Patents

Literature

2263 results about "L-shell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The L-shell, L-value, or McIlwain L-parameter (after Carl E. McIlwain) is a parameter describing a particular set of planetary magnetic field lines. Colloquially, L-value often describes the set of magnetic field lines which cross the Earth's magnetic equator at a number of Earth-radii equal to the L-value. For example, "L=2" describes the set of the Earth's magnetic field lines which cross the Earth's magnetic equator two earth radii from the center of the Earth.

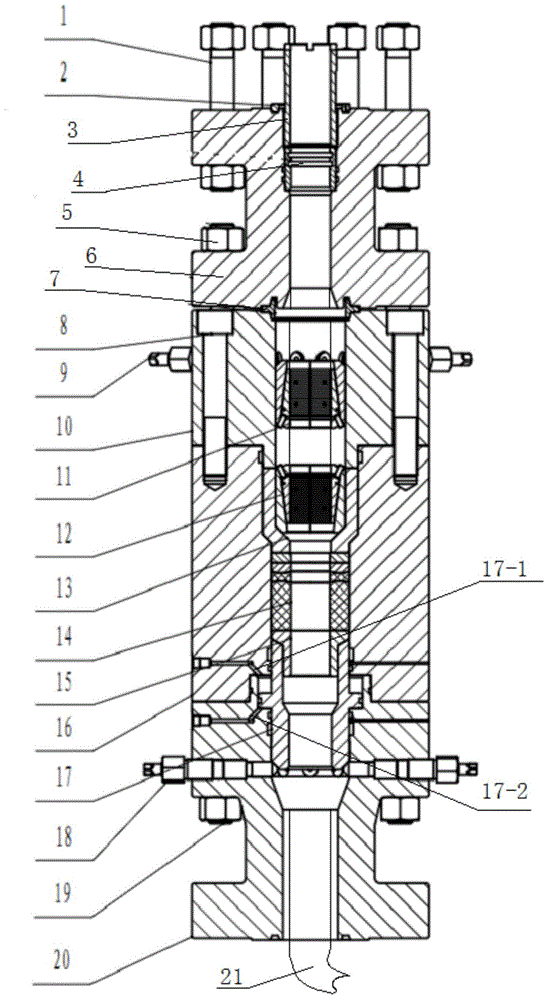

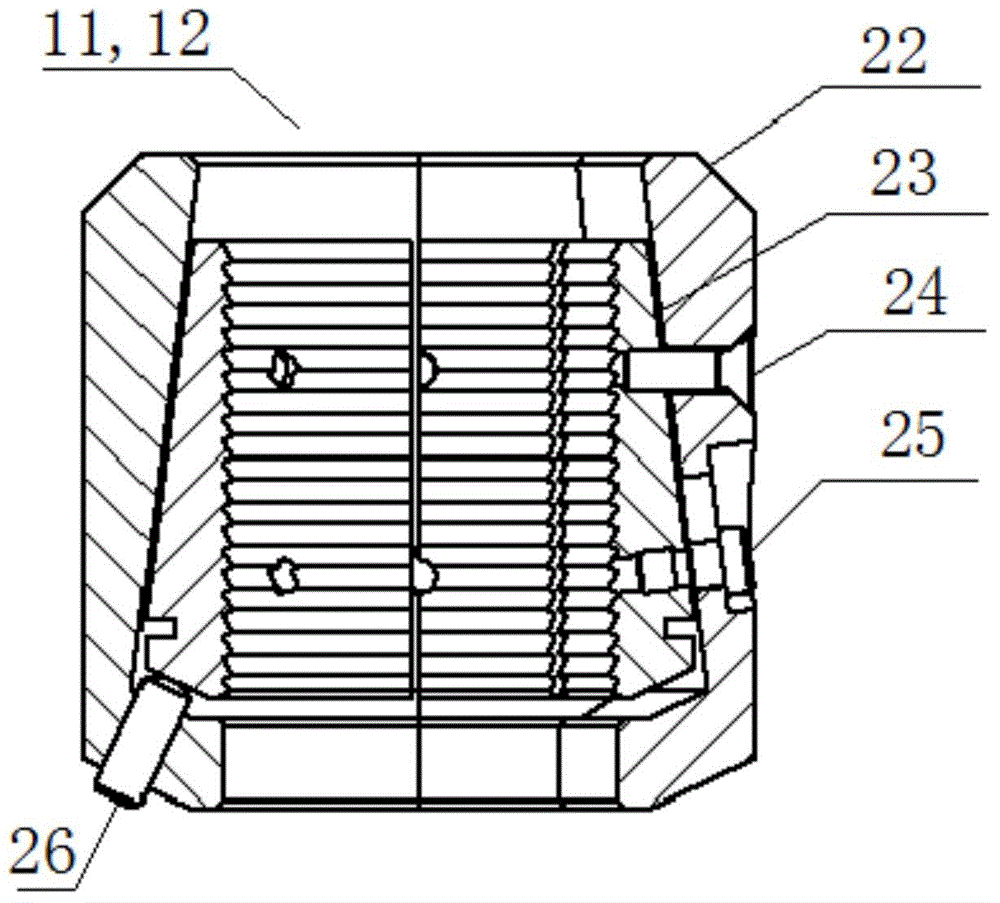

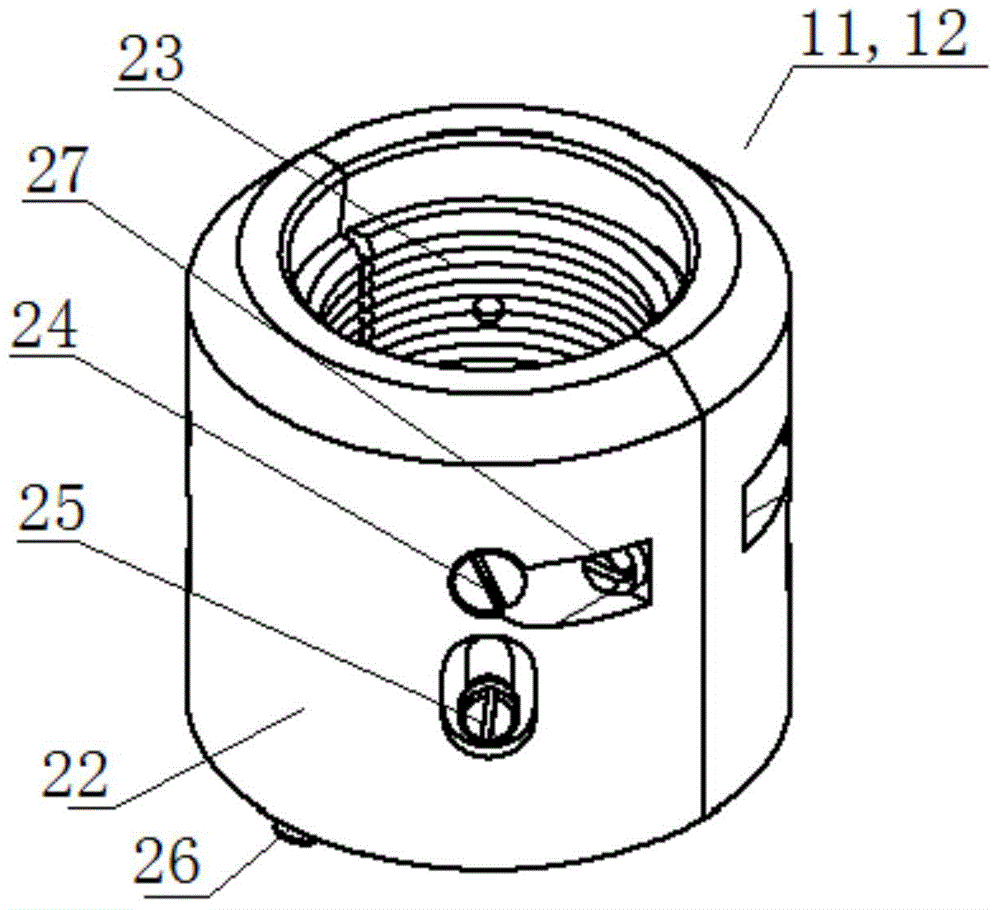

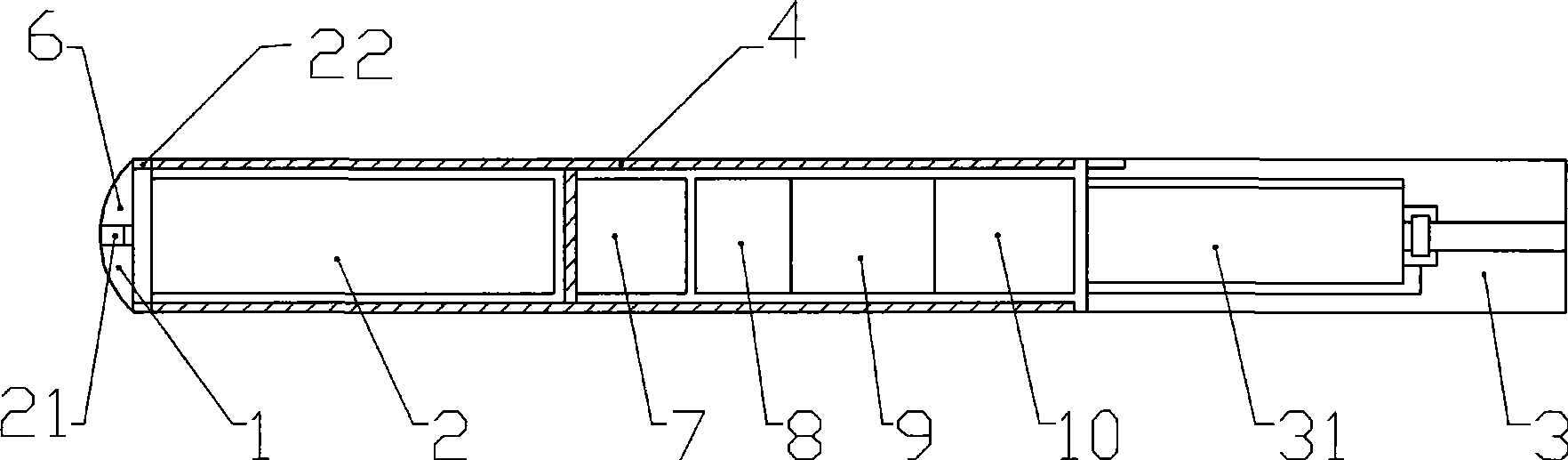

Continuous oil pipe hanger for velocity tubular column

ActiveCN104358536AGuaranteed sealing performanceFix the leakBorehole/well accessoriesCoiled tubingEngineering

The invention relates to a continuous oil pipe hanger for a velocity tubular column. The continuous oil pipe hanger comprises a continuous oil pipe, an I-shaped flange, an upper slip assembly, a lower slip assembly, an upper shell, a middle shell and a lower shell, wherein vertically penetrating central holes are formed in the upper shell, the middle shell and the lower shell; the I-shaped flange is fixedly arranged at the top of the upper shell; the continuous oil pipe passes through the I-shaped flange and the central holes of the upper shell, the middle shell and the lower shell in turn; the upper slip assembly is clamped on an inner wall of the central hole of the upper shell; the lower slip assembly is located in the central hole of the middle shell; a connecting pipe sealing set is fixedly arranged on an inner wall of the central hole of the middle shell and the lower side of a hanging supporting sleeve; at least one pair of driving pistons is arranged on the inner walls of the central holes of the middle shell and the lower shell and under the connecting pipe sealing set; an upper oil port and a lower oil port respectively communicated with the driving pistons are arranged on the side walls of the middle shell and the lower shell. The continuous oil pipe hanger has the beneficial effect of capability of hanging the continuous oil pipe.

Owner:JEREH ENERGY SERVICES

Electronic cigarette

ActiveCN101390659AWon't ageNot transgenderCoil arrangementsTobacco devicesElectronic cigaretteEngineering

The invention discloses an electronic cigarette which comprises a cigarette-like shell with a hollow cavity, an electrical source, a cigarette pellet and cigarette rod fittings. The electrical source, a pneumatic switch, a magnetostrictive vibrator and an electromagnetic induction heater are arranged in sequence inside the shell from the front end to the back end; wherein, a high frequency generator is respectively connected with the magnetostrictive vibrator, the electromagnetic induction heater and the pneumatic switch through leads. A light-emitting diode is arranged at the front end of the shell and is respectively connected with the pneumatic switch and the electric source through leads. The back end of the shell is connected with the cigarette pellet in which a tobacco solution chamber is arranged.

Owner:BEIJING SHUIWUTANG TECH & TRADE CO LTD

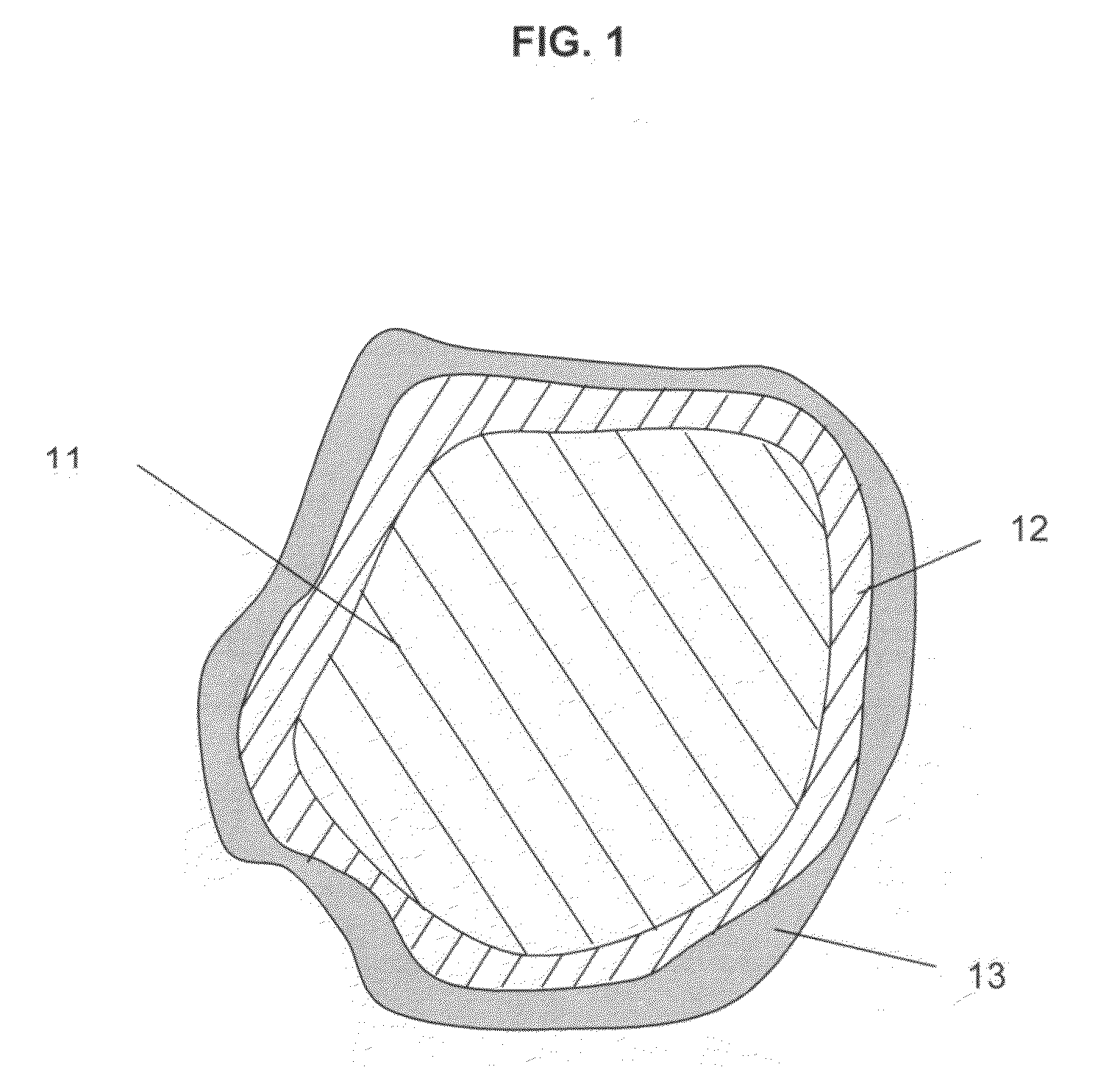

Core / shell-type catalyst particles comprising metal or ceramic core materials and methods for their preparation

ActiveUS20100092841A1High specific activityLow precious metal contentMaterial nanotechnologyCell electrodesFuel cellsAlloy

The invention is directed to core / shell type catalyst particles comprising a Mcore / Mshell structure with Mcore=inner particle core and Mshell=outer particle shell, wherein the medium diameter of the catalyst particle (dcore+shell) is in the range of 20 to 100 nm, 5 preferably in the range of 20 to 50 nm. The thickness of the outer shell (tshell) is about 5 to 20% of the diamet the inner particle core of said catalyst particle, preferably comprising at least 3 atomic layers. The inner particle core (Mcore) of the particles comprises metal or ceramic materials, whereas the material of the outer shell (Mshell) comprises precious metals and / or alloys thereof. The core / shell type catalyst particles are preferably supported on suitable support materials such as carbon black and can be used as electrocatalysts for fuel cells and for other catalytic applications.

Owner:UMICORE AG & CO KG

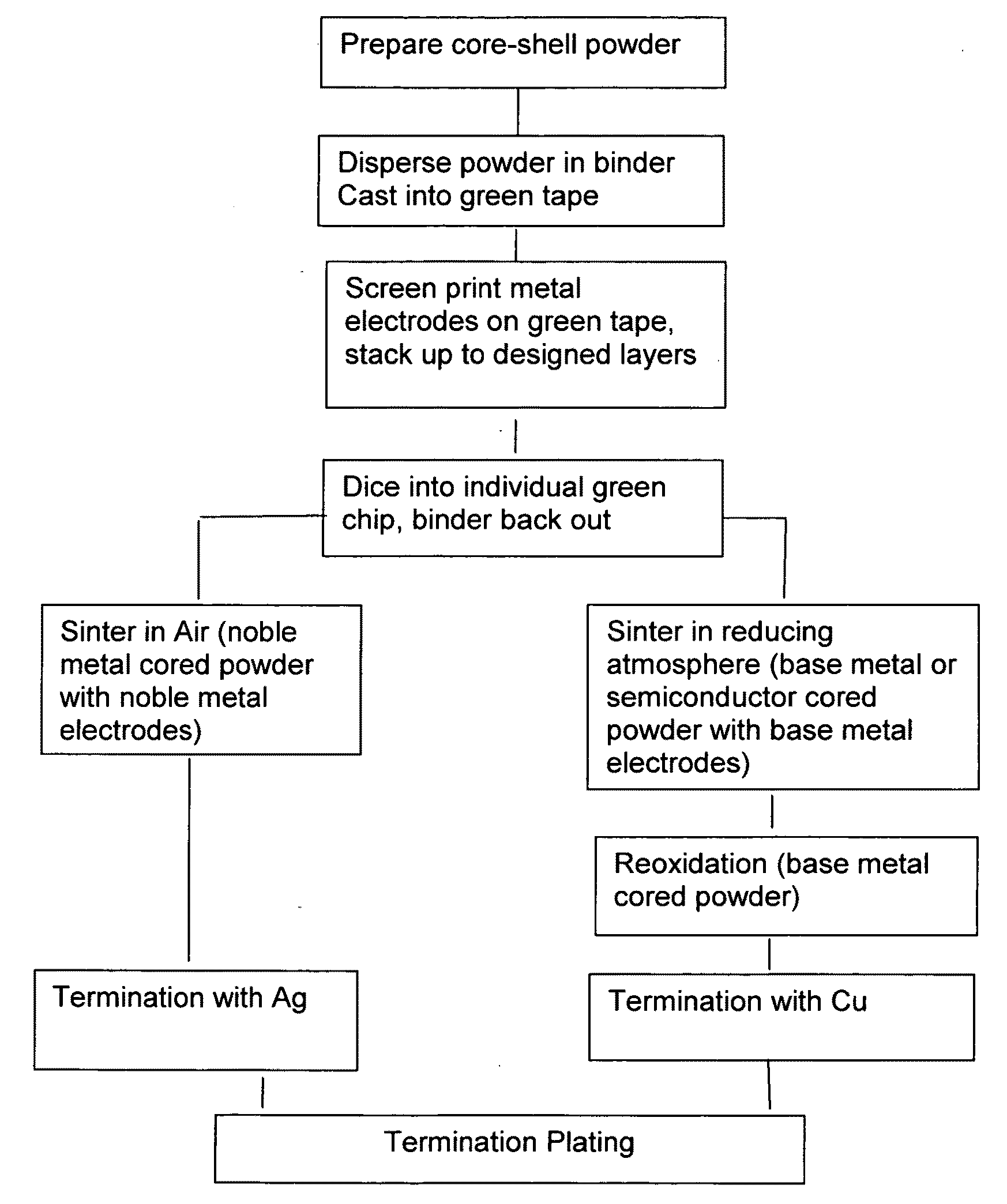

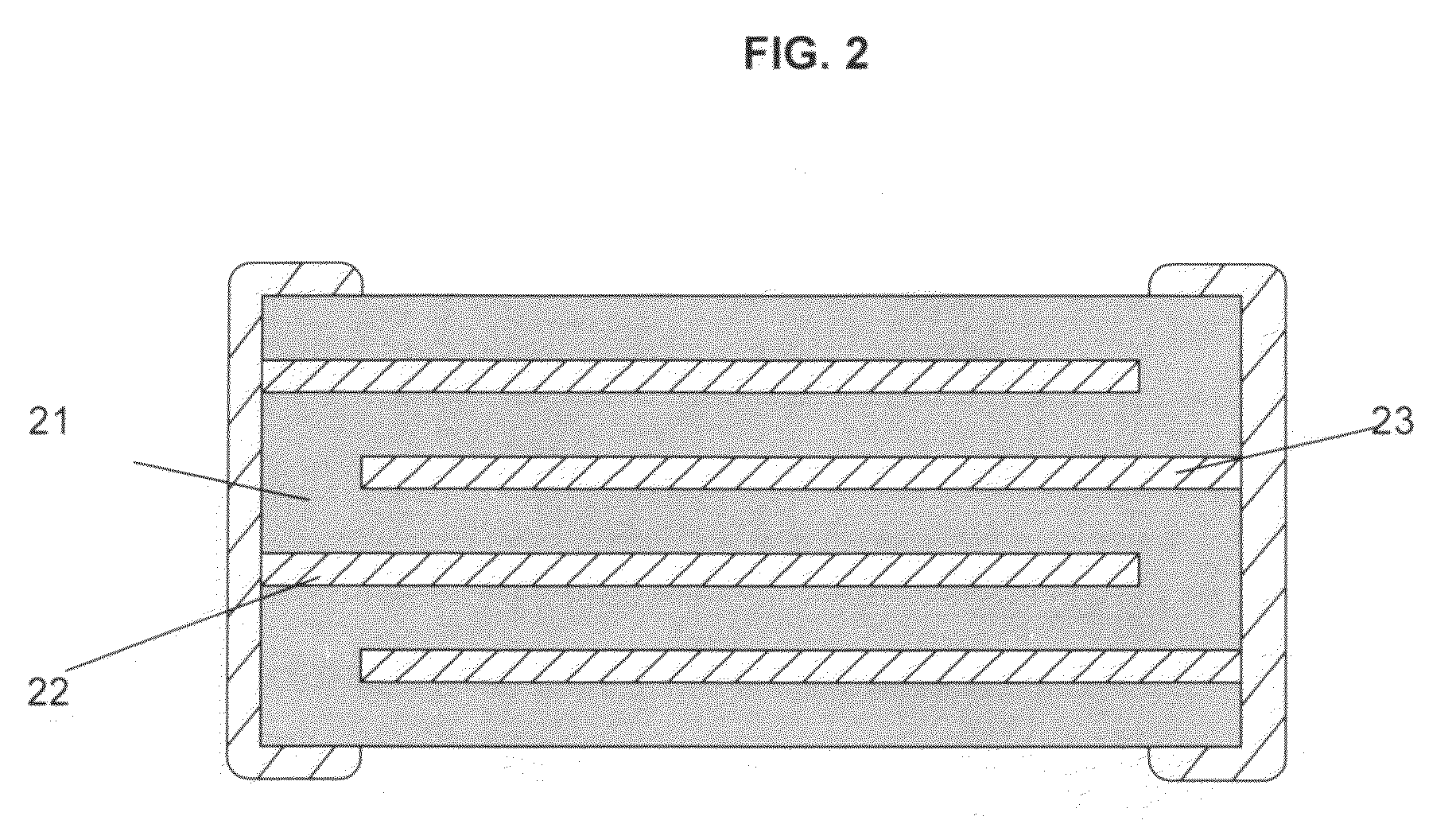

Core-shell structured dielectric particles for use in multilayer ceramic capacitors

InactiveUS20100110608A1Simplifies MLCC manufacturing processImprove propertiesFixed capacitor dielectricStacked capacitorsCapacitanceThin shells

This invention provides a method to make core-shell structured dielectric particles which consist of a conductive core and at least one layer of insulating dielectric shell for the application of multilayer ceramic capacitors (MLCC). The use of said core-shell instead of conventionally solid dielectric particles as the capacitor's active layers simplifies the MLCC manufacturing processes and effectively improves the MLCC properties. In particular, the use of core-shell particles with a thin shell of high permittivity dielectric material improves the capacitance volumetric efficiency, and the use of core-shell particles with a thick shell of dielectric will improve capacitor device's energy storage capacity as the results of improved electrical and mechanical strength.

