Patents

Literature

84 results about "Oscillatory flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oscillatory flow mixing occured when a fluid in a tube fitted with orifice plate baffles was oscillated. A method of process intensification of batch saponification process was discussed using the OFR technology. An OFR for this saponification process provided excellent heat and mass transfer, efficient mixing and plug flow in a compact reactor.

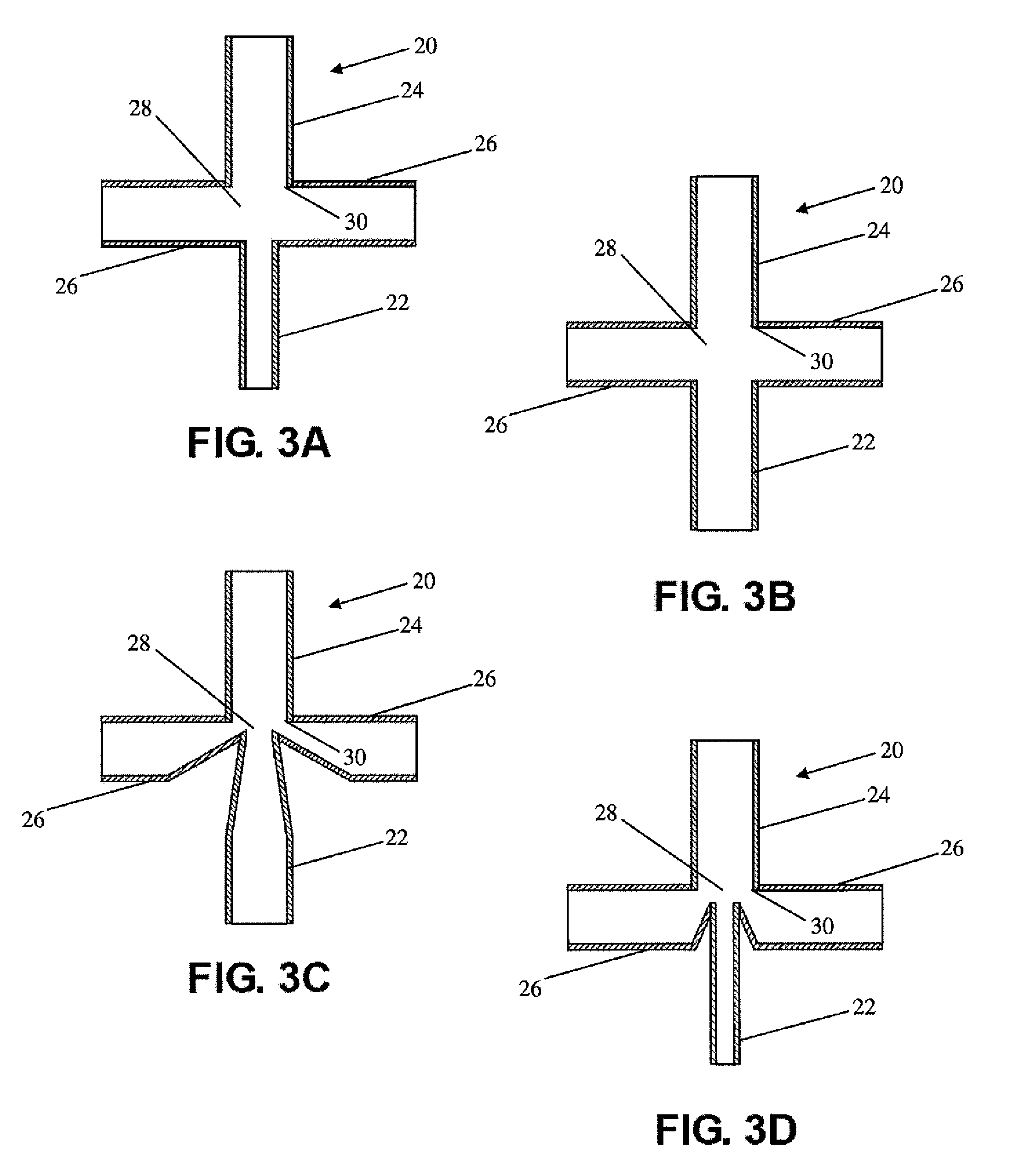

Method and system for flow control with fluidic oscillators

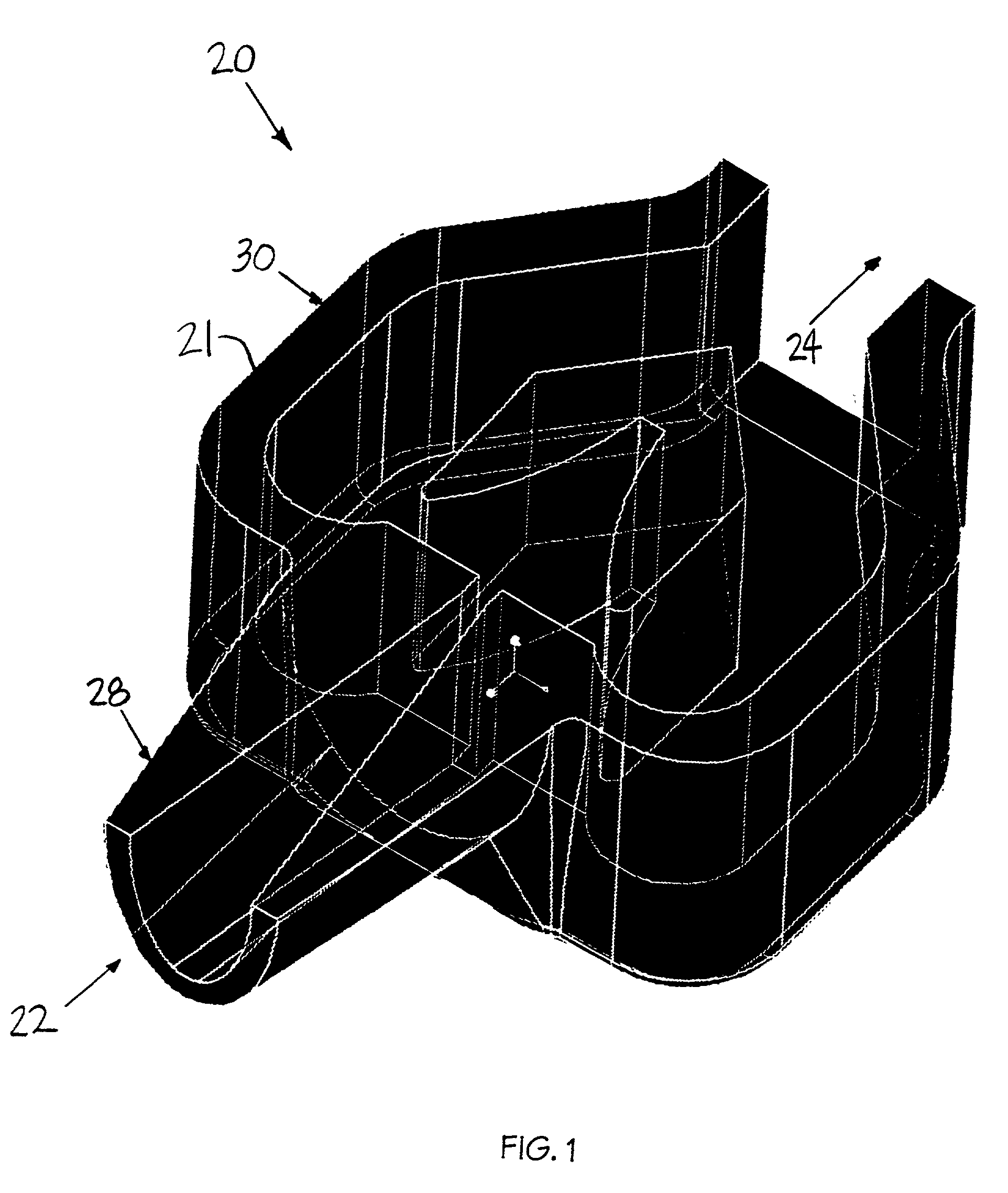

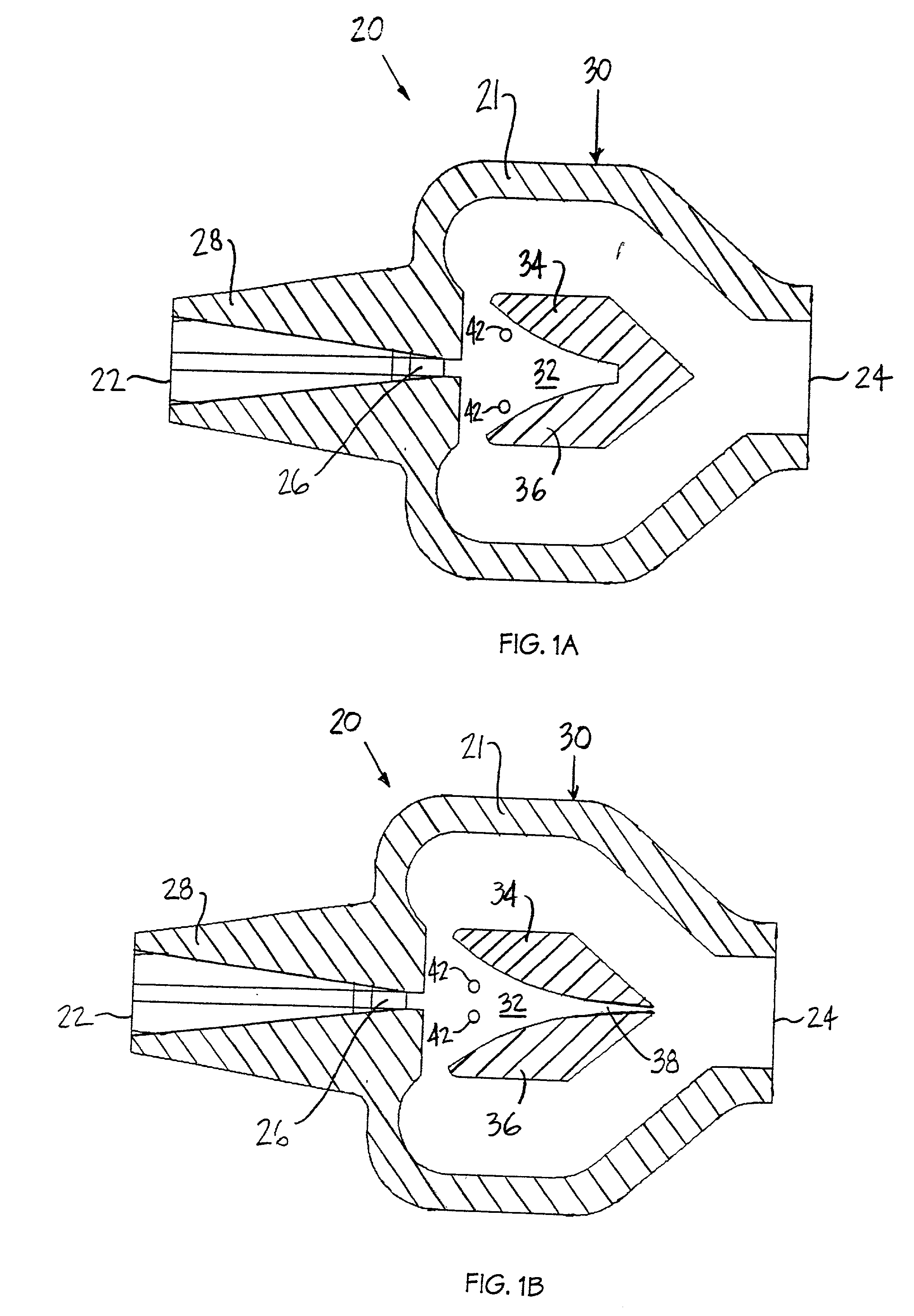

A system for control of a fluid flow. The system includes an array of fluidic oscillators. Each fluidic oscillator carries an oscillating flow of the fluid and includes a throat, an input port connected to the throat, two control ports connected to the throat and two output ports extending from the throat. A feedback line is connected to each of the two output ports and each of the two control ports. The system further includes a plenum connected to the input ports of the fluidic oscillators to supply the fluid to the fluidic oscillators and a feedback chamber disposed along each feedback line of each fluidic oscillator to provide a feedback path for the control fluid to cause oscillatory fluid motion between the first output port and the second output port, the frequency of which may be modulated by adjusting the volume of the feedback chamber.

