Patents

Literature

193 results about "Carbon ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition: Carbonate is an ion consisting of one carbon and three oxygen atoms. The molecular formula for the carbonate ion is CO32-.

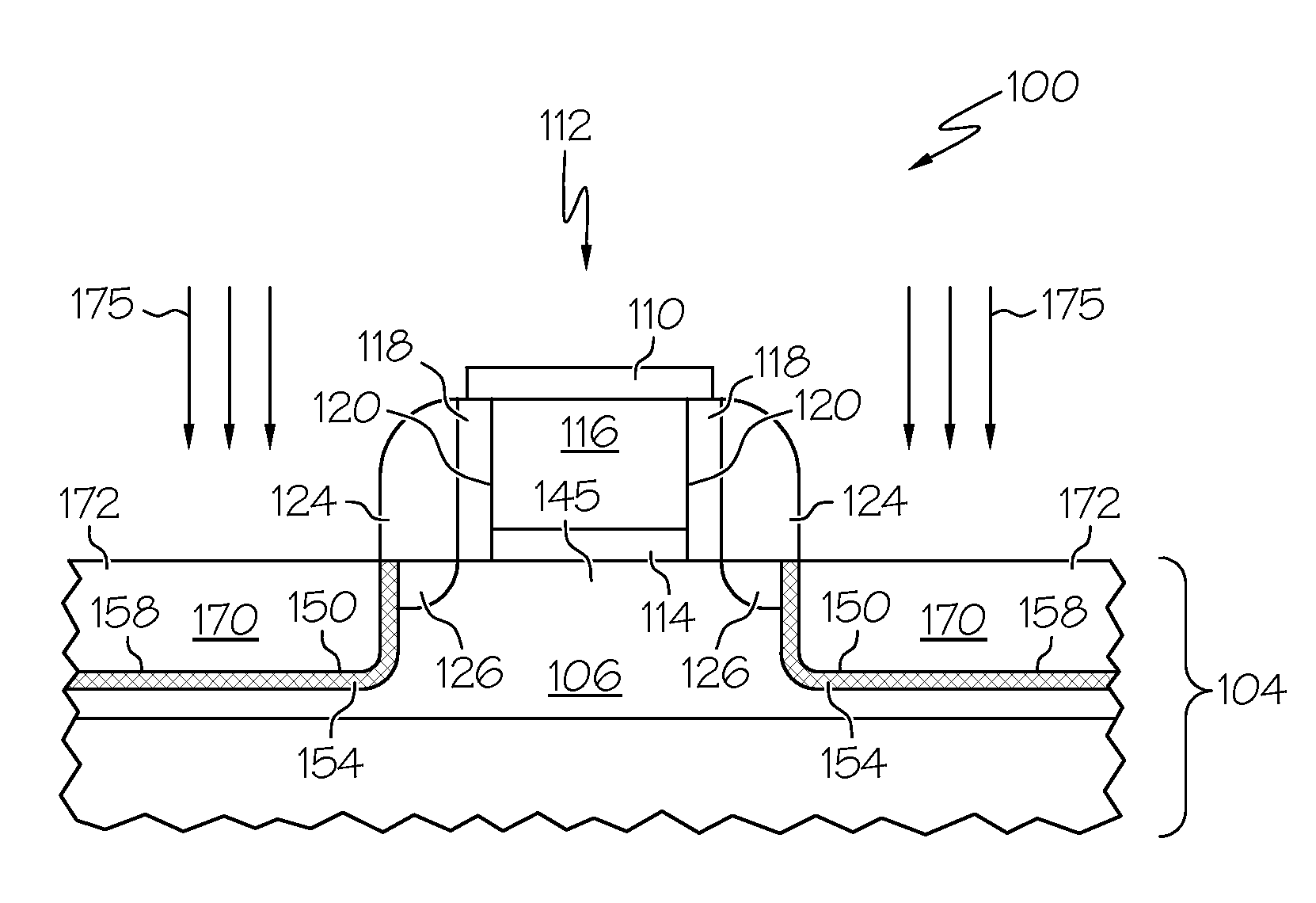

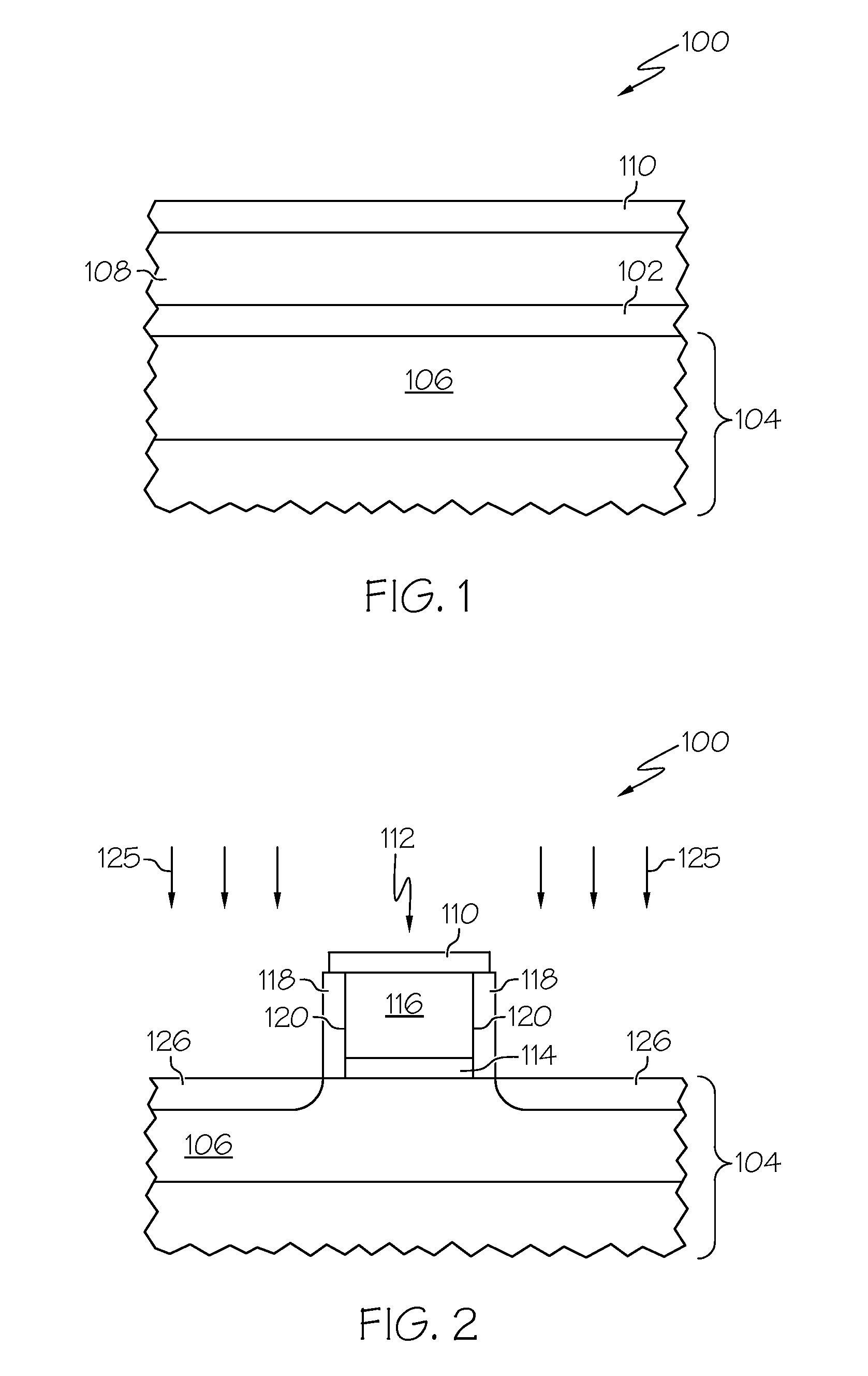

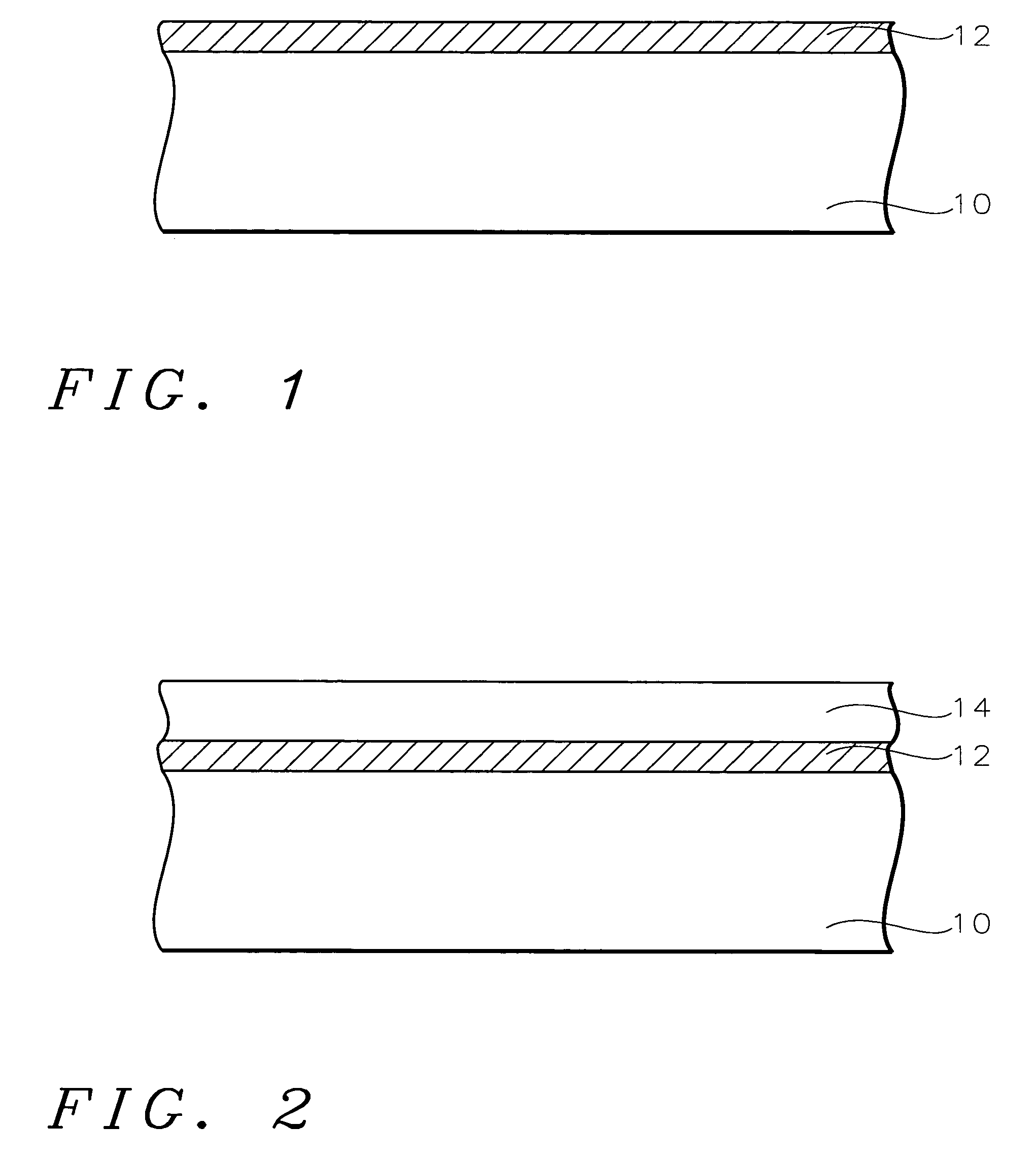

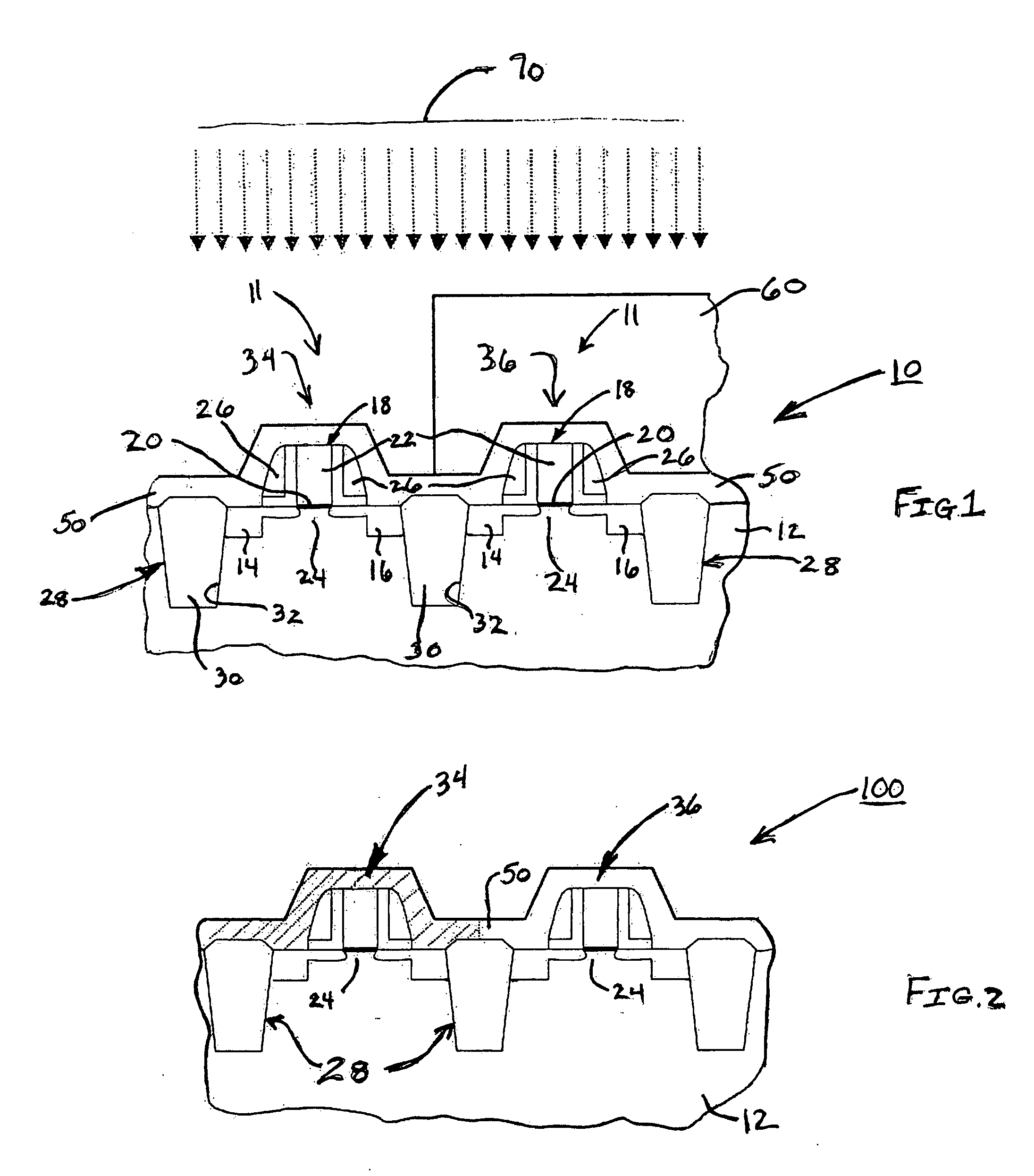

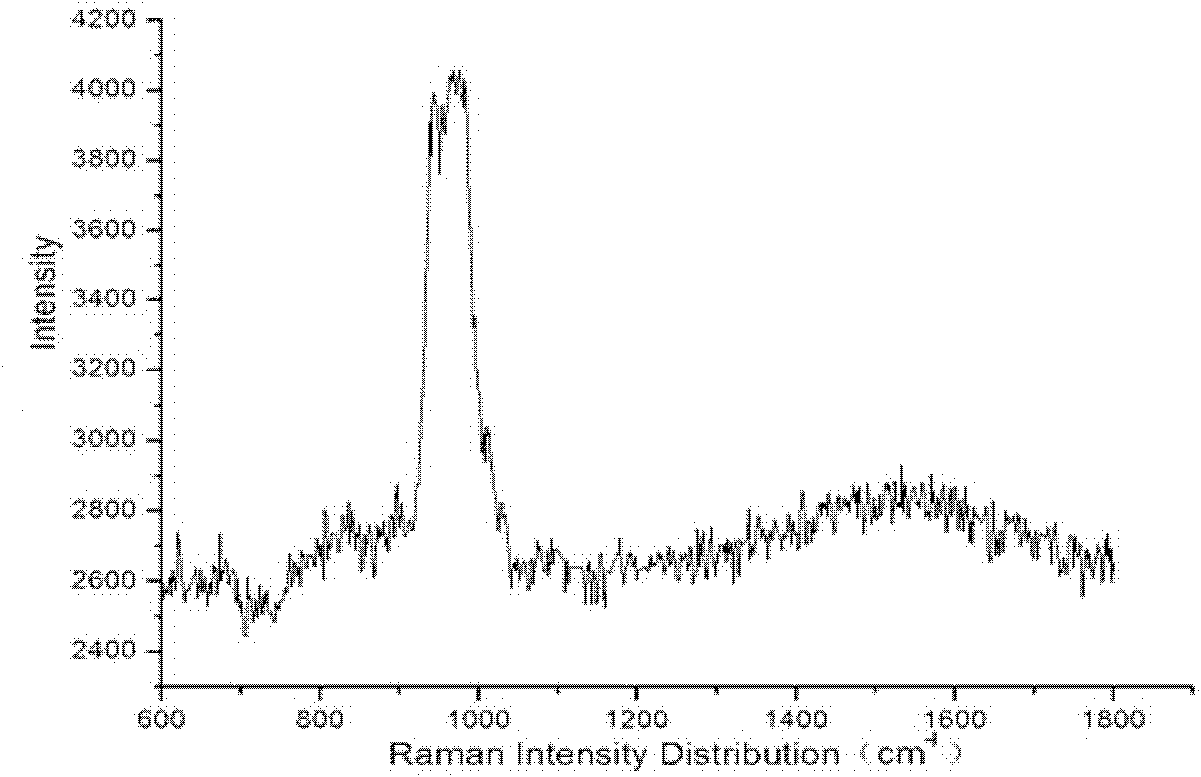

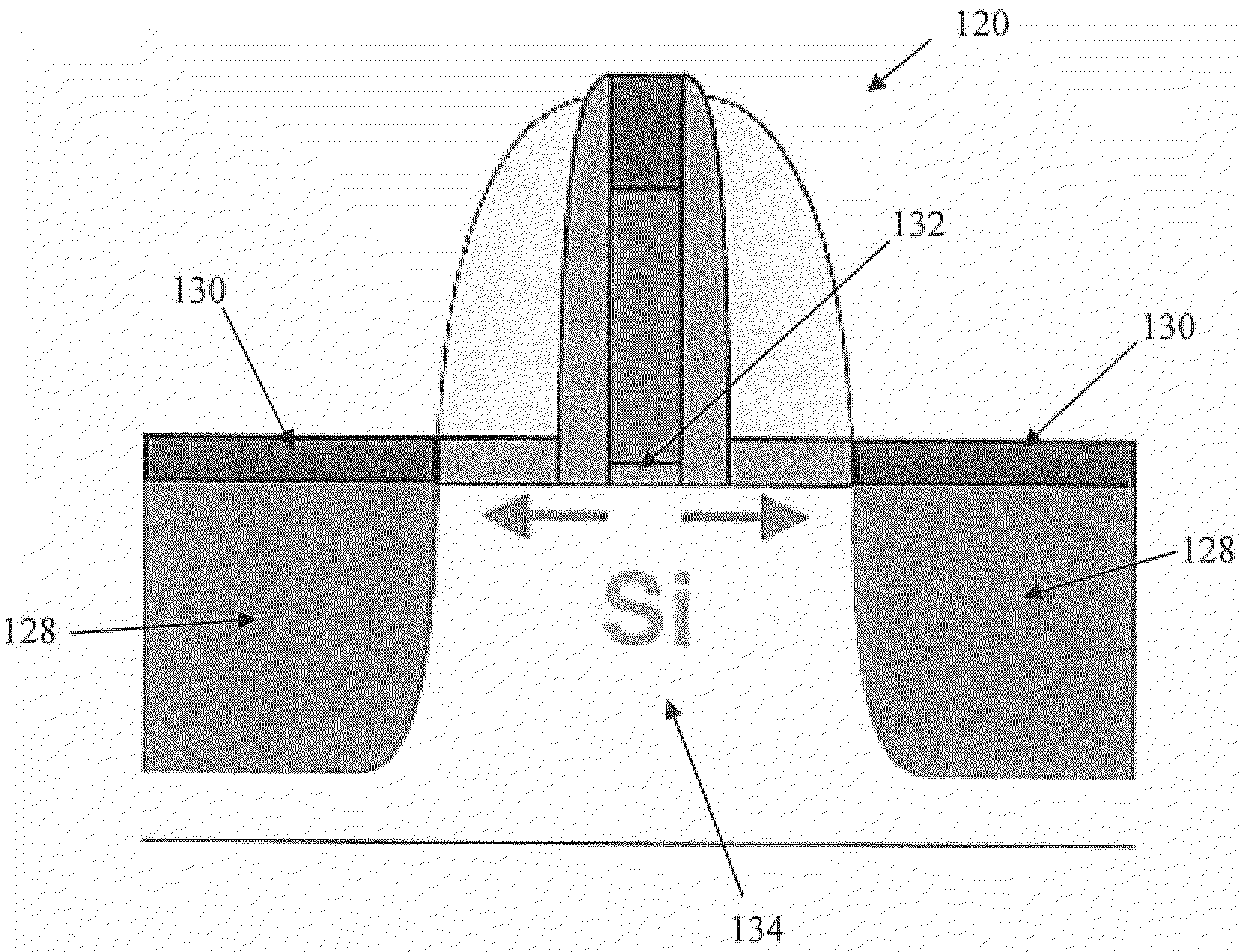

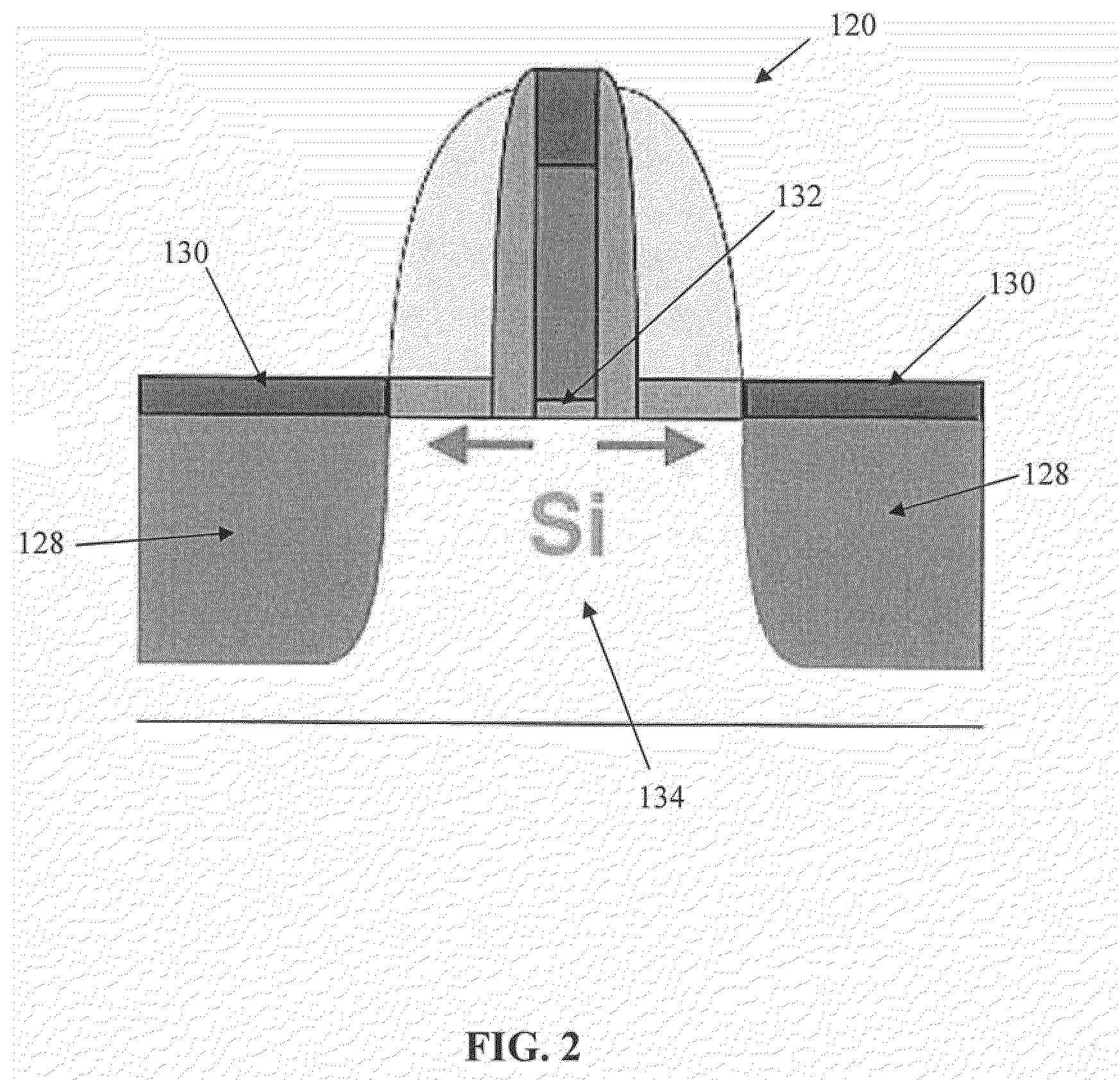

Metal oxide semiconductor devices having implanted carbon diffusion retardation layers and methods for fabricating the same

InactiveUS20100012988A1Reduce the probability of spreadingPromote activationTransistorSemiconductor/solid-state device manufacturingCarbon ionImpurity

Semiconductor devices and methods for fabricating semiconductor devices are provided. One exemplary method comprises providing a silicon-comprising substrate having a first surface, etching a recess into the first surface, the recess having a side surface and a bottom surface, implanting carbon ions into the side surface and the bottom surface, and forming an impurity-doped, silicon-comprising region overlying the side surface and the bottom surface.

Owner:GLOBALFOUNDRIES INC

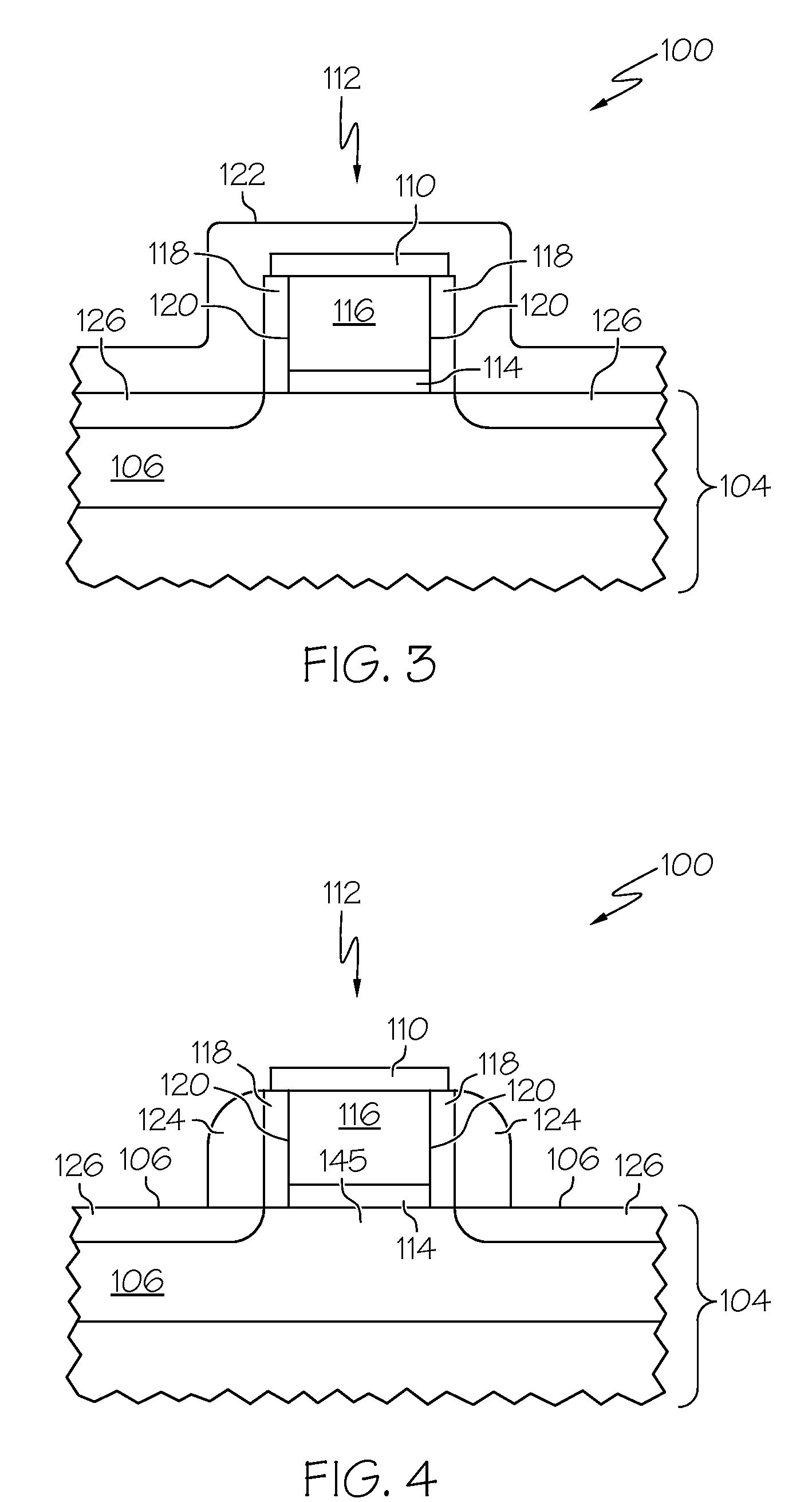

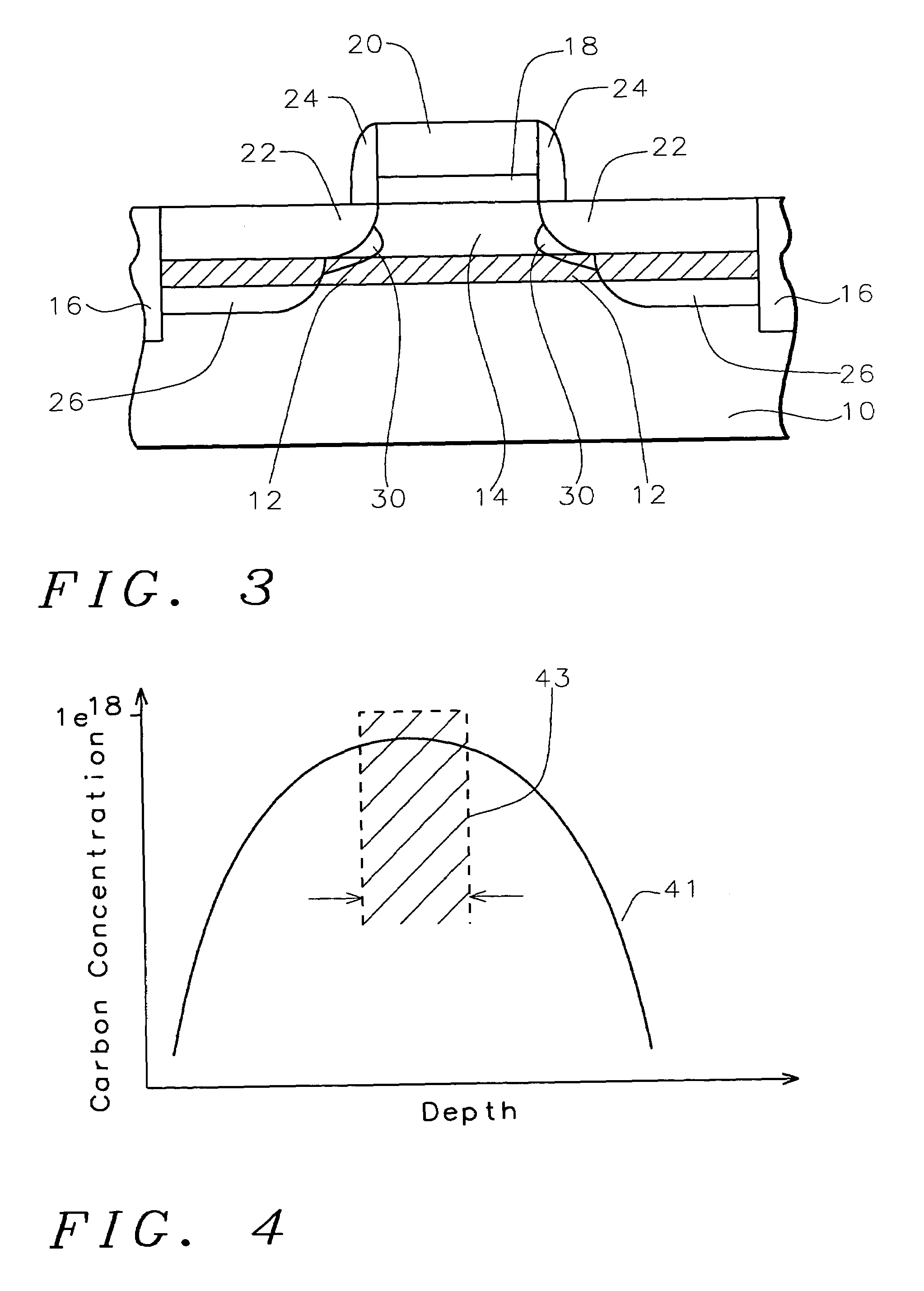

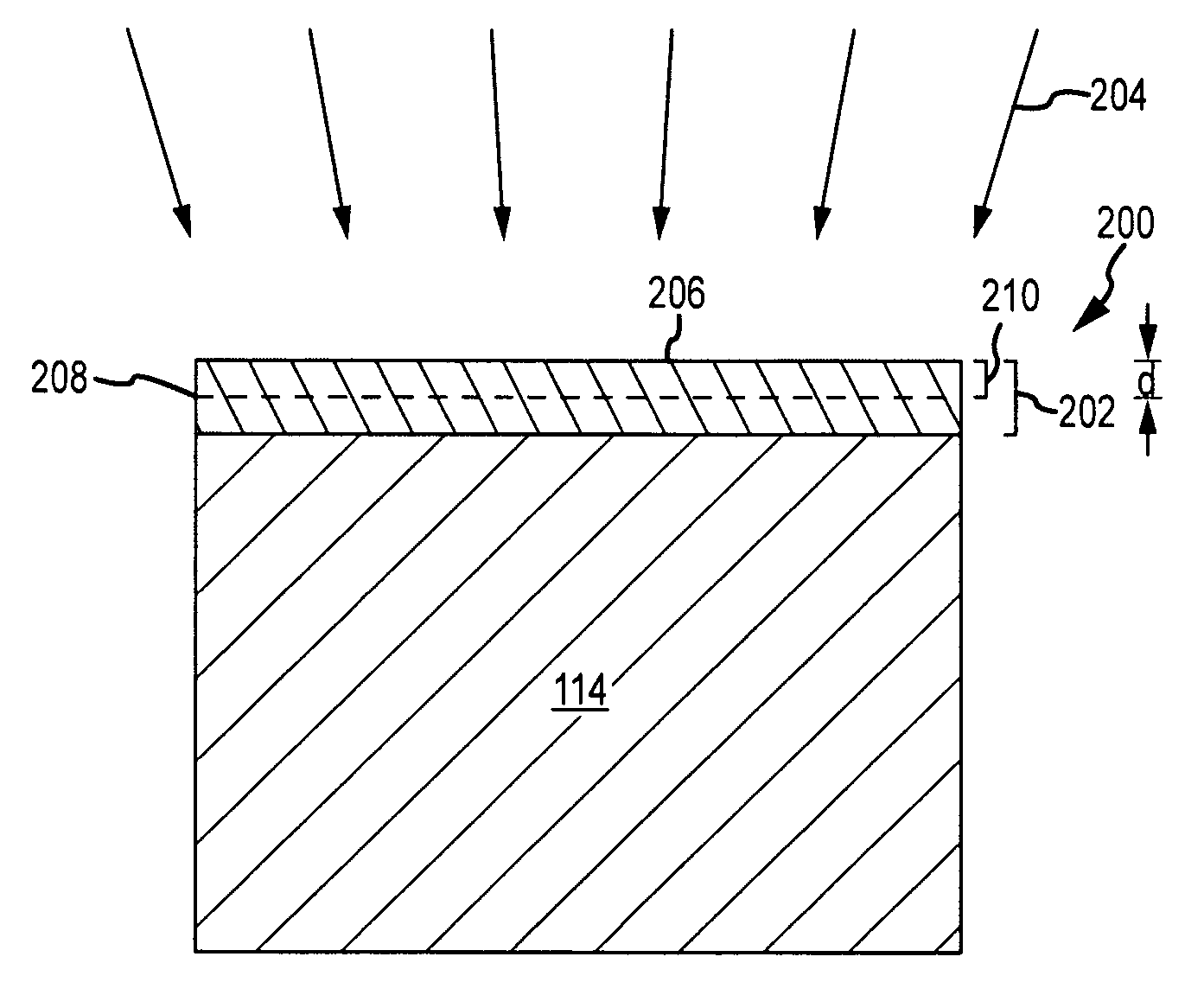

End of range (EOR) secondary defect engineering using substitutional carbon doping

A method for incorporating carbon into a wafer at the interstitial a-c silicon interface of the halo doping profile is achieved. A bulk silicon substrate is provided. A carbon-doped silicon layer is deposited on the bulk silicon substrate. An epitaxial silicon layer is grown overlying the carbon-doped silicon layer to provide a starting wafer for the integrated circuit device fabrication. An integrated circuit device is fabricated on the starting wafer by the following steps. A gate electrode is formed on the starting wafer. LDD and source and drain regions are implanted in the starting wafer adjacent to the gate electrode. Indium is implanted to form halo implants adjacent to the LDD regions and underlying the gate electrode wherein the halo implants extend to an interface between the epitaxial silicon layer and the carbon-doped silicon layer wherein carbon ions in the carbon-doped silicon layer act as a silicon interstitial sink for silicon interstitials formed by the halo implants to prevent end of range secondary defect formation.

