Patents

Literature

551results about How to "Improve high frequency performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

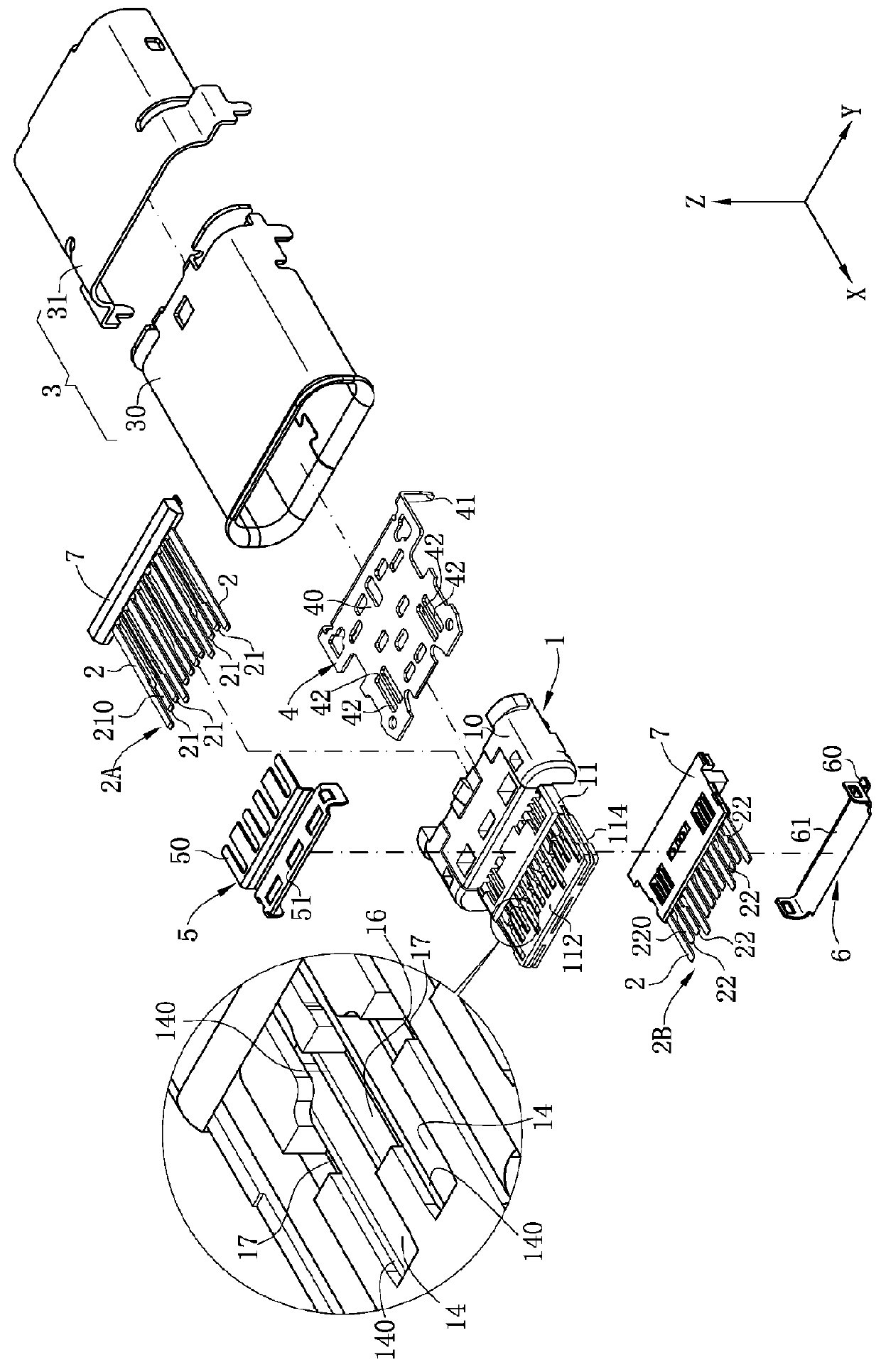

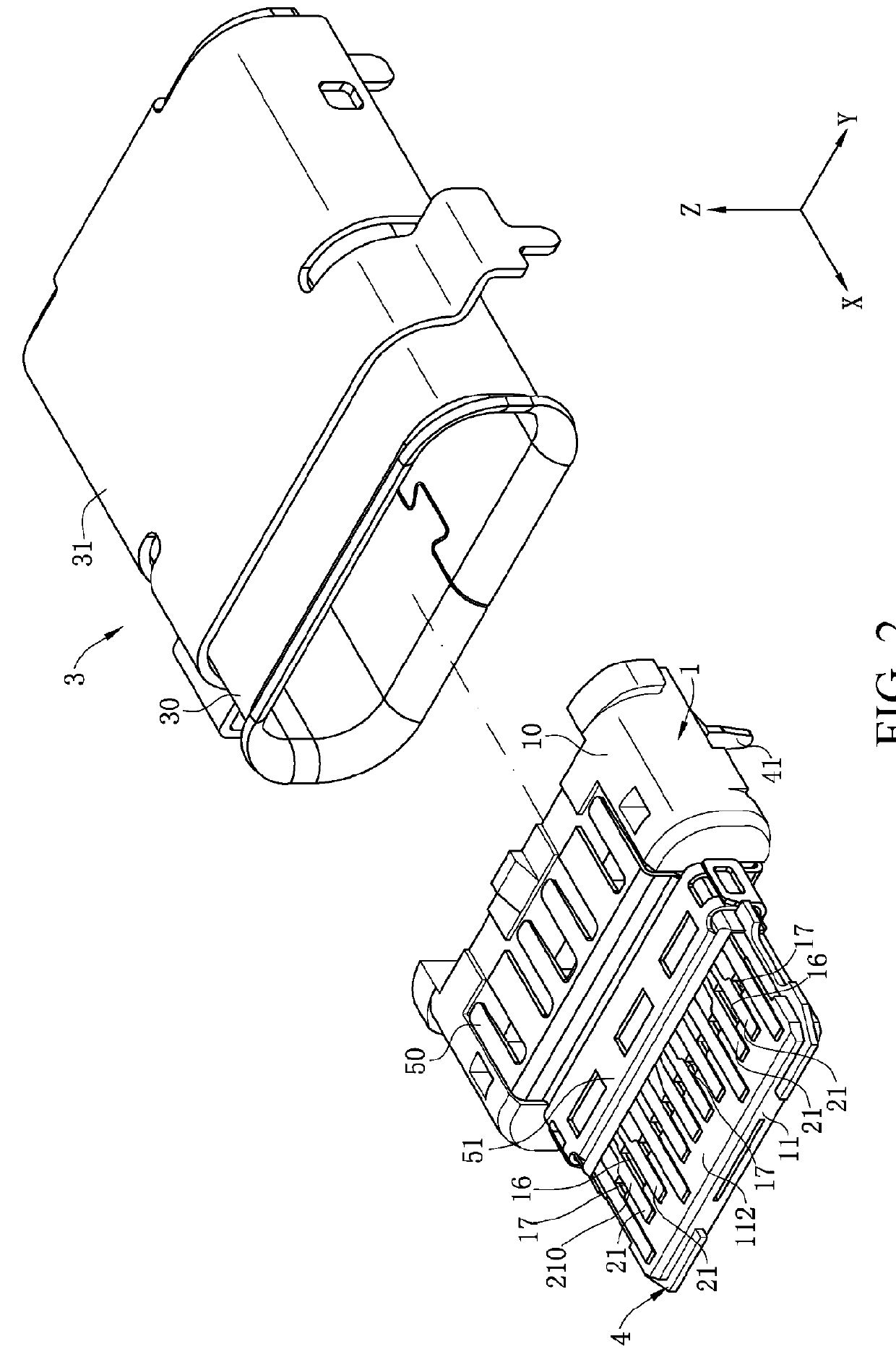

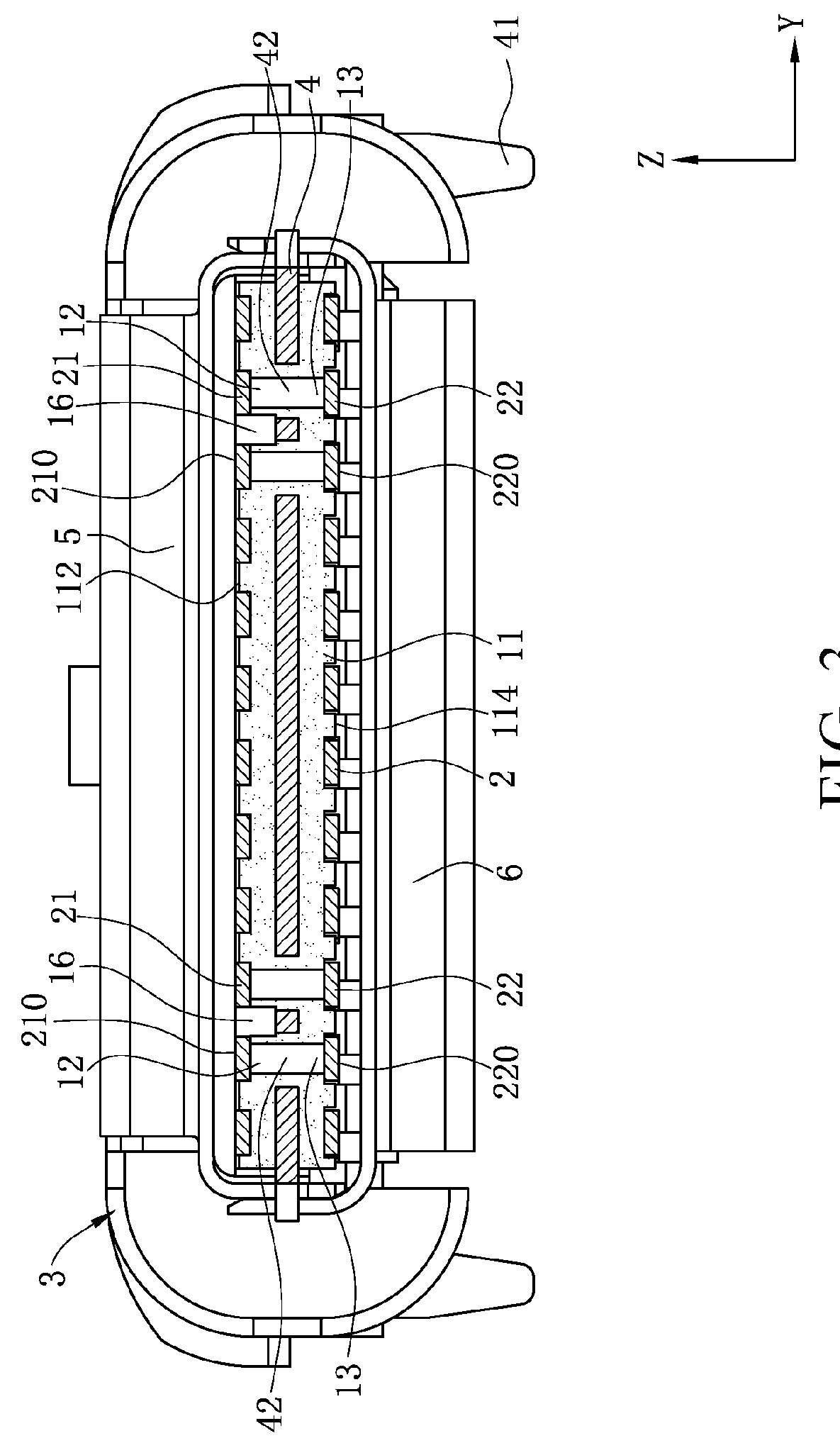

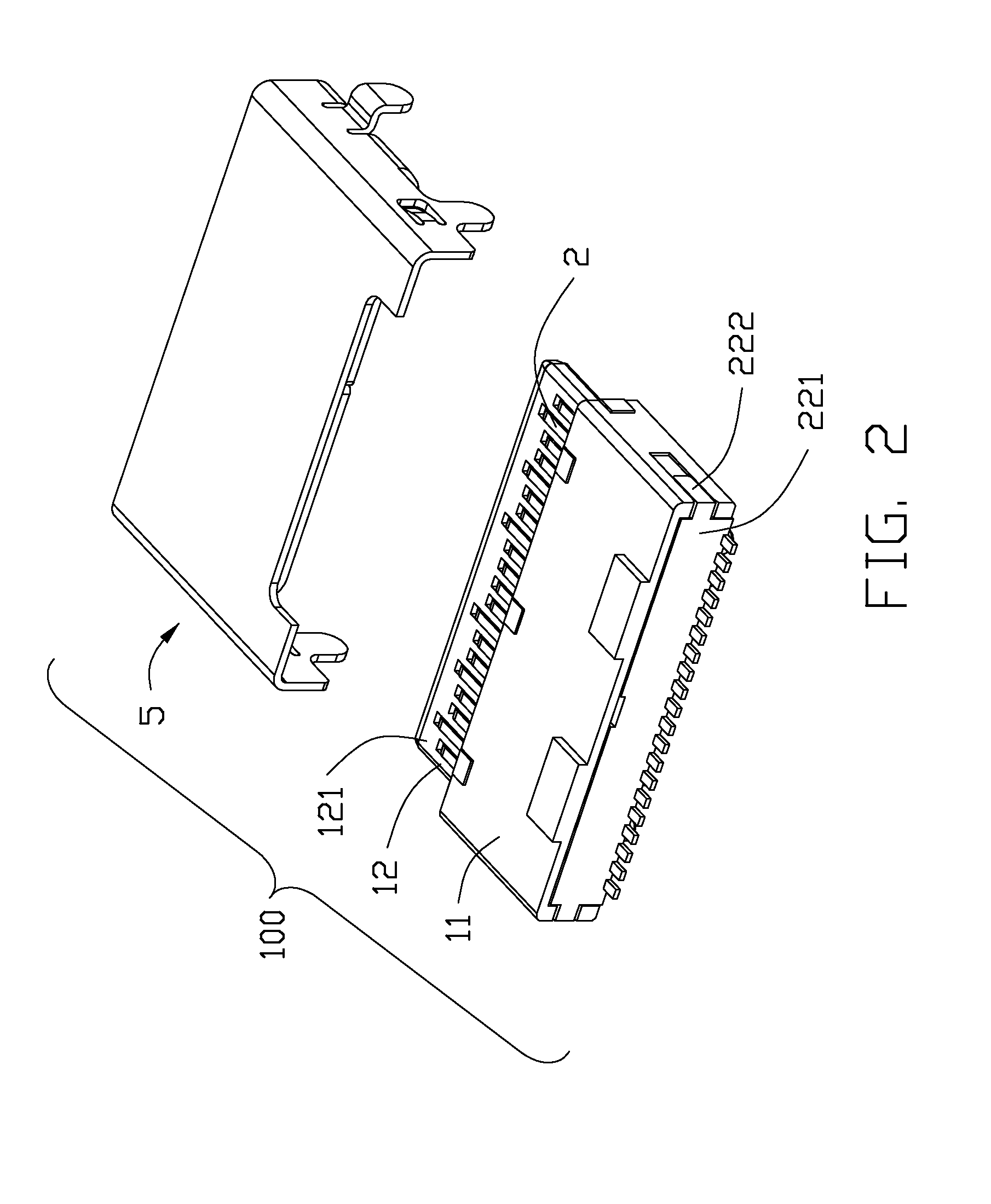

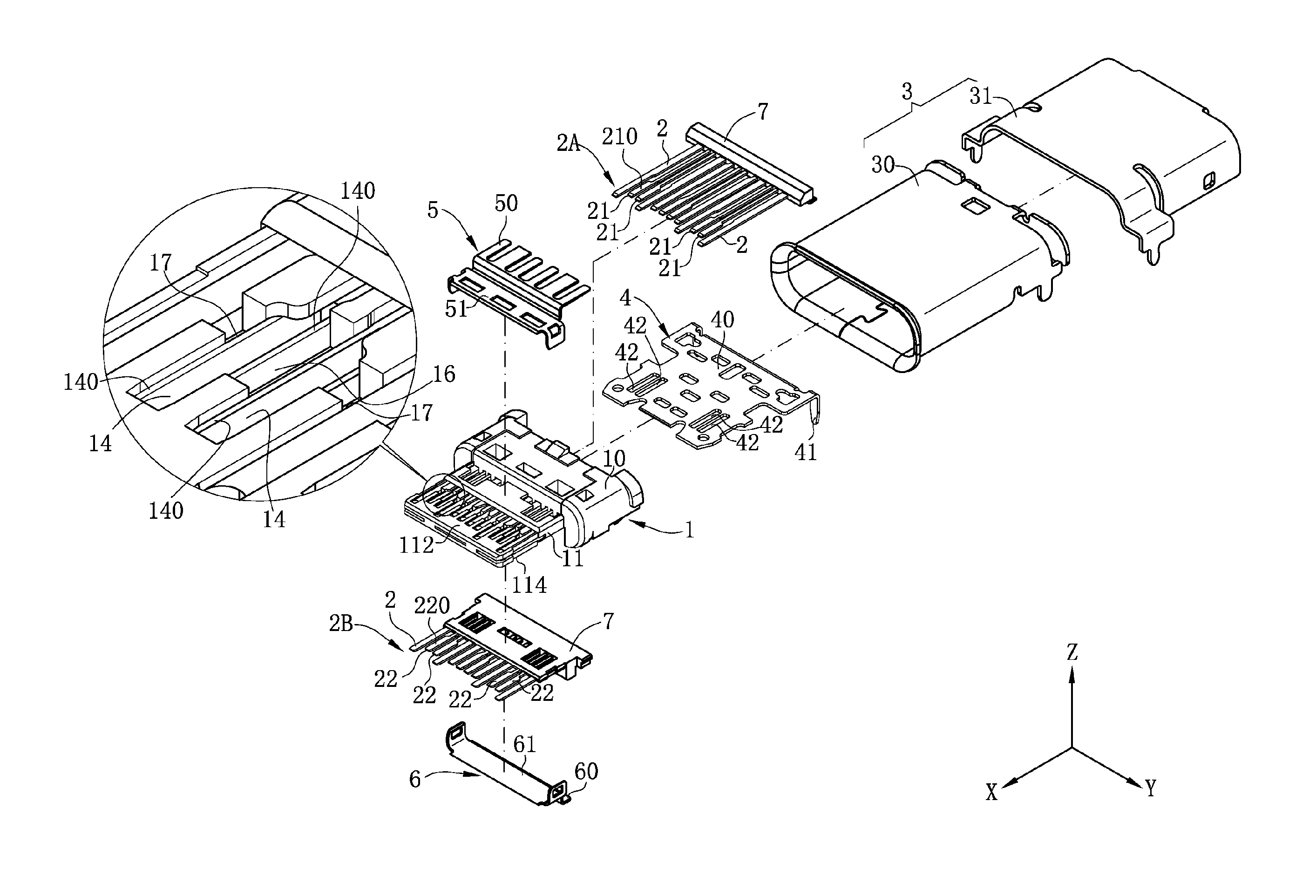

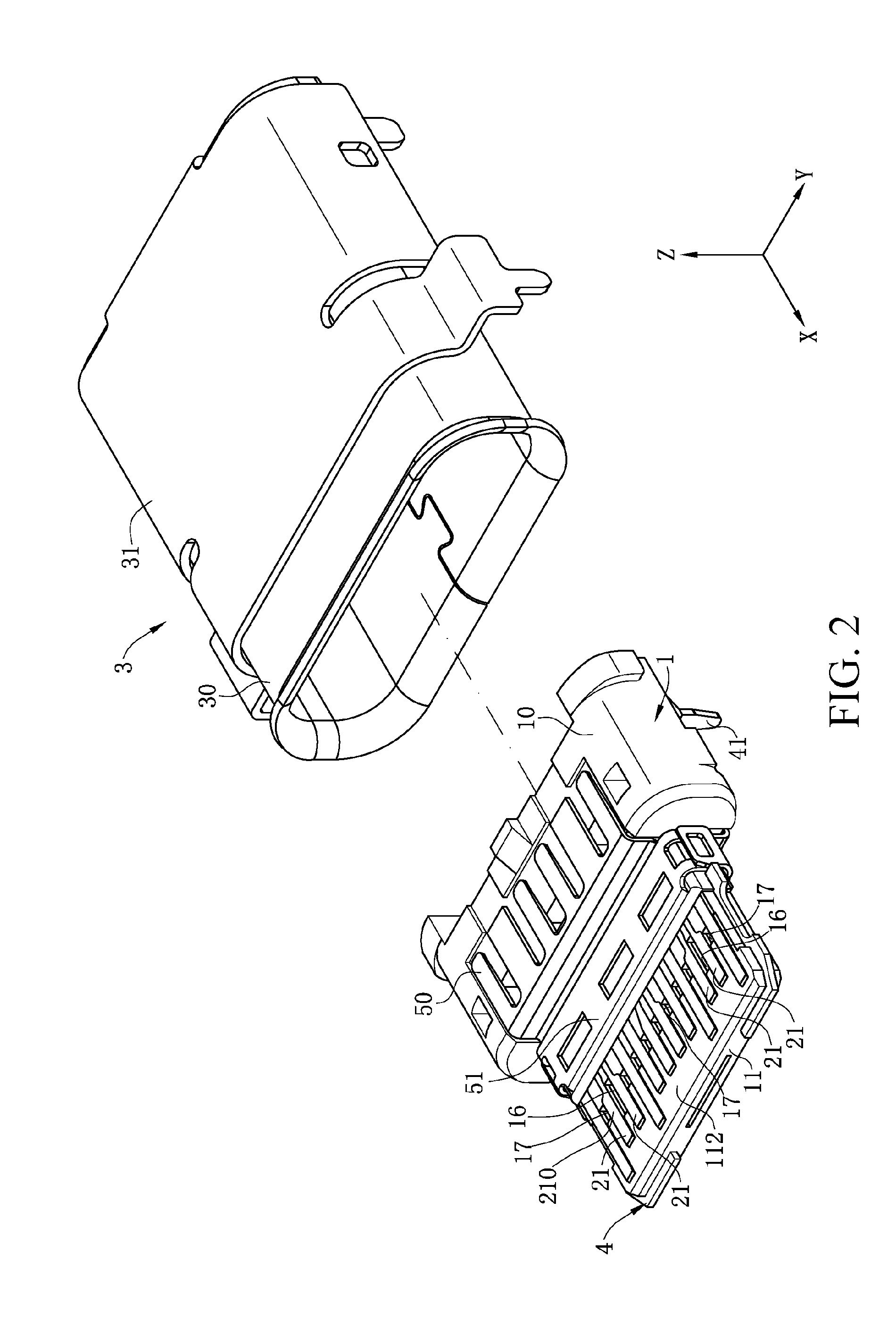

Electrical connector for transferring high frequency signal

ActiveUS9231356B1Reduced insertion lossPlastic material to shrinkContact member cases/bases manufactureCoupling device detailsElectricityDifferential signaling

An electrical connector includes a body having a tongue, a row of first terminals insert-molded in the body, a depressed slot, and a positioning slot. The tongue includes a first surface having multiple receiving slots. Each first terminal has a contact portion accommodated in the receiving slot and exposed from the first surface. The first terminals include a pair of differential signal terminals and multiple non-high-speed terminals. The depressed slot is depressed from the first surface, located between contact portions of two differential signal terminals, and in communication with two adjacent receiving slots. The positioning slot is depressed from the first surface, located between contact portions of two adjacent non-high-speed terminals, or of adjacent non-high-speed terminal and differential signal terminal, and in communication with two adjacent receiving slots. The length of the positioning slot is less than the length of the depressed slot.