Owner:GENERAL ELECTRIC CO

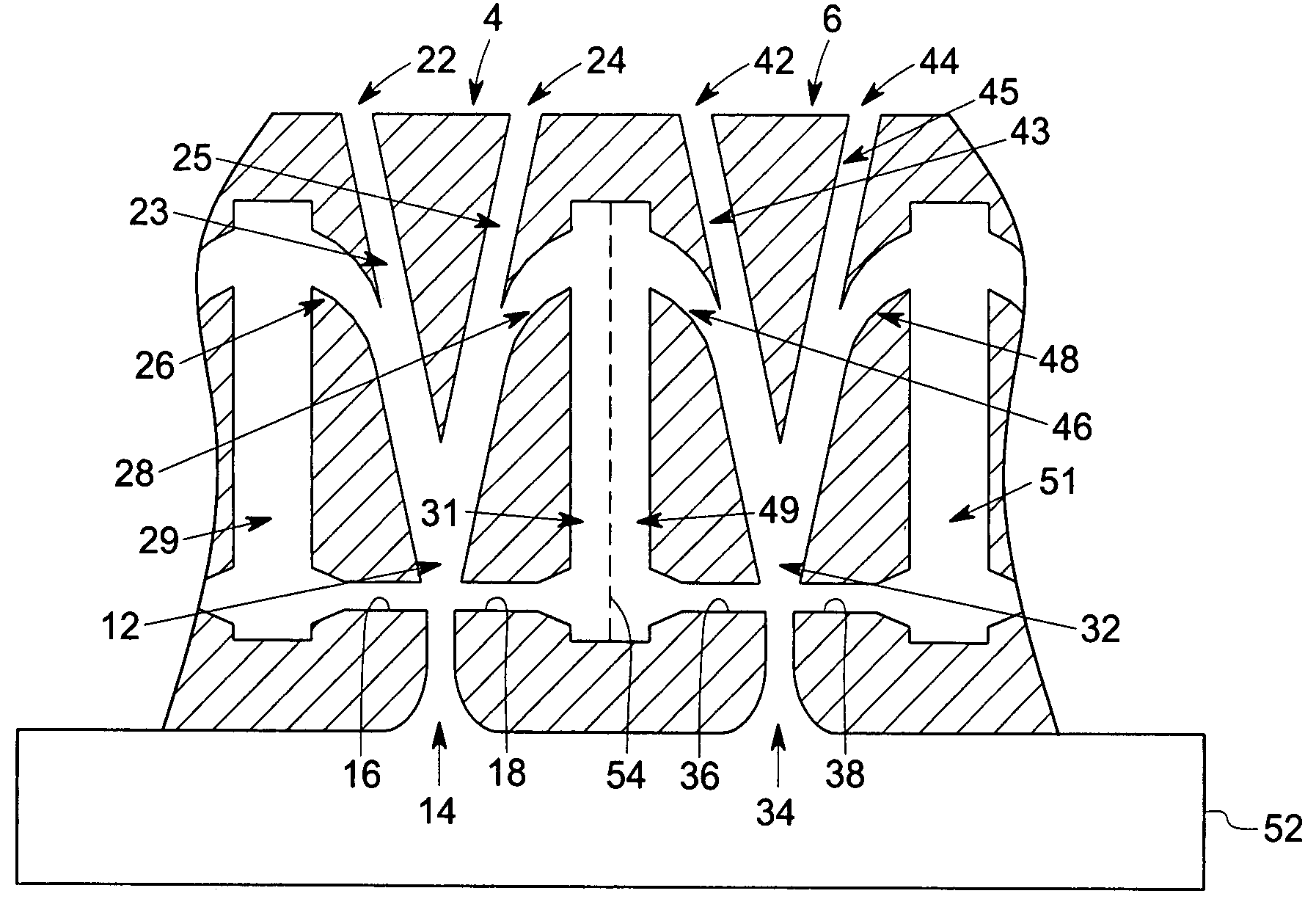

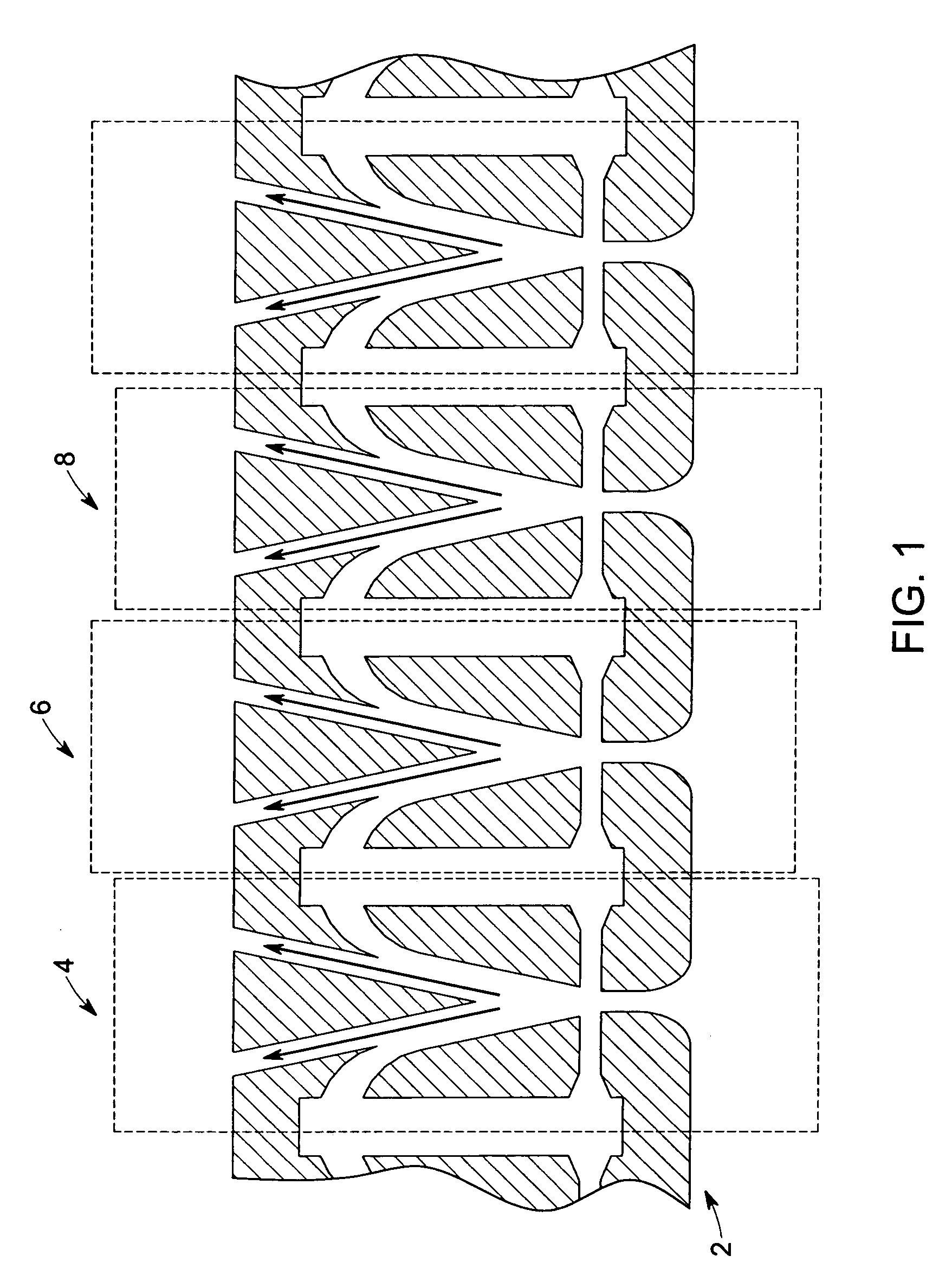

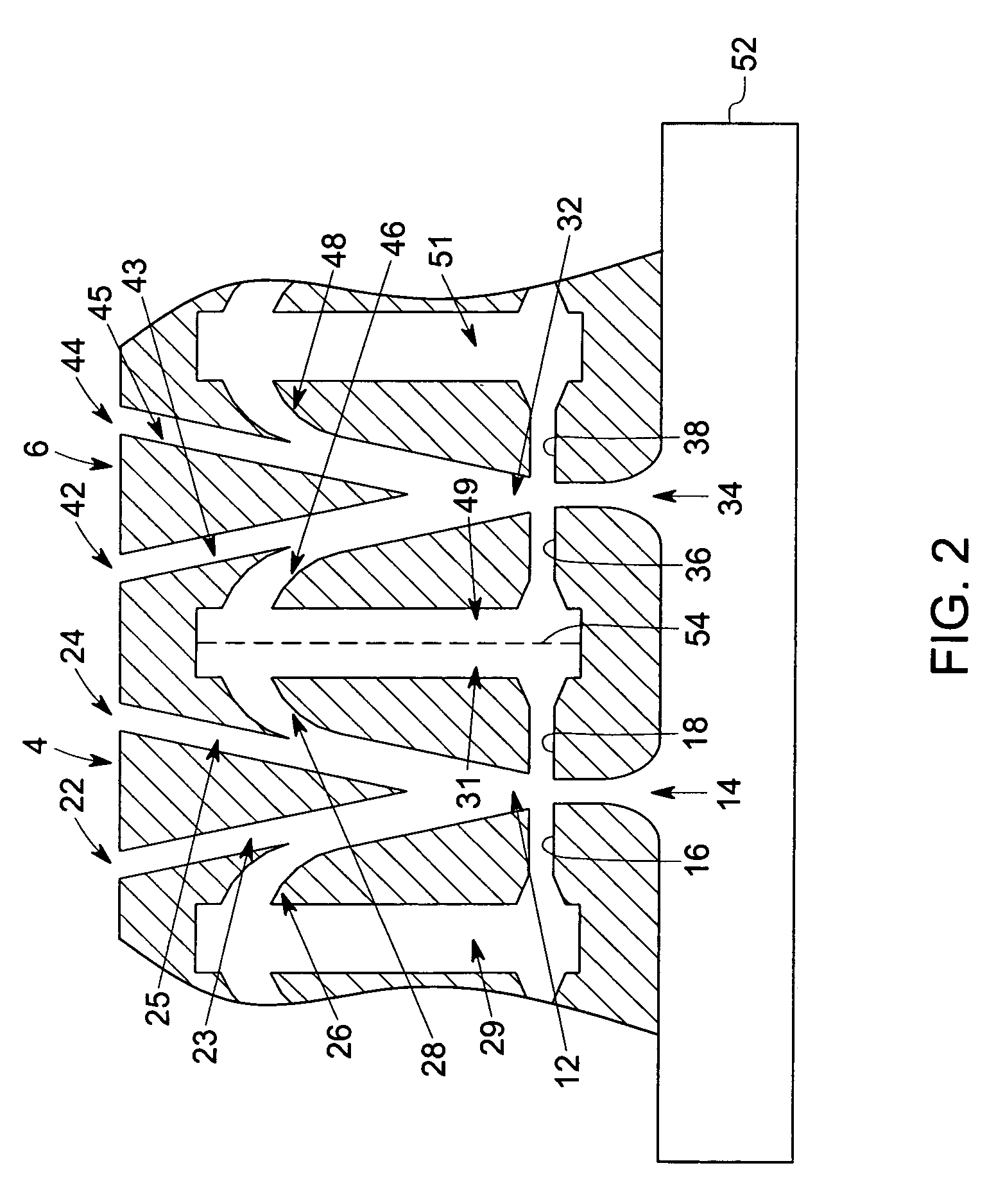

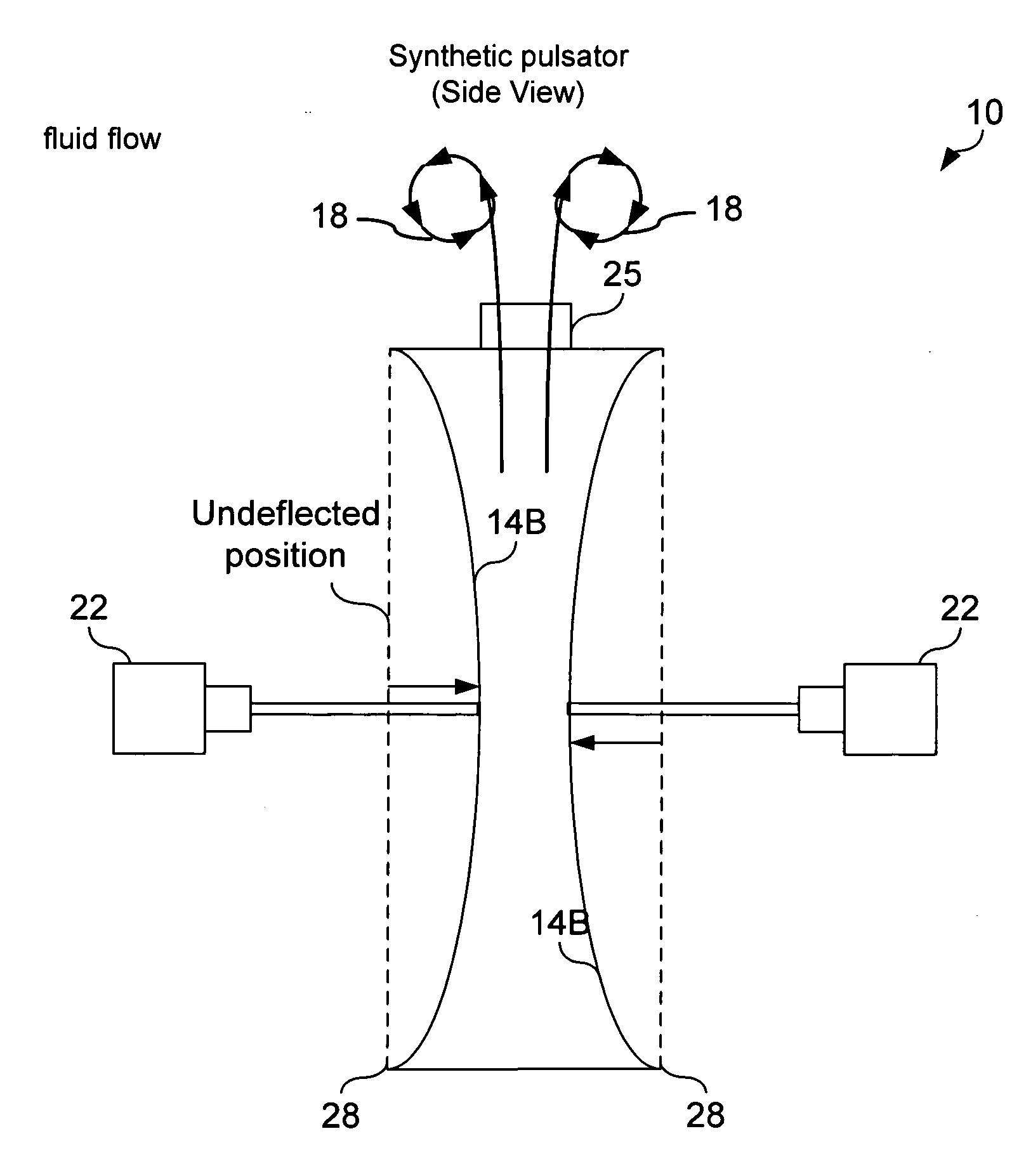

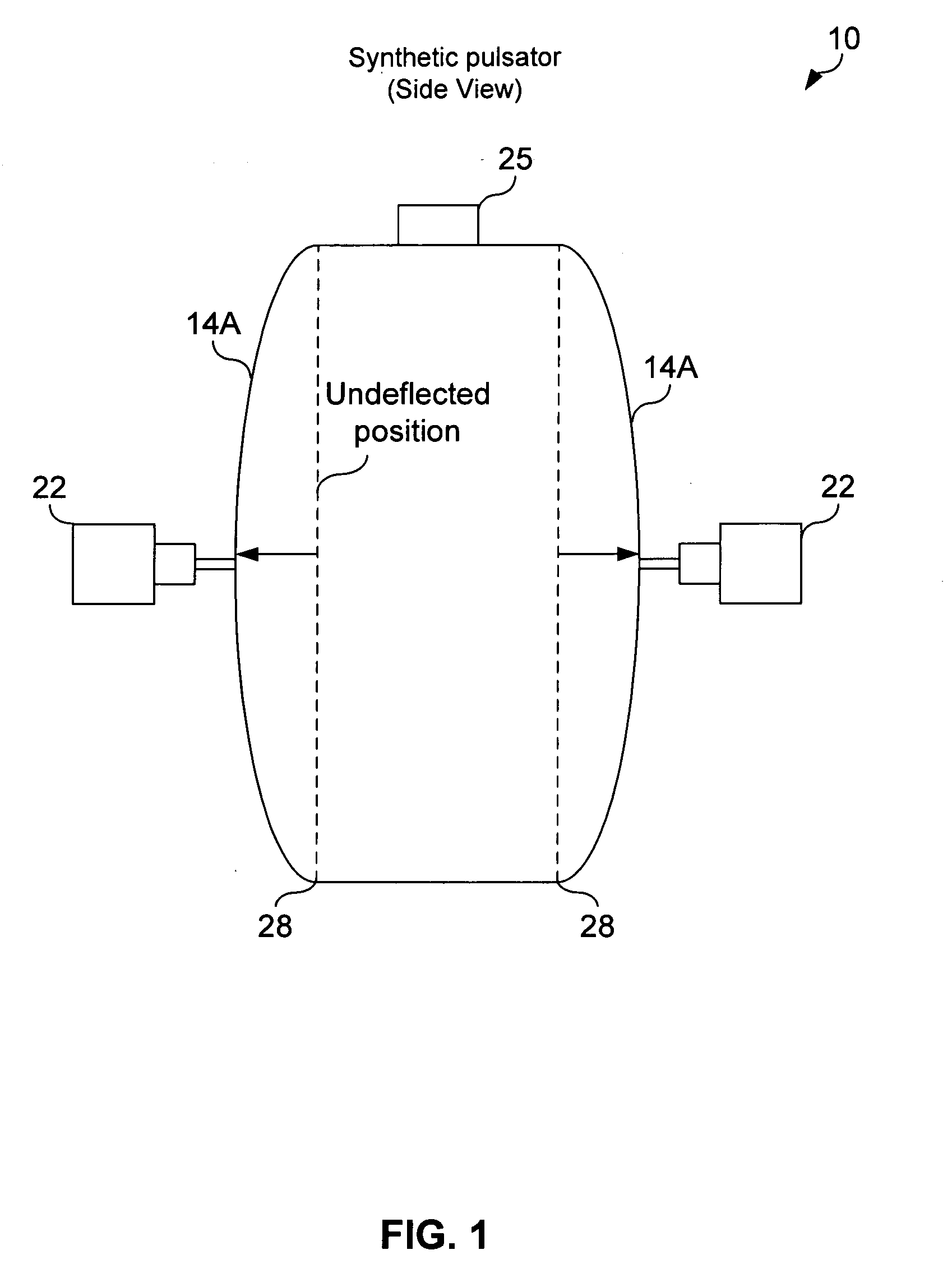

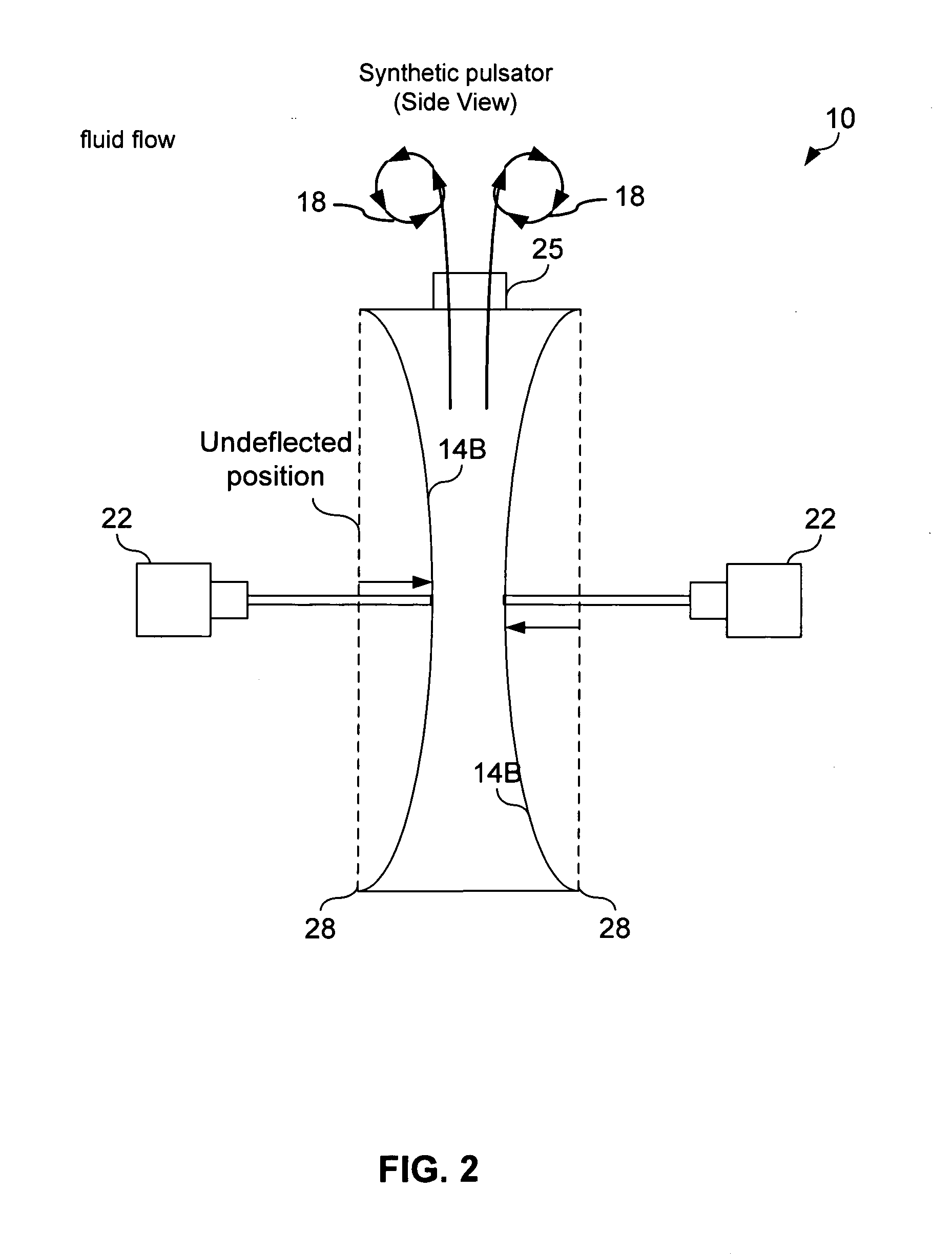

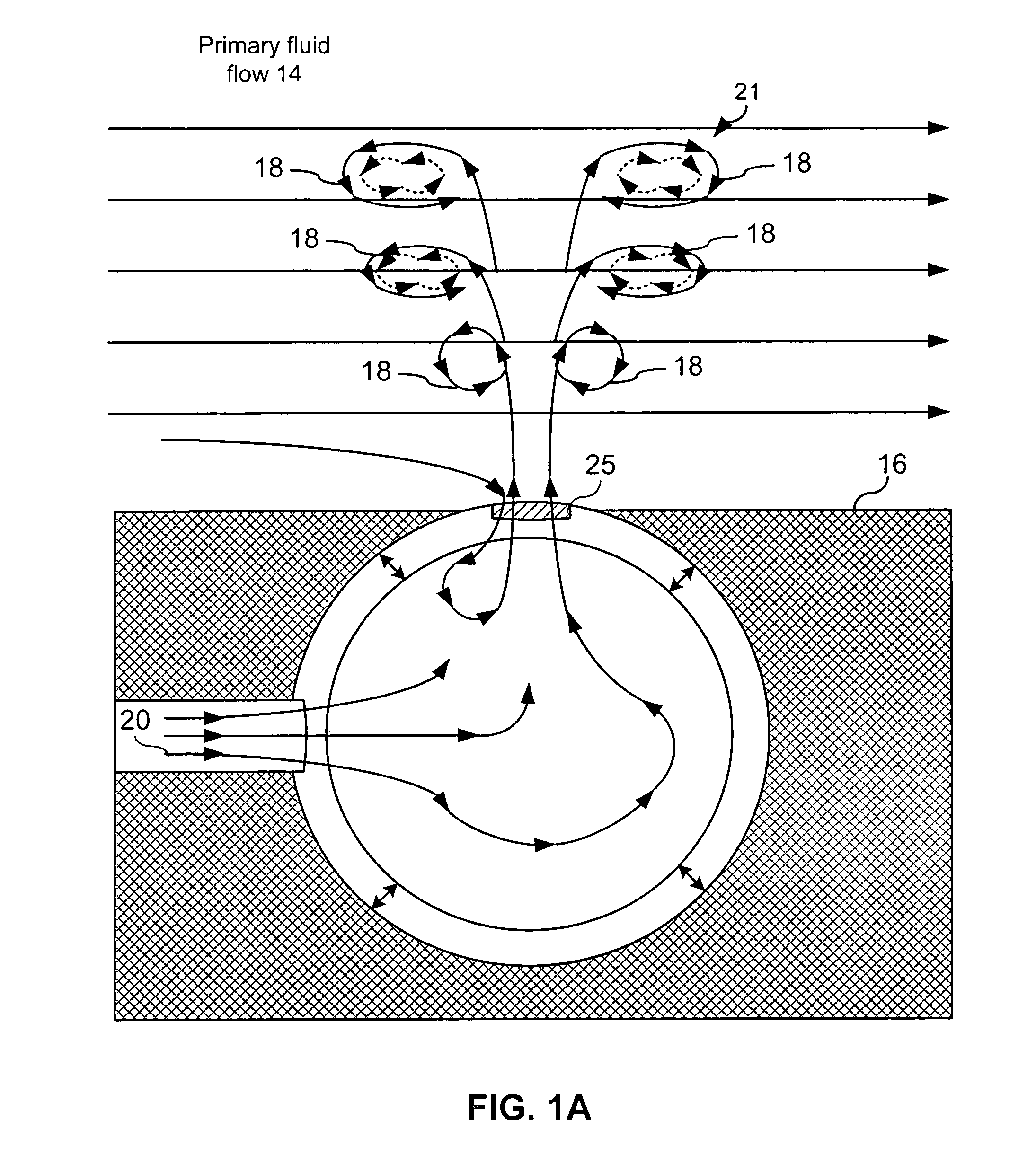

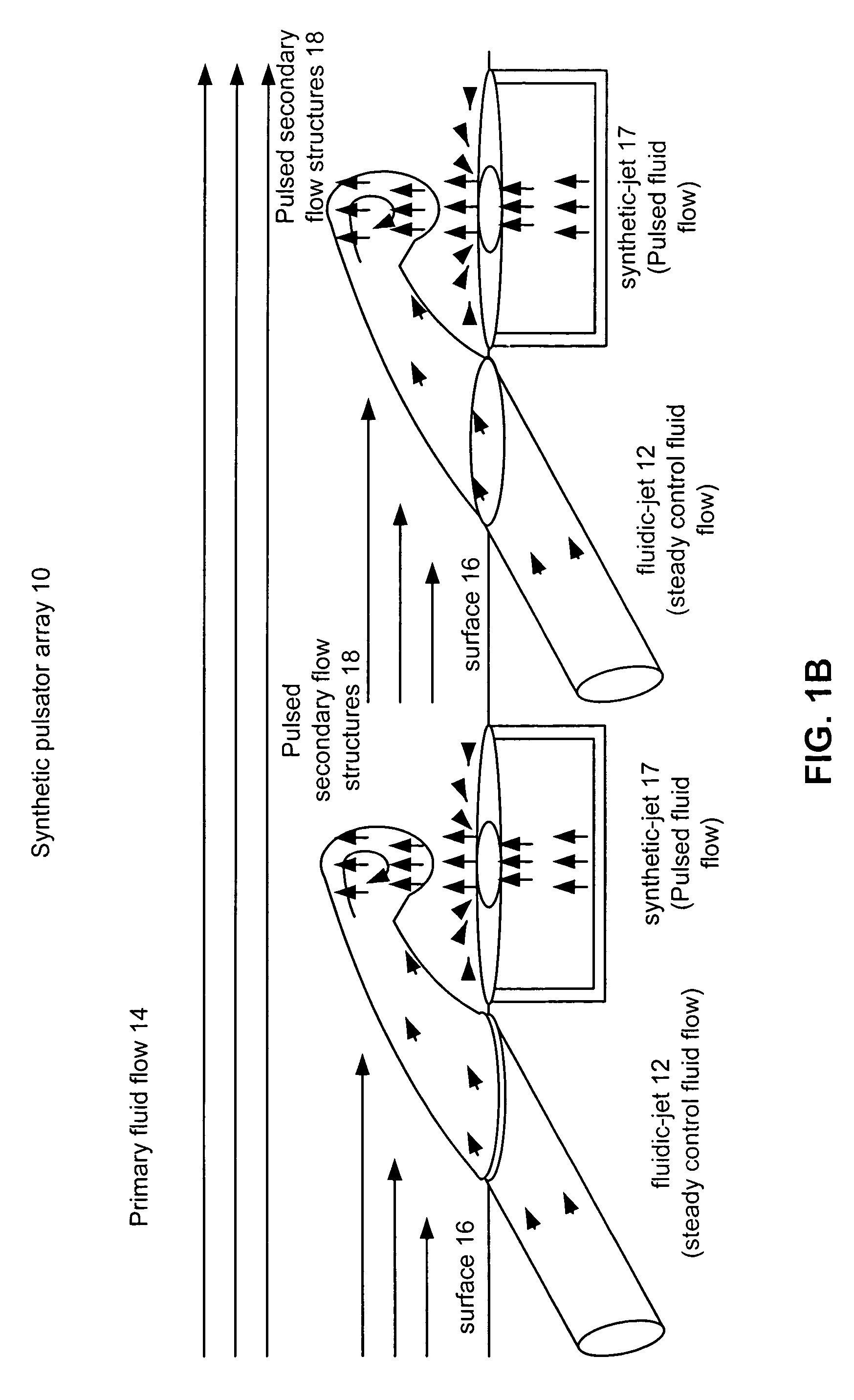

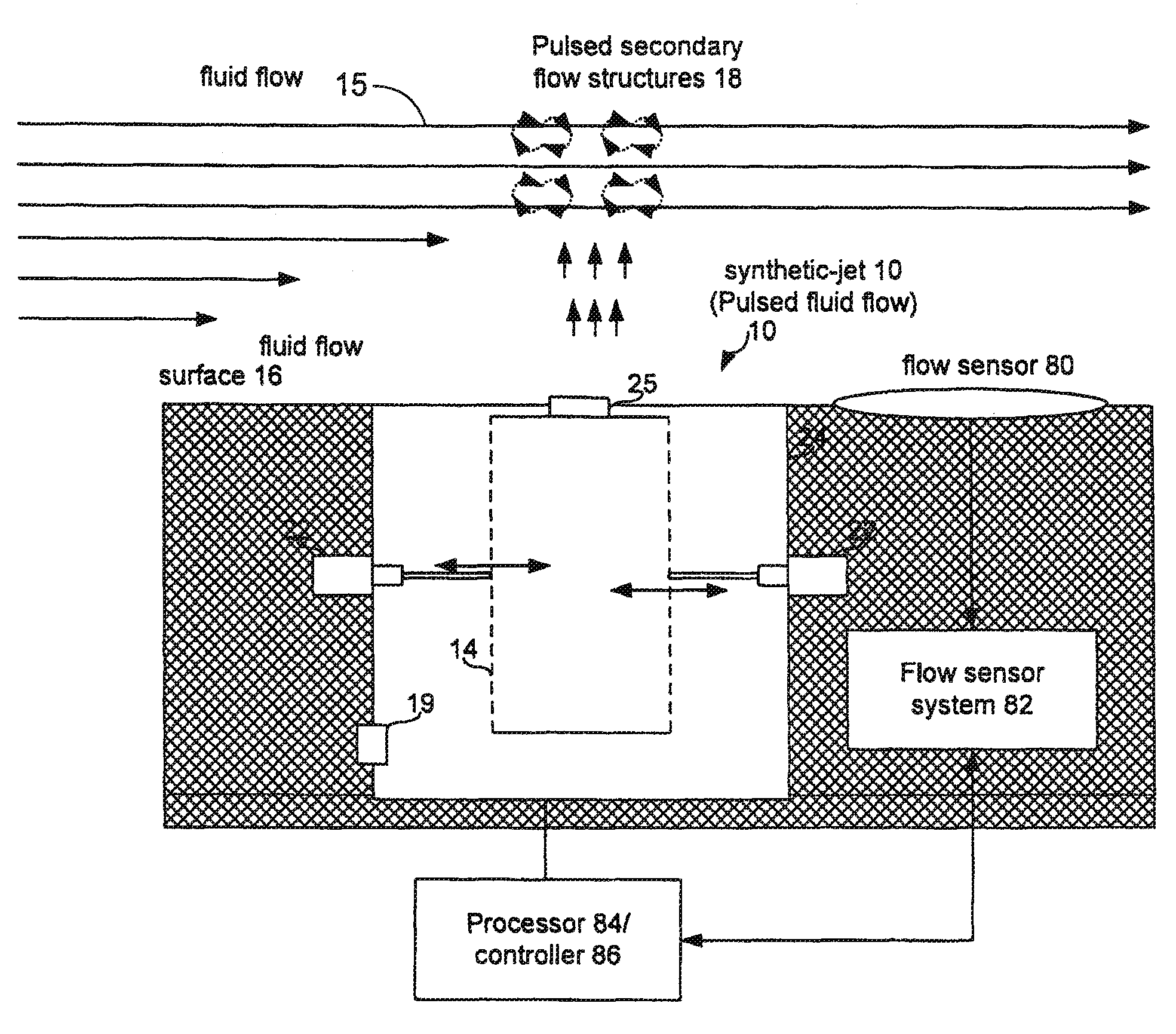

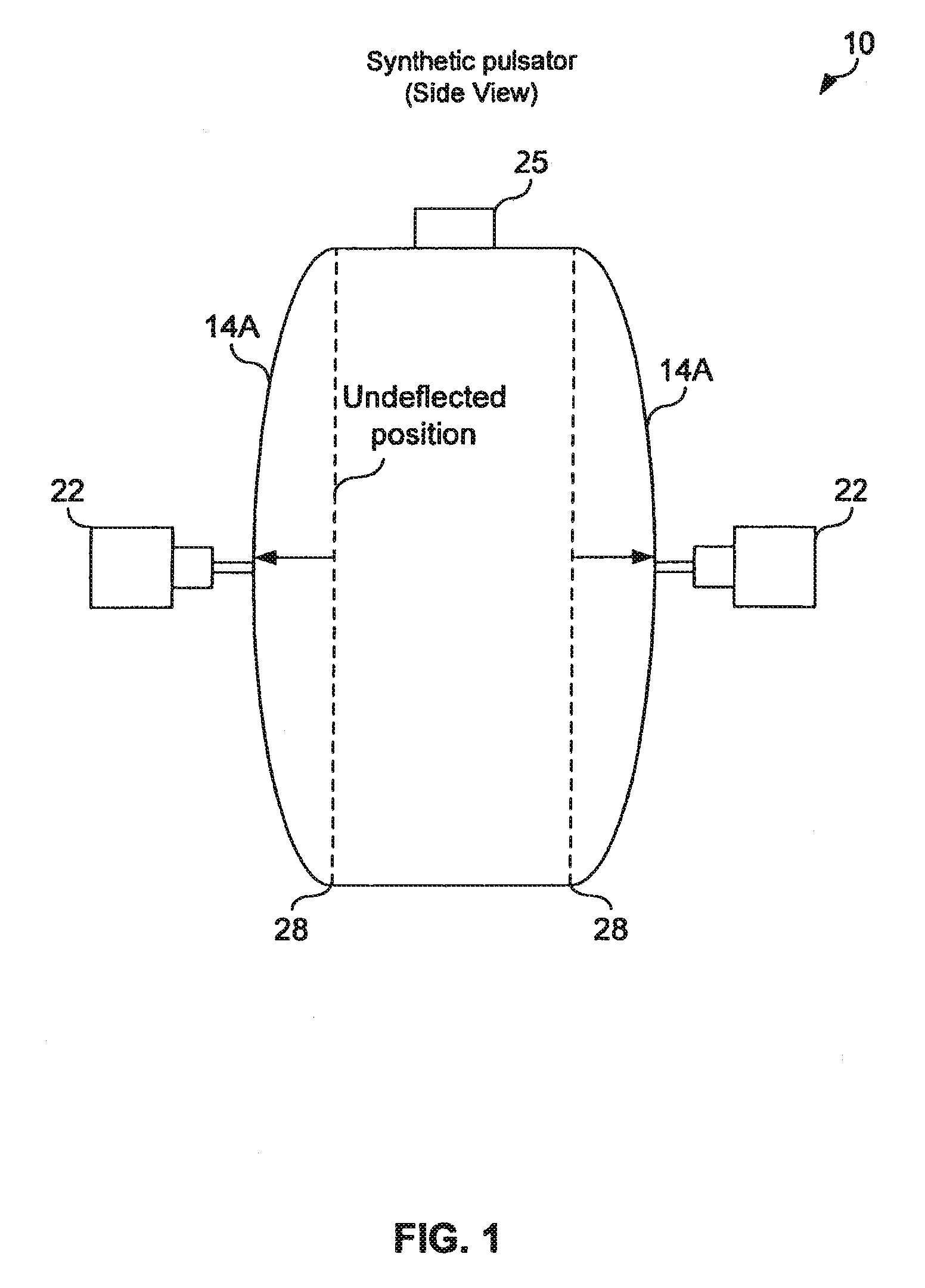

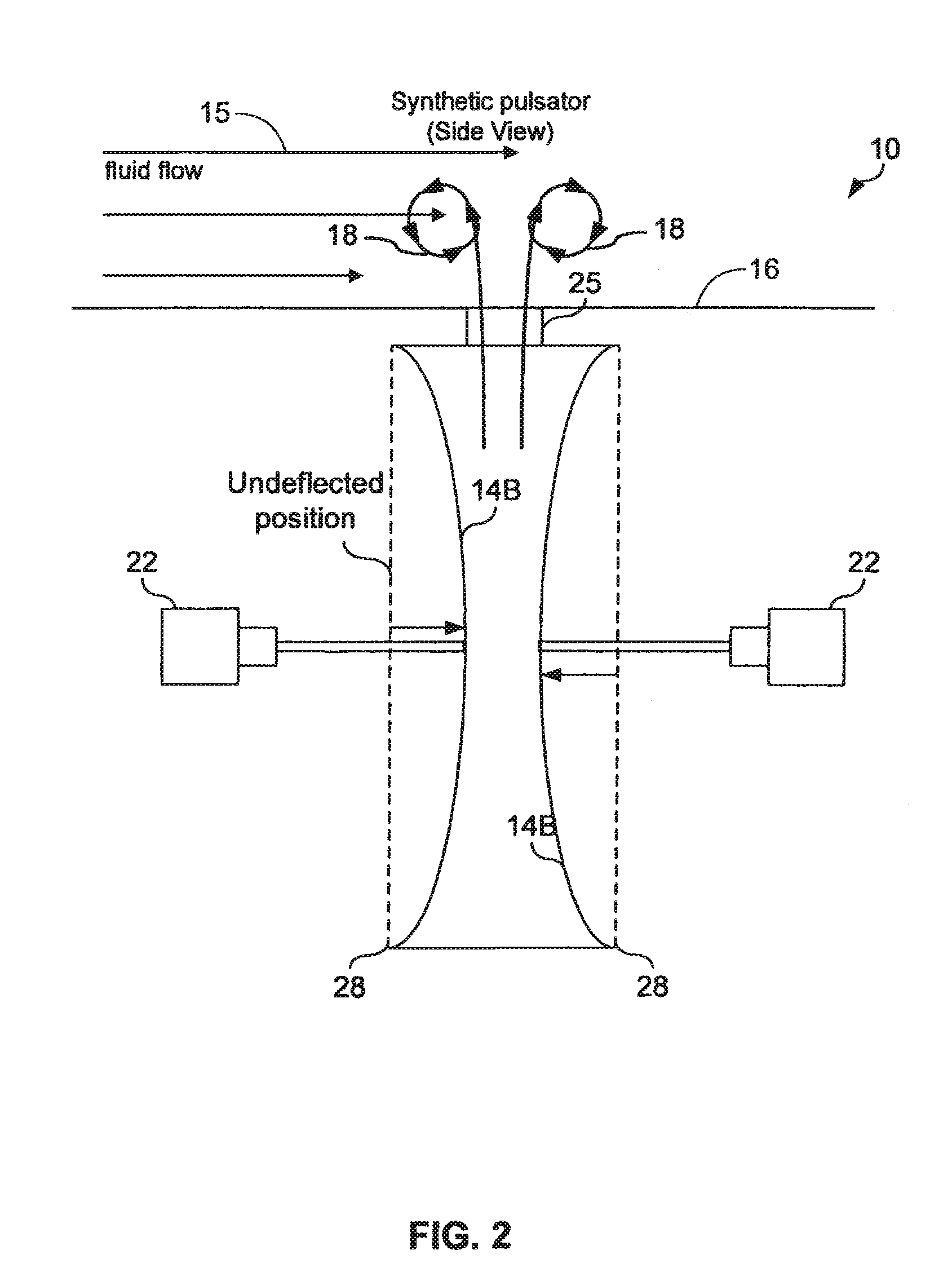

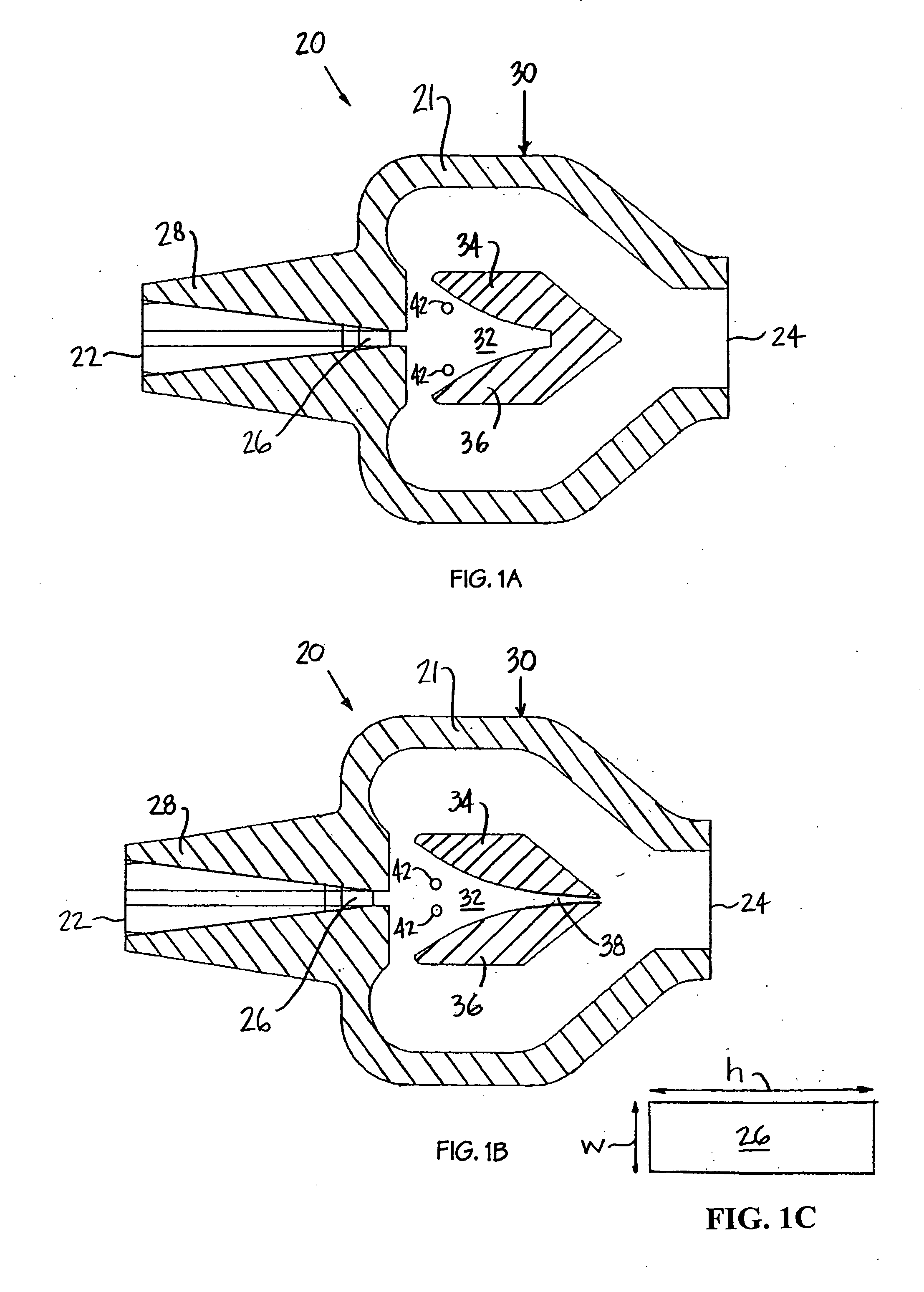

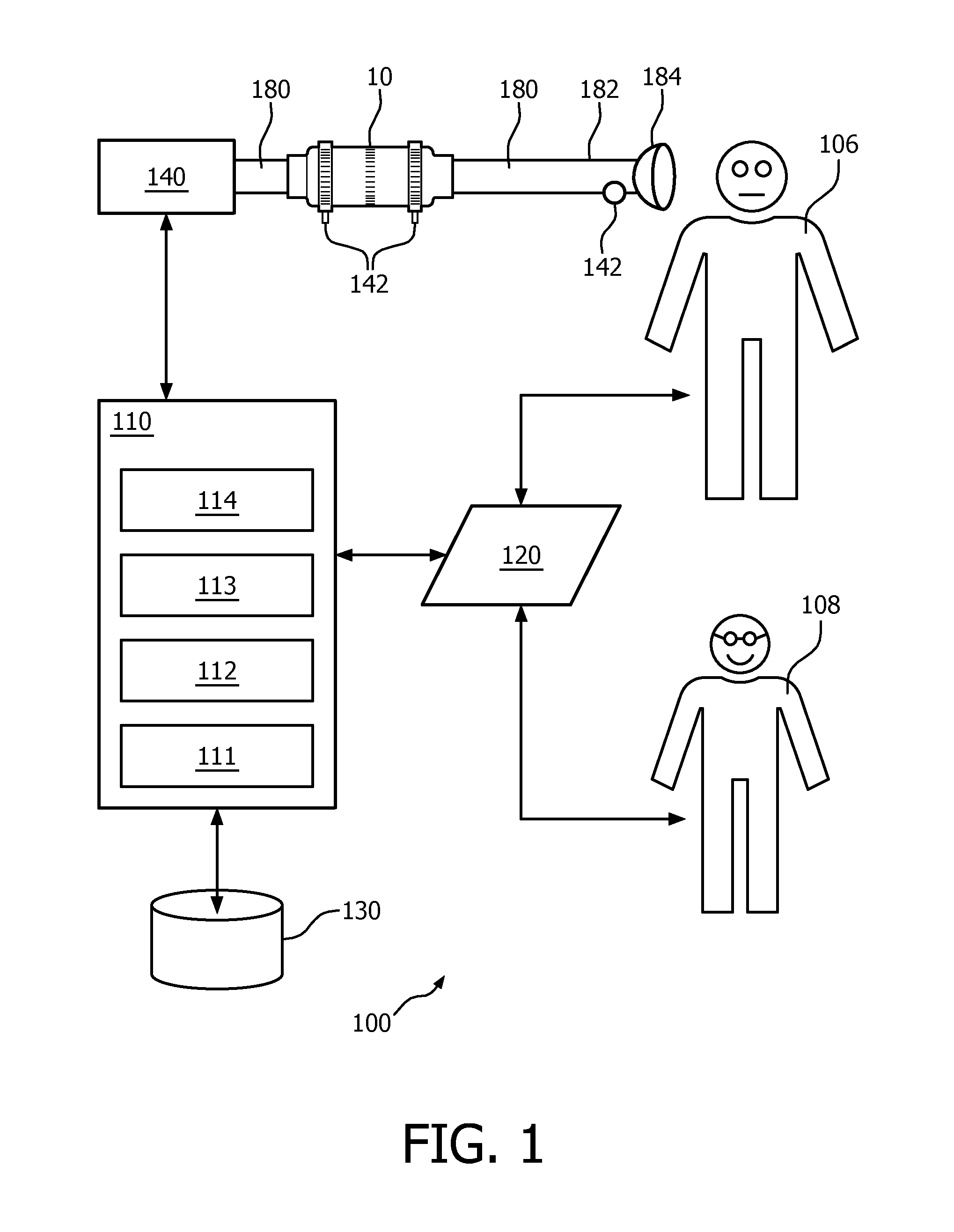

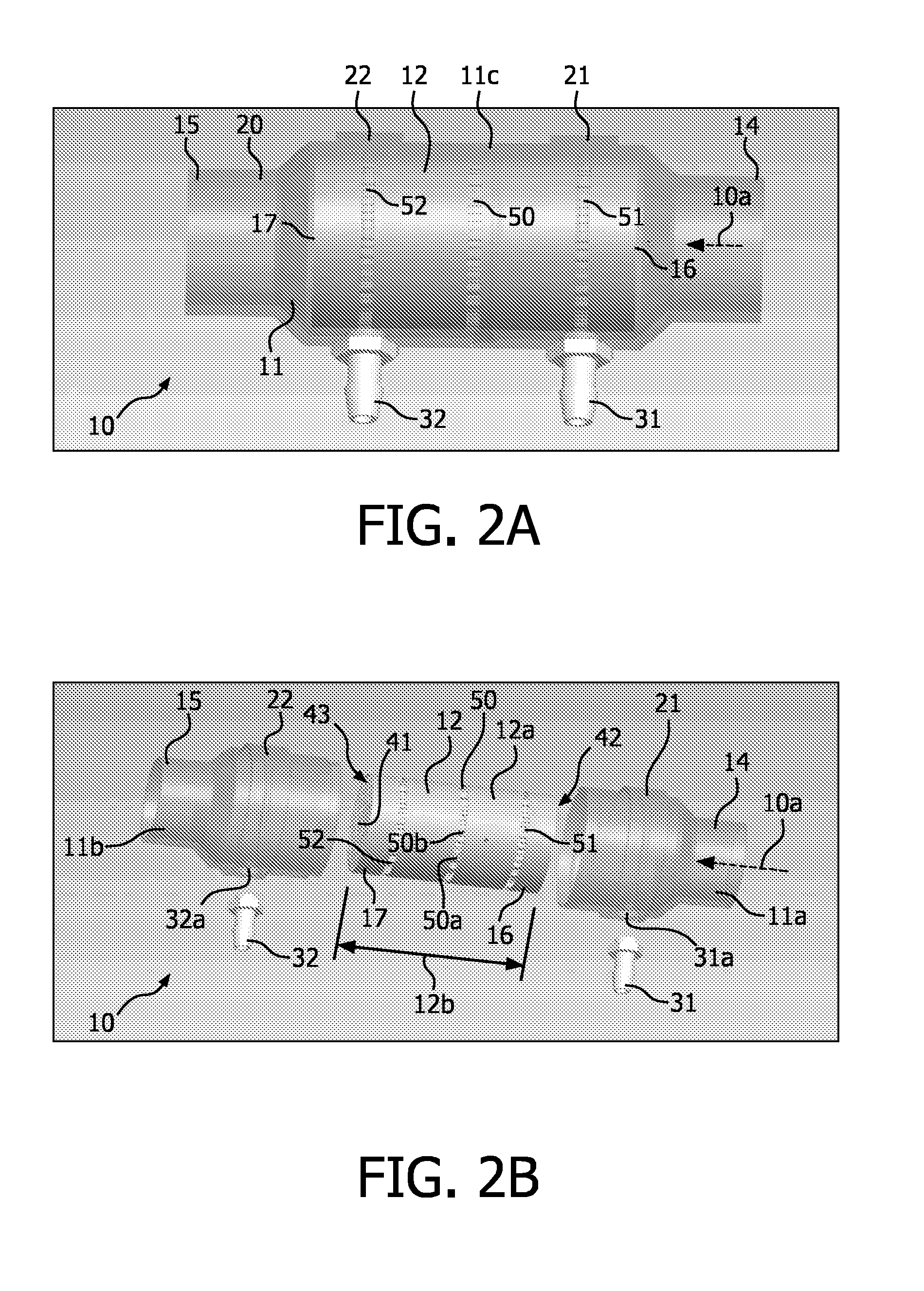

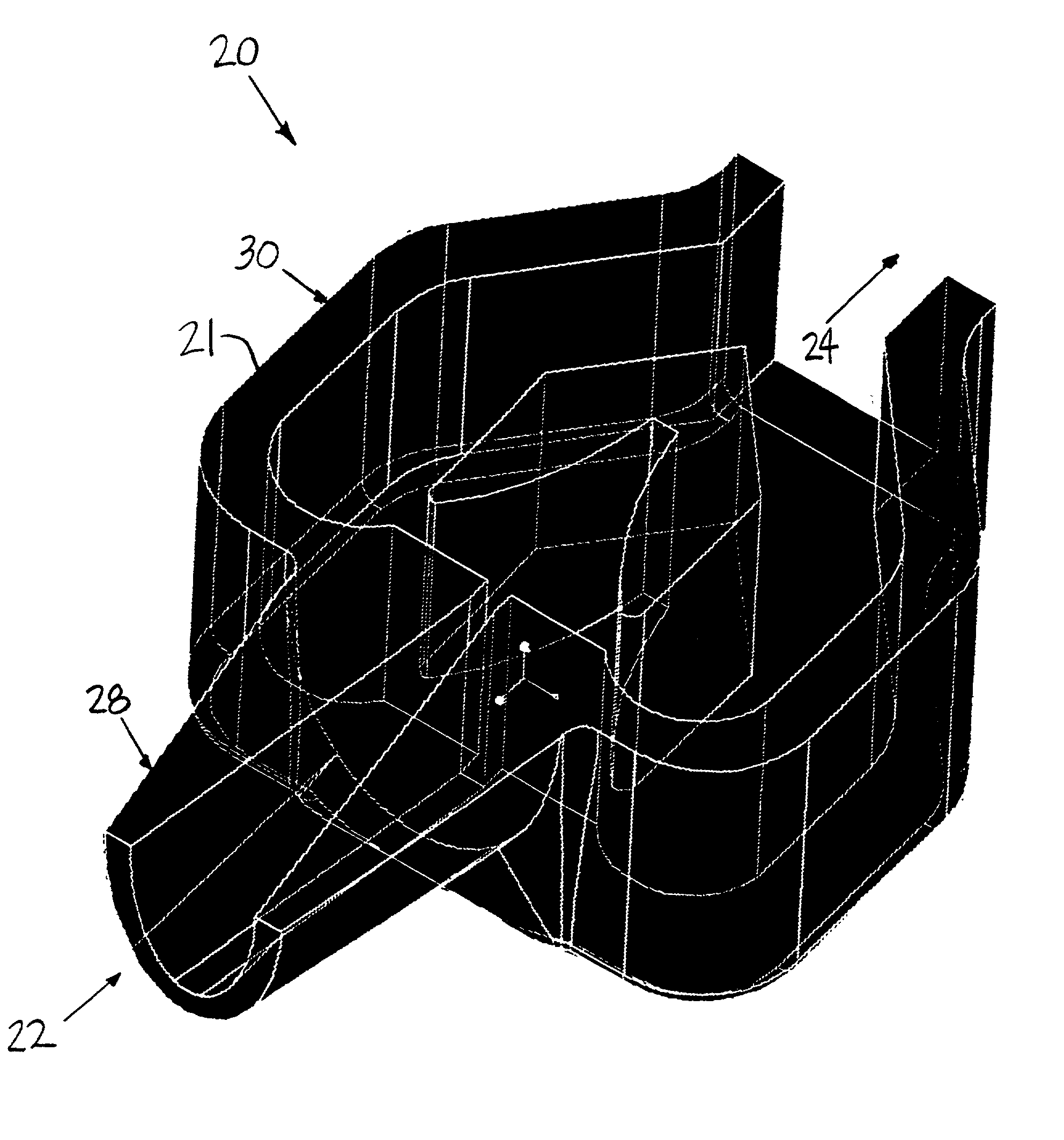

High performance synthetic valve/pulsator

ActiveUS20080087771A1Well mixedImprove performanceAircraft navigation controlFlexible wall reciprocating enginesEngineeringActuator

