Patents

Literature

70 results about "Oscillating flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

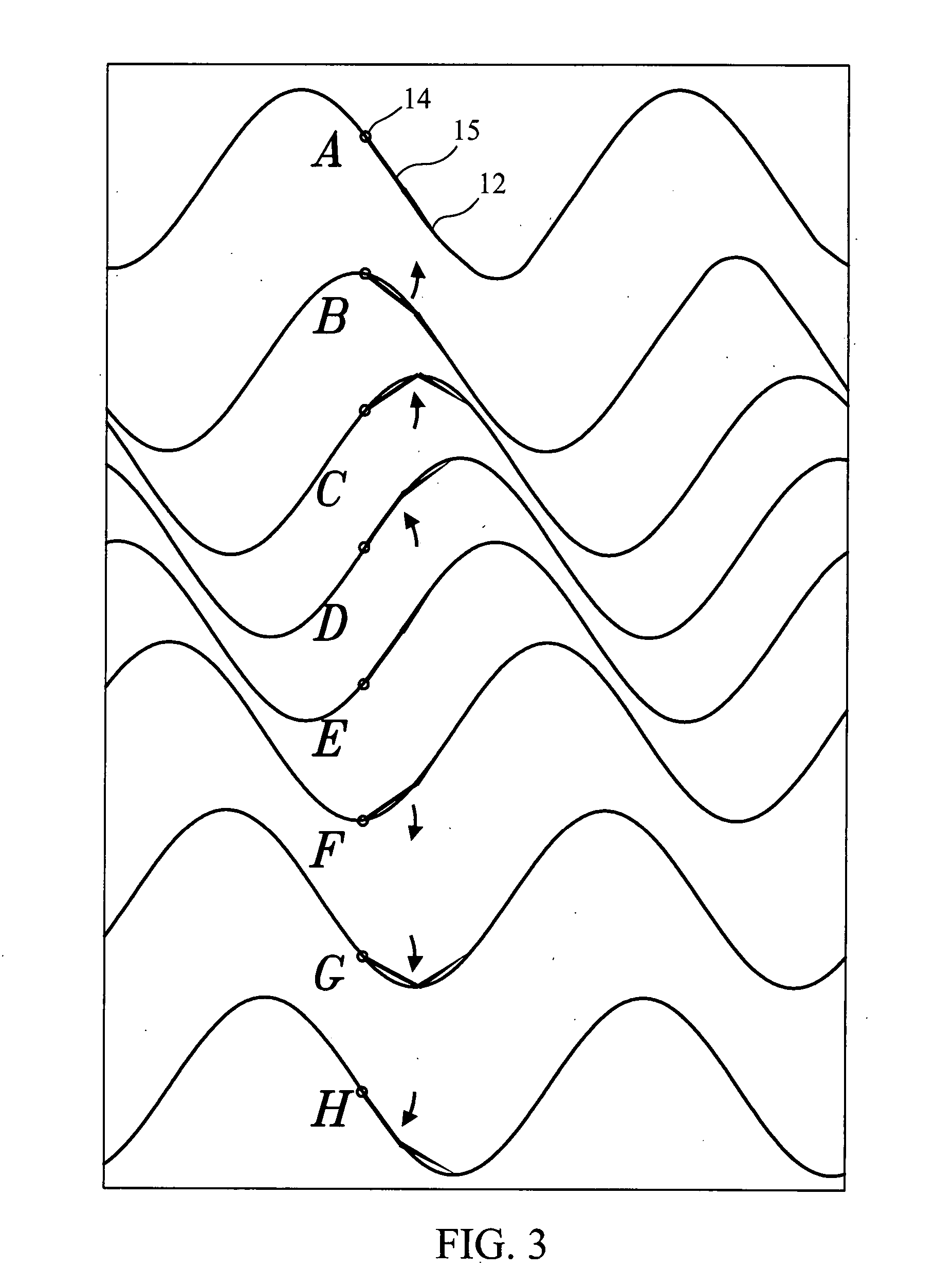

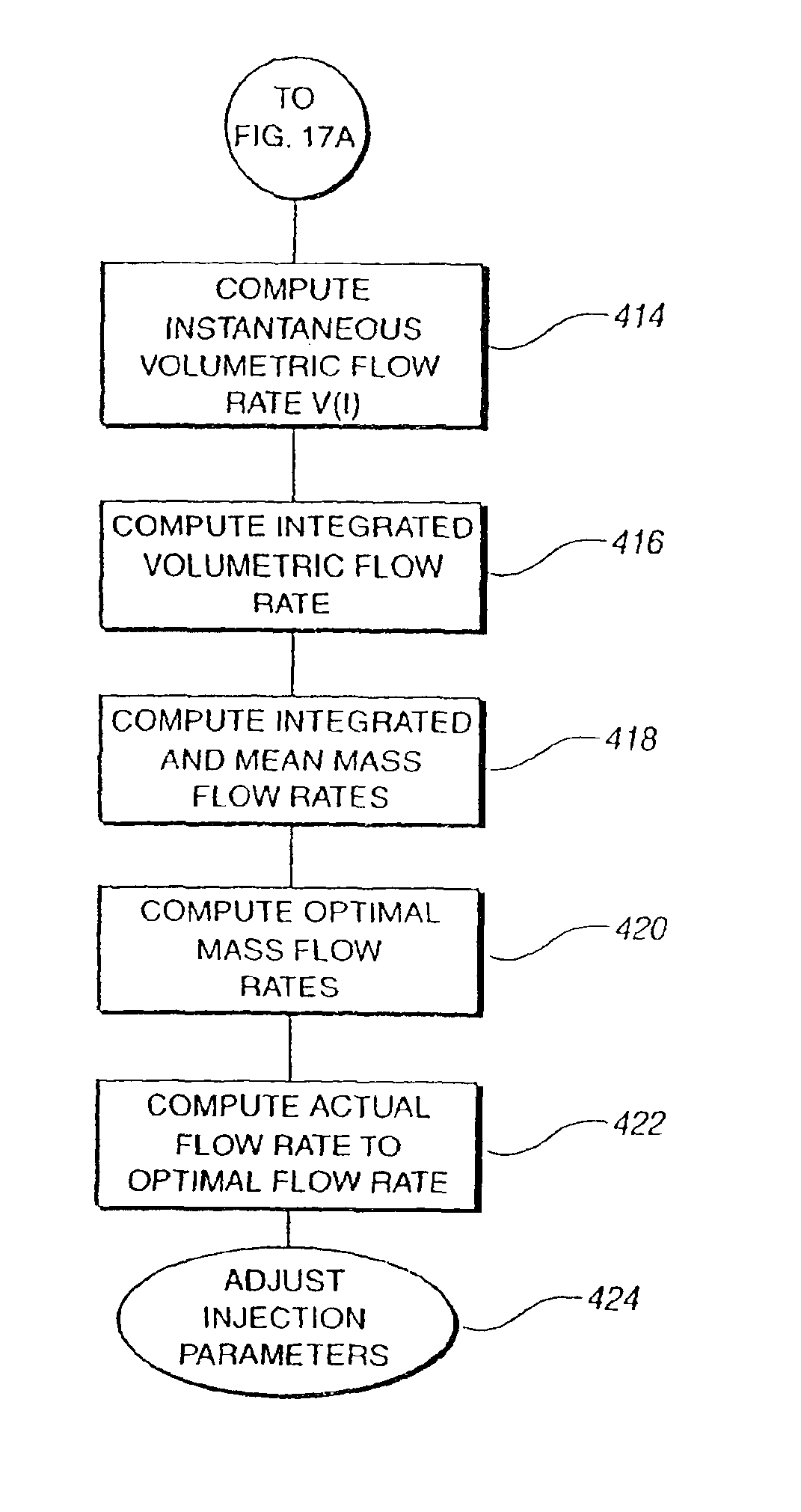

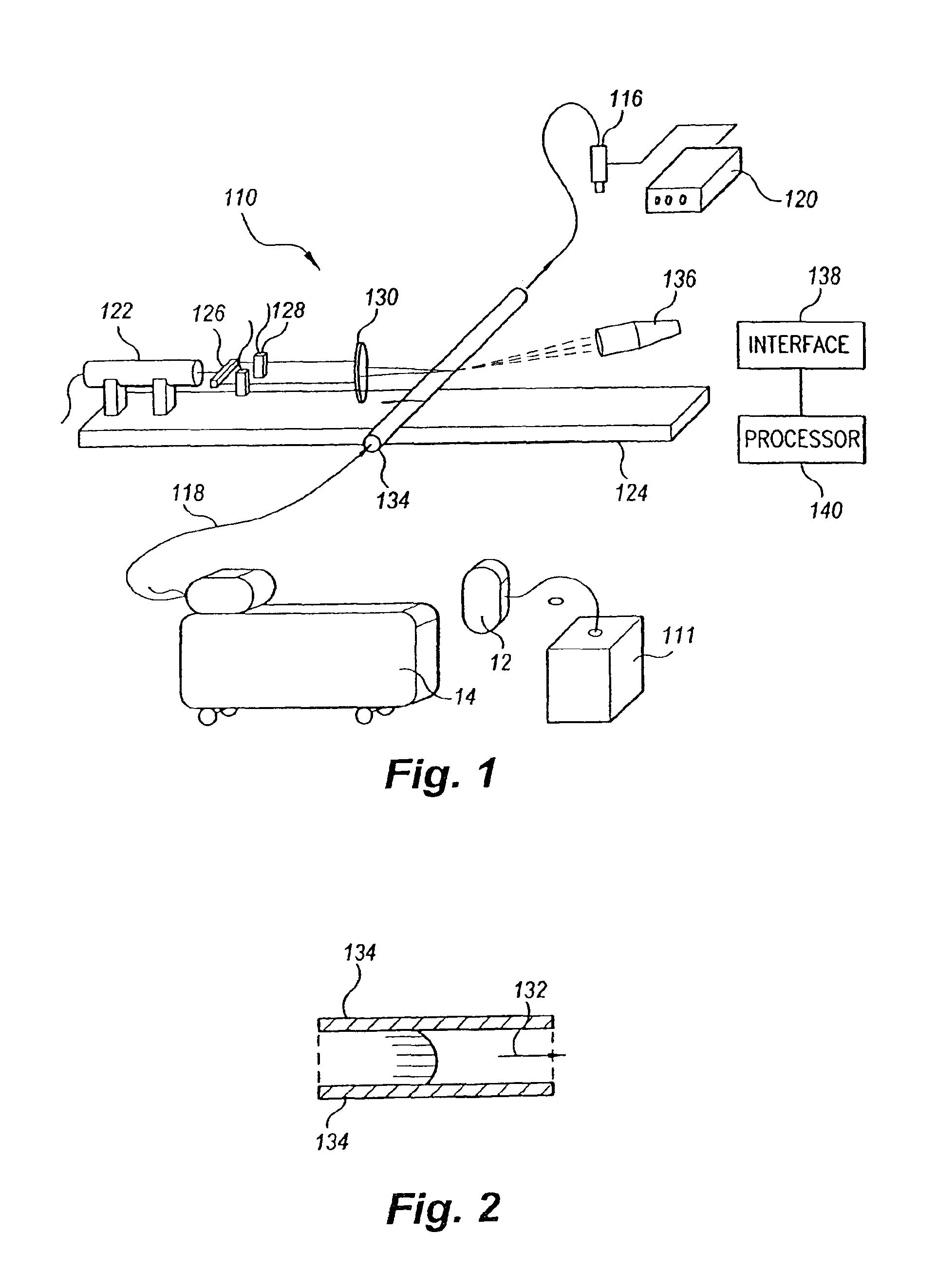

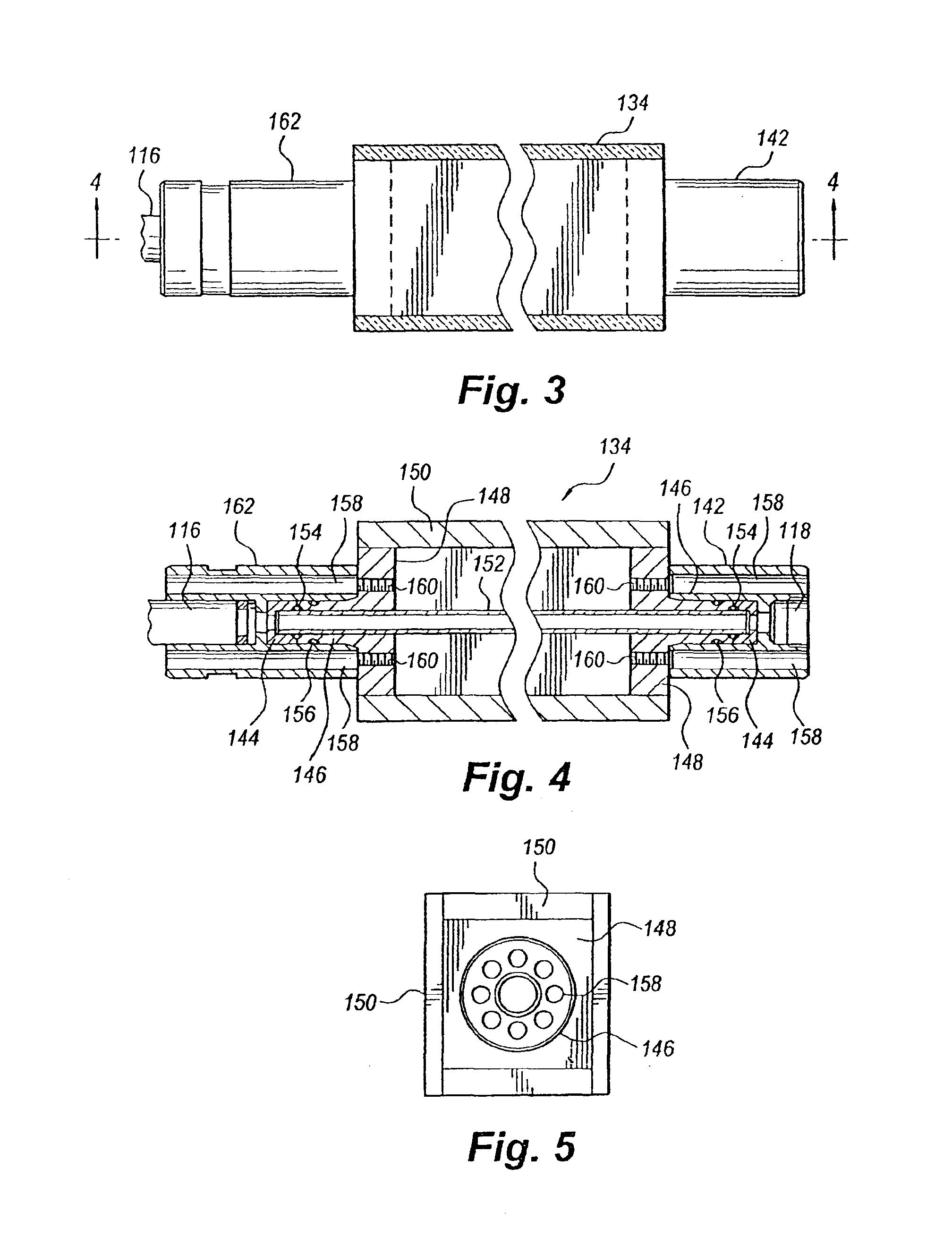

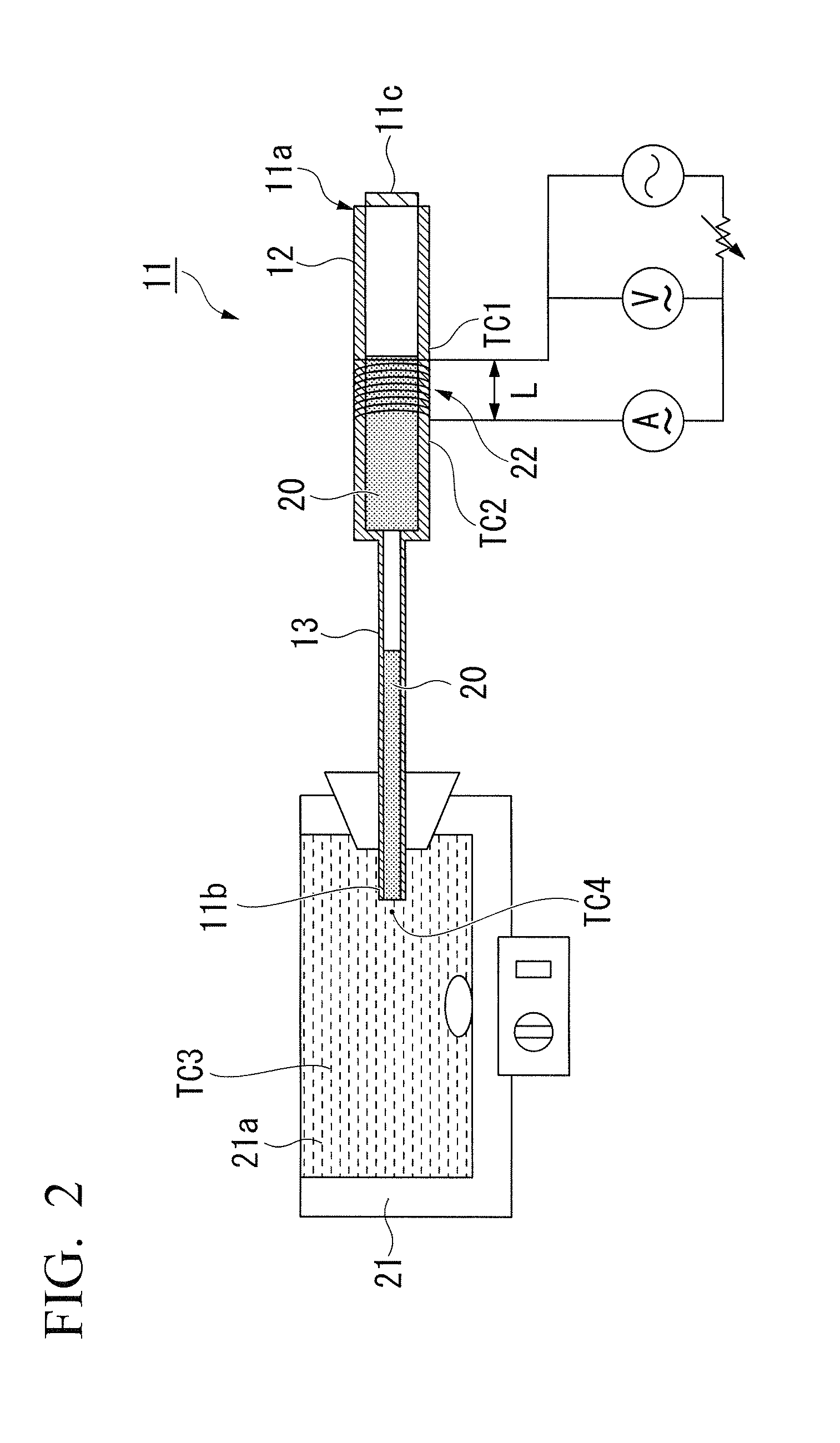

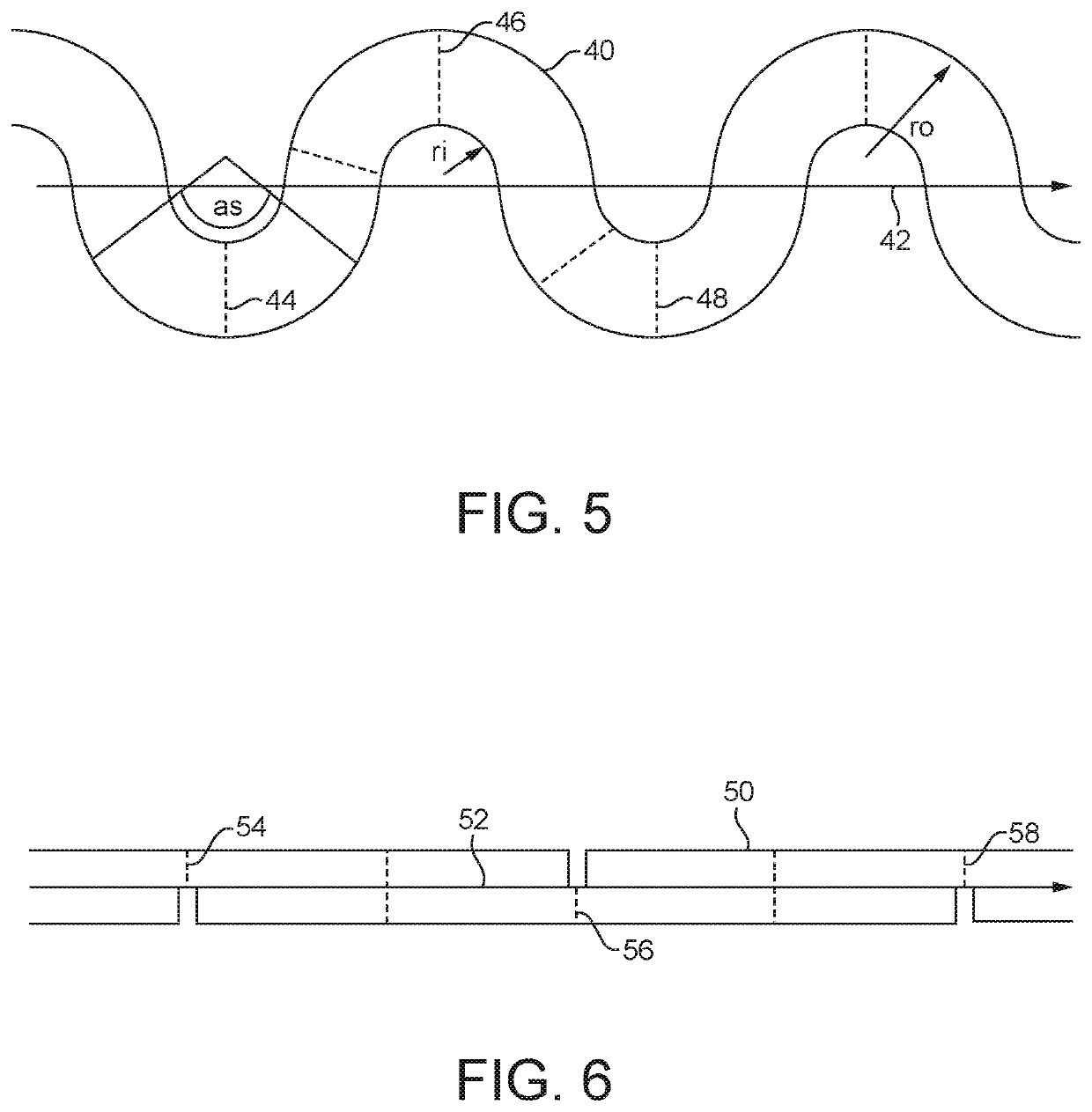

Flow meter

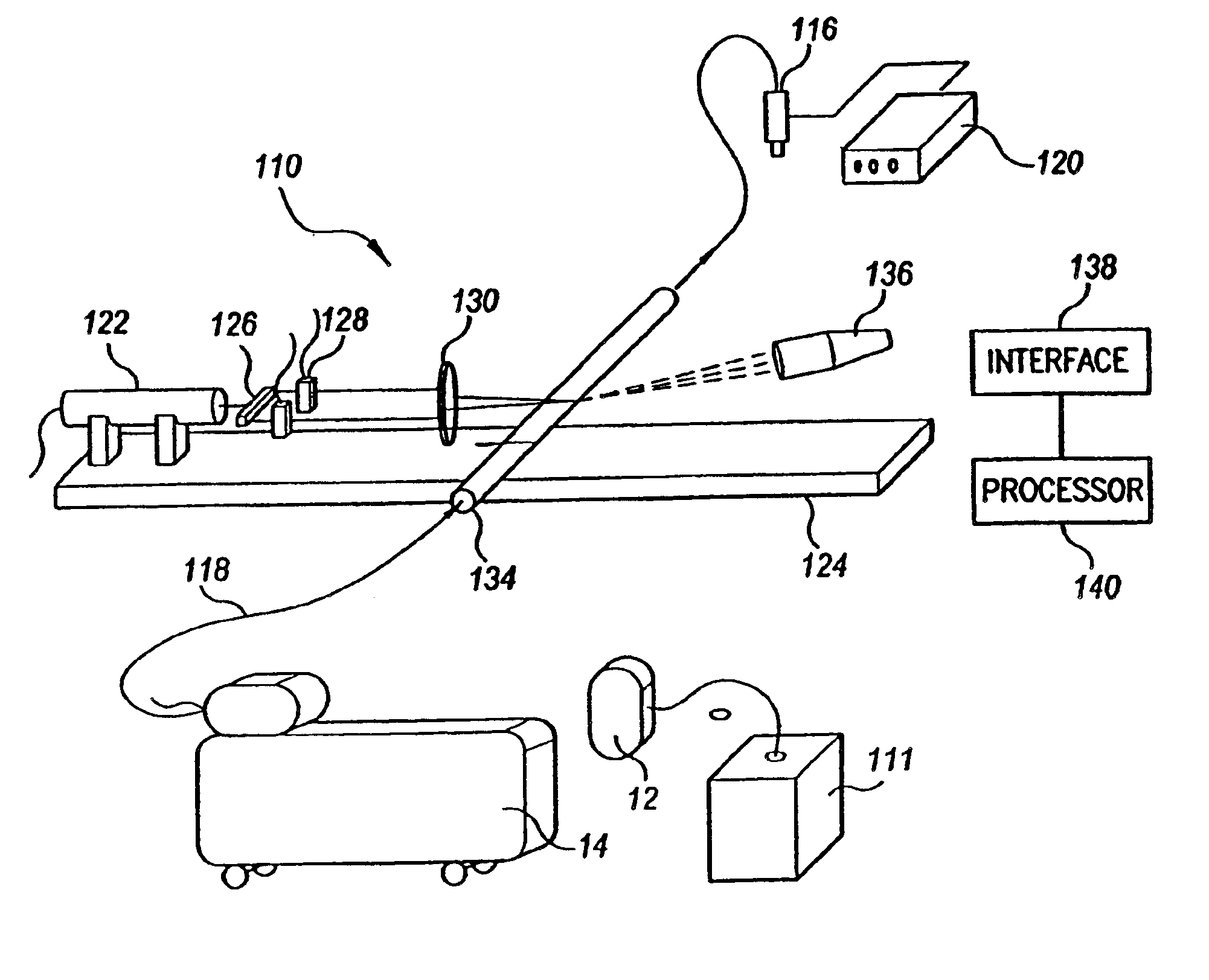

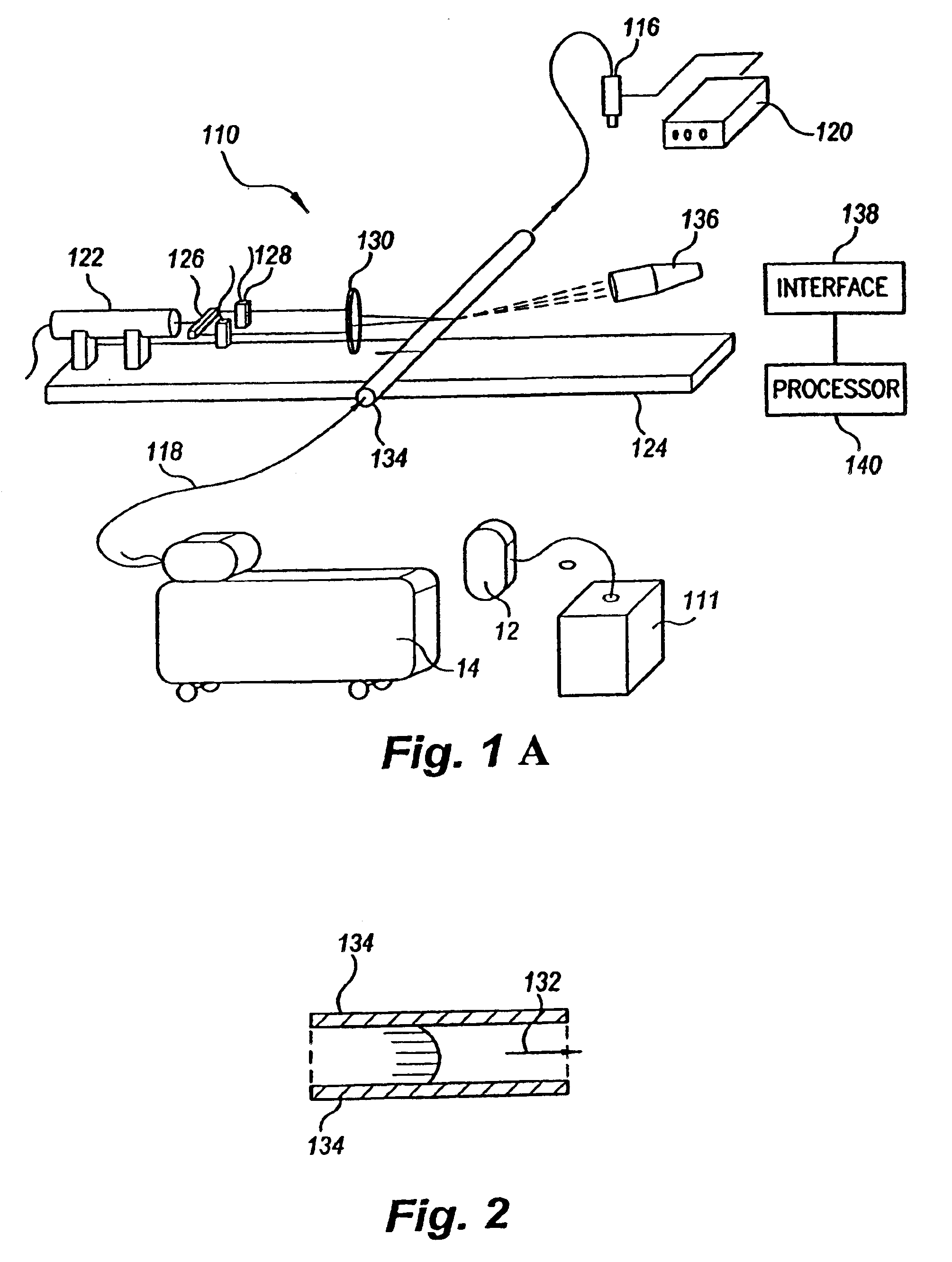

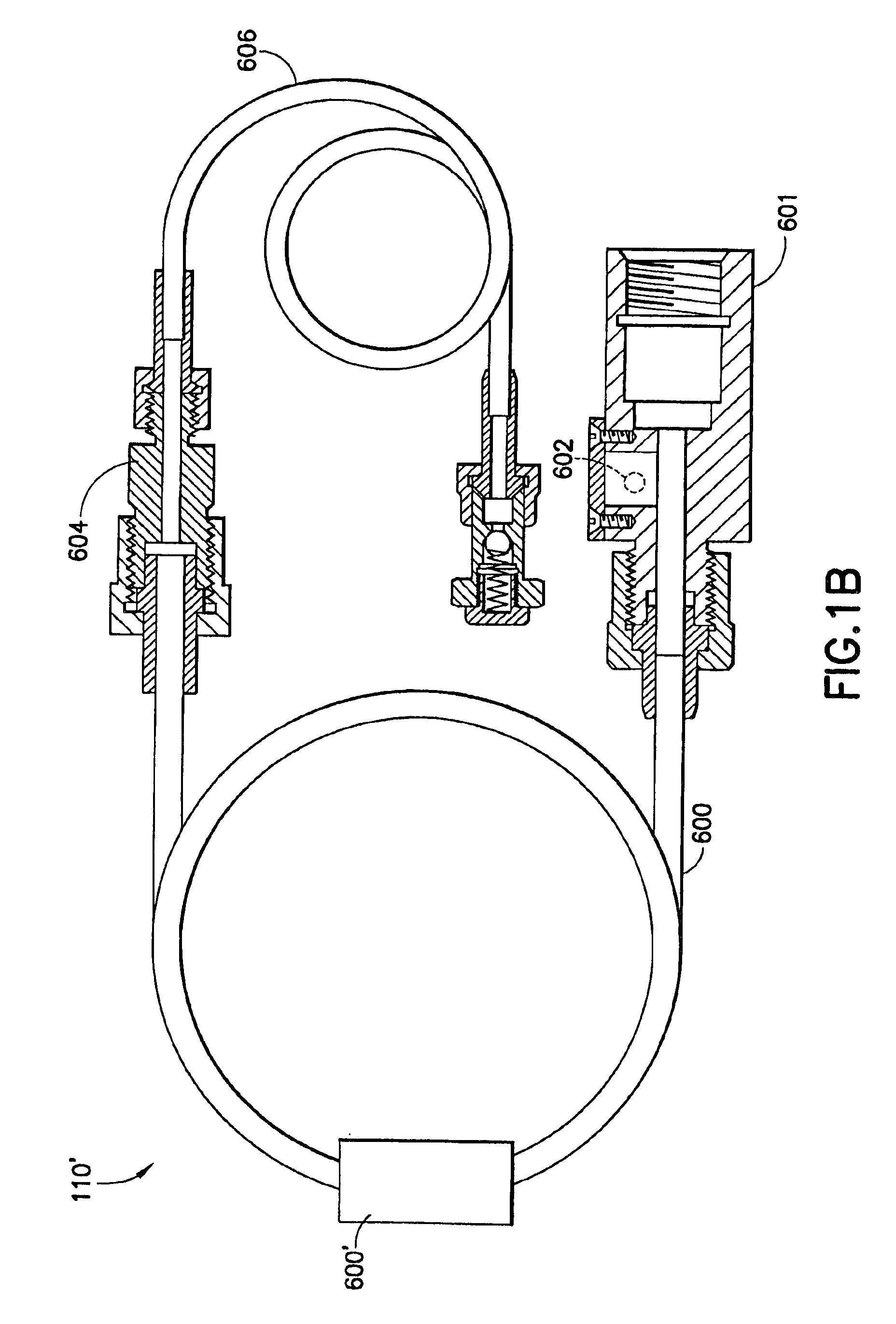

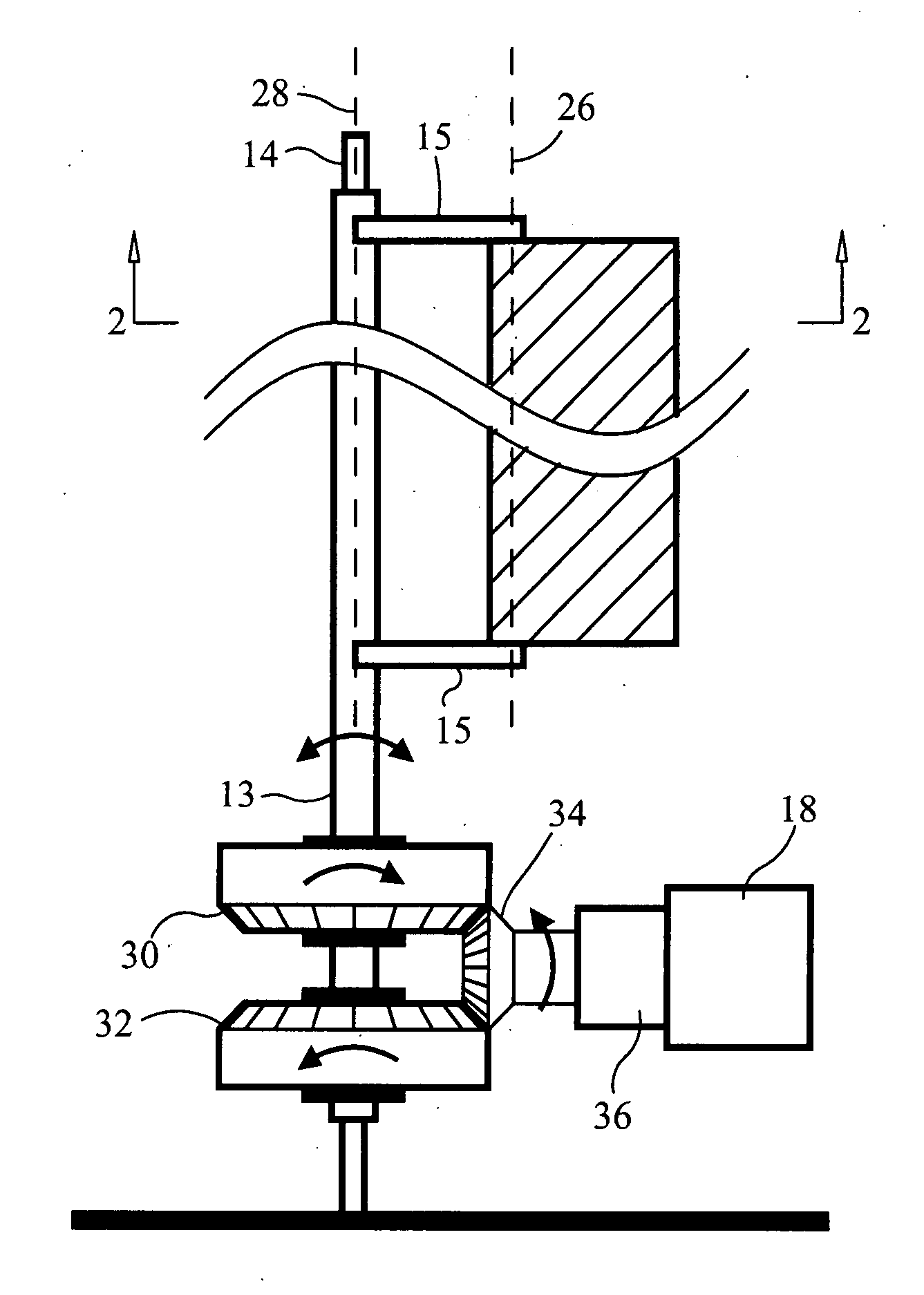

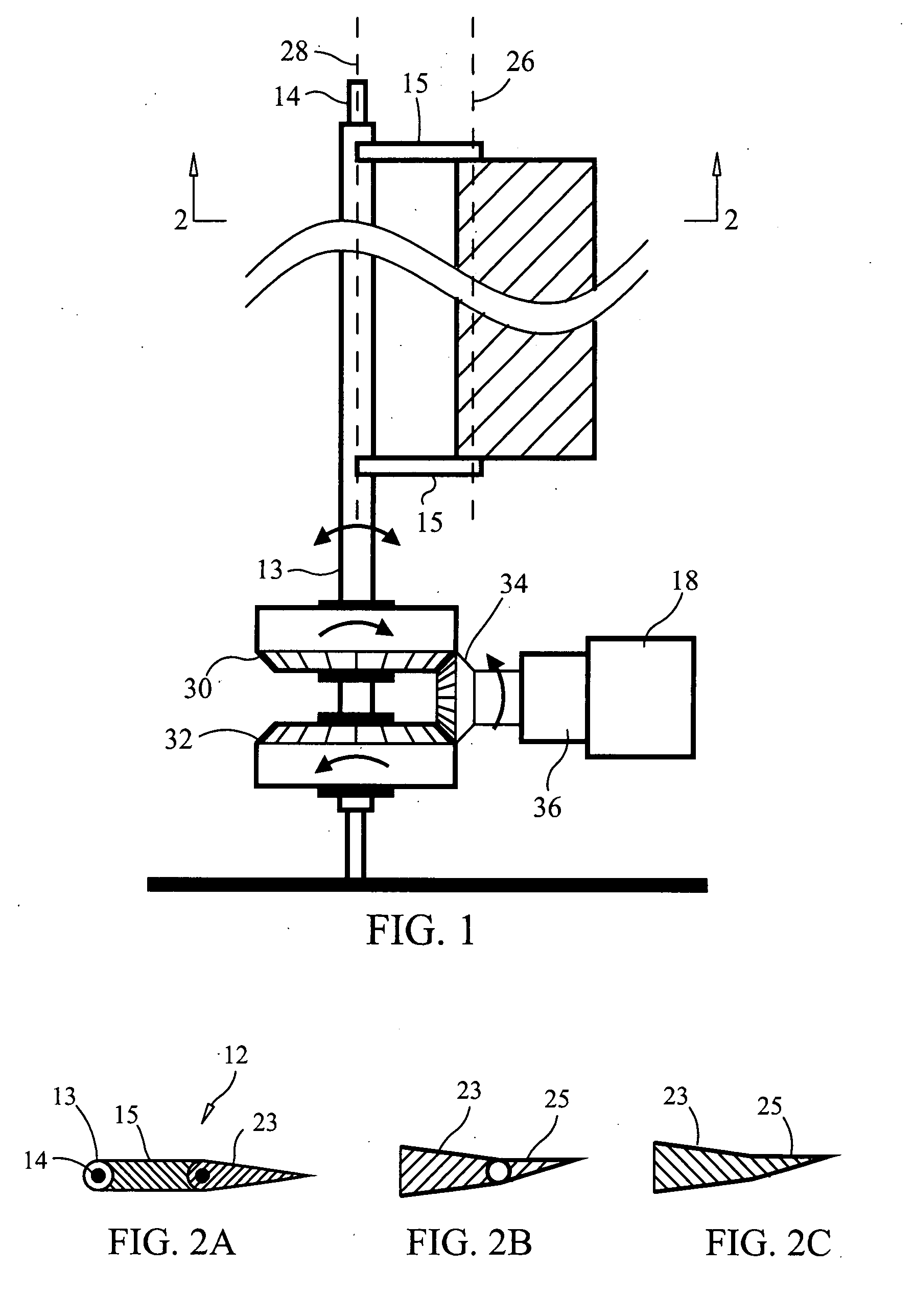

Various embodiments of the present invention provide a flow meter device having a laser Doppler anemometer (LDA) which measures the instantaneous center line velocity of fluid flow in a pipe. The flow meter may process the instantaneous velocity so obtained to compute the volumetric flow rate, mass rate, and / or other flow characteristics (e.g., as instantaneous quantities and / or integrated over a time interval) The flow meter may use an electronic processing method. The electronic processing method may provide essentially an exact solution to the Navier-Stokes equations for any periodically oscillating flow.

Owner:COMBUSTION DYNAMICS

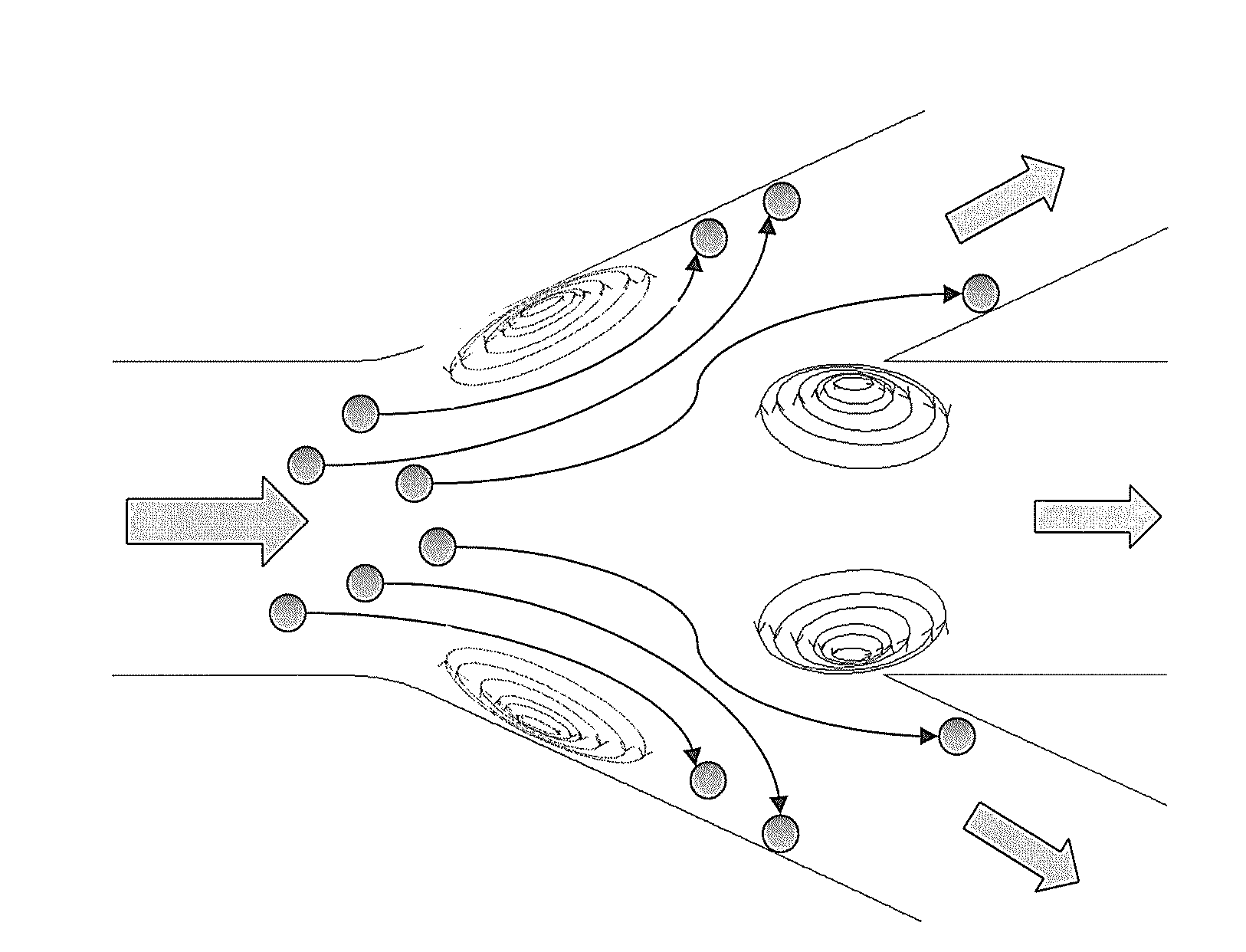

Method and system for flow control with fluidic oscillators

A system for control of a fluid flow. The system includes an array of fluidic oscillators. Each fluidic oscillator carries an oscillating flow of the fluid and includes a throat, an input port connected to the throat, two control ports connected to the throat and two output ports extending from the throat. A feedback line is connected to each of the two output ports and each of the two control ports. The system further includes a plenum connected to the input ports of the fluidic oscillators to supply the fluid to the fluidic oscillators and a feedback chamber disposed along each feedback line of each fluidic oscillator to provide a feedback path for the control fluid to cause oscillatory fluid motion between the first output port and the second output port, the frequency of which may be modulated by adjusting the volume of the feedback chamber.

Owner:GENERAL ELECTRIC CO

Oscillating fluid power generator

