Patents

Literature

8280 results about "Argon gas" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

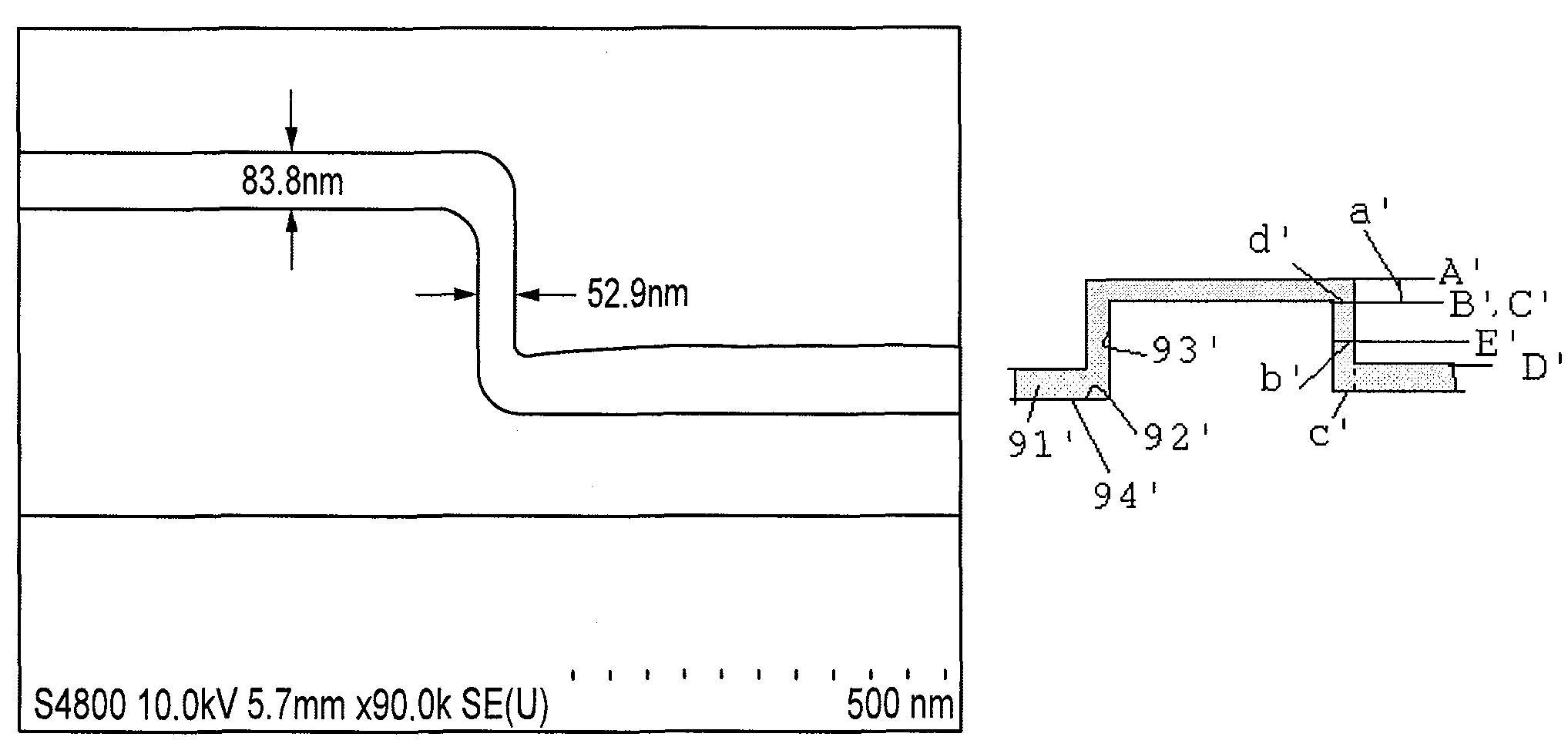

Method of forming a layer and method of forming a capacitor of a semiconductor device having the same

InactiveUS20060063346A1Improve reliabilityLow costSemiconductor/solid-state device manufacturingCapacitorsKryptonDevice material

In a method of forming a layer using an atomic layer deposition process, after a substrate is loaded into a chamber, a reactant is provided onto the substrate to form a preliminary layer. Atoms in the preliminary layer are partially removed from the preliminary layer using plasma formed from an inert gas such as an argon gas, a xenon gas or a krypton gas, or an inactive gas such as an oxygen gas, a nitrogen gas or a nitrous oxide gas to form a desired layer. Processes for forming the desired layer may be simplified. A highly integrated semiconductor device having improved reliability may be economically manufactured so that time and costs required for the manufacturing of the semiconductor device may be reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

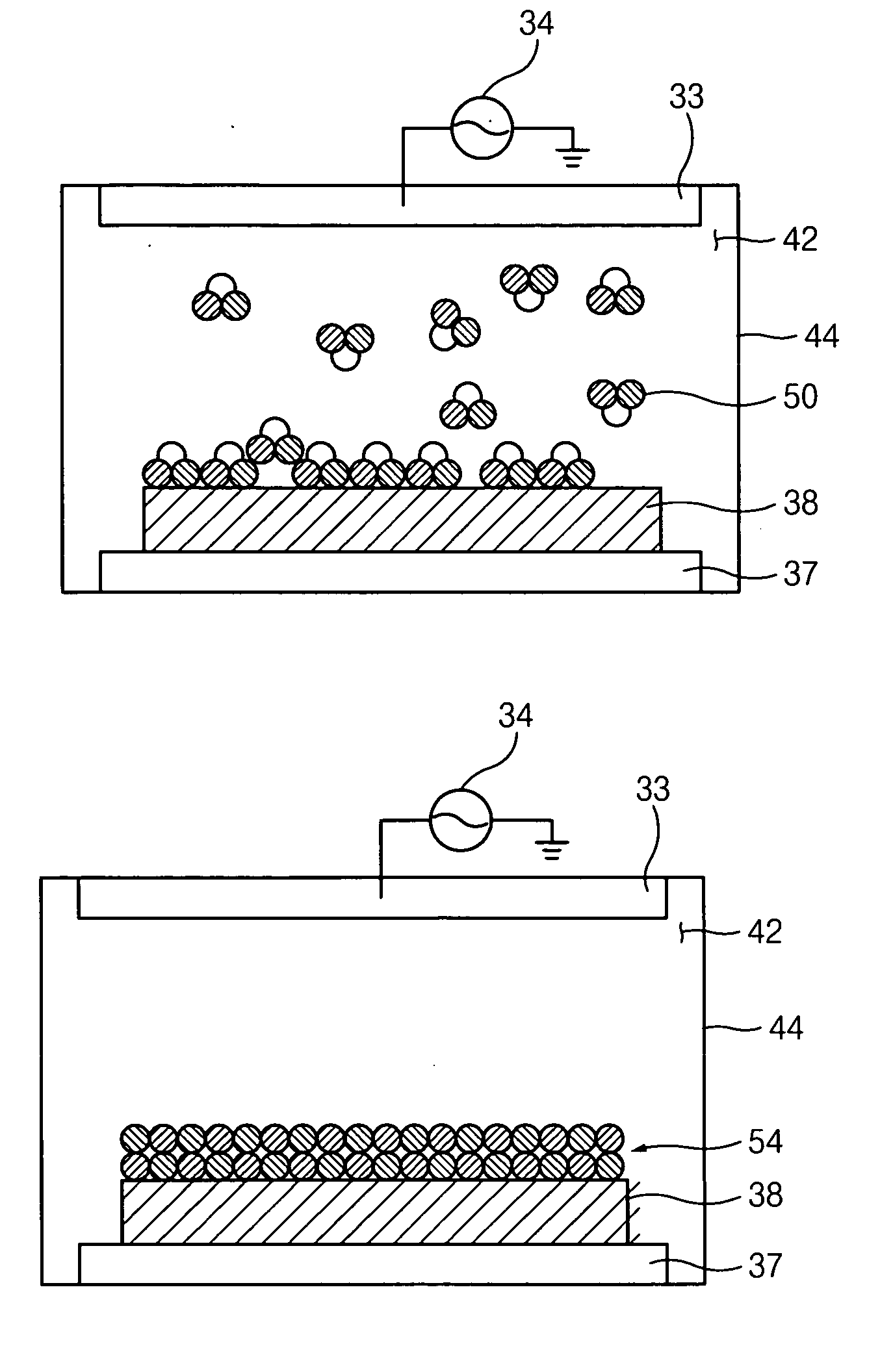

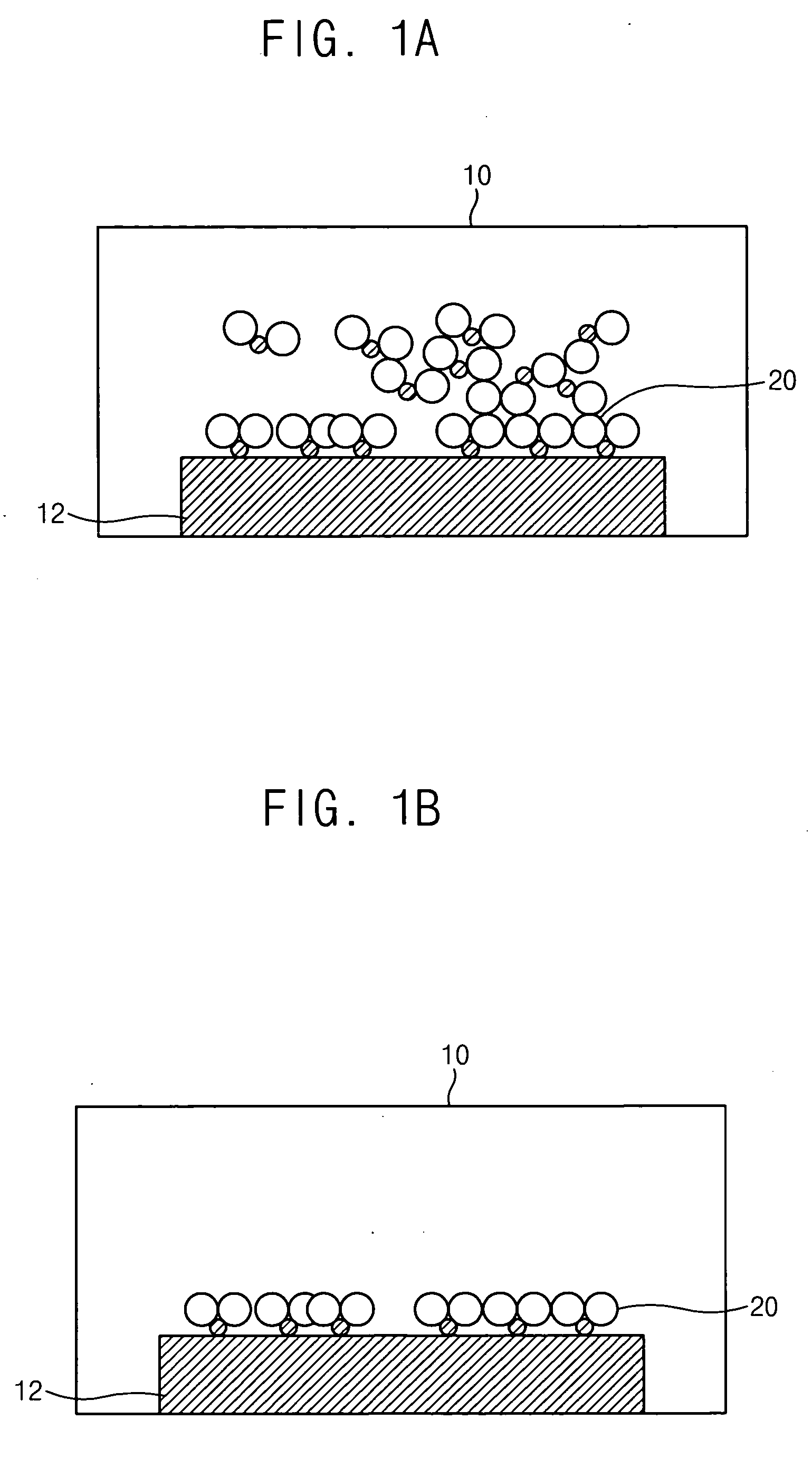

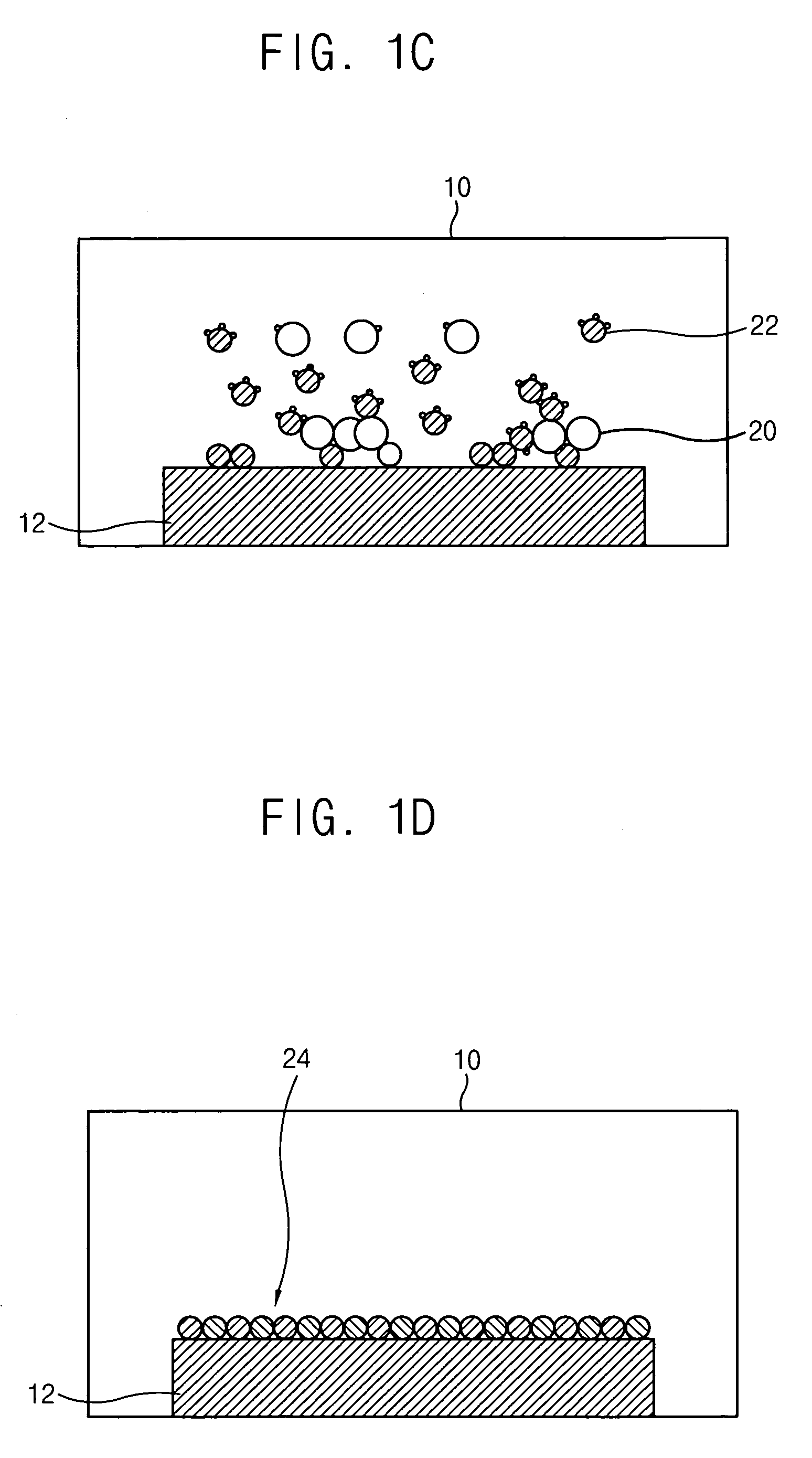

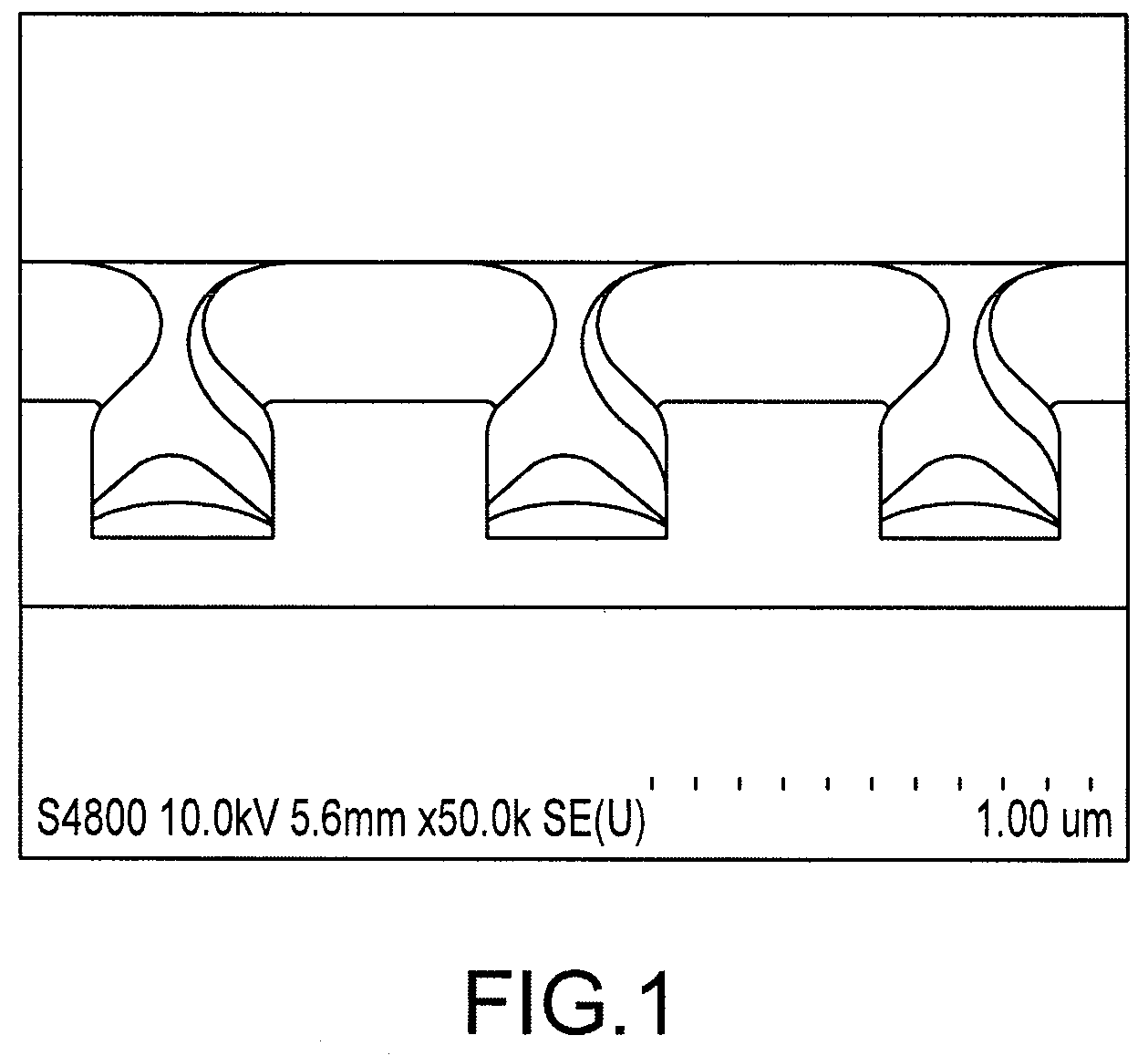

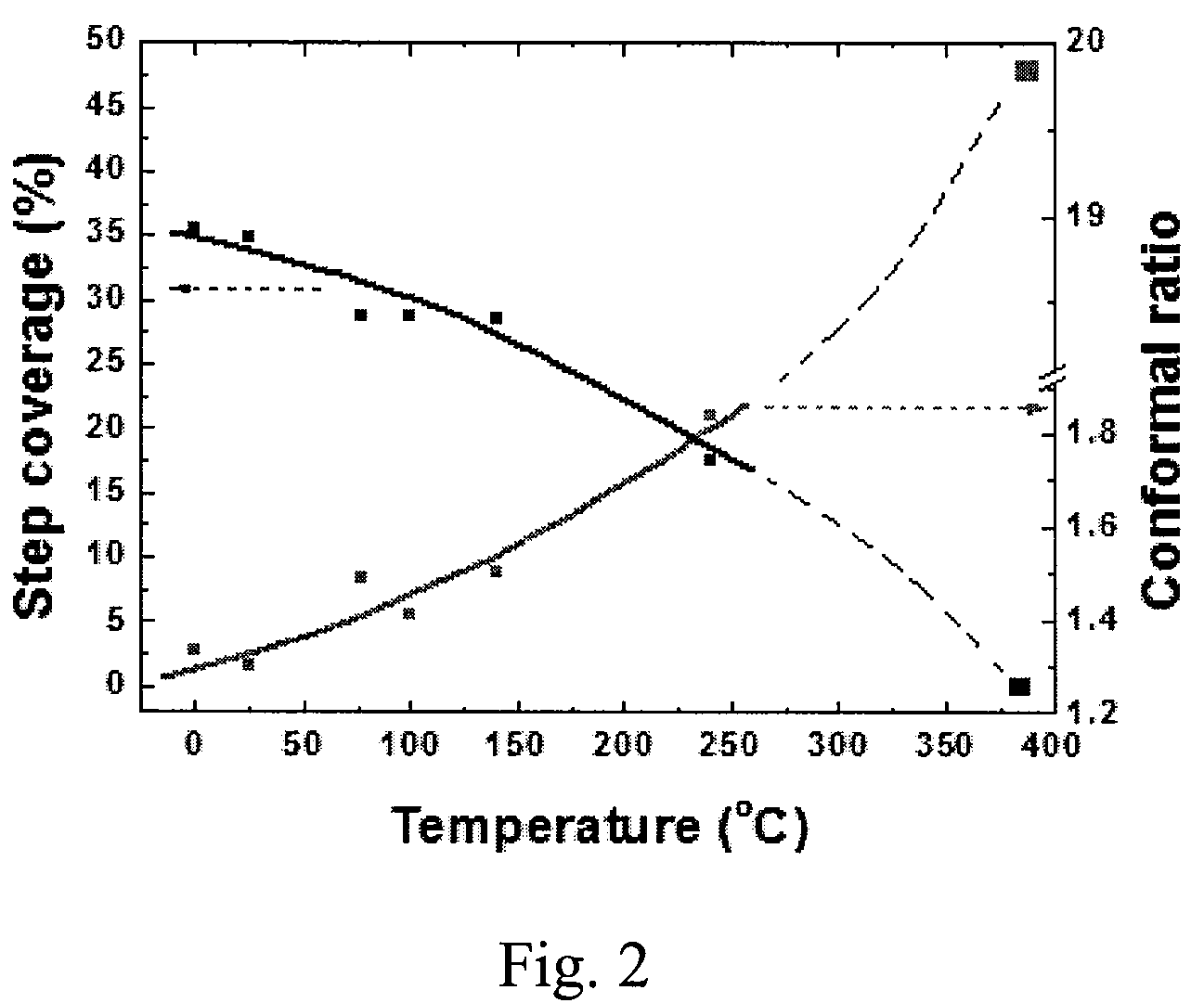

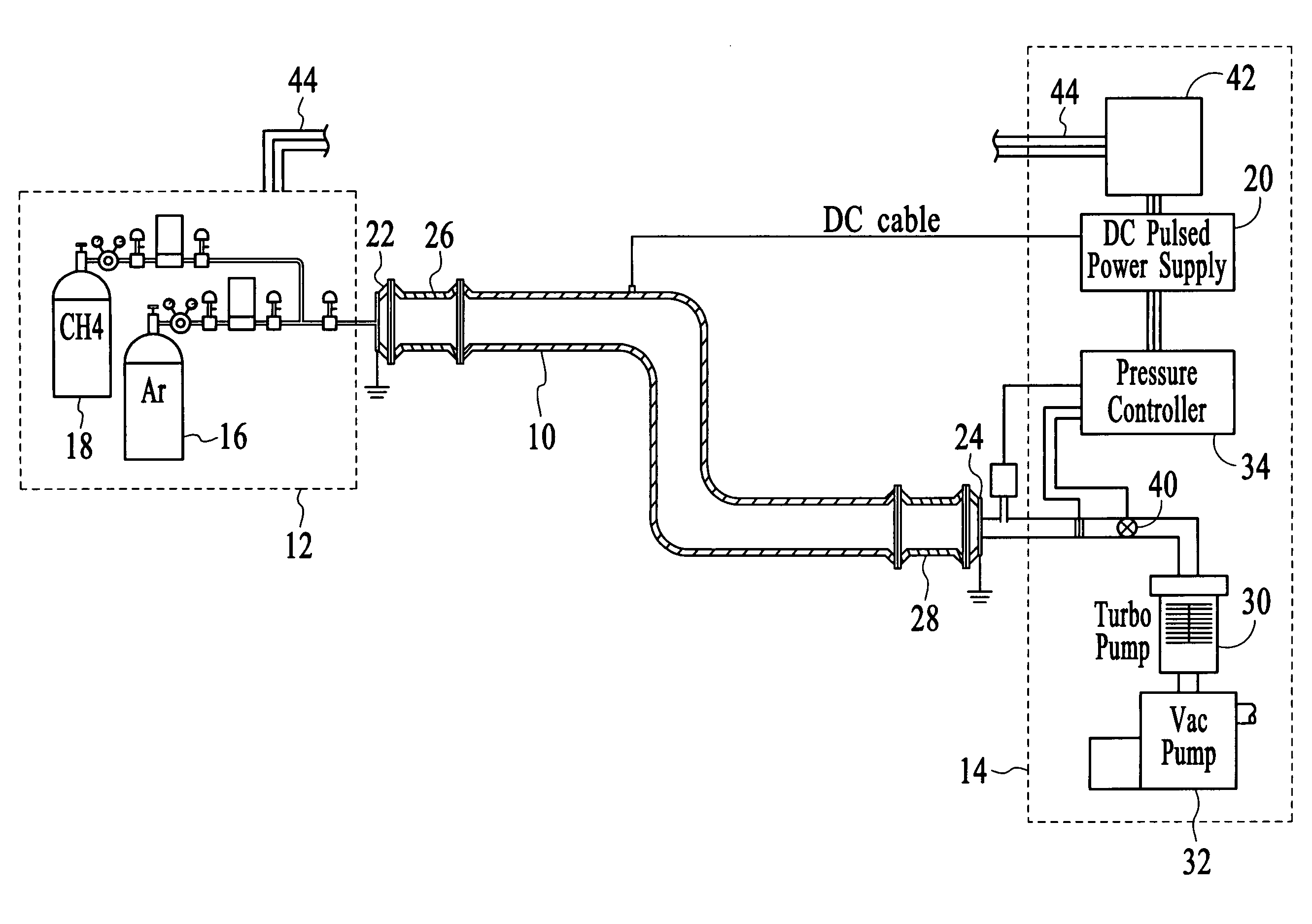

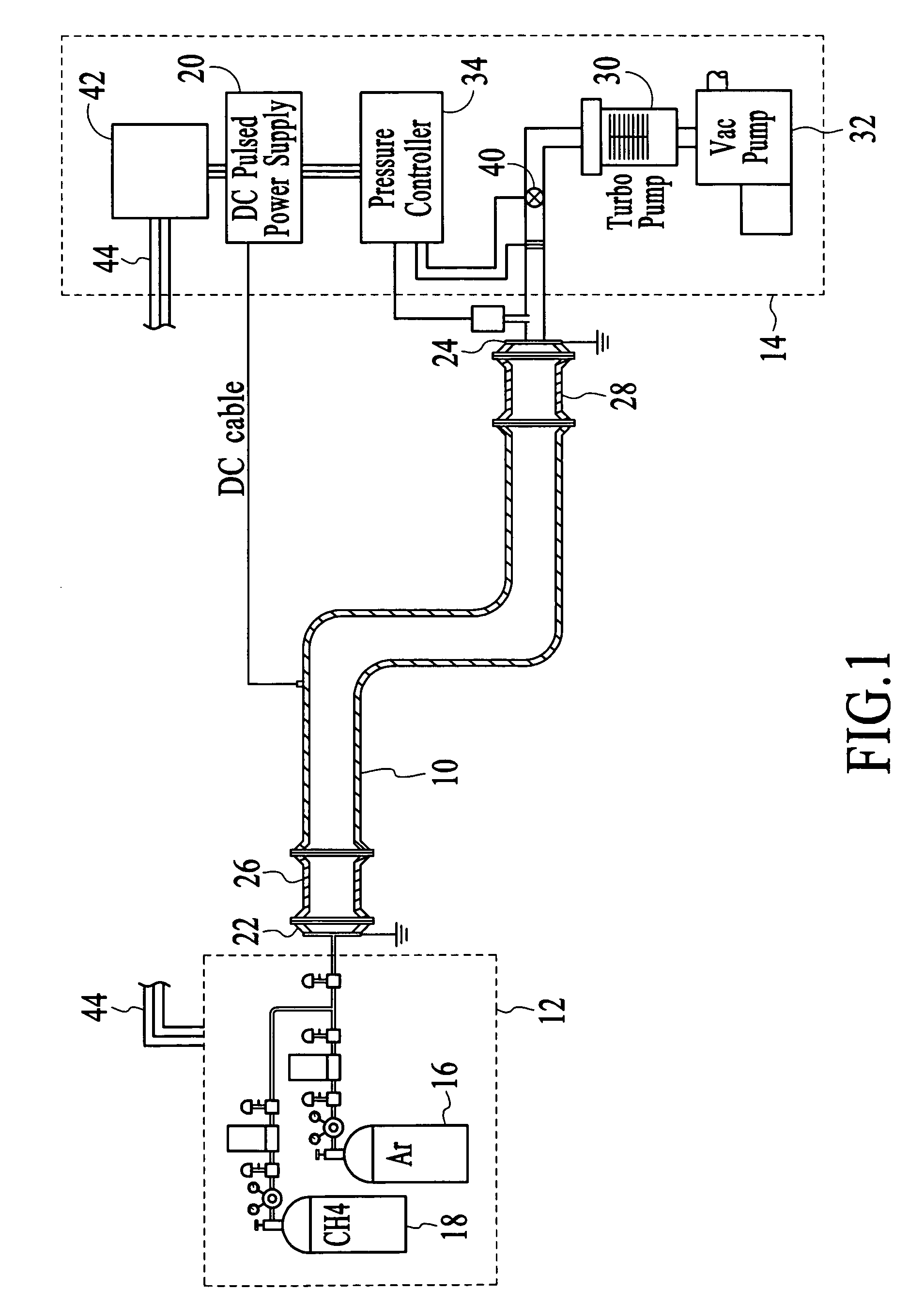

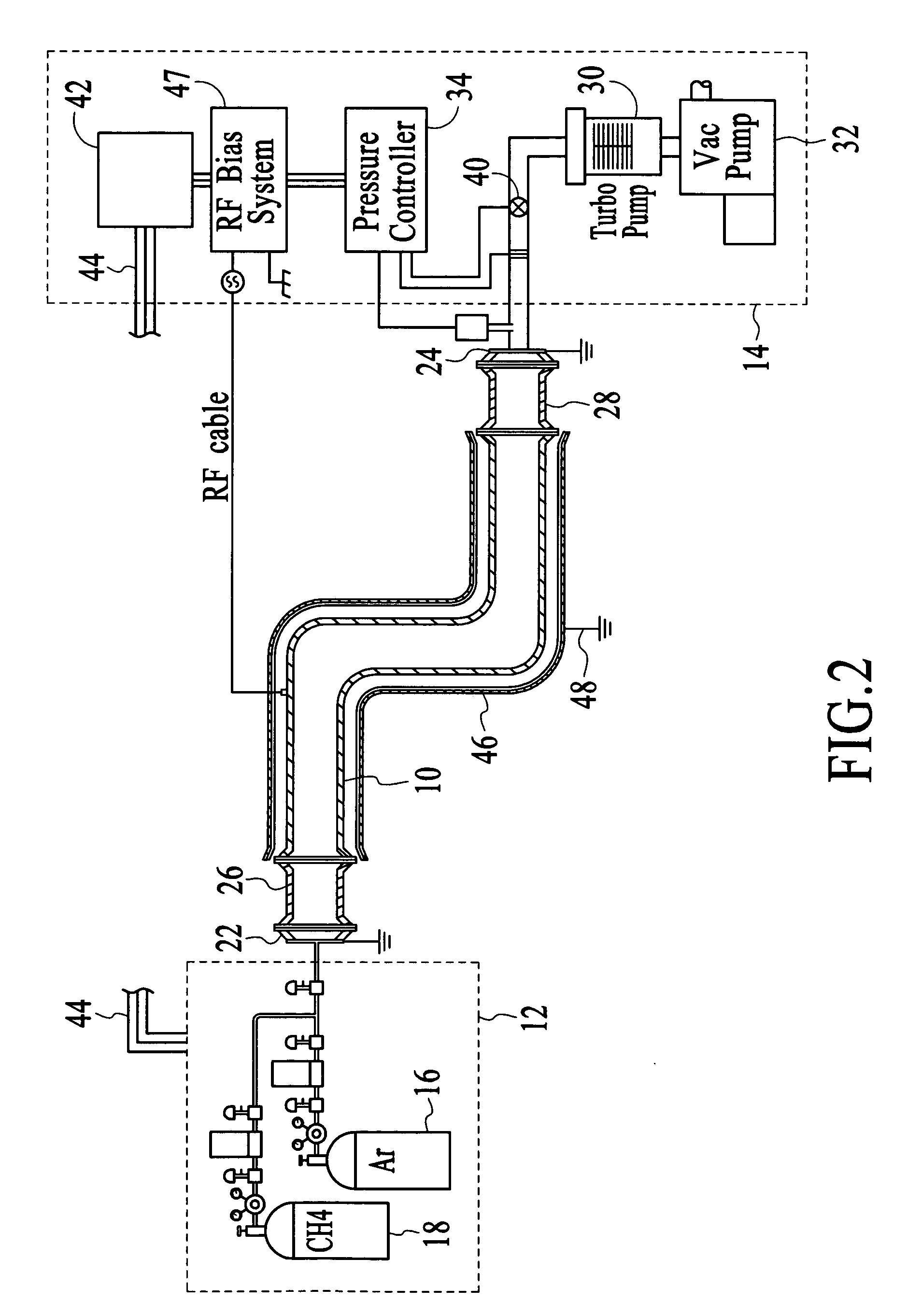

Method of forming highly conformal amorphous carbon layer

ActiveUS7842622B1Easily ionizedReduce riskSemiconductor/solid-state device manufacturingChemical vapor deposition coatingCarbon layerSemiconductor

A method of forming a conformal amorphous hydrogenated carbon layer on an irregular surface of a semiconductor substrate includes: vaporizing a hydrocarbon-containing precursor; introducing the vaporized precursor and an argon gas into a CVD reaction chamber inside which the semiconductor substrate is placed; depositing a conformal amorphous hydrogenated carbon layer on the irregular surface of the semiconductor substrate by plasma CVD; and controlling the deposition of the conformal ratio of the depositing conformal amorphous hydrogenated carbon layer. The controlling includes (a) adjusting a step coverage of the conformal amorphous hydrogenated carbon layer to about 30% or higher as a function of substrate temperature, and (b) adjusting a conformal ratio of the conformal amorphous hydrogenated carbon layer to about 0.9 to about 1.1 as a function of RF power and / or argon gas flow rate.

