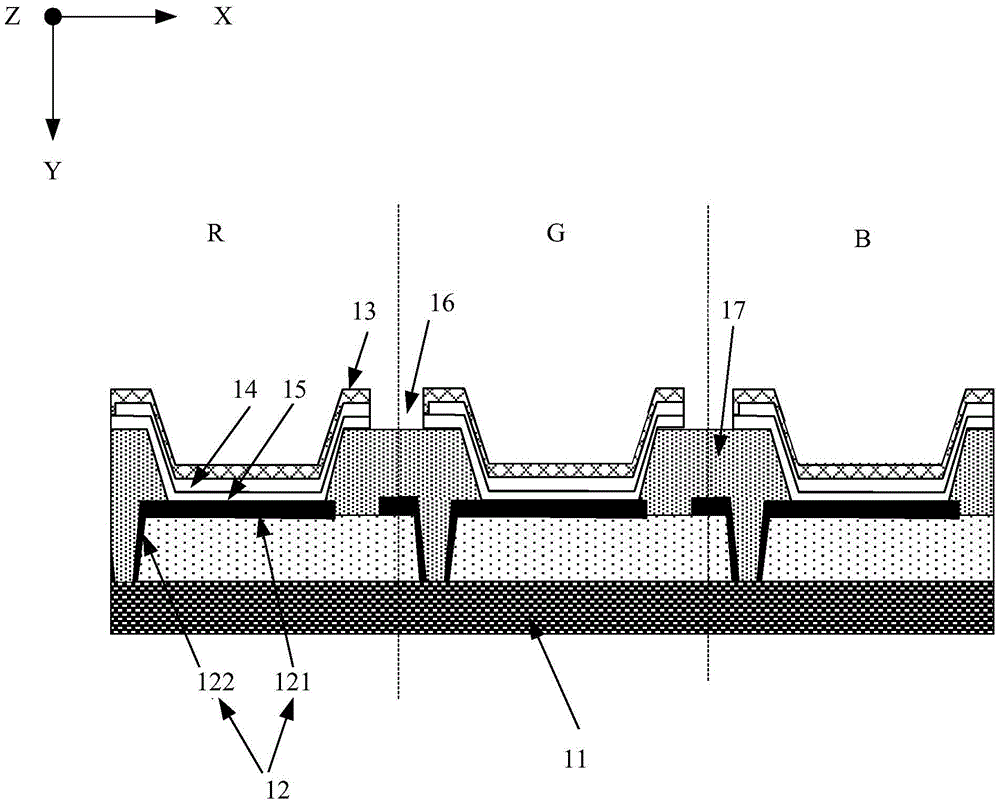

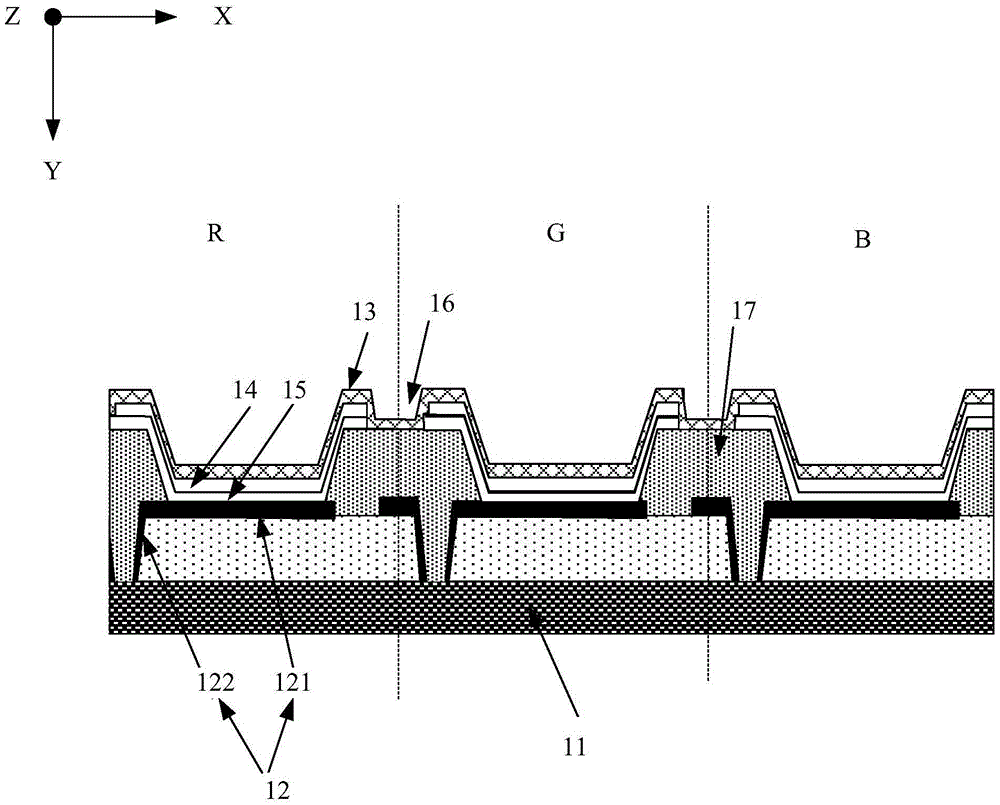

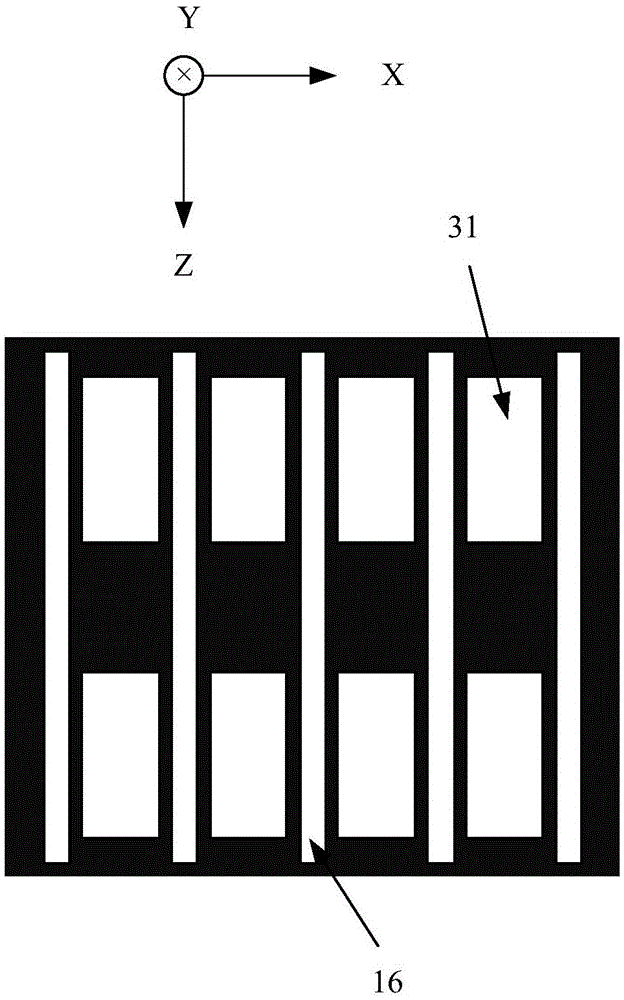

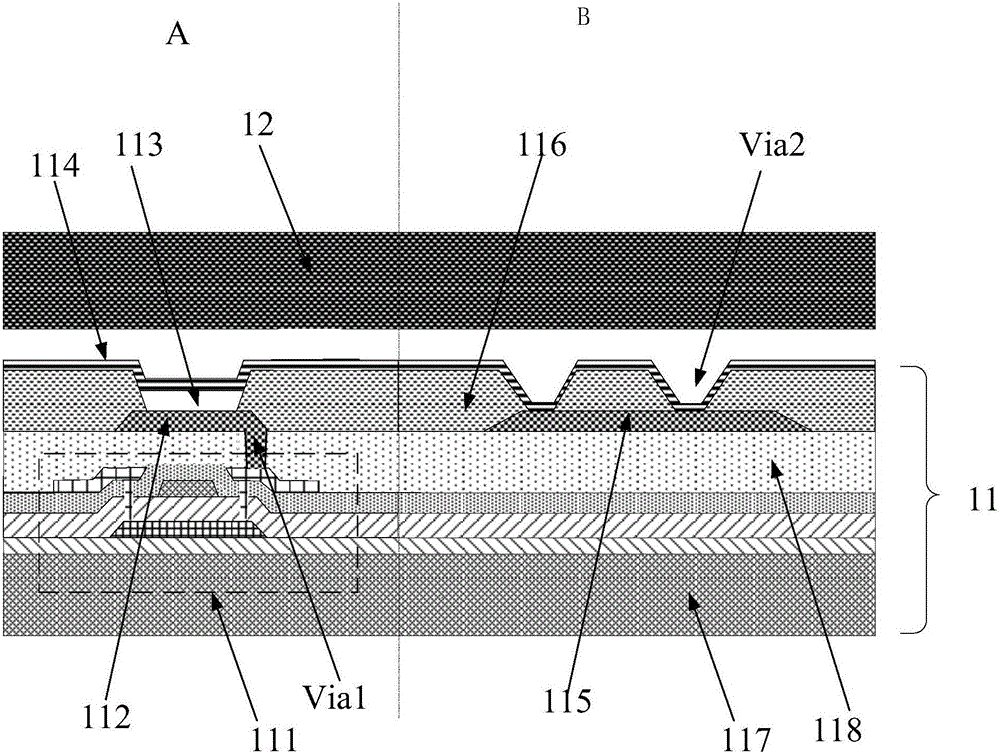

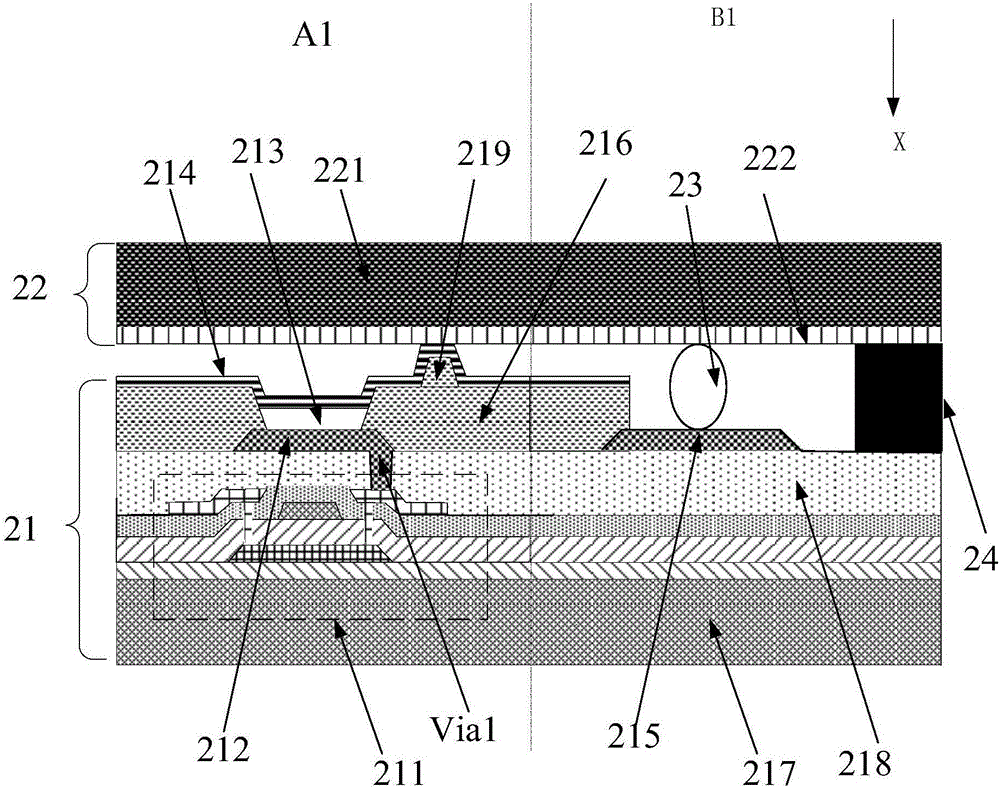

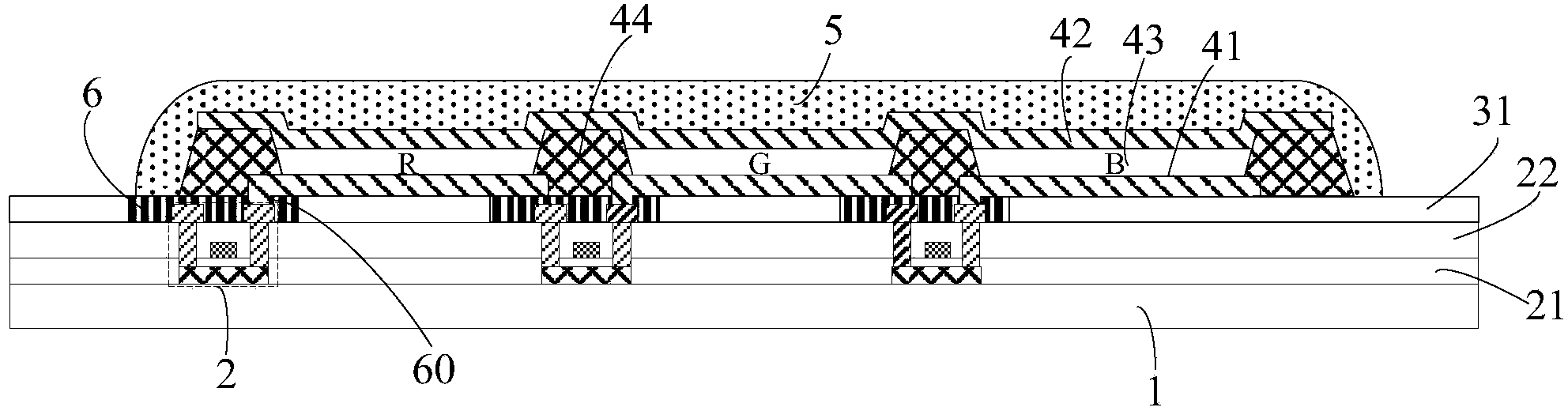

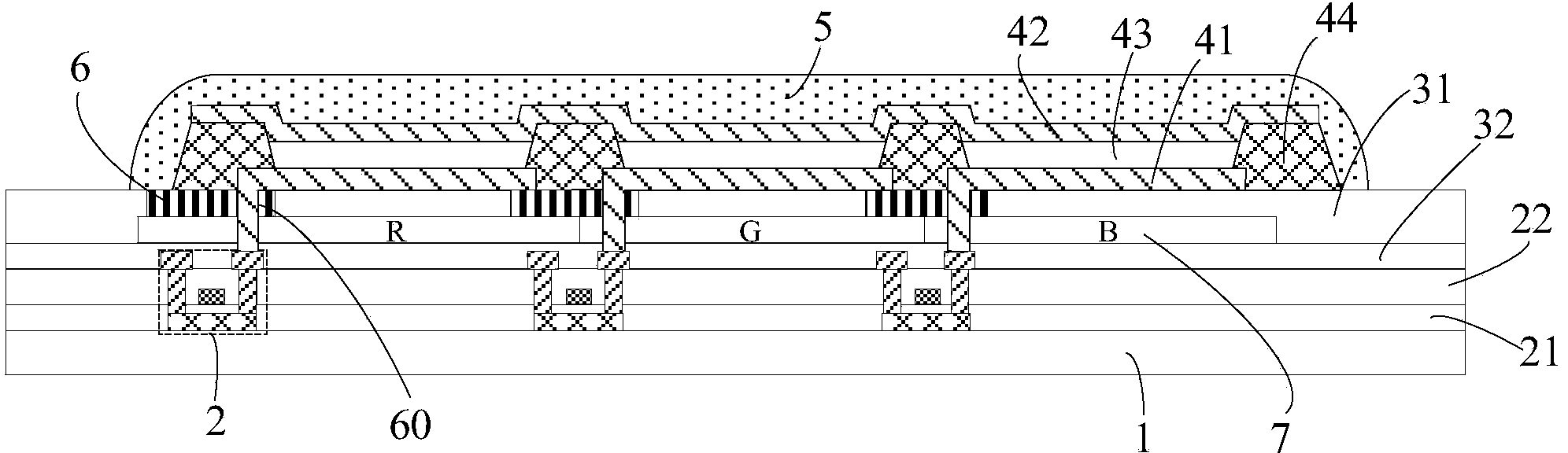

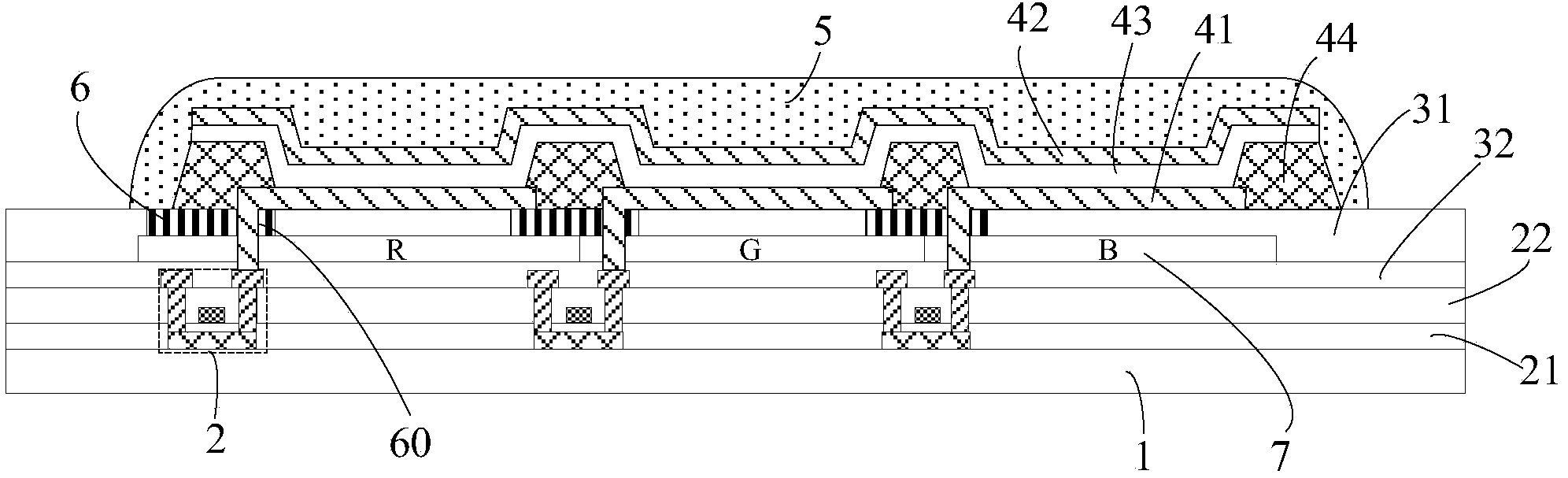

Display panel, manufacturing method and electronic equipment

InactiveCN105552107AAvoiding Leaky Glow IssuesGuaranteed display effectSolid-state devicesSemiconductor/solid-state device manufacturingLight emissionElectron

The invention discloses a display panel, electronic equipment and a manufacturing method. The display panel comprises a substrate, a positive electrode layer and a negative electrode layer arranged on the same side of the substrate, and a light emitting function layer arranged between the positive electrode layer and the negative electrode layer, wherein the positive electrode layer and the negative electrode layer are arranged in opposite in a direction perpendicular to the substrate; the positive electrode layer is arranged between the substrate and the negative electrode layer, and the positive electrode layer is divided into multiple positive electrodes; the light emitting functional layer comprises at least a sub function layer; the light emitting functional layer is divided into multiple pixel units in array arrangement; the pixel units are in one-to-one correspondence with the positive electrodes in the direction perpendicular to the substrate; a cut-off structure is arranged between at least two adjacent pixel units in a first direction; the cut-off structure enables the at least one sub functional layer to be cut off between the two pixel units; and the first direction is parallel to the substrate. According to the display panel, the phenomenon of light emission caused by leakage current is avoided, and the image display effect is ensured.

Owner:SHANGHAI TIANMA AM OLED +1

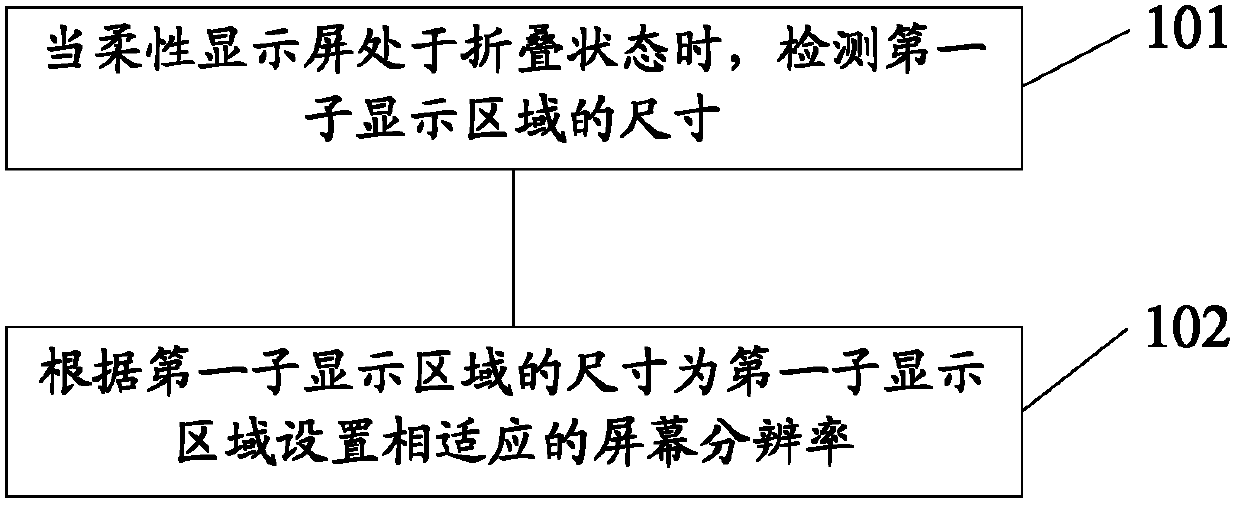

Electronic equipment and method for adjusting resolution ratios

ActiveCN103295510AImprove experienceImprove the display effectStatic indicating devicesDigital data processing detailsImage resolutionFlexible display

The invention provides electronic equipment and a method for adjusting resolution ratios. The method is applied to the electronic equipment. The electronic equipment is provided with a flexible display screen. The flexible display screen can be in a spread state and a folding state. When being in the spread state, the flexible display screen is provided with a first display area. When being in the folding state, the first display area at least forms a first sub-display-area and a second sub-display-area through a folding line. The method comprises the steps of detecting the size of the first sub-display-area when the flexible display screen is in the folding state; setting a corresponding resolution ratio for the first sub-display-area according to the size of the first sub-display-area.

