Patents

Literature

35results about How to "Good temperature uniformity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

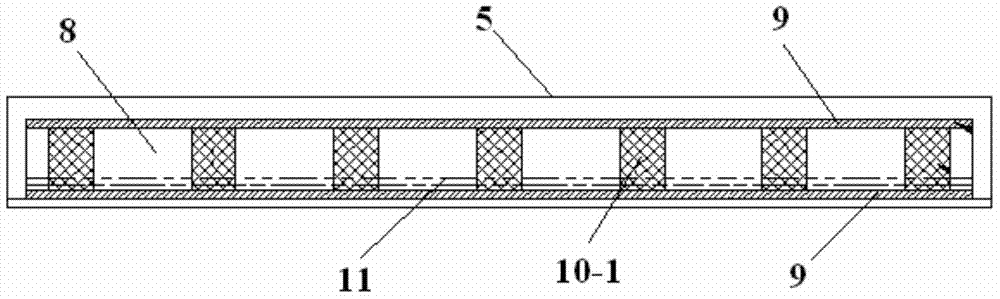

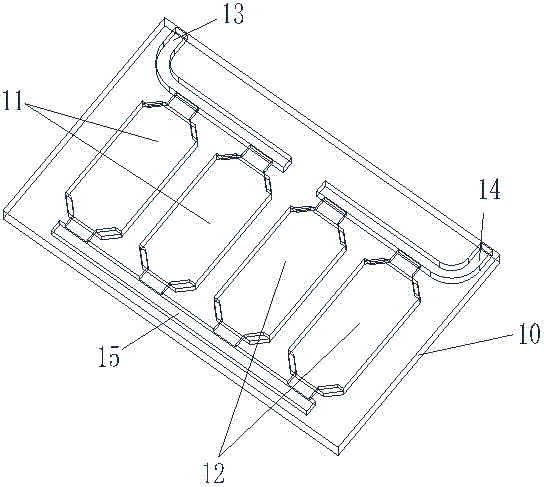

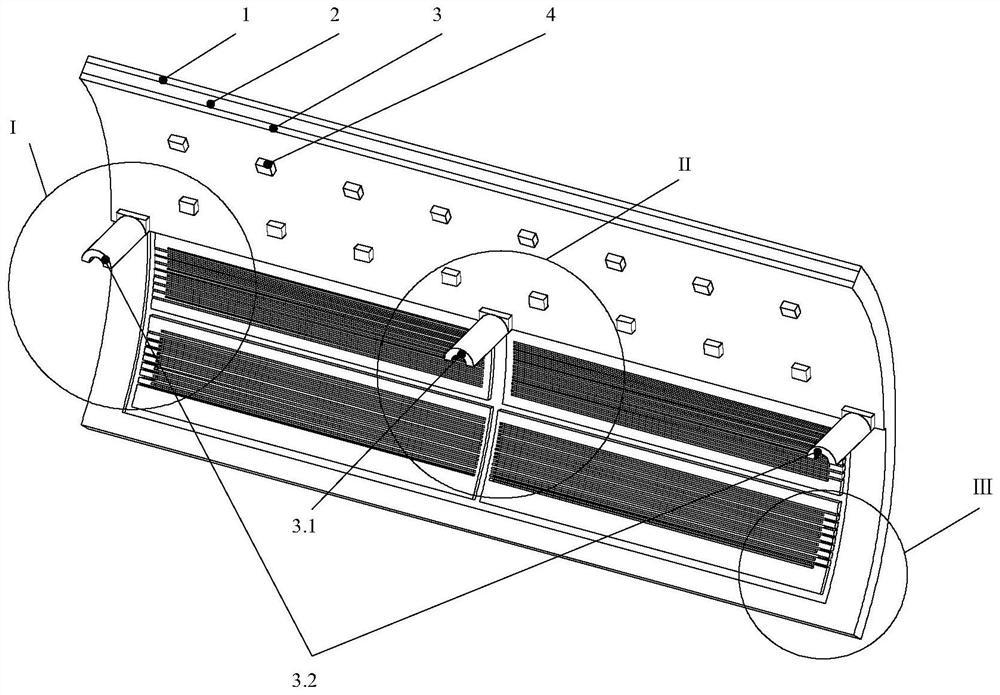

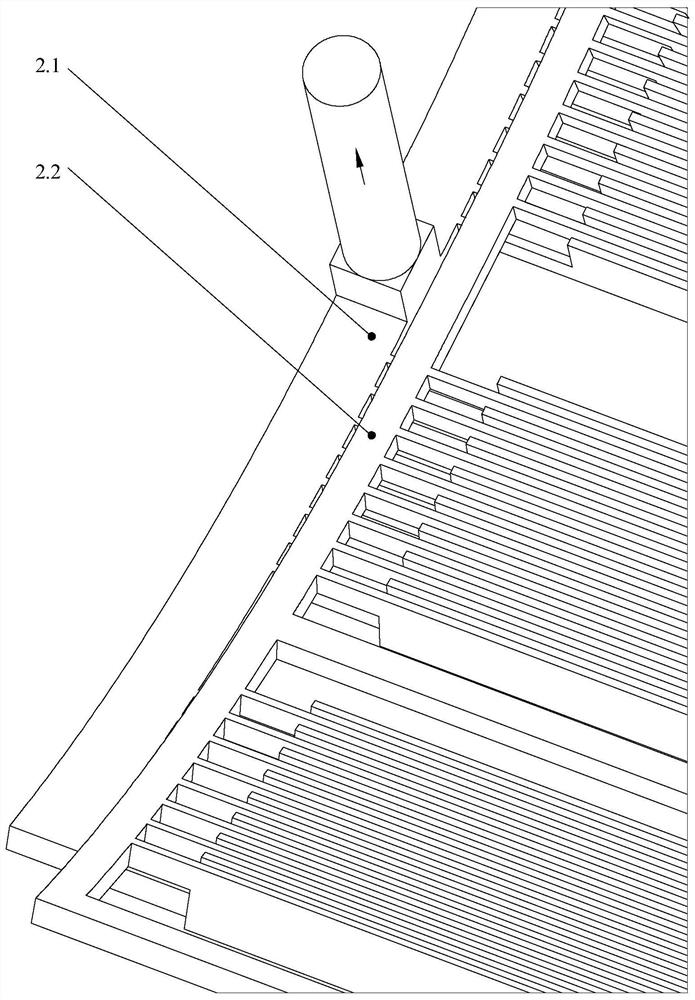

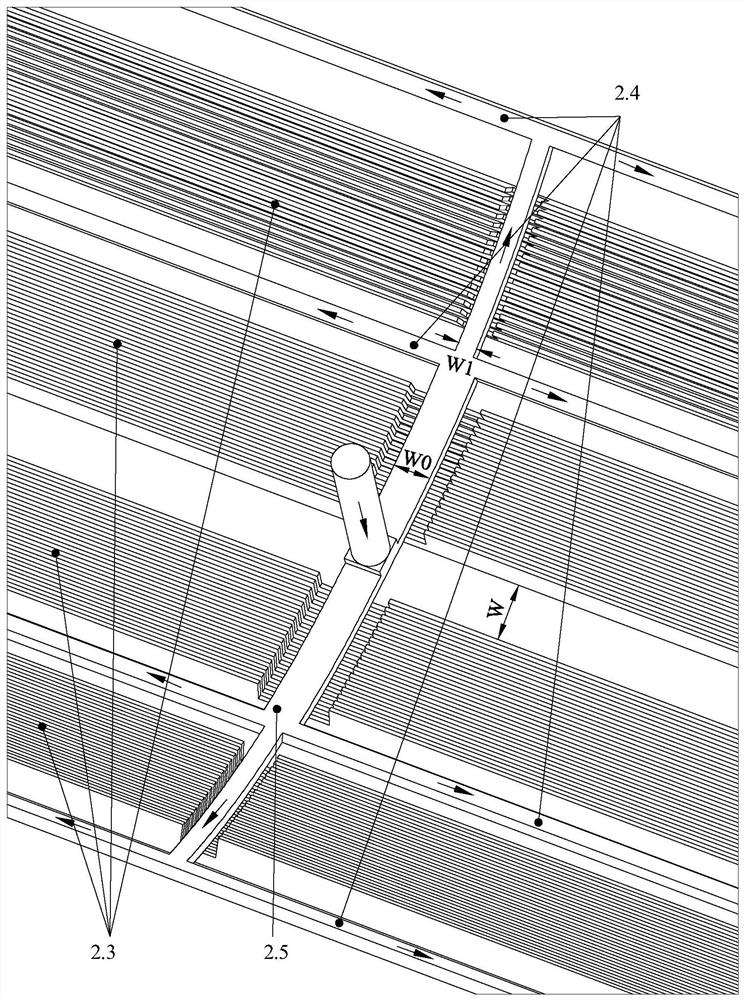

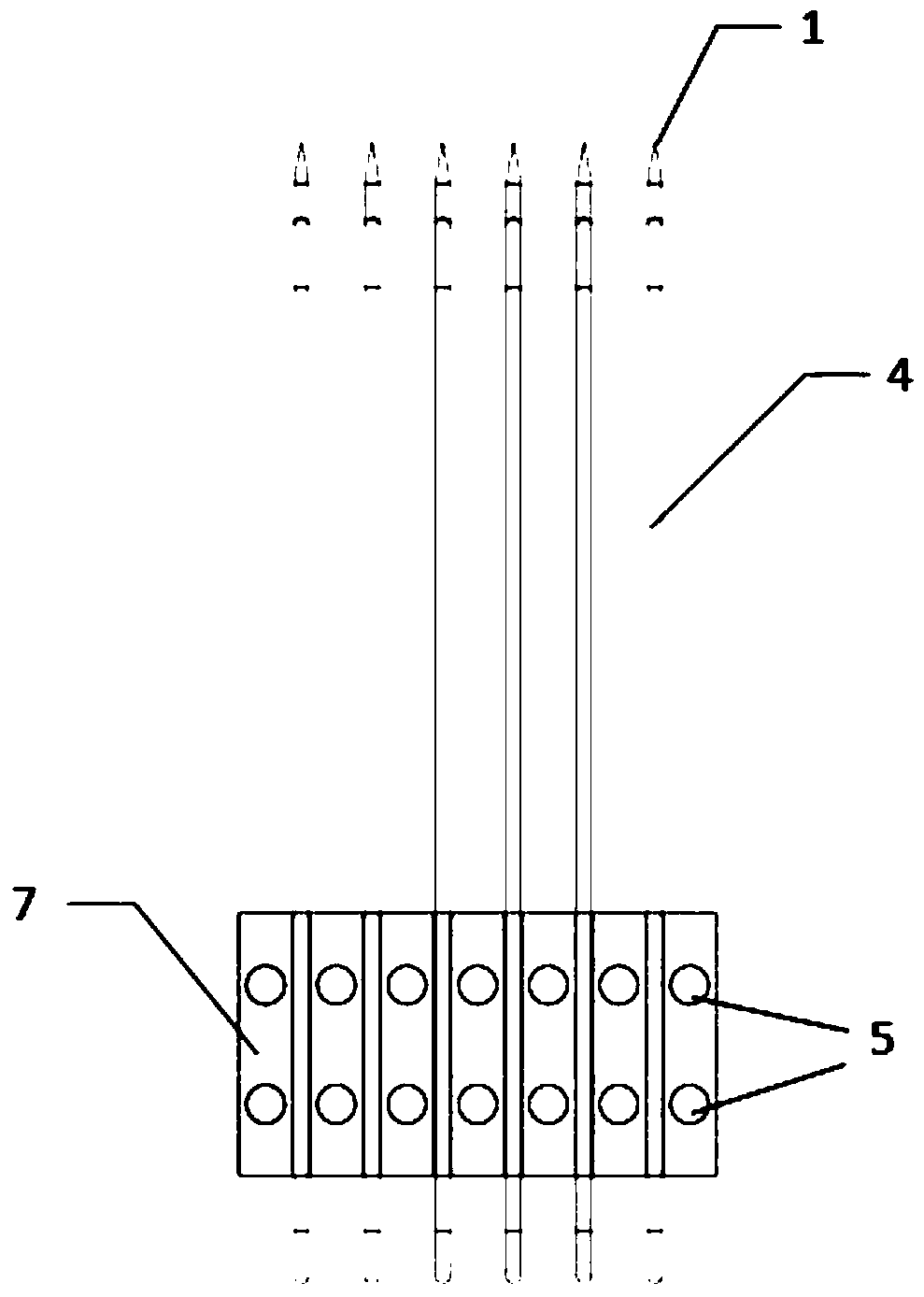

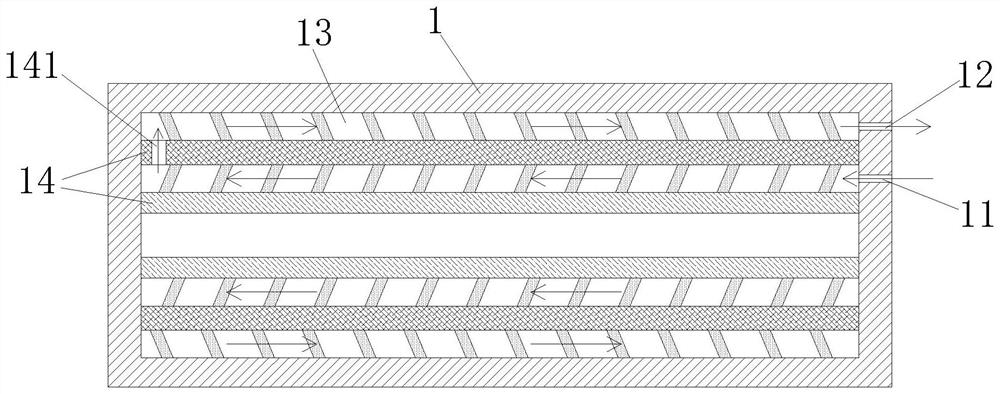

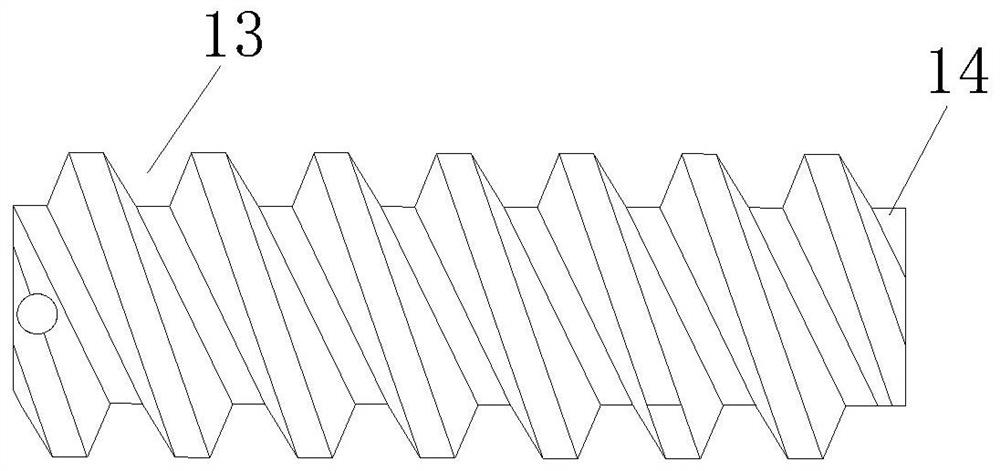

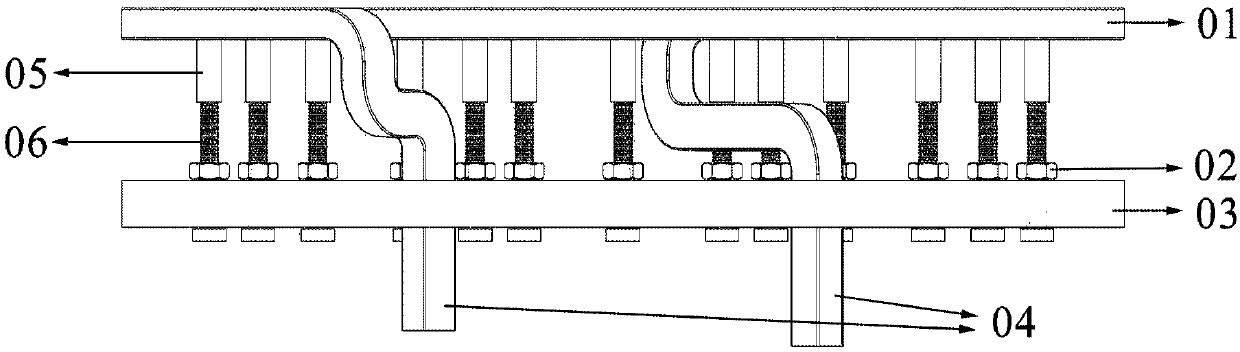

Abnormal channel array jet flow impact cold plate

InactiveCN103415190AIncrease profitGood temperature uniformityCooling/ventilation/heating modificationsJet flowEngineering

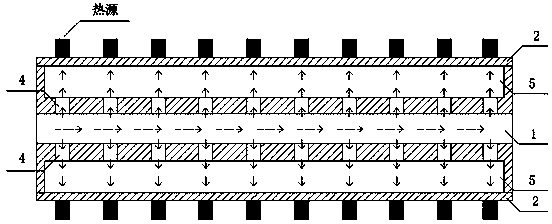

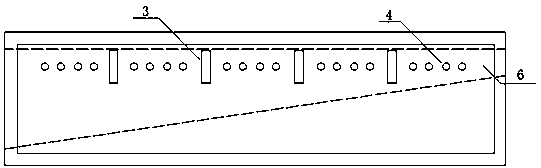

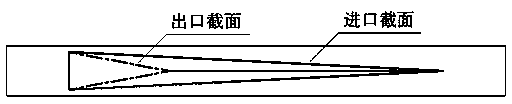

The invention discloses an abnormal channel array jet flow impact cold plate. The abnormal channel array jet flow impact cold plate comprises impact cavities and a middle layer, wherein the middle layer is located between the two impact cavities. The longitudinal section of a flow channel of the middle layer is triangular, and the area of the section is gradually reduced in the length direction, so that flow of all jet flow holes is equal. Reinforcing ribs are arranged inside the impact cavities, strength of the impact cavities is enhanced, and interference of turbulent flow between the jet flow holes is prevented.