Owner:WEI FRANK +1

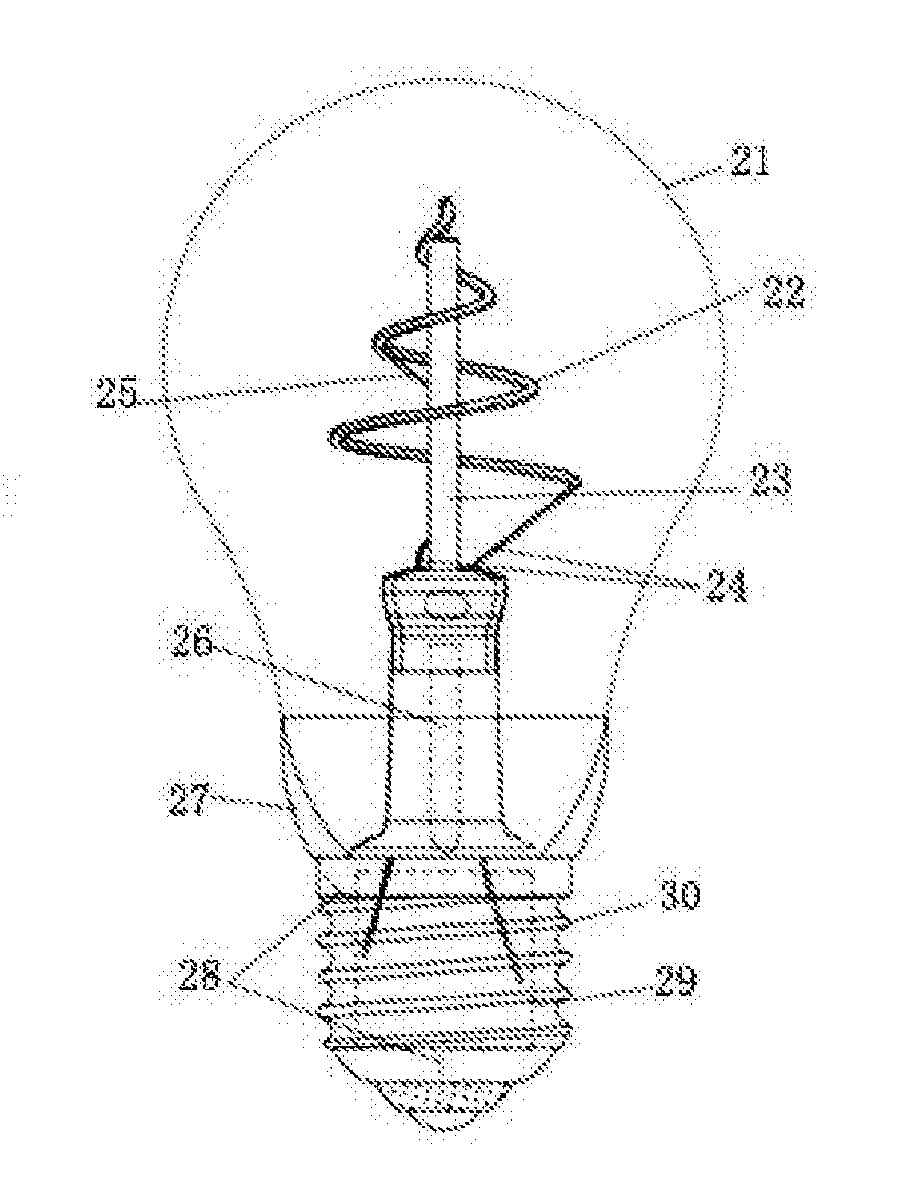

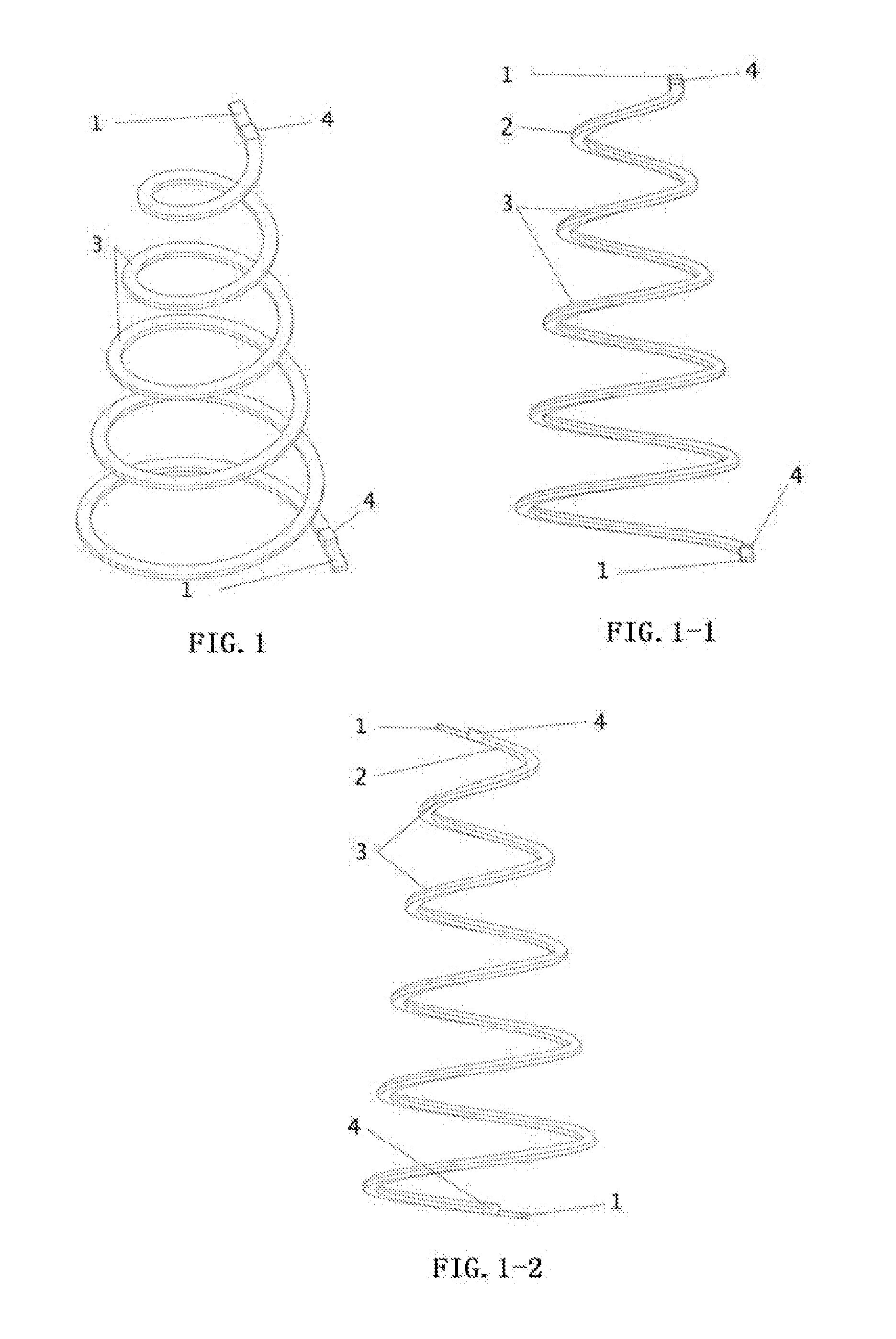

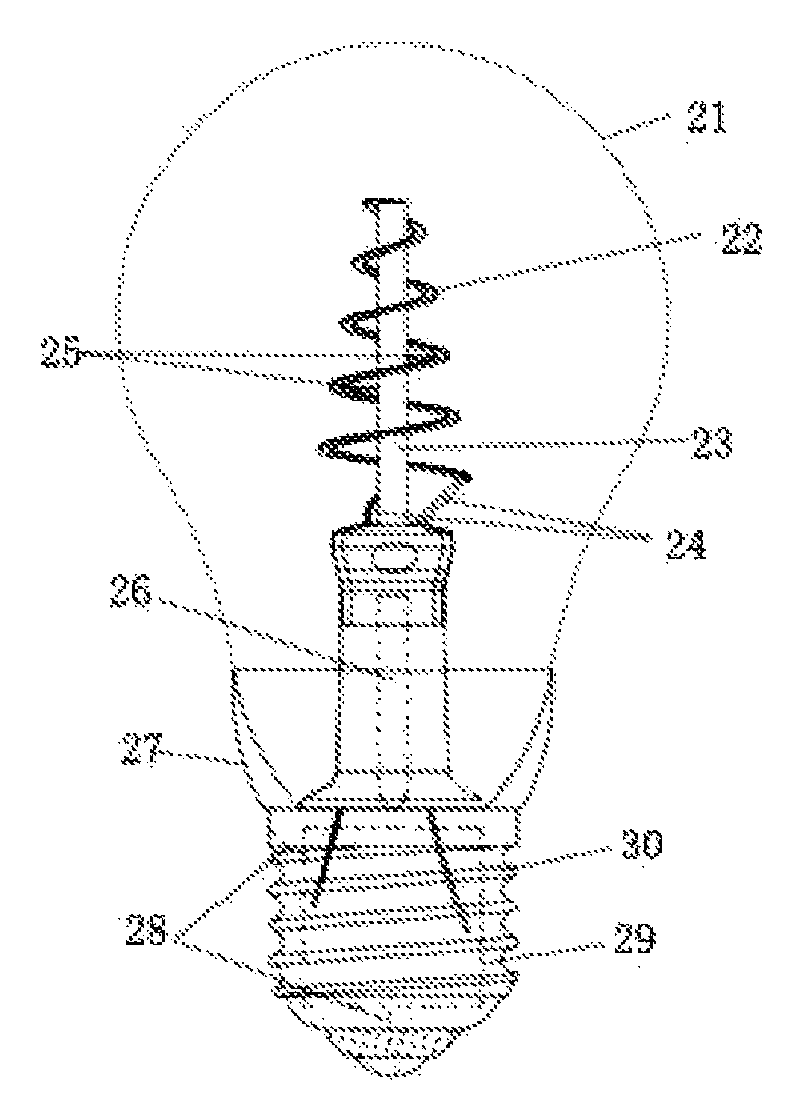

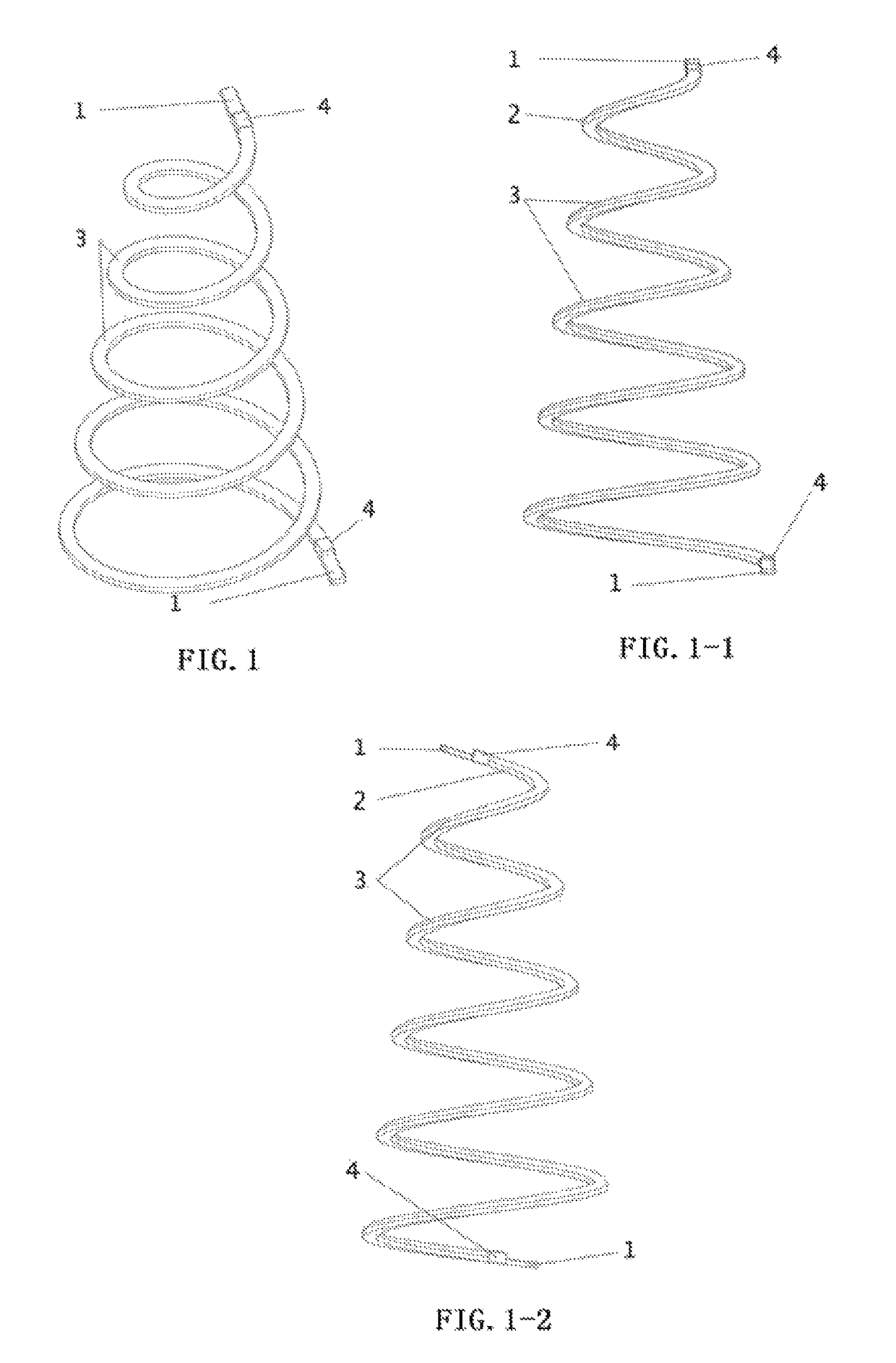

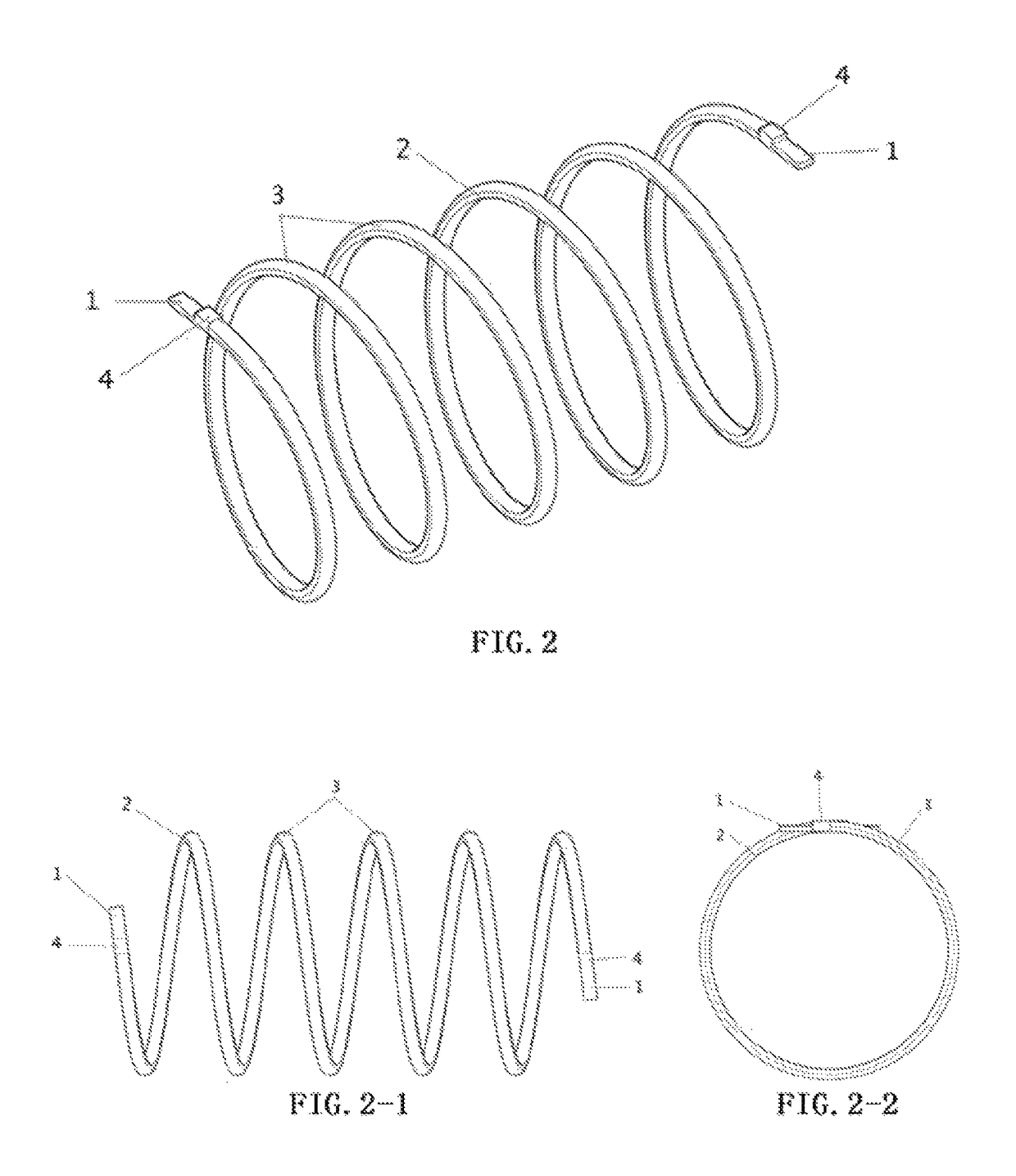

Spiral LED filament and light bulb using spiral LED filament

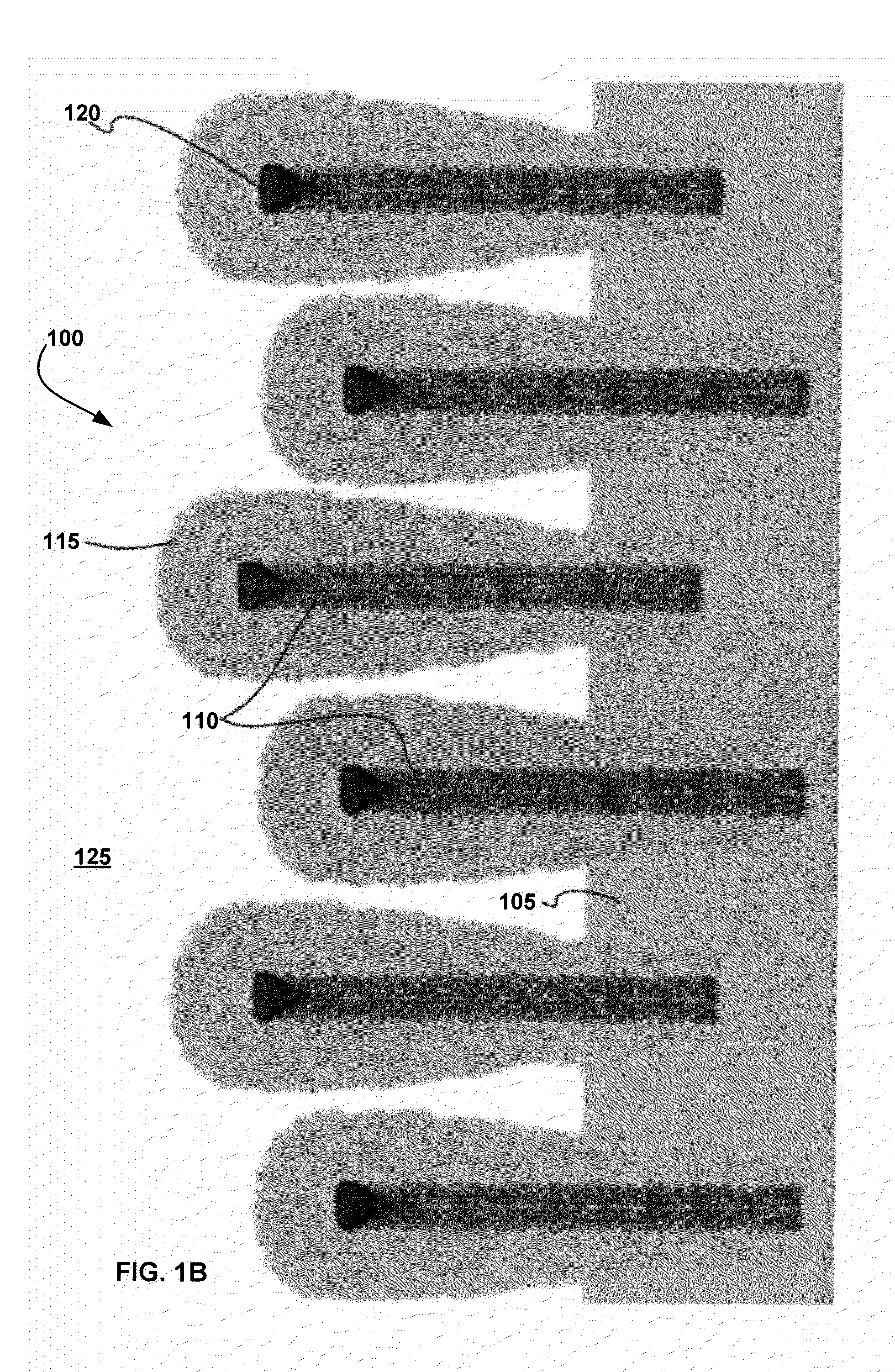

ActiveUS20160377237A1Simple manufacturing processImprove light distribution designElectric circuit arrangementsSolid-state devicesEngineeringElectrical connector

A spiral LED packaging filament comprises a substrate, a plurality of LED chips disposed on the top surface of the substrate, a medium layer sealing the plurality of LED chips and the top surfaces of the substrate into a sealed LED package; two electrode wires being electric connected to the plurality of LED chips, wherein the sealed LED package has a spiral shape. A light bulb with the spiral LED packaging filament comprises a bulb shell; a stem having a supporting pole, an electrical wire and a stem exhaust pipe, at least one spiral LED packaging filament is fixed on the stem; the electrode wire is connected to the electrical connector via the drive; and the bulb shell and the stem are respectively sealed.