Owner:LENOVO (BEIJING) LTD

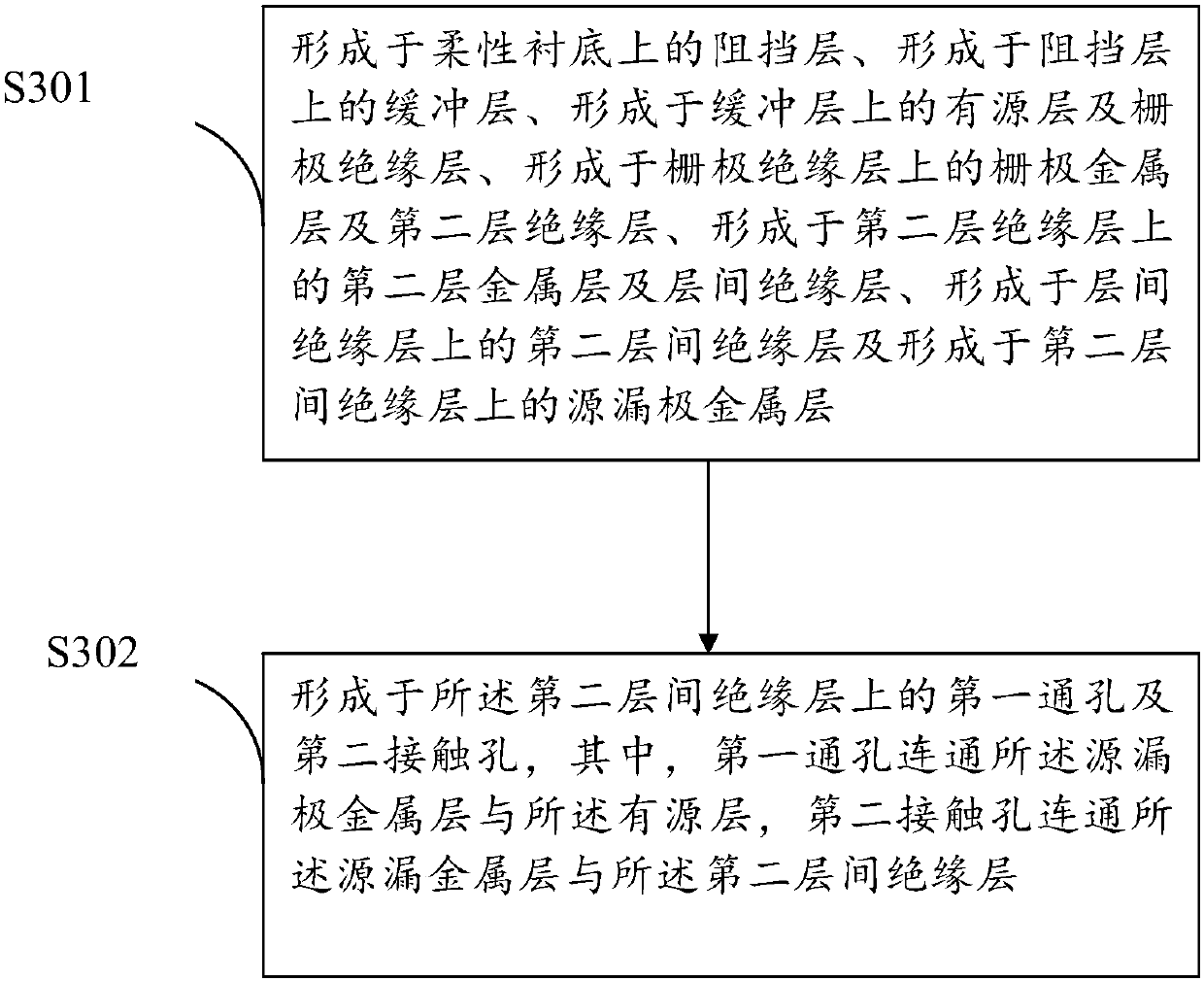

Flexible display panel, flexible display panel manufacturing method and display device

InactiveCN107910335ANot easy to breakGuaranteed normal displaySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringContact hole

The invention provides a flexible display panel including a flexible substrate, a barrier layer formed on the flexible substrate, a buffer layer formed on the barrier layer, an active layer and a gateinsulation layer formed on the buffer layer, a gate metal layer and a second insulation layer formed on the gate insulation layer, a second metal layer and an inter-layer insulation layer formed on the second insulation layer, a second inter-layer insulation layer formed on the inter-layer insulation layer and a source drain electrode metal layer formed on the second inter-layer insulation layer.The second inter-layer insulation layer is provided with a first through hole communicating the source drain electrode metal layer and the active layer and a second contact hole communicating the source drain metal layer and the second inter-layer insulation layer. The invention also provides a flexible display panel manufacturing method and a display device comprising the display panel. The flexible display panel provided by the invention can ensure normal display of the flexible display panel in a bending process.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

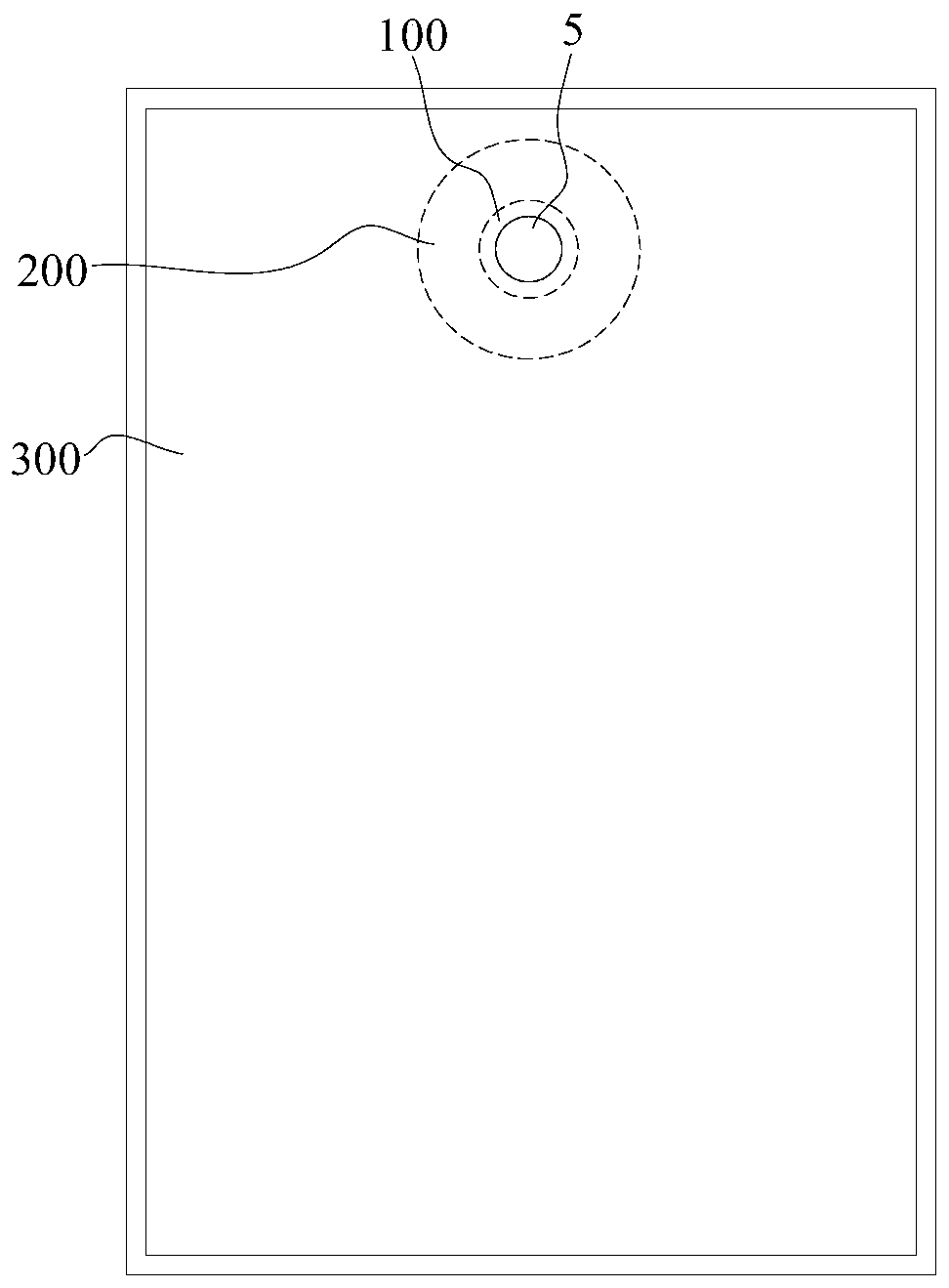

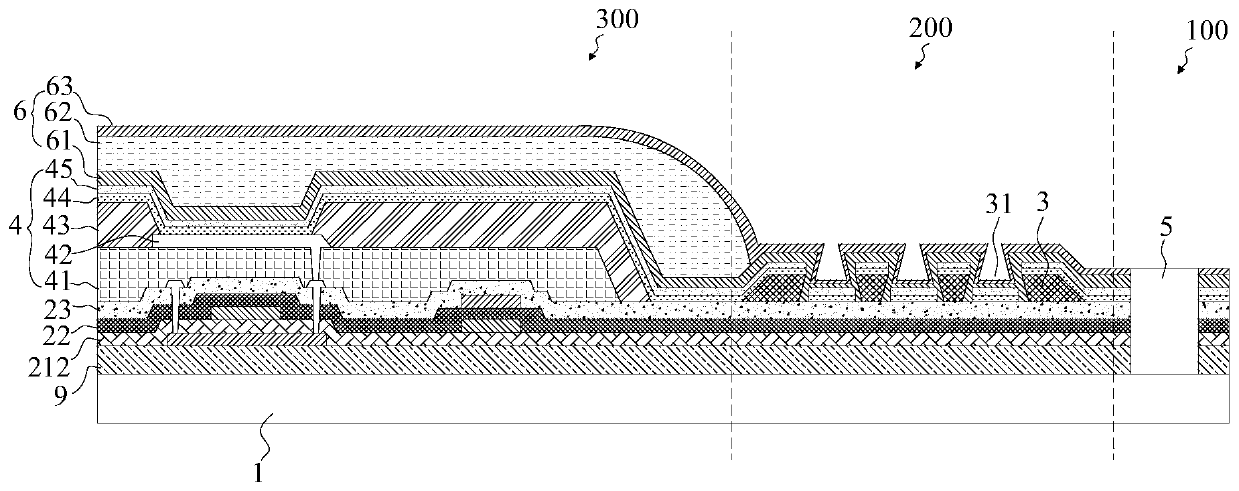

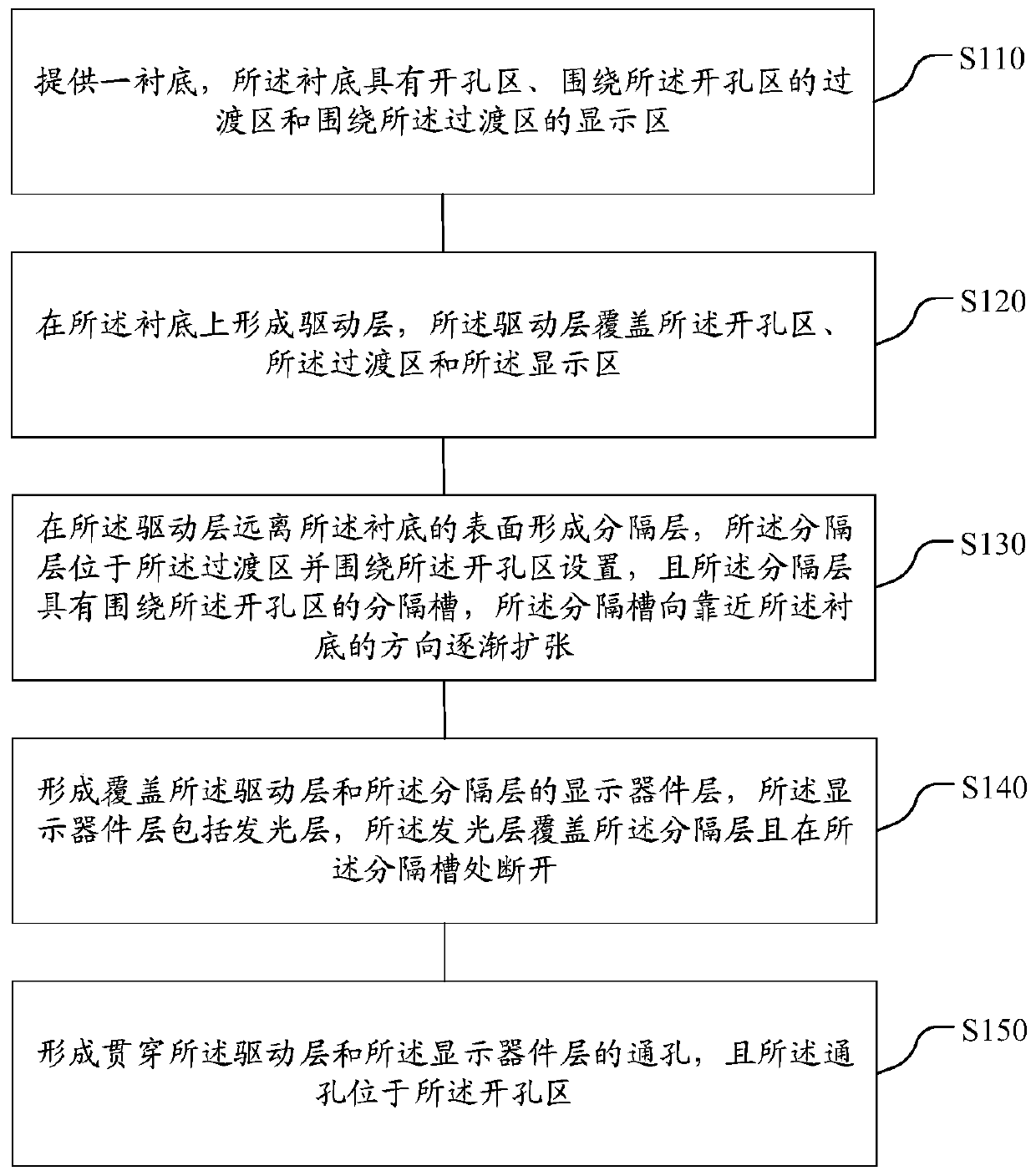

Display device, display panel and manufacturing method thereof

InactiveCN109801956AAvoid erosionGuaranteed display effectSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringDisplay device

The invention provides a display device, a display panel and a manufacturing method thereof, and relates to the technical field of display. The display panel comprises a substrate, a driving layer, aseparation layer, a display device layer and a through hole. The substrate has an opening region, a transition region surrounding the opening region, and a display region surrounding the transition region. The driving layer is arranged at one side of the substrate and covers the opening area, the transition area and the display area. The separation layer is arranged on the surface, away from the substrate, of the driving layer and located in the transition area, and the separation layer is arranged around the opening region and provided with a separation groove surrounding the opening region.The separation groove gradually expands in the direction close to the substrate. The display device layer covers the driving layer and the separation layer, and the display device layer comprises a light-emitting layer, wherein the light-emitting layer covers the separation layer and is disconnected at the separation groove. The through hole passes through the driving layer and the display devicelayer and is located in the opening region. According to the display panel, water and oxygen can be prevented from entering the display area, and a display device is prevented from being eroded.

Owner:BOE TECH GRP CO LTD

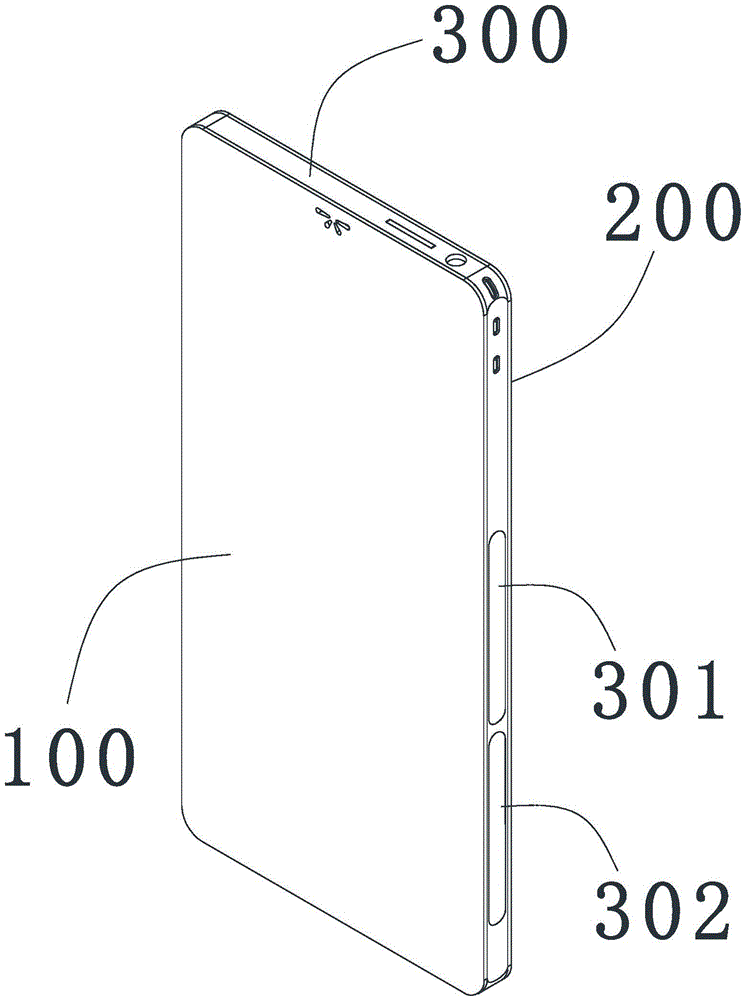

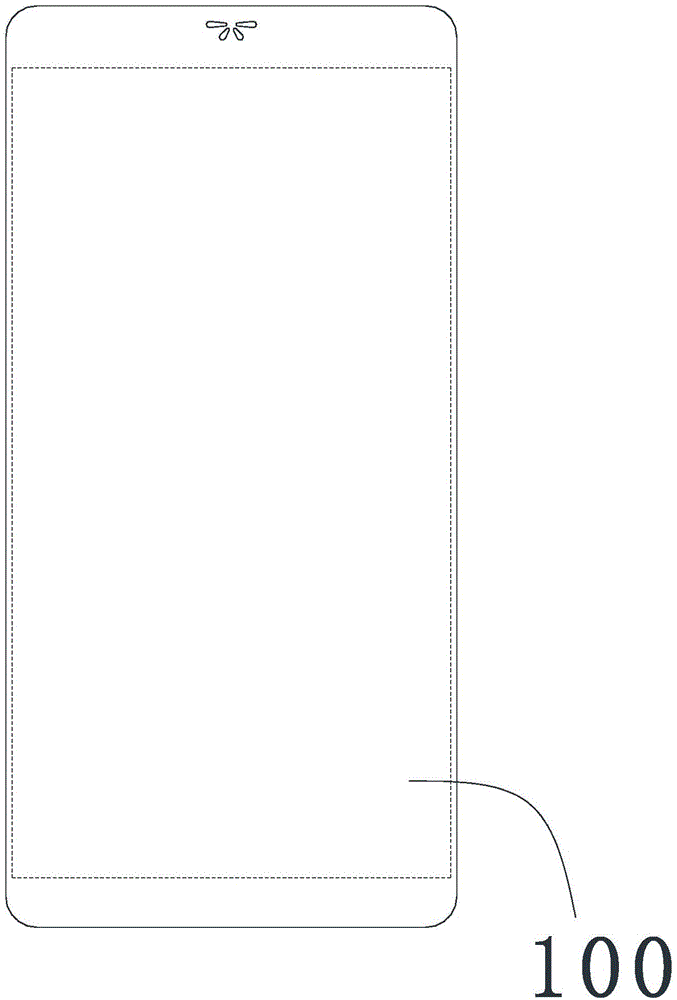

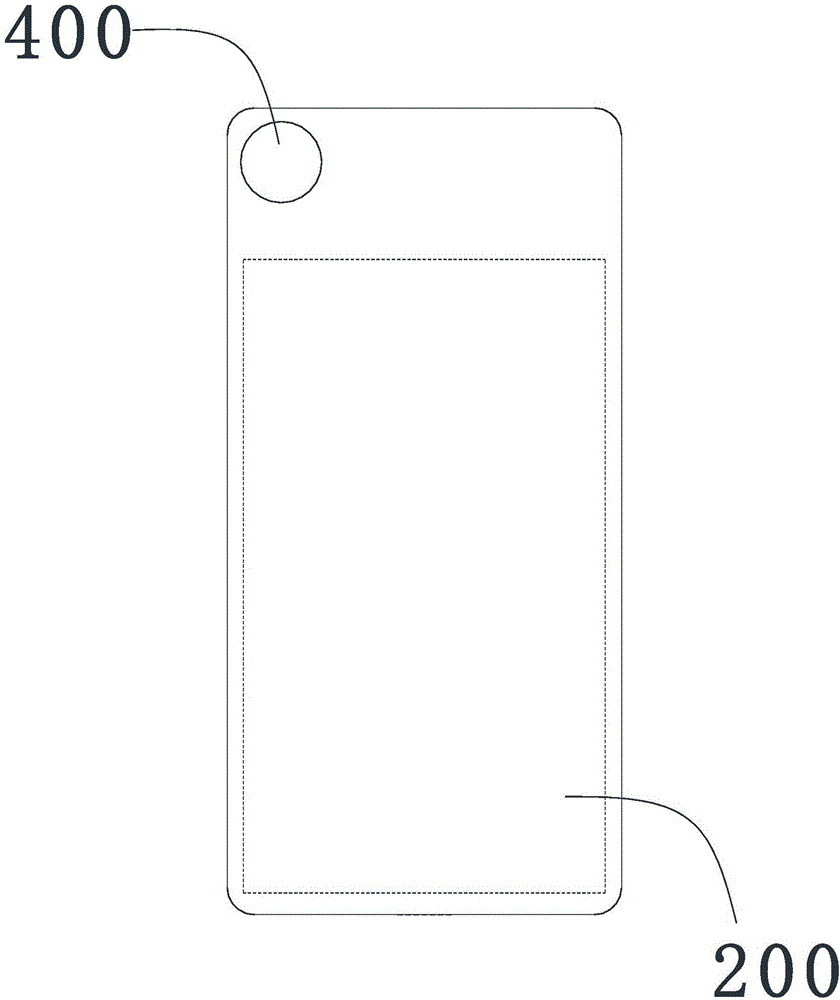

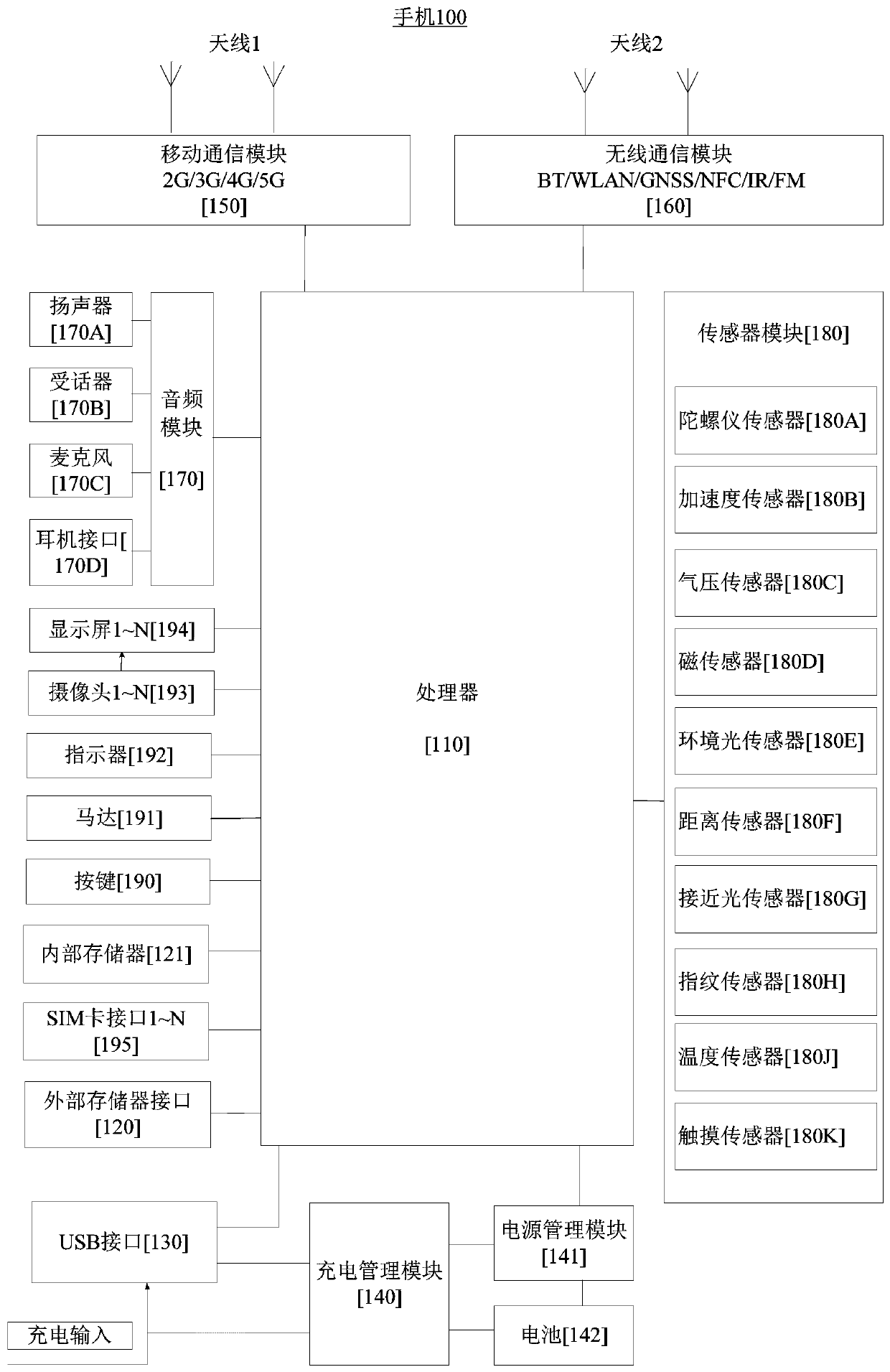

Dual-surface dual-screen intelligent mobile terminal

InactiveCN105334916AQuick switchGuaranteed battery lifeDevices with multiple display unitsCathode-ray tube indicatorsComputer moduleComputer engineering

The invention discloses a dual-surface dual-screen intelligent mobile terminal. The dual-surface dual-screen intelligent mobile terminal comprises a terminal body, a main screen and an auxiliary screen, wherein the main screen and the auxiliary screen are mounted on the front surface and the back surface of the terminal body respectively; the main screen and the auxiliary screen share a microprocessor; independent driving control on the main screen and the auxiliary screen is realized through a main screen control module and an auxiliary screen control module arranged in the microprocessor; and quick switching of the main screen and the auxiliary screen is correspondingly realized by utilizing a switching control module in the microprocessor according to a switching control instruction of a user. According to the dual-surface dual-screen intelligent mobile terminal, the display resolutions of the screens are adjusted and controlled for different operation conditions of the main screen and the auxiliary screen, so that the display effect is effectively ensured; and in addition, a drawer-type dual-battery structure adopted by the invention can effectively ensure battery life.

