Patents

Literature

45results about How to "Easy loading and unloading of workpieces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

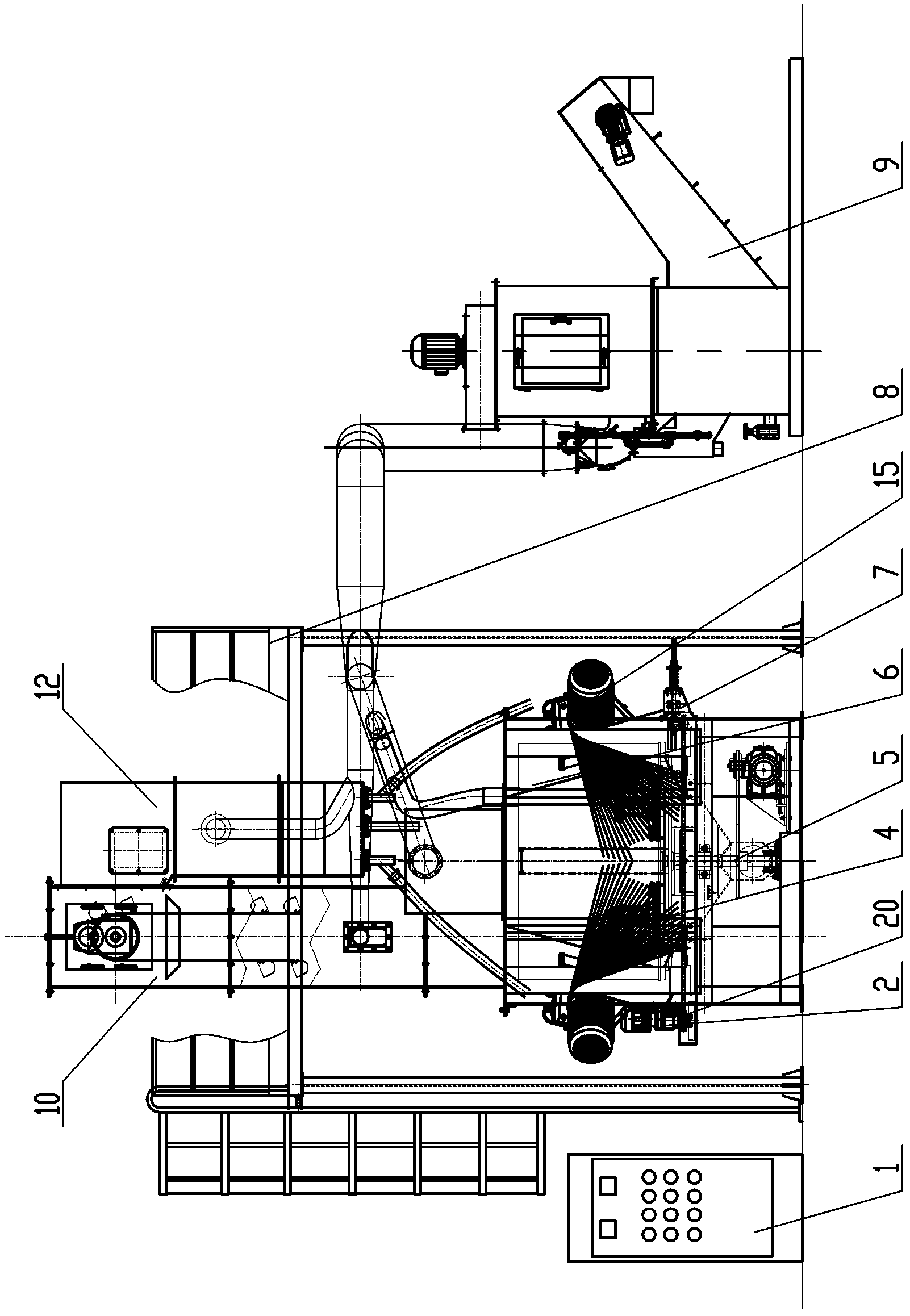

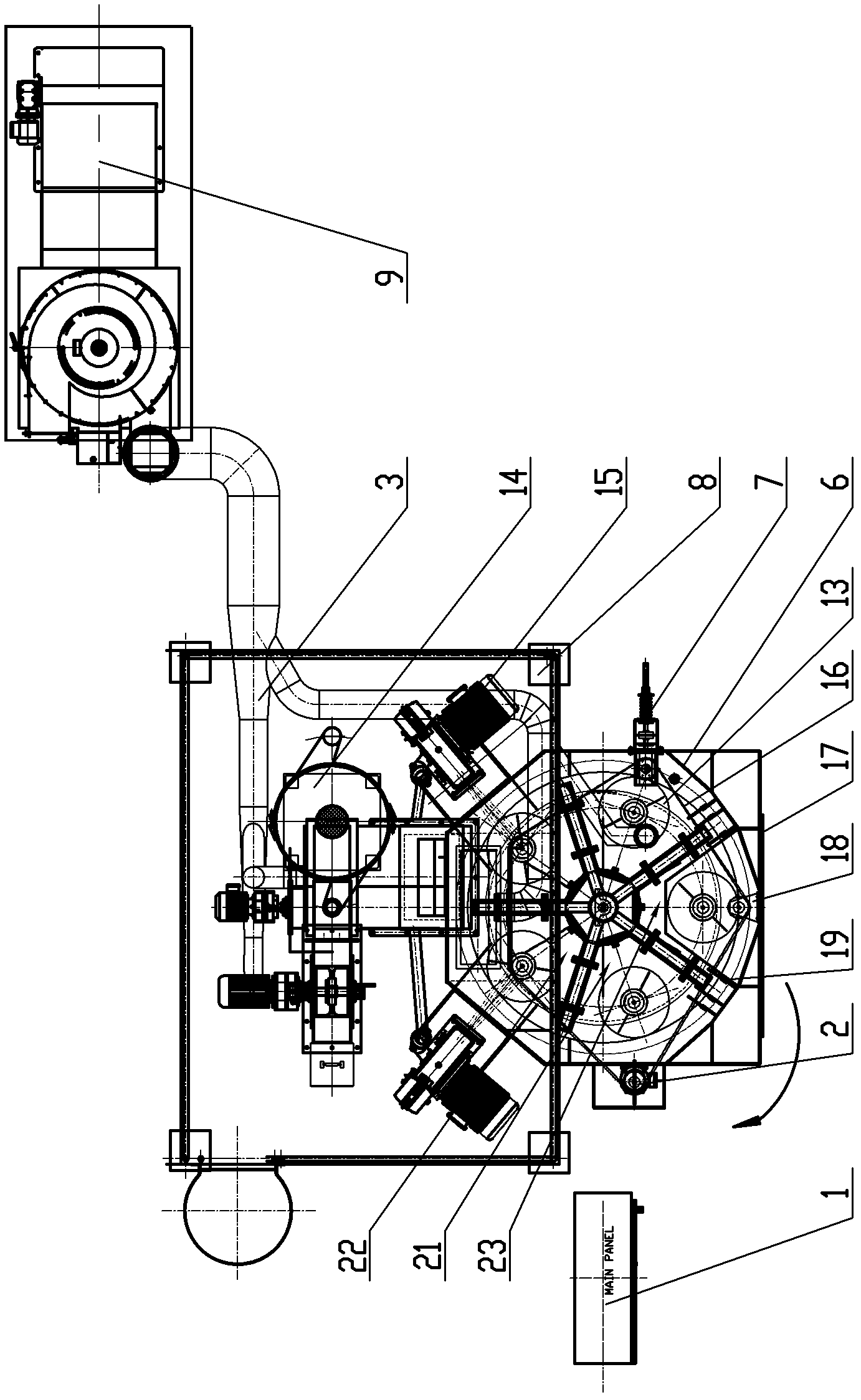

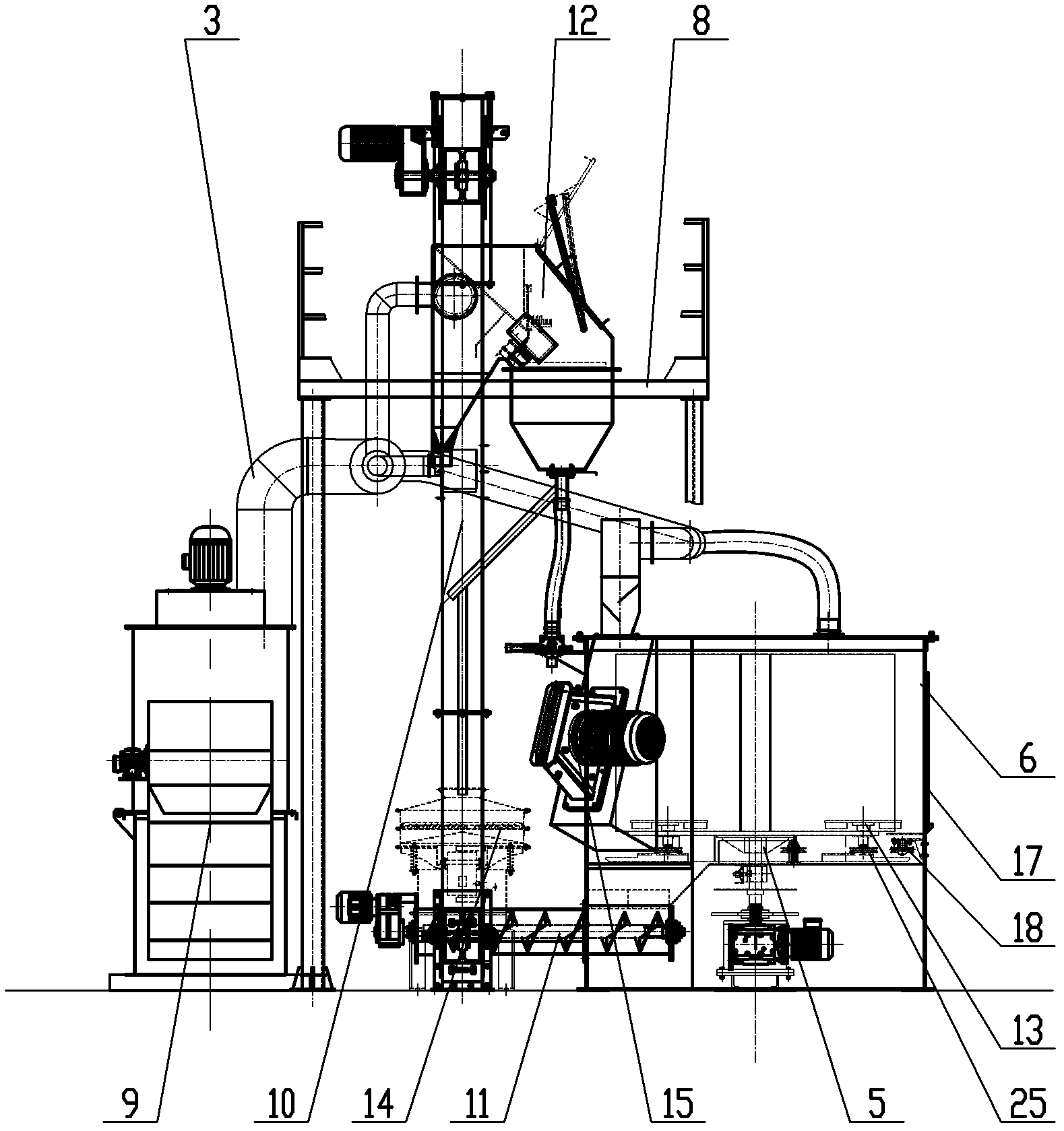

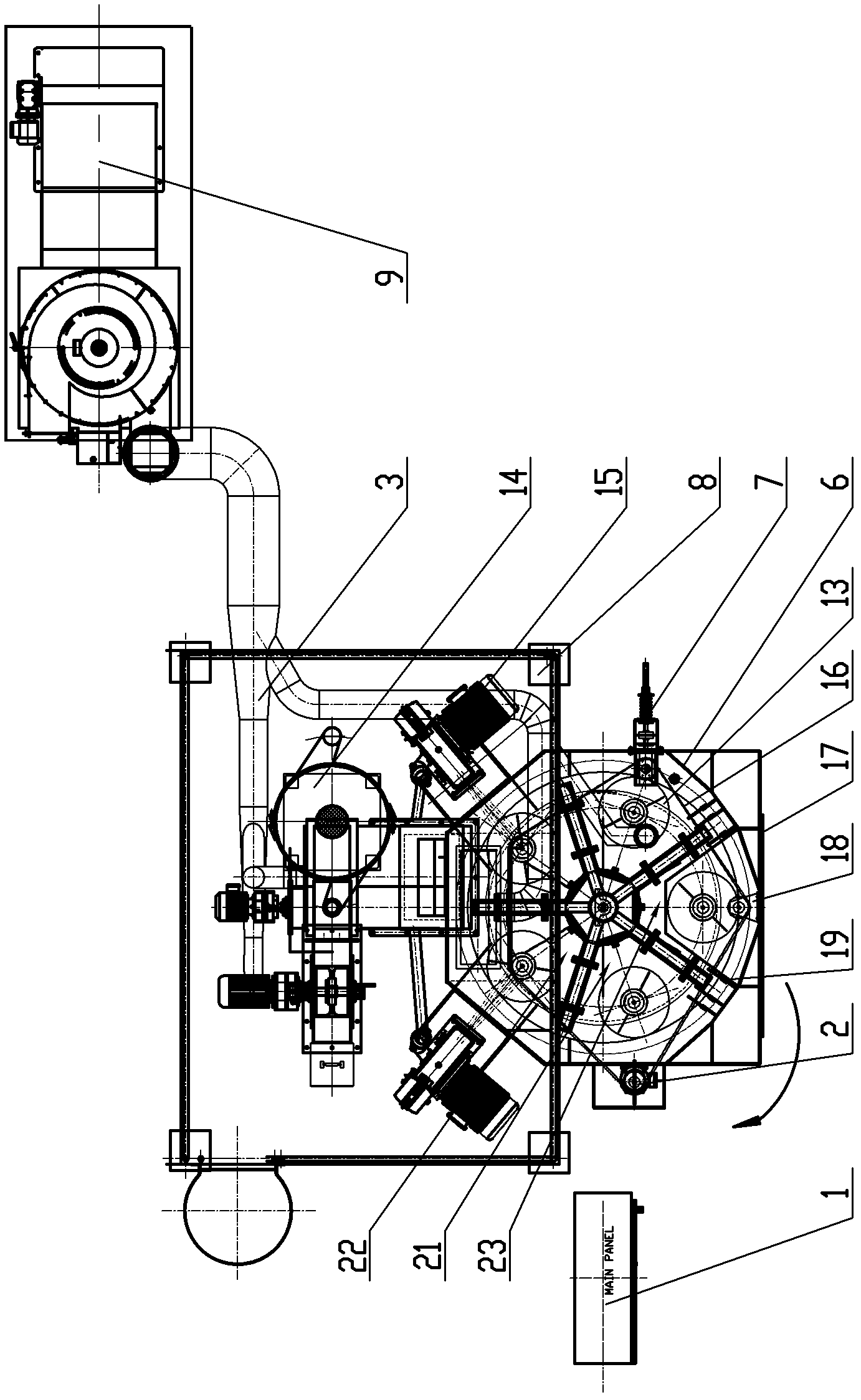

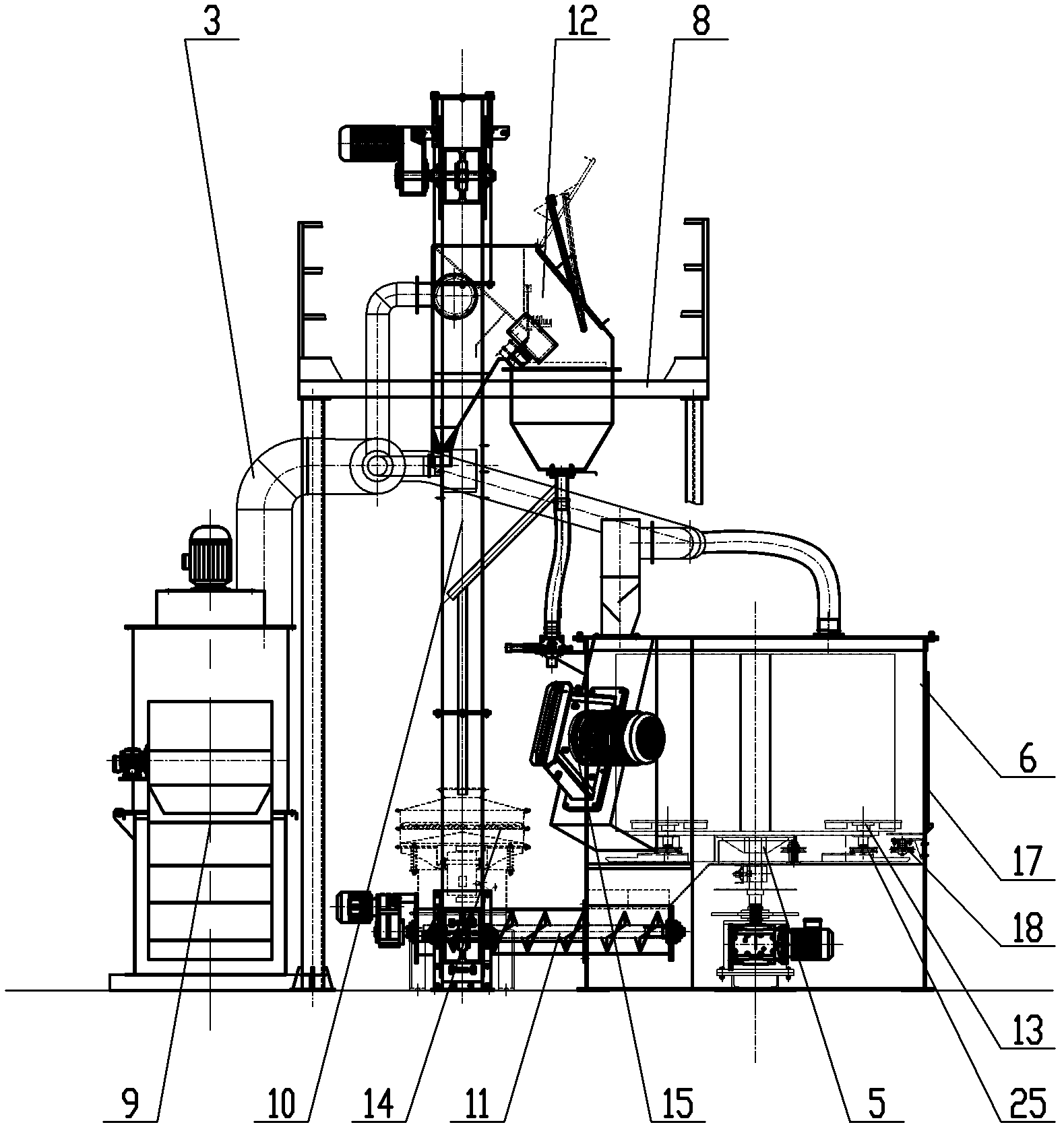

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493APrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

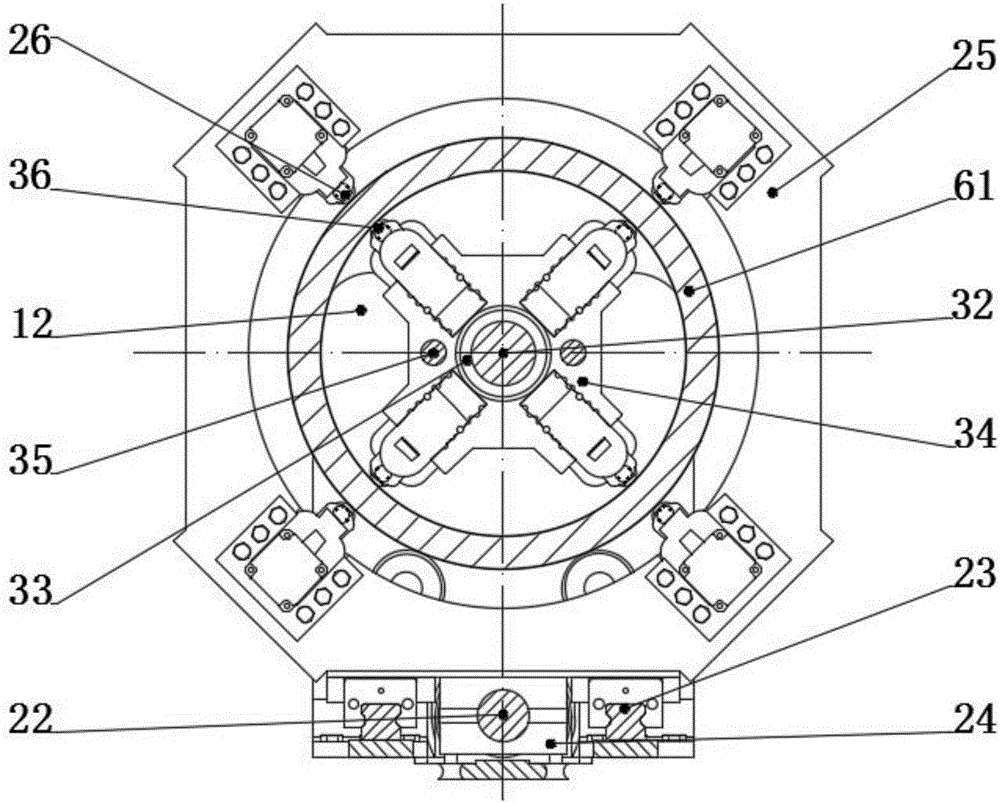

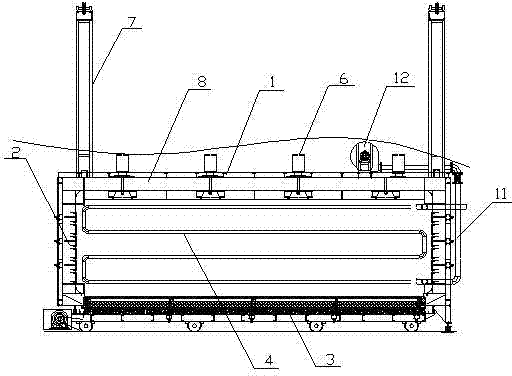

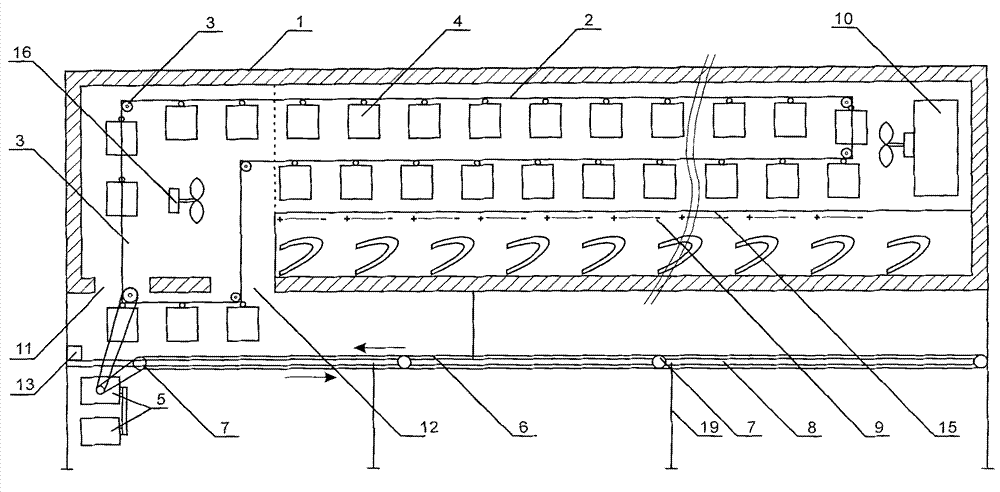

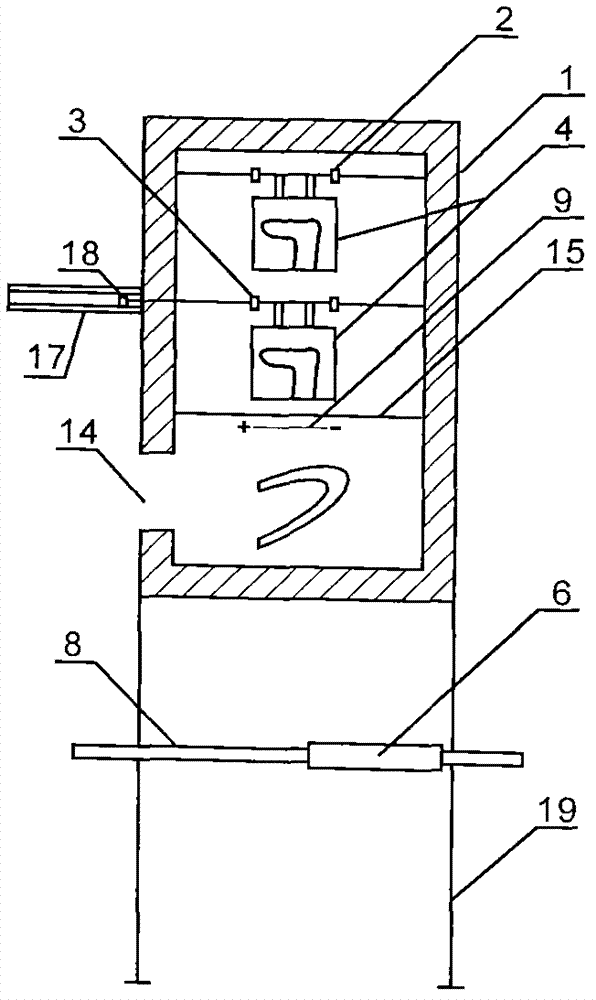

The invention relates to a reinforced shot blast machine for a multi-position turntable. A main rotary worktable is mounted in a shot blast cleaning room, a shot blast machine is arranged out of the shot blast cleaning room, a steel shot selector is fixed above the shot blast cleaning room, a helical conveying device is fixed below the shot blast cleaning room, a hopper-type lifter is arranged behind the shot blast cleaning room, a feeding port and a discharging port of the hopper-type lifter are respectively connected with the helical conveying device and the steel shot selector, a discharging port of a steel shot separator is connected with the shot blast machine; the main rotary worktable is fixed with a partition wall assembly for partitioning the table-board of the main rotary worktable into five stations which are respectively two shot blast stations, two isolation stations and a loading-unloading station, and each station is rotatably equipped with a planetary worktable. The main rotary worktable is partitioned into the shot blast stations, the isolation stations and the loading-unloading station, the isolation stations are arranged between the loading-unloading station andthe shot blast stations with the effect of sealing; therefore, the shot can be prevented from flying out from the shot blast station, and the security is good.

