Automobile engine heat dissipating device based on oscillatory flow heat pipes

A technology of oscillating flow heat pipe and automobile engine, which is applied to the cooling of engine components, machines/engines, and engines, etc. It can solve the problems of restricting the development of automobile engine heat sinks, the difficulty in reducing the consumption of copper and aluminum materials, and the low heat dissipation efficiency of heat dissipation pipes. Achieve the effects of good temperature uniformity, low material consumption and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

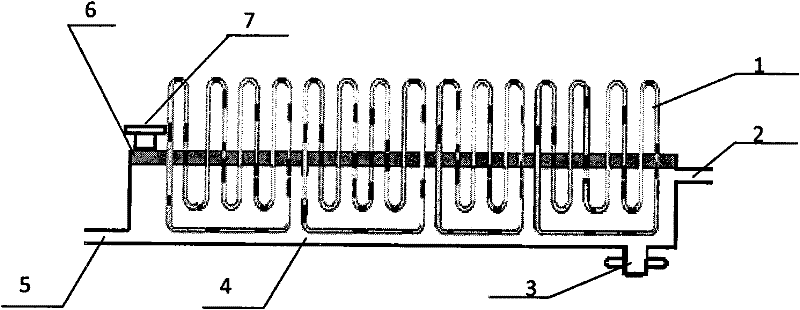

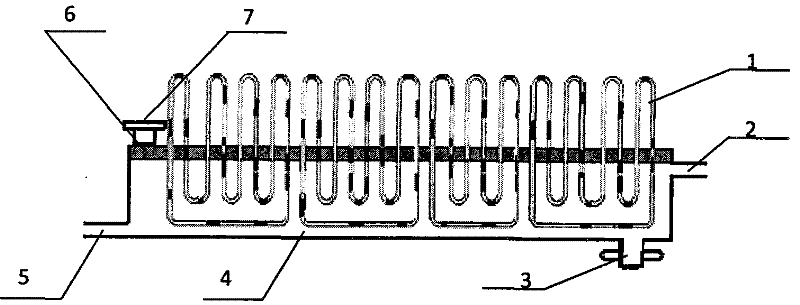

[0018] as attached figure 1 As shown: it consists of a water tank 4 and multiple groups of oscillating flow heat pipes 1. One end of the oscillating flow heat pipe 1 is in the thermal fluid channel in the water tank 4, and conducts the heat of circulating water to the other end of the oscillating flow heat pipe 1. The oscillating flow The other end of the heat pipe 1 completes convection heat dissipation with the outside air, dissipates the heat into the air, and cools the circulating water.

[0019] Each group of oscillating flow heat pipes 1 passes through the upper surface of the water tank 4 through the heat pipe fixing assembly, and is sealed and fixed with the water tank 4, and each group of oscillating flow heat pipes 1 is independently installed through the fixing assembly.

[0020] The water inlet 5 of the water tank 4 links to each other with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com