Patents

Literature

821 results about "Natural convection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Natural convection is a type of flow, of motion of a liquid such as water or a gas such as air, in which the fluid motion is not generated by any external source (like a pump, fan, suction device, etc.) but by some parts of the fluid being heavier than other parts. The driving force for natural convection is gravity. For example if there is a layer of cold dense air on top of hotter less dense air, gravity pulls more strongly on the denser layer on top, so it falls while the hotter less dense air rises to take its place. This creates circulating flow: convection. As it relies of gravity, there is no convection in free-fall (inertial) environments, such as that of the orbiting International Space Station. Natural convection can occur when there are hot and cold regions of either air or water, because both water and air become less dense as they are heated. But, for example, in the world's oceans it also occurs due to salt water being heavier than fresh water, so a layer of salt water on top of a layer of fresher water will also cause convection.

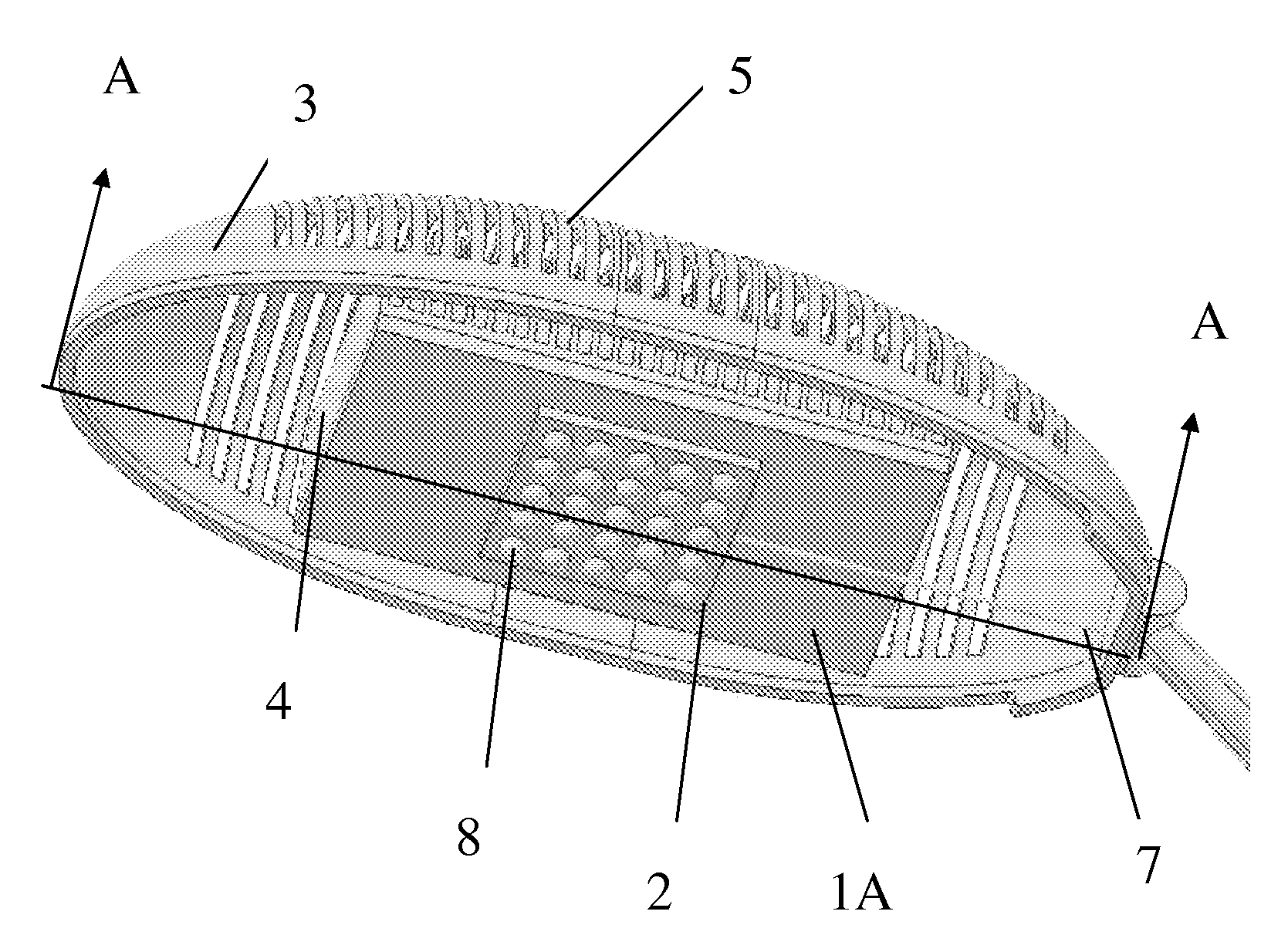

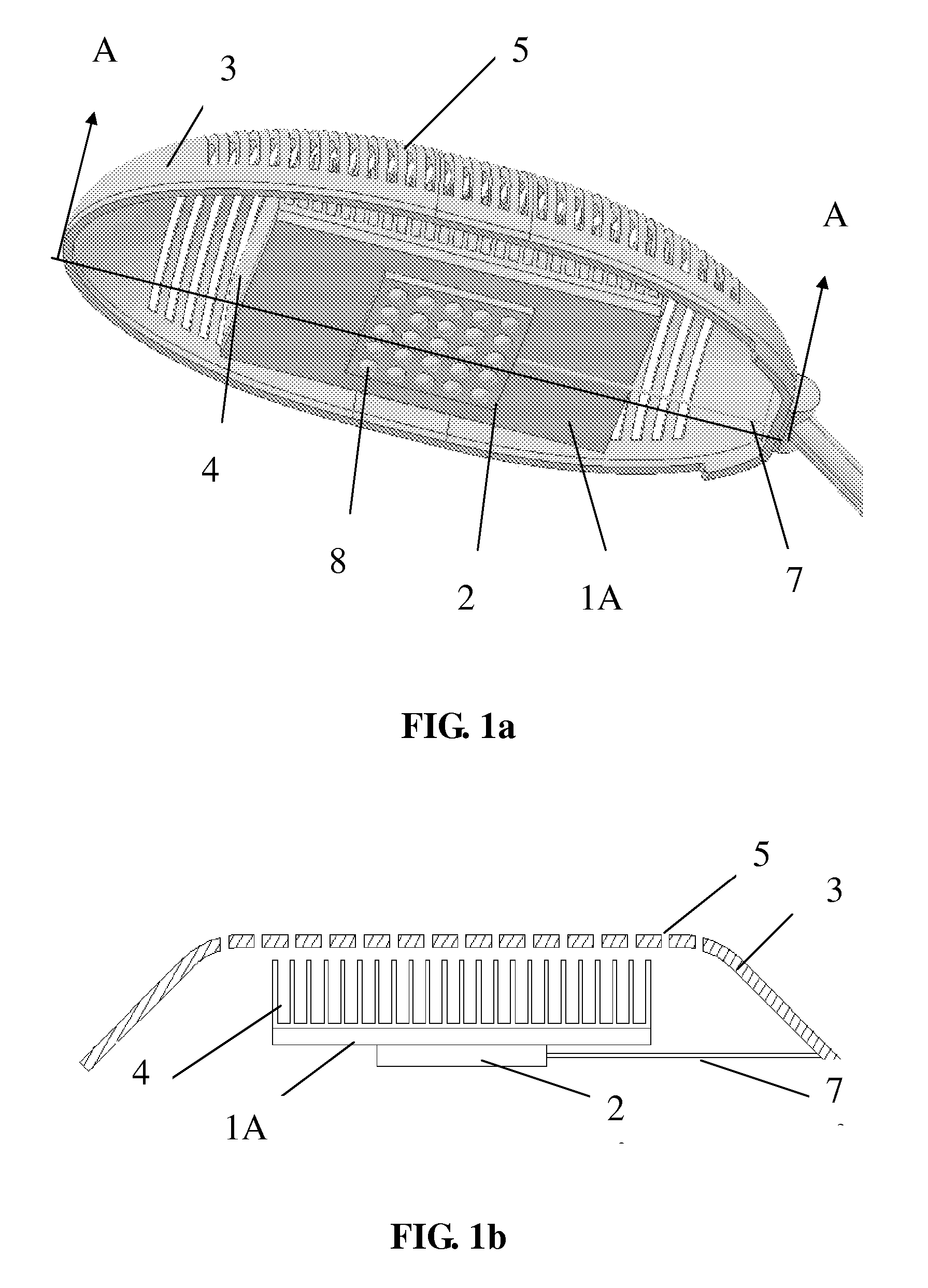

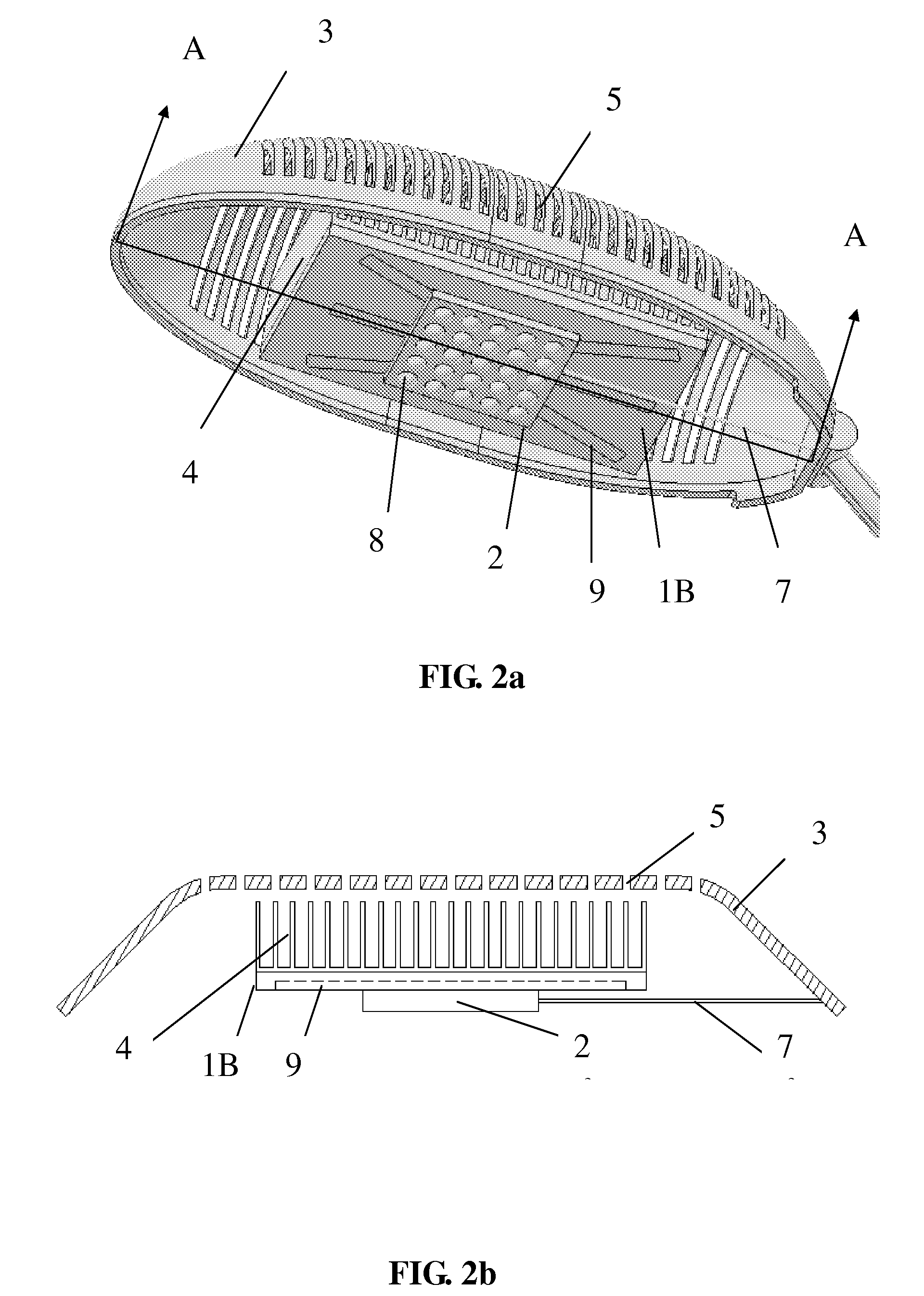

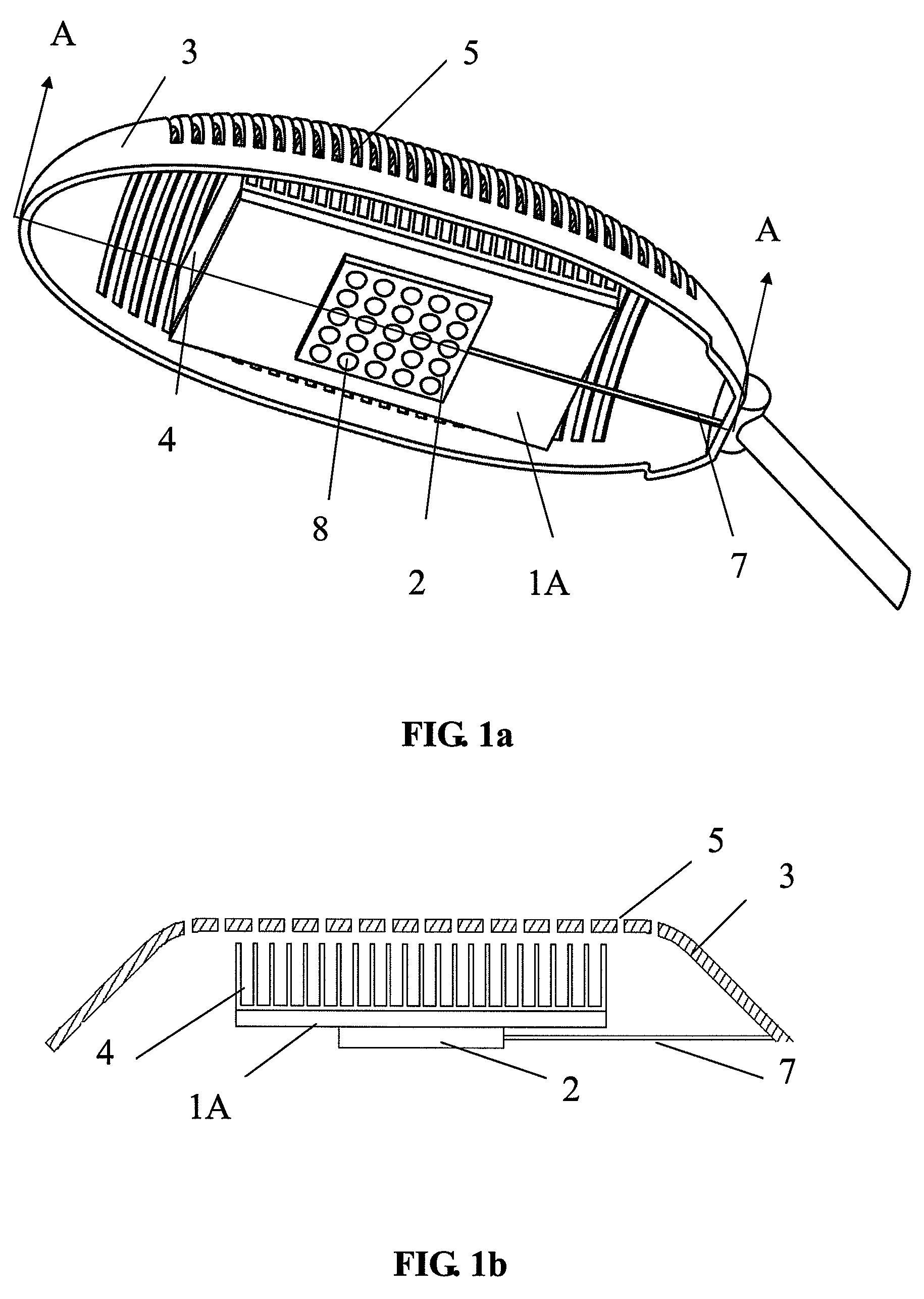

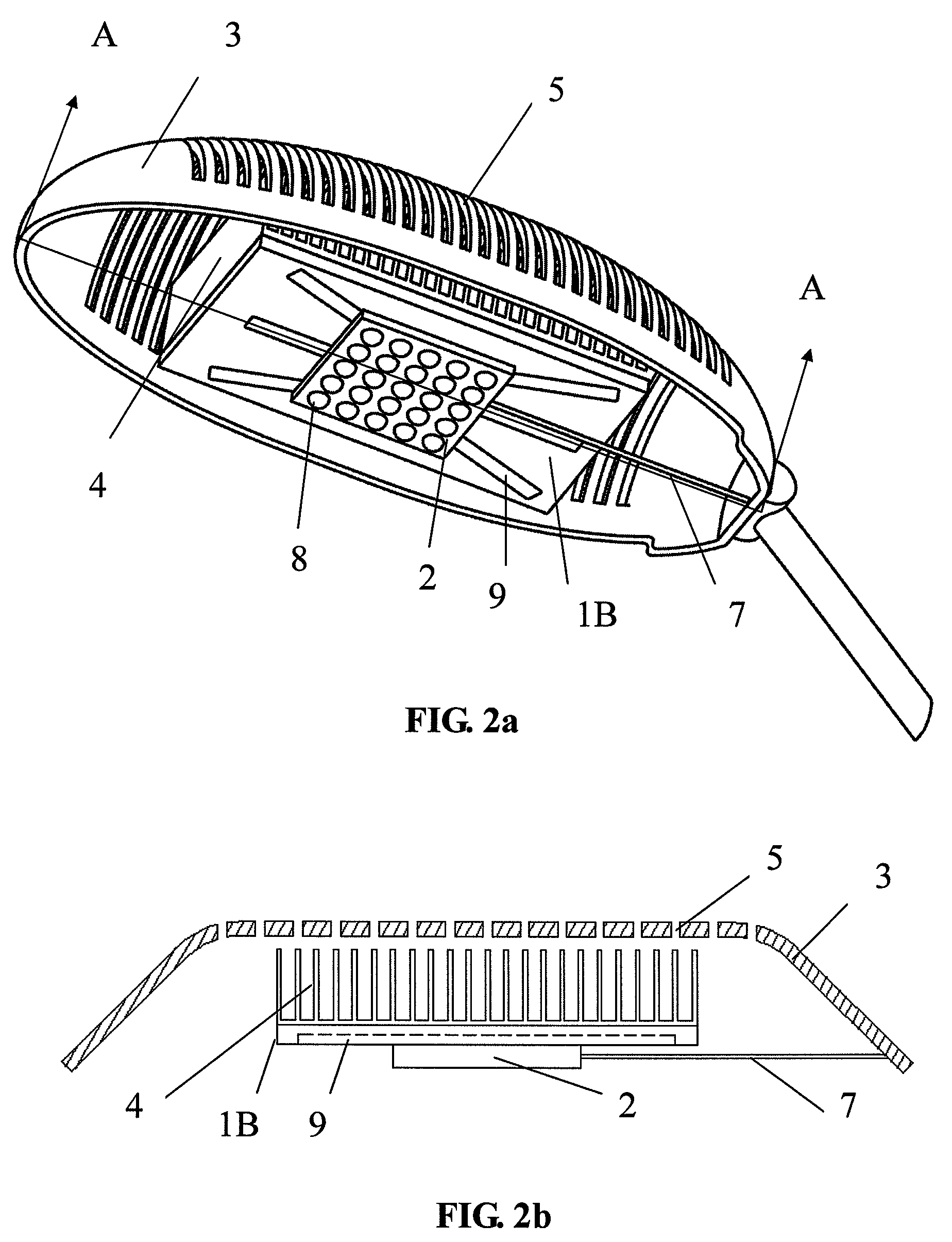

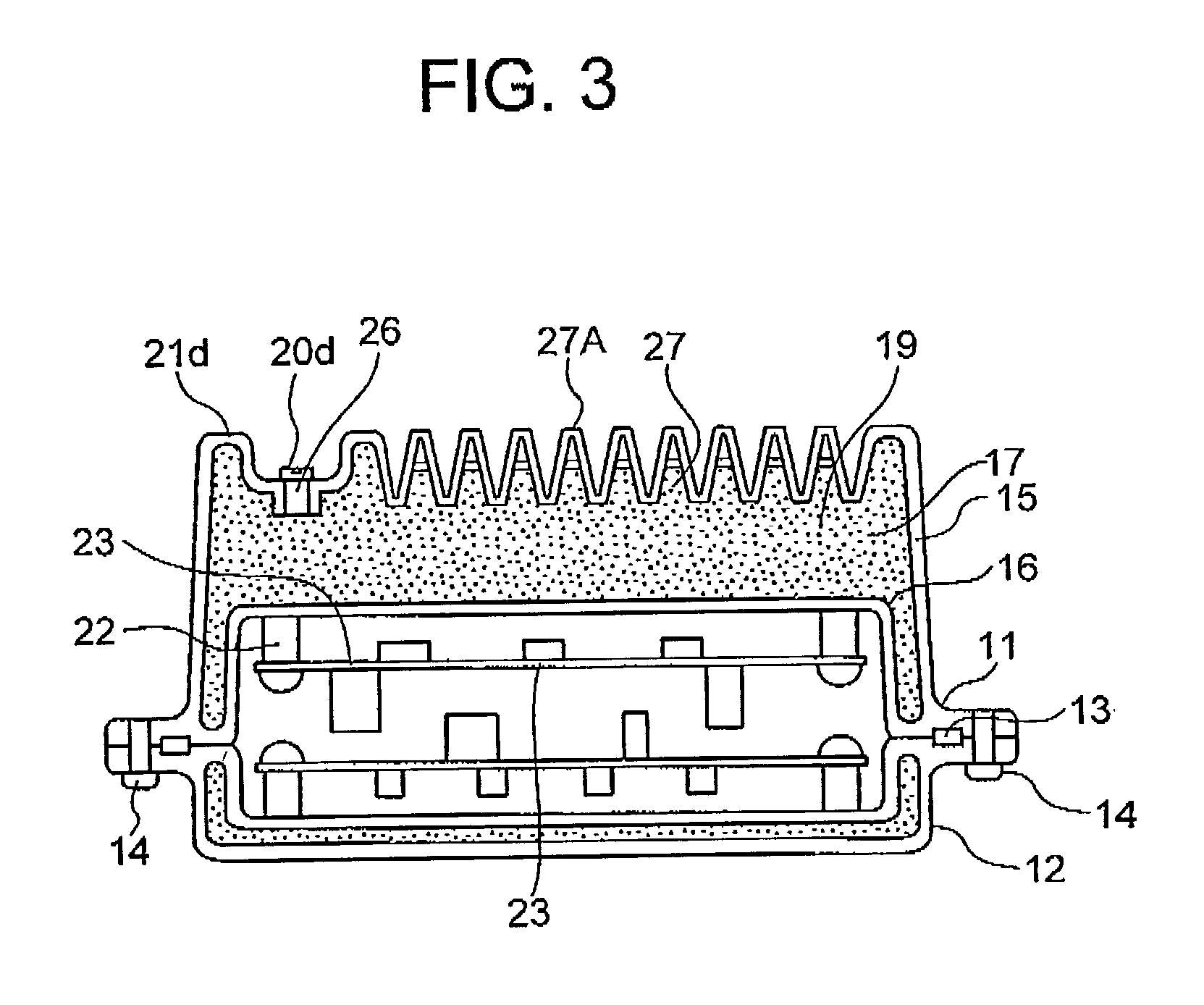

Heat dissipation devices for and LED lamp set

This invention discloses heat dissipation devices for an LED lamp set with a plate-type heat spreader as the core unit. The plate-type heat spreader is either a flat-plate heat pipe or a metal plate embedded with heat pipes. The high-power LED lamps are thermally connected to the bottom surface of the heat spreader so that the heat generated by the LED lamps is absorbed by the evaporation region of the flat-plate heat pipe or the embedding heat pipes. The heat is spread by internal vapor motion of the working fluid toward different regions of the heat spreader. The top surface of the heat spreader is connected with a finned heat sink, where the heat is delivered to the ambient air. The hot air leaves by buoyancy through the openings on a lamp housing located above the finned heat sink. An alternative design is that the inner surface of the lamp housing is connected with the top surface of the plate-type heat spreader, with the heat dissipated out at the surface of the housing by natural convection.

Owner:NATIONAL TSING HUA UNIVERSITY

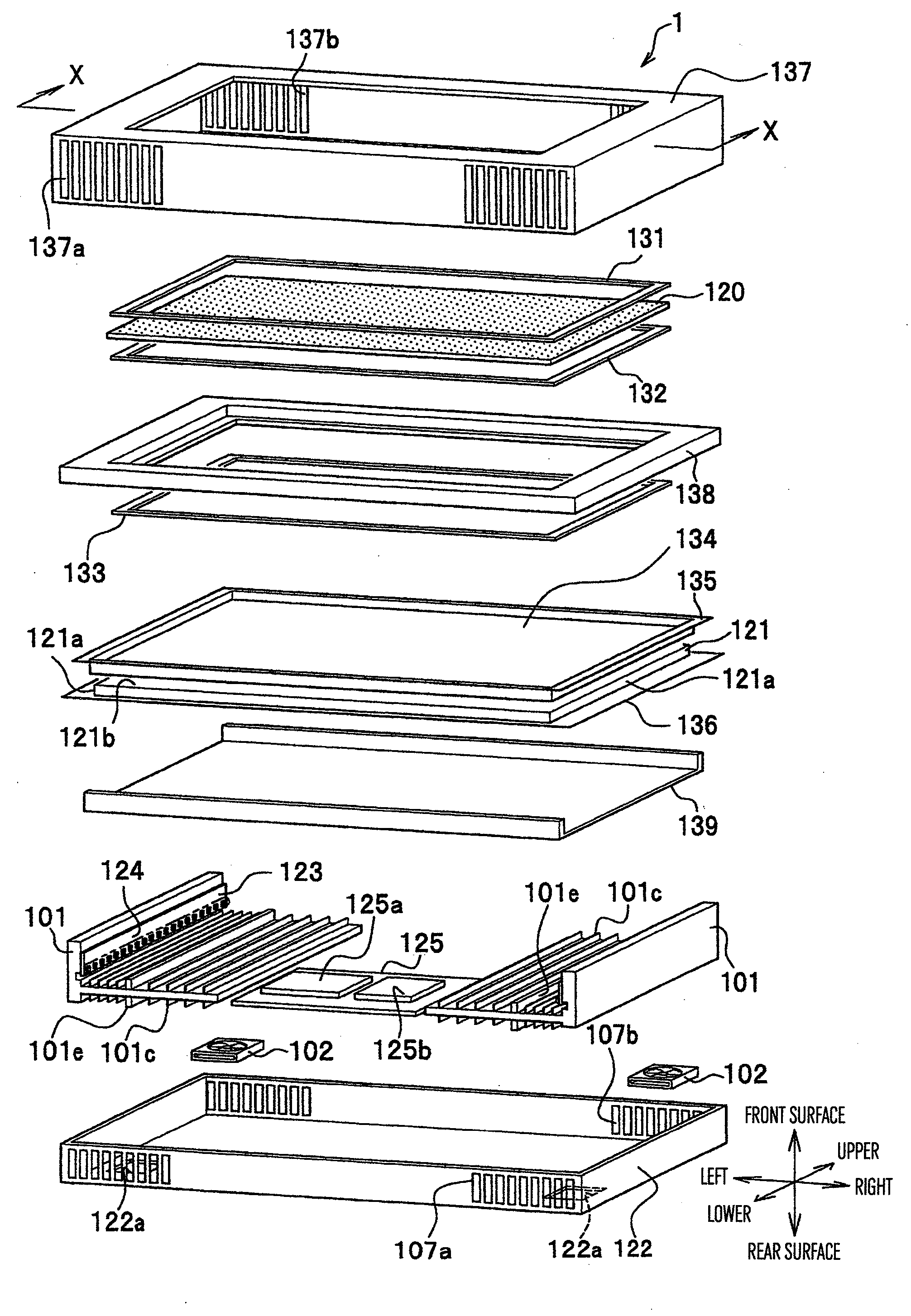

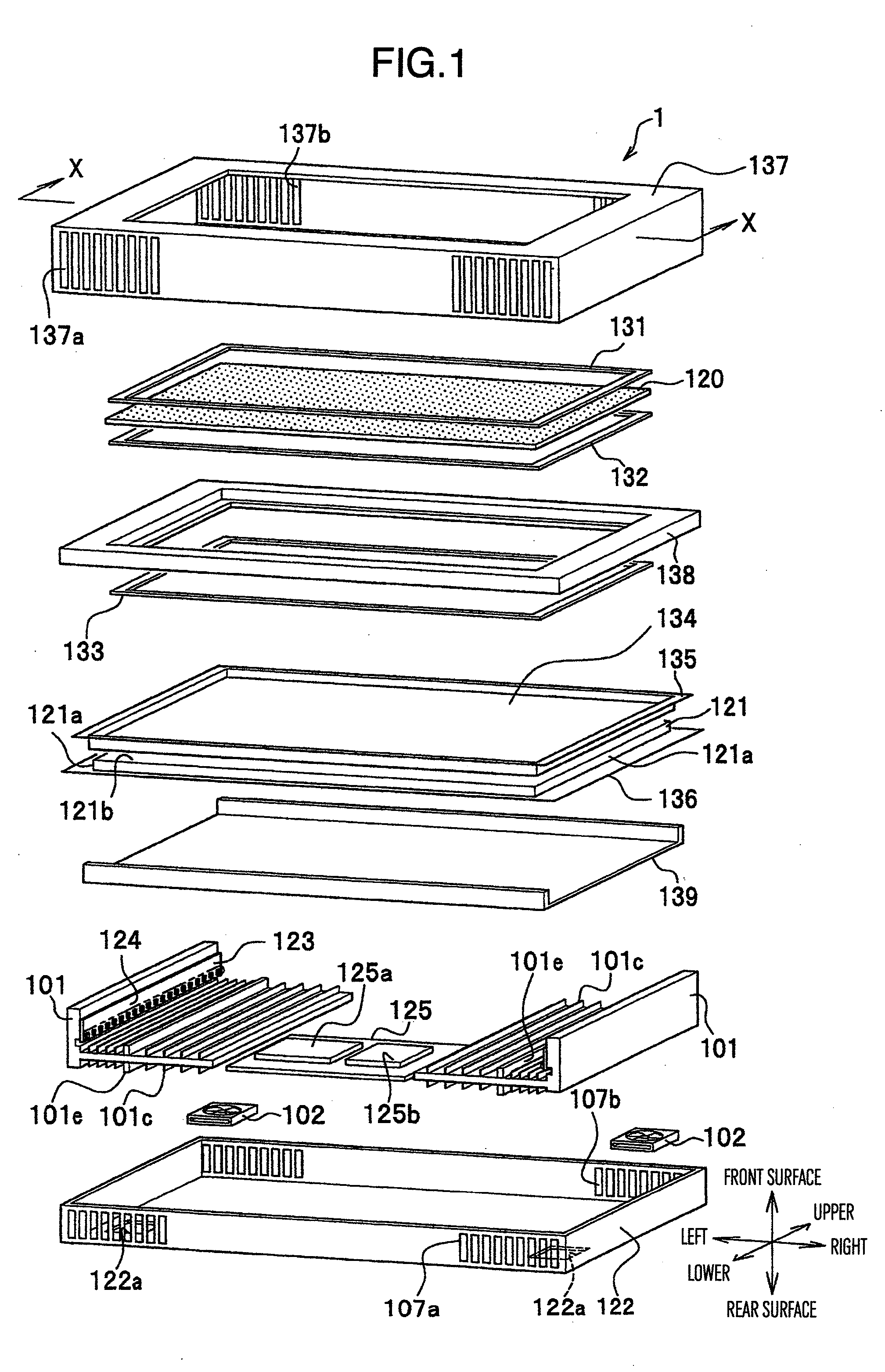

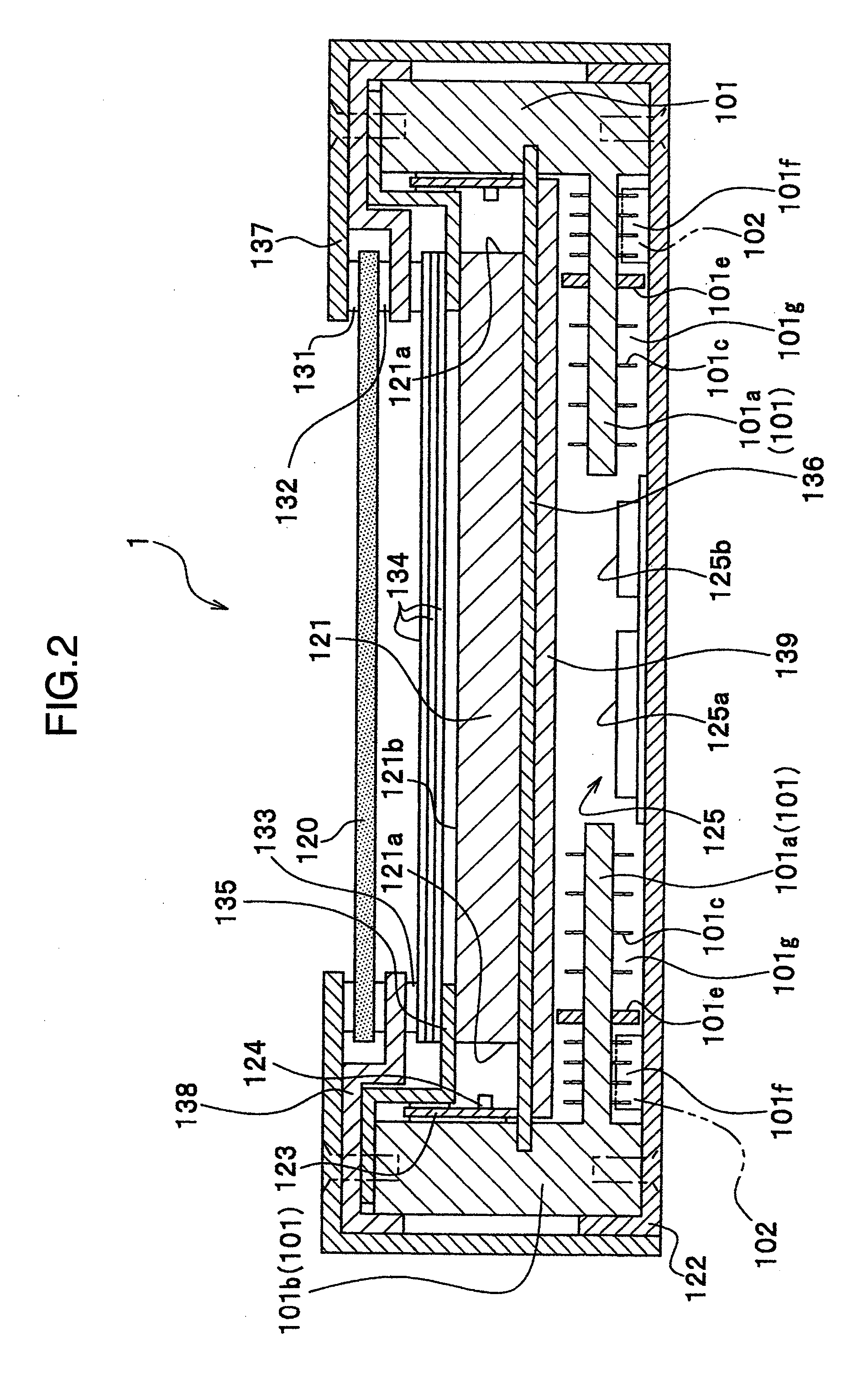

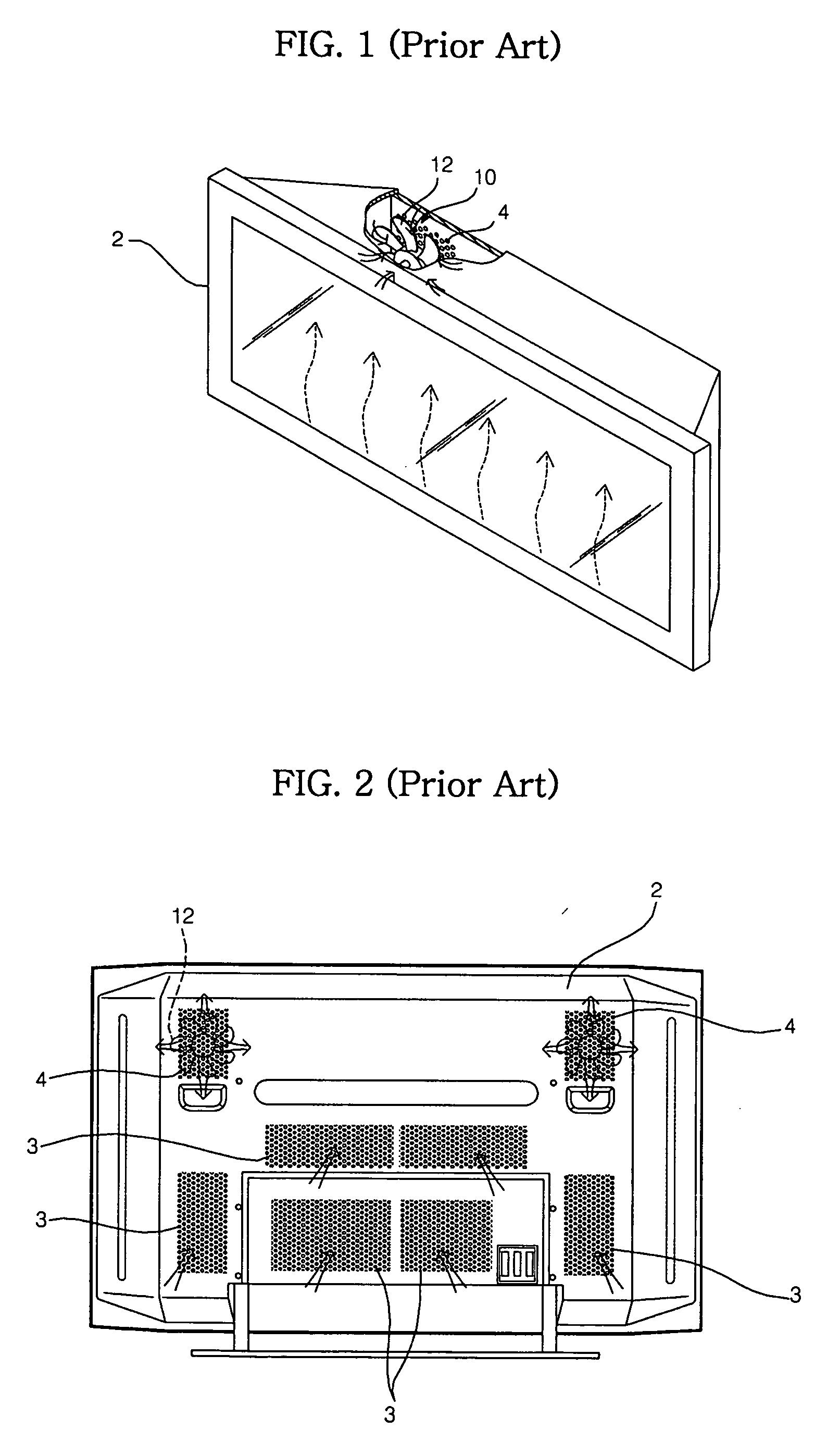

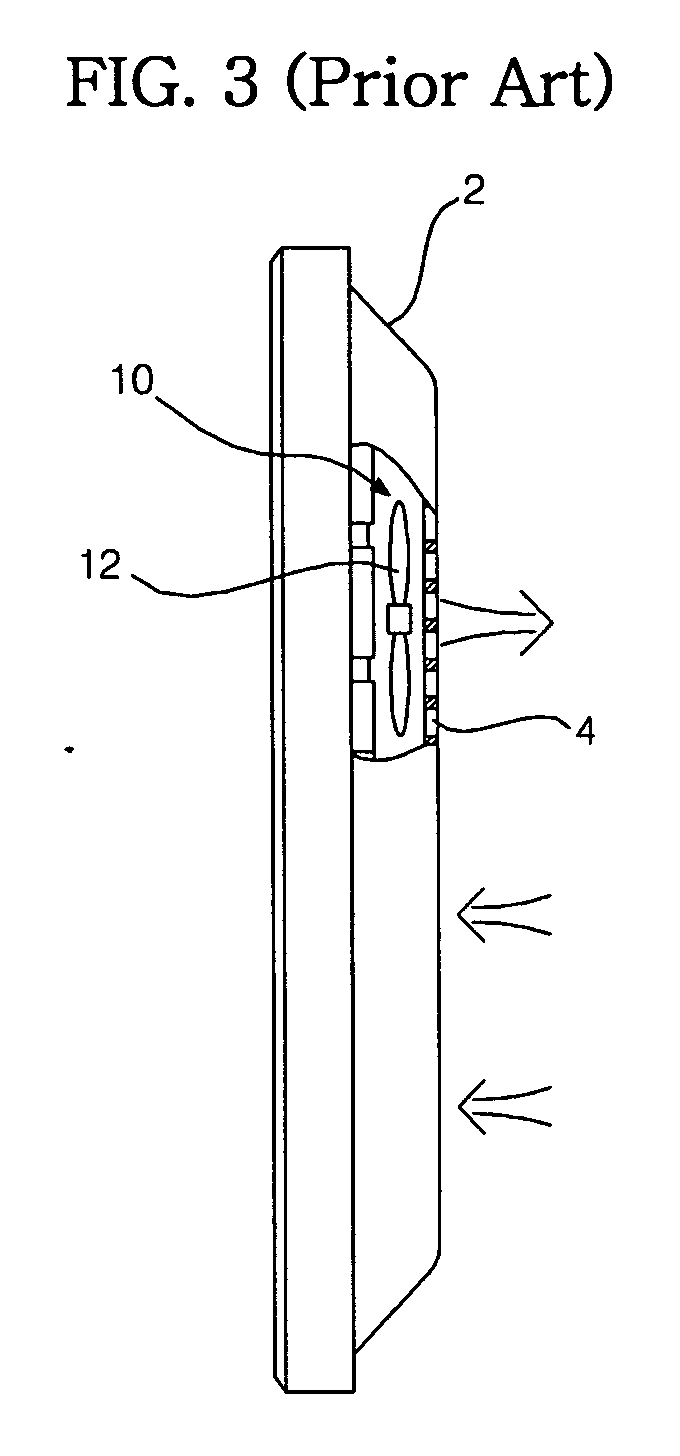

Liquid crystal display device

InactiveUS20080285290A1Lighting heating/cooling arrangementsPlanar/plate-like light guidesLiquid-crystal displayNatural convection

If a forced convection is generated by a cooling fan, there is generated a problem that a natural convection is prevented and a cooling effect in a region of the natural convection is lowered. The invention provides a structure in which an air flow generated by a forced convection does not come into contact with an air flow generated by a natural convection, by setting a partition all between a forced convection path in which the air flows on the basis of a forced convection generated by a cooling fan, and a natural convection path in which the air flows on the basis of a natural convection. Further, the partition wall is not provided near an upper end so as to draw in the air flowing through the natural convection path to a side of the forced convection path, thereby promoting the natural convection of the natural convection path.