Owner:LOTES

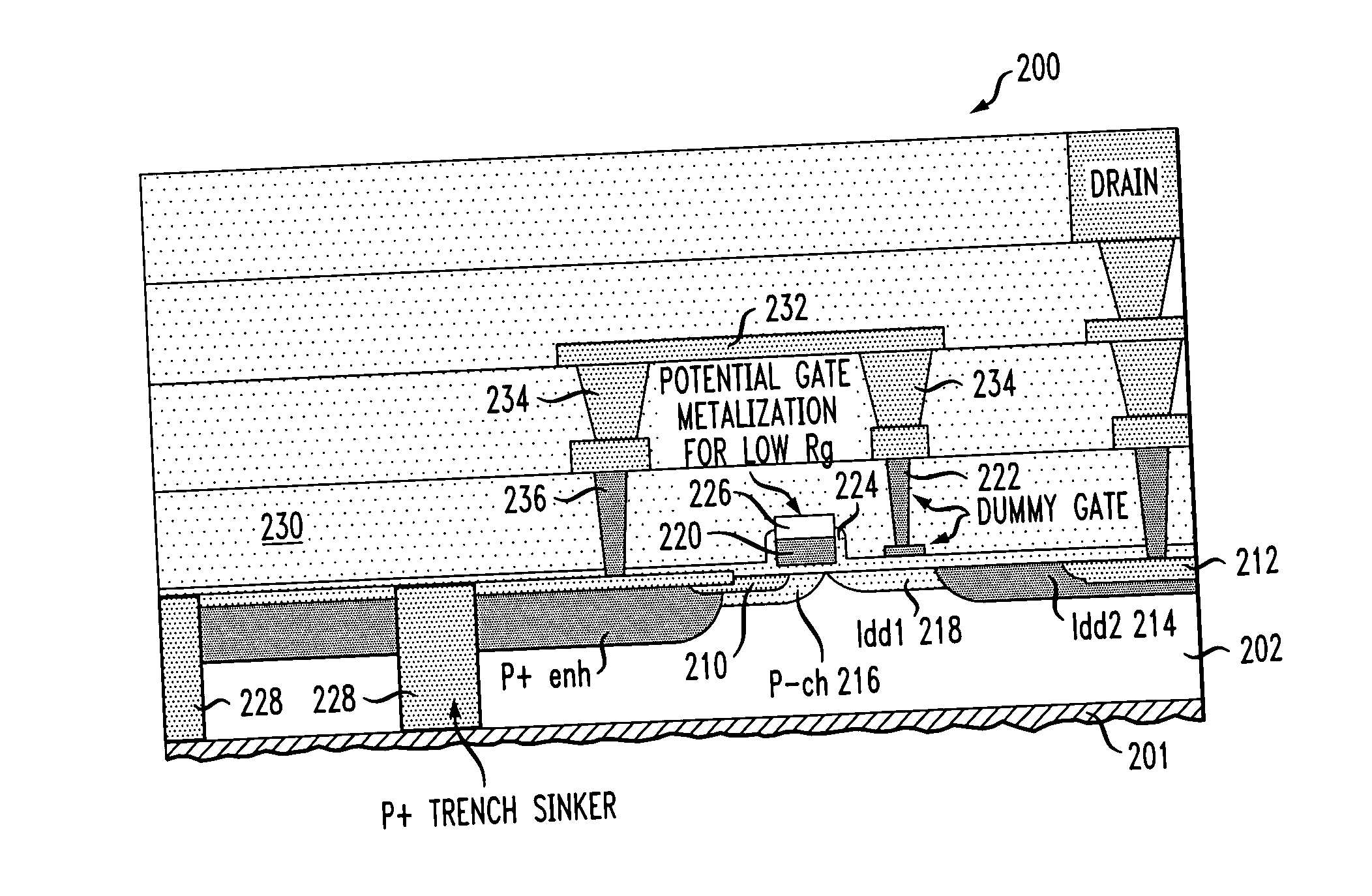

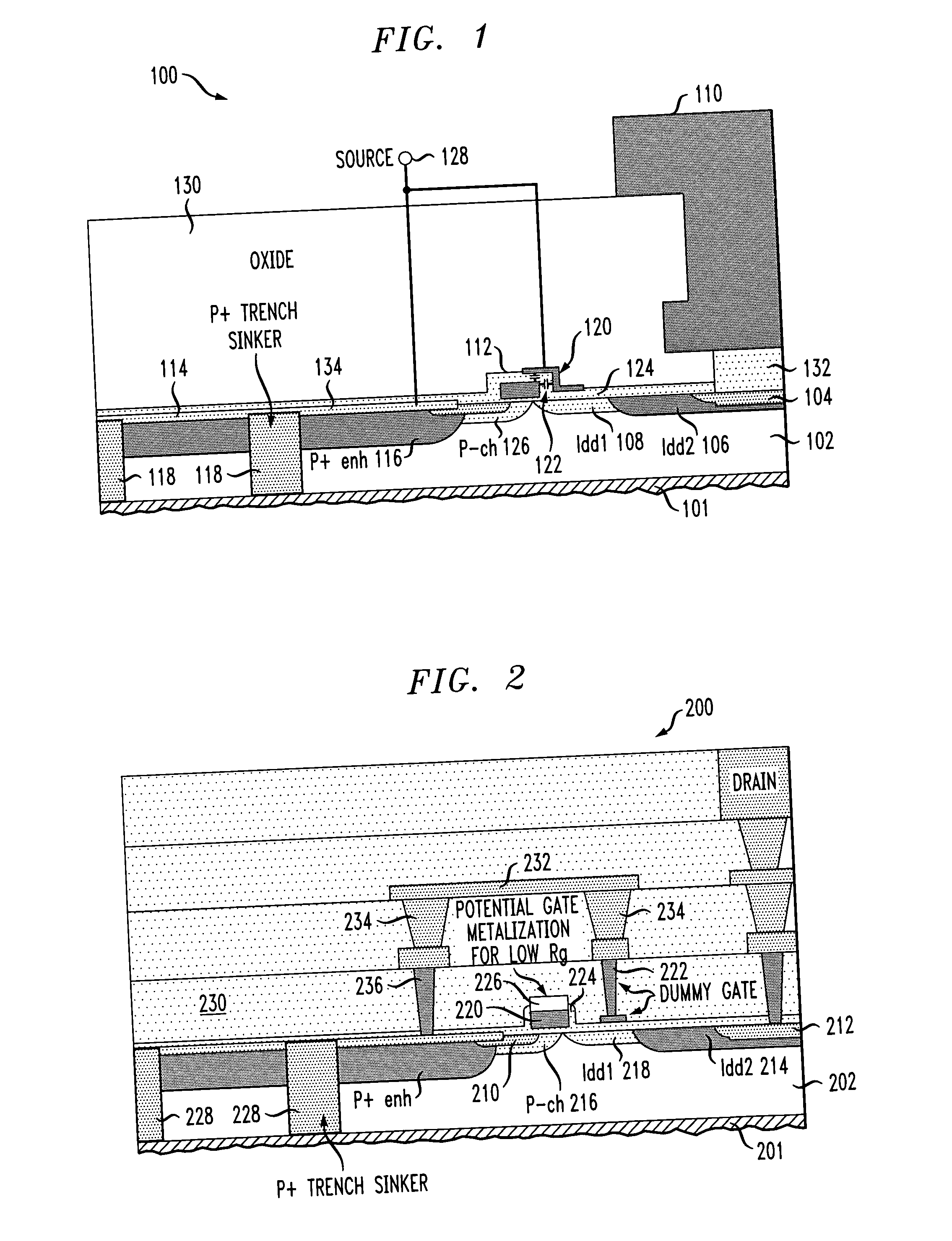

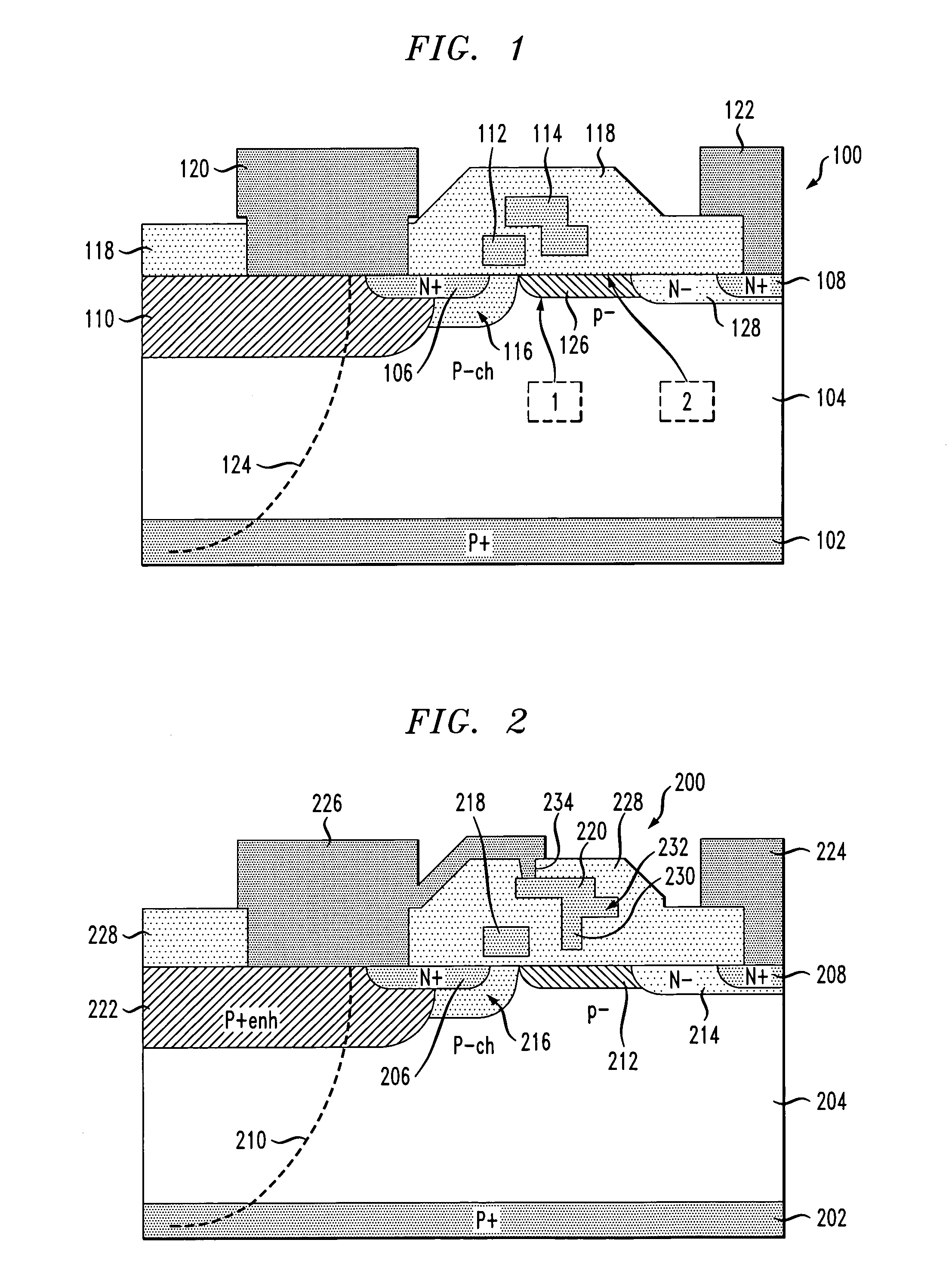

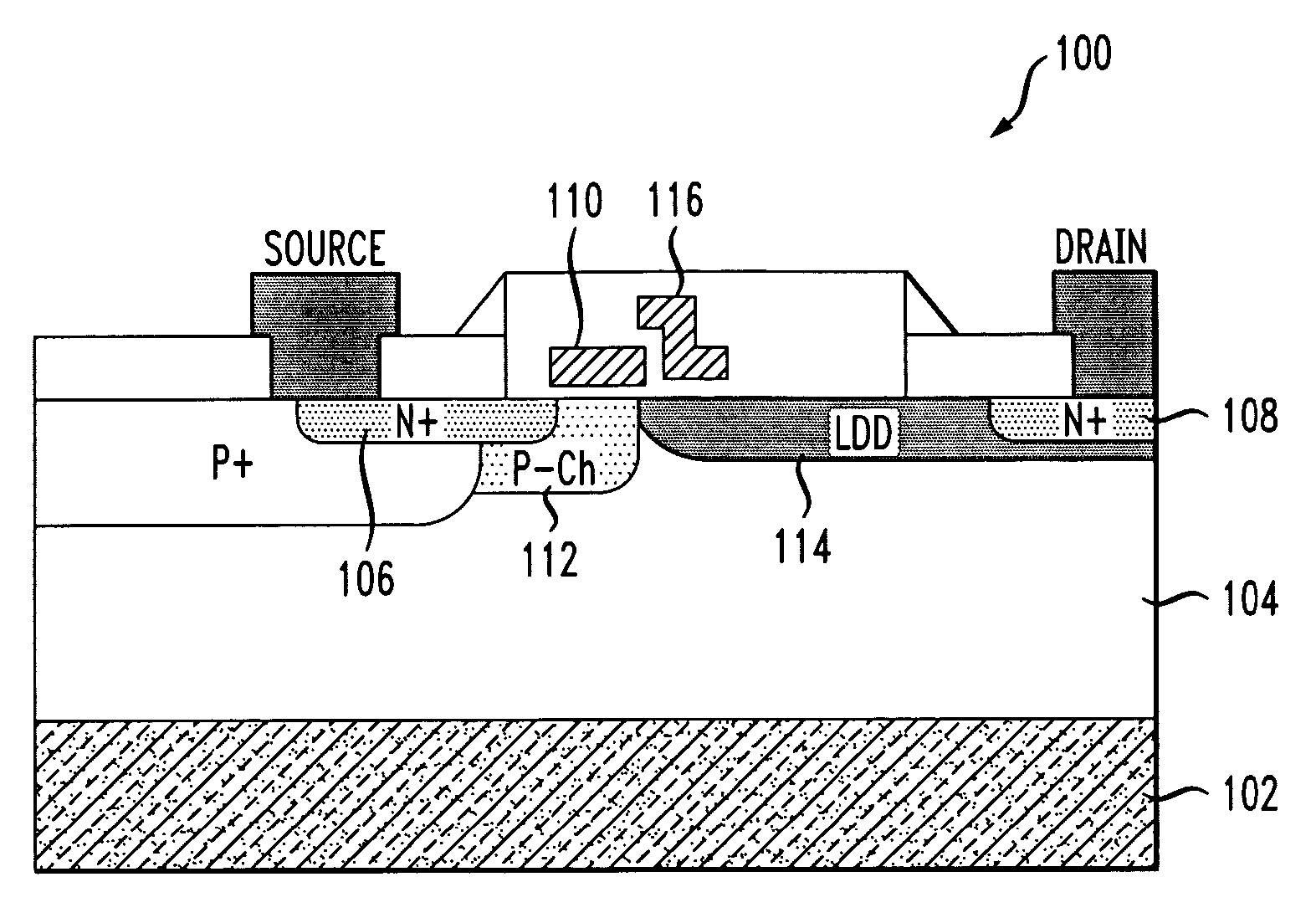

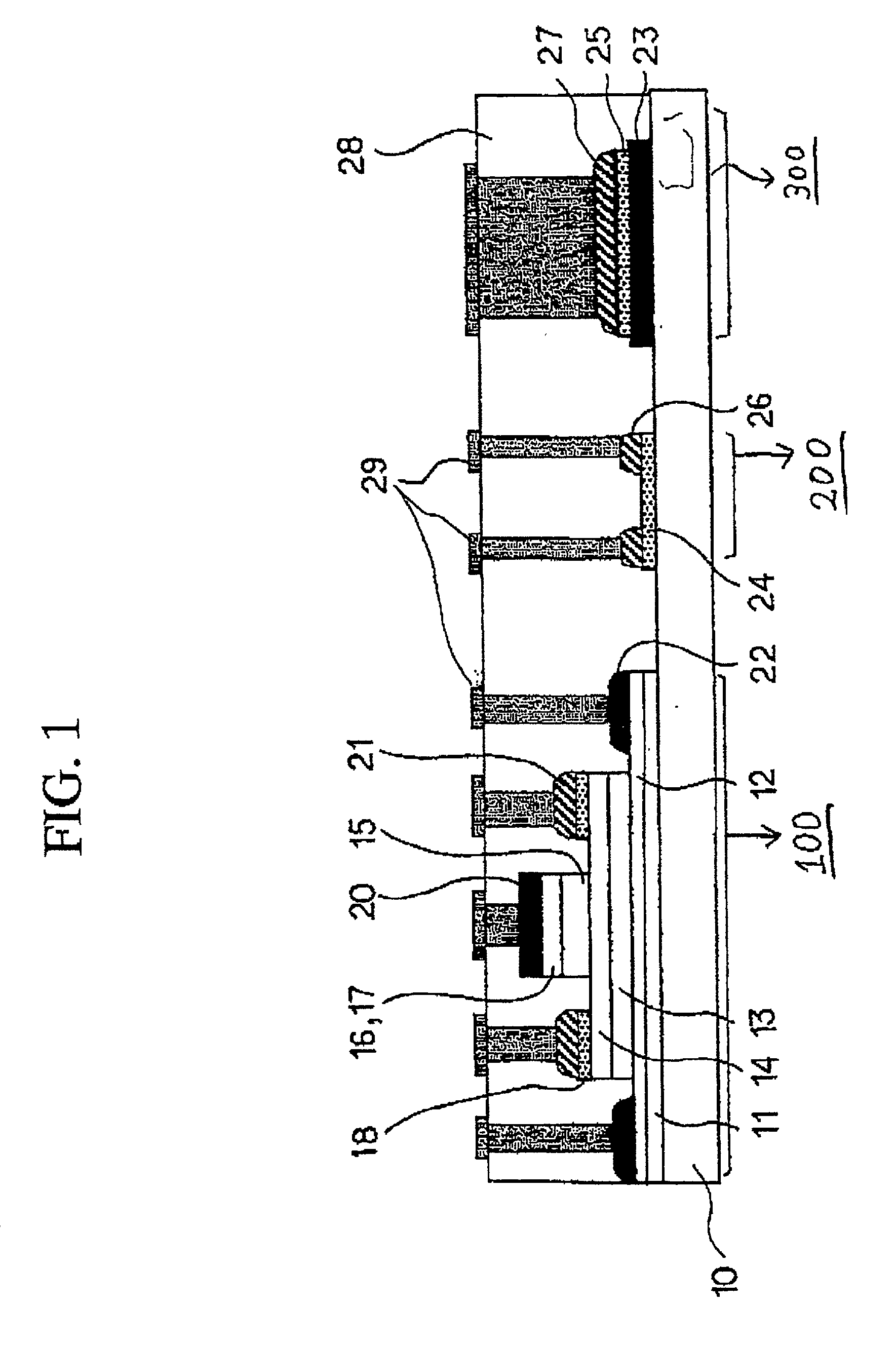

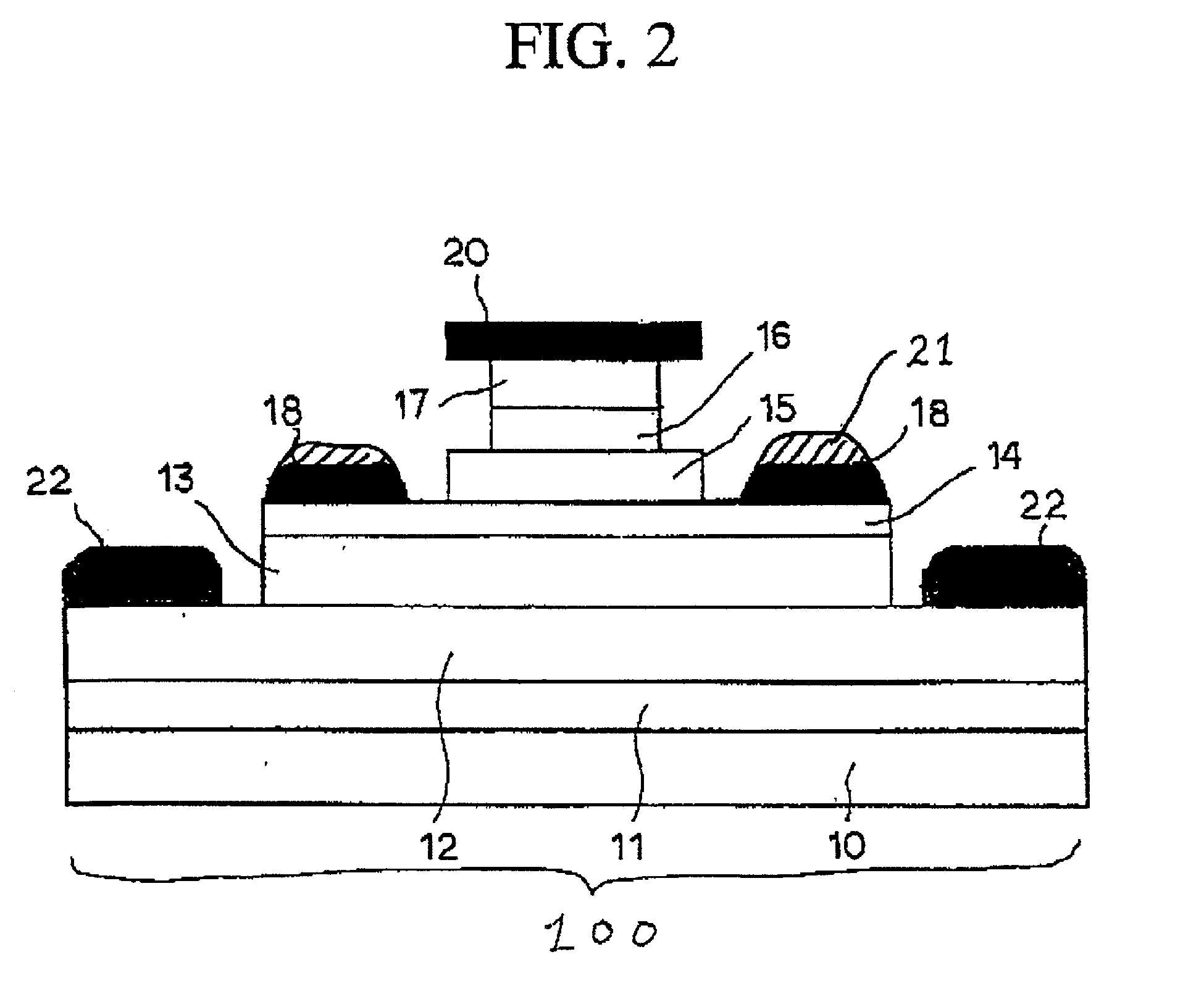

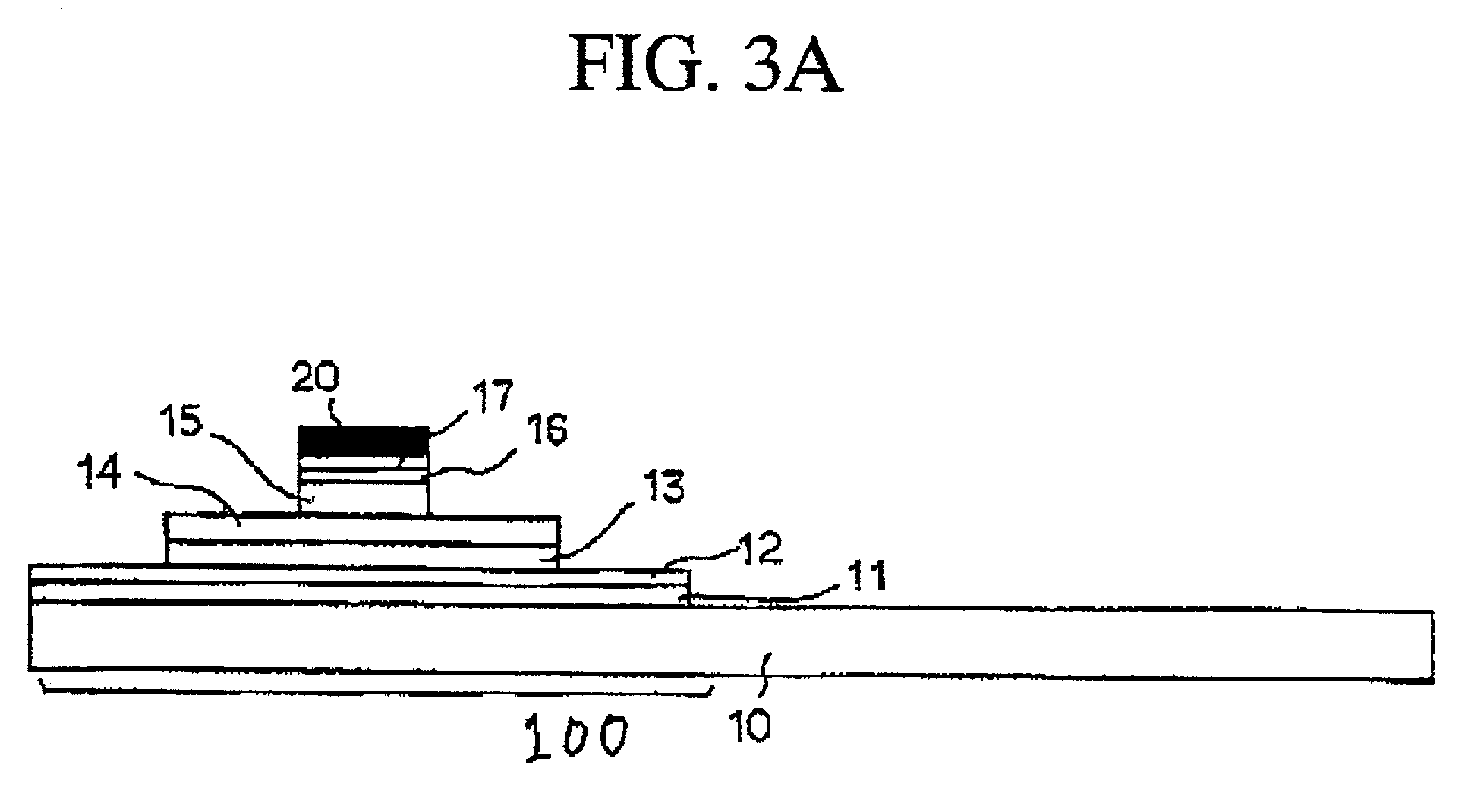

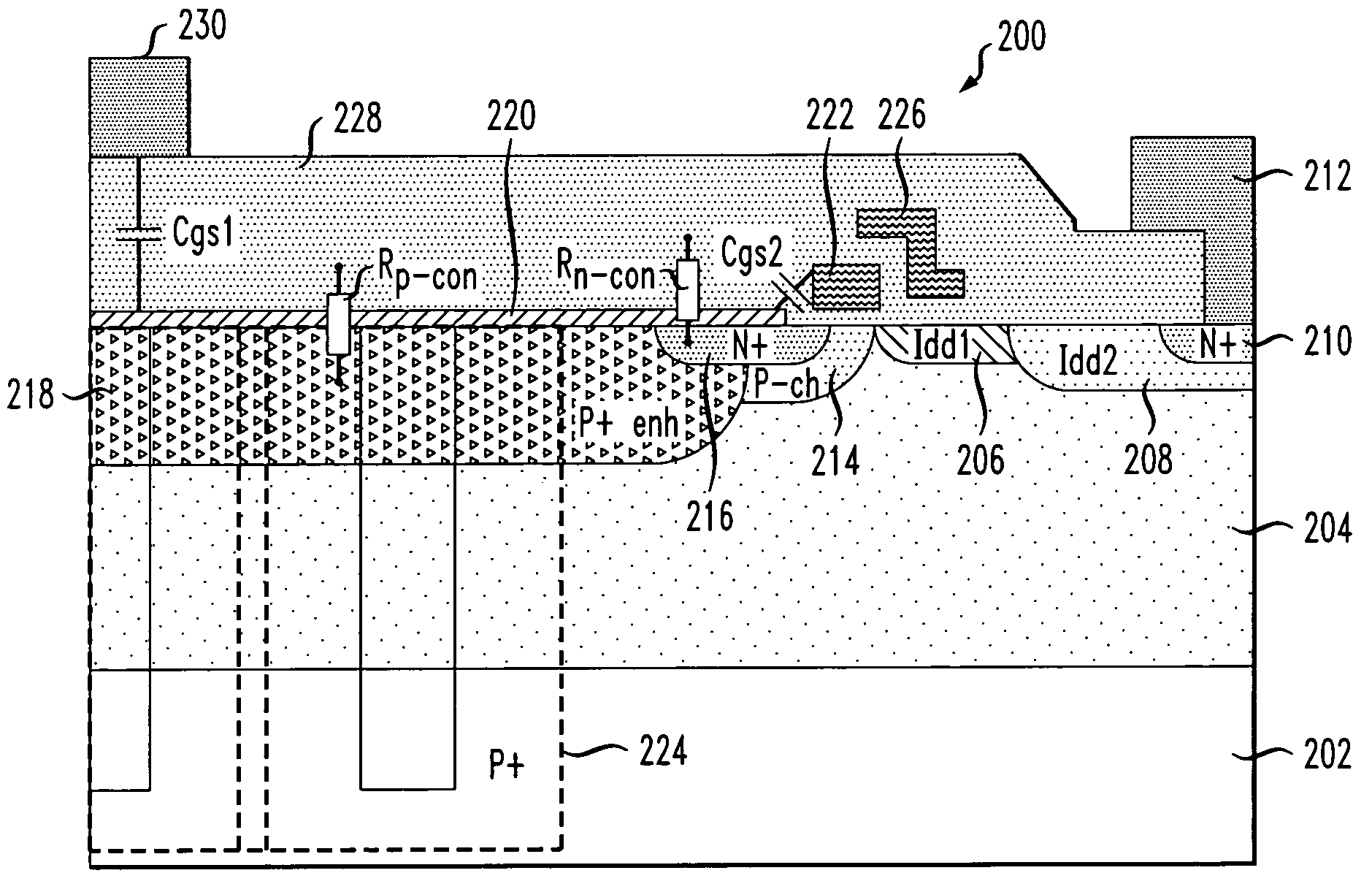

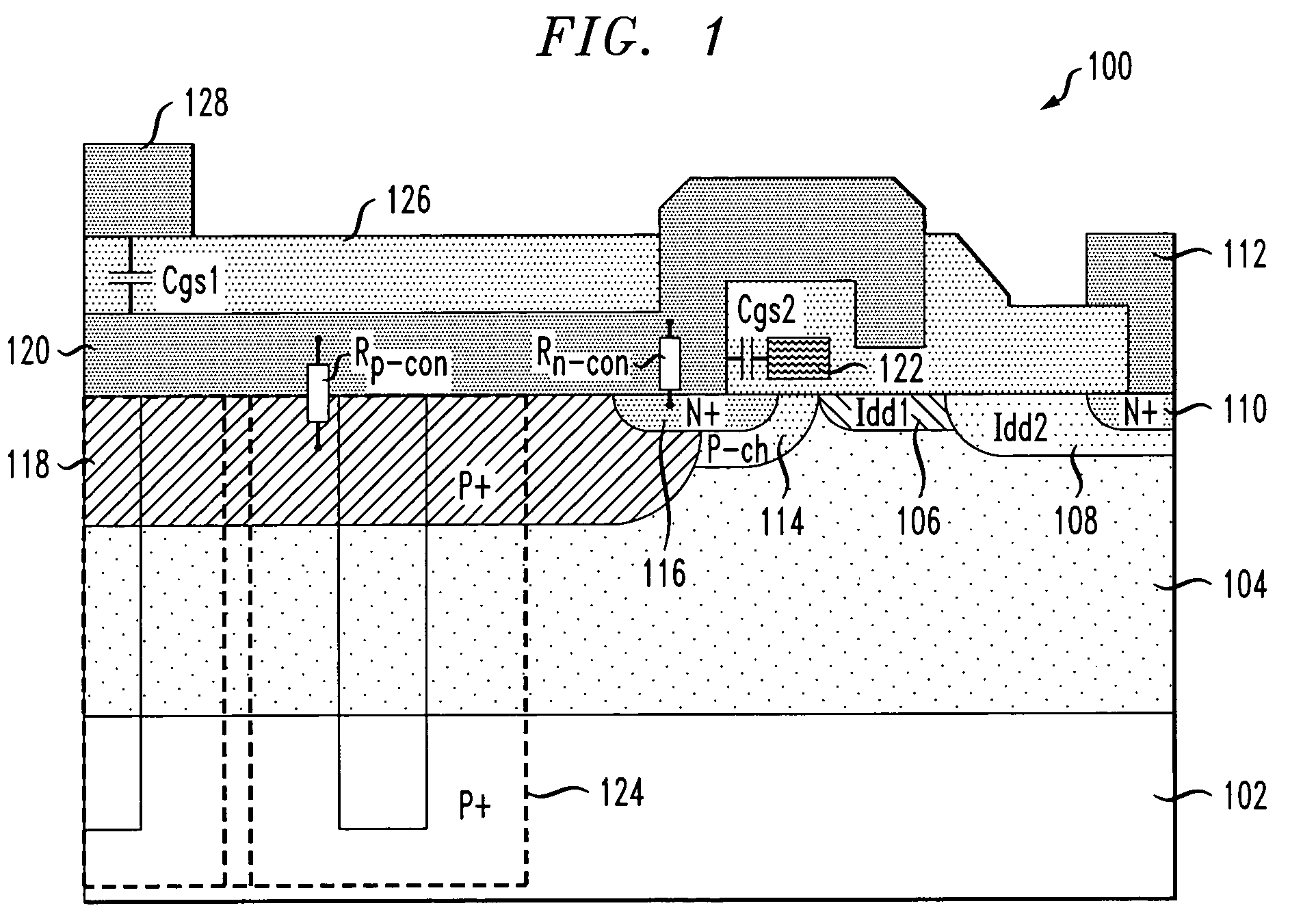

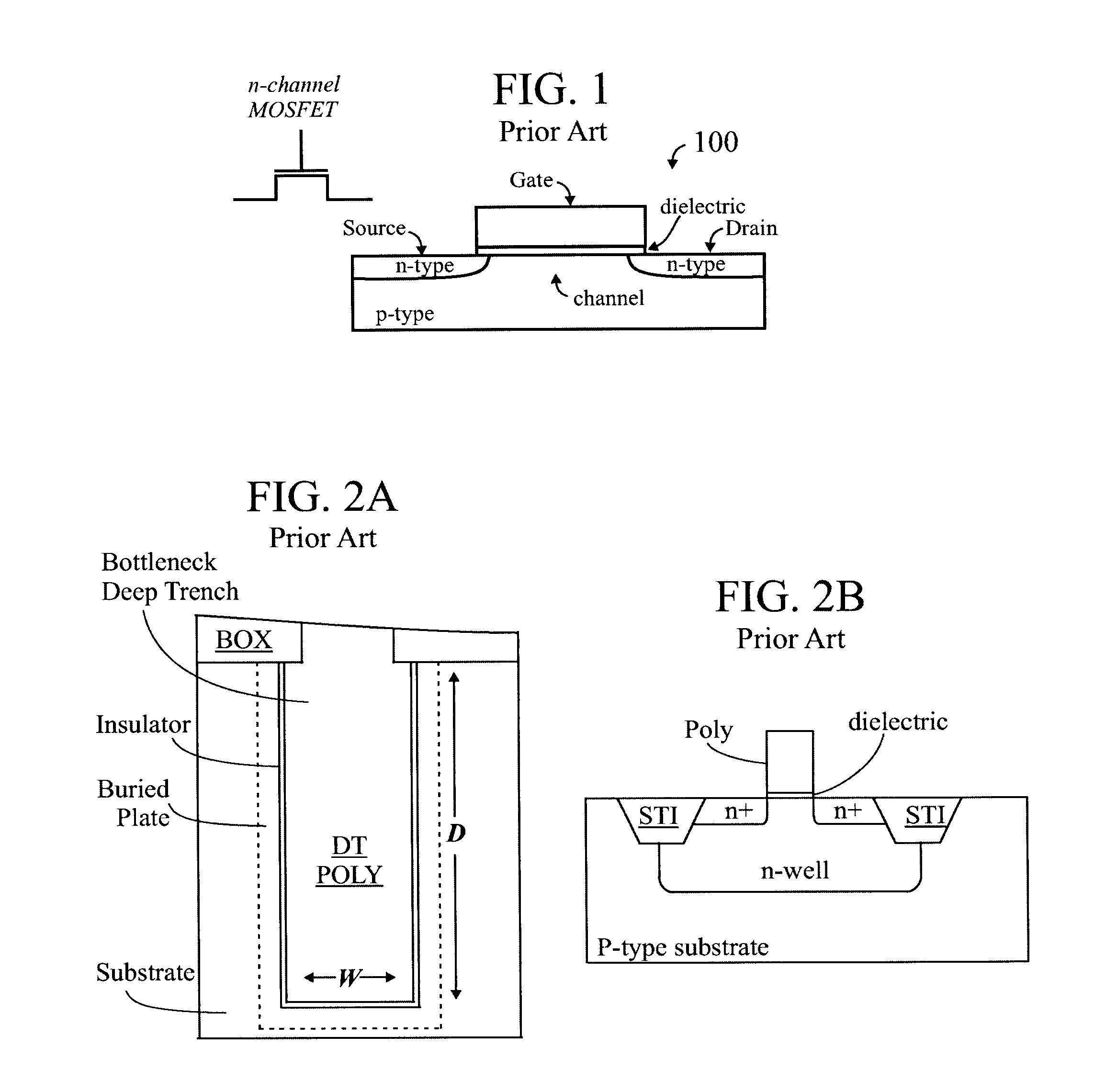

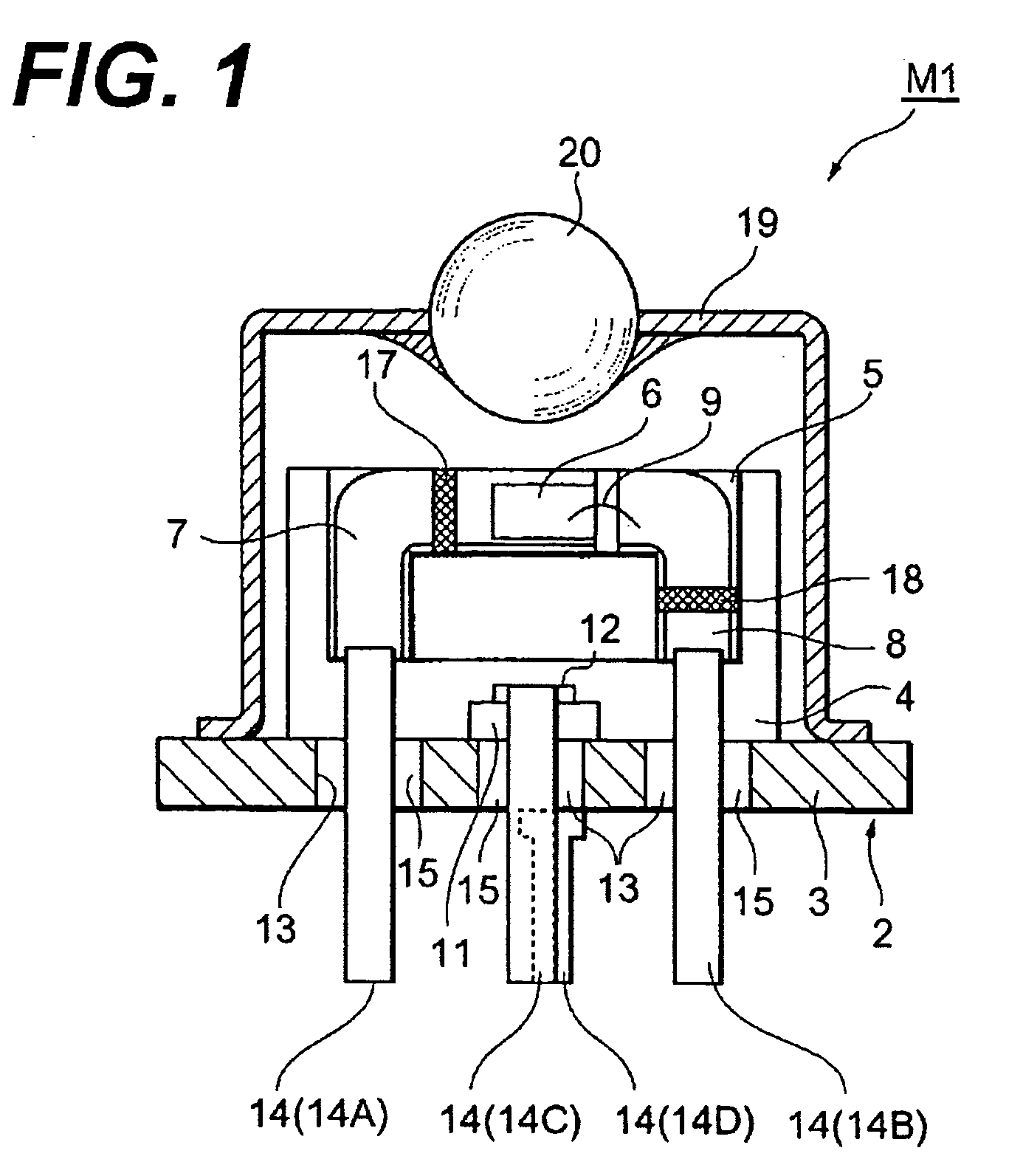

Shielding structure for use in a metal-oxide-semiconductor device

InactiveUS20050017298A1Improve high frequency performanceLow costTransistorSemiconductor/solid-state device detailsSemiconductorCmos process

An MOS device is formed comprising a semiconductor layer of a first conductivity type, a first source / drain region of a second conductivity type formed in the semiconductor layer, and a second source / drain region of the second conductivity type formed in the semiconductor layer and spaced apart from the first source / drain region. The MOS device further comprises a gate formed proximate an upper surface of the semiconductor layer and at least partially between the first and second source / drain regions, and a shielding structure formed proximate the upper surface of the semiconductor layer and between the gate and the second source / drain region, the shielding structure being electrically connected to the first source / drain region, the shielding structure being spaced laterally from the gate and being non-overlapping relative to the gate. In this manner, the MOS device is substantially compatible with a CMOS process technology.

Owner:BELL SEMICON LLC

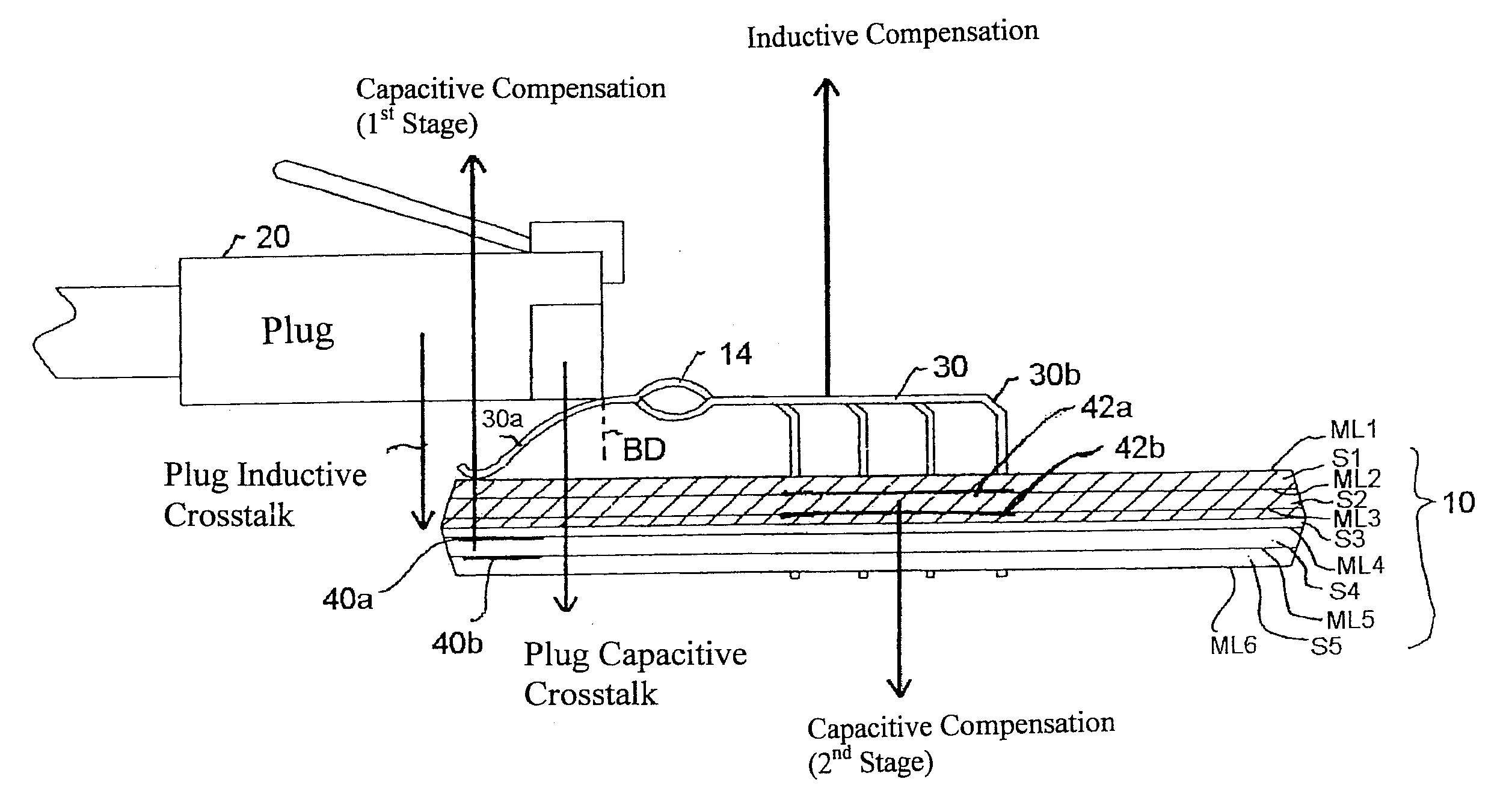

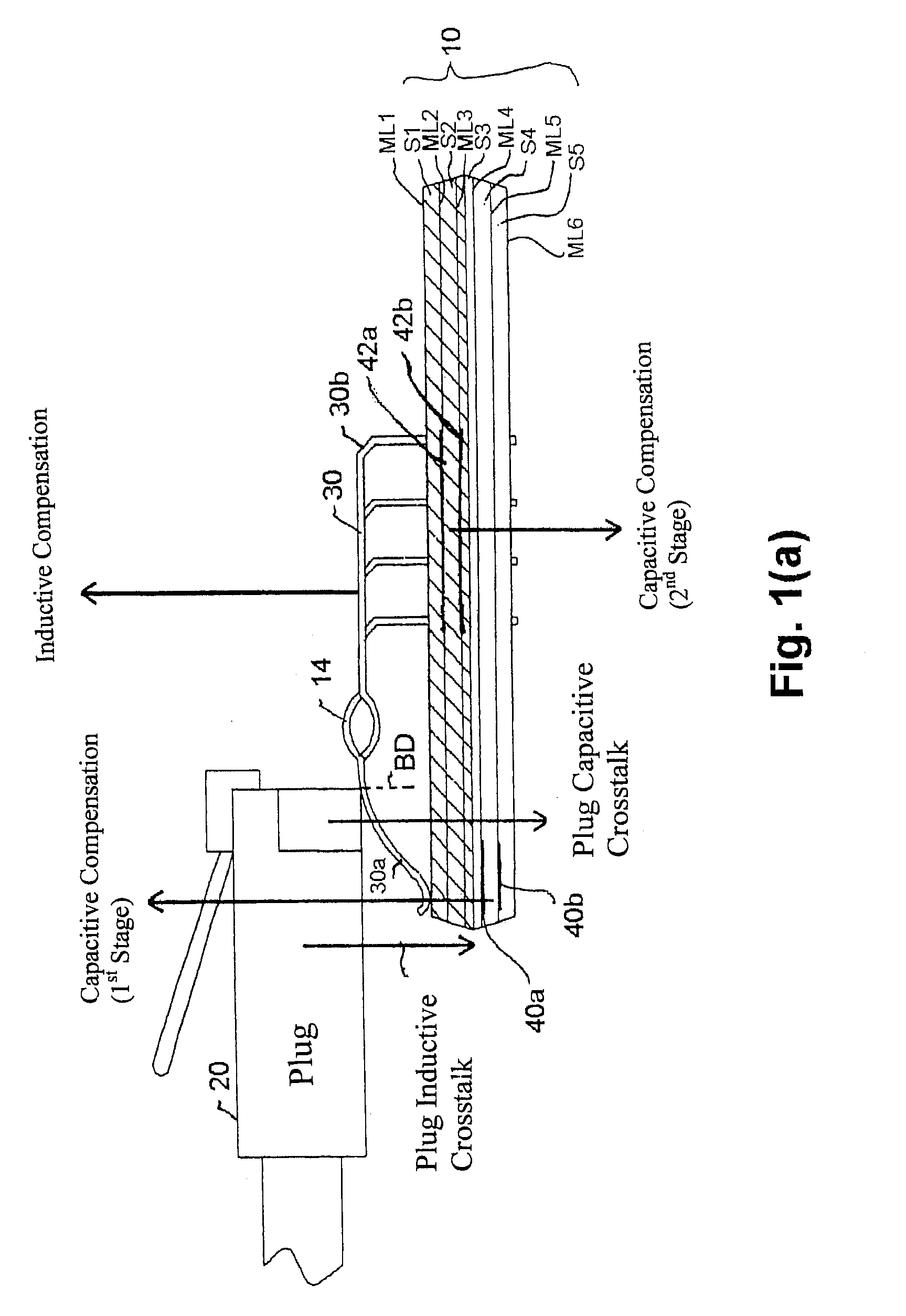

Next high frequency improvement using hybrid substrates of two materials with different dielectric constant frequency slopes

ActiveUS7265300B2Reducing NEXT in connectorsImprove high frequency performanceCross-talk/noise/interference reductionPrinted circuit aspectsConstant frequencyFrequency characteristic

