Adjustable induction coil device

An induction coil, adjustable technology, applied in the direction of coil device, coil, induction heating, etc., can solve the problems of no adjustment and shape change, difficult control of temperature uniformity, no improvement effect of temperature uniformity, etc., to achieve optimal temperature uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

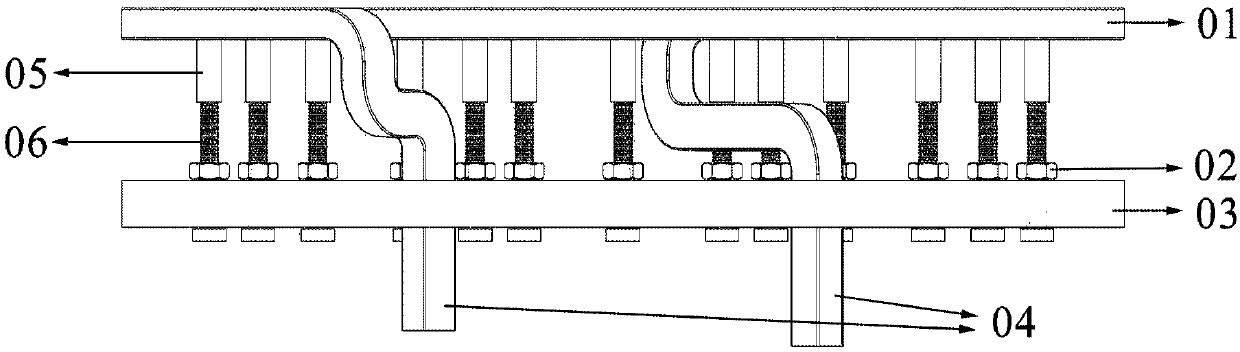

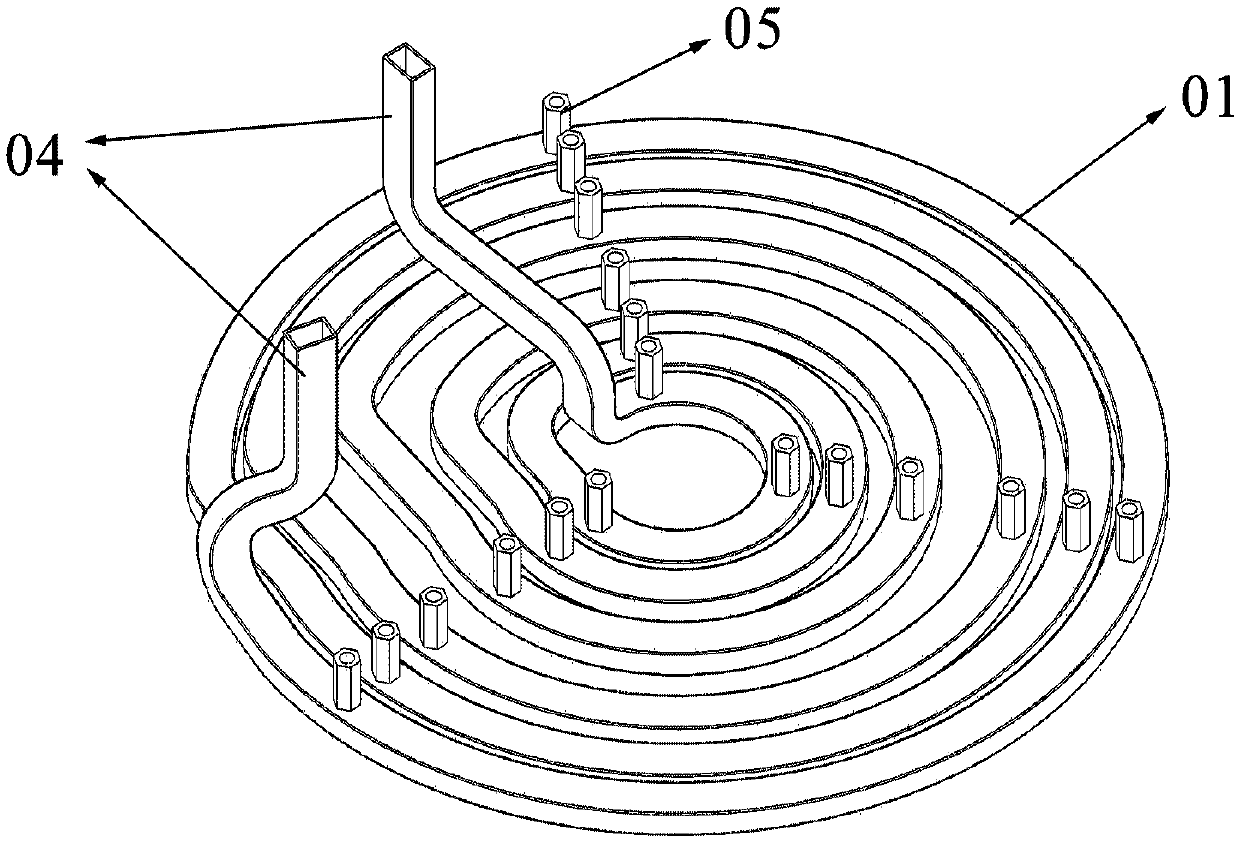

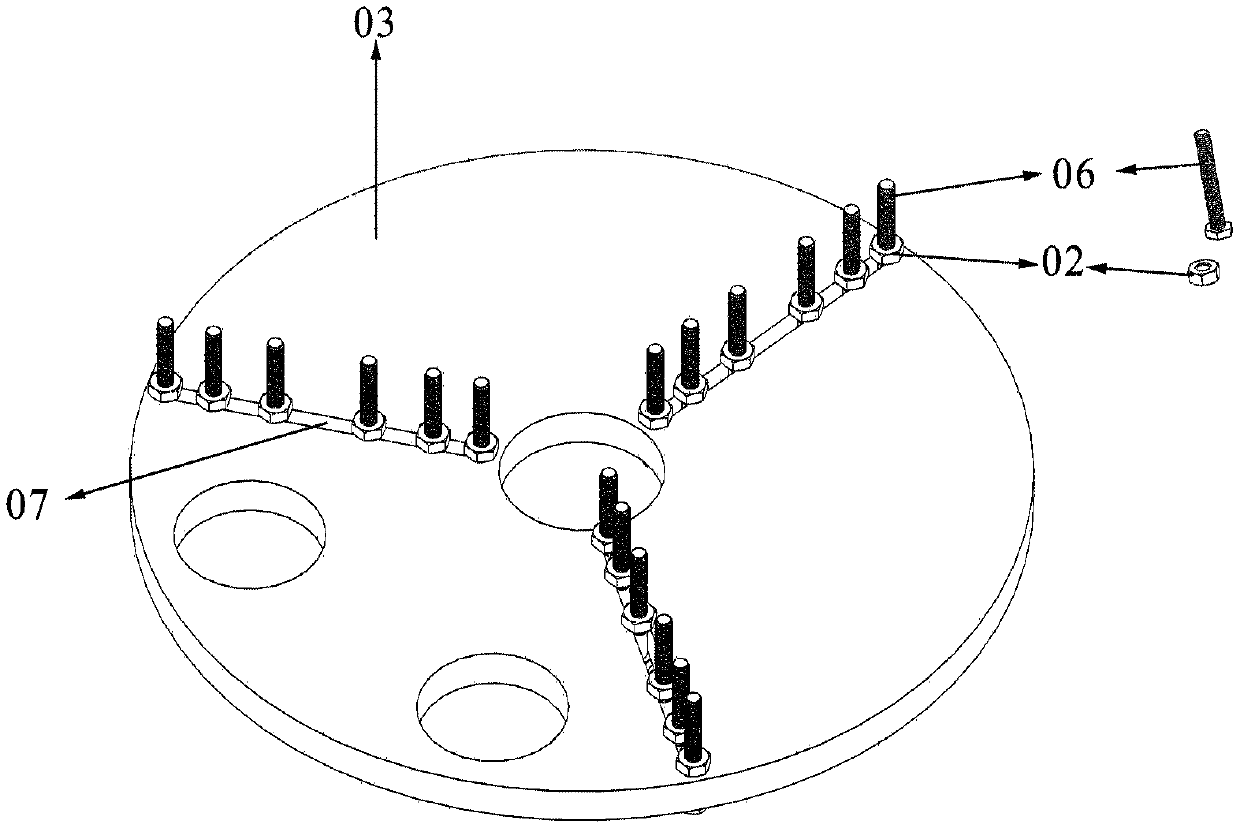

[0030] The present disclosure provides an adjustable induction coil device. The tray on which the substrate is placed is located on the ceramic plate fixed to the induction coil, parallel to the plane where the induction coil is located, and through the cooperation of bolts and nuts, each turn of the induction coil is vertically The height in the plane direction of the coil is adjustable, so as to change the distance between each turn of the induction coil and the ceramic disc, thereby changing the distance between each turn of the coil and the tray respectively, and changing the distance between each turn of the coil and the tray by adjusting the distance between each turn of the coil and the tray The temperature of each area of the tray is uniform or consistent to achieve the overall excellent temperature uniformity of the tray, which is simple, convenient, and flexible to adjust.

[0031] In order to make the purpose, technical solutions and advantages of the present discl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com