Owner:MAXELL HLDG LTD

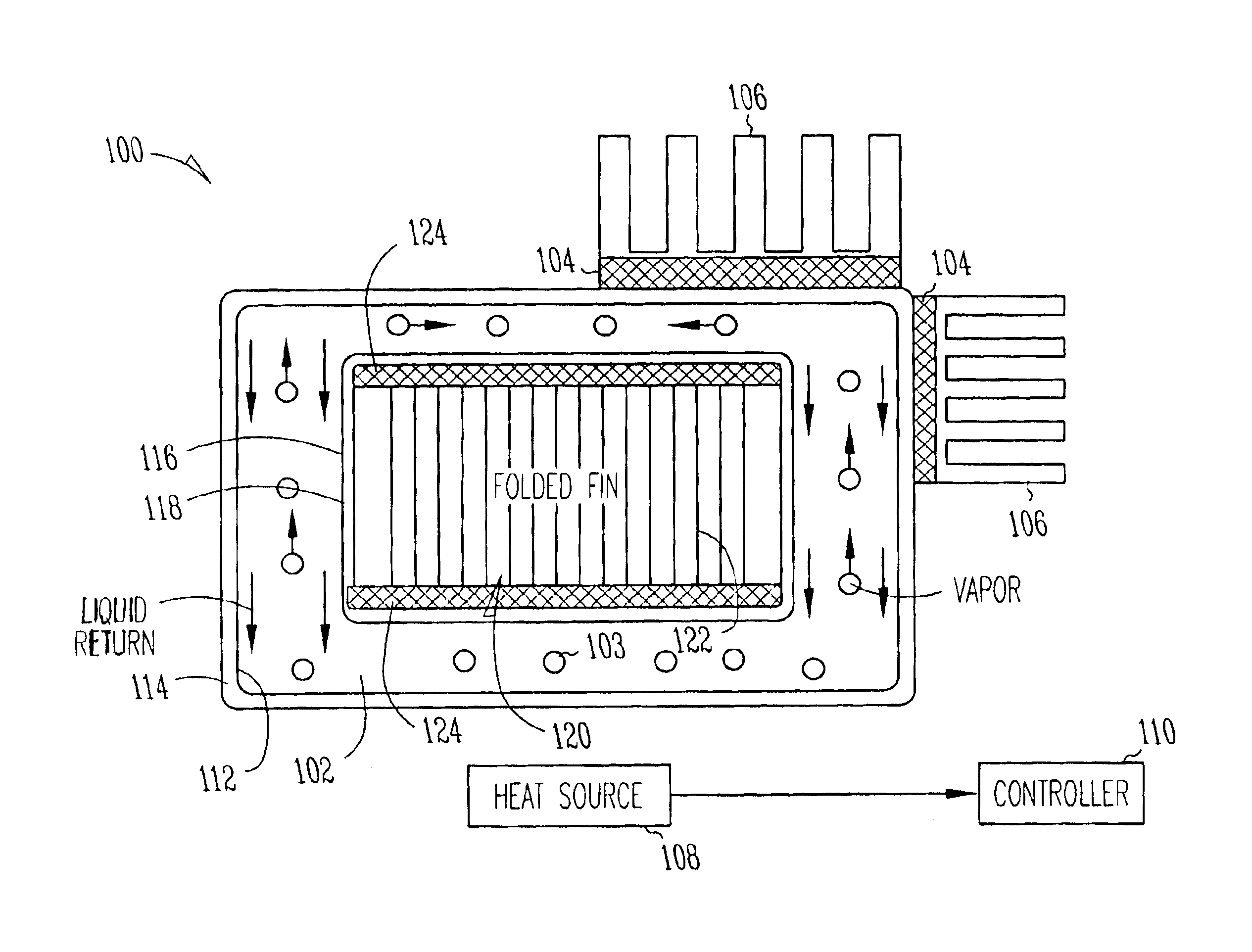

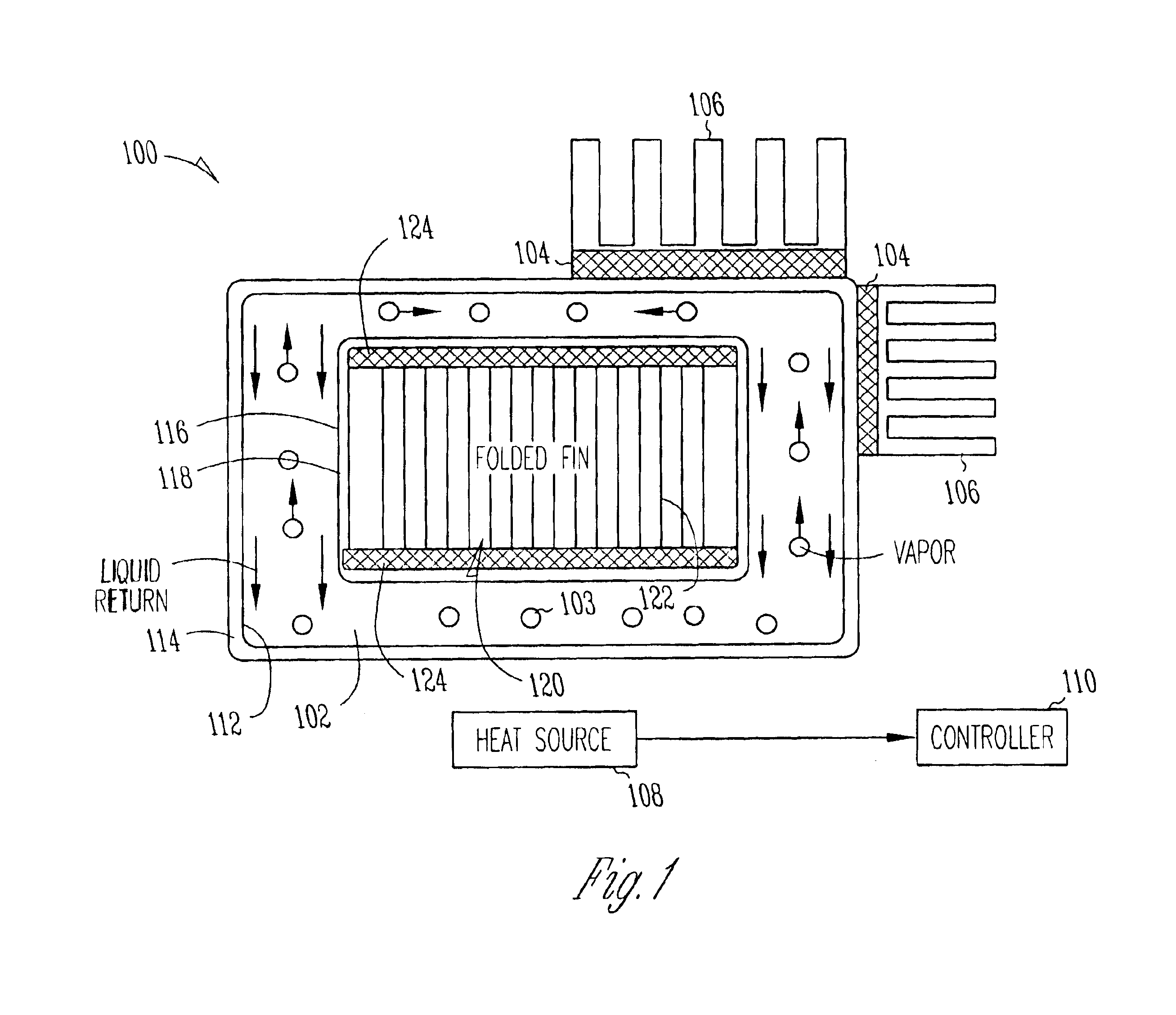

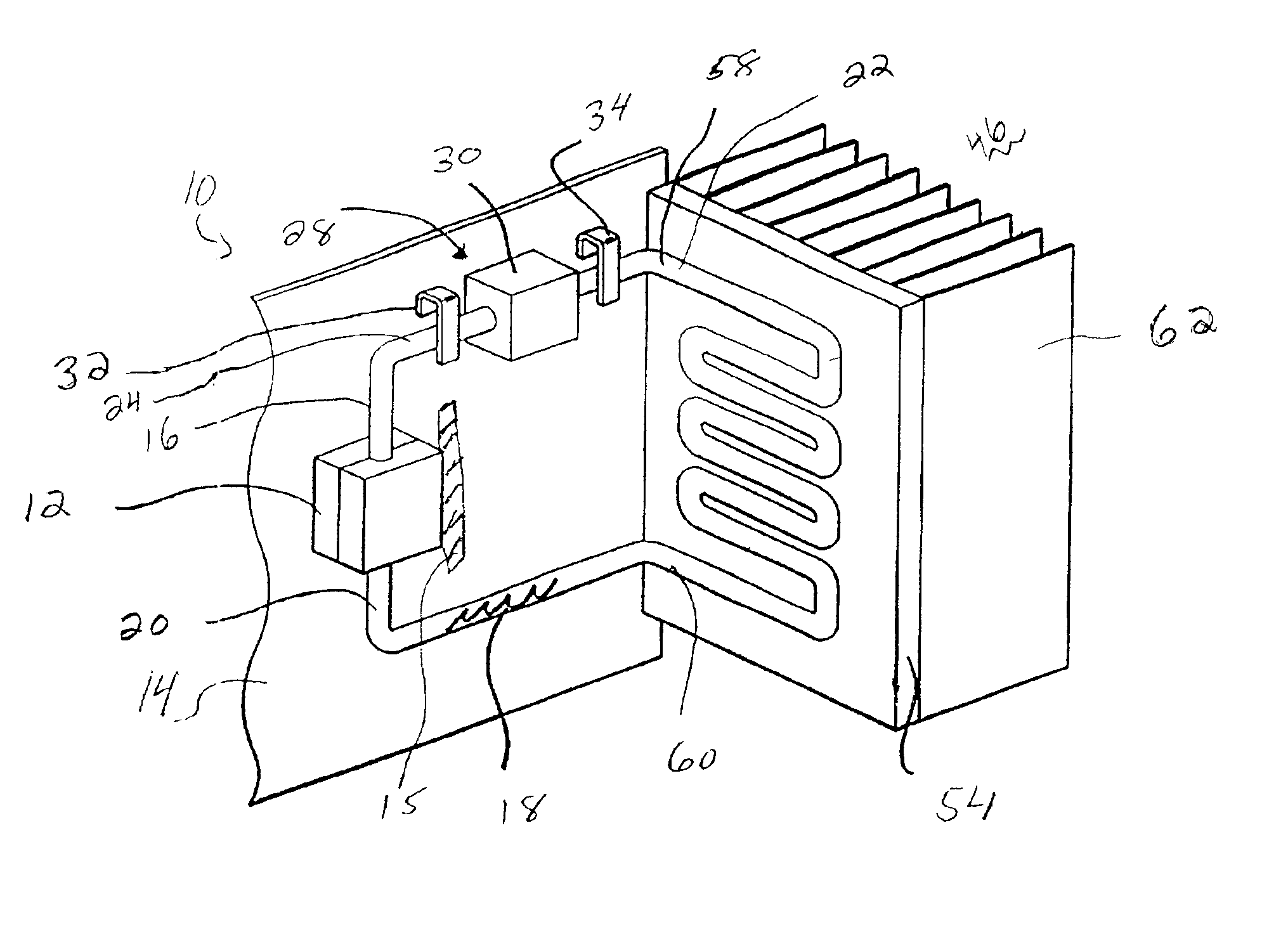

Phase-change refrigeration apparatus with thermoelectric cooling element and methods

InactiveUS6845622B2Thermoelectric device with peltier/seeback effectIndirect heat exchangersEnergy transferThermoelectric cooling

A heat-transfer device has a sealed vapor chamber with a phase-change fluid therein, and a thermoelectric cooling (TEC) element with a cooled side in thermal contact with the vapor chamber and a heated side in contact with heat-dissipation fins. The TEC element decreases the temperature of the vapor chamber and increases the temperature of the fins for improved efficiency. The vapor chamber is defined between concentrically positioned tubes, and a tunnel region is located within the inner tube. Additional TEC elements within the tunnel region further dissipate heat. In two-phase natural convection embodiments, TEC elements may further cool liquid returning to the heat source. Parallel heat dissipation paths may also be provided. In a two-phase forced convection embodiment, a TEC element may further cool liquid returning to the heat source, and additional TEC elements may be provided on the condenser. In some embodiments, active feedback controls the amount of energy transferred by a TEC element.

Owner:INTEL CORP

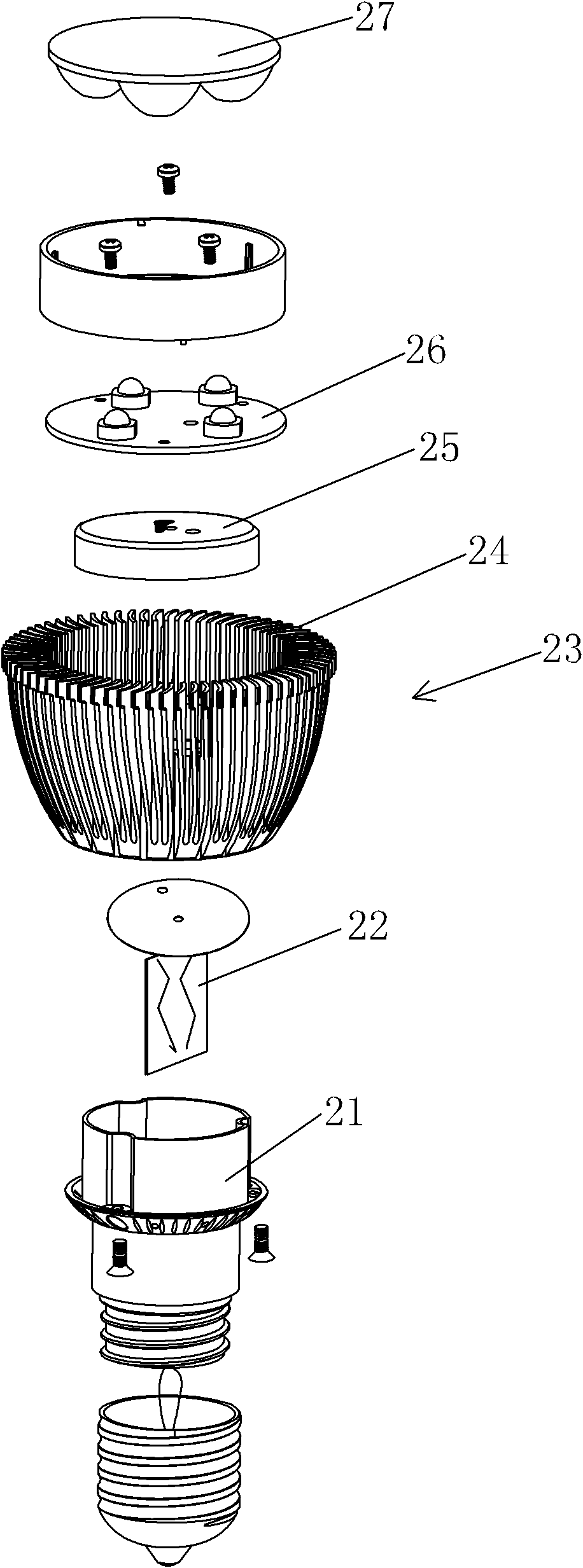

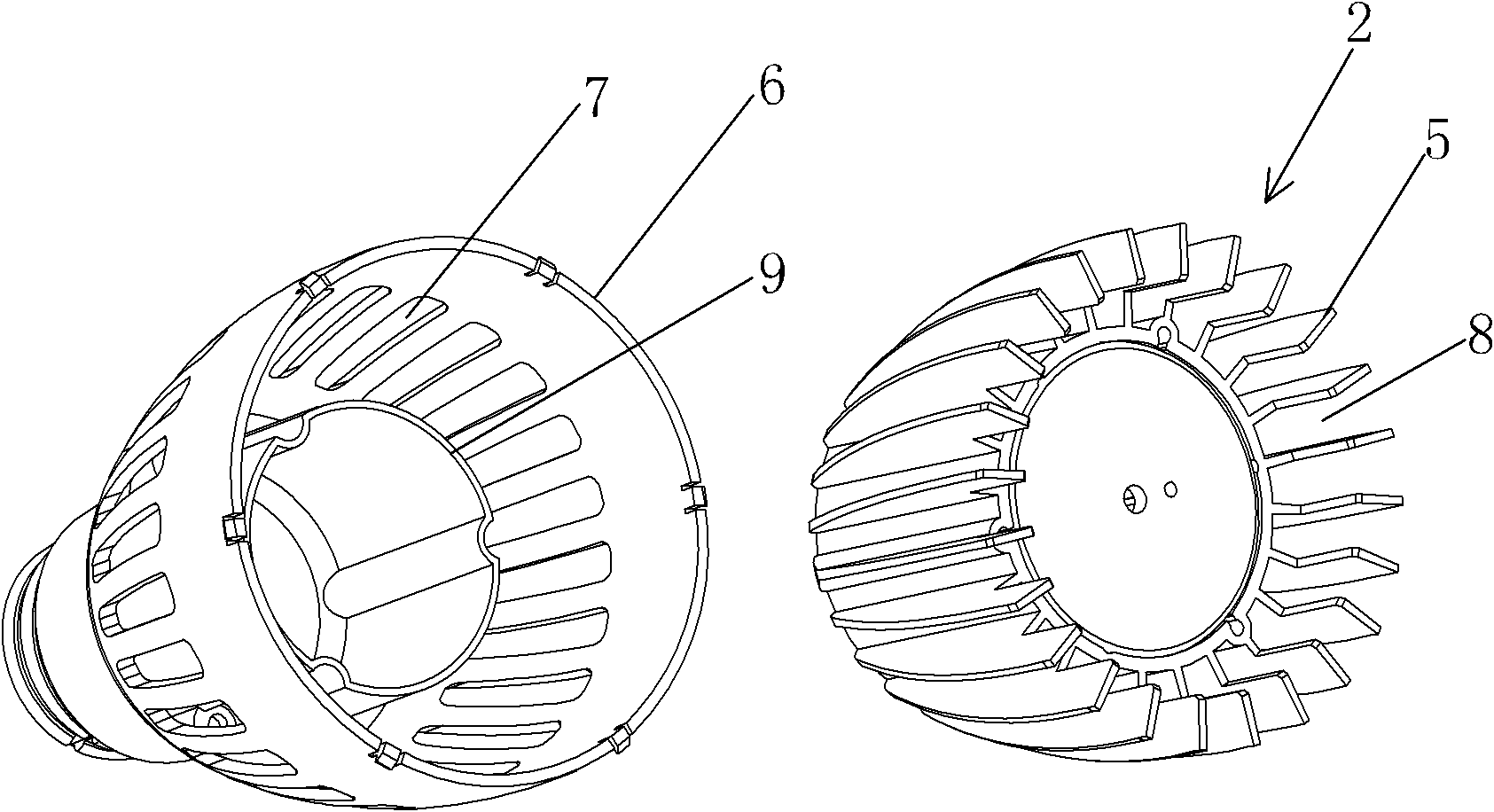

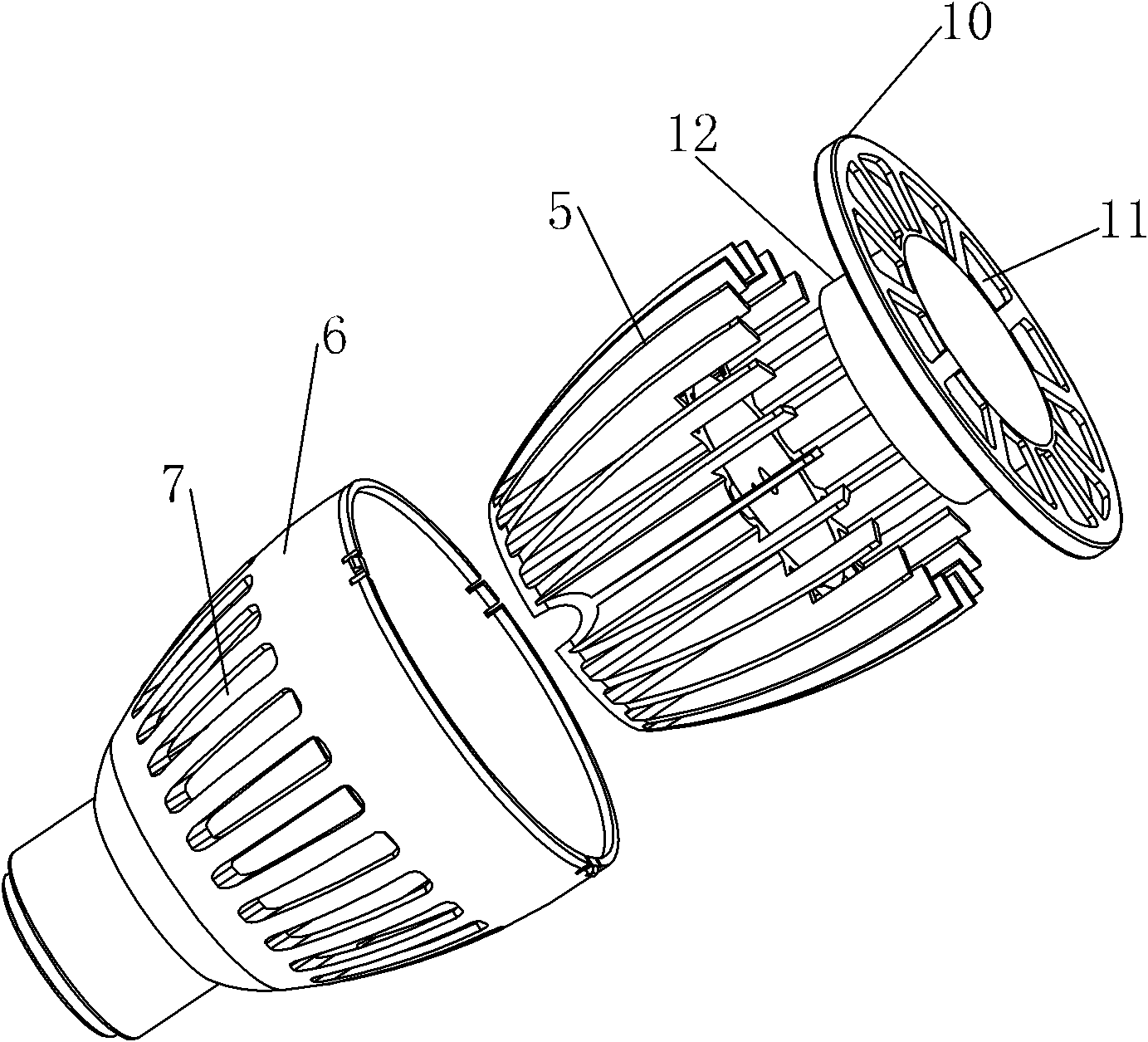

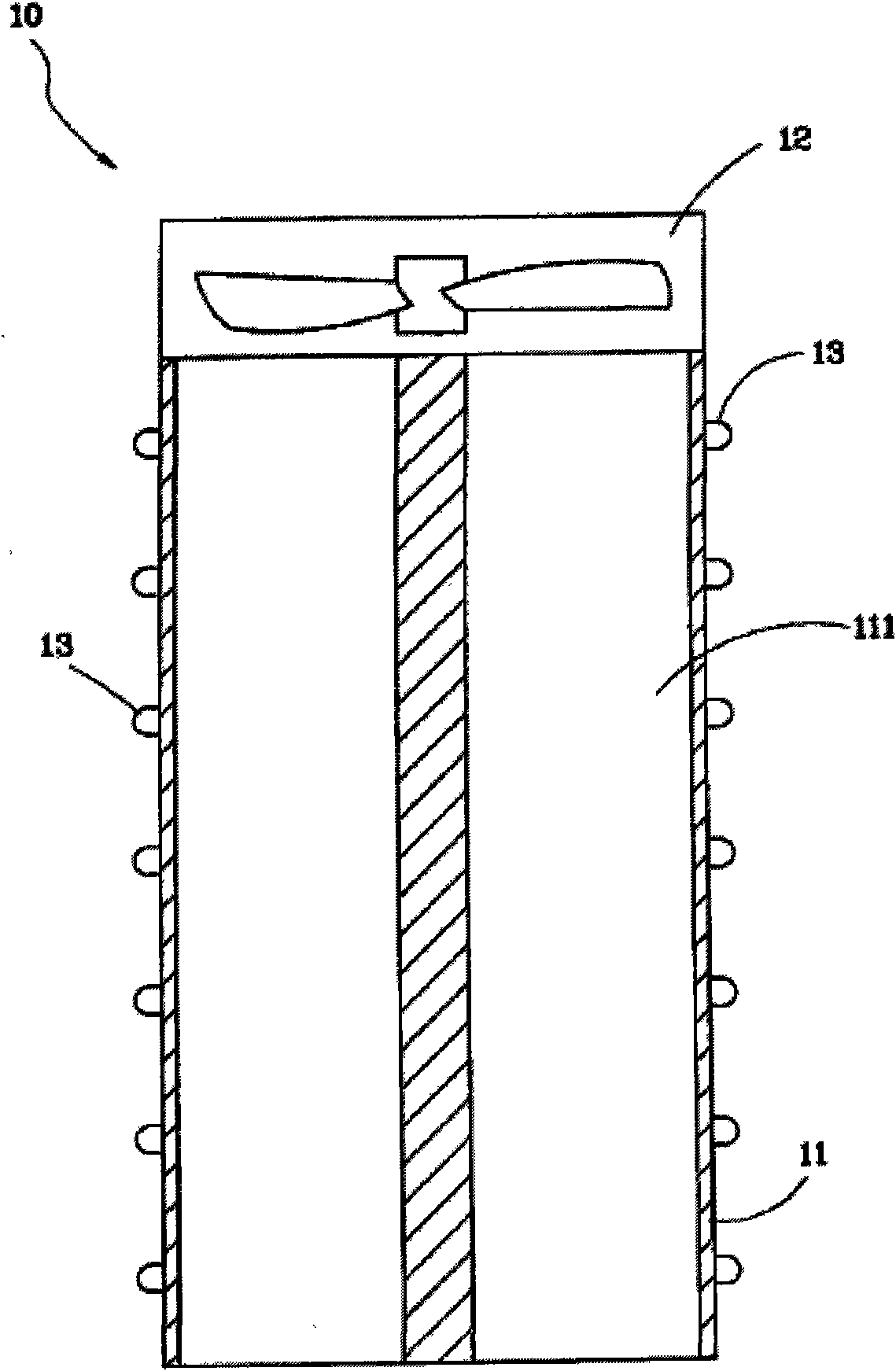

Combined LED lamp cup

InactiveCN102032491AProtect from scratchesProtection from burnsPoint-like light sourceLighting heating/cooling arrangementsNatural convectionForced-air

The invention discloses a combined LED lamp cup, which comprises a radiating component. A cavity is formed inside the radiating component; a plurality of longitudinally arranged radiating fins are uniformly distributed on the outer surface of the radiating component; a plastic shell is sleeved outside the radiating component; and a plurality of radiating holes are formed on the plastic shell. Due to the arrangement of the plastic shell outside the radiating component, a user is effectively prevented from being scratched by edges of the radiating fins, and the user is prevented from being scalded by the surfaces of the radiating fins when a lamp works; moreover, a plurality of air ducts are formed through the radiating holes to force air to enter the radiating channel upwards from the lower end of the lamp cup and flow out of the radiating holes. Therefore, high-efficiency convection heat dissipation is formed, and compared with that of the conventional natural convection heat dissipation mode of exposing the lamp cup, the radiating effect is improved.

Owner:ZHEJIANG SHENGHUI LIGHTING

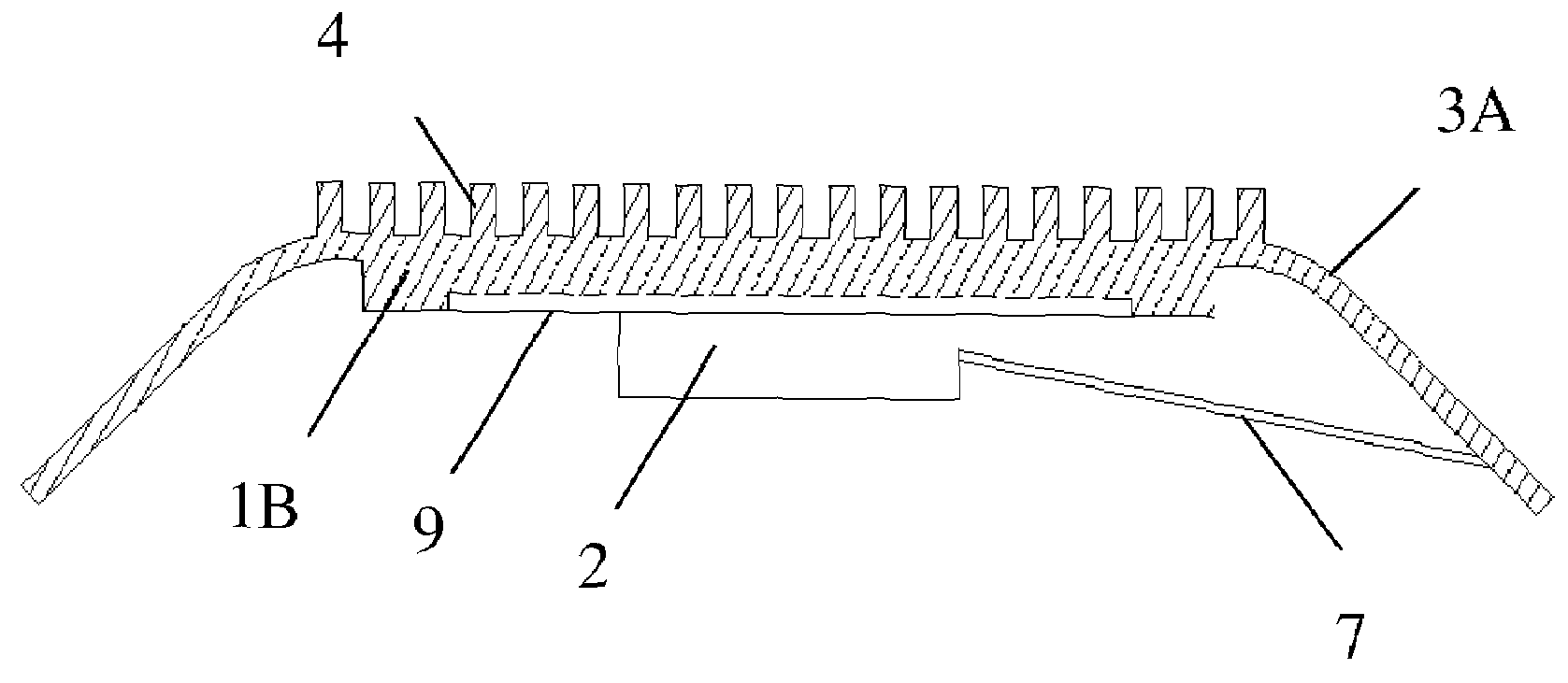

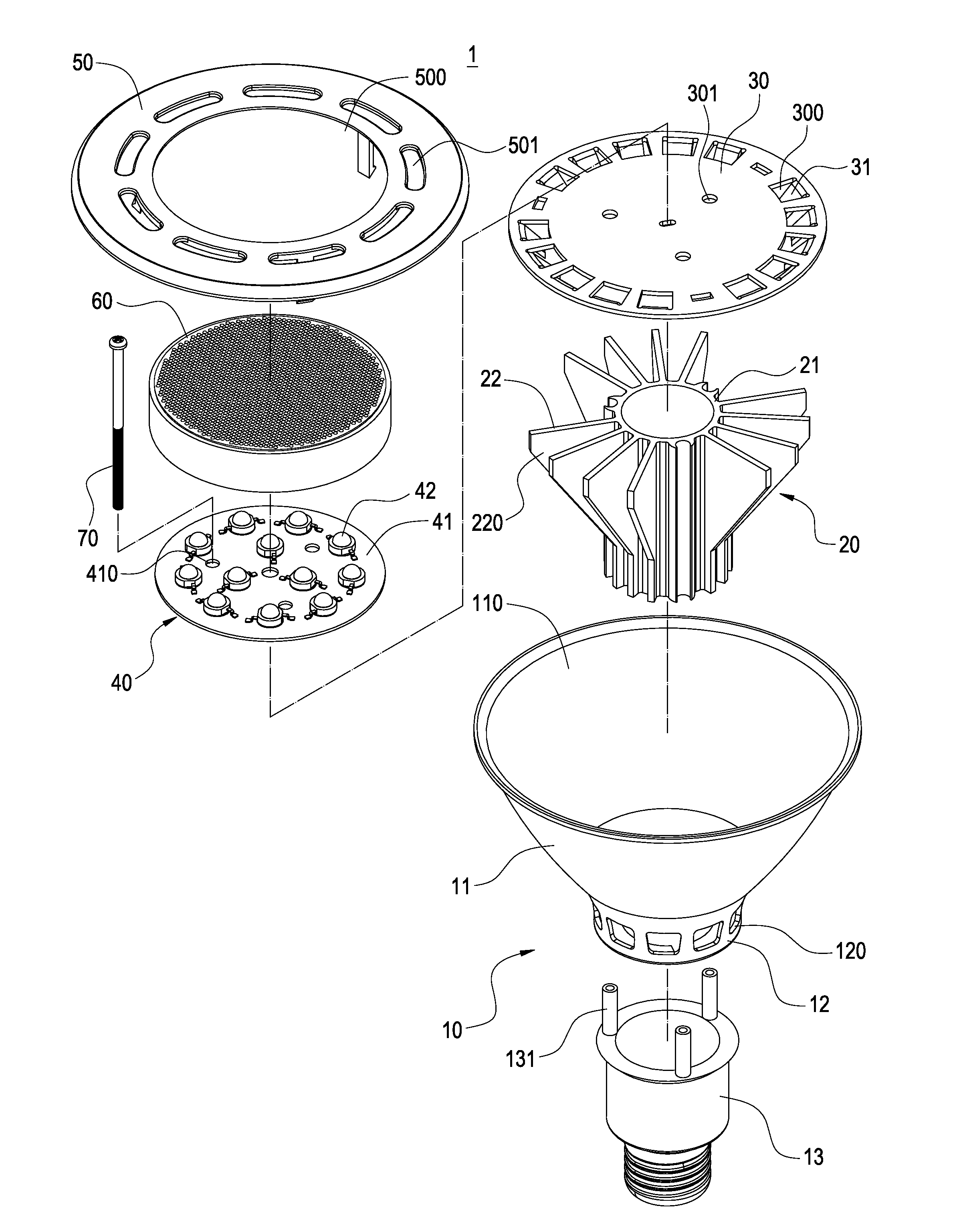

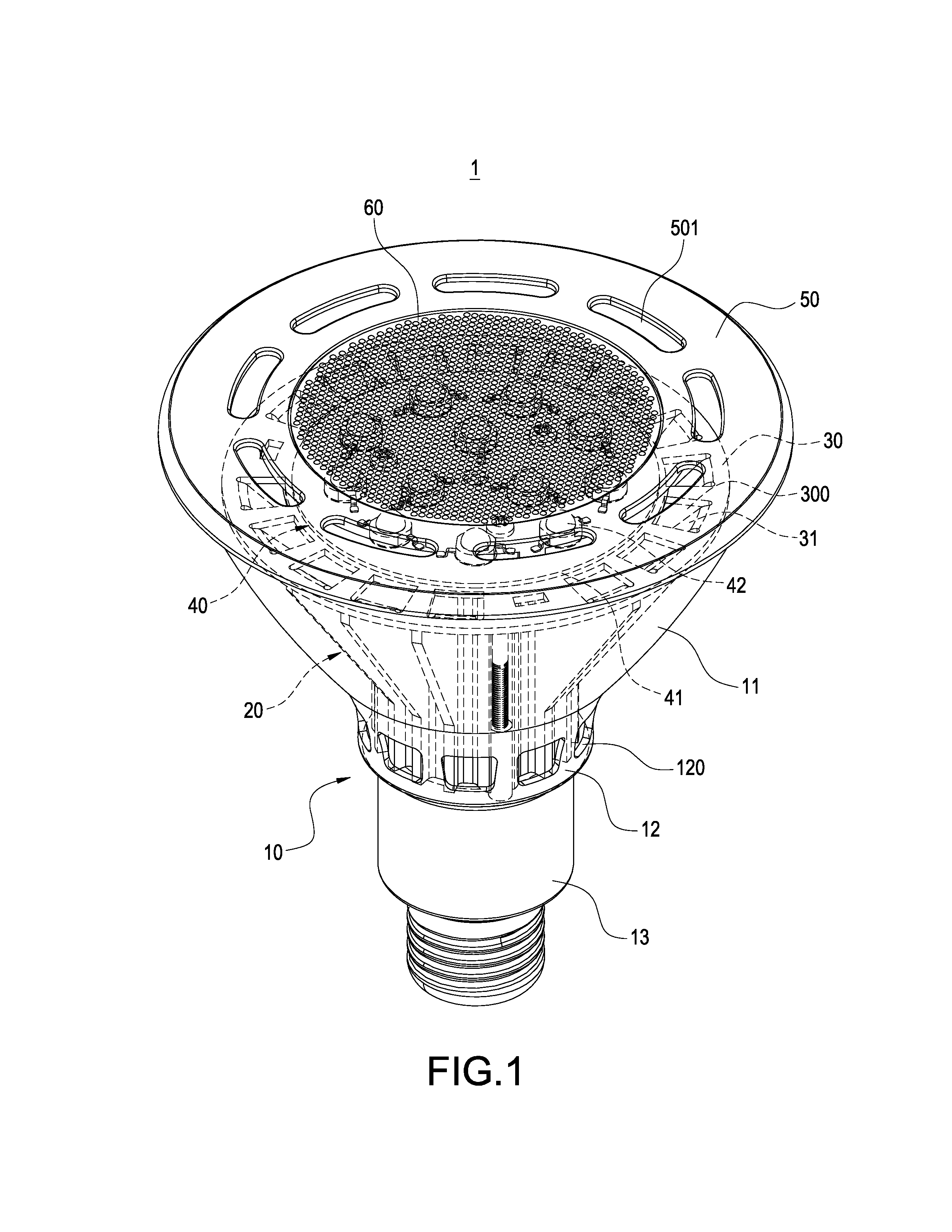

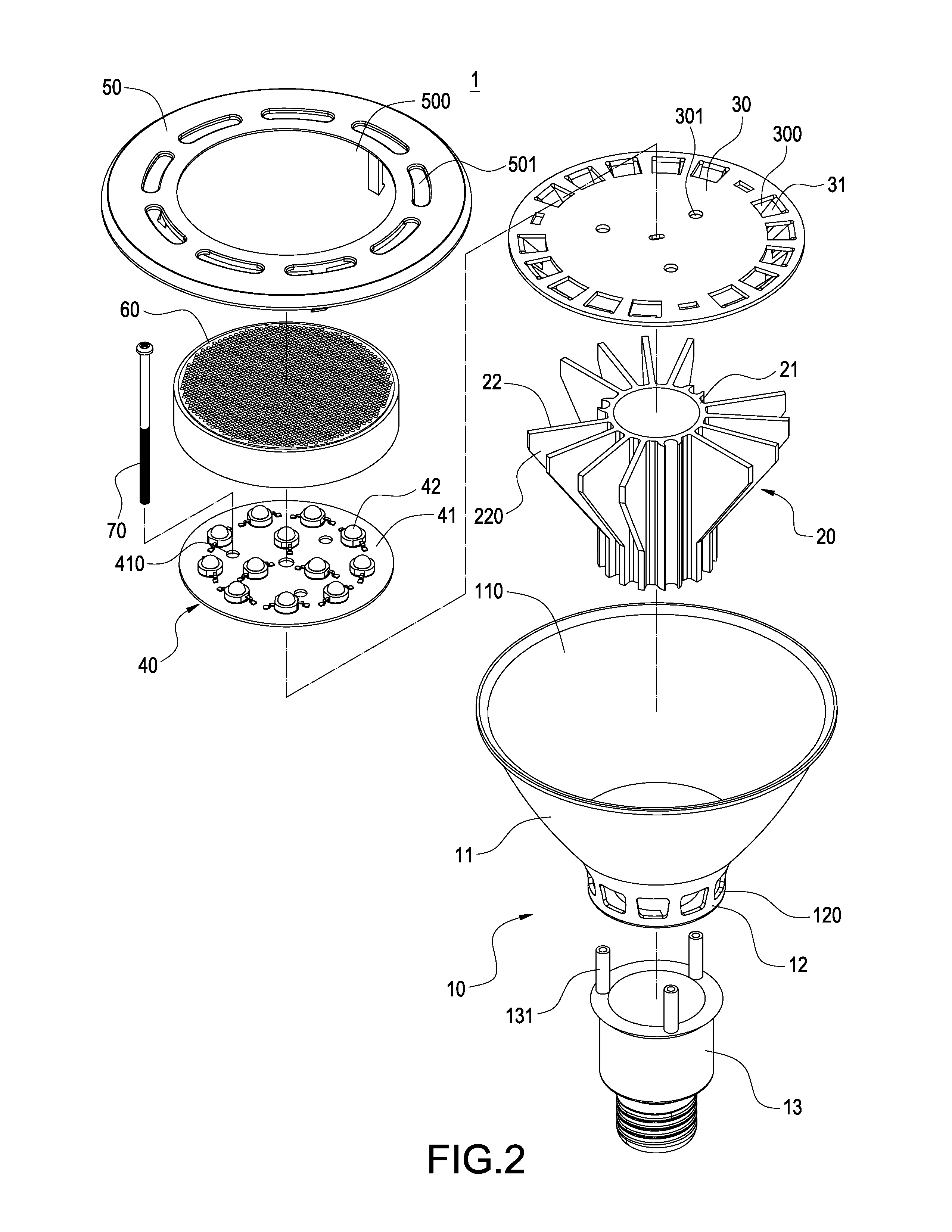

Heat dissipation devices for an LED lamp set

Heat dissipation devices for an LED lamp set has a plate-type heat spreader as the core unit. The plate-type heat spreader is either a flat-plate heat pipe or a metal plate embedded with heat pipes. The high-power LED lamps are thermally connected to the bottom surface of the heat spreader so that the heat generated by the LED lamps is absorbed by the evaporation region of the flat-plate heat pipe or the embedding heat pipes. The heat is spread by internal vapor motion of the working fluid toward different regions of the heat spreader. The top surface of the heat spreader is connected with a finned heat sink, where the heat is delivered to the ambient air. The hot air leaves by buoyancy through the openings on a lamp housing located above the finned heat sink. The inner surface of the lamp housing can be connected with the top surface of the plate-type heat spreader, with the heat dissipated out at the surface of the housing by natural convection.