Owner:无锡国达机械设备有限公司

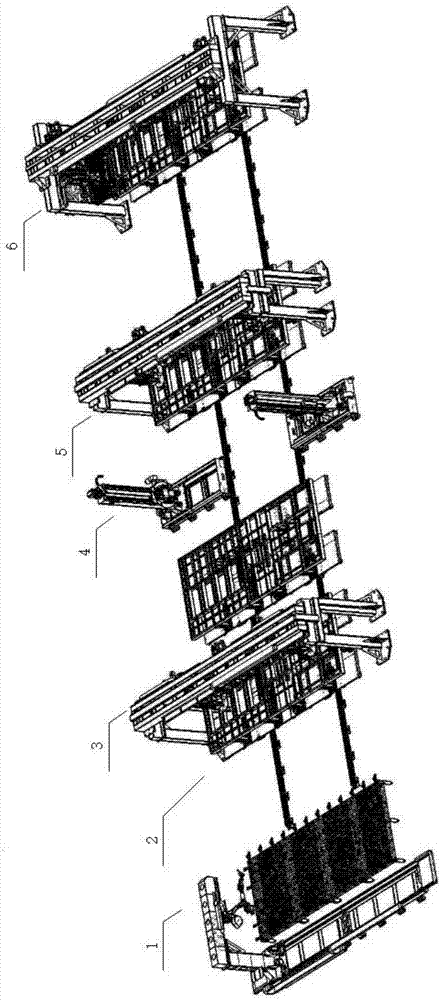

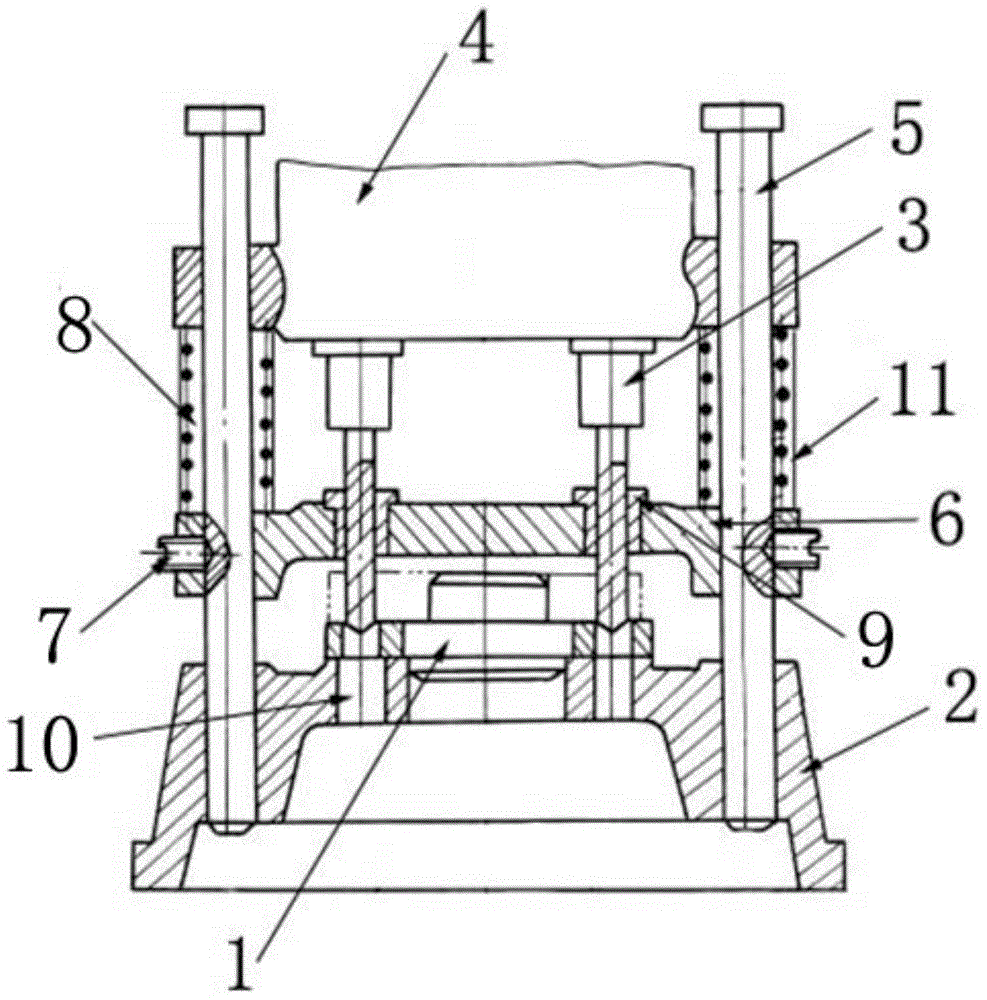

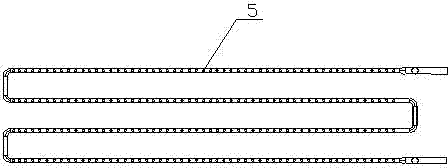

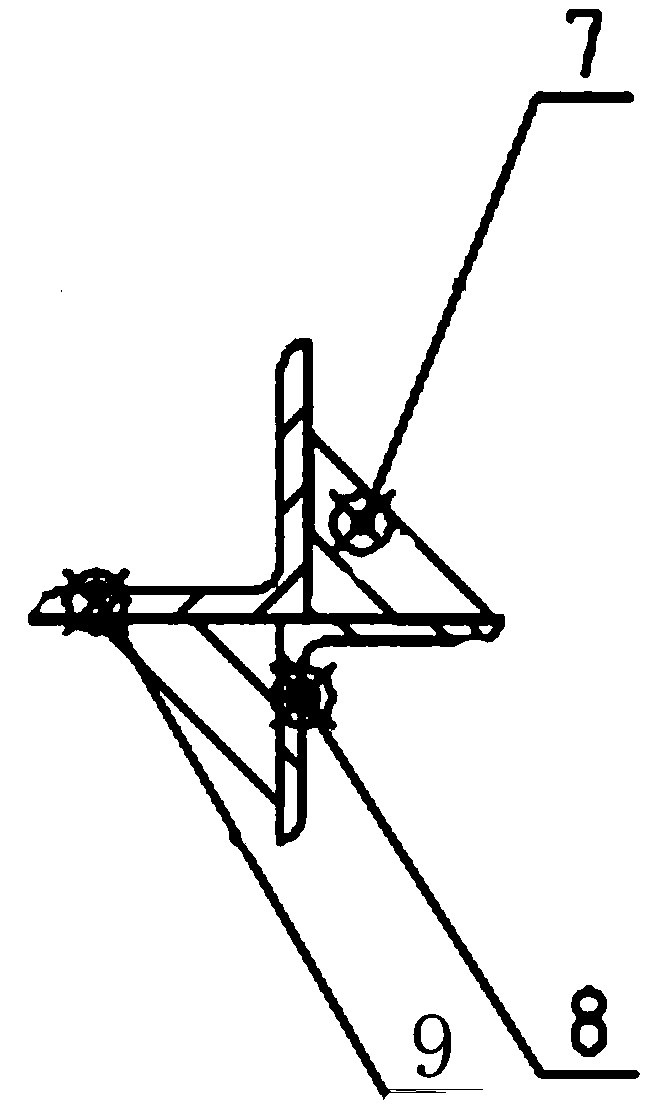

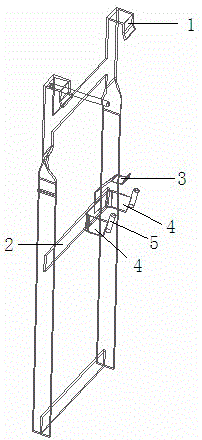

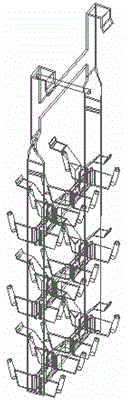

Flexible robot welding tool for chassis frame of maize harvesting machine

InactiveCN104043936AEasy loading and unloading of workpiecesReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesTurning framesEngineering

The invention relates to a welding tool for a chassis frame of a maize harvesting machine, in particular to a flexible robot welding tool for the chassis frame of the maize harvesting machine. The flexible robot welding tool for the chassis frame of the maize harvesting machine is low in machining and manufacturing cost and convenient to clamp, labor intensity of workers is low, the locating precision of transverse beams and longitudinal beams of the frame can be guaranteed, welding deformation can be reduced, flexibility is good, interference cannot be generated during welding after overturn, and a front face and a back face can be welded on one tool through one-time locating. The flexible robot welding tool for the chassis frame of the maize harvesting machine has the advantages that the workers can load and unload workpieces conveniently, and labor intensity is low; the position of a frame transverse beam locating mechanism and the position of a frame longitudinal beam locating mechanism on a bearing frame can be adjusted continuously, welding of frames of different series and different types can be achieved, and flexibility is good; overturn of the tool can be achieved through a welding positioner, and robot welding is achieved; the machining and manufacturing cost is low, operation is convenient, working efficiency is improved, and needs of enterprises are met.

Owner:CHINA AGRI UNIV

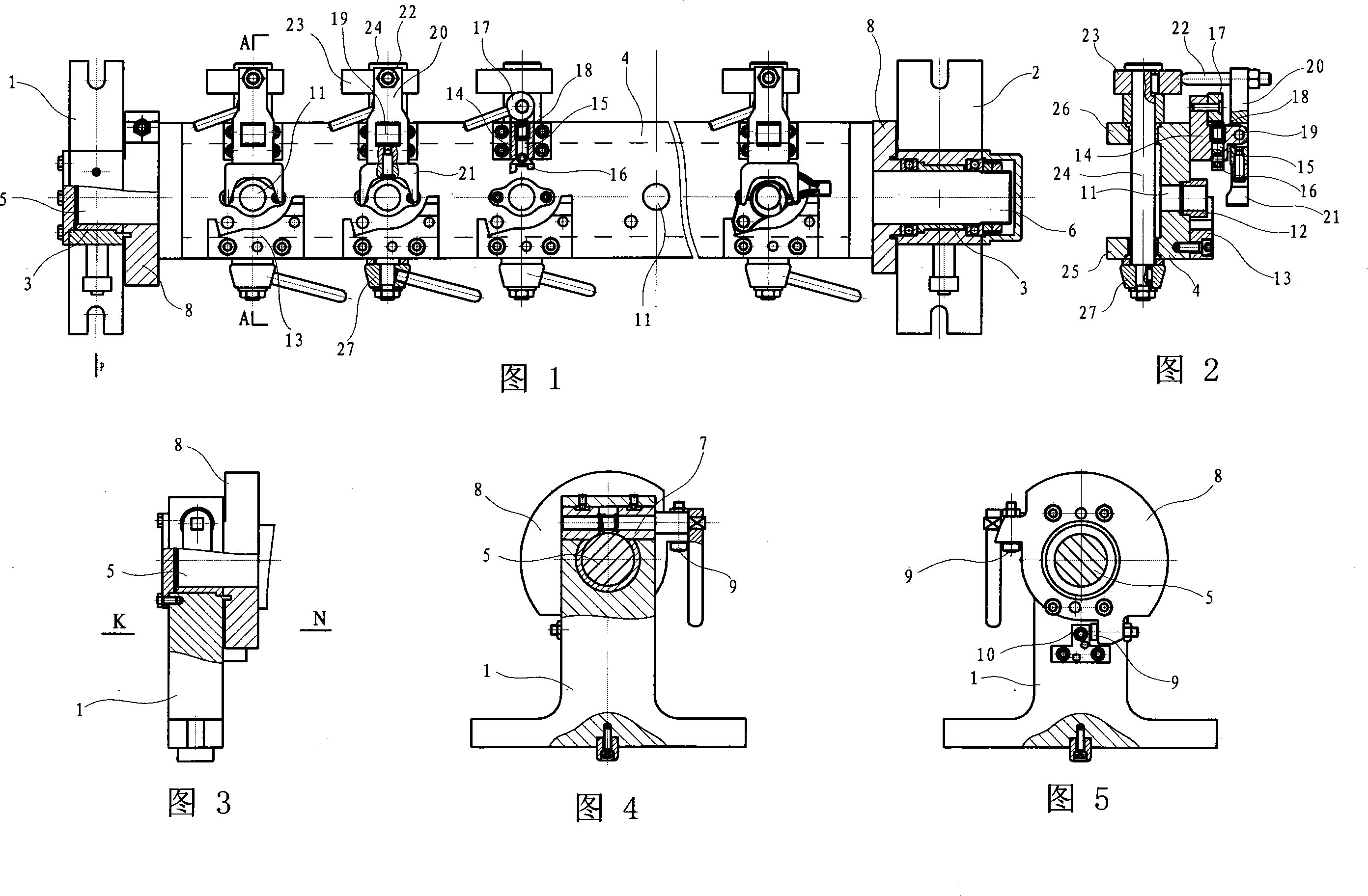

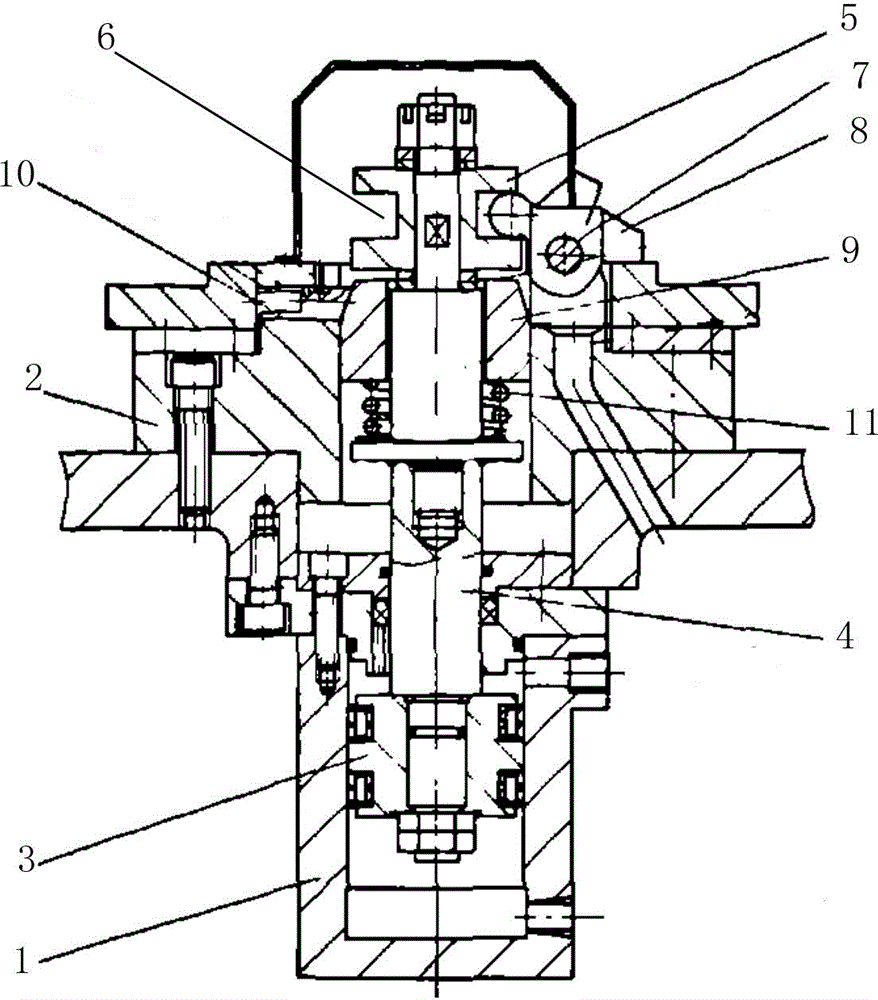

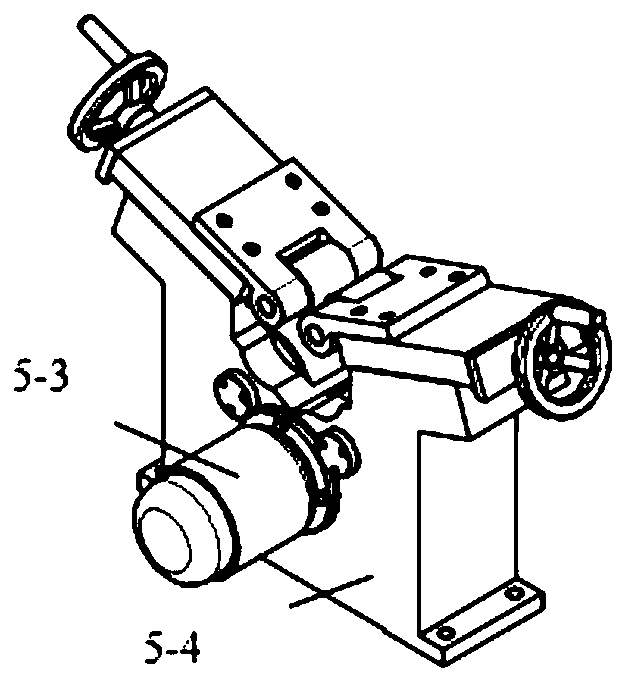

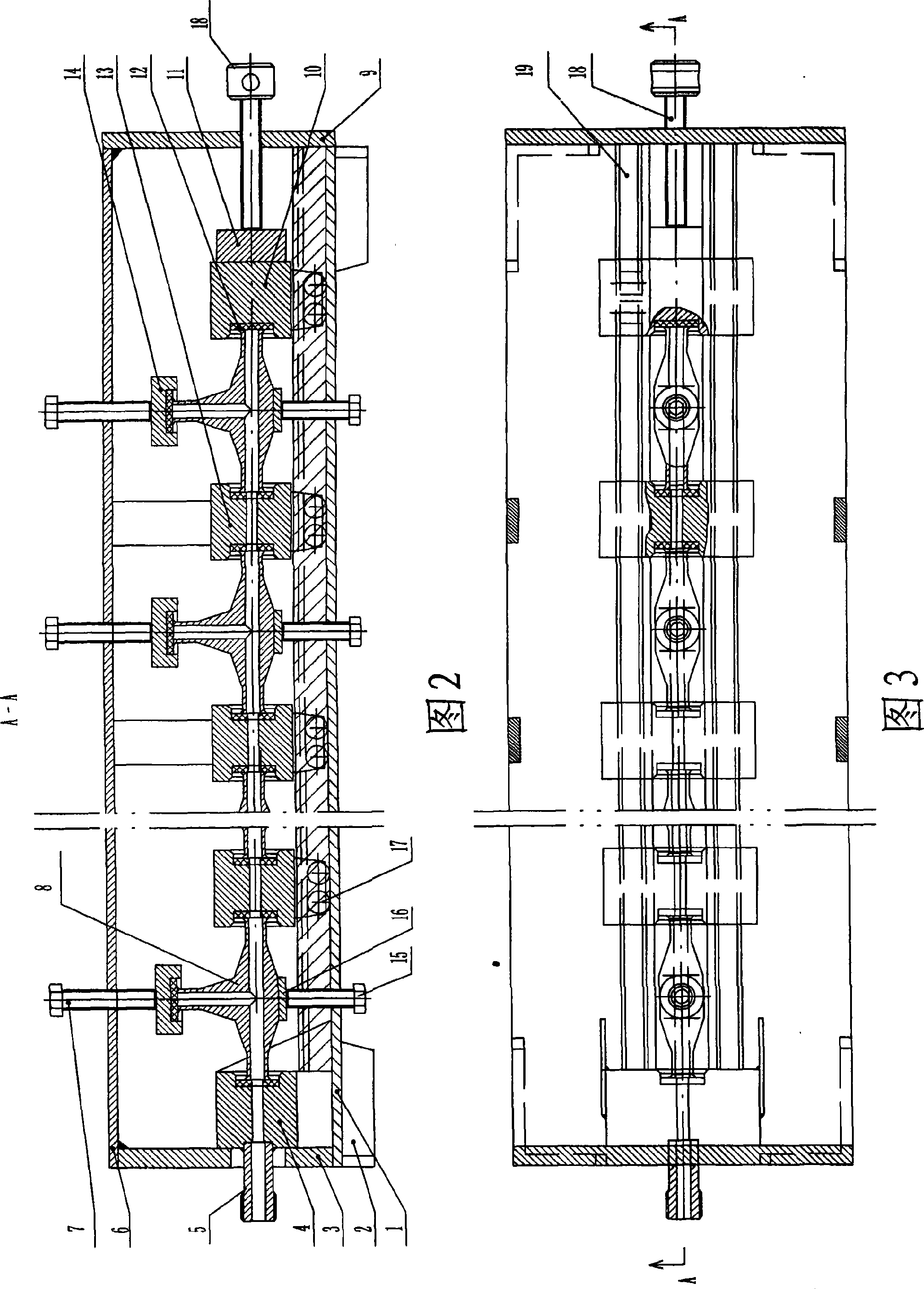

Motor car engine rocker processing chucking appliance

ActiveCN101229621AEasy loading and unloading of workpiecesNo deformationPositioning apparatusMetal-working holdersEngineeringCam

The invention relates to a processing clamp apparatus for a rocker of an automobile engine. A rectangular slot-shaped clamp apparatus body is arranged between a left supporting seat and a right supporting seat; six to ten chip removal holes coordinated with shaft holes of the rocker is uniformly distributed on a slot bottom of the clamp apparatus body along the left and right directions while a supporting ring is arranged on an upper hole port of the chip removal hole on the external side of the slot bottom of the clamp apparatus body; a front saddle is arranged in the front of the upper hole port and a mandril slideway is arranged in the rear part of the upper hole port along the left and the right directions; a mandril is positioned inside the mandril slideway and a mandril cam is pressed against and connected with the rear end of the mandril; a spring is positioned between the mandril and the mandril slideway; a levers in front and rear direction with fulcrums above the mandril slideway is arranged in the rear part of the upper hole port; a pressure fork is articulated with the front end of the lever while a link rod is arranged on the rear end of the lever; a link rod cam is pressed against and connected with the lower end of the link rod and the front end of a cam shaft is provided with a hand wheel. The invention has multi-station and can fulfill the assembly and disassembly of workpieces by rotating two cams of the mandril cam and the lever cam, which provides great convenience to the assembly and the disassembly of the workpieces. In addition, when a blank is placed on the clamp apparatus, the blank is strictly constrained and stably clamped on the clamp apparatus, without deformation due to reasonable force bearing.