Owner:TAIWAN SEMICON MFG CO LTD

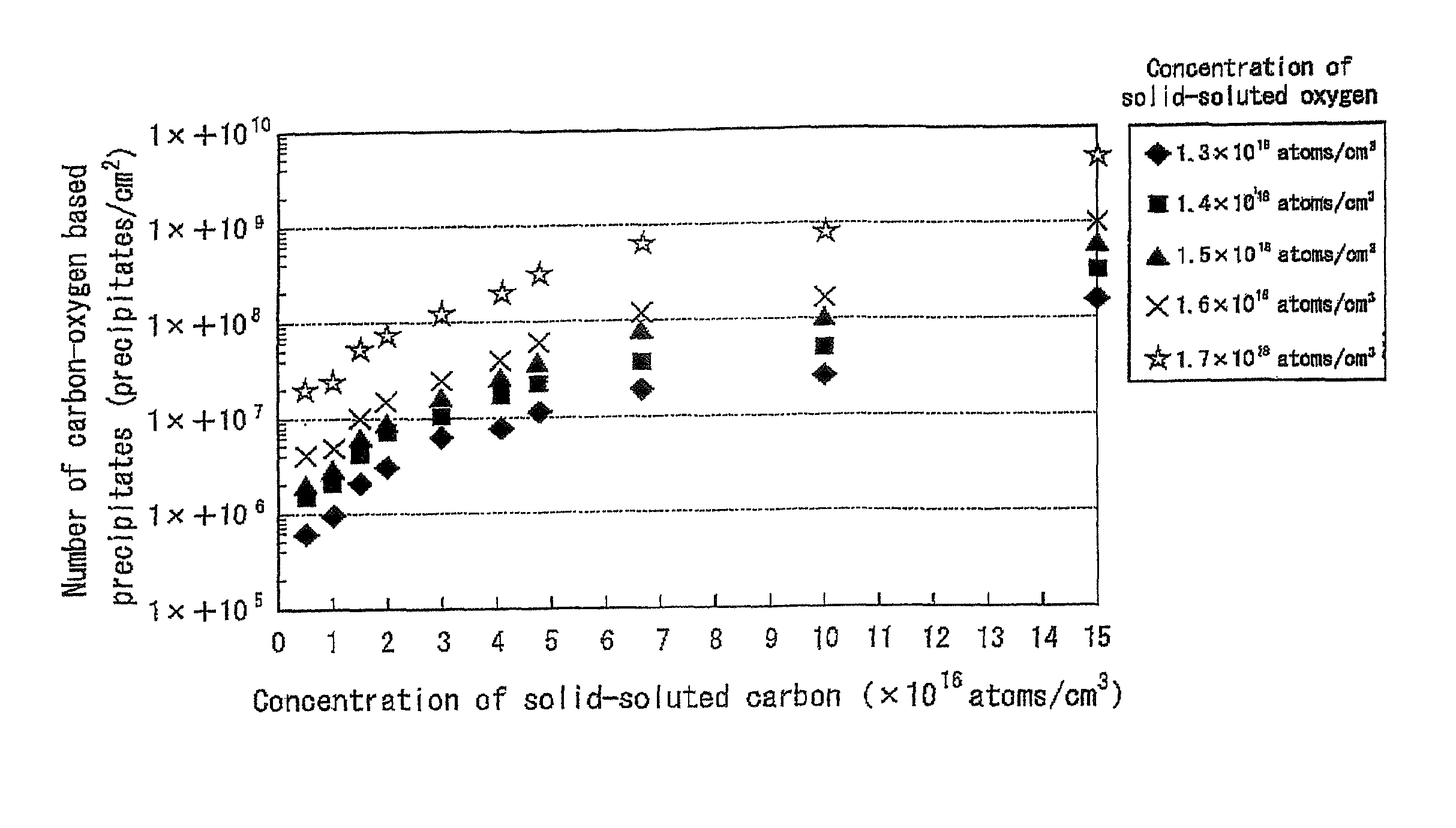

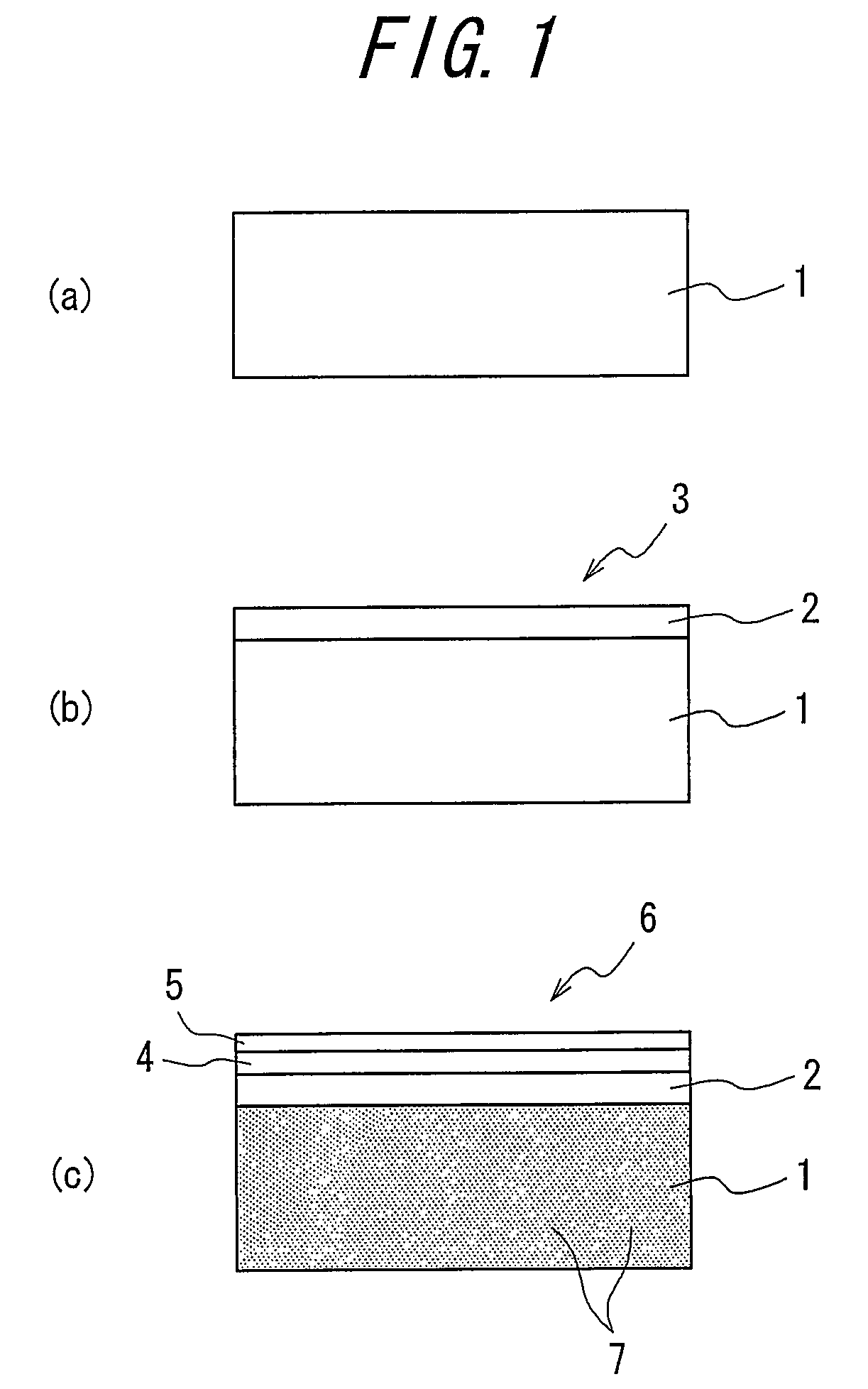

Semiconductor substrate for solid-state image sensing device as well as solid-state image sensing device and method for producing the same

ActiveUS8063466B2Improve inhalation effectGood electric characteristicPolycrystalline material growthAfter-treatment detailsCarbon ionOxygen

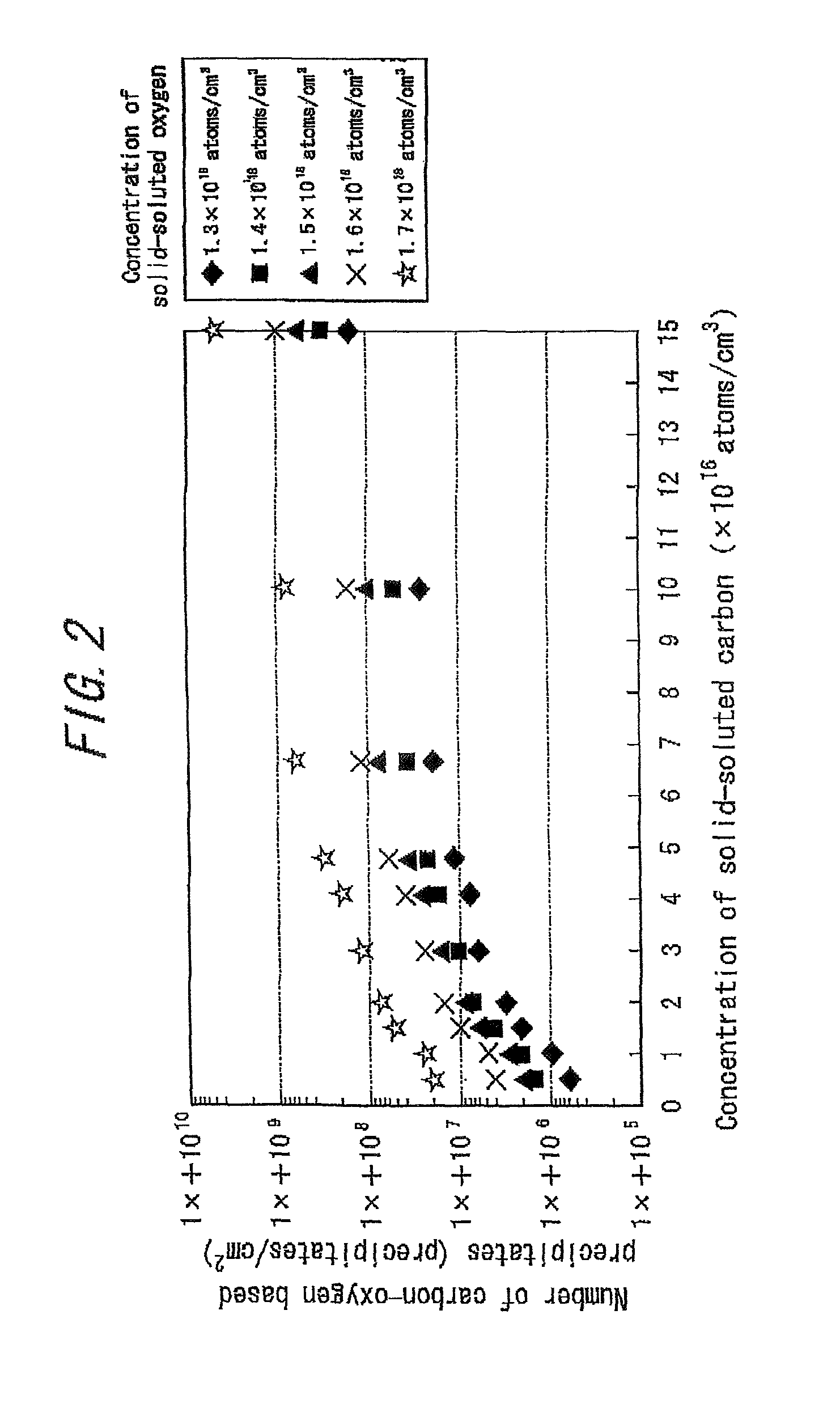

There is provided a semiconductor substrate for solid-state image sensing device in which the production cost is lower than that of a gettering method through a carbon ion implantation and problems such as occurrence of particles at a device production step and the like are solved.Silicon substrate contains solid-soluted carbon having a concentration of 1×1016-1×1017 atoms / cm3 and solid-soluted oxygen having a concentration of 1.4×1018-1.6×1018 atoms / cm3.

Owner:SUMCO CORP

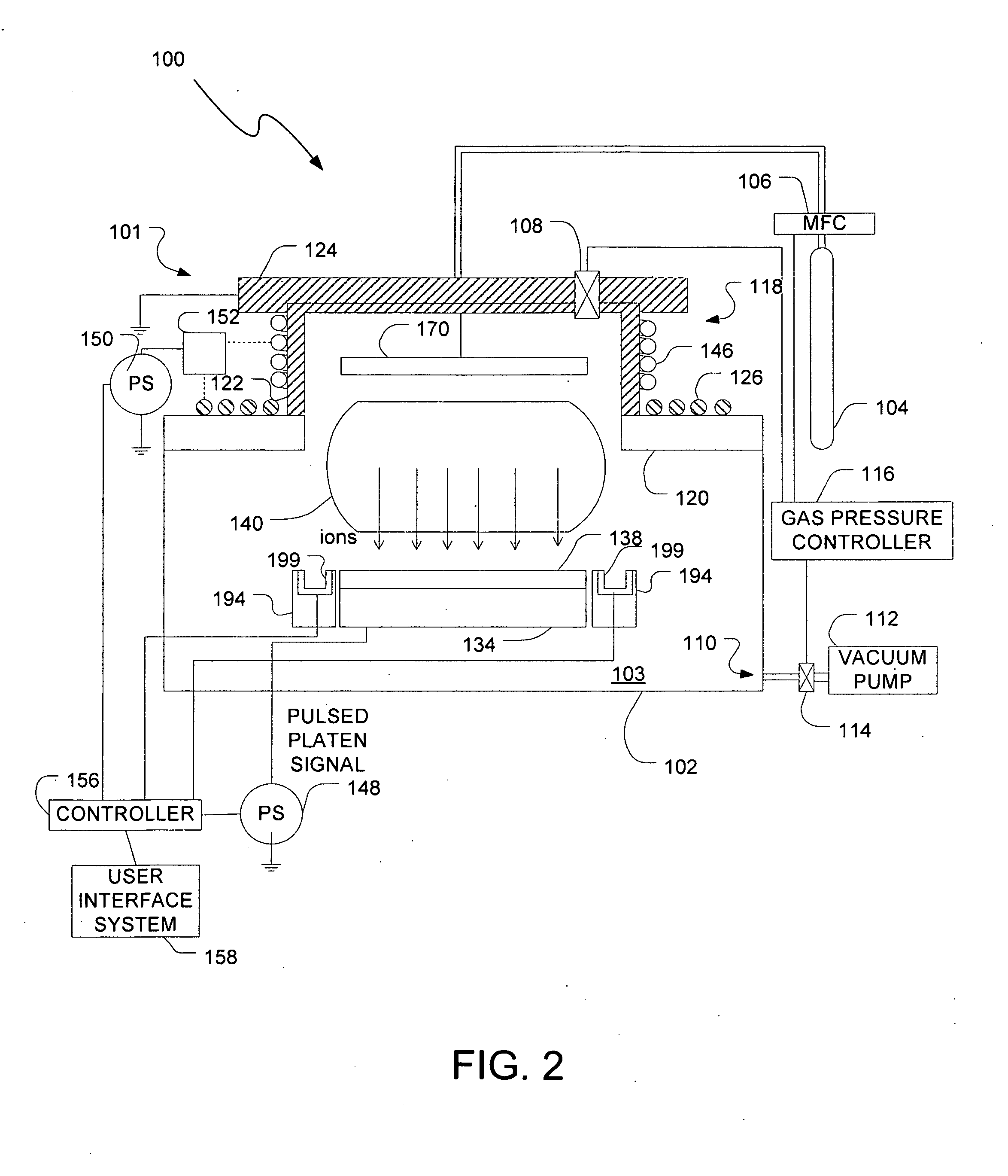

Method to Synthesize Graphene

A method of using ion implantation techniques to create graphene is disclosed. Carbon ions are implanted in a substrate, such as a metal foil, using a plasma doping system or a beam line implanter. The implant is performed at an elevated temperature, to allow a large number of carbon ions to be absorbed by the foil. As the temperature is reduced, the excessive number of carbon atoms causes the foil to be saturated, and the carbon atoms diffuse to the surface, thereby producing graphene. In another embodiment, a plasma doping system is used, where a plasma containing carbon and other species is created. These additional species are also implanted, thereby causing the diffused atoms to contain both carbon and the additional species.

Owner:VARIAN SEMICON EQUIP ASSOC INC

Polycrystalline diamond compact, methods of fabricating same, and applications therefor

Embodiments of the invention relate to polycrystalline diamond compacts (“PDCs”) comprising a polycrystalline diamond (“PCD”) table including a catalyst material therein that has been implanted with ions (e.g., carbon ions) and / or infiltrated from a host material implanted with carbon ions. In an embodiment, a PDC comprises a substrate and a PCD table bonded to the substrate. The PCD table includes a plurality of bonded diamond grains defining a plurality of interstitial regions. The PCD table includes an upper surface from which a region inwardly extends. At least a portion of the interstitial regions of the region includes a catalyst material disposed therein. At least a portion of the catalyst material may be at least saturated with carbon.

Owner:US SYNTHETIC CORP

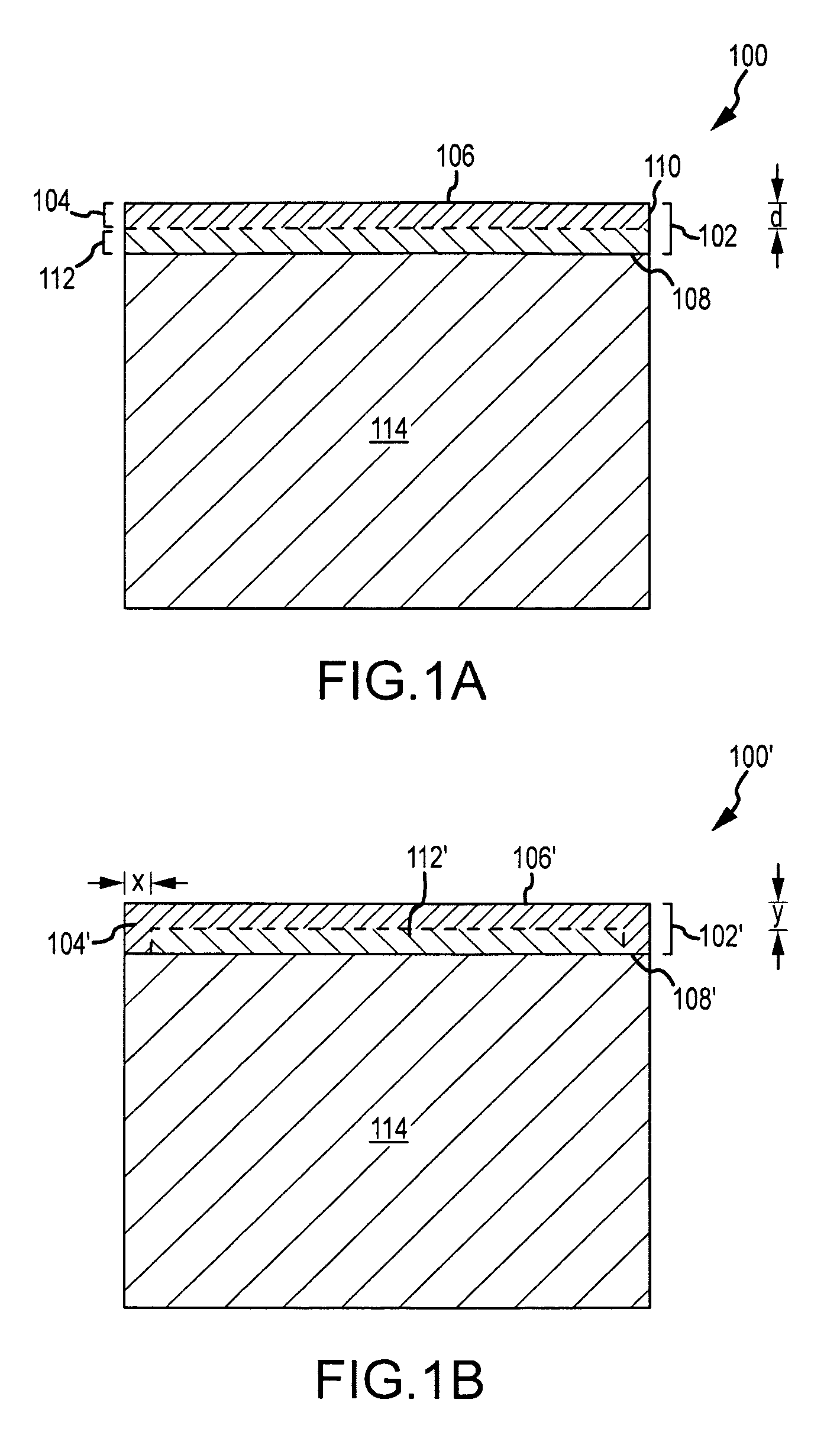

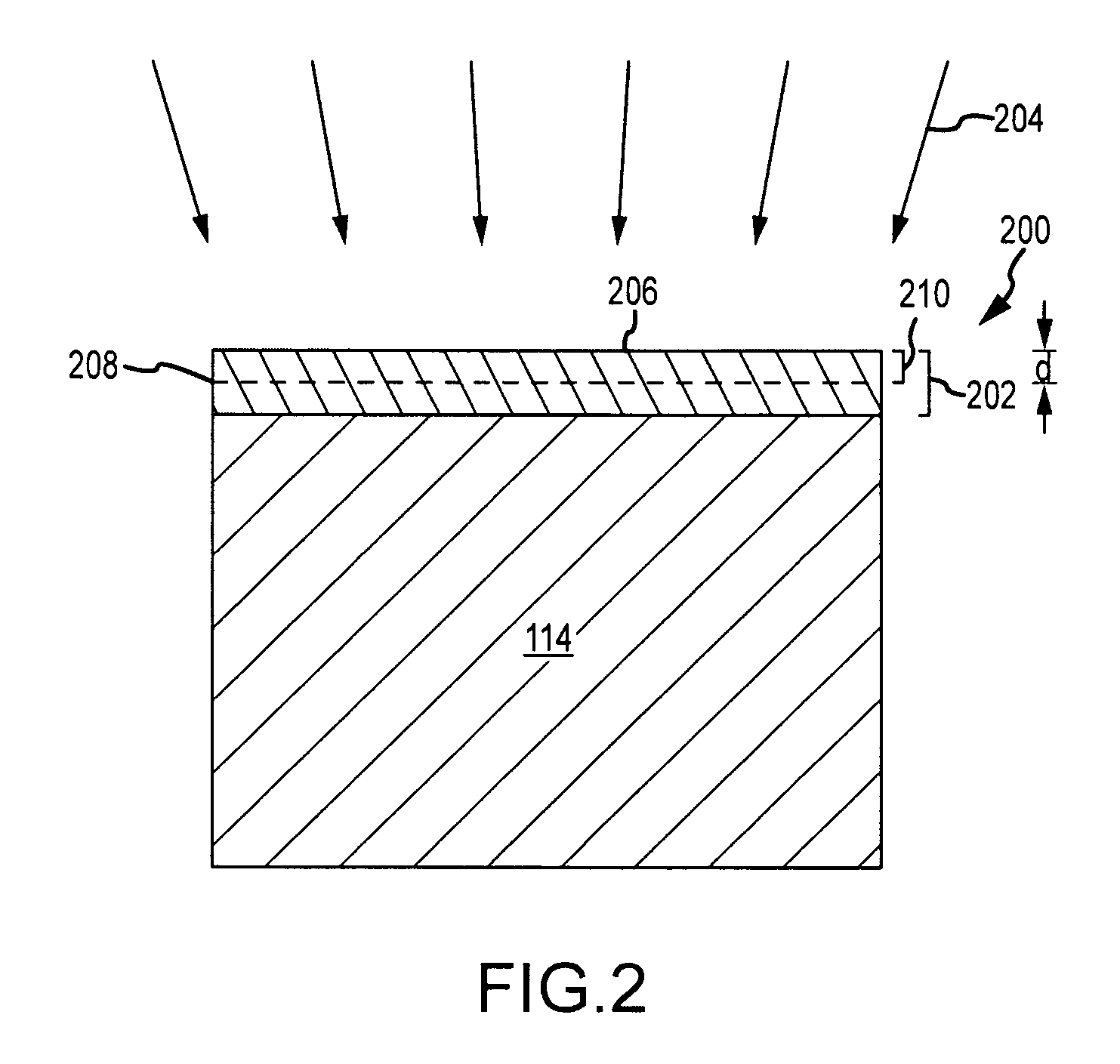

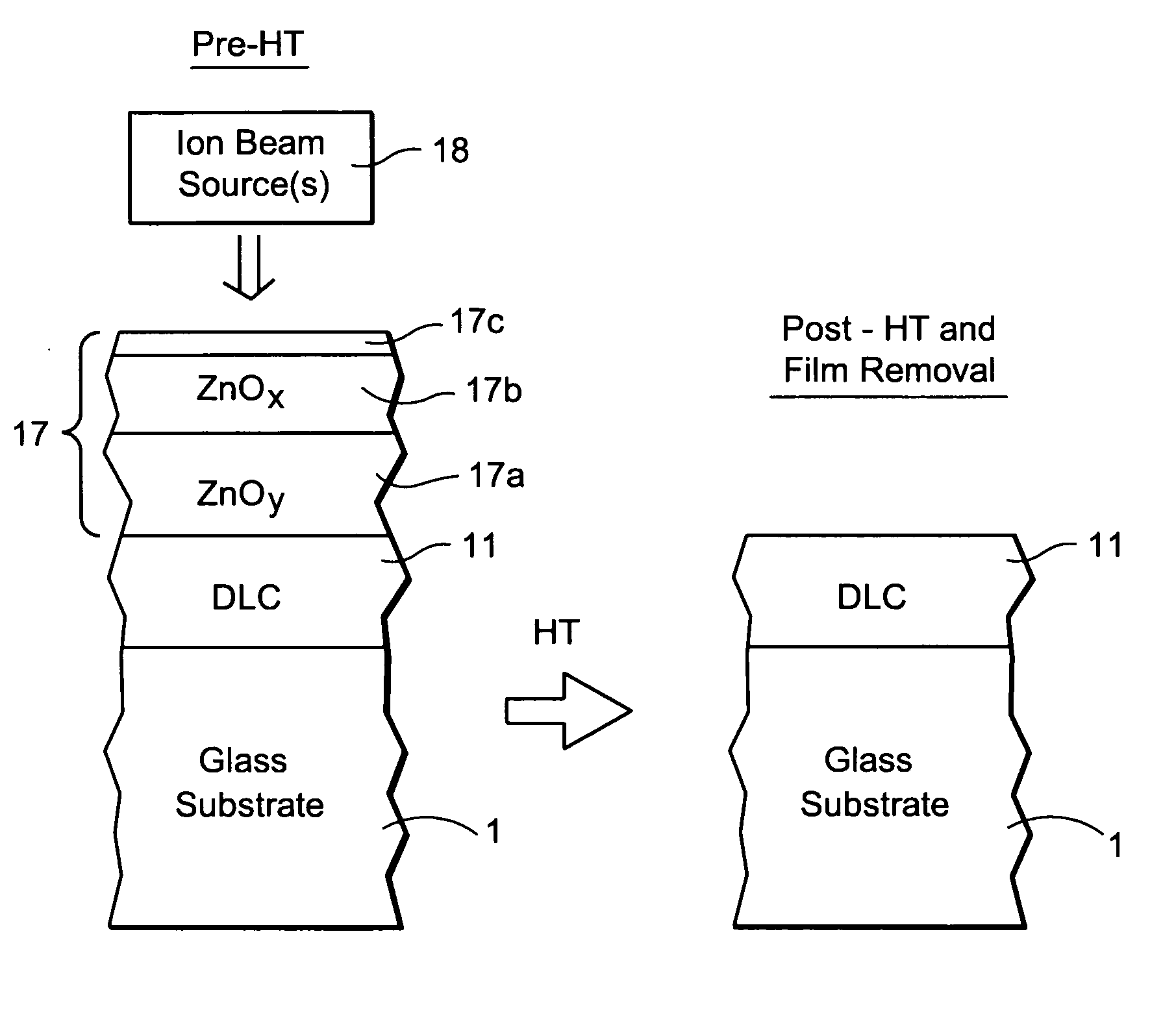

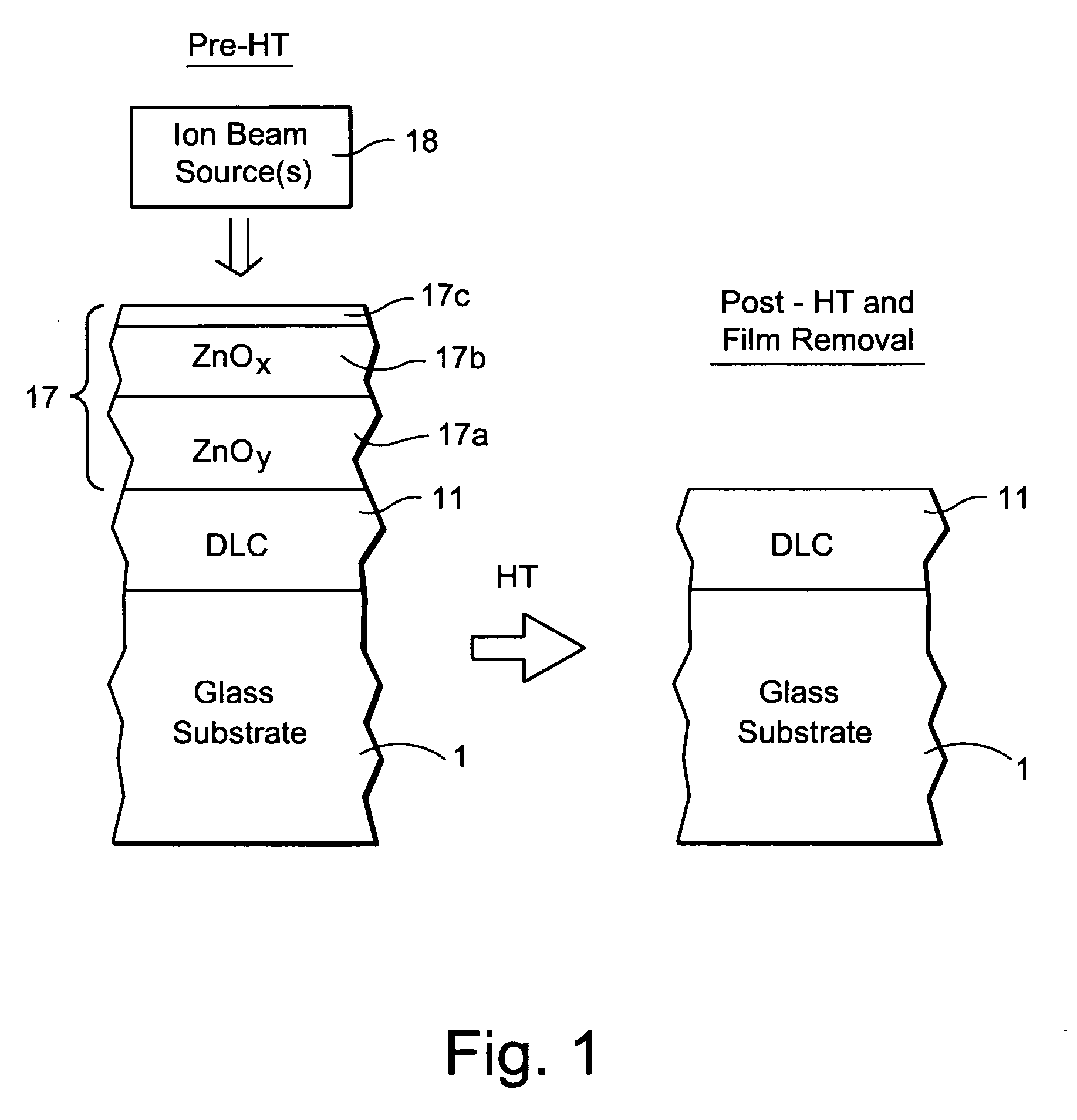

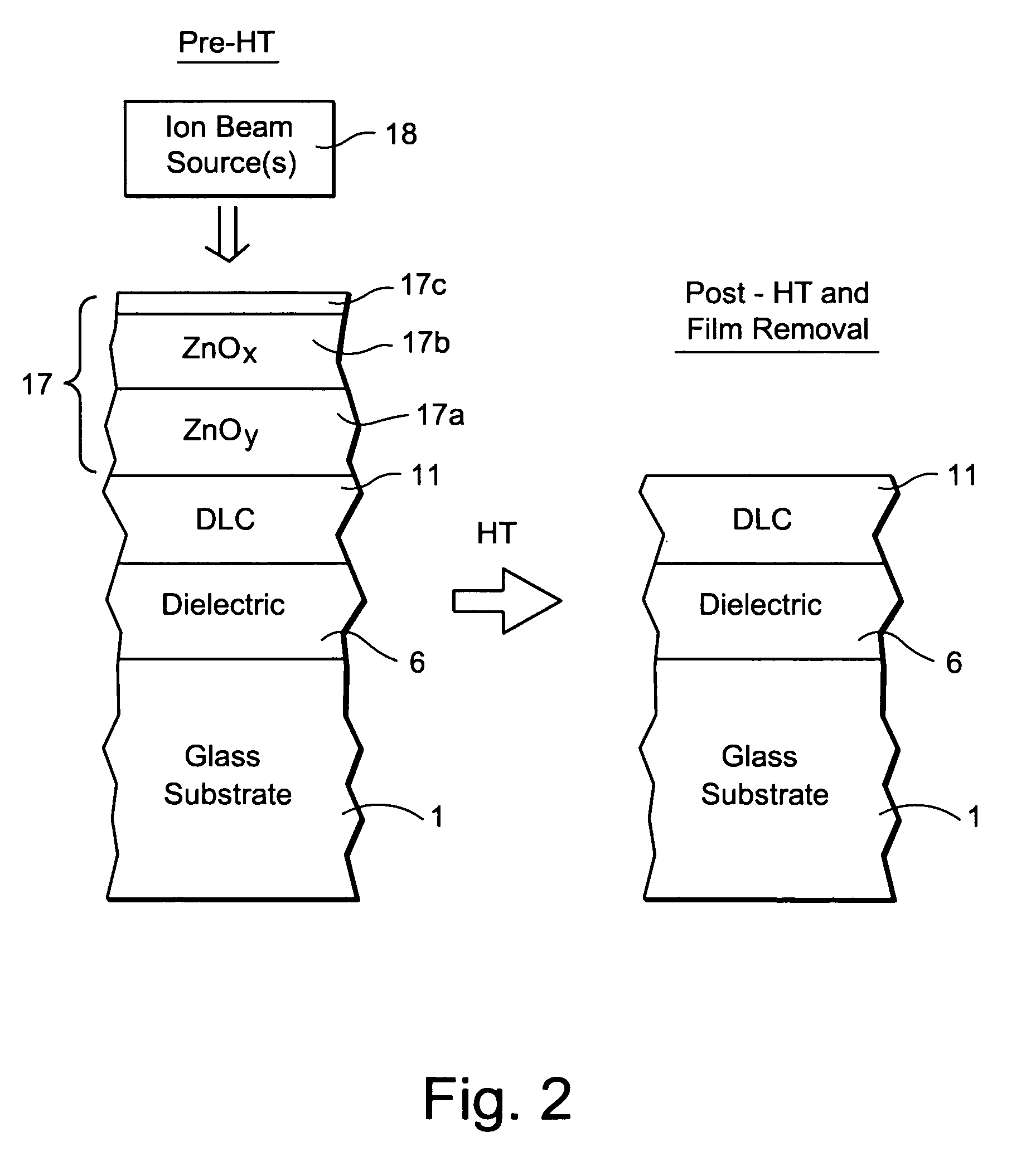

Method of making coated article including ion beam treatment of metal oxide protective film

There is provided a method of making a heat treated (HT) coated article to be used in shower door applications, window applications, or any other suitable applications where transparent coated articles are desired. For example, certain embodiments of this invention relate to a method of making a coated article including a step of heat treating a glass substrate coated with at least a layer of or including diamond-like carbon (DLC) and an overlying protective film (e.g., of or including zinc oxide) thereon. In certain example embodiments, the protective film may be ion beam treated with at least carbon ions. It has been found that the ion beam treatment improves the shelf-life of the product prior to HT. Following and / or during heat treatment (e.g., thermal tempering, or the like), the protective film may be removed.