Owner:ASM JAPAN

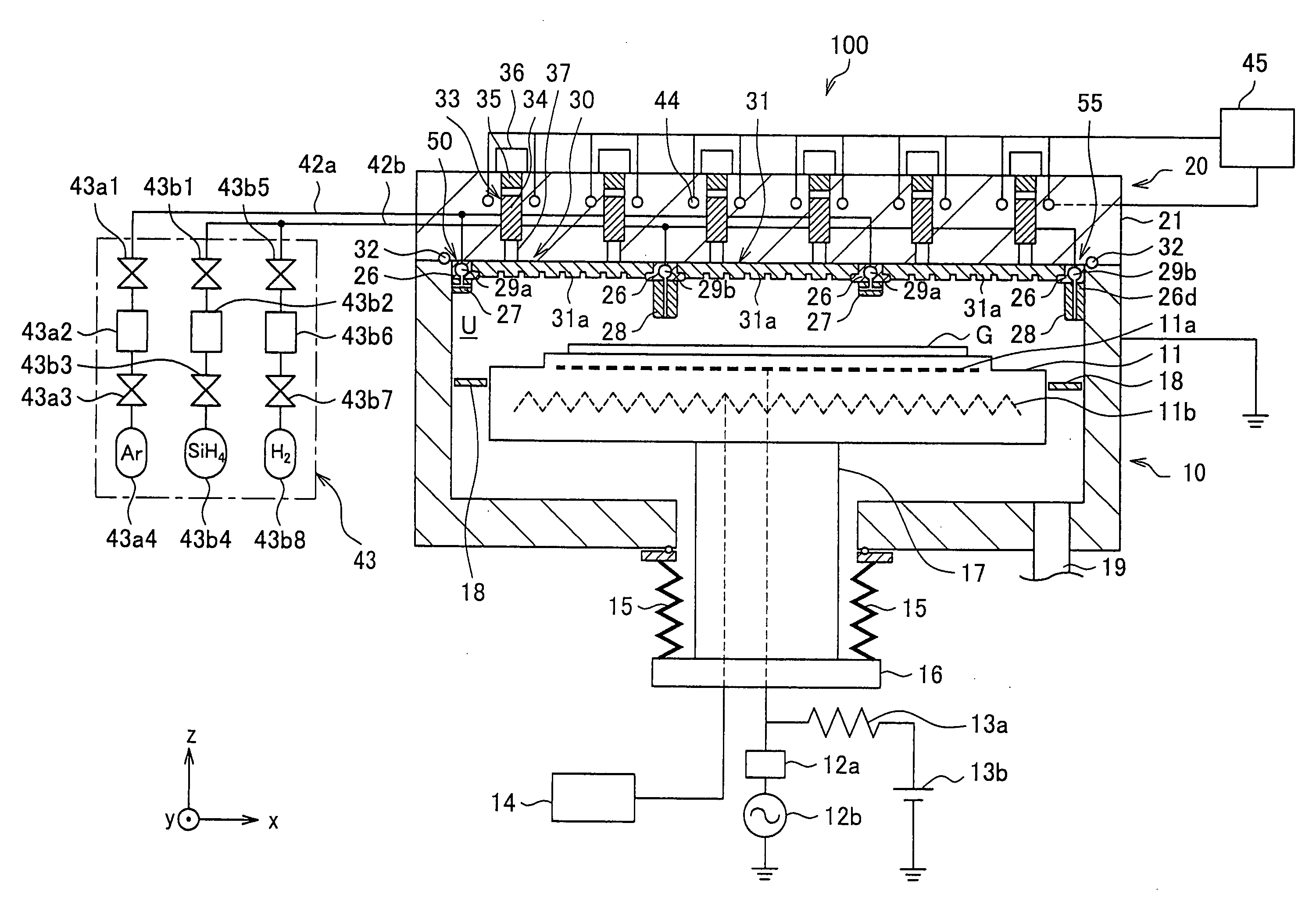

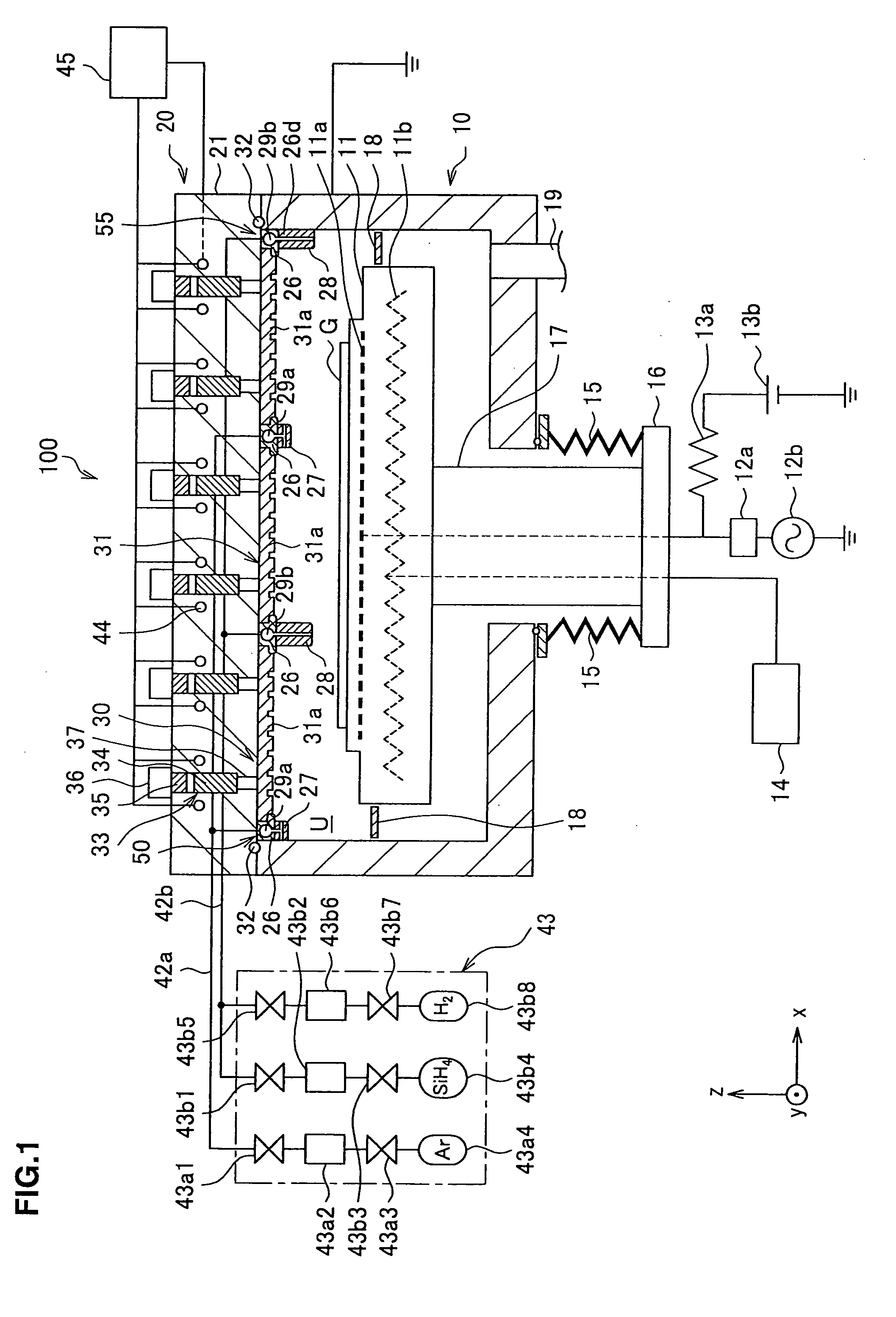

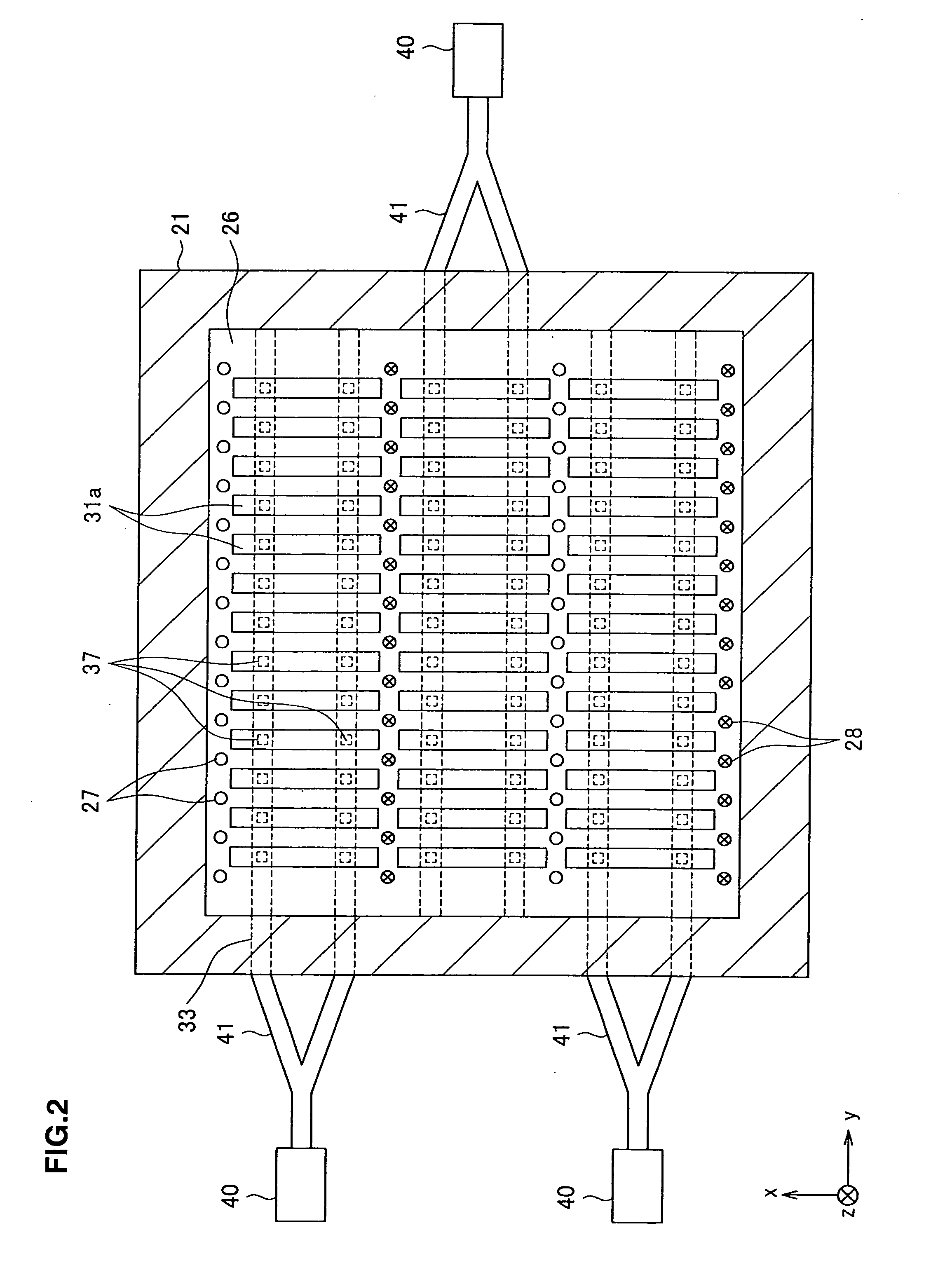

Plasma processing apparatus and plasma processing method

At a frame 26 in a microwave plasma processing apparatus 100, numerous horizontal spray gas nozzles 27 formed therein injection holes A and numerous vertical gas nozzles 28 formed therein injection holes B are fixed. A first gas supply means 50 injects argon gas through the injection holes A into an area near each dielectric parts 31a. A second gas supply means 55 injects silane gas and hydrogen gas through the injection holes B into a position at which the gases do not become over-dissociated. The gases injected as described above are raised to plasma with a microwave transmitted through each dielectric parts 31a. Since the vertical gas nozzles 28 are mounted at positions at which they do not block the flow of plasma traveling toward a substrate G, ions and electrons do not collide with the vertical gas nozzles 28 readily.

Owner:TOKYO ELECTRON LTD

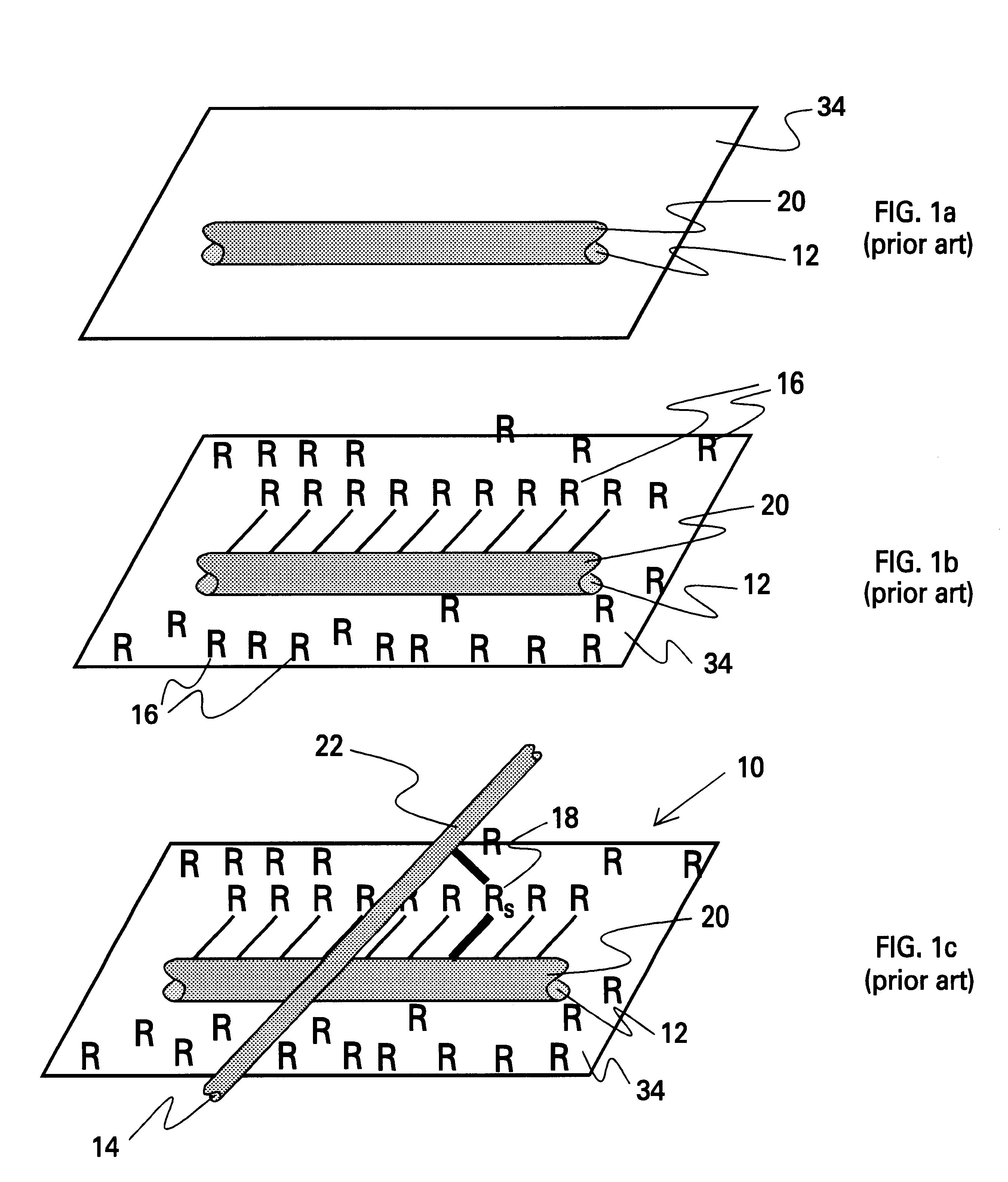

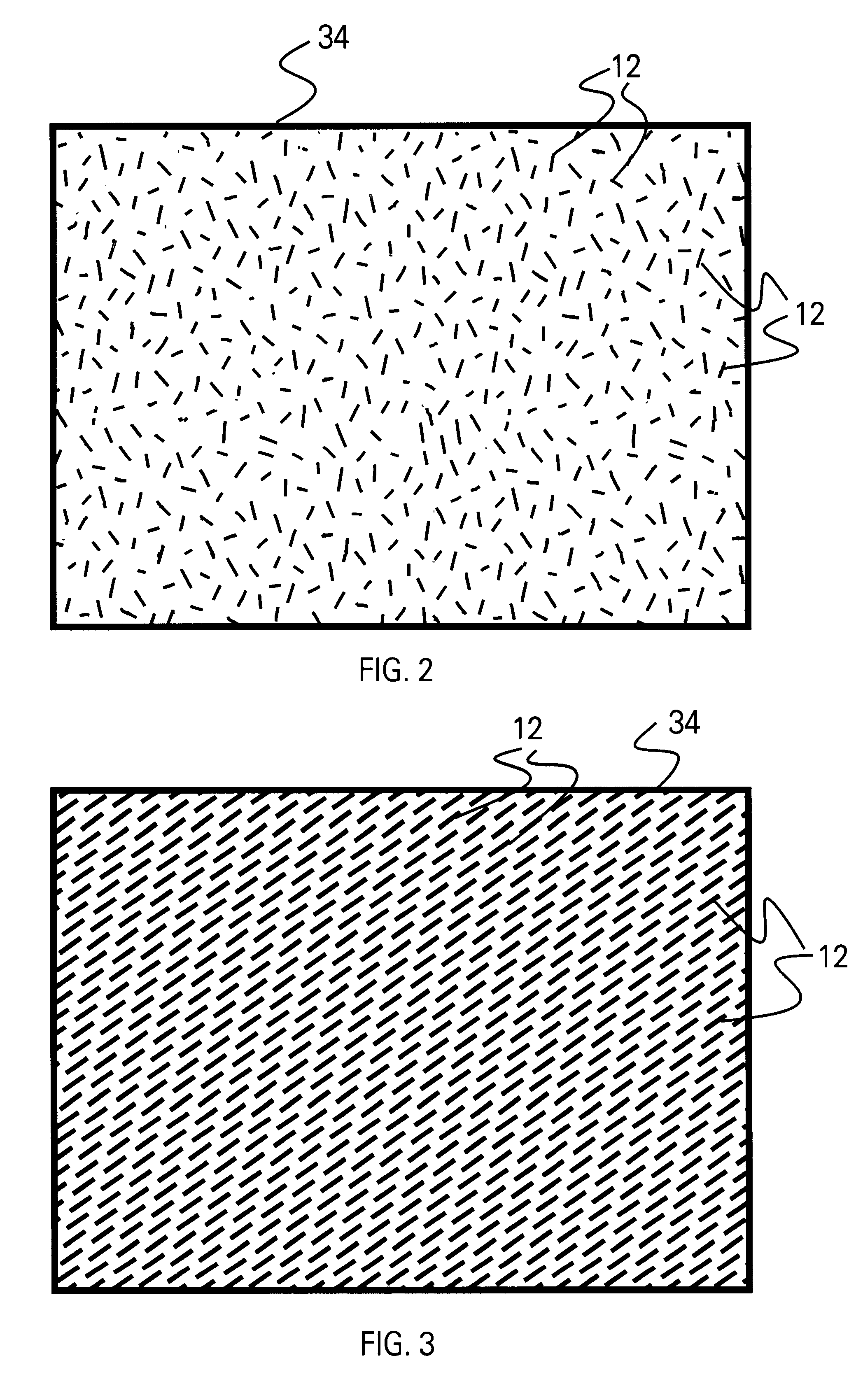

Method of aligning nanowires

A method of aligning nanowires on a substrate is provided. First, a plurality of the nanowires is formed on the substrate, then the plurality of nanowires is exposed to a flux of energetic ions, e.g., argon at an ion energy of 5 KV and an integrated flux density of about 6x1015 ions / cm2. The flux of energetic ions serves to align the nanowires parallel to each other. The flux of energetic ions may also be used to align the nanowires parallel to the substrate surface.