Owner:铁岭天河机械制造有限责任公司

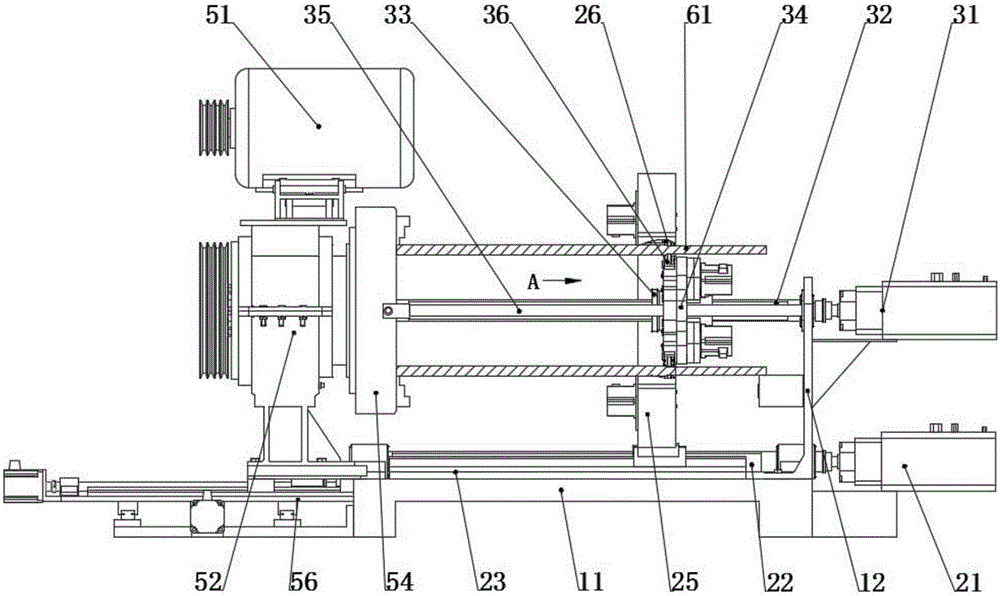

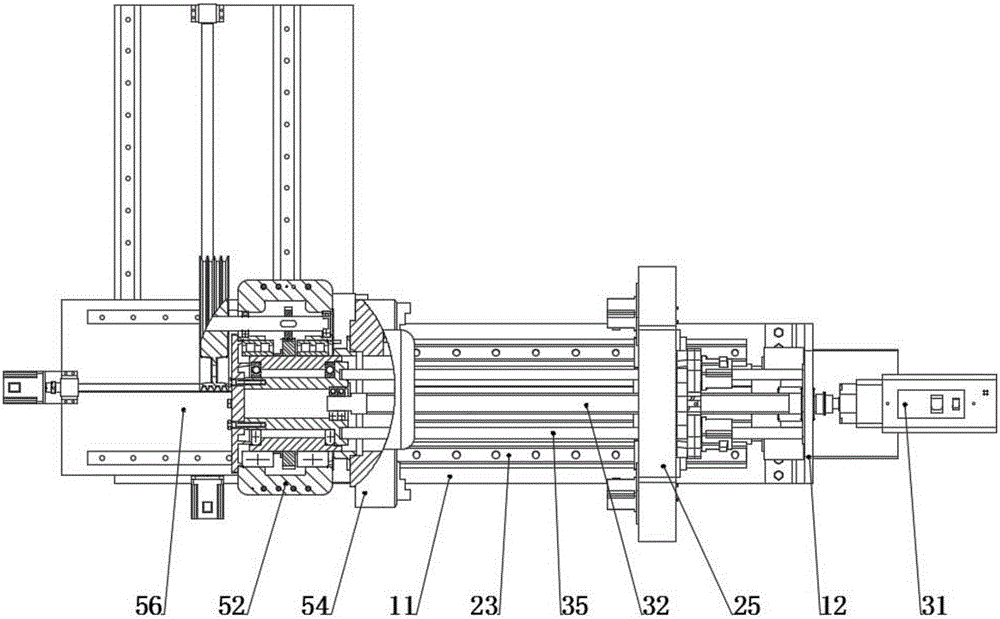

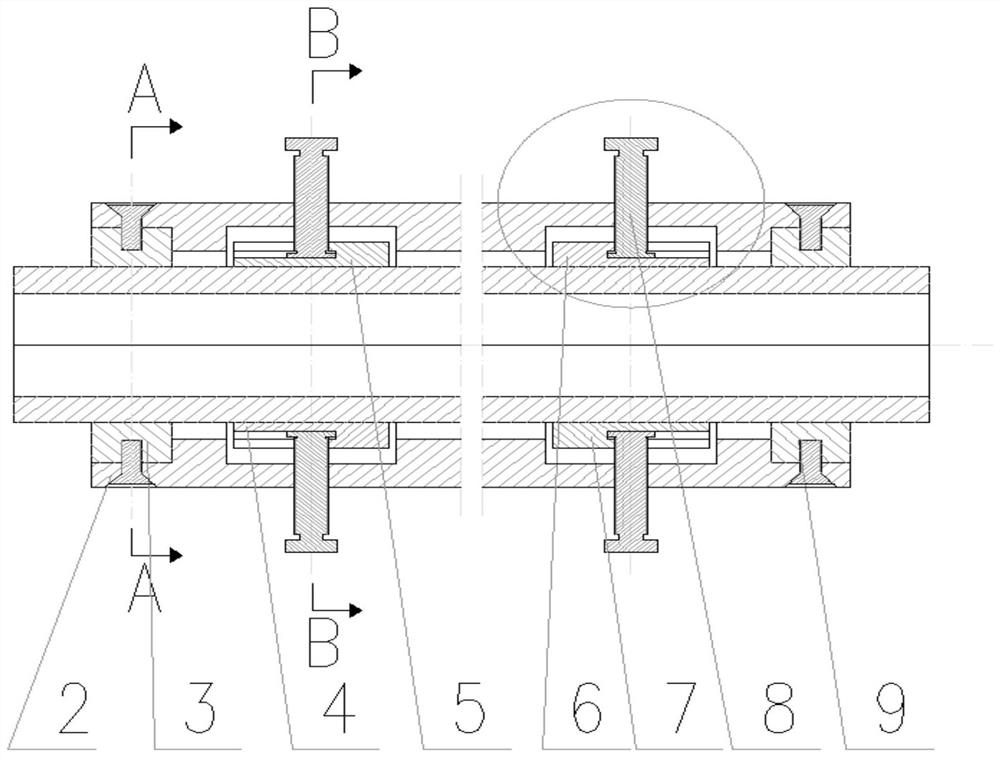

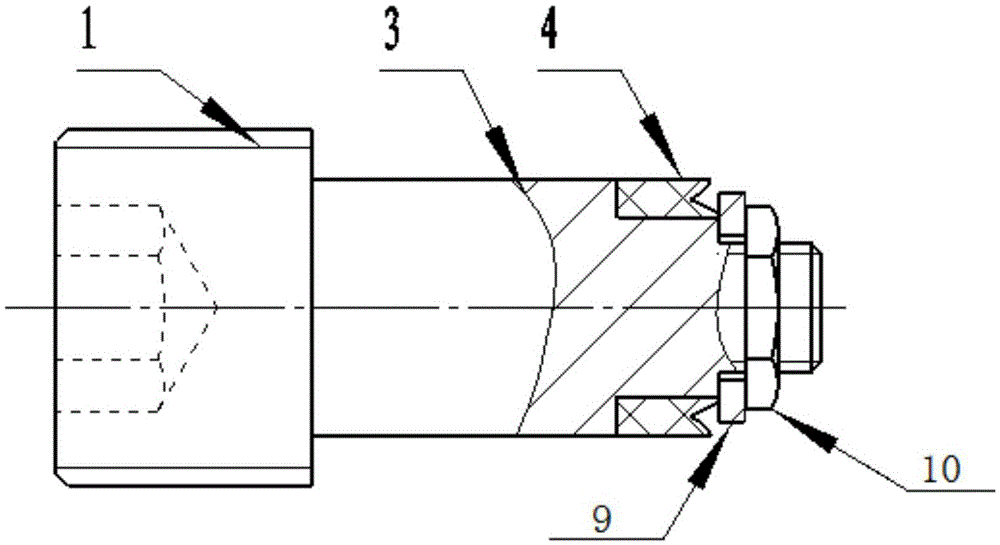

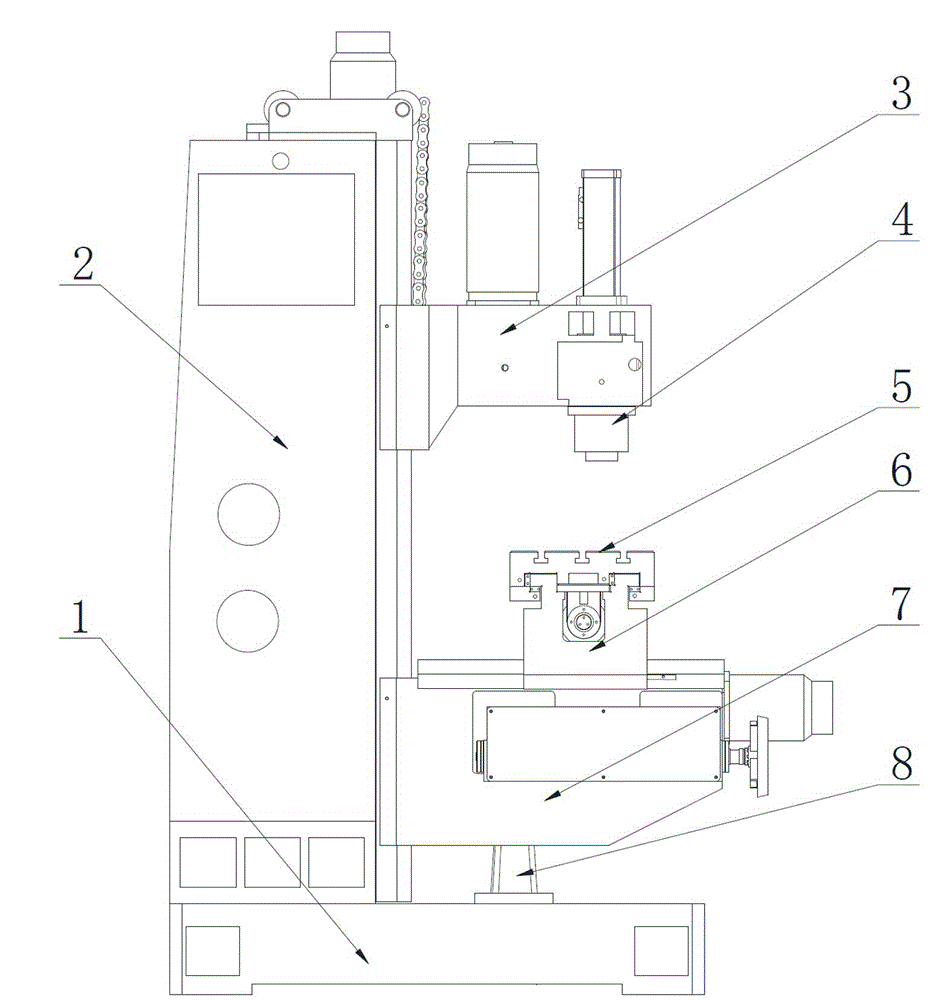

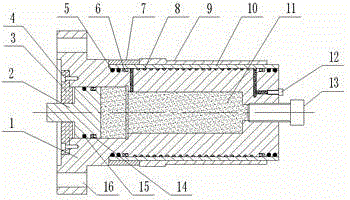

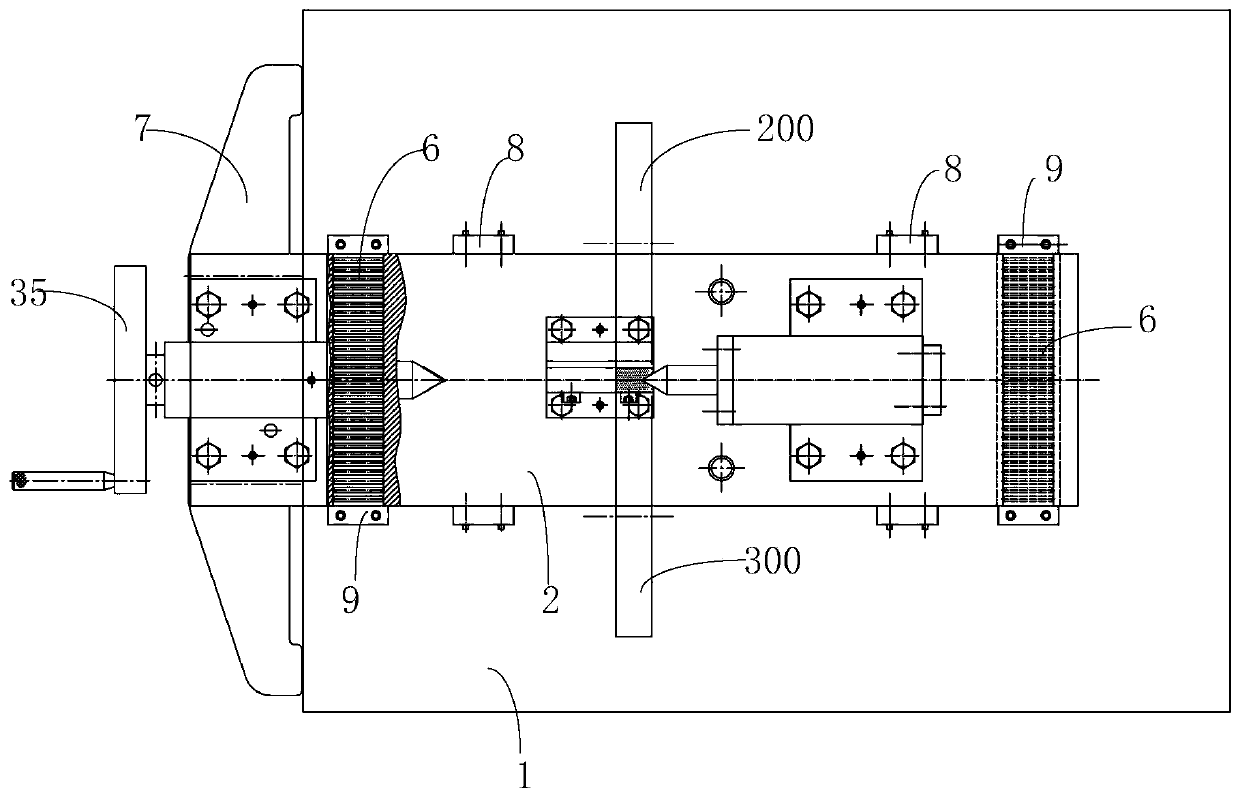

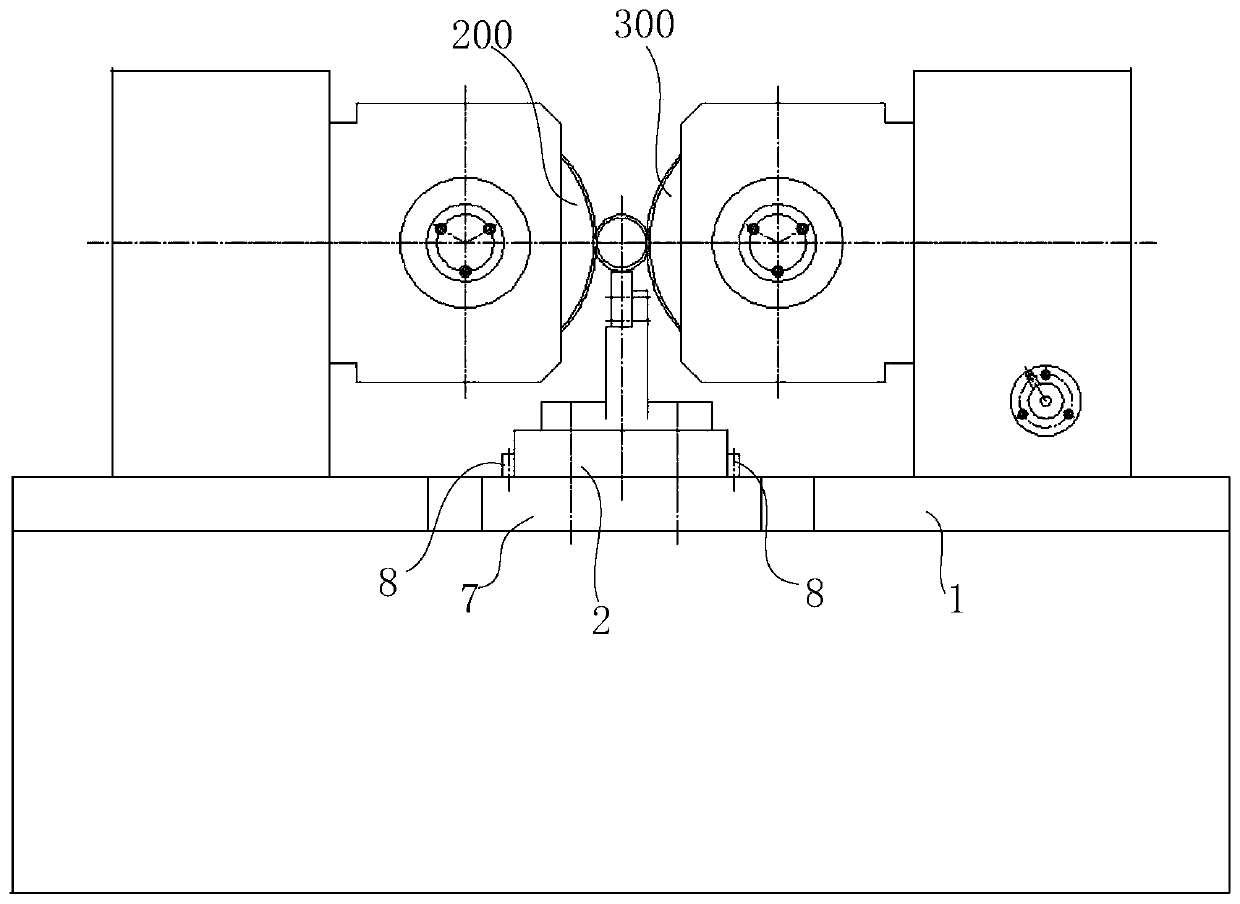

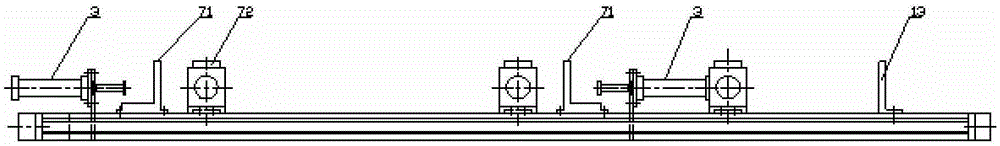

Full-electricity servo type dispersing multi-power large horizontal opposite roller spinning equipment

ActiveCN106391809AReduced Power RequirementsEasy loading and unloading of workpiecesElectricityEngineering

The invention provides full-electricity servo type dispersing multi-power large horizontal opposite roller spinning equipment which comprises a base. An external spinning roller of an external spinning roller mechanism connected with a horizontal ball linear guide rail on the base and an internal spinning roller of an internal spinning roller mechanism connected with the horizontal ball linear guide rail on the base cooperate to clamp a pipe blank, one end of the pipe blank is arranged on a supporting plate connected with the base, and the other end of the pipe blank is clamped on a self-centering chuck of a movable rotating device. A servo motor of the external spinning roller mechanism is connected with one end of a horizontal ball lead screw. A ball lead screw nut is fixed to the bottom of an external spinning roller plate which is installed on the horizontal ball linear guide rail. A servo motor of the internal spinning roller mechanism is connected with a main lead screw arranged horizontally. The main lead screw is installed on the movable rotating device through a bearing. A lead screw nut is installed in the middle of an internal spinning roller plate. One end, penetrating a guide column, of the internal spinning roller plate is fixed onto the supporting plate, and the other end of the internal spinning roller plate is fixed into a lead screw moving supporting part. Multiple sets of spinning roller feeding mechanisms are uniformly distributed and installed on the inner periphery of the external spinning roller plate and the outer periphery of the internal spinning roller plate. According to the equipment, the horizontal structure is adopted, and the machining efficiency is high.

Owner:XI AN JIAOTONG UNIV

Machining method for symmetrically split thin-wall aluminum cylinder part

ActiveCN112077542AGuaranteed machining accuracyImprove machining accuracyEngineeringMechanical engineering

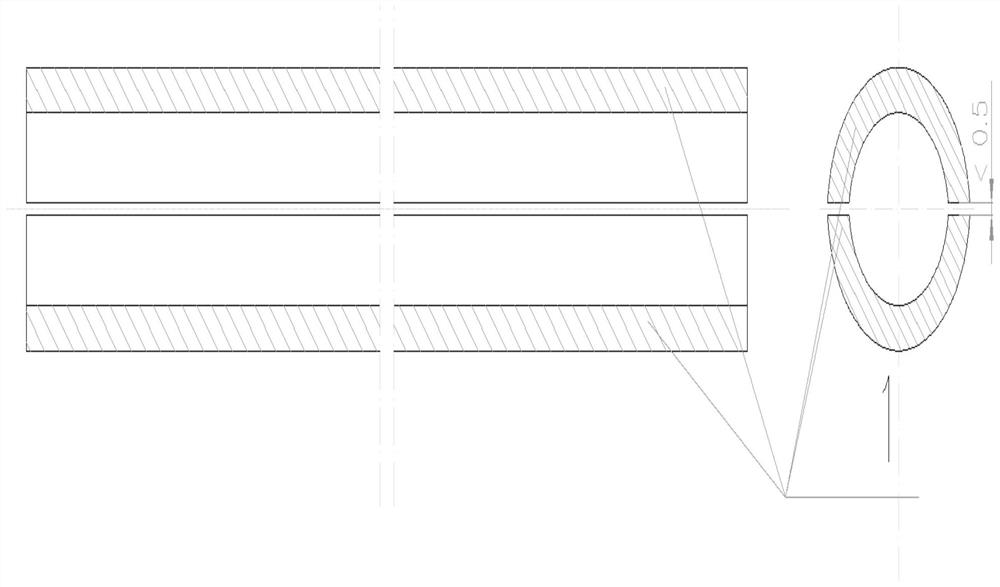

The invention relates to a machining method for a symmetrically split thin-wall aluminum cylinder part. The machining method is characterized by comprising the following steps of: blanking or formingan aluminum cylinder blank; roughly machining the length of the aluminum cylinder blank, splitting the roughly machined aluminum cylinder blank from a symmetrical center line, and finely turning positioning steps at the two ends of the symmetrically split aluminum cylinder; finely turning the outer diameter of the residual part of the symmetrically split aluminum cylinder to the size of a finishedproduct; and turning the inner diameter of the finished product of the symmetrically split aluminum cylinder. By the machining method, the machining accuracy of the symmetrically split precise thin-wall aluminum cylinder is ensured; in different machining stages, machining procedures are creatively adjusted; and by adopting various clamps, central symmetry adjustment and positioning clamping of the symmetrically split precise thin-wall aluminum cylinder are realized, and the problem of part scrapping caused by deformation due to internal stress release after the precise thin-wall aluminum cylinder is split in product production is solved. The machining method is high in positioning accuracy and easy to operate, workpieces are convenient to assemble and disassemble, and clamping force canuniformly act on the clamped workpieces.