Owner:GENERAL ELECTRIC SA

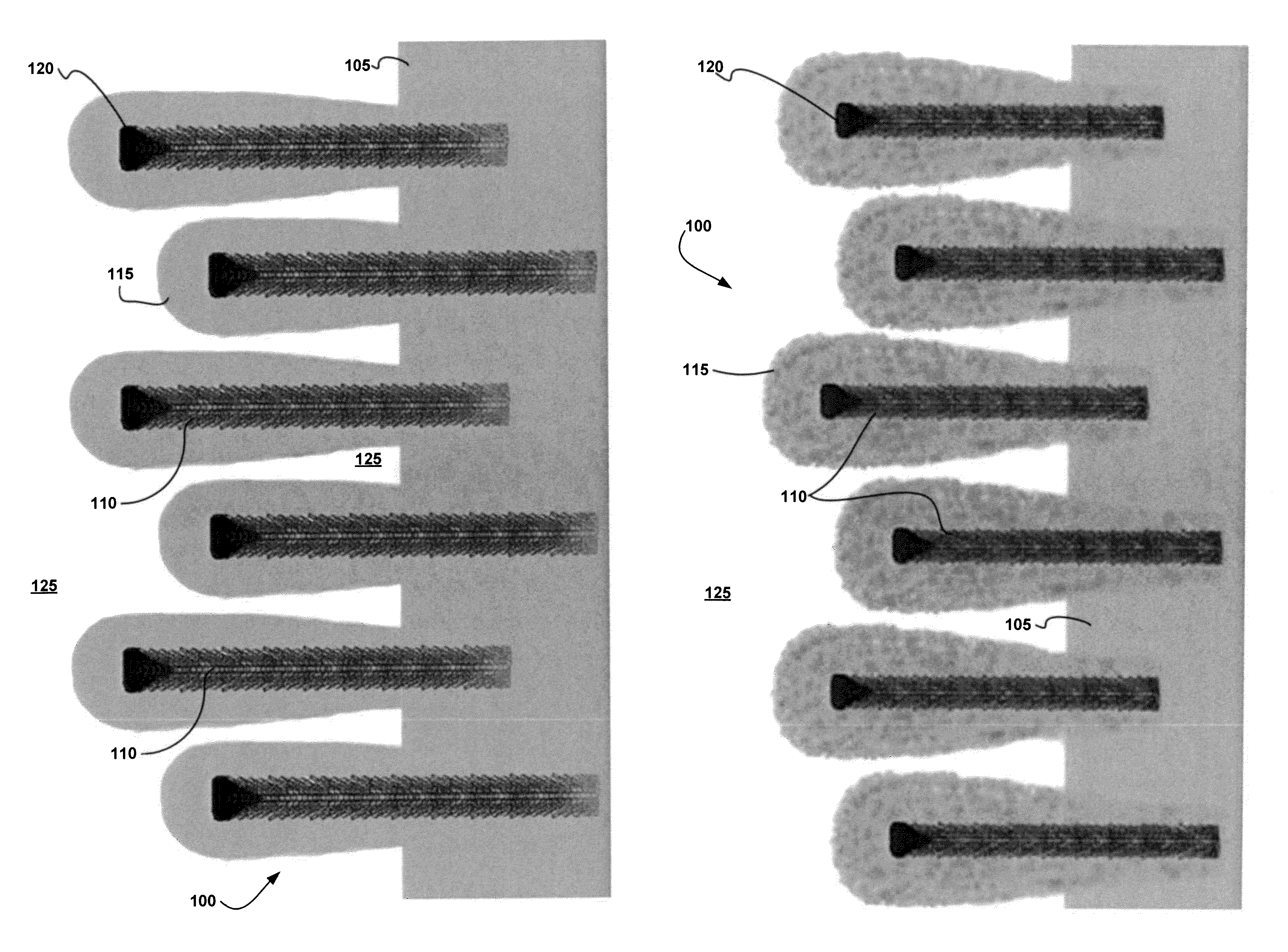

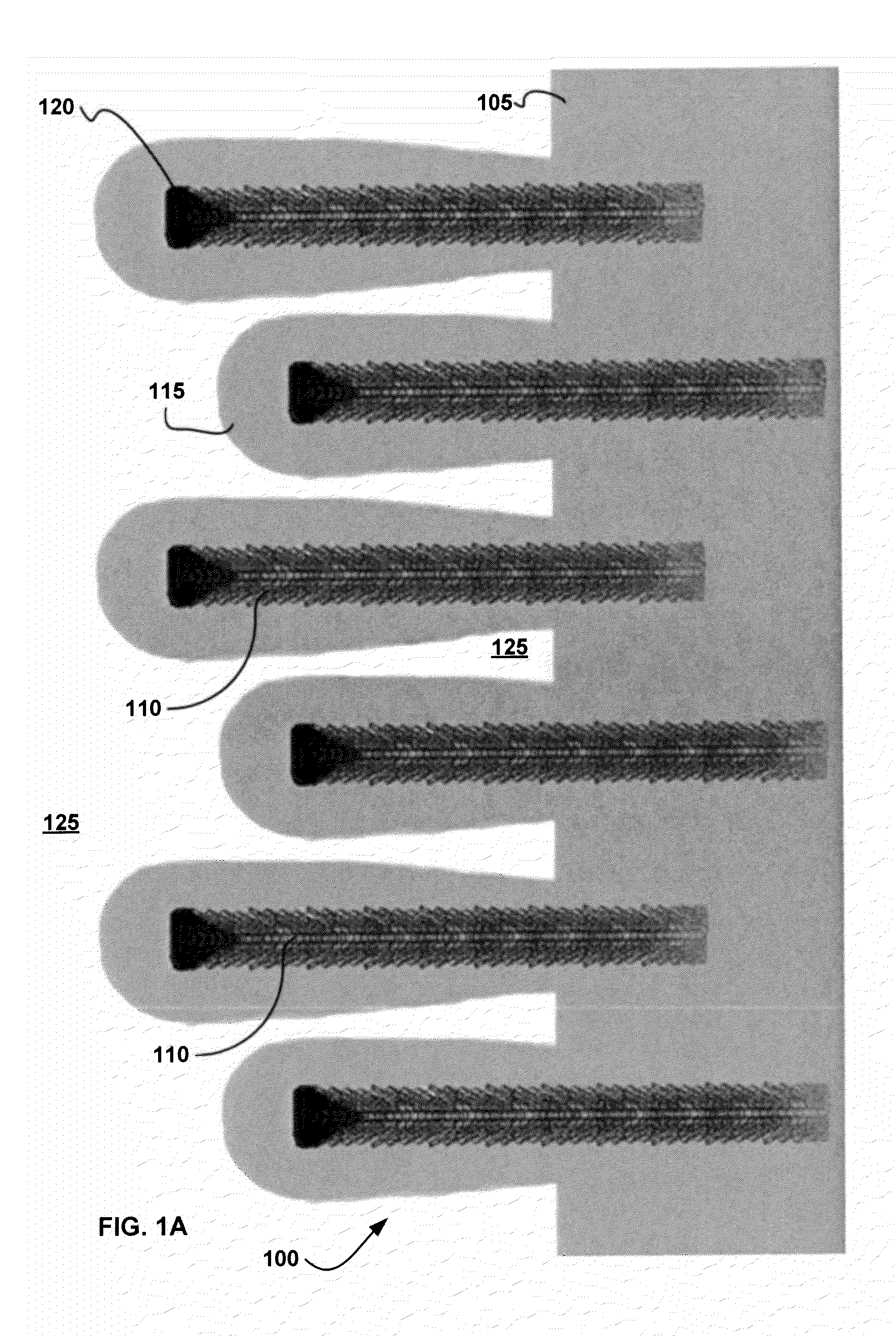

Hybrid Energy Storage Device Charging

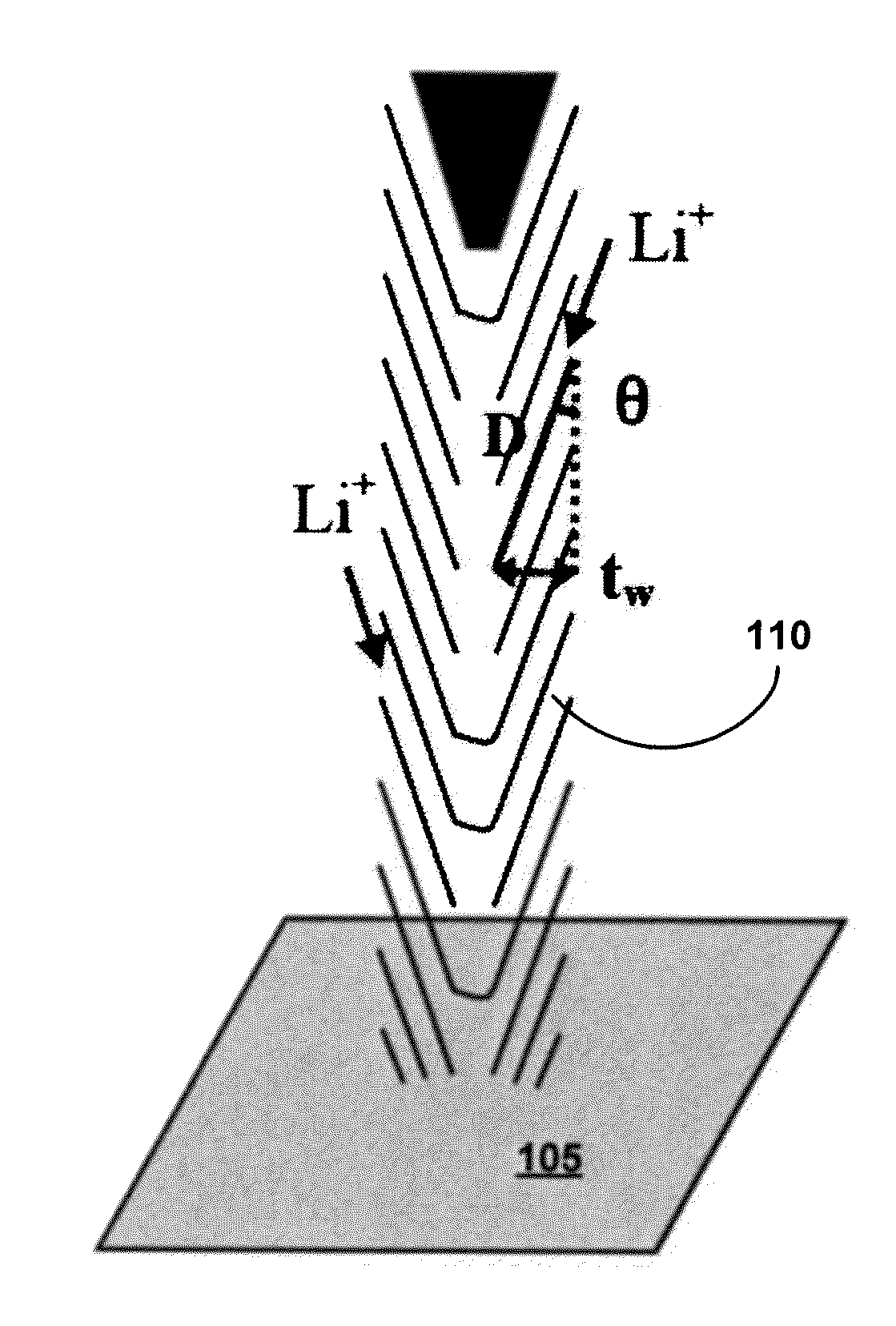

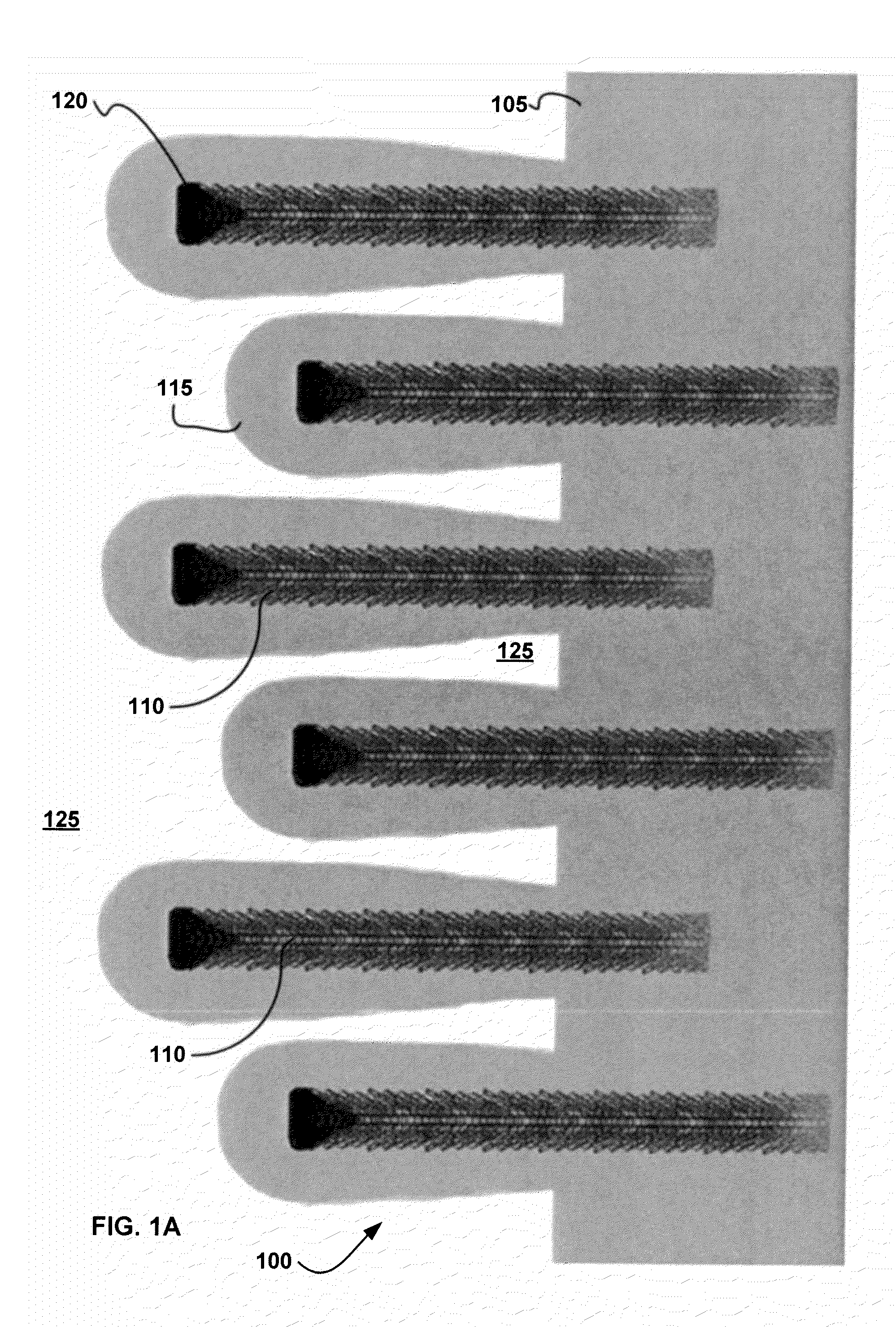

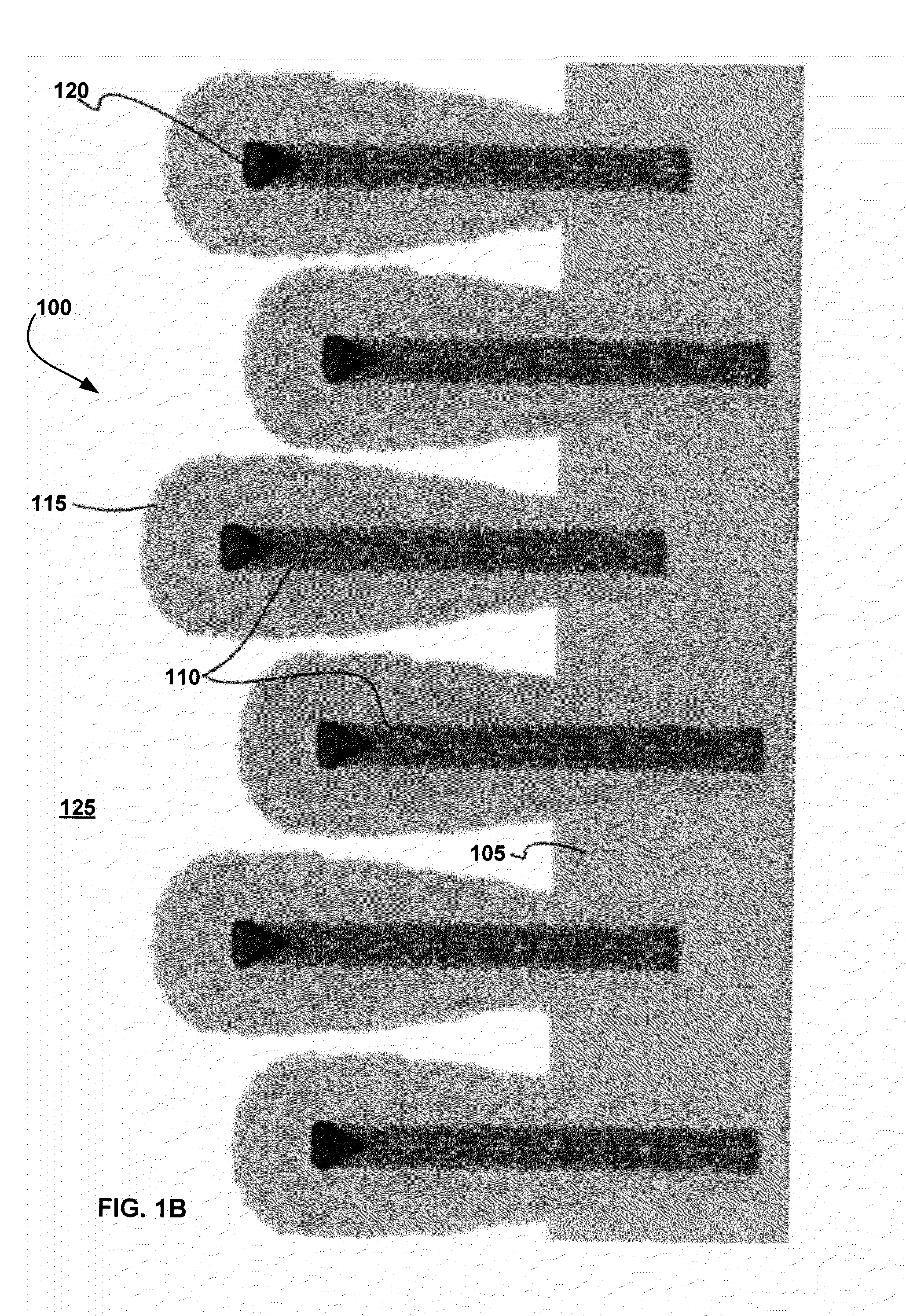

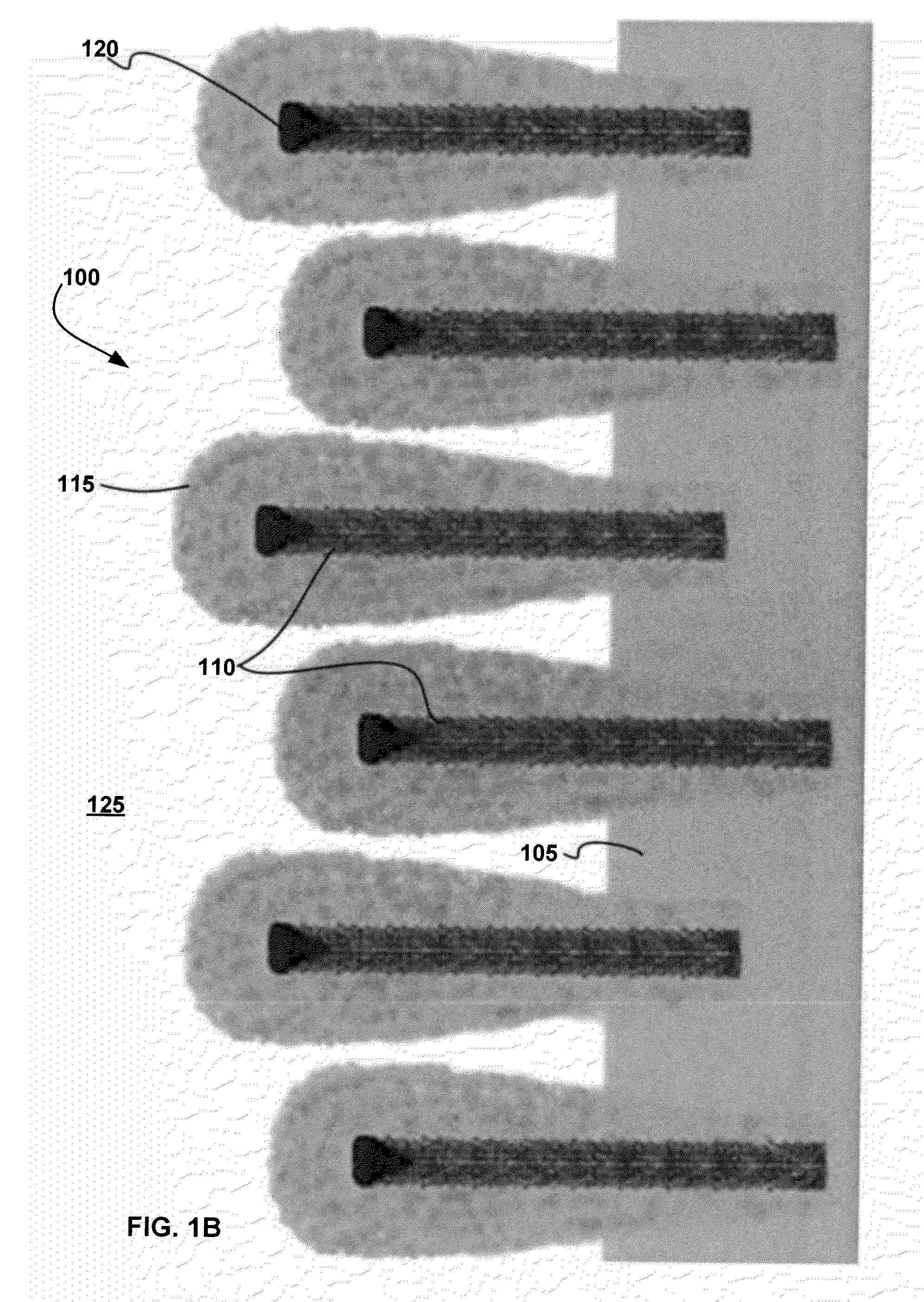

A novel hybrid lithium-ion anode material based on coaxially coated Si shells on vertically aligned carbon nanofiber (CNF) arrays. The unique cup-stacking graphitic microstructure makes the bare vertically aligned CNF array an effective Li+ intercalation medium. Highly reversible Li+ intercalation and extraction were observed at high power rates. More importantly, the highly conductive and mechanically stable CNF core optionally supports a coaxially coated amorphous Si shell which has much higher theoretical specific capacity by forming fully lithiated alloy. Addition of surface effect dominant sites in close proximity to the intercalation medium results in a hybrid device that includes advantages of both batteries and capacitors.

Owner:CF TRAVERSE LLC

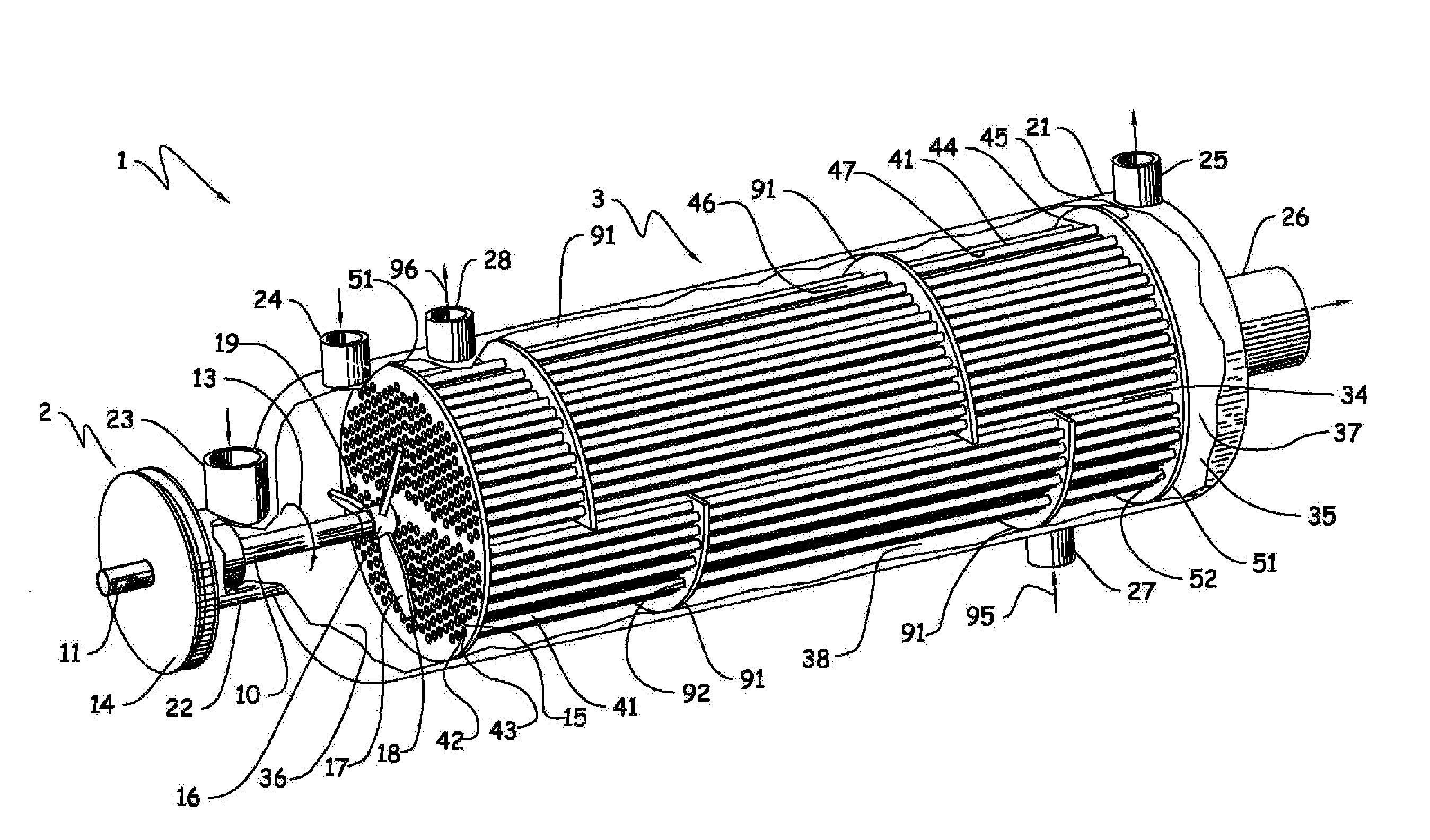

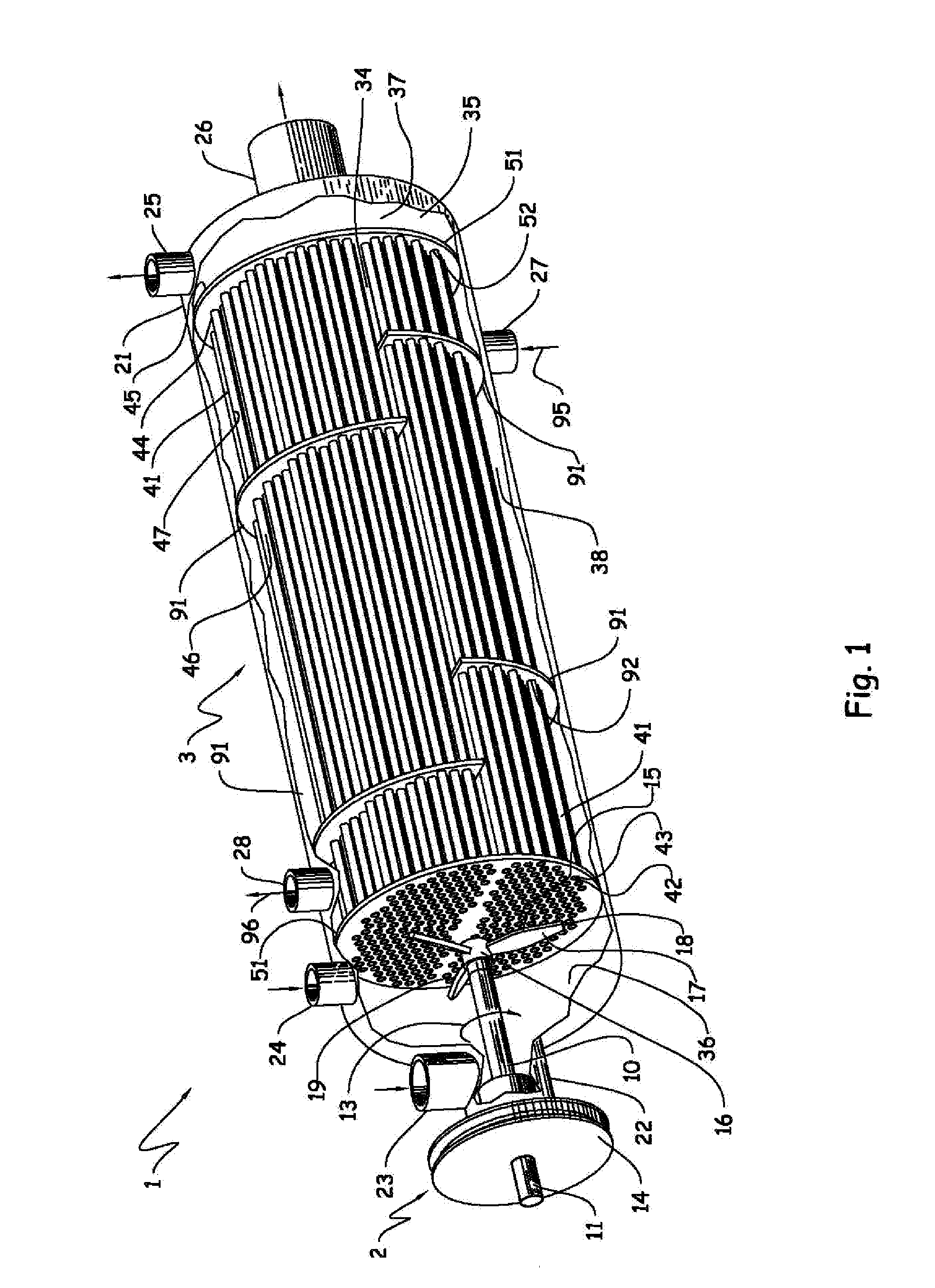

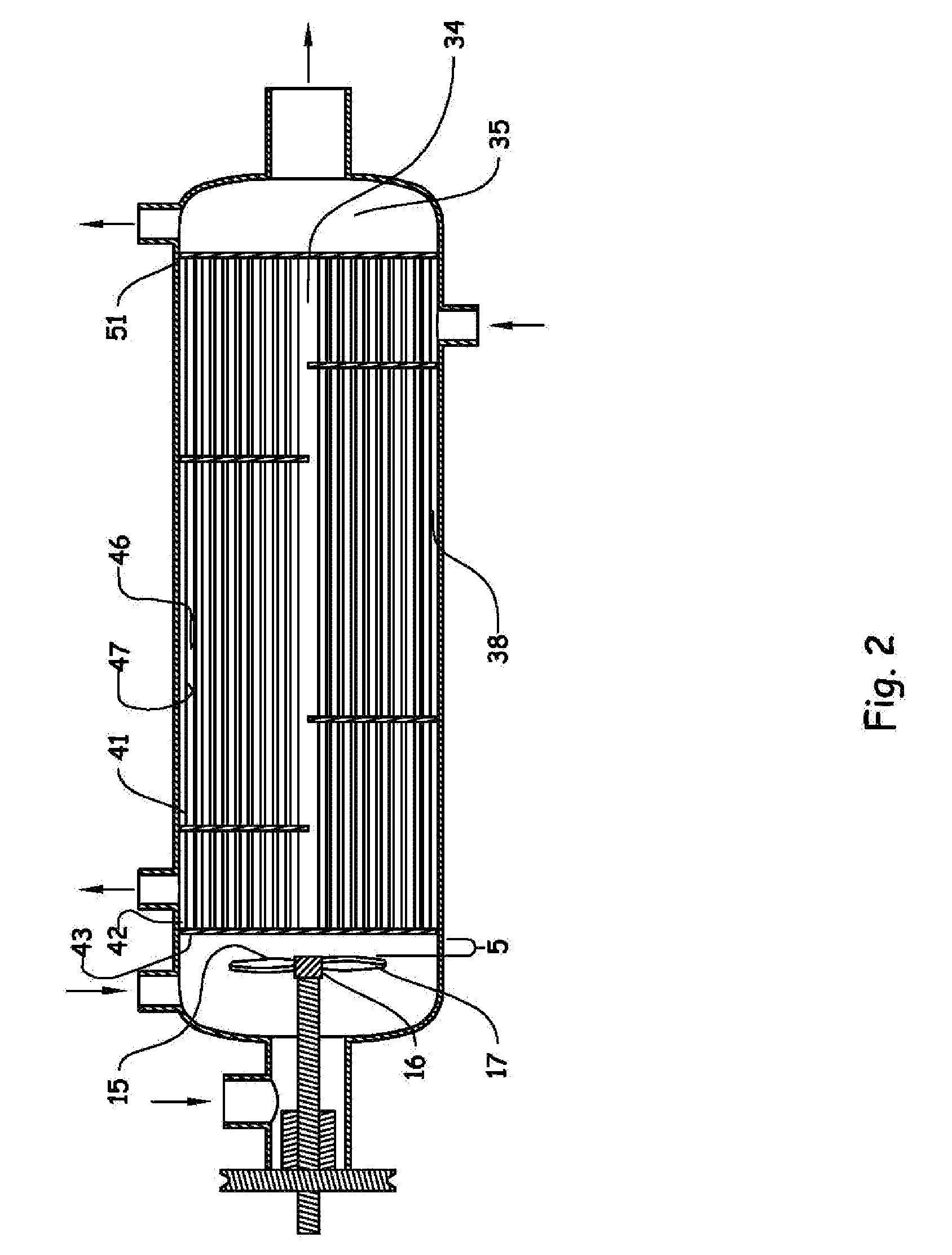

Vertical falling film shell and tube heat exchanger

InactiveUS6089312AMilk preservationEvaporators/condensersPlate heat exchangerShell and tube heat exchanger

The present invention provides a vertical falling film shell and tube heat exchanger, where the falling film is formed on the exterior surface of the tubes. A distribution plate is provided below an upper tubesheet, and a sparger plate having sparger holes is provided between the upper tubesheet and the distribution plate. A plurality of vertical, parallel tubes pass through the distribution and sparger plates and are sealingly engaged with the upper tubesheet and the sparger plate. The distribution plate has oversized holes through which the tubes pass, an annular space being defined around each tube where the tube passes through the distribution plate. The first fluid passes one time through the tubes, and the second fluid is fed to the shell side as two streams, a liquid stream and a vapor stream. The liquid stream is introduced to the shell between the upper tubesheet and the sparger plate and drains downwardly onto the second distribution plate through the sparger holes. The liquid stream forms a falling film on the tubes as the liquid passes through the annular space around each tube. The vapor stream is introduced to the shell below the distribution plate and is condensed / absorbed into the falling film.

Owner:INT ENGINEERS & FABTORS CO

Tube-side sequentially pulsable-flow shell-and-tube heat exchanger appratus, system, and method

ActiveUS20100243208A1Increase heat exchange rateReduce dirtCorrosion preventionStationary tubular conduit assembliesChemical treatmentShell and tube heat exchanger

The present invention relates to a tube-side sequentially pulsable-flow, shell-and-tube heat exchanger apparatus and a chemical processing system comprising and methods of heat exchange employing the same.

Owner:DOW GLOBAL TECH LLC

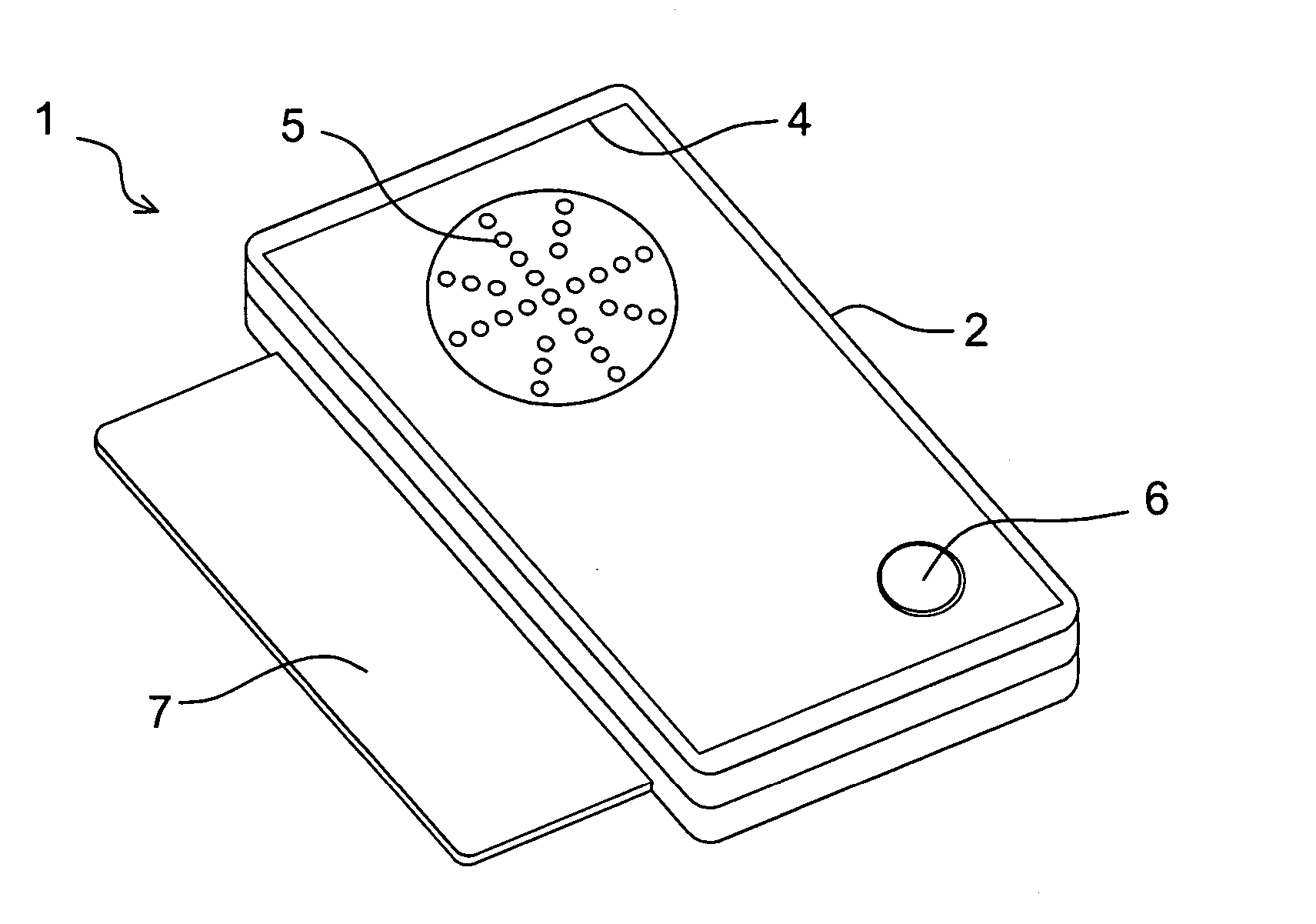

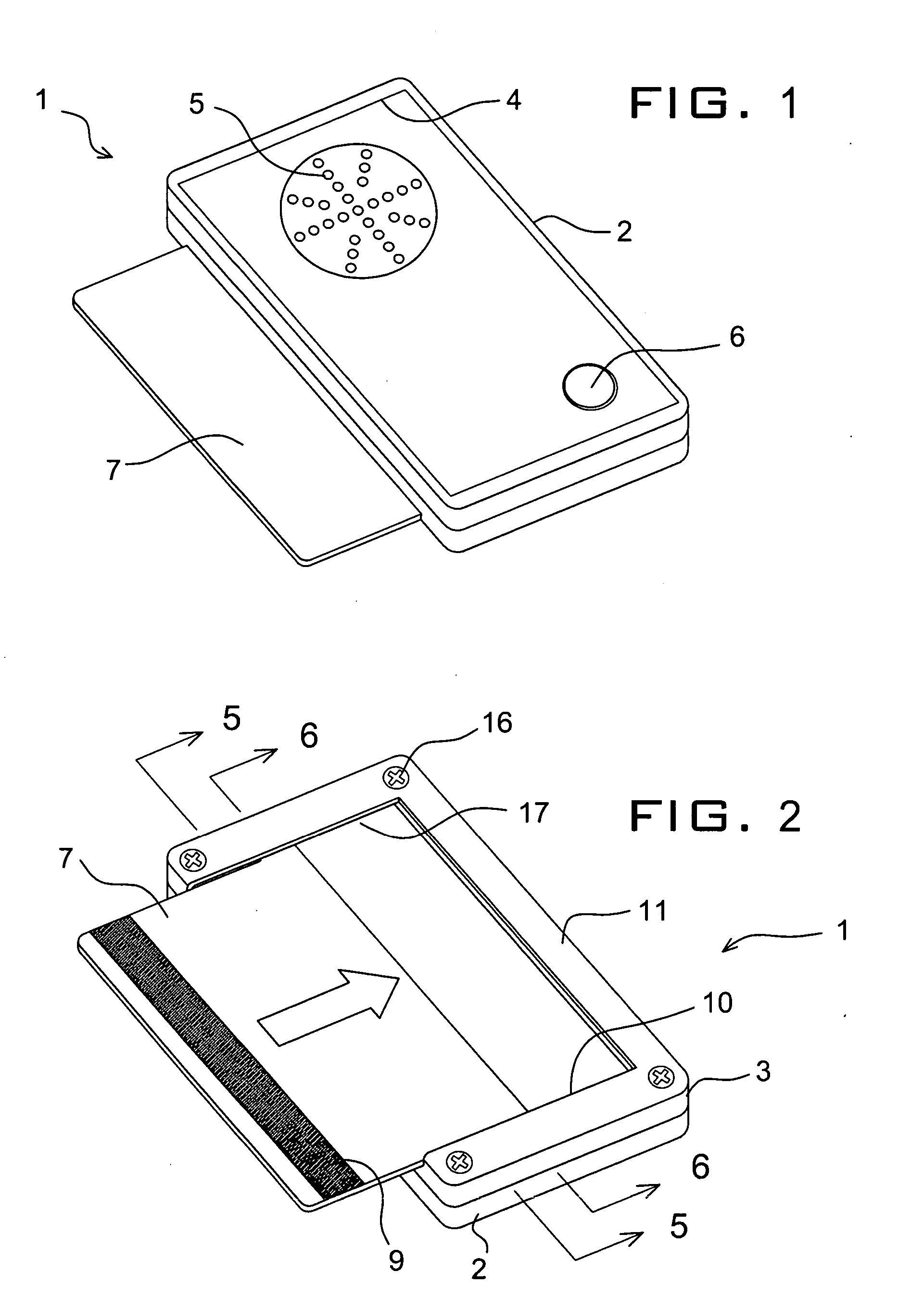

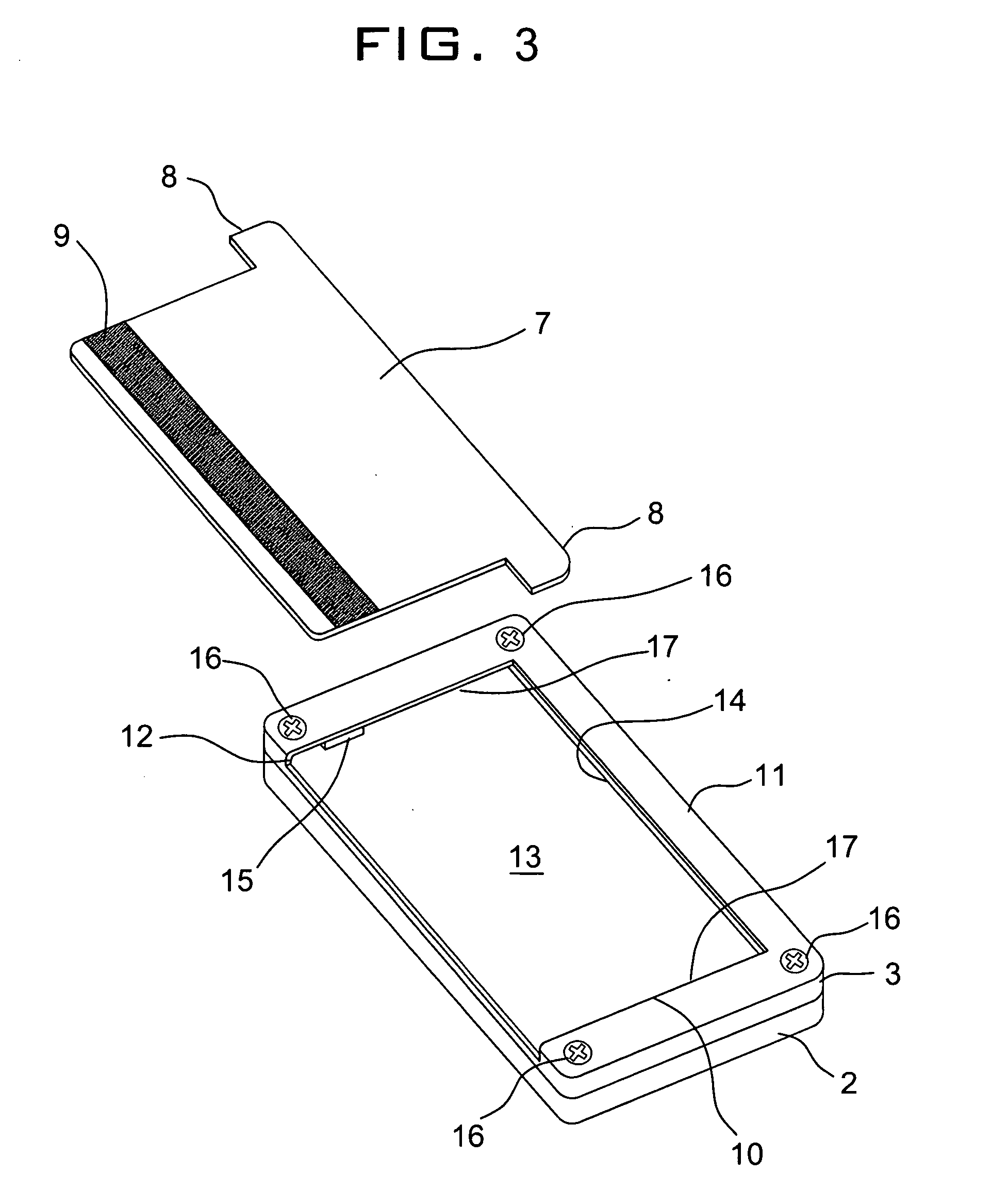

Slide-out gift card

ActiveUS20070215694A1Easy to readAcutation objectsSensing by galvanic contactsCredit cardComputer hardware

A stored value card device has a housing comprising an upper shell and a lower shell. The card device is dimensioned similar to typical credit cards and contains a circuitry for producing an audio / visual message in an inner space formed between the upper and lower shells, which are shaped like opposing trays. The two shells join together through a simple complementary engagement. A card component slides out from the bottom of the lower shell, which has two-tiered structure for mounting the card component. An electronic message device is retained in the cubic space of the housing which includes a power supply, a processing device, an audio and / or video player, and a switch triggered by a push button on the upper shell, thereby the stored value card device provides two independent operations as an electronic message player and as a convertible card in a thin profile at the same time.