Owner:SAMSUNG ELECTRONICS CO LTD

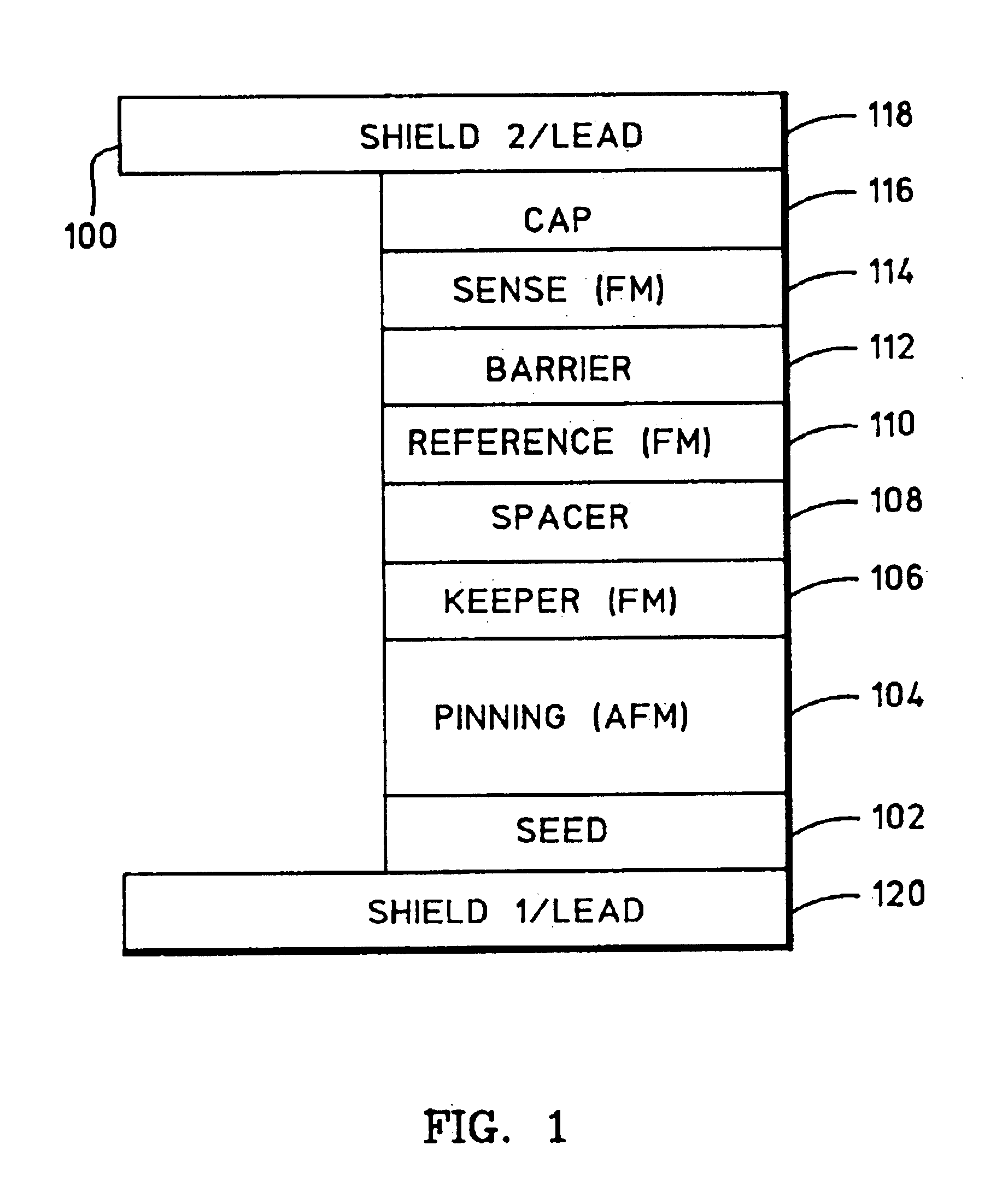

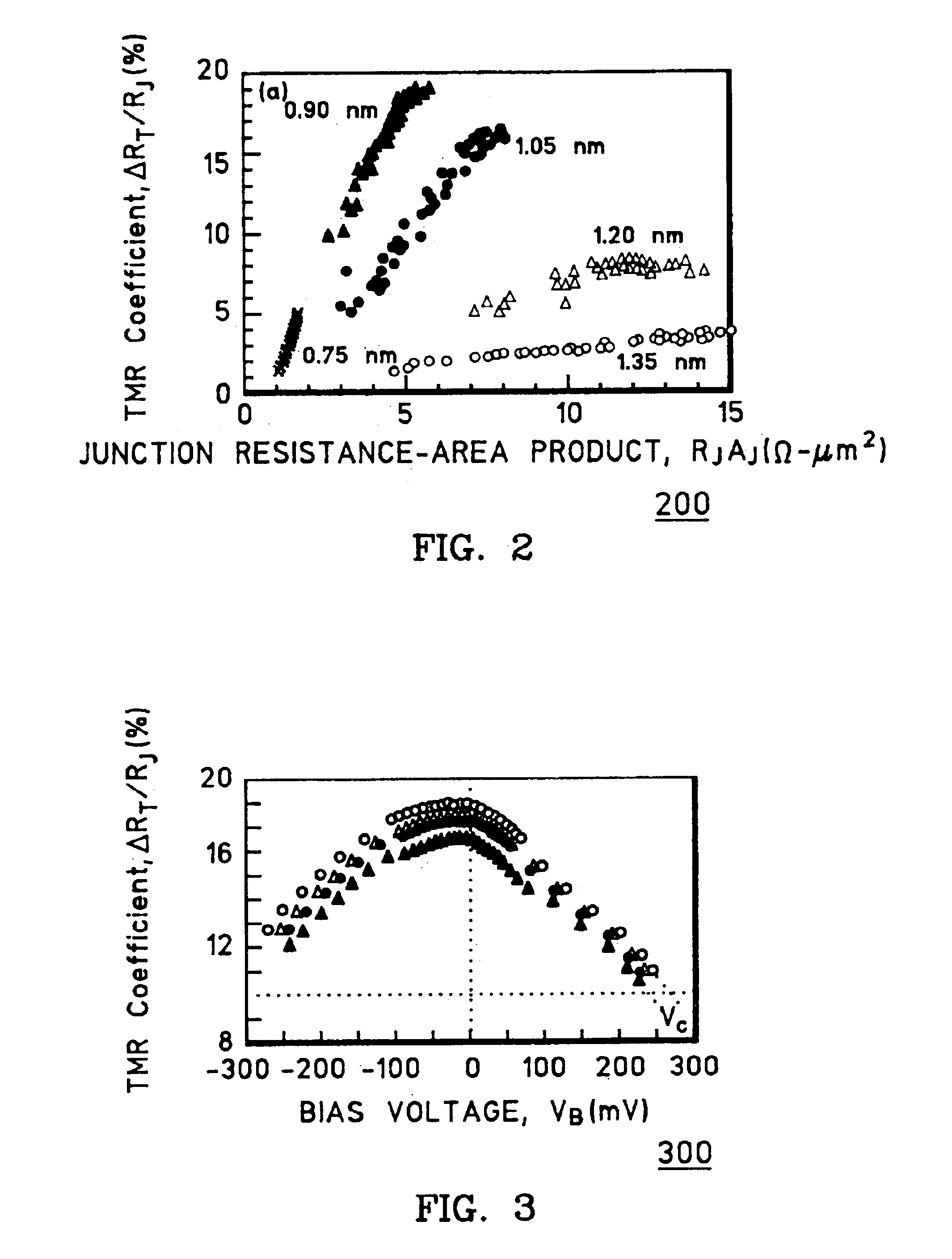

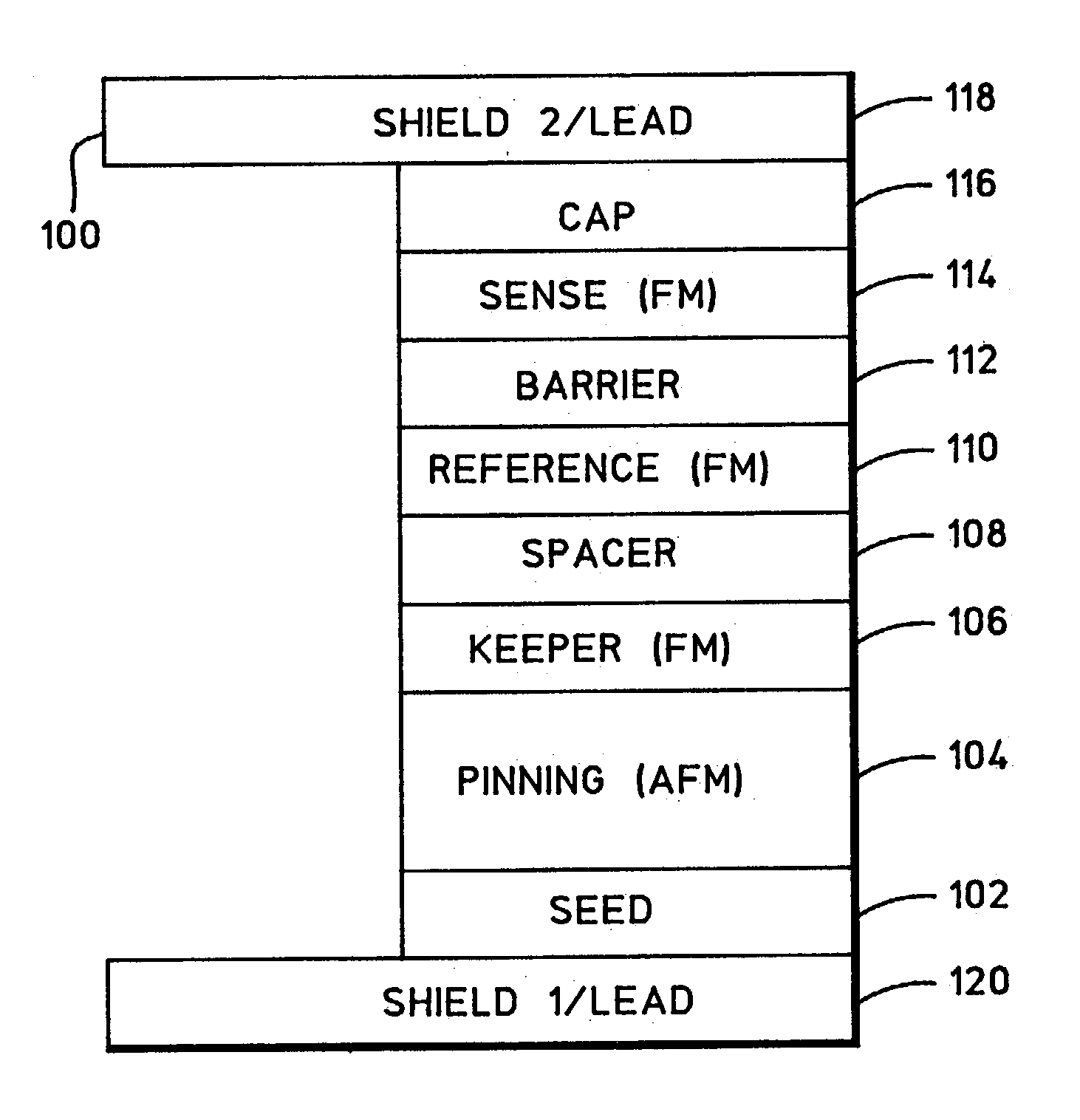

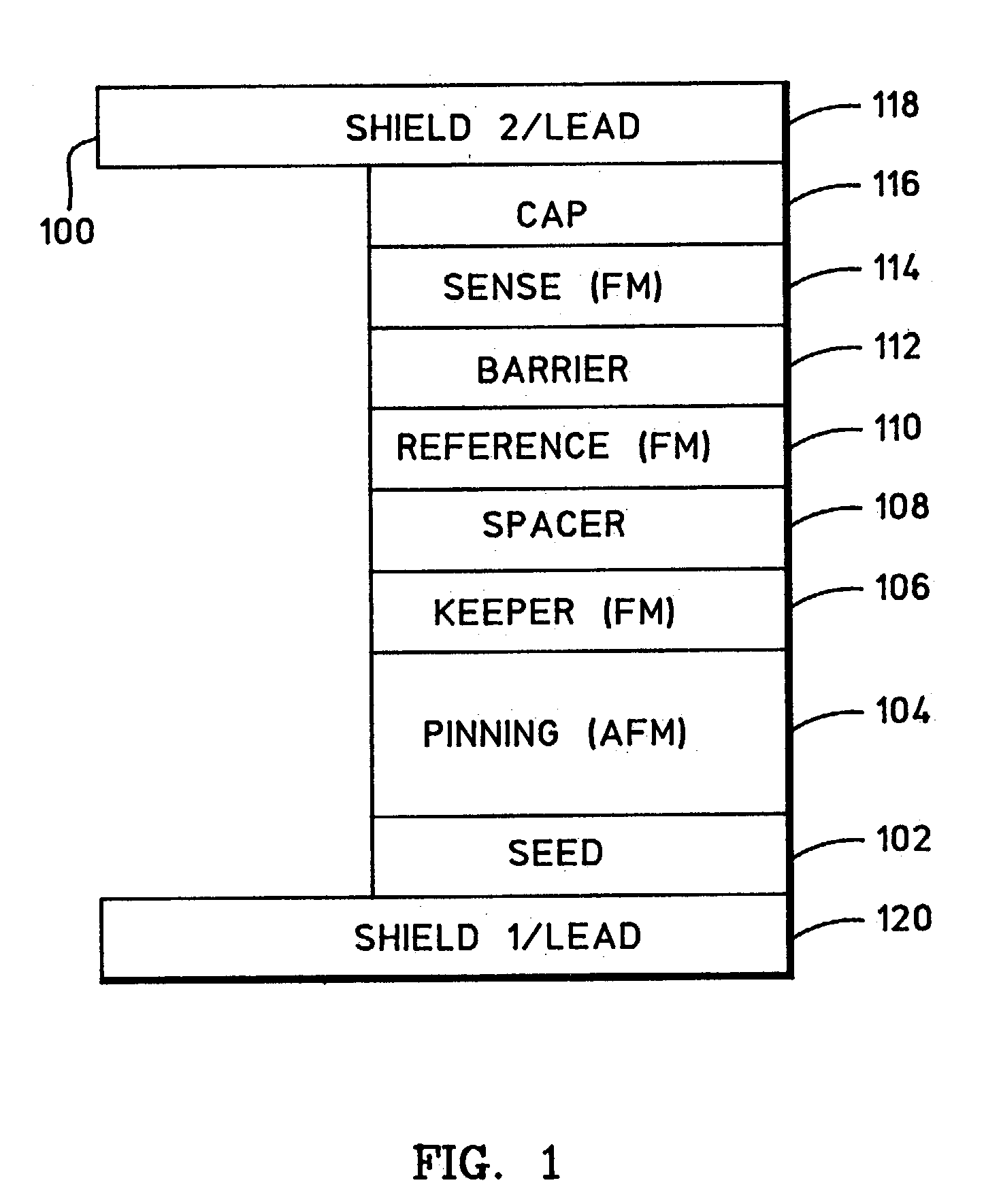

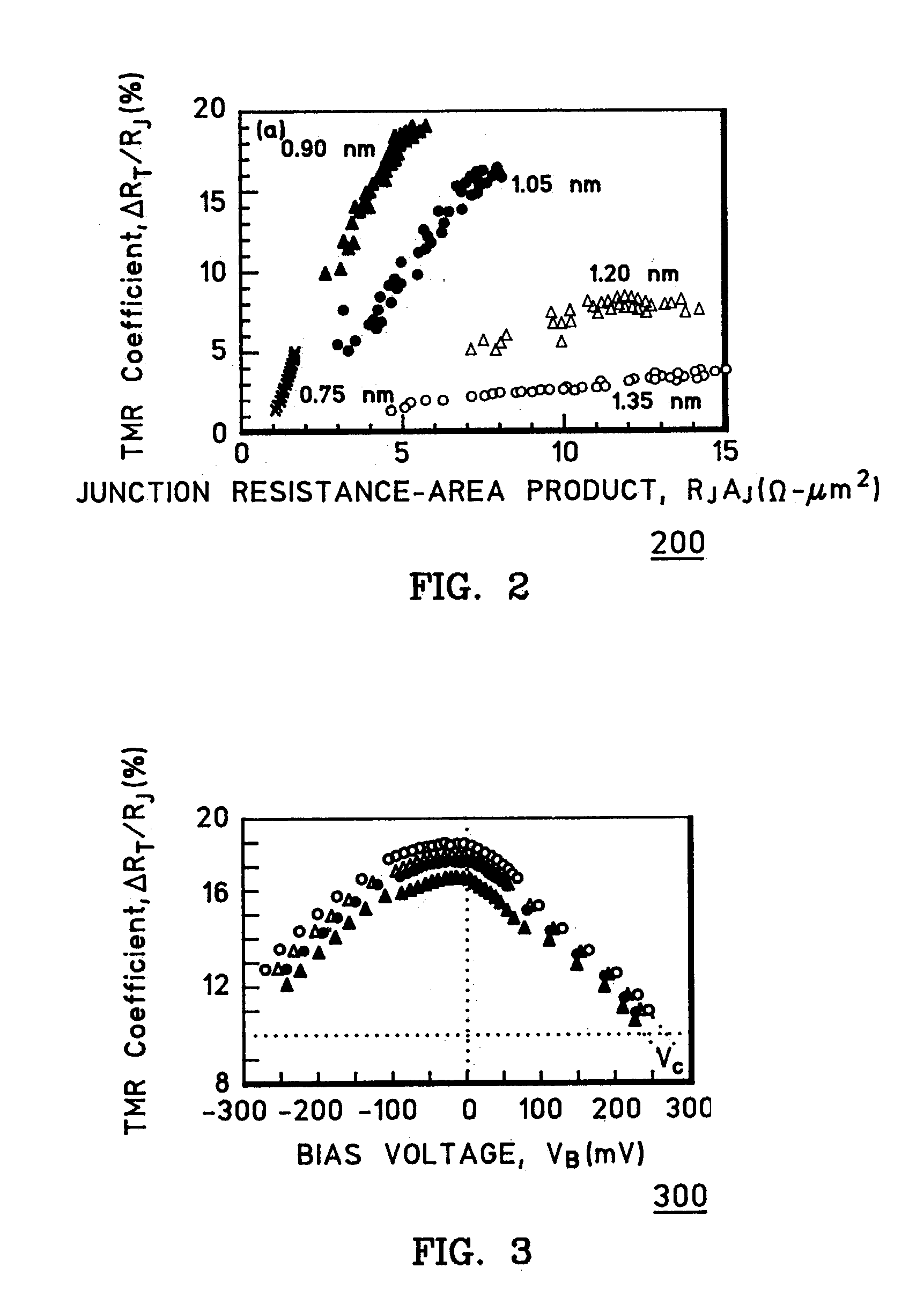

Method of forming a barrier layer of a tunneling magnetoresistive sensor

InactiveUS6841395B2Prevent electrostatic dischargeMagnetic and TMR propertyNanostructure applicationNanomagnetismIon beamXenon

Owner:GLOBALFOUNDRIES INC

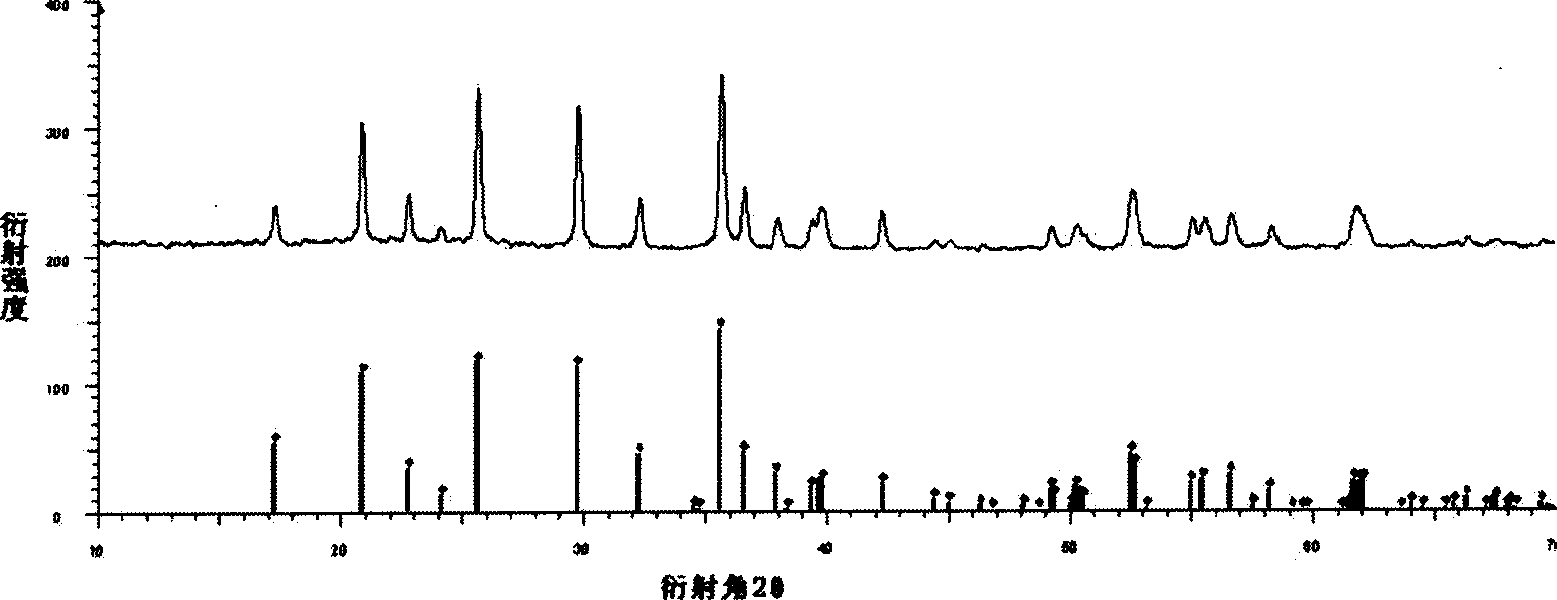

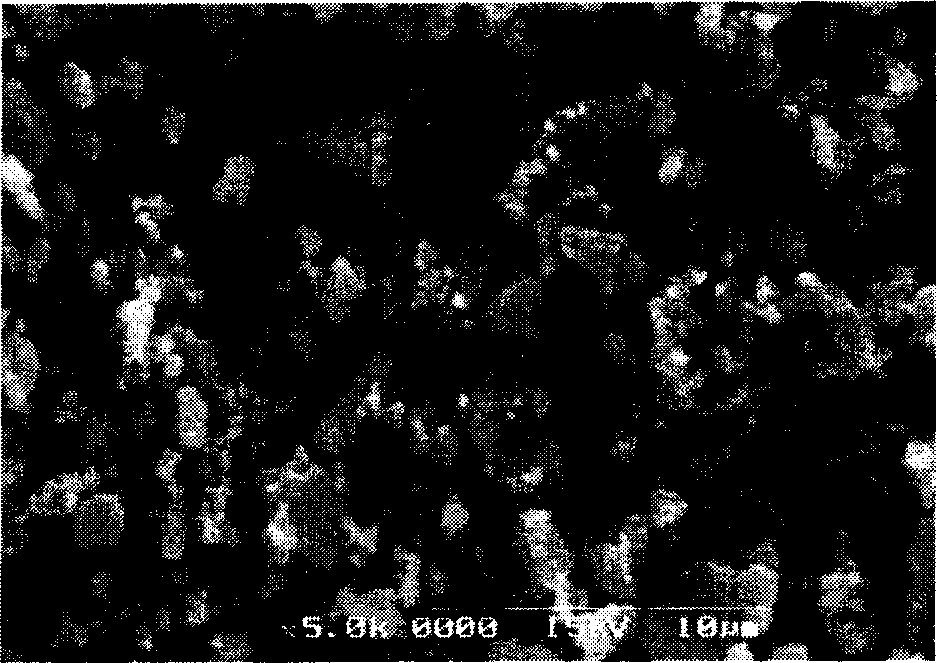

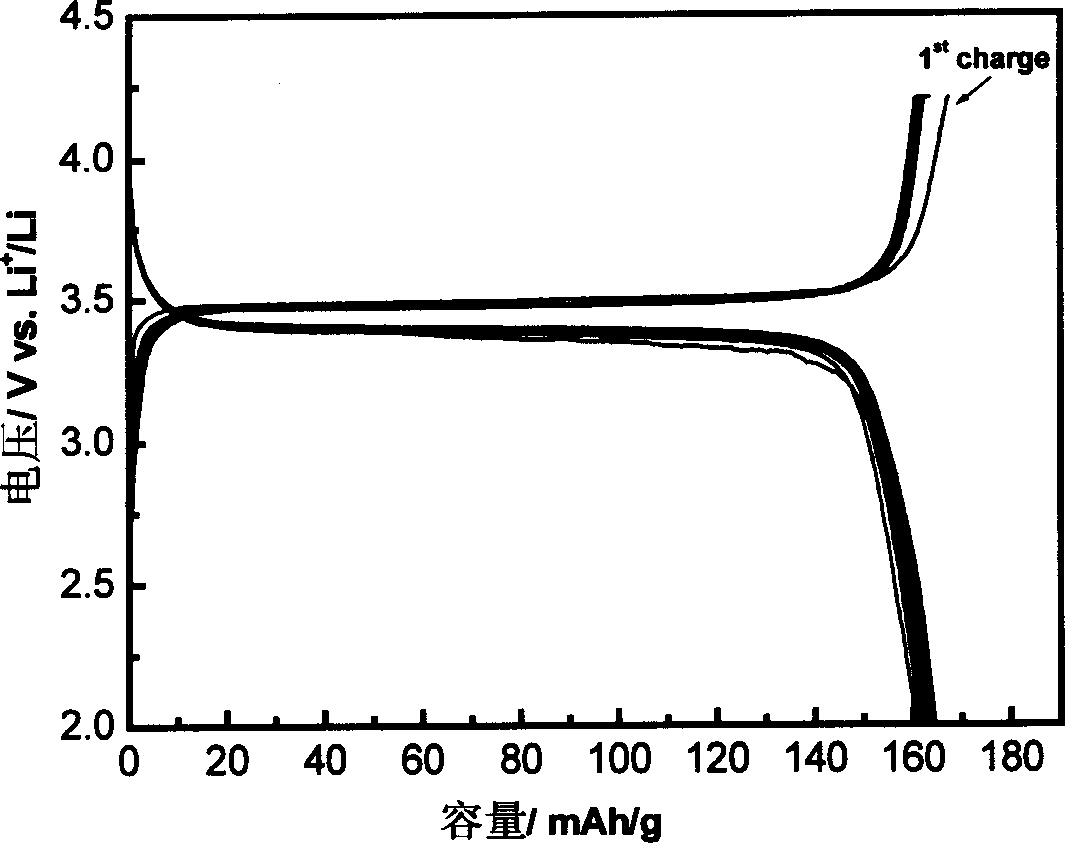

Method for preparing lithiumion cell positive material Iron-lithium phosphate

ActiveCN1581537AAvoid synthetic stepsSolve the problem of impurityElectrode manufacturing processesLithium compoundsPhosphateNitrogen gas

Mechanical solid phase method for synthesizing lithium ferric phosphate includes following steps: mixing iron powder, ferric phosphate, lithium phosphate, doping elements of phosphate, conducting agent or predecessor of conducting agent according to proportion evenly; placing the mixed admixture into ball milling container with inert gases being filled and ball milling for 18-36 hours; then putting the produced result from ball milling into high-temperature furnace with inert gases such as nitrogen gas and argon gas being filled; heating up in 10-30 deg.C / minute heating rate, baking at constant temperature 450-750 deg.C for 10-60 minutes; then cooling at 10-30 deg.C / minutes cooling rate, cooling the admixture to room temperature so as to obtain powder of lithium ferric phosphate or powder of doped powder of lithium ferric phosphate. Advantages are: feasible, no pollution, high specific capacity and good cycle performance.

Owner:SHANGHAI SINOPOLY JIAHUA BATTERY TECH

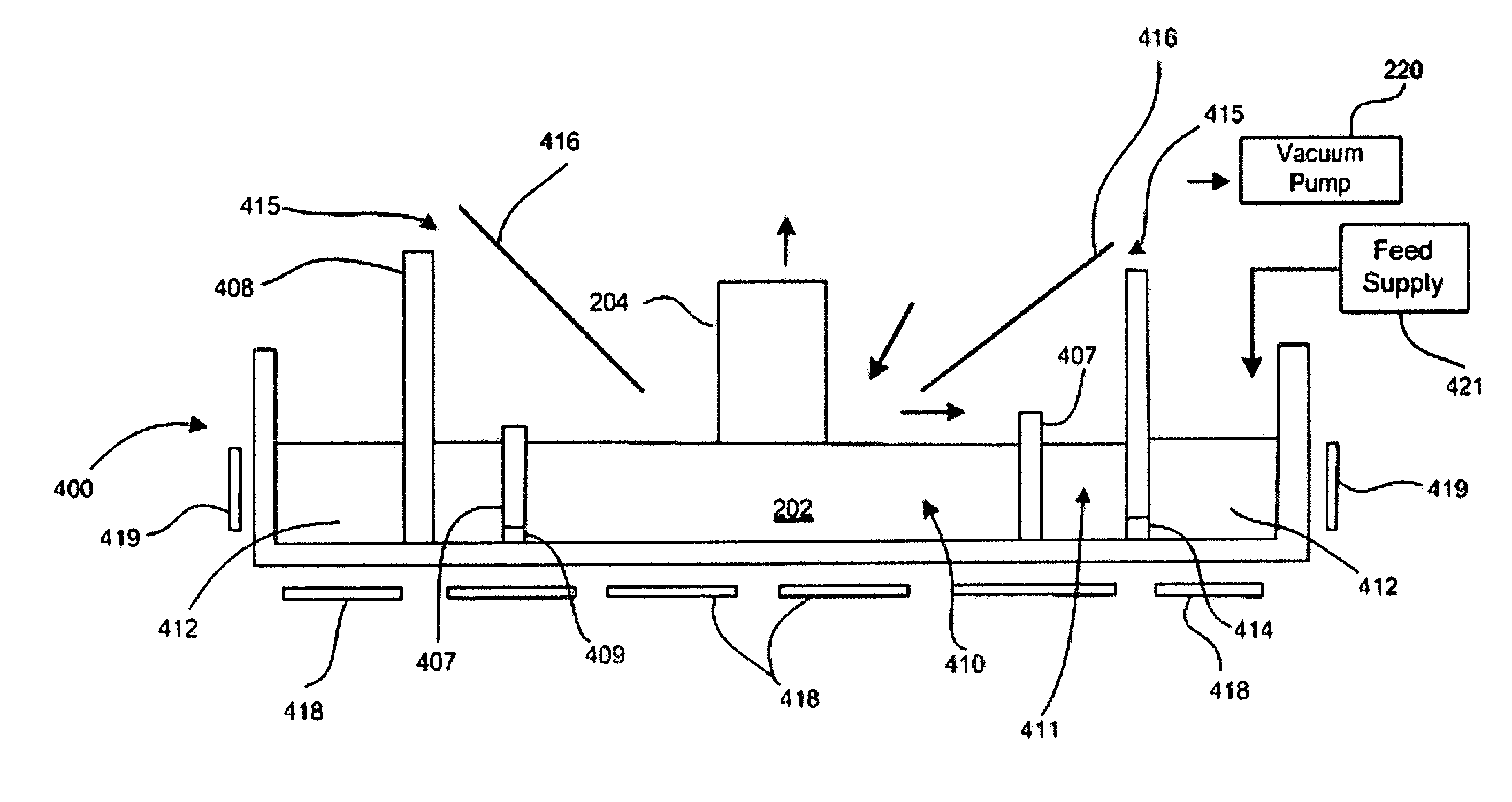

Method and system for coating internal surfaces of prefabricated process piping in the field

ActiveUS7300684B2Improve adhesionIncreases magnitudeLiquid surface applicatorsVacuum evaporation coatingHydrocarbon mixturesDiamond-like carbon

The coating of internal surfaces of a workpiece is achieved by connecting a bias voltage such that the workpiece functions as a cathode and by connecting an anode at each opening of the workpiece. A source gas is introduced at an entrance opening, while a vacuum source is connected at an exit opening. Pressure within the workpiece is monitored and the resulting pressure information is used for maintaining a condition that exhibits the hollow cathode effect. Optionally, a pre-cleaning may be provided by introducing a hydrocarbon mixture and applying a negative bias to the workpiece, so as to sputter contaminants from the workpiece using argon gas. Argon gas may also be introduced during the coating processing to re-sputter the coating, thereby improving uniformity along the length of the workpiece. The coating may be a diamond-like carbon material having properties which are determined by controlling ion bombardment energy.

