Patents

Literature

2225results about How to "Guaranteed sealing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

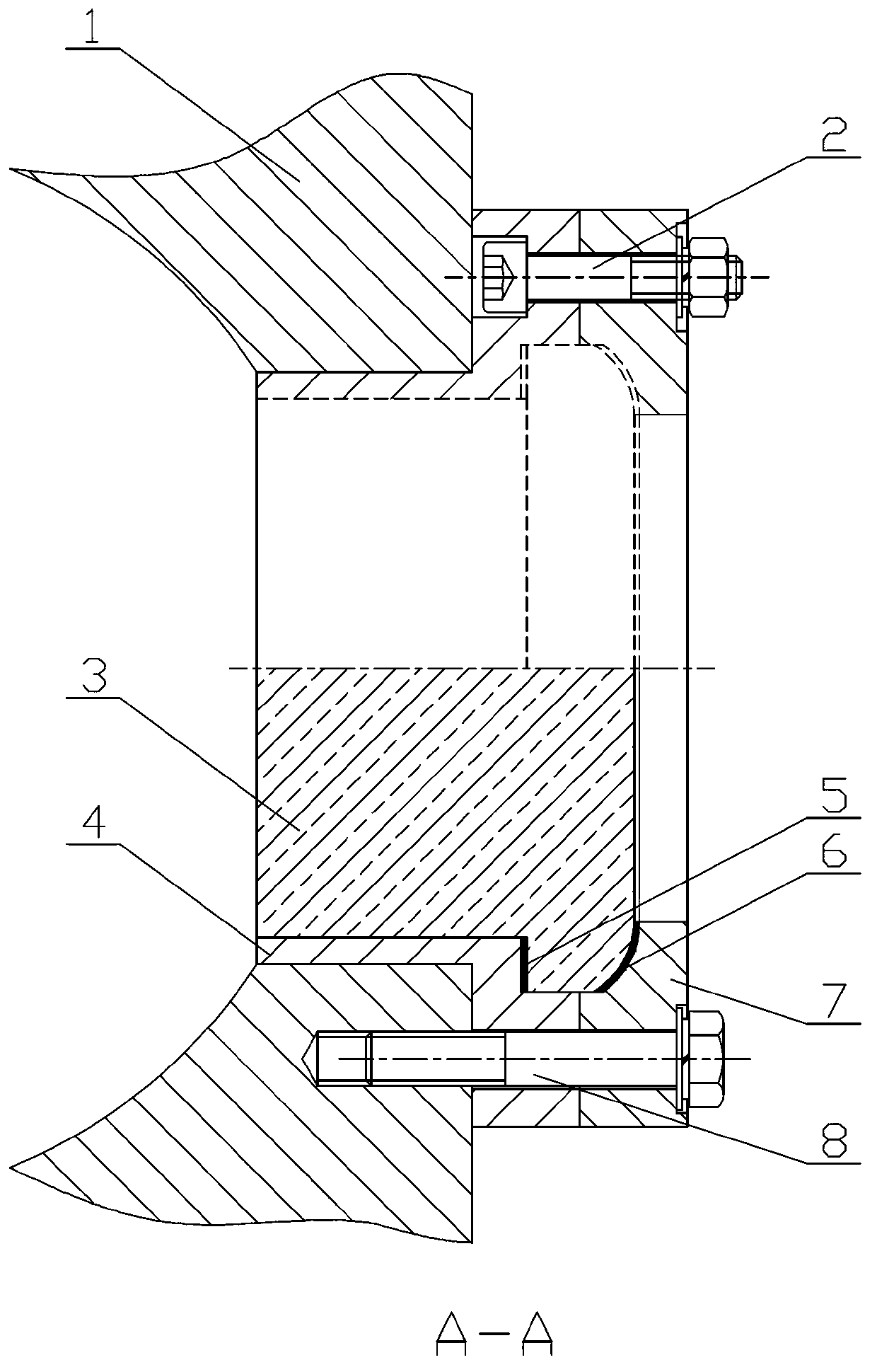

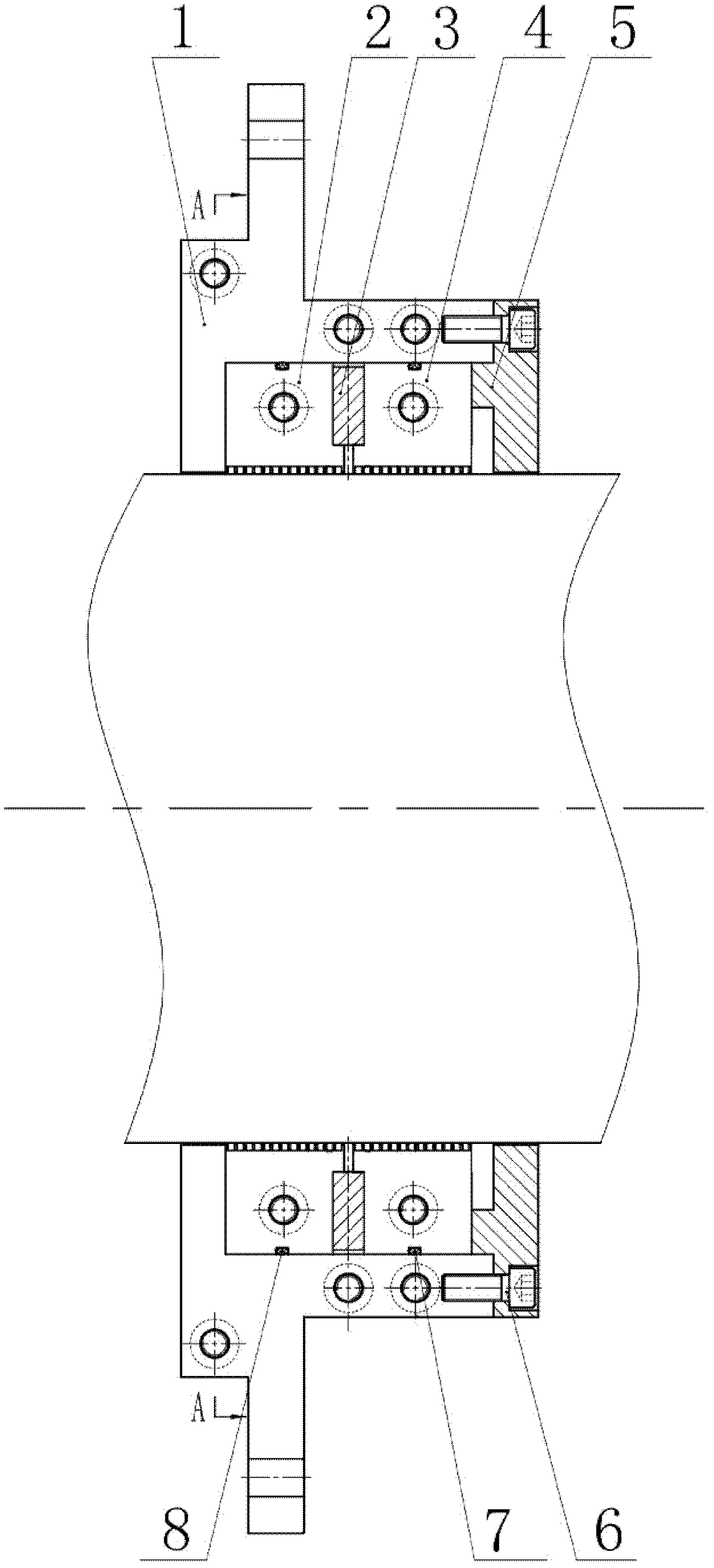

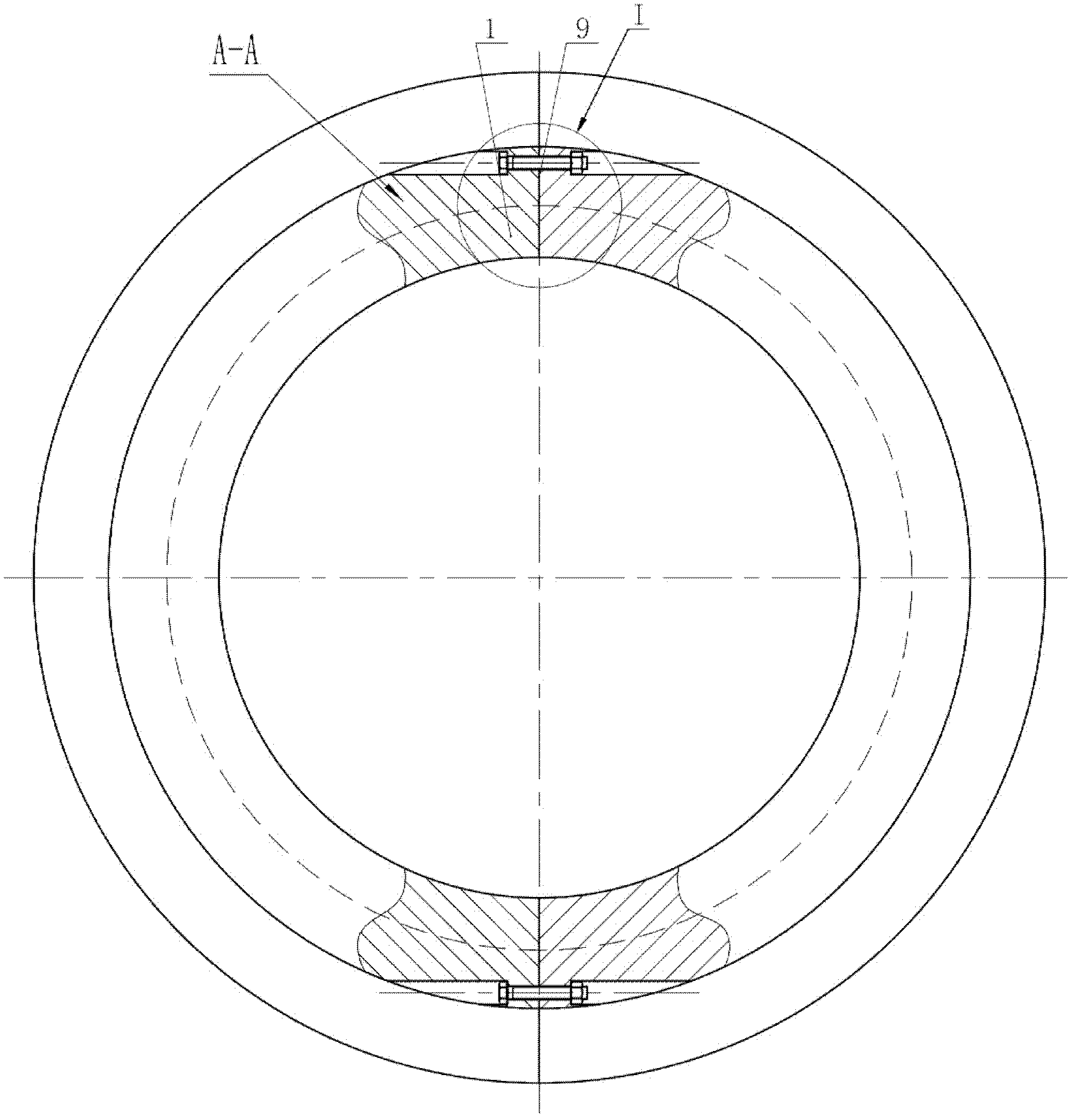

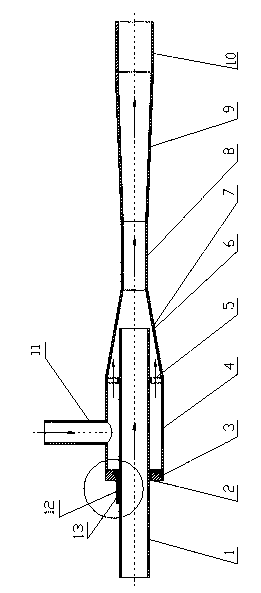

Continuous oil pipe hanger for velocity tubular column

ActiveCN104358536AGuaranteed sealing performanceFix the leakBorehole/well accessoriesCoiled tubingEngineering

