Method for preparing double-layer heat-uniformizing pot

A hot pot and double-layer technology, applied to special materials for cooking utensils, cooking utensils, household utensils, etc., can solve problems such as easy to fall off, easy to stick to the pan, human health and safety hazards, etc., to ensure structural adhesion and good temperature uniformity effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

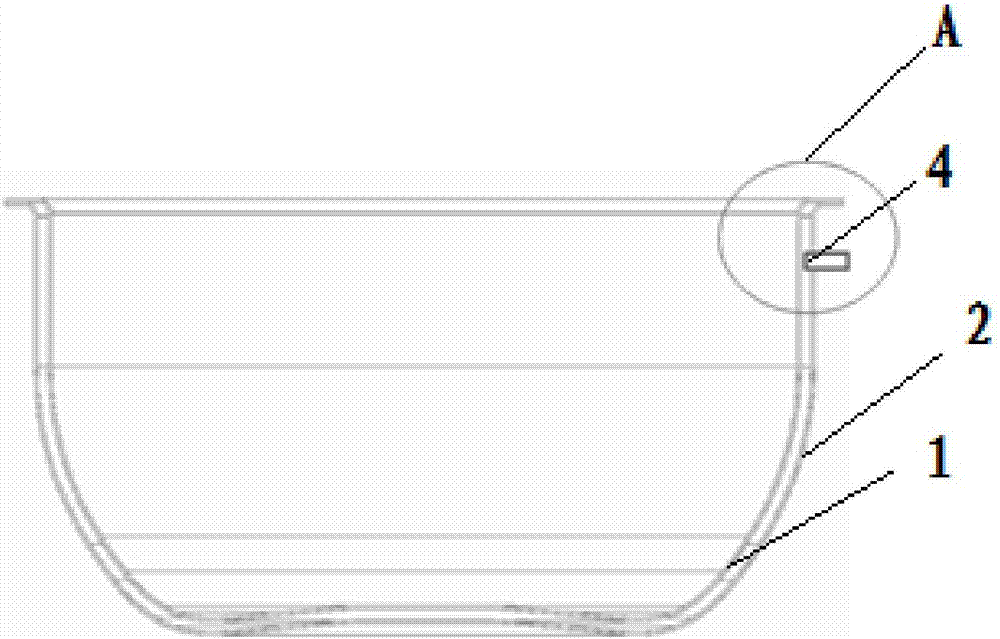

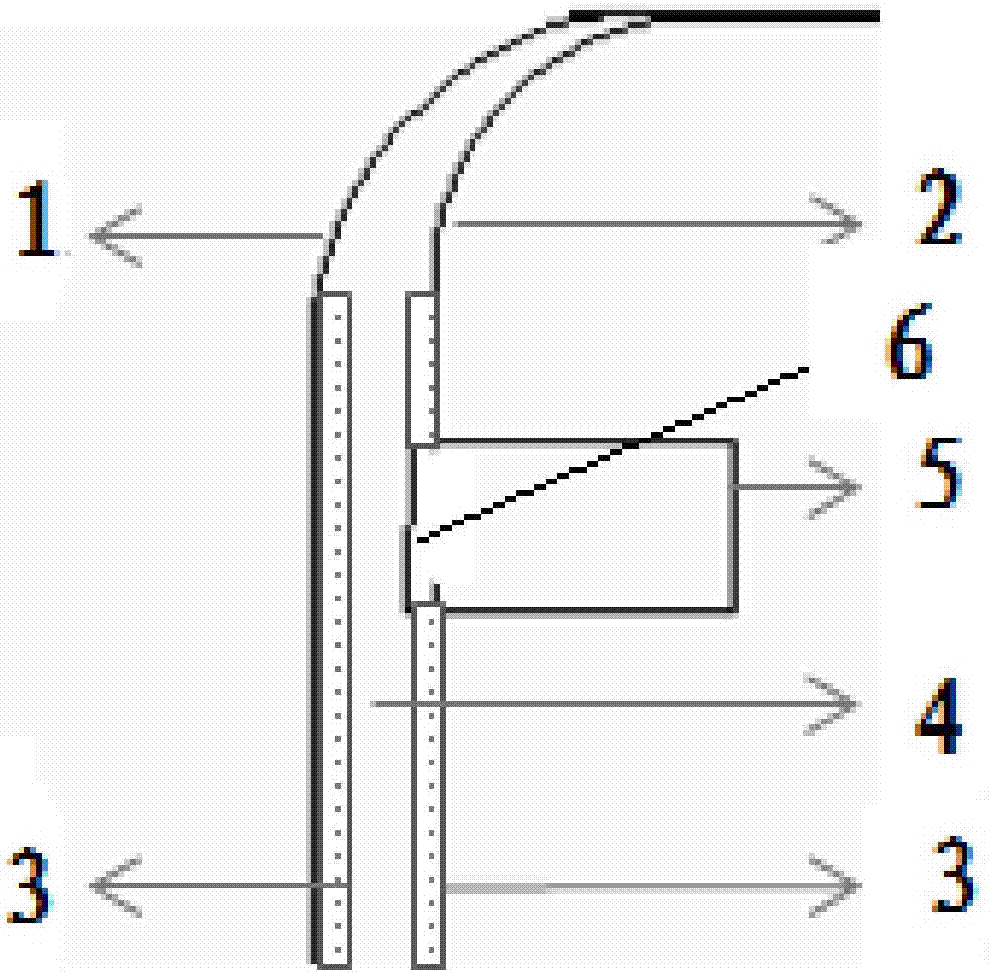

[0037] The preparation method of the following double-layer soaking pot of the present invention: step 1, adopt the 403 stainless steel thin plate that thickness is 1mm, press molding in mold, make outer pot, the thickness is the 304 stainless steel thin plate of 1mm, in the same shape and ratio The outer pot mold is stamped and formed in a mold with a small size to make an inner pot, and the top edges of the inner pot and the outer pot have an extended platform-like structure;

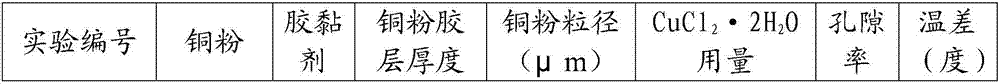

[0038] Step 2, coating the inner surface of the outer pot and the outer surface of the inner pot with a copper powder adhesive layer made of pure copper powder containing a binder and an average particle size of about 60-80 μm. The copper po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com