Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

A technology of iron-based nanocrystals and soft magnetic alloys, applied in magnetic materials, magnetic objects, electrical components, etc., can solve the problems of low saturation magnetization, low coercive force, and high alloy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

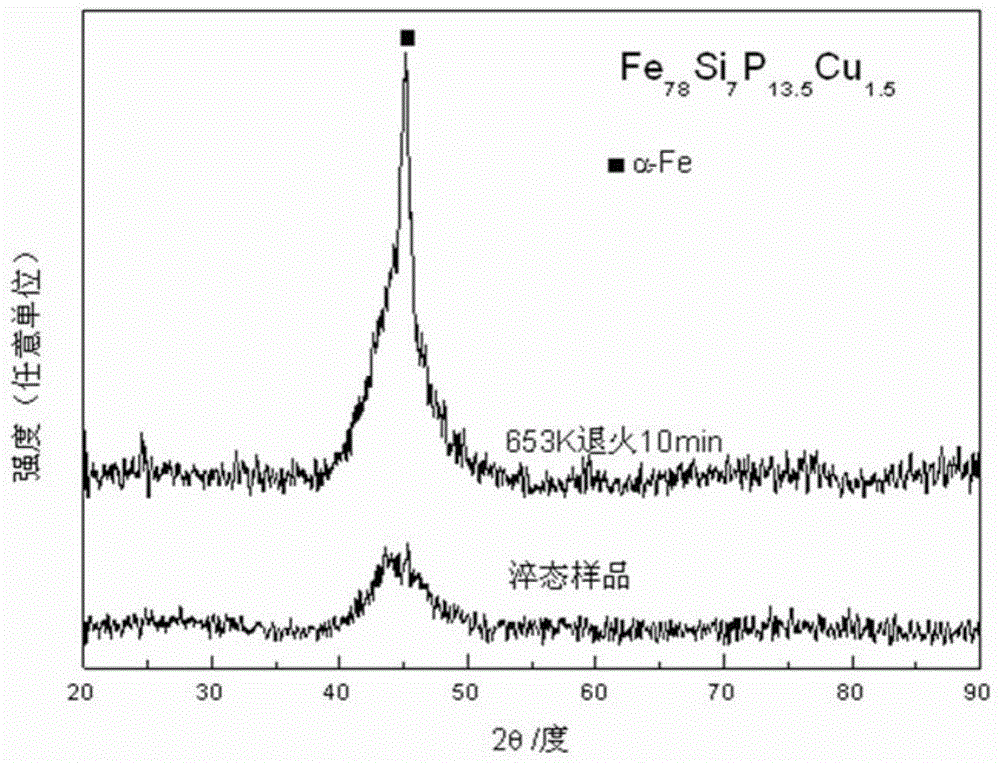

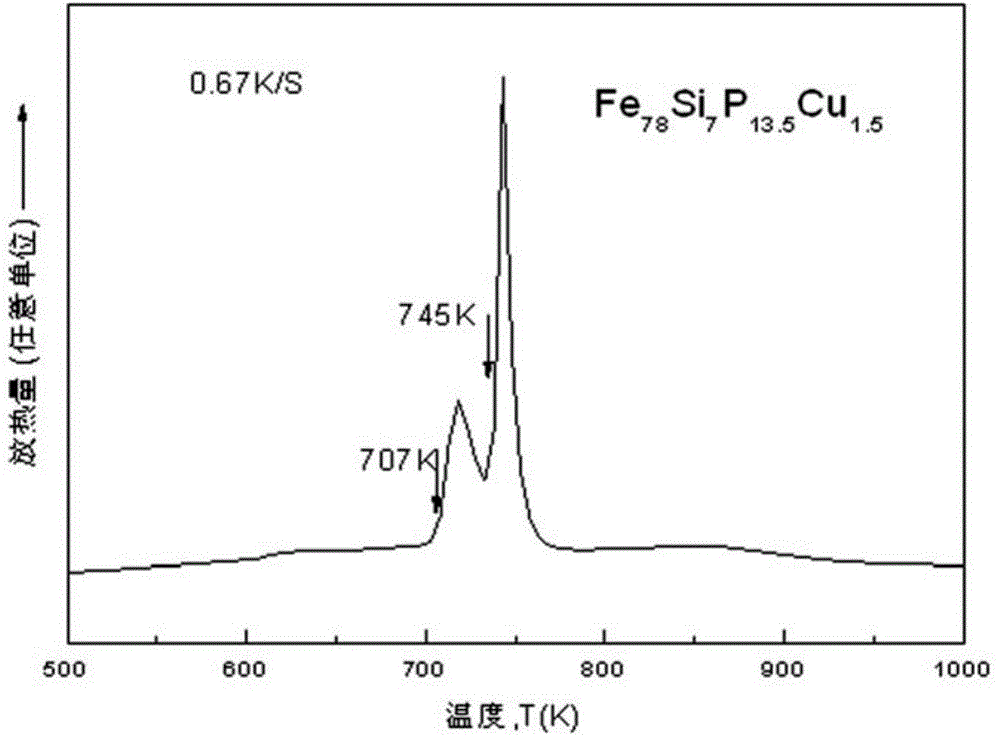

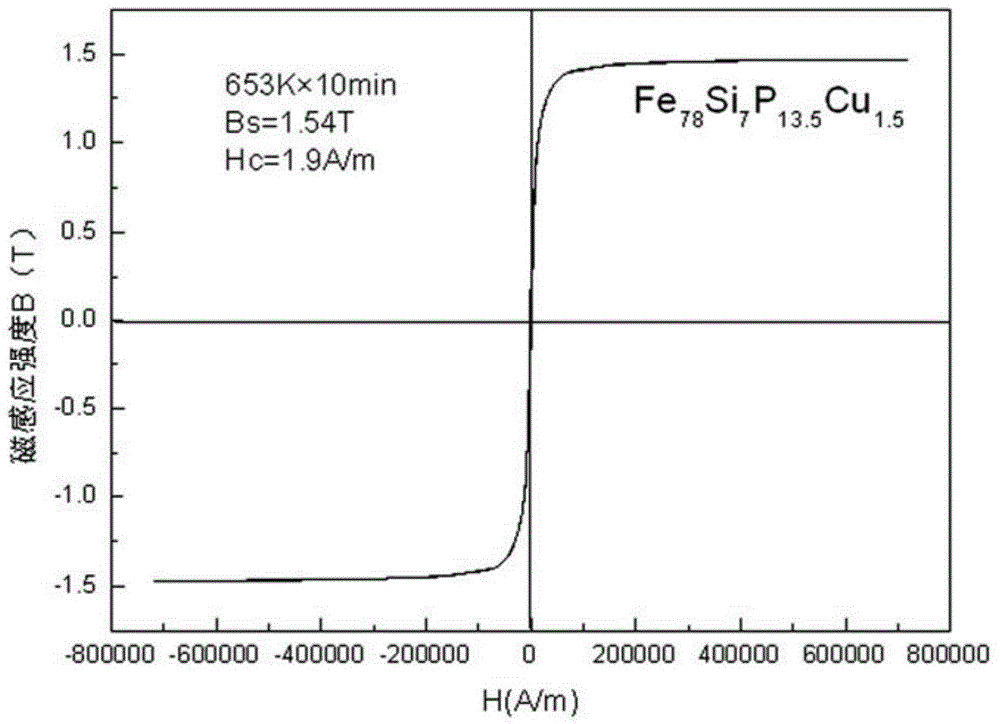

Embodiment 1

[0045] The expression Fe of the iron-based nanocrystalline alloy according to the present invention a Si b P c Cu x m y and its content to prepare a group of alloy samples when y=0, wherein the specific composition of each sample is as shown in Table 1, sample number 4-14 is the alloy sample prepared in this embodiment, and the alloy sample of number 1-3 is Comparative example (which contains B elemental component). The preparation method of contrast sample and alloy sample of the present invention is identical, and concrete preparation steps are as follows:

[0046] 1) Pure Fe, pure Si, pure Cu and Fe-P alloys with a purity greater than 99.5% are classified according to the alloy composition Fe a Si b P c Cu x m y (atomic percentage) ratio;

[0047] 2) Then put the proportioned raw materials into the ceramic crucible of the induction melting furnace, and first evacuate to 5×10 -3 Pa, and then filled with argon gas until the pressure is 0.09MPa for melting, fully sm...

Embodiment 2

