Patents

Literature

205 results about "Curve design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

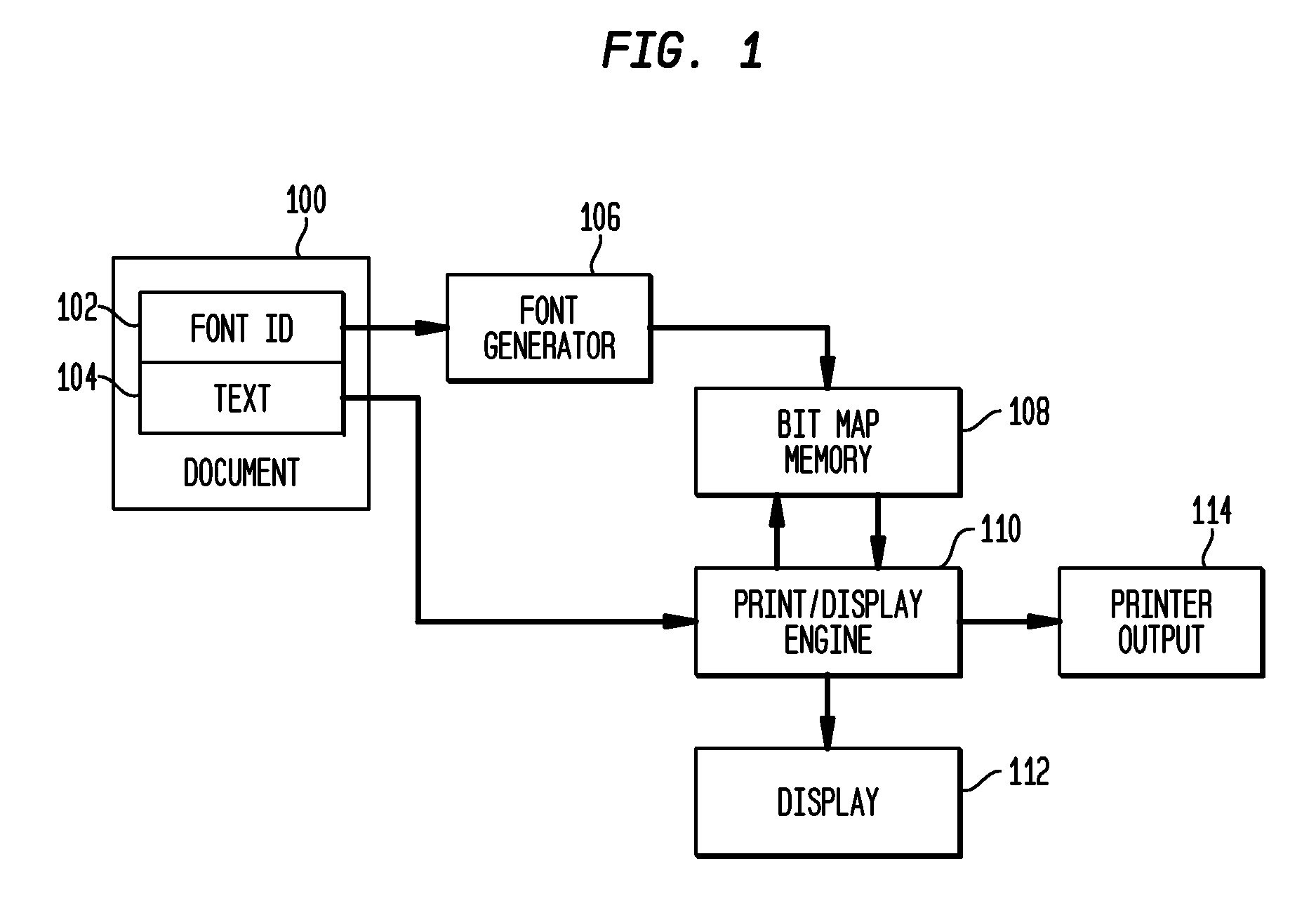

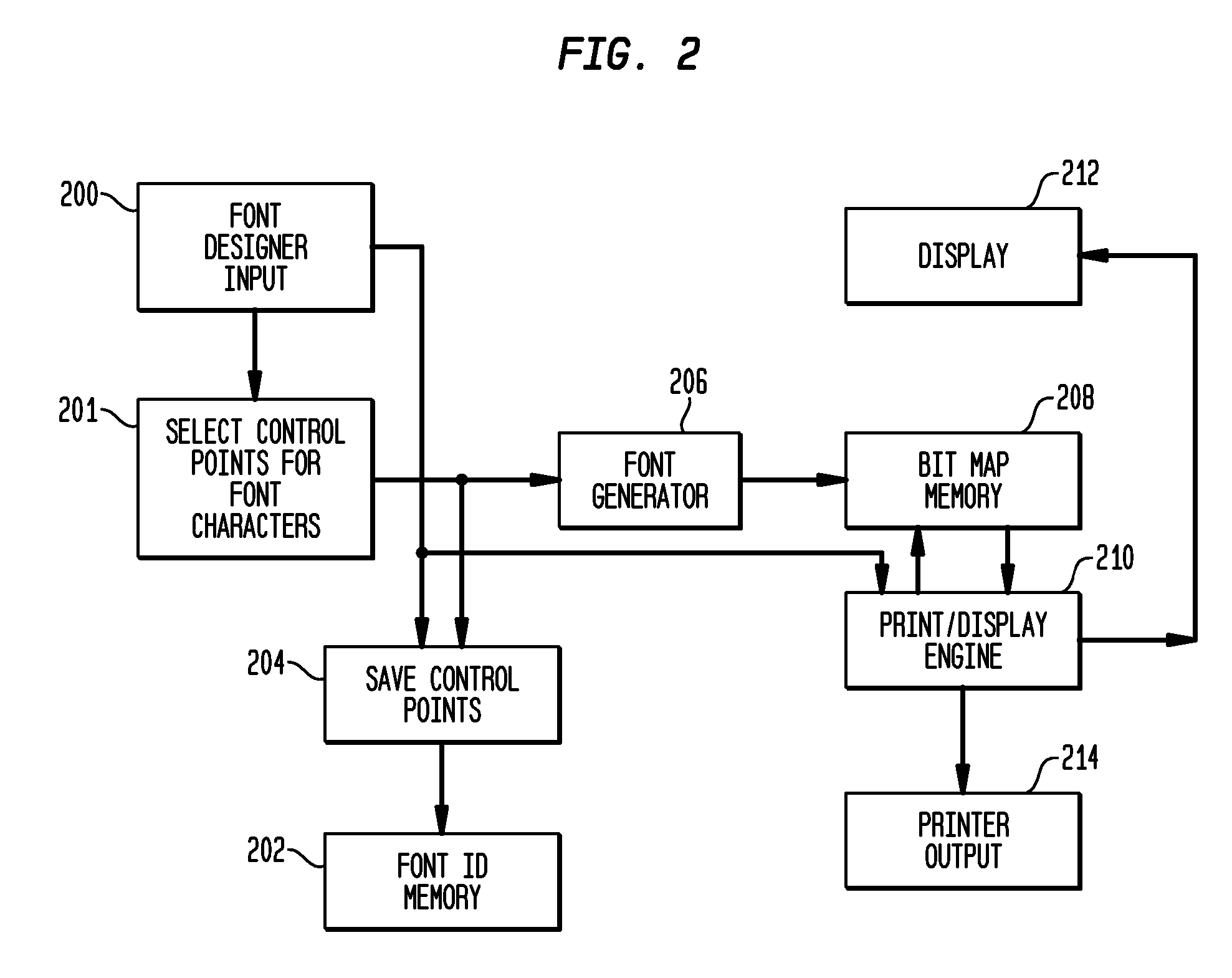

Method and apparatus for interactive curve generation

ActiveUS20080005212A1Drawing from basic elementsDigital function generatorsComputer scienceCurve design