Owner:AGM CONTAINER CONTROLS

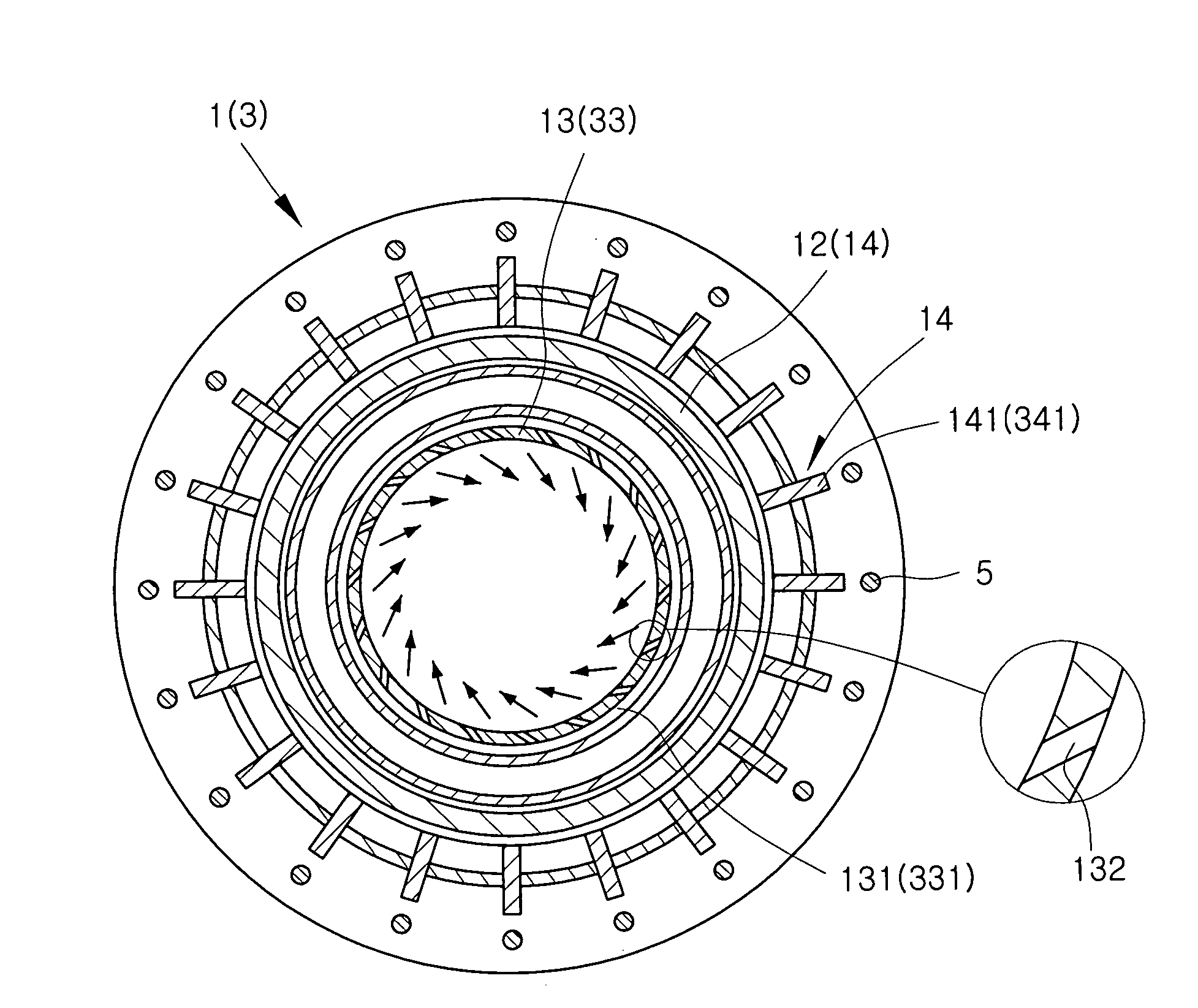

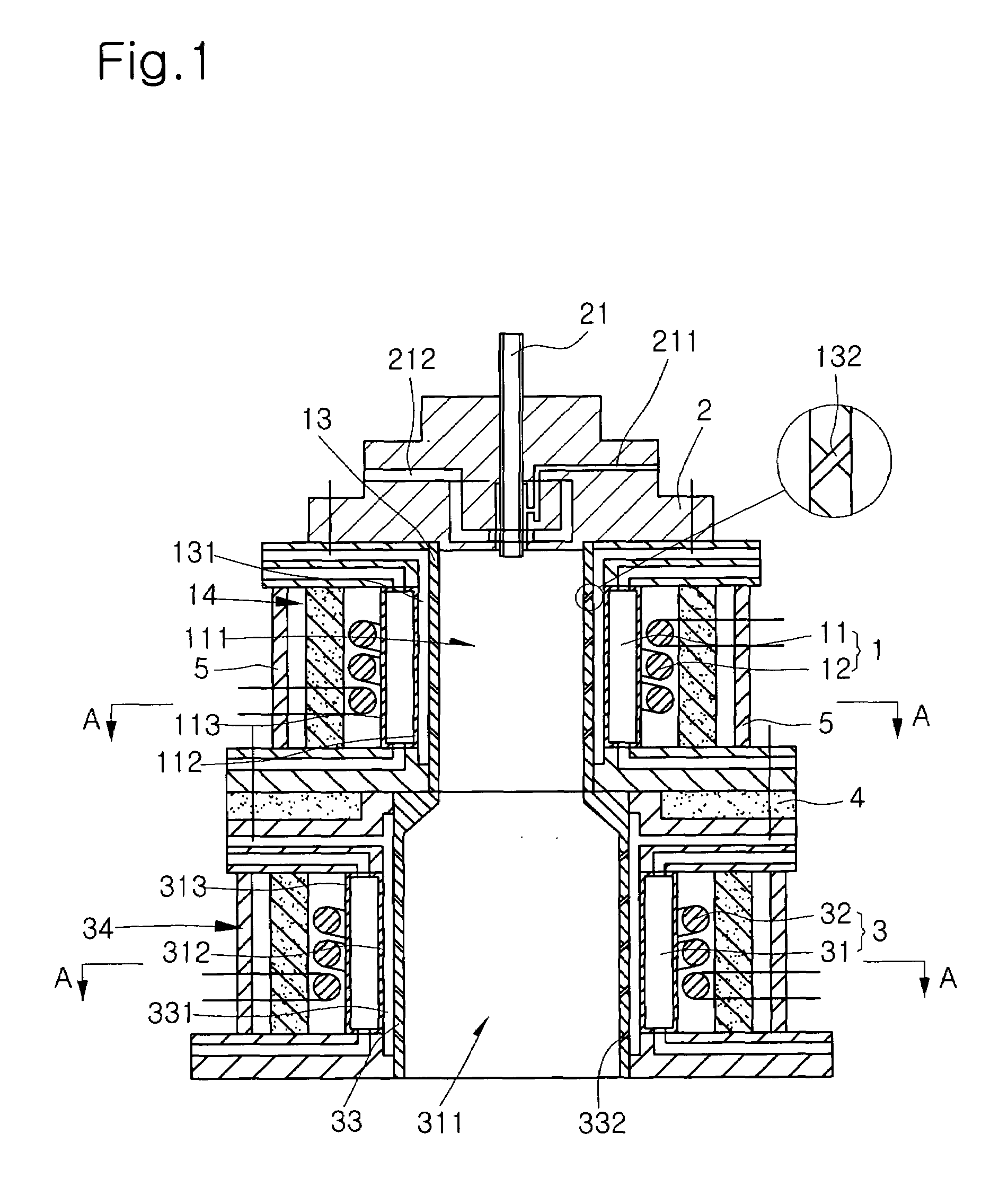

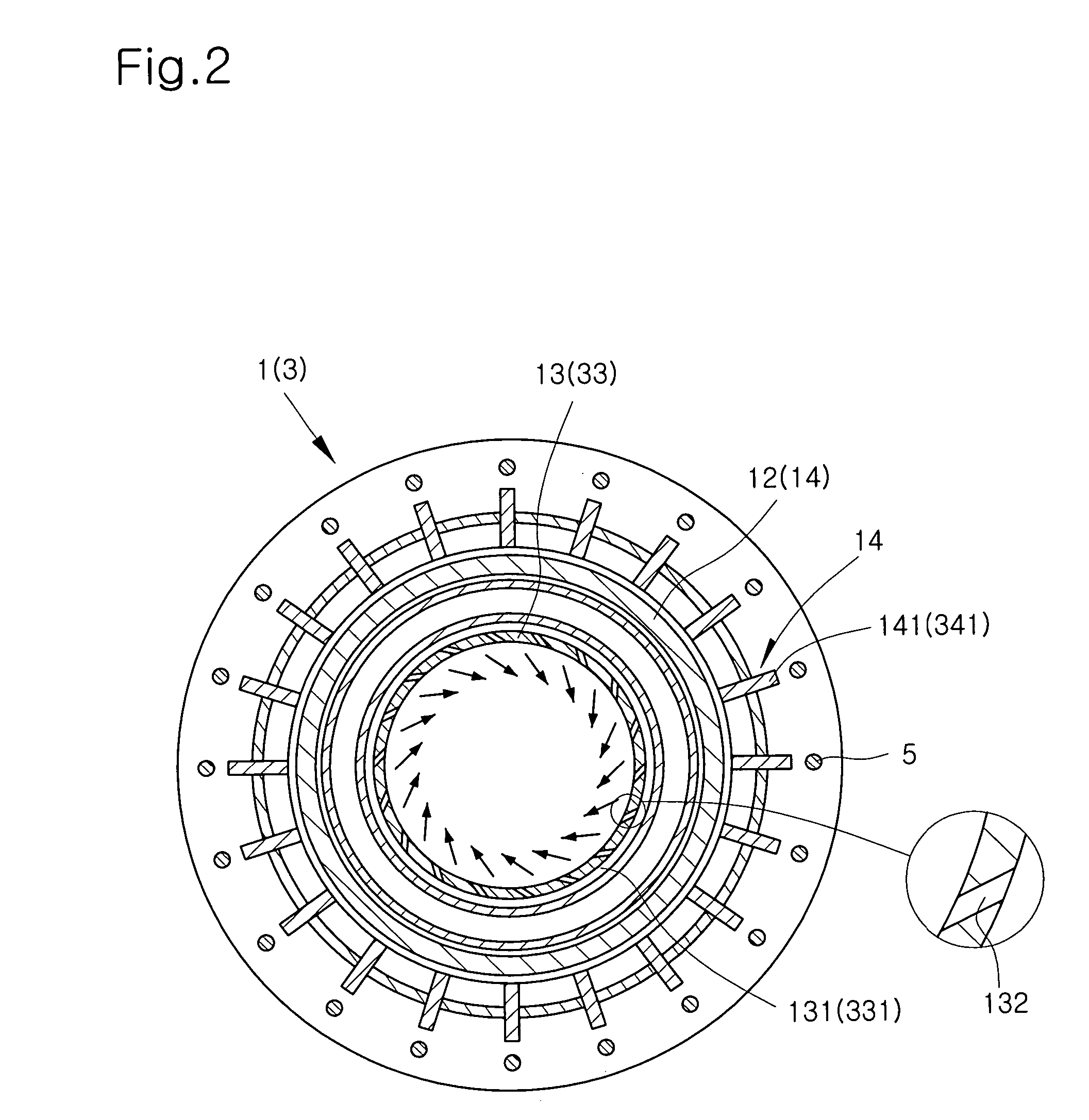

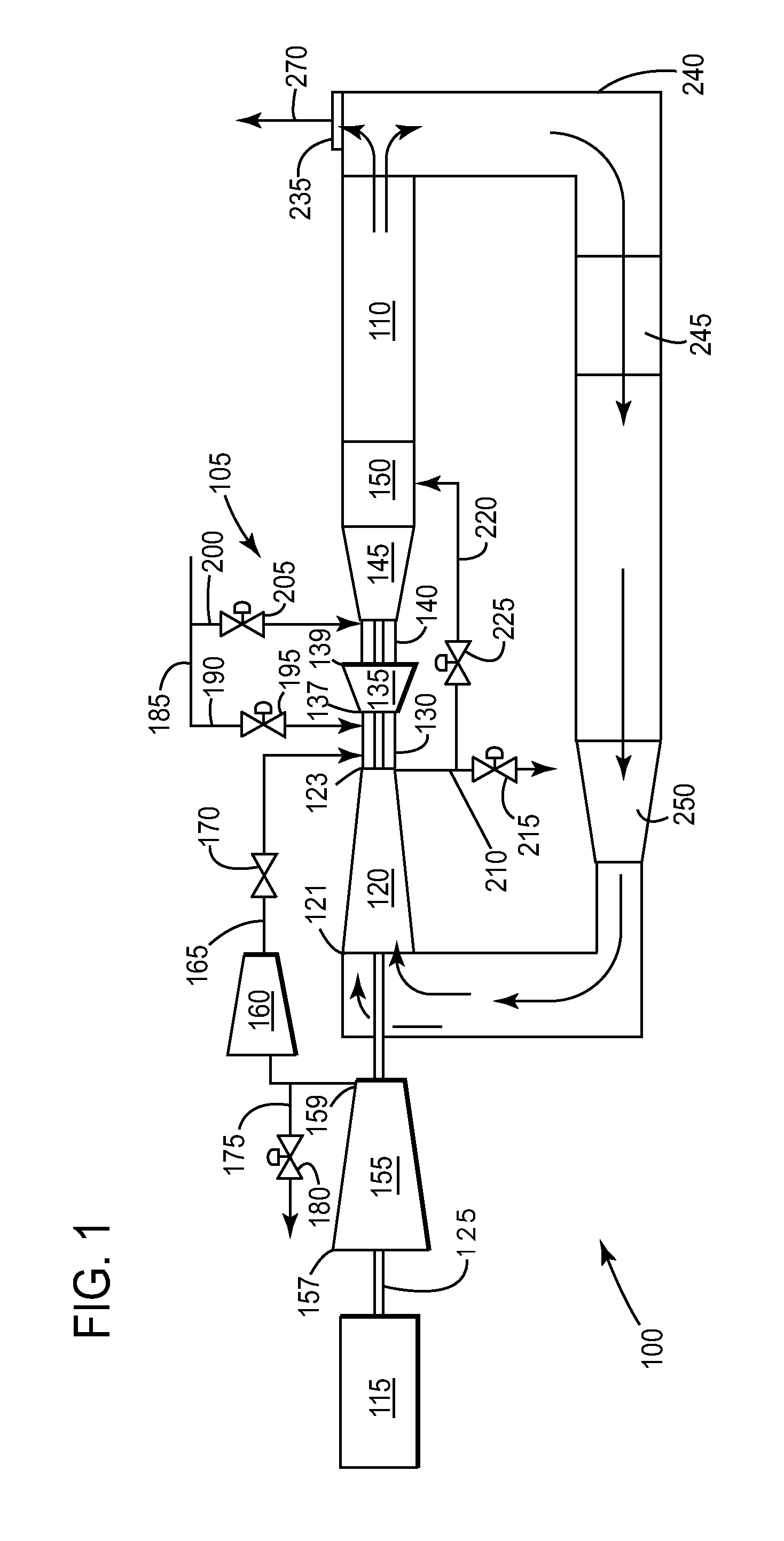

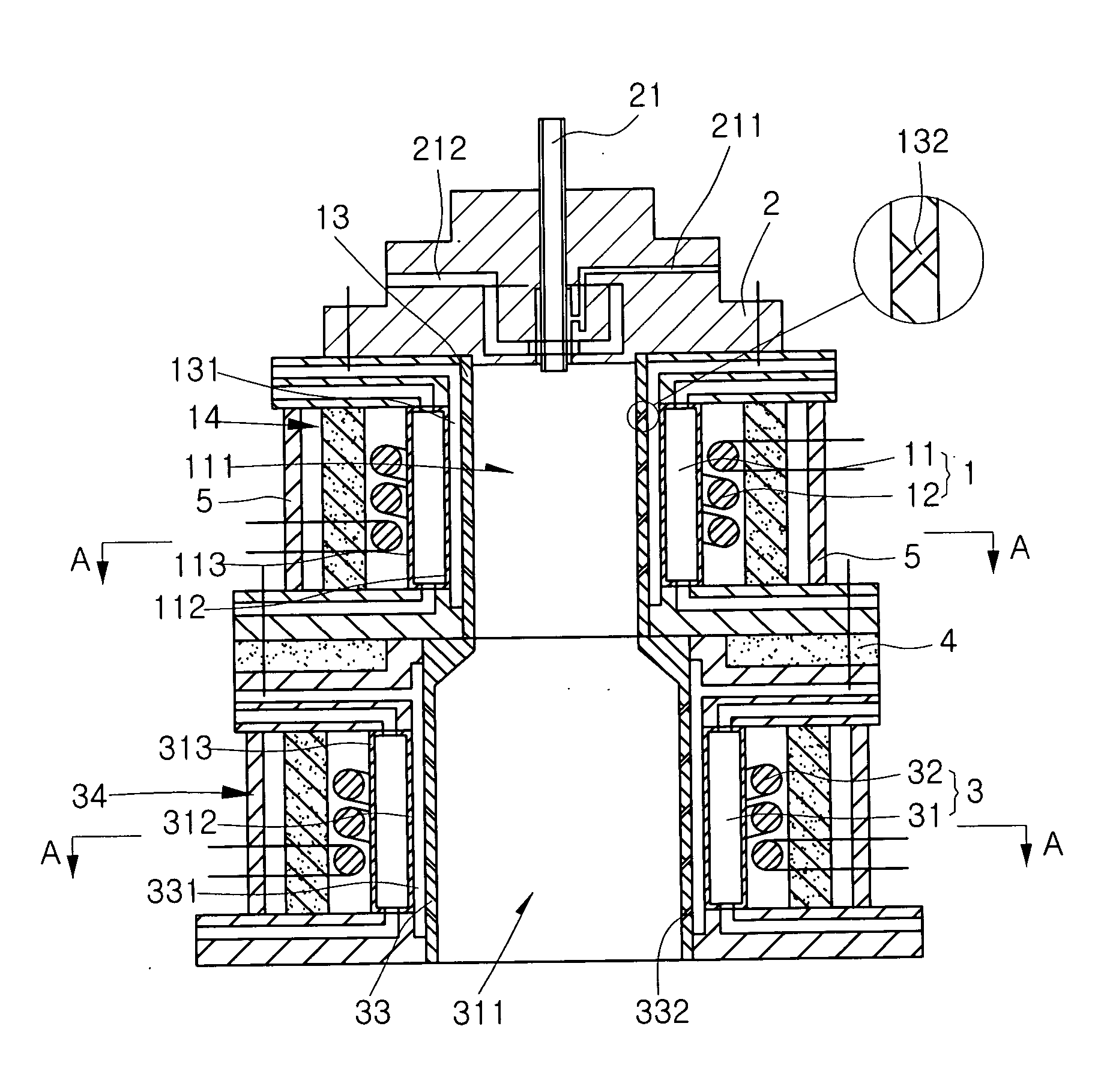

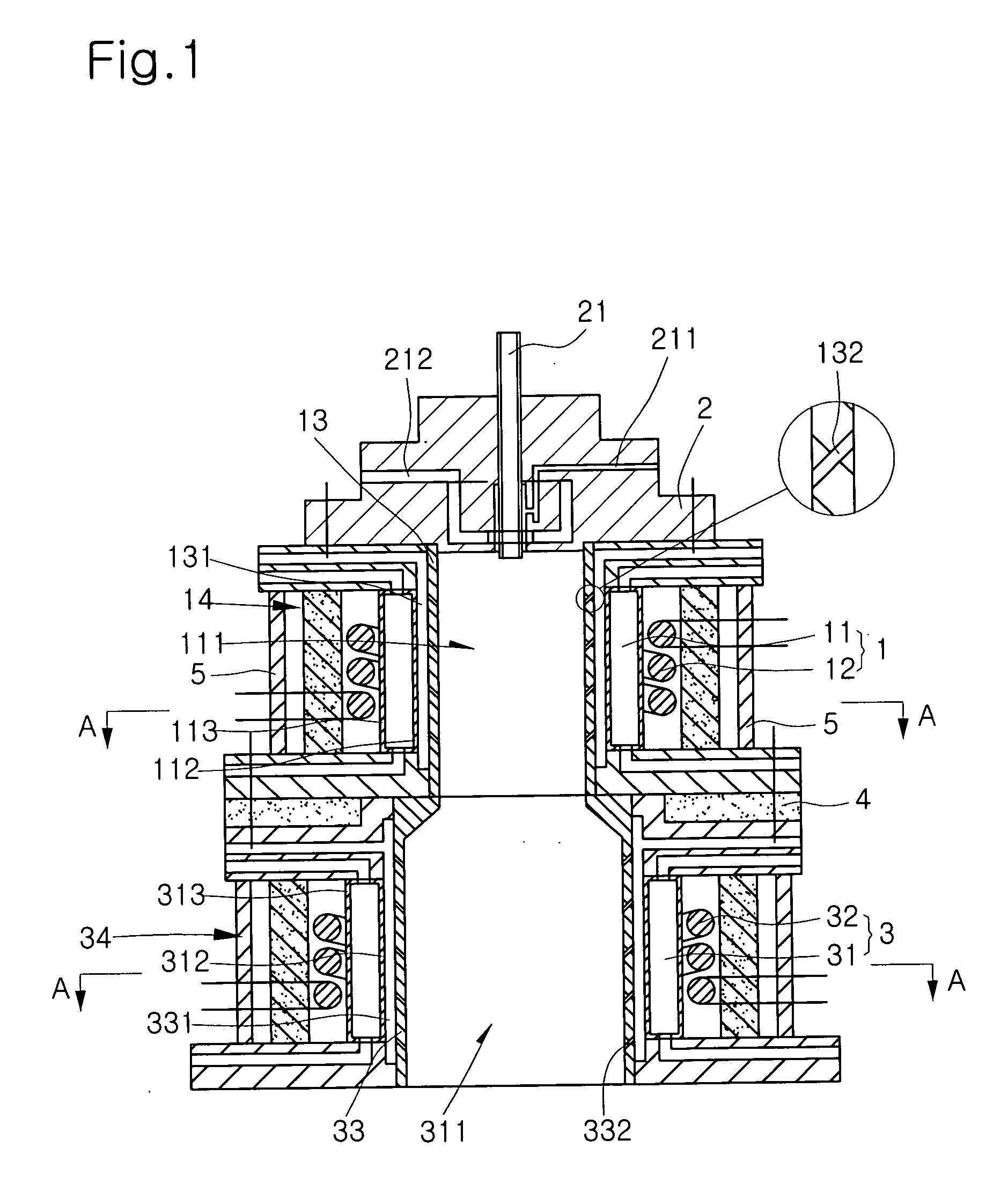

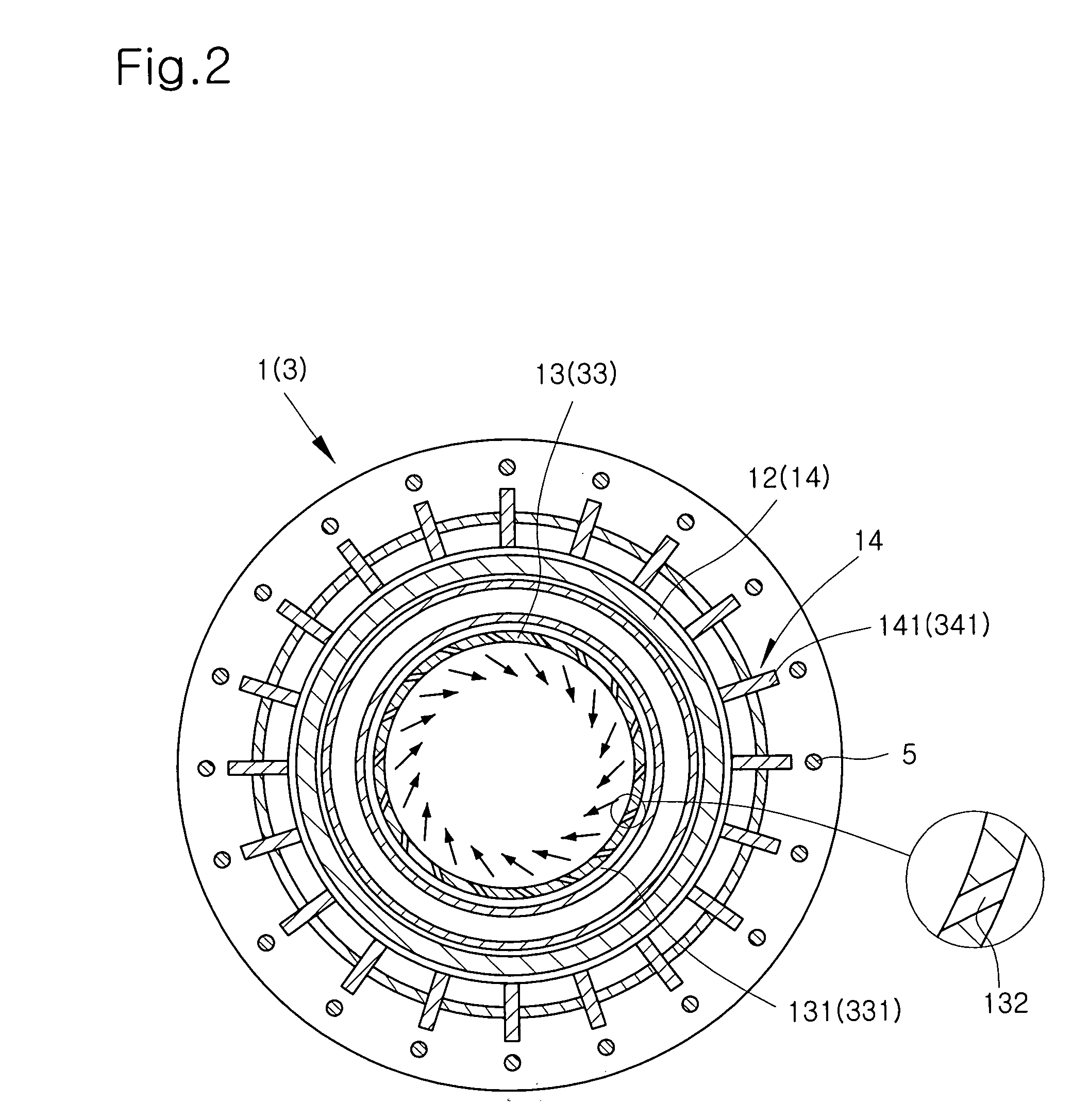

Inductively coupled plasma reactor for producing nano-powder

InactiveUS7323655B2Growth inhibitionGuaranteed to move normallyNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

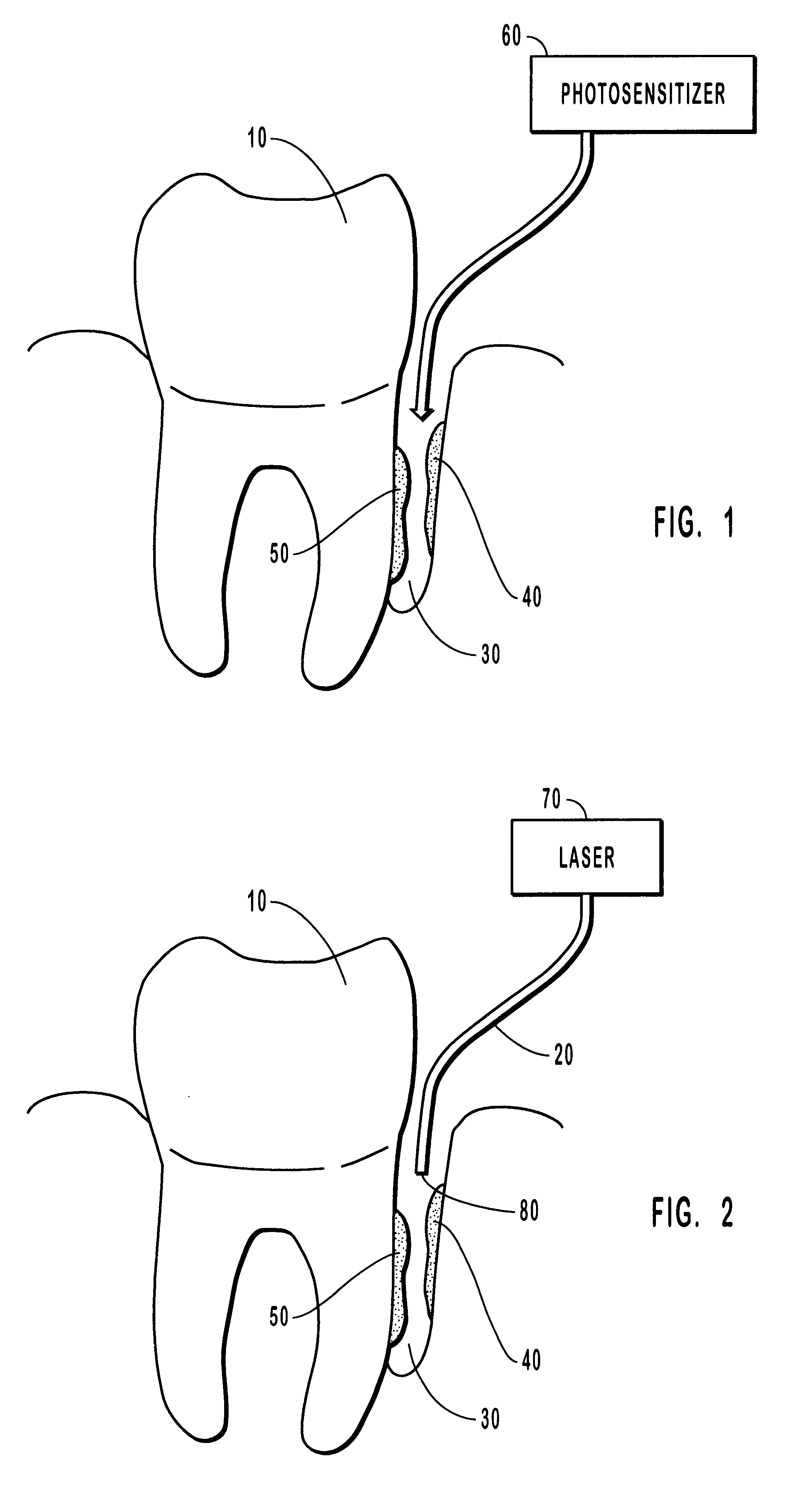

Methods for treating periodontal disease

Methods for treating periodontal disease and other diseased tissues that utilize a dye composition and laser energy. The laser energy (typically about 450 nm to about 600 nm) heats and destroys the diseased tissue and bacteria, while the dye composition causes the laser energy to be selectively absorbed by the targeted tissue. An argon gas laser that emits blue-green light may be used in conjunction with a red-orange dye that strongly absorbs light energy emitted by the argon gas laser. An 810 diode laser may be used in conjunction with the argon laser in order to provide additional heating properties.

Owner:ANDERSEN SCOT N +1

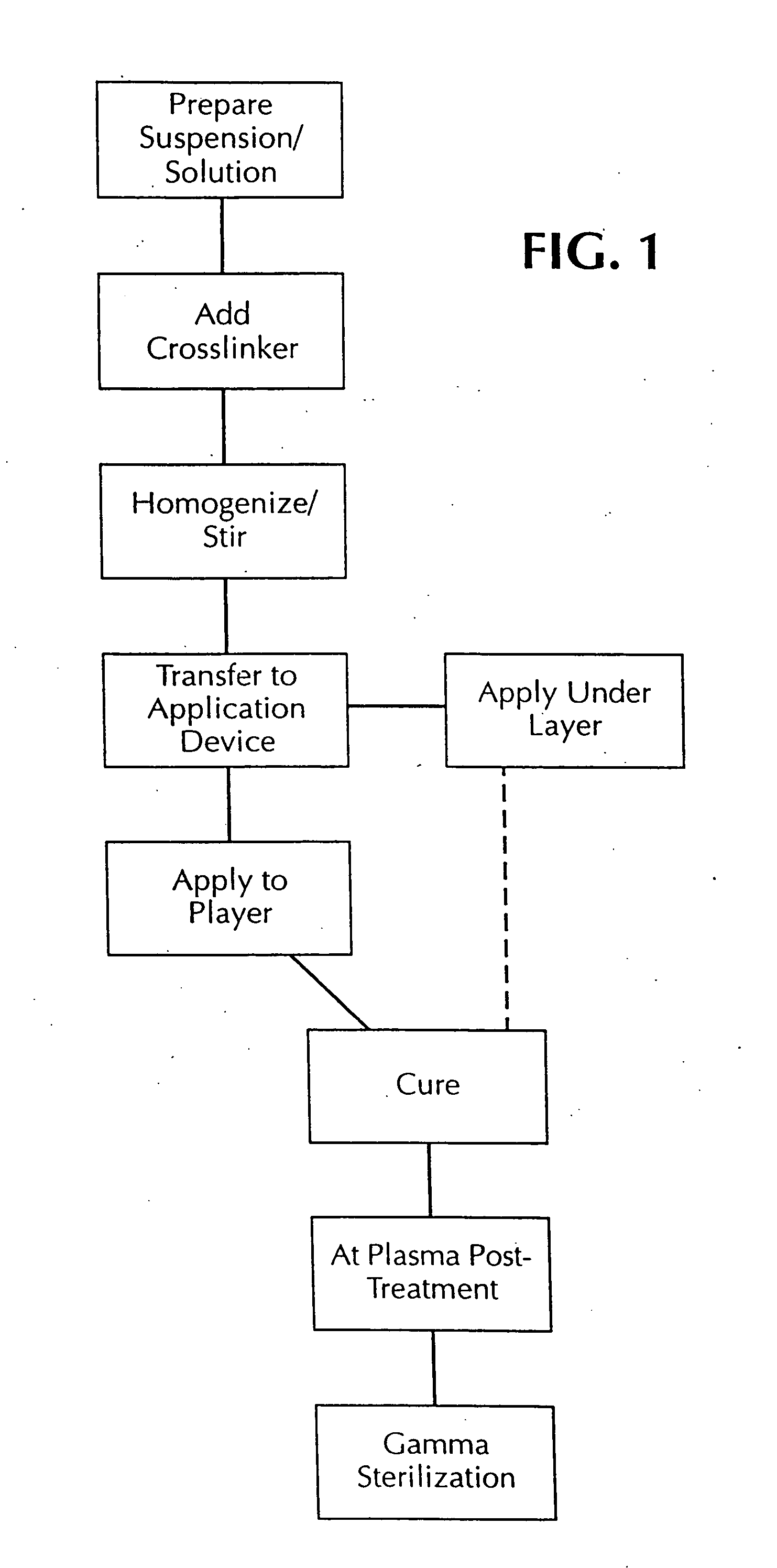

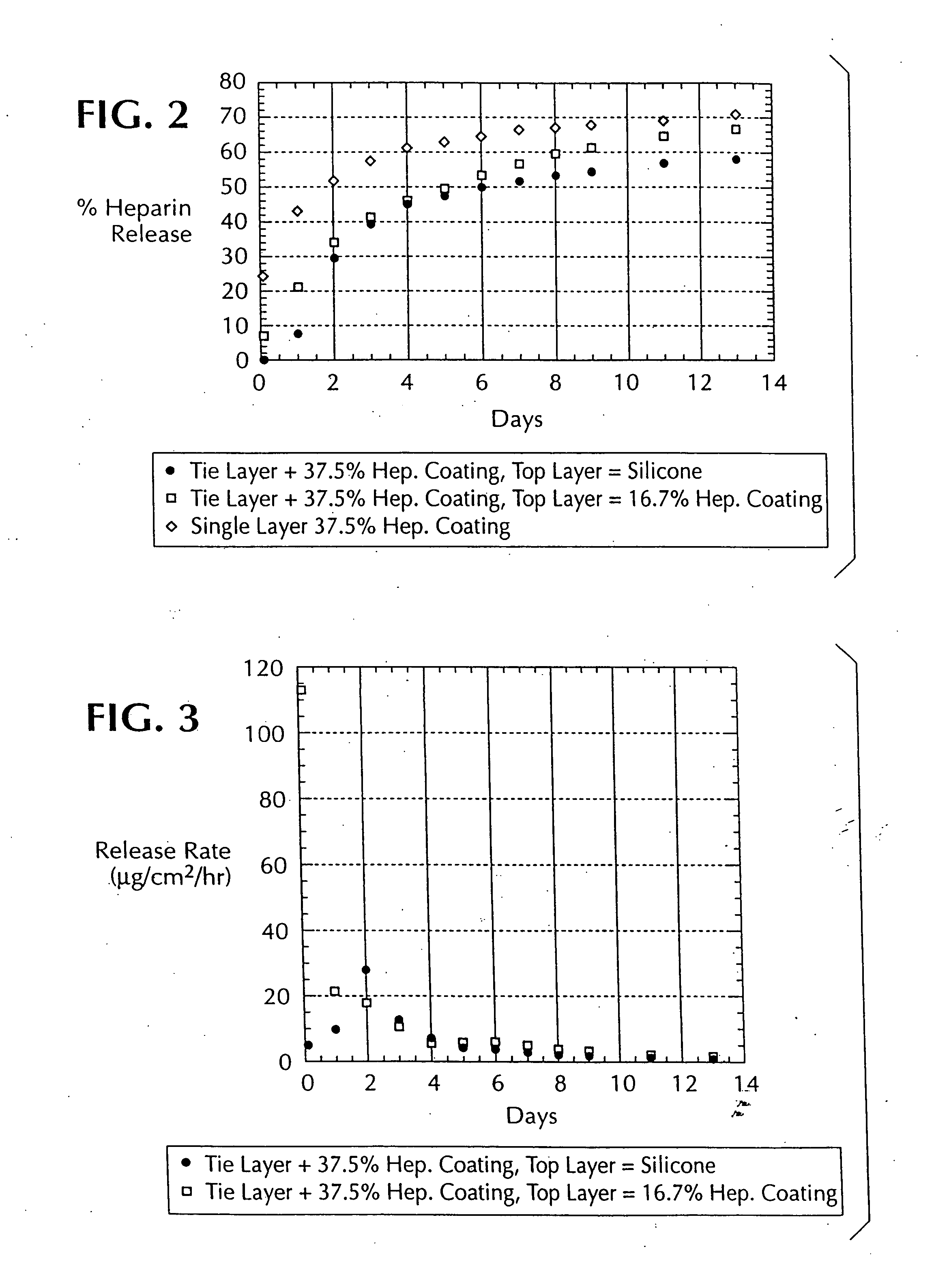

Medical device with drug

A method of coating implantable open lattice metallic stent prosthesis is disclosed which includes sequentially applying a plurality of relatively thin outer layers of a coating composition comprising a solvent mixture of uncured polymeric silicone material and crosslinker and finely divided biologically active species, possibly of controlled average particle size, to form a coating on each stent surface. The coatings are cured in situ and the coated, cured prosthesis are sterilized in a step that includes preferred pretreatment with argon gas plasma and exposure to gamma radiation electron beam, ethylene oxide, steam.

