Patents

Literature

1103results about How to "Low processing and manufacturing costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

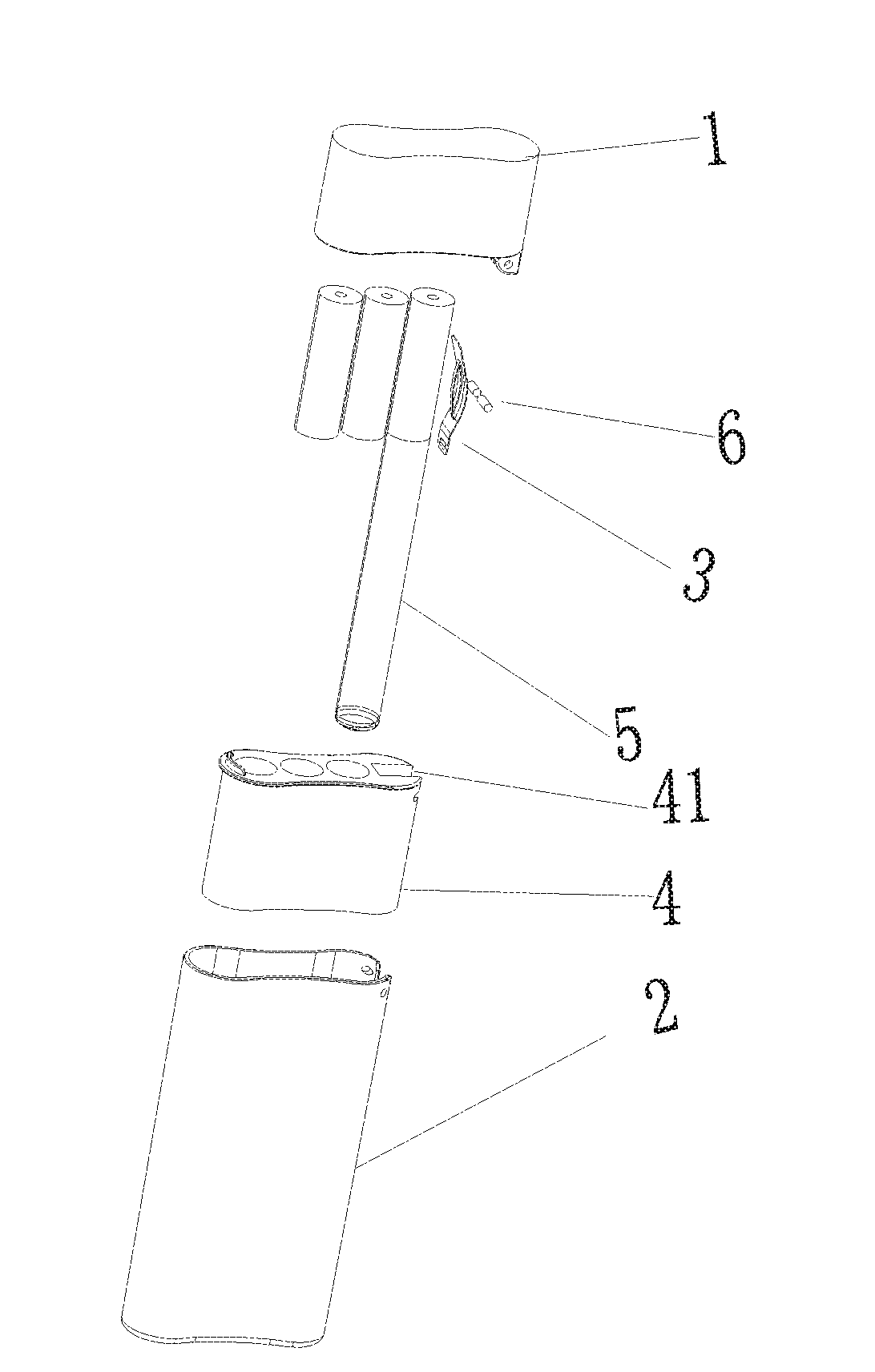

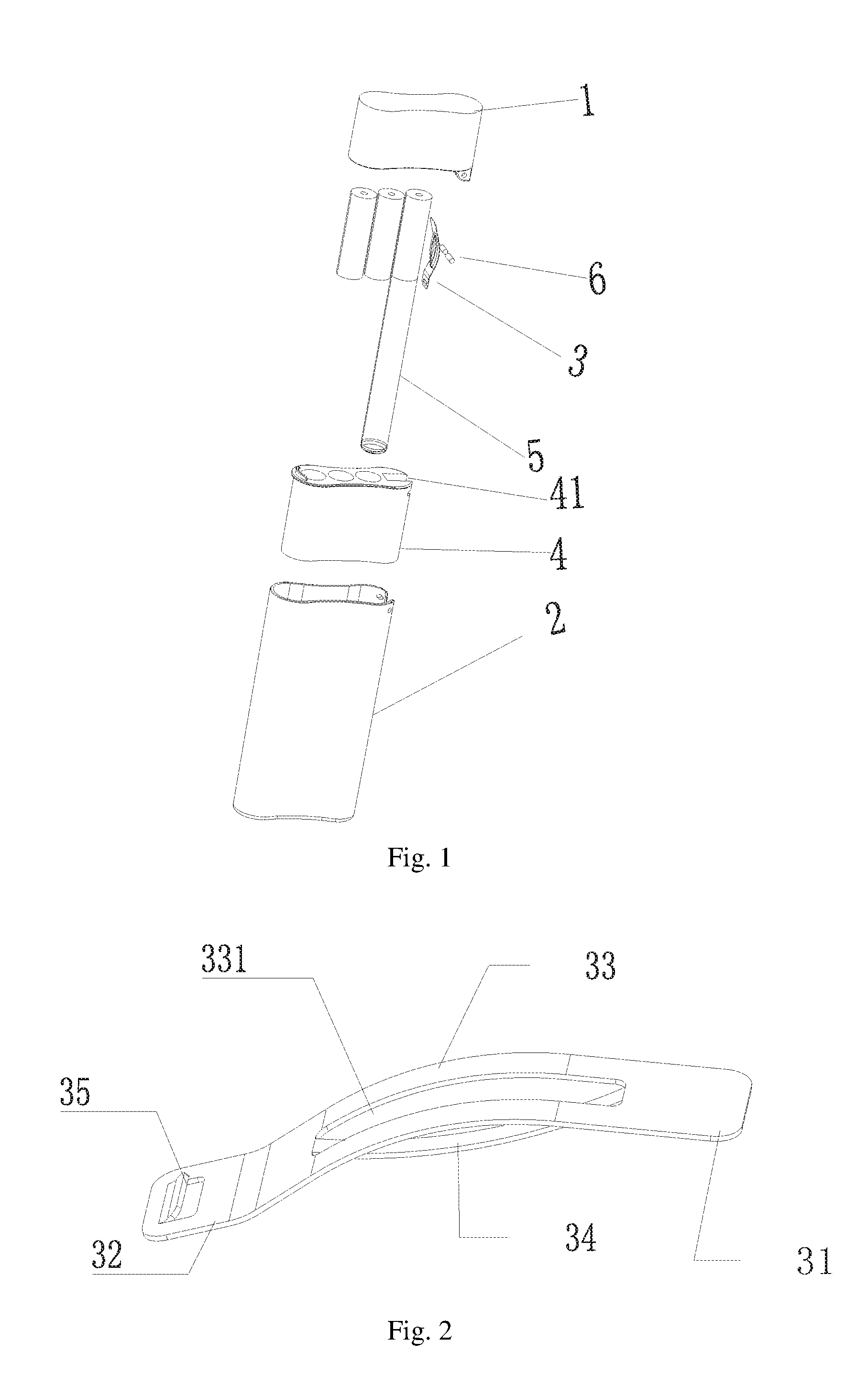

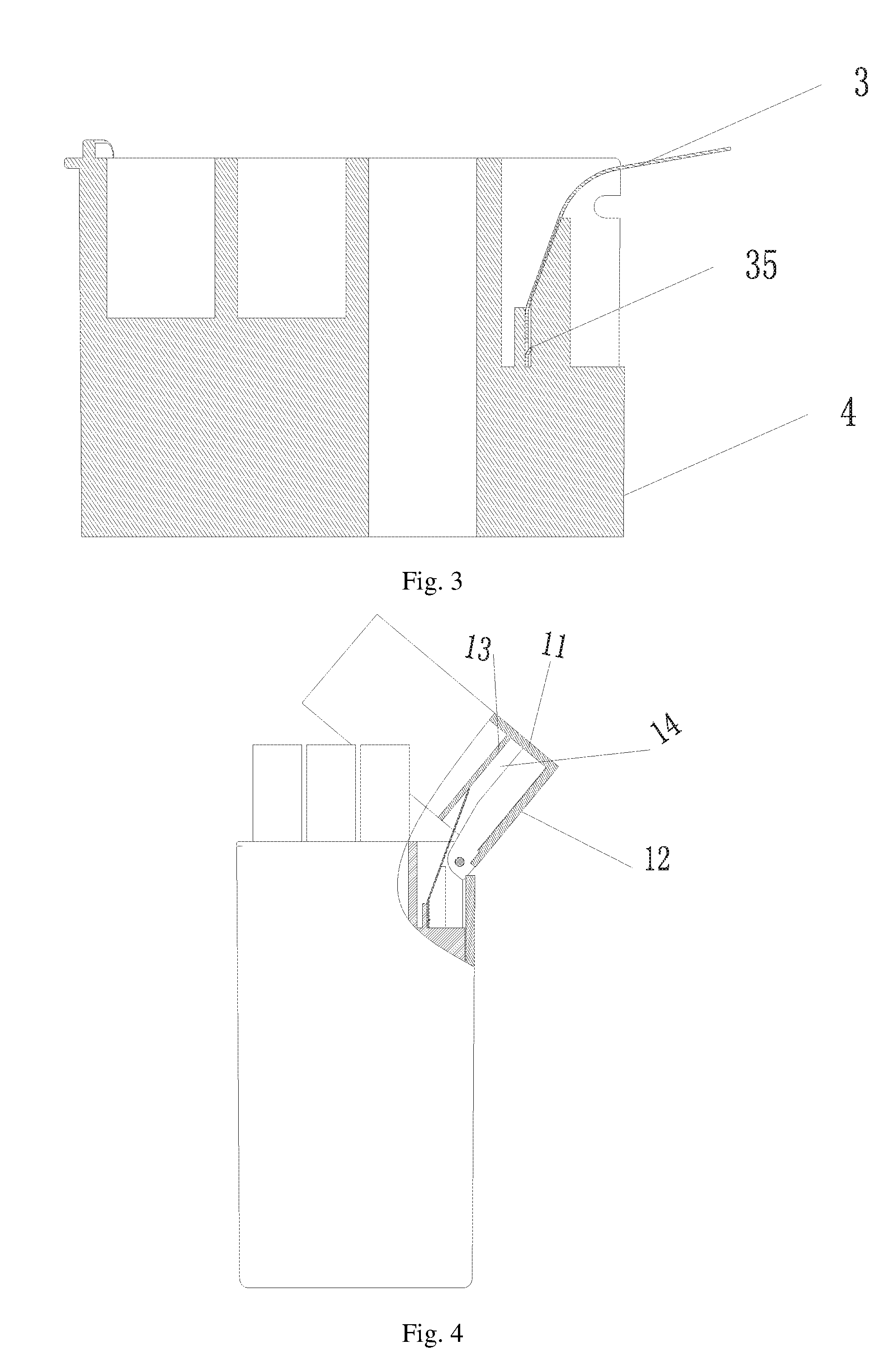

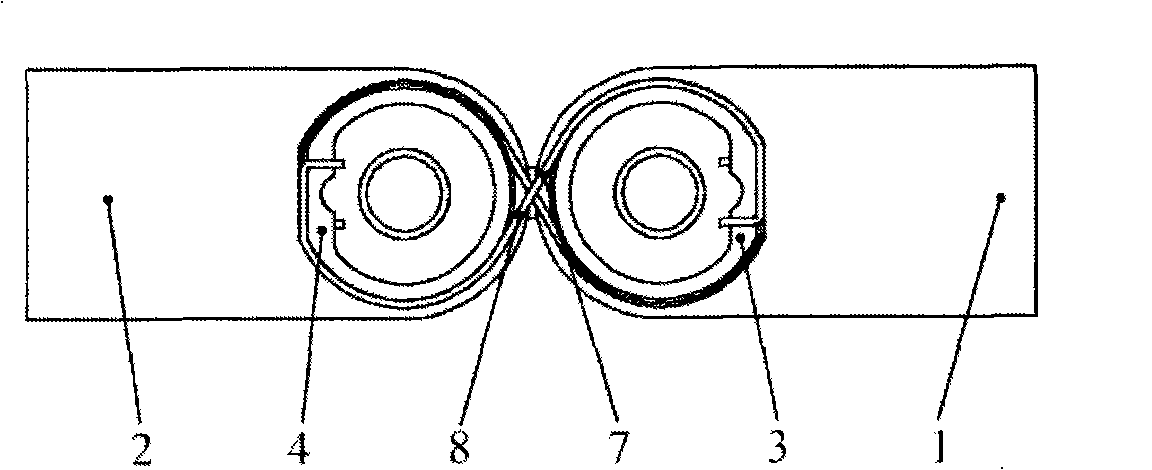

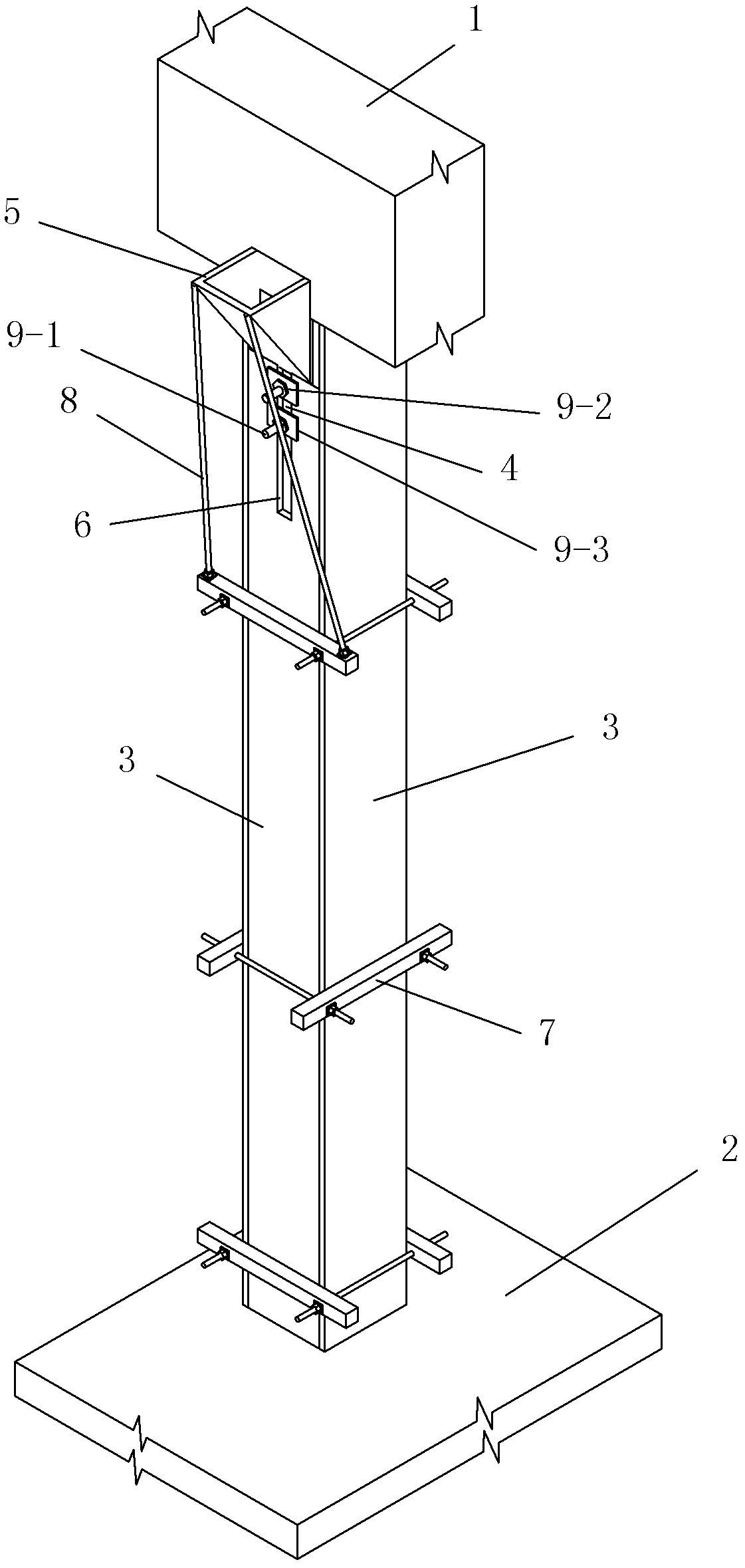

Electronic cigarette case

InactiveUS20160165952A1Few assembly componentImprove reliabilityContainers for flexible articlesPackaging cigaretteStructural engineeringElectronic cigarette

An electronic cigarette case, comprising a case body (2) and a case cover (1) movably connected to the case body (2), also comprising a flexible structure (3). One end of the flexible structure (3) is connected to the case body (2), while the other end is connected to the case cover (1). When opening the case cover (1), the flexible structure (3) undergoes a first elastic deformation along a moving direction of the case cover (1) relative to the case body (2). When closing the case cover (1), the flexible structure (3) undergoes a second elastic deformation in a direction opposite to the moving direction in which the first elastic deformation occurs. The electronic cigarette case is structurally simple and low-cost.