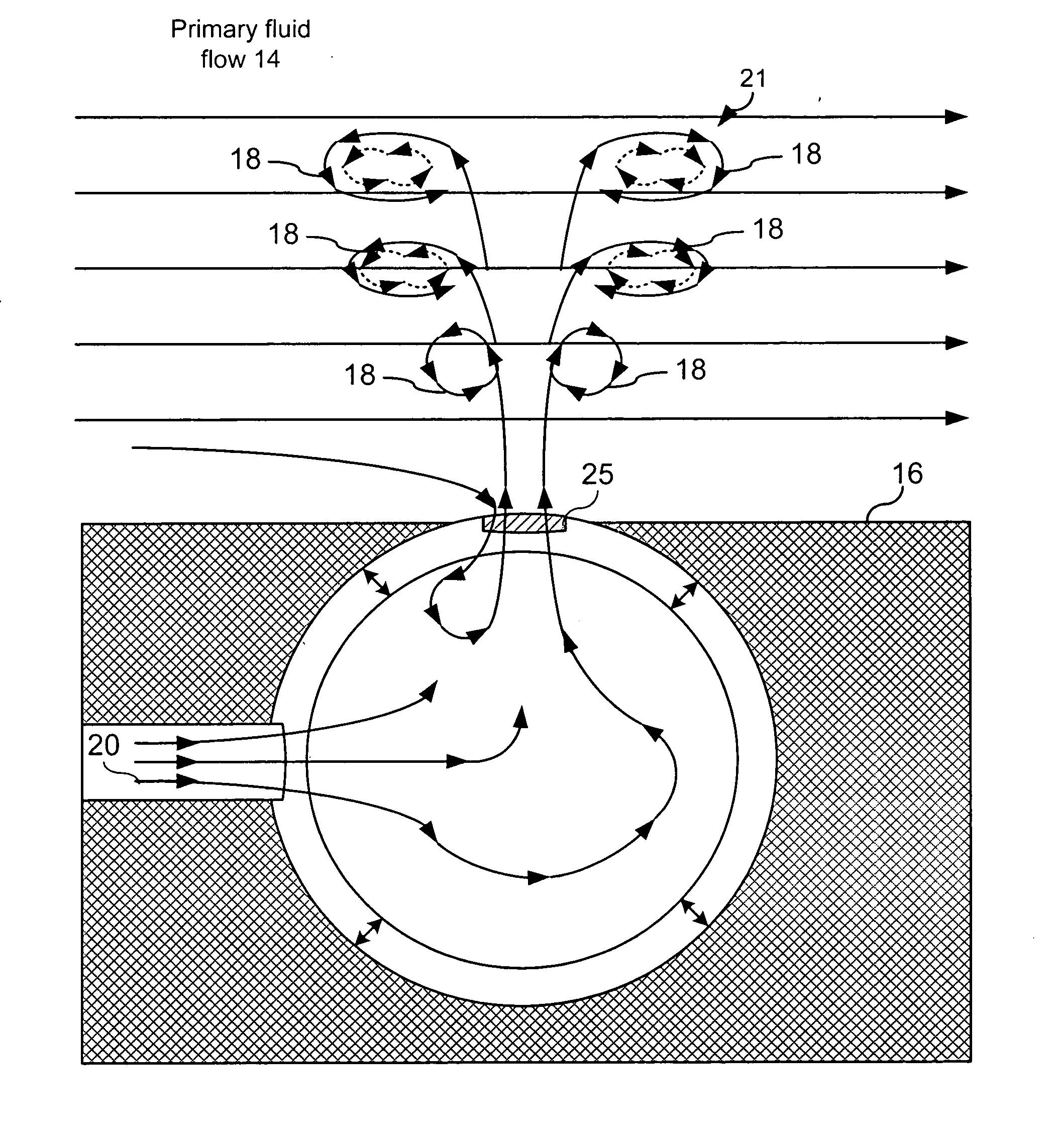

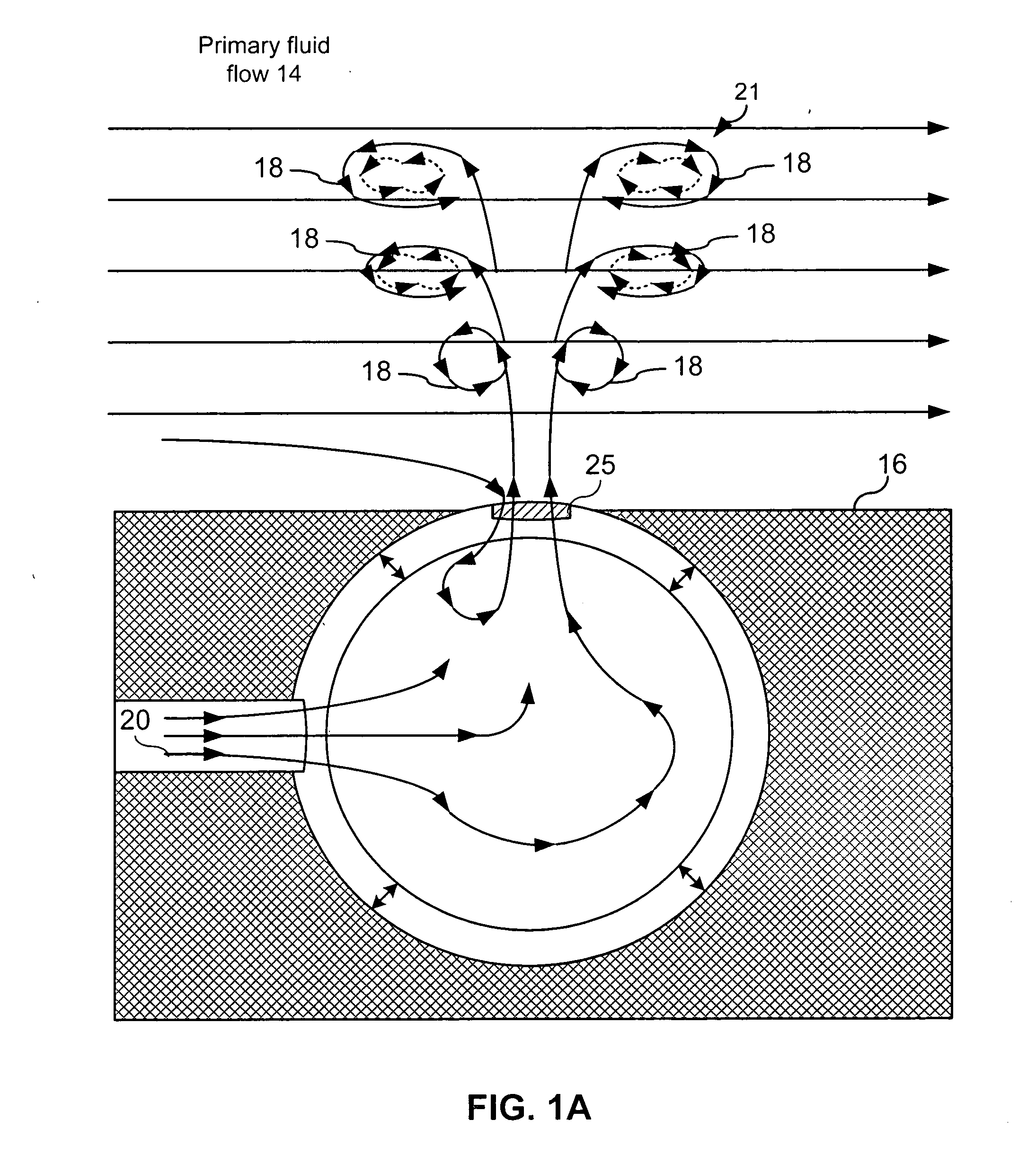

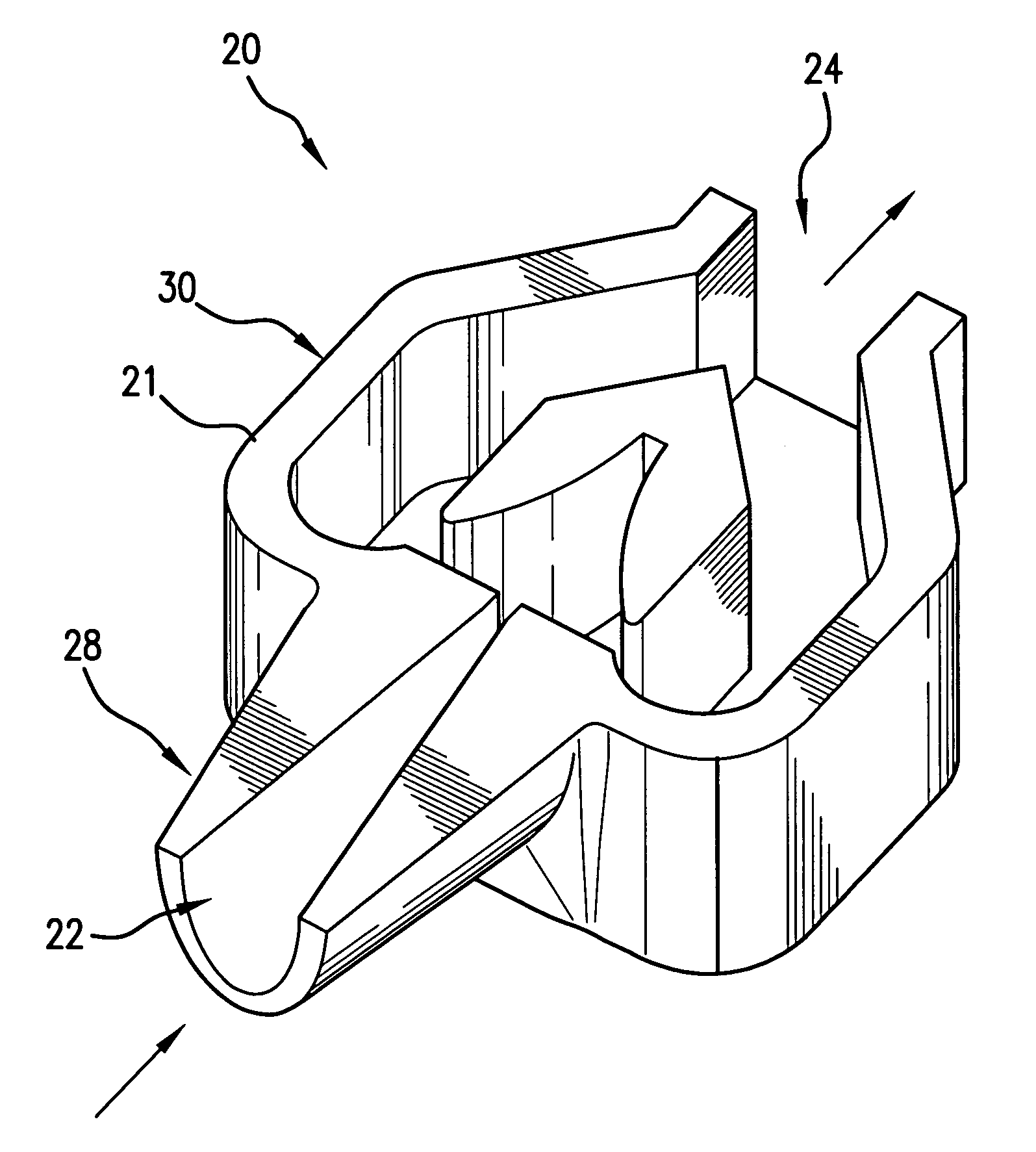

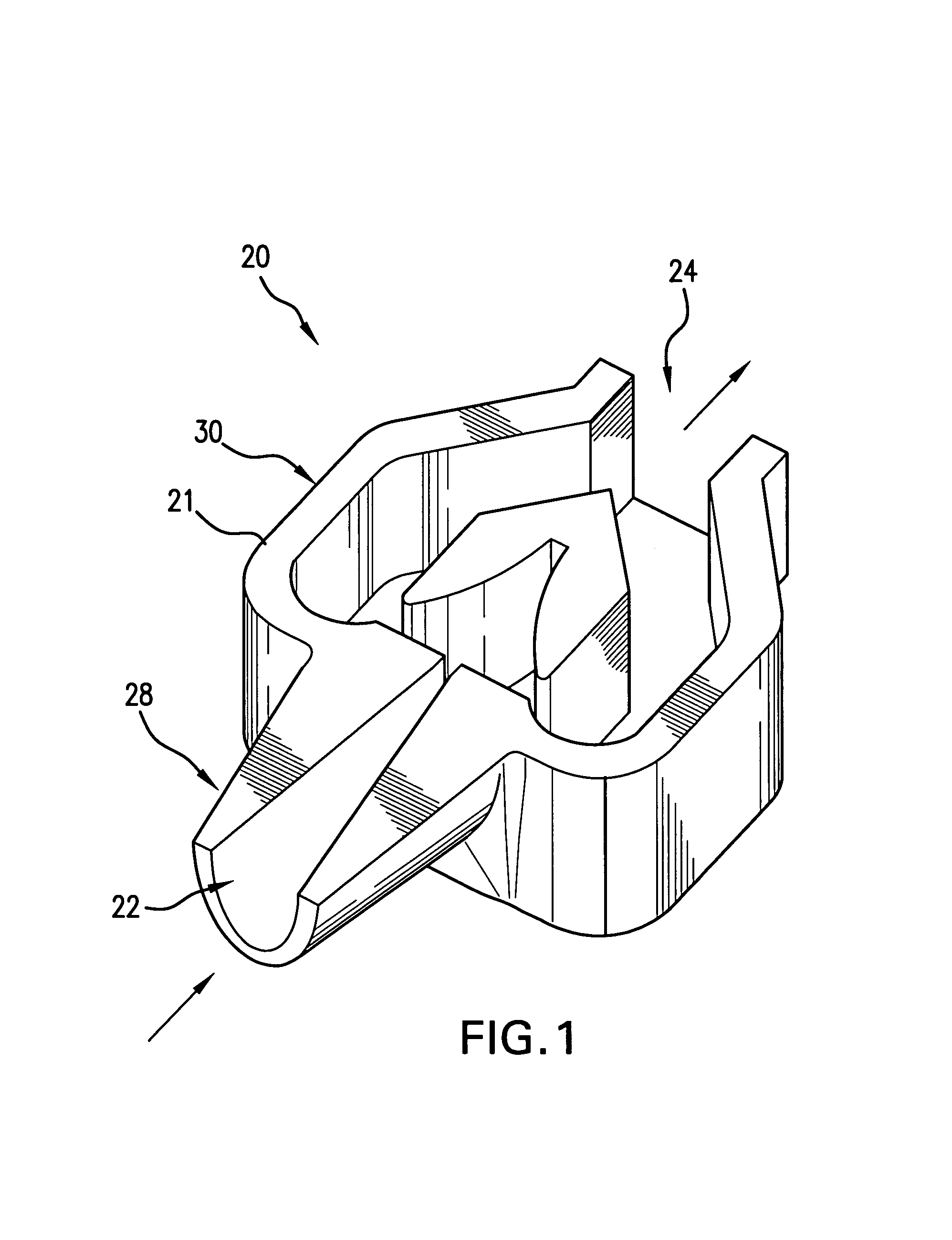

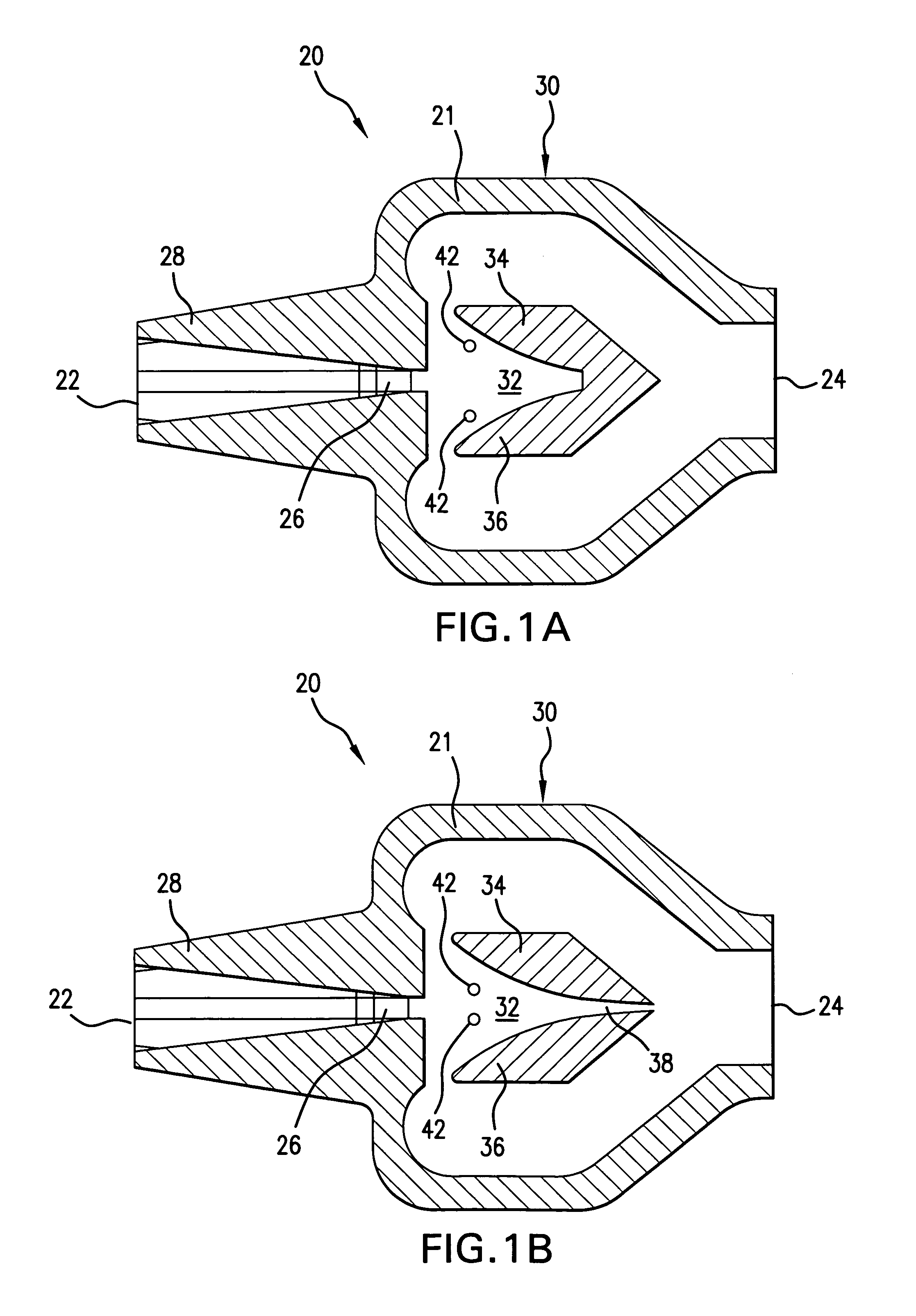

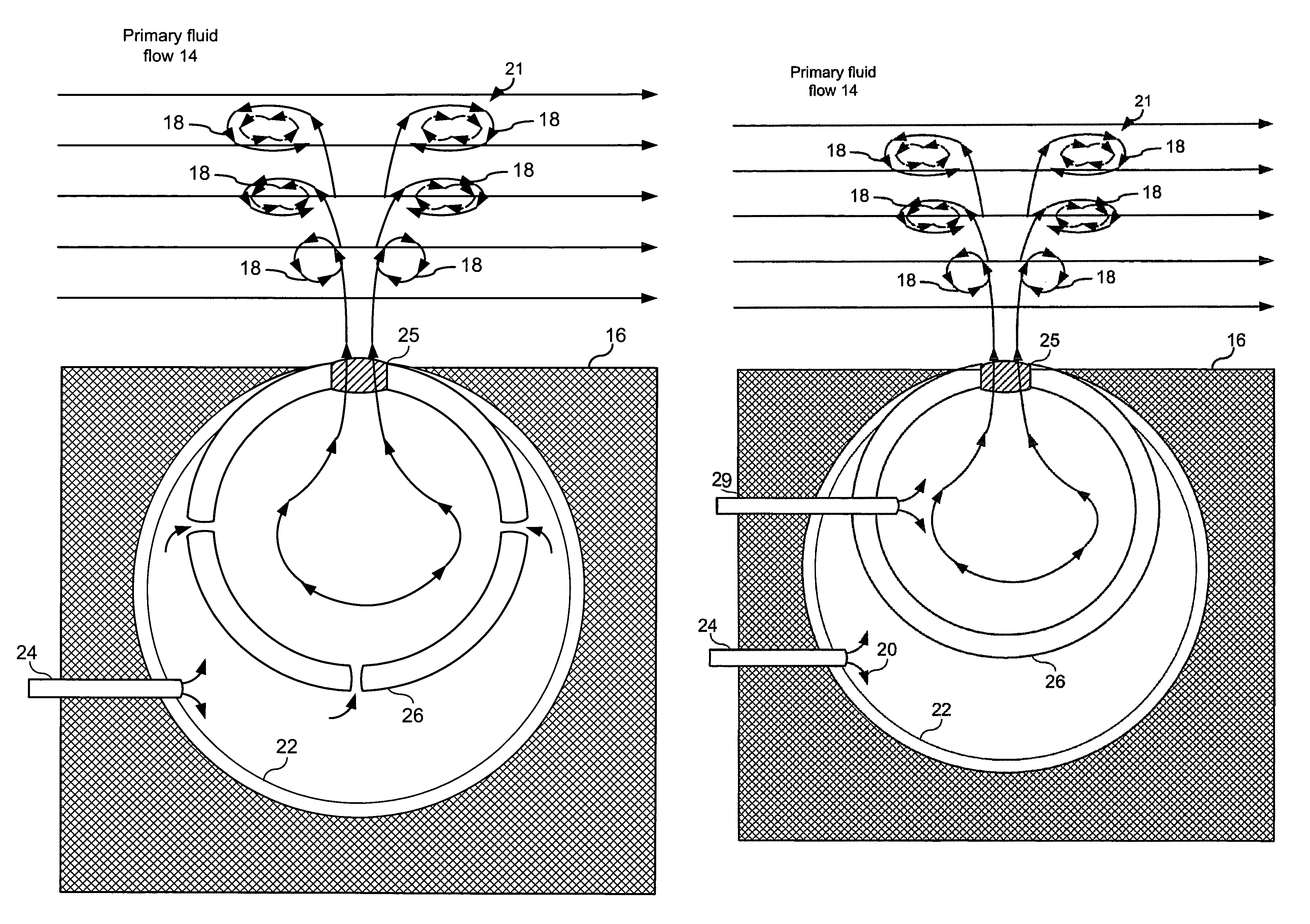

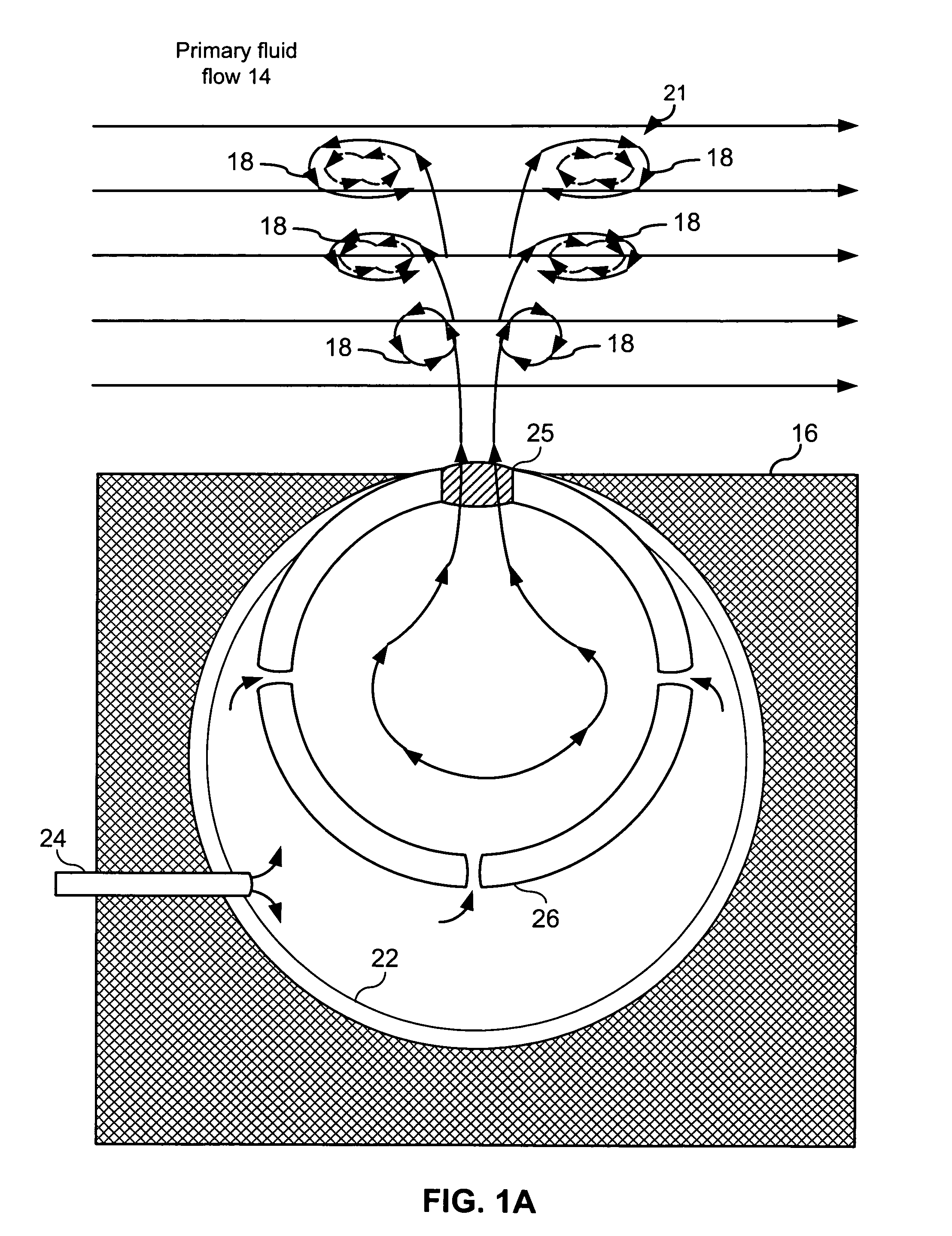

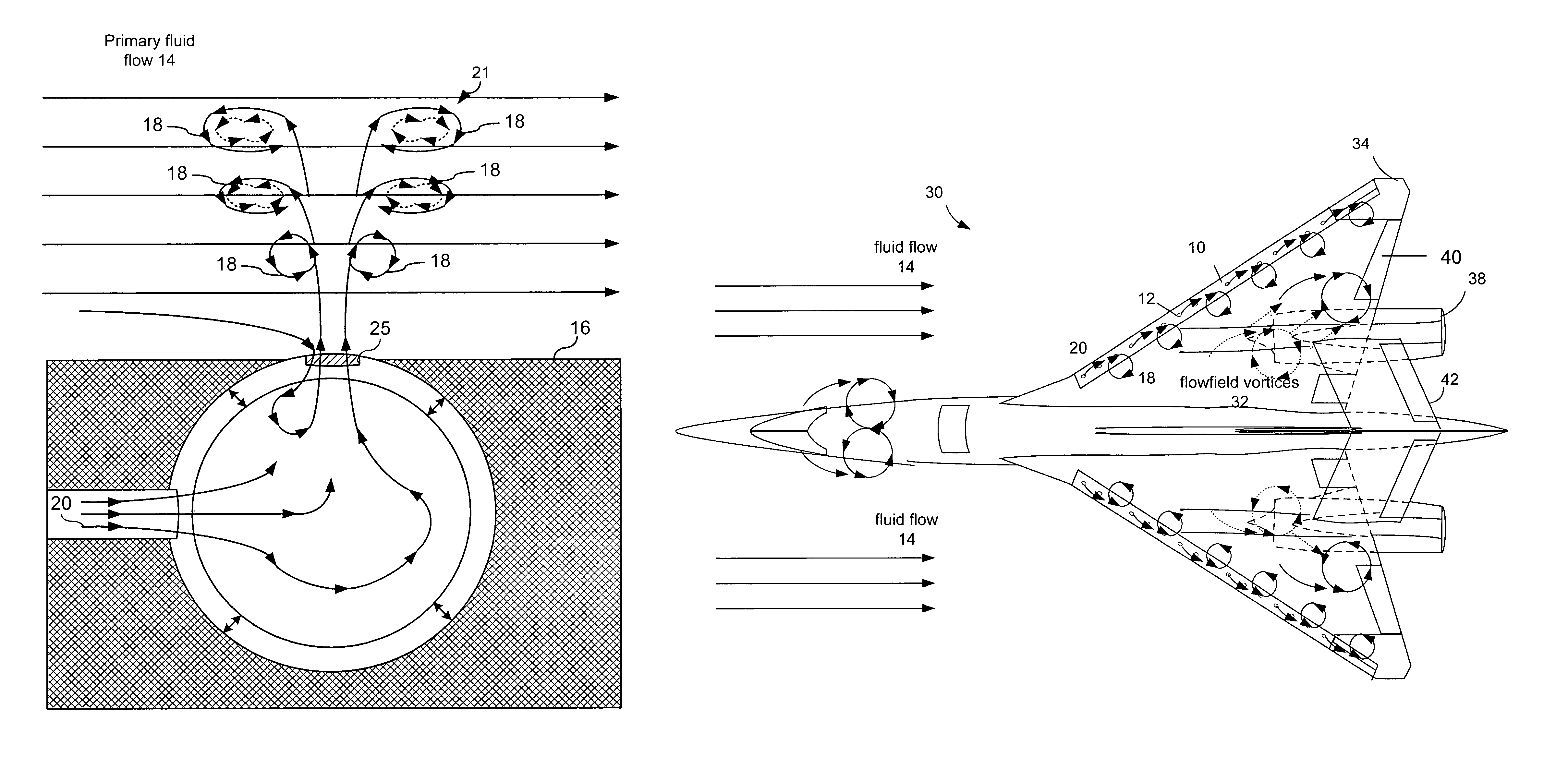

The present invention provides a system and method for actively manipulating fluid flow over a surface using synthetic pulsators. Synthetic pulsators produce pulsed jet operable to manipulate the primary fluid flow proximate to the synthetic pulsator. The synthetic pulsator includes a dual diaphragm synthetic jet coupled to high performance dual actuator solenoids, wherein the synthetic jet is operable to produce an oscillatory flow. The oscillatory flow of the synthetic jet(s) produces the pulsed jet operable to manipulate the primary fluid flow. These synthetic pulsators may then be actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

Dual bimorph synthetic pulsator

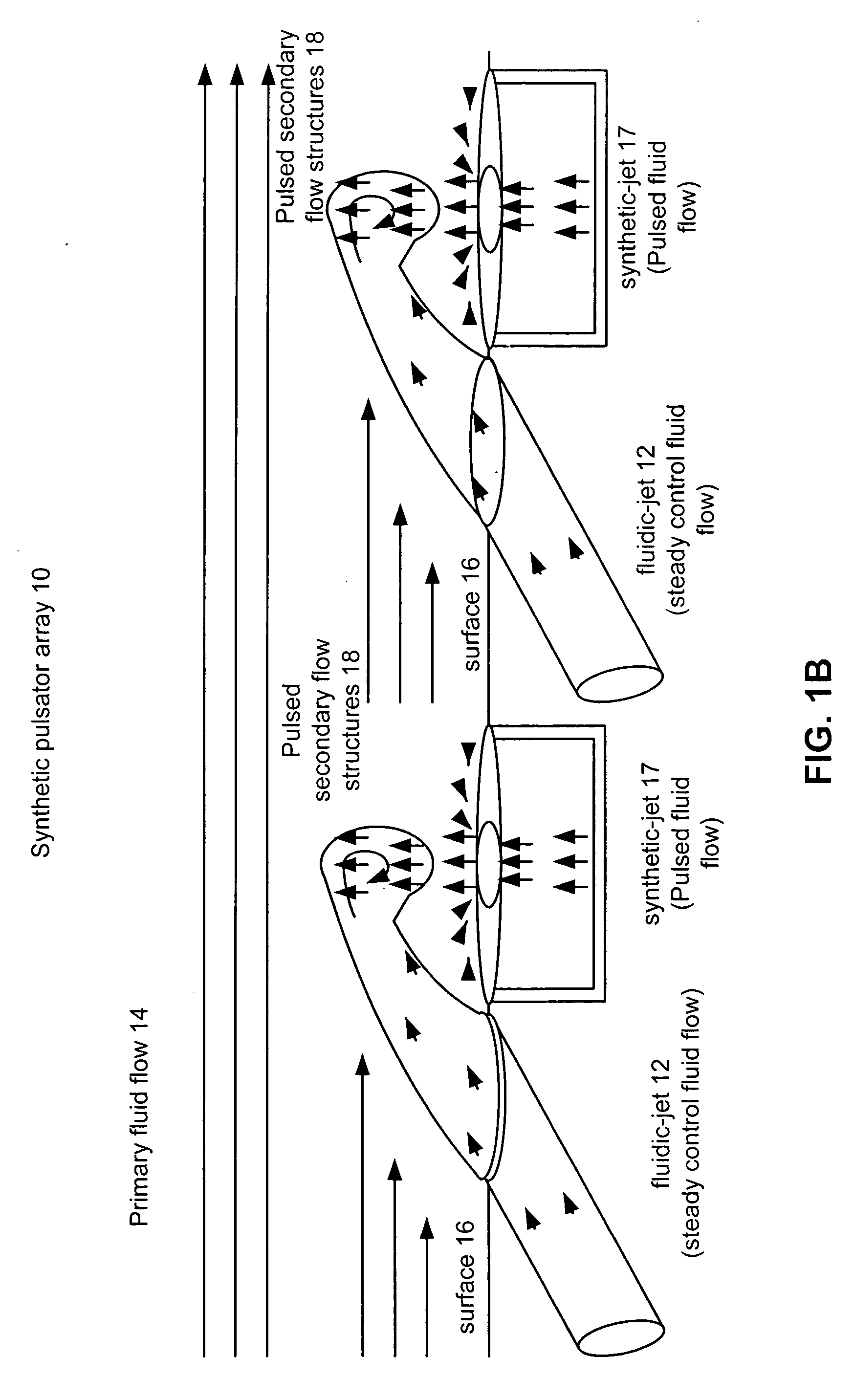

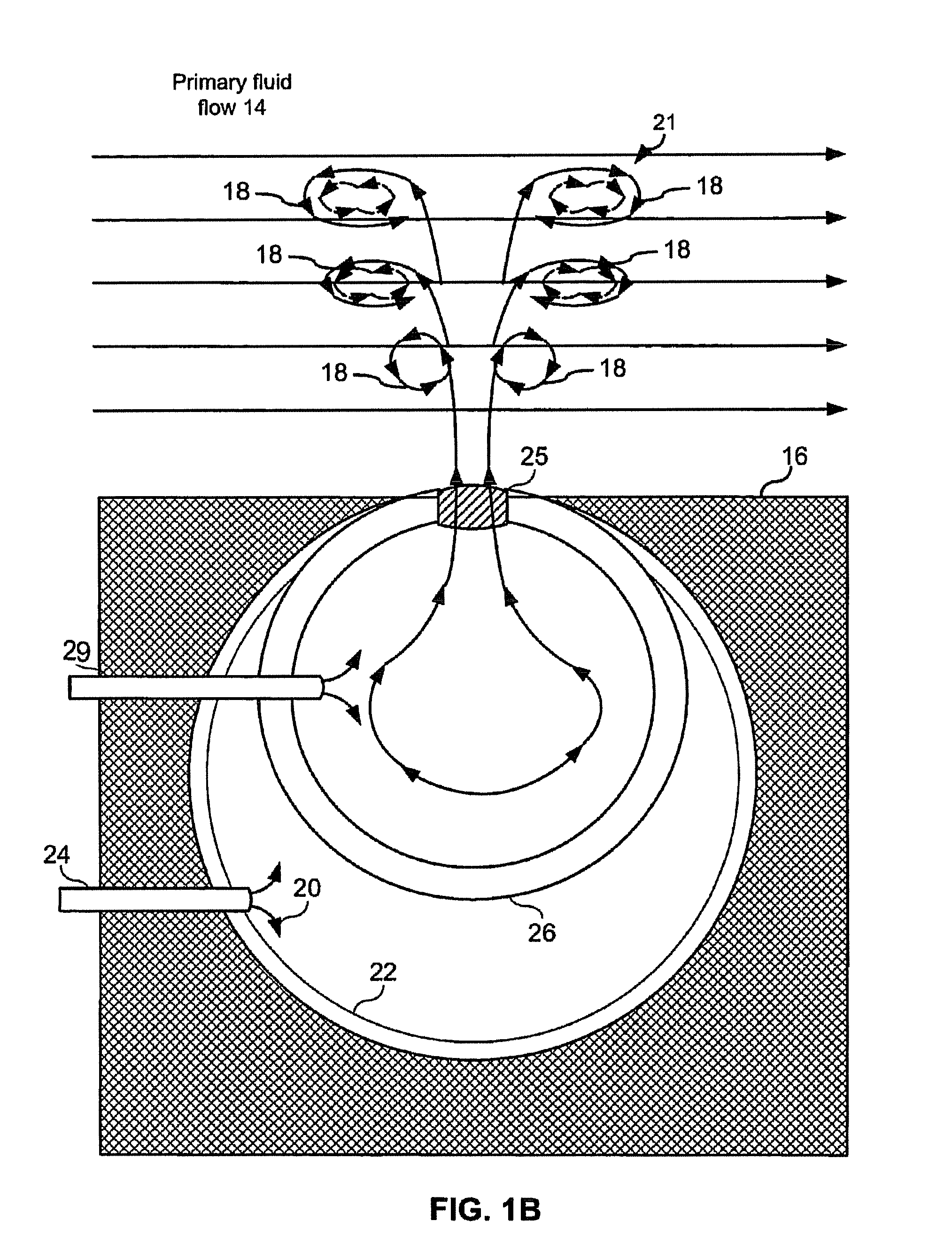

The present invention provides a system and method for actively manipulating fluid flow over a surface using synthetic pulsators. Synthetic pulsators produce pulsed jet operable to manipulate the primary fluid flow proximate to the synthetic pulsator. The synthetic pulsator includes a synthetic jet actuator(s) operable to produce an oscillatory flow, and fluidic jet(s) operable to provide a continuous fluid flow. The oscillatory flow of the synthetic jet(s) and the continuous fluid flow of the fluidic jet(s) combine or mix to produce the pulsed jet operable to manipulate the primary fluid flow. These synthetic pulsators may then be actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