Owner:BOSTON SCI SCIMED INC

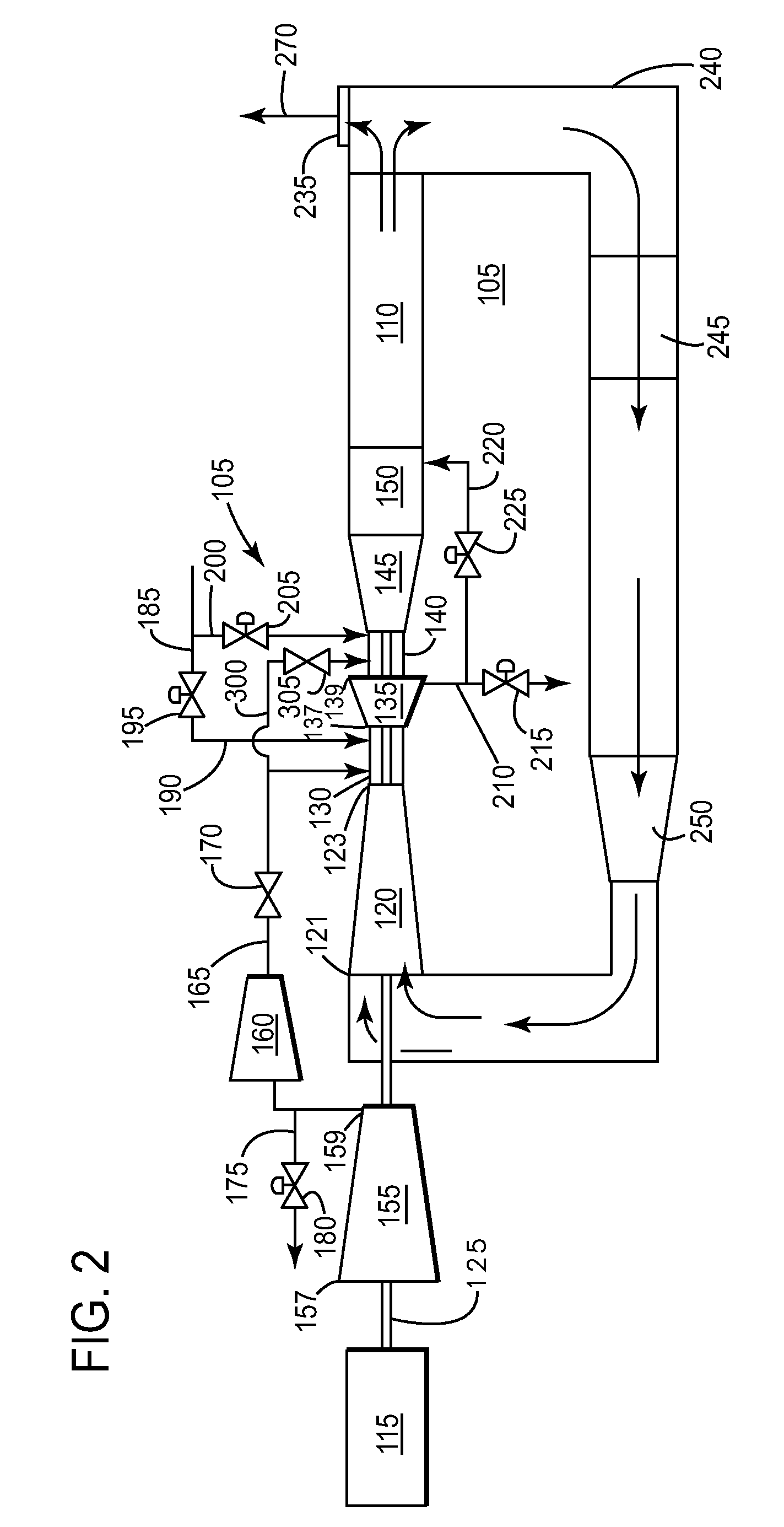

Method and system for controlling a stoichiometric egr system on a regenerative reheat system

Embodiments of the present invention provide a S-EGR process that yields an exhaust stream that includes a relatively high concentration of a desirable gas and is also substantially oxygen-free. This desirable gas includes, but is not limited to: Carbon Dioxide (CO2), Nitrogen (N2), or Argon.

Owner:GENERAL ELECTRIC CO

Inductively coupled plasma reactor for producing nano-powder

InactiveUS20050258766A1Inhibit growthAvoid adsorptionNanostructure manufactureElectric discharge tubesGas passingInduction plasma technology

Disclosed herein is a high-frequency induction plasma reactor apparatus for producing nano-powder, which is configured to continuously manufacture nano-powder in large quantities using solid-phase powder as a starting raw material and to manufacture high-purity nano-powder by completely vaporizing the material powder. The high-frequency induction plasma reactor apparatus comprises an upper body and a cover. The upper body is provided with a reaction pipe receiving a reactor extending vertically inside thereof, a high-frequency coil surrounding the outer periphery of the reaction pipe and a ceramic inner wall provided inside the reaction pipe. The ceramic inner wall is formed with a plurality of gas passing bores and defines a gas movement passage with the inner side wall of the reaction pipe therebetween for allowing the inflow of argon gas from the outside into the reactor. The cover is mounted to the upper end of the reactor and adapted to seal the reactor. The cover is provided with a powder injection tube communicating with the reactor.

Owner:NPC CO LTD

Method for manufacturing high thermal conductivity graphite film

InactiveCN103011141AEasy to separateImprove cooling effectCarbon compoundsThin membraneManufactured material

The invention discloses a method for manufacturing a high thermal conductivity graphite film, which adopts polyimide films as raw materials and is formed through two processes of carbonization and graphitization. The technological processes of the high thermal conductivity graphite film comprise the steps as follows: a, the polyimide films are selected as the raw materials, and a piece of graphite paper is clamped between each layer of the polyimide films; b, the polyimide films which are provided with the graphite paper at intervals, crossed and stacked are placed into a carbonization furnace to be carbonized in an environment of nitrogen or argon, the carbonized temperature ranges from 1000 DEG C to 1400 DEG C, and the time is controlled from 1 hour to 6 hours; and c, after the carbonization, the graphitization is performed also in the environment of nitrogen or argon, the temperature is controlled in a range from about 2500 DEG C to 3000 DEG C, and the time is controlled within 12 hours. The method for manufacturing the high thermal conductivity graphite film has a simple manufacturing process, the high heat dissipation capacity of the graphite film is guaranteed, the bending-resistant performance is enhanced, and a requirement for a thin and light electronic product of a consumer is met to a certain extent.

Owner:NINGBO JINSHAN NEW MATERIAL

Olefinic polymerization catalyst carried by carrier of sphere MgCl-alcohol-organic complexing agent and preparation method

The invention discloses an defin polymerization catalyst loaded on spherical MgCl2-alcohol-organic complexing agent camier and its preparation method. Said method includes the following steps: under the protection of argon gas using TiCl4 and MgCl2-alcohol-organic complexing agent spherical carrier, stirring them at -30 deg.c-0 deg.C in reaction still and making them produce reaction for 10-30 min., heating to 60 deg.C-80 deg.C, adding internal doner residues, and more heating to 90 deg.C-140 deg.C, thermostatically stirring and making reaction for 1-3 hr., then removing liquid phase, adding TiCl4 to make treatment once, and removing liquod phase, washing by using solvent, removing solvent, vacuum drying so as to obtain spherical catalyst. Said spherical catalyst uses spherical MgCl2-alcohol-organic complexing agent as carrier, and the preparation process of said catalyst is retatively simple, and small in environmental pollution. Said invention can effectively regulate grain size of catalyst and its distribution by controlling grain size of spherical MgCl2-alcohol-organic copmlexing agent carrier and its distribution, after the olefin is catalyzed and polymerized, the spherical polyolefin can be obained.

Owner:ZHEJIANG UNIV

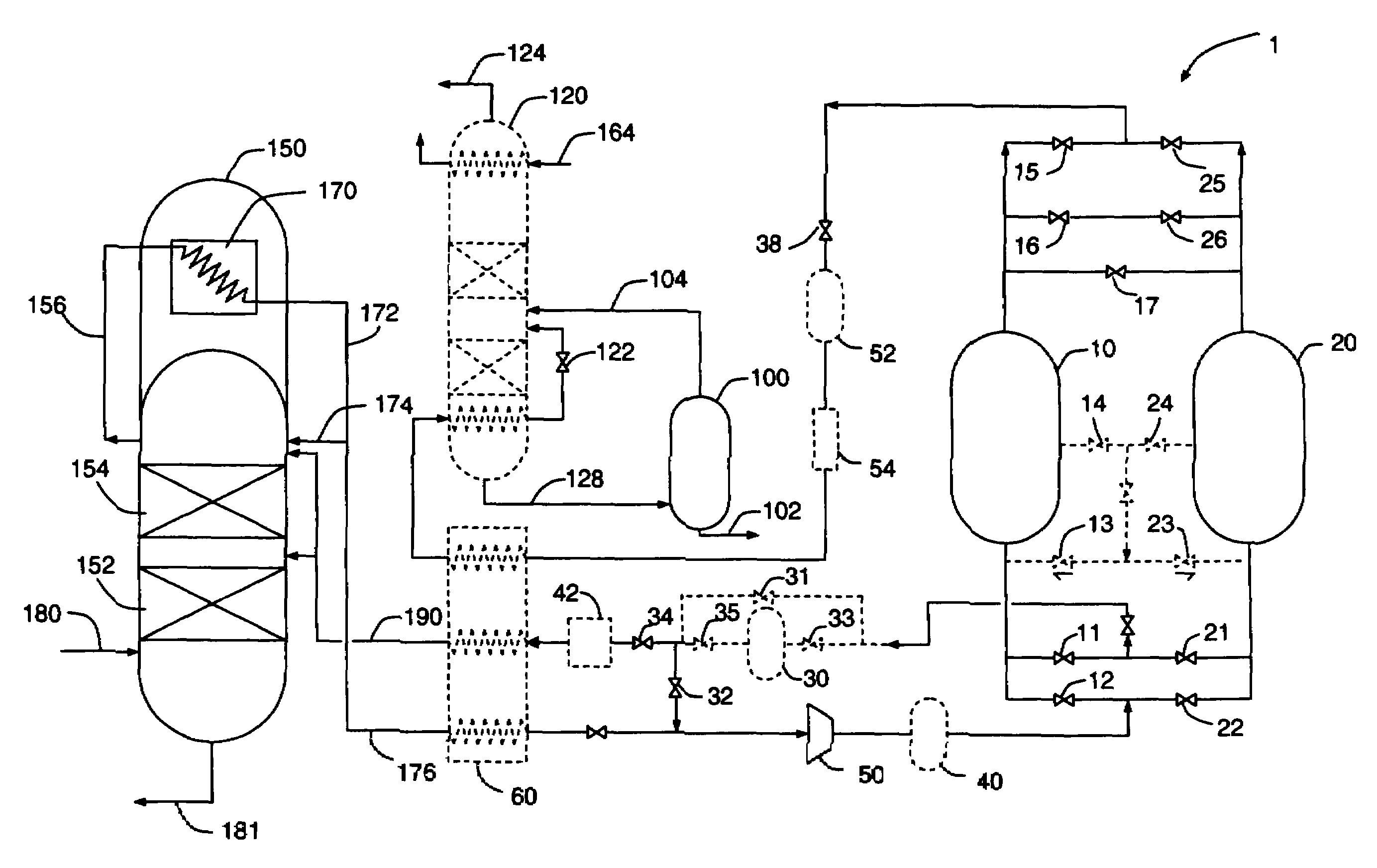

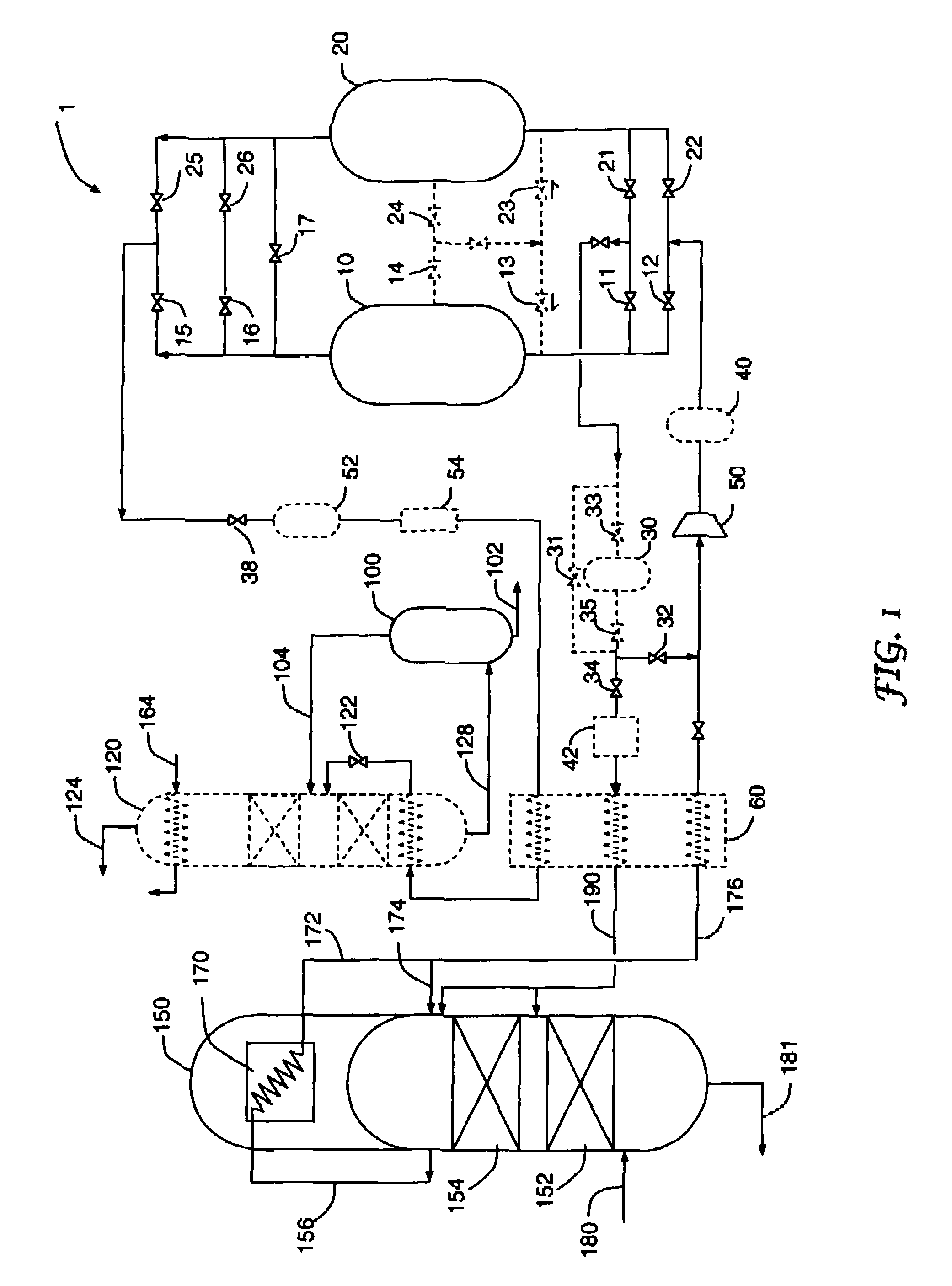

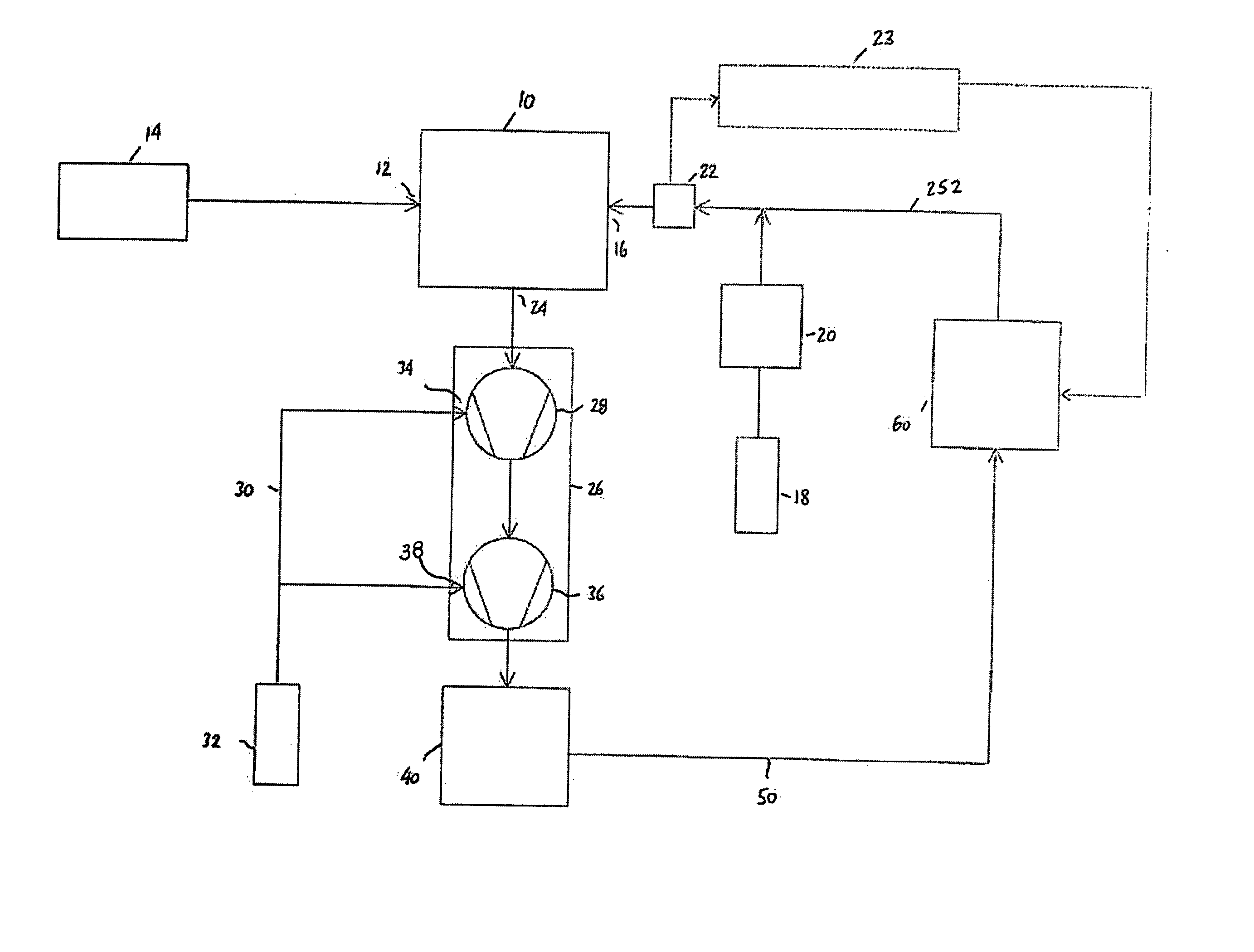

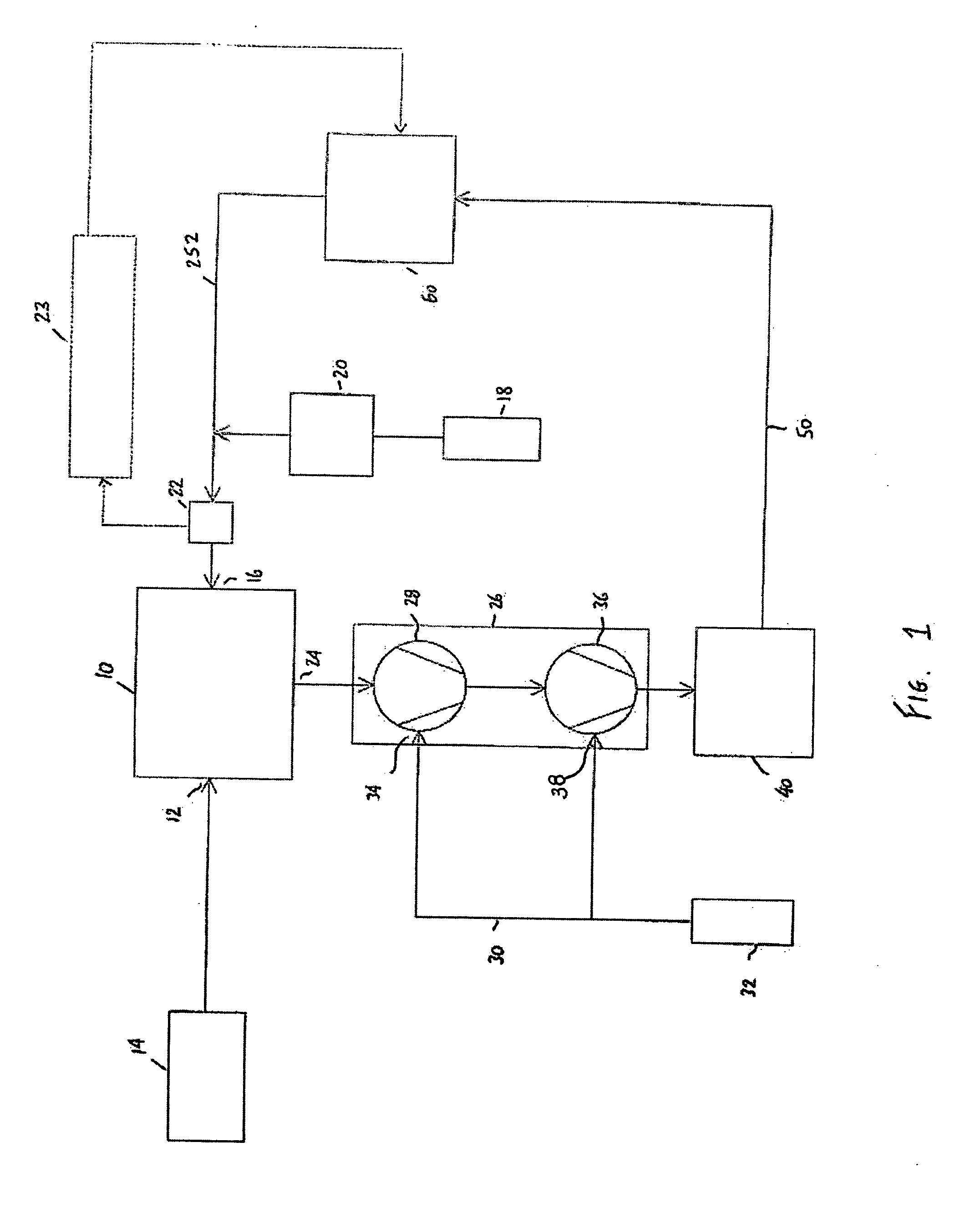

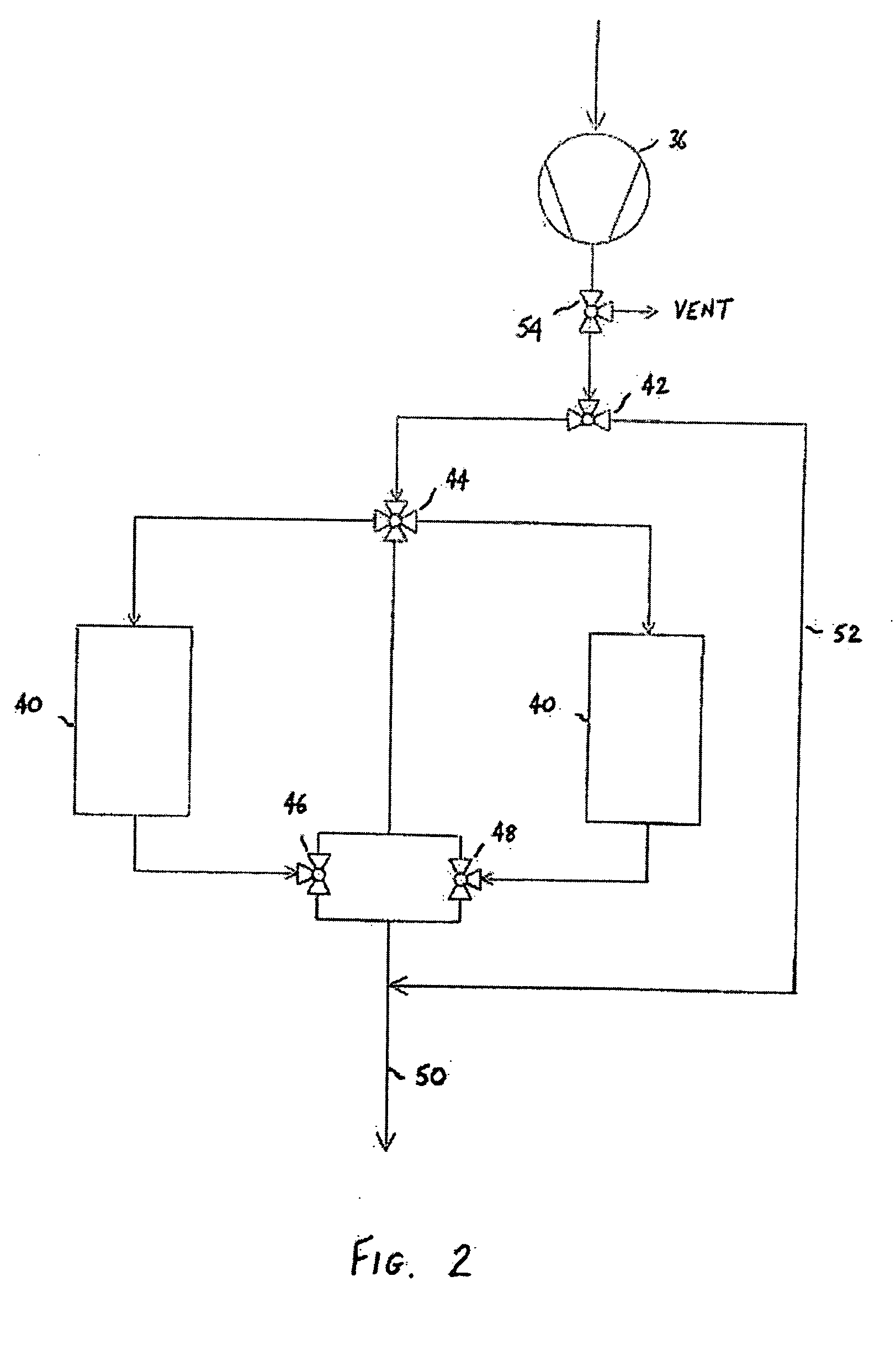

Combined cryogenic distillation and PSA for argon production

ActiveUS7501009B2Improvements in the refining of crude argonSpeed up the processSolidificationLiquefactionParticulatesFiltration

A method and apparatus for producing high purity argon by combined cryogenic distillation and adsorption technologies is disclosed. Crude argon from a distillation column or a so-called argon column is passed to a system of adsorption vessels for further purification. Depressurization gas from adsorption is introduced back, in a controlled manner, to the distillation column and / or a compressor or other means for increasing pressure. Particulate filtration and getter purification may optionally be used.