Owner:NANJING UNIV OF SCI & TECH

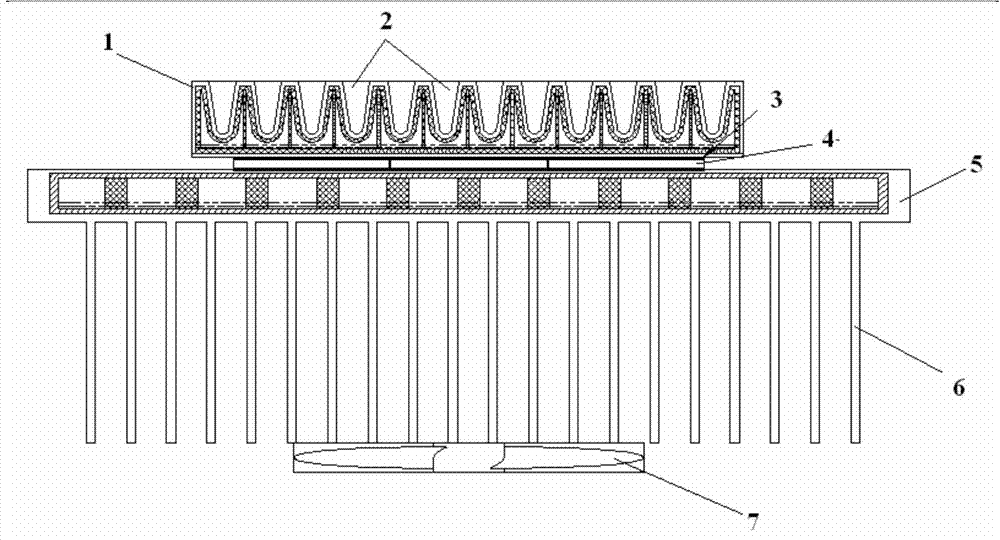

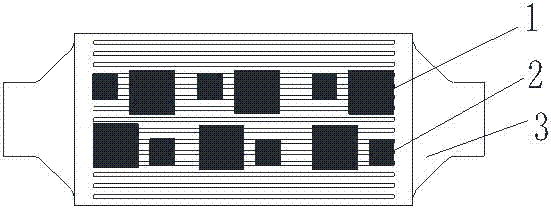

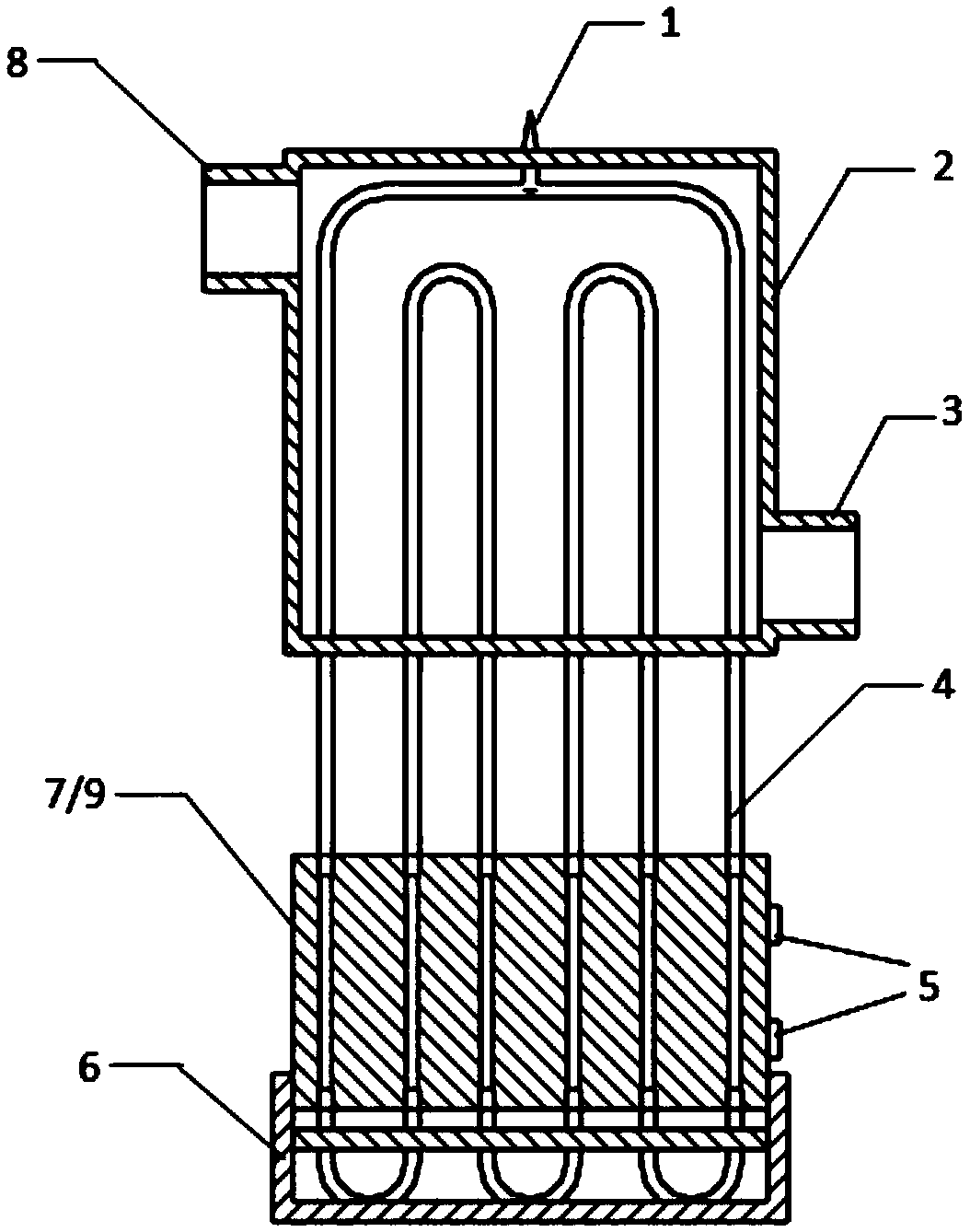

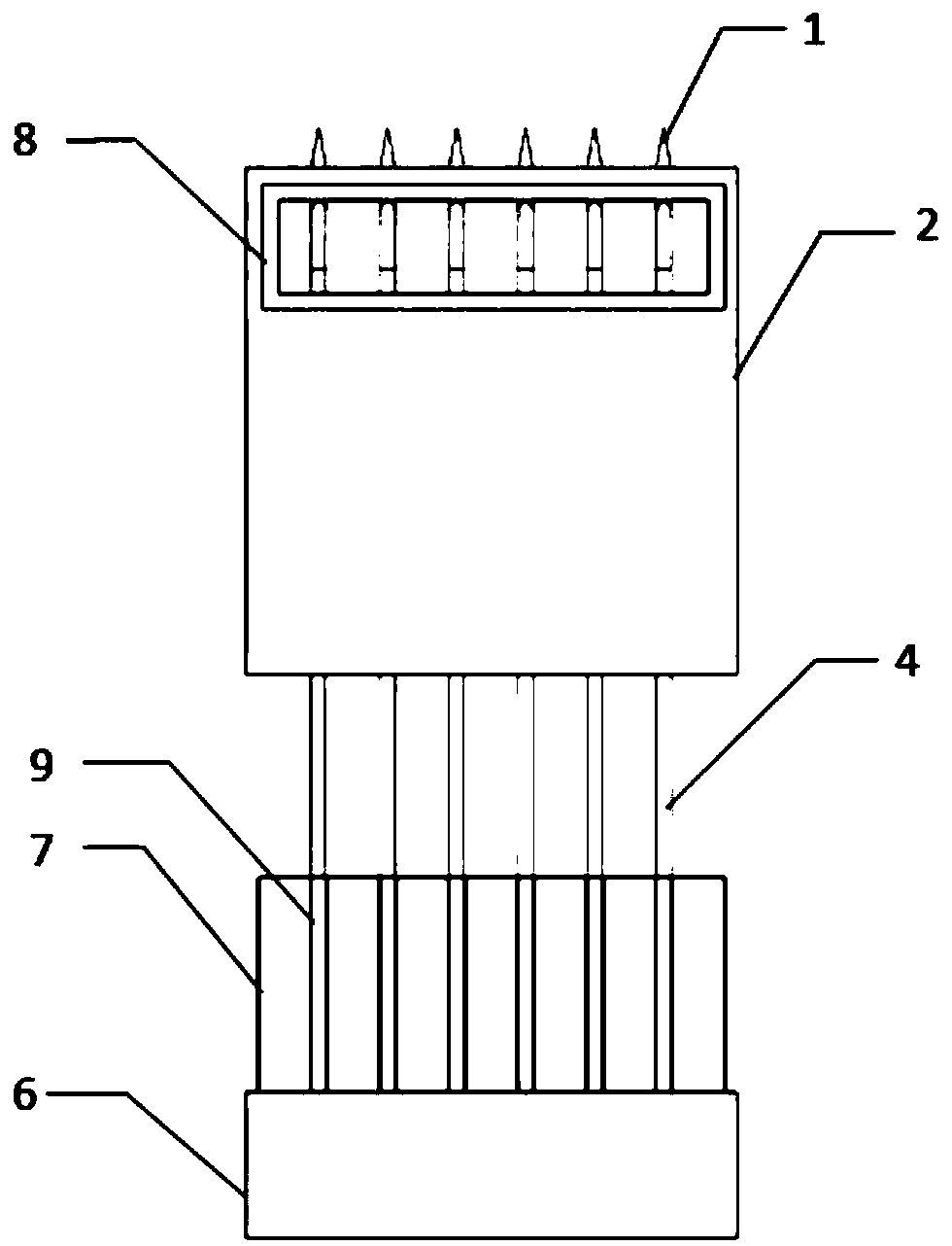

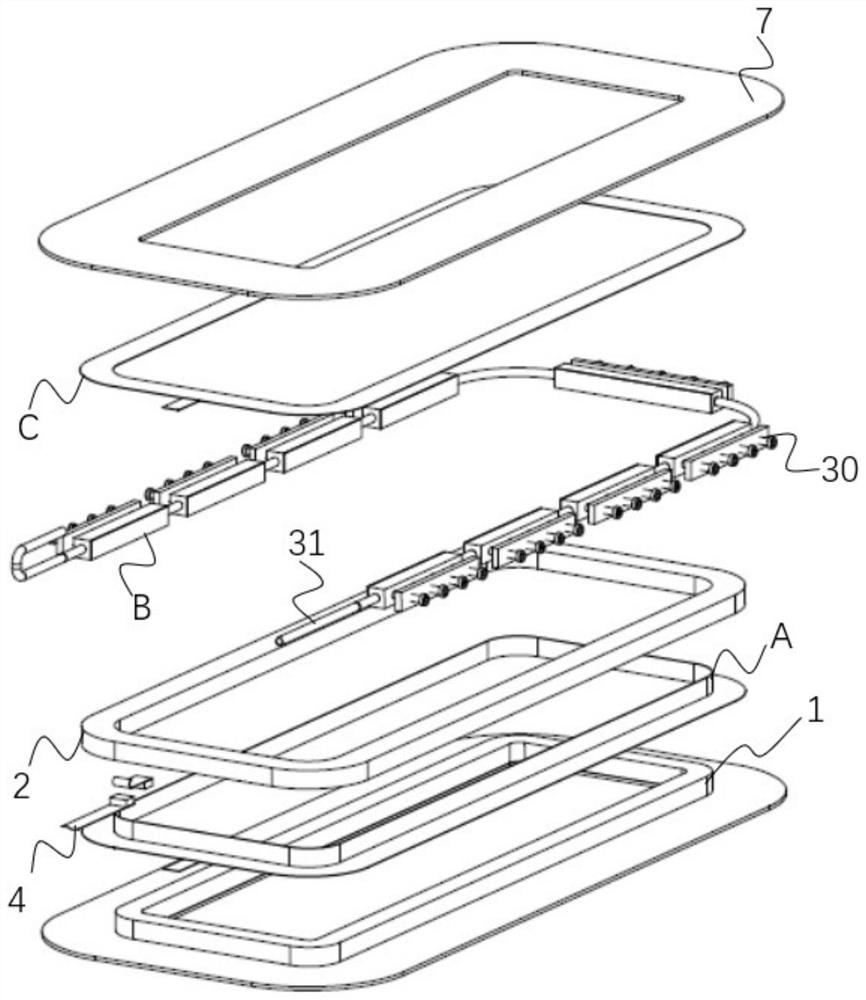

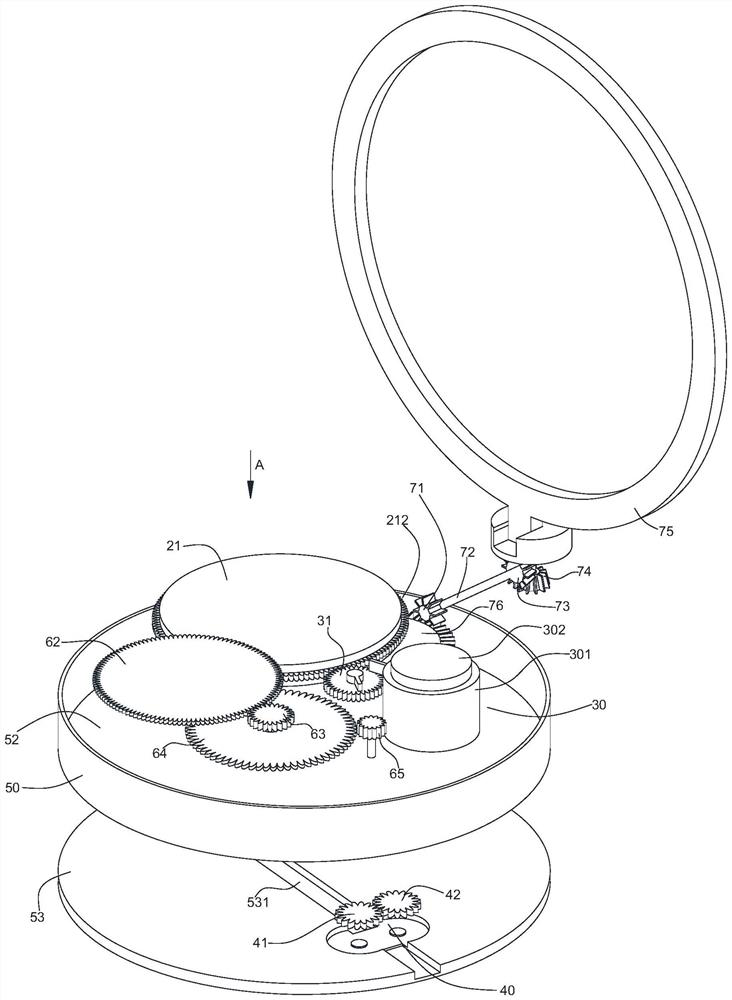

Thermal module for biochemical reaction

ActiveCN103752360AGood heat consistencyGood temperature uniformityHeating or cooling apparatusTest tubeHeat sink

The invention provides a thermal module for biochemical reaction. The thermal module is characterized in that a semiconductor heating-cooling fin is arranged on the bottom surface of a pedestal, wherein a thermal interface material layer is arranged between the top surface of the semiconductor heating-cooling fin and the bottom surface of the pedestal, a soaking plate is arranged on the bottom surface of the semiconductor heating-cooling fin, a thermal interface material layer is arranged between the bottom surface of the semiconductor heating-cooling fin and the top surface of the soaking plate, and the bottom surface of the soaking plate is mounted on cooling fins; a soaking plate temperature-equalizing cavity structure is machined in the soaking plate, and a pedestal temperature-equalizing cavity structure is machined in the pedestal. According to the thermal module, the temperature-equalizing cavity structure is arranged in the pedestal, the heating uniformity of the pedestal is high due to the temperature uniformity property of each point and ultra-low thermal resistance of a temperature-equalizing cavity, and the temperature uniformity of a test tube in each test tube hole is good; furthermore, by arranging the temperature-equalizing cavity structure between the pedestal and each cooling fin, two key problems of rapid heat transfer and uniform heat transfer are solved.

Owner:XIAN TIANLONG SCI & TECH

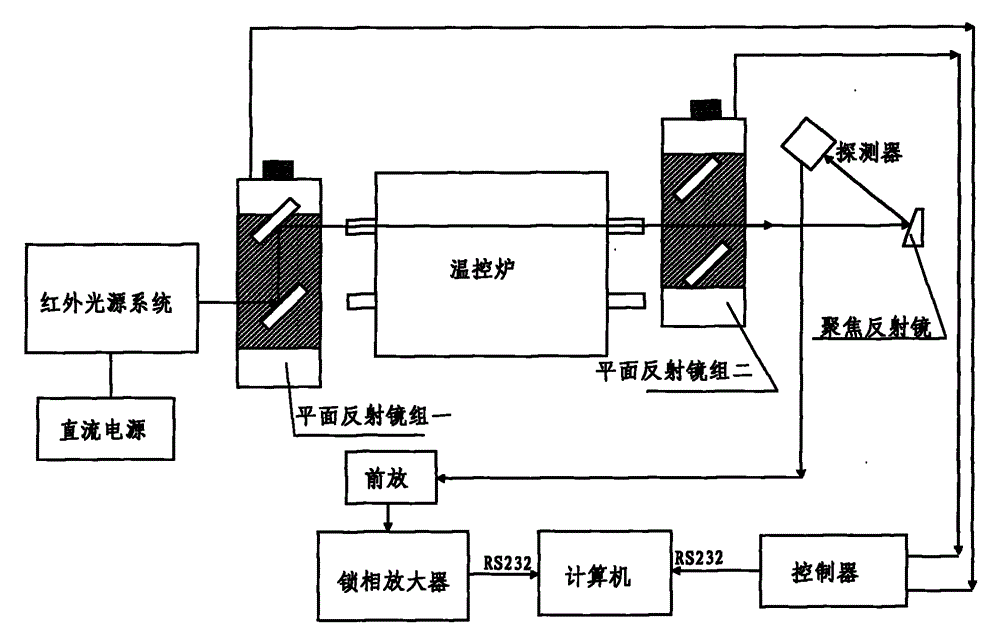

Optical material high temperature transmittance testing device

ActiveCN103185707AGood temperature uniformityImprove measurement accuracyTransmissivity measurementsPhysicsOptical path

The invention discloses an optical material high temperature transmittance testing device. The device adopts a silicon carbide rod as an infrared source, adopts a narrow band filter for filtering and providing infrared monochromatic light, adopts a chopper to modulate the infrared light, adopts a precise temperature control furnace to heat a sample material, uses the alternating current phase locked amplification technology to measure an infrared signal, and uses a planar reflecting mirror group to split one beam of infrared light into two beams for a sample light path and a reference light path respectively. As a result, the high temperature transmittance of the infrared band with temperature ranging from room temperature to 700 DEG C and wavelength ranging from 1 micron to 14 microns can be measured.

Owner:中国兵器工业第二0五研究所

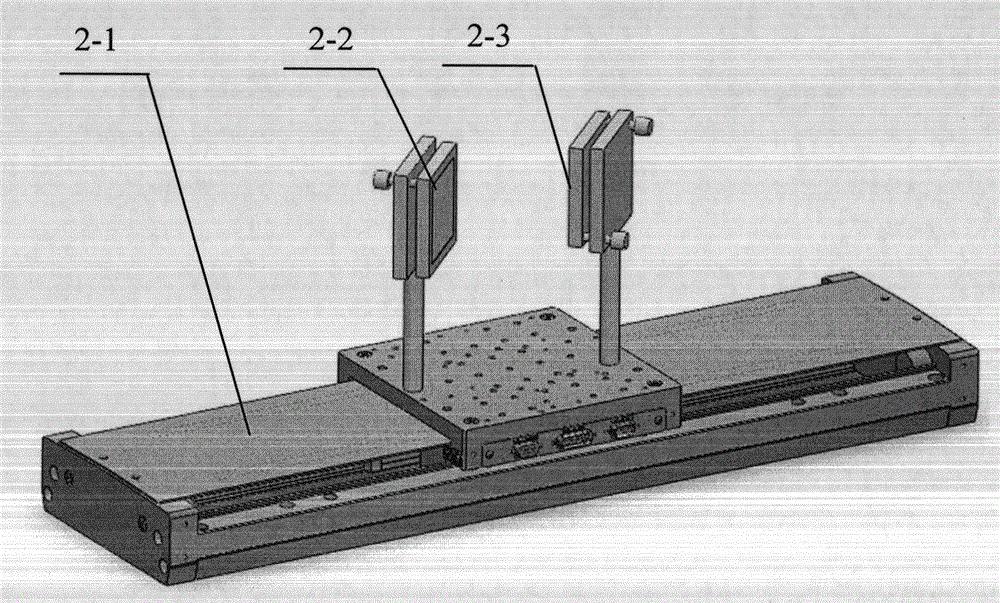

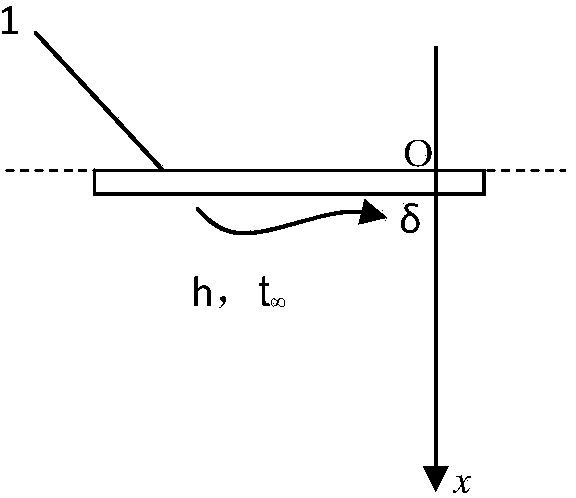

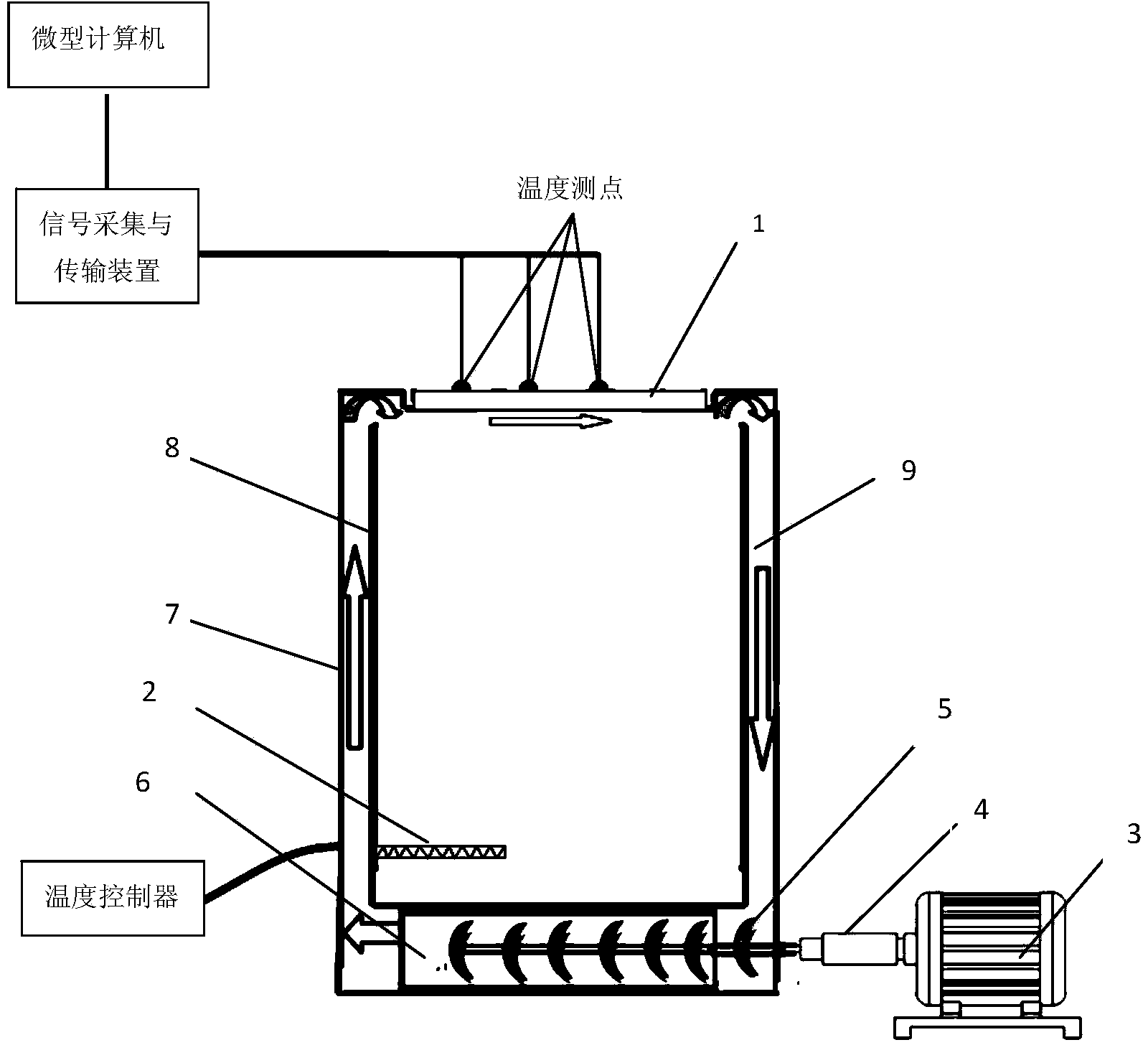

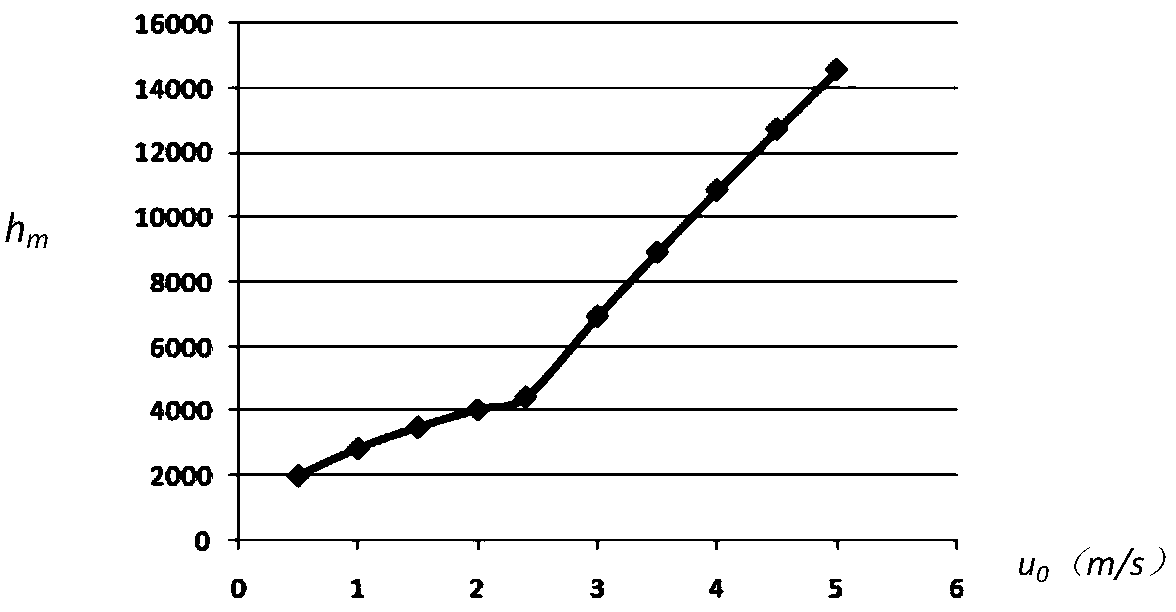

Method and system for testing thermal diffusion coefficient of solid material

ActiveCN103954650AGood temperature uniformityGuaranteed test accuracyMaterial heat developmentWater circulationTest sample

The invention relates to the technical field of test of thermophysical parameters of materials and discloses a method and a system for testing a thermal diffusion coefficient of a solid material. The method comprises the following steps: generating a circulating water flow in a water circulation system, contacting the circulating water flow with one side of a flat sample, and performing heat convection, wherein a heat convection coefficient between the circulating water flow and the sample surface is large enough, so that a Boit number Bi goes to infinity; controlling the temperature of the circulating water flow through a temperature control system, so that constant temperature is kept; acquiring surface temperature change on an insulating side of the flat sample through a temperature acquisition and analysis system, and calculating to obtain the thermal diffusion coefficient value of the tested sample through a mathematical model. High-temperature circulating water serves as a heat source, thermal contact resistance does not exist between the heat source and the tested sample, and enough test precision is guaranteed. The Boit number is controlled, so that the heat exchange process under the first type of boundary conditions is realized between the water and a sample surface, and an aim of directly calculating the thermal diffusion coefficient is achieved.

