Patents

Literature

80results about How to "Increase working speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

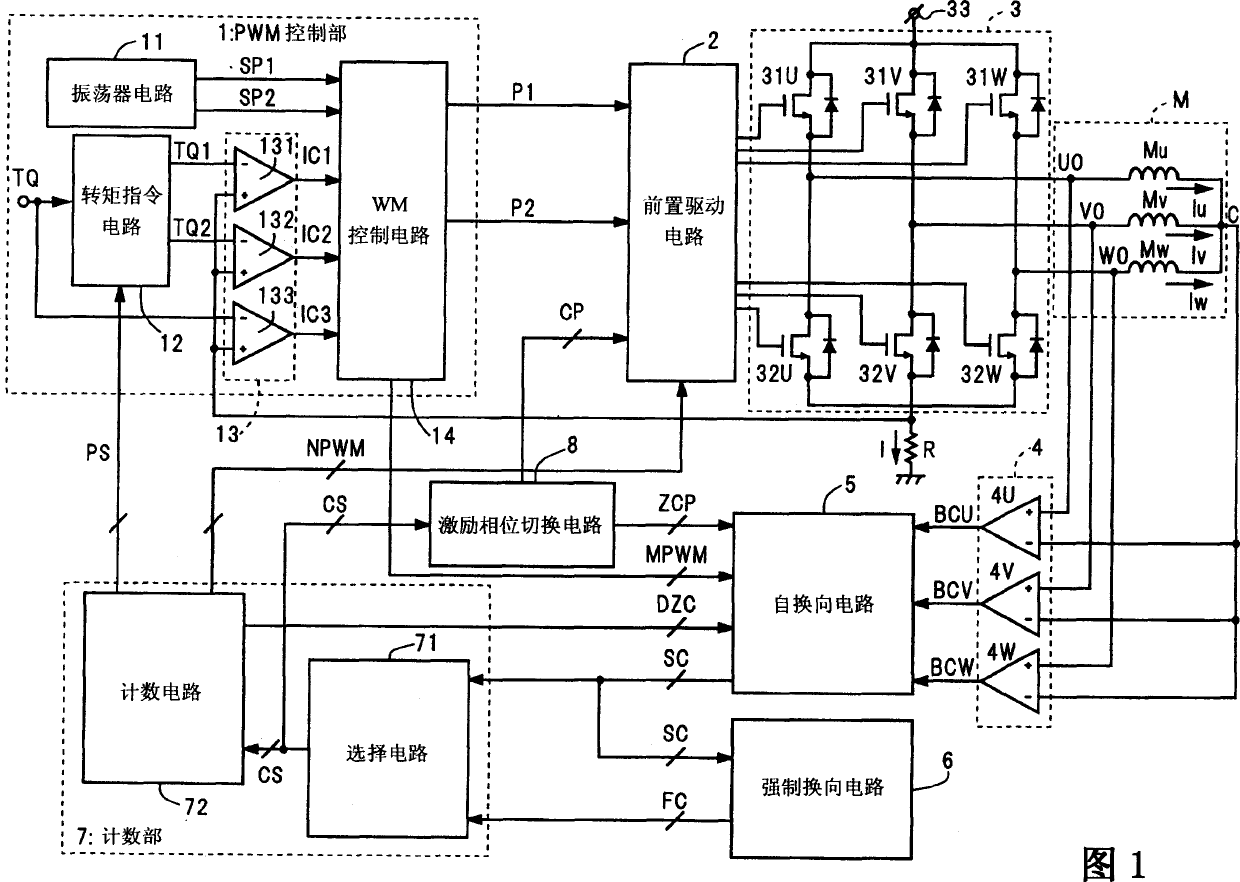

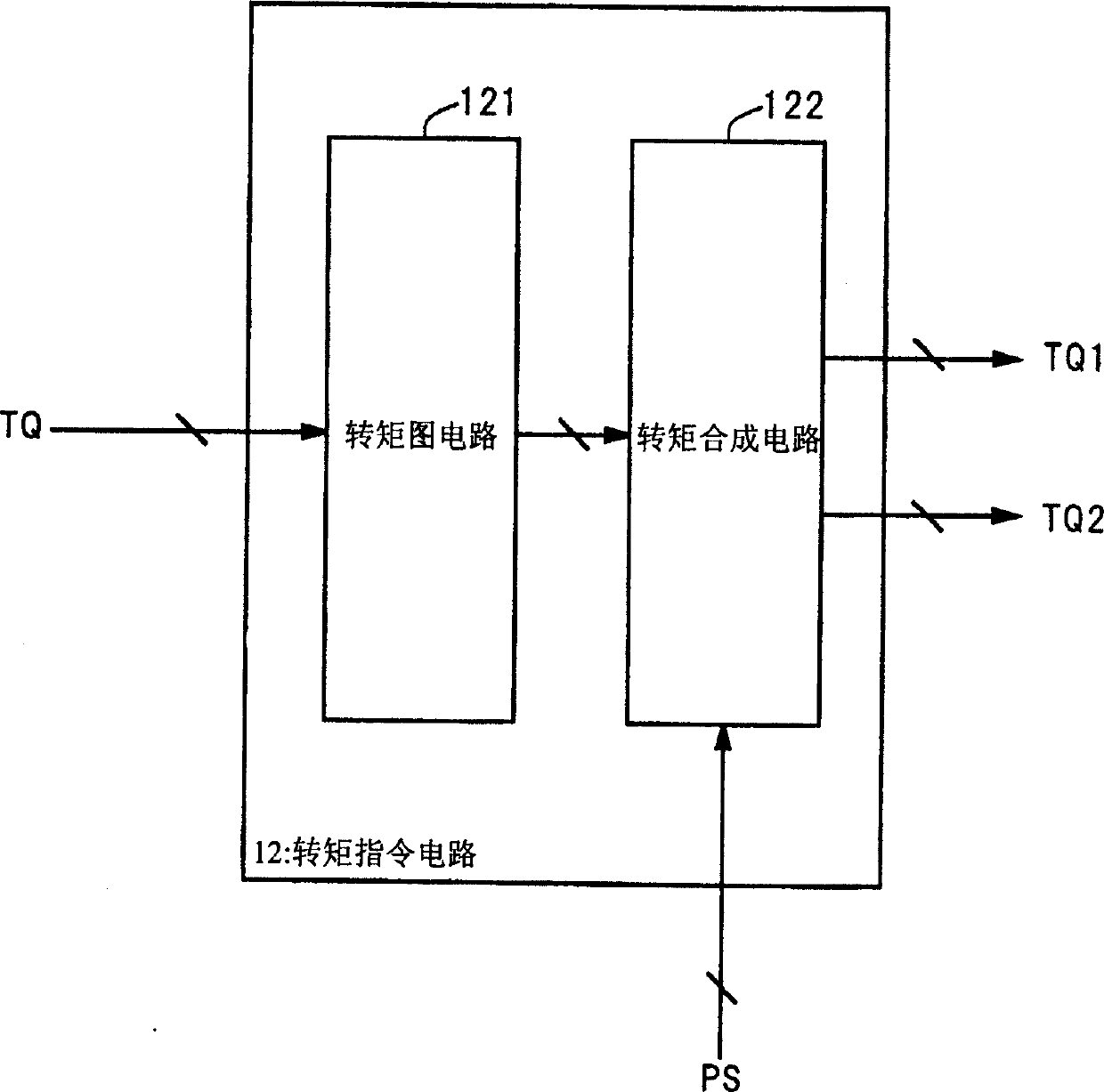

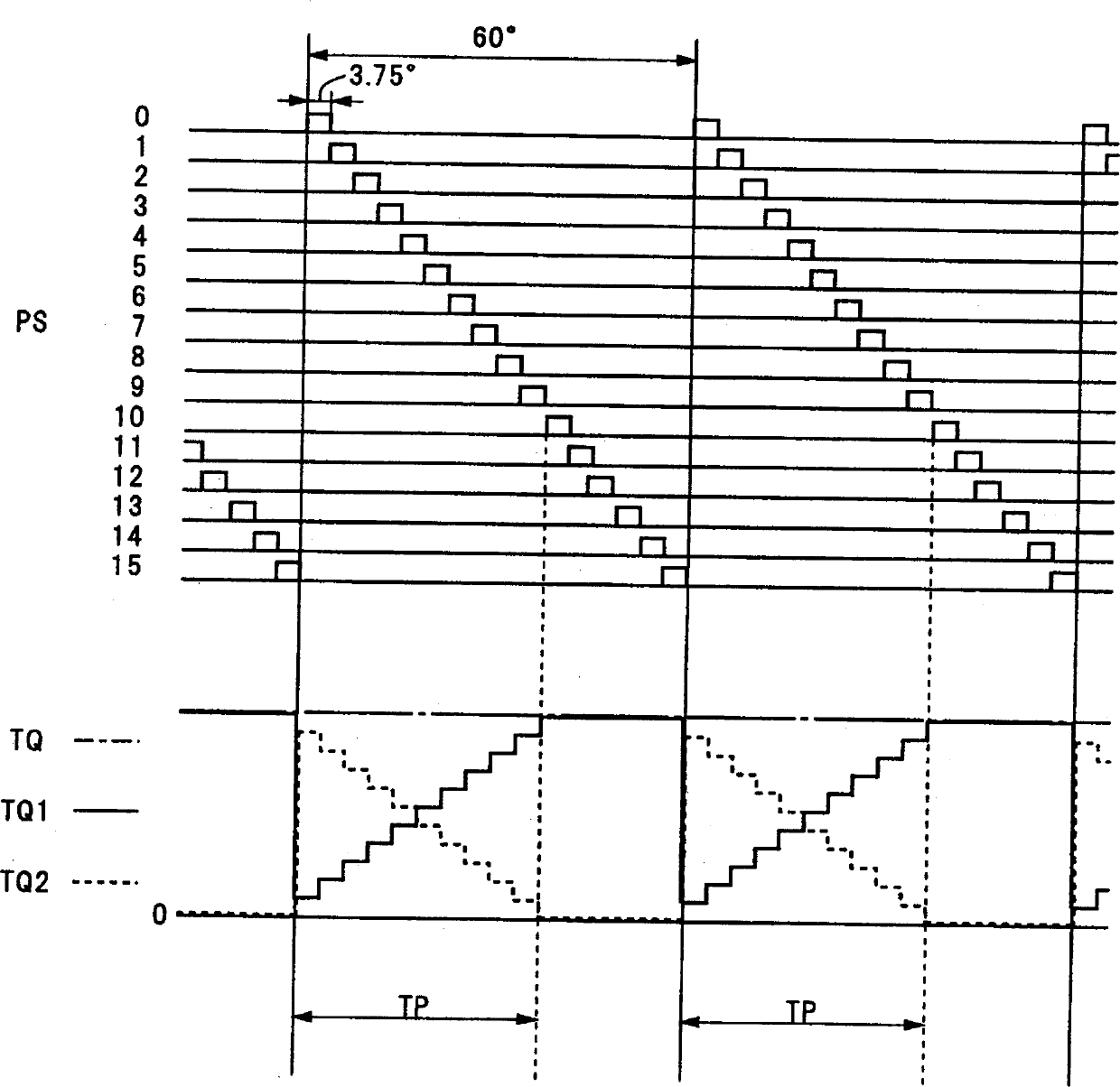

Sensorless motor driving device and its driving method

InactiveCN1578104AEnsure non-stimulus periodIncrease torqueAC motor controlDC motor speed/torque controlPhase currentsMotor drive

Sensorless motor driving device and its driving method. A PWM control section (1) gently changes phase currents (Iu, Iv, and Iw) under a current driving control over a pre-drive circuit (2) and an output circuit (3). The pre-drive circuit (2) suspends energizing of the specific motor coil (Mu, Mv, and Mw) according to a PWM disable signal (NPWM) at PWM disable periods. A self-commutation circuit (5) performs zero crossing detection according to a BEMF detection signal (DZC) during BEMF detection periods. A count section (7) selects either a self-commutation signal (SC) or a forced commutation signal (FC) as a commutation signal (CS), whichever enters earlier, and, based on its intervals, generates the PWM disable signal (NPWM) and the BEMF detection signal (DZC). The BEMF detection period starts after the start of the PWM disable period, and finishes together with the PWM disable period at the switching of the energization phases.