Owner:COMMSCOPE INC

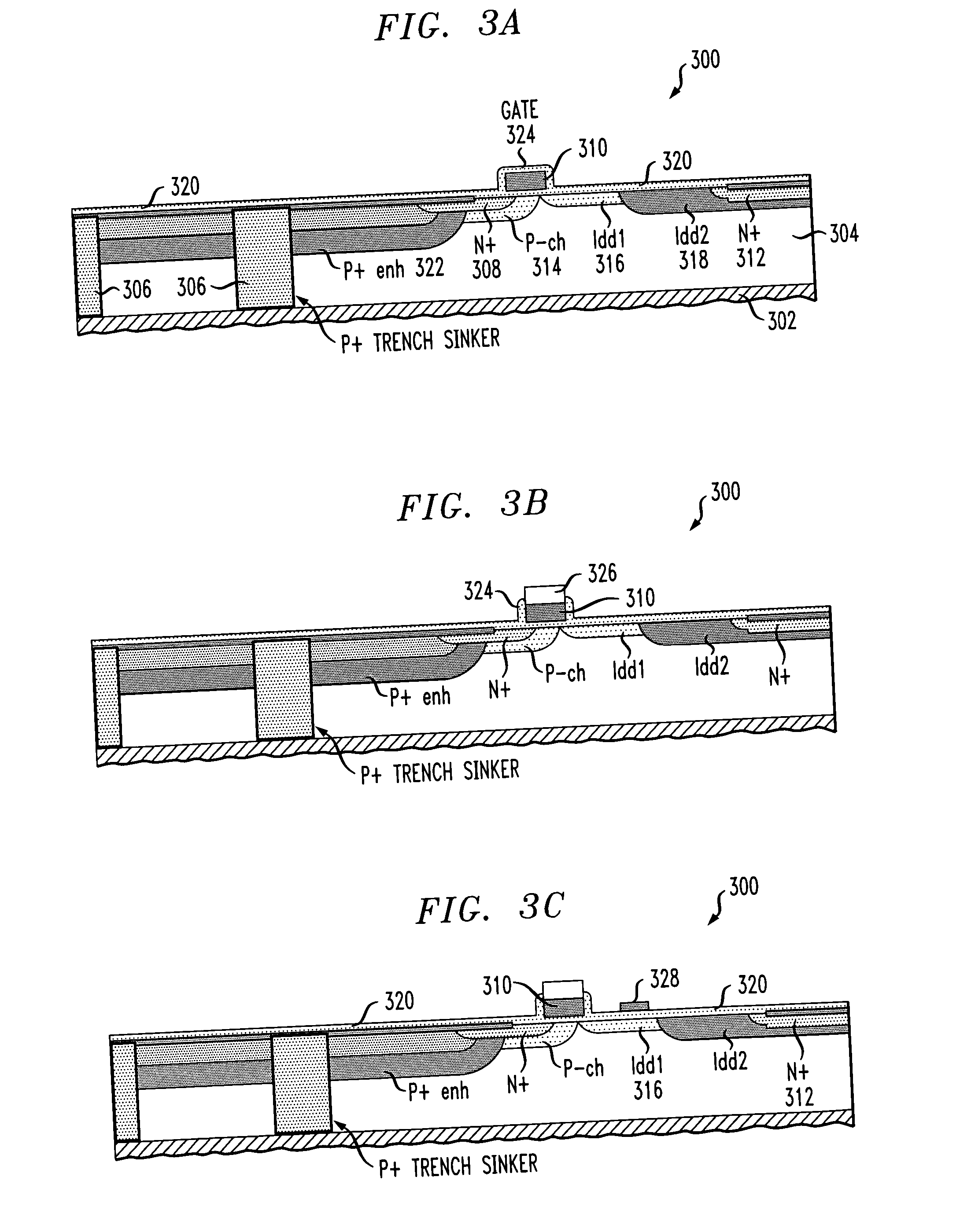

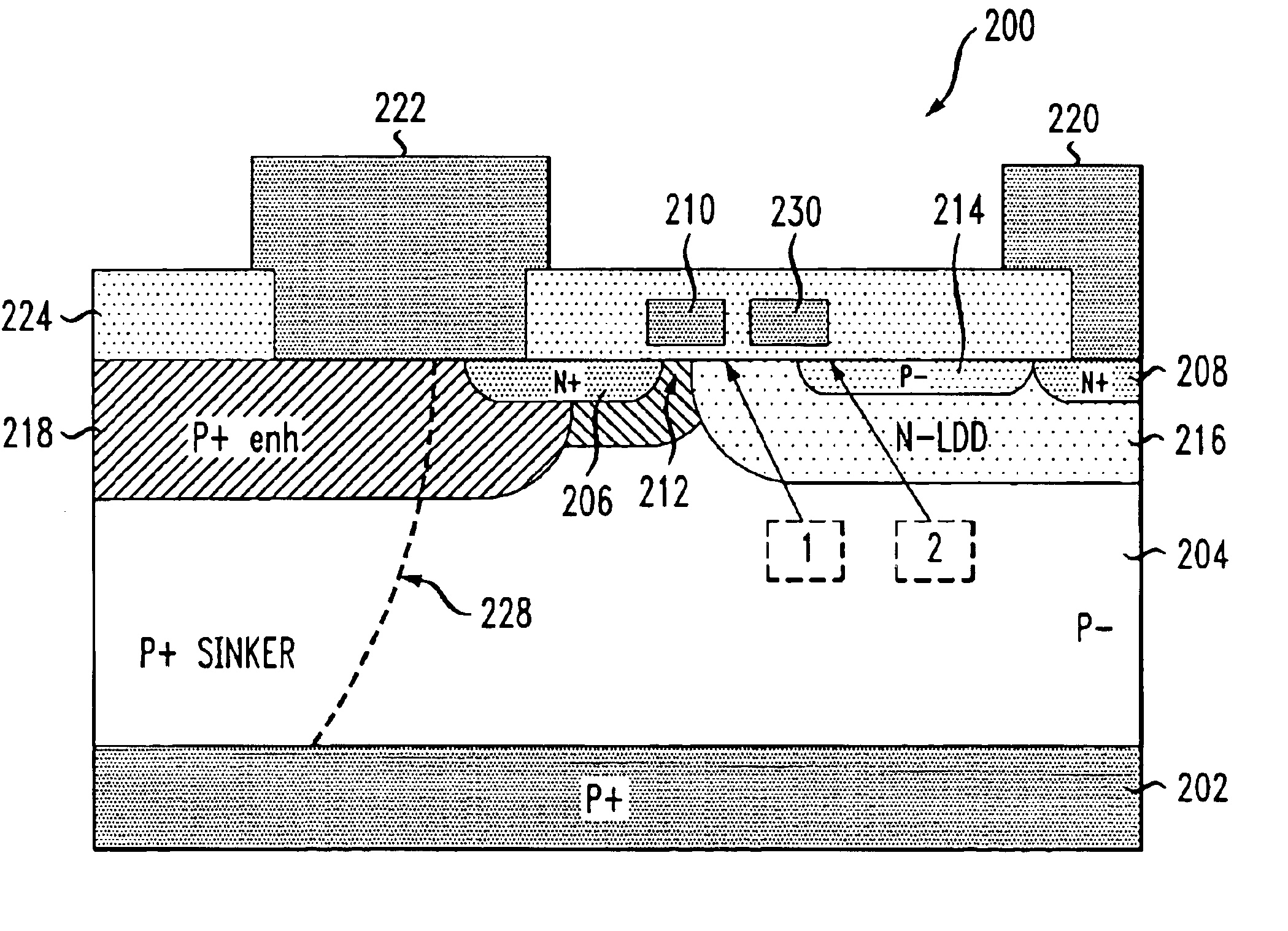

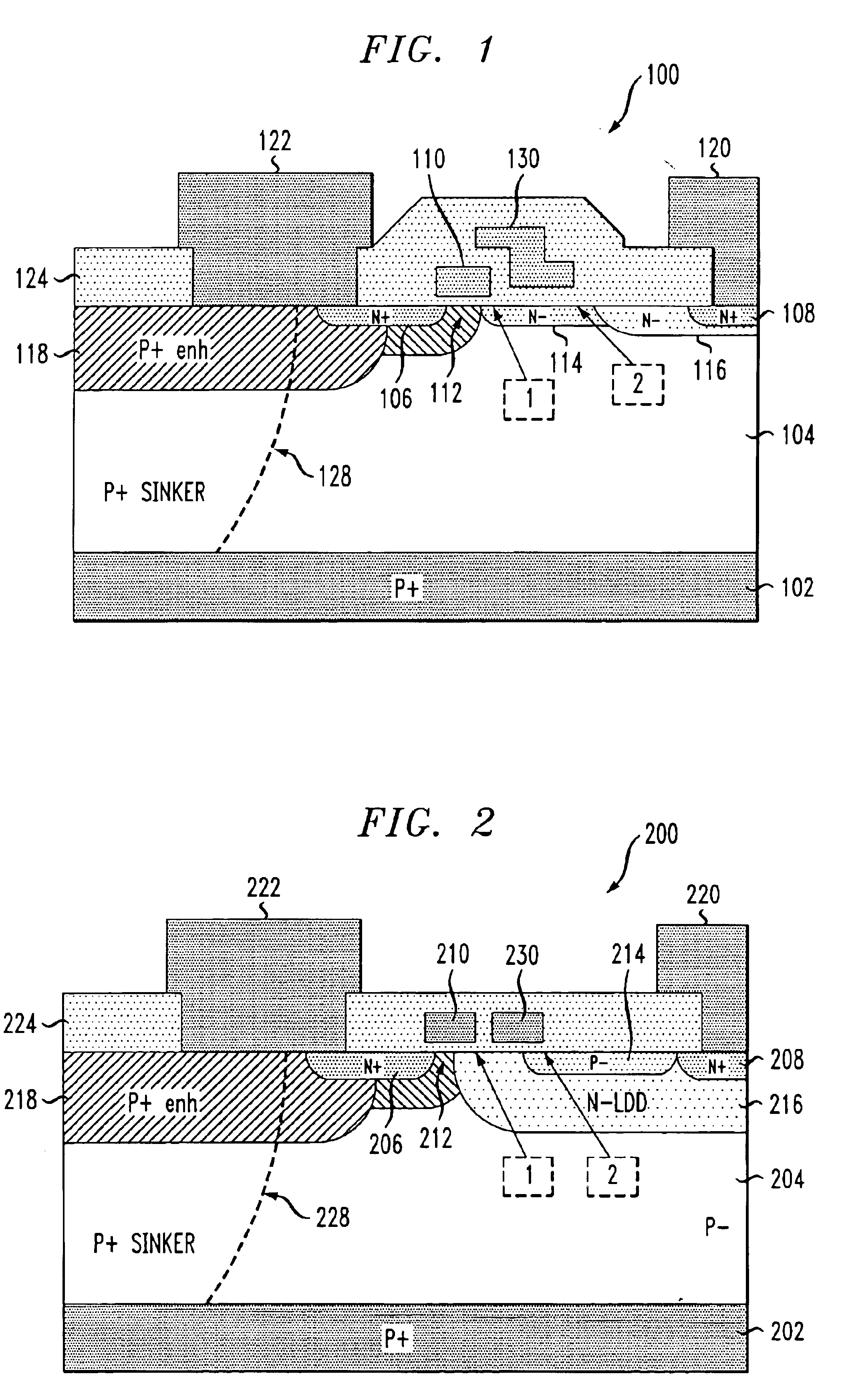

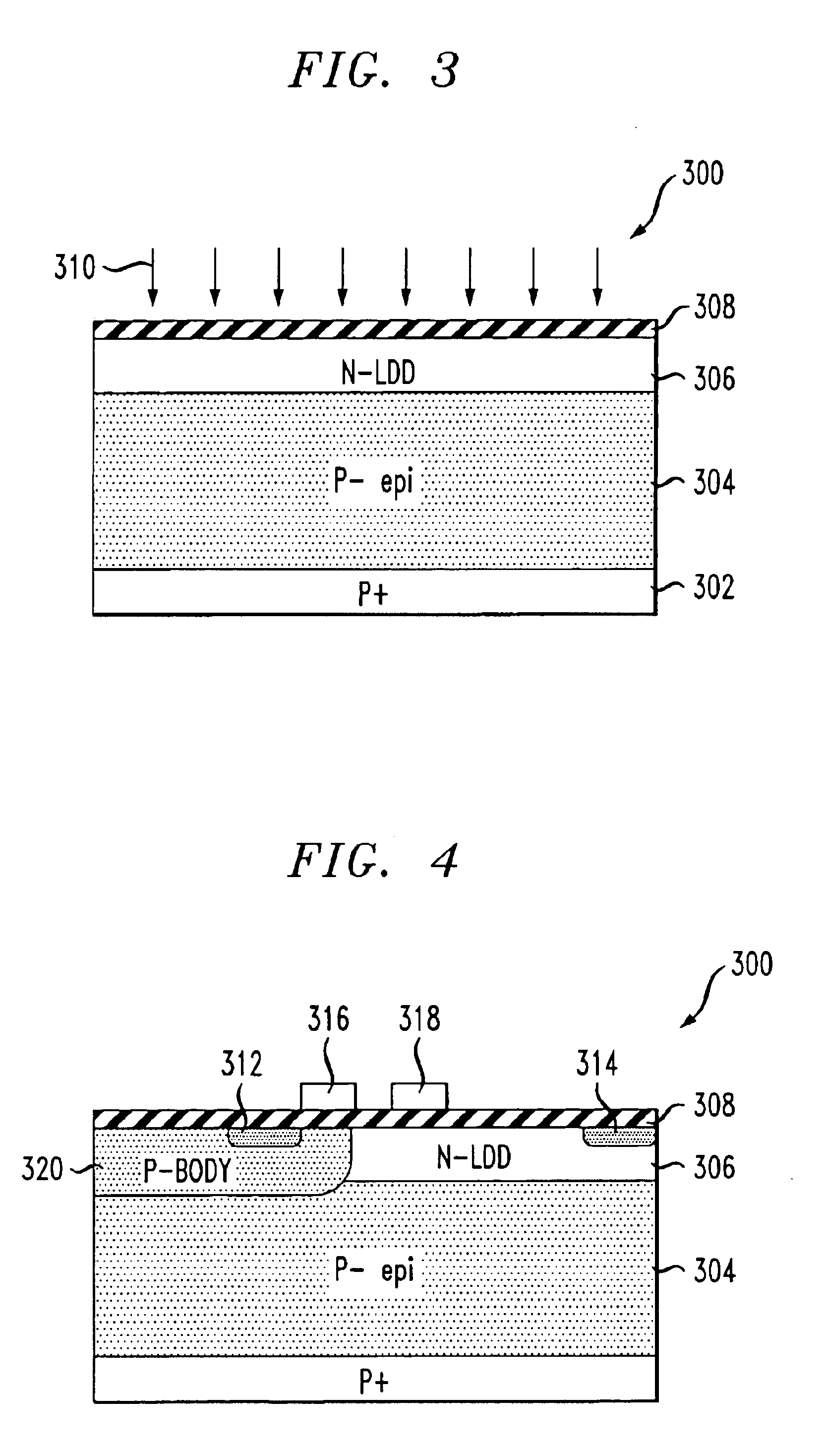

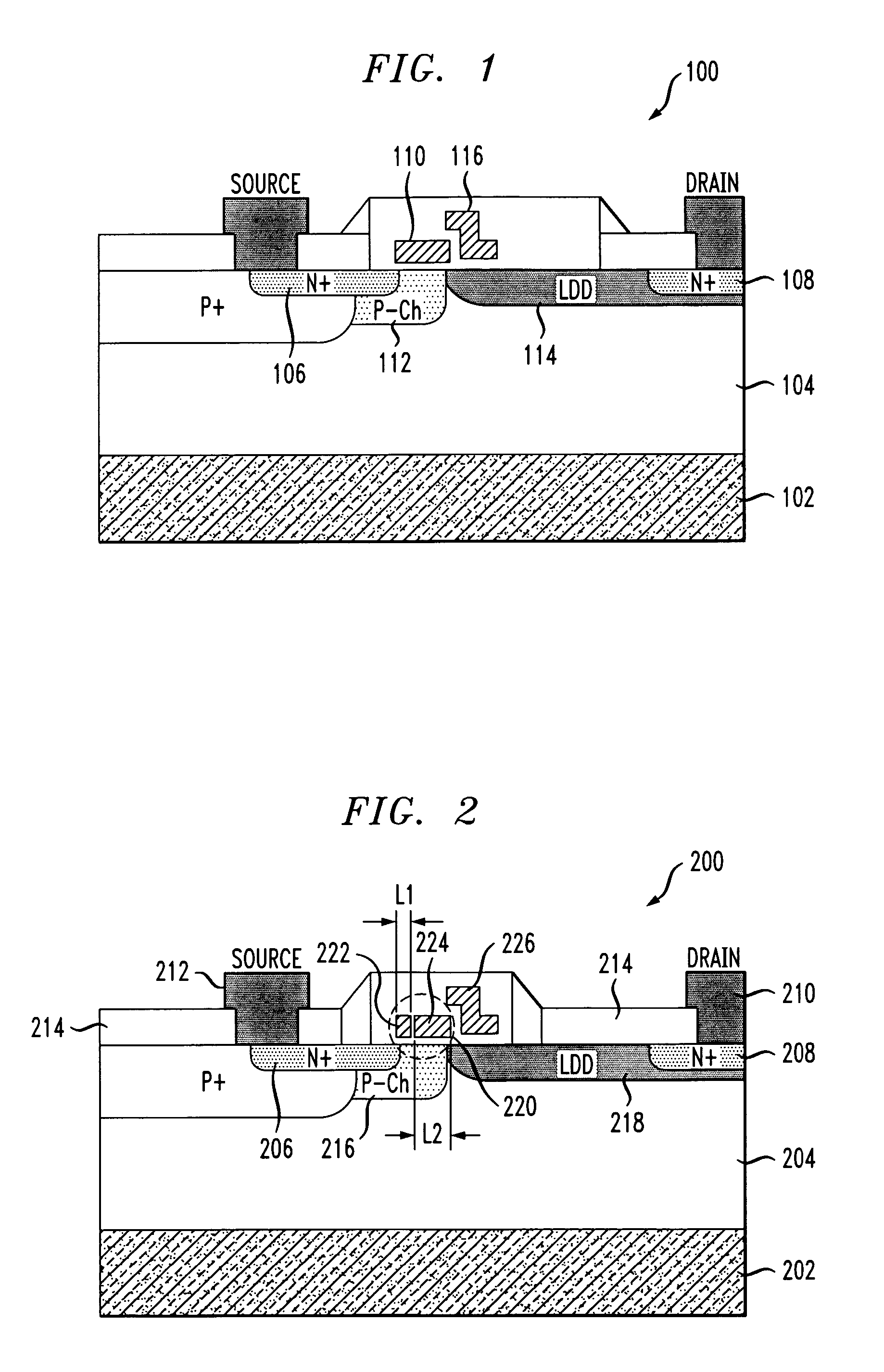

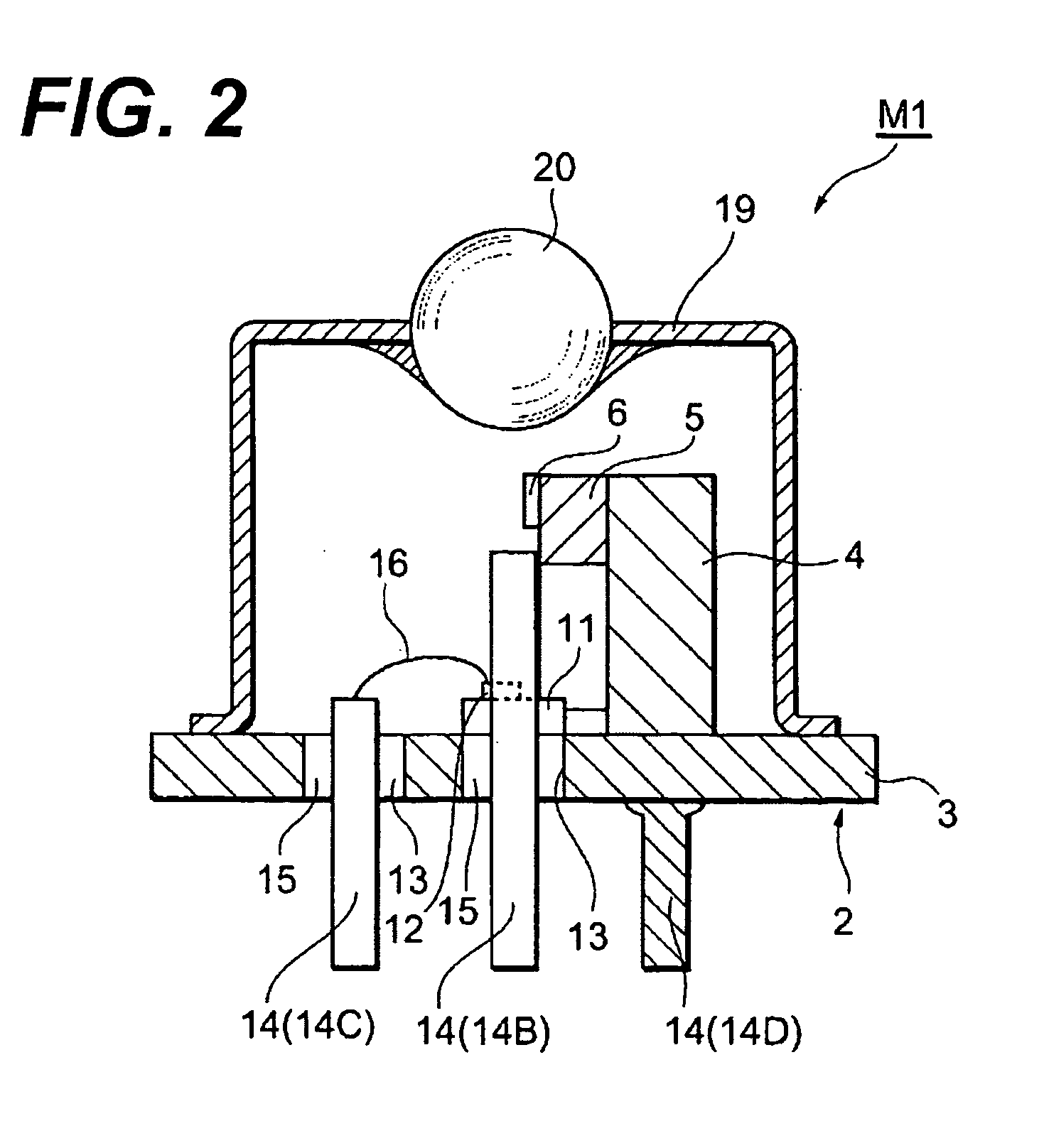

Graded conductive structure for use in a metal-oxide-semiconductor device

ActiveUS7148540B2Improve high frequency performanceLower breakdown voltageSemiconductor/solid-state device detailsSolid-state devicesSemiconductorMetal

An MOS device comprises a semiconductor layer of a first conductivity type and source and drain regions of a second conductivity type formed in the semiconductor layer, the source and drain regions being spaced apart from one another. A drift region is formed in the semiconductor layer proximate an upper surface of the semiconductor layer and between the source and drain regions, and a insulating layer is formed on the semiconductor layer above at least a portion of the drift region. A gate is formed on the insulating layer and at least partially between the source and drift regions. The MOS device further includes a conductive structure comprising a first end formed on the insulating layer and spaced apart from the gate, and a second end formed on the insulating layer and extending laterally toward the drain region above at least a portion of the drift region. The conductive structure is configured such that a thickness of the insulating layer under the second end of the conductive structure increases as the second end extends toward the drain region.

Owner:BELL SEMICON LLC

Metal-oxide-semiconductor device including a buried lightly-doped drain region

InactiveUS6927453B2Improve performanceImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesCondensed matter physicsSemiconductor