Owner:ANHUI UNIV OF SCI & TECH

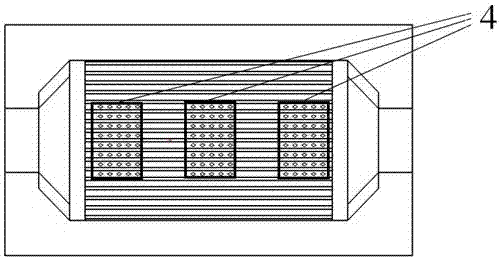

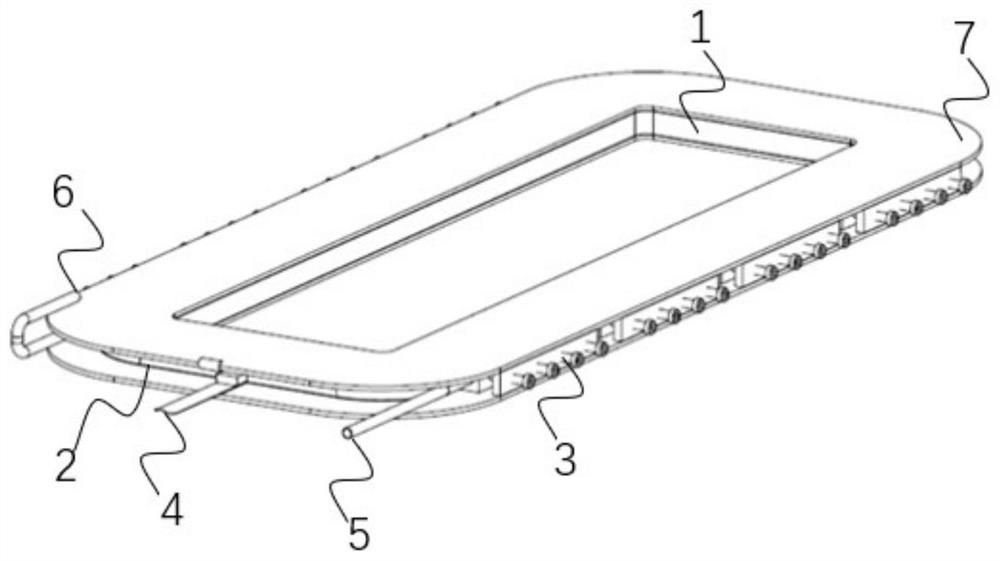

Modular IGBT liquid-cooled plate and manufacturing method thereof

PendingCN107275300AUniform channel flow distributionGood temperature uniformitySemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

The invention discloses a modular IGBT liquid-cooled plate and a manufacturing method thereof. The IGBT liquid-cooled plate comprises a substrate. First and second liquid flow tanks are arranged in series in the upper end of the substrate. The first liquid flow tanks are provided in a communication manner with a liquid inlet flow path, and the second liquid flow tanks are provided in a communication manner with a liquid outlet flow path. The first and second liquid flow tanks are connected through an intermediate liquid flow path. The first and second liquid flow tanks are both formed by connection of a plurality of liquid flow grooves of the same size in parallel. A sealing ring for sealing IGBT modules is arranged above the substrate. A cover plate covering the substrate and the sealing ring is arranged above the substrate. In the invention, the channel flow distribution under each IGBT module is uniform through the IGBT liquid-cooled plate, the surface of the liquid-cooled plate has good temperature uniformity, the pressure drop of the inlet and outlet is controlled within a reasonable range, the heat dissipation is high, and the overall sealing property is good.

Owner:SOUTH CHINA UNIV OF TECH +1

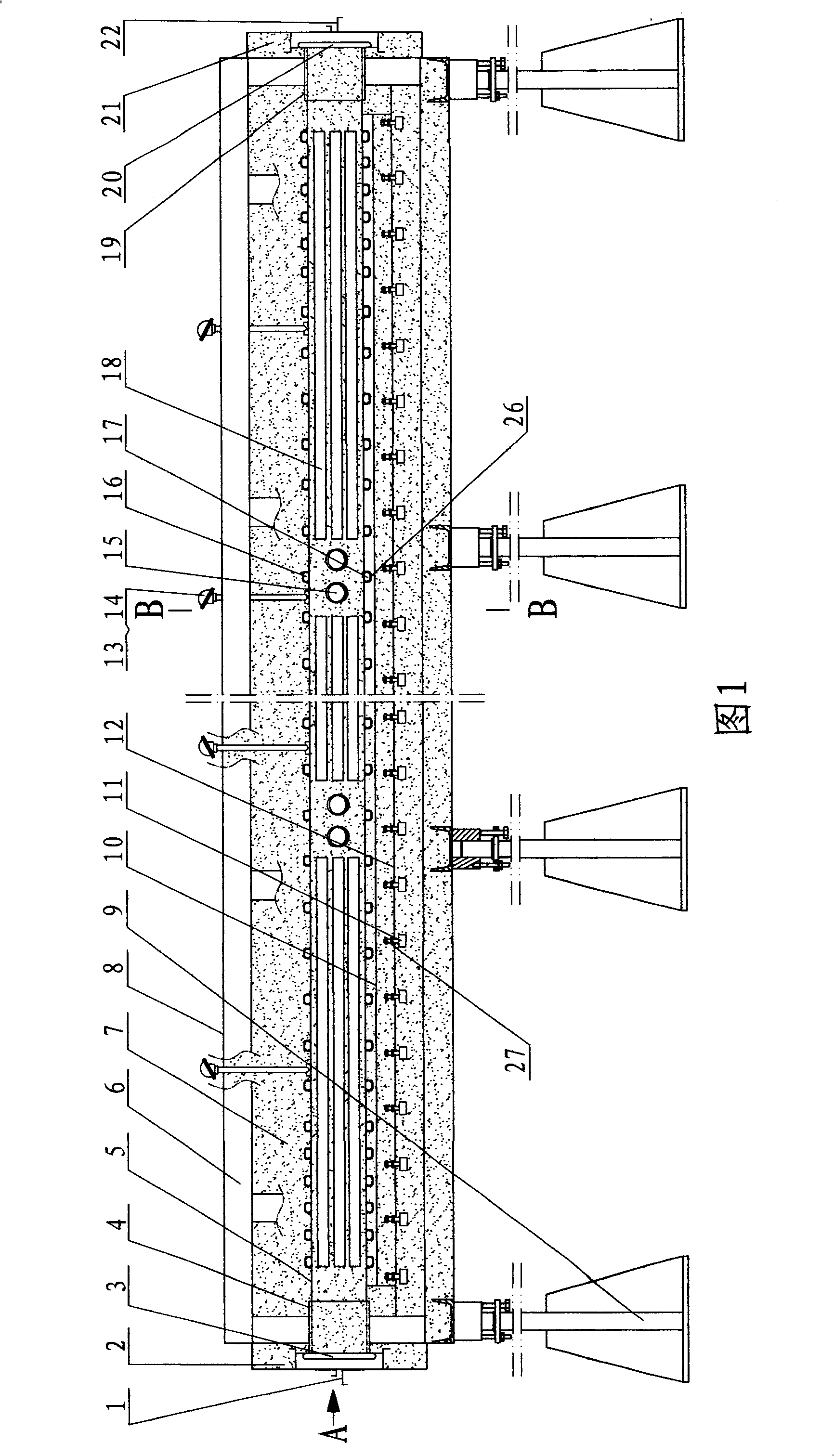

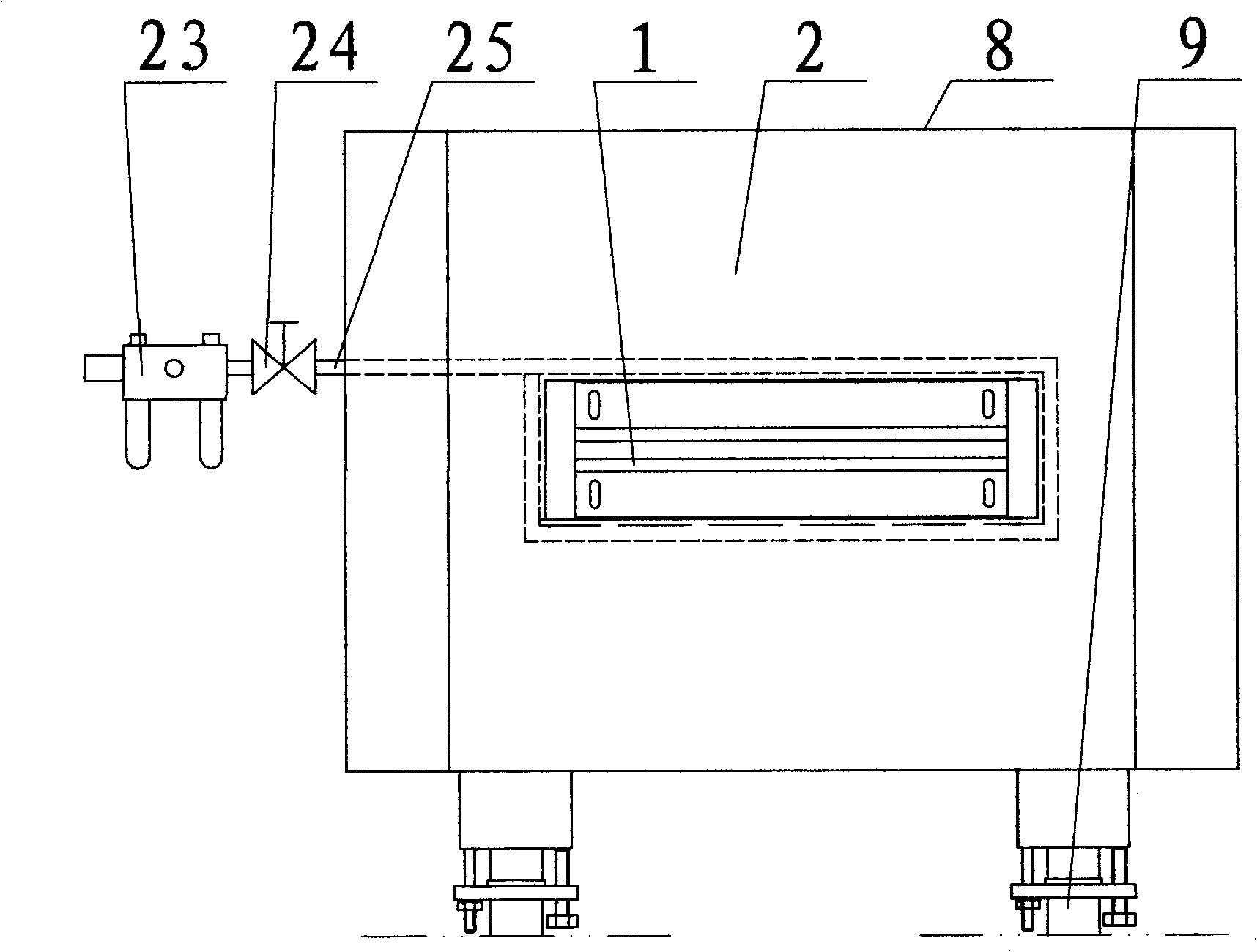

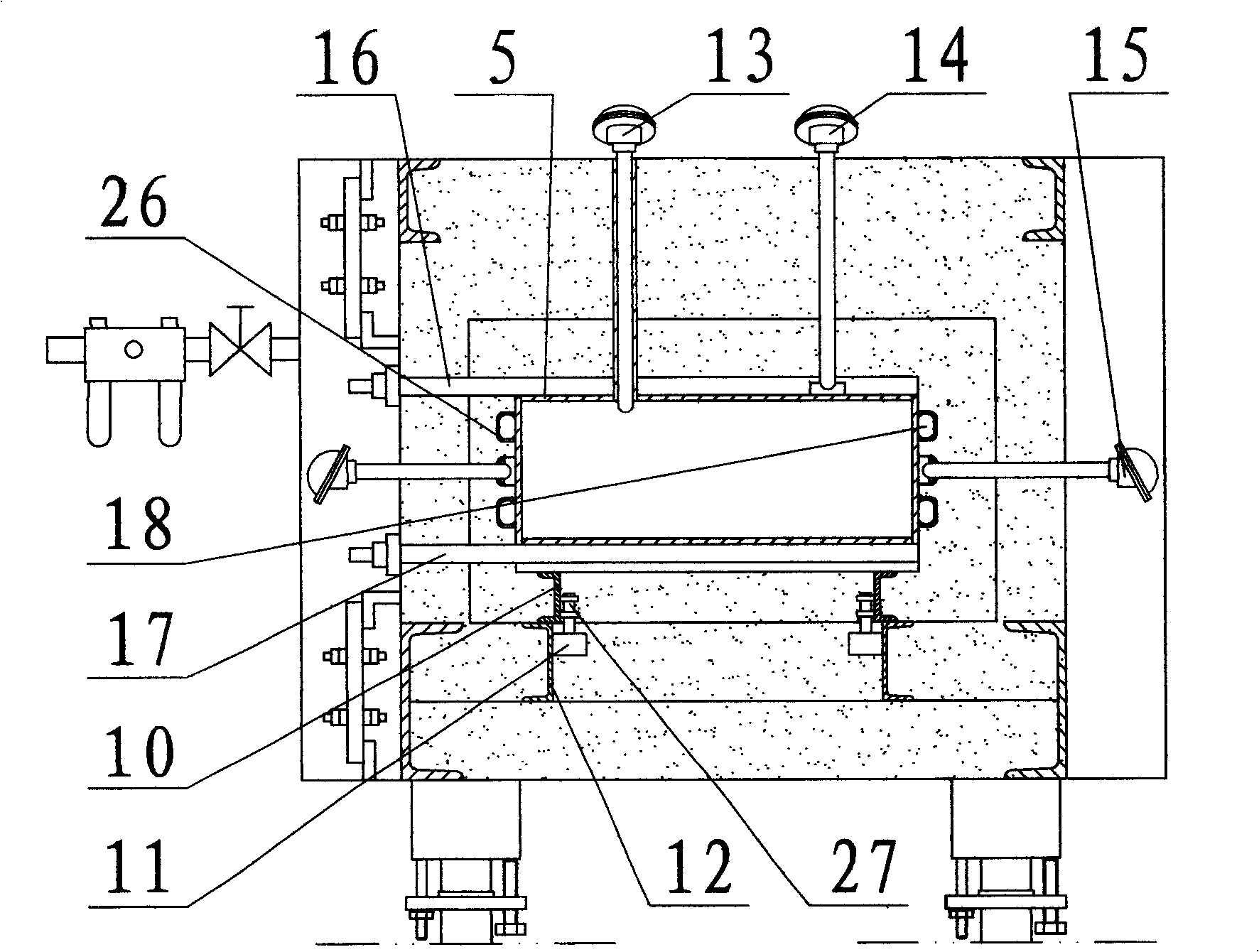

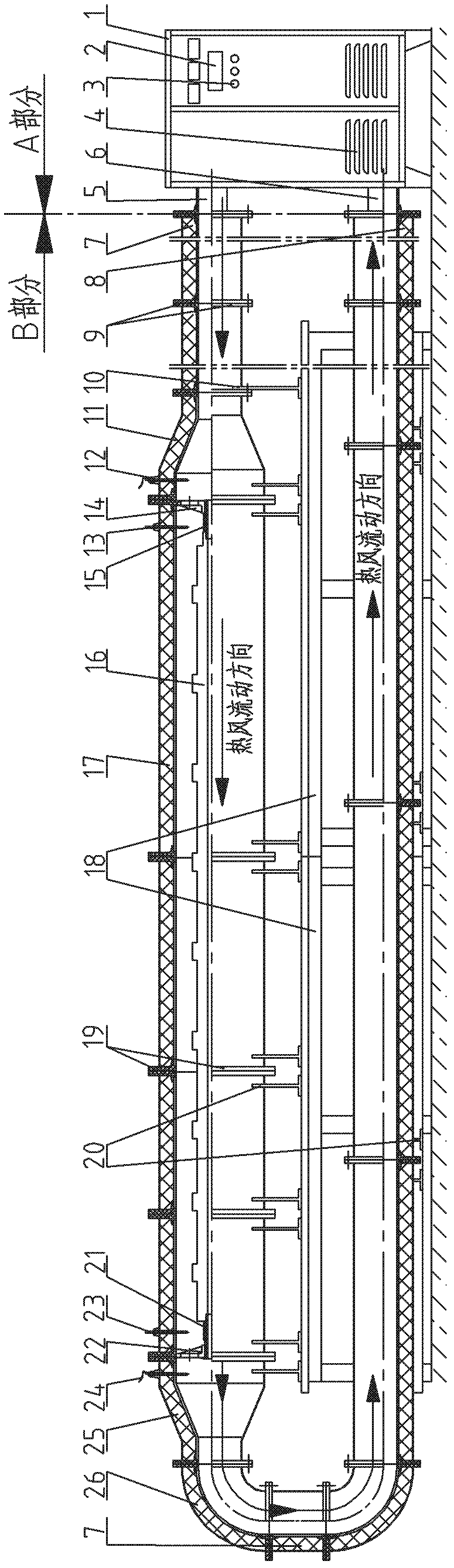

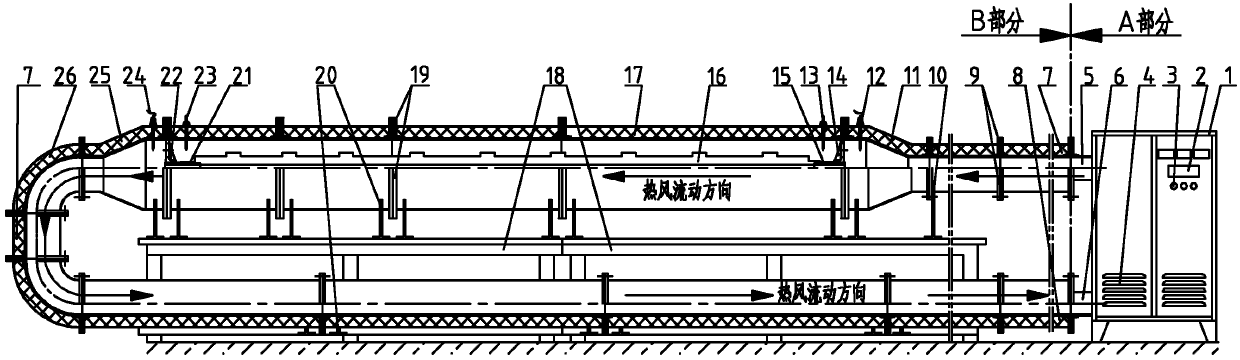

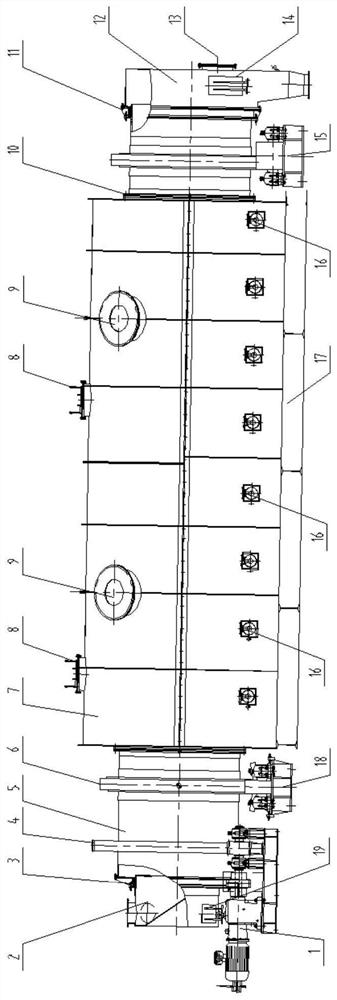

Super strength high molecule fibre intelligent high temperature thermo-setting machine