Owner:コラボイノベーションズインコーポレイテッド

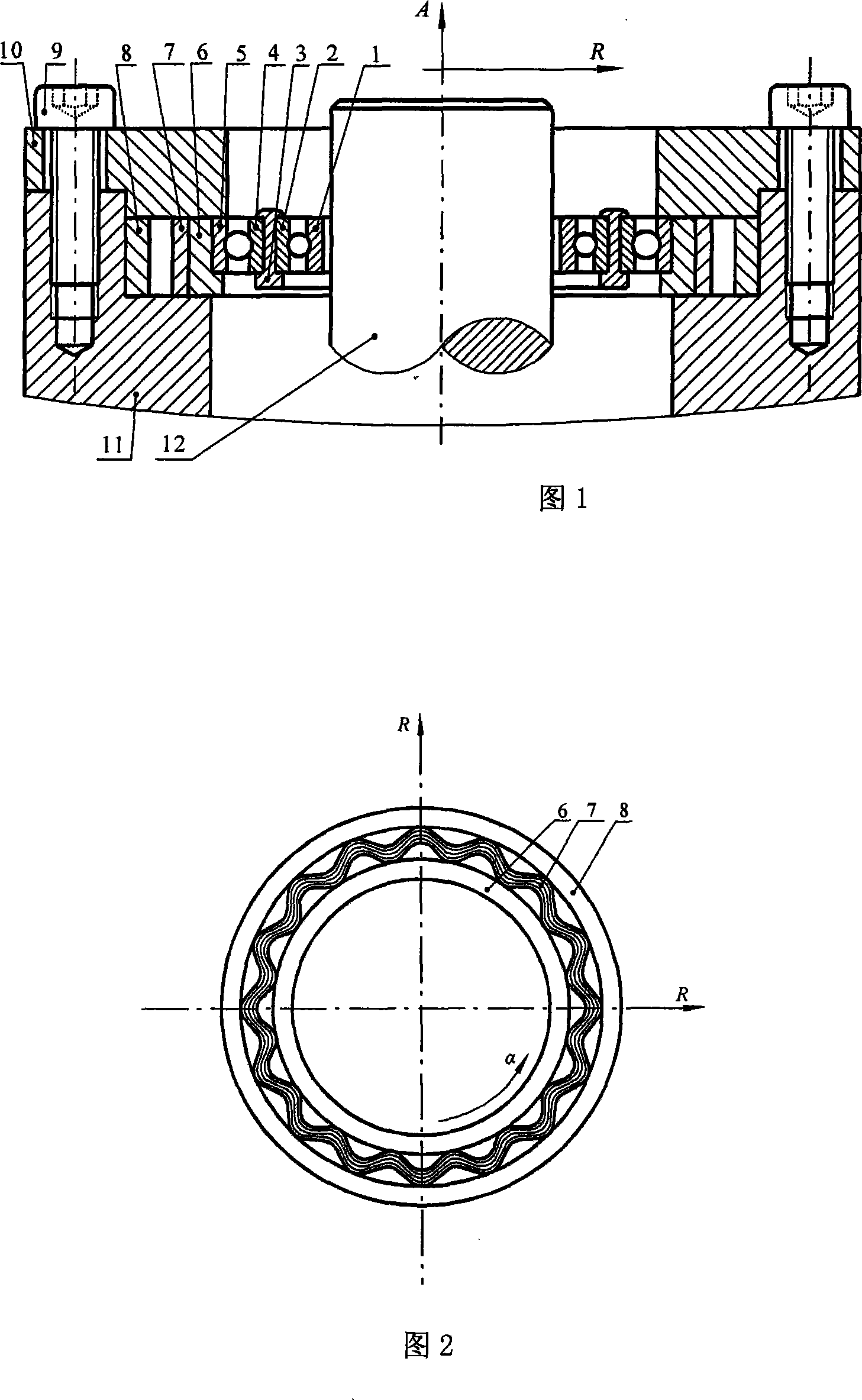

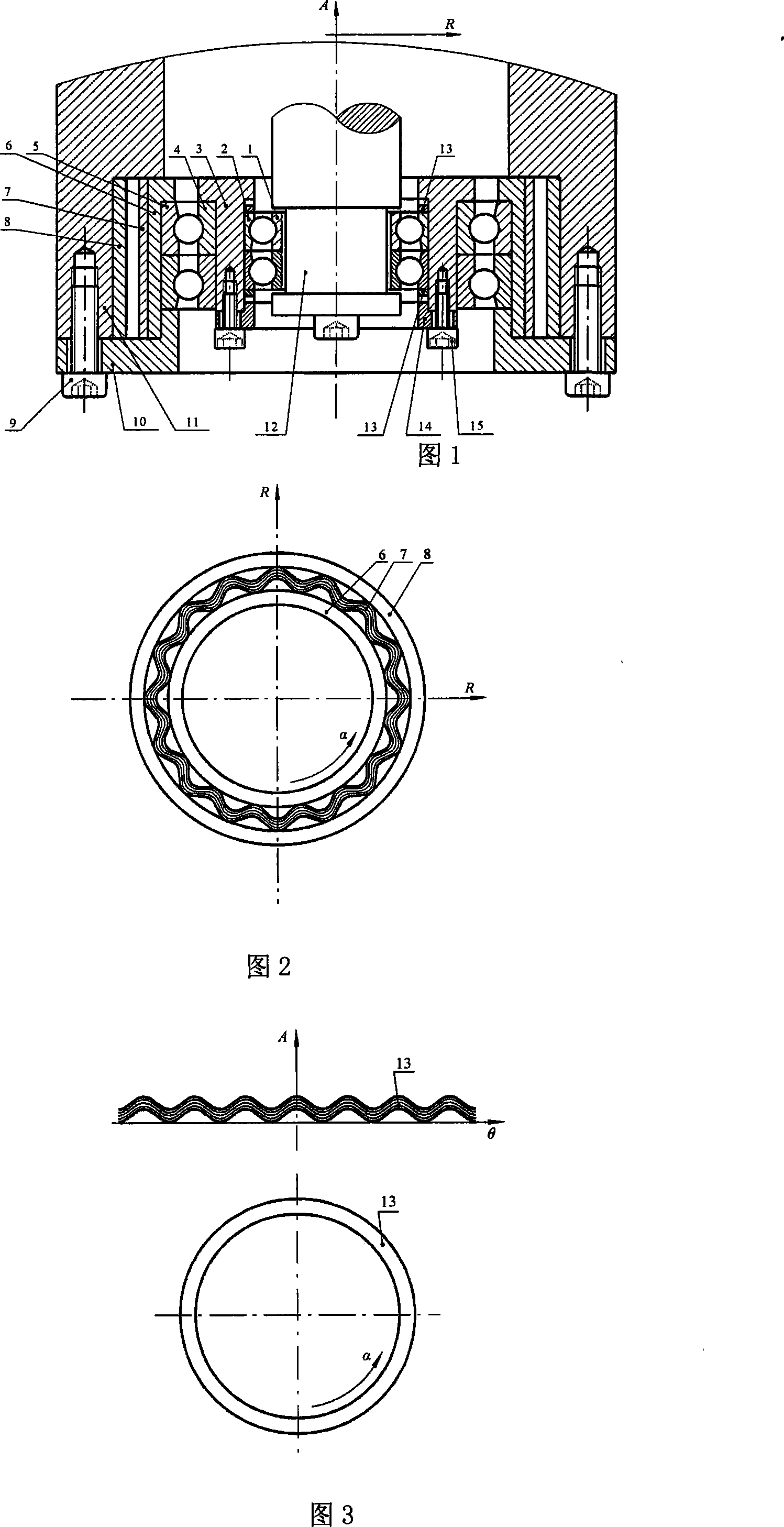

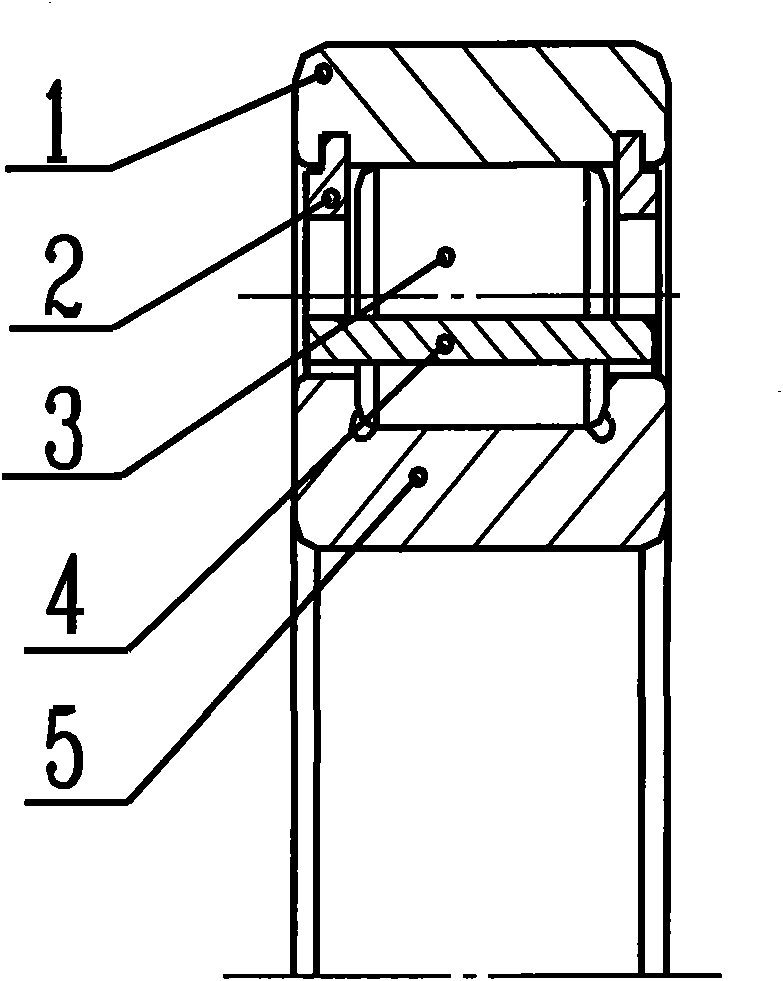

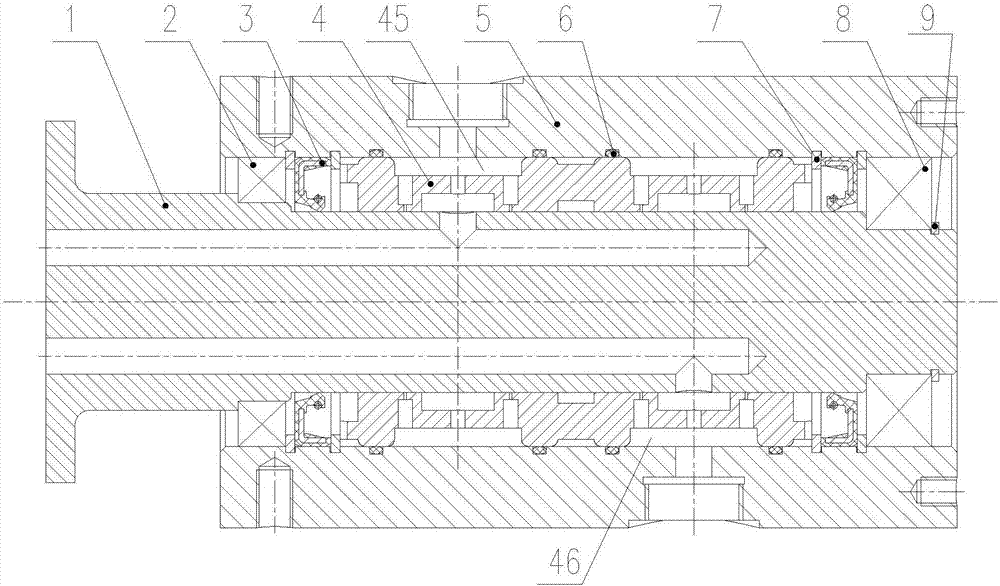

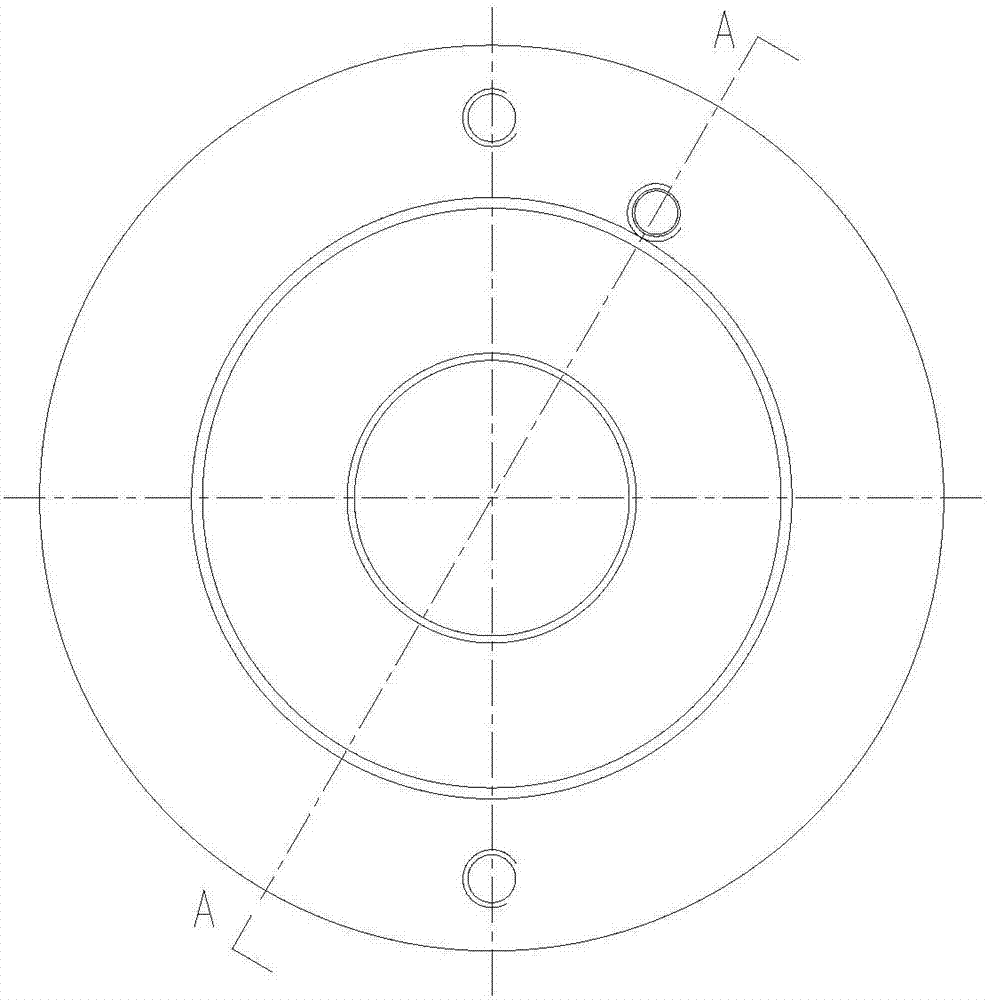

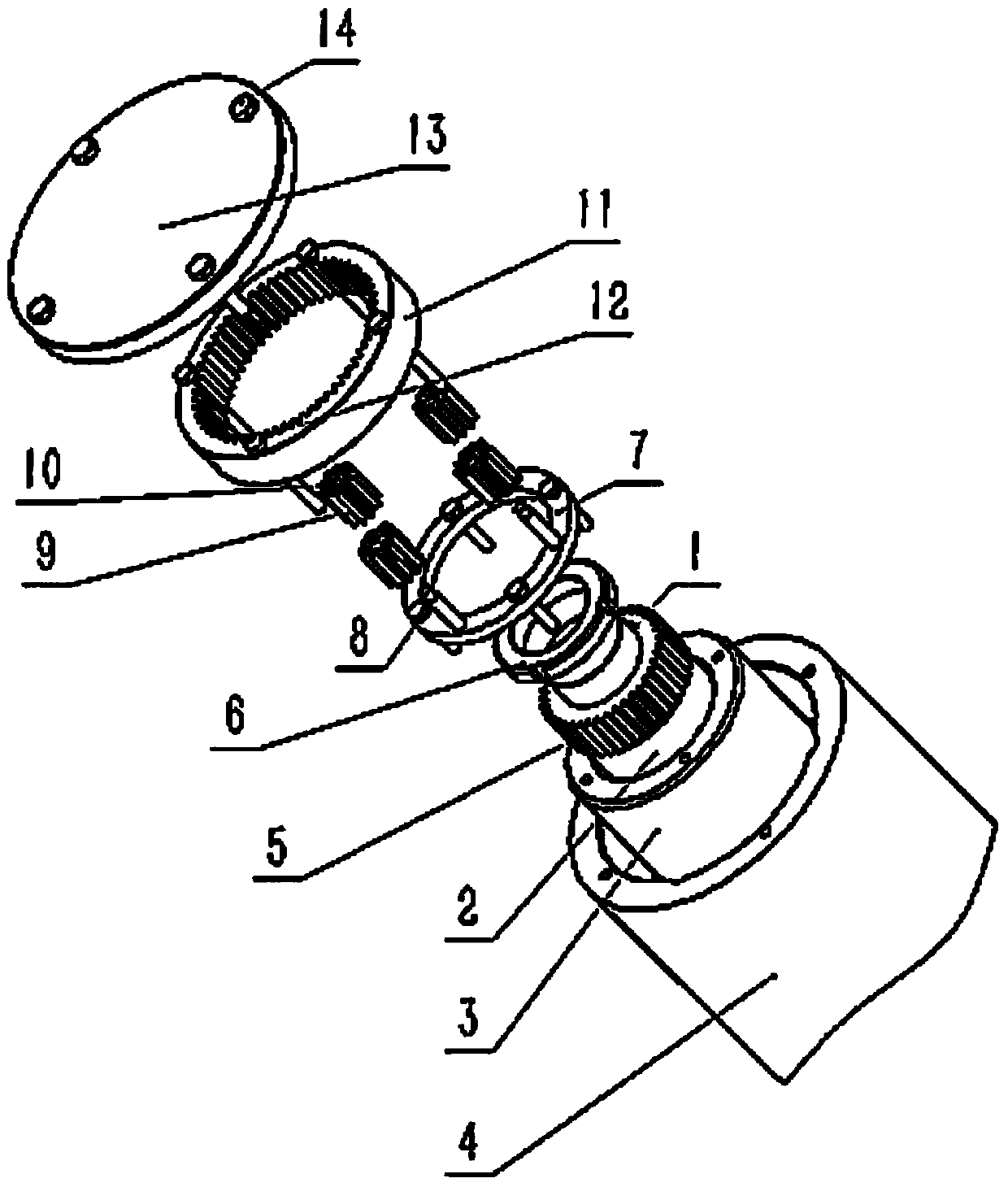

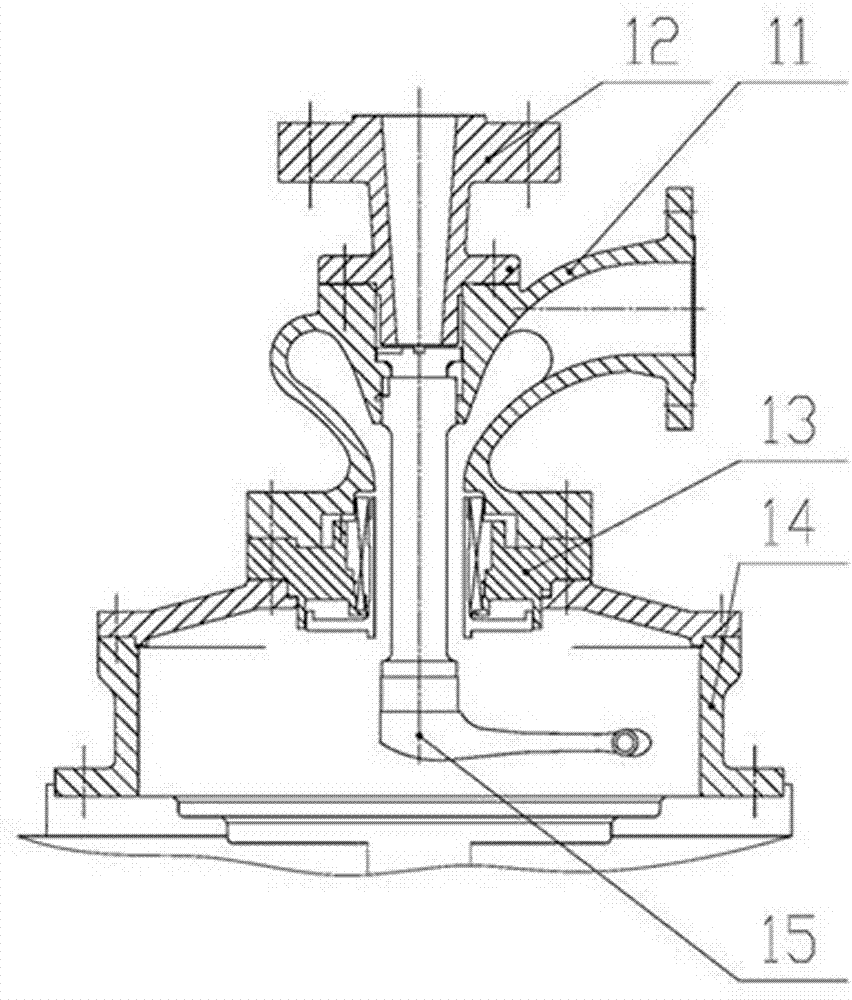

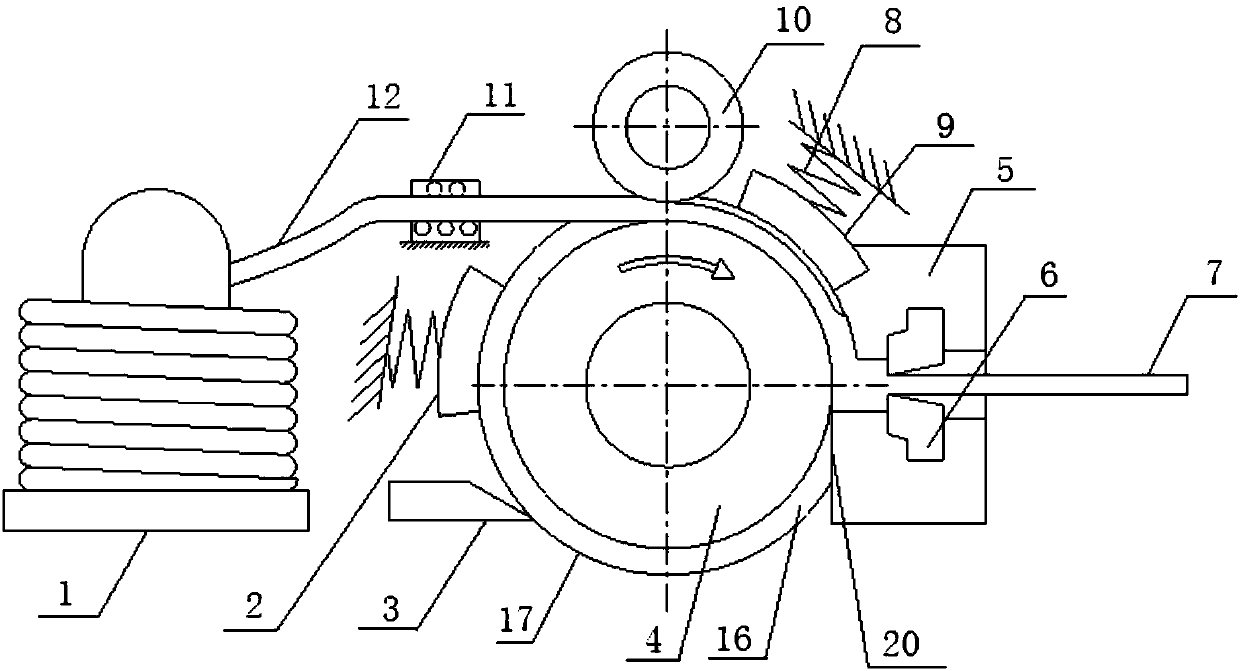

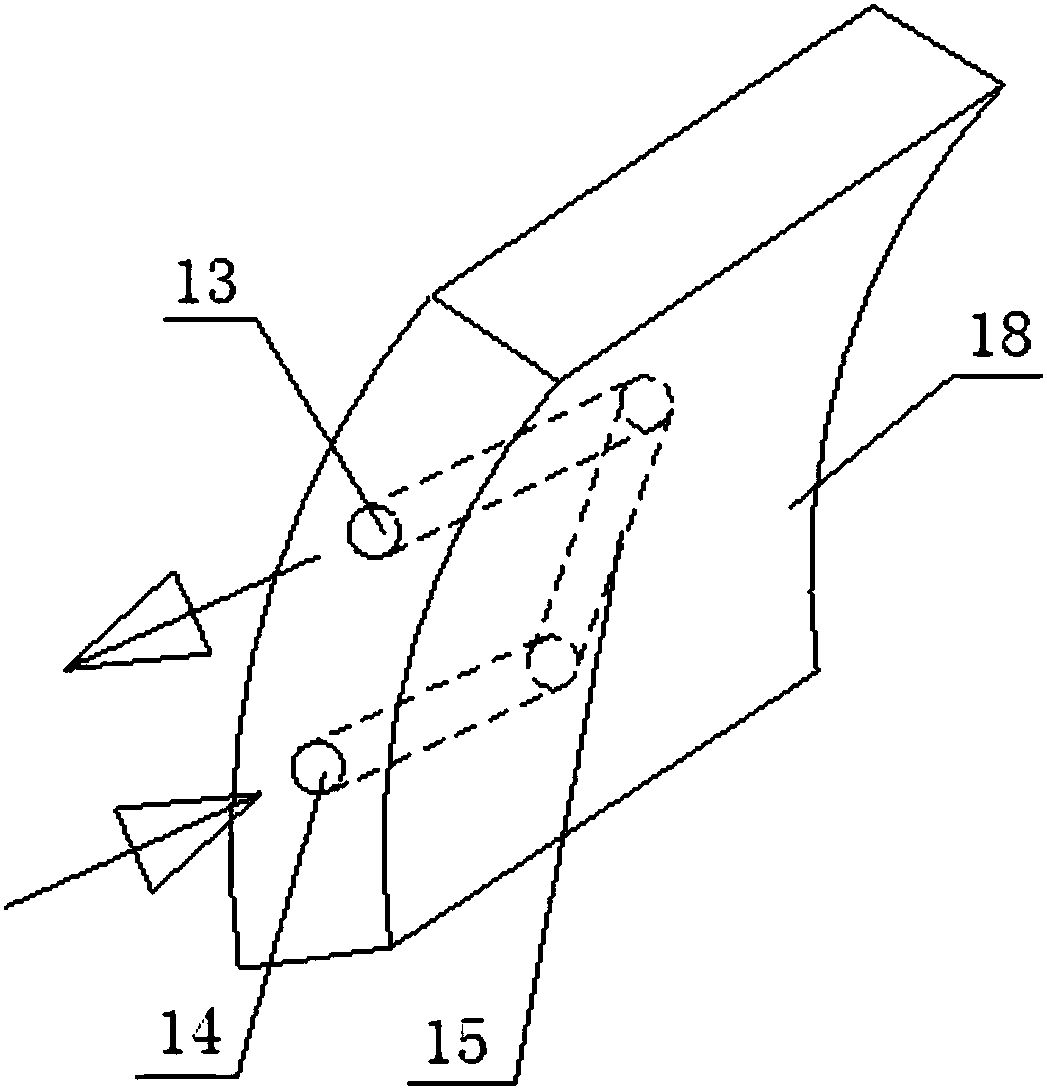

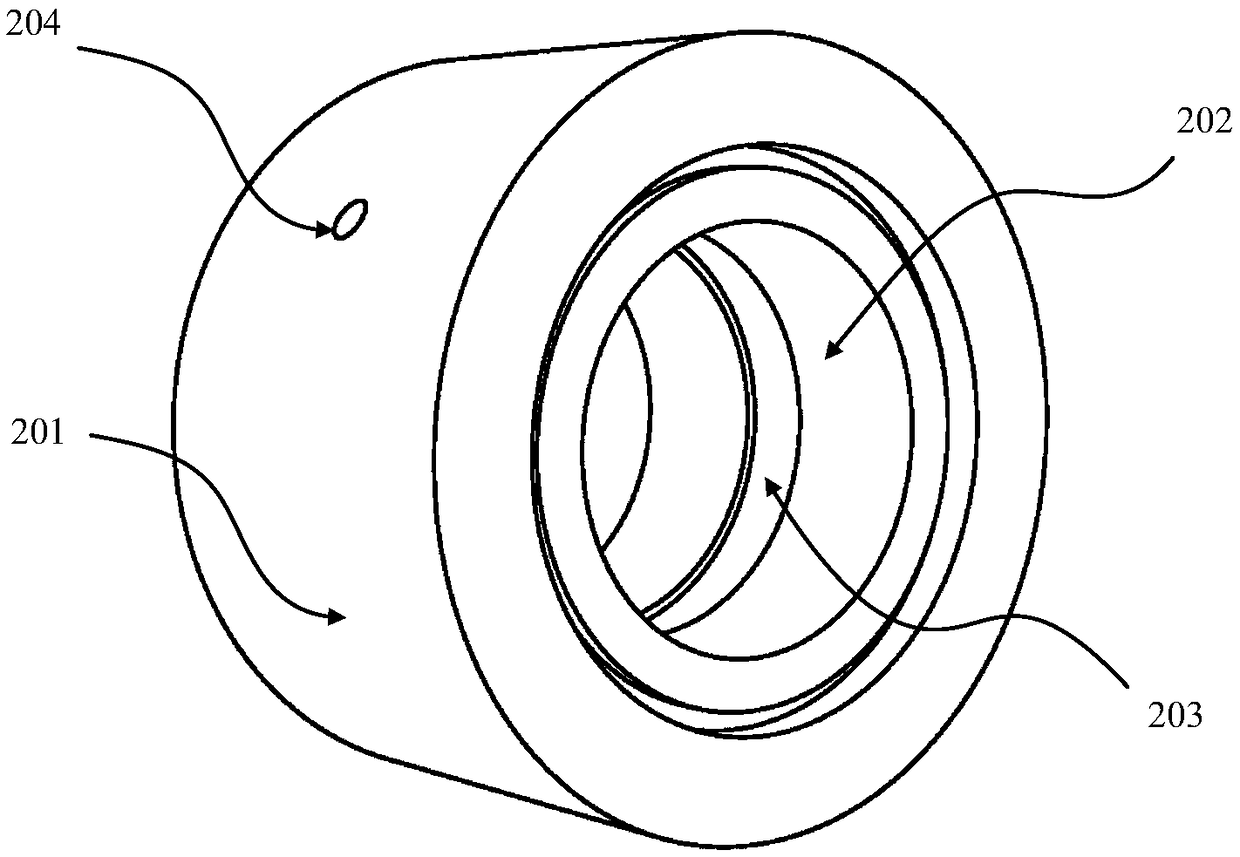

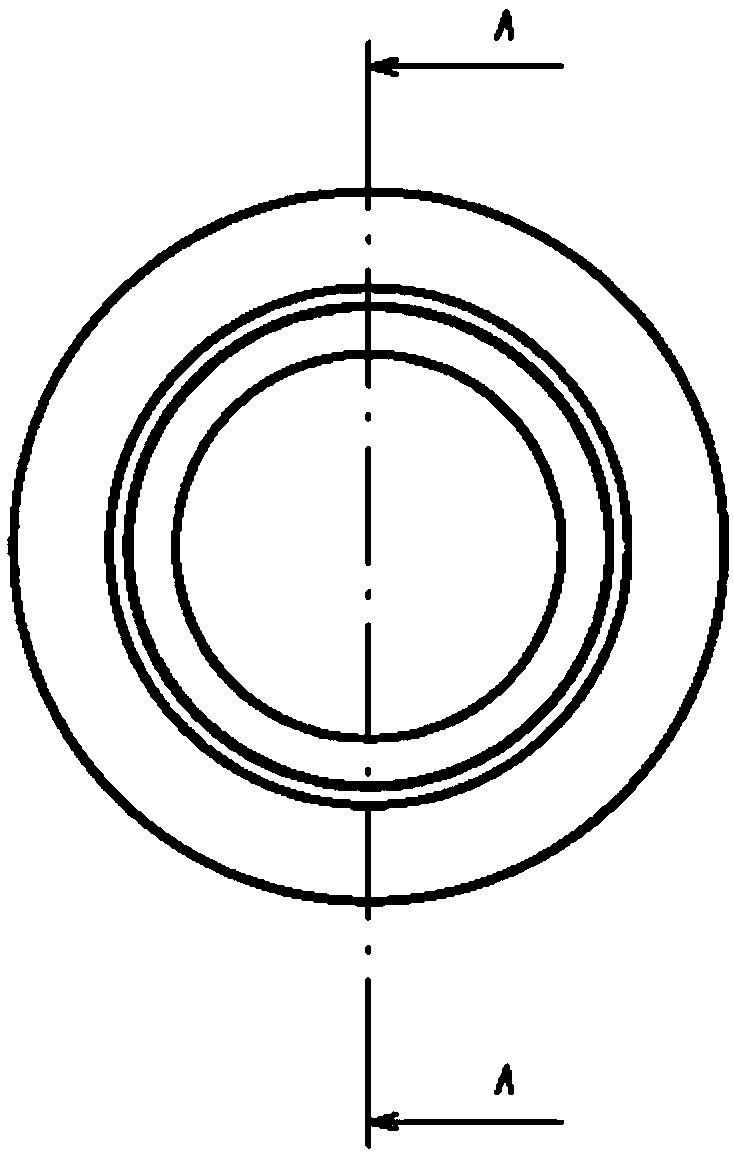

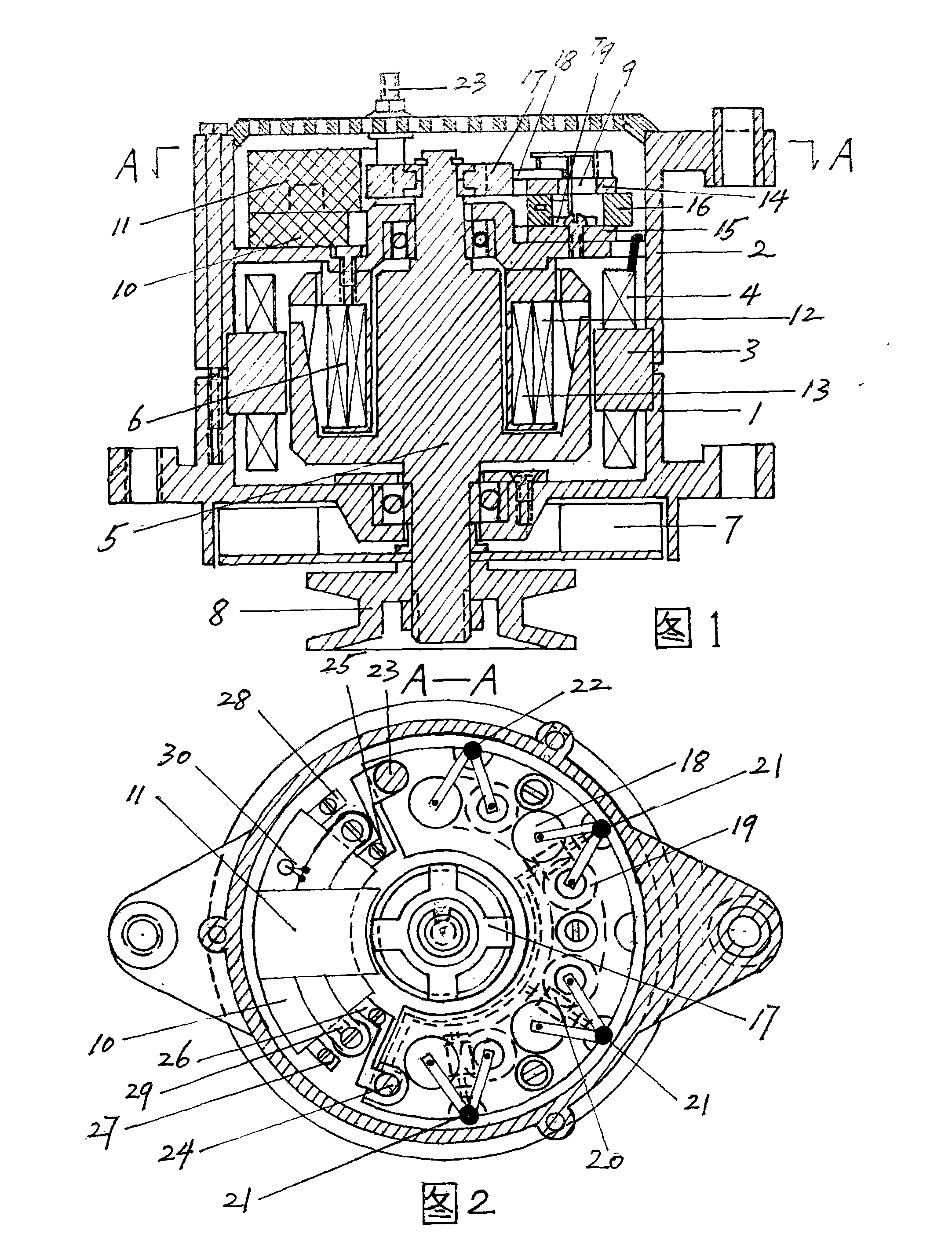

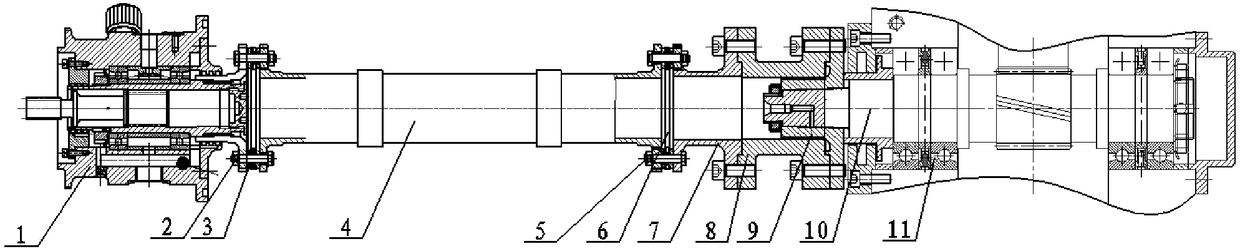

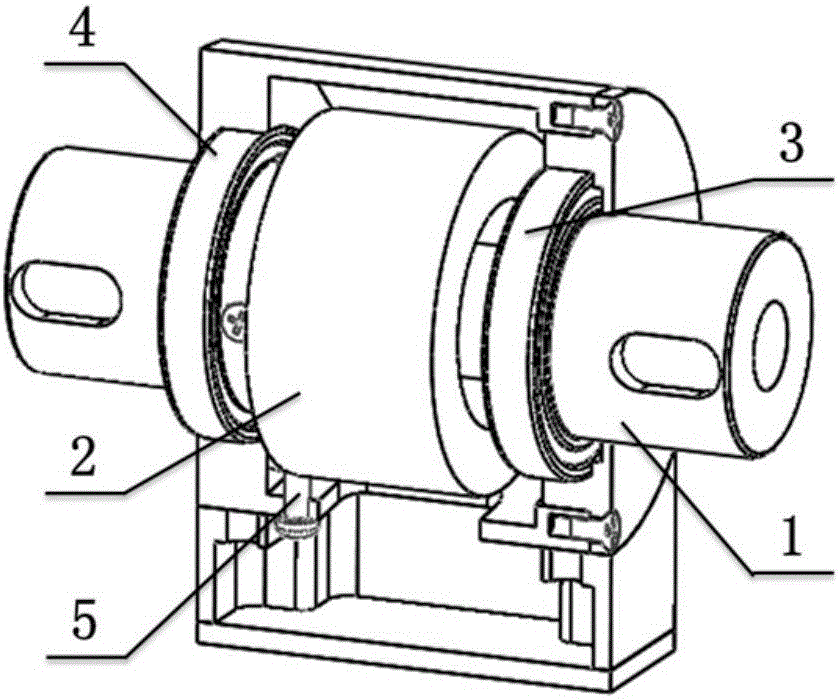

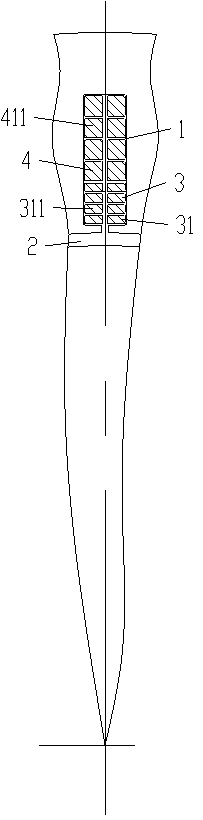

Centripetal protection bearing for magnetic levitation bearing system

InactiveCN101187405AIncrease working speedExtend your lifeBearing assemblyBall bearingsRolling-element bearingSwitching loop

A centripetal protection bearing for a magnetic levitation bearing system belongs to a magnetic levitation bearing, which comprises an inner ring (1) and an outer ring (2) of one first layer rolling bearing, a switching loop, an inner ring (4) and an outer ring (5) of a second layer rolling bearing, a radial elasticity damper which is constituted by an inner ring (6) and an outer ring (8) of the radial elasticity damper and radial multi-layer corrugated steel with 3-20 layers, a screw (9), an end cap (10), a base (10), and a rotor assembly (12). The rotary speed which is undertaken by one rolling bearing in a traditional structure is changed to undertake by two or two more bearings, which increases the working rotary speed of the bearing. Energy which is generated by vibration and impact is absorbed through doing work by the radial elasticity deformation of the radial elasticity damper and the friction on tangential direction, which raises the life of the protection bearing. The invention can not only be used as a centripetal protection bearing for supporting radial load in the magnetic levitation bearing system, but also be used as a rolling bearing with higher rotary speed, vibration and impact resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

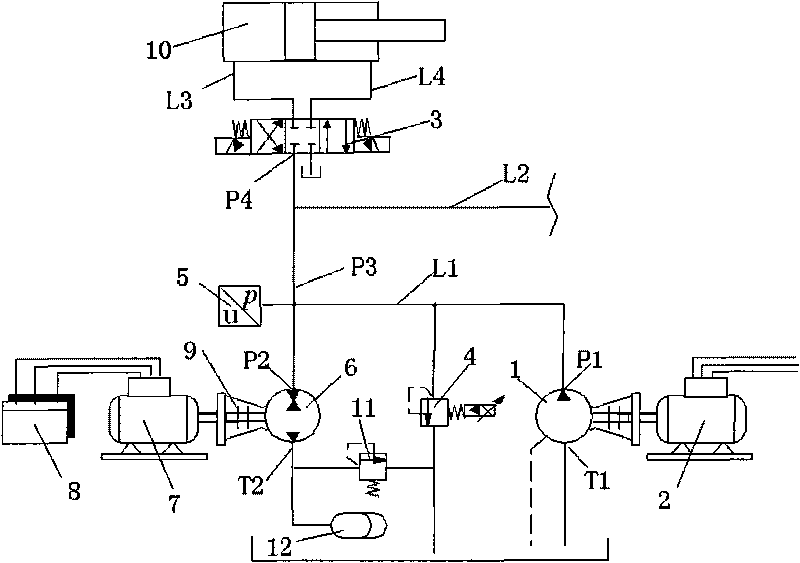

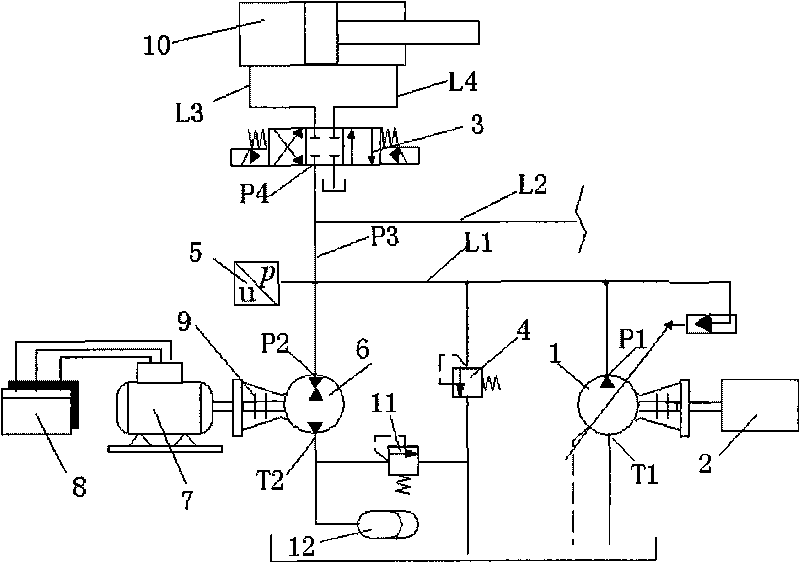

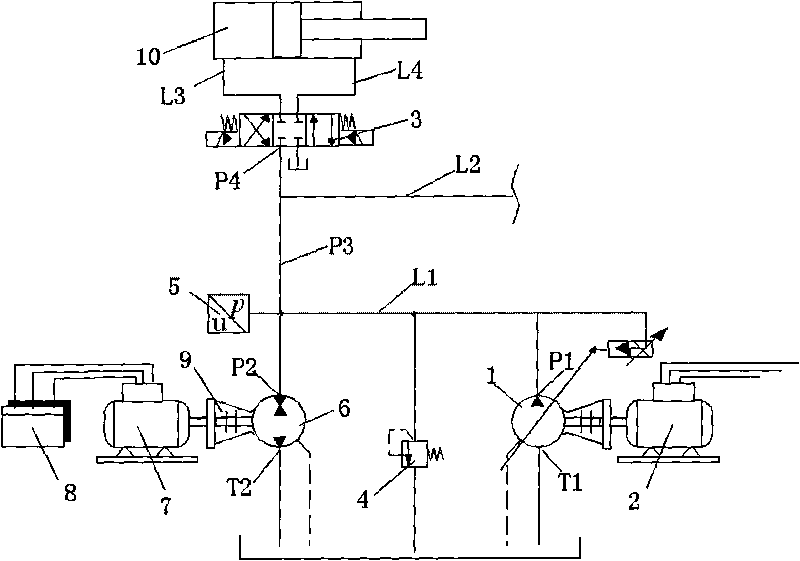

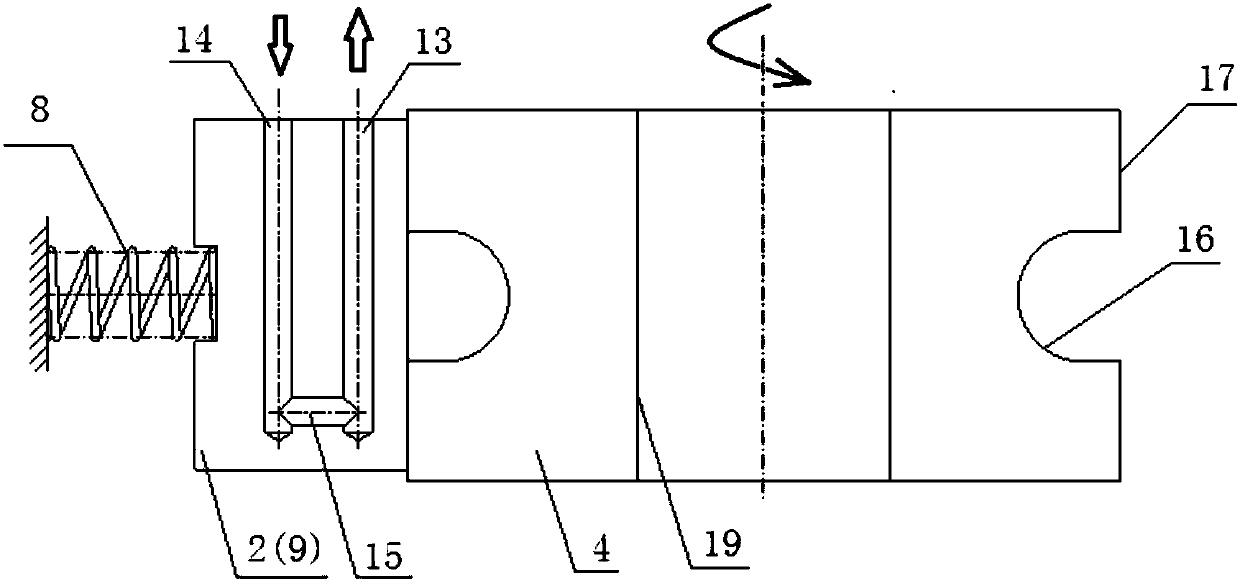

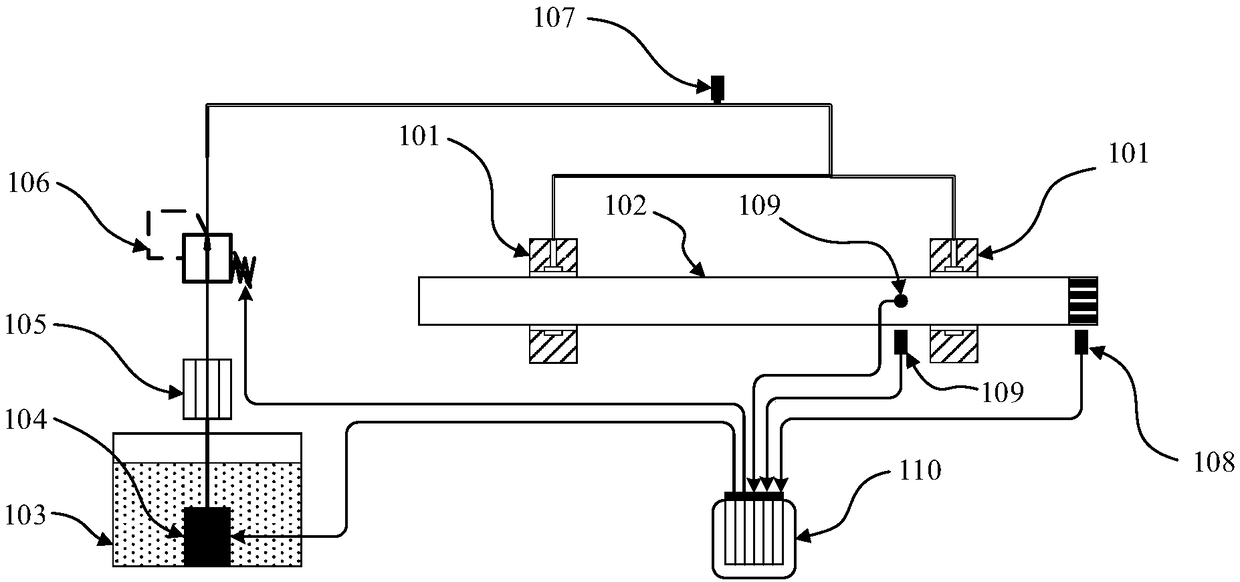

Hydraulic pump flow regulating device

InactiveCN101691878AImprove oil absorption capacityIncrease working speedServomotor componentsHydraulic pumpEngineering

The invention relates to a hydraulic pump flow regulating device which is characterized in that a flow regulating system is additionally arranged in a system, i.e. a motor drives a bidirectional rotation hydraulic pump through a shaft coupling; a motor rotation speed controller controls the direction and magnitude of rotation of the motor; a first oil port of the bidirectional rotation hydraulic pump is communicated with an oil outlet of a unidirectional rotation hydraulic pump through a hydraulic tube; the hydraulic tube is communicated with a main oil outlet; the main oil outlet is communicated with an oil inlet of a control valve; and a second oil port of the bidirectional rotation hydraulic pump is communicated with an energy accumulator and a safety valve. The invention uses a servo motor with smaller power to continuously control the output flow of the whole hydraulic system in a lager power range, thereby reducing the control cost of the system; the bidirectional rotation hydraulic pump is adopted to enable the system to have an energy storage function; and the second oil port of the bidirectional rotation hydraulic pump is communicated with the energy accumulator, thereby improving the oil absorbing ability and the working rotation speed of the pump. The invention is suitable for traveling machinery driven by hybrid power.