Owner:DESI INT CO LTD

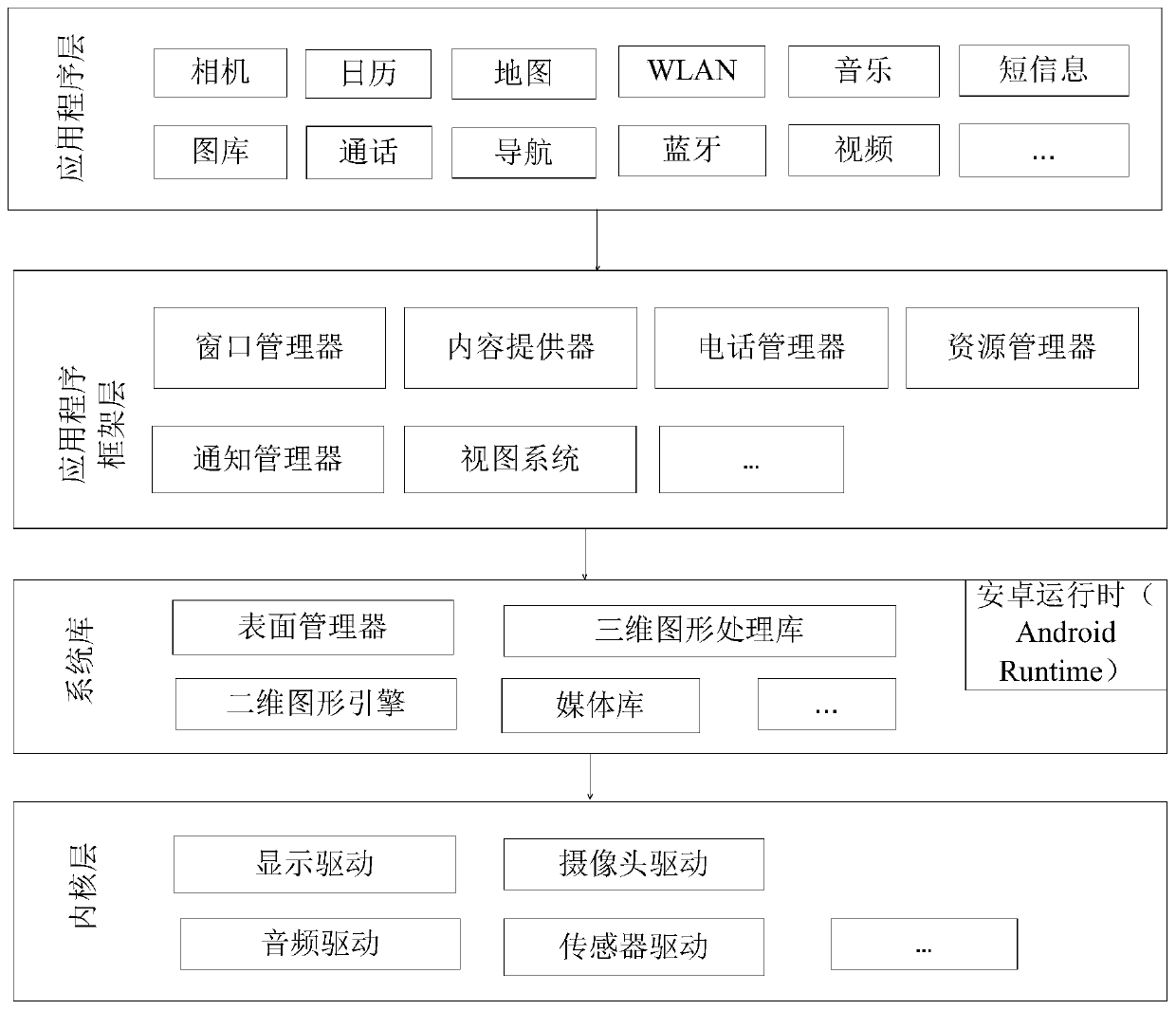

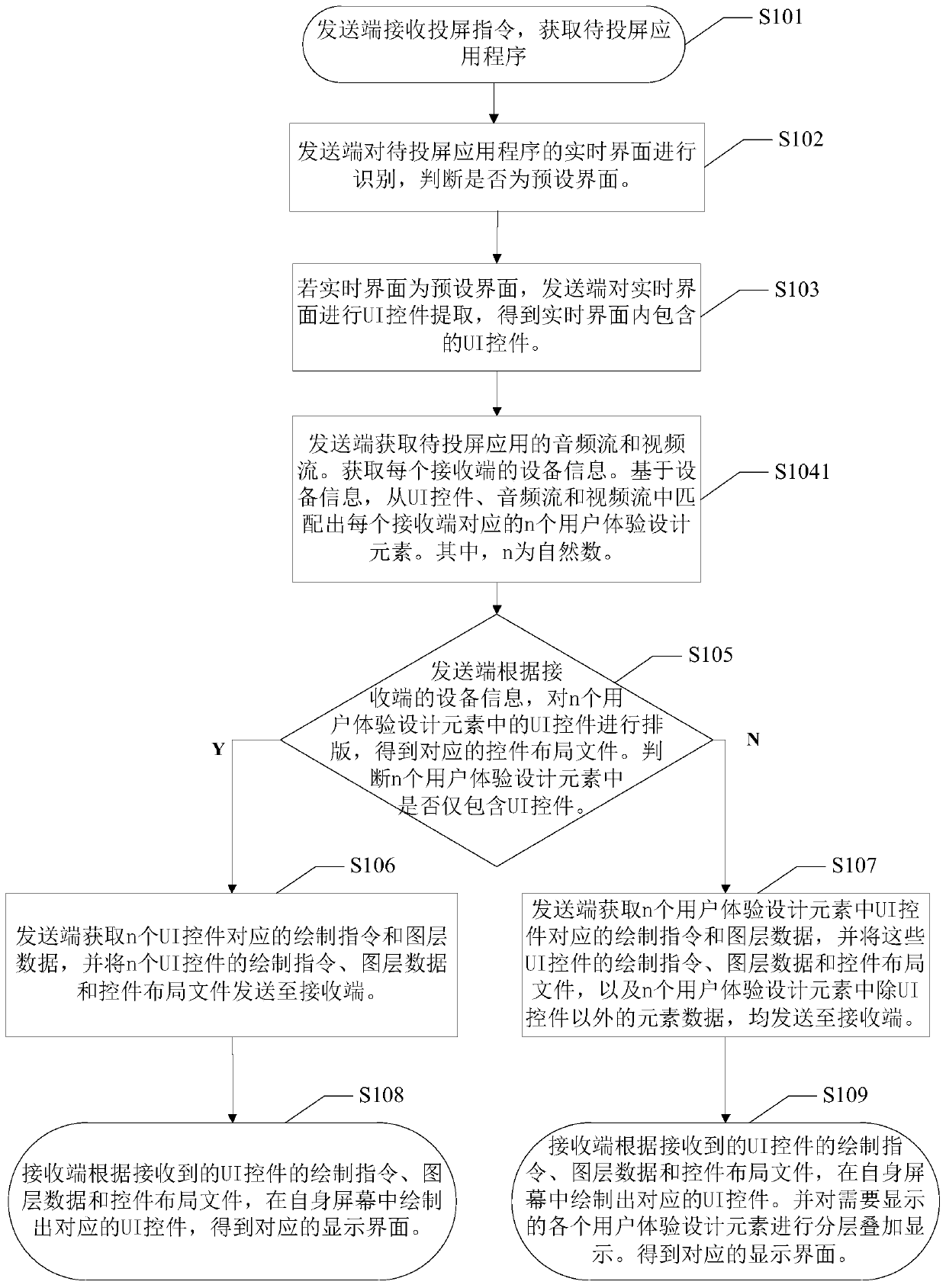

Screen projection method and terminal equipment

ActiveCN111324327ARealize adaptive projectionChoose flexibleStatic indicating devices2D-image generationComputer hardwareComputer graphics (images)

The invention provides a screen projection method and device and terminal equipment, and relates to the technical field of screen projection. The method comprises the steps that if a screen projectioninstruction is obtained, a real-time interface of a to-be-projected screen application program and equipment information of one or more receiving ends are obtained, first to-be-projected screen datacorresponding to all the receiving ends are obtained from the real-time interface according to the equipment information, and the first to-be-projected screen data are video streams, audio streams and / or user interface controls; and sending the first to-be-projected screen data to the corresponding receiving ends, so that each receiving end generates a corresponding display interface according tothe received first to-be-projected screen data. According to the embodiment of the invention, a screen projection mode with more abundant functions and more flexible operation can be realized.

Owner:HUAWEI TECH CO LTD

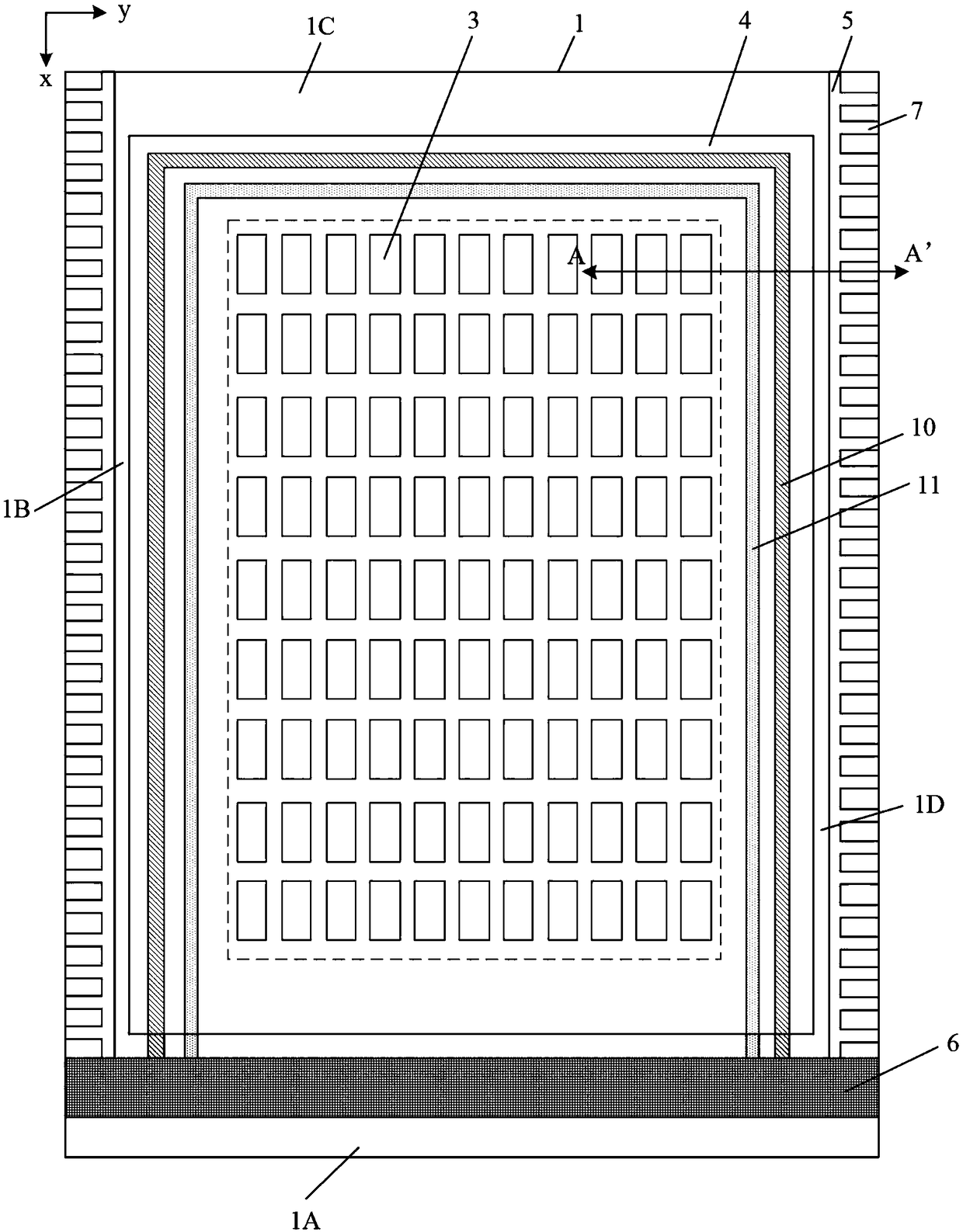

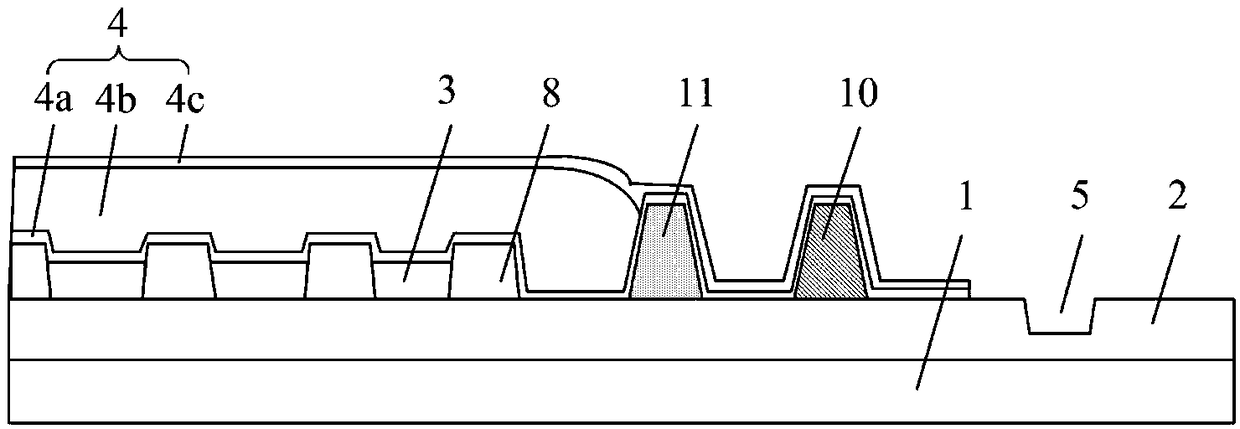

Display panel and display device

ActiveCN108873512AImprove ESD resistance performanceGuaranteed display effectNon-linear opticsInput/output processes for data processingElectricityDisplay device

The invention discloses a display panel and a display device. The display panel comprises a substrate, a hollow part, a first non-display region, a display region and a second non-display region; thefirst non-display region surrounds the hollow part, the display region surrounds the first non-display region, and the second non-display region surrounds the display region; the display region comprises a plurality of thin film transistors, a plurality of touch electrodes and a plurality of touch wires; each thin film transistor comprises a semiconductor part, a grid electrode, a source electrodeand a drain electrode, wherein the semiconductor part is arranged on the substrate; the second non-display region comprises at least one static electricity protective component; the first non-displayregion comprises an electric conducting ring, the electric conducting ring surrounds the hollow part and is electrically connected with the static electricity protective component through at least one outgoing line, and the outgoing lines and the touch wires are located on the same film layer. Compared with the prior art, the ESD resistance of the hollow part is effectively improved, meanwhile, the utilization efficiency of wires connected with no touch signal in the film layer is effectively improved, and the anti-static-electricity cost is lowered.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

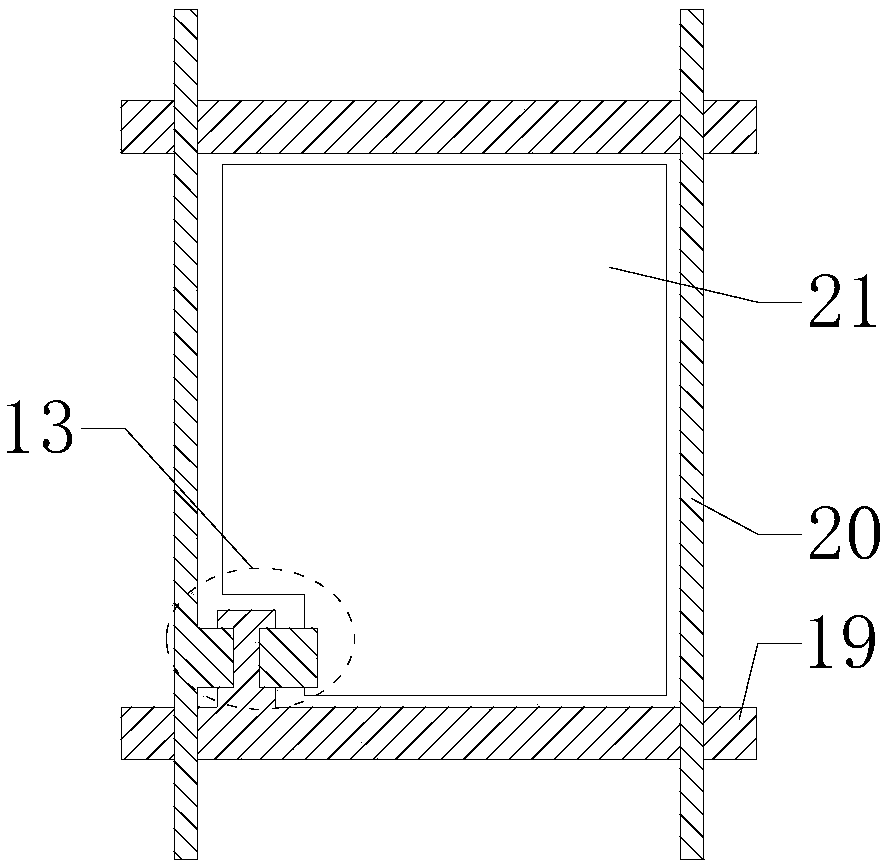

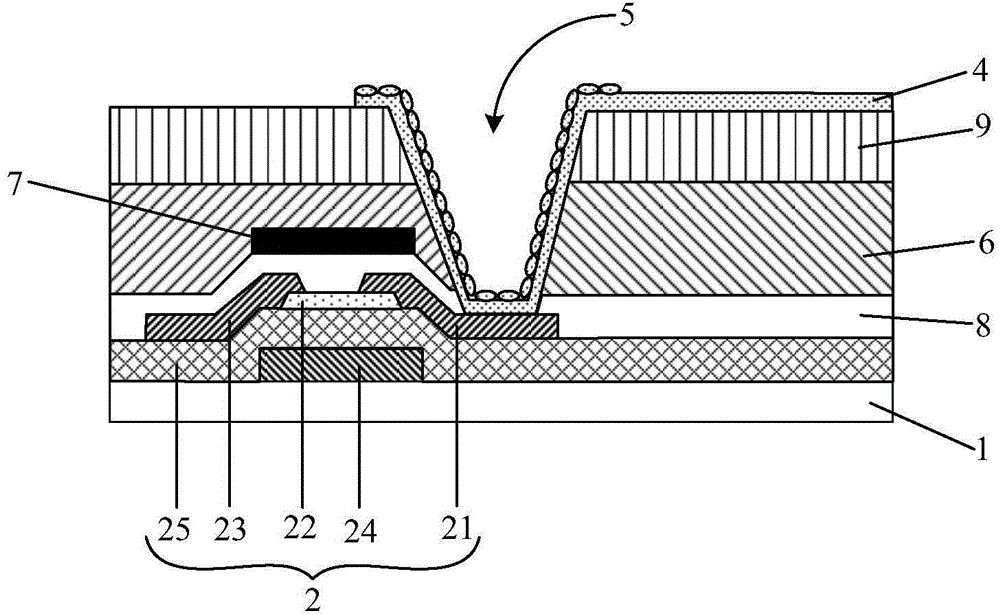

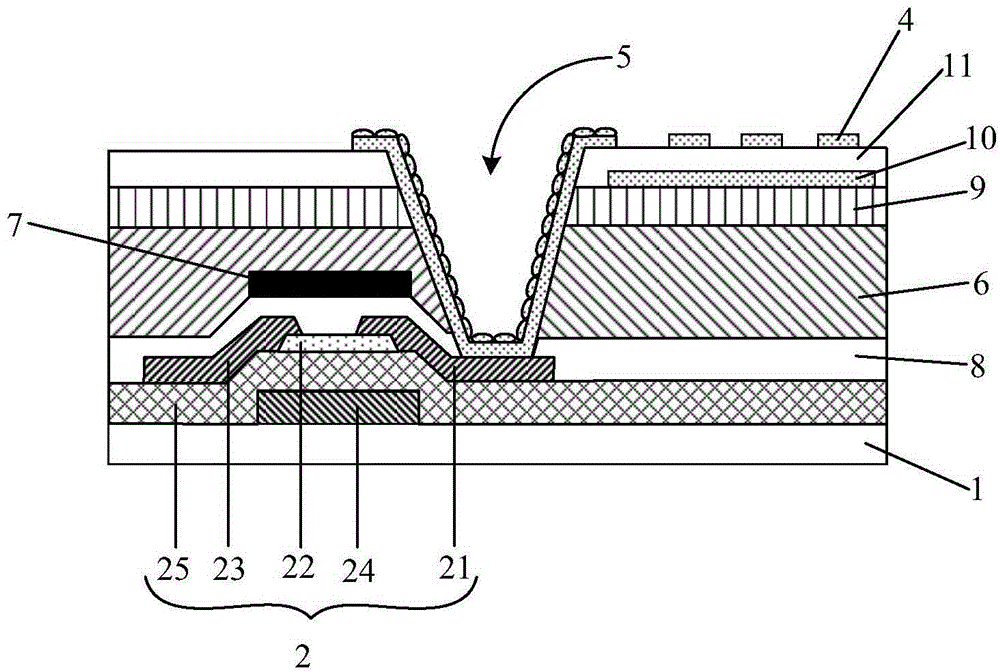

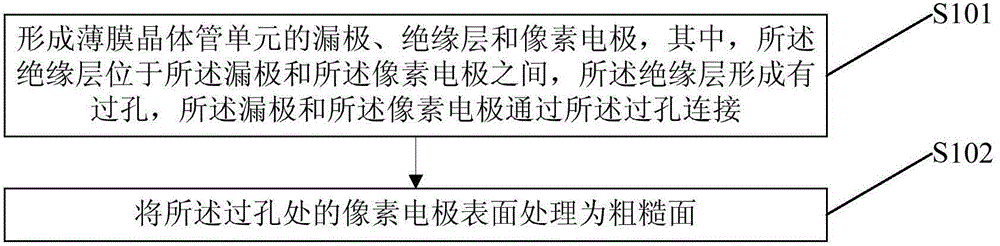

Array substrate, manufacturing method of array substrate, and display device

InactiveCN103985717AReduce light transmittanceReduce reflexesSemiconductor/solid-state device detailsSolid-state devicesDisplay deviceOptoelectronics

The embodiment of the invention discloses an array substrate, a manufacturing method of the array substrate, and a display device, and relates to the technical field of displaying. A drain electrode can be prevented from reflecting light, and the display effect of the display device is guaranteed. The array substrate comprises the drain electrode, an insulating layer and a pixel electrode of a thin film transistor unit, wherein the insulating layer is located between the drain electrode and the pixel electrode and provided with a via hole, the drain electrode and the pixel electrode are connected through the via hole, and the surface, at the via hole, of the pixel electrode is rough.