Owner:TARGET BRANDS

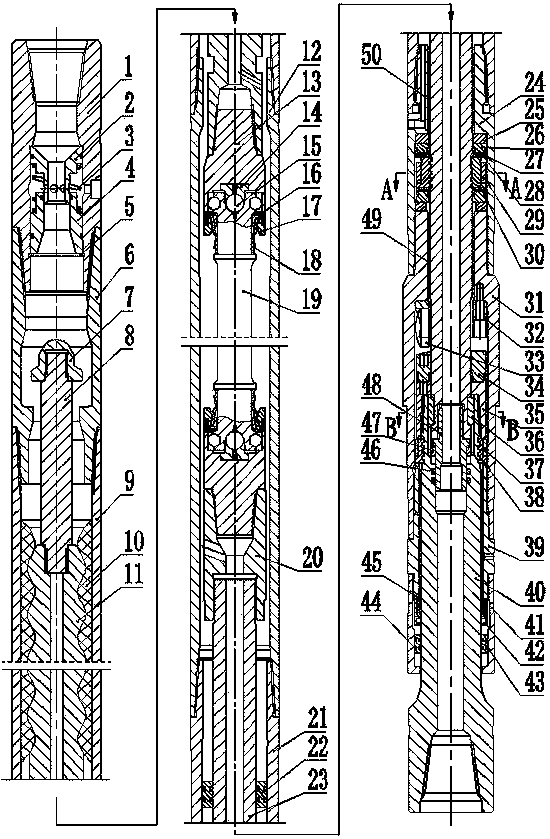

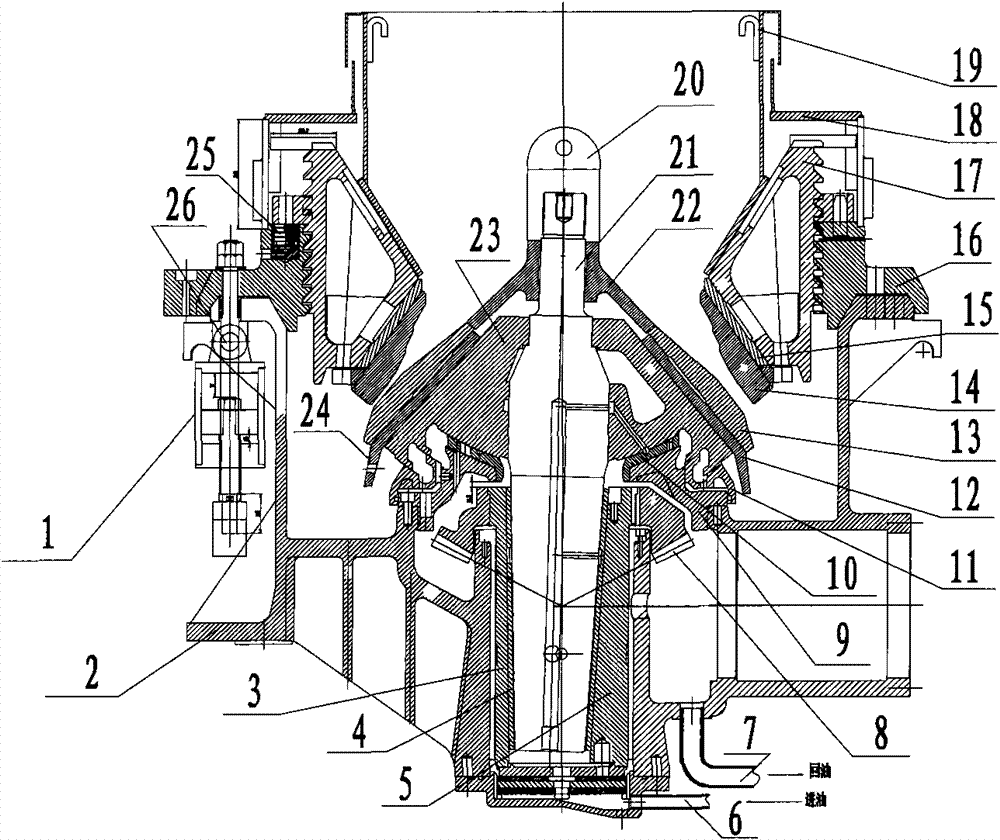

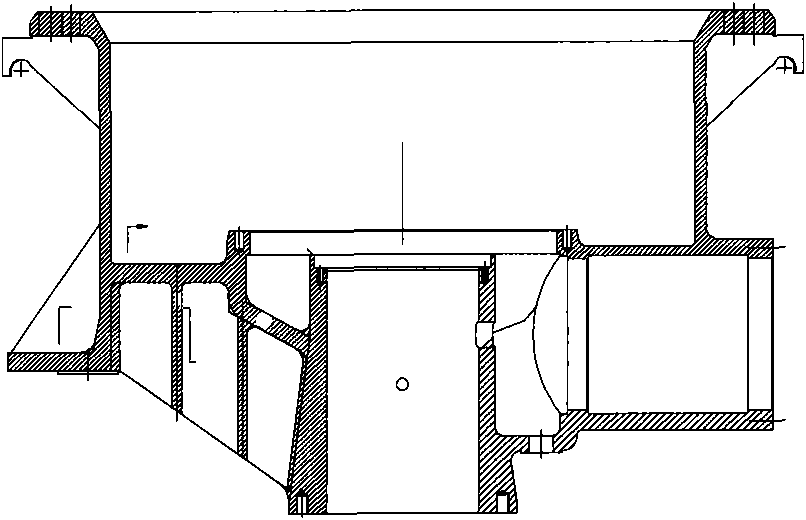

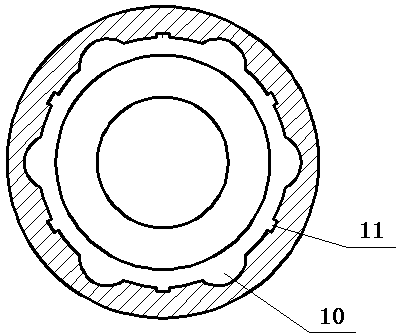

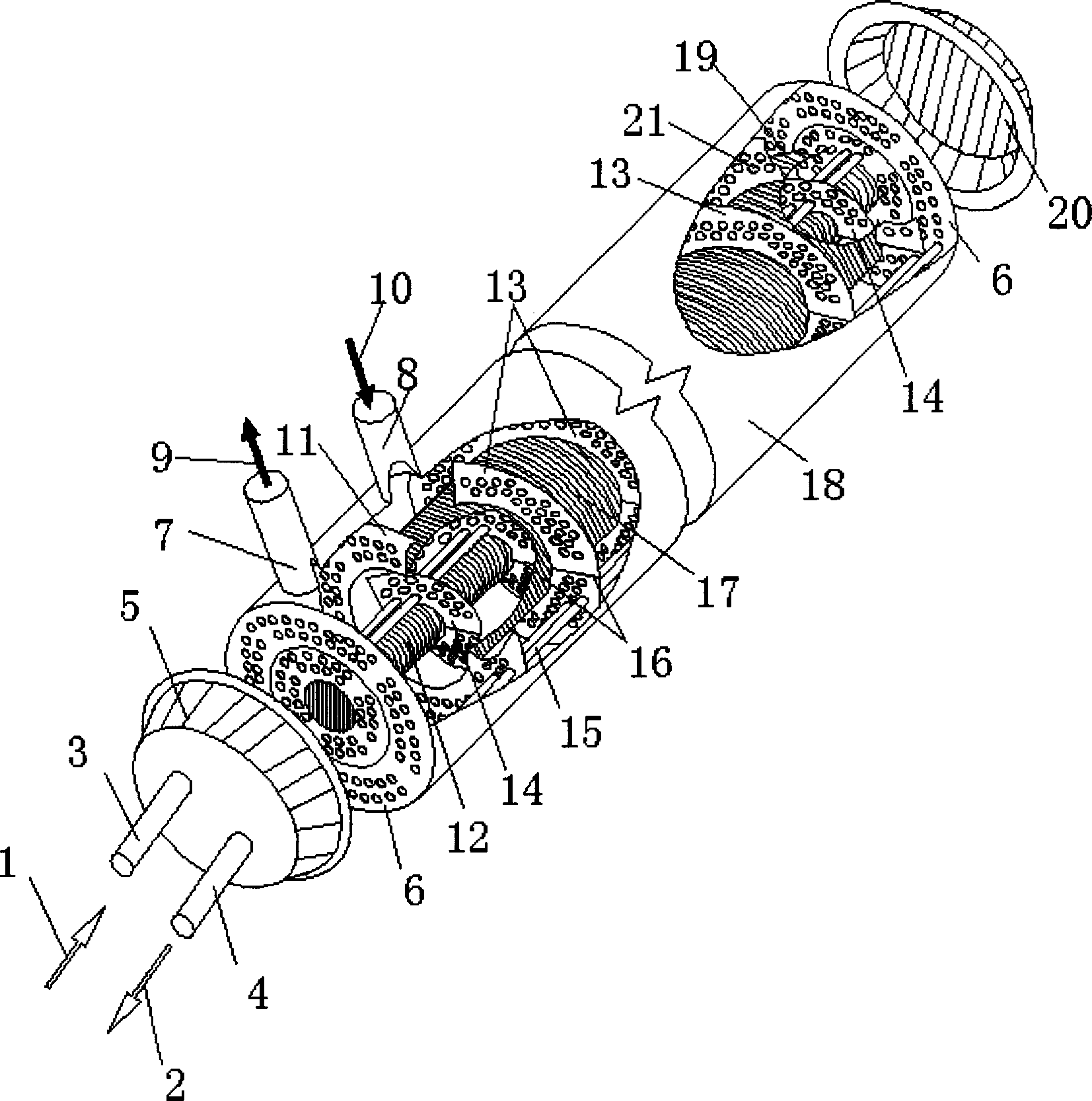

Rotary screw drill tool

InactiveCN104033113AImprove rock breaking abilityExtended service lifeDrilling rodsDrilling casingsSplit ringWell drilling

The invention discloses a rotary screw drill tool used in fields of petroleum drilling and the like and solves the problem about crushing efficiency of hard rocks in extradeep wells. The technical scheme includes that a bypass valve shell, a fall prevention joint, a motor shell, a universal shaft shell, an outer shell, a bearing shell, an outer cam shell, a bottom piston shell and a lower shell are sequentially connected through screw threads; an upper shaft and a lower shaft are connected through a spline, and eight spline pins are evenly and circumferentially distributed between the upper shaft and the lower shaft; a roller holder is fixed on the outer cam shell through three bolts which are circumferentially and evenly distributed, a cam is circumferentially fixed on the cam bushing through three evenly distributed bolts, a roller is mounted on a roller holder, the cam bushing is connected to the lower shaft in a threaded manner, and a lower split ring is clamped in the lower shaft through a serrated trough and is fixed through a lower retaining ring. By the arrangement, the lower shaft of the screw drill tool is enabled to generate soft axial impact with a certain frequency and stable in size, efficiency of rock breaking of a drill is improved, mechanical drilling rate is increased, and drilling cost is thereby lowered.

Owner:SOUTHWEST PETROLEUM UNIV

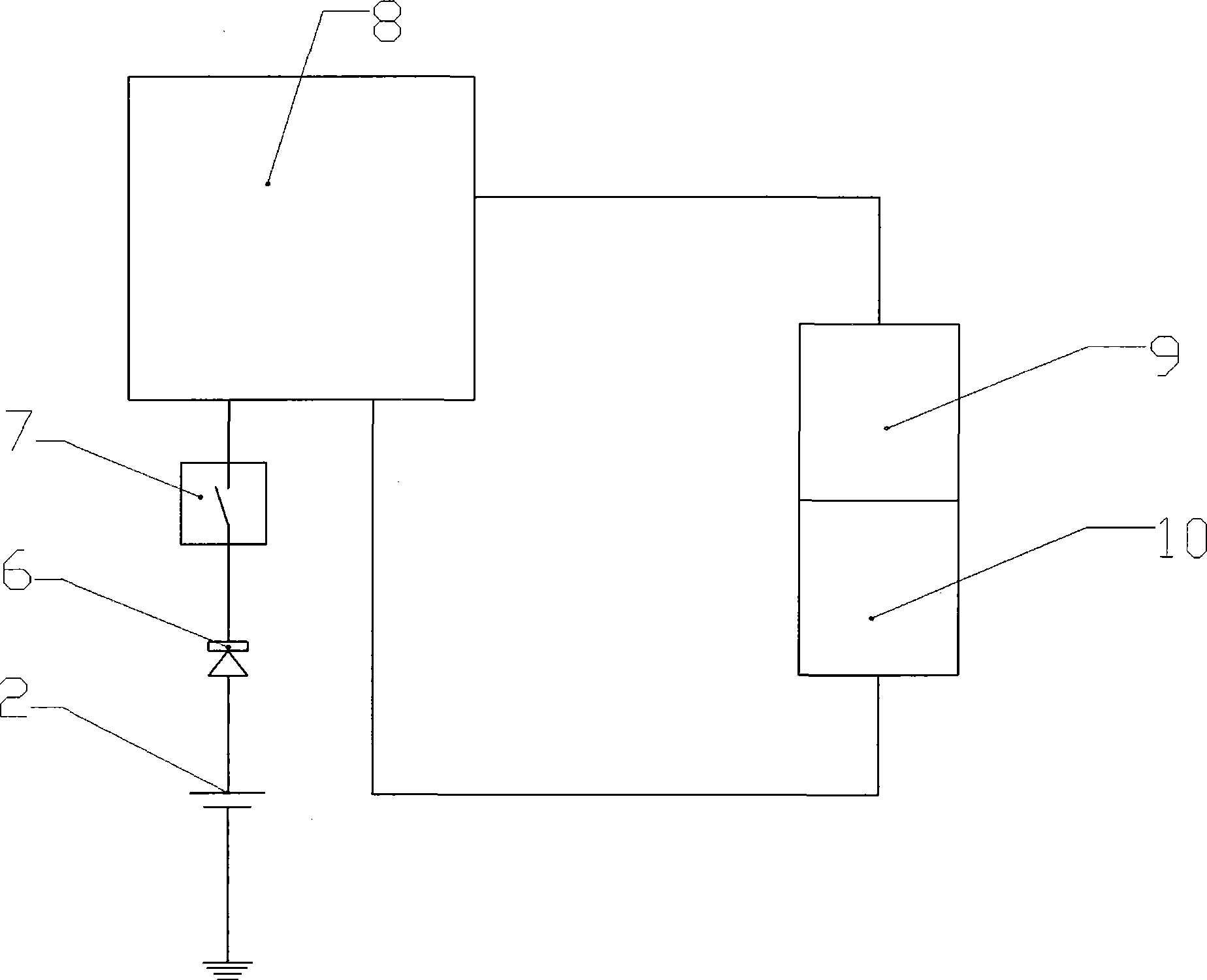

Piezoelectric self-powersupply low power consumption remote controller

InactiveCN101447748AThe amount of deformation is easy to controlReduce power consumptionBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesElectricityElectrical battery

The invention relates to a piezoelectric self-powersupply low power consumption remote controller, belonging to the technical field of energy resources and electronics. The metal substrate of a bending piezoelectric vibrator is fixed on a lower shell by a pressing block; the piezoelectric vibrator is connected with a power circuit on a printing circuit board by a lead; the printing circuit board is fixed on an upper shell; the upper shell is provided with an upper locating block; the inside of the lower shell is fixedly connected with a lower locating block; the two shaft ends of a rotary force-applying mechanism are connected with the inclined slideway of a shell in a sliding way; a button is connected with the rotary force-applying mechanism in a pressing way; an offsetting spring is connected with a top block; the top block is contacted and connected with the rotary force-applying mechanism; the shaft of the rotary force-applying mechanism is fixedly connected with two groups of locating gears and a group of tines; the power circuit is connected with the circuit of the remote controller. The piezoelectric self-powersupply low power consumption remote controller has the advantage of utilizing a piezoelectric generating device to supply power for the remote controller, thus being capable of avoiding the problems of inconvenient use brought by replacing batteries and incapable use brought by not replacing the batteries in time when the power is out of use; and being capable of avoiding the secondary cost in use and the environment pollution caused by a plurality of waste batteries.

Owner:JILIN UNIV

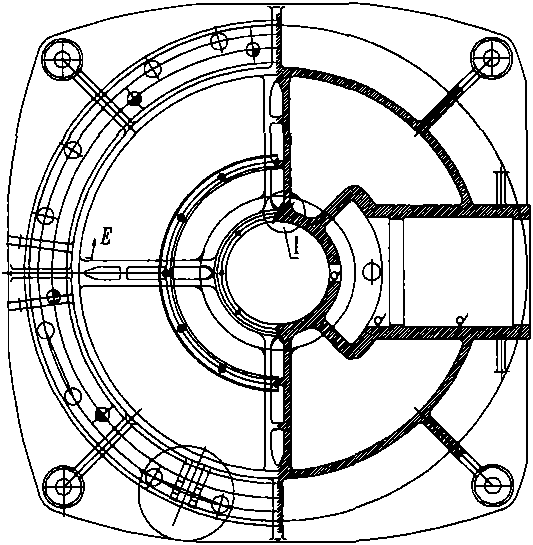

Cone sand making machine and sand making method

The invention relates to a cone sand making machine and a sand making method with high efficiency, low energy consumption and high sand making yield. A big bevel gear is sleeved on an eccentric shaft sleeve which is sleeved in an axle hole in the centre of a lower shell through a copper jacket; a main shaft is positioned in the eccentric shaft sleeve through an inner copper sleeve; a spherical seat is positioned on a shell supporting ring of the positioning axle hole in the lower shell; a movable cone is sleeved on the main shaft through a spherical copper bearing bush and pushed by the main shaft to swing; a movable sleeve bushing is sleeved on the conical surface of the movable cone; an anti-wear movable sleeve is sleeved on the conical surface of the movable sleeve bushing; an inserteris sleeved on the main shaft and locked by a locking nut; an upper shell and the lower shell are connected together and three or more adjusting oil cylinders are arranged between the outer turned edges of the upper and lower shells; the inner wall of the upper shell is provided with annular spiral sawteeth which are engaged with those on the outer wall of an adjusting screw sleeve; and the adjusting screw sleeve has a double-trumpet structure, the lower trumpet-shaped wall of the adjusting screw sleeve is connected with an anti-wear fixed sleeve through a fixed sleeve bushing, and the upper trumpet-shaped wall of the adjusting screw sleeve is used for supporting a hopper assembly.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

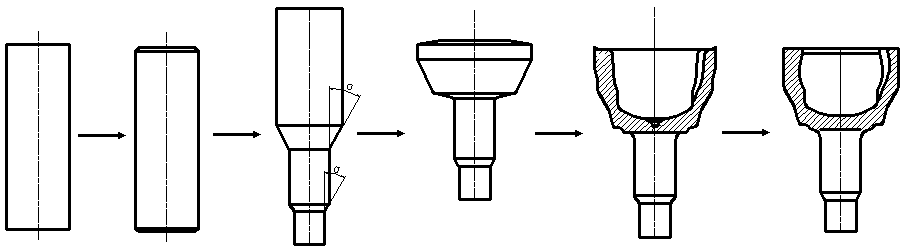

Precision-forging plastic molding technology of bell shell of ball-cage type universal joint

InactiveCN102861861AReduce workloadImprove product qualityRailway componentsForging/hammering/pressing machinesSand blastingUniversal joint

The invention discloses a precision-forging plastic molding technology of a bell shell of a ball-cage type universal joint, comprising steps of warm-forging plastic molding and cold-forging plastic molding. The warm-forging plastic molding technology comprises the following steps: a. blanking; b. manufacturing a blank; c. coating; d. heating; e. directly extruding; f. upsetting; g. extruding reversely; h. normalizing, shaping, sand blasting, parkerising, and treating the surface by a manner of saponification; and adopting the forging plastic molding technology of combining the warm-forging plastic molding technology with the cold-forging plastic molding technology, firstly upsetting to obtain the pre-molding blanking material, secondly, extruding reversely in the chamber of the molding mold to form a ball channel and finally forming the inner spherical surface by using the cold-forging plastic molding technology. The product quality is steady, the production efficiency is improved, the production period is short, the method for adopting the machine tool after the hot-forging is replaced, the workload of the machine tool process is reduced, the precision requirements are met, the manufacturing cost and the period are reduced, and the development trend of the manufacturing field in the world is met.

Owner:张太良

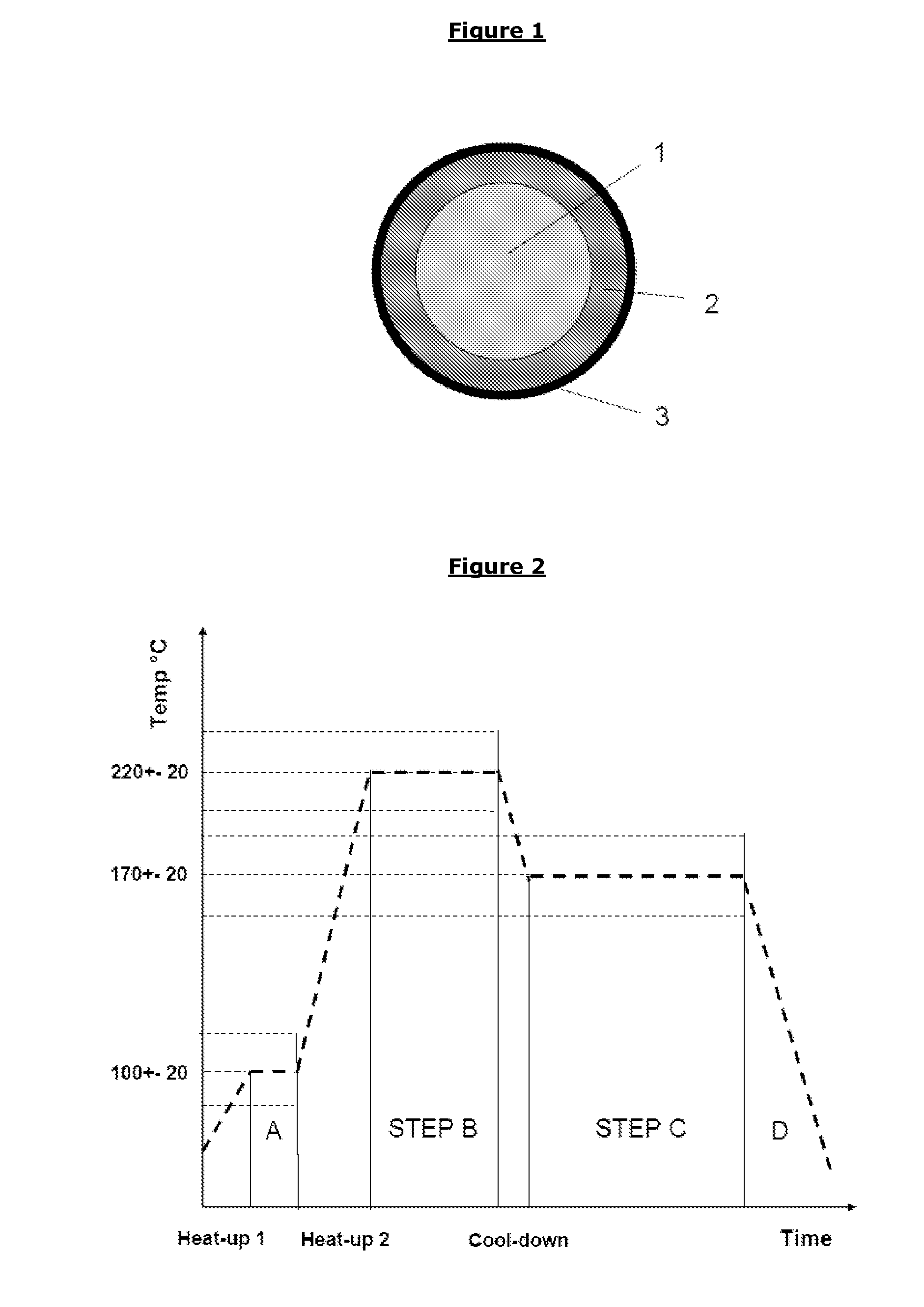

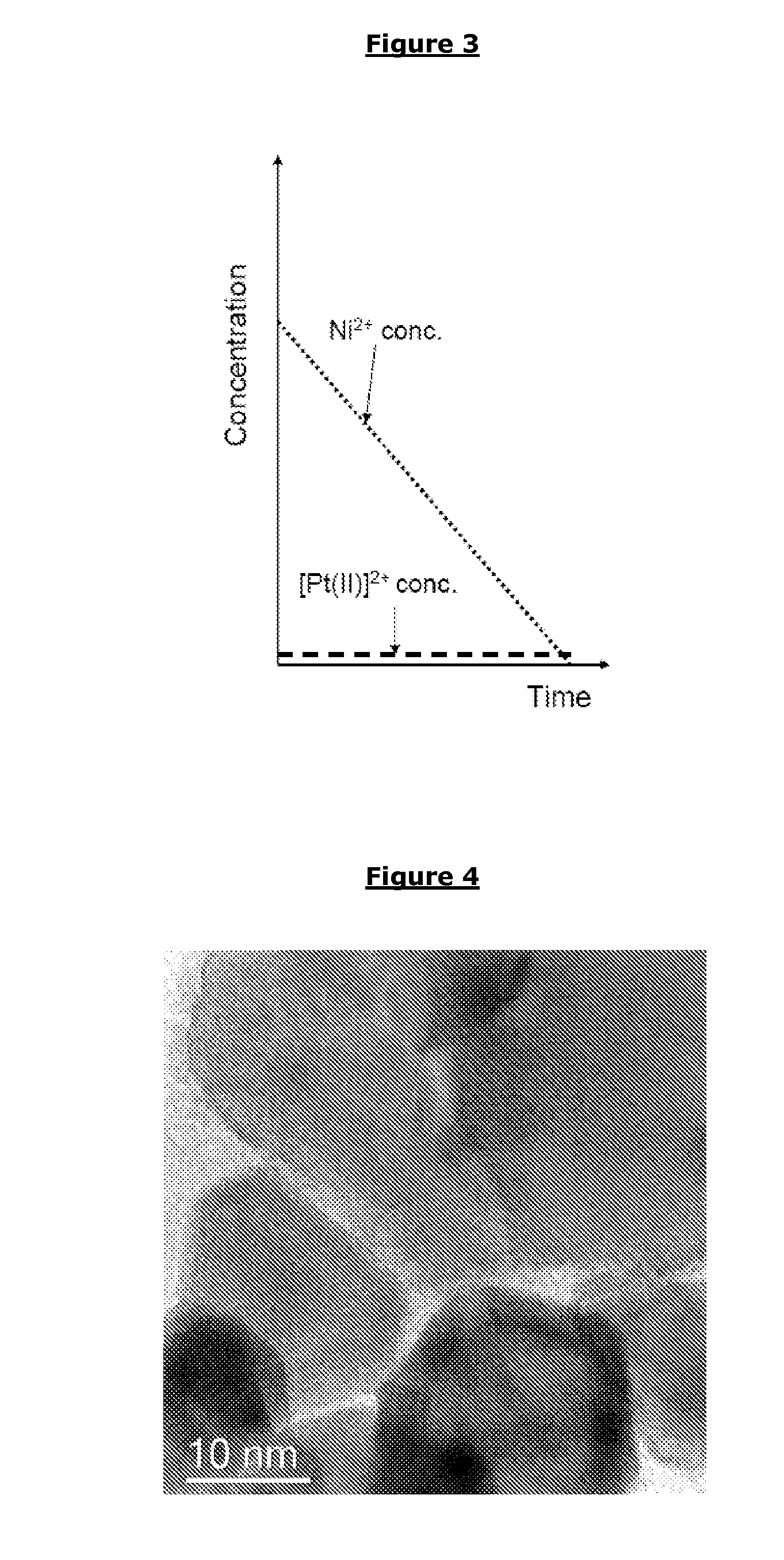

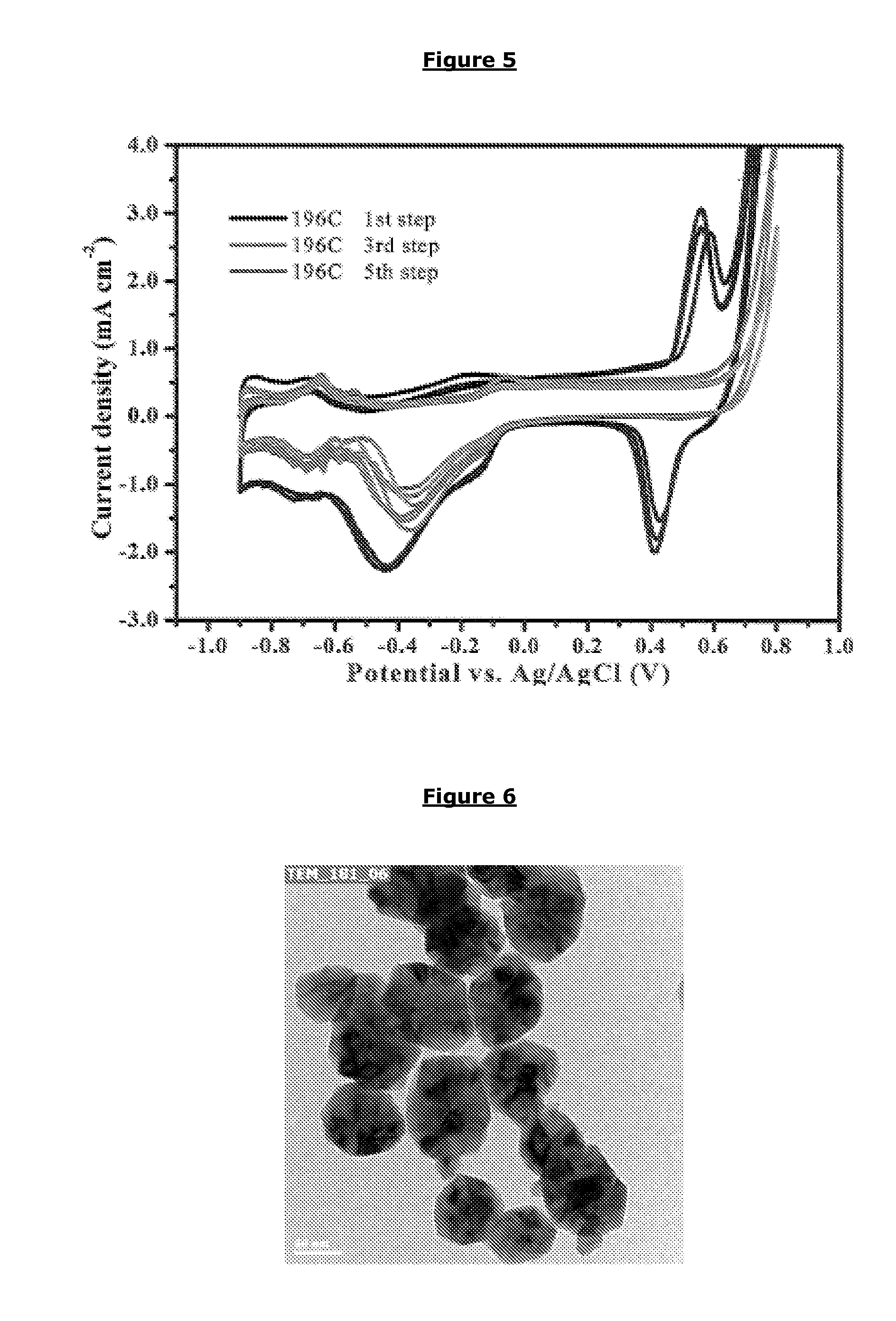

Catalyst particles comprising a layered core-shell-shell structure and method of their manufacture

ActiveUS20140171290A1Improve performanceLow platinum loadingCatalyst protectionCell electrodesFuel cellsGas phase

The present invention is directed to catalyst particles comprising a layered core-shell-shell structure and to a method of their manufacture. The catalyst particles have the general formula BM / IL / PM in which BM is a base metal core (selected from Co, Ni or Cu), PM is a precious metal outer shell (selected from Pt, Ir or Pd) and IL is an intermediate layer comprising a base metal / precious metal alloy with a concentration gradient of base metal to the outside PM layer. The particles of the present invention comprise a core-shell-shell structure and a substantially continuous precious metal shell layer. They find use in various catalytic applications, for example in gas-phase catalysis, in electrocatalysts for fuel cells, in catalytic converters for automobiles and in electronic or medical applications.