Owner:BELL SEMICON LLC

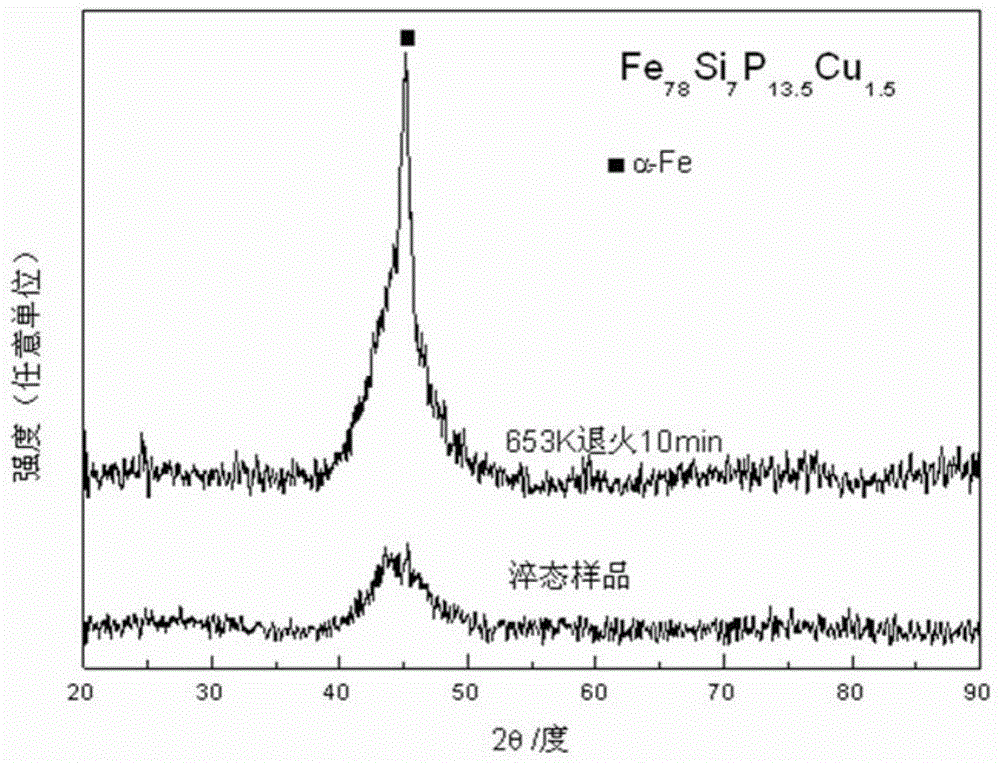

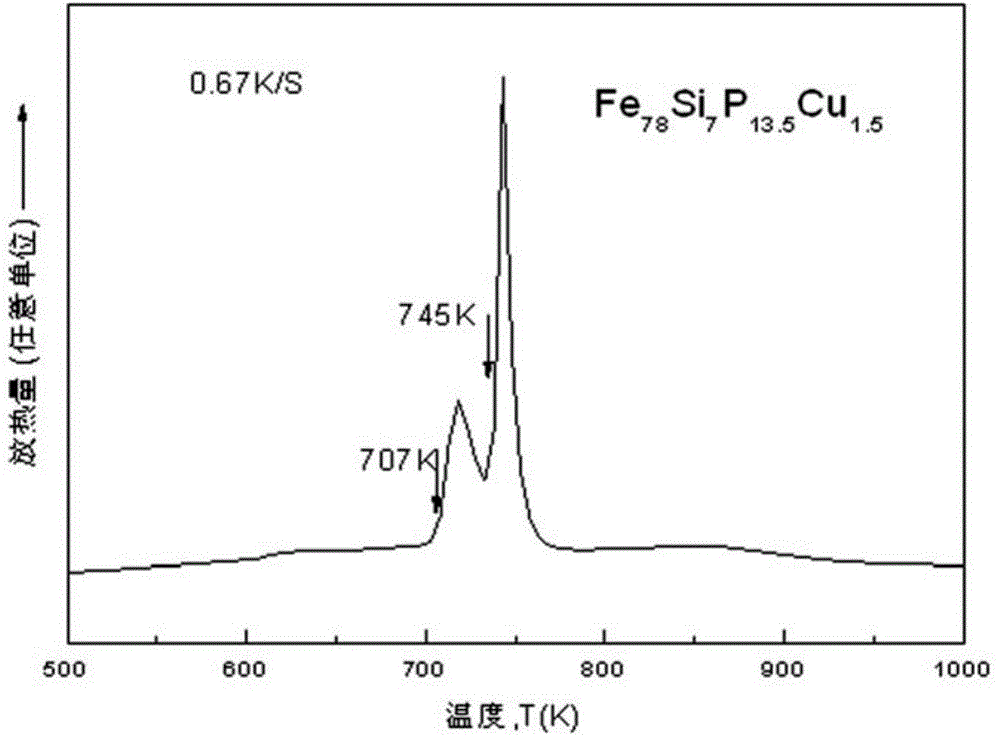

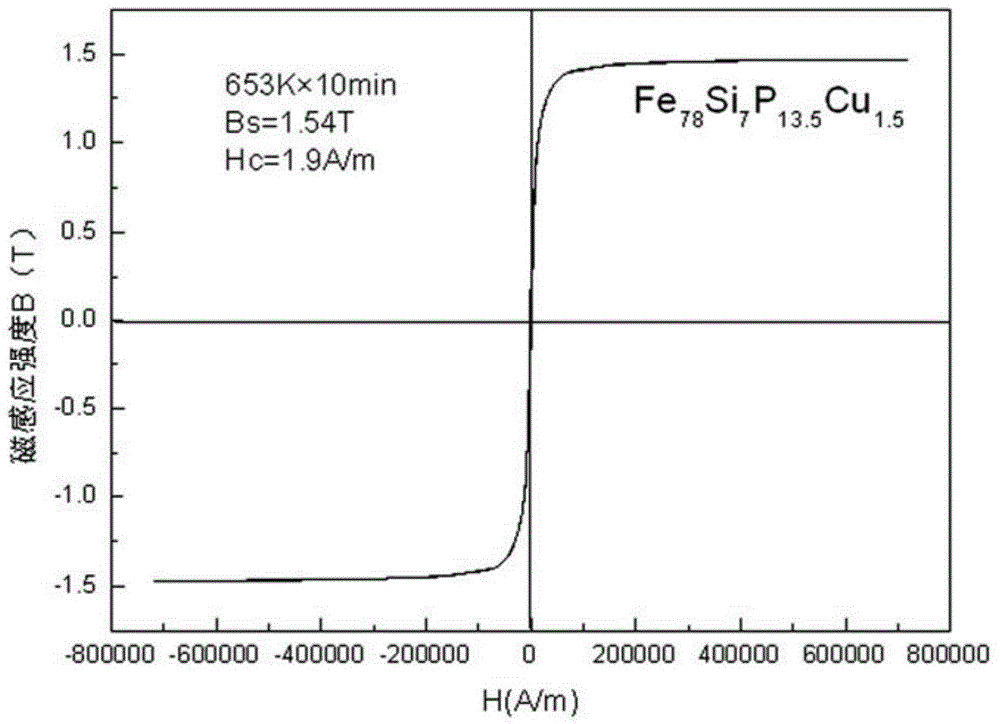

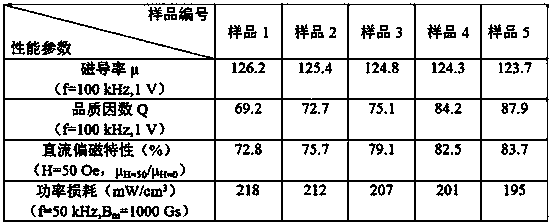

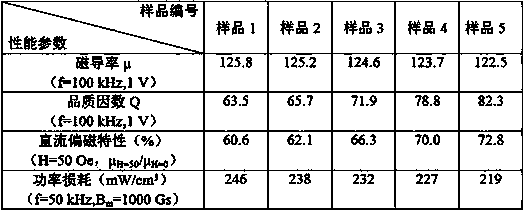

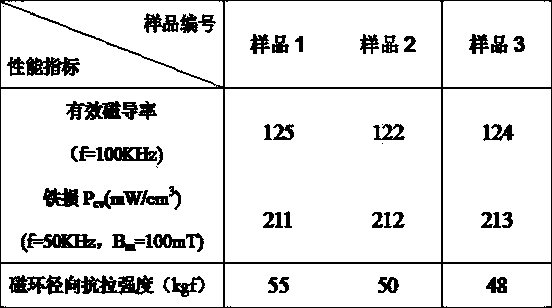

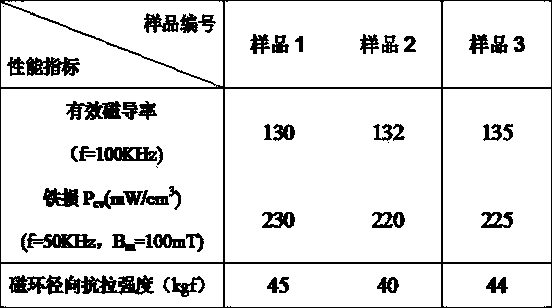

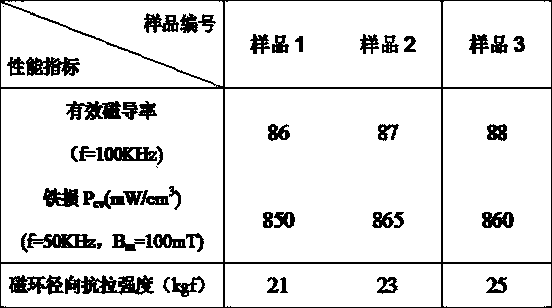

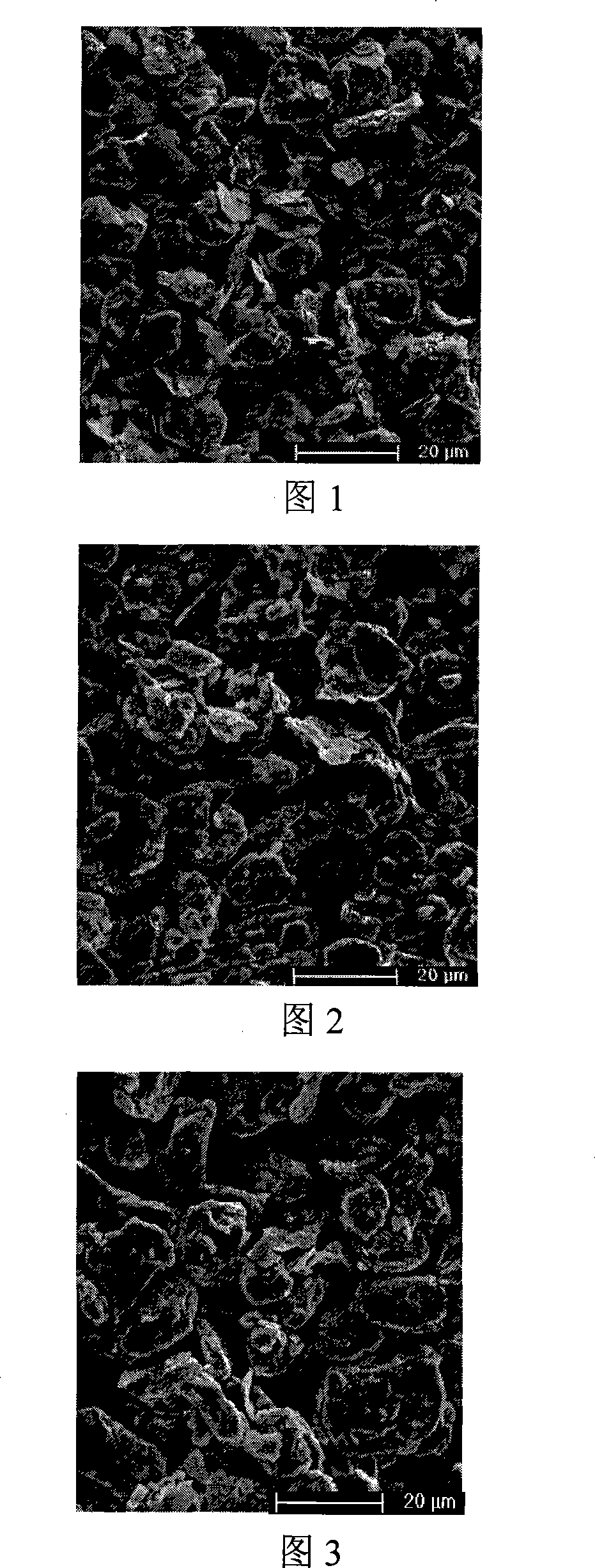

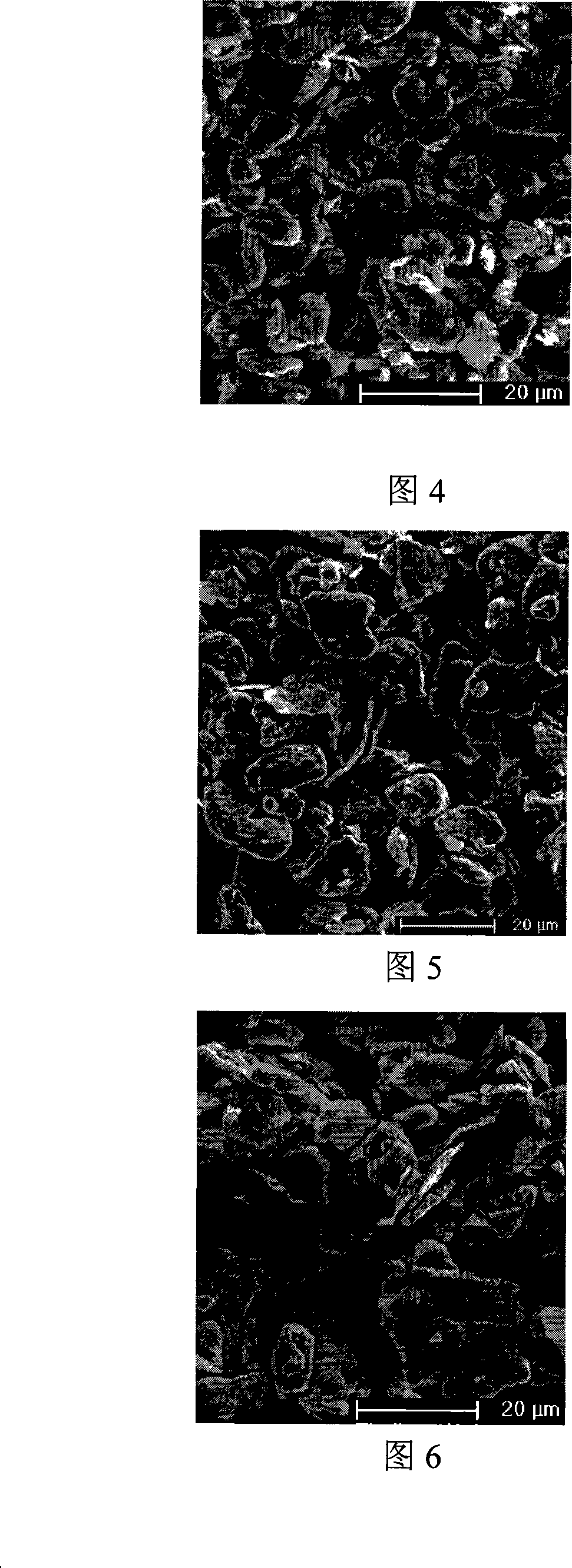

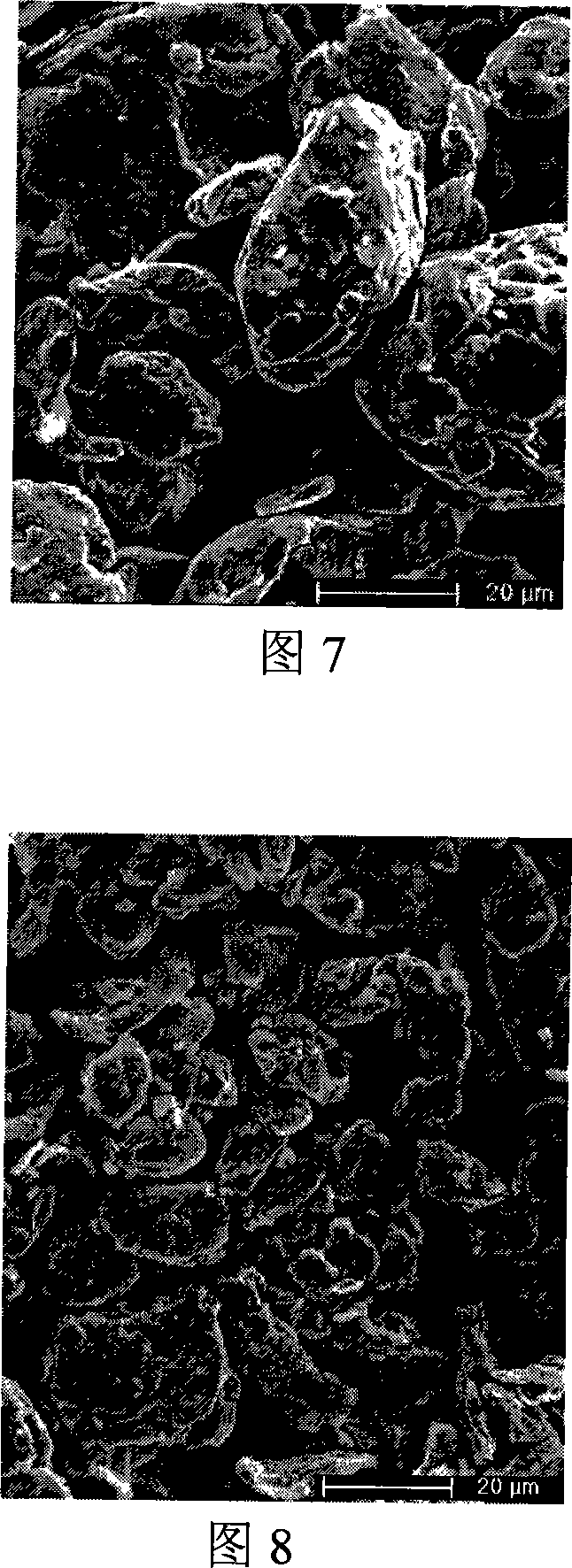

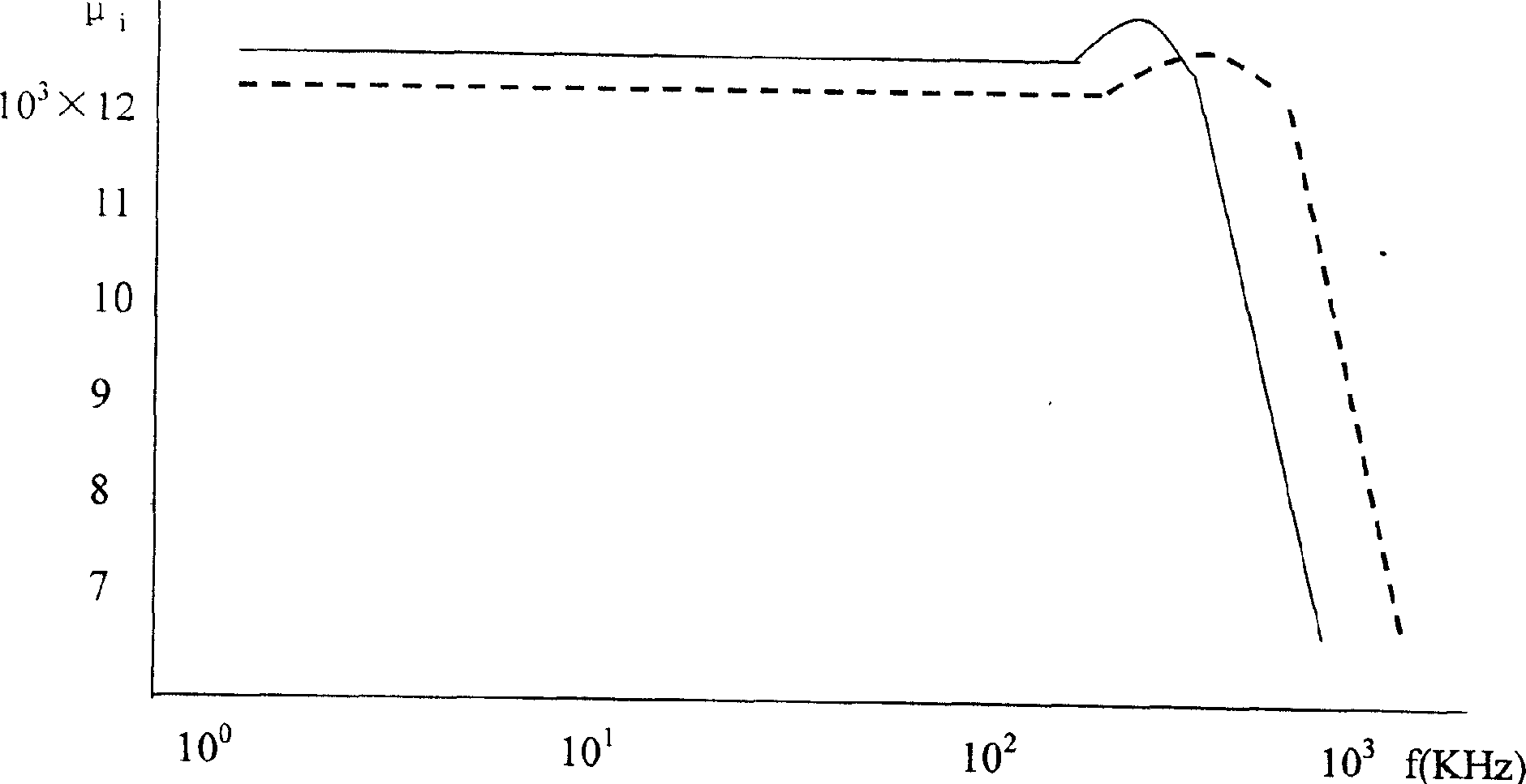

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

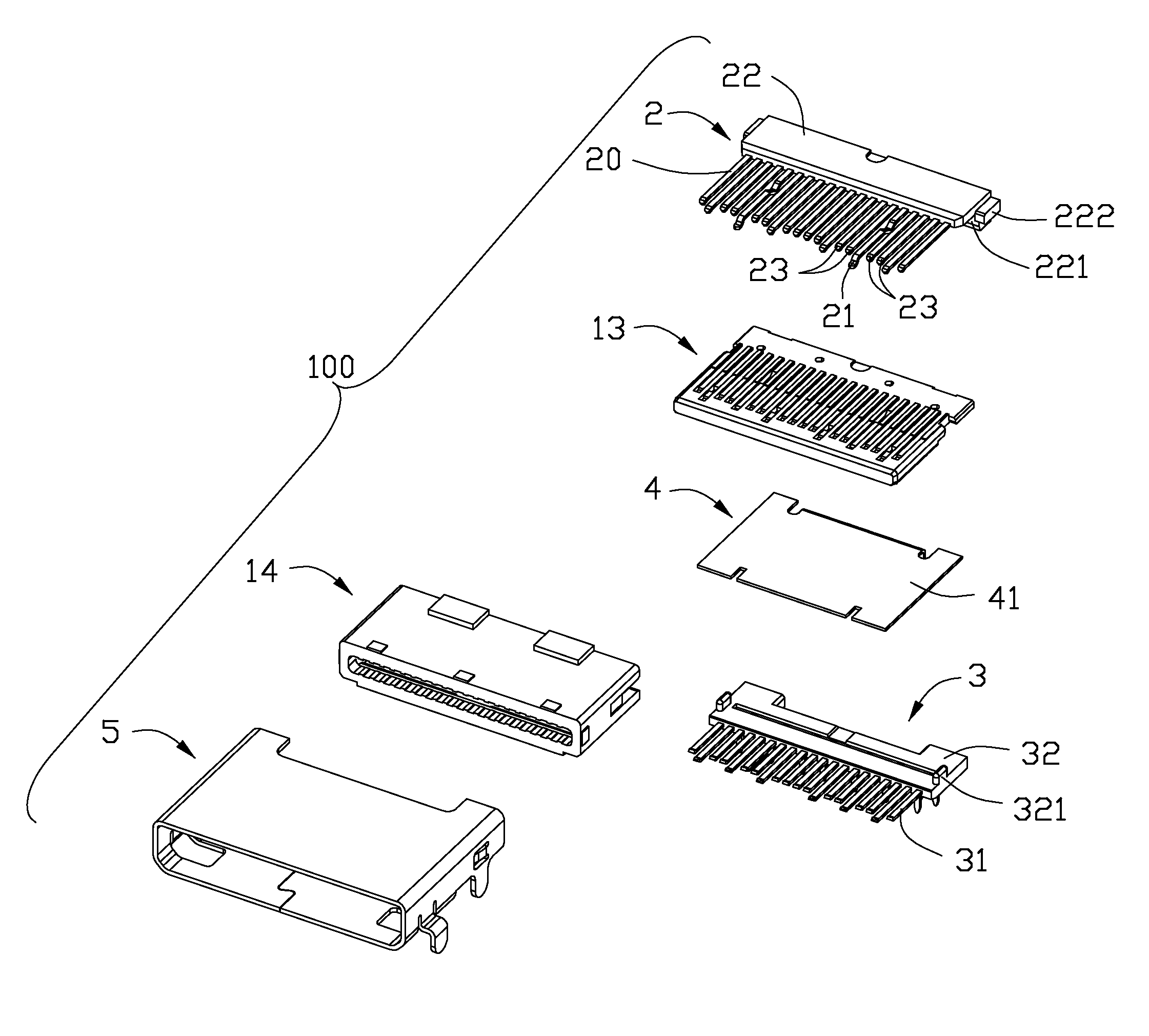

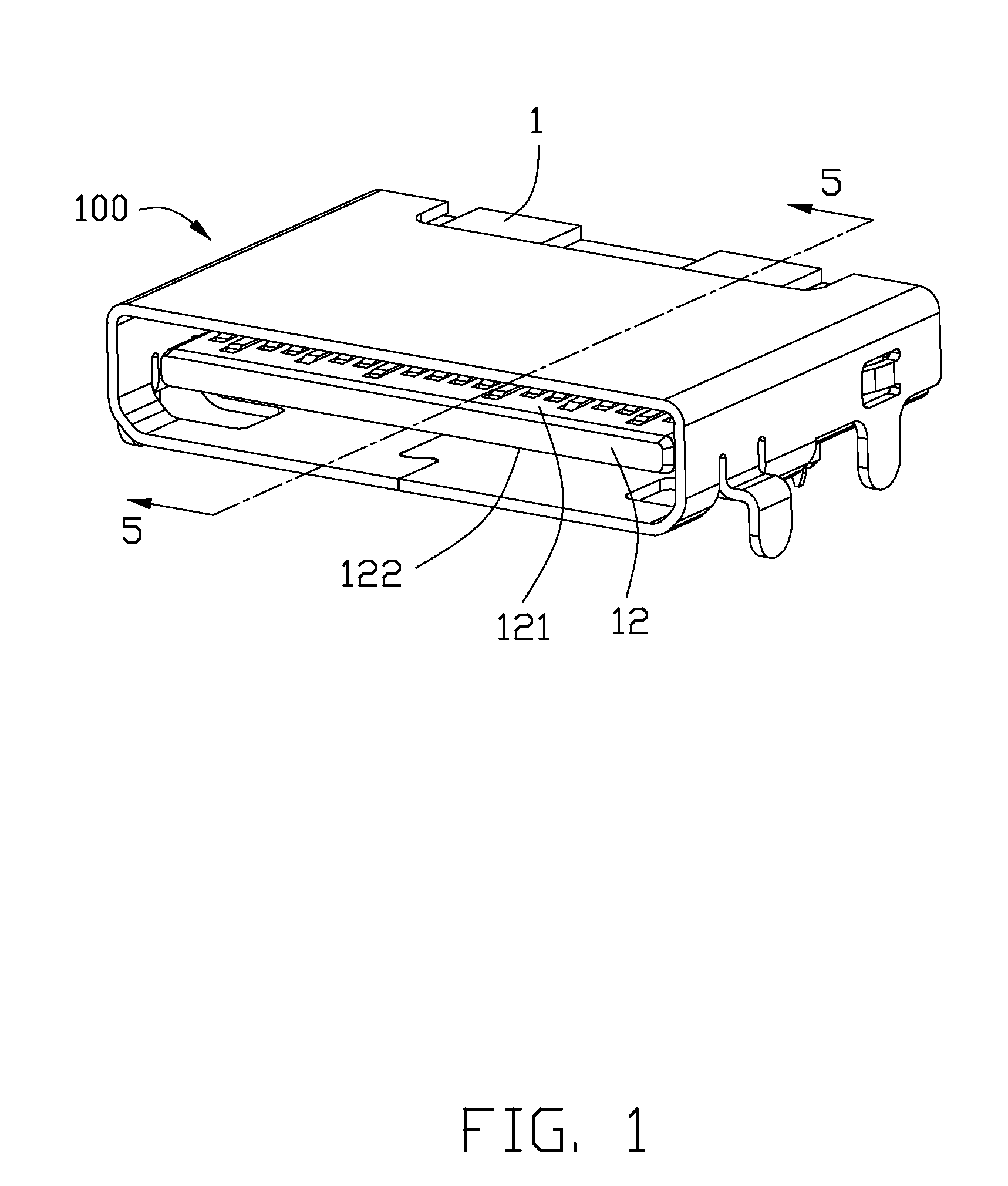

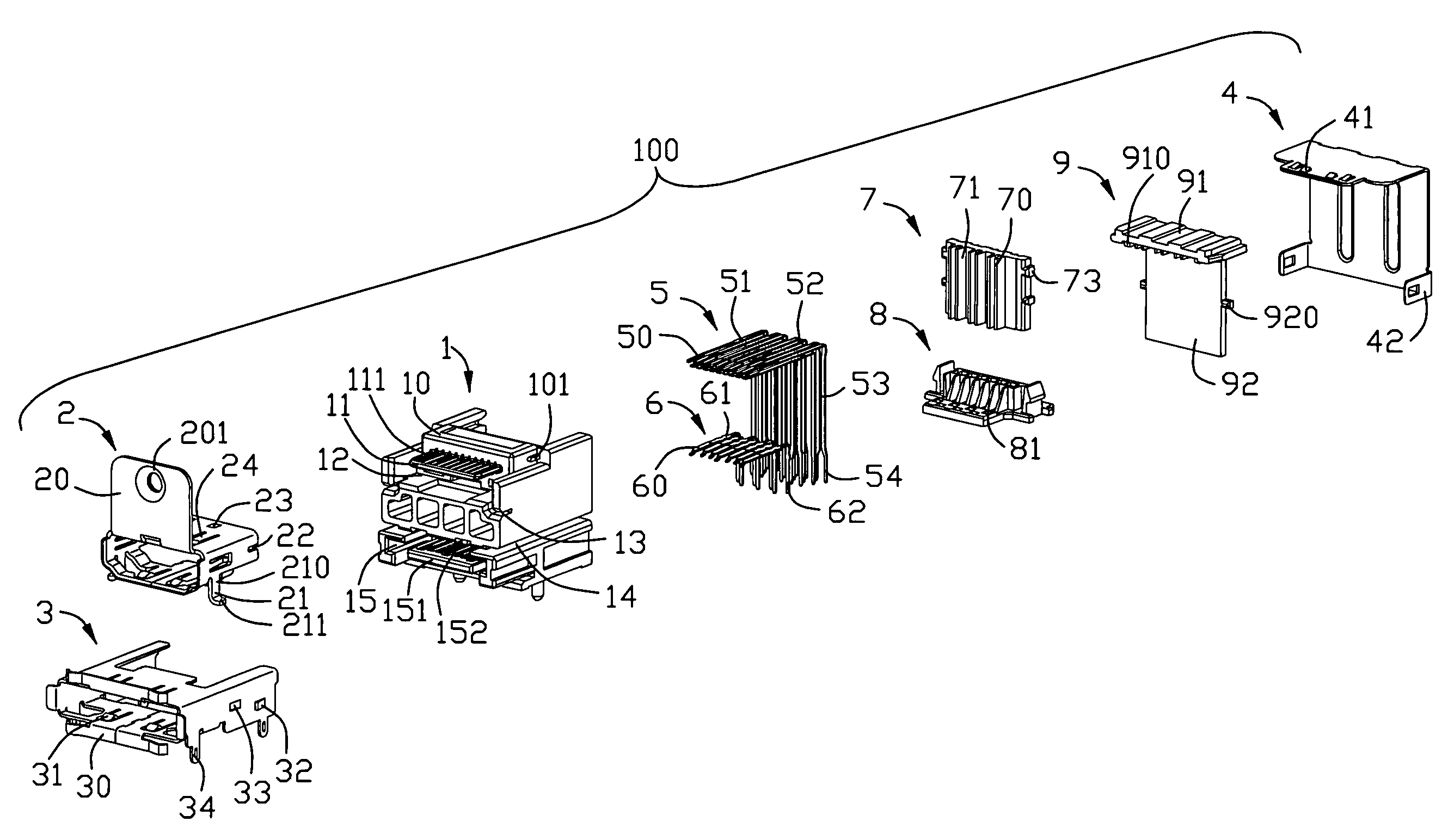

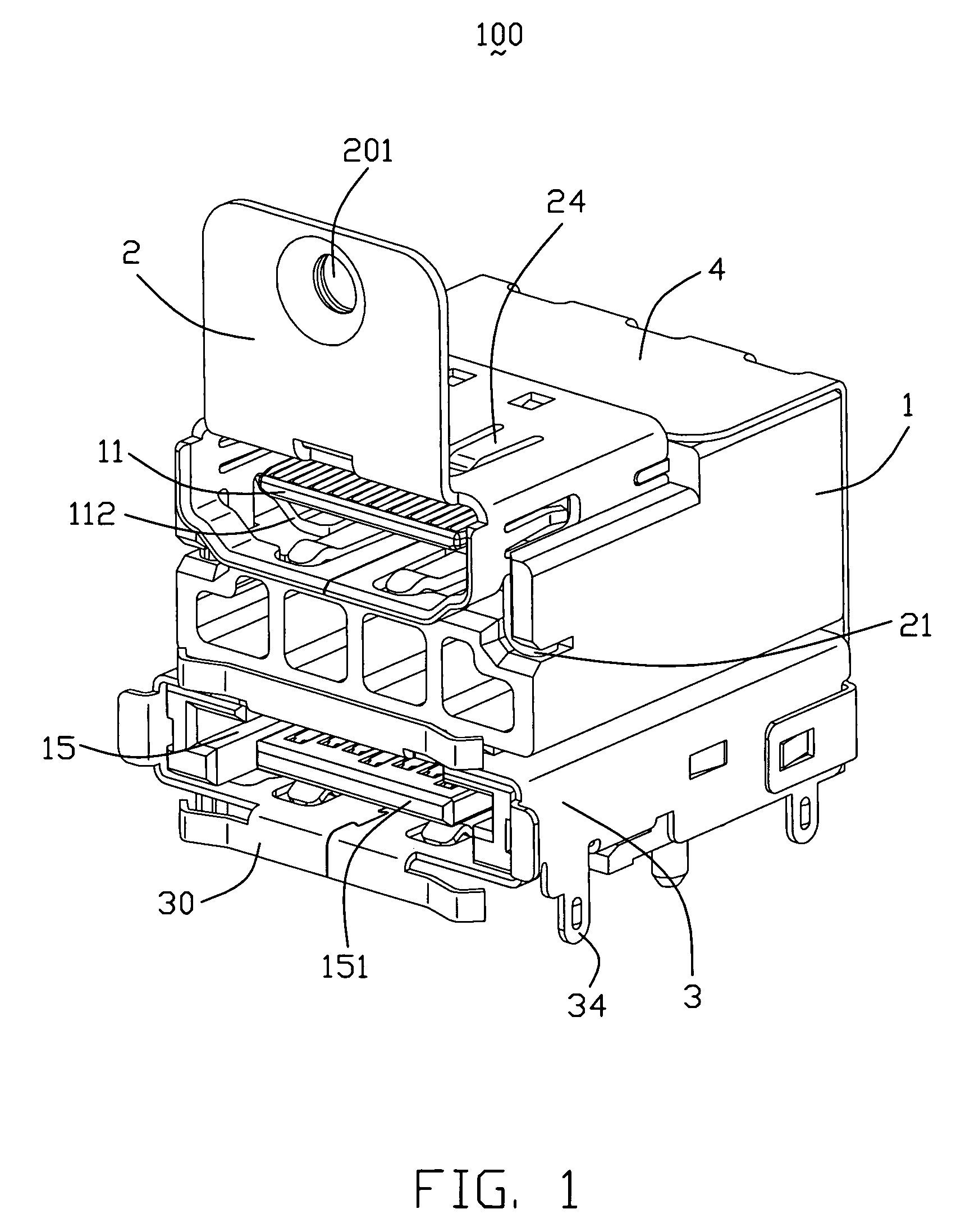

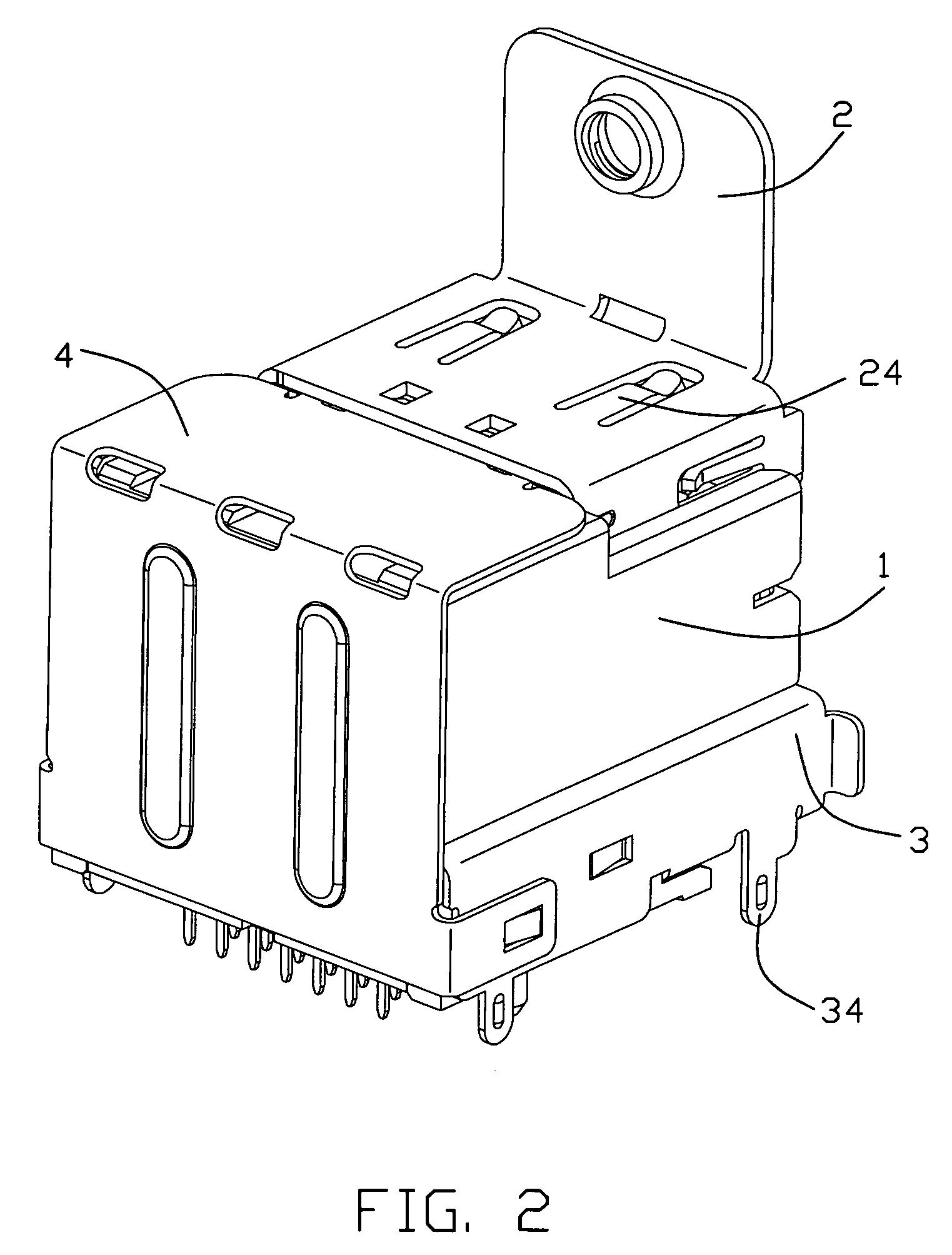

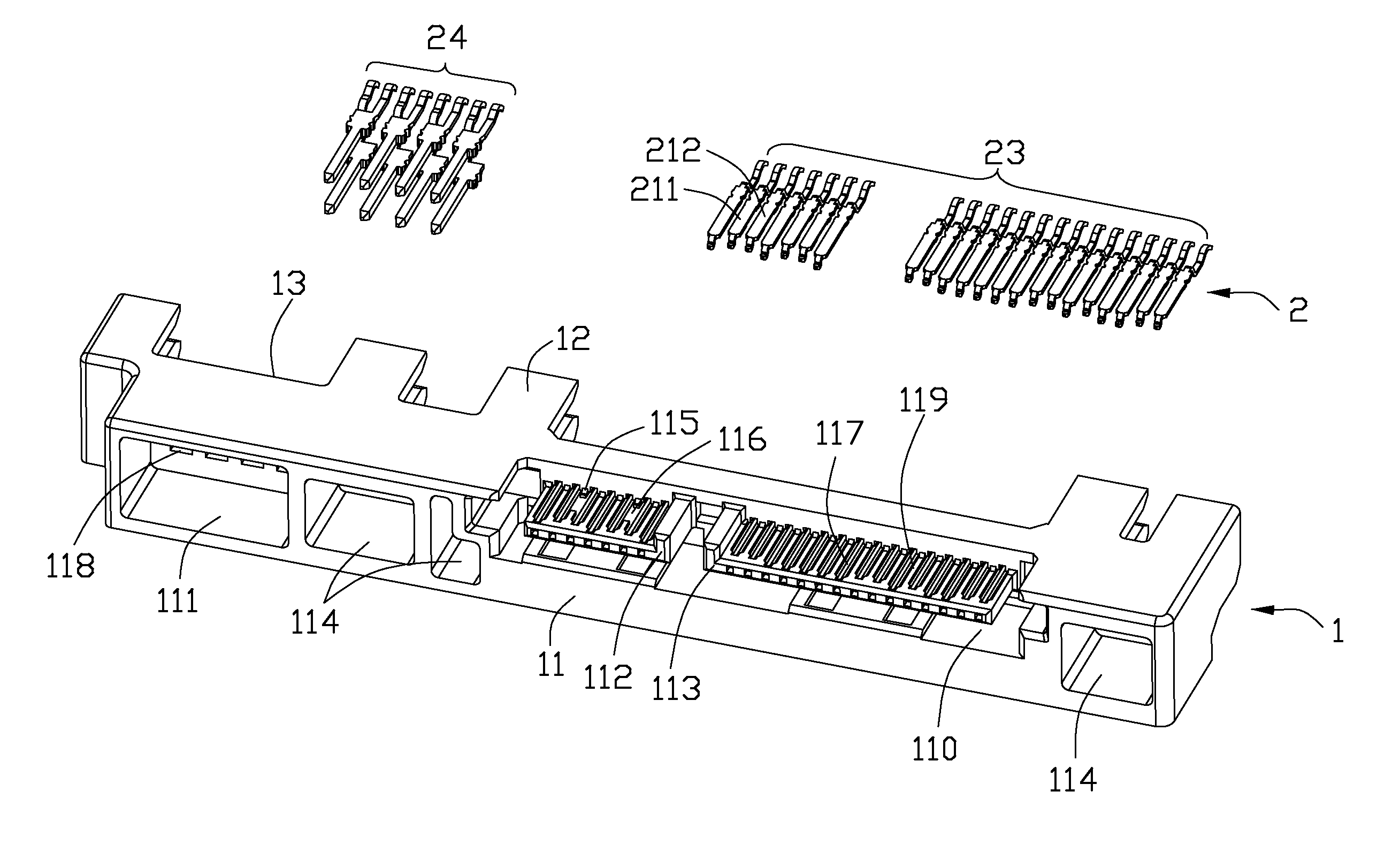

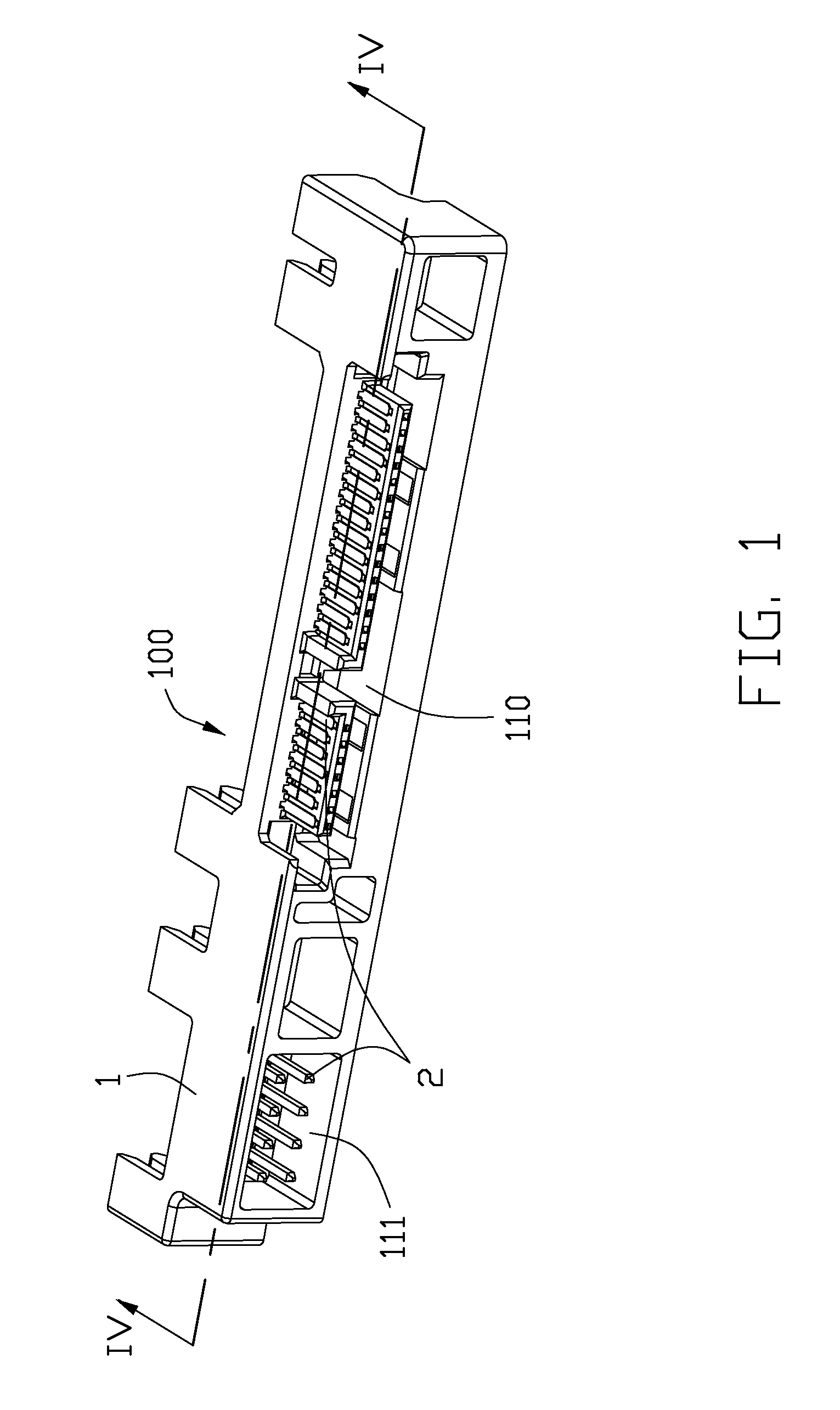

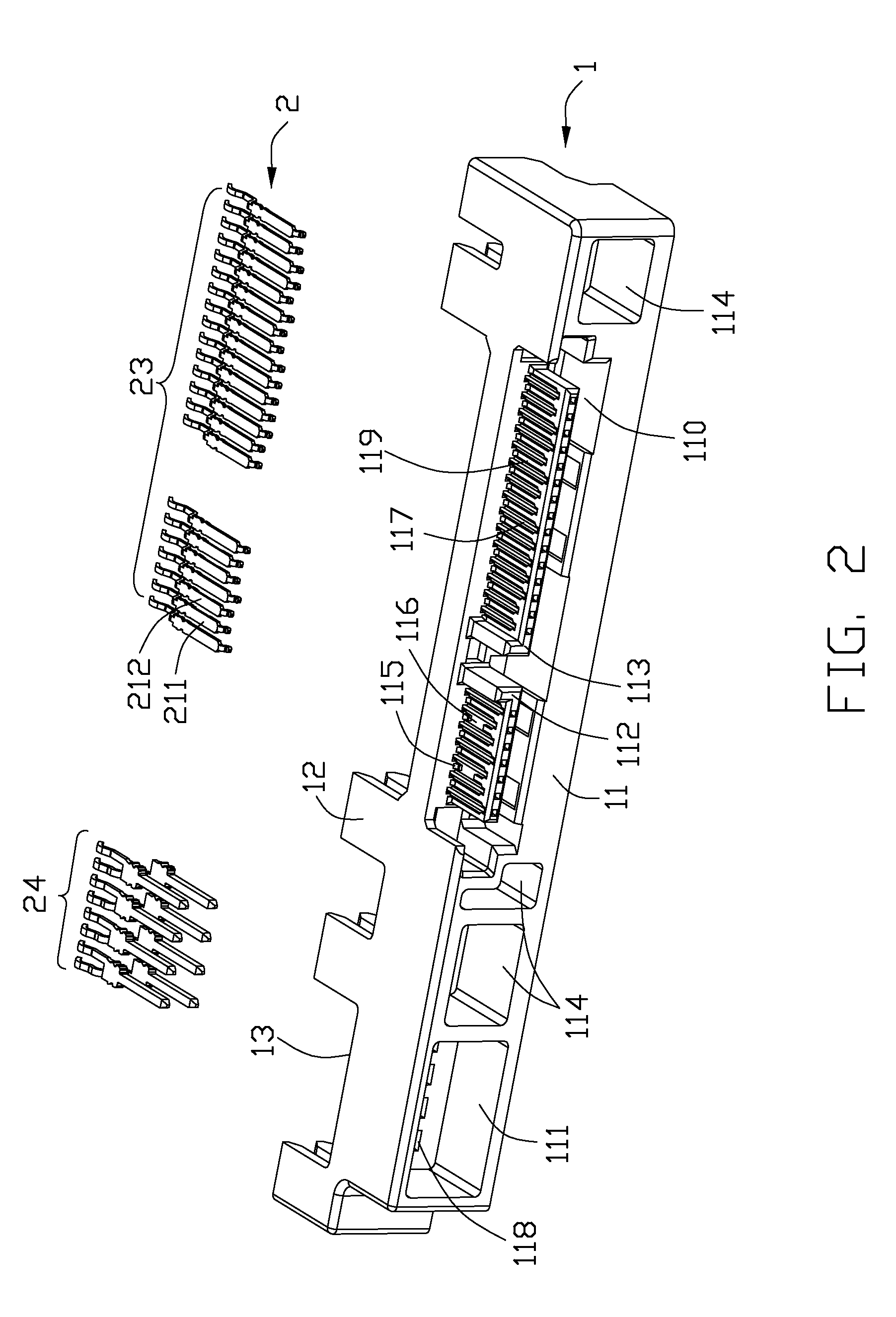

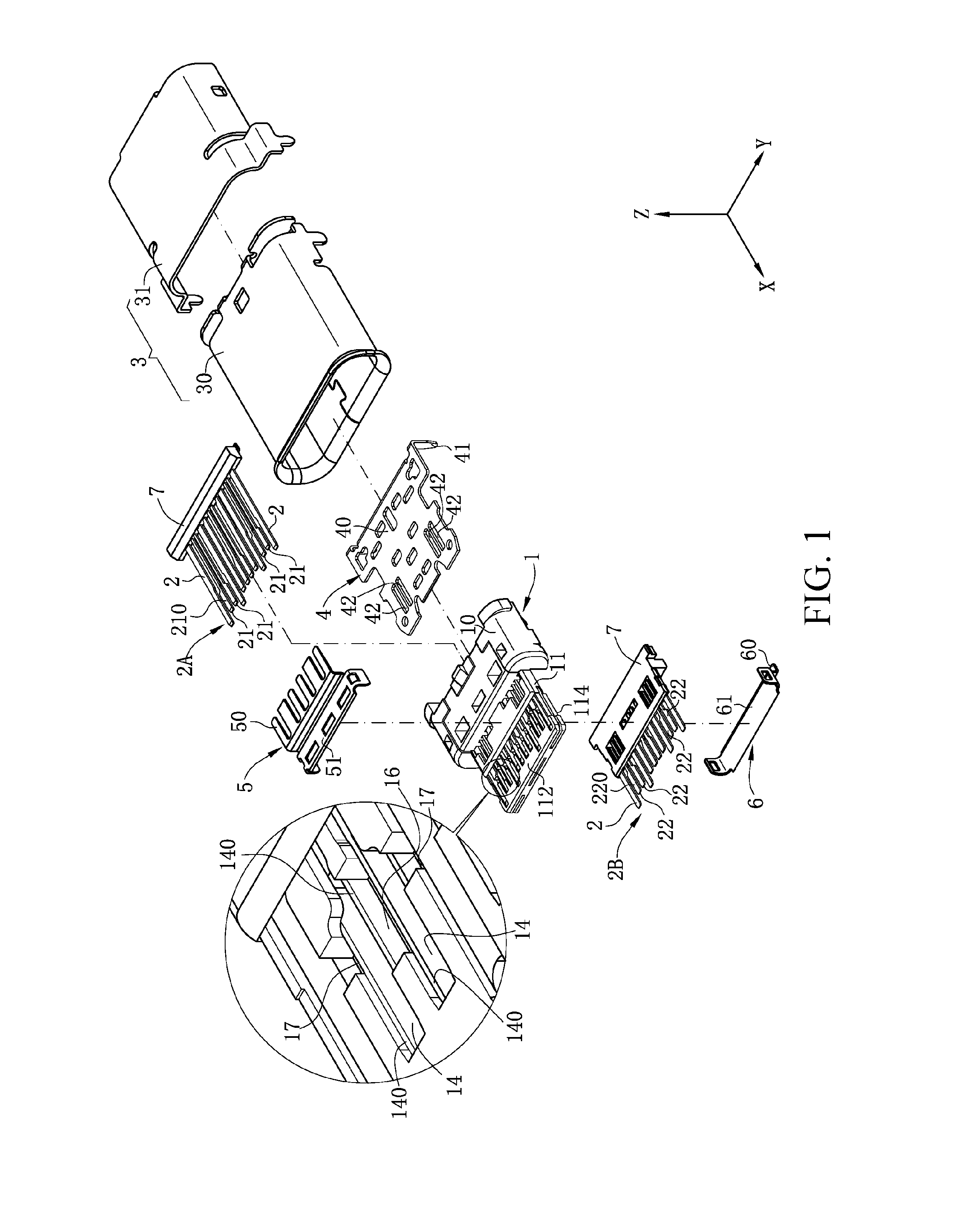

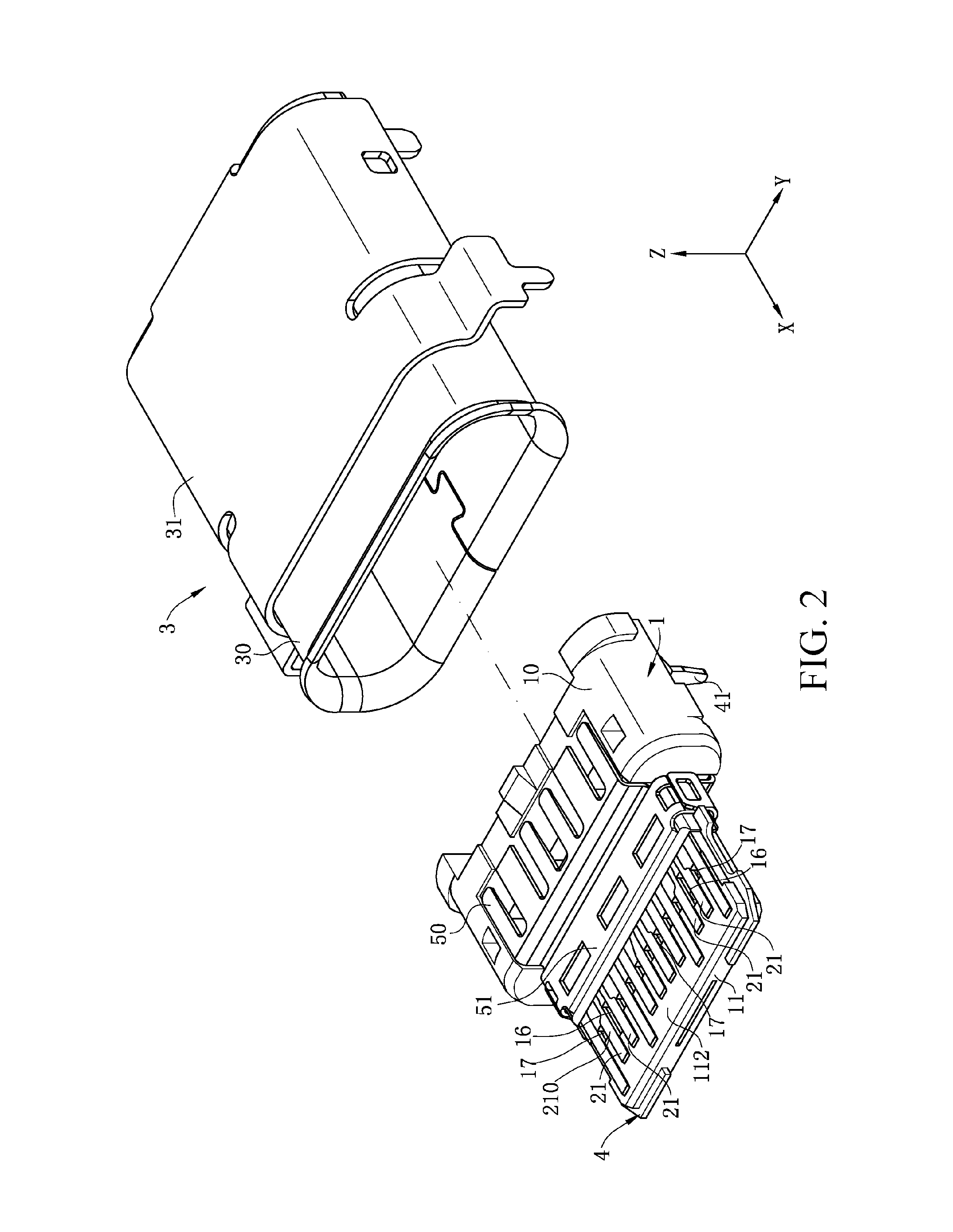

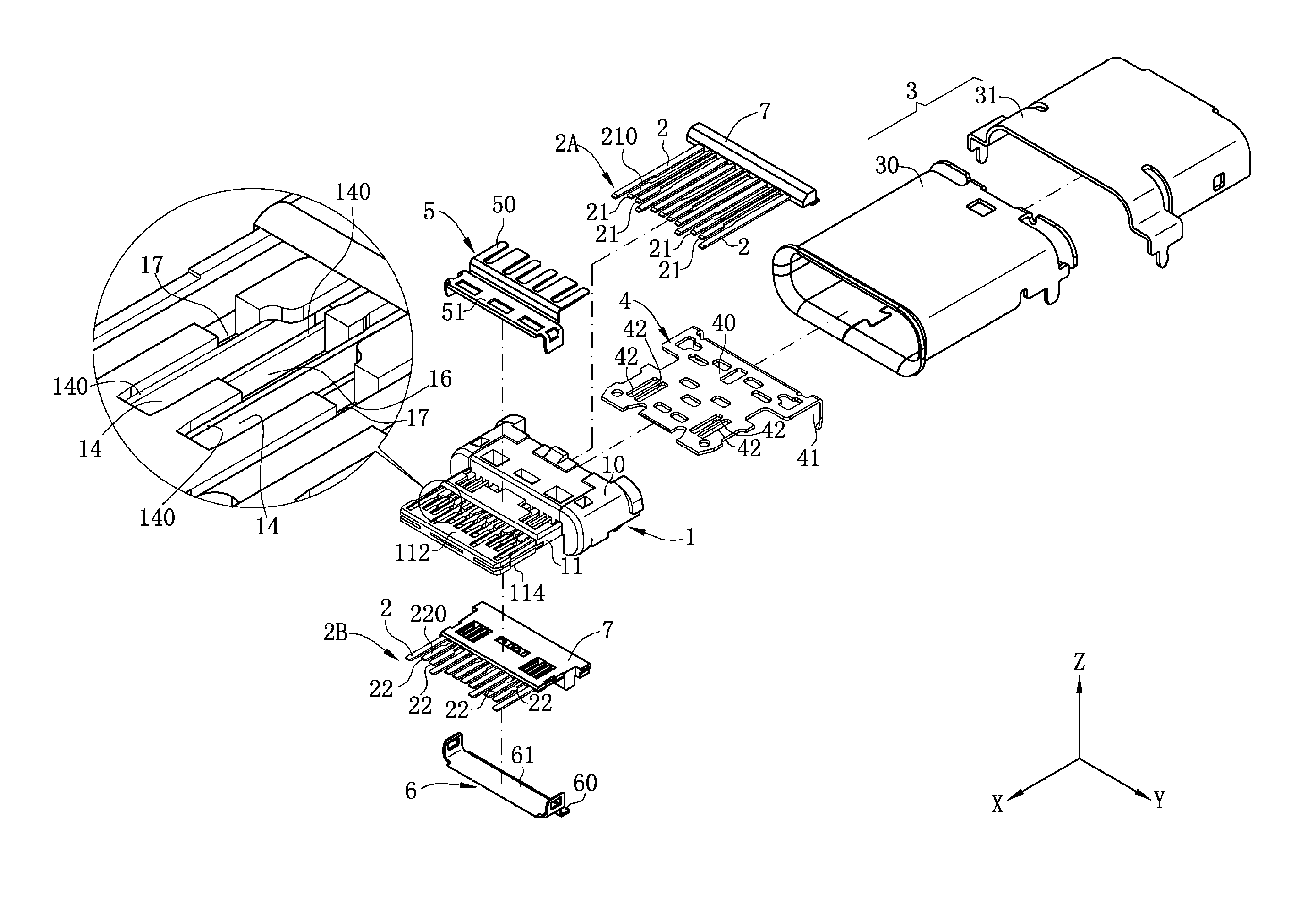

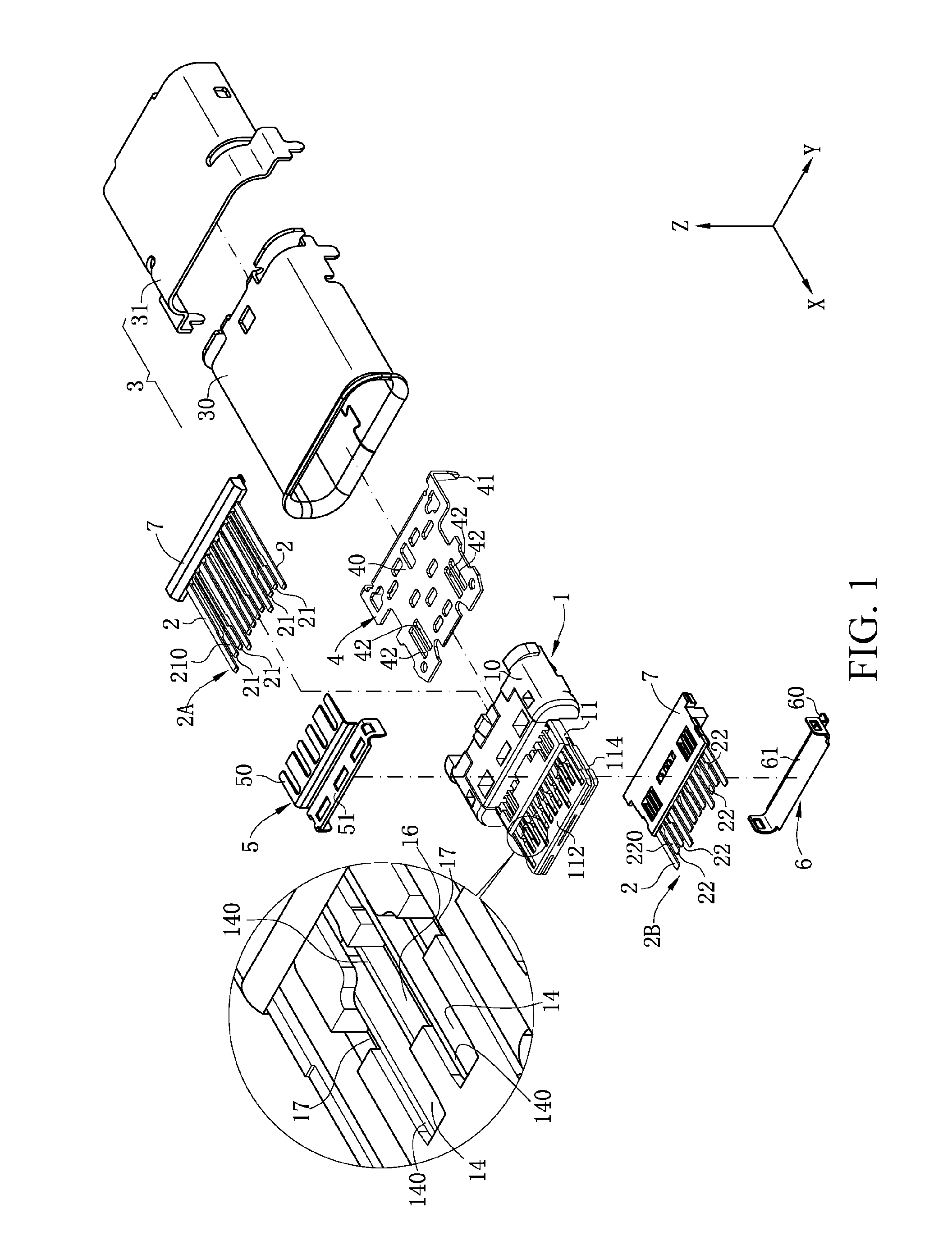

Electrical connector used for transmitting high frequency signals

ActiveUS9312641B2Improve high frequency performanceElectric discharge tubesTwo-part coupling devicesGround contactComputer module

Owner:HON HAI PRECISION IND CO LTD

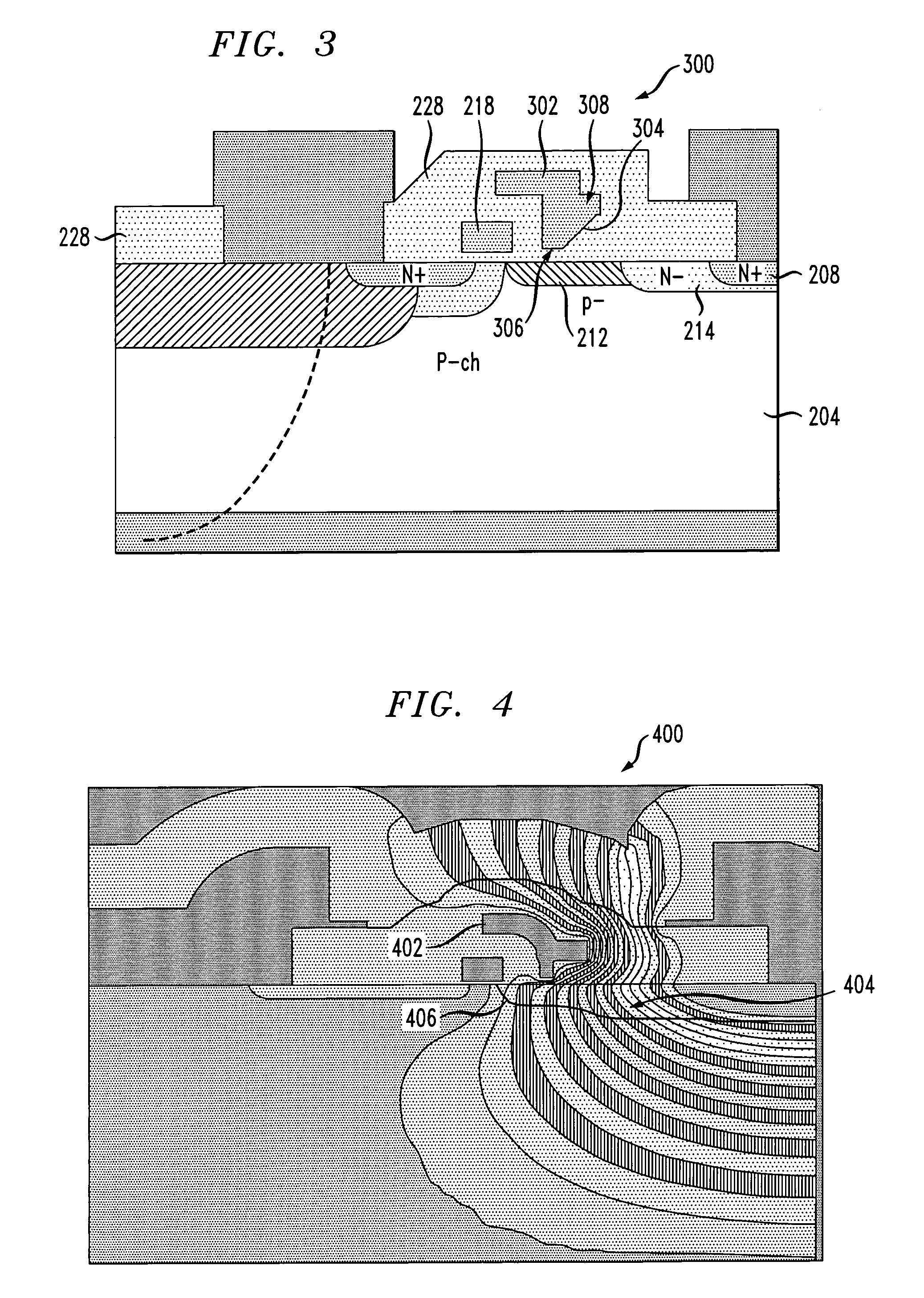

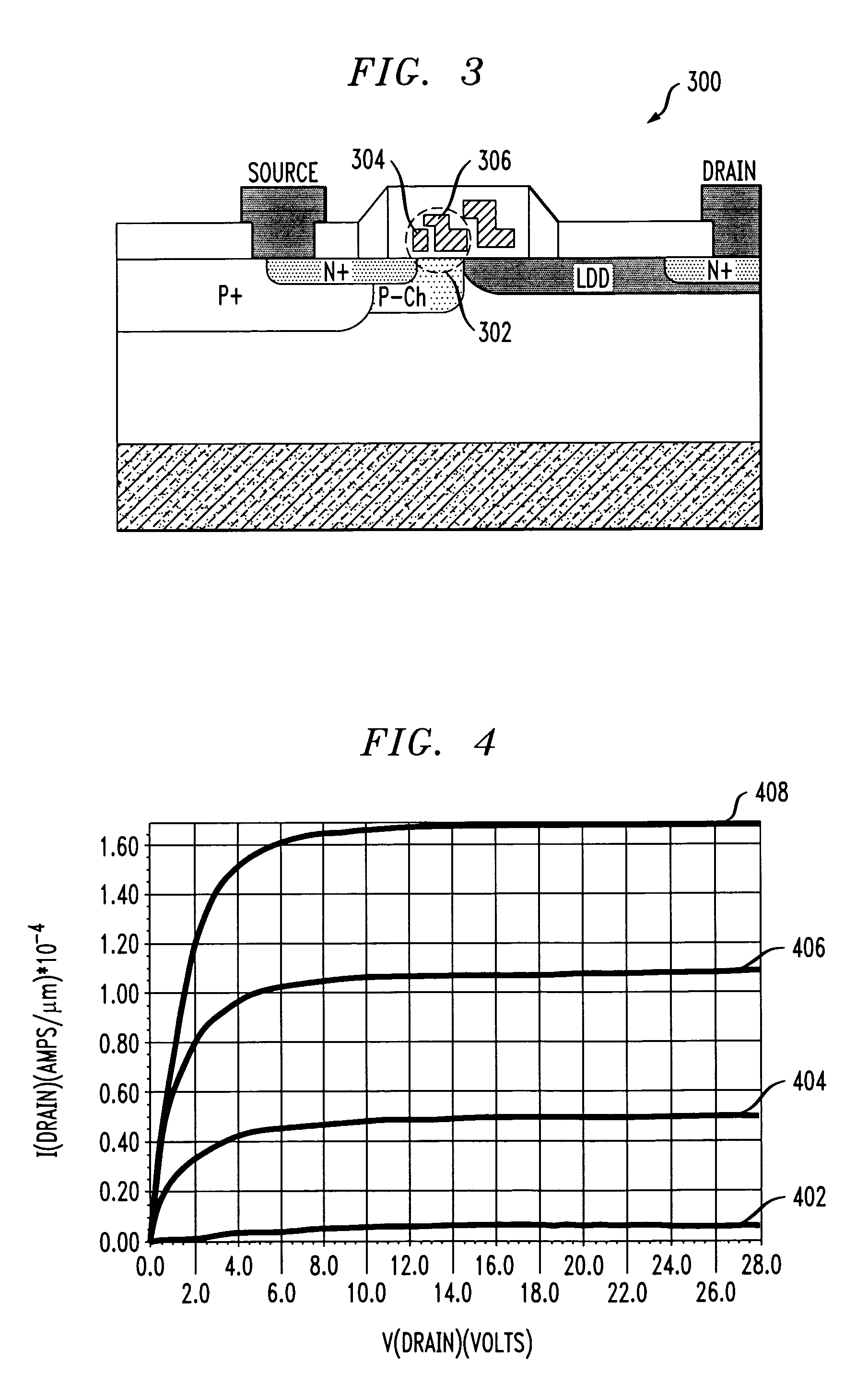

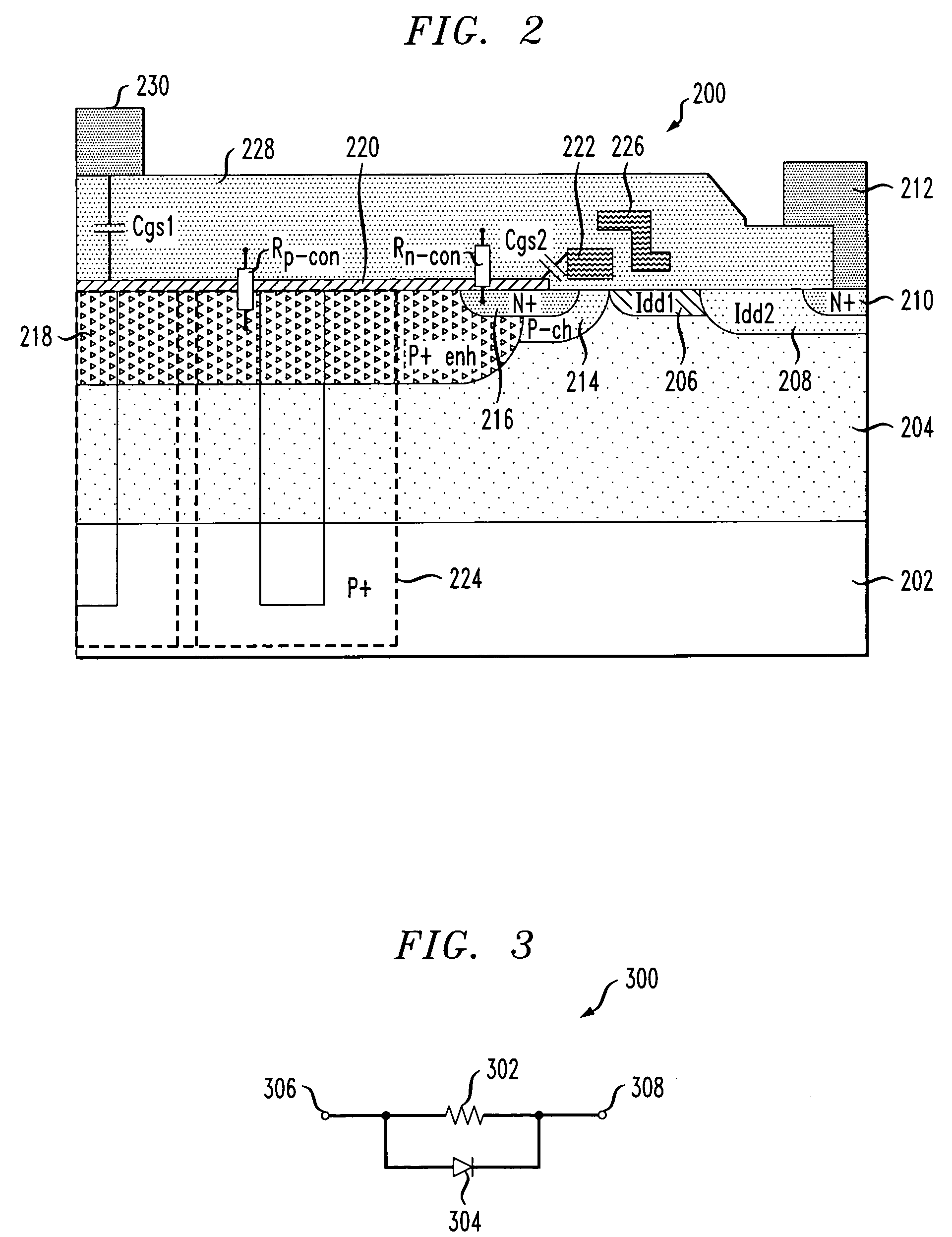

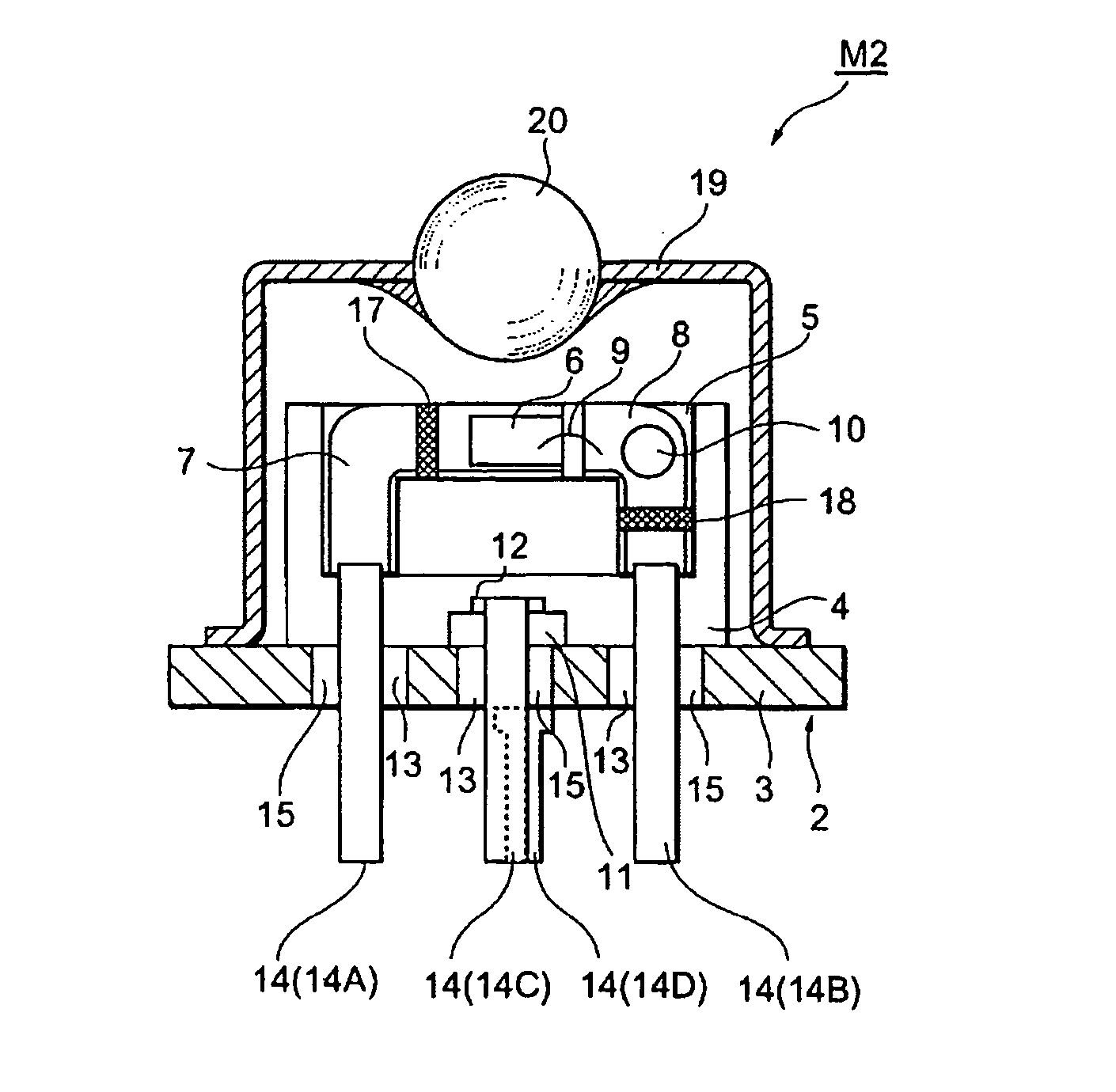

Dual-gate metal-oxide semiconductor device

ActiveUS20060113601A1Improve high frequency performanceIncreasing HCI degradationSemiconductor devicesSemiconductorMetal

An MOS device includes first and second source / drain regions of a first conductivity type formed in a semiconductor layer of a second conductivity type proximate an upper surface of the semiconductor layer, the first and second source / drain regions being spaced apart relative to one another. A non-uniformly doped channel region of the first conductivity type is formed in the semiconductor layer proximate the upper surface of the semiconductor layer and at least partially between the first and second source / drain regions. An insulating layer is formed on the upper surface of the semiconductor layer. A first gate is formed on the insulating layer at least partially between the