Owner:HUIZHOU KIMREE TECH

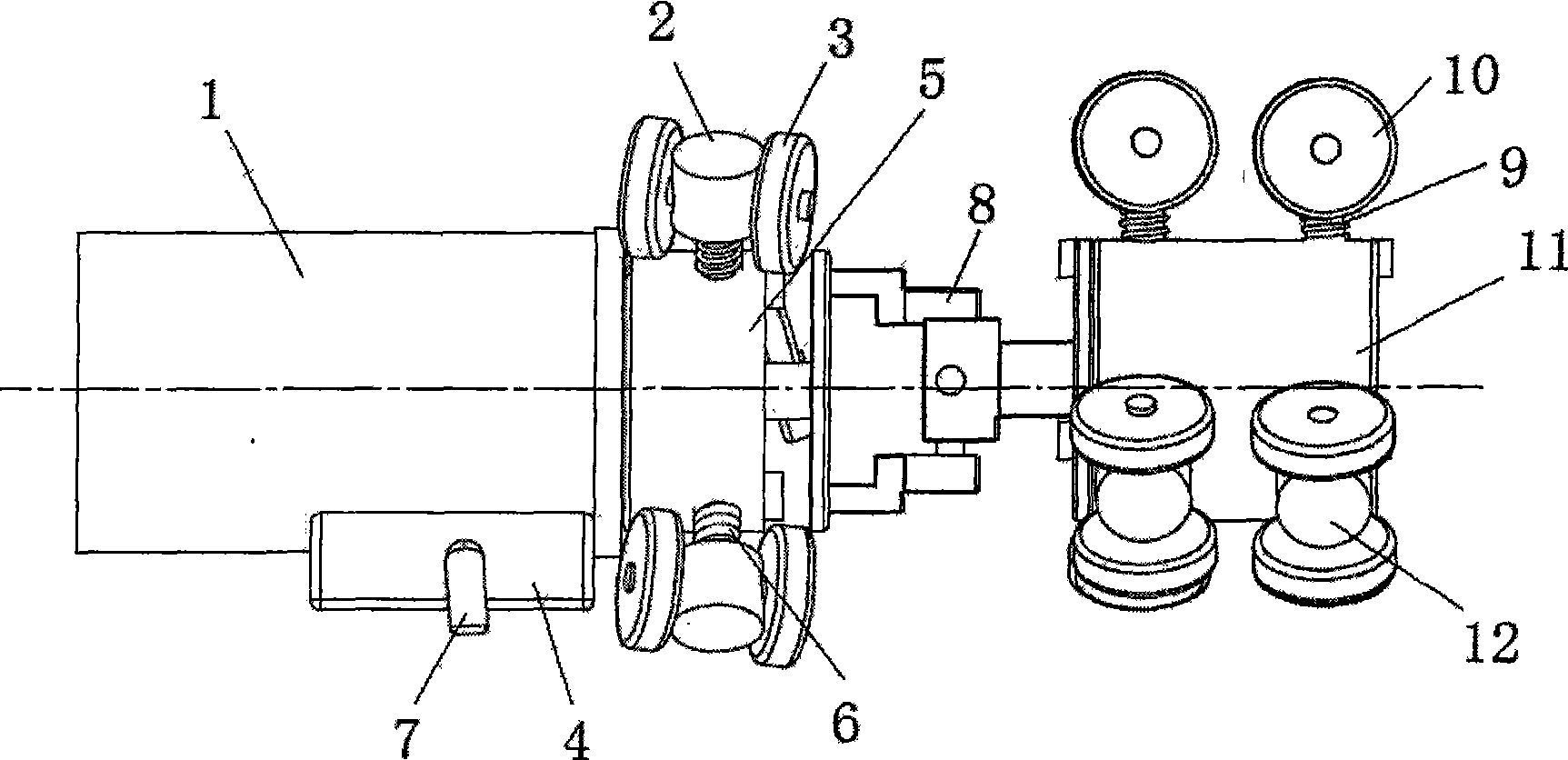

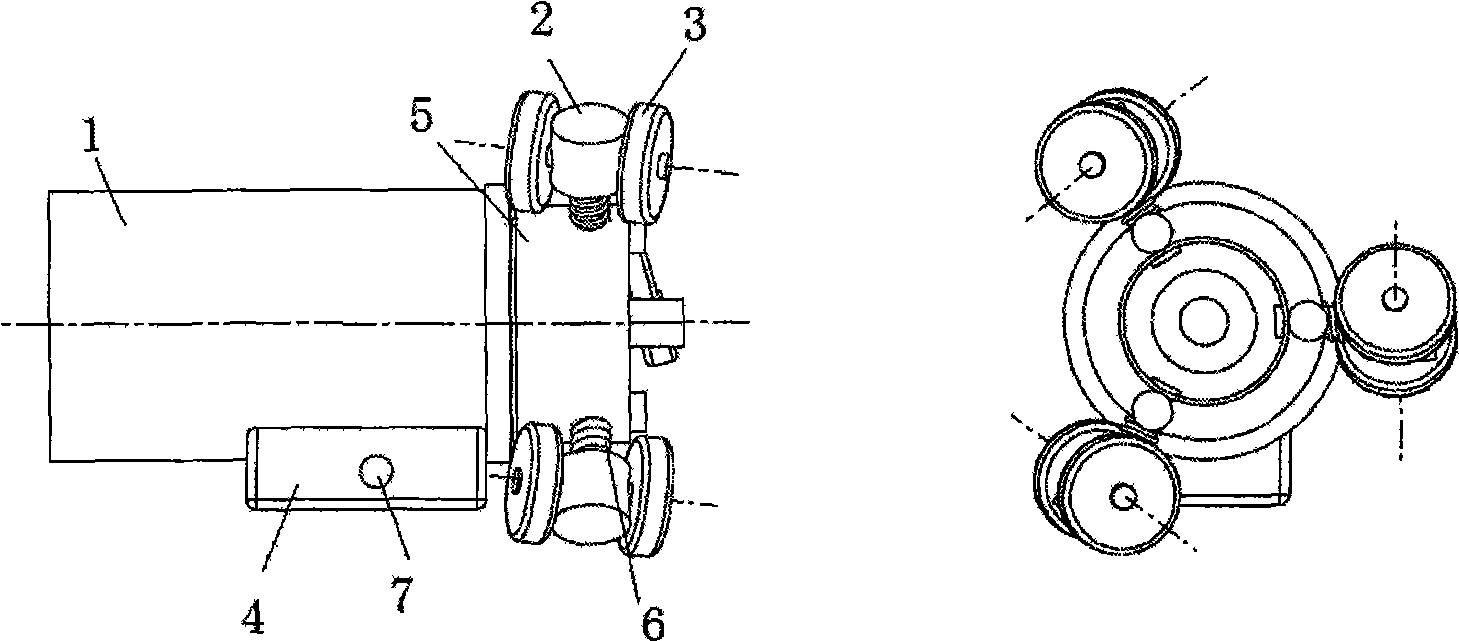

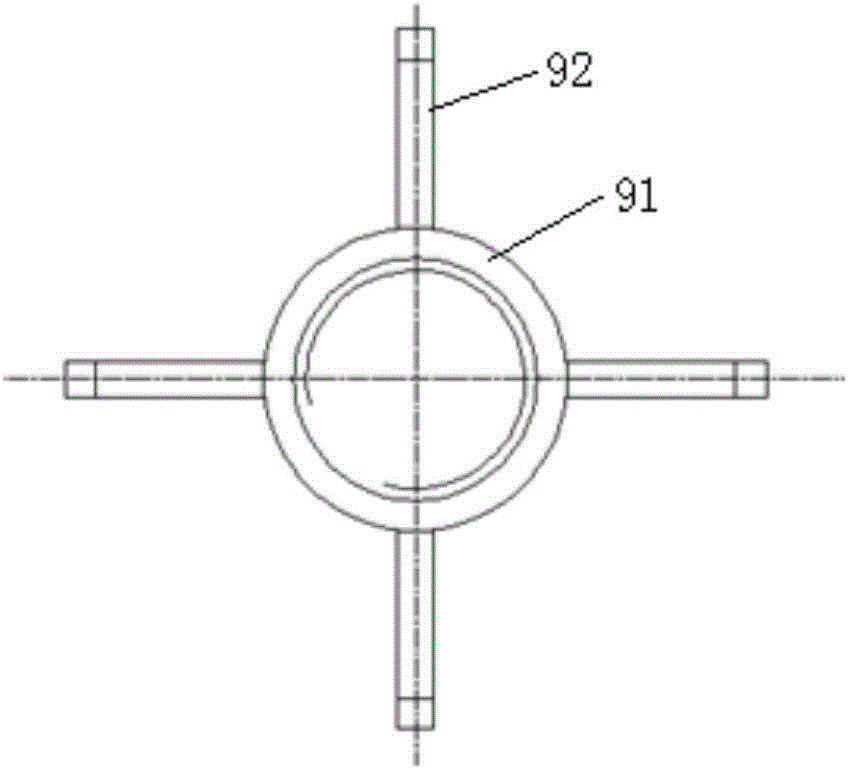

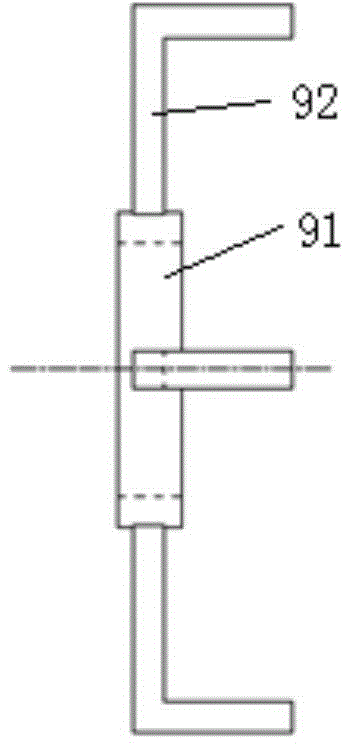

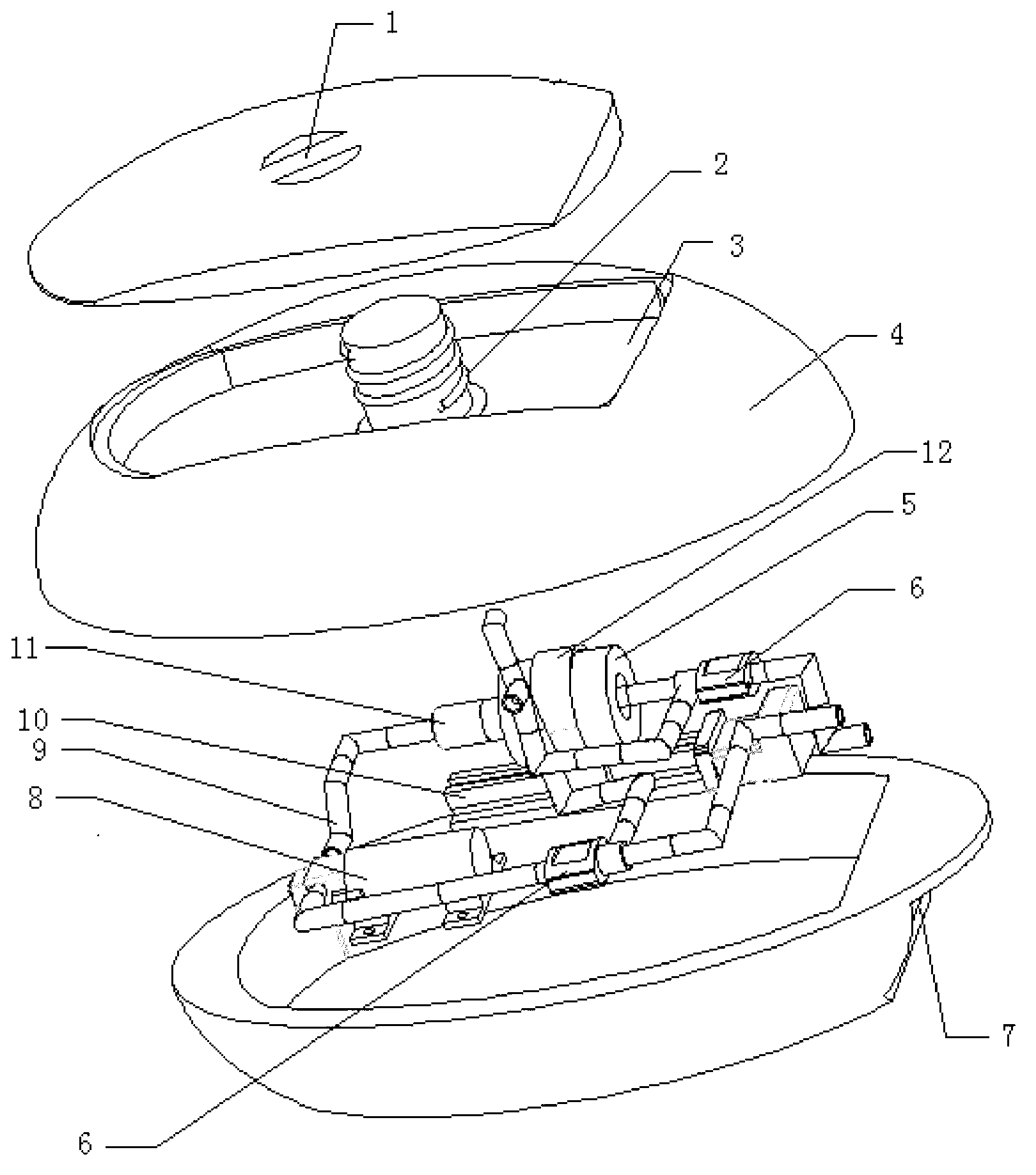

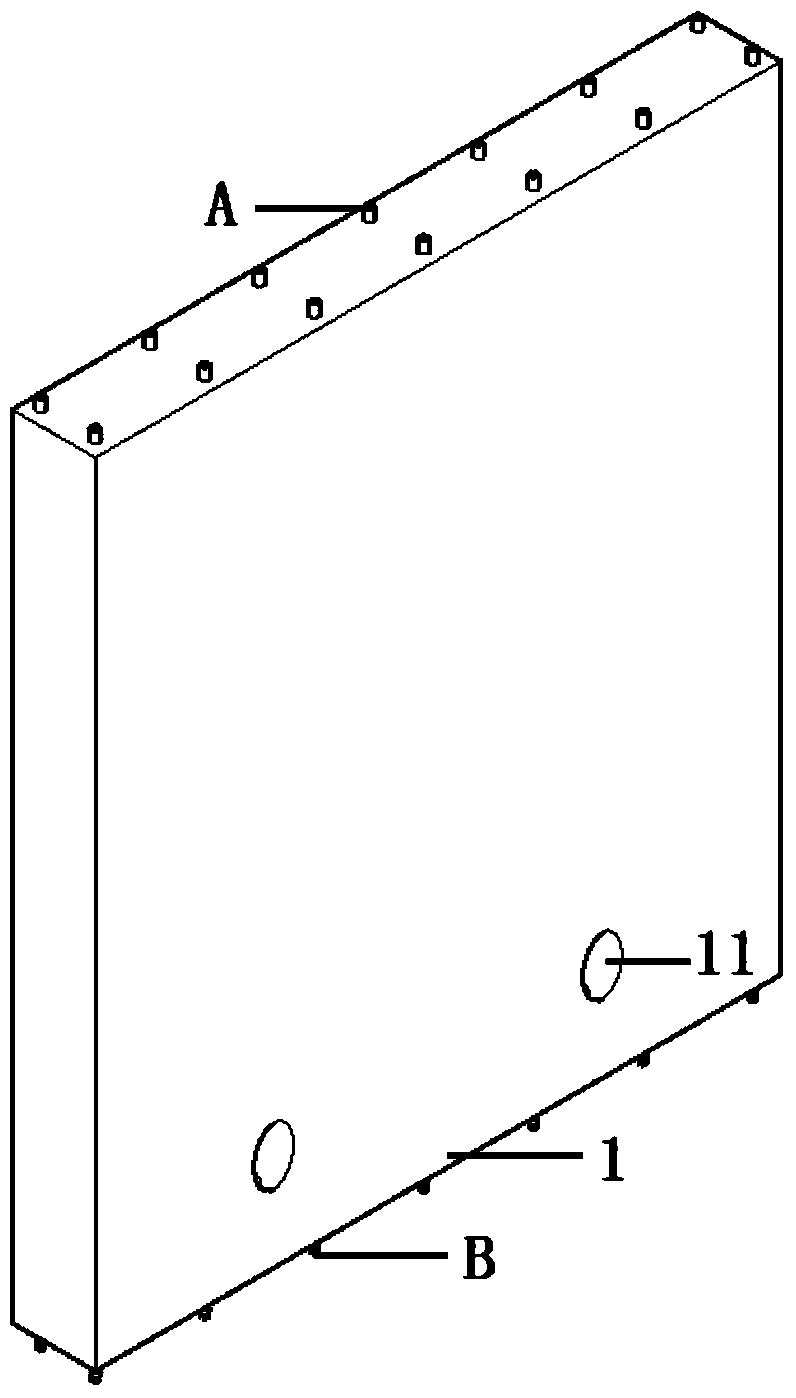

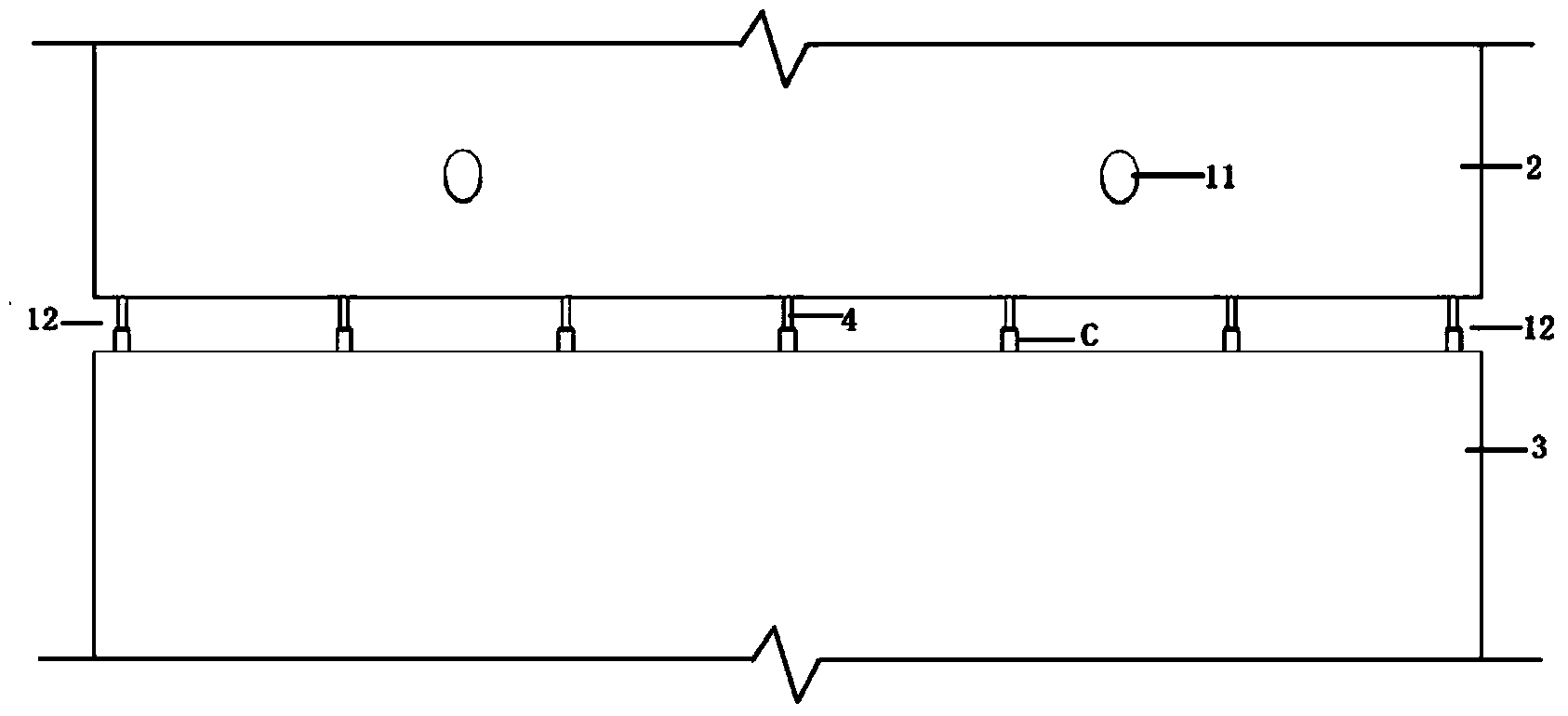

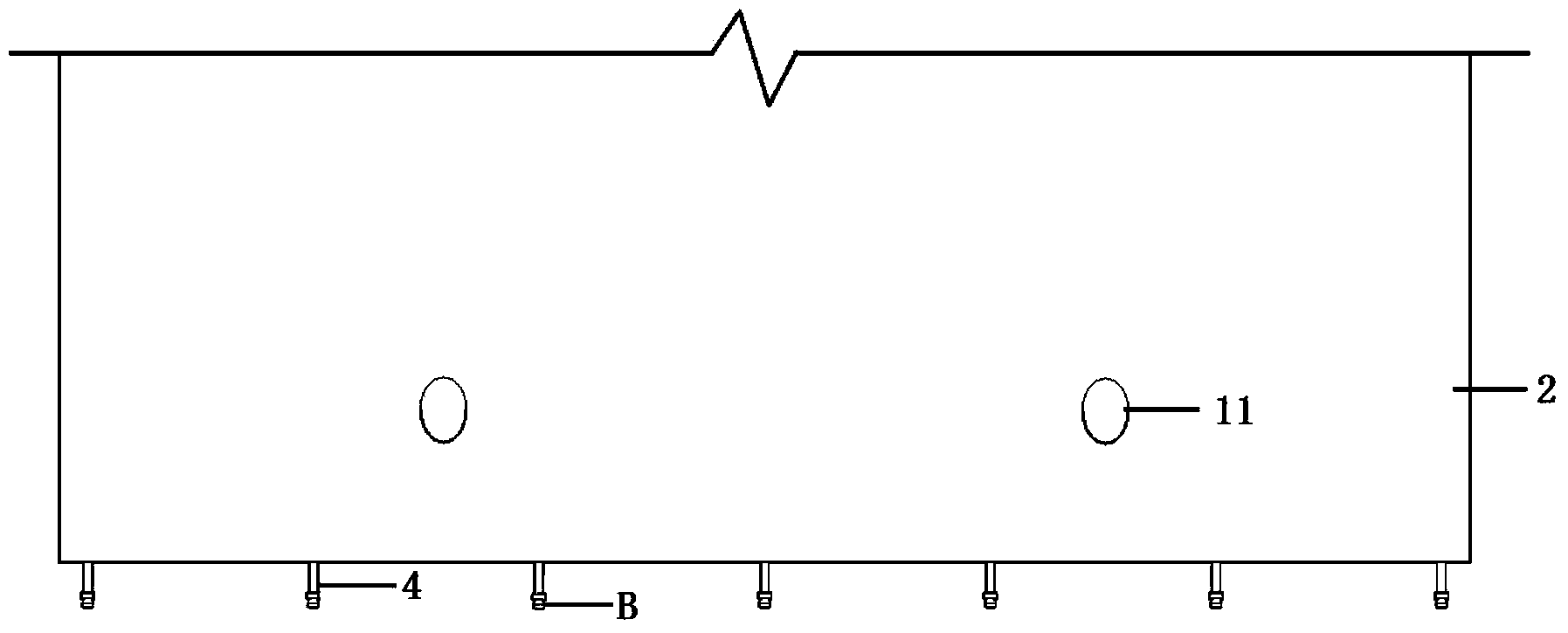

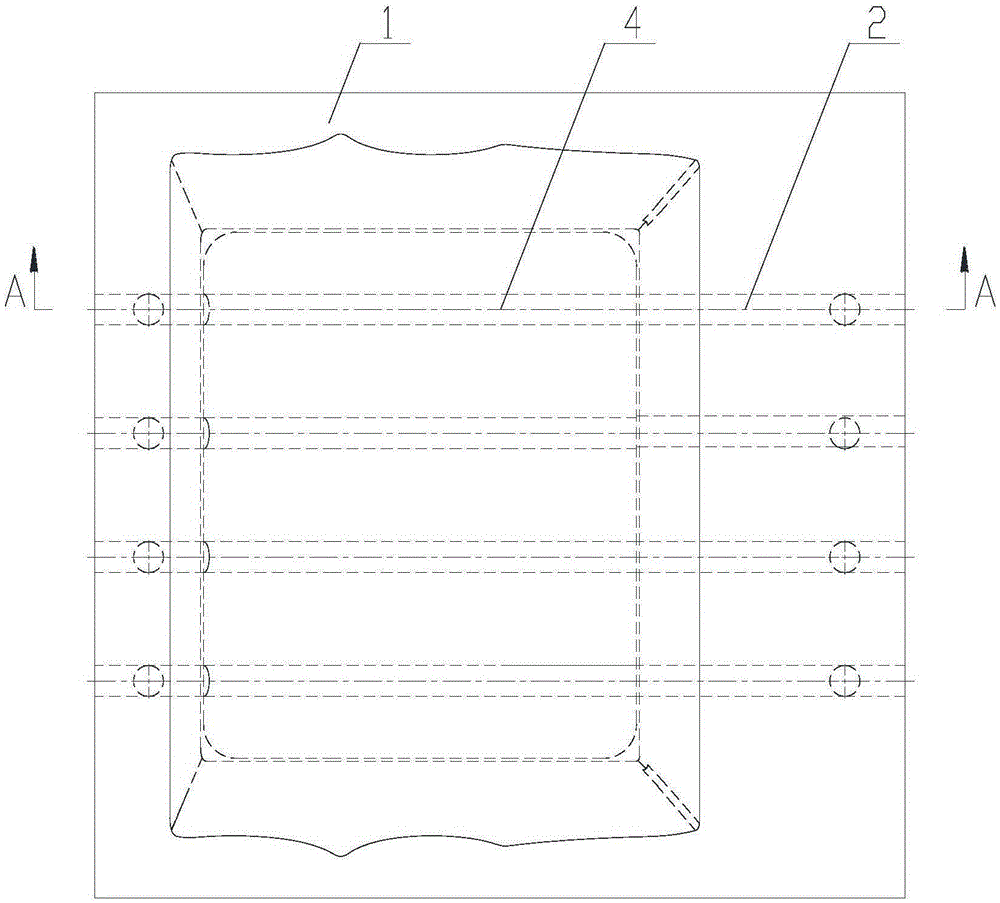

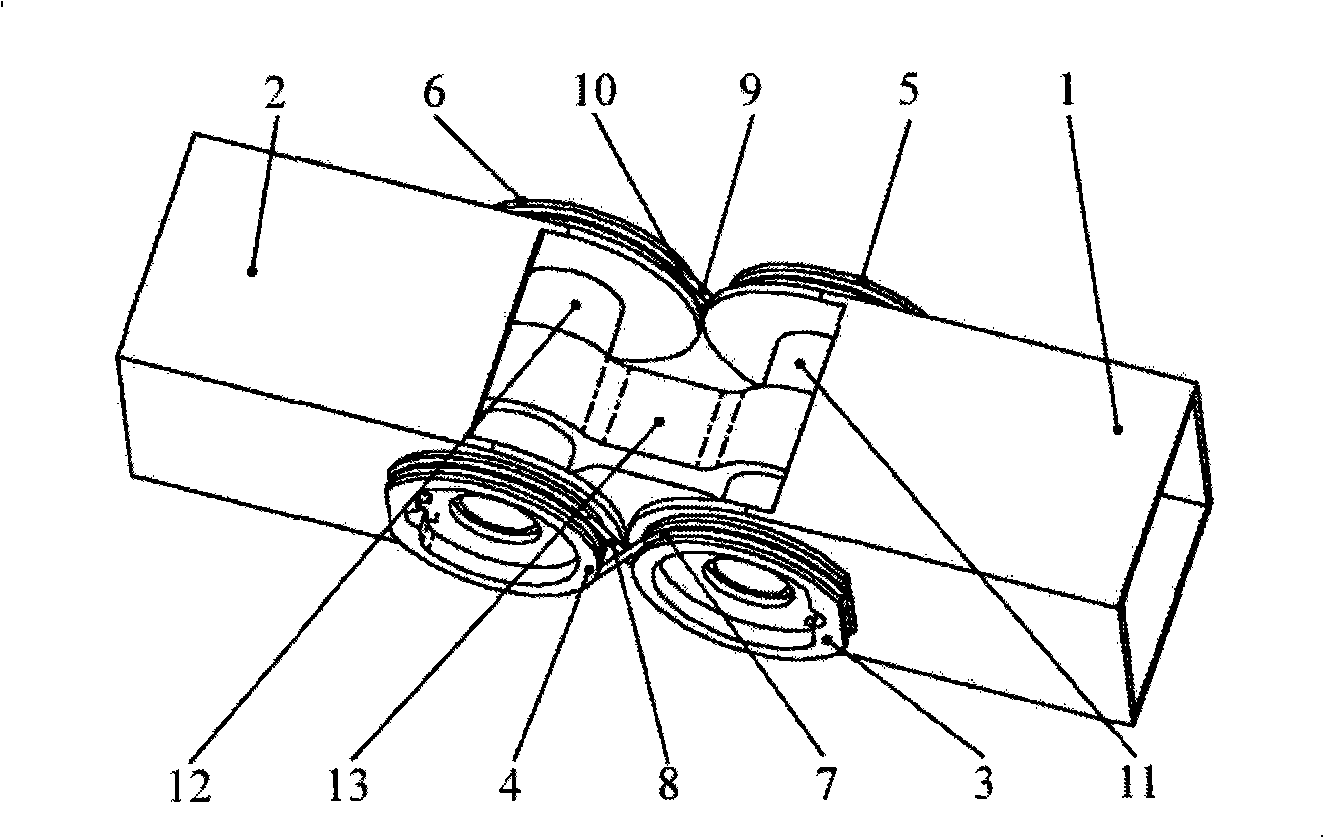

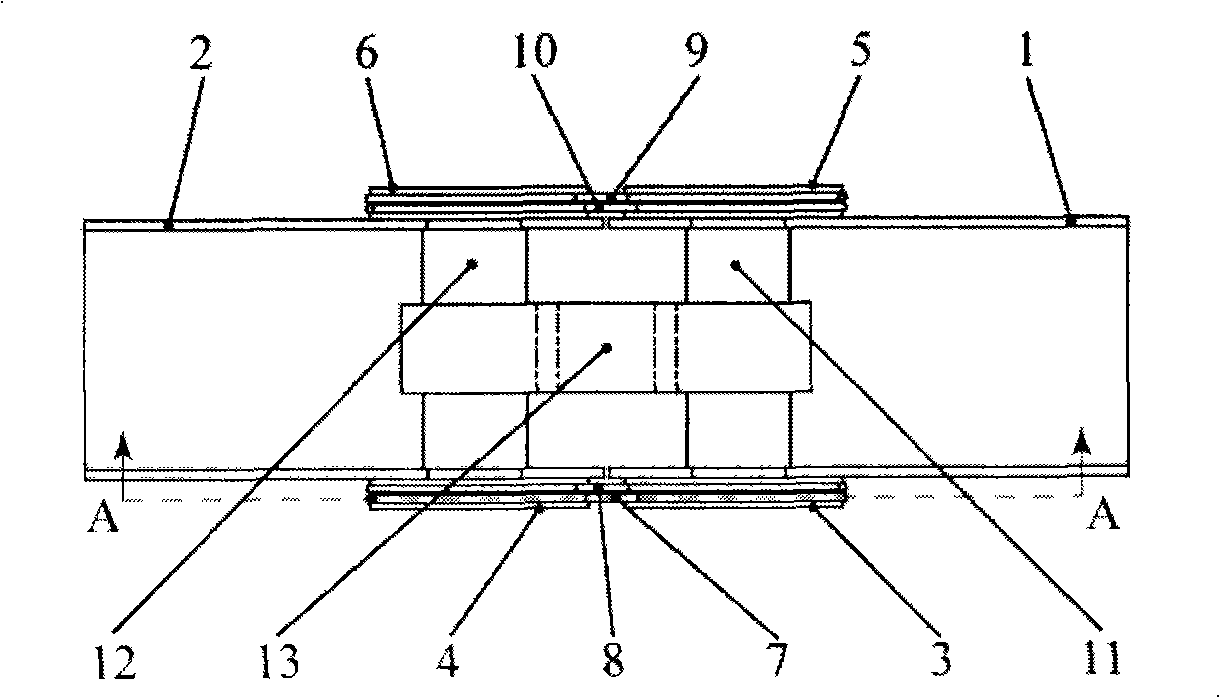

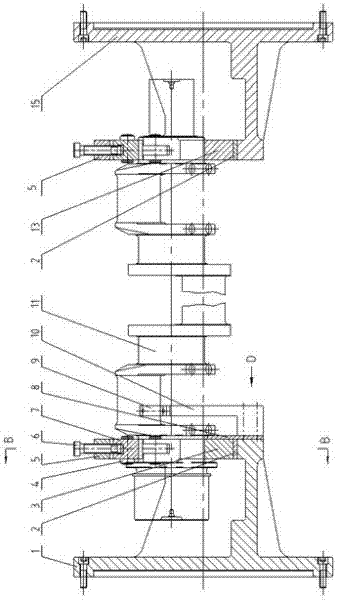

Spirally driven walking robot in pipe

InactiveCN101531217AMove freelySmooth travelRailway tunnelsRailway componentsElevation angleMotor drive

The invention provides a spirally driven walking robot in a pipe, which consists of a power-driven device, a walking guide device and a universal joint (8) connecting the power-driven device and the walking guide device; the power-driven device is formed by a motor (1) driving a circular rotor (5); the outer wall of the circular rotor (5) is respectively provided with three groups of symmetrically distributed wheel carriers (2); each group of wheel carrier (2) is provided with two wheels (3), and the rotating axes of the two wheels forms an acute elevation angle with the axes of the rotor (5); the walking guide device consists of three groups of symmetrically distributed guide wheel carriers (12) which are arranged on the outer wall of a cylinder or a cylindrical body (11); each group of guide wheel carrier (12) is provided with two wheels (10), and the rotating axes of the two wheels is vertical to the axes of the cylindrical body (11); and the wheel carriers (2) on the rotor (5) of the power-driven device and the guide wheel carriers (12) on the cylinder or the cylindrical body (11) of the walking guide device are all floating bodies, and certain radial dilation generated by a spring (9) is used to make all wheels on the wheel carriers (2) and the guide wheel carriers (12) always attach to the inner wall of the pipe. The motor drives the walking robot in the pipe to advance or retreat along the axes direction of the pipe.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

