Process for glow ion hydrogen-free carbonizing titanium surface

A technology of glow ion and process method, which is applied in the field of surface modification of metal materials, can solve problems affecting the carburizing quality of titanium materials, and achieve the effect of improving wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

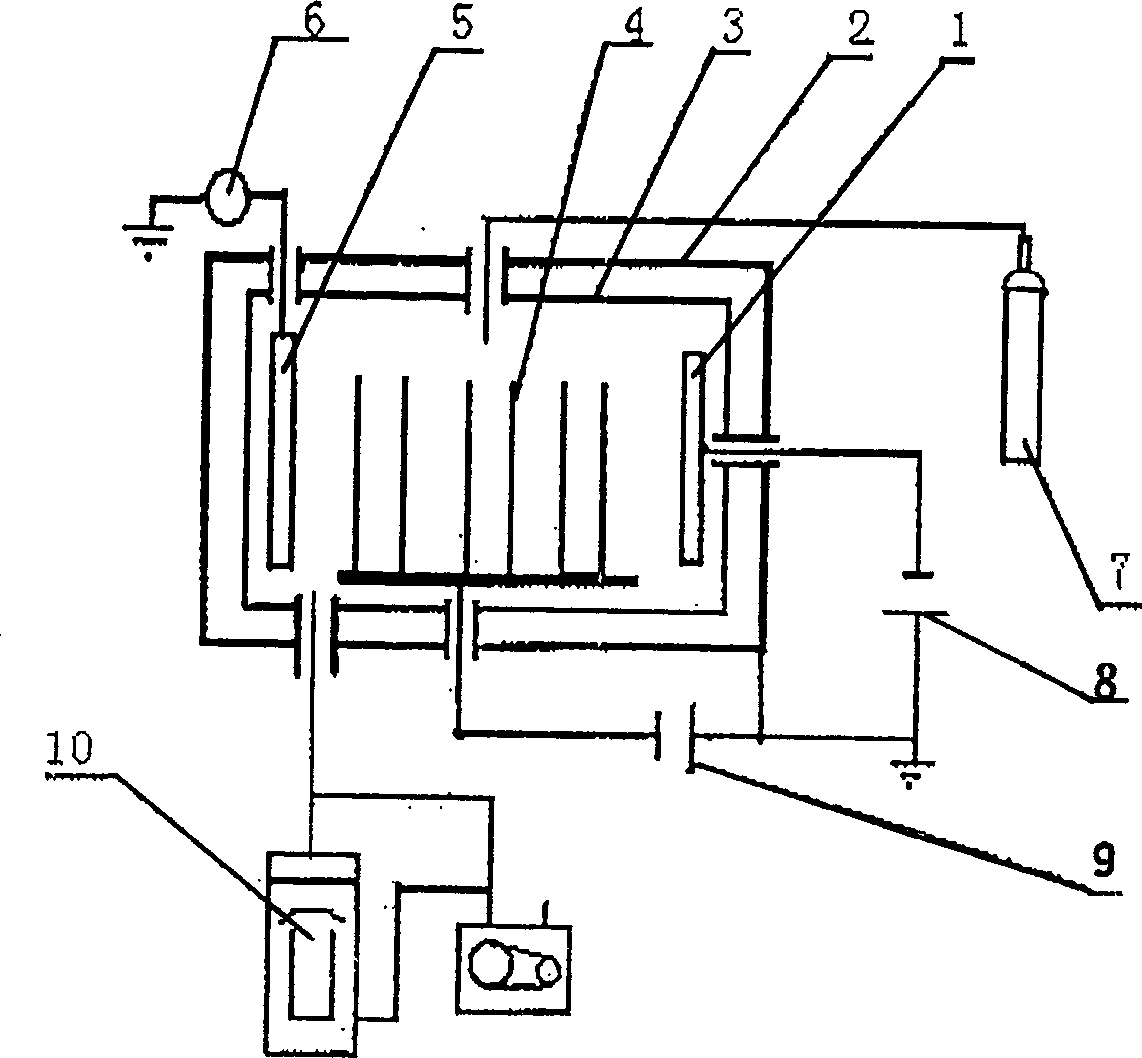

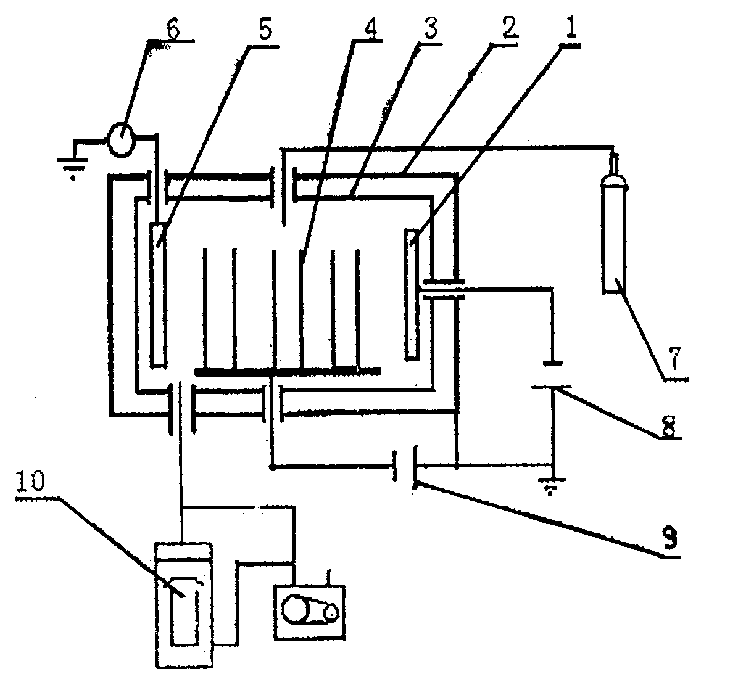

Method used

Image

Examples

Embodiment 1

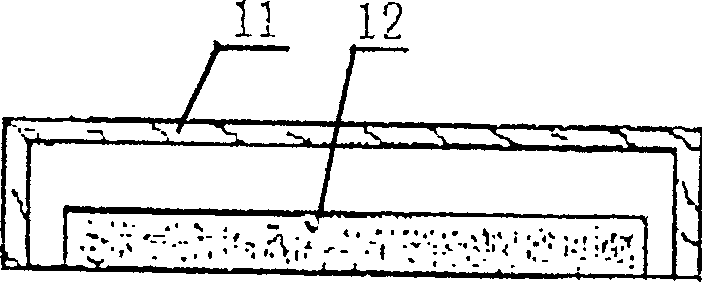

[0019] Put the TA2 pure titanium sample and the graphite source into the vacuum chamber, use a vacuum unit to evacuate, and the vacuum reaches 5×10 -3 After Pa, fill high-purity argon gas with a mass flow meter to make the partial pressure of argon gas reach 100Pa. At the same time, add a bias voltage of titanium workpiece from 200V to 700V and a source voltage of 200V to 700V to make the gap between the titanium workpiece and the source The hollow cathode discharge is generated, and the temperature of the workpiece is controlled according to the bias voltage of the titanium workpiece and the source voltage. When the temperature of the workpiece is controlled at 950°C, the voltage of the source is raised to 1200V, and the bias voltage of the titanium workpiece is adjusted to 700V. After 4 hours of constant temperature, it was cooled with the furnace. After detection and analysis, the average thickness of the carburized layer in the sample was 220 μm, and the surface hardness re...

Embodiment 2