Owner:GUARDIAN GLASS LLC

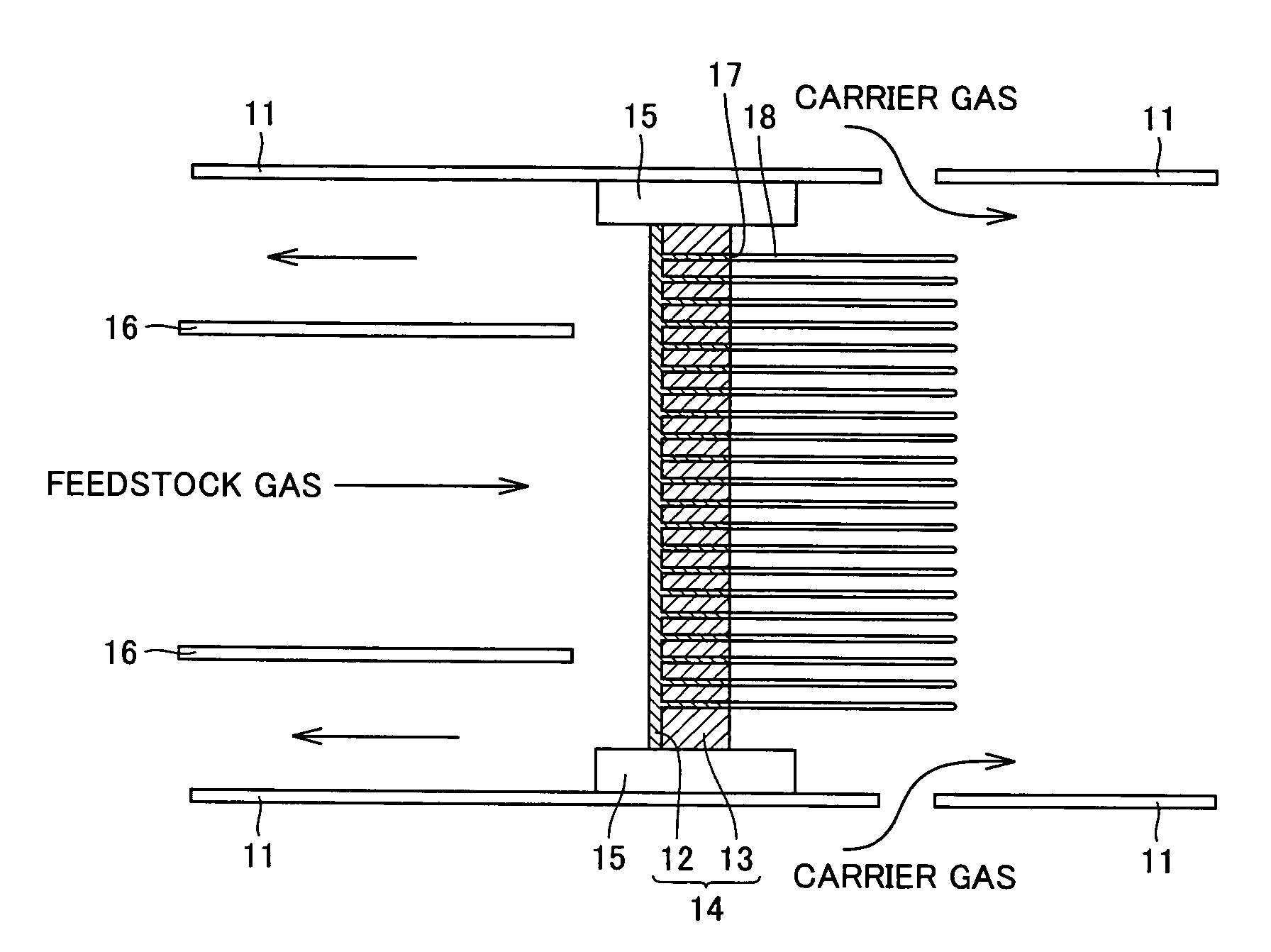

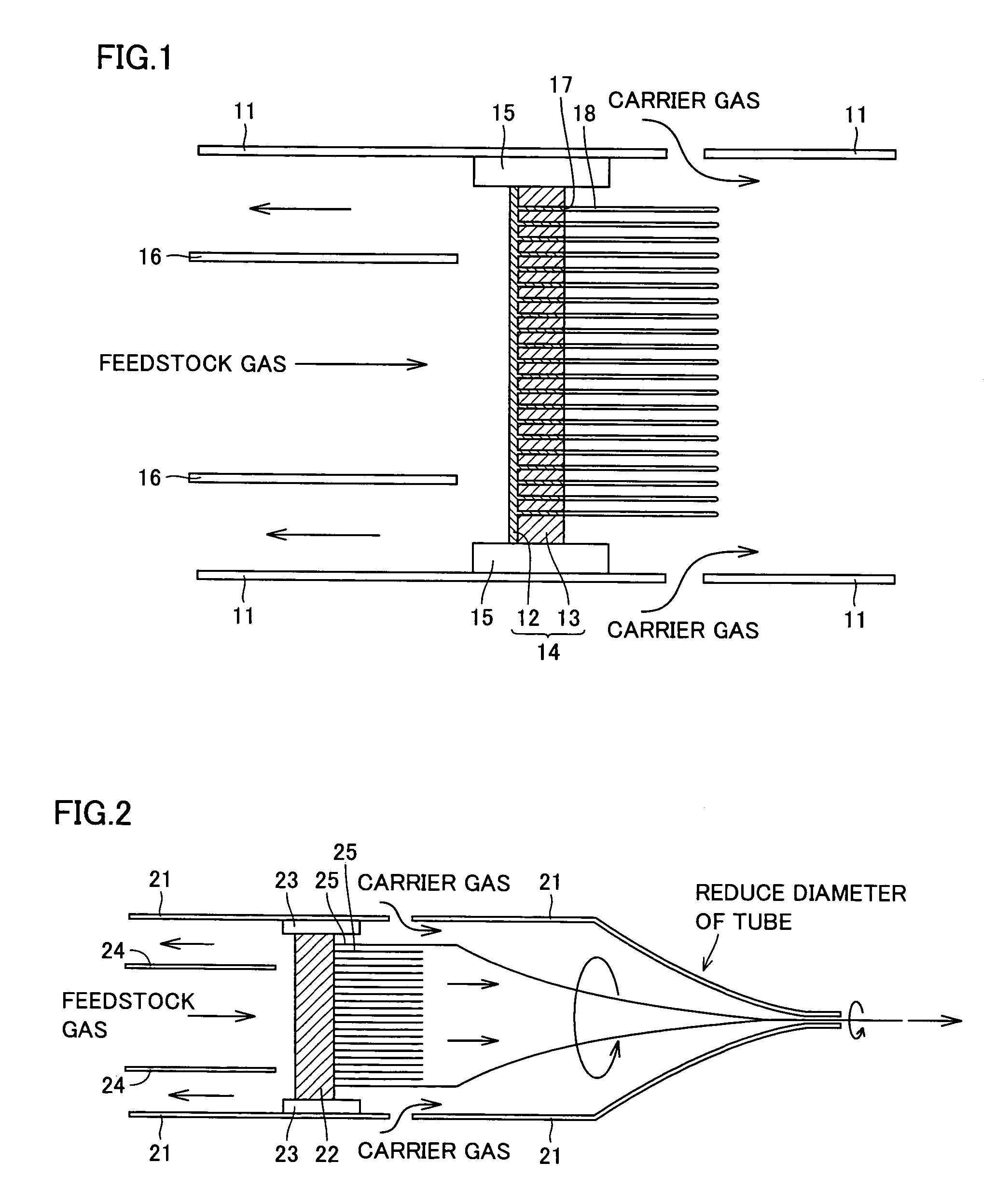

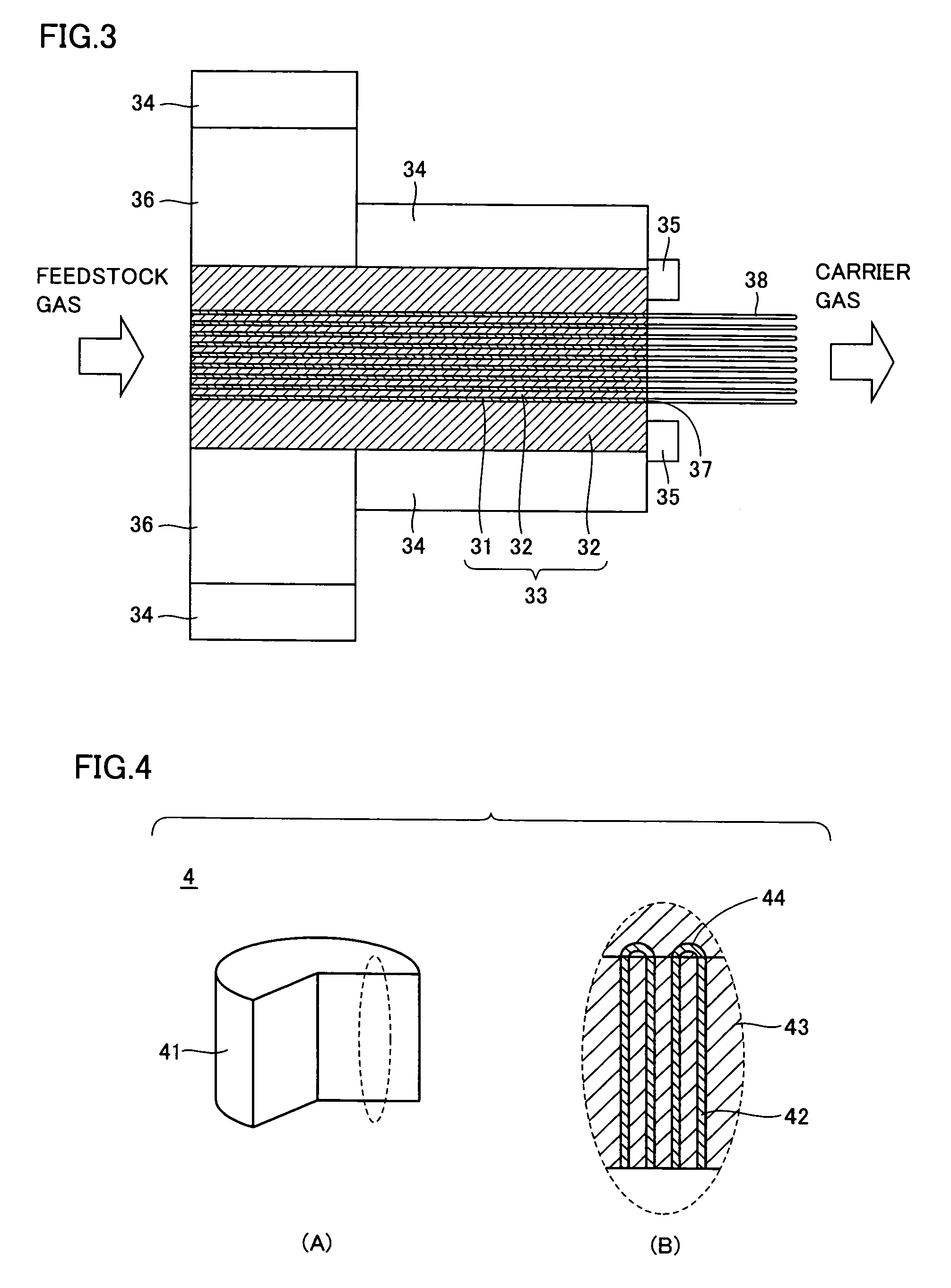

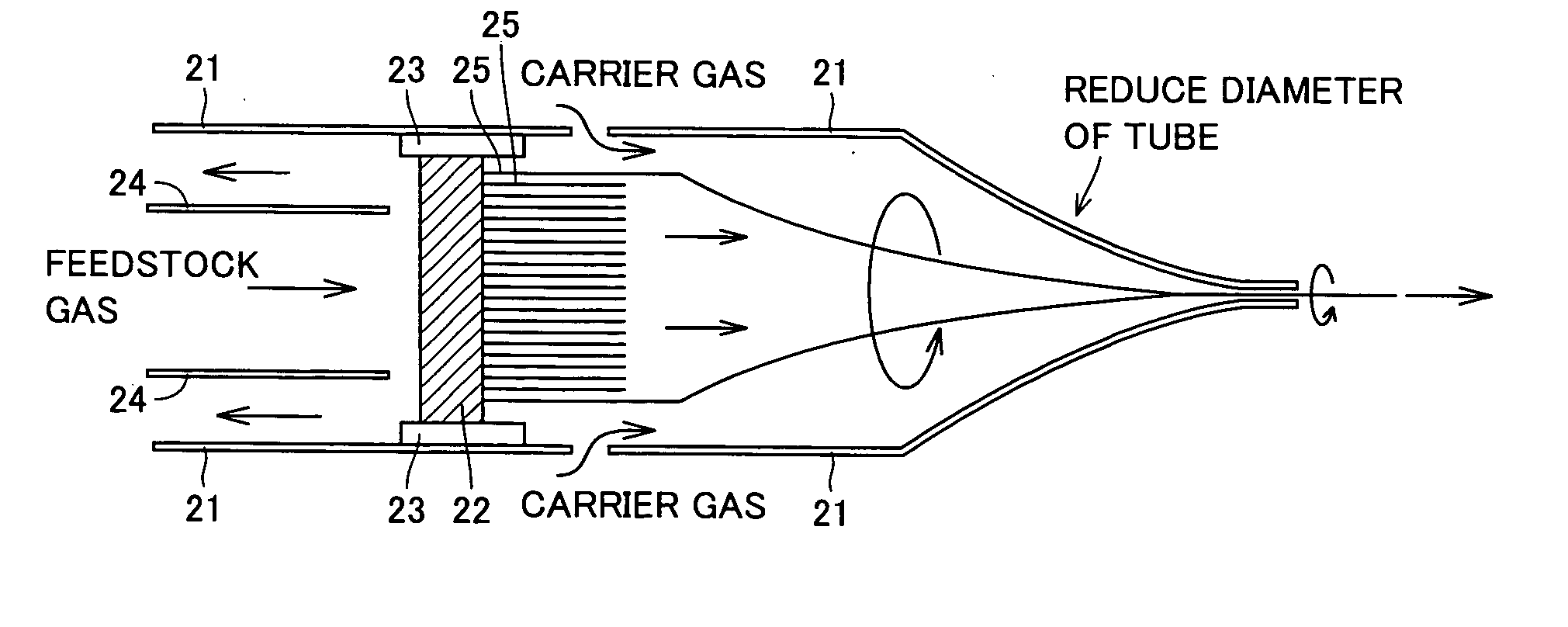

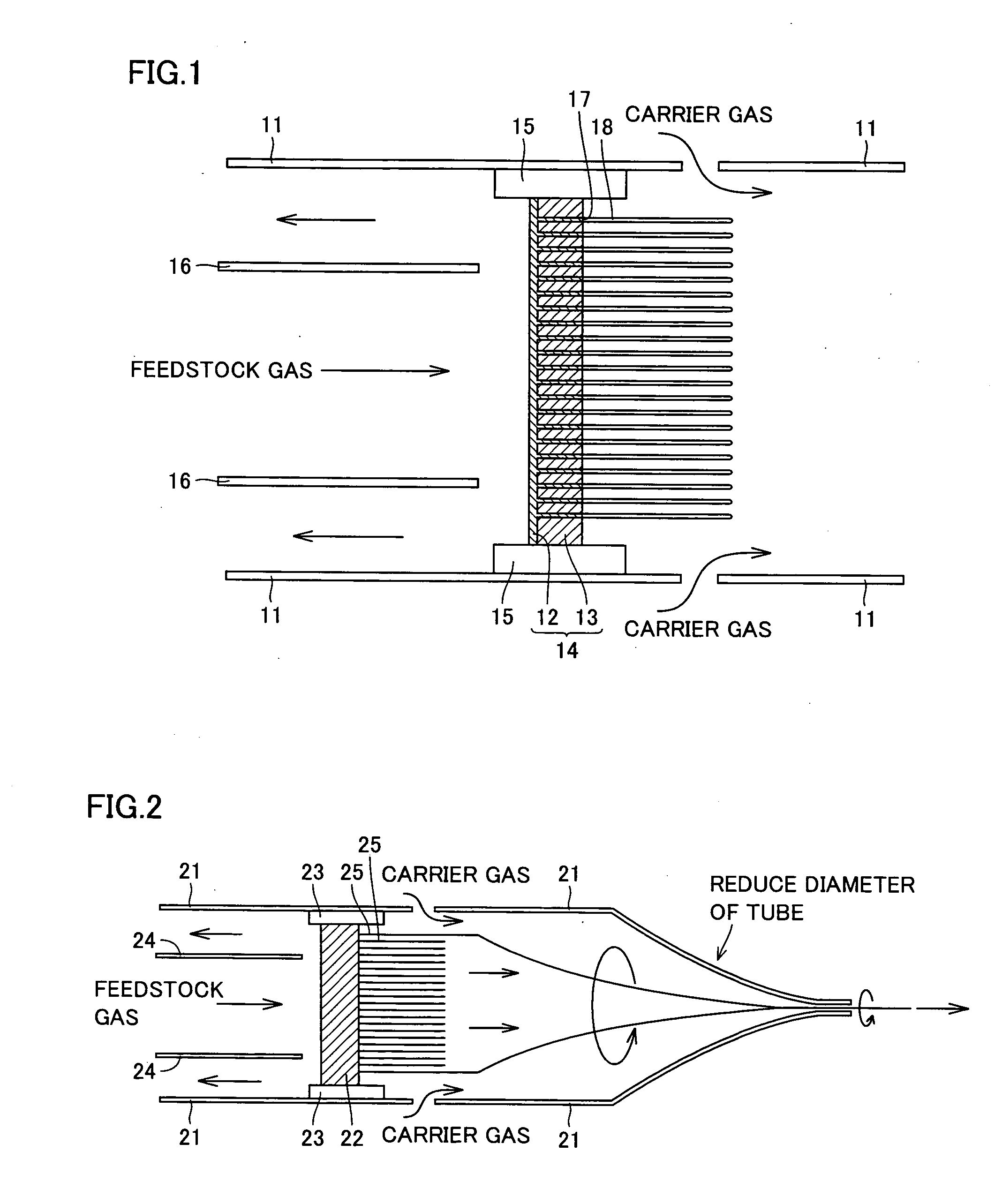

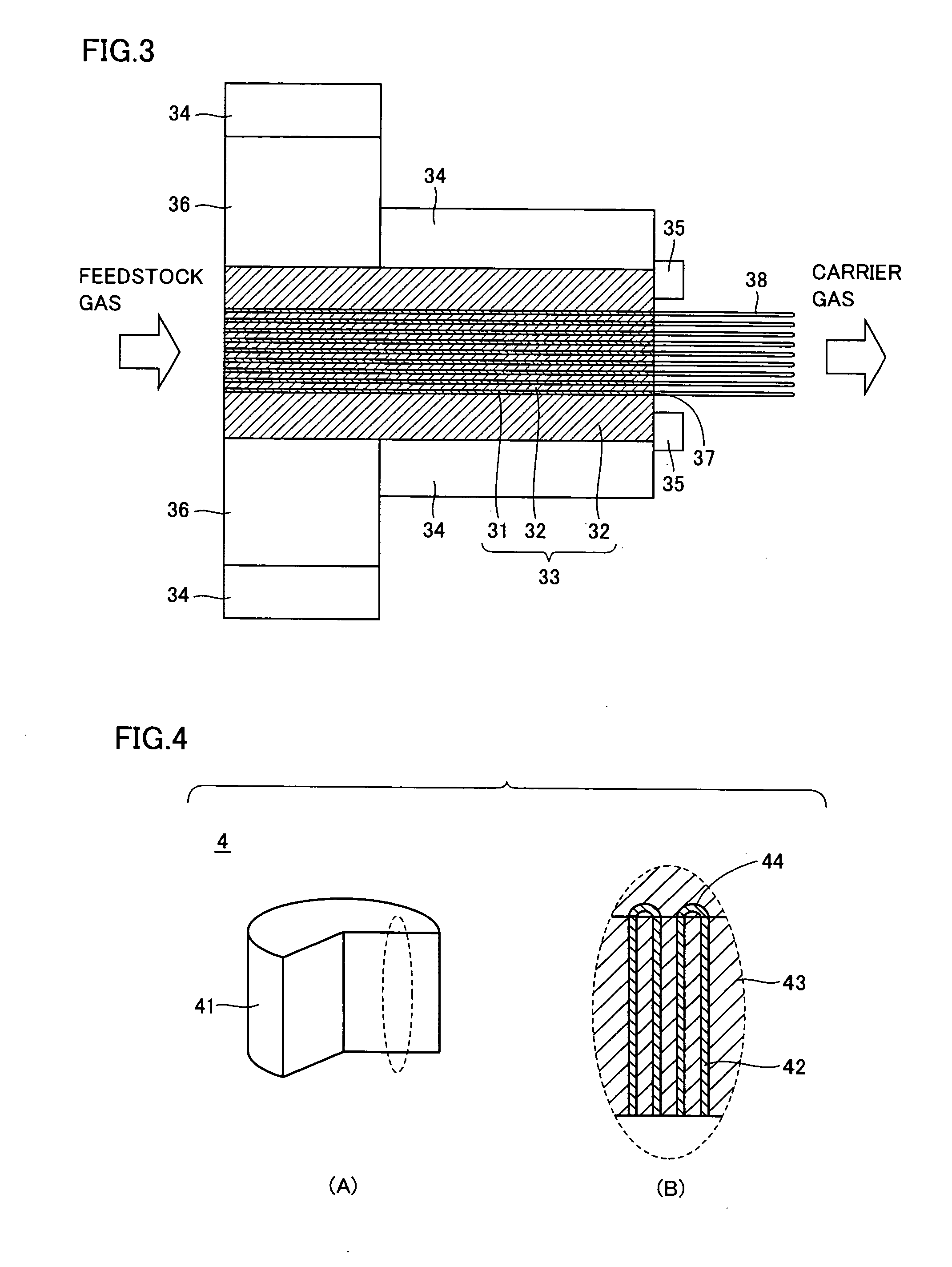

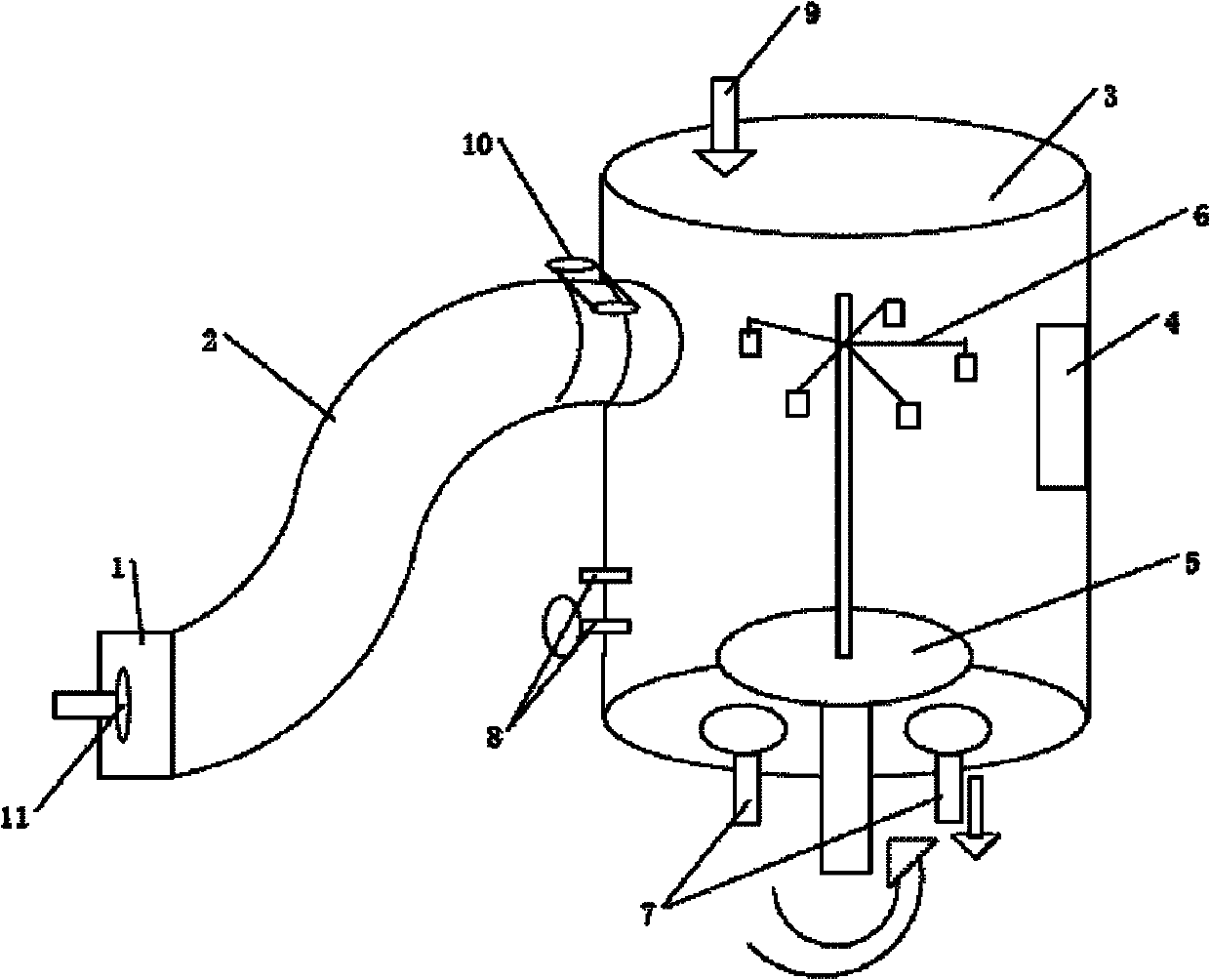

Method of manufacturing carbon nanostructure

ActiveUS7785558B2Uniform shapeHigh purityMaterial nanotechnologyPigmenting treatmentCarbon ionGas phase

The present invention relates to a method of manufacturing a carbon nanostructure for growing crystalline carbon by vapor deposition from a crystal growth surface of a catalytic base including a catalytic material, and in particular, to a method of manufacturing a carbon nanostructure where at least two gases including a feedstock gas are brought into contact with the catalytic base simultaneously. Preferably, the at least two gases are constituted by at least one feedstock gas and at least one carrier gas. Preferably, the carrier gas is brought into contact with the crystal growth surface, and the feedstock gas is brought into contact with at least a part of a region except for the crystal growth surface with which the carrier gas has been brought into contact. Preferably, the material gas contains an ion, and further preferably, it contains a carbon ion.

Owner:SUMITOMO ELECTRIC IND LTD

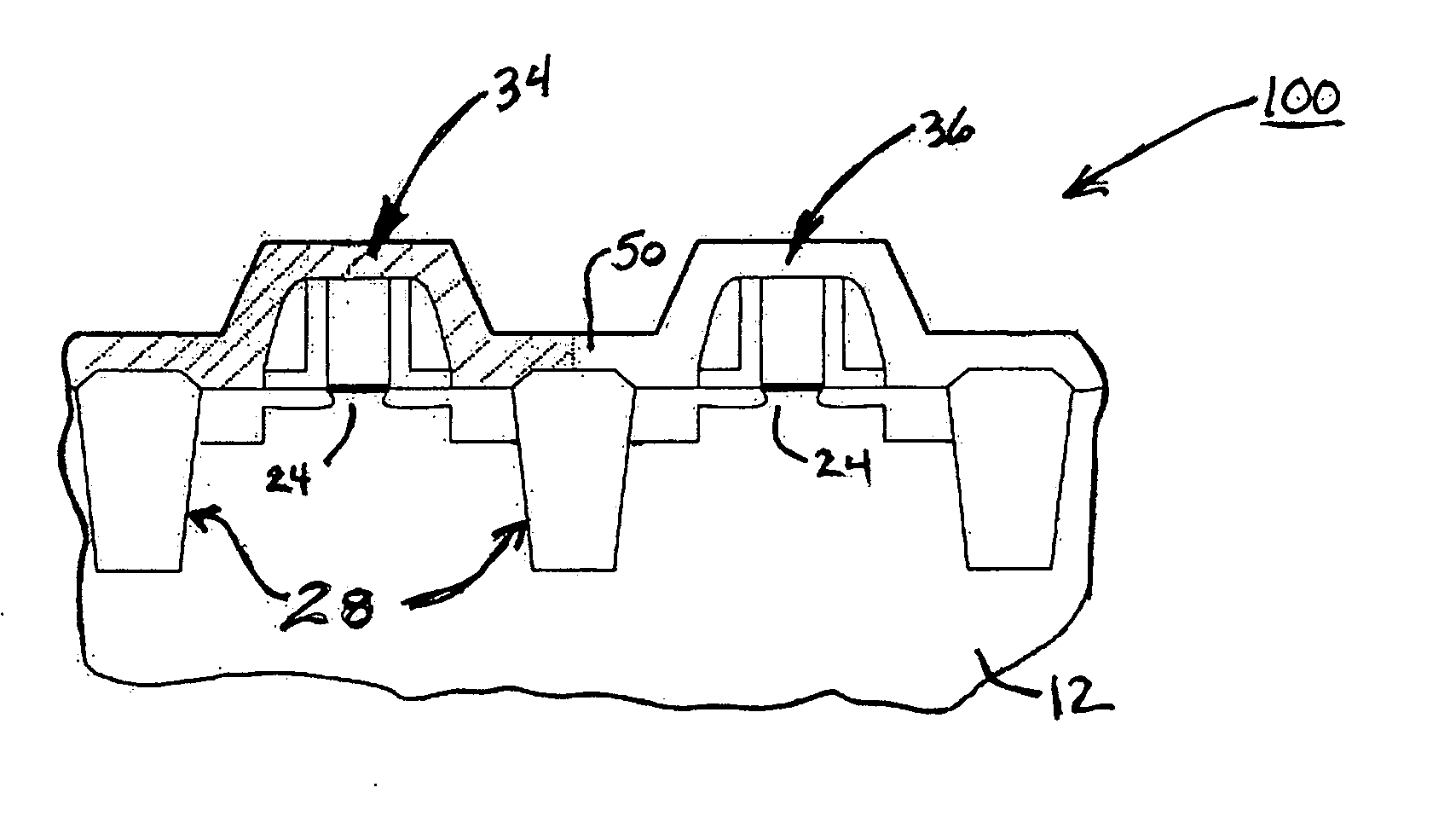

Method and structure for CMOS device with stress relaxed by ion implantation of carbon or oxygen containing ions

InactiveUS20050186722A1Prevent implantationRelaxation stressSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSCarbon ion

Stress in a silicon nitride contact etch stop layer on a CMOS structure having NMOS and PMOS devices is selectively relieved by selective implantation of oxygen-containing or carbon-containing ions resulting in there being no tensile stress in areas of the layer above the PMOS devices and no compressive stress in areas of the layer above the NMOS devices.

