Super strength high molecule fibre intelligent high temperature thermo-setting machine

A kind of polymer fiber and intelligent technology, applied in the direction of heating/cooling fabrics, heat treatment of artificial filaments, textiles and papermaking, etc., can solve the problems of high temperature heat setting of aramid fiber tow, large temperature difference and poor thermal efficiency and other problems, to achieve good temperature uniformity, prevent heat leakage, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

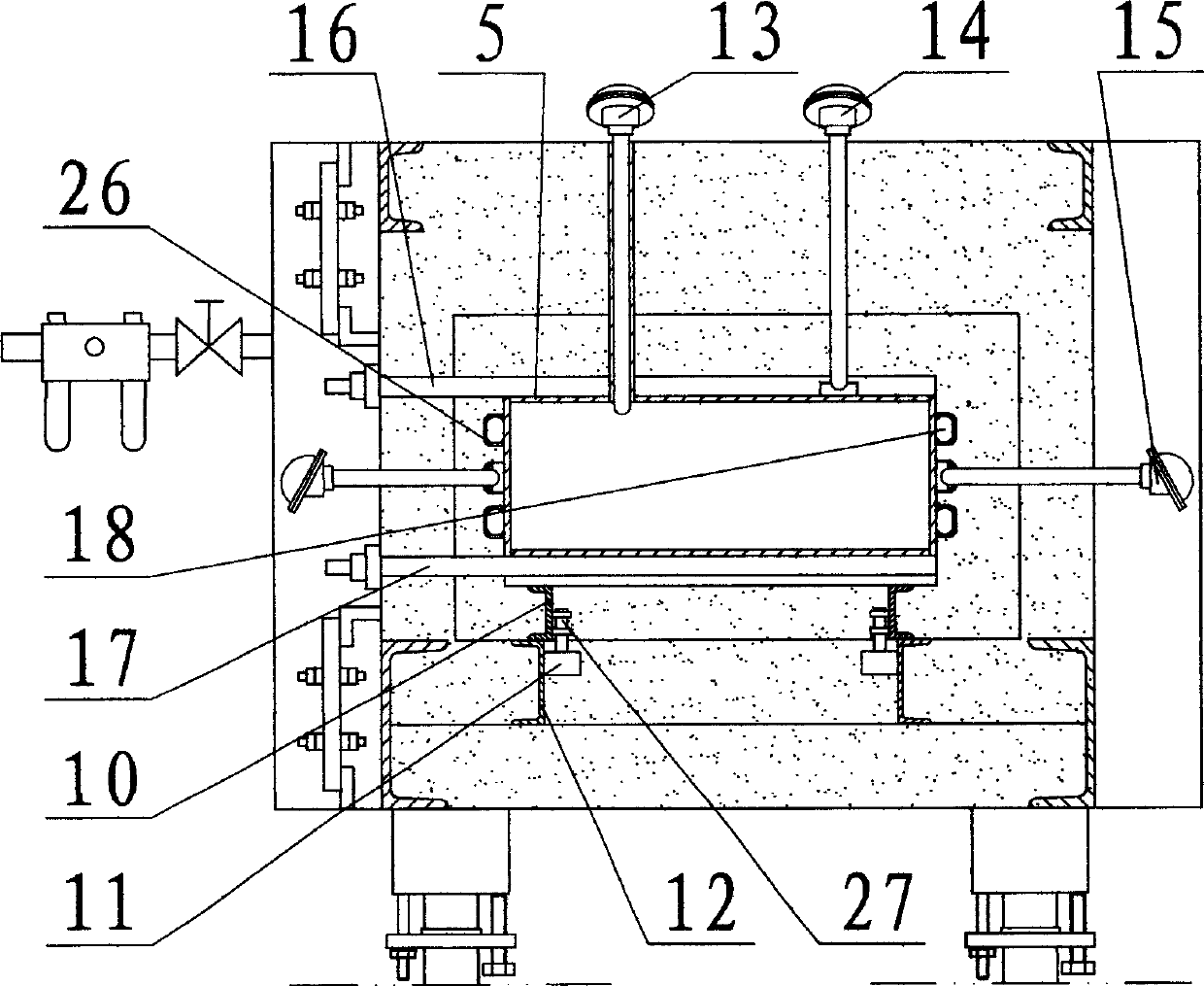

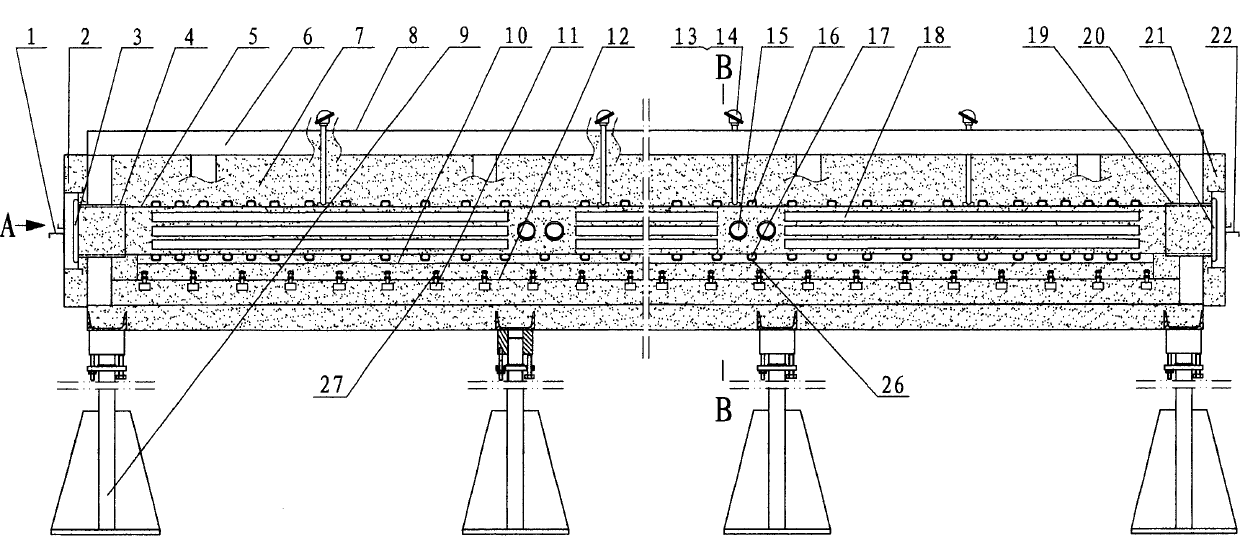

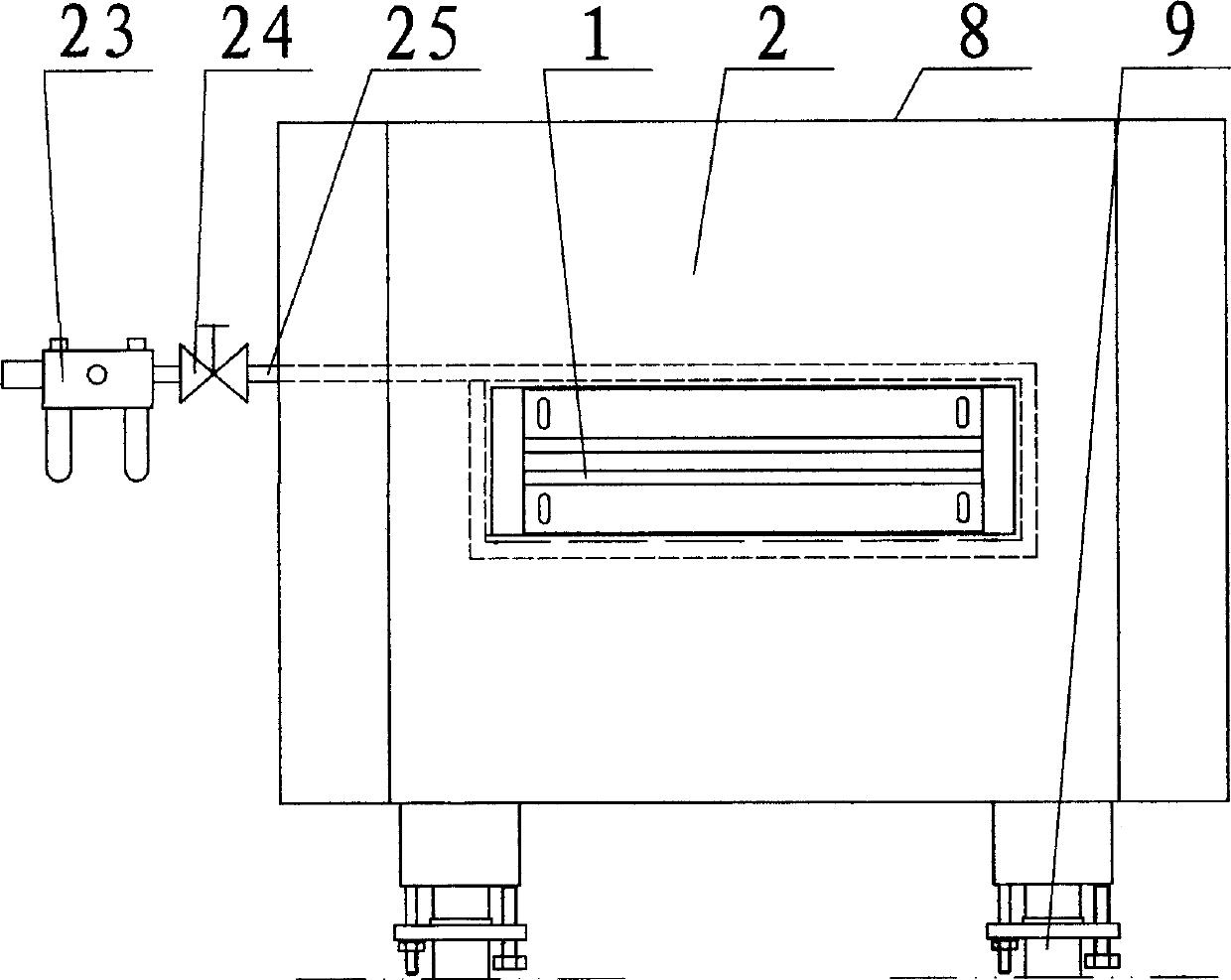

[0021] figure 1 and image 3 Among them, the casing is composed of a body frame 6 and an outer plate 8 arranged on the frame. The bottom of the housing is provided with a plurality of adjustable bases 9 . The left end expansion joint 4 and the right end expansion joint 19 are tubular structures with a rectangular cross section, and the left end expansion joint 4 and the right end expansion joint 19 are respectively provided with the left and right ends of the body frame 6 . The inner cavity body 5 is a tubular structure with a rectangular cross section, and the two ends of the inner cavity body 5 are sheathed in the inner holes of the left end expansion joint 4 and the right end expansion joint 19 respectively and can move therein. Straight beams 10 are arranged at a distance from the inner ends of the left end expansion joint 4 and the right end expansion joint 19 at the bottom of the inner cavity body 5 . The straight beam 10 is positioned on the top of the guide rail 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com