ActiveUS20070297903A1Reduce purchasing costsIncrease technical and economic viabilityEngine fuctionsWorking fluid for enginesOscillating flowEngineering

A system and method for harvesting the kinetic energy of a fluid flow for power generation with a vertically oriented, aerodynamic wing structure comprising one or more airfoil elements pivotably attached to a mast. When activated by the moving fluid stream, the wing structure oscillates back and forth, generating lift first in one direction then in the opposite direction. This oscillating movement is converted to unidirectional rotational movement in order to provide motive power to an electricity generator. Unlike other oscillating devices, this device is designed to harvest the maximum aerodynamic lift forces available for a given oscillation cycle. Because the system is not subjected to the same intense forces and stresses as turbine systems, it can be constructed less expensively, reducing the cost of electricity generation. The system can be grouped in more compact clusters, be less evident in the landscape, and present reduced risk to avian species.

Owner:MORRIS DAVID C

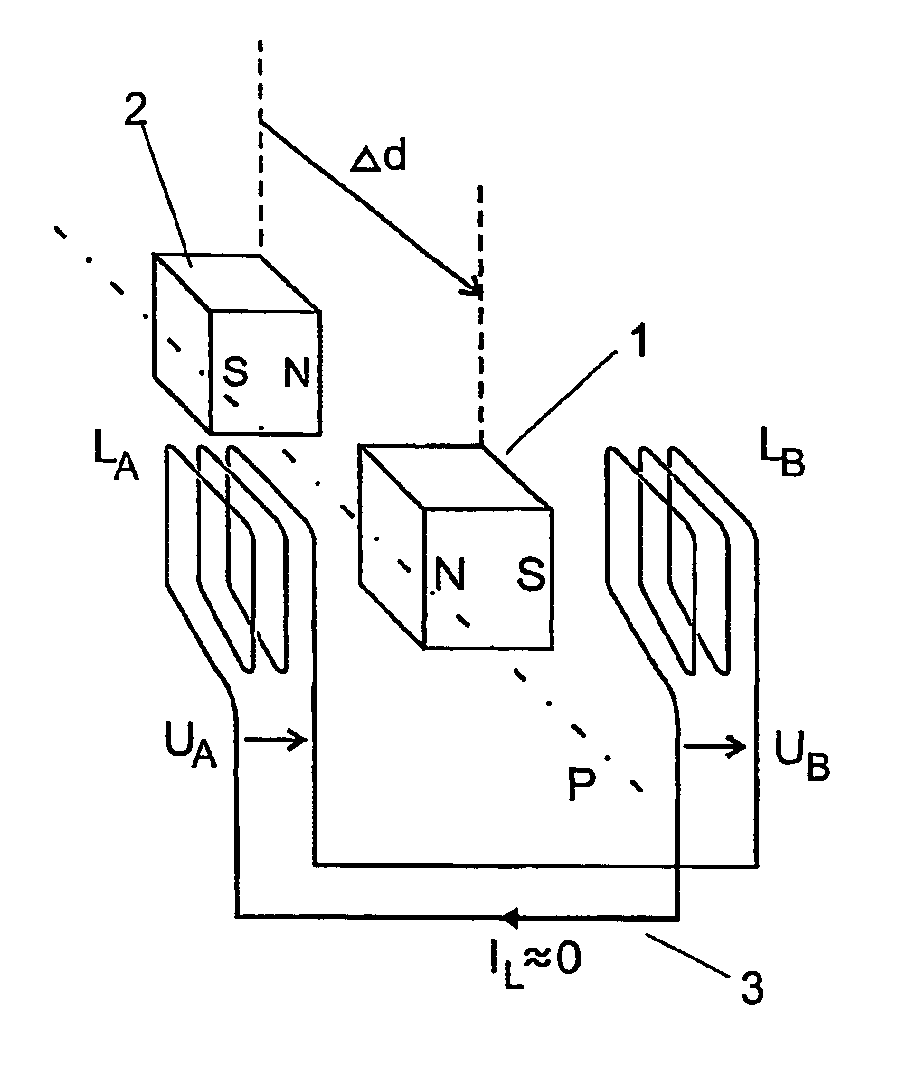

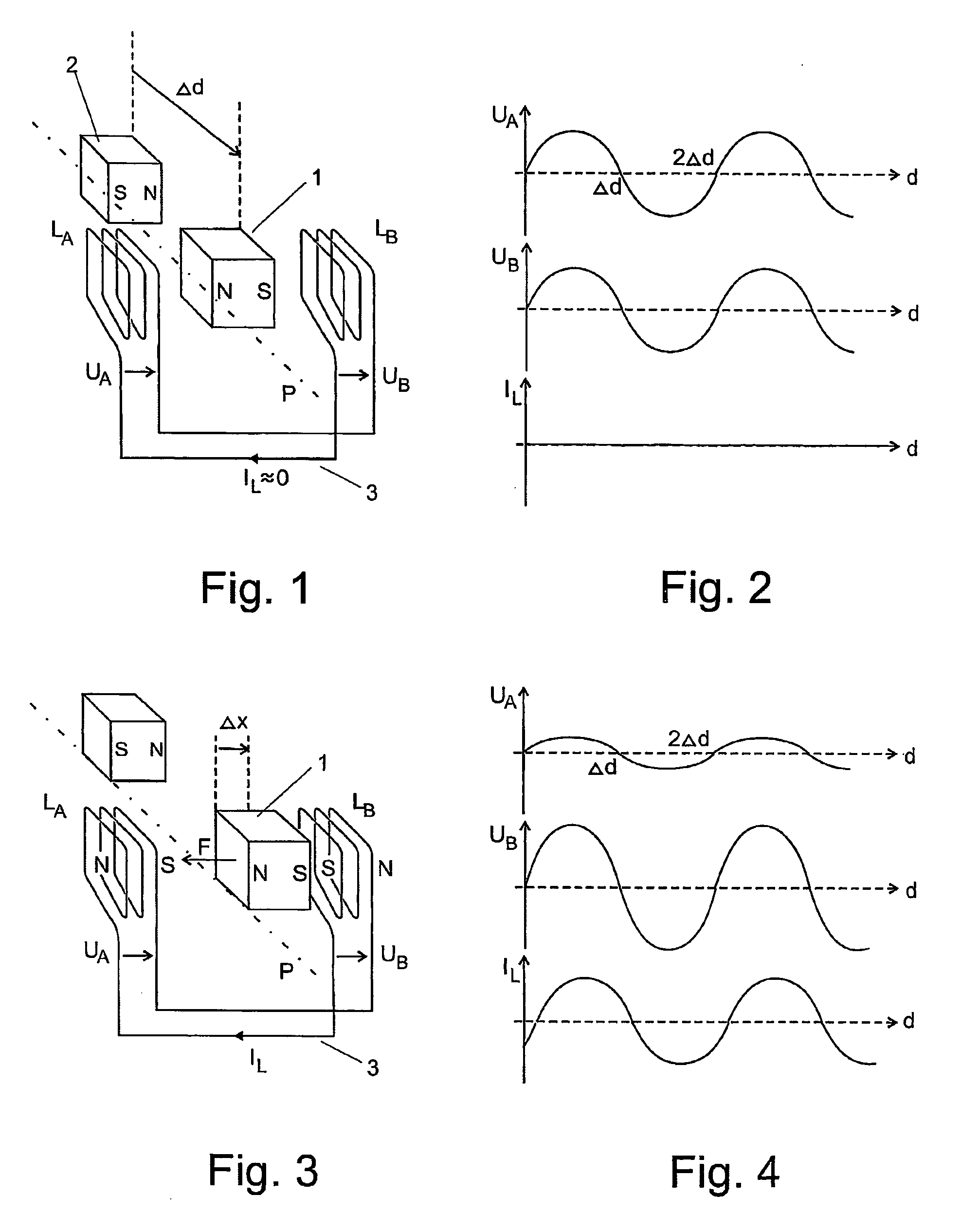

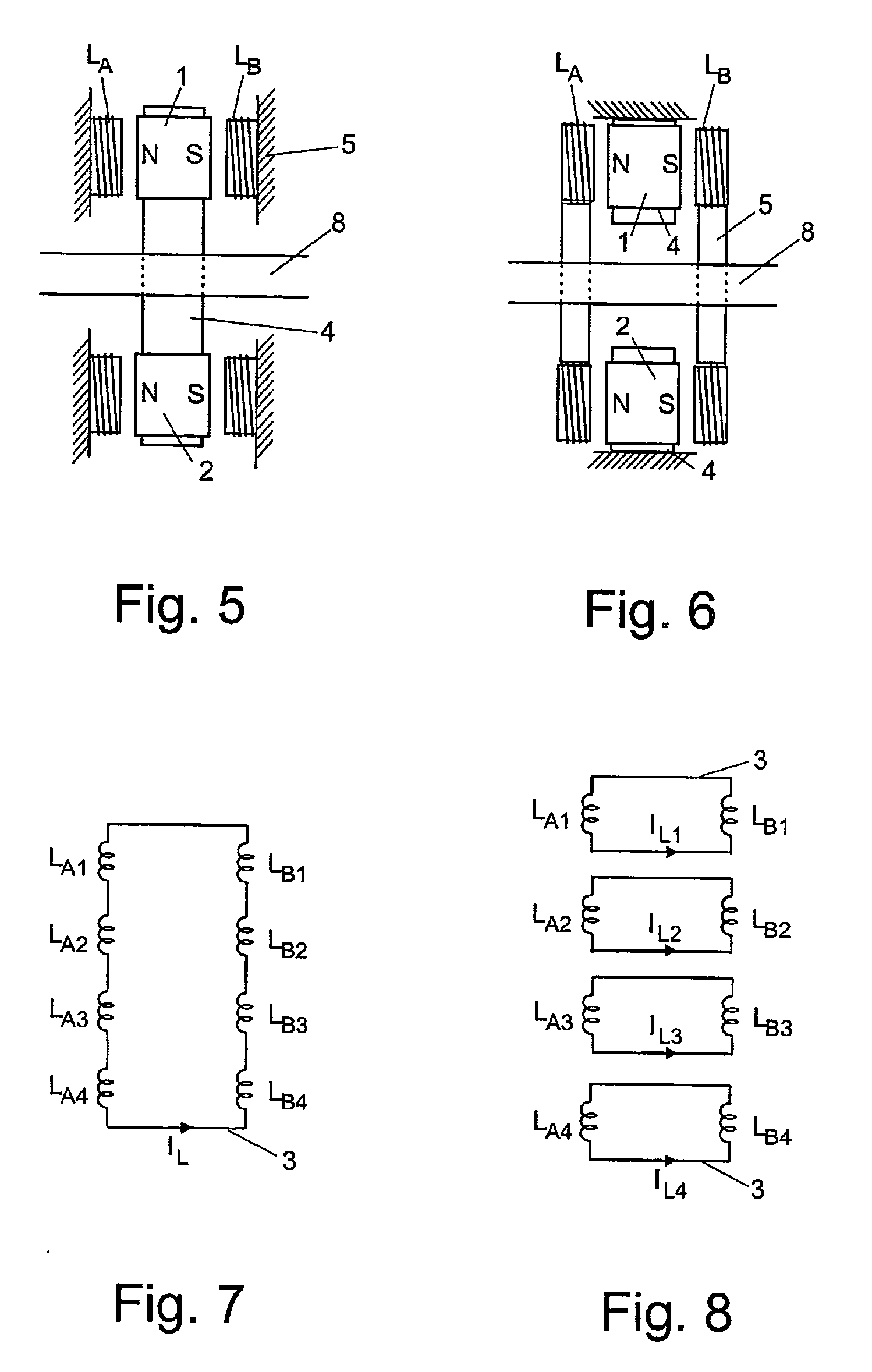

Passive dynamically stabilizing magnetic bearing and drive unit

InactiveUS20060279149A1Easy to produceMechanical energy handlingBearingsMagnetic bearingAlternating polarization

The passive axial magnet bearing comprises permanent magnets (1, 2) arranged with alternating polarization on a rotor (1, 2, 8). These cause an oscillating flow through the coils (L) on both sides of the rotor (1, 2, 8). All coils (L) are series connected in an electric circuit (3). As long as the rotor (1, 2, 8) rotates in the middle position, no current flows in the electric circuit (3), since the voltages across the coils (L) cancel each other due to the symmetry. However, when the rotor (1, 2, 8) deviates from the center position, a current flows and the coils (L) exert electromagnetically a restoring force on the permanent magnets (1, 2). The bearing can also be equipped with an integrated drive. For this purpose, it is extended by drive coils. The production of the bearing is simple and inexpensive.

