OLED array substrate, manufacturing method thereof and display device

A technology of an array substrate and a manufacturing method, which is applied in the display field, can solve the problems of affecting the display effect, and the TFT is easily exposed to light, and achieves the effect of ensuring the display effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

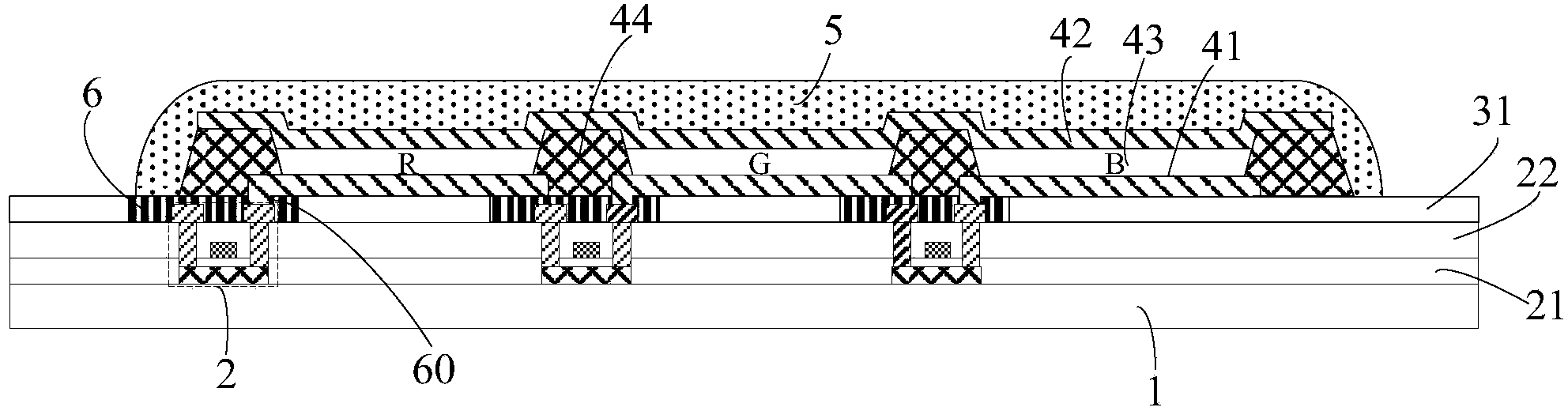

[0049] Such as figure 1 As shown, the OLED array substrate provided by the embodiment of the present invention includes a TFT2 disposed on a base substrate 1 , a gate insulating layer 21 and an interlayer insulating layer 22 , and a first protective layer 31 is disposed above the TFT2. A first electrode 41, a light-emitting layer 43, and a second electrode 42 are sequentially arranged above the first protective layer 31 from bottom to top, wherein the light-emitting layer 43 is a color including three colors of red (R), green (G), and blue (B). luminous layer. The black matrix 6 above the TFT 2 is disposed on the same layer as the first protection layer 31 , and the black matrix 6 is provided with a via hole 60 . The first electrodes 41 are connected to the TFT 2 through via holes 60 , and adjacent first electrodes 41 are separated by barrier walls 44 . In addition, an encapsulation layer 5 is usually provided above the second electrode 42 .

[0050] Preferably, the first e...