first and second source / drain regions and above at least a portion of the channel region, and at least a second gate formed on the insulating layer above at least a portion of the channel region and between the first gate and the second source / drain region. The second gate has a length which is substantially greater than a length of the first gate, the first and second gates being electrically isolated from one another.

Owner:BELL SEMICON LLC

Capacitors with insulating layer having embedded dielectric rods

InactiveUS7679926B2Increase capacitanceImprove high frequency performanceAnti-noise capacitorsFeed-through capacitorsPrinted circuit boardCapacitor

A circuit structure is provided. The circuit structure includes a capacitor including a top capacitor electrode; a bottom capacitor electrode parallel to the top capacitor electrode; and an insulating layer between the top and the bottom capacitor electrodes. The insulating layer includes a dielectric rod enclosed by a dielectric material. The dielectric rod has a higher dielectric constant than that of the dielectric material. The circuit structure may be a printed circuit board or packaging substrate, wherein the capacitor is formed between the two layers of the capacitor. Additional dielectric rods may be formed in the insulating layer of the capacitor and spaced apart from the dielectric rods.

Owner:TAIWAN SEMICON MFG CO LTD

Electrical connector

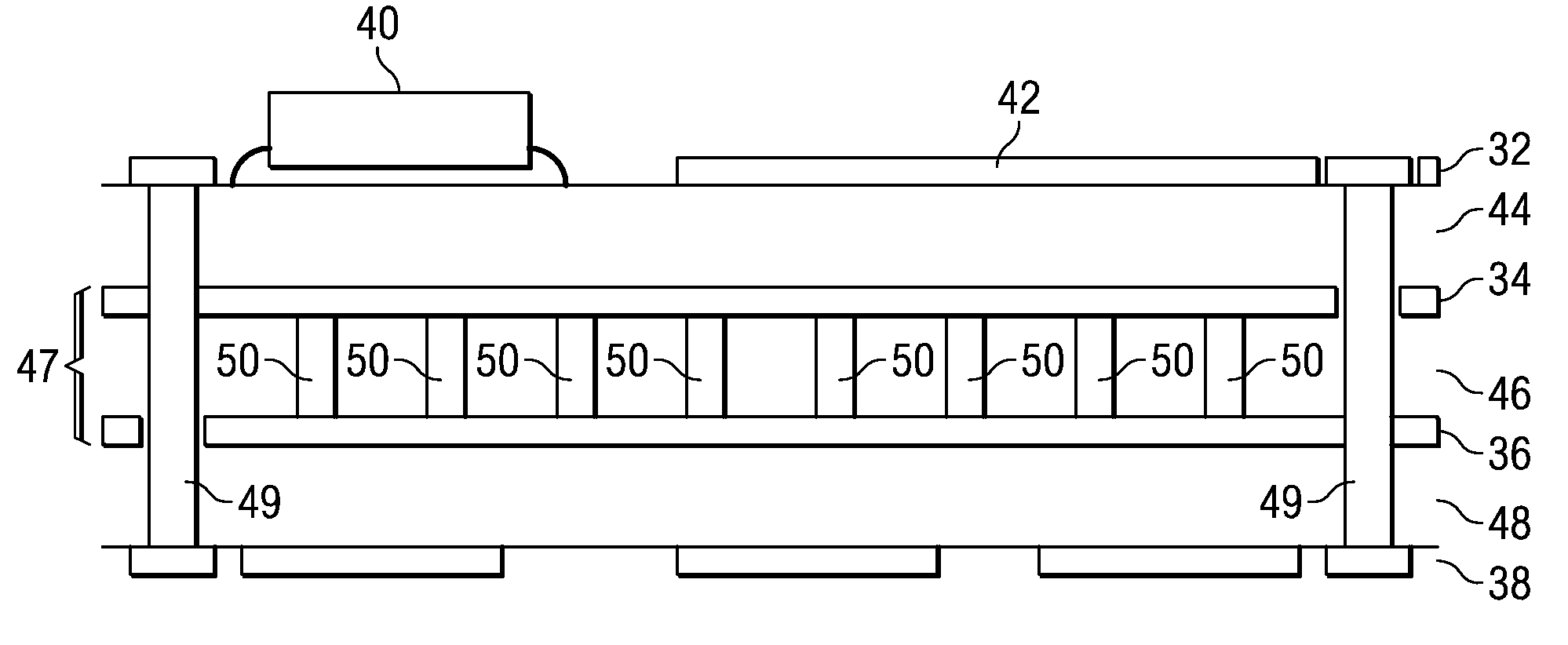

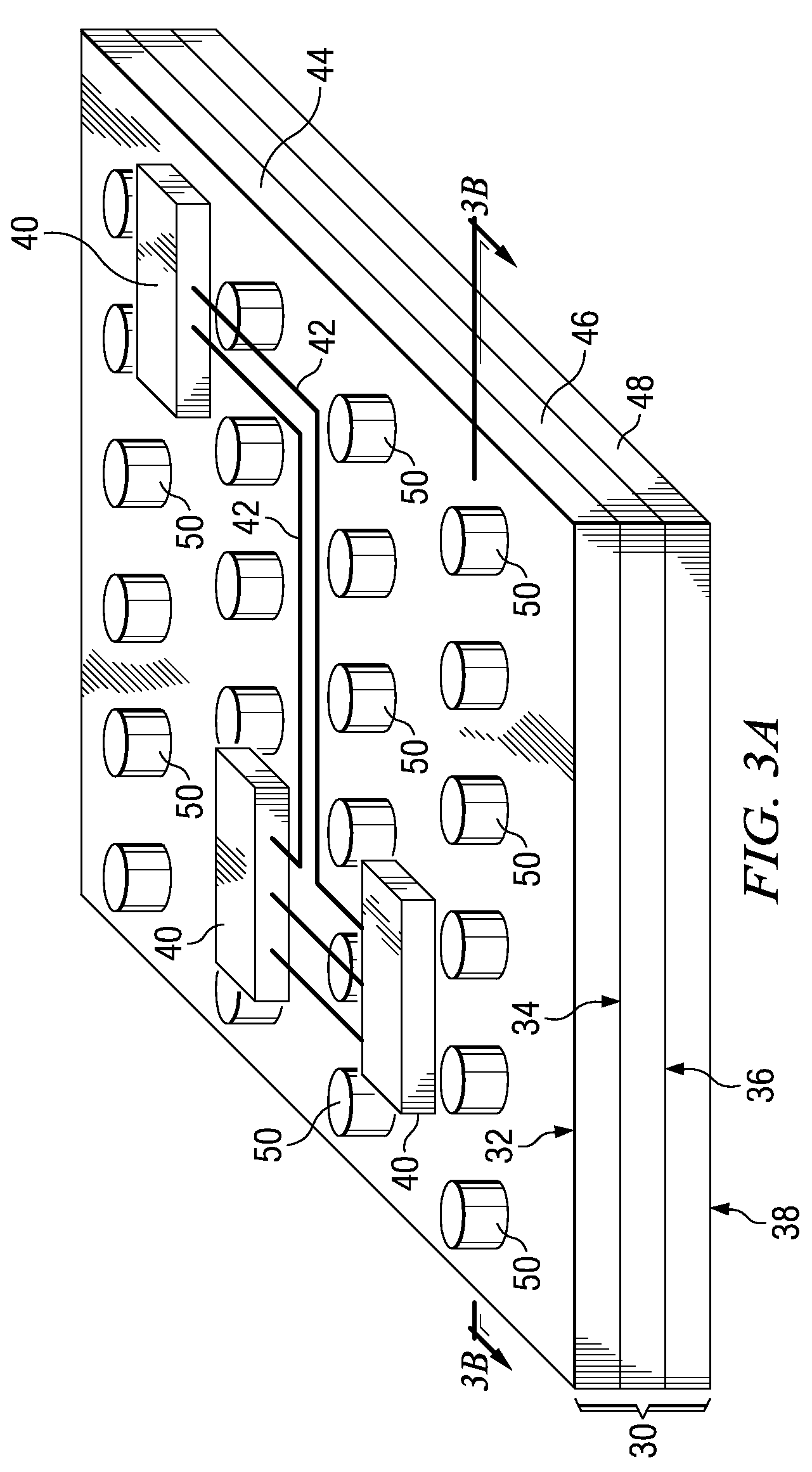

InactiveUS7473136B2Improve high frequency performancePrinted circuitsCoupling protective earth/shielding arrangementsEngineeringElectrical connector

An electrical connector for mating with a plug includes an insulative housing, a number of first contacts retained in the indulative housing. The insulative housing includes a first contact area. Each first contact has a contact portion extending into the first contact area, a soldering portion extending out of the insulative housing and a connecting portion extending therebetween. The connecting portions are arranged in several rows along a front to back direction of the housing. A first spacer is assembled to the insulative housing along the front to back direction and is arranged between the rows of the connecting portions to separate the first contacts from each other.