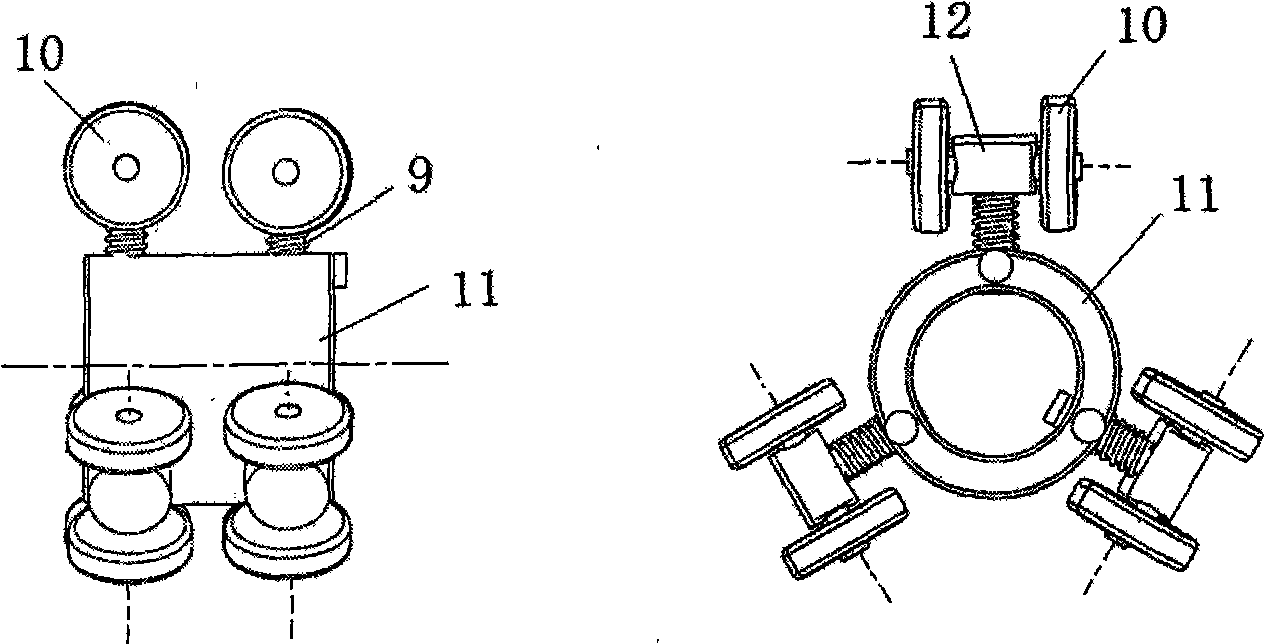

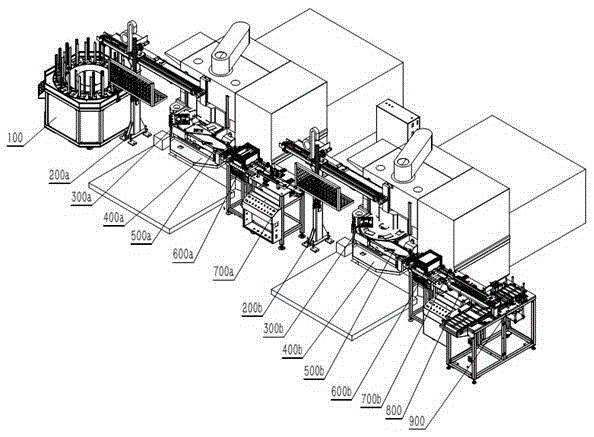

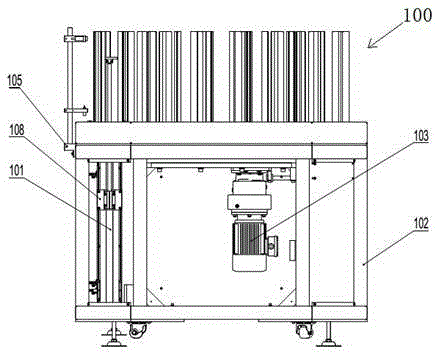

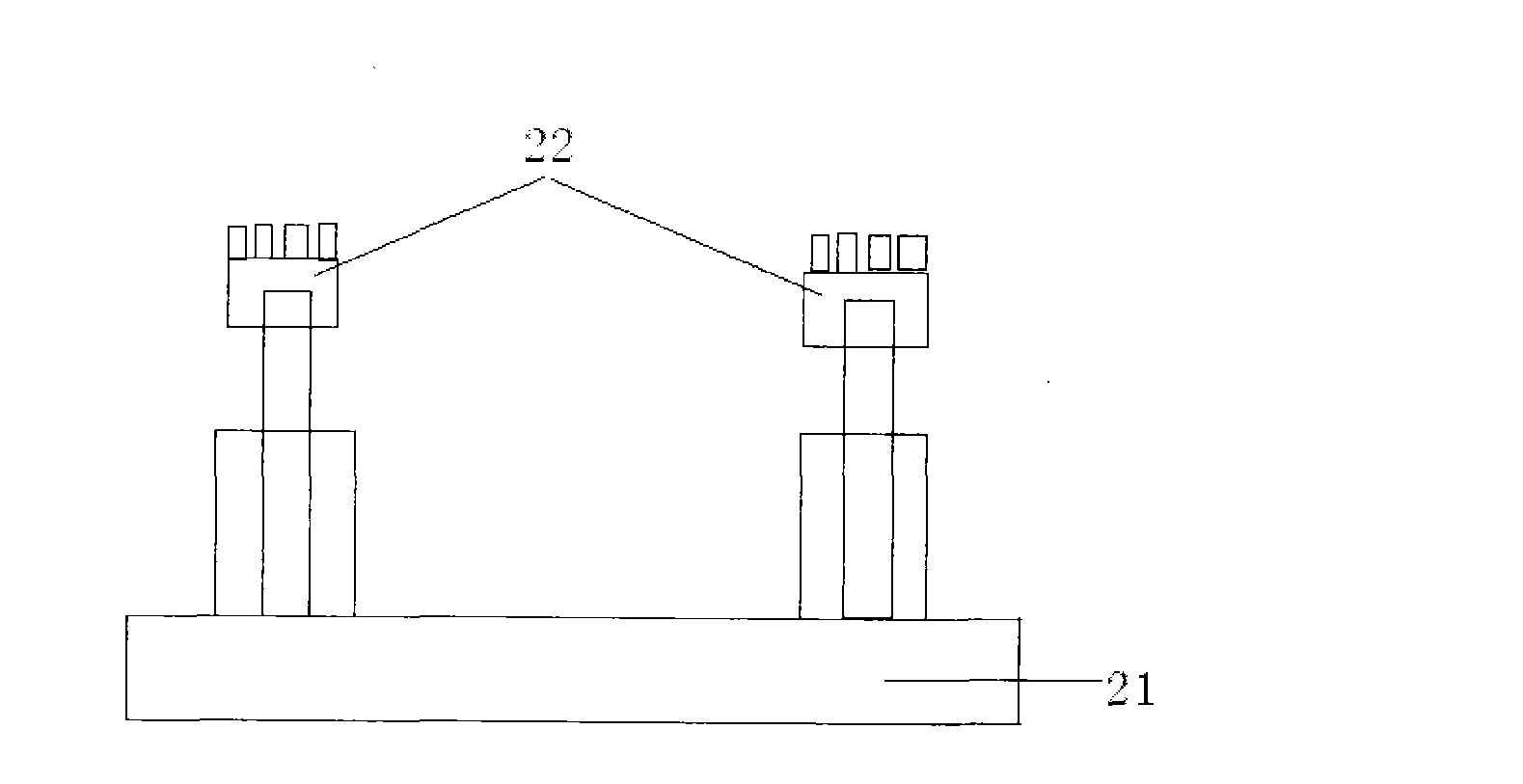

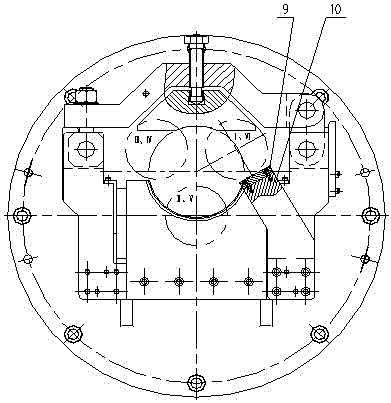

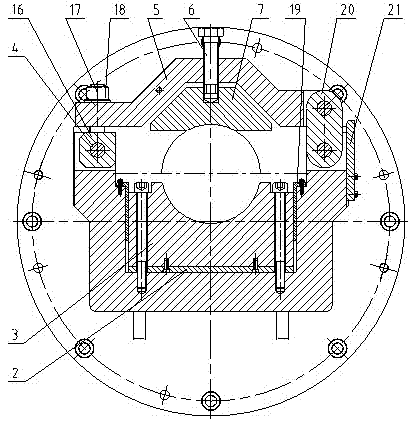

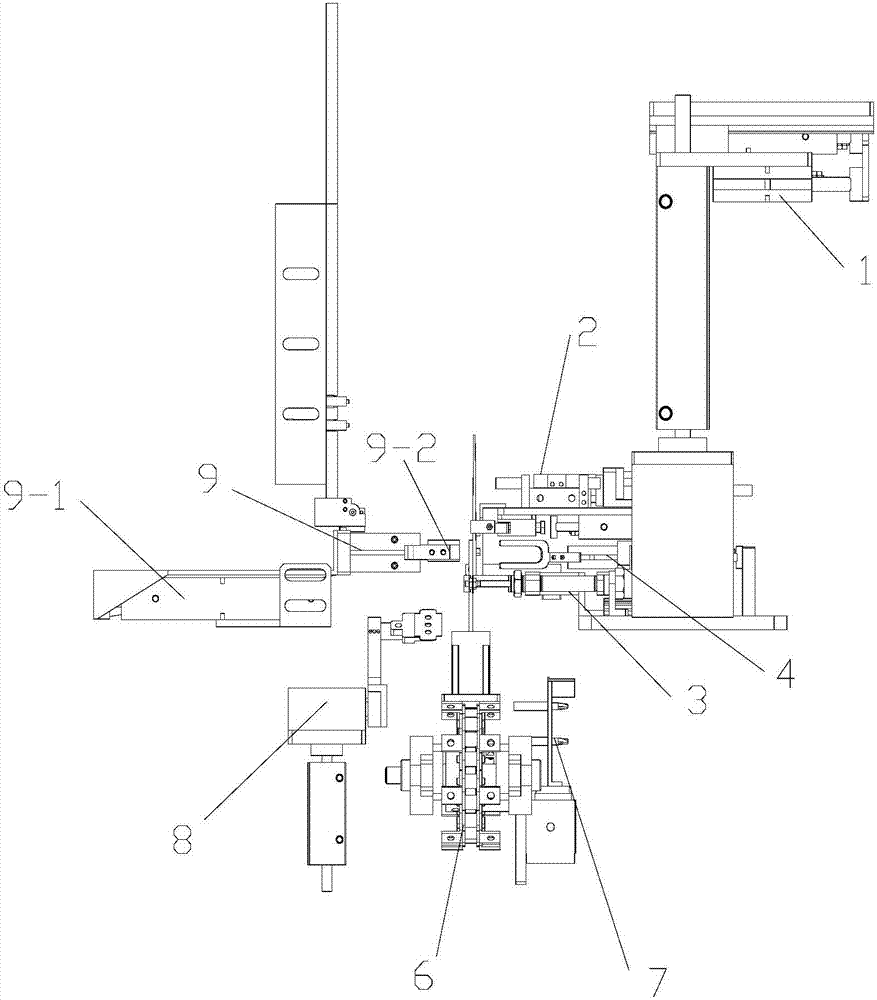

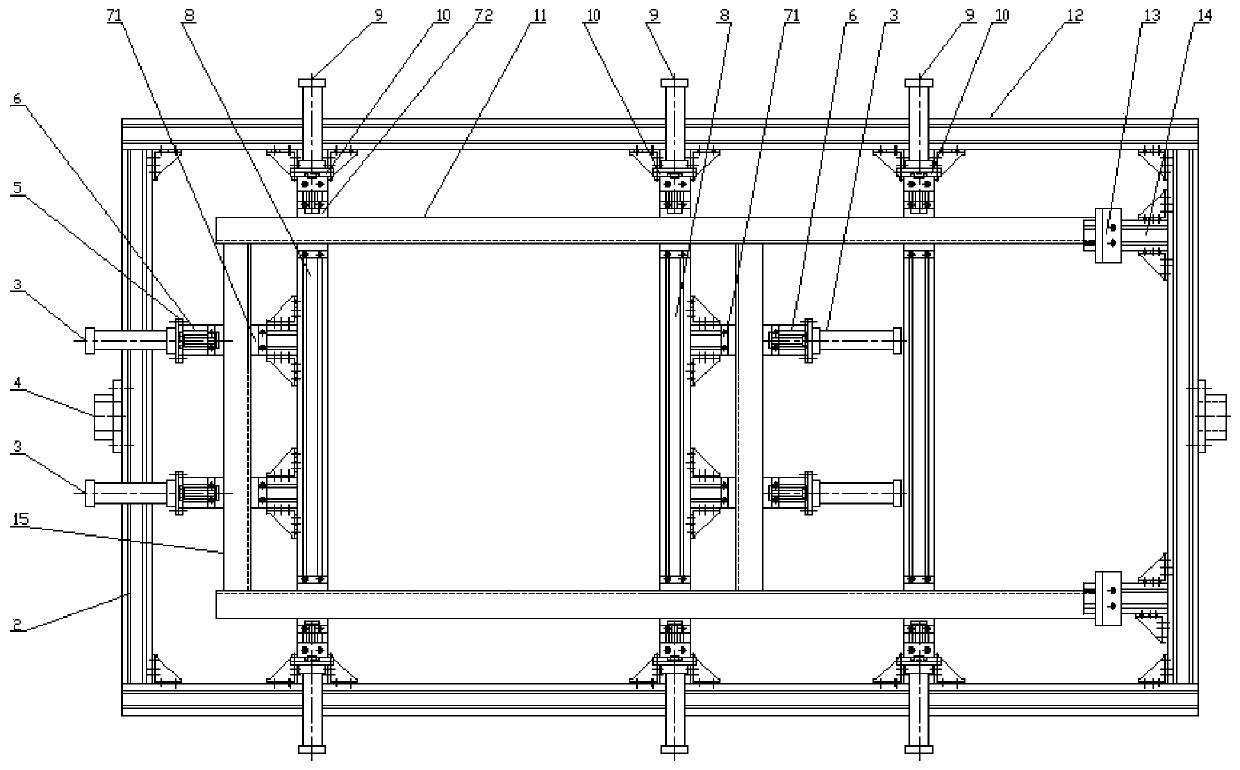

Full-automatic double-end-face grinding production line

ActiveCN105382650AGap adjustmentLow processing and manufacturing costsGrinding feedersPlane surface grinding machinesProduction lineManipulator

The invention discloses a full-automatic double-end-face grinding production line. The production line is arranged in a straight line and sequentially comprises a feeding mechanism, a feeding mechanical arm, a first double-end-face grinding machine, a first transfer conveying belt, a first washing mechanism, a first detecting device, a transfer mechanical arm, a second double-end-face grinding machine, a second transfer conveying belt, a second washing mechanism, a second detecting device, a discharging mechanical arm and a discharging mechanism, wherein the first double-end-face grinding machine is provided with a first grinding machine material drop plate which is engaged with the feeding mechanical arm; the second-end-face grinding machine is provided with a second grinding machine material drop plate which is engaged with the transfer mechanical arm. The full-automatic double-end-face grinding production line disclosed by the invention can be used for grinding a wide range of materials, is capable of implementing feeding, grinding, washing, detection and discharging of a work piece material by one time, is high in automation degree and has the effects of guaranteeing the machining quality, reducing the rejection rate, also greatly alleviating the labor strength, reducing the labor and lowering the machining cost and the manufacturing cost for enterprises.

Owner:HUNAN YUHUAN INTELLIGENT EQUIP CO LTD

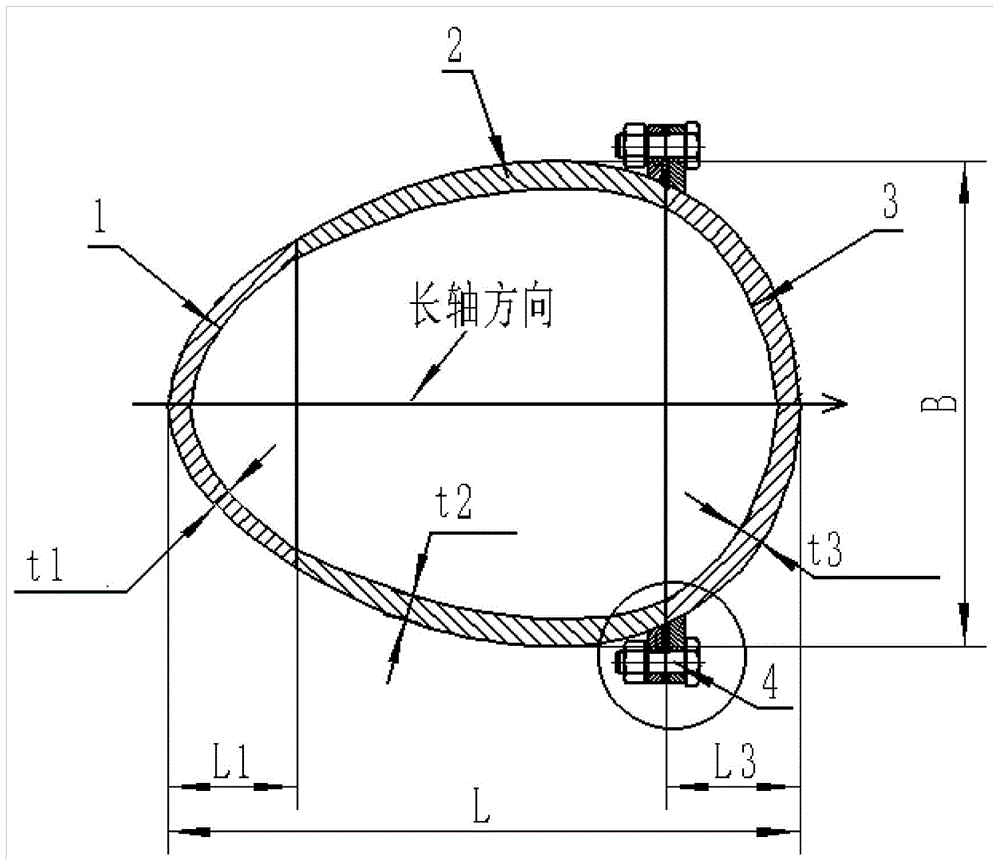

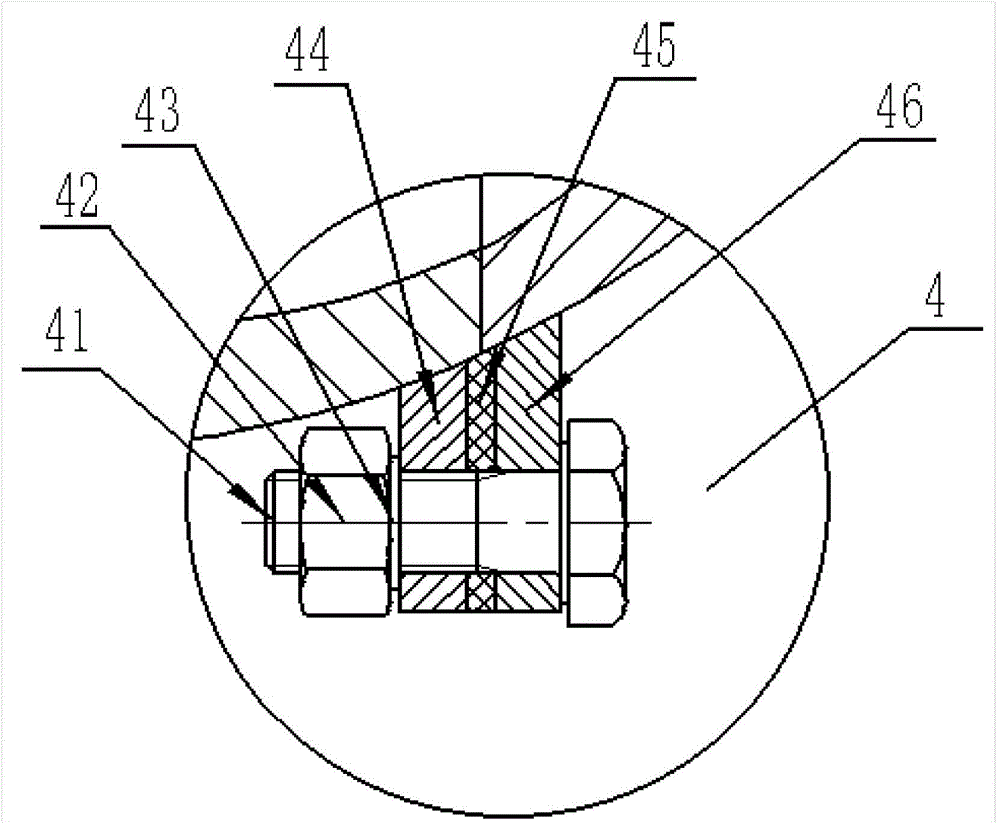

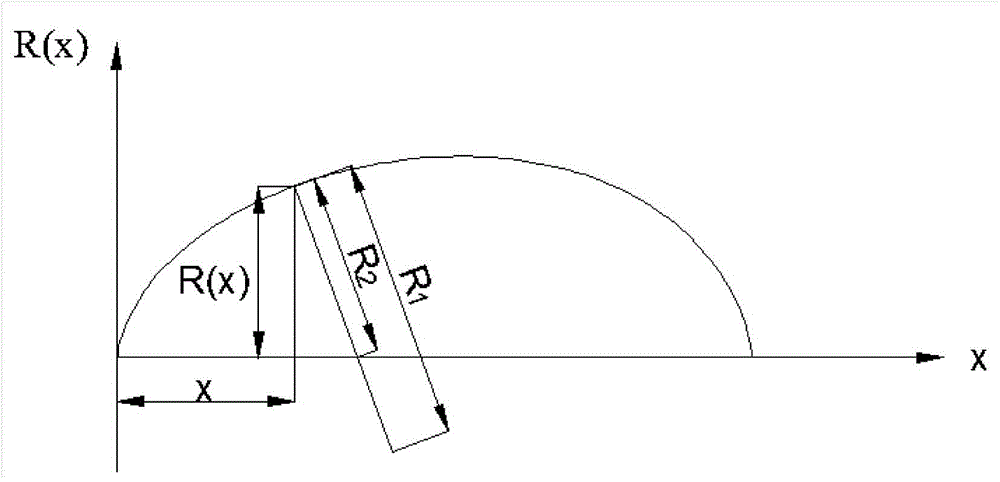

Deep sea bionic pressureproof shell

ActiveCN104648638AGood pressure resistanceStreamlinedUnderwater vesselsUnderwater equipmentVariable thicknessCarrying capacity

The invention discloses a deep sea bionic pressureproof shell. An axial-symmetry eggshell-shaped structure with the length of L, the width of B and the turning radius of R(x) is formed by a left end socket, a right end socket and a middle shell, wherein the thickness t2 of the middle shell is of an equal-strength variable-thickness structure, the thickness t1 of the left end socket and the thickness t3 of the right end socket are respectively of an equal-thickness structure, the left end socket and the middle shell are fixedly connected, and the right end socket and the middle shell are connected by a flange bolt or a movable hatch cover with a seal ring. The deep sea bionic pressureproof shell has good mechanical properties, in-shell space utilization rate, hydrodynamic characteristics and passenger comfort, and comprehensive improvement on safety, carrying capacity, mobility and diving time of a diving device is facilitated; meanwhile, the weight of the pressureproof shell is lightened, the reserve buoyancy of the pressureproof shell is increased, and the processing and manufacturing difficulty and cost are reduced.

Owner:JIANGSU UNIV OF SCI & TECH

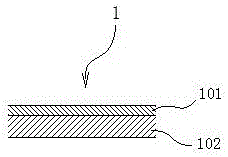

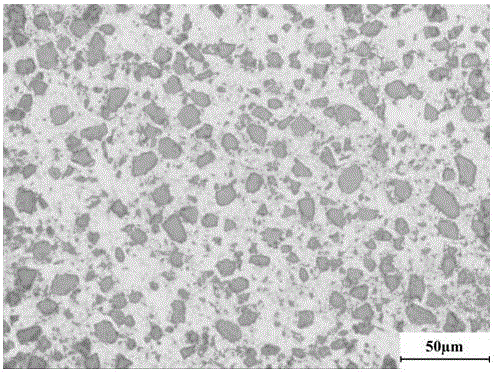

Aluminum-based composite brake disc and manufacturing method

ActiveCN106812837AImprove toughnessImprove reliabilityBraking discsFriction liningThermal expansionLow density

The invention discloses an aluminum-based composite brake disc, comprising a disc body, wherein the disc body comprises a composite structure formed by a disc core and a friction layer covering the disc core, the disc core is made of aluminum alloy, and the friction layer is made of a particle reinforced aluminum-based composite material. The non-friction surface (disc core) of the brake disc is casted by using the aluminum alloy with good ductility and toughness, the friction surface (friction layer) is casted by using the particle reinforced aluminum-based composite material based on the disc core, and the brake disc having the interior made of the aluminum alloy and the surface made of the particle reinforced aluminum-based composite material is finally formed. The brake disc has the advantages of low density, high specific strength and specific rigidity, small thermal expansion coefficient, good heat conductivity, excellent wearability and the like, besides, the toughness of the brake disc during assembly is improved, the machining cost is reduced, and the service reliability of the brake disc is improved.

Owner:徐骏 +1

Novel light-wave absorbing carbon fiber composite material preparation method

InactiveCN1730555ASimple processLow processing and manufacturing costsArtificial filament chemical after-treatmentCelluloseMaterials preparation

The invention discloses a novel light-wave absorbing carbon fiber composite material preparation method which comprises, subjecting cellulose viscose to carbonization and activation, obtaining active adhesive based carbon fiber, making the active carbon fiber to 5-50mm short carbon fiber, charging into bisphenol type A epoxy resin, mixing homogeneously, mixing with low-molecular-weight polyamide curing agent, finally agitating homogeneously and hot-setting.

Owner:TIANJIN UNIV

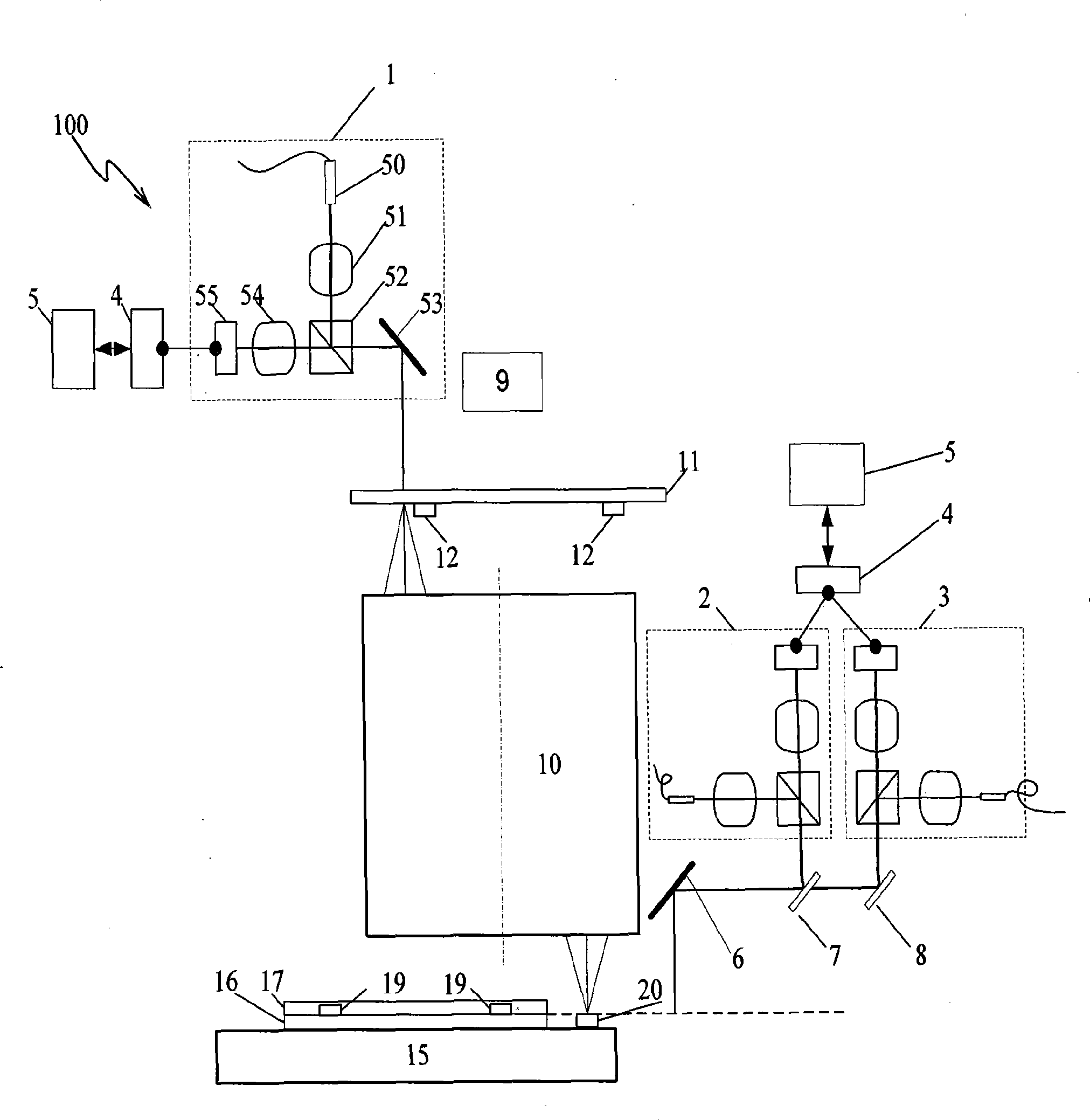

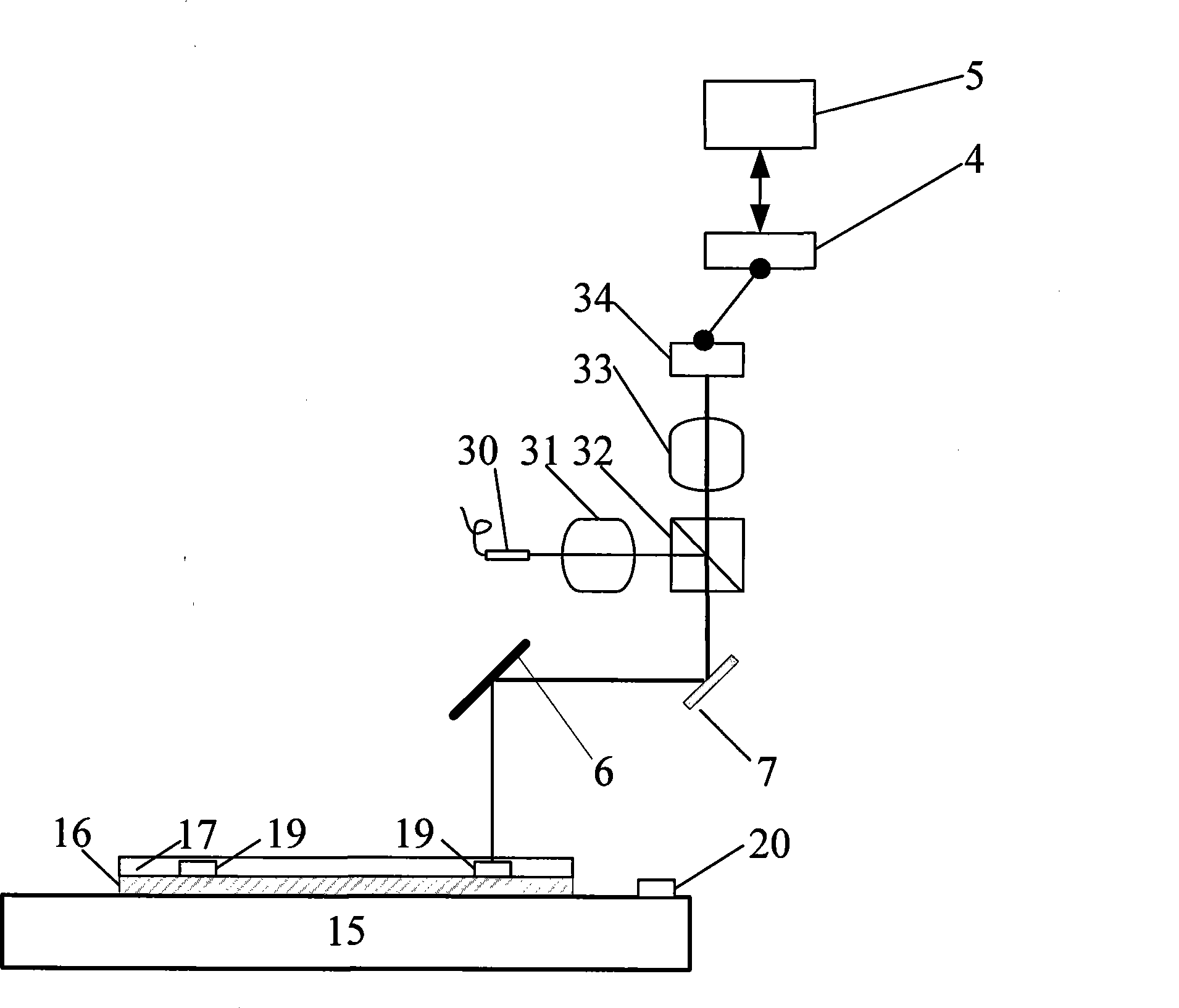

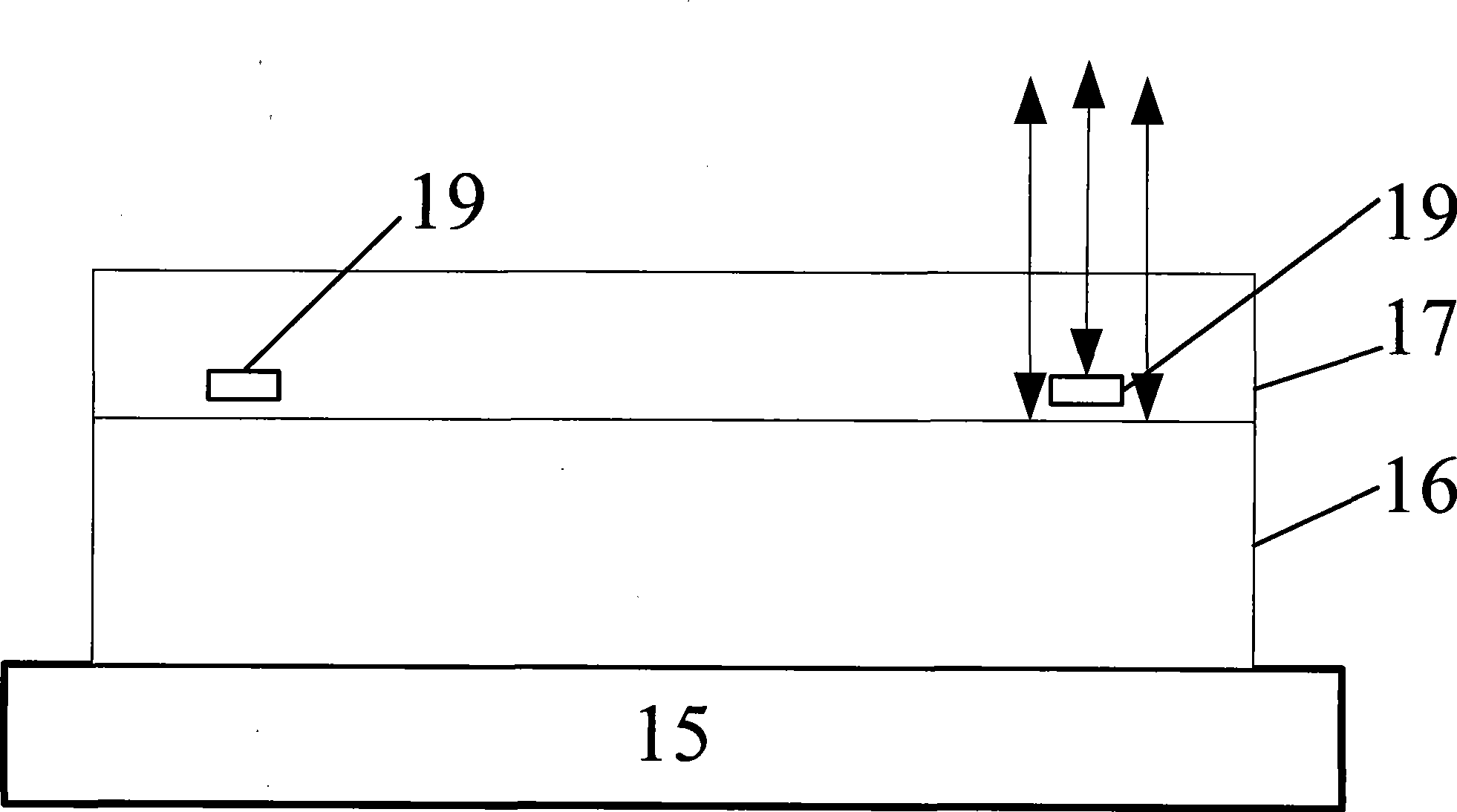

Double-surface position alignment apparatus and method

ActiveCN101436006AReduce design complexity and structure design complexityLow processing and manufacturing costsPhotomechanical exposure apparatusMicrolithography exposure apparatusPiece tableSilicon chip

The invention provides a double-side position aligning device and a double-side position aligning method. The double-side position aligning device comprises a mask plate provided with a mask aligning mark, a work piece table provided with a reference aligning mark, a silicon chip illuminating system and an optical projecting system, and also comprises a mask position aligning device, an exposure object, a first side position aligning device, a second side position aligning device, an image collecting and processing system, and a control system, wherein the mask plate is horizontally arranged. The double-side position aligning device and the method can complex structural design and assembly of the exposure object and the work piece table, and can also improve technological adaptability of a back position aligning device for a silicon chip to a back aligning mark of the silicon chip.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Energy dissipation and shock absorption mechanism

The invention provides an energy dissipation and shock absorption mechanism. The energy dissipation and shock absorption mechanism comprises a metal damper, a supporting or rigid wall for arranging the damper, and a connecting device connected with a structure. Two external connecting mechanisms are arranged on the metal damper; one of the external connecting mechanisms is connected with other connecting structures on a building, and the other external connecting mechanisms is connected with the building through the supporting or rigid wall; and the connection is riveting, bolt pin connection, bolt connection or welding. The energy dissipation and shock absorption mechanism comprises the metal damper, so the compression performance of the metal is used for dissipating the energy; the hysteresis curve of the energy is saturated, namely, under the condition of very small deformation (such as small vibration), the energy dissipation and shock absorption mechanism can enter plastic energy dissipation from the full section; moreover, the required quantity of materials is low, so the energy dissipation and shock absorption mechanism is convenient to install and exchange; compared with the conventional stickness damper, the energy dissipation and shock absorption mechanism has the characteristics of long durability and maintenance freedom.