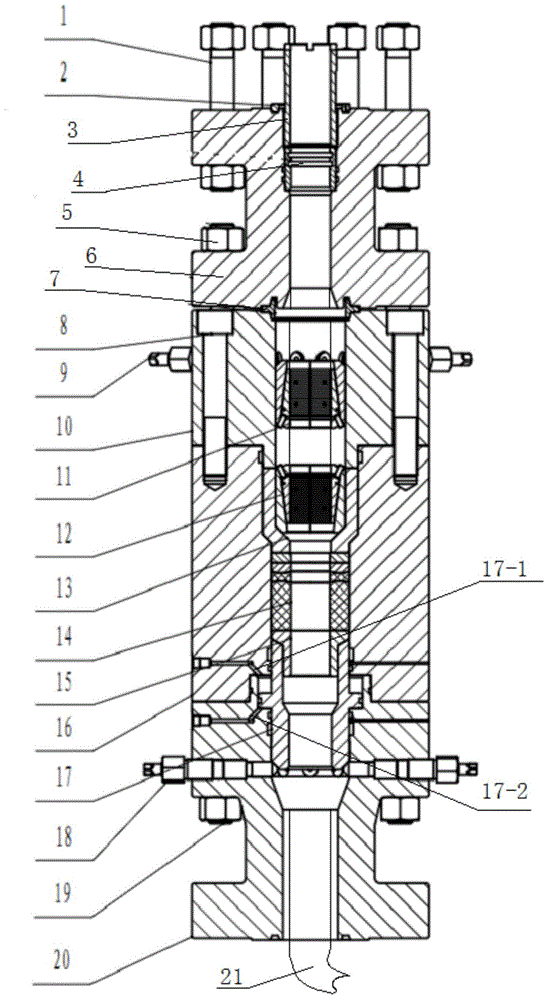

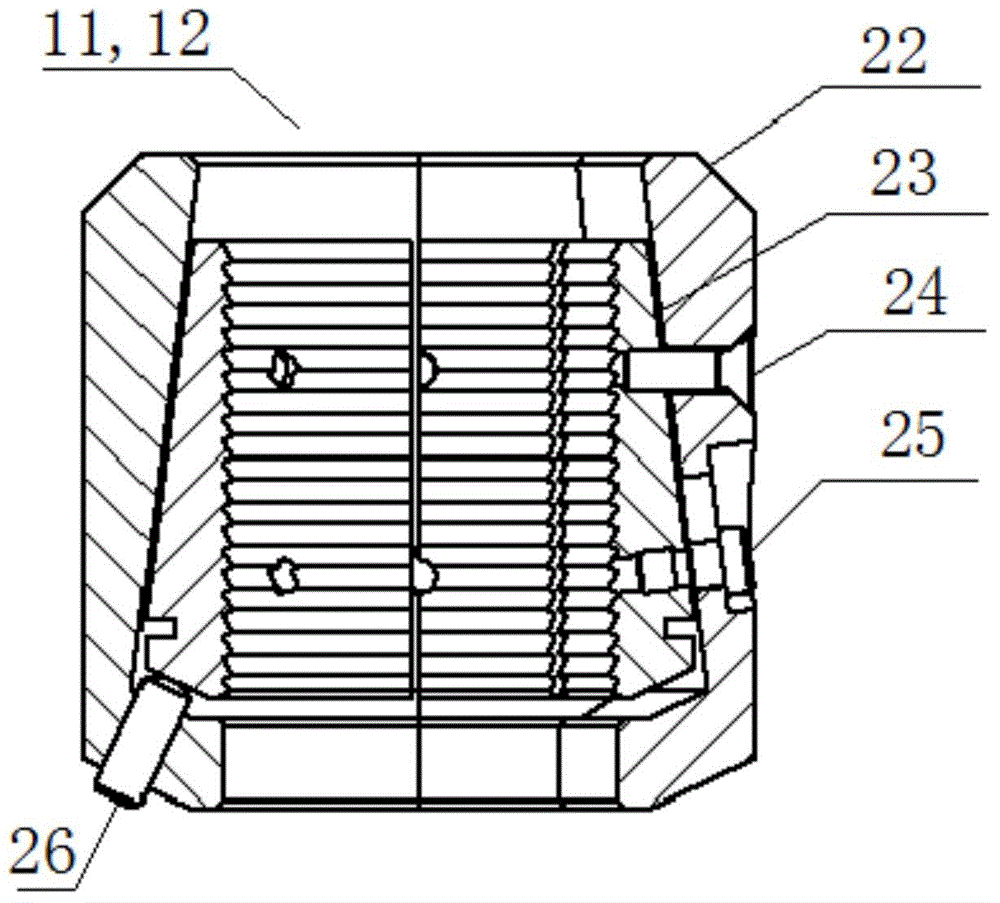

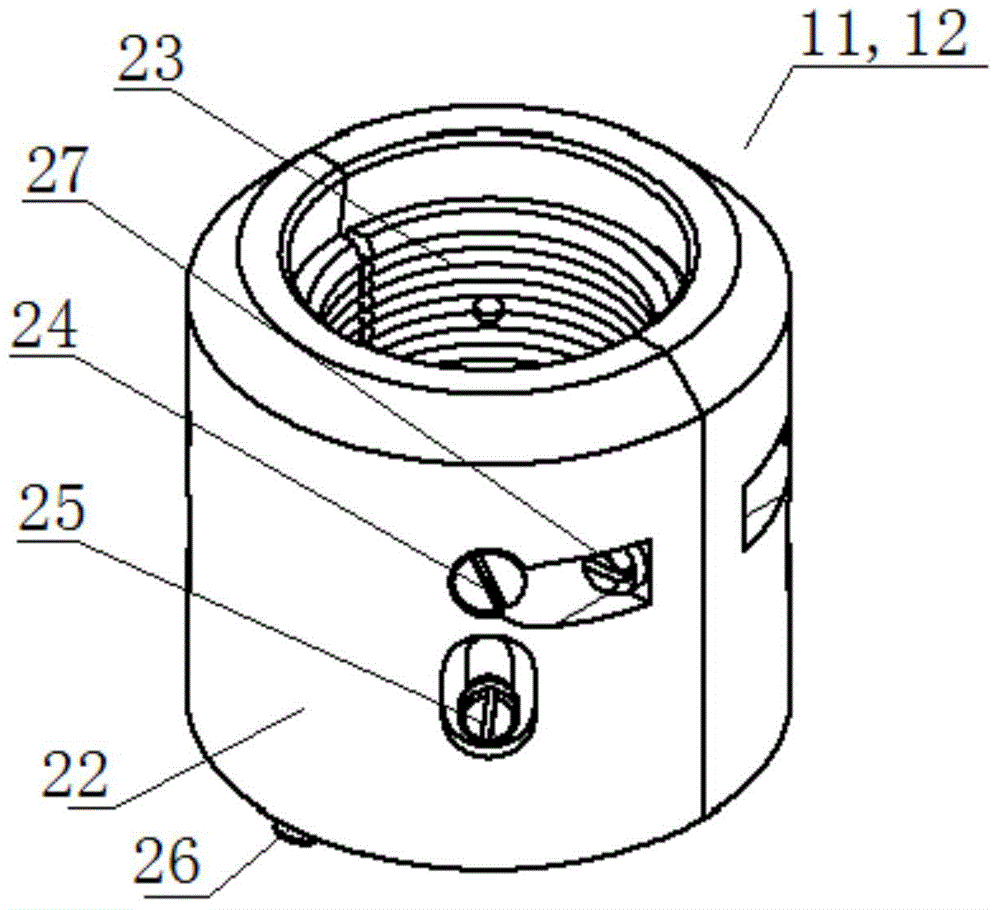

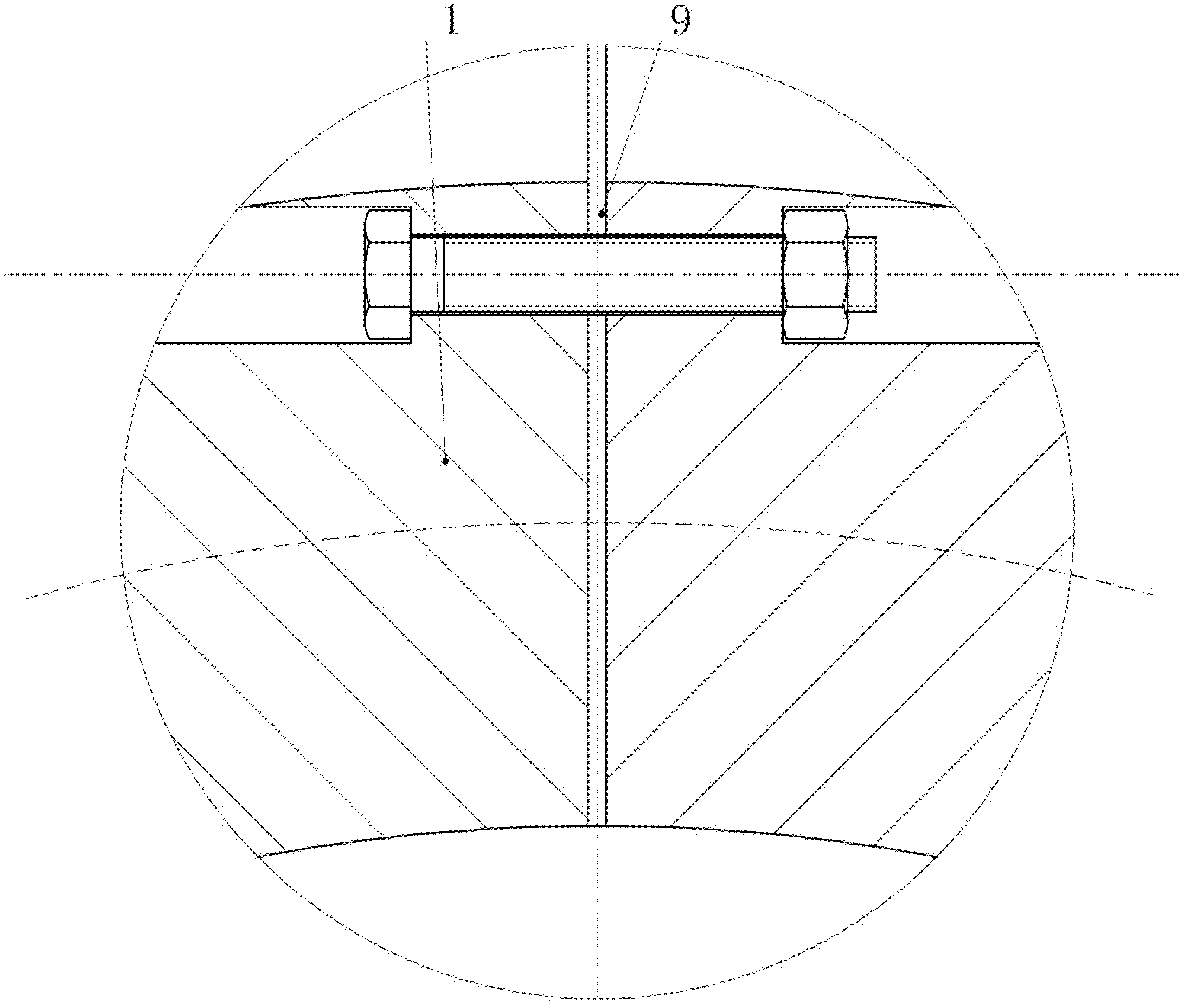

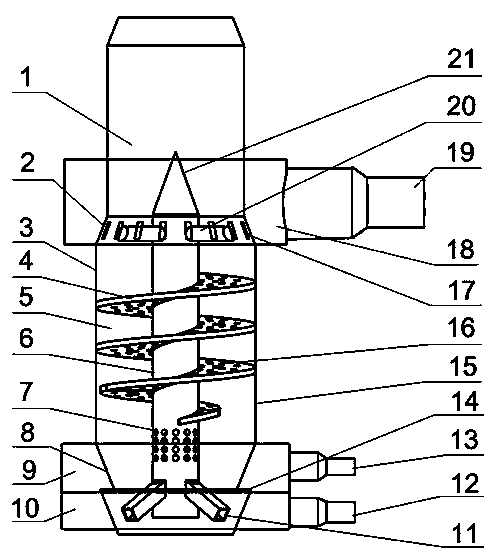

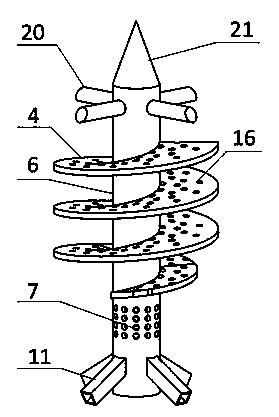

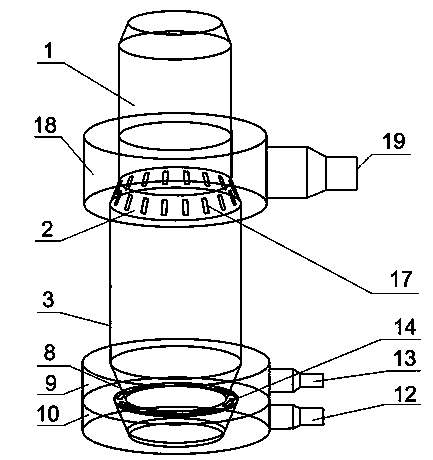

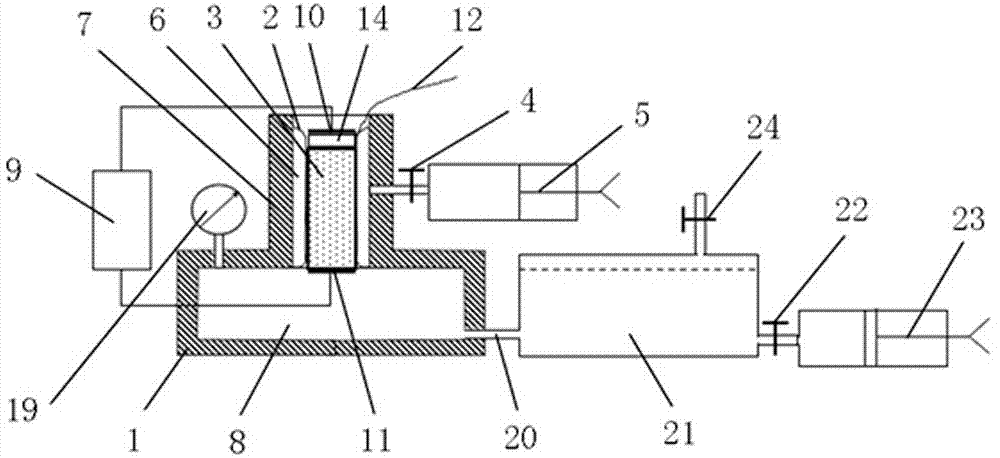

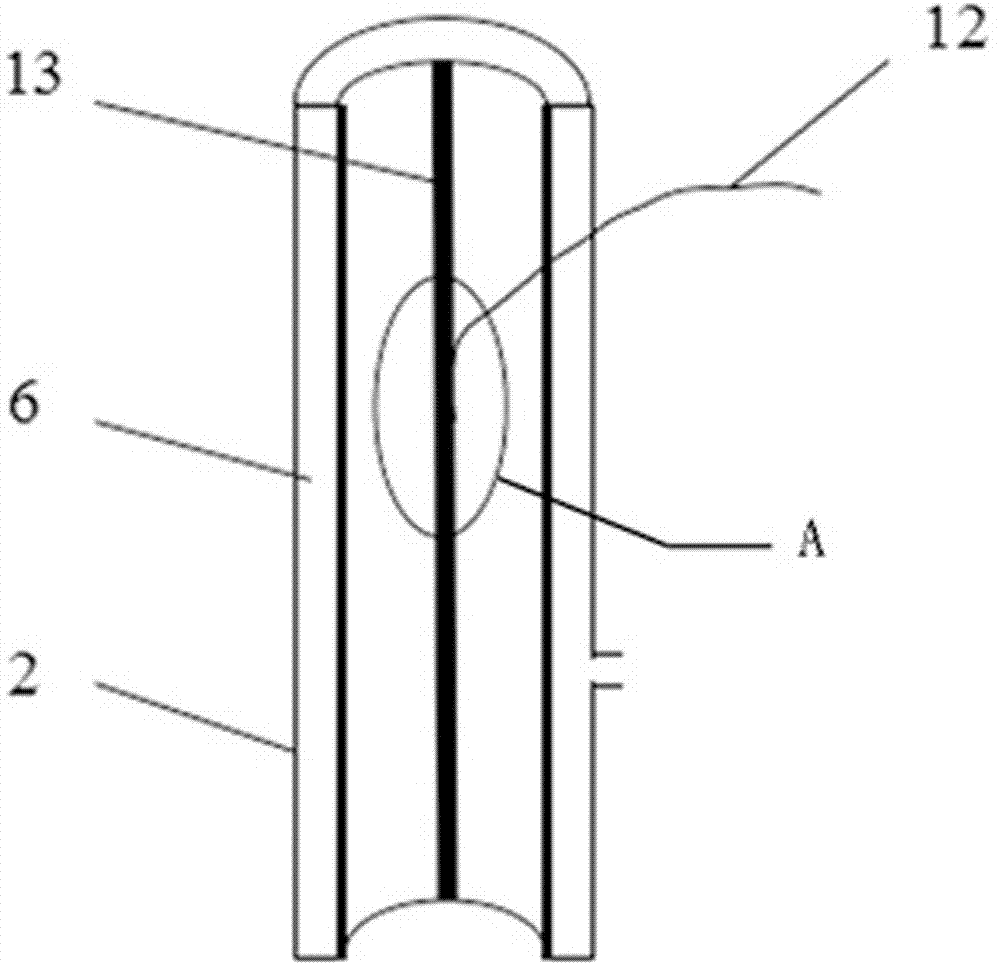

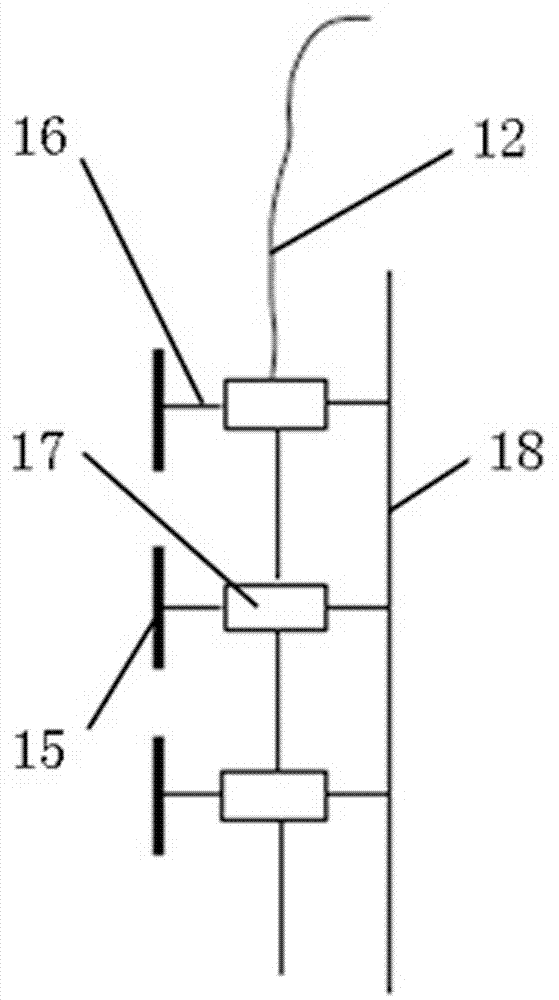

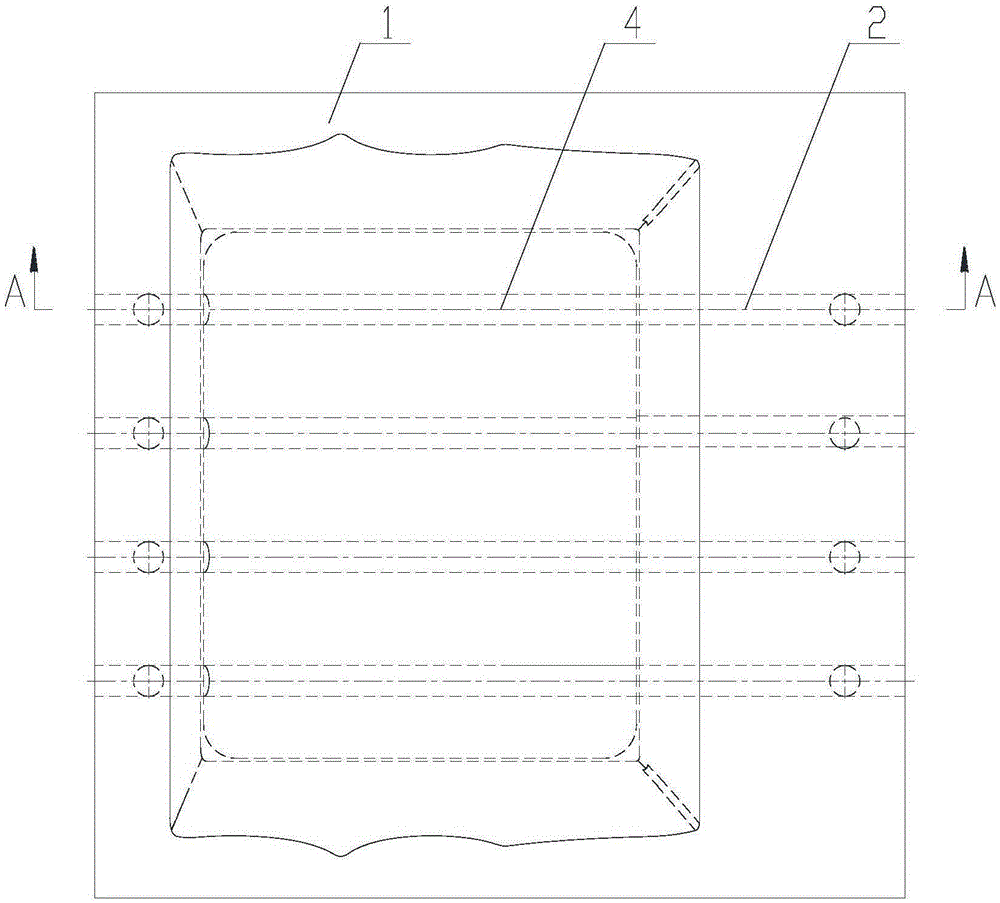

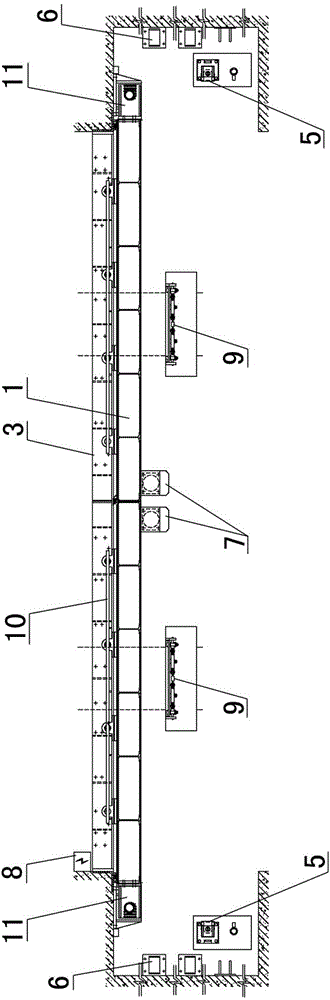

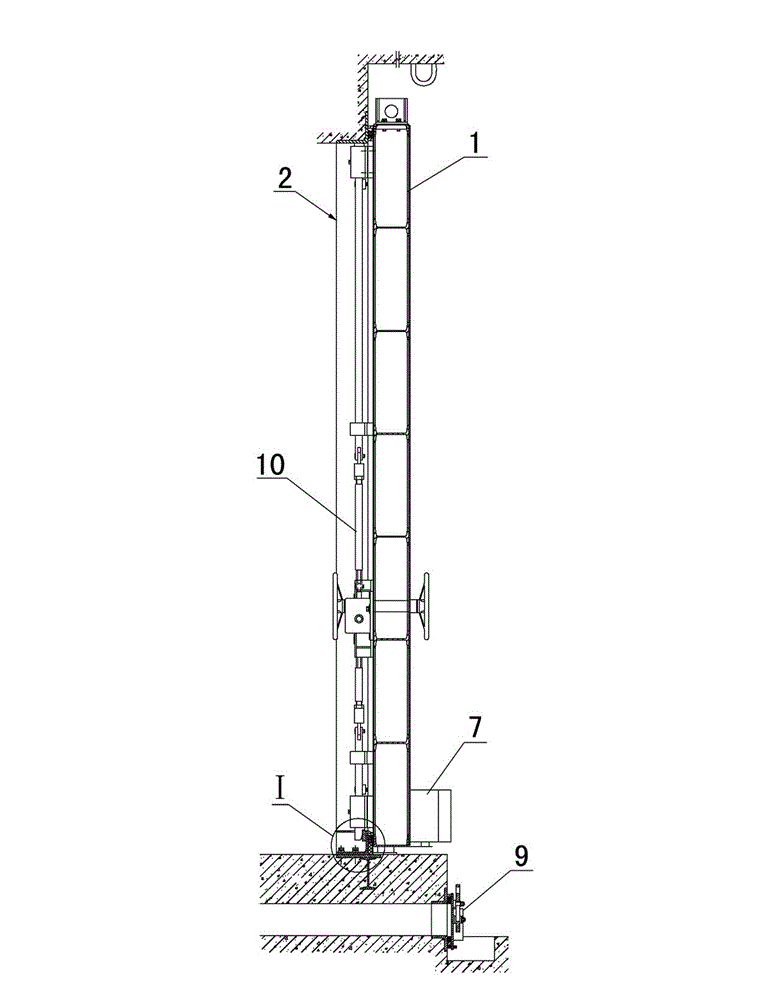

The invention relates to a continuous oil pipe hanger for a velocity tubular column. The continuous oil pipe hanger comprises a continuous oil pipe, an I-shaped flange, an upper slip assembly, a lower slip assembly, an upper shell, a middle shell and a lower shell, wherein vertically penetrating central holes are formed in the upper shell, the middle shell and the lower shell; the I-shaped flange is fixedly arranged at the top of the upper shell; the continuous oil pipe passes through the I-shaped flange and the central holes of the upper shell, the middle shell and the lower shell in turn; the upper slip assembly is clamped on an inner wall of the central hole of the upper shell; the lower slip assembly is located in the central hole of the middle shell; a connecting pipe sealing set is fixedly arranged on an inner wall of the central hole of the middle shell and the lower side of a hanging supporting sleeve; at least one pair of driving pistons is arranged on the inner walls of the central holes of the middle shell and the lower shell and under the connecting pipe sealing set; an upper oil port and a lower oil port respectively communicated with the driving pistons are arranged on the side walls of the middle shell and the lower shell. The continuous oil pipe hanger has the beneficial effect of capability of hanging the continuous oil pipe.

Owner:JEREH ENERGY SERVICES

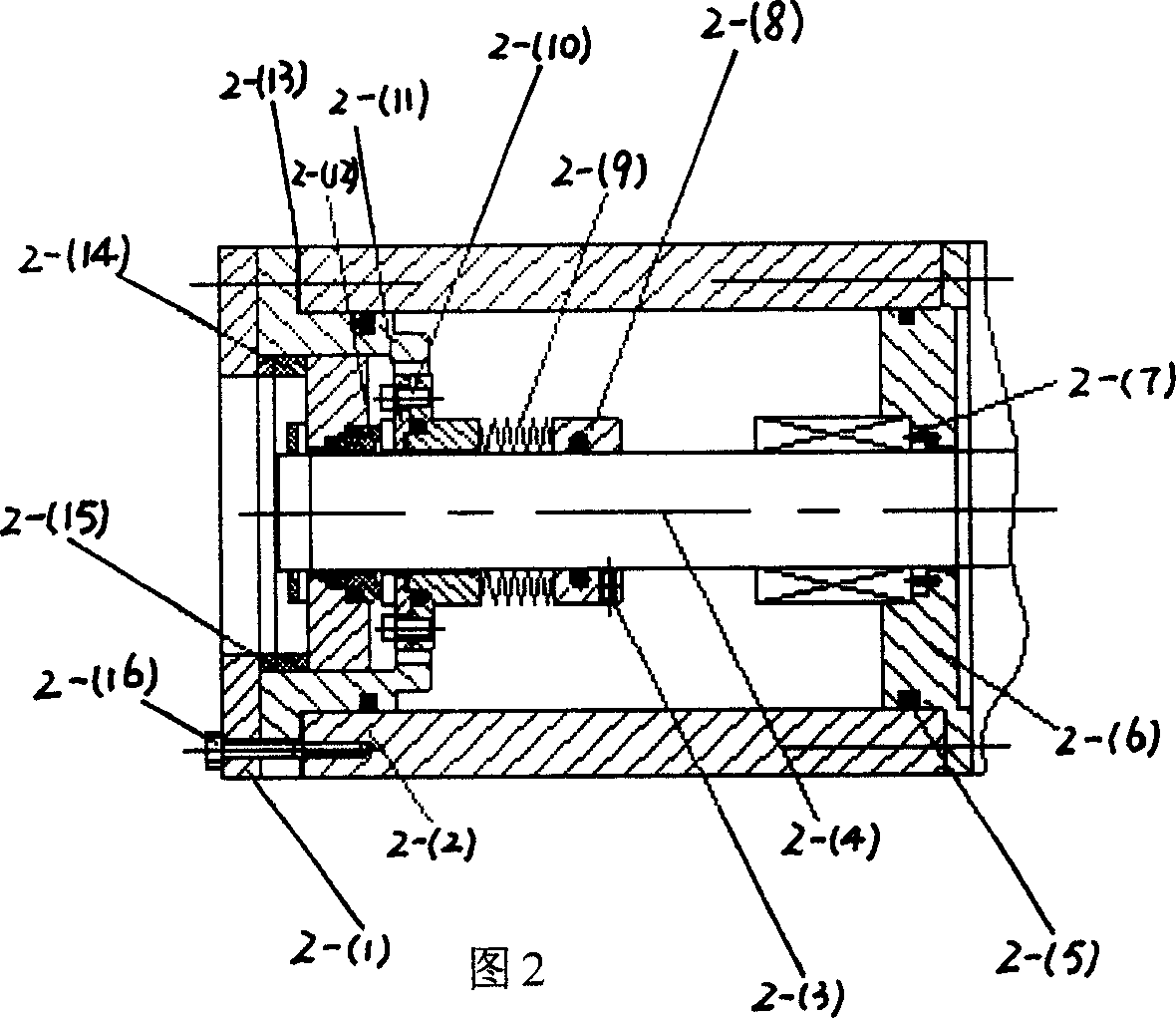

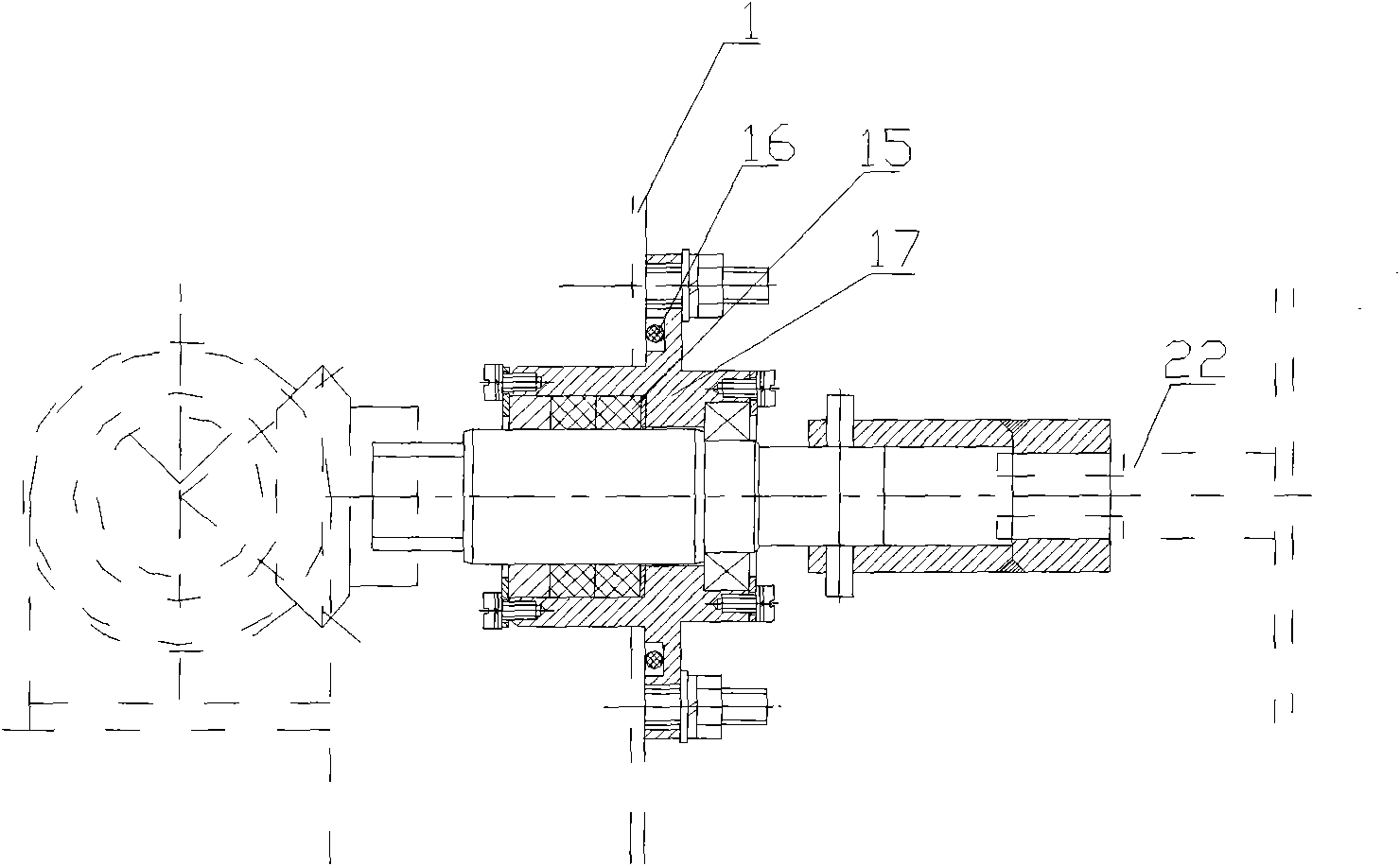

Multi-parameter controllable high-rotating speed mechanical sealing performance tester

InactiveCN1825083AEasy to controlReduce stressMachine part testingHydrodynamic testingControl systemData acquisition

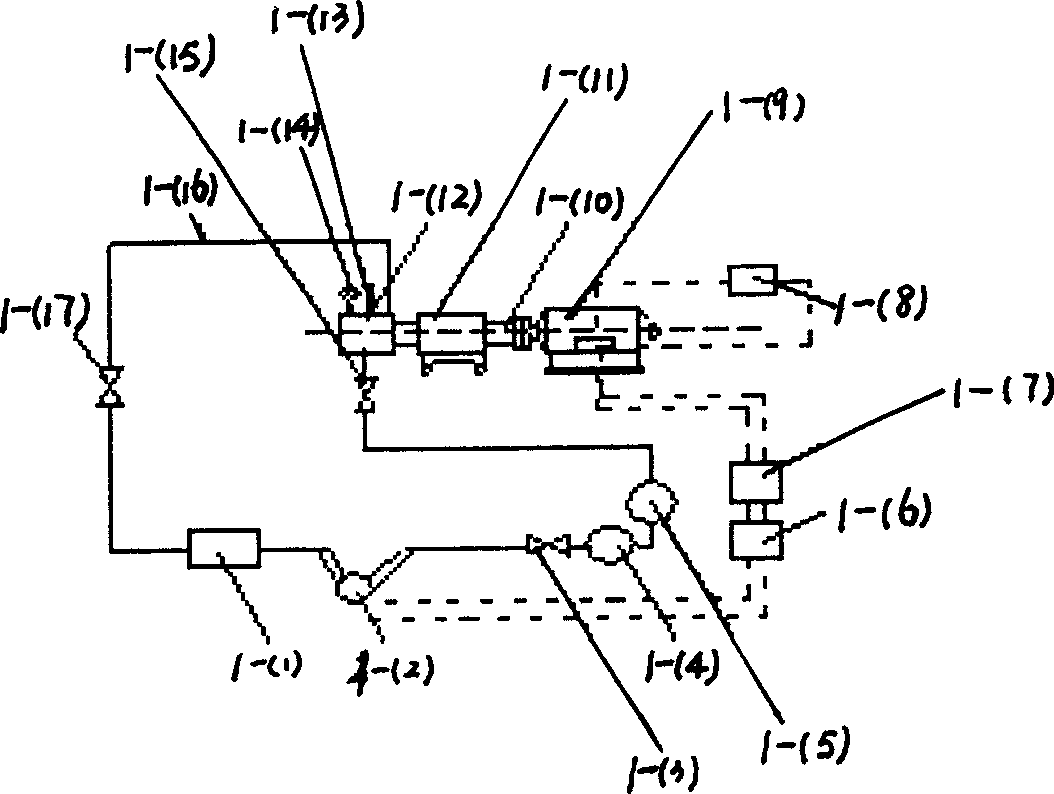

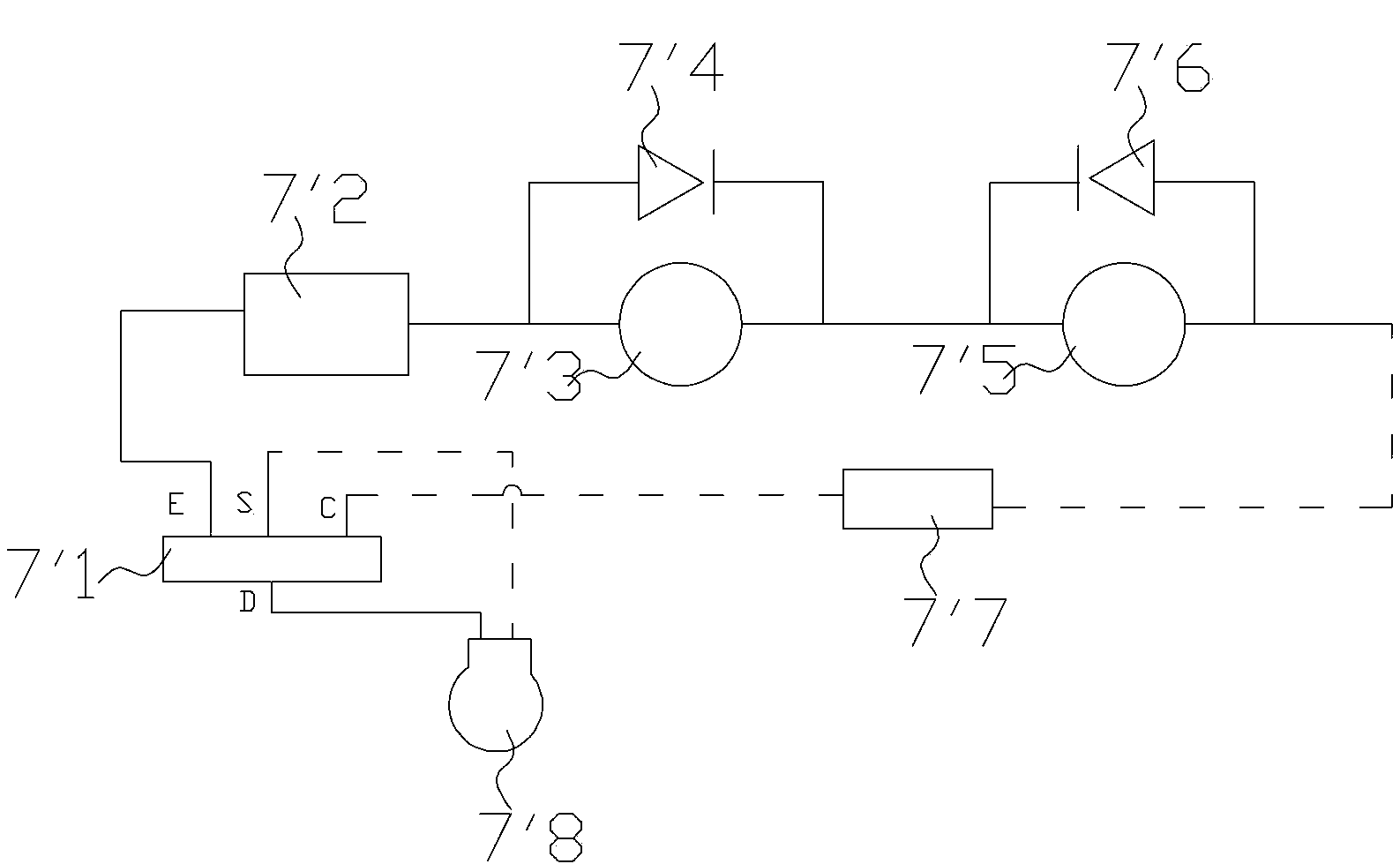

The invention relates to a mechanism sealing controllable testing device that includes sealing system, driving system, end face specific pressure loading and servo feed back system, end face attrition torque and end face specific pressure testing system, film thickness testing system, leakage testing system, static loop temperature feedback system, medium temperature and pressure measuring system, experiment medium pressurizing recycling system, data collection and control system. The invention has wide application range, and would be researched under different conditions.

Owner:NANJING COLLEGE OF CHEM TECH

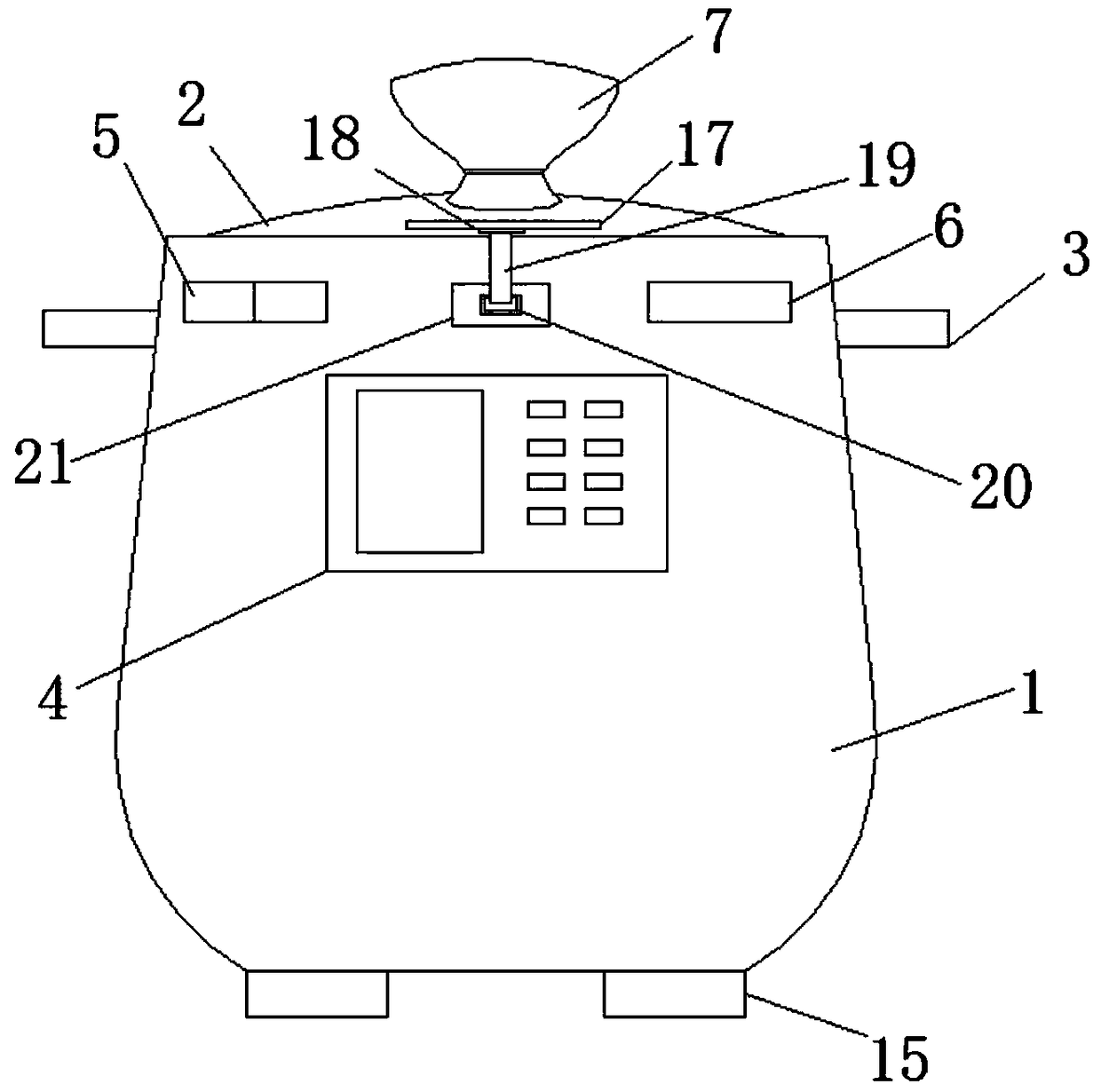

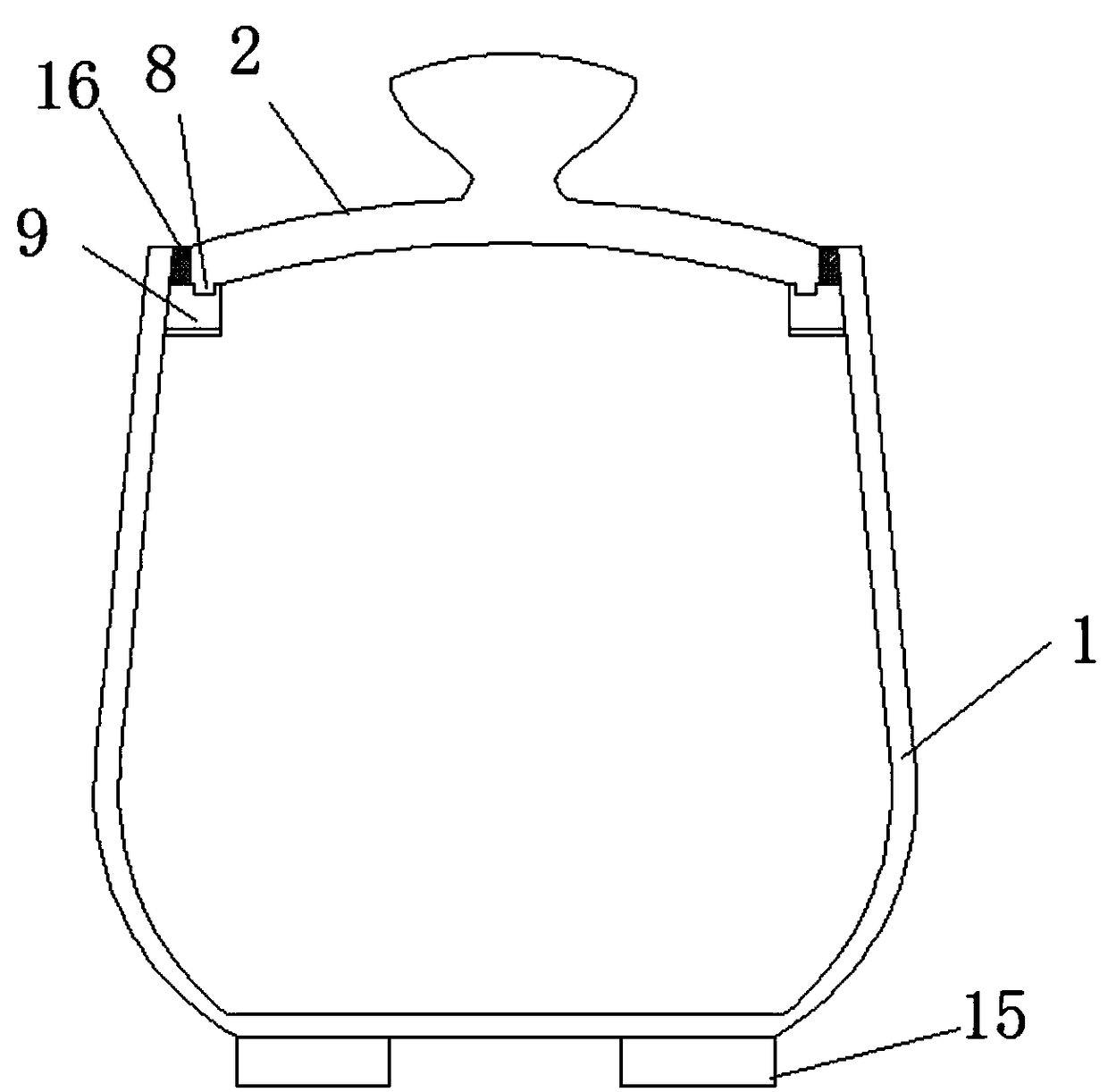

Electric pressure cooker with cover closing detector

The invention discloses an electric pressure cooker with a cover closing detector. The electric pressure cooker comprises a pressure cooker body and a pressure cooker cover; the pressure cooker coveris arranged in the top of the pressure cooker body, handle rods are arranged symmetrically in the left and right sides of the pressure cooker body and fixedly connected to the pressure cooker body, the front side of the pressure cooker body is provided with a control panel, an indicating lamp is arranged in the left upper portion of the control panel, and a warning loudspeaker is arranged in a right upper portion of the control panel; and the top of the pressure cooker cover is provided with a fixed protruded column, the fixed protruded column is fixedly connected with the pressure cooker cover, the bottom edge of the pressure cooker cover is provided with touch protruded columns, and cover closing detection assemblies are arranged below the touch protruded columns respectively. The coverclosing detection assemblies are additionally arranged in the pressure cooker body, and the pressure cooker cover is provided with the corresponding touch protruded columns, and in the contact processof the cover closing detection assemblies and the touch protruded columns, whether the cooker is closed is warned and detected; and the electric pressure cooker is simple in the whole structure and strong in functions.

