Method for manufacturing a reinforced shell for forming component parts for aircraft and shell for component parts for aircraft

一种航空器、壳体的技术,应用在制造用于形成航空器用部件的增强壳体以及用于航空器用部件的壳体领域,能够解决不能保证等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

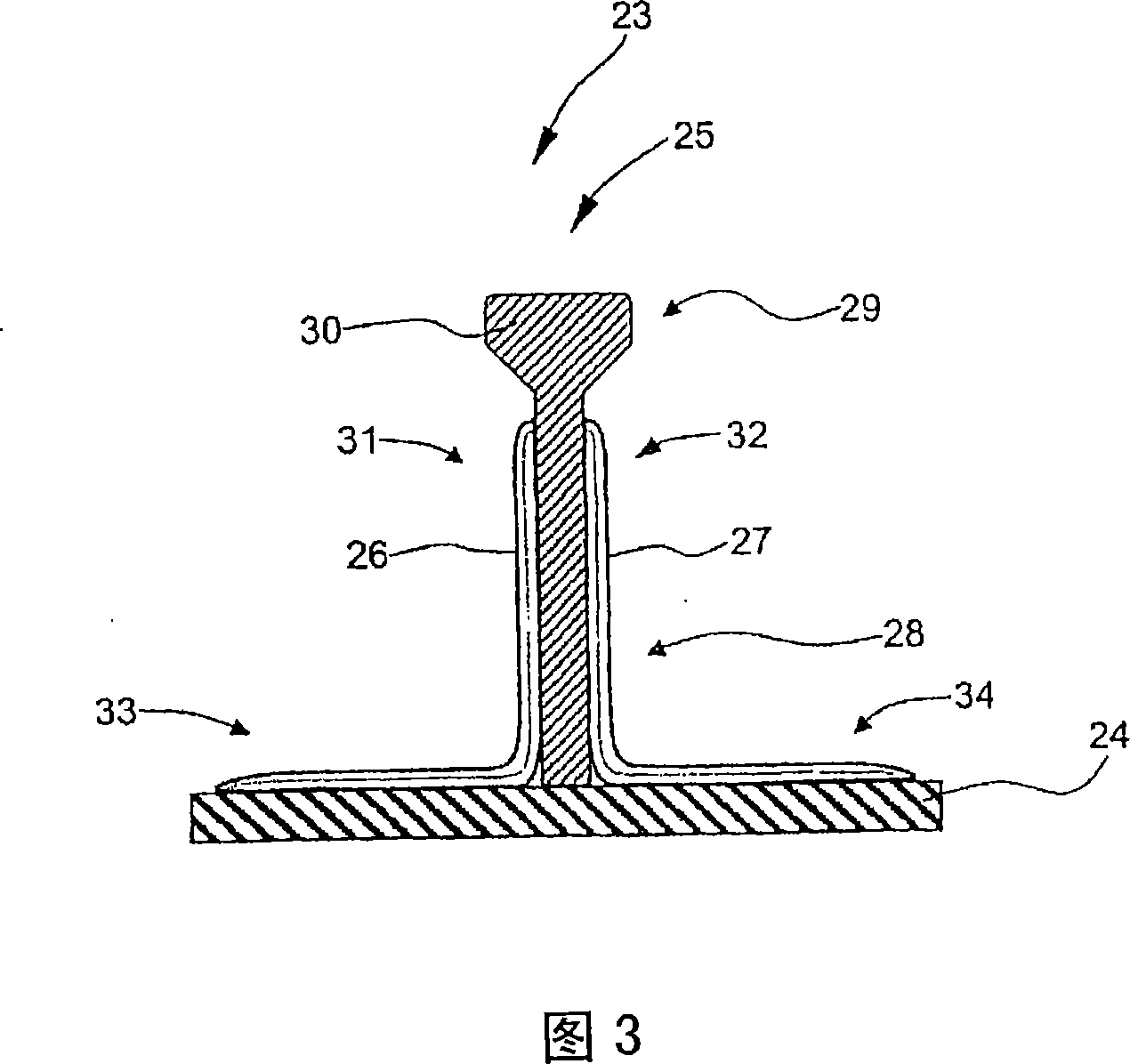

[0027] 1 to 3, the following is an explanation of the inventive method and the inventive housing.