Owner:NATIONAL TSING HUA UNIVERSITY

Disk array device

ActiveUS7133282B2Increased durabilityMaintenance operationReducing temperature influence on carrierBatteries circuit arrangementsElectrical batteryStandby power

A disk array device can carry out battery backup including a destage process of data by a battery mounted in a case body of the disk array device and can enhance instantaneous power failure durability to an instantaneous power failure. A logic box mounts a channel controlling unit, a disk controlling unit, a cache memory and a switch; and a hard disk box mounts a plurality of memory devices. A battery box mounts a nickel hydrogen battery for supplying a backup power source at the time of a power failure and is disposed at a lower portion of each case body including the logic box and the hard disk box. The nickel hydrogen battery of the battery box is cooled through natural convection of air created inside the case body by a fan for cooling each of the logic box and the hard disk box.

Owner:RAKUTEN GRP INC

Telecommunication device including a housing having improved heat conductivity

InactiveUS7040383B2Improve Radiation PerformanceImprove propertiesSemiconductor/solid-state device detailsSolid-state devicesPressure riseNatural convection

A telecommunication device includes a housing formed by gas-assist injection molding and having an inner wall, outer wall and a hollow space formed therebetween and receiving therein gas refrigerant. The hollow space has a plurality of vertical channels wherein the gas refrigerant cools the internal of the housing by natural convection within the vertical channels. A movable wall is disposed in the vertical channel for controlling a pressure rise occurring upon a temperature rise.

Owner:NEC CORP

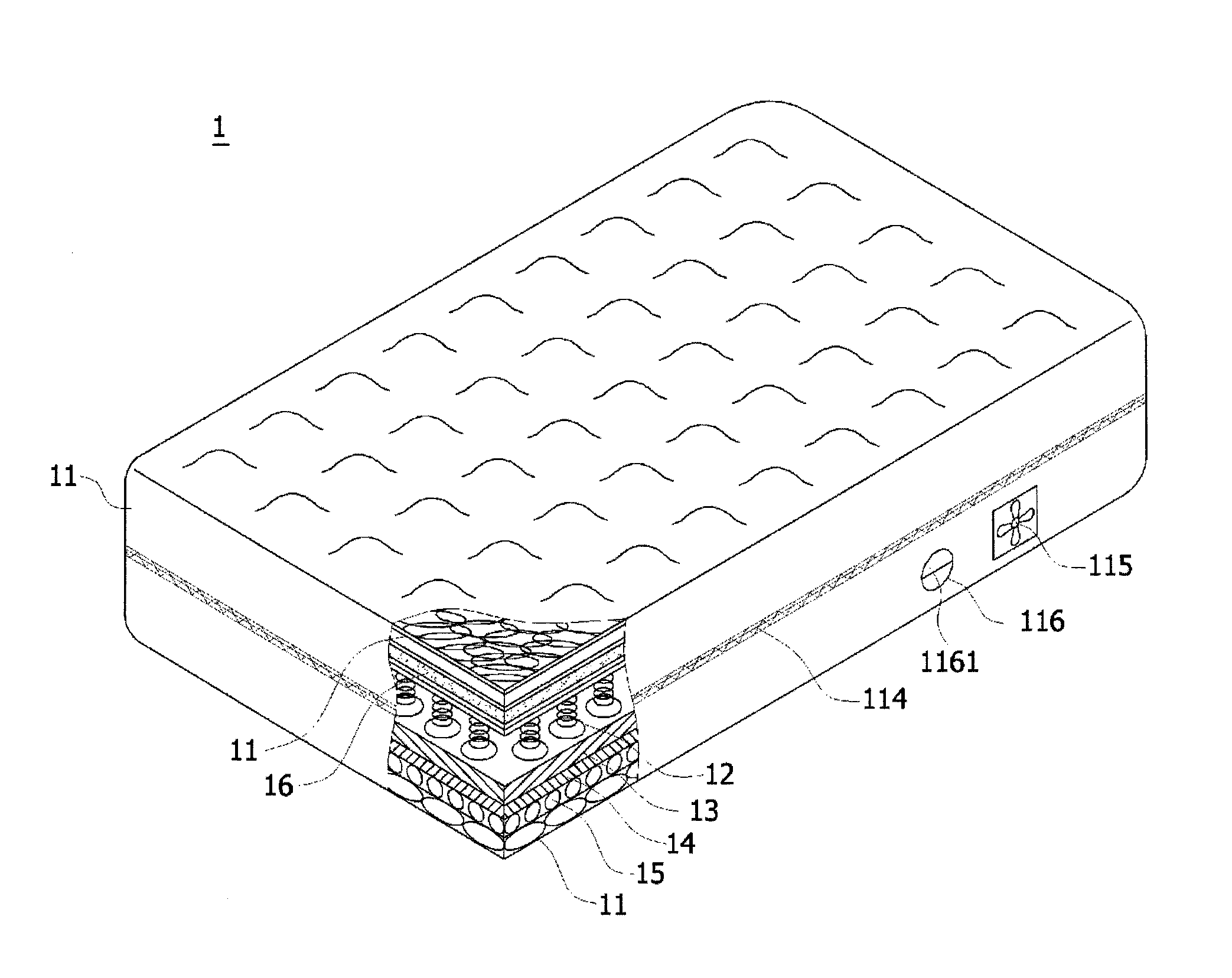

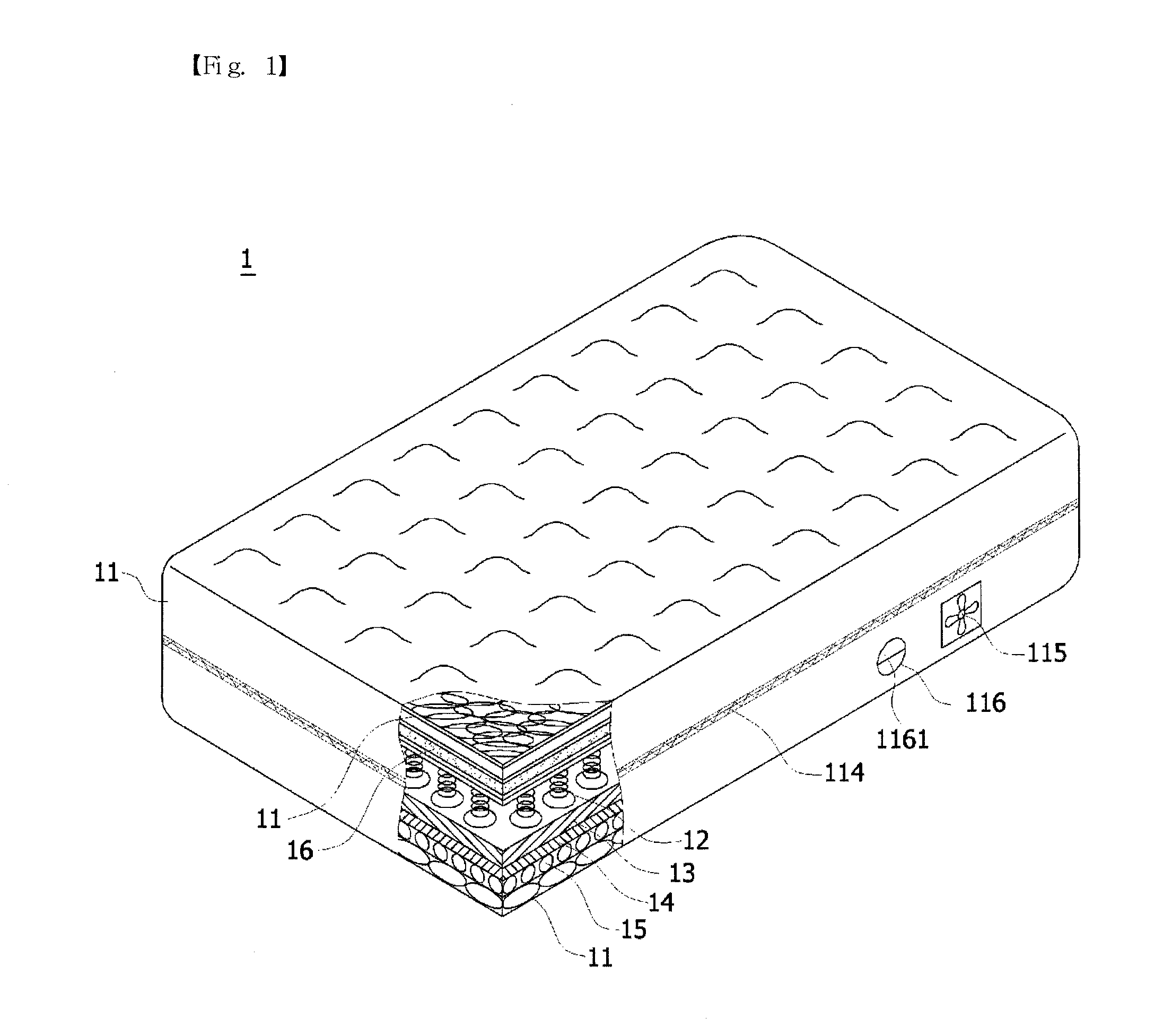

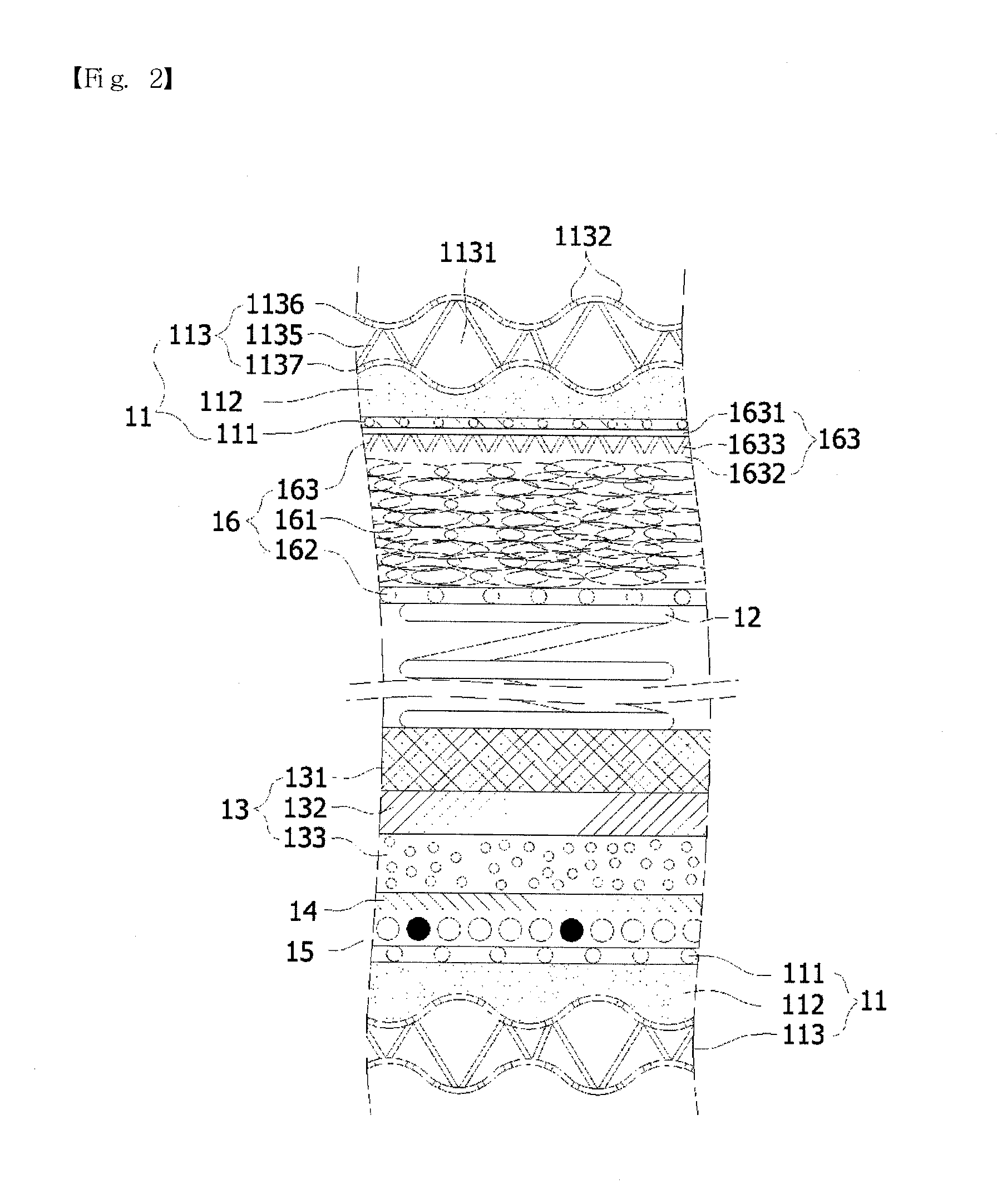

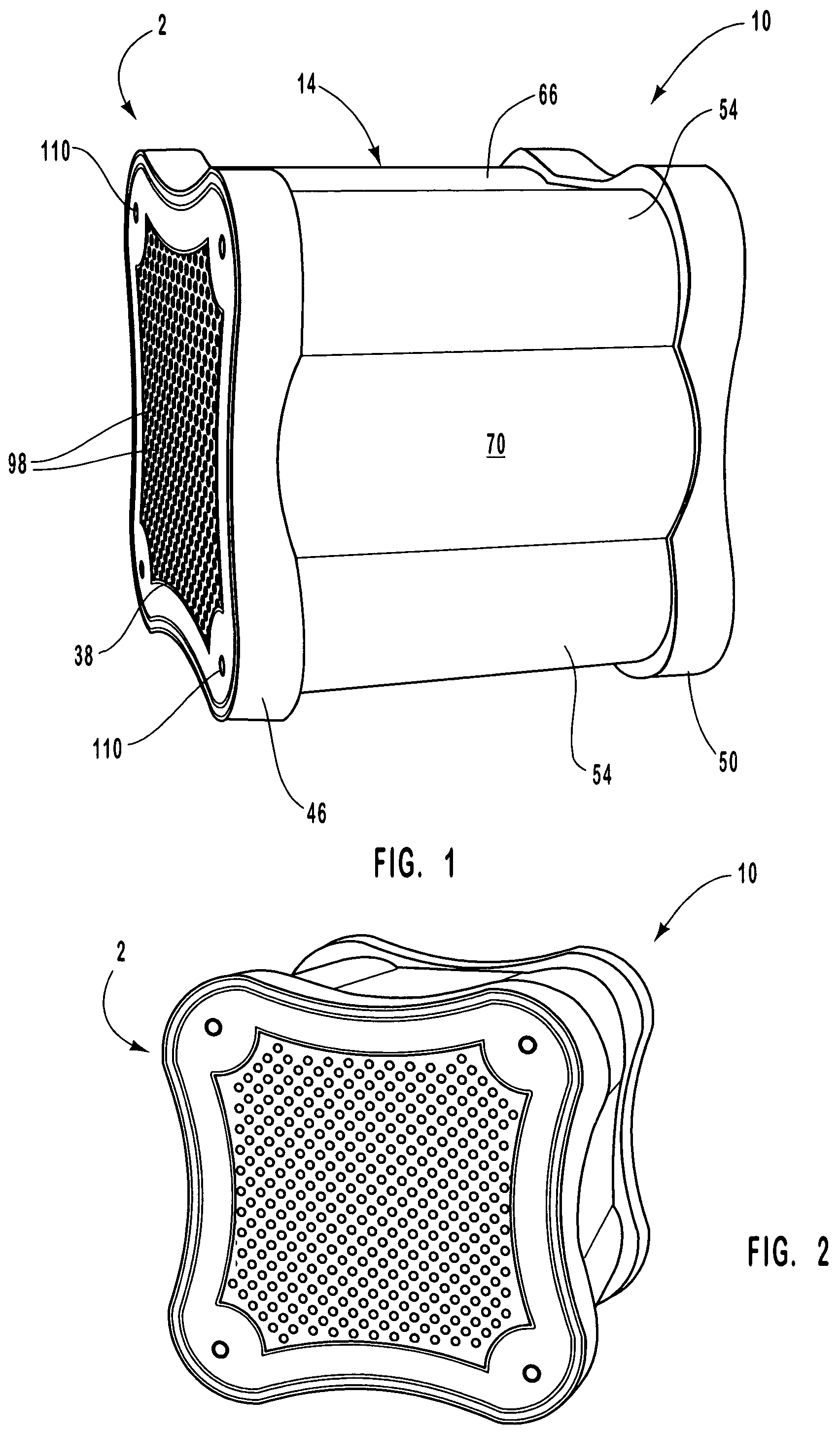

Mattress with cooling and heating function

InactiveUS20120110734A1Comfortable sleeping environmentSuccessfully performedStuffed mattressesSpring mattressesCushioningNatural convection

Disclosed is a mattress, which performs a cooling function under a high temperature environment owing to air permeability thereof and a thermal function under a low temperature environment via natural convection, thereby providing a pleasant sleep environment in all temperature conditions. The mattress includes a cushioning member to perform a cushioning operation, a thermal laminate member disposed on one surface of the cushioning member, a heating element to perform a heating operation upon receiving power and to exhibit elasticity, a cooling laminate member disposed on the other surface of the cushioning member and having air permeability, and a cover member to surround an outermost portion of the mattress. By simply changing the orientation of the mattress and using the elastic cooling and heating members, the mattress is compatibly used all the year round to provide a pleasant sleep environment without deterioration of an intrinsic cushioning function and load dispersing / supporting function.

Owner:AN JUNG HO

LED lamp with flow guide function

InactiveUS8164237B2Avoid heatEnhanced natural convectionPlanar light sourcesElectric discharge tubesNatural convectionEngineering

An LED lamp with a flow guide structure guides external air to dissipate heat from the LED lamp includes a lamp base, a heat dissipating body, a heat dissipating plate and an LED module installed in the lamp base, and heat dissipating holes formed on the lamp base. The heat dissipating body includes heat dissipating fins, and a heat dissipating passage defined between any two fins and disposed corresponding to the heat dissipating hole. The LED module is in a thermal contact with the heat dissipating plate. The heat dissipating plate is attached onto the heat dissipating fins and includes openings. A flow guide plate is formed at a lateral edge of each opening and extended from the heat dissipating plate for guiding external air into the heat dissipating passage and out from the heat dissipating hole to expedite a natural convection in the lamp and prevent a thermal aggregation.

Owner:GEM SUN TECH

Method and apparatus for converting dissipated heat to work energy

InactiveUS6856037B2Digital data processing detailsSemiconductor/solid-state device detailsNatural convectionEngineering

A method for converting lower temperature dissipated heat to other useful energy and apparatus therefore. Heat energy is transferred to a fluid contained within a conduit, and natural convection of the fluid is utilized to transfer kinetic energy of the heat to another type of energy such as electrical energy.

Owner:SONY CORP +1

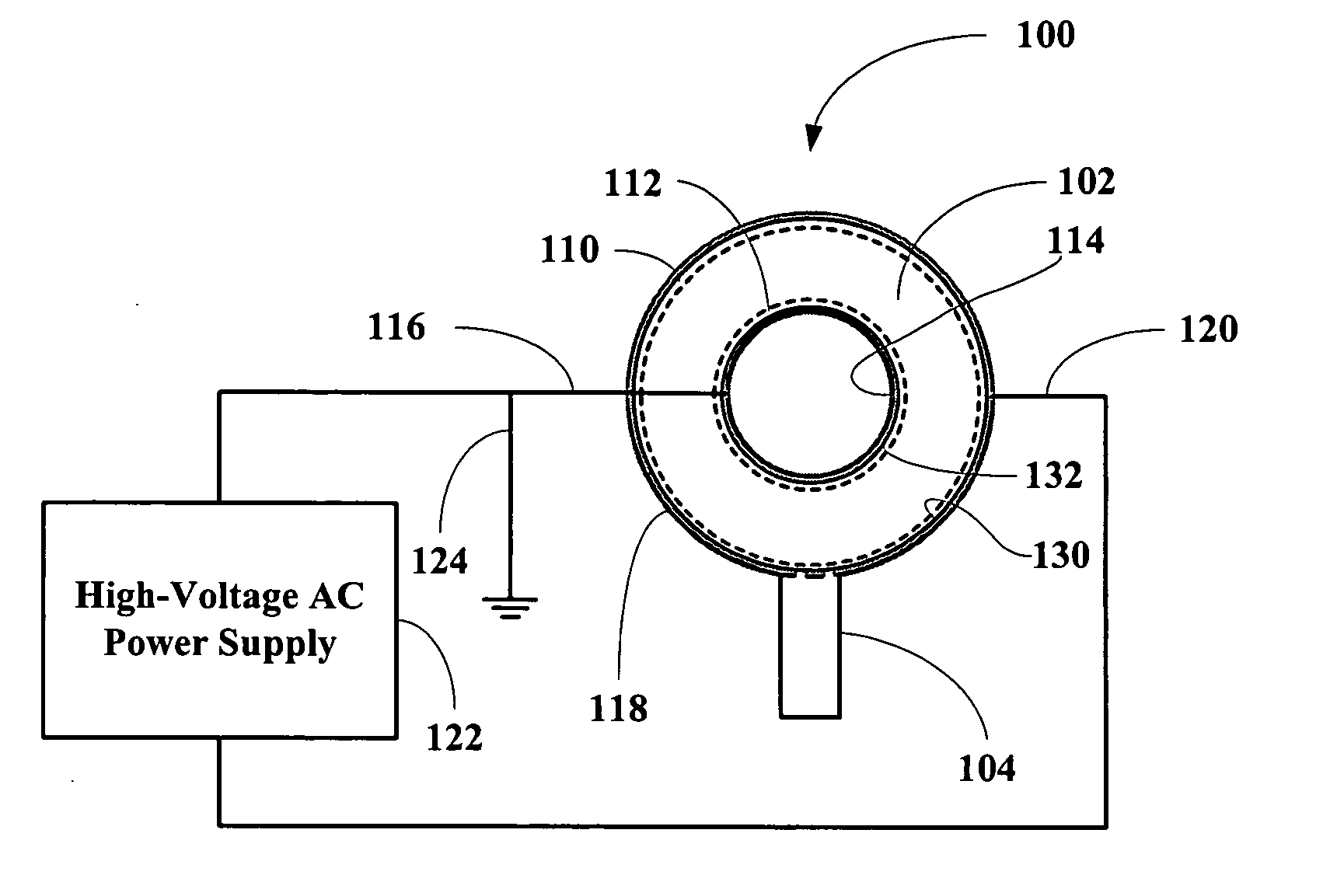

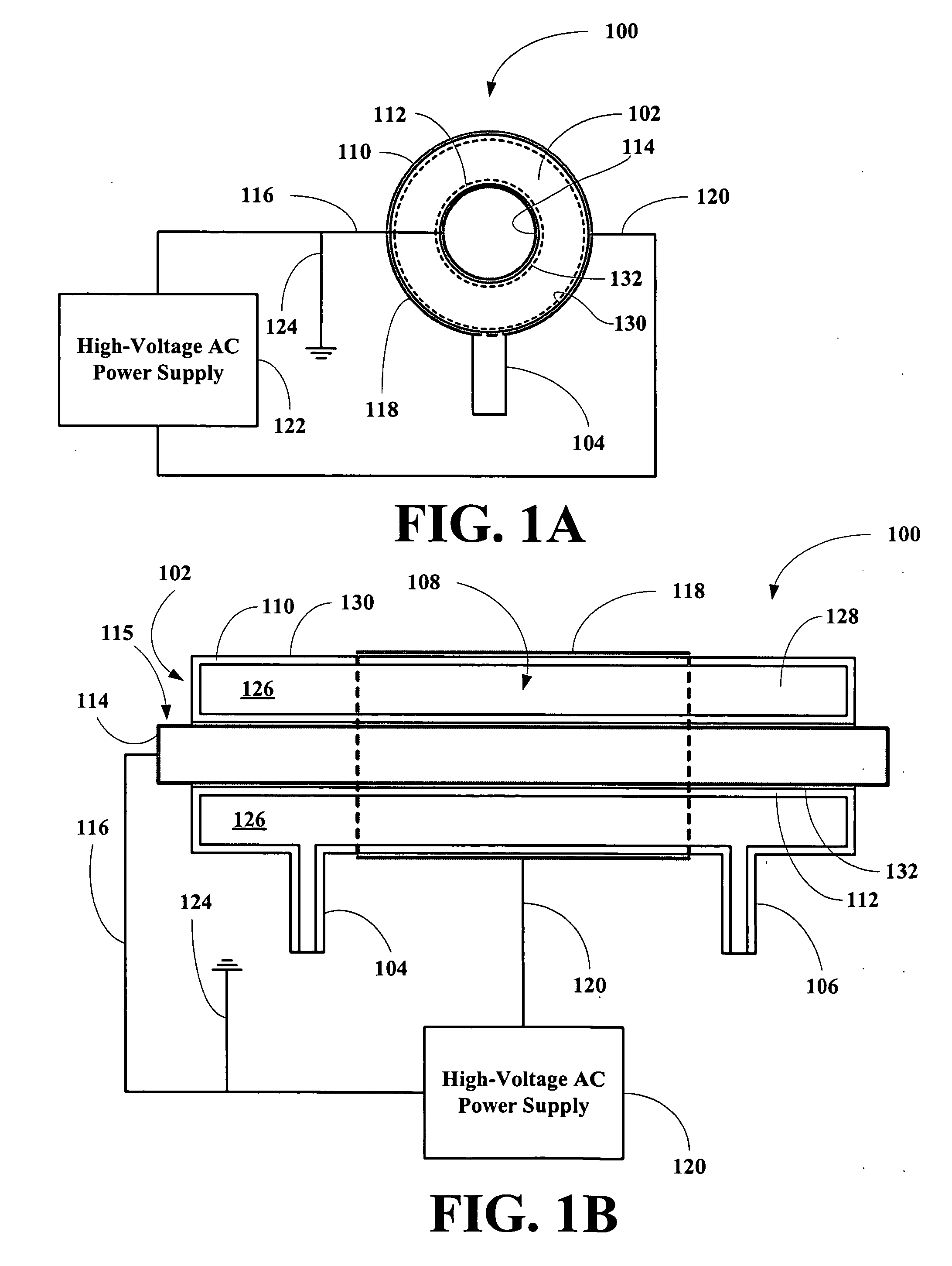

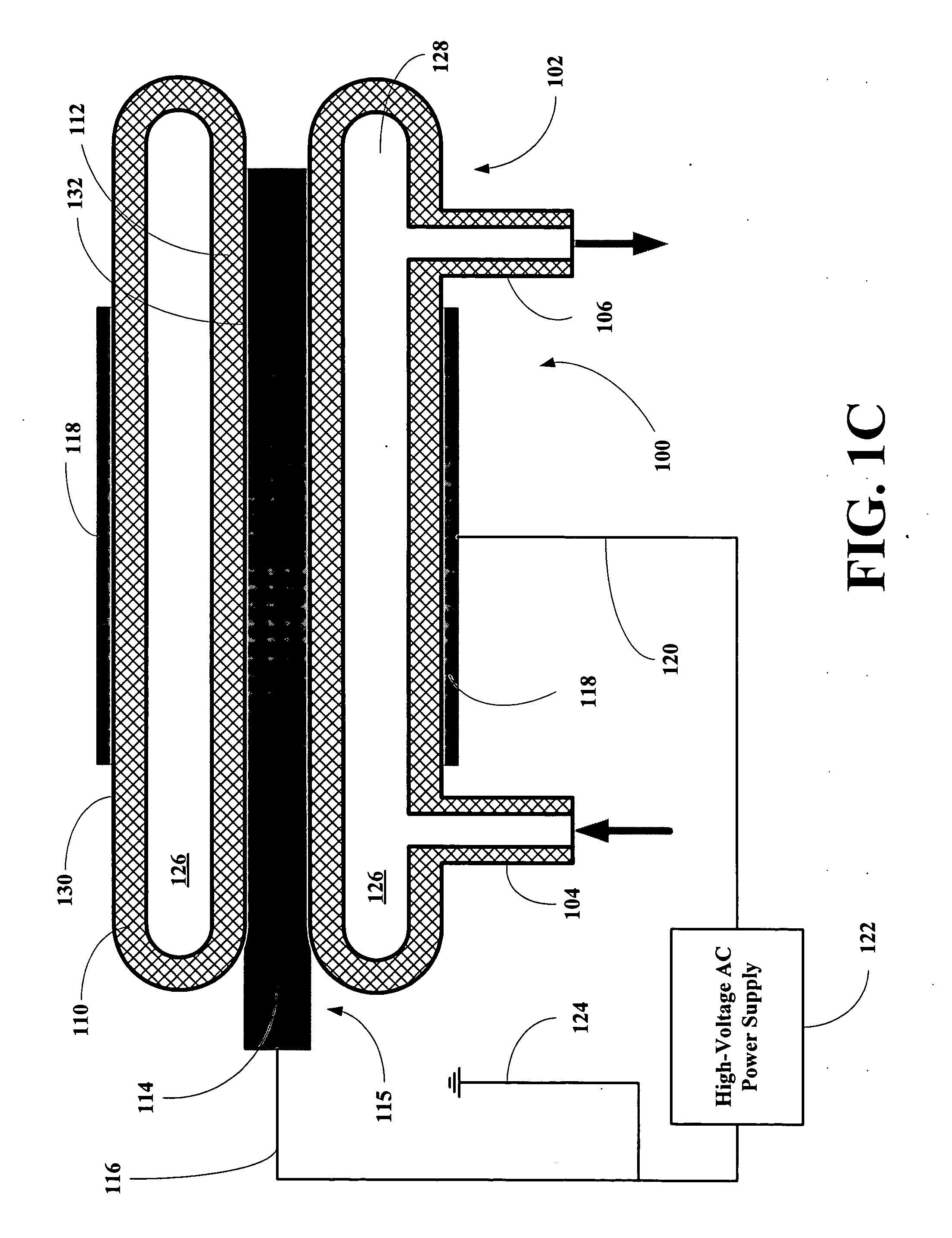

Ozone generator with dual dielectric barrier discharge and methods for using same

InactiveUS20050199484A1Electrical discharge ozone preparationEnergy based chemical/physical/physico-chemical processesPush pullEngineering

A new and novel ozone generator with a dual dielectric barrier discharge design is disclosed where high-purity ozone is generated and whose concentration can be varied over a wide range. The simplified design of the ozone generator cell possesses a gas inlet and outlet connected to an annular, sealed dielectric gas envelope that supports both inner and outer electrodes that do not come into contact with the gas. The design eliminates the need for gaskets, o-rings or other methods applied to seal the ozone cell and reduces problems associated with potential interaction resulting from material compatability issues. The applied high voltage is provided by a simple self-resonating, push-pull oscillating circuit whose efficiency is optimized through application of an appropriate impedance matching device. The ozone is concentration is adjusted by varying the pulse width duty cycle of the applied voltage and gas flow rate. The design configuration of the ozone generating cell also eliminates the need for forced air or liquid cooling by natural convective air currents and conductive means.