Owner:SHANGHAI SAFE SEISMIC RETROFIT & VIBRATION CONTROL TECH +2

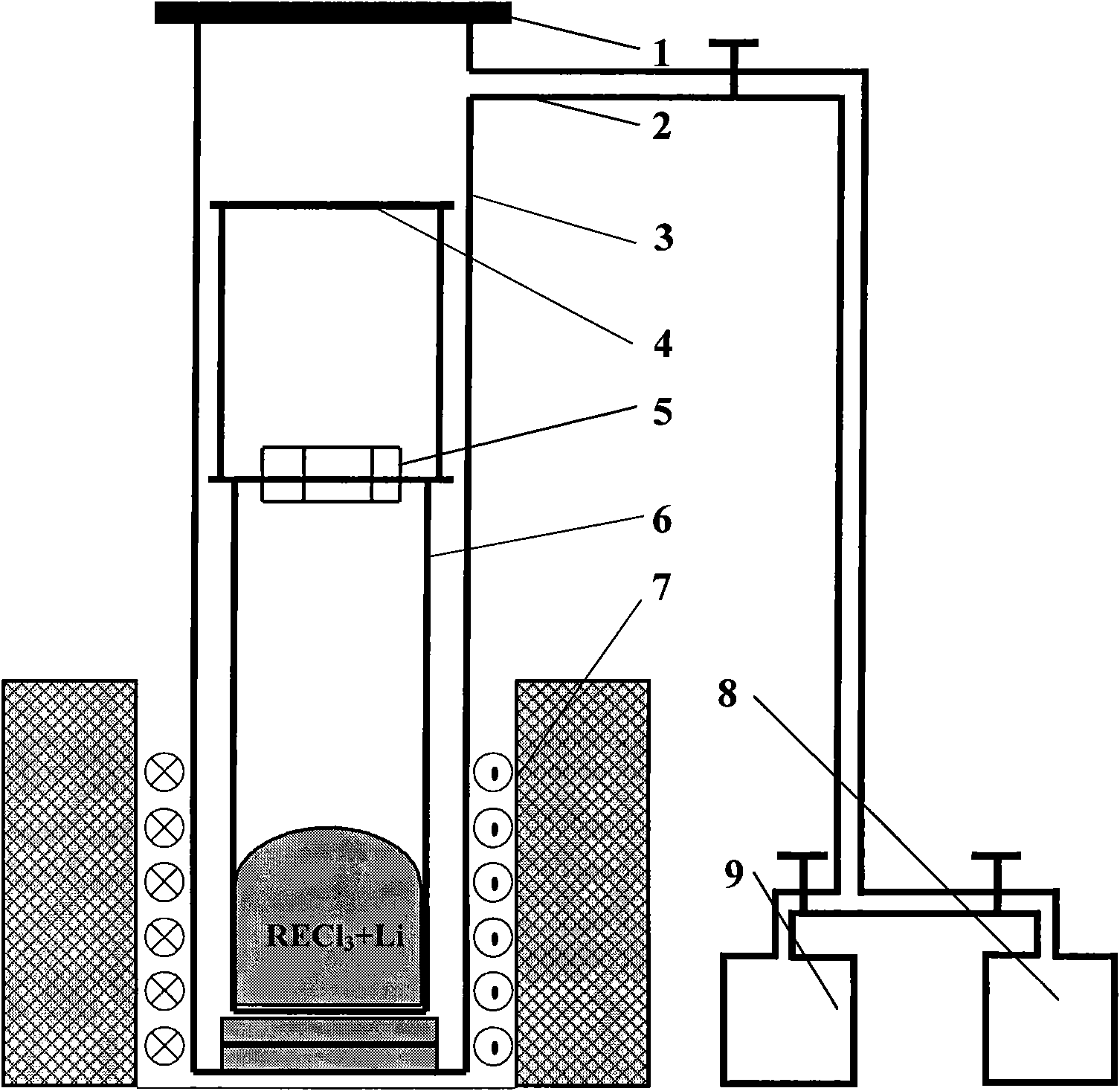

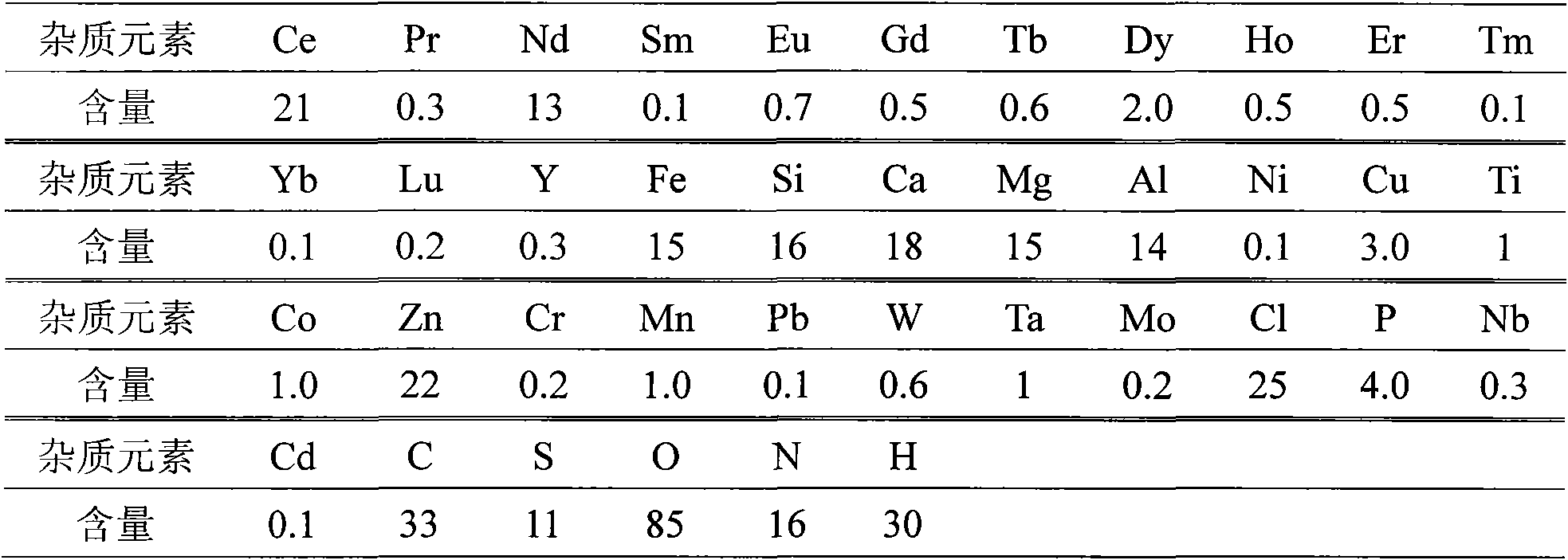

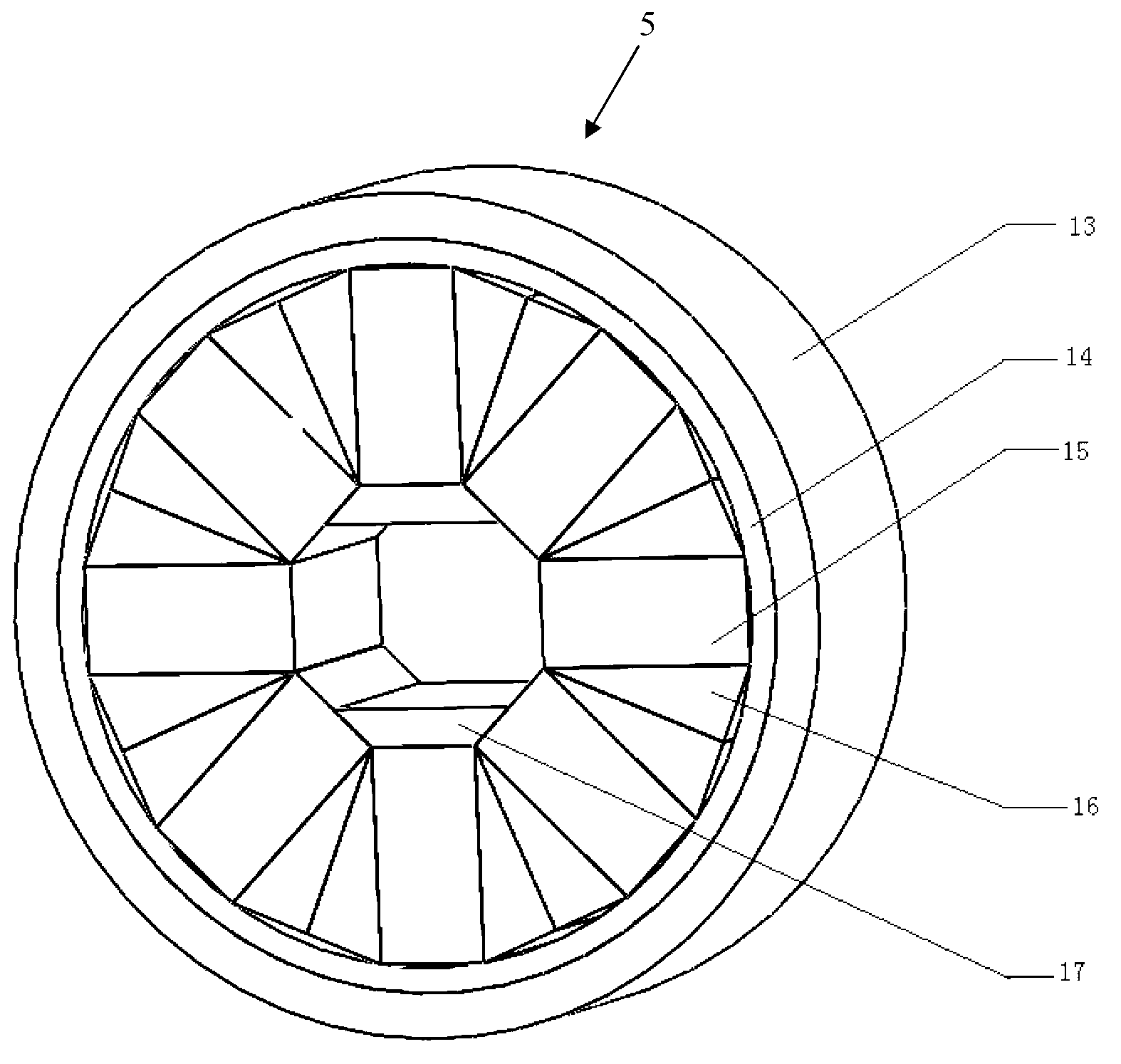

Method for preparing high purity rare earth metal and its apparatus

InactiveCN102465210AAvoid pollutionHigh purityProcess efficiency improvementChemistryDisplacement reactions

The invention relates to a method for preparing a high purity rare earth metal and its apparatus, which is characterized in that a lithium thermal reduction-vacuum distillation combined technology is used for preparing the high purity rare earth metal. The method comprises the following steps: taking rare earth chloride as a raw material and lithium metal as a reducing agent, placing in a reaction container, in a reaction system, carrying out a liquid-liquid displacement reaction of lithium metal and rare earth chloride under the inert gas protection (the pressure is 0.1-0.5 MPa) and the temperature of 850-1100 DEG C, then vacuum-pumping the reaction system to 10<-1>-10<-3> Pa, wherein the temperature is controlled at 900-1200 DEG C, evaporating lithium metal and lithium chloride, separating slag and metal to obtain the high purity rare earth metal. The reaction apparatus is composed of a furnace cover (1), a communicating pipe (2), a collector (3), a furnace body (4), a thermal baffle (5), a reactor (6), a heating device (7), an inflation system (8) and a vacuum system (9). The invention has the advantages of short process flow, high yield of rare earth metal and low production cost; the purity of the prepared rare earth metal is high. The used apparatus is simple and is easy to enlarge, and is suitable for large batch of industrial production.

Owner:GRIREM ADVANCED MATERIALS CO LTD

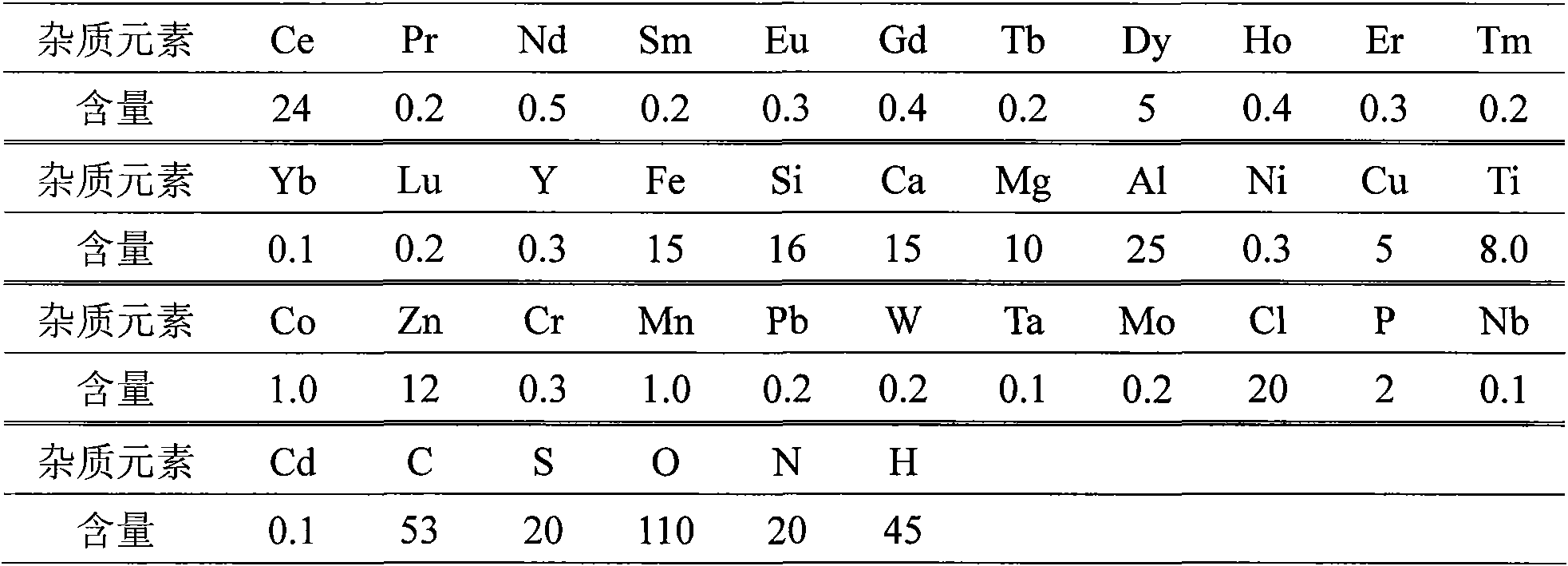

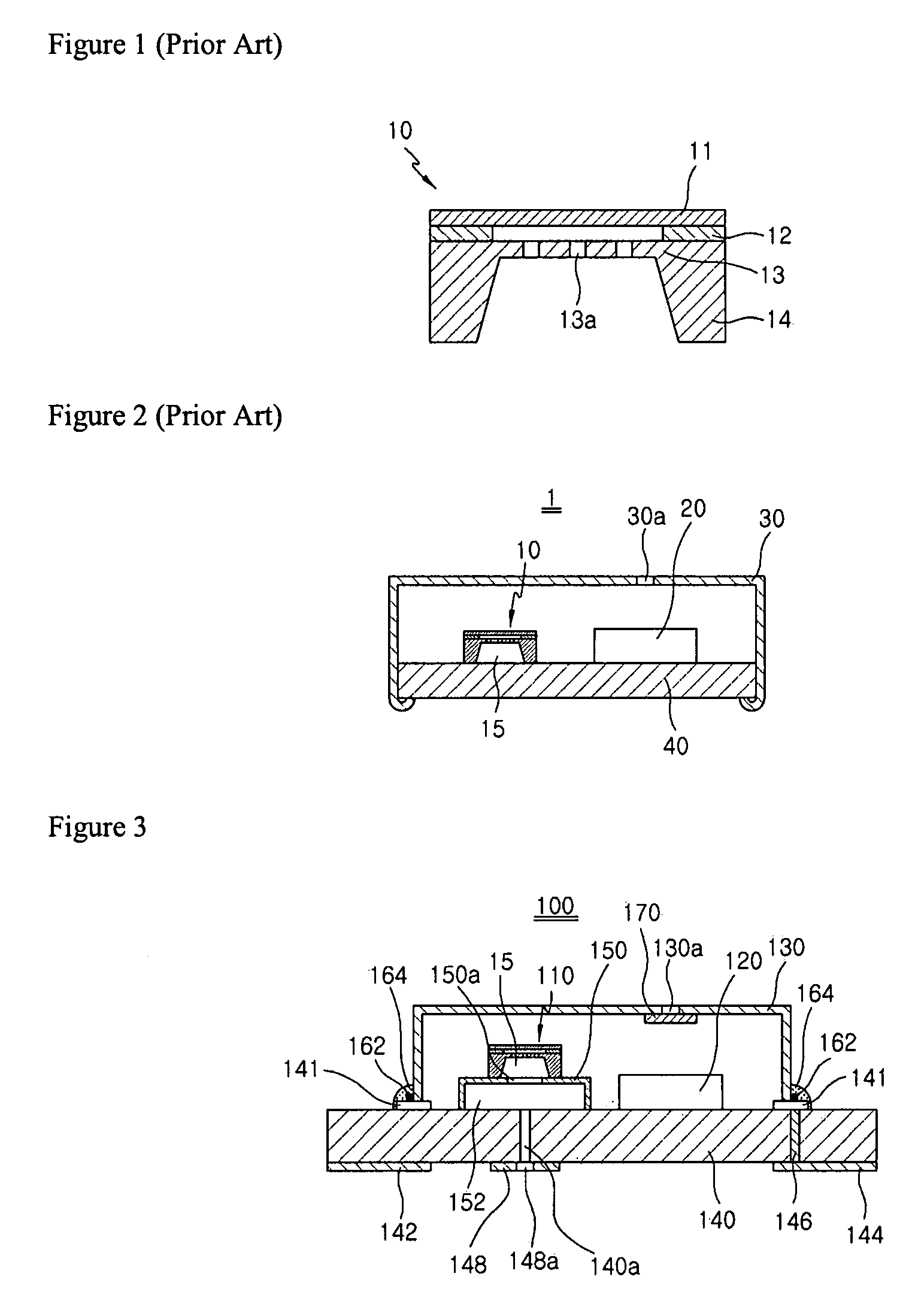

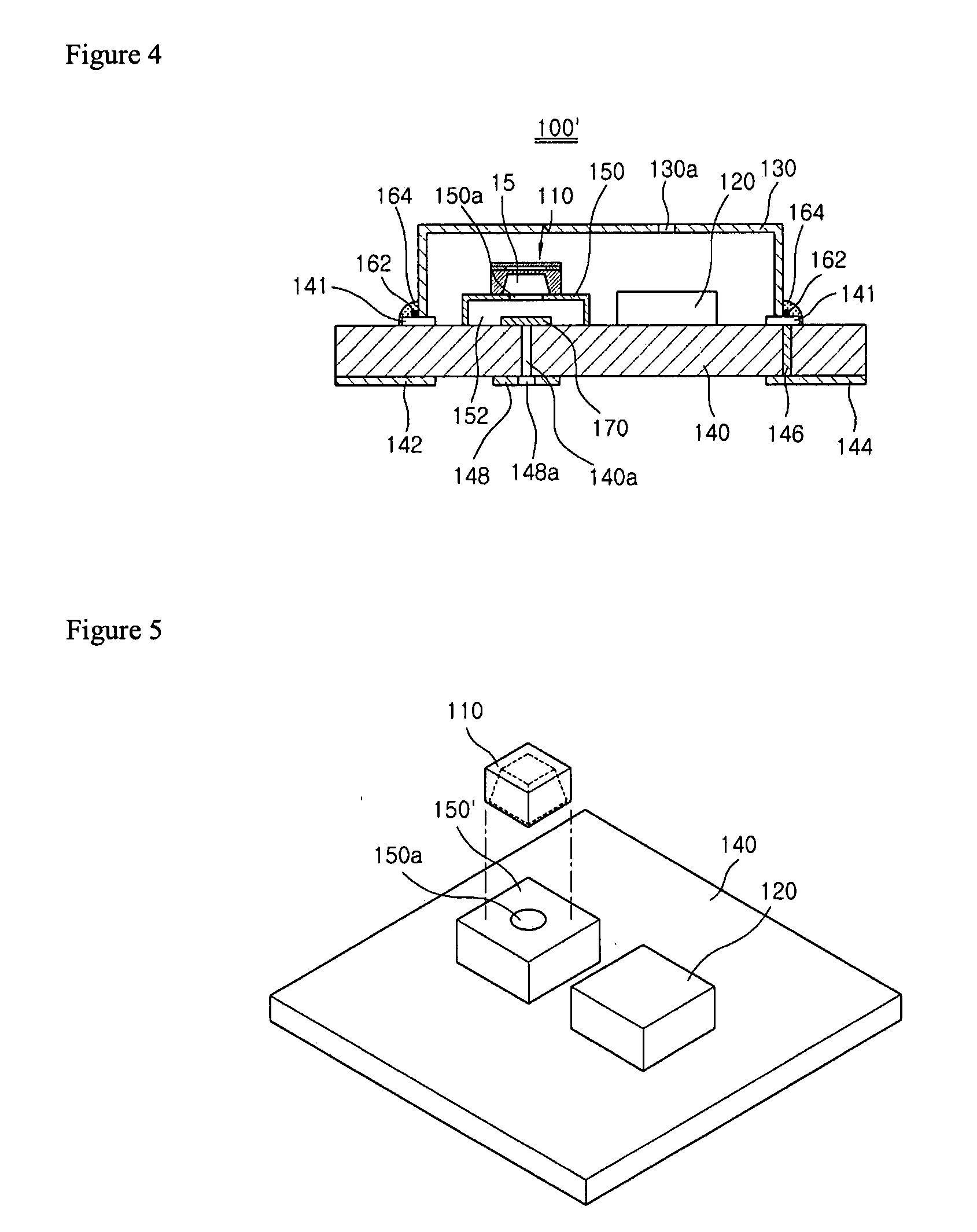

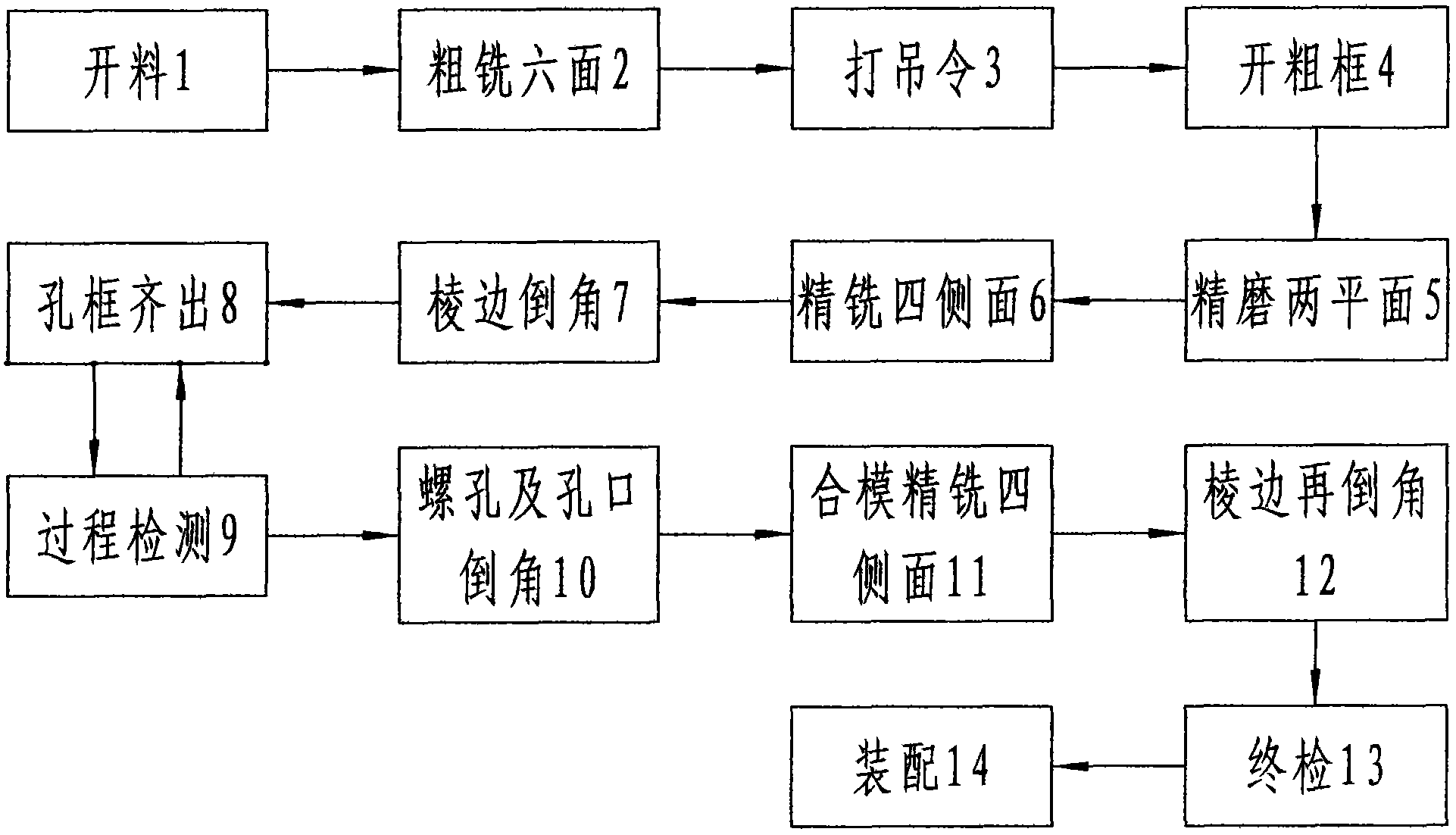

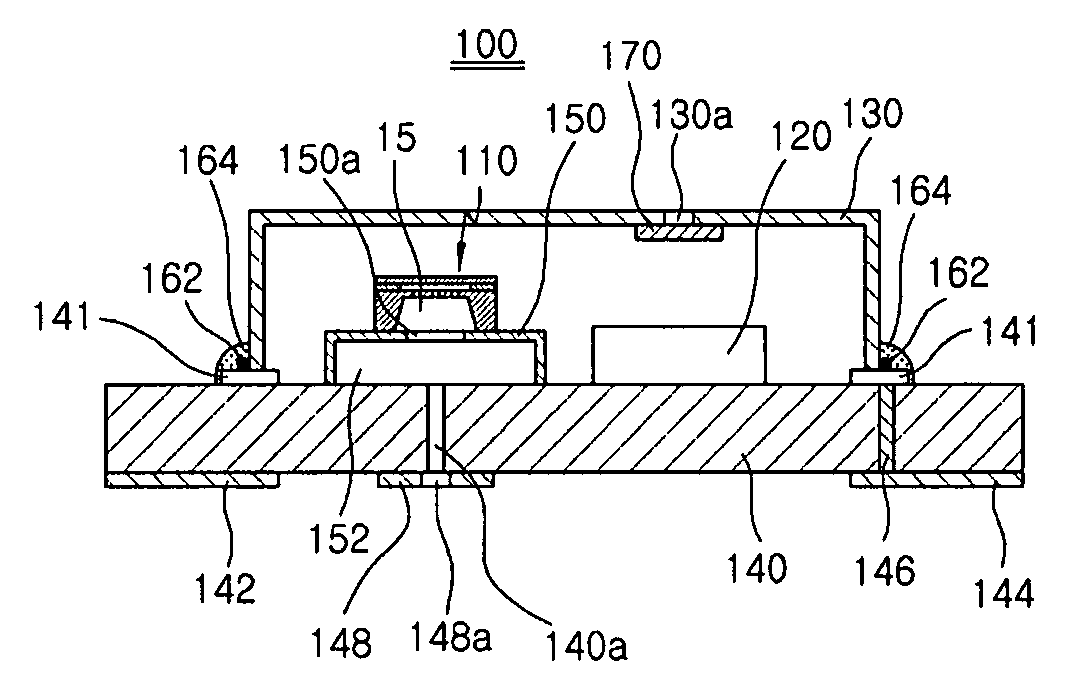

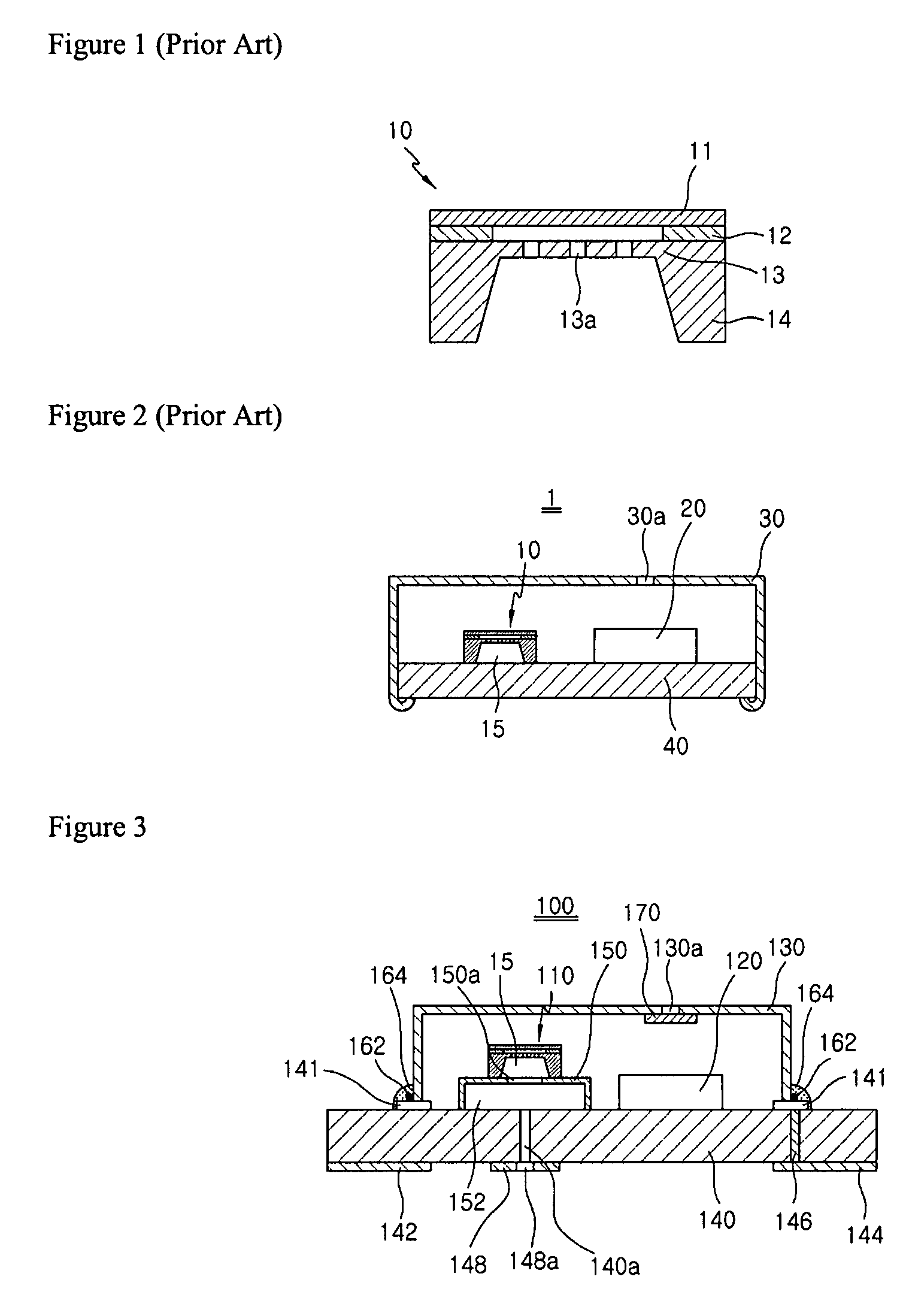

Directional silicon condenser microphone having additional back chamber

InactiveUS20090074222A1Robust to external noiseReduce manufacturing costPiezoelectric/electrostrictive microphonesMicrophonesCondenser microphoneAdhesive

A directional silicon condenser microphone having an additional back chamber is disclosed. The directional silicon condenser microphone comprises a case having a front sound hole for passing through a front sound; a acoustic delay device for delaying a phase of a sound; a substrate including a chamber case, a MEMS chip having an additional back chamber formed by the chamber case, an ASIC chip for operating the MEMS chip, a conductive pattern for bonding the substrate to the case, and a rear sound hole for passing through a rear sound; a fixing means for fixing the case to the substrate; and an adhesive for bonding the case and the substrate, wherein the adhesive is applied to an entirety of a bonding surface of the case and the substrate fixed by the fixing means.