Owner:TAIWAN SEMICON MFG CO LTD

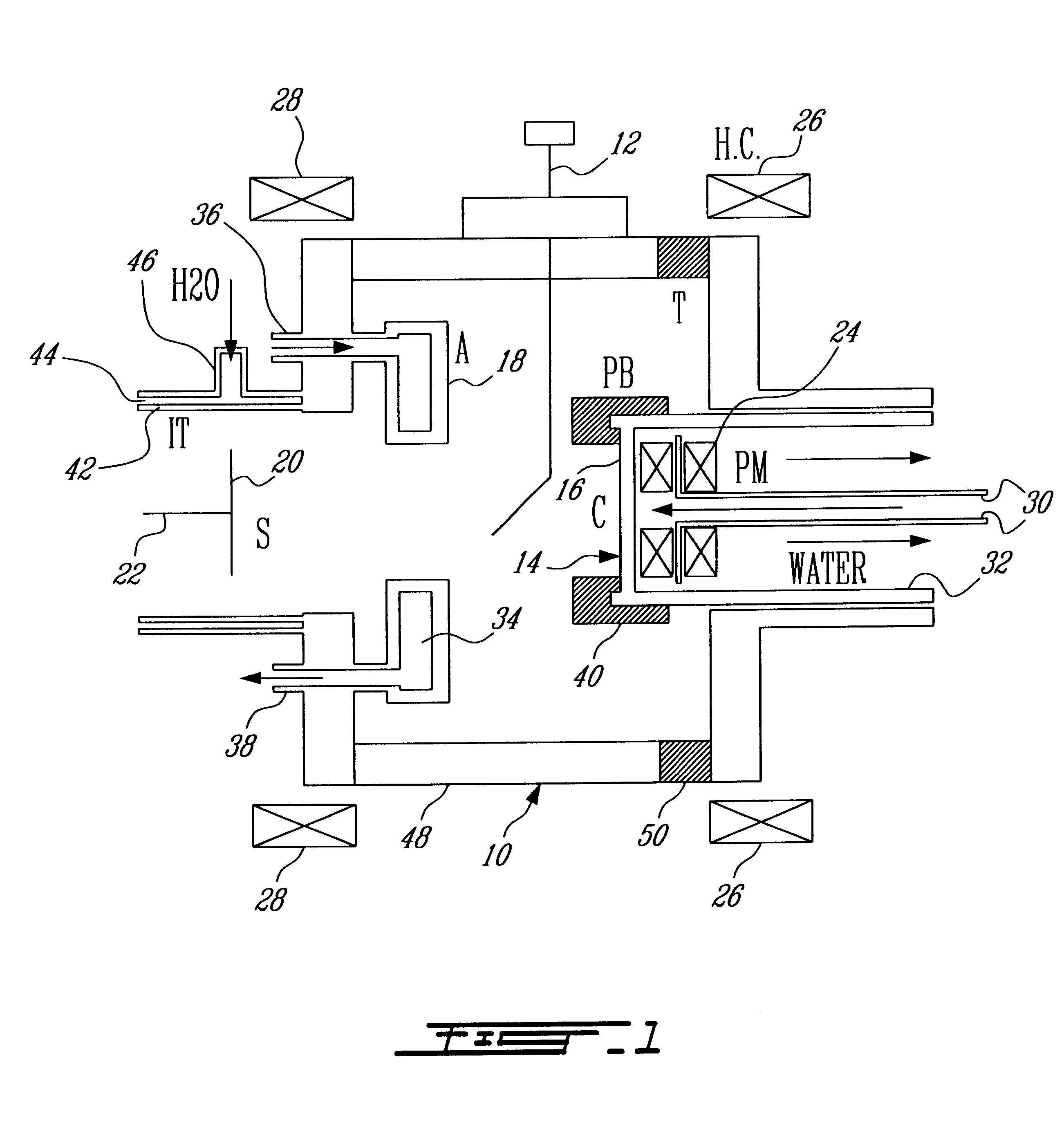

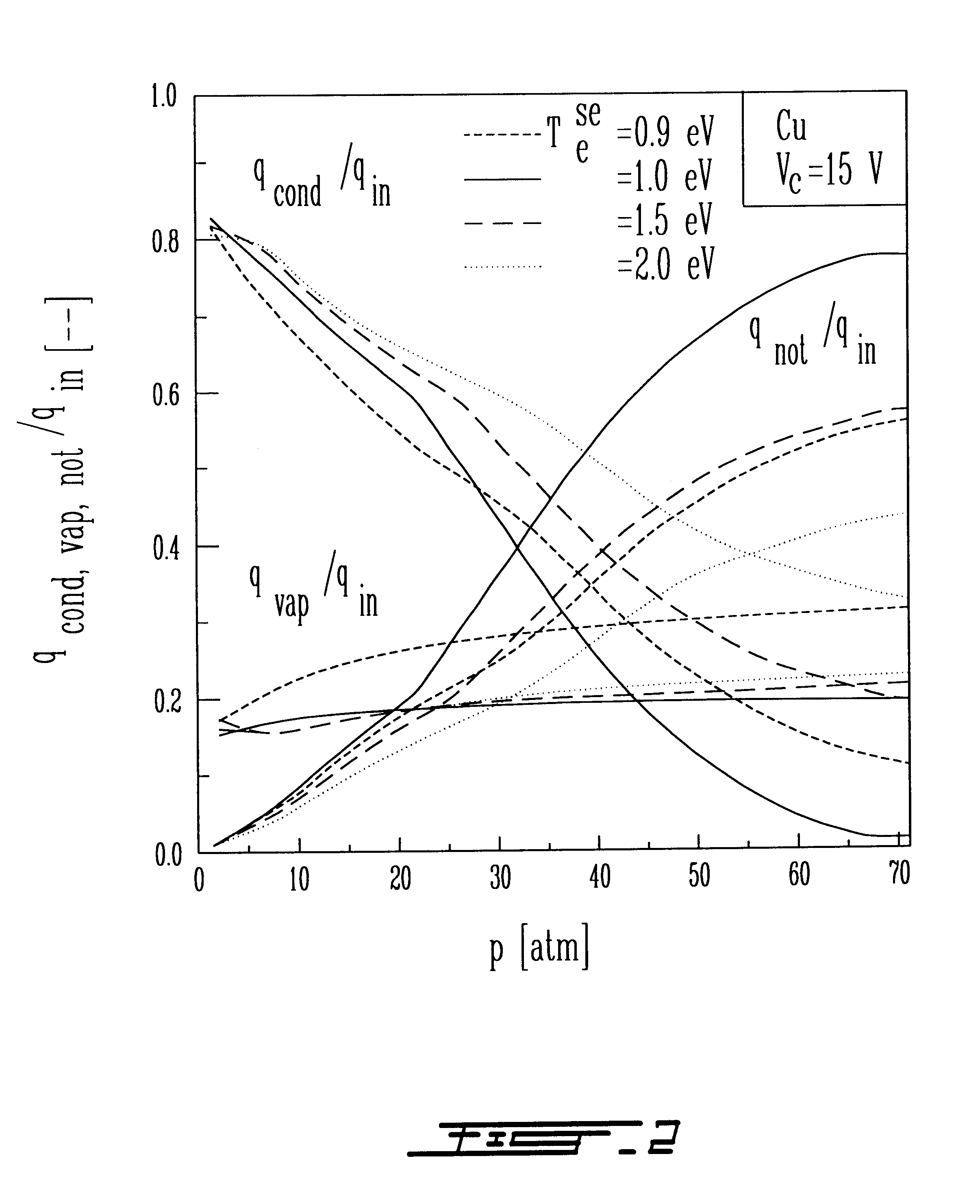

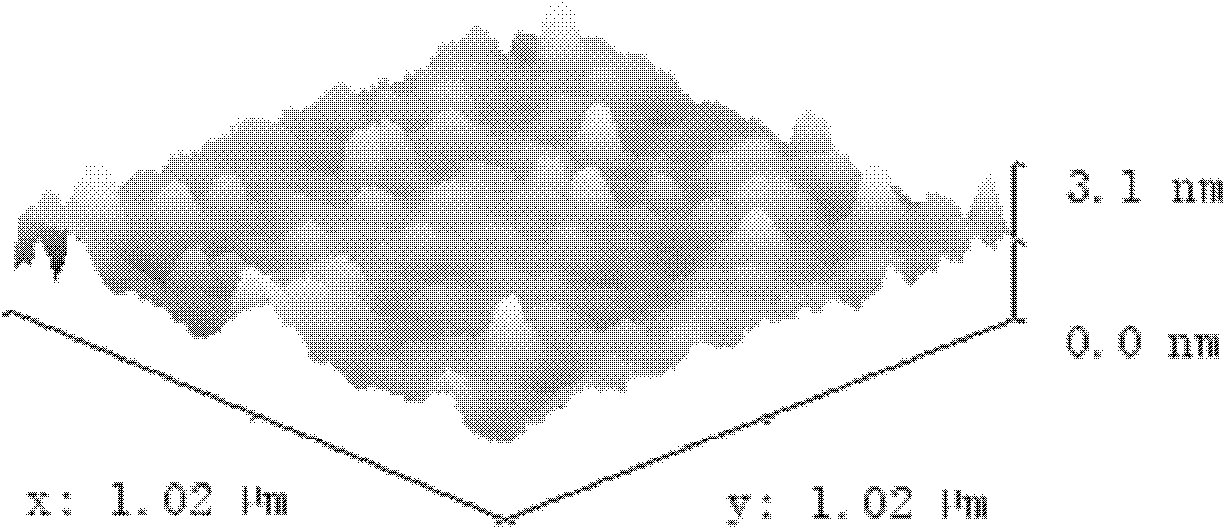

Particle-free cathodic arc carbon ion source

A method and apparatus for vacuum arc deposition of carbon on a substrate inhibits or eliminates emission of contaminating carbon particles in the ion plasma by maintaining an elevated local plasma pressure at the cathode or target surface, thereby minimizing the role of heat conduction in the creation of the particles and strongly increasing the electron emission cooling effects.

Owner:MCGILL UNIV

Method for preparing amorphous carbon composite coating on surface of hard alloy material and high-speed steel material

InactiveCN101781748AHigh hardnessImprove toughnessVacuum evaporation coatingSputtering coatingCarbon filmCarbon composites

The invention provides a novel method for preparing an amorphous tetrahedral carbon composite coating on the surface of hard alloy material and high-speed steel material. The method comprises substrate pretreatment, ion cleaning, plating of CrTiAlN intermediate coating, arc discharge and carbon ion deposition. The amorphous tetrahedral carbon film composite coating prepared through the method has the advantages that the bonding strength is high, rigidity is high, the friction coefficient is small, the coating is thin, the toughness is excellent, the coating is very suitable for knives and gauges such as screw taps, reamers, plug gauges and the like having strict requirements on dimensions, the content of SP3 bond structure in the coating is more than or equal to 85 percent, the rigidity is more than or equal to 85GPa, the friction coefficient is less than or equal to 0.15 and the bonding strength between the film and the substrate is more than or equal to 35N; and compared with the DLC prepared through the traditional technology, the friction coefficient is smaller, the rigidity is higher, the service life is improved by more than six times and the coating is very suitable for being selected and used at present.

Owner:XI AN JIAOTONG UNIV

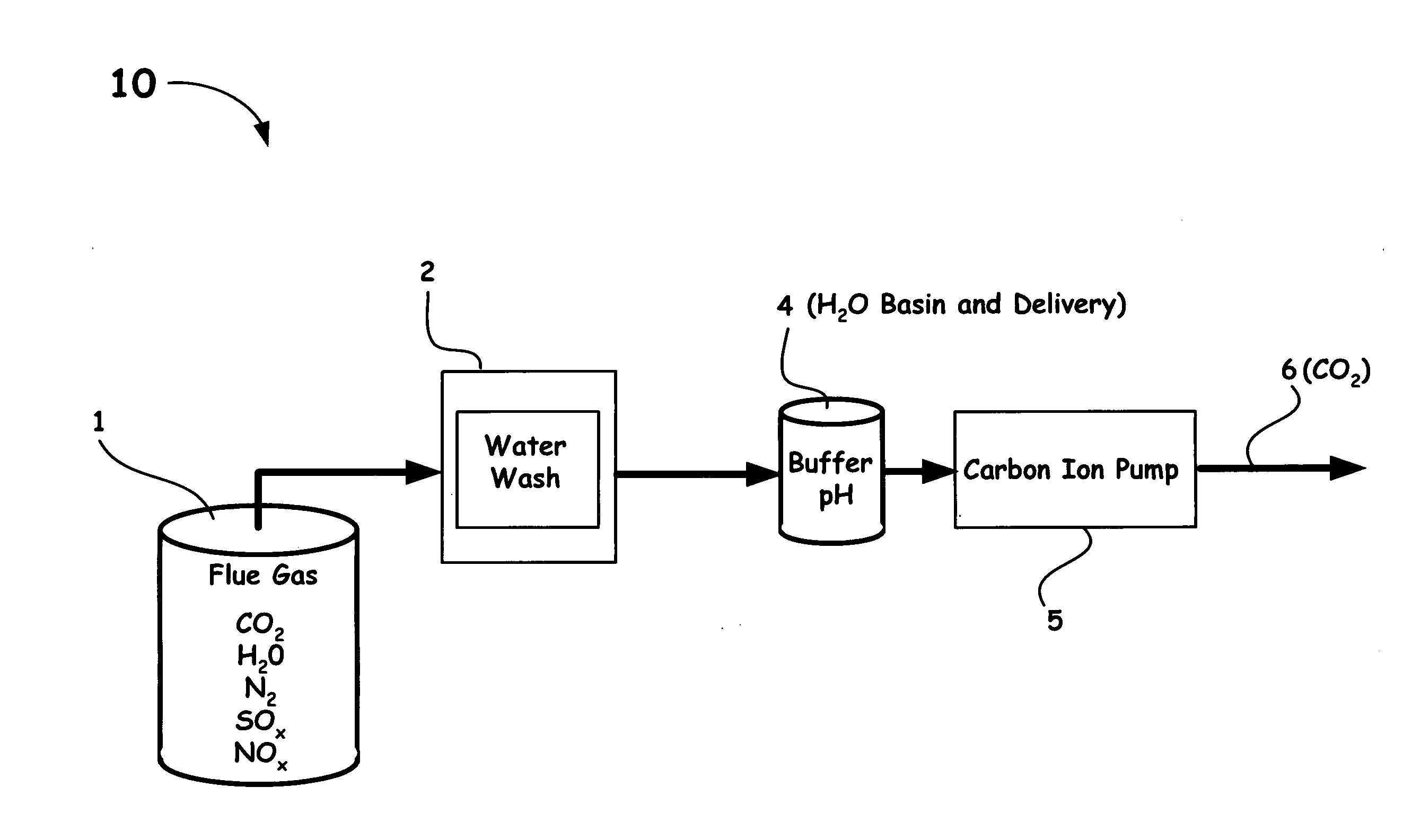

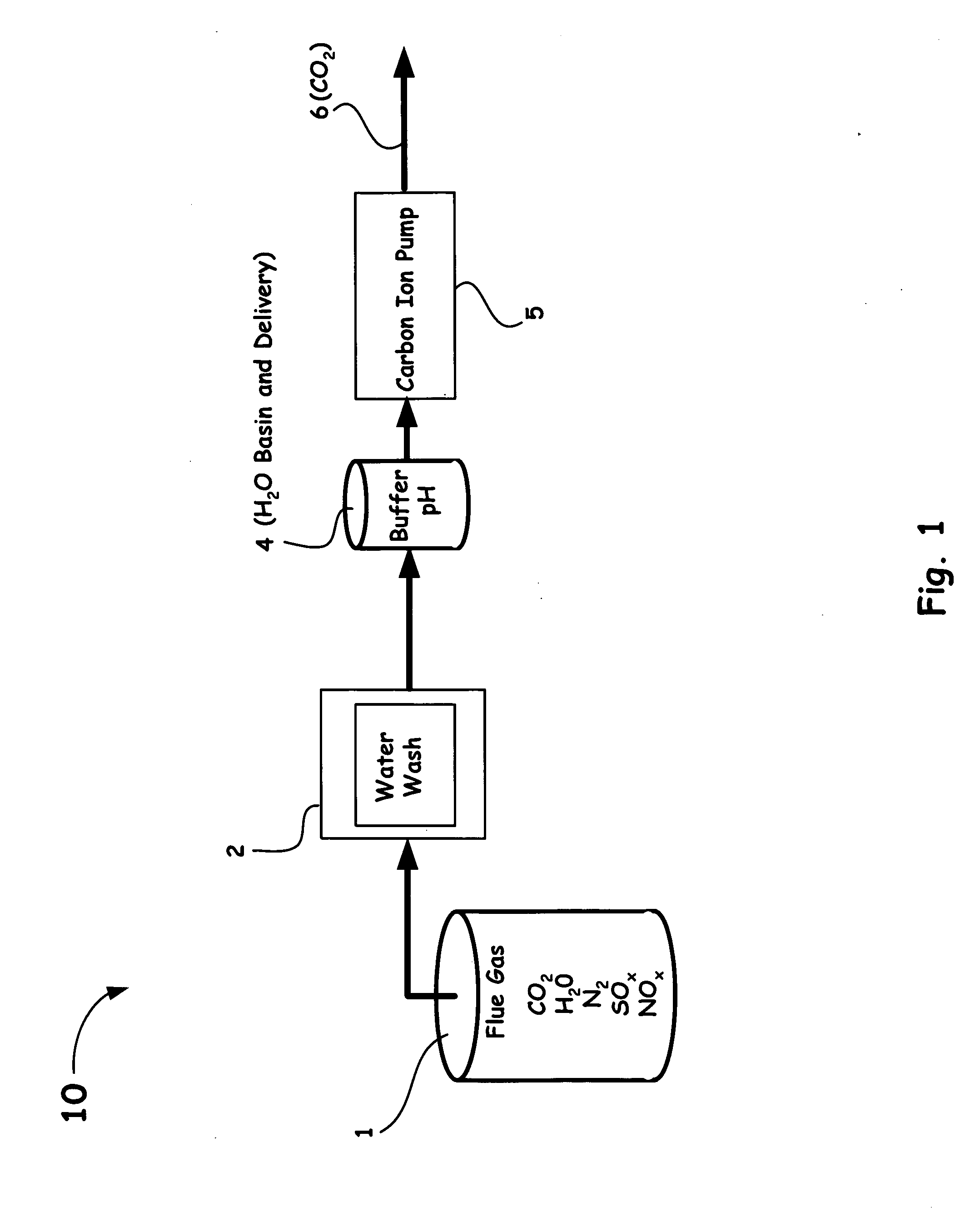

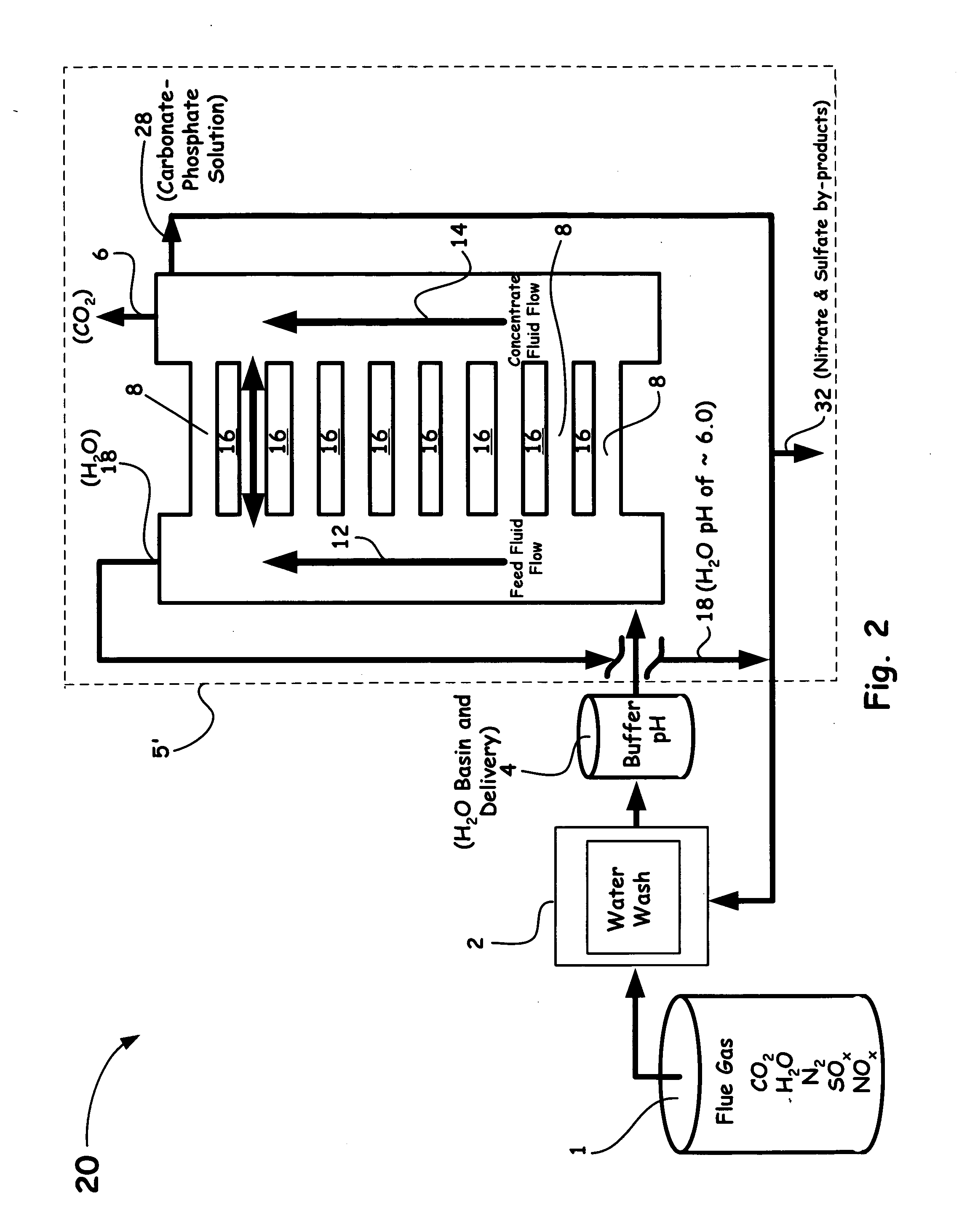

Carbon ion pump for removal of carbon dioxide from combustion gas and other gas mixtures

InactiveUS20070169625A1Improve concentrationIncrease vapor pressureLiquid separation by electricityCarbon compoundsCarbon ionReverse osmosis

A novel method and system of separating carbon dioxide from flue gas is introduced. Instead of relying on large temperature or pressure changes to remove carbon dioxide from a solvent used to absorb it from flue gas, the ion pump method, as disclosed herein, dramatically increases the concentration of dissolved carbonate ion in solution. This increases the overlying vapor pressure of carbon dioxide gas, permitting carbon dioxide to be removed from the downstream side of the ion pump as a pure gas. The ion pumping may be obtained from reverse osmosis, electrodialysis, thermal desalination methods, or an ion pump system having an oscillating flow in synchronization with an induced electric field.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

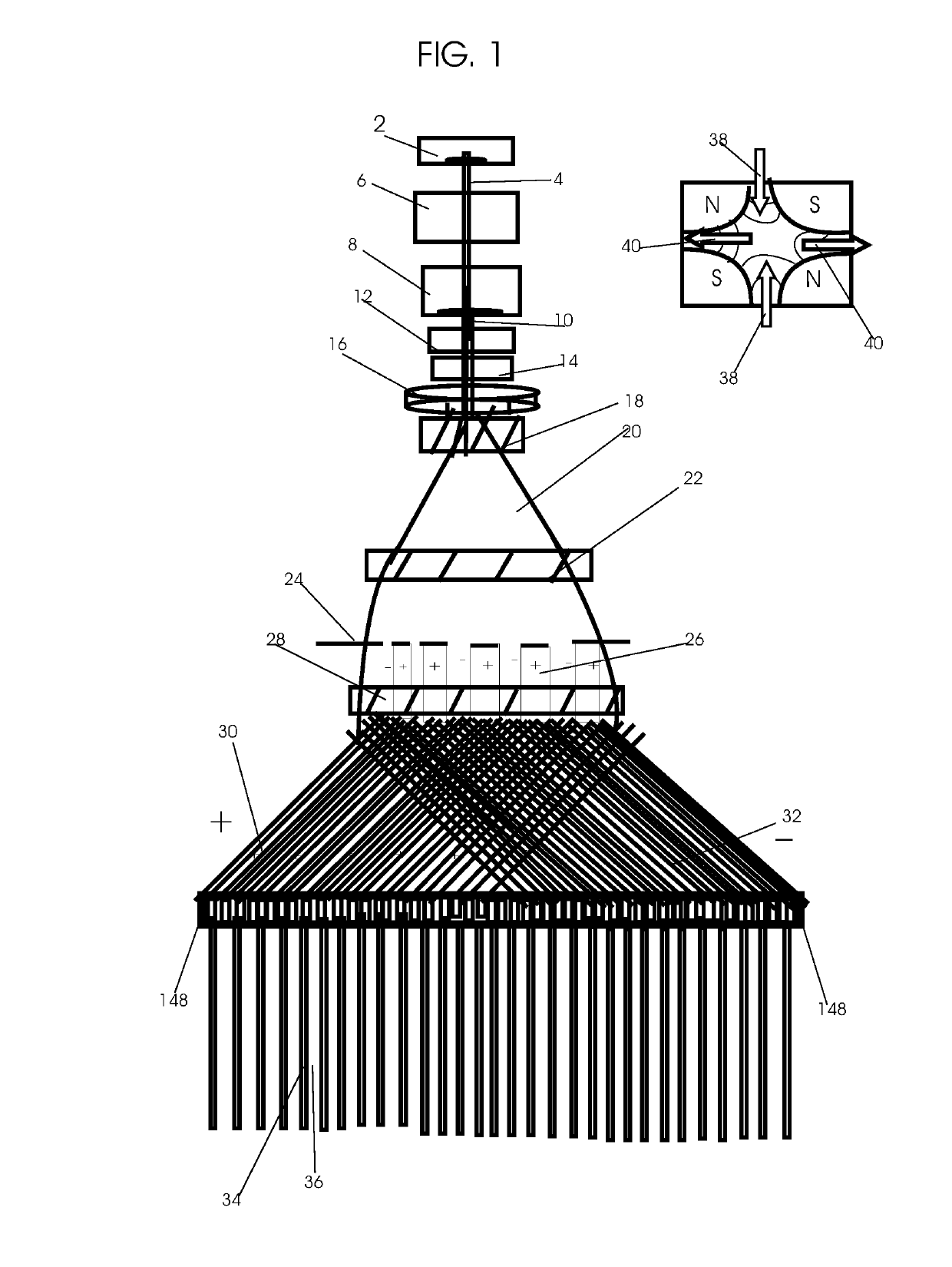

Preparation method of graphene film

InactiveCN103695869AControl growth patternControl the speed at which the substrate is bombardedChemical vapor deposition coatingCarbon ionSingle crystal

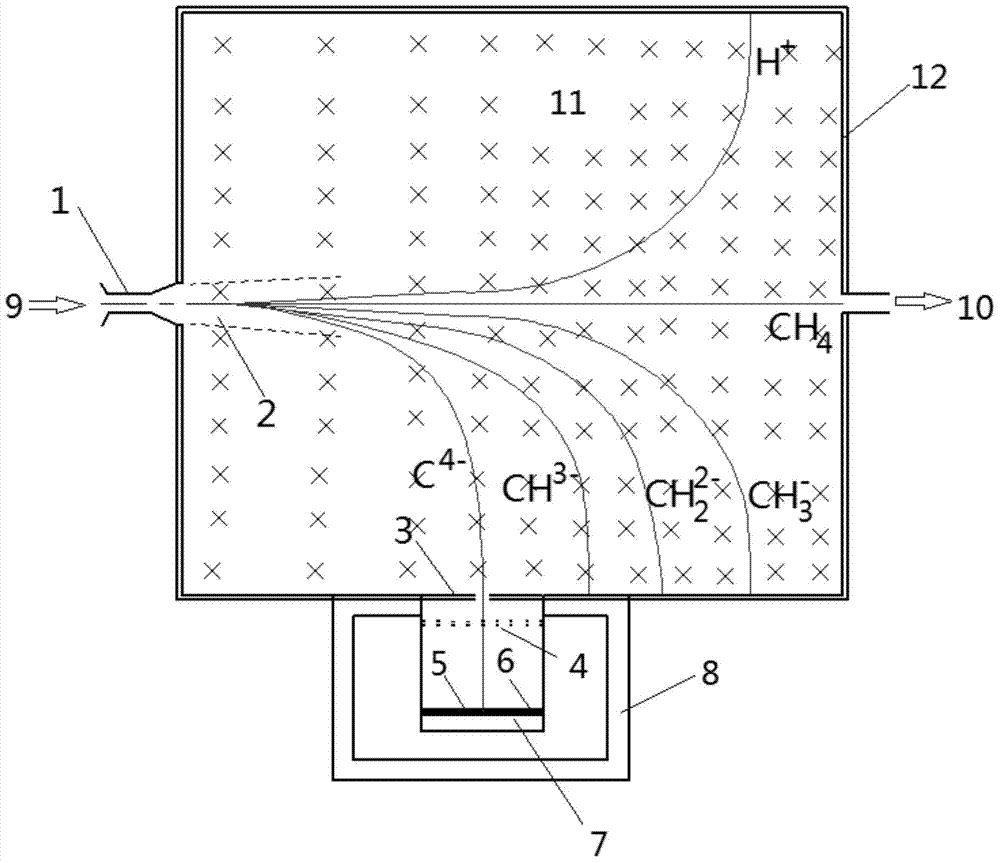

The invention discloses a preparation method of a graphene film. The preparation method comprises the following steps: providing a graphene growth substrate, and placing the substrate in a high-temperature area formed by heating; applying accelerating electric fields and screening magnetic fields vertical to the substrate and along a surface normal direction of the graphene film needing deposition along the substrate in sequence, and taking the substrate as a positive electrode of the accelerating electric fields; heating the substrate, a screening magnetic field area and an accelerating electric field area; ventilating a carbon-containing gas as a carbon source, ionizing the carbon-containing gas into plasmas before ventilating into the screening magnetic field area, and enabling the plasmas to enter the screening magnetic field area in a jet-flow form, wherein charged ions in the jet-flow have different movement radiuses under action of different screening magnetic fields according to difference of charged quantity; and enabling the screened carbon ions to enter the accelerating electric fields, accelerating the carbon ions to a certain speed under action of the accelerating electric fields to collide the substrate surface, so that graphene growth is realized. The preparation method disclosed by the invention can greatly improve production efficiency of the graphene and can obtain high-quality large-dimension graphene by virtue of continuous growth.

Owner:上海中电振华晶体技术有限公司

Graphene preparation method without substrate transferring

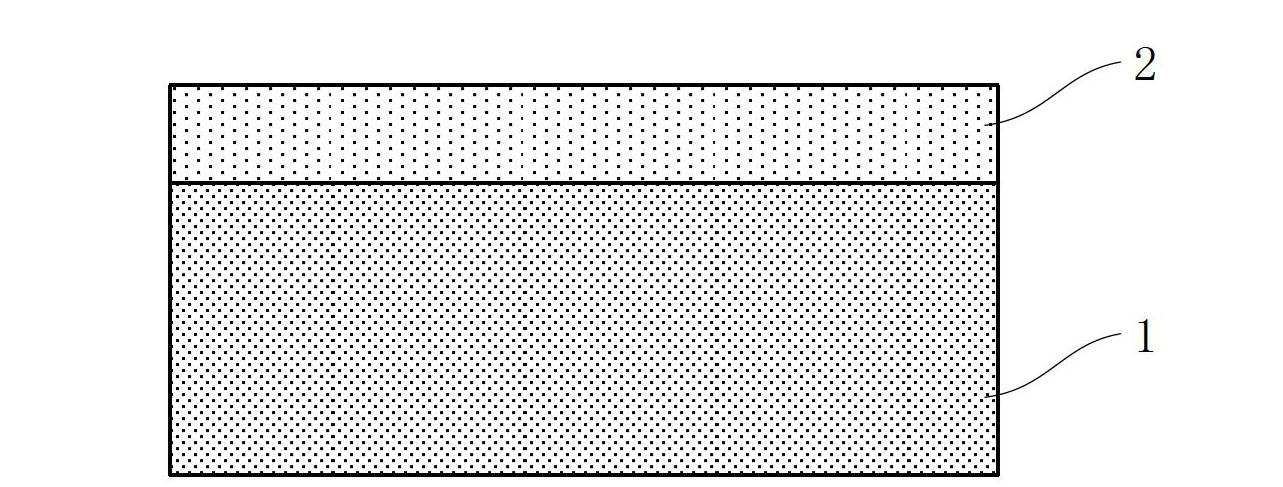

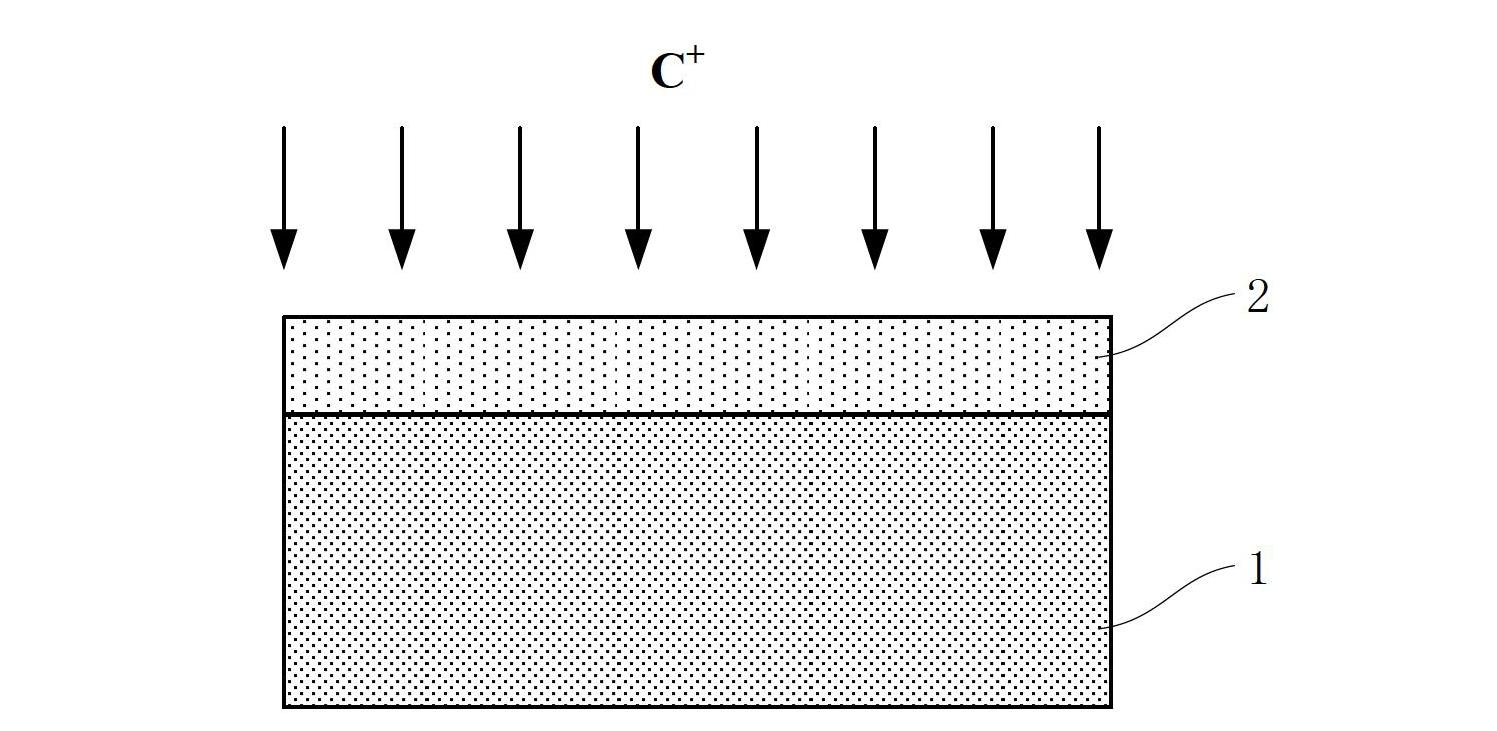

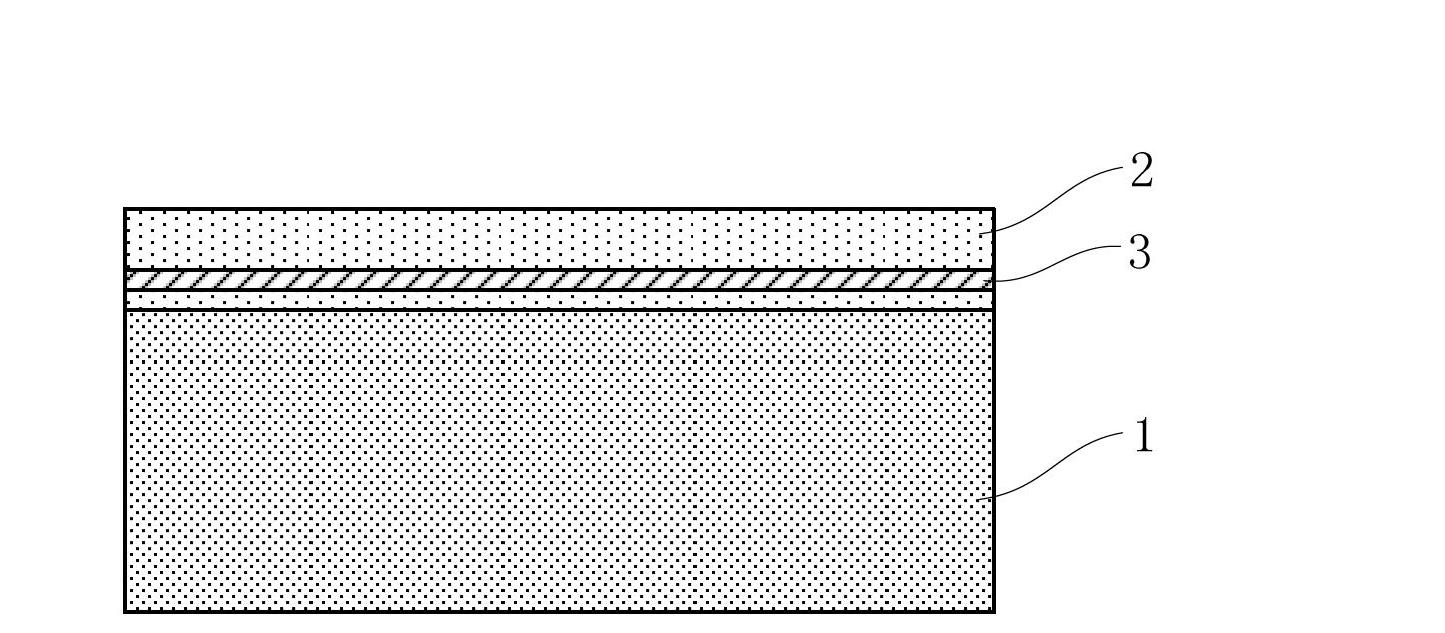

The invention provides a graphene preparation method without substrate transferring. According to the graphene preparation method, a catalytic metal layer is deposited on a substrate; then, carbon ions are injected into the catalytic metal layer to form a carbon-atom-saturated face by using an ion implantation technology, and the carbon-atom-saturated face can be located at a position close to the substrate and a catalytic metal layer interface through controlling injected energy; then, the substrate is subjected to high-temperature annealing, carbon-atom layers, i.e. graphene films, are precipitated on the catalytic metal layer and a substrate interface; and finally, the catalytic metal layer is removed, and thus the graphene films are prepared on the substrate. The graphene preparation method without the substrate transferring has the advantages that the processing steps for preparing graphene are simplified, the graphene can be directly prepared on any substrate without transferring, the damage and the pollution to the structure of the graphene cannot be accordingly caused, and the graphene with high quality can be directly applied to a desired substrate, so that the preparation method can faster promote the wide application of the graphene in different fields.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