Owner:OLSTOWSKI FRANEK

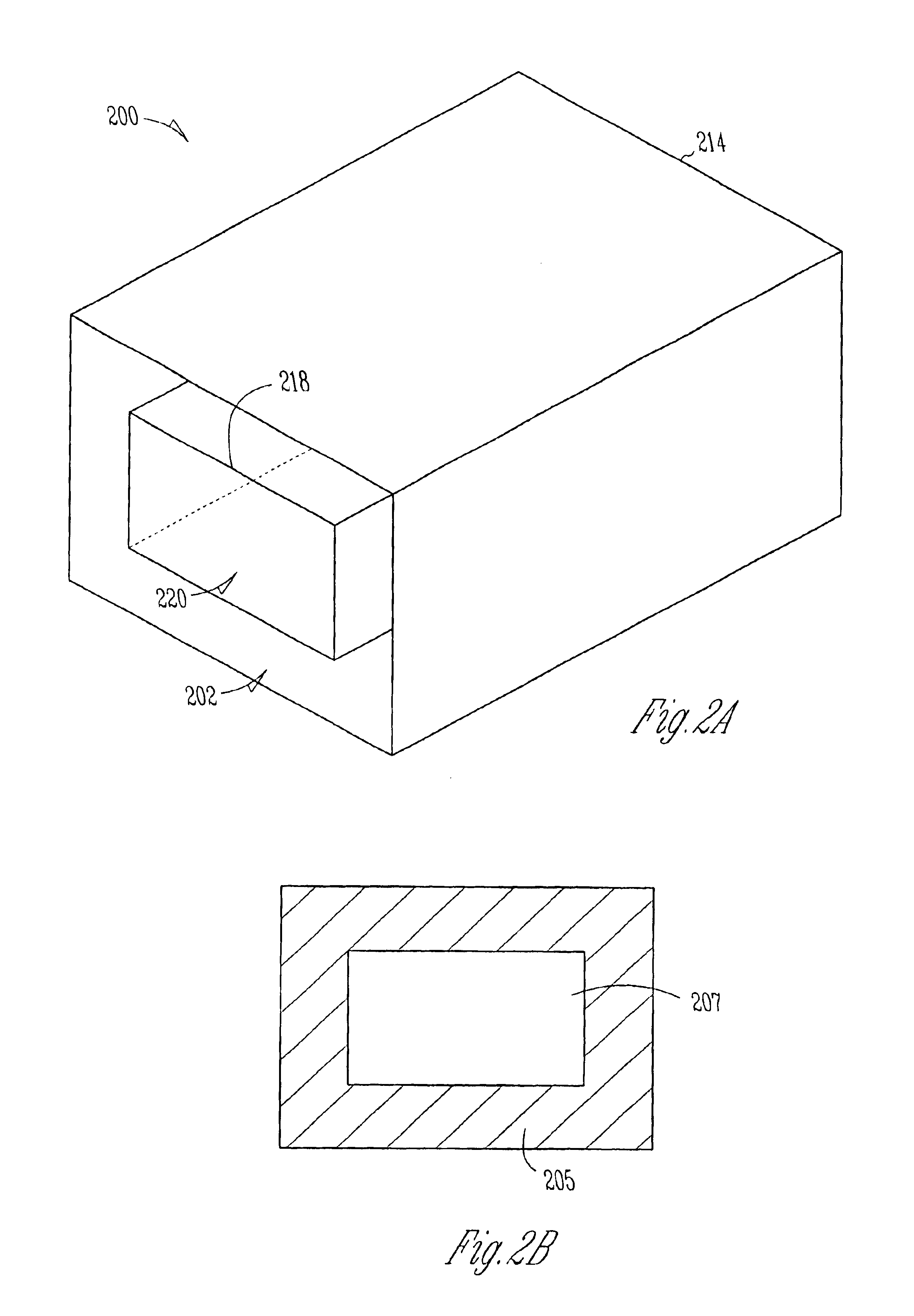

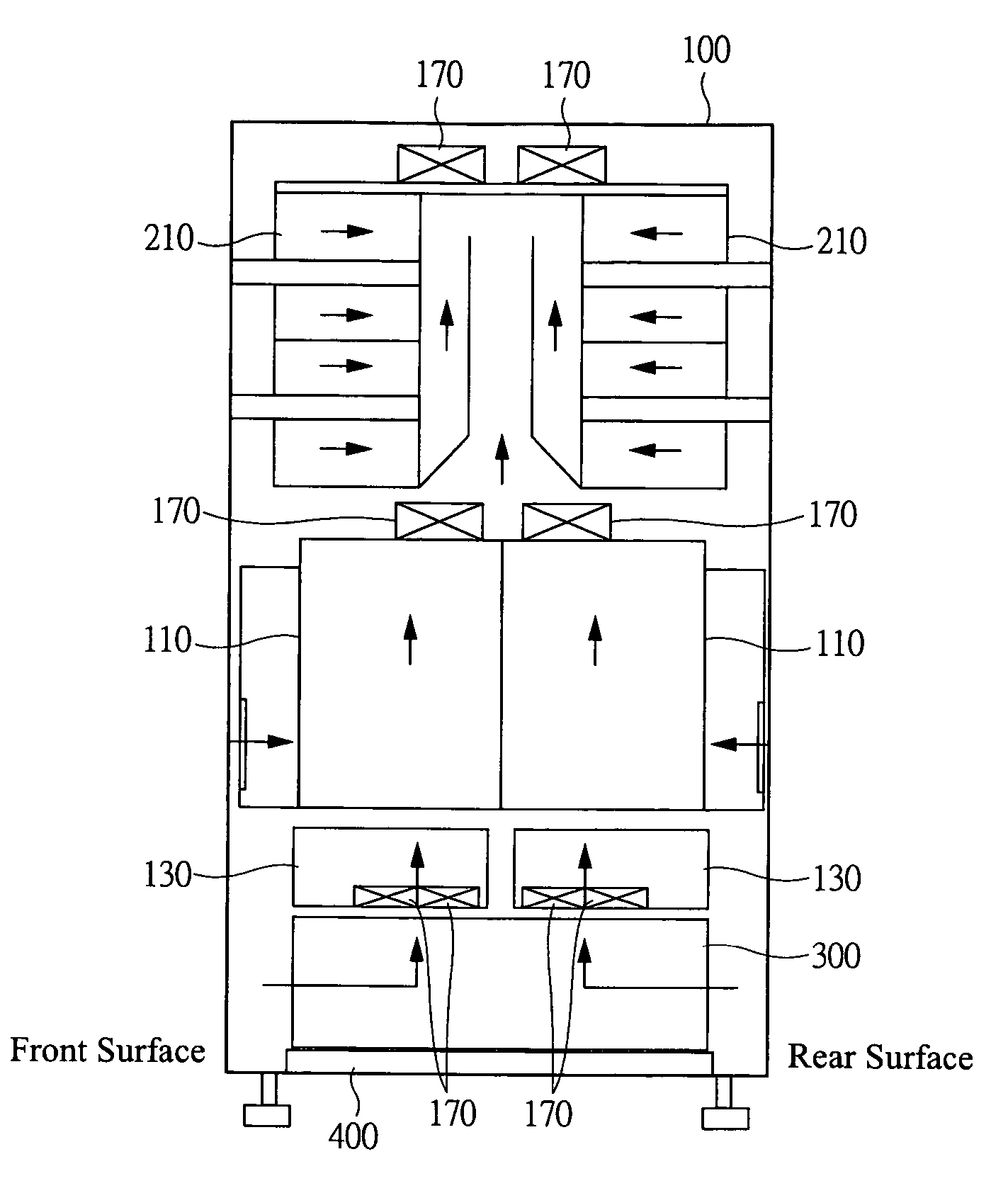

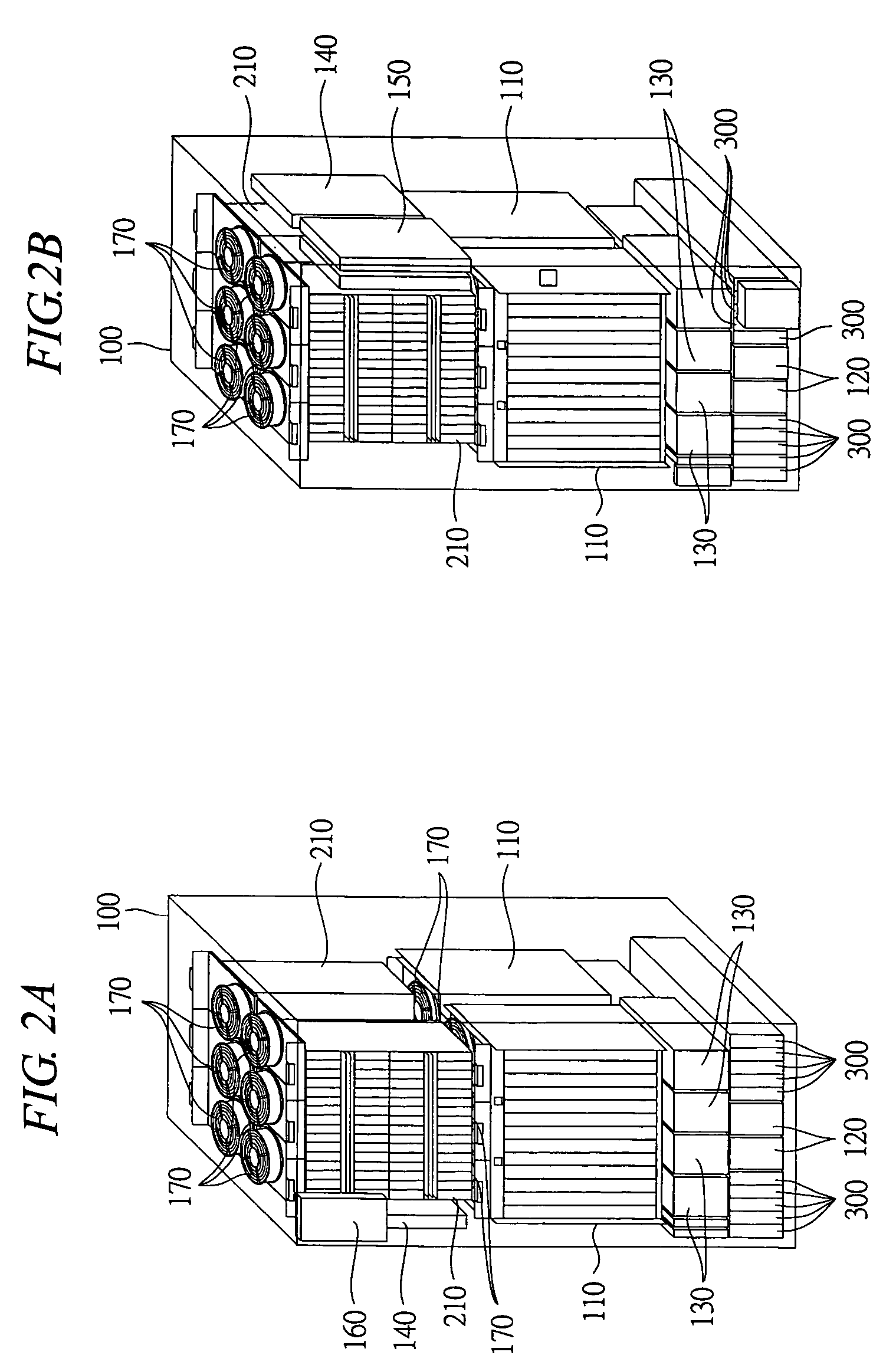

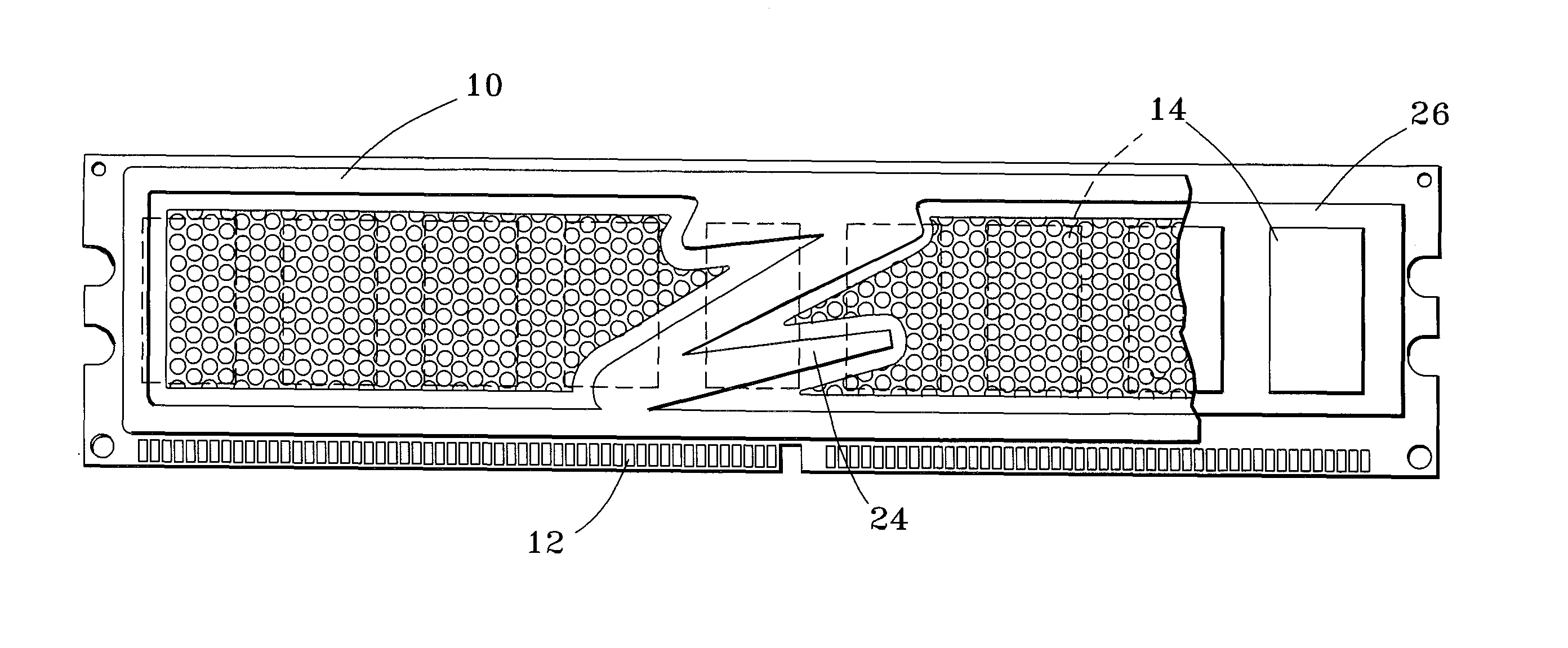

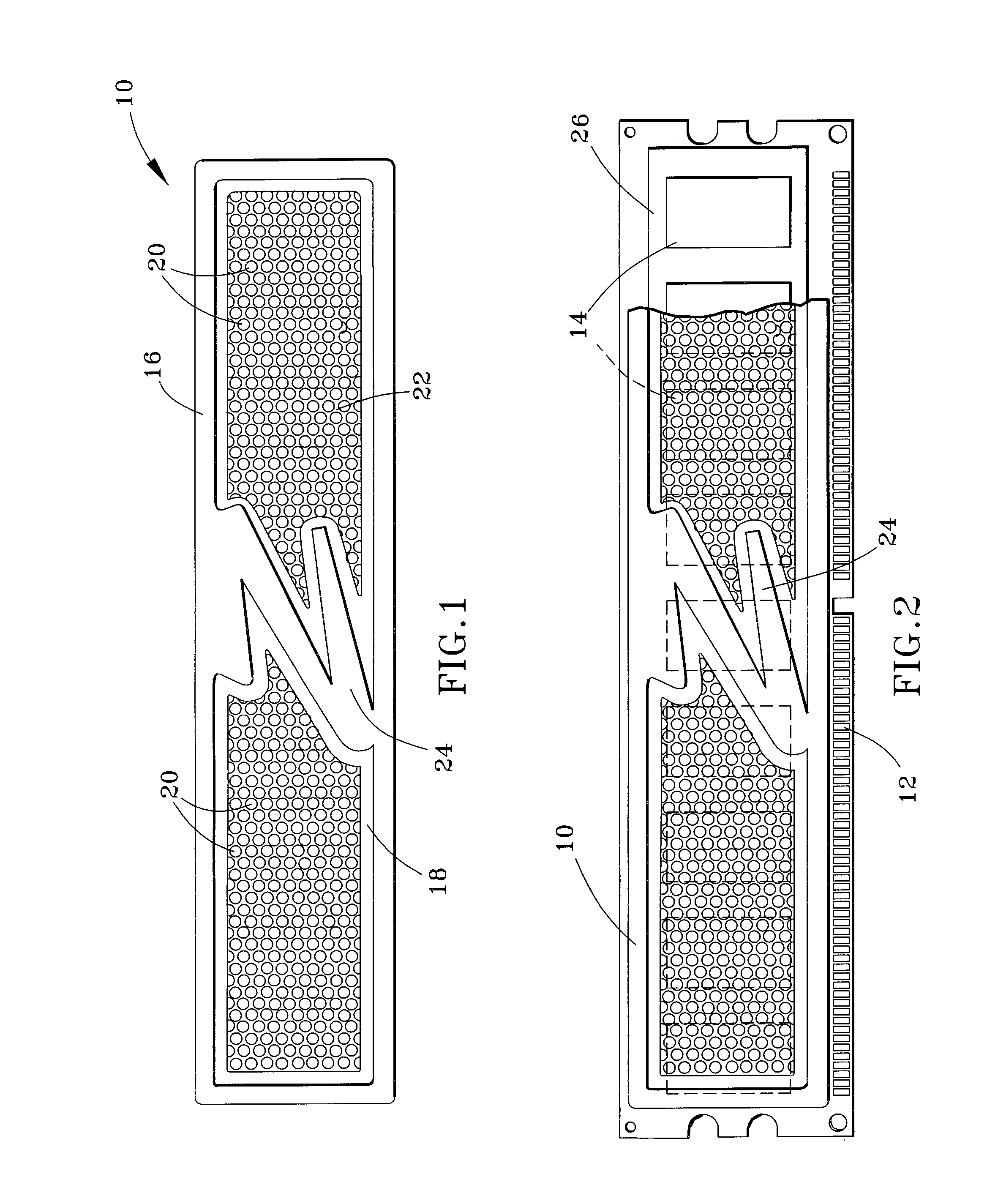

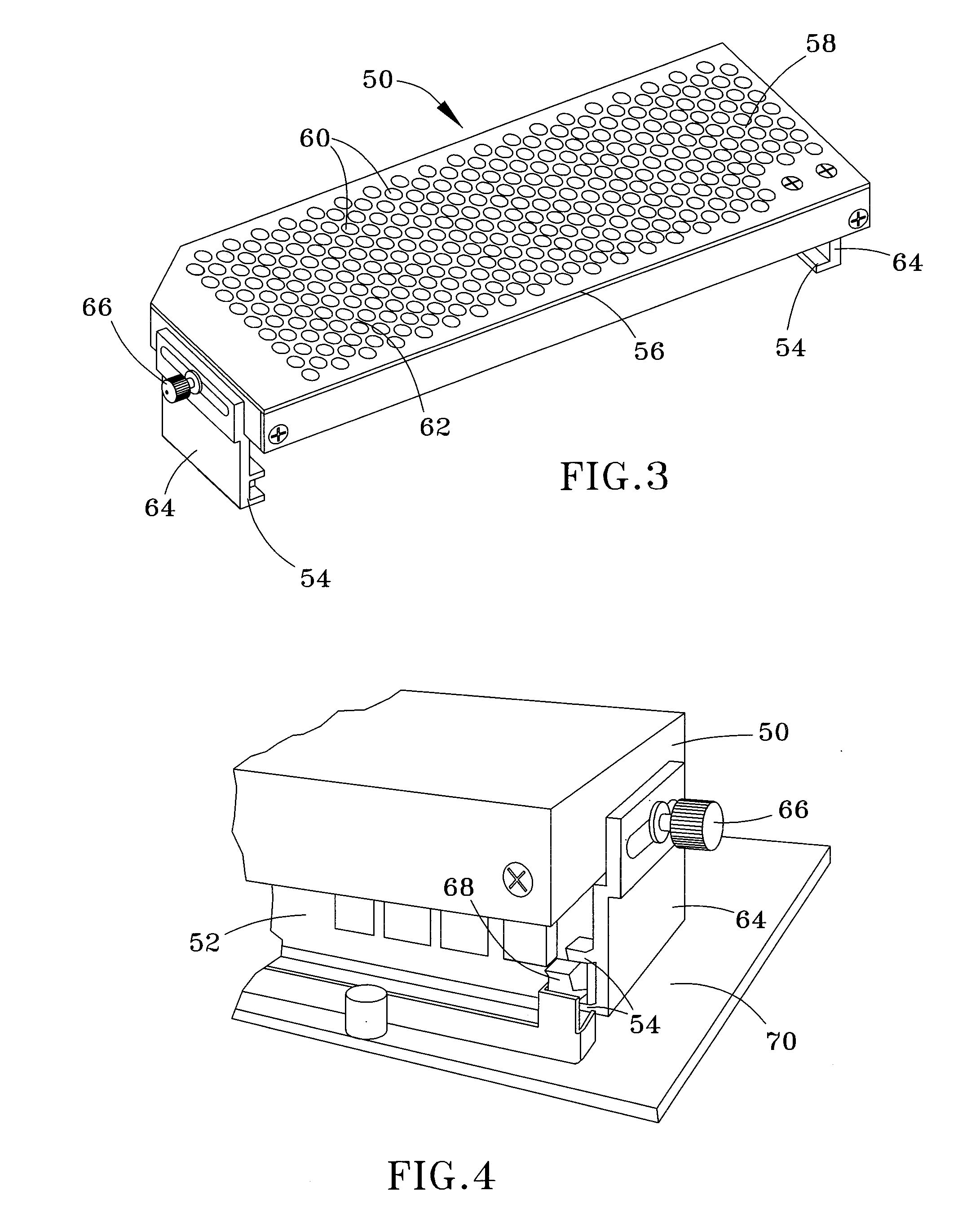

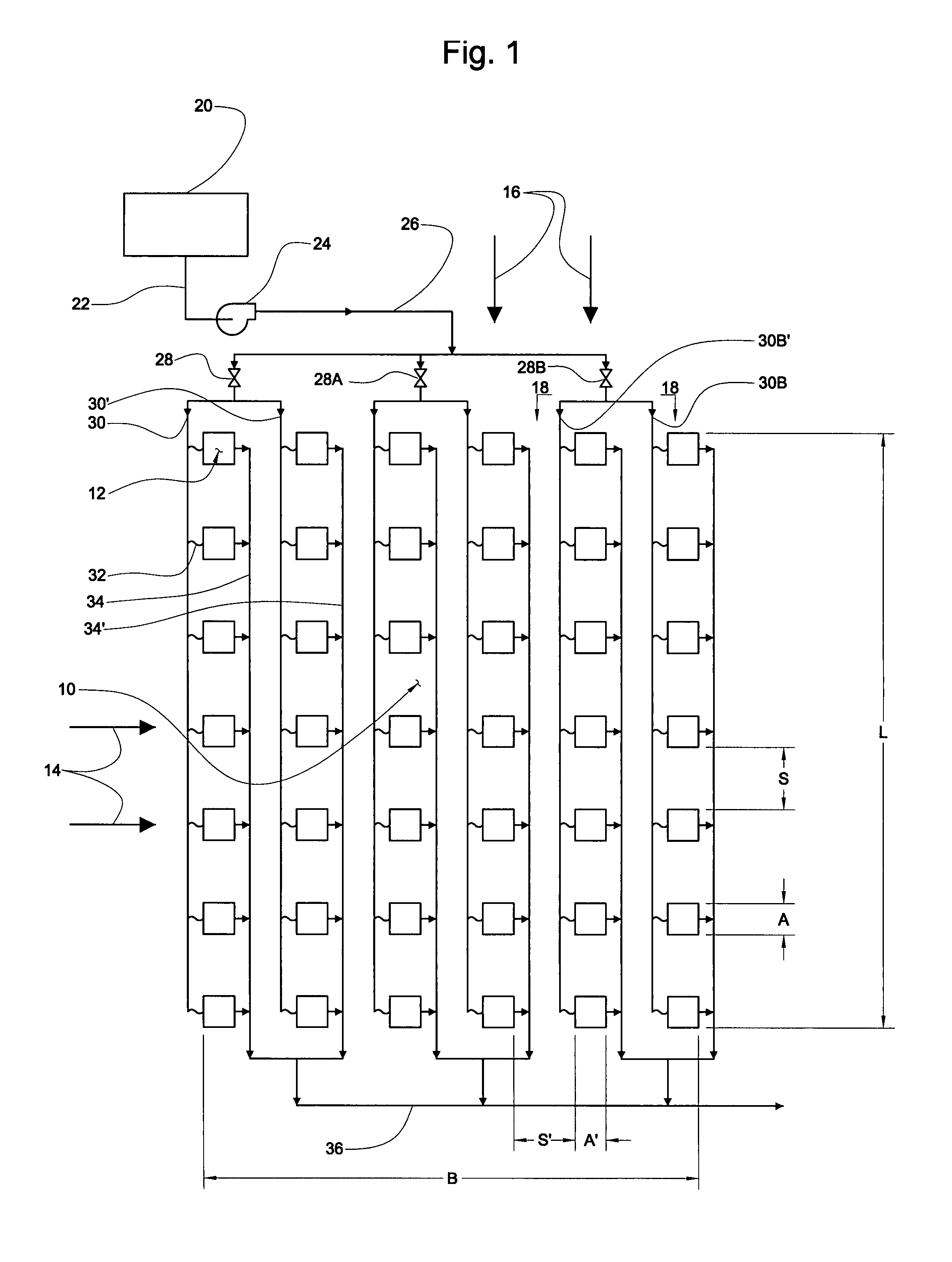

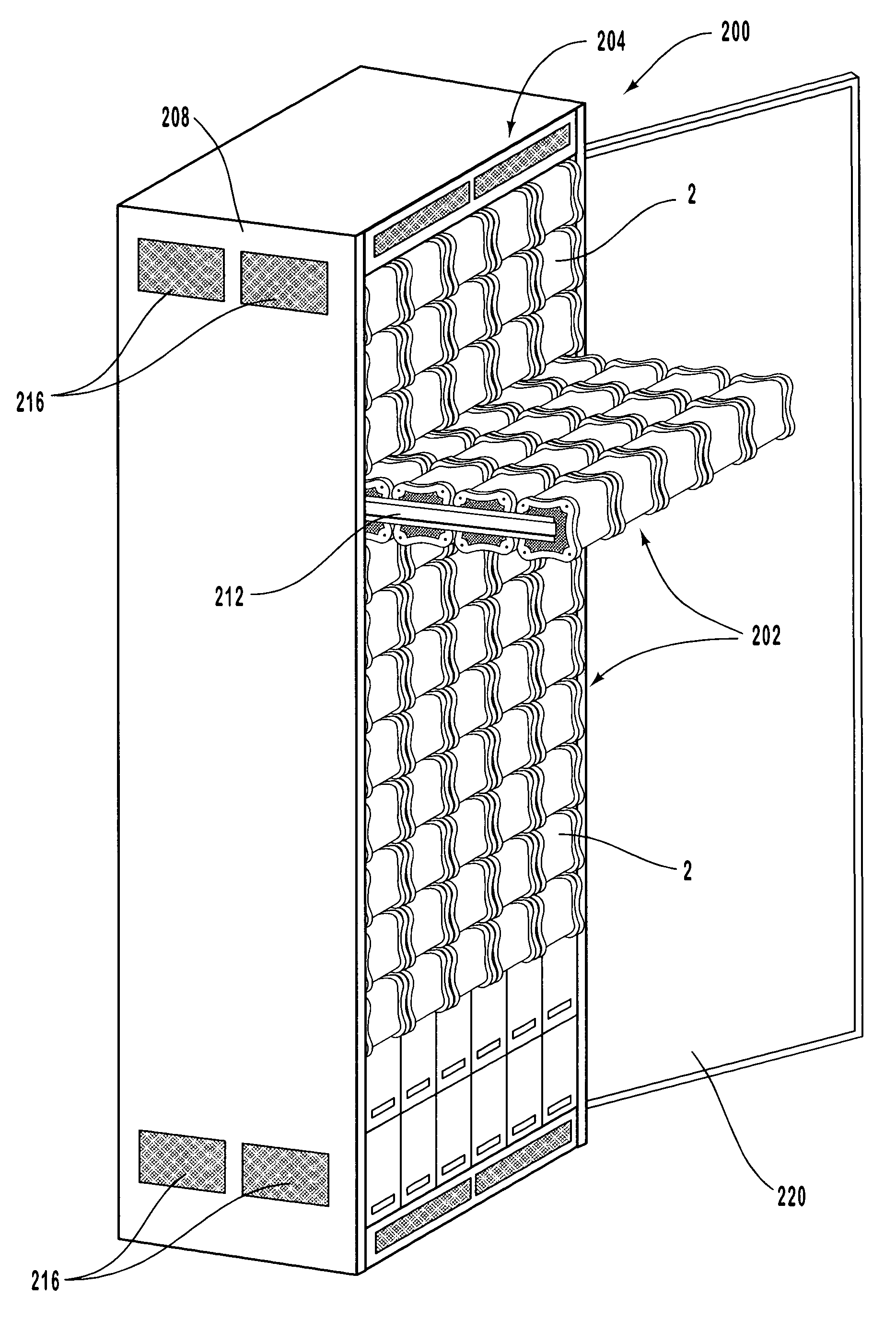

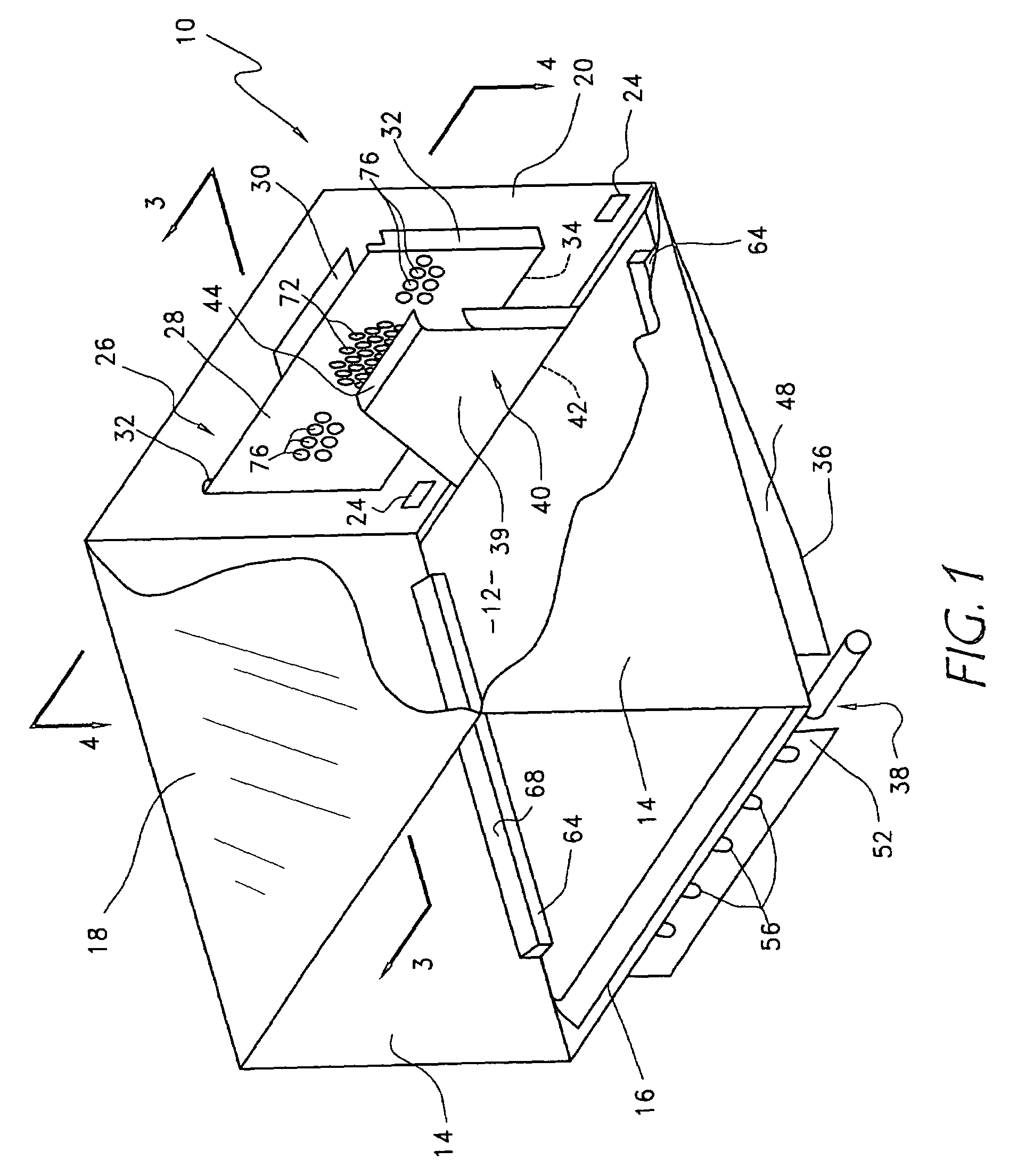

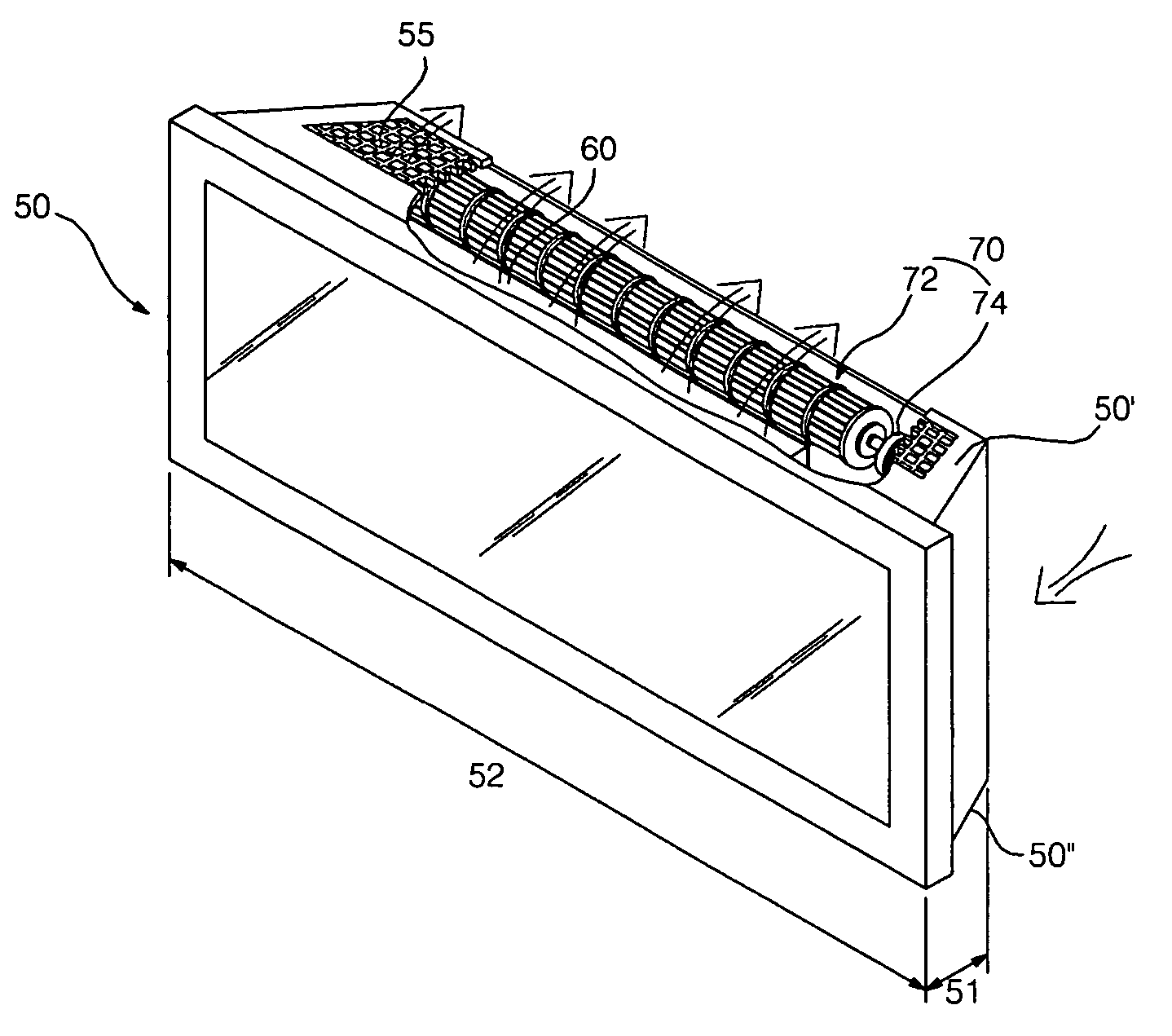

Method and apparatus for thermal management of computer memory modules

ActiveUS7738252B2Facilitate heat exchangeSpeed up the flowDigital data processing detailsSemiconductor/solid-state device detailsInterior spaceComputer module

Owner:KIOXIA CORP

Thermogenic Augmentation System

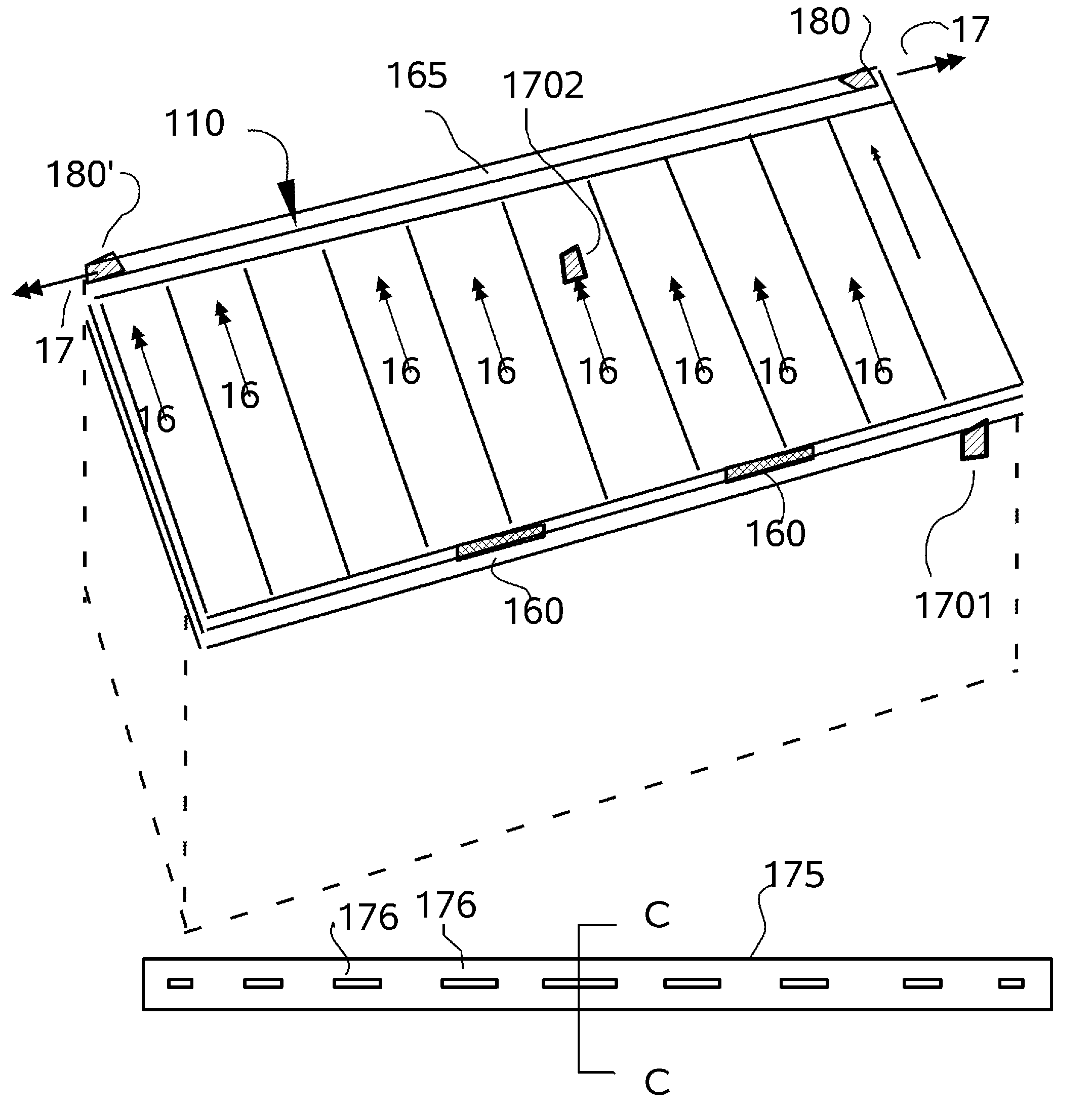

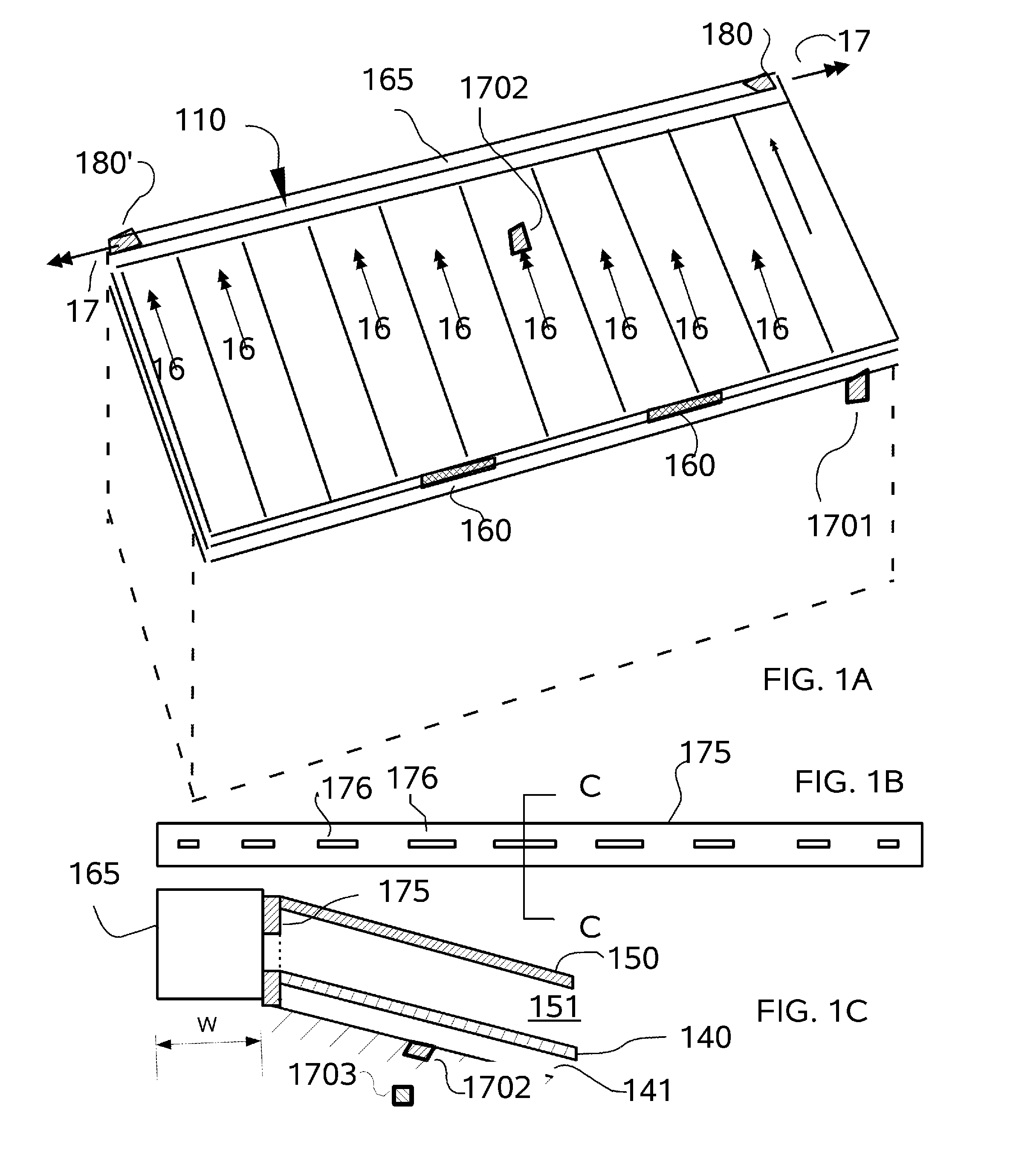

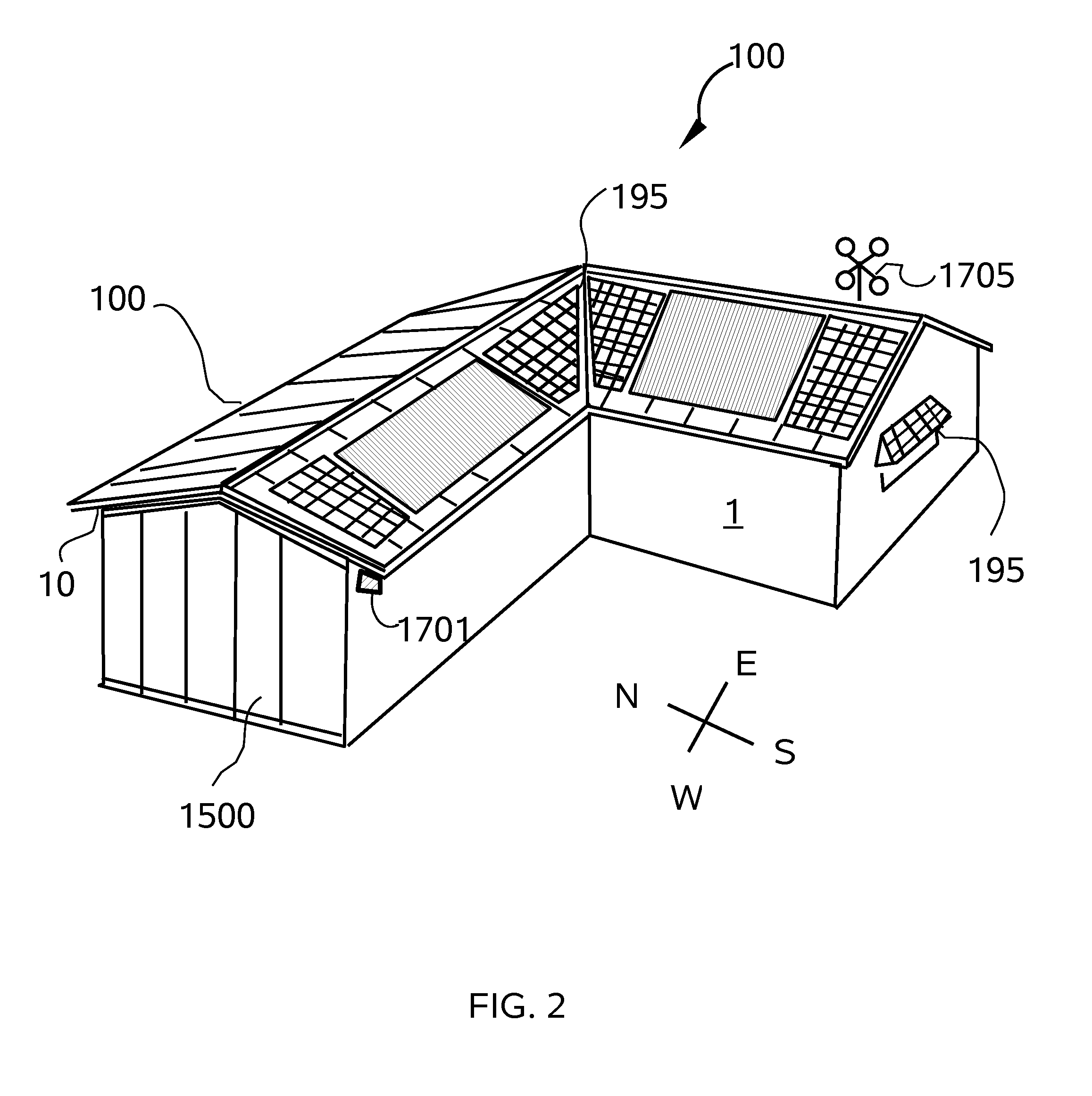

ActiveUS20120149291A1Reduce electricalReduce other power consumption/generationMechanical apparatusSpace heating and ventilation safety systemsNatural convectionRadiant barrier

A dual air cavity roof has a continuous upper cavity which is cooled by fans, while the lower cavity is generally sealed. Preferably the cavities are separated by a radiant barrier. The fans are preferably powered by one or more photovoltaic cells that are also disposed on the roof. The roof can be pre-cooled with cooler night air and fans only activated when necessary to remove heat from the solar load on the upper cavity. When it is desirable to remove heat, the fan speed is optimized in each zone of the roof to enhance the natural convective flow to the optimum level. A radiant barrier can also cover the roof substrate, which is optionally an existing roof that is in need of repair. The roof structure is preferably assembled in parallel modules using insulating support brackets that support the outer surface and the barrier that separates the upper and lower cavity.

Owner:RODERICK DAVID

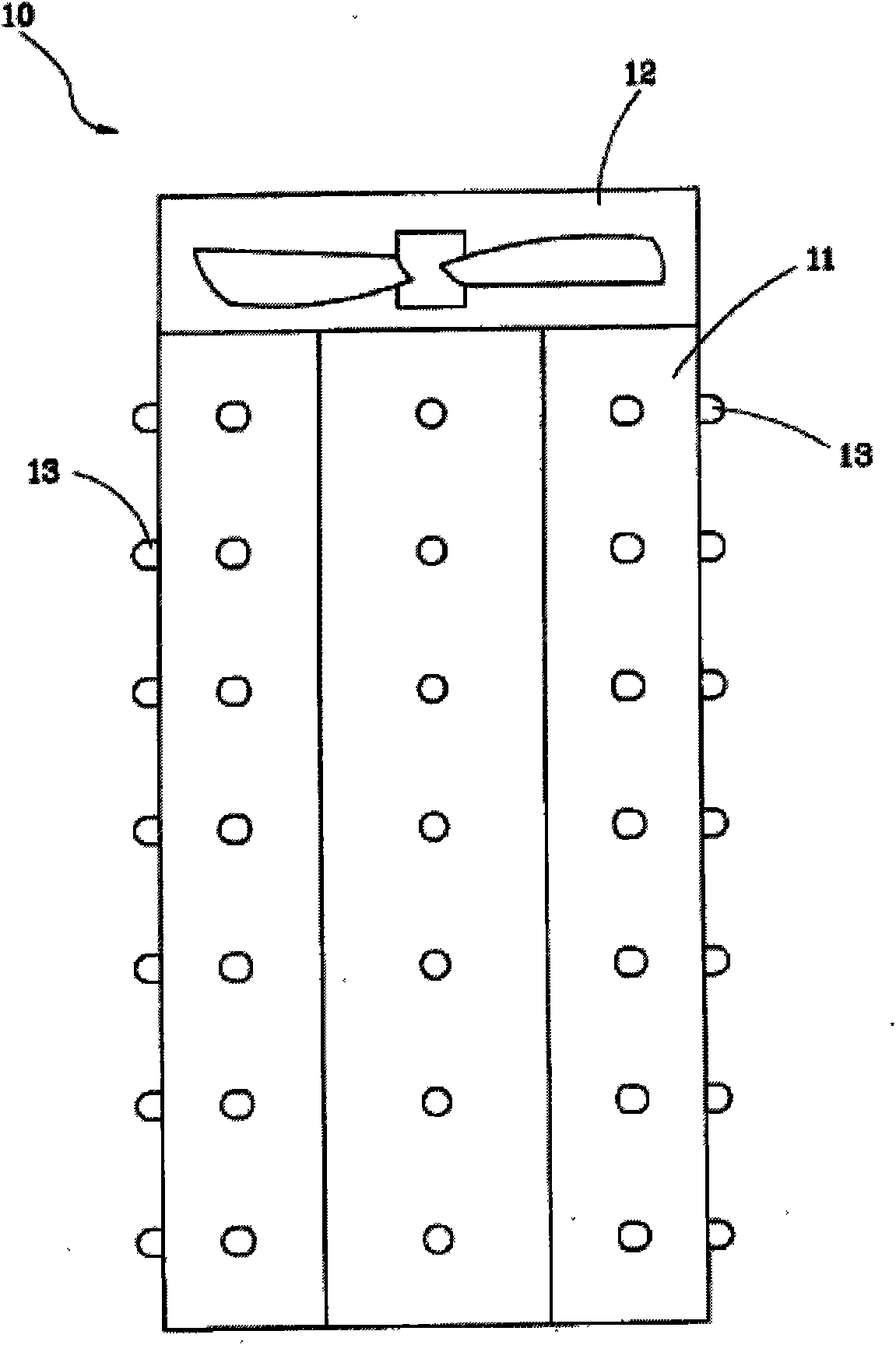

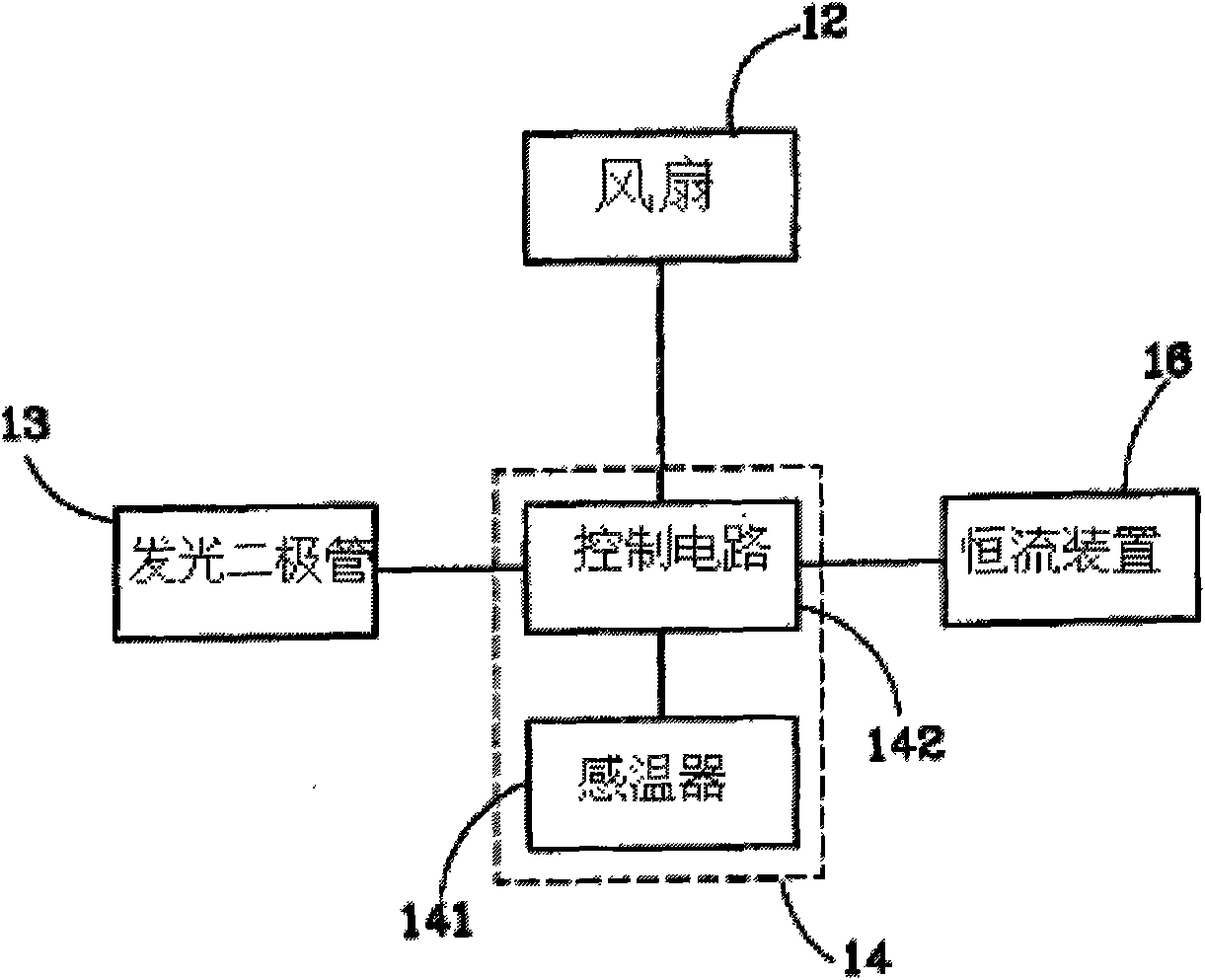

Light emitting diode lamp with radiating structure

InactiveCN101592328AImprove cooling effectKeep cooling functionPoint-like light sourceElongate light sourcesNatural convectionLight-emitting diode

The invention provides a light emitting diode lamp with a radiating structure. The lamp comprises a cylindrical radiator, a fan, at least one light emitting diode and a controller, wherein at least one air channel passing through the radiator along the vertical direction is arranged inside the radiator; the fan is arranged at the top end of the radiator and the air channel; the at least one light emitting diode is attached to the surface of the radiator; and the controller is electrically connected with the fan and the light emitting diode, controls the operation of the fan to lead air flow to move upwards, and controls the light emitting diode to radiate. The light emitting diode lamp has better radiating effect of natural convection, and still maintains the radiating function even when external heat is transferred to the light emitting diode lamp.