Owner:BOE TECH GRP CO LTD

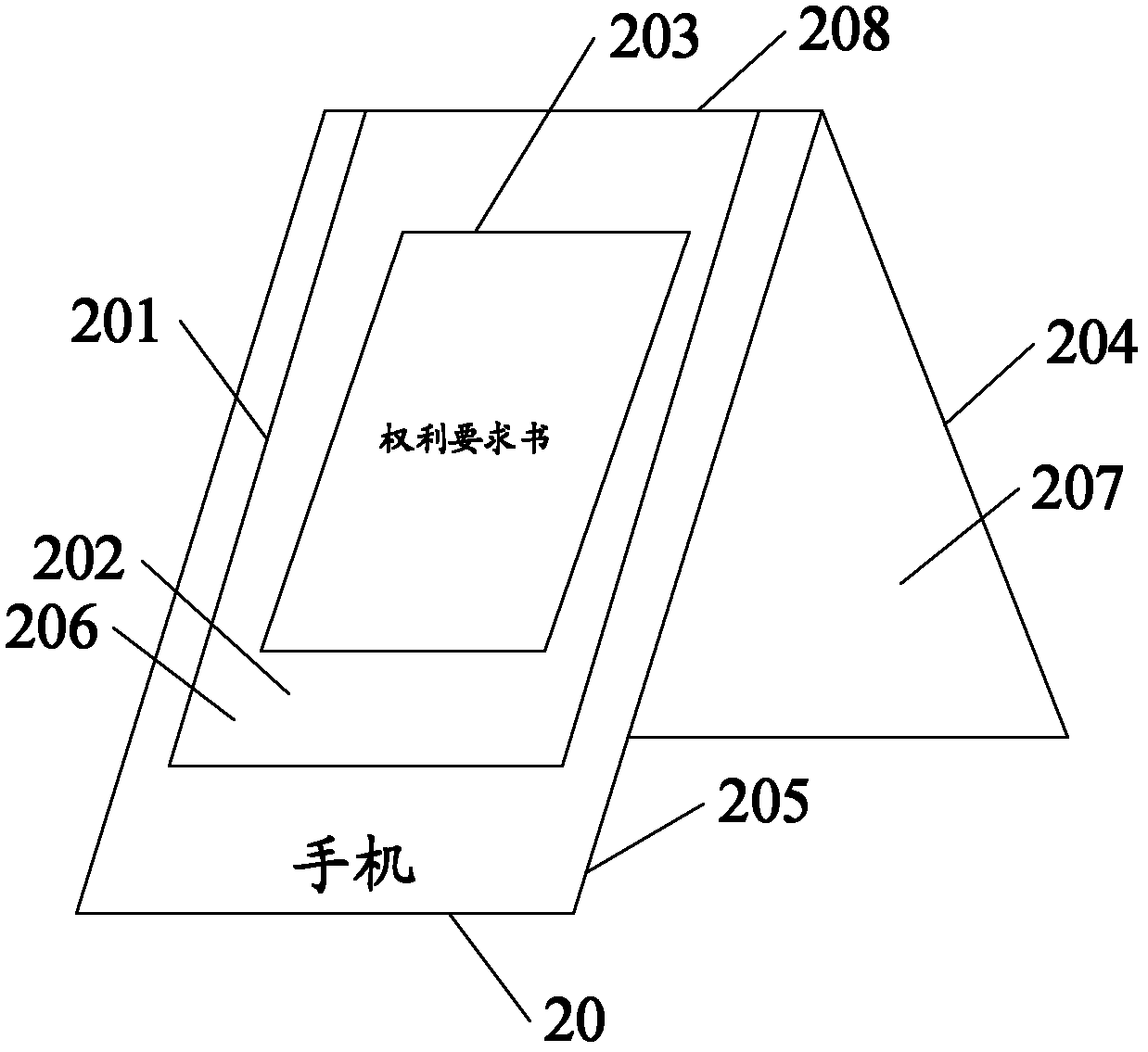

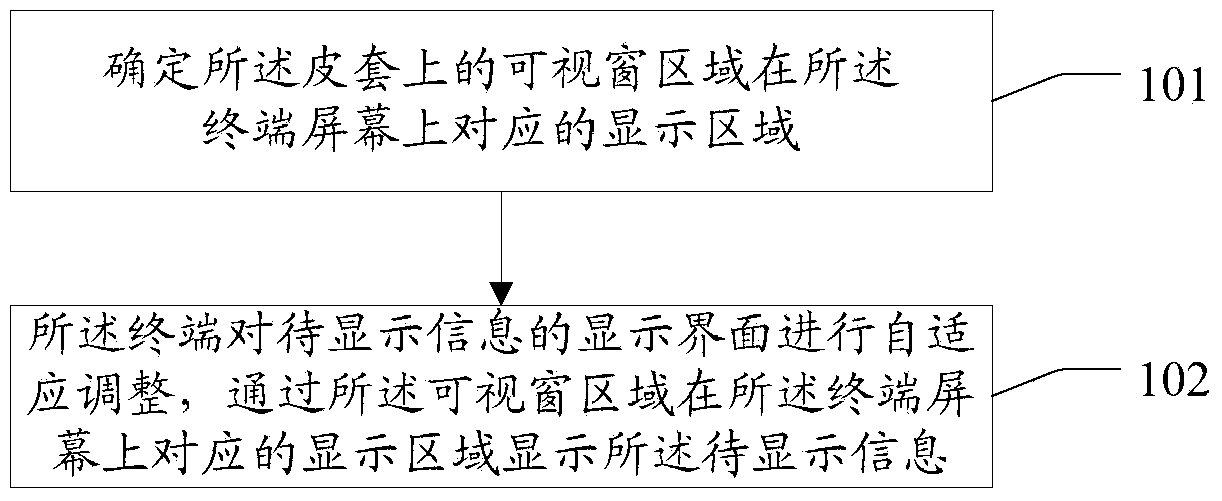

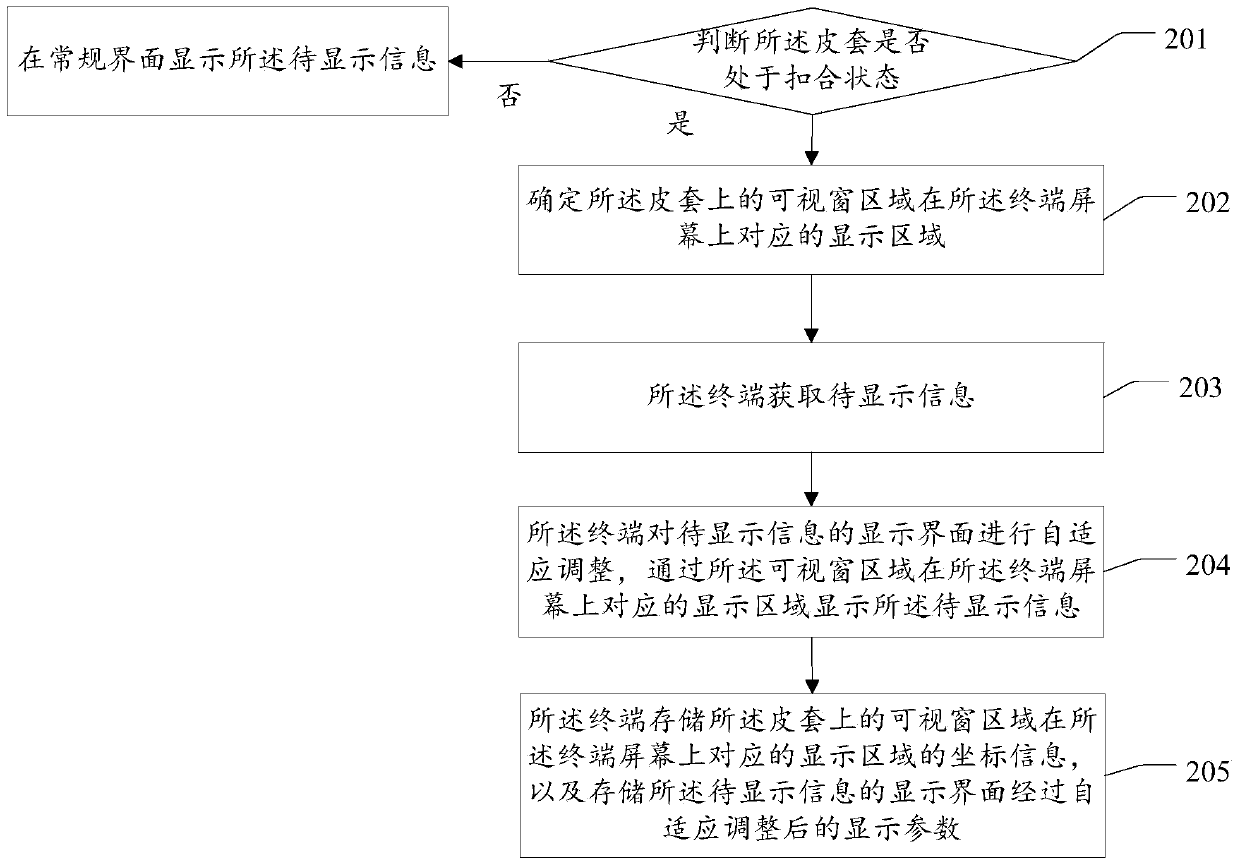

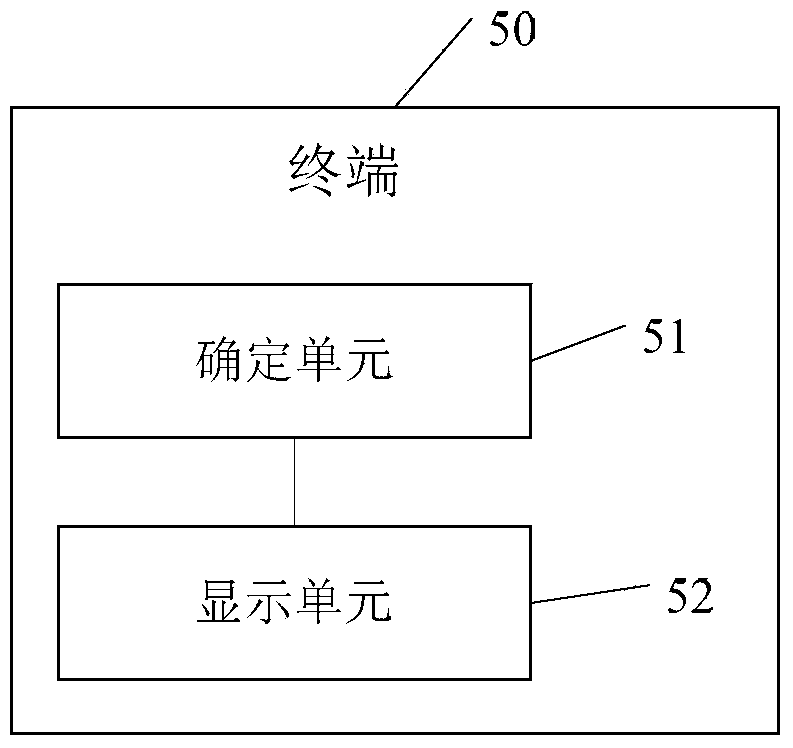

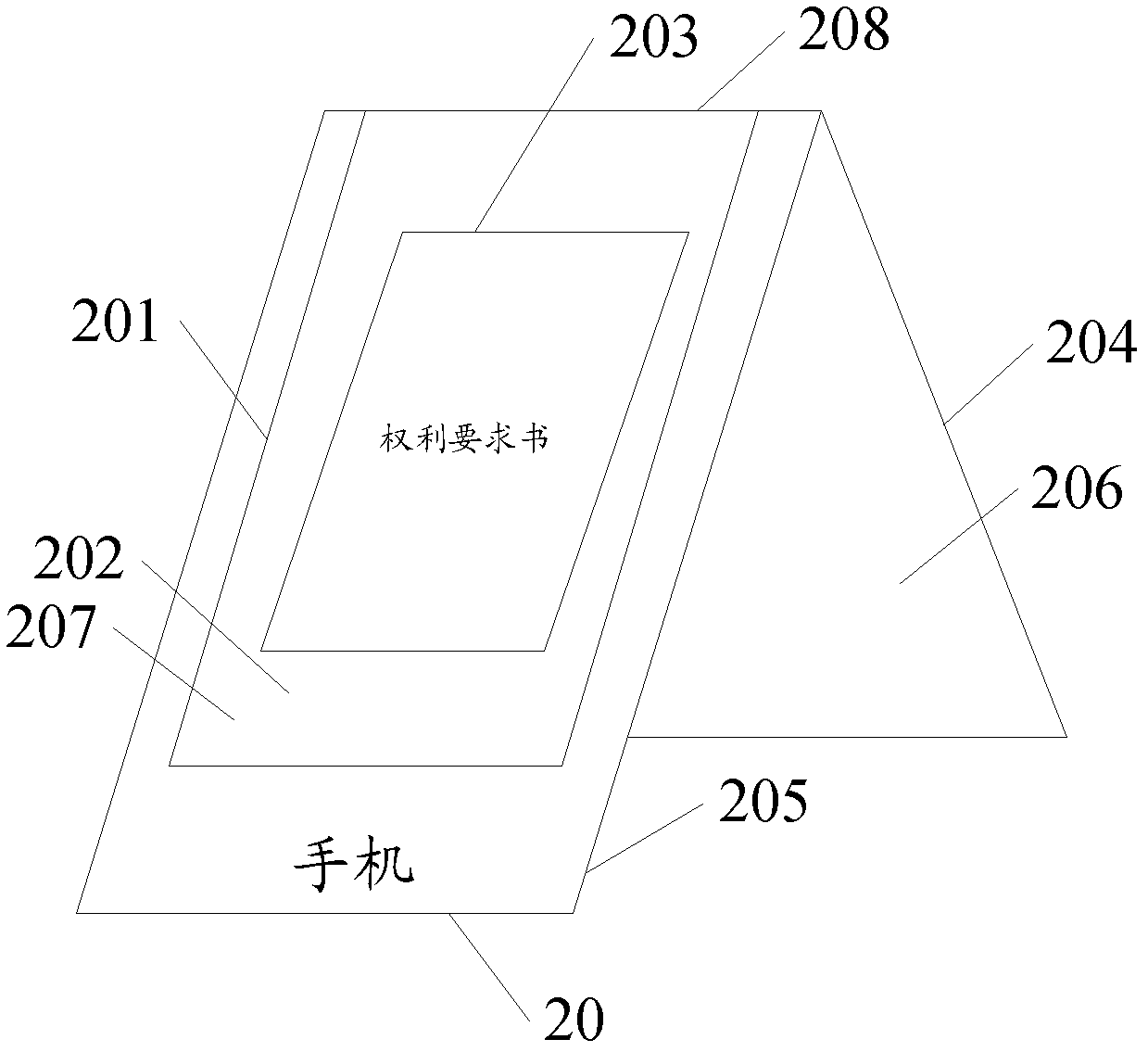

User interface display method and terminal

ActiveCN103747134AImprove experienceGuaranteed display effectSubstation equipmentSelf adaptiveMobile phone

The invention, which relates to the intelligent terminal field, discloses a user interface display method and a terminal. With the method and the terminal, the defect that the existing mobile phone leather sheath needs to be customized and has no universal application function in the prior art can be overcome. According to the invention, the user interface display method comprises the following steps that: the terminal detects the leather sheath and determines a display zone corresponding to a visual window zone of the leather sheath at the terminal screen; and the terminal carries out adaptive adjustment on a display interface of to-be-displayed information and the to-be-displayed information is displayed at the display zone, corresponding to the visual window zone, of the terminal screen. The provided method and the terminal is suitable for the intelligent terminal field and can be used for displaying a user interface.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

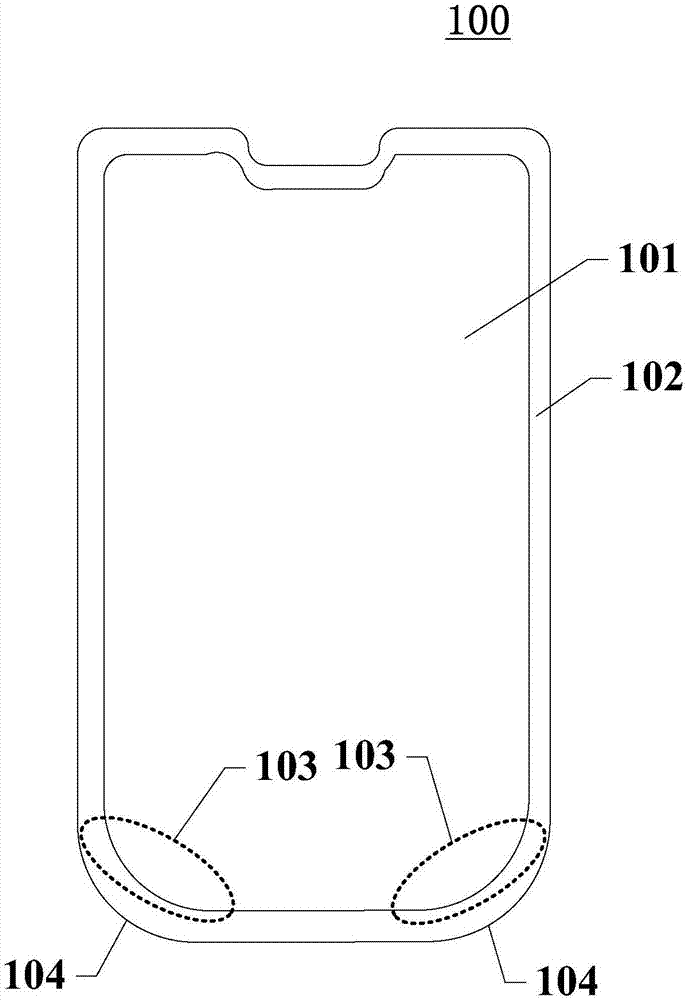

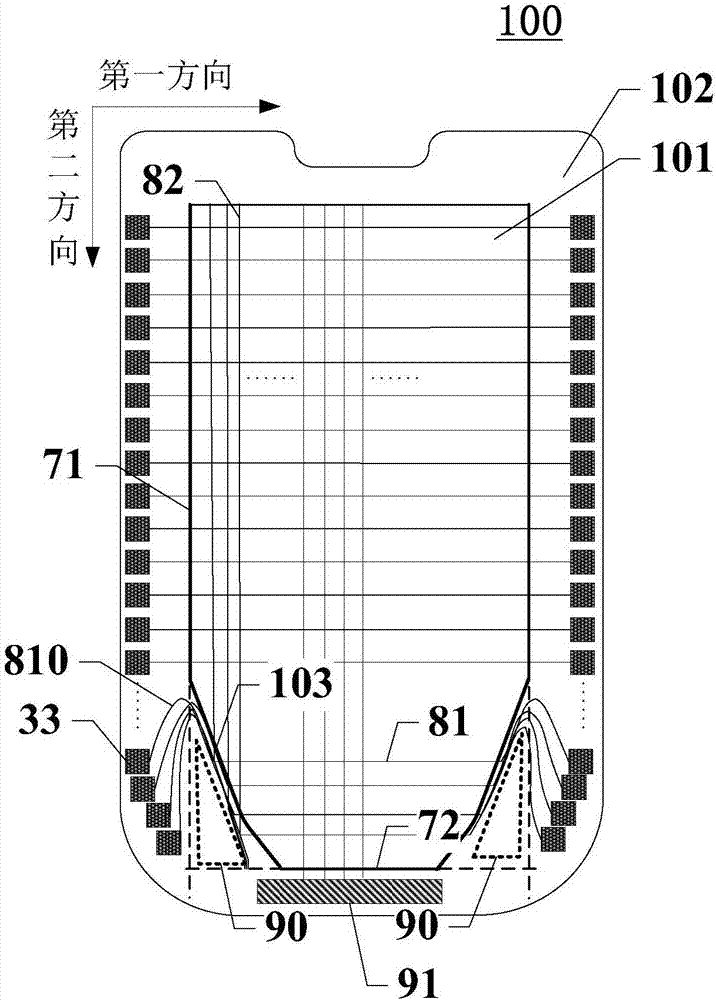

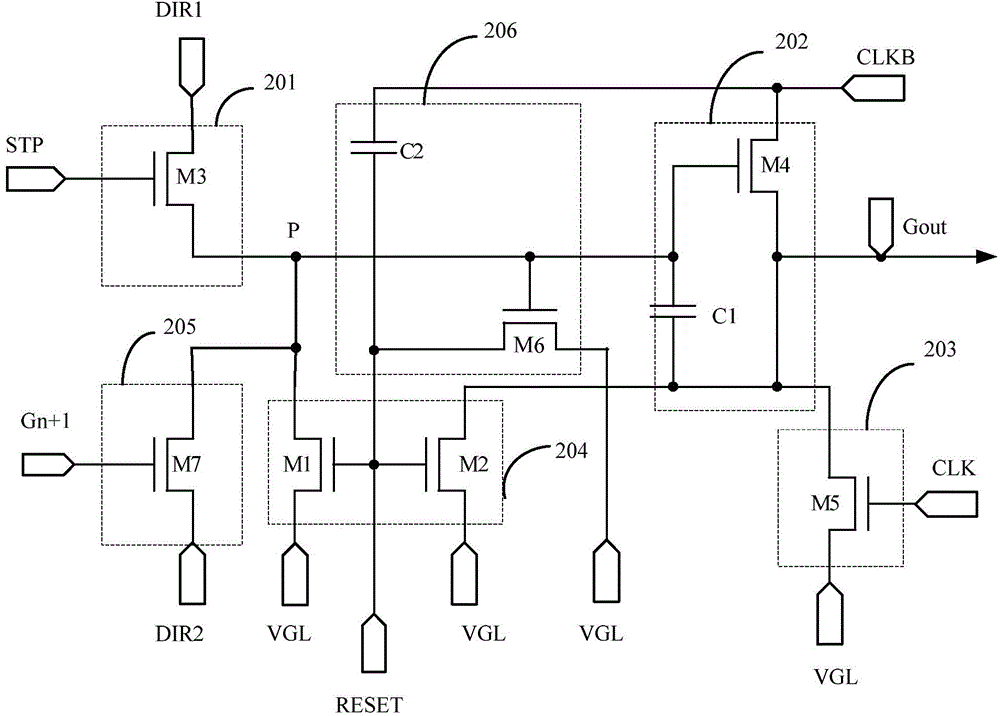

Display panel and display device

ActiveCN107991799AFunction increaseGuaranteed display effectStatic indicating devicesDigital storageShift registerDisplay device

The invention discloses a display panel and a display device, and relates to the technical field of display. A display area of the display panel is provided with an arc boundary; the display panel includes a plurality of gate lines and a plurality of data signal lines, in the display area, the gate lines extend in a first direction and are distributed in a second direction, and all the data signallines are distributed in the first direction and extend in the second direction; a non-display area is provided with a plurality of gate driving circuits, and each gate driving circuit comprises a plurality of cascaded shift registers electrically connected with the corresponding gate lines respectively; the non-display area is further provided with a first circuit placement area located at the side, away from the display area, of the arc boundary; in the non-display area at the arc boundary, the gate lines led out from the shift registers wind from one side of the first circuit placement area to the display area; in the non-display area at the arc boundary, the data signal lines are located between the first circuit placement area and the display area. According to the scheme, the improvement of the display effect of the display panel and the display device is facilitated.