Owner:UMICORE AG & CO KG

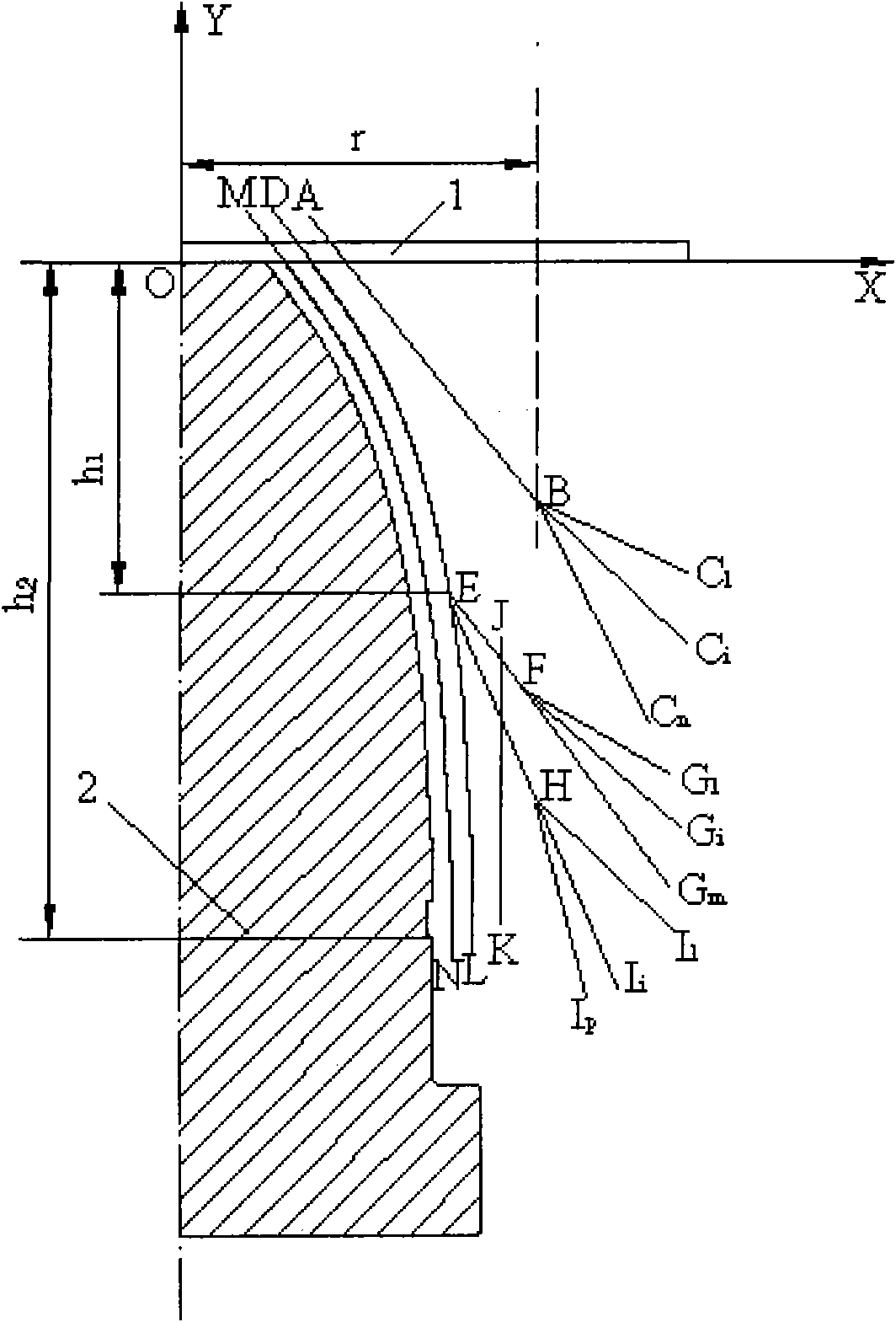

Method for forming large complex thin-wall shell with circumferential inner ribs

The invention relates to a method for forming a large complex thin-wall shell with circumferential inner ribs. The large complex thin-wall shell with the circumferential inner ribs is formed by adopting a composite spinning method combining strong spinning and general spinning. The method comprises the steps of: in forming, firstly determining the radius of an initial position to be ribbed on a plate blank, the height of the head of a filmed spin-forming part and the axial distance between a final ribbed position of a spinning piece and the top end of the spinning piece, and then forming by composite spinning in multiple rounds. In the method, under the conditions that only one core die and one set of rotary wheels are adopted, a prefabricated blank is not needed, intermediate annealing phase does not need to be adopted and no subsequent machining is needed, due to adoption of a reasonable composite spinning process, the flat plate blank is spun to form the large complex thin-wall shell with the circumferential inner ribs, so that the forming period is shortened, the cost is reduced, and large amount of manpower resources, material resources and financial resources are saved. The invention provides scientific basis for the spin-forming process scheme of the large complex thin-wall shell with the circumferential inner ribs and the determination of tracks of the rotary wheels, which is beneficial to promotion of further development of the advanced theory and technology of spinning.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

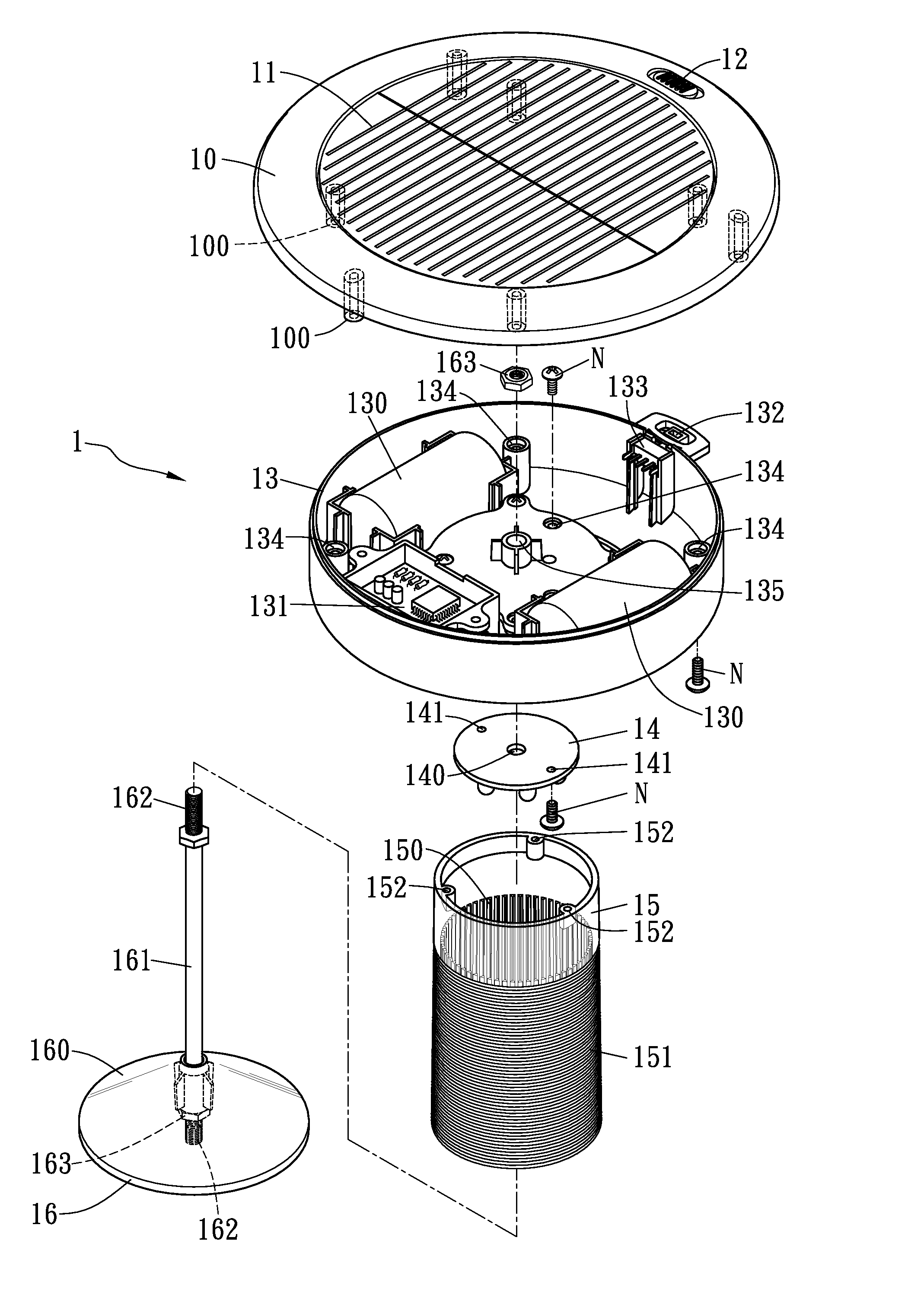

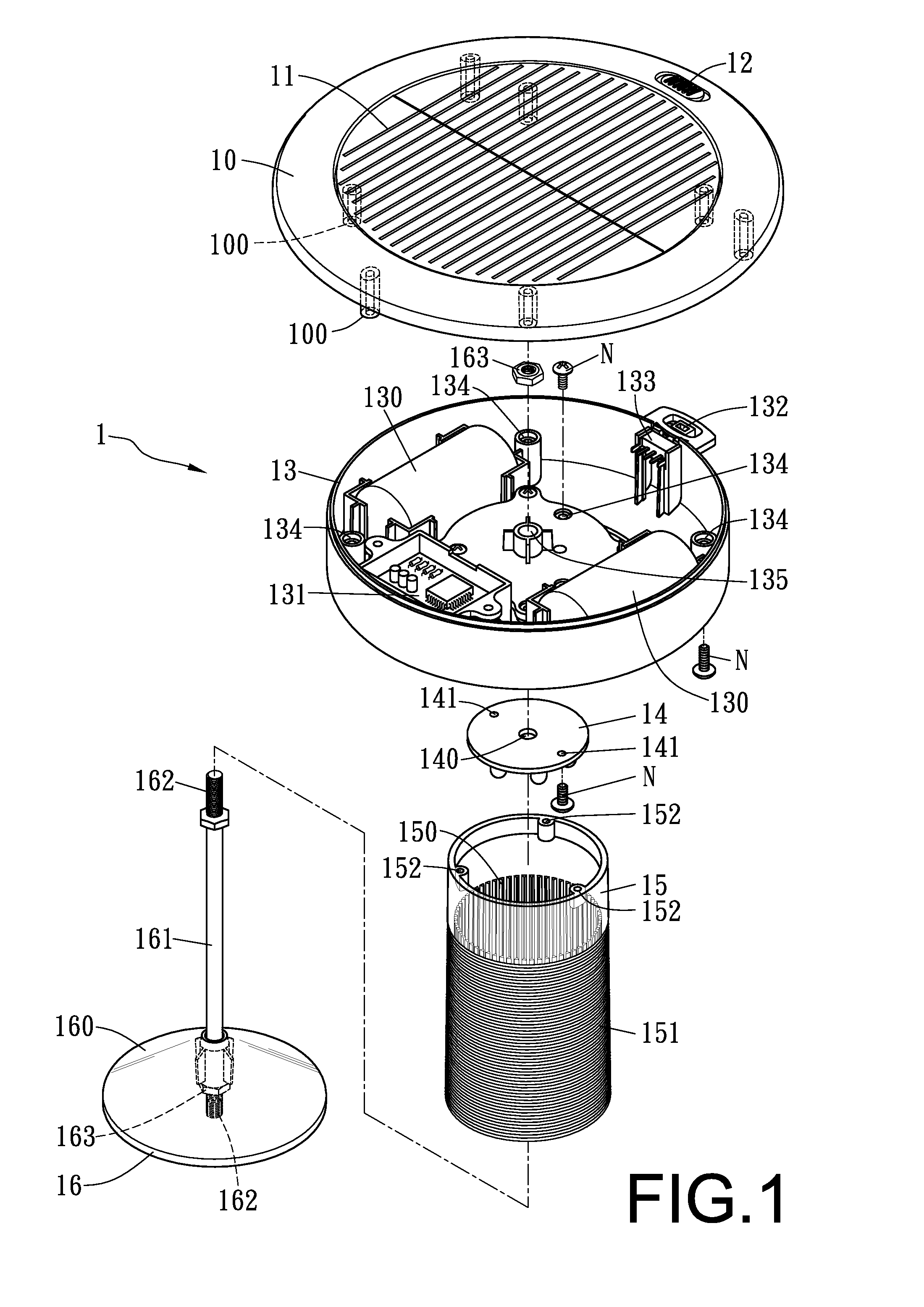

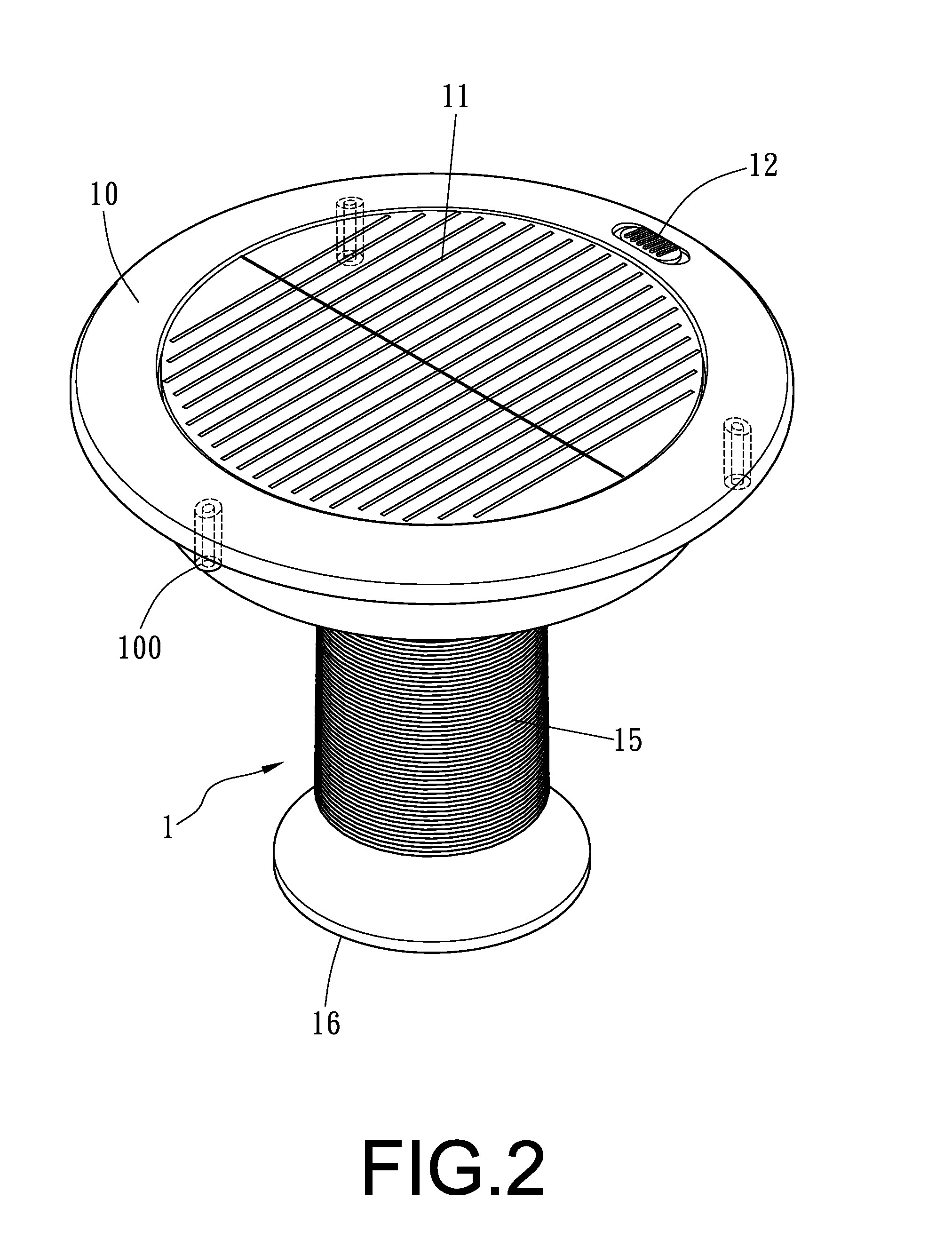

Solar lamp

A solar lamp includes a supporting board for being loaded with a solar panel, a lower shell, an LED board, a light diffusion tube and a reflecting base. The lower shell is fixed under the supporting board, having a battery and a circuit board. The LED board and the reflecting base are threadably engaged the lower shell. The light diffusion tube possesses refracting grooves on its wall. The reflecting base is positioned under the light diffusion tube by means of an adjustment rod. The solar lamp, able to convert sunlight into power energy without any wiring connection, can be easily assembled in any lamp base to create a great light diffusion via the alternate refraction of the refracting grooves and reflecting surfaces of the lower shell and the reflecting base.

Owner:WANG CHING HSIANG

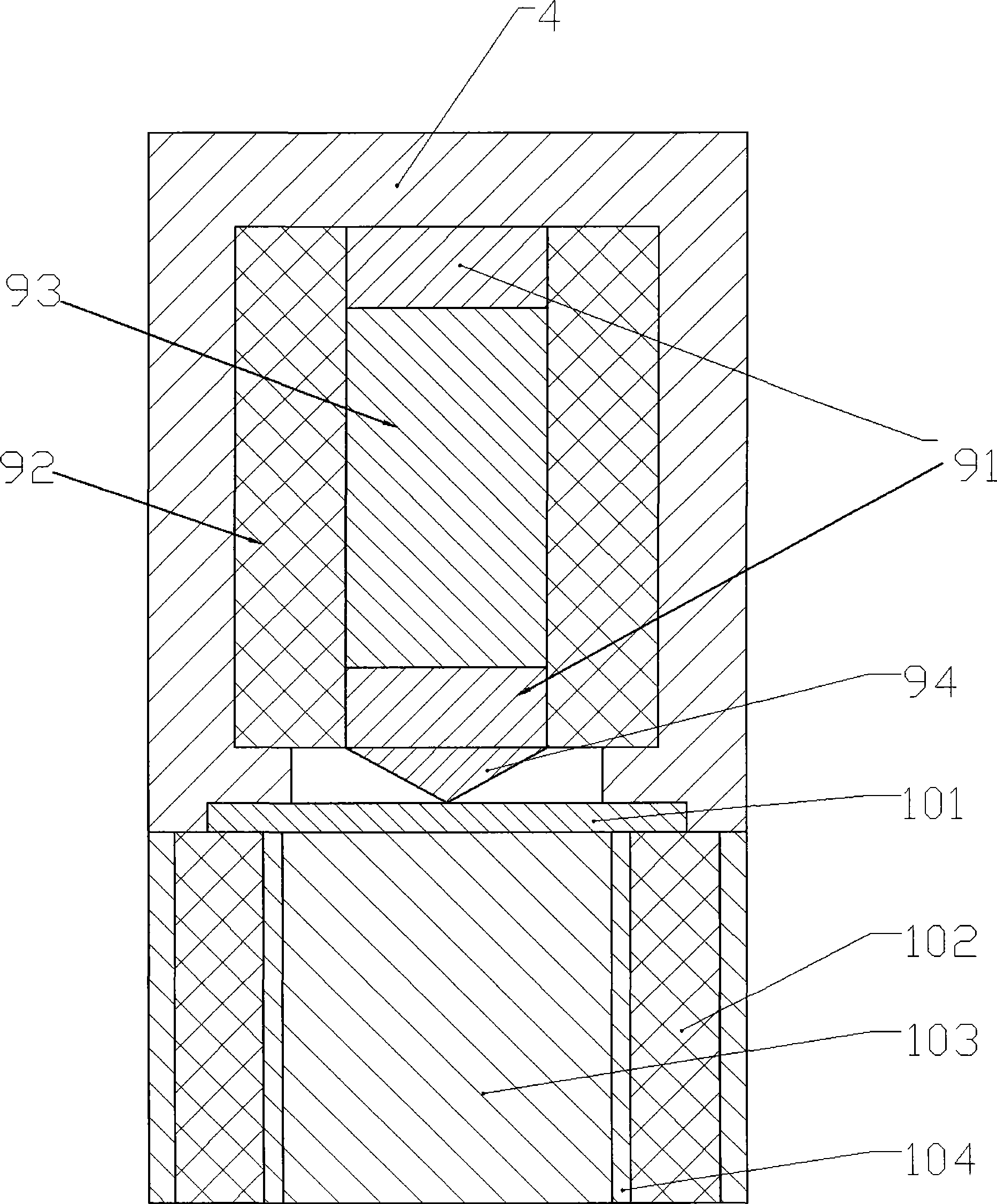

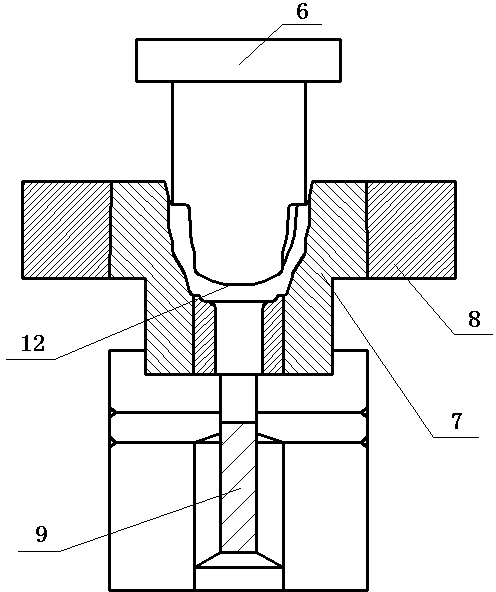

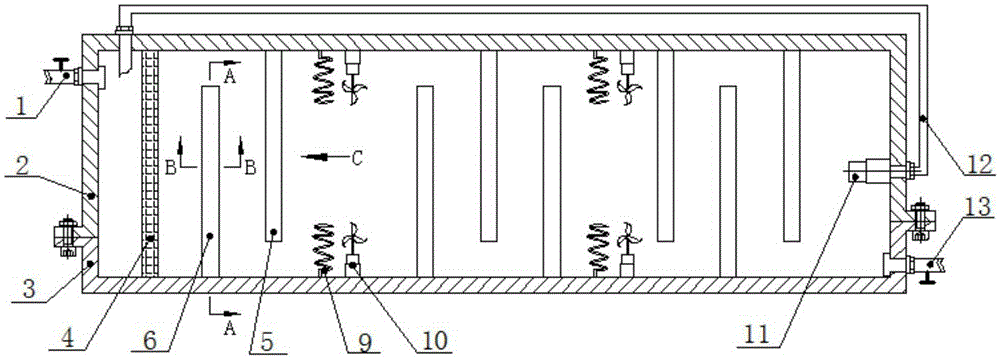

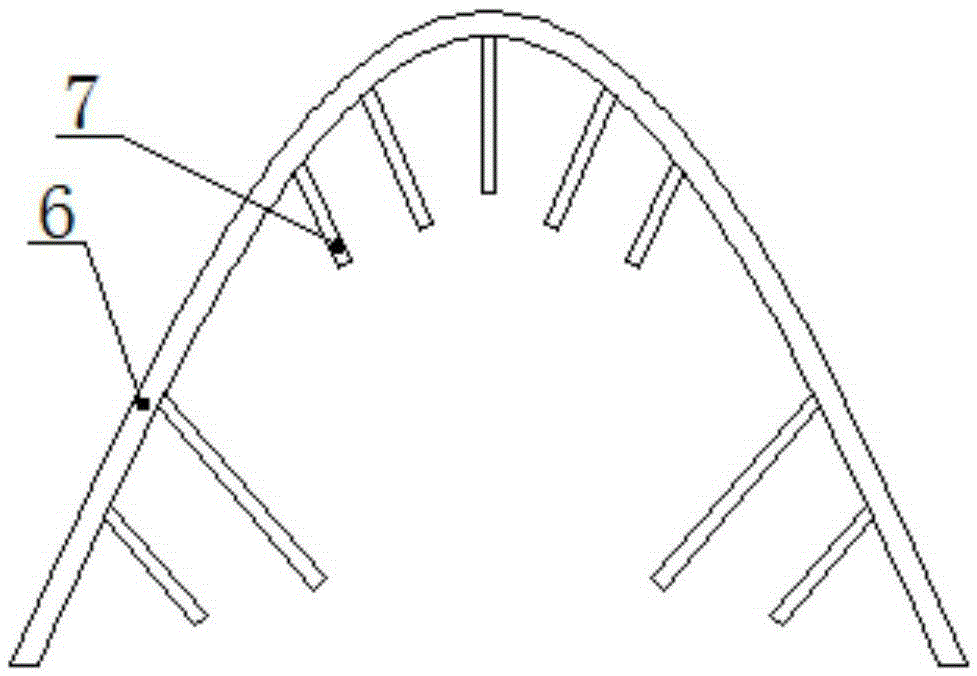

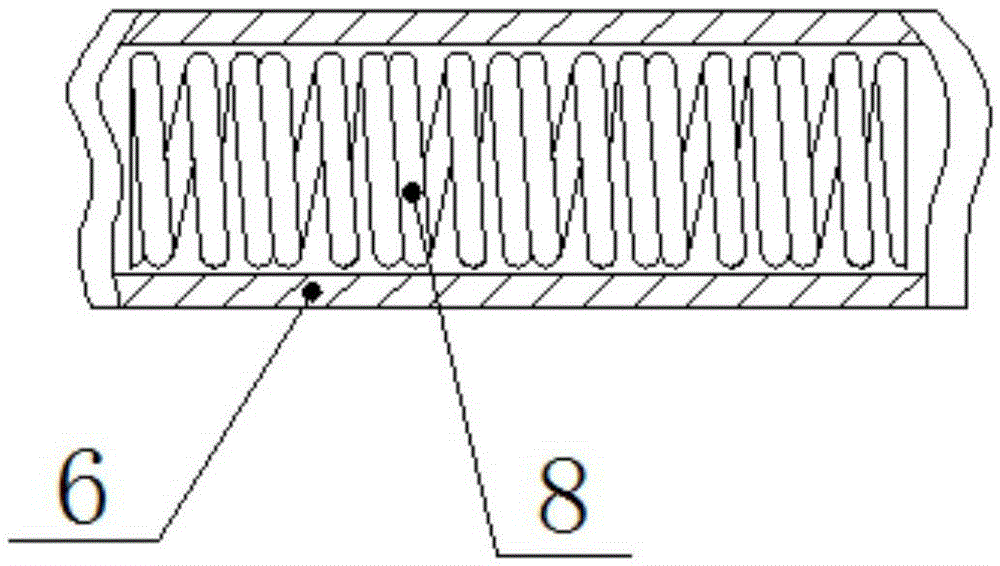

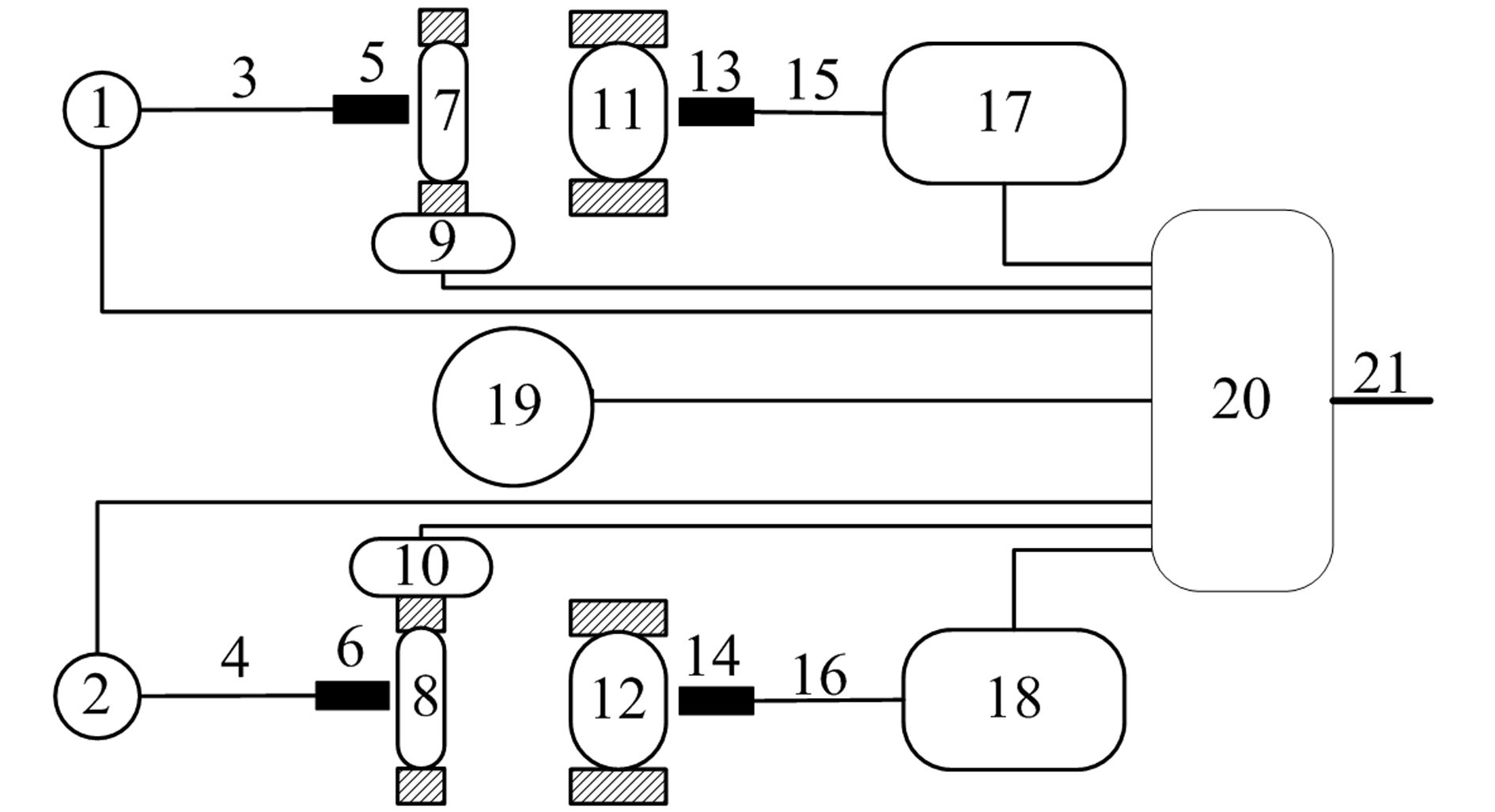

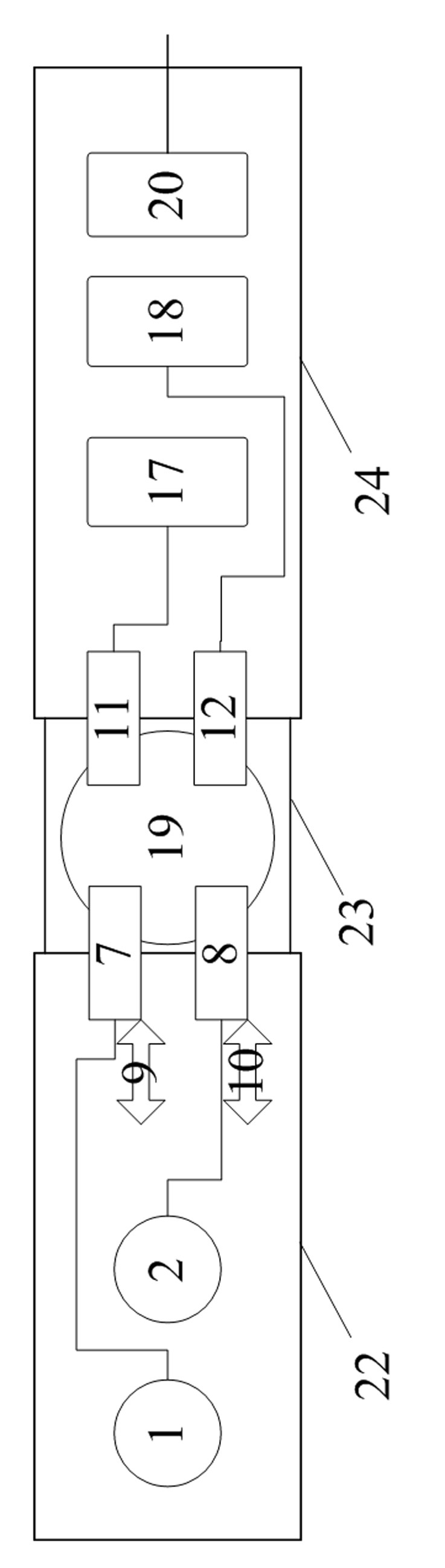

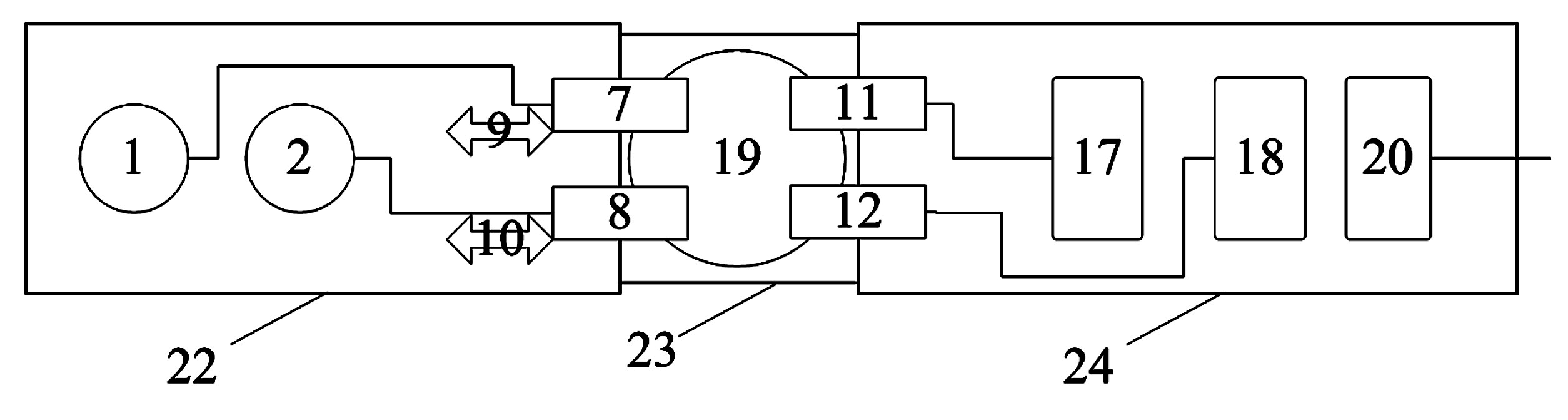

Magnetorheological fluid recycling device and control method and component manufacturing method thereof

PendingCN105417834AEasy to separateIncrease contact rateTreatment involving filtrationWater/sewage treatment by magnetic/electric fieldsFiltrationMagnetorheological fluid

The invention discloses a magnetorheological fluid recycling device and a control method and component manufacturing method thereof, and belongs to the technical field of mechanical manufacturing. The magnetorheological fluid recycling device comprises an inlet stop valve, an upper shell, a lower shell, an electrostatic filter plate, upper adsorption pipes, lower adsorption pipes, rib pipes, coils, heaters, stirrers, a pump, a return pipe and an outlet stop valve. The upper shell is connected with the lower shell through bolts, seal rings are arranged on the attached positions of the upper shell and the lower shell, and the inlet stop valve is arranged on the upper shell. Meanwhile, the invention further provides the control method and key component manufacturing method of the magnetorheological fluid recycling device. According to the magnetorheological fluid recycling device and the control method and component manufacturing method thereof, primary treatment on mixed liquid is completed through filtration and adsorption of the electrostatic filter plate, and then treatment on the mixed liquid is further completed through adsorption of the upper adsorption pipes, the lower adsorption pipes and the rib pipes; the heaters, the stirrers and a circulatory system are additionally arranged, and the purpose of thoroughly separating magnetic substances from solvent is achieved.