Owner:齐齐哈尔建华机械有限公司

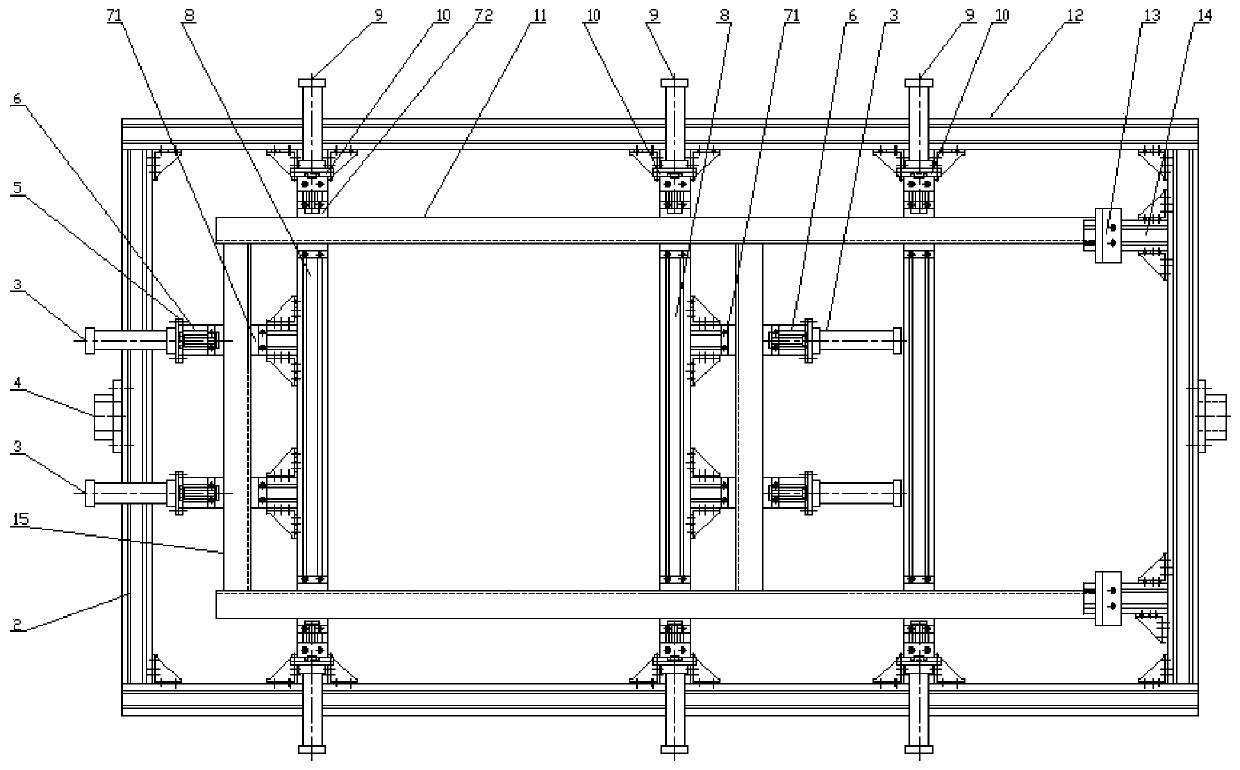

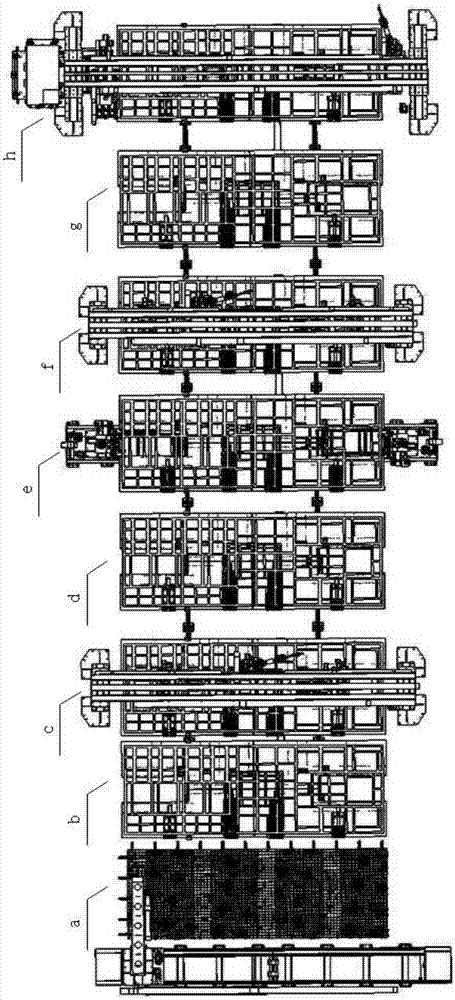

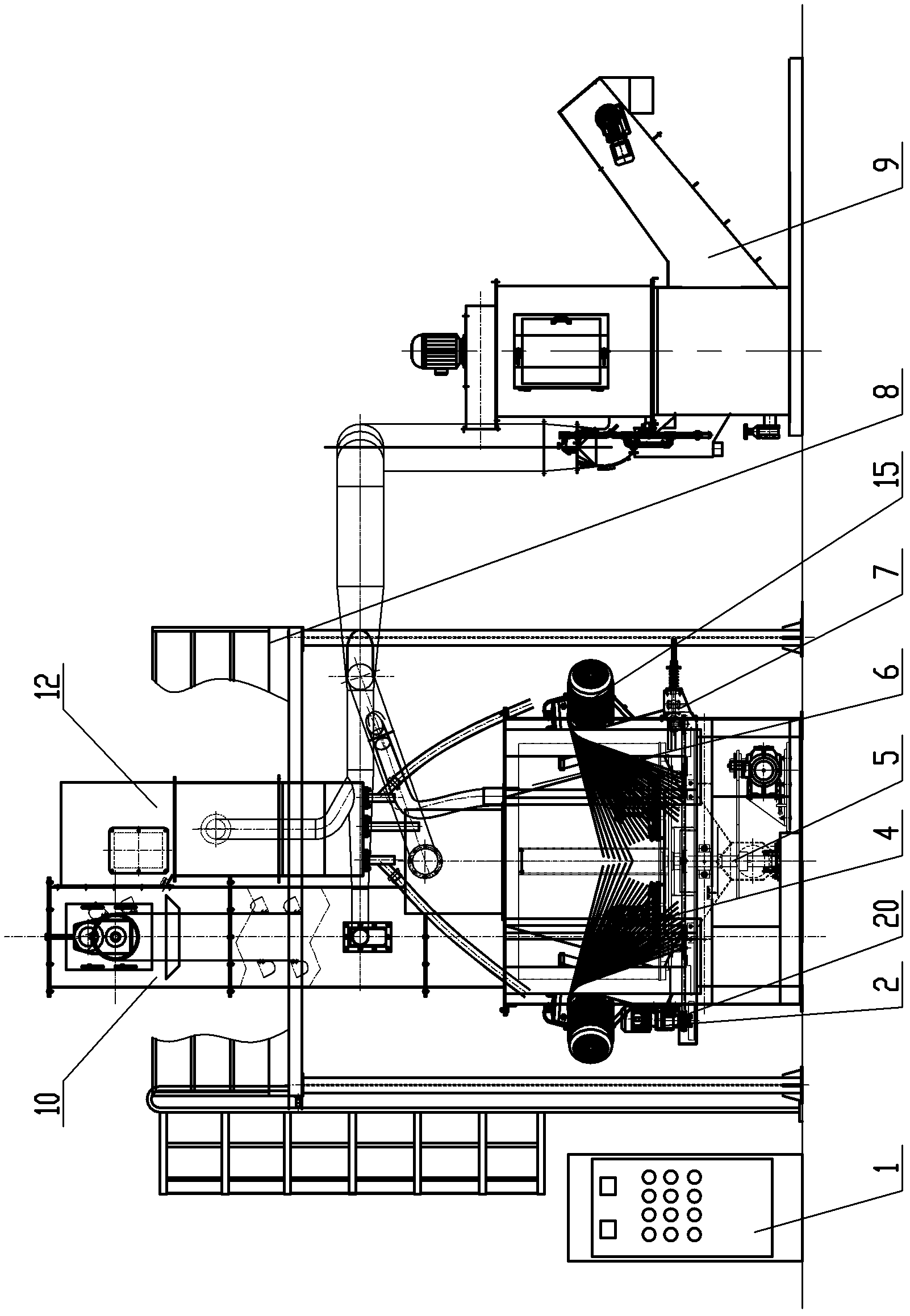

Robot automatic flexible welding production line of box-type substation and production process

ActiveCN107953045AEasy loading and unloading of workpiecesReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesProduction lineEngineering

The invention discloses a robot automatic flexible welding production line of a box-type substation and a production process. The production line comprises conveying equipment, and assembly spot welding equipment, reverse welding equipment, overturning equipment, front welding equipment and panel welding equipment arranged in sequence, wherein the assembly spot welding equipment comprises a firstwelding robot assembly and a flexible platform for assembling a frame, and is used for frame assembly and primary welding; the reverse welding equipment comprises a second welding robot assembly, andis for welding the reverse surface of the frame; the overturning equipment is used for clamping, vertically moving and overturning the frame; the front welding equipment comprises a third welding robot assembly, and is for welding the front surface of the frame; and the panel welding equipment comprises a panel loading table device and a fourth welding robot assembly, and is used for welding a panel onto the frame. The robot automatic flexible welding production line is suitable for welding of box-type substations with different specifications, improves the welding efficiency and the welding quality, and reduces the production cost.

Owner:NINGXIA LICHENG ELECTRIC GROUP +1

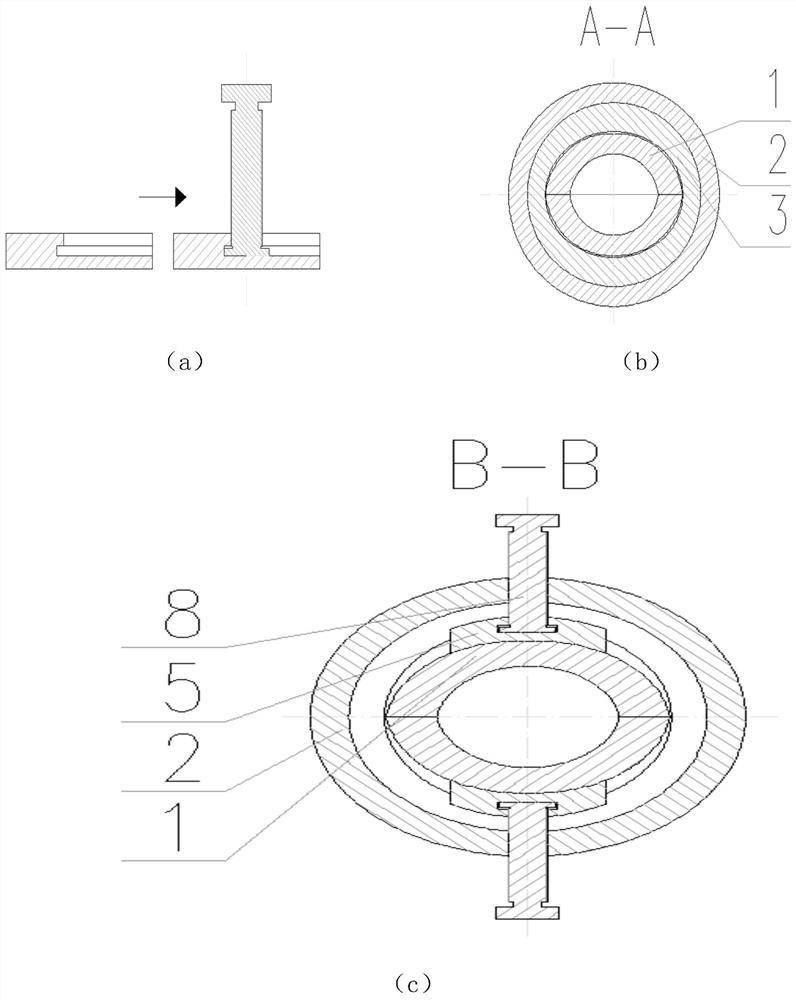

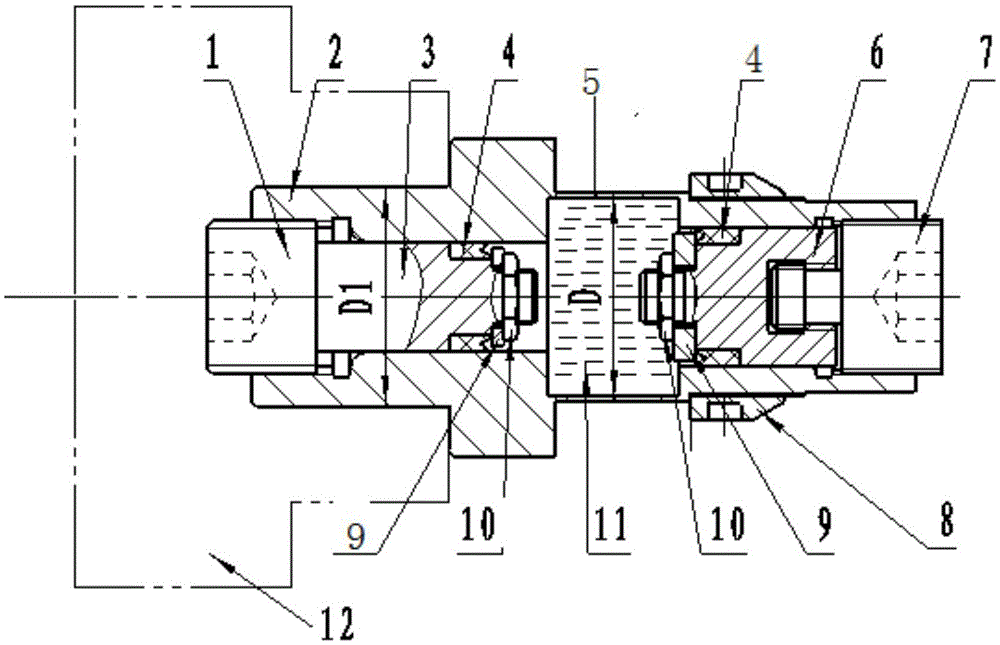

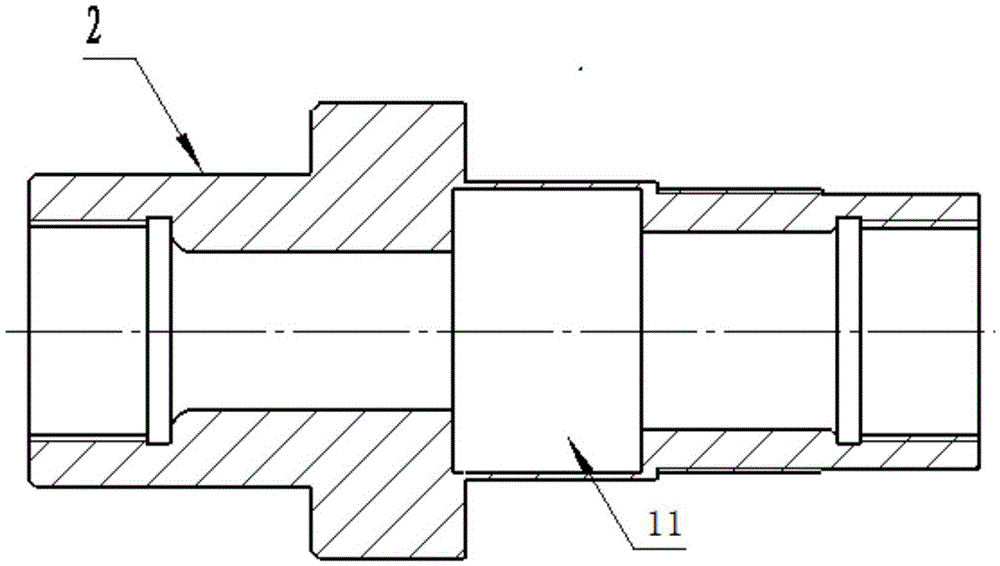

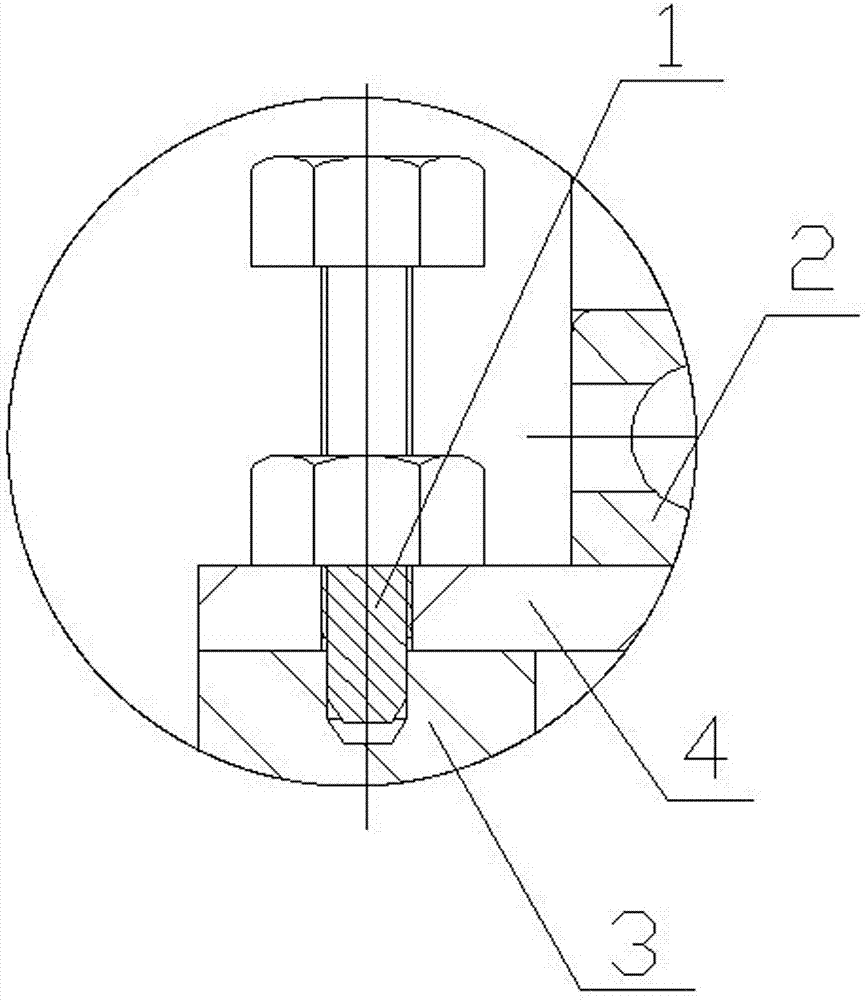

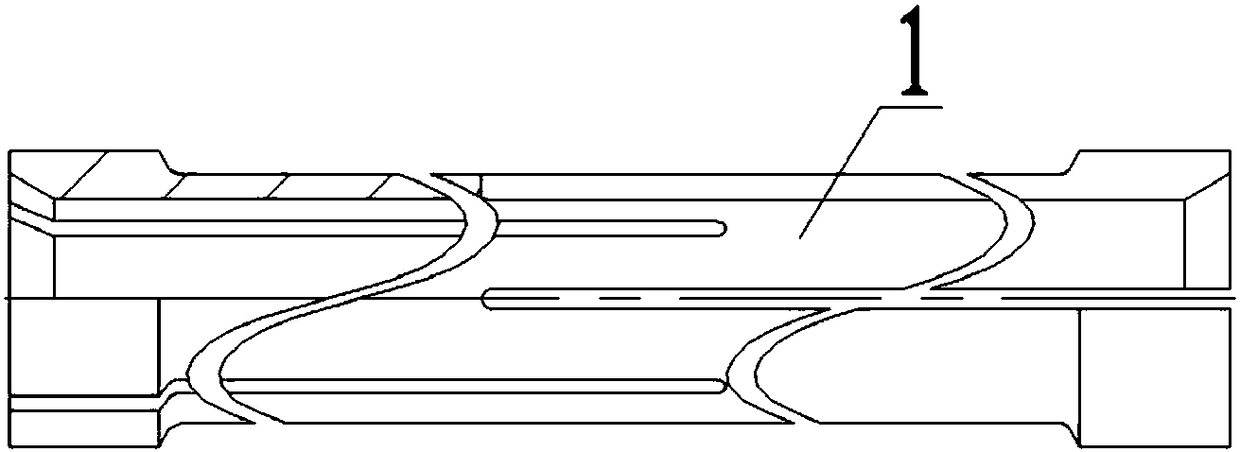

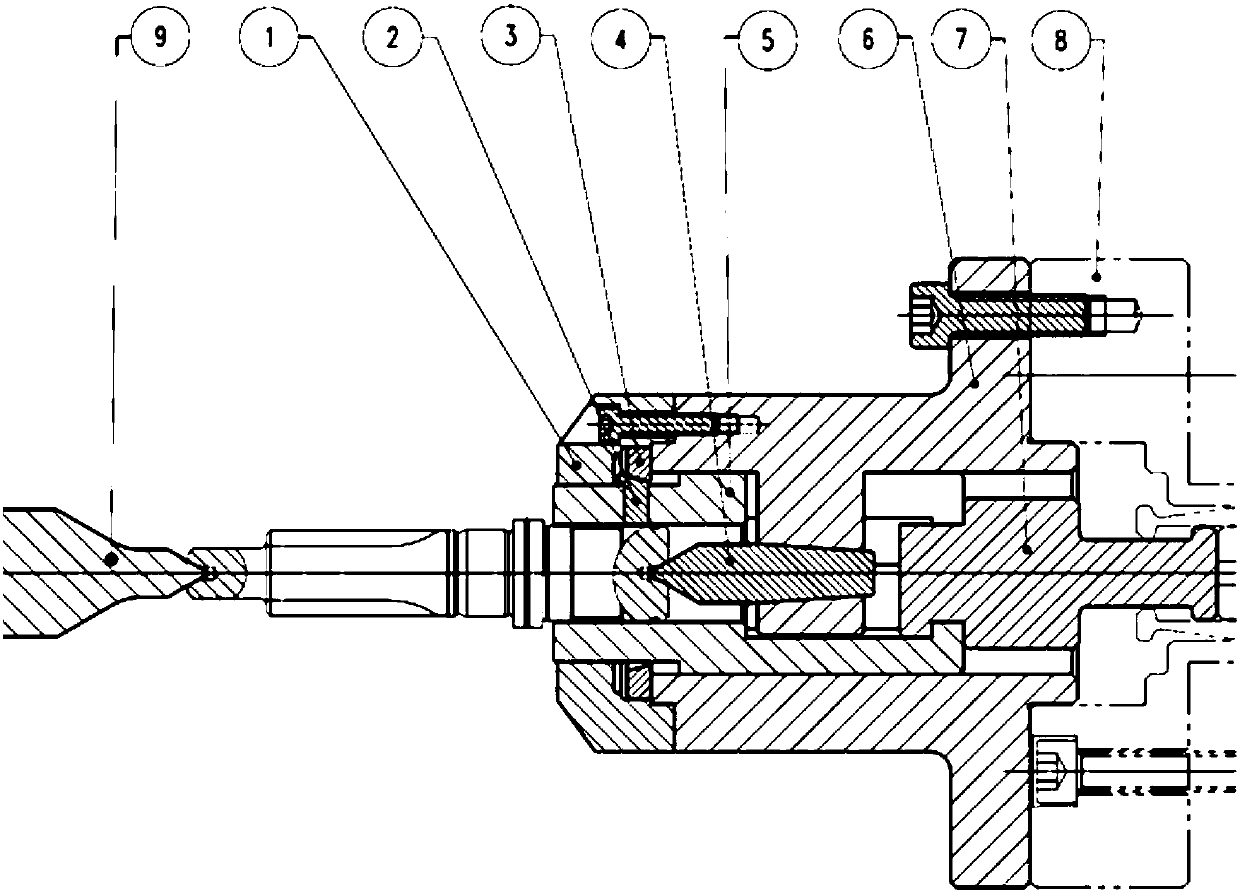

Hydraulic tensioning clamping mandrel for thin-wall shaft sleeve

InactiveCN105458317AReliable positioning and clampingSimple structureExpansion mandrelsEngineeringMachine tool

The invention discloses a hydraulic tensioning clamping mandrel for a thin-wall shaft sleeve. The hydraulic tensioning clamping mandrel is provided with a mandrel body located to the end face of a machine tool chuck or a spring sleeve. A step shaft table for locating the end face of a part to be machined is manufactured on the mandrel body, and step holes for assembling of plungers and a hydraulic oil cavity communicated with the step holes are formed in the two ends. The left pressure adjusting plunger (3) is sealed at the left end of the hydraulic oil cavity from the leftward step hole of the mandrel body (2), the right pressure adjusting plunger (6) is sealed at the right end of the hydraulic oil cavity from the rightward step hole of the mandrel body, and a closed container is formed. The to-be-machined part assembled on a rightward barrel of the mandrel body is clamped between the end face of the step shaft table of the mandrel body and a compressing nut (10) through the compressing nut (10). Sealing screws (7) are screwed down to drive the plungers to move and compress hydraulic oil in the hydraulic oil cavity, and the to-be-machined part clamped on the external circle tensioning mandrel body on the thin wall of the hydraulic oil cavity is expanded through pressure generated by the hydraulic oil cavity under the action of oil pressure. The hydraulic tensioning clamping mandrel is easy to manufacture and high in clamping precision, and a clamping area is stable and reliable in clamping.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

Multi-drill bit rapid drilling device

InactiveCN104439377AImprove drilling efficiencySimple structureDrilling/boring measurement devicesDrill jigsEngineeringBody function

The invention discloses a multi-drill bit rapid drilling device. The multi-drill bit rapid drilling device comprises a clamp body functioning as a base additionally and used for positioning a workpiece, and a driving plate arranged above the clamp body and provided with at least two drill bits, wherein the driving plate is connected with the clamp body through two guide posts; the upper parts of the guide posts extend into guide holes in the end parts of the driving plate, and the lower parts of the guide posts extend into guide sleeves on the end parts of the clamp body; a drilling template for guiding drilling is further arranged between the driving plate and the clamp body; the two ends of the drilling template penetrate through the guide posts and are fixed on the guide posts through tightening screws; springs sleeve the guide posts between the driving plate and the drilling template. The multi-drill bit rapid drilling device drills the workpiece required to be drilled with parallel holes by using multiple drill bits, so that the workpiece drilling efficiency is significantly improved; after drilling, the drilling template exits along with the multiple drill bits, so that a space is emptied, and accordingly, assembly and disassembly of the workpiece and removal of cuttings are very convenient.

Owner:NINGBO ZHENHAI XIUYANG ADVERTISEMENT DECORATION

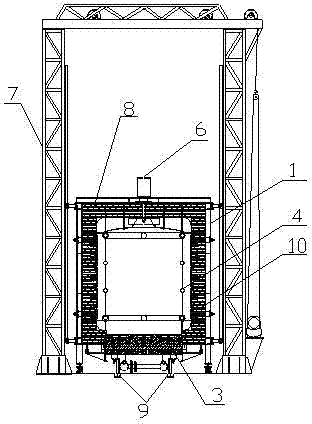

Atmosphere passing cover type mobile trolley furnace

ActiveCN104515393AUniform temperature distributionImprove heat treatment efficiencyMaintainance of heating chambersFurnace typesEngineeringPortal frame

The invention discloses an atmosphere passing cover type mobile trolley furnace. The atmosphere passing cover type mobile trolley furnace comprises a furnace body having openings in the bottom and the front and back ends, furnace doors, a trolley, a trolley walking mechanism positioned at the bottom of the furnace body, a furnace door lifting portal frame, an electric heating element and an electric appliance control system, and further comprises an atmosphere passing device and a furnace body guide sealing mechanism, wherein the atmosphere passing device comprises a gas generator, an air inlet pipe and a surrounding steel pipe; on the one hand, the internal temperature of a hearth is distributed more evenly, and on the other hand, the heating temperature rises, and the heat treatment efficiency is high; sand groove and hollow sealing strips are arranged around the trolley; the sand groove sealing bars are mainly used for preventing the leakage of heat; the hollow sealing strips are mainly used for sealing the furnace body with the furnace doors and the trolley to eliminate the micro uneven influence of two contact surfaces; the furnace doors are respectively arranged at the two ends of the furnace body; after workpieces enter the hearth from the furnace door at one end of the furnace body for heating, the workpieces are discharged from the furnace door at the other end to enter the next procedure; the whole process is fully automatic; the loading / unloading of the workpieces is simple; and the rejection rate of the workpieces is reduced.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Lathe processing eccentric deep hole clamp

InactiveCN103878606AEasy loading and unloading of workpiecesPrecise positioningPositioning apparatusMetal-working holdersDeep holeFlange

The invention relates to the field of mechanical manufacturing, in particular to a lathe processing eccentric deep hole clamp which comprises a clamping sleeve. The center line of the clamping sleeve is coaxial with the center line of a lathe main shaft. The front end and the rear end of the clamping sleeve are provided with a front eccentric flange and a rear eccentric flange respectively. An installation hole I is formed in the front eccentric flange and an installation hole II is formed in the rear eccentric flange. The center line of the installation hole I and the center line of the installation hole II are coaxial with the center line of a workpiece to be processed. A balancing weight is arranged on the outer side of the clamping sleeve. The lathe processing eccentric deep hole clamp has the advantages of being capable of conveniently and rapidly detaching and assembling the workpiece, high in processing precision, little in damage to the workpiece and suitable for batched eccentric deep hole processing.