Owner:SHANGHAI AVIC OPTOELECTRONICS

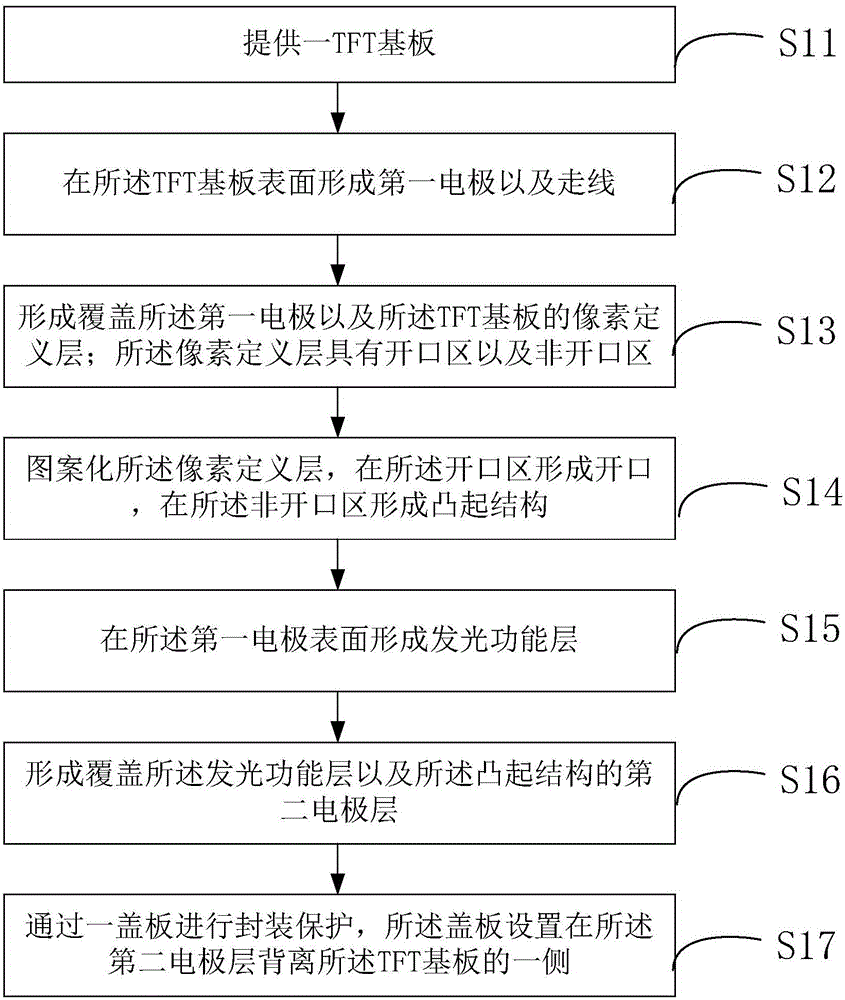

Display panel and manufacture method thereof

ActiveCN105845712ASimple designSimple preparation processSolid-state devicesSemiconductor/solid-state device manufacturingVoltage dropEngineering

The invention discloses a display panel and a manufacture method thereof. The display panel comprises a display area and a border area. The display panel comprises a cover plate and a display substrate, wherein the cover plate and the display substrate are oppositely arranged. The cover plate comprises a first conductive layer. The display substrate comprises a TFT substrate and a pixel definition layer which is arranged on one side, which faces the cover plate, of the TFT substrate. The pixel definition layer comprises an opening area and an opening-free area. The opening area is provided with a light-emitting function layer. A first electrode is arranged between the light-emitting function layer and the TFT substrate. The opening-free area is provided with a raised structure facing the cover plate. A second electrode layer is arranged on the light-emitting function layer and the surface of the raised structure. The second electrode layer is electrically connected with the first conductive layer at a position corresponding to the raised structure. Wiring is arranged in a preset area, which is corresponding to the border area, of the display substrate. The wiring is used for providing the work voltage of the second electrode layer. The first conductive layer is electrically connected with the wiring. According to the display panel, the width of the border area is reduced, and the problem of voltage drop of the second electrode layer is avoided.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD +1

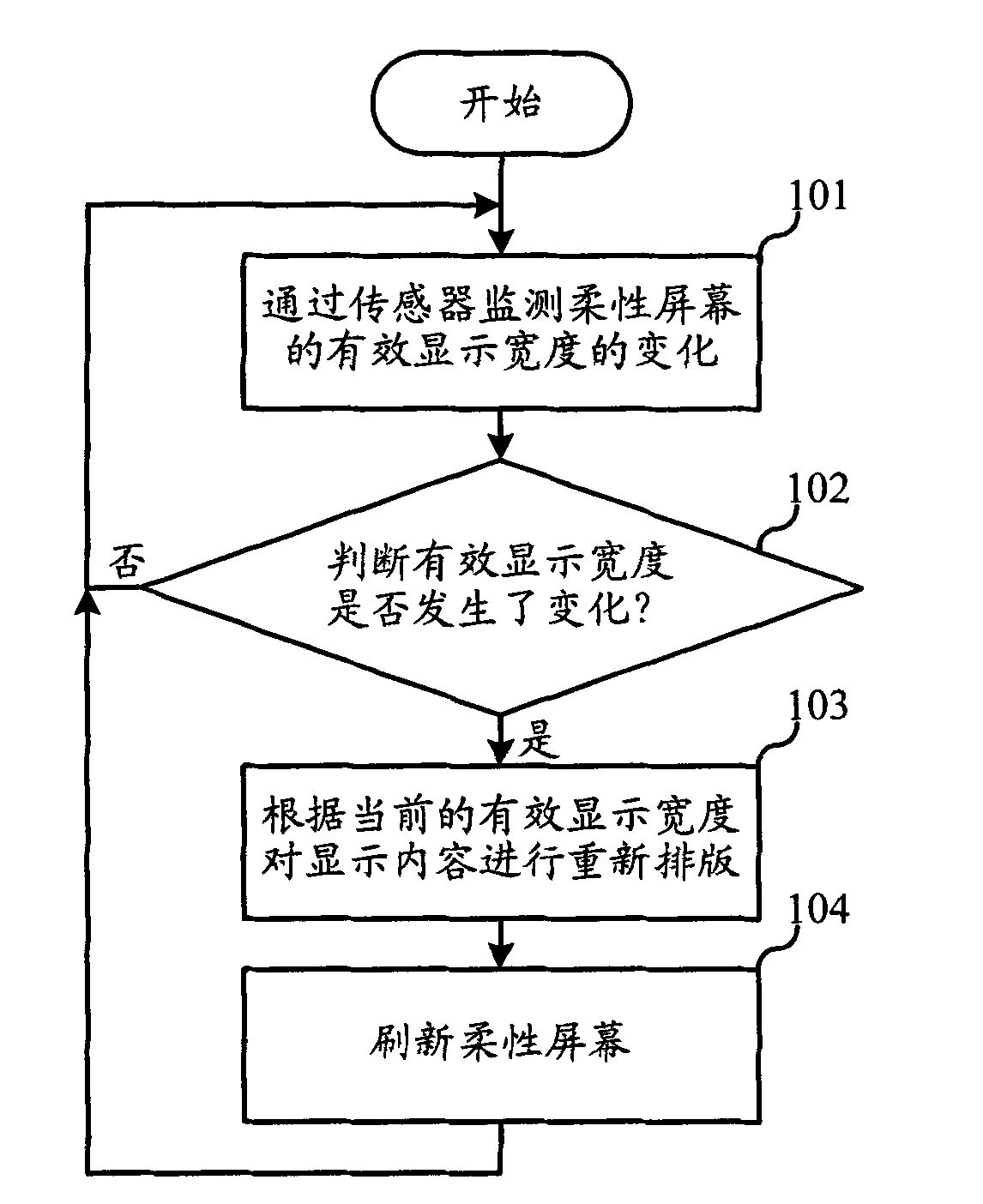

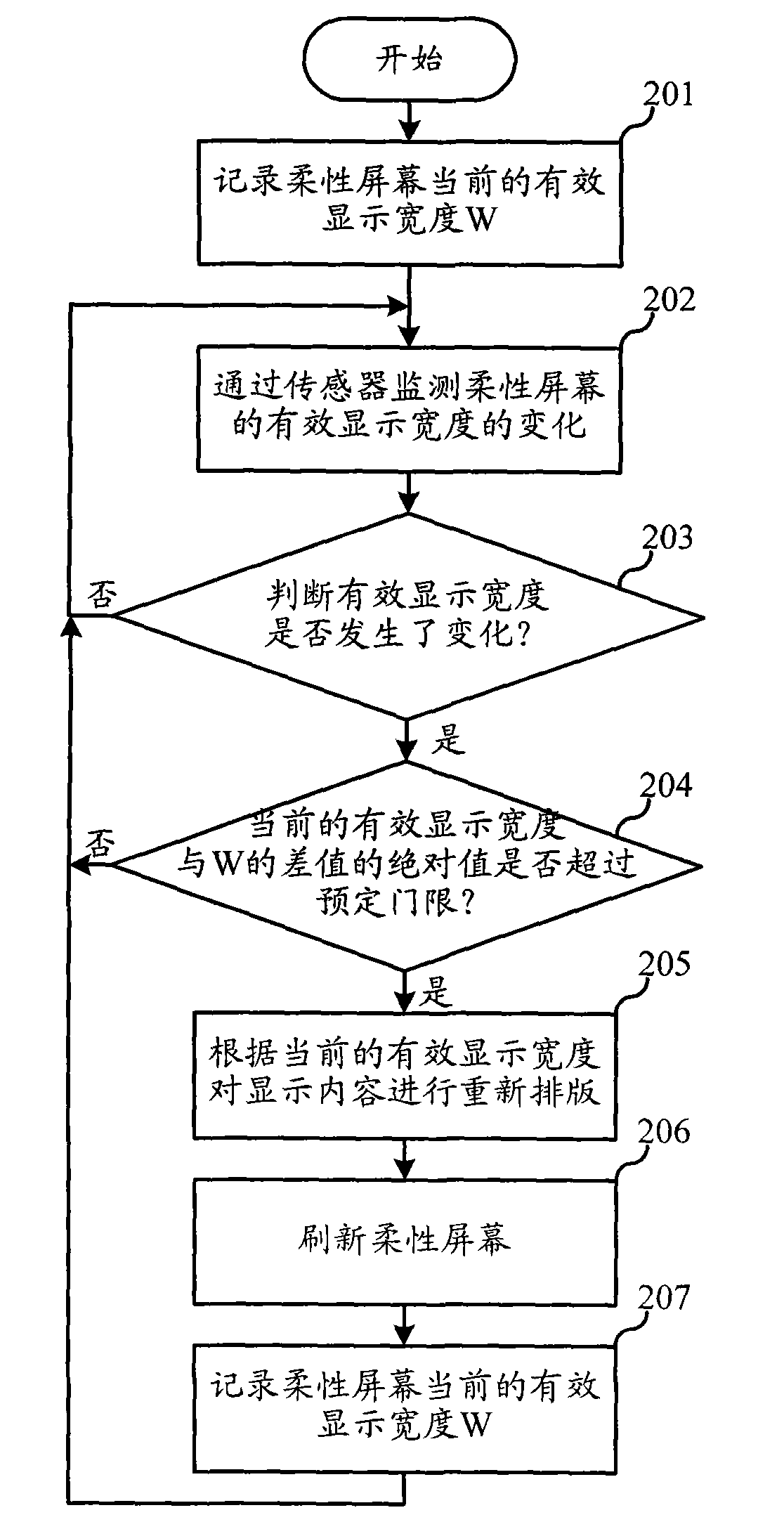

Electronic information reader and display method thereof

InactiveCN101887663ANo invisible situationsEasy to useStatic indicating devicesIdentification meansElectronic informationComputer science

The invention relates to the field of electronic information readers and discloses an electronic information reader and a display method thereof. In the invention, a sensor is used for monitoring the change of the effective display width of a flexible screen and carrying out renewal type-setting according to the current effective display width after a change occurs so as to ensure that a display mode is in optimal match with the effective part of the flexible screen without the occurrence of the situation of partially invisible content. When the change of the effective display width of the flexible screen is large enough or after the change is stopped, renewal type-setting and refreshment are carried out so as to reduce the frequency of type-setting and refreshment and the consumption of precious electric energy.

Owner:扬州易狄欧电子科技有限公司

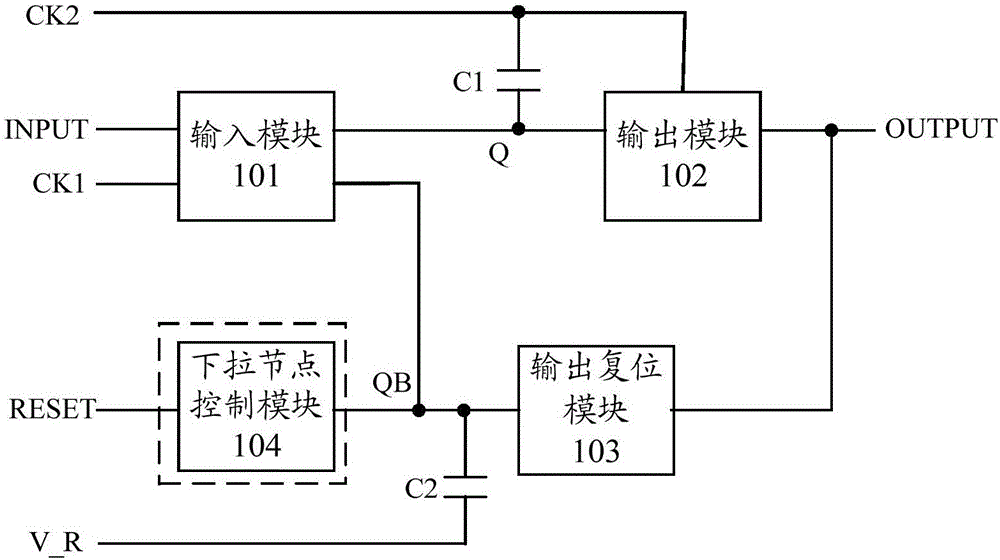

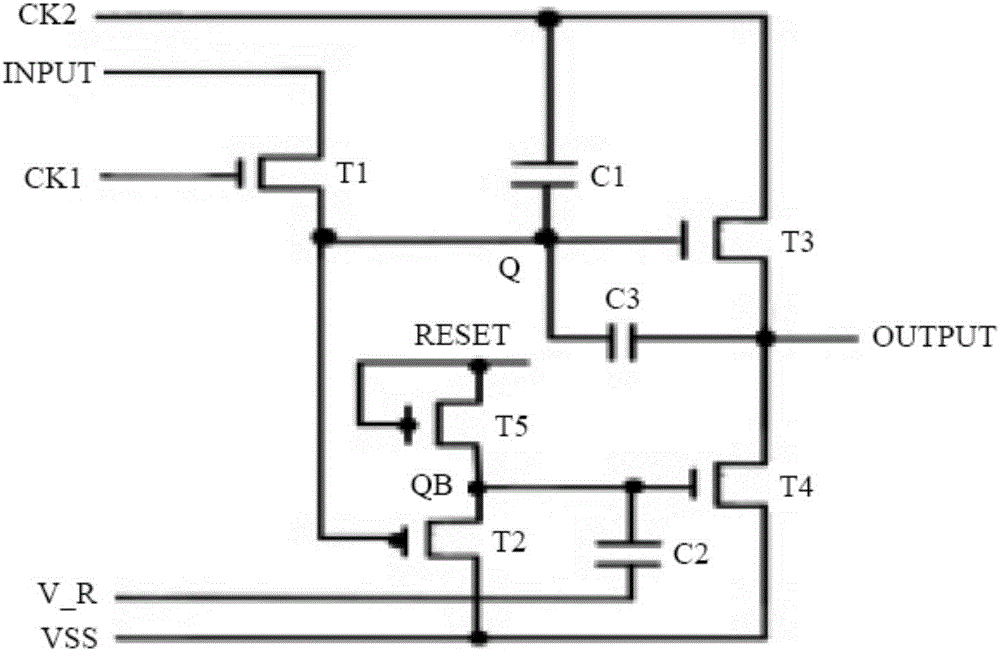

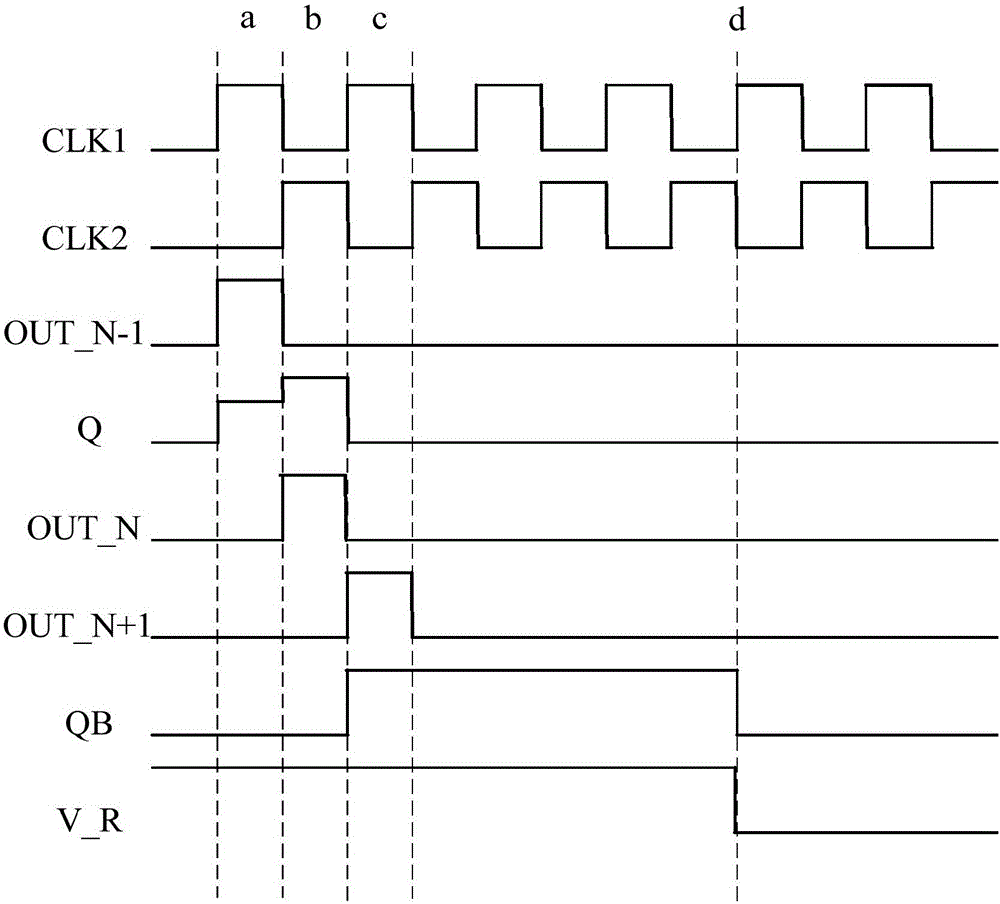

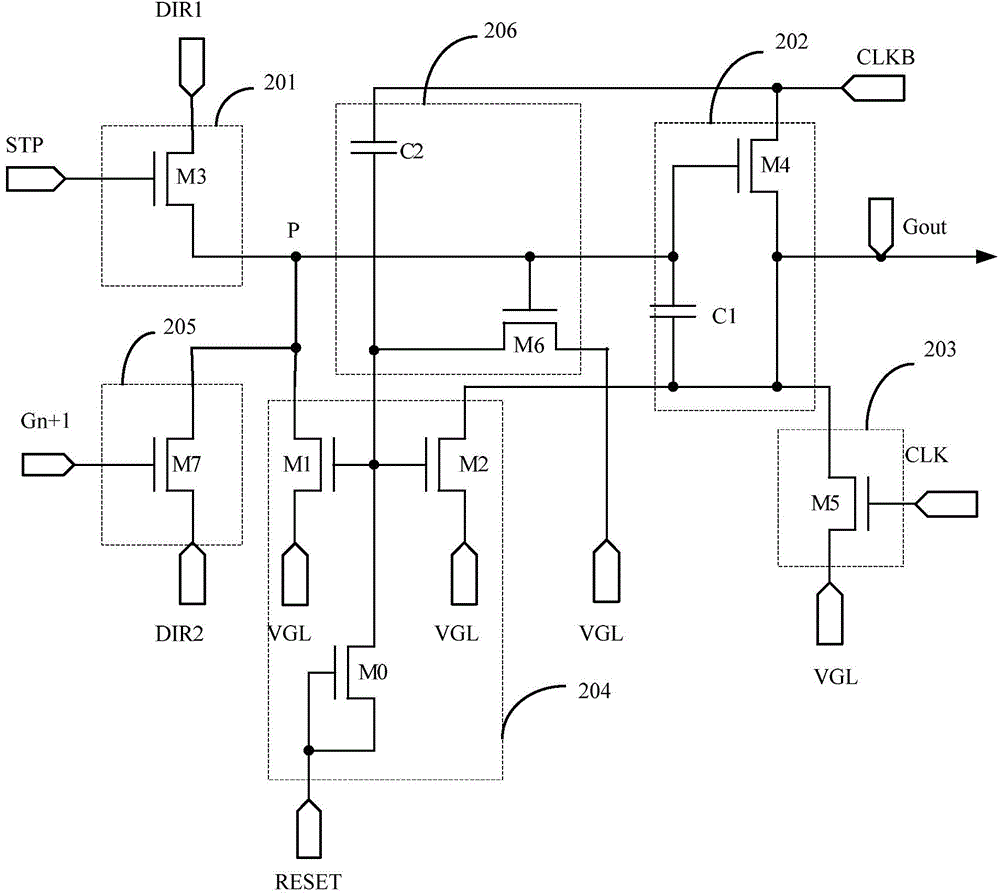

Shifting register unit, grid electrode drive circuit and drive method

InactiveCN106847221ASimple structureWith full swing outputStatic indicating devicesDigital storageShift registerCapacitance

The invention discloses a shifting register unit, a grid electrode drive circuit comprising the shifting register unit and a drive method used for the shifting register unit. The shifting register unit comprises an input module, an output module, an output return module and a first capacitor, wherein the first capacitor is connected between an upper pulling node and a second clock signal end, and is configured to keep high electrical level of the upper pulling node by a second clock signal accessed through a second clock signal end. The shifting register unit further comprises a second capacitor which is connected between a lower pulling node and a first voltage input end, and is configured to reduce electric level of the lower pulling node by reverse bias voltage accessed through the first voltage input end within blanking time after one-frame scanning is ended. The shifting register unit is simple in structure, has full-oscillation-amplitude output, is low in power loss, is small in noise, and restores drifting of threshold voltage of a film transistor connected with an output end, so that normal display of a liquid crystal panel is kept.