Owner:黄文才

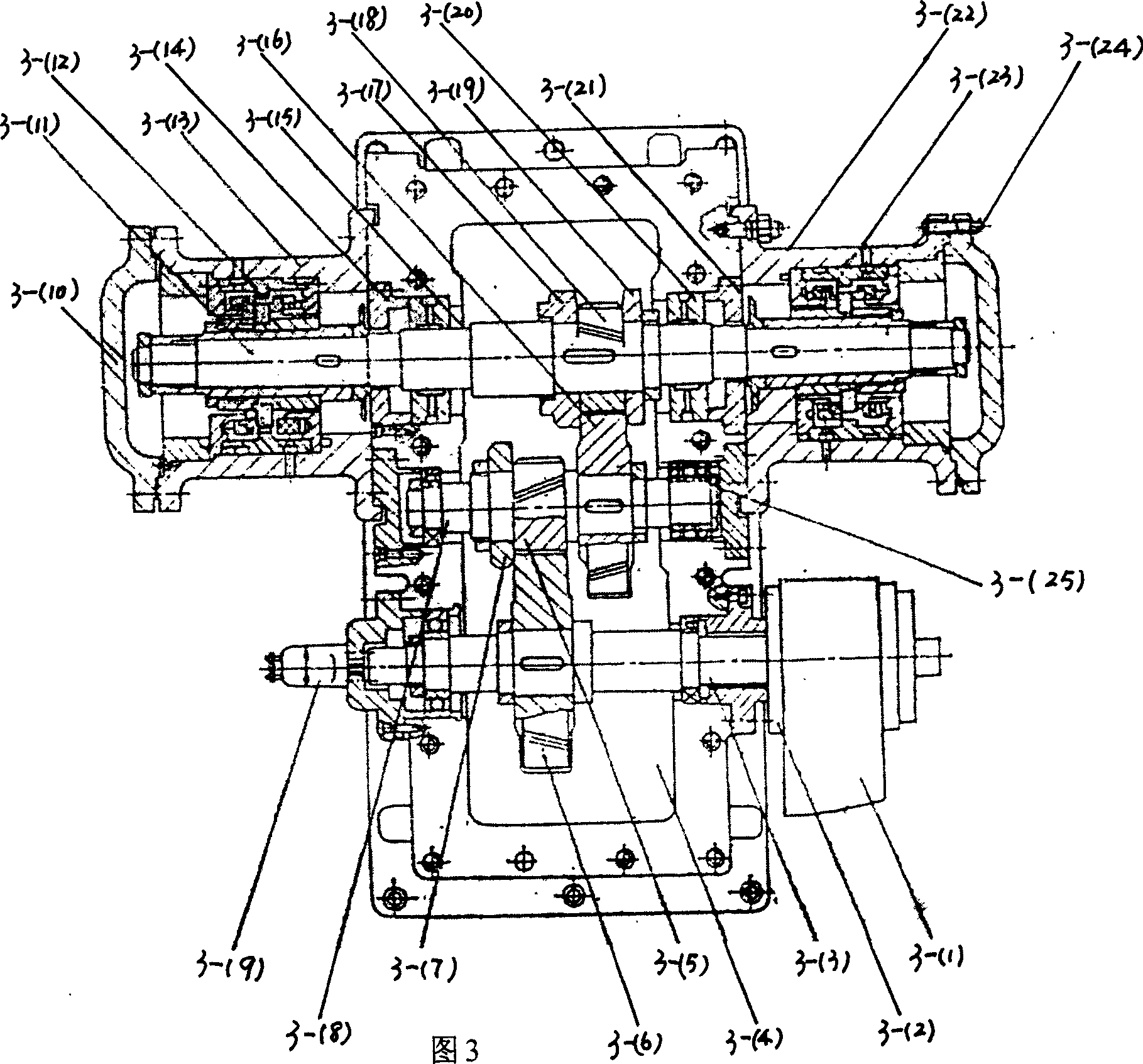

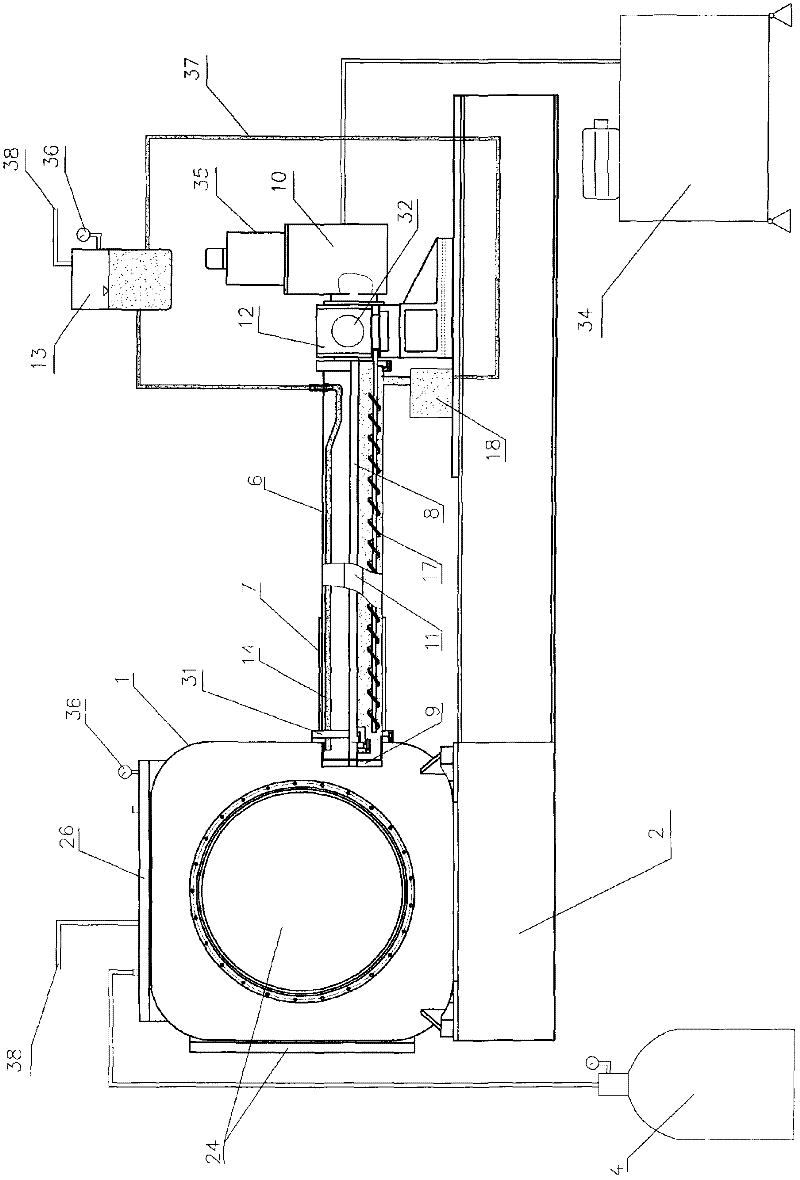

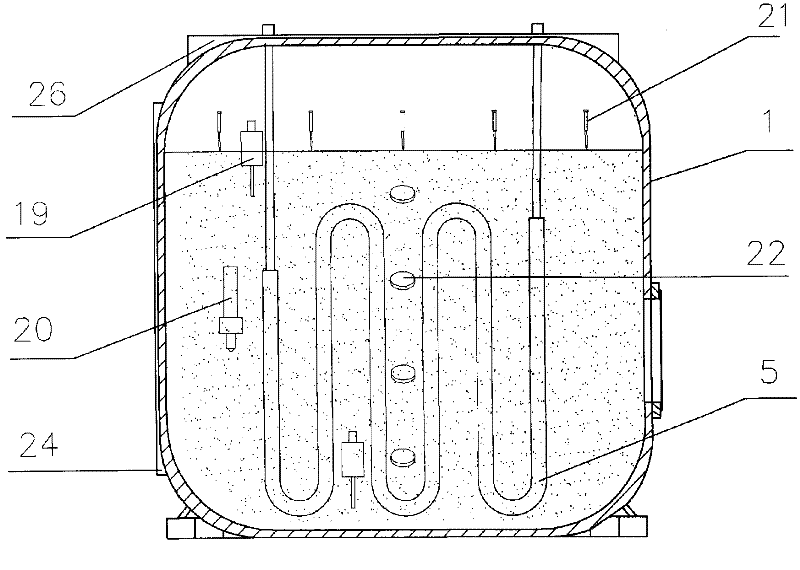

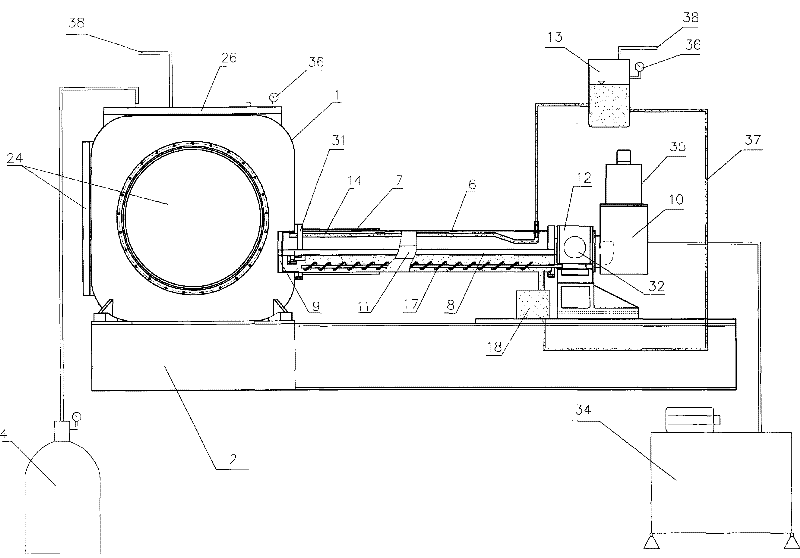

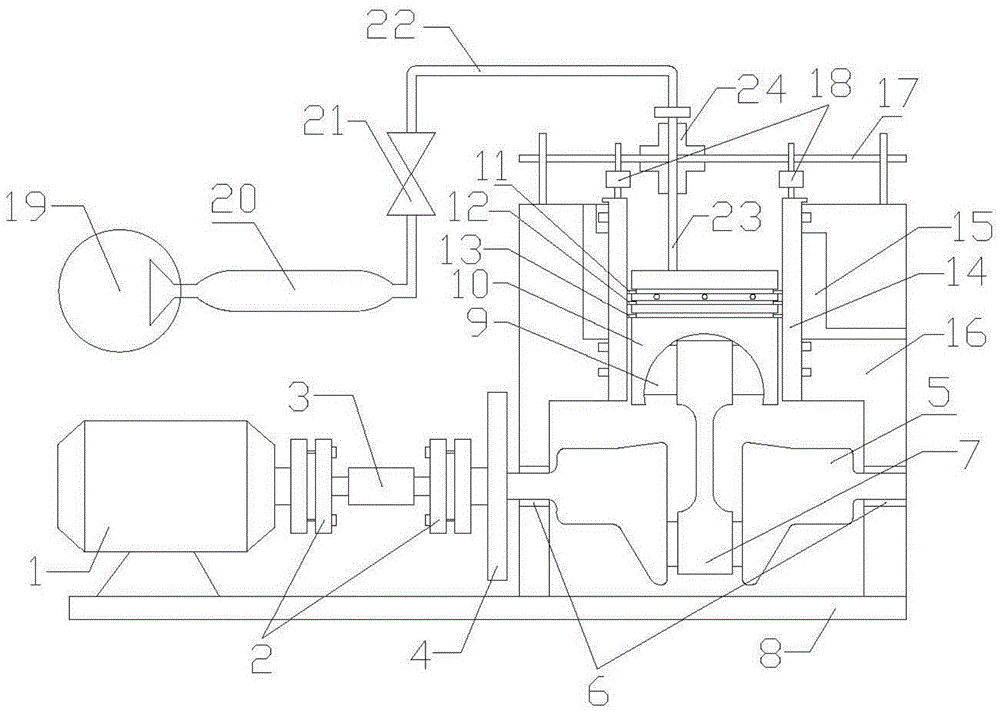

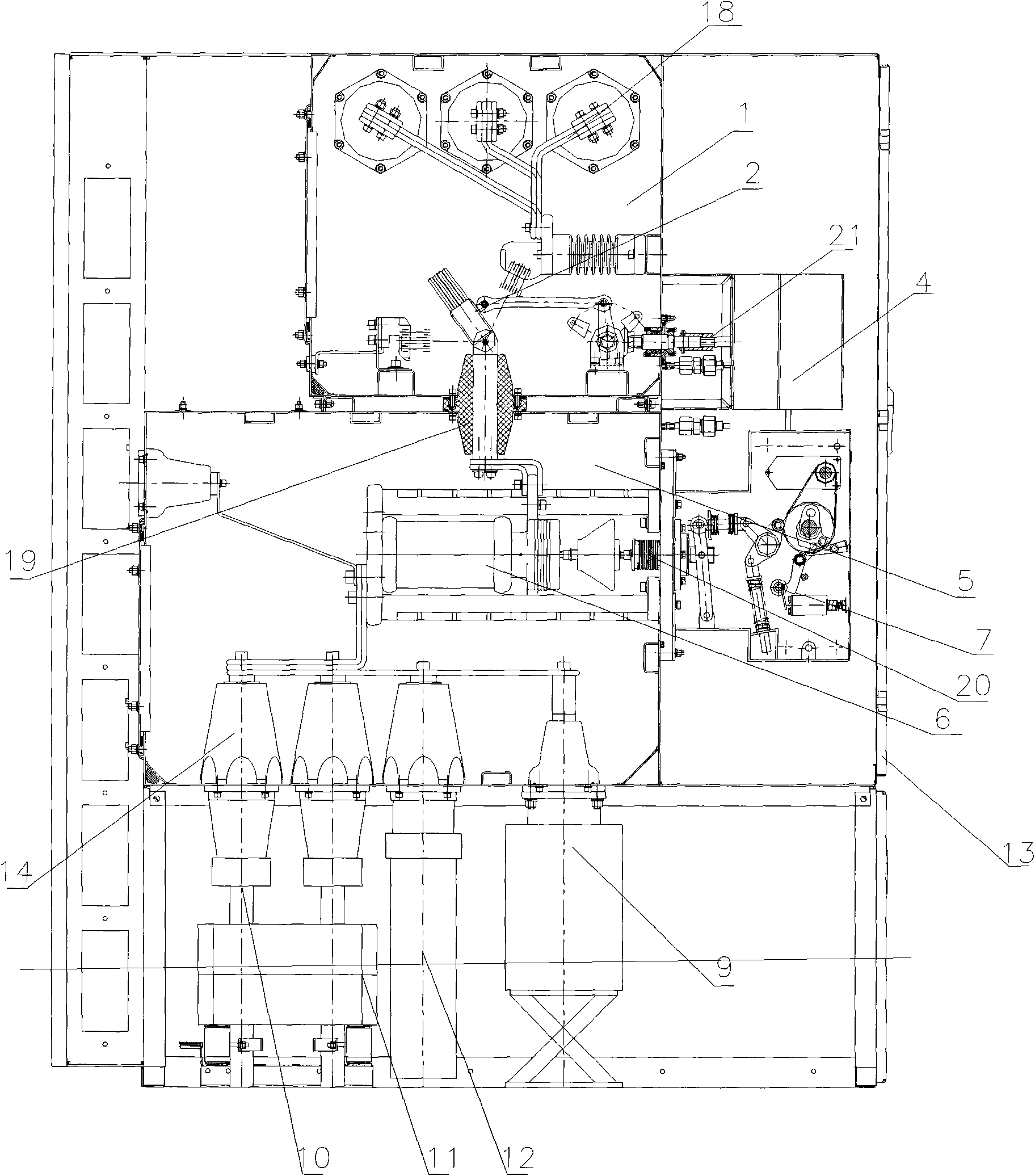

Muddy water balance type shield simulation testing system

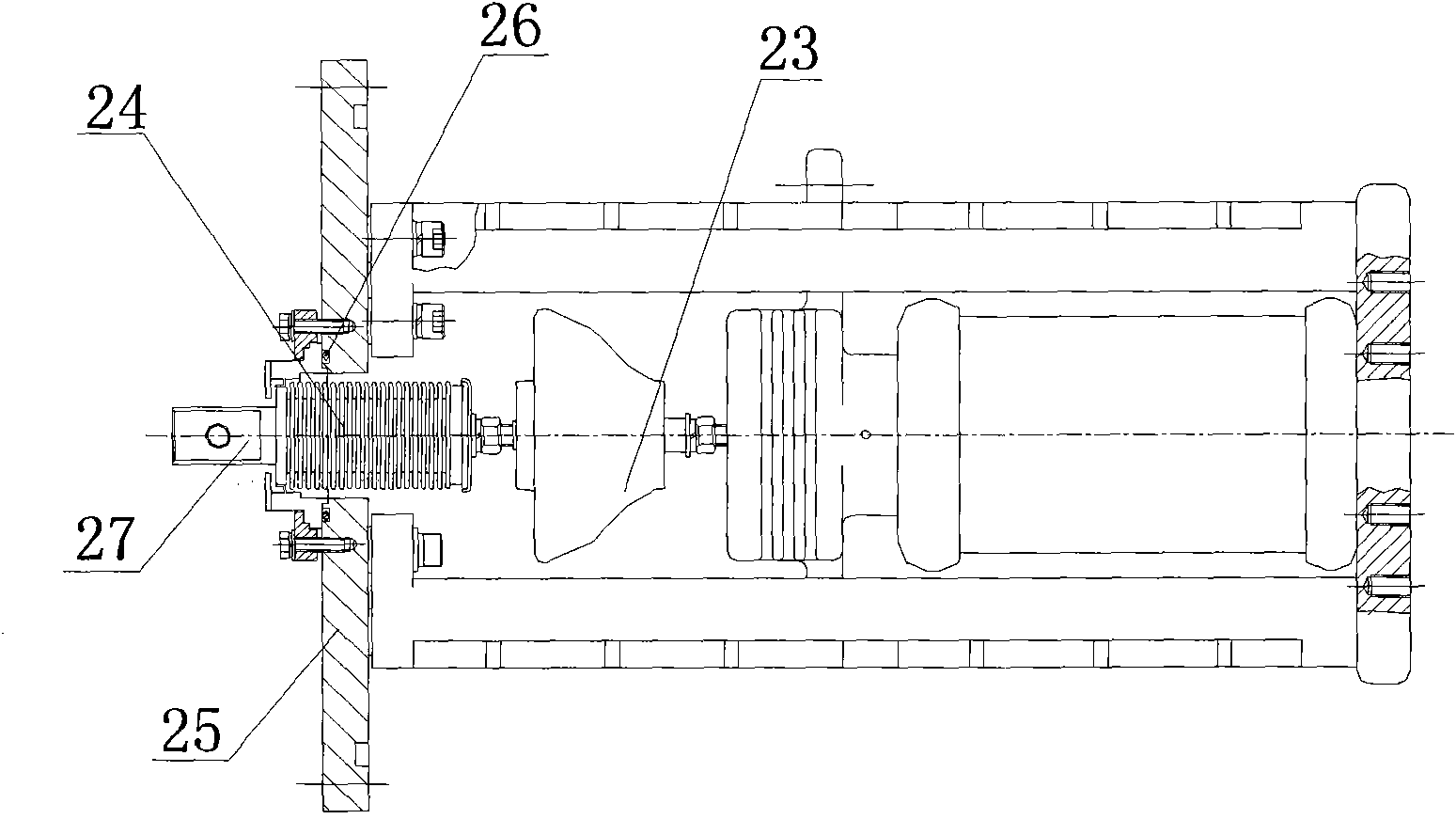

ActiveCN102221474AAppropriate tunneling parametersReliable experimental basisStructural/machines measurementPore water pressureEngineering

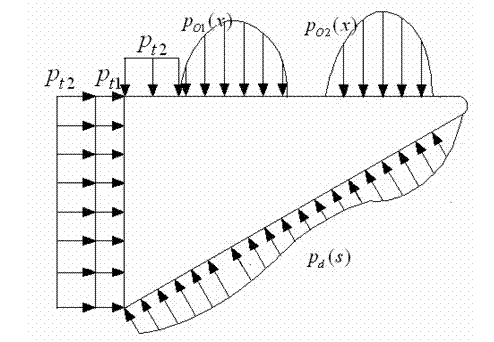

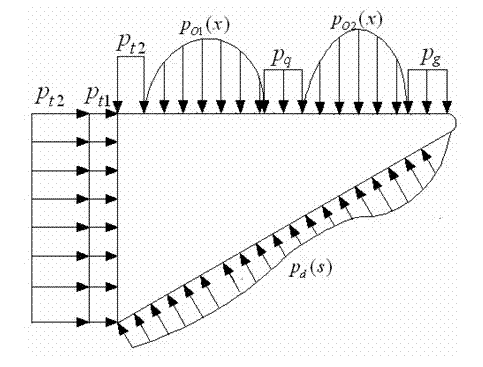

The invention relates to a muddy water balance type shield simulation testing system. In the structure of the system, a model box for holding soil is fixed on a base; a refrigeration freezing device is communicated with a freezing pipe in the model box; the front part of a shield machine enters the model box through a guide sleeve on the side of the model box; a cutter disk at the front part of the shield machine is connected with the output shaft of a gearbox of a hydraulic power system through a main shaft; jacks at the left and right sides of the shield machine are connected between the model box and the gearbox; a space between a partition plate behind the cutter disk of the shield machine and the cutter disk forms a muddy water cabin; and an injection pipe of a muddy water pot, whichis connected with an air pressure boosting device, penetrates into the shield machine from the tail part of the shell of the shield machine. The system provided by the invention can simulate the tunneling process of the muddy water shield machine in a submerged tunnel construction with high water pressure and can synchronously record soil pressure, water pressure, displacement and the tunneling parameters of the shield machine, thereby finding out and analyzing the mechanism and conditions of muddy water pressure balance country rock and providing more reliable experiment basis for submerged tunnel construction and the design of a muddy water shield machine.