Owner:马鞍山清净环保科技有限公司

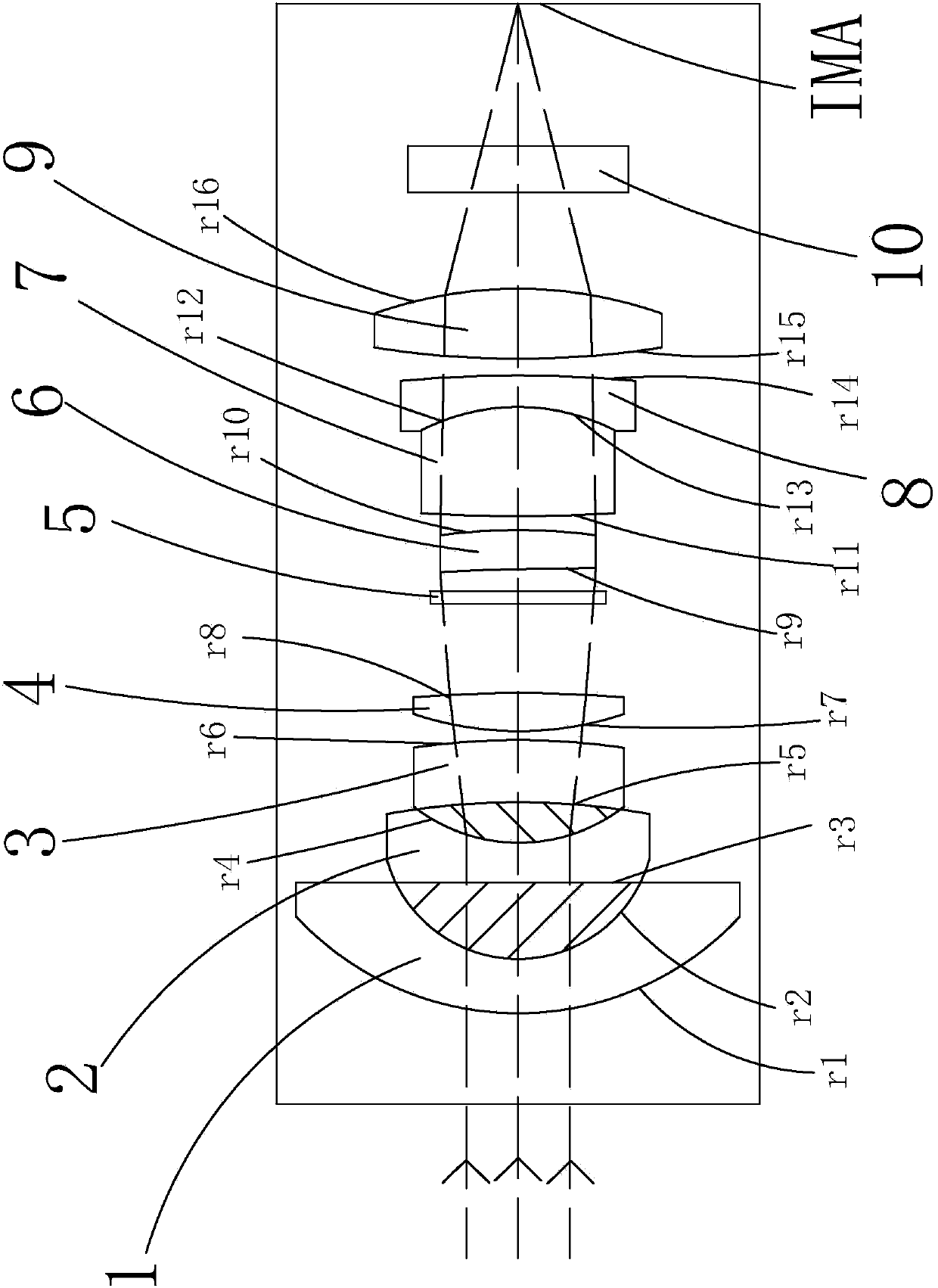

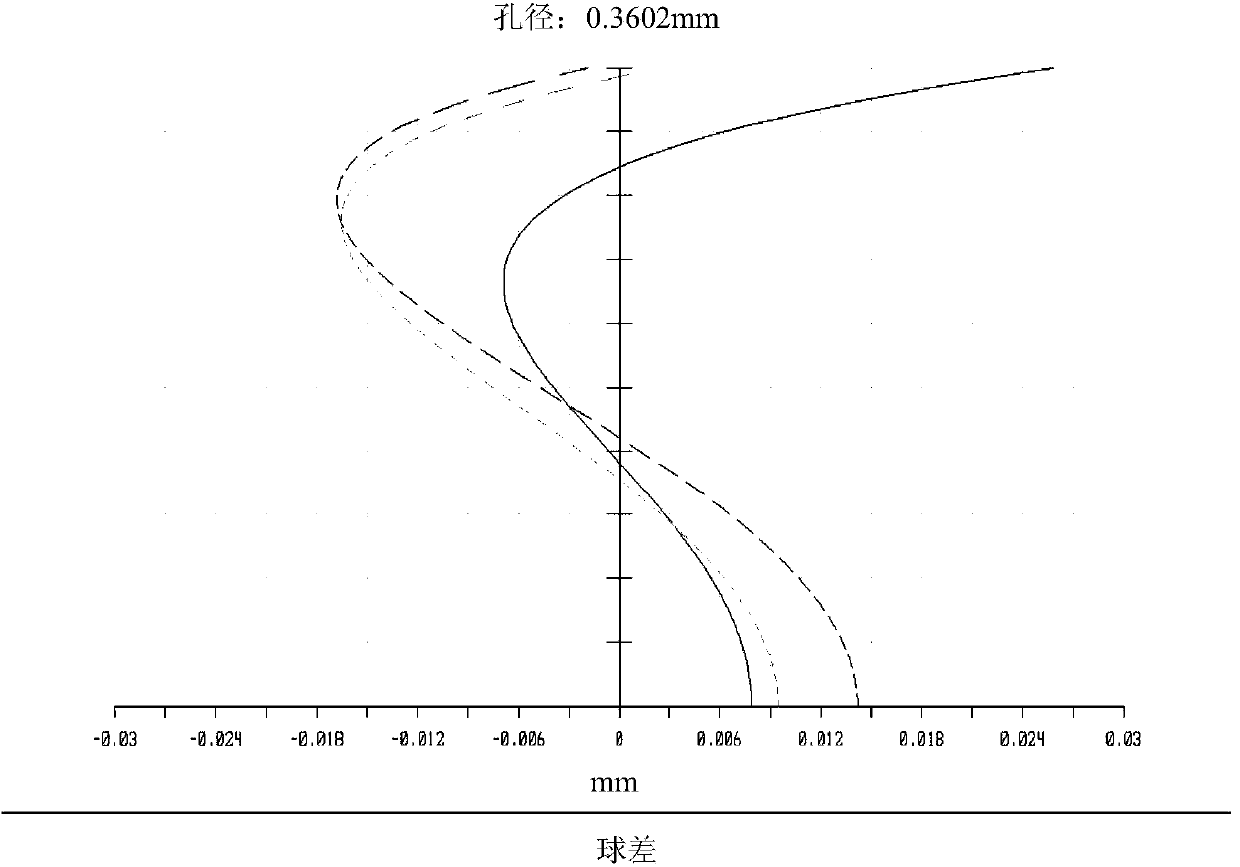

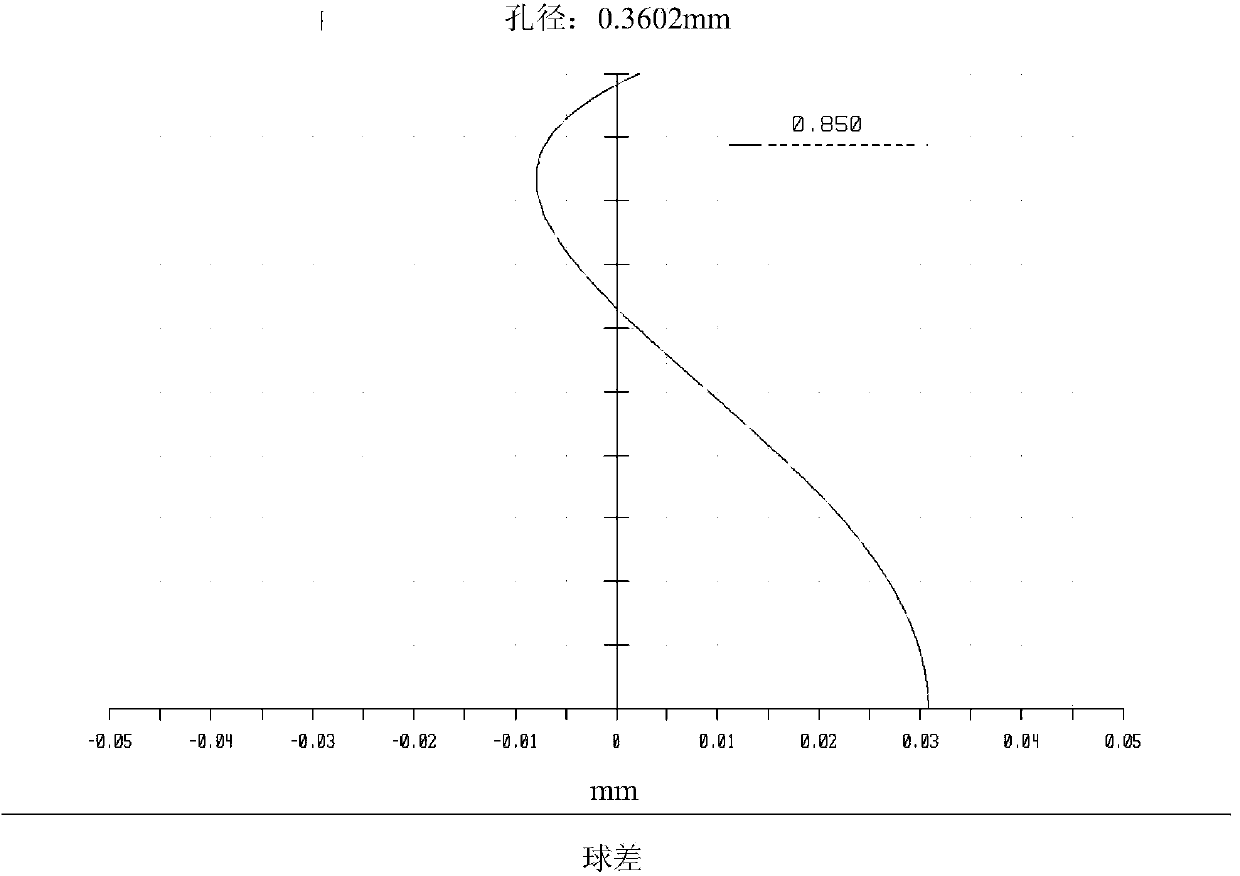

Novel ultra wide angle lens

The invention discloses a novel ultra wide angle lens. The novel ultra wide angle lens comprises a lens shell. Pieces of optical glass sequentially arranged from the object space to the image space inside the lens shell include a first lens, a second lens, a third lens, a fourth lens, a diaphragm component, a fifth lens, a sixth lens, a seventh lens and an eighth lens, wherein the first lens is a strawhat-type lens with the negative focal power, the second lens is a biconcave lens or a plane concave lens with the negative focal power, the third lens is a falcate lens or a biconvex lens with the positive focal power, the fourth lens is a falcate lens or a biconvex lens with the positive focal power, the fifth lens is a falcate lens or a biconvex lens with the positive focal power, the sixth lens is a biconvex lens with the positive focal power, the seventh lens is a falcate lens with the negative focal power, the eighth lens is a biconvex lens with the positive focal power, and the eighth lens is connected with a color filter. The visible light wave band and the near-infrared wave band guided in by the lens are focused in the same focal plane, so that the novel ultra wide angle lens can conduct clear imaging in the day and night modes.

Owner:舜宇光学(中山)有限公司

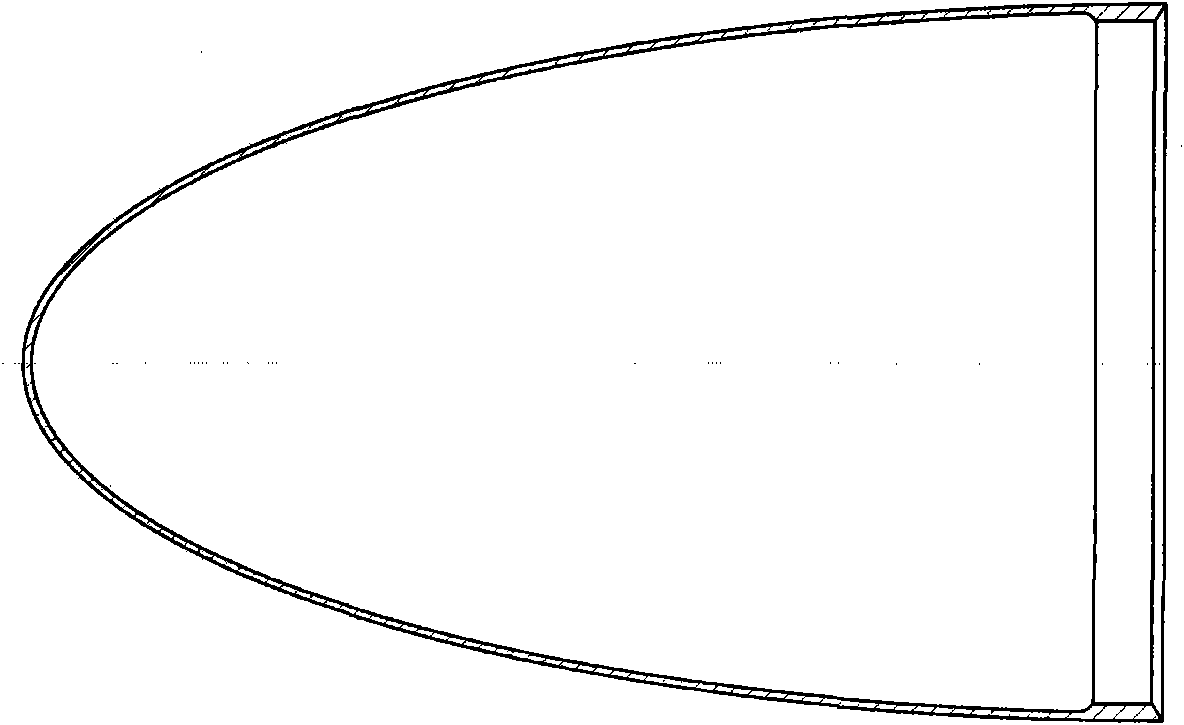

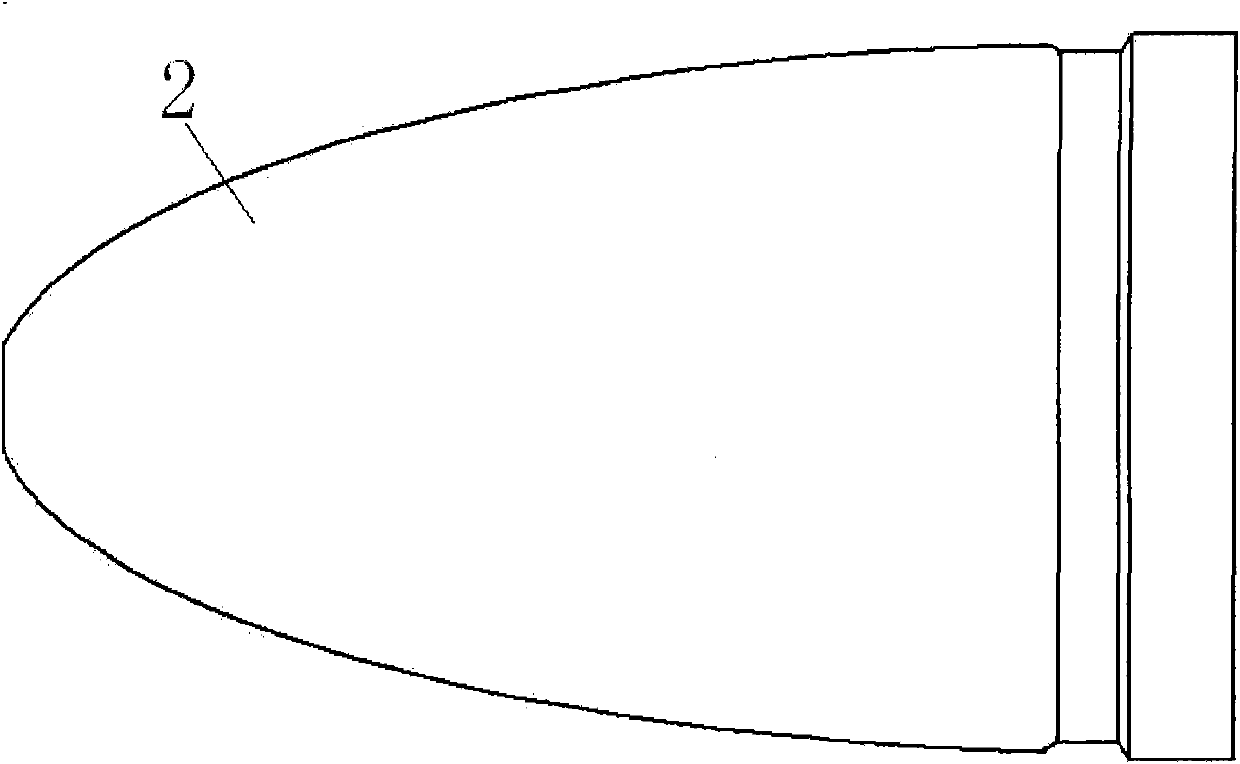

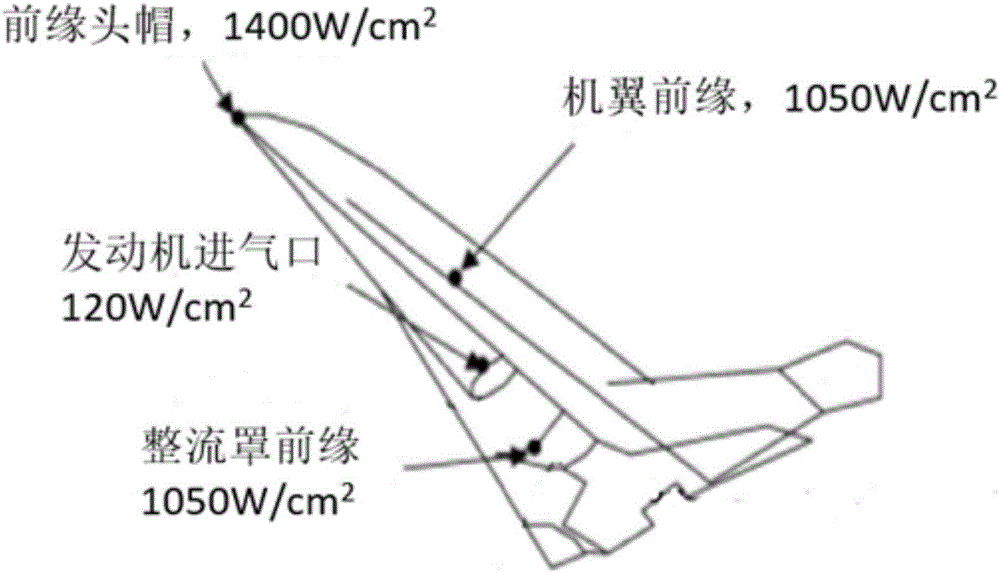

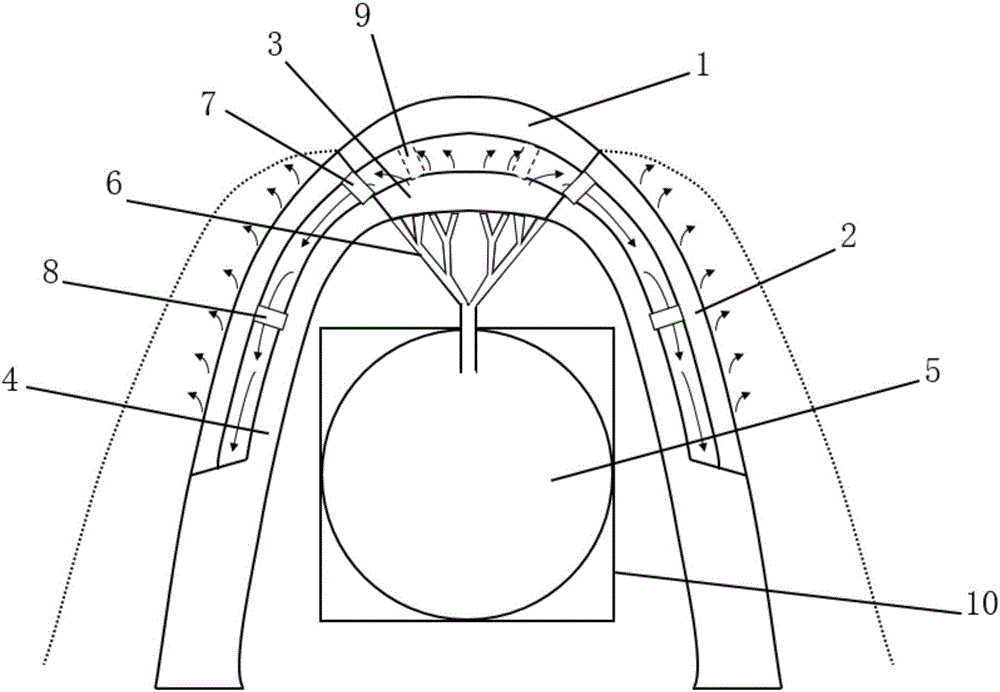

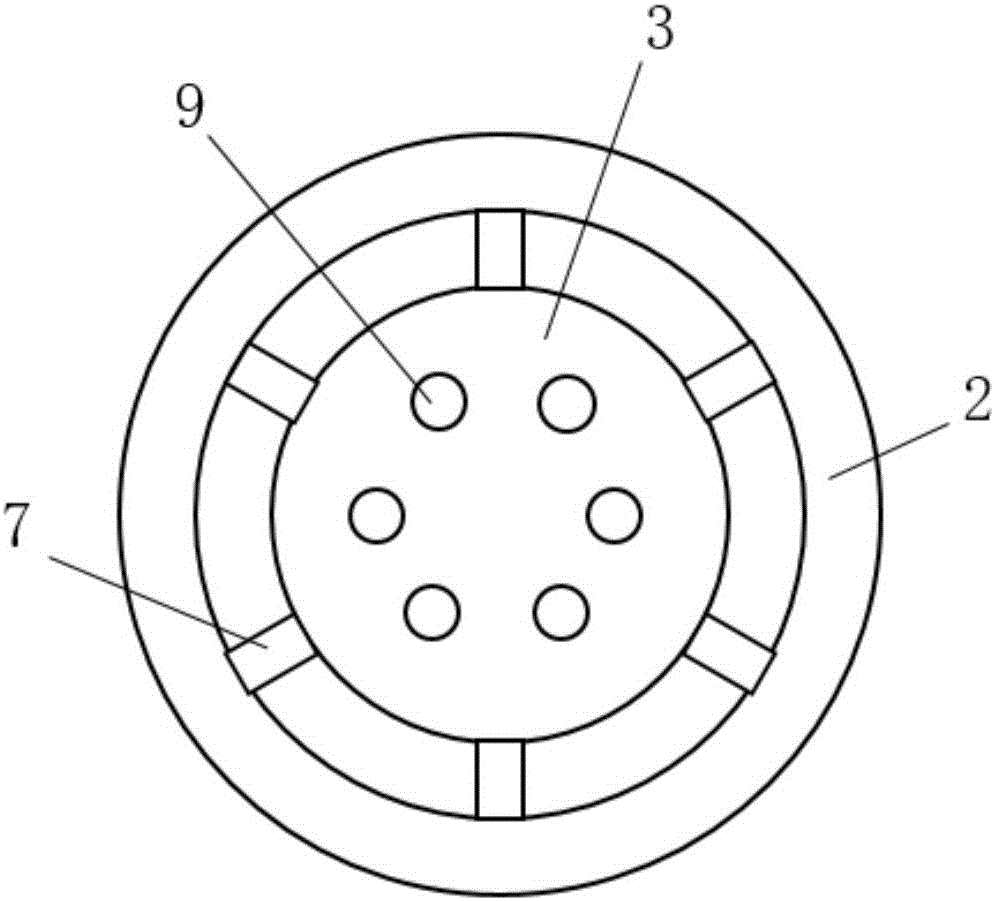

Thermal protection structure for leading edge of hypersonic vehicle

The invention relates to a thermal protection structure for the leading edge of a hypersonic vehicle. The thermal protection structure is sequentially composed of a shell layer and an inner wall layer from outside to inside. The shell layer comprises a first head cap located at the top end of the leading edge and a leading edge side wall shell fixedly connected with the first head cap. The first head cap is made from high temperature resistant materials, and the leading edge side wall shell is made from steel-based porous materials. The inner wall layer comprises a second head cap arranged corresponding to the first head cap, and a metal shell fixedly connected with the second head cap and arranged corresponding to the leading edge side wall shell. The second head cap is made from steel-based porous materials. A cooling channel is formed between the inner wall layer and the shell layer which are connected through a plurality of supporting ribs. A water storage capsule used for storing coolants is arranged inside the inner wall layer and connected with the second head cap through a tree-shaped capillary fractal structure and provides the coolants needed for transpiration cooling for the second head cap.