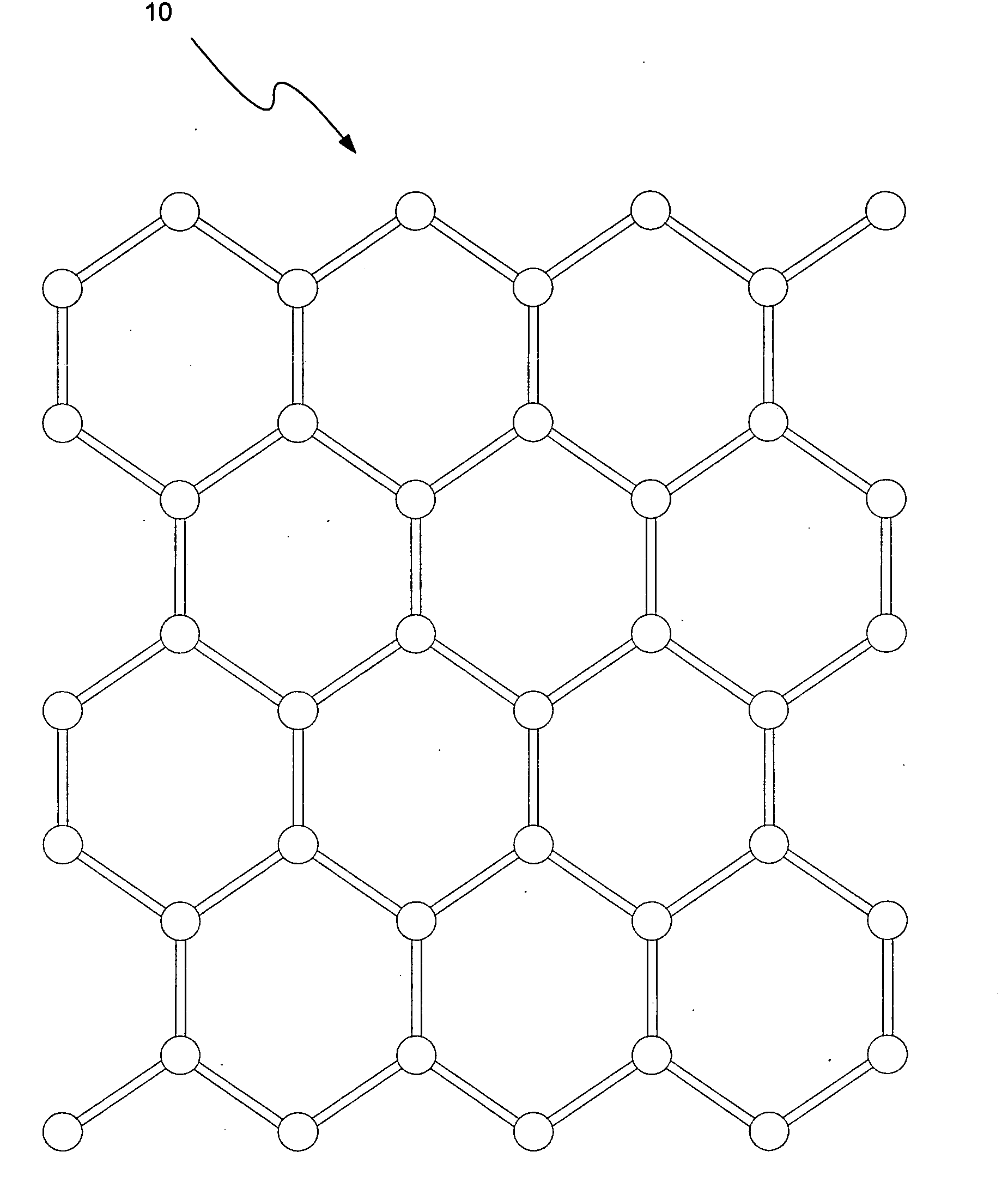

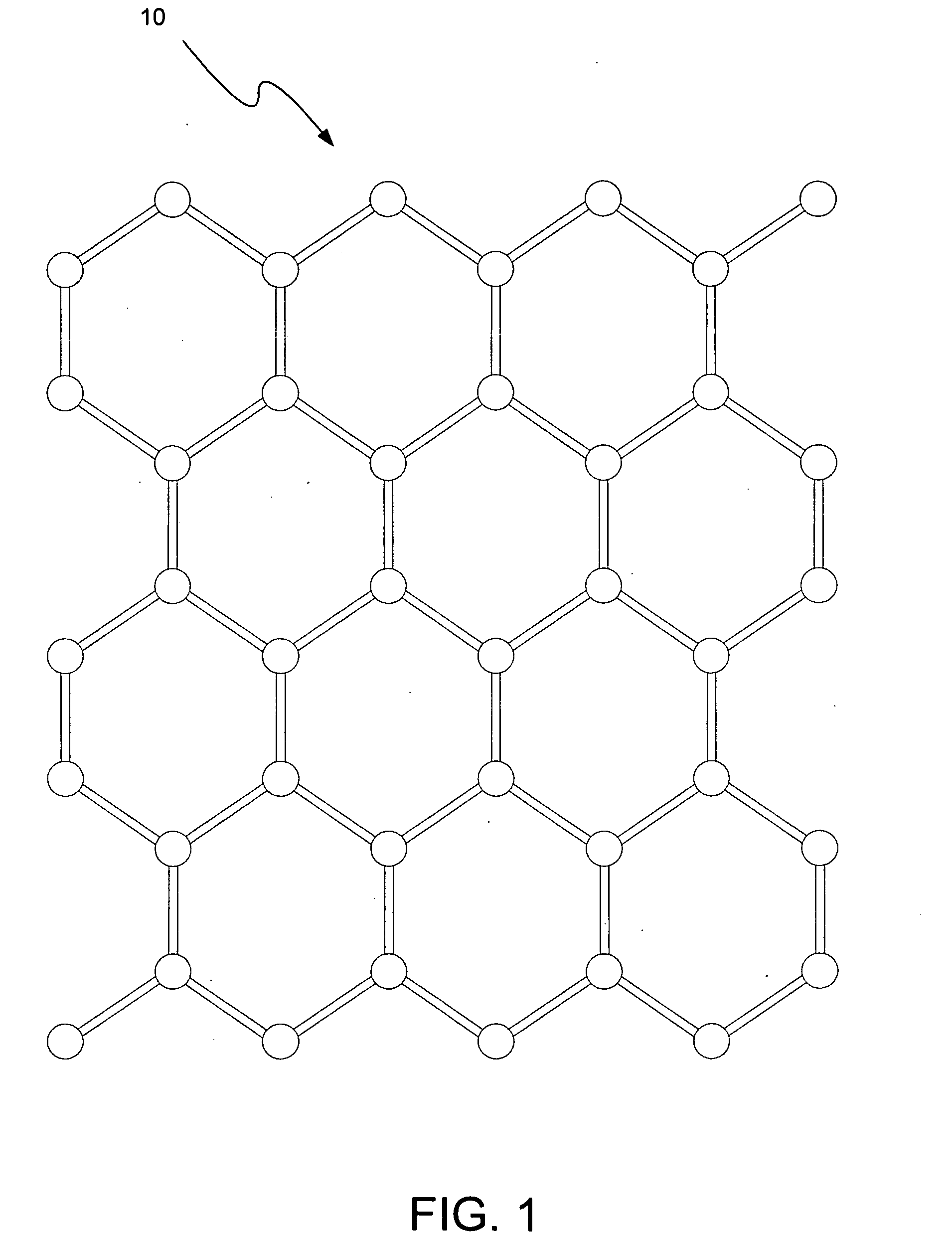

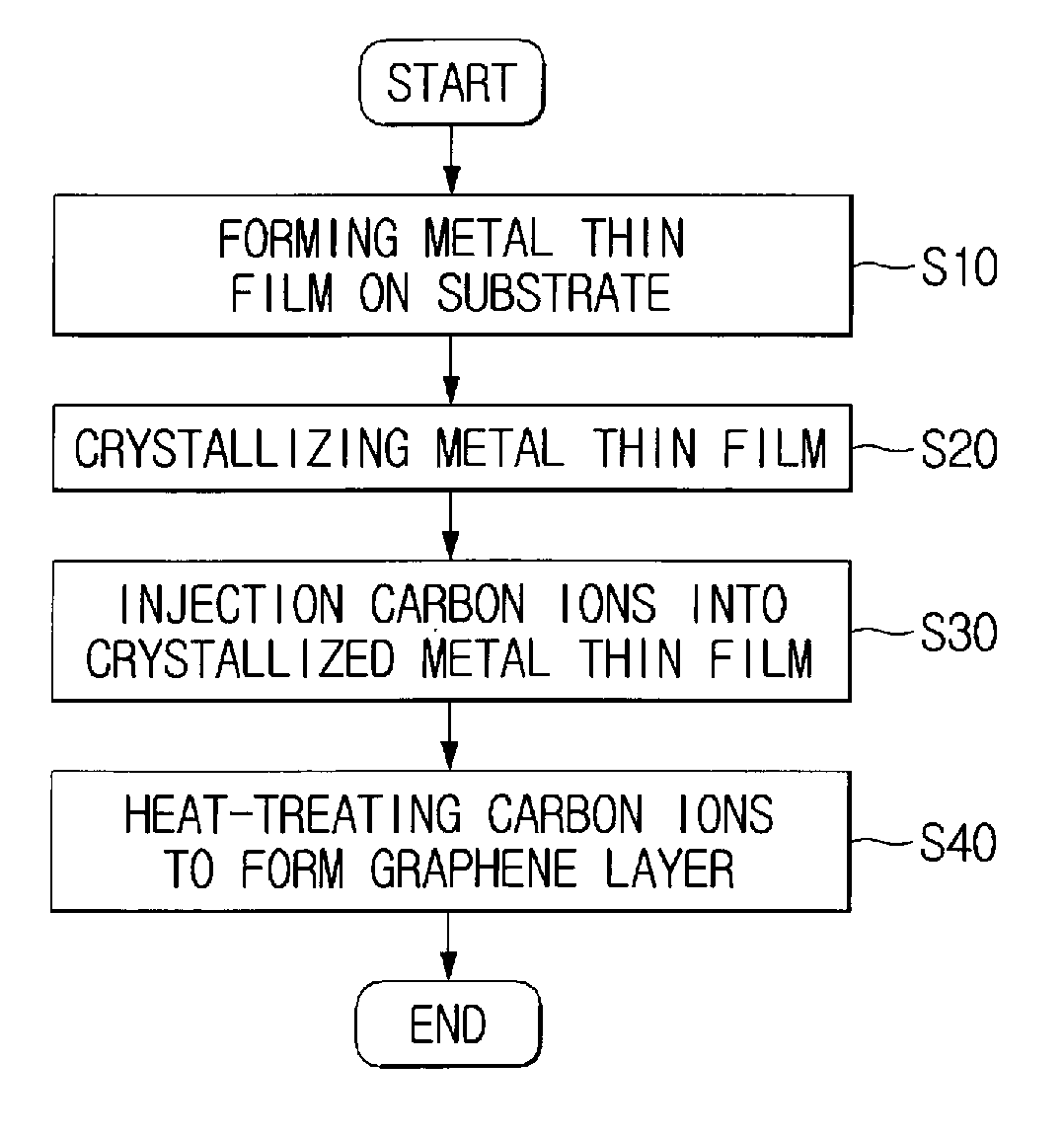

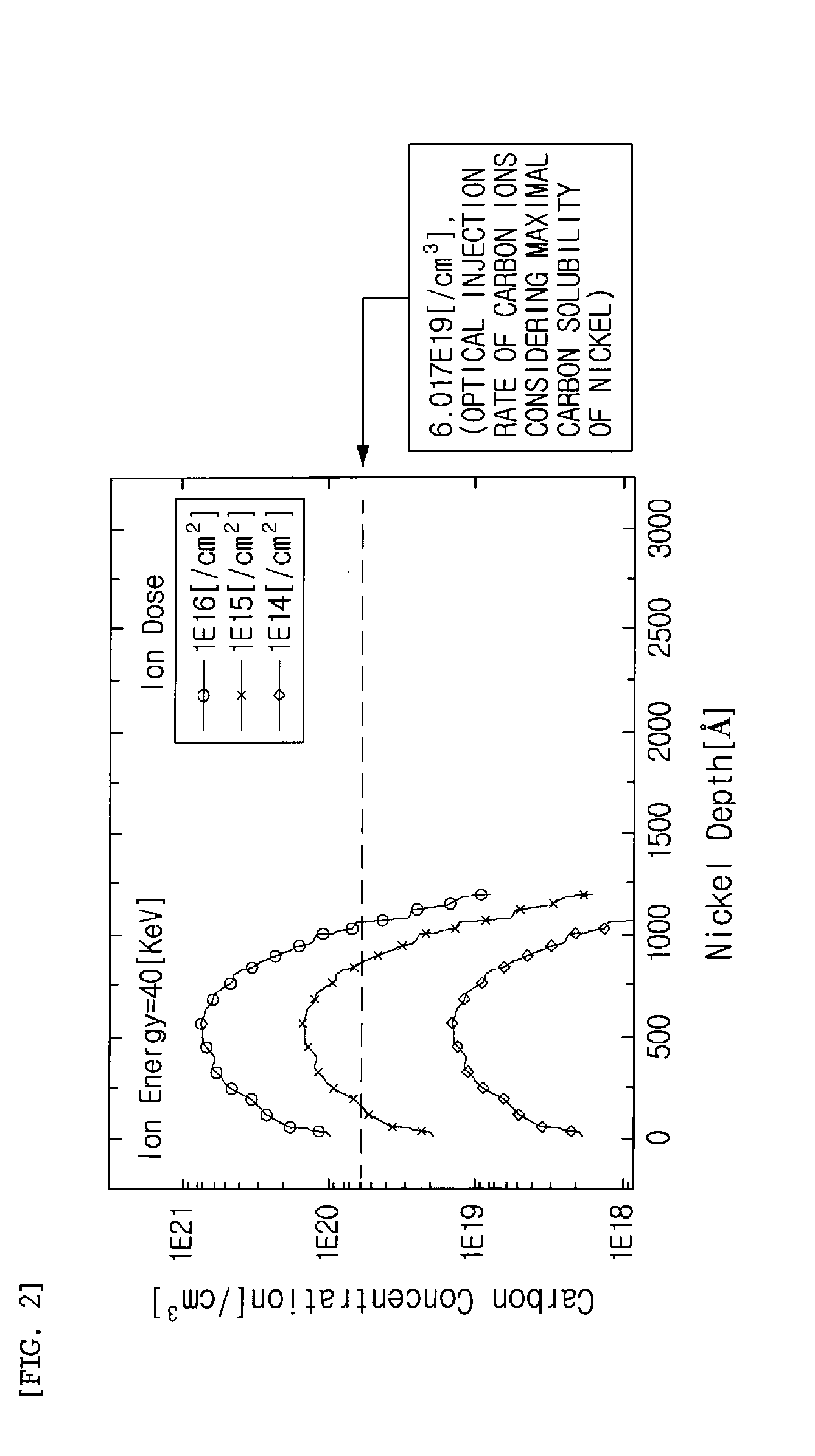

Method of forming graphene layer

The present invention relates to a method of forming a graphene layer, and, more particularly, to a method of forming a graphene layer which is a two-dimensional thin film composed of carbon atoms arranged in a honeycomb-style lattice and having one atom thick and which is put to practical use in the field of electric devices, transparent electrodes or microwave circuits. The method includes the steps of: (a) forming a metal thin film on a substrate; (b) injecting carbon ions into the metal thin film; and (c) heat-treating the carbon ions injected into the metal thin film to form a graphene layer on the metal thin film. The method is advantageous in that a graphene layer is formed by uniformly injecting an accurate amount of carbon ions into a metal thin film depending on the maximum solubility of carbon in the metal thin film and then heat-treating the injected carbon ions, thus uniformly forming the graphene layer on the metal thin film.

Owner:KOREA ADVANCED INST OF SCI & TECH

Device and methods for adaptive resistance inhibiting proton and carbon ion microbeams and nanobeams radiosurgery

ActiveUS10413755B1Eliminate inefficienciesGood prospectsX-ray/gamma-ray/particle-irradiation therapyDiamond-like carbonCarbon ion

This invention relates to adaptive resistance inhibiting 100 to 10,000 Gy, single fraction proton and carbon ion microbeam and nanobeam radiosurgery, proton spray chemotherapy and proton spray gadolinium and boron neutron capture therapy with least normal tissue toxicity. Secondary neutrons, protons, ions and radiation from the accelerator and the patient specific collimator are removed with tissue equivalent collimator that also generates proton and carbon ion microbeam and nanobeam. Laser interaction with micrometer and nanometer thick metallic and diamond like carbon targets are also used for proton and carbon ion beam generation. Polyenergetic proton beam is spatially separated. Ion beam and Laser ion beam is accelerated in a hybrid RF accelerator. It is split into microbeam and nanobeam. Secondary neutrons, protons and gamma radiation are removed with tissue equivalent collimators that also generate microbeams and nanobeams. Adaptive resistance to cancer treatment is inhibited by dual target radiation, DNA strands break and enzymes inactivation.

Owner:SAHADEVAN VELAYUDHAN

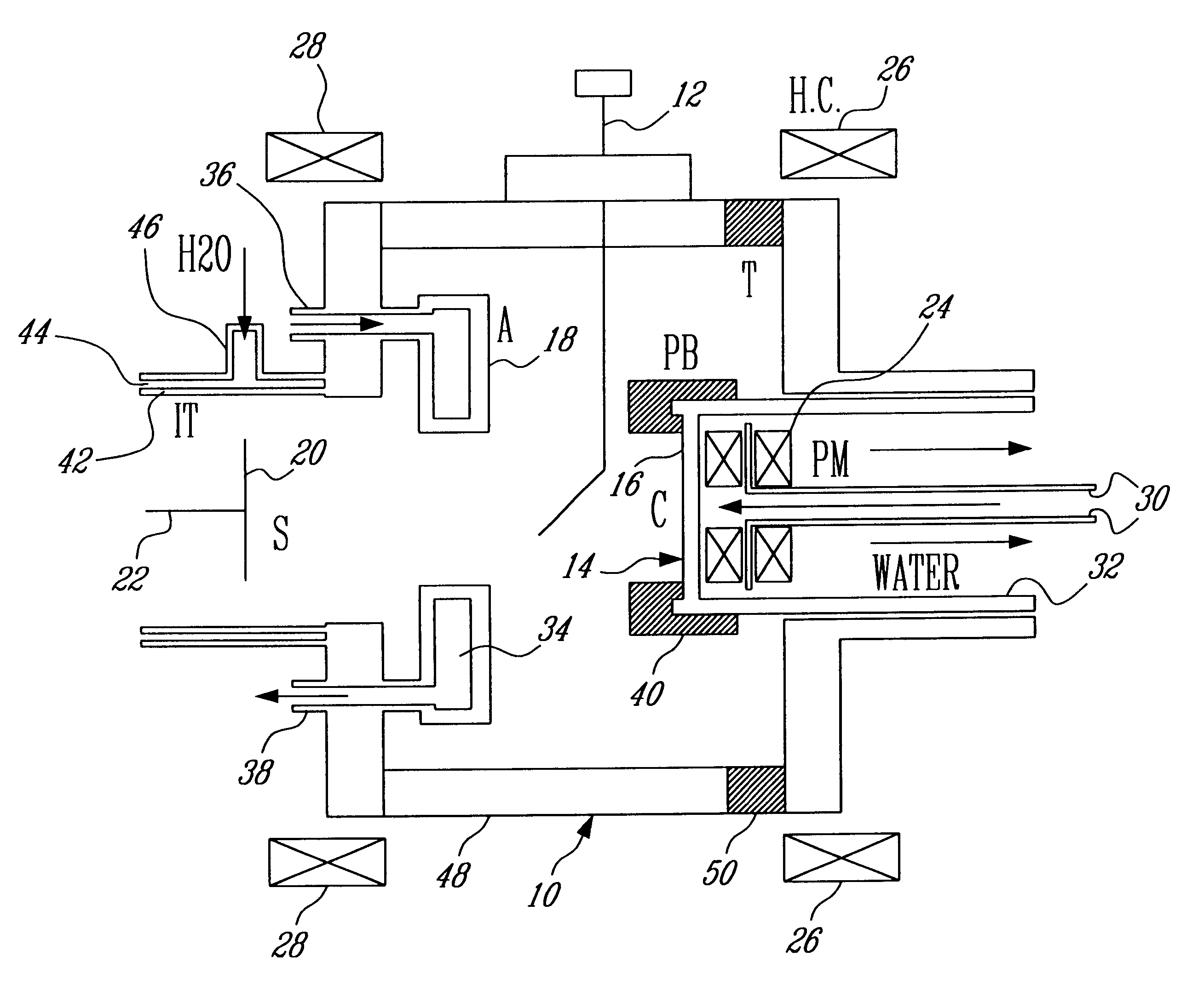

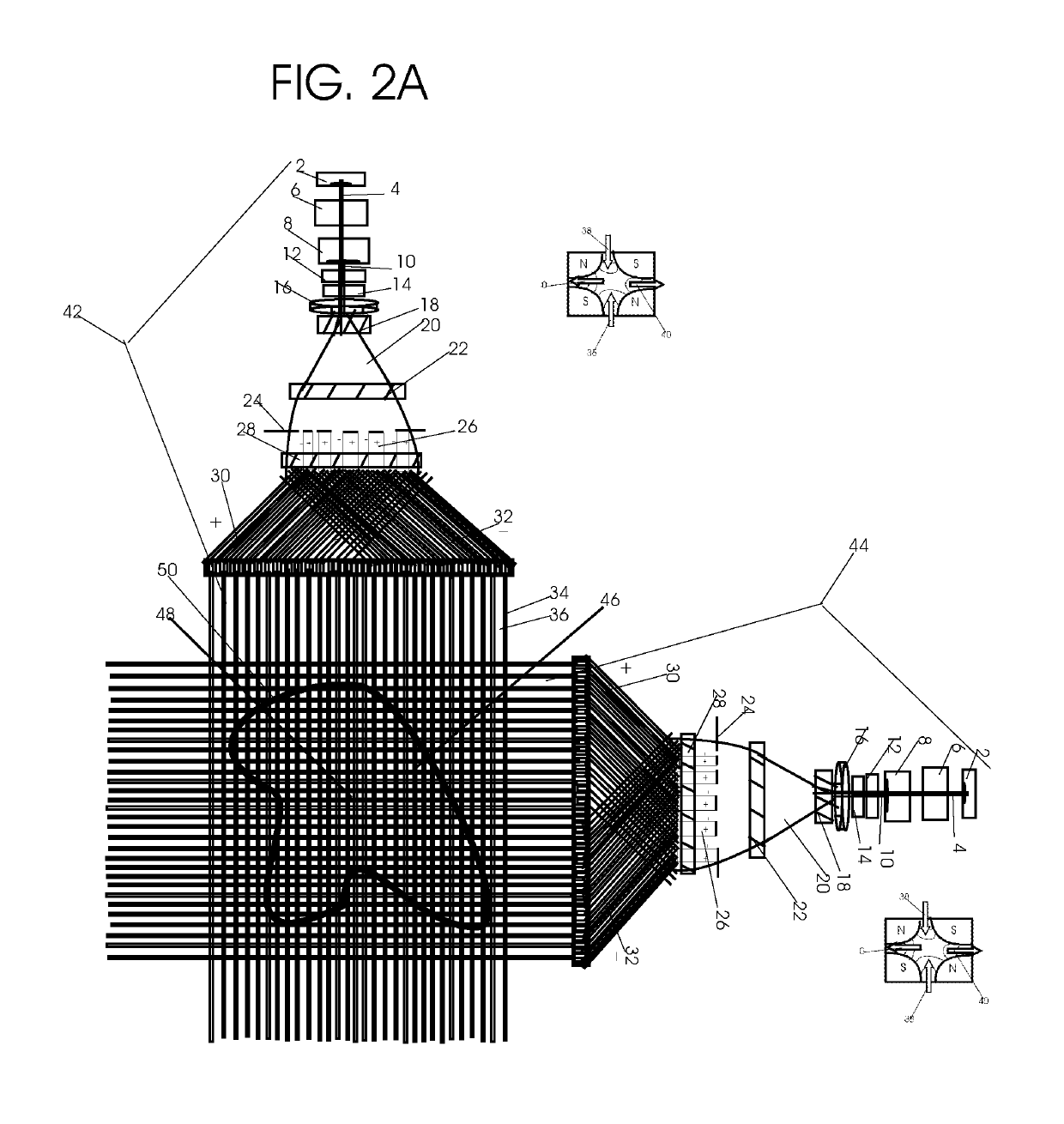

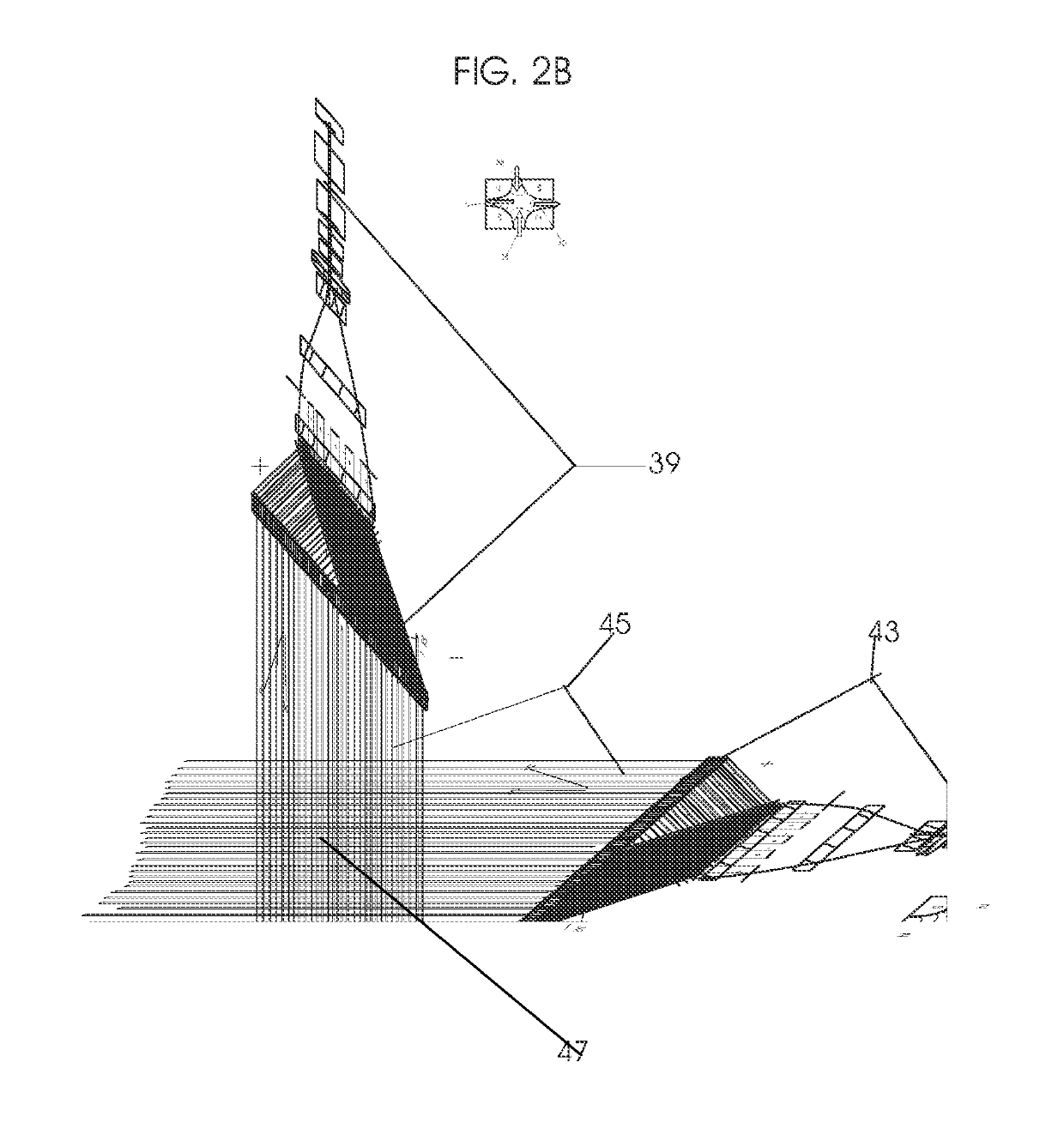

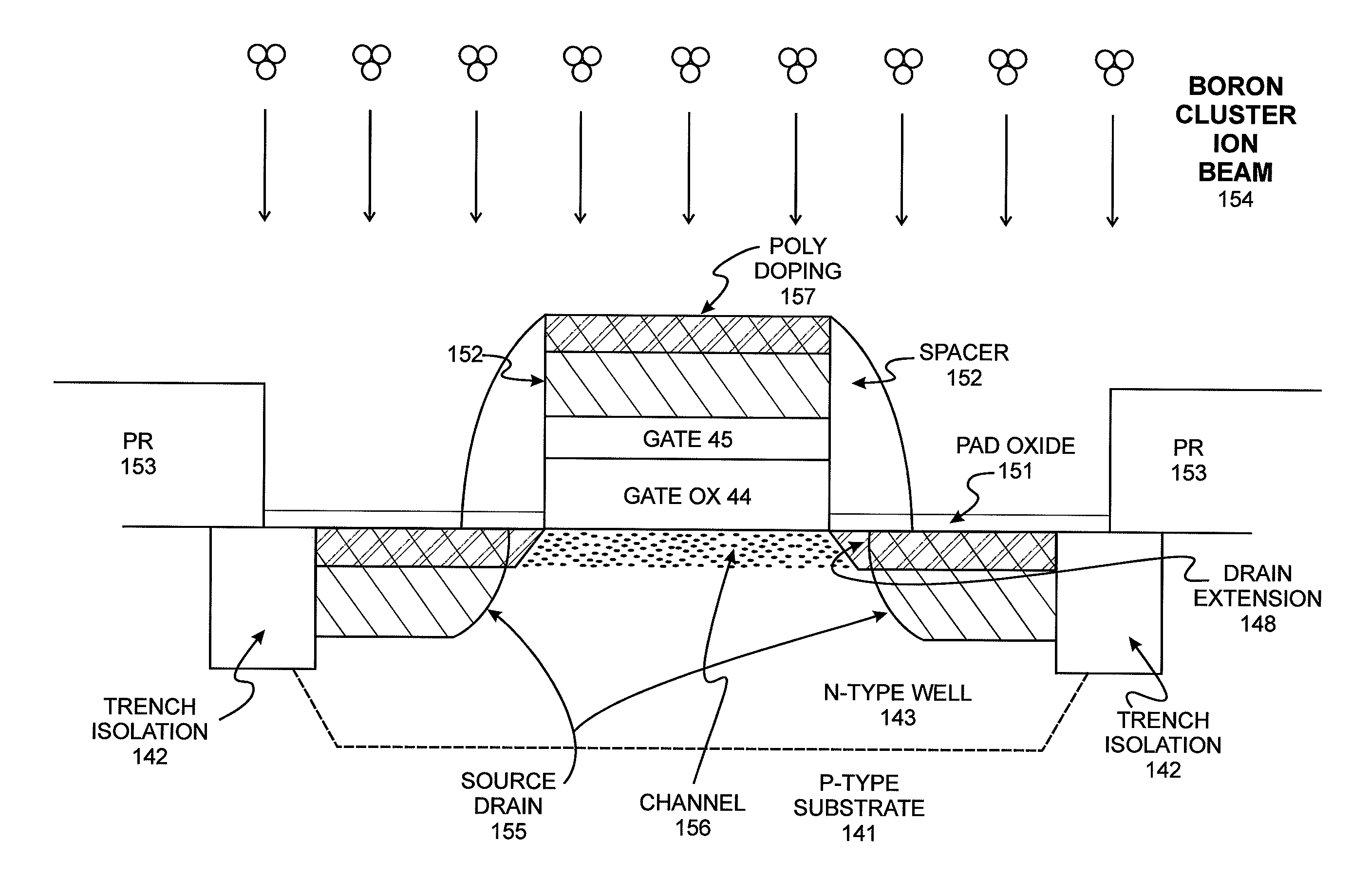

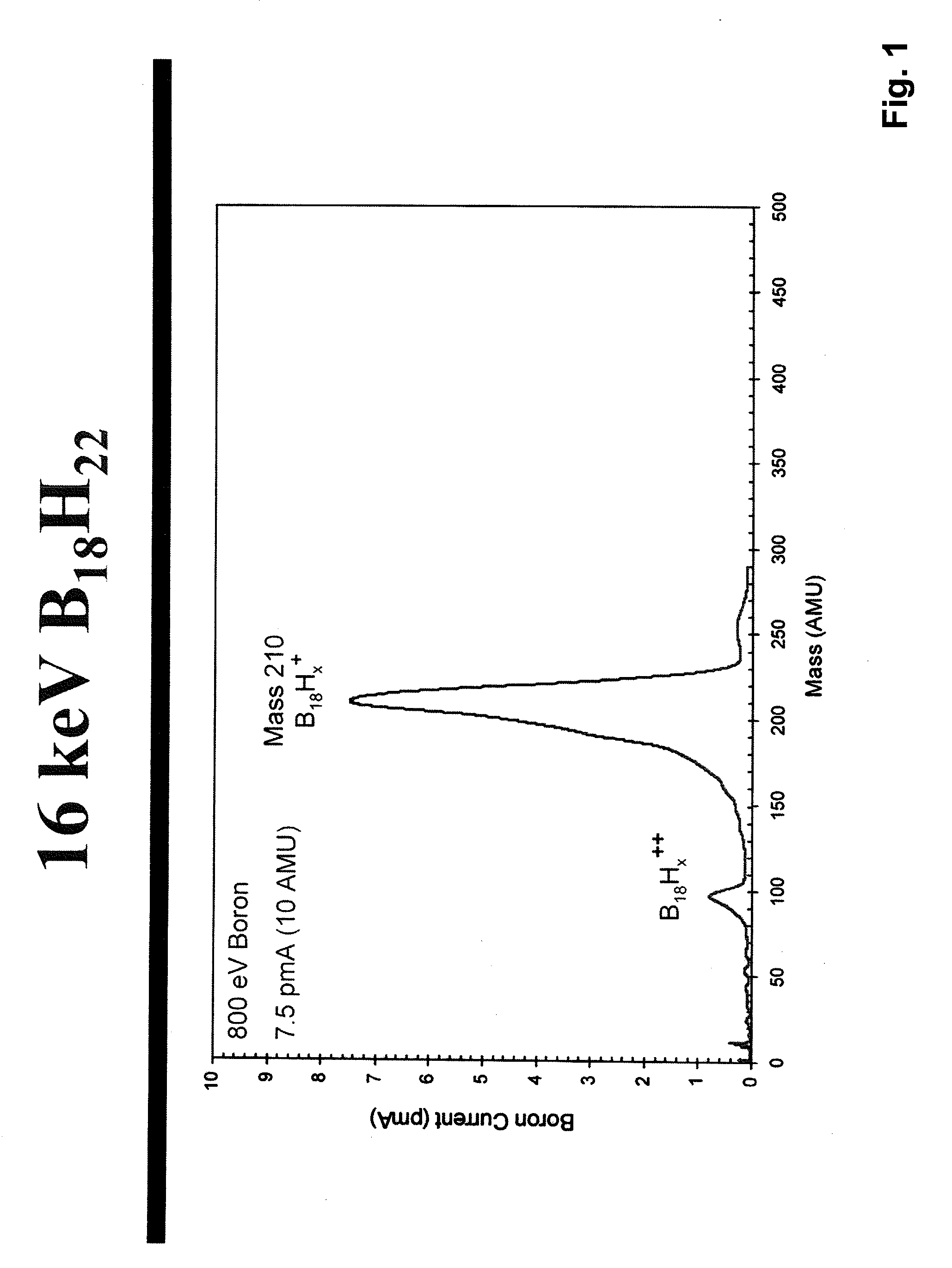

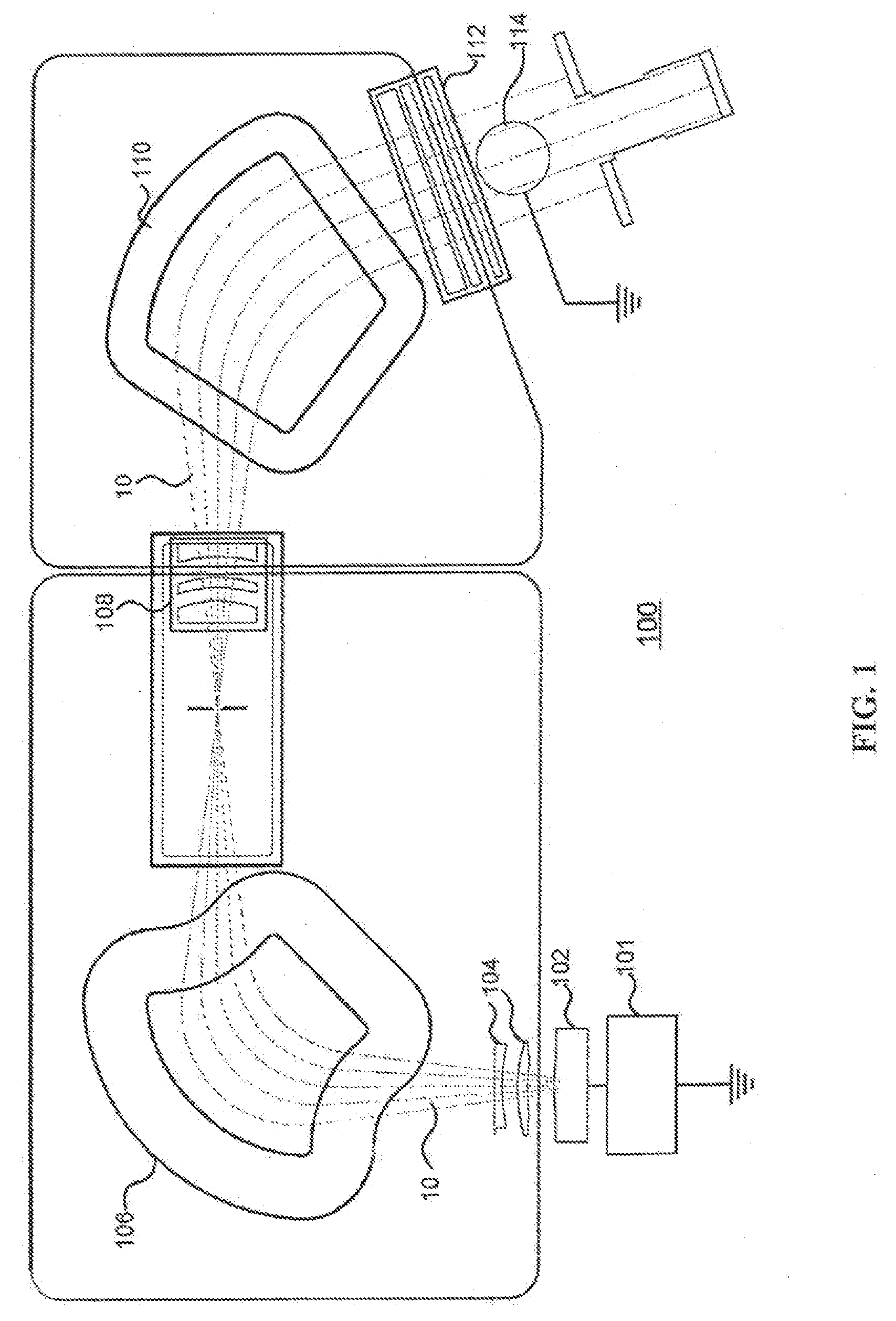

System and method for the manufacture of semiconductor devices by the implantation of carbon clusters