Owner:BSE CO LTD

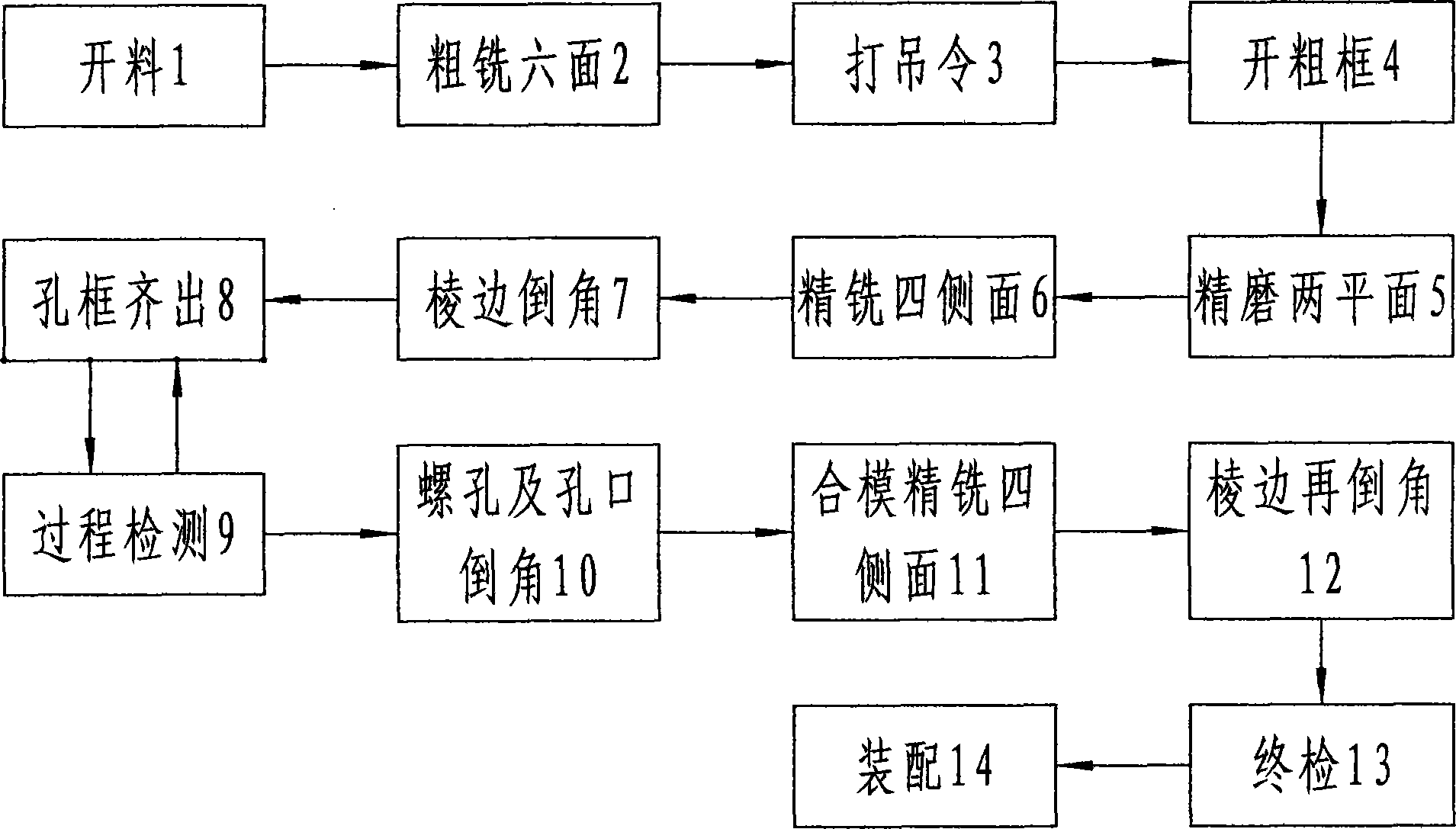

Method for processing bi-color mold blank

ActiveCN102699647AGet rid of dependenceLow processing and manufacturing costsNumerical controlEngineering

The invention discloses a method for processing a bi-color mold blank comprising the following steps in turn: sawing material (1), roughly milling six surfaces (2), operating a crane (3), forming a coarse frame (4), refining two planes (5), finish-milling four lateral surfaces (6), chamfering edges (7), extruding a hole frame (8), inspecting process (9), chamfering screw holes and hole-heads (10), closing mold and finish-milling four lateral surfaces (11), chamfering edges again (12), finally inspecting (13) and assembling (14). According to the method, the adopted technical scheme is as follows: one plate selected from the bearing plate of a movable mold and a bearing plate of a fixed mold of the bi-color mold is adopted as a sample plate, the normal measuring tools and a general numerical control processing center are adopted to process so as to ensure the precision of the sample plate, and the sample plate is adopted to correct and process the fit precision of other plates, so that the problems and shortcomings that the cost is high and the process can not be implemented in the general numerical control processing center in the prior art can be solved; and the technical scheme utilizes the correction action of the sample plate to realize the aims that the products of the bi-color mold blank are processed in the general numerical control processing center and the cost is lowered.

Owner:宁波富信模胚有限公司

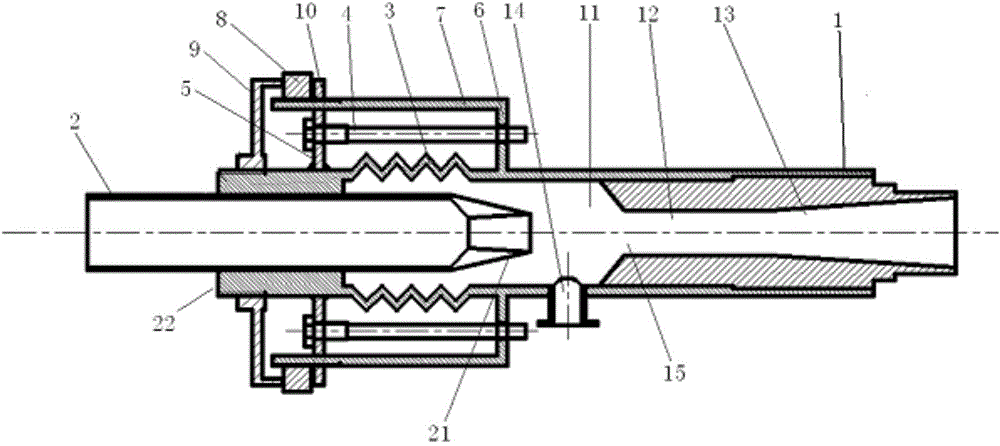

Nozzle-adjustable steam ejector

ActiveCN104675760AImprove performanceSave power steamJet pumpsMachines/enginesInjectorMixing chamber

The invention discloses a nozzle-adjustable steam ejector. The nozzle-adjustable steam ejector comprises an ejector housing with a suction chamber, a mixing chamber and a diffusing chamber inside, and a spray pipe which is partially inserted into the suction chamber, wherein the spray pipe is provided with a nozzle which faces to the mixing chamber. The nozzle-adjustable steam ejector further comprises a retractable pipe which is hermetically connected with the ejector housing and the spray pipe, and an adjusting device which is used for adjusting the distance between the nozzle and the mixing chamber; a guide mechanism is arranged between the spray pipe and the ejector housing. The nozzle-adjustable steam ejector disclosed by the invention has the advantages that of simple structure, low manufacturing cost and simplicity and convenience in installation and disassembling. Not only can the distance between the nozzle and the inlet of the mixing chamber be adjusted, can the performance of the steam ejector be improved and can the ejector be kept to have the optimum working performance within a wider operating range, but also the sealing performance is not influenced during adjustment of the distance between the nozzle and the suction chamber since the spray pipe is hermetically connected with the nozzle with the ejector housing by adopting the retractable pipe, and the problem of leakage caused by a reason that the sealing performance is poor or becomes deteriorated does not exist.

Owner:ZHEJIANG UNIV

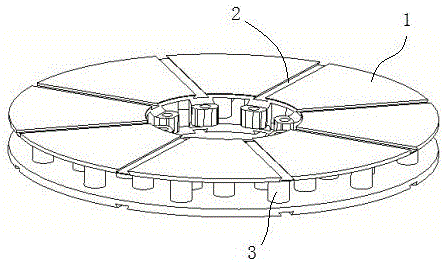

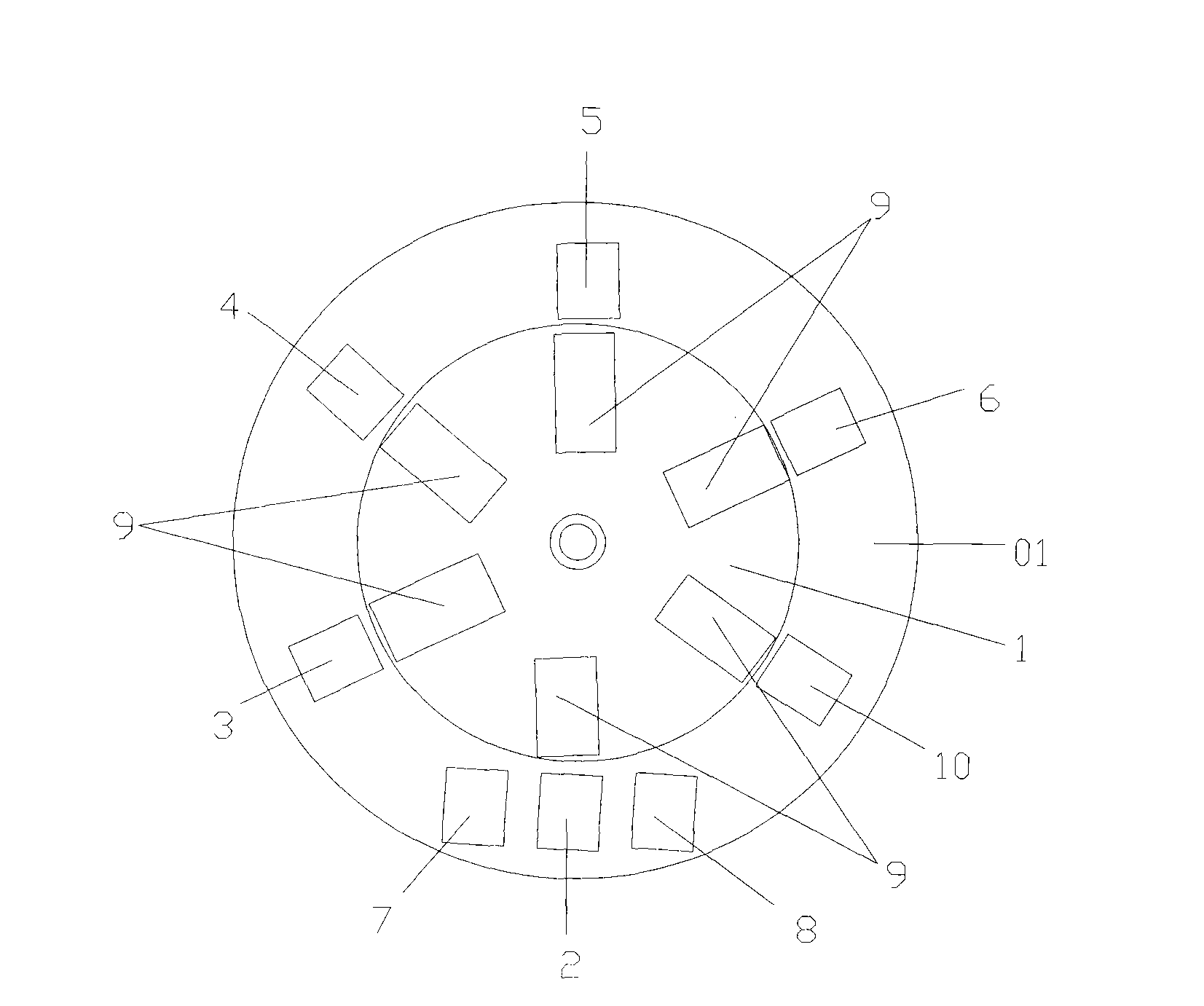

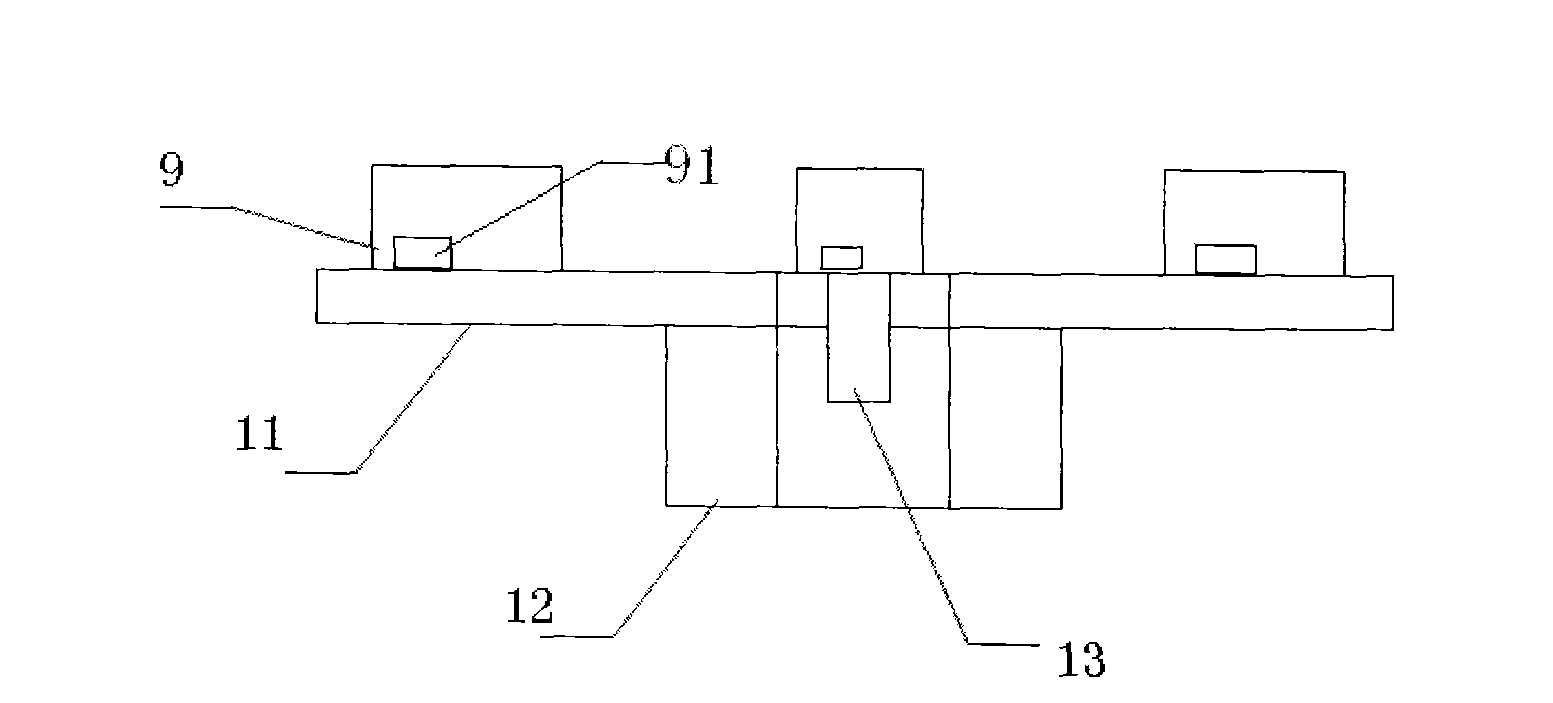

Vacuum liquid filling equipment for soft-package battery

InactiveCN102496691AShorten the soaking timeShorten the production cycleCell component detailsElectrical batteryEngineering

The invention belongs to the field of production equipment for lithium ion batteries, and particularly relates to vacuum liquid filling equipment for a soft-package battery. The vacuum liquid filling equipment for the soft-package battery comprises a machine frame and a multi-workstation turnplate which is arranged on the machine frame, wherein a drawer-type sealed box body is installed on any workstation of the multi-workstation turnplate; a battery fixing clamp is fixedly installed inside the drawer-type sealed box body; a battery loading and unloading unit, a battery packaging bag sucking-open unit, a vacuumizing unit, a liquid filling unit and a sealing unit which correspond to the workstations of the multi-workstation turnplate are fixedly arranged on the periphery of the multi-workstation turnplate sequentially; two sides of the battery loading and unloading unit are fixedly connected with a front filled liquid weighing unit and a back filled liquid weighing unit respectively; and each unit is fixedly connected on the machine frame. Compared with the prior art, the vacuum liquid filling equipment for the soft-package battery has the advantages that the electrolyte soaking time can be reduced, the space occupied by the equipment can be reduced, a surplus liquid filling pump can be saved, the investment cost of the equipment can be reduced, the liquid filling precision and the stability can be improved and the waste of the electrolyte can be reduced.

Owner:DONGGUAN AMPEREX TECH +1

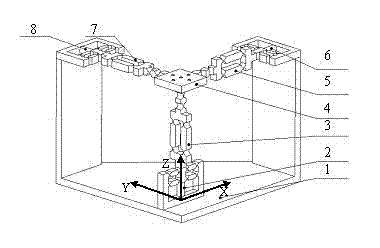

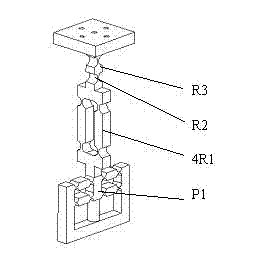

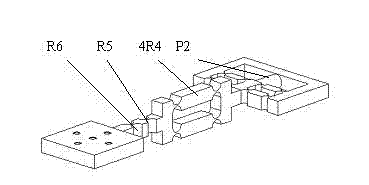

Three-degree-of-freedom microoperation orthogonal parallel operating platform used for ultraprecise location

The invention discloses a three-degree-of-freedom microoperation orthogonal parallel operating platform used for ultraprecise location, which realizes space three-dimensional translation ultraprecise location. The three-degree-of-freedom microoperation orthogonal parallel operating platform is provided with a static platform and a movable platform, wherein a piezoelectric ceramic driver is fixedly vertically arranged on each panel of the static platform, a drive of each piezoelectric ceramic driver is connected with the top end of a branched chain, the tail end of each branched chain is vertically connected with the movable platform, three branched chains are formed by sequentially serially connecting a flexible movable pair, a parallelogram structure, a first rotating pair and a second rotating pair according to position relationships of vertical, vertical and parallel among axial lines, the top end of each branched chain is a movable pair, the tail end of each branched chain is a second rotating pair, the three movable pairs are mutually orthogonal, and the three second rotating pairs are mutually orthogonal. According to the invention, the advantages of a parallel mechanism and a flexible movement pair are combined, a movement is generated by depending self elastic deformation, and output reaches high precision of micro level even nano level.

Owner:JIANGSU UNIV

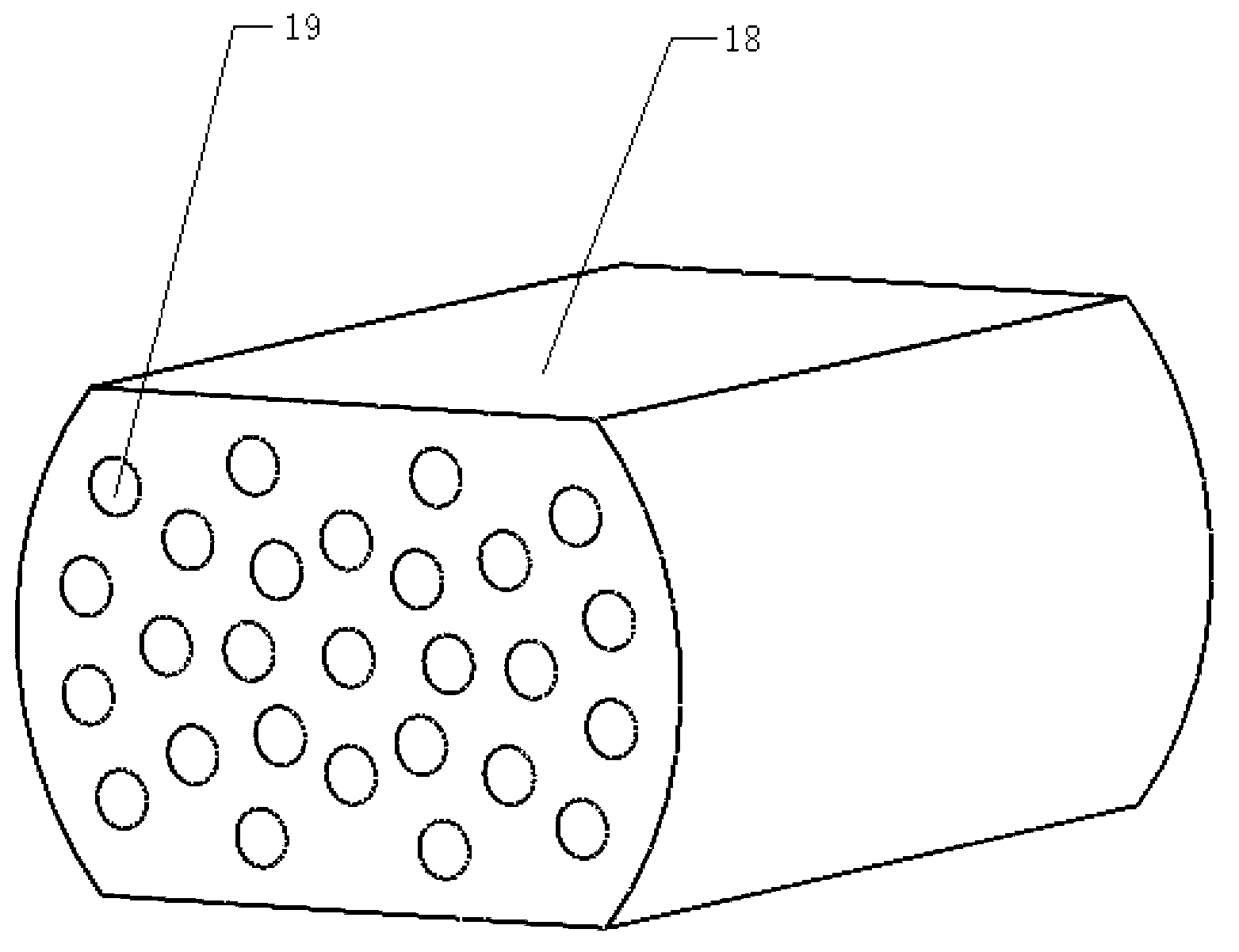

Magnetic refrigerating portable refrigerator and refrigeration method

InactiveCN103062973ATo achieve the purpose of coolingSimple and fast operationEnergy efficient heating/coolingDomestic refrigeratorsWaste processingFilling materials

The invention discloses a magnetic refrigerating portable refrigerator and a refrigeration method. The magnetic refrigerating portable refrigerator belongs to the field of domestic electrical appliances and comprises a shell, a storage box arranged in the shell, a permanent magnet group, a magnetic working medium and the like, wherein the permanent magnet group is a tube-shaped body the centre of which is provided with a through hole; and the magnetic working medium is provided with multiple through holes and is closely sleeved in a magnetic working medium shell with a concave slideway. The function of the magnetic refrigeration portable refrigerator is realized by that the magnetic working medium is fixed, straight guide rails drive the permanent magnet to do a reciprocating straight motion relatively to the magnetic working medium, and the magnetic working medium realizes an excitation and demagnetizing process, so that the refrigeration of the refrigerator is realized; the relative movement method of the magnetic working medium and the permanent magnet is simple to operate, relatively stable in motion, and easy to control in the realizing manner; the structure of the magnetic working medium solves the problems that the filling materials is difficult to process and manufacture, and gaps among the filling materials are difficult to guarantee and the like; and a permanent magnet is simple in structure and convenient to process, so that the non-waste processing is realized, and the processing and manufacturing cost is greatly saved.

Owner:NORTHEASTERN UNIV

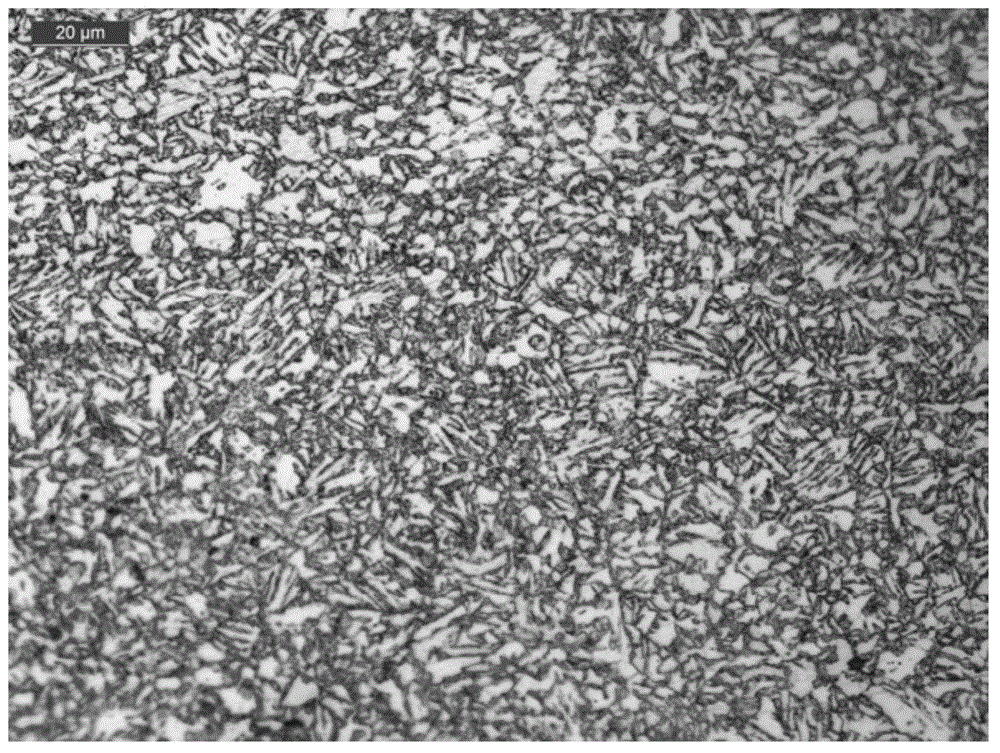

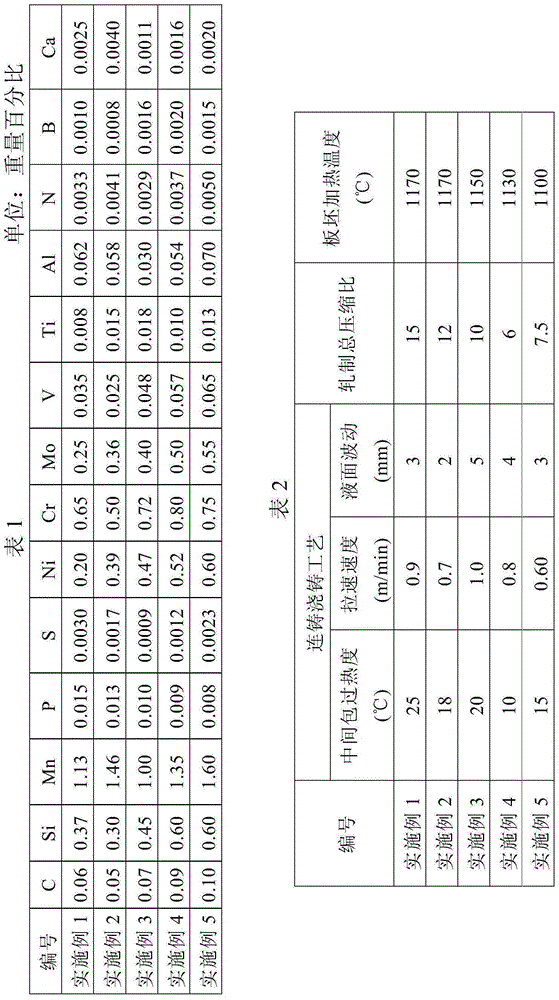

Low-cost high-machinability steel for engineering machine and manufacturing method of steel

The invention discloses low-cost high-machinability steel for an engineering machine and a manufacturing method of steel. The steel comprises components including, by weight, 0.06% to 0.10% of C, 0.30% to 0.60% of Si, 1.00% to 1.60% of Mn, not larger than 0.015% of P, not larger than 0.0030% of S, 0.20% to 0.60% of Ni, 0.50% to 0.80% of Cr, 0.25% to 0.55% of Mo, 0.025% to 0.065% of V, 0.0008% to 0.0020% of B, 0.008% to 0.018% of Ti, 0.030% to 0.070% of Al, not larger than 0.0050% of N, 0.0010% to 0.0040% of Ca, and the balance Fe and inevitable impurities. Mn / C is larger than 15, {steel plate quenching temperature*[(%Cr)+3.3(%Mo)+1.75(%V)+2.15(%Si)]} / [11.7(%C)<1 / 2>+1.23(%Mn)+0.36(%Cu)+(%Ni)] is larger than or equal to 415 and smaller than or equal to 565, Ca / S ranges from 0.80 to 1.50, and (%Ca)*(%S) is larger than or equal to 2.5*10<-6> and smaller than or equal to 2.5*10<-3>. Controlled rolling and two-phase-area quenching and tempering technologies are combined, high strength is obtained, and meanwhile, low-temperature toughness, cold machining moldability, welding performance and fatigue-resisting impact load properties of a steel plate are also excellent.