Owner:TAIYUAN UNIV OF TECH

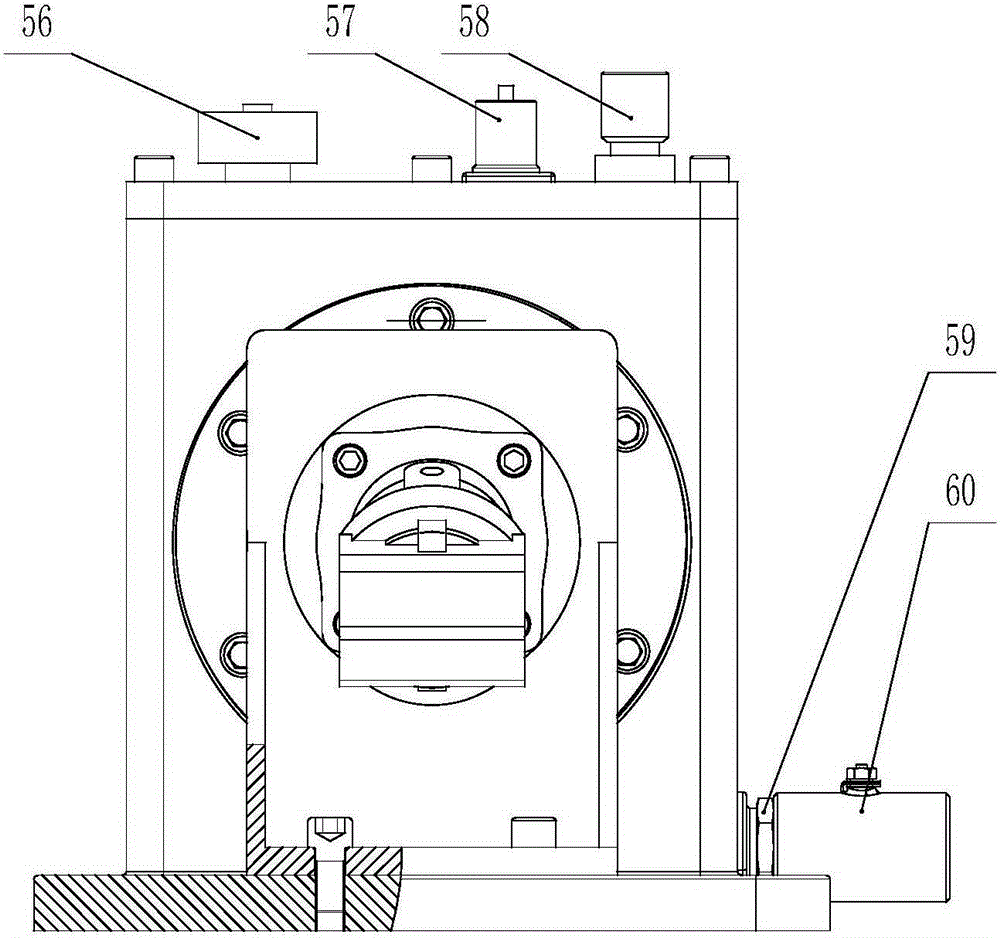

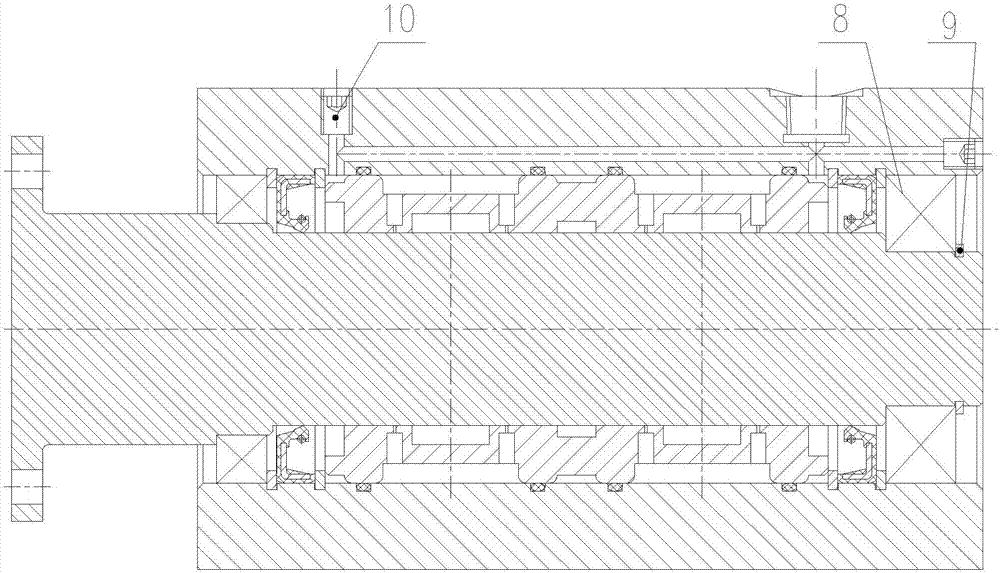

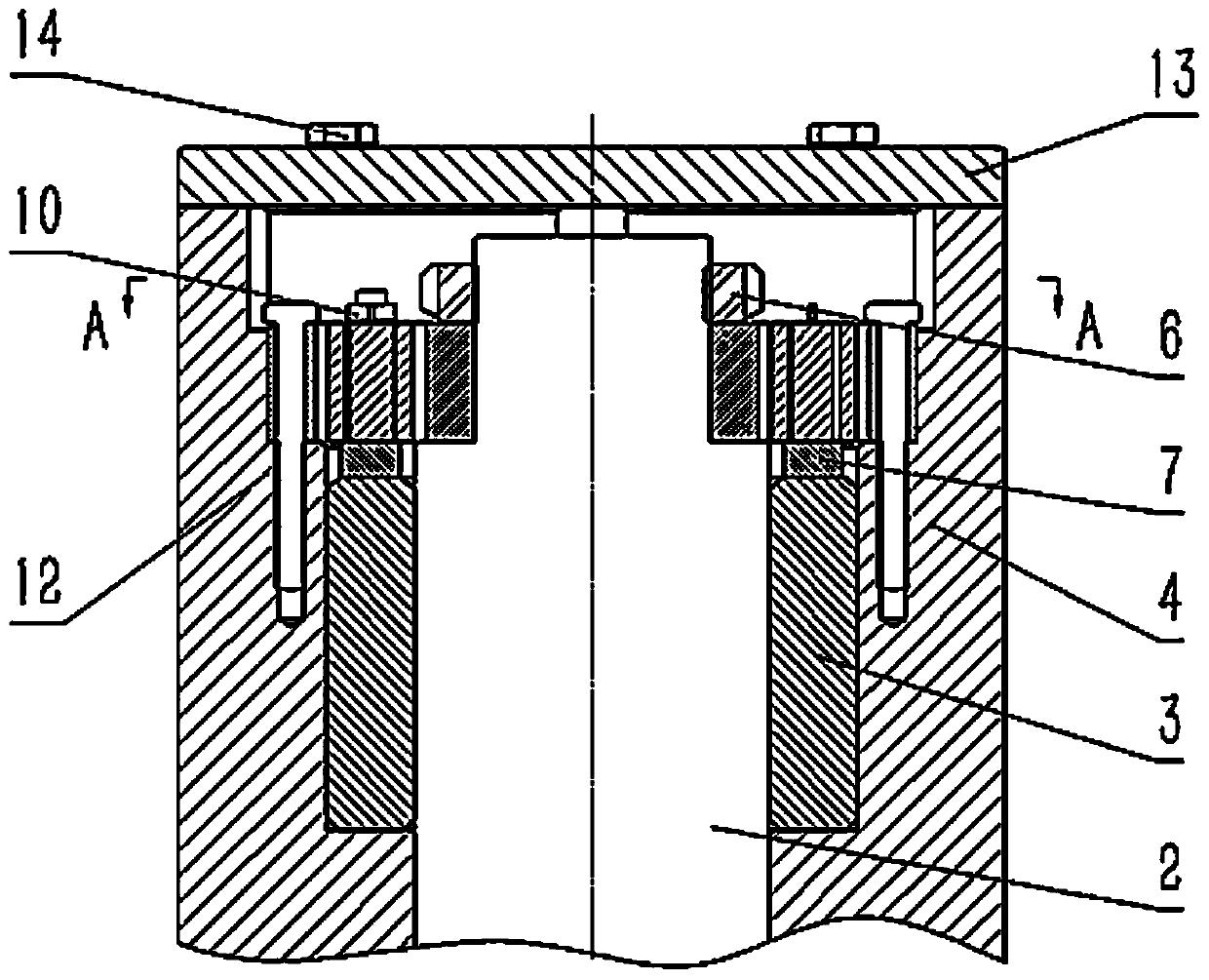

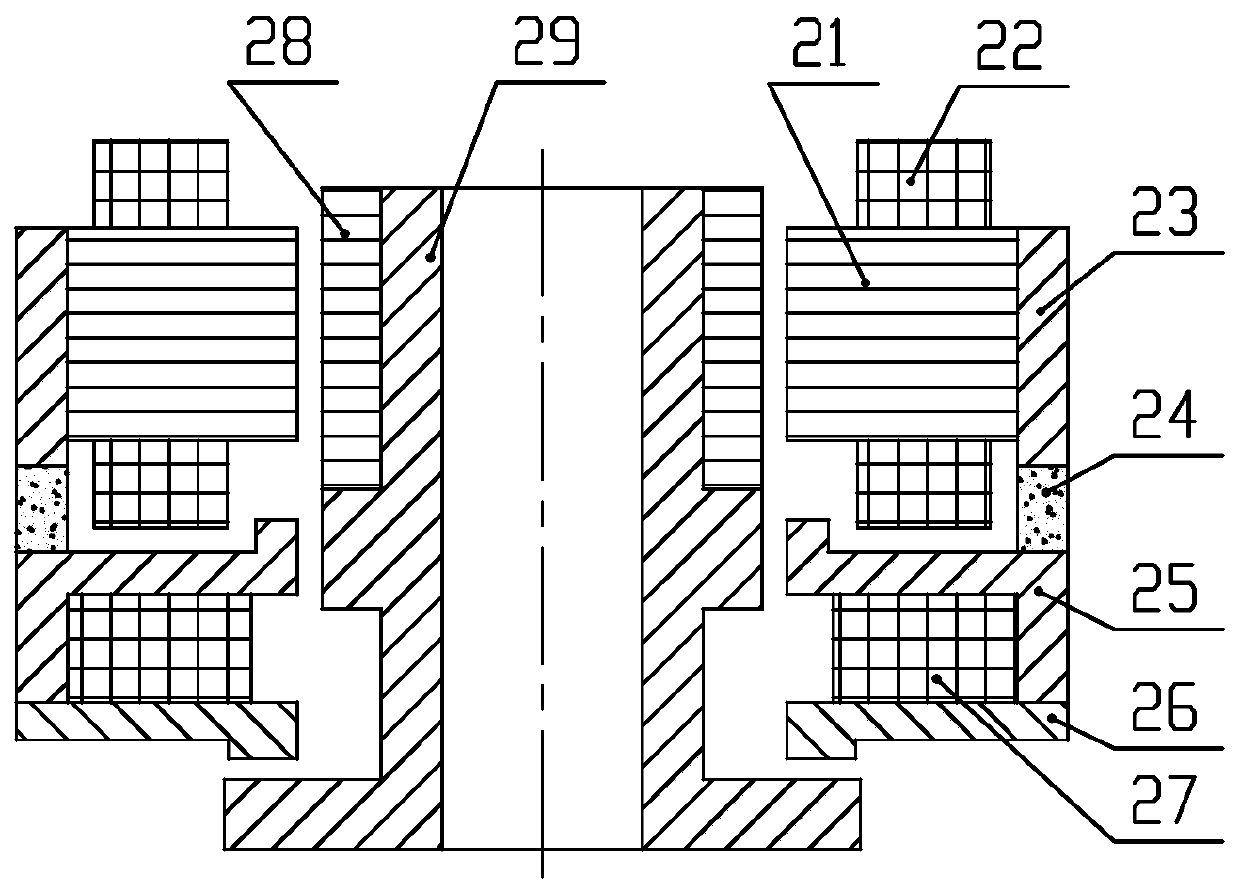

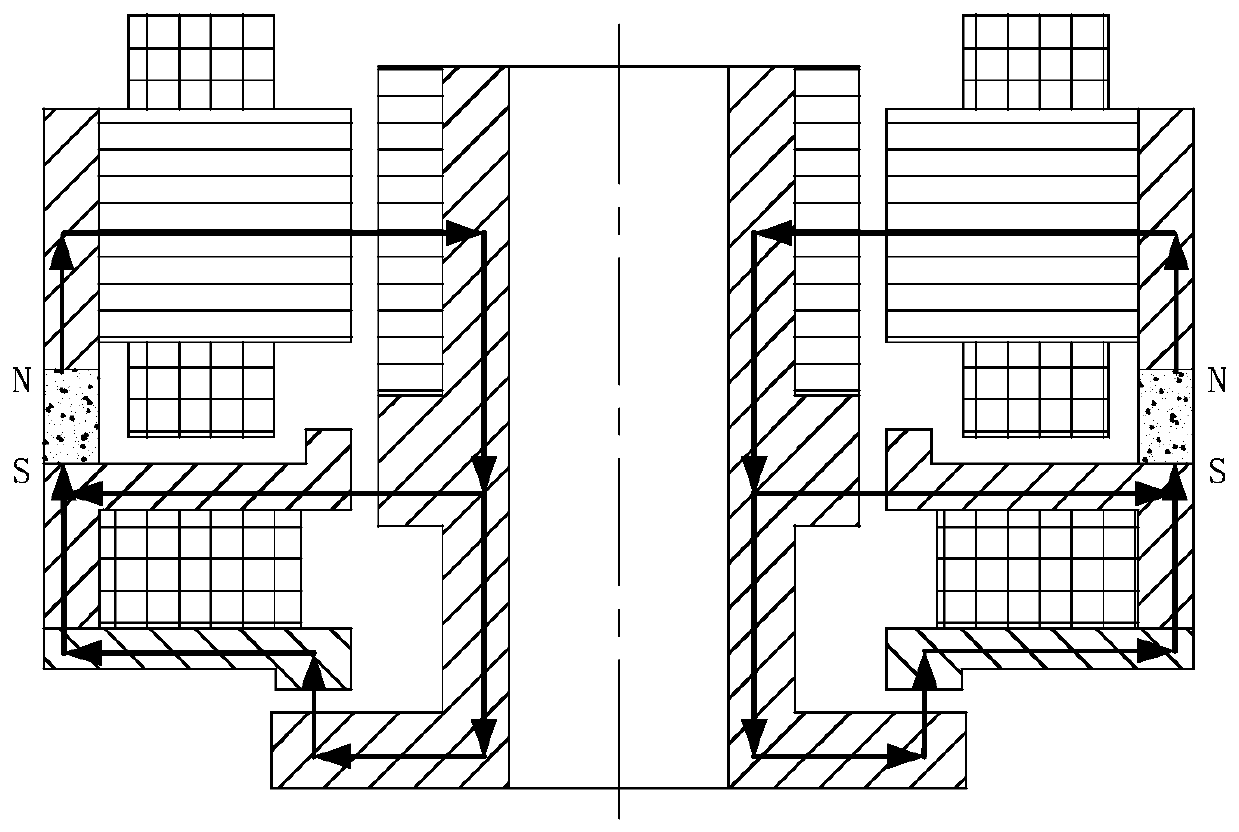

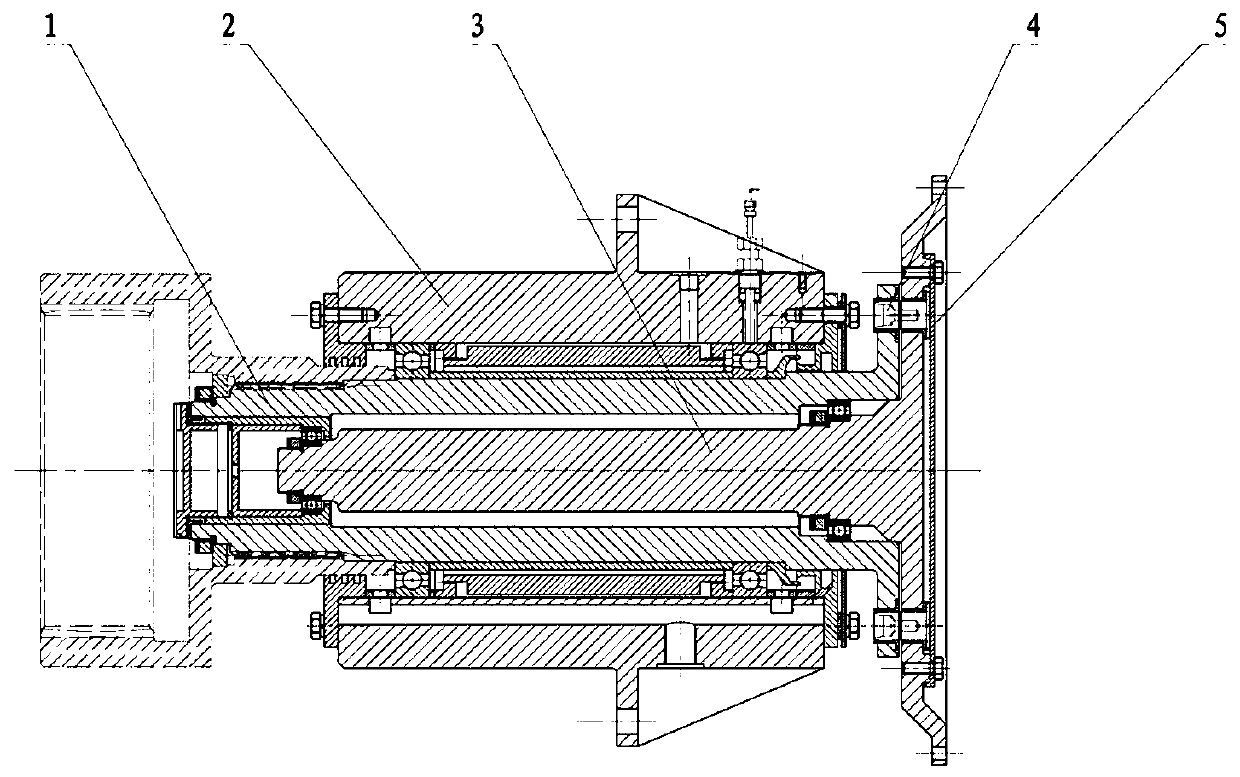

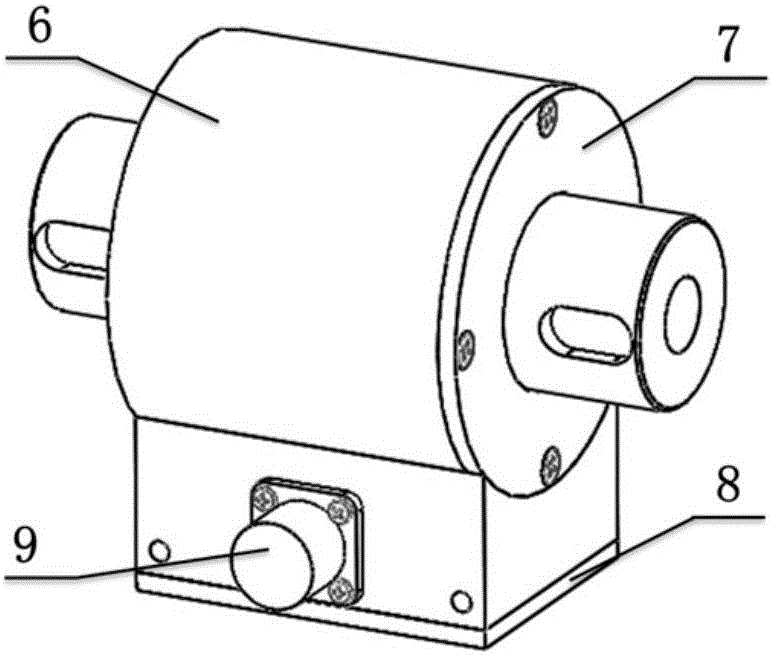

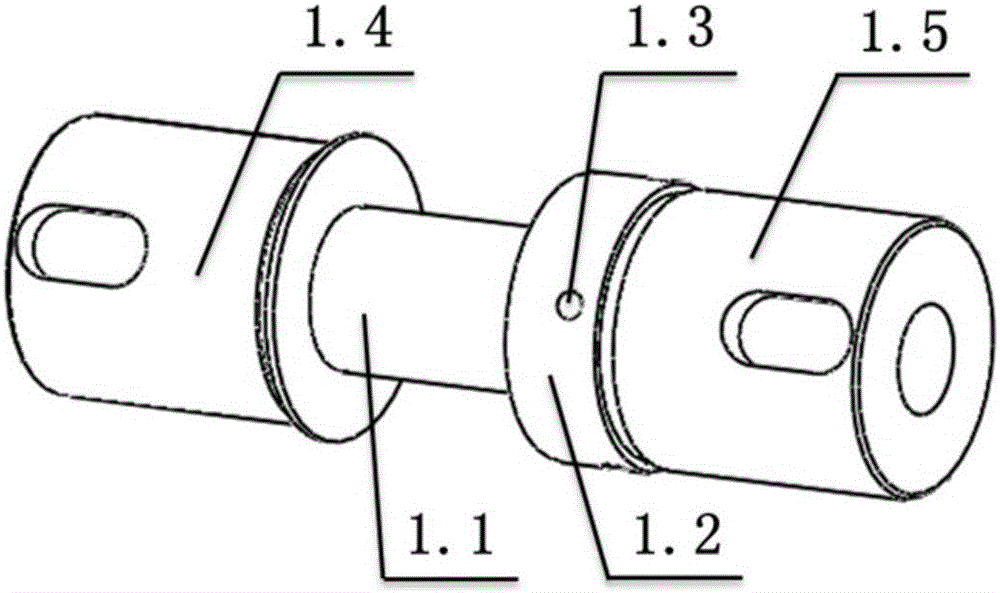

Centripetal thrust force protection bearing used for magnetic suspension bearing system

InactiveCN101191521AIncrease working speedWork lessRolling contact bearingsBearing assemblySteel platesRoller bearing

The invention relates to a centripetal thrust protection bearing used for a magnetic suspension bearing system, which belongs to a magnetic suspension bearing. The invention comprises inner rings and outer rings of a first set of roller bearings, adapter rings, inner rings and outer rings of a second set of roller bearings, an inner ring and an outer ring of a radial elastic damper, a radial three-layer to twenty-layer corrugated steel plate, a first set of bolts, an end cover, a machine foundation, a rotor component, an axial elastic damper, a gland and a second set of bolts. The rotating speed born by a roller bearing in the prior structure is born by two sets or over two sets of bearings, and energy generated by vibration and impact is absorbed by utilization of elastic deformation in the radial direction and the axial direction of the dampers and friction power applying work in the tangent direction of the dampers, thereby working speed and service life of the bearings are improved. The invention can be taken as the centripetal thrust protection bearing for simultaneously bearing radial load and axial load in the magnetic suspension bearing system and also can be taken as a roller bearing having the advantages of higher rotating speed and vibration and compact resistance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

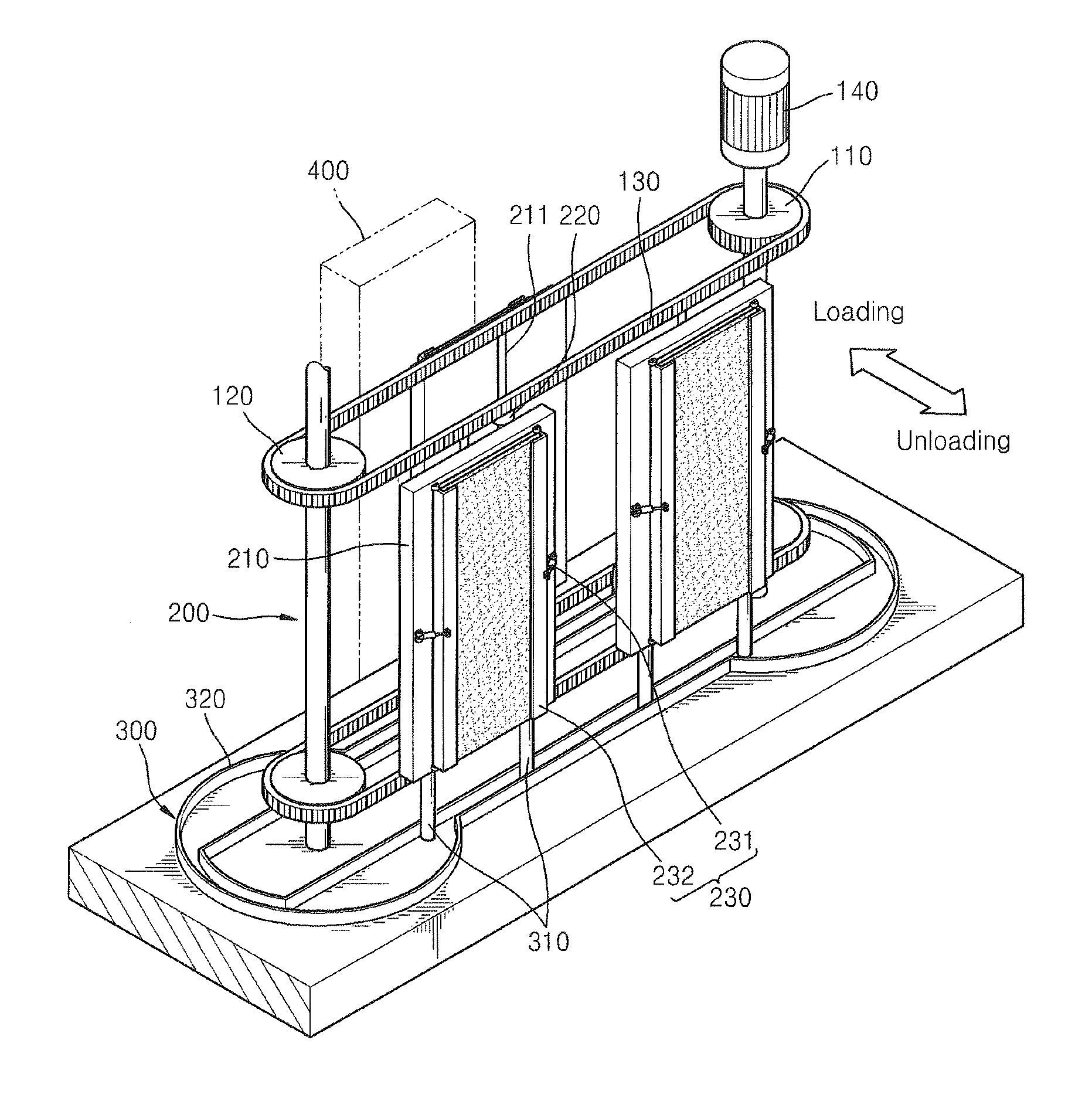

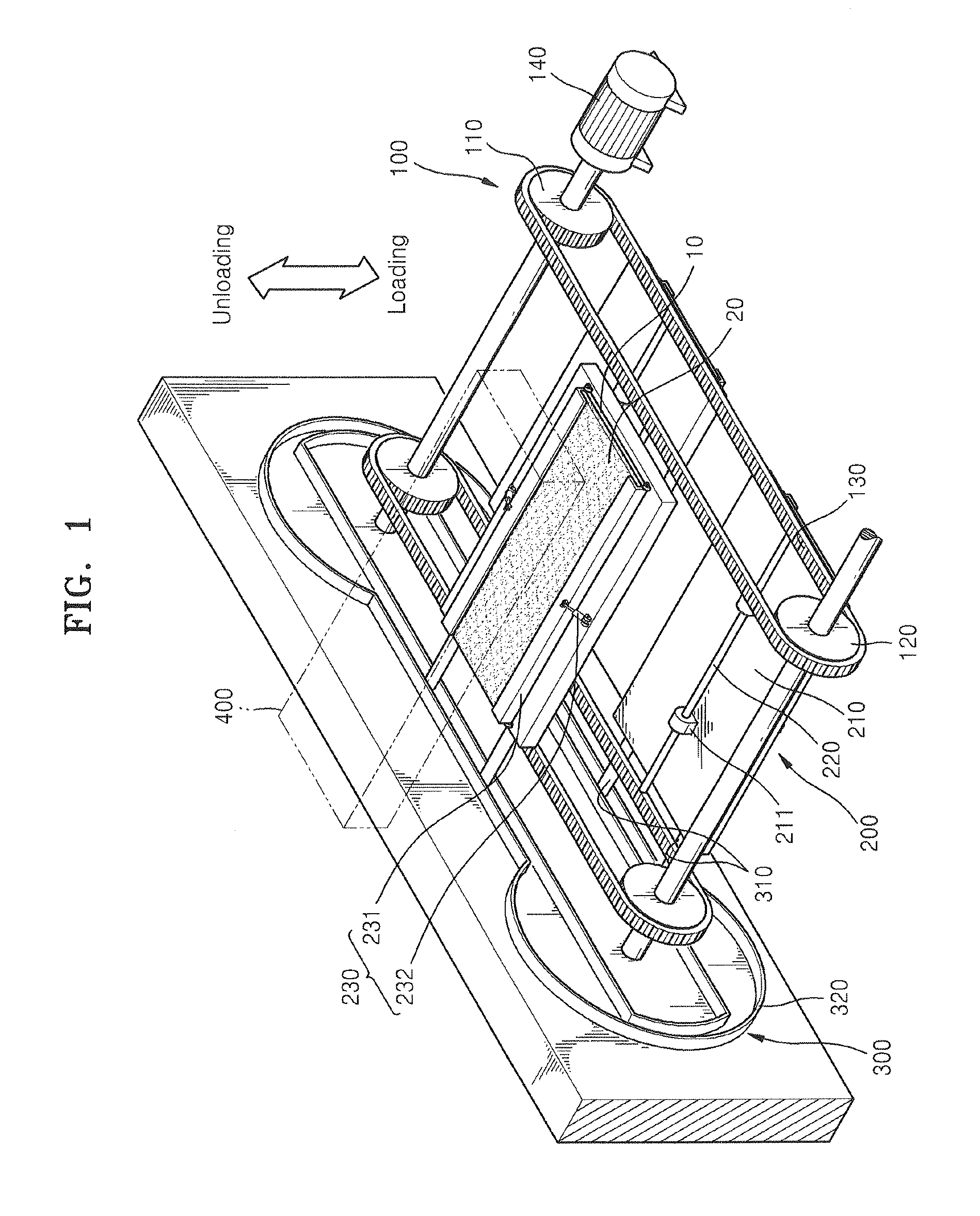

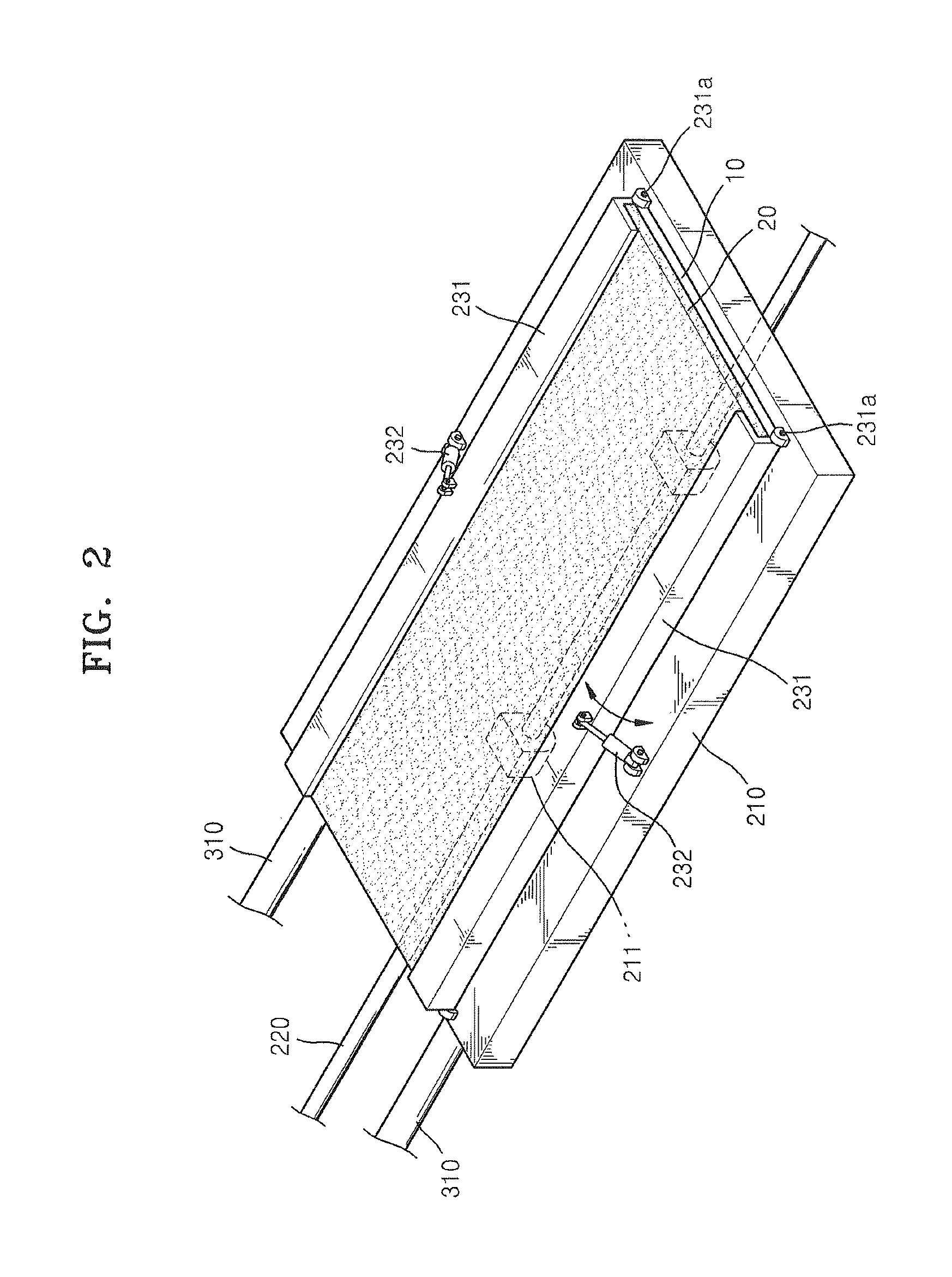

Rotating type thin film deposition apparatus and thin film deposition method used by the same

ActiveUS20130115373A1Increase working speedSmall sizeVacuum evaporation coatingSputtering coatingReciprocating motionThin layer

A rotating type thin film deposition apparatus having an improved structure that allows continuous deposition, and a thin film deposition method used by the rotating type thin film deposition apparatus are provided. The rotating type thin film deposition apparatus includes a deposition device; a circulation running unit that runs a deposition target on a circulation track via a deposition region of the deposition device; and a support unit that supports the deposition target and moves along the circulation track. Thin layers can be precisely and uniformly formed on the entire surface of a deposition target, and since deposition is performed while a plurality of deposition targets move along a caterpillar track, a working speed is faster compared to a method involving a general reciprocating motion, and the size of the thin film deposition apparatus can be reduced.