InactiveUS20090286367A1Increase junction depthReduce leakage currentTransistorElectric discharge tubesCarbon ionHigh doses

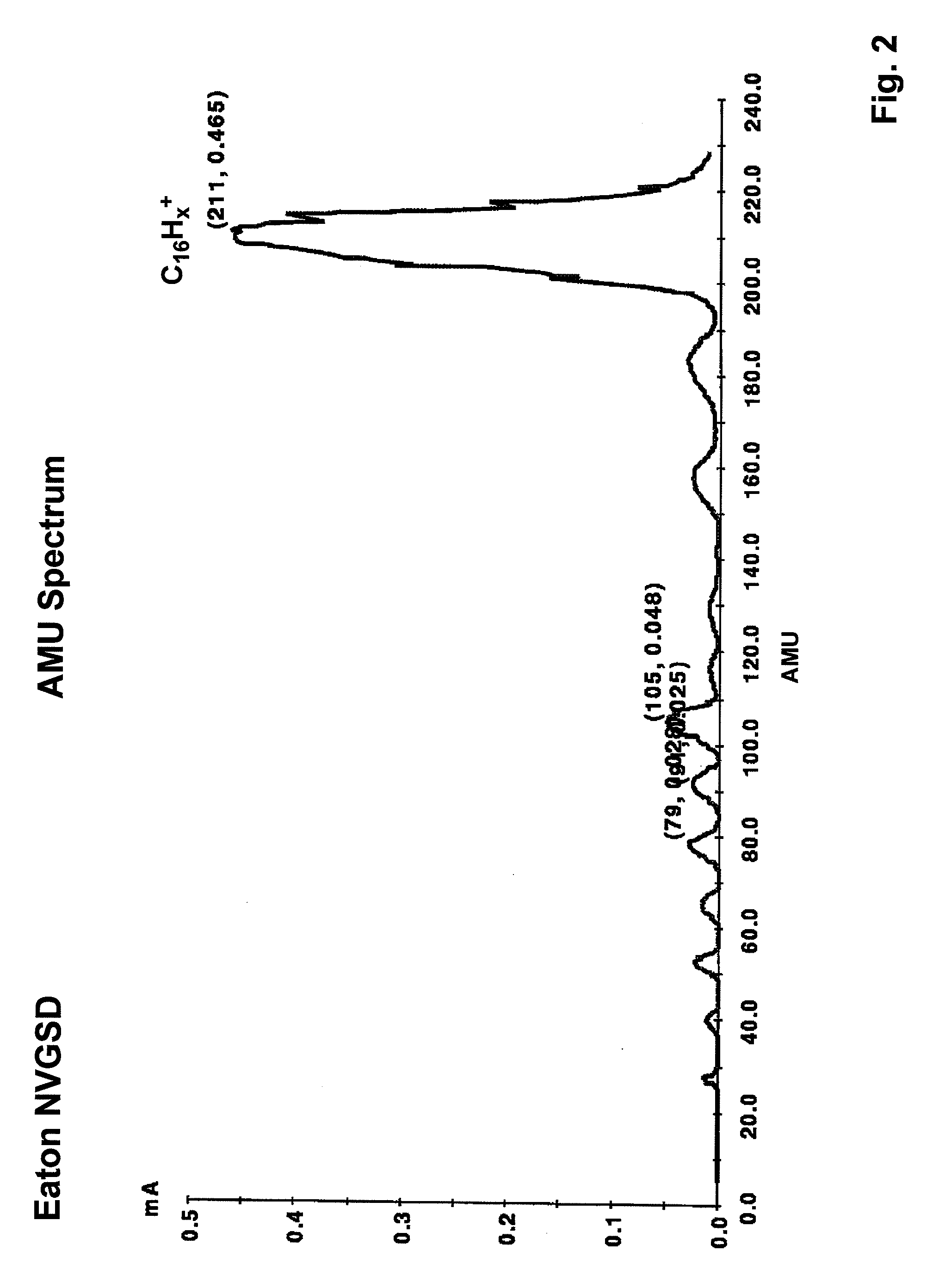

A process is disclosed which incorporates implantation of a carbon cluster into a substrate to improve the characteristics of transistor junctions when the substrates are doped with Boron and Phosphorous in the manufacturing of PMOS transistor structures in integrated circuits. There are two processes which result from this novel approach: (1) diffusion control for USJ formation; and (2) high dose carbon implantation for stress engineering. Diffusion control for USJ formation is demonstrated in conjunction with a boron or shallow boron cluster implant of the source / drain structures in PMOS. More particularly, first, a cluster carbon ion, such as C16Hx+, is implanted into the source / drain region at approximately the same dose as the subsequent boron implant; followed by a shallow boron, boron cluster, phosphorous or phosphorous cluster ion implant to form the source / drain extensions, preferably using a borohydride cluster, such as B18Hx+ or B10Hx+. Upon subsequent annealing and activation, the boron diffusion is reduced, due to the gettering of interstitial defects by the carbon atoms.

Owner:SEMEQUIP

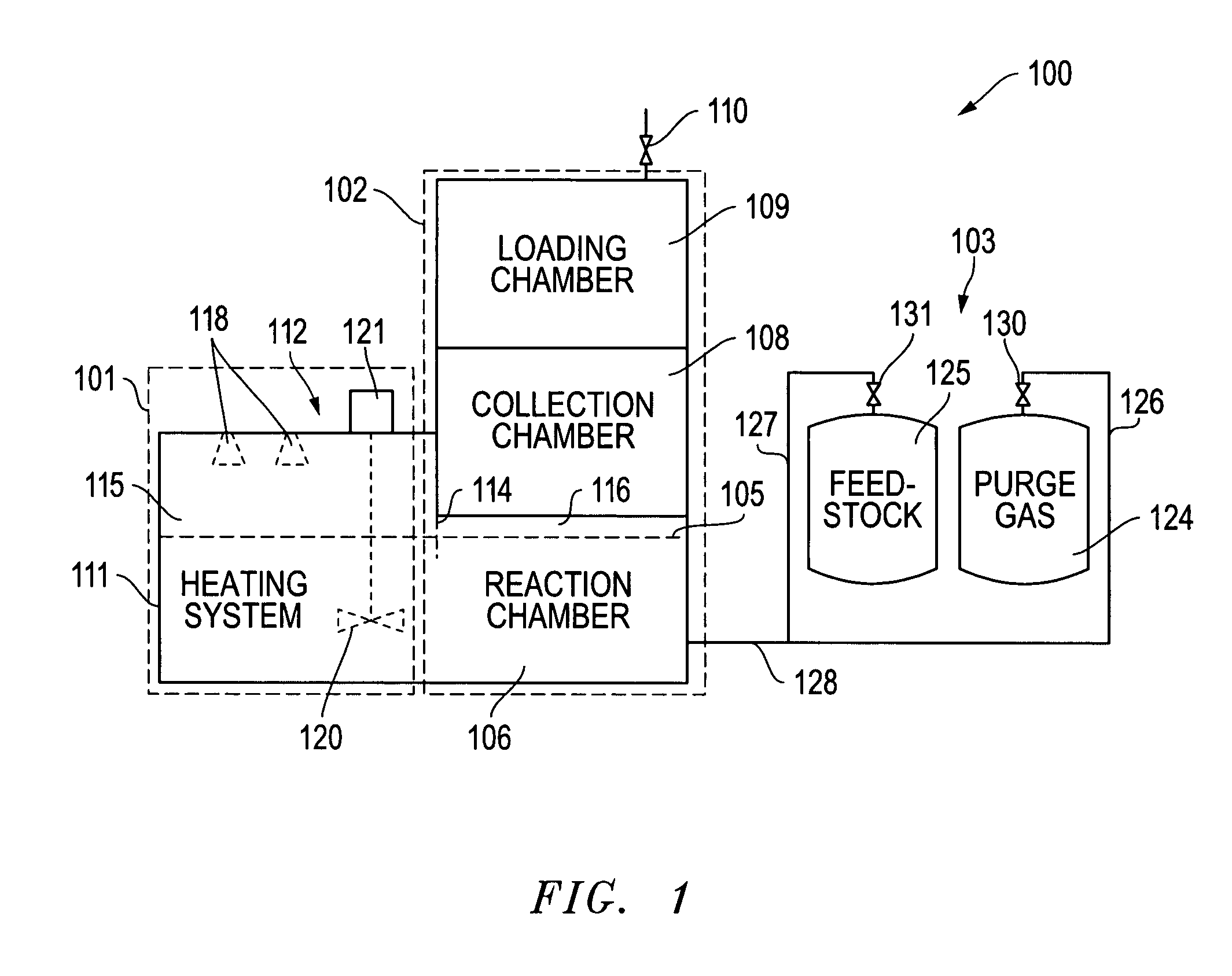

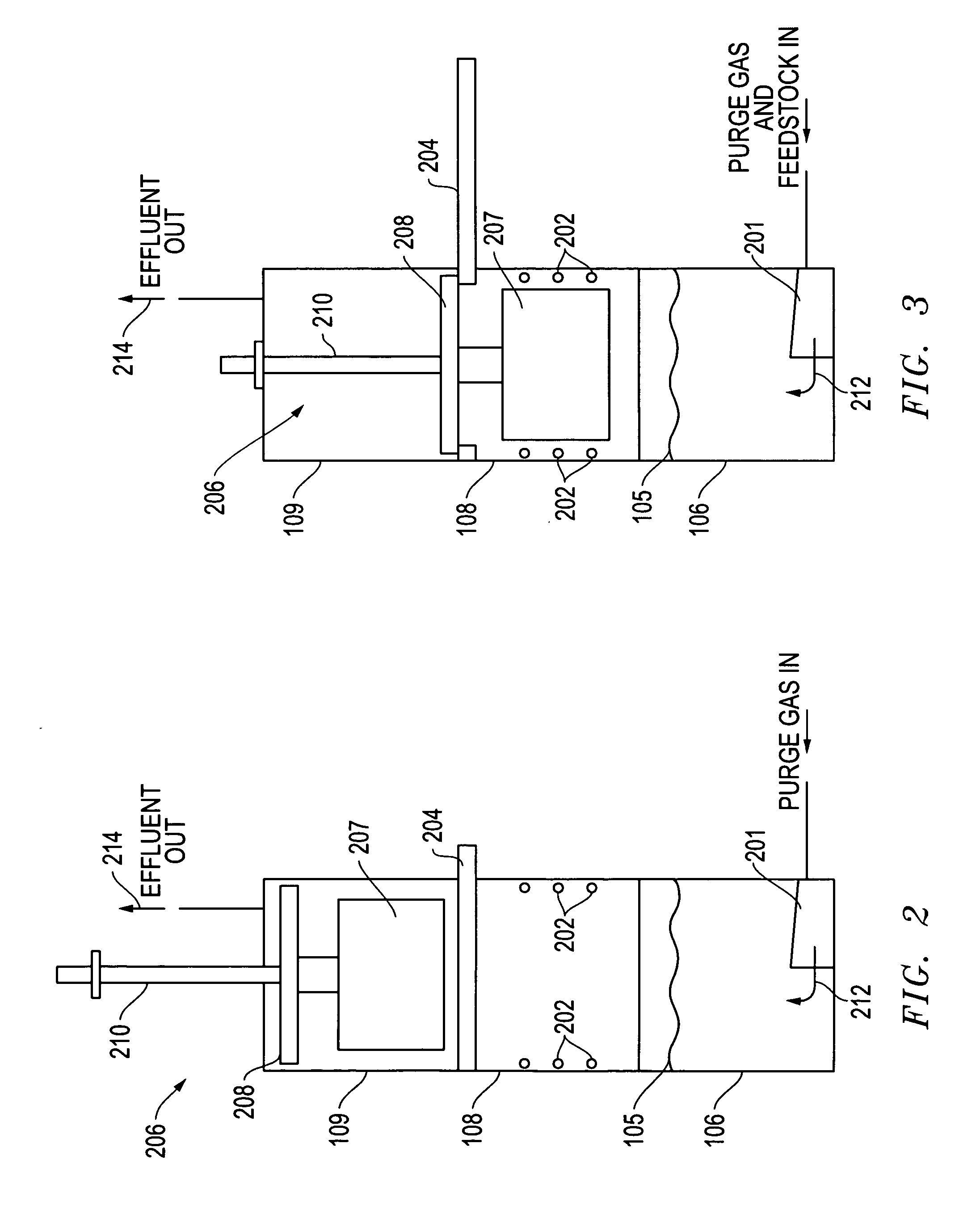

Spherical carbon nanostructure and method for producing spherical carbon nanostructures

Owner:CLEAN TECH INT

Method of Manufacturing Carbon Nanostructure

ActiveUS20070224107A1Uniform shapeHigh purityMaterial nanotechnologyPigmenting treatmentCarbon ionGas phase

A method of manufacturing carbon nanostructures that allows carbon nanostructures having more uniform shape to be produced in high purity and in a stable manner is provided. The present invention relates to a method of manufacturing a carbon nanostructure for growing crystalline carbon by means of vapor deposition from a crystal growth surface of a catalytic base including a catalytic material, and in particular, to a method of manufacturing a carbon nanostructure where at least two gases including a feedstock gas are brought into contact with the catalytic base simultaneously. Preferably, the at least two gases are constituted by at least one feedstock gas and at least one carrier gas. Preferably, the carrier gas is brought into contact with the crystal growth surface, and the feedstock gas is brought into contact with at least a part of a region except for the crystal growth surface with which the carrier gas has been brought into contact. Preferably, the material gas contains an ion, and further preferably, it contains a carbon ion.

Owner:SUMITOMO ELECTRIC IND LTD

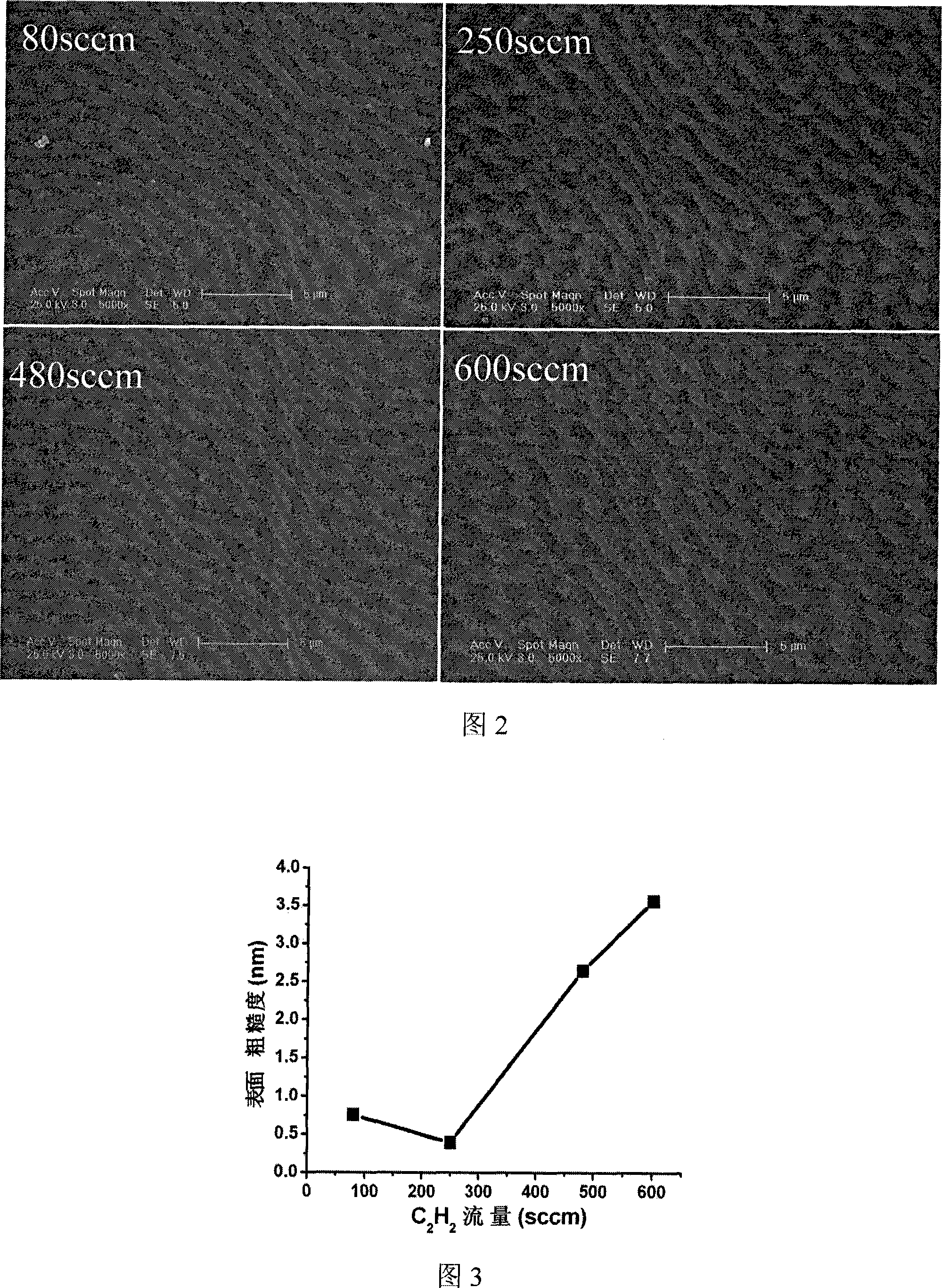

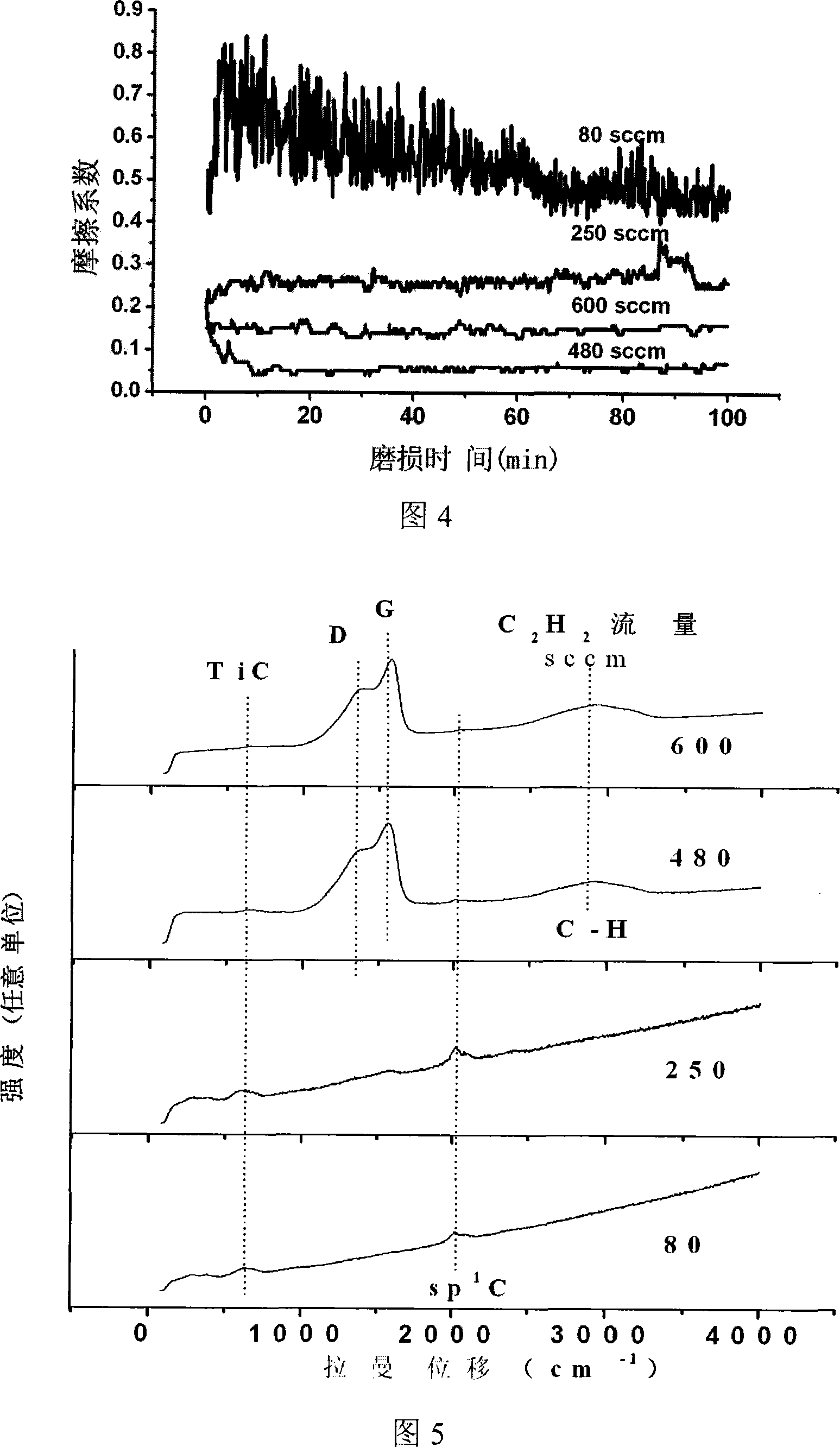

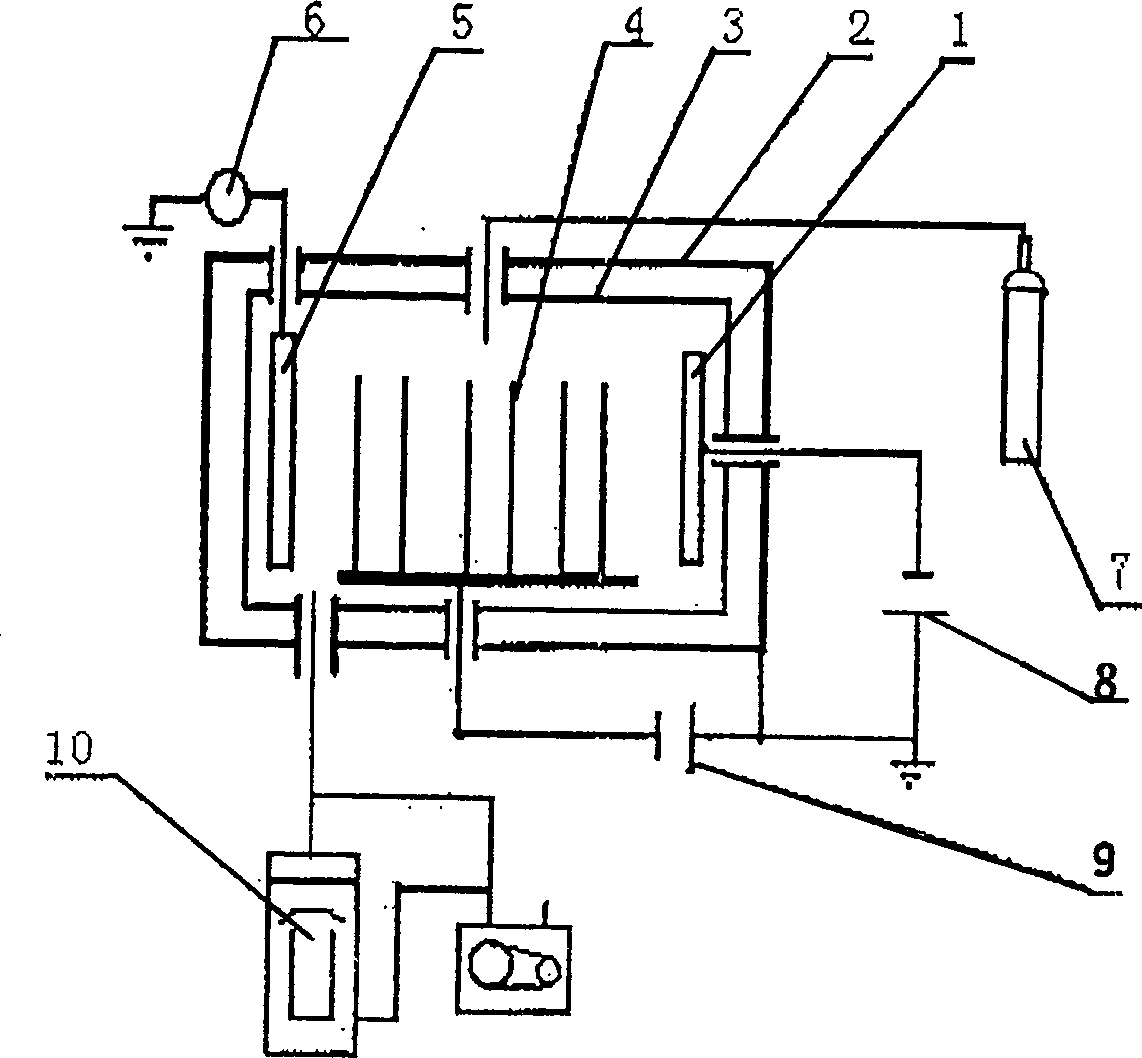

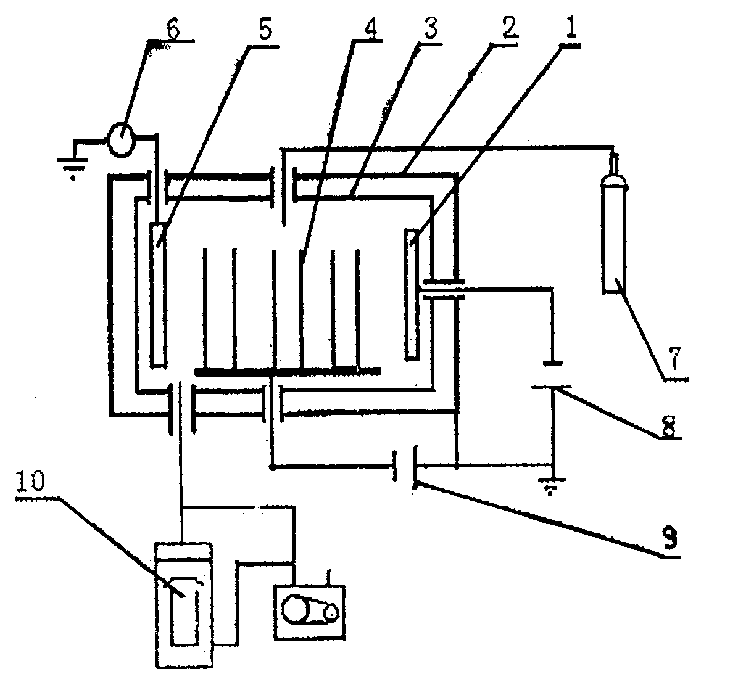

Method for preparing nano composite diamond coating

InactiveCN101113516AIncrease growth rateEliminate pollutionChemical vapor deposition coatingCarbon ionAlloy

The invention discloses a preparation method of a nano complex diamond-like coating layer. The method utilizes the cathode arc discharge controlled by a magnetic field, and excessive ethyne gas is introduced to the front of a metal target, and a metal carbide layer is formed on the target surface, metal carbide can be steamed from the target surface while the arc moves; furthermore, under the function of an auxiliary magnetic field, the front of the arc target utilizes the arc discharge to generate strong plasma ionized ethyne gas, and generate high ionized carbon ions; under the function of bias, the metal carbide steamed from the target surface and carbon ions generated by ethyne form a carbide doped nano complex diamond-like coating layer. The diamond-like coating layer prepared by the invention has the advantages of high coating hardness, strong adhesive force, high coating growing speed and production efficiency, low production cost and simple equipment structure, etc.; the invention can be applied to preparing the diamond-like coating layer of different thickness on all kinds of workpieces such as hard alloy, high speed steel, stainless steel, carbon steel, die steel, etc. according to different using requirements.