Owner:AIR PROD & CHEM INC

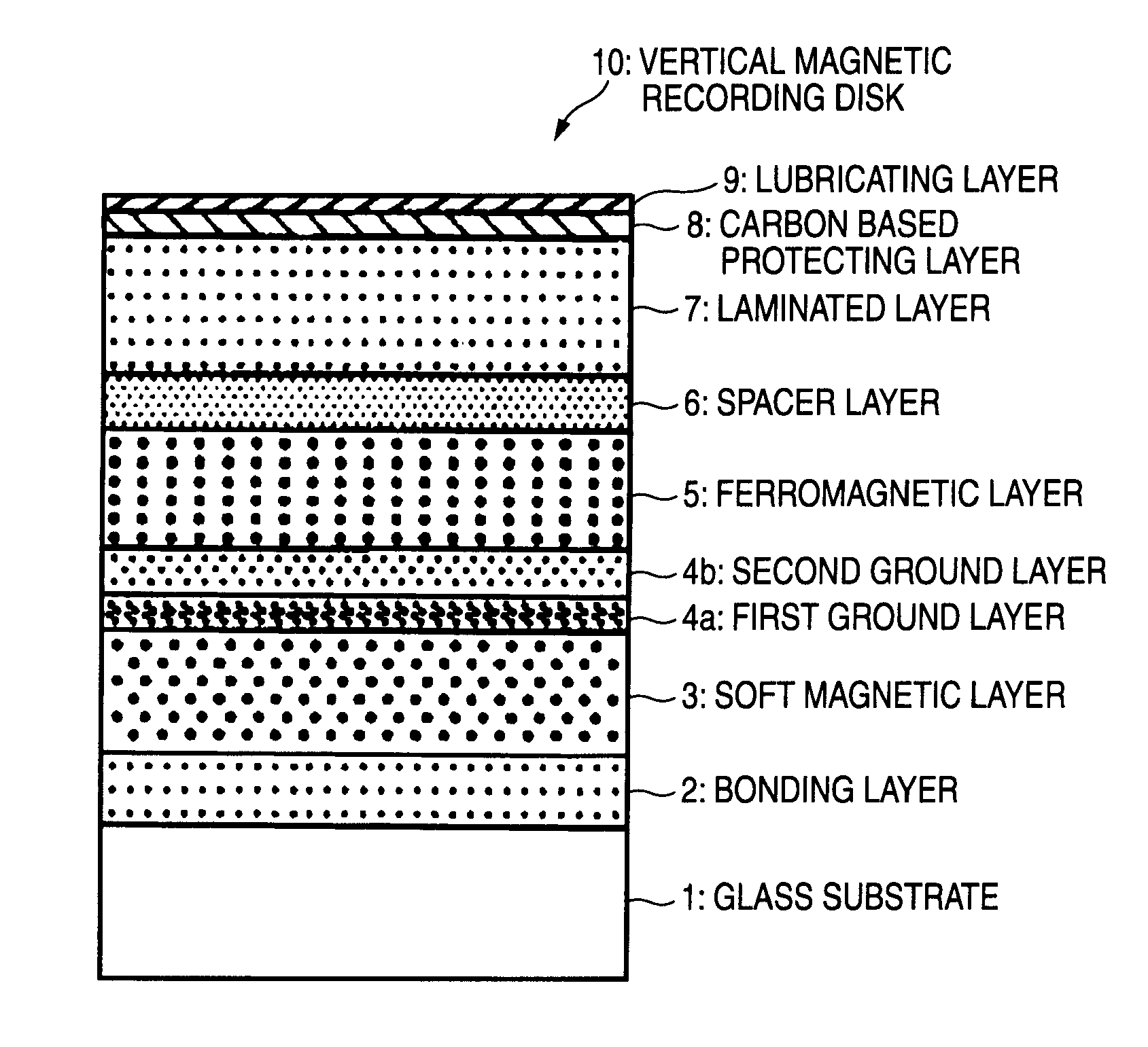

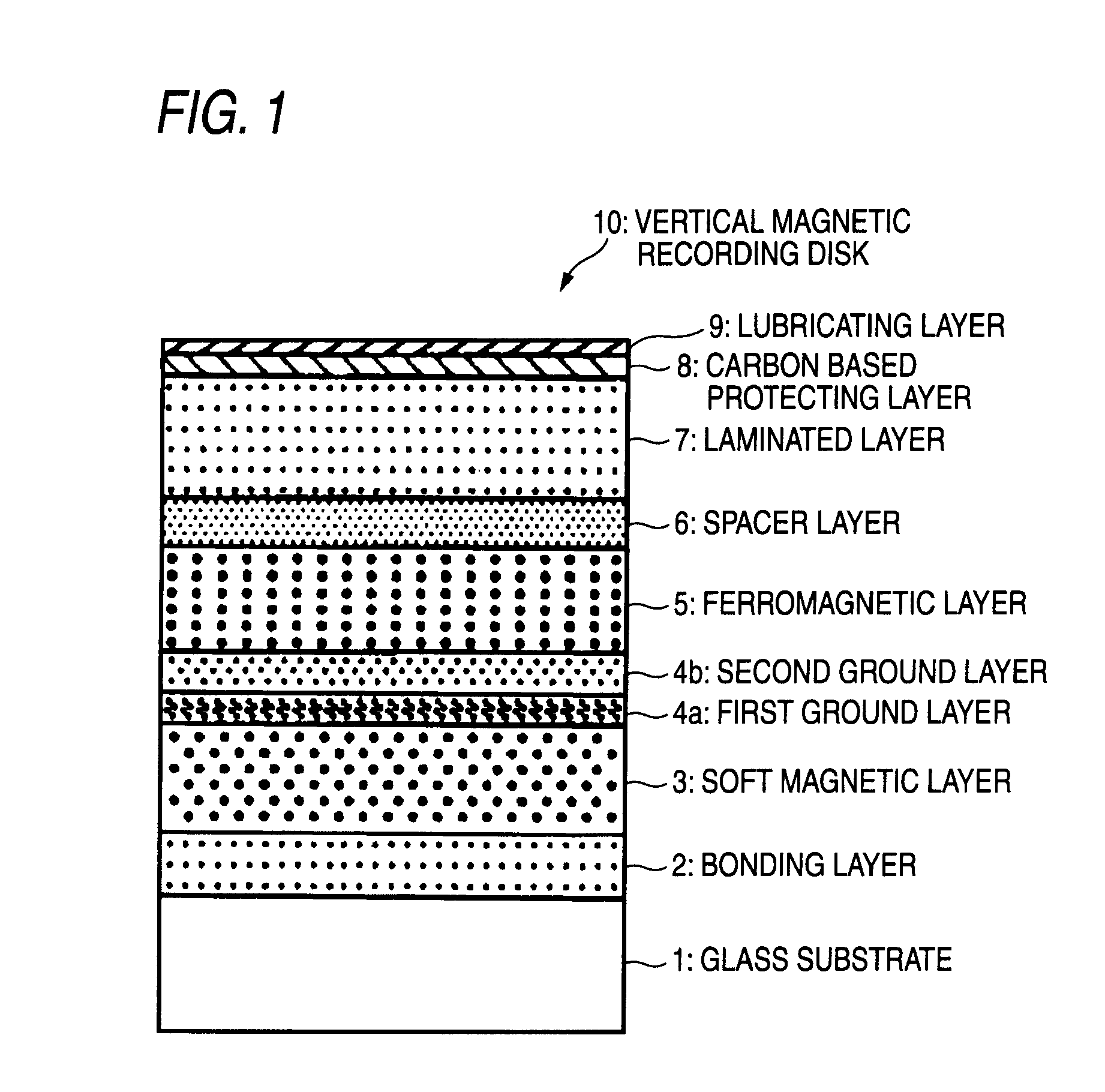

Vertical magnetic recording disk manufacturing method and vertical magnetic recording disk

ActiveUS20090202866A1Improve magnetic propertiesImprove recording densityVacuum evaporation coatingSputtering coatingKryptonSputtering

In a method of manufacturing a magnetic disk including at least a magnetic recording layer on a substrate 1 and used for vertical magnetic recording, in a step of forming, on the substrate 1, the magnetic recording layer composed of a ferromagnetic layer 5 having a granular structure and an exchange energy control layer 7 constituted by a laminated layer formed on the ferromagnetic layer 5, at least the exchange energy control layer 7 is formed through sputtering in an atmosphere of a rare gas having a greater mass than an argon gas. The rare gas having a greater mass than the argon gas is a krypton (Kr) gas, for example. The exchange energy control layer 7 is a laminated layer composed of a first layer containing Co or a Co-alloy and a second layer containing palladium (Pd) or platinum (Pt), for example.

Owner:WESTERN DIGITAL TECH INC

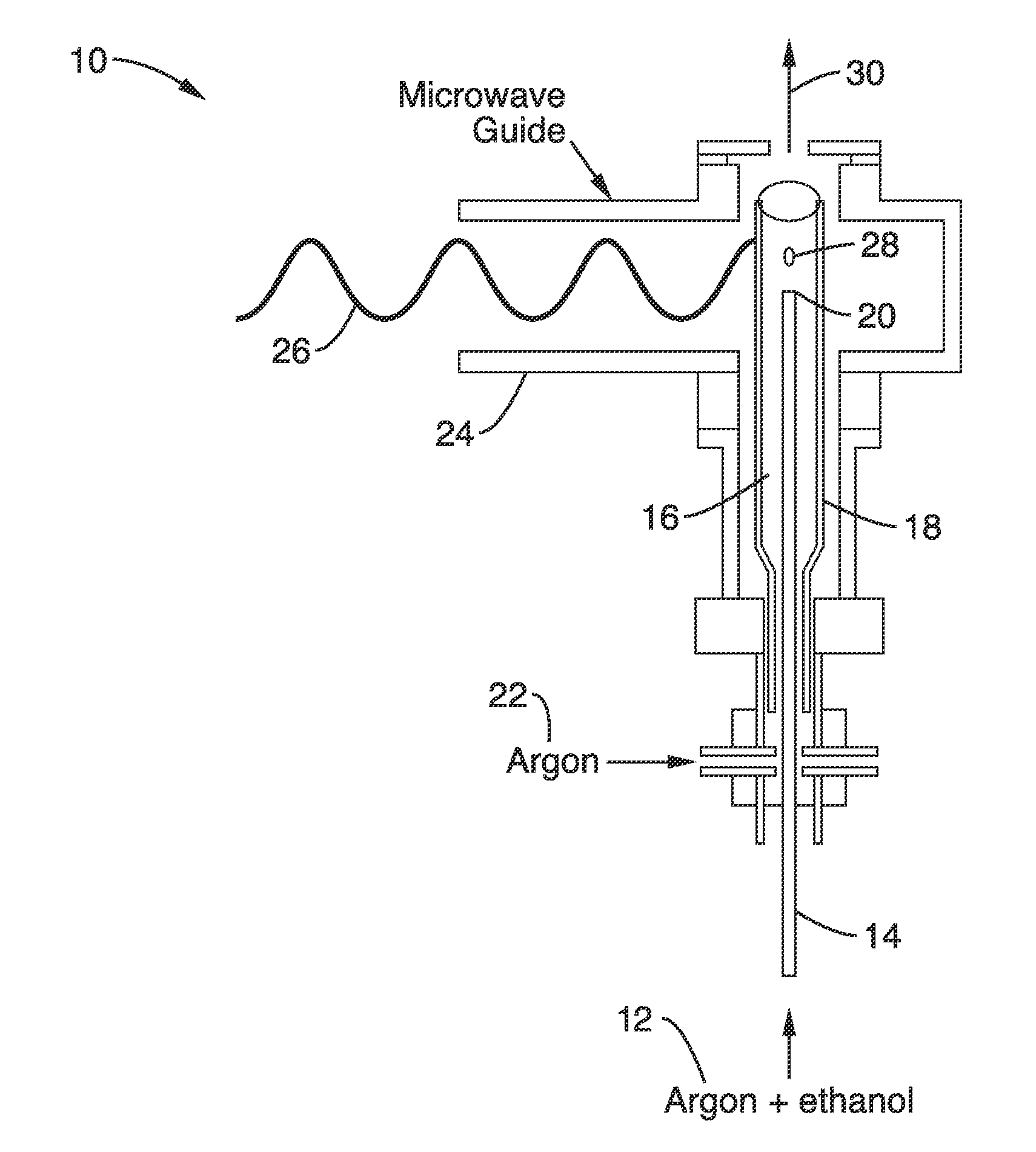

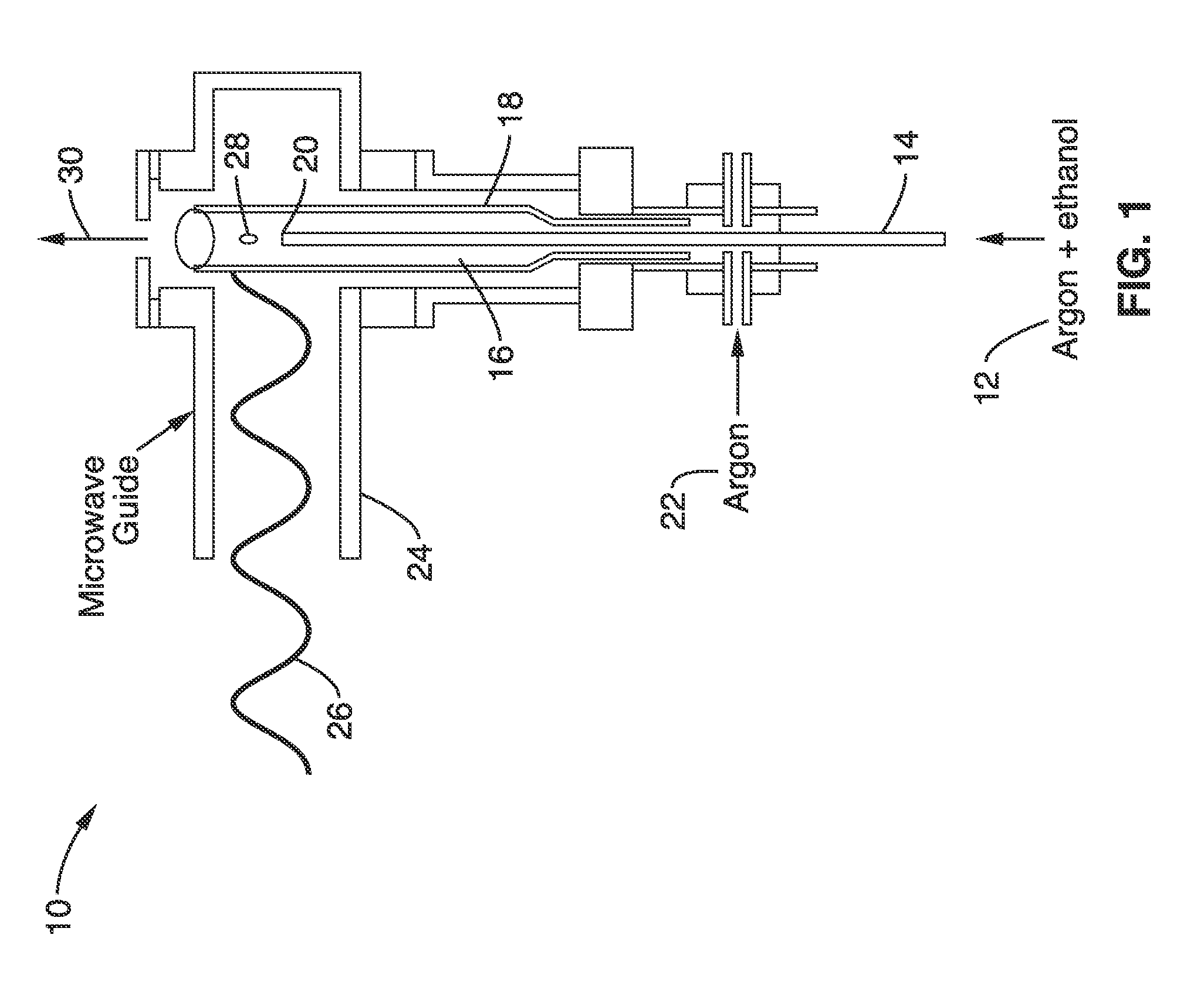

Substrate-free gas-phase synthesis of graphene sheets

InactiveUS20100301212A1Uniform and easy to produceEasy to produceMaterial nanotechnologyMaterial analysis using wave/particle radiationGas phaseOxygen

A substrate-free gas-phase synthesis apparatus and method that is capable of rapidly and continuously producing graphene in ambient conditions without the use of graphite or substrates is provided. Graphene sheets are continuously synthesized in fractions of a second by sending an aerosol consisting of argon gas and liquid ethanol droplets into an atmospheric-pressure microwave-generated argon plasma field. The ethanol droplets are evaporated and dissociated in the plasma, forming graphene sheets that are collected. The apparatus can be scaled for the large-scale production of clean and highly ordered graphene and its many applications. The graphene that is produced is clean and highly ordered with few lattice imperfections and oxygen functionalities and therefore has improved characteristics over graphene produced by current methods in the art. The graphene that is produced by the apparatus and methods was shown to be particularly useful as a support substrate that enabled direct atomic resolution imaging of organic molecules and interfaces with nanoparticles at a level previously unachievable.

Owner:RGT UNIV OF CALIFORNIA

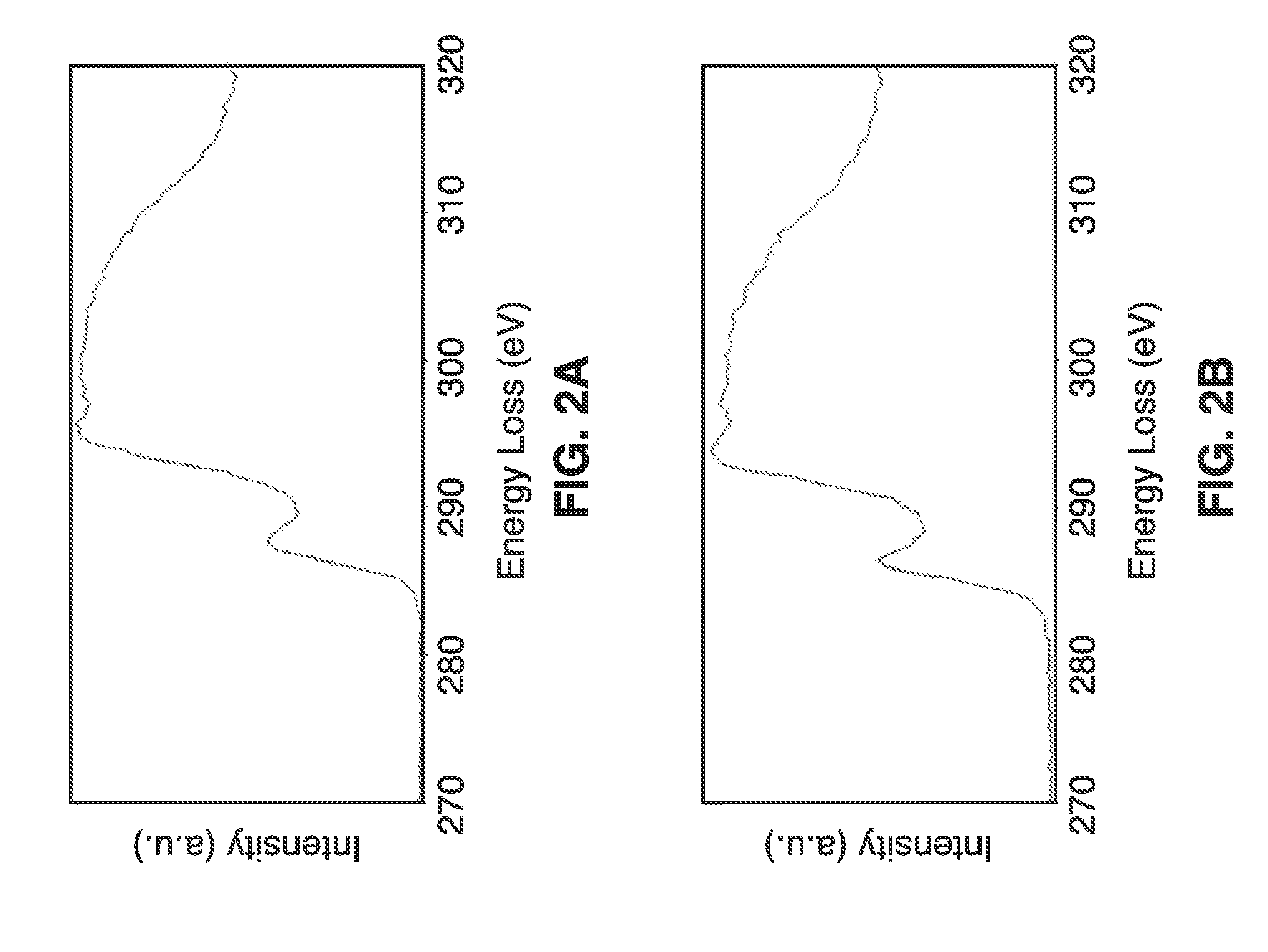

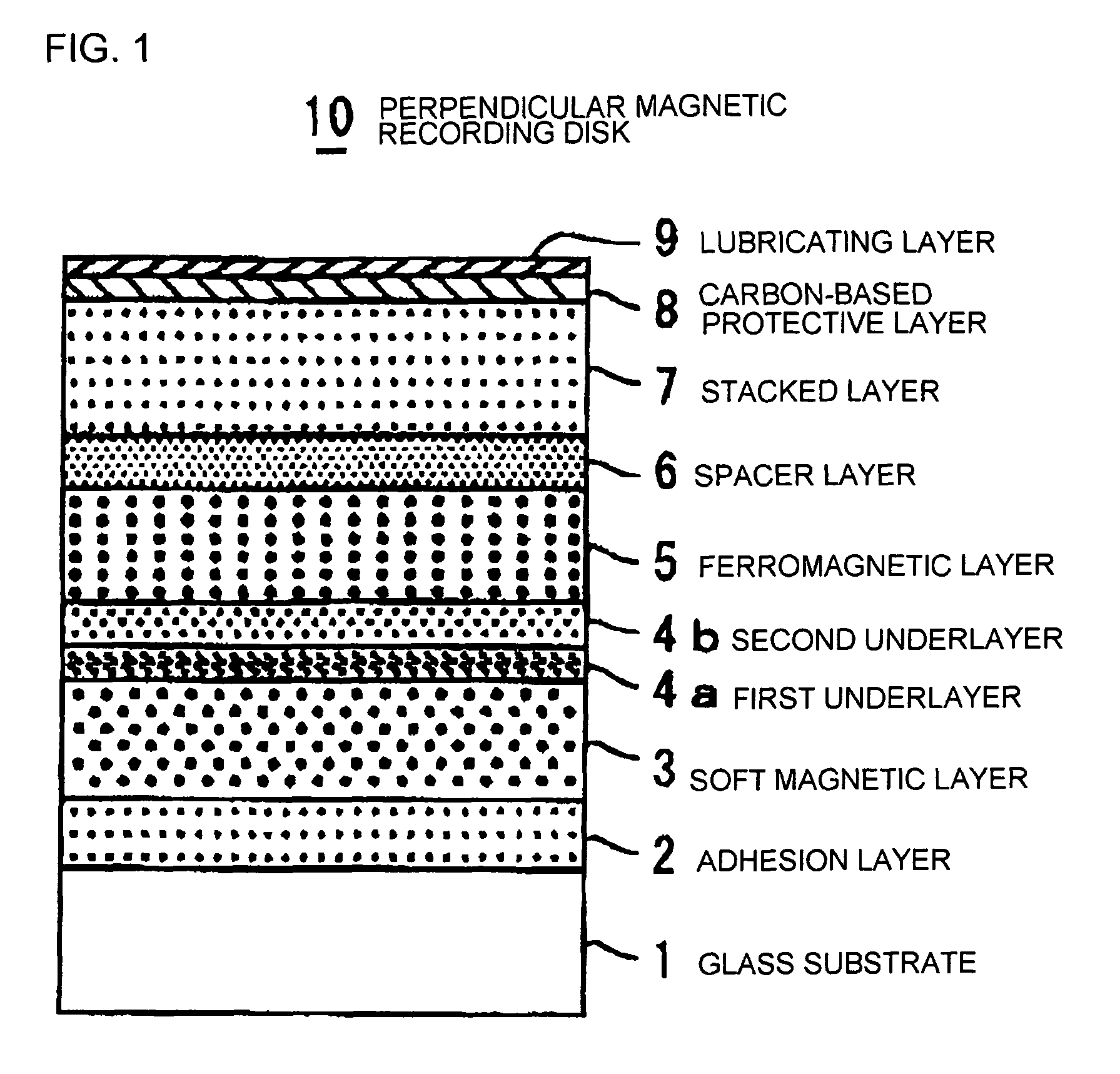

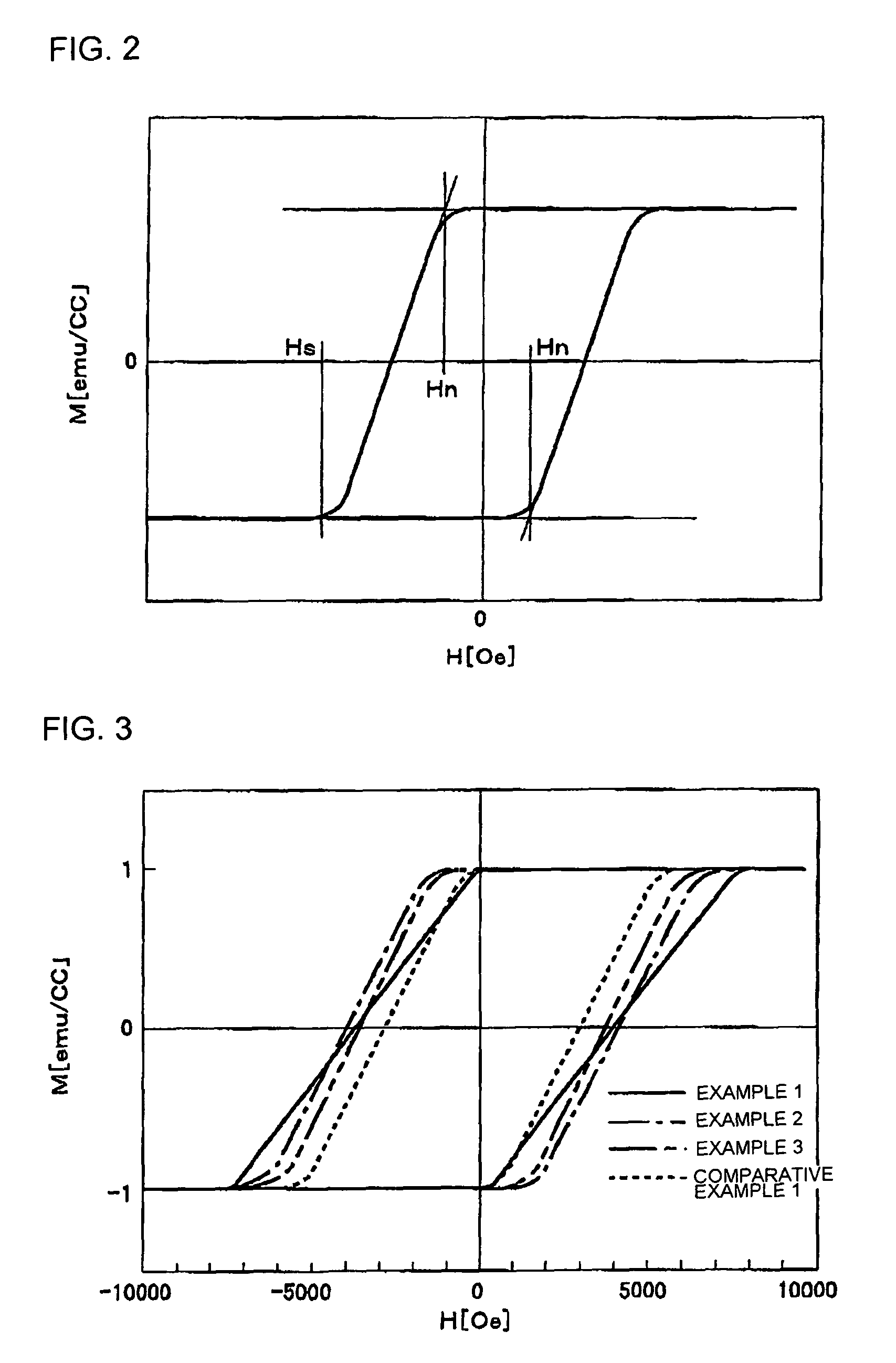

Perpendicular magnetic recording disk and manufacturing method thereof

ActiveUS8603650B2Improve noiseImprove recording densityNanomagnetismVacuum evaporation coatingAlloyRecording layer

A magnetic disk 10 for use in perpendicular magnetic recording has at least a magnetic recording layer on a substrate 1. The magnetic recording layer is composed of a ferromagnetic layer 5 of a granular structure containing silicon (Si) or an oxide of silicon (Si) between crystal grains containing cobalt (Co), a stacked layer 7 having a first layer containing cobalt (Co) or a Co alloy and a second layer containing palladium (Pd) or platinum (Pt), and a spacer layer 6 interposed between the ferromagnetic layer 5 and the stacked layer 7. After forming the ferromagnetic layer 5 on the substrate 1 by sputtering in an argon gas atmosphere, the stacked layer 7 is formed by sputtering in the argon gas atmosphere at a gas pressure lower than that used when forming the ferromagnetic layer 5.

Owner:WESTERN DIGITAL TECH INC

Coprecipitation method for preparing ultra fine zinc oxide powder possessing high electric conductivity

ActiveCN1590302AImprove conductivityVolume resistivity is stableZinc oxides/hydroxidesIndiumGas phase

The invention relates to a preparation method for preparing nano-scale oxidized zinc powder with high conductivity. The method simultaneously drip mixed salt solution of zincic soluble salt and doping elements such as aluminum, gallium, indium, Yt, scandium, tin, germanium, silicon, as well as precipitating agent into water, to generate coprecipitation to generate doped zinc bloom precursor basic zinc carbonate in condition of controlling temperature and PH value of entire reaction system, and at last, calcining the product in mixed gas atmospheres of hydrogen gas and argon gas, doped superfine zinc bloom conductive powder material can be obtained. The powder material prepared by the invention has small particle-size, uniform grain fineness distribution, and which mean particle diameter is about 10 to 80 nanometer. The electric volume resistivity of the powder can reach 2.5*10^-3 omega.cm, thus its electro conductivity is better than the sample prepared by plasma method and gas-phase method in current market. The preparation method further enhances whiteness degree and conductivity of the oxidized zinc powder, and further reduces the cost.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Polarized element and method for manufacturing same

InactiveCN1482472AExtended service lifeNot easy to damagePolarising elementsNanoopticsCarbon nanotubeAtmospheric pressure

The invention discloses an optical polarized light element and method for manufacturing the same, wherein the method comprises, providing a silicon base having a smooth surface, depositing iron catalyst onto the silicon base surface, feeding the silicon base into a reaction furnace, heating the reaction furnace and feeding in the mixture gas of acetylene and argon, controlling the flow capacity of the mixture gas, controlling the mixture ratio of acetylene and argon gas, gripping and pulling a bundle of carbon nanometer tubes using a clamp, arranging the carbon nanometer tubes rope compactly and parallelly onto a transparent base sheet.

Owner:BEIJING FUNATE INNOVATION TECH +1

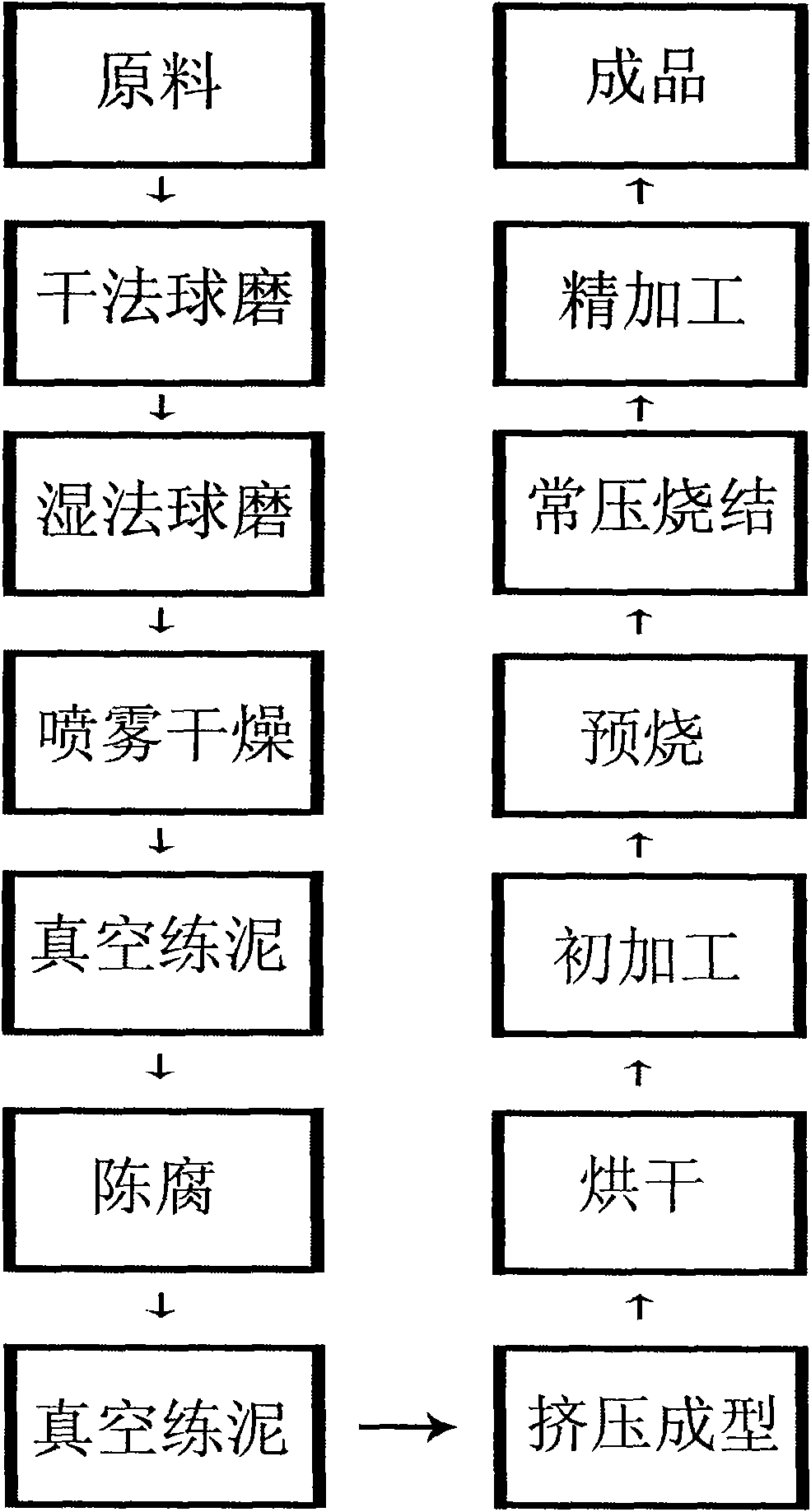

Preparation method for silicon carbide ceramic tube or rod

ActiveCN101560104AEvenly dispersedUniform moisture contentCeramic shaping apparatusClay processing apparatusShielding gasSlurry

The invention relates to a preparation method for a silicon carbide ceramic tube or rod. An extrusion moulding method is adopted to form a blank body; a normal pressure sintering method is adopted for sintering; and submicron level silicon carbide powder and additives are taken as main raw materials. The preparation method comprises the following steps: 1) carrying out ball milling on the main raw materials by a dry method, adding water, a dispersant, a plasticizer, a lubricant and a liquid state binder, and then carrying out ball milling by a wet method; 2) adopting a spray granulation process to granulate silicon carbide slurry; 3) extruding the blank body by a one-shot direct extrusion moulding method after vacuum pug, corrosion, and vacuum pug; 4) drying the molded blank body by a stage drying mechanism; and 5) placing the blank body of the silicon carbide ceramic tube or rod in a vacuum furnace and carrying out sintering for two times by taking argon gas as protective gas. The high temperature resisting strength and the corrosion resistance of the silicon carbide ceramic tube or rod prepared by the method are both better than those of a reactive sintered product. Compared with a hot press sintering method, the method has lower limit on the product shape and size, and lower cost. The method is suitable for the industrialized production.