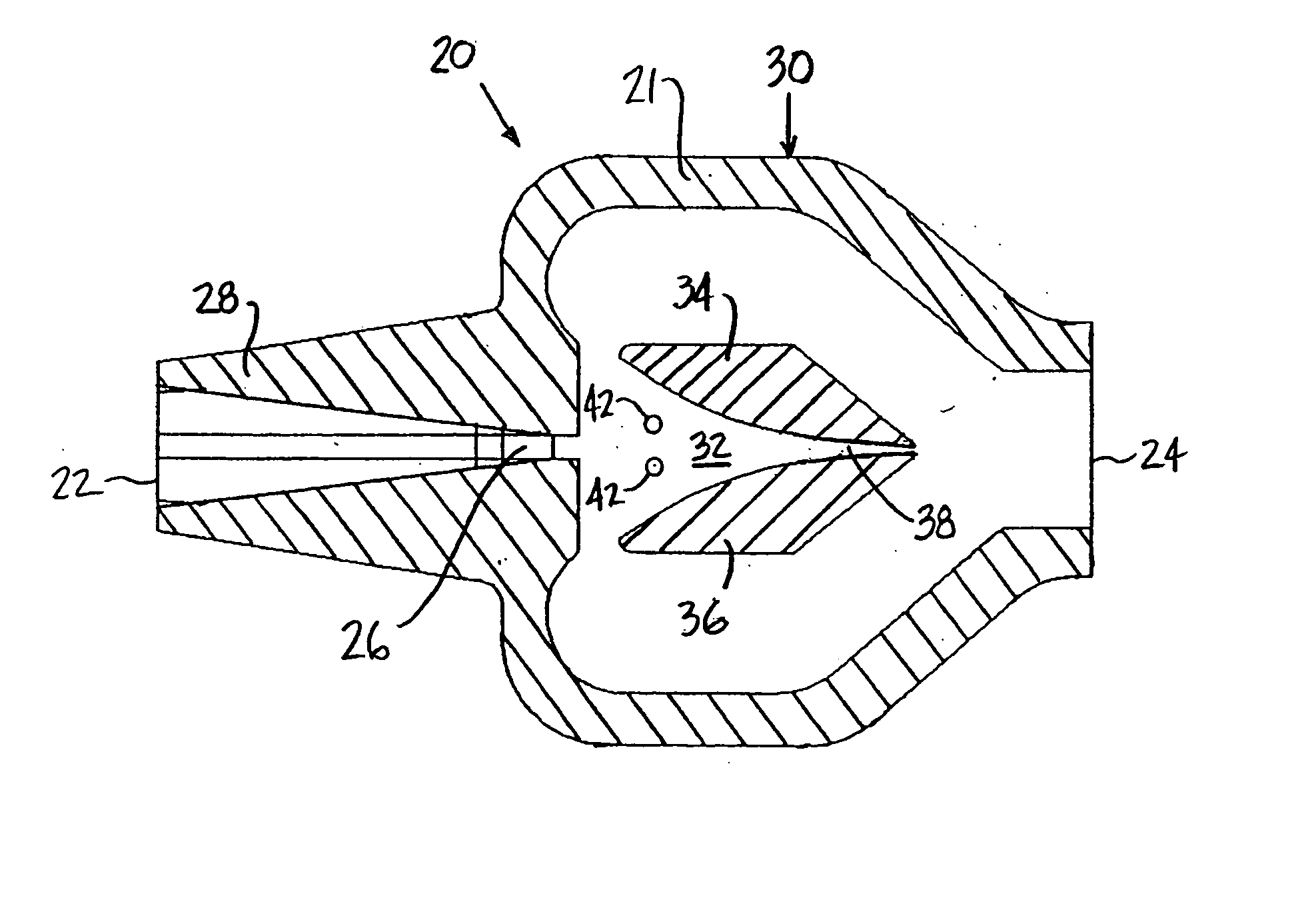

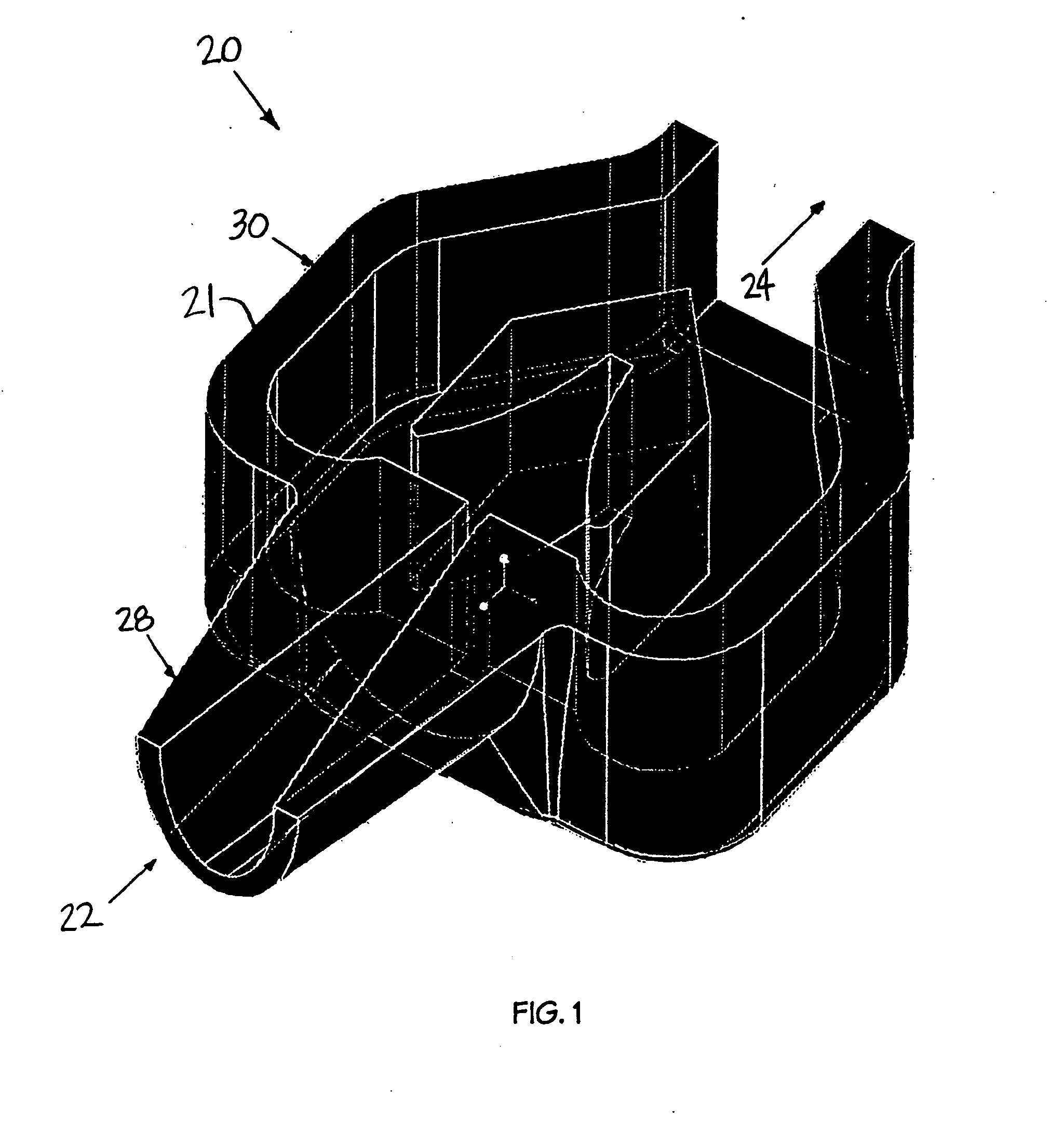

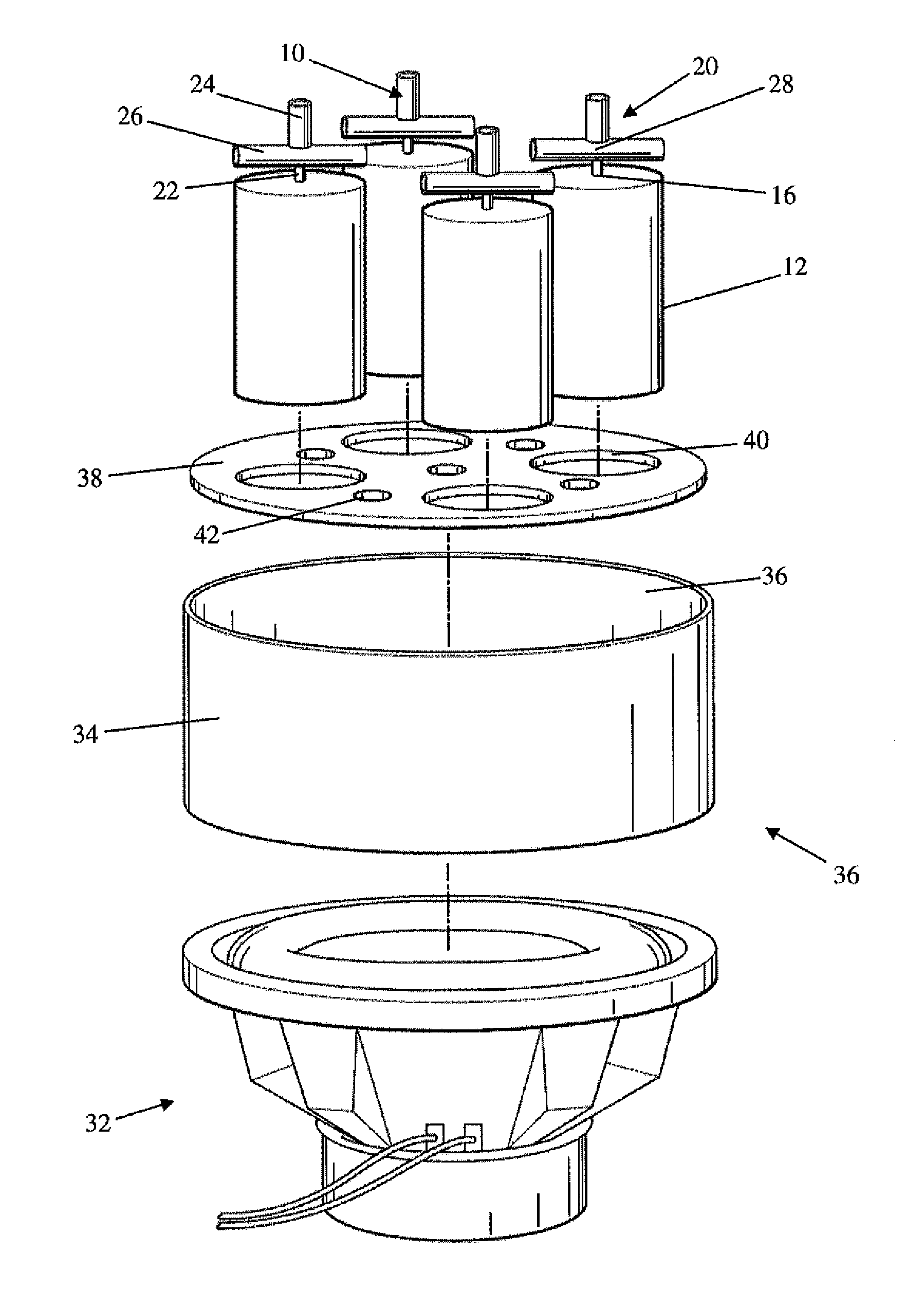

Spirometer

InactiveUS7094208B2Easily and accurately used in a home environmentSmall and portableRespiratory organ evaluationSensorsMedicineFluidic oscillator

A spirometer for measuring fluid flow, particularly associated with exhalation of respiratory patients. The spirometer of this invention preferably has a fluidic oscillator wherein the fluid oscillates within a chamber of the fluidic oscillator. An oscillation frequency of the fluid flow within the chamber is correlated to a flow rate. A computer is used to process input data, such as data representing frequency of the oscillatory flow within the chamber, to a flow rate passing through the spirometer. The spirometer of this invention may have no moving parts, which results in the need for only a design calibration and no periodic calibrations throughout use of the spirometer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Dual bimorph synthetic pulsator

The present invention provides a system and method for actively manipulating fluid flow over a surface using synthetic pulsators. Synthetic pulsators produce pulsed jet operable to manipulate the primary fluid flow proximate to the synthetic pulsator. The synthetic pulsator includes a synthetic jet actuator(s) located within an ambient pressure chamber, wherein the synthetic jet actuator is operable to produce an oscillatory flow. The oscillatory flow of the synthetic jet(s) produces the pulsed jet operable to manipulate the primary fluid flow. These synthetic pulsators may then be actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

Dual bimorph synthetic pulsator

The present invention provides a system and method for actively manipulating fluid flow over a surface using synthetic pulsators. Synthetic pulsators produce pulsed jet operable to manipulate the primary fluid flow proximate to the synthetic pulsator. The synthetic pulsator includes a synthetic jet actuator(s) operable to produce an oscillatory flow, and fluidic jet(s) operable to provide a continuous fluid flow. The oscillatory flow of the synthetic jet(s) and the continuous fluid flow of the fluidic jet(s) combine or mix to produce the pulsed jet operable to manipulate the primary fluid flow. These synthetic pulsators may then be actively manipulated to control the flow behavior of the ducted fluid flow, influence the inception point and trajectory of flow field vortices within the fluid flow, and reduce flow separation within the primary fluid flow.

Owner:LOCKHEED MARTIN CORP

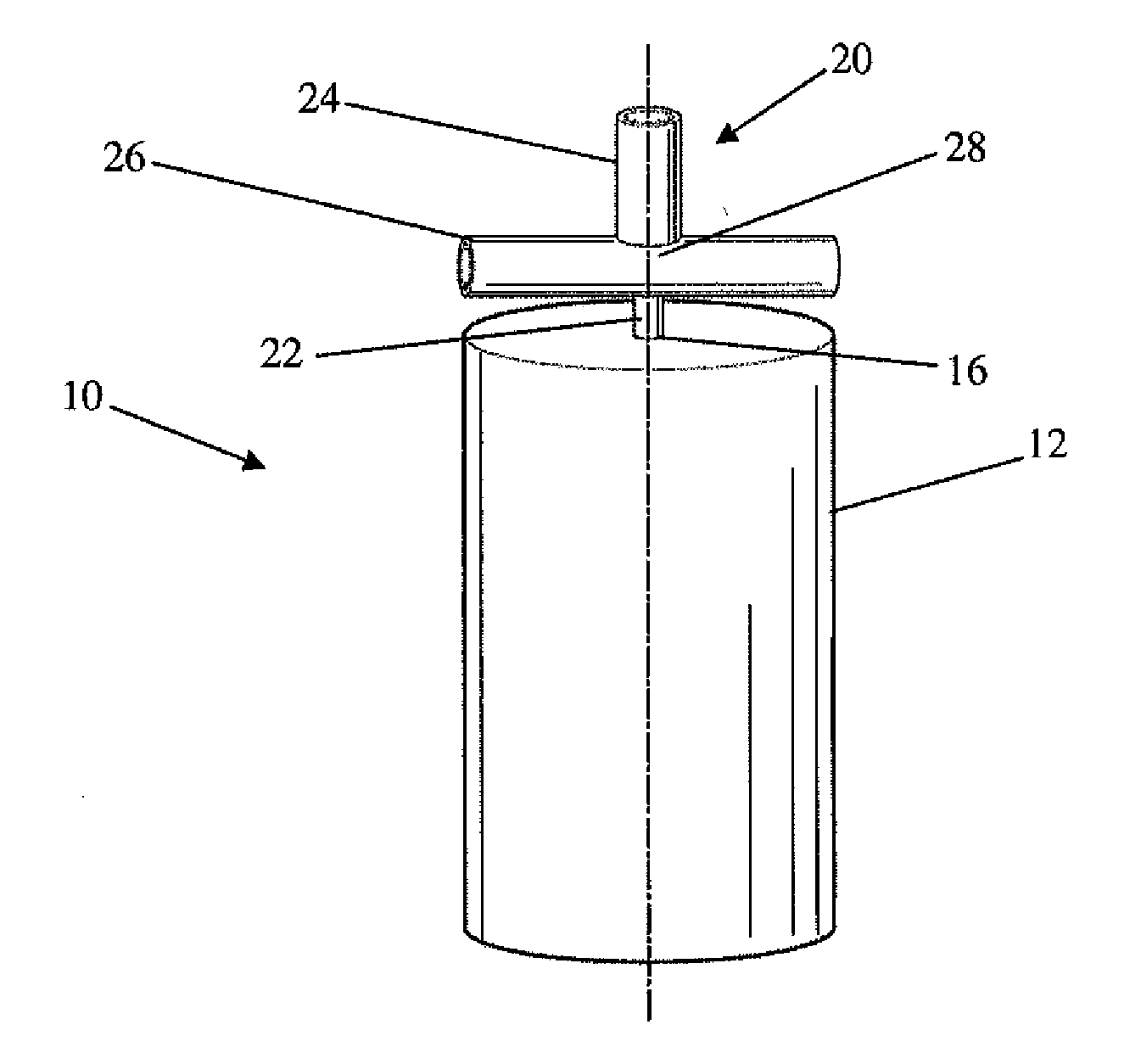

apparatus and process for producing crystals

InactiveUS20110288060A1Organic active ingredientsNervous disorderUltrasonic radiationUltrasound Radiation

This invention provides an oscillating baffled reactor apparatus for preparing crystalline particles of at least one substance comprising: a reactor vessel; means for supplying a first flowing stream; means for oscillating fluid within the reactor vessel; a plurality of baffles; source of ultrasonic radiation; and means for collecting said particles.

Owner:PROSONIX

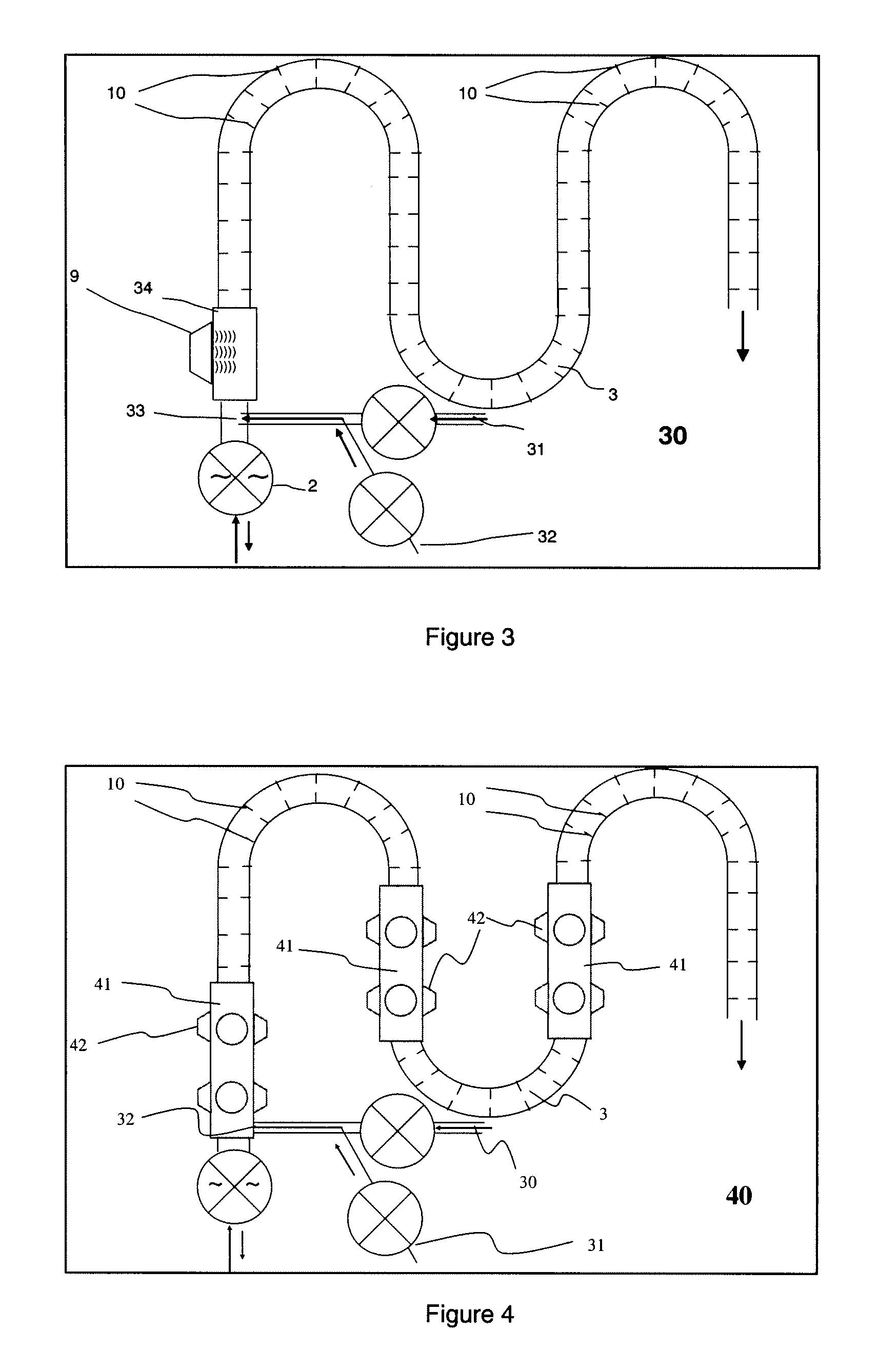

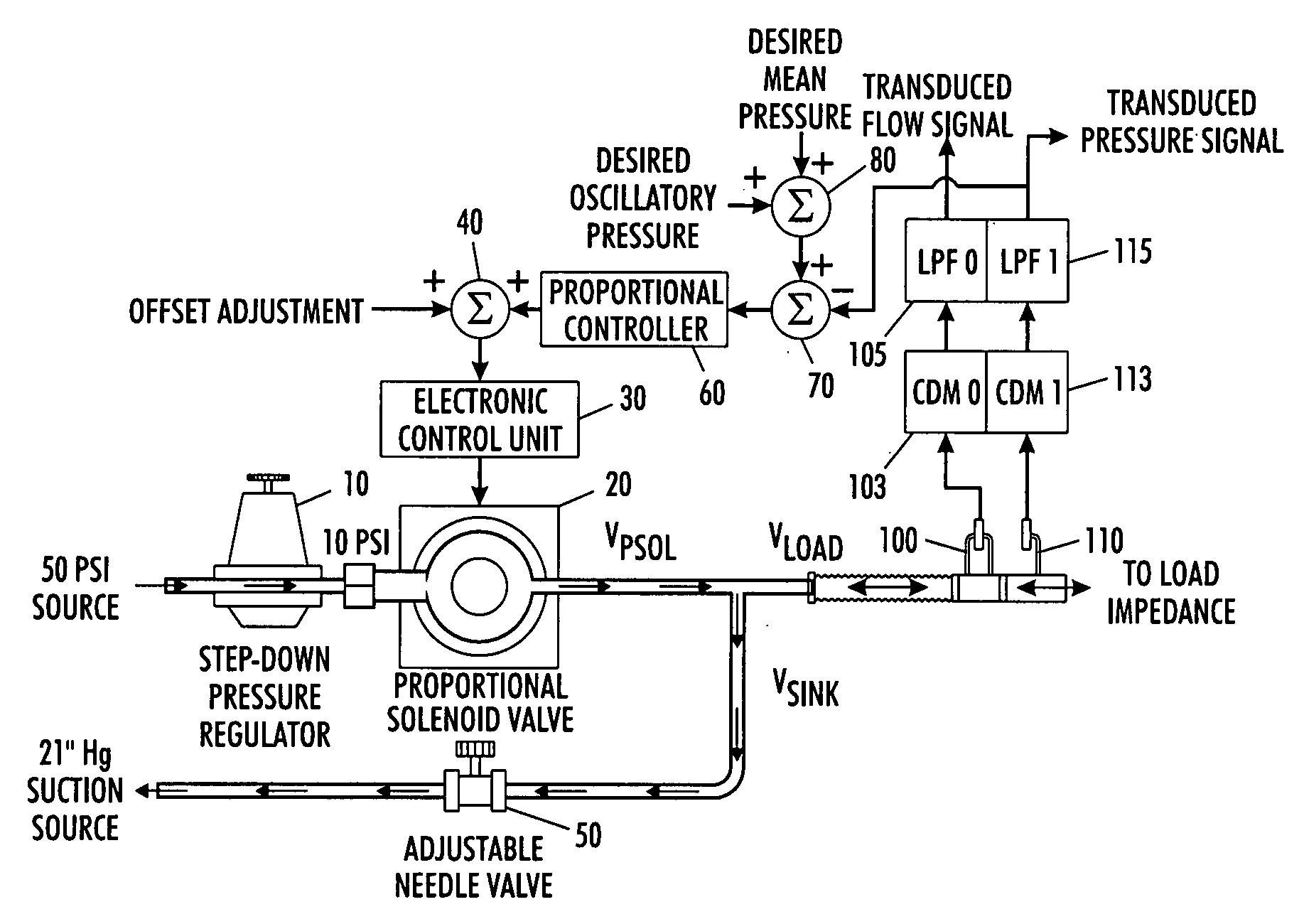

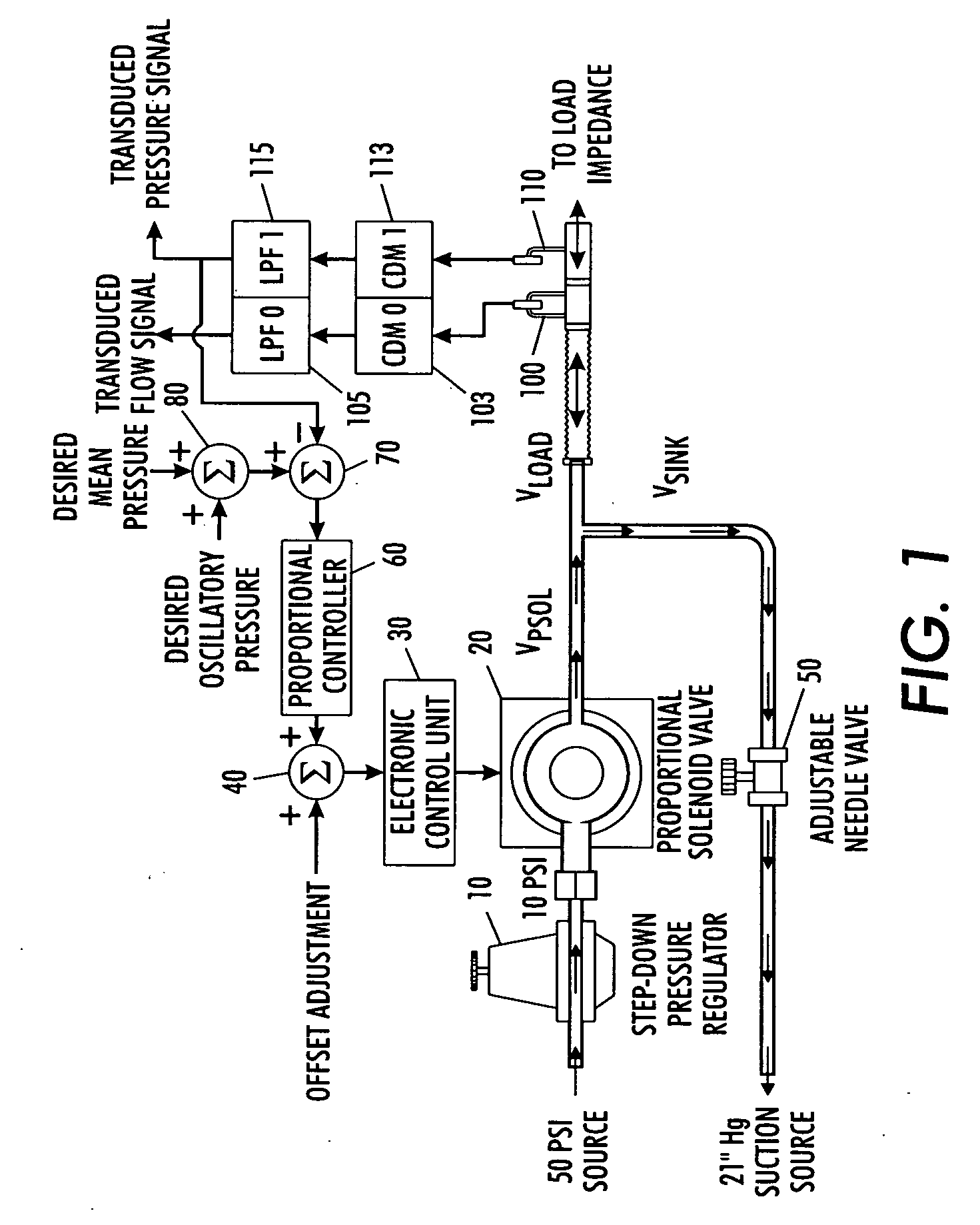

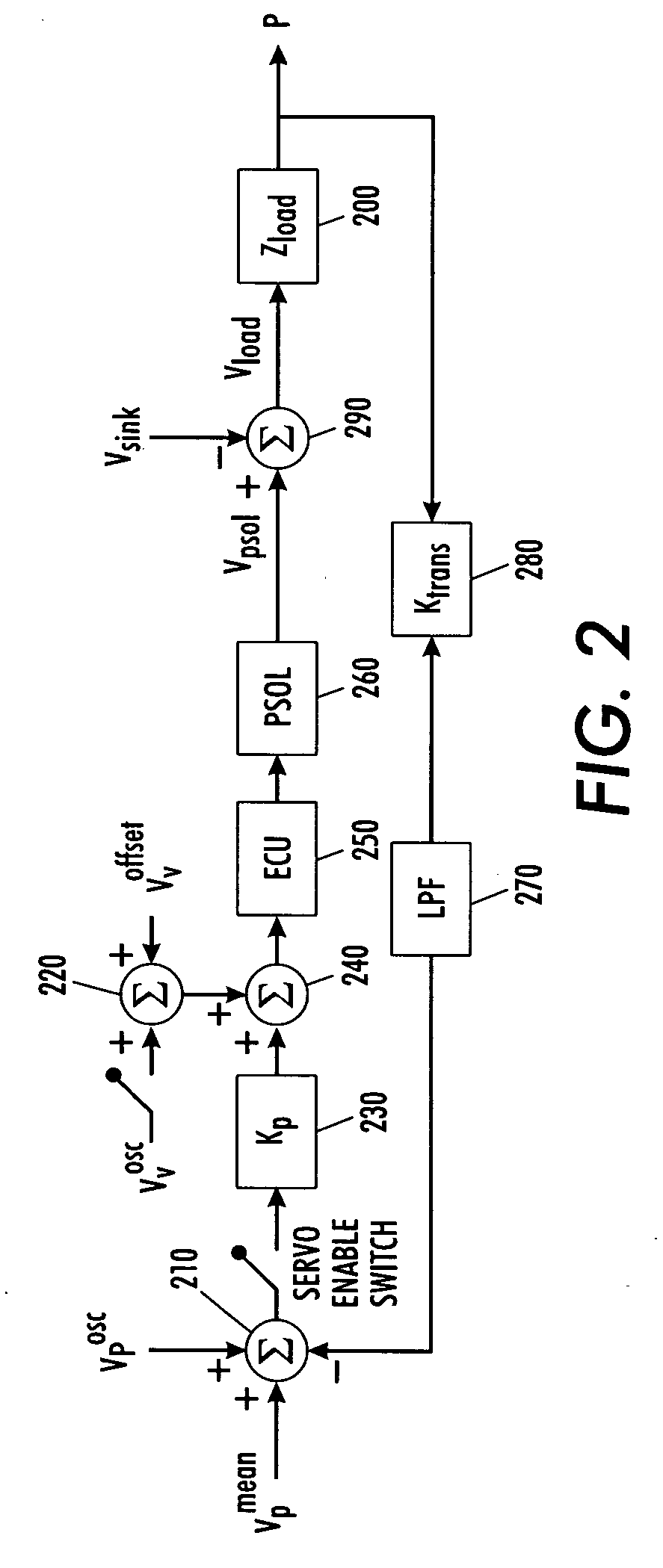

Servo-controlled pneumatic pressure oscillator for respiratory impedance measurements and high-frequency ventilation

A pneumatic ventilation system delivers high amplitude, low frequency oscillatory flows while maintaining the load impedance at a specified mean pressure, thereby accurately controlling mean airway pressure, oscillation amplitude, and frequency content allowing use in applications to optimize high frequency ventilation protocols in patients. The pneumatic ventilation system includes a pneumatic pressure oscillator based on a proportional solenoid valve to provide forced oscillatory excitations to a respiratory system over a bandwidth suitable for mechanical impedance measurements and high frequency ventilation.