Owner:TSINGHUA UNIV

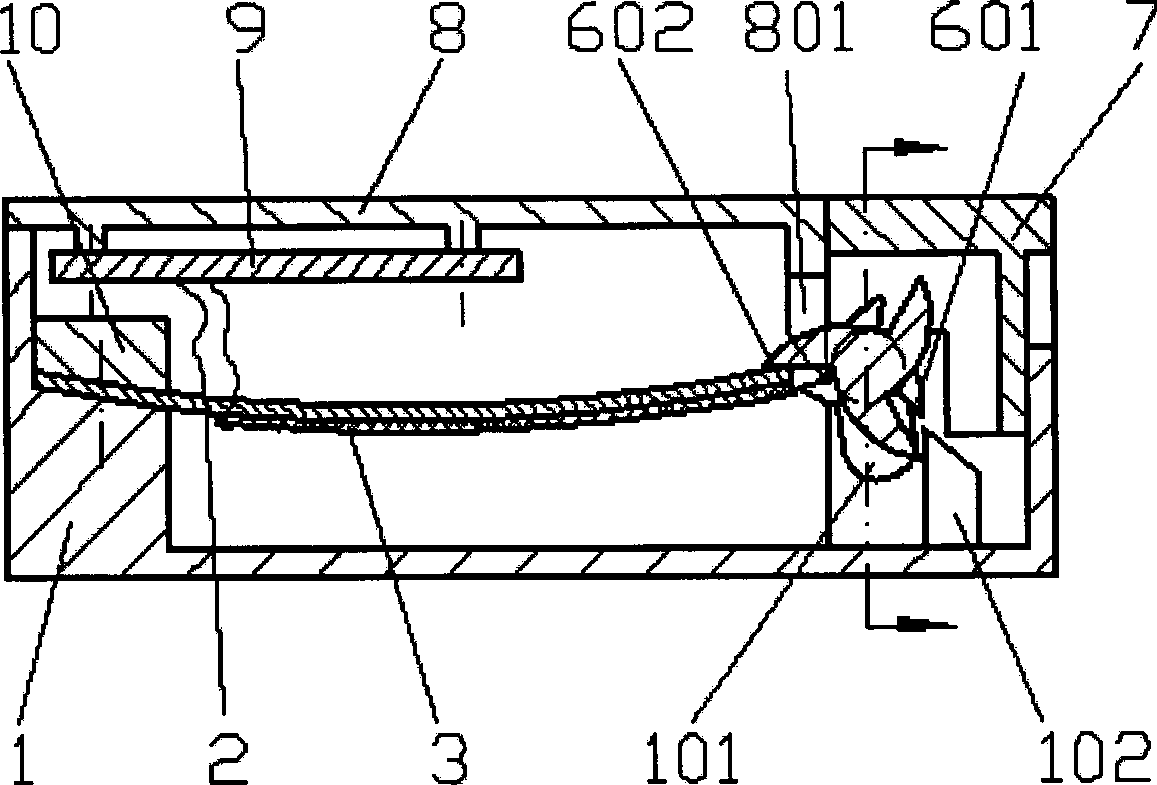

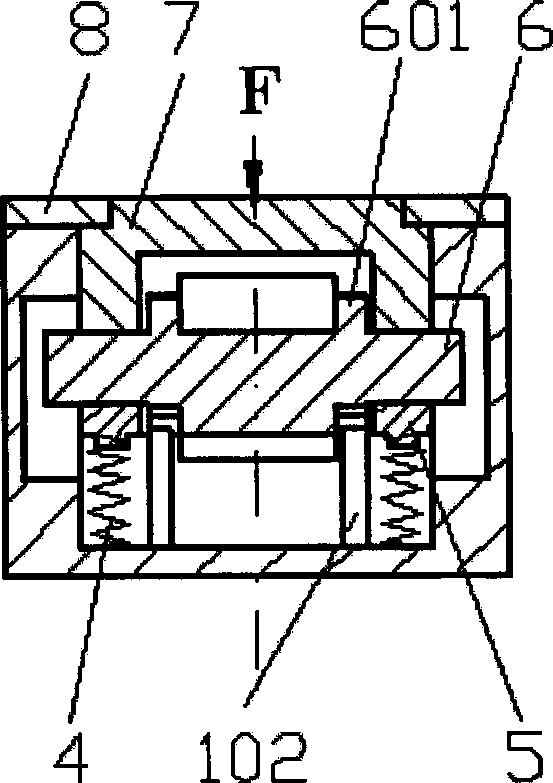

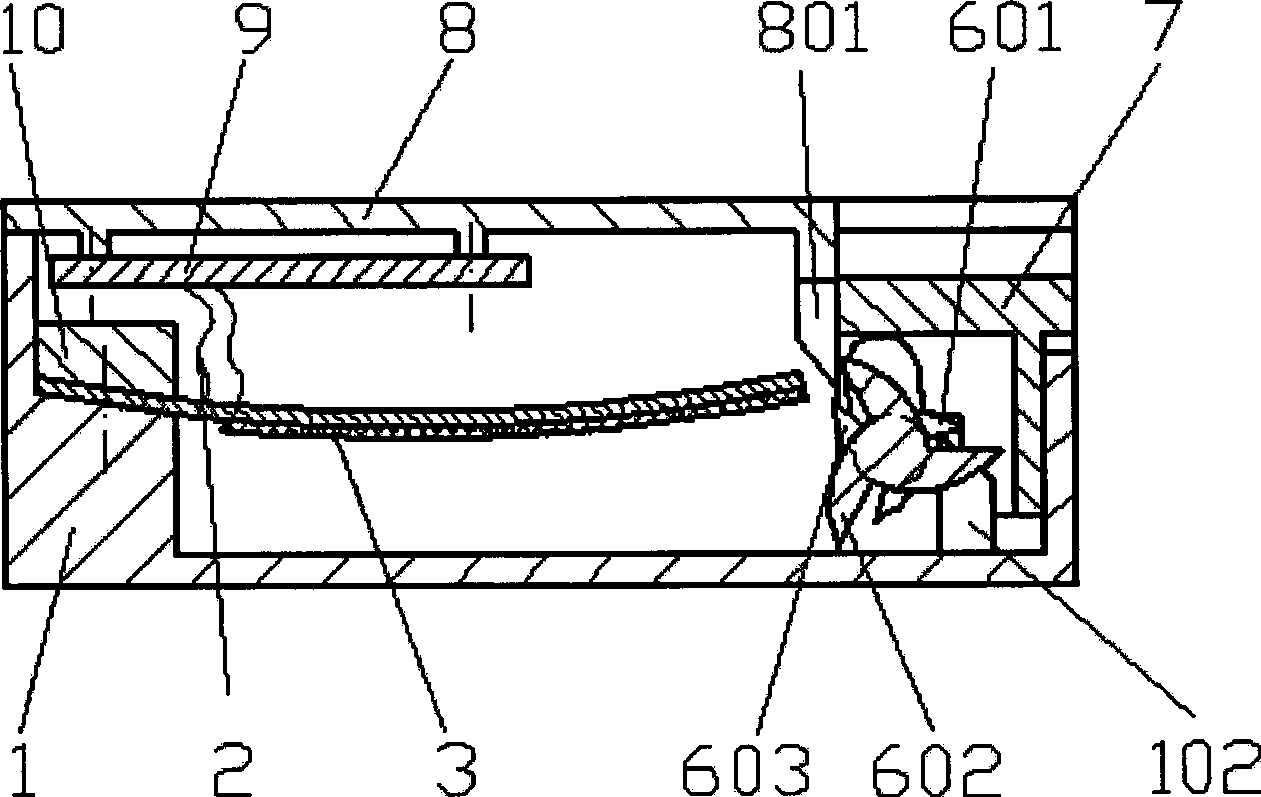

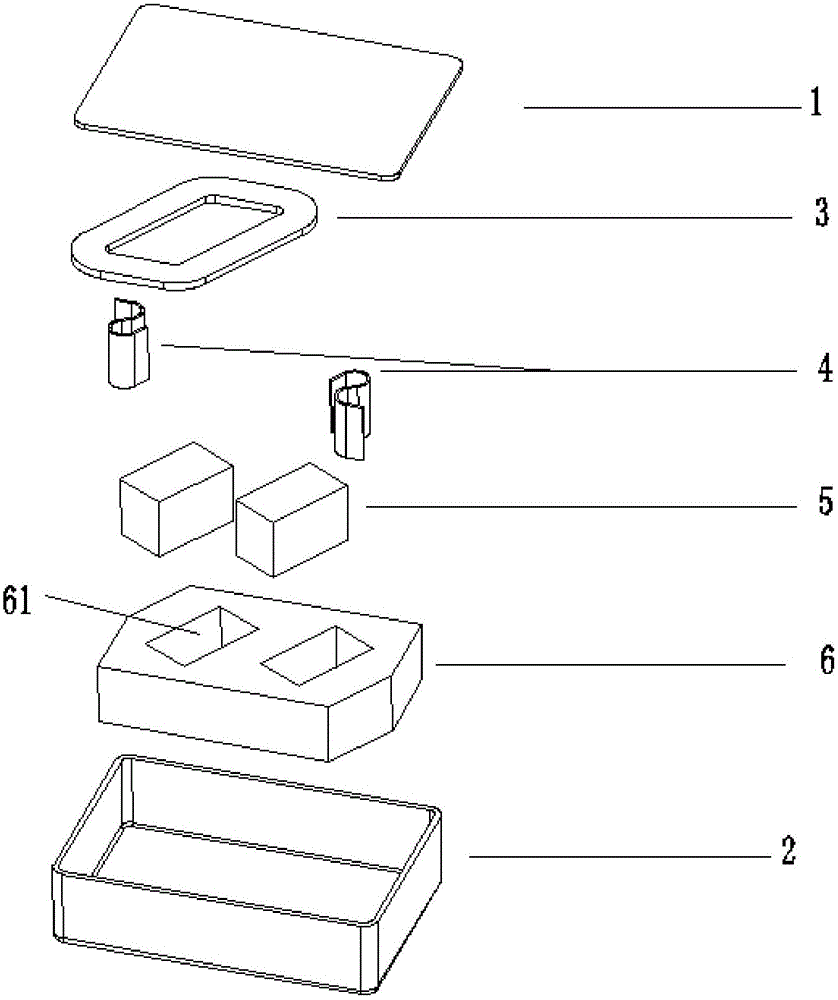

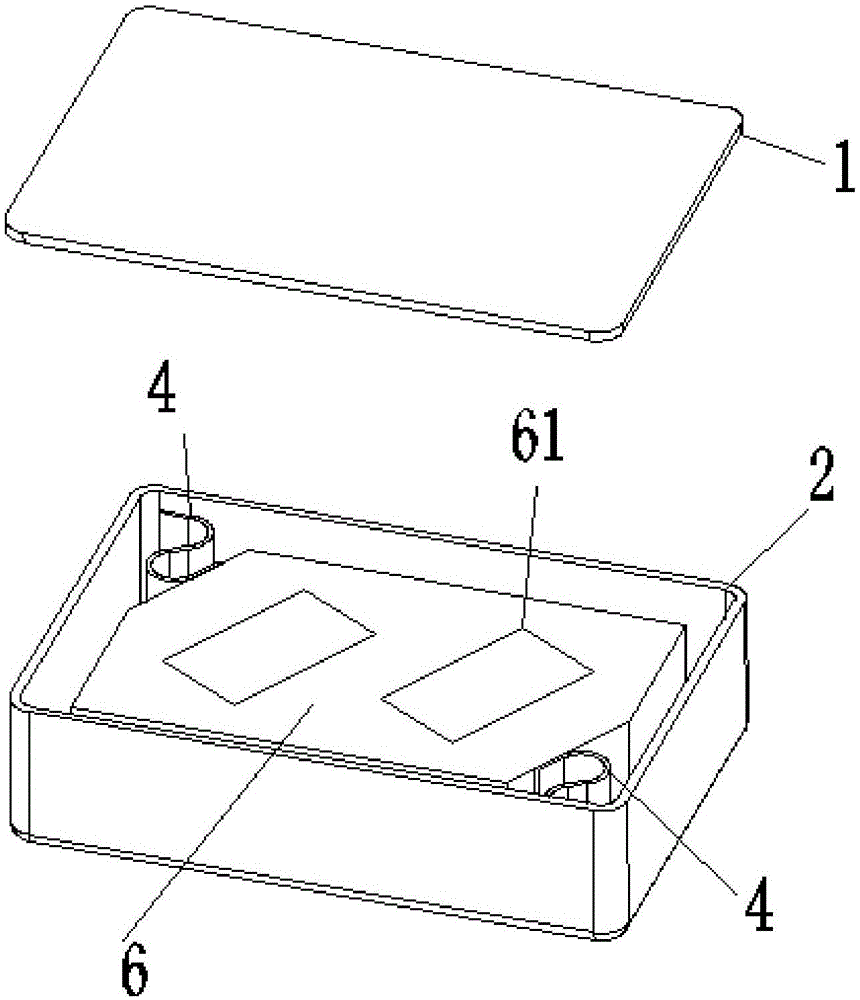

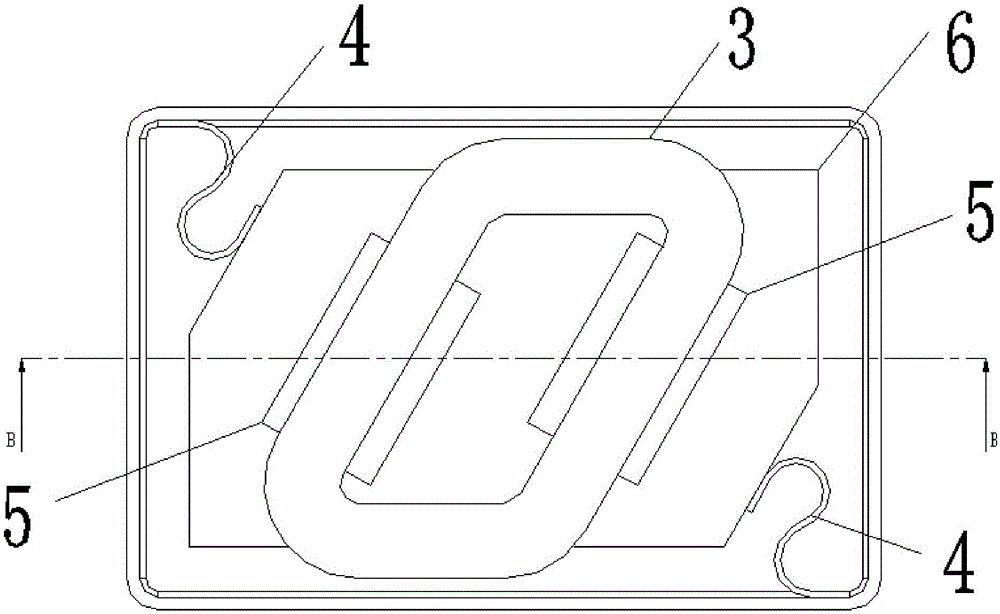

Vibration motor electronic equipment

Disclosed in the invention is a vibration motor comprising a housing formed by an upper shell 1 and a lower shell 2. A coil 3, spring plates, magnets, and a mass block are accommodated into a cavity encircled by the housing. The mass block 6 contains accommodation grooves 61 with the shapes matching the external profiles of the magnets 5; and the magnets 5 are accommodated into the accommodation grooves 61 and are used for providing magnetic fields for the vibration motor. The coil 3 that is fixed on the upper shell 1 and is connected with an external power supply is used for making induction with the magnets 5 during electrification to generate a driving force. The spring plates 4 are respectively arranged at diagonal positions of the lower shell 2. The mass block 6 that is connected to the lower shell 2 by the spring plates and is suspended inside the housing makes vibration horizontally along the diagonal direction of the housing under the effect of the driving force. According to the invention, the diagonal vibration of the motor can be realized and thus a multi-azimuth vibration effect with vibration at the X direction and the Y direction can be realized, so that the good user experience can be provided. Moreover, on the basis of the principle that the diagonal line is the longest, displacement needed by vibration can be met and thus space is saved.

Owner:GOERTEK INC

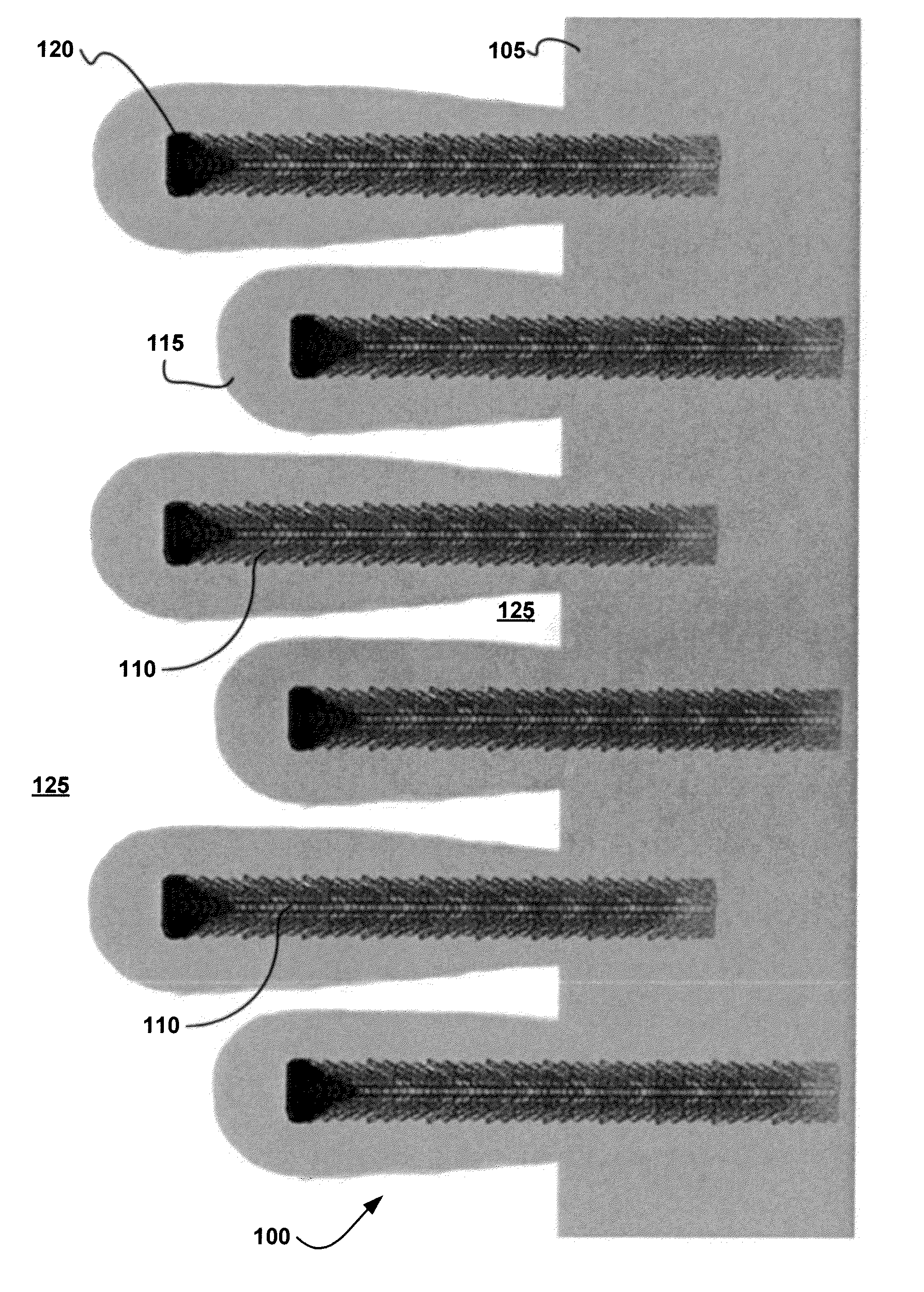

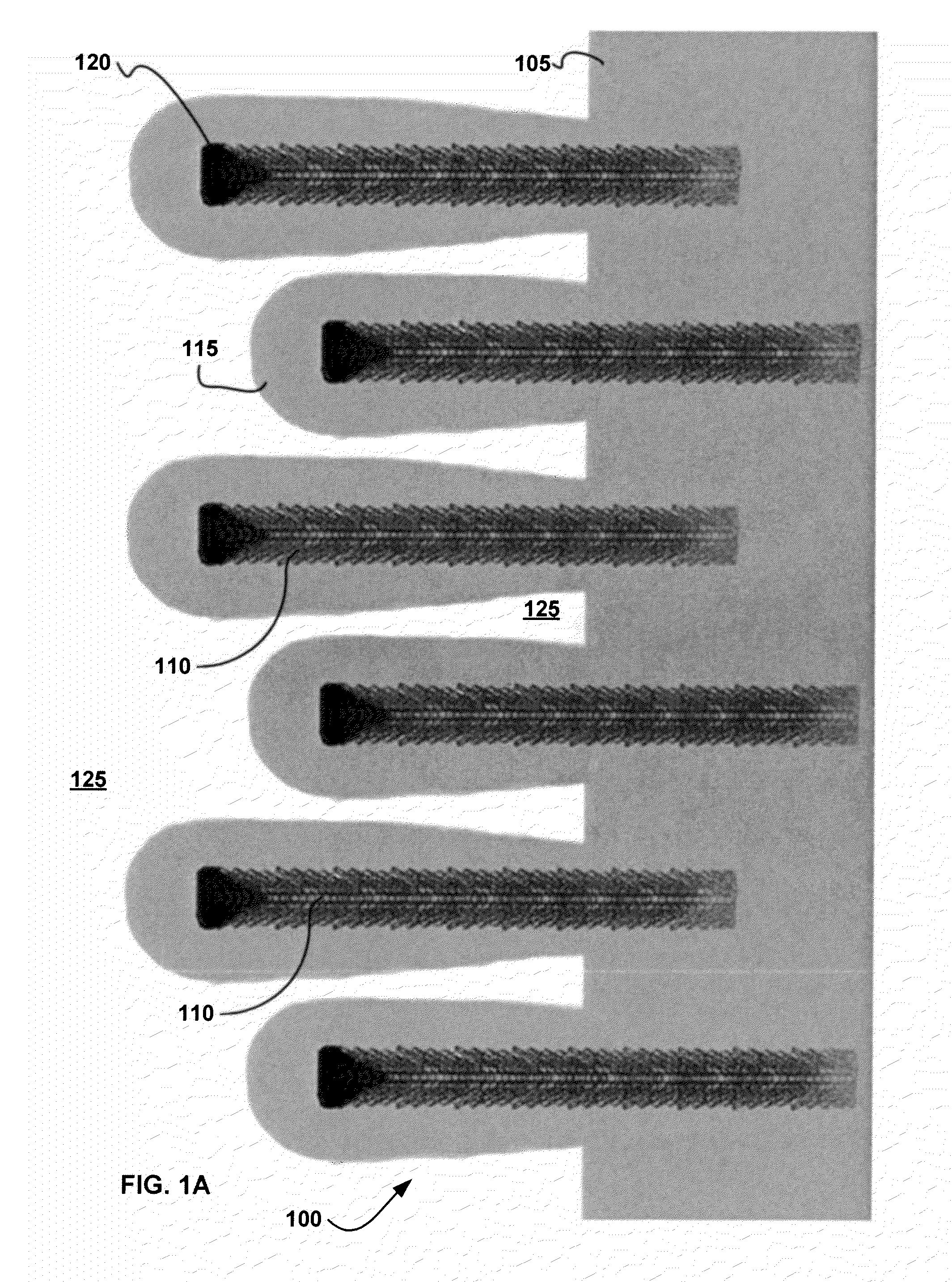

Hybrid Energy Storage Devices

A novel hybrid lithium-ion anode material based on coaxially coated Si shells on vertically aligned carbon nanofiber (CNF) arrays. The unique cup-stacking graphitic microstructure makes the bare vertically aligned CNF array an effective Li+ intercalation medium. Highly reversible Li+ intercalation and extraction were observed at high power rates. More importantly, the highly conductive and mechanically stable CNF core optionally supports a coaxially coated amorphous Si shell which has much higher theoretical specific capacity by forming fully lithiated alloy. Addition of surface effect dominant sites in close proximity to the intercalation medium results in a hybrid device that includes advantages of both batteries and capacitors.

Owner:CF TRAVERSE LLC

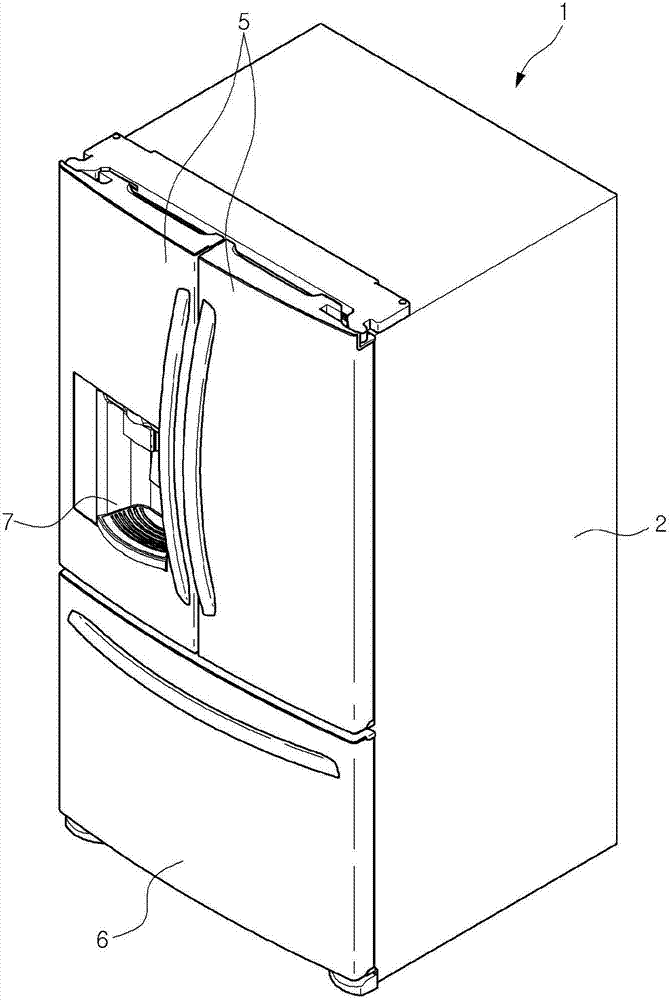

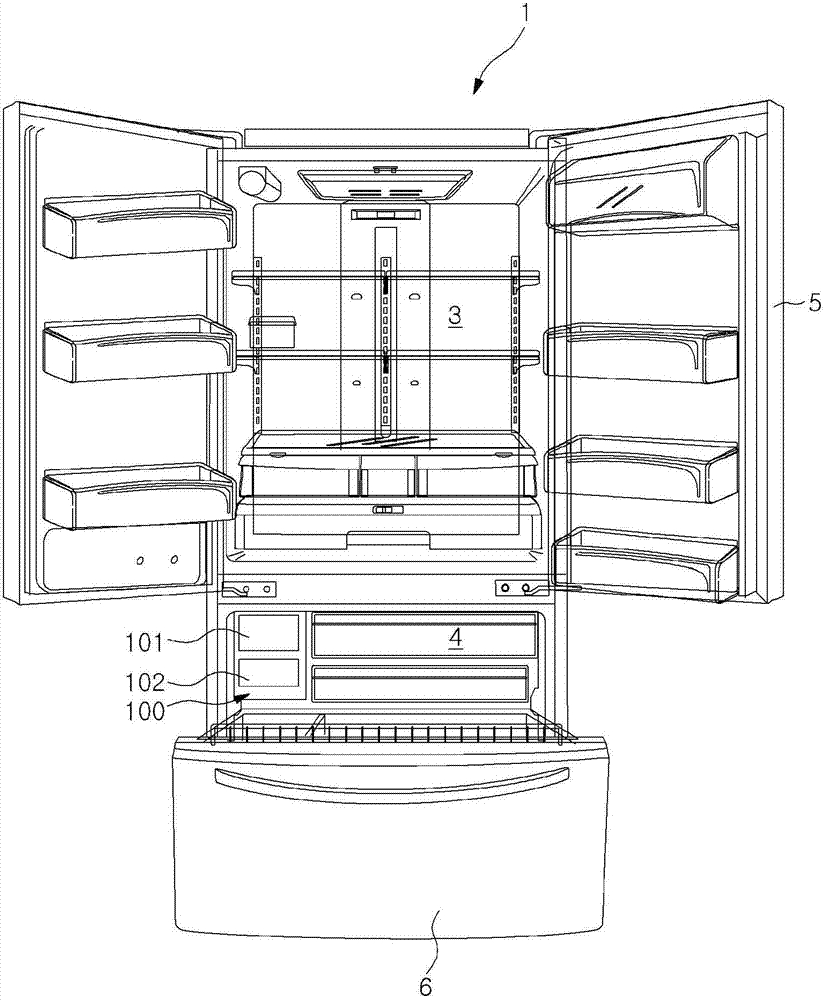

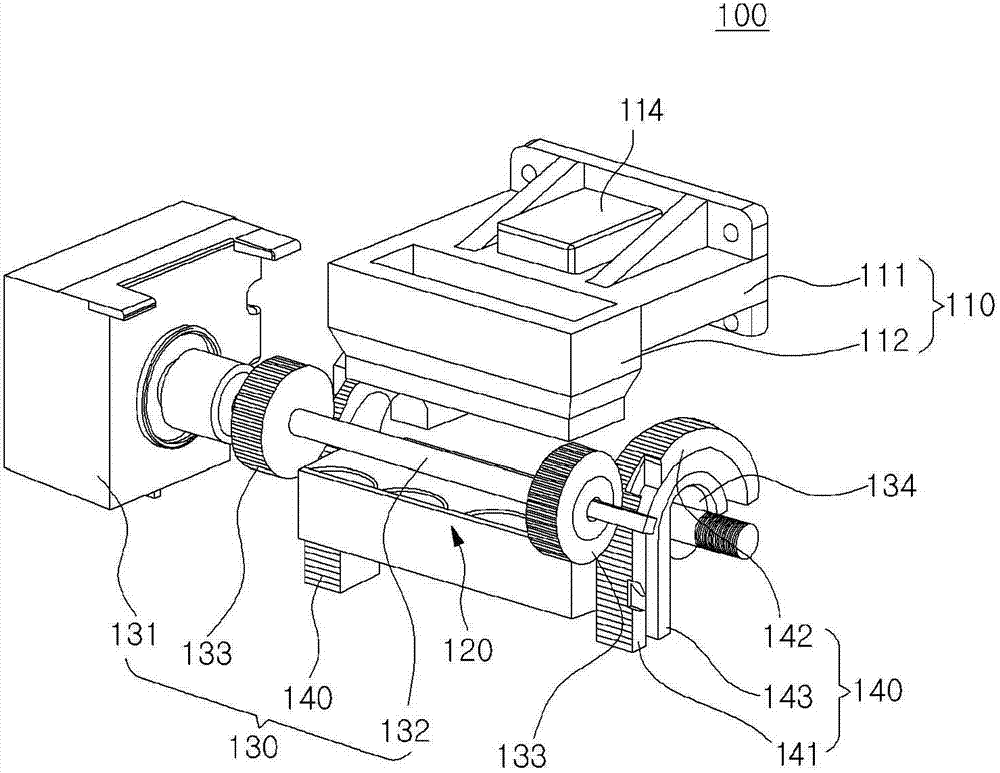

Ice maker

ActiveCN102878744AAvoid tanglesImprove storage effectLighting and heating apparatusIce productionEngineeringIcemaker

Owner:LG ELECTRONICS INC

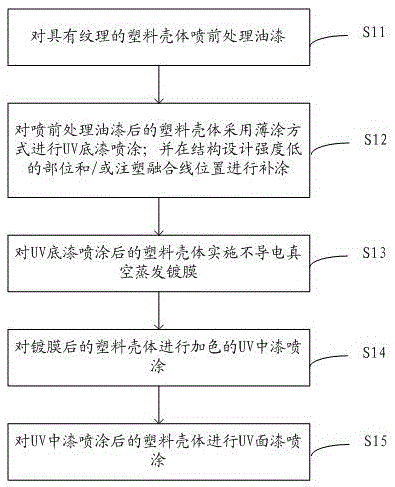

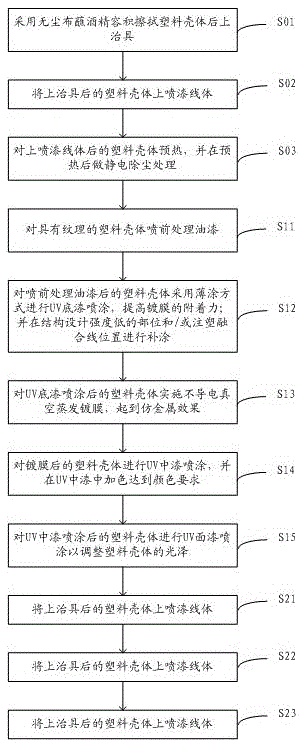

Machining method for achieving metal texture of plastic shell with grain appearance and shell

InactiveCN105598018AThe texture effect is highlightedTexture effect ensuresPretreated surfacesCoatingsLacquerUltimate tensile strength

The invention discloses a machining method for achieving metal texture of a plastic shell with grain appearance. The method includes the following steps that pretreatment paint is sprayed to the plastic shell with grains; UV primer spraying is conducted on the plastic shell where the pretreatment paint is sprayed in a thin coating mode, and adhesion of a coating film is improved; supplementary coating is conducted on portions with low structural design strength and / or injection molding fusion line positions; non-conductive vacuum evaporation film coating is conducted on the plastic shell where UV primer is sprayed, and a metal-imitating effect is achieved; UV intermediate paint spraying is conducted on the plastic shell subjected to film coating, and UV intermediate paint is colored to meet the color requirement; UV surface paint spraying is conducted on the plastic shell sprayed with the UV intermediate paint so as to adjust the gloss of the plastic shell. The primer thin coating technology and the electroplating technology are combined, on the premise that the performance and the texture effect of the shell are guaranteed, the metal texture effect is achieved on a plastic substrate, and the requirements of customers for economical efficiency and appearance metal texture are met.

Owner:QINGDAO HISENSE MOBILE COMM TECH CO LTD

Hybrid Energy Storage Device Production

ActiveUS20130171340A1Electrode manufacturing processesHybrid capacitor electrodesLithiumCarbon nanofiber

A novel hybrid lithium-ion anode material based on coaxially coated Si shells on vertically aligned carbon nanofiber (CNF) arrays. The unique cup-stacking graphitic microstructure makes the bare vertically aligned CNF array an effective Li+ intercalation medium. Highly reversible Li+ intercalation and extraction were observed at high power rates. More importantly, the highly conductive and mechanically stable CNF core optionally supports a coaxially coated amorphous Si shell which has much higher theoretical specific capacity by forming fully lithiated alloy. Addition of surface effect dominant sites in close proximity to the intercalation medium results in a hybrid device that includes advantages of both batteries and capacitors.