Owner:SILPHENIX

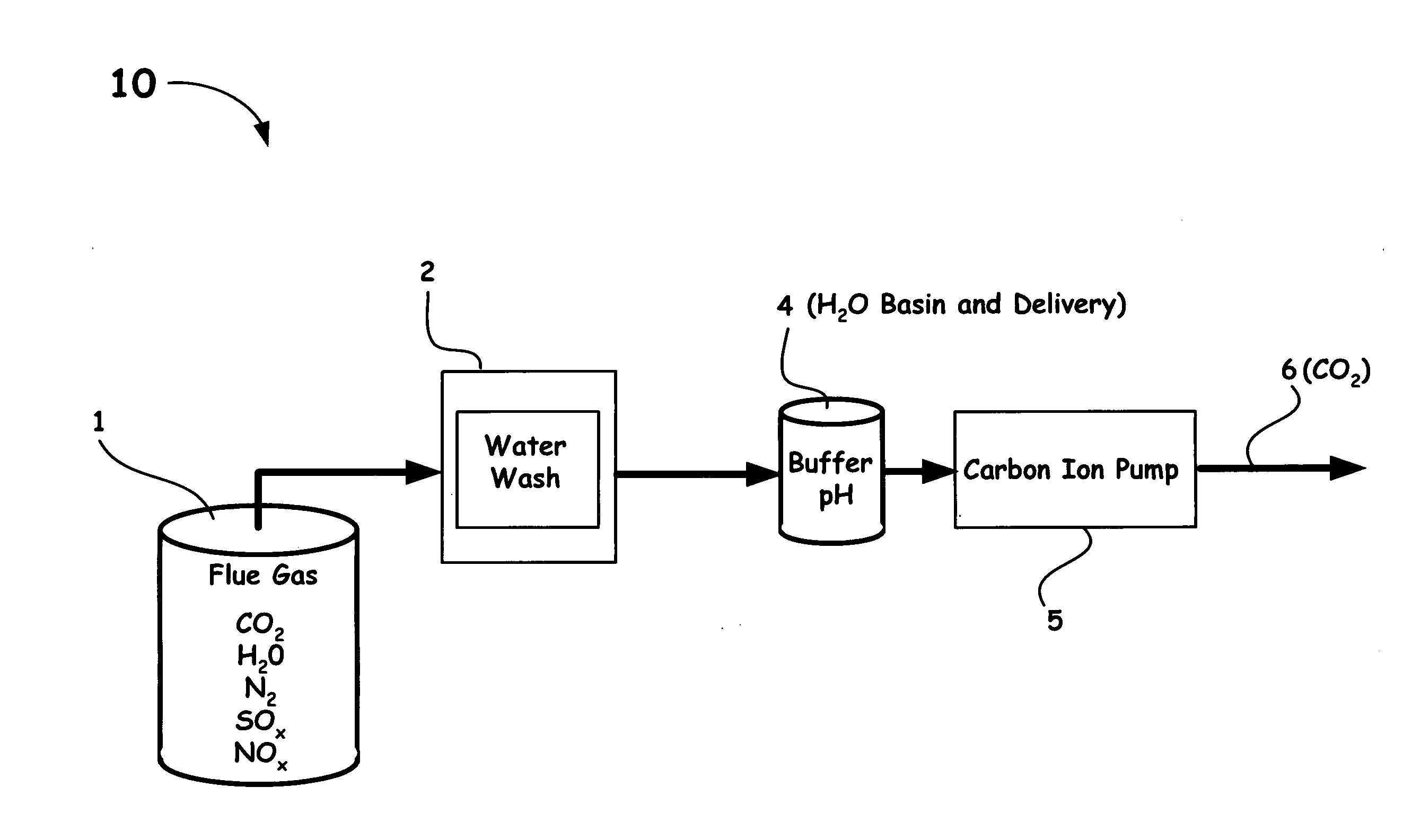

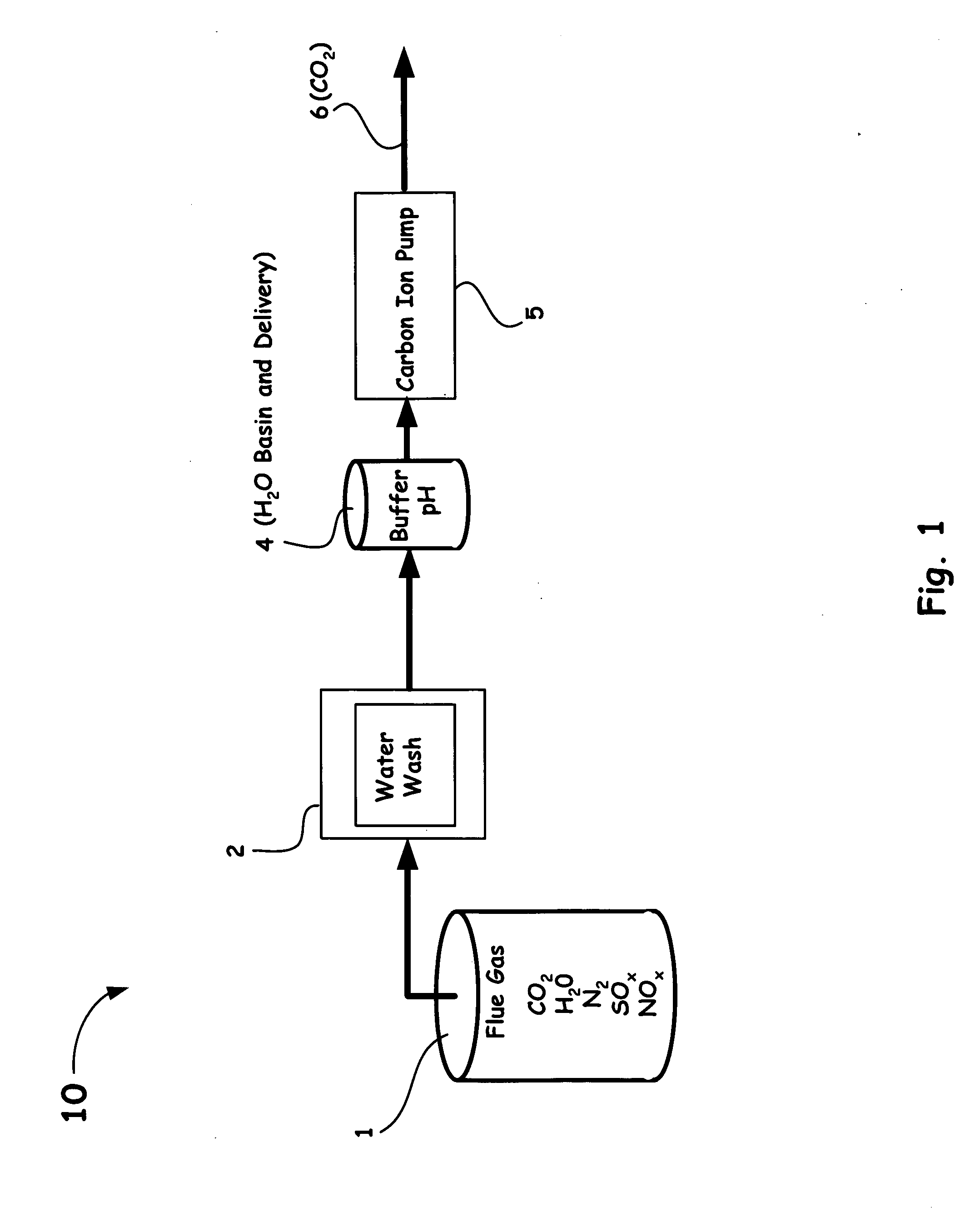

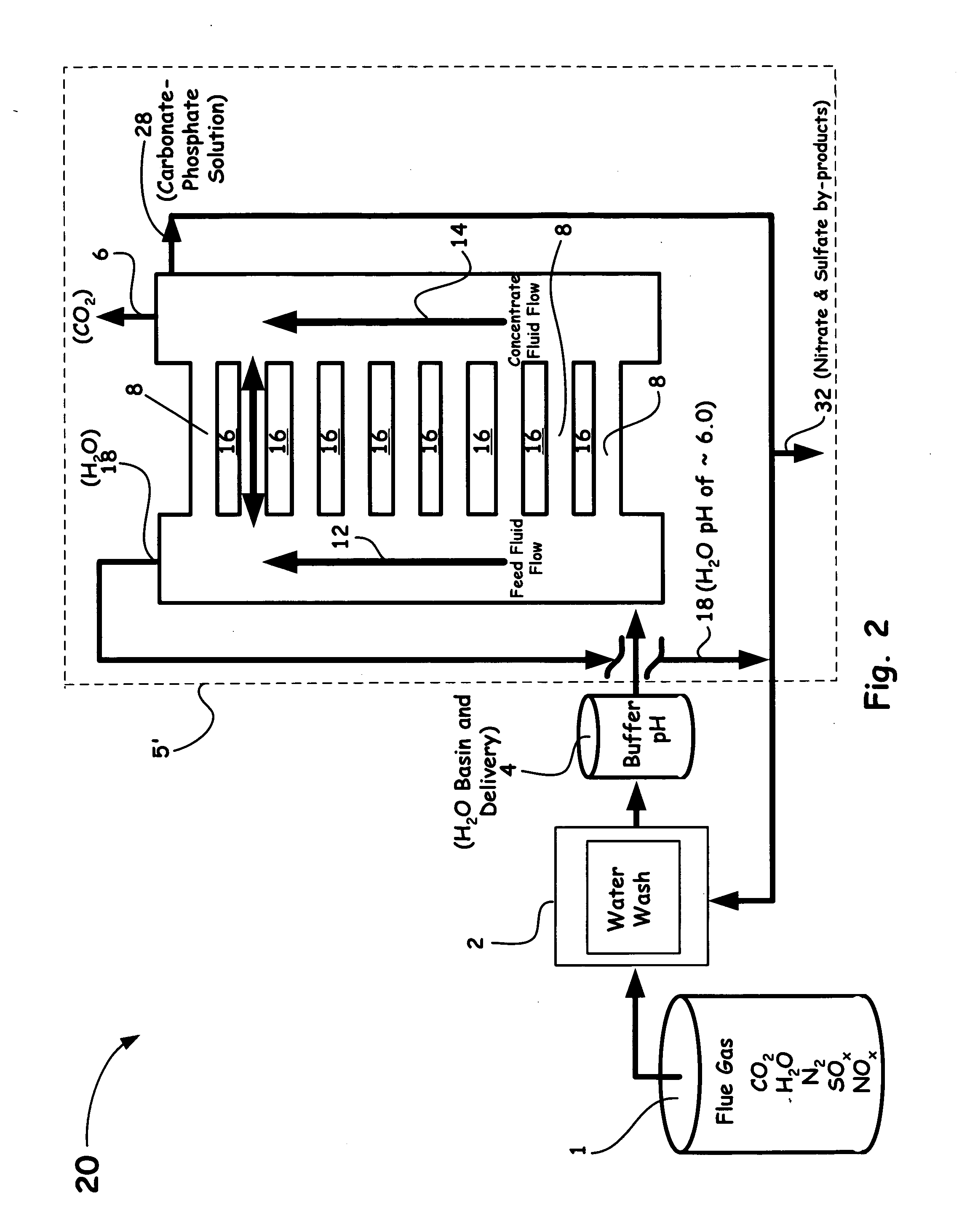

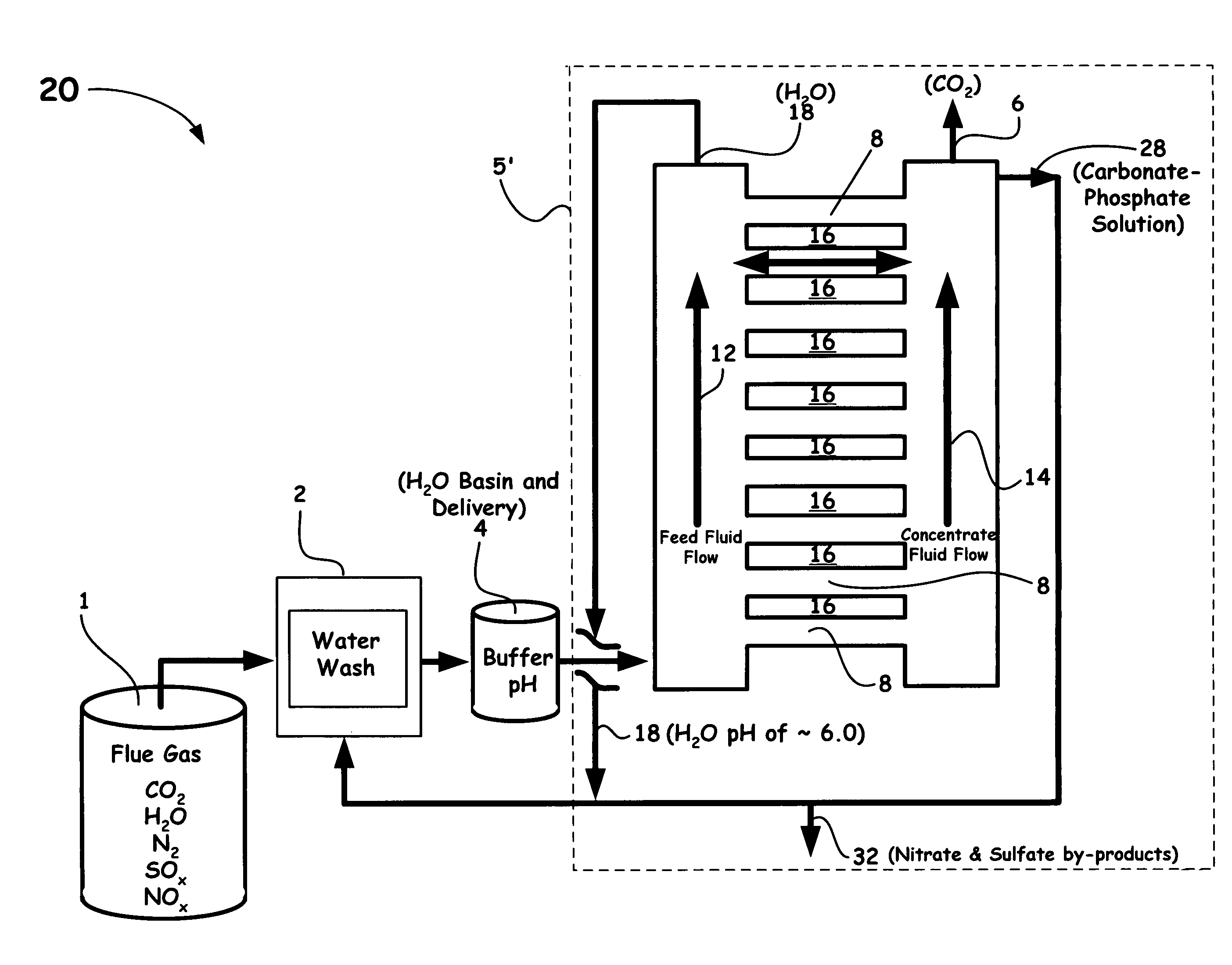

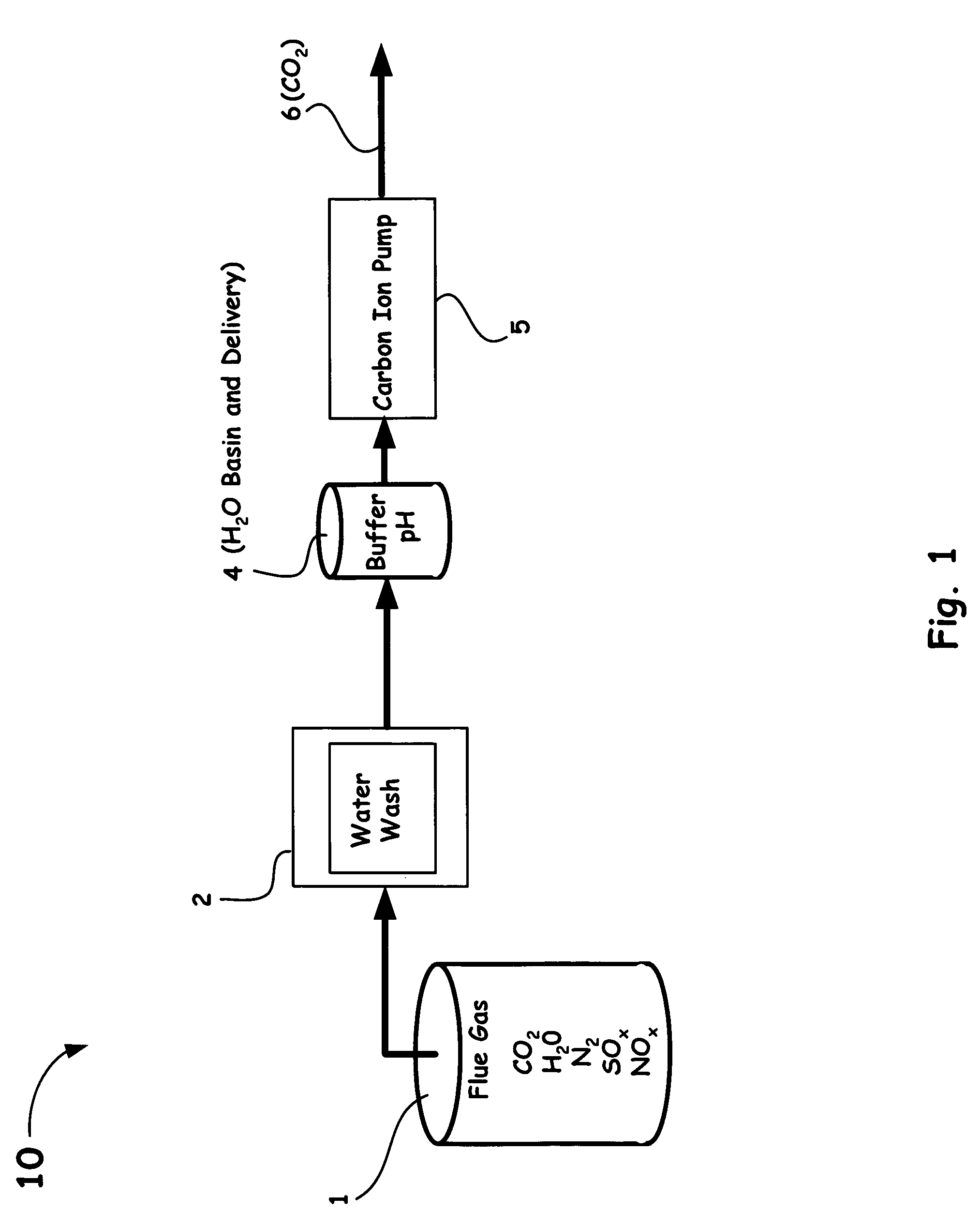

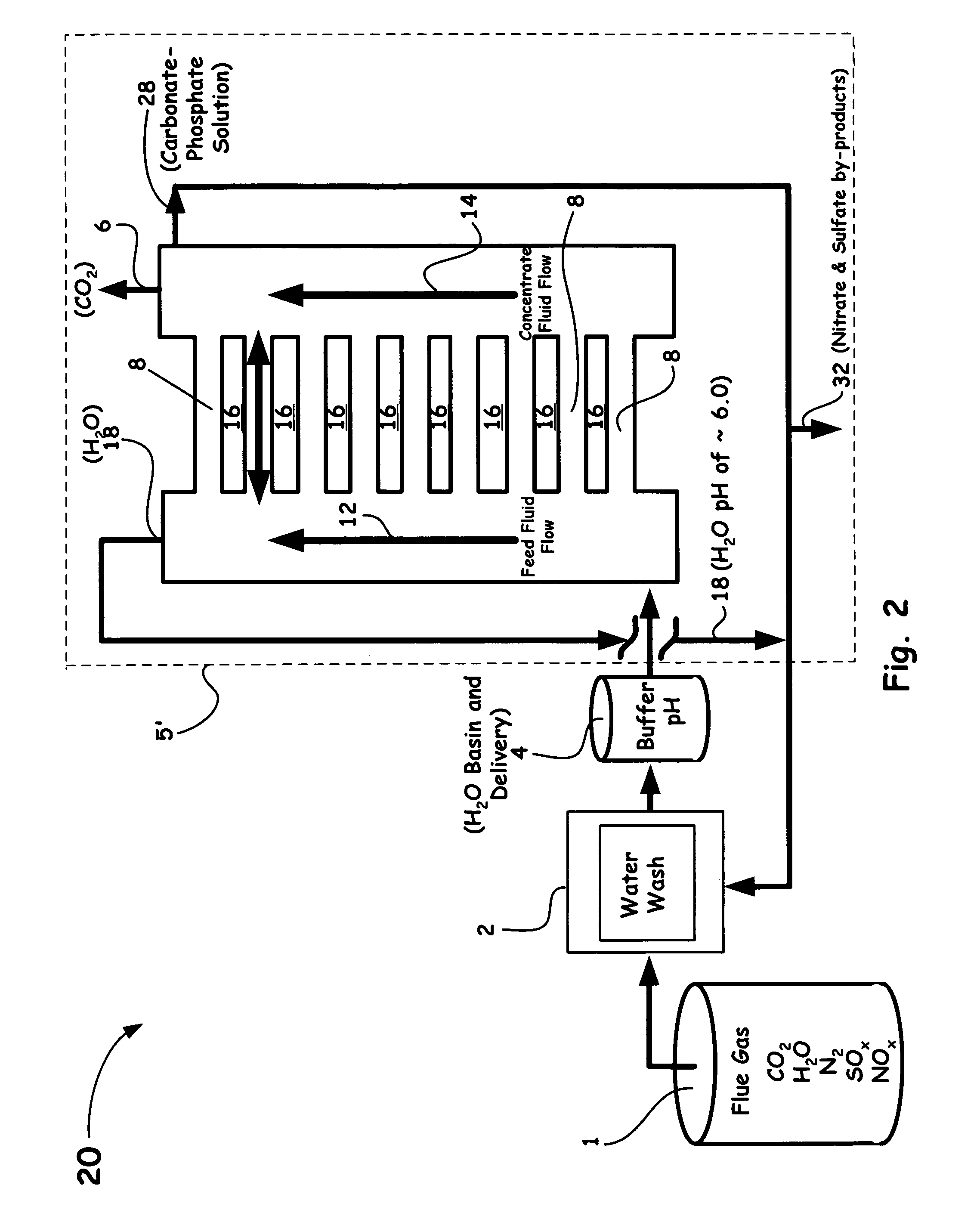

Carbon ion pump for removal of carbon dioxide from combustion gas and other gas mixtures

InactiveUS20070169625A1Improve concentrationIncrease vapor pressureLiquid separation by electricityCarbon compoundsCarbon ionReverse osmosis

A novel method and system of separating carbon dioxide from flue gas is introduced. Instead of relying on large temperature or pressure changes to remove carbon dioxide from a solvent used to absorb it from flue gas, the ion pump method, as disclosed herein, dramatically increases the concentration of dissolved carbonate ion in solution. This increases the overlying vapor pressure of carbon dioxide gas, permitting carbon dioxide to be removed from the downstream side of the ion pump as a pure gas. The ion pumping may be obtained from reverse osmosis, electrodialysis, thermal desalination methods, or an ion pump system having an oscillating flow in synchronization with an induced electric field.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

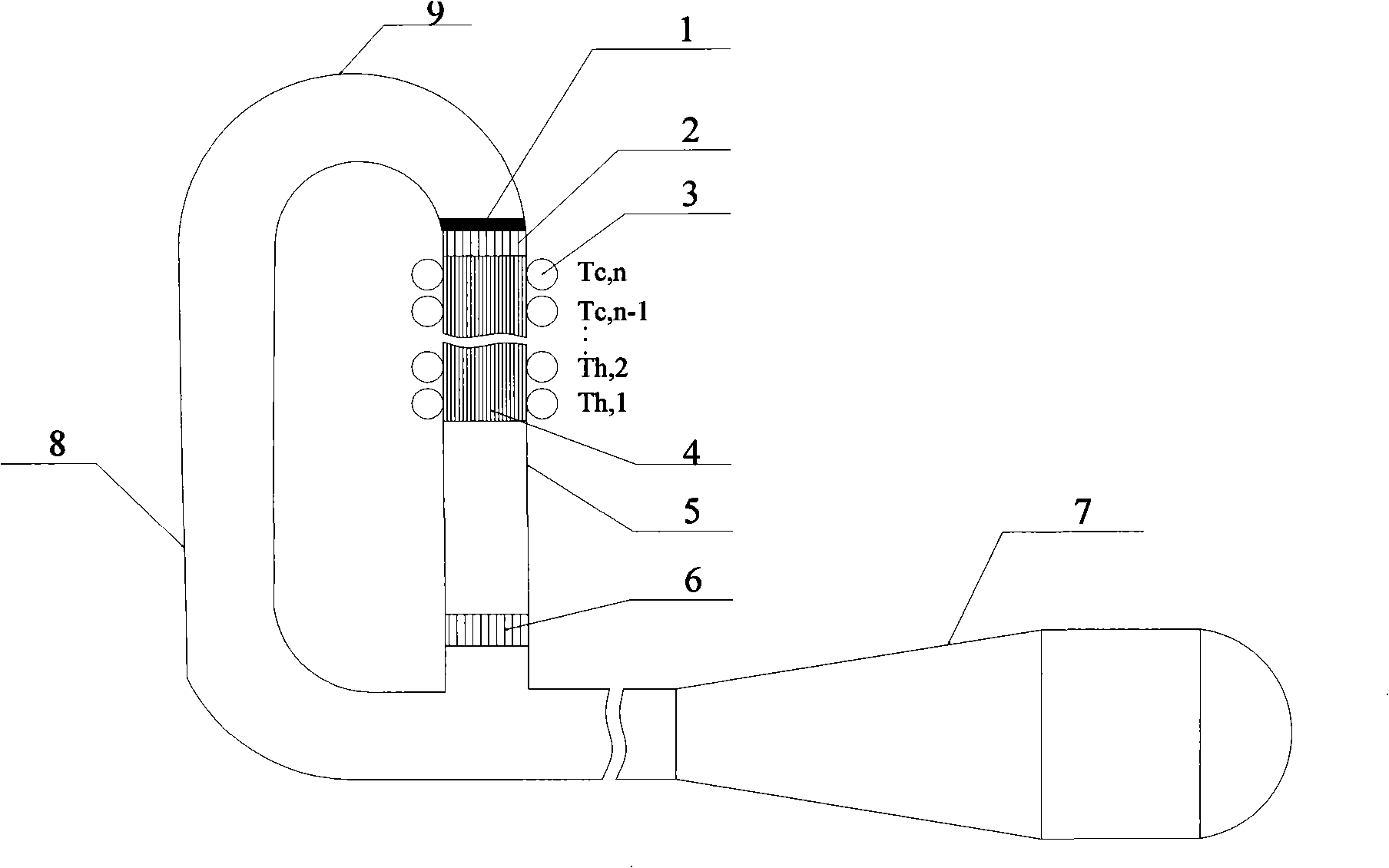

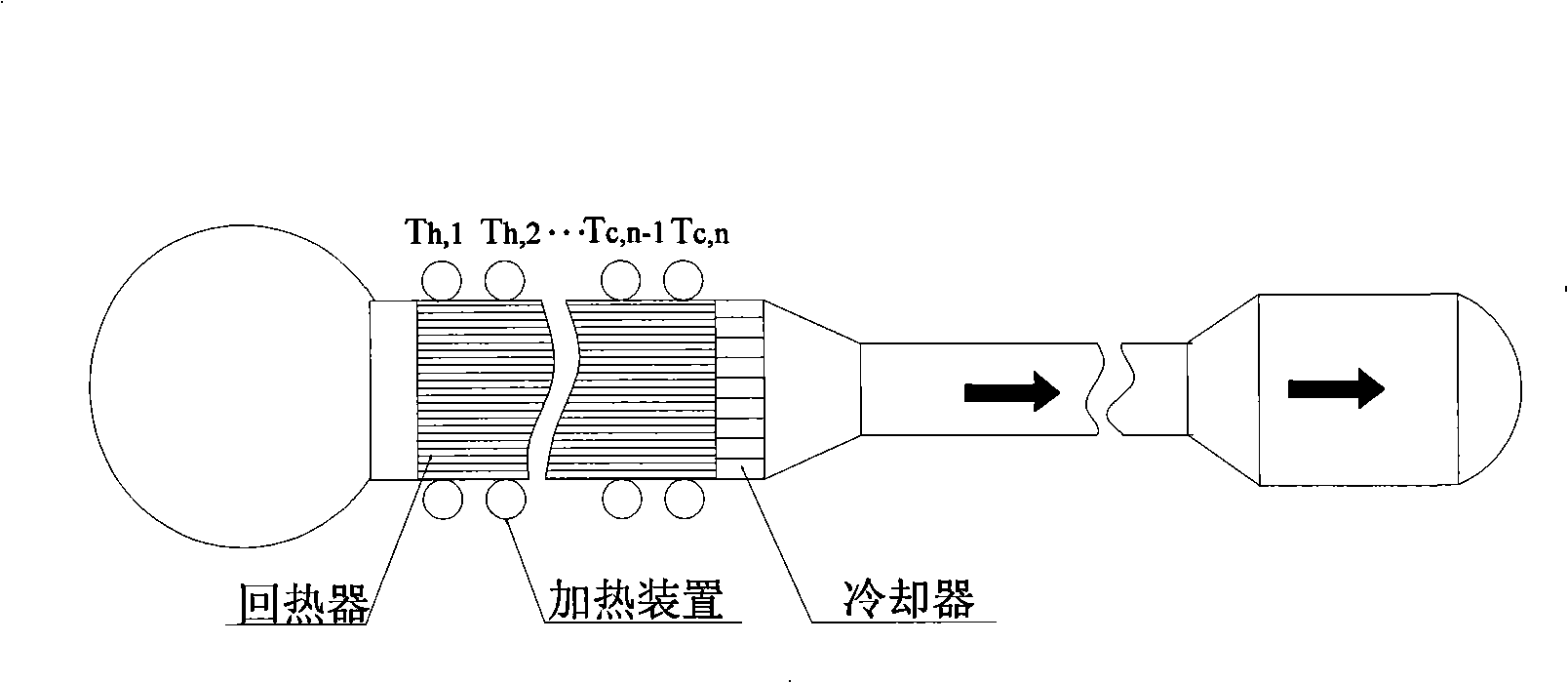

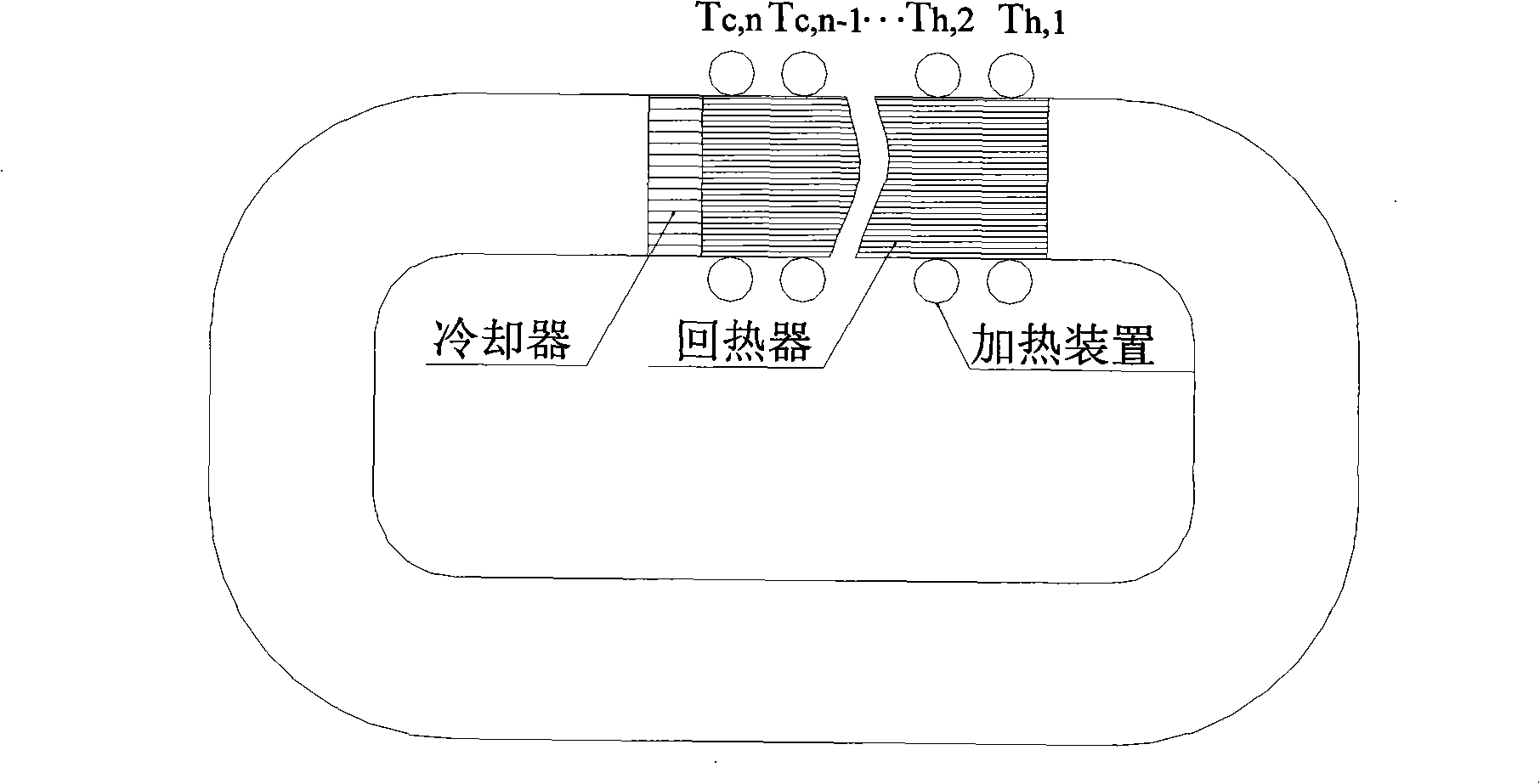

Heat phonomotor capable of utilizing multi-temperature position heat power supply drive

InactiveCN101275542ALow efficiencyNo loss of efficiencyMachines/enginesMechanical power devicesCapacitanceThermoacoustics

The invention discloses a thermo-acoustic engine driven by a multi-temperature-level heat source, comprising a traveling wave circuit of the thermo-acoustic engine and a resonance tube of the thermo-acoustic engine. The traveling wave circuit of the thermo-acoustic engine consists of a direct current inhabitation component, a main cooler, a heat regenerator, a heat buffer tube, a secondary cooler, a deflector, a feedback loop and an acoustic capacitance, characterized in that the heat regenerator is provided with a heating device on the outside, the heating device is a multi-temperature-level heating device with high temperature level and low temperature level being arranged from the high temperature end to the lower temperature end successively. The invention makes full use of the thermoacoustic effect and the regenerative function of the thermo-acoustic engine in oscillating flow, the multi-temperature-level heat source is used for heating the different positions in the axial direction of the engine, thus the temperature level of an available heat source is lowered, the heat-power conversion efficiency of the thermo-acoustic engine is improved, and the structures of the heat regenerator and the heating device become more compact.

Owner:ZHEJIANG UNIV

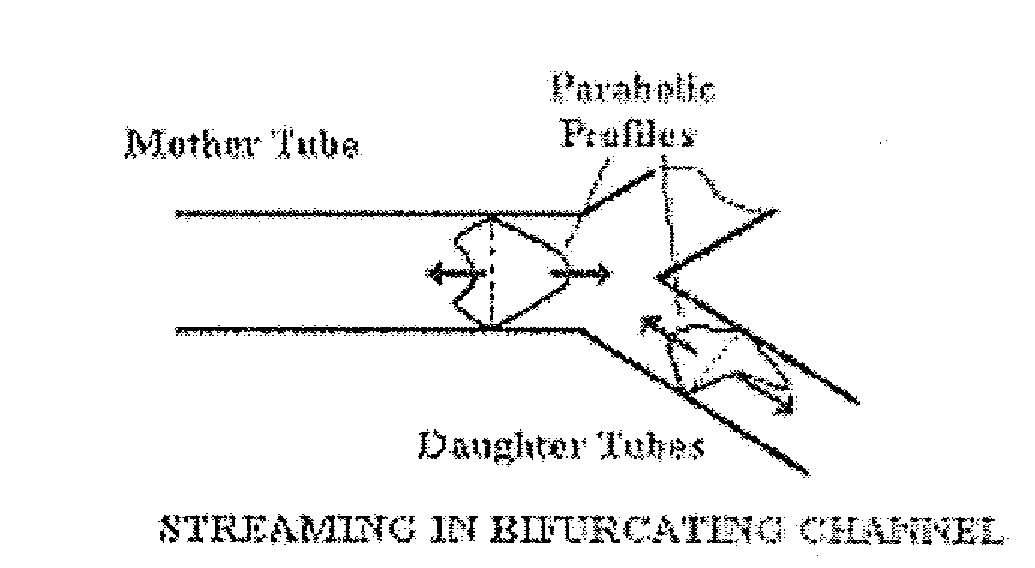

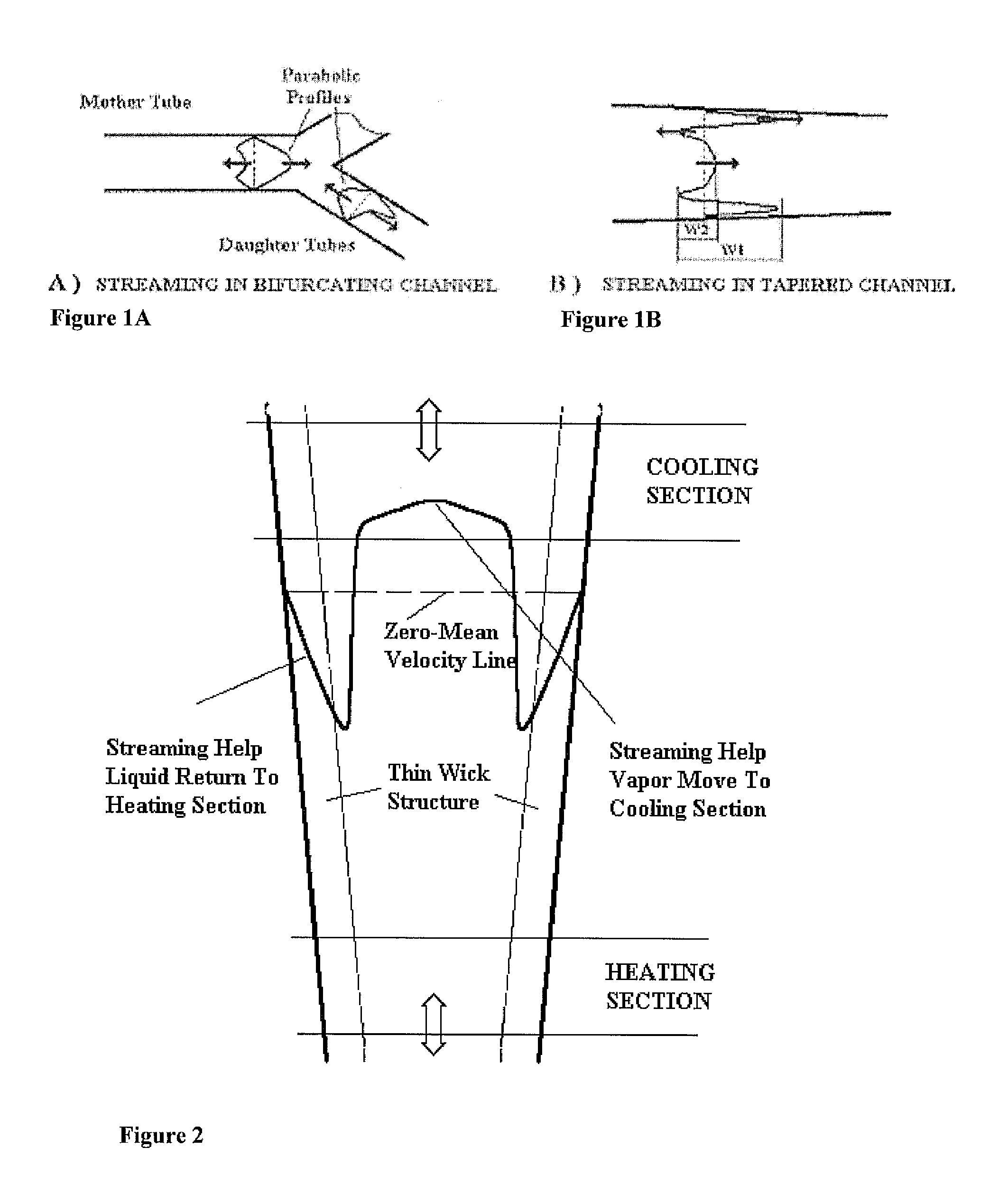

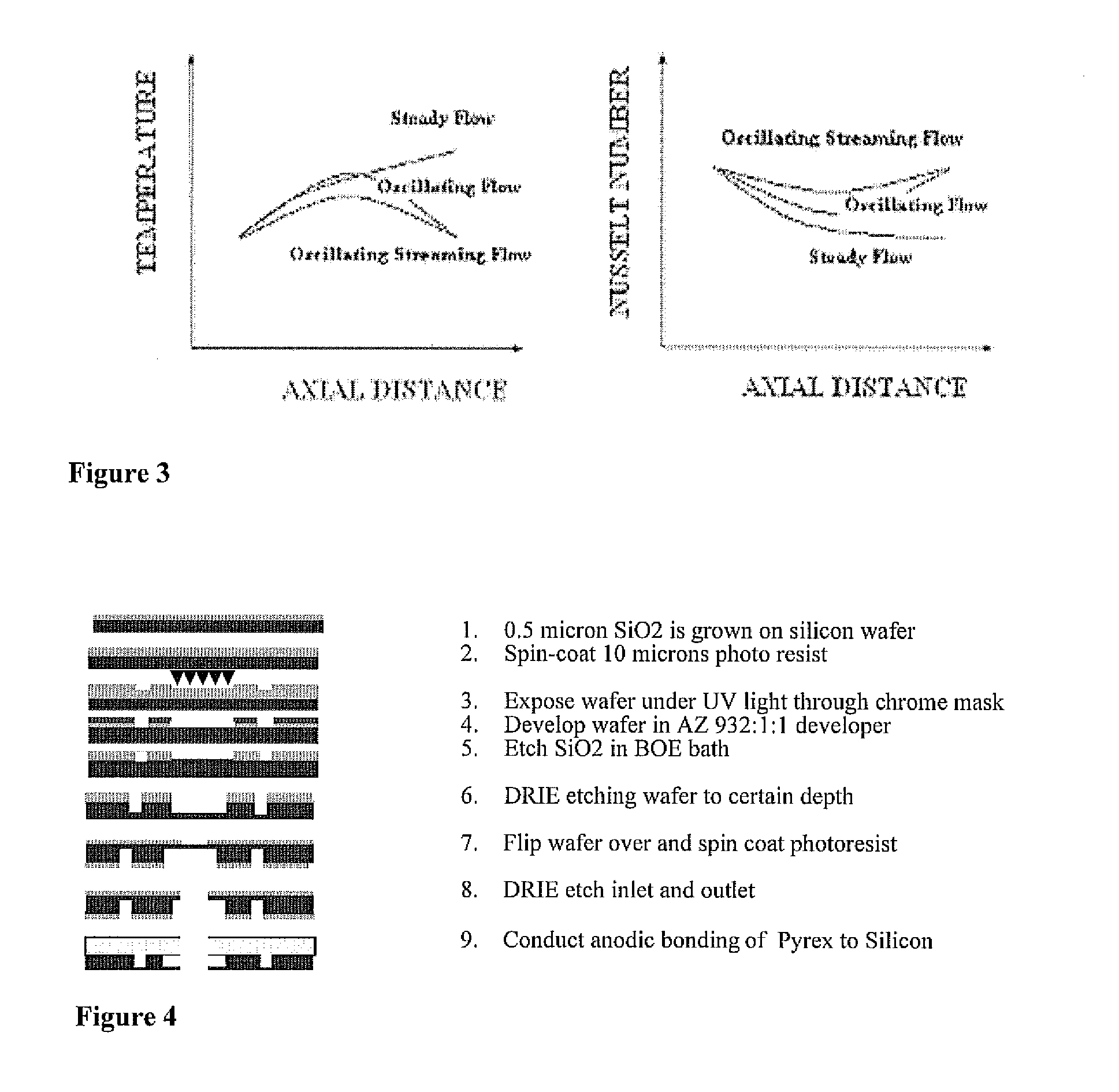

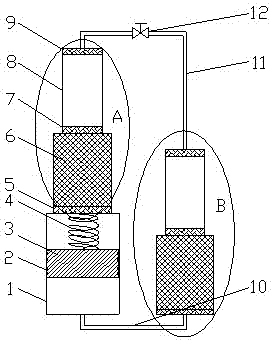

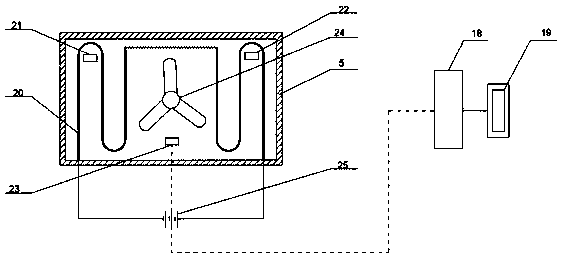

Streaming-based micro/mini channel electronic cooling techniques

InactiveUS20100091459A1Easy to createEfficient transportWave amplification devicesSemiconductor/solid-state device detailsHigh densityElectronics cooling

Micro-cooling technology for thermal control in the fabrication and operation of micro- and nano-scale such as high speed, high density micro scale electronic devices, micro sensors and micro machines Micro / mini heat exchangers and heat pipes have at least one channel through which the streaming flow is passed therethrough. The oscillating flow can be generated by diaphragms, vibrators, electrokinenatic force and thermal acoustic force.