Owner:宁波欧翔精细陶瓷技术有限公司

Olefinic polymerization catalyst carried by carrier of sphere MgCl-alcohol-organic complexing agent and preparation method

The invention discloses an defin polymerization catalyst loaded on spherical MgCl2-alcohol-organic complexing agent camier and its preparation method. Said method includes the following steps: under the protection of argon gas using TiCl4 and MgCl2-alcohol-organic complexing agent spherical carrier, stirring them at -30 deg.c-0 deg.C in reaction still and making them produce reaction for 10-30 min., heating to 60 deg.C-80 deg.C, adding internal doner residues, and more heating to 90 deg.C-140 deg.C, thermostatically stirring and making reaction for 1-3 hr., then removing liquid phase, adding TiCl4 to make treatment once, and removing liquod phase, washing by using solvent, removing solvent, vacuum drying so as to obtain spherical catalyst. Said spherical catalyst uses spherical MgCl2-alcohol-organic complexing agent as carrier, and the preparation process of said catalyst is retatively simple, and small in environmental pollution. Said invention can effectively regulate grain size of catalyst and its distribution by controlling grain size of spherical MgCl2-alcohol-organic copmlexing agent carrier and its distribution, after the olefin is catalyzed and polymerized, the spherical polyolefin can be obained.

Owner:ZHEJIANG UNIV

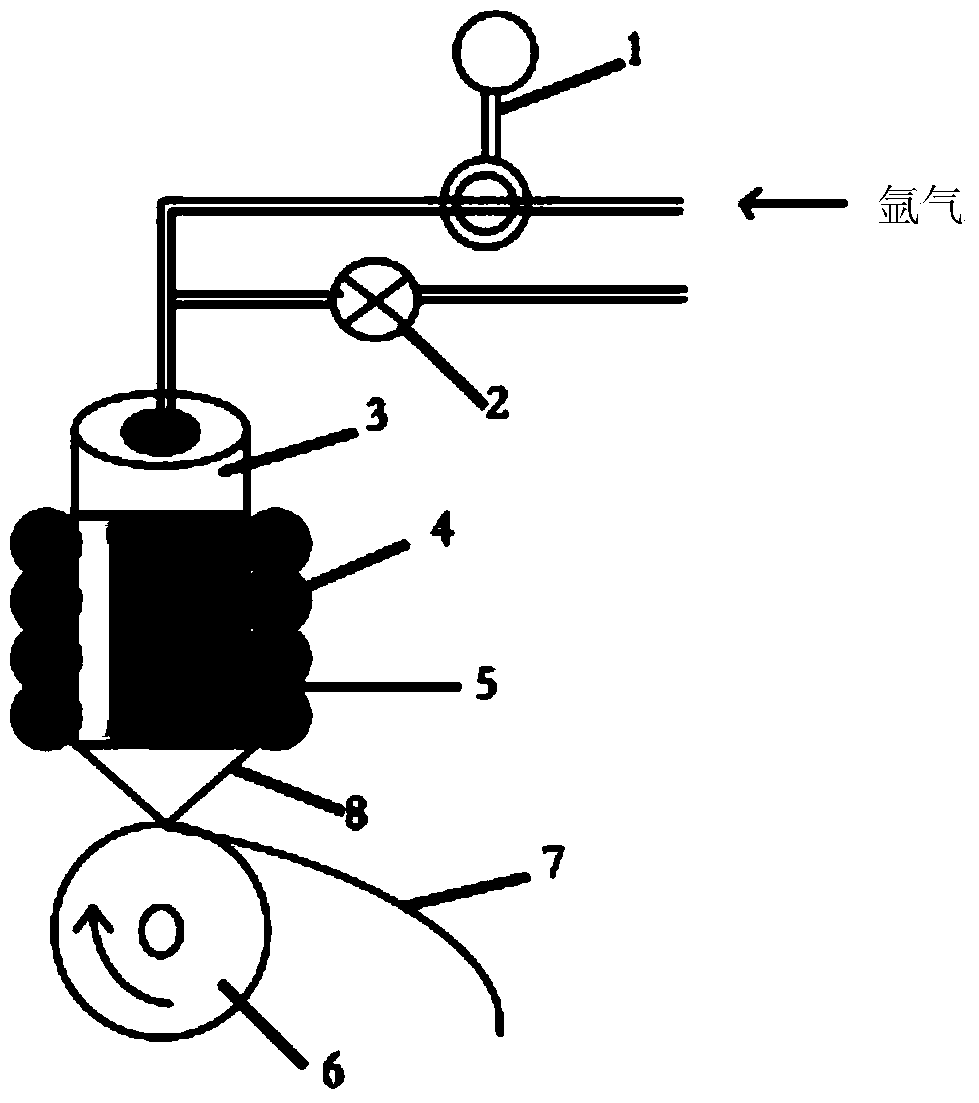

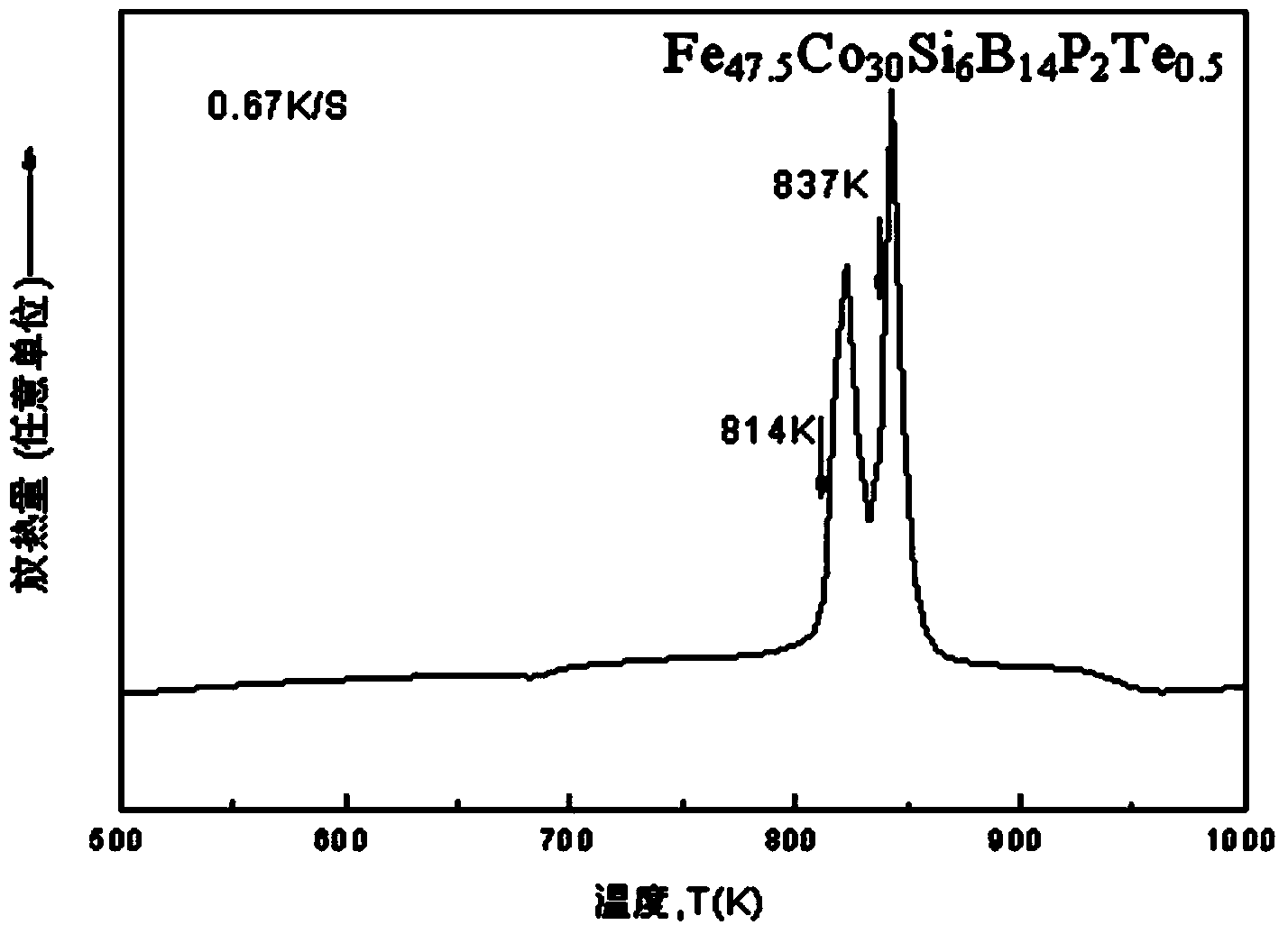

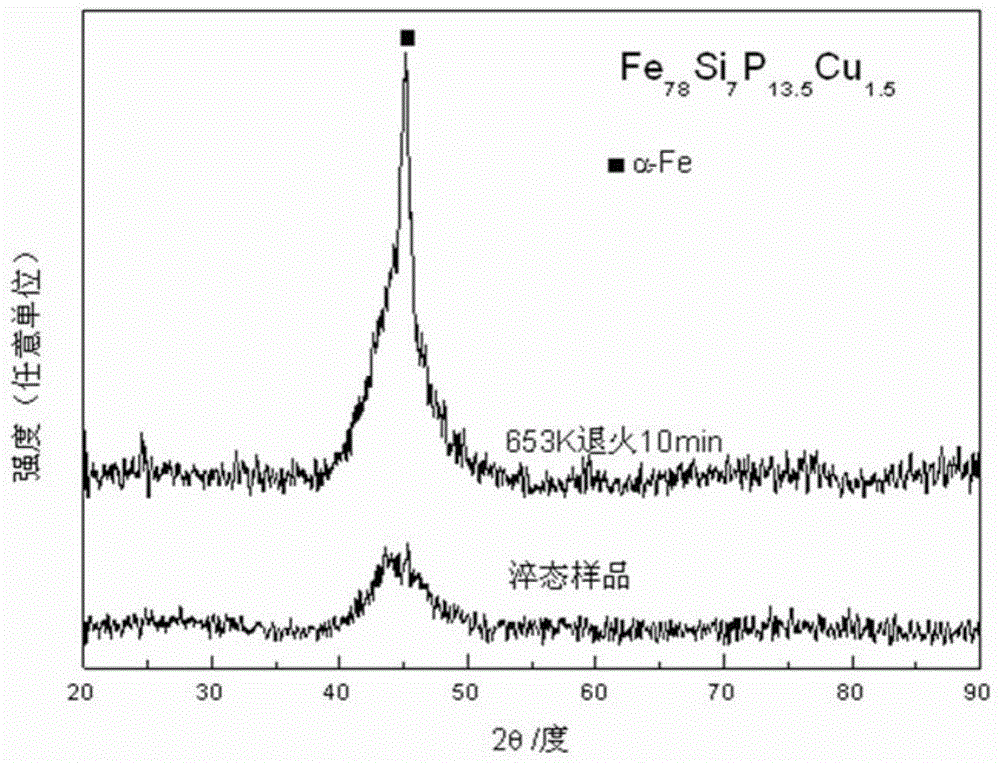

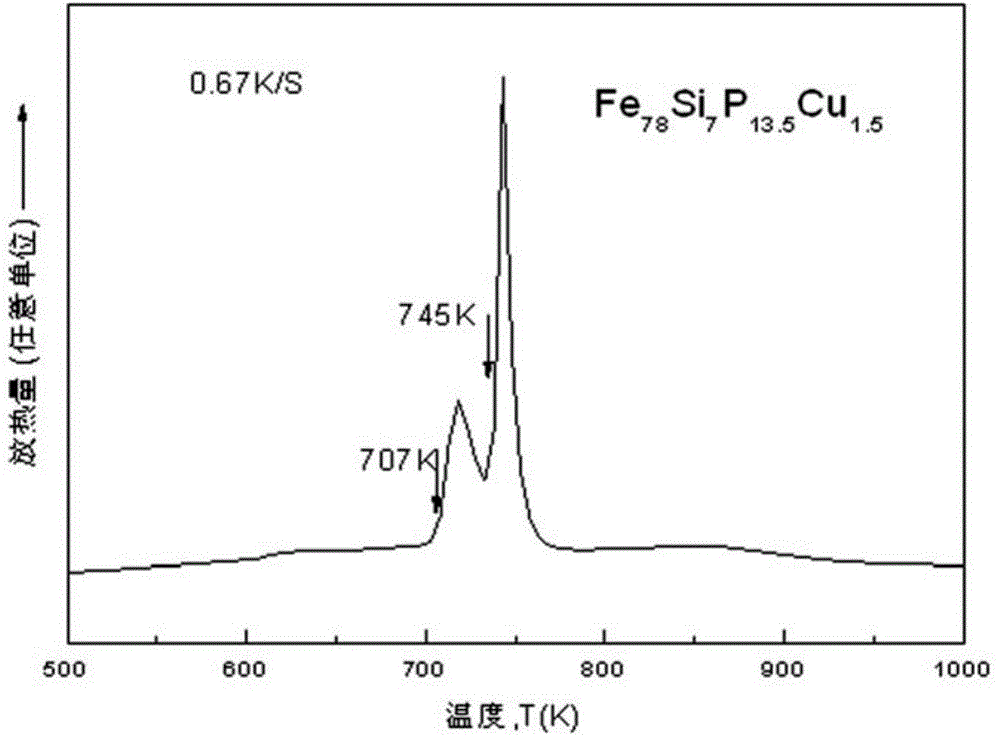

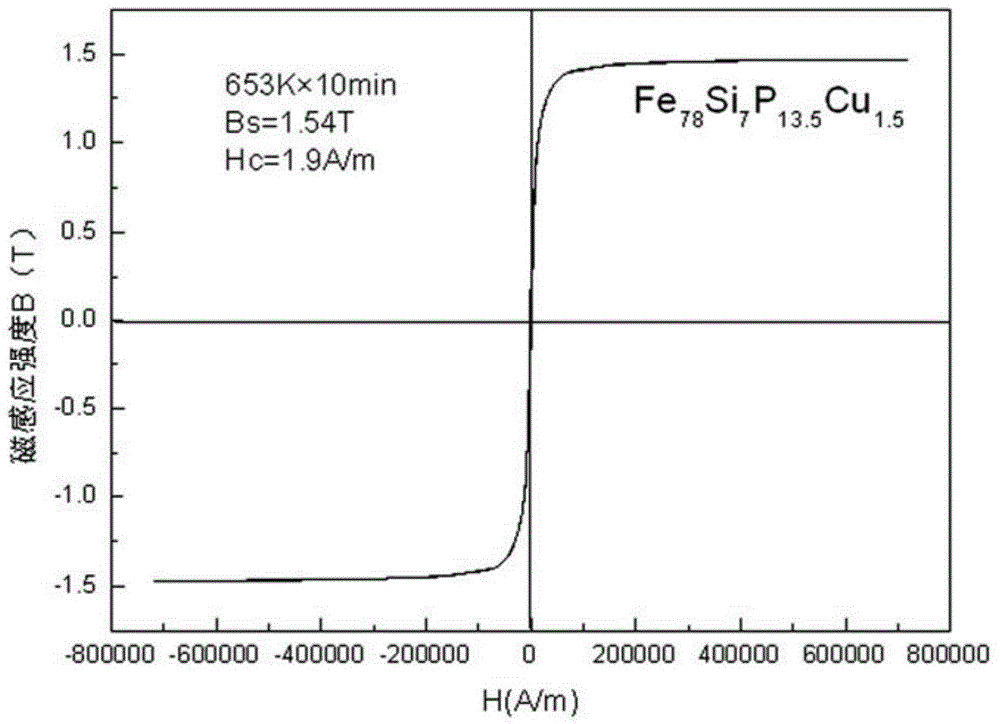

Iron-based amorphous magnetically soft alloy with uniform element distribution and preparation method thereof

ActiveCN104073749AImprove thermal stabilityHigh saturation magnetic inductionMagnetic materialsTransformerMaterials science

The invention discloses an iron-based amorphous magnetically soft alloy with uniform element distribution and a preparation method thereof. The expression of the alloy is FeaSibBcPdMe, a, b, c, d and e in the expression represent the atomic percent contents of corresponding components respectively, and meet the following conditions: a is not less than 70 and not greater than 84, b is not less than 2 and not greater than 10, c is not less than 5 and not greater than 18, d is not less than 0.001 and not greater than 8, e is not less than 0.0001 and not greater than 2.5, a+b+c+d+e=100%, and M is one or more of C, N, Sn, Ge, Ga, Al, S, Te, Be, Pb, Mg and Cu. The amorphous strip prepared from the alloy under a high vacuum and argon shield has the characteristic of uniform element distribution, particularly solves the problem of non-uniform distribution of element P in the amorphous alloy, has excellent magnetically soft performance, and is suitable for transformers, engines, power generators, magnetic sensors and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

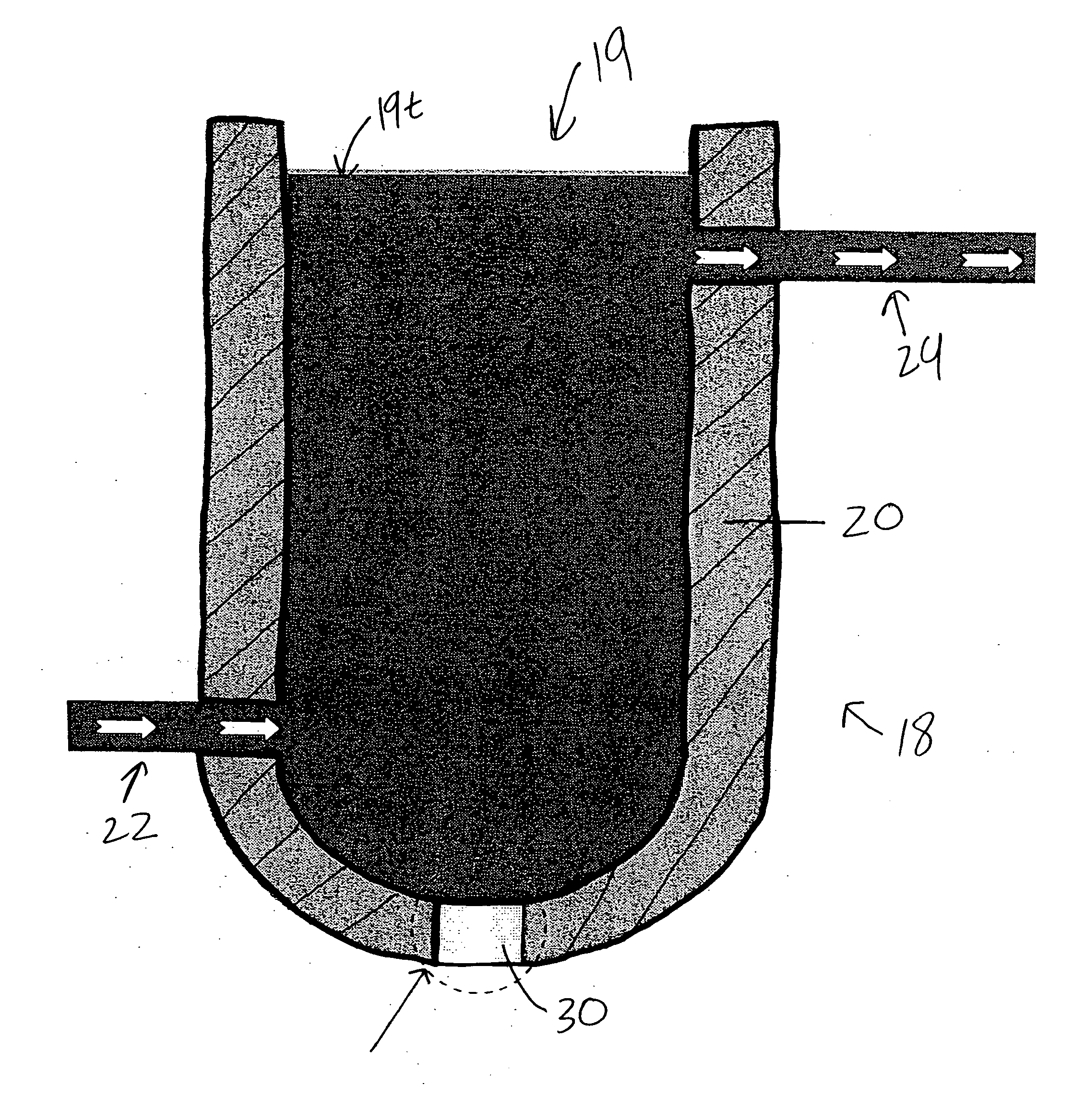

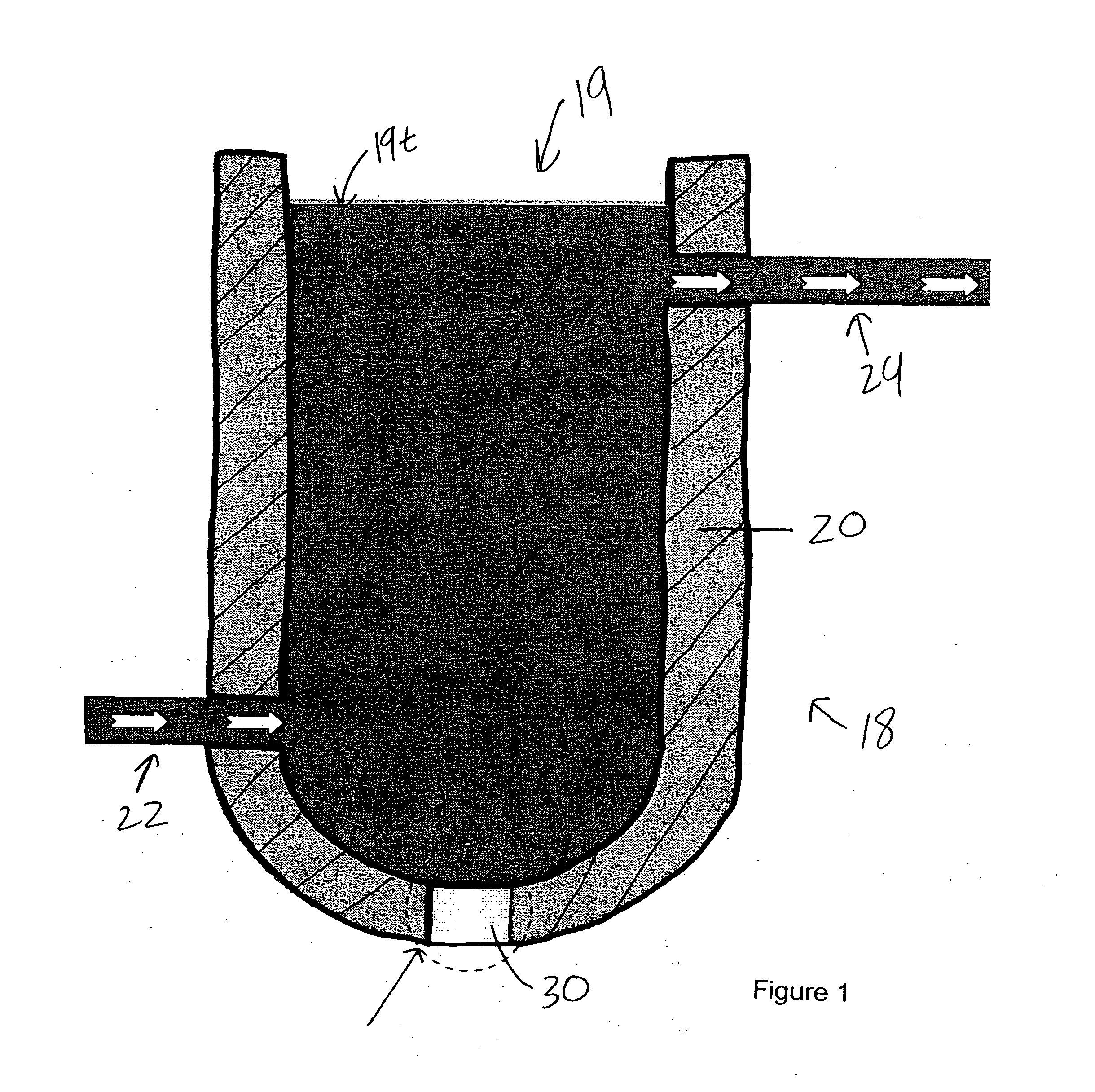

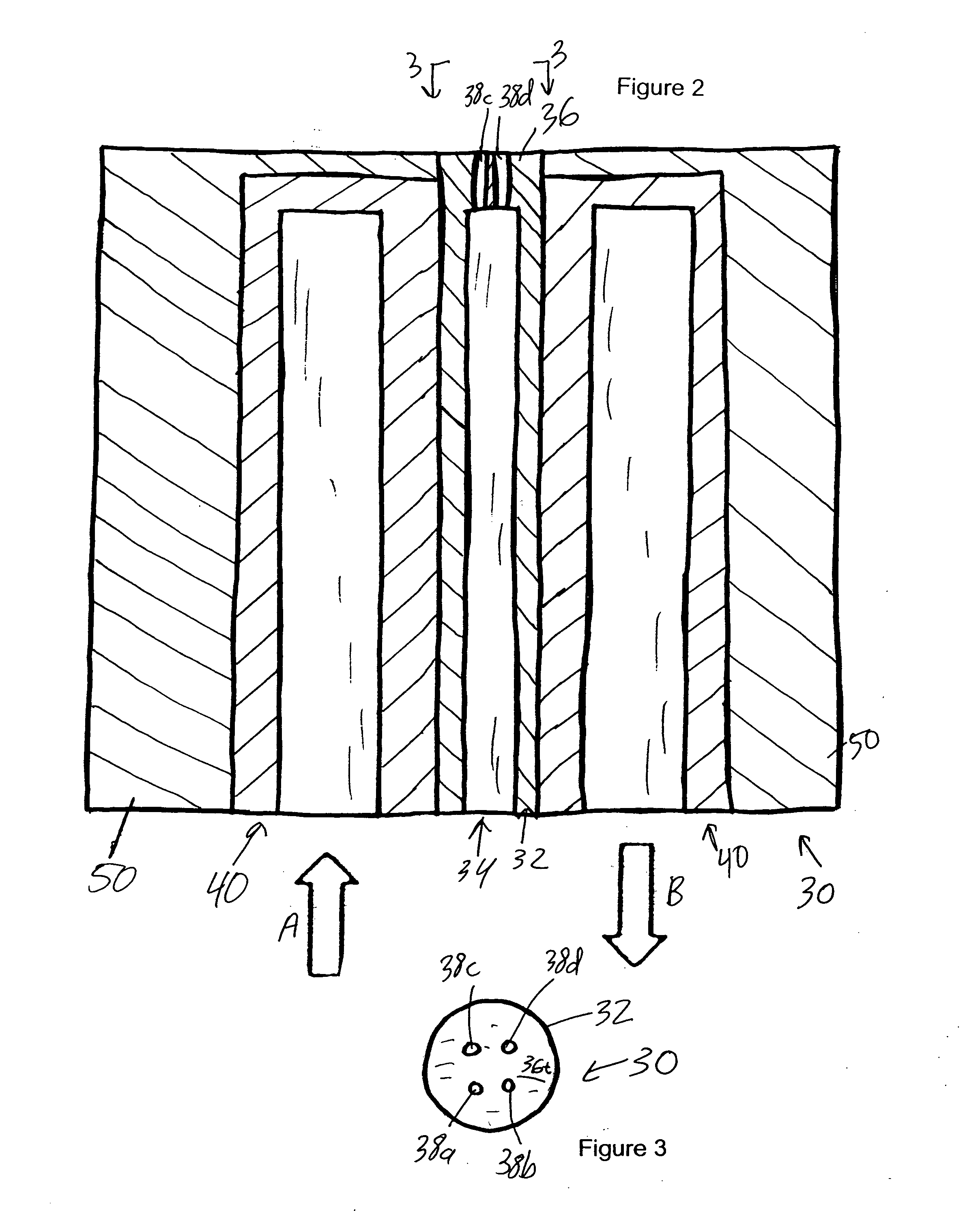

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS20070235159A1Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

Treatment of effluent gases

A method is described for recovering a noble gas, such as xenon or krypton, from a first gas mixture comprising a plurality of components, one of which is the noble gas and the others are typically helium and / or nitrogen, argon, and relatively light fluorocarbons. The gas mixture is first conveyed to a gas chromatography column for separating the noble gas from the other components of the gas mixture. As the noble gas travels relatively slowly through the column, the other components are exhaust from the column before the relatively slow noble gas. Following the exhaust of these other components, a purge gas is supplied to the column to flush the noble gas therefrom. A second gas mixture comprising the noble gas and the purge gas is conveyed from the column to a membrane separator to separate the second gas mixture into a noble gas-rich gas stream and a purge gas-rich gas stream, which may be recirculated back to the column for re-use.