Owner:HON HAI PRECISION IND CO LTD

Monolithic compound semiconductor integrated circuit and method of forming the same

InactiveUS20010042867A1Improve high frequency performanceLow costTransistorSemiconductor/solid-state device detailsEngineeringElectrode Contact

A monolithically integrated semiconductor device comprises: a hetero-junction bipolar transistor having at least an electrode contact layer which contacts directly with at least one of collector, base and emitter electrodes; and at least a passive device having at least a passive device electrode and at least a resistive layer, wherein the electrode contact layer and the resistive layer comprise the same compound semiconductor layer.

Owner:NEC ELECTRONICS CORP

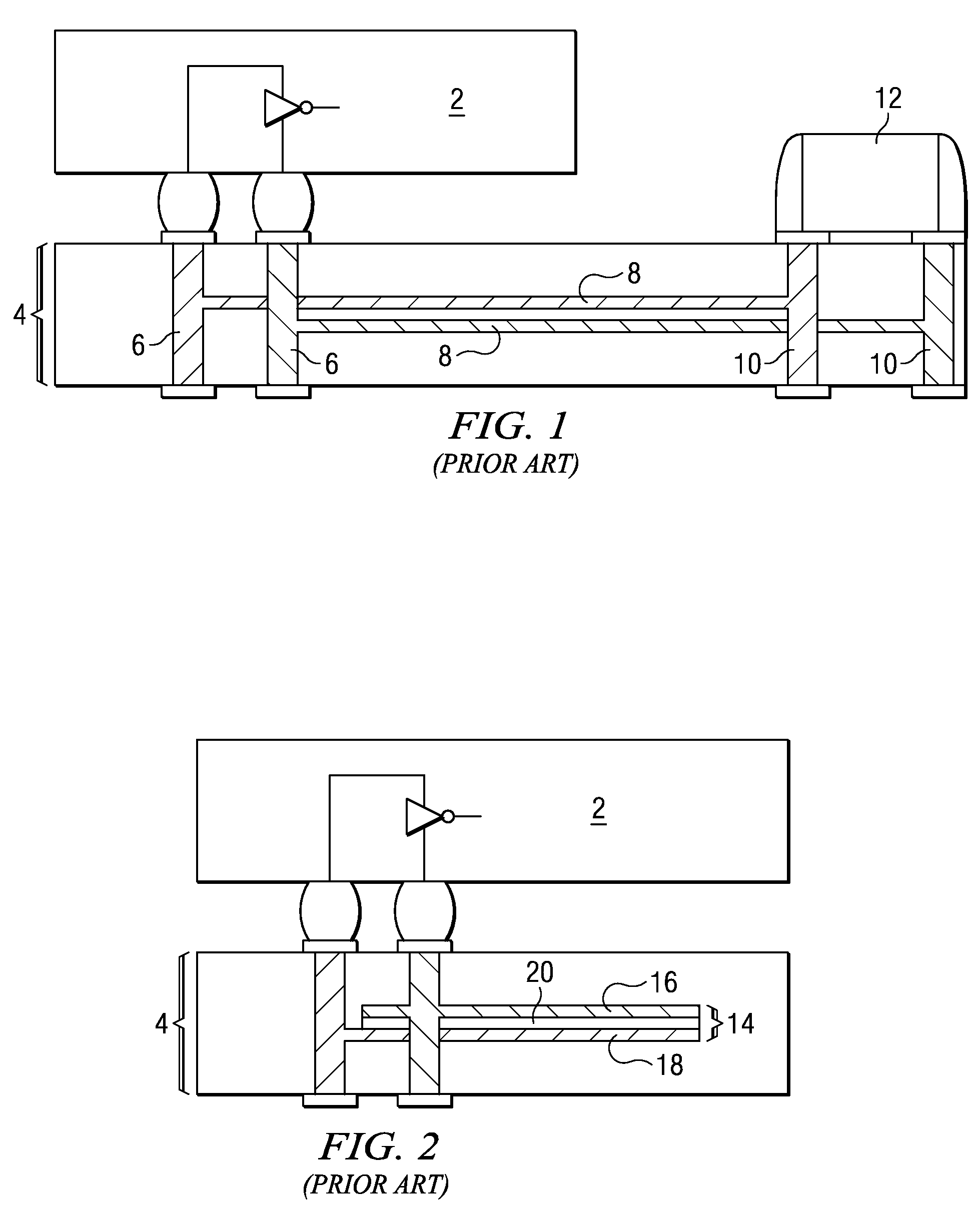

High frequency electrical connector

InactiveUS7914302B1Improve high frequency performanceAvoid crosstalkSecuring/insulating coupling contact membersPrinted circuitsEngineeringElectrical connector

An electrical connector assembly has an elongated insulative housing and a plurality of signal contacts secured in corresponding passageways defined in the housing. Each signal contact has a retention portion retained in the passageway, a contact portion extending from the retention portion and a soldering portion extending from the retention portion. The contact portion defines a first face exposing an exterior of the passageways and a second face opposite to the first face. Wherein each of signal contacts defines a recess on the second face. The signal contacts become thinner so as to prevent signal contacts from crosstalk and improve high frequency performance.

Owner:HON HAI PRECISION IND CO LTD

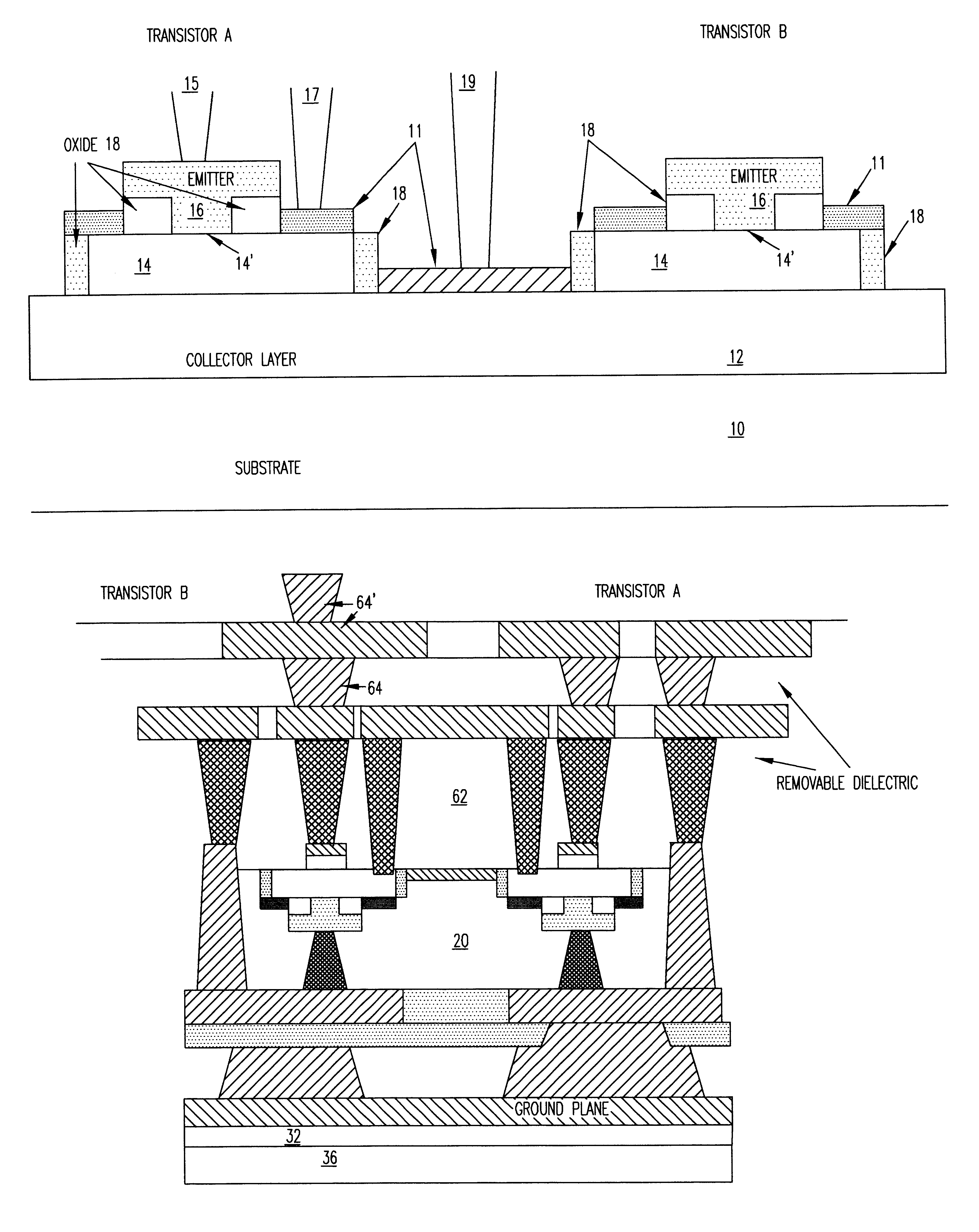

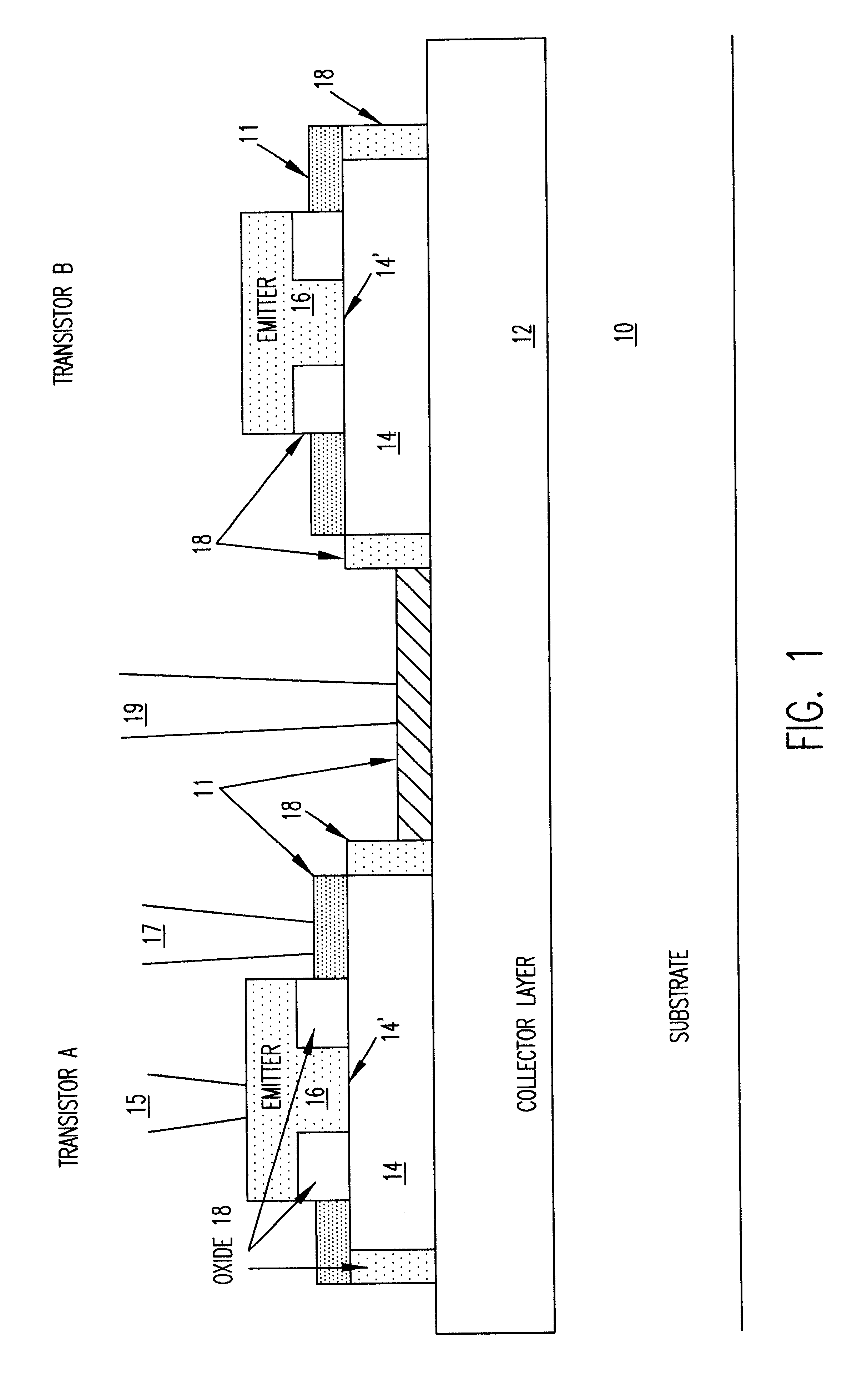

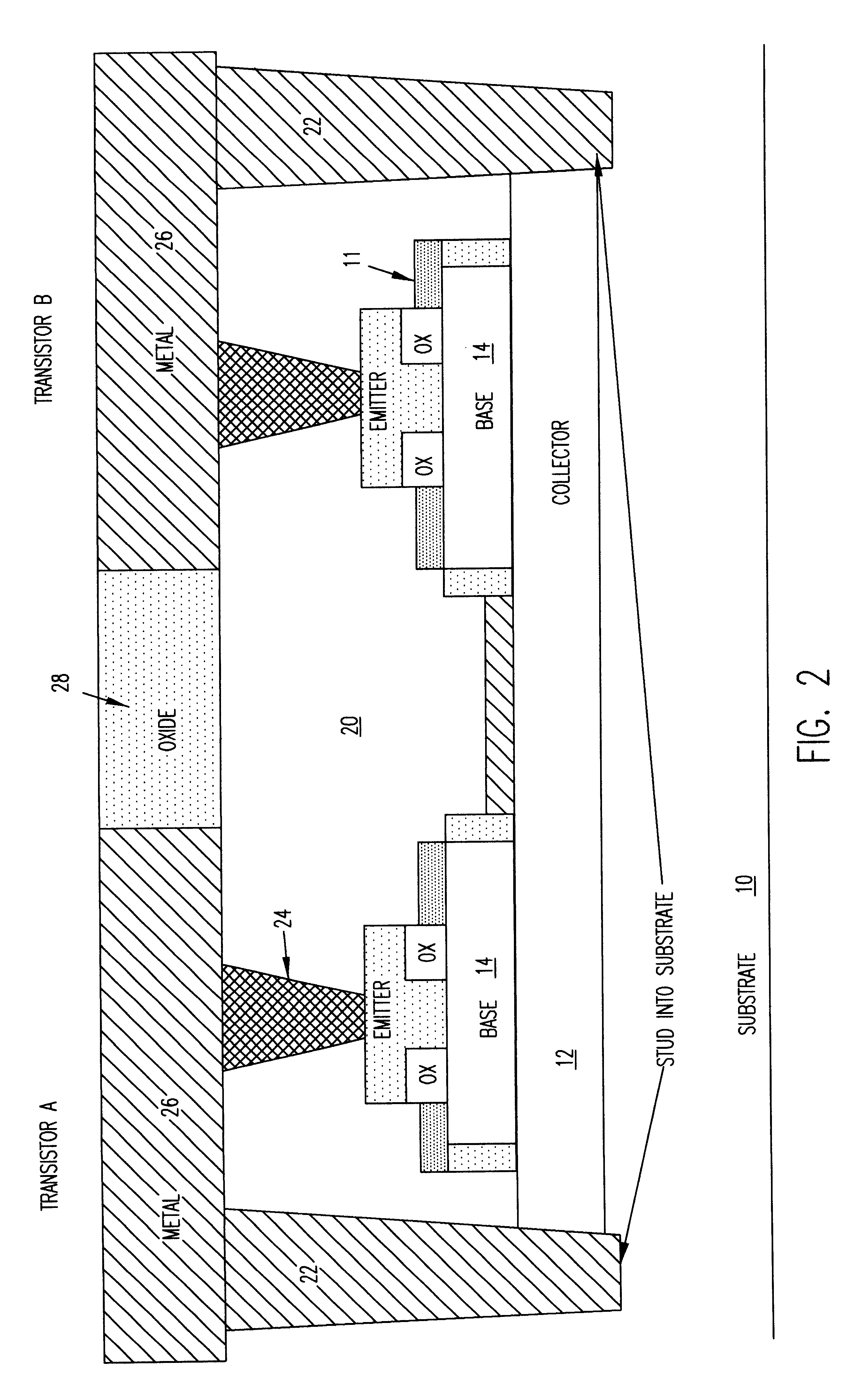

Process and structure for 50+ gigahertz transistor

InactiveUS6414371B1Improve high frequency performanceTransistorSemiconductor/solid-state device detailsSemi insulatingEngineering

High frequency performance of transistor designs is enhanced and manufacturing yield improved by removing and reducing sources of parasitic capacitance through combinations of processes from different technologies. After formation of collector, base and emitter regions on a substrate and attachment of a second substrate, the original substrate is wholly or partially removed, the inactive collector area is removed or rendered semi-insulating and wiring and contacts are made from the original back side of the chip. Dielectric material used in the manufacturing process can be removed to further reduce capacitance. The high frequency transistors can be bonded to CMOS chips or wafers to form BICMOS chips.

Owner:GLOBALFOUNDRIES INC

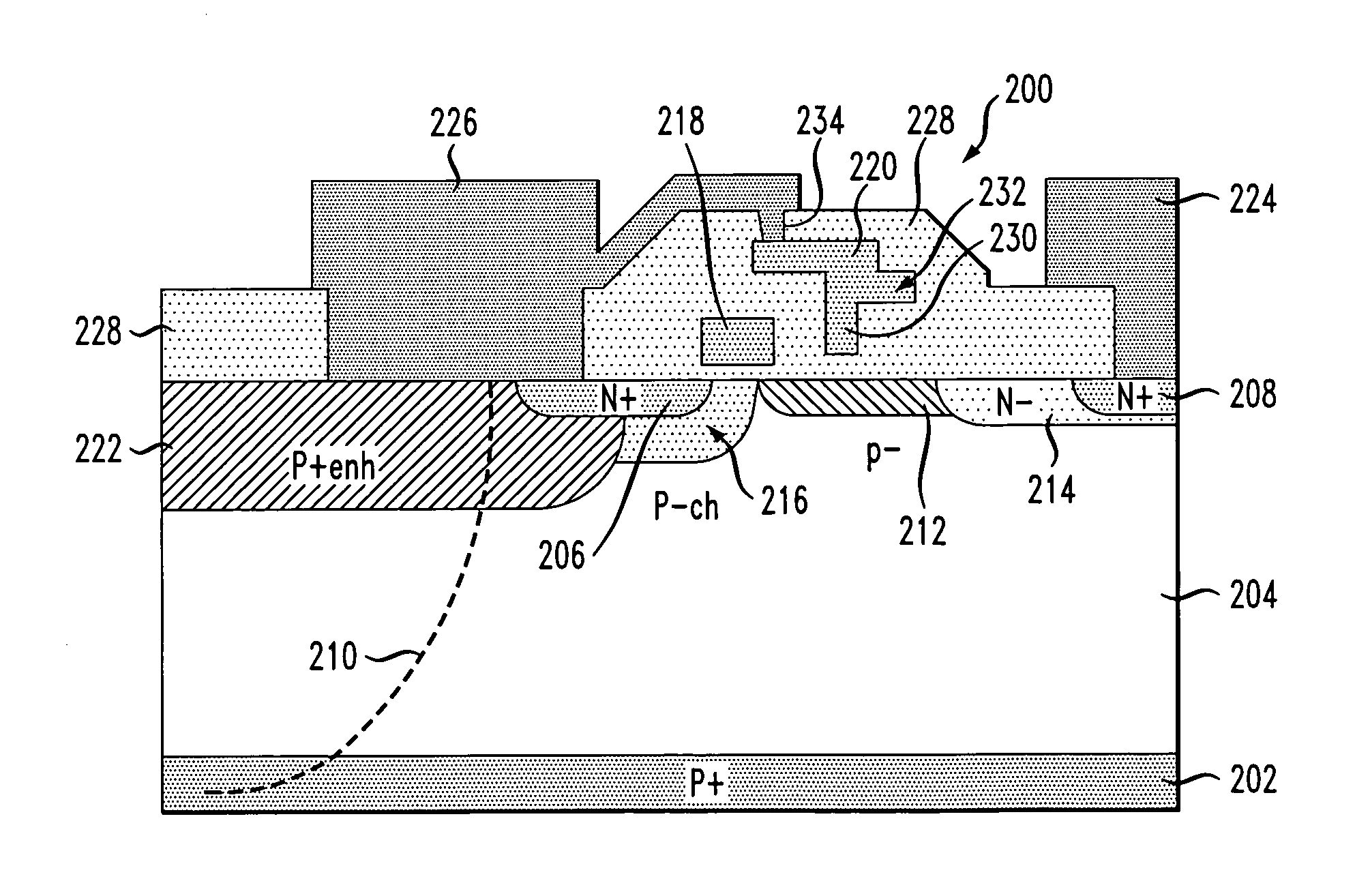

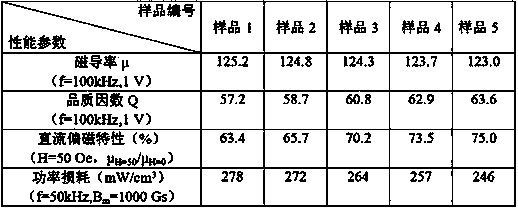

Metal-oxide-semiconductor device with enhanced source electrode

ActiveUS7126193B2Reduce input capacitanceImprove device performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical connectionSemiconductor

An MOS device is formed including a semiconductor layer of a first conductivity type, a first source / drain region of a second conductivity type formed in the semiconductor layer, and a second source / drain region of the second conductivity type formed in the semiconductor layer and spaced apart from the first source / drain region. A gate is formed proximate an upper surface of the semiconductor layer and at least partially between the first and second source / drain regions. The MOS device further includes at least one contact, the at least one contact including a silicide layer formed on and in electrical connection with at least a portion of the first source / drain region, the silicide layer extending laterally away from the gate. The contact further includes at least one insulating layer formed directly on the silicide layer.

Owner:CICLON SEMICON DEVICE

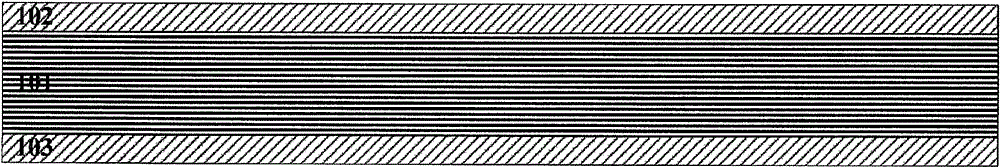

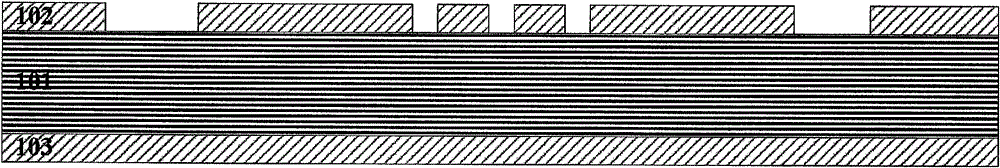

Preparing method of metal magnetic powder core

InactiveCN104036902AImprove processing performanceShorten milling timeInorganic material magnetismAlloy elementQuenching

The invention discloses a preparing method of a metal magnetic powder core. The preparing method includes the following steps that (1) master alloy is melt through a vacuum induction furnace, and an alloy thin belt is obtained through a quick quenching device; (2) ball milling is conducted on the thin belt; (3) annealing is conducted on powder; (4) particle size distribution is conducted on the annealed powder; (5) passivant is added into the distributed powder to conduct passivating on the powder, and then a binding agent and an insulating agent are added into the powder to conduct insulating bonding and wrapping on the powder; (6) a lubricating release agent is then added, the mixture is mixed, and compression moulding is conducted; (7) annealing is conducted on a sample obtained through compression moulding, and the sample is cooled along with the furnace, and spraying and coating are conducted to obtain the target product. According to the preparing method, the master alloy contains an appropriate number of alloy elements, so that the alloy processing performance is improved; the alloy powder and an insulating medium are mixed and pressed to be the magnetic powder core, so that eddy-current loss under a high frequency can be greatly reduced; meanwhile, the problem that alloy materials are limited in use due to single shapes is solved through shape diversity of the magnetic powder core.

Owner:ZHEJIANG MINGHE STEEL PIPE CO LTD +1

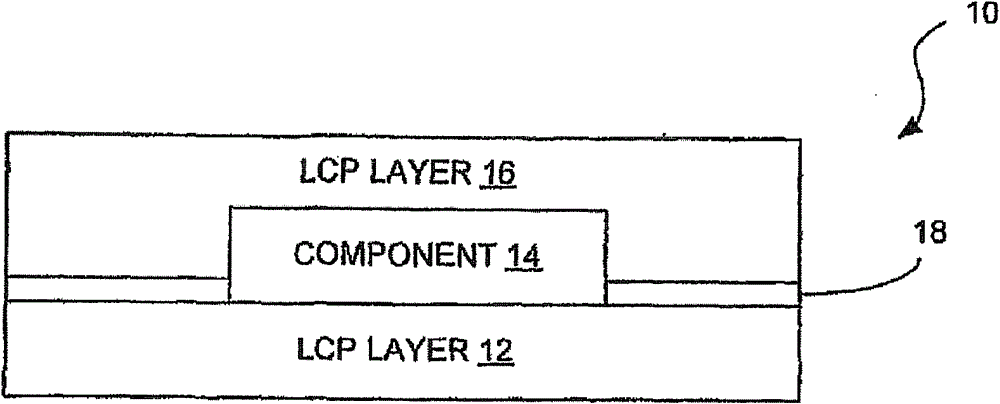

A method of fabricating a multilayer organic liquid crystal polymer substrate structure

ActiveCN102683220BGet Rid of CTE Matching IssuesImprove performancePrinted circuit assemblingSemiconductor/solid-state device manufacturingMicrowaveHigh density

The invention discloses a method for making a multi-layer organic liquid crystal polymer (LCP) substrate structure. The method comprises the following steps: providing a first LCP core substrate and a second LCP core substrate; connecting an active device to the first LCP core substrate in an inverted manner; arranging a passive device on the second LCP core substrate by means of surface mounting, sequentially overlapping and stacking the second LCP core substrate mounted with the passive device, an LCP dielectric layer and the first LCP core substrate connected with the active device in an inverted manner, and thermoforming to obtain the multi-layer LCP substrate structure embedded with both the active device and the passive device. The multi-layer LCP substrate structure can be used for making a microwave / millimeter wave system level module and has the characteristic of achieving a system with high density, small size, high performance, high frequency, low value and low consumption.

Owner:NAT CENT FOR ADVANCED PACKAGING CO LTD

Insulative adhesive for preparing metallic and soft magnetic composite material and using method thereof

ActiveCN104031601AImprove thermal stabilityImprove insulation performanceNon-macromolecular adhesive additivesInorganic material magnetismAdhesiveOrganosilicon

The invention discloses an insulative adhesive for preparing a metallic and soft magnetic composite material and a using method thereof. The insulative adhesive disclosed by the invention is a nano-modified organic silicon resin insulative adhesive which comprises organic silicon resin and an inorganic nano dispersion liquid. The insulative adhesive greatly improve the heat-resisting temperature of the organic silicon resin and improve the mechanical strength of a magnetic powder core, is reasonable in component selection and good in using effect and has a good insulative adhering effect to Fe-based, nickel-based and metallic soft magnetic powder of other metals. The magnetic powder core prepared by the insulative adhesive prepared by the invention has excellent magnetic performance and mechanical performance.

