Compound vertical-type milling machine

A vertical milling machine and duplex technology, applied in the direction of milling machines, milling machine equipment, large fixed members, etc., can solve problems such as insufficient rigidity, inability to choose the best working height, and unstable processing quality, so as to shorten the empty travel distance and improve the machine tool function. Humanized, easy-to-digital control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

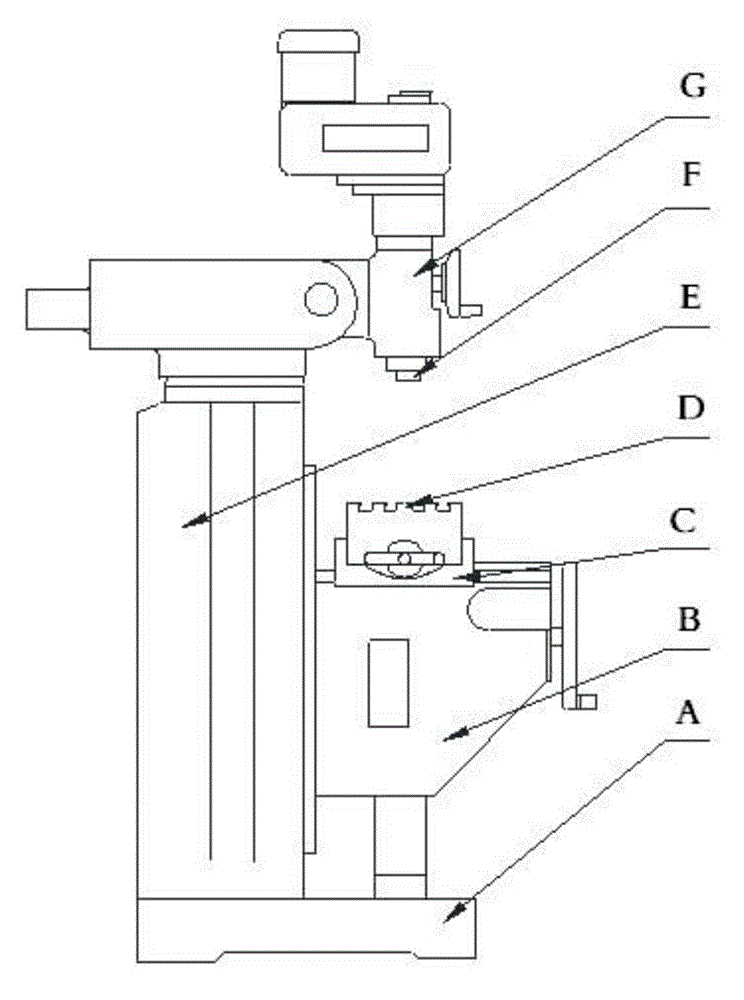

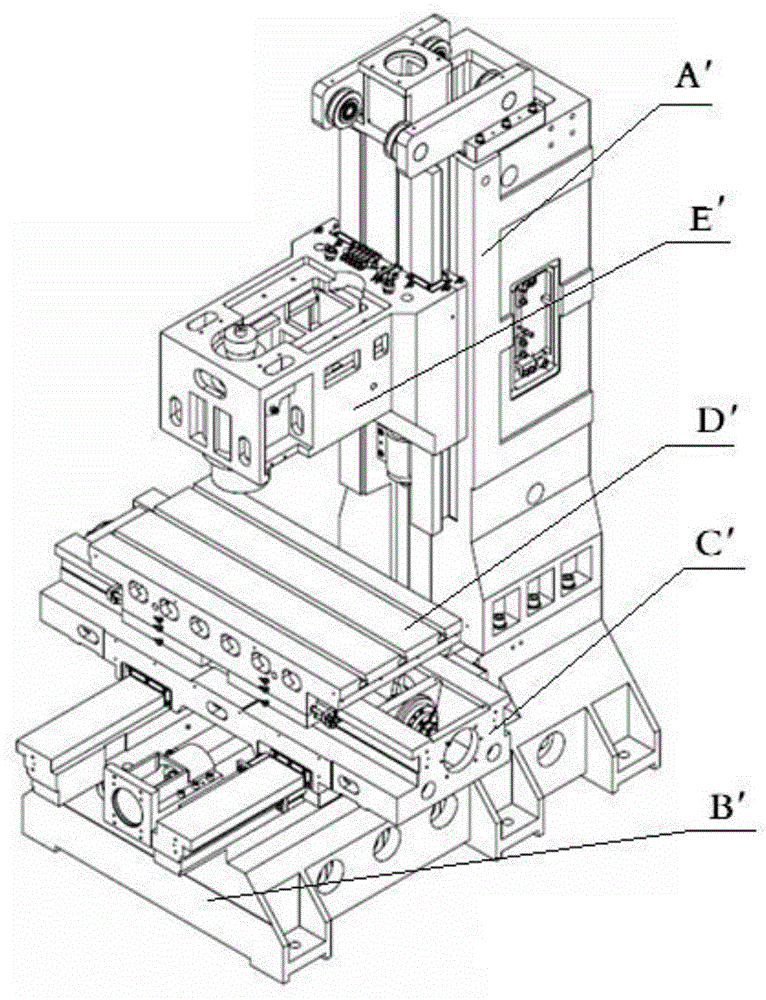

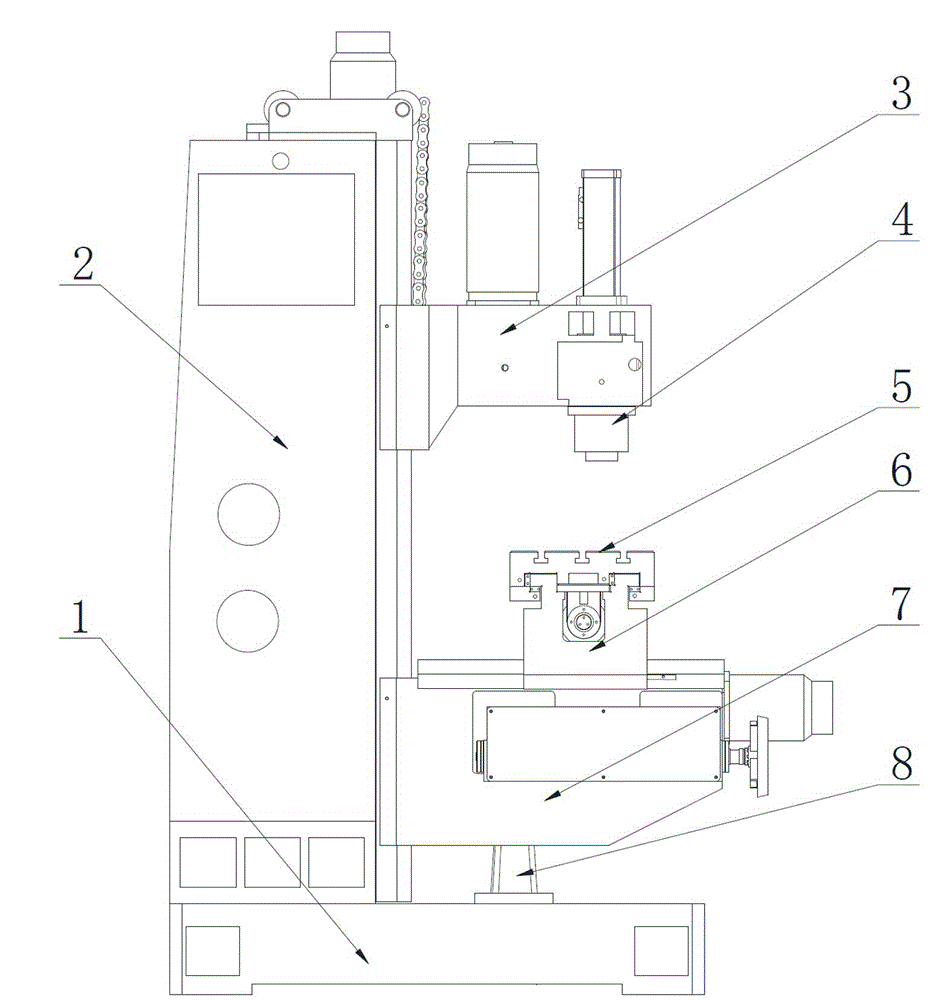

[0011] Such as image 3 Shown, the present invention mainly is made up of base 1, column 2, main shaft box 3, main shaft 4, workbench 5, sliding saddle 6, lifting table 7, screw mandrel nut pair 8, control system. The column 2 is fixedly installed on the base 1 of the machine tool. The workbench 5 is fitted on the guide rail of the saddle 6 and can reciprocate laterally (X direction) along the saddle. The saddle 6 is fitted on the guide rail of the lifting platform 7 and can reciprocate longitudinally (Y direction) along the lifting platform. The inner side of the lifting platform 7 is connected to the column 2 through the column guide rail, and the bottom is supported on the base 1 through the screw nut pair 8, and the height (Z direction) position of the lifting platform can be adjusted through the screw. The main shaft 4 is installed in the spindle box 3 to form the milling head part, and the inner side of the whole milling head part is fitted on the column guide rail and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com