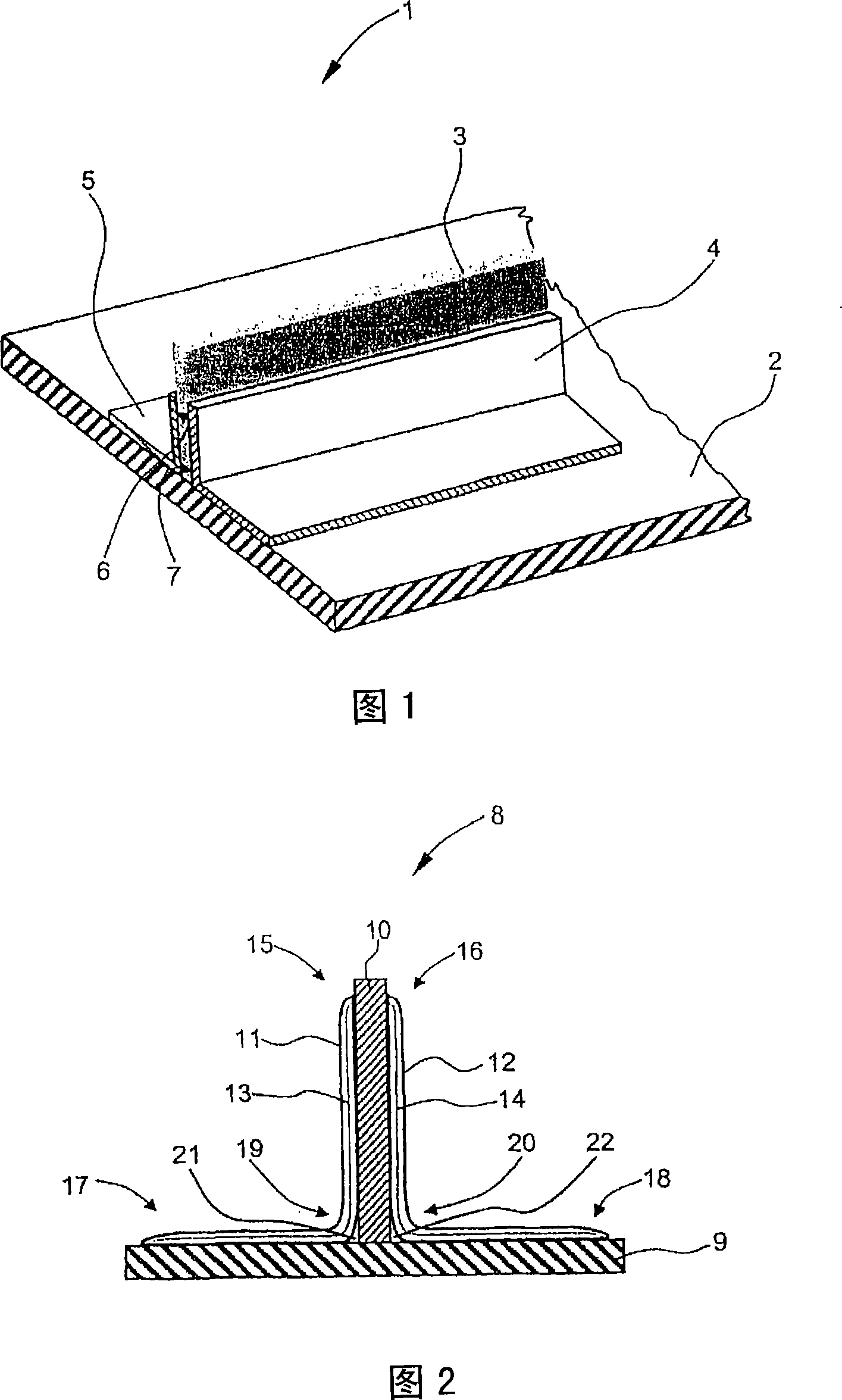

[0028] Figure 1 shows a partial perspective view of a housing to which reinforcing elements have been attached, according to a first embodiment of the method of the invention.

[0029] The housing 1 comprises a housing skin 2 , a reinforcing element 3 , and connecting elements 4 and 5 . As shown in Table 1, the reinforcing element 3 has a substantially rectangular cross-section. However, the reinforcing element 3 can also have other cross-sectional shapes. The connection elements 4 and 5 are connection corner pieces with a substantially L-shaped cross-section. The shell skin 2, the reinforcing elements 3 and the connecting elements 4 and 5 are produced from a plurality of semi-finished parts in the form of curable prepregs. Prepregs are carbon fiber reinforced sheet-like components impregnated or impregnated with curable epoxy resin. In their uncured state, virtually arbitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com