Ultra-thin telephone receiver

A receiver, ultra-thin technology, applied in the field of receivers, can solve the problem that the thickness cannot be installed with mobile phones, etc., achieve the effect of thickness reduction, front cavity space reduction, and enhanced high frequency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

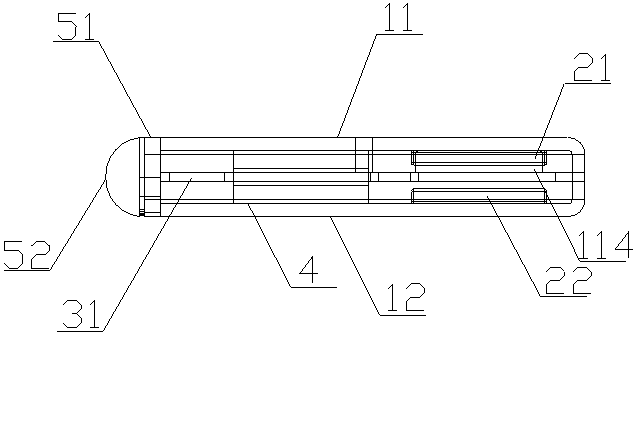

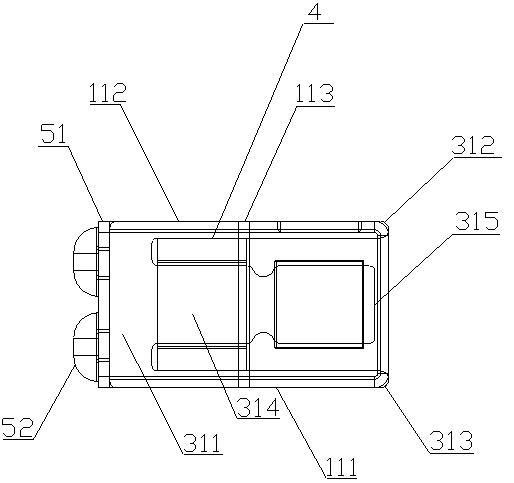

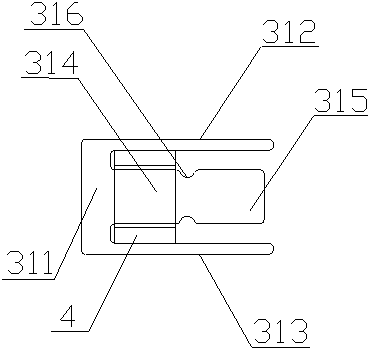

[0033] Such as Figure 1-6 As shown, the ultra-thin receiver in this embodiment includes a housing 1, a driving mechanism and a circuit board 51. The driving mechanism includes: an armature part 31, which is E-shaped, and the armature part 31 includes an integrally formed base part 311, Two side wing parts and a middle part, the two side wing parts are a first side wing part 312 and a second side wing part 313, the middle part includes a root part 314 located on the base part 311, and the root part 314 extends forward to form a diaphragm part 315; The coil part 4 is sleeved on the root part 314 in a gap, and it does not contact the root part 314. The coil part 4 has two starting lines and a termination line to be electrically connected to the positive and negative poles of the circuit board 51 respectively, that is, to connect On the welding platform 52, the armature part 31 can be made of soft magnetic alloy; the housing 1 includes: an upper housing 11, which is covered on th...

Embodiment 2

[0046] Others are the same as those described in Embodiment 1, except that the above-mentioned upper casing 11 and the lower casing 12 are fixedly connected, steps are provided around the inner side of the lower casing 12, the base 311, the first side wing The part 312 and the second side wing part 313 are fixedly connected on the step, and the fixed connection method can be welded, and a plurality of welding spots can be set on the above-mentioned positions for connection.

[0047] The working principle of the present invention is introduced below:

[0048] Both the original diaphragm and the armature part are combined into the current armature part 31, the root part 314 of the middle part of the armature part 31 is used for gap winding the coil 4, and the part extending forward of the root part 314 is used to replace the existing diaphragm Diaphragm part 315, so that the space occupied by the original diaphragm is firstly compressed; the original shell and the iron core for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com