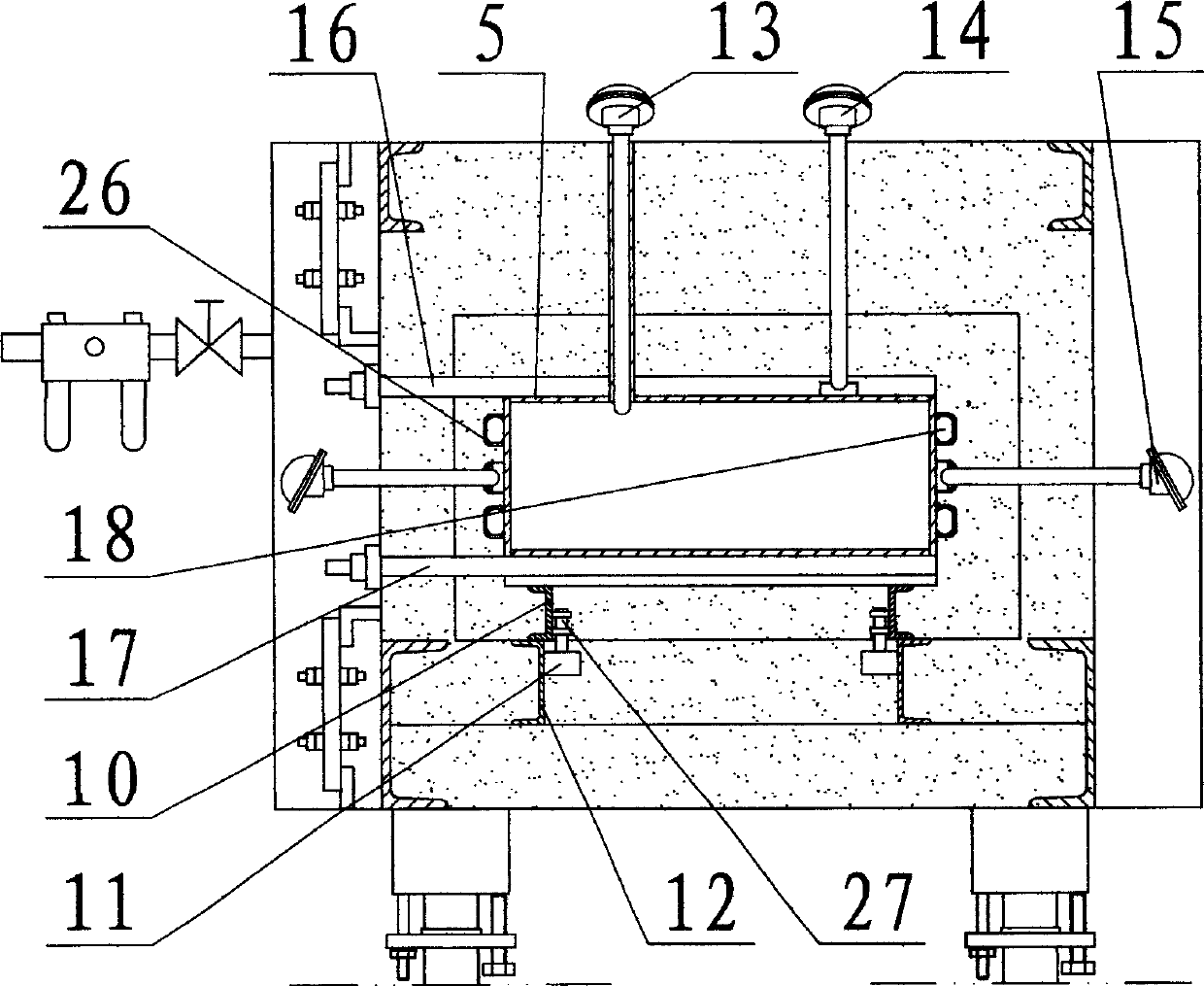

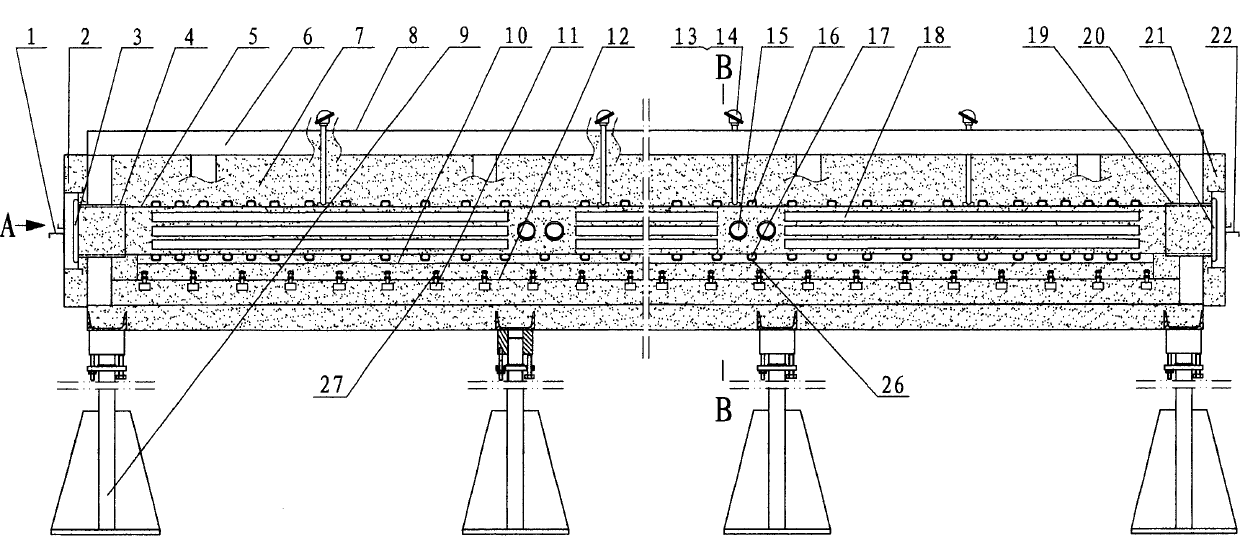

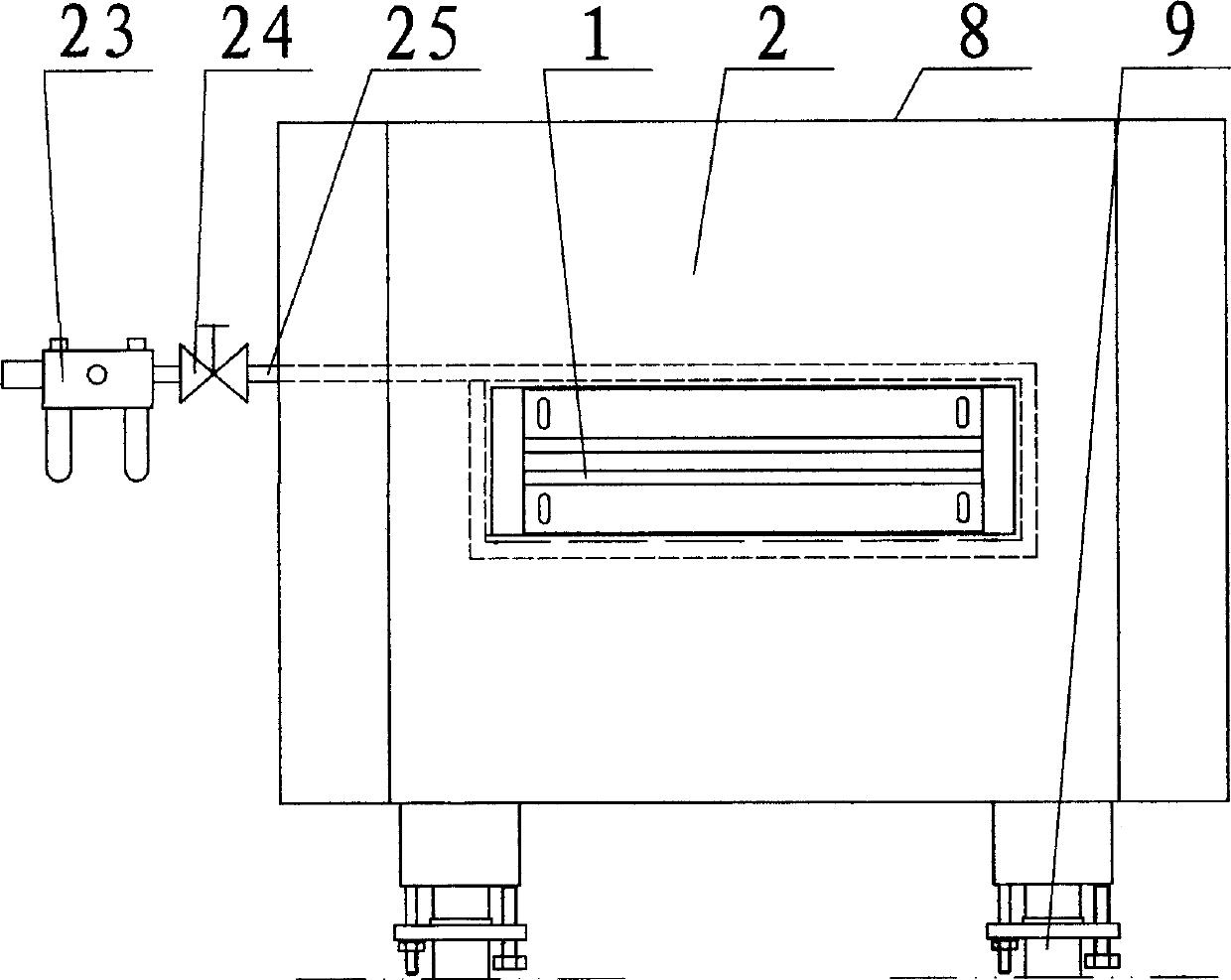

InactiveCN101245496APrevent leakageMeet the process requirements of high temperature heat settingFilament manufactureHeating/cooling textile fabricsElectrical controlEngineering

The invention discloses an intelligent high temperature thermal shaping machine for ultra intense polymer fiber. The machine comprises an electrical heater, thermoscopes, an electric control device, a shell, and adjustable feet, and further comprises an inner cavity body, a left end expansion joint, a right end expansion joint, a left end seal, a right end seal and a port sealing device. Inner holes of the left end expansion joint and the right expansion joint are internally and respectively penetrated and covered by the two ends of the inner cavity body, and the two ends can move in the inner holes. The electrical heater has flat shaped structure and is longitudinally arranged on the upper surface and the lower surface of the inner cavity body and transversely arranged on the two side faces of the inner cavity. The thermoscopes are arranges above the inner cavity body along the width direction in two lines; probes of one line of the thermoscopes are inserted into the inner cavity body, and the probes of the other line are contacted with the surface of the inner cavity body. Insulation cotton is filled into the space between the inner cavity body and the external side board arranged on a machine frame. The machine can meet the technique requirement of high temperature thermal shaping for tow in the production process of aramid and save energy.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

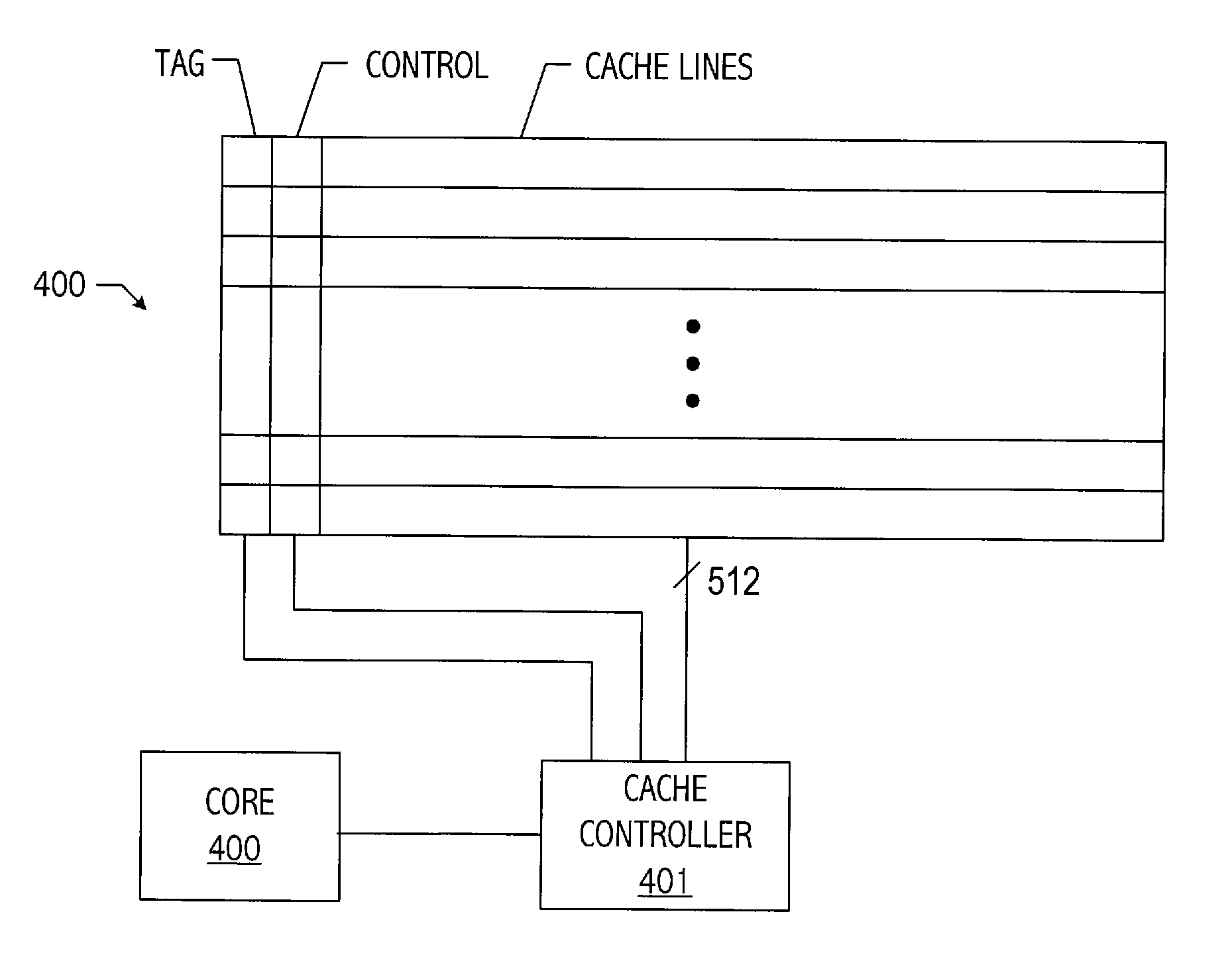

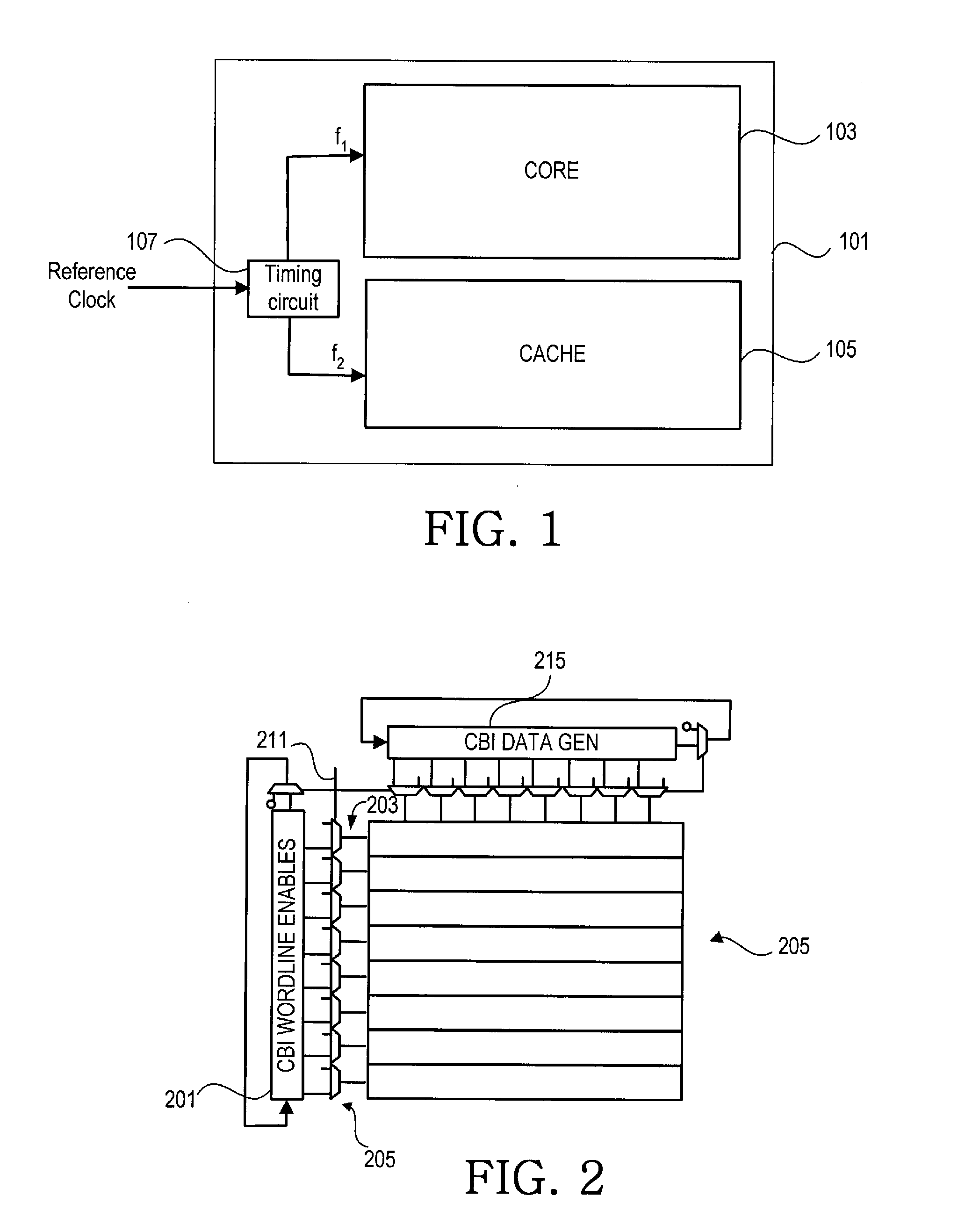

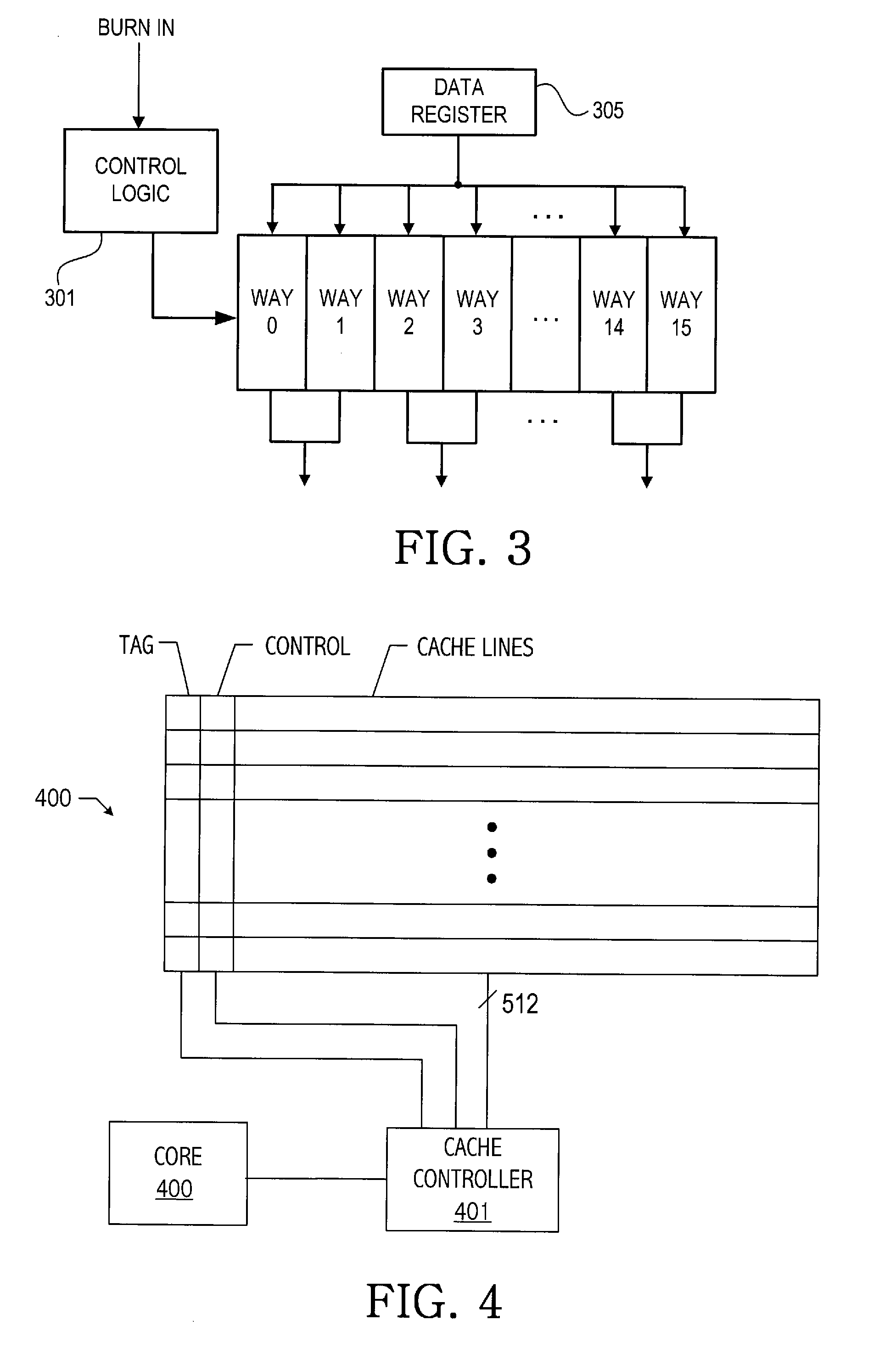

Method and apparatus to achieve more level thermal gradient

ActiveUS20080147976A1Good temperature uniformityIncrease activityMemory adressing/allocation/relocationDigital storageIntegrated circuitAcceleration Unit

Achieving better uniformity of temperature on an integrated circuit while performing burn-in can result in reduced burn-in time and more uniform acceleration. One way to achieve better temperature uniformity is to control dynamic power in the core and cache by operating at different frequencies and increasing switching activity in the cache(s) during burn-in by changing operation of the cache so that during burn-in a plurality of memory locations in the cache(s) are accessed simultaneously, thereby increasing activity in the cache to achieve higher power utilization in the cache during burn-in.