Owner:WUHAN UNIV

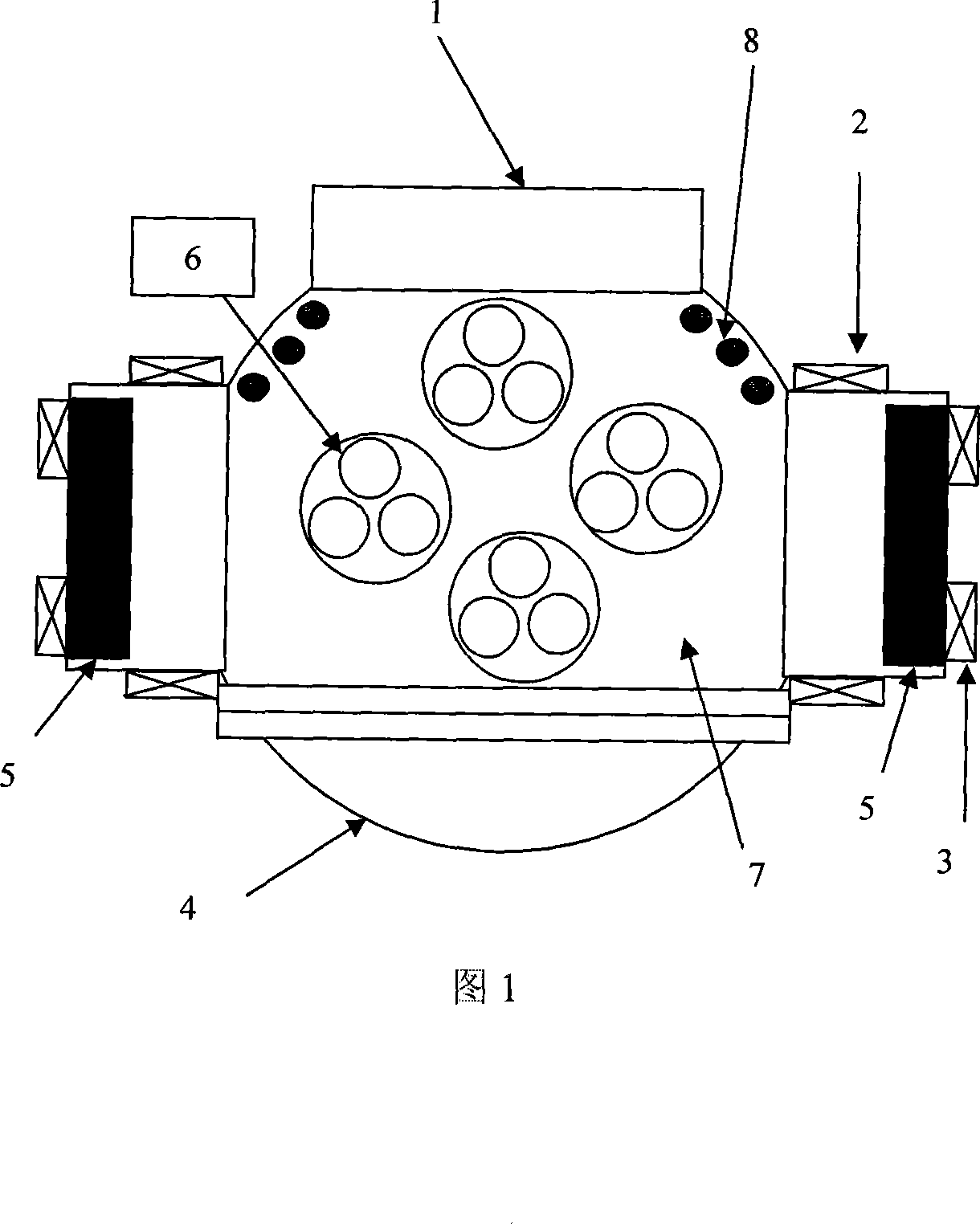

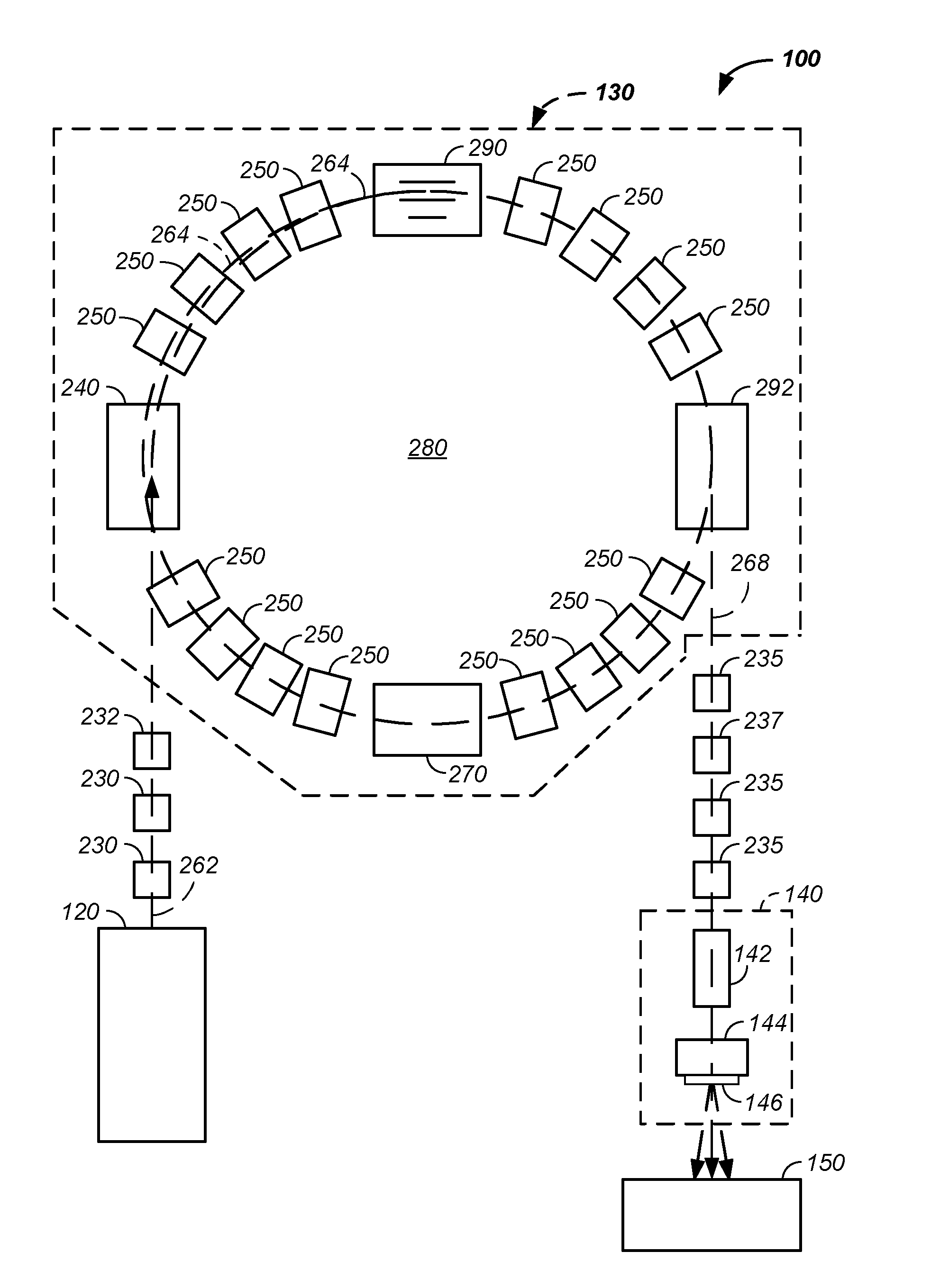

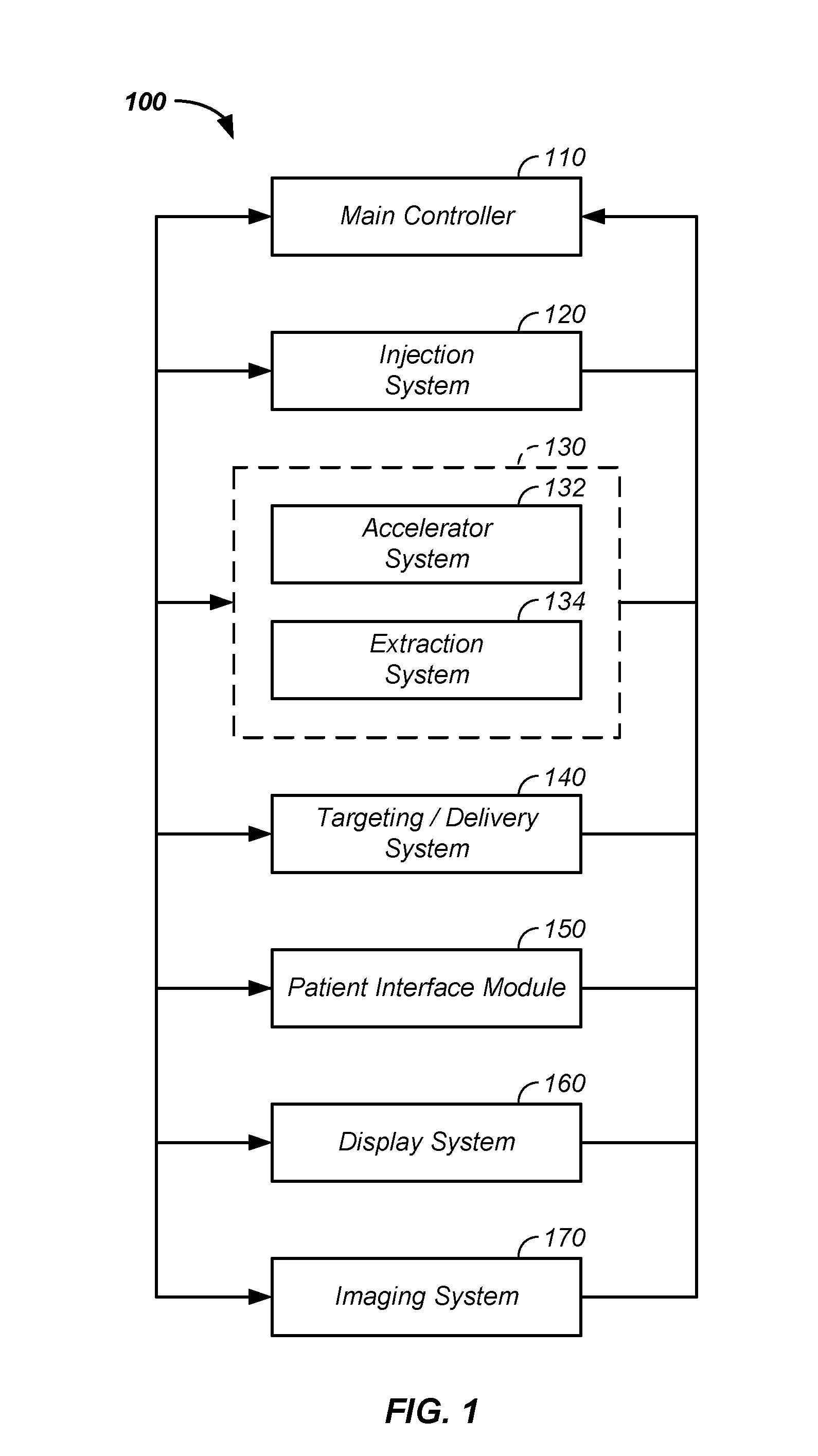

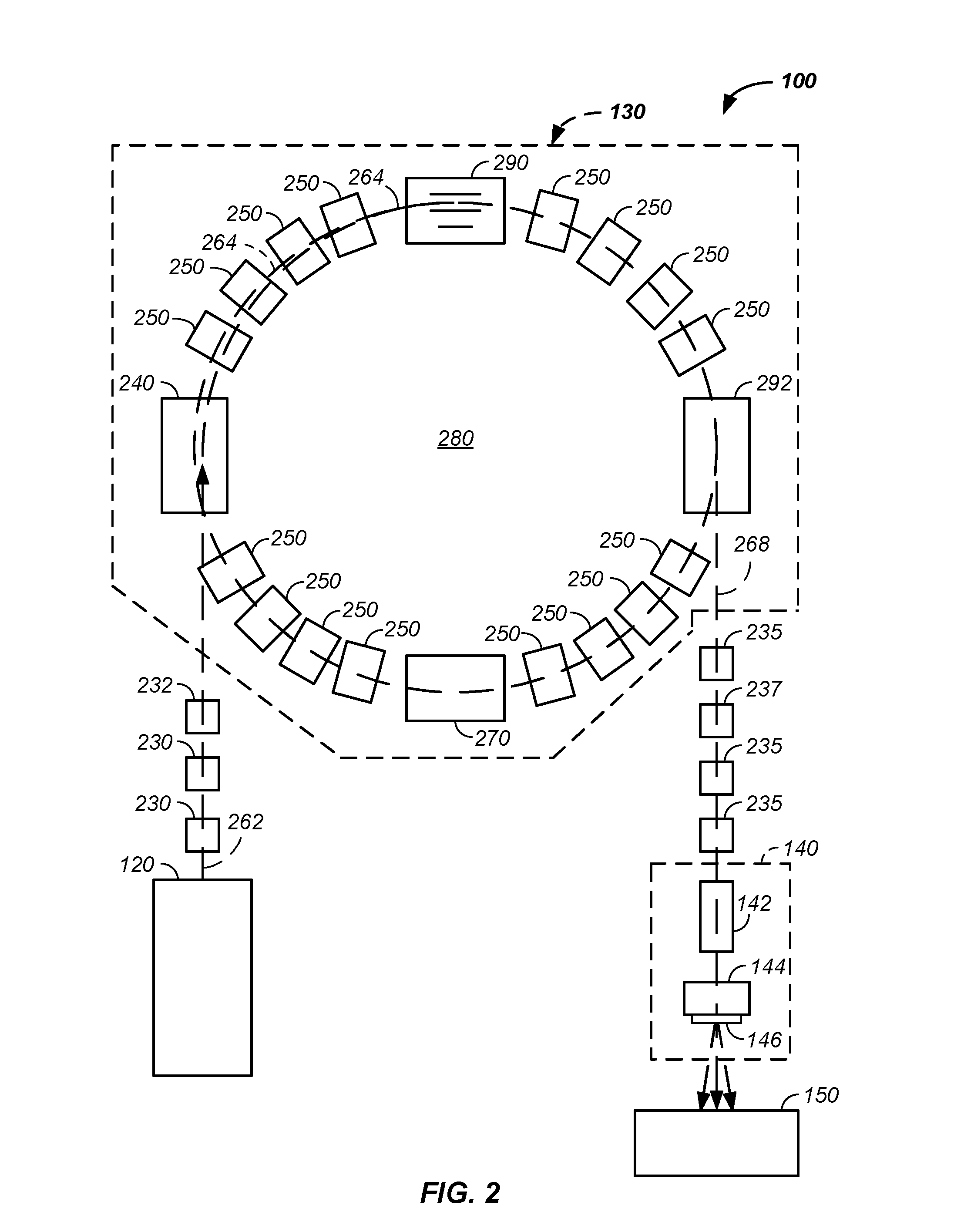

Integrated tomography - cancer treatment apparatus and method of use thereof

The invention relates to a method and apparatus for generation of two-dimensional images using X-rays, proton tomography, and / or carbon ion tomography to form one or more independent and / or integrated three-dimensional images of a tumor, where the proton and carbon cation beams use common elements of a tumor treatment beam, such as an injector, accelerator, and / or beam transport device. A previously collected image of the tumor and / or a current / real-time image control slice is used in control of a multi-axes and / or a multi-field tumor irradiation system for cancer irradiation.

Owner:BALAKIN ANDREY VLADIMIROVICH +1

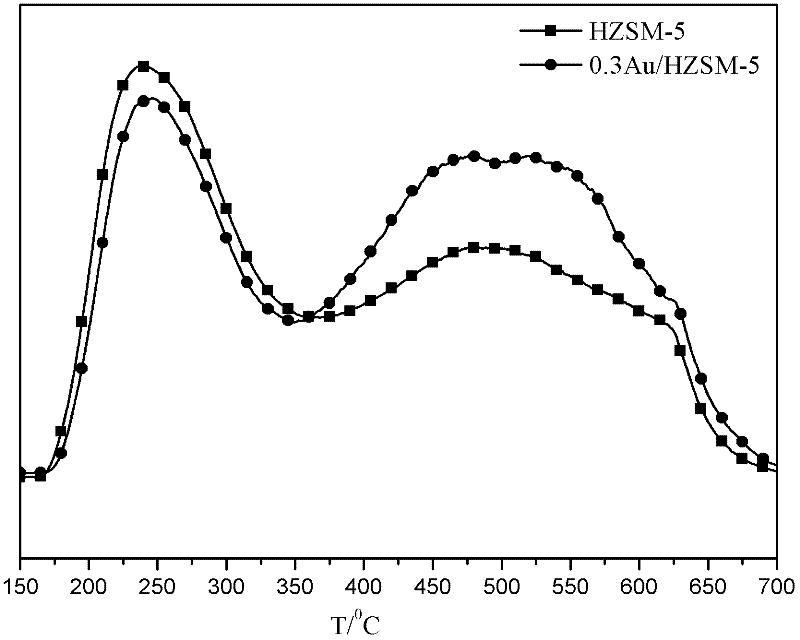

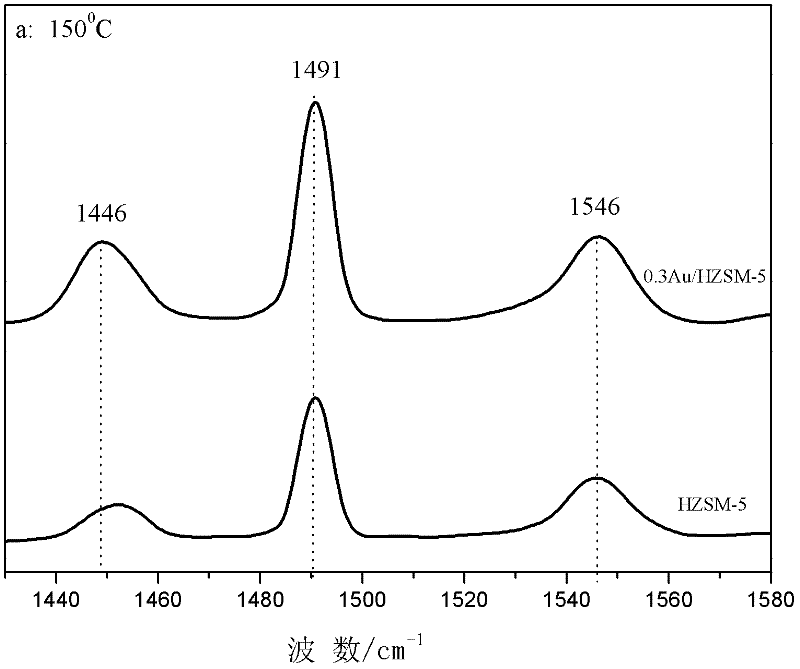

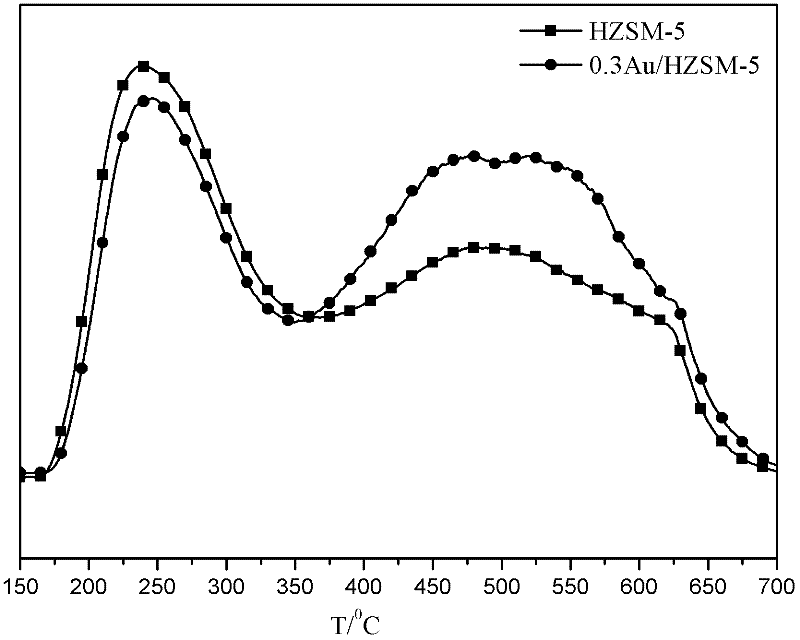

Method for converting n-alkane into isoalkane by gold-loaded molecular sieve catalyst

InactiveCN102416341AEasy to prepareIncrease acidityHydrocarbon by isomerisationMolecular sieve catalystsAlkaneIsomerization

A method for converting n-alkane into isoalkane by a gold-loaded molecular sieve catalyst belongs to the technical field of catalysts. After a molecular sieve is treated by completely negative pressure degasification and purification, a gold precursor is loaded on the molecular sieve carrier by a negative pressure deposition precipitation method so as to form a Si-O(H)-Au structure. The molecular sieve is a high-silica zeolite molecular sieve; the preparation of gold-loaded catalyst under a negative pressure condition by the deposition precipitation method facilitates the purification of the internal and external surfaces and pore channels of the molecular sieve; and Au is easy to enter the pore channels of the molecular sieve to reach high dispersion, and can be combined with silicon hydroxyls on the internal and external surfaces to form the Si-O(H)-Au structure. The method can dehydrogenize n-alkanes to generate alkenes under the difunctional action of metal and the carrier; the alkenes obtain protons at the acid sites to form carbonium ions; and isoalkanes are generated by skeletal isomerization and hydrogenation desorption of the carbonium ions.

Owner:DALIAN UNIV OF TECH

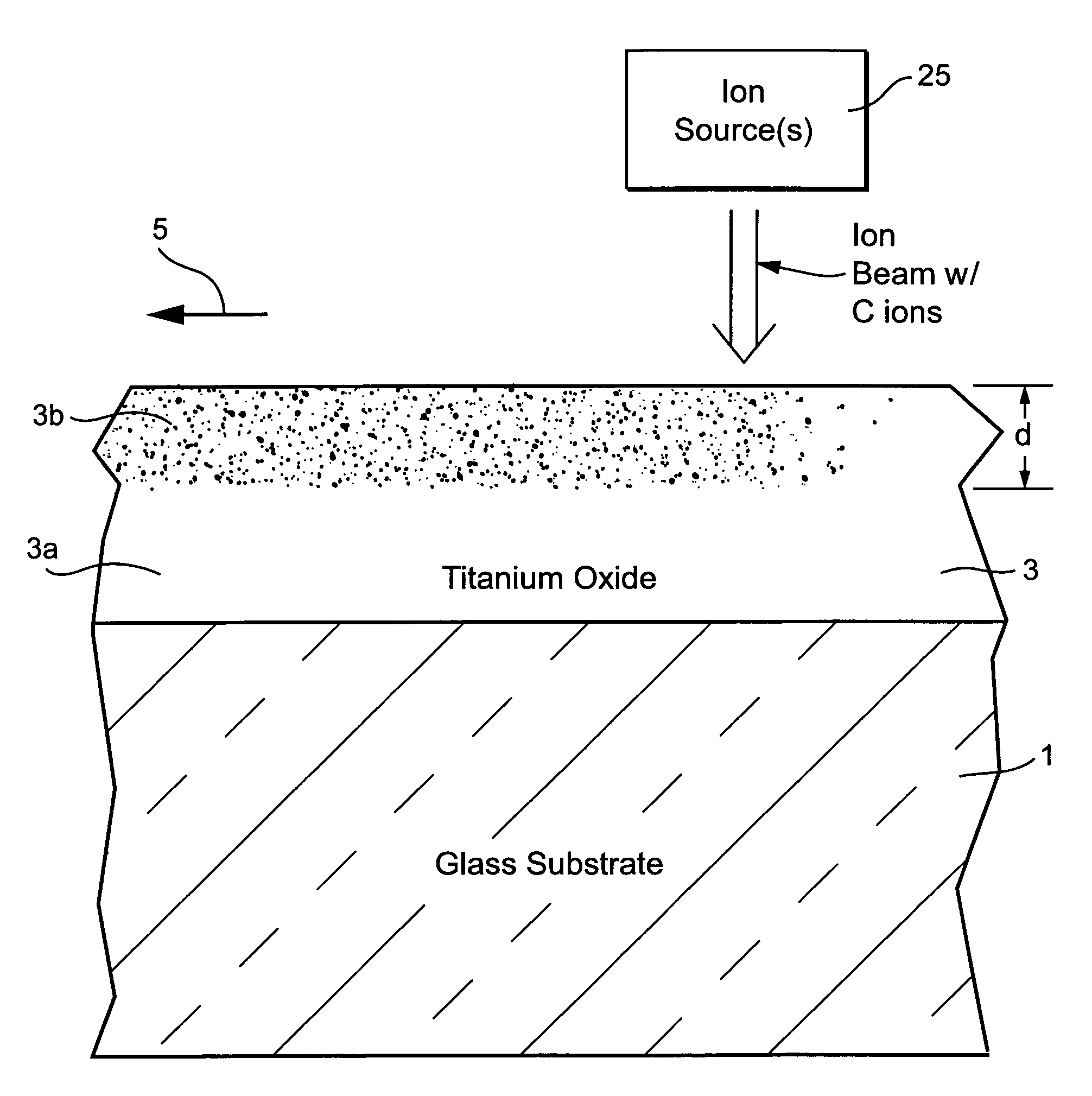

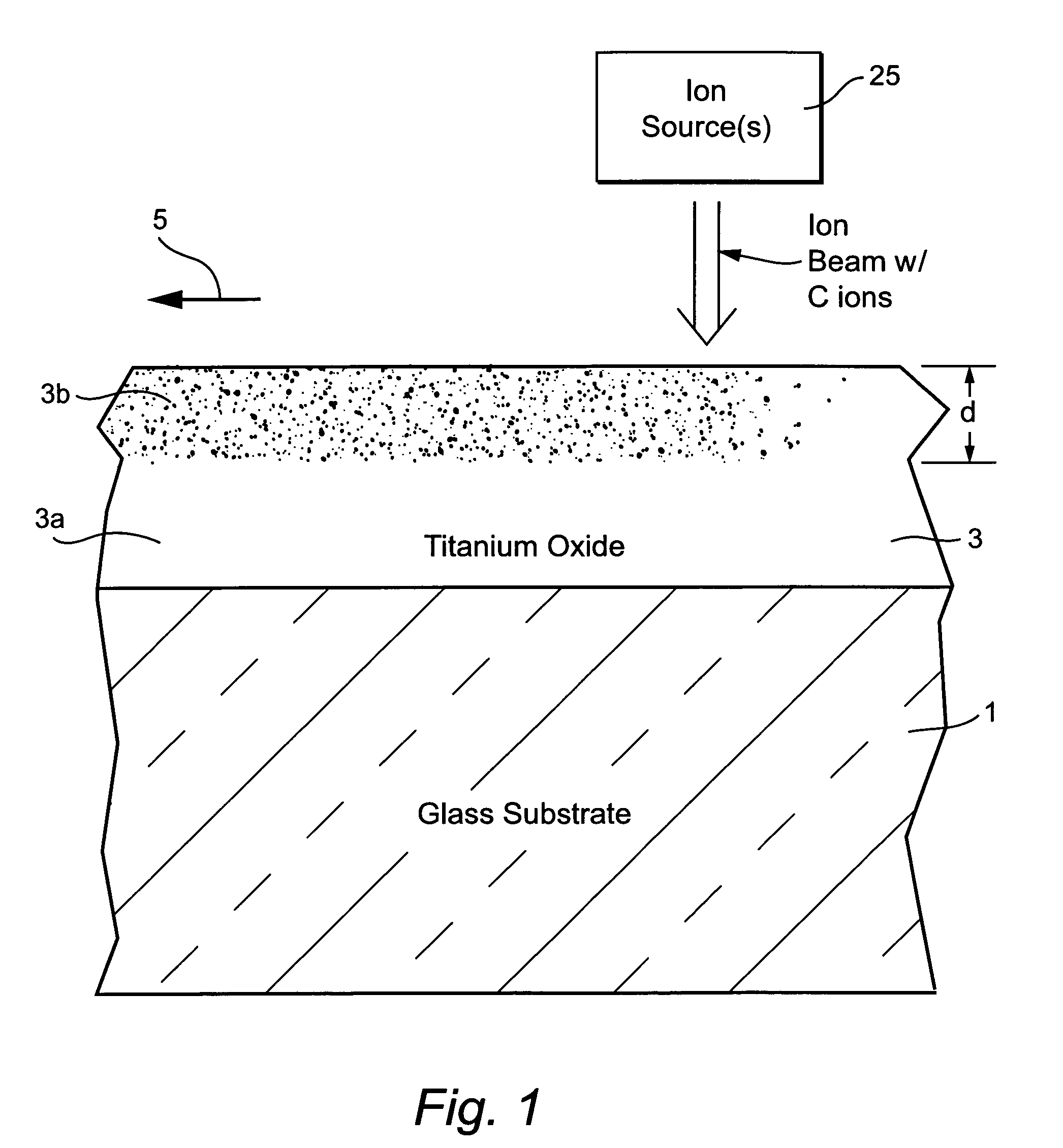

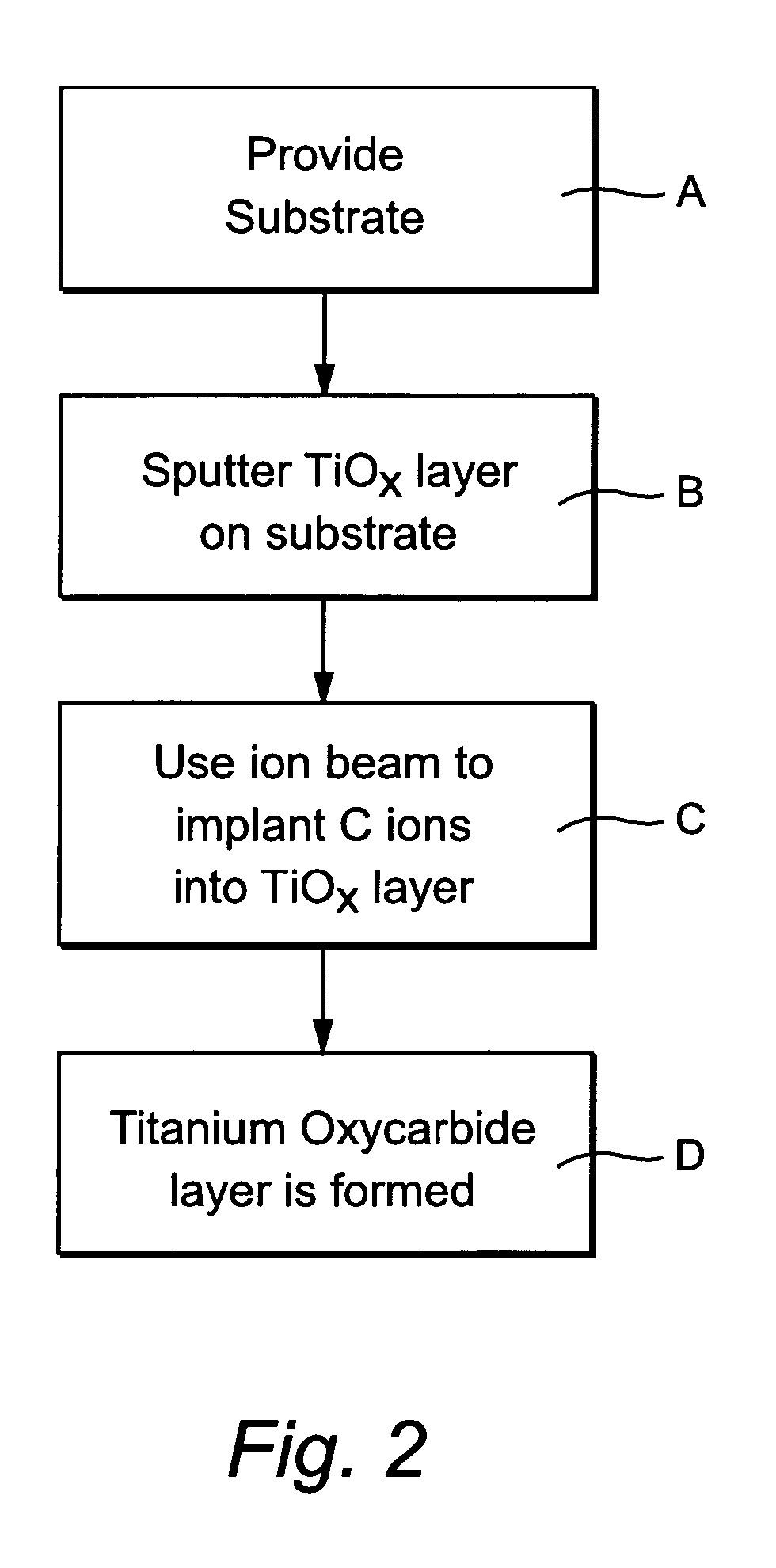

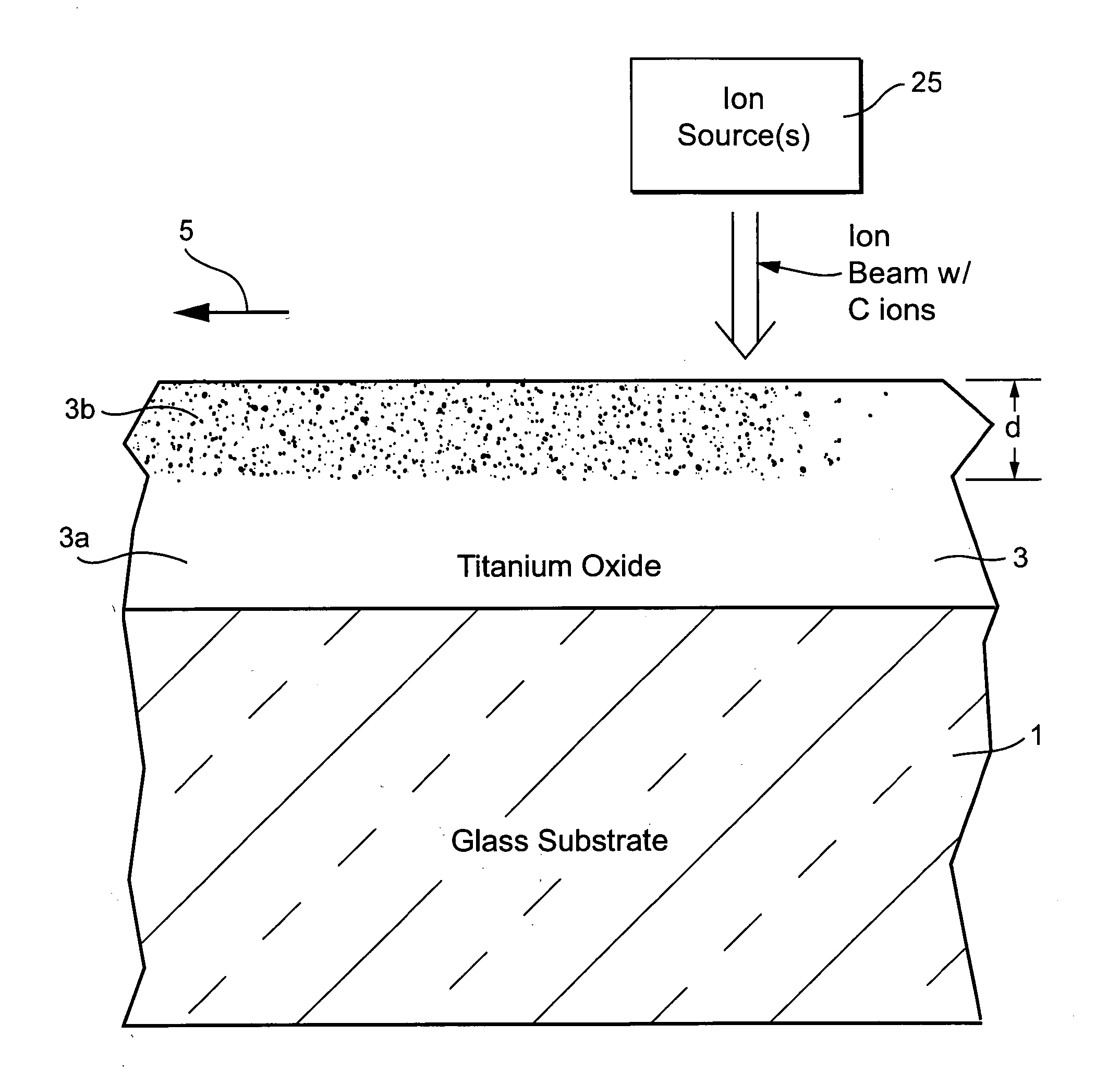

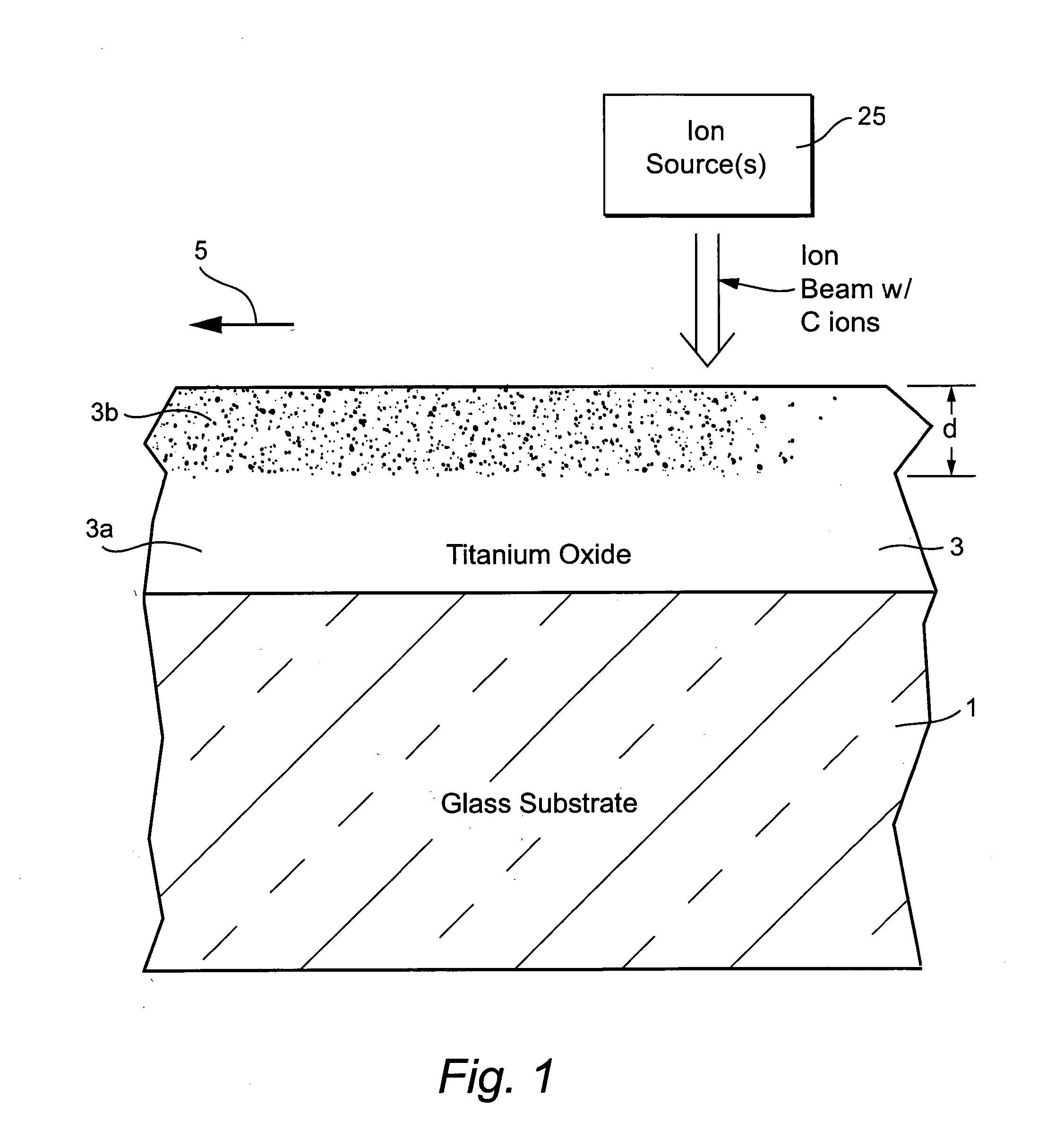

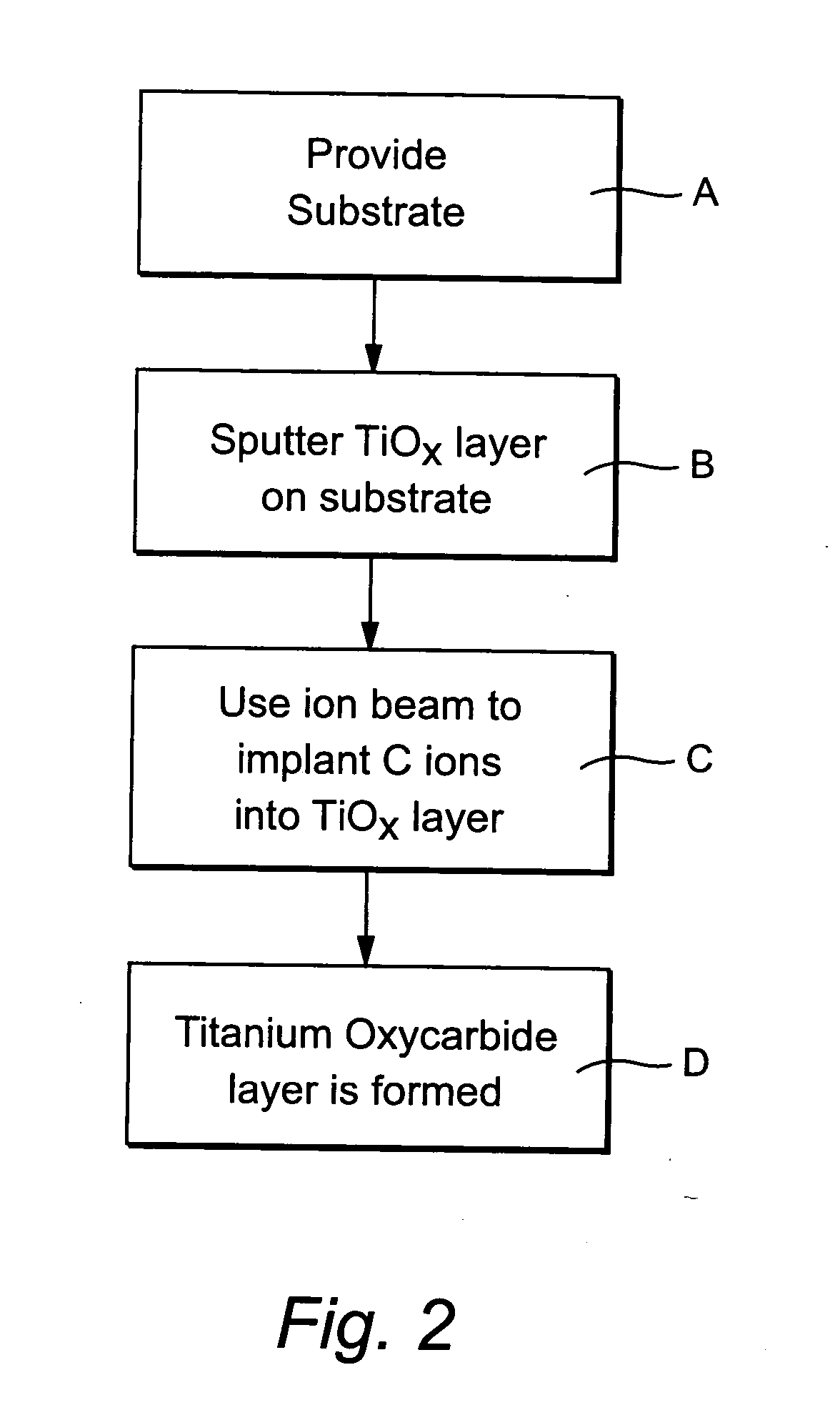

Coated article including titanium oxycarbide and method of making same

InactiveUS7052585B2Improve scratch resistanceLower contact angleVacuum evaporation coatingSputtering coatingSputteringCarbon ion

A coated article is provided which includes a layer including titanium oxycarbide. In order to form the coated article, a layer of titanium oxide is deposited on a substrate by sputtering or the like. After sputtering of the layer including titanium oxide, an ion beam source(s) is used to implant at least carbon ions into the titanium oxide. When implanting, the carbon ions have sufficient ion energy so as to knock off oxygen (O) from TiOx molecules so as to enable a substantially continuous layer comprising titanium oxycarbide to form near a surface of the previously sputtered layer.