Owner:JIGANG GRP

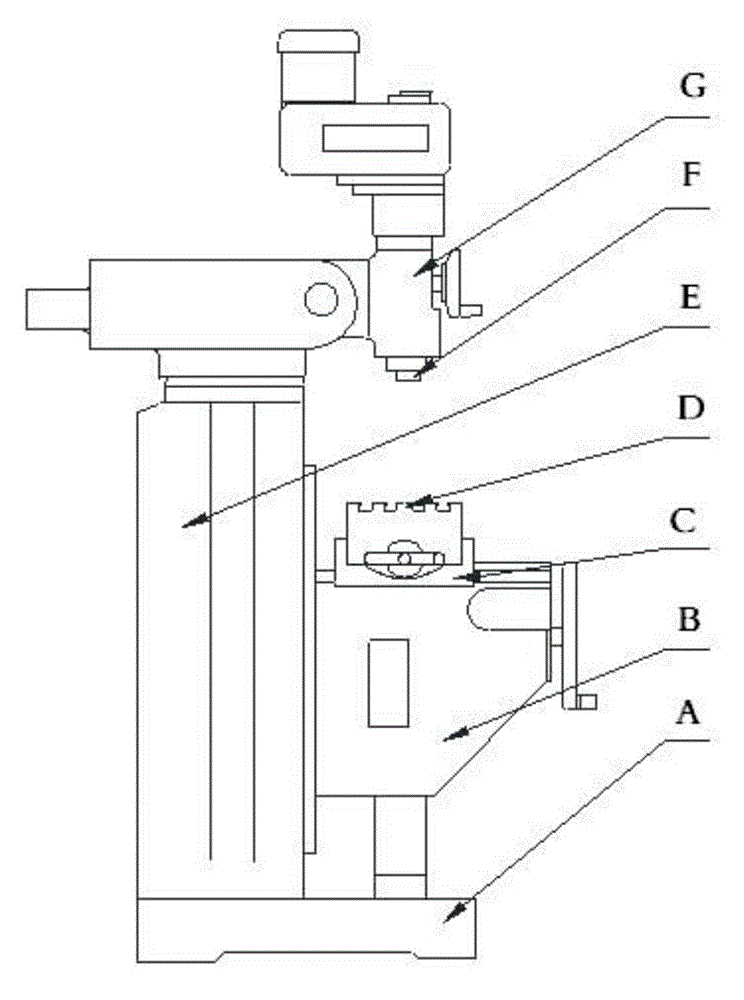

Compound vertical-type milling machine

InactiveCN104907615AReduce stressReduce weightMilling machinesFeeding apparatusReciprocating motionEngineering

The invention discloses a compound vertical-type milling machine. The compound vertical-type milling machine comprises a base (1), a stand column (2), a main shaft box (3), a main shaft (4), a working bench (5), a saddle (6), a lifting platform (7), a screw-nut pair (8) and a numerical control system. The stand column (2) is fixedly installed on the base (1). The working bench (5) is assembled to a guide rail of the saddle (6) and can carry out traverse reciprocating motion along the saddle. The saddle (6) is assembled to a guide rail of the lifting platform (7) and can carry out vertical reciprocating motion along the lifting platform. The compound vertical-type milling machine is a novel structure compound vertical-type milling machine with high motion rigidity and high rotation rate.

Owner:云南锦润数控机械制造有限责任公司

Hydraulic clamping mechanism

InactiveCN105562747AThe amount of deformation has little effectHigh centering accuracyExpansion mandrelsPressure transmissionBiochemical engineering

The invention relates to a hydraulic clamping mechanism, which comprises a base body, a piston, an elastic sleeve, sealing rings, a positioning sleeve and pressure transferring media. The hydraulic clamping mechanism is characterized in that a step-shaped middle hole is formed in the middle part of the base body; the piston is arranged at one end of the middle hole of the base body, and can move in the axial direction in the middle hole of the base body; the other end of the middle hole of the base body is sealed and plugged by a second screw; a threaded groove, an elastic sleeve and a fixing hole are arranged in the outer part of the base body; the threaded groove and the elastic sleeve are tightly matched; the starting end of the threaded groove communicates with the base body hole; the ending end of the threaded groove communicates with an oil opening; the oil opening is sealed and plugged by a first screw; the threaded groove and the middle hole of the whole base body are fully filled with the pressure transferring media; a sealed oil path is formed; and the positioning sleeve and a workpiece are arranged on the elastic sleeve. The hydraulic clamping mechanism has the advantages that the centering precision is high; the workpiece mounting and dismounting are fast and convenient; the influence on the deformation quantity of an inner hole of the workpiece is small; the production auxiliary time is short; the production efficiency is improved; the production cost is reduced; the product quality is guaranteed; and the hydraulic clamping mechanism is particularly suitable for processing sleeve type workpieces.

Owner:赵慧霞

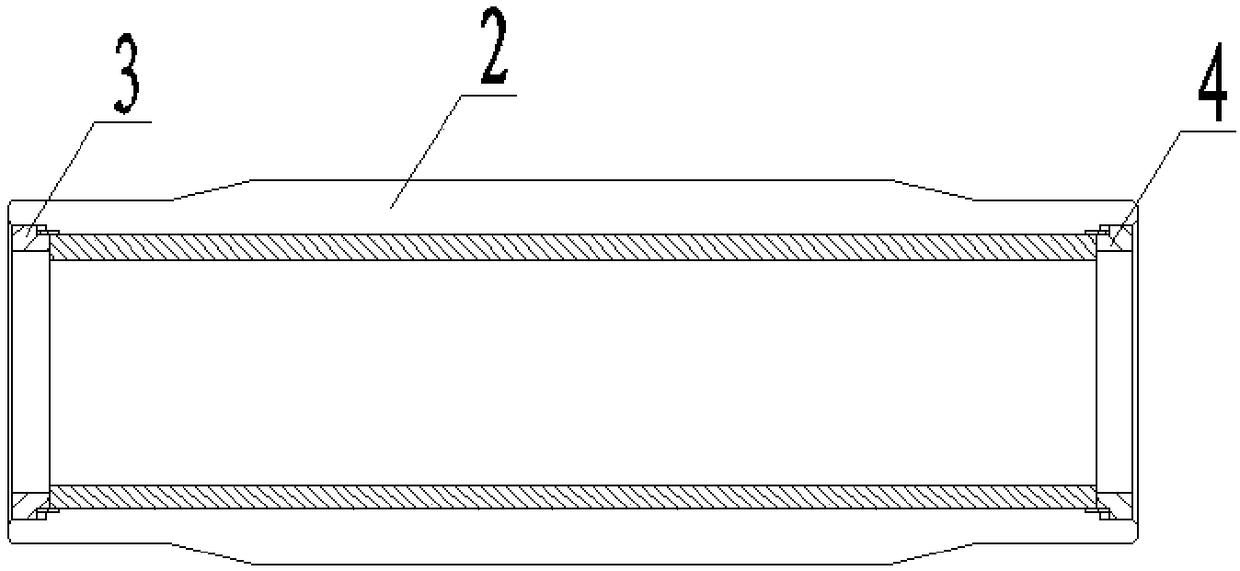

Aluminum cylinder part machining method

ActiveCN108581388AAchieve positioningGuaranteed machining accuracyTurning machinesPosition toleranceRoughcast

The invention discloses an aluminum cylinder part machining method. The aluminum cylinder part machining method specifically comprises the following steps: blanking or forming an aluminum cylinder part blank, roughly machining the outer diameter of the aluminum cylinder part blank and the overall length of a workpiece, roughly turning an inner hole of an aluminum cylinder part, performing stability treatment, finely turning an appearance, finely turning the inner hole, and performing final inspection. The aluminum cylinder part machining method ensures the machining precision of a precise thin-walled aluminum cylinder part; the precise thin-walled aluminum cylinder part is positioned and clamped by adopting various clamps in different machining stages; and the problem about deformation ofthe precise thin-walled aluminum cylinder part under the action of clamping force in product production is solved. An aluminum cylinder part with the wall thickness of 3 to 6 mm can be machined; the dimensional tolerance is within 0.05 mm; the shape and position tolerance can also be ensured within 0.05 mm; the aluminum cylinder part machining method is applicable to machining various precise thin-walled aluminum cylinder parts; the positioning precision is high; the operation is simple; the workpiece is convenient to load and unload; the clamping force can act on a clamped workpiece uniformly; and the clamping force can be adjusted according to different situations.

Owner:齐齐哈尔建华机械有限公司

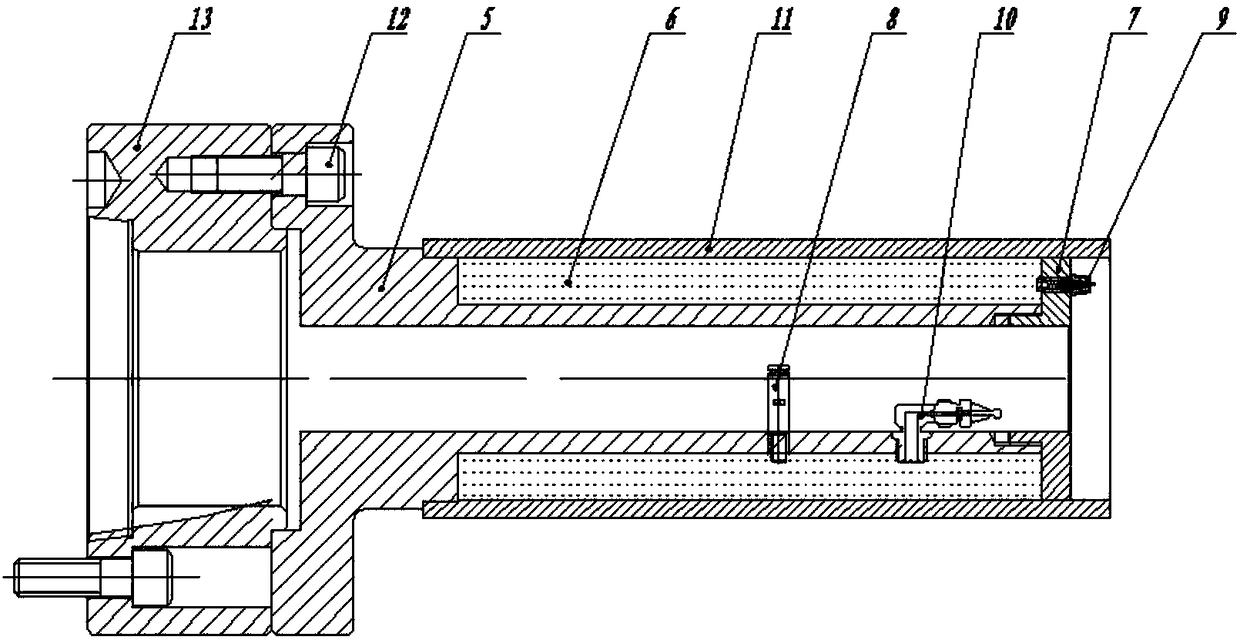

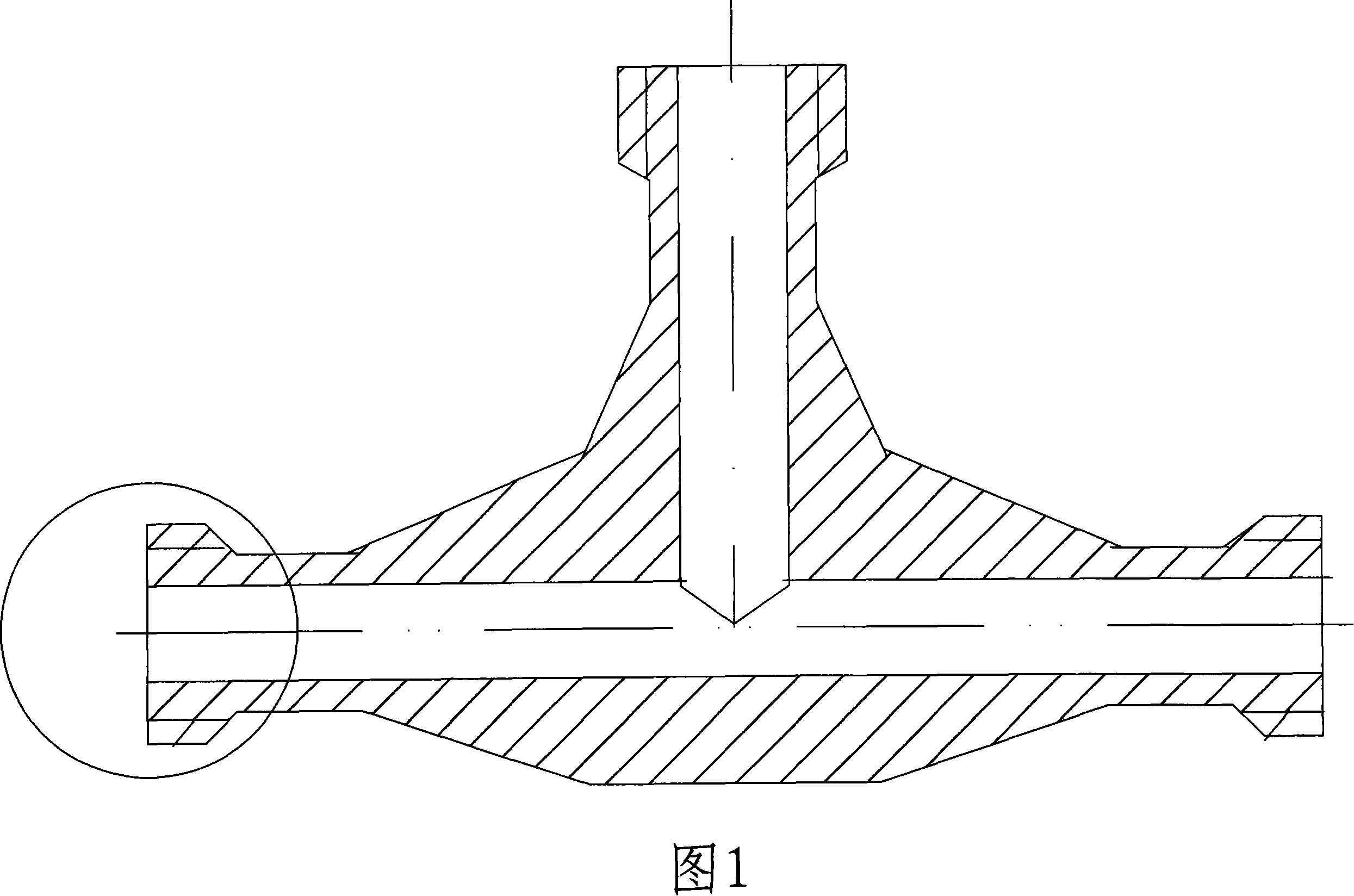

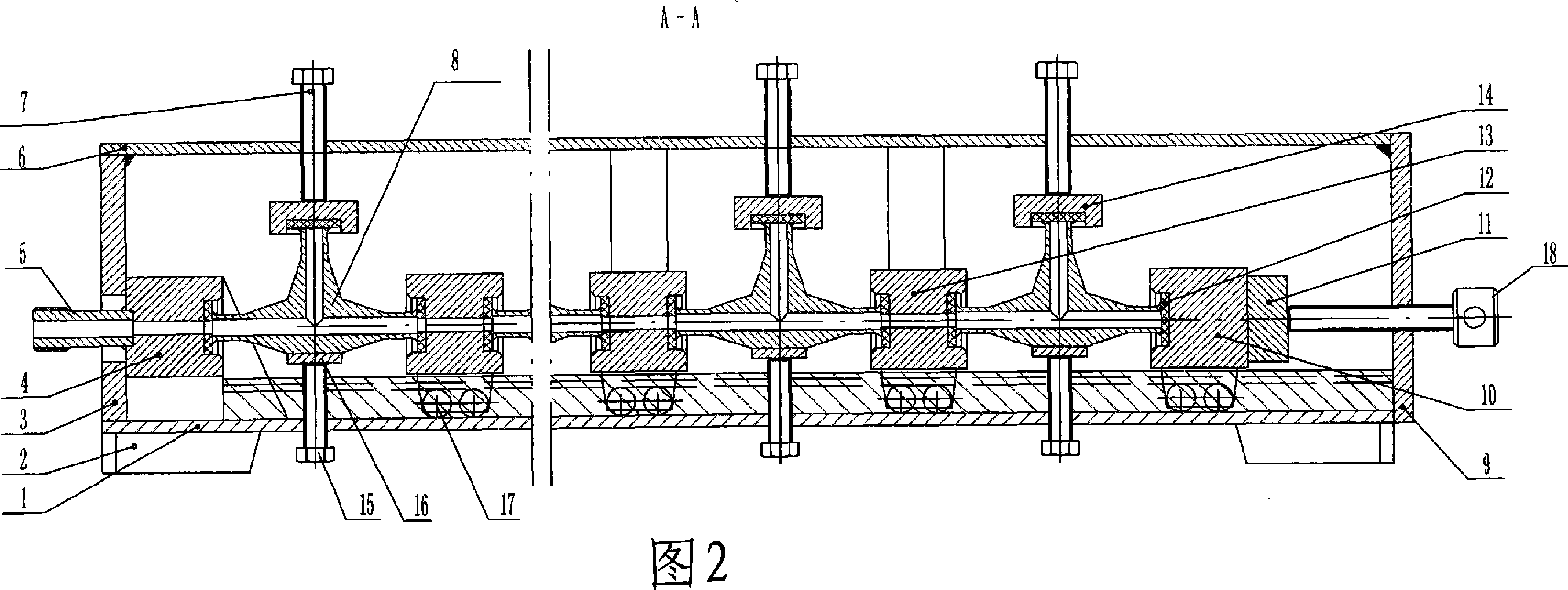

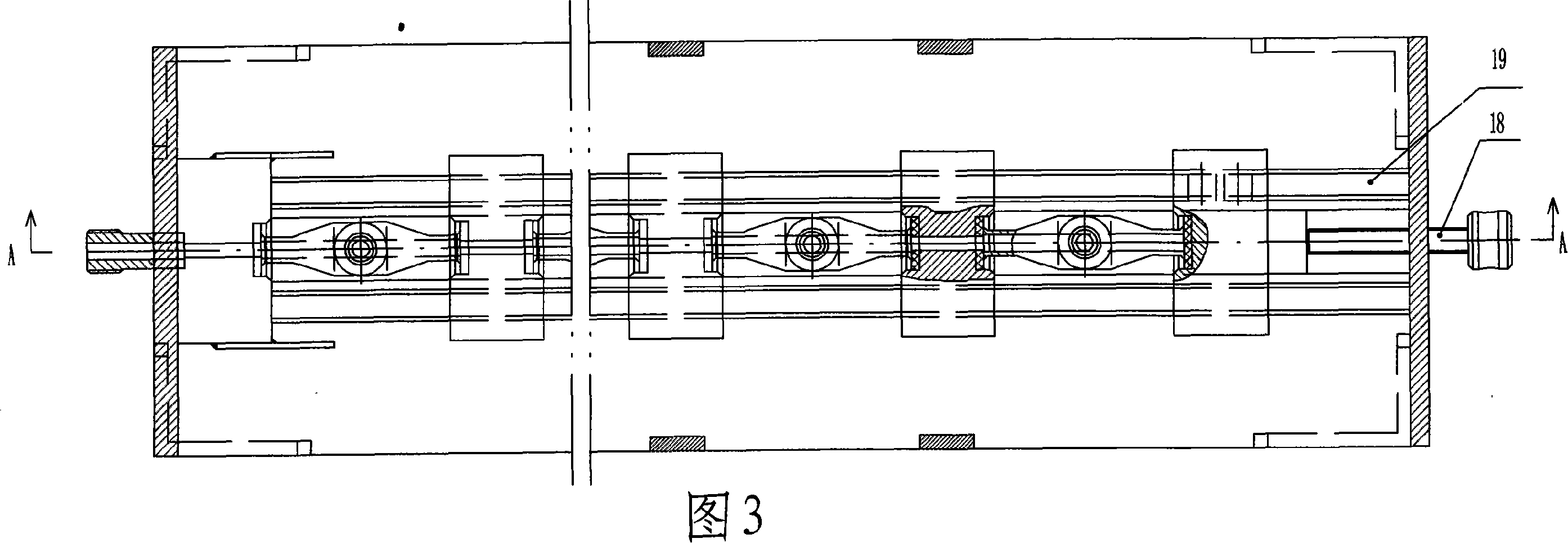

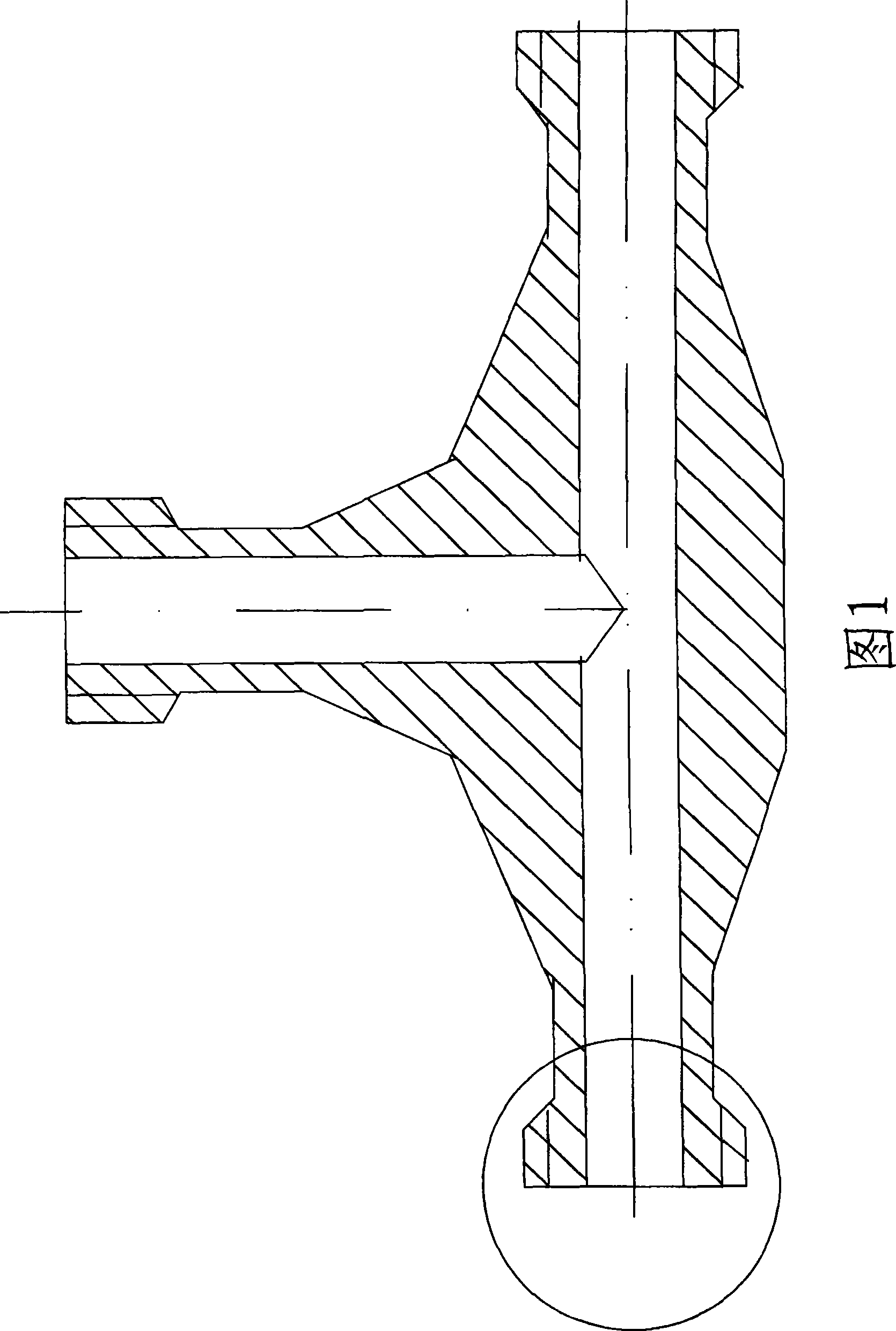

Hydraulic experiment device for three-way piece group and the method thereof

ActiveCN101059387AEasy loading and unloading of workpiecesReduce labor intensityMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumHydraulic pumpUltimate tensile strength

The invention relates to a three-way element group hydraulic test device and a relative method, wherein upper and lower ends of a left side plate and a right side plate are respectively fixed with an upper lift plate and a bottom plate, the bottom plate is arranged with a track, while a sliding block can move along the bottom plate. A plurality of screw lift rod groups connect two screw lift rods in preset distance with the upper top plate and the bottom plate via screws, a T-type screw lift rod is connected with the right side plate via screw. The three-way group is clamped and positioned via rolling a rolling wheel and rotating screw lift rod. And the test method comprises that adjusting the height of the screw lift rods on the bottom plate, according to the size of the three-way element, arranging the grouped three-way element on the screw lift rods, using the screw lift rods on the upper lift plate to press the three-way element, using the T-type screw lift rod on the right side plate to clamp the three-way element after finding the position of the three-way element, using a hydraulic pump to increase pressure via preset pressure to process test. The invention has the advantages that the invention can process group hydraulic test of the three-way element in final product state, with simple detachment and installment of work-piece, reduced labor strength, shortened period and saved material.