Owner:TRUSTEES OF BOSTON UNIV

High performance synthetic valve/pulsator

ActiveUS7748664B2Well mixedImprove performanceAircraft navigation controlFlexible wall reciprocating enginesJet flowEngineering

Owner:LOCKHEED MARTIN CORP

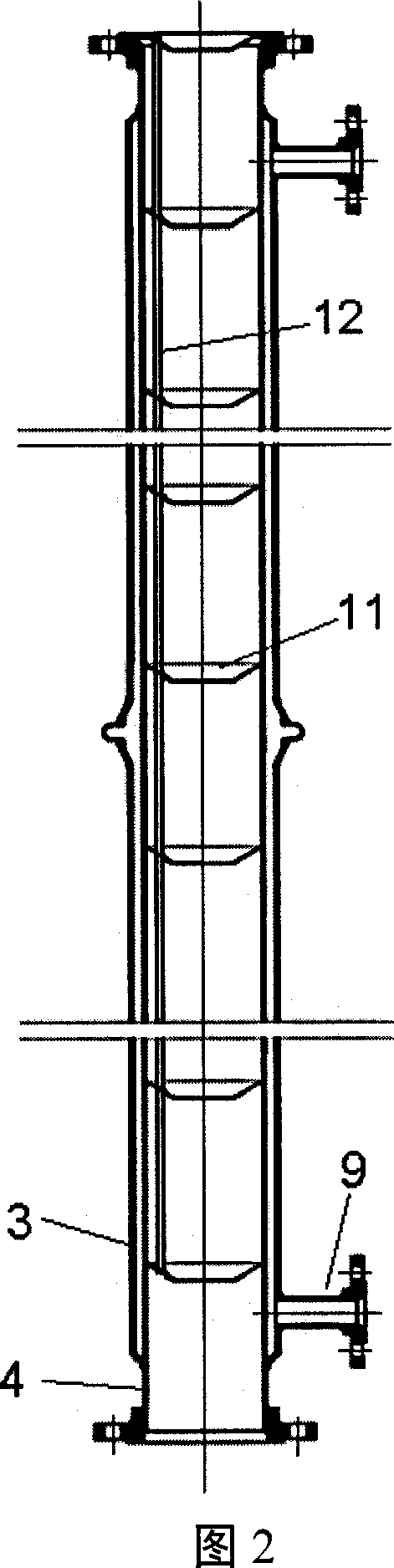

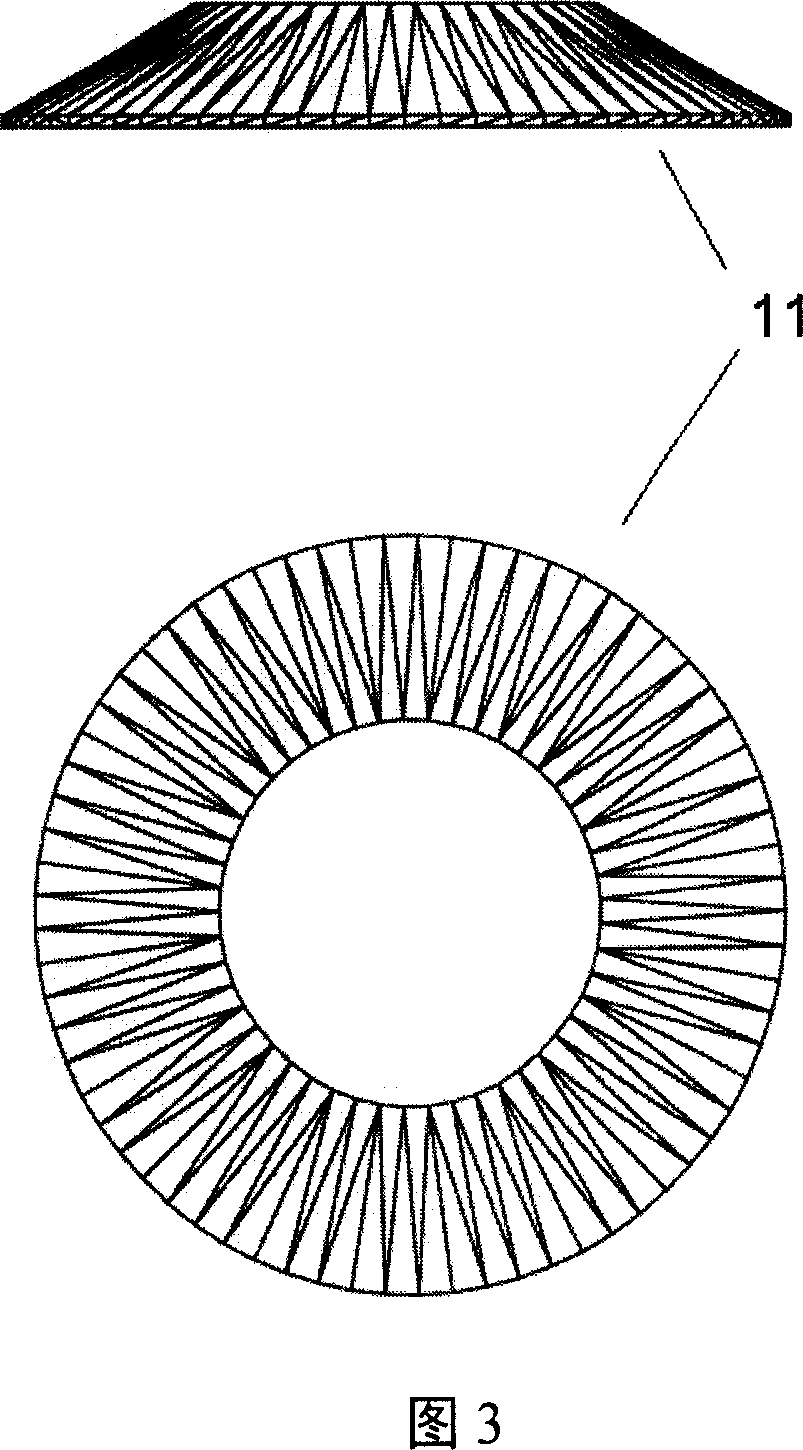

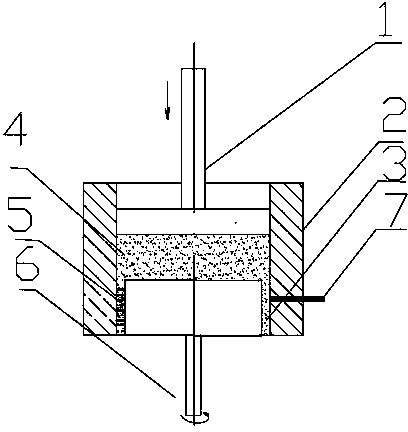

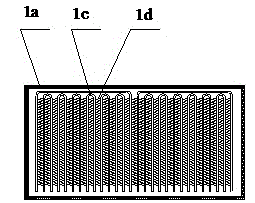

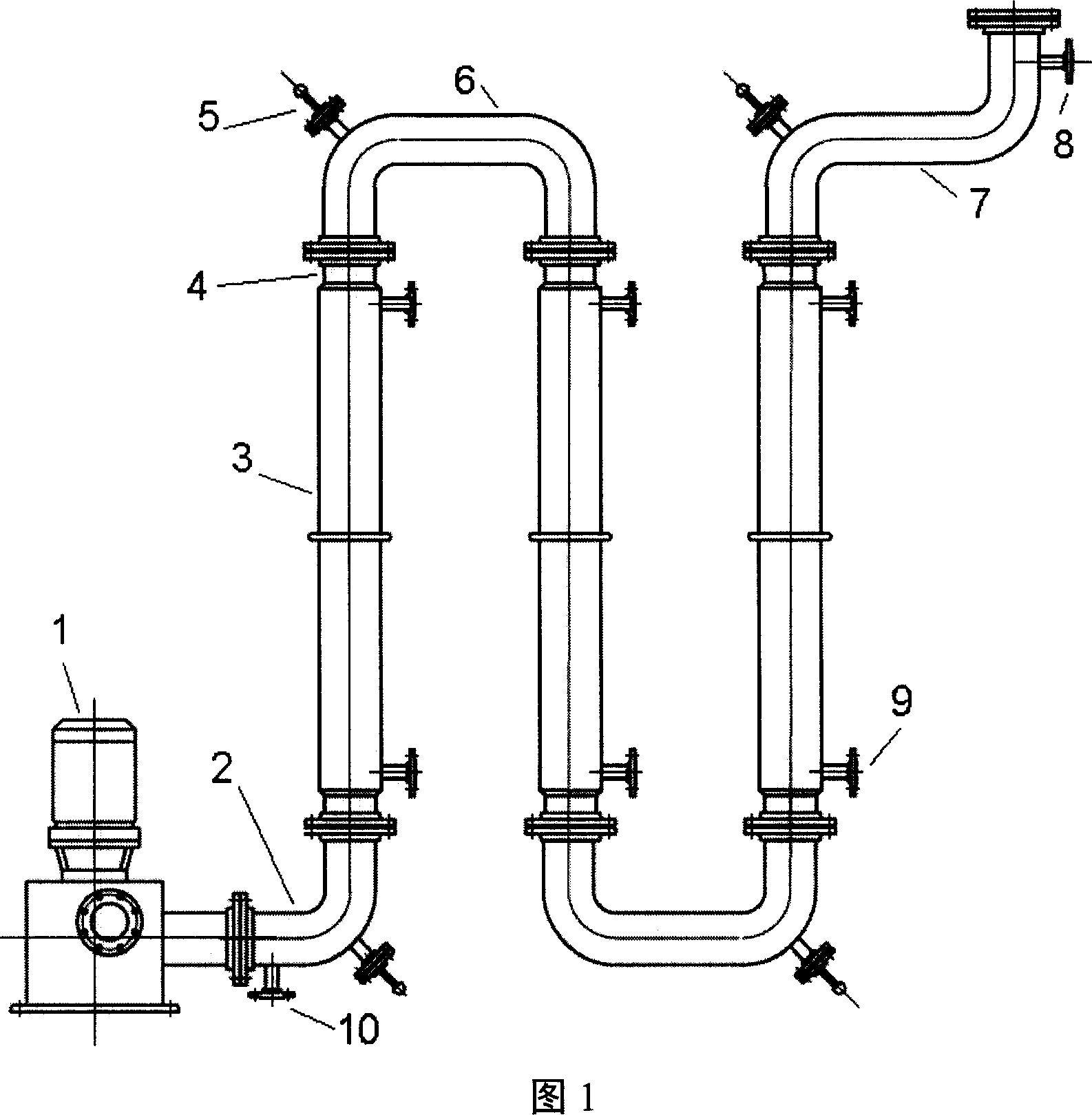

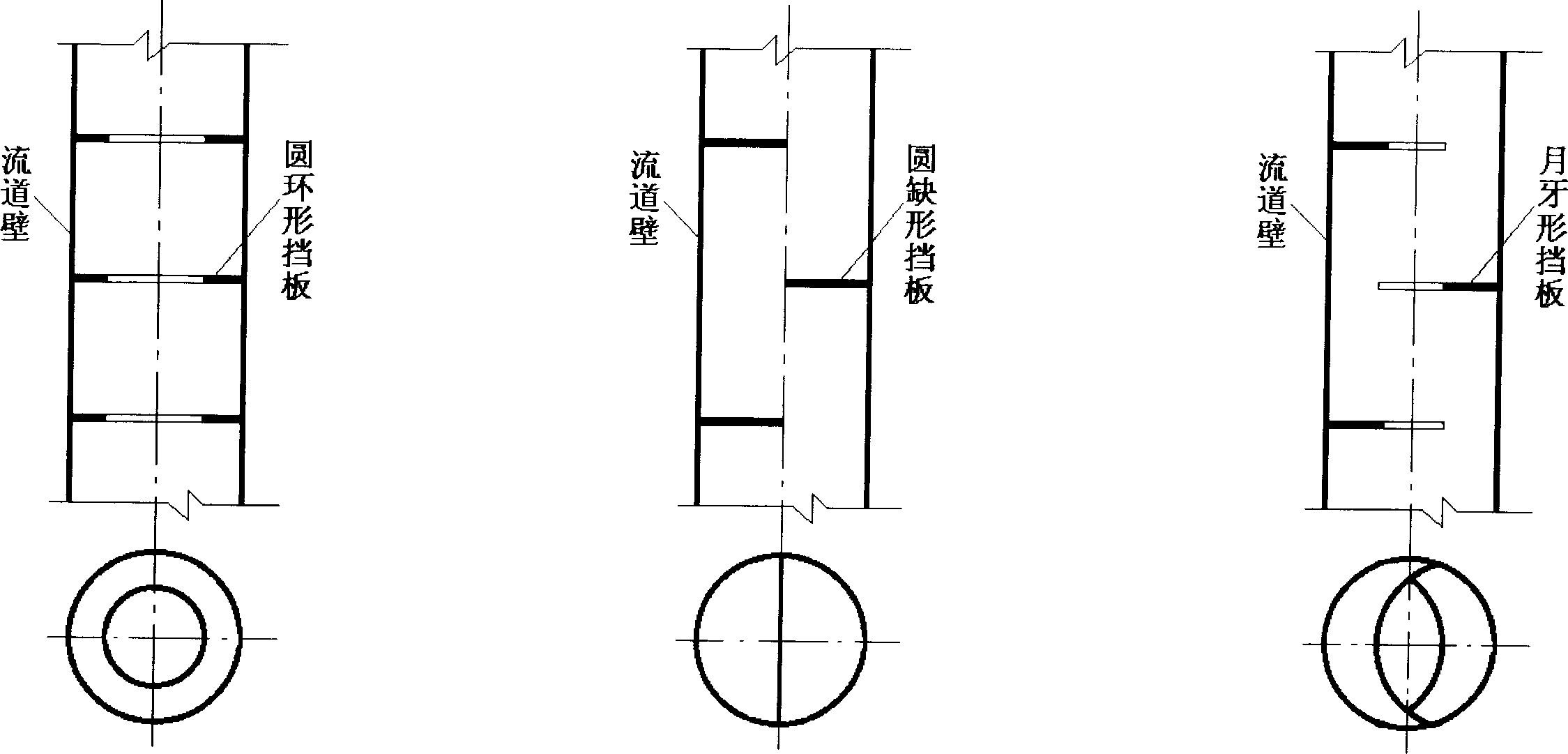

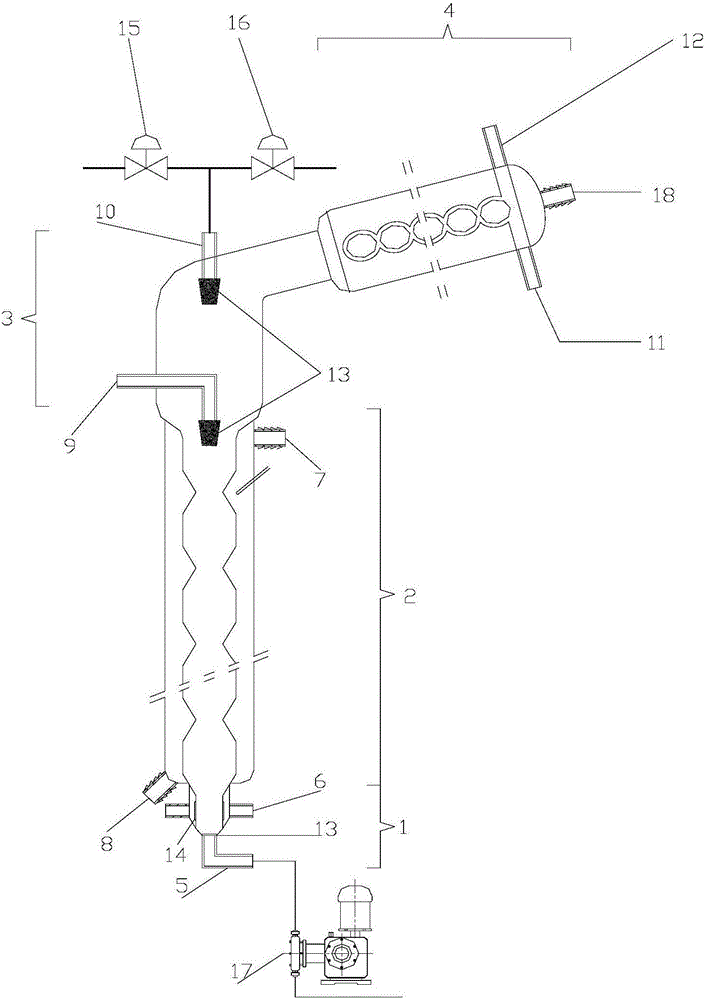

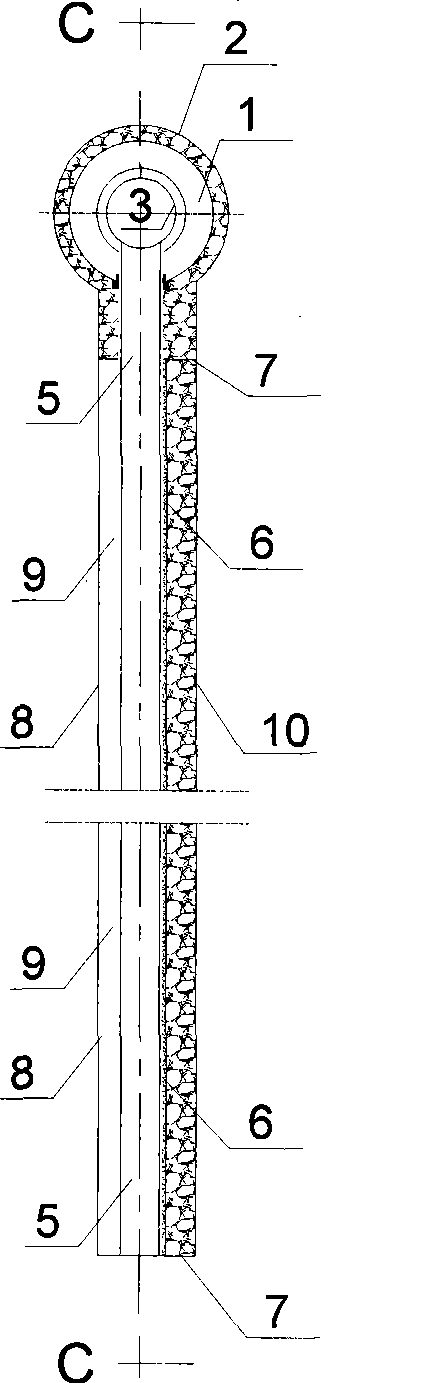

Oscillatory flow tubular reactor of balking ring baffle

InactiveCN1958143AUniform residence time distributionImprove heat transfer performanceChemical/physical processesEngineeringSolid particle

An oscillating flow type tubular reactor with annular conic barrier plates is composed of oscillation generating mechanism, inlet segment with inlet, reaction segment formed by vertical circular reaction pipe with internal annular conic barrier plates for dividing its internal space into several chambers, and outlet segment with outlet. It is suitable for the reaction of liquid-solid suspension system with high content of solid.

Owner:ZHEJIANG UNIV

Spirometer

InactiveUS20060100537A1Small and portableEliminate needRespiratory organ evaluationSensorsFluidic oscillatorSpirometer

A spirometer for measuring fluid flow, particularly associated with exhalation of respiratory patients. The spirometer of this invention preferably has a fluidic oscillator wherein the fluid oscillates within a chamber of the fluidic oscillator. An oscillation frequency of the fluid flow within the chamber is correlated to a flow rate. A computer is used to process input data, such as data representing frequency of the oscillatory flow within the chamber, to a flow rate passing through the spirometer. The spirometer of this invention may have no moving parts, which results in the need for only a design calibration and no periodic calibrations throughout use of the spirometer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

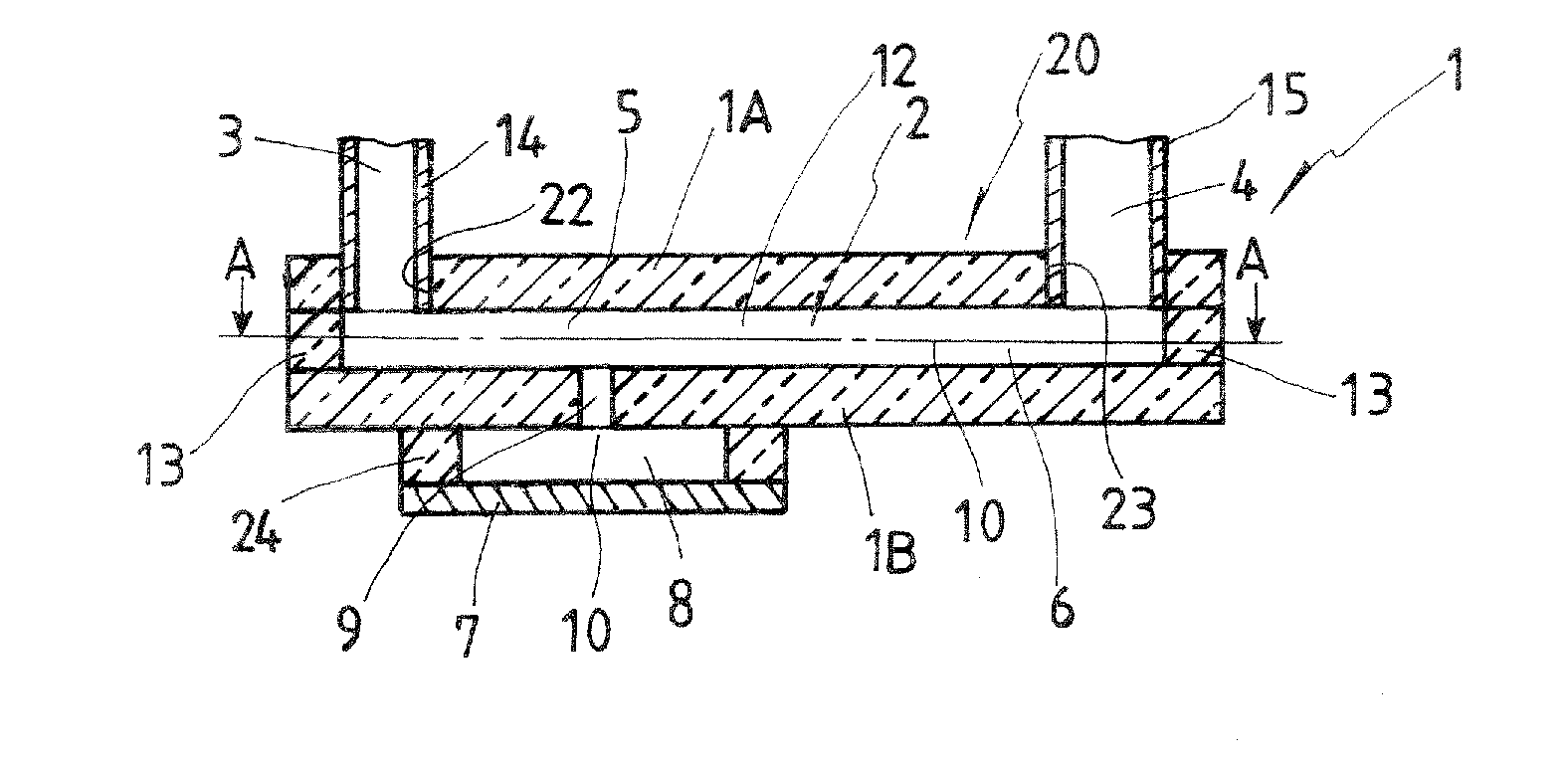

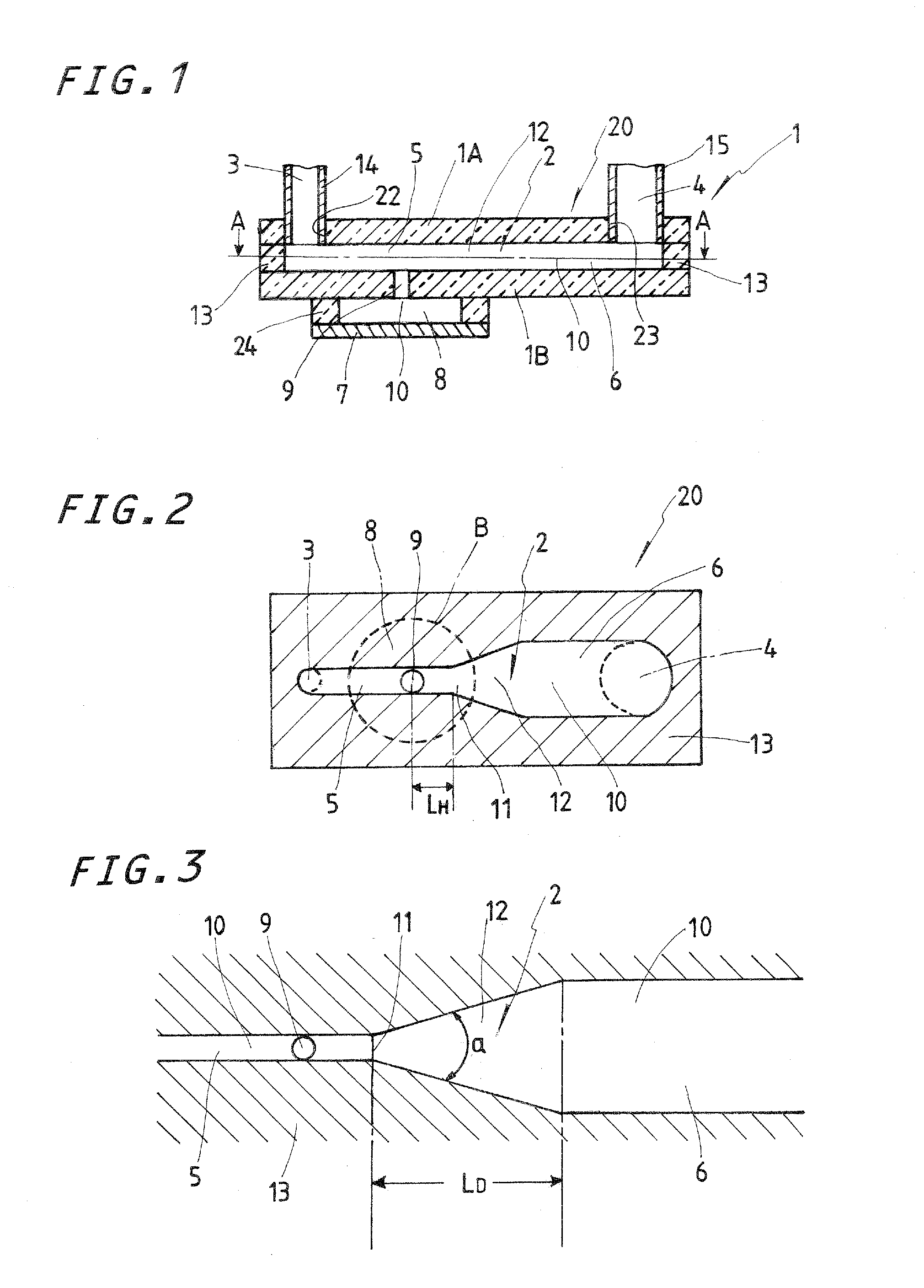

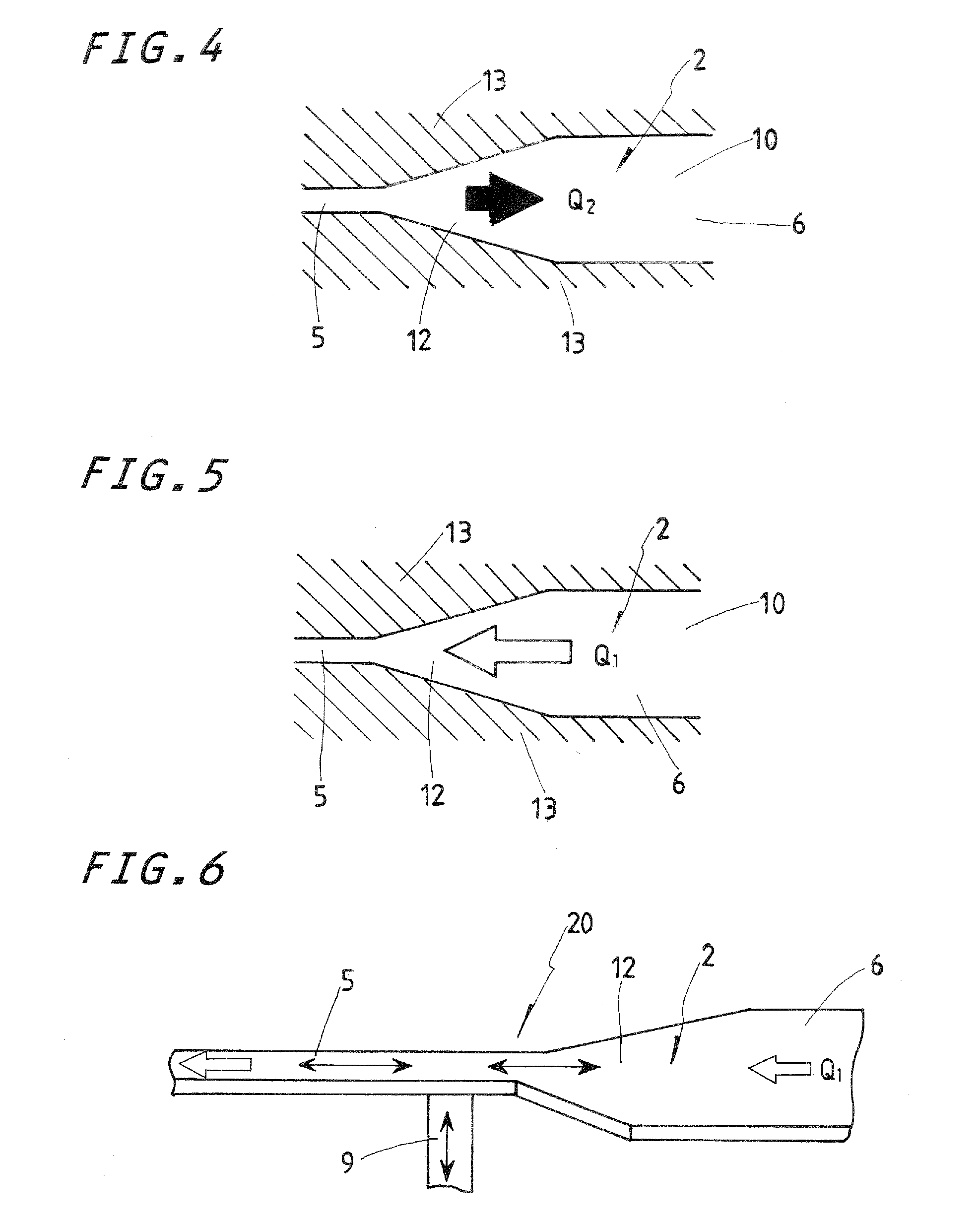

Valveless micropump

InactiveUS20100158720A1Low flow resistancePositive displacement pump componentsFlexible member pumpsVolume variationEngineering

A valveless micropump for transforming a pressure variation of fluid in a volume variation chamber (8) into an oscillatory flow of fluid (10) by means of a piezoelectric element (7), making the fluid (10) to flow smoothly in channels (5, 6). A channel (2) is formed as an asymmetric diffuser-shaped channel (12) having a narrow channel (5) on the diffuser inlet (3) side and a wide channel (6) on the diffuser outlet (4) side, and the volume variation chamber (8) provided with the piezoelectric element (7) is communicated with the narrow channel (5). Vibration generated by applying a voltage to the piezoelectric element (7) causes a pressure variation of the fluid in the volume variation chamber (8) to generate a nozzle flow. The fluid (10) is made to flow smoothly from the wide channel (6) to the narrow channel (5) by the nozzle flow.

Owner:NAT UNIV CORP KYUSHU INST OF TECH (JP)

High shear rate flowing vertically accumulative oscillatory rheology test method and device

The invention relates to a high shear rate flowing vertically accumulative oscillatory rheology test method and a high shear strength flowing vertical accumulative oscillatory rheology device, The method is characterized in that material in a material barrel passes through a circular seam type die under the extruding of a plunger to form a main flow field with high shear strength, and according to the speed of the plunger, the pressure gradient of a complete development flowing area, the shape of the die, the interface size of the plunger and the like, the values of the shear stress and the shear rate of the main flow field are obtained via calculation; material in a gap of the die is driven via the movement of the oscillatory motion of a die core rotor to generate a vertically accumulative oscillatory flow field, the value of the shear stress and the shear strain and the shear rate of the accumulative oscillatory flow field are obtained via calculation according to the torsional moment and oscillation frequency of the die core rotor, the size of the material barrel, the size of the die core rotor and the like, and further the functions of various material are obtained; a heater is mounted on the material barrel and used for ensuring that a material flow is at a constant temperature in an experiment process. The method and device can be used for characterizing the viscoelasticity and the micro structure of the material at the high shear rate, inspect the constitutive equation of the material at high shear rate, and guide forming processing.