Embodiment 2

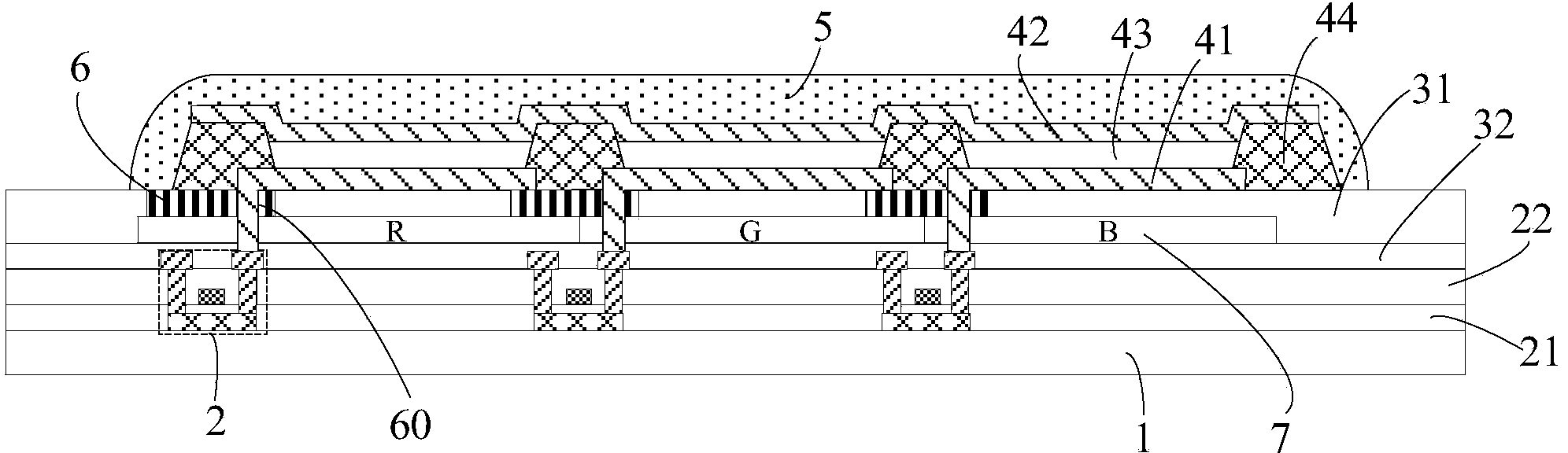

[0063] Such as figure 2 and image 3 As shown, the OLED array substrate provided by the embodiment of the present invention includes a TFT2, a gate insulating layer 21 and an interlayer insulating layer 22 arranged on the base substrate 1, and above the TFT2 are arranged red (R), green (G), The color filter layer 7 of three colors of blue (B), and the first protective layer 31 is arranged on the color filter layer 7 . A first electrode 41 , a light emitting layer 43 , and a second electrode 42 are sequentially disposed above the first protective layer 31 from bottom to top, wherein the light emitting layer 43 is a white light emitting layer. The black matrix 6 above the TFT 2 is disposed on the same layer as the first protection layer 31 , and a via hole 60 penetrating through the black matrix 6 and the color filter layer 7 is opened. The first electrodes 41 are connected to the TFT 2 through via holes 60 , and adjacent first electrodes 41 are separated by barrier walls 44 ...

Embodiment 3

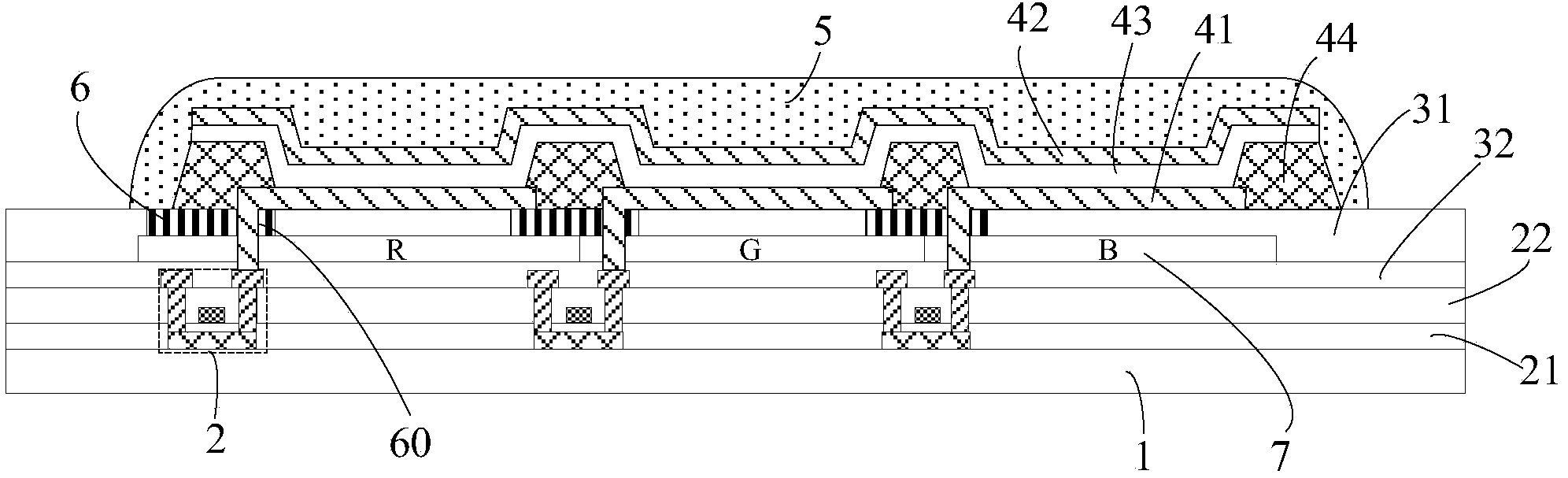

[0082] The embodiment of the present invention is basically the same as embodiment 2, the difference is that, as Figure 4 and Figure 5 As shown, in this embodiment, the black matrix 6 and the color filter layer 7 are arranged in the same layer, and the via hole 60 penetrates through the first protection layer 31 , the black matrix 6 and the second protection layer 32 .

[0083] In the OLED array substrate provided by the embodiment of the present invention, a black matrix 6 is arranged above the TFT 2, and the first electrode 41 of the OLED passes through the via hole 60 penetrating the first protective layer 31, the black matrix 6 and the second protective layer 32. Connect with TFT2. During the display process of TFT2 driving the OLED, the black matrix 6 can block the light emitted by the OLED and prevent the TFT2 from being illuminated, so the current in the OLED driven by the TFT2 will not be wrong, thereby ensuring the display of the active matrix OLED display device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com