Owner:BOARD OF GOVERNORS FOR HIGHER EDUCATION STATE OF RHODE ISLAND & PROVIDENCE

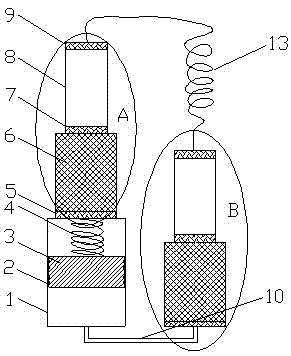

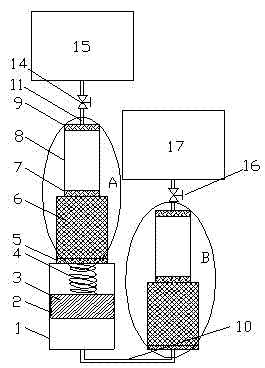

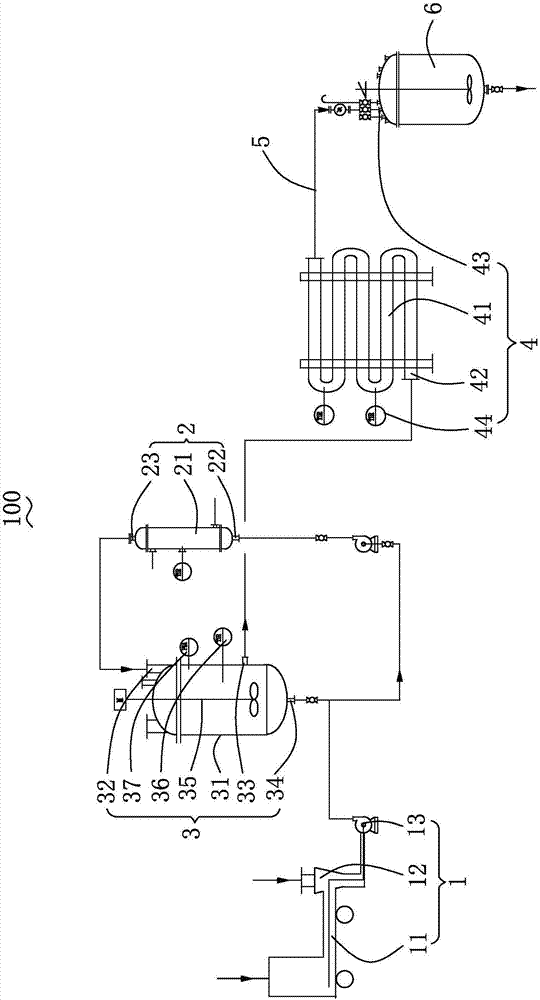

Pulse Tube Refrigerator System Using Vehicle Vibration Energy

InactiveCN102297540AMinor fuel consumptionSmall power and other effectsCompression machinesPulse tube refrigeratorOscillating flow

The invention discloses a pulse tube cooler system using automobile vibration energy, which comprises an air cylinder, a first pipeline, a second pipeline, a first pulse tube cooler, a second pulse tube cooler and a phase adjusting structure, wherein the air cylinder, the first pulse tube cooler, the phase adjusting structure, the second pipeline and the second pulse tube cooler are sequentially connected; the second pulse tube cooler is connected with the air cylinder through the first pipeline; a piston is arranged in the air cylinder and is provided with a spring; a groove is arranged on the periphery of the piston; and the first pulse tube cooler and the second pulse tube cooler respectively comprise a heat exchanger of a heat regenerator, a heat regenerator, a pulse tube cold-end heat exchanger, a pulse tube and a pulse tube heat-end heat exchanger. The pulse tube cooler system has the characteristics that an inertia force generated by vibration of the automobile does work to generate work medium oscillating flow of the pulse tube coolers, thereby, cold energy is generated; and in addition, the pulse tube cooler system has a compact structure, small size and no power supply.

Owner:ZHEJIANG UNIV

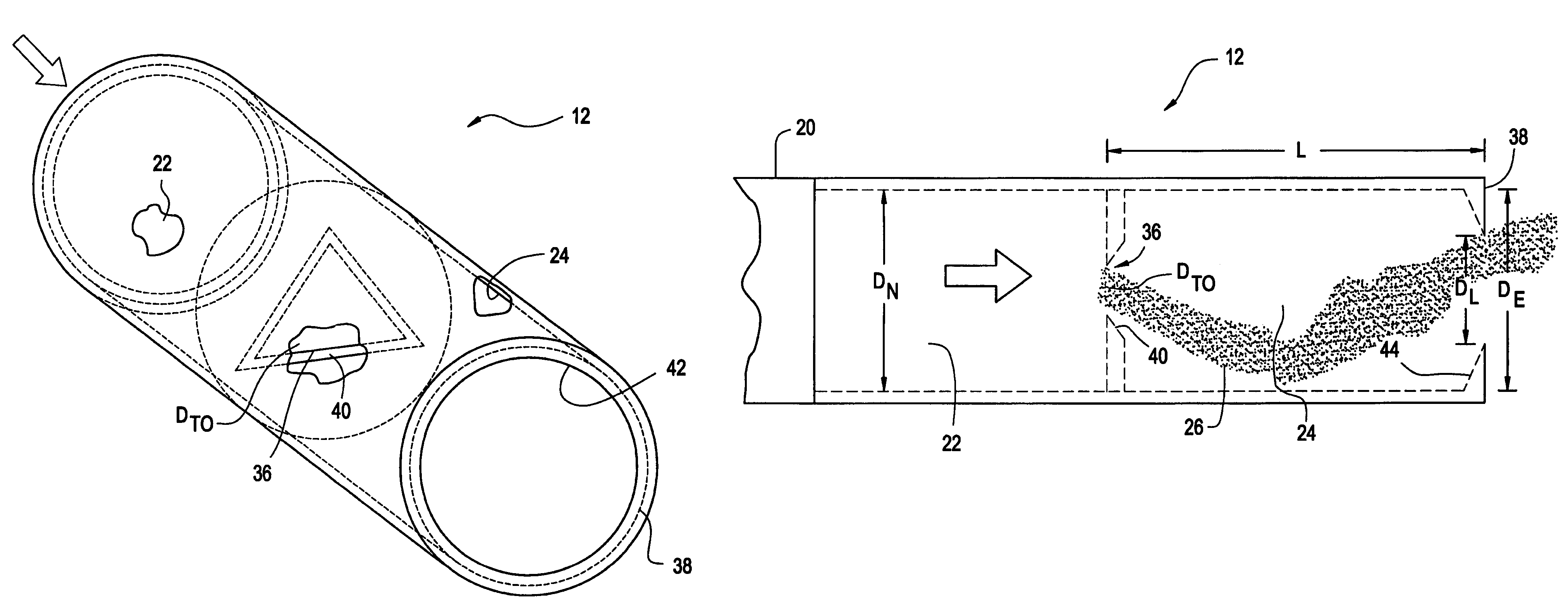

Device for reducing jet engine exhaust noise using oscillating jets

ActiveUS7308966B2Well mixedReduce exhaust noiseInfluencers by generating vorticesEngine manufactureJet engineOscillating flow

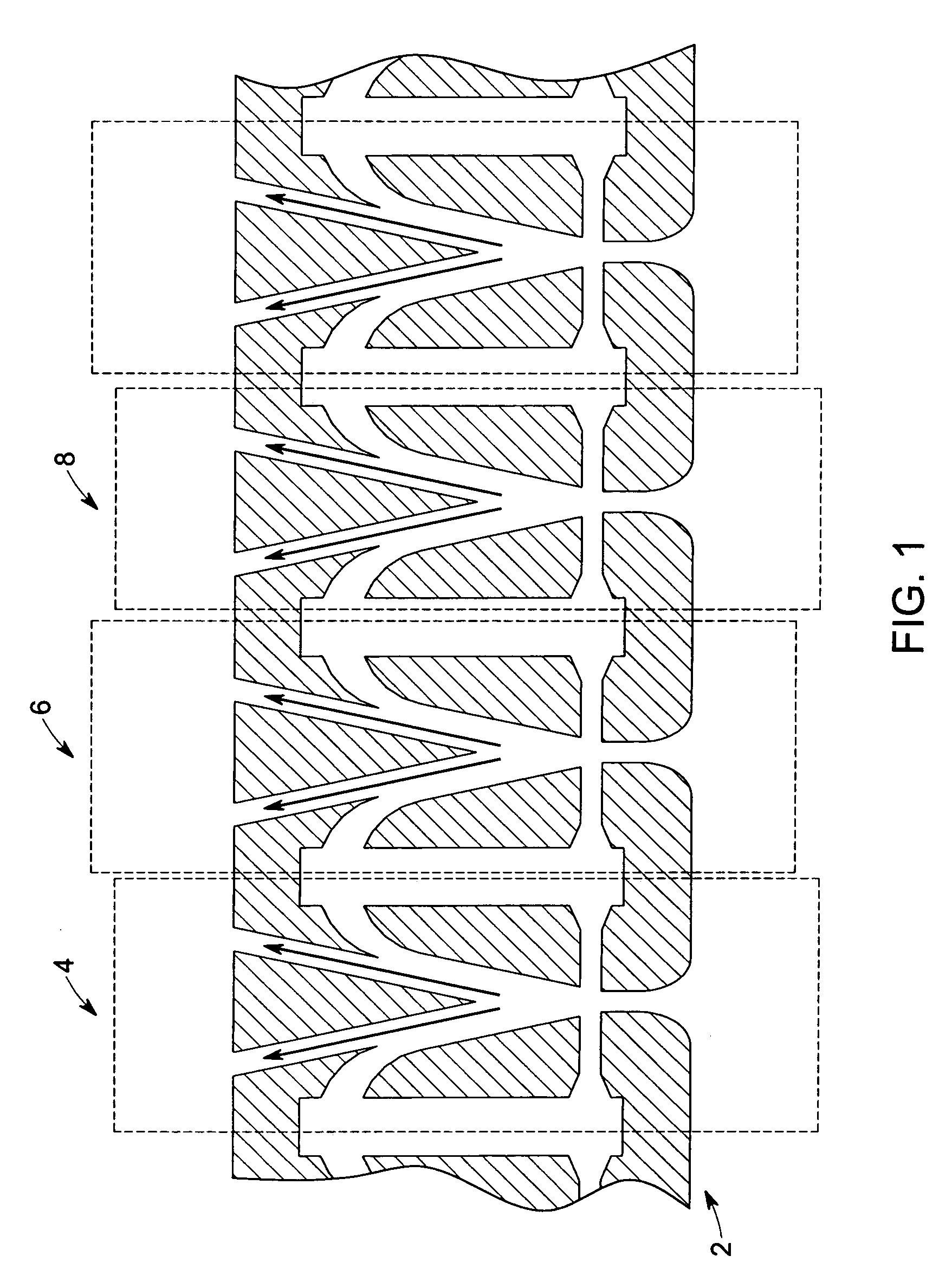

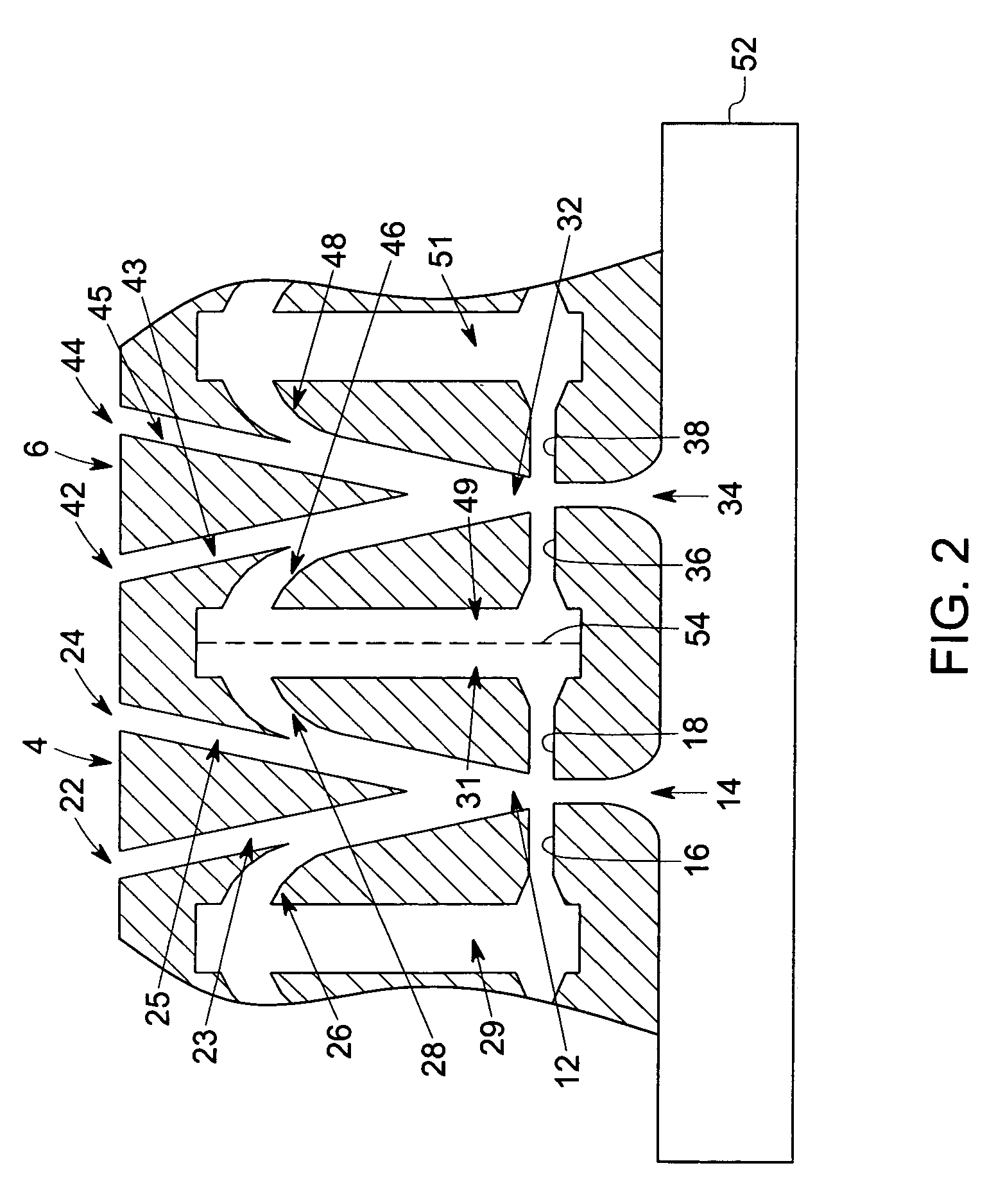

A device for reducing engine exhaust noise in an aircraft engine includes a number of oscillating jets which direct an oscillating flow into the engine exhaust. The oscillating jets are connected via channels to a turbomachinery source of high pressure gas, where the source is located upstream from the engine exhaust portion. The high pressure gas passes through the oscillating jets, which have a nozzle with a triangular shaped orifice and an exhaust pipe, and exits the oscillating jets having a oscillating flow. The oscillating flow mixes with the engine exhaust thus reducing the noise created by the engine exhaust.

Owner:GENERAL ELECTRIC CO

Carbon ion pump for removal of carbon dioxide from combustion gas and other gas mixtures

InactiveUS7828883B2Increase vapor pressureElectrostatic separatorsLiquid separation by electricityCarbon ionReverse osmosis

A novel method and system of separating carbon dioxide from flue gas is introduced. Instead of relying on large temperature or pressure changes to remove carbon dioxide from a solvent used to absorb it from flue gas, the ion pump method, as disclosed herein, dramatically increases the concentration of dissolved carbonate ion in solution. This increases the overlying vapor pressure of carbon dioxide gas, permitting carbon dioxide to be removed from the downstream side of the ion pump as a pure gas. The ion pumping may be obtained from reverse osmosis, electrodialysis, thermal desalination methods, or an ion pump system having an oscillating flow in synchronization with an induced electric field.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

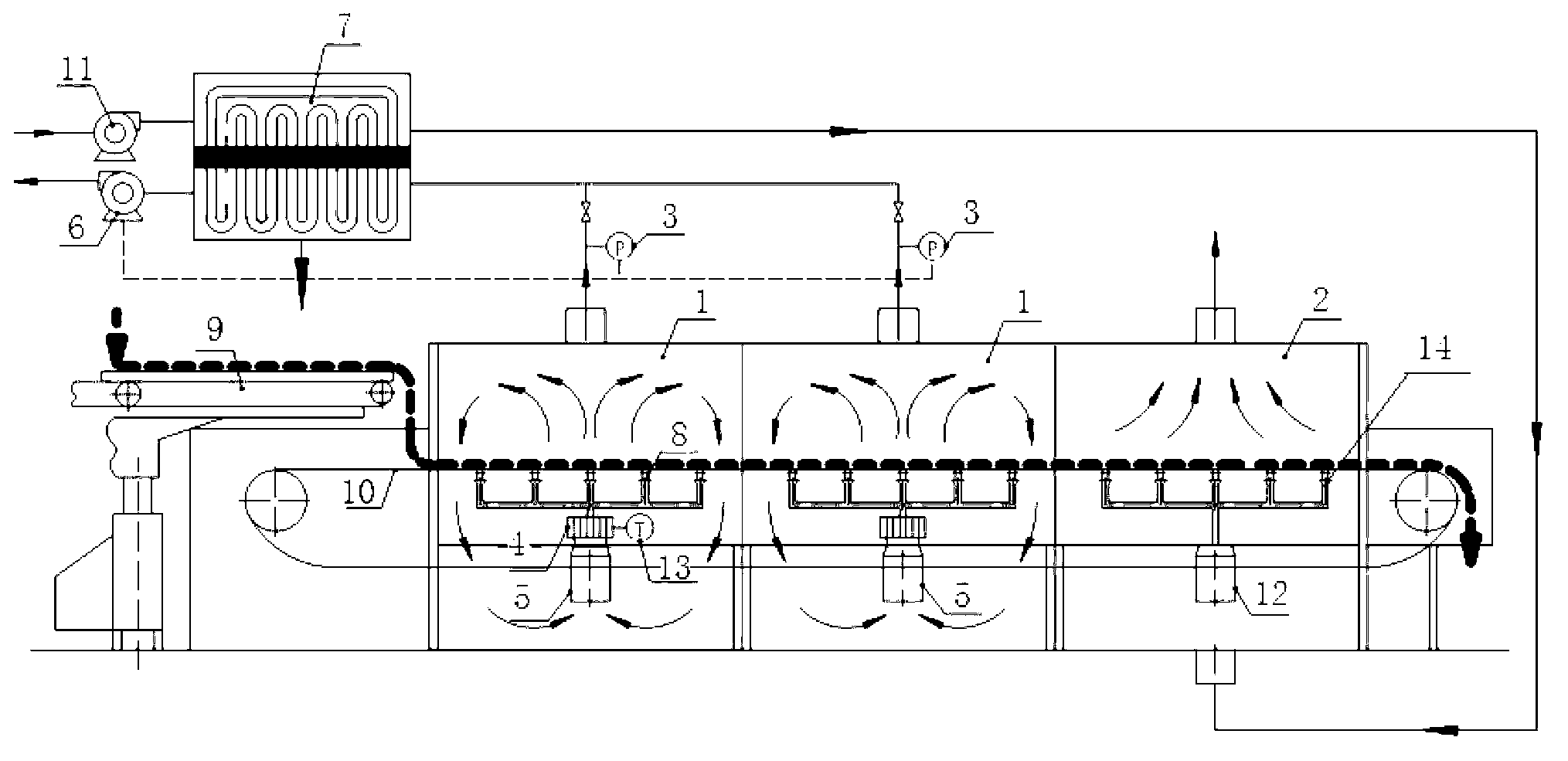

Drying and adjusting process and device for viscose fibers

ActiveCN102797064AImprove heat transfer efficiencyFlexible formArtificial filament washing/dryingTextile/flexible product manufactureWater vaporOscillating flow

The invention discloses a drying and adjusting process for viscose fibers. The process comprises the following steps of: 1) feeding the viscose fibers into a superheated vapor drier in a front area by a feeder; feeding a drying medium heated by a vapor coil into a drying chamber of the superheated vapor drier in the front area; drying the viscose fibers; evaporating water of the viscose fibers during drying; increasing pressure; and discharging out excessive water vapor to an oscillating-flow heat pipe heat exchanger through the linkage of a pressure controller and an induced draft fan; 2) under an effect of a chain conveying device, conveying the viscose fibers to a superheated vapor drier in a middle area, wherein the drying process in the middle area is similar to that in the front area; meanwhile, discharging out the excessive water vapor to the oscillating-flow heat pipe heat exchanger; and 3) heating the recycled water vapor in the oscillating-flow heat pipe heat exchanger into fresh air; feeding the fresh air into a hot air drier in a back area, so as to finish deep drying and adjusting of the viscose fibers; obtaining the dried viscose fibers; and emptying tail gas. The invention further discloses a device of the process. The viscose fibers with high qualities can be obtained; and energy consumption is reduced by 35-40%.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

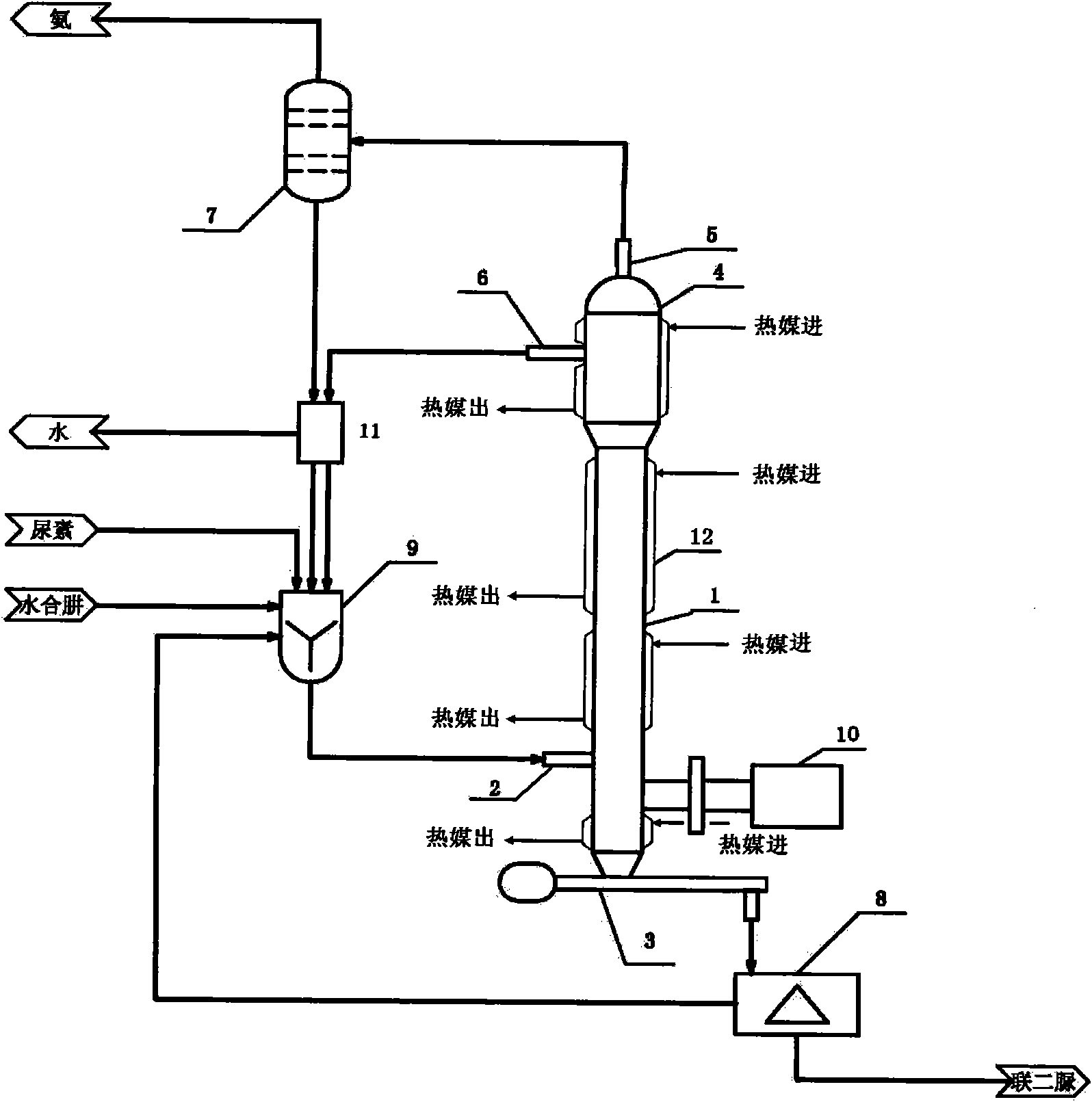

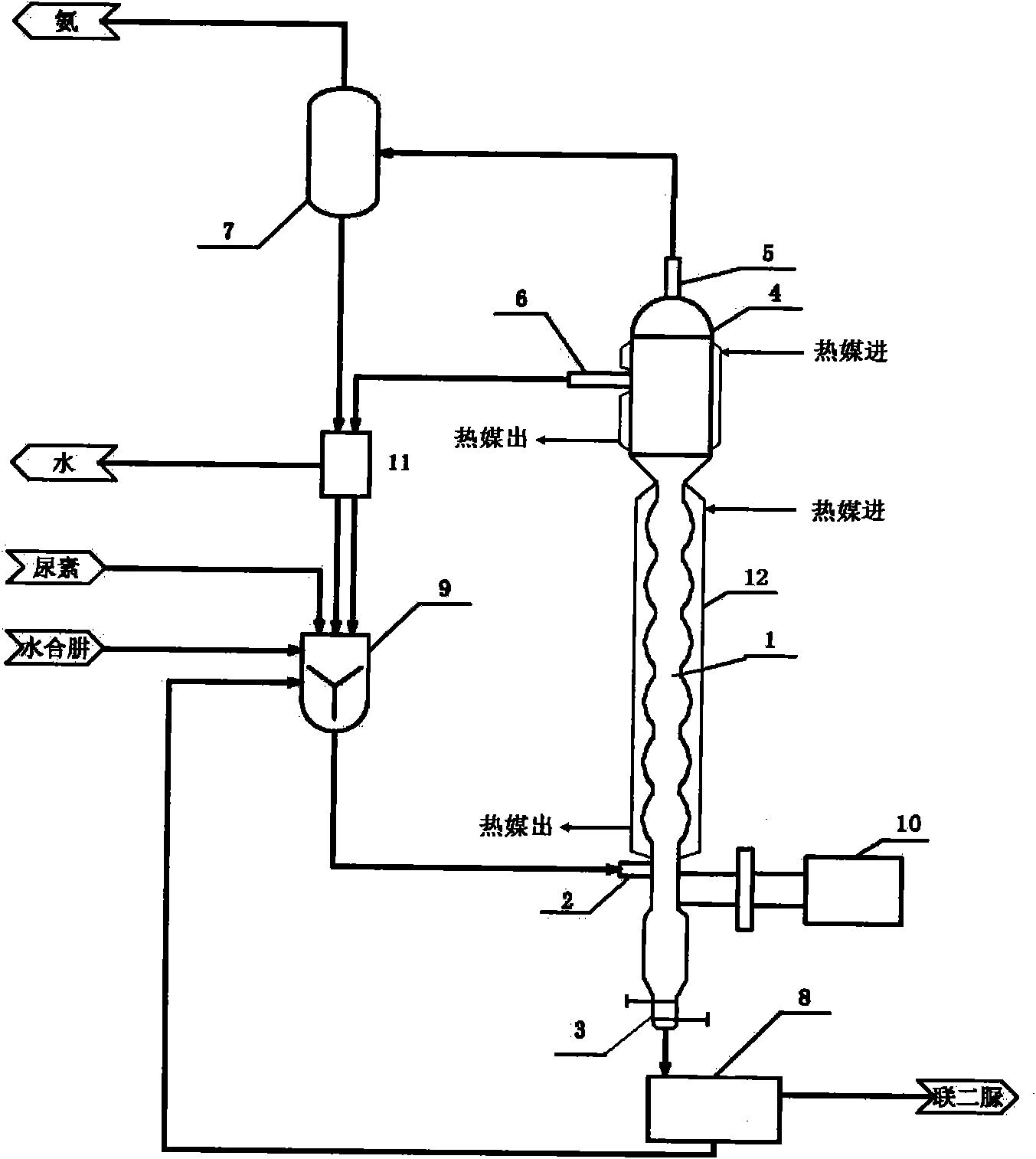

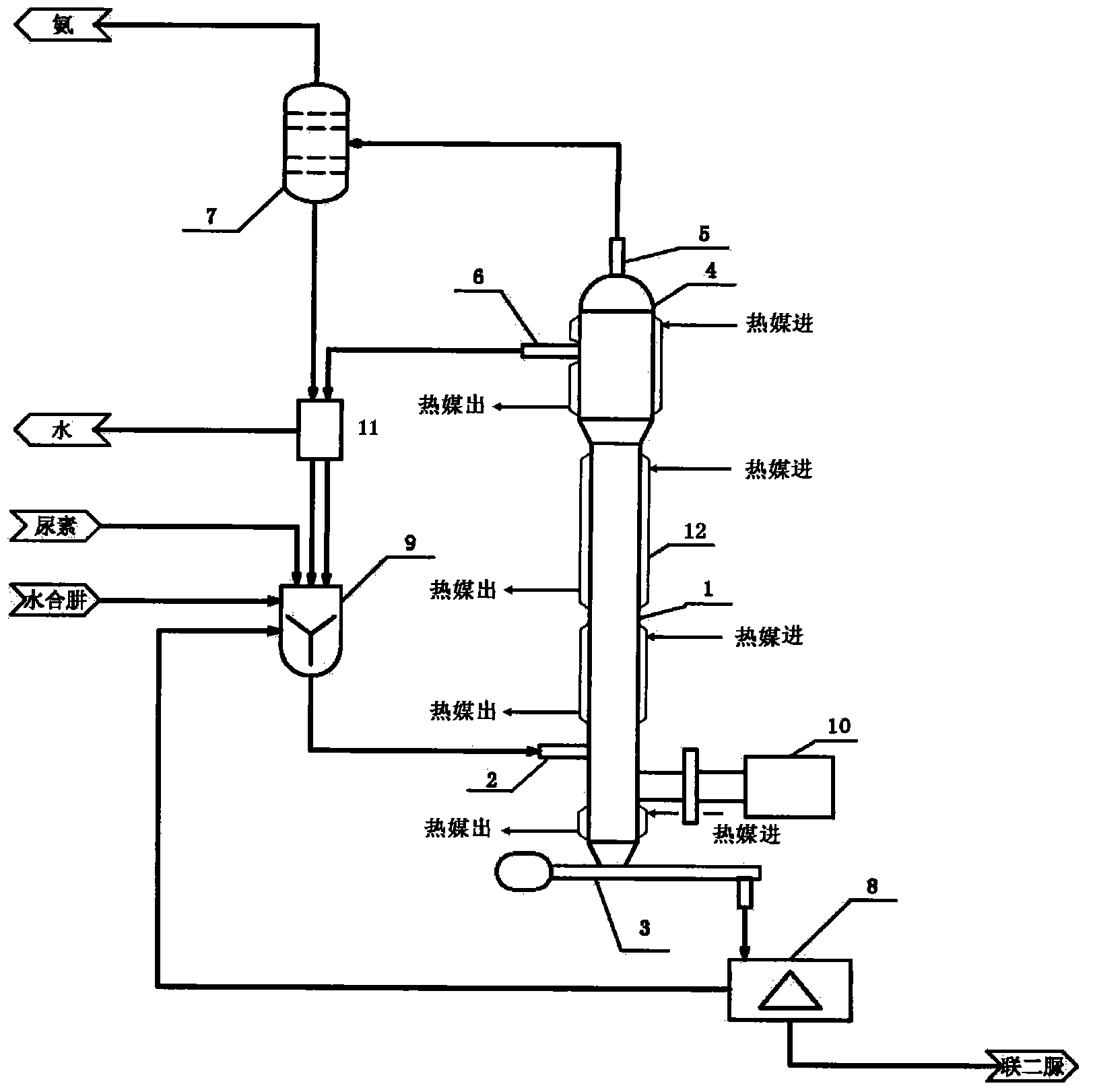

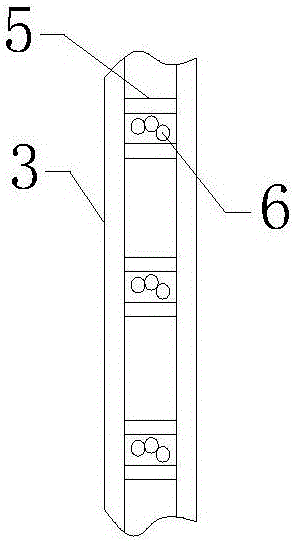

Continuous production method and continuous production device for synthesizing biruea

ActiveCN101967114ANarrow residence time distributionWith selective suspensionUrea derivatives preparationOrganic compound preparationReaction rateOscillating flow

The invention discloses a continuous production method for synthesizing biruea, comprising the following steps of: (1) continuously adding hydrazine hydrate and a urea solution into the middle lower part of an oscillating flow tubular reaction crystallizer to react and generate biruea grains; (2) along with the processes of reaction and crystallization, gradually increasing the grain diameter of the biruea grains, settling the biruea grains at the bottom of the reaction crystallizer, continuously discharging the biruea grains settled at the bottom of the reaction crystallizer, separating solids and liquid and cleaning to obtain the biruea; and (3) continuously discharging mother liquid with unconverted reactants from the upper part of the reaction crystallizer and continuously dischargingammonia as a by-product from the top of the reaction crystallizer. The invention also discloses the oscillating flow tubular reaction crystallizer which is used for implementing the production method. The continuous production method is suitable for alkaline condensation technology, increases an average reaction rate, has high production capacity of unit reactor volume and can control the grain diameter of the biruea to separate subsequently and reduce purification cost.