Owner:CF TRAVERSE LLC

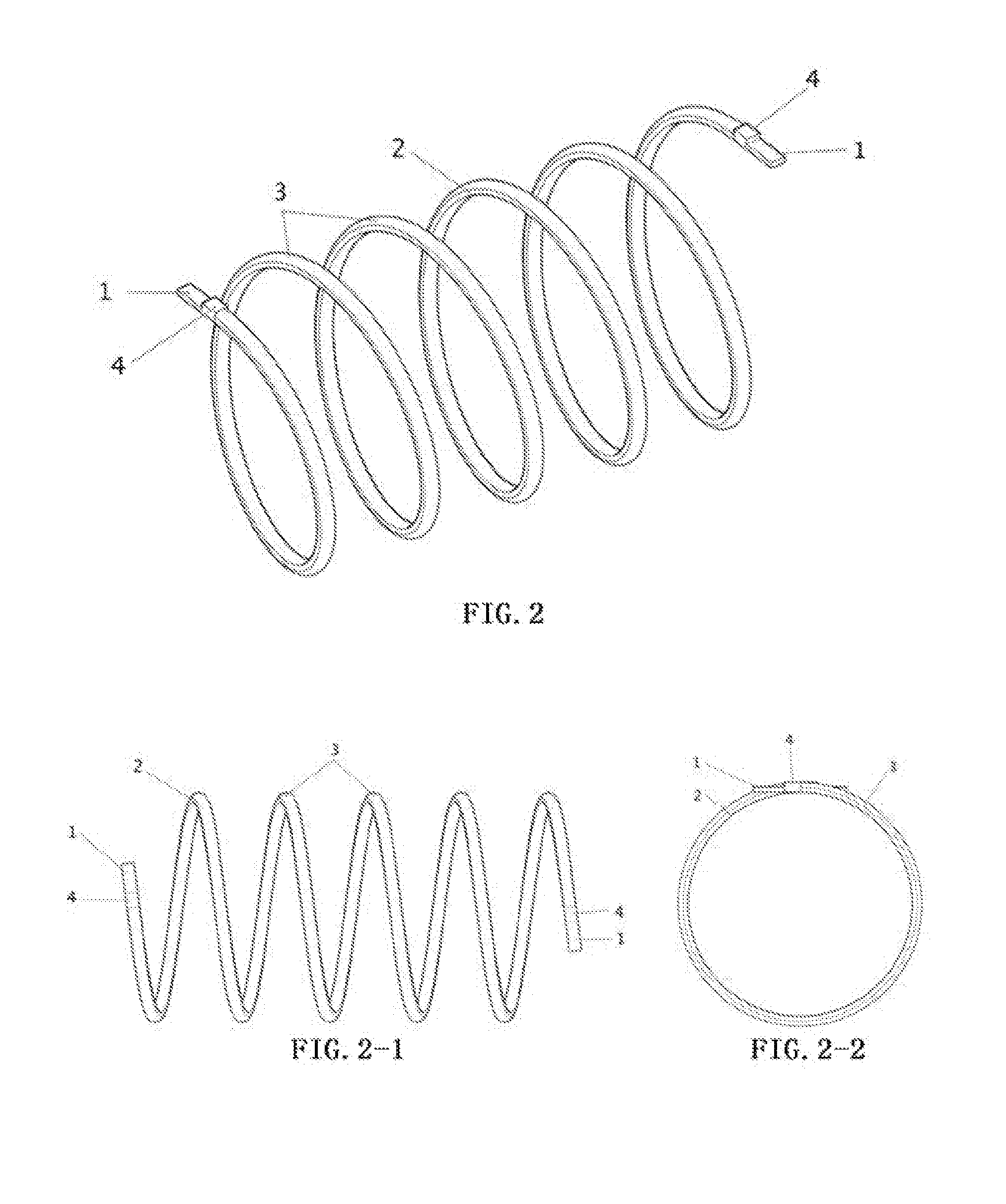

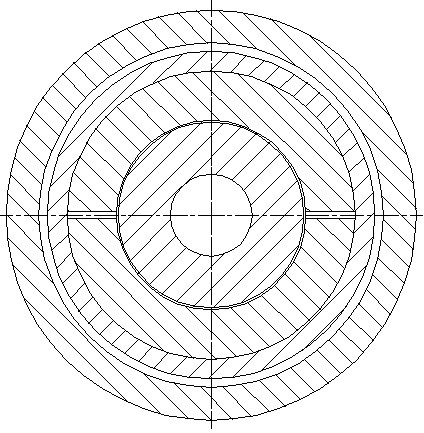

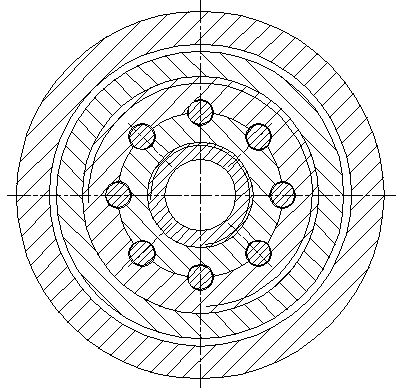

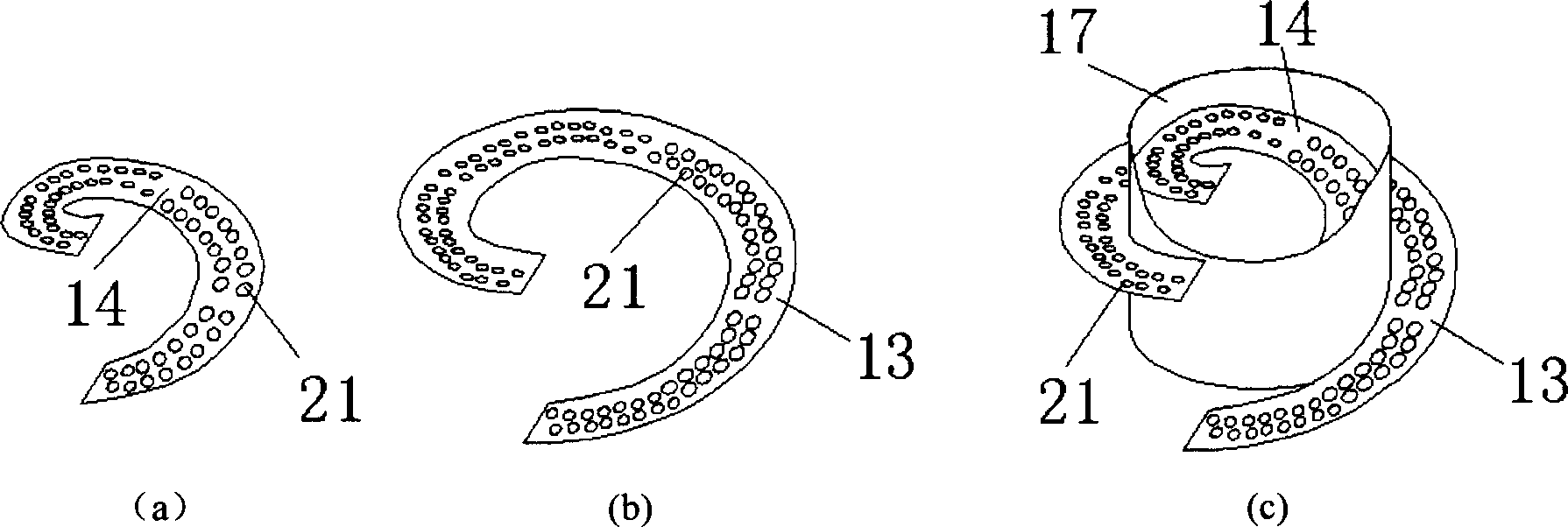

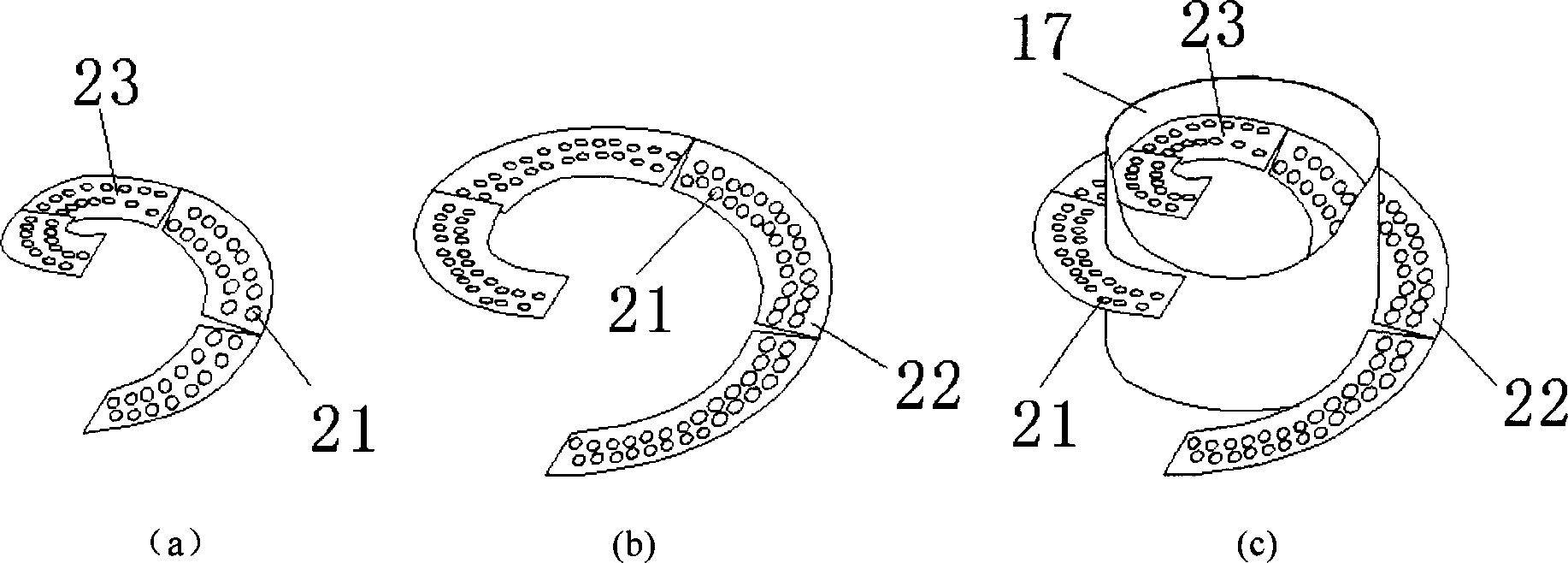

Multiple shell passes shell-and-tube helica-baffle heat exchangers

ActiveCN1821700ACompact structureExtended service lifeHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

The multiple shell spiral baffle shell-and-tube heat exchanger includes one shell, one central tube in the center oft shell, two tube plates on ends of the shell and with separate end covers, one inlet pipe and one outlet pipe beside the tube, one heat exchange tube bundle, one inlet pipe and one outlet pipe beside the shell, one external spiral baffle plate and one internal spiral baffle plate, and one internal casing between the external spiral baffle plate and the internal spiral baffle plate. The shell, the external spiral baffle plate and the internal casing enclose one external spiral shell pass; and the internal casing, the internal spiral baffle plate and the central tube enclose one internal spiral shell pass, so that one two-shell pass spiral baffle plate shell-and-tube heat exchanger is formed. Adopting two or more internal casings can form multiple spiral shell pass. The present invention has raised heat exchange efficiency, compact heat exchanger structure, less vibration, high safety, less scaling and long service life.

Owner:上海益焓能源科技有限公司

On-line broad-spectrum water quality analyzer

InactiveCN102042965AImprove the use environmentWide coverageColor/spectral properties measurementsAction spectrumUnderwater

The invention provides an on-line broad-spectrum water quality analyzer, which is characterized by comprising an ultraviolet visible light detection device, a near infrared light detection device, a controller in circuit connection with the ultraviolet visible light detection device and the near infrared light detection device respectively, a head shell, a connecting plate connected with the head shell, and a tail shell connected with the connecting plate, wherein the head shell, the connecting plate and the tail shell have sealing structures. Optical devices are hermetically arranged in a sealed inner chamber and are connected by optical fibers simultaneously, so that equipment meets the requirement of on-line underwater using and the using environment of the equipment is further widened; and spectrums of an ultraviolet visible light source and a near infrared light source are combined into a broad spectrum, so that a detection spectrum can cover a wider spectrum range.

Owner:上海衡伟环保工程有限公司

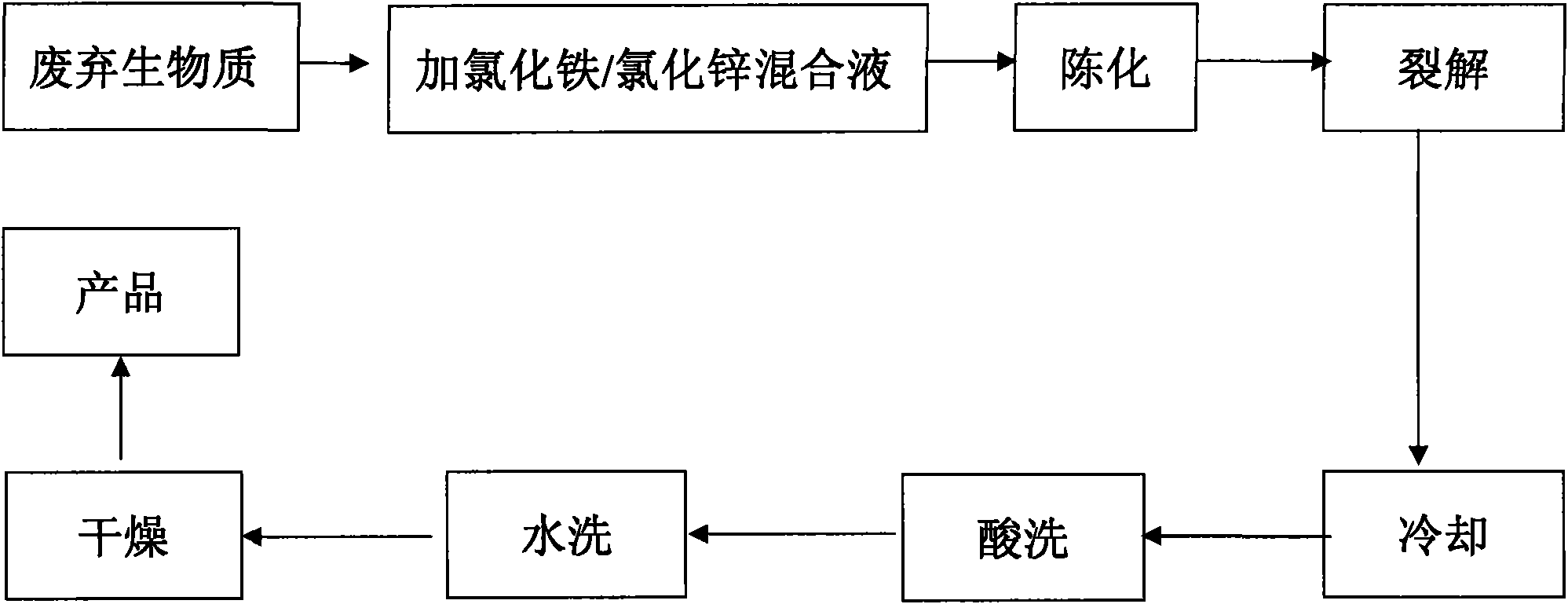

Novel process for preparing C-Fe shell-core magnetic active carbon by utilizing waste biomasses

The invention relates to a novel process for preparing magnetic active carbon with a C-Fe shell-core structure by utilizing waste biomasses. The process overcomes the defects of complicated preparation process, high cost and high price of the traditional shell-core active carbon, and by utilizing the form change of the waste biomasses in the presence of heating, the processes of carbonization, activation, magnetism giving and protection of the biomasses are achieved in one step. The key of the process lies in selecting an appropriate activating agent, controlling an appropriate carbonizing and heating system and carbonizing atmosphere and ensuring that the active carbon completely coats iron in the production process. The obtained active carbon has high specific surface area, pore volume and magnetic intensity and the C-Fe shell-core structure. Proved by experiments, after the active carbon is soaked in a 2M salpeter solution for 2h, the magnetism cannot be lost, and a product can be used in a strongly acidic solution.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

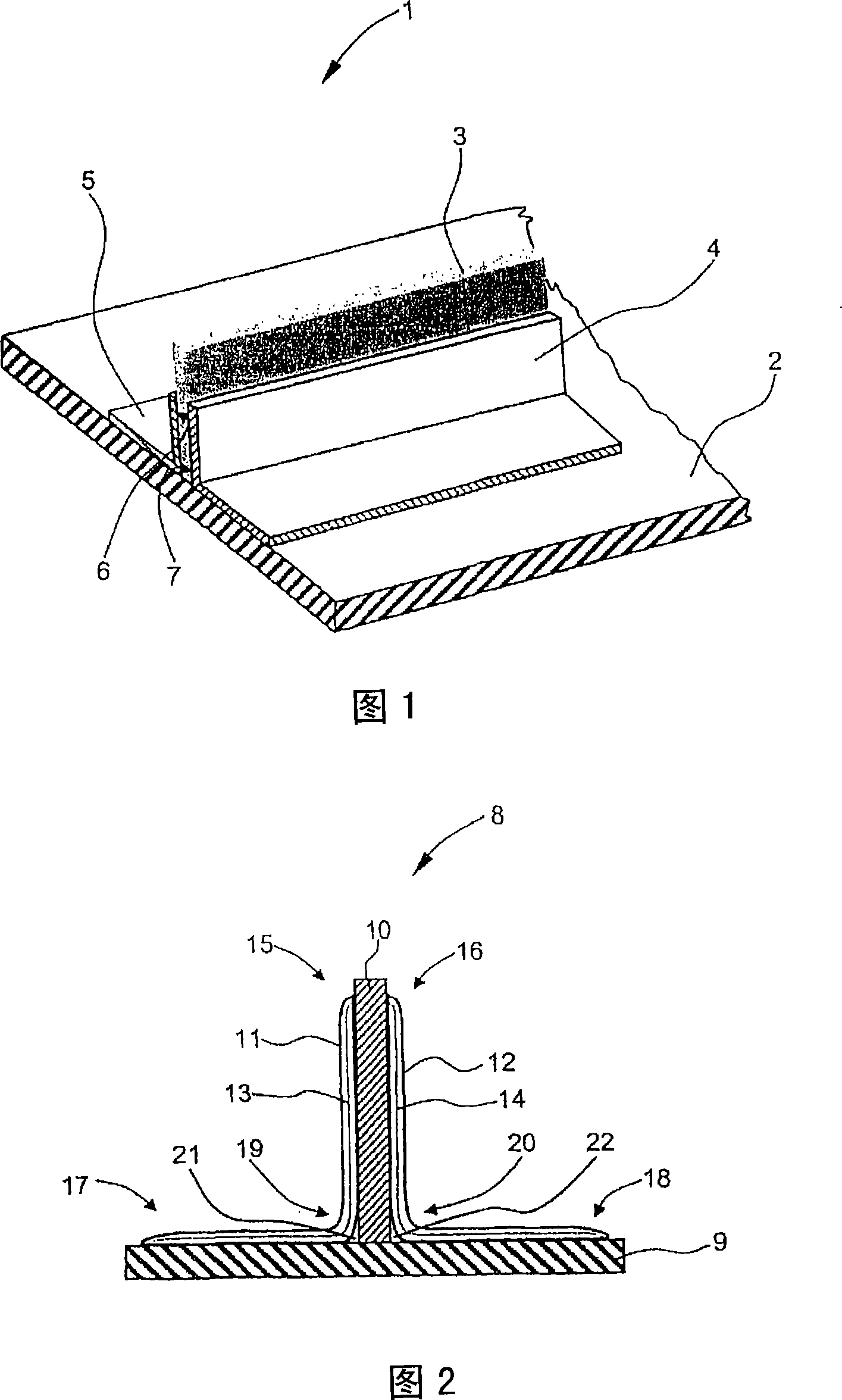

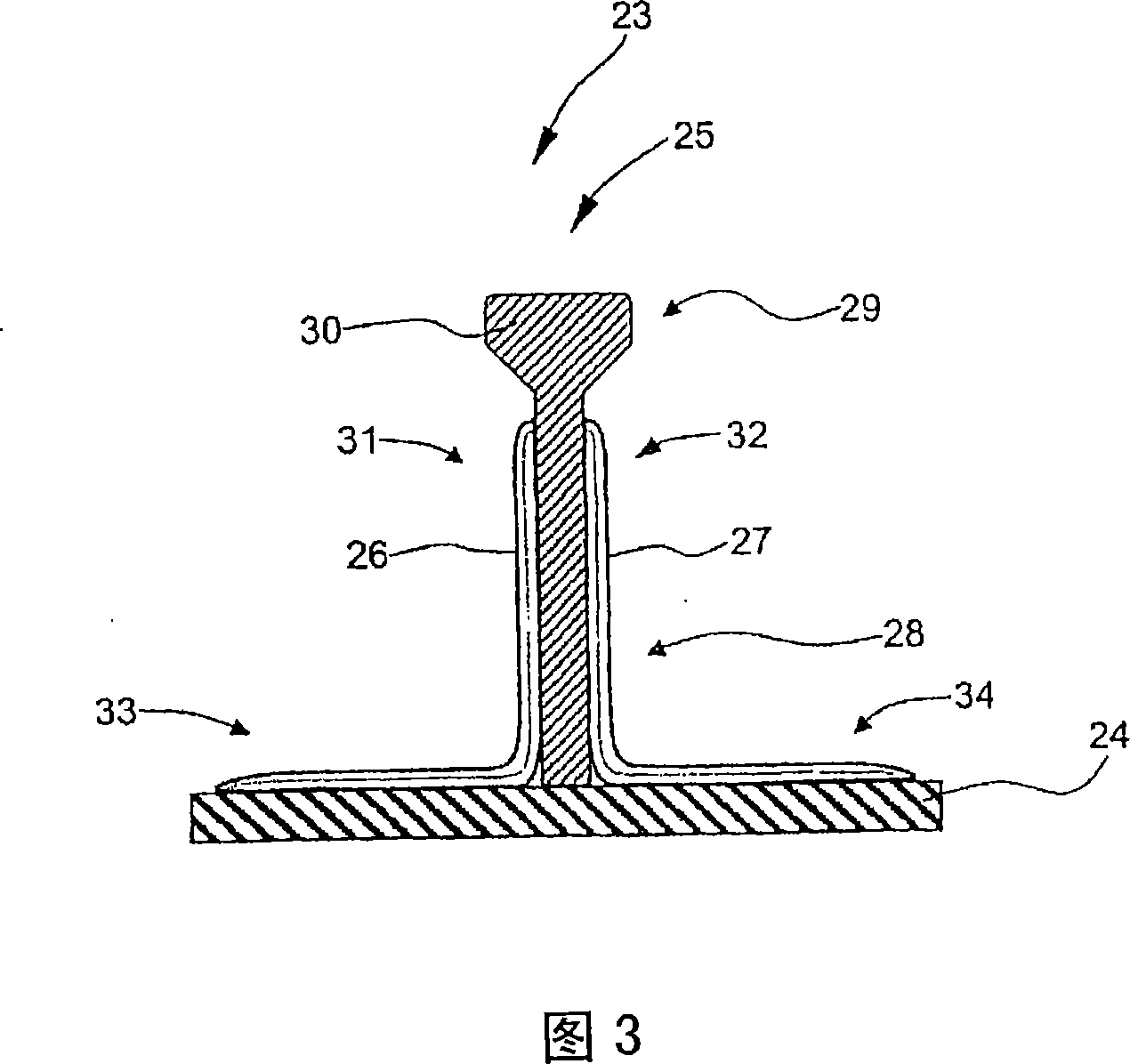

Method for manufacturing a reinforced shell for forming component parts for aircraft and shell for component parts for aircraft

The invention concerns a method for manufacturing a shell, in particular a fuselage shell, a wing shell, a horizontal stabilizer shell or a vertical stabilizer shell, that is reinforced with a plurality of stiffening elements, for forming component parts for aircraft with high dimensional stability, wherein the stiffening elements and a shell skin are made with epoxy resin from at least partially cured carbon fiber reinforced semi-finished parts, the method comprising the following steps: positioning the stiffening elements on the shell skin, abutting connecting elements against the shell skin and the stiffening elements, and curing the connecting elements to form the shell. The invention also concerns a shell, in particular a fuselage shell, a wing shell, a horizontal stabilizer shell or a vertical stabilizer shell, manufactured in accordance with the inventive method.

Owner:AIRBUS OPERATIONS GMBH

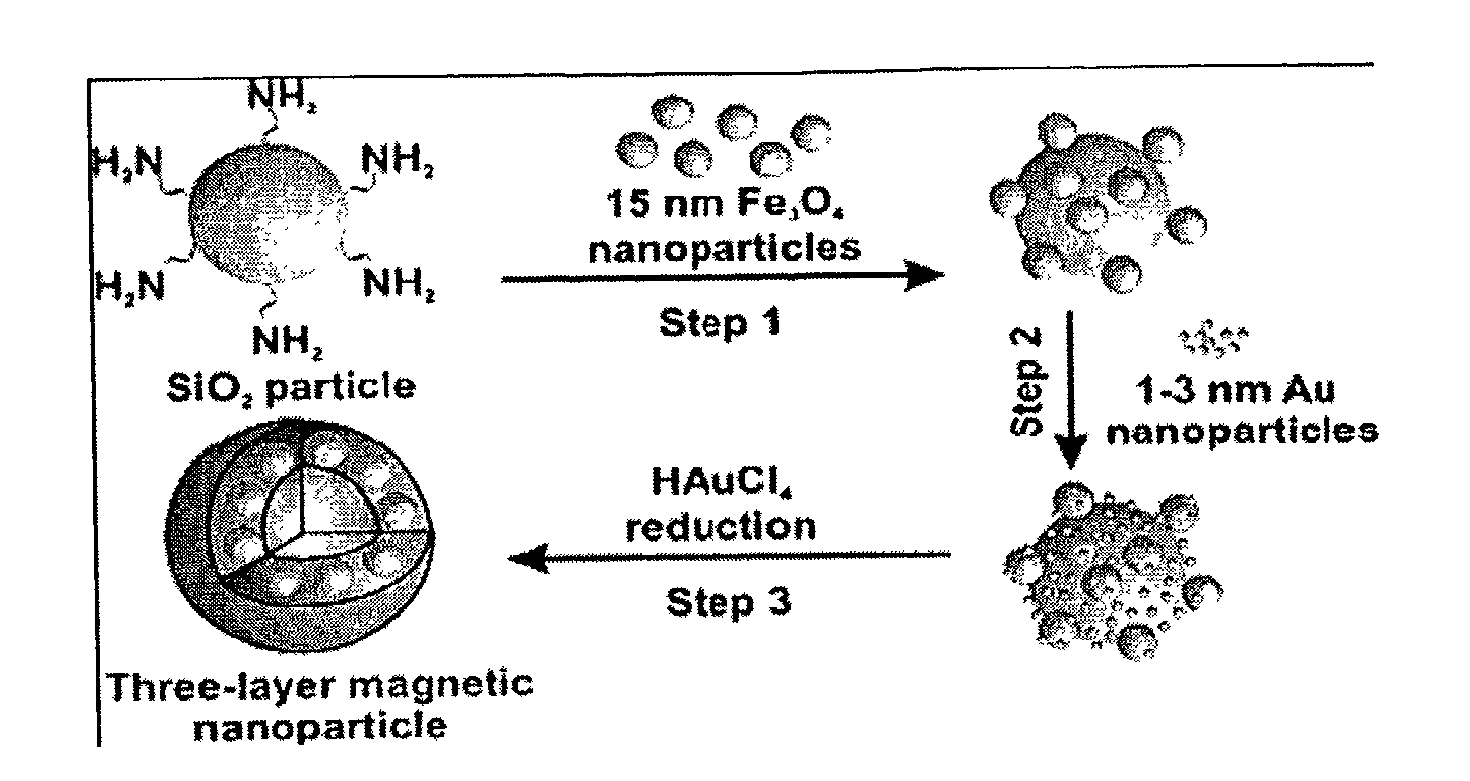

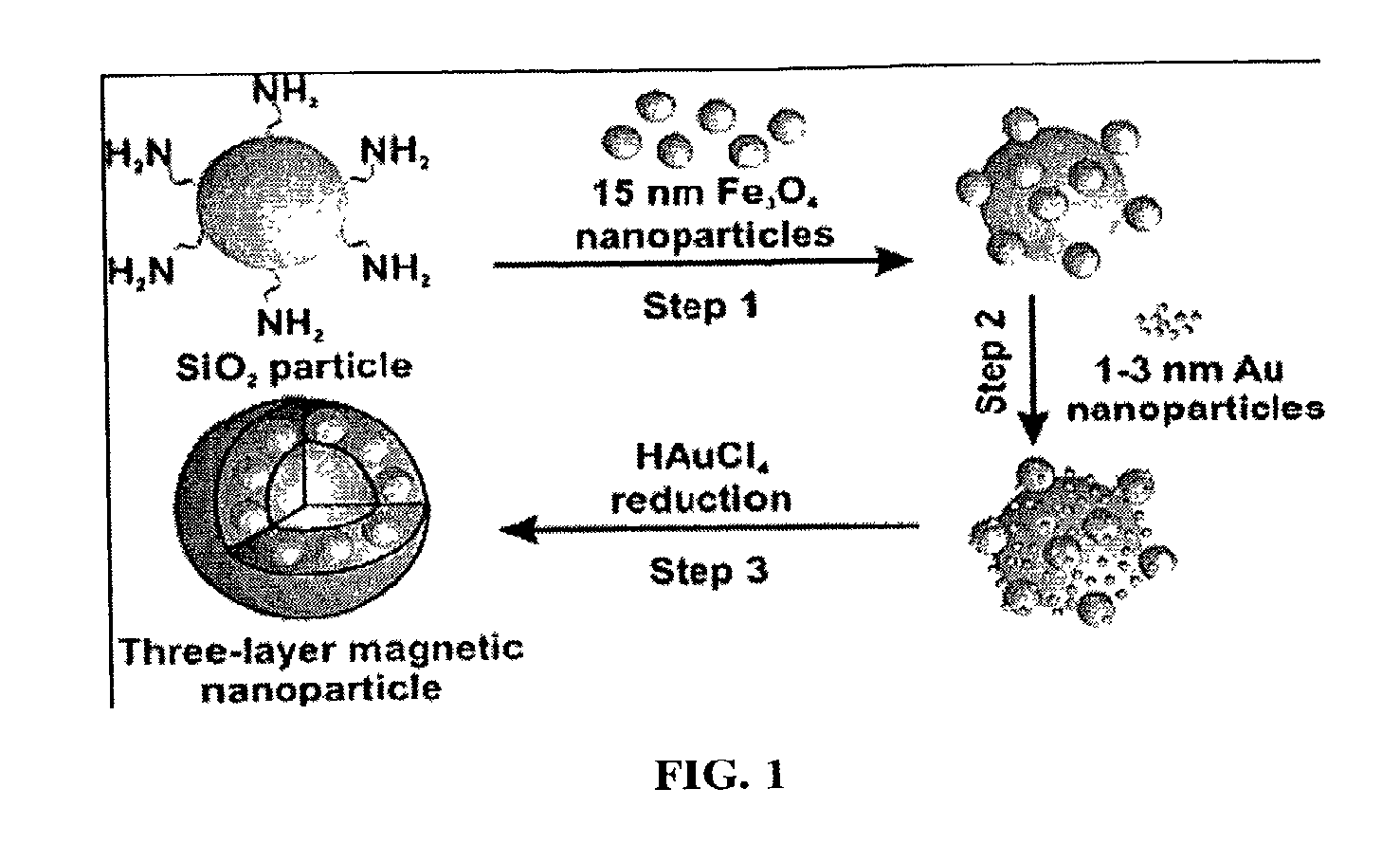

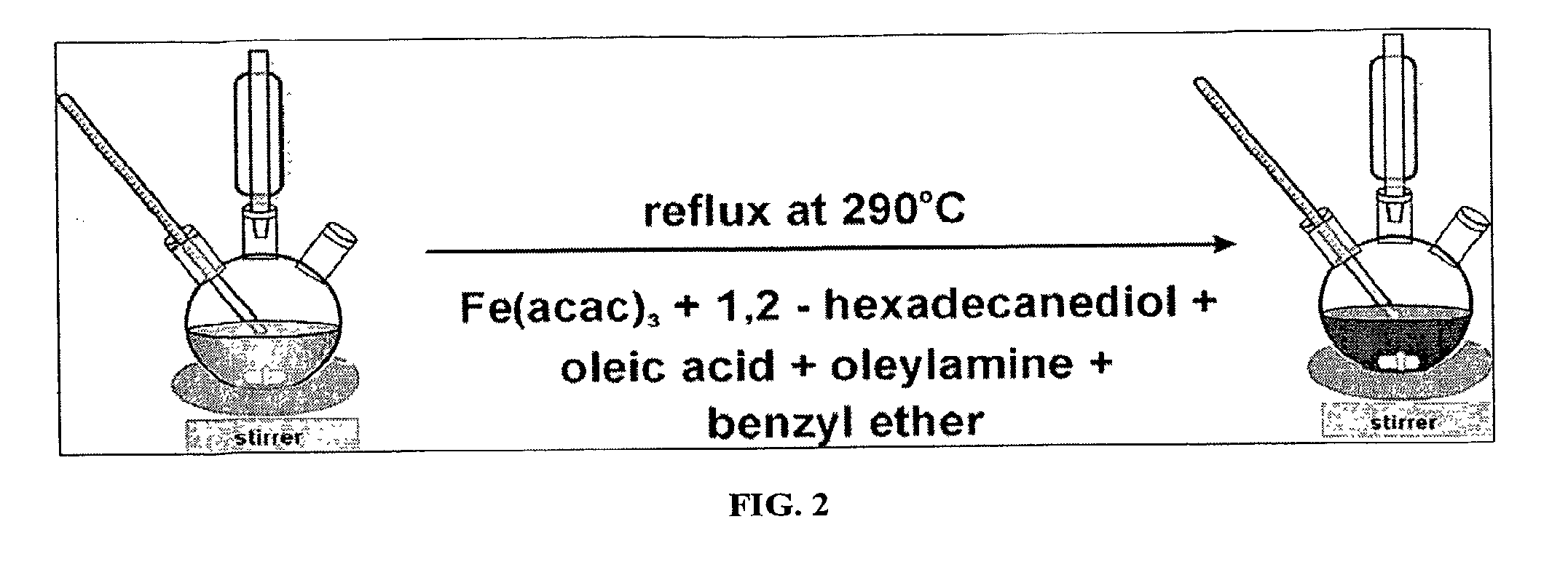

Composite particles

Composite particles and methods of synthesizing a composite particle are disclosed, in particular, methods of synthesizing a composite particle comprising a dielectric component, a magnetic component, and a gold shell are disclosed. Further disclosed herein are methods of detecting a target compound using the composite particles of the present invention. Also disclosed are photonic crystals that can be manipulated with an external magnetic field comprising the composite particles of the present invention.

Owner:NORTHWESTERN UNIV

Spiral LED filament and light bulb using spiral LED filament

ActiveUS10066791B2Simple manufacturing processImprove light distribution designElectric circuit arrangementsSolid-state devicesEngineeringElectrical connector

A spiral LED packaging filament comprises a substrate, a plurality of LED chips disposed on the top surface of the substrate, a medium layer sealing the plurality of LED chips and the top surfaces of the substrate into a sealed LED package; two electrode wires being electric connected to the plurality of LED chips, wherein the sealed LED package has a spiral shape. A light bulb with the spiral LED packaging filament comprises a bulb shell; a stem having a supporting pole, an electrical wire and a stem exhaust pipe, at least one spiral LED packaging filament is fixed on the stem; the electrode wire is connected to the electrical connector via the drive; and the bulb shell and the stem are respectively sealed.

Owner:GENERAL ELECTRIC SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com