Owner:BOE TECH GRP CO LTD +1

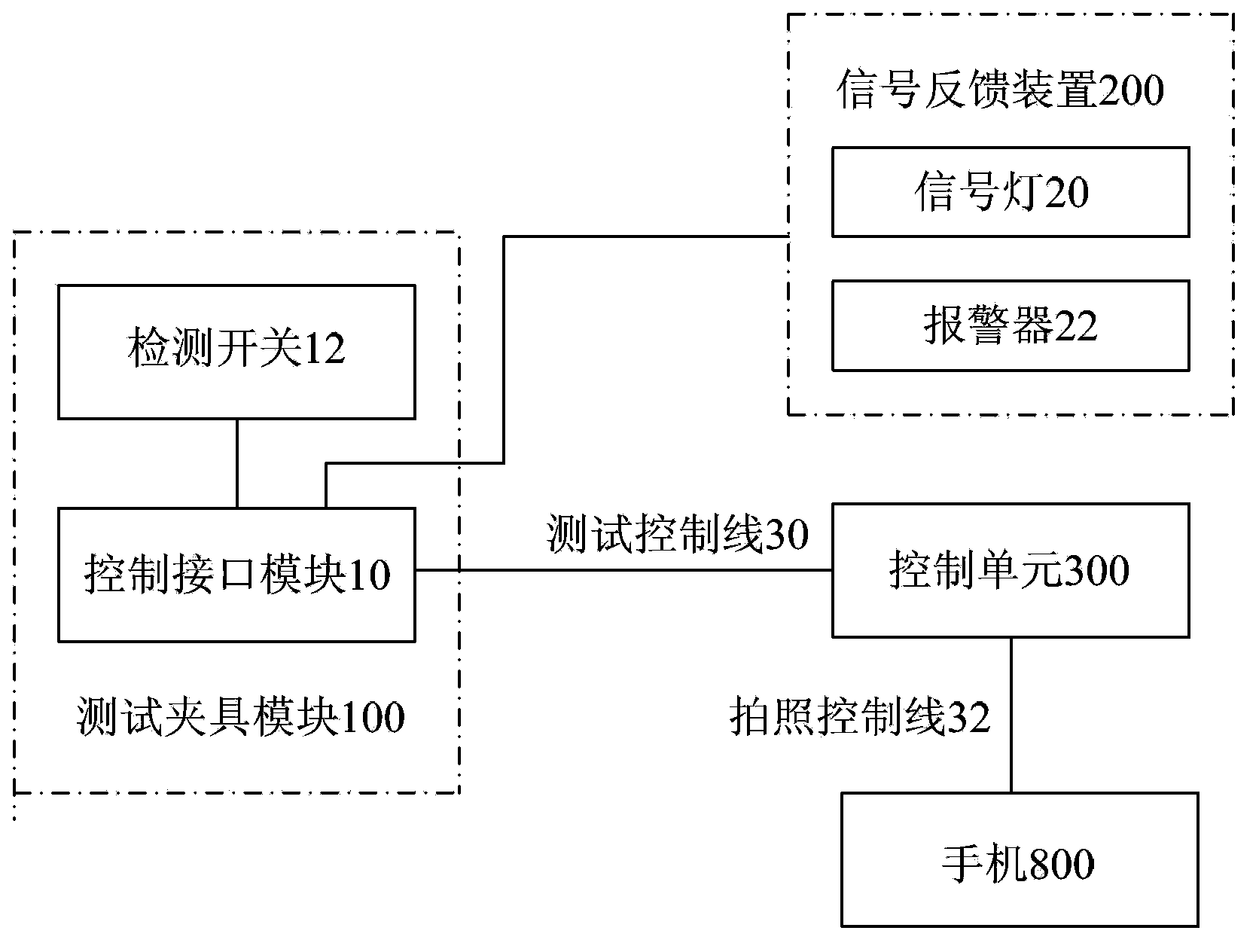

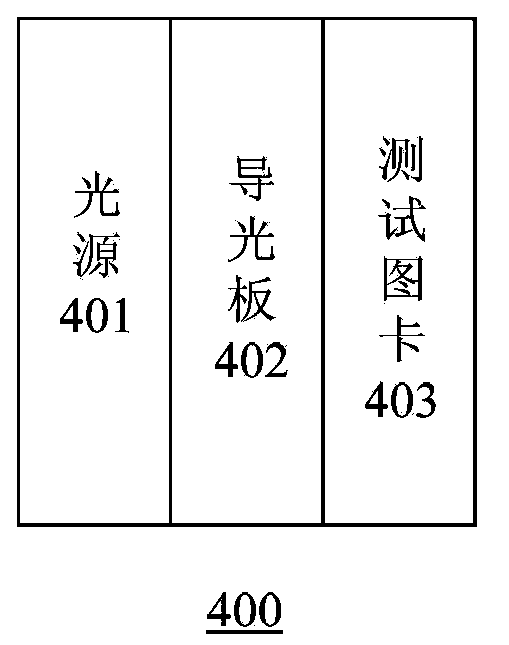

Automatic detection system and detection method for mobile phone camera

InactiveCN104104761AMeet the requirements of different locationsBest shot imageSubstation equipmentTest cardControl line

Disclosed is an automatic detection system for a mobile phone camera. The system comprises a test clamp module for placing a mobile phone; a signal feedback device for leading out a test result; a control unit which is electrically connected with the test clamp module through a test control line so as to control a test to start or end and output whether the test result is qualified and is eclectically connected with the mobile phone through a shooting control line so as to send a shooting instruction and feed a shot test image; and a test cart card module which is opposite to the test clamp module for shooting and comparison of the camera. The mobile phone is placed on the test clamp module, a control interface module sends a signal to be detected to the control unit, the control unit sends a test starting instruction to the mobile phone through the shooting control line so as to drive the mobile phone to start a test, after the test card chart module is shot, the mobile phone transmits a detected image to the control unit through the shooting control line for comparison calibration, and the control unit, according to a comparison analysis result, gives a feedback to a signal feedback device so as to output and display whether the test result is qualified.

Owner:赛龙通信技术(深圳)有限公司

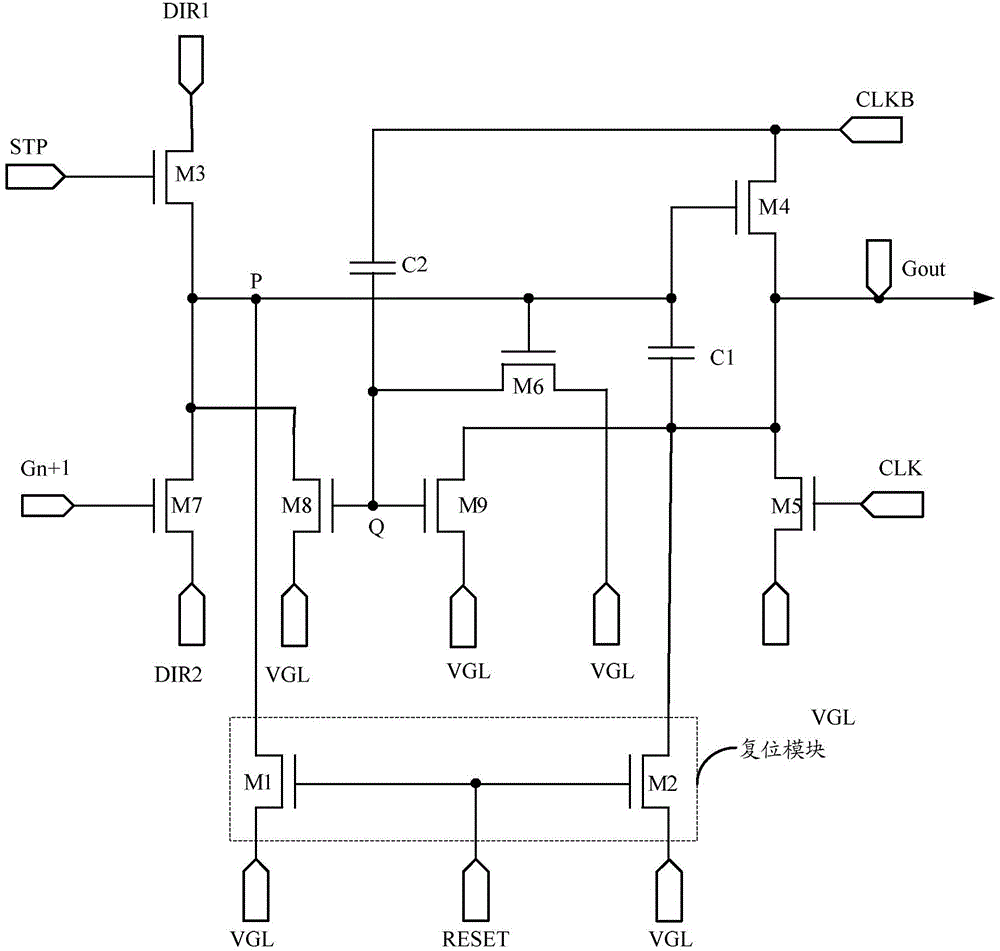

Shifting register and driving method thereof

ActiveCN104575419AGuaranteed display effectSolve the display exceptionStatic indicating devicesDigital storageShift registerComputer module

The invention discloses a shifting register and a driving method thereof. The shifting register comprises a plurality stages of cascaded shifting register circuits, a first reset module and a second reset module, wherein each stage of shifting register circuit comprises a main output end, a main input module, a first output module and a second output module; the node between each main input module and each first output module is a first node; the first reset module is used for resetting the first nodes and the main output ends to low level according to a first reset signal input by a reset signal input end; the second reset module is used for receiving a second reset signal output by the next stage of shifting register circuit to reset the first nodes and the main output ends to low level. Before inputting an initial signal, the first reset module resets voltage of the first nodes and the main output ends, so that the gate driving signals are not influenced by the threshold voltage shifting of thin film transistors and the problem that the display units display abnormally due to the threshold voltage shifting of the thin film transistors in the prior art is solved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD +1

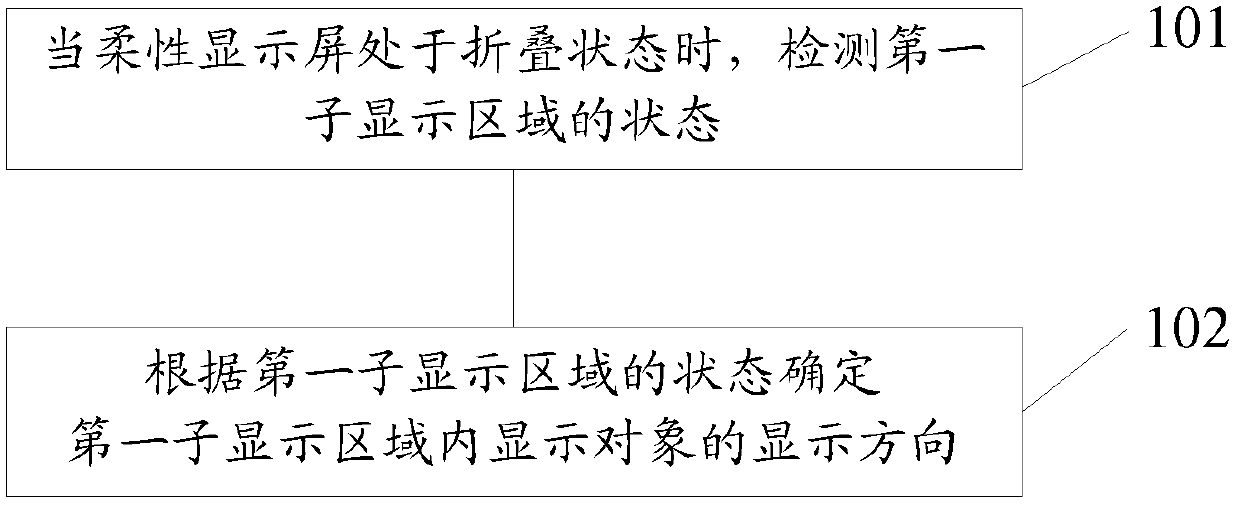

Display method and electronic equipment

ActiveCN103294369AImprove experienceImprove the display effectInput/output processes for data processingComputer hardwareComputer graphics (images)

The invention discloses a display method and electronic equipment. The method is applied to the electronic equipment. The electronic equipment is provided with a flexible display screen; the flexible display screen is provided with an unfolding state and a folding state; when the flexible display screen is in the unfolding state, the flexible display screen is provided with a first display region; and when the flexible display screen is in the folding state, the first display region at least forms a first sub display region and a second sub display region through at least one folding line. The method comprises the steps as follows: when the flexible display screen is in the folding state, detecting a state of the first sub display region; and determining a display direction of a display object in the first sub display region according to the state of the first sub display region.

Owner:LENOVO (BEIJING) LTD

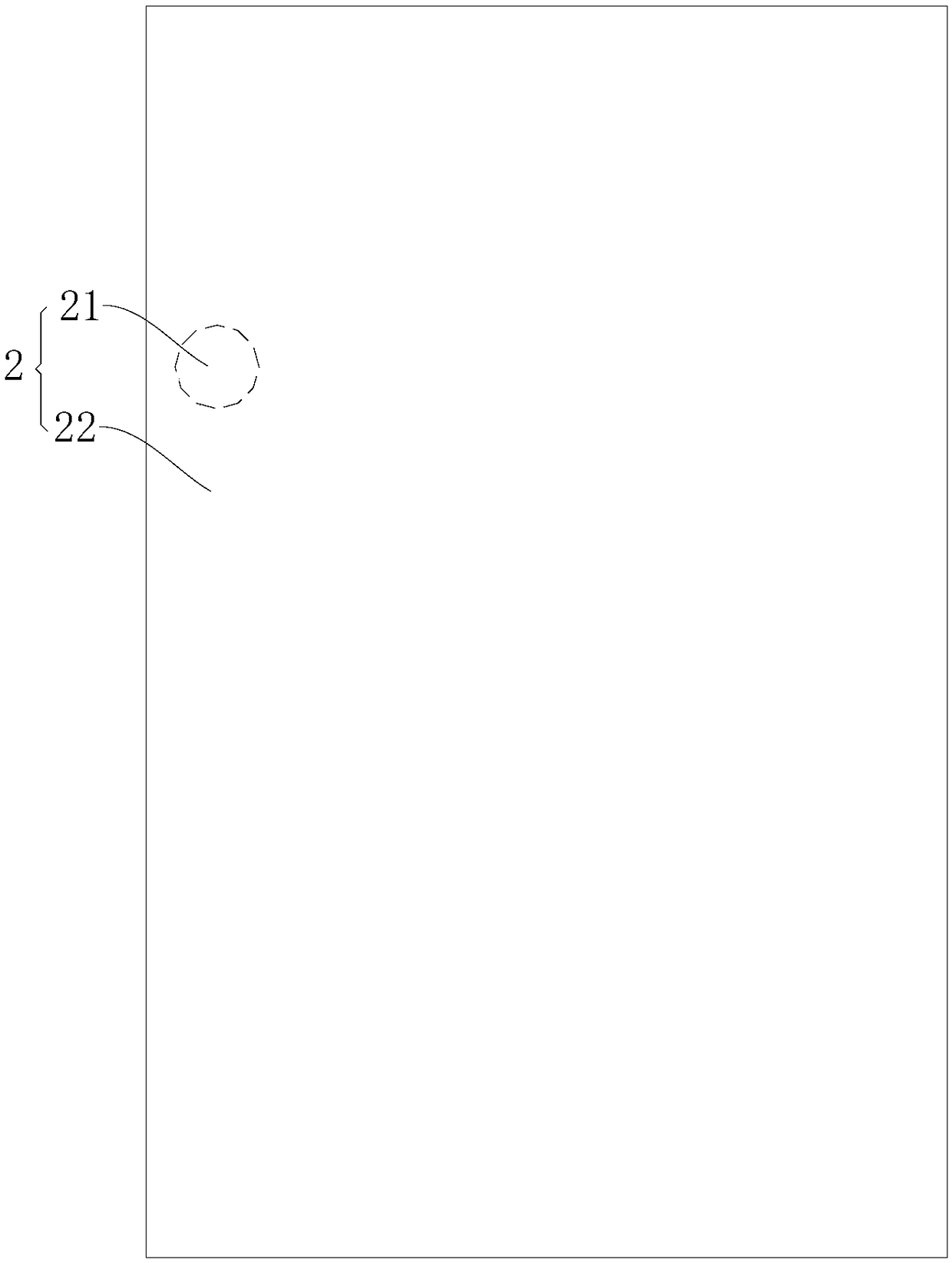

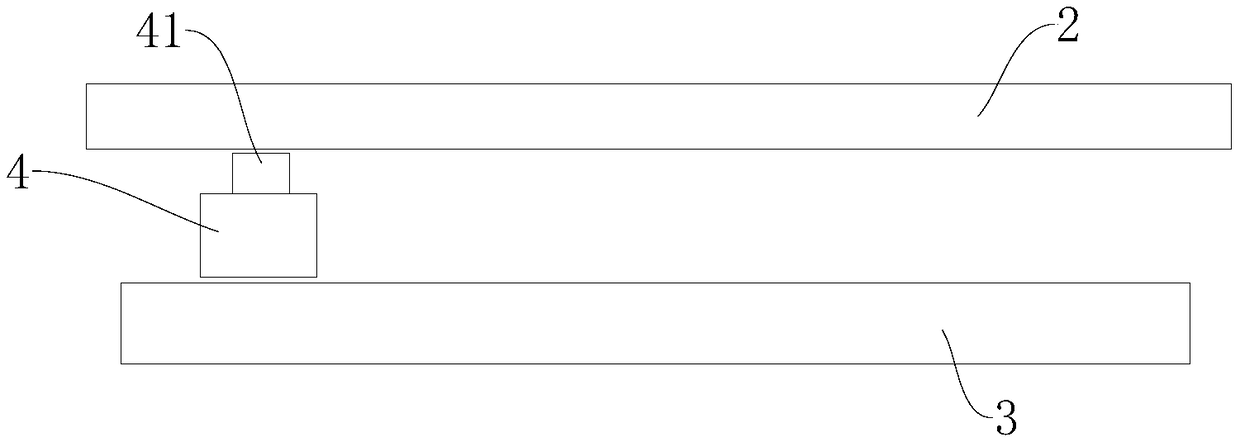

Electronic device and control method thereof

ActiveCN108983872AIncrease the screen ratioRealize full screenDigital data processing detailsTelephone set constructionsCamera lensImage resolution

The invention discloses an electronic device and a control method thereof. The electronic device comprises a main board, a display screen and a camera. The display screen is connected to the motherboard. The display screen includes a first display area and a second display area. The camera is connected to the motherboard. The camera is arranged on the side of the display screen adjacent to the main board, the lens of the camera is opposite to the first display area, the resolution of the first display area is smaller than the resolution of the second display area when the camera is in the working state, and the resolution of the first display area is the same as the resolution of the second display area when the camera is in the non-working state. According to the present application, thescreen occupancy ratio of the electronic device can be improved, the overall screen of the electronic device is facilitated, the light transmittance of the first display area can be increased and theimaging quality of the camera is guaranteed when the camera is in operation. Meanwhile, the display effect of the first display area is guaranteed when the camera is not in operation, thereby ensuringthe display effect of the whole display screen.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