Owner:中国船舶集团渤海造船有限公司

Automobile steering knuckle rod part thread machining clamp and device

PendingCN110181303AEasy loading and unloading of workpiecesGuaranteed space for plastic deformationPositioning apparatusMetal-working holdersEngineeringProduct Part

The invention provides an automobile steering knuckle rod part thread machining clamp and device. The automobile steering knuckle rod part thread machining clamp comprises a supporting table and a base arranged on the supporting table, wherein two ejector pin mechanisms are arranged on the base in a positive opposite mode, and the ejector pin of one ejector pin mechanism can float in the axial direction; and the base is supported on the supporting table through a plurality of roller pins, the axes of the roller pins is parallel to the axis direction of the steering knuckle rod part, so that the base can horizontally float along the axis perpendicular to the axis of the steering knuckle rod on the supporting table, and a limiting structure used for limiting the horizontal floating range ofthe base is arranged on the supporting table or the base. According to the automobile steering knuckle rod part thread machining clamp and device, the steering knuckle is positioned and clamped through the front and back ejector pin mechanisms, the base can float on the supporting table in the left-right direction, the plastic deformation space of the product part and the product quality are ensured through a floating gap of the clamp.

Owner:QINGLING MOTORS GRP +1

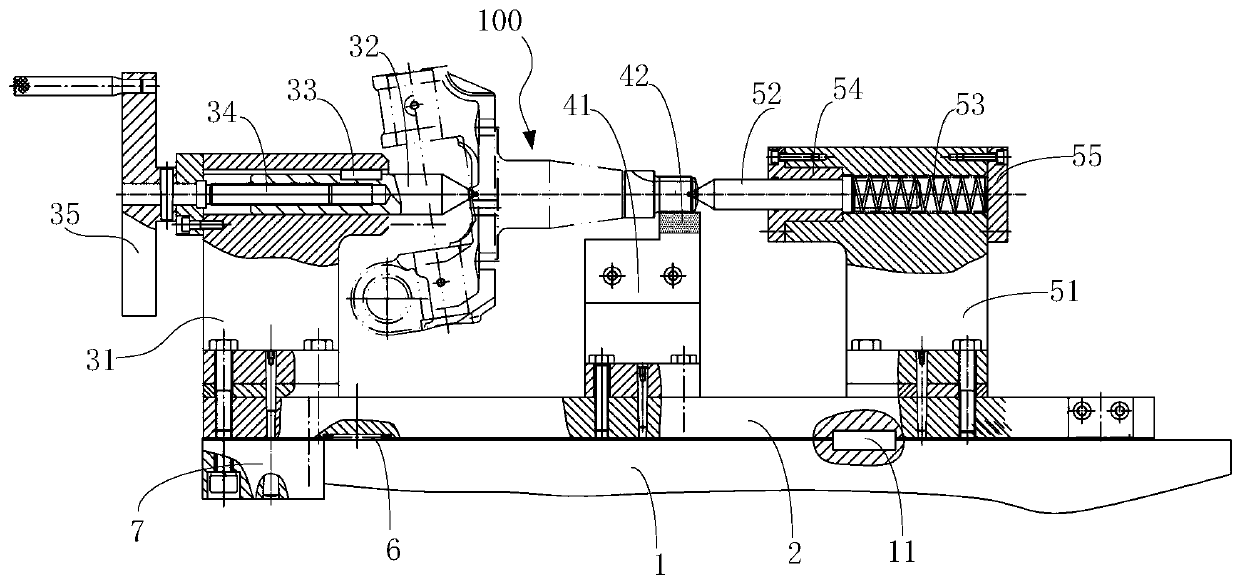

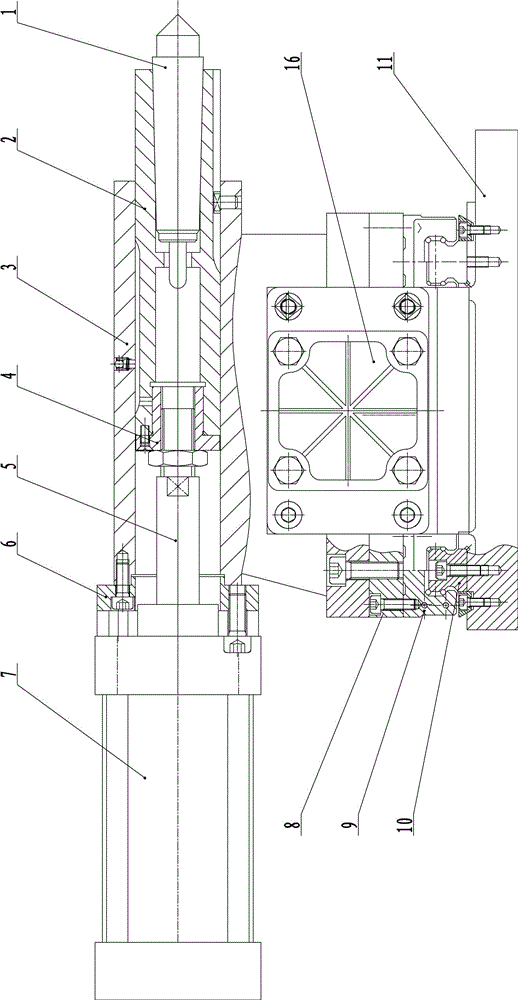

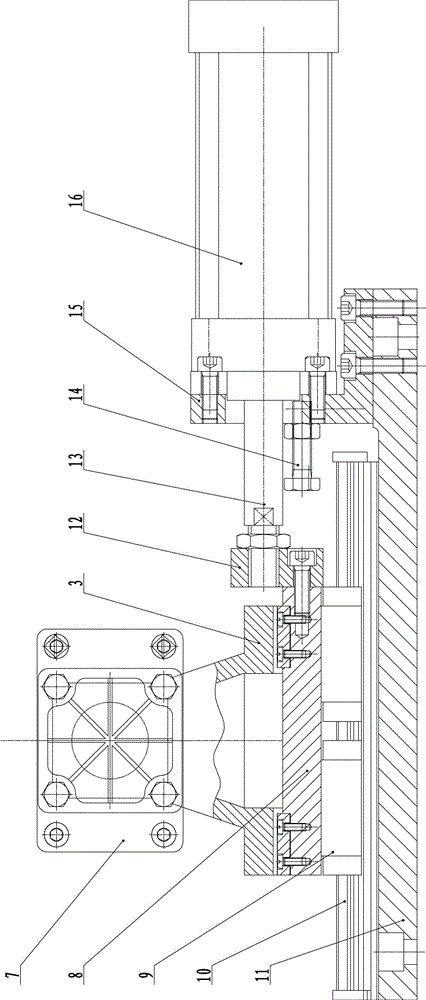

Automatic-jacking tailstock capable of rapidly moving

InactiveCN102909398AEasy loading and unloading of workpiecesShorten the timeTailstocks/centresEngineeringTailstock

The invention discloses an automatic-jacking tailstock capable of rapidly moving, which has the advantages that the use is convenient and the working efficiency is greatly improved. The automatic-jacking tailstock comprise a bottom plate, wherein a linear slide rail is fixedly connected to the bottom plate; a moving cylinder is fixedly connected to one end of the bottom plate and is provided with a moving cylinder piston rod; the central line of the moving cylinder piston rod is parallel to the walking direction of the linear slide rail; a tailstock backing plate is fixedly connected to the free end of the moving cylinder piston rod; a slide block is fixedly connected below the tailstock backing plate; the slide block is connected with the linear slide rail in a sliding manner; a tailstock body is fixedly connected to the tailstock backing plate; the tailstock body is hollow; a tailstock sleeve is connected in the tailstock body in a sliding manner; a jacking cylinder is fixedly connected to the rear end of the tailstock body and is provided with a jacking cylinder piston rod; the free end of the jacking cylinder piston rod is fixedly connected with the rear end of the tailstock sleeve; a tip is sleeved at the front end of the tailstock sleeve; and the contact surface of the tip and the tailstock sleeve is conical. The free end of the moving cylinder piston rod is connected with the tailstock backing plate via a connecting block.

Owner:SHANDONG LUNAN MACHINE TOOL

Shoe upper and shoe tree vertical circulation two-in-one dryer

InactiveCN103082580AImprove sanitationNot easy to loseShoemaking devicesProduction lineProcess engineering

A shoe upper and shoe tree vertical circulation two-in-one dryer comprises a shared drying oven, a conveying chain, transmission wheels, a shoe tree hanging bracket, a speed regulation and reducing machine, an air source heat pump, an electric heating system, a table board conveying belt, an electric control cabinet and an operation table. The shared drying oven is fixed on a machine frame, and the conveying chain enters the shared drying oven from an inlet of the drying oven through the transmission wheels, operates towards one end and returns upwards at 360 degrees to exist from an outlet of the drying oven to form a circulation loop. The shoe tree hanging bracket is hung on the conveying chain, the group of transmission wheels is connected with the speed regulation and reducing machine, the air source heat pump is arranged at one end of the shared drying oven, and a convection fan is arranged at the other end of the drying oven. A separation board is arranged in the shared drying oven to divide the shared drying oven into a production line drying zone and a shoe upper heating zone, and therefore the two-in-one dryer has the function of drying two products simultaneously.

Owner:宗占国

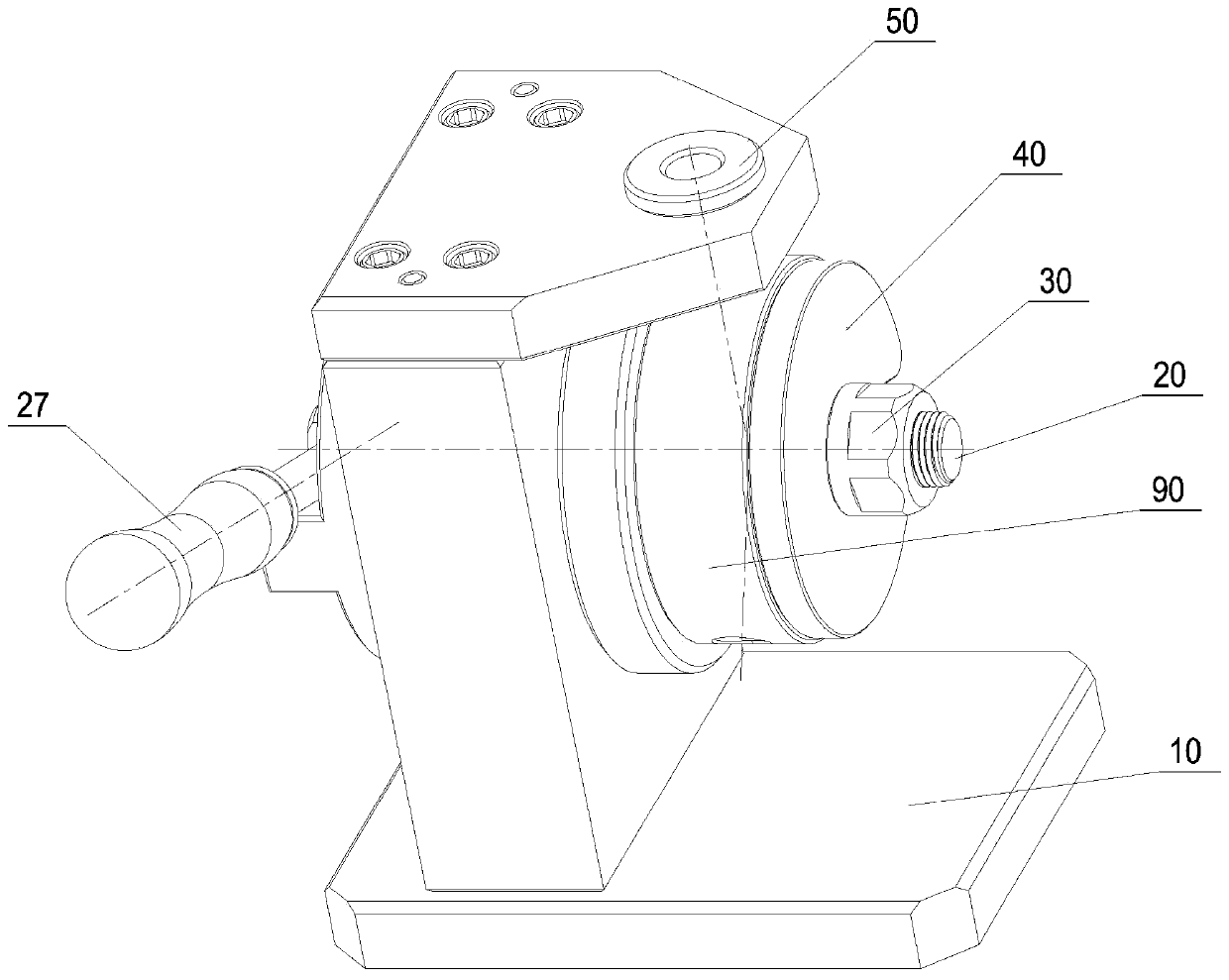

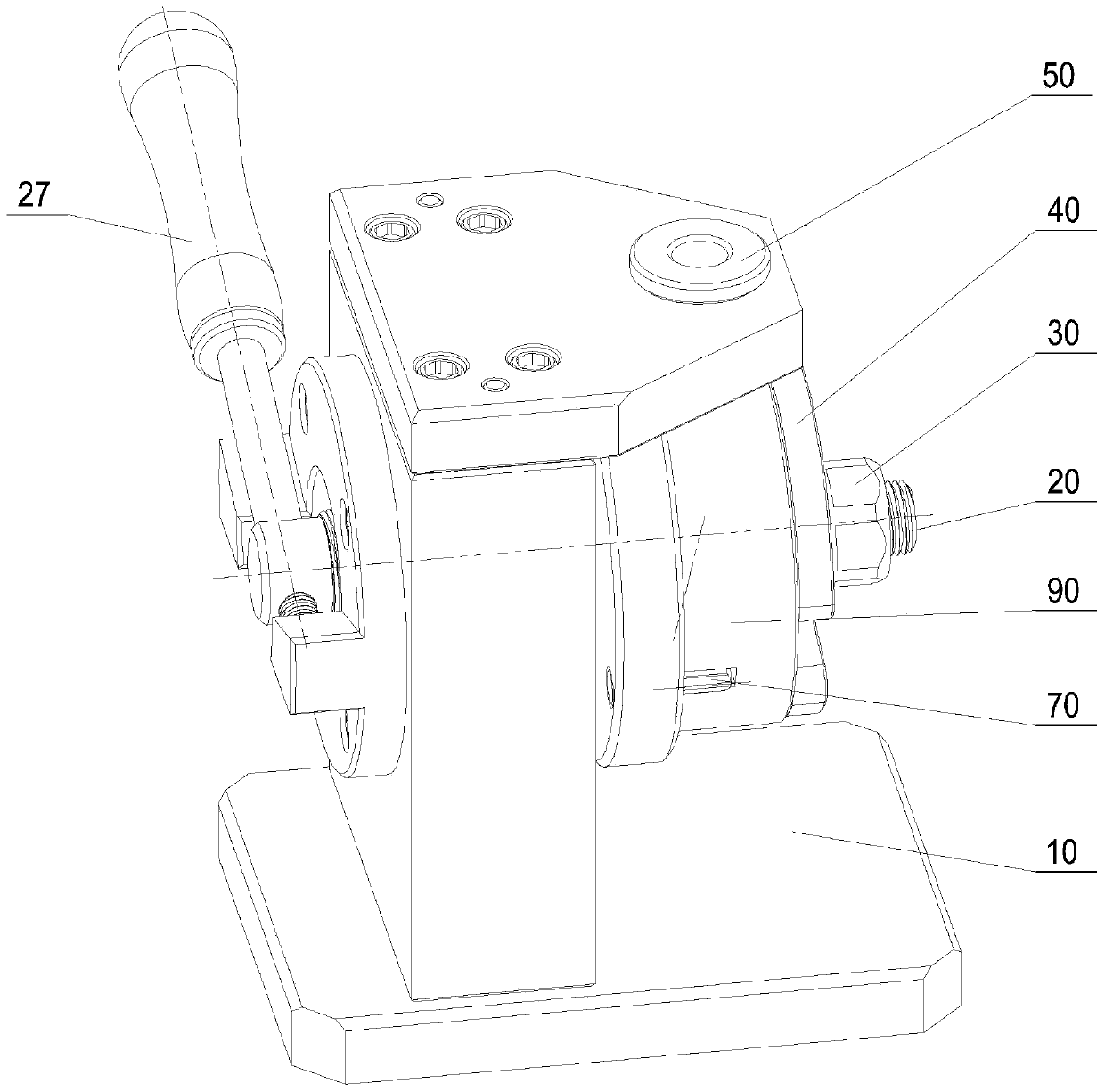

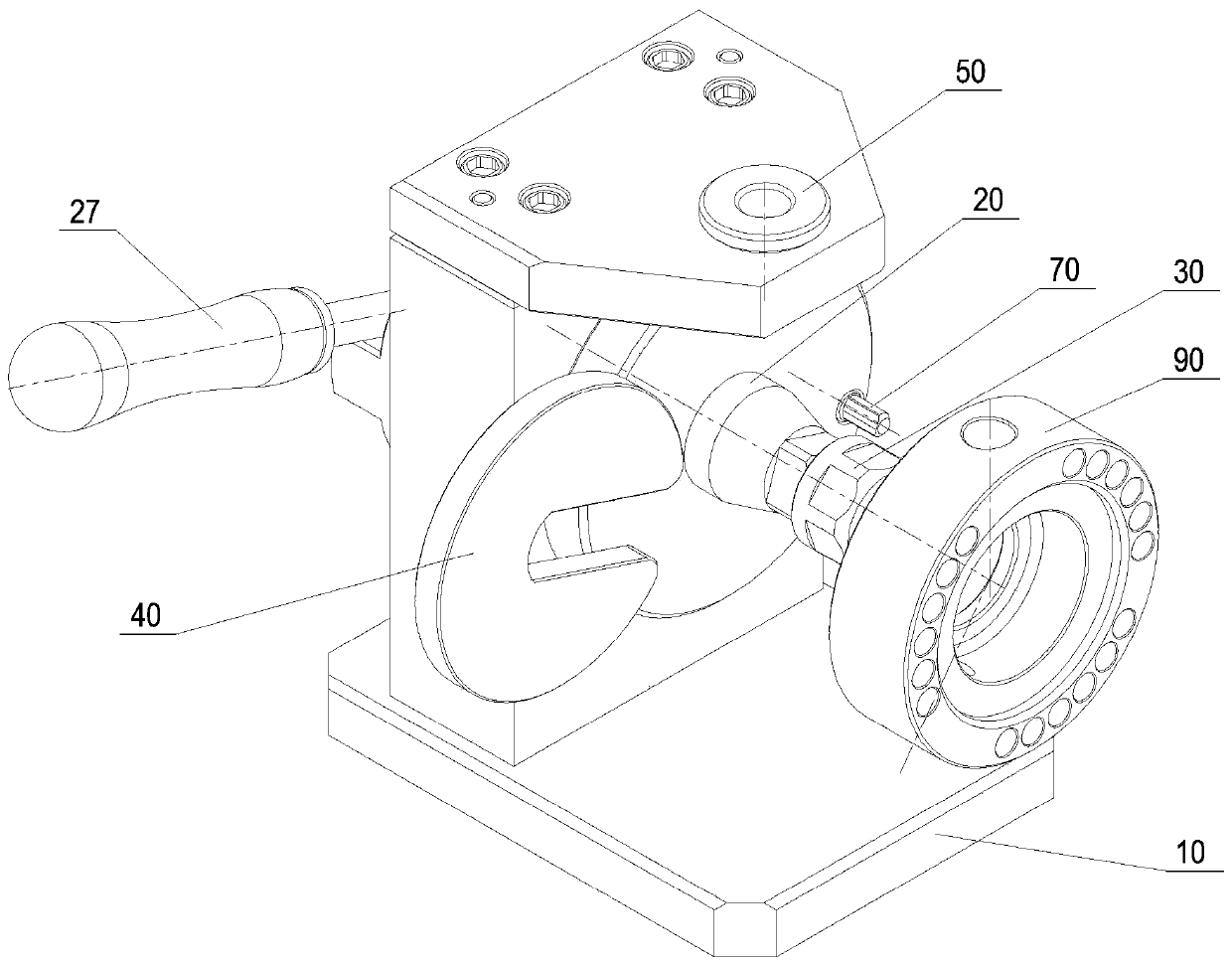

Rotary shaft type drilling tool

PendingCN110253044ASmall and simple structureEasy loading and unloading of workpiecesLarge fixed membersPositioning apparatusEngineeringMechanical engineering

The invention discloses a rotary shaft type drilling tool which comprises a clamp body, a rotary shaft, an opening washer and a compression nut. The rotary shaft is rotationally arranged on the clamp body, and the opening washer and the compression nut are matched with the rotary shaft to be used for pressing a workpiece to be processed. The rotary shaft type drilling tool has the advantages that the rotary shaft type drilling tool is compact and simple in structure, facilitates loading and unloading of the workpiece, facilitates turning and drilling and does not need tool setting each time.

Owner:NANJING COLLEGE OF INFORMATION TECH

Automatic centering clamp for disk sleeve parts

InactiveCN104308577AReduce labor intensityHigh precisionChucksPositioning apparatusHydraulic cylinderEngineering

The invention relates to the field of mechanical auxiliary devices, in particular to an automatic centering clamp for disk sleeve parts. The automatic centering clamp for the disk sleeve parts comprises a hydraulic cylinder and a clamp body and is characterized in that a piston is arranged in the hydraulic cylinder and is connected with a hinge through a piston rod which is fixedly connected with the piston; three grooves which are distributed at an angle of 120 degrees are formed in the hinge; an opening of each groove is far away from the center of the hinge; the three grooves are connected with a clamping claw through bumps of three stirring forks which are arranged on the clamp body and correspond to the three grooves; small holes are formed in the positions, on the upper side and the lower side of the piston, on the hydraulic cylinder. The automatic centering clamp for the disk sleeve parts is high in concentricity accuracy, simple in structure, high in positioning accuracy, high in universality degree and long in service life; the centering and clamping functions are reliable, a workpiece is convenient to load and unload, the working efficiency is improved, and the labor intensity of workers is alleviated.

Owner:SHAANXI QIYUAN TECH DEV

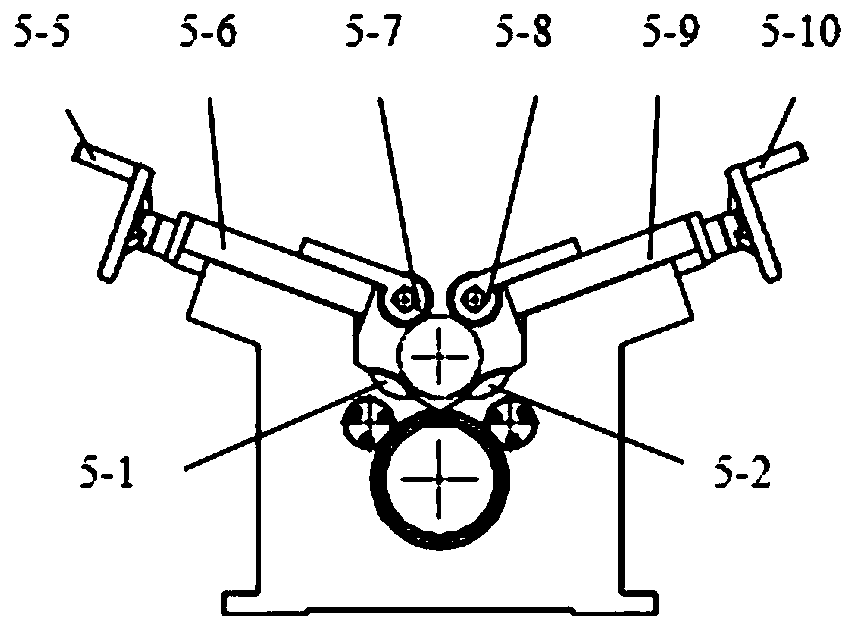

Steel pipe chamfering machine

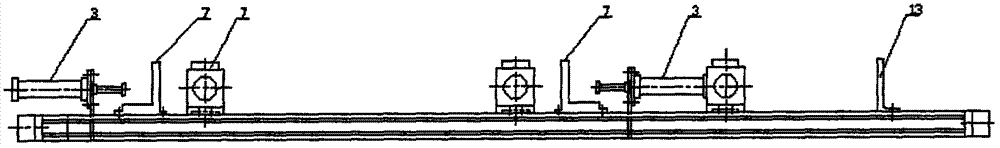

InactiveCN111266605AExpand the scope of processingEasy loading and unloading of workpiecesLarge fixed membersTurning machinesDrive wheelElectric machinery

The invention discloses a steel pipe chamfering machine. The steel pipe chamfering machine comprises two knife rests, two central frames and a power device, wherein the two knife rests are used for machining one end or two ends of a steel pipe; the two central frames are positioned at the two ends of the steel pipe and used for supporting the steel pipe and increasing the rigidity of a system; andthe power device is arranged between the two central frames and comprises a motor, two driving wheels, two upper pressing wheels and a driving device. The motor drives the two driving wheels to rotate through a transmission device, and the driving wheels are used for driving the steel pipe to rotate; the upper pressing wheels press a workpiece; and the two upper pressing wheels are connected withthe driving device, so that the upper pressing wheels are close to and away from the steel pipe.