Owner:星准有限公司

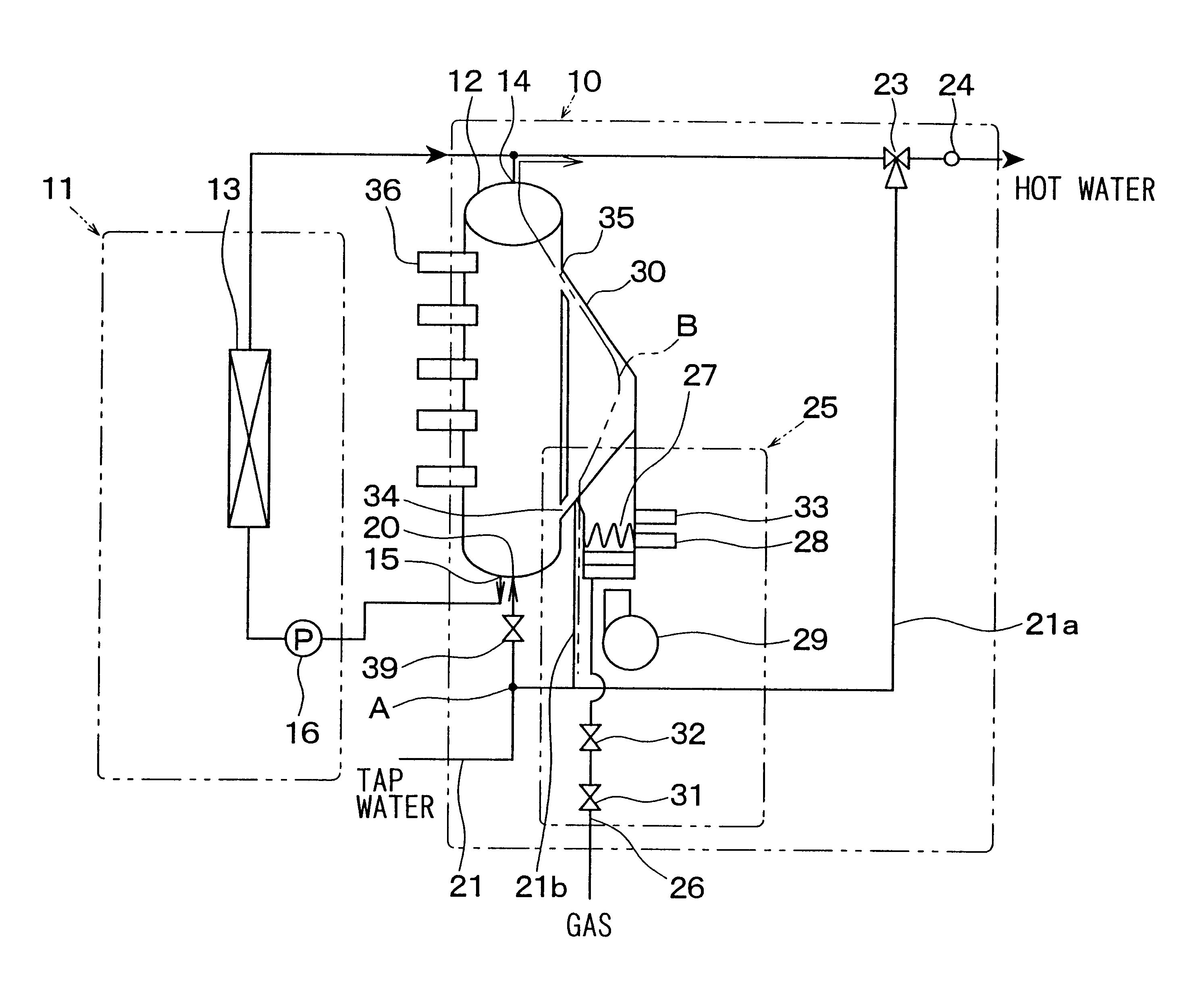

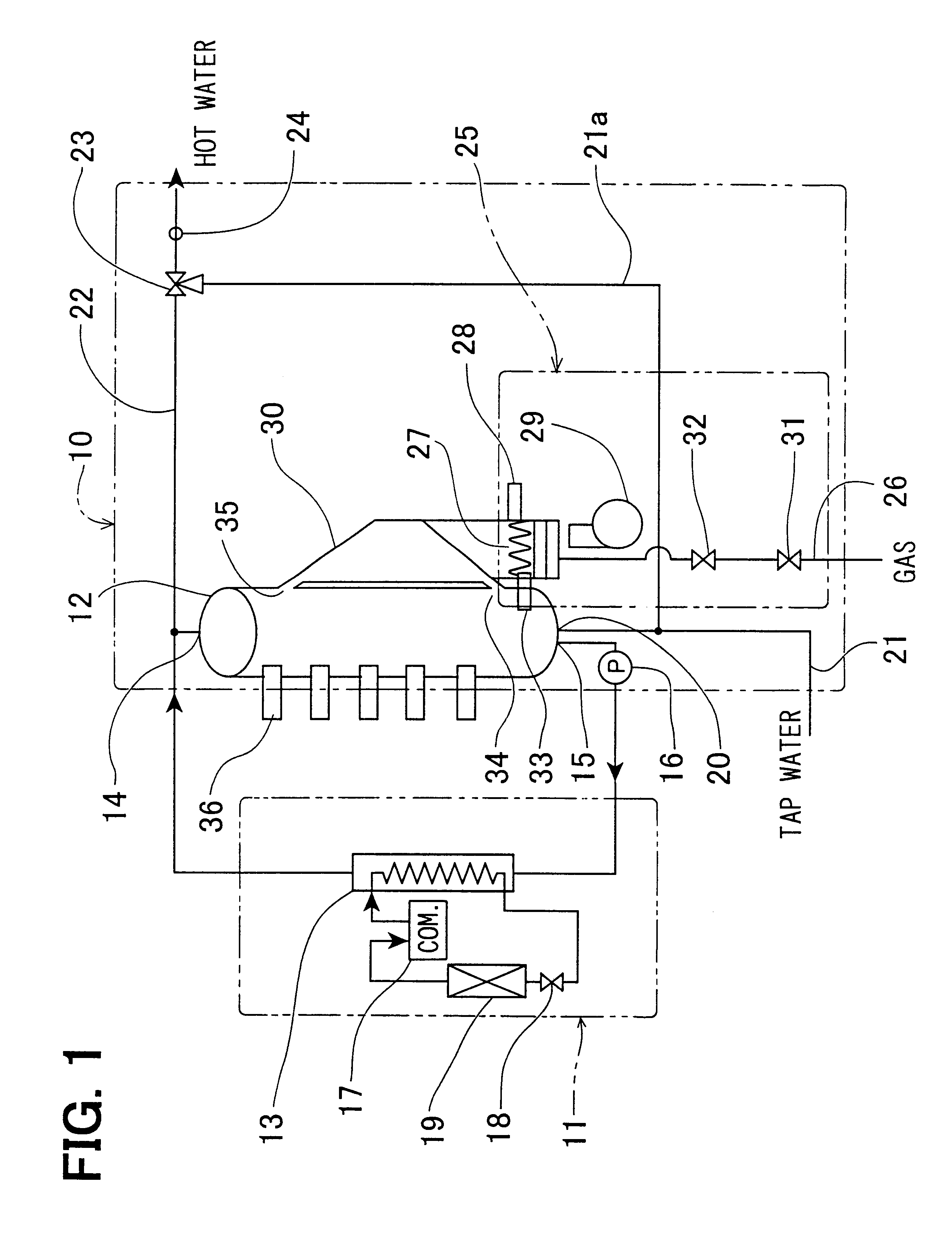

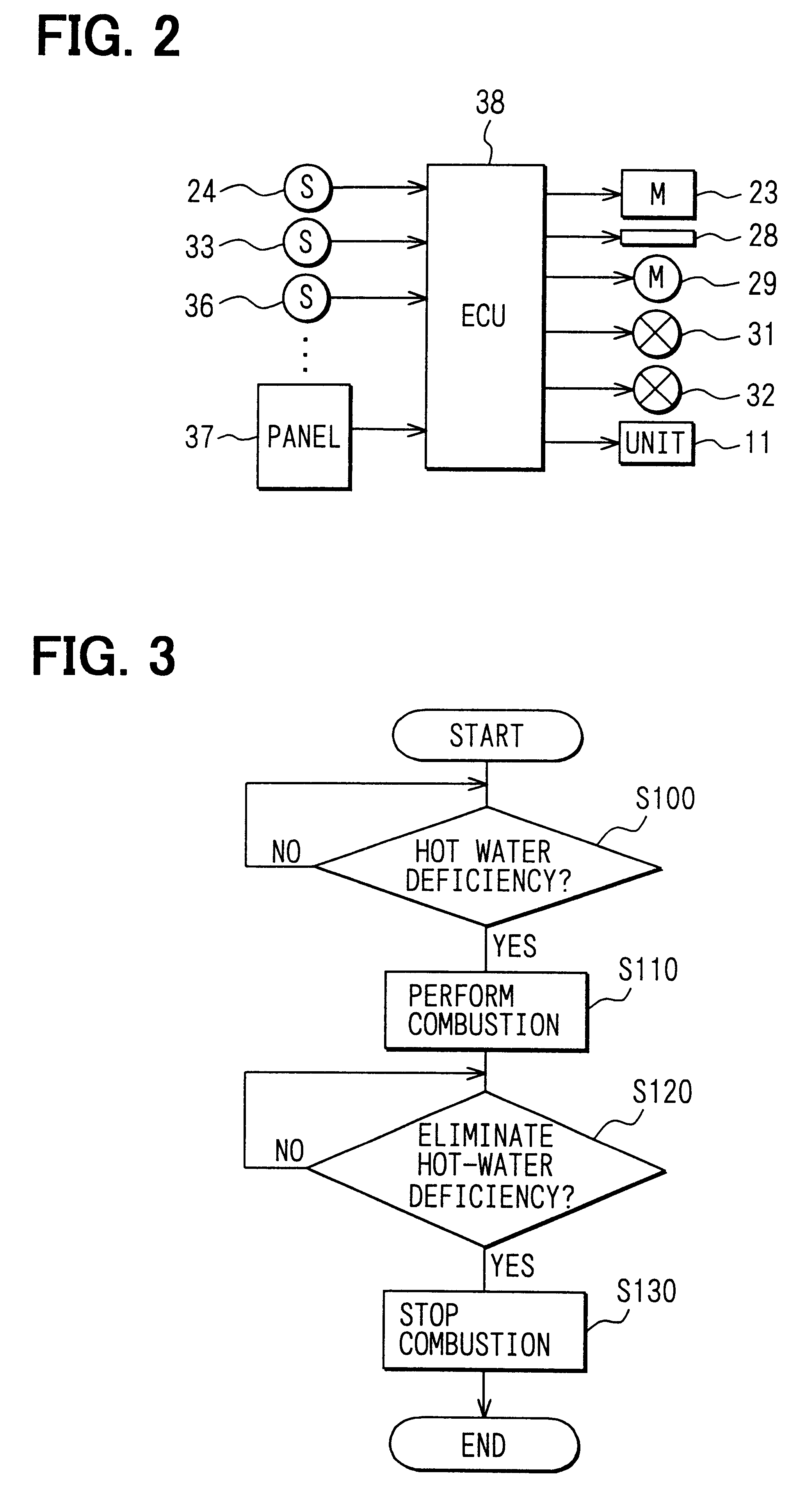

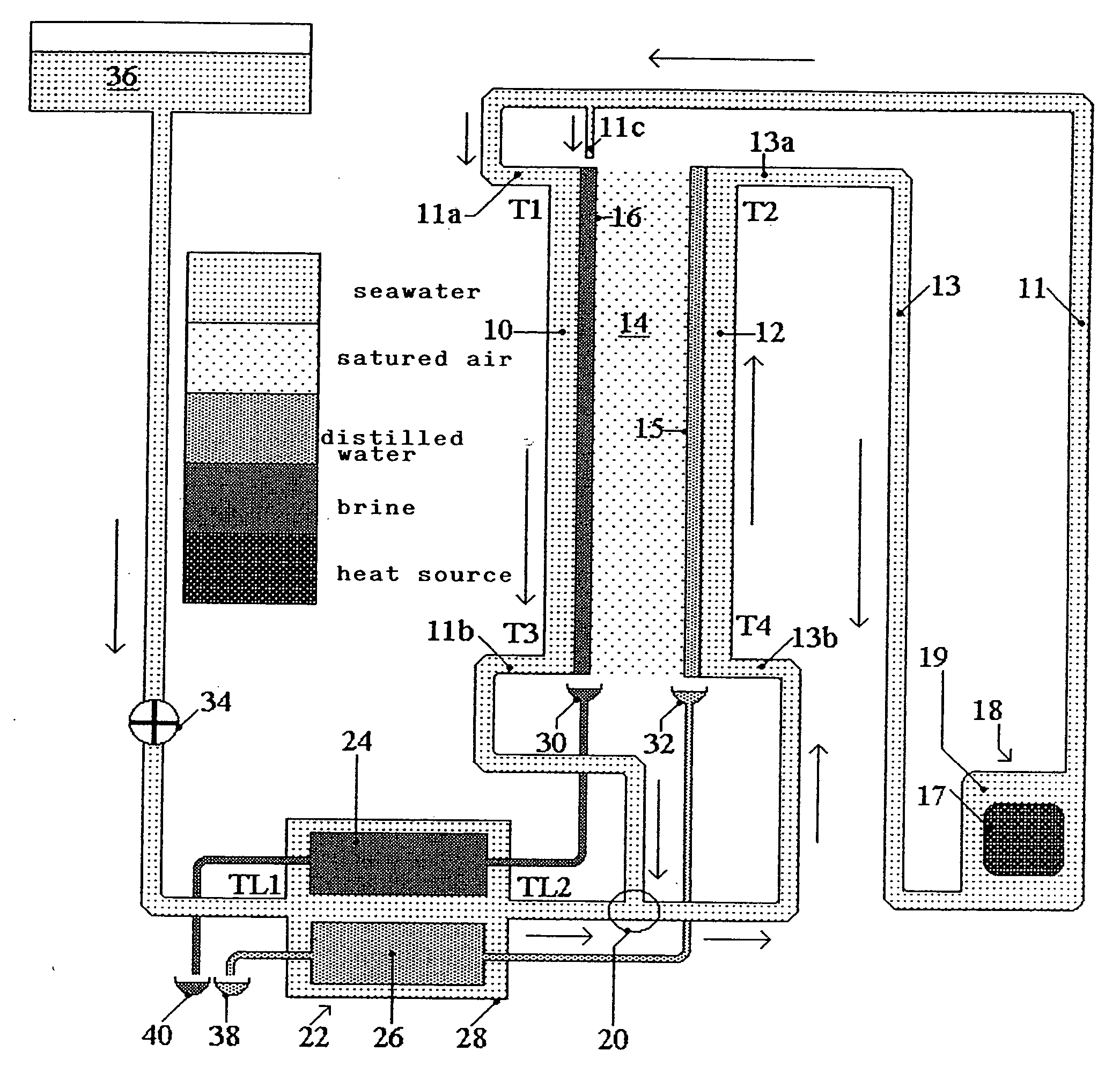

Hybrid water heater with electrical heating unit and combustor

InactiveUS6640047B2Simple system structureEasy to useHeating fuelDomestic stoves or rangesCombustorNatural convection

In a hybrid water heater, a heat pump unit and a combustion heating unit are combined for heating water to be stored in a hot water tank. The combustion heating unit includes a combustor for heating water in a chamber by combustion operation. The chamber of the combustion heating unit communicates with the hot water tank through a first water port provided at an upper side of the hot water tank and a second water port provided at a lower side of the hot water tank, so that hot water heated in the chamber flows into the upper side in the hot water tank through the first water port, by using natural convection. Further, water in the hot water tank at the lower side flows from the second water port into the chamber.

Owner:DENSO CORP

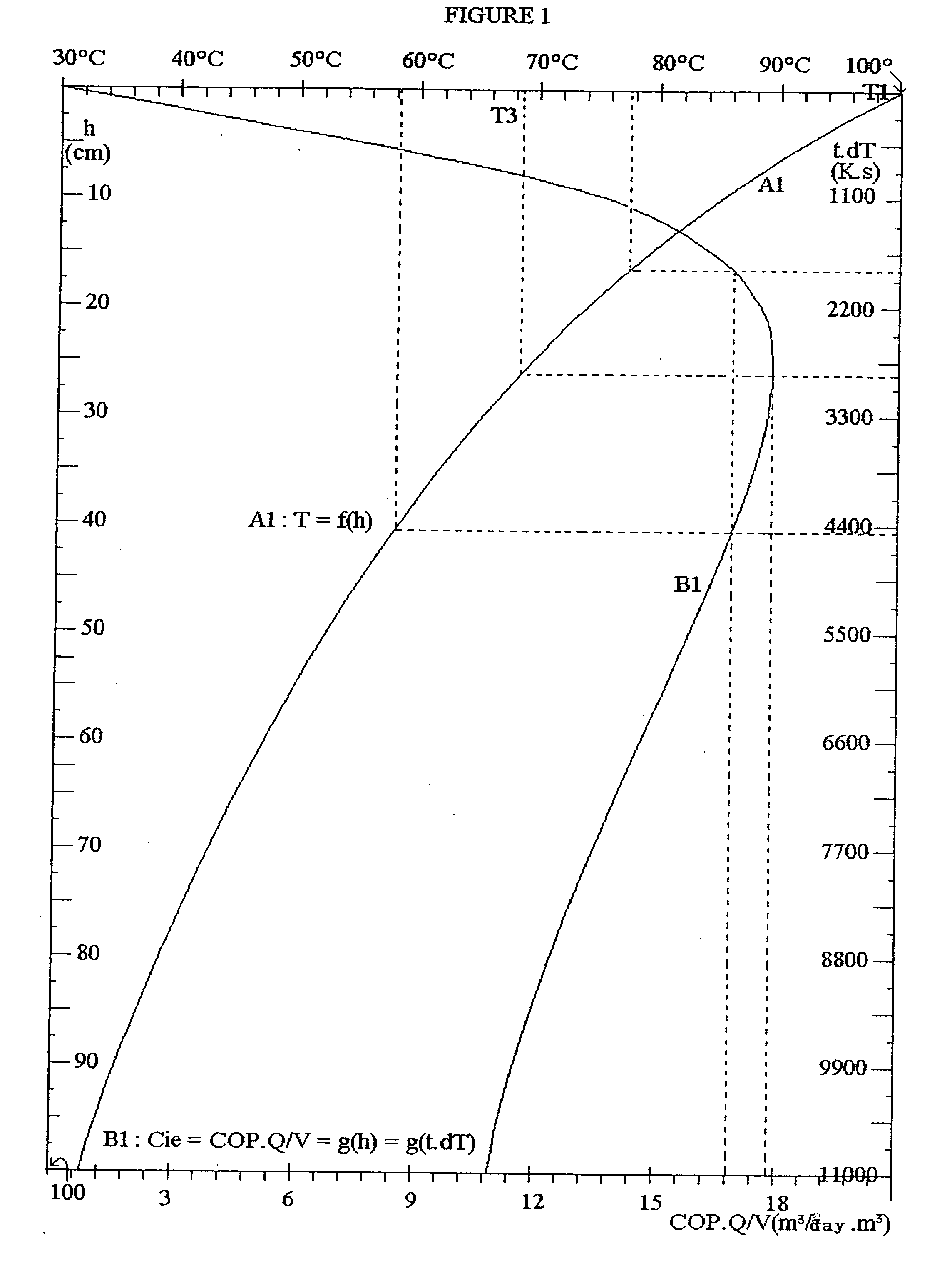

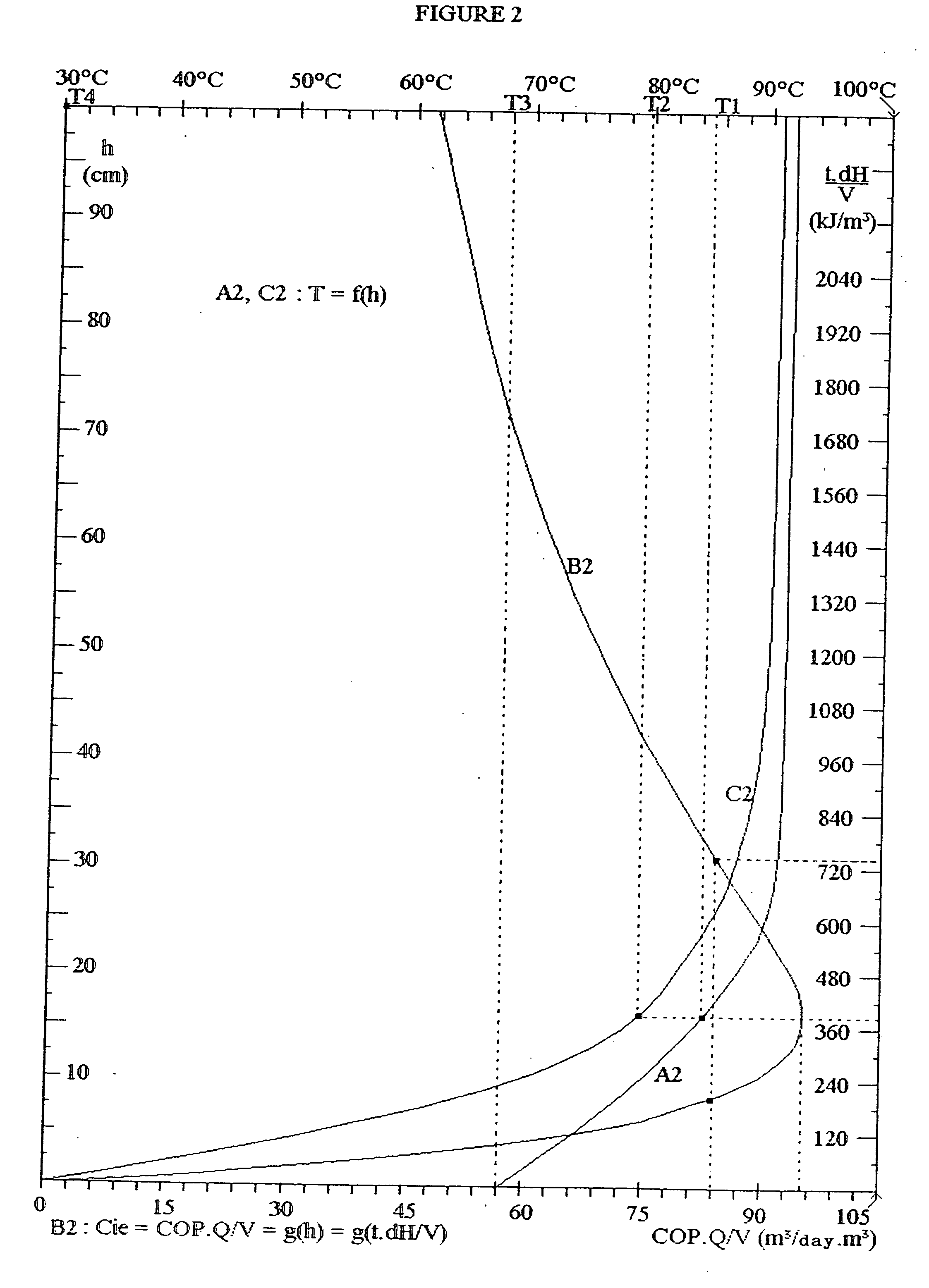

Distillation methods and devices in particular for producing potable water

InactiveUS20060272933A1Improve efficiencyHigh densityGeneral water supply conservationAuxillariesEngineeringSeawater

The inventive device is embodied in the form of a chamber-oven for diffusing vapour and saturated hot air which circulate in a closed circuit by natural convection. Said device is embodied in the form of a domestic-use solar energy collecting device provided with a greenhouse whose surface is equal to 1 m2 and produces from 50 to 100 litres / day of distilled water. The device comprises a distillation unit arranged between two furnaces (59′, 79′) in a temperature-controlled container (48′). Said distillation unit comprises 100 flat thin hollow plates having a surface of 20 dm2 by face and an active volume of 200 dm3. The fine and tensioned walls (54) of said plates are provided with a hydrophilic coating (60′) and internal (56′) and inter-plate (58′) spaces. The lower chimney (59′) comprises a greenhouse (118′, 119′) whose bottom is embodied in the form of an impermeable black layer provided with a thin hydrophilic carpet on the rear part thereof. Saturated hot air at a temperature of 80° C. enters inside (56′) hollow plates from bellow and exits from the top at a temperature of 50° C. A high chimney (79′) is provided with a monoblock heat exchanger (84′) which is transversed by a non-potable water to be distilled which, afterwards is spread warm (40° C.) over the hydrophilic coating (60′). During passage through the heat exchanger (84) the air is cooled to 30° C. and moved down by gravity to the inter-plate spaces (58′) and exits therefrom at a temperature of 78° C. The distilled water condensed in the plates and by the heat exchanger is collected and removed. Brine is received in the bottom of the inter-plate space and distributed along the thin hydrophilic carpet of the bottom (122′) of the greenhouse. An air current passes along said hot carpet is heated and saturated and enters the plates. The brine liquor finally flows in an air-preheating tank (63′) which is emptied each morning. The greenhouse can be substituted by a heating tube transversed by a heating fluid or associated with another steam-jet tube. The more powerful chamber-ovens can produce at least 200 m3 / day of distilled water for collective consumption. Said invention can be used for salt removal from seawater, co-generating electricity and potable water and for producing food concentrates.