Owner:ADVANCED MICRO DEVICES INC

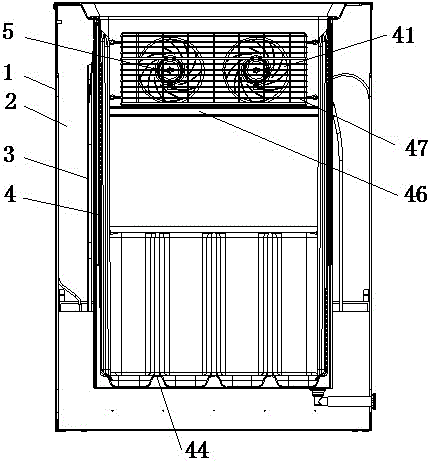

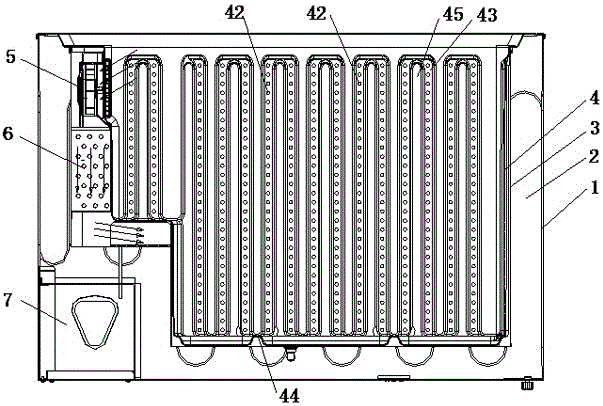

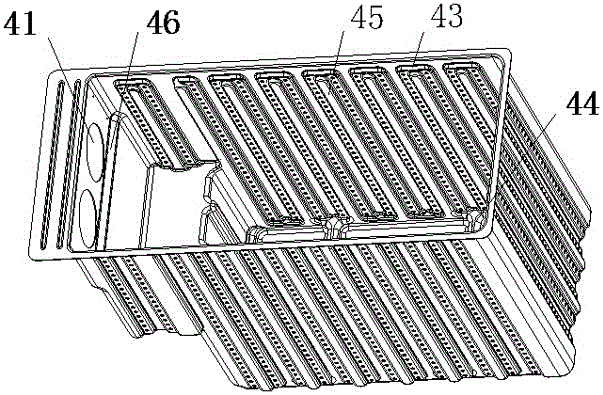

Air-cooled frostless horizontal refrigerator and manufacturing method thereof

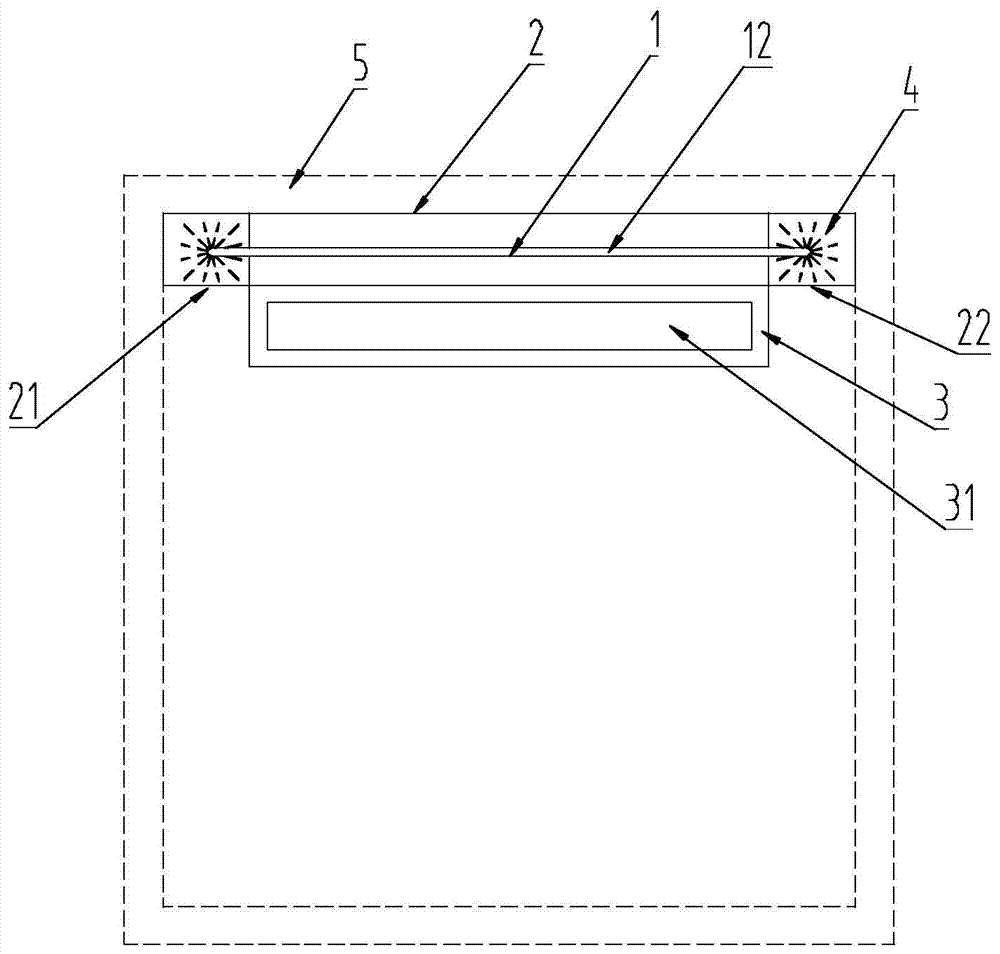

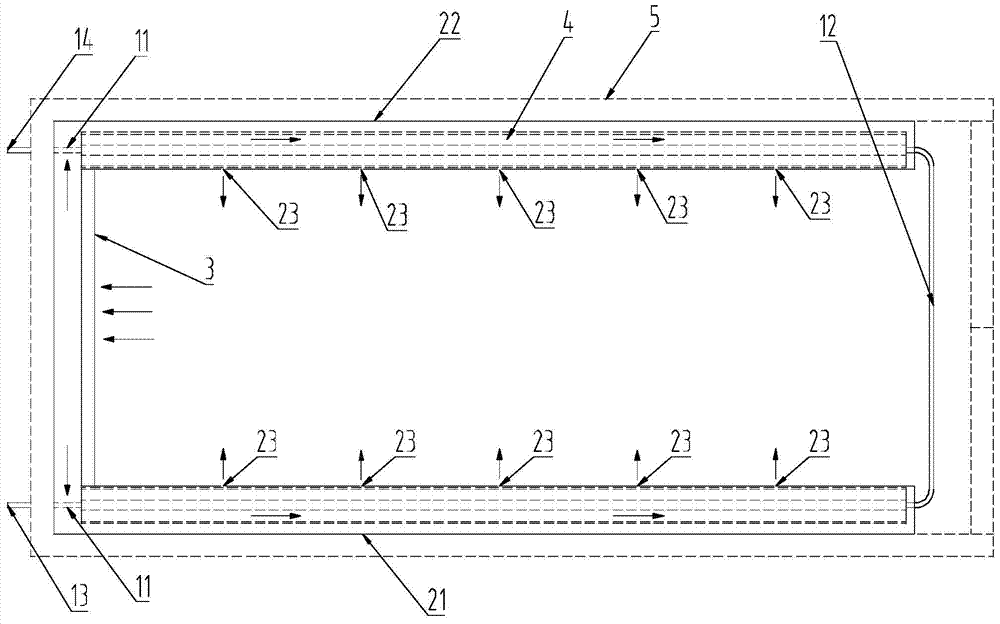

ActiveCN106839575AFast coolingGood temperature uniformityLighting and heating apparatusDomestic refrigeratorsInterior spaceAirflow

Owner:HISENSE RONSHEN GUANGDONG FREEZER

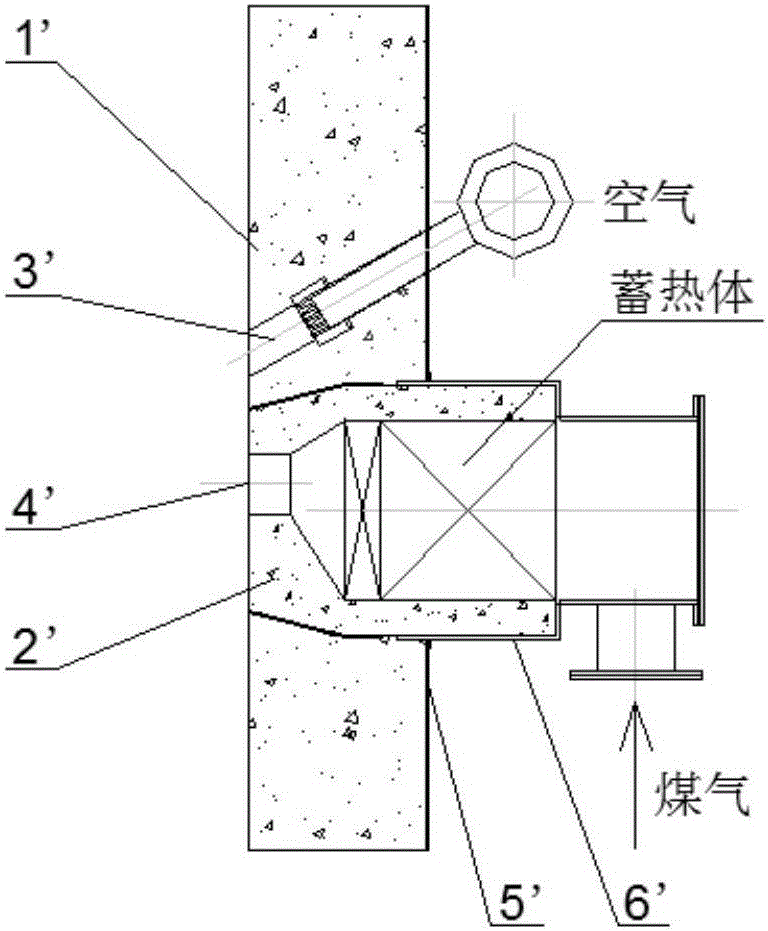

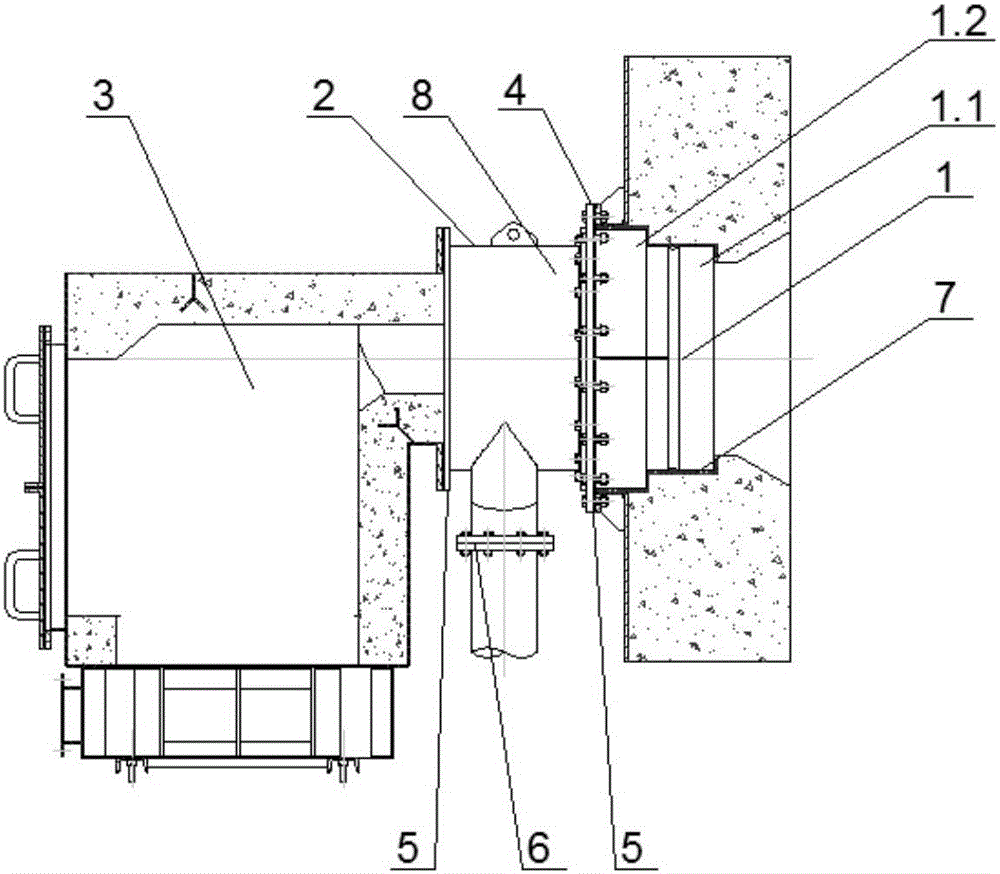

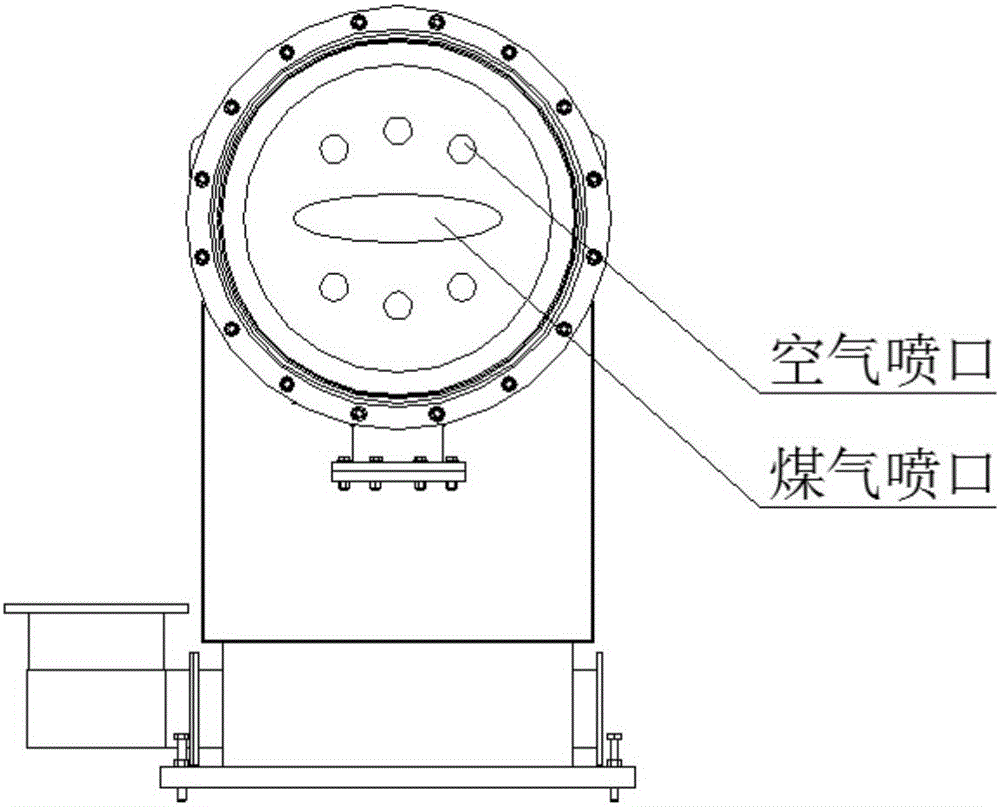

Heat accumulating type burner for heating furnace

ActiveCN105002317AImprove combustion efficiencyGood temperature uniformityBlast furnace detailsProcess engineeringCombustion

The invention discloses a heat accumulating type burner for a heating furnace. The heat accumulating type burner comprises a burner block part, an air inlet unit, a thermal storage tank, a first flange arranged between the burner block part and the furnace wall, second flanges arranged on the two sides of the air inlet unit and a third flange arranged between the air inlet unit and an air pipeline, wherein the air inlet unit is arranged between the burner block part and the thermal storage tank; the burner block part comprises a burner block prepared from high temperature resistant and flushing resistant mullite castabale, and a metal shell part; during production, the two parts are poured to form an integral body; an air channel and a coal gas channel are combined on the separate burner block; the structure of the burner is the same as that of the conventional burner, namely, the inner ring is a coal gas nozzle, and the outer ring is an air nozzle, so that combustion is effectively implemented. According to the invention, the heat accumulating type burner is high in combustion efficiency, changeable and good in temperature uniformity, and solves a plurality of defects of the conventional heat accumulating type burner; the product quality is improved; the enterprise cost is reduced; the working condition of workers is improved.

Owner:FIVES STEIN METALLURGICAL TECH SHANGHAI CO LTD

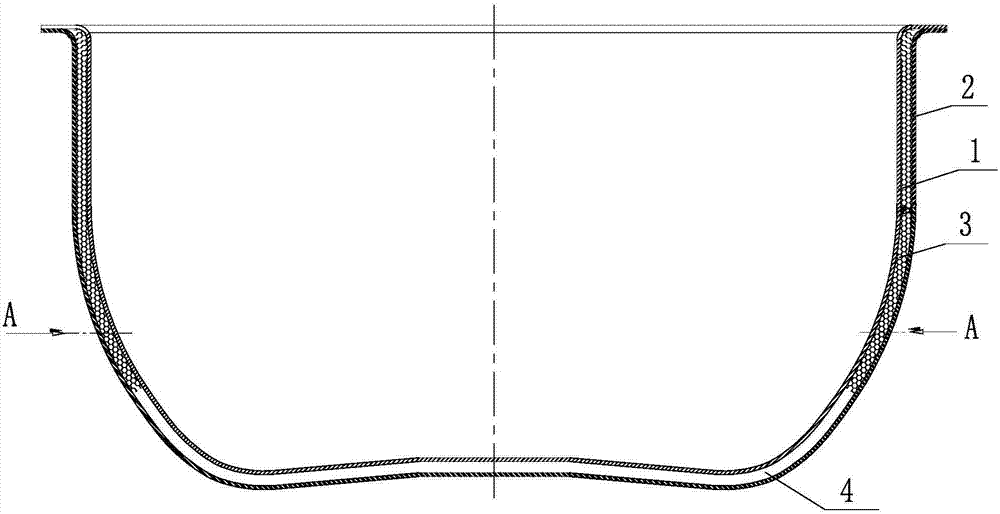

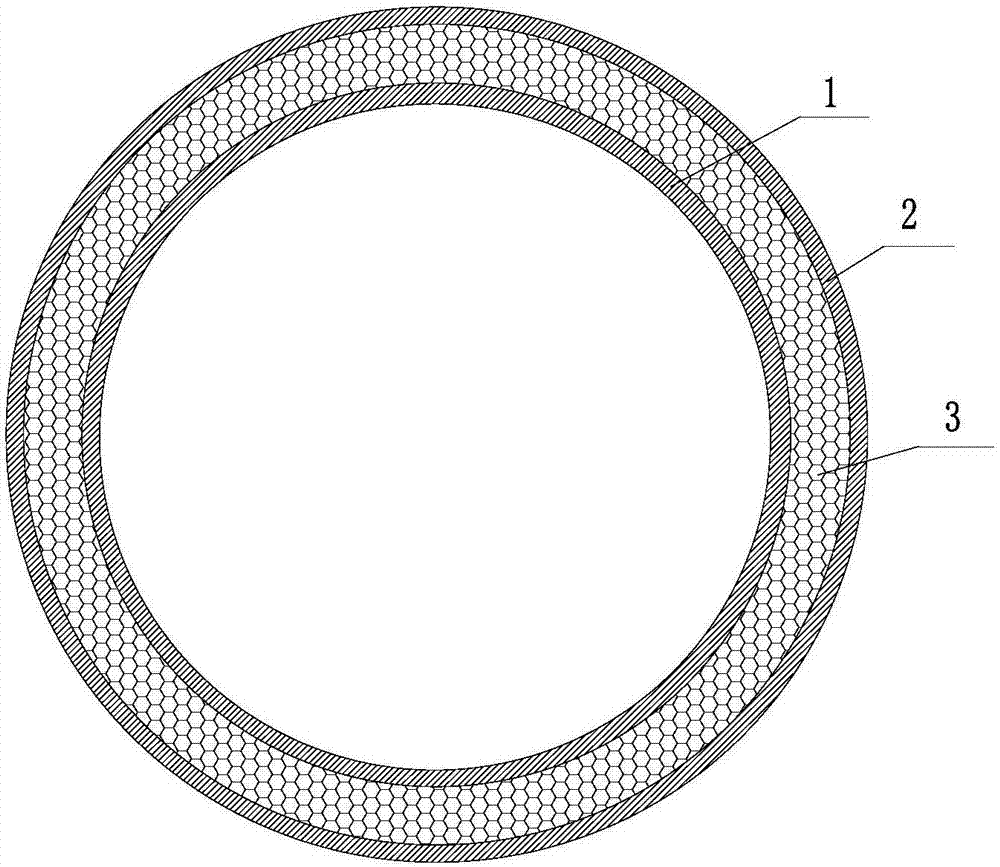

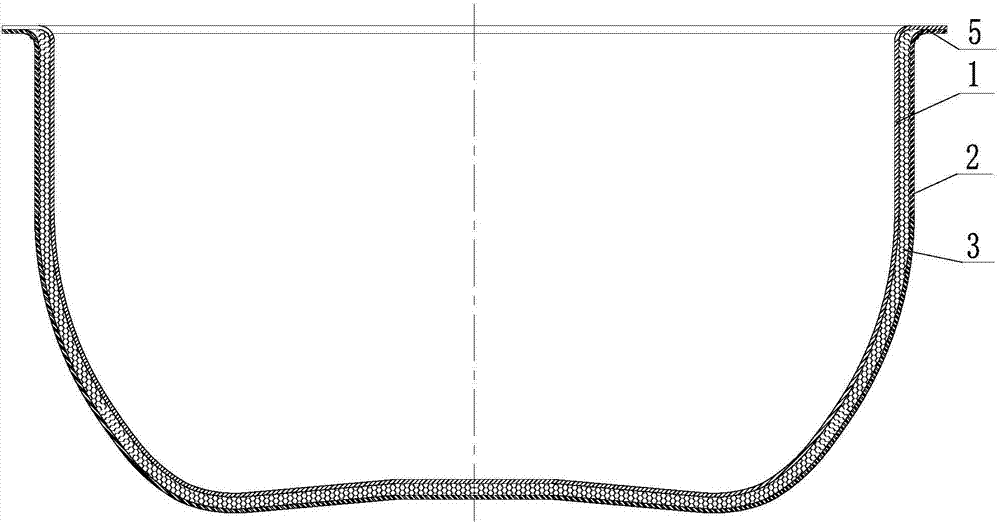

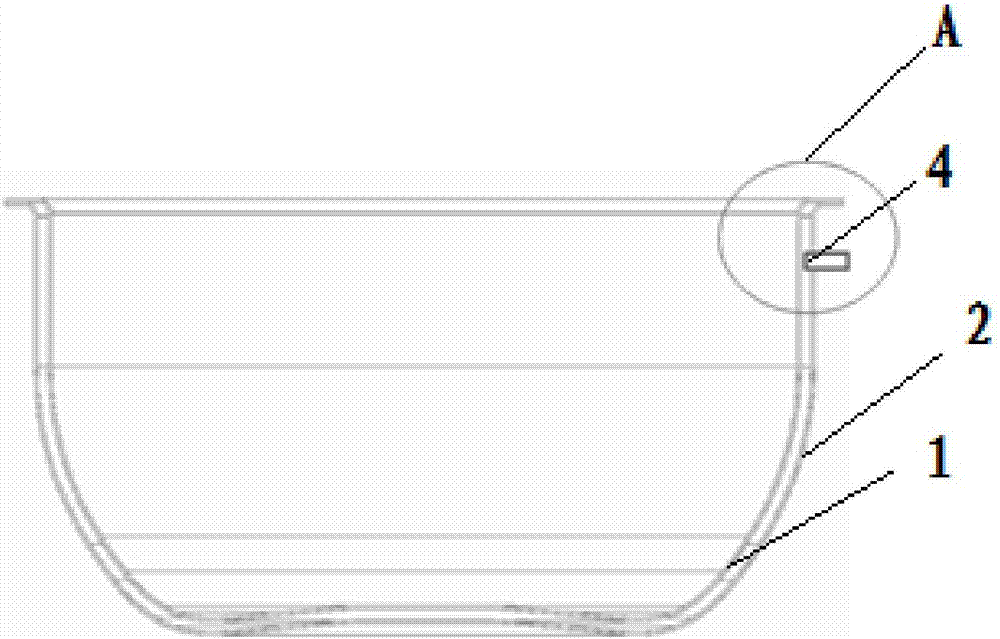

Temperature-uniformizing non-stick cooker

ActiveCN107397424AGood effectGood temperature uniformityCooking vessel constructionsCookerEngineering

The invention relates to a temperature-uniformizing non-stick cooker which comprises an inner pot, an outer pot and a liquid absorbing core, wherein the outer pot sleeves the outer side of the inner pot, and the upper end of the outer pot is in sealed connection with the upper end of the inner pot to form a sealed vacuum cavity; the liquid absorbing core is of an annular structure, sleeves the outer side of the inner pot and is located in the vacuum cavity, or the liquid absorbing core fills the vacuum cavity. The liquid absorbing core is fixed to the outer side wall of the inner pot and / or the inner side wall of the outer pot. A liquid phase change working medium capable of being converted into a gaseous state from a liquid state when heated is arranged in the vacuum cavity. By arrangement of the liquid absorbing core which is of the annular structure and sleeves the outer side of the inner pot, the temperature in the cooker tends to be uniform more quickly, and the cooker is better in temperature-uniformizing and non-stick effect. By using the liquid absorbing core to fill the vacuum cavity, a temperature uniformizing effect can be better, the condensed liquid phase change working medium can flow back to the cooker bottom more quickly, and the time for uniformizing the temperatures of the upper portion and the lower portion of the cooker is shortened.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD

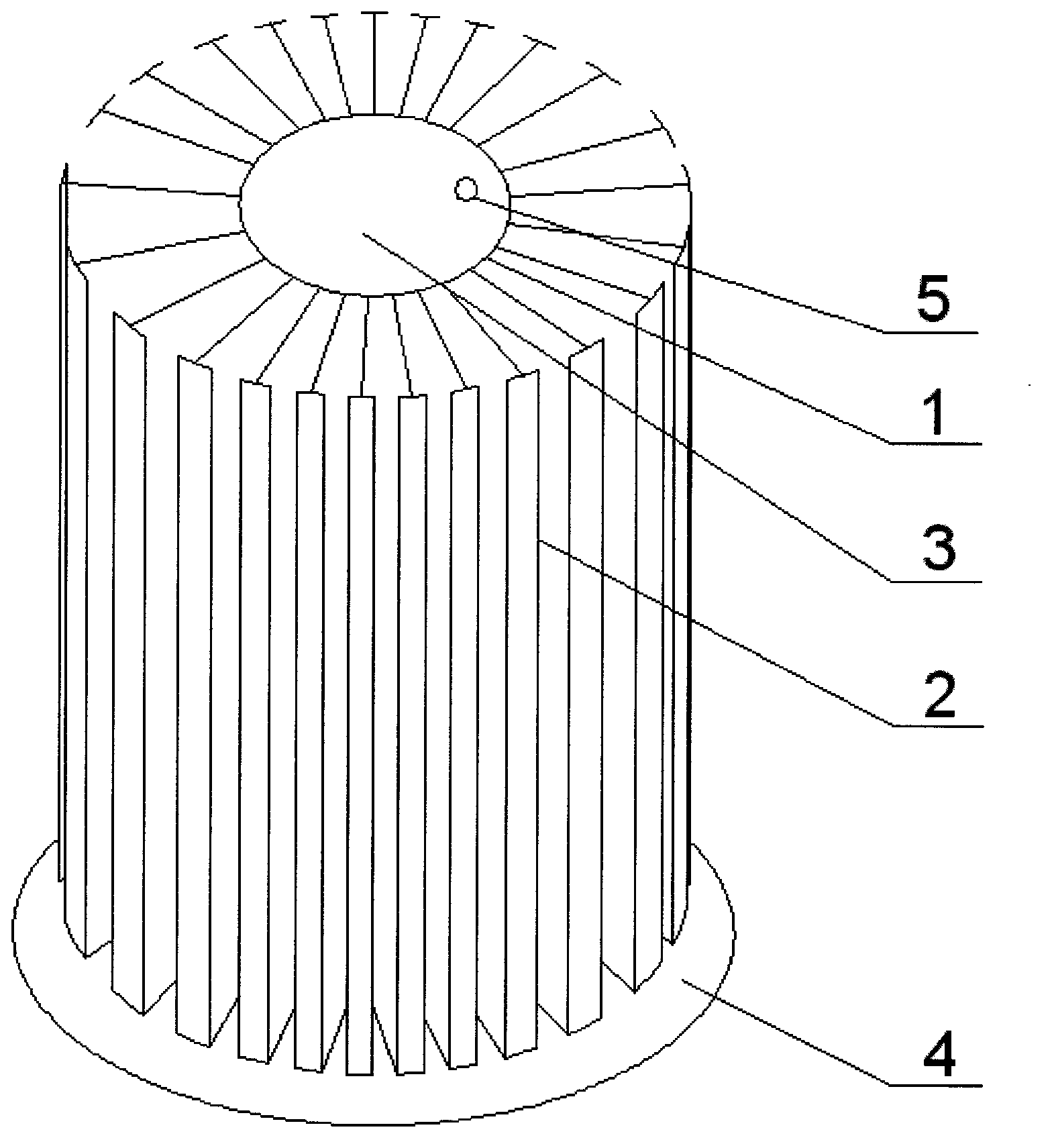

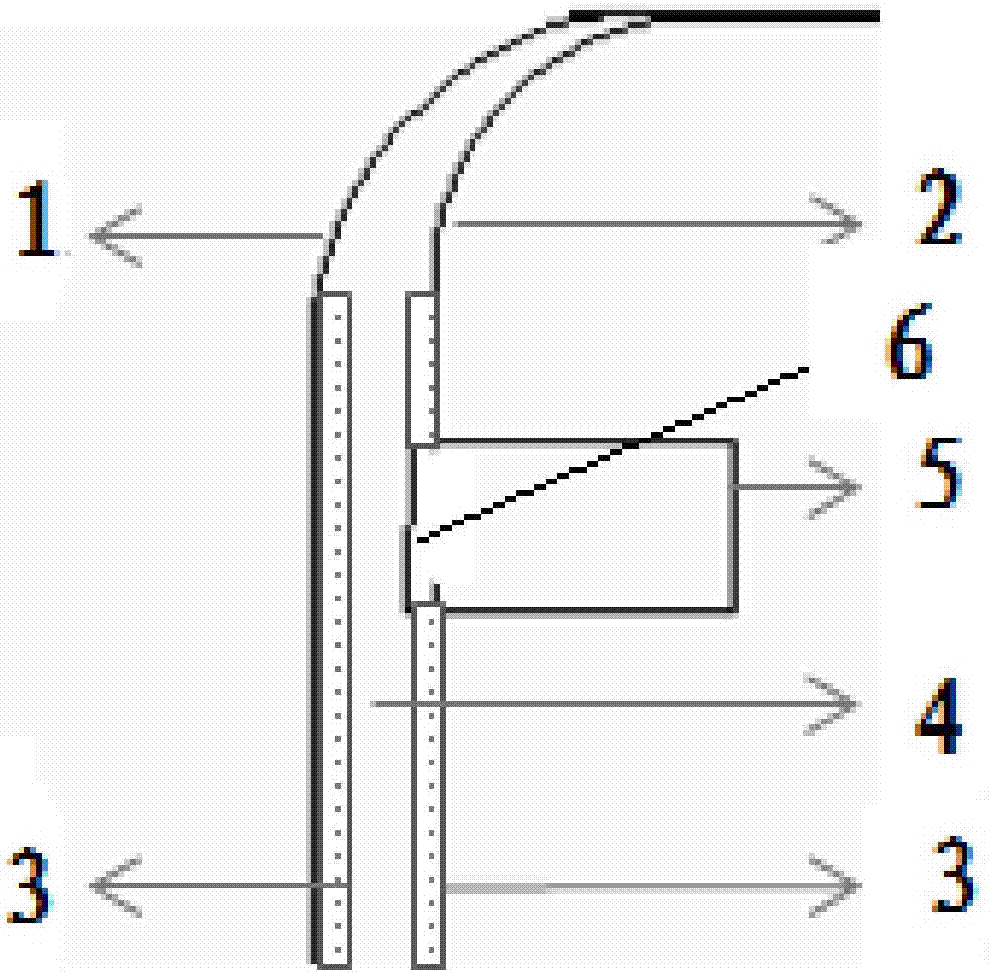

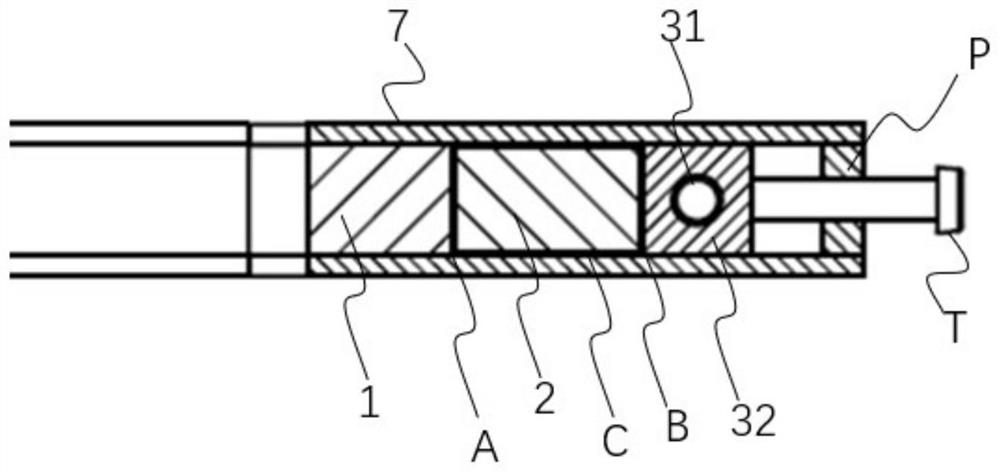

Movable heat pipe radiator used for heating coal stove

InactiveCN103900405AGood thermal conductivityGood temperature uniformityIndirect heat exchangersTubular elementsCoalEngineering

The invention provides a movable heat pipe radiator used for a heating coal stove. The movable heat pipe radiator comprises a heat-conducting pipe (1), radiating fins (2), a pipe opening sealing head (3), a sealing head end plate (4) and a working medium pouring opening (5). By means of the movable heat pipe radiator used for the heating coal stove, the radiating area of the heating coal stove can be increased, radiating ability and radiating efficiency of the heating coal stove are improved, and efficient heating, emission reduction and energy saving are achieved. The movable heat pipe radiator is light in weight, low in price and easy to manufacture.

Owner:陈庆山

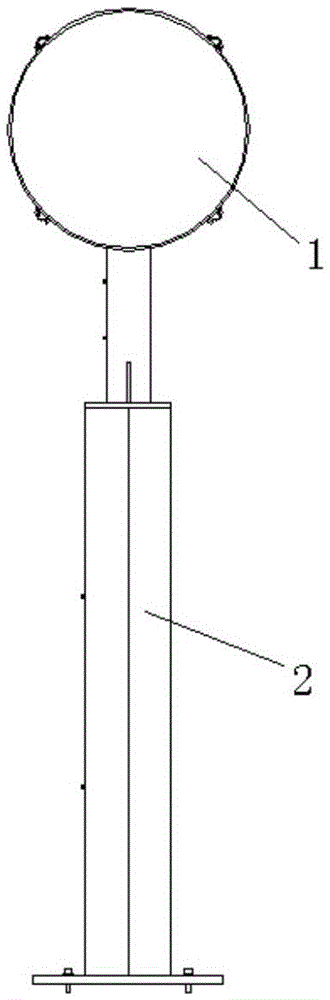

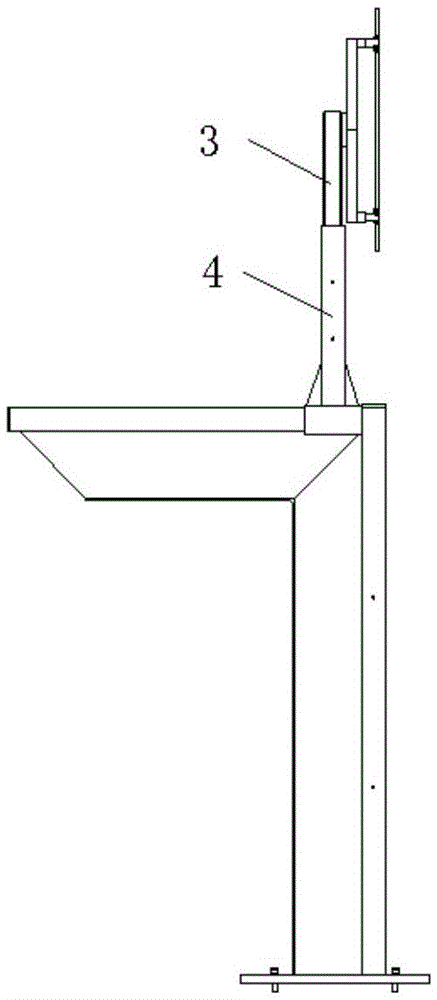

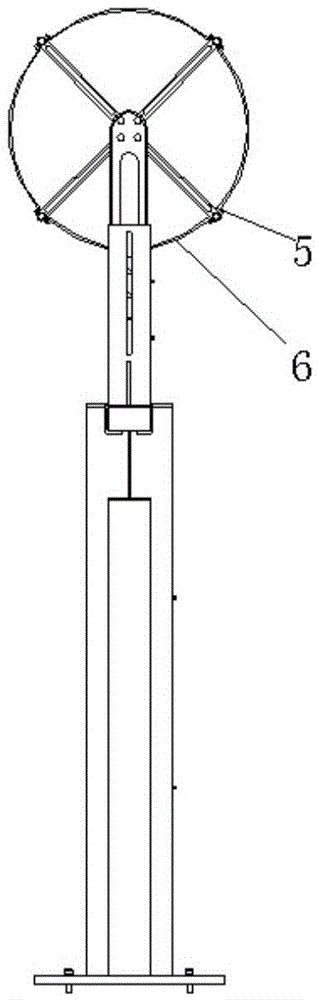

Open earth simulator applied to three-axis air bearing table

ActiveCN105480440AGood temperature uniformityLong-term working temperature stability is goodCosmonautic condition simulationsElectric heatingThermal radiation

The invention provides an open earth simulator applied to a three-axis air bearing table. The open earth simulator applied to the three-axis air bearing table is characterized by comprising a simulated earth radiant panel, a supporting base, a telescopic rod, a sleeve rod, a connecting rod, a heat insulating ring and a connecting rod grabhook, wherein the simulated earth radiant panel is made of an electric heating earth infrared simulated source panel; the front surface of the simulated earth radiant panel is a vapour chamber; and black treatment is made on the surface of the simulated earth radiant panel. According to the invention, good temperature uniformity and long-time working temperature stability of the simulated earth radiant panel are realized and high technical index level is realized; and the universality of a three-axis air bearing table system in simulating earth thermal radiation is enhanced.

Owner:SHANGHAI INST OF SATELLITE EQUIP

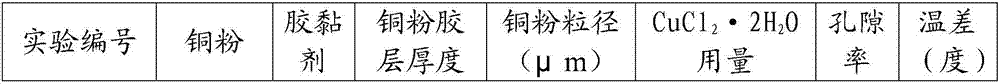

Method for preparing double-layer heat-uniformizing pot

ActiveCN107397422AGuaranteed structural adhesionGood temperature uniformityCooking-vessel materialsLiquid phaseCopper

The invention relates to a method for preparing a double-layer heat-uniformizing pot. The method comprises the steps that an inner pot and an outer pot are prepared; the outer side of the inner pot and / or the inner side of the outer pot are / is coated with a metal powder glue layer, and pressing, baking and sintering are performed; the inner pot is sleeved with the outer pot, the tops of the inner pot and the outer pot are sealed and fixedly connected, and a heat conduction cavity is formed between the inner pot and the outer pot; air in the heat conduction cavity is extracted from a vacuumizing hole formed in the outer pot, so that the heat conduction cavity is in a negative pressure state, a liquid phase change working medium is injected through the vacuumizing hole, and the vacuumizing hole is sealed. A porous metal layer is manufactured through the method. The porous copper layer can ensure that after the liquid phase change working medium is volatized into gas, the gas is passed to the condensed end at the top of the heat conduction cavity to be diffused, cooled liquid flows along the porous copper layer to the bottom of the heat conduction cavity and is heated again and evaporates, the heating process is repeated, and it is ensured that the temperature field at each part of the whole inner pot is basically kept consistent.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

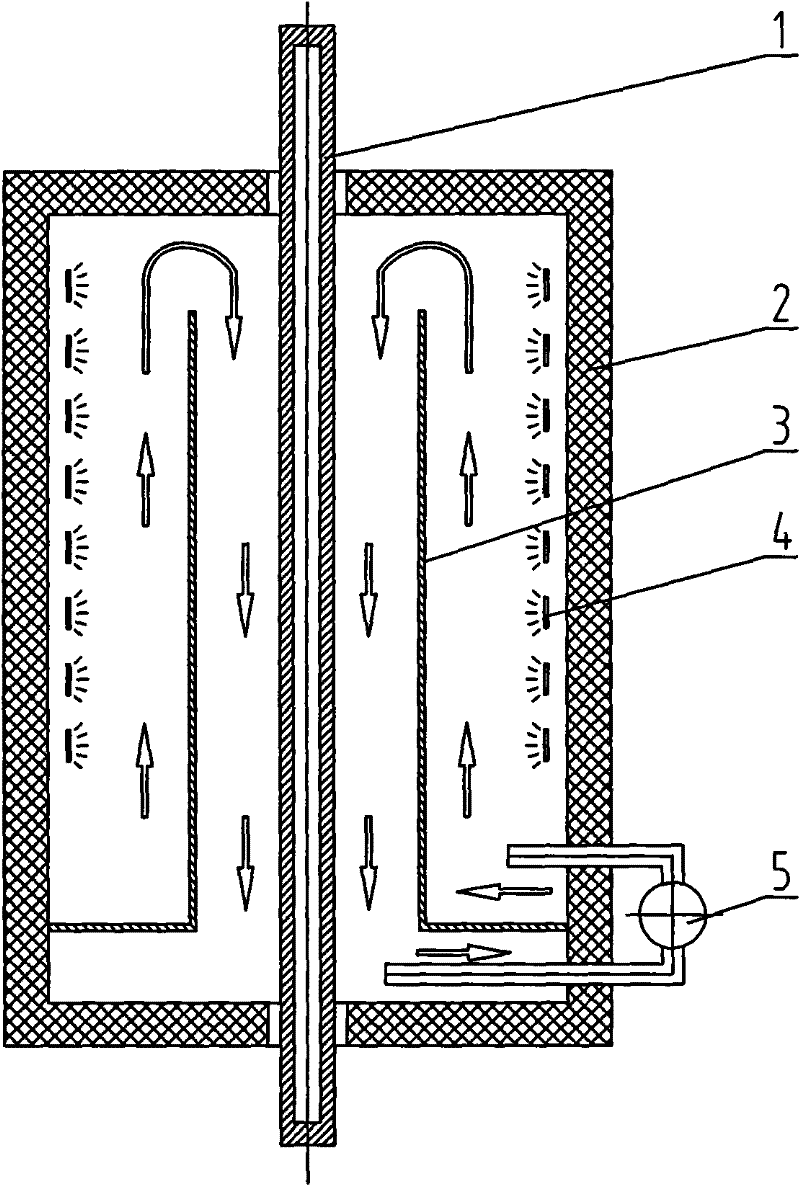

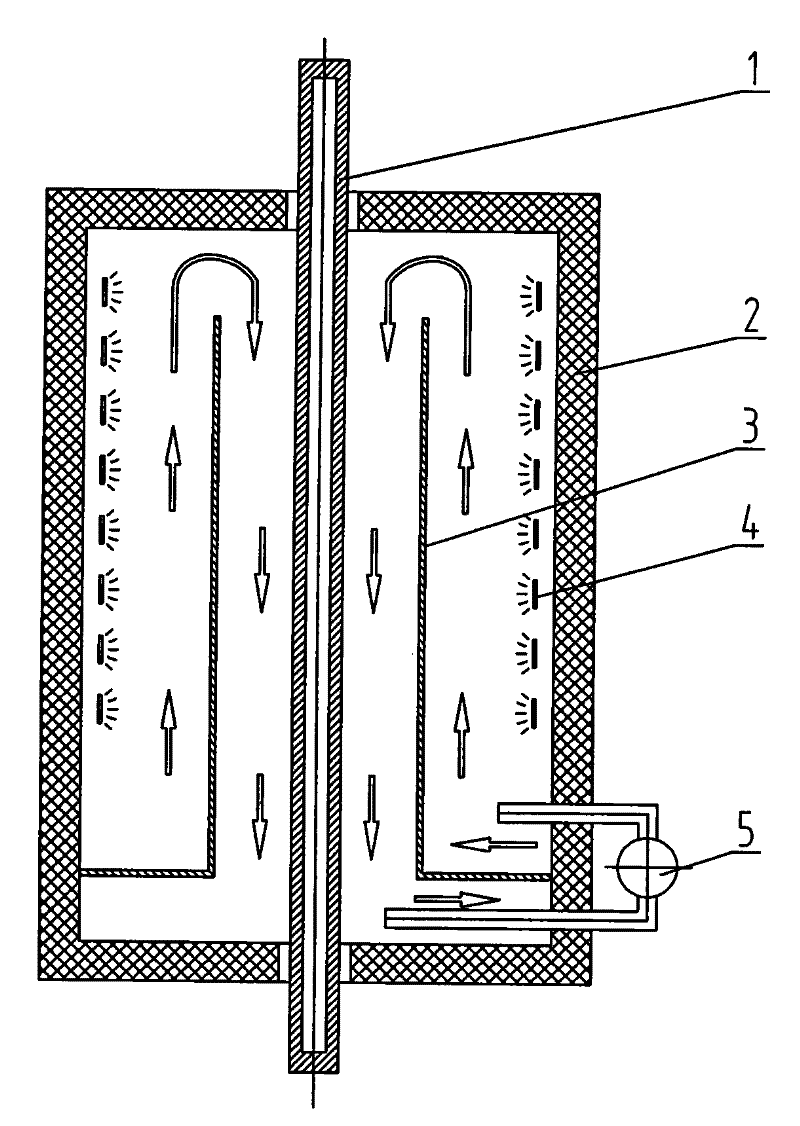

Non-magnetic high-temperature test device

InactiveCN102385010AGood temperature uniformityStepless adjustment of temperatureElectrical testingHeating systemEngineering

The invention discloses a non-magnetic high-temperature test device, which is characterized in that: a heating device is non-magnetic, and the temperature can be precisely controlled. The invention adopts the technical scheme that: the non-magnetic high-temperature test device comprises a hot-air generator and a working chamber, wherein the hot-air generator consists of a box body, a heating system and a temperature control system, the box body is provided with a temperature control instrument, a starting button, an air passage, an upper port and a lower port; the working chamber consists of an upper hot-air circulating passage, a lower-part hot-air circulating passage, a hot-air circulating transitional passage, a drying box, a hot-air circulating passage elbow or a steering pipe, the working chamber is fixed on a working platform through the upper-part and the lower-part hot-air circulating passages and a drying box supporting device to form a whole, the upper part hot-air circulating passage and the lower-part hot-air circulating passage are respectively connected with the upper and the lower ports to collectively form a hot-air circulating closed passage which is respectively used for the outflow of the heated hot-air and the inflow of the used hot-air, the hot air flows uni-directionally inside the hot-air circulating closed passage, the components of the working chamber are fixedly connected with each other, the hot-air generator is separated from the drying box, and the components forming the working chamber are made of non-magnetic materials.

Owner:建宇(上海)石油科技有限公司

Conformal countercurrent liquid cooling radiator

ActiveCN111757656AGood temperature uniformityImprove space utilizationCooling/ventilation/heating modificationsEngineeringSi substrate

The invention discloses a conformal countercurrent liquid cooling radiator. The conformal countercurrent liquid cooling radiator comprises a cover plate, a partition plate and a substrate, wherein thecover plate, the partition plate, the substrate and electronic equipment are conformal; the cover plate is positioned at the top of the conformal countercurrent liquid cooling radiator; the partitionplate comprises a converging channel, a flow dividing channel, a countercurrent channel, a transverse channel and a longitudinal channel; the base plate comprises an inlet connector and an outlet connector; the converging channel is located under the outlet connector; the longitudinal channel is located under the inlet connector; the flow dividing channel is located above the converging channel and staggered with the converging channel; and the countercurrent channel is composed of a left flow channel, a right flow channel, a flow channel layering opening and a flow channel liquid dividing opening, and such a structure enables cooling media in the left flow channel and the right flow channel to flow in opposite directions. The conformal countercurrent liquid cooling radiator can be used as a liquid cooling radiator of curved-surface electronic equipment, and has the advantages of small thickness, good temperature uniformity and good comprehensive heat dissipation performance.