Owner:HUNAN UNIV OF TECH

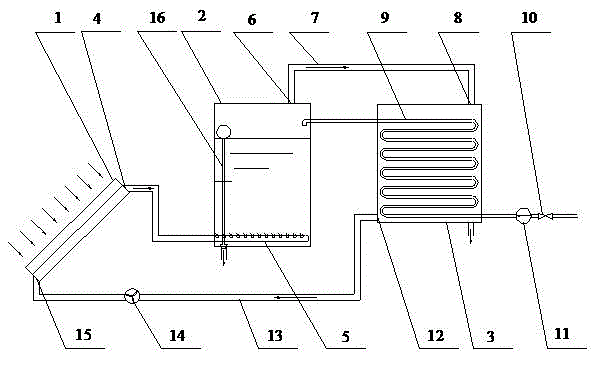

Solar seawater desalination device

InactiveCN102910696ANo foulingScaling is not obviousGeneral water supply conservationSeawater treatmentFreshwater dischargeFresh water

The invention discloses a solar seawater desalination device. The device comprises an oscillatory flow heat pipe air heat collector, an evaporator and a condenser, wherein the oscillatory flow heat pipe air heat collector is provided with a steam outlet and a steam inlet; the evaporator is provided with an air outlet and a seawater outlet; a gas distributor is arranged at the bottom of the evaporator; the condenser is provided with a wet air inlet, a steam outlet and a freshwater discharge outlet; a condensing coil is arranged in the condenser; one end of the condensing coil is connected with a seawater pump and the other end thereof is led into the evaporator; the steam outlet of the oscillatory flow heat pipe air heat collector is connected with the gas distributor; the air outlet of the evaporator is connected with the wet air inlet of the condenser; and the steam outlet of the condenser is connected with the steam inlet of the solar air heat collector. The device has the following advantages: the device reduces corrosion to the heat collector and improves the heat collection efficiency of the heat collector; the seawater temperature is low during operation, so the whole device does not have obvious scales; and the device has simple structure and small volume, can operate under normal pressure and has broad market prospects.

Owner:SHANDONG KEYUAN TIANLI ENERGY CONSERVATION ENG

Combined oscillatory flow heat pipe with evaporation and heat exchange connecting section

InactiveCN101907414AImprove heat transfer performanceExtend heat transfer distanceIndirect heat exchangersHeat transmissionEvaporation

The invention belongs to the field of heat transfer, in particular to a combined oscillatory flow heat pipe with an evaporation and heat exchange connecting section. In the invention, a condensation end of a primary oscillatory flow heat pipe and an evaporation end of a secondary oscillatory flow heat pipe are both arranged in an evaporation and heat exchange connecting section and respectively, horizontally and fixedly connected to the lower part and the upper part of the evaporation and heat exchange connecting section; the evaporation and heat exchange connecting section is internally vacuumized, filled with a working solution and then sealed; the working solution immerses the condensation end of the primary oscillatory flow heat pipe to form an oscillatory flow heat pipe combination unit, and 1-3 stages of oscillatory flow heat pipe combination units are connected in series to form the combined oscillatory flow heat pipe with the evaporation and heat exchange connecting section; and the primary and the secondary oscillatory flow heat pipes of the oscillatory flow heat pipe combination unit can also be formed by connecting 2-5 oscillatory flow heat pips in parallel. The purpose of prolonging a heat transmission distance is achieved through the serial combination of the oscillatory flow heat pipes, and the purpose of expanding the heat radiating area is achieved through a parallel combination, thus the heat transmission capacity of the oscillatory flow heat pipes is obviously improved. The invention is suitable for the fields of high-efficiency compact heat exchangers, industrial afterheat recovery, solar energy utilization, and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Differential pressure flow sensor

A differential pressure flow sensor that includes a plurality of channels divided into multiple sets of channels having different characteristics. Primary channels establish fluid communication between an inlet and an outlet of the flow sensor. Secondary channels establish fluid communication between the inlet and a first pressure port, but not the outlet. Tertiary channels establish fluid communication between the outlet and a second pressure port, but not the inlet. Signals generated at the first and second pressure port are used to determine a rate of flow through of gas through the sensor. Due to the structural features of the device, the phase delay of individual oscillatory flow components compared to corresponding oscillatory pressure components remains substantially constant across a wide range of flow rates.

Owner:KONINKLJIJKE PHILIPS NV

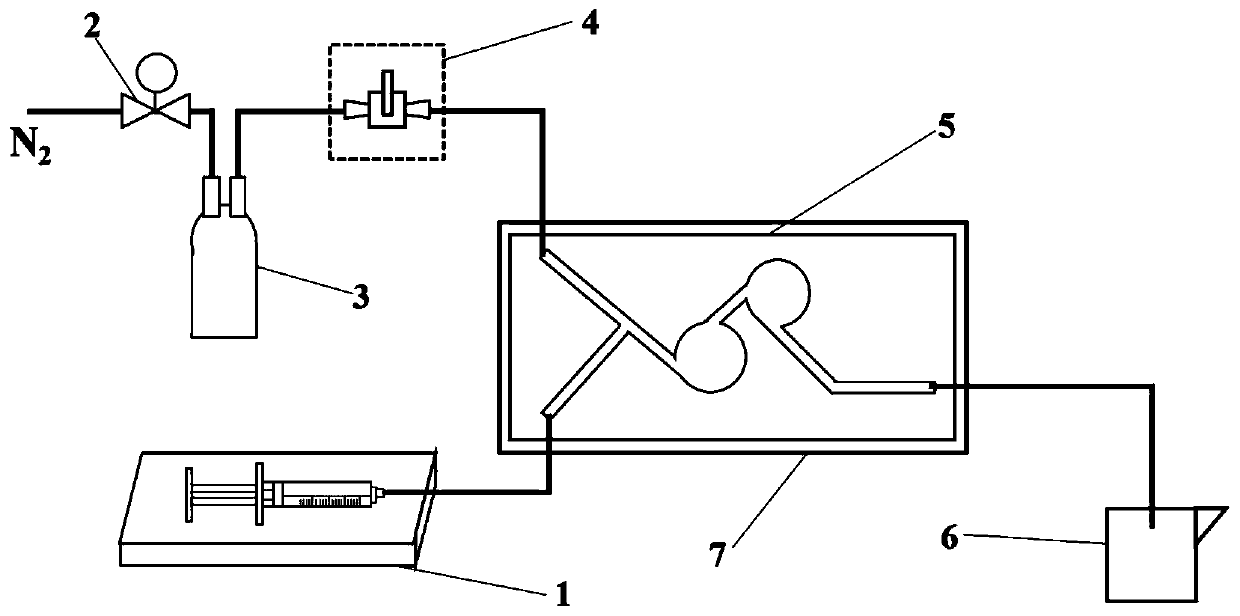

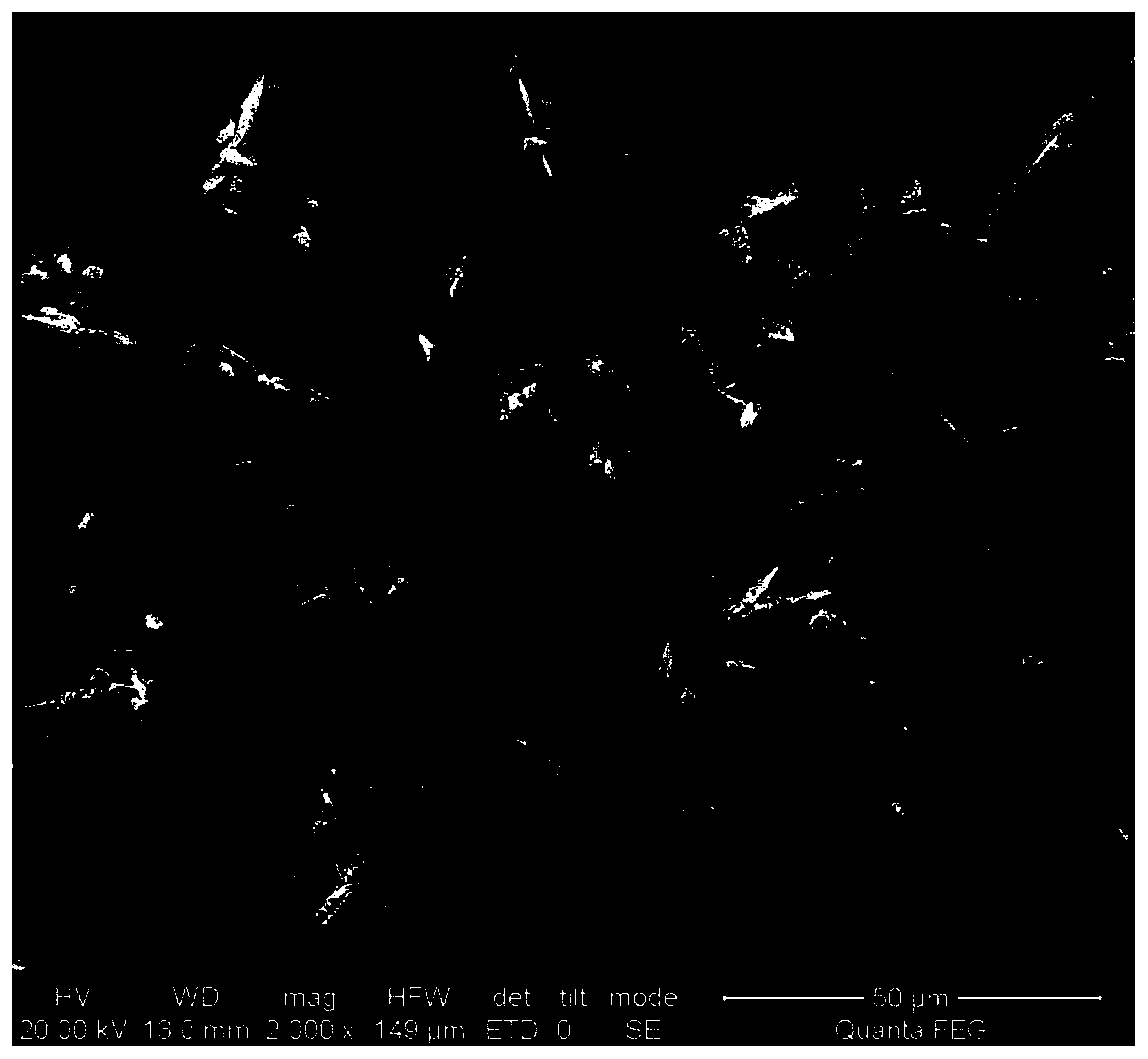

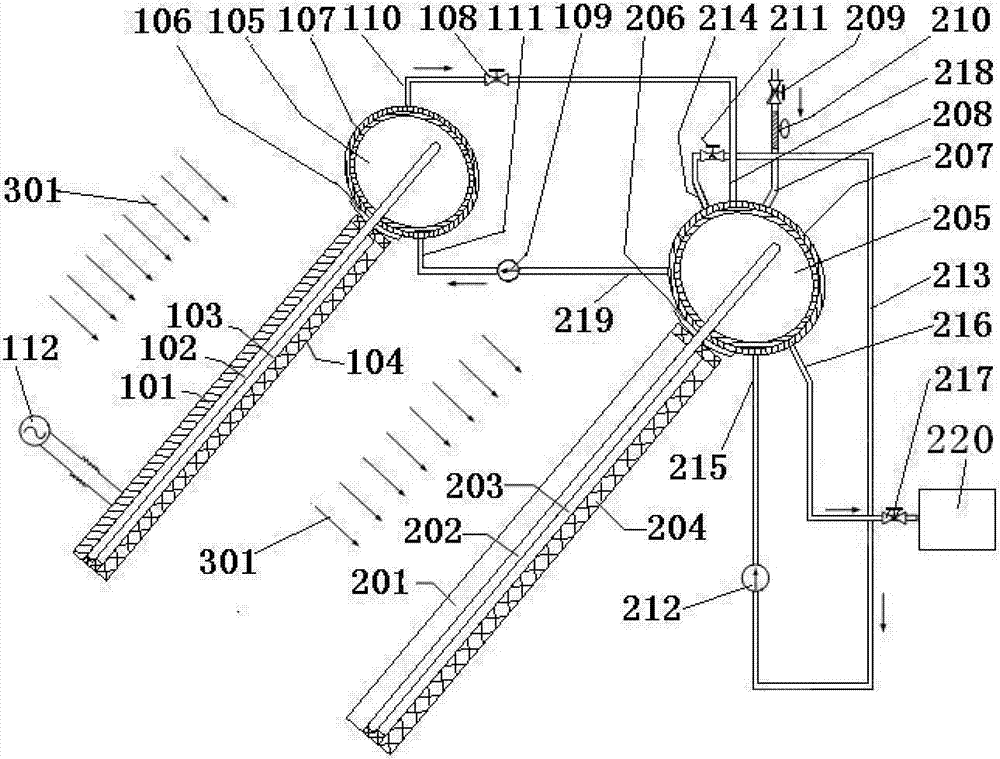

Active microfluidic platform-based CL-20 crystal form control method

InactiveCN110592677ASimple structureExperimental conditions are easy to adjustPolycrystalline material growthFrom normal temperature solutionsMicrofluidicsFiltration

The invention belongs to the field of preparation of an energetic material and particularly relates to an active microfluidic platform-based CL-20 crystal form control method. An active microfluidic platform comprises an oscillatory flow driving unit, a steady flow driving unit, a recrystallization unit and a sample collecting unit. The method particularly comprises the following steps: putting anonsolvent solution into a sealing tank and putting a solvent solution into the steady flow driving unit; setting recrystallization temperature and pressure value and enabling the nonsolvent to flow towards a micro-mixer; setting parameters of the steady flow driving unit and enabling the solvent solution to flow towards the micro-mixer; collecting turbid liquid flowing out of the micro-mixer intothe sample collecting unit, and performing washing, suction filtration and drying to obtain CL-20 explosive particles; and changing experiment conditions and repeating the above steps until obtainingCL-20 explosives with different crystal appearance. The CL-20 explosive is prepared by the microfluidic platform, the structure is simple and small-dosage preparation can be realized; and furthermore, the experiment conditions are easy to adjust and the method is suitable for optimizing and screening the experiment parameters in the control process of the CL-20 explosive crystal form.

Owner:NANJING UNIV OF SCI & TECH

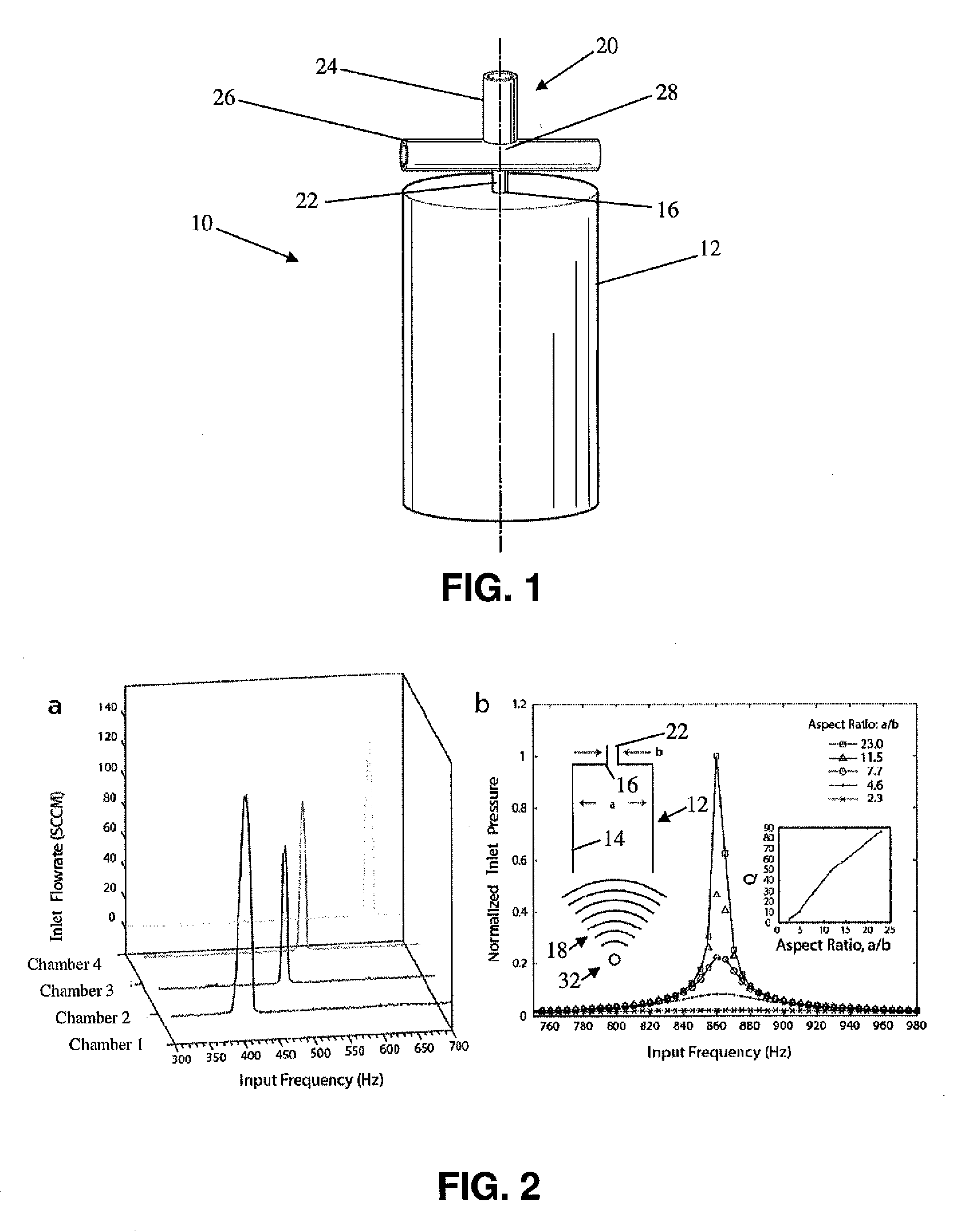

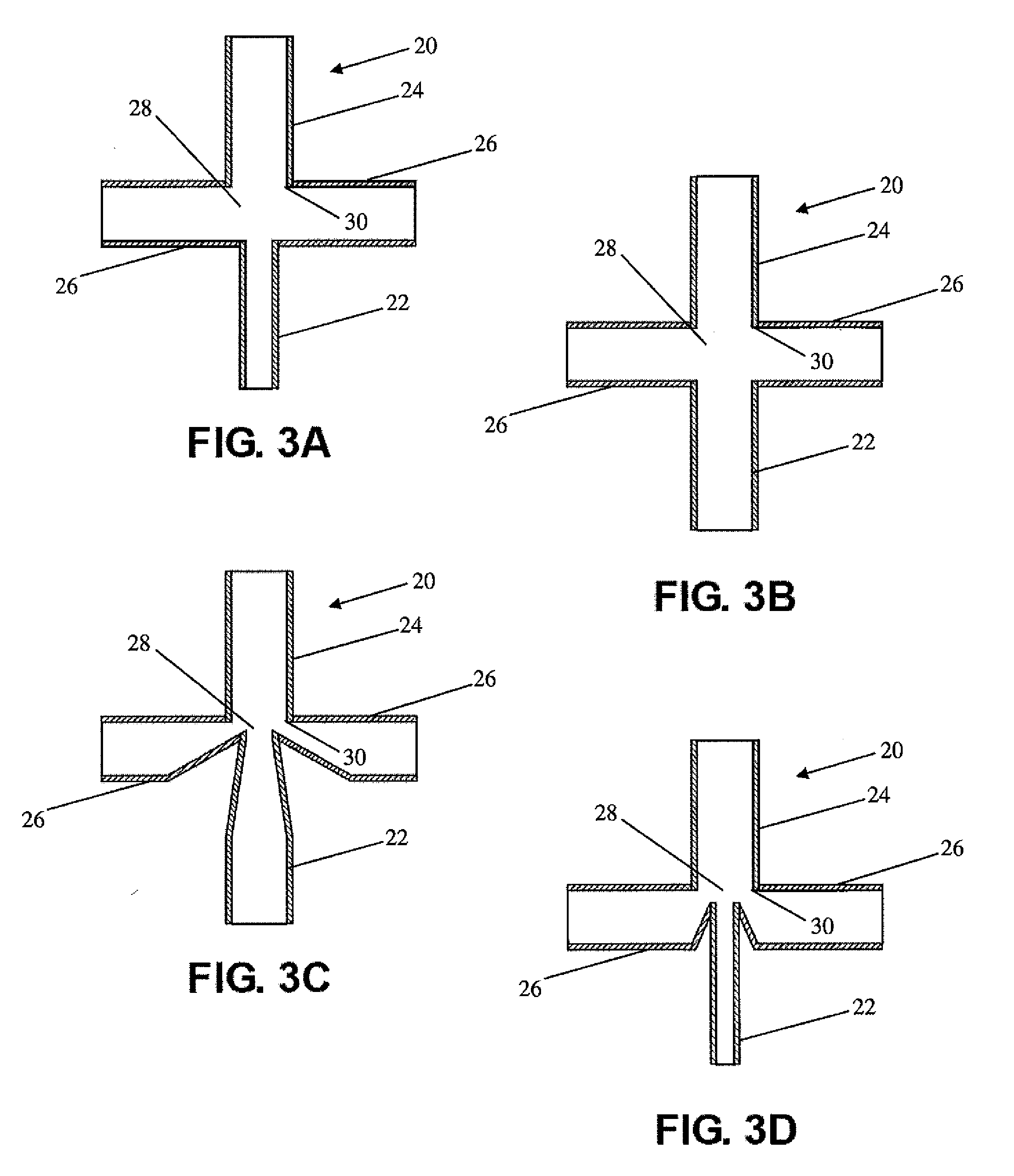

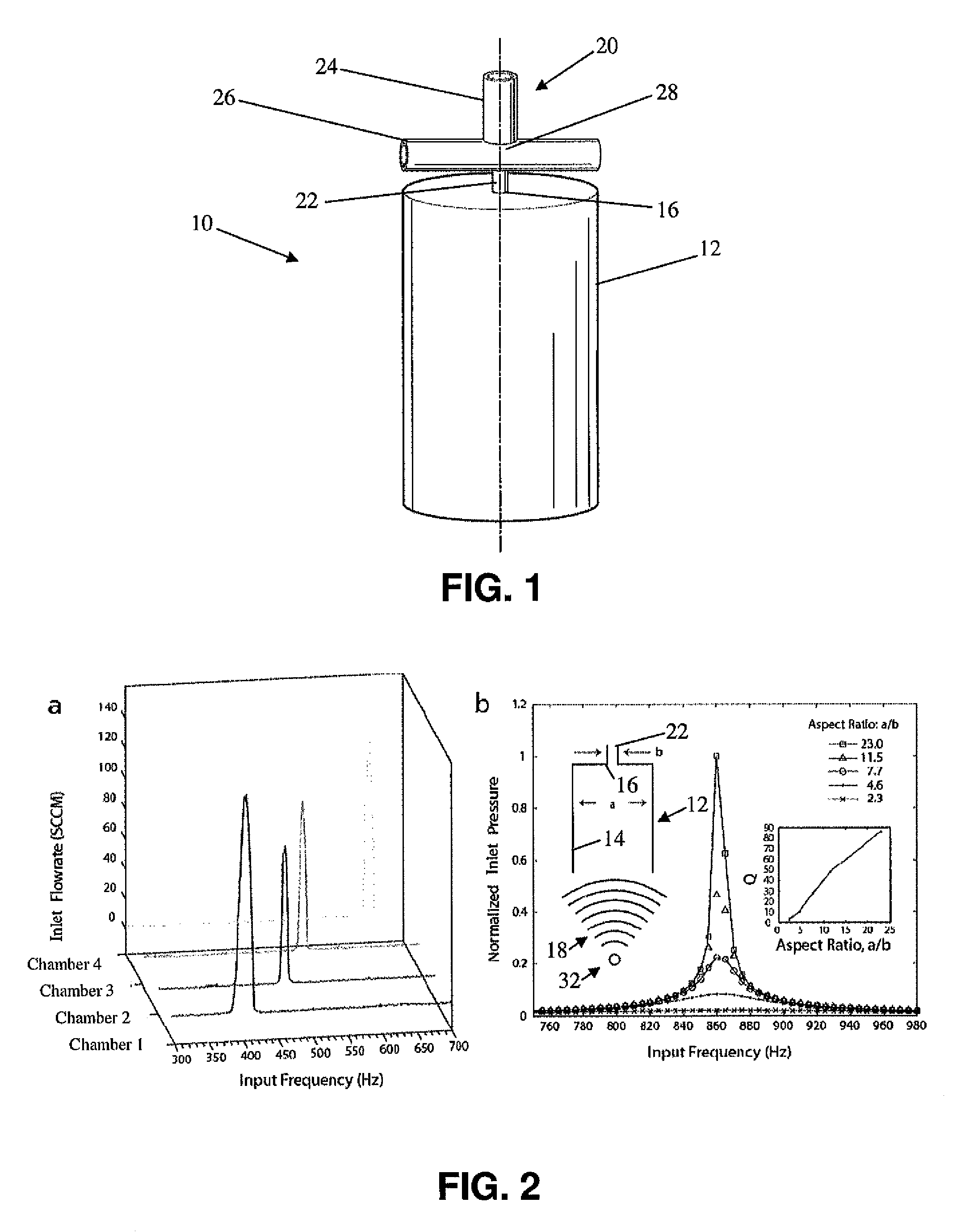

Acoustical Fluid Control Mechanism

ActiveUS20110277848A1Oscillatory flow of the working fluid is maximizedEliminating directional flowCircuit elementsFluid dynamicsWorking fluidFluid control

An acoustical fluid control mechanism and a method of controlling fluid flow of a working fluid with the acoustical fluid control mechanism are provided. The mechanism comprises a resonance chamber that defines a cavity. The resonance chamber has a port. The cavity is sealed from the ambient but for the port for enabling oscillatory flow of a working fluid into and out of the cavity upon exposure of the resonance chamber to an acoustic signal containing a tone at a frequency that is substantially similar to a particular resonance frequency of the resonance chamber. The mechanism further includes a rectifier for introducing directional bias to the oscillatory flow of the working fluid through the port. The rectifier has an inlet connected to the port and an outlet for transmitting the directional flow of the working fluid away from the cavity. The outlet is in fluid communication with the port of the resonance chamber at least during transmission of the directional flow of the working fluid therethrough.