Owner:SHANDONG UNIV

Method for oxidizing brake master cylinder

The invention discloses a method for oxidizing a brake master cylinder, which comprises the following steps of: 1, hanging, namely hanging the brake master cylinder to a rack special for oxidizing the brake master cylinder; 2, performing weak acid oil removal treatment; 3, preparing anode oxidizing tank liquor; 4, performing anode oxidization treatment; and 5, taking out the brake master cylinder, cleaning, and performing enclosed drying treatment. The brake master cylinder treated by the method meets the industrial requirements on quality such as film thickness, roughness, hardness and the like.

Owner:JIANGSU RUIER LONGDING IND CO LTD

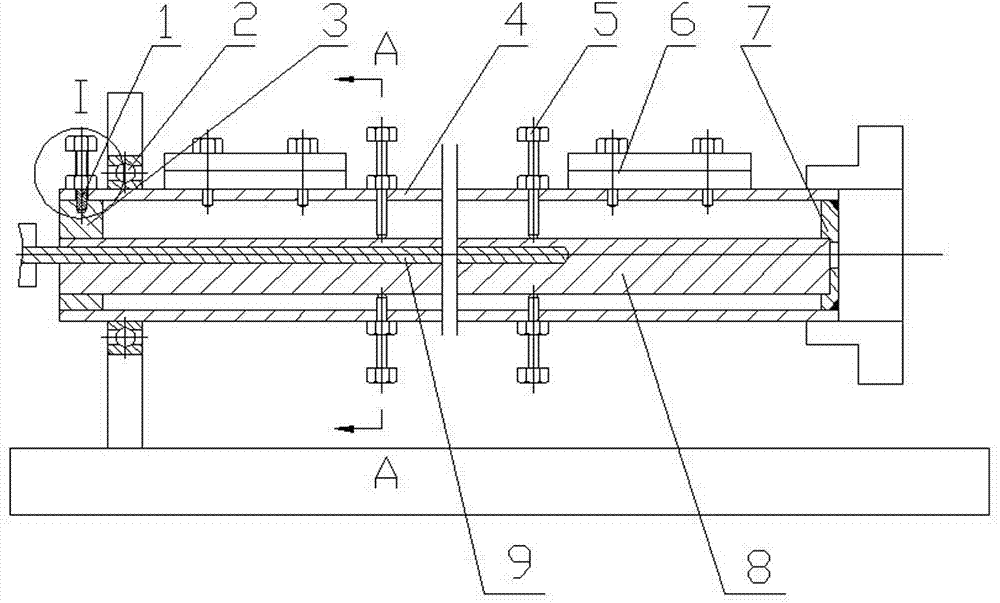

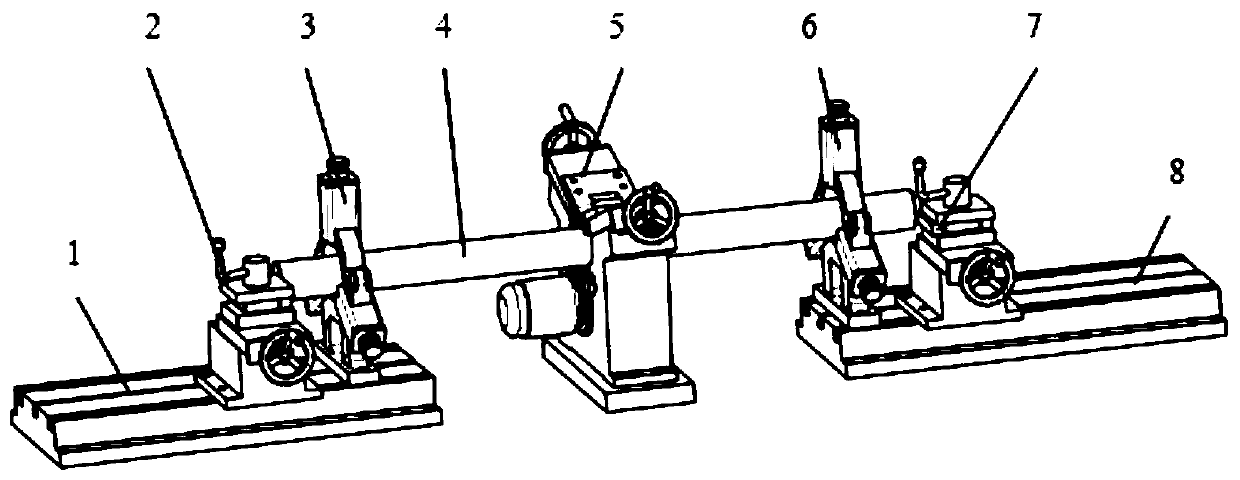

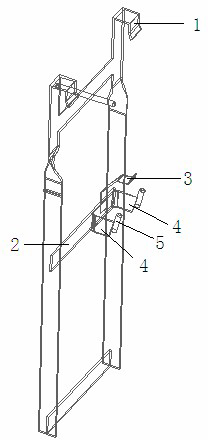

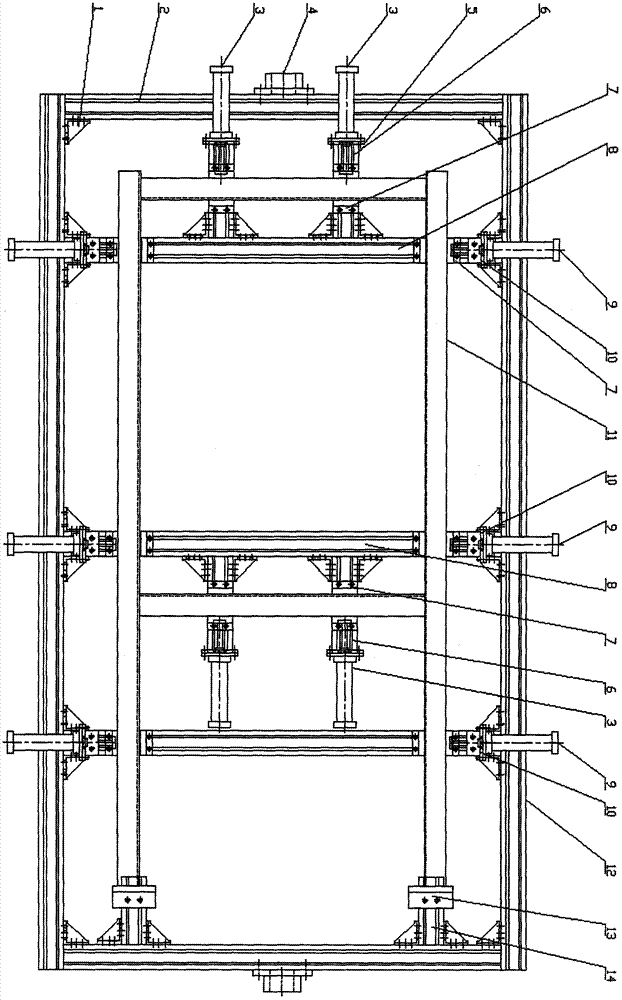

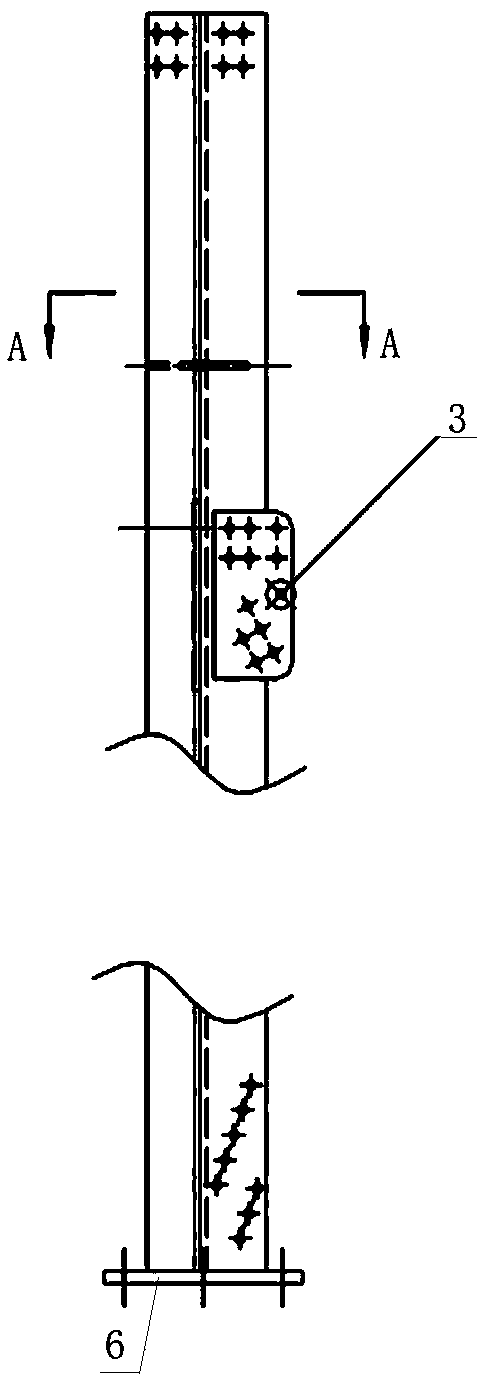

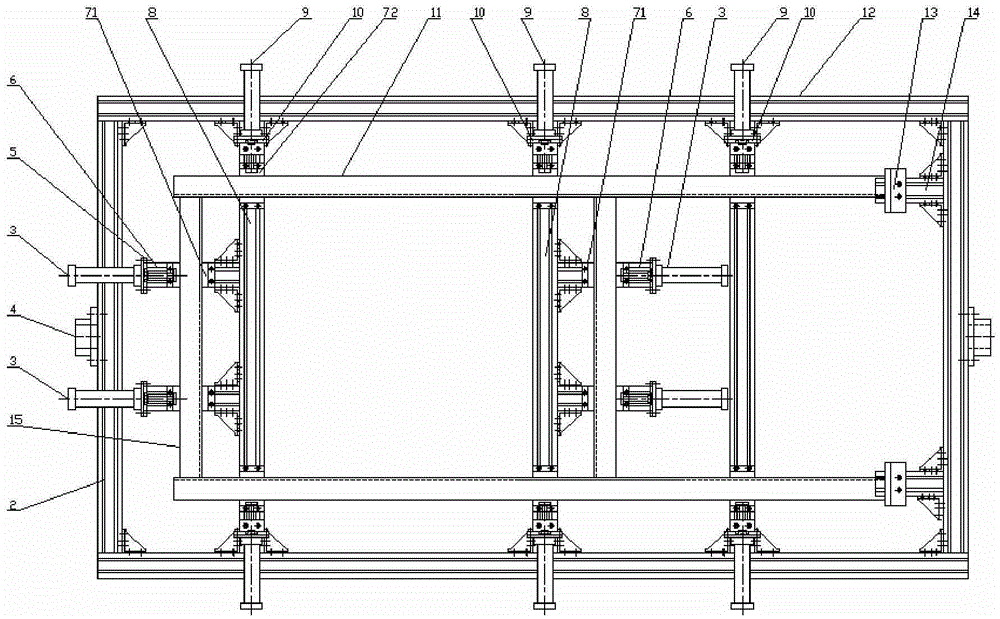

Flexible welding fixture for vehicle frame

InactiveCN106944777AEasy loading and unloading of workpiecesReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameRolling chassis

The invention relates to a flexible welding fixture for a vehicle frame, in particular to a flexible welding fixture for the vehicle frame of an agricultural mechanical chassis. The whole equipment is divided into a loading turnover mechanism, a vehicle frame beam positioning mechanism, a vehicle frame stringer positioning mechanism and a limit mechanism. When the flexible welding fixture works, positions of the vehicle frame beam positioning mechanism and the vehicle frame stringer positioning mechanism on a loading frame can be adjusted constantly, welding of the vehicle frames in various series and types can be achieved, and the flexibility is good; turnover of the fixture can be achieved to complete welding through a positioner; the flexible welding fixture for the vehicle frame has the advantages of being convenient to load and unload workpieces manually, low in labor intensity, low in manufacturing cost, convenient to operate, and high in work efficiency and can meet needs of vehicle manufacture enterprises

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

Reinforced shot blast machine for multi-position turntable

InactiveCN102248493BPrevent flying outPrevent splashAbrasive blasting machinesEngineeringLoading unloading

Owner:无锡国达机械设备有限公司

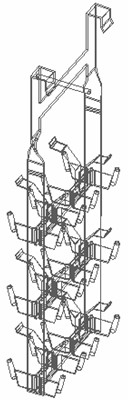

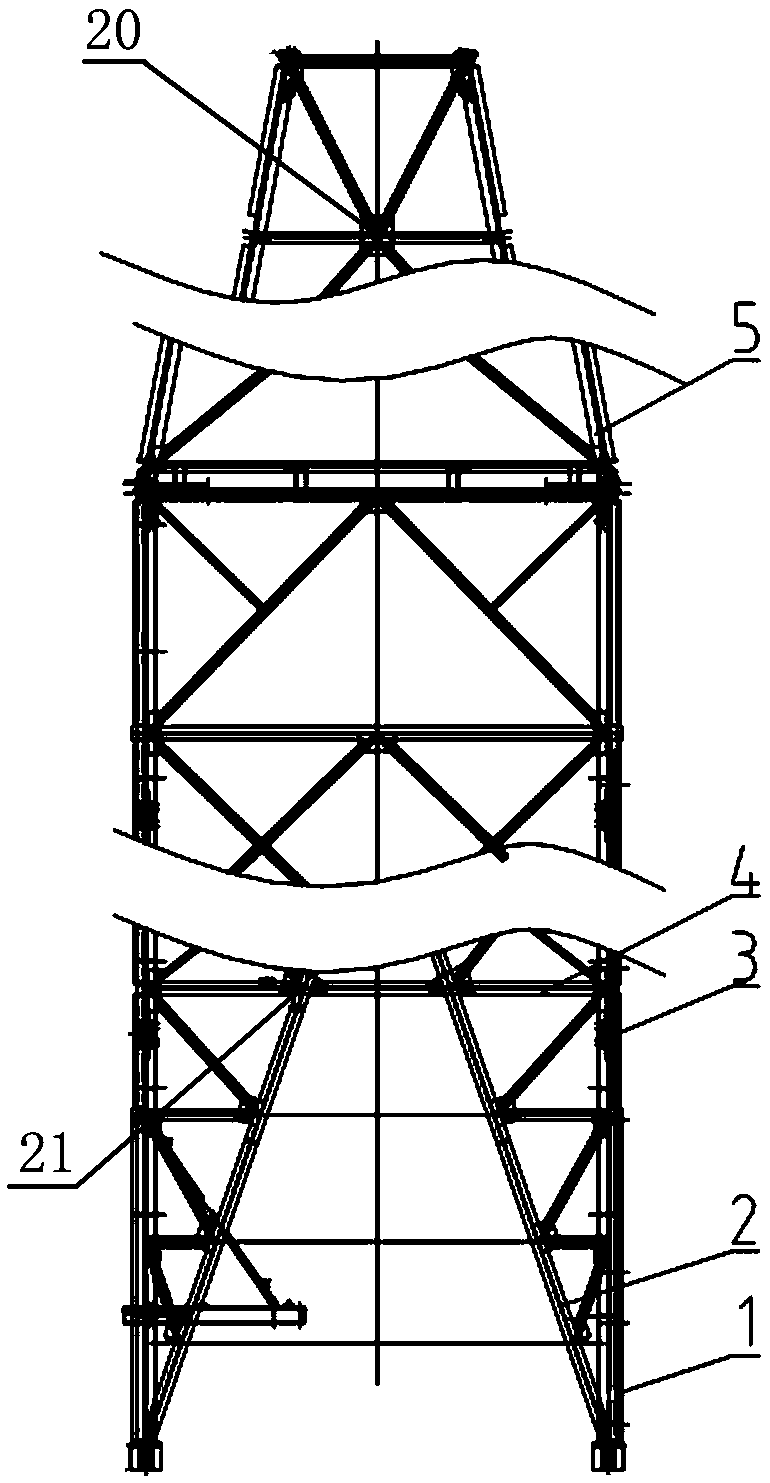

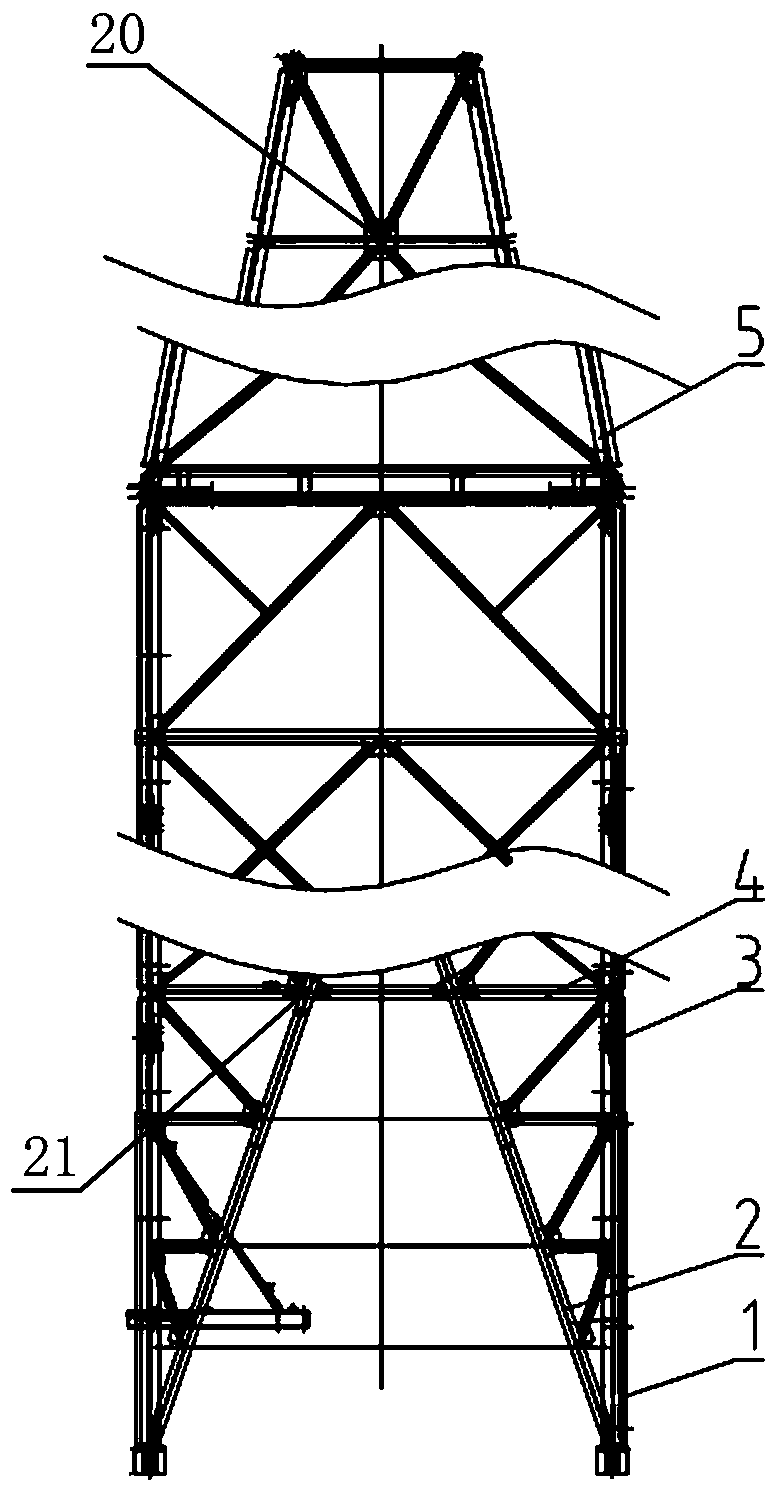

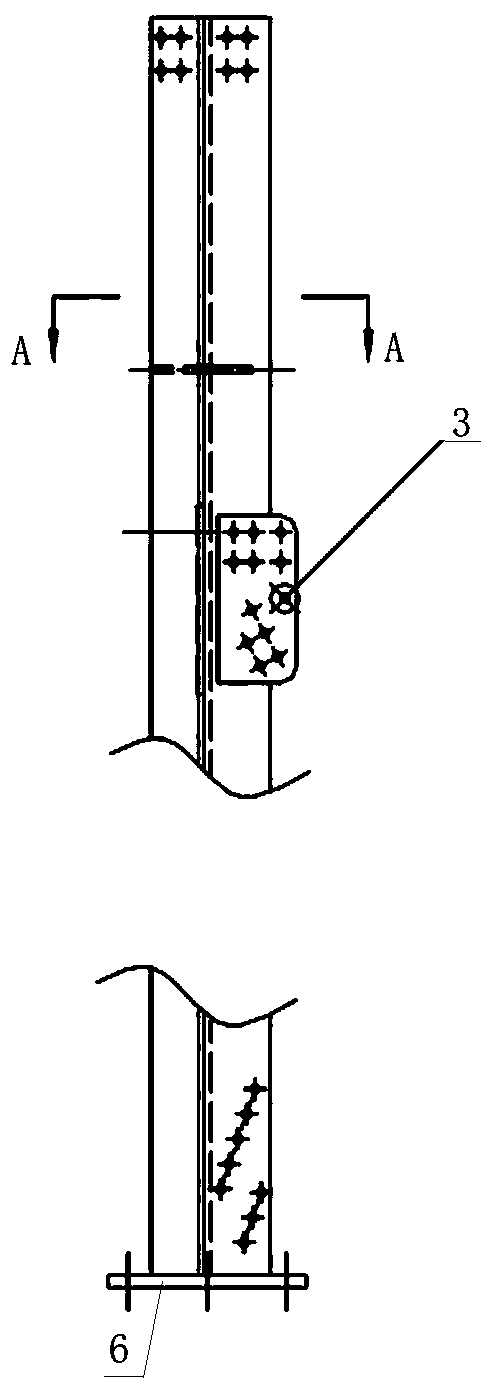

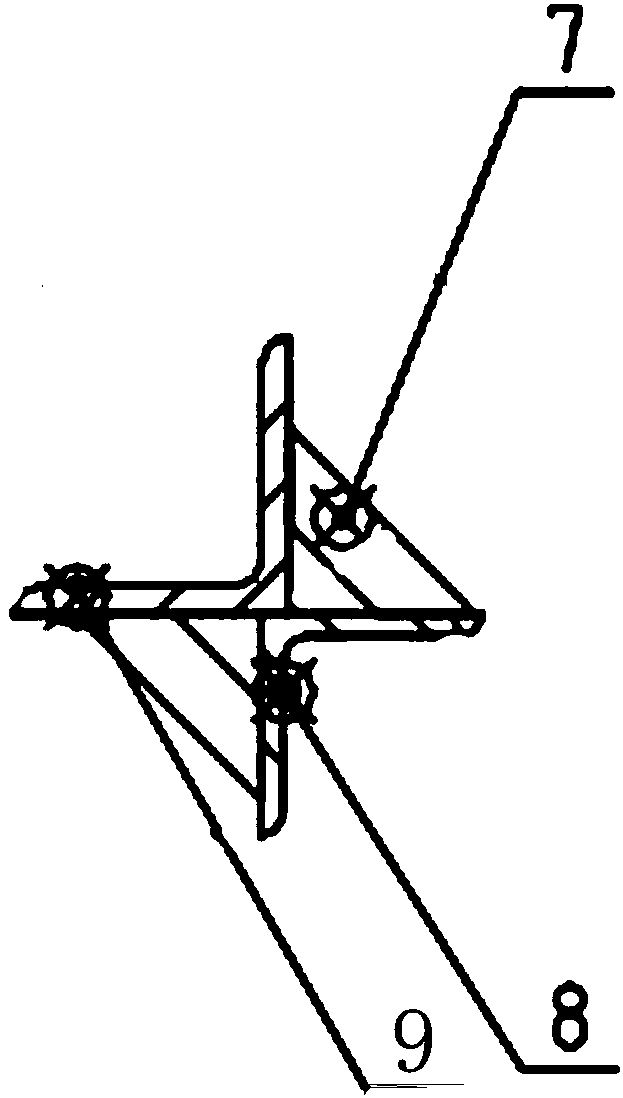

Novel ocean bottleneck type tower-shaped derrick and manufacturing method thereof

ActiveCN105370215ATotal light weightGuaranteed assembly qualityDerricks/mastsTowerUltimate tensile strength

The invention discloses a novel ocean bottleneck type tower-shaped derrick and a manufacturing method thereof. The derrick is obtained through combining, welding and manufacturing by a structural steel assembly welding tool and integral connection by bolts, the assembly welding tool enables cross splice welding structural members of upright angle iron to be located and clamped fast, advanced manufacturing and welding processes are adopted for a clamping tool, and welding and fast machining of connection devices are completed. Compared with the prior art, the derrick is purely formed by assembling and welding structural steel and is simple in structure, light in total weight, high in strength and good in rigidity; the combination quality of the derrick is guaranteed, and the problems that assembly of work-pieces is difficult, the welding quality is poor, welding deformation occurs and positioning deviation of connection holes occurs in the manufacturing process are solved.