Owner:THE THIRD MILLENIUM WATER

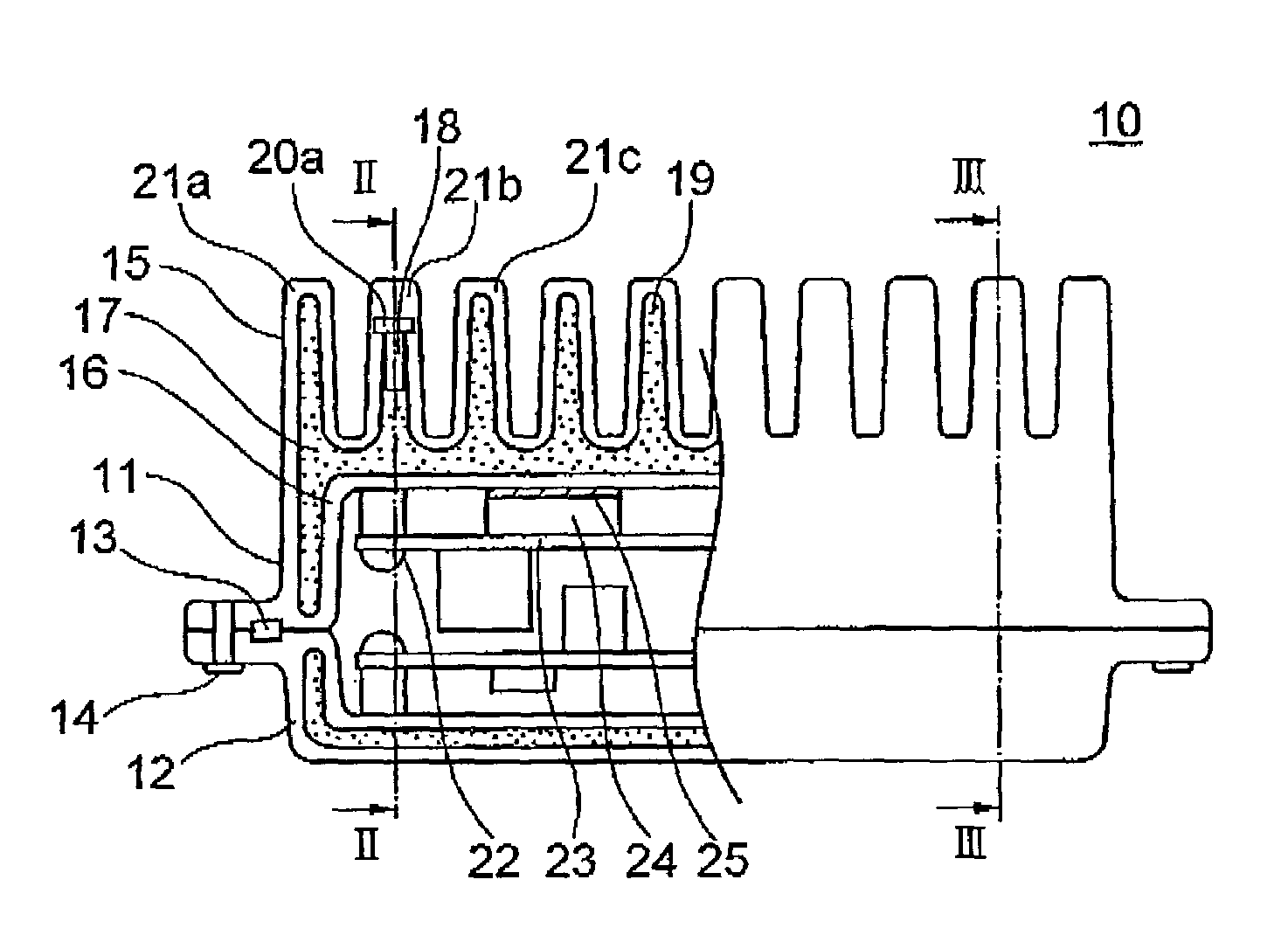

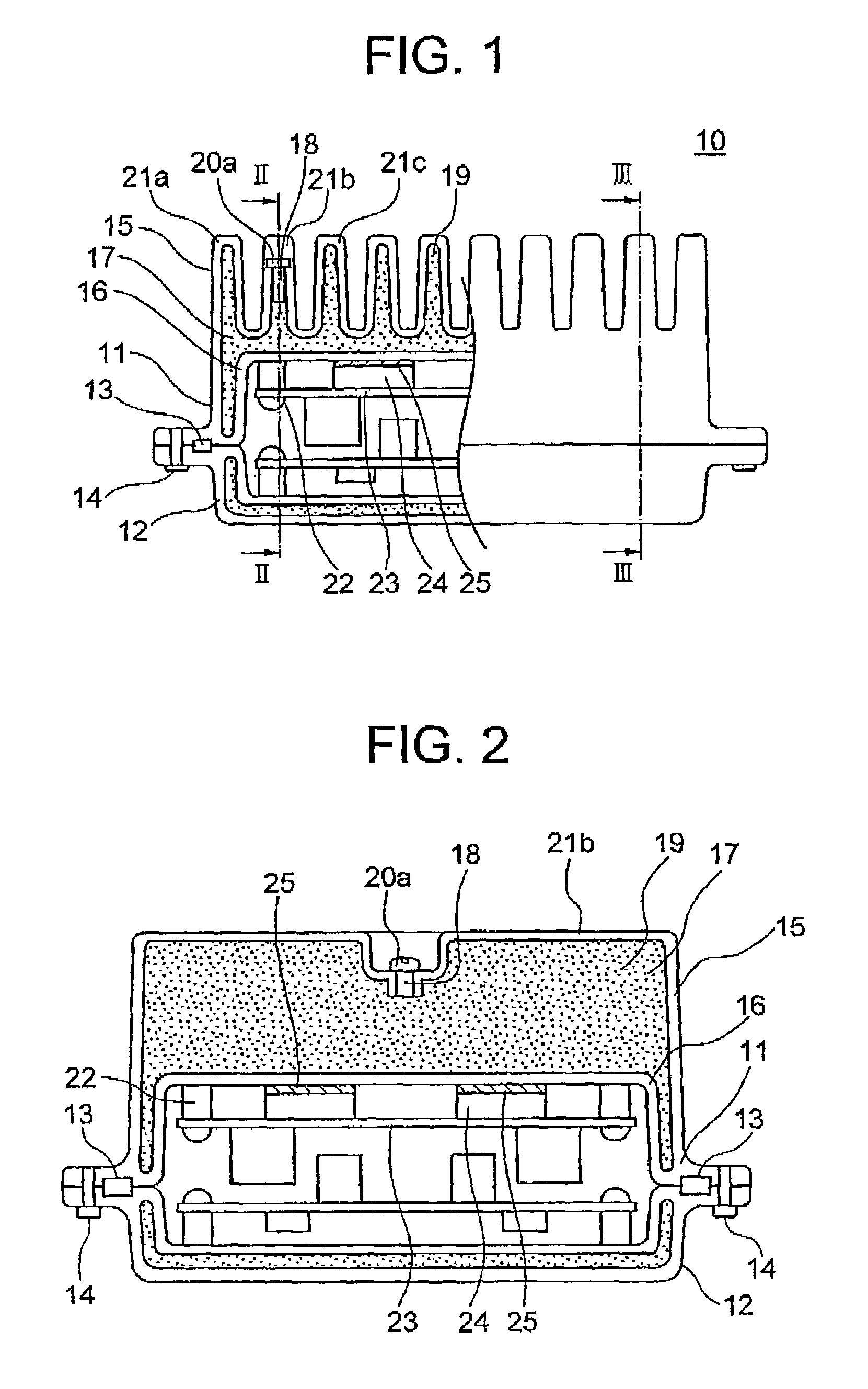

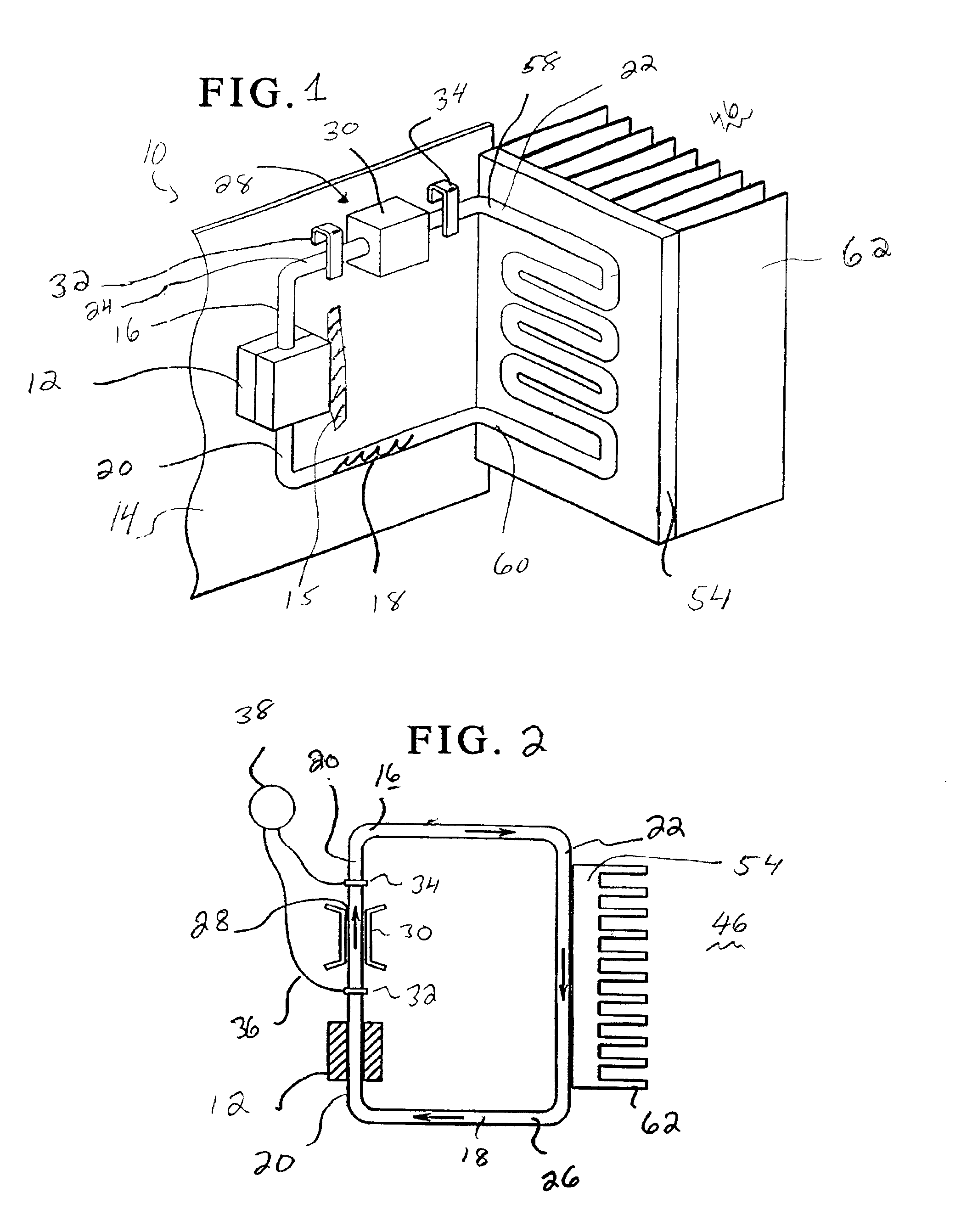

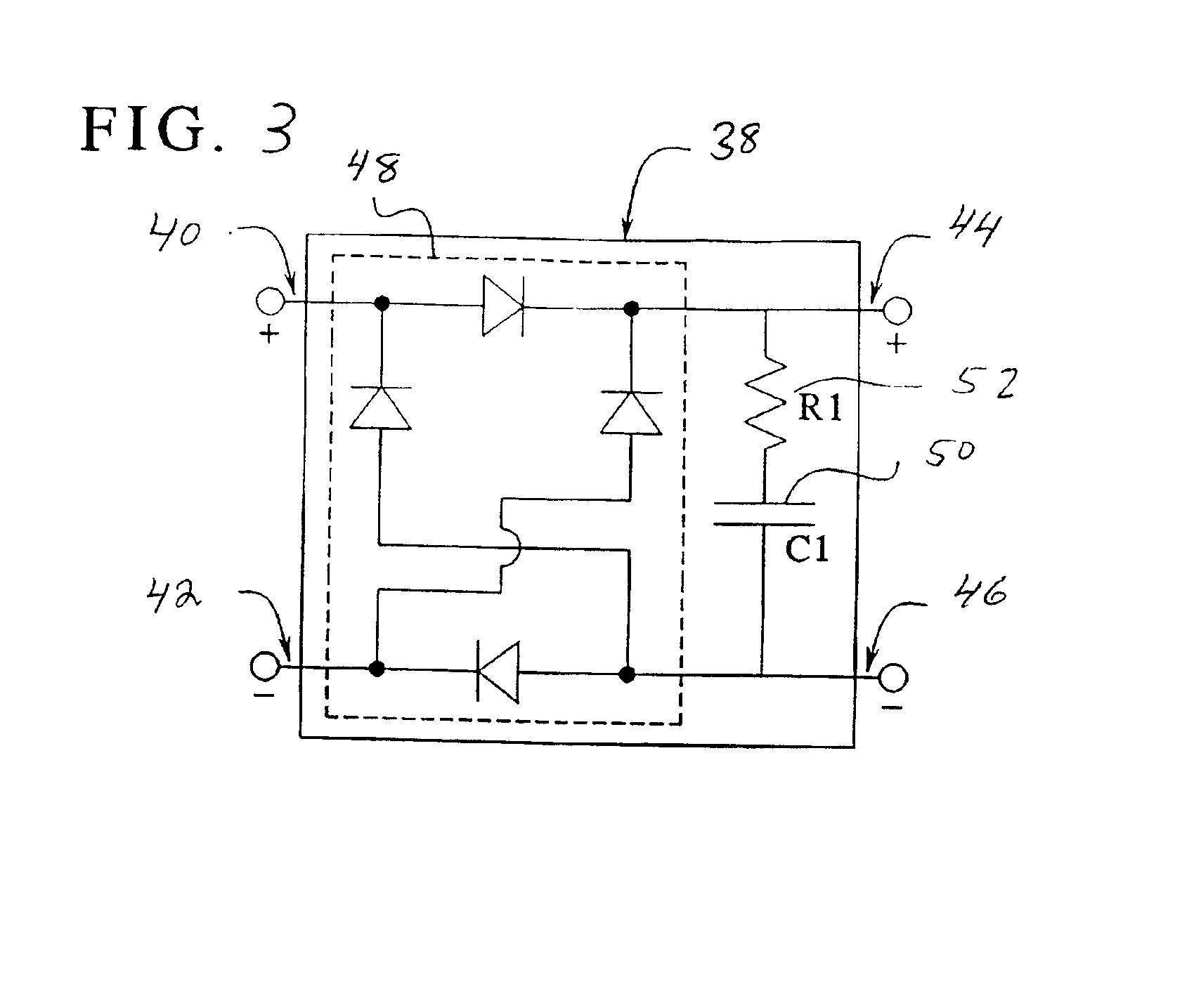

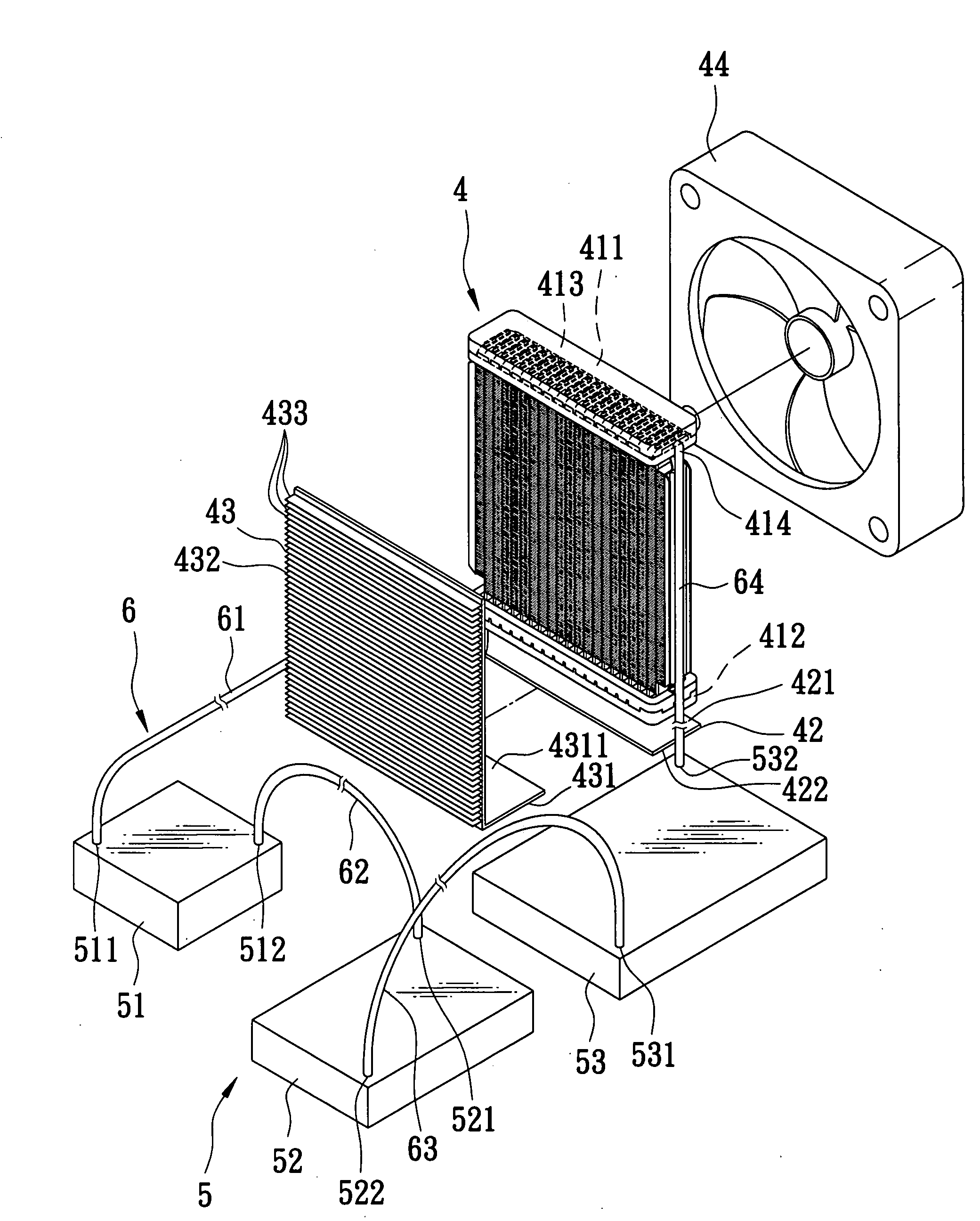

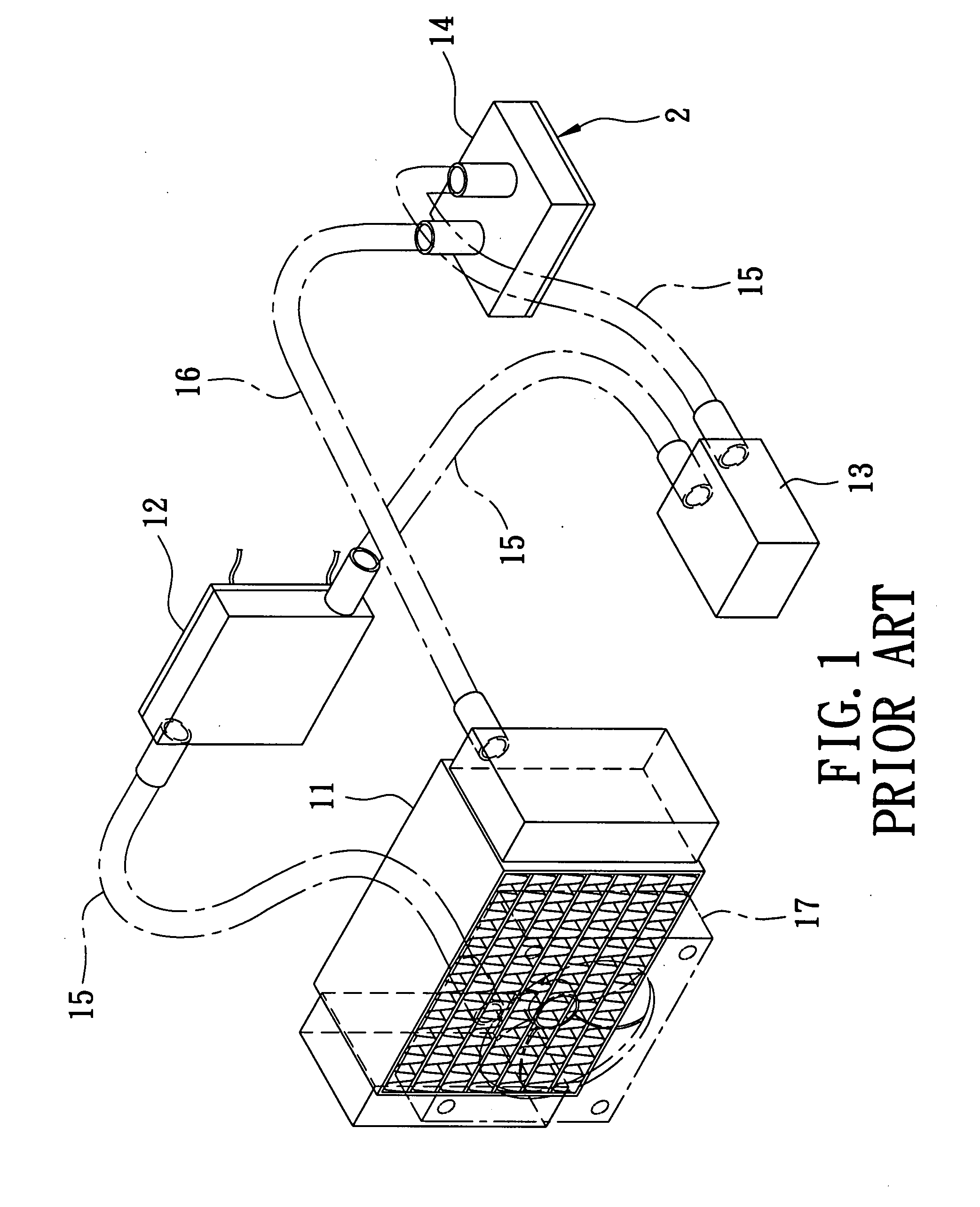

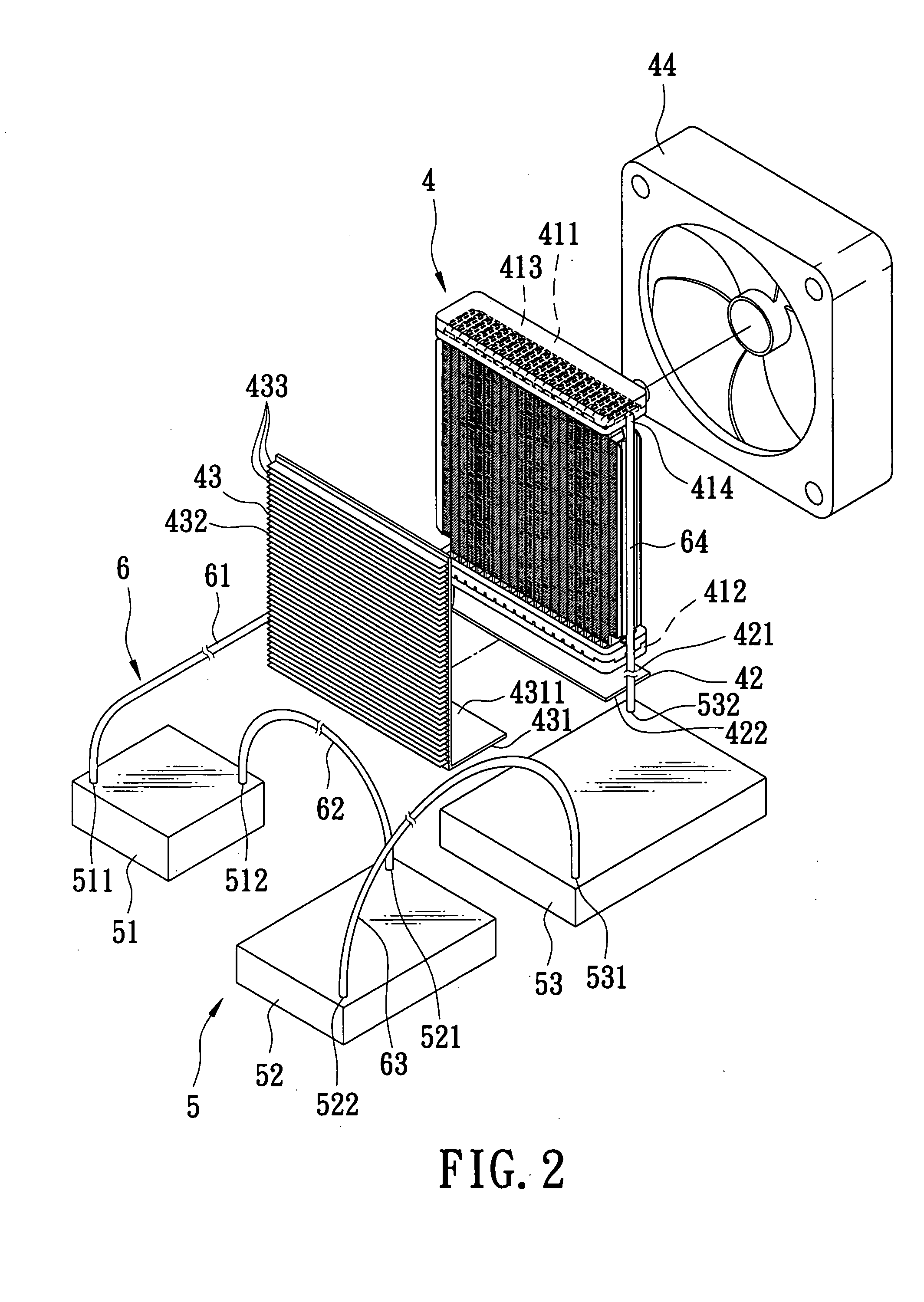

Heat dissipating system and method

InactiveUS20080078202A1Reduce noiseImprove cooling effectThermoelectric device with peltier/seeback effectDigital data processing detailsWorking fluidNatural convection

A heat dissipating system includes: a heat-absorbing unit having at least one cavity body adapted to contact a heat source, and a working fluid received in the cavity body; a condenser to condense the working fluid; and a tubing unit connected fluidly to the condenser and the heat-absorbing unit. The working fluid flows through the tubing unit to circulate from the condenser to the heat-absorbing unit by gravity and from the heat-absorbing unit to the condenser by natural convection. The tubing unit forms a closed circulating loop with the heat-absorbing unit and the condenser.

Owner:LUO CHIN KUANG

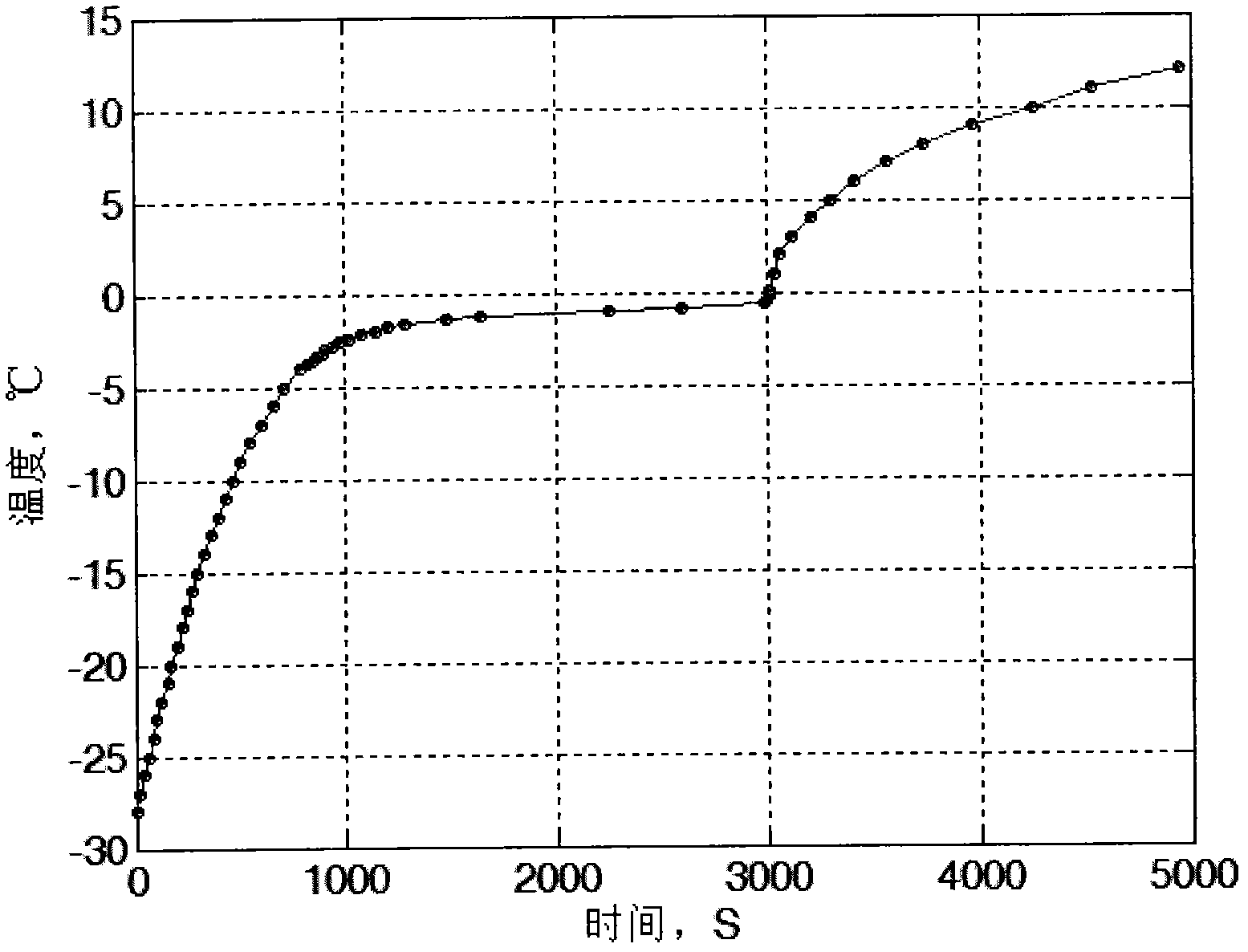

Method for testing content of unfrozen water in frozen earth

The invention provides a method for testing content of unfrozen water in frozen earth. The method is mainly applied to the testing on the content of unfrozen water in natural frozen earth and artificial frozen earth. The method comprises the steps of firstly processing the tested soil sample obtained in place according to the specified specification; subsequently freezing the tested soil sample to the low-temperature range of -30 to -15 DEG C; subsequently heating and melting the tested soil sample by natural convection under the room temperature air condition of 20 to 35 DEG C; recording thechange of the central temperature of the sample with the time; establishing a calculation model reflecting the temperature change process of the frozen earth according to a Newton cooling law; analyzing the convection heat transmission coefficient between air and soil; determining phase change time and phase change temperature so as to further calculate the content of unfrozen water under the frozen state; and finally calculating the characteristic curve of unfrozen water content during the melting process according to the test results. The method is simple and feasible and the testing resultis exact and reliable.

Owner:刘波 +1

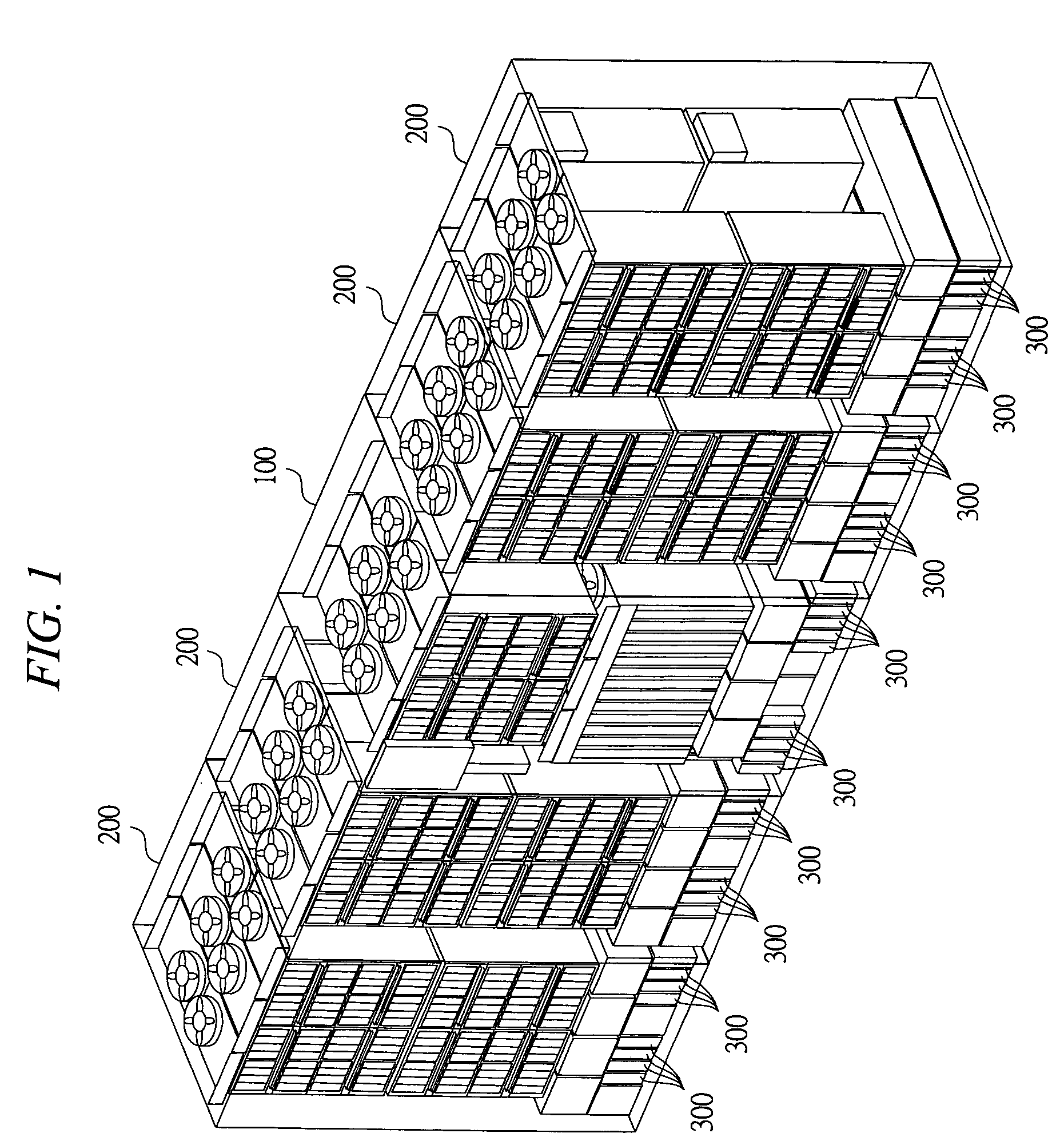

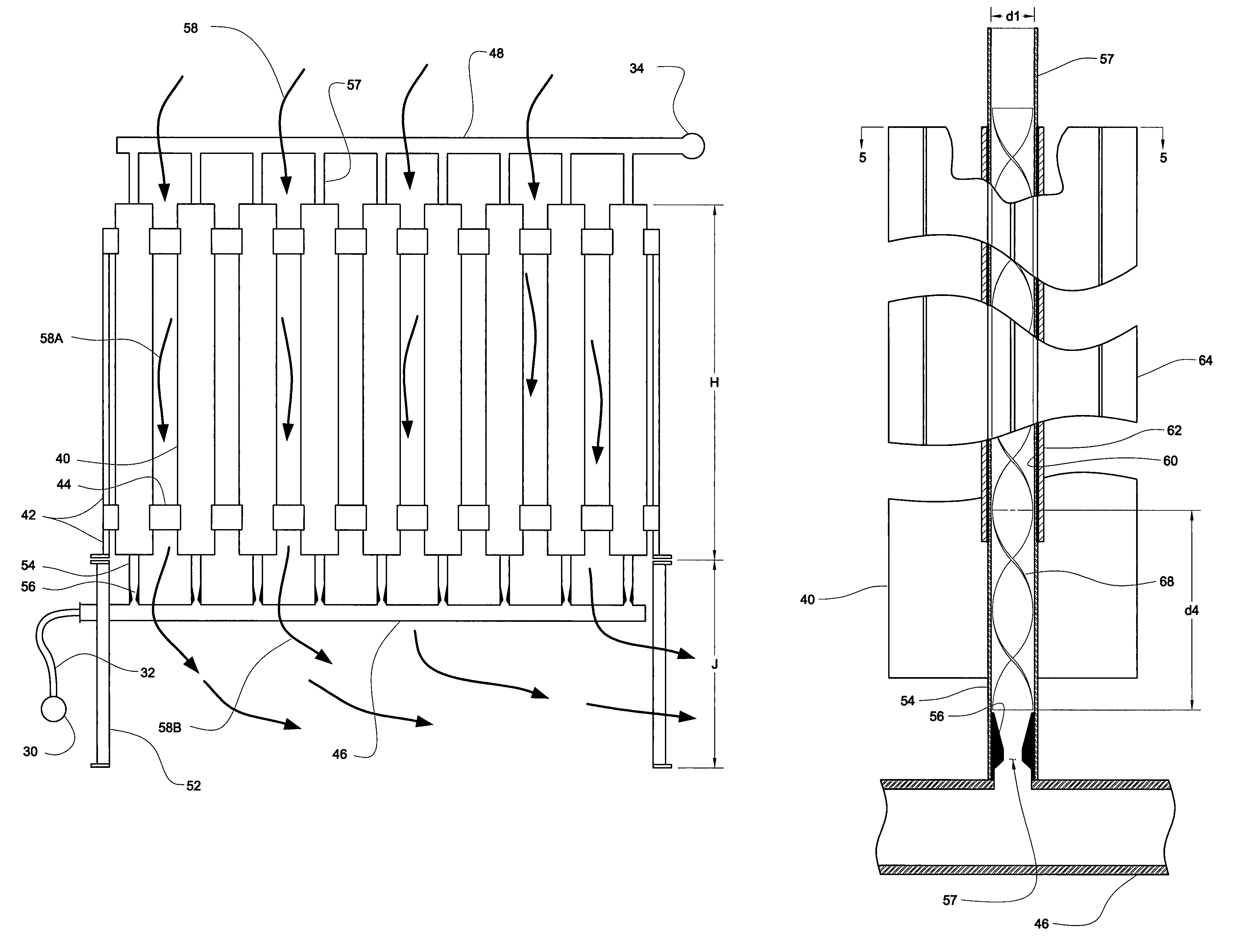

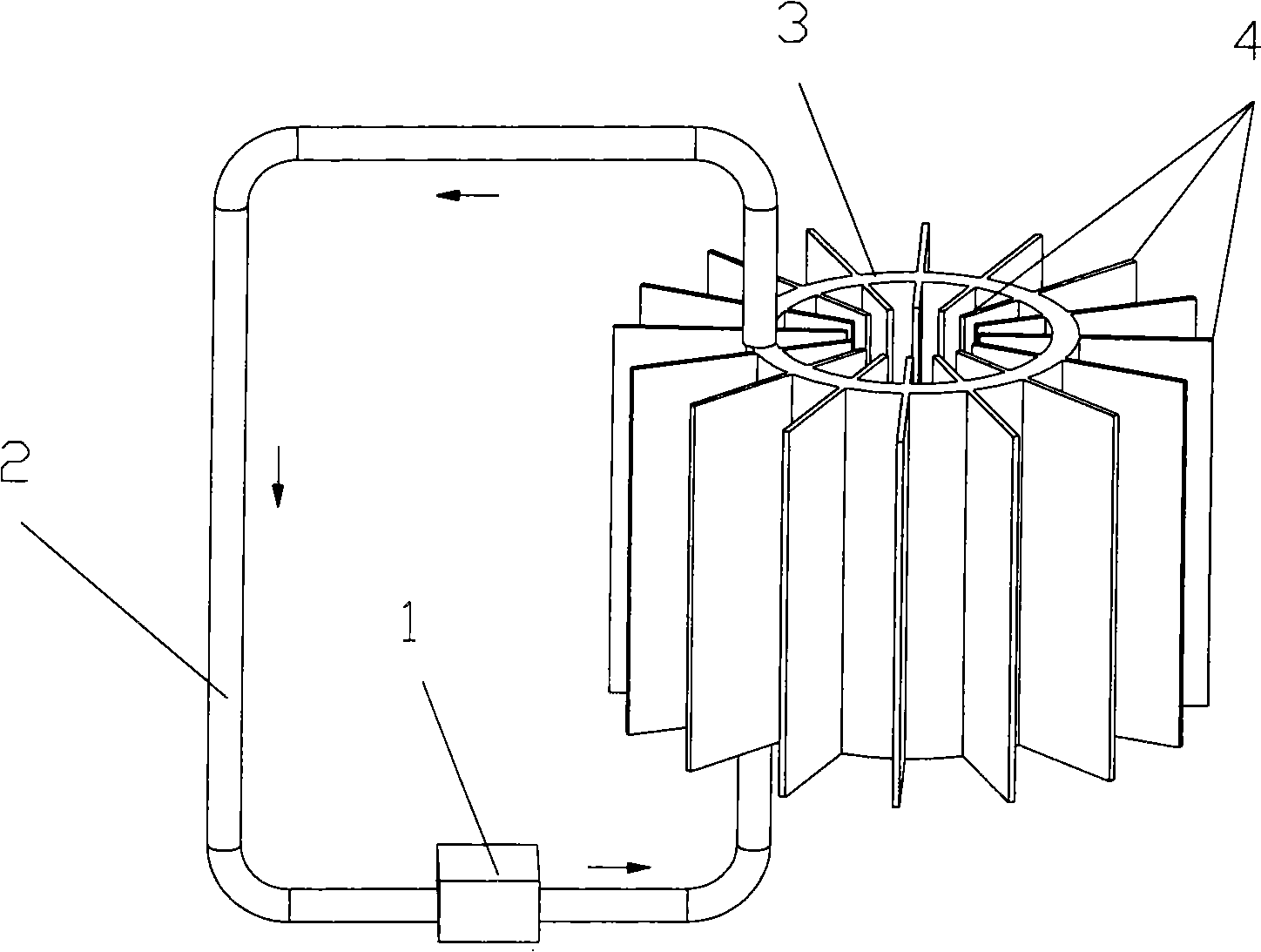

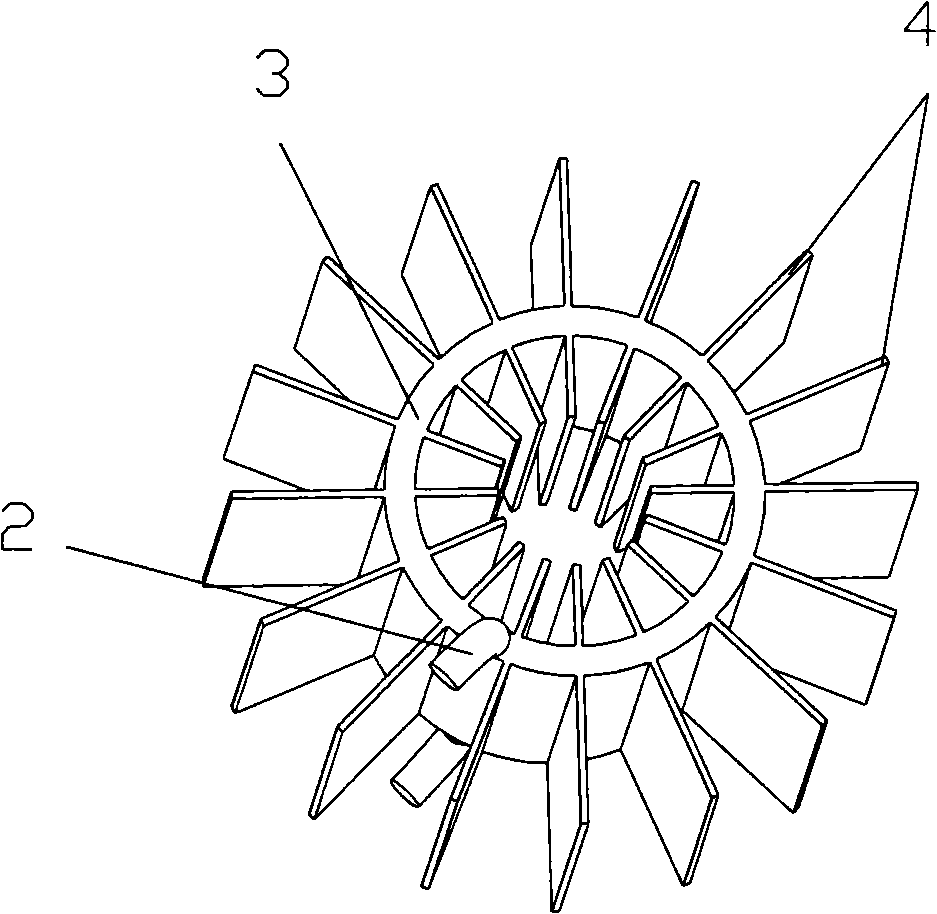

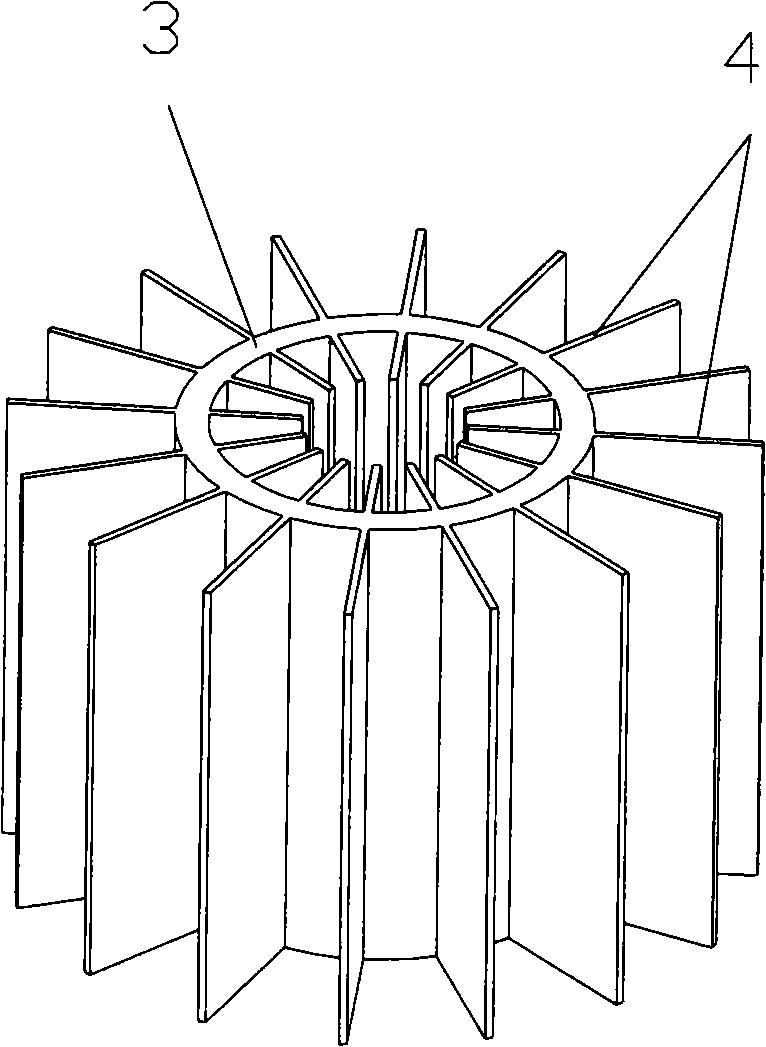

Heat transfer in the liquefied gas regasification process

ActiveUS8069678B1Enhanced internal heat transferIncrease airflowGas handling/storage effectsStationary conduit assembliesAtmospheric airNatural convection

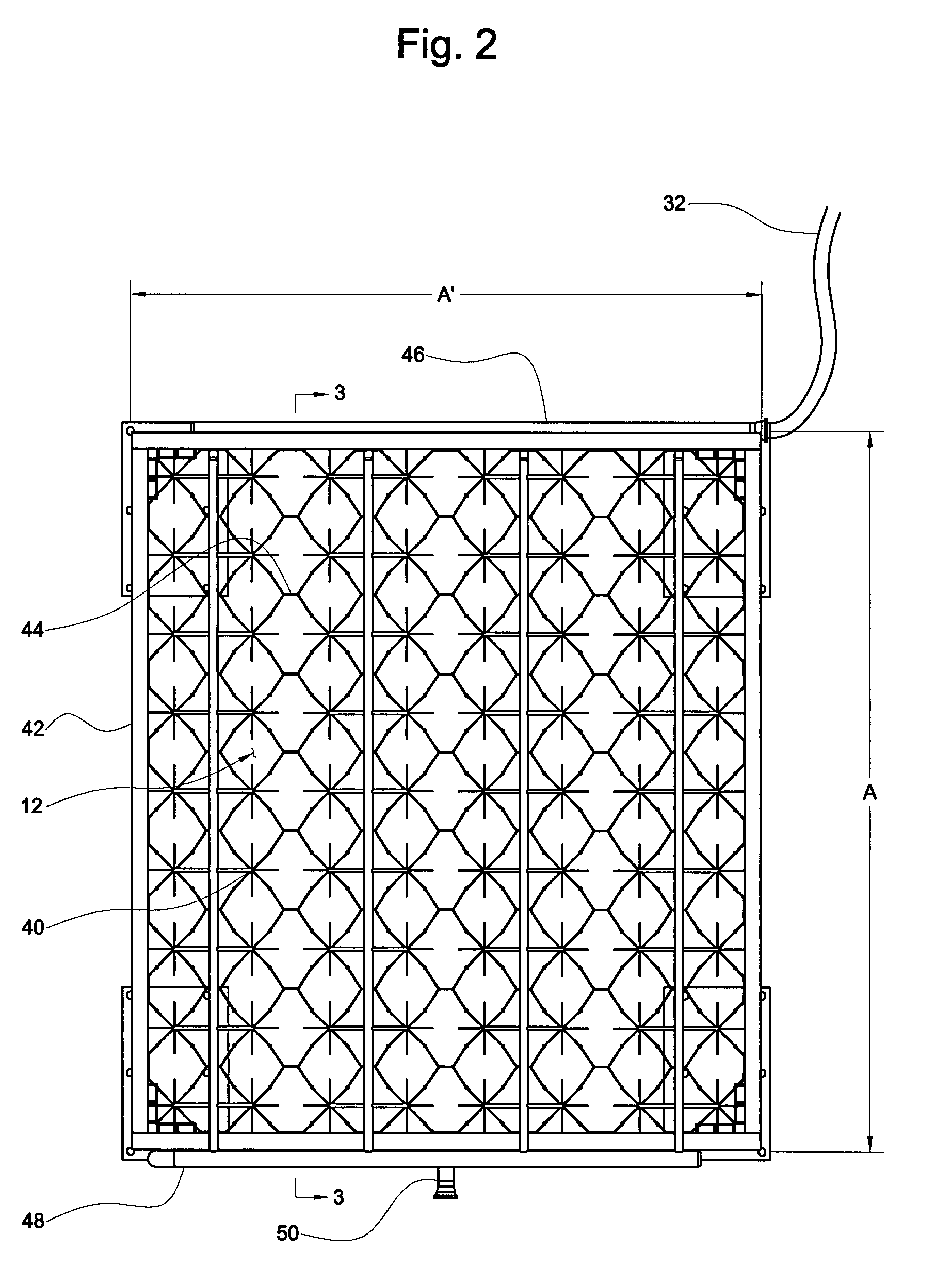

A system and apparatus for regasifying liquefied natural gas (LNG) and other cryogenic liquids on a continuous basis utilizing improved atmospheric air vaporizer heat exchangers of the vertical single pass and parallel connected type. A multiplicity of such heat exchangers is positioned on a defined grid, such as to improve the natural convection of the ambient air heat source. An improved heat exchange system includes heat exchange elements within the heat exchangers comprised of hybrid externally finned elements, smooth interior stainless steel tubes thermally bonded within the externally finned elements, the tubes containing vortex generators. Flow distributors in the form of venturi shaped injectors are positioned at the inlet of each tube of the multiplicity of heat exchangers of the system.

Owner:U S BANK TRUST CO NAT ASSOC ASTHE NOTES COLLATERAL AGENT

Non-peripherals processing control module having improved heat dissipating properties

ActiveUS7256991B2Improve computing powerReliable constructionDigital computersDigital data processing detailsThermoelectric coolingComputer module

The present invention features a non-peripherals-based processing control unit having an encasement module that is very small and durable compared to conventional computer encasement structures. The process control unit is capable of being incorporated into various devices and / or environments, of accepting applied and impact loads, of functioning as a load bearing structure, as well as being able to be processed coupled together with one or more processing control units to provide scaled processing power. The processing control unit of the present invention further features a unique method of cooling using natural convection, as well as utilizing known cooling means, such as liquid or thermoelectric cooling.