Owner:SAMSUNG DISPLAY CO LTD

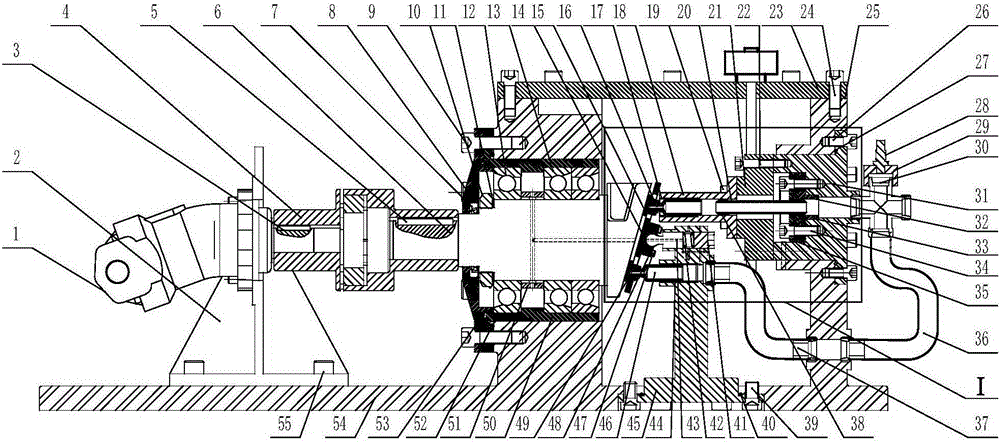

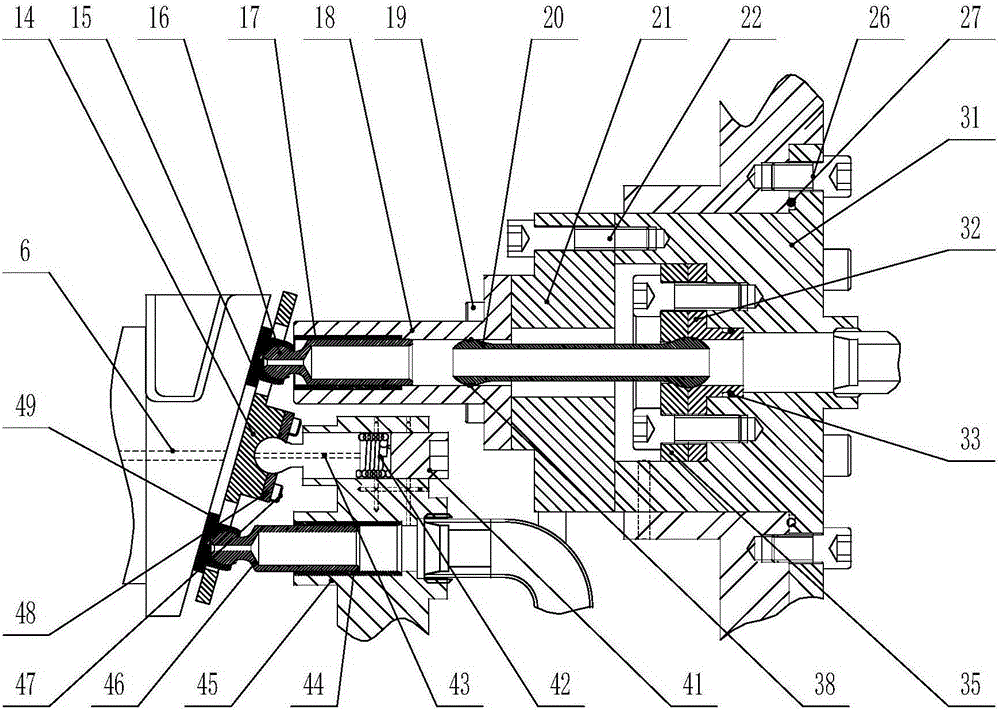

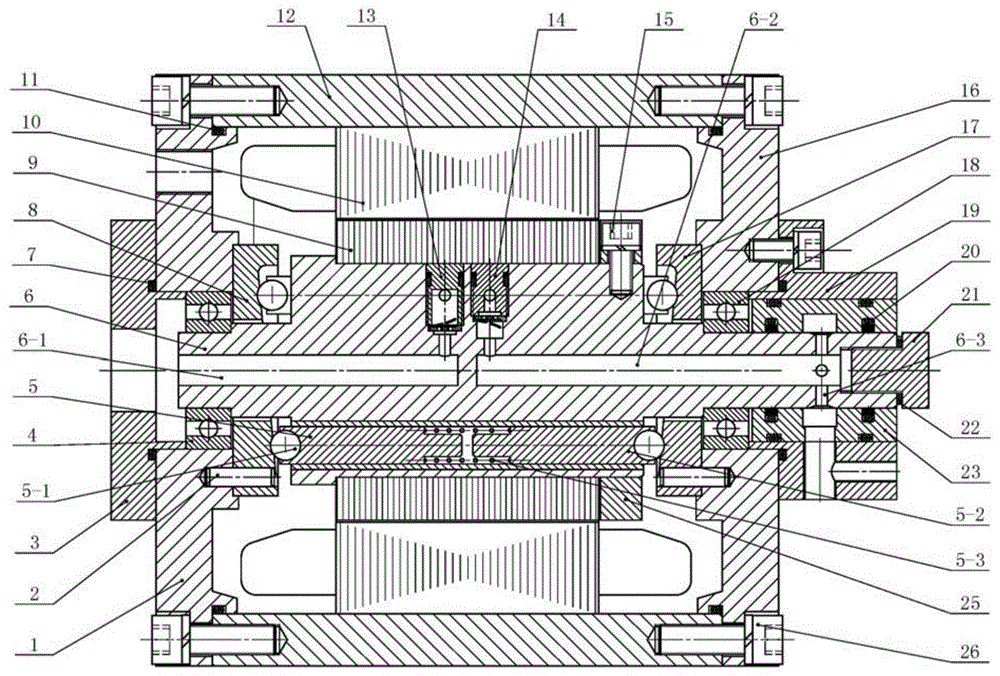

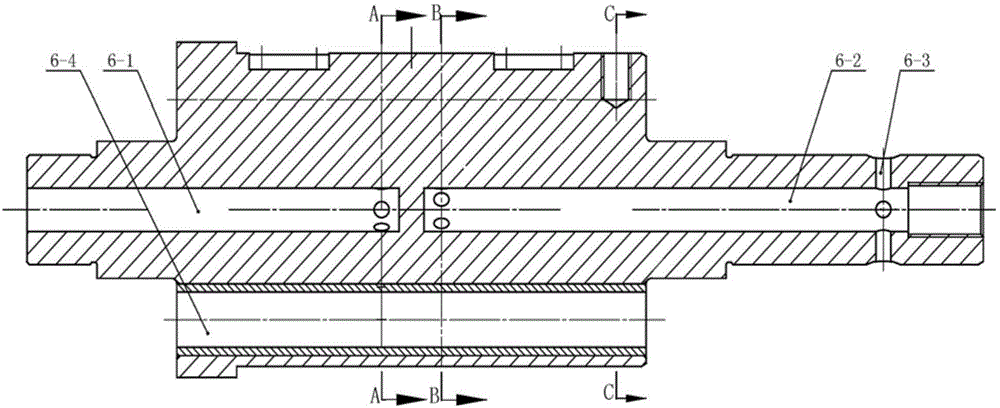

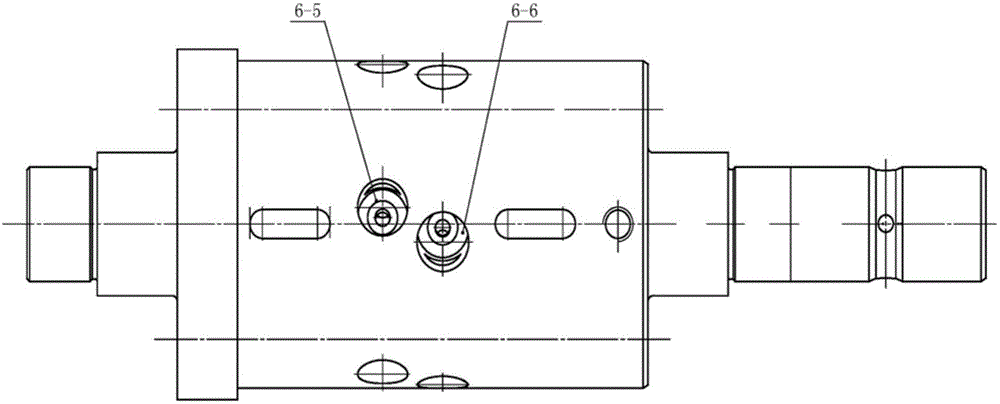

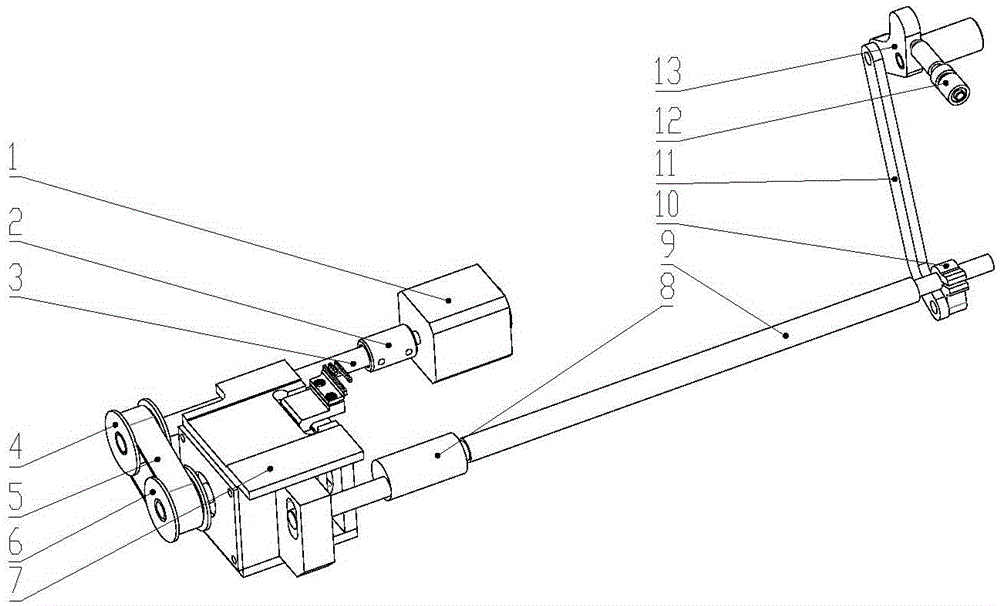

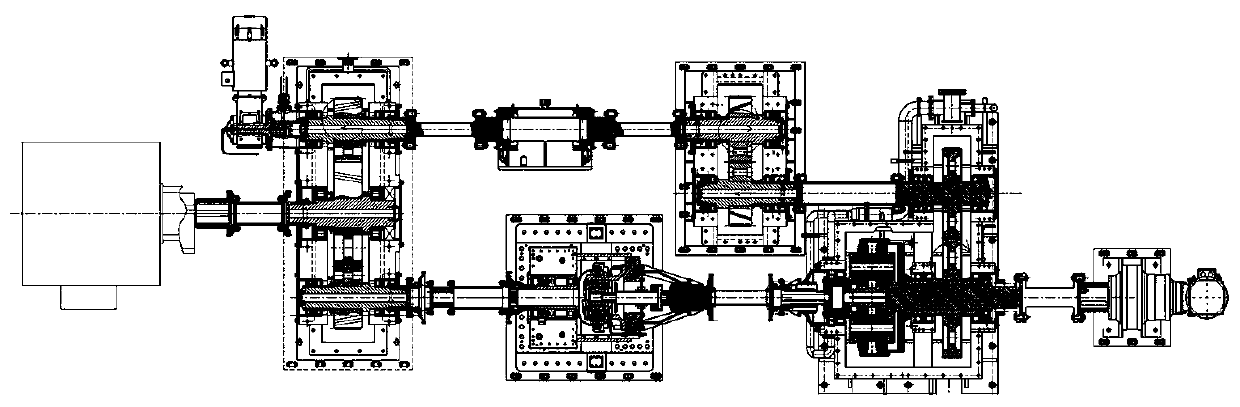

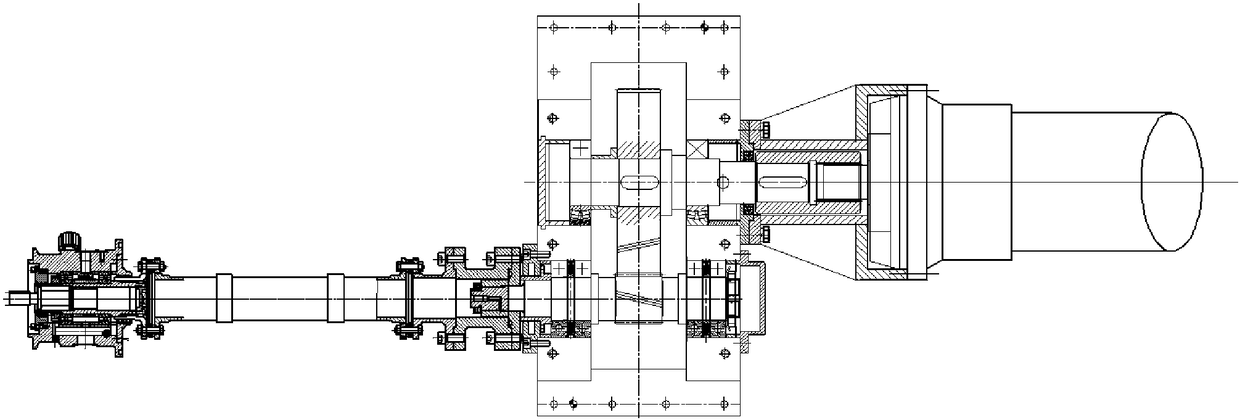

High-pressure high-speed axial piston pump piston pair four-axis force testing device

ActiveCN105181205ASimple structureCompact and reliableApparatus for force/torque/work measurementDynamic balanceInterference factor

The invention discloses a high-pressure high-speed axial piston pump piston pair four-axis force testing device which is mainly composed of a swash plate shaft, a bearing assembly, a tested piston pair, an auxiliary piston pair, a four-axis force sensor, an oil lead piston, a piston base, a piston shoe press plate, a preloaded piston, a compression spring, a spring seat and the like. The ingenious lubrication structure of the ball head and hinge joint of the preloaded piston with adjustable pretension and the bearing assembly, the swash plate shaft in a dynamic balance balancing structure, the tested piston pair, the auxiliary piston pair, the oil lead piston and the four-axis force sensor with a center through hole structure are designed. The tested piston pair and the auxiliary piston pair are symmetrically arranged. The ball head structure of different sizes on both ends and the ball hinge pair of the oil lead piston are connected. Interference factors on the tested piston pair are eliminated. Three-dimensional direction action force and axial torque of a high-pressure high-speed piston pair are measured. The device has the advantages of simple and reliable overall structure, easy part replacing and low machining and detection cost.

Owner:ZHEJIANG UNIV

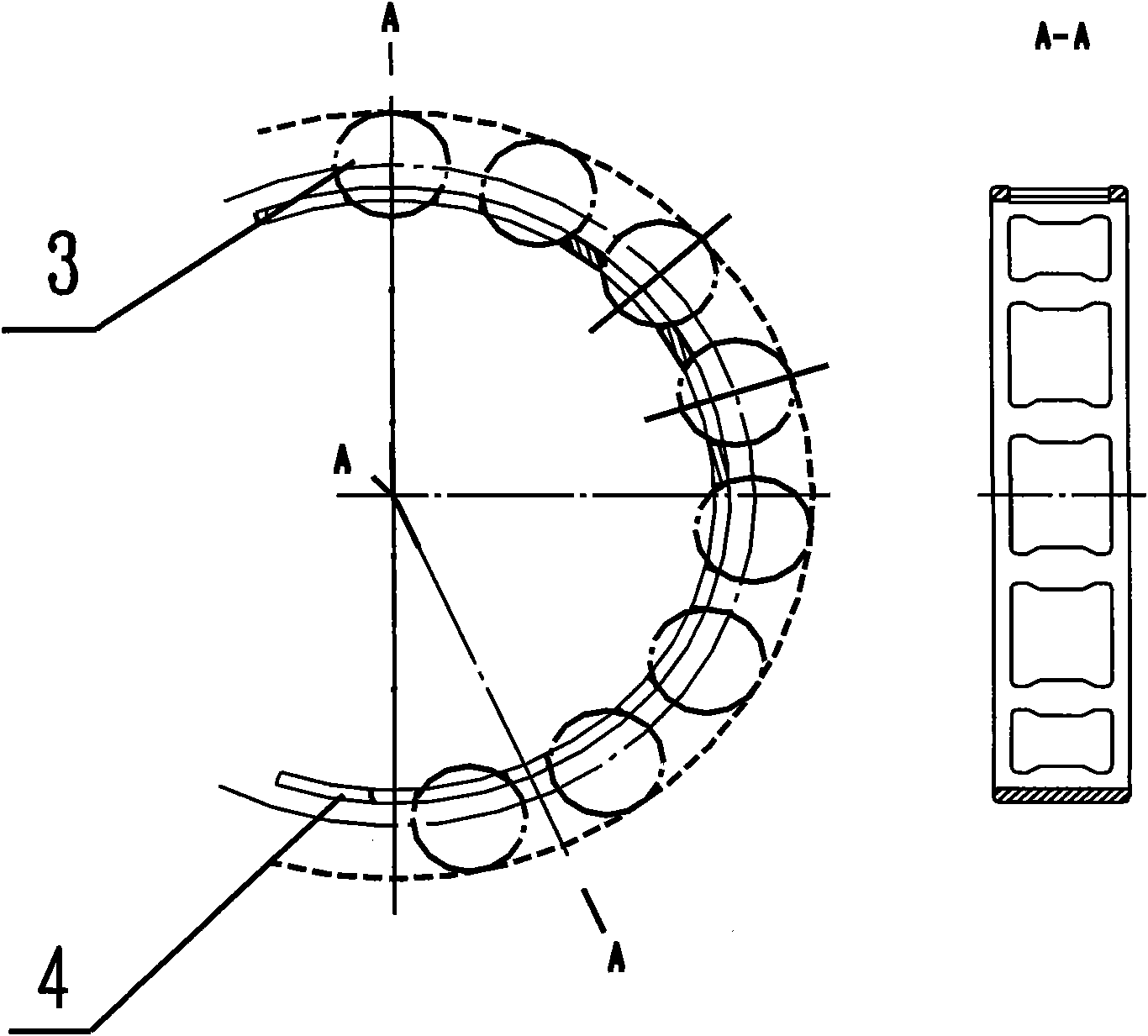

Novel high strength and high stability stamping retainer of cylinder roller bearing

The invention relates to a novel high strength and high stability stamping retainer of a cylinder roller bearing. The retainer uses the steel plates with thickness being not more than 2mm as the materials, thus fully reducing the dead weight of the bearing and improving the rotating speed of the bearing. The pockets and the appearance of the retainer are stamped once and finally undergo secondary reshaping and phosphating. The pockets of the retainer are square, thus reducing the machining difficulty and fully meeting the requirement of mass production. The width of the pockets of the retainer is 0.985 times the diameter of the roller in design and the length thereof is 1.02 times that of the roller in design, thus ensuring the external diameter of the roller set not to interfere with the outer ring flange, ensuring final smooth assembly of the bearing, tightly pressing sag of the retainer and effectively improving the stability of operation.

Owner:WAFANGDIAN BEARING GRP CO LTD

High-performance multi-channel rotary joint for water

The invention discloses a high-performance multi-channel rotary joint for water. A two-stage non-contact sealing mode is adopted by the joint, the first stage of sealing is clearance sealing, and the second stage of sealing is lip sealing. The clearance of the first stage of clearance sealing refers to the clearance between a floating ring and a rotary shaft, part of a water medium enters the micro clearance between the rotary shaft and the floating ring via a throttling hole and forms a fluid film, the fluid film has the hydrostatic effect and the hydrodynamic effect at the same time, the fluid hydrostatic effect plays a leading role under a low speed, and the fluid hydrodynamic effect plays the leading role under a high speed. Lip sealing, as the second stage of sealing, is used for sealing a small quantity of water medium leaked at the first stage of sealing, as for a sealing mechanism of lip sealing, a continuous fluid lubricating film is formed on an interface between a sealing lip and the rotary shaft from the micro perspective, the sealing lip and the rotary shaft are separated from each other by the fluid film, and medium leakage is restrained through a dynamic pressure pumping effect. The high-performance multi-channel rotary joint for water can effectively seal high-pressure media, adapt to an extremely high operation rotation speed and reduces the probability of a wear-out failure.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

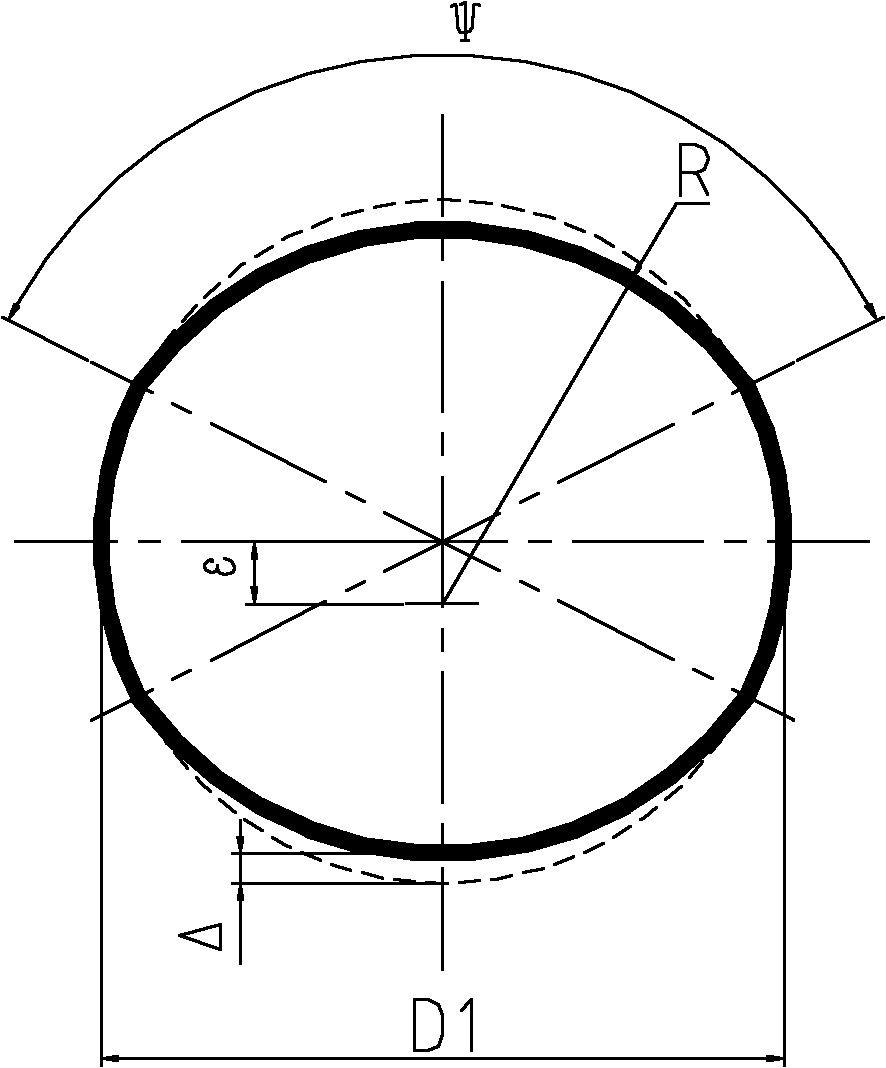

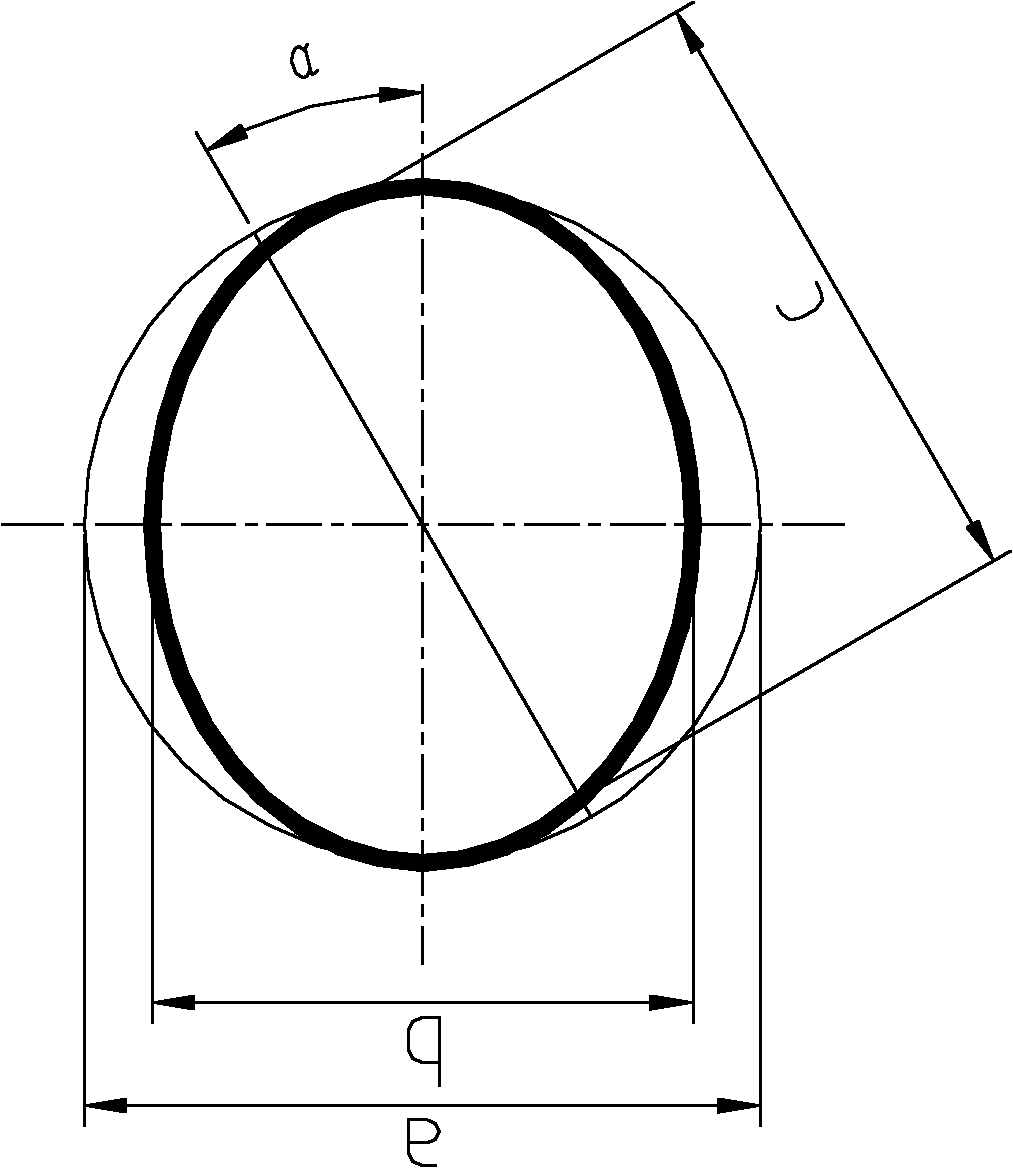

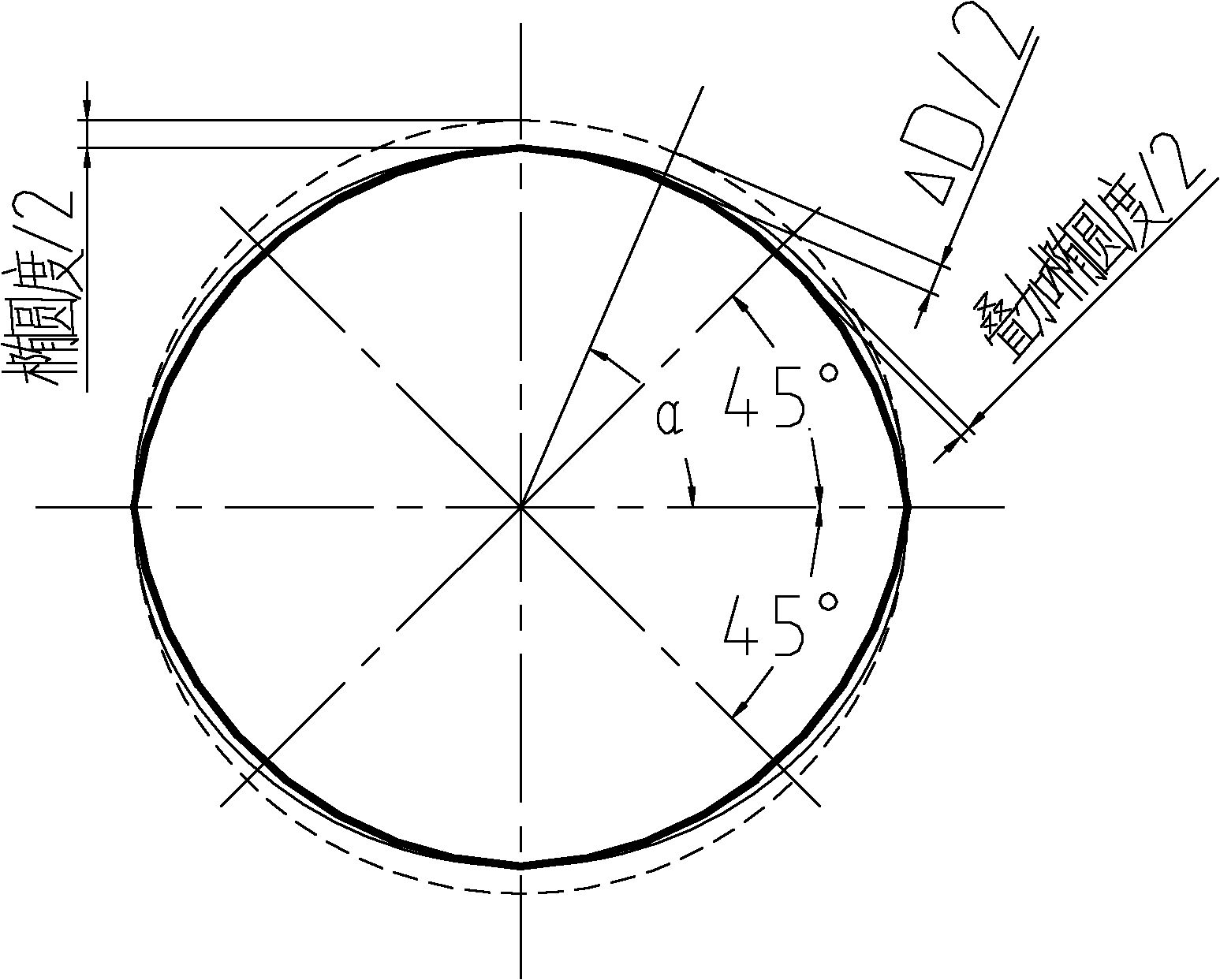

Piston and method for optimizing skirt profile section of piston

The invention discloses a piston. The cross section curve of the profile meets the following ellipse-like diameter variable parametric equation shown in the specification, wherein Tn / 2 means the radial maximum spacing between the nth curve and the previous curve; alpha means the angle between the cross section and the long axis of an ellipse; J means the included angle between the starting point of the curve and the long axis of the ellipse; J' means the included angle between the terminal point of the curve and the long axis of the ellipse; mu' means a variation coefficient; and delta D means an ellipse-like diameter variation. According to the invention, because the adopted equation is a simple and harmonic curve which has a less peak acceleration and a limit phase step value and has continuous displacement, velocity and acceleration curve properties; the dynamic loading can be reduced by the acceleration, the high-speed response requirement of a cutter feed system can be relieved, and the working rotation speed in cutting can be improved; the stability of the operation of the system can be improved by the limit saltus; and the rigid shock and flexible shock in the cutting process can be avoided by virtue of the continuation of the displacement curve, the velocity curve and the acceleration curve. The invention also provides a method for optimizing a skirt profile section of a piston.