Owner:THE BOC GRP PLC

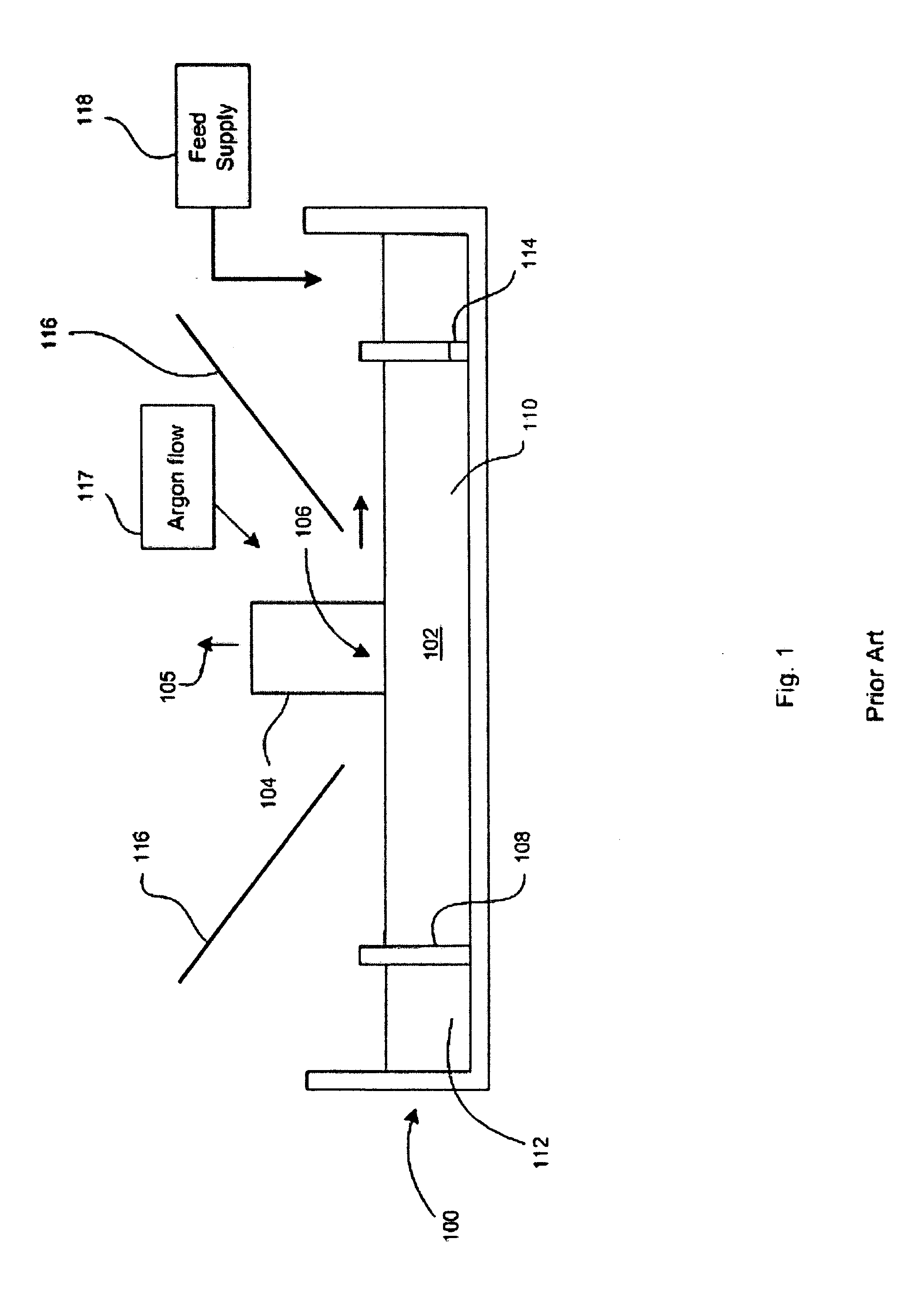

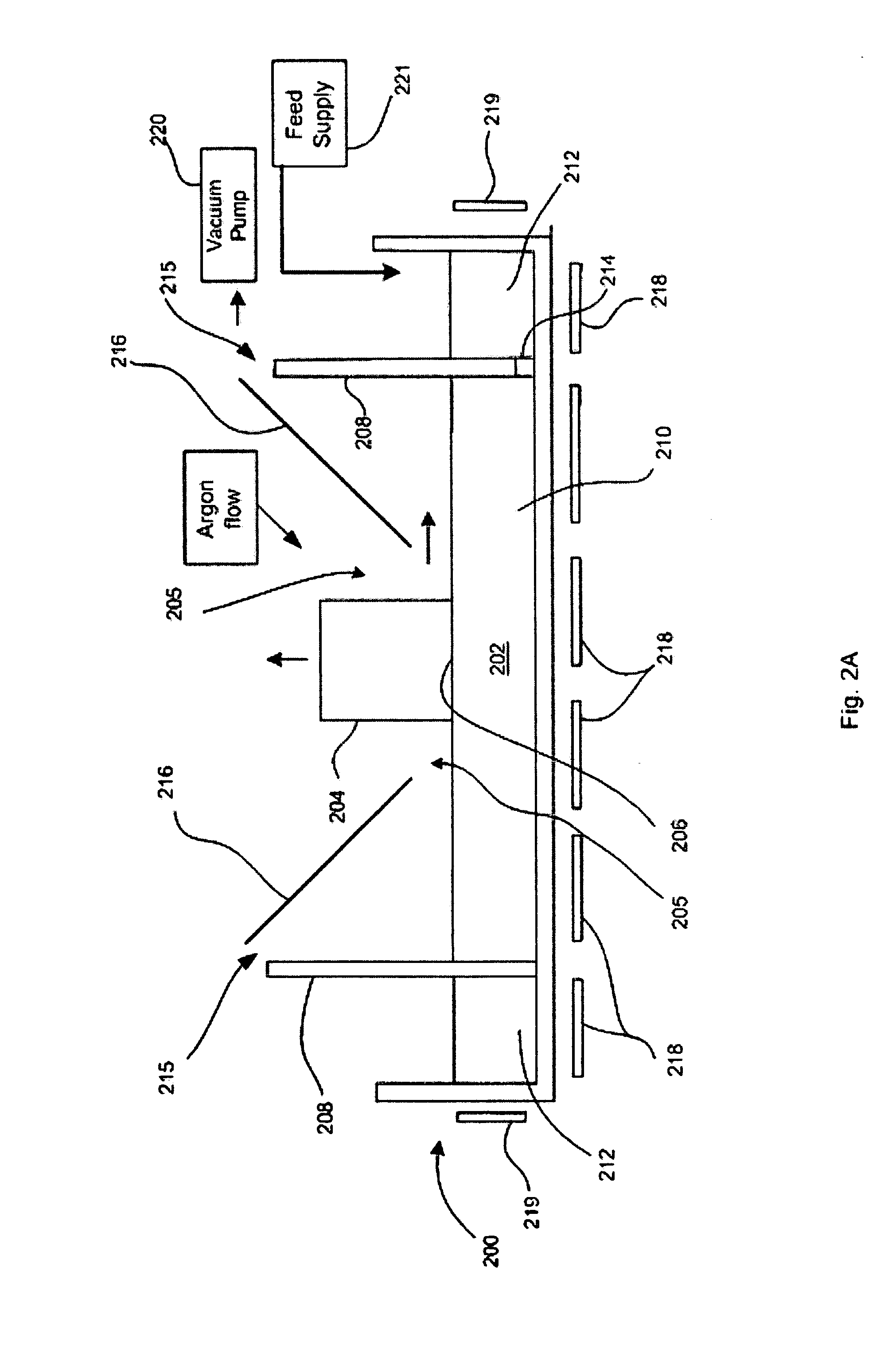

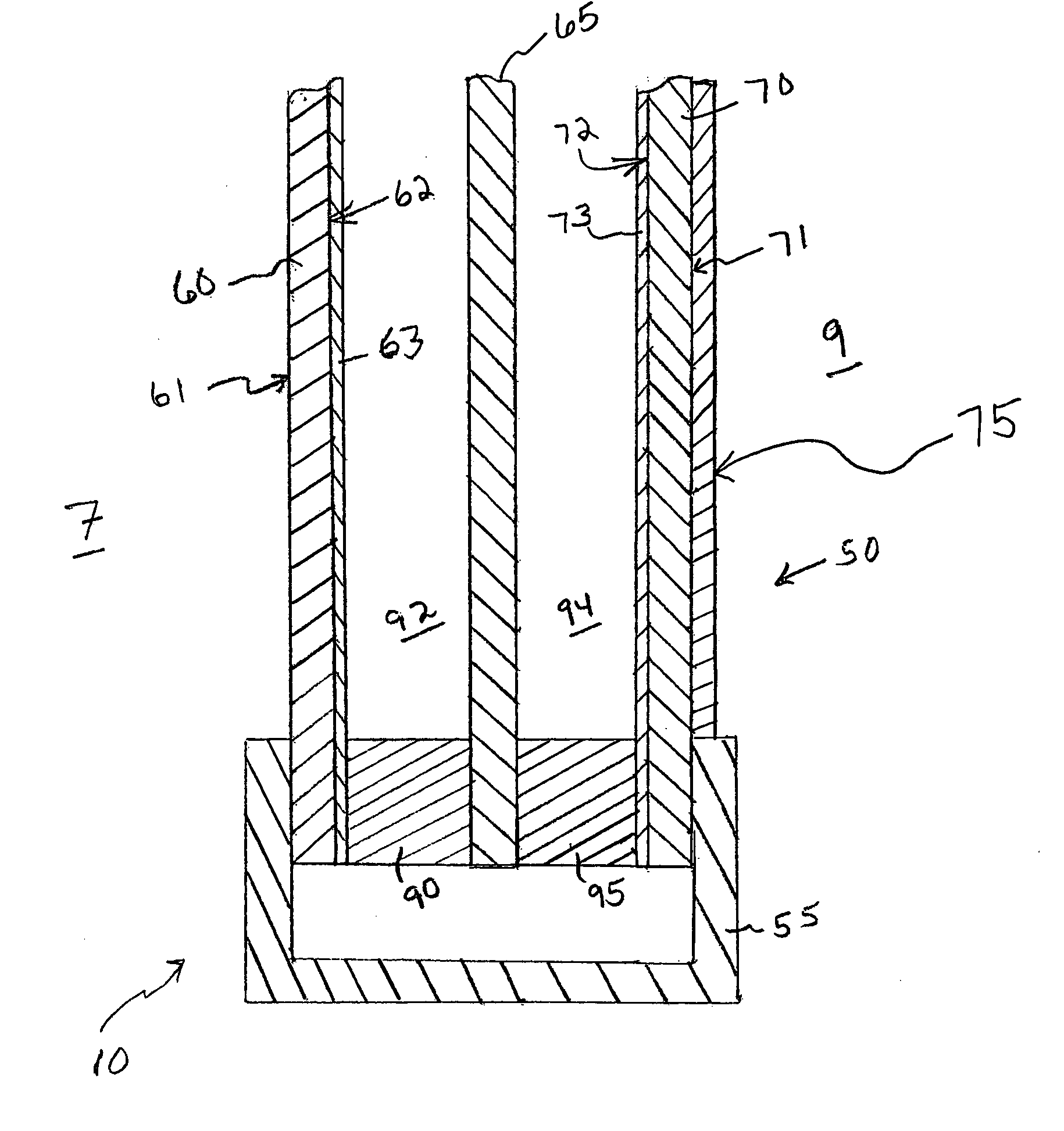

Weir design providing optimal purge gas flow, melt control, and temperature stabilization for improved single crystal growth in a continuous Czochralski process

ActiveUS8262797B1Increase path lengthExtended transit timePolycrystalline material growthBy pulling from meltSingle crystalEngineering

A weir is extended vertically to define an optimal annular gap between the top of the weir and the underside of a super-adjacent heat shield. The annular gap provides a high velocity stream of argon gas to be directed from the growth region to the melt region to substantially eliminate the transport of airborne particles from the melt region to the growth region. The tall weir may be configured as a modular, reusable weir extension supportably engaged with an outer (and / or inner) weir.

Owner:CORNER STAR LTD

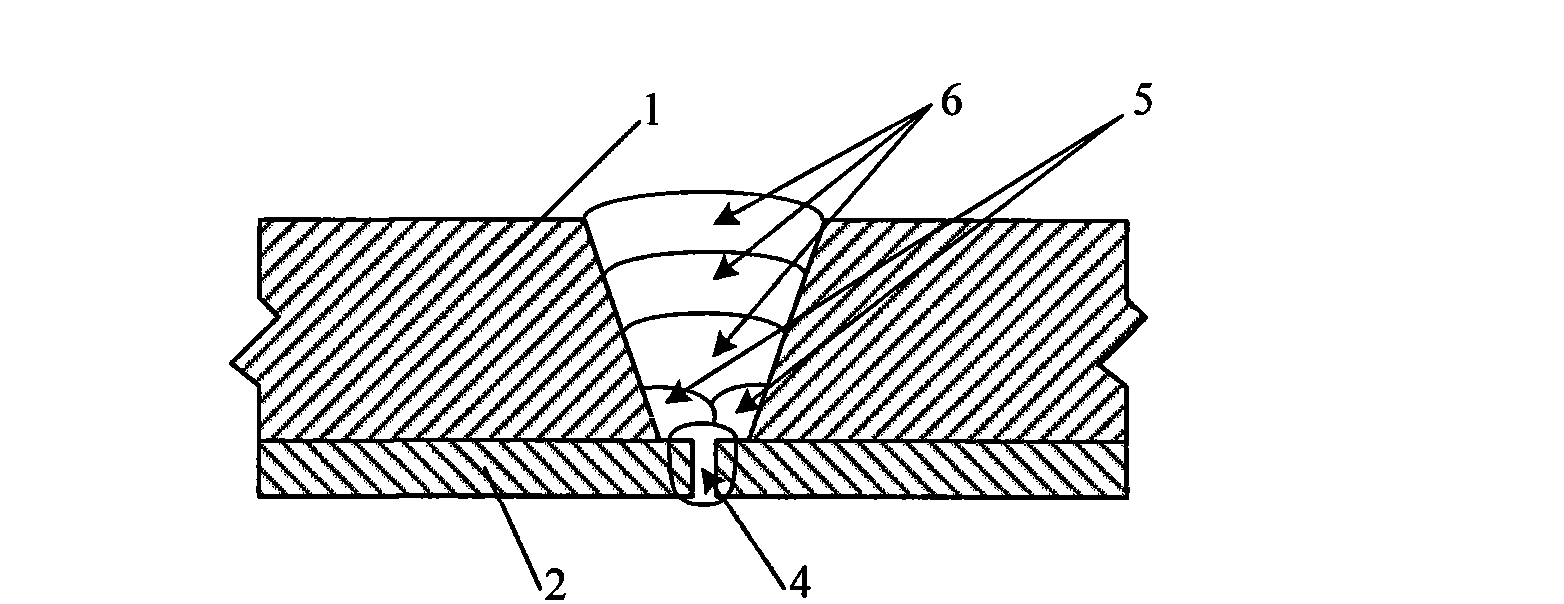

Welding method of girth weld of inner cladding thin-walled stainless steel composite tube

InactiveCN101633074AResolving ingredient matchesSolve the corrosion resistanceWelding/cutting auxillary devicesAuxillary welding devicesChemical industryWeld seam

The invention relates to a welding method of a girth weld of an inner cladding thin-walled stainless steel composite tube. The welding method comprises the following steps: girth welds of the inner cladding stainless steel composite tube are respectively and gradually welded by three welding seams, an inner cladding layer welding seam and a transition layer welding seam are welded by argon tungsten-arc welding, the stainless steel inner cladding layer welding seam adopts welding wires with the same quality thereof, the transition layer welding seam adopts ER309 welding wires, and the base layer is welded by shielded metal arc welding or CO2 gas shielded welding and adopts a welding material matched with the strength of the base layer; and the inner cladding layer, the transition layer and the first layer of the base layer are welded under back argon gas protection. The welding method guarantees corrosion resistance of a joint of the inner cladding layer and mechanical property of a welding joint of the base layer; and the method plays an important role in promoting wide application of the inner cladding stainless steel composite tube in businesses such as oil-gas delivery, chemical industry, oil refining and the like, improving corrosion resistance of an inner wall of a pipe, and solving the problems of high cost and the like caused by adopting a full wall-thickness stainless steel pipe.

Owner:XI AN JIAOTONG UNIV

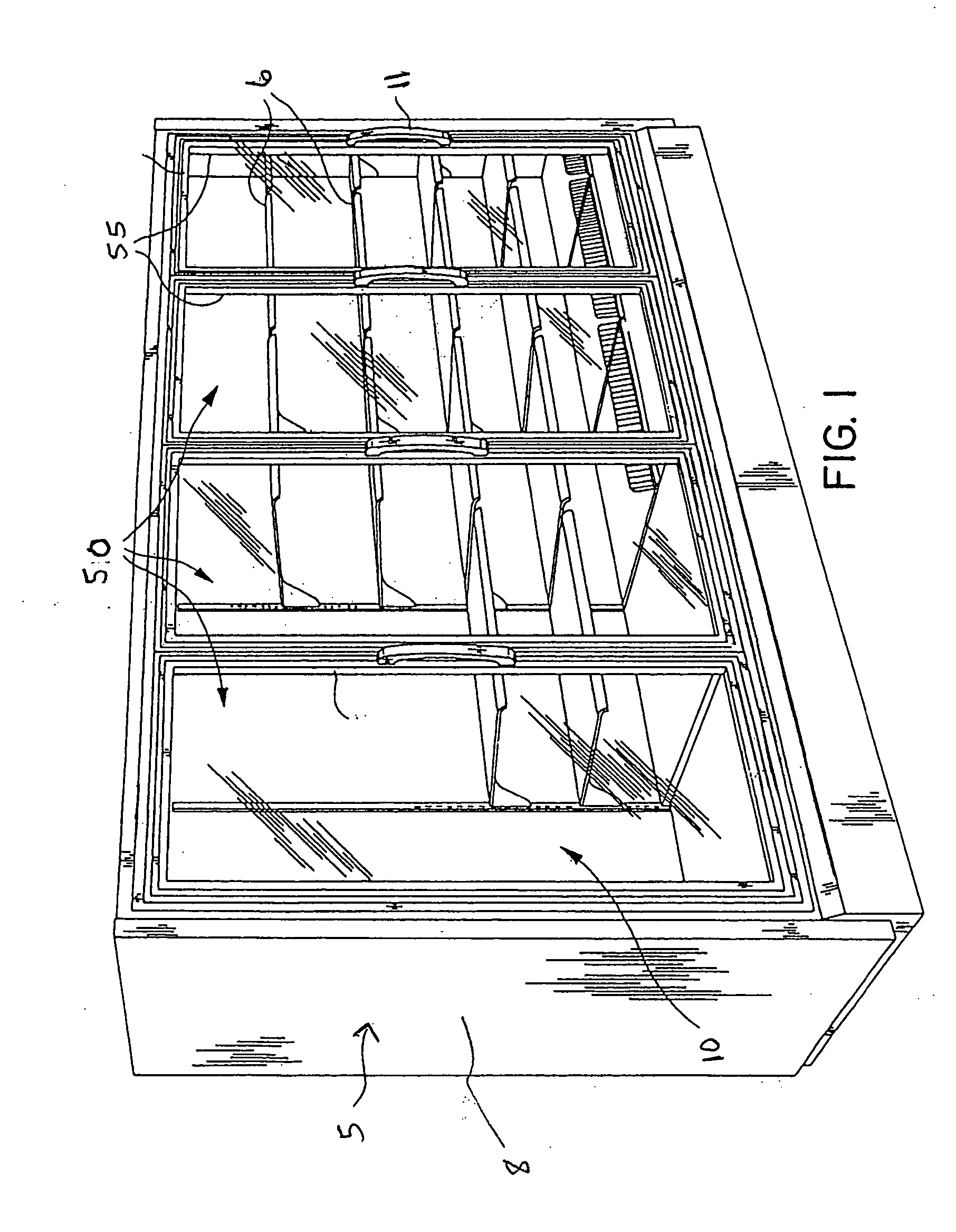

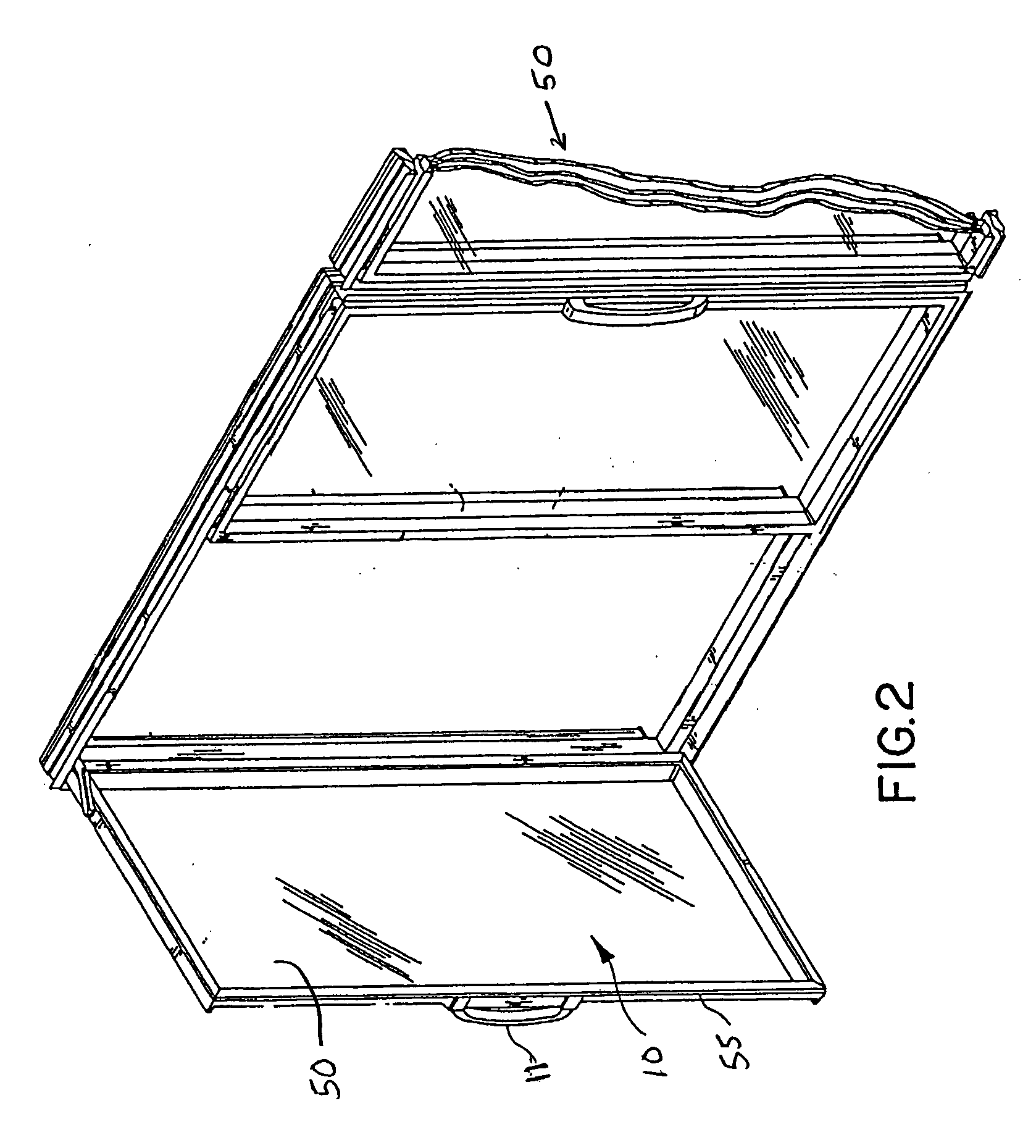

Anti-fog refrigeration door and method of making the same

InactiveUS20060265979A1BurdeningIncreased energy costShow cabinetsRailway roofsThermal insulationLow emissivity

The energy-free refrigeration door of the present application provides a way to control condensation when the door of a refrigeration unit is opened by providing thermal insulation to the door with glass panels which have a low emissivity coating. The door includes a door frame housing and an insulating glass unit comprising inner, middle and outer sheets of glass. A first sealant assembly disposed around the periphery of the inner and middle sheets of glass forms a first chamber between the inner and middle sheets of glass. A second sealant assembly disposed around the periphery of the middle and outer sheets of glass forms a second chamber between the middle and outer sheets of glass. A gas, such as krypton, air, or argon is held in the first and second chambers. The outer sheet of glass and inner sheet of glass each have an unexposed surface that faces the middle sheet of glass. A low emissivity coating is disposed on the unexposed surfaces of the inner and outer sheets of glass so that the glass door as a whole avoids formation of condensation on the outer surface of the outer sheet of the glass door, without the application of electricity to heat the door, while also providing the desired evaporation rate of condensation from the inner side of the inner sheet of the glass door. An anti-fog or anti-frost coating is included on a surface of one of the sheets of glass.

Owner:AGC FLAT GLASS NORTH AMERICA INC

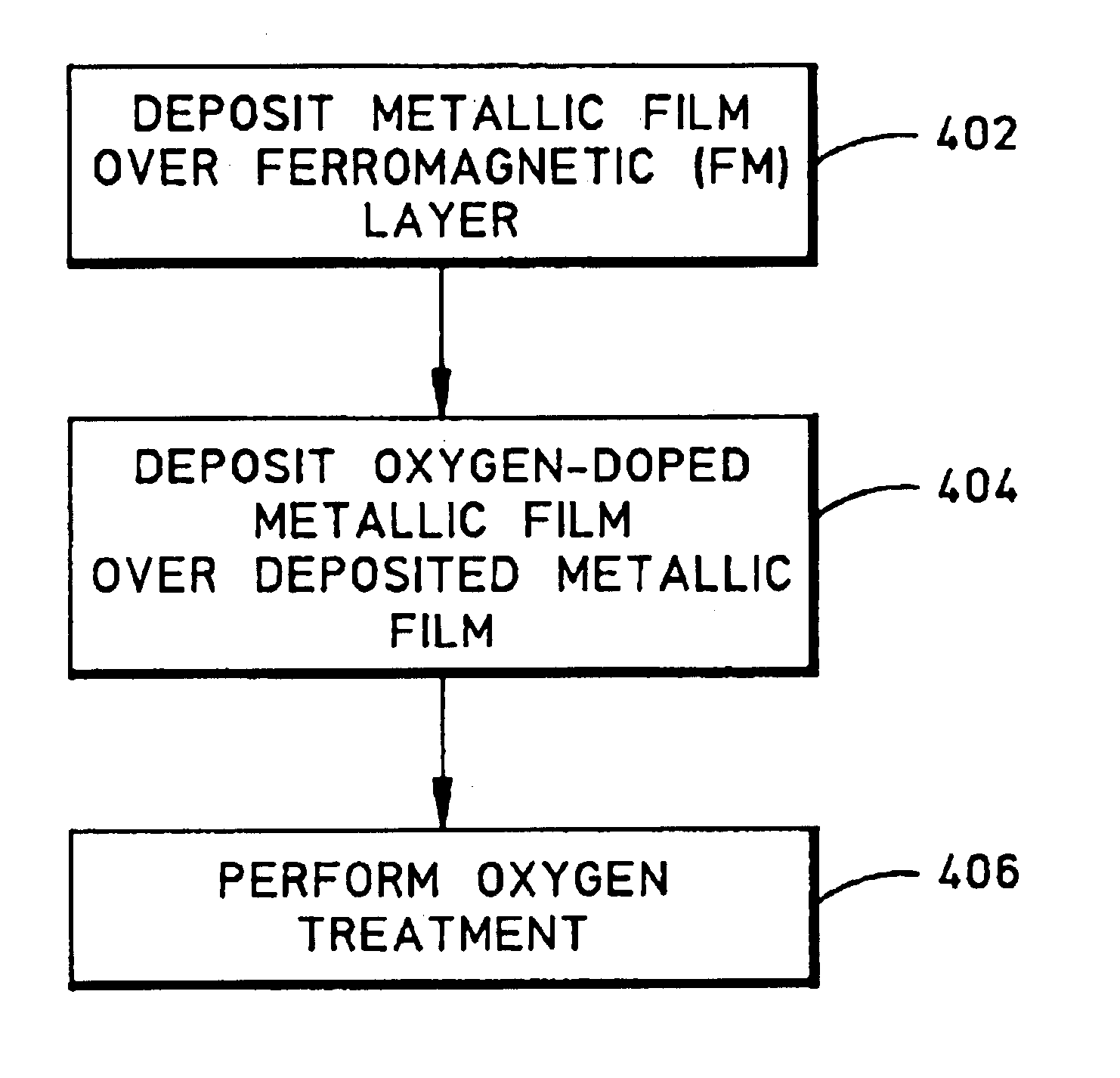

Method of forming a barrier layer of a tunneling magnetoresistive sensor

A fabrication process for a tunneling magnetoresistance (TMR) sensor is disclosed. In particular, a unique method of forming a barrier layer of the TMR sensor is utilized so that the TMR sensor exhibits good magnetic and TMR properties. In one particular example, the barrier layer is formed by depositing a metallic film in an argon gas in a DC magnetron sputtering module, depositing an oxygen-doped metallic film in mixed xenon and oxygen gases in an ion-beam sputtering module, and oxidizing these films in an oxygen gas in an oxygen treatment module. This three-step barrier layer formation process minimizes oxygen penetration into ferromagnetic (FM) sense and pinned layers of the TMR sensor and optimally controls oxygen doping into the barrier layer. As a result, the FM sense and pinned layers exhibit controlled magnetic properties, the barrier layer provides a low junction resistance-area product, and the TMR sensor exhibits a high TMR coefficient.

Owner:GLOBALFOUNDRIES INC

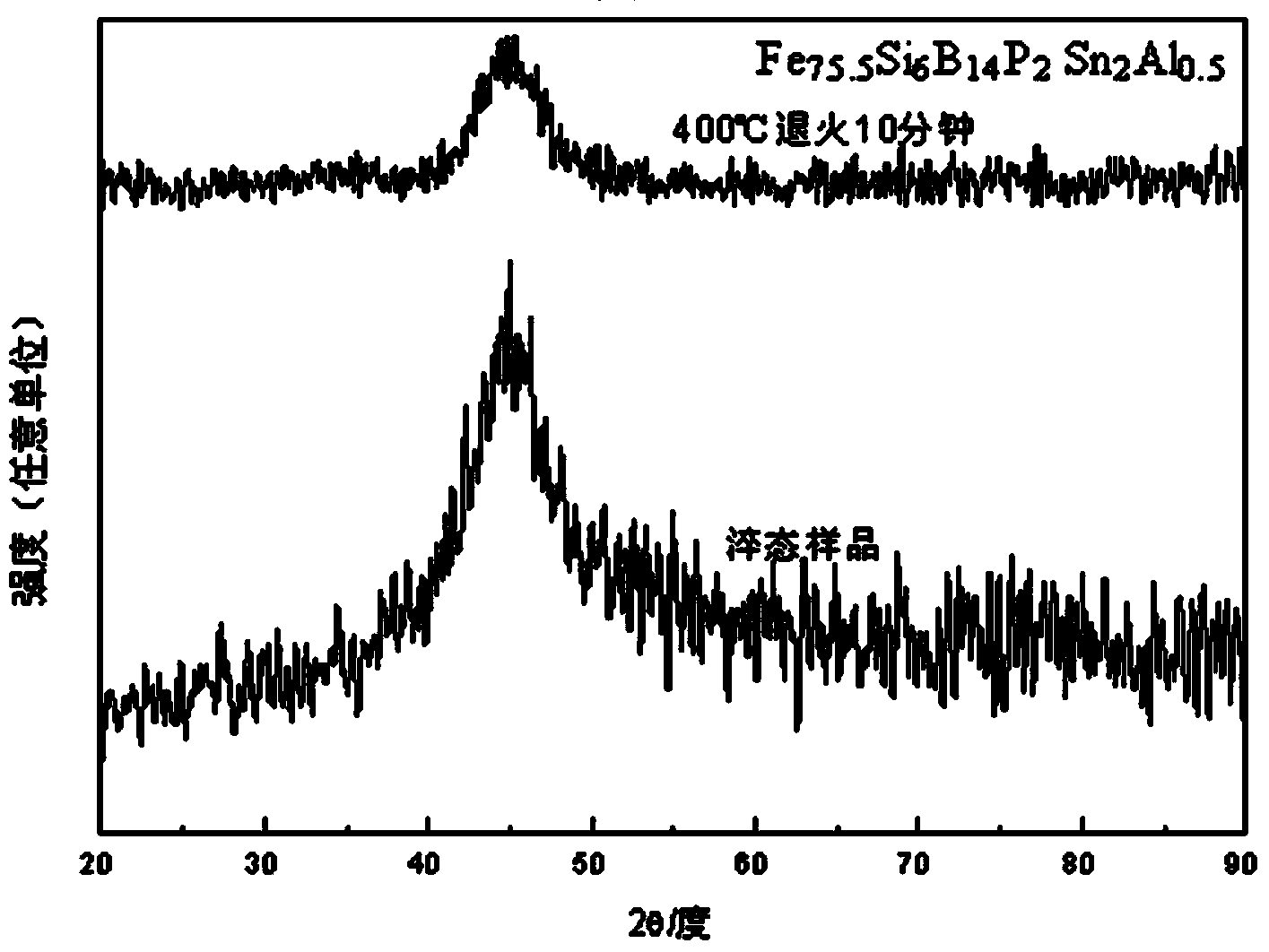

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com