Owner:ATD VENTURES

Passive Thermal Management System

InactiveUS20090014154A1Heat dissipationLighting heating/cooling arrangementsIndirect heat exchangersNatural convectionEngineering

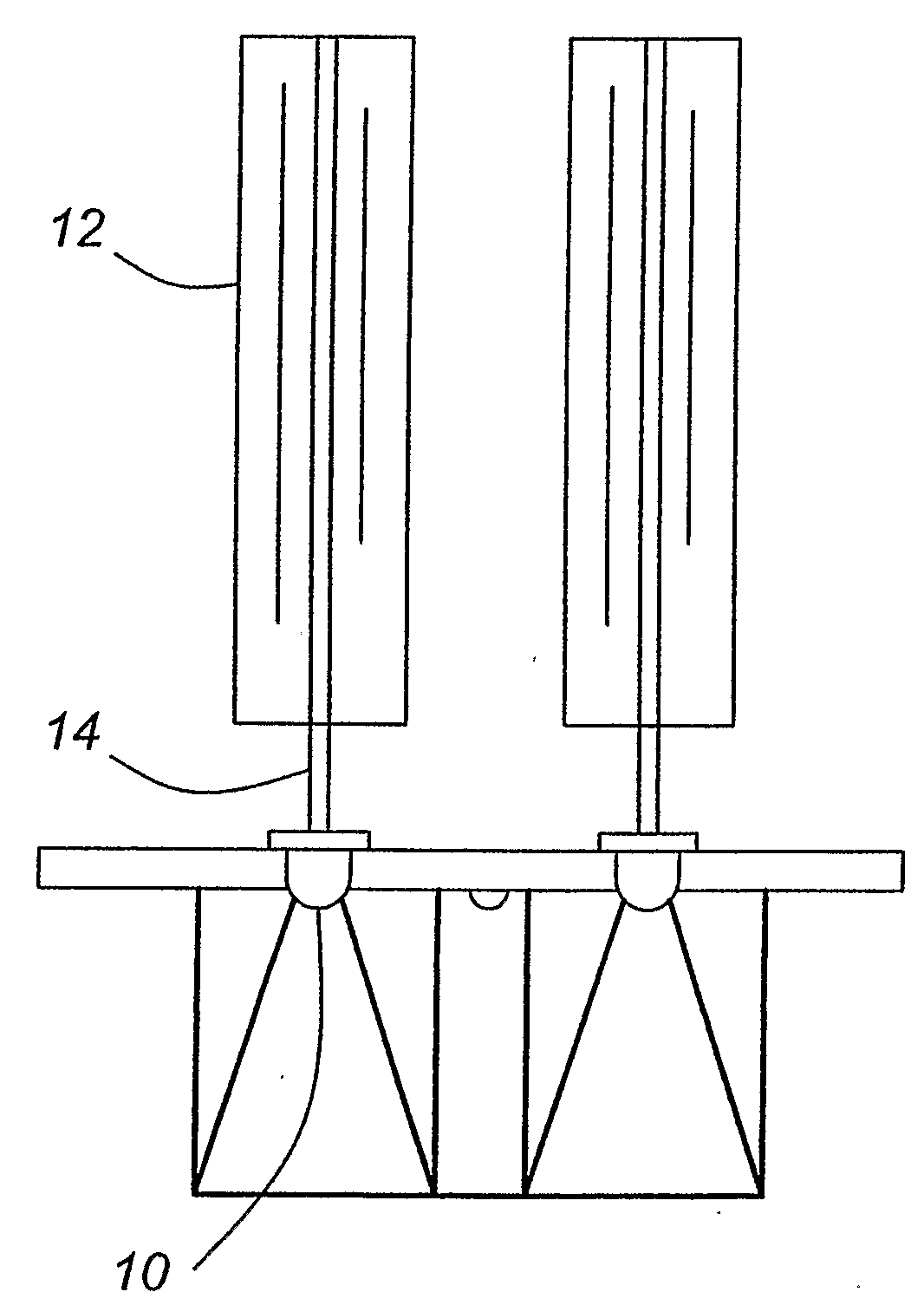

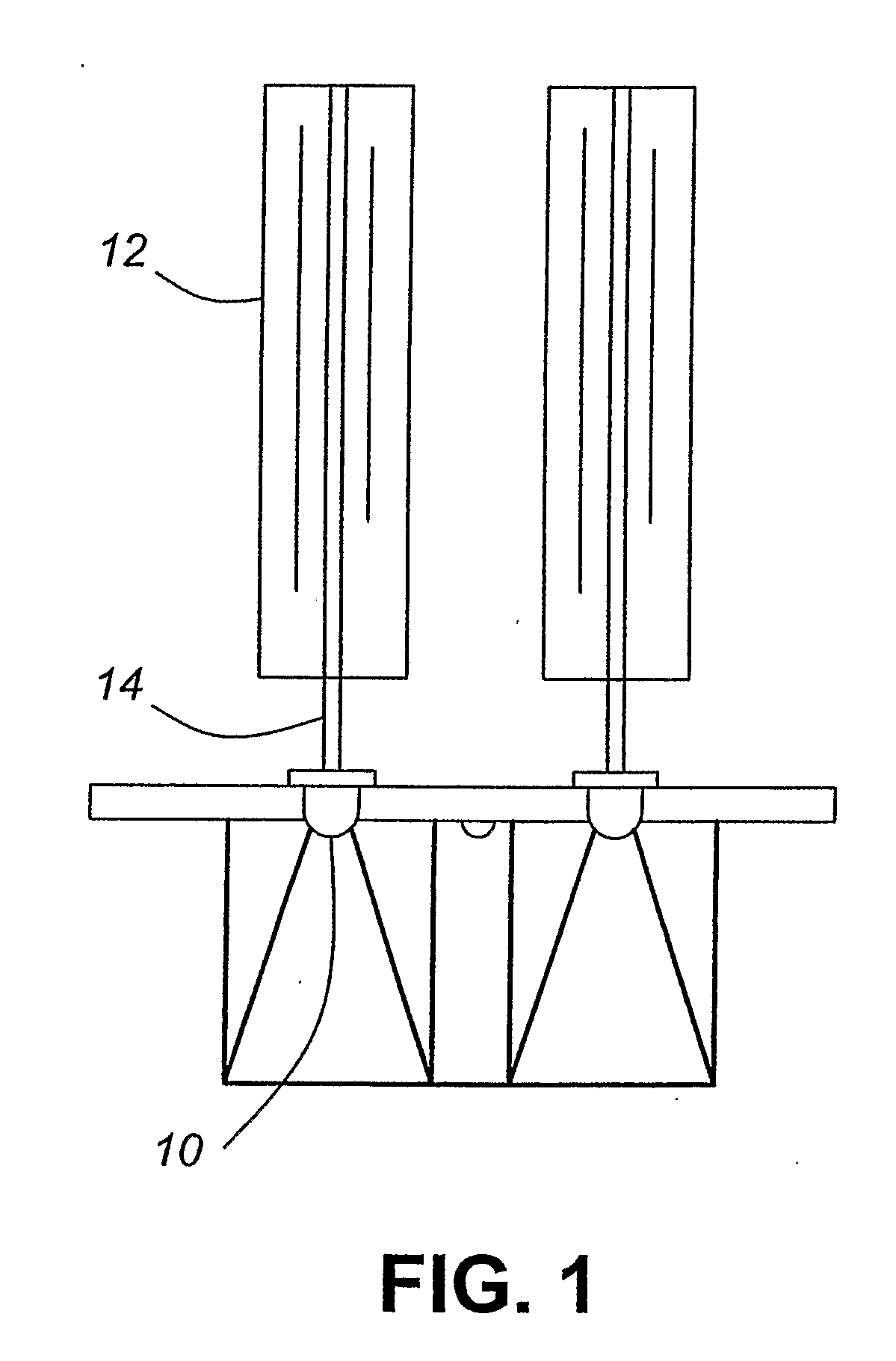

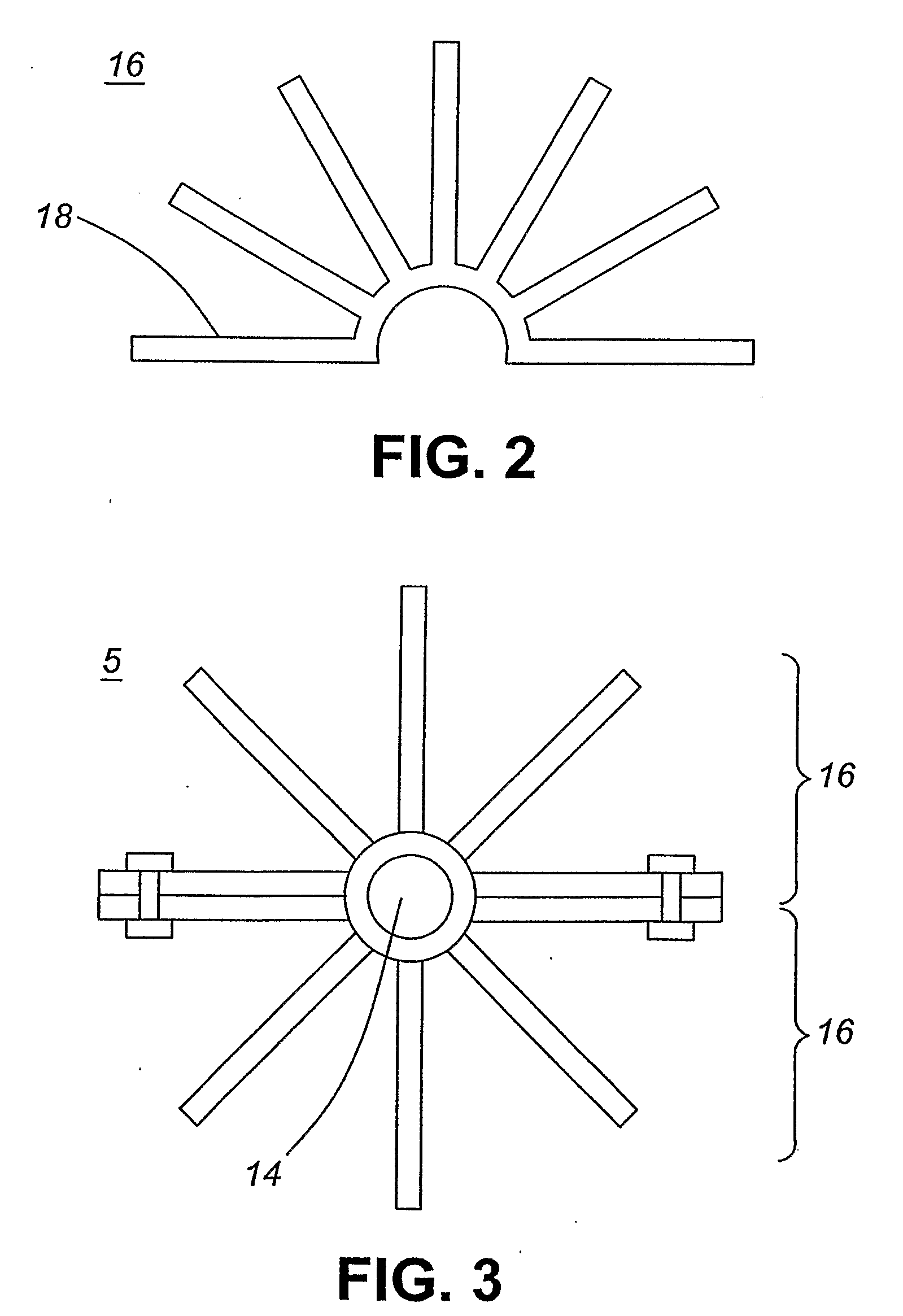

A traditional passive thermal management system can only be used effectively in a single orientation because it relies on the buoyancy of the heated air to create natural convection. A passive thermal management system is provided which includes means for transferring heat away from a heat source (10) in any orientation. The system comprises a heat pipe (14) which is thermally coupled to the heat source (10). The heat pipe (14) is capable of transferring heat away from the heat source (10), wherein this heat is transferred along the length of the heat pipe (14). Thermally coupled to the heat pipe (14) is a fin system (12), which provides a means for extraction of the heat from the heat pipe (14) and transfer of this heat to the environment thereby dissipating the heat generated at the heat source (10). The fin system (12) is configured to provide a desired level of heat transfer to the environment independent of the orientation of the thermal management system.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

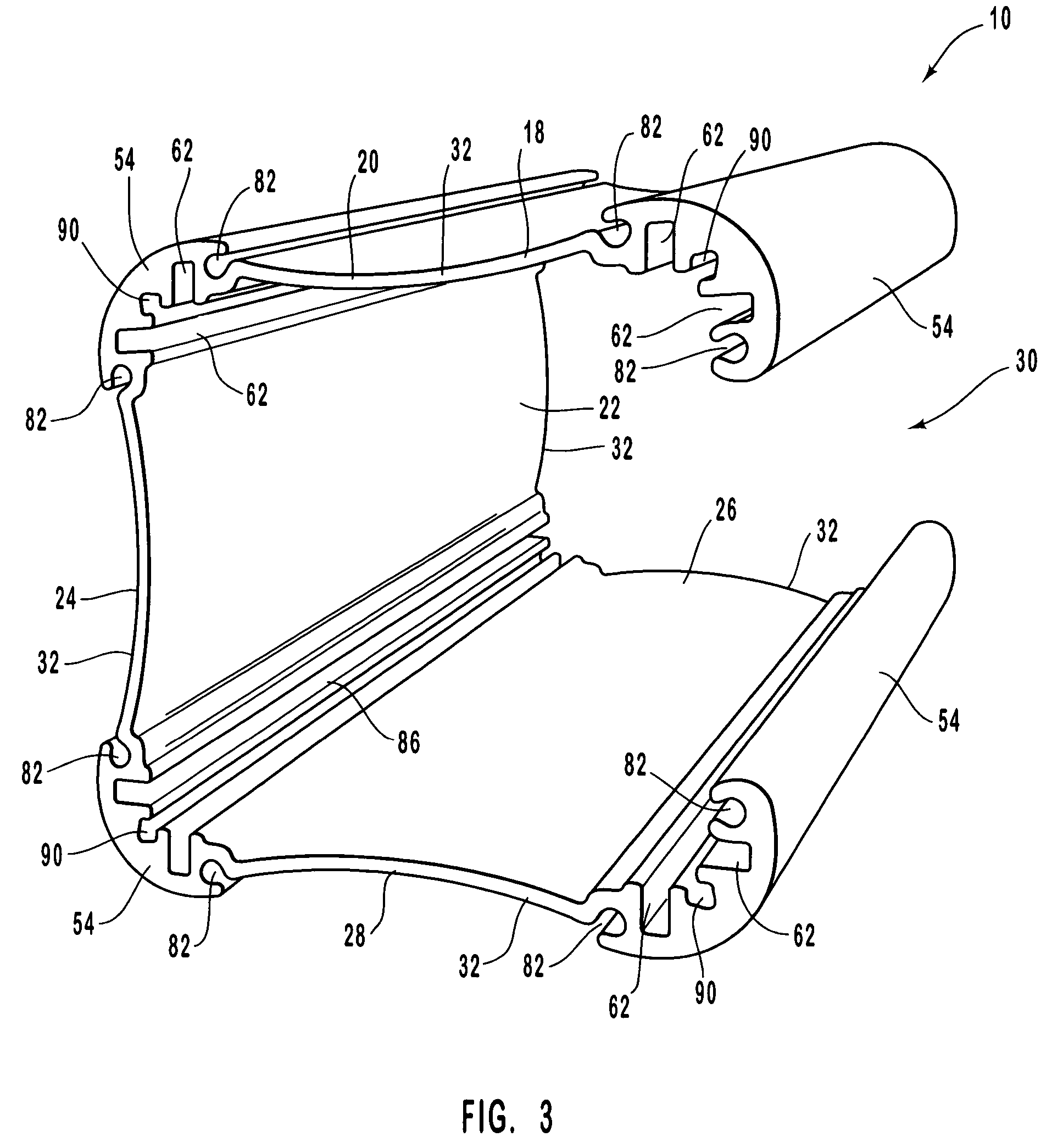

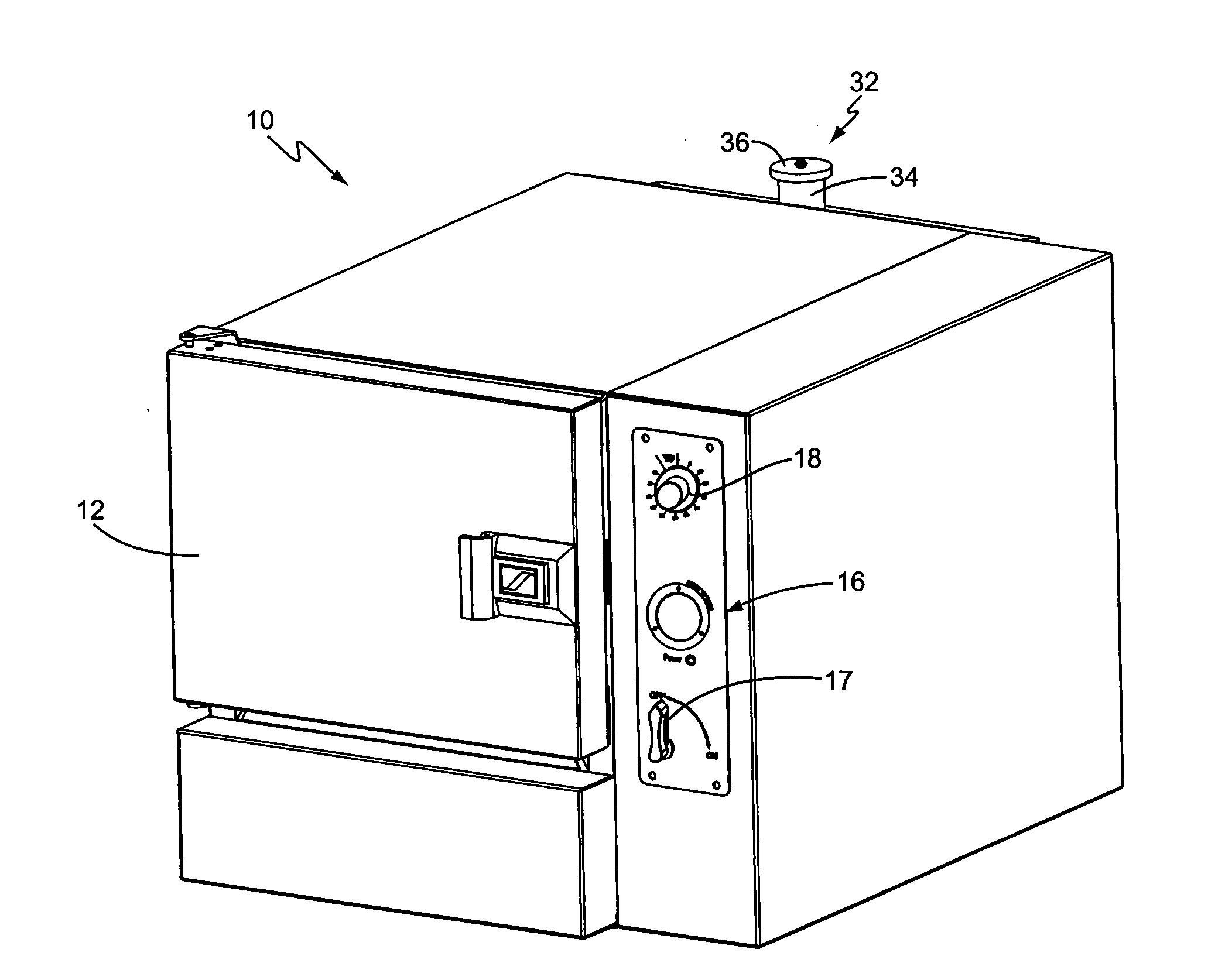

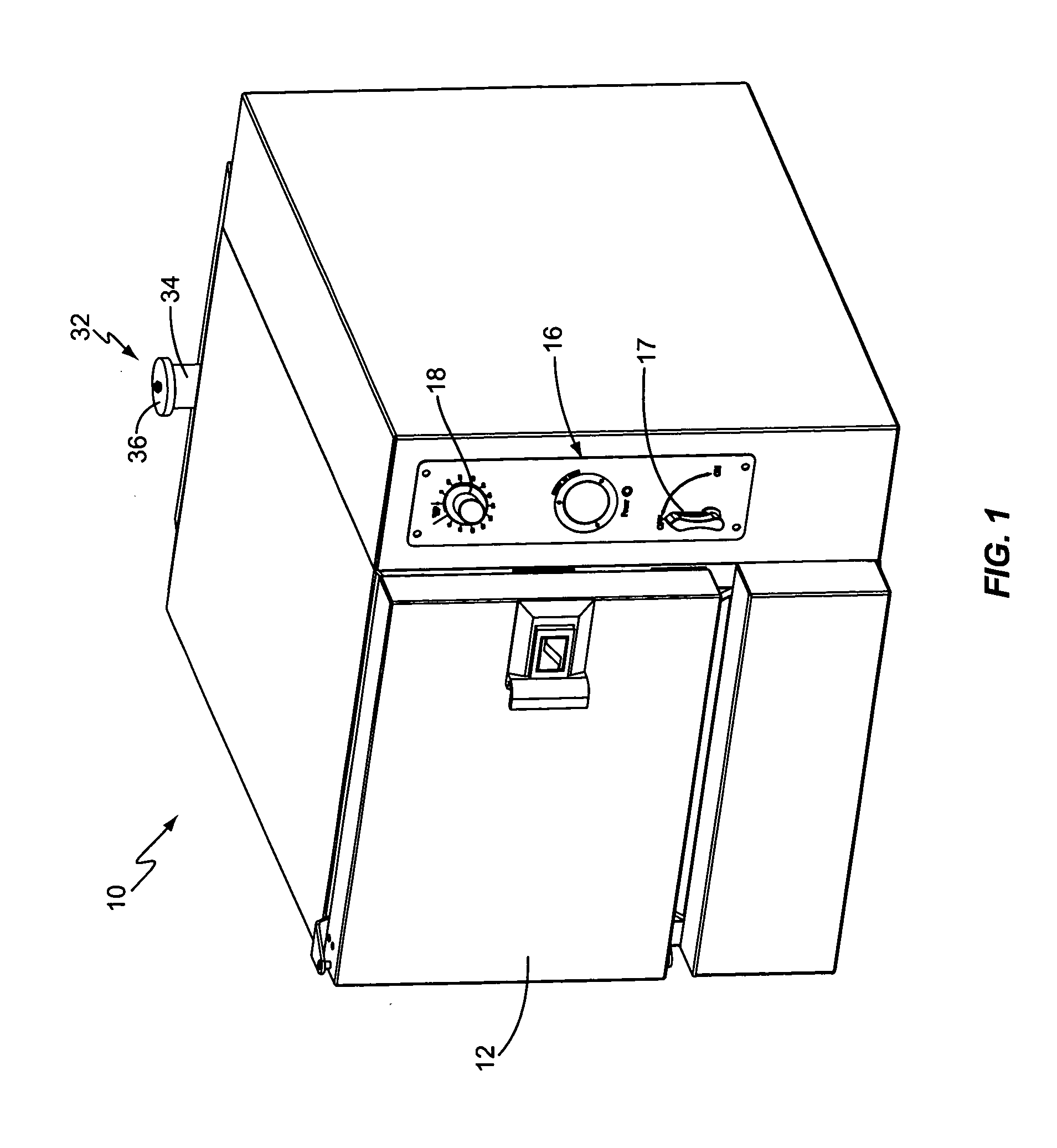

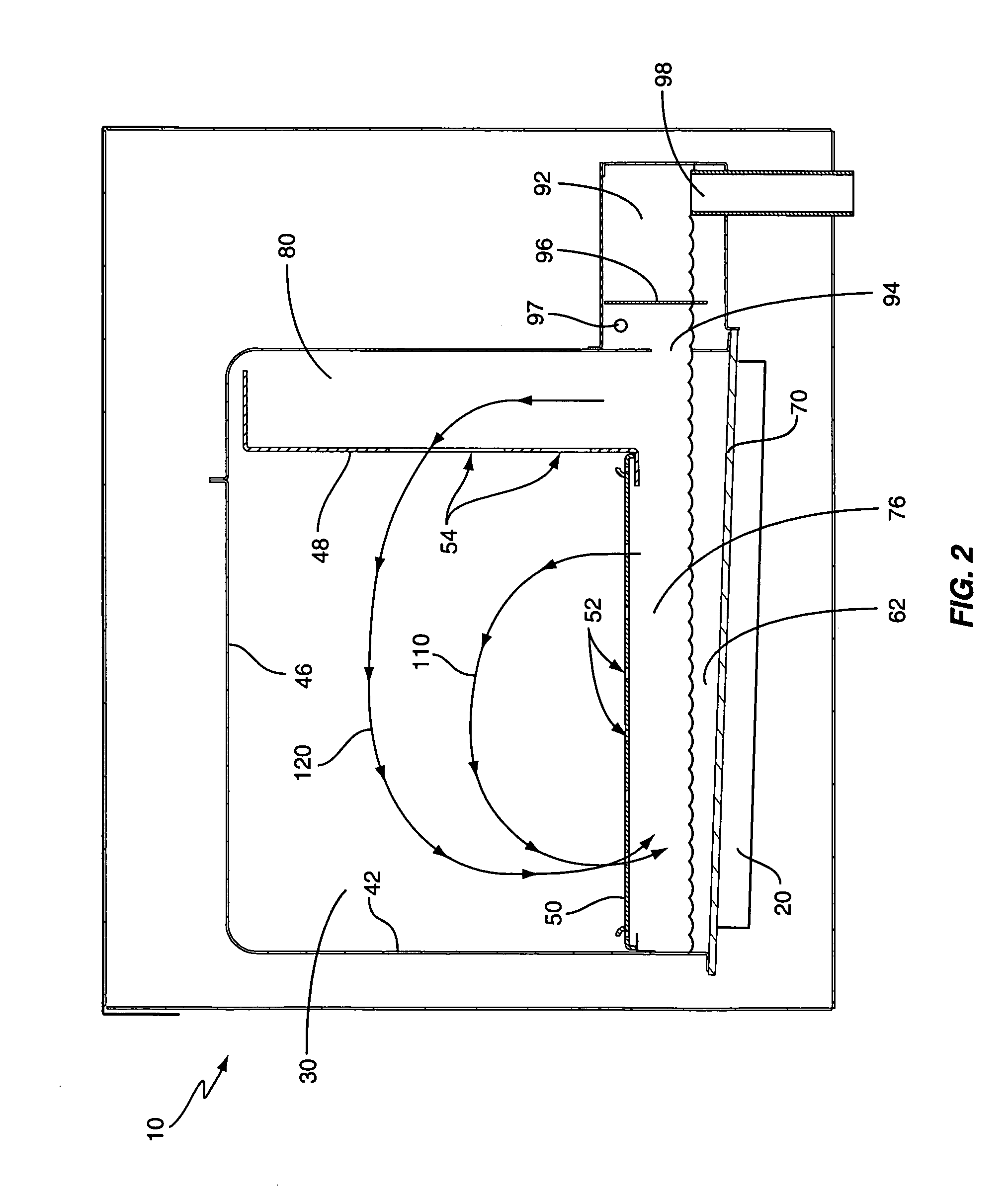

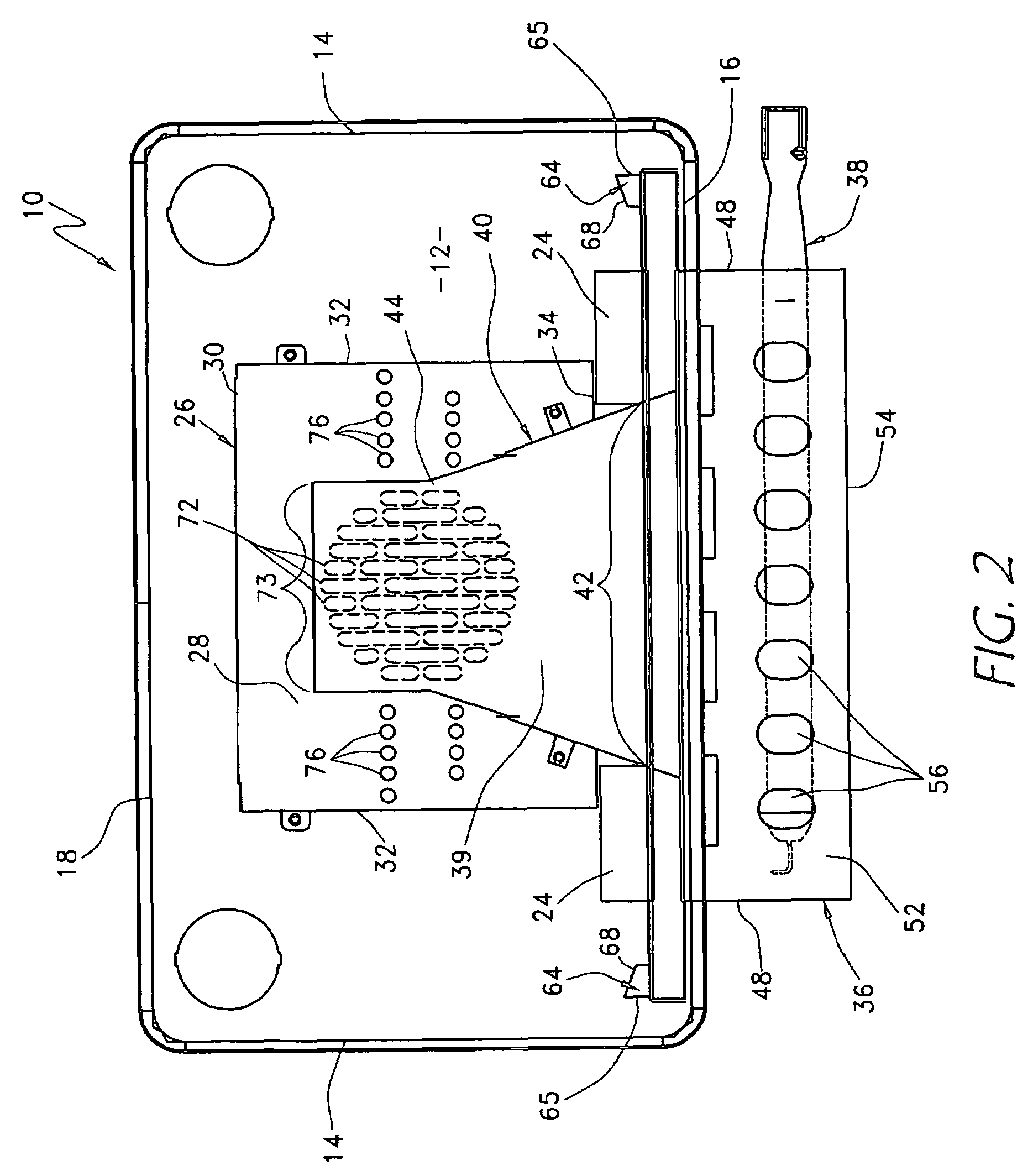

Natural convection steam cooking device

InactiveUS20060081592A1Domestic stoves or rangesOven air-treatment devicesSteam cookingNatural convection

A natural convection steam cooking device with a cooking cavity having a floor defining a lower boundary thereof and a sidewall defining a side boundary thereof, the floor having a plurality of first holes therein, the sidewall having a plurality of second holes therein; a steam chamber disposed below the cooking cavity and along the sidewall, the steam chamber having a pool disposed below the floor; wherein the steam enters the cooking cavity from the steam chamber via both the first holes and the second holes; and wherein the steam circulates within the device in an unforced manner by natural convection. The first holes and the second holes may have a ratio of cross-sectional areas of approximately 2:3. And method(s) of providing steam to, and design of steam flow for, a cooking cavity of a commercial steam cooking device.

Owner:MIDDLEBY MARSHALL

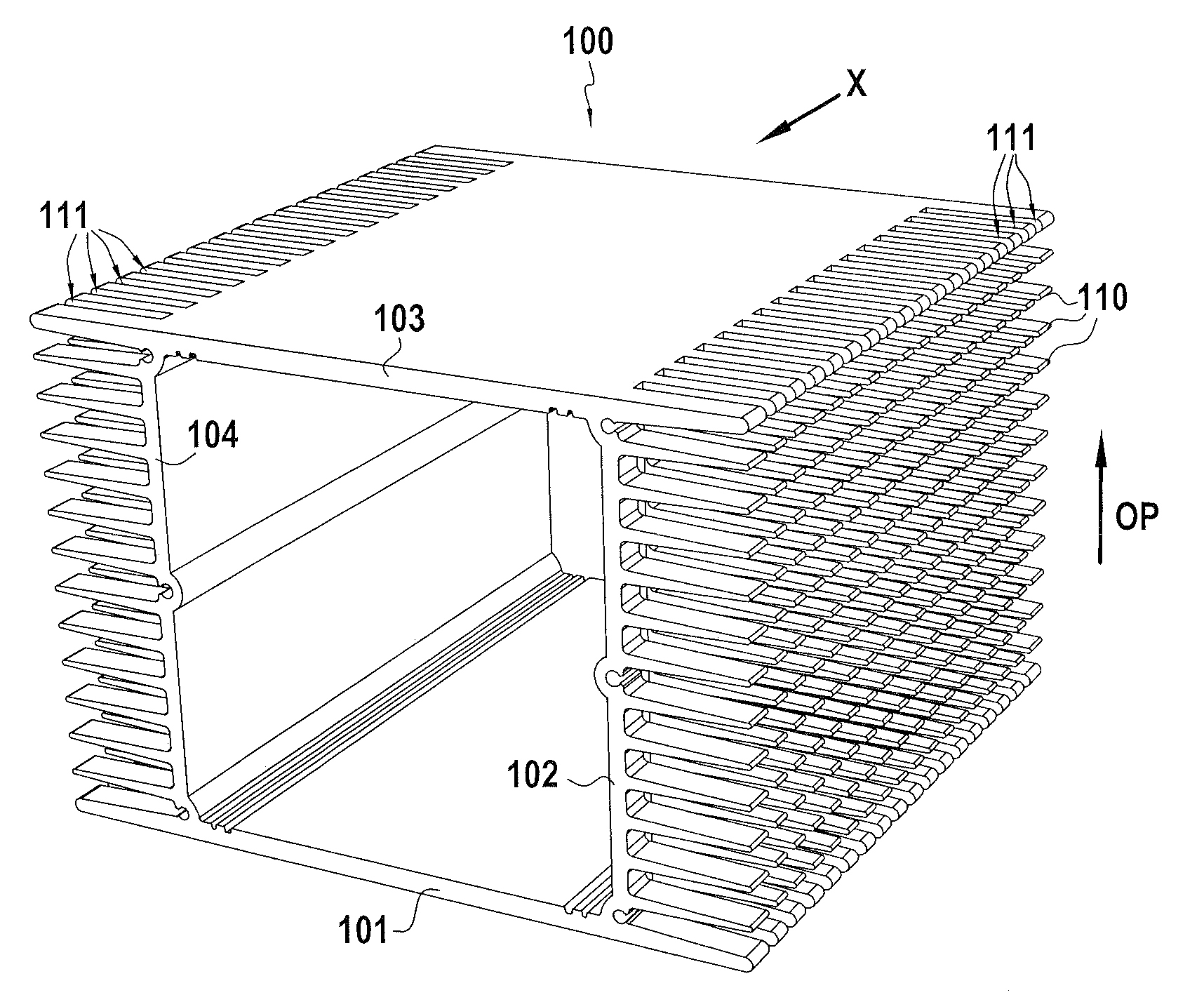

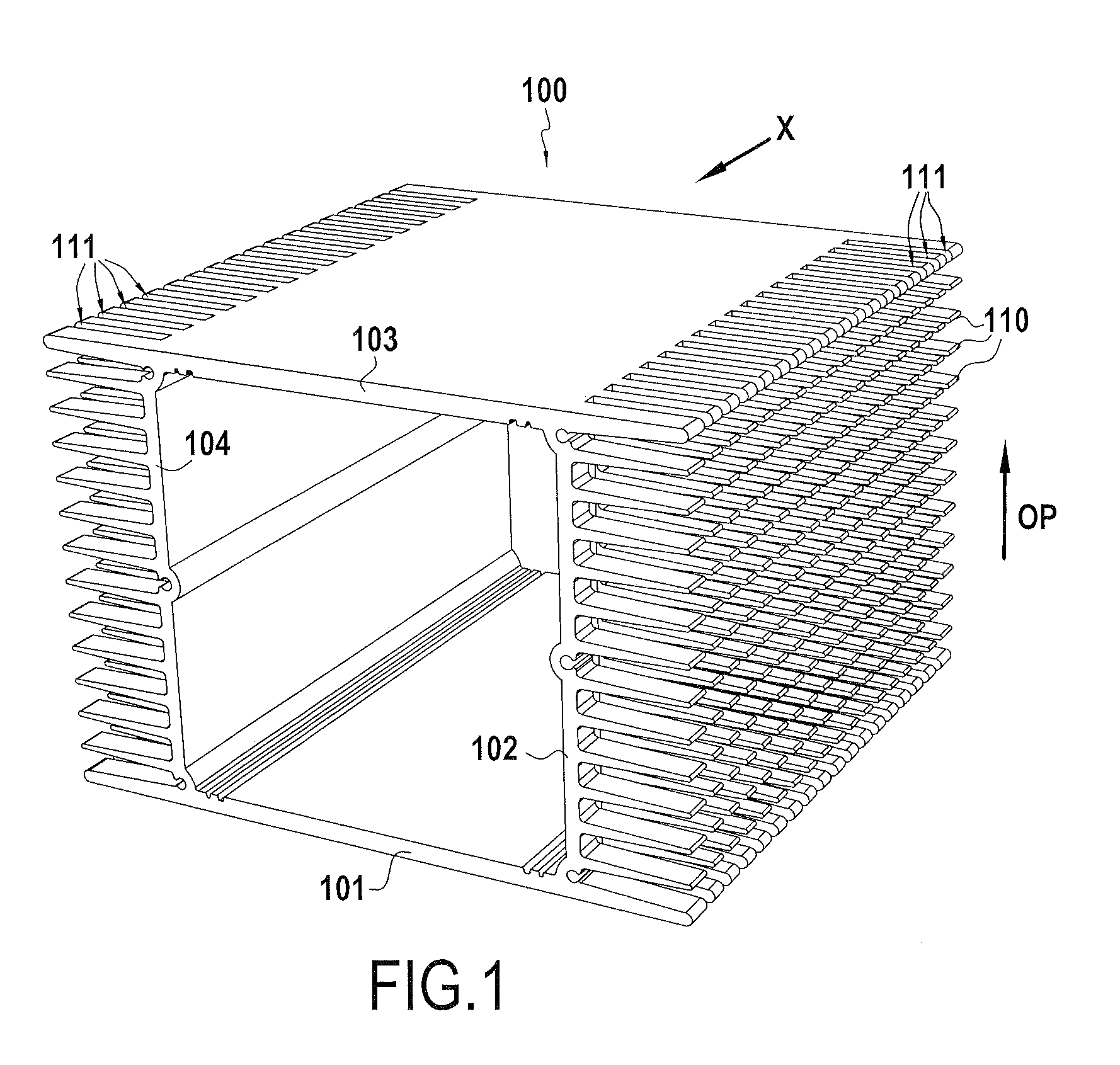

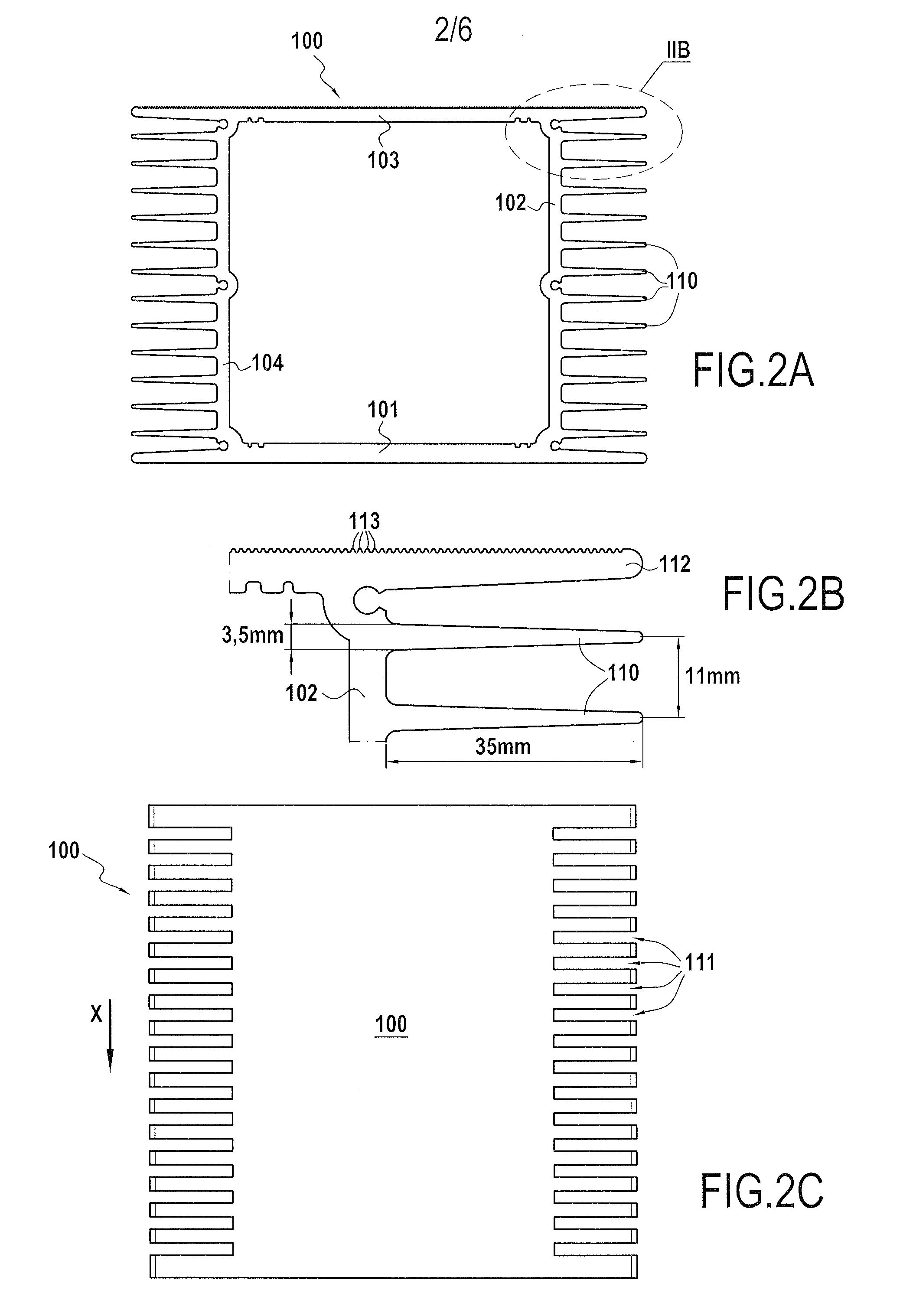

Multi-position housing made of metal extruded section member for manufacturing a waterproof power electronic device

ActiveUS20090180251A1Mitigate such drawbackSatisfies requirementModifications for power electronicsHeat exchange apparatusNatural convectionEngineering

The extruded section forms a tunnel that is substantially rectangular and is provided with fins on at least one side of the rectangle. The fins allow air to flow outside the housing by natural convection in the extrusion directions. A side without fins serves as a base for fastening the housing and as a support for power electronic components of the power electronic device. The fins are machined transversely to the extrusion direction to form notches in the fins. The notches being aligned in succession to allow air to flow outside the housing by natural convection in the optimum direction.

Owner:INTELLIGENT ELECTRONICS SYST IES

Loop circuit heat pipe condenser

InactiveCN101270961AIncrease the area where the working fluid condensesEnhanced natural convectionStationary conduit assembliesTubular elementsWorking fluidCooling effect

The invention discloses a loop heat pipe condenser, consisting of an evaporation chamber, a heat pipe and a sealed hollow condensation cavity, wherein the condensation cavity and the evaporation chamber are both provided with a working fluid inlet and a working fluid outlet; the working fluid outlet of the evaporation chamber is communicated with the working fluid inlet of the condensation cavity; the working fluid outlet of the condensation cavity is communicated with the working fluid inlet of the evaporation chamber through another pipe; the surface of the condensation cavity is provided with a plurality of fins. The heat pipes of the prior loop heat pipe devices directly extend through the fins; therefore, the condensation effect is not good; especially in case of heat dissipation through natural convection, the cooling effect is very poor. On the basis of the prior loop heat pipe devices, the invention is provided with a condensation cavity, and the evaporation chamber is connected with the condensation cavity through a pipeline; and then fins are arranged on the surface of the condensation cavity, thereby increasing the condensation area of the working fluid; at the same time, the loop structure of the condensation cavity effectively increases the effects of natural convection.