Owner:湖南江滨机器(集团)有限责任公司

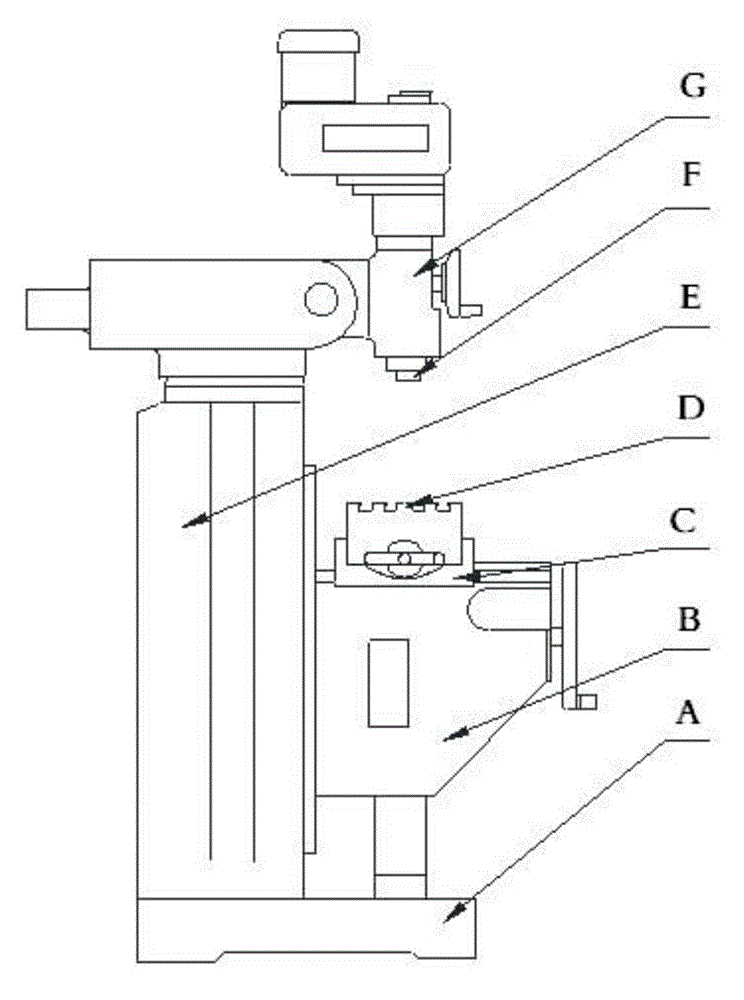

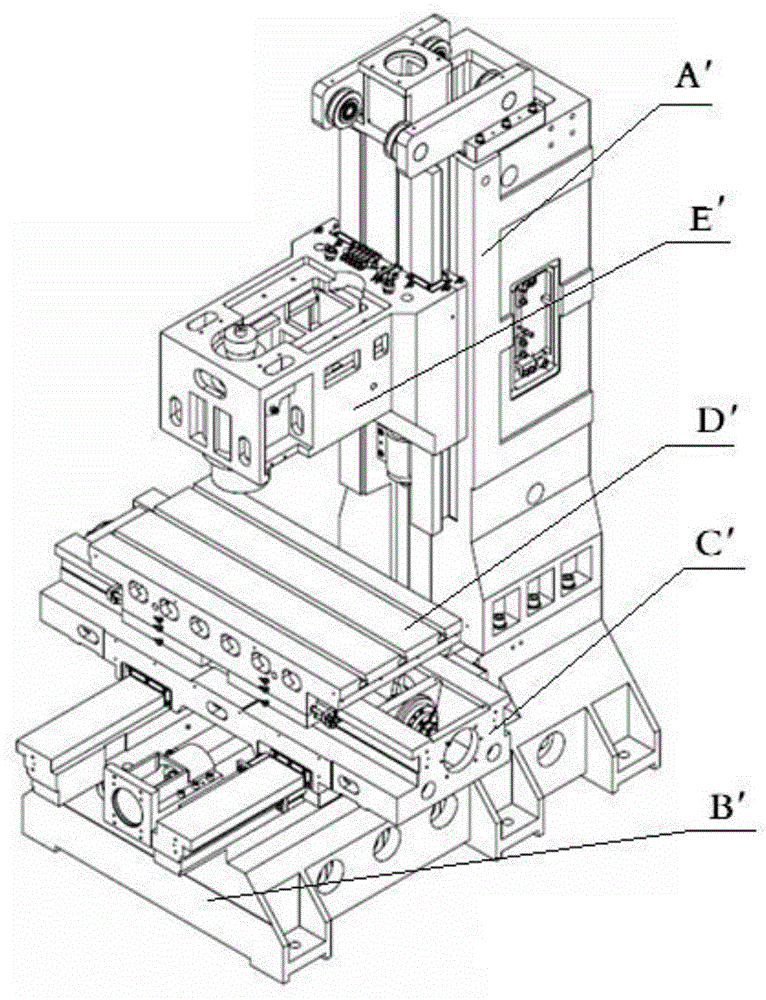

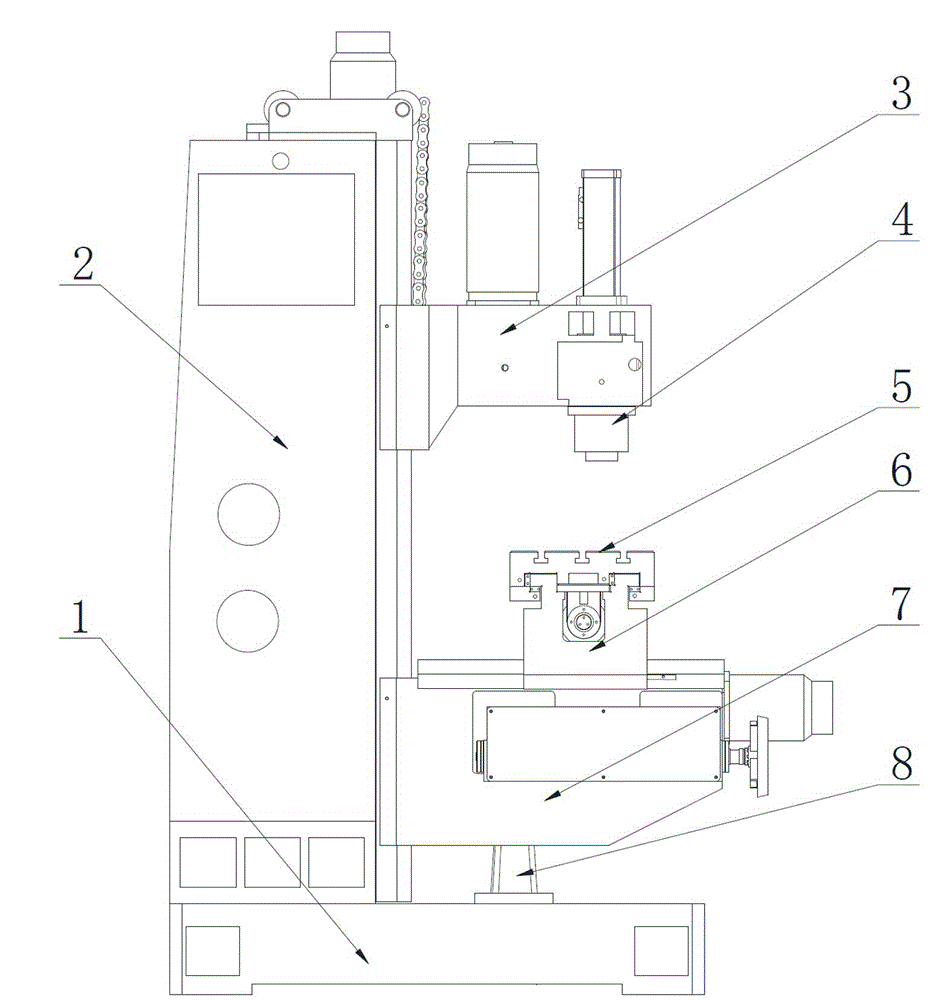

Compound vertical-type milling machine

InactiveCN104907615AReduce stressReduce weightMilling machinesFeeding apparatusReciprocating motionEngineering

The invention discloses a compound vertical-type milling machine. The compound vertical-type milling machine comprises a base (1), a stand column (2), a main shaft box (3), a main shaft (4), a working bench (5), a saddle (6), a lifting platform (7), a screw-nut pair (8) and a numerical control system. The stand column (2) is fixedly installed on the base (1). The working bench (5) is assembled to a guide rail of the saddle (6) and can carry out traverse reciprocating motion along the saddle. The saddle (6) is assembled to a guide rail of the lifting platform (7) and can carry out vertical reciprocating motion along the lifting platform. The compound vertical-type milling machine is a novel structure compound vertical-type milling machine with high motion rigidity and high rotation rate.

Owner:云南锦润数控机械制造有限责任公司

Axial plunger type motor pump

ActiveCN104100486AEasy to processConducive to miniaturization and light weightPositive displacement pump componentsPumpsLiquid mediumCylinder block

The invention provides an axial plunger type motor pump, which belongs to an axial plunger pump in a hydraulic power source and solves the problems that the existing axial plunger pump is larger in axial size, and a conical flat valve generates violent vibration and noise during work. The axial plunger type motor pump comprises a shell, a left end cover, a right end cover, a left tilting tray, a right tilting tray, a motor stator, a motor rotor and a cylinder body shaft, wherein the left end and the right end of the cylinder body shaft are respectively provided with an axial suction hole passage and an axial discharge hole passage, the cylinder body shaft is axially provided with N plunger through holes which are uniformly distributed along the circumference, plunger assemblies are arranged in the plunger through holes, the cylinder body shaft is radially provided with N uniformly distributed suction valve seat holes and N uniformly distributed extrusion valve seat holes, suction valve assemblies and extrusion valve assemblies are respectively arranged in the suction valve seat holes and the extrusion valve seat holes for forming N identical suction valves and N identical extrusion valves. The axial plunger type motor pump is more compact and lighter in structure, high in power density and low in working noise, the working medium can be oil, water or other liquid medium, and the working rotating speed of a plunger pump of a flow distributing valve can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Water-lubricated sliding bearing

InactiveCN103994204ADecrease Relative Motion Swipe SpeedIncrease working speedPortable liftingToothed gearingsEngineeringGear drive

Owner:XI AN JIAOTONG UNIV

Piston transmission mechanism and two-dimensional compressor

ActiveCN109209819ARealize flow distributionVolume increase and decreasePositive displacement pump componentsPiston pumpsNeedle roller bearingCoupling

The invention discloses a piston transmission mechanism which comprises a motor and a piston shaft. The motor has an output shaft which is fixedly provided with a coupling, the coupling is provided with a side groove, and a piston shaft is provided with a needle bearing which is limited in the side groove with a sliding fit. The piston shaft is orderly provided with two rotating shaft holes, a rotating shaft is inserted into each of the rotating shaft holes, at least one end of the each of the rotating shafts is fixedly provided with a roller, a raceway is fixedly arranged between the rotatingshafts, and a left cam raceway and a right cam raceway are symmetrically distributed at two sides of raceway and are provided with cam curved surfaces. When the output shaft rotates, the coupling drives the piston shaft to rotate, and the rollers on the rotating shafts roll along the cam curved surfaces on the corresponding left cam raceway and right cam raceway to allow the piston shaft to reciprocate linearly along the central axis of the piston shaft. The piston transmission mechanism has the advantages of light weight, high pressure, high efficiency, oil-free compression and low noise andvibration.

Owner:JIAXING UNIV +1

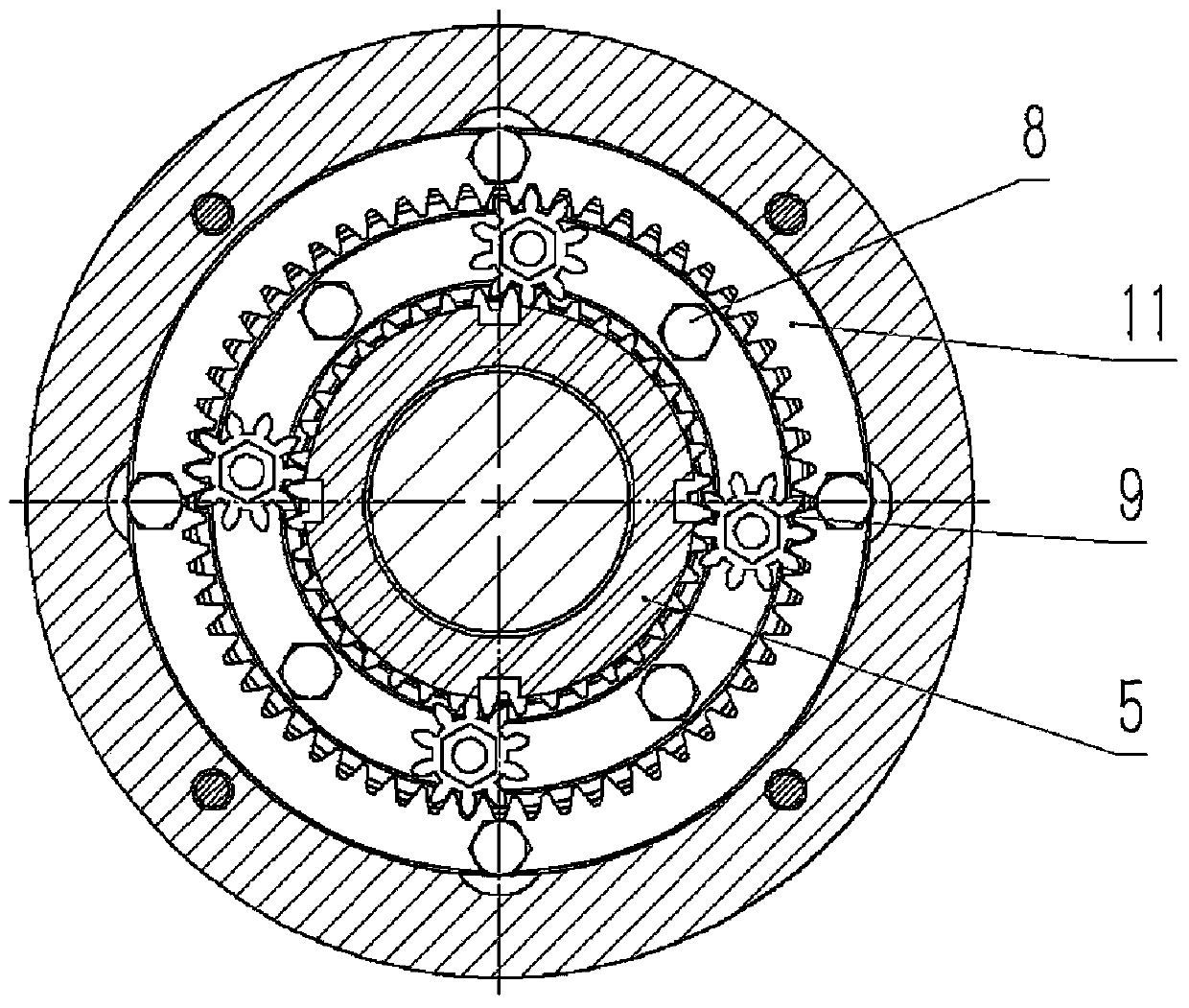

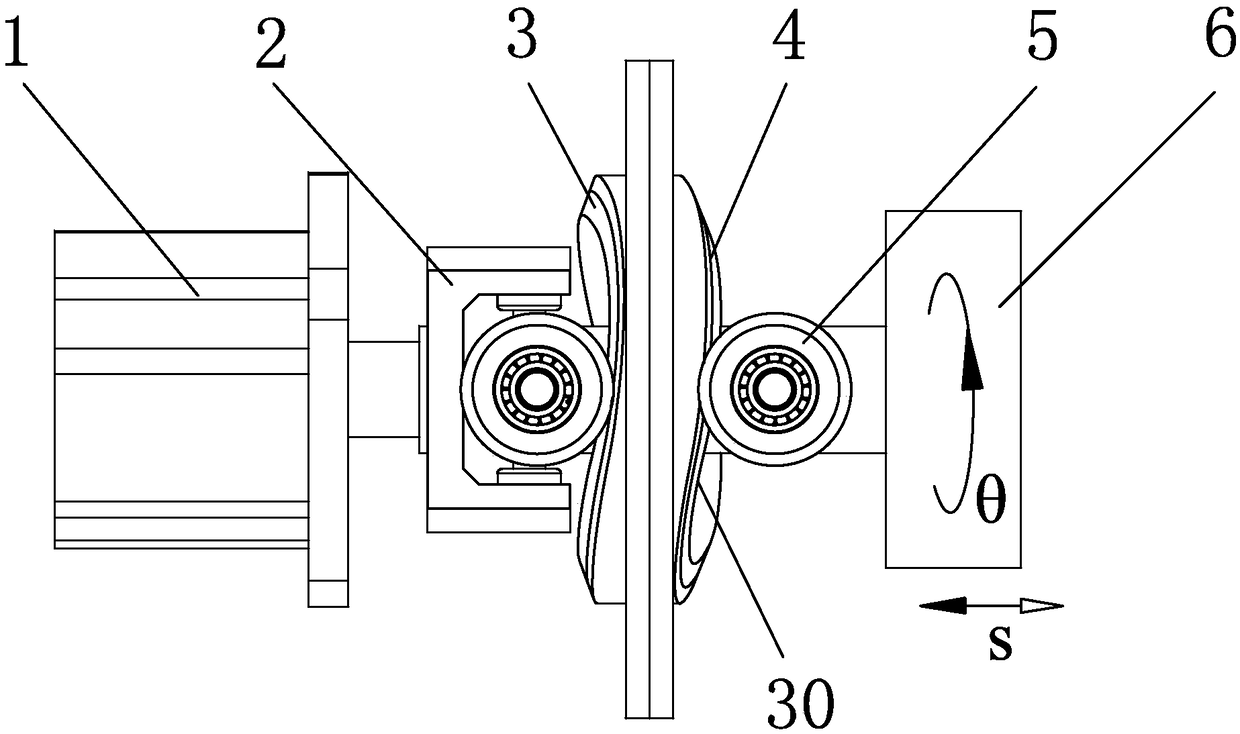

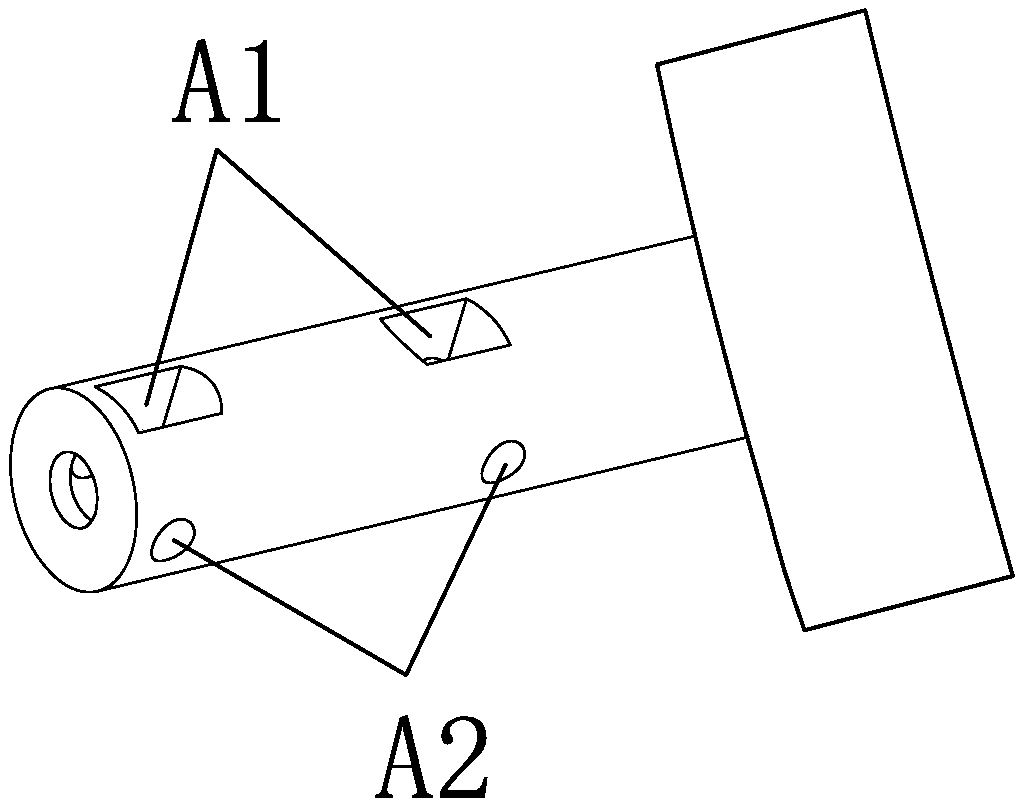

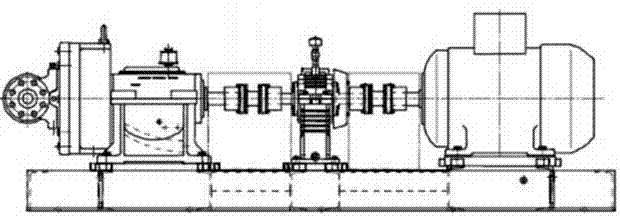

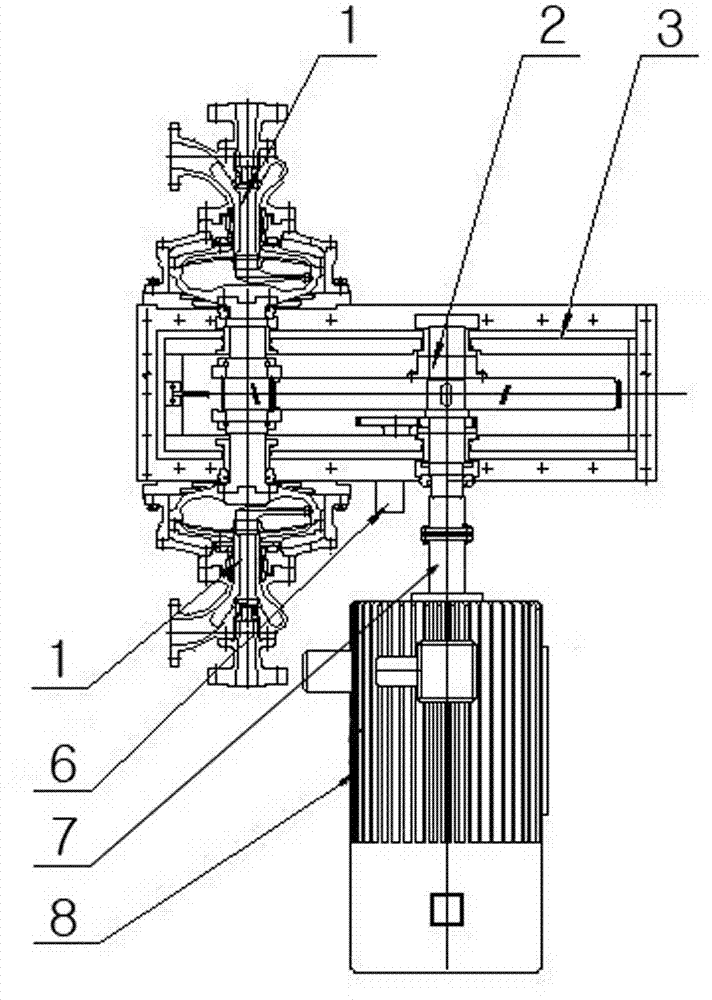

Gear speed increasing assembly type high speed rotating casing pump unit

InactiveCN104265639ASmall form factorImprove anti-cavitation performancePump installationsRadial flow pumpsCavitationLow speed

The invention relates to a high speed rotating casing pump unit, in particular to a rotating casing pump unit composed of a gear speed increasing assembly type high speed rotating casing pump. The pump unit comprises the gear speed increasing assembly type high speed rotating casing pump, an integrated shaft head oil pump, a coupler and a driving motor. The coupler enables the driving motor to be connected with a low speed shaft of the gear speed increasing assembly type high speed rotating casing pump. The gear speed increasing assembly type high speed rotating casing pump is composed of a stator part, a rotor part and a box body part. The stator part is composed of two rotating casing pump suction / discharging parts, a protection casing of the stator part is connected onto a location flange of the box body part, and a shaft seal part is located on the inlet side of each suction part. The rotor part is composed of a high speed shaft system and a low speed shaft system and adopts a single-oblique-tooth gear pair, each rotating casing pump rotor is directly connected with the high speed shaft, and double-side thrust discs for balancing residual axial force are arranged on two sides of the small gear tooth width direction of the high speed shaft to meet the alternating axial load work condition. The high speed rotating casing pump unit is compact in appearance, small in axial force borne by the bearing, large in pump unit flow application range and good in anti-cavitation performance.

