Air preheater of oscillatory flow type heat pipe, and energy saving drying technique of using the preheater

A technology of oscillating flow heat pipe and air preheater, used in indirect heat exchangers, drying machines, dryers, etc., can solve the problems of large size of waste heat recovery equipment, poor recovery effect, heat waste, etc., to reduce heat The effect of pollution, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

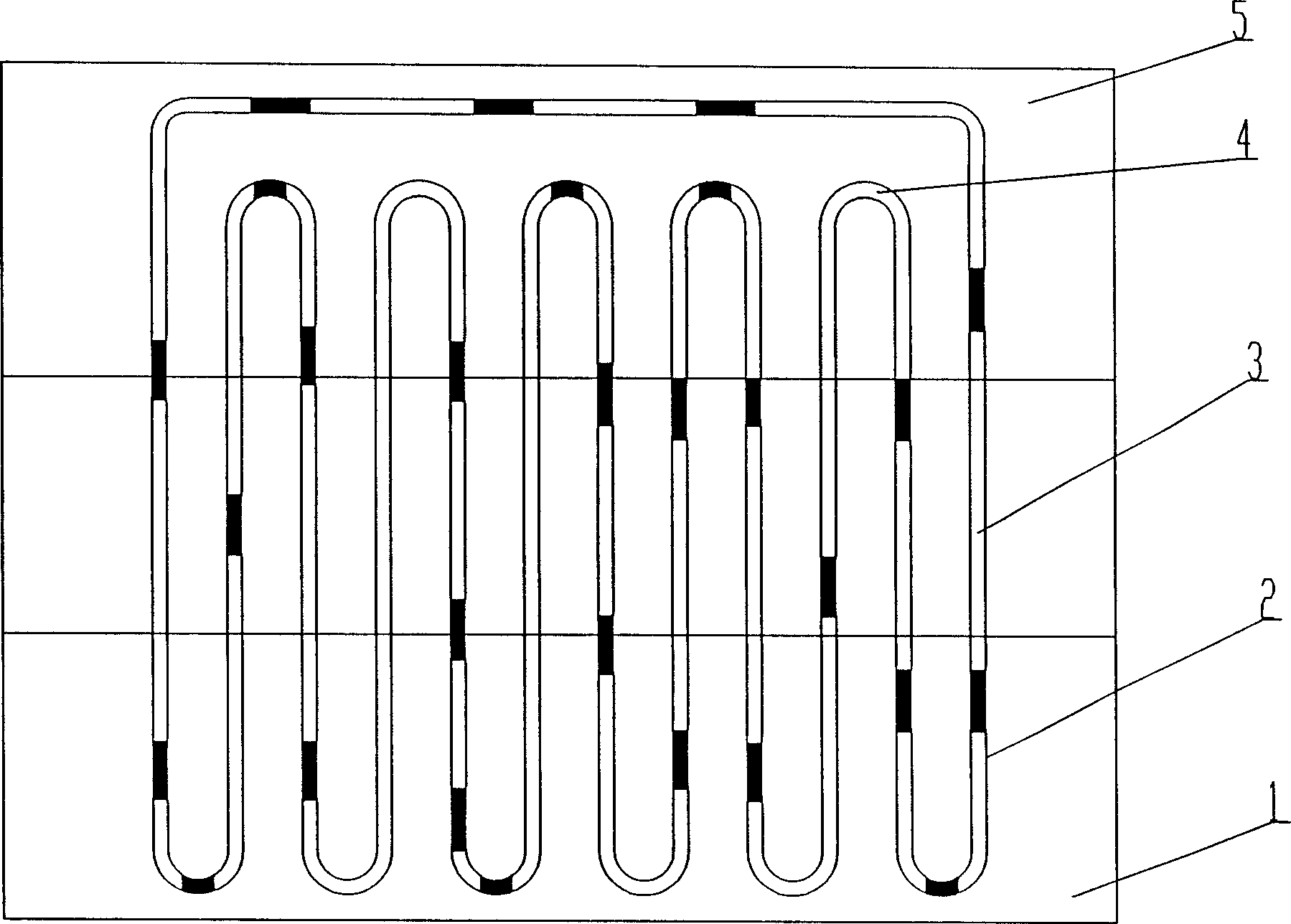

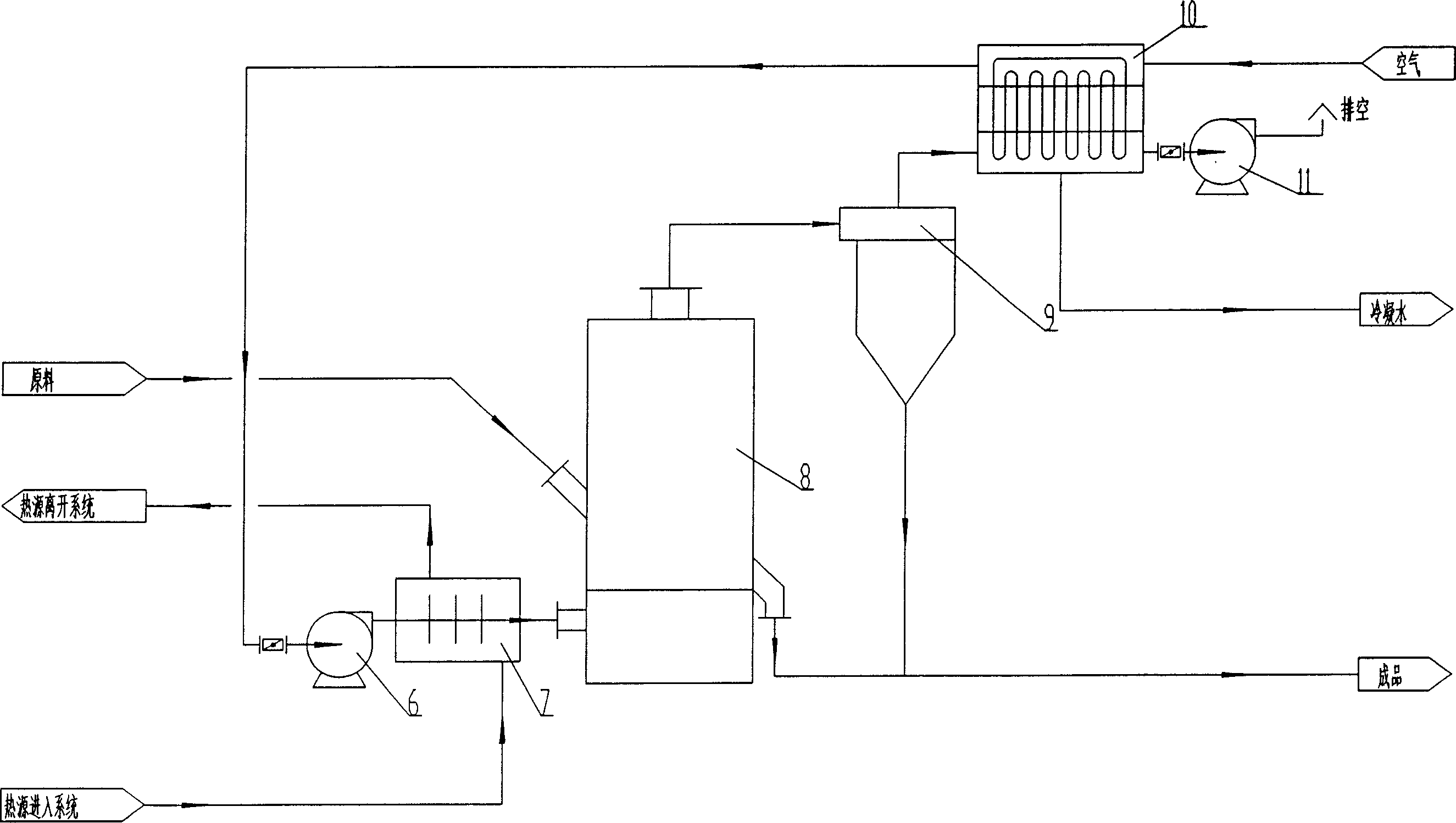

[0029] figure 1 Among them, the oscillating flow heat pipe heat exchanger 10 is a box structure, in which the oscillating flow heat pipe is made of at least one row of Φ1-Φ5mm copper pipes or pipes made of other materials, bent into a serpentine closed loop, and placed vertically. Two adjacent rows of heat pipes are arranged in a staggered manner, making reasonable use of space and increasing the heat exchange area. The vacuum degree in the tube is 1×10 -1 ~1×10 -2 Pa, the working fluid packaged in the tube is pure distilled water or absolute ethanol or acetone or Freon, and the filling rate is 40% to 70%. The heating end 1 of the oscillating flow heat pipe is arranged in the exhaust gas header 2, and the exhaust gas header 2 is located at the bottom of the oscillating flow heat pipe heat exchanger 10; the cooling end 4 of the oscillating flow heat pipe is arranged in the air header 5, and the air header 5 is located in the oscillating flow The top of the heat pipe heat exc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com