Owner:ZHEJIANG ENG DESIGN +2

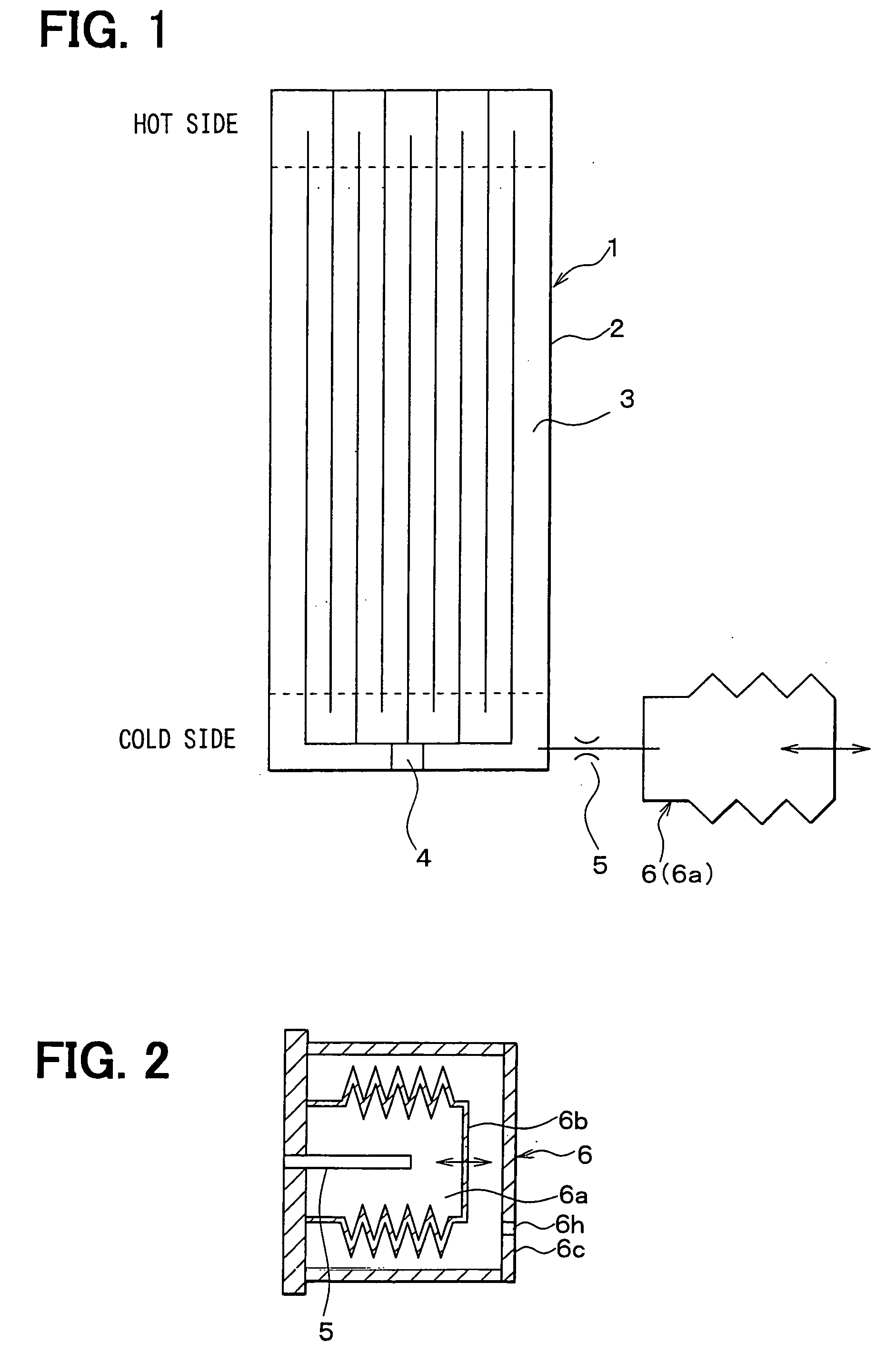

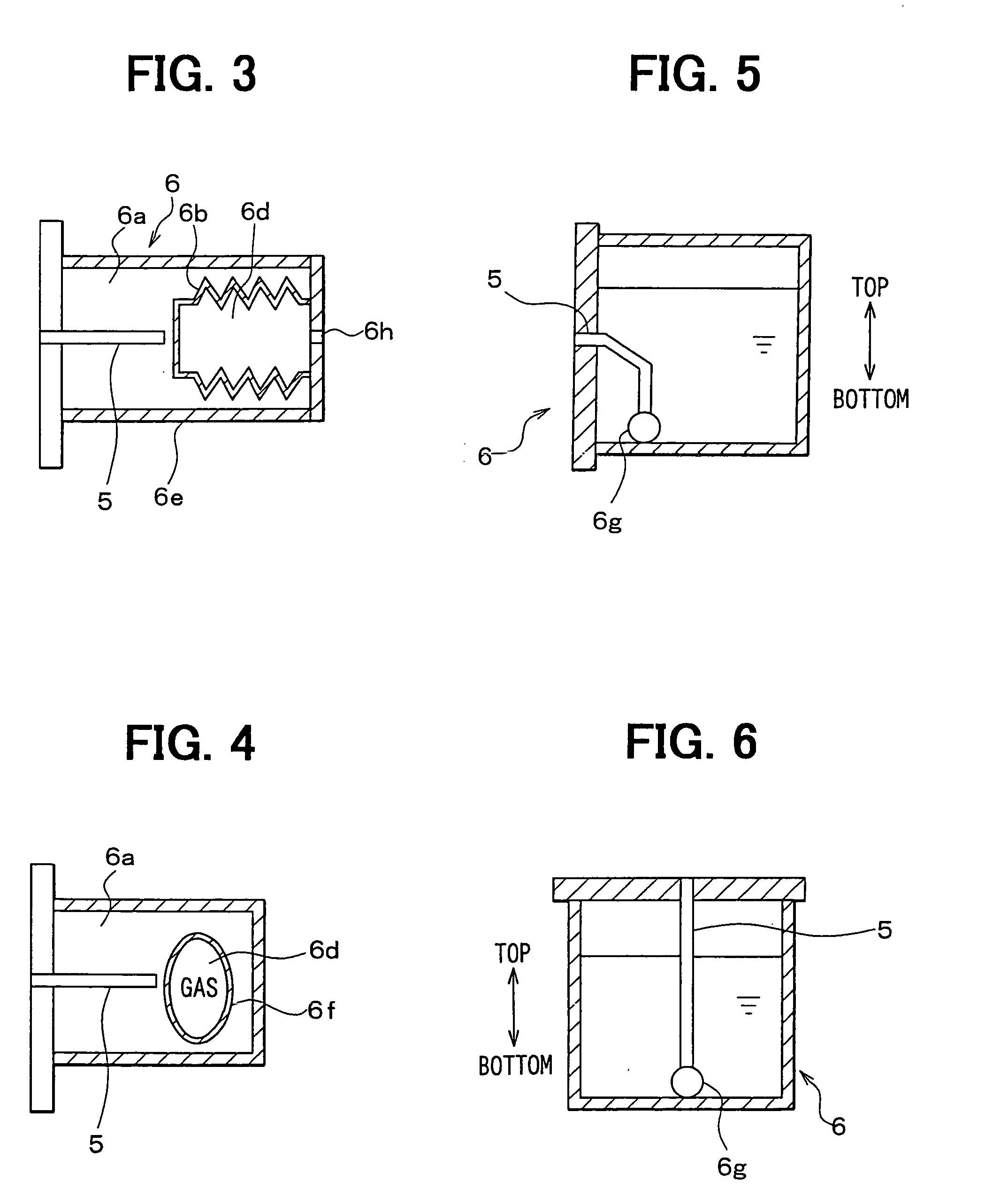

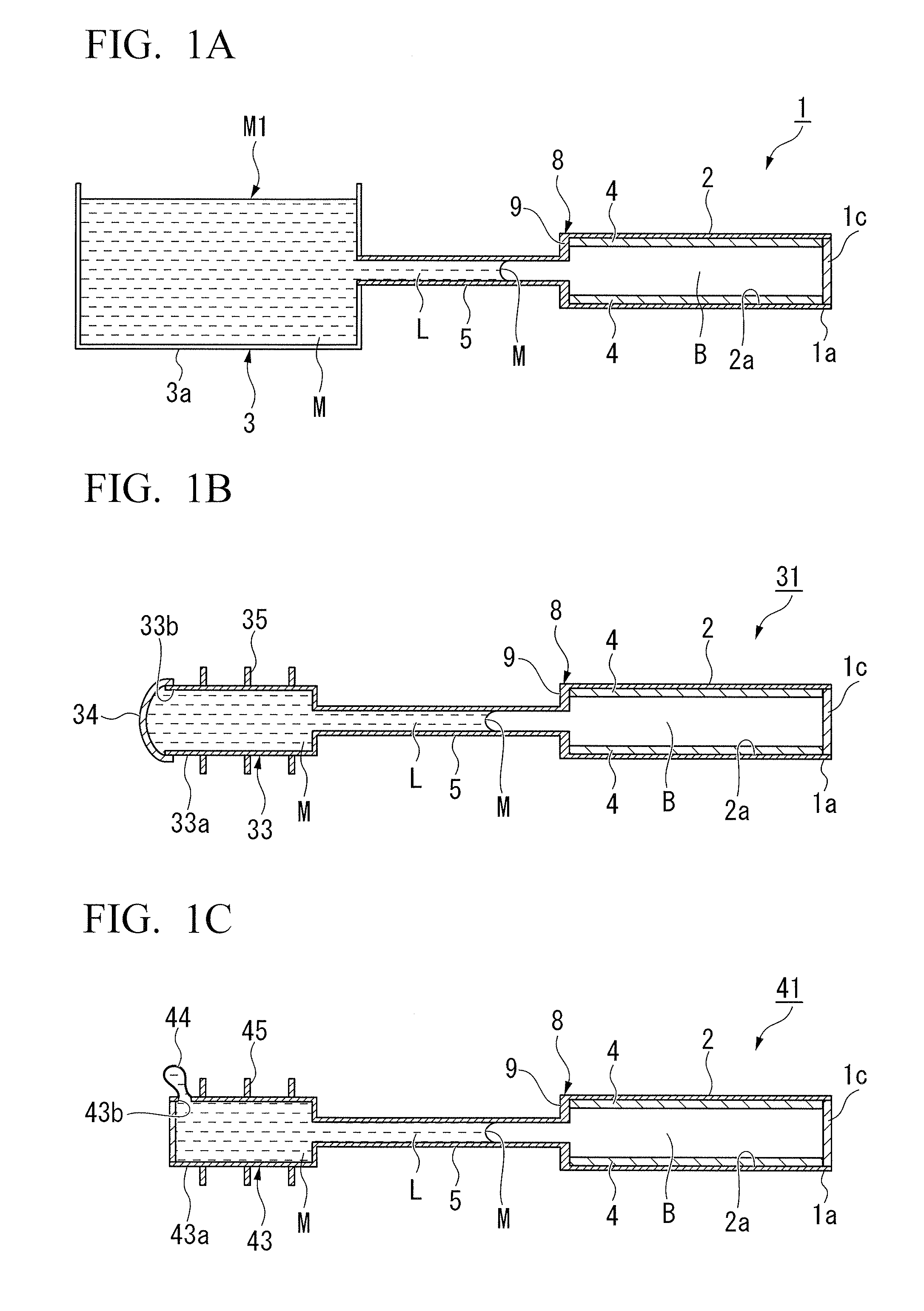

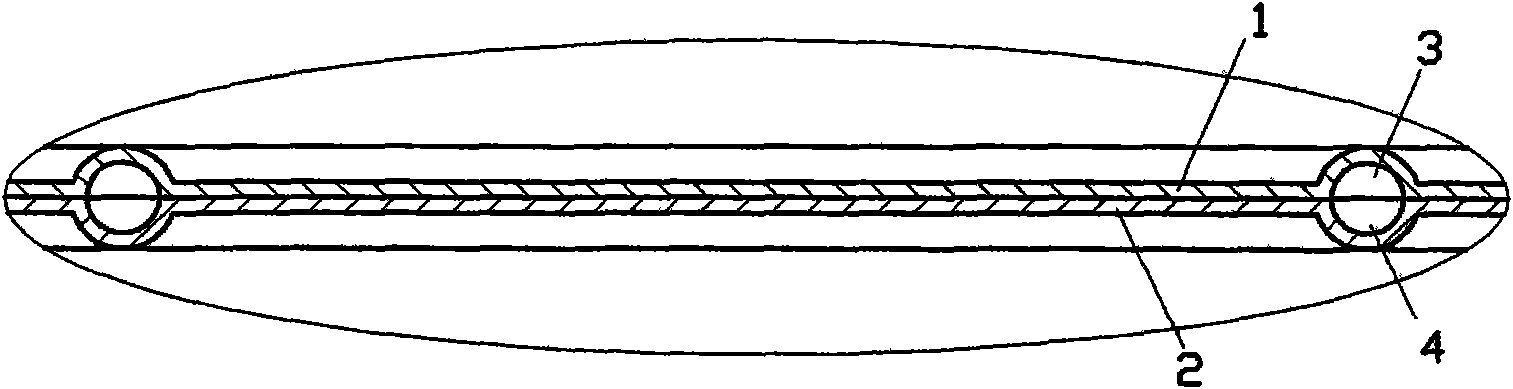

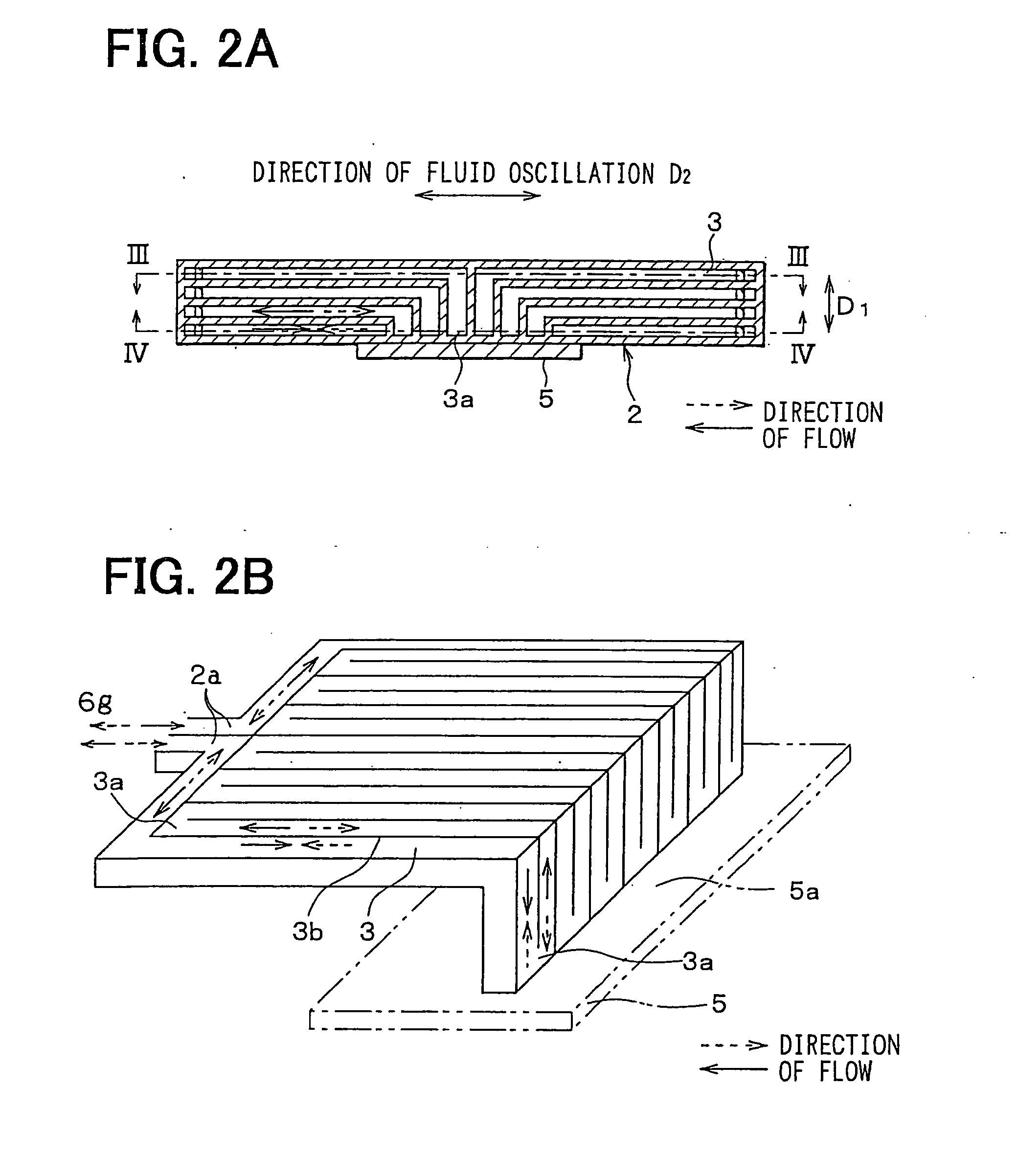

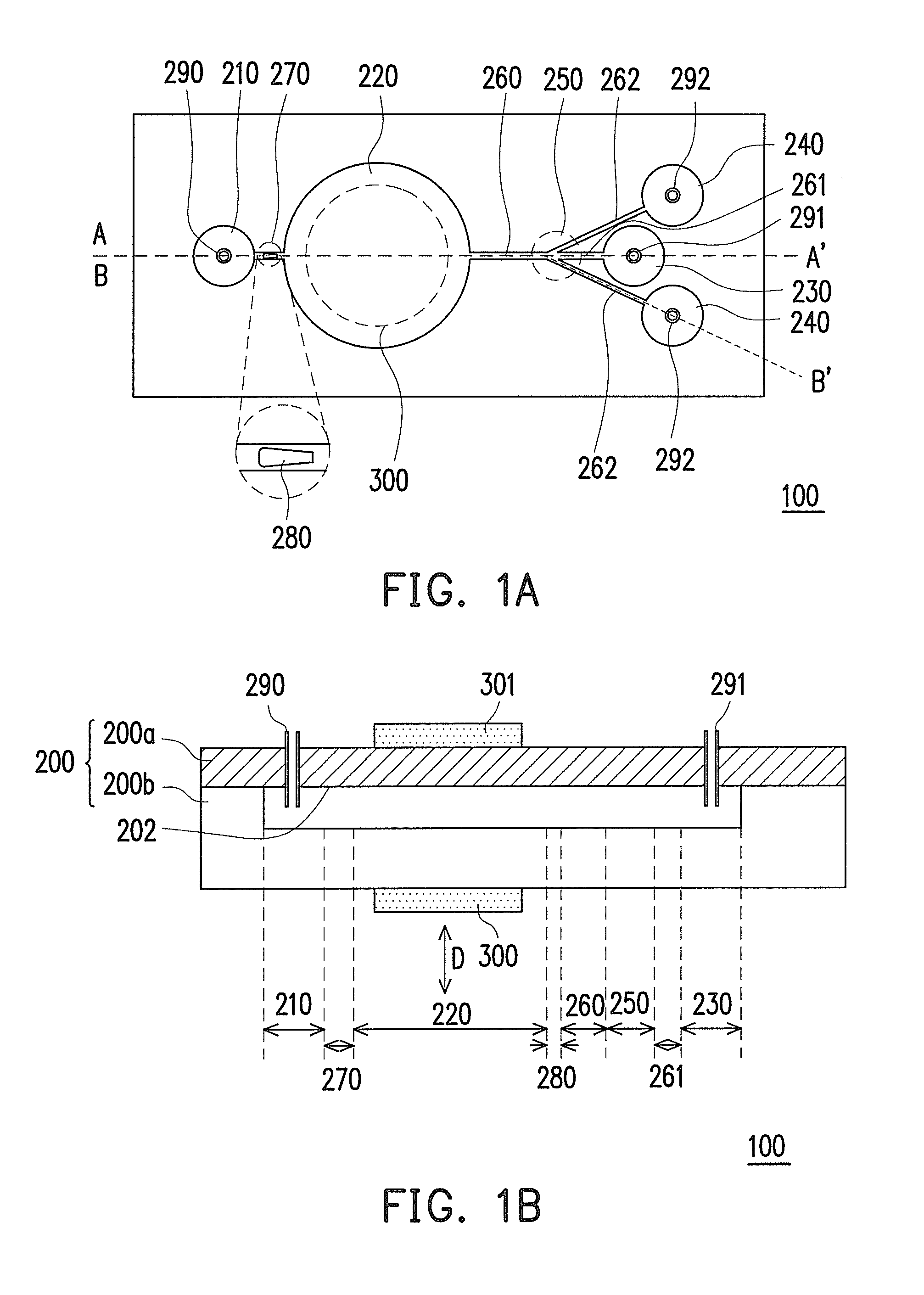

Counter-stream-mode oscillating-flow heat transport apparatus

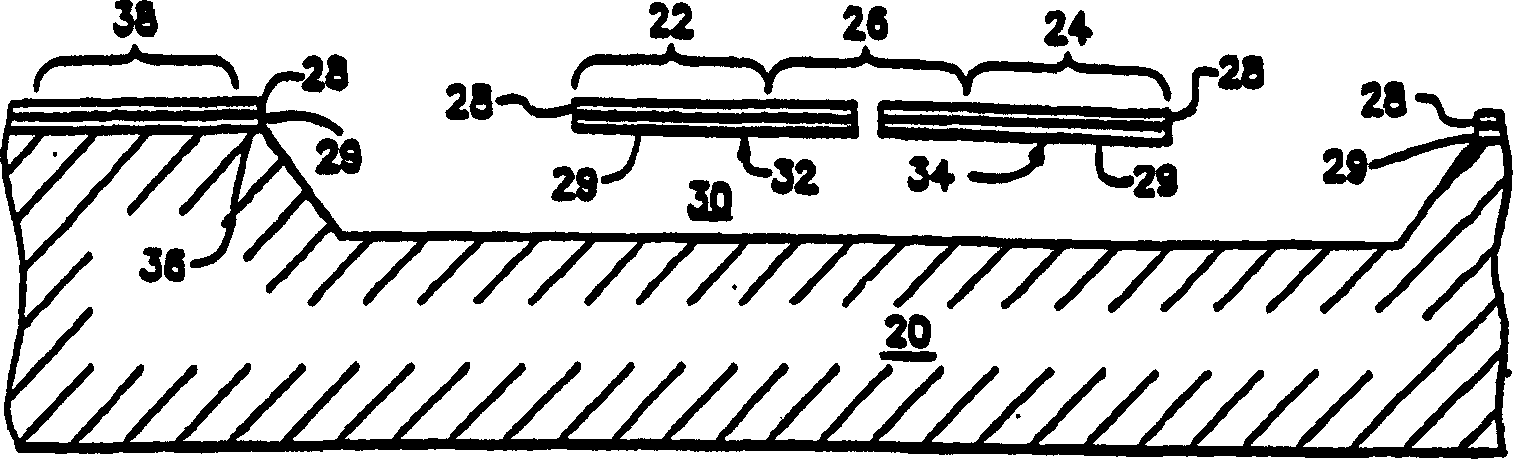

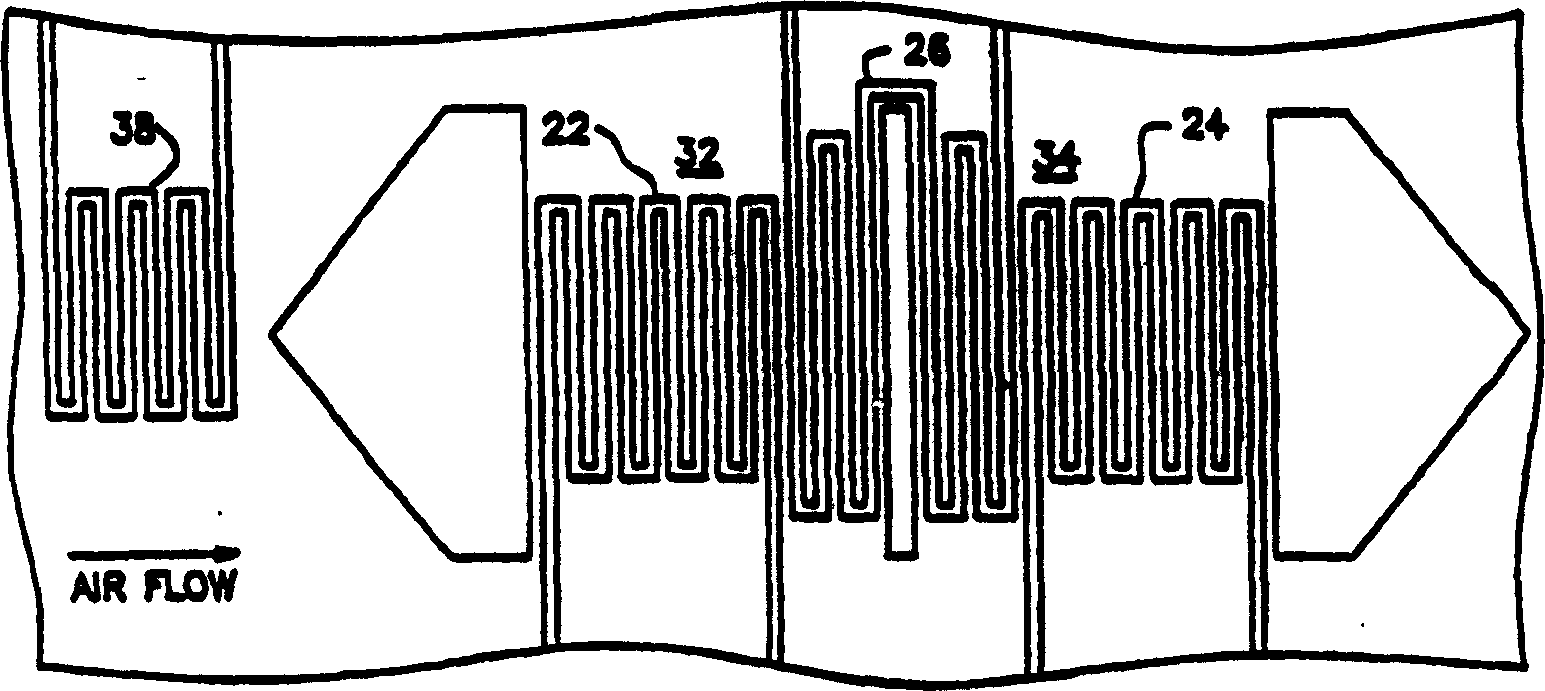

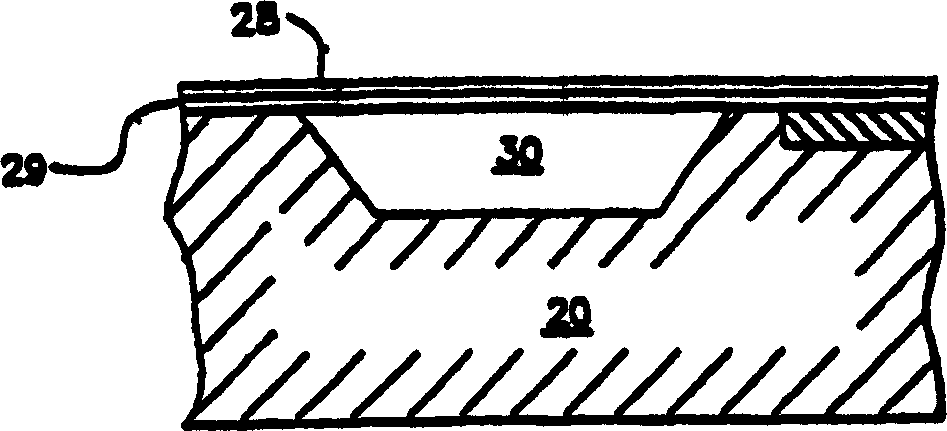

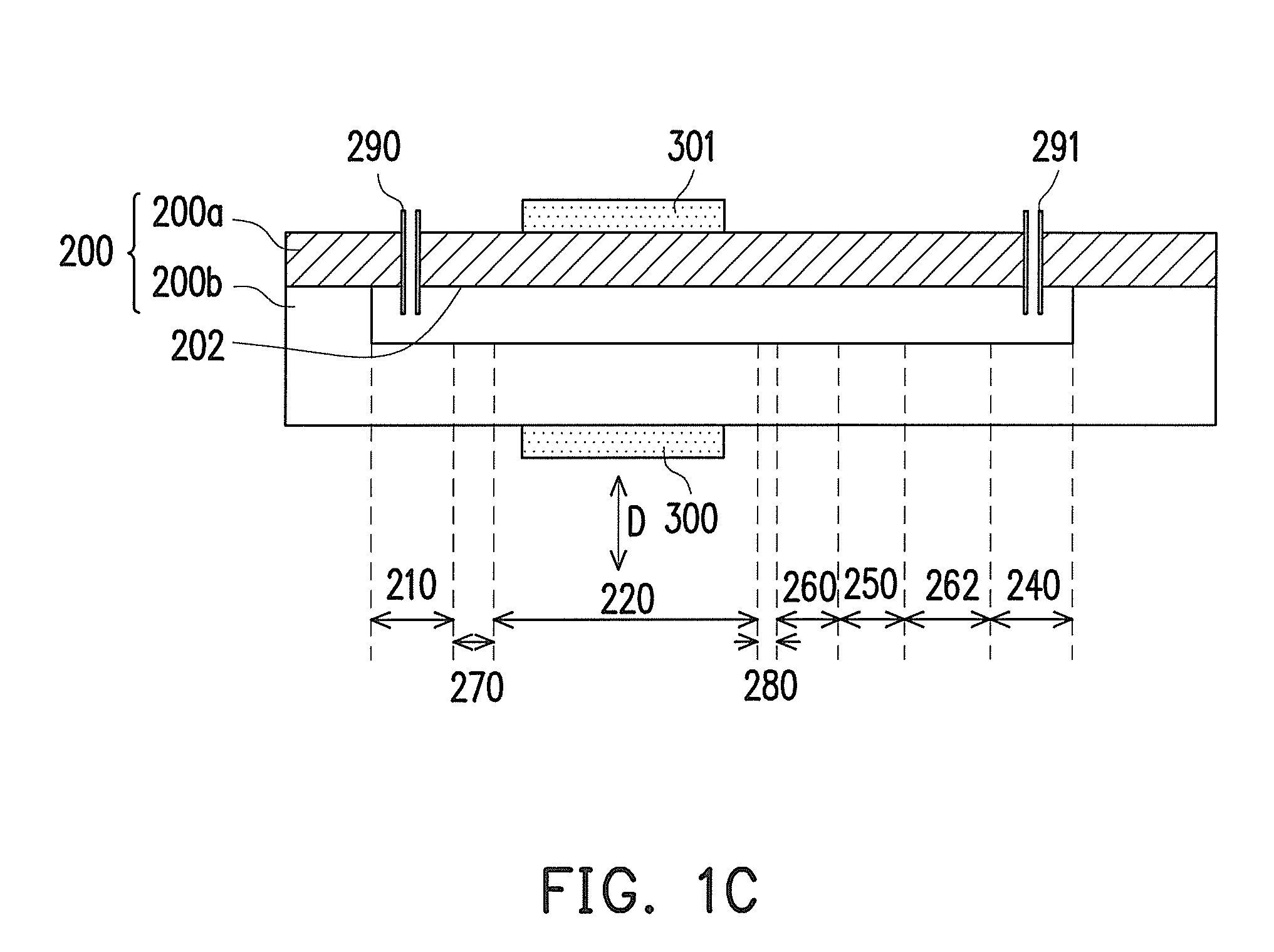

InactiveUS20050022977A1Preventing degradation in heat transport capabilityReduce heatSemiconductor/solid-state device detailsSolid-state devicesBuffer tankOscillating flow

A counter-stream-mode oscillating-flow heat transport apparatus accommodates a change in volume of a liquid while preventing reduction in heat transport capability. A flow path and a buffer tank are placed in communication with each other via a throttle such as a capillary tube. This prevents a channel connecting the flow path and the buffer tank from having an excessively reduced channel resistance (flow path resistance). This prevents the fluid in a heat transport device assembly (the flow path) from only going back and forth between the heat transport device assembly and the buffer tank without experiencing liquid (pressure) oscillations in the heat transport device assembly. Accordingly, the liquid in the heat transport device assembly is prevented from being reduced in amplitude of oscillation, thereby preventing degradation in heat transport capability of the counter-stream-mode oscillating-flow heat transport apparatus.