Owner:江苏海狮泵业制造有限公司

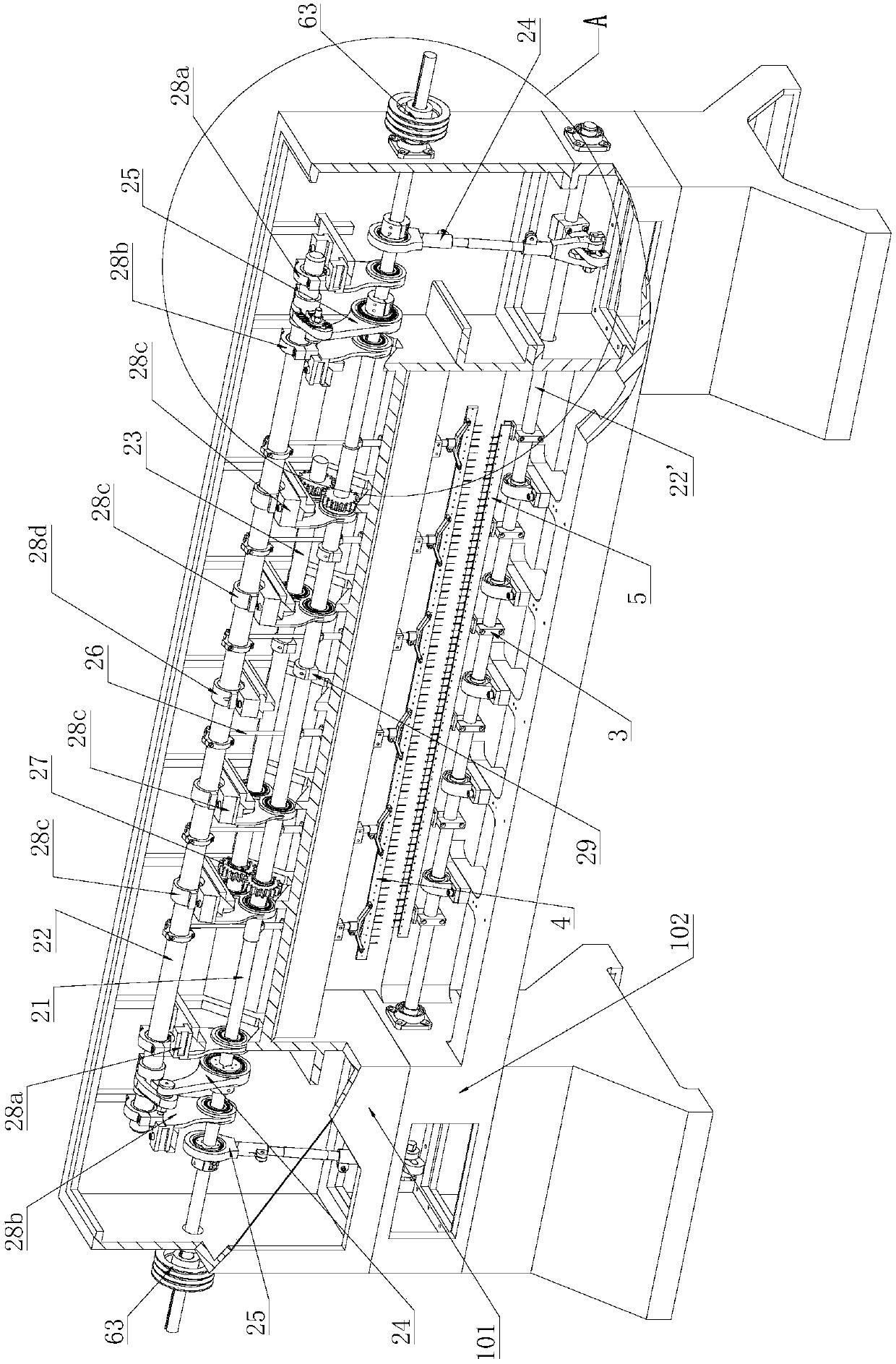

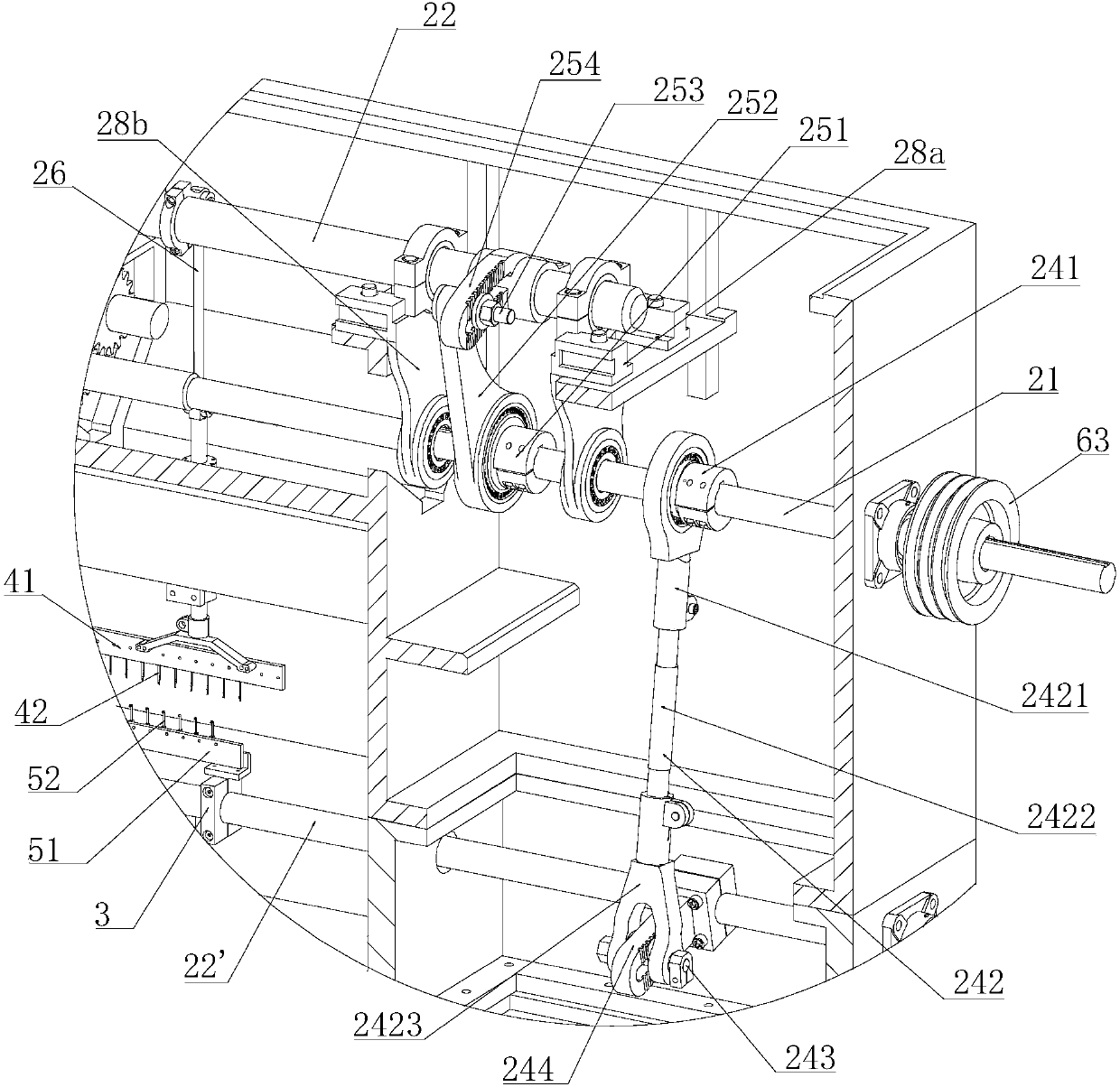

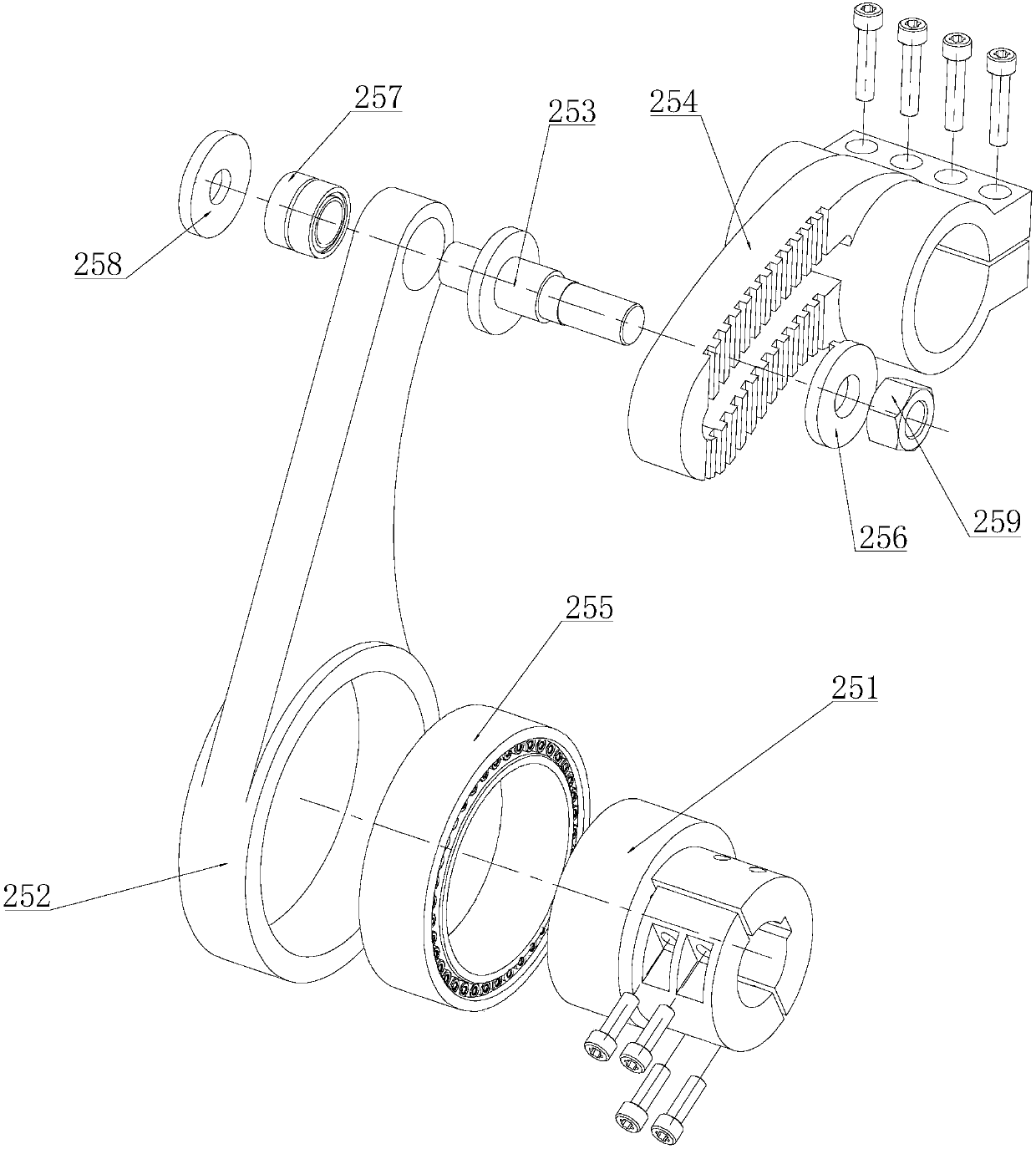

Dynamic balance high-speed main shaft device and carpet tufting machine with same

InactiveCN107653591AIncrease working speedSimple designTufting apparatusEffective solutionDrive shaft

The invention relates to a dynamic balance high-speed main shaft device and a carpet tufting machine with the same. The device comprises a driving shaft installed on a rack, at least one driven shaftwhich is installed on the rack and arranged to be parallel to the driving shaft, a crank linkage connected with the driving shaft and the driven shaft and a dynamic balance device. The dynamic balancedevice comprises a synchronizing shaft, a gear set and at least one eccentric weight, the synchronizing shaft is installed on the rack and arranged to be parallel to the driving shaft, the synchronizing shaft synchronously rotates with the driving shaft through the gear set, and the eccentric weight is fixed to the driving shaft and / or the synchronizing shaft. For the main shaft device, the dynamic balance device is additionally arranged in structure design, an effective solution is provided for the dynamic unbalance problem of the main shaft device in the carpet tufting machine, and the working speed of the main shaft device can be greatly increased.

Owner:CHANGHZOU WUDING CARPET MACHINERY

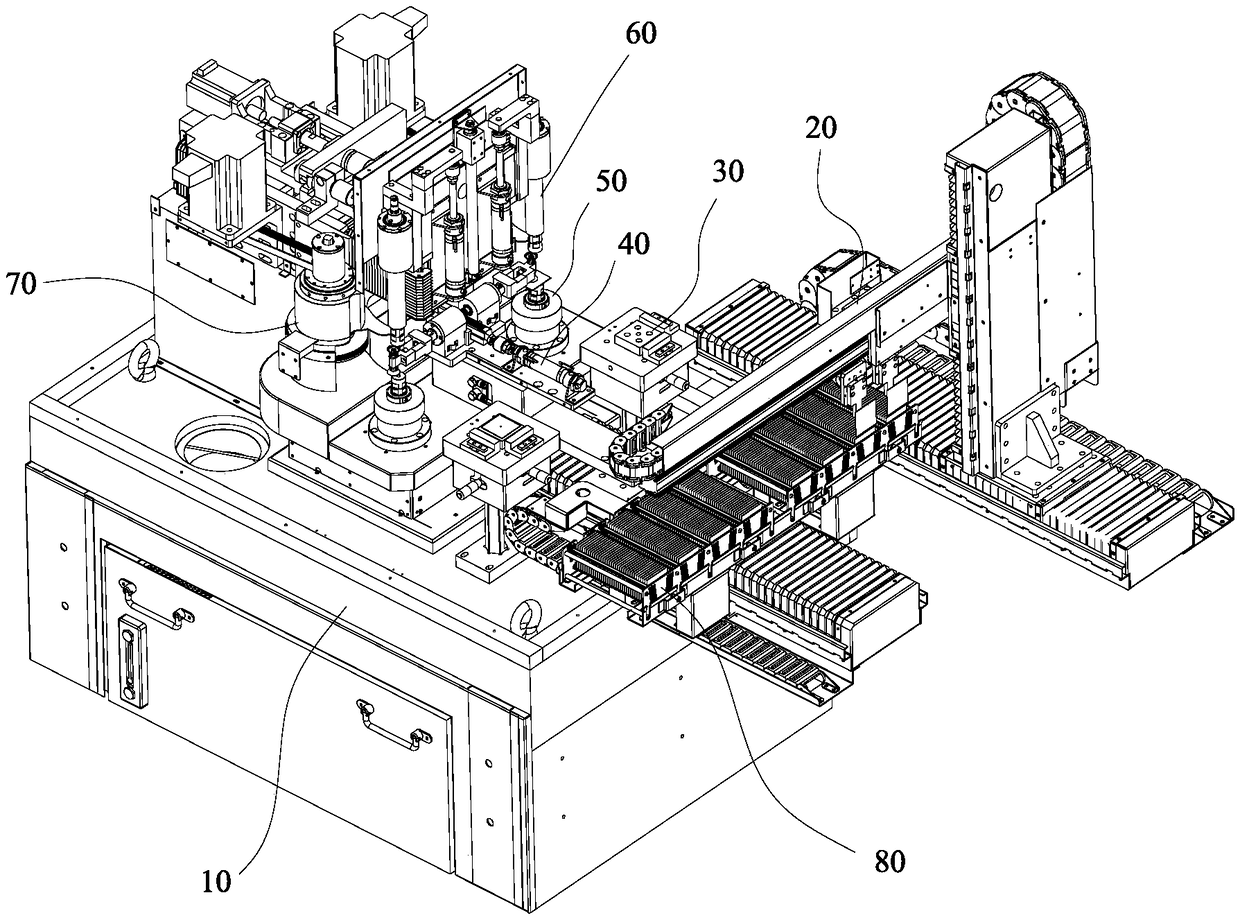

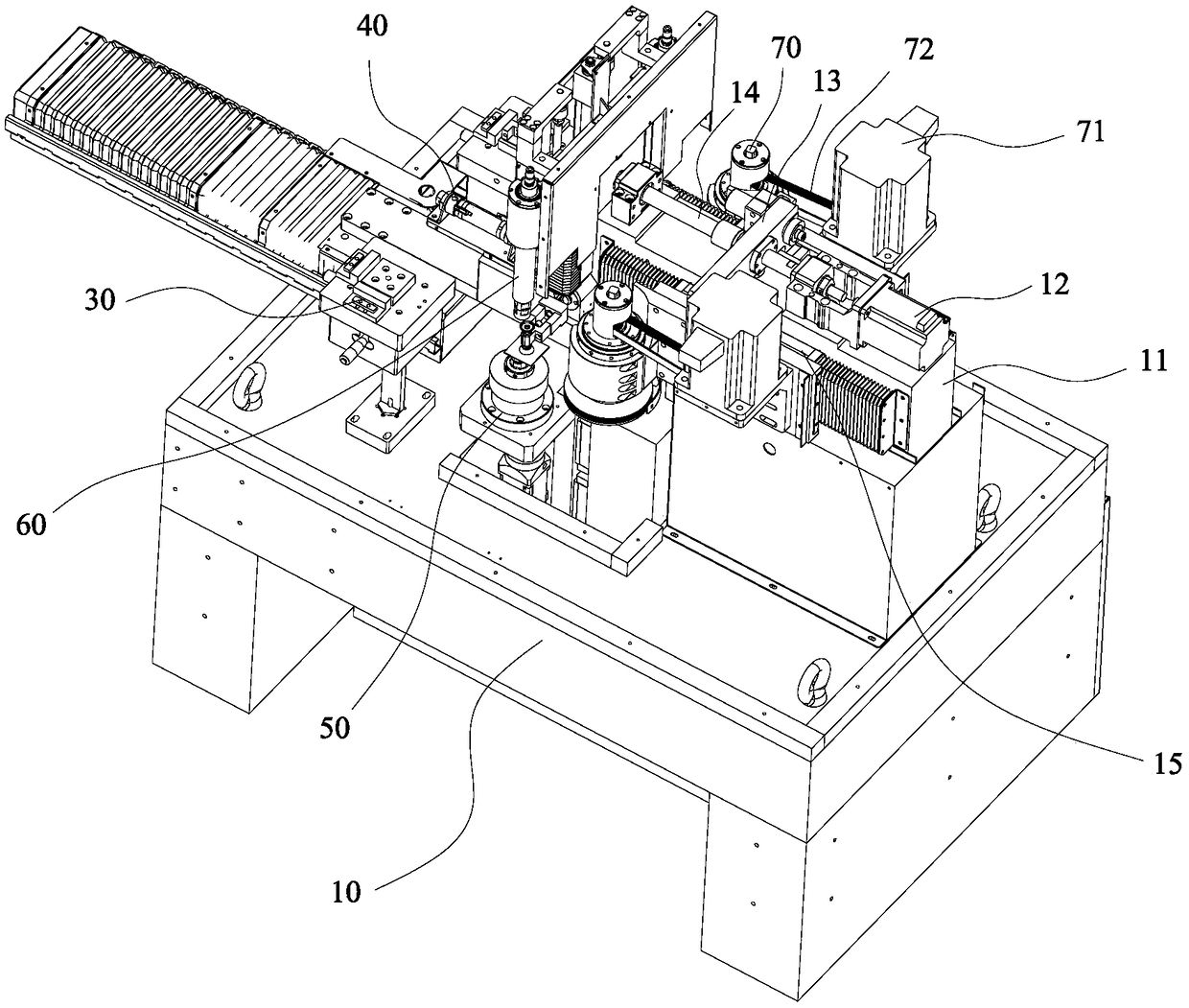

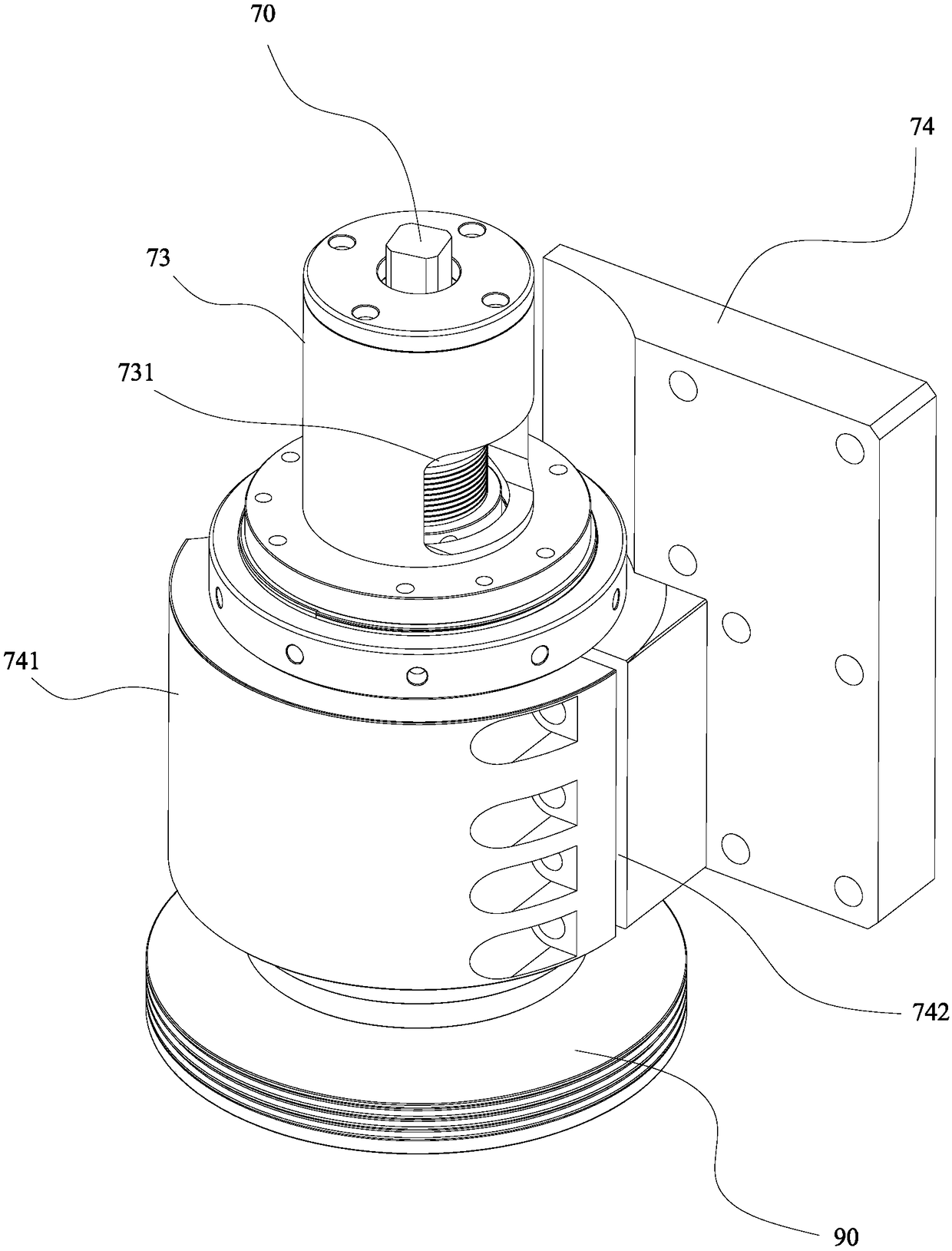

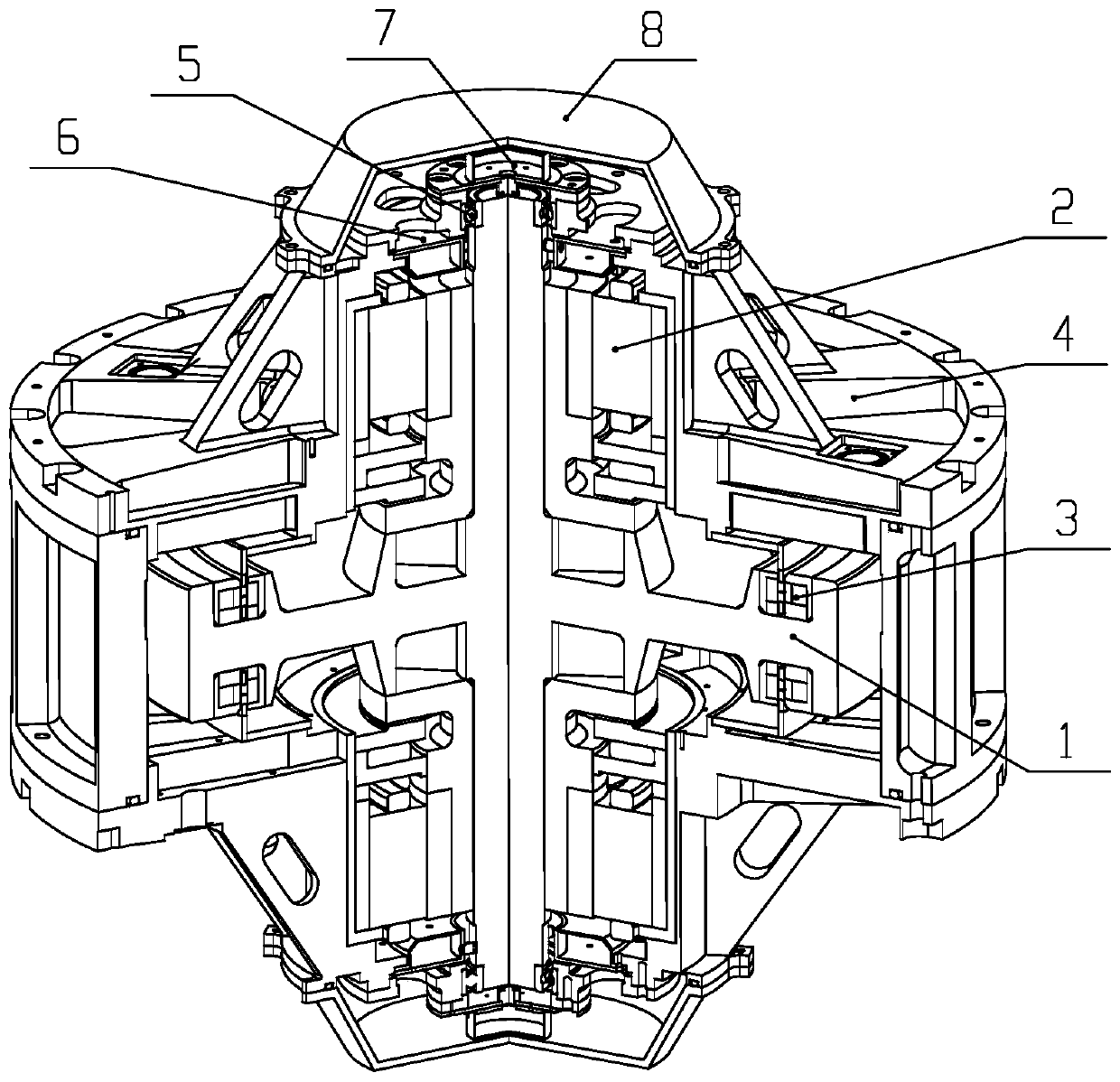

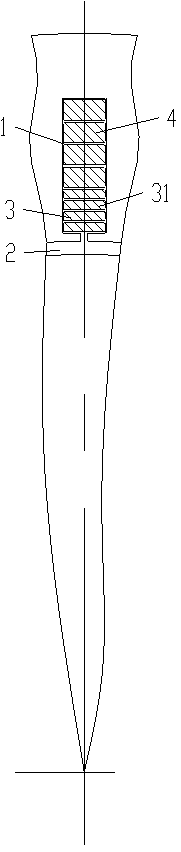

Numerical control precise double-station grinding machine

PendingCN109483366AReduce laborReduce offsetOptical surface grinding machinesLensNumerical controlManipulator

The invention discloses a numerical control precise double-station grinding machine. The machine comprises a stand; a loading mechanism, positioning mechanisms and grinding mechanisms are arranged onthe stand in a lens feeding direction in sequence; two sets of positioning mechanisms and two sets of grinding mechanisms are provided and arranged side by side; the loading mechanism comprises a groove and a loading manipulator; a taking manipulator is arranged between the two sets of positioning mechanisms; each set of the grinding mechanisms comprise lens clamping mechanisms and grinding wheeldriving mechanisms; the lens clamping mechanisms comprise lens rotating shafts and lens clamping shafts; the grinding wheel driving mechanisms comprise grinding wheels and grinding wheel main shafts;the lens rotating shafts are mounted on the back sides of the positioning mechanisms; the lens clamping shafts are mounted above the lens rotating shafts; the grinding wheel main shafts are mounted onthe back sides of the lens rotating shafts; and the grinding wheels are mounted on the grinding wheel main shafts, and can be driven to rotate by the grinding wheel main shafts. The machine realizesfull automation of the lens grinding, and improves the lens grinding efficiency and quality.

Owner:东莞市华思智能装备科技有限公司

Magnetic suspension control moment gyroscope high-speed rotor device

ActiveCN110435931AShorten the axial lengthIncrease working speedCosmonautic vehiclesSpacecraft guiding apparatusAxial displacementGyroscope

The invention discloses a magnetic suspension control moment gyroscope high-speed rotor device. The device comprises a flywheel, three-degree-of-freedom integrated magnetic bearings, a high-speed motor, a gyroscope case, a protective bearing, a radial displacement sensor, an axial displacement sensor and an end cover, wherein a rotor component of the device is composed of the flywheel, a rotor part of the high-speed motor and rotor parts of the three-degree-of-freedom integrated magnetic bearings, a stator component is composed of the gyroscope case, a stator part of the high-speed motor, stator parts of the three-degree-of-freedom integrated magnetic bearings and the end cover, and high-speed rotation of a rotor is achieved between the rotor component and the stator component through thehigh-speed motor to provide angular momentum for output torque of a gyroscope. According to the device, through supporting by the two three-degree-of-freedom integrated magnetic bearings which are symmetrically arranged, radial and axial non-contact stable suspension of the rotor can be achieved, so that a magnetic bearing supporting system is compact in layout, the size and weight of the device are reduced, the axial length of the rotor can be shortened so that higher rotor inherent frequency and higher rotating speed can be obtained.

Owner:BEIHANG UNIV

Continuous extruding machine with cooling device outside extruding wheel

PendingCN108097732AReduce the temperature difference between inside and outsideIncrease working speedExtrusion profiling toolsMagnesiumCooling channel

The invention relates to extrusion production equipment, in particular to extrusion production equipment of nonferrous metal products such as copper, aluminum, magnesium and alloys thereof. The invention provides a continuous extruding machine with a cooling device outside an extruding wheel. The continuous extruding machine is characterized in that the extruding wheel is provided with an annulargroove, the periphery of the circumference of the extruding wheel is sequentially provided with a compaction wheel for pressing an extruded metal rod material, a cavity with an arc sealing surface anda scraper used for cleaning the outer surface of the extruding wheel along the rotation direction of the extruding wheel; cooling blocks are arranged on the periphery of the extruding wheel, arc surfaces are arranged on the inner sides of the cooling blocks, and the arc surfaces are in close contact with the outer surface of the extruding wheel and can slide relative to the outer surface of the extruding wheel; and cooling channels are arranged in the cooling blocks, and flowing cooling mediums are led into the cooling channels. According to the continuous extruding machine, the cooling blocks with the arc surfaces are adopted for directly cooling the outer surface of the extruding wheel so that the temperature of the outer surface of the extruding wheel can be effectively reduced, the production efficiency of continuous extrusion is improved, and the service life of the extruding wheel is prolonged.