Owner:RG PETRO MACHINERY GROUP

A marine bottleneck tower derrick and its manufacturing method

ActiveCN105370215BQuick disassemblyGuaranteed assembly qualityDerricks/mastsTowerUltimate tensile strength

The invention discloses a novel ocean bottleneck type tower-shaped derrick and a manufacturing method thereof. The derrick is obtained through combining, welding and manufacturing by a structural steel assembly welding tool and integral connection by bolts, the assembly welding tool enables cross splice welding structural members of upright angle iron to be located and clamped fast, advanced manufacturing and welding processes are adopted for a clamping tool, and welding and fast machining of connection devices are completed. Compared with the prior art, the derrick is purely formed by assembling and welding structural steel and is simple in structure, light in total weight, high in strength and good in rigidity; the combination quality of the derrick is guaranteed, and the problems that assembly of work-pieces is difficult, the welding quality is poor, welding deformation occurs and positioning deviation of connection holes occurs in the manufacturing process are solved.

Owner:RG PETRO MACHINERY GROUP

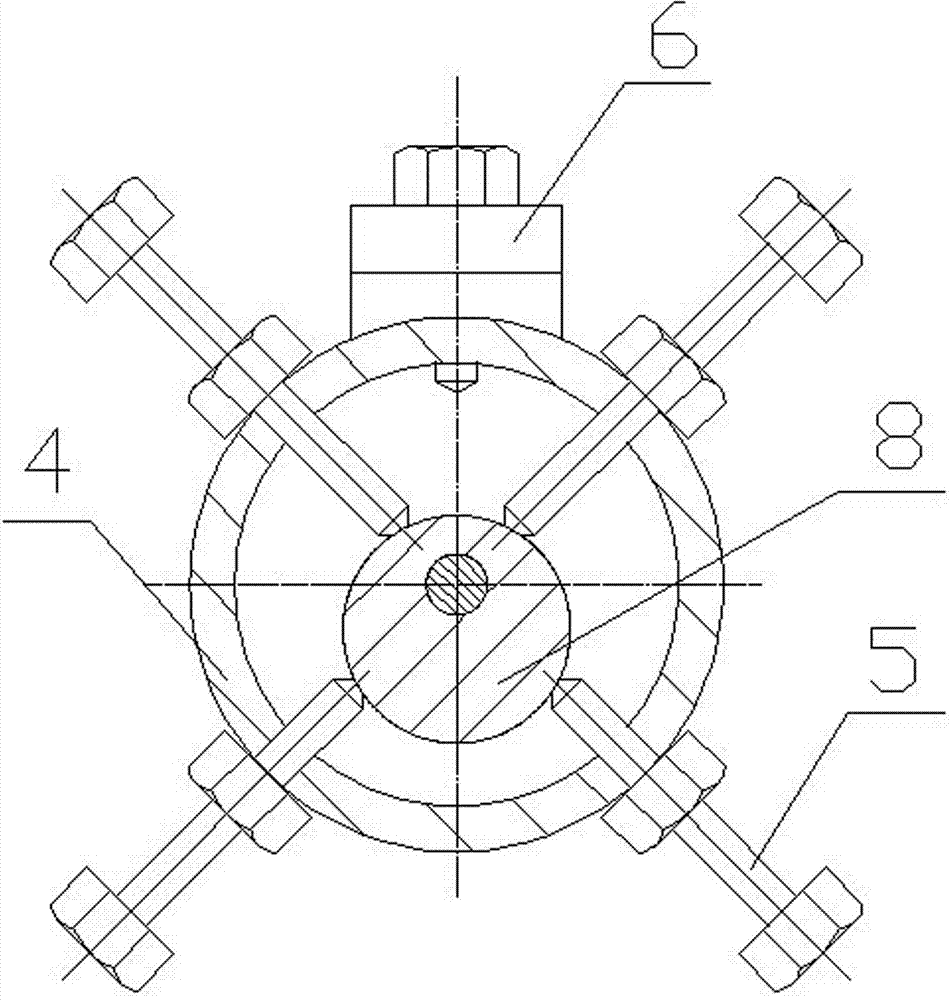

Floating clamping drive device for hobbing gear

PendingCN108044204ANo movementSimple structureGear-cutting machinesGear teethHobbingMechanical engineering

The invention relates to a floating clamping drive device for a hobbing gear. The floating clamping drive device comprises a base, a clamp body arranged on the base, a wedge-shaped clamping unit arranged in the clamp body and used for clamping a workpiece, a first tip and a second tip, wherein the first tip and the second tip which are used for abutting against the two ends of the workpiece are correspondingly arranged at the axes of the two ends of the workpiece. A cone hole is formed in the axis of the clamp body along the axis. The second tip is matched with the cone hole and is fixedly connected into the clamp body. The floating function is achieved when an oblique wedge unit is used for clamping, and the clamping and positioning interference in the clamping process are lowered effectively. Compared with the prior art, the floating clamping drive device has the beneficial effects of being high in product clamping accuracy, reliable in clamping effect and capable of being suitable for automatic feeding and discharging.

Owner:上海格尔汽车科技发展有限公司

Method for oxidizing brake master cylinder

The invention discloses a method for oxidizing a brake master cylinder, which comprises the following steps of: 1, hanging, namely hanging the brake master cylinder to a rack special for oxidizing the brake master cylinder; 2, performing weak acid oil removal treatment; 3, preparing anode oxidizing tank liquor; 4, performing anode oxidization treatment; and 5, taking out the brake master cylinder, cleaning, and performing enclosed drying treatment. The brake master cylinder treated by the method meets the industrial requirements on quality such as film thickness, roughness, hardness and the like.

Owner:JIANGSU RUIER LONGDING IND CO LTD

A flexible robot welding tool for the chassis frame of a corn harvester

InactiveCN104043936BEasy loading and unloading of workpiecesReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringUltimate tensile strength

The invention relates to a welding tool for a chassis frame of a maize harvesting machine, in particular to a flexible robot welding tool for the chassis frame of the maize harvesting machine. The flexible robot welding tool for the chassis frame of the maize harvesting machine is low in machining and manufacturing cost and convenient to clamp, labor intensity of workers is low, the locating precision of transverse beams and longitudinal beams of the frame can be guaranteed, welding deformation can be reduced, flexibility is good, interference cannot be generated during welding after overturn, and a front face and a back face can be welded on one tool through one-time locating. The flexible robot welding tool for the chassis frame of the maize harvesting machine has the advantages that the workers can load and unload workpieces conveniently, and labor intensity is low; the position of a frame transverse beam locating mechanism and the position of a frame longitudinal beam locating mechanism on a bearing frame can be adjusted continuously, welding of frames of different series and different types can be achieved, and flexibility is good; overturn of the tool can be achieved through a welding positioner, and robot welding is achieved; the machining and manufacturing cost is low, operation is convenient, working efficiency is improved, and needs of enterprises are met.

Owner:CHINA AGRI UNIV

Hydraulic experiment device for three-way piece group and the method thereof

ActiveCN100498263CEasy loading and unloading of workpiecesReduce labor intensityMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumHydraulic pumpEngineering

The invention relates to a three-way element group hydraulic test device and a relative method, wherein upper and lower ends of a left side plate and a right side plate are respectively fixed with an upper lift plate and a bottom plate, the bottom plate is arranged with a track, while a sliding block can move along the bottom plate. A plurality of screw lift rod groups connect two screw lift rods in preset distance with the upper top plate and the bottom plate via screws, a T-type screw lift rod is connected with the right side plate via screw. The three-way group is clamped and positioned via rolling a rolling wheel and rotating screw lift rod. And the test method comprises that adjusting the height of the screw lift rods on the bottom plate, according to the size of the three-way element, arranging the grouped three-way element on the screw lift rods, using the screw lift rods on the upper lift plate to press the three-way element, using the T-type screw lift rod on the right side plate to clamp the three-way element after finding the position of the three-way element, using a hydraulic pump to increase pressure via preset pressure to process test. The invention has the advantages that the invention can process group hydraulic test of the three-way element in final product state, with simple detachment and installment of work-piece, reduced labor strength, shortened period and saved material.

Owner:中国船舶集团渤海造船有限公司

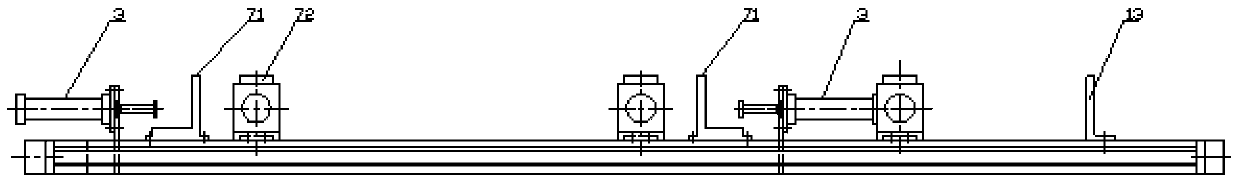

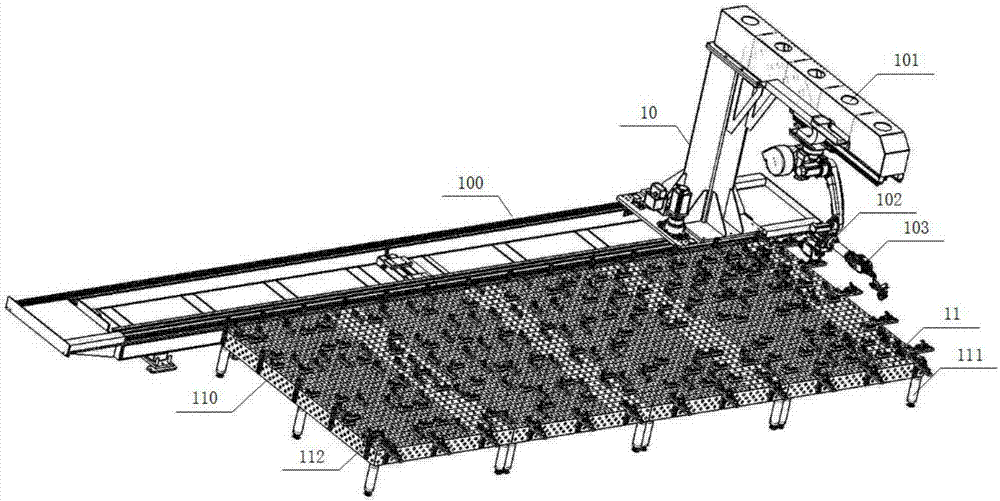

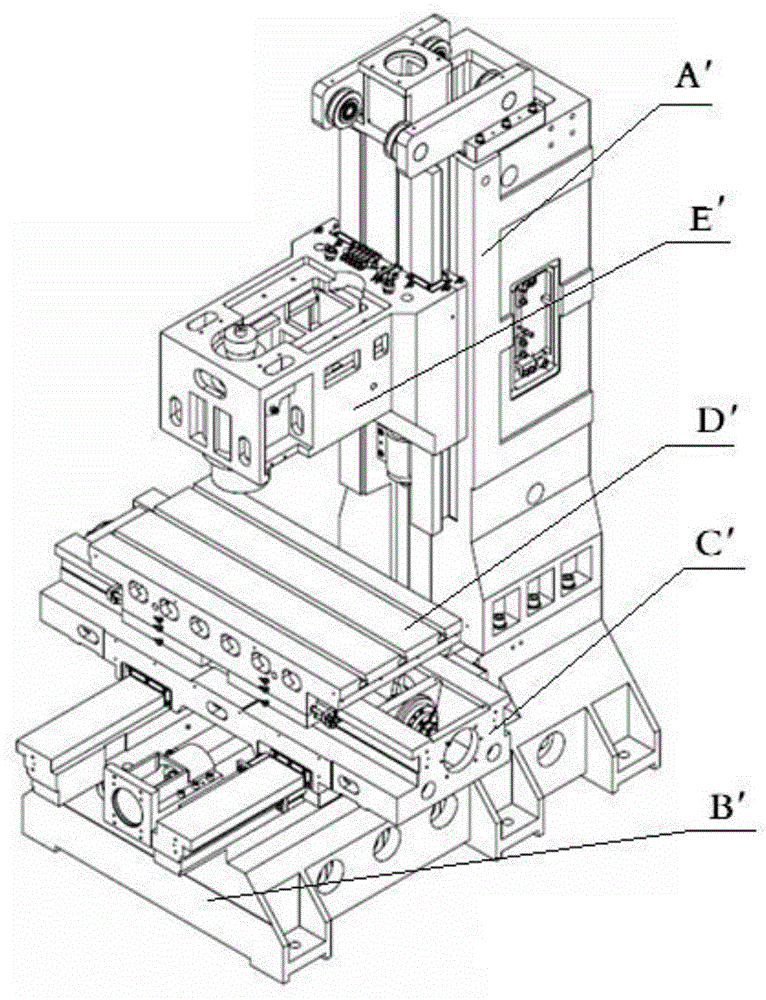

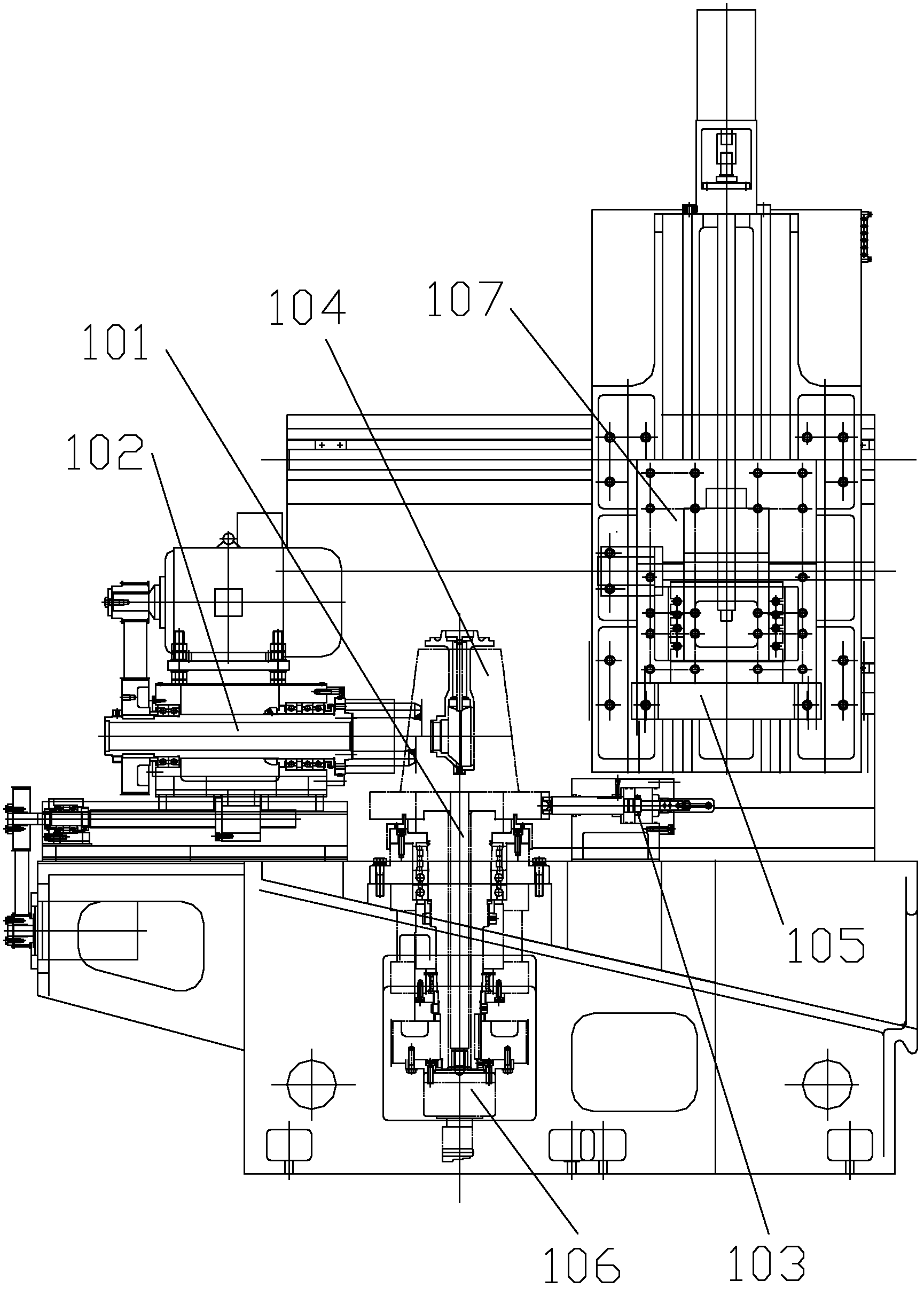

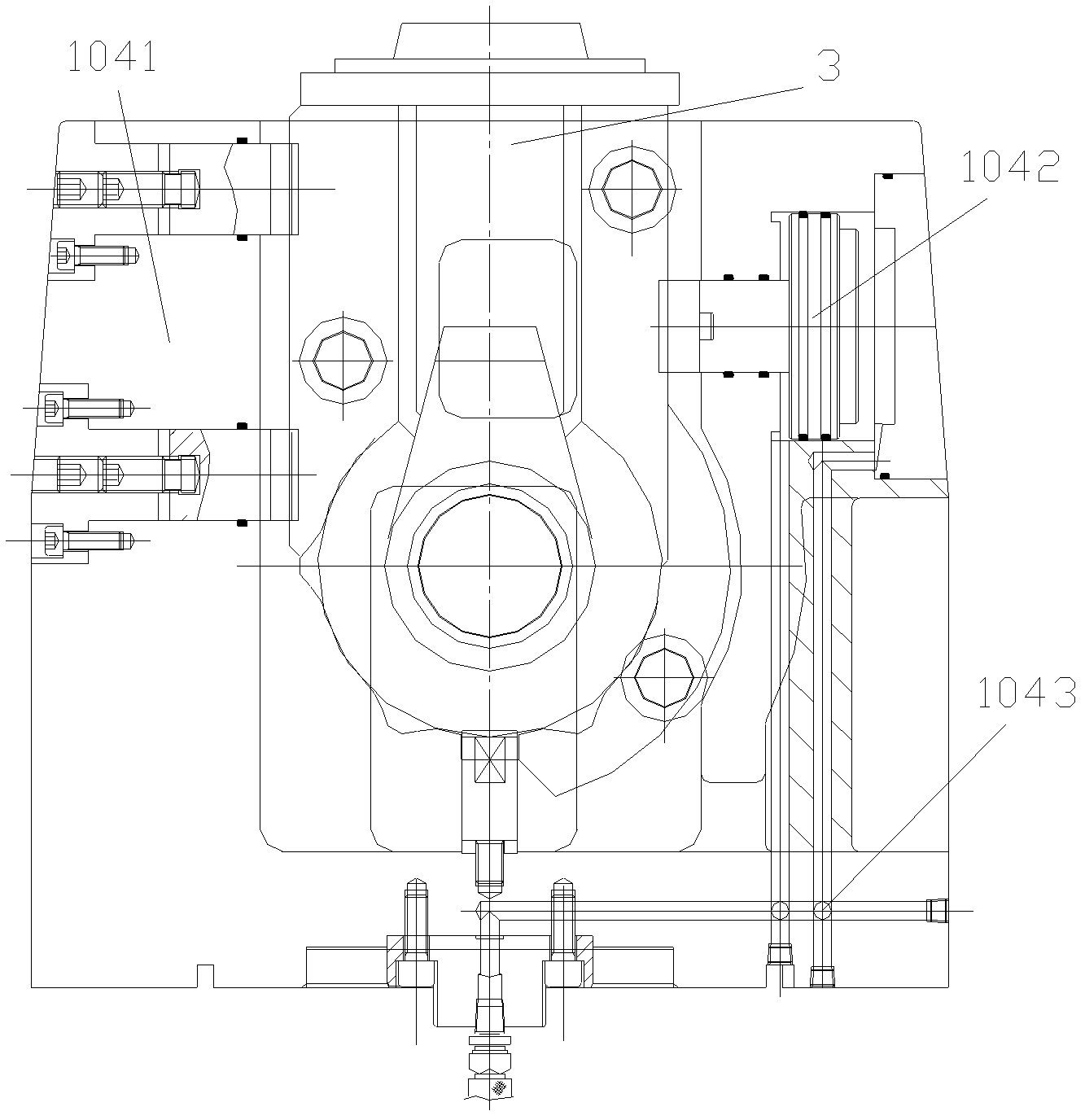

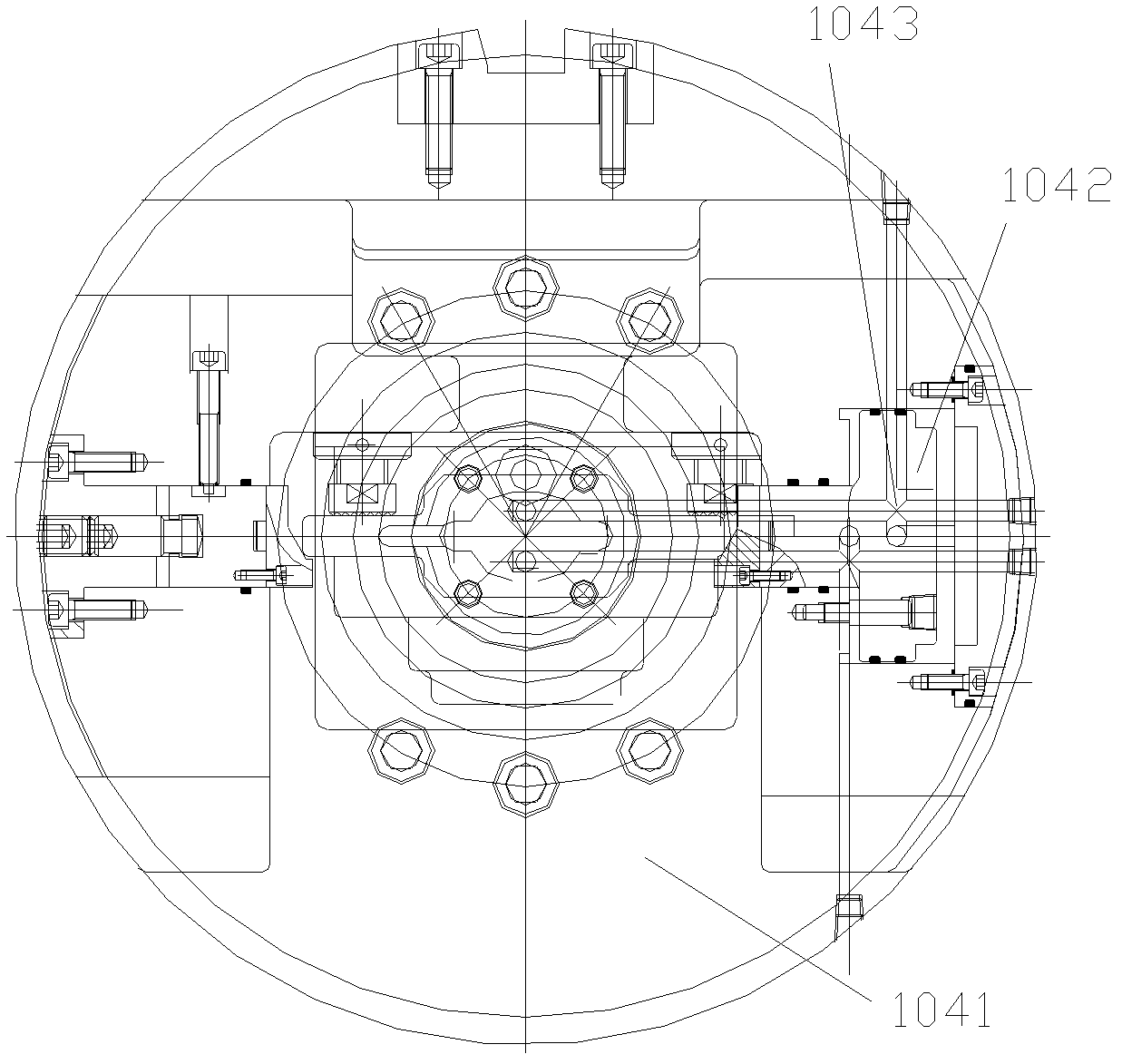

Numerical control product line of agricultural mini-tiller walking box

ActiveCN103381551AHigh indexing accuracyHigh positioning accuracyPrecision positioning equipmentOther manufacturing equipments/toolsProduction lineNumerical control

A numerical control product line of an agricultural mini-tiller walking box is formed by sequential arrangement of two parts together, namely, a three coordinate perpendicular double main shafts numerical control lathe and a rotatable combined machine tool, wherein firstly, the three coordinate perpendicular double main shafts numerical control lathe comprises a first main shaft (101), a second main shaft (102), a main shaft locking device (103), a dedicated hydraulic fixture (104), a turret (105), an oil-distribution system (106), a two coordinate universal driving shaft (107), and a machine tool body; secondly, the rotatable combined machine tool is specific a six station rotatable combined machine tool comprising a combined machine tool body (201), a positioning seat (202), a drill hole power head (203), a tapping power head (204), and a hydraulic overturn clamp (205). According to the invention, the process route is obviously shortened, the situation that several processes are combined to one is realized, each standard precision of one-time clamping is extremely high, the whole line is shorted more than 60 % than an original product line, the pitch time is shortened more than 50 %, and the product qualified rate is improved more than 20 %.

Owner:沈阳盛京精益数控机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com