Owner:BAOSHAN IRON & STEEL CO LTD

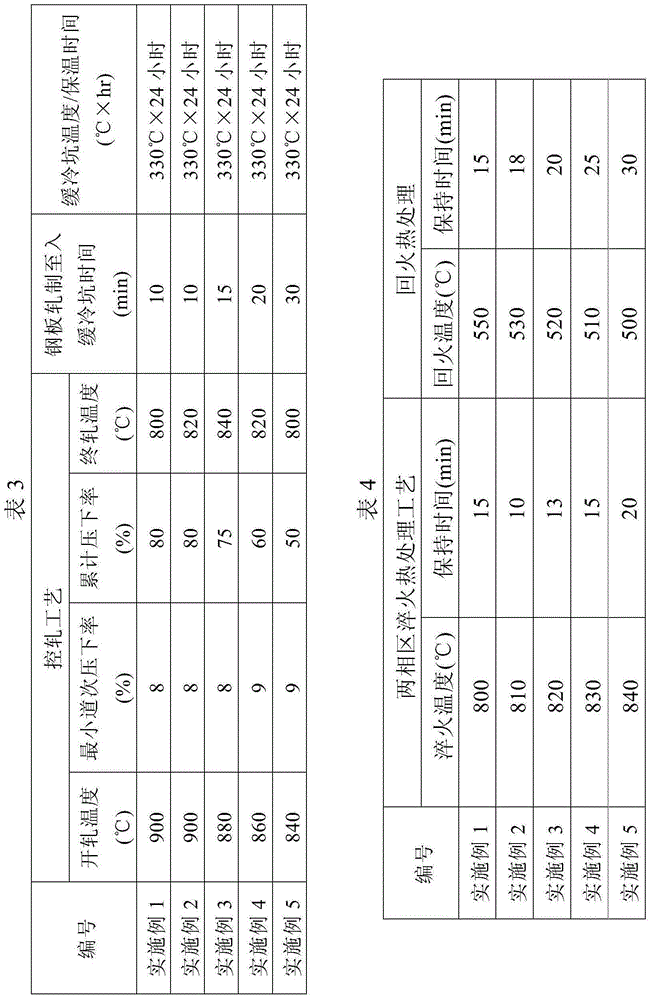

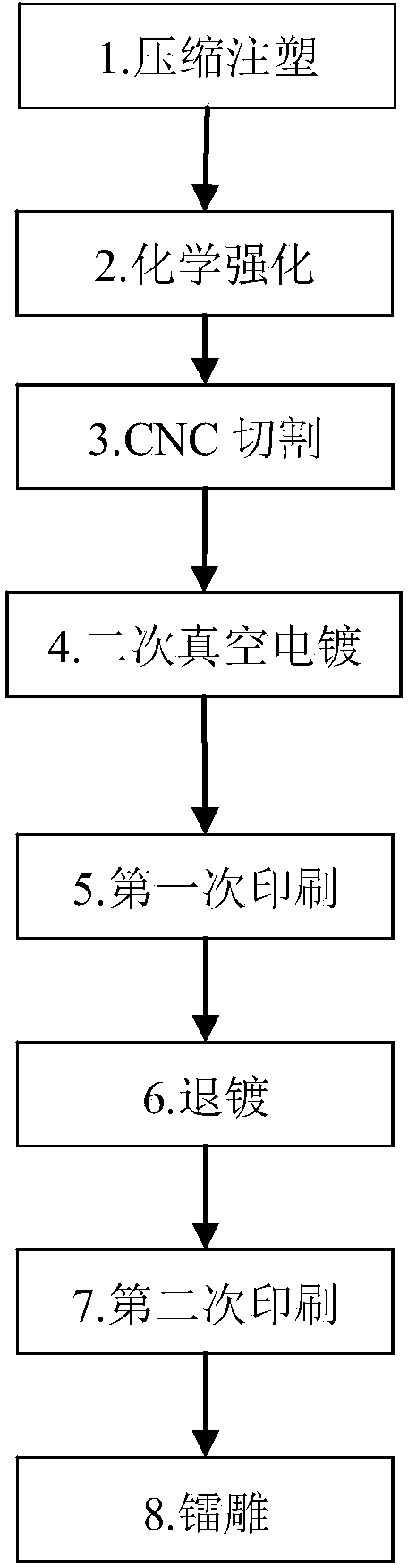

Strengthened organic glass window for cellphone and manufacture method of window

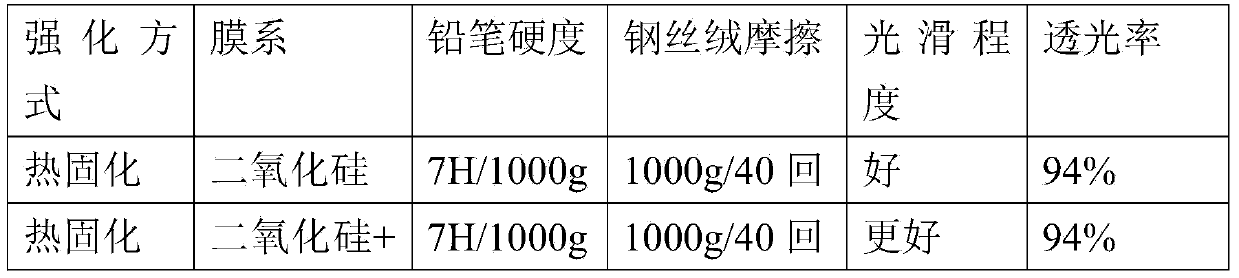

ActiveCN103738008AHigh hardnessHigh light transmittanceGlass/slag layered productsTelephone set constructionsTransmittanceHardness

The invention discloses a strengthened organic glass window for a cellphone. The strengthening organic glass window comprises an organic glass lens, wherein the organic glass lens comprises a base plate and a strengthening layer which is used for carrying out chemical strengthening treatment on the outer surface of the base plate; the inner surface of the base plate is coated with a decorating layer, and the outer surface of the strengthening layer is coated with a first vacuum electroplated layer. The invention also discloses a manufacture method of the strengthening organic glass window for the cellphone. The strengthening organic glass window disclosed by the invention has the advantages that the outer surface of a window lens strengthening layer is coated with the vacuum electroplated layer, and the hardness, smooth degree and light transmittance of the surface of the window can be effectively improved.

Owner:DONGGUAN HUAQING OPTICAL TECH

Long rail laying and welding construction technology under conditions of large temperature difference and strong wind and sand

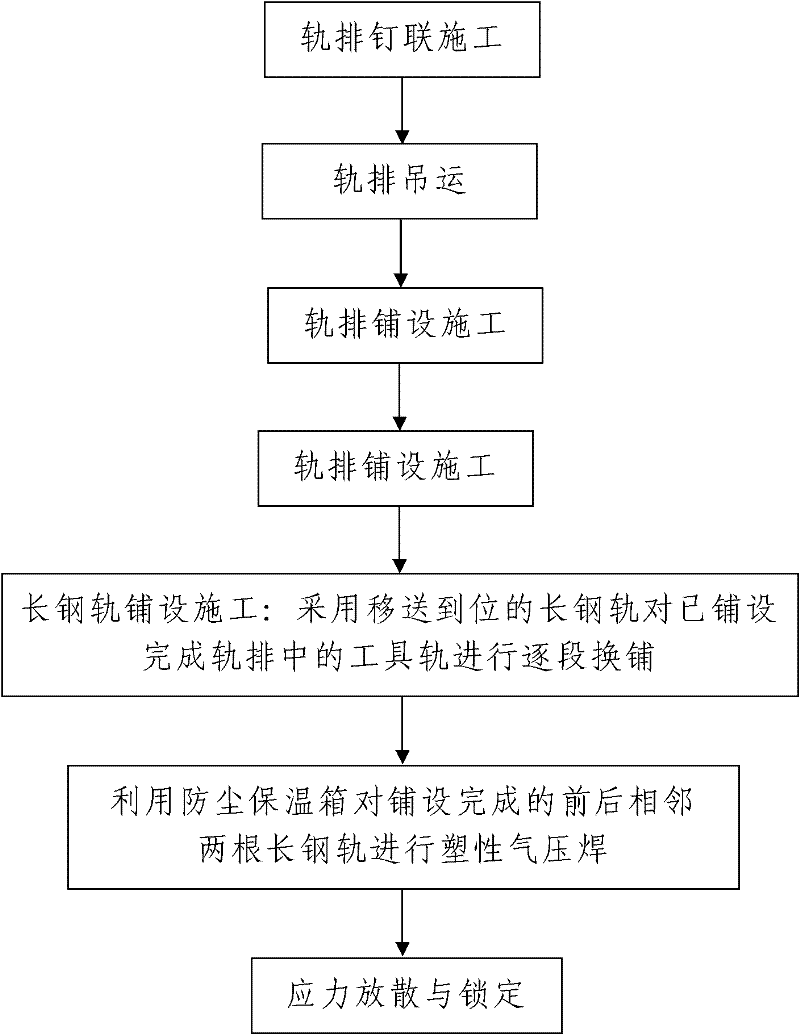

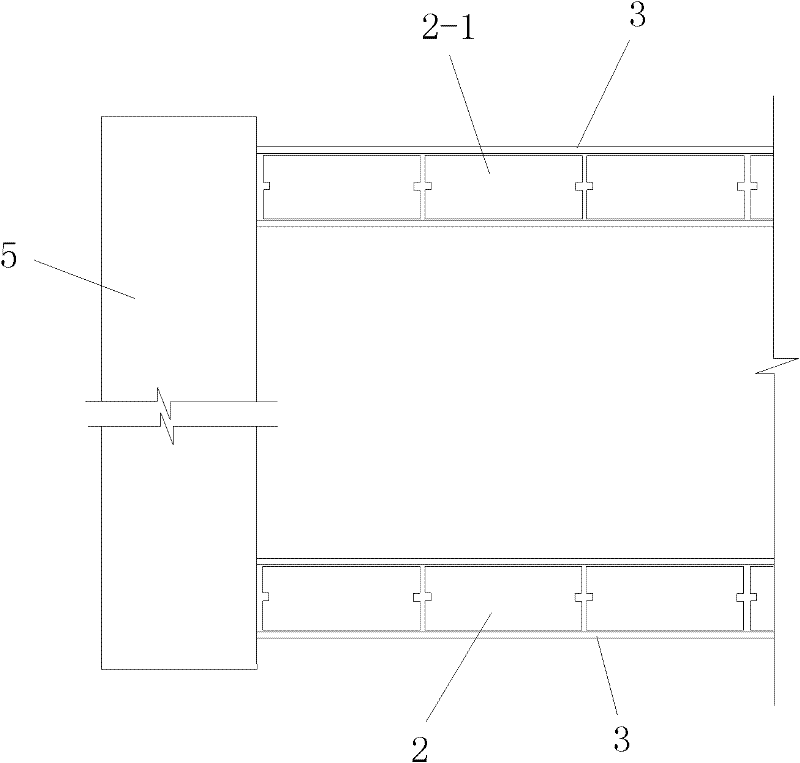

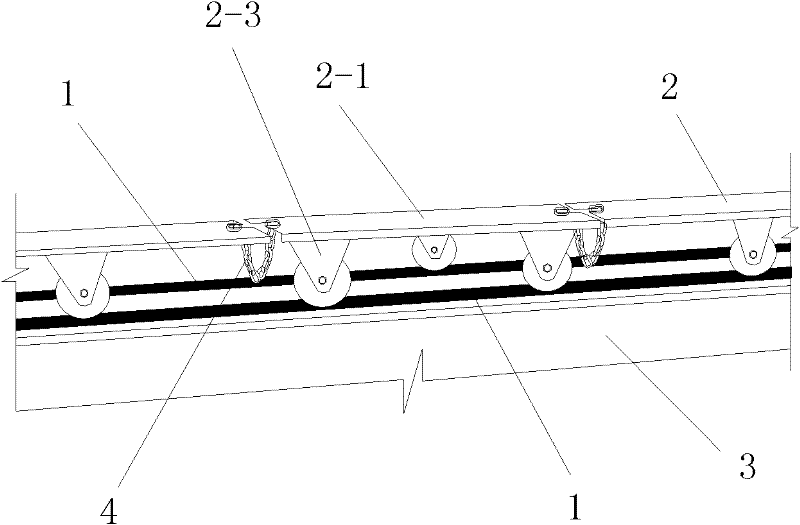

ActiveCN102296495AThe process steps are simpleEasy constructionRailway track constructionEngineeringTemperature difference

The invention discloses a long steel rail laying and welding construction process under the conditions of large temperature differences and strong sandstorms. The process comprises the following steps: carrying out track panel nail interlocking construction: nail interlocking construction is continuously carried out on a plurality of track panels used for construction by adopting track panel nailinterlocking lines, wherein the track panel comprises a plurality of sleepers and two tool rails arranged on the sleepers; 2. carrying out track panel lifting; 3. carrying out track panel laying construction; 4. carrying out long steel rail laying construction: the construction process comprises the two steps of displacing long steel rails and replacing and laying the tool rails in the laid trackpanels segment by segment by adopting the long steel rails; 5. carrying out plastic gas pressure welding on the two adjacent laid long steel rails by utilizing a dustproof incubator; and 6. carrying out stress dispersion and locking construction. The long steel rail laying and welding construction process provided by the invention is reasonable in design, simple in construction steps, convenient in realization, short in construction period and high in construction quality, and can be used for solving the problems of long construction period, low construction efficiency, poor construction effect and difficultly controlled welding quality and the like existing in the long steel rail laying construction under the conditions of large temperature differences and strong sandstorms.

Owner:THE FOURTH ENG CO LTD OF CHINA RAILWAYNO 20 BUREAU GRP +1

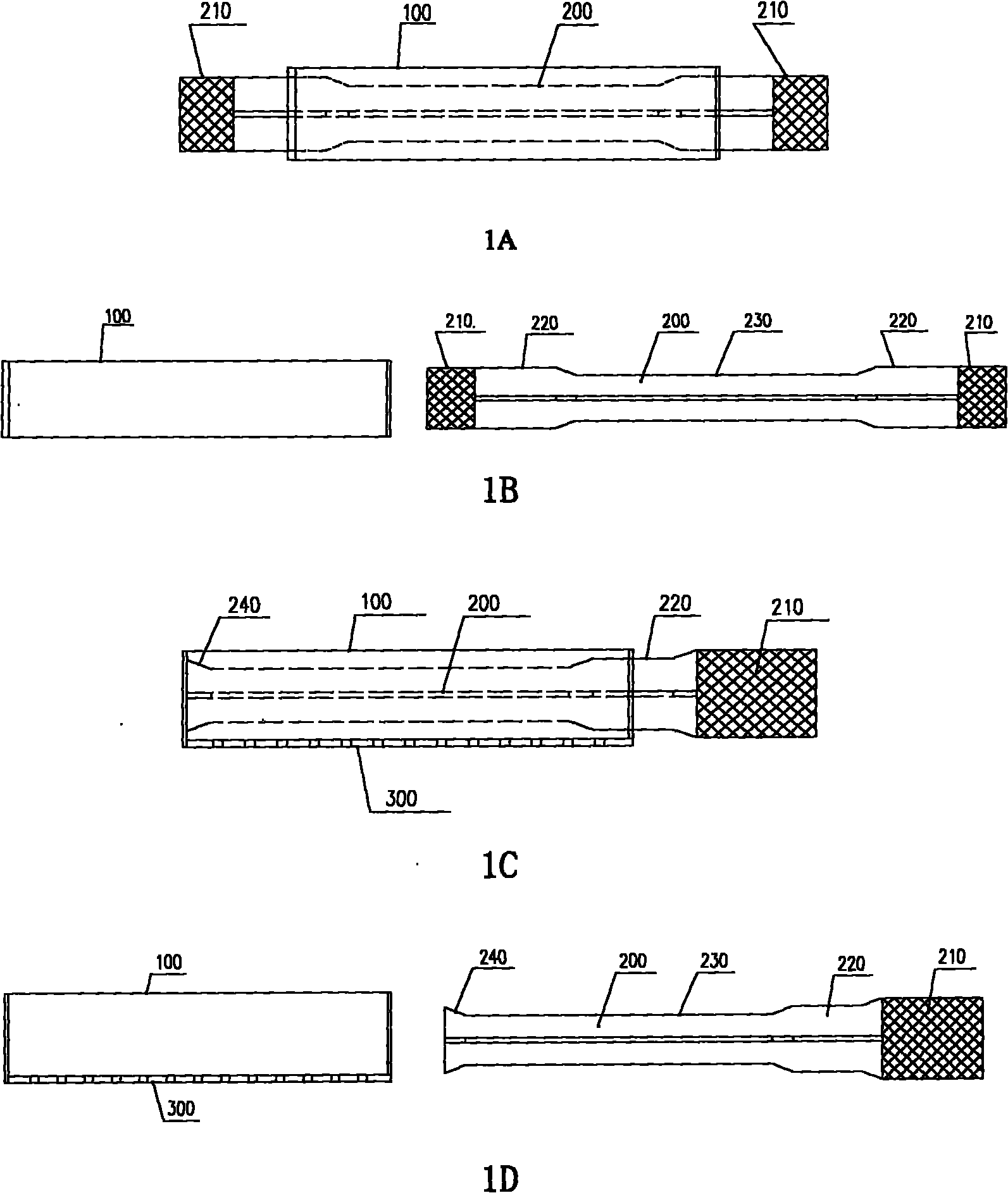

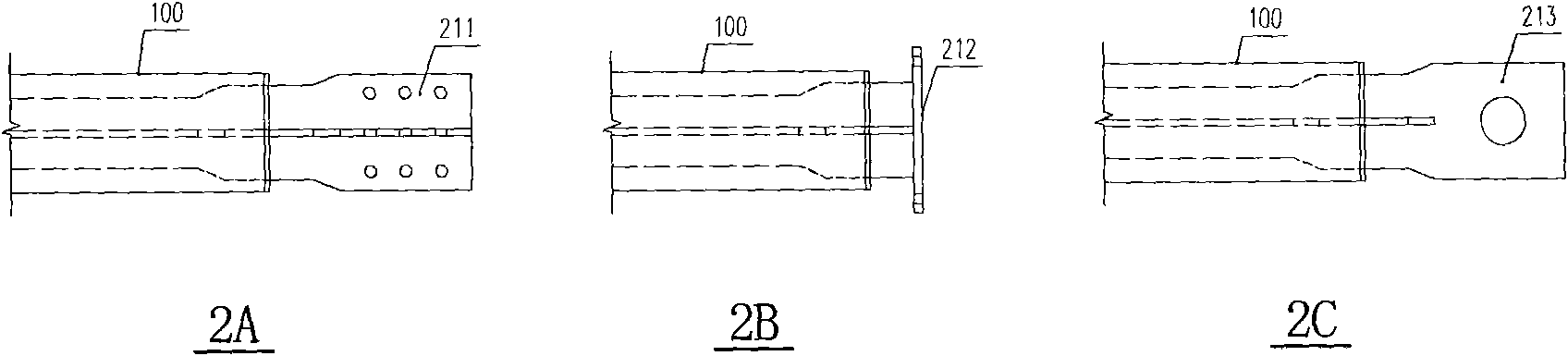

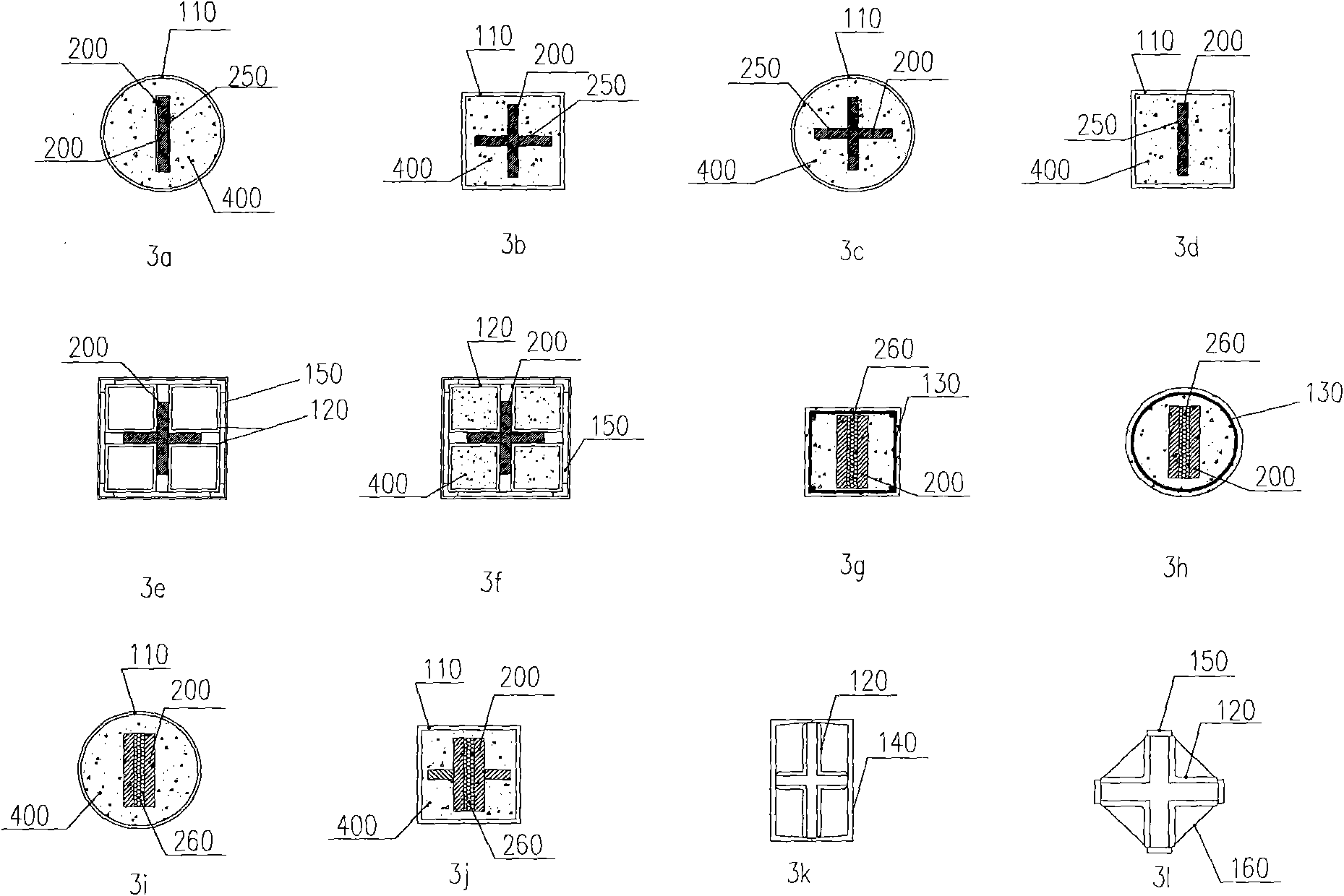

Precast concrete member connected by straight thread and pier head lock anchor grouting sleeve, and method for assembling same

The invention relates to a precast concrete member connected by a straight thread and a pier head lock anchor grouting sleeve, and a method for assembling the precast concrete member, belonging to the technical field of constructional engineering assembly concrete structures. The method of connecting by the straight thread and the pier head lock anchor grouting sleeve is adopted; one end of a reinforcing steel bar is processed into the straight thread (6), and the other end of the reinforcing steel bar is processed into a pier head (5); the inner wall of the end with smaller diameter of a connecting sleeve is processed into a thread (9) which is connected with the reinforcing steel by the straight thread (6) and is used for transmitting force; the inner wall of the end with larger diameter of the connecting sleeve is processed into a thread (16) which is connected with a matched plug ring (10) by an external thread (17); after grouting is carried out through a grouting hole, the original way that the tensile force of the reinforcing steel bar of a prefabricated part connected by grouting is transmitted mainly by bonding is changed by the reinforcing steel bar through lock anchor extrusion and bonding force transmission among the pier head of the reinforcing steel bar, the plug ring, grouting material and the sleeve. The safety and economical efficiency of the connection of the novel precast concrete member are improved.

Owner:CHINA CONSTR ENG DESIGN GROUP +1

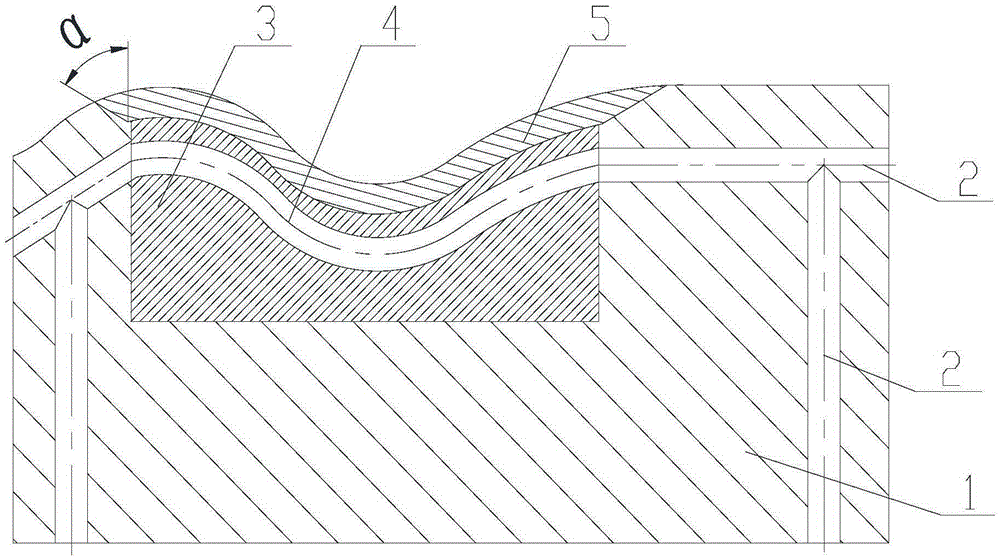

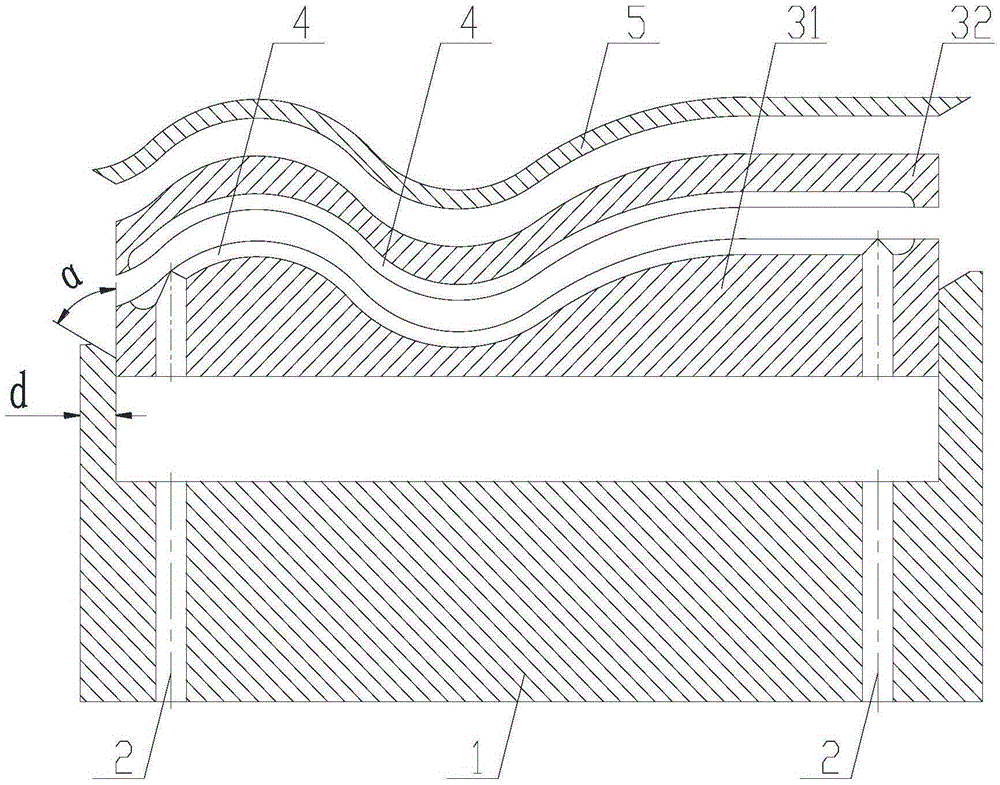

Conformal cooling waterway mold structure and processing method

InactiveCN105252728ALow processing and manufacturing costsGood for promotion and application3D printingMaterials science

The invention discloses a conformal cooling waterway mold structure and a processing method, relates to the technical field of mold manufacturing, and solves the problems that the conventional 3D printed conformal cooling waterway mold has high cost, and the print size is limited. According to the technical scheme, the conformal cooling waterway mold structure comprises a basal body and an insert, wherein a groove is formed in the molding surface of the basal body, and at least two waterways communicated with the groove are arranged in the basal body; the insert is mounted in the groove, and conformal waterways are arranged on the two sides of the contact surface of the insert and the basal body or in the insert and communicated with the waterways in the basal body to form channels; a cladding layer is arranged at the seam line of the insert and the basal body, and the external surface of the cladding layer is the molding surface. The conformal cooling waterway mold structure is detachably processed, and the insert can be processed in the conventional mechanical processing way or the selective laser melting 3D printing processing way. The liquid and gas sealing in the waterways is ensured, the processing and manufacturing cost is significantly reduced, and the popularization and application of the conformal cooling waterway is facilitated.

Owner:四川长虹模塑科技有限公司

Large angle rotary type joint mechanism of mechanical arm

InactiveCN101323110ASimple and compact structureNeat appearanceProgramme-controlled manipulatorSacroiliac jointManipulator

The invention relates to a large-angle rotary joint mechanism of manipulators, belonging to the technical field of machinery, which is characterized in that, a first steel wire rotary table, a third steel wire rotary table and a first joint shaft are fixedly arranged at the root of a first arm respectively; a second steel wire rotary table a fourth steel wire rotary table and a second joint shaft are fixedly arranged at the root of a second arm respectively; a joint shaft connecting rod is arranged on the first joint shaft and the second joint shaft, which can rotate respectively and freely along the axis of the first joint shaft and the second joint shaft; the first to the fourth wire ropes are respectively wound on the U-shaped grooves of the first to the fourth steel wire rotary table; an 8 shape is formed after being wound, and the tension state is maintained. The large-angle rotary joint mechanism has the advantages that the contradiction between the stiffness of the rotary joint mechanism of the manipulator and the dimension of a rotational angle is solved; a large-angle rotary joint mechanism having an angle ranging from about positive 180 degrees to negative 180 degrees is provided; meanwhile, the joint mechanism has simple and compact structure, neat appearance, light weight, large stiffness, no need of precision parts for manufacturing and processing, low cost, and the like, and application space is large.