Owner:大连康丰科技有限公司

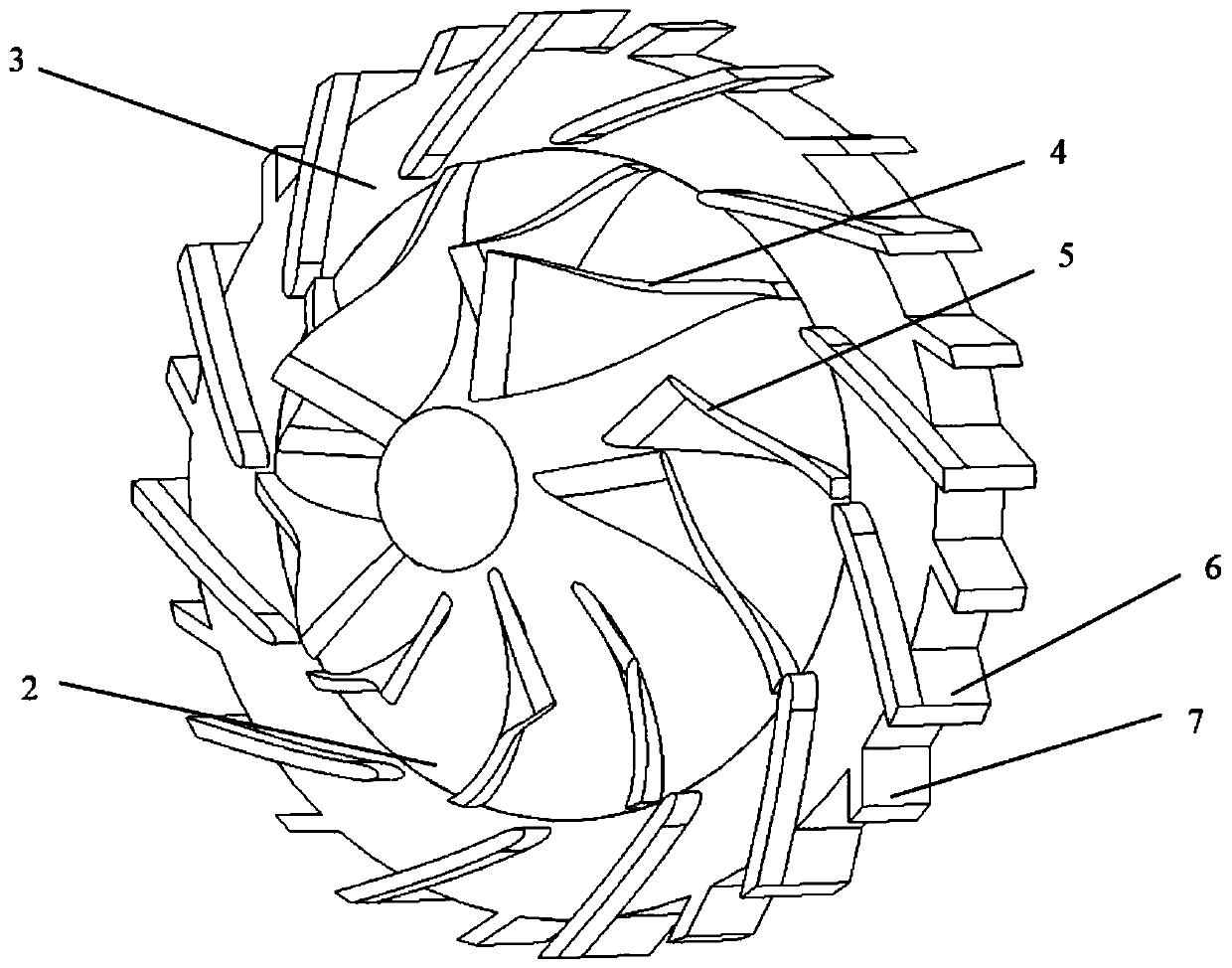

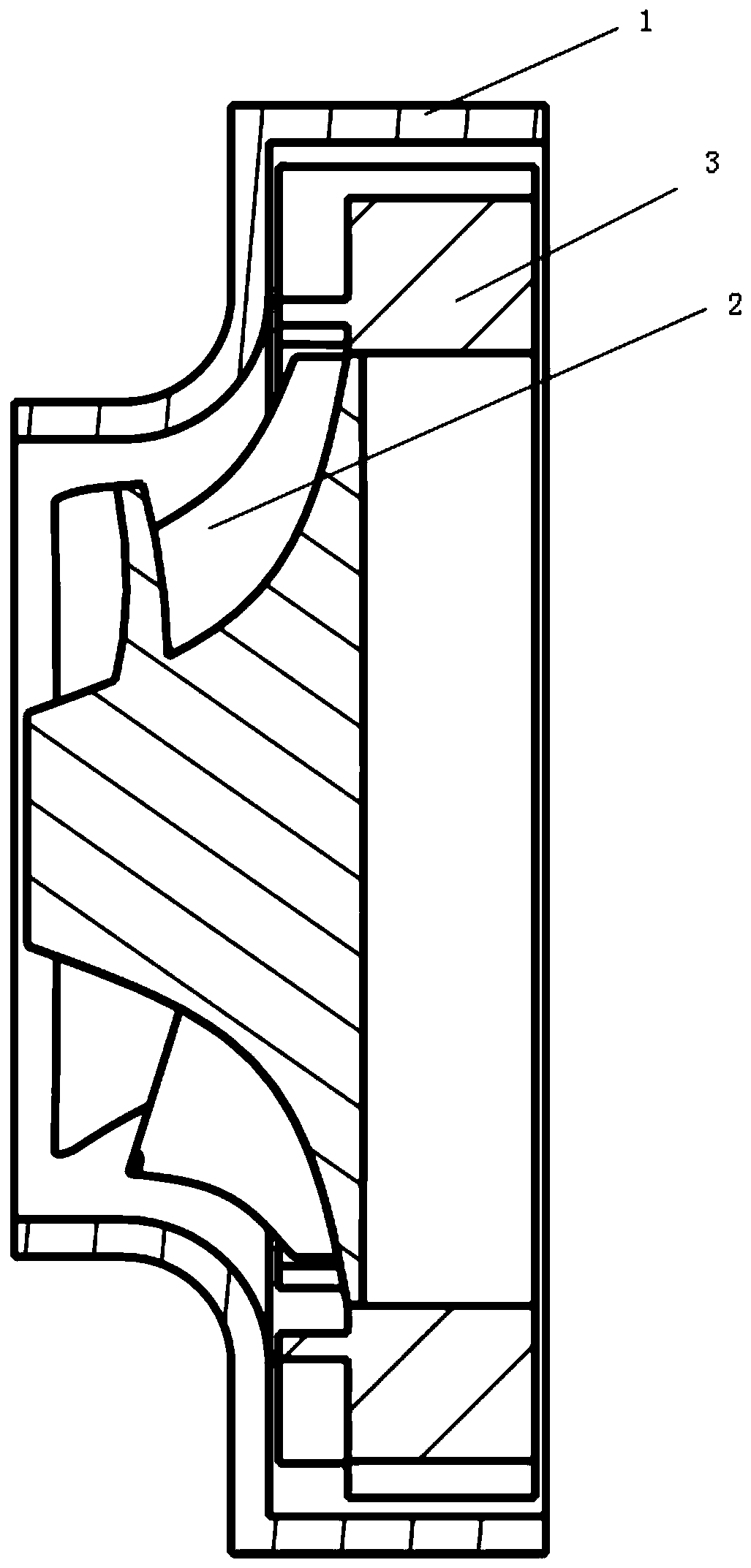

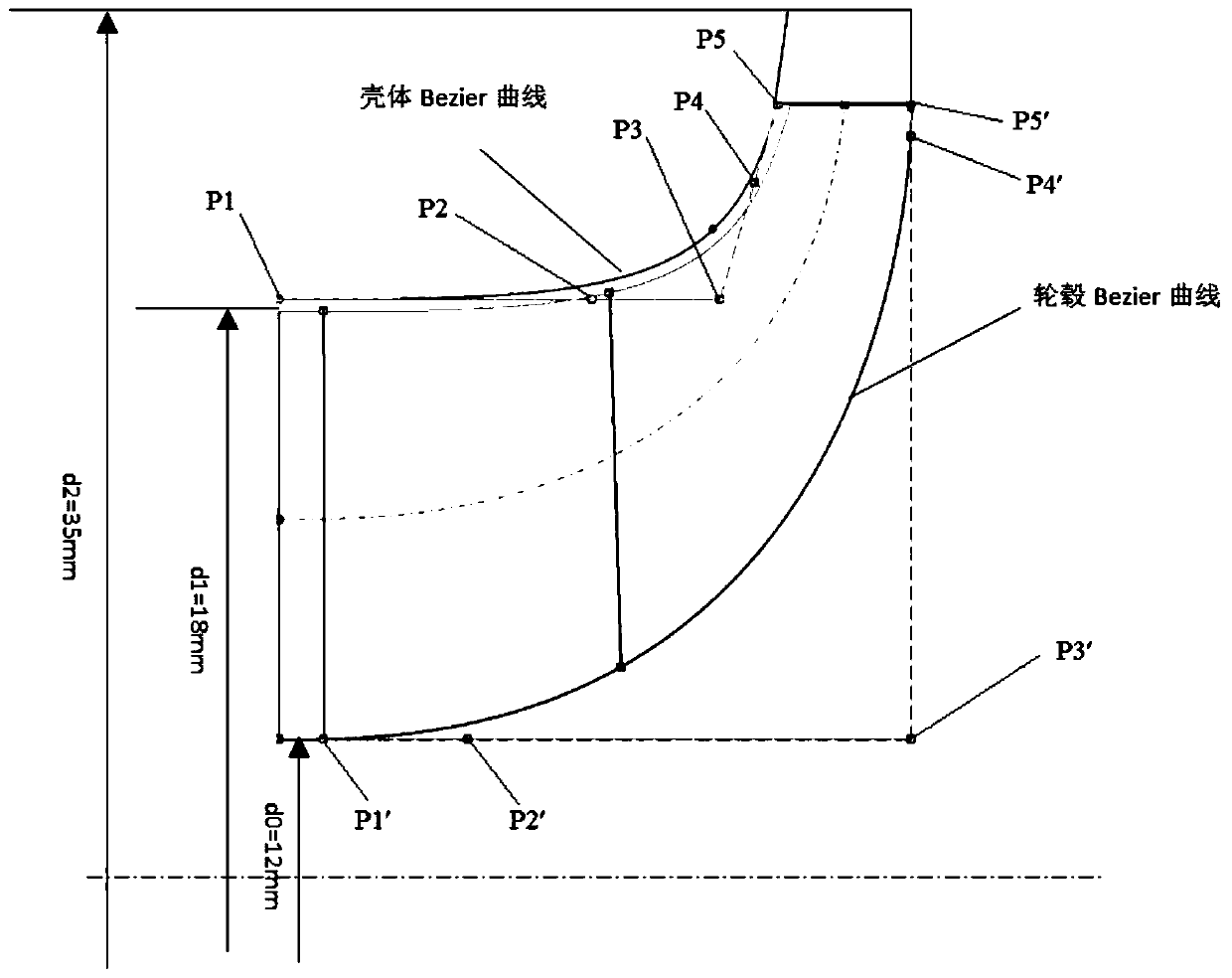

Design method of centrifugal compressor and diffuser structure

ActiveCN110608195AImprove flow statusReduce flow lossPump componentsPumpsEngineeringCentrifugal compressor

The invention discloses a design method of a centrifugal compressor and a diffuser structure. The centrifugal compressor comprises a shell, an impeller and a diffuser, wherein the impeller comprises ahub and impeller blades, the diffuser comprises diffuser blades; and the design method comprises the following steps that curve segments of the shell and the hub of the impeller adopt Bezier curve design, and curve segments of the impeller blades adopt 3D free curve design; and curve segments of the diffuser blades adopt spiral curve design. Through the parametric design method, a gas inlet angleat a gas inlet hole and a gas outlet angle at a gas outlet hole are optimized, a gas flow state is improved, the uniformity of an outlet gas flow is improved, the gas flow loss is reduced, and high gas compressing capability and diffusion capability are obtained under the condition of small size.

Owner:CHANGCHUN UNIV OF SCI & TECH

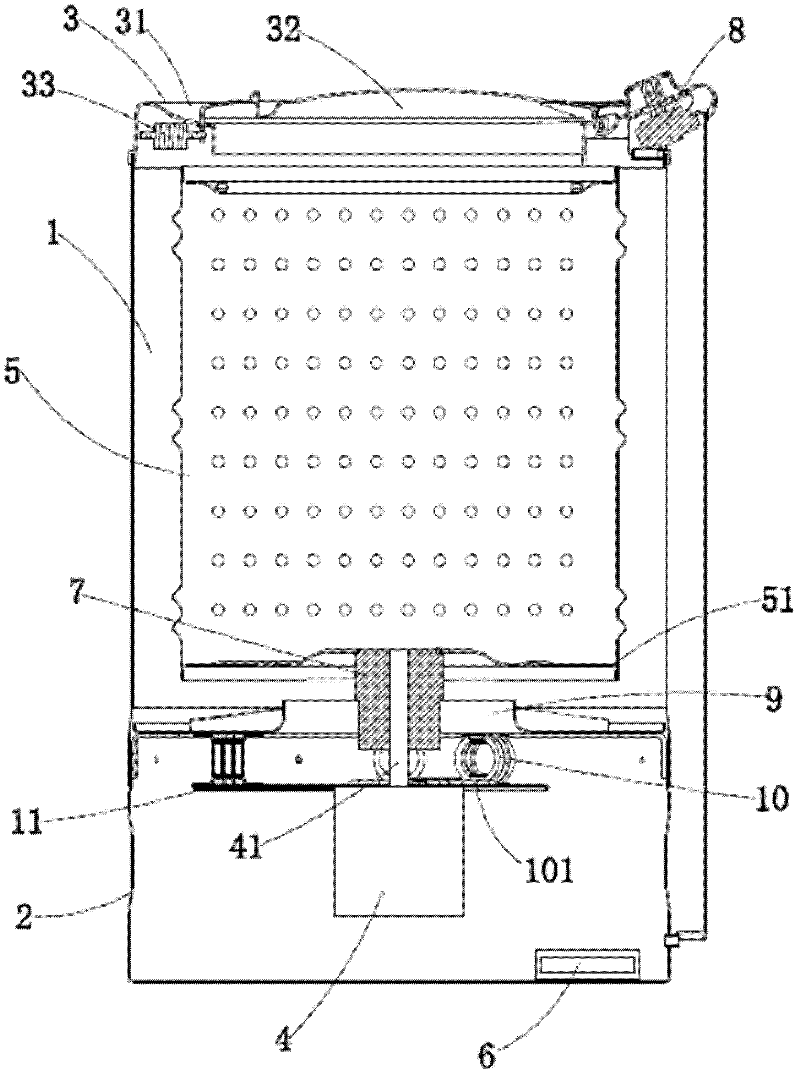

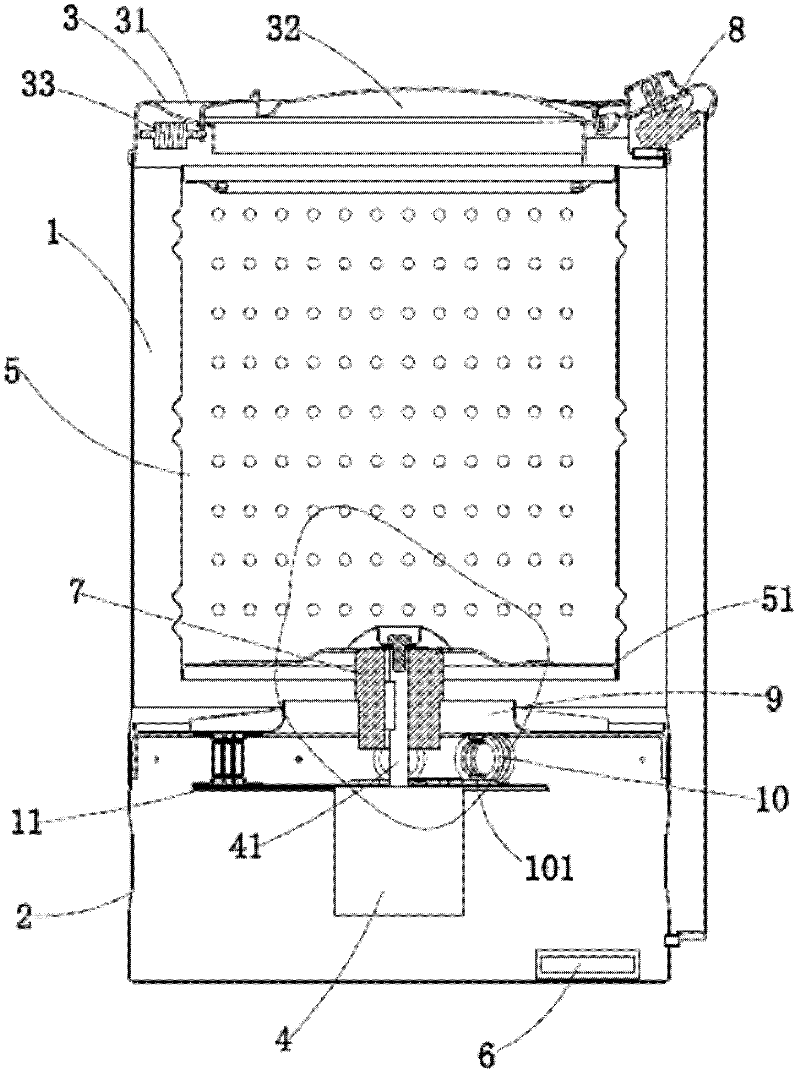

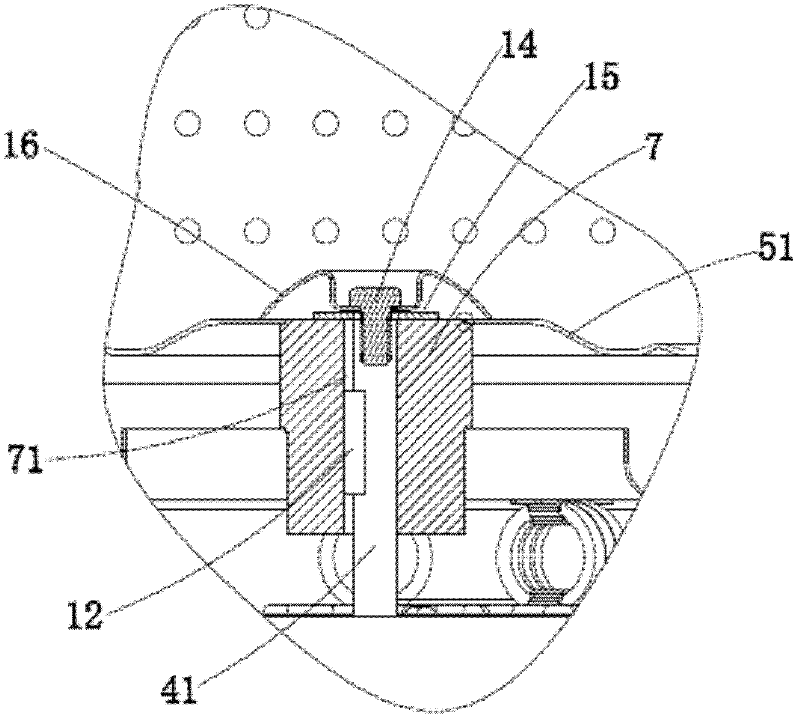

Suspension dehydrator

InactiveCN102286870AStable jobImprove connection strengthTextiles and paperSpin-dryersElectric machineryEngineering

The invention discloses a suspended dehydrator, comprising a cover frame part, a barrel body, a rotating cage, a base and a motor, wherein the barrel body is fixed on the base in which an electric component is arranged; the cover frame part is fixed at the upper end of the barrel body and is provided with a dehydration timer which is matched with the electric component; the motor is positioned inside the base; the rotating cage is positioned inside the barrel body; a connecting shaft sleeve is fixed on a rotating cage base plate at the bottom end of the rotating cage; a motor shaft is matchedwith the connecting shaft sleeve to form a link structure; a base end plate is arranged at the joint of the base and the barrel body; the base is internally provided with a motor mounting plate; a plurality of flexible connecting components are arranged between the base end plate and a motor mounting frame; each flexible connecting component is fixedly connected with the base end plate and the motor mounting plate by a fastening component; and the motor is fixed on the motor mounting plate. The base end plate is flexibly connected with the motor mounting plate to absorb the vibration generated by the motor during working, so that the whole machine is stable during working, and the working speed can be increased to 1,200r / min.

Owner:宁波乐士洗涤科技有限公司

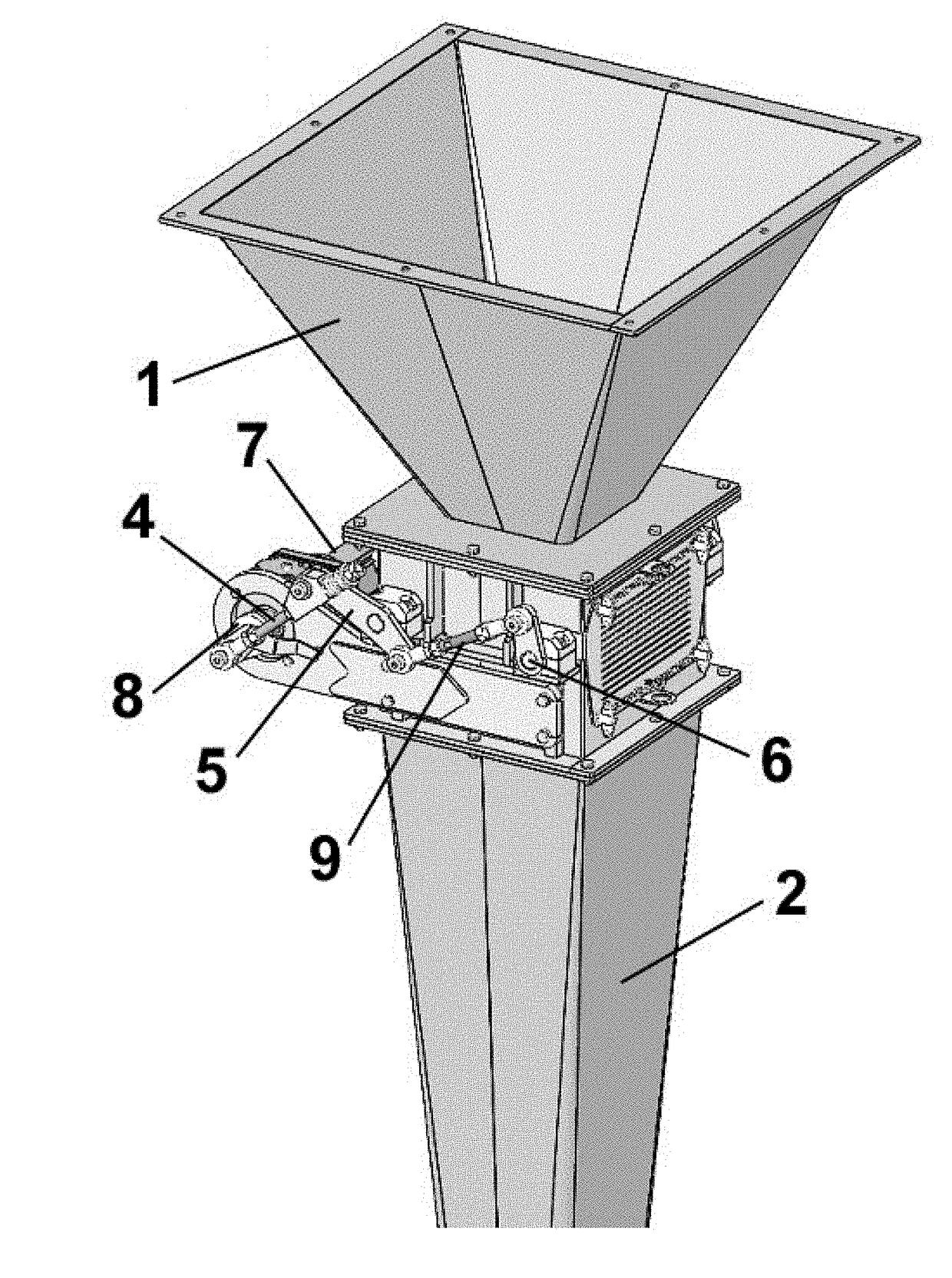

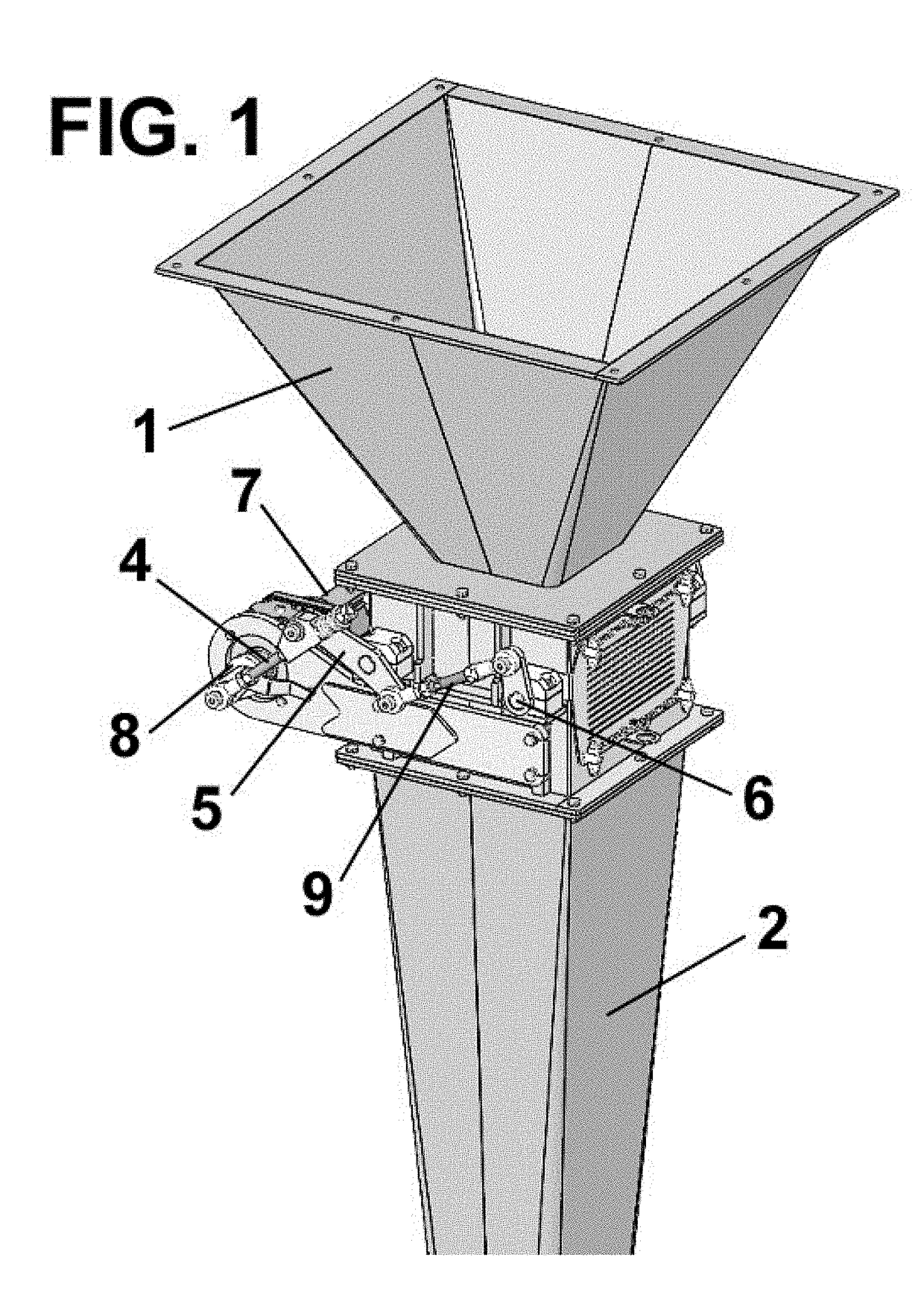

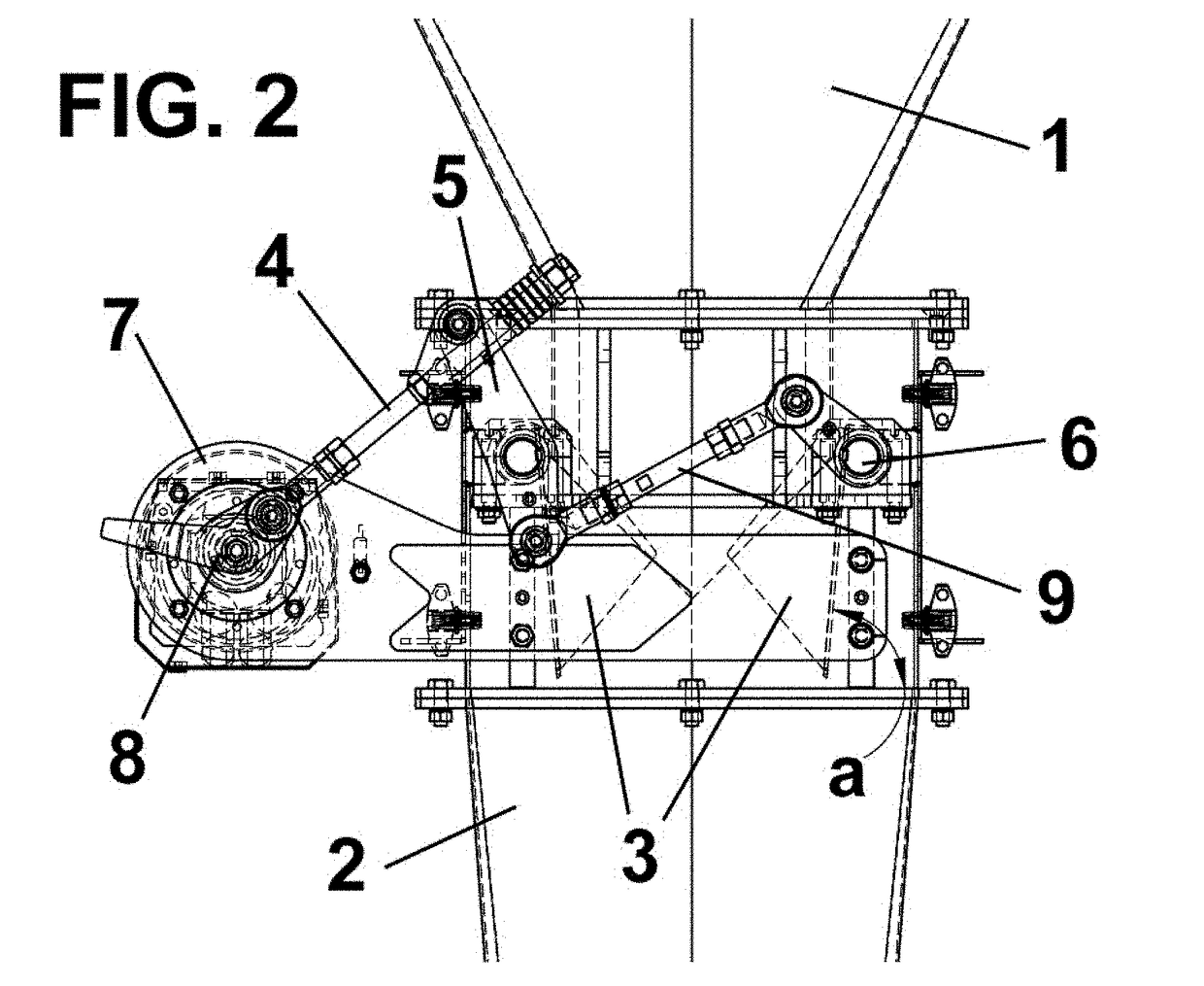

Product discharge control device for a form-fill-seal machine

ActiveUS20180141690A1Short timeShort discharge timeSolid materialPackaging automatic controlElectric machineryEngineering

The invention relates to a discharge control device, comprising a hopper (1) receiving a metered product amount where it is deposited, discharge control elements (3) movable between a closed position and an open position by driving means, and a fill tube (2) connecting the discharge control device with a fill nozzle of the form-fill-seal machine whereby a bag is filled with product, wherein the driving means of the discharge control elements (3) comprise a motor (7) driving the movement of one of the discharge control elements (3), and a synchronizing connecting rod (9) synchronizing the movement of the discharge control element (3) driven by the motor (7) with the other discharge control element (3).The invention allows filling bags reliably and more quickly.

Owner:PAYPER

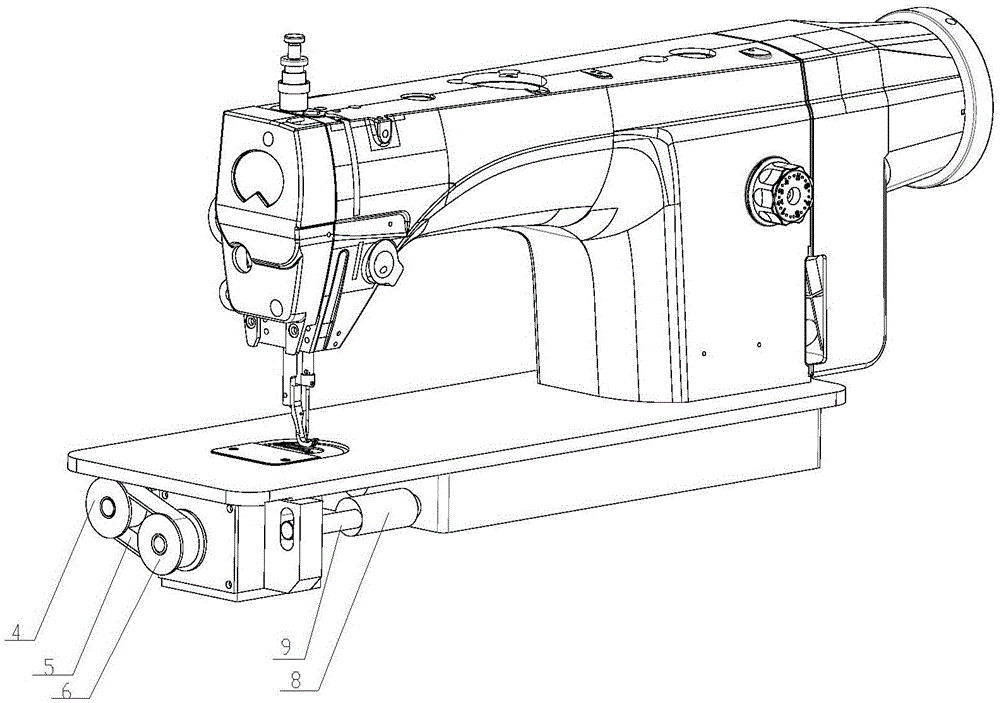

Cloth delivery mechanism

The invention discloses a cloth delivery mechanism which comprises a swivel case and a cloth delivery mechanism. An inner rotor and an outer rotor rotate in a rotary chute in the swivel case, a spring is connected with a slide block, and a fixed semi-swivel and a sliding semi-swivel are arranged on the two sides of the swivel case body. The chute is connected to one end of a tooth rack, and cloth delivery tooth are installed on the top of the tooth rack. A coupler is connected to a cloth delivery motor shaft and the cloth delivery shaft, a first synchronizing wheel is installed on the cloth delivery shaft, and a second synchronizing wheel is installed on the outer end of the swivel case. A synchronous belt winds on the second synchronizing wheel and the first synchronizing wheel, and a needle distance adjusting shaft is connected with the swivel case, and a needle distance adjusting rocking bar is arranged on the needle distance adjusting shaft. The needle distance adjusting shaft connects the needle distance adjusting rocking bar and a needle distance base, and same forward and backward needle distances are ensured. Wrinkling and skidding of cloth delivery can be minimized, vibration and noise during delivering cloth at high speed can be reduced, and working rotating speed is increased. The cloth delivery mechanism is easy to realize modular production and assembly, and assembly efficiency is improved.