Owner:SOUTHWEST JIAOTONG UNIV

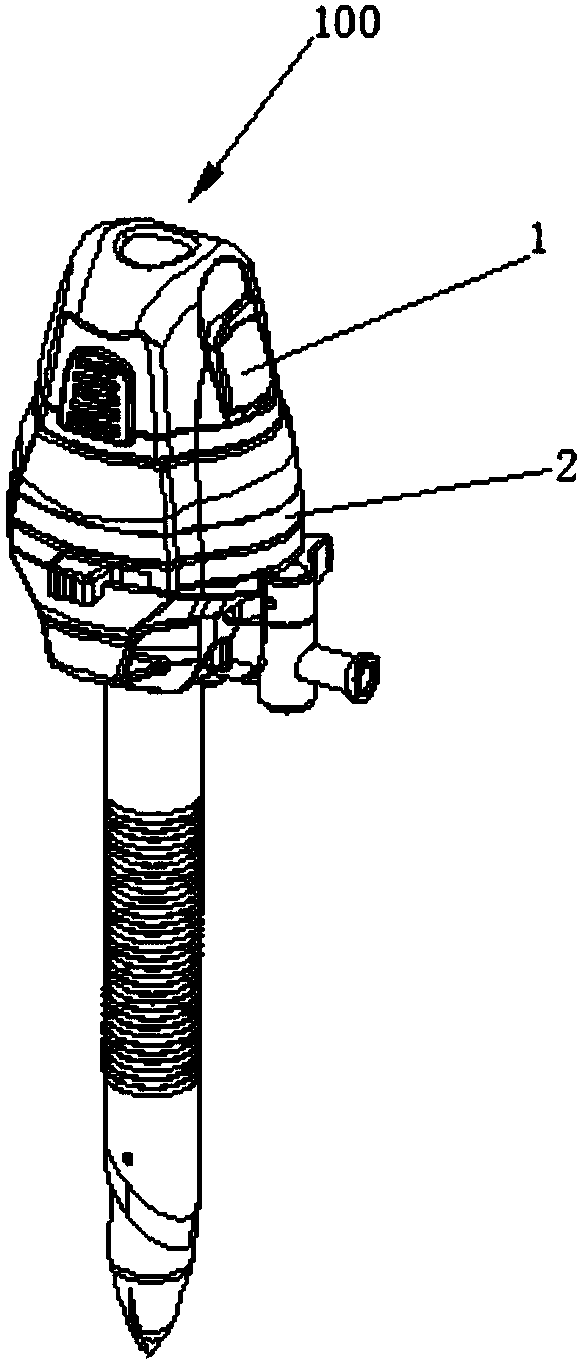

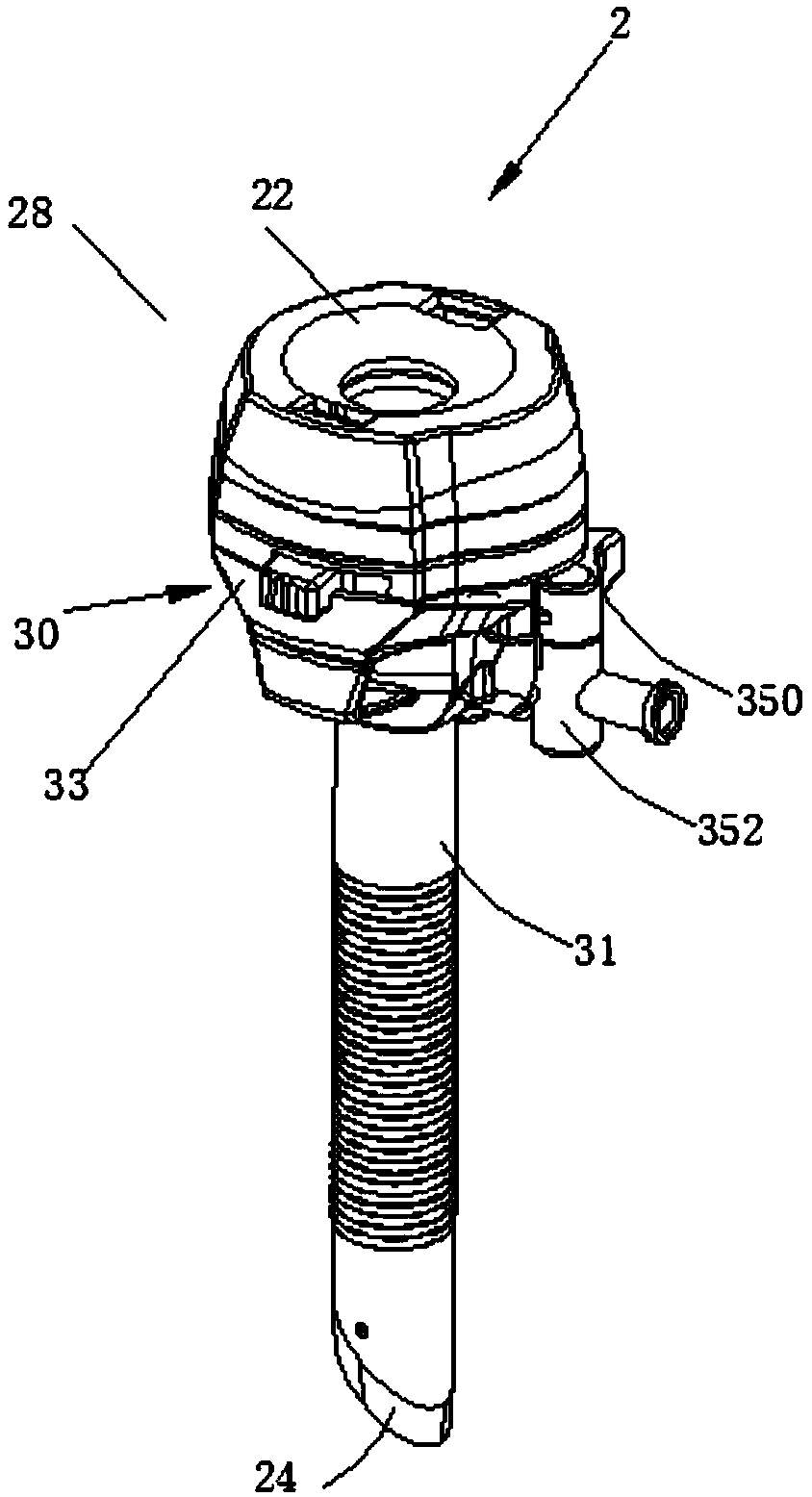

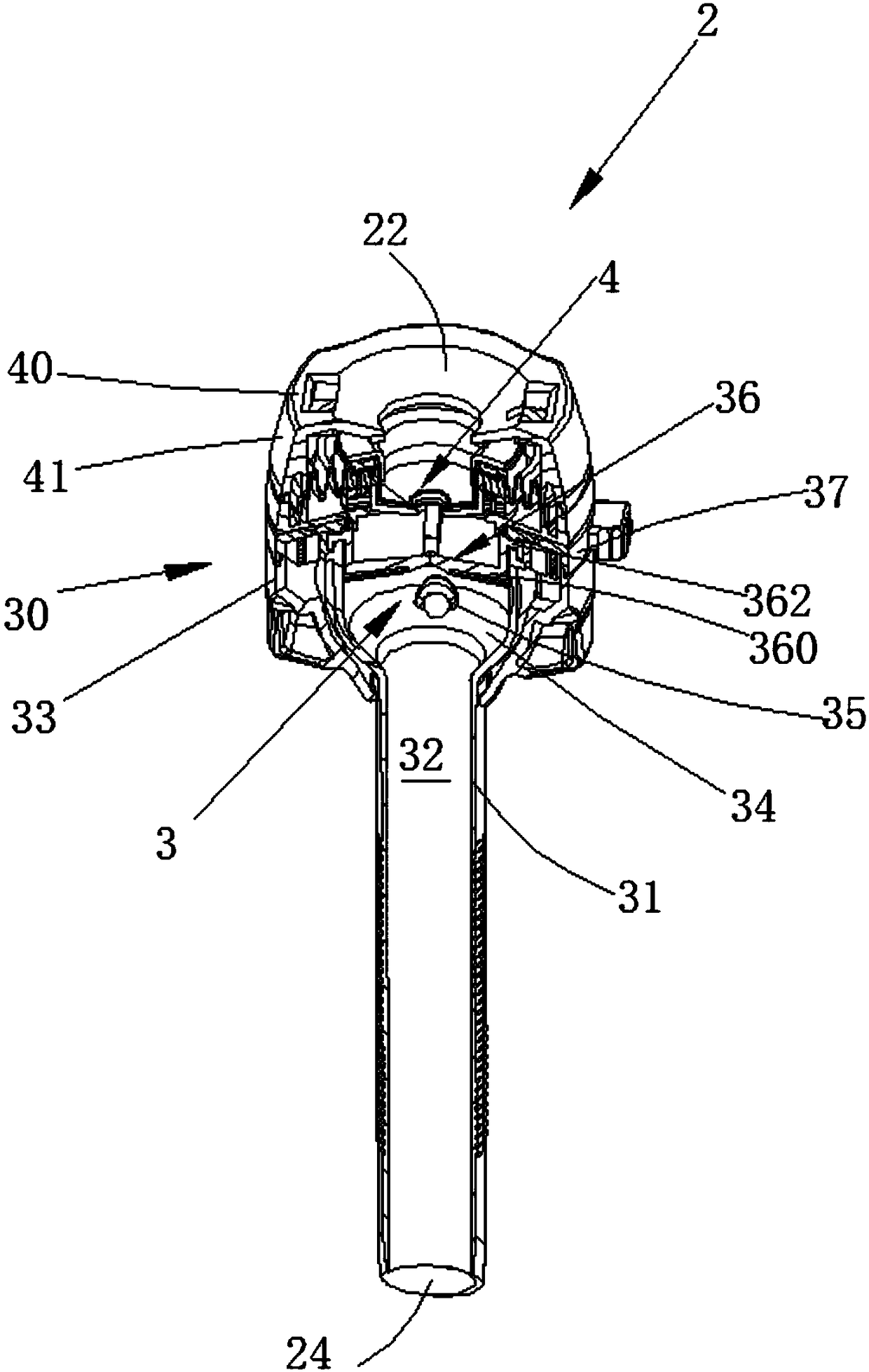

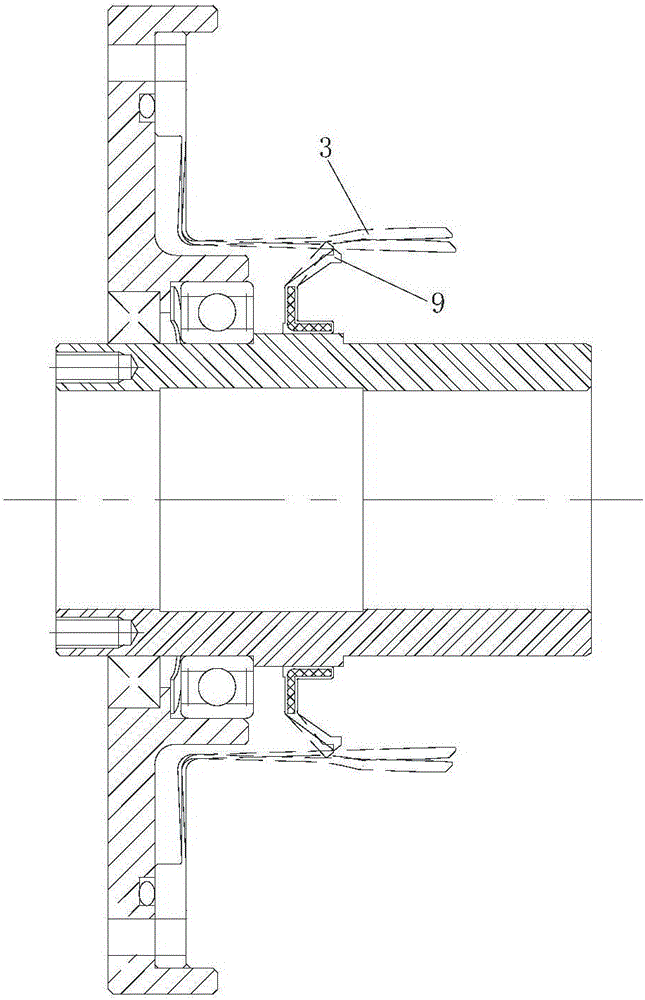

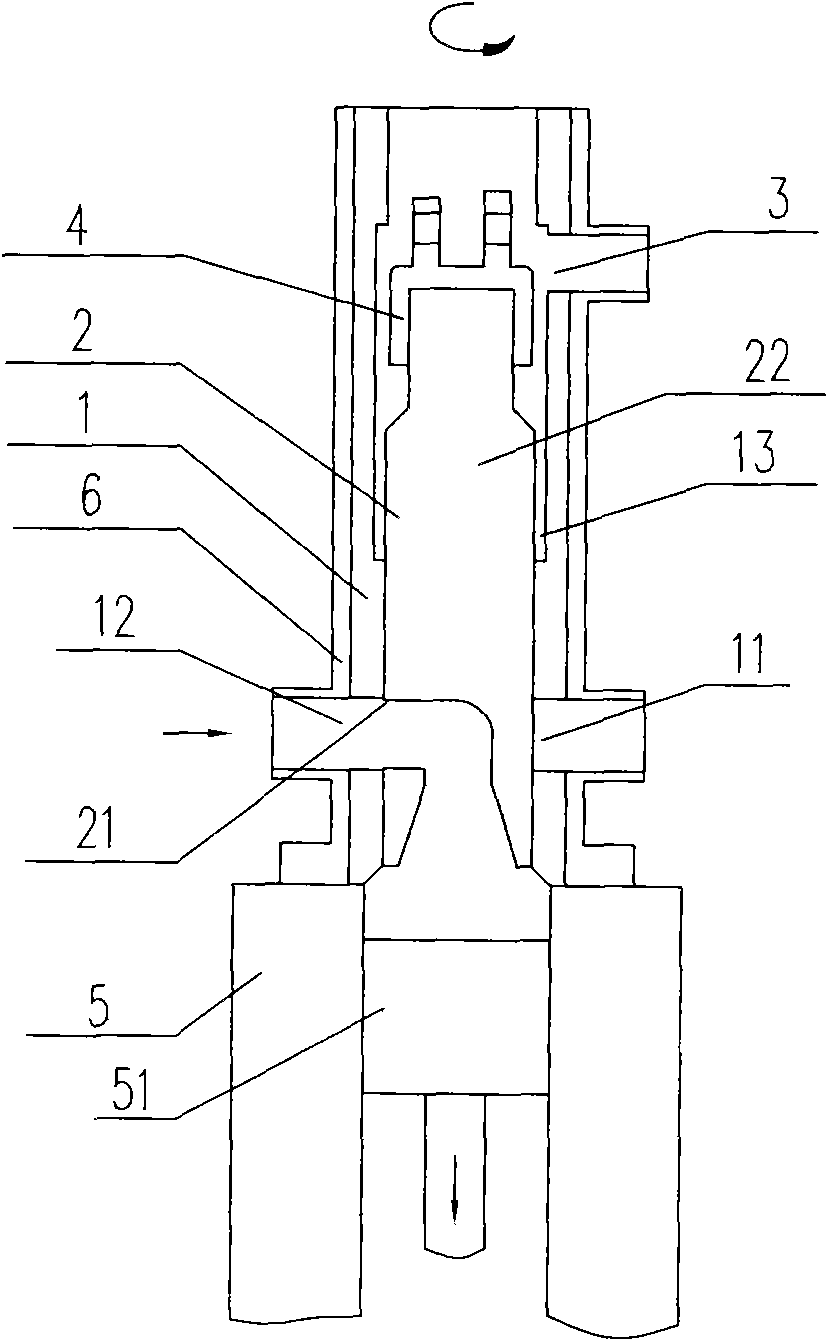

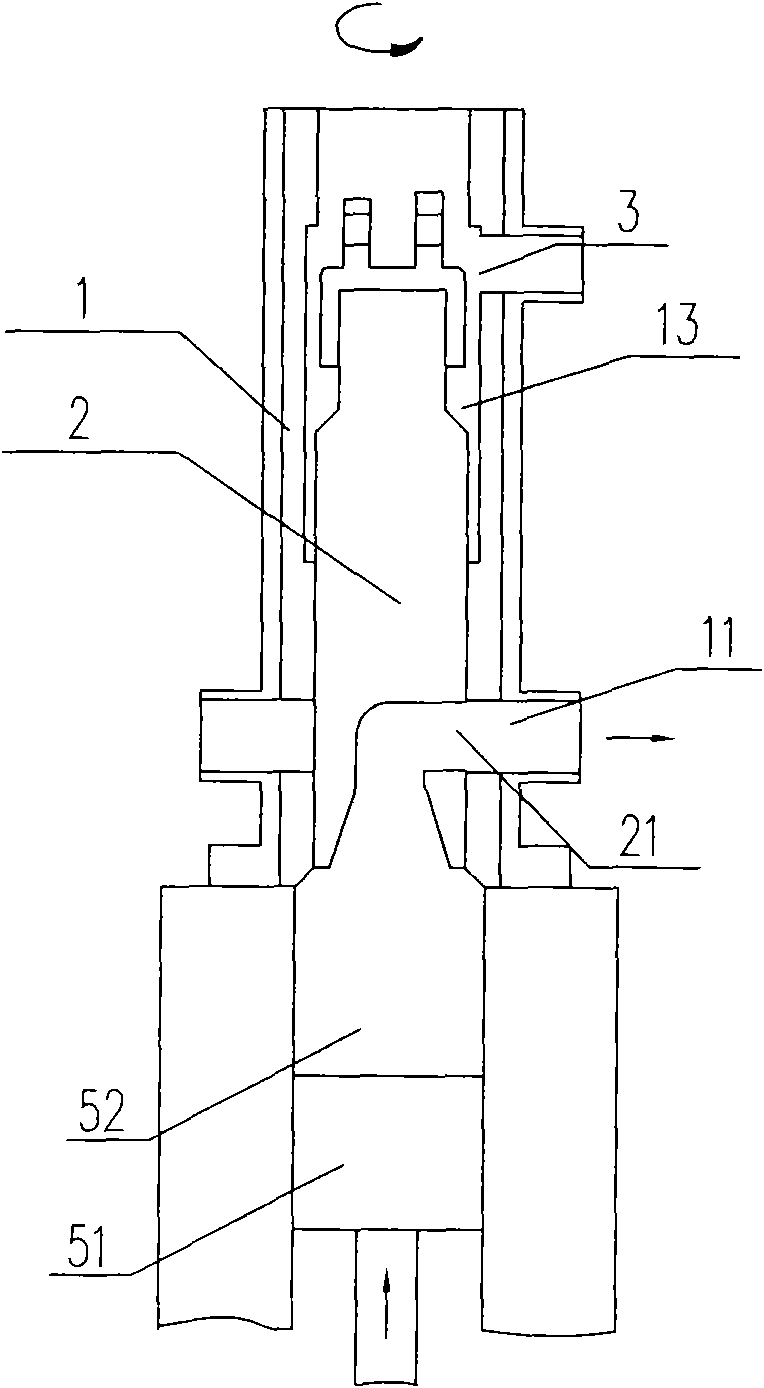

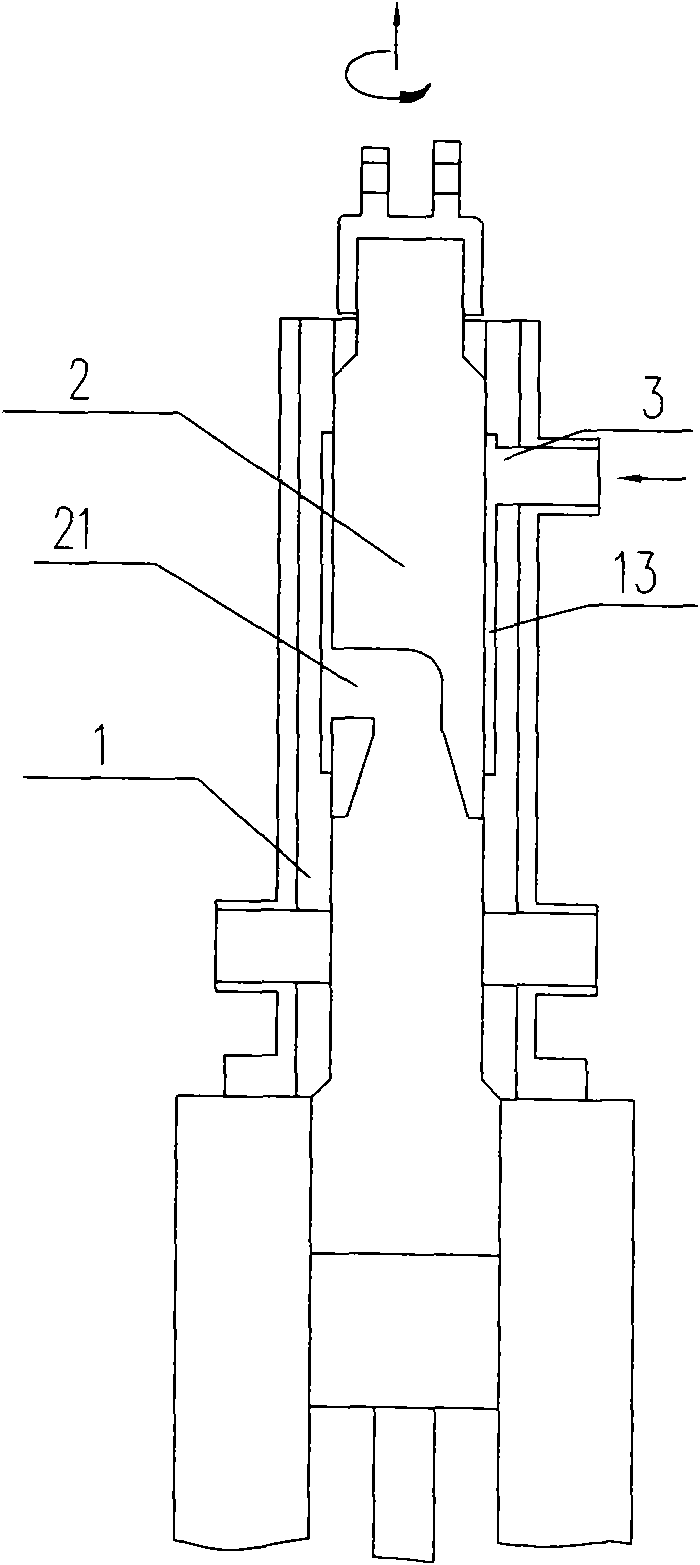

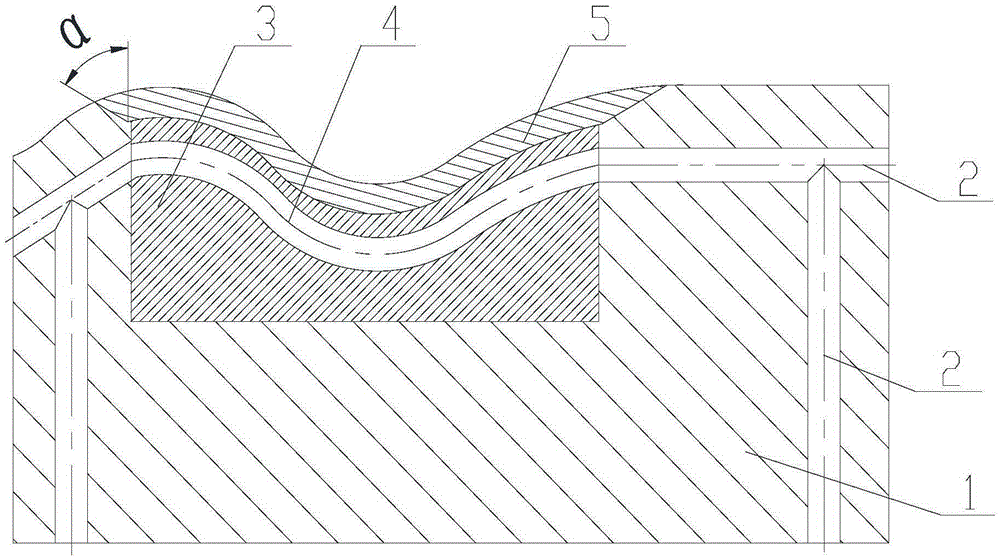

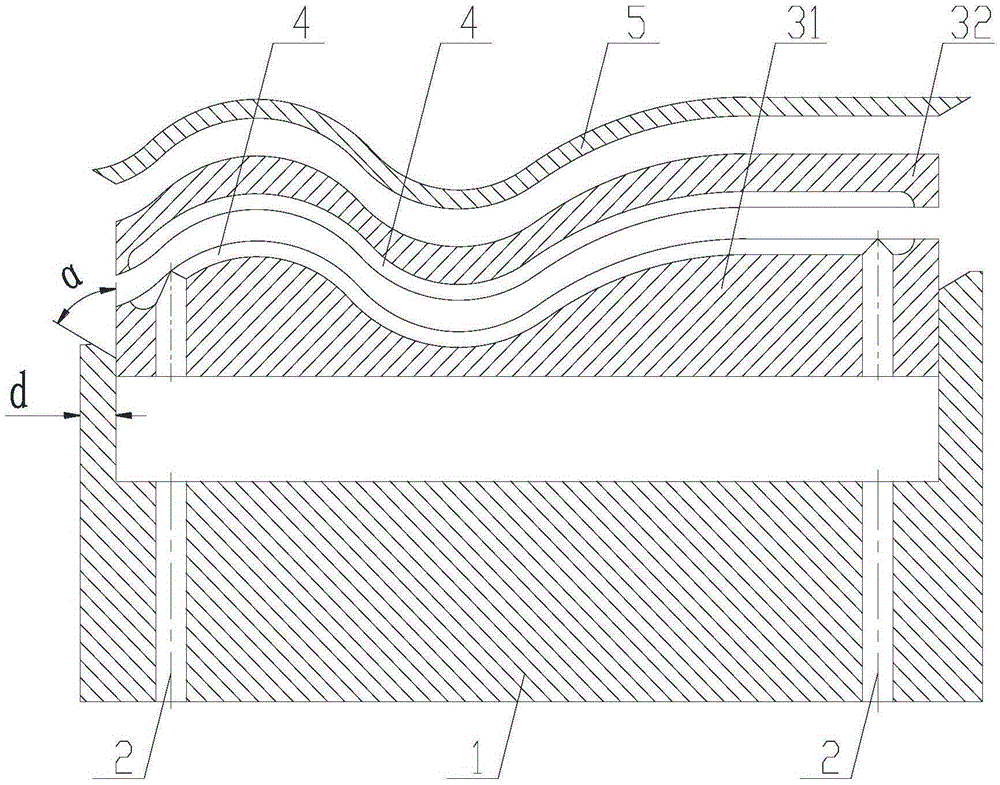

Sealing film, sealing assembly using sealing film and puncturing device using sealing assembly

InactiveCN108652713AReduce the real contact areaIncrease in circumferenceCannulasSurgical needlesHermetic sealEngineering

The invention discloses a sealing film for a puncturing device. The sealing film includes a proximal opening, a distal opening and a sealing wall extending from the distal opening to the proximal opening. The distal opening is formed by a sealing lip for accommodating an inserted apparatus and forming hermetic seal. The sealing wall comprises a plurality of corrugations circumscribing the distal opening and extending laterally from the distal opening, and the corrugations comprises corrugation peaks and corrugation valleys. The sealing wall further comprises at least two thickened portions, each thickened portion is disposed laterally between the two adjacent corresponding corrugations, and the thickened portions are located between the corresponding corrugation peaks and the correspondingcorrugation valleys. The corrugations can increase the circumferential perimeter, can reduce the wrapping area, and can reduce the true contact area between an instrument and the sealing film; and the sealing wall is further provided with the thickening portions, the thickening portions increase the axial tensile rigidity, greatly reduce the frictional resistance and improve the stick slip, and reduce the probability of occurrence of sealing film introversion.

Owner:FENGH MEDICAL CO LTD

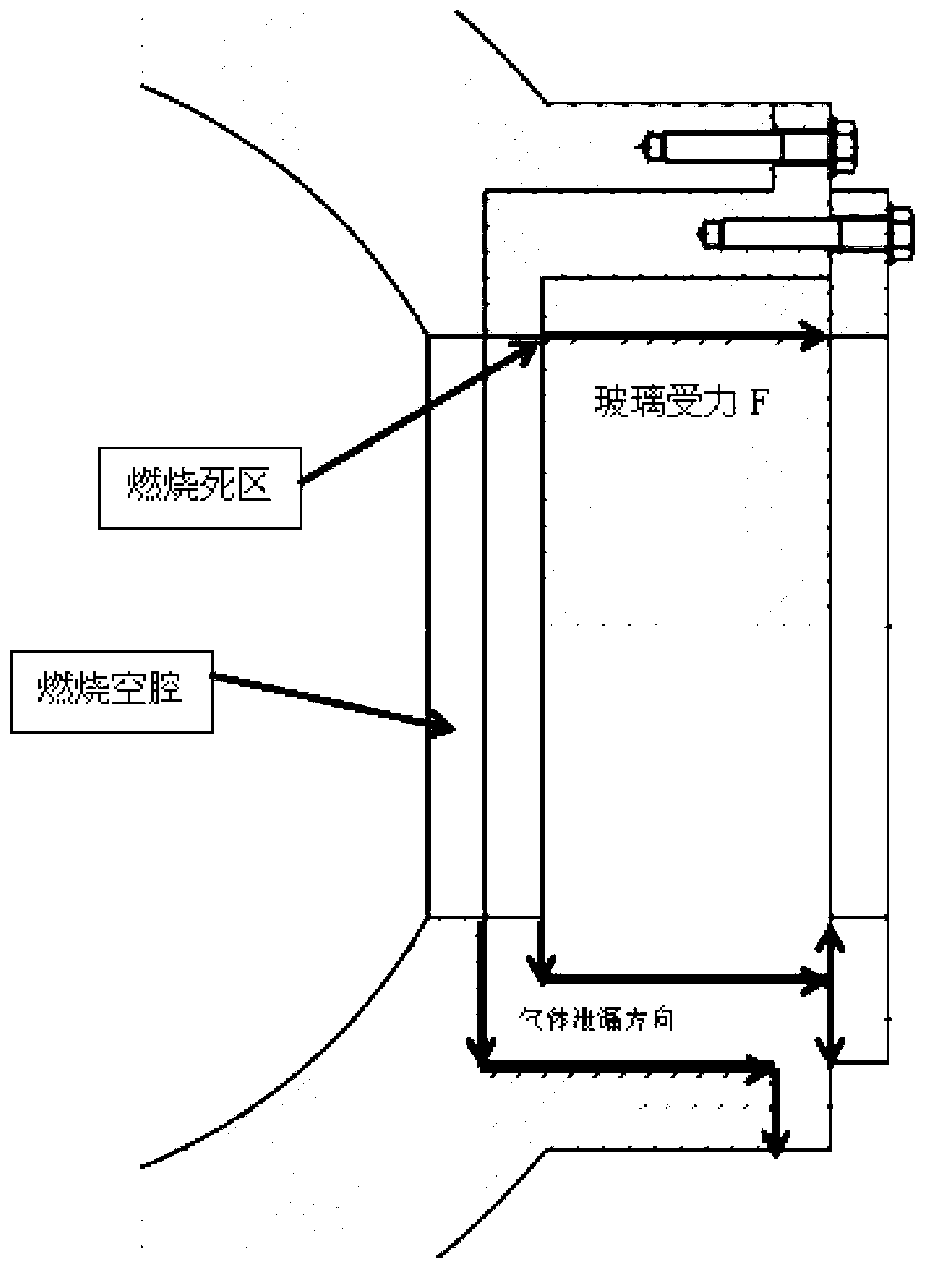

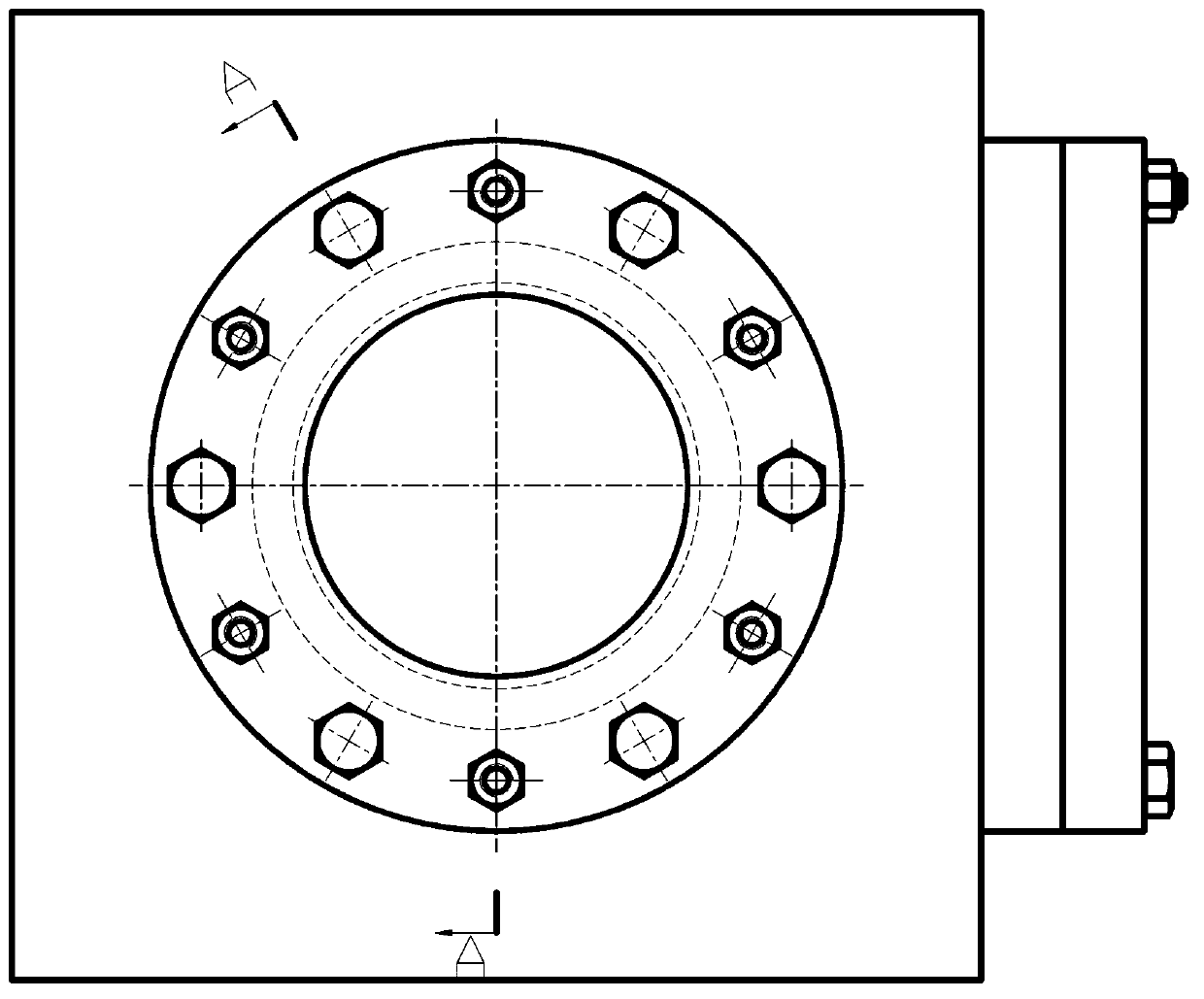

Constant volume combustion device for observing mutual effect of flame and pressure wave

InactiveCN103278331ASmooth structureReduce interlacingInternal-combustion engine testingCombustionEngineering

The invention discloses a constant volume combustion device for observing the mutual effect of a flame and a pressure wave. A combustion bomb body is provided with an observation hole provided with an optical observation window; the optical observation window comprises optical glass provided with an annular boss on the outer side; the inner side and the outer side of the optical glass are respectively provided with an embedding end cover and a compressing end cover which are mutually connected through a bolt; the embedding end cover and the compressing end cover are arranged on the combustion bomb body through bolts; and high-temperature resistant gaskets are respectively arranged among the embedding end cover, the compressing end cover and the optical glass. According to the constant volume combustion device, the influence of the installation of the optical observation window of the combustion bomb body to the regularity of the inner cavity shape of the optical observation window is reduced, and the inner cavity smoothness is improved, so that the reflection effects of an inner flow field and a wall pressure wave are improved; and meanwhile, the stress manner of glass in the traditional optical observation window is changed, the thickness of the glass is reduced, and the device is beneficial to observation and shooting effects of experiments.

Owner:TIANJIN UNIV

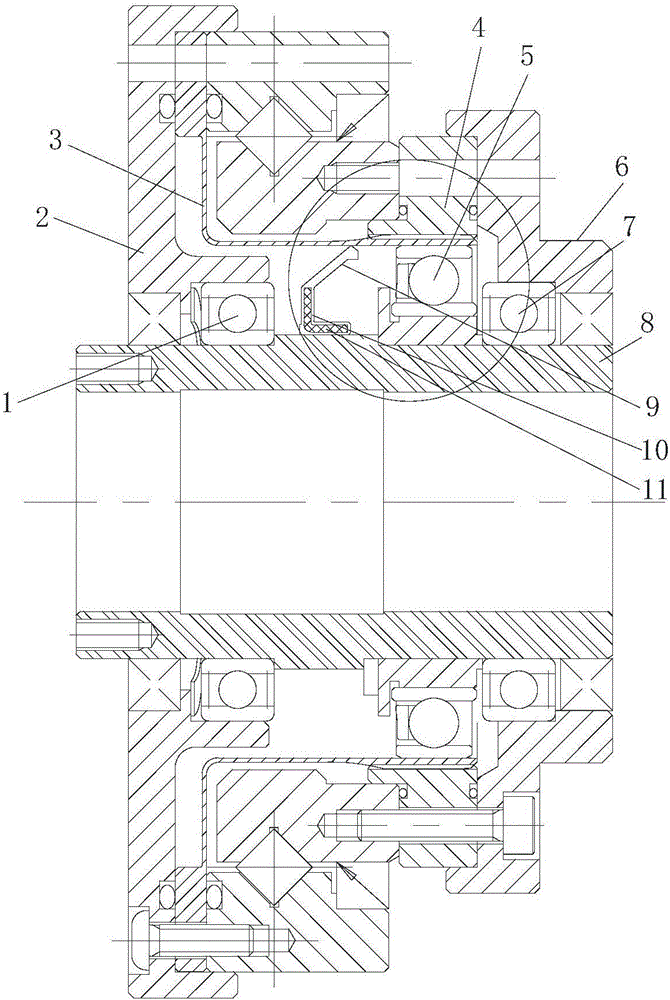

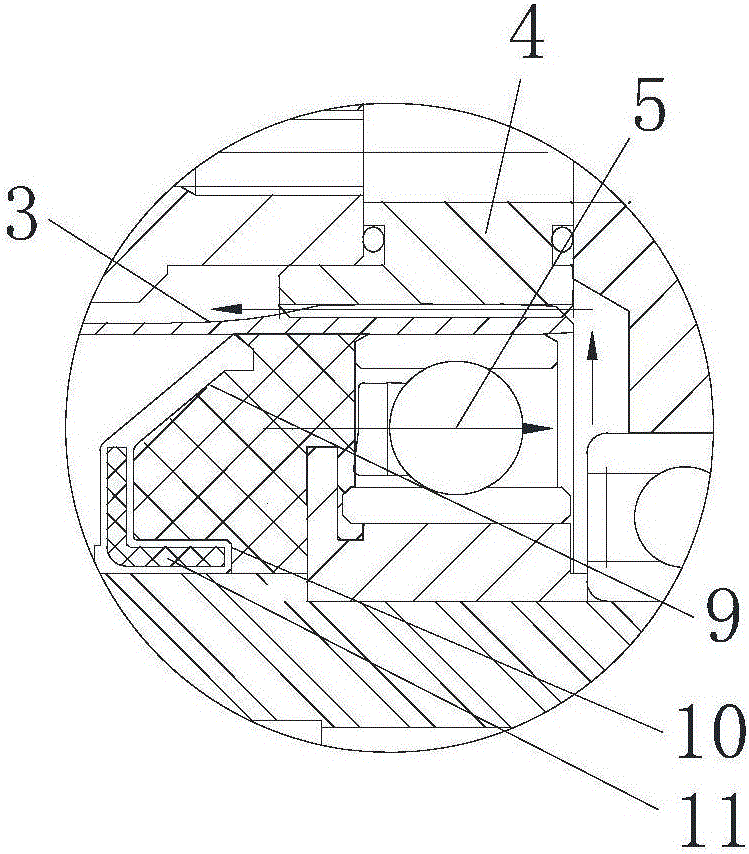

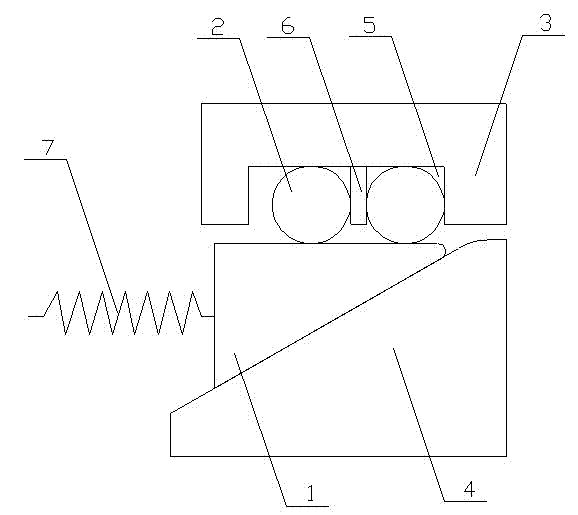

Self-lubricating harmonic reducer

ActiveCN105864365AReduce weightGuaranteed sealing performanceToothed gearingsGear lubrication/coolingHarmonicReduction drive

The invention discloses a self-lubricating harmonic reducer. The self-lubricating harmonic reducer comprises a wave generator, a rigid gear and a flexible gear, wherein the rigid gear is meshed with the flexible gear; the wave generator is in contact with the inner wall of the flexible gear; an oil seal is arranged on an input shaft of the wave generator or an output end of the reducer in a sealing manner; a lubricant cavity is formed among the oil sea, the wave generator and the flexible gear; the oil seal comprises a ring-shaped base part; an elastic lip edge overhangs outwards from the outer side wall of the base part; the elastic lip edge is slantly arranged toward the wave generator; the overhanging tail end of the elastic lip edge tightly presses against the inner wall of the flexible gear. According to the reducer disclosed in the invention, the lubricant cavity, rather than the whole cavity in the flexible gear, is filled with the lubricant, so that the weight of the lubricant is decreased; the lubricating supply for the rigid gear and the flexible gear can be completed, and the flowing direction of the lubricant is not influenced by the mounting direction of the harmonic reducer, so that the favorable lubrication for the rigid gear and the flexible gear is ensured, the torn-up scrap iron of the rigid gear and the flexible gear is prevented from flowing back to the flexible bearing along with the lubricant, and the service life of the reducer is prolonged.