Owner:ZHEJIANG UNIV

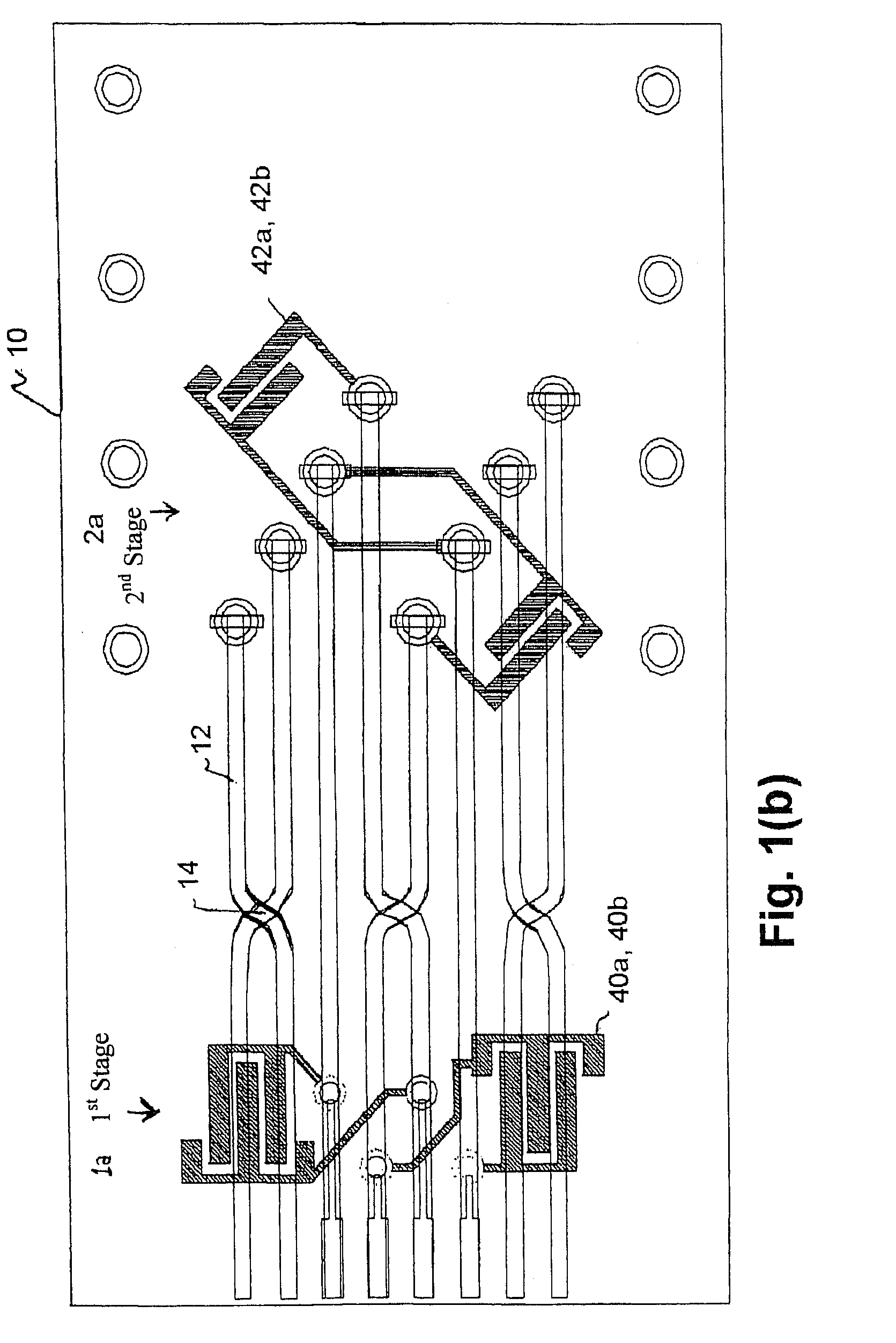

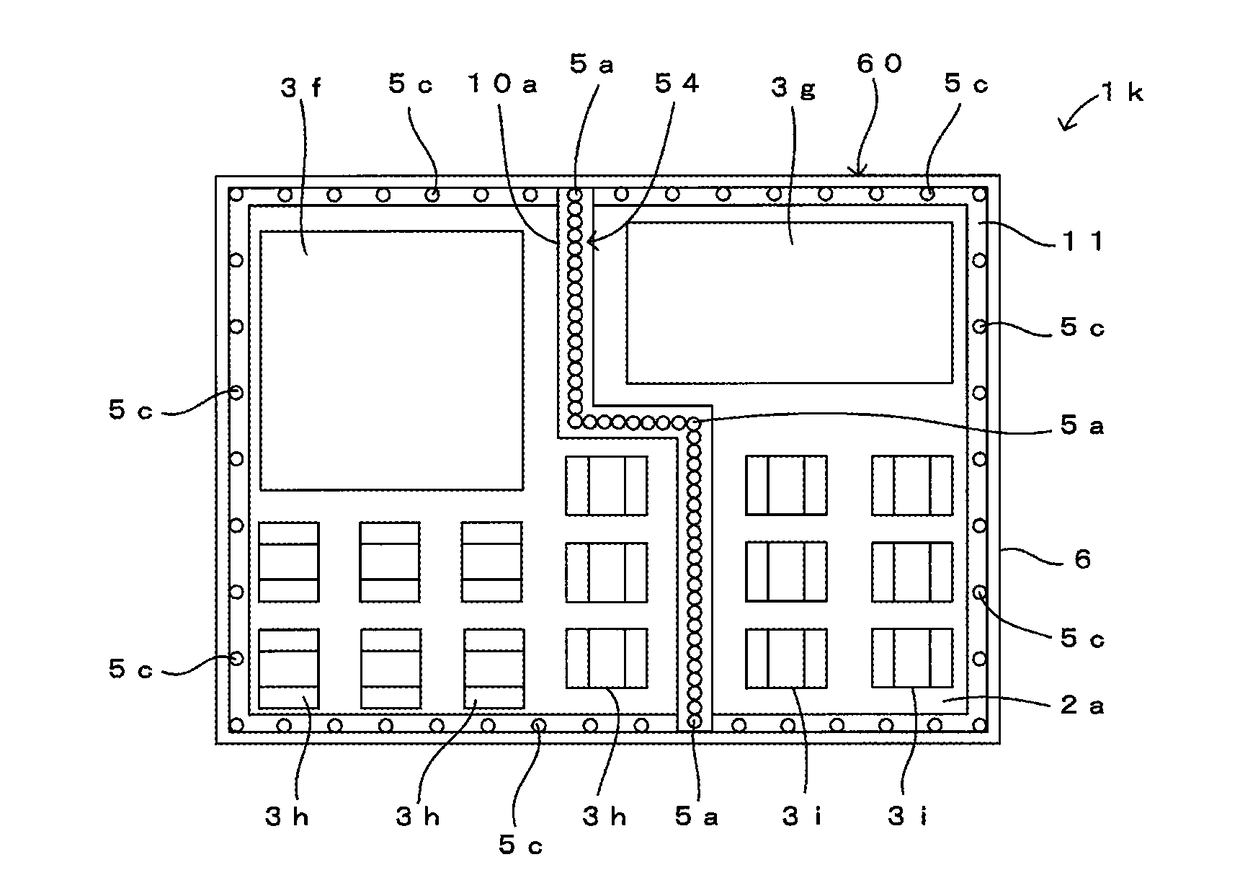

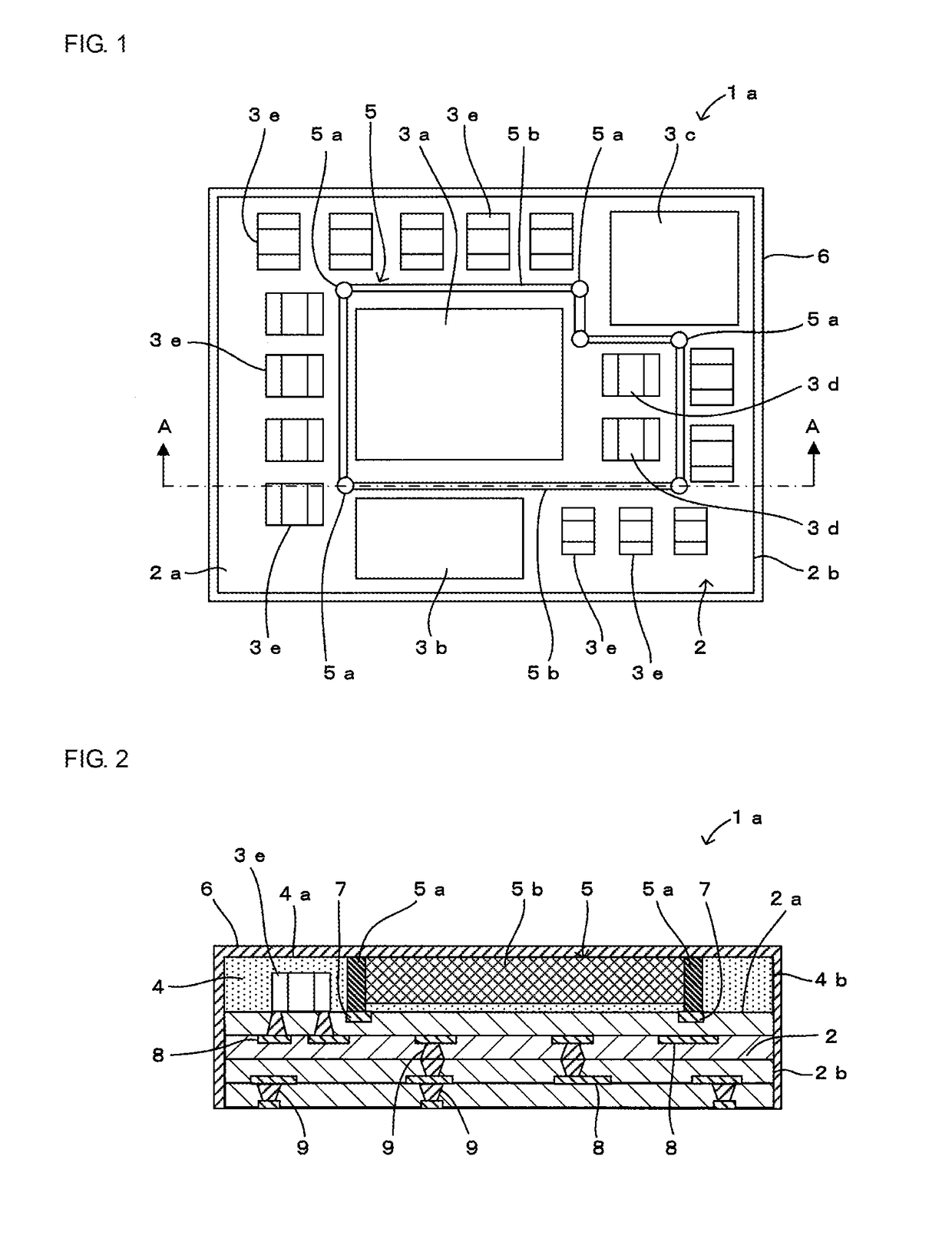

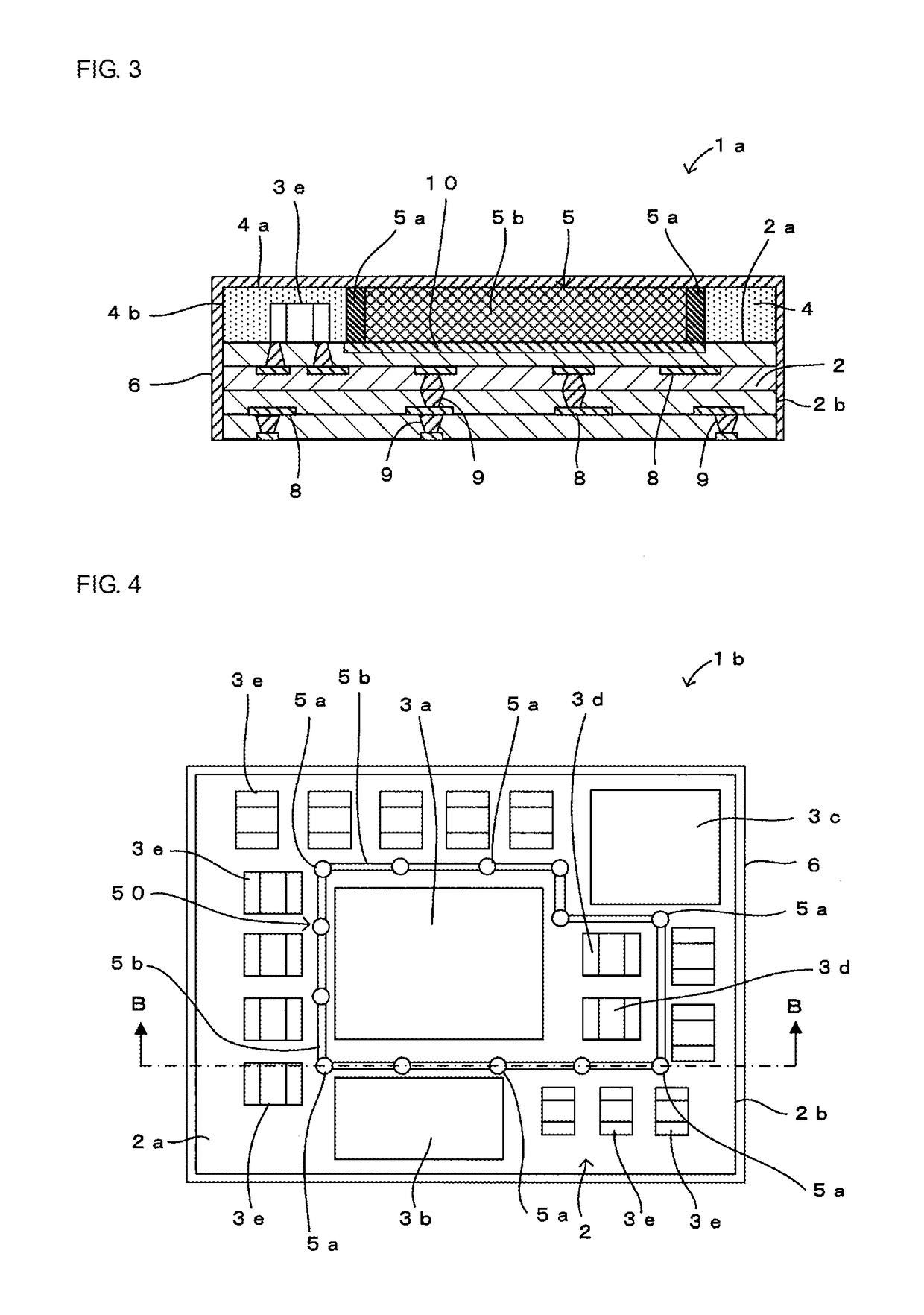

High-frequency module

ActiveUS20180092257A1Improve featuresReduce resistanceMagnetic/electric field screeningFinal product manufactureEngineeringMechanical engineering

The characteristics of a shield wall that prevents the mutual interference of the noise between components are improved by lowering the resistance of the shield wall. A high-frequency module 1a includes a wiring board 2, a plurality of components 3a to 3e mounted on an upper surface 2a of the wiring board 2, a sealing resin layer 4 stacked on the upper surface 2a of the wiring board 2 to seal the components 3a to 3e, and a shield wall 5 disposed between the adjacent components in the sealing resin layer 4. A part of the shield wall 5 is constituted of metal pins 5a standing on the upper surface 2a of the wiring board 2.

Owner:MURATA MFG CO LTD

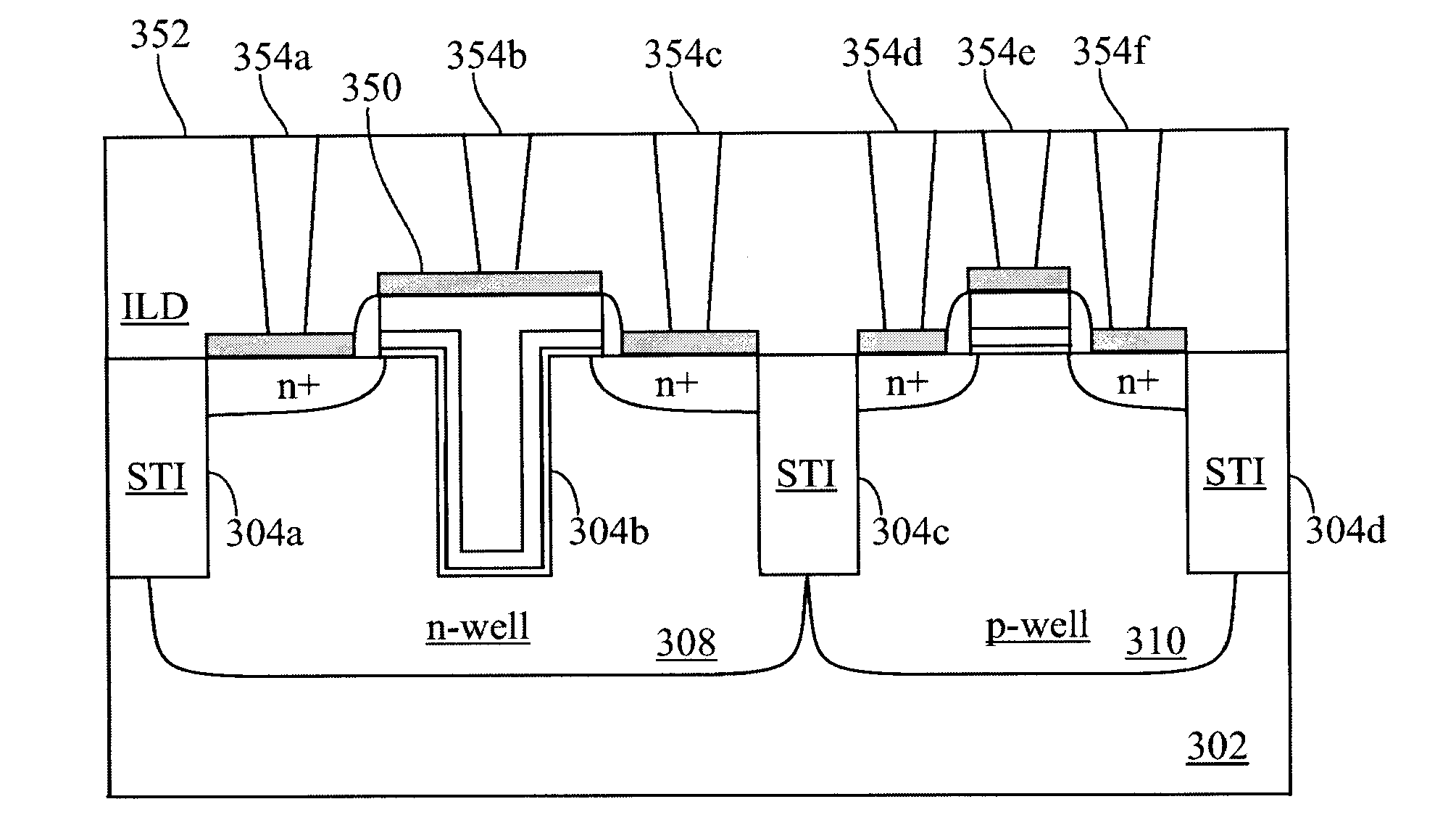

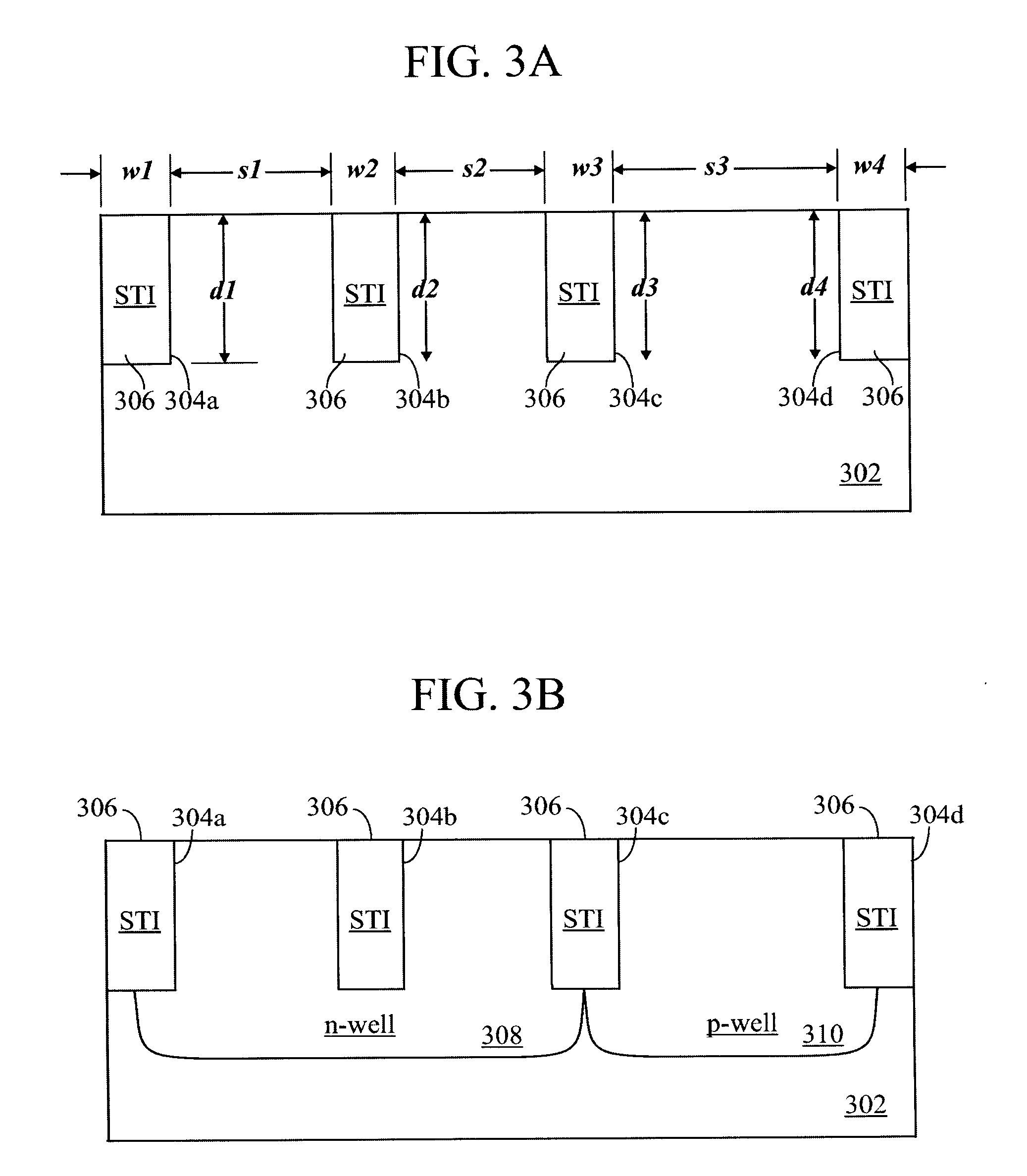

Shallow trench capacitor compatible with high-k / metal gate

InactiveUS20090242953A1Improve performanceHigh densityTransistorSolid-state devicesCapacitanceCells/well

Forming a shallow trench capacitor in conjunction with an FET by forming a plurality of STI trenches; for the FET, implanting a first cell well having a first polarity between a first and a second of the STI trenches; for the capacitor, implanting a second cell well having a second polarity in an area of a third of the STI trenches; removing dielectric material from the third STI trench; forming a gate stack having a first portion located between the first and the second of the STI trenches and a second portion located over and extending into the third trench; and performing a source / drain implant of the same polarity as the second cell well, thereby forming a FET in the first cell well, and a capacitor in the second cell well. The second polarity may be opposite from the first polarity. An additional implant may reduce ESR in the second cell well.

Owner:GLOBALFOUNDRIES US INC

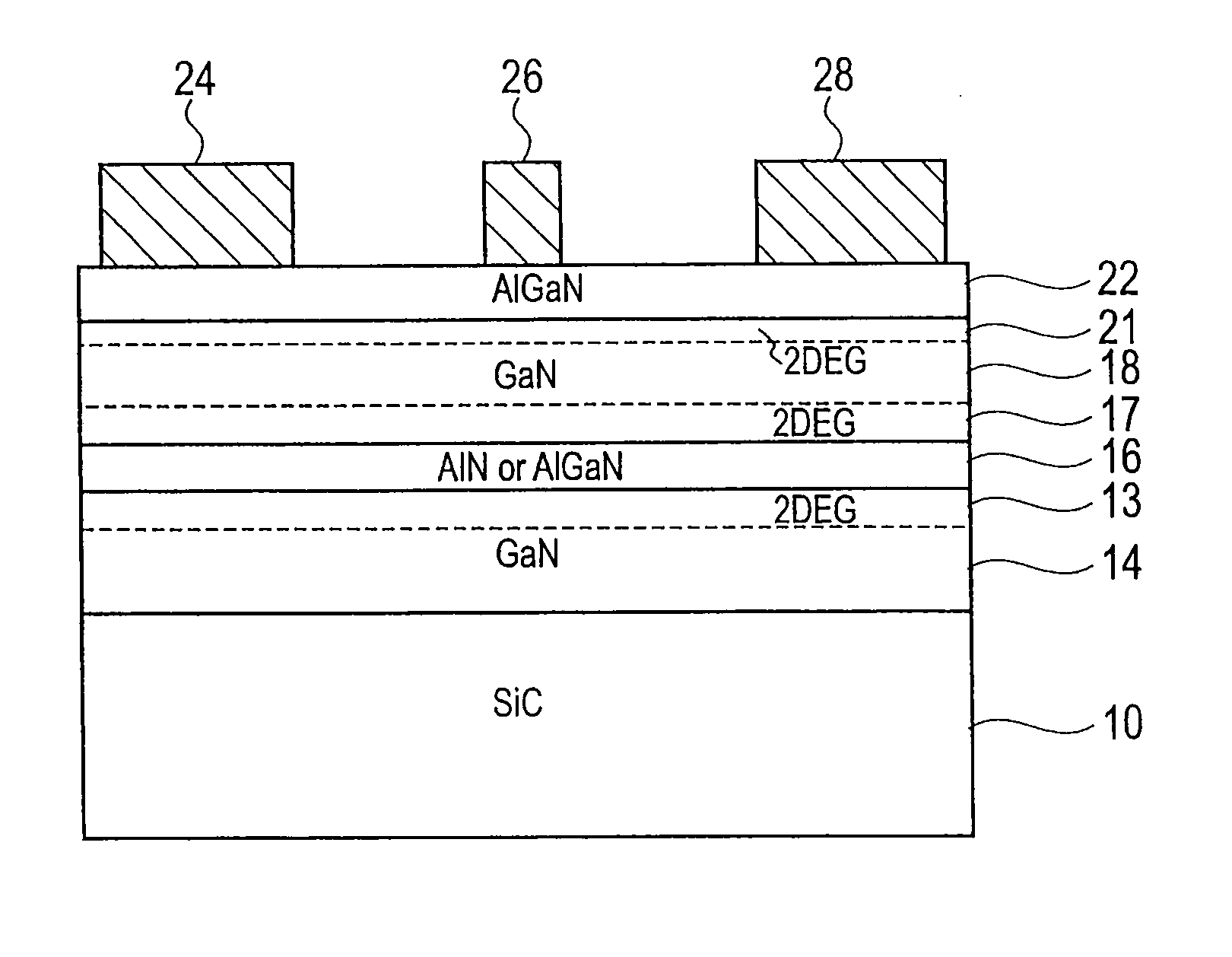

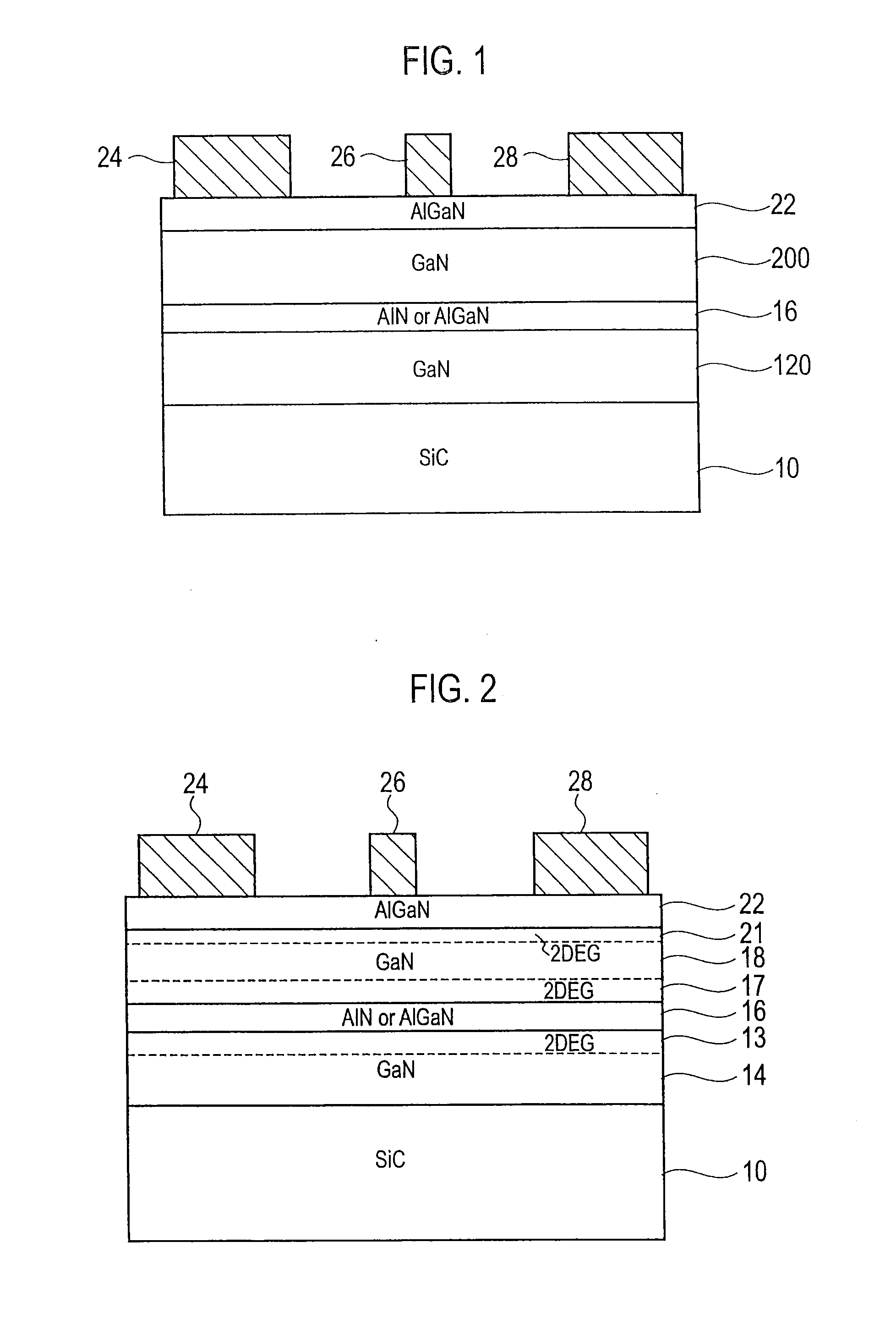

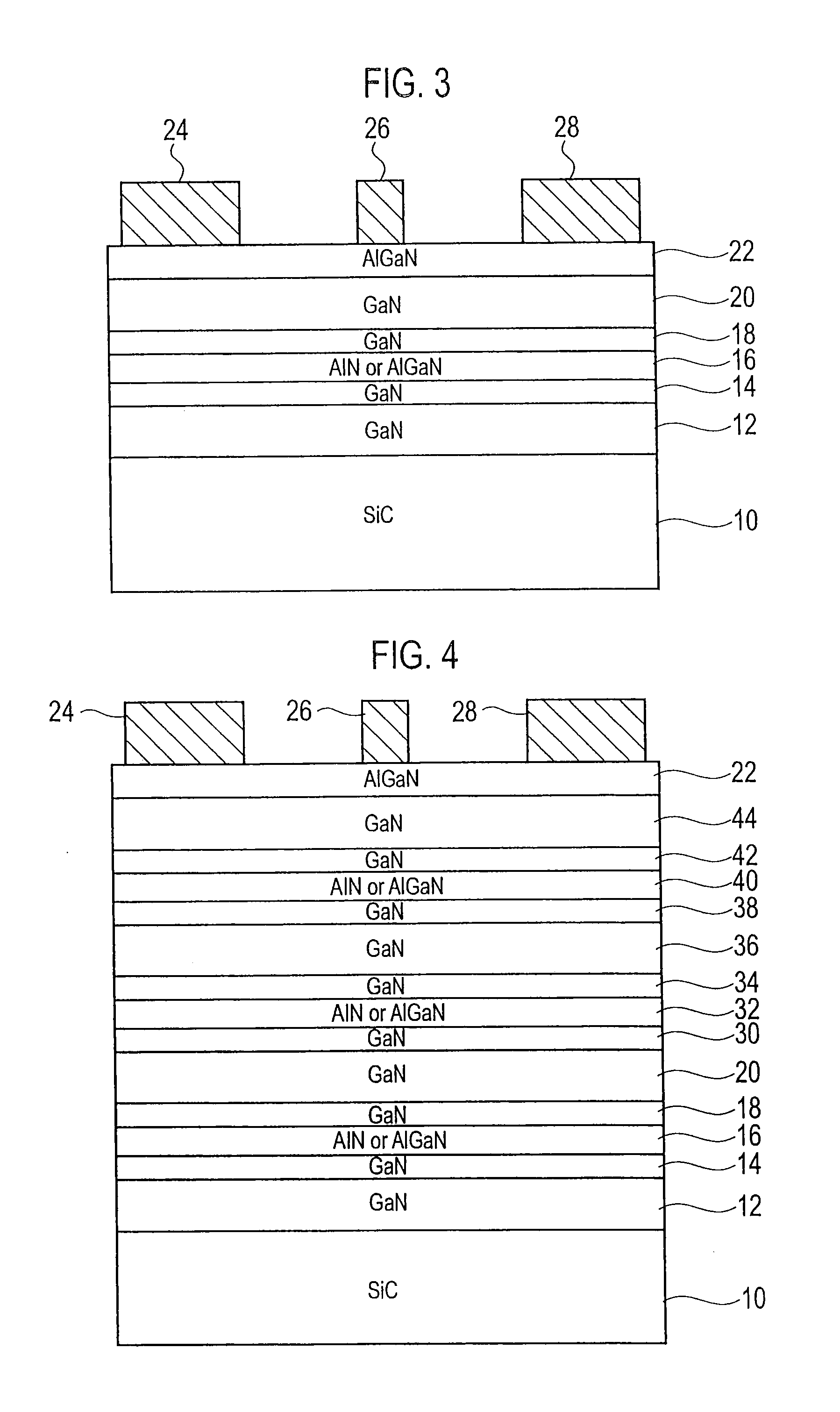

Semiconductor device and fabrication method of the semiconductor device

InactiveUS20090189188A1Improve efficiencyImprove featuresTransistorSemiconductor/solid-state device manufacturingTransition metal atomsHigh resistivity

A semiconductor device and a fabrication method of the semiconductor device, the semiconductor device including: a substrate; a nitride based compound semiconductor layer placed on the substrate and doped with a first transition metal atom; an aluminum gallium nitride layer (AlxGa1-xN) (where 0.1<=x<=1) placed on the nitride based compound semiconductor layer; a nitride based compound semiconductor layer placed on the aluminum gallium nitride layer (AlxGa1-xN) (where 0.1<=x<=1) and doped with a second transition metal atom; an aluminum gallium nitride layer (AlyGa1-yN) (where 0.1<=y<=1) placed on the nitride based compound semiconductor layer doped with the second transition metal atom; and a gate electrode, a source electrode, and a drain electrode which are placed on the aluminum gallium nitride layer (AlyGa1-yN) (where 0.1<=y<=1). Accordingly, piezo charge is inactivated, leakage current and current collapse are reduced, high frequency characteristics can be improved by obtaining a high resistivity semiconductor layer, and stable high frequency performance can be obtained.

Owner:KK TOSHIBA

Semiconductor laser module having a co-axial package and transmission lines for complementary driving signal

ActiveUS20050013561A1Improve high frequency performancePacked tightlyLaser detailsSolid-state devicesEngineeringPhotodiode

The present invention provides a semiconductor laser module in which parasitic inductance due to the bonding wire is removed, accordingly, the high frequency performance thereof can be enhanced. The laser module of the present invention has a sub-mount, on which the semiconductor laser diode is installed and transmission lines for supplying the signal to the laser diode is formed. The transmission lines on the sub-mount are directly connected to corresponding lead pins provided in the base of the package without any bonding wires. Between the lead pins and under the sub-mount is provided a photo diode for monitoring light emitted from the laser diode.

Owner:SUMITOMO ELECTRIC IND LTD

Electrical connector

ActiveUS20160020560A1Improve high frequency performanceReduce decreaseContact member cases/bases manufactureTwo-part coupling devicesElectrical connectorElectrical and Electronics engineering

An electrical connector includes a body having a tongue, a pair of first differential signal terminals and a pair of second differential signal terminals fixed to the body, and a middle shielding sheet fixed to the tongue, and located between the first and second differential signal terminals. The tongue includes an upper surface having two depressed first receiving slots and a lower surface having two depressed second receiving slots. A first groove is depressed from each first receiving slot. A second groove is upward depressed from each second receiving slot. Each first differential signal terminal has a first contact portion fixed to and exposed from the upper surface of the tongue. Each second differential signal terminal has a second contact portion fixed to and exposed from the lower surface of the tongue. The first and second contact portions are partially accommodated in the first and second receiving slot respectively.

Owner:LOTES

Electrical connector for transferring high frequency signal

ActiveUS20160020568A1Improve high frequency performanceReduced insertion lossContact member cases/bases manufactureElectric discharge tubesElectricityDifferential signaling

Owner:LOTES

Making method for electromagnetic wave interference resisting iron ,silicon, aluminum and nickel alloy

The invention discloses a preparation method for electromagnetic wave interference resistant iron silicon aluminum nickel alloys. The invention comprises the following steps: firstly, ferrum, aluminum, silicon and nickel with a purity more than 99.9 weight percent are taken as raw materials and laid into a medium frequency vacuum induction furnace for smelting, and a master alloy is obtained; secondly, the master alloy after smelting is laid into a quick quenching device; an alloy ingot casting is quickly poured on a water-cooling roll wheel which rotates at high speed after arc remelting under the protection of high purity inert gases, and a quickly condensed sheet band or a quickly condensed sheet is obtained; thirdly, the sheet band or the sheet is laid into a ball mill for ball milling flat processing, and flat powder is obtained; fourthly, the flat powder is laid into a stainless steel tube which is then vacuumized and filled with high purity inert gases for protection, and then the stainless steel tube is laid into a tube furnace for heating, heat preservation and cooling along with the furnace; fifthly, the flat powder and binding agents are mixed and milled for processing the sheet. The preparation method for the electromagnetic wave interference resistant iron silicon aluminum nickel alloys adds adequate nickel into Sendust alloys, thereby the processability of the alloys is improved; the ball milling time is reduced; the cost of industrial production is saved; simultaneously the magnetic conductivity can be improved and the magnetic shielding effect can be improved.

Owner:ZHEJIANG UNIV +1

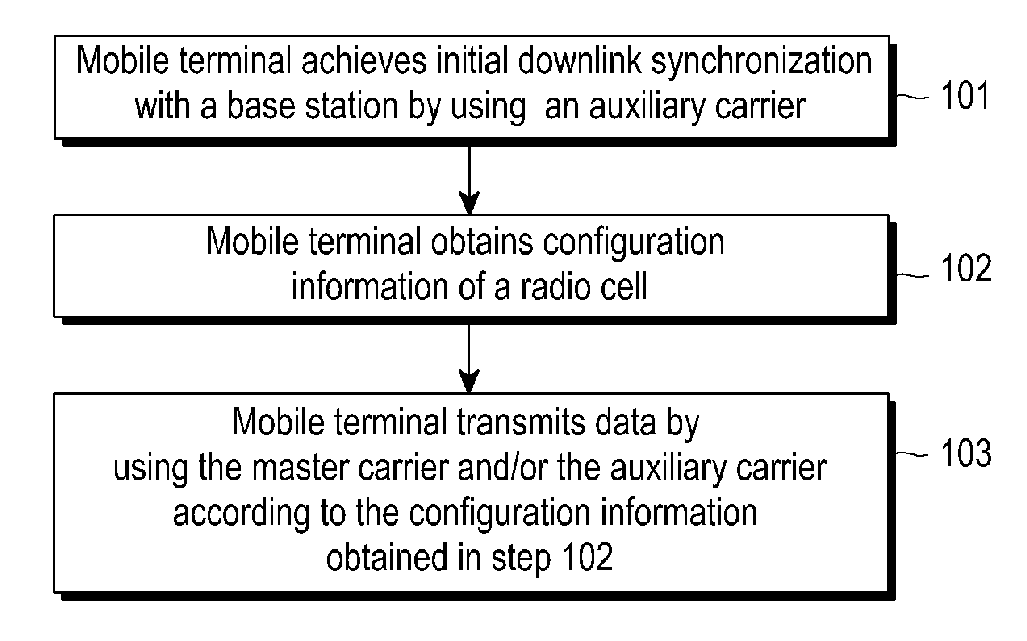

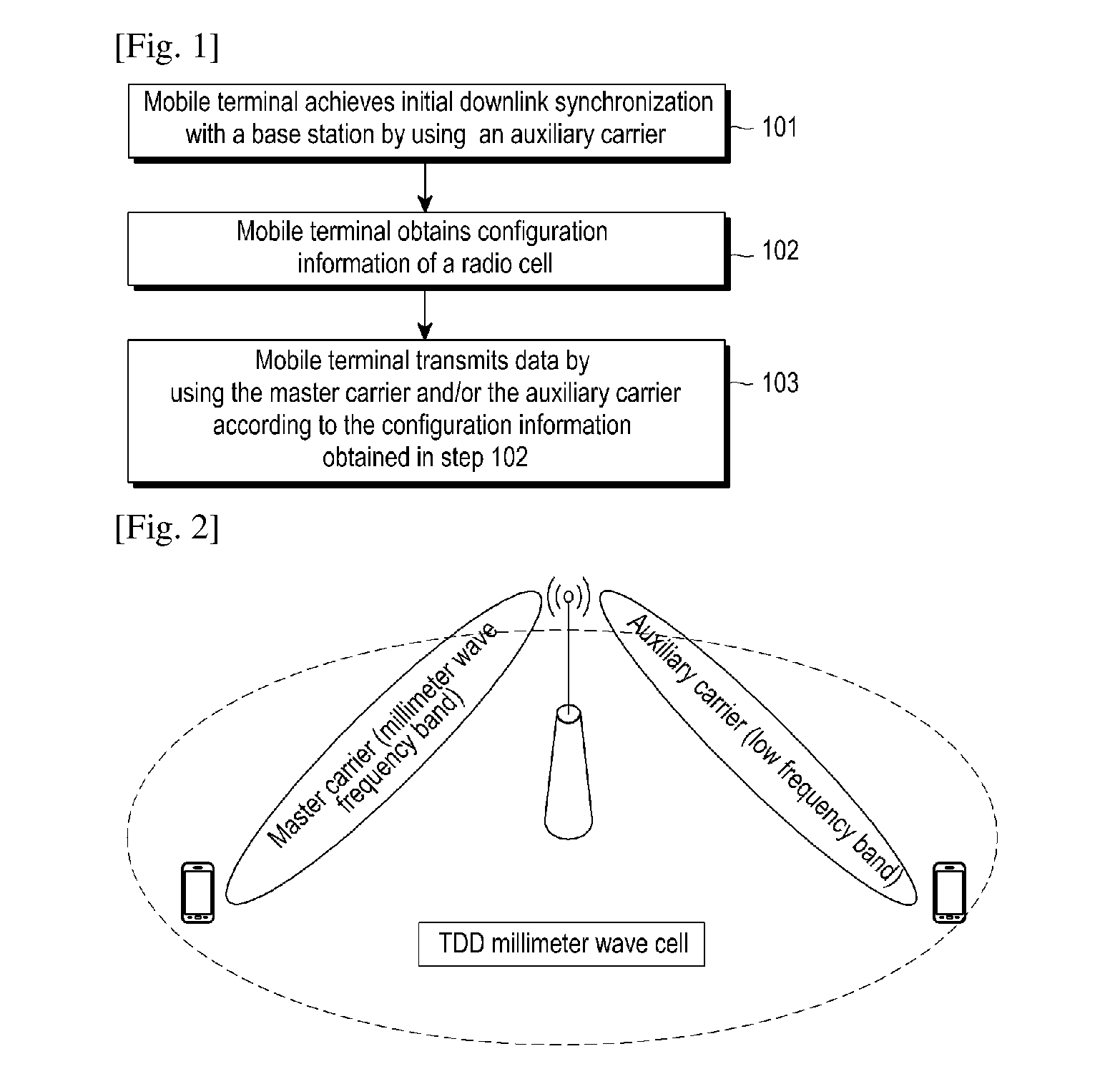

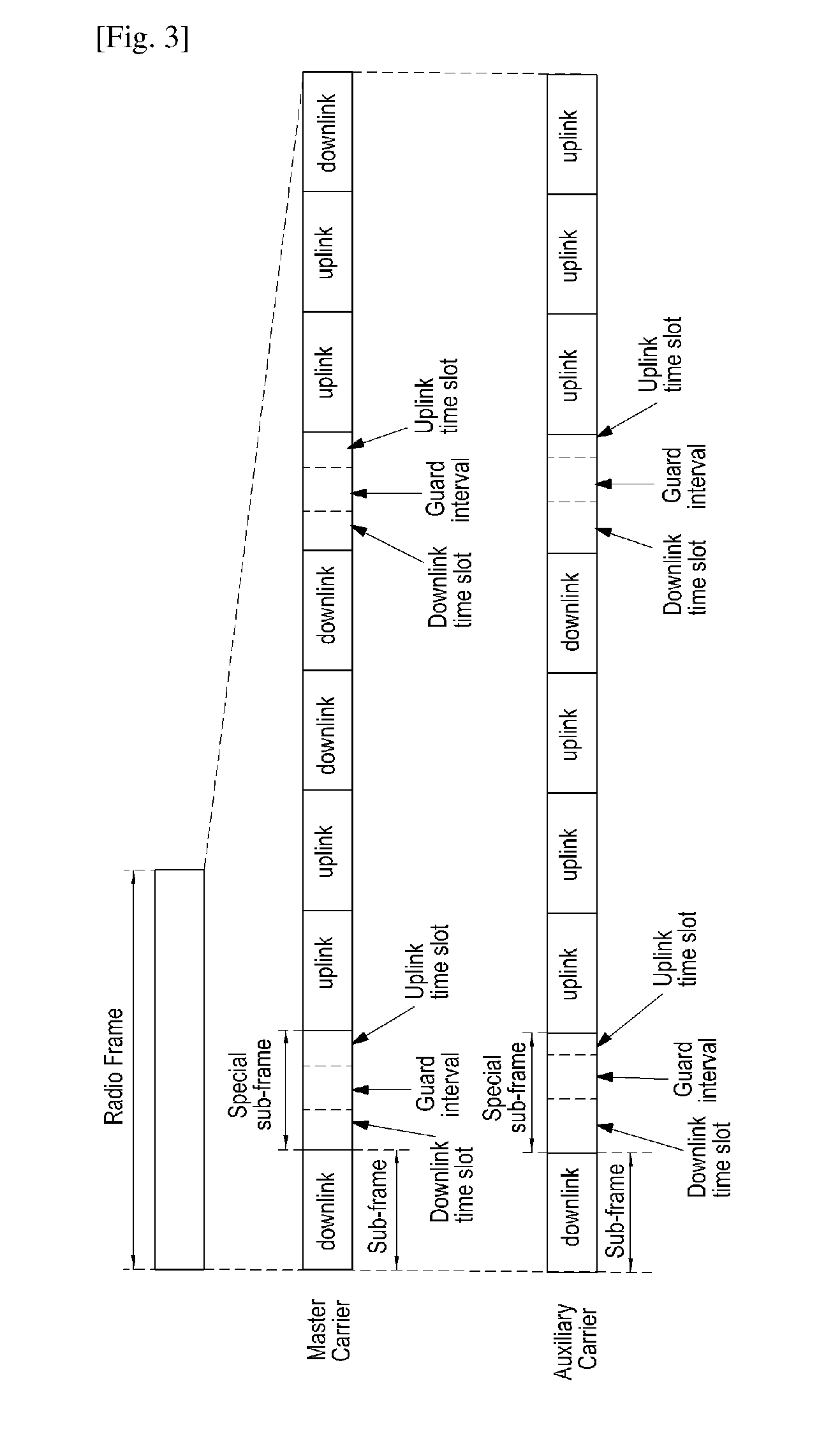

Mobile terminal and method for data transmission in a radio cell thereof

ActiveUS20160219535A1Reliable signalWide rangeSynchronisation arrangementCarrier signalLow frequency band