[0058] In the iron-based nanocrystalline alloy Fe of the present invention a Si b P c Cu x m y (wherein y is not equal to 0) composition range prepares a group of different alloy samples, wherein the composition of sample is as shown in table 1 sample number 15-41, according to the alloy formed in table 1, by the same step as in embodiment 1 , to prepare iron-based nanocrystalline alloy strips, and then test the properties of samples 15-41 by the same test method as in Example 1, and the measured results are shown in Table 1. The alloy in this embodiment has added M-type metal elements, because there are many samples, the following examples are given to illustrate, as in Table 1, sample number 15 (Fe 85 Si 5 P 6.5 Cu 1.5 Zr 2 ), using high vacuum and argon protection to avoid the embrittlement, edge burnt and segregation of P elements, and the surface of the prepared strip is bright, while ensuring the excellent soft magnetic properties and high thermal stability of th...

Embodiment 3

[0065] In the iron-based nanocrystalline alloy Fe of the present invention a Si b P c Cu x m y Composition Range Prepare a group of different alloy samples. The magnetic properties of the same product obtained under different heat treatment conditions are shown in Table 2. Sample numbers 42-44 are a group of examples prepared according to the present invention. The preparation method is the same as in Example 1, and the properties of samples 42-44 are tested by the same test method as in Example 1, and the measured results are shown in Table 2.

[0066] From the sample analysis results of this example, it can be seen that the soft magnetic properties of the same product are basically stable at different heat treatment temperatures, indicating that the product of the present invention has a thermally stable temperature range of about 200°C and has high thermal stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com