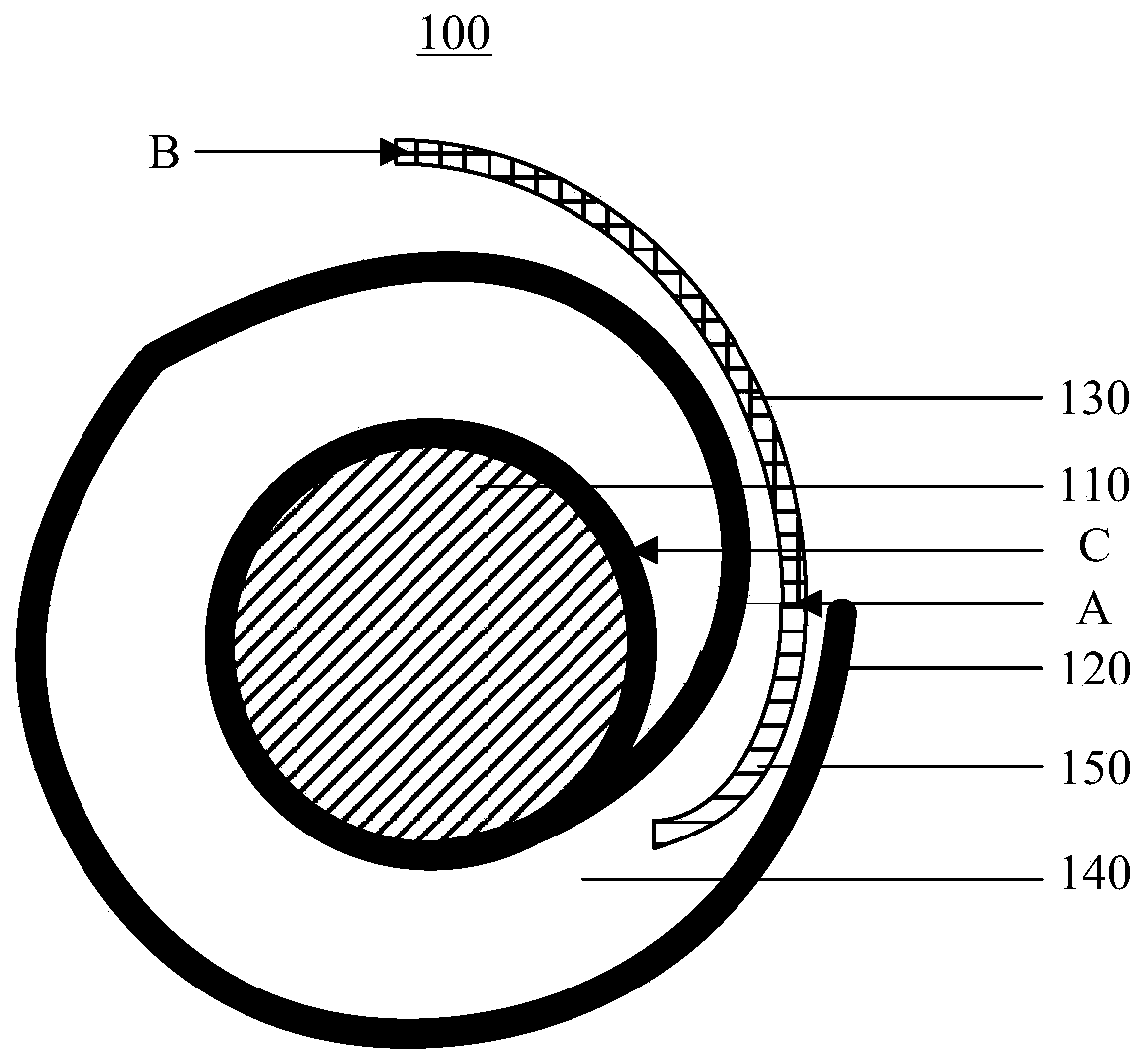

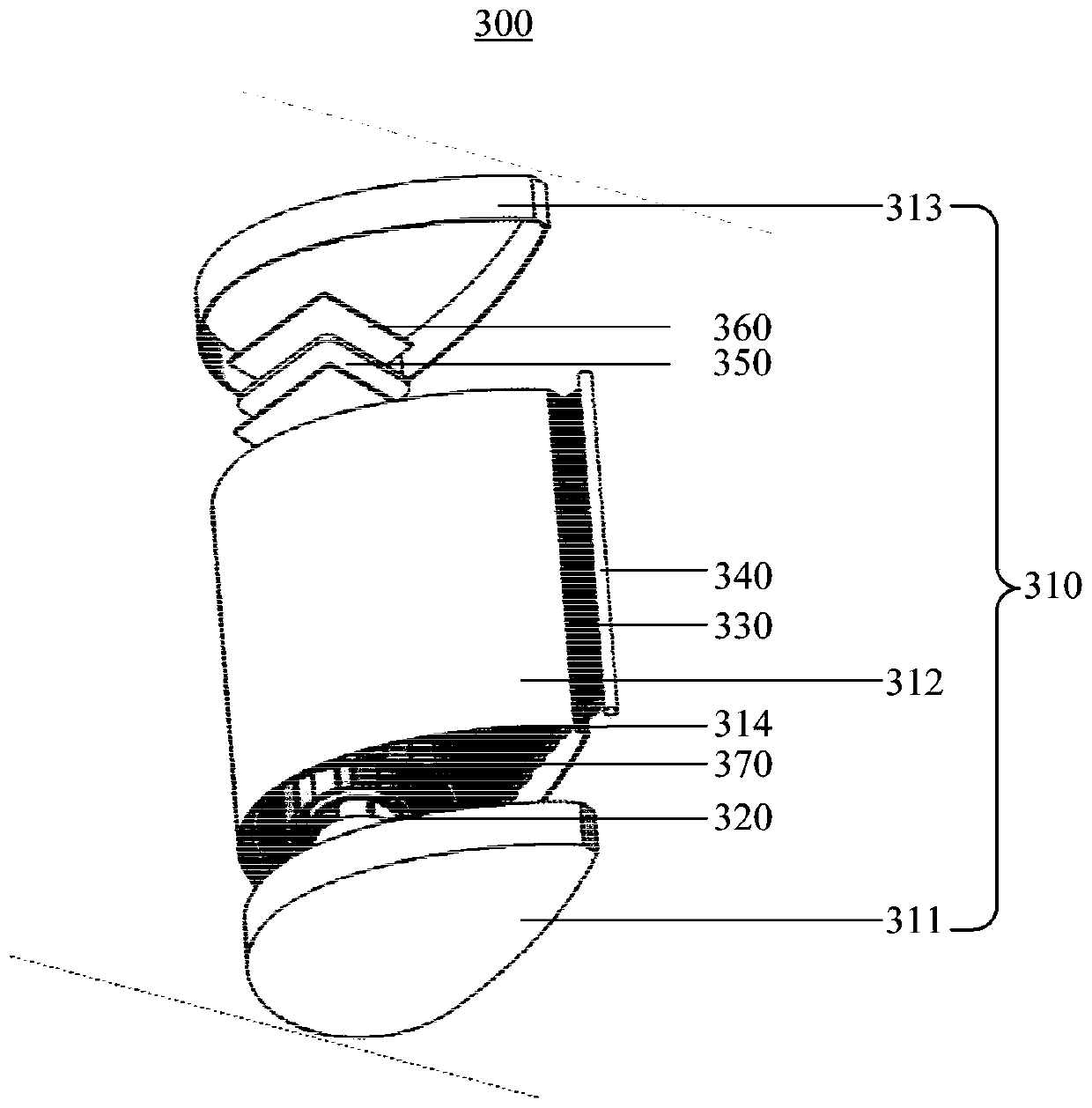

Winding device and flexible display device

ActiveCN110599911AAvoid damageGuaranteed display effectIdentification meansFlexible circuitsFlexible display

The present invention provides a winding device and a flexible display device. The winding device is used for accommodating a flexible screen and comprises a reel and a supporting piece, and the supporting piece is wound on the reel, wherein the flexible screen comprises a first end and a second end, the first end is connected with a flexible printed circuit board, the flexible printed circuit board is accommodated in a gap formed by the supporting piece, the flexible screen is at least partially wound on the supporting piece, when the second end of the flexible screen is pulled by external force, the flexible screen extrudes the supporting piece so as to shrink the supporting piece, and when the external force is removed, the supporting piece is used for enabling the flexible screen to rebound. According to the technical scheme, the flexible printed circuit board can be prevented from being damaged due to excessive pulling, completeness of components in the area of the flexible printed circuit board is guaranteed, and normal display of the flexible screen is guaranteed.

Owner:YUNGU GUAN TECH CO LTD

A flexible display panel and a flexible display device

InactiveCN109003998AGuaranteed display effectReduce adverse effectsSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFlexible display

The embodiment of the invention provides a flexible display panel and a flexible display device, which relate to the technical field of display. A flexible display panel provided by an embodiment of the present invention includes: flexible substrate, An insulating layer, a plurality of light emitting devices and an encapsulation film, the flexible substrate includes a display area and a peripheralarea surrounding the display area, An insulating layer is located in the peripheral region, At least one first groove is arrange on that insulating lay, the first groove is located on the side of theedge of the packaging film away from the display area, and the extending direction of the first groove is the same as the extend direction of the edge of the flexible substrate on the side thereof. The technical proposal of the invention can improve the encapsulation ability of the encapsulation film.

Owner:YUNGU GUAN TECH CO LTD

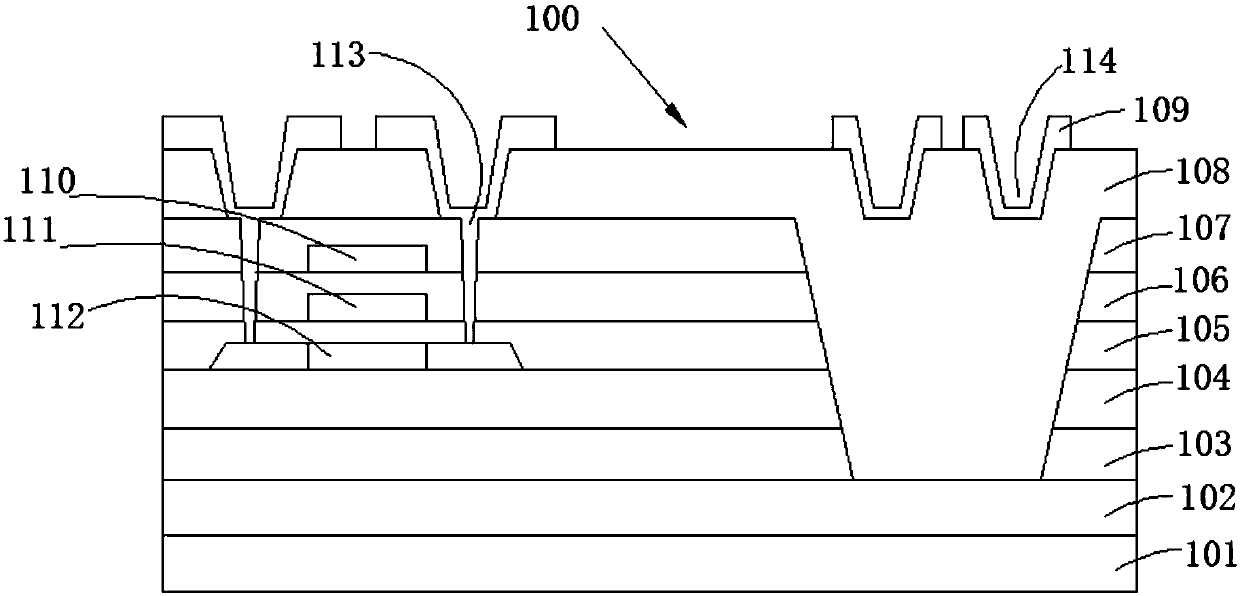

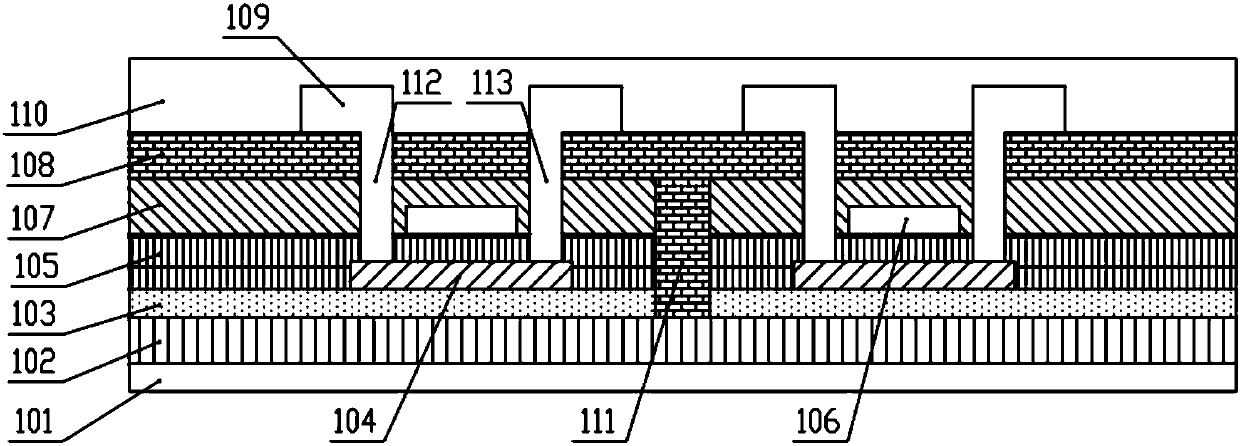

OLED array substrate, manufacturing method thereof and display device

ActiveCN103456764AAvoid lightNo errorsSolid-state devicesSemiconductor/solid-state device manufacturingActive matrixDisplay device

The embodiment of the invention discloses an OLED array substrate, a manufacturing method of the OLED array substrate and a display device with the OLED array substrate, and belongs to the technical field of display. The OLED array substrate, the manufacturing method of the OLED array substrate and the display device with the OLED array substrate solve the technical problems that a TFT of an existing active matrix type OLED display device is easily illuminated by light, and the display effect is influenced. The OLED array substrate comprises thin film transistors arranged on a substrate, wherein black matrixes are arranged on the thin film transistors, a through hole is formed in each black matrix, first electrodes, a luminous layer and a second electrode are arranged on the tops of the black matrixes in sequence from bottom to top, the first electrodes are connected with the thin film transistors through the through holes, and every two adjacent first electrodes are separated through a blocking wall. The OLED array substrate can be applied to display devices such as OLED panels, television sets, displayers, digital photo frames, mobile phones and tablet personal computers.

Owner:BOE TECH GRP CO LTD

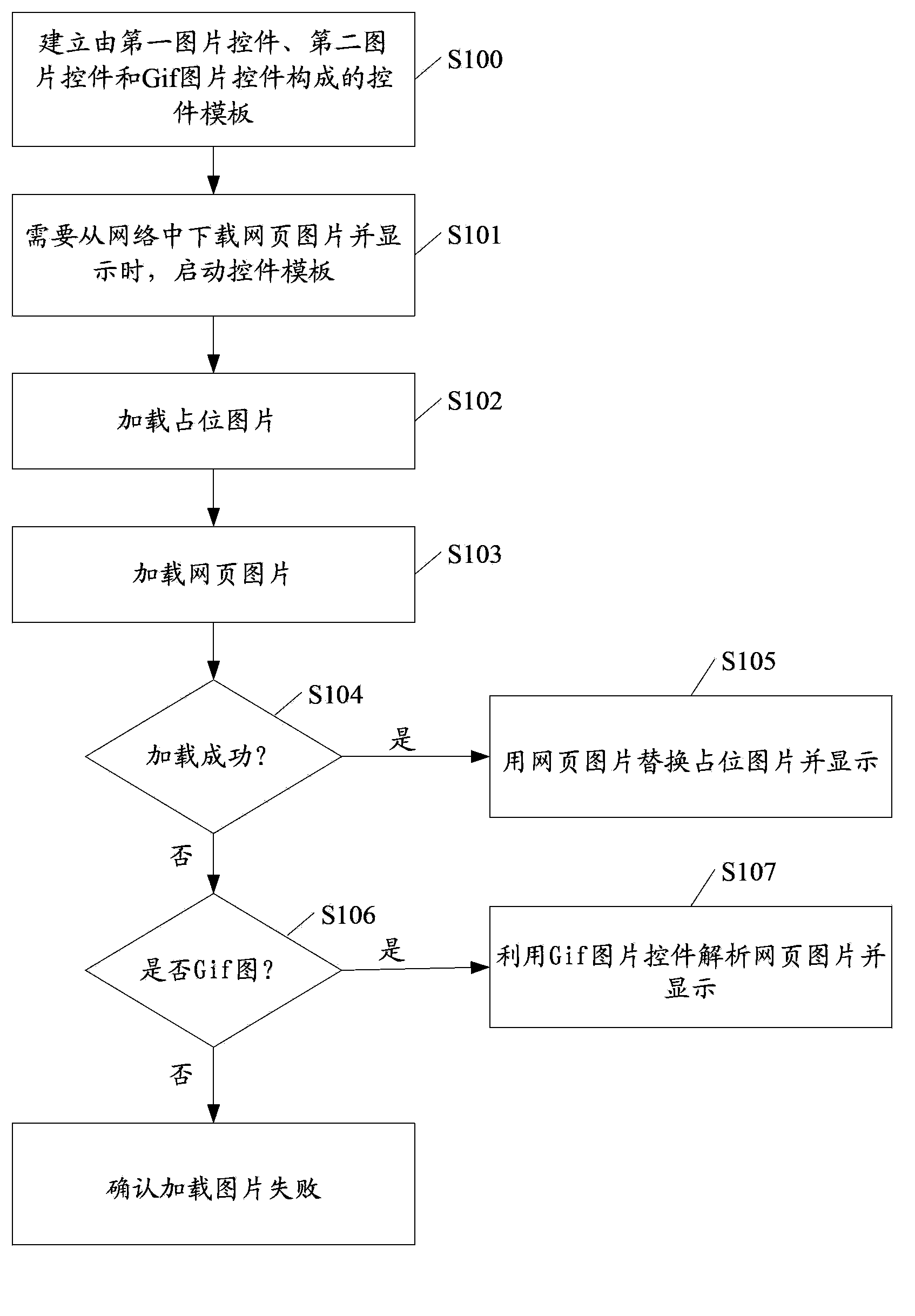

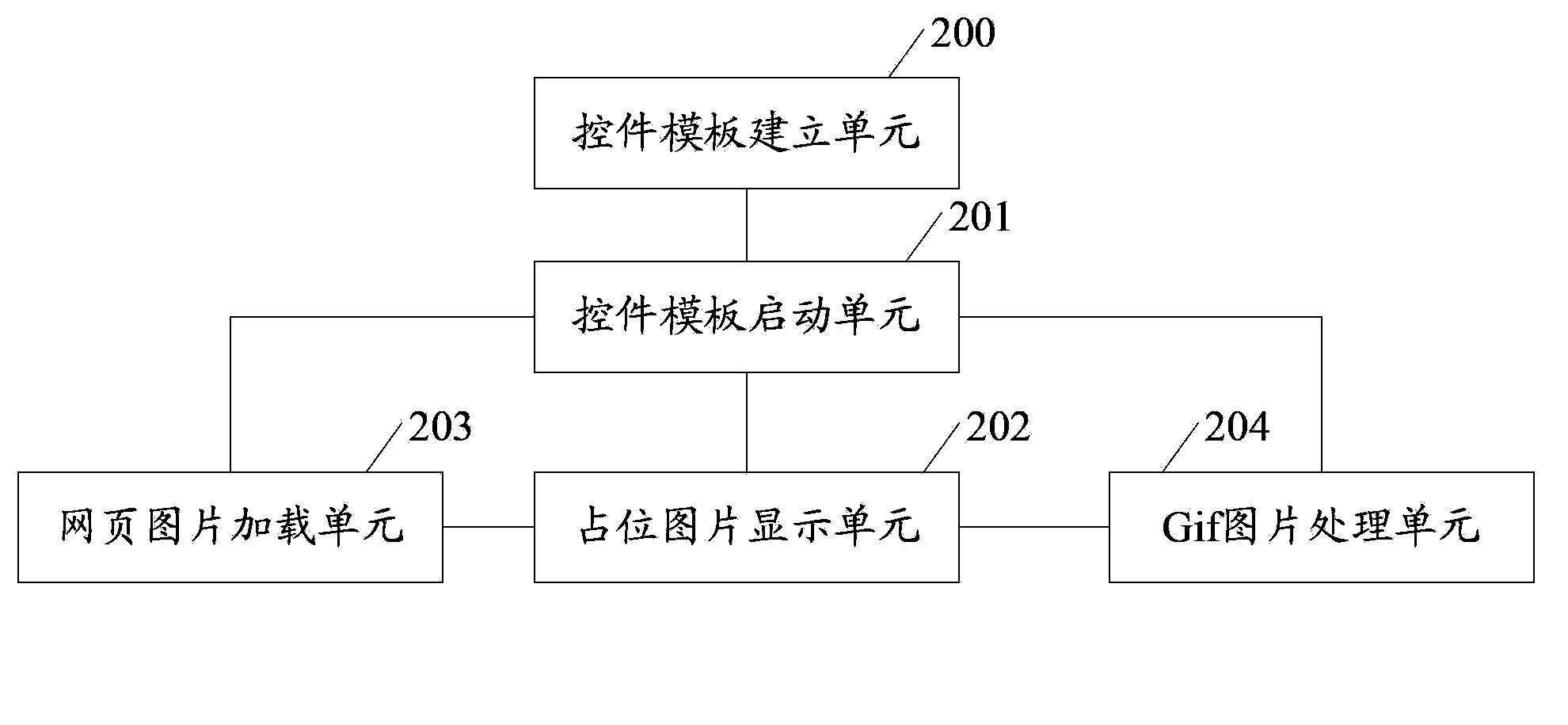

Method and device for presenting web graphics in mobile terminal platform

ActiveCN103914450AImprove performanceImprove experienceSpecial data processing applicationsComputer terminalWeb page

The invention discloses a method and a device for presenting web graphics in a mobile terminal platform. The method for presenting the web graphics in the mobile terminal platform includes the steps: building a control template comprising a first graphic control, a second graphic control and a Gif (graphic interchange format) graphic control; starting the control template when a mobile terminal needs to download and display web graphics from a network; loading associated occupied graphics by the aid of the first graphic control, and displaying the occupied graphics at positions needing display of the web graphics; associating the web graphics with the second graphic control, loading the associated web graphics by the aid of the second graphic control after the web graphics are downloaded, replacing the occupied graphics by the aid of the loaded web graphics when the associated web graphics are successfully loaded, and judging the types of the web graphics when the associated web graphics are not successfully loaded; analyzing the web graphics by the aid of the Gif graphic control when the web graphics are Gif graphics, and replacing the occupied graphics by the aid of the analyzed web graphics and displaying the web graphics.

Owner:BEIJING FEINNO COMM TECH

Flexible array substrate and manufacturing method thereof

ActiveCN107946247AGuaranteed display effectSemiconductor/solid-state device detailsSolid-state devicesEngineeringSurface plate

The invention provides a flexible array substrate and a manufacturing method thereof. The array substrate comprises a glass substrate, a flexible substrate, a buffer layer, an active layer, a gate insulation layer, a first metal layer, an interlayer insulating layer, a flexible organic layer, a second metal layer and a passivation layer, the flexible organic layer comprises at least two first viaholes, and the first via holes penetrate through the interlayer insulating layer, the gate insulation layer and the buffer layer in sequence. The beneficial effects of the flexible array substrate andthe manufacturing method thereof are that the continuous first via holes are arranged between adjacent film transistors, and the first via holes are filled with flexible organic materials so that a flexible display panel has higher bending resistance, and the display effect of the flexible display panel with small radius of curvature is guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

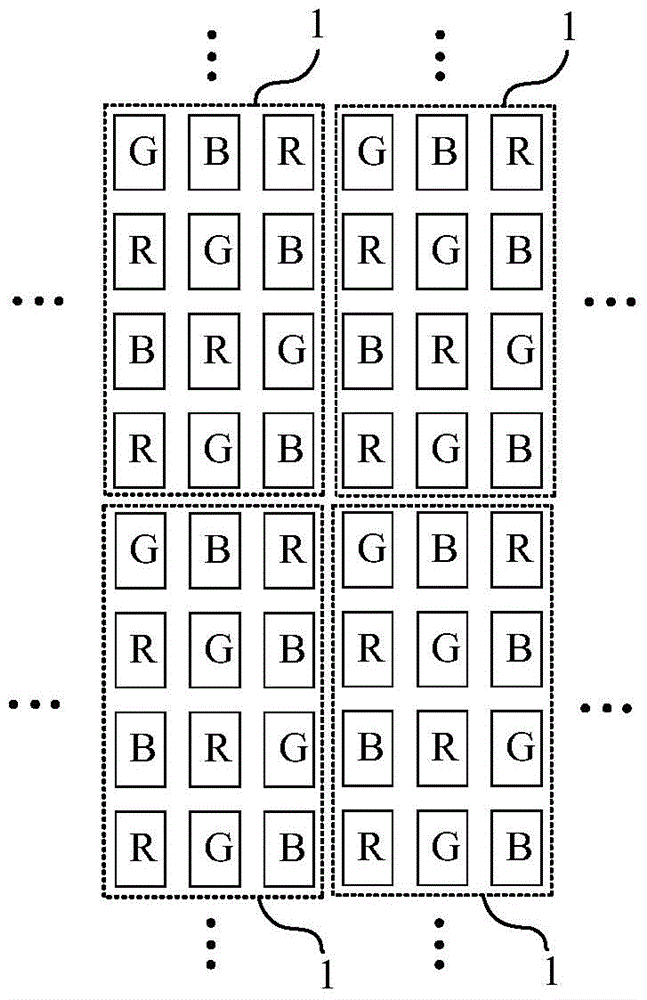

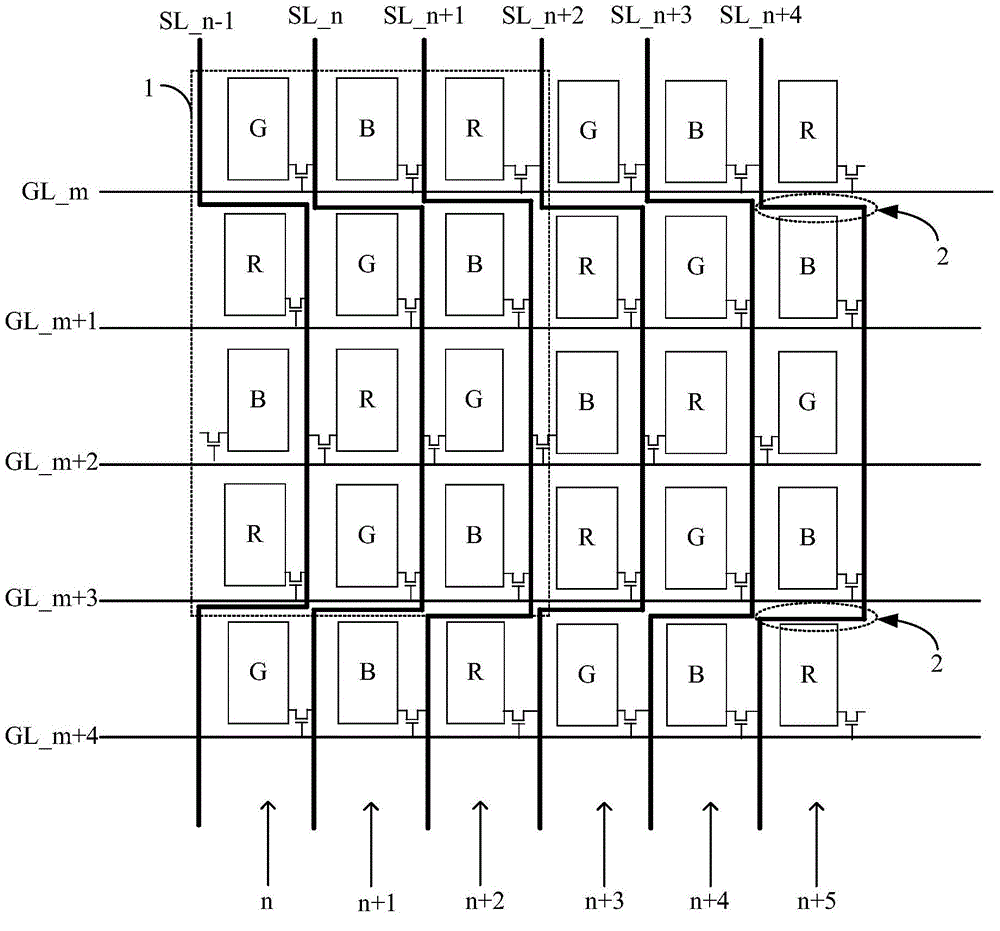

Array substrate, display panel and display device

ActiveCN104992957AReduce power consumptionIncrease charging timeStatic indicating devicesSolid-state devicesDisplay deviceMiddle line

The invention discloses an array substrate, a display panel and a display device. The array substrate comprises multiple grid lines and data lines. All the grid lines and data lines define sub-pixel arrays. Each of the sub-pixel arrays comprises multiple repetitive units. Each of the repetitive units comprises 12 sub pixels in four lines and three rows. Any three sub pixels in the line and row directions of continuous nine sub pixels in three lines in each of the repetitive units have different colors. Three sub pixels in the other line in the corresponding repetitive unit is in the same arranging sequence with the three sub pixels in the middle line of the continuous three lines. Each of the data lines is connected with the sub pixel with the same color in the corresponding three lines of pixels in the sub pixel array. According to the invention, the sub pixels connected to the data lines have the same color, so when an image having the pure color is displayed, all the signals in the data lines are direct current signals, thereby reducing power consumption of the display device.