[0021] Put the TC4 titanium alloy sample and the graphite source into the vacuum chamber, evacuate, and the vacuum reaches 5×10 -3 After Pa, use a mass flowmeter to fill high-purity argon gas to make the partial pressure of argon gas reach 20Pa. At the same time, add a bias voltage of 200V~700V for the titanium workpiece and a source voltage of 200V~700V to make a gap between the titanium workpiece and the source. Hollow cathode discharge, the temperature of the workpiece is controlled according to the bias voltage of the titanium workpiece and the source voltage, and the auxiliary heater is used for auxiliary heating. When the temperature of the workpiece is controlled at 1150°C, the voltage of the source is raised to 1200V, and the titanium workpiece After the bias voltage was adjusted to 800V, the temperature was kept constant for 4 hours, and cooled with the furnace. After detection and analysis, the average thickness of the carburized layer in the sample is 496 μm, and th...

Embodiment 3

[0023] Ti 3 The Al high-temperature titanium alloy sample and the graphite source were put into the vacuum chamber, and the vacuum was evacuated to 5×10 -3 After Pa, fill high-purity argon gas with a mass flowmeter to make the partial pressure of argon gas reach 50Pa. At the same time, add a bias voltage of 200V~700V for the titanium workpiece and a source voltage of 200V~700V to make a gap between the titanium workpiece and the source. The hollow cathode is discharged, and the temperature of the workpiece is controlled according to the bias voltage of the titanium workpiece and the source voltage. When the temperature of the workpiece is controlled at 1300°C, the voltage of the source is raised to 1200V. After 3 hours, cool in the furnace. After detection and analysis, the average thickness of the carburized layer in the sample is 145μm, and the surface hardness reaches 2800HV.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com