Owner:铂睿(山东)精密工业有限公司

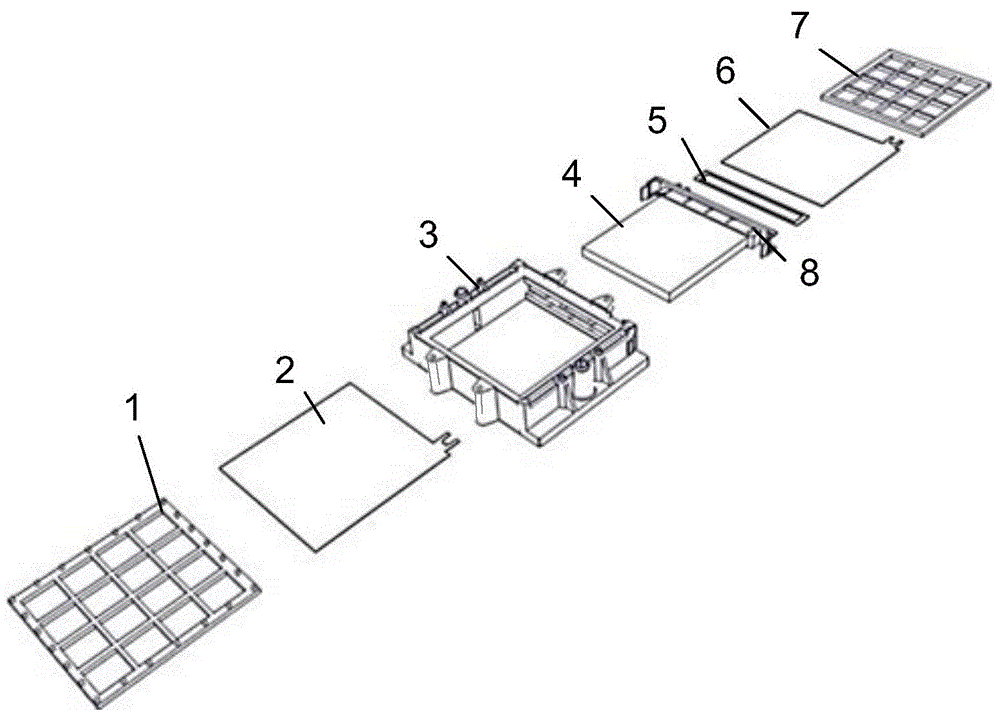

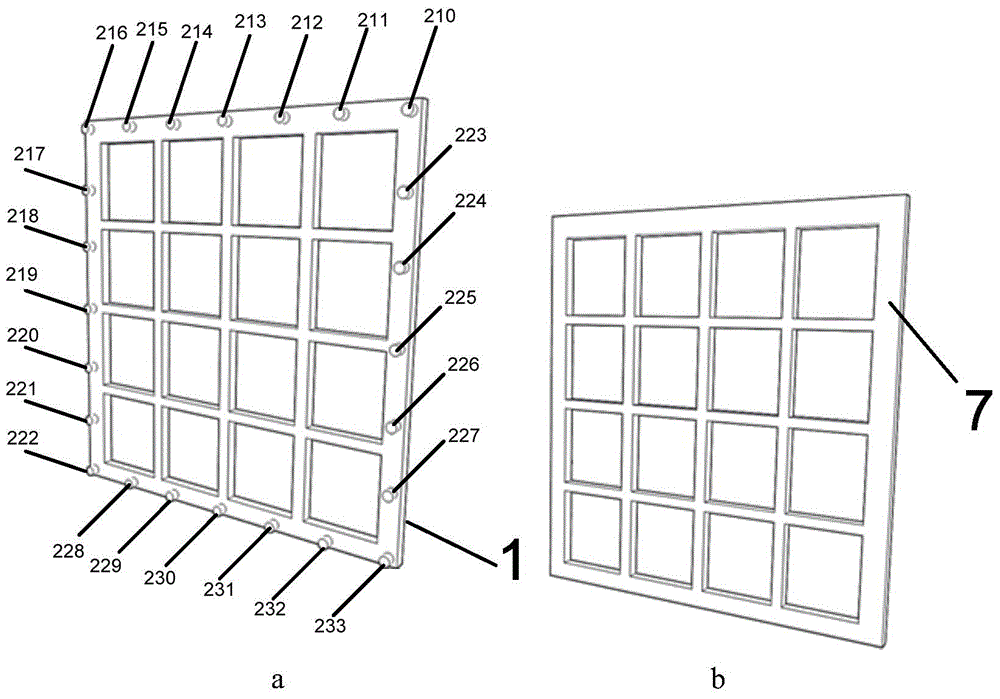

Liquid circuit built-in aluminium air fuel cell monomer and cell stack

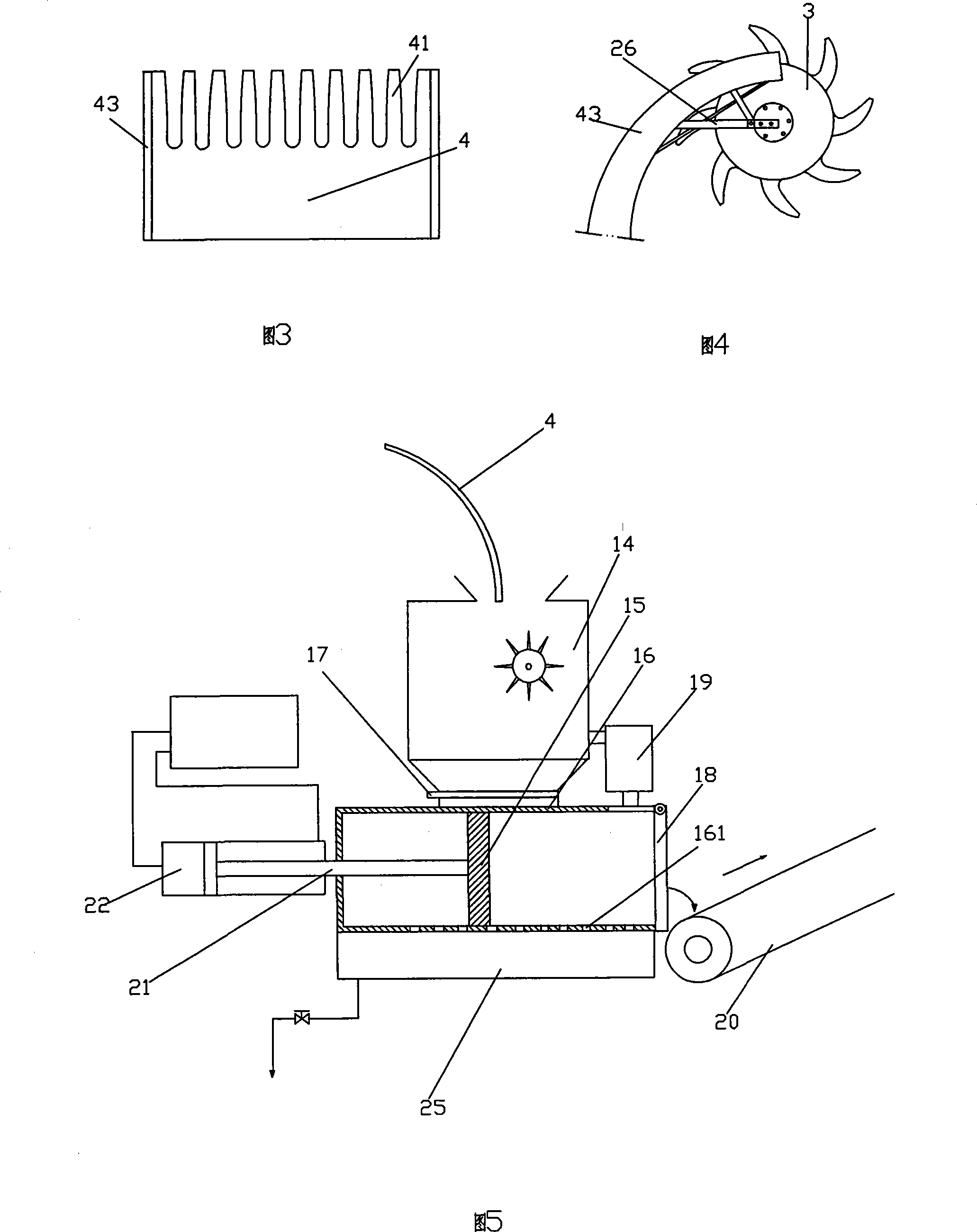

InactiveCN104577262ASmooth entryReduce interaural distanceFuel and primary cellsFuel cells groupingFuel cellsMonomer

The invention relates to a liquid circuit built-in aluminium air fuel cell monomer and a cell stack. The liquid circuit built-in aluminium air fuel cell monomer comprises a first flat grid mesh, a first air electrode, a matrix frame, a second air electrode and a second flat grid mesh which are sequentially arranged, wherein the first air electrode is used as a cathode; the matrix frame is provided with a side port for enabling an aluminium alloy electrode used as an anode to be inserted in; a first electrolyte pipe orifice and a second electrolyte pipe orifice are also formed outside the matrix frame. The cell stack comprises a plurality of liquid circuit built-in aluminium air fuel cell monomers which are connected in series and a gap is reserved between every two adjacent cell monomers; support pillars are arranged at the edges of the first flat grid meshes; the first electrolyte pipe orifice in each cell monomer is connected with the second electrolyte pipe orifice in the adjacent cell monomer; the first and second air electrodes in each cell monomer are connected with the aluminium alloy electrode used as the anode in the adjacent cell monomer. According to the invention, a fuel cell pipeline is simple, the engineering degree is high, the guarantee is simple, the operation is convenient, the processing consistency is good, and the recycling and reusing can be realized.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

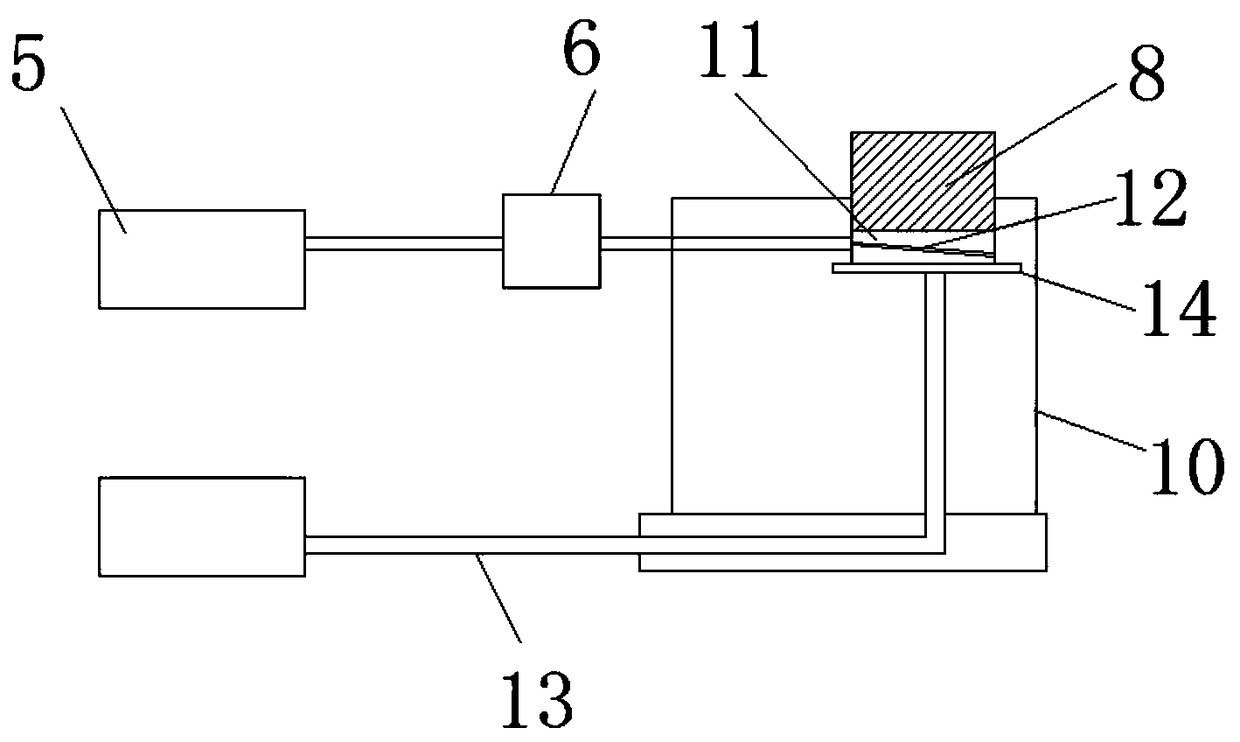

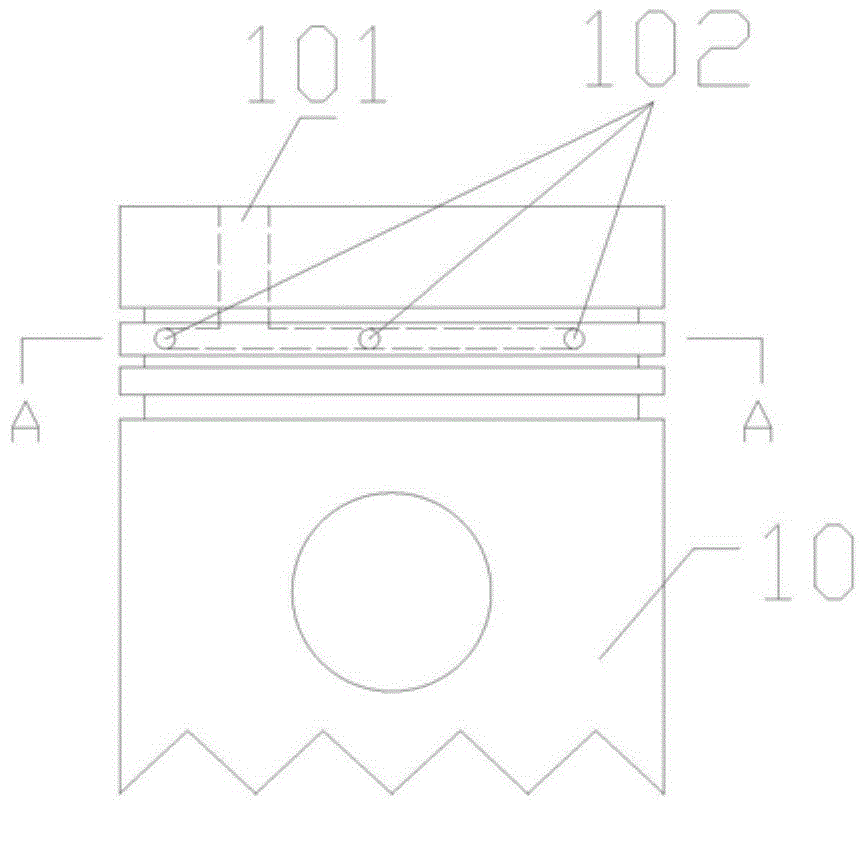

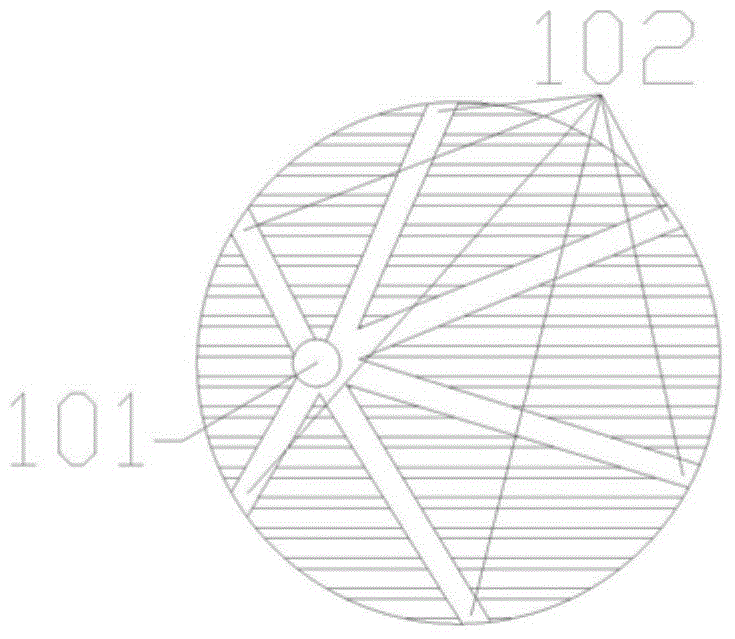

Test device and method for friction force of cylinder sleeve and piston assembly

ActiveCN104568275AAchieving Radial LoadingResolve measurementsApparatus for force/torque/work measurementPiston ringEngineering

The invention relates to a test device and method for friction force of a cylinder sleeve and a piston assembly, and belongs to the technical field of friction and abrasion tests. A power unit of the test device is connected with a piston through a piston pin, the piston is connected with the cylinder sleeve in a sealed mode through a first gas ring, a second gas ring and an oil scraping ring arranged in annular grooves of the piston, the cylinder sleeve is fixed to a cylinder body with a heating / cooling cavity in a sealed mode, a baffle is fixed to the cylinder body, a gap is formed between the baffle and the cylinder body, a friction force sensor is fixed in the gap between the baffle and the cylinder body, a gas supply unit is connected with a gas inlet hole of the piston, and a plurality of gas outlet holes are evenly distributed along the periphery of the piston at the position, between the annular groove I provided with the first gas ring and the annular groove II provided with the second gas ring, of the piston. The test device and method for friction force of the cylinder sleeve and the piston assembly have the advantages that the device adopts high-pressure gas to simulate fuel gas pressure, radial loading is carried out on the multiple piston rings, the restraint of mechanical radial loading to peripheral rotation of the piston rings is eliminated, and the test device and method enable the movement state of the piston rings to be more similar to that of the piston rings in an ignition state.

Owner:DALIAN MARITIME UNIVERSITY +1

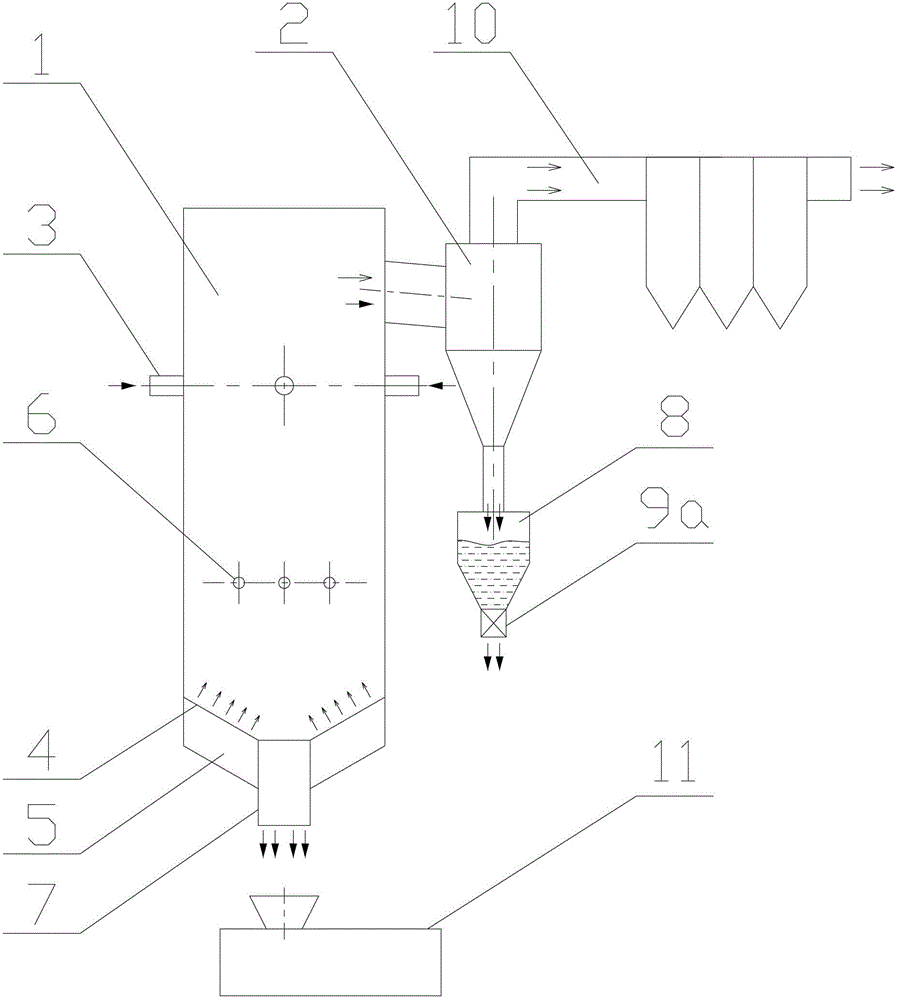

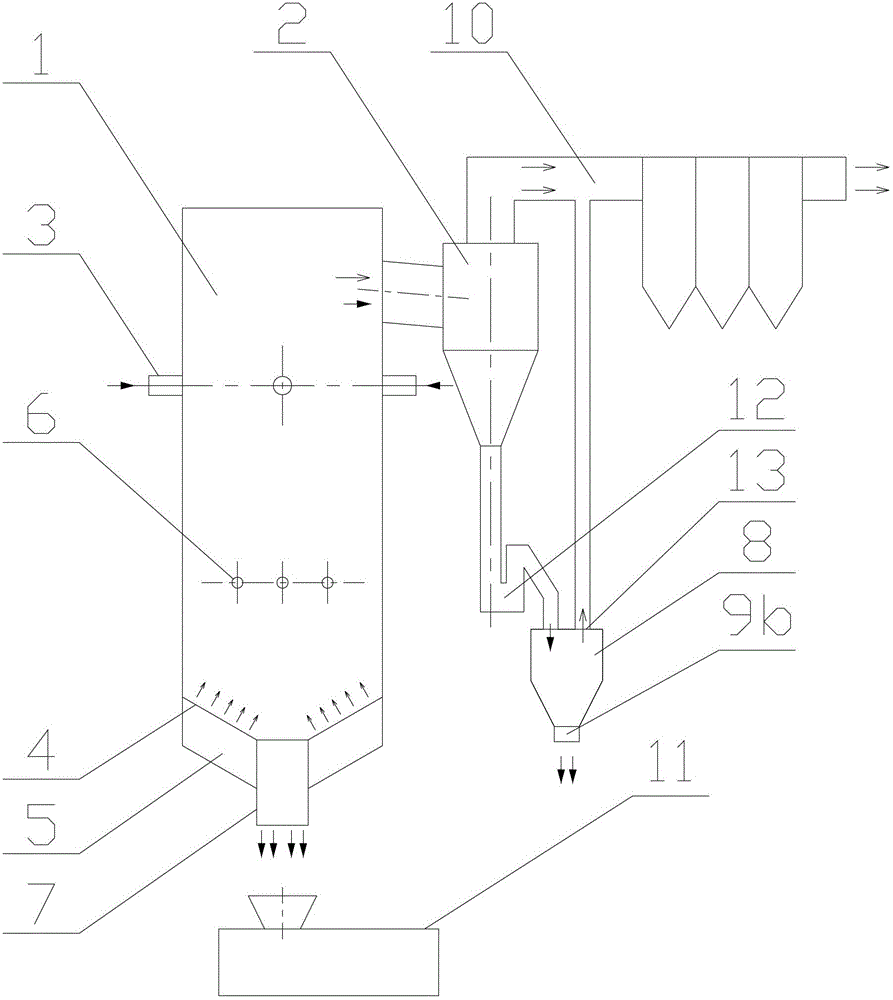

Pneumatic particle size classifying device for solid particles

InactiveCN102716857AAffect balanceAffect normal working conditionsGas current separationSolid particleEngineering

A pneumatic particle size classifying device for solid particles comprises a fluidized bed main body, a cyclone separator, material inlets, an air distributing system, a secondary air port, a coarse material outlet and a fine material collecting and discharging system. The material inlets are positioned on the middle upper portion of the fluidized bed main body and are distributed on four walls in a multi-point manner, the hopper-shaped air distributing system consists of an inclined air distributing plate, the coarse material outlet is arranged in the center of the inclined air distributing plate, the fine material collecting and discharging system consists of a fine material collecting chamber and an intermittent discharging valve and is directly connected with a lower particle outlet of the cyclone separator, or the fine material collecting and discharging system can consist of a fine material collecting chamber and a fine material discharge port and is connected with a particle outlet of a feedback valve. The pneumatic particle size classifying device is simple in structure, effective pneumatic particle size classification for selective coking coal particles is carried out by fluidization technology, retaining time of the particles in the bed body can be effectively prolonged, the pneumatic particle size classifying device is stable in running and fine in separation effect, and energy and coking coal resources are greatly saved.

Owner:TSINGHUA UNIV

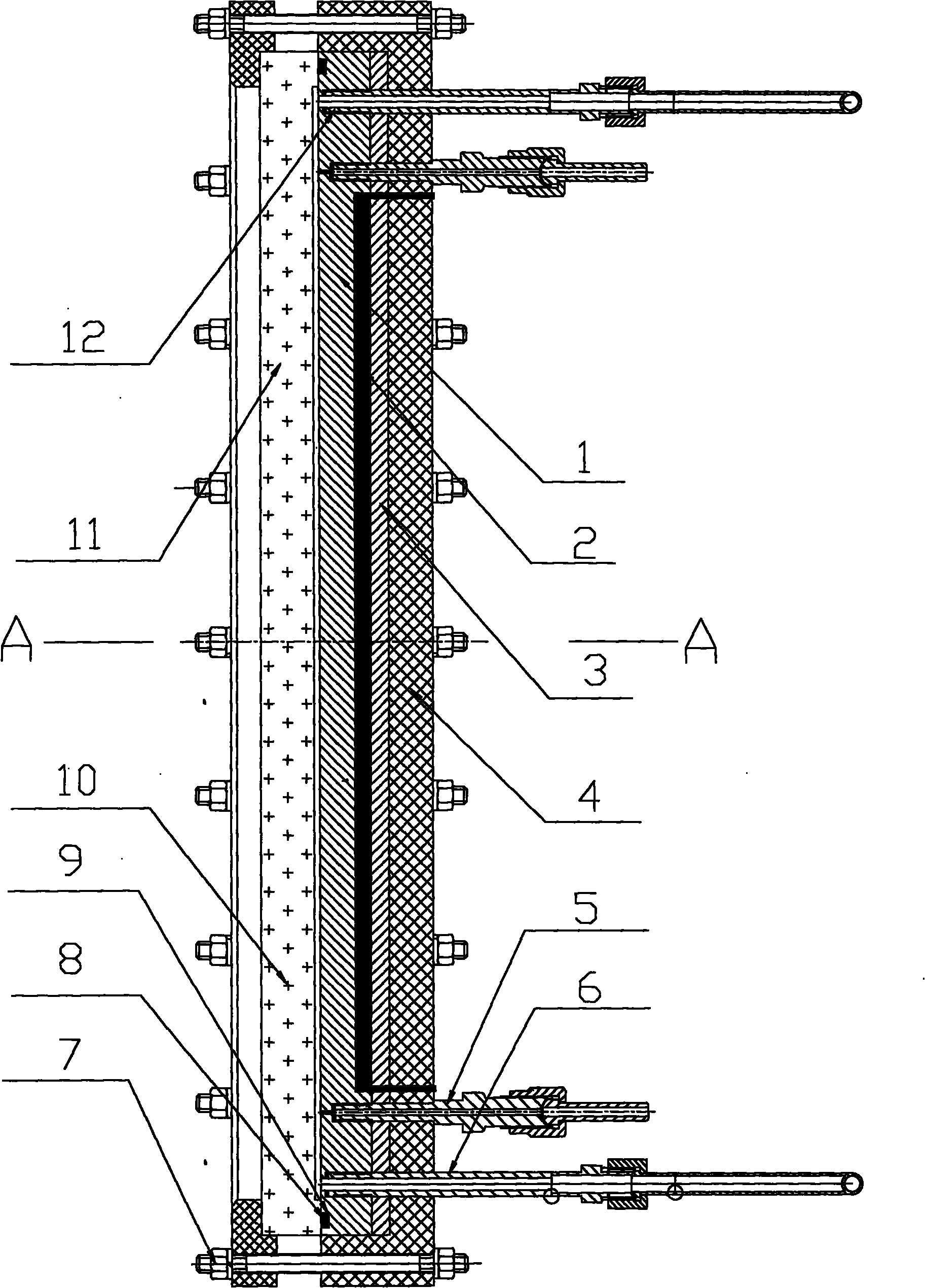

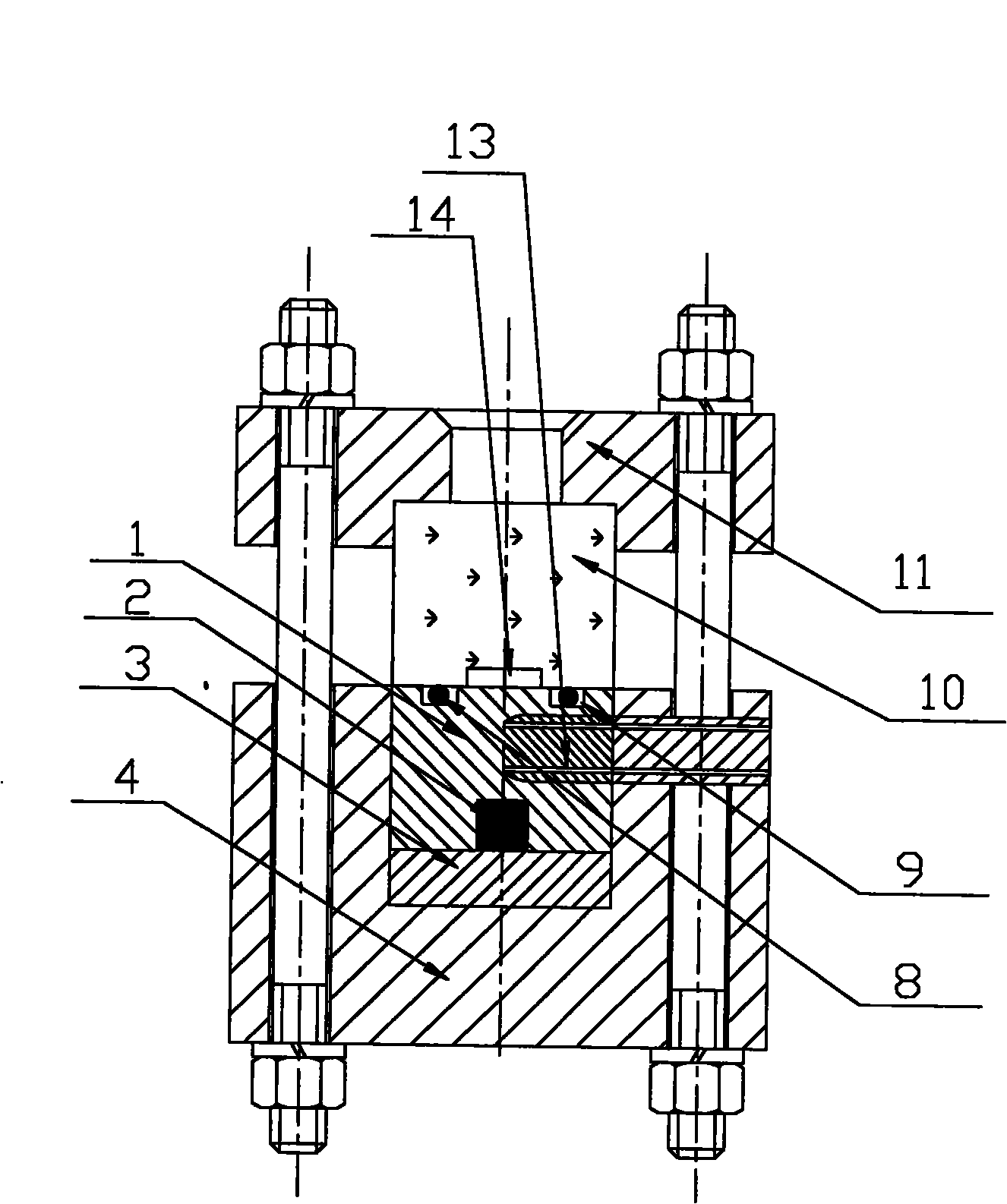

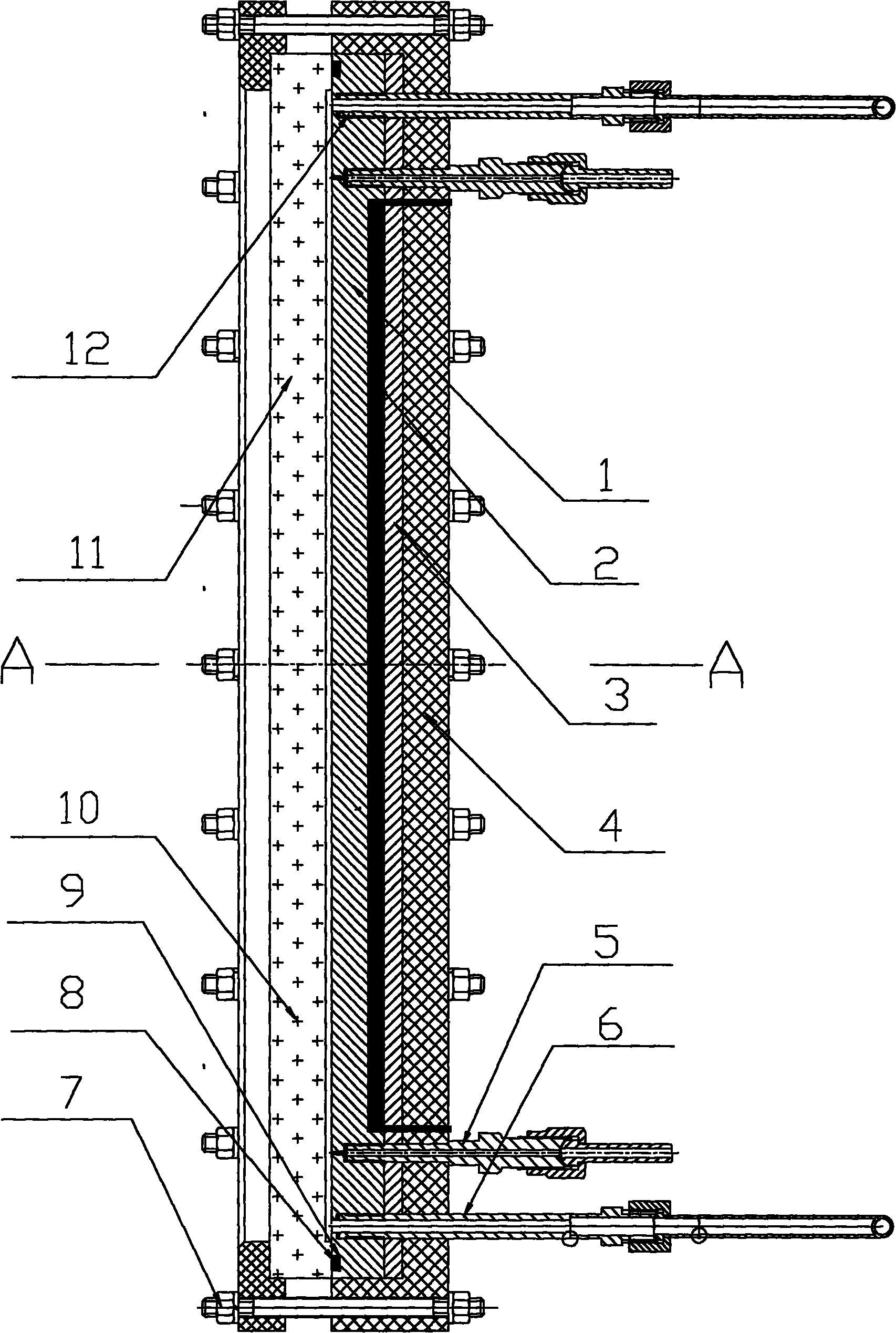

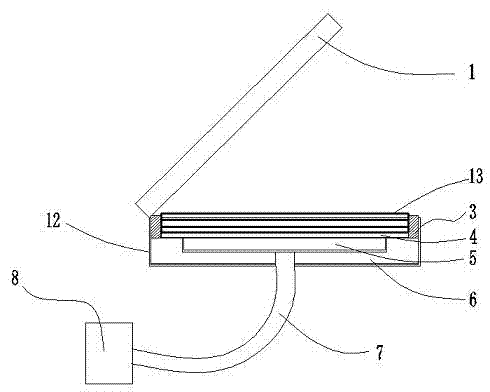

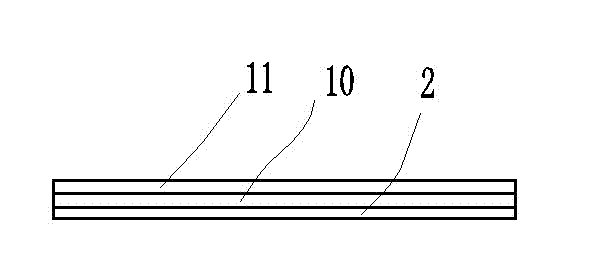

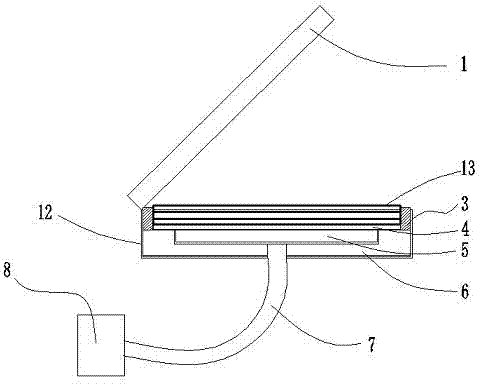

Experimental device of rectangular narrow seam for single-phase and two-phase three-dimensional visualization