Owner:DENSO CORP

Flow meter

InactiveUS6938611B2Improve fuel economyIncrease engine powerElectrical controlInternal combustion piston enginesOn boardEngineering

The flow meter is a device having a laser Doppler anemometer (LDA) which measures the instantaneous center line velocity of fluid flow in a pipe and processes the instantaneous velocity so obtained to compute the volumetric flow rate, mass rate, and other flow characteristics as instantaneous quantities and / or integrated over a time interval using an electronic processing method which provides an exact solution to the Navier-Stokes equations for any periodically oscillating flow. The flow meter is particularly adapted for measuring the flow characteristics of high pressure automotive fuel injection systems. Three embodiments of the flow meter are described, including a stationary stand for off-line bench testing flow rate in a fuel injection system, a portable flow meter for inline testing in a vehicle's fuel line, and an on-board flow meter sensor connected to an engine control module.

Owner:COMBUSTION DYNAMICS

Self-oscillating fluid sensor

A method and apparatus for determining properties of said fluid using a self-oscillating fluid sensor. In a preferred embodiment, a sensor is provided that operates at a frequency that is related to the time-of-flight of temperature disturbances flowing through the fluid. Based on this transit time, selected fluidic properties of the fluid can be determined.

Owner:HONEYWELL INC

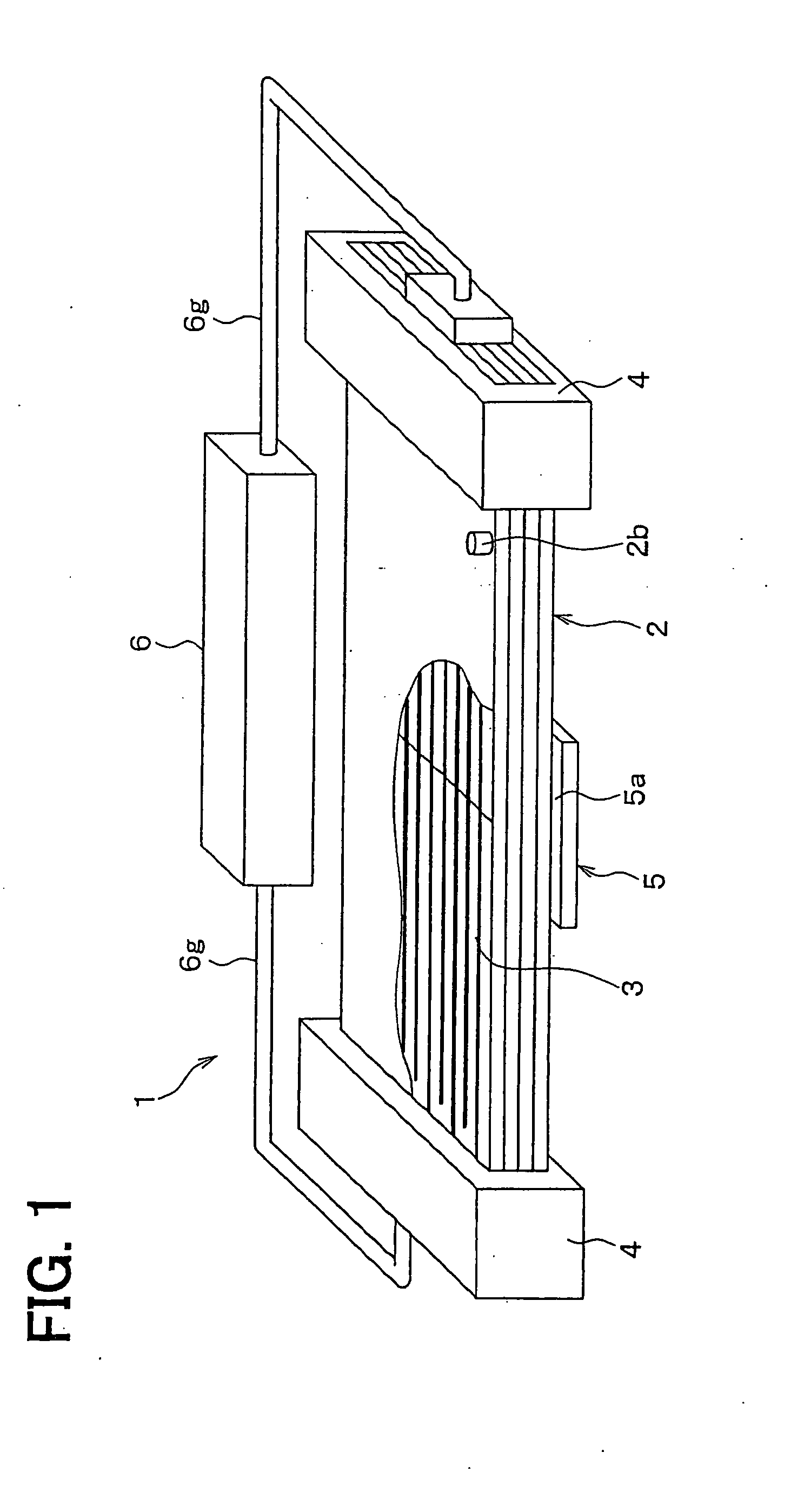

Self-excited oscillating flow heat pipe

InactiveUS20100319884A1Improve transportation capacityIndirect heat exchangersWorking fluidSelf excited

A self-excited oscillating flow heat pipe includes a heating unit having a wick therein; a cooling unit filled with a working fluid; a connection channel which rectilinearly connects the heating unit with the cooling unit, and has a smaller channel cross-sectional area than the channel cross-sectional area of the heating unit; a liquid plug protruding into the connection channel from the cooling unit and containing the working fluid; and a vapor plug in the heating unit containing the vaporized working fluid. The liquid plug oscillates self-excitedly in the connection channel.

Owner:NAT UNIV CORP YOKOHAMA NAT UNIV

High-power LED (light emitting diode) heat radiator

InactiveCN102767809AMeet the requirements for timely releasePoint-like light sourceLighting heating/cooling arrangementsBoiling pointOscillating flow

The invention belongs to the technical field of high heat flux density electronic elements and relates to a high-power LED (light emitting diode) heat radiator, wherein an outer wall of a cylindrical heat conduction cavity is fixedly connected with 4-16 ring-shaped fins; one divergent oscillating-flow heat pipe is coaxially and fixedly connected to each fin; a heating section of the divergent oscillating-flow heat pipe is arranged in a cavity body of the heat conduction cavity after passing through the outer wall of the heat conduction cavity; the divergent oscillating-flow heat pipe is fixedly and hermetically connected with the outer wall of the heat conduction cavity; a round LED base is coaxially and fixedly connected to the lower end face of the heat conduction cavity; an LED chip is fixedly connected to the centre of the LED base; a sealed container is used as the heat conduction cavity, and heat conduction media are filled in the heat conduction cavity. With the adoption of the united running of the divergent oscillating-flow heat pipe and the heat conduction cavity filled with low boiling-point heat conduction medium or heat conduction oil, heat generated by the LED is released in time, so that the heat radiator is an efficient, portable and beautiful high-power LED heat radiator which is suitable for the radiation of high heat flux density electronic elements and particularly suitable for the heat radiation of high-power LEDs.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

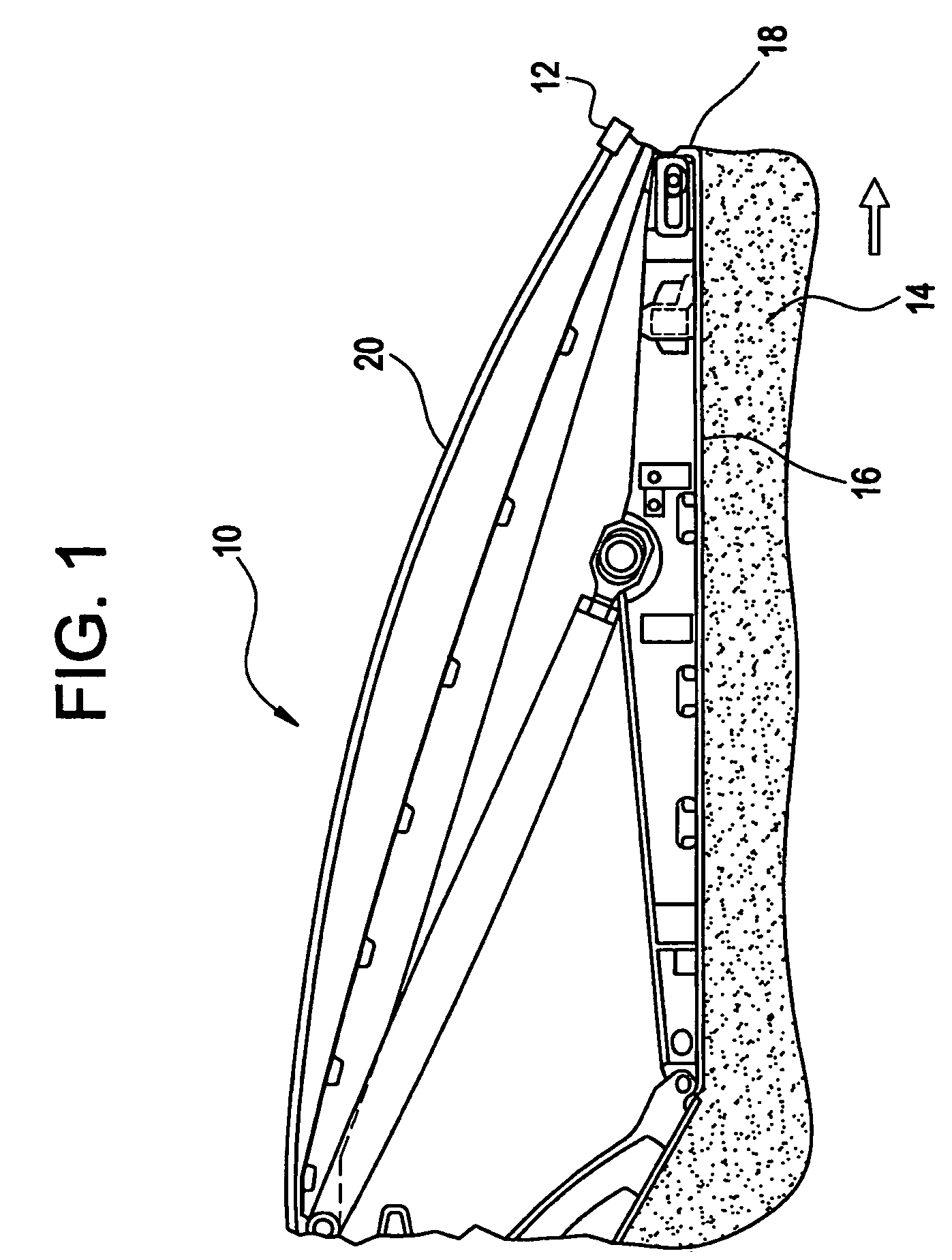

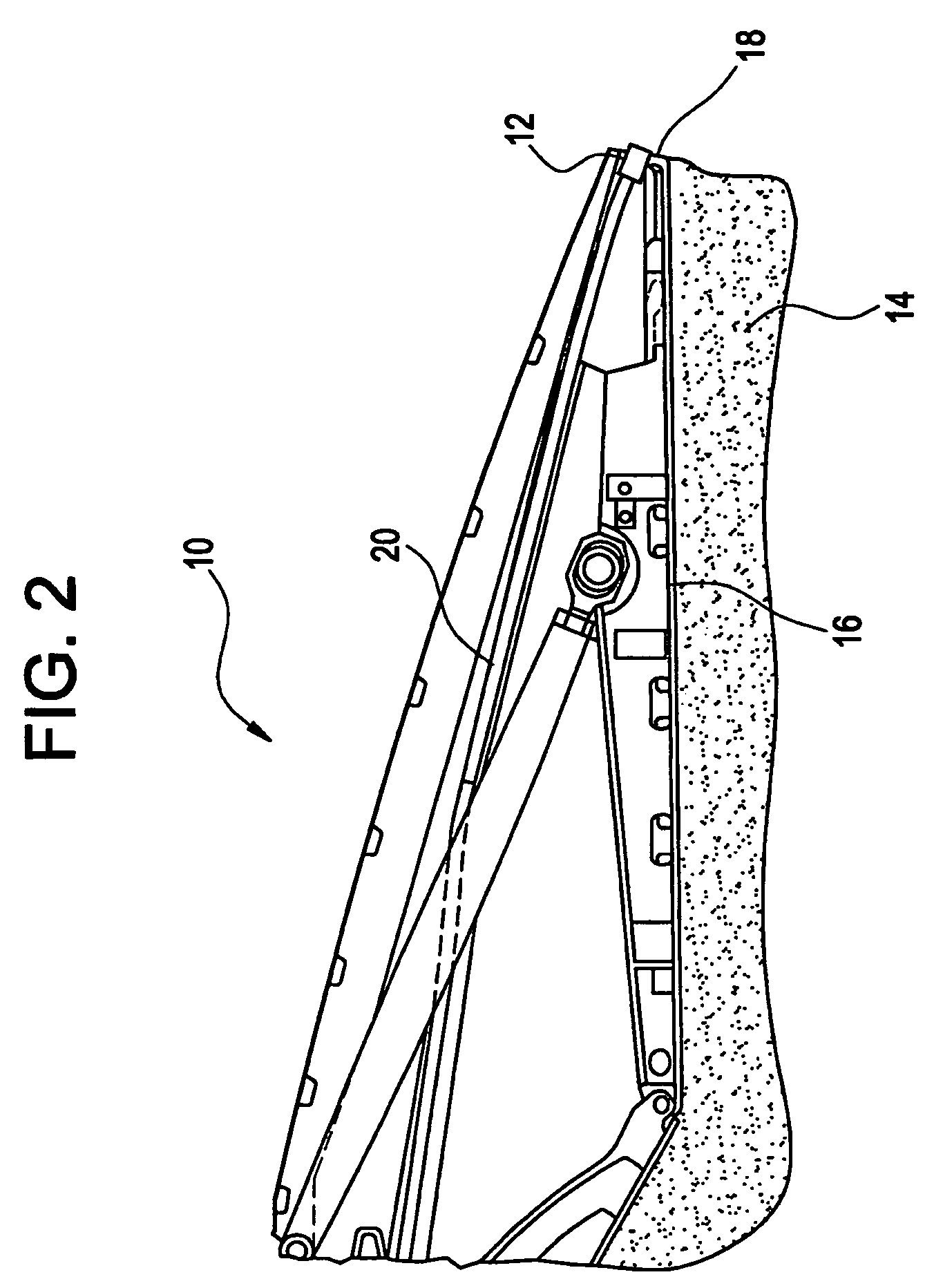

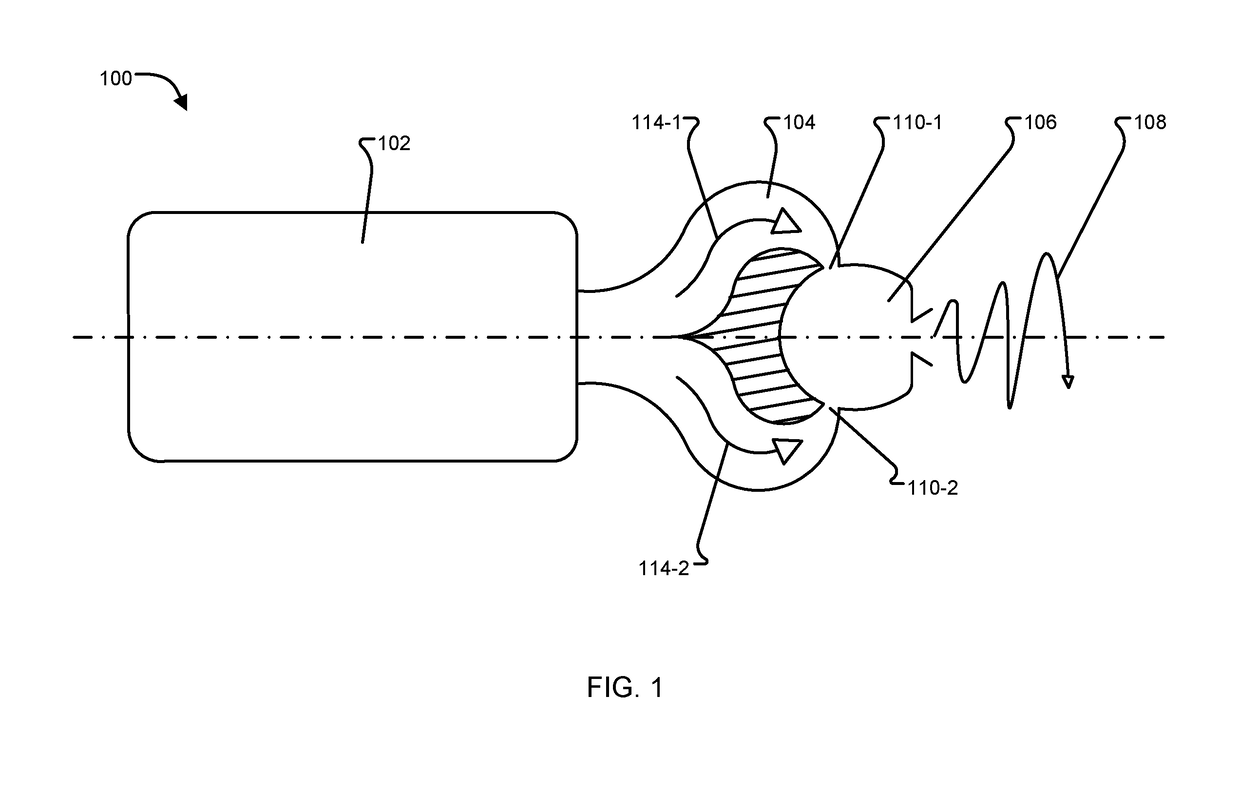

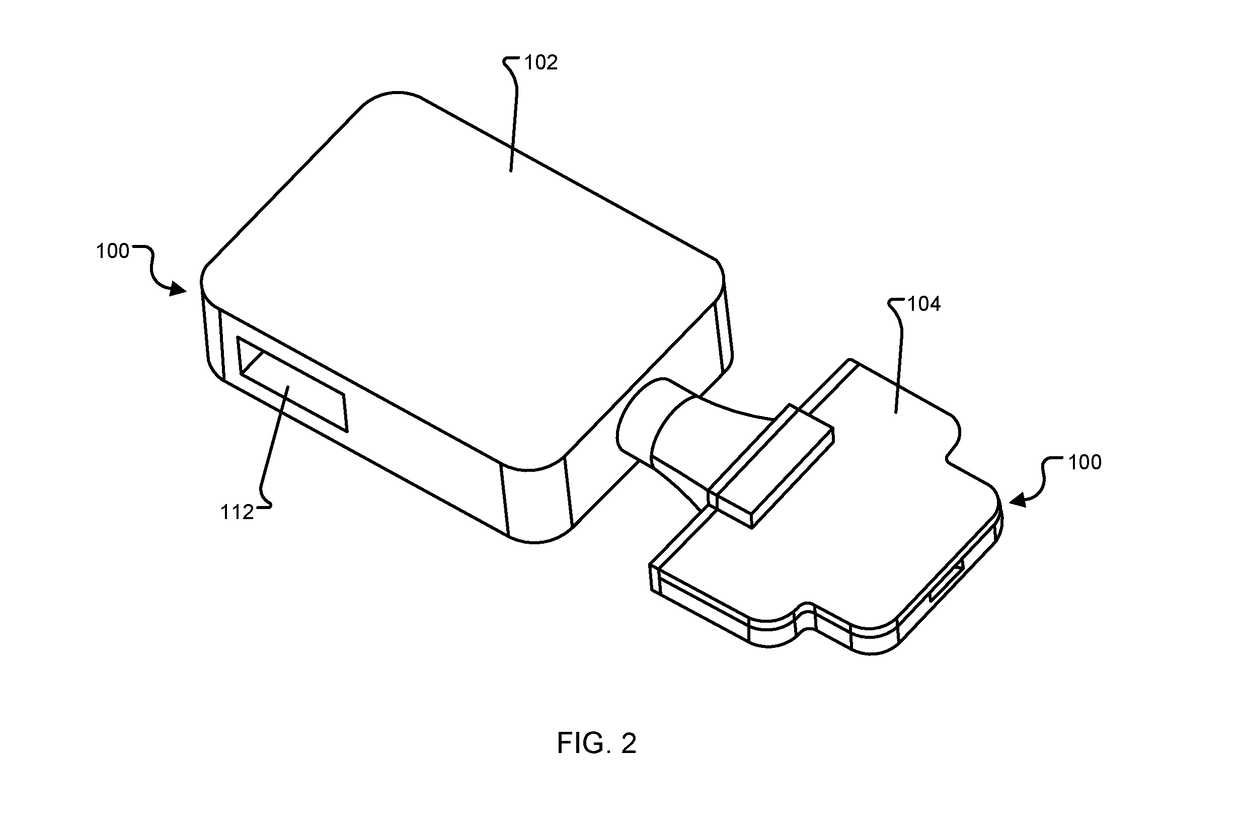

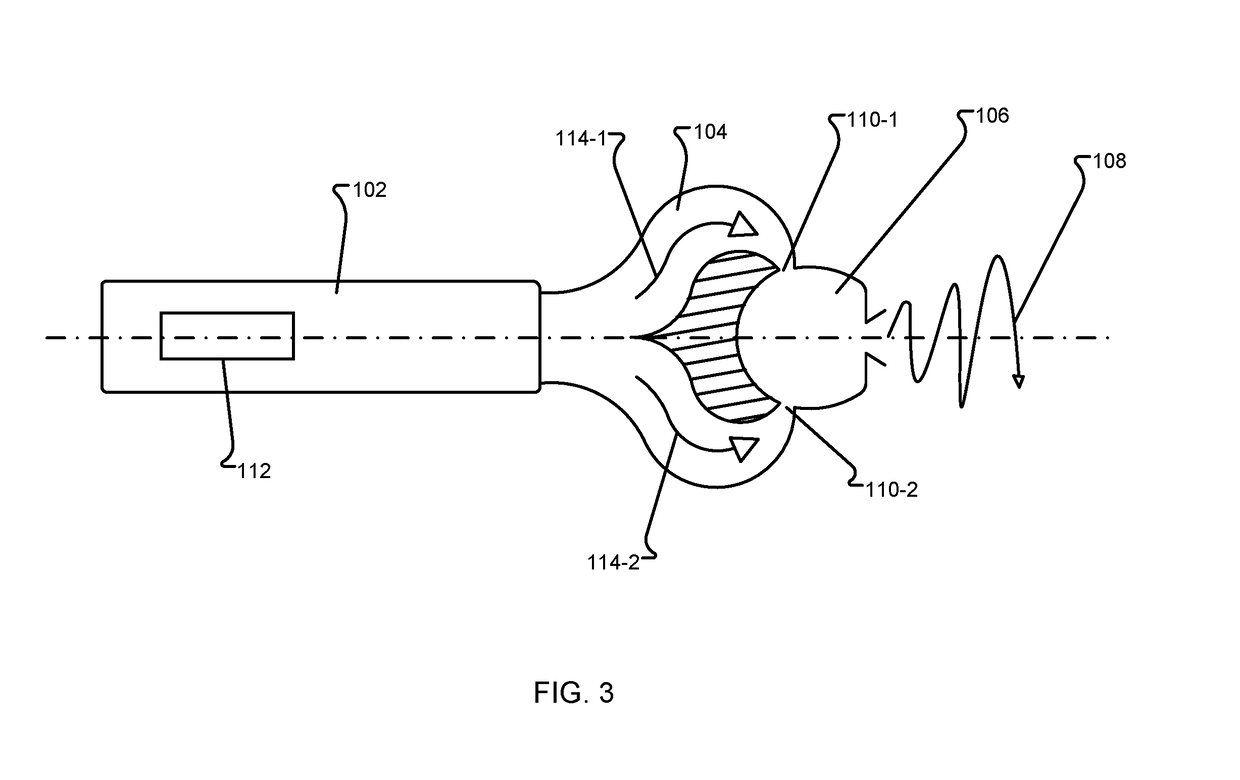

Integrated aerodynamic flow control system with air source

An aerodynamic flow control system includes a plurality of actuator units integrated at predetermined locations along a span of an aerodynamic surface of a vehicle to provide aerodynamic active air flow control, wherein each of the plurality of actuator units includes an electrically powered compressor to compress air; a transitional component to receive the compressed air from the compressor and provide two streams of the compressed air; and a fluidic oscillator having two inlet ports that receive the two streams of the compressed air, and an exit port that discharges a single oscillating flow of air at a predetermined velocity.

Owner:ADVANCED FLUIDICS LLC

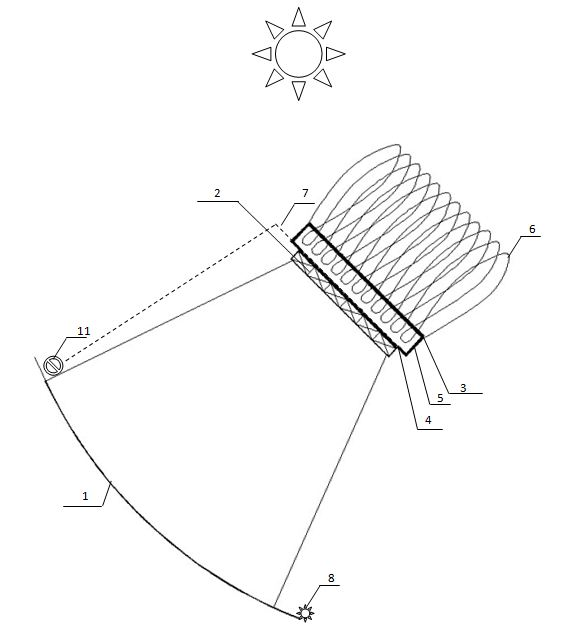

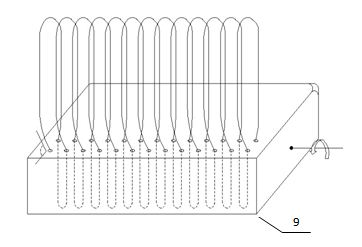

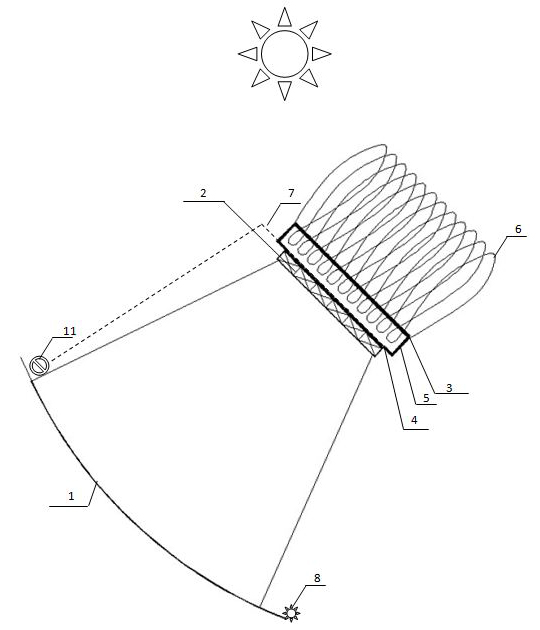

Cooling system of high concentration solar generating battery assembly

ActiveCN101867329AReduce the temperatureExtended service lifePhotovoltaicsPhotovoltaic energy generationHigh concentrationEvaporation

The invention relates to a cooling system of a high concentration solar generating battery assembly for rapidly reducing the temperature of a high concentration solar battery assembly with high efficiency and improving the photoelectric conversion efficiency of a high concentration solar battery provided with a cooling device by 35 percent from 13 percent at present. The cooling system comprises a high concentration device, a solar battery assembly and an oscillating-flow heat-pipe heat radiator which is integrally packaged with the solar battery assembly, wherein an evaporation section is formed at one end of the oscillating-flow heat-pipe heat radiator close to the solar battery assembly and made from a high-thermal-conductivity material containing a U-shaped microchannel, a condensation section is formed at the other end of the oscillating-flow heat-pipe heat radiator, and a condensation section heat pipe is abutted on a U-shaped microchannel opening of the evaporation section to form a mutually communicated loop, is arranged in atmospheric environment and naturally cooled by an outdoor airflow. The whole cooling system is not provided with motion parts, does not need external mechanical power for heat transfer and has simple structure, great equivalent transferring heat, high efficiency, low price and long service life.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Self-excitation oscillating-flow heat pipe with netted pipeline

ActiveCN102759291ASolve the blockageImprove temperature uniformityIndirect heat exchangersHeat exchange apparatusLiquid mediumOscillating flow

A self-excitation oscillating-flow heat pipe with a netted pipeline is spliced by two metal plates. Grooves are formed on at least one metal plate integrally, form a pipeline for sealing up working media on the spliced plane of the two metal plates, and have a crisscross grid structure when being viewed from a direction perpendicular to the planes of the metal plates. With the self-excitation oscillating-flow heat pipe with the pipe network, blockage of the pipeline is overcome well. The self-excitation oscillating-flow heat pipe with the netted pipeline has the advantages of good temperature-equalizing performance, quick heat-transfer, quick returning of working liquid media and the like. What's more, the starting temperature of the self-excitation oscillating-flow heat pipe is reduced, and heat transfer performance thereof is improved remarkably.