Owner:SHANGHAI JIAO TONG UNIV

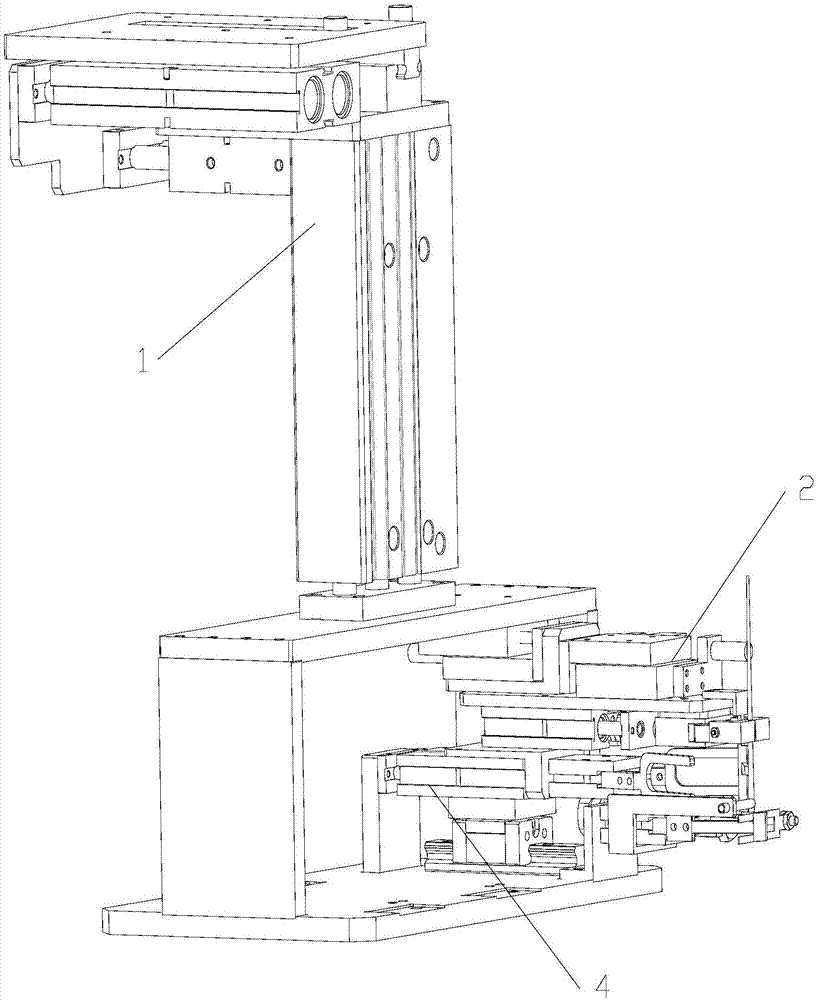

Angular precision positioning device for crank of crankshaft

InactiveCN102513890AAchieve precise indexingFast batch processingRevolution surface grinding machinesGrinding work supportsEngineeringTailstock

The invention relates to an angular precision positioning device for a crank of a crankshaft, which comprises a left fixture, a right fixture, a left clamping mechanism, a right clamping mechanism, a left arc block, a right arc block, gaskets, side gaskets, an angular precision positioning device body and an axial positioning plate. The left arc block and the right arc block are fixed to support arc centers of the left fixture and the right fixture by fasteners, the gaskets which are used for adjusting distances from centers of the corresponding arc blocks to the rotation center of a spindle of a tailstock are respectively placed between the left arc block and the left fixture and between the right arc block and the right fixture, the side gaskets are placed on side surfaces of the left arc block and the right arc block, and are used for correcting the axis of the spindle of the crankshaft so that the axis of the spindle of the crankshaft is coincident with the rotation center, the left clamping mechanism and the right clamping mechanism which are used for clamping the crankshaft to be processed are respectively mounted on the left fixture and the right fixture, and the angular precision positioning device body and the axial positioning plate are mounted on the left fixture. The angular precision positioning device has the advantages that the angular precision positioning device is simple in structure, simple and convenient in operation, fast and time-saving in indexing, high in production efficiency, low in processing and manufacturing costs and wide in indexing, and is safe and reliable, and the fixtures are high in rigidity.

Owner:SHANGHAI MACHINE TOOL WORK

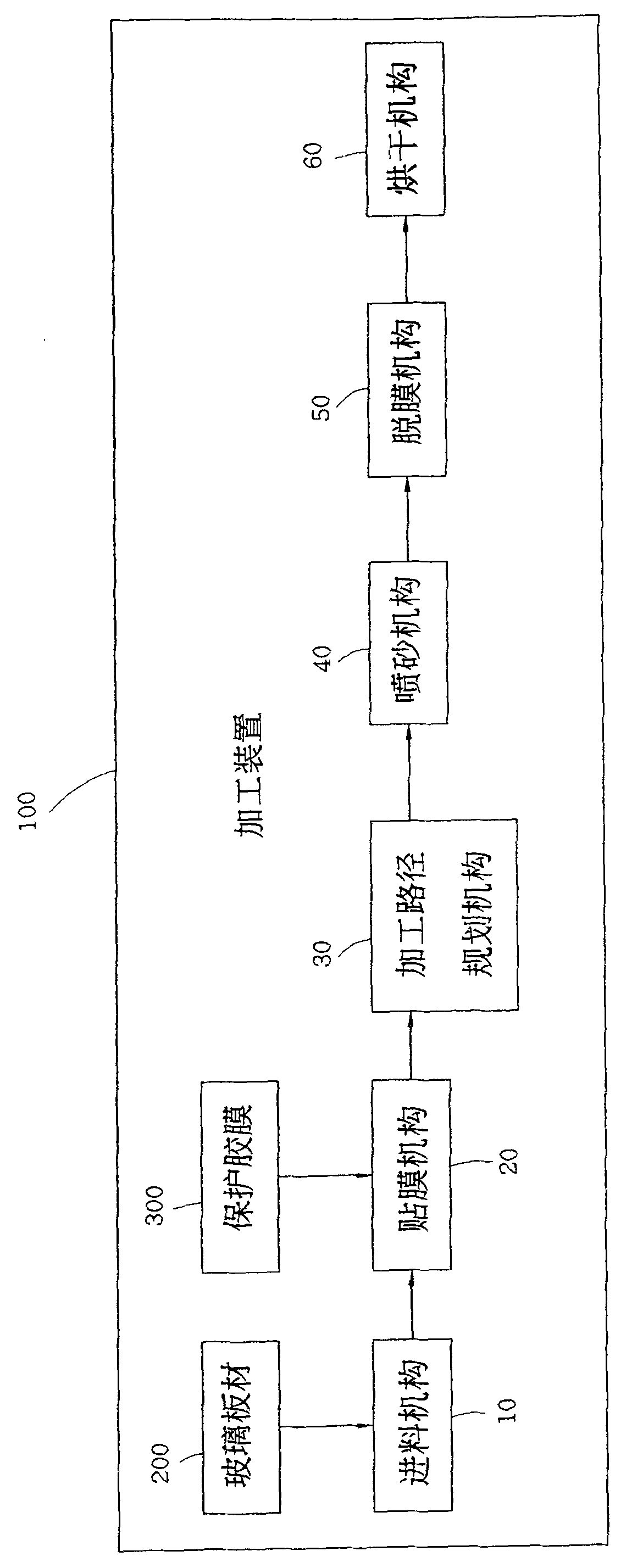

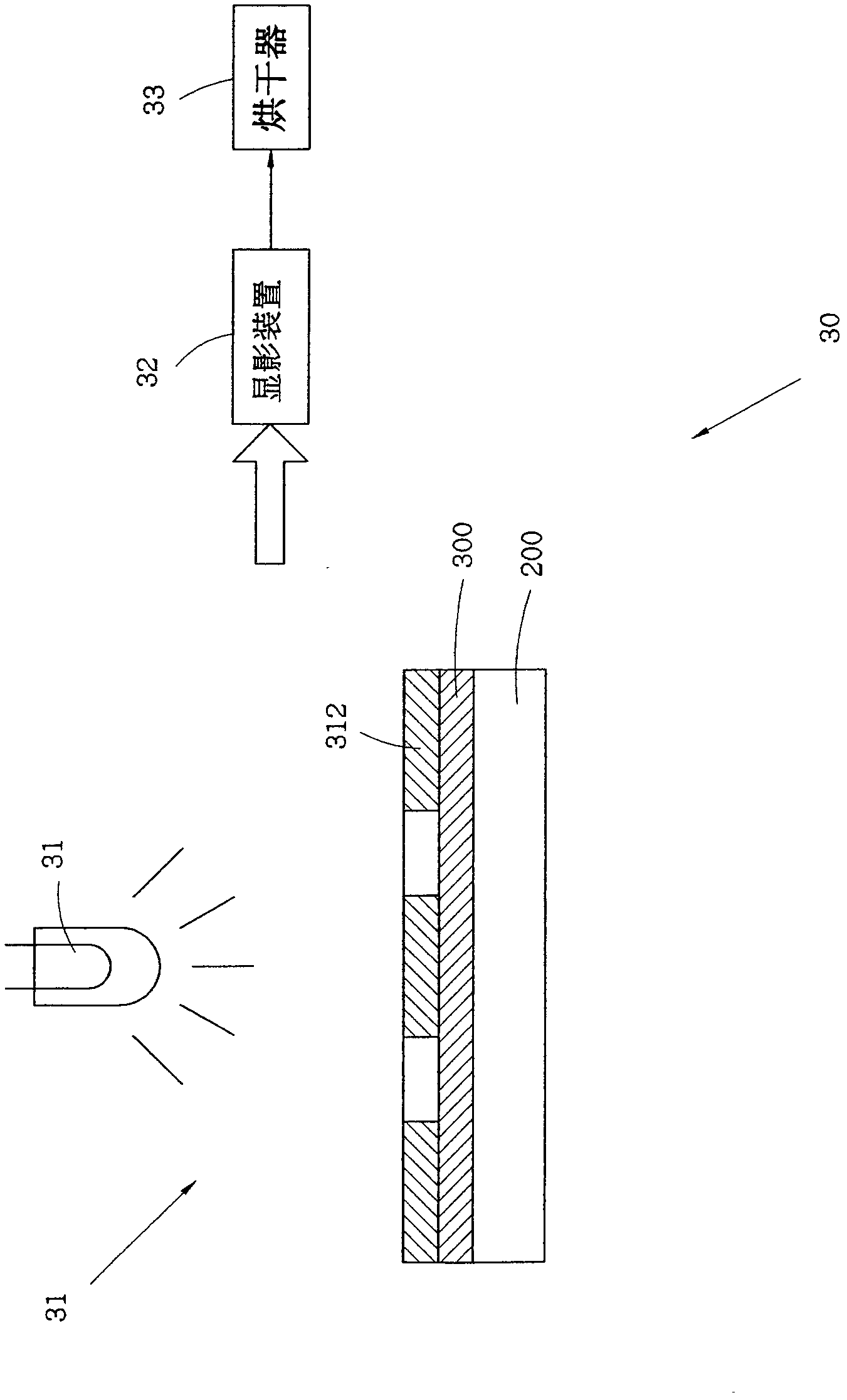

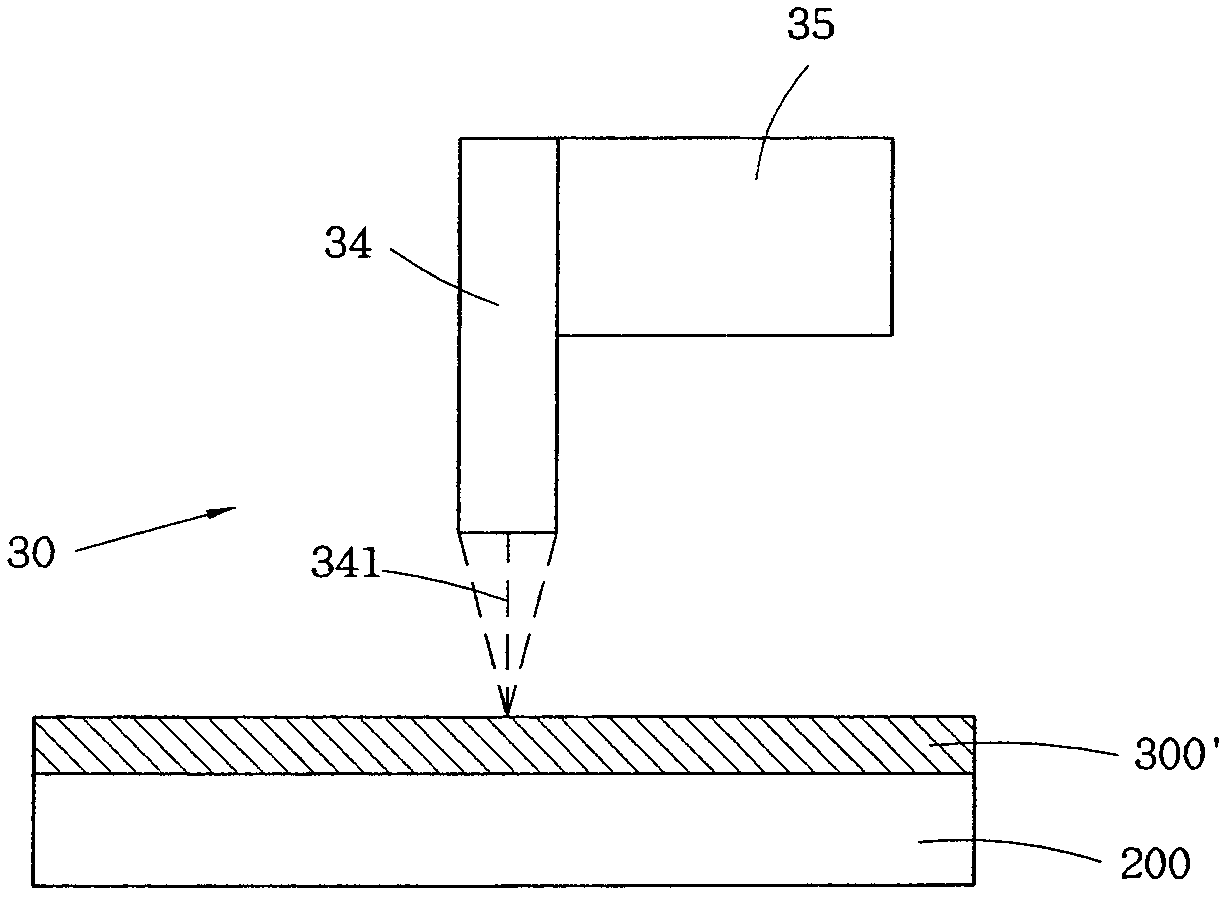

Device and method for processing glass sheet material

InactiveCN102690051AImprove and ensure processing qualityNo cracking damageGlass severing apparatusCutting glassEngineering

The invention discloses a device and a method for processing a glass sheet material. The device comprises a feeding mechanism, a film pasting mechanism, a processing route planning mechanism, a sandblast mechanism, a demolding mechanism and a drying mechanism, wherein the feeding mechanism realizes automatic feeding of a glass sheet material needing to be processed; the film pasting mechanism automatically pastes a glue film layer on at least one side of the glass sheet material; the processing route planning mechanism removes glue film parties which are located on the glass sheet material and do not need protection so that cutting processing routes are obtained; the sandblast mechanism carries out sand blast etching of the surface of the glass sheet material by high-speed micro-powder particles according to the cutting processing routes so that the glass sheet material is cut according to the cutting processing routes; the demolding mechanism carries out washing and glue film removal processes on the cut glass sheet material; and the drying mechanism dries the washed glass sheet material so that the glass sheet material forms a single mother plate or is divided into multiple sub-plates. The device and the method save a lot of a processing manufacture cost of a glass sheet material, and is suitable for the fields of processing functions and application of small radius arcs, drill holes or grooves of a glass sheet material.

Owner:海邦科技股份有限公司

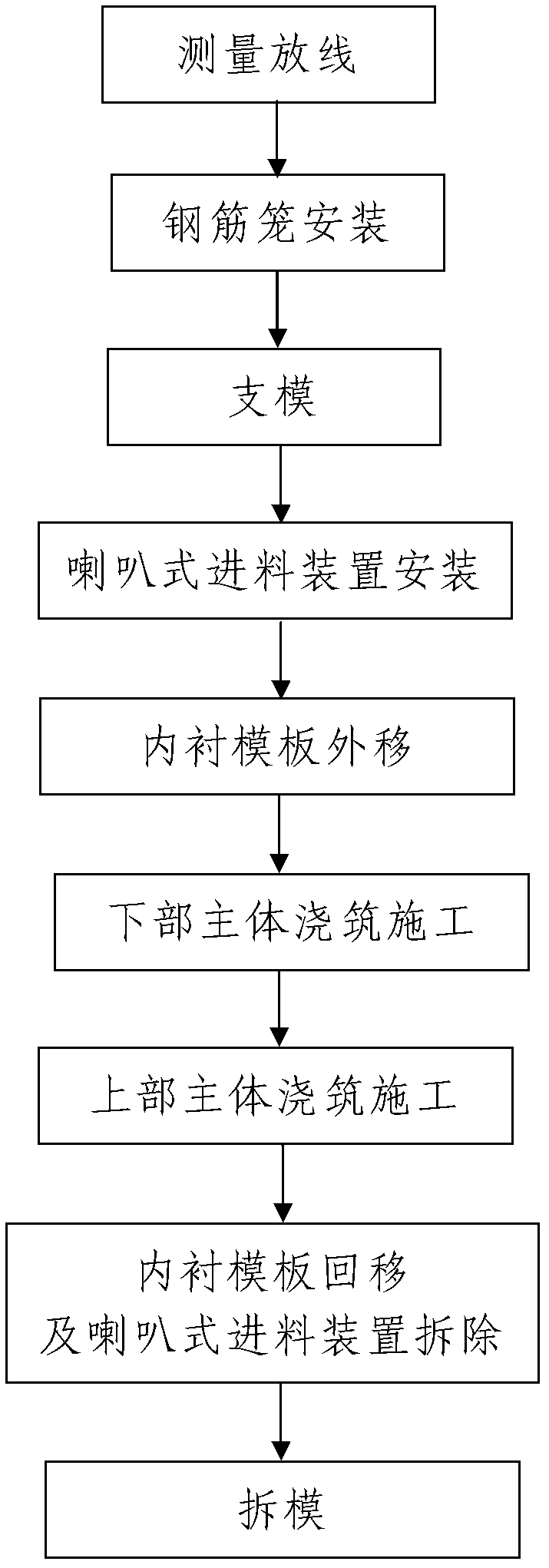

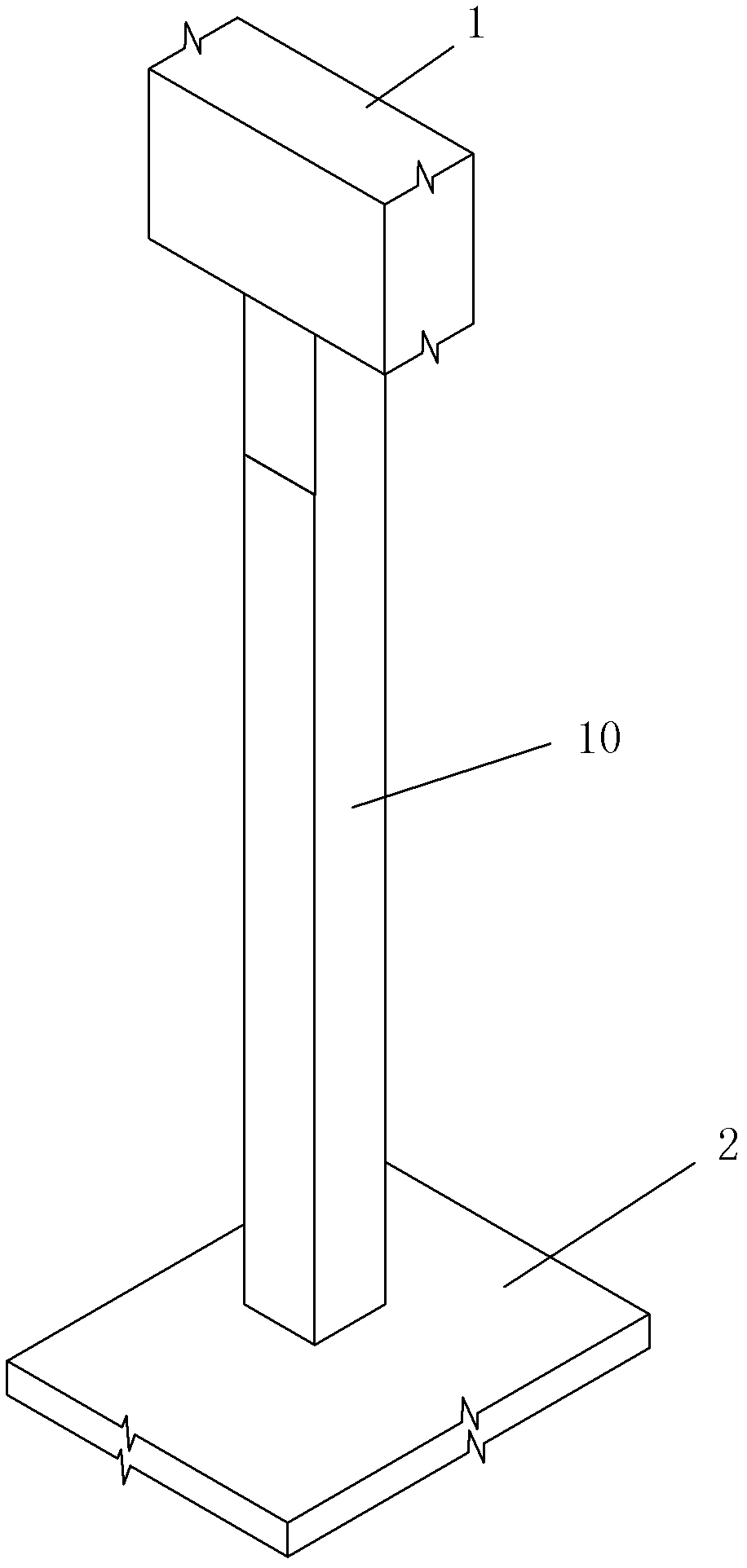

Casting molding template and casting molding process for constructional columns of infilled walls

InactiveCN102561681ASimple structureReasonable designForms/shuttering/falseworksBuilding material handlingMaterials scienceBuilding construction

The invention discloses a casting molding template and a casting molding process for constructional columns of infilled walls. The molding template comprises a lining template and a principal template, wherein the upper end part of the principal template is provided with a lining template installing slot for installing the lining template, the lining template and the principal template are assembled so as to form a constructional column template; and the lining template installing slot is provided with a horn-type feeding device, the lining template is a movable template which can carry out up-and-down motions or left-and-right motions on the inner wall of the principal template, and a template moving component is arranged on the outside surface of the lining template; and the molding process comprises the steps of 1, carrying out survey layout; 2, installing a reinforcement cage; 3, erecting the template; 4, installing the horn-type feeding device; 5, moving the lining template outwards; 6, carrying out casting construction; 7, moving back the lining template and removing the horn-type feeding device; and 8, removing the template. The casting molding template disclosed by the invention is reasonable in structure, simple in operation, economic, practical, time-saving, labor-saving and good in application effect, and can effectively solve various actual problems existing in the current construction on constructional columns of infilled walls.

Owner:陕西建工集团有限公司

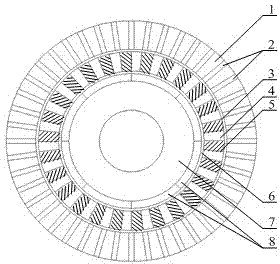

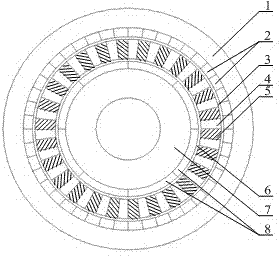

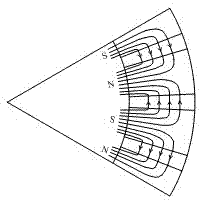

Outer rotor magnetic flux collecting magnetic gear

ActiveCN102312986AIncreased torque transfer capabilityIncrease air gap flux densityGearingMagnetic fluxCondensed matter physics

The invention discloses an outer rotor magnetic flux collecting magnetic gear. The magnetic gear has an axial structure, and the section of the magnetic gear comprises a magnetic gear outer rotor, a magnetic flux adjusting ring and a magnetic gear inner rotor from outside to inside in sequence; the magnetic gear outer rotor, the magnetic flux adjusting ring and the magnetic gear inner rotor are coaxial and are independent of one another; an outer air gap (3) is formed between the magnetic gear outer rotor and the magnetic flux adjusting ring; an inner air gap (6) is formed between the magnetic flux adjusting ring and the magnetic gear inner rotor; the magnetic gear outer rotor and the magnetic gear inner rotor freely rotate and are connected with a driving or driven component to perform torque transfer respectively; and the middle magnetic flux adjusting ring is in a stationary state and is fixed at the two axial ends. Through the outer rotor magnetic flux collecting magnetic gear, the torque transfer capacity of the magnetic gear can be improved.