InactiveCN102313641AGuaranteed sealing performanceEvenly distributedFlow propertiesHydrodynamic testingStereoscopic visualizationBottom pressure

The invention belongs to a simulation device for research of a single-phase and two-phase bubble behavior and a flow pattern, which comprises a thermal conduction copper plate, a visual window, an electric heating component, a bottom pressure-bearing body, a pressure measuring component and other components. The thermal conduction copper plate and a concave flow channel of a rectangular narrow seam of the visual window for a closed channel of the rectangular narrow seam, and thus an experimental device of the rectangular narrow seam for research on single-phase and two-phase three-dimensional visualization is formed. The single-phase flow state, the three-dimensional bubble state, the flow pattern conversion and other evolution laws in the rectangular narrow seam channel can be observed based on wide-surface and narrow-surface three-dimensional visualization, and conditions can be provided for in-depth revealing of flow and heat transfer mechanism in the narrow channel.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

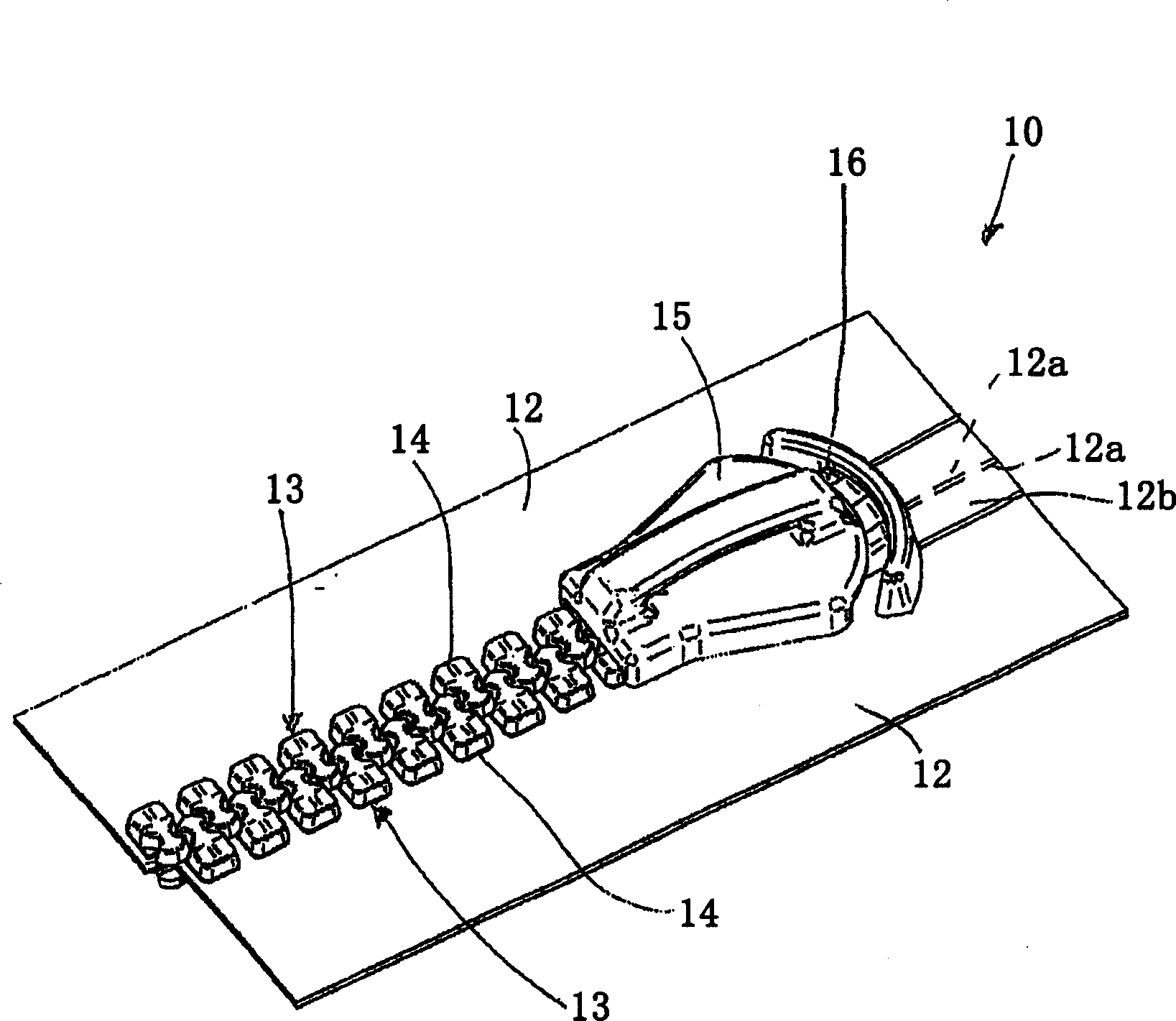

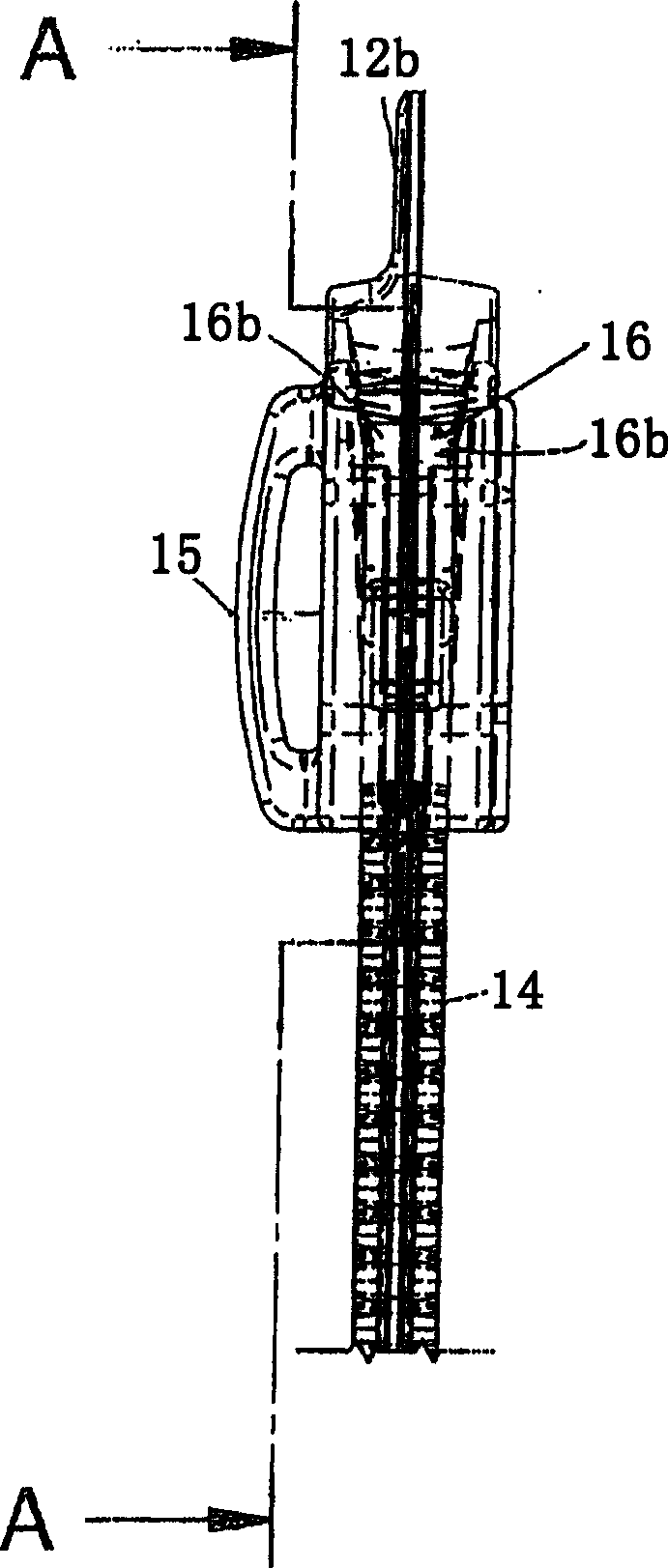

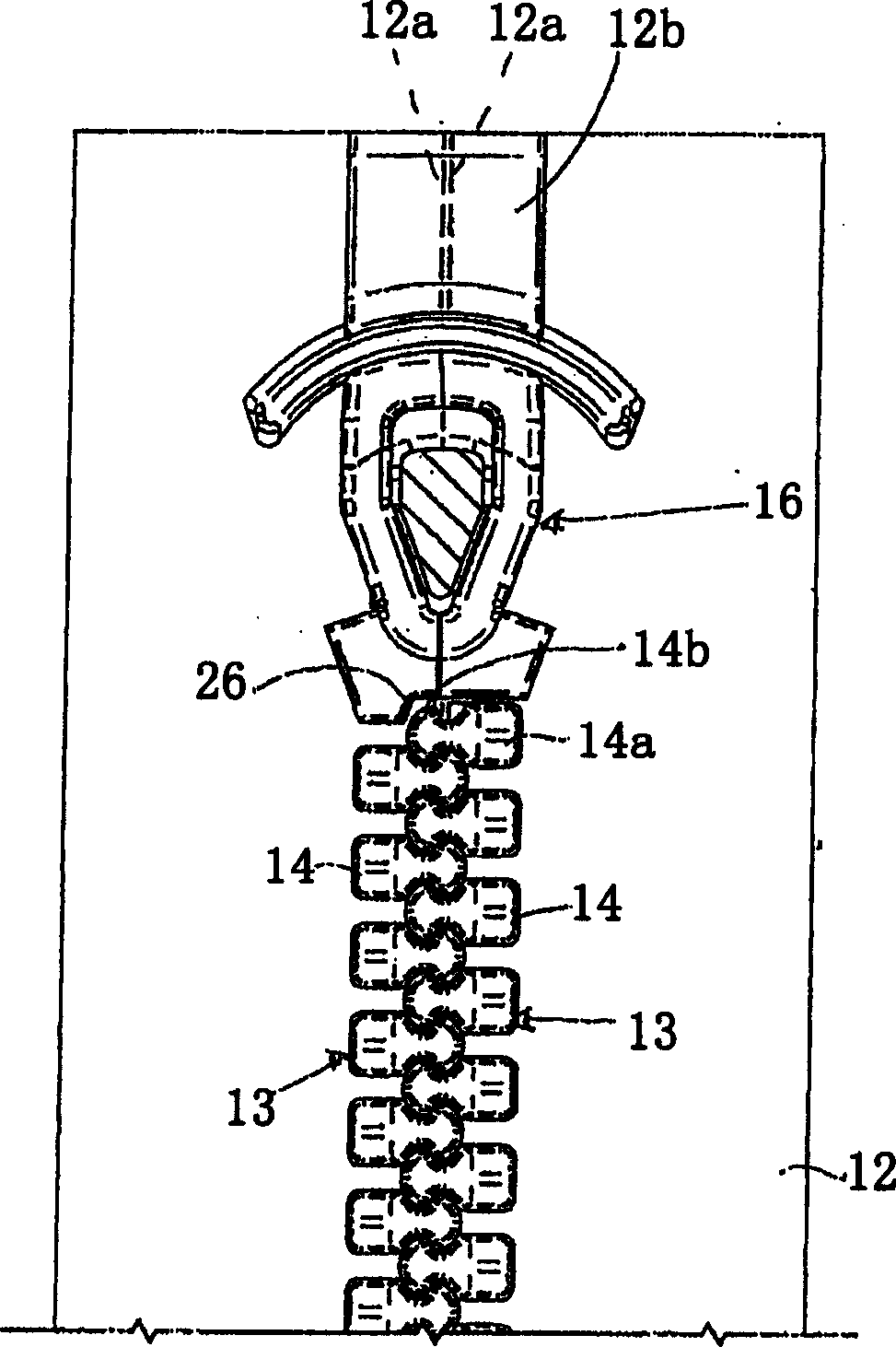

Fluid-tight slide fastener

The present invention regards a fluid tight slide fastener (10) of the type comprising a slider (15) slidably associated with opposite edges (12a) of two flanking strips (12) to provide for their closure, and an upper end stop (16) with which said slider (15) is removably engaged upon closure, characterised in that in said upper stop (16) and in said slider (15) respective means (19,21) and counter-means (46,47) are provided for and adapted to make, upon upper stop (16)-slider (15) engagement, a clearance-recovery taper fit, so-called clearance-recovery wedge. The present invention also regards an upper stop and a slider for a slide fastener of the aforesaid type.

Owner:RIRI

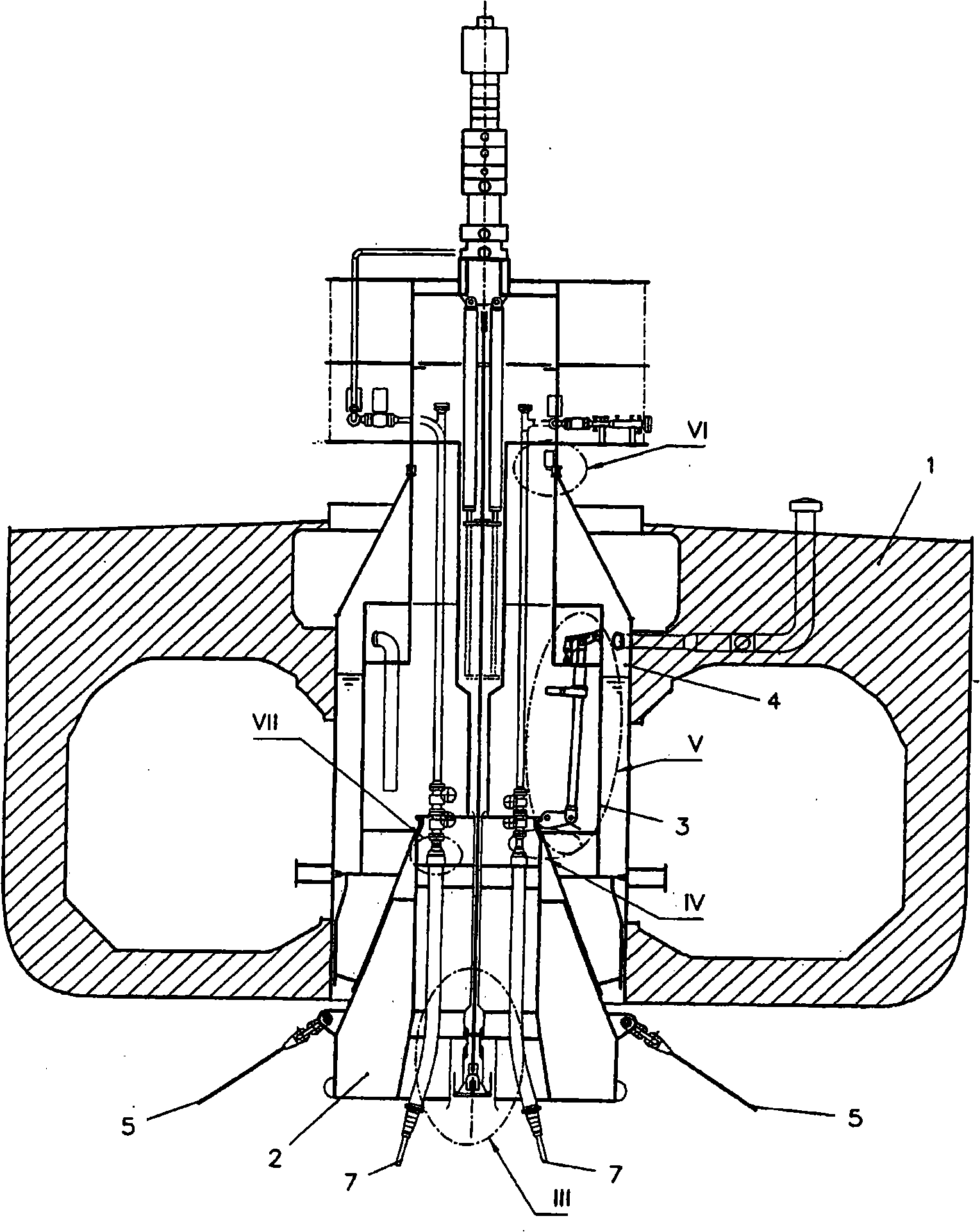

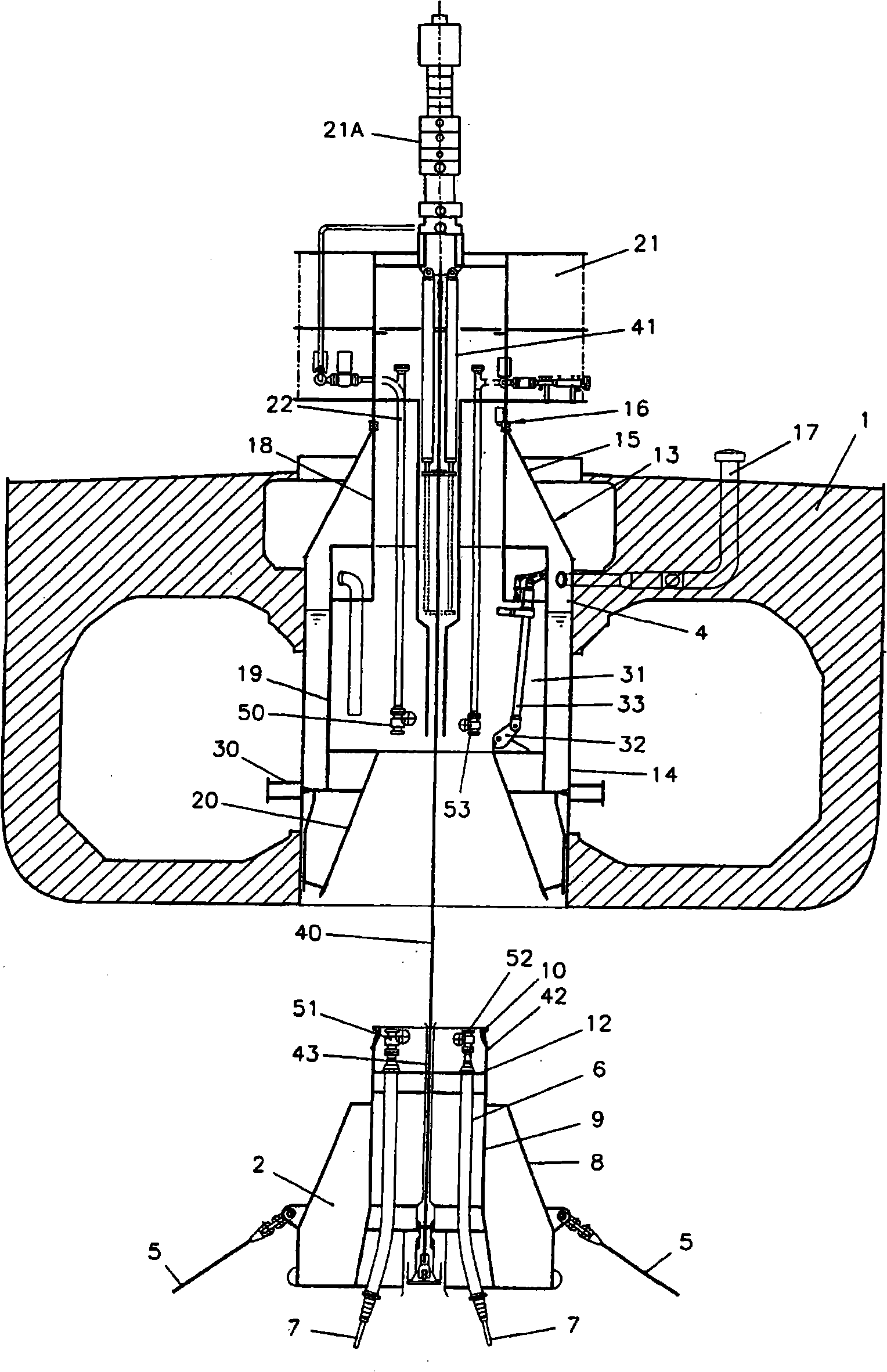

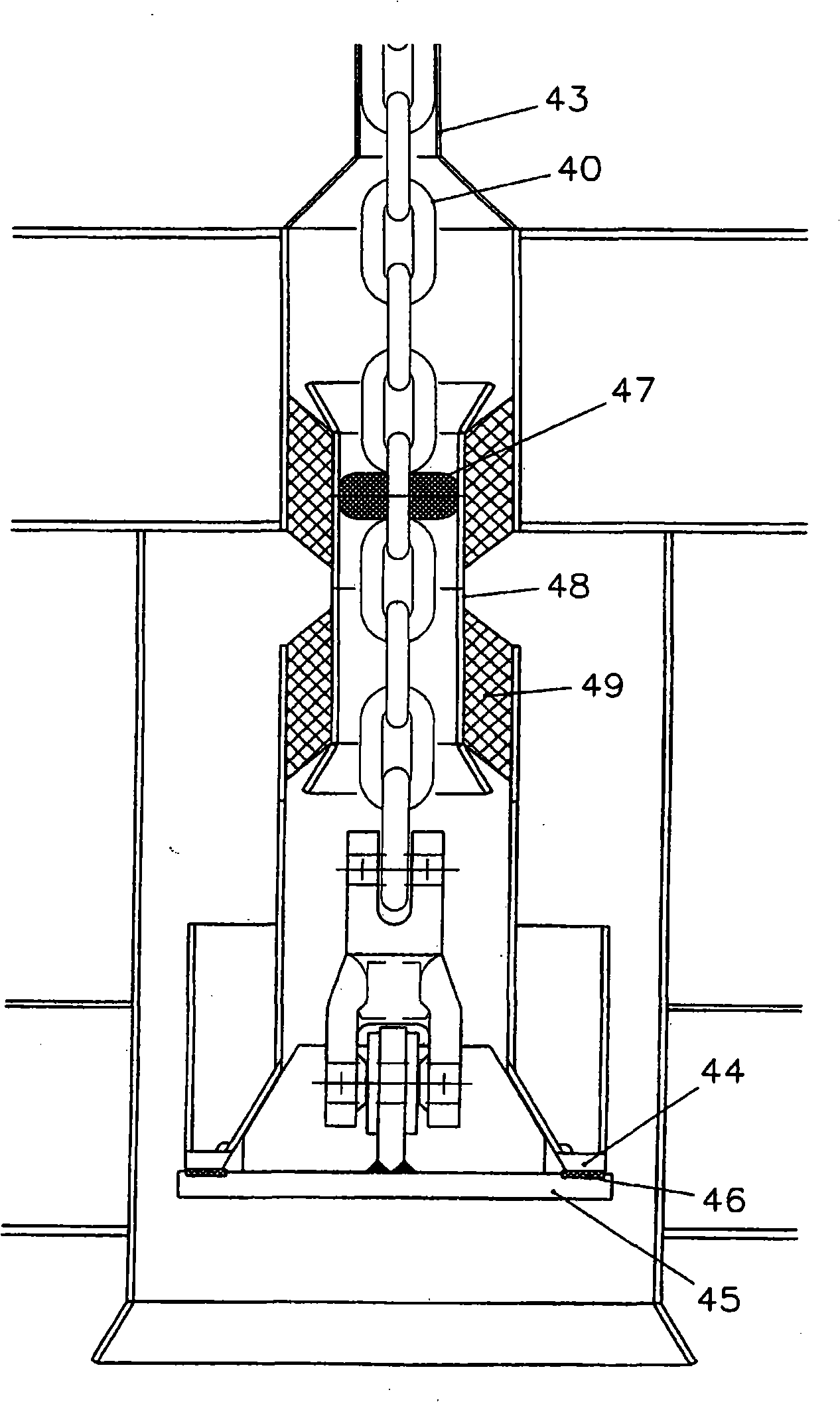

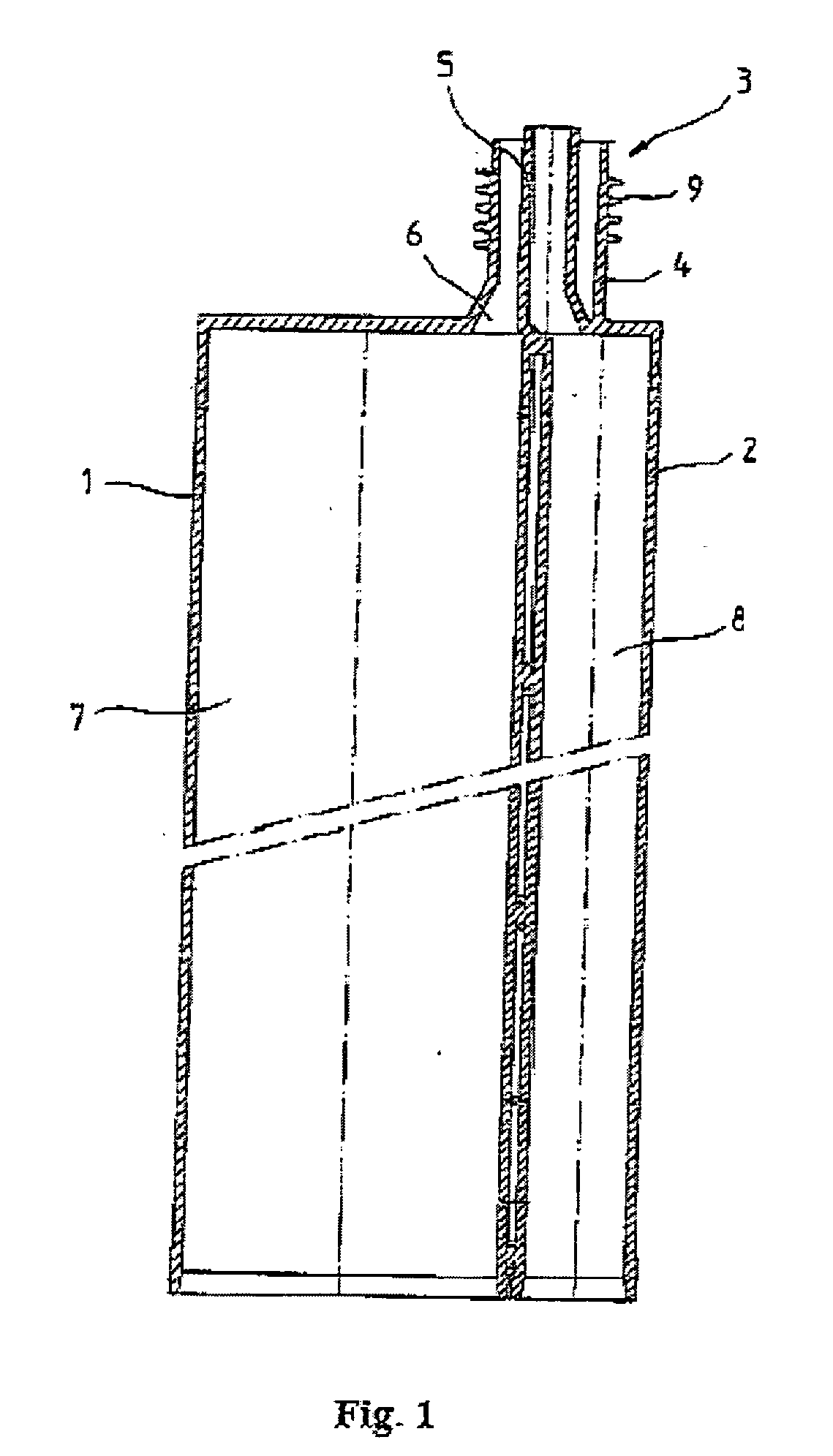

Disconnectable mooring system for a vessel

ActiveCN101336190AGuaranteed sealing performanceBonding guaranteeBuoysAnchoring arrangementsVertical tubeMooring system

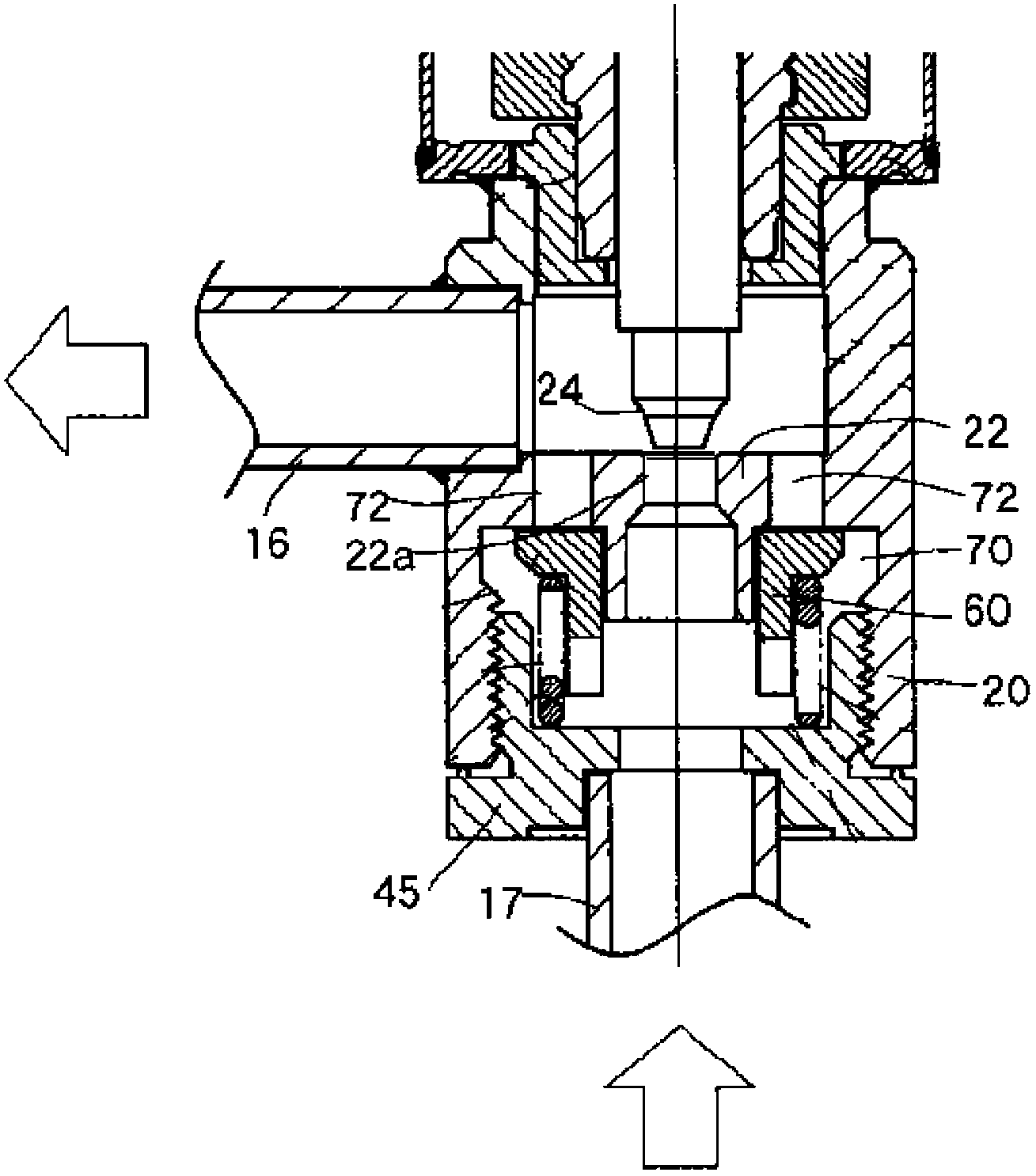

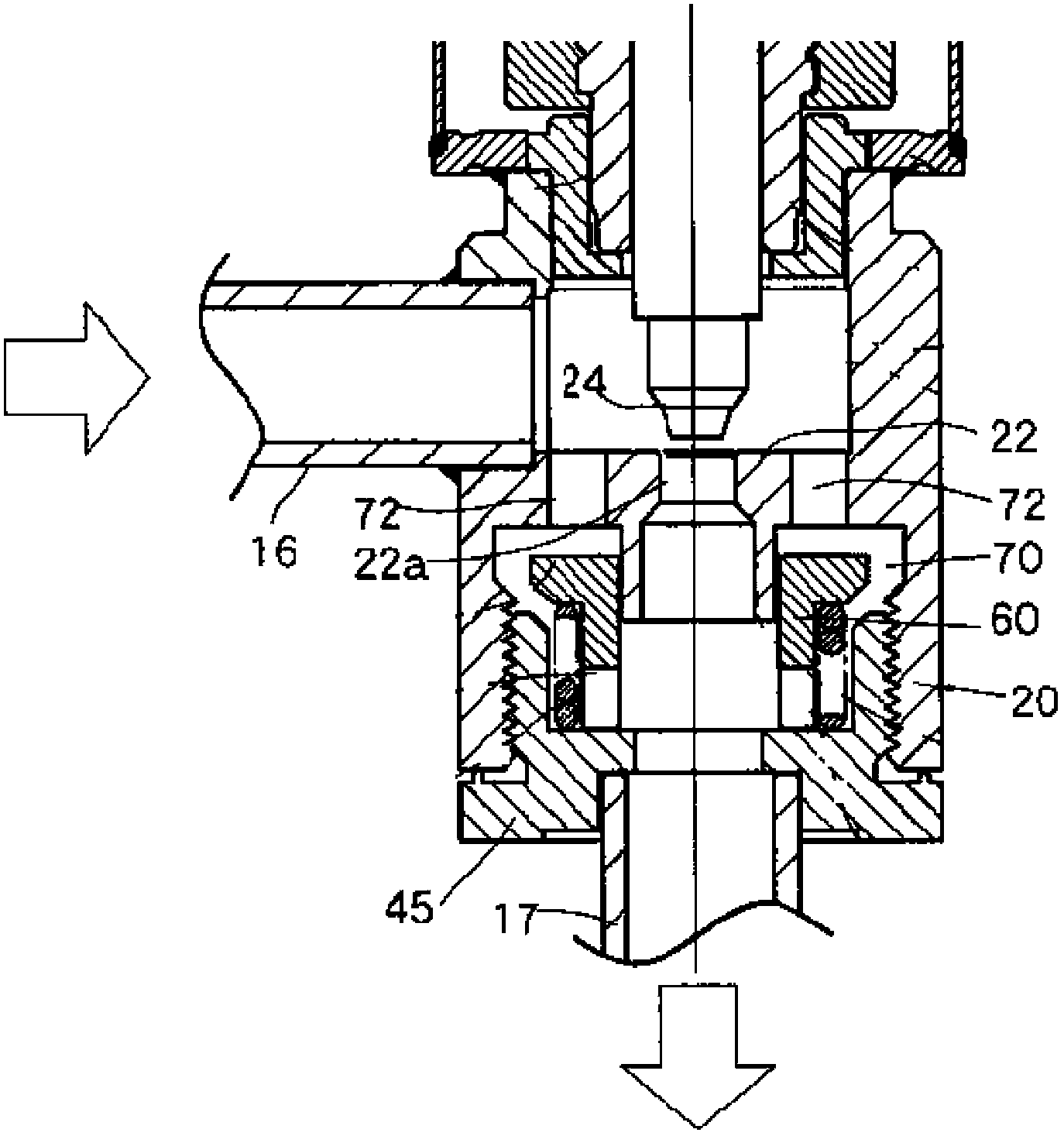

A disconnectable mooring system for a vessel comprises a mooring buoy member (2) and a turret structure (3), mounted in a moonpool (4) of the vessel (1). The mooring buoy has a plurality of passages (6) each adapted to receive a riser (7). The turret structure has a receptacle for receiving the buoy member and locking means for locking the buoy member in the receptacle. The turret structure (3) accommodates a plurality of conduits to be connected to risers installed in passages of the buoy member and the turret structure is rotatably supported in the moonpool (4) of the vessel (1) by means of at least a bearing assembly (16) mounted above sea level. The turntable (21) is supported on the bearing assembly (16) in a manner allowing rotation with respect to the turret structure (3) to align the conduits with the risers (7) when the buoy member (2) is received and locked in the receptacle of the turret structure (3).