Owner:FOSHAN KAICHANG LIGHTING ELECTRICAL APPLIANCE

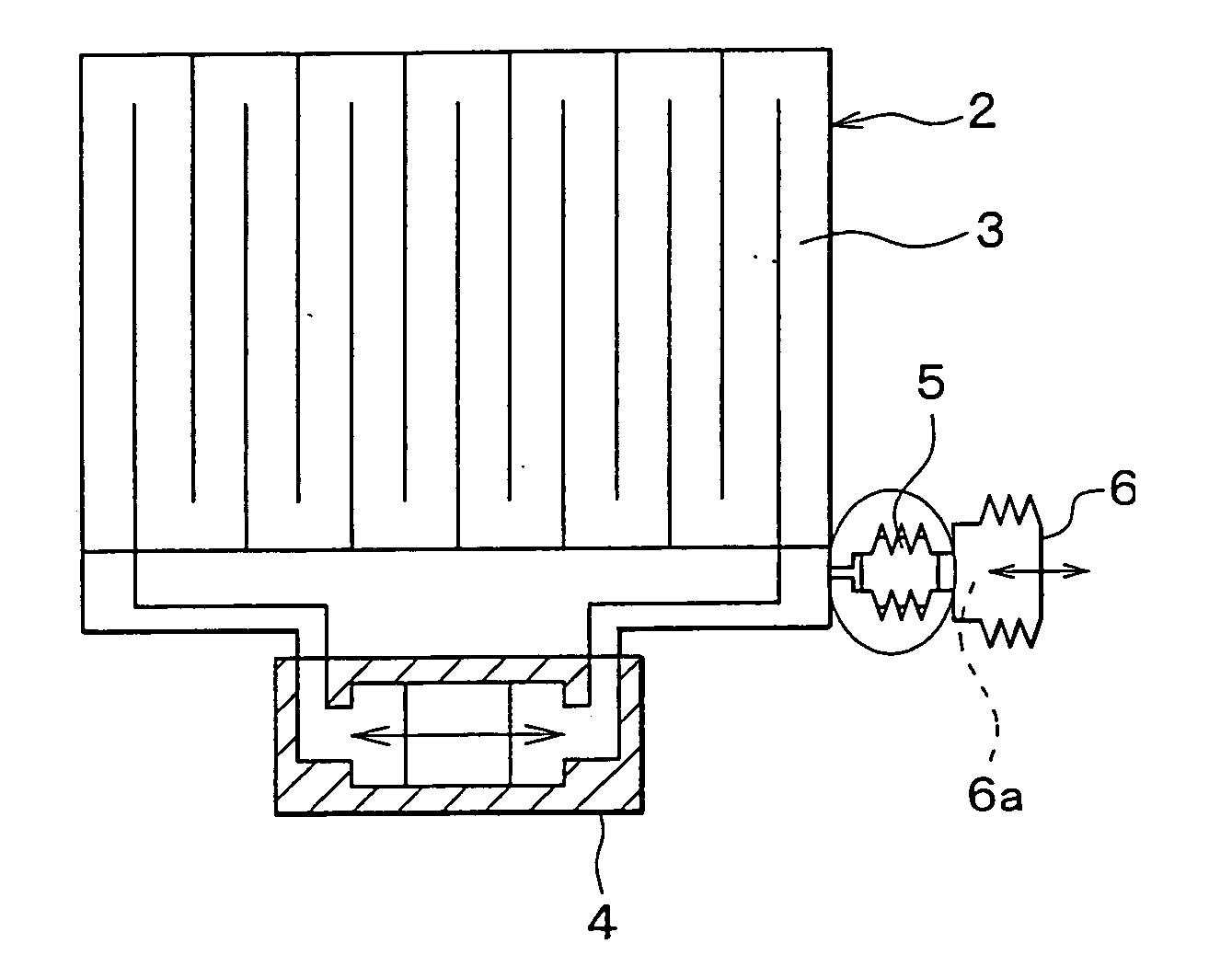

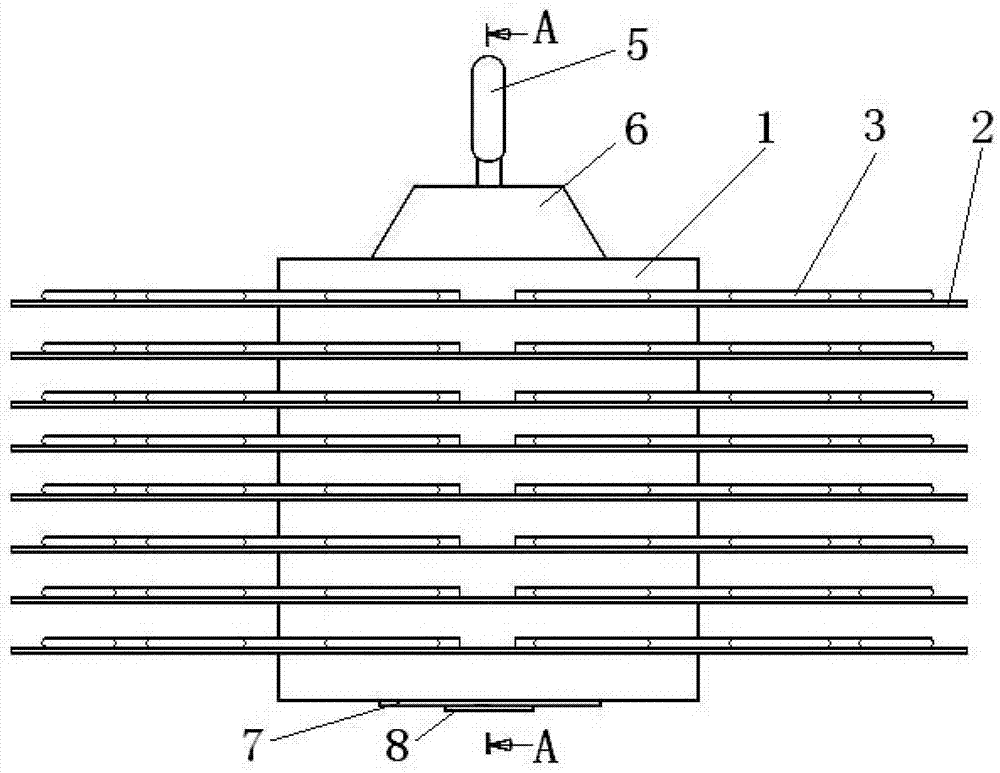

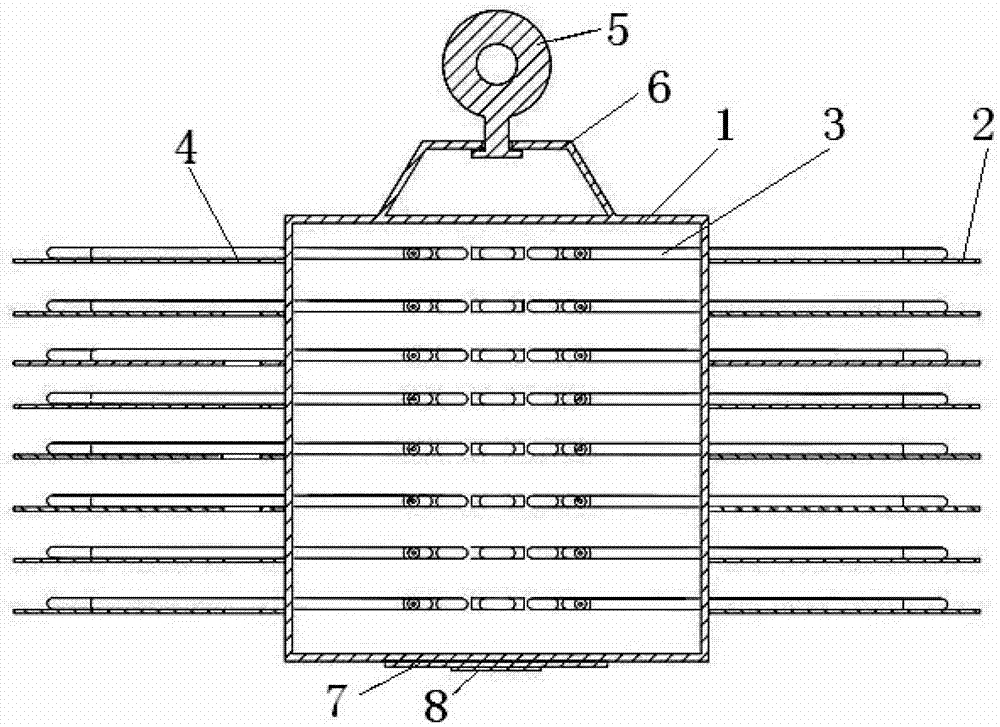

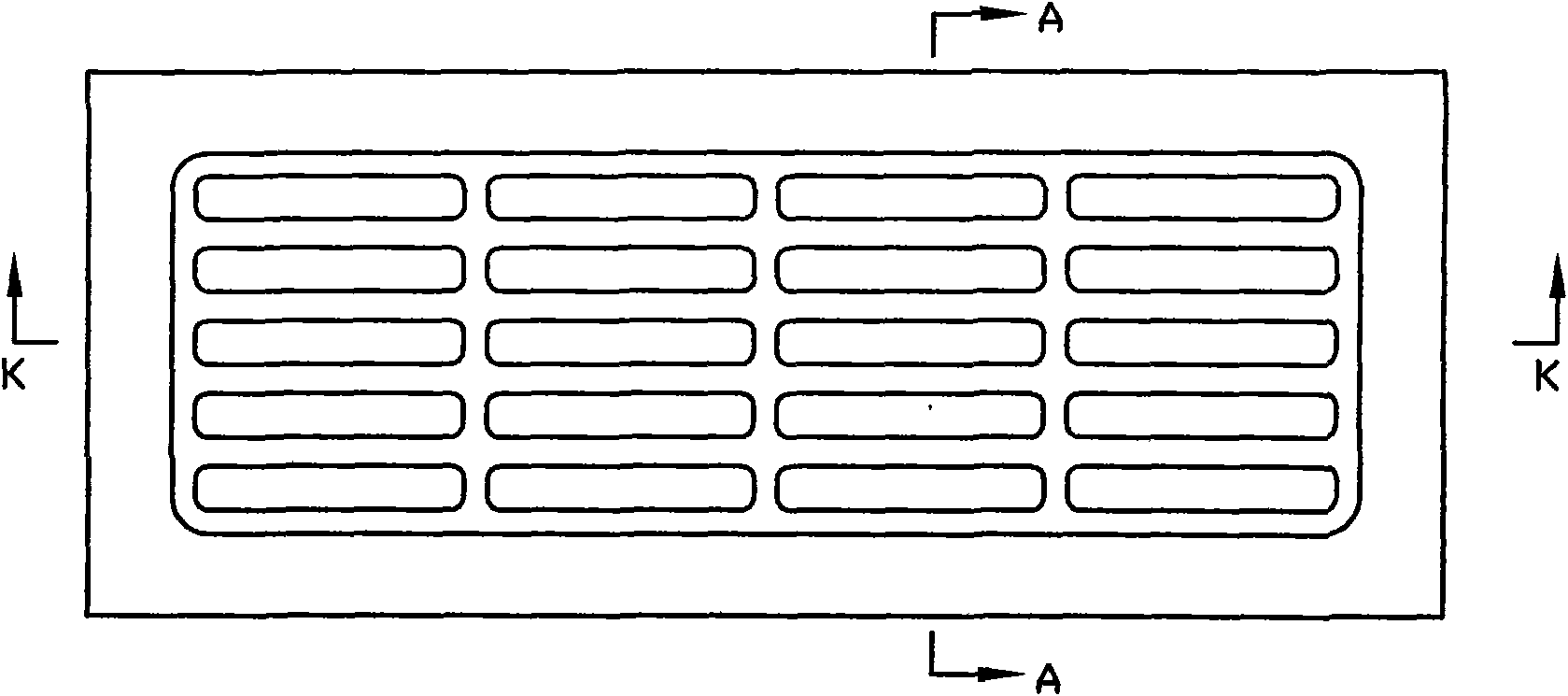

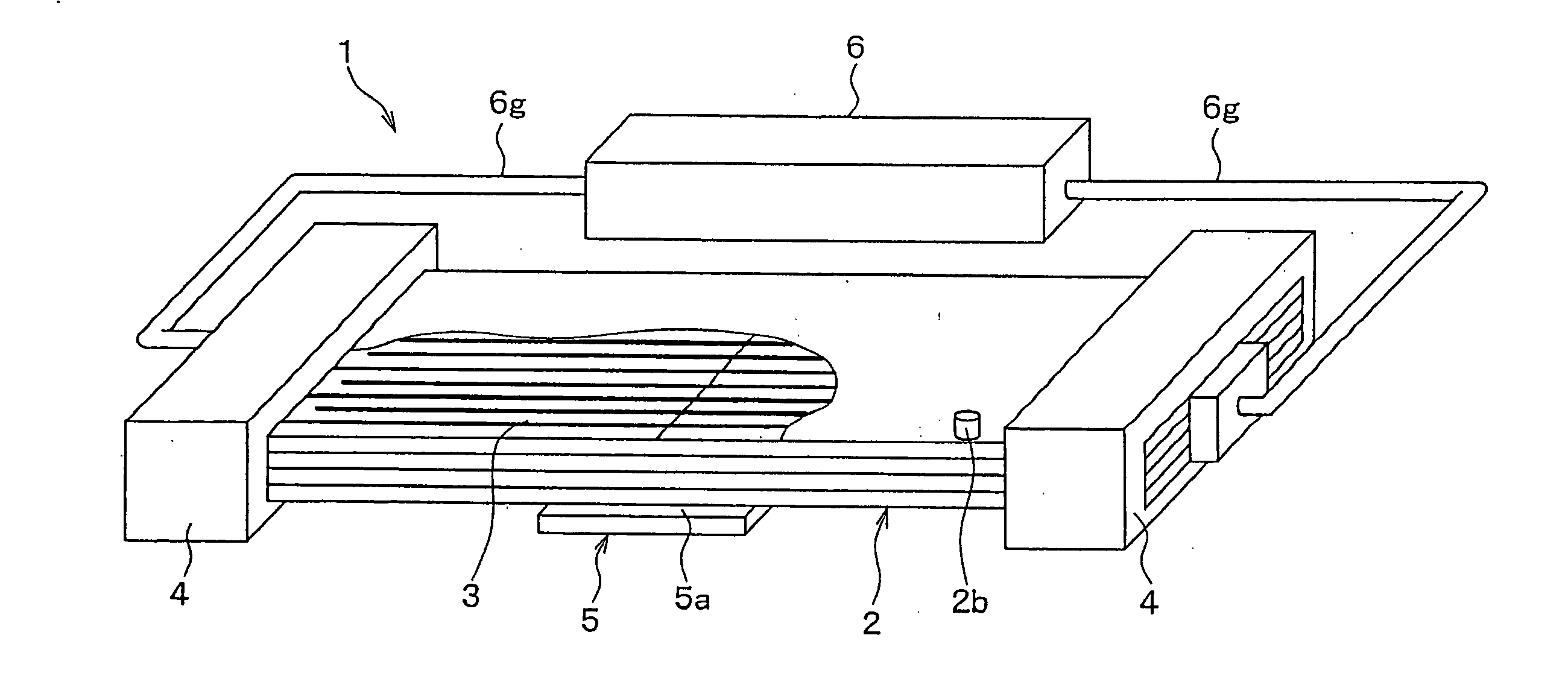

Counter-stream-mode oscillating-flow heat transport apparatus

InactiveUS20090014162A1Low costImprove heat transfer performanceSemiconductor/solid-state device detailsSolid-state devicesOscillating flowMechanical engineering

A counter-stream-mode oscillating-flow heat transport apparatus improves heat transport capability by imparting oscillatory displacement to a fluid located near a heat-generating element such that the fluid is directed toward the heat-generating element. Turning portions of serpentine flow paths are disposed to face the heat-generating element. The flow paths are stacked in multiple layers in the direction from the heat-generating element to the flow paths, and a plurality of flow paths are disposed adjacent to the heat-generating element in the direction of fluid oscillation.

Owner:DENSO CORP

High heat-dissipation brake disc

The invention discloses a high heat-dissipation brake disc, which comprises a disc body. Annular opening slots are formed in side walls of the disc body; a plurality of selfexcited oscillating-flow heat pipes are arranged in the opening slots; and two ends of the selfexcited oscillating-flow heat pipes are connected with the top parts and the bottom parts of the opening slots. The high heat-dissipation brake disc with the structure has the advantages of rapidness and promptness in cooling during a brake process.

Owner:重庆市永川区中川科技发展有限责任公司

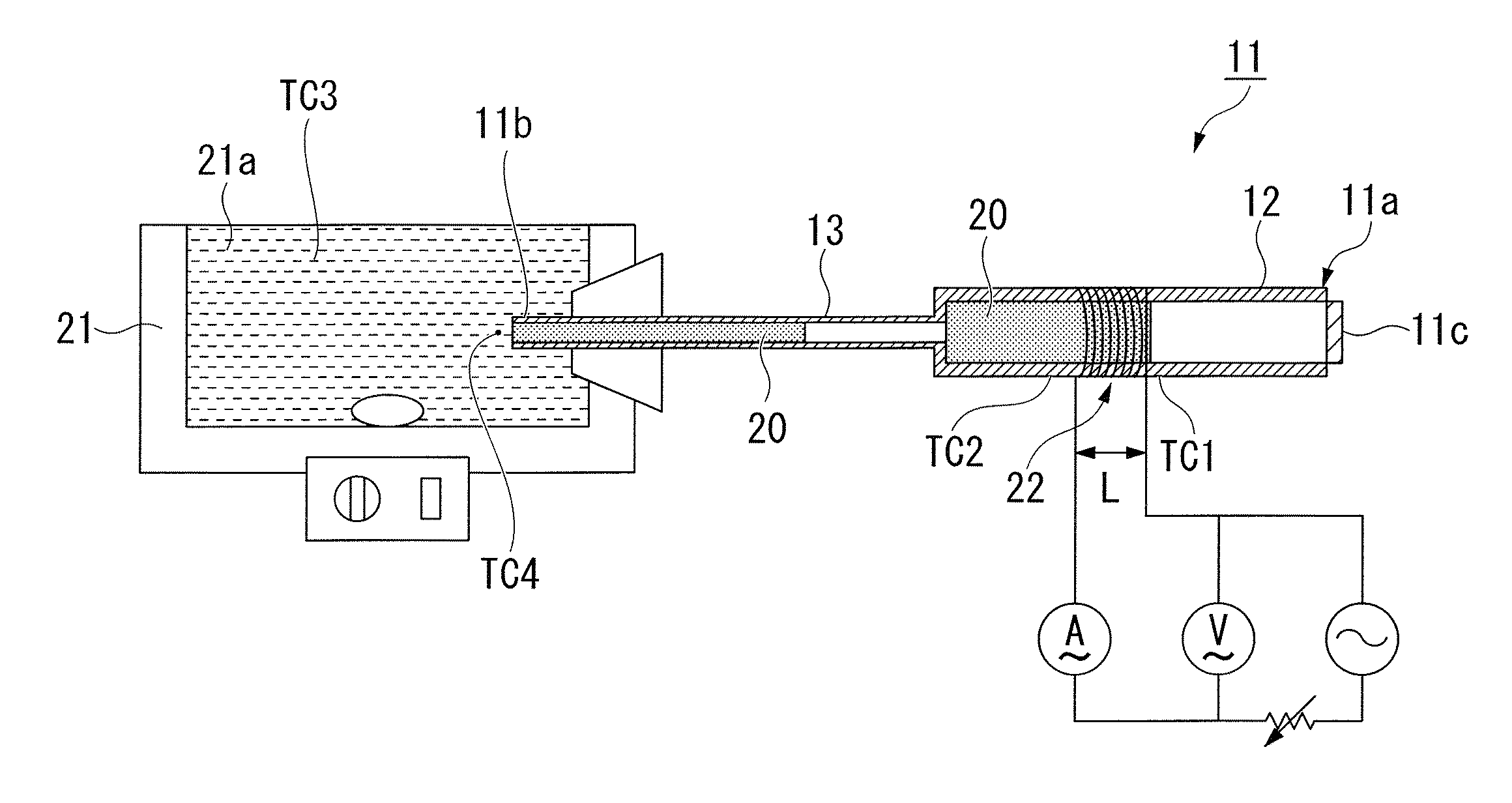

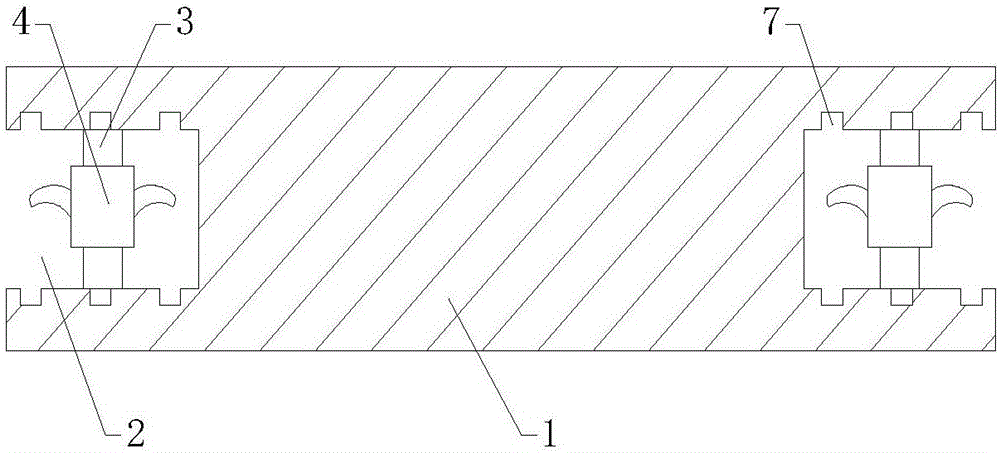

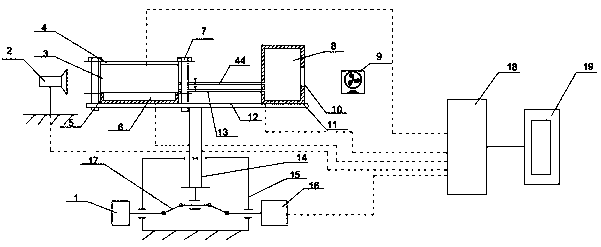

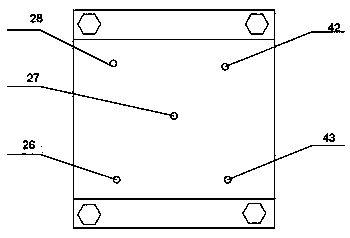

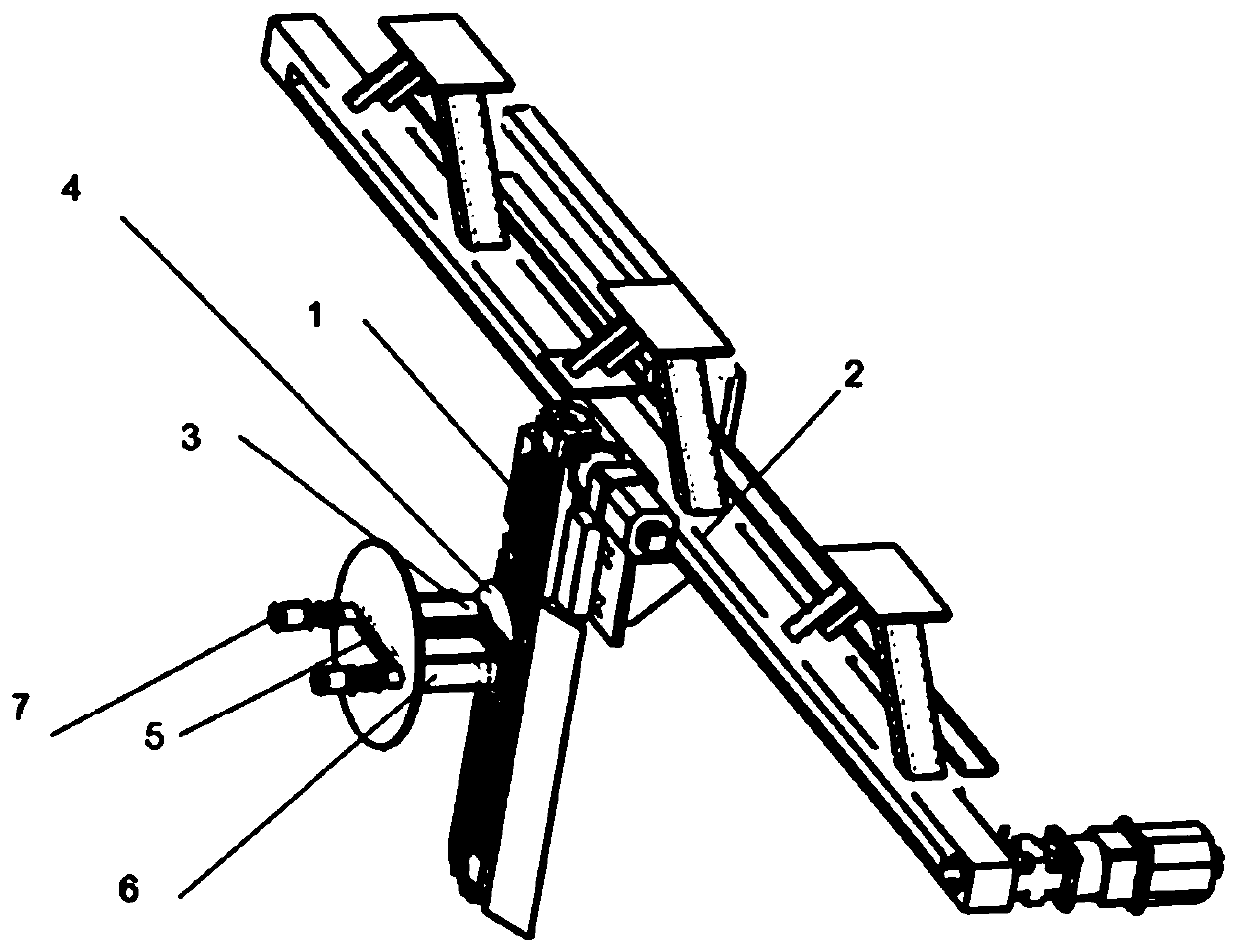

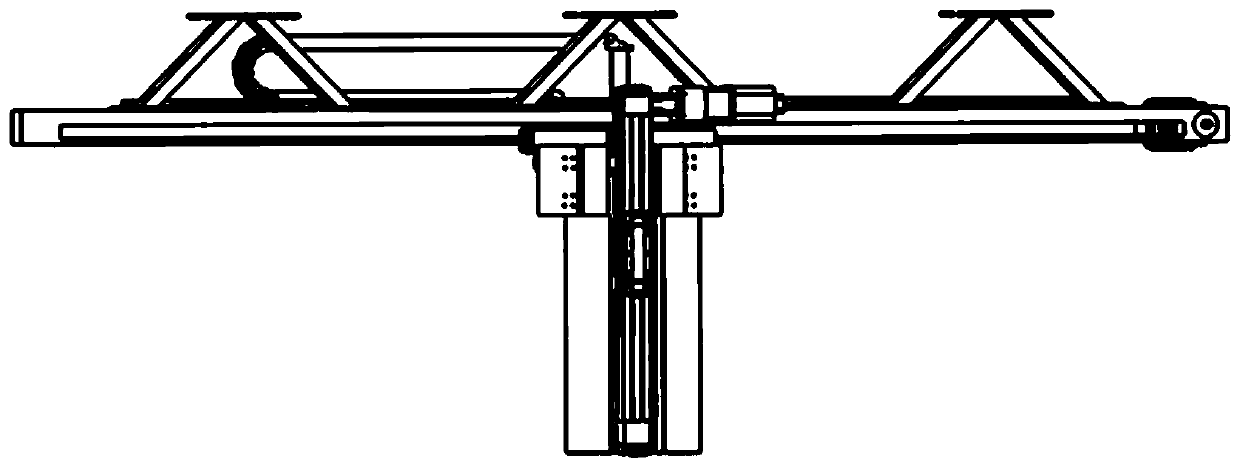

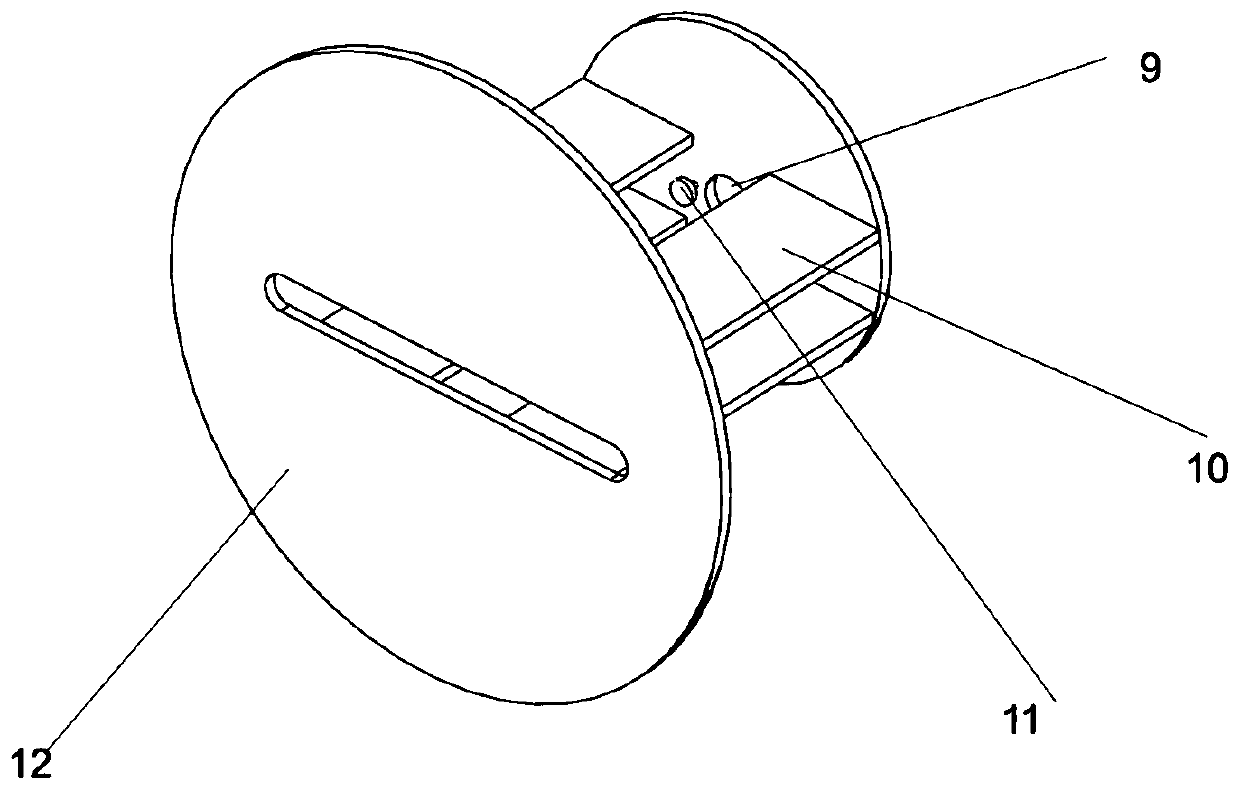

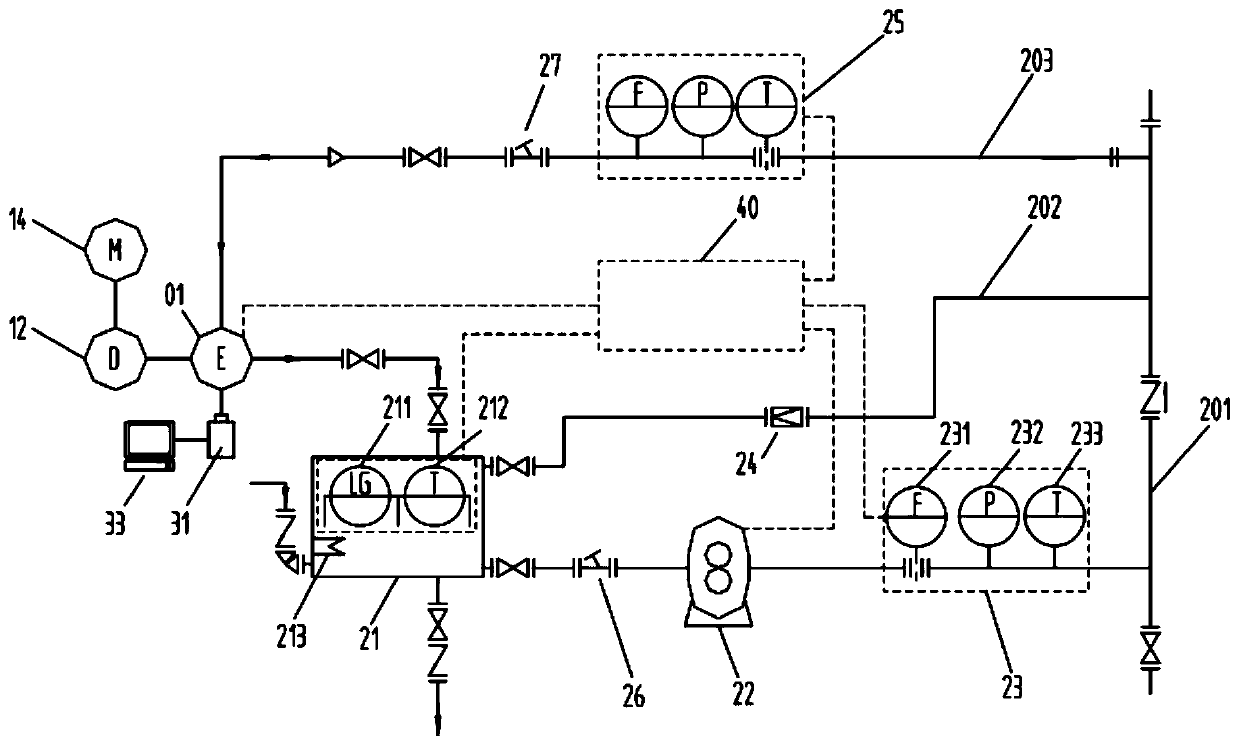

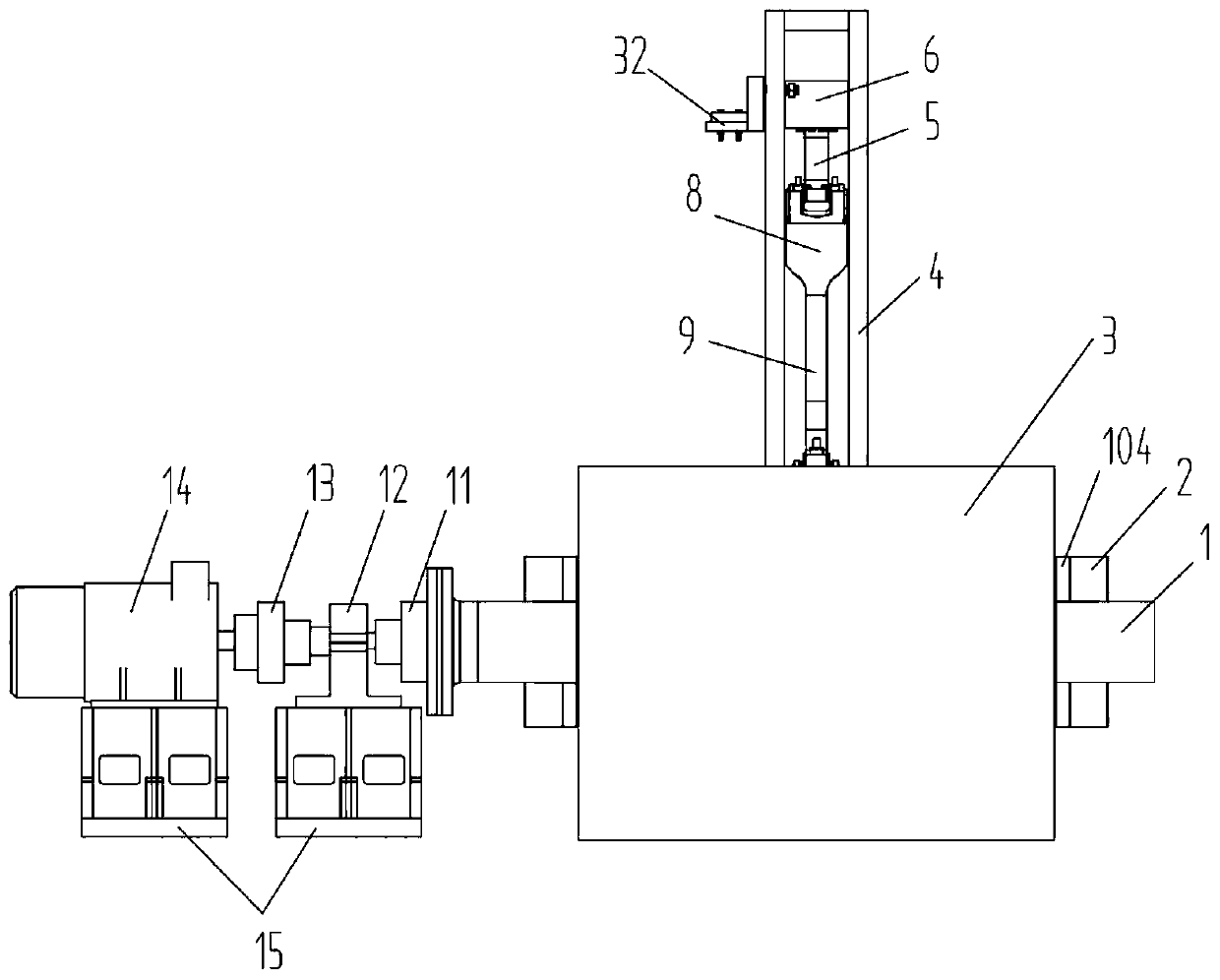

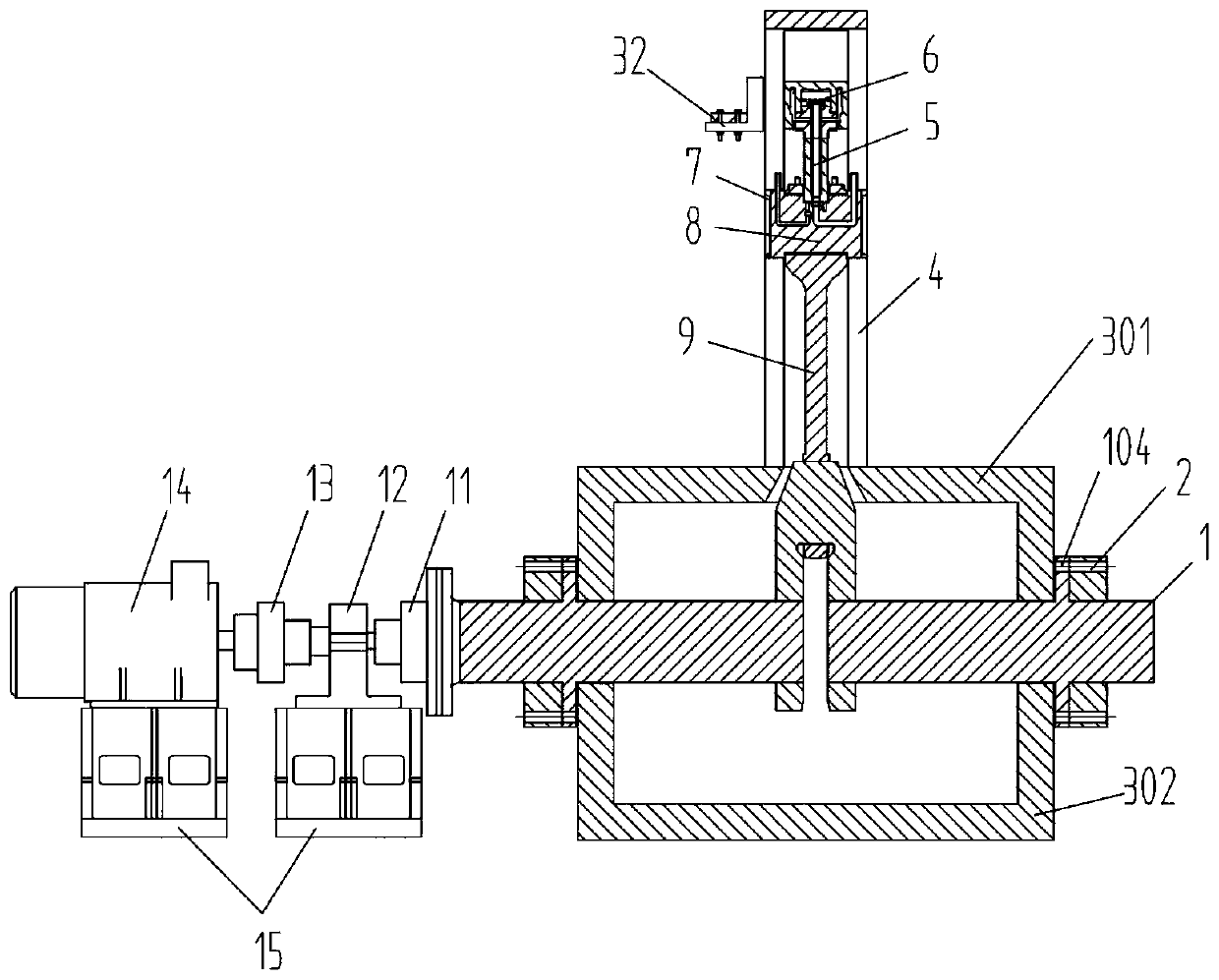

Simulation device and test method for oscillating heat transfer performance of cold oil duct in piston