Owner:GUARDIAN GLASS LLC

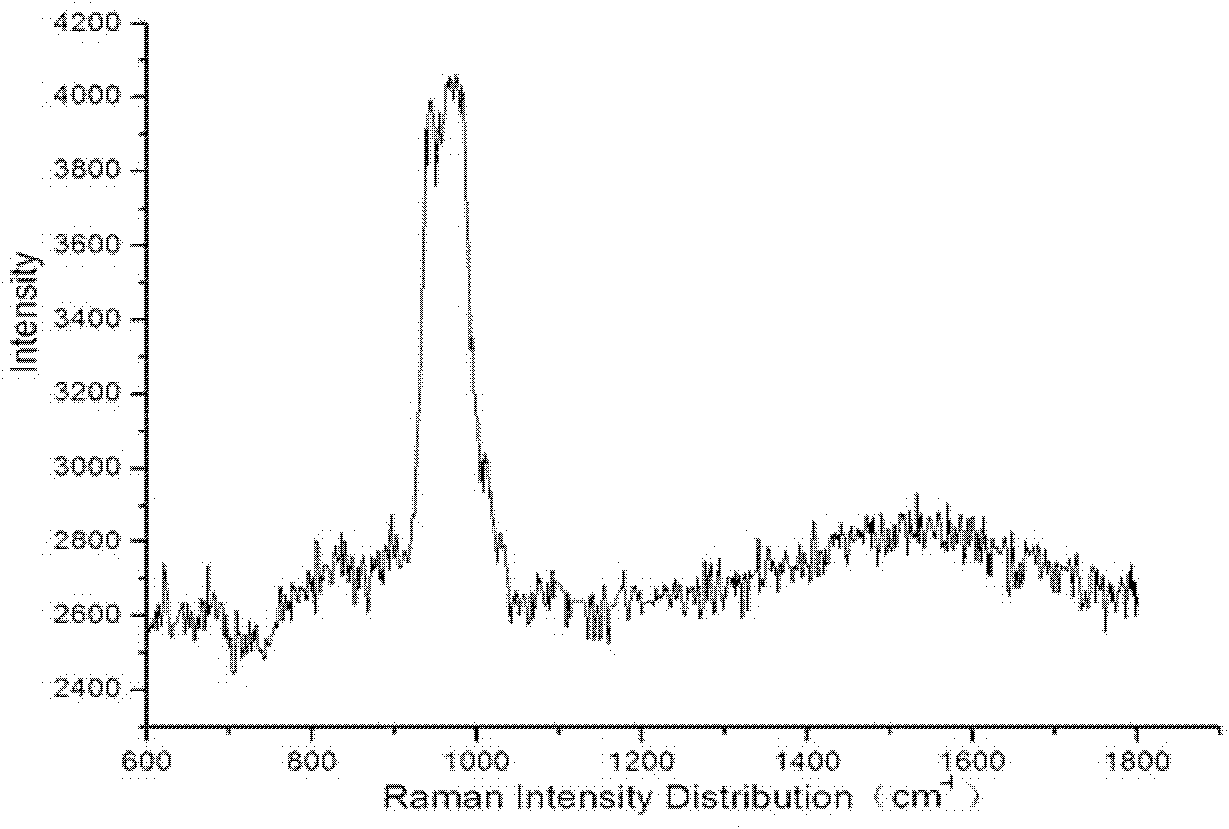

Diamond-like film preparation method

ActiveCN101319324AHigh densityIncrease the number ofVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention discloses a method for preparing diamond-like carbon film (DLC), belonging to the metal or non-metal surface modification treatment technical field. The method adopts pulsed arc discharge by using graphite as a cathode electrode and a physically and chemically combined vapor deposition method for the decomposition and ionization of hydrocarbons gas to produce DLC deposition on a surface of a workpiece. The invention comprises the main operation steps of ultrasonic cleaning, vacuumizing, ion cleaning and DLC deposition, wherein argon gas is passed through in the ion cleaning step; a pulse frequency of the arc discharge in the DLC deposition step is 5 and 35Hz with voltage of between 200 and 400V; methane, ethane or propane are preferred as the hydrocarbons gas. A high-speed and high-energy carbon plasma ion beam is formed to generate collide decomposition and ionization to the passed through hydrocarbons gas through specific pulsed arc discharge to increase increasing density of the carbon ion and diffraction performance, thereby improving deposition speed and adhesive force of DLC, reducing internal stress, and improving precision and performance of DLC.

Owner:庄严

Method for preparing amorphous carbon coating on surface of medical stainless steel knife saw

InactiveCN101768720AGood biocompatibilityImprove corrosion resistanceVacuum evaporation coatingSputtering coatingCarbon filmCarbon ion

The invention discloses a method for preparing an amorphous carbon coating on the surface of a medical stainless steel knife saw. The method includes the following steps: preprocessing, ion cleaning, electric arc discharging, and carbon ion depositing. An amorphous tetrahedral carbon film prepared by the method has the characteristics of high bonding strength, excellent biological property and good corrosion resisting performance; after a salt fog test for 48 hours, no corrosion spot is incurred on the amorphous tetrahedral carbon film. After the surfaces of resin, stainless steel and the like are coated, the corrosion and abrasion resisting properties are greatly enhanced, the anti-ageing function is obvious, and the service life is greatly prolonged. After the above surfaces are coated, material bacteria cannot be adhered, so as to solve the cleaning problem of an oral cavity after artificial teeth are installed, thereby being beneficial for the health of the oral cavity. After the above surfaces are coated, the growth of cells on the surfaces is in good condition, and the cell density is higher; moreover, the thicker the film, the better the growth of the cells. The coating stainless steel knife saw prepared by the method in the invention has the following characteristics: the rigidity of the knife saw can be up to more than 85GPa, the content of an SP3 bond structure of a coating is equal to or higher than 85%, the friction coefficient is within 0.08 to 0.15, and the binding force between the film and a basal body is within 35 to 45N.

Owner:XI AN JIAOTONG UNIV

Hard resin lens and organic glass lens surface ultra-hard coat coating method

InactiveCN101806928AReduce the impactGood light transmissionVacuum evaporation coatingSputtering coatingCarbon filmCarbon ion

The invention discloses a hard resin lens and organic glass lens surface ultra-hard coat coating method, which comprises the following steps that: an amorphous tetrahedral carbon film is formed on the surface of the lens through pretreatment, glow discharge cleaning, electric arc discharge and carbon ion precipitation, the film has good light transmission and good corrosion resistance, the abrasion resistance of the coated lens is remarkably improved compared with that of the non-coated lens, the coherence force between the amorphous tetrahedral carbon film and the resin and organic glass substrate is strong, the film is difficult to drop of, and the ultraviolet light test indicates that the ultraviolet transmission rate can be effectively reduced by the coat; and the hardness of the coated lens which is prepared with the method can reach more than 85 GPa, the SP3 key structure content in the coat is more than or equal to 85 percent, the friction coefficient is small, the abrasion resistant time is long, and the abrasion resistance is greatly improved.

Owner:XI AN JIAOTONG UNIV

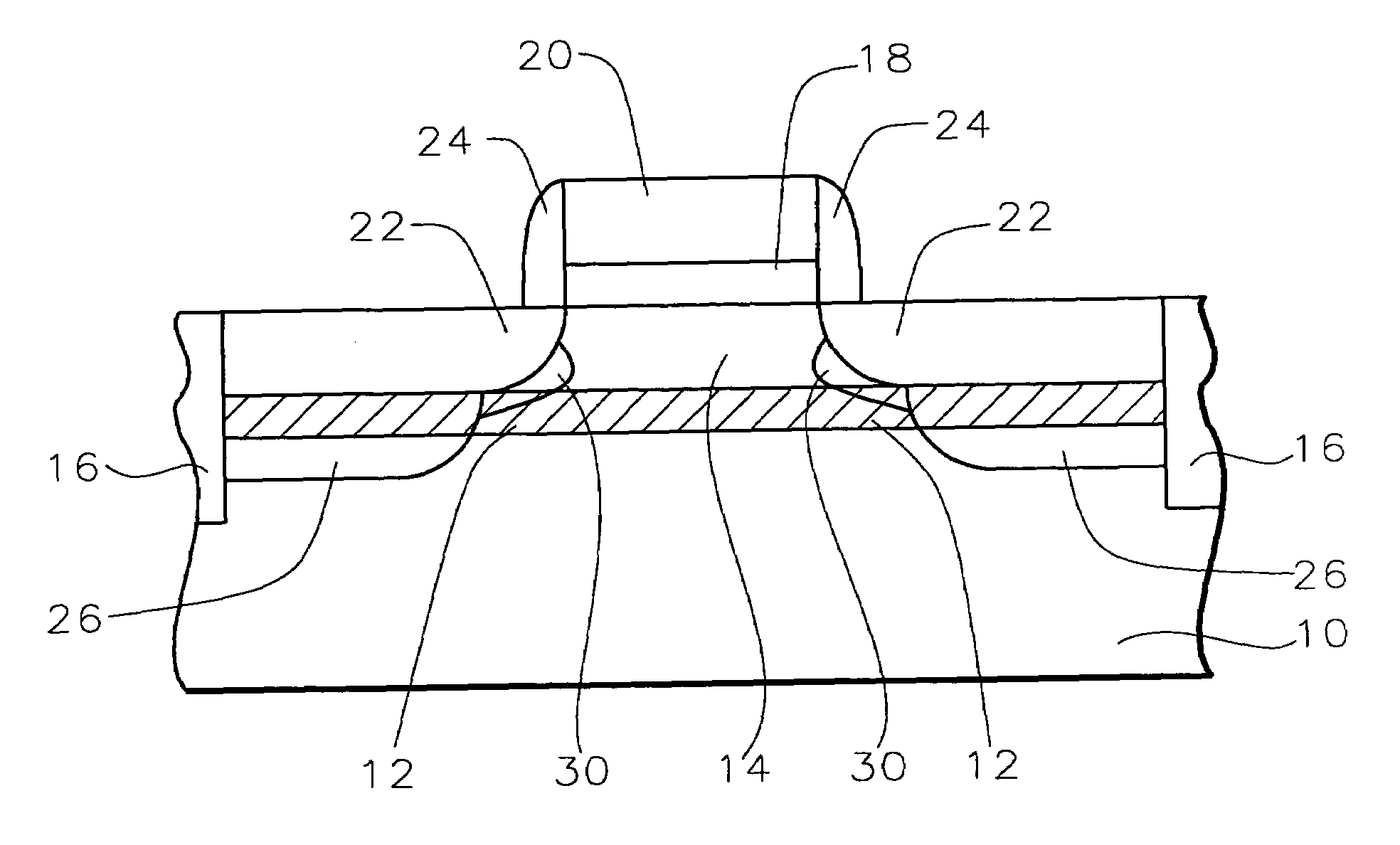

Formation Of Raised Source/Drain On A Strained Thin Film Implanted With Cold And/Or Molecular Carbon

InactiveUS20100279479A1Increase pressureEnhancing in regionSemiconductor/solid-state device manufacturingSemiconductor devicesDopantCarbon ion

Owner:VARIAN SEMICON EQUIP ASSOC INC

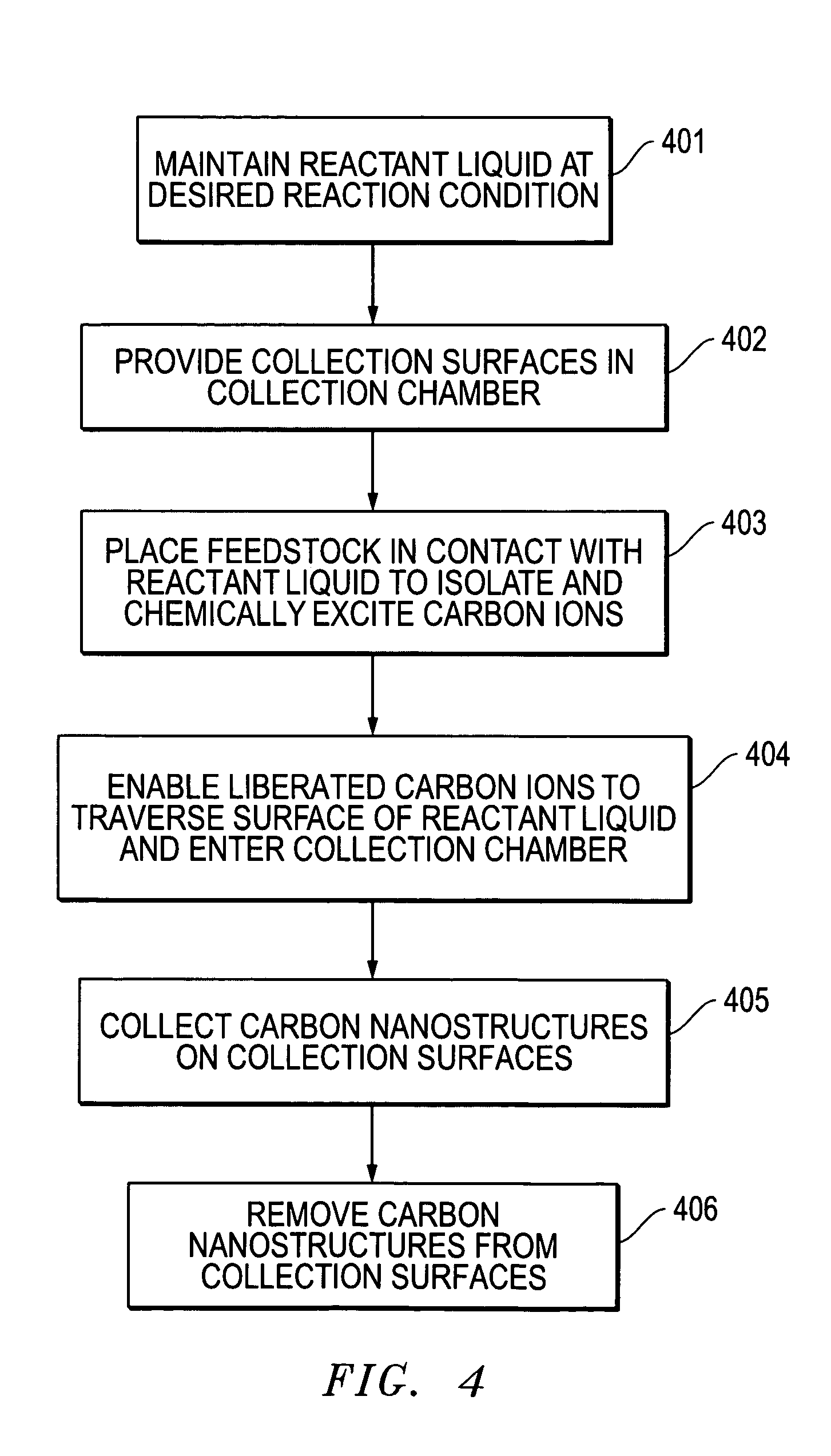

Spherical carbon nanostructure and method for producing spherical carbon nanostructures

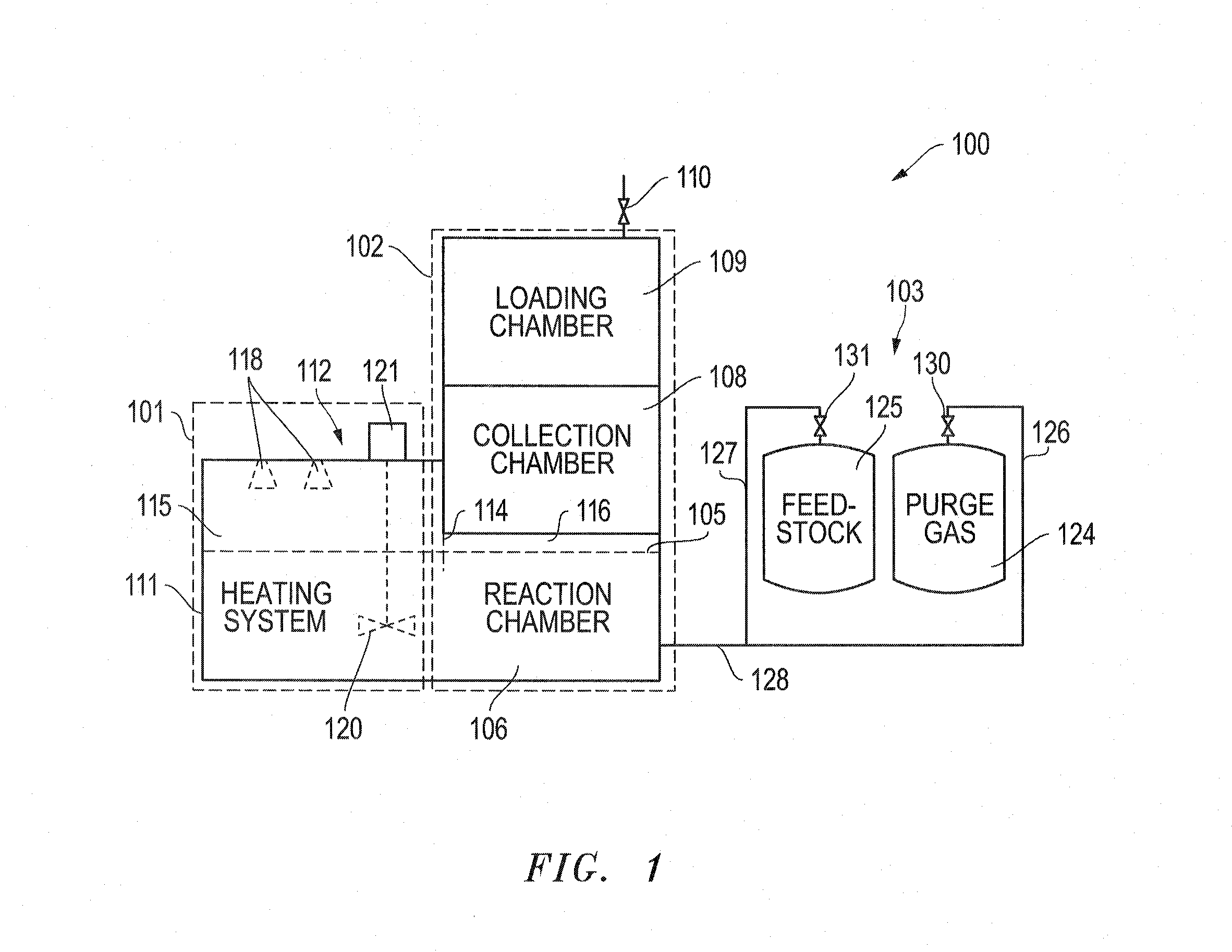

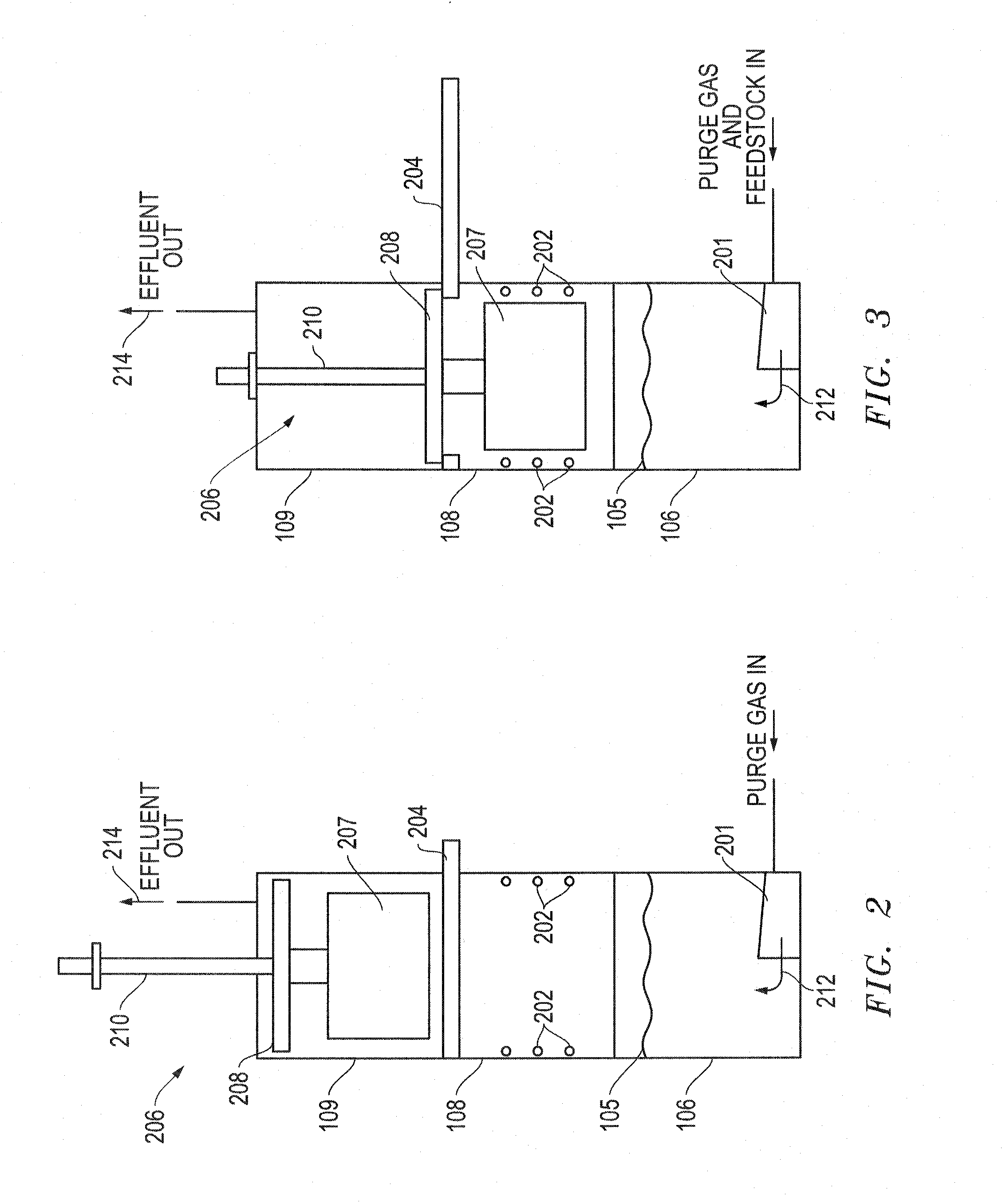

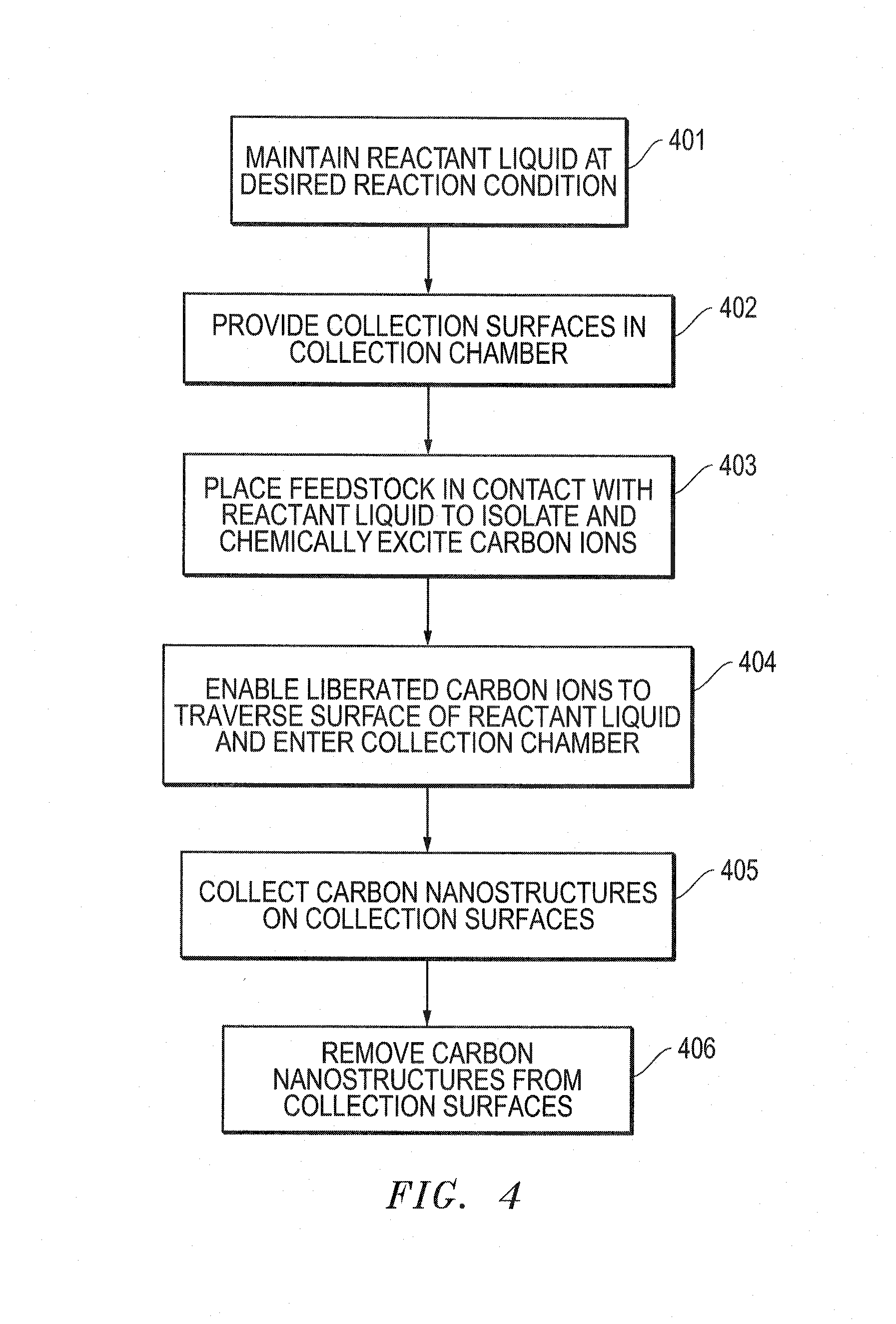

A method for producing carbon nanostructures according to the invention includes injecting acetylene gas into a reactant liquid. The injected acetylene molecules are then maintained in contact with the reactant liquid for a period of time sufficient to break the carbon-hydrogen bonds in at least some of the acetylene molecules, and place the liberated carbon ions in an excited state. This preferred method further includes enabling the liberated carbon ions in the excited state to traverse a surface of the reactant liquid and enter a collection area. Collection surfaces are provided in the collection area to collect carbon nanostructures.

Owner:CLEAN TECH INT

Process for glow ion hydrogen-free carbonizing titanium surface

A non-hydrogen glow ion process for carbonizing the surface of titanium (or Ti alloy) is characterized by that under the action of electric bias field and inert energy, the carbon ions (or atoms) sputted out from graphite electrode in glow plasmas reach to the surface of hot titanium workpiece, and under the action of thermal diffusion and ion bombardment the carbon ions (or atoms) come in the surface of titanium to form titanium carbide. Its advantages are high surface hardness (3000 HV) and antiwear nature, and deep carbonized layer.

Owner:太原理工大学表面工程研究所 +1

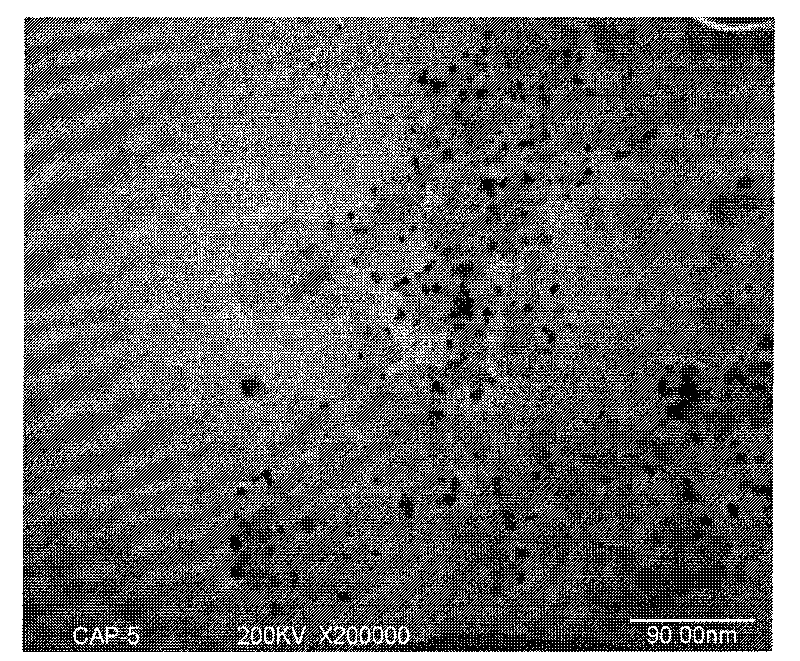

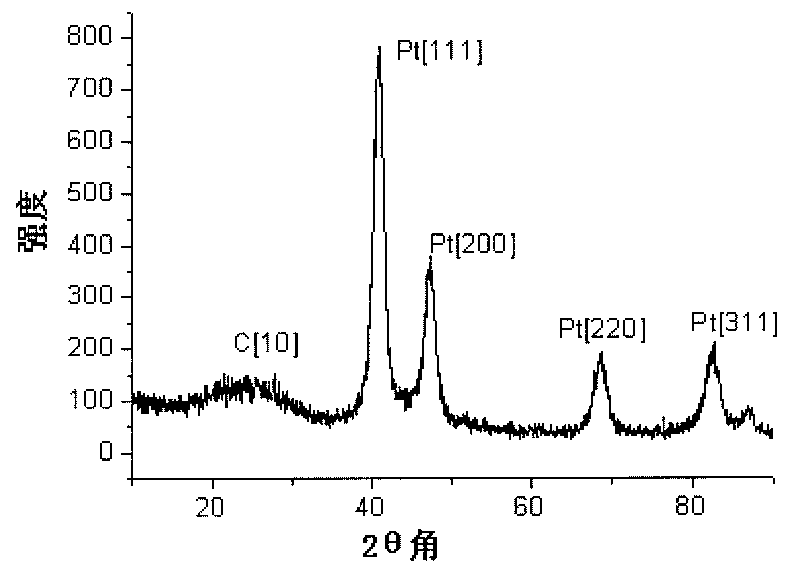

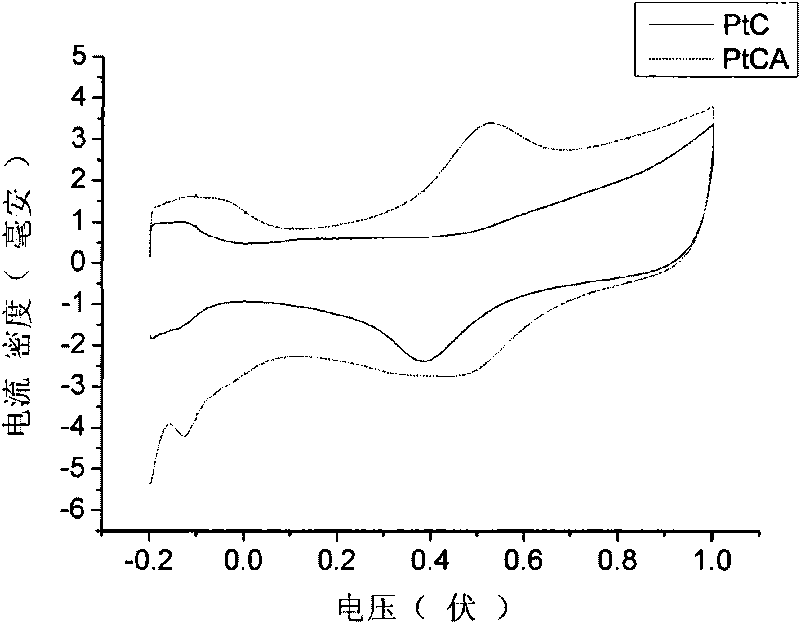

Platinum/carbon aerogel catalyst used for fuel cells and preparation method thereof

InactiveCN101740784AImprove utilization efficiencyAvoid explosionCell electrodesCarbon ionPt element

The invention relates to a platinum / carbon aerogel catalyst used for fuel cells and a preparation method thereof. A catalyst carrier is carbon aerogel, the active component is platinum, and the platinum carrying capacity is 15-60wt%. The preparation method comprises the following steps: dispersing the carbon aerogel to ethylene glycol solution, adding ethylene glycol solution of chloroplatinic acid, wherein, the chloroplatinic acid accounts for 15-60% of the weight of the carbon aerogel in terms of the platinum; adjusting the pH value of the solution to be 8-12; heating mixed liquor by a batch-type microwave oven; filtering, washing until Cl- does not exist; drying filter cakes at the temperature of 60-90 DEG C for 10-24h to obtain the platinum / carbon aerogel catalyst used for fuel cells.The platinum / carbon aerogel catalyst used for fuel cells prepared by the invention has evenly distributed carbon ions, fine particles and simple preparation process.

Owner:BEIJING UNIV OF CHEM TECH

Coated article including titanium oxycarbide and method of making same

InactiveUS20060165996A1Improve scratch resistanceIncrease contact angleVacuum evaporation coatingSputtering coatingSputteringCarbon ion

A coated article is provided which includes a layer including titanium oxycarbide. In order to form the coated article, a layer of titanium oxide is deposited on a substrate by sputtering or the like. After sputtering of the layer including titanium oxide, an ion beam source(s) is used to implant at least carbon ions into the titanium oxide. When implanting, the carbon ions have sufficient ion energy so as to knock off oxygen (0) from TiOx molecules so as to enable a substantially continuous layer comprising titanium oxycarbide to form near a surface of the previously sputtered layer.

Owner:GUARDIAN GLASS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com