Owner:BLUEWATER ENERGY SERVECES BV

Box-sharing gas-insulated metal enclosed switching device

InactiveCN102044849AReduce volumeReduce areaBus-bar/wiring layoutsSwitchgear arrangementsTransformerPotential transformer

The invention discloses a box-sharing gas-insulated metal enclosed switching device. An upper sealed air box and a lower sealed air box are arranged in a cabinet body; a three-position isolating switch, a main bus casing and a main bus are arranged in the upper air box; an output shaft of a three-position spring operating mechanism extends into the upper air box and is connected with the three-position isolating switch through a rotary sealed connector; the three-position isolating switch is connected with a vacuum circuit breaker in the lower air box through a bus connector; the vacuum circuit breaker is connected with a spring mechanism through a metal corrugated pipe sealing mechanism; the vacuum circuit breaker is connected with an inner conical insulator which is sealed and fixed on the wall of the lower air box through a lead; and the inner conical insulator is inserted into a voltage transformer, a cable joint, a zero sequence transformer and a lightning arrester respectively. The switching device has the characteristics of good sealing effect, long service life, small size and wide application range and is safe and reliable.

Owner:昇辉智能科技股份有限公司

Feeding and discharge switch valve for food filling

ActiveCN101767760AExtended service lifeGuaranteed sealing performanceSpindle sealingsLiquid bottlingThermal deformationEngineering

The invention provides a feeding and discharging switch valve for food filling, which comprises a valve body and a valve core; a discharging port and a feeding port are arranged on the valve body, the valve core is provided with a switch joint port for the discharging port and the feeding port, and the valve body adopts ceramic material on the periphery of the discharging port and the feeding port, and the valve core to realize seal fit and form isolation of material. As the technical scheme of the invention is adopted, the sealing of valve core and the valve body is guaranteed only through size accuracy, no additional seal element is needed, the material isolation is realized and the sealing is realized, as the abrasion resistance of the ceramic is higher, the service life of the switch valve is longer due to smaller abrasion; as the ceramic material has stability, the thermal deformation coefficient is very small, the condition that the valve body and the valve core cannot rotate and axially slide due to thermal expansion interference after being heated is not happened so the high position CIP cleaning can be realized conveniently.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

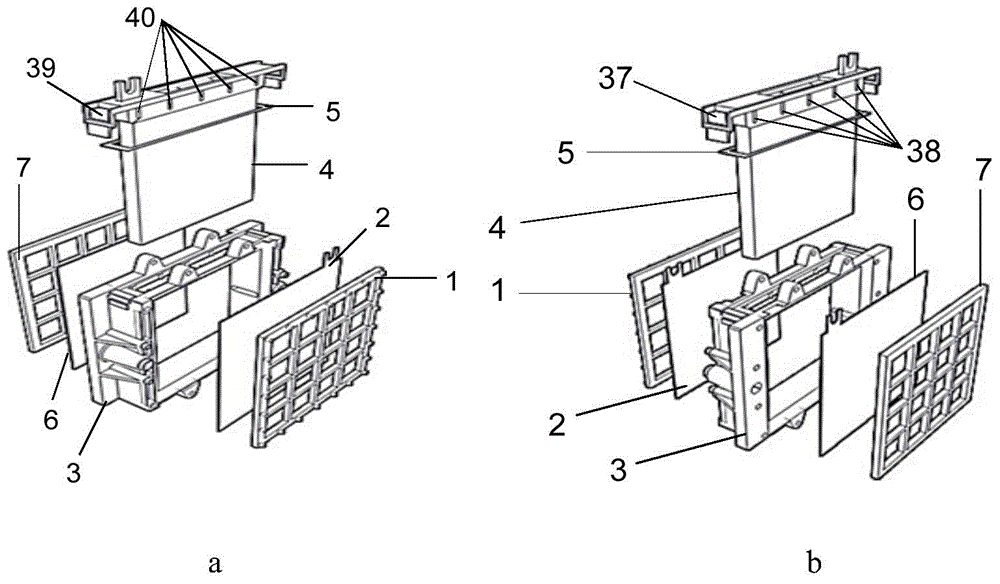

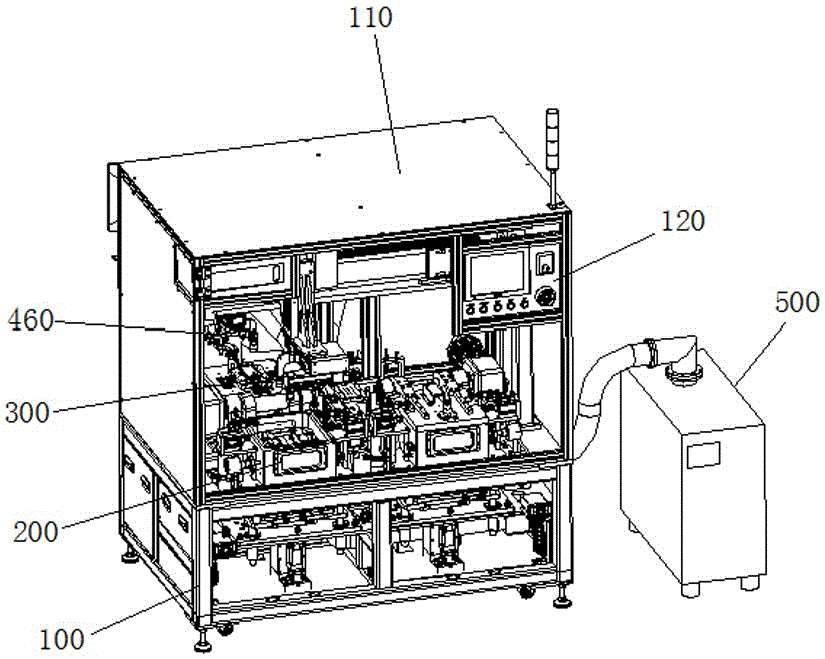

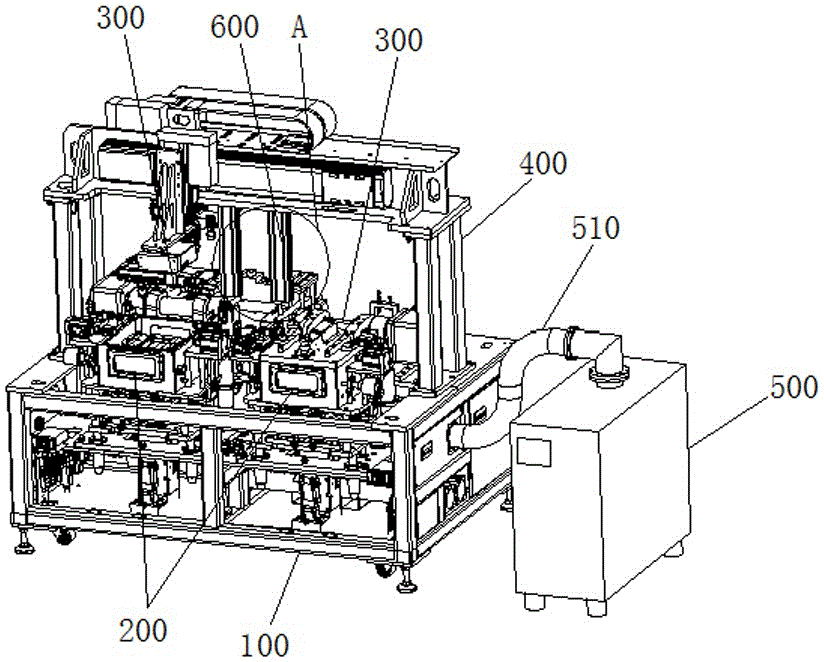

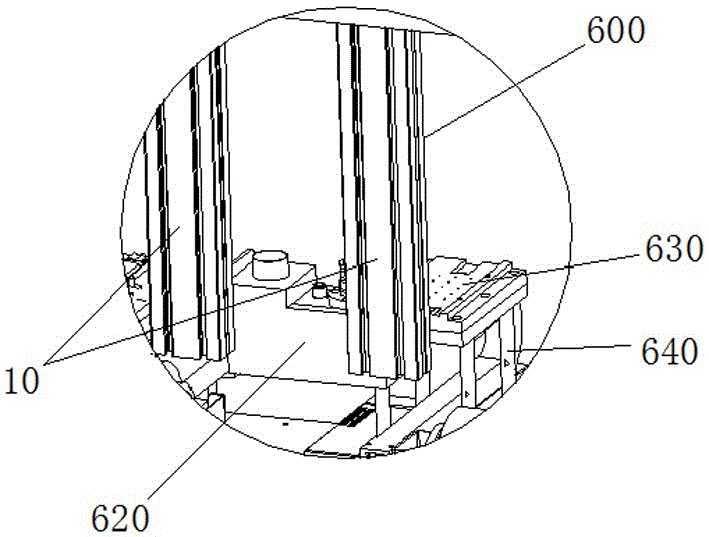

Multipurpose attaching machine for 3D glass curved screens

The invention discloses a multipurpose attaching machine for 3D glass curved screens. The multipurpose attaching machine comprises a rack, and two vacuum cavities, a vacuumizing mechanism, a glass conveying mechanism and two turning mechanisms are arranged in the rack; the vacuum cavities are used for containing Film protection films, and each vacuum cavity comprises a Film protection film positioning mechanism and a Film protection film fine tuning mechanism; the vacuumizing mechanism is used for vacuumizing the vacuum cavities; the glass conveying mechanism is used for automatically conveying 3D glass, and CCD vision inspection units matched with the Film protection film fine tuning mechanisms are arranged at the bottom of the glass conveying mechanism; the turning mechanisms are used for positioning and turning the glass, and each turning mechanism comprises a cavity cover plate, a glass positioning fixture, a pneumatic clamping mechanism and a rotating shaft; after the 3D glass is manually placed in the glass positioning fixtures in parallel to be clamped, driving mechanisms drive the 3D glass to turn along with the cavity cover plates to the position over the Film protection films to complete attaching of the glass and the Film protection films. The multipurpose attaching machine for the 3D glass curved screens has the advantages of being in precise in glass positioning and Film protection film positioning, good in cavity sealing and vacuumizing effect, high in attaching efficiency, good in attaching effect and the like.

Owner:HUIZHOU LONGHAI TECH

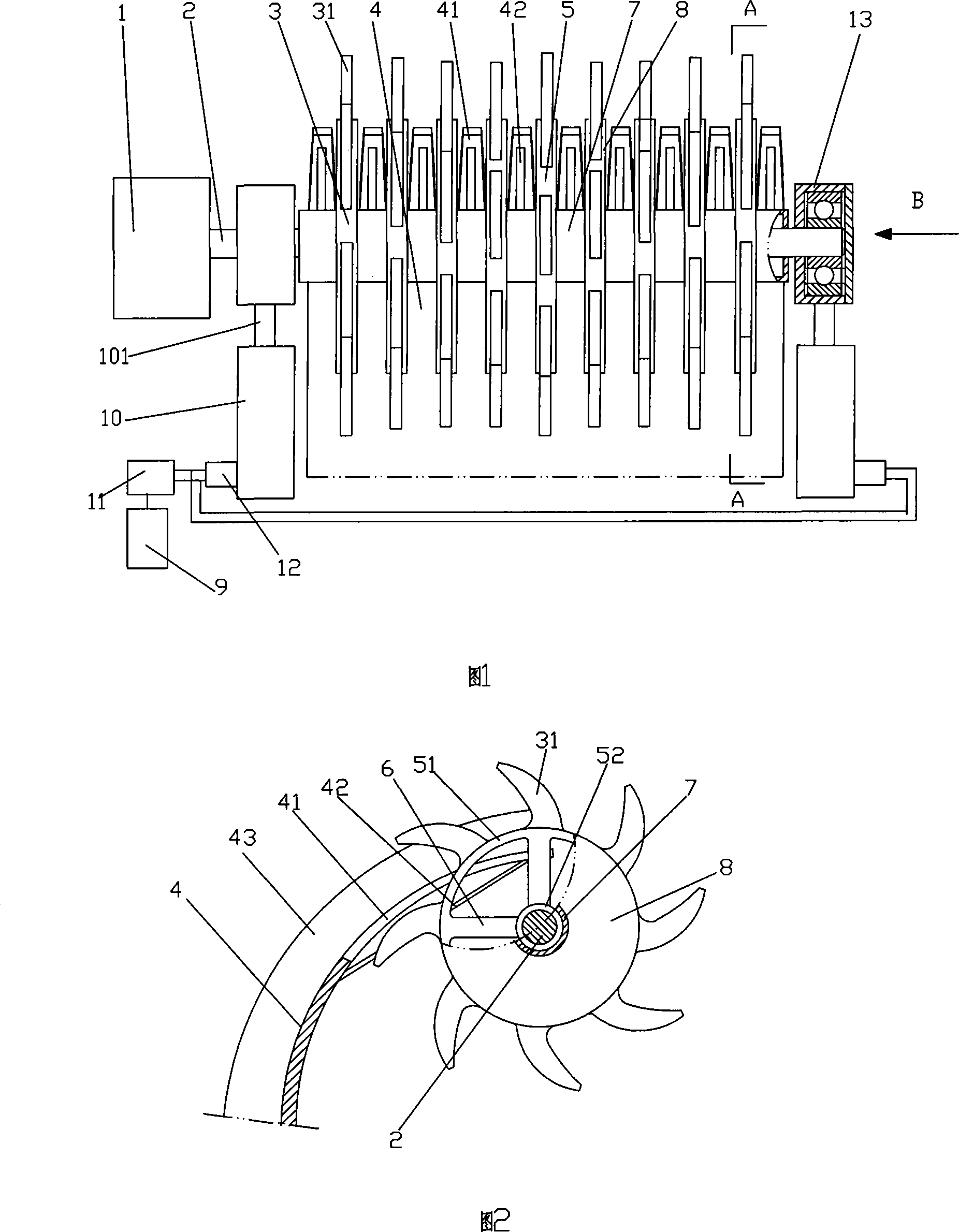

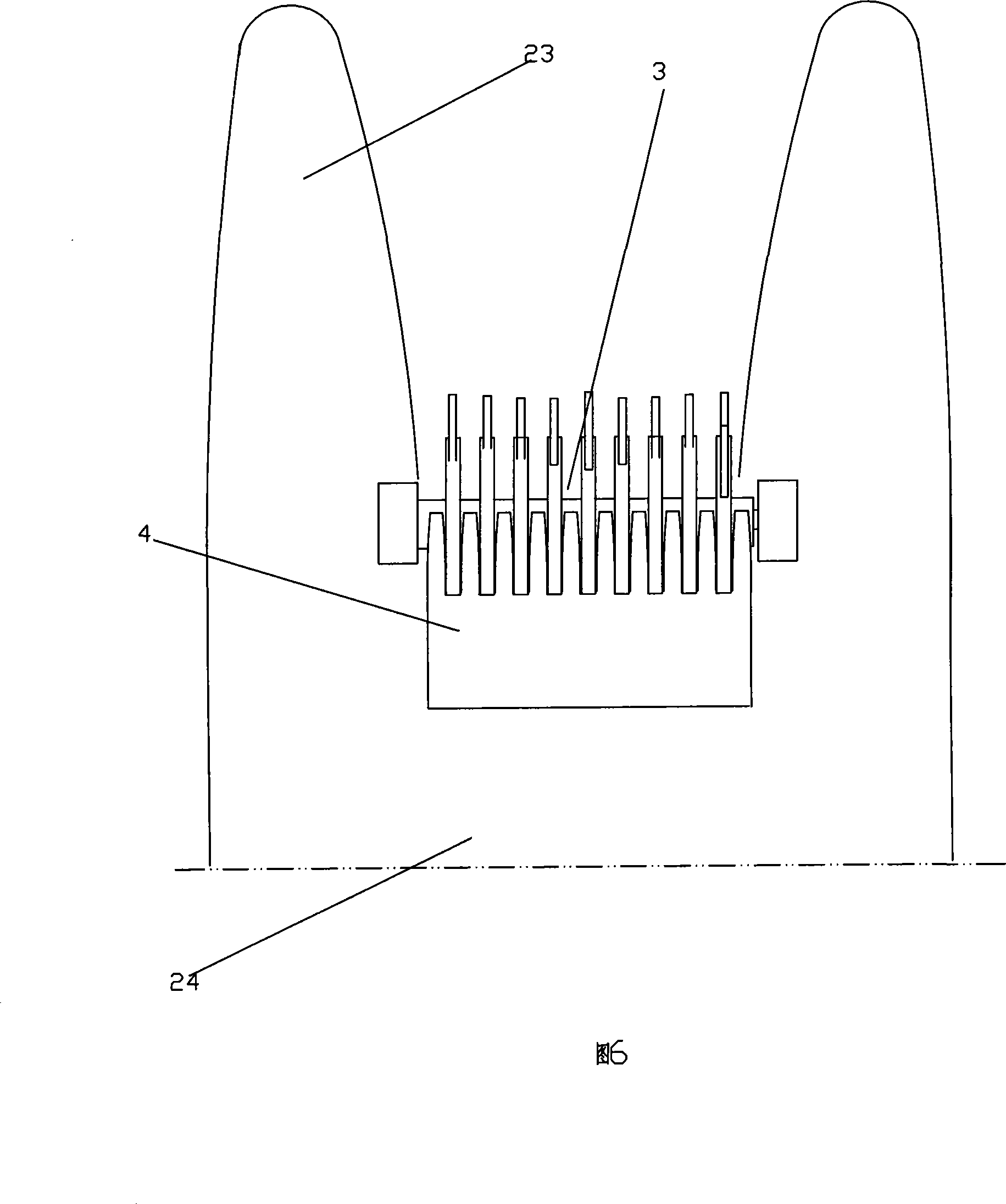

Device for cleaning waters floating material

The invention discloses a water area flotage cleaning device, which comprises a power device, a catcher, a separator and a flotage processing and recycling device, wherein the catcher comprises a rotary shaft and at least one catching gear, the power device matches with the rotary shaft to drive the rotary shaft, the catcher gear is arranged relative to the rotary shaft radial direction and is fixed and matched with the rotary shaft, the separator and the non-rotary part of the catcher are relatively fixed, the separator is arranged from the upper side to the lower side, the upper side is set in a comb gear shape, the comb gear shape is composed of at least two separating gears arranged in axial direction, the adjacent separate gears are arranged on both sides of the catcher gear with a gap to the catcher gears. The invention has simple and compact structure, high mechanic degree, small energy consumption, short flow, small occupancy area, easy operations, high work efficiency, environment protection property, convenient maintenance, simple process, and can maximally save labors, resources and process cost.

Owner:CHONGQING UNIV

Sealing method for split type magnetic liquid sealing device

InactiveCN102537366AIntegrity guaranteedGuaranteed sealing performanceEngine sealsMagnetic liquidsSealant

A sealing method for split type magnetic liquid sealing device belongs to the field of mechanical engineering sealing, and solves the problems that as the present large-diameter magnetic liquid rotation sealing device applies sealant at the jointed surface of a two-flap structure, the redundant sealant is extruded out after installation and remains on pole teeth at the inner circles of pole shoes, and uneven application influences the sealing performance at the same time. The sealing method is realized as follows: a stainless steel sheet is heated and kept at a temperature between 300 DEG C and 35 DEG C; the stainless steel sheet is stuck into a clearance between a sealing shaft and the pole teeth of the pole shoes; the stainless steel starts from a point at the jointed clearance between two half-pole shoes, and moves along the circumferences of the half-pole shoes to return the start point, so that the sealant extruded from the jointed surfaces of the pole shoes is vaporized; the thickness of the stainless steel sheet is smaller than the clearance between the sealing shaft and the pole teeth of the pole shoes, so as to enable the stainless steel sheet to stick into the clearance; a medical injector is used for sucking magnetic liquid at the jointed clearance between the two half-casings of the split type magnetic liquid sealing device, and the injector starts from a point at the jointed clearance, and continuously injects the magnetic liquid along the circumferences till returning the start point.

Owner:BEIJING JIAOTONG UNIV

Electronic expansion valve

ActiveCN103512288AThe spring force can be set smallReduce settingsCheck valvesEfficient regulation technologiesEngineeringHigh pressure

The invention discloses an electronic expansion valve. According to the electronic expansion valve, a piston part (4) and a valve needle part (3) are located on the same side of a valve element seat (2) so that a bypass through hole (212) can be blocked by the piston part (4) when a refrigerant flows in the forward direction, the refrigerant flows to one end of a vertical connecting pipe (52) through a valve element valve port (211), and the valve needle part (3) moves in the axial direction to adjust the open degree of the valve element valve port (211); when the refrigerant flows in the backward direction, the piston part (4) moves upwards in the axial direction to open the bypass through hole (212), and the refrigerant flows to one end of a transverse connecting pipe (51) through the bypass through hole (212). According to the electronic expansion valve, on one hand, the valve element valve port can be sealed easily by the valve needle part under the high-pressure condition when the refrigerant flows in the forward direction, and the valve needle part is prevented from being ejected open by the high-pressure refrigerant; on the other hand, the axial size and radial size of a valve seat can be reduced, and flow resistance when the refrigerant flows in the backward direction is reduced.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Vertical-type spiral particle waste heat recycling device and method for sintering waste heat power generation system

InactiveCN104048516AAvoid increased resistanceReduce compressive stressEnergy industryIncreasing energy efficiencyControllabilityFlat panel

The invention discloses a vertical-type spiral particle waste heat recycling device and method for sintering waste heat generation. A device body is sequentially provided with a prestoring segment, a chute segment, a cooling segment and a lower conical segment from top to bottom. The device body is internally provided with an air supply body. The air supply body is a cylinder and is hollow. The top of the air supply body is provided with a pointed cone. The upper portion of the air supply body is provided with four cross-shaped supporting rods. The outer ends of the four supporting rods are fixedly connected with the chute segment. A heat exchange cavity is formed between the air supply body and a tank body of the cooling segment. The outer side of the middle of the air supply body is provided with a spiral discharging channel. The periphery of the upper portion of the spiral discharging channel is connected with the cooling segment. The lower portion of the air supply body is provided with an upward-inclined cross-shaped air channel. The cross-shaped air channel is connected with the lower portion of the lower conical segment. The bottom of the lower conical segment is provided with a bulkhead gate. A closed-type vibrating feeder is arranged below the bulkhead gate. The vertical-type spiral particle waste heat recycling device meets the specific requirement of sintering ore for a cooling device and is high in controllability, the service life of the vertical-type spiral particle waste heat recycling device is prolonged, gas resistance is reduced, flow and temperature uniformity are improved, and the waste heat utilization rate is improved.

Owner:ZHEJIANG UNIV

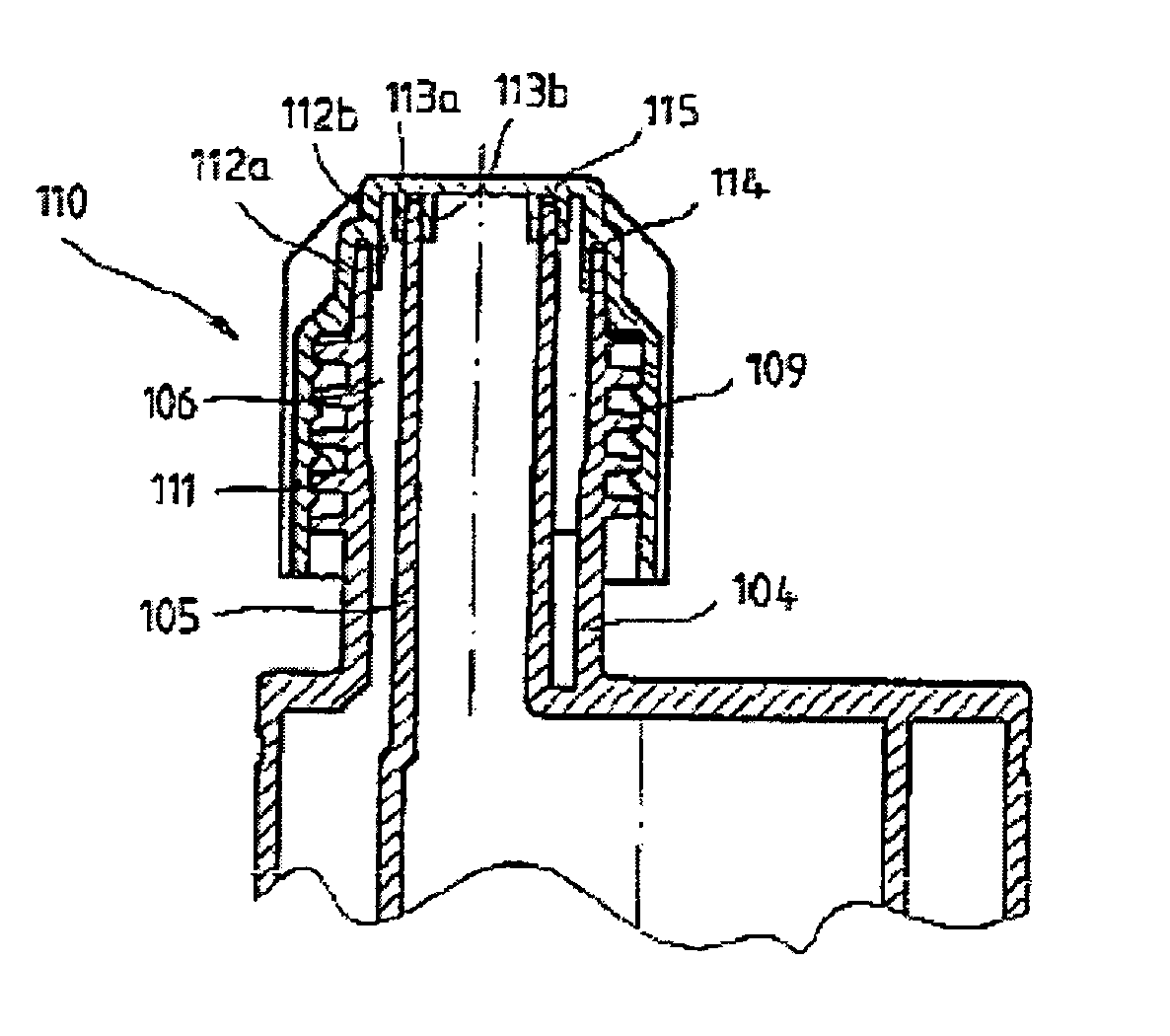

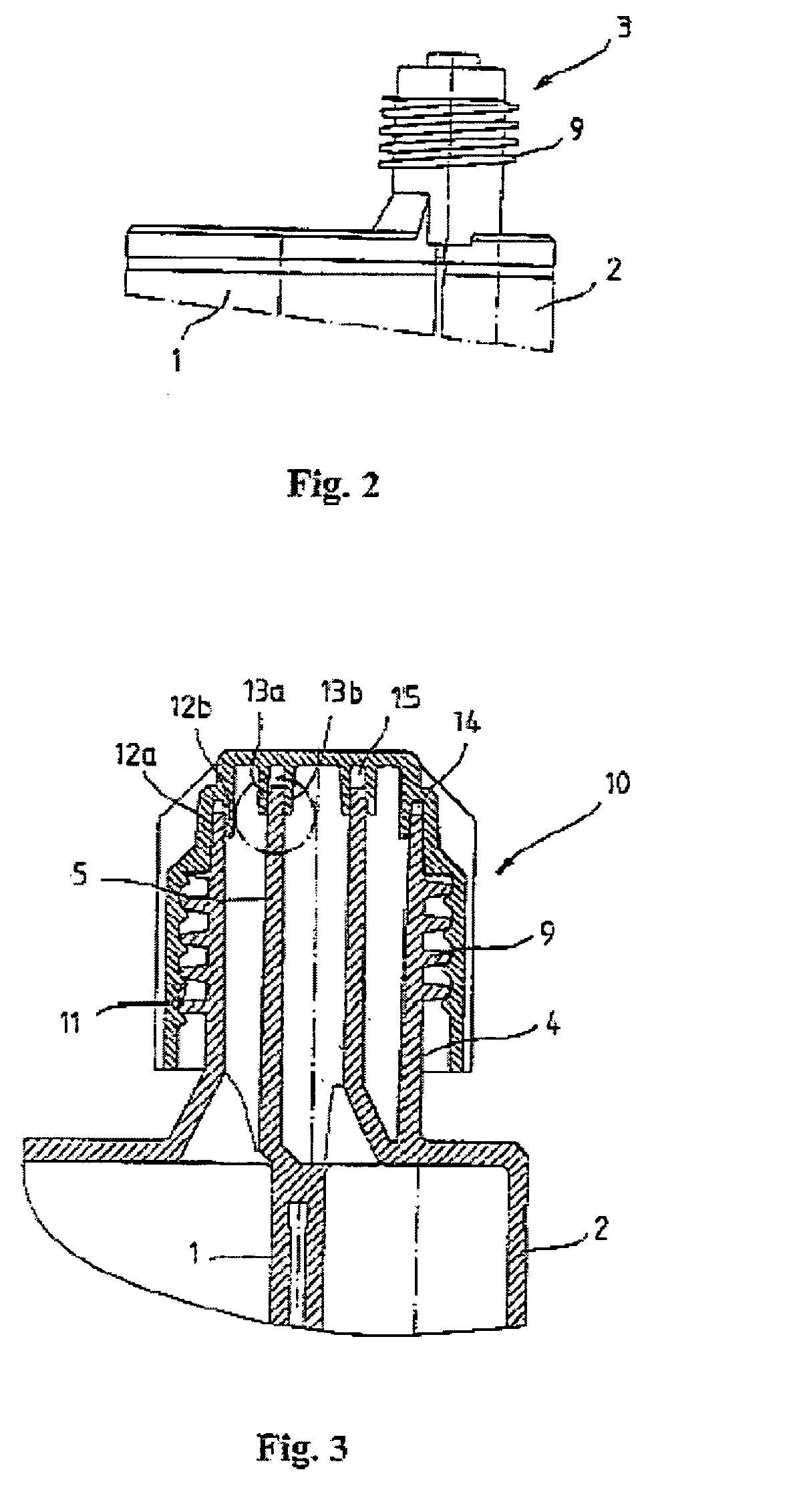

Multicomponent cartridge

ActiveUS20050051576A1Increase surface pressureHigh sealing pressureLiquid surface applicatorsInternal framesEngineeringFlange

A multicomponent cartridge, particularly a two-component cartridge, contains a coaxial outlet with an outer outlet tube and an inner outlet tube concentric to the outer tube. A cap detachably connected to the coaxial outlet. A seal with at least one seal flange is arranged on the cap for contact on the inner and / or outer outlet tube. A simplified and improved seal is thus enabled, such that the seal includes at least one laterally projecting sealing edge, which extends around the inner and / or outer side of the inner and / or outer outlet tube of the coaxial outlet and / or on the side of the one or more seal flanges facing the outer and / or inner side of the inner and / or outer outlet tube.