Owner:SOUTHEAST UNIV

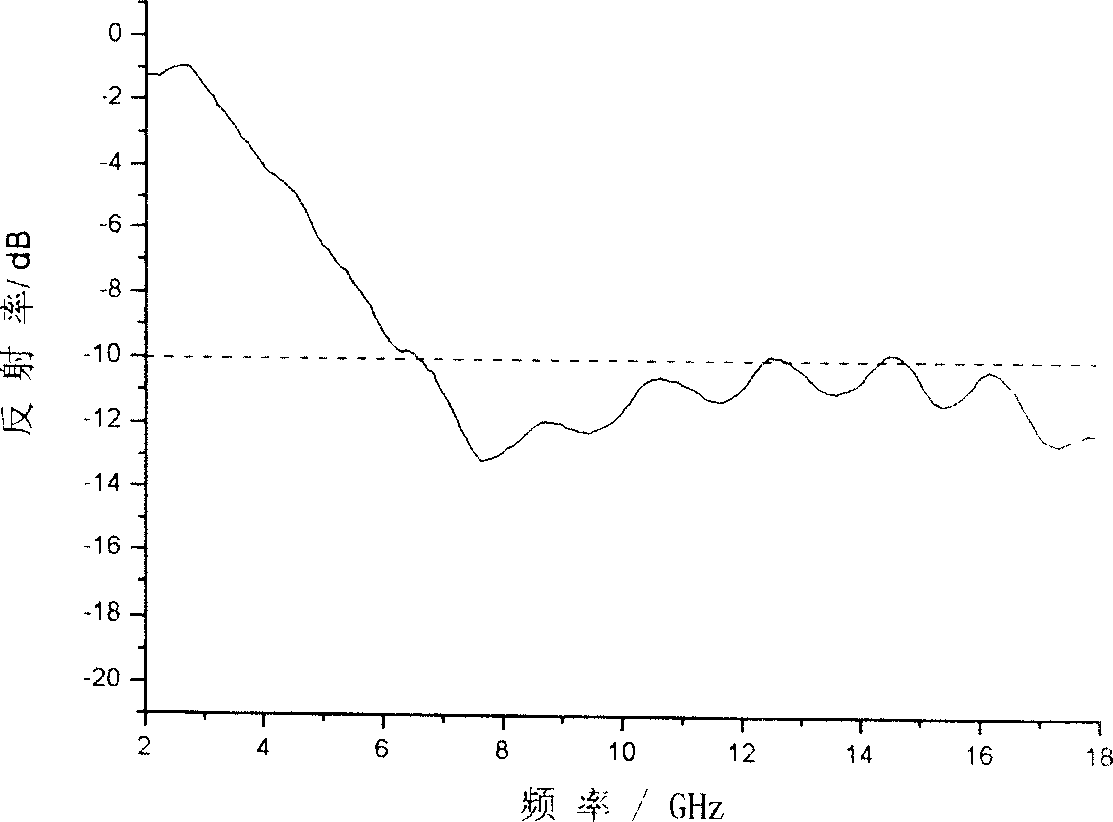

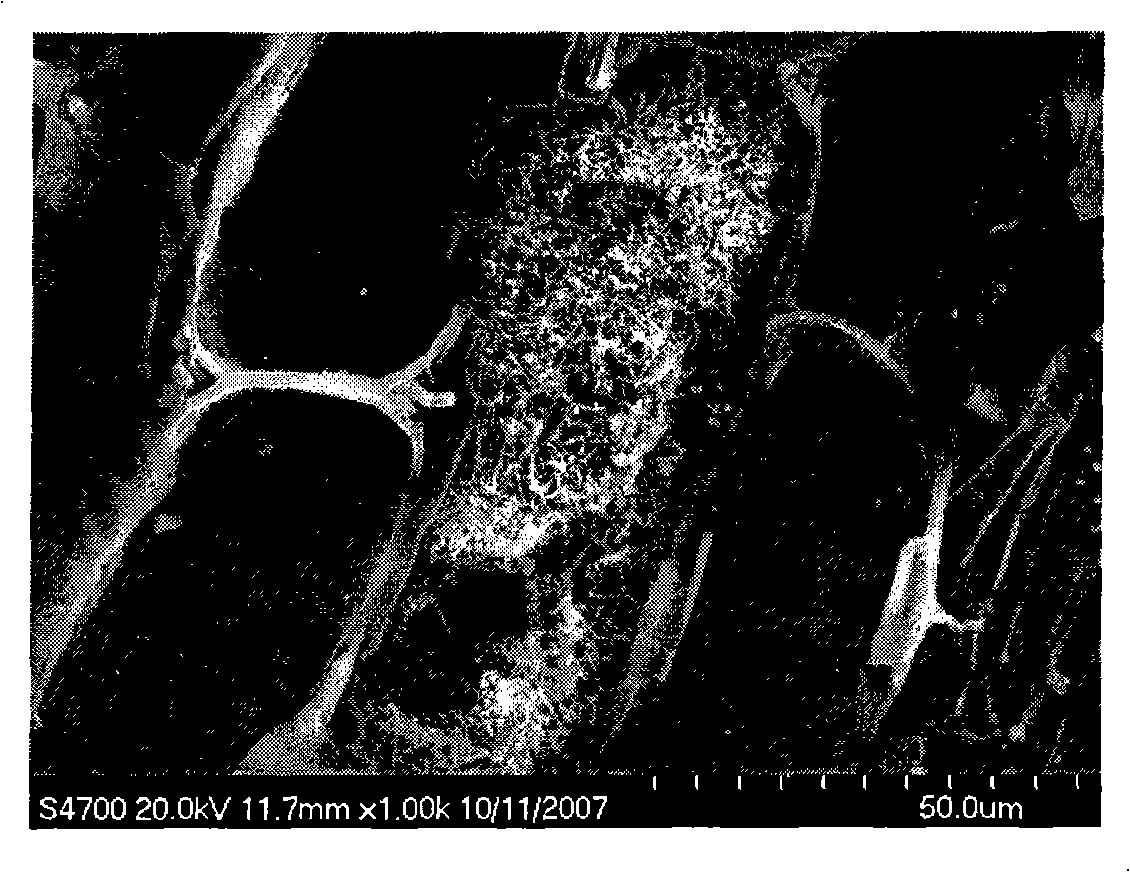

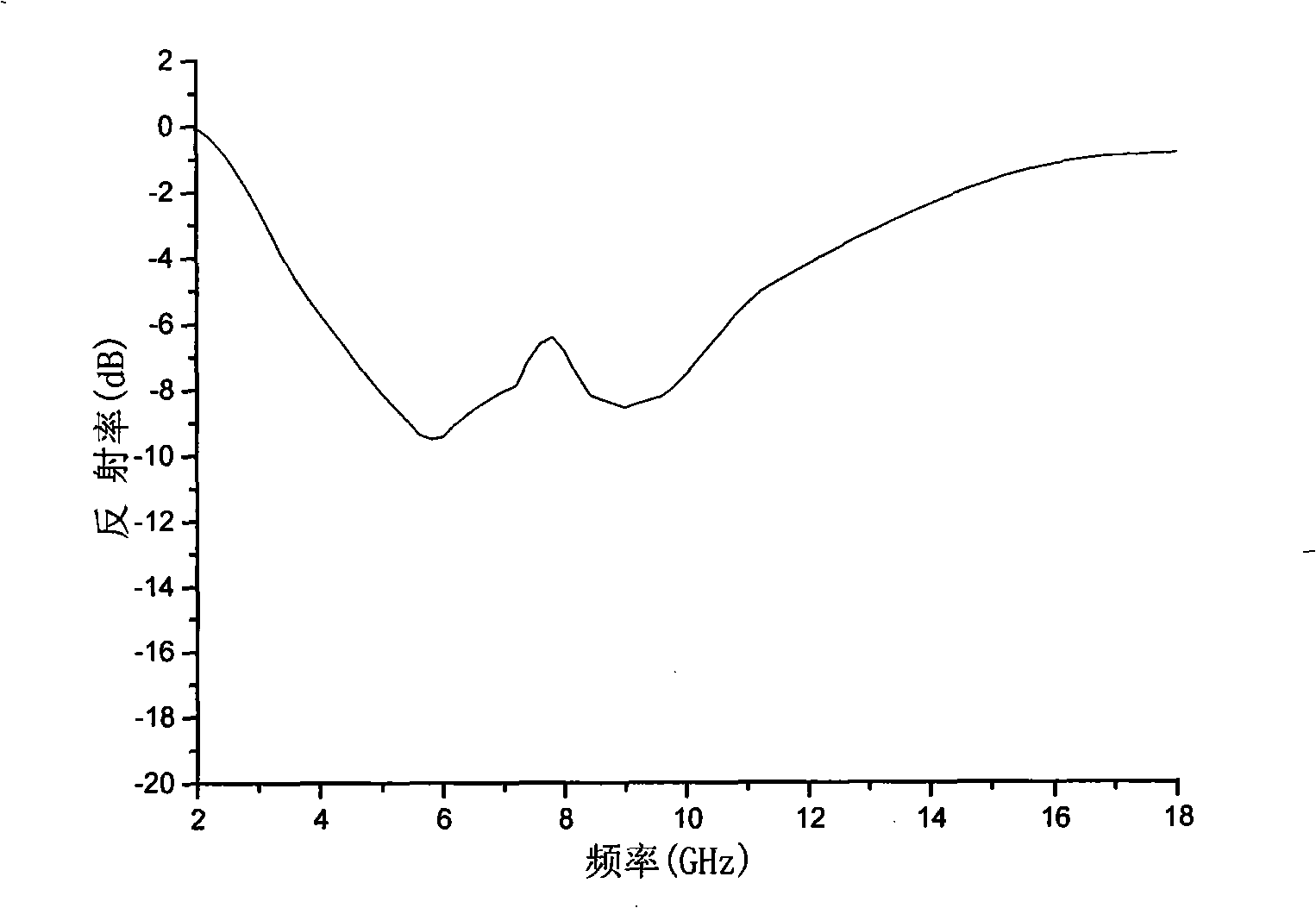

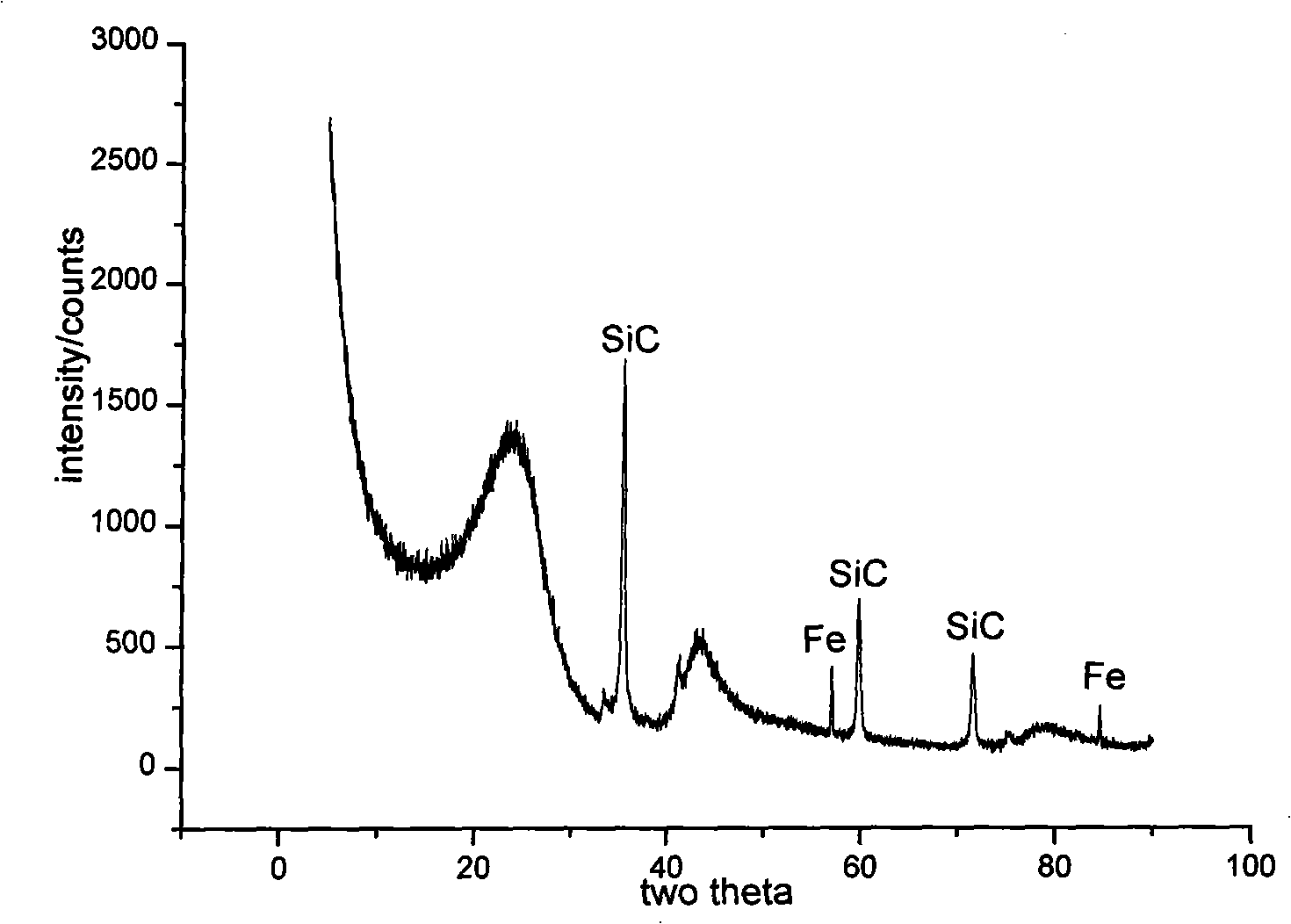

Surface ceramic bovine stephanoporate bamboo charcoal wave-suction material of load magnetic metal and method of producing the same

InactiveCN101269992ASimple processLow processing and manufacturing costsMagnetic/electric field screeningMagnetic mediaWhiskers

The present invention relates to a porous ceramic bamboo charcoal absorbing material that is used on the surface of load magnetic metal, and a preparation method thereof, belonging to the field of the absorbing material of electromagnetic wave. The generation of the ceramic surface of the bamboo charcoal, the inner load magnetic metal and the silicon-based ceramic crystal whisker in the pore channel can simultaneously has the functions of three loss mechanisms that comprise resistance, dielectric and magnetic media, so as to effectively absorb electromagnetic radiation.

Owner:BEIJING UNIV OF CHEM TECH +1

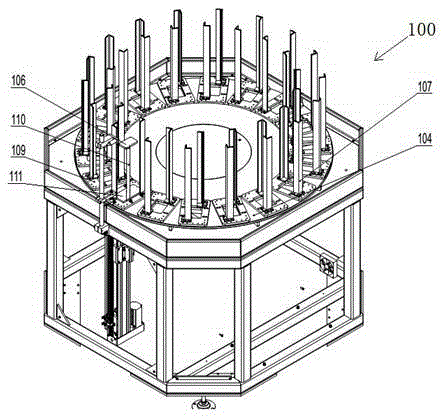

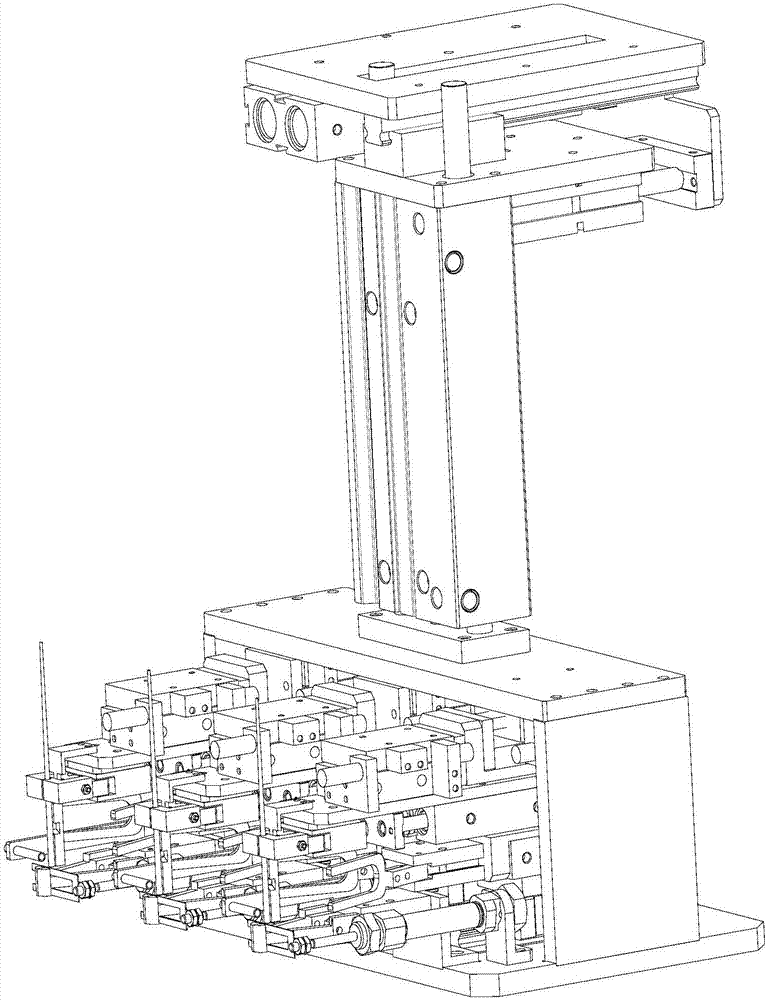

Multi-plant synchronous vegetable seedling grafting device

ActiveCN107047073AGrafting Accuracy ImprovementLow processing and manufacturing costsGraftingAgricultural engineeringSeedling

The invention relates to a multi-plant synchronous vegetable seedling grafting device. The multi-plant synchronous vegetable seedling grafting device comprises a rootstock source mechanism, a scion source mechanism, a scion clamping mechanism, a rootstock clamping mechanism, a cutting mechanism, an upper clamping mechanism and a translation mechanism; the translation mechanism is used for driving the scion clamping mechanism and the rootstock clamping mechanism to move; the scion clamping mechanism arranged on the translation mechanism is used for clamping scions on the scion source mechanism; the rootstock clamping mechanism arranged on the translation mechanism is used for clamping rootstocks on the rootstock source mechanisms; the scion clamping mechanism is positioned above the rootstock clamping mechanism; the cutting mechanism is used for cutting the scions and the rootstocks which cling to each other in parallel; and a grafting clamp for fixing the scions and the rootstocks is arranged on the upper clamping mechanism. The multi-plant synchronous vegetable seedling grafting device can remarkably increase the grafting speed, increase the survival rate of the grafted seedlings and improve the grafting efficiency, and belongs to the technical field of vegetable seedling grafting.

Owner:SOUTH CHINA AGRI UNIV

Directional silicon condenser microphone having additional back chamber

InactiveUS7940944B2Improve featuresNoise robustPiezoelectric/electrostrictive microphonesMicrophonesAdhesiveEngineering

A directional silicon condenser microphone having an additional back chamber is disclosed. The directional silicon condenser microphone comprises a case having a front sound hole for passing through a front sound; a acoustic delay device for delaying a phase of a sound; a substrate including a chamber case, a MEMS chip having an additional back chamber formed by the chamber case, an ASIC chip for operating the MEMS chip, a conductive pattern for bonding the substrate to the case, and a rear sound hole for passing through a rear sound; a fixing means for fixing the case to the substrate; and an adhesive for bonding the case and the substrate, wherein the adhesive is applied to an entirety of a bonding surface of the case and the substrate fixed by the fixing means.

Owner:BSE CO LTD

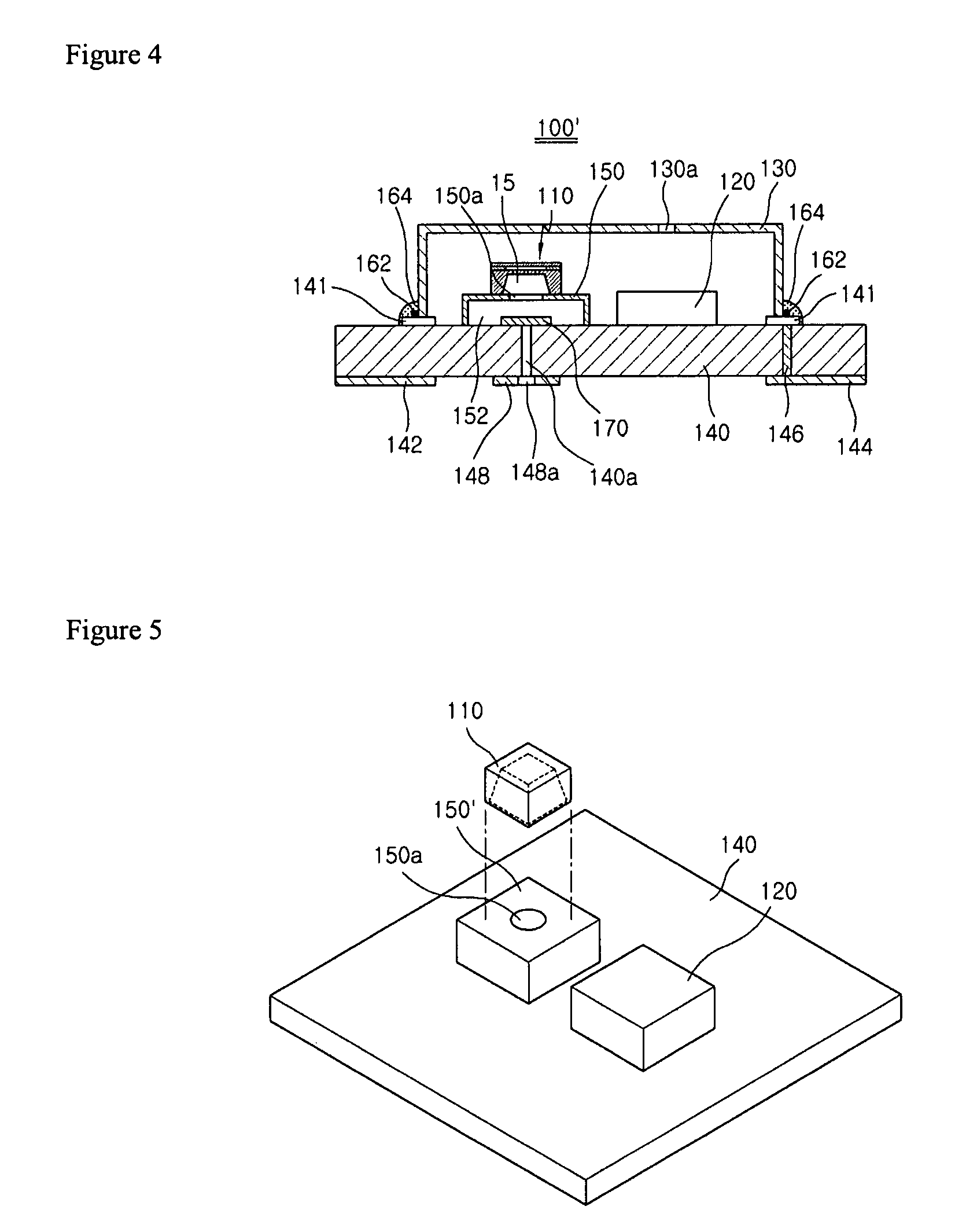

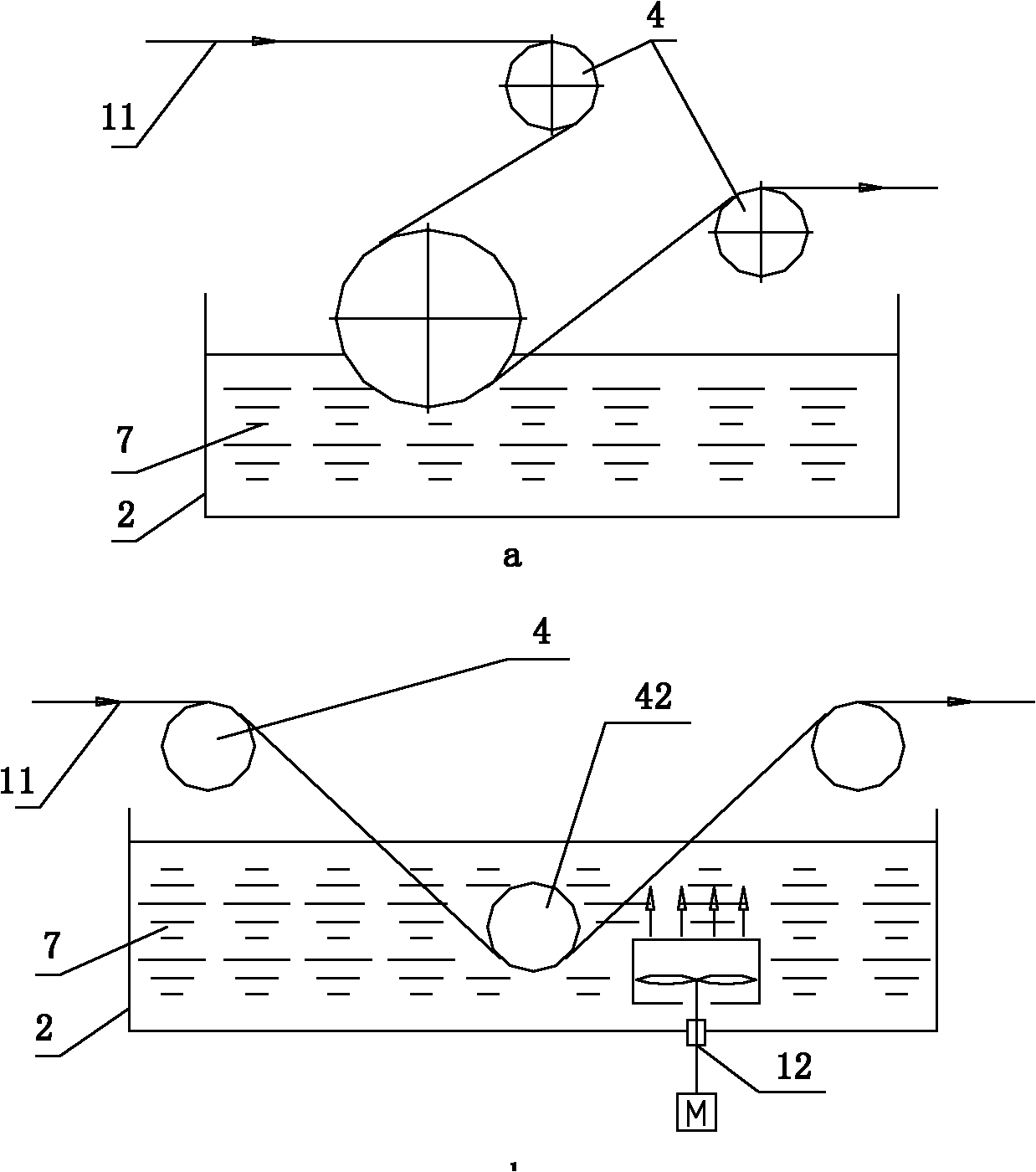

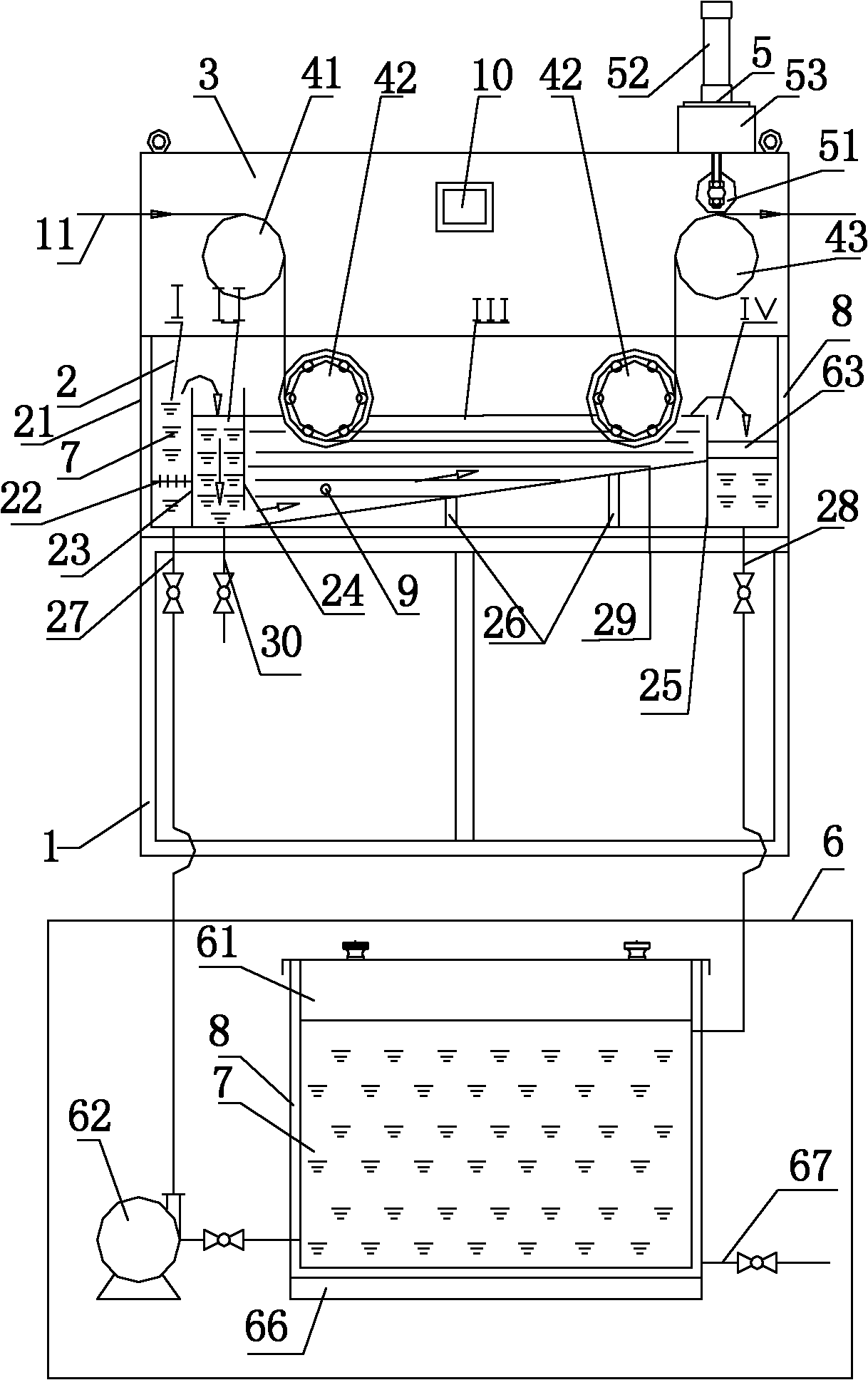

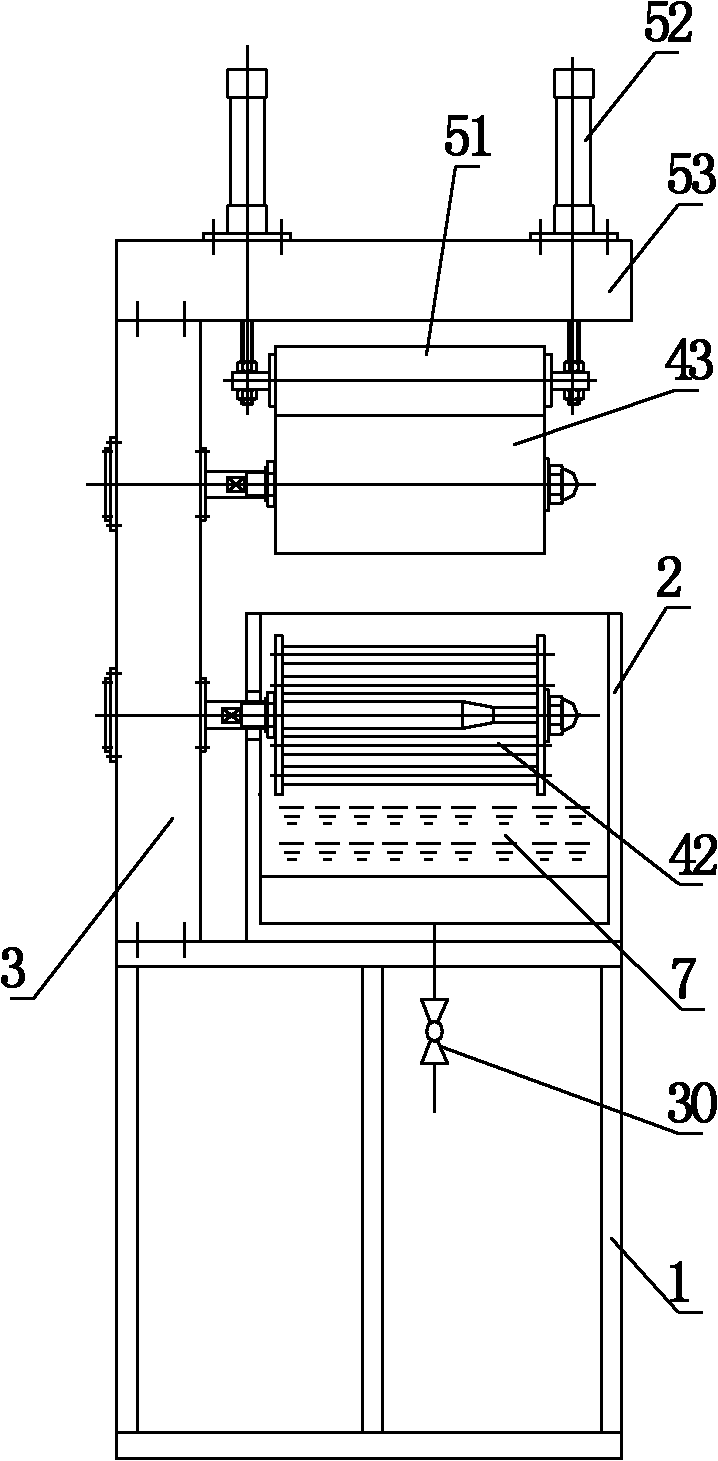

Sizing machine for producing continuous carbon fibers

InactiveCN102031654AAvoid Shaft Sealing ProblemsFlexible rotationTextile treatment rollersLiquid/gas/vapor yarns/filaments treatmentFiberCarbon fibers

The invention belongs to a sizing machine for producing continuous carbon fibers, comprising a box body, a sizing groove arranged in the box body and a driving device fixed on the box body, wherein the sizing groove comprises a groove body and a partition board, a liquid distribution plate and an overflow plate which are arranged in the groove body from left to right and are vertical to the bottom of the groove body; the driving device comprises an inlet driving roller arranged at the upper-left part of the sizing groove, two sizing driving rollers positioned in a sizing area and an outlet driving roller arranged at the upper-right part of the sizing groove; the two sizing driving rollers are horizontally arranged and positioned between the inlet driving roller and the outlet driving roller; and driving shafts of the two sizing driving rollers are higher than the liquid level of a sizing agent of the sizing area. The invention solves the problems of long stay time of the carbon fibers in the sizing agent, poor sizing effect, complex structure, high manufacturing cost and inconvenience for daily cleaning and maintenance caused by the traditional sizing machine. By using the invention, the processing and manufacturing cost of the equipment can be reduced, the time of the carbon fibers in the sizing agent can be prolonged and the favorable sizing effect can be obtained.

Owner:西安航科等离子体科技有限公司

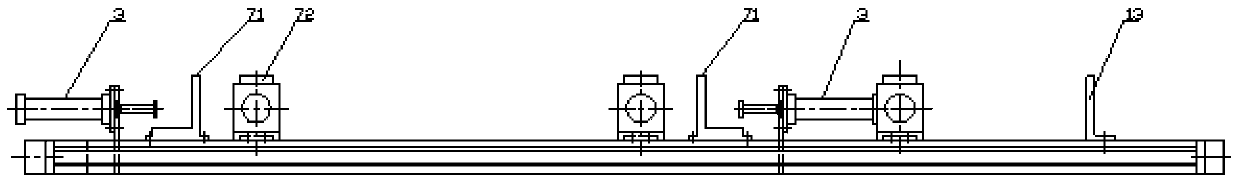

Flexible robot welding tool for chassis frame of maize harvesting machine

InactiveCN104043936AEasy loading and unloading of workpiecesReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesTurning framesEngineering

The invention relates to a welding tool for a chassis frame of a maize harvesting machine, in particular to a flexible robot welding tool for the chassis frame of the maize harvesting machine. The flexible robot welding tool for the chassis frame of the maize harvesting machine is low in machining and manufacturing cost and convenient to clamp, labor intensity of workers is low, the locating precision of transverse beams and longitudinal beams of the frame can be guaranteed, welding deformation can be reduced, flexibility is good, interference cannot be generated during welding after overturn, and a front face and a back face can be welded on one tool through one-time locating. The flexible robot welding tool for the chassis frame of the maize harvesting machine has the advantages that the workers can load and unload workpieces conveniently, and labor intensity is low; the position of a frame transverse beam locating mechanism and the position of a frame longitudinal beam locating mechanism on a bearing frame can be adjusted continuously, welding of frames of different series and different types can be achieved, and flexibility is good; overturn of the tool can be achieved through a welding positioner, and robot welding is achieved; the machining and manufacturing cost is low, operation is convenient, working efficiency is improved, and needs of enterprises are met.

Owner:CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com