Owner:BULLMER ELECTROMECHANICAL TECH

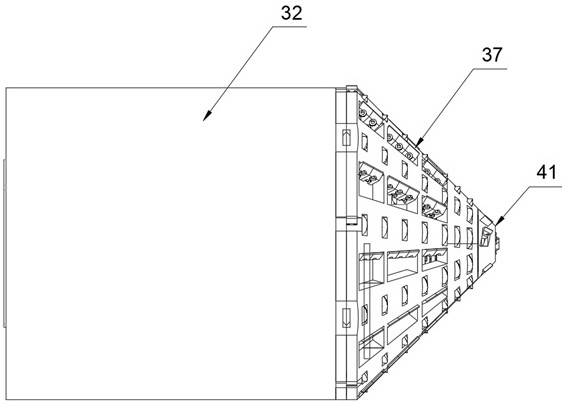

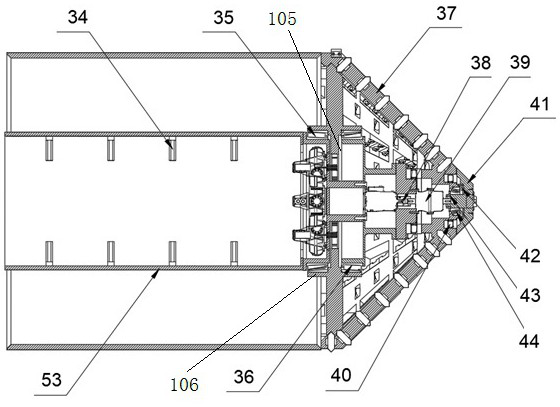

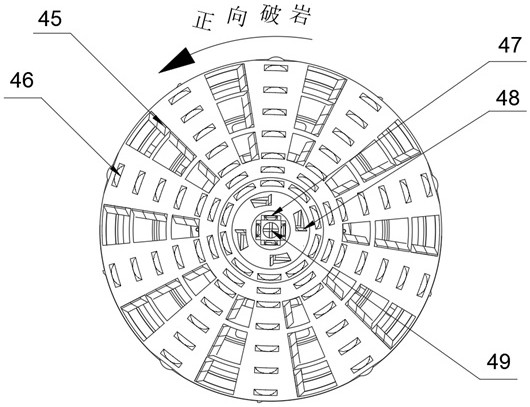

Multi-stage decoupling conical cutter head for full-section tunnel boring machine

PendingCN114753857AImprove rock breaking efficiencyIncrease the area of actionTunnelsTunnel boring machineIndustrial engineering

The multi-stage decoupling conical cutter head comprises a circular-truncated-cone-shaped main cutter head and a circular-truncated-cone-shaped auxiliary cutter head, the large-diameter end of the circular-truncated-cone-shaped main cutter head is matched with a heading machine body in a rotating mode through a main cutter head driving unit, and the small-diameter end of the circular-truncated-cone-shaped main cutter head is connected with the large-diameter end of the circular-truncated-cone-shaped auxiliary cutter head in a rotating mode. And the large-diameter end of the circular-truncated-cone-shaped sub-cutterhead is in rotary fit with the heading machine main body through the sub-cutterhead driving unit. According to the invention, the multi-stage circular-truncated-cone-shaped cutterhead is used for replacing a traditional planar cutterhead, so that the acting area of the cutterhead and an excavation surface is increased, stress concentration is avoided, a certain space can be provided for improving the installed power of a cutterhead driving system, and the internal space of the cutterhead is increased by the conical structure of the multi-stage decoupling circular-truncated-cone-shaped cutterhead; convenience is provided for maintenance and operation of the cutterhead, and the personal safety of maintenance personnel is guaranteed.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD +1

Intelligent dynamic pressure bearing

The invention provides an intelligent dynamic pressure bearing. A control system of the bearing comprises a sensor and a control unit, wherein the sensor is used for monitoring at least one operationparameter of a bearing body or a rotor supported by the bearing body and sending the monitored parameter to the control unit; the at least one operation parameter is used for at least characterizing arotary speed of the rotor or at least characterizing an operation load of the bearing body or the rotor. When the rotary speed of the rotor is less than a pre-set speed or when the operation load ofthe bearing body or the rotor is greater than a pre-set load, lubrication liquid is supplied to the bearing body through a liquid supply system, so that the intelligent dynamic pressure bearing is used as a liquid dynamic pressure bearing to work. When the rotary speed of the rotor is greater than or equal to the pre-set speed and when the operation load of the bearing body or the rotor is less than or equal to the pre-set load, the liquid supply system stops supplying the lubrication liquid to the bearing body, so that the intelligent dynamic pressure bearing is used as a gas dynamic pressurebearing to work. The intelligent dynamic pressure bearing has the advantages of the gas dynamic pressure bearing and the liquid dynamic pressure bearing.

Owner:TSINGHUA UNIV

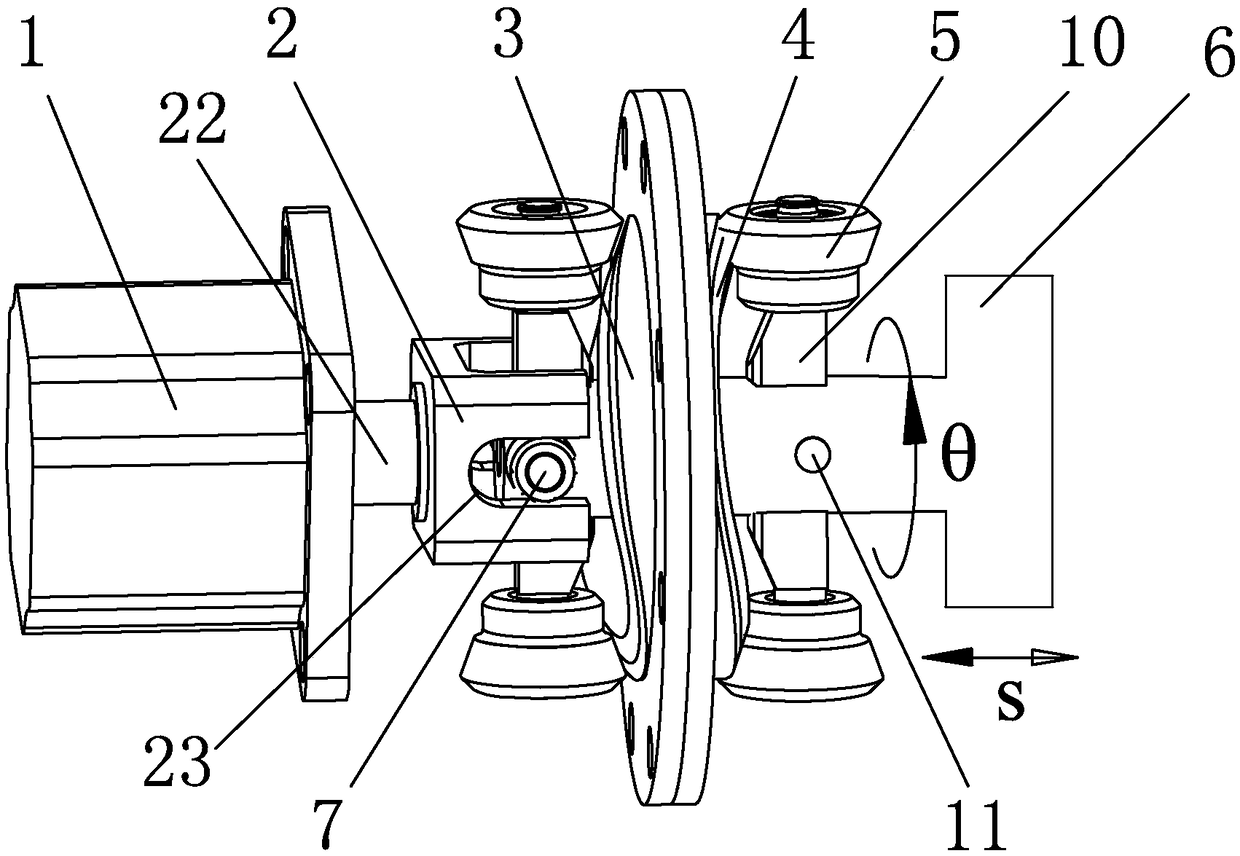

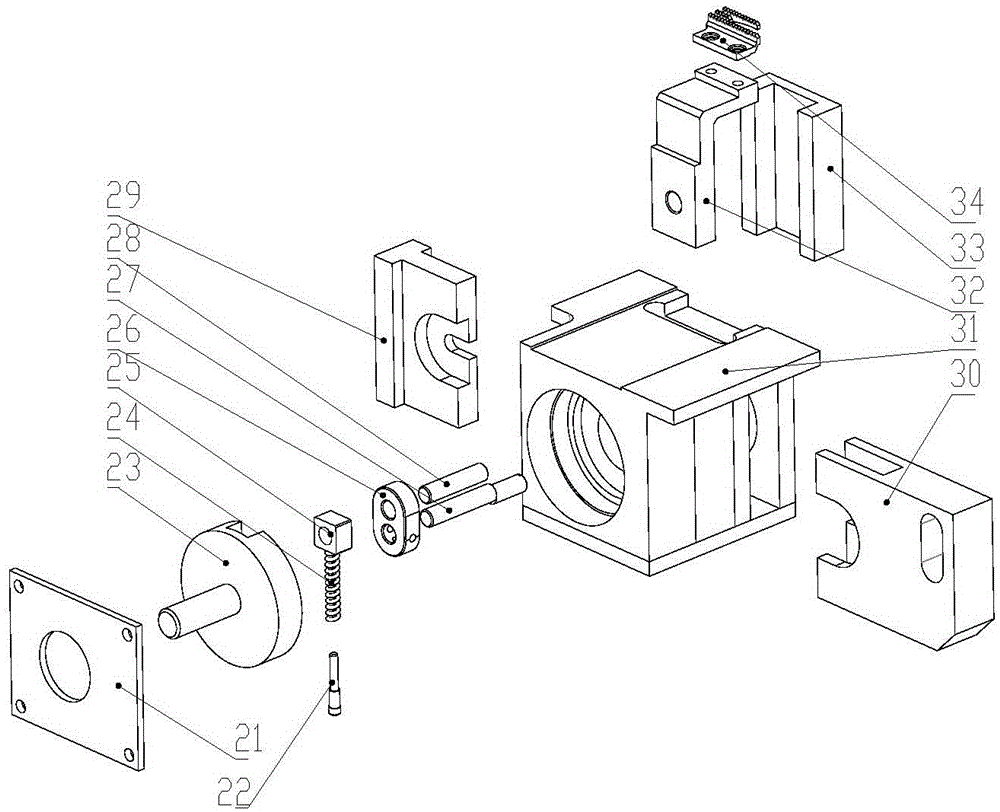

Adjustable over-torque protection structure for high-speed heavy-load shaft system

PendingCN109578452AImprove stabilityIncrease working speedCouplings with disconnecting safety membersEngineeringHeavy load

The invention belongs to the technical field of mechanical transmission equipment, and particularly relates to an adjustable over-torque protection structure for a high-speed heavy-load shaft system.The adjustable over-torque protection structure comprises an outer transmission shaft system, an external connecting bearing base, an inner transmission shaft system, an adjustable over-torque protection pin assembly and an anti-flying pressure plate, wherein the outer transmission shaft system with an inner spline interface structure is connected to a high-speed heavy-load planetary gear box; theexternal connecting bearing base is connected to the box body of the gearbox; the outer transmission shaft system is connected with the inner transmission shaft system through the adjustable over-torque protection pin assembly; and the anti-flying pressure plate is connected to the inner transmission shaft system through a bolt. After the structure is adopted, the number and the structures of theover-torque protection pin assemblies are changed, so that safety, during operation and test, of a test part and a matched tester can be improved, and extreme load of safe operation can be obtained.The adjustable over-torque protection structure has the characteristics of being high in working rotation speed, compact in structure, high in universality, quick and reliable in dismounting, and effectively avoiding the test part damage risk.

Owner:HARBIN GUANGHAN POWER TRANSMISSION

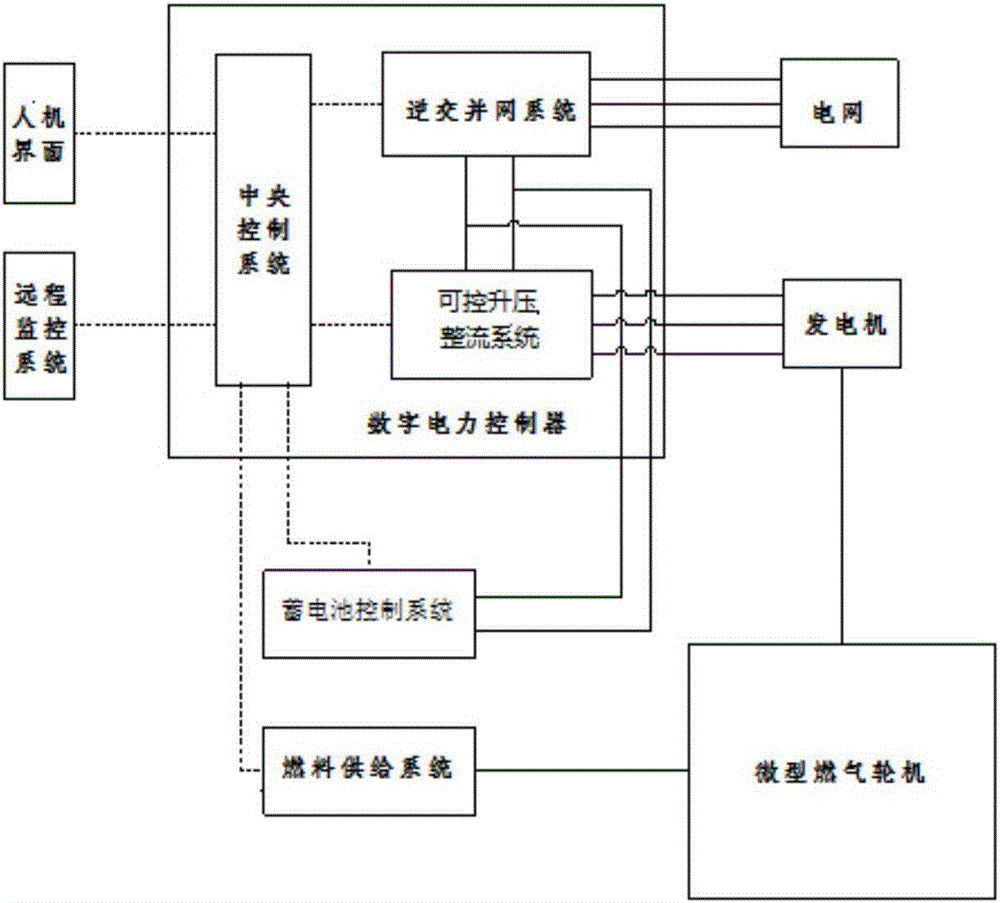

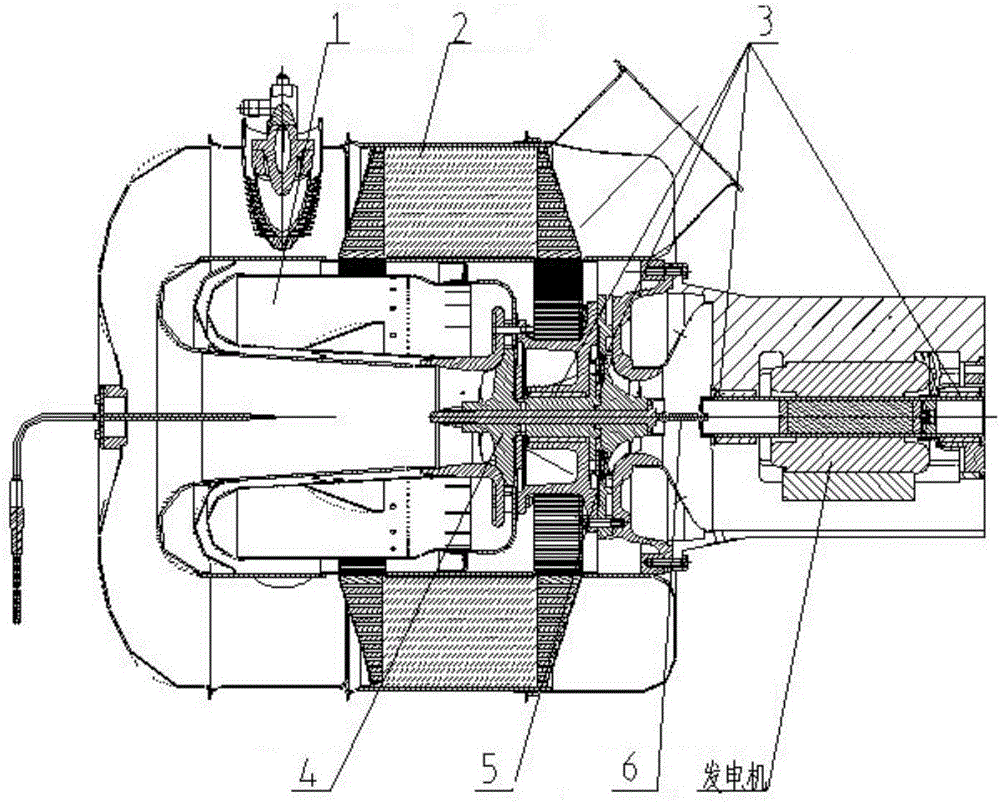

Micro gas-turbine power station

InactiveCN106321243AReduce noiseOvercome the problems that cannot be applied in the field of distributed power supplyTurbine/propulsion engine ignitionTurbine/propulsion engine startersPower stationControl system

The invention discloses a micro gas-turbine power station, and belongs to the field of power generation equipment. The power station mainly comprises a digital electric controller, a power generator and a micro gas turbine, wherein a plate fin type heat regenerator is arranged on the micro gas turbine, and the plate fin type heat generator surrounds the outer part of the micro gas turbine; the digital electric controller comprises a controllable boosting and rectifying system, an inverter grid-connected system and a central control system; the micro gas turbine is coaxially flexibly connected with the power generator; the power generator, the controllable boosting and rectifying system and the inverter grid-connected system are sequentially connected through cables; and the controllable boosting and rectifying system and the inverter grid-connected system are connected with the central control system through cables. According to the power station disclosed by the invention, noises are small, tail gas is convenient to recycle and maintenance cost is low; and the power station is wide in applied range, and effectively overcomes the problem that the power station cannot be applied in the distribution type power supply field due to the fact that existing diesel engine power generation equipment has a cylinder pulling phenomenon.

Owner:BEIJING POWER MACHINERY INST

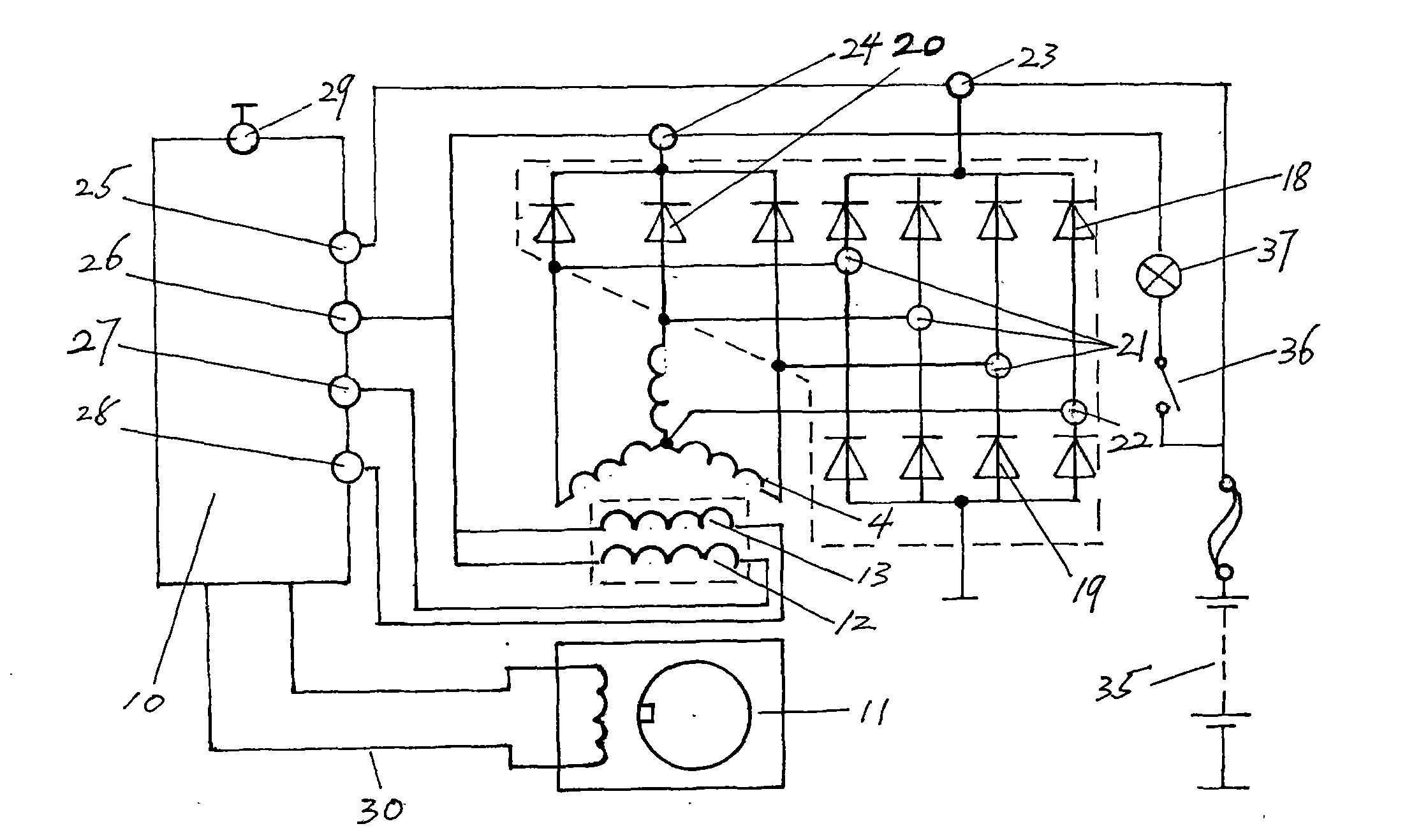

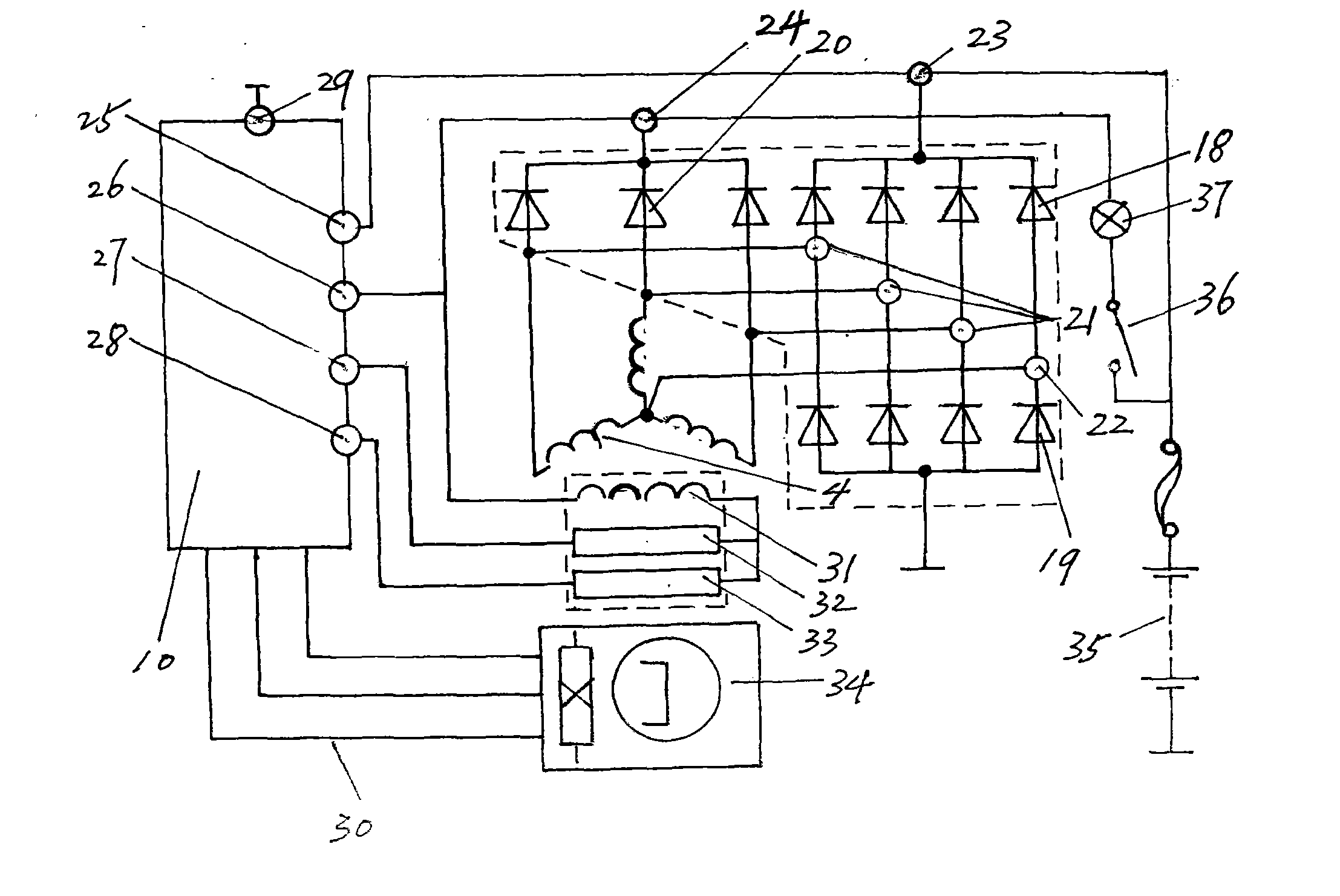

Variable excitation brushless alternating-current generator

InactiveCN102710086AIncrease working speedIncrease the magnetic field strengthStructural associationWindings conductor shape/form/constructionElectricityRectifier diodes

The invention discloses a variable excitation brushless alternating-current generator which has the advantages of good charging performance in low speed operation, middle speed operation and high speed operation and being free from frequent maintenance. The generator is characterized by consisting of a rotor assembly assembled in an inner ring of a stator assembly between a front end cover and a rear end cover, a rectifier fixed at the rear end of the rear end cover, a variable excitation and voltage adjustor, and a speed sensor of the generator, wherein three leads of the head end of stator three-phase winding of the stator assembly and one lead of the middle point of the stator three-phase winding of the stator assembly are electrically connected with four groups of rectifier diodes of the rectifier respectively; the variable excitation and voltage adjustor is electrically connected a lead at the head end of the rotor assembly double-excitation winding and two leads at the tail end of the rotor assembly double-excitation winding, an output of the rectifier and exciting pins through pins respectively, wherein the rotor assembly is fixed on the rear end cover; and the leads are electrically connected with the speed sensor of the generator.

Owner:李慧杰

High speed shaft system with torque measuring function

PendingCN108194623AIncrease working speedQuick disassemblyGearboxesGearing detailsTransfer mechanismControl theory

The invention discloses a high speed shaft system with a torque measuring function, and mainly solves the problems that real accessories are prone to being damaged and the cost is high on trial. The high speed shaft system with the torque measuring function comprises a transferring mechanism (1), a hinge hole bolt A (2), a hinge hole bolt B (5), a membrane A (3), a membrane B (6), an intermediateshaft (4), a transferring flange (7), a high speed torque meter (8), a conical surface flange (9), and a gear case high speed shaft (10); the high speed shaft system with the torque measuring functionis characterized in that a spline end opening of the connected device is connected with the transferring mechanism (1) provided with an outer spiline shaft; a right end flange of the transferring mechanism (1) is connected with the left end of the intermediate shaft through the hinge hole bolt A (2) and the membrane A (3); the right end of the intermediate shaft (4) is connected with the left endof the transferring flange through the hinge hole bolt B (5) and the membrane B (6); the left end of the transferring flange is connected with the high speed torque meter; and the high speed torque meter (8) is connected with the a load gear case high speed shaft (10) through the conical surface flange (9). The high speed shaft system with the torque measuring function has the characteristics ofreliable connection, on-line torsion measuring, compact structure and high working speed.

Owner:中国船舶重工集团公司第七0三研究所

Dynamic torque measurement sensor with speed measurement function

InactiveCN106644196ASimple structureIncrease working speedForce measurementLinear/angular speed measurementElastomerEngineering

The invention discloses a dynamic torque measurement sensor with a speed measurement function. The sensor comprises an integral conductive slip ring, an elastomer spindle, bearings, a shell, and fastening screws. The integral conductive slip ring has an inner ring and an outer ring which can rotate relative to each other, and the inner ring and the outer ring lead out multiple wires respectively. The wires are connected inside the slip ring. The integral conductive slip ring sleeves the elastomer spindle. The elastomer spindle is rotationally supported on the shell through the bearings. The inner ring of the slip ring is fixed on the elastomer spindle by screws, and can rotate together with the elastomer spindle. The outer ring of the slip ring is fixed on the shell by a stop screw. The wires of the inner ring of the slip ring are connected with a strain gauge on the elastomer spindle. The wires of the outer ring of the slip ring are connected with a socket on the shell. Voltage and electrical signals are transmitted between the moving and static parts of the sensor through the integral conductive slip ring. The working speed range of the dynamic torque sensor is broadened, and the service life is prolonged. Moreover, the sensor is additionally provided with a speed measurement function.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Flat wire motor winding in-groove structure with conductors with different thicknesses

PendingCN110829661AThe skin effect is obviousWeak skin effectWindings conductor shape/form/constructionElectrical conductorElectric machine

The invention provides a flat wire motor winding in-groove structure with conductors with different thicknesses. The structure can be used to reduce a skin effect and a motor copper loss, and has a high groove filling rate and high efficiency. A plurality of conductors are arranged in a wire groove in a radial direction of a motor. At least one conductor close to an air gap is composed of more than two layers of sub-conductors arranged in the radial direction of the motor. At least one conductor, far away from the air gap, is an integral layer in the radial direction of the motor, the thickness of each sub-conductor in the radial direction of the motor is smaller than that of the integral layer far away from the air gap, and a sectional area of each conductor composed of the sub-conductors, close to the air gap, is the same as that of the integral layer conductor far away from the air gap.

Owner:NANJING HAOLONG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com