Owner:RGT UNIV OF MICHIGAN

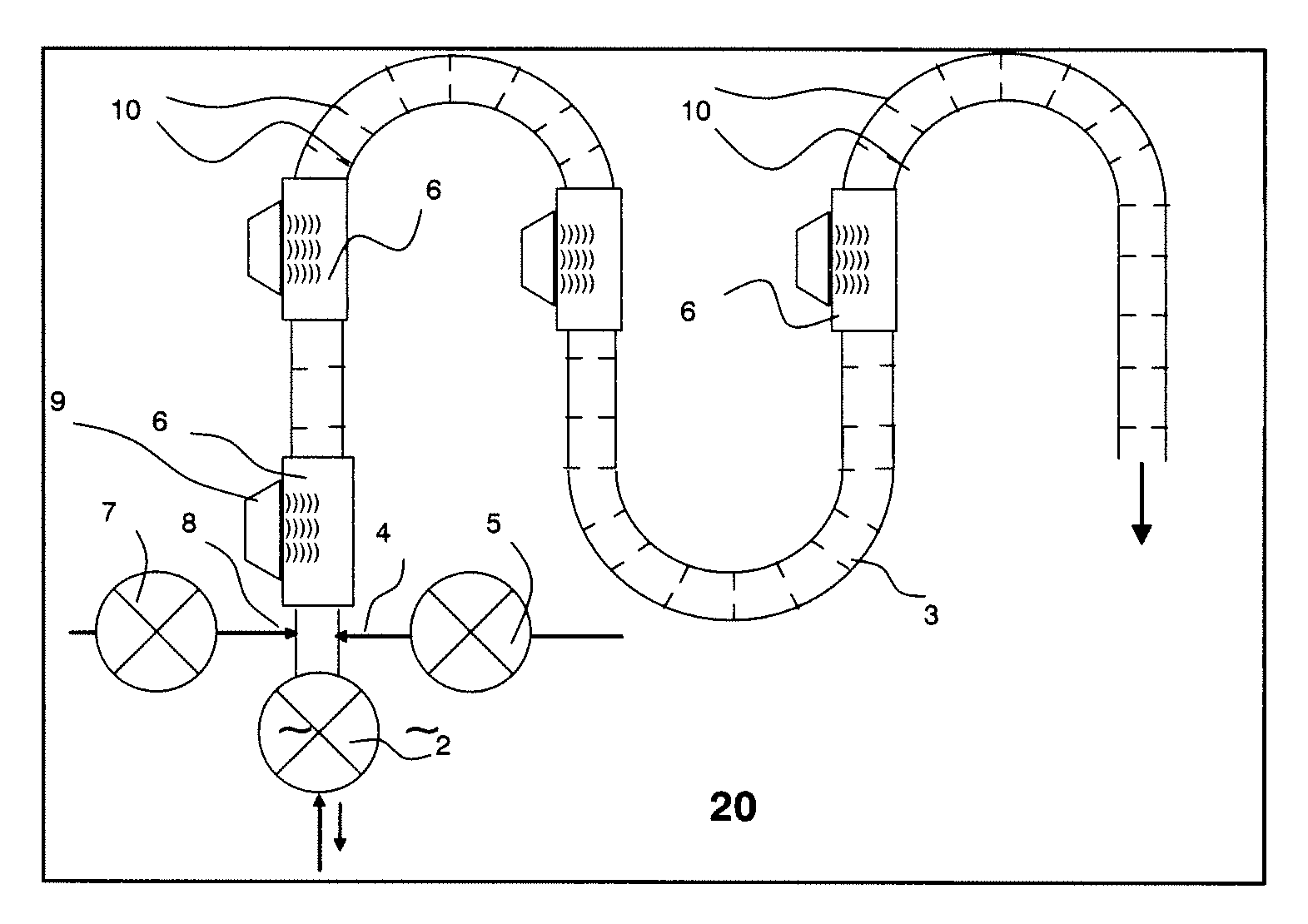

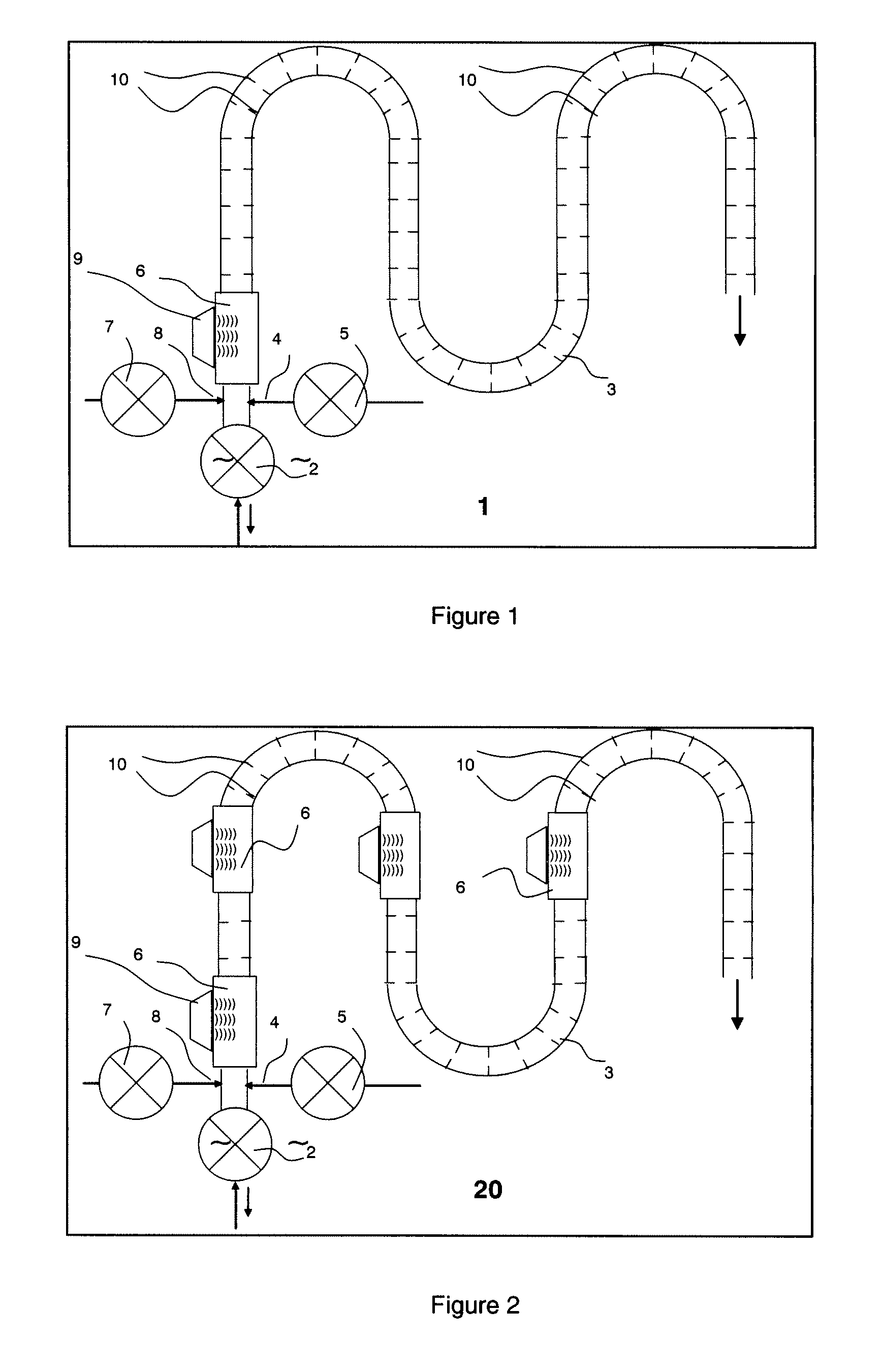

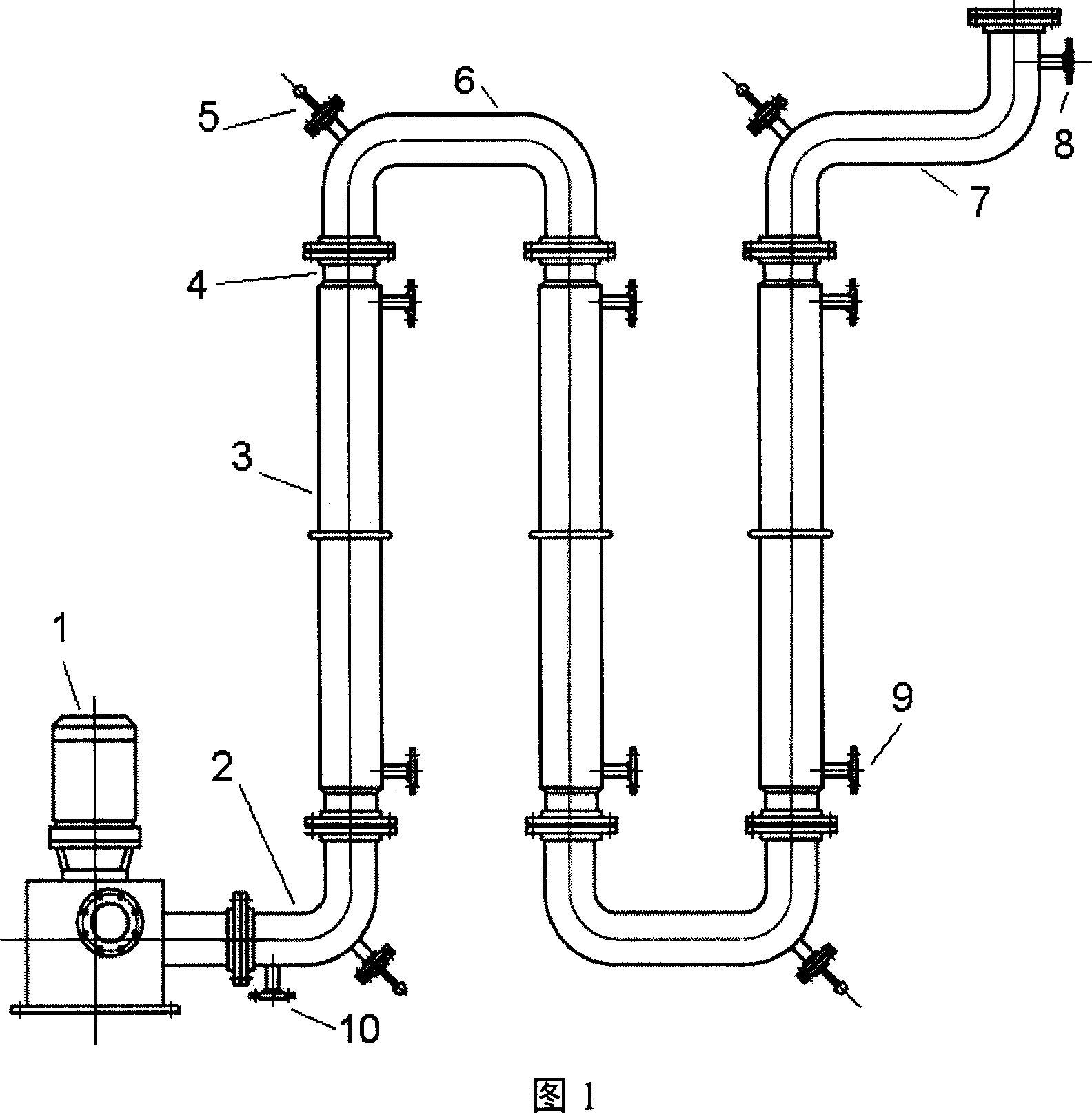

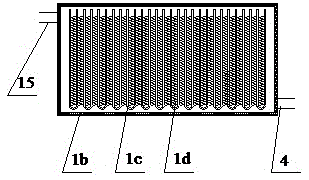

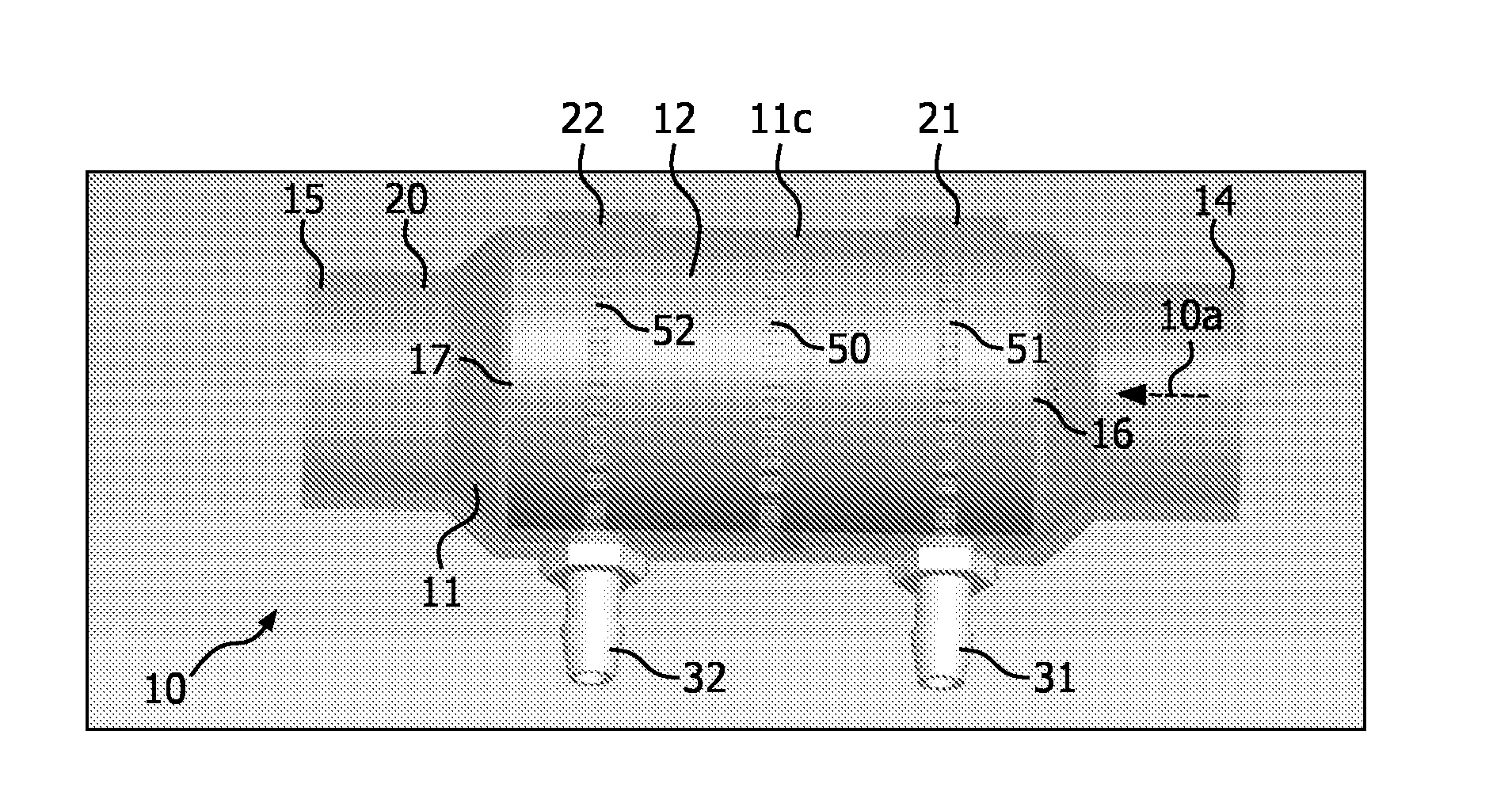

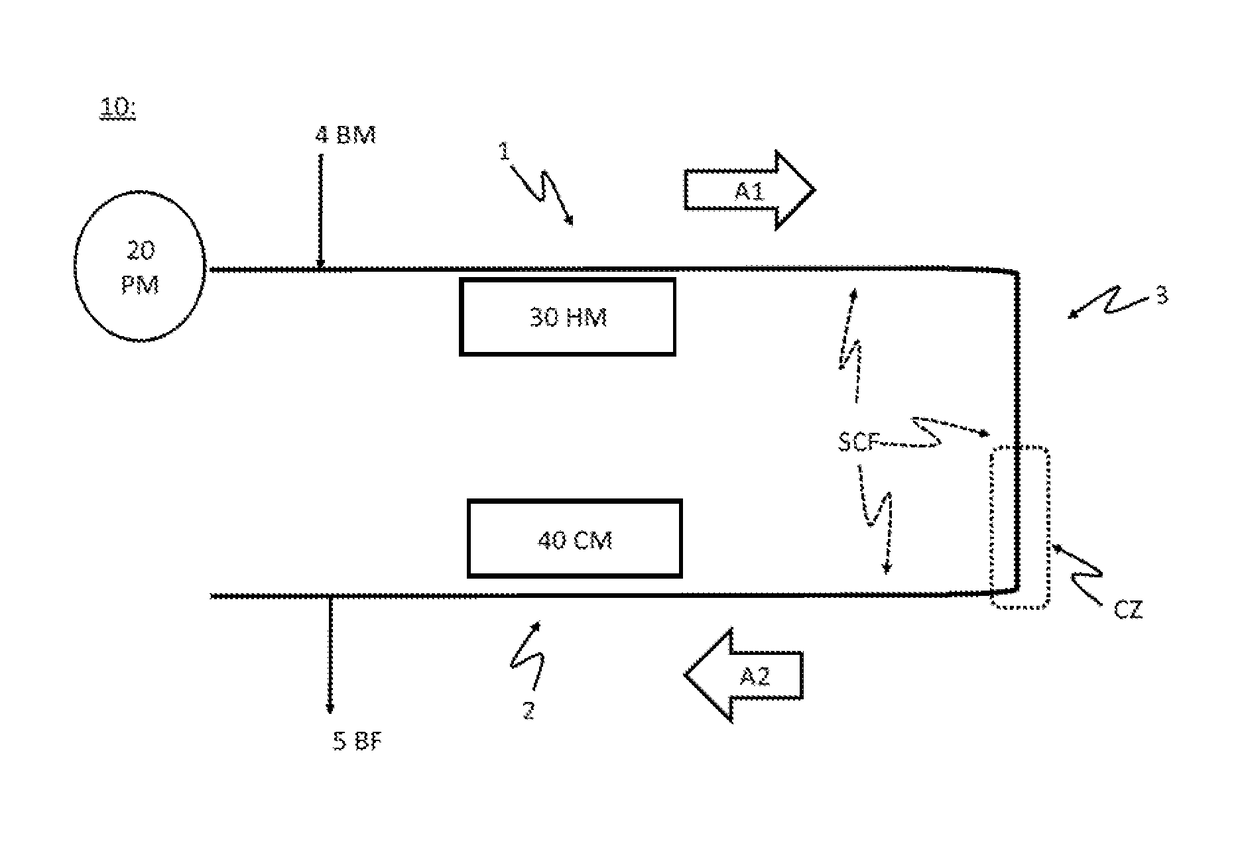

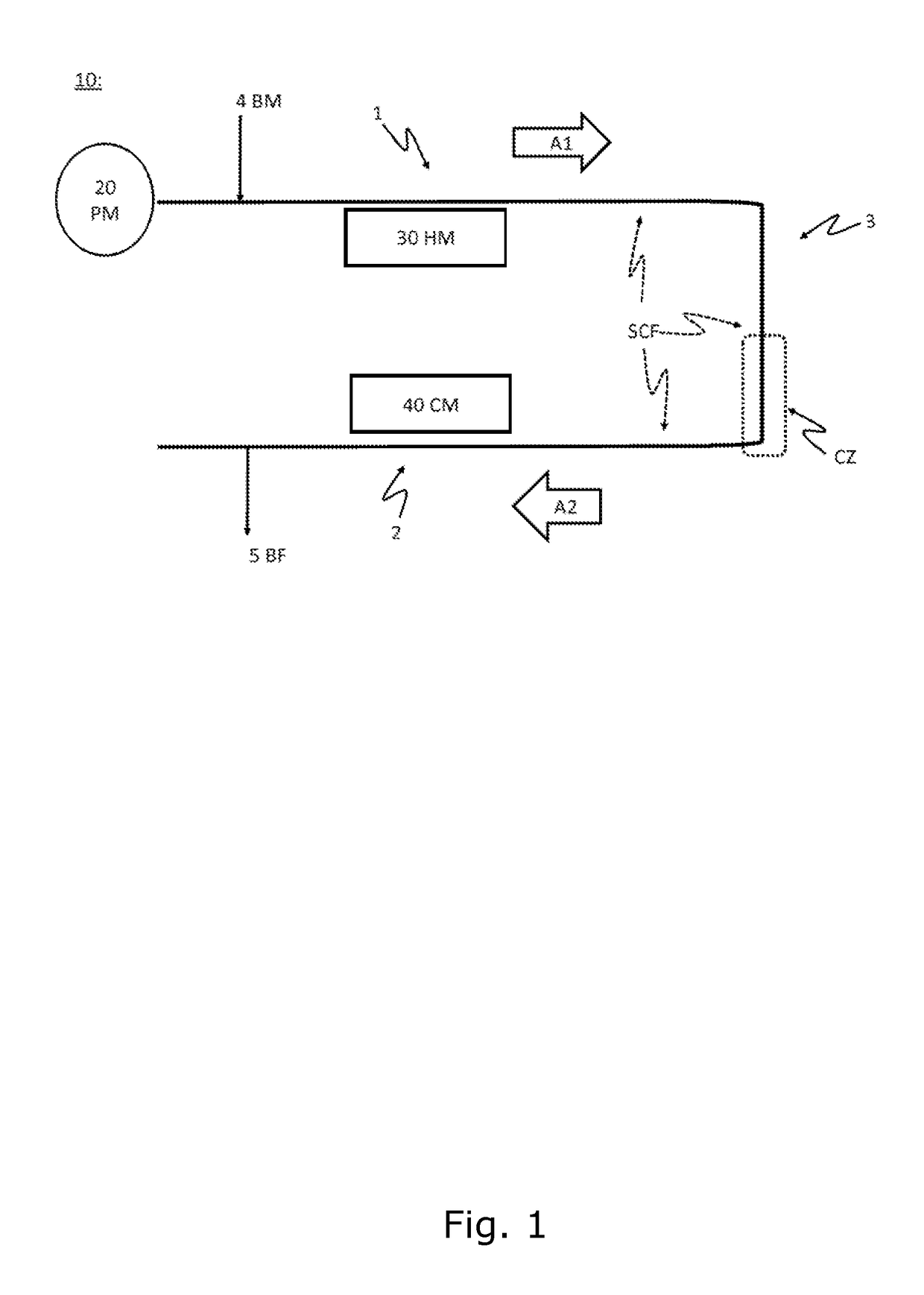

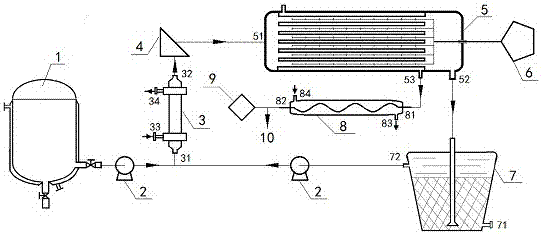

A method and apparatus for producing biofuel in an oscillating flow production line under supercritical fluid conditions

ActiveUS20170233327A1Increase heatImprove cooling effectivenessOrganic compound preparationCarboxylic acid esters preparationProduction lineBiofuel

The invention discloses a method for producing bio-fuel (BF) from a high-viscosity biomass using thermo-chemical conversion of the biomass in a production line (10) with pumping means (PM), heating means (HM) and cooling means (CM). The method has the steps of 1) operating the pumping means, the heating means and the cooling means so that the production line is under supercritical fluid conditions (SCF) to induce biomass conversion in a conversion zone (CZ) within the production line, and 2) operating the pumping means so that at least part of the production line is in an oscillatory flow (OF) mode. The invention is advantageous for providing an improved method for producing biofuel from a high-viscosity biomass. This is performed by an advantageous combination of two operating modes: supercritical fluid (SCF) conditions and oscillatory flow (OF).

Owner:CIRCLIA NORDIC APS

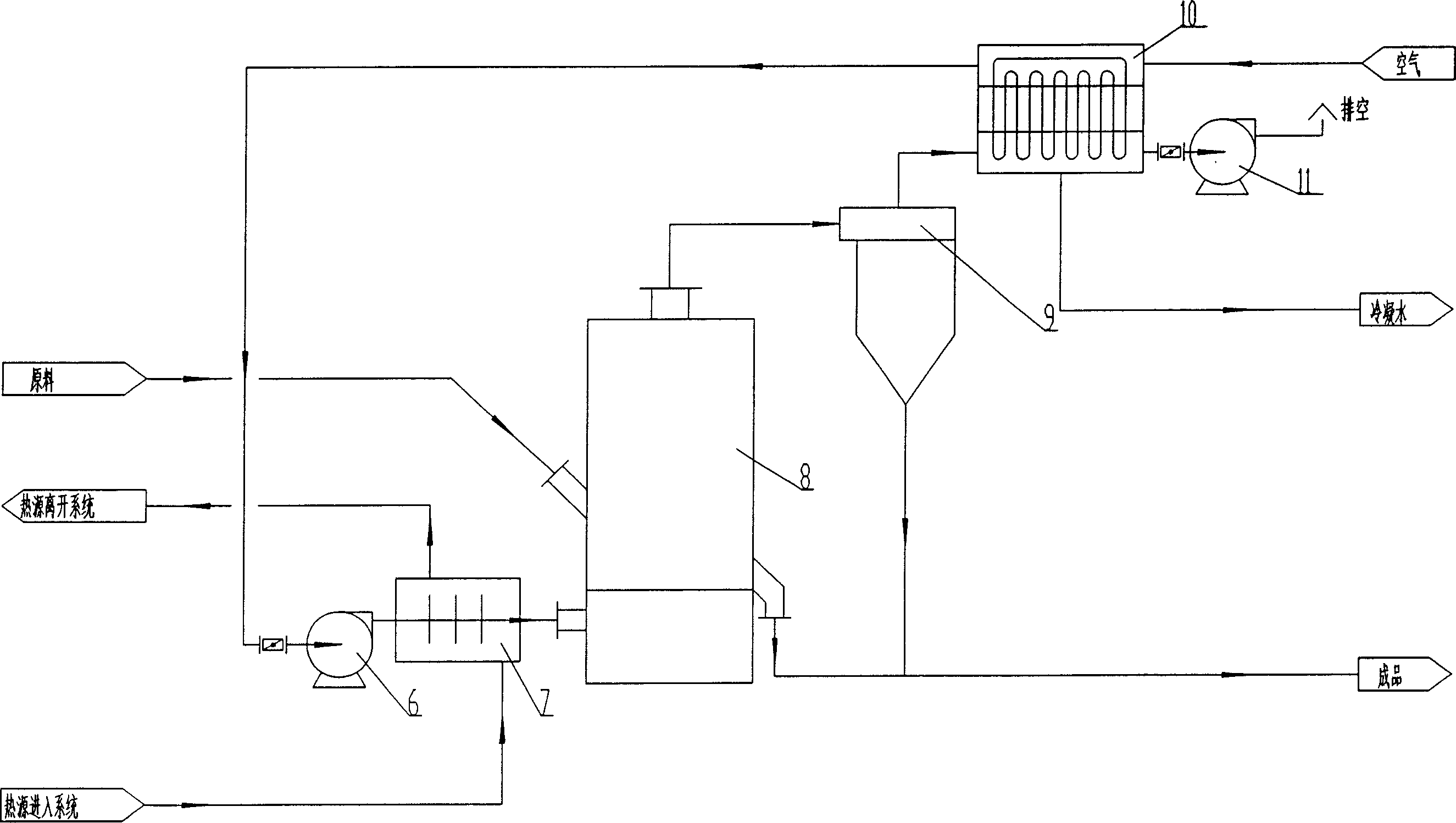

Air preheater of oscillatory flow type heat pipe, and energy saving drying technique of using the preheater

InactiveCN1916546AReduce volumeSimple structureIndirect heat exchangersHeating arrangementThermal energyAir preheater

An energy- saving dry process using air preheater of oscillation stream heat tube includes sending wet material into dryer by conveying device, preheating natural air by said air preheater then using blower to pressurize it and to send it to heat exchanger, heating air to be required temperature and sending it to dryer for drying material in dryer, discharging dried material out from dryer and conveying it together with dried powder collected from cyclone dust remover to final product area, sending tail gas from dryer to said air preheater through draught fan after it is purified by said dust remover and using it to preheat drying media then exhausting it to the air.

Owner:SHAN DONG TIAN LI DRYING EQUIP

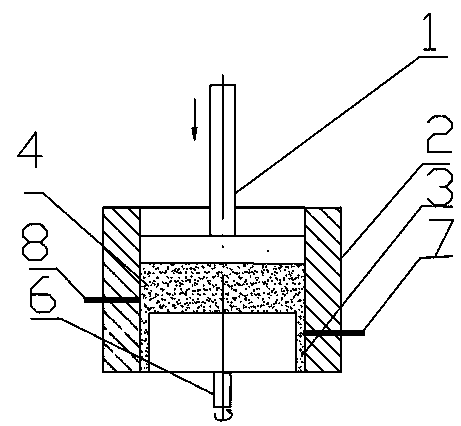

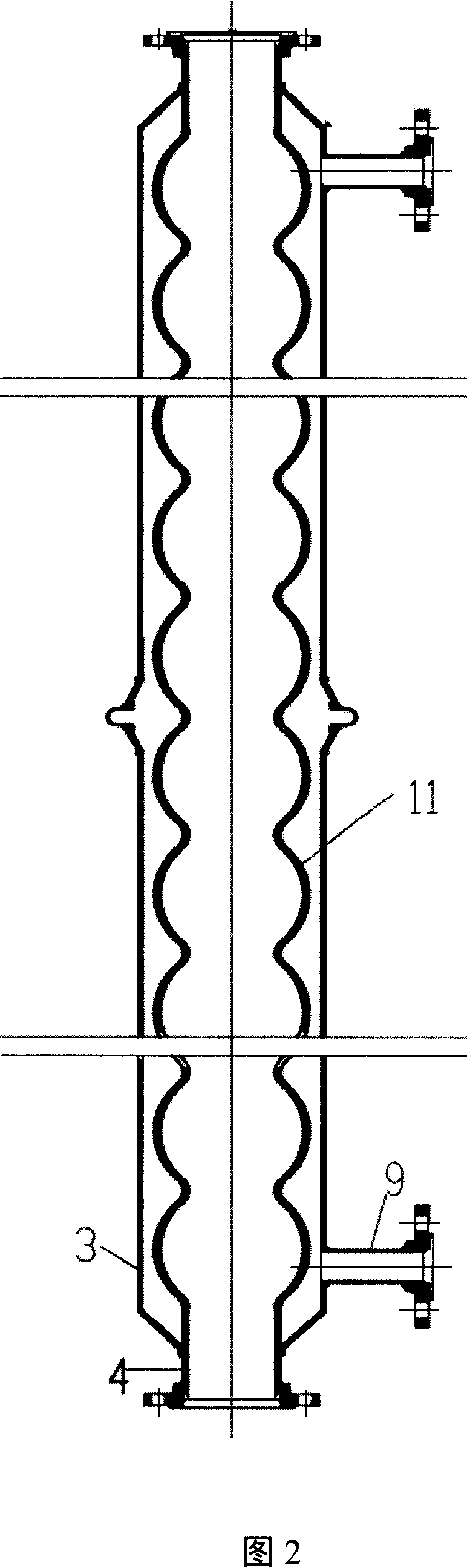

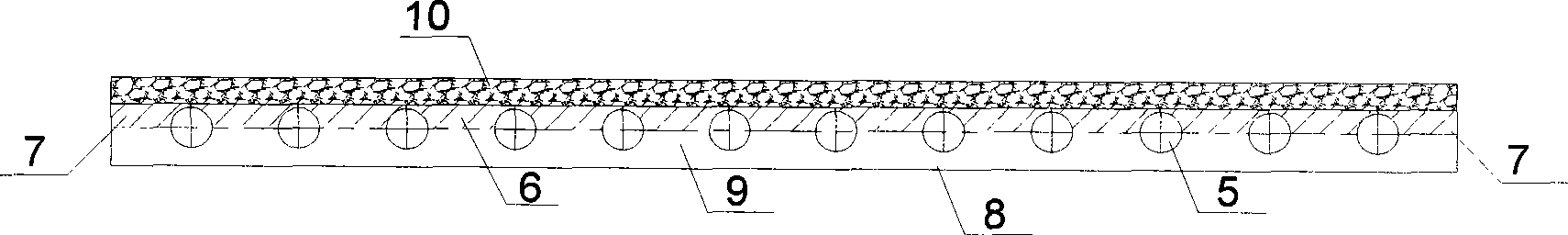

Oscillatory flow tubular reactor with ripple wall

InactiveCN1958144AEasy to passEnhanced transfer processChemical/physical processesSolid particleEngineering

An oscillating flow type tubular reactor with corrugated wall is composed of oscillation generating mechanism, inlet segment with inlet, reaction segment formed by vertical circular reaction pipe with corrugated wall for dividing its internal space into several chambers, and outlet segment with outlet. It is suitable for the reaction of liquid-solid suspension system with high content of solid.

Owner:ZHEJIANG UNIV

Distributed solar heat and power combination energy system

InactiveCN102734942ALow conversion efficiencyLow reliabilitySolar heating energySolar heat devicesDevice formWater circulation

The invention belongs to the field of solar, and in particular relates to a distributed solar heat and power combination energy system. The system comprises an oscillatory flow heat pipe radiating solar photocell generation device, an oscillatory flow heat pipe heat collecting solar water heating device, a user power supply system and a user water heating system. According to the system, the solar generation device absorbs heat from the back side of a high temperature solar photovoltaic panel by using an oscillatory flow heat pipe, so that temperature of the photovoltaic panel is decreased, photoelectric conversion efficiency is significantly improved, and stable operation and power supply of the photovoltaic panel are ensured; the solar water heating device heats water in a hot water tank by using the oscillatory flow heat pipe heat collecting device to absorb photon heat; and a cooling water circulation device for the solar photovoltaic panel in the solar generation device and a hot water circulation device in the solar water heating device form a closed cooling water circulation loop to exchange heat, so that heat generated by the solar panel in light is utilized. The distributed solar heat and power combination energy system meets the requirement of a user for solar heat and power combination, and is applicable to power and heat supply for a single user or collective users.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

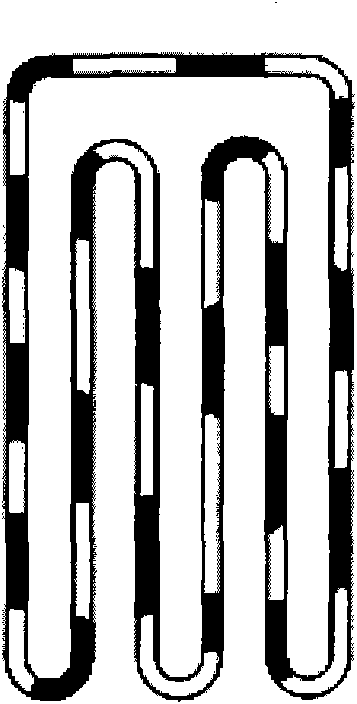

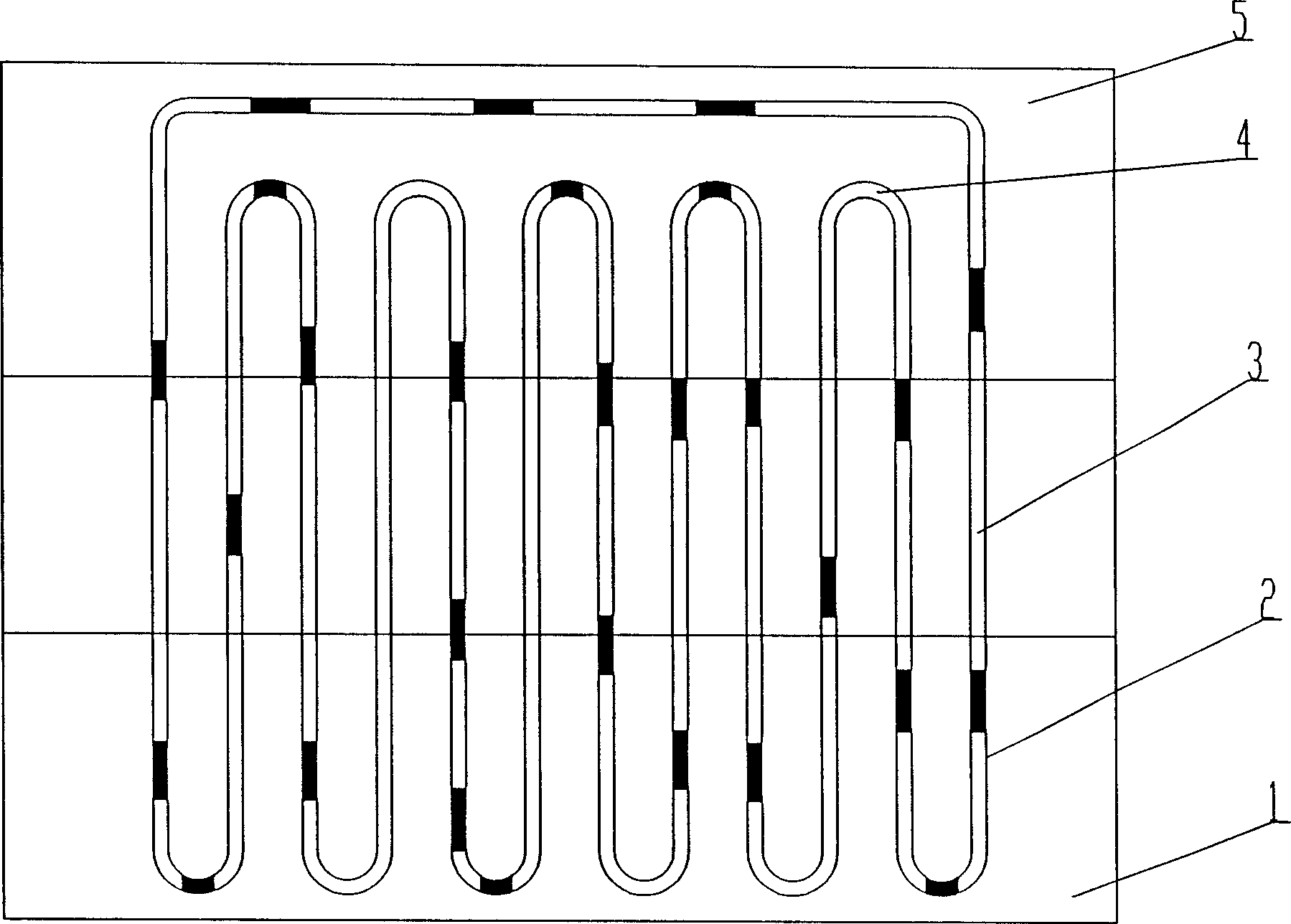

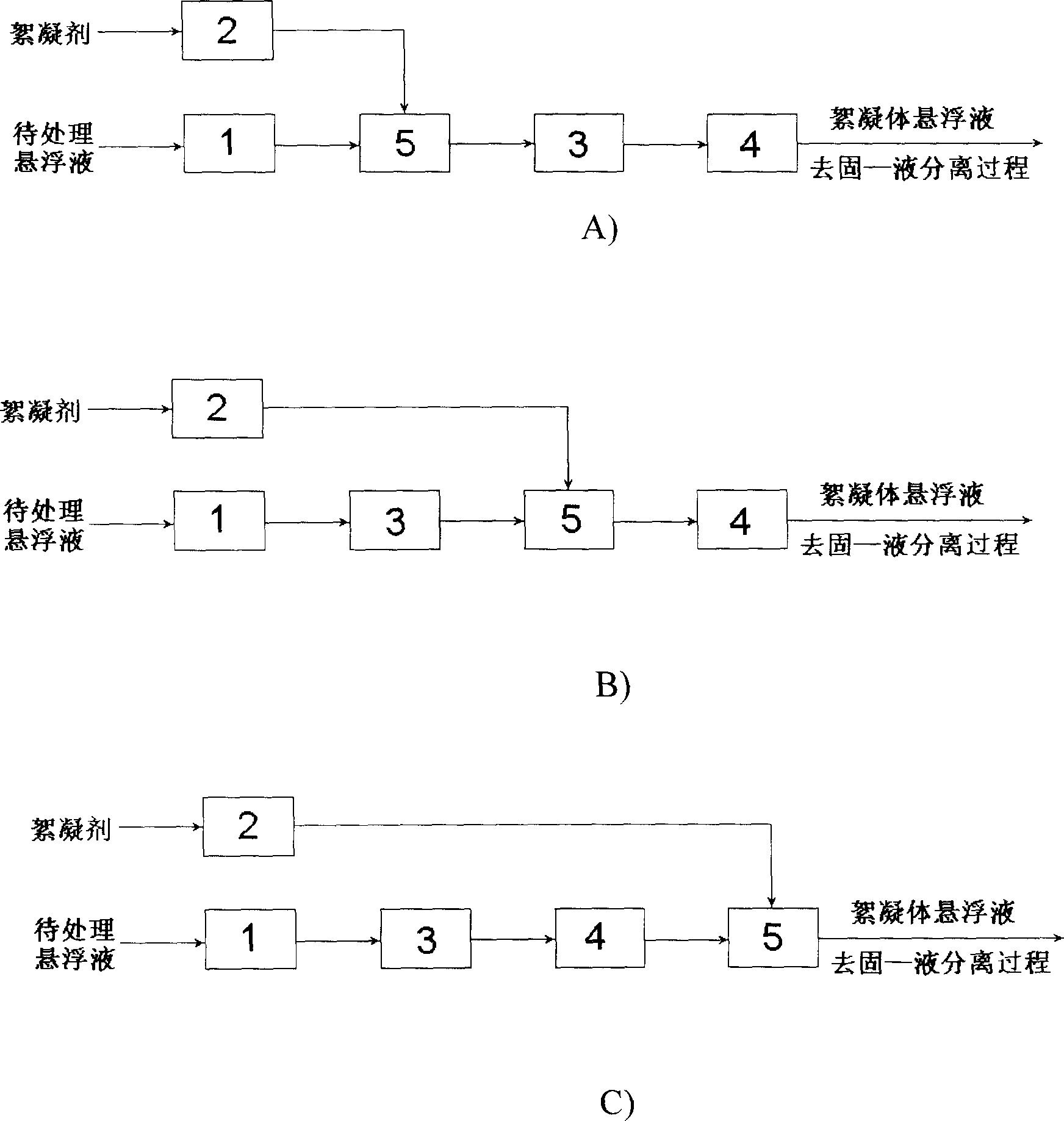

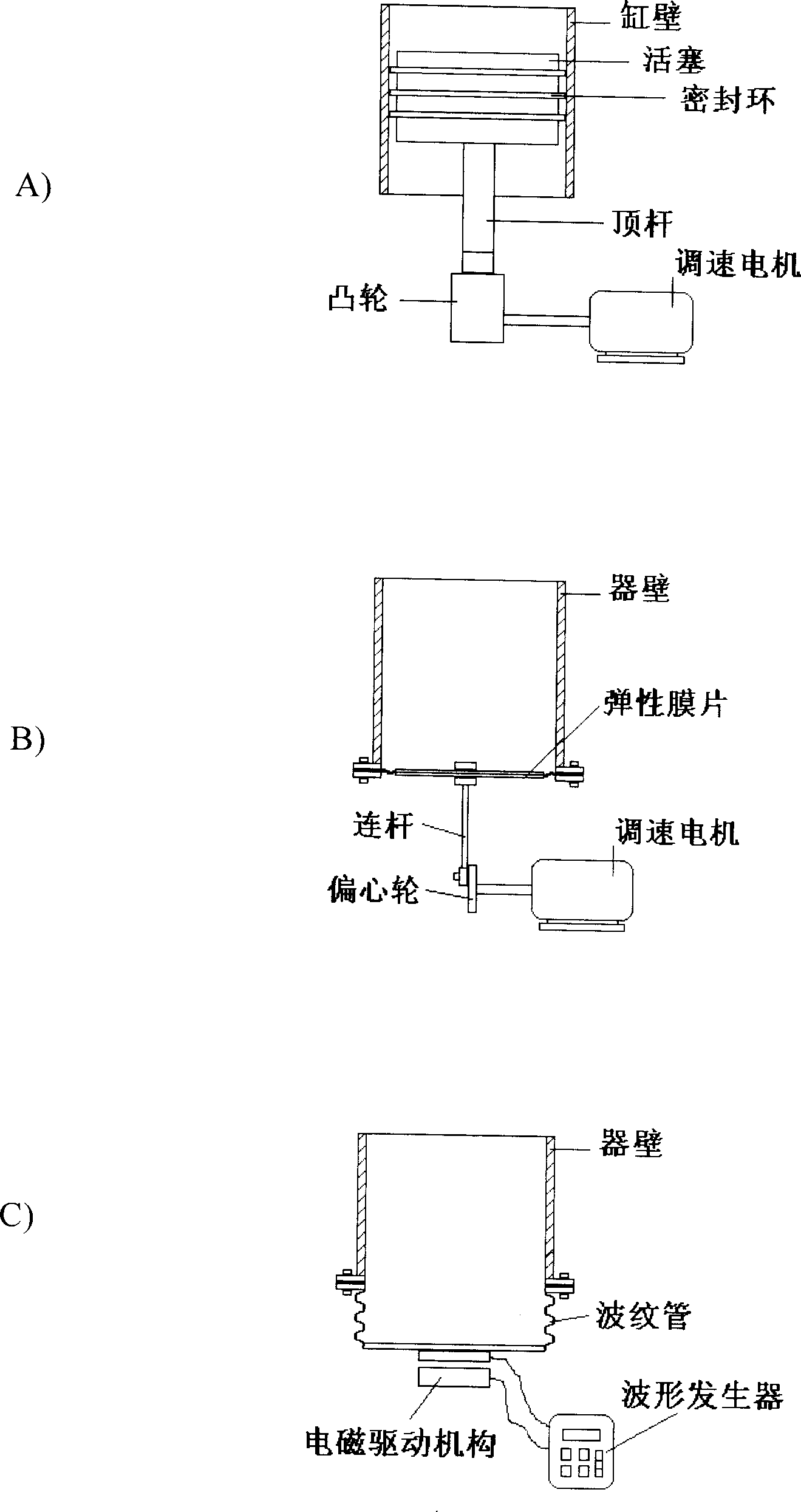

Oscillation-flow flocculating process and apparatus

InactiveCN1440828AExcellent macro mixExcellent micro-mixing effectSedimentation separationFluid fieldChemical process