InactiveCN110057859AVisually observe oscillatory flow characteristicsMaterial thermal conductivityMaterial heat developmentOscillating flowEngineering

The invention relates to a simulation device and test method for oscillating heat transfer performance of a cold oil duct in a piston.The simulation device for oscillating heat transfer performance ofthe cold oil duct in the piston comprises a main body oscillating device, a rectangular cavity heating device, a coolant supply collecting device, a high-speed photographic device, bolts, a mountingplatform, a control box, and a computer;the mounting platform is mounted on the upper side of the main body oscillating device and connected with the main body oscillating device,the rectangular cavity heating device is fixed to one end of the upper surface of the mounting platform through the bolts, the coolant supply collecting device is fixedly mounted on the other end of the upper surface of the mounting platform,the control box is connected with the computer, the main body oscillating device, the rectangular cavity heating device, the coolant supply collecting device, and the high-speed photographic device through wires for data transmission. According to the simulation device and test method for oscillating heat transfer performance of the cold oil duct in the piston, the oscillatingworking condition under the actual working condition of the piston is dynamically simulated, the oscillating flow characteristic of a coolantcan be intuitively observed by using the high-speed camera, at the same time the wall surface heat transfer coefficient can be calculated, and the oscillating heat transfer performance of the cold oil duct in the piston is further analyzed.

Owner:KUNMING UNIV OF SCI & TECH

Particle separating method

InactiveUS20090277845A1Low costEasy to separateWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsOscillating flowFluid field

Owner:SHEEN HORN JIUNN +1

Method for preparing iminodiacetic acid through continuous hydrolysis and self-oscillating reactor

ActiveCN106905176AHigh yieldEnhanced mass transferProcess control/regulationSequential/parallel process reactionsIminodiacetic acidOscillatory reaction

The invention discloses a method for preparing iminodiacetic acid through continuous hydrolysis. The method comprises the following steps: mixing reaction material imidogen diacetonitrile and water in proportion; providing a perfectly mixed reactor, conveying the reaction material into the perfectly mixed reactor, so as to perform hydrolysis reaction; providing a tubular reactor, and conveying reaction liquid in the perfectly mixed reactor into the tubular reactor under the action of liquid level difference pressure; providing a product storage tank, ensuring that the reaction material performs periodic self-oscillating flowing between the tubular reactor and a product storage tank, discharging a product into the product storage tank after reaction. The method for preparing iminodiacetic acid through continuous hydrolysis improves the reaction yield. The invention further provides a self-oscillating reactor.

Owner:XIANGTAN UNIV

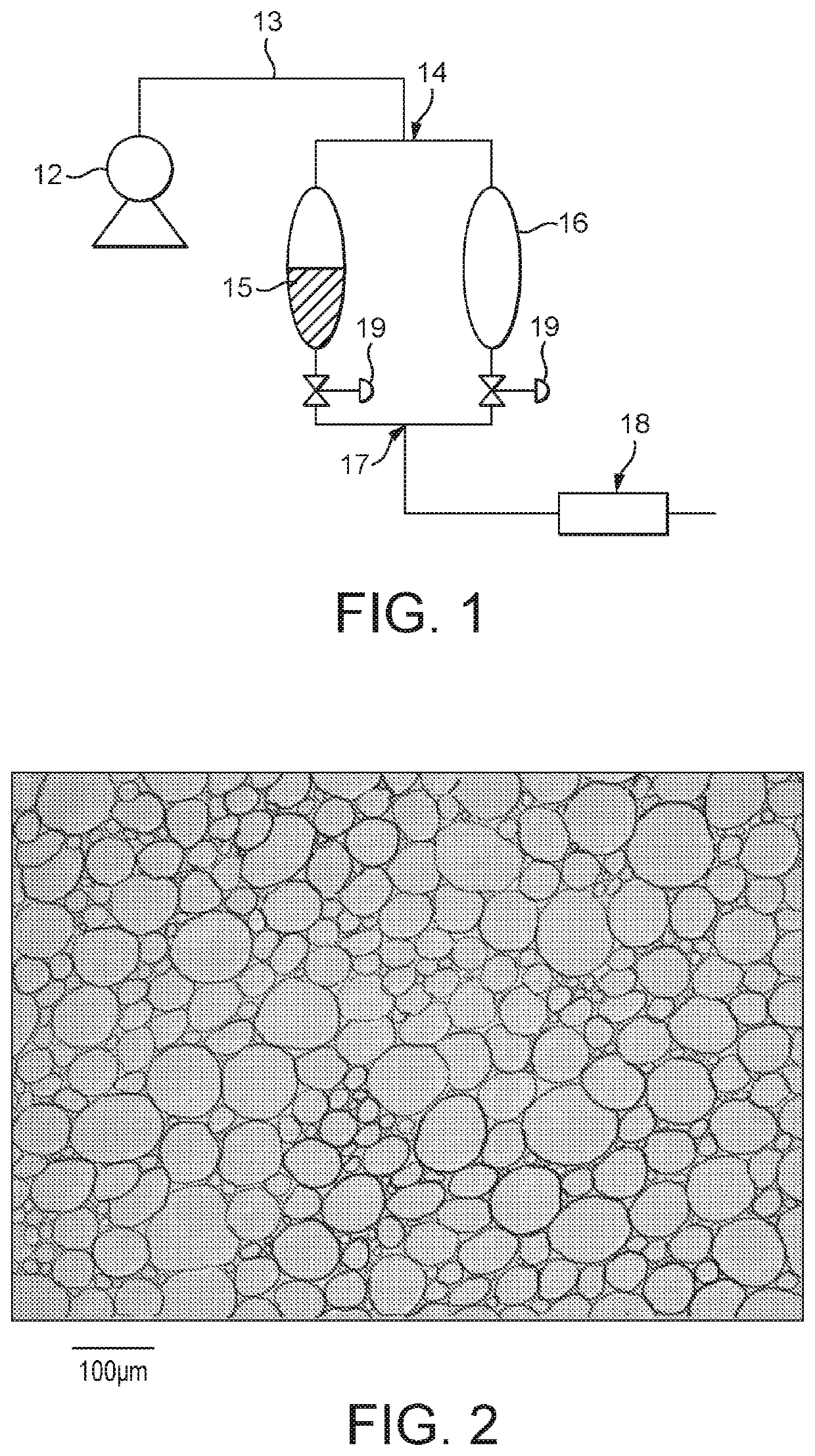

Apparatus and method for generating a microfoam

ActiveUS20200023323A1Minimizes and prevents appearanceCheap to makeAdditive manufacturing apparatusFlow mixersMicro bubbleOscillating flow

An apparatus or method for generating a microfoam, the apparatus comprising a channel having an inlet and an outlet, a source of foamable liquid and pressurised gas arranged to feed into the inlet, wherein the channel is comprised of a spatially oscillating flow channel to provide an oscillating flow direction, the spatially oscillating flow channel oscillating about a bulk flow direction, the spatially oscillating flow channel providing a sequence of planar cross-sections perpendicular to the flow direction, with a sub-sequence of planar cross-sections that are perpendicular to the bulk flow direction in the plane in question, the sub-sequence comprising at least one plane that does not overlap with at least one other plane in the sub-sequence.

Owner:TRIPLE LINE TECH LTD

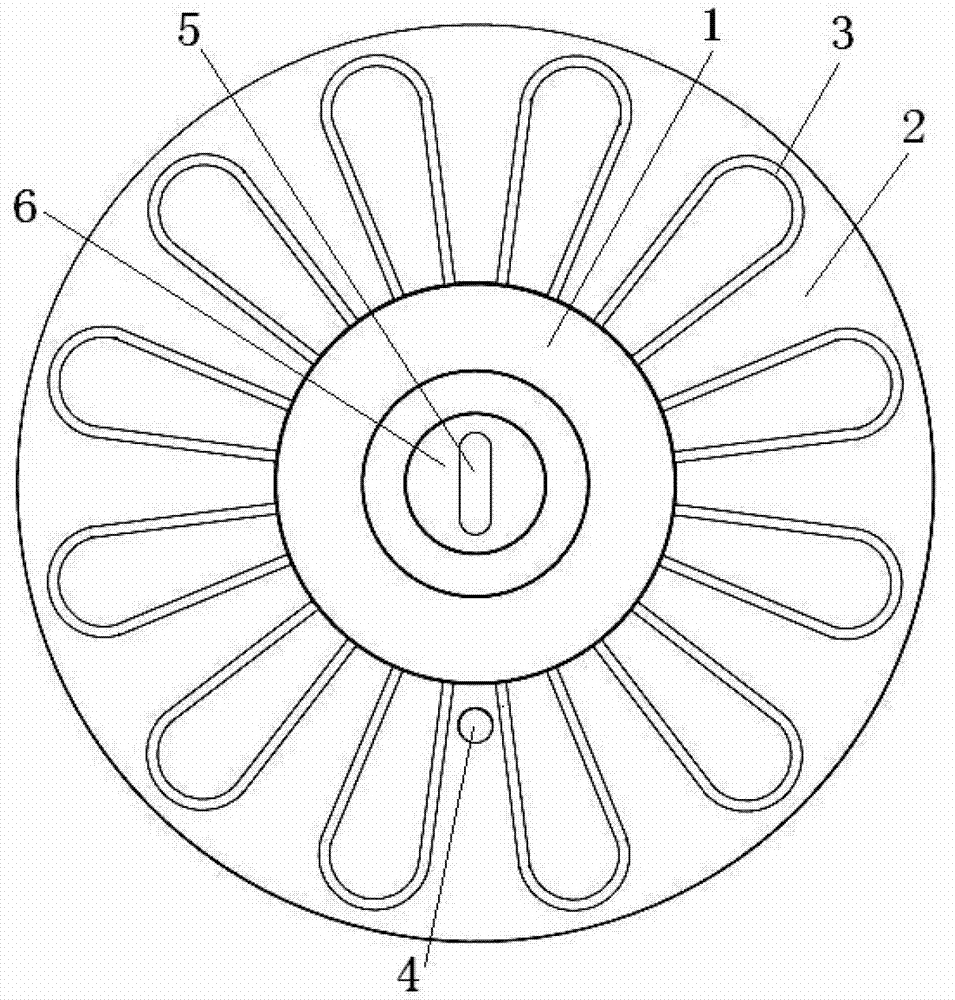

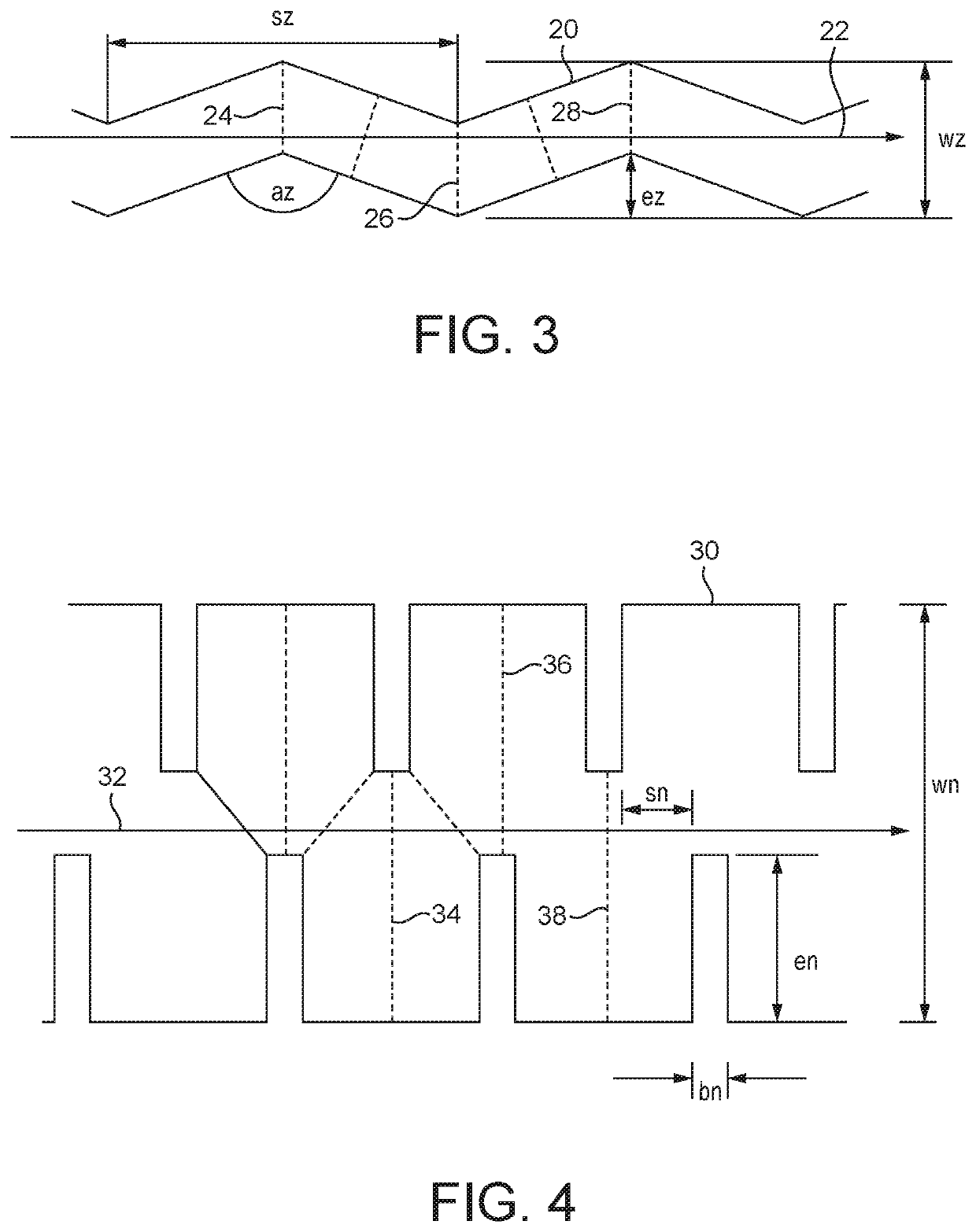

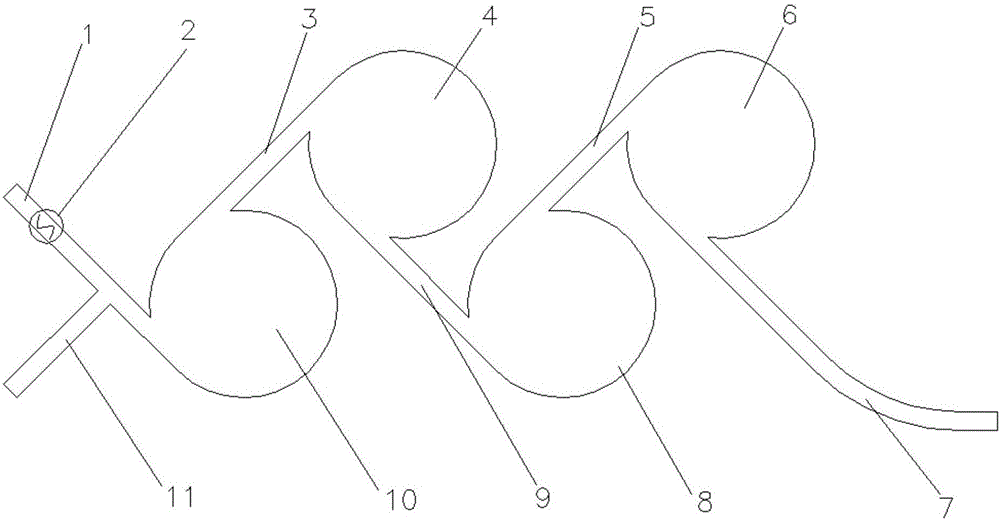

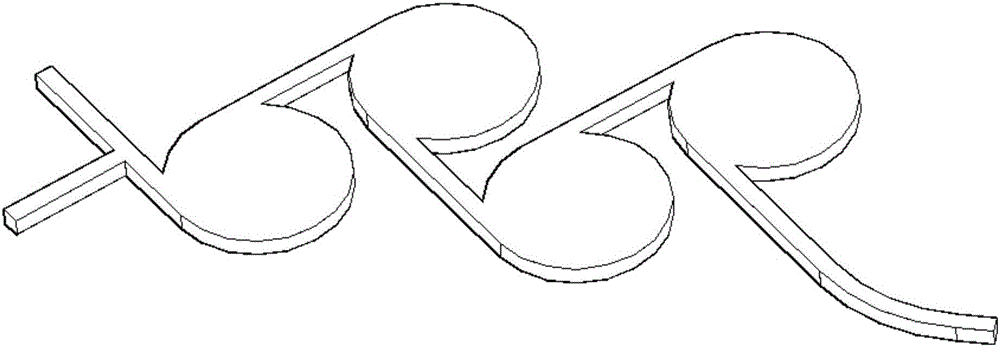

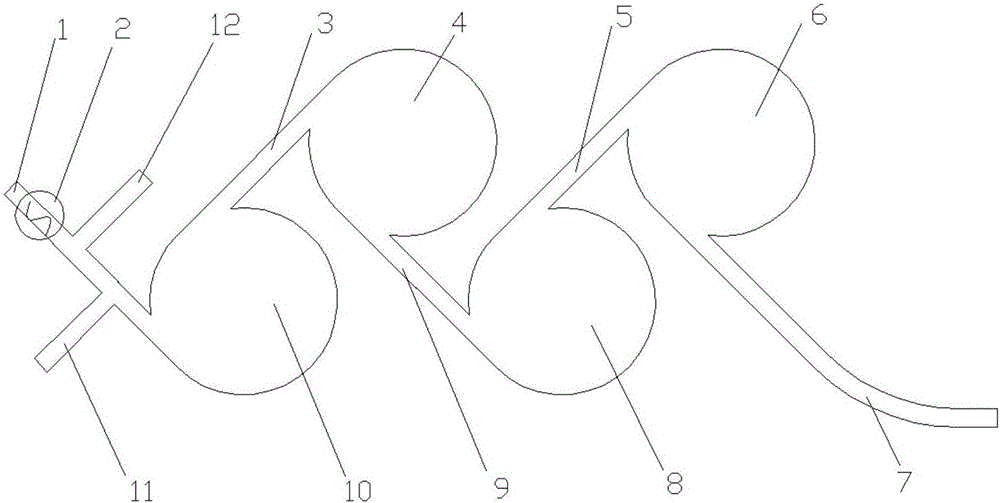

Oscillating flow micromixer

ActiveCN106823946AWell mixedImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingInlet channelOscillating flow

The invention discloses an oscillating flow micromixer which comprises an oscillator, an inlet channel, circular chambers, connecting channels and an outlet channel; the oscillator, the inlet channel, the circular chambers, the connecting channels and the outlet channel are positioned in the same one plane; the oscillator is arranged at the inlet channel; a first inlet channel is tangentially connected with the first circular chamber, the first connecting channel is tangential to the first circular chamber and the second circular chamber, and the position of the first connecting channel is positioned at the position close to the oscillator; the remaining connecting channels are sequentially tangential to the excircles of the two circular chambers which are connected, and the remaining connecting channels are perpendicular to the front connecting channel and are positioned between the connected circular chambers and the front circular chamber; the outlet channel is tangential to the excircle of the last circular chamber, is perpendicular to the cth connecting channel and positioned between the last two circular chambers. The micromixer is applicable to mixing of high-flow fluid with wide viscosity range, and has better universality.

Owner:NANJING UNIV OF SCI & TECH

Test device for vortex-induced vibration response of parallel flexible riser

ActiveCN110146241AHigh precisionNo rotationHydrodynamic testingVibration testingModular designOscillating flow

The present invention provides a measuring device for the vortex-induced vibration response of a parallel flexible riser. The measuring device is characterized in that: adjustment of a distance between the parallel flexible risers is implemented by rotating the bolts; the magnitude of the dynamic response parameters such as the relevant stress and strain is measured; the angle of the plane formedby two risers with respect to the flow field direction is arbitrarily changed; the conditions of the deep water experimental pool are fully used to simulate the response environment of the vortex-induced vibration; by moving the whole device to make the whole device move relative to the fluid, the uniform flow field and the oscillating flow field are simulated; the magnitude of the pre-tension isadjusted by using a tensioner connected at the end of each flexible riser, and the tensioner acts as a buffer during the vibration process; and the influence of the change of the flow field on the riser during the movement is eliminated by using a baffle. According to the technical scheme of the present invention, the device is easy to install, a modular design is used, adjustment of the distancebetween the two risers is independent of the angle adjustment, and the device is easily improved into a multi-riser vibration test device with good adaptability.

Owner:SHANGHAI JIAO TONG UNIV

Visual simulation device for oscillating flow in cooling oil passage in piston of crosshead type diesel engine

InactiveCN110207991AVersatilityEasy to operateInternal-combustion engine testingOscillating flowEngineering

Owner:HARBIN ENG UNIV

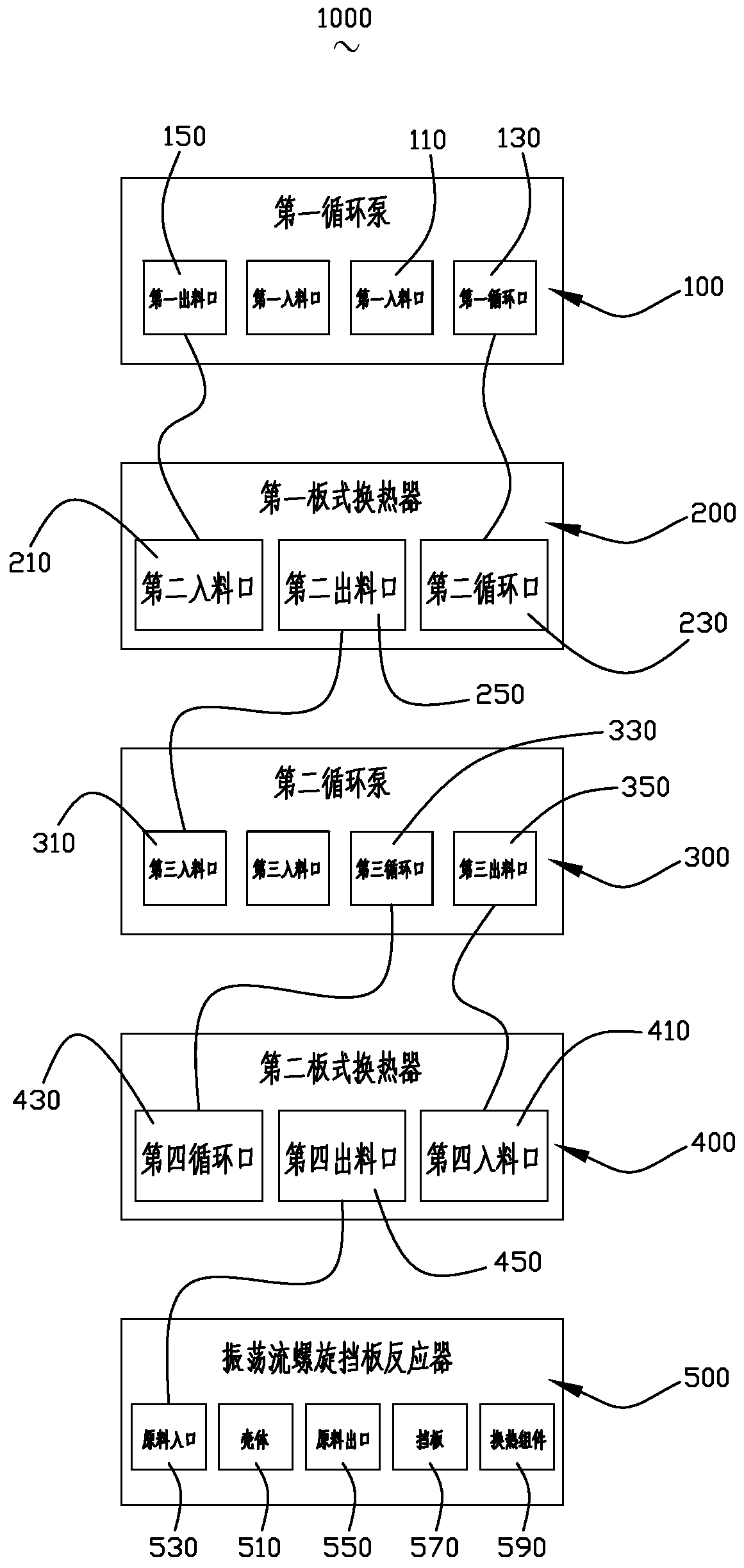

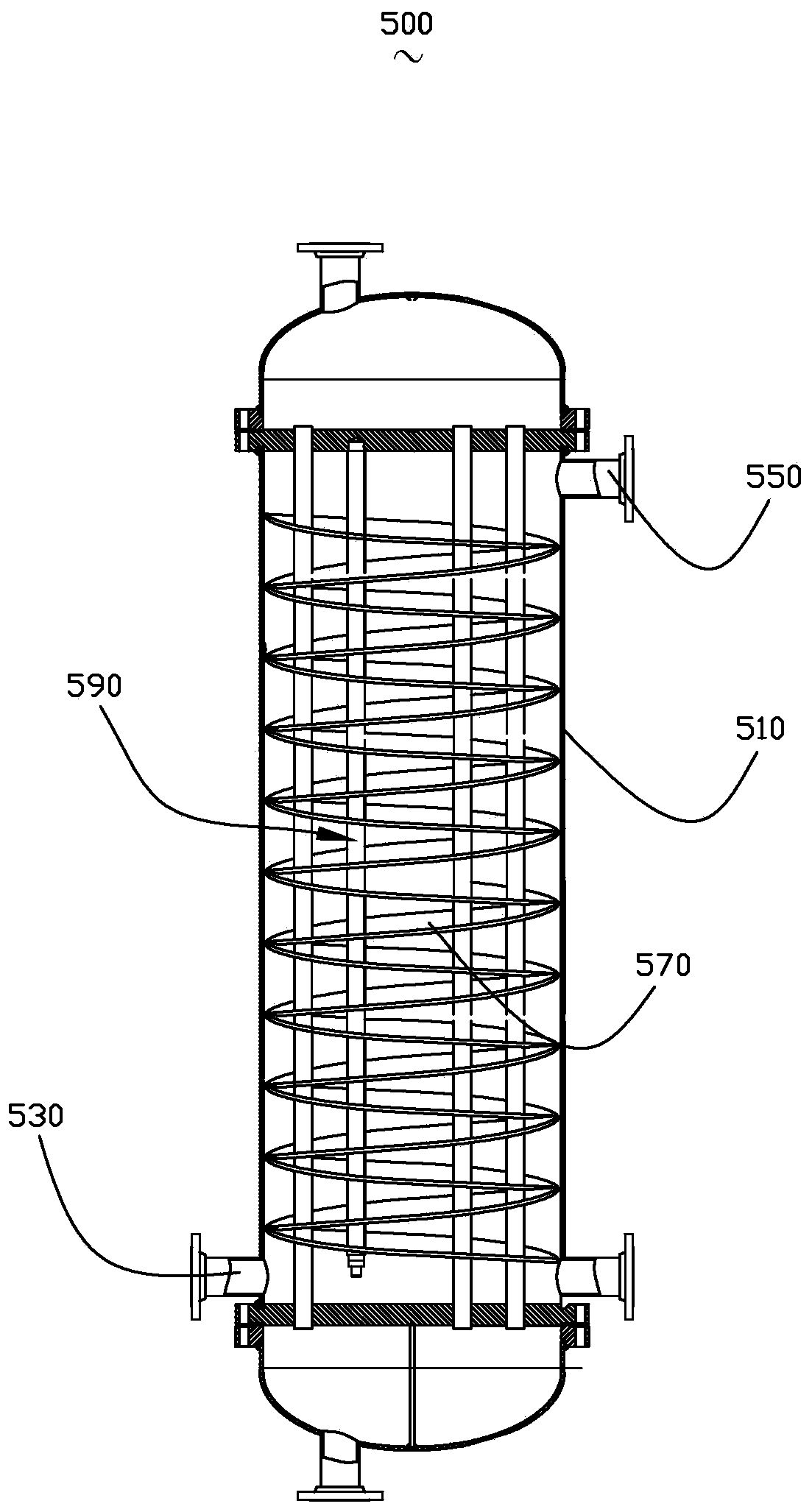

Device and synthesis method for continuously synthesizing 4-bromo-2-p-chloro-5-trifluoromethyl pyrrole-3-nitrile

PendingCN109776376AImprove heat transfer efficiencyImprove production efficiencyOrganic chemistrySynthesis methodsBromine

The invention provides a device for continuously synthesizing 4-bromo-2-p-chloro-5-trifluoromethyl pyrrole-3-nitrile, which comprises a first circulating pump, a first plate type heat exchanger, a second circulating pump, a second plate type heat exchanger and an oscillating flow spiral baffle reactor which are sequentially communicated, wherein the oscillating flow spiral baffle reactor comprisesa shell with an accommodating space, a raw material inlet and a raw material outlet provided in the shell and a baffle plate erected in the accommodating space; the baffle plate is a baffle board; two ends of the baffle plate are respectively communicated with the raw material inlet and the raw material outlet; the baffle plate cuts the accommodating space into a continuous bending structure. Compared with the related art, the device for continuously synthesizing 4-bromo-2-p-chloro-5-trifluoromethyl pyrrole-3-nitrile has the advantages that the reaction time is short; the reaction process iseasy to control with less by-products and high product yield.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com