Owner:SUN YAT SEN UNIV

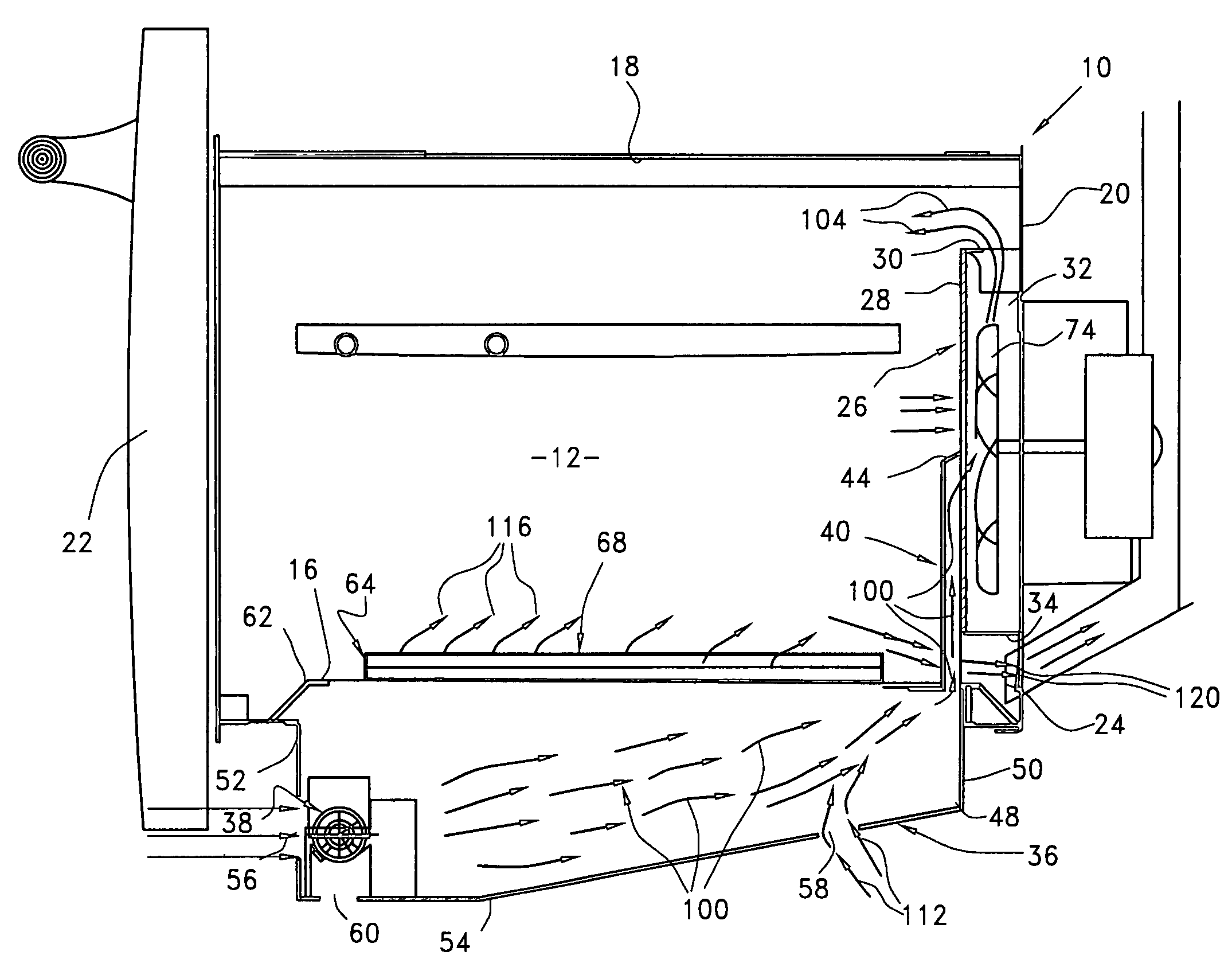

Gas "true" convection bake oven

InactiveUS7422009B2Domestic stoves or rangesLighting and heating apparatusNatural convectionEngineering

Disclosed is a convection oven capable of producing a “true” convection cooking environment with a single gas burner disposed underneath the oven bottom in a combustion box. A fan compartment is disposed substantially at the center of the back wall, and defined by a baffle plate with a central fan inlet, a plurality of rearward-extending flanges, and a portion of the oven back wall. A centrifugal fan is disposed within the fan compartment. A flue spout is disposed between the oven cavity and the fan compartment and is adapted to join the combustion box and the oven cavity in fluid communication. Thus the centrifugal fan, located substantially centrally within the fan compartment will draw hot air and flue products upward from the combustion box, through the flue spout, through the central fan inlet, and blow the hot air and flue products into the oven cavity through peripheral fan outlets formed in the fan compartment. The oven may alternatively be operated in a fan-off mode, thus allowing the oven cavity to be heated by the upward flow of air due to natural convection.

Owner:DYNAMIC COOKING SYST

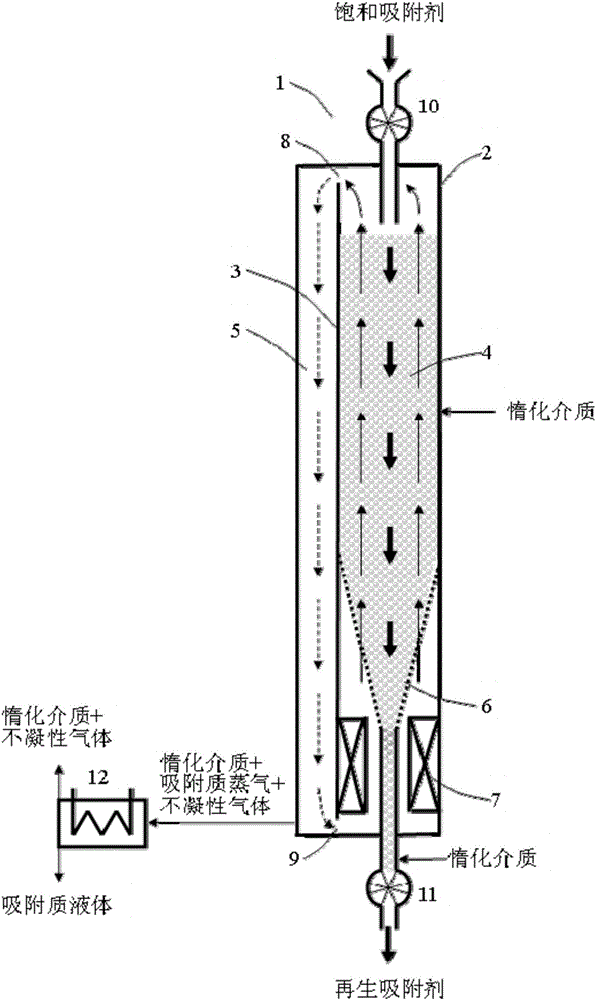

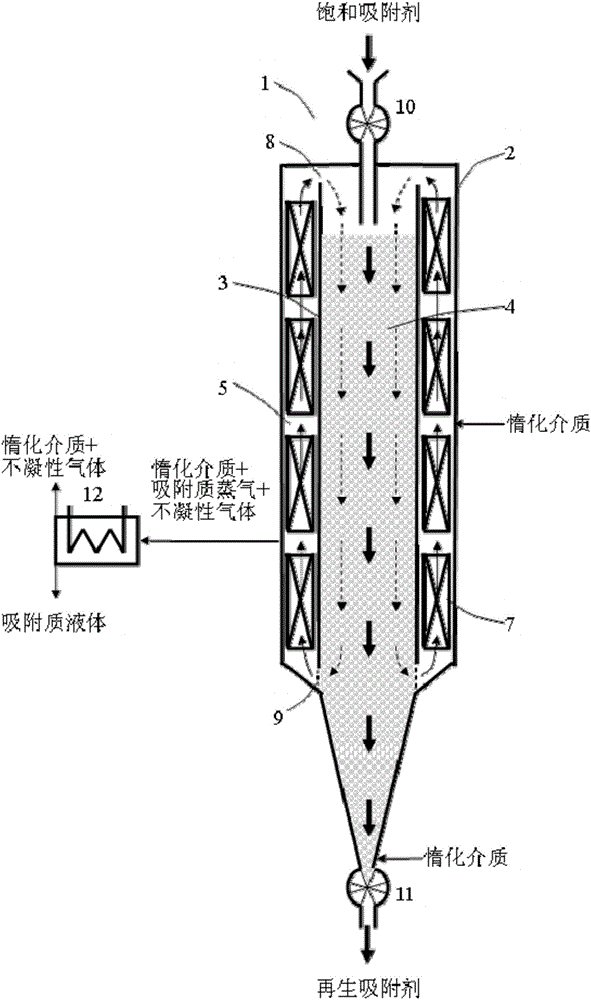

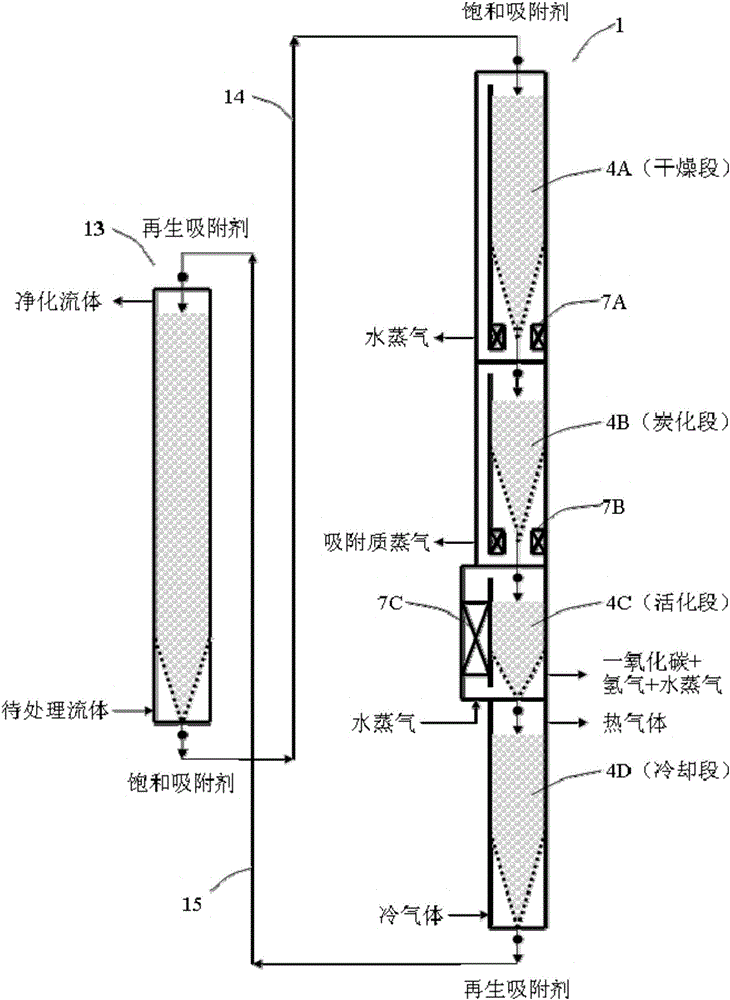

A solid adsorbent regenerating device and an adsorption device applying the regenerating device

InactiveCN106563428AReduce consumptionReduce heat lossGas treatmentSpecific water treatment objectivesSorbentNatural convection

A solid adsorbent regenerating device and an adsorption device applying the regenerating device are disclosed. The regenerating device includes a regenerating heater and an absorbent bed. The regenerating device is configured in a manner that heating by the regenerating heater allows gas in the regenerating device to circularly flow between the regenerating heater and the adsorbent bed, and heat provided by the regenerating heater is transferred through the circular airflow to the adsorbent bed so that an adsorbent is heated and regenerated. According to one embodiment, the inside of a furnace body of the regenerating device is divided into two parts, top ends of the two parts are communicated with each other, bottoms of the two parts are communicated with each other, and the regenerating heater is in one of the two parts. The adsorption device applying the regenerating device is also disclosed. Circular heating in a natural convection manner is utilized to regenerate the solid adsorbent. The regenerating device and the adsorption device have advantages of low consumption of inert gas, no or extremely low waste emission, a high heat efficiency, simple equipment, a low cost, and the like.

Owner:GUANGDONG UNIV OF TECH

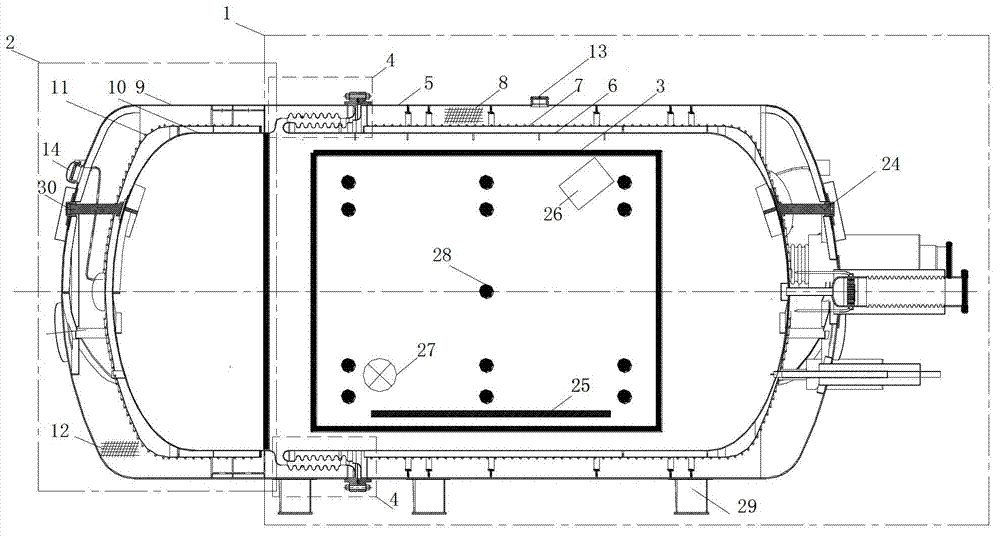

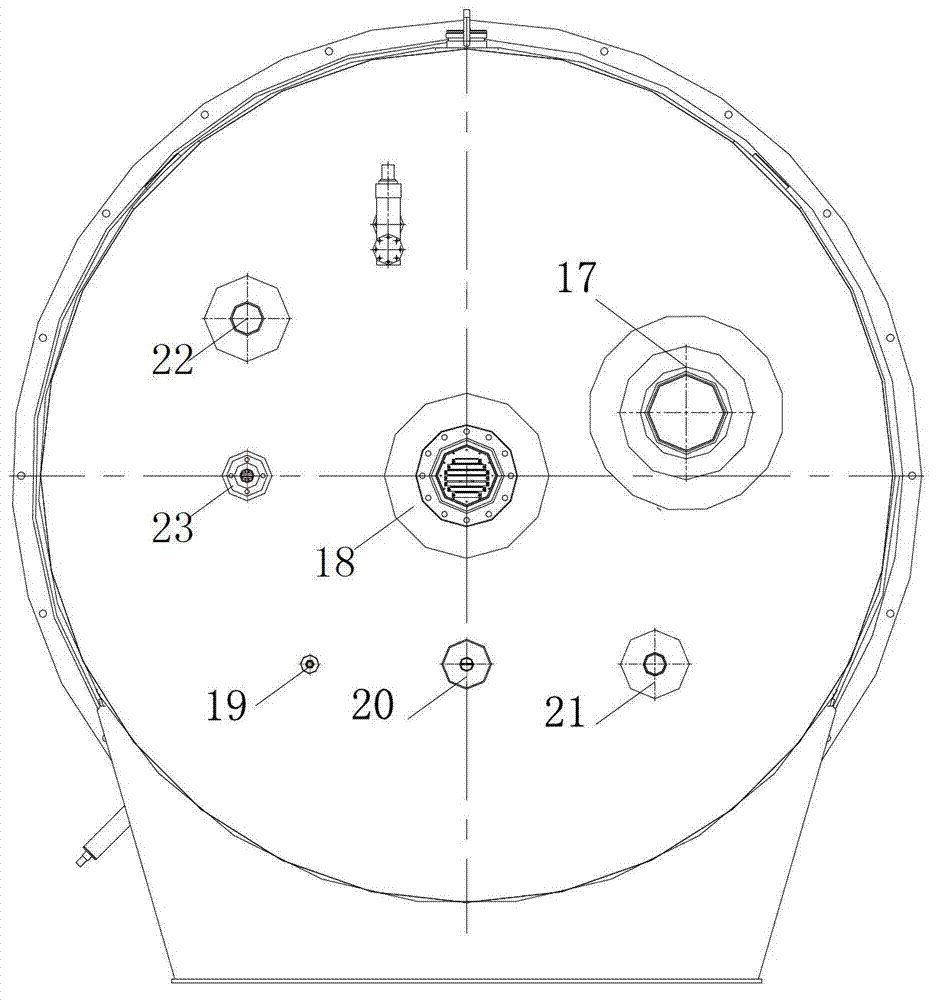

High/low temperature space environment simulating container with high temperature change rate

ActiveCN102890006AFast heating and cooling rateGood temperature uniformityStructural/machines measurementSpace environmentNatural convection

The invention relates to a high / low temperature space environment simulating container with a high temperature change rate, comprising a main cabin body, a cabin door, a head sink arranged in the main cabin body, a door sealing structure for connecting the main cabin body and the cabin door, an insulating channel passing through the main cabin body, a sample carrier table, a high / low temperature camera assembly, a high / low temperature fluid stirrer, a temperature measuring system, a pressure measuring system and a vacuumizing structure. A non-high-vacuum environment is formed in the container and is filled with helium; besides radiative heat transfer same as the heat transfer manner of a heat vacuum tank, natural convection heat transfer, even forced convection heat transfer, is added in the cabin, so heat transfer speed is increased greatly, a high / low temperature environment (68K-373K) with a high temperature change rate and even temperature is provided to a sample to be measured. The high / low temperature space environment simulating container is stable, safe and reliable to work.

Owner:SHANGHAI JIAO TONG UNIV

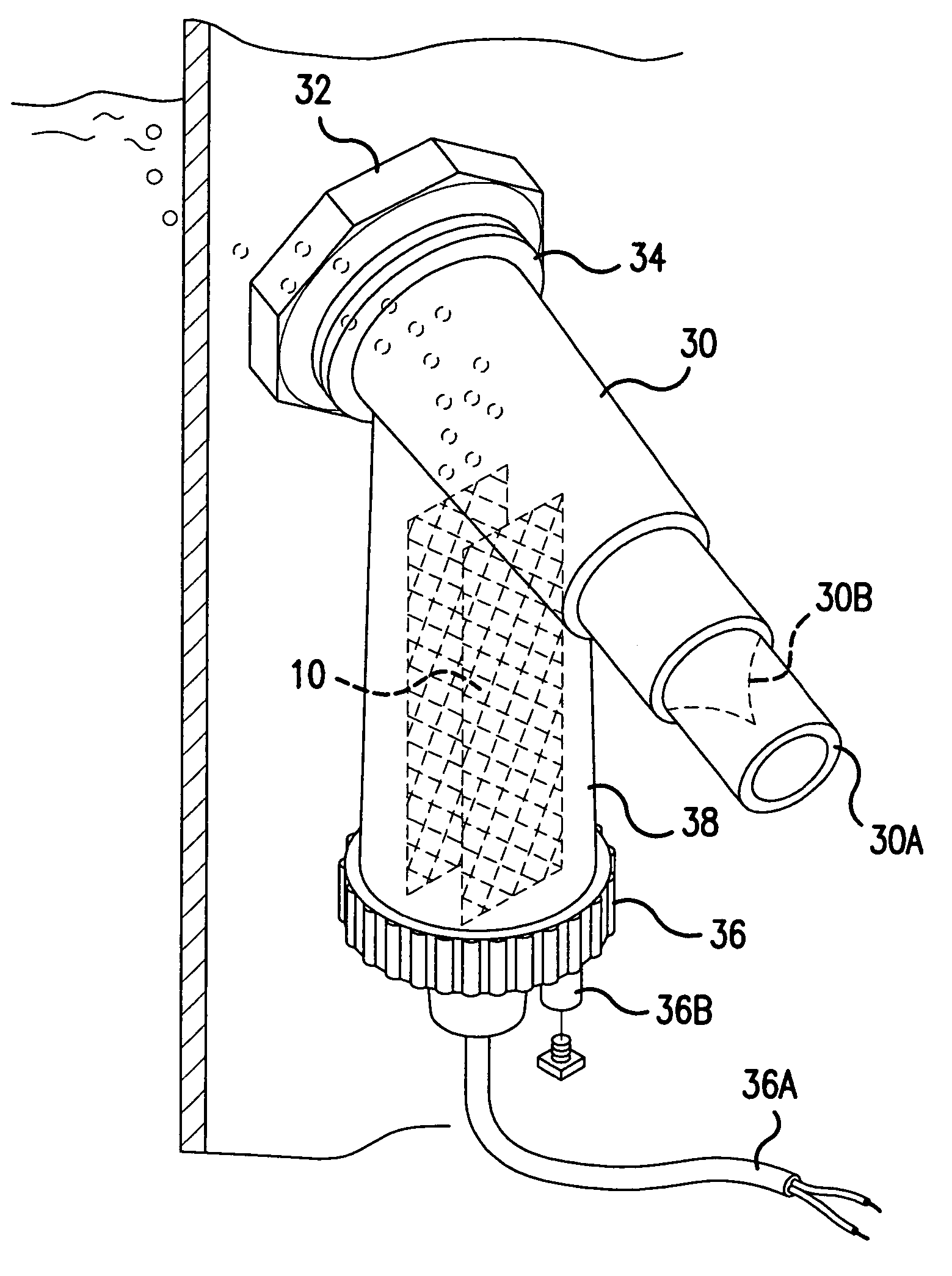

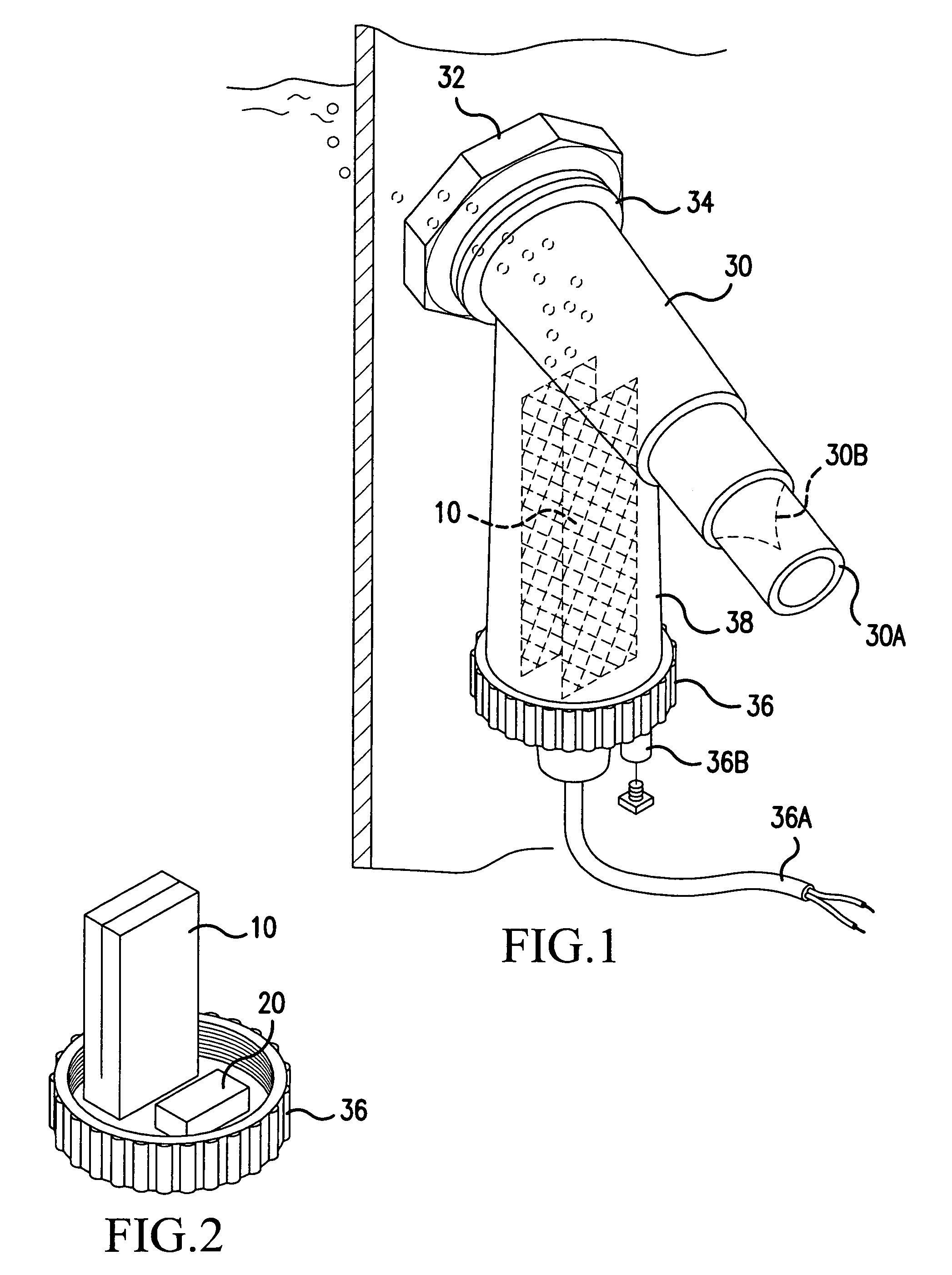

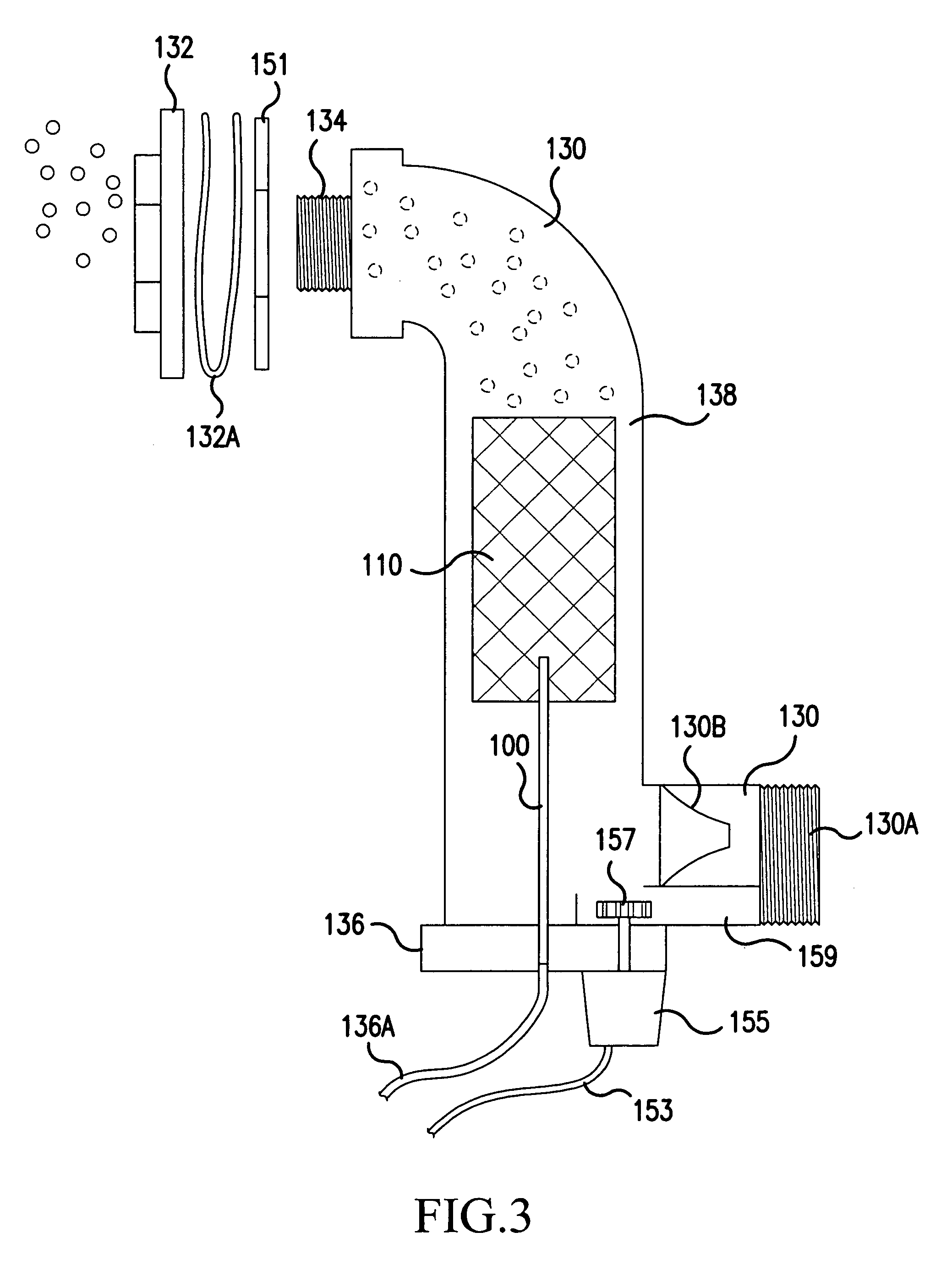

Salt chlorine generator

ActiveUS7014753B2Low costEasy to installSludge treatmentPhotography auxillary processesFiltrationEngineering

An electrolytic cell combined into a unitary structure with a liquid circulation fitting, which purifies water by electrode plates inside the cell when an aqueous solution is present. The unitary structure replaces the existing water return fitting. This integrated structure is well suited for use in pools, tubs, spas, fountains or similar large liquid containers. The production of halogen inside the structure is not required to coincide with the cycle of the existing pool filtration system. Rather, the electrodes receive a continuous supply of low level power and the halogen produced inside the structure is disbursed back into the body of water through the fitting using an integrated, dedicated circulation pump, special channels in the surface and a check valve to insure one directional flow from the pool pump and natural convection. Using fresh water drawn from the vessel, halogen is then disbursed back into the vessel with the water at a location different from where the fresh water was drawn. The level of halogen production may be regulated using a timing mechanism and / or sensors in the circuitry.

Owner:SMARTPOOL

Display device and blower thereof

InactiveUS20060164804A1Minimized in sizeAdequate heat dissipationTelevision system detailsNon-linear opticsNatural convectionDisplay device

A display device, and a blower thereof are disclosed. The display device includes an axial flow fan within a case, which has a display panel encased therein. The axial flow fan is provided in a width direction within the case, so that, while being rotated within the case, the axial flow fan generates forced air flow suitable to the case. The forced air flow is generated in a forward direction along with air flow by natural convection within the case.

Owner:LG ELECTRONICS INC

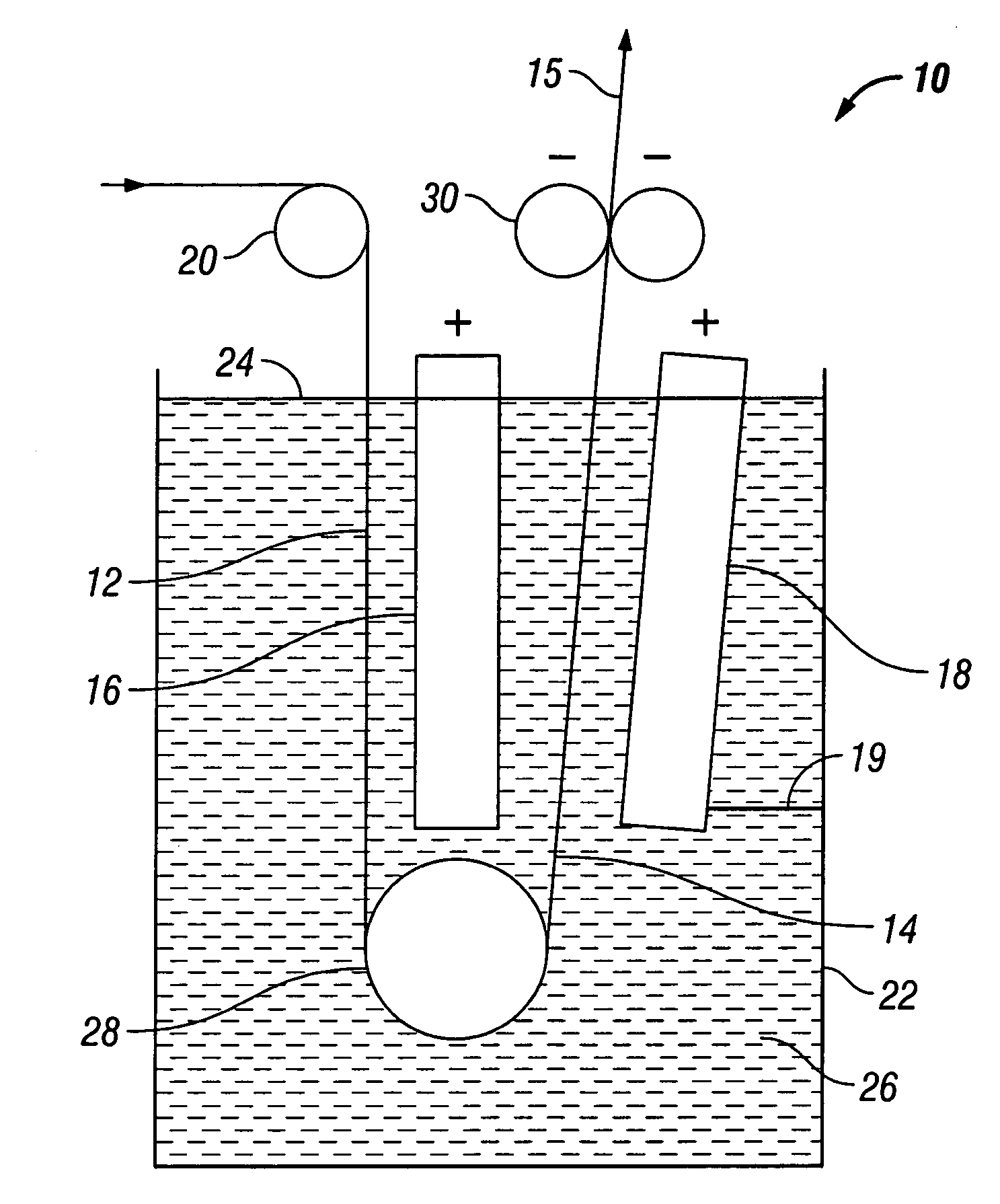

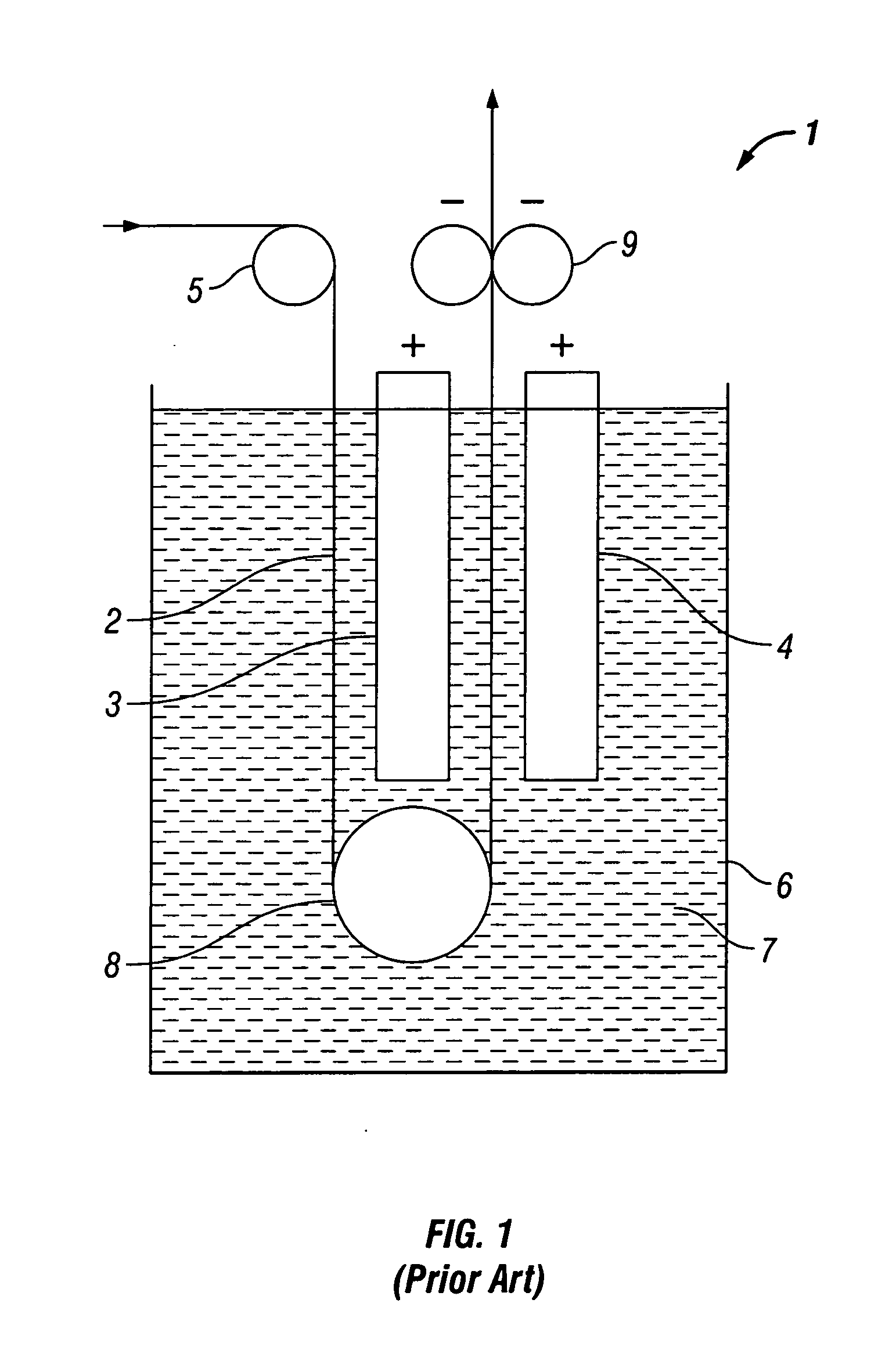

Apparatus and foam electroplating process

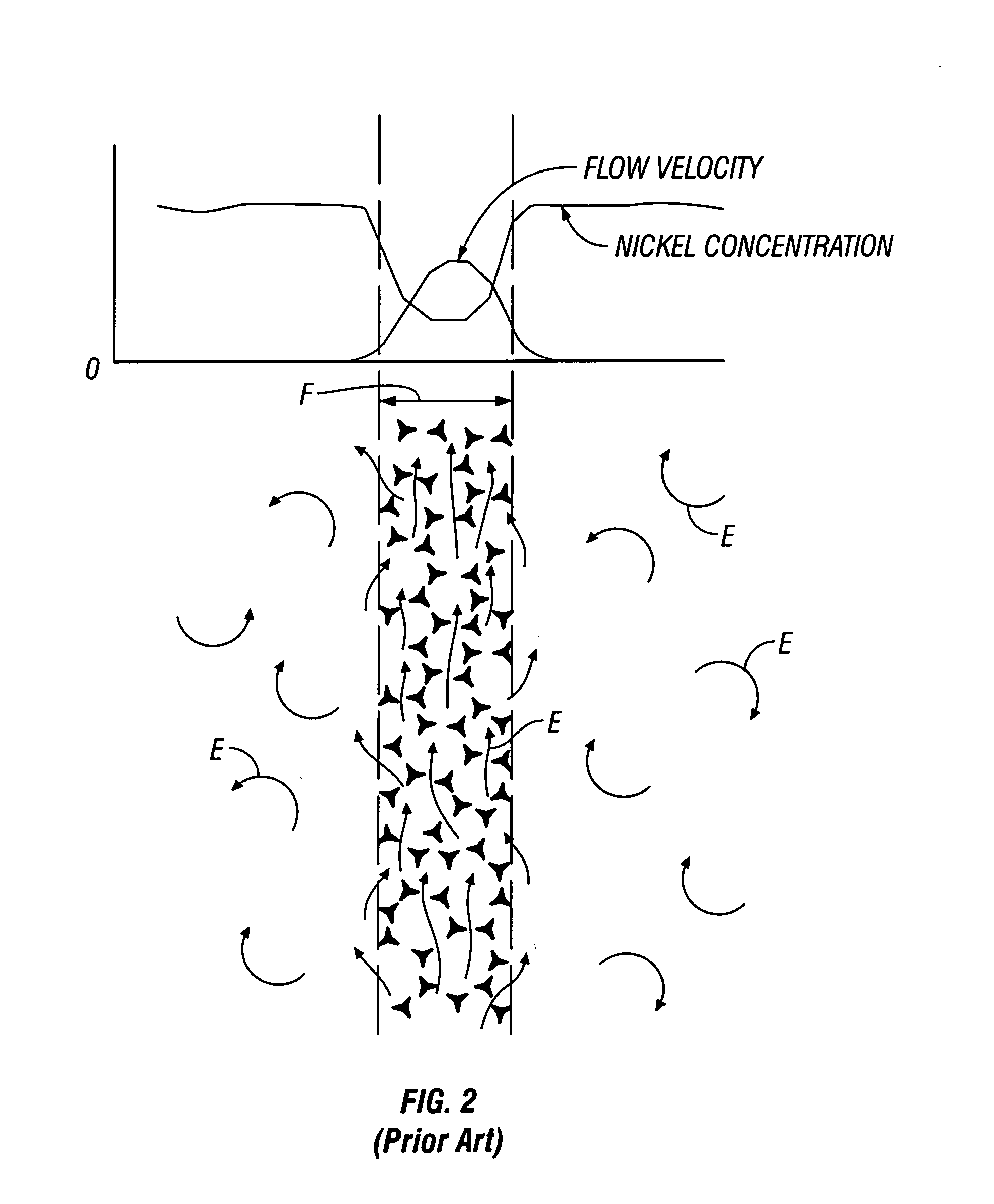

InactiveUS20070278105A1Increasing mass transportReduce current densityCurrent insulating devicesElectroforming processesNatural convectionMetal foam

An improved apparatus and method of producing metal foam is provided which involves optimizing the natural convection of electrolyte through a foam being electroplated by inclining the foam during plating. A diagonal flow of electrolyte though the foam enhances electrolyte turnover within the foam while increasing electroplating efficiency. Further increases in plating efficiency are provided by shifting current density from higher plating zones to lower plating zones.

Owner:INCO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com