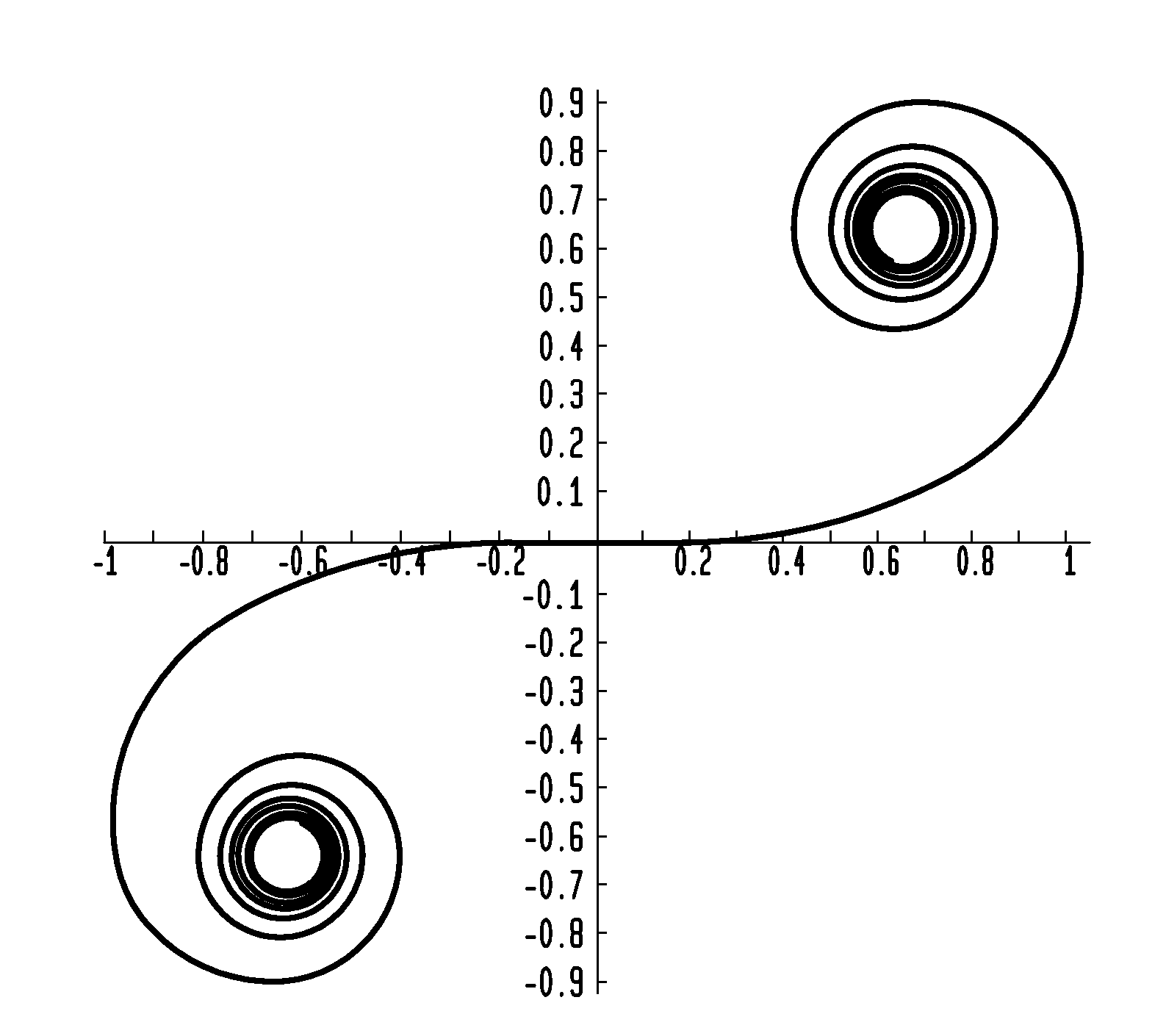

A system of curve generation takes a sequence of control points and constraint codes for each control point, and outputs a curve in which each of the constraints is satisfied. The set of constraints is chosen from the tangent angle, curvature, first derivative of curvature, and second derivative of curvature. The interactive curve design uses as its primitive, a curve whose curvature is a polynomial function of arclength (whose intrinsic equation is a polynomial). At each control point, a choice of G2 curvature continuity (tangent angle and curvature) or G4 curvature continuity (tangent angle and curvature plus first and second derivatives of curvature are continuous) is input. The desired curve is expressed as the solution to the chosen set of constraints.

Owner:LEVIEN RAPHAEL L