Owner:BOE TECH GRP CO LTD +1

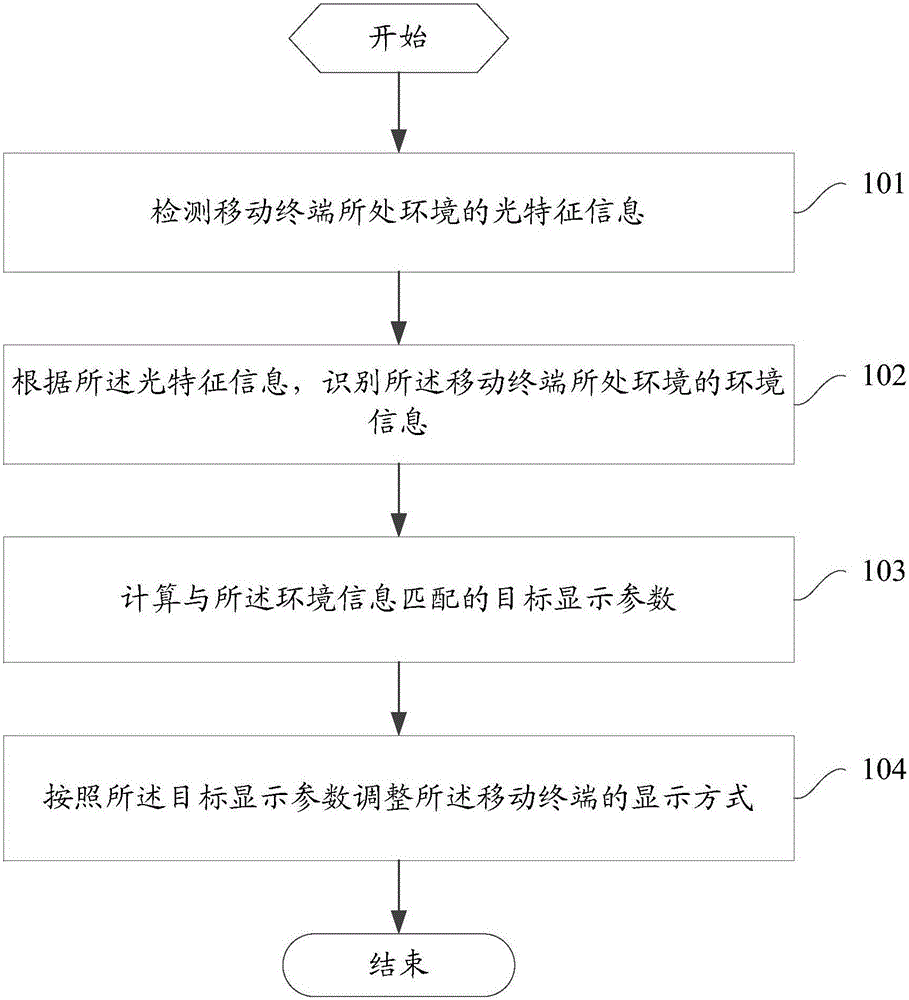

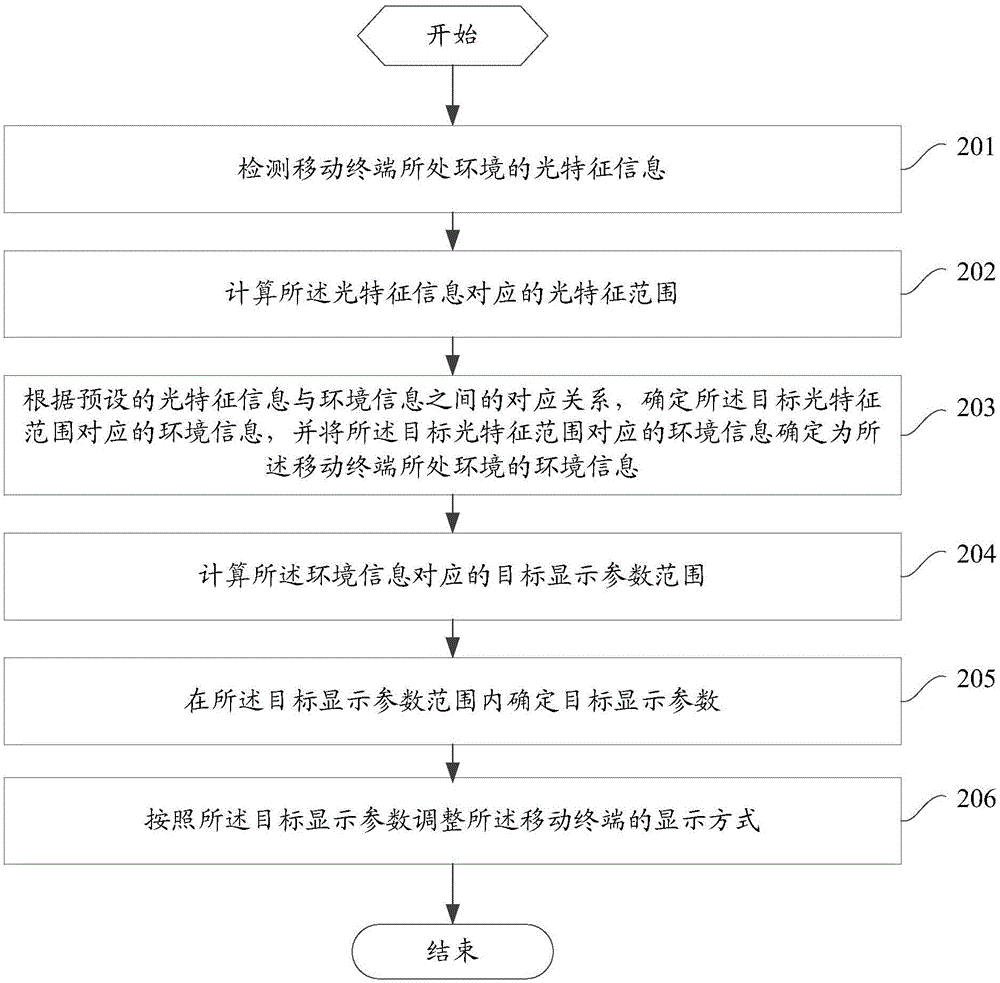

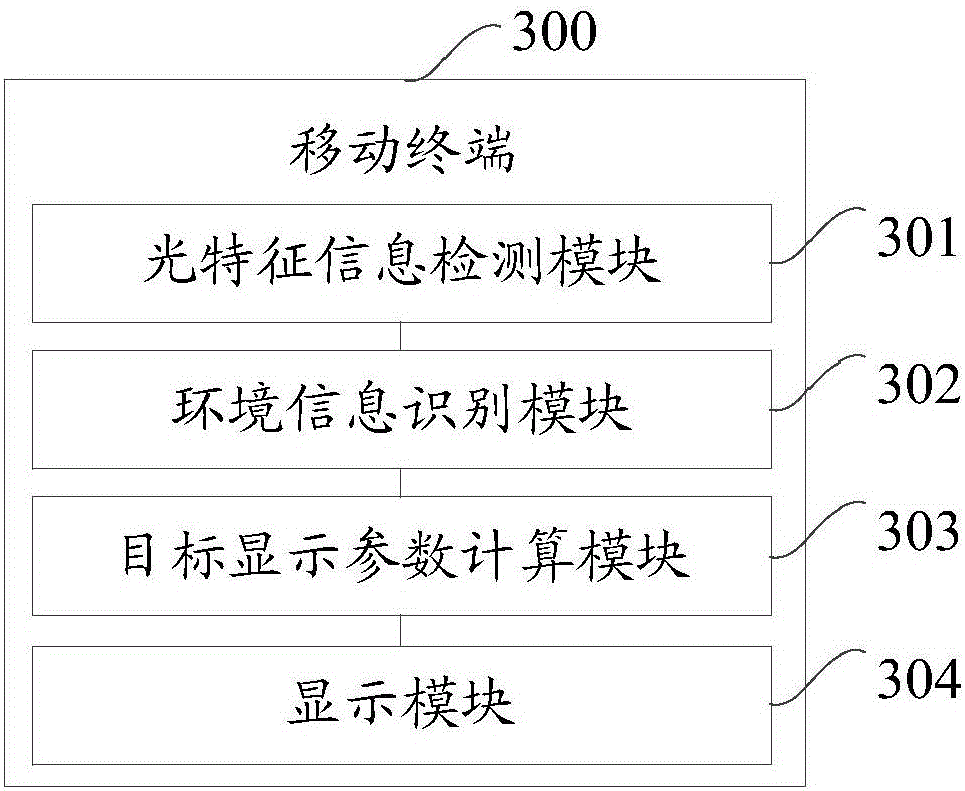

Display method for mobile terminal and mobile terminal

InactiveCN105955585AImplement Adaptive Display AdjustmentImplement filteringInput/output processes for data processingFiltrationSelf adaptive

Embodiments of the present invention provide a display method of a mobile terminal and the mobile terminal, the method comprising: detecting light feature information of the environment where the mobile terminal is located; and identifying environmental information of the environment where the mobile terminal is located according to the light feature information Calculating target display parameters matching the environmental information, wherein the target display parameters include at least one or more of saturation, color temperature, and brightness; adjusting the display mode of the mobile terminal according to the target display parameters. The display method of the mobile terminal provided by the embodiment of the present invention, on the one hand, adjusts the display mode of the mobile terminal adaptively to the environment, and does not add a warm-colored mask to the display interface, and does not need to stick a film on the screen, which can ensure On the other hand, the display is adaptive to the environment, which improves the utilization rate of display performance, reduces the intensity, component and other attributes of blue light, and realizes the filtering of blue light.

Owner:VIVO MOBILE COMM CO LTD

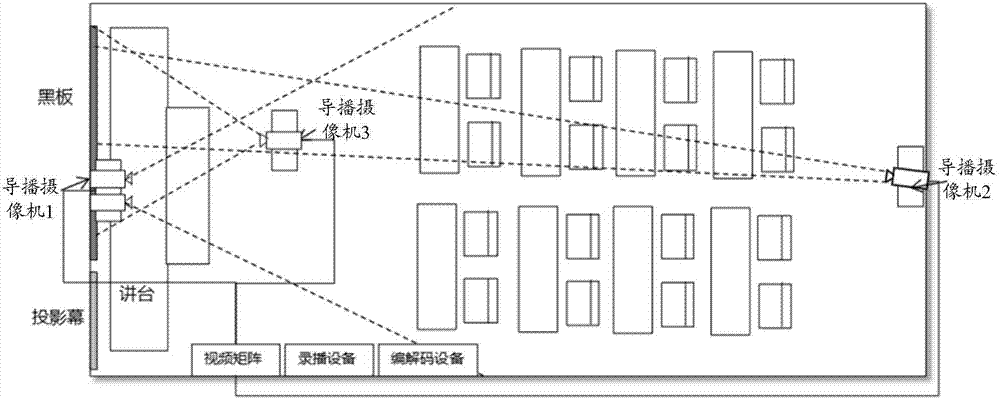

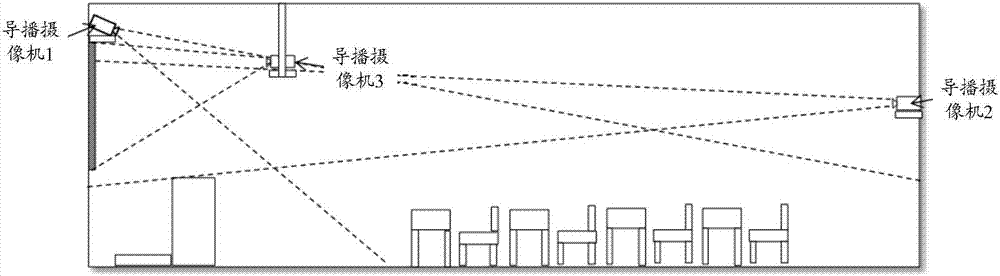

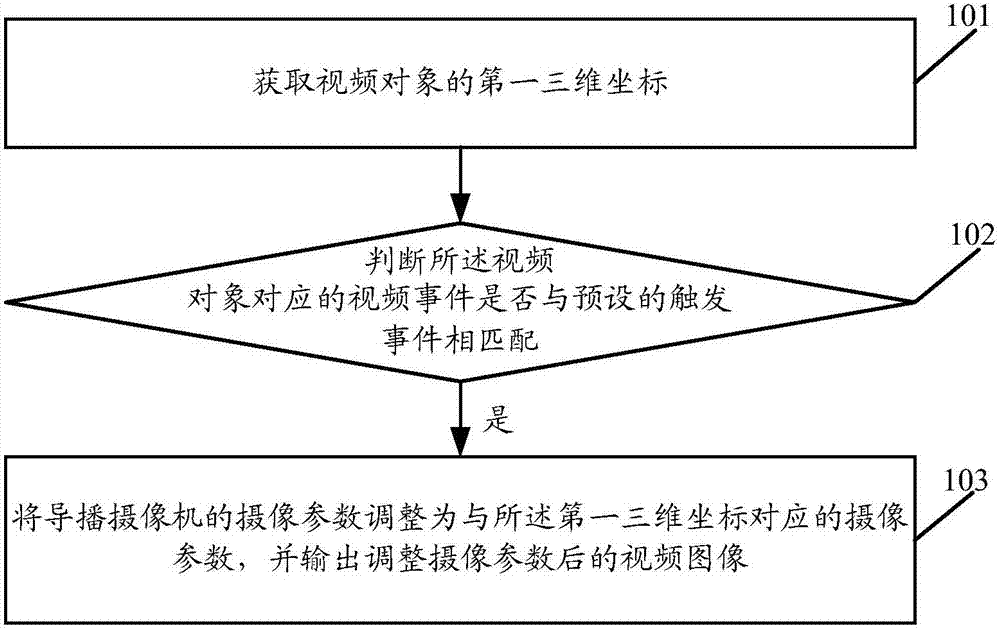

Camera parameter adjustment method, directed camera, and directed camera system

InactiveCN107507243AHigh precisionImprove accuracyImage enhancementImage analysisVideo imageObject detection

The embodiment of the invention discloses a camera parameter adjustment method, a directed camera, and a directed camera system. The method comprises: a first three-dimensional coordinate of a video object is obtained, wherein the first three-dimensional coordinate is a three-dimensional coordinate of the video object under a first coordinate system corresponding to the directed camera; whether a video event corresponding to the video object matches a preset trigger event is determined; if so, a shooting parameter of the directed camera is adjusted to be one corresponding to the first three-dimensional coordinate and a video image after shooting parameter adjustment is outputted. Therefore, the accuracy of object detection and tracking can be improved based on three-dimensional coordinate detection, so that the accuracy of parameter adjustment is enhanced and the equipment cost is lowered.

Owner:HUAWEI TECH CO LTD

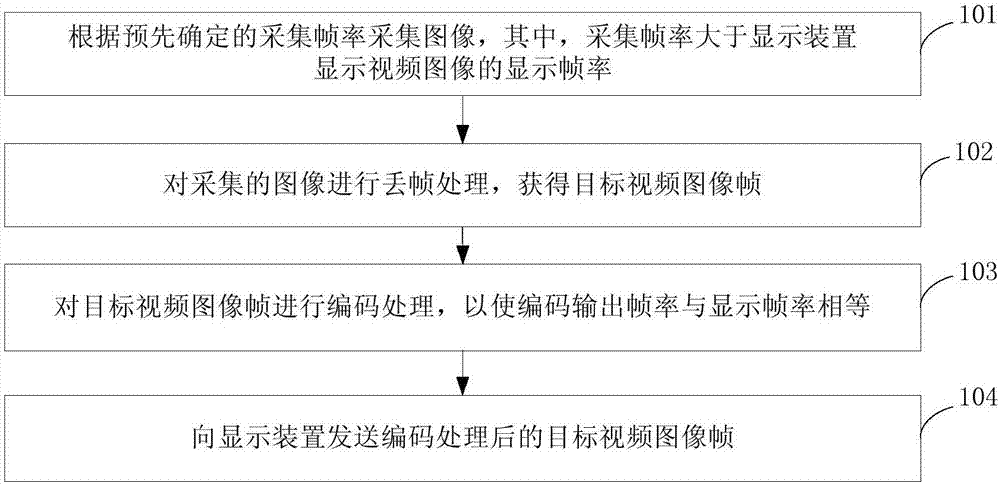

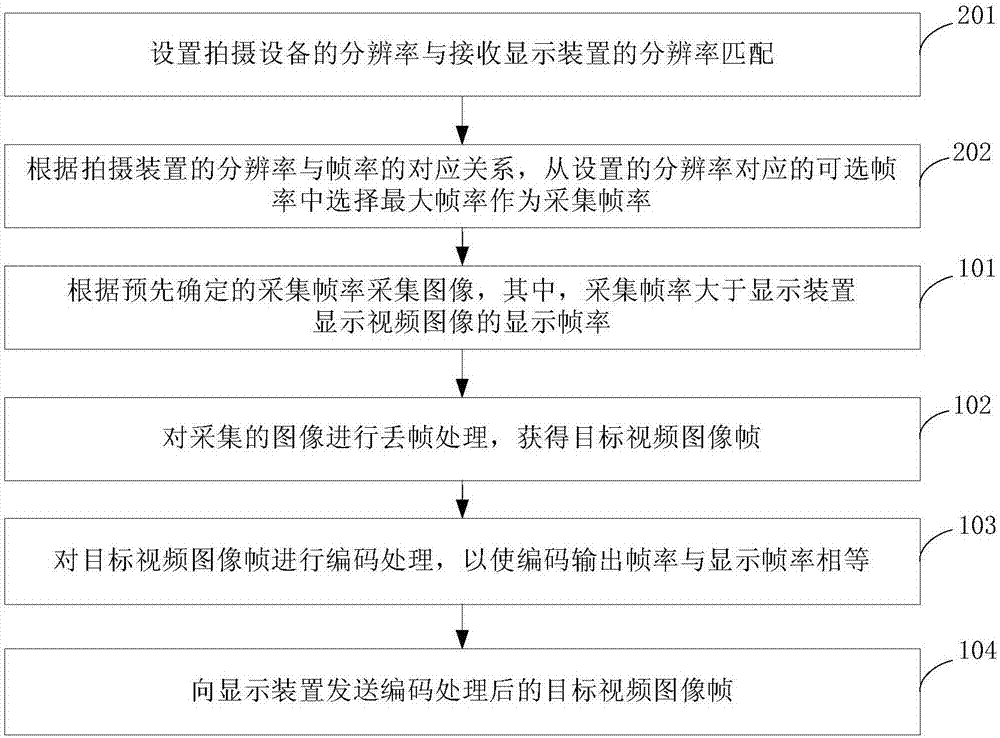

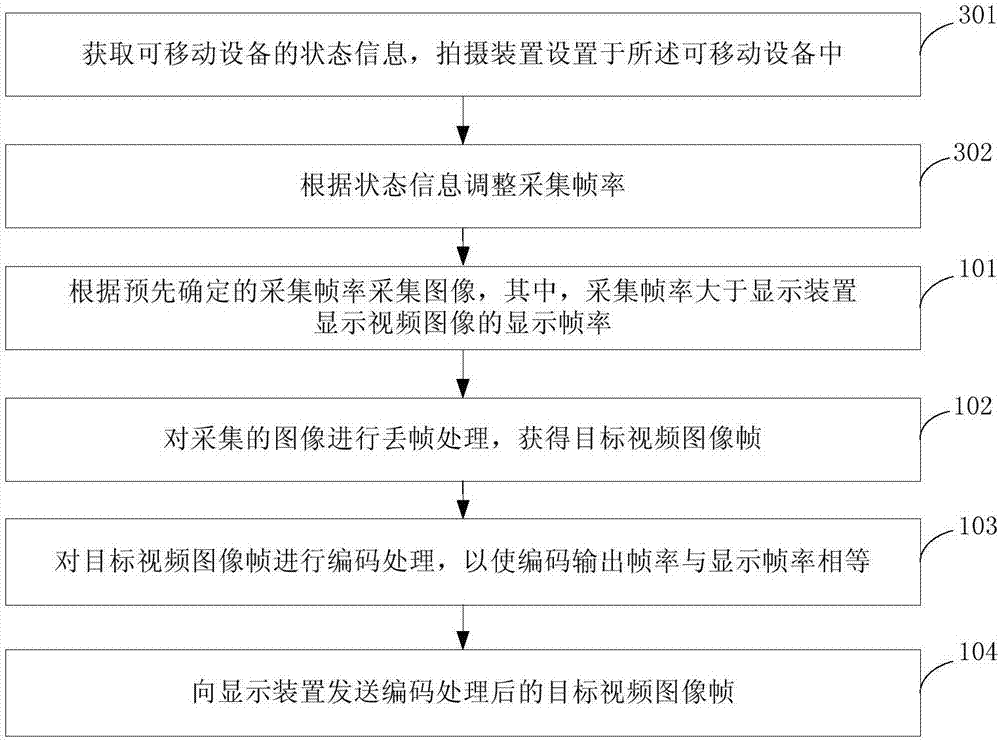

Method, system and device for video data transmission, and photographic apparatus

ActiveCN107079135AImprove real-time performanceGuaranteed display effectClosed circuit television systemsConversion by changing video signal frequencyComputer graphics (images)Video transmission

A method, a system and a device for video data transmission, and a photographic apparatus, said method comprising: collecting an image according to a predetermined frame collection rate, the frame collection rate being greater than a frame display rate at which a display device displays a video image; performing frameskip processing on the collected image to obtain a target video image frame; performing an encoding processing on the target video image frame so that the frame rate of the encoding output is equal to the frame display rate; and sending to the display device the encoding-processed target video image frame. The invention increases the real-time performance of video data transmission by means of collecting a video image at a frame collection rate that is higher than the frame display rate so that the transmission delay of the video data from an aerocraft end to a display end is reduced by reducing the collect delay.

Owner:SZ DJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com