Owner:XIDIAN UNIV +1

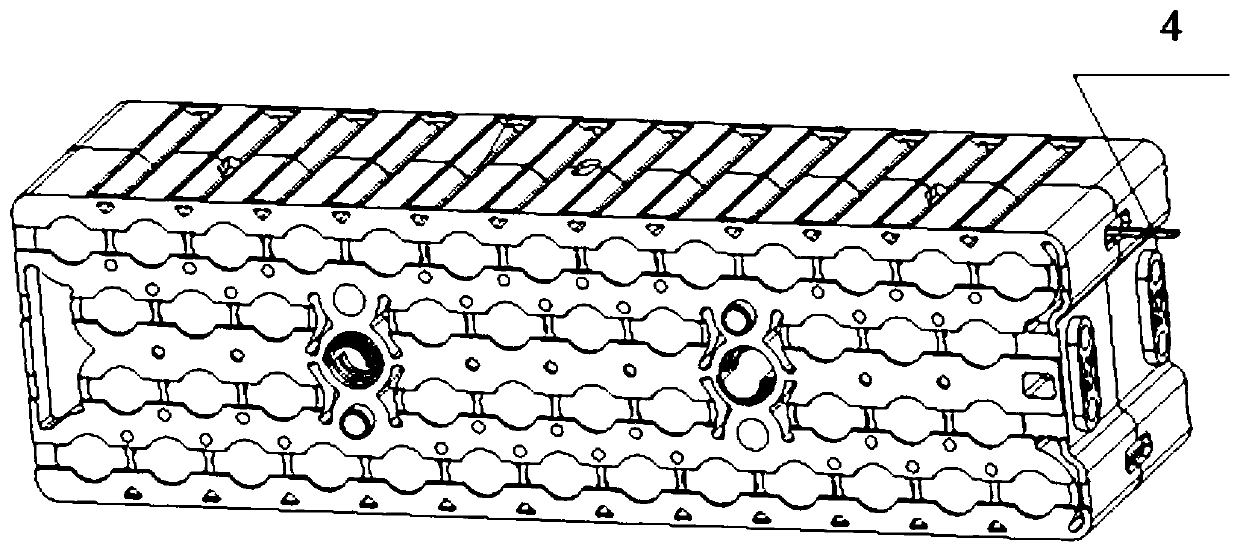

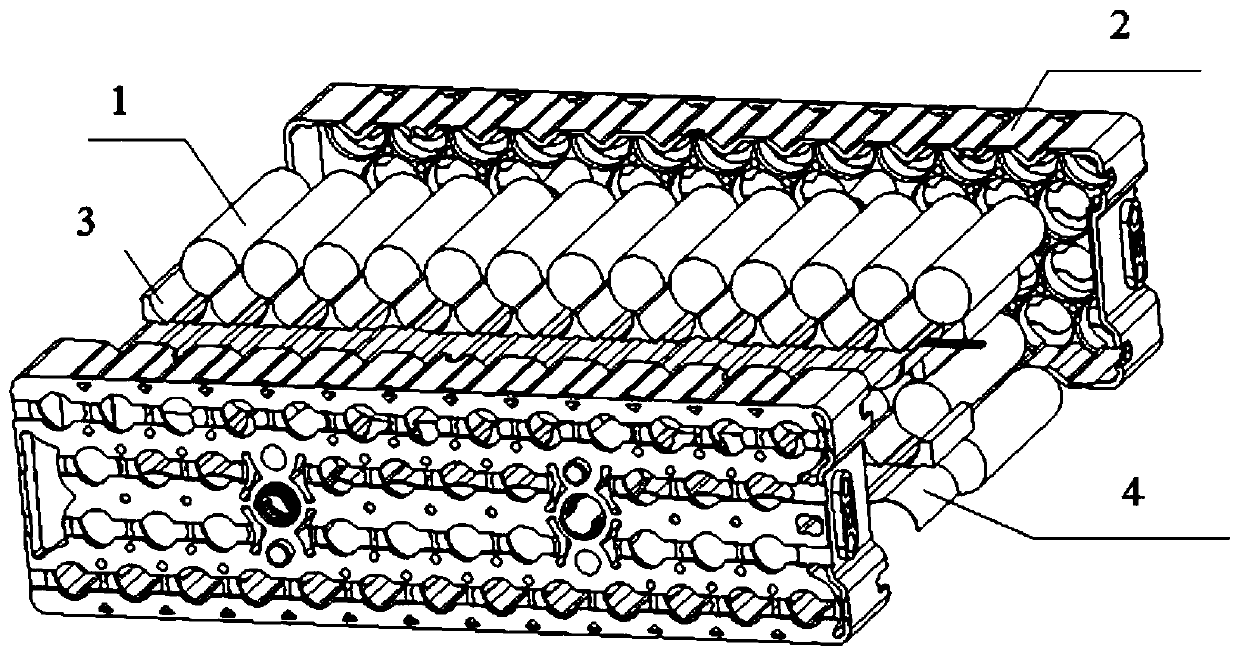

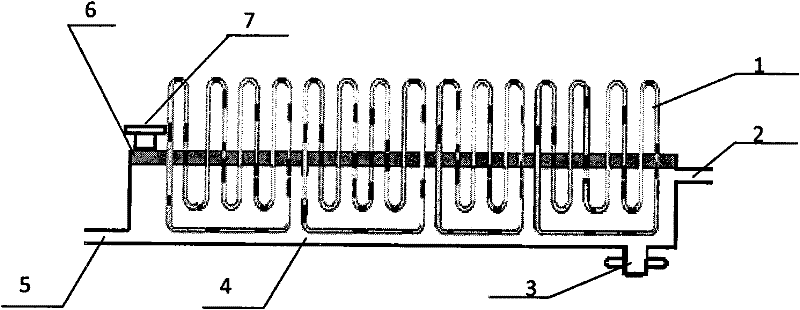

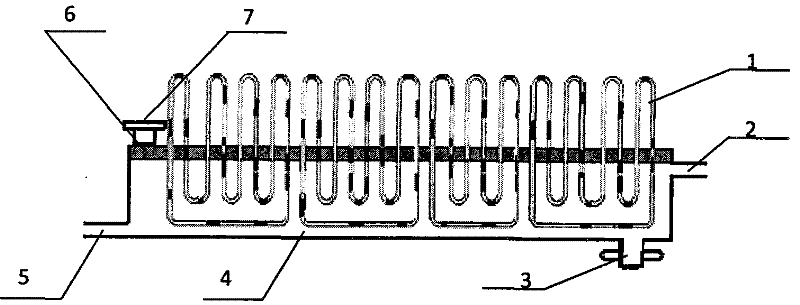

Lithium battery module based on pulsating heat pipe radiation

InactiveCN109346794AGood temperature uniformityReduce processing difficultySecondary cellsElectrical batteryRadiation

The invention provides a lithium battery module based on pulsating heat pipe radiation. The lithium battery module comprises a plurality of battery units, pulsating heat pipes, metal plates and a condensing section box, wherein the metal plates are fixed between the adjacent battery units; evaporating flow passages are formed in the metal plates; the metal plate are externally connected with the pulsating heat pipes; the pulsating heat pipes and the evaporating flow passages form a closed-loop pipeline; the condensing section box is arranged outside a plurality of the pulsating heat pipes; thepulsating heat pipes are filled with a working medium; the evaporating flow passages are U-shaped, a plurality of U-shaped evaporating flow passages are formed in the metal plates side by side, and the plurality of U-shaped evaporating flow passages and the pulsating heat pipes form the closed-loop pipeline; the evaporating flow passages are linear, a plurality of linear evaporating flow passagesare formed in the metal plates in parallel, and the two ends of the plurality of linear evaporating flow passages are connected with the pulsating heat pipes respectively to form the closed-loop pipeline. The lithium battery module has the characteristics of large heat dissipation, high heat dissipation efficiency, simple processing and convenience in use.

Owner:JIANGSU UNIV

Heat-conducting connecting foam and preparation method thereof

The invention relates to heat-conducting connecting foam and a preparation method thereof. The foam comprises the raw material components in parts by weight: 8 to 10 parts of polycarbonate diol, 12 to15 parts of xylylene diisocyanate, 4 to 9 parts of vinyl polysiloxane, 2 to 4 parts of 2-hydracrylic acid, 0.6 to 1.0 part of graphene oxide, 20 to 30 parts of pentaerythritol, 15 to 20 parts of polyethyleneimine, 0.5 to 1 part of lauryl sodium sulfate, 1 to 3 parts of N-phenyl-2-naphthylamine, 0.1 to 0.4 part of guar gum hydroxypropyl trimethyl ammonium chloride, 3 to 8 parts of a foaming agent,2 to 3 parts of a curing agent and 1 to 1.5 parts of a flame retardant. The heat-conducting connection foam provided by the invention is good in heat conductivity, high in foaming rate in the foam, uniform and fine in foam holes, stable in performance in all aspects, excellent in compression resilience, flame retardance, waterproofness and structural stability, low in production cost and wide inapplication prospect.

Owner:深圳市象形科技有限公司

Conduction cooling large-scale high-temperature superconducting magnet structure

PendingCN113035489ASimple structureGood temperature uniformitySuperconducting magnets/coilsSuperconducting CoilsConduction cooling

The invention provides a conduction cooling large-scale high-temperature superconducting magnet structure. The conduction cooling large-scale high-temperature superconducting magnet structure comprises a coil framework, a high-temperature superconducting coil group and a cooling channel assembly, wherein the high-temperature superconducting coil assembly is provided with an electric connection assembly, and the electric connection assembly is used for exciting the high-temperature superconducting coil assembly; a second insulating layer made of a heat conduction material is arranged between the cooling channel assembly and the high-temperature superconducting coil assembly and is used for preventing the cooling channel assembly from being wholly electrified; two sides of the second insulating layer are in thermal contact with the high-temperature superconducting coil assembly and the cooling channel assembly respectively; the cooling channel assembly is provided with a gas inlet used for inputting low-temperature helium and a gas outlet used for discharging the low-temperature helium. The structure is simple in structure, easy to process and suitable for conduction cooling of large-scale high-temperature superconducting magnets; The large-scale high-temperature superconducting magnet adopting the structure has better temperature uniformity in the operation process, the cooling effect is improved, and the refrigeration cost is reduced.

Owner:SUZHOU BAMA SUPERCONDUCTIVE TECH CO LTD

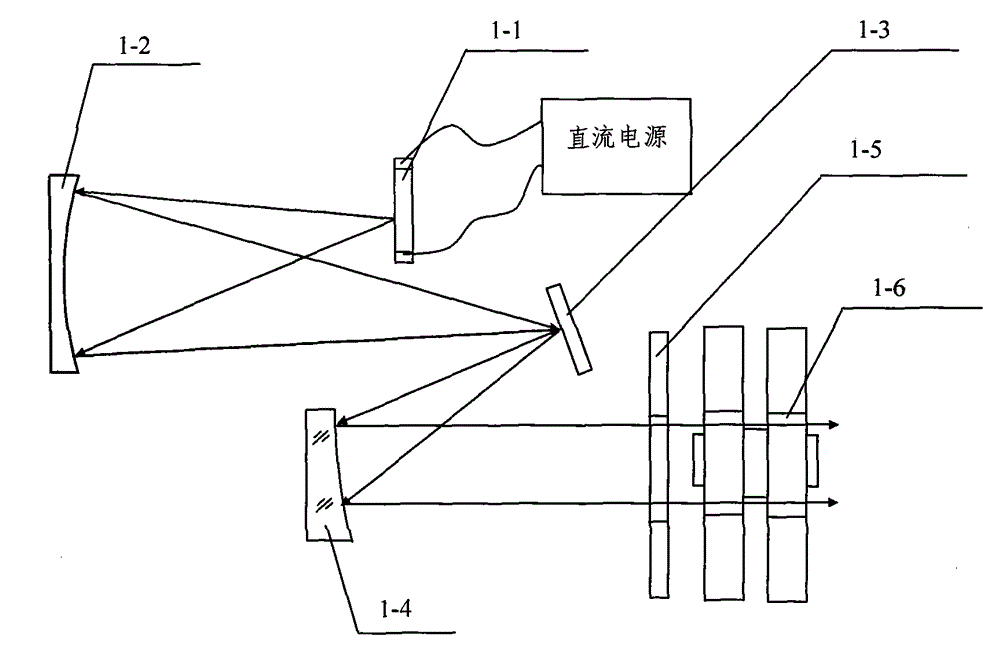

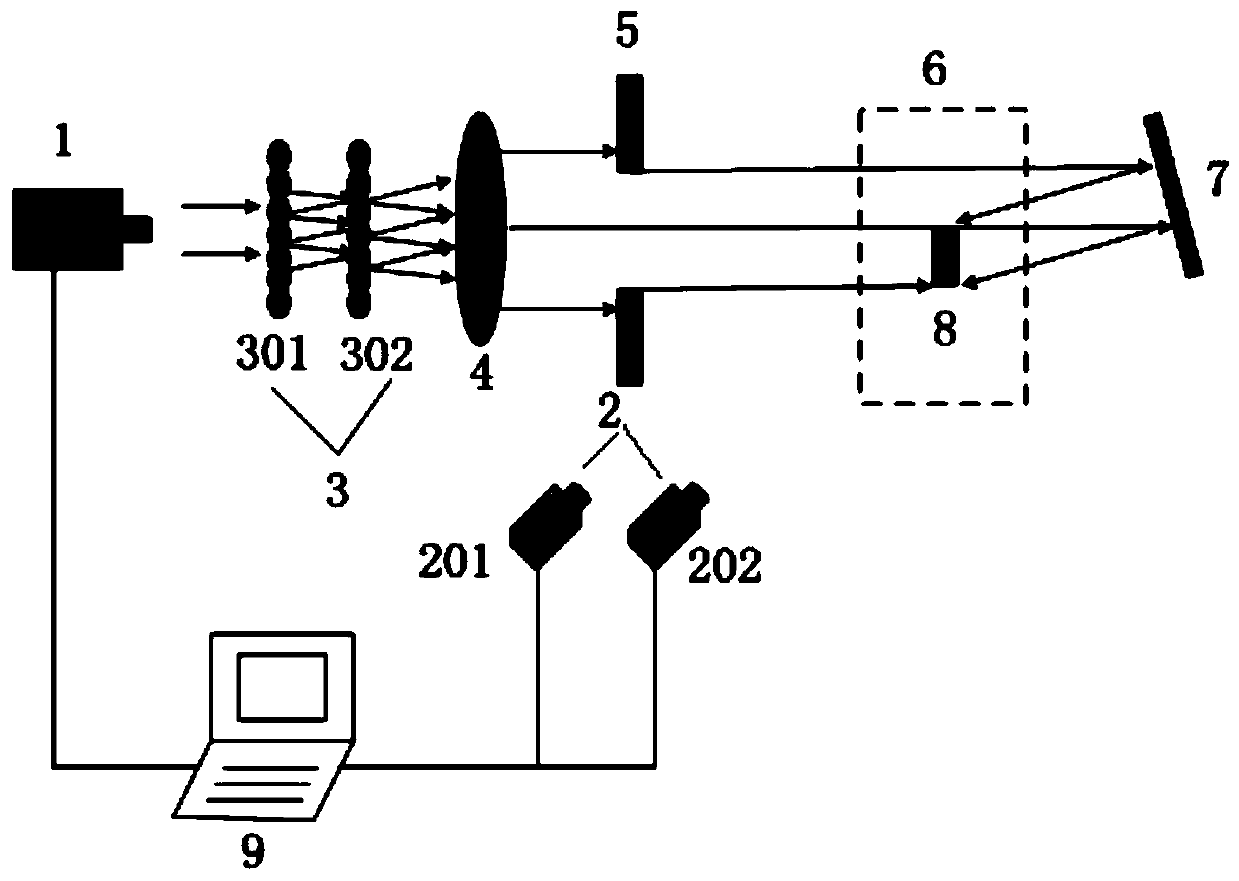

System and method for testing high-temperature mechanical property-temperature rise rate correlation parameters of composite material

InactiveCN110031327AFast heatingGood temperature uniformityMaterial strength using tensile/compressive forcesRise rateEngineering

The invention relates to a system and a method for testing high-temperature mechanical property-temperature rise rate correlation parameters of a composite material, which overcomes the defects of slow temperature rise rate, inconstant temperature rise rate, small test temperature range and the like of the traditional test system based on a laser double-side irradiation heating mode. The system comprises a laser, a micro lens array, a collimating lens, a diaphragm, a total reflector, a temperature measuring device, a temperature control servo system and a universal testing machine. The laser double-side irradiation is adopted to heat the test piece, the temperature measuring device is used for testing the temperature of the surface of the test piece, temperature data are output to the temperature control servo system in a current signal mode, and the temperature control servo system controls the current increase or decrease of the laser through calculation to realize the adjustment ofthe output power of the laser.

Owner:NORTHWEST INST OF NUCLEAR TECH

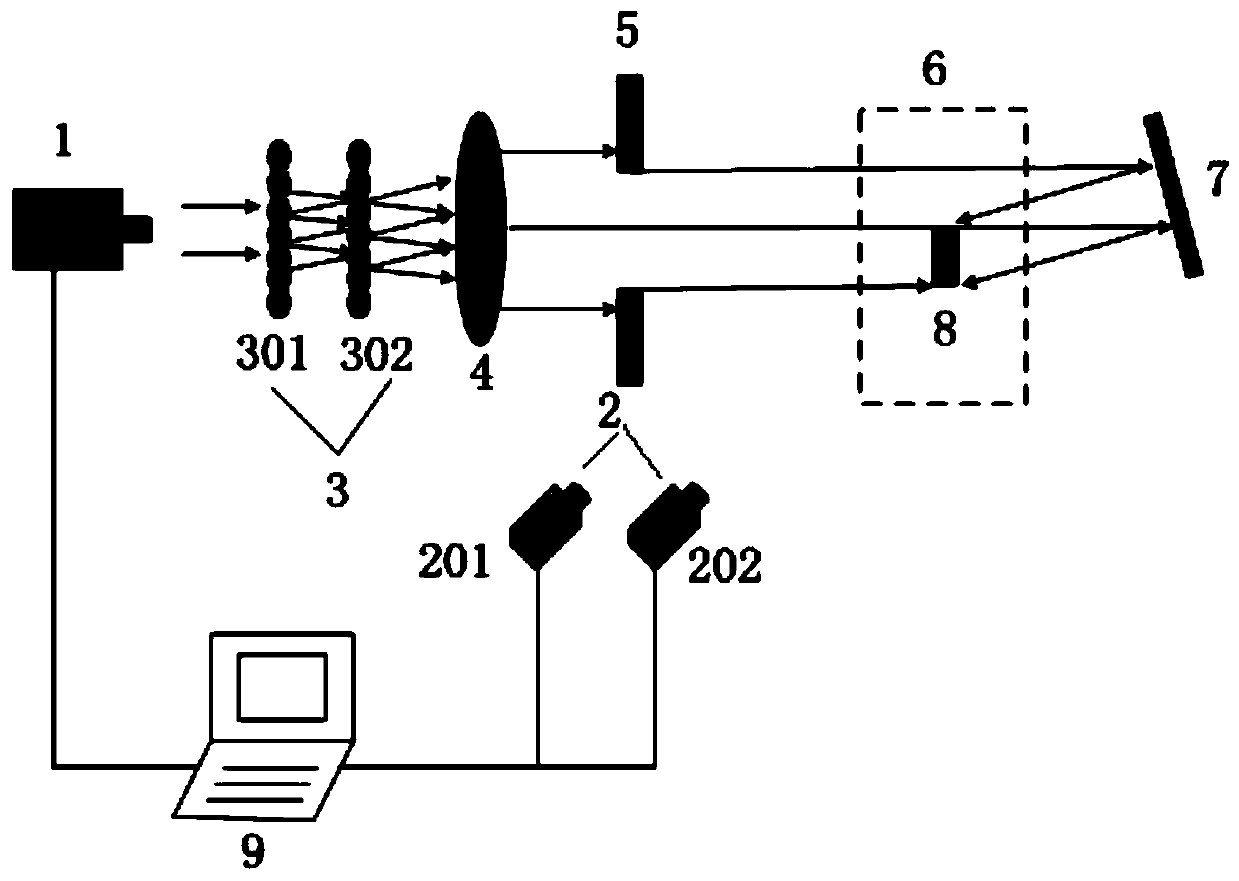

Novel dried tail gas waste heat step recovering system

ActiveCN101776354BEffective absorption of waste heat recoveryEfficient absorption of latent heat of vaporizationHeat pumpsHeat recovery systemsWater vaporEngineering

The invention discloses a novel dried tail gas waste heat step recovering system, which can effectively recover the dried tail gas waste heat. The tail gas waste heat can be effectively recovered, and vaporization latent heat of water vapor in the tail gas can be recovered. The novel dried tail gas waste heat step recovering system structurally comprises at least one sensible heat recovering device and at least one latent heat recovering device, wherein the sensible heat recovering device and the latent heat recovering device are in cascade connection, the sensible heat recovering device is communicated with the tail part of a drying operation device for receiving the tail gas of drying equipment and pumped heat media, and the latent heat recovering device is connected with heat users andexhaust equipment.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Heat exchange roller with multi-layer built-in flow channels and working method thereof

PendingCN113983834AGood temperature uniformityImprove membrane product qualityStationary tubular conduit assembliesTubular elementsPhysicsMechanical engineering

Owner:宣城市雍基超镜面精密机械制造有限公司

High temperature and high pressure kettle air heating device

InactiveCN101664659BNo burningNo pollution in the processPressure vessels for chemical processInsulation layerHeat losses

The invention relates to an air heating device for a high-temperature and high-pressure kettle. At present, the way of obtaining high temperature is achieved by convective heat transfer of heat transfer oil at home and abroad. It has the following disadvantages: easy to leak, low thermal efficiency, poor controllability, poor furnace temperature uniformity, slow heating and cooling, and relatively low comprehensive performance parameters. Difference. The invention includes a kettle body, a heater, a fan, a thermal insulation layer, and an air guide tube. The thermal insulation layer includes an outer shell, an intermediate thermal insulation cotton, and an inner layer plate; An air duct is provided, and the air duct is divided into an inner air duct and an outer air duct through the air guide tube, and a heater is installed in the outer air duct; the air outlet of the inner air duct and the air inlet of the outer air duct are arranged at the lower end of one side of the insulation layer, It is connected by a fan to form a hot air circulation channel. The invention has the advantages of small heat loss, low thermal efficiency, few maintenance points, strong controllability, good temperature uniformity, fast heating speed, rapid cooling, and good comprehensive performance parameters.