Owner:SULZER CHEMTECH AG

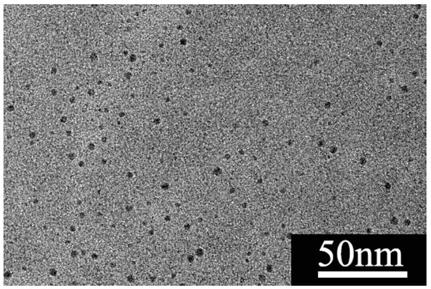

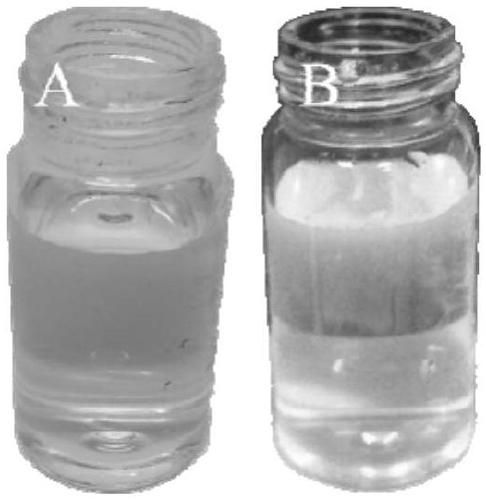

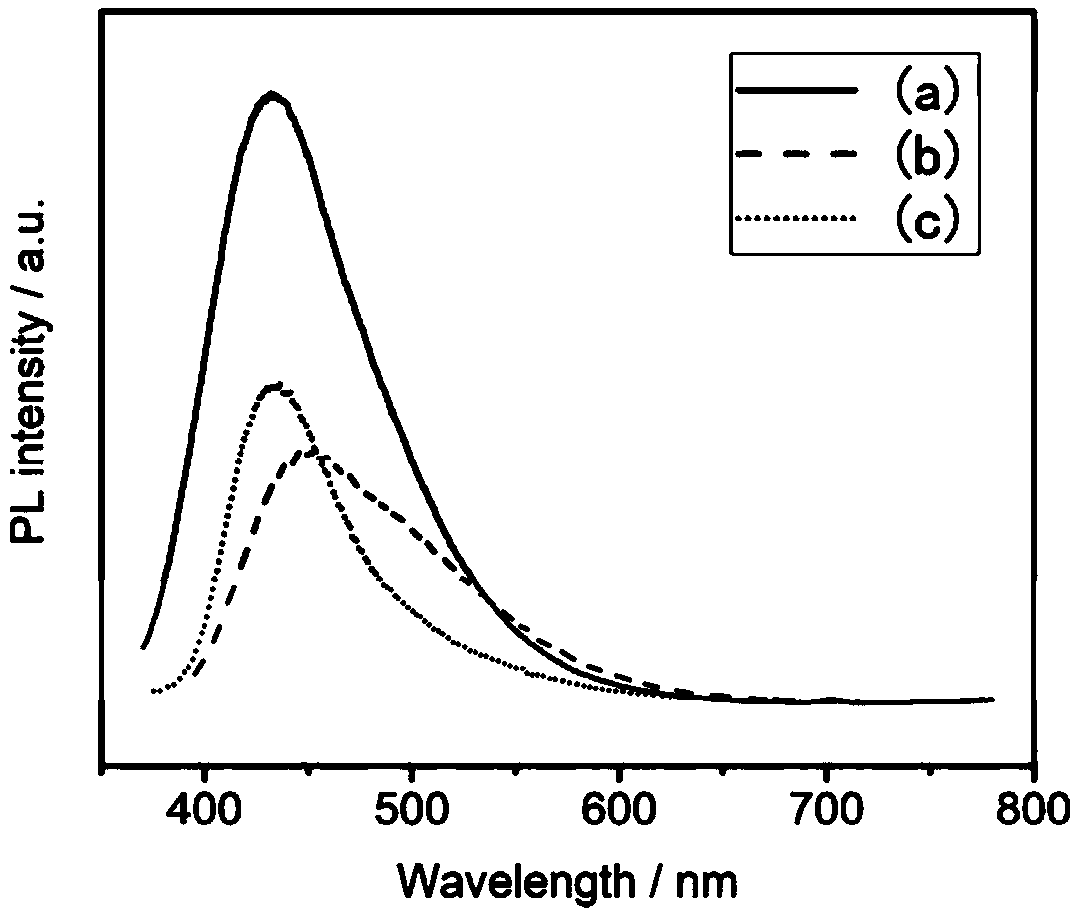

Carbon quantum dot and green preparation method and application thereof

The invention belongs to the technical field of nanometer materials, and particularly relates to a carbon quantum dot and a green preparation method and application thereof. The preparation method includes: dissolving natural macromolecular carbohydrates or derivatives thereof in water, mixing with a dilute acid aqueous solution or a dilute alkali aqueous solution, heating with stirring to obtaina mixed solution; heating the obtained mixed solution in a sealed autoclave and preserving heat to obtain dispersion liquid; subjecting the obtained dispersion liquid to ultrasonic dispersion and centrifugal separation to obtain upper-level solution which is an operational carbon quantum dot solution. The preparation method of the carbon quantum dot is simple, low in equipment requirements and easy for mass production, no organic solvent is used in a whole process, no pollution is generated, and the prepared carbon quantum dot can be used for cell marking, optical imaging, medicine transporting, biosensing and the like.

Owner:LUOYANG NORMAL UNIV

Carving and molding process of leather

InactiveCN102642437AReduce processing costsSimple and fast operationDecorative surface effectsWater coolingUltimate tensile strength

The invention relates to a treatment process of leather, in particular to a carving and molding process of leather with a concave-convex arabesquitic pattern structure. The process comprises the following steps of: 1), manufacturing a corresponding plastic absorbing mold according to a selected stereoscopic figure or pattern; 2), putting the leather above the plastic absorbing mold in a vacuum plastic absorbing device, folding the leather with the plastic absorbing mold after the leather is heated to 90-120 DEG C, sealing four sides of the leather with four sides of the plastic absorbing mold, and applying vacuum, so that the leather is clung on the surface of the plastic absorbing mold to be molded; and 3), cooling the molded leather through an air cooling or water cooling way, and carrying out demolding to obtain a leather product with a concave-convex carved and molded structure. By using the carving and molding process, the plastic absorbing carving and molding are adopted; the whole flow is simple and convenient; the operation cost is low; the plastic adsorbing mold only needs one mold; moreover, a material does not need quite high strength; and thus, the carving and molding process is also lower in the machining cost of the mold.

Owner:东莞市顺琦手袋实业有限公司

Potential-based spontaneous percolation measuring device

ActiveCN104297123AUnderstanding Water Absorption RateUnderstanding Capillary ForcePermeability/surface area analysisMeasurement deviceEngineering

The invention discloses a potential-based spontaneous percolation measuring device which comprises a confining pressure control system, a potential monitoring system and a pressure difference control system. The confining pressure control system comprises a rack, a rubber cylinder, a core, a confining pressure valve, a confining pressure pump and hydraulic oil. The potential monitoring system comprises a constant-voltage power supply, a mesh-shaped positive electrode, a meshed-shaped negative electrode, a data transmission line, a potential measuring sheet and a fixed-value resistor disc. The pressure difference control system comprises a pressure meter, a water storage space, a communicating pipe, a pond, a communicating valve, a hand pump and an emptying valve. The potential-based spontaneous percolation measuring device is simple in structure, easy to realize, and capable of monitoring the change of saturability on all circumferential places of the core in a spontaneous percolation process over time; the potential-based spontaneous percolation measuring device is capable of measuring the change of the saturability of the core in the spontaneous percolation process over time under the condition of applying different confining pressures; the potential-based spontaneous percolation measuring device is further capable of measuring the change of the saturability of the core in a displacement process over time under the condition of applying different pressure differences to two ends of the core, and knowing parameters such as a water absorption rate, a capillary force and a water absorption quality of the core.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Conformal cooling waterway mold structure and processing method

InactiveCN105252728ALow processing and manufacturing costsGood for promotion and application3D printingMaterials science

The invention discloses a conformal cooling waterway mold structure and a processing method, relates to the technical field of mold manufacturing, and solves the problems that the conventional 3D printed conformal cooling waterway mold has high cost, and the print size is limited. According to the technical scheme, the conformal cooling waterway mold structure comprises a basal body and an insert, wherein a groove is formed in the molding surface of the basal body, and at least two waterways communicated with the groove are arranged in the basal body; the insert is mounted in the groove, and conformal waterways are arranged on the two sides of the contact surface of the insert and the basal body or in the insert and communicated with the waterways in the basal body to form channels; a cladding layer is arranged at the seam line of the insert and the basal body, and the external surface of the cladding layer is the molding surface. The conformal cooling waterway mold structure is detachably processed, and the insert can be processed in the conventional mechanical processing way or the selective laser melting 3D printing processing way. The liquid and gas sealing in the waterways is ensured, the processing and manufacturing cost is significantly reduced, and the popularization and application of the conformal cooling waterway is facilitated.

Owner:四川长虹模塑科技有限公司

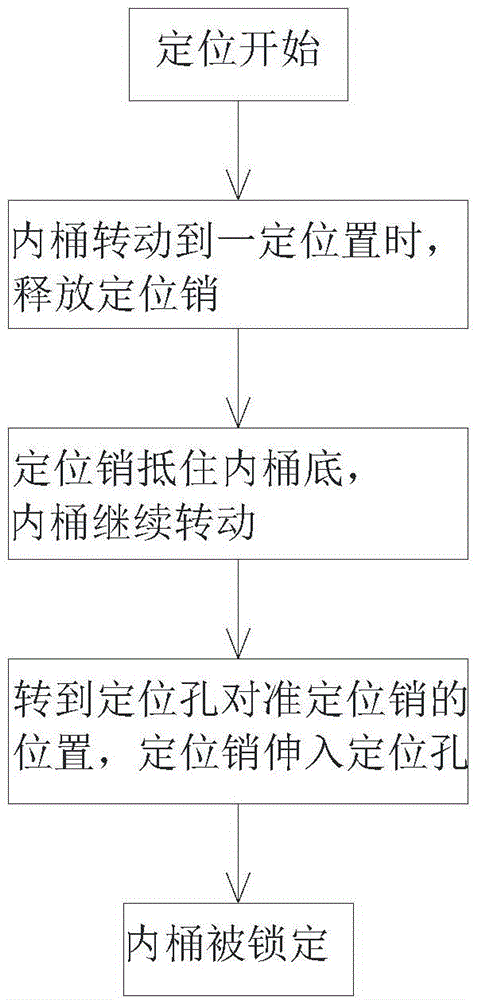

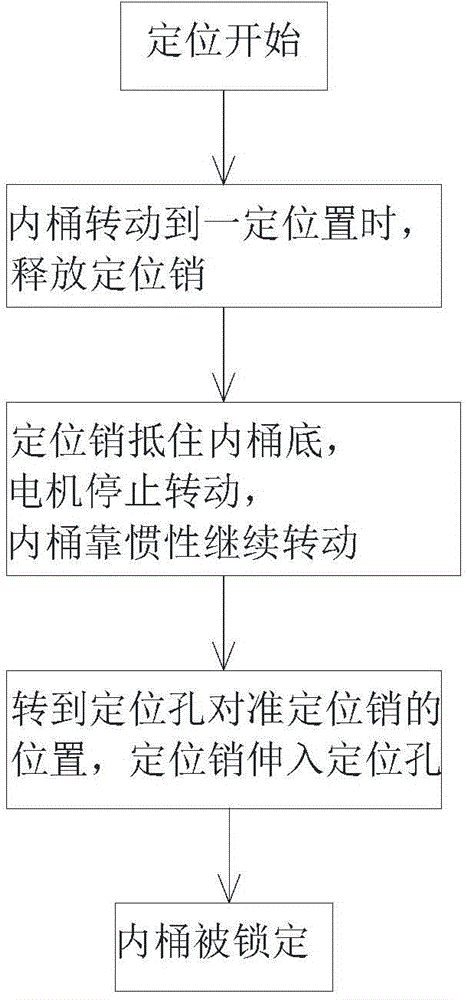

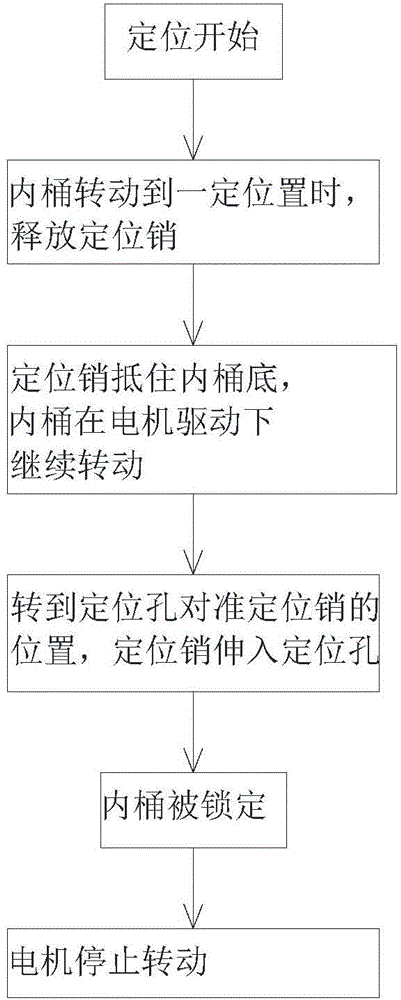

Automatic positioning inner barrel control method

ActiveCN106032618AAvoid shakingGuaranteed sealing performanceOther washing machinesControl devices for washing apparatusWater leakageEngineering

The invention relates to an automatic positioning inner barrel control method; the bottom of the inner barrel is provided with a positioning hole; the bottom of the outer barrel is provided with a positioning pin; the positioning pin is provided with a structure driving the positioning pin to telescope; when the inner barrel rotates to certain position, the positioning pin is released to press the bottom of the inner barrel; the inner barrel continuously rotate until the positioning hole aligns with the positioning pin, the positioning pin can extend into the positioning hole so as to lock the inner barrel. After the positioning pin is released, the inner barrel continuously rotate under inertia effect, or the inner barrel is driven by a motor to continuous rotate; when the inner barrel rotates and the positioning hole aims at the positioning pin, the positioning pin can extend into the positioning hole, thus automatically positioning and locking the inner barrel; a water outlet and a draining control structure can be ensured to be sealed, thus preventing water leakage.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

Adjustable annular jet pump

InactiveCN103233924AGuaranteed sealing performanceRealize fully automatic controlJet pumpsMachines/enginesThroatWorking fluid

An adjustable annular jet pump comprises a rectifying assembly, a mixing pipe (7), a throat pipe (8), a diffusing pipe (9) and an outlet pipe (10) which are sequentially connected. The rectifying assembly comprises a rectifying pipe (4), an absorbed fluid pipe (1) and a working fluid pipe (11); the rectifying pipe (4) is communicated with the working fluid pipe (11); one end of the rectifying pipe (4) is provided with an end cover (3); the absorbed fluid pipe (1) which penetrates through the end cover (3) can perform axial movement relative to the end cover (3); the outer end of the end cover (3) is provided with a scale (12); and the absorbed fluid pipe (1) is provided with a pointer (13). The adjustable annular jet pump has the advantages of being adjustable in area ratio and enabling the performance to be adjusted according to the working condition; being capable of achieving that an absorbed fluid channel smoothly and stably moves along an axis and simultaneously guaranteeing sealing for high pressure working fluids by increasing the existing mature transmission devices on the market; and being simple to operate namely that manual control can be performed and full-automatic control can also be achieved according to a scheduled program, simple in structure, low in cost and beneficial to promotion and application due to high cost performance.

Owner:WUHAN UNIV

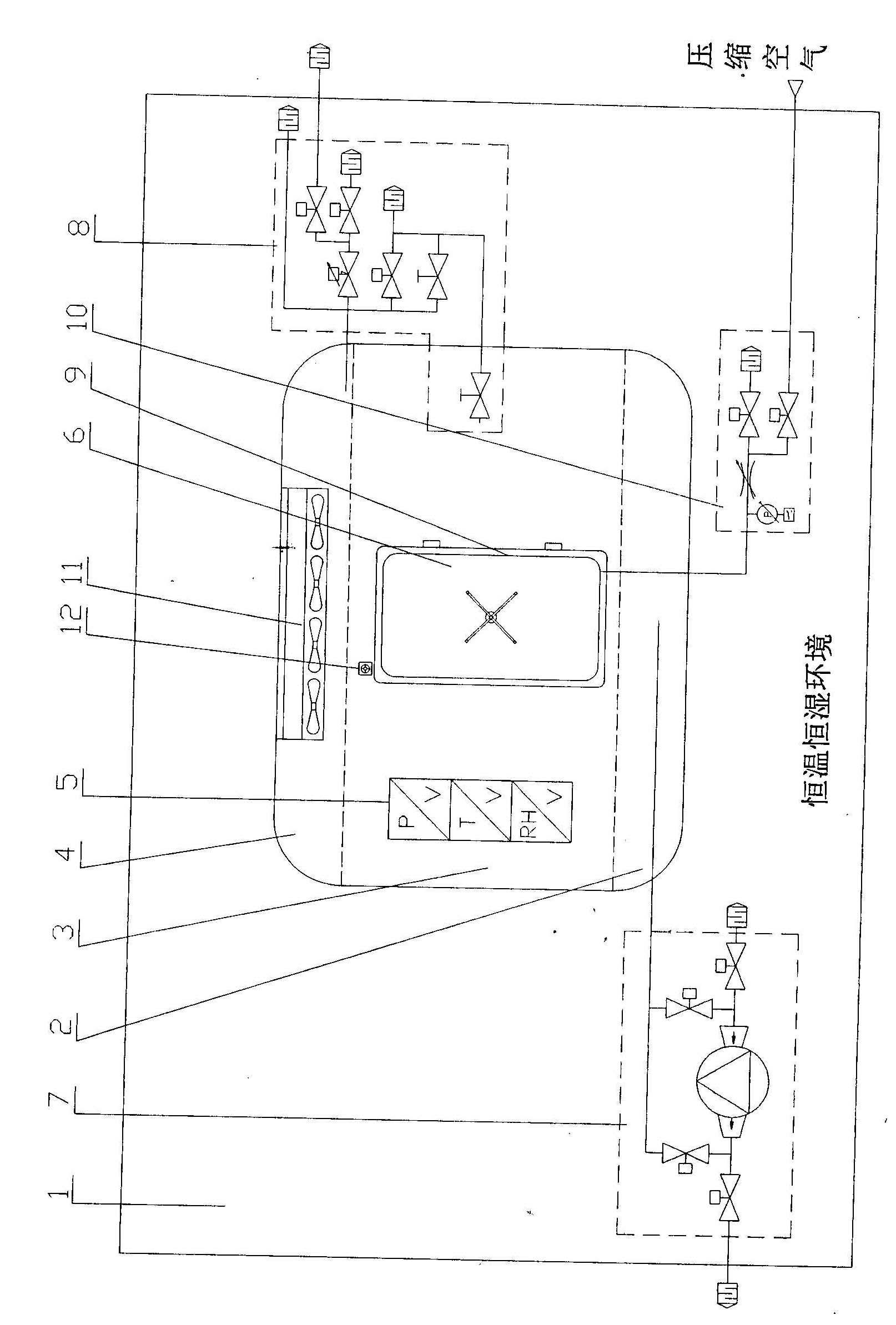

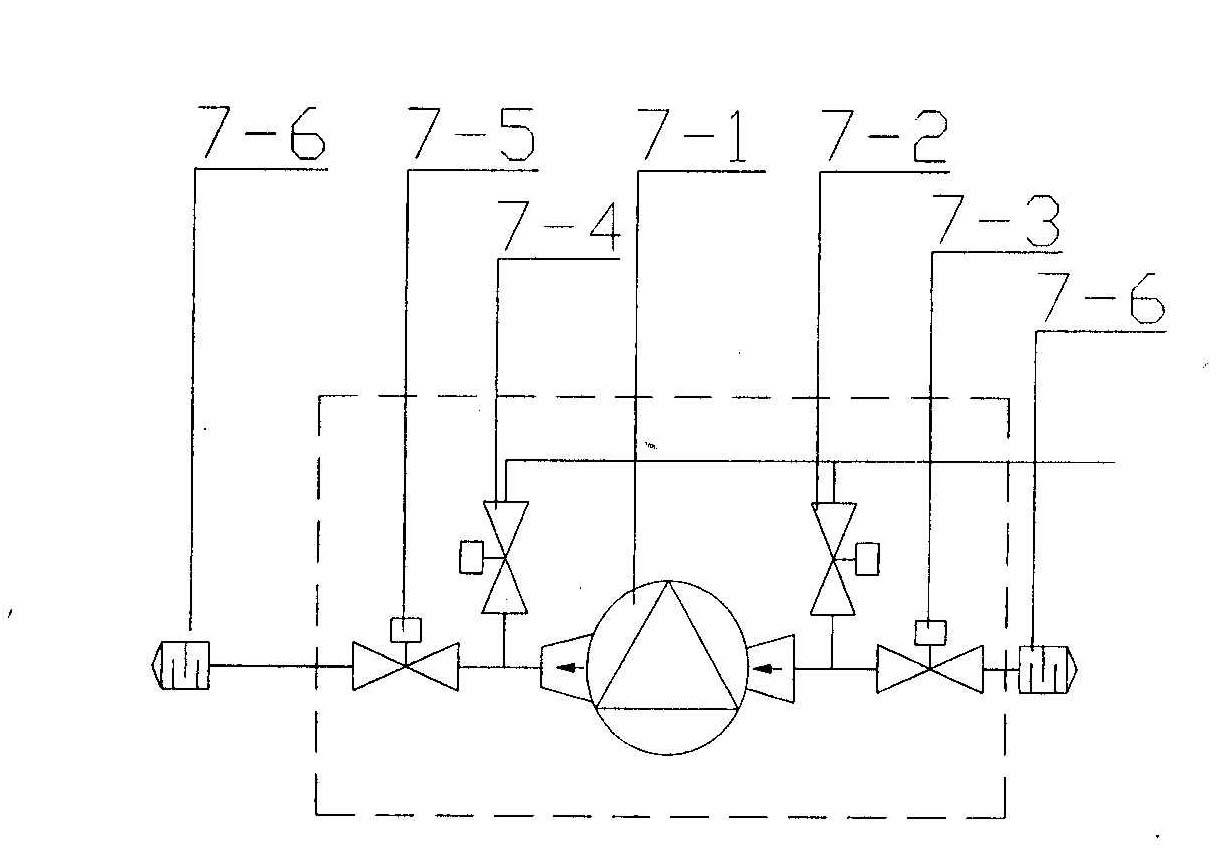

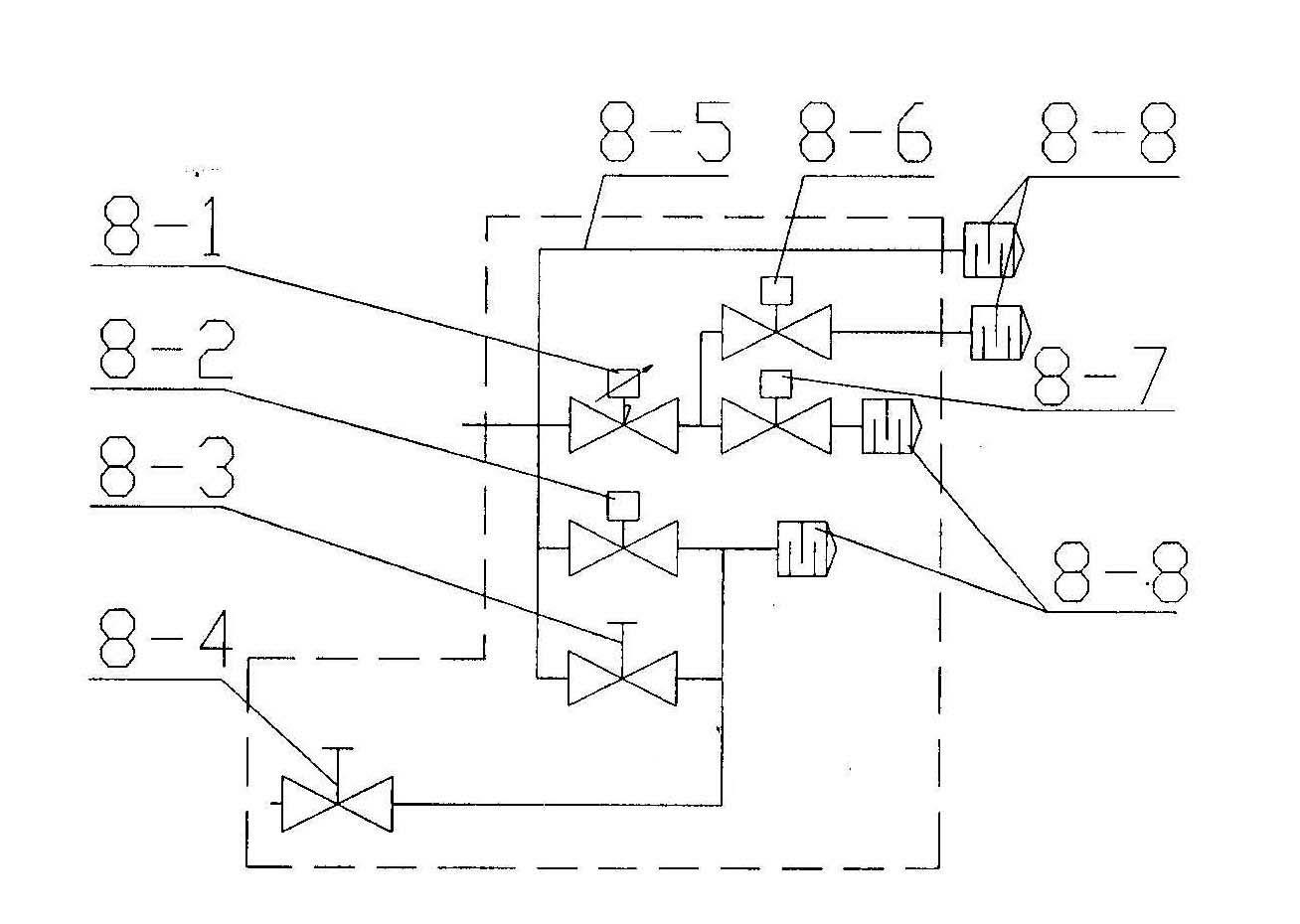

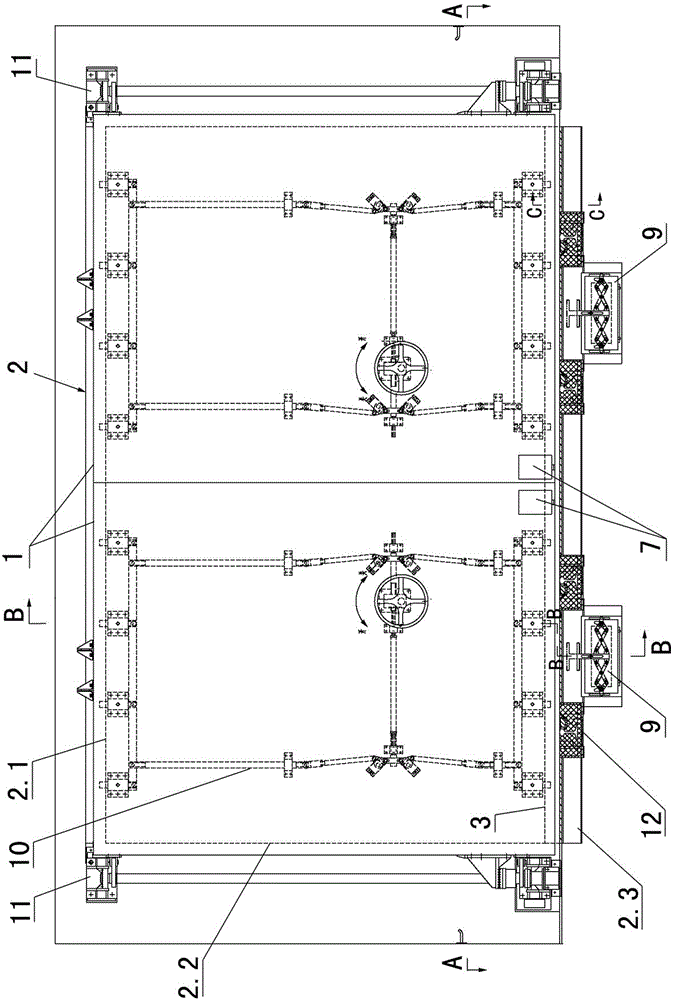

Experiment cabin system capable of adjusting atmospheric environmental pressure

ActiveCN102489350AHigh control precisionLarge internal spaceAir-pressure/air-lock chambersInterior spacePressure generation

The invention provides an experiment cabin system capable of adjusting atmospheric environmental pressure. The system is characterized by comprising an experiment cabin arranged in a constant-temperature constant-humidity environmental chamber and a positive and negative pressure generation unit, a ventilation adjusting unit, an air purification unit, a meteorological sensor and a system control unit controllable both in and out of the cabin, which are arranged to be communicated with the cabin. Compared to the prior art, the invention has the following advantages: 1, the system can realize control of the environment condition of atmospheric pressure in research and experiments on tobacco and is applicable to control of atmospheric pressure in most regions where people live; 2, the inner space of the system is great, which enables a plurality of staff to simultaneously carry out experiments; 3, the comprehensive air purification unit is provided in the cabin, which enables collection and purification of harmful gas generated after combustion of tobacco to be realized; 4, the system is simple to operate and enables single-key operation and comprehensive information prompting to be realized in normal usage; and 5, security design and humanized design of the system are considerate, an automatic safety device is arranged in the cabin, and hand-operated safety devices are arranged in and out of the cabin.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Double-leaf protective closure obstruction door for subway one-hole and two-lane section

InactiveCN102913107ALow costEnsure safe use in wartimeSills/thresholdSealing arrangementsEngineeringMechanical engineering

A double-leaf protective closure obstruction door for a subway one-hole and two-lane section comprises door leafs, a door frame, jack devices, latches and hinges, wherein the door frame consists of an upper door frame, two lateral door frames and a lower door frame; the door leafs are structured in a double-leaf form and are provided with a center joint sealing device therebetween; the lower door frame is equipped with a movable doorsill slot thereon and is connected with a detachable movable doorsill; the movable doorsill includes a movable doorsill beam, a bearing plug fixedly connected to the movable doorsill beam and matched with the movable doorsill slot, and a railway sealing piece fixedly connected to the movable doorsill beam and matched with a railway sealing box; and the movable doorsill beam is additionally connected with a bottom sealing device. The obstruction door disclosed by the invention is suitable for the section partition of urban subway traffic civil defense engineering with two lanes in a tunnel, the use safety for wartime of the one-hole and two-lane section or a two-lane tunnel section with smaller interval can be ensured, and the great convenience can be brought to the transformation from peacetime to wartime.

Owner:4TH DESIGN & RES INST OF ENGINEER CENT STAFF PLA

Sealing structure of tapered slip ring with self-compensating property

InactiveCN102410374AIncreasing the thicknessImprove impact resistanceEngine sealsInternal pressureRight triangle

The invention discloses a sealing structure of a tapered slip ring with a self-compensating property, which comprises a tapered slip ring, an O-ring, a cylinder barrel and a shaft sleeve, wherein the O-ring is arranged in a sealing ring groove of the cylinder barrel; a mobile annular retaining ring is arranged between the O-ring; the tapered slip ring is arranged between the cylinder barrel and the shaft sleeve and the cross section is a right triangle; an elastic element is arranged on the end face of the slip ring; the tapered slip ring moves rightward along the inclined plane of the shaft sleeve under the action of the elastic element and the internal pressure; the O-ring is extruded when the slip ring moves rightward; the deformed O-ring reacts on the slip ring as the diameter compression ratio of the cross section changes along with the internal pressure of a sealing cavity; and the contact pressure on the dynamic sealing surface of the slip ring is wavy to form serrated sealing effect. The sealing structure has simple structure, low cost and good sealing performance. The wear loss can be automatically compensated by the tapered slip ring, the problem of wear is fundamentally solved, the stress condition of the O-ring is improved, and the service life of the O-ring is prolonged.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com