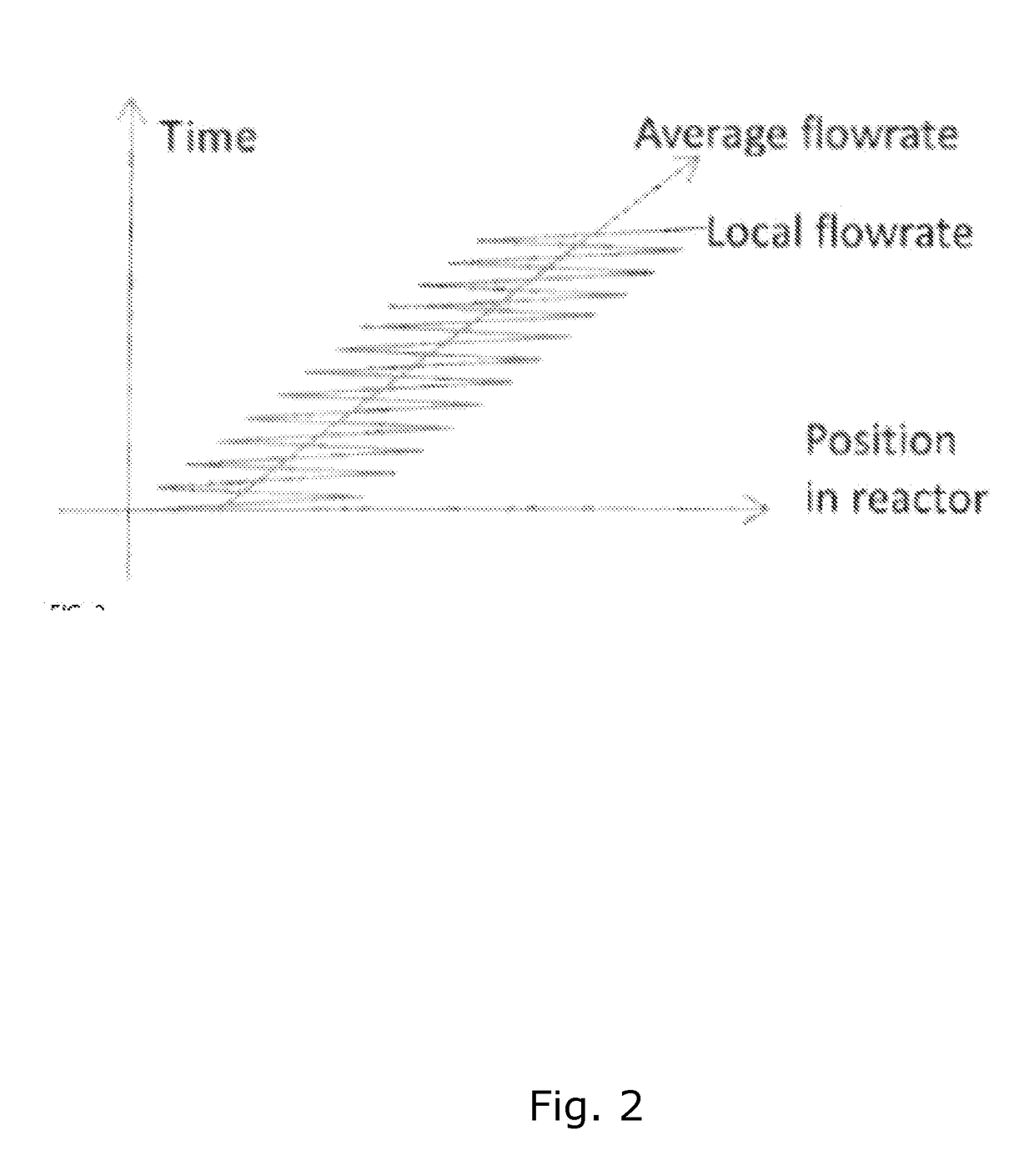

The present invention relates to oscillation-flow flocculating process and apparatus. The suspension with particle is made to flow through a tubular passage with inner baffle part continuously, and one oscillation speed component produced by one oscillation flow generating mechanism sis superposed onto the average flow speed. Inside the oscillation flow field, are realized the dispersing and mixing of the flocculant in the suspension liquid, adsorption between the flocculant and suspension particle surface, collision and merging between the suspension particles, the formation and growth of flocculant, and other physical and chemical processes. By means of the oscillation flow reinforced transmission process, suspension with large flocculant is obtained in the outlet of the apparatus, and this is favorable to the subsequent liquid / solid separation.

Owner:HANGZHOU ZJU HOLLEY TECH

Spirometer

InactiveUS20030191407A1Easily and accurately used in a home environmentSmall and portableRespiratory organ evaluationSensorsFluidic oscillatorMechanics

A spirometer for measuring fluid flow, particularly associated with exhalation of respiratory patients. The spirometer of this invention preferably has a fluidic oscillator wherein the fluid oscillates within a chamber of the fluidic oscillator. An oscillation frequency of the fluid flow within the chamber is correlated to a flow rate. A computer is used to process input data, such as data representing frequency of the oscillatory flow within the chamber, to a flow rate passing through the spirometer. The spirometer of this invention may have no moving parts, which results in the need for only a design calibration and no periodic calibrations throughout use of the spirometer.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

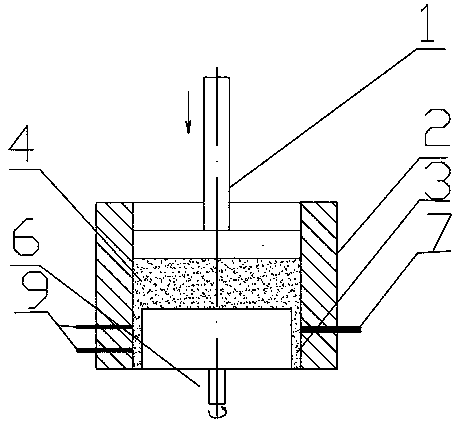

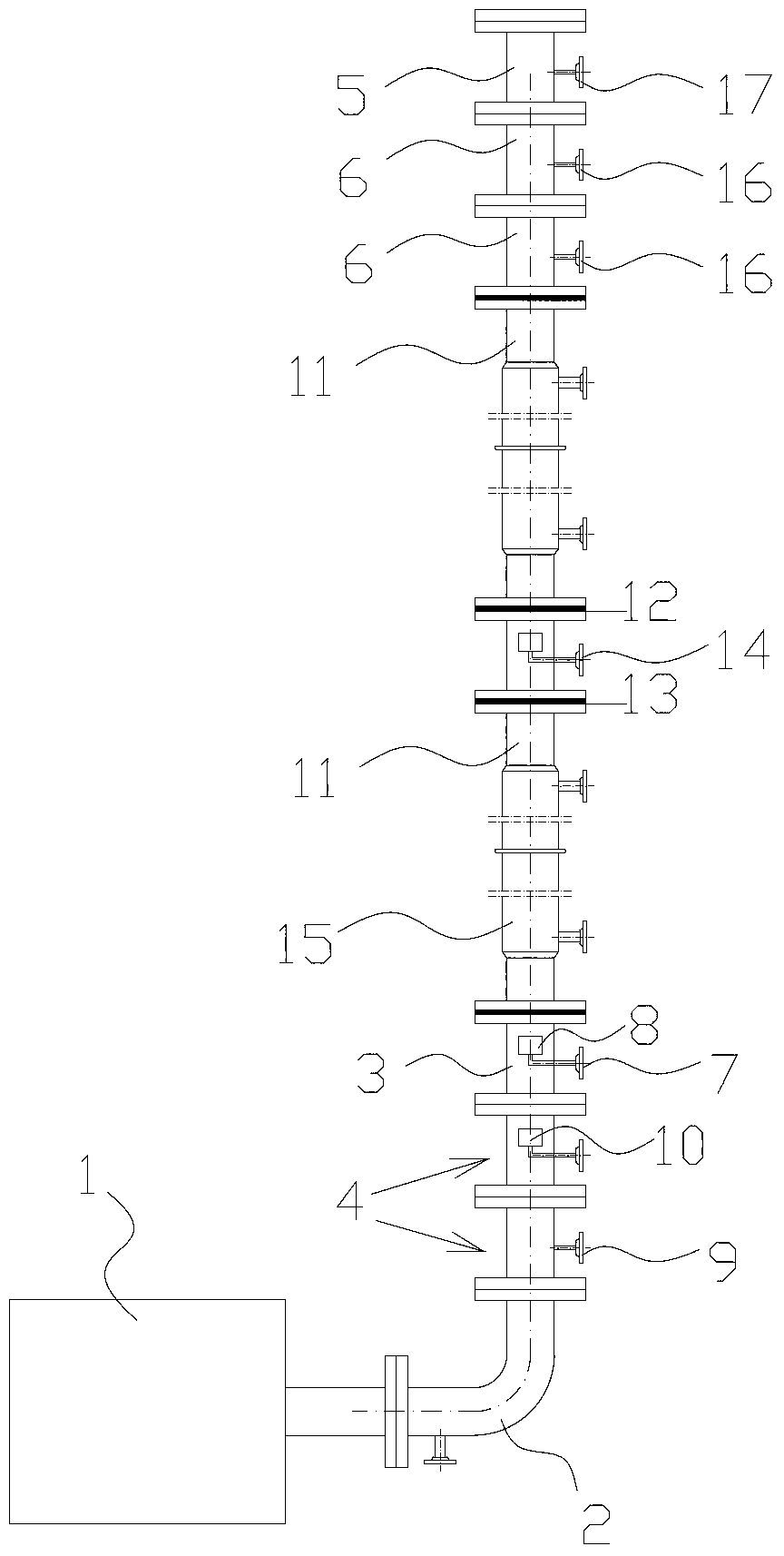

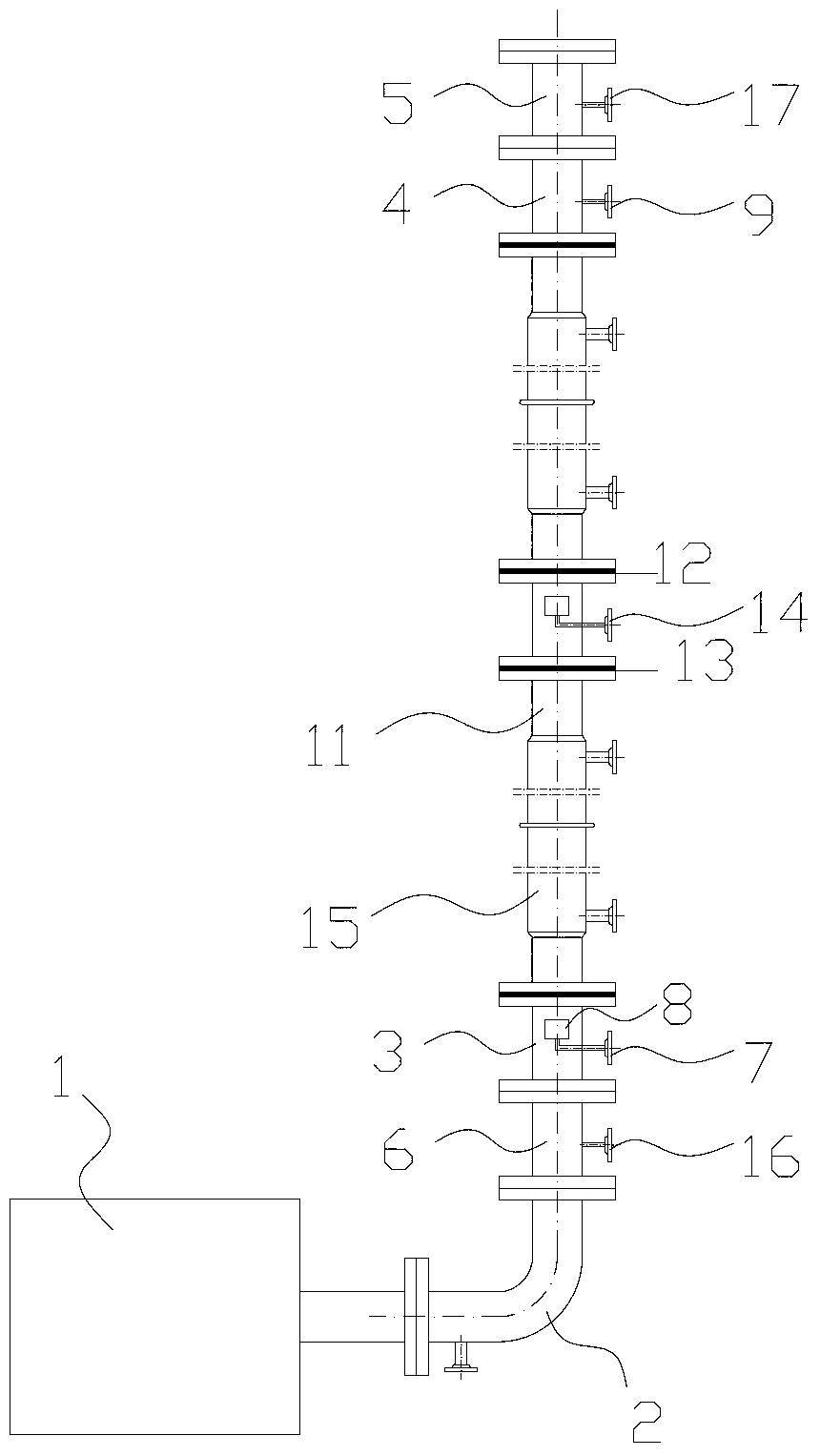

Oscillatory flow reactor of packed bed

The invention discloses an oscillatory flow reactor of a packed bed. The oscillatory flow reactor comprises an oscillation generating mechanism, an inlet segment, a reaction segment and an outlet segment which are sequentially connected, wherein the inlet segment is composed of an air inlet segment and a liquid inlet segment which are connected in series, and the outlet segment is composed of an air outlet segment and a liquid outlet segment which are connected in series; the air inlet segment is provided with an air feeding hole and an air distributor located at the downstream of an air discharging hole; the liquid inlet segment is provided with a liquid feeding hole and a liquid distributor located at the downstream of a liquid discharging hole; the reaction segment is provided with a vertically-arranged reaction tube which is filled with filler or solid catalyst particles in the middle, a supporting device at the bottom and a pressing device at the top. The oscillatory flow reactor of the packed bed is suitable for industrial gas-liquid reaction taking the liquid phase as a main body, gas-liquid-liquid reaction or gas-liquid-solid three-phase reaction system containing a solid catalyst and can continuously and stably operate for a long term.

Owner:吴嘉

Oscillatory flow reactor used for preparing cumene hydroperoxide (CHP) in catalytic oxidation of cumene and method for preparing cumene hydroperoxide in catalytic oxidation of cumene

ActiveCN106475020AIncrease in sizeReduce sizeOrganic compound preparationCatalytic liquid-gas reactionReaction temperatureCatalytic oxidation

The invention relates to an oscillatory flow reactor used for preparing cumene hydroperoxide (CHP) in catalytic oxidation of cumene and a method for preparing CHP in catalytic oxidation of the cumene. The oscillatory flow reactor comprises a feed distribution section, a reaction section, a gas-liquid separation section and a condensation section; the feed distribution section comprises gas inlets, a gas distributor, a liquid inlet and a liquid-solid separator, and the liquid-solid separator is connected with an oscillation pump; the main body of the reaction section comprises a corrugated reaction tube with multiple sections which are in sectoral arc connection to form a concave-convex corrugated shape integrally, a heat tracing layer is arranged on the outer side of the corrugated reaction tube, and heat tracing medium enters from a heat tracing liquid inlet and flows out from a heat tracing liquid outlet; each of the upper, middle and lower section of the main body of the reaction section is provided with a temperature measuring point; the gas-liquid separation section is provided with a discharge hole with the liquid-solid separator, a safe injection hole and an electromagnetic valve and an electrically operated valve which are connected with the safe injection hole; the condensation section is of a double-layer tube shell structure, a gas exit is arranged in the tube layer, and a condensate inlet and a condensate outlet for the condensate medium are arranged in the shell layer. By the arrangement, quick reaction under lower reaction temperature and pressure is achieved, and meanwhile, higher CHP selectivity is acquired.

Owner:CHINA PETROLEUM & CHEM CORP

Acoustical fluid control mechanism

ActiveUS8636032B2Oscillatory flow of the working fluid is maximizedEliminating directional flowPiezoelectric/electrostriction/magnetostriction machinesCircuit elementsWorking fluidFluid control

Owner:RGT UNIV OF MICHIGAN

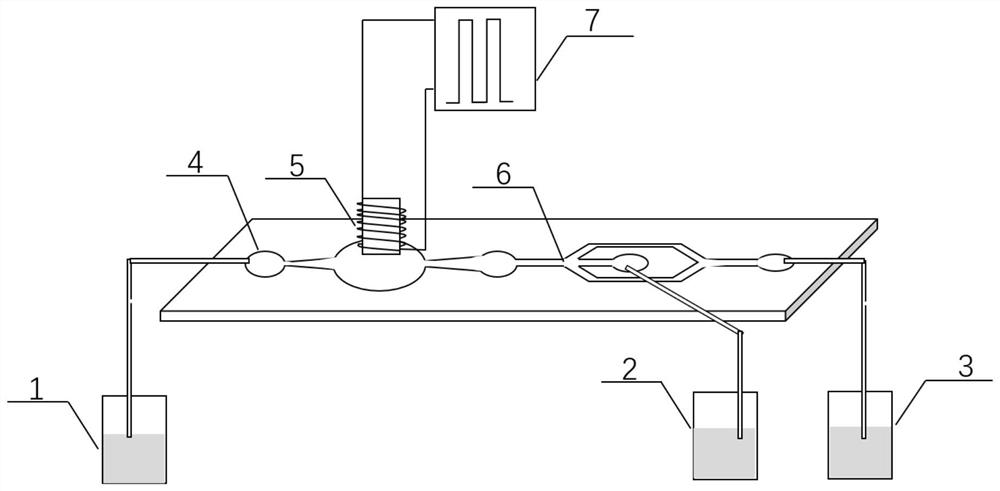

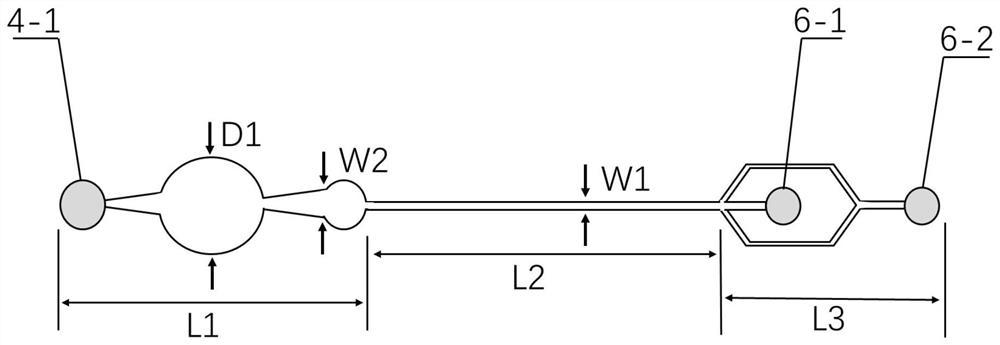

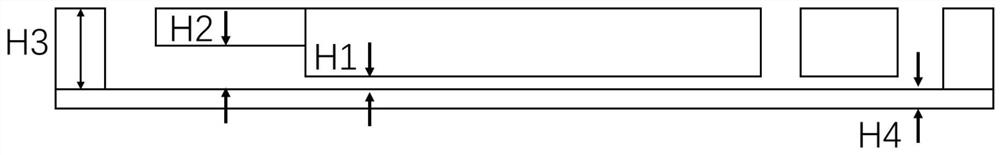

High-integration-level micro-nano particle convergence micro-fluidic device utilizing oscillatory flow

ActiveCN113333040AEfficient aggregationHighly integratedLaboratory glasswaresFluid controllersControl systemLiquid storage tank

The invention belongs to the technical field of micro-fluidic chips, and provides a high-integration micro-nano particle convergence micro-fluidic device utilizing oscillatory flow, which mainly comprises a micro-fluidic chip (comprising a valveless micropump and a convergence channel), a pump membrane control system (comprising an electromagnet and a singlechip), a liquid storage tank and a conduit. The device provided by the invention can realize efficient and convenient micro-nano particle convergence. The micro-fluidic device for converging the micro-nano particles, provided by the invention, is high in integration level, ingenious in design and simple to operate. Oscillatory flow design is utilized to realize 'infinite long channel' flow in a short channel, and a valveless micropump is utilized to drive fluid, so that integration and miniaturization of the device are realized; the elastic lift force and the inertial lift force are combined, convergence and enrichment of the micro-nano particles can be successfully achieved, and the device is used for research in the fields of biology, chemistry and environment.

Owner:DALIAN UNIV OF TECH

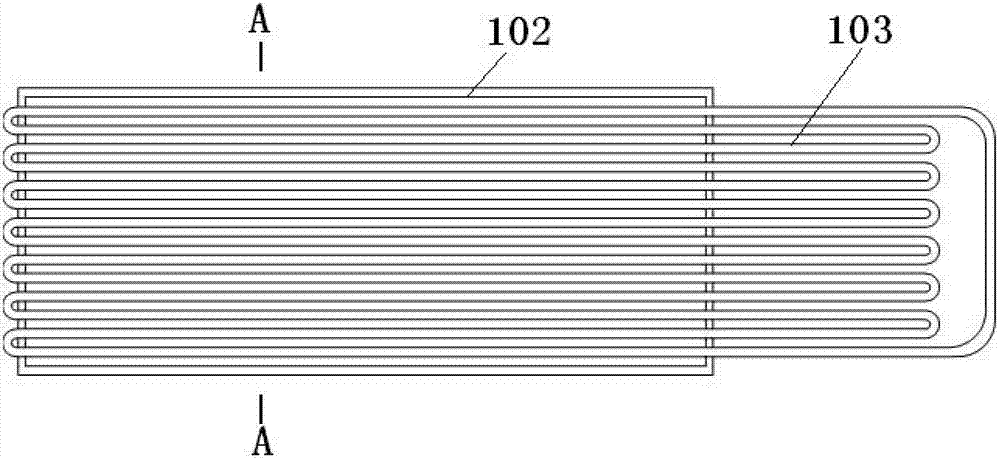

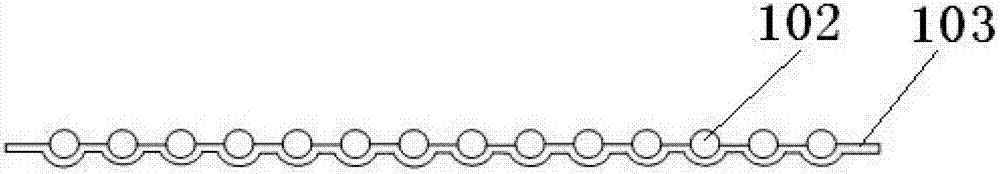

Closed-loop capillary pipe plate type solar heat collector

InactiveCN101387451AImprove heat collection effectImprove the heat collection performance, which is beneficial to increase the heat supply temperature of the heat collectorSolar heating energySolar heat devicesInsulation layerCollector device

The invention discloses a closed loop capillary flat plate type solar heat collector, which belongs to the field of solar heat collector. The solar heat collector is characterized in that the device comprises a header tube, a fin tube, capillary metal tubes, a graphite heat transfer layer, a metal frame, plate glass and an insulation layer; the inner diameter of each capillary metal tube is between 2 and 5 millimeters, and the capillary metal tubes are connected with the fin tube to form a closed pipe system. The capillary metal tubes are filled with a heat transfer medium; during work, after absorbing solar energy, the heat transfer medium forms a vapor and liquid alternated column, enters the fin tube along the capillary metal tubes, flows back to the capillary metal tubes after being cooled down and condensed by media outside the tube, and then absorbs solar energy again for vaporization; and the cycle is repeatedly carried out. The closed loop capillary flat plate type solar heat collector has the advantages that the oscillatory flow heat pipe effect caused by the closed loop capillary metal tubes increases the heat transfer rate of the heat collector; the graphite heat transfer layer facilitates the improvement of the heat collection performance of the heat collector; and the tube diameter of each capillary metal tube is small, thereby improving the bearing capacity of the heat collection tube.

Owner:DALIAN UNIV OF TECH

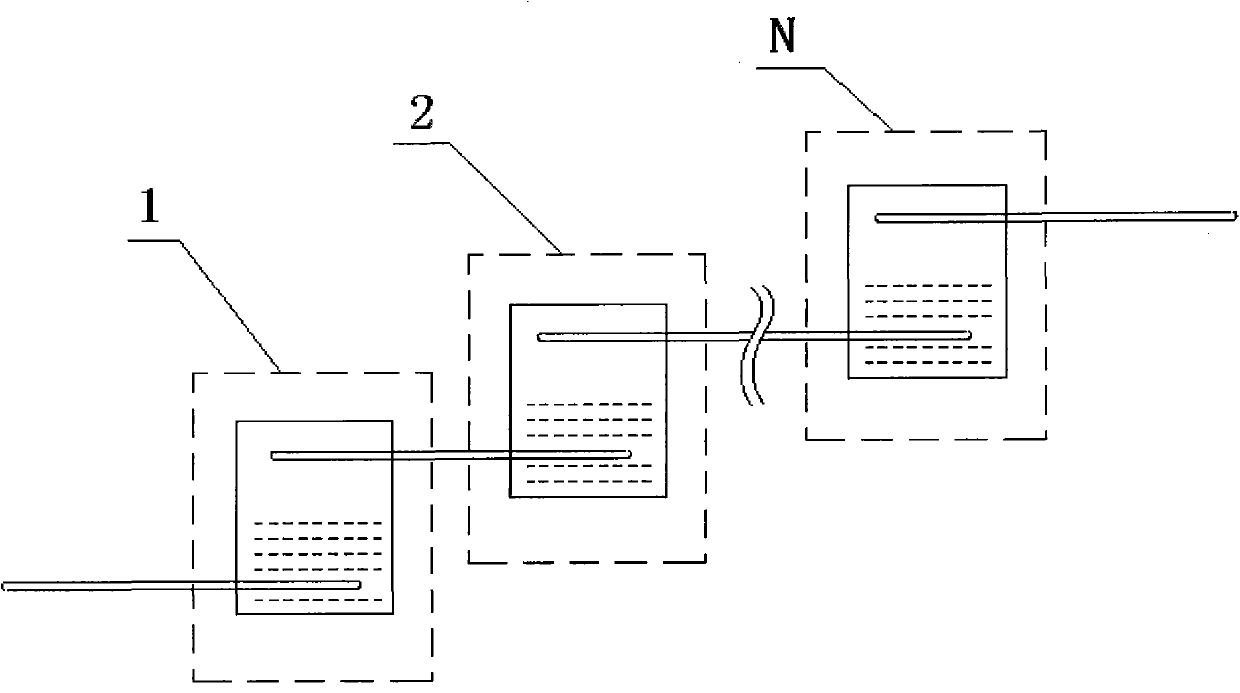

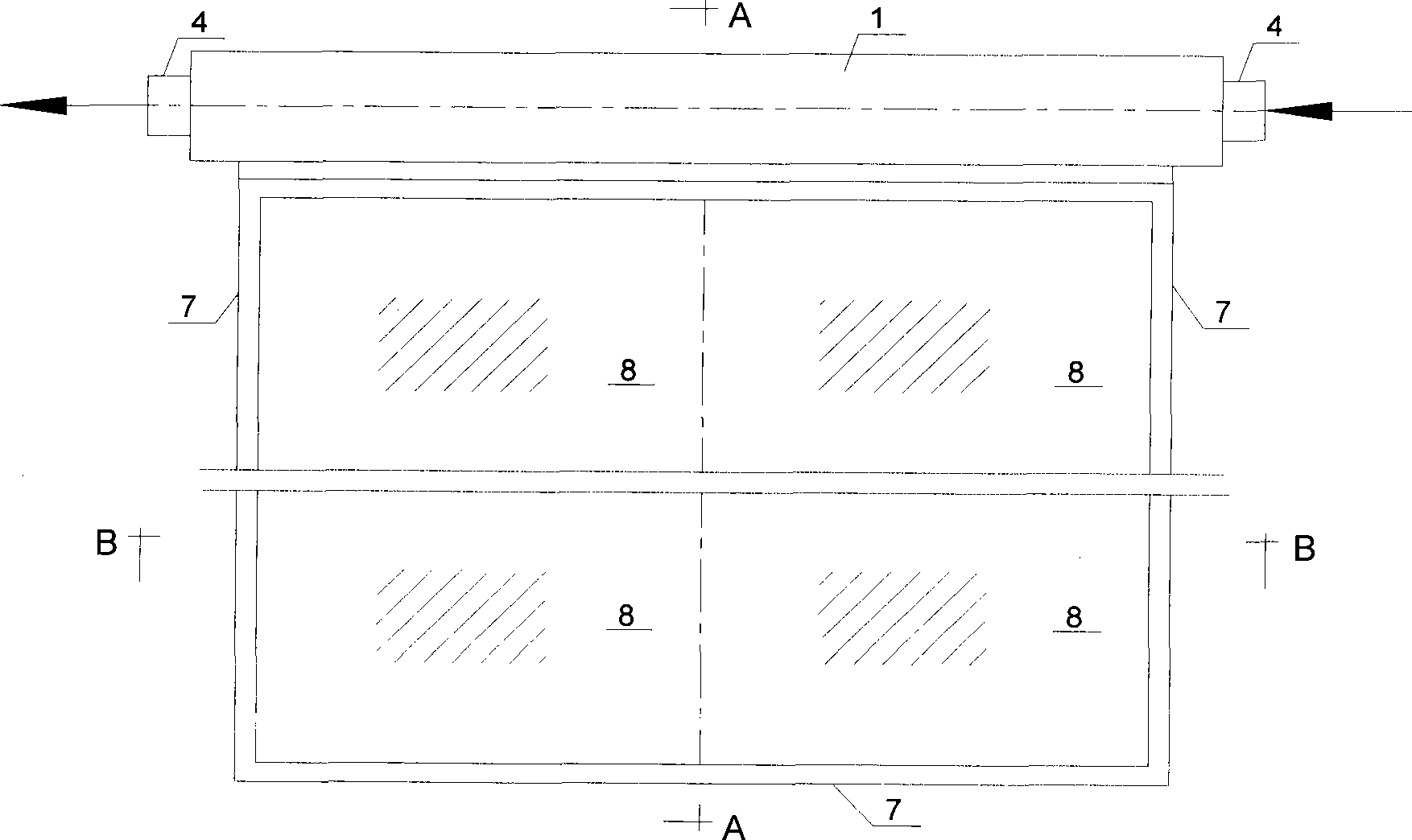

Continuous oscillatory flow membrane crystallization method of erythritol

PendingCN106946656AImprove liquidityGood conditionVibration crystallizationHydroxy compound separation/purificationConcentration polarizationWater vapor

The invention relates to a continuous oscillatory flow membrane crystallization method of erythritol. The technical scheme is as follows: erythritol crystallization mother liquor is preheated and then sent into a hydrophobic hollow tubular membrane module; by arranging a circular baffle plate in the membrane module and producing oscillatory flow, fluid flowing and micromixing state on the surface of the membrane is remarkably improved, and the technical problem that concentration polarization is easy to happen in the membrane crystallization process or crystals on the membrane surface are easy to deposit and solvent out is effectively solved; water in the crystallization mother liquor entering the membrane module penetrates through the membrane in the form of water vapor and then is drawn out from the other side of the membrane by a vacuum pump and condensed into liquid water; the crystallization mother liquor which leaves the membrane module is concentrated to be saturated and then sent into a crystallizer; erythritol crystals undergo fluidization-suspension for growth; the upper layer of crystallization mother liquor in the crystallizer is pumped into the membrane module for internal circulation; and an erythritol crystallization product is led out of the lower part of the crystallizer. The method of the invention also has advantages as follows: continuous production is realized; and erythritol crystallization production cost can be effectively reduced.

Owner:WUHAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com