Owner:XIAN ELECTRIC FURNACE INST

Vehicle liquefied natural gas carburetor and refrigeration transport vehicle provided with the carburetor

InactiveCN104514981AReasonable layoutGood temperature uniformityAir-treating devicesVehicle heating/cooling devicesLiquefied natural gasEngineering

The invention relates to a vehicle liquefied natural gas carburetor and a refrigeration transport vehicle provided with the carburetor. The carburetor comprises a carburating tube, a heat exchange shell and a suction fan. The heat exchange shell includes a left shell and a right shell; the straight sections at left and right sides are respectively arranged on respective side of heat exchange channel constituted by the heat exchange shell; air outlets are arranged on the left and right sides of the shell; the suction fan blows the inhaled air into the heat exchange channels, so as to conduct heat exchange with the carburating tube; and cool air after heat exchange is blown out through the air outlet on the heat exchange shell. The straight sections at left and right sides of the carburetor and the left and right shells are arranged on the left and right sides of the top of the compartment, and extend from the head of the compartment to the tail. The invention has the beneficial effect that the carburetor has reasonable structure and layout and good temperature uniformity in the compartment, avoids energy waste, and improves the utilization rate of the inner space of the compartment.

Owner:JIANGSU HUAMAI GAS EQUIP SALES

Four-inlet four-outlet hot press plate

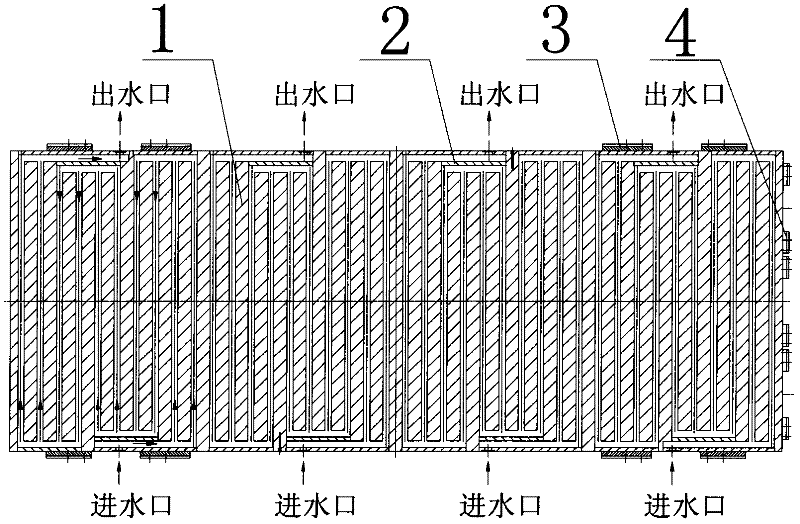

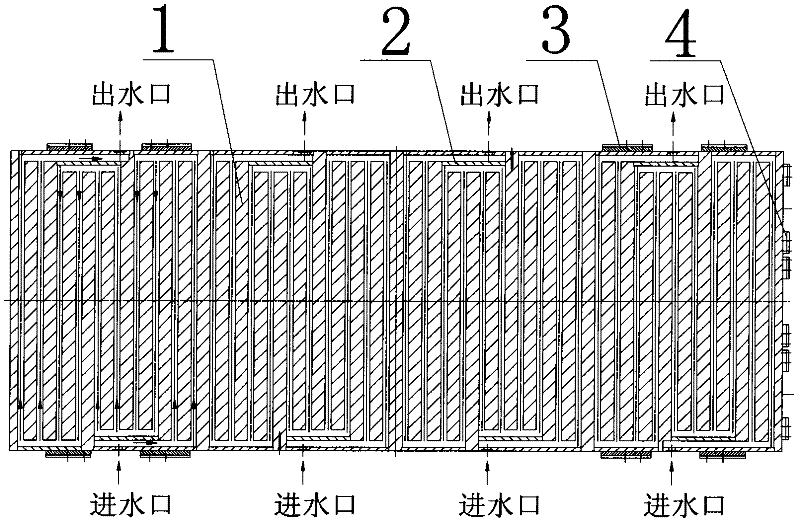

InactiveCN102407556AGood temperature uniformityHigh utilization rate of thermal efficiencyWood working apparatusDomestic articlesHeat pressEngineering

The invention provides a four-inlet four-outlet hot press plate, particularly a large format hot press plate in a hot press for a fireproof plate production line. The four-inlet four-outlet hot press plate comprises a hot press plate, a supporting plate, a sealing plate and a groove plate; the supporting plate is mounted on the hot press plate; the sealing plate is used for sealing hole channels of the hot press plate according to a certain rule; and the groove plate is welded on the hot press plate. The four-inlet four-outlet hot press plate has the advantages of good temperature uniformity, economy, compactness, high utilization rate of heat energy, good effect, safeness, reliableness, and the like.

Owner:SUZHOU XINXIELI MACHINE MFG

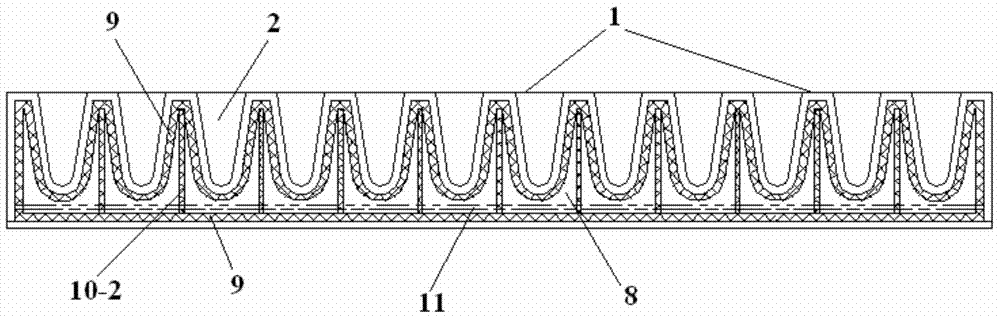

Super strength high molecule fibre intelligent high temperature thermo-setting machine

InactiveCN101245496BPrevent leakageMeet the process requirements of high temperature heat settingFilament manufactureHeating/cooling textile fabricsElectrical controlEngineering

The invention discloses an intelligent high temperature thermal shaping machine for ultra intense polymer fiber. The machine comprises an electrical heater, thermoscopes, an electric control device, a shell, and adjustable feet, and further comprises an inner cavity body, a left end expansion joint, a right end expansion joint, a left end seal, a right end seal and a port sealing device. Inner holes of the left end expansion joint and the right expansion joint are internally and respectively penetrated and covered by the two ends of the inner cavity body, and the two ends can move in the inner holes. The electrical heater has flat shaped structure and is longitudinally arranged on the upper surface and the lower surface of the inner cavity body and transversely arranged on the two side faces of the inner cavity. The thermoscopes are arranges above the inner cavity body along the width direction in two lines; probes of one line of the thermoscopes are inserted into the inner cavity body, and the probes of the other line are contacted with the surface of the inner cavity body. Insulation cotton is filled into the space between the inner cavity body and the external side board arranged on a machine frame. The machine can meet the technique requirement of high temperature thermal shaping for tow in the production process of aramid and save energy.

Owner:JIANGSU GUANGSHENGYUAN TECH DEV

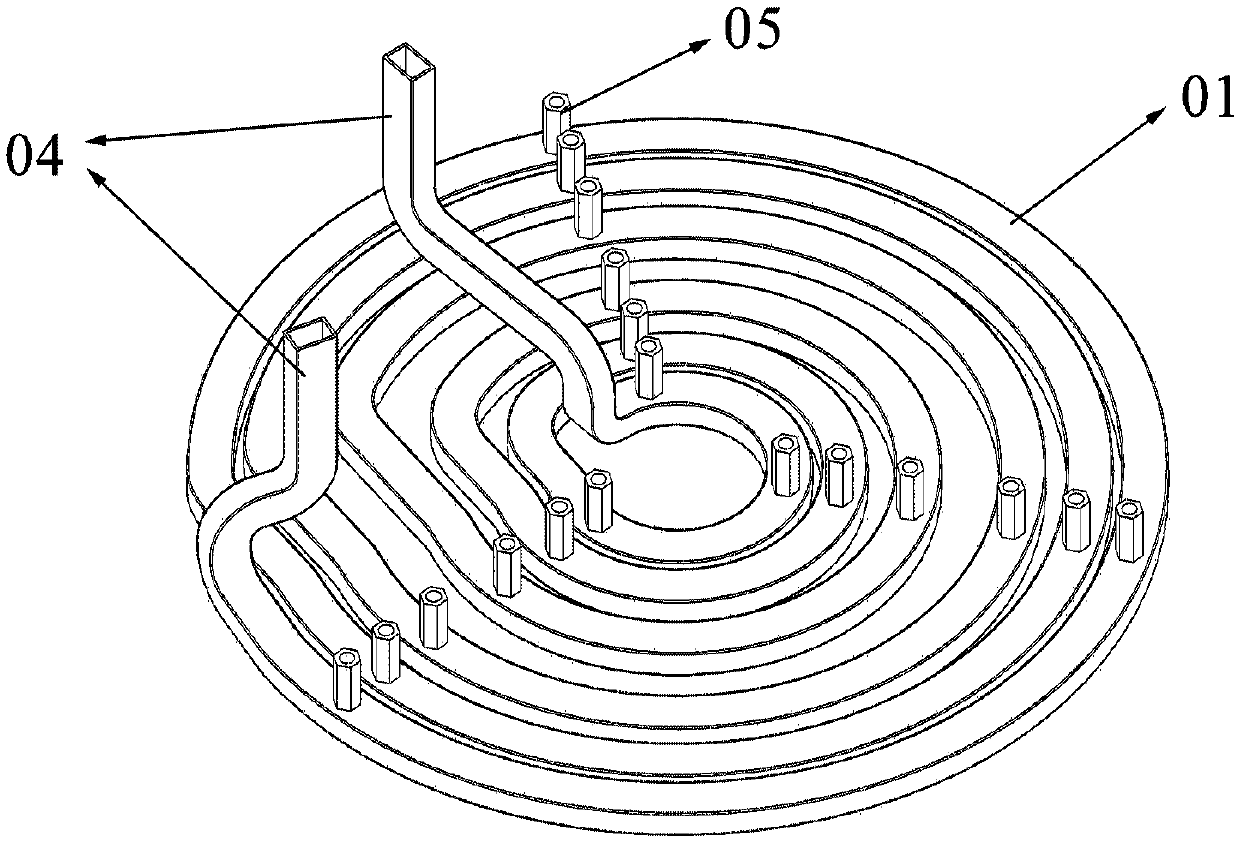

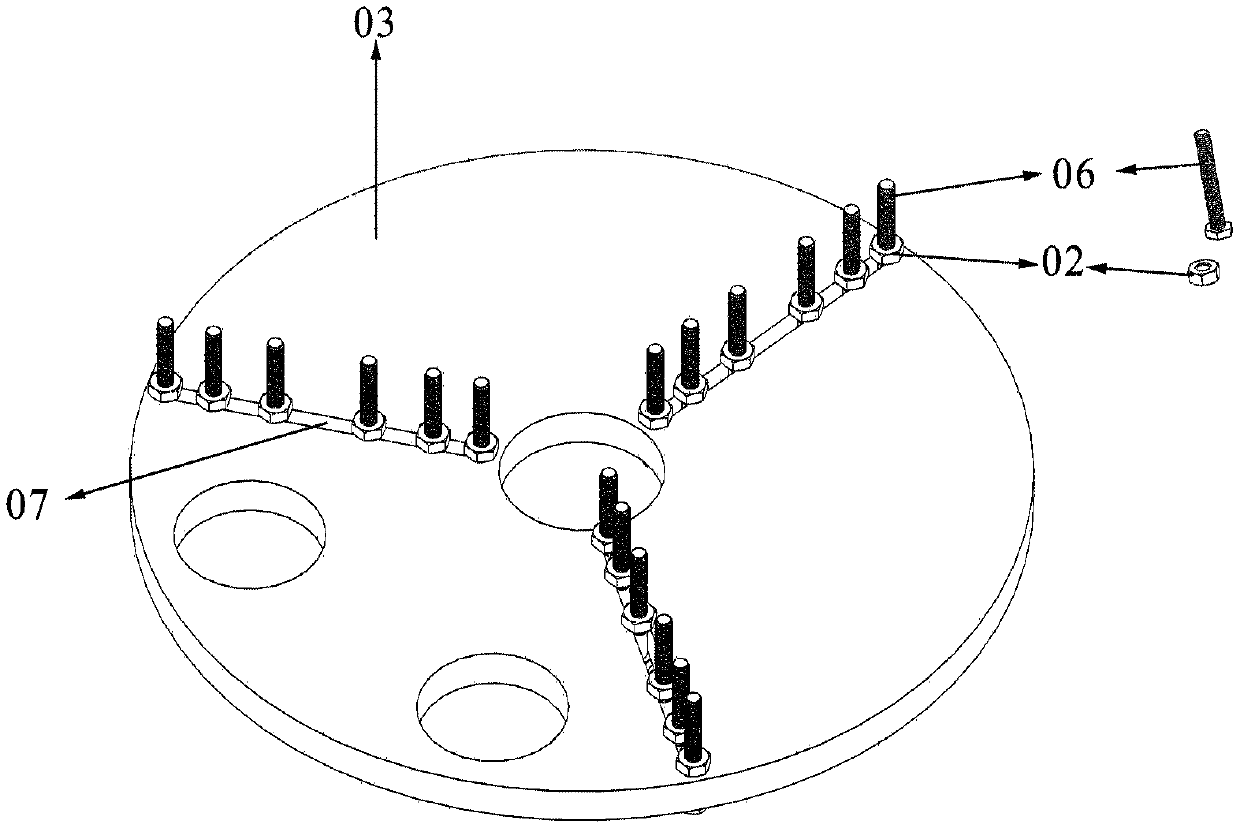

Adjustable induction coil device

InactiveCN109600873AGood temperature uniformityFlexible adjustmentCoil arrangementsCoilsMaterial growthMaterials science

The invention discloses an adjustable induction coil device. The adjustable induction coil device comprises N turns of induction coils, a ceramic disc, a bolt, a nut and coil electrodes, wherein N isa positive integer, the ceramic disc is arranged in parallel to a plane wherein the induction coils are arranged, the bolt and the nut are used for connecting and fixing the N turns of induction coilsand the ceramic disc, the height of each turn of induction coil along a direction perpendicular to a coil plane is adjustable by matching of the bolt and the nut so that the distance between each turn of induction coil and the ceramic disc is changed, and the coil electrodes are respectively led out of an initial end and a tail end of the N turns of induction coils and are used for connecting anAC power supply so as to supply power to the induction coils. The temperature of each region of a tray is changed by adjusting the distance between each turn of coil and the tray so that the temperature is uniform or consistent and the integral excellent temperature uniformity of the tray is achieved, and simple adjustment, convenient practicality and flexible adjustment of the temperature uniformity of thin film material growth equipment employing an induction heating mode are achieved.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

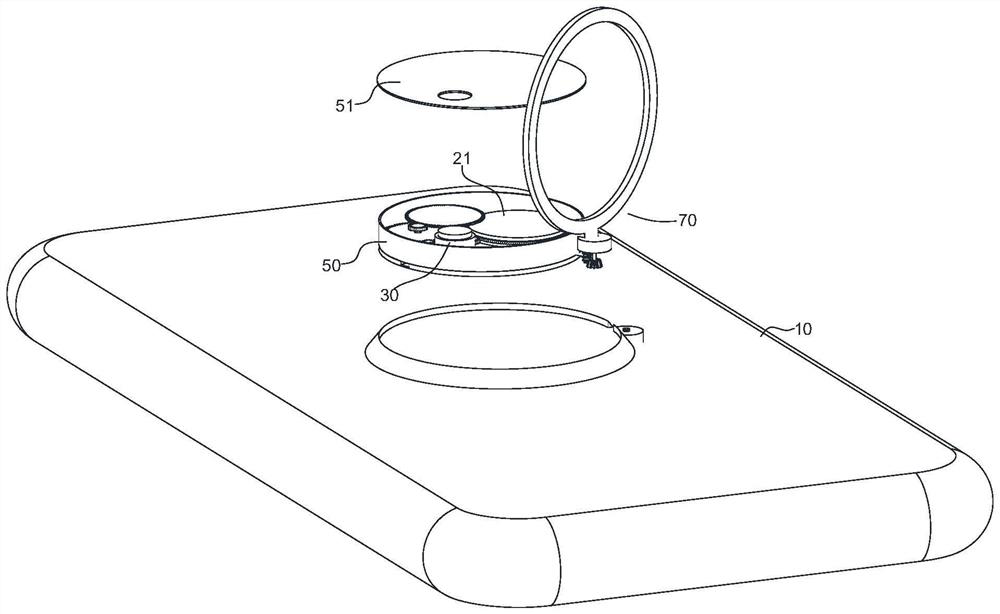

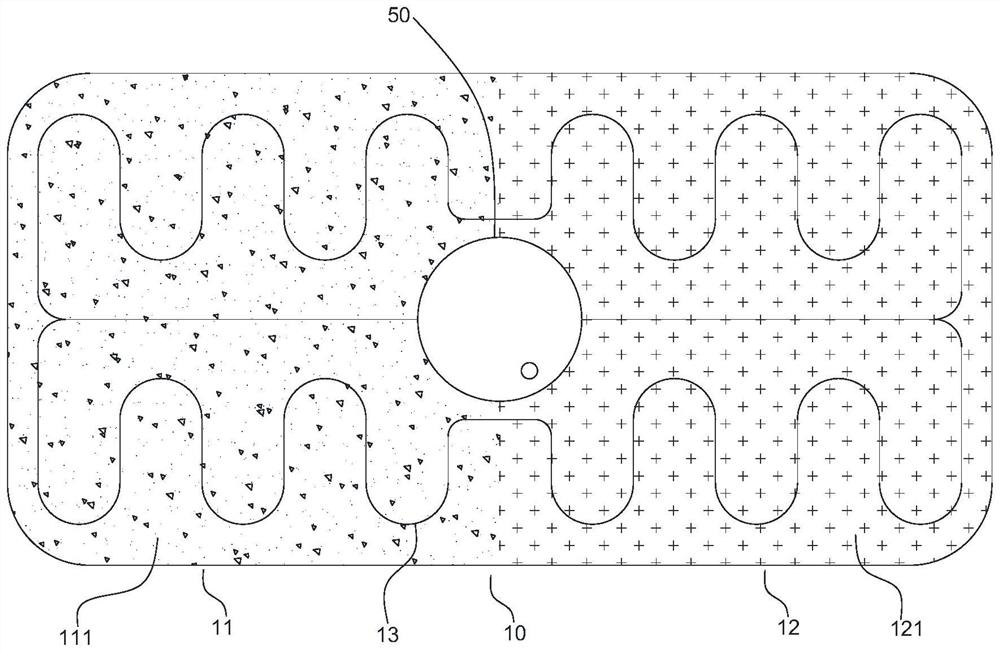

Heat dissipation shell of electronic equipment and electronic equipment

PendingCN114302627AGood temperature uniformityApplicable cooling requirementsCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsThermodynamicsEngineering

The invention discloses a heat dissipation shell of electronic equipment and the electronic equipment. The heat dissipation shell of the electronic equipment comprises a shell body, a spring box, a pump, a driving assembly and a switch assembly. The shell comprises a first area and a second area, a first phase change material filler is distributed in the first area, and a second phase change material filler is distributed in the second area; a fluid channel in which a heat-conducting medium is arranged is arranged in the shell, and the fluid channel penetrates through the first area and the second area; the power output end of the spring box is connected to the pump, and the liquid inlet end and the liquid outlet end of the pump communicate with the two ends of the fluid channel correspondingly. The driving assembly is connected to the power input end of the spring box and comprises a holding part; the switch assembly is used for controlling the power output end of the spring box to rotate or stop rotating. According to the invention, the surface of the heat dissipation shell has a better uniform temperature characteristic, the heat dissipation capability of the electronic equipment in a high-power-consumption scene is improved, and the electronic equipment is small in size and convenient to carry.

Owner:SHANGHAI WINGTECH INFORMATION TECH CO LTD

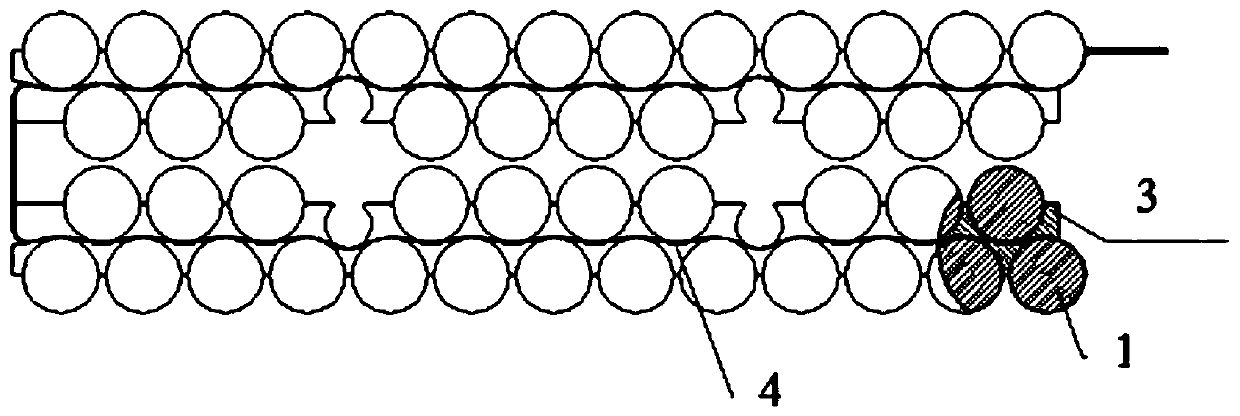

Heating battery module

PendingCN110707394AConsistent contact areaGood temperature uniformitySecondary cellsChemistryElectrical and Electronics engineering

The invention discloses a heating battery module. The heating battery module comprises battery cells, a matching support, a silica gel block and a PI type heating sheet, the matching support, the silica gel block and the PI type heating sheet are installed at the front end and the rear end of the battery cell respectively and used for fixing the battery cells, each battery cell is cylindrical, thecylindrical surfaces of the battery cells are tightly attached to the PI type heating sheet, the silica gel block is parallel to the battery cells, and the silica gel block is tightly attached to thePI type heating sheet. According to the heating battery module, the contact area of the heating sheet and each battery cell can be ensured to be consistent, and the heating temperature uniformity isgood.

Owner:NANJING JINLONG NEW ENERGY AUTOMOBILE RES INST

Automobile engine heat dissipating device based on oscillatory flow heat pipes

InactiveCN101761380BEasy to operateReduce manufacturing costLiquid coolingMachines/enginesHeat flowFriction loss

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Roasting furnace

PendingCN114440619AGood temperature uniformityHigh temperature control accuracyRotary drum furnacesCharge manipulationCombustorMetallurgy

The invention provides a roasting furnace which comprises a barrel, a feeding unit, a discharging unit and combustors, the feeding unit and the discharging unit are communicated with the barrel, the barrel is provided with a plurality of cavities, and the combustors are arranged in the cavities. According to the roasting furnace, the multiple cavities are adopted, the characteristic of large treatment capacity can be achieved at the same time, the requirement for controlling the roasting temperature can be met under the condition that the treatment capacity is large, and the requirement for the roasting technology is met.

Owner:CHINA PETROLEUM & CHEM CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com