The present application discloses a method for data transmission in a radio cell of a mobile terminal. The radio cell includes an auxiliary carrier in a low frequency band and at least one master carrier in a high frequency band, the method including: the mobile terminal achieving downlink synchronization with the radio cell through the auxiliary carrier in the low frequency band, and after achieving the downlink synchronization, obtaining configuration information of the radio cell, and transmitting data by using the master carrier and / or the auxiliary carrier according to the configuration information. The present application also provides a mobile terminal. By using the present application, radio cell coverage and transmission performance may be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

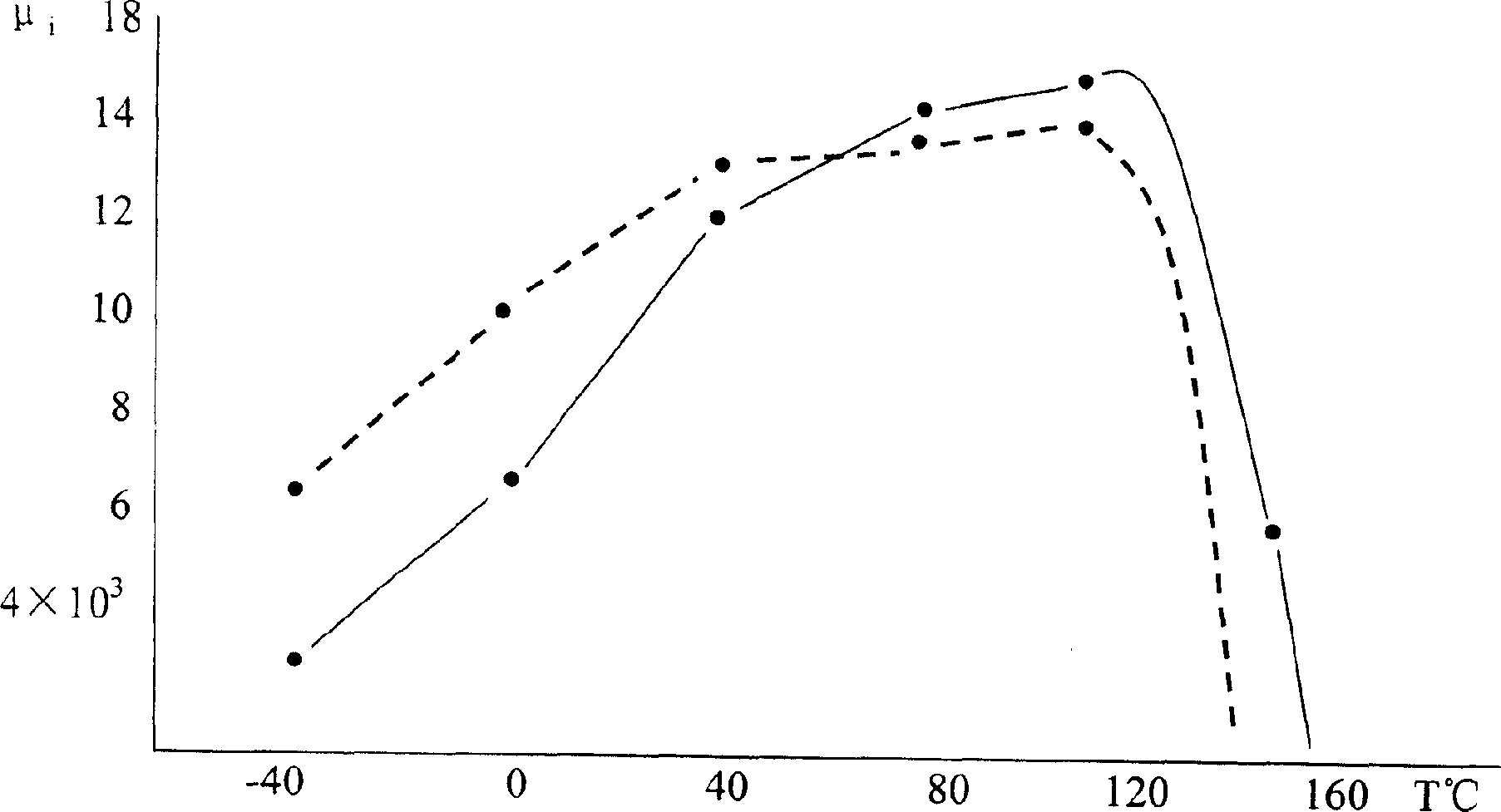

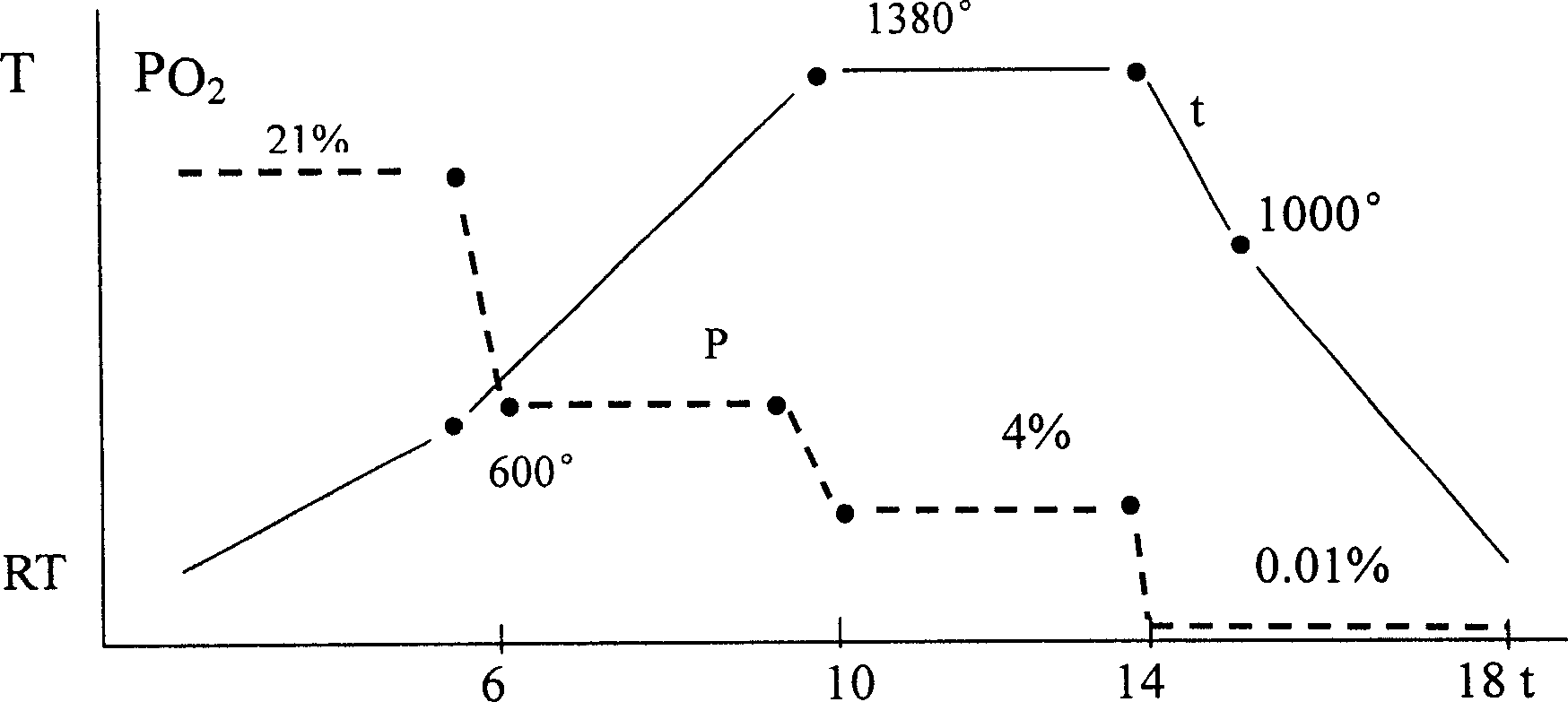

Ferrite magnet material of manganese-zinc, and Method for preparing high conductive ferrite of manganese-zinc from material

ActiveCN1697094AIncrease temperatureImprove performanceInorganic material magnetismManganese oxideTitanium oxide

Mixed main material including 51.5-52.8 mol% ferric oxide, 23.3-26.0 mol% manganese oxide, and 22.5-24.0 mol% zinc oxide is processed through shake grinding and pre-burning procedures. Next, auxiliary materials including 500-1000ppm calcium oxide, 300-1500ppm titanium oxide and 100-400ppm bismuth oxide are added to the said processed main material. Then, procedures including sand mill, granulation, body blank and burning are carried out in sequence to produce products. Advantages are: reasonable compounding ratio between main and auxiliary materials provides precondition for producing the disclosed product in high magnetic permeability and low coefficient of specific loss; optimized curve of agglomeration technology prevents oxidation of products, and improves temperature and even atmosphere in kiln. The product shows preferred initial permeability, coefficient of specific loss and coefficient of specific temperature.

Owner:SUZHOU GUANDA MAGNET

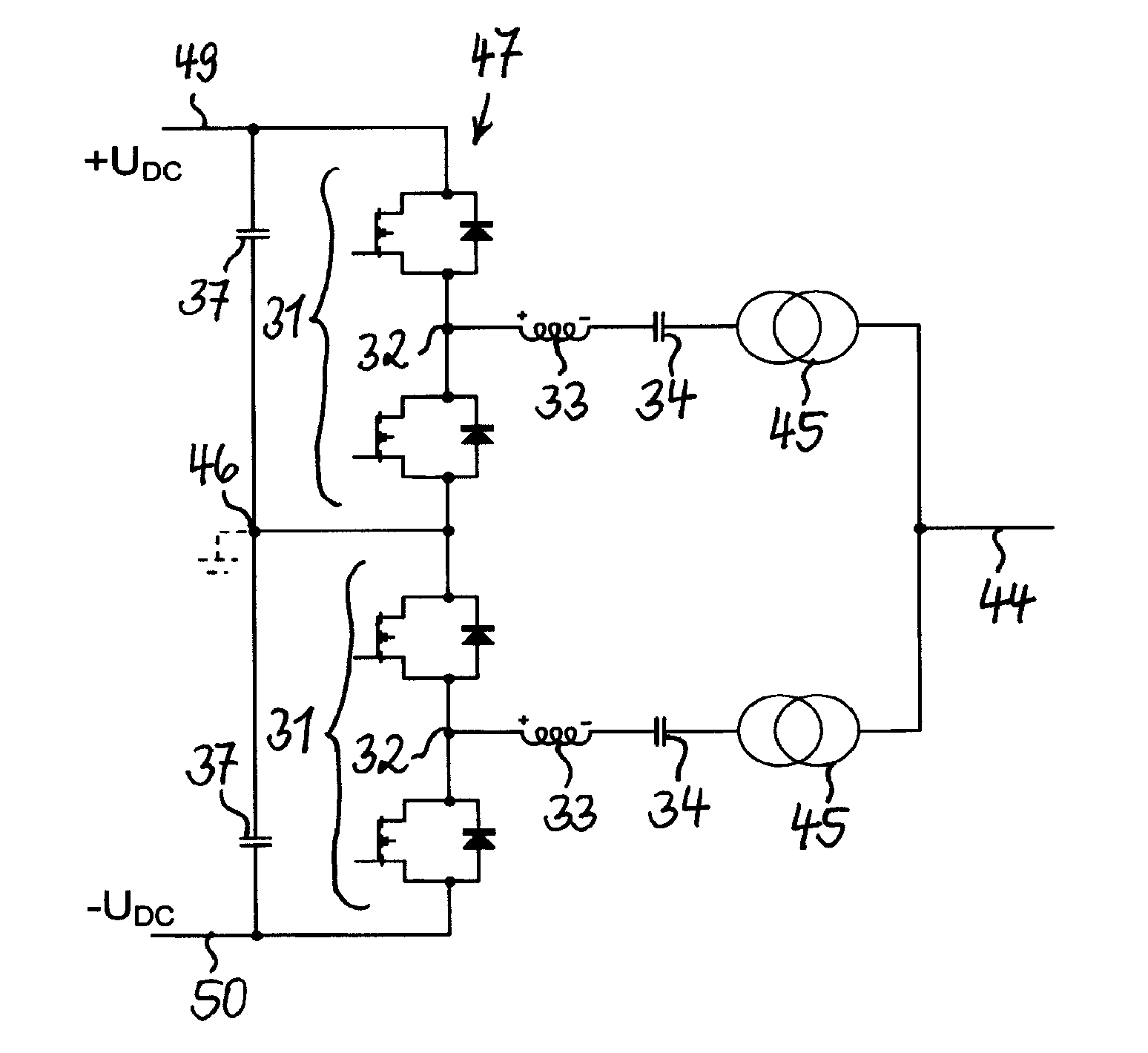

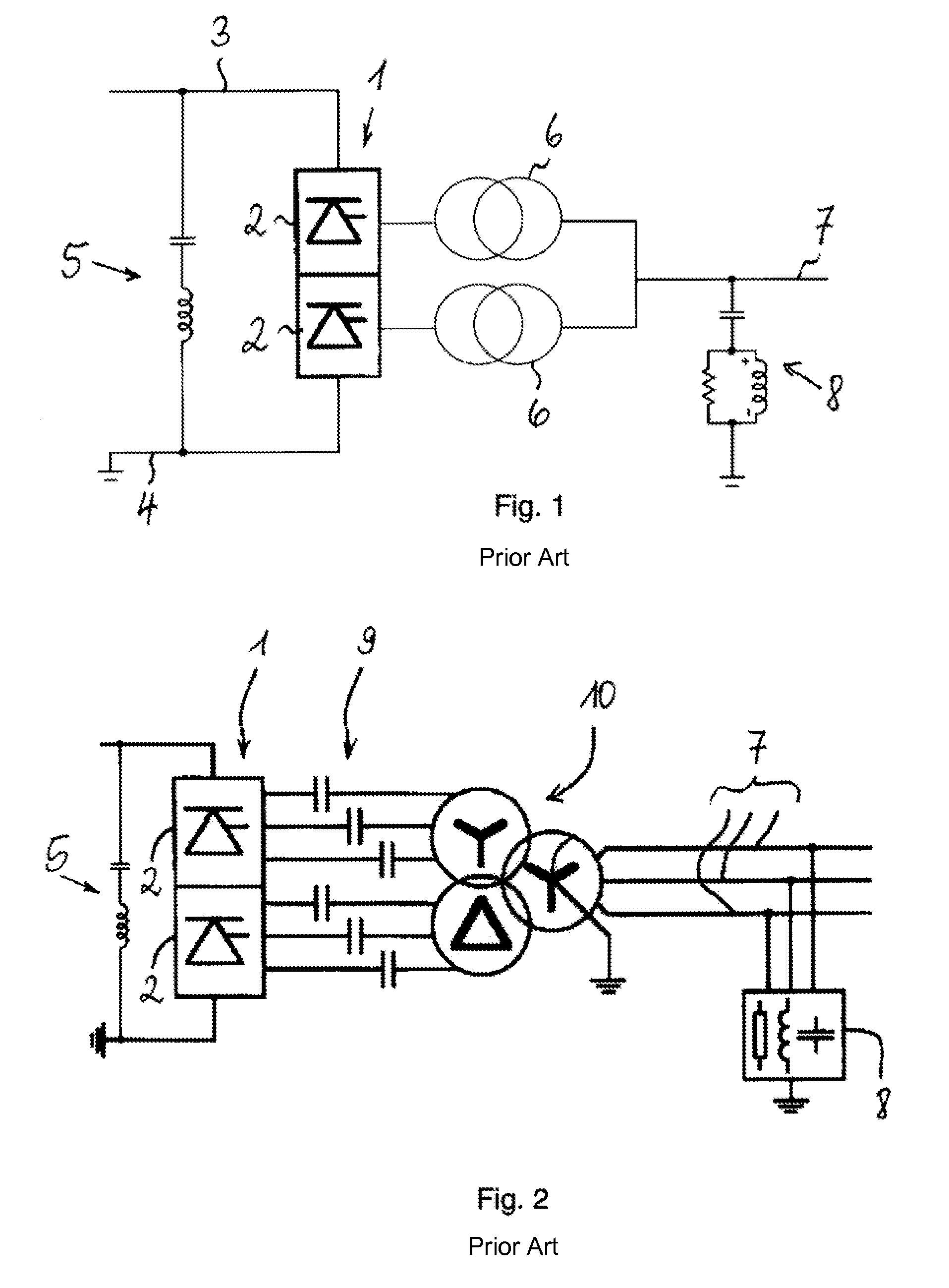

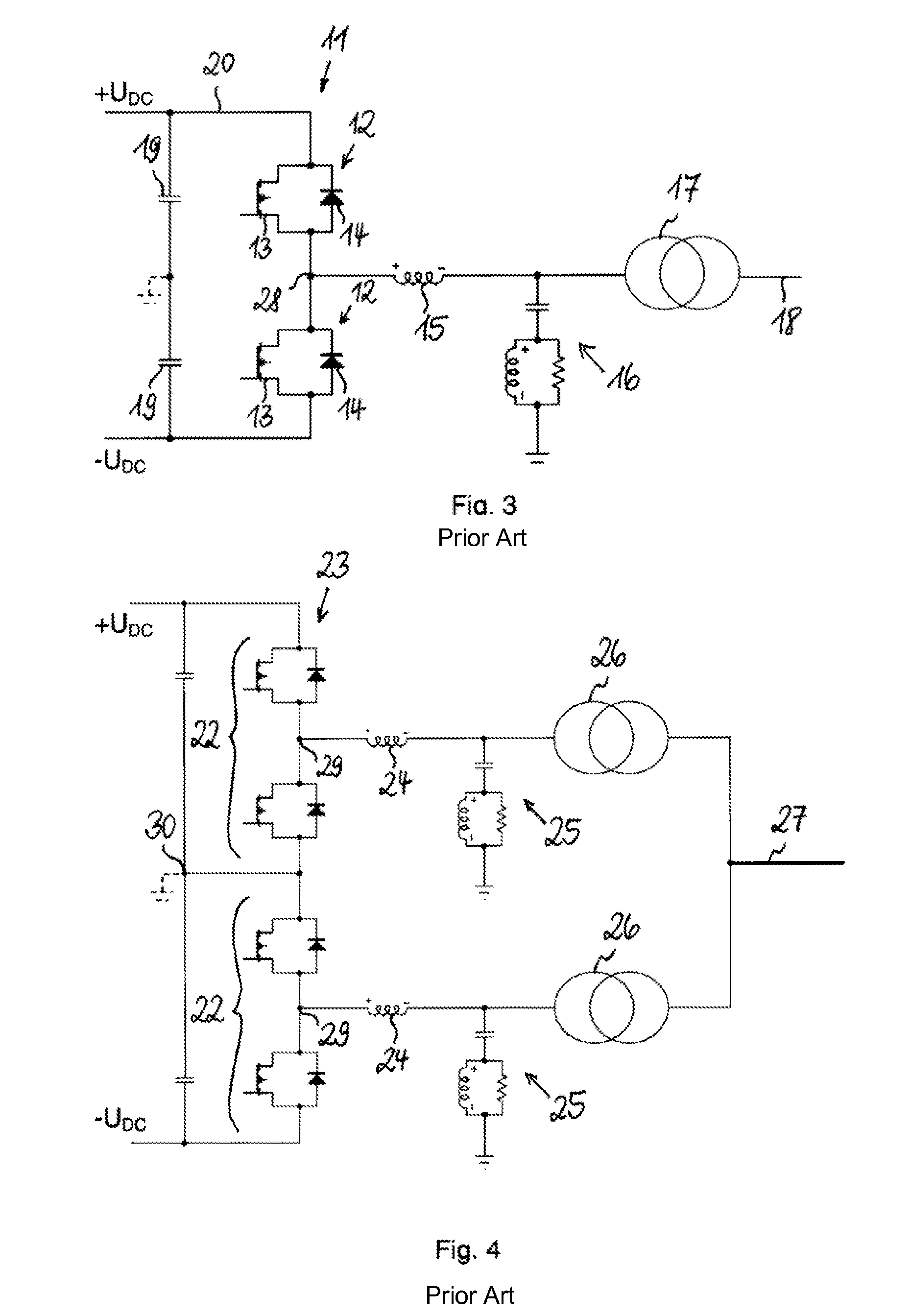

Voltage source converter for high voltage direct current power transmission

InactiveUS8345457B2Low costReduce effortAc-dc conversion without reversalElectric power transfer ac networkTransformerHigh-voltage direct current

A high voltage AC / DC or DC / AC power conversion system including a voltage source converter with at least two series-connected converter valve bridges, at least two reactors, where each of the reactors is connected to one of the AC phase terminals of the at least two bridges and at least one transformer connected to an AC supply voltage. In order to block a DC voltage from the at least one transformer, one of at least two capacitors is connected in series with each of the at least two reactors and is connected between the corresponding reactor and the at least one transformer.

Owner:ABB POWER GRIDS SWITZERLAND AG

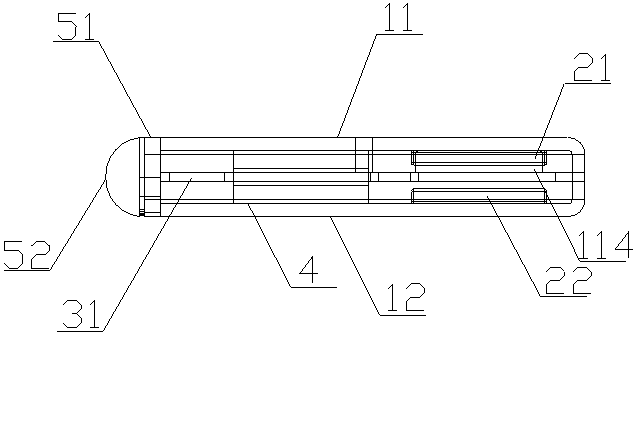

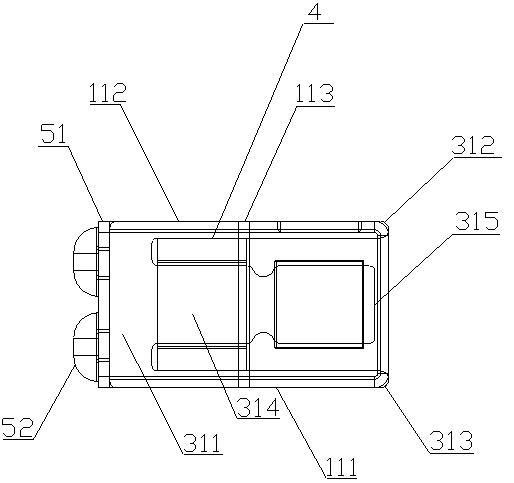

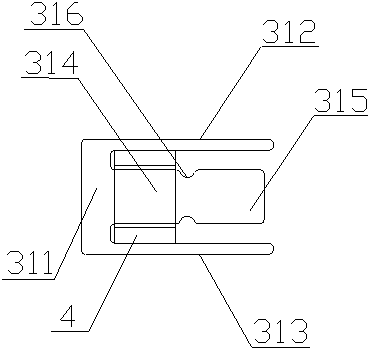

Ultra-thin telephone receiver

ActiveCN103067806AReduce thicknessReduced anterior chamber spaceEarpiece/earphone attachmentsAlloyEngineering

The invention discloses an ultra-thin telephone receiver. A driving mechanism of the ultra-thin telephone receiver comprises an armature section and a coil section, wherein the armature section is E-shaped and comprises a base portion, two wing portions and a middle portion, the base portion, the two wing portions and the middle portion are formed in an integrated mode, the middle portion comprises a root part located on the base portion, the root part extends forward to form a vibrating diaphragm part, and the coil section is arranged on the root part in a sleeved mode at intervals. A shell of the ultra-thin telephone receiver comprises an upper shell and a lower shell, wherein the upper shell is arranged at the top of the driving mechanism in a covered mode, and comprises a cover plate and cover edges which are formed by extending downward from the periphery of the cover plate, a first magnet is fixedly connected to the inner wall, covered at the top of the vibrating diaphragm part, of a section of the cover plate, the upper shell is made of magnetically soft alloy, the lower shell is arranged at the bottom of the driving mechanism in a covered mode relative to the upper shell, a second magnet is fixedly connected to the inner wall of the lower shell relative to the first magnet, the lower shell is made of magnetically soft alloy, and a sounding hole is formed in the upper shell or the lower shell. According to the ultra-thin telephone receiver, the thickness of an existing telephone receiver is reduced to the largest extent, and the ultra-thin telephone receiver is more suitable for the structure of a mobile phone with a narrow frame or a mobile phone which is nearly frameless.

Owner:SUZHOU YICHUAN TECH CO LTD

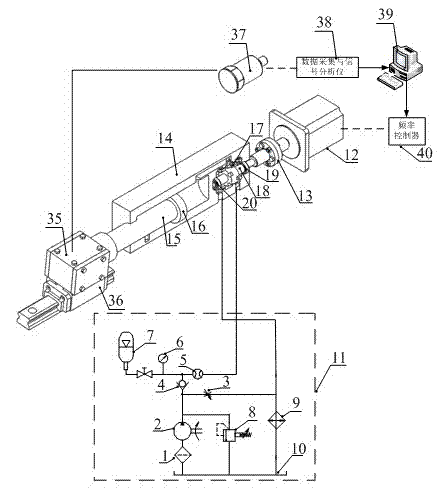

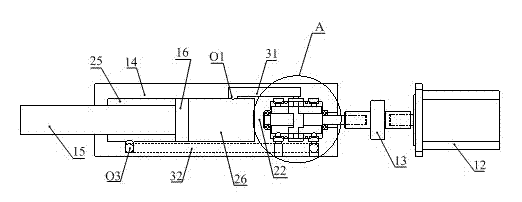

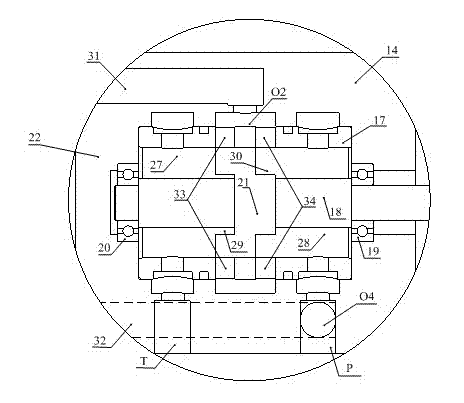

Electrohydraulic vibration exciter

InactiveCN102734279ARealize high frequency commutationHigh control precisionFluid-pressure actuator componentsCouplingEngineering

The invention discloses an electrohydraulic vibration exciter which comprises a step motor and a vibration excitation device. An accommodation cavity inside a case of the vibration excitation device is divided into a first chamber and a second chamber by a clapboard. The first chamber is divided into a rod cavity and a rodless cavity by a piston with a single-acting piston rod. A single-shoulder valve plug provided with a valve sleeve is arranged inside the second chamber and is connected with a main shaft of the step motor through a coupling. The second chamber is divided into a third cavity and a fourth cavity by the shoulder of the single-shoulder valve plug, an oil return port is arranged on the wall of the third cavity, and an oil inlet port is arranged on the wall of the fourth cavity. A first flow channel and a second flow channel are arranged on the wall of the accommodation cavity; the rodless cavity is communicated with the second chamber through the first flow channel, and the rod cavity is communicated with the oil inlet port through the second flow channel. First and second grooves which can be communicated with the first flow channel are arranged on the two sides of the shoulder of the single-shoulder valve plug along the circumferential direction at intervals. Along with the rotation of the single-shoulder valve plug, an opening at the other end of the first flow channel is communicated with either of the first and second grooves all the time.

Owner:ZHEJIANG UNIV

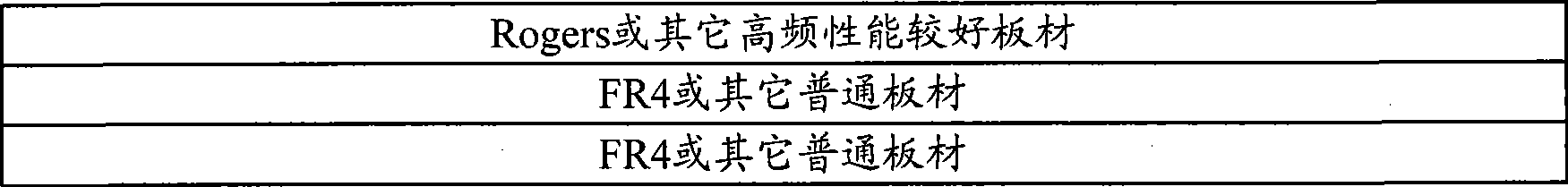

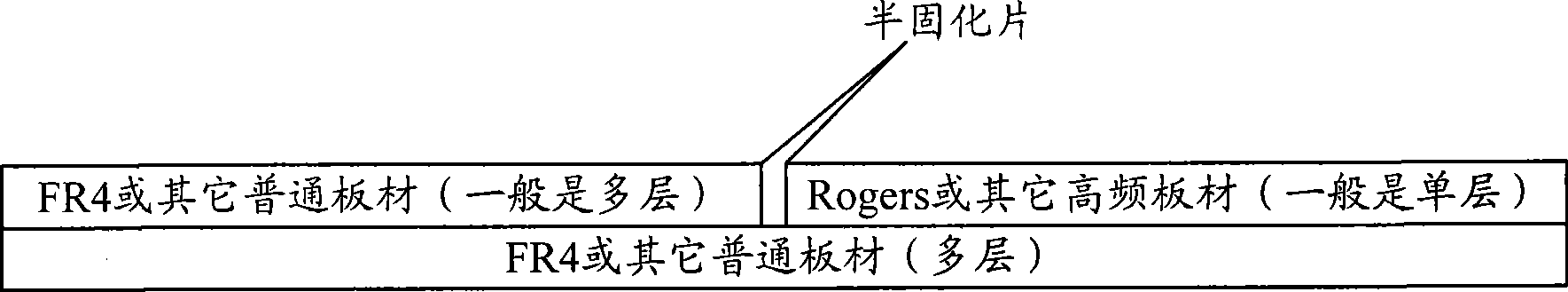

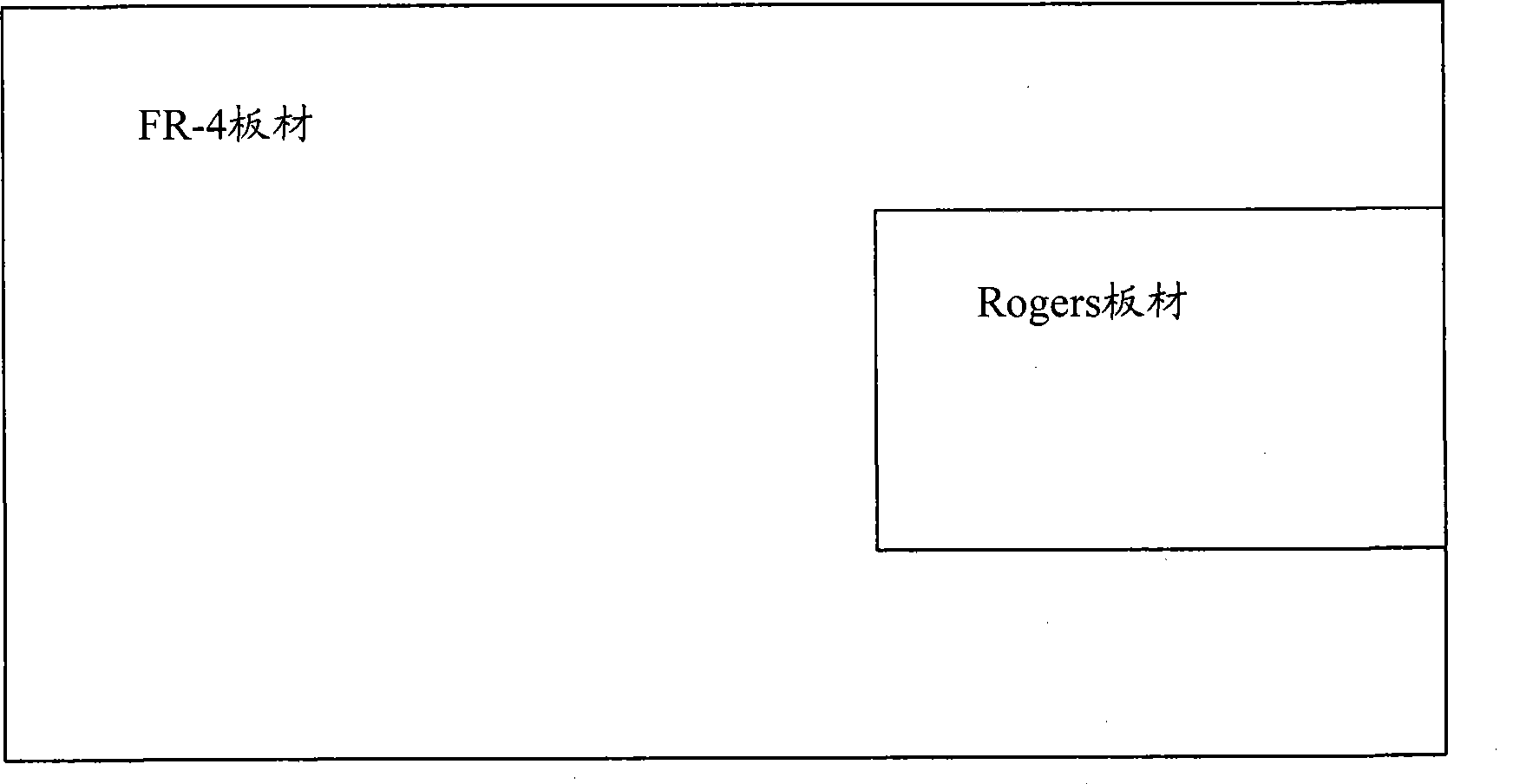

Multi-layer mixed pressing printed circuit board and manufacturing method, apparatus thereof

InactiveCN101426333ALow costQuality improvementPrinted circuit detailsPrinted circuit aspectsPrinted circuit board

The present invention discloses a multi-layer mixed-compression printed circuit board which comprises at least one layer on the top, wherein each layer is respectively formed by the splicing of at least one board in the first series of board and at least one board in the second series of board. The multi-layer mixed-compression printed circuit board also comprises other layers under the top, wherein the other layers are composed of at least one board in the first series of board. The top layer and other layers under top are combined through the modes of laminating and mixed compression. The invention simultaneously discloses a manufacturing method and a manufacturing device of the multi-layer mixed-compression printed circuit board. A mixed-compression circuit board different from the prior art can be provided according to the invention for obtaining an effect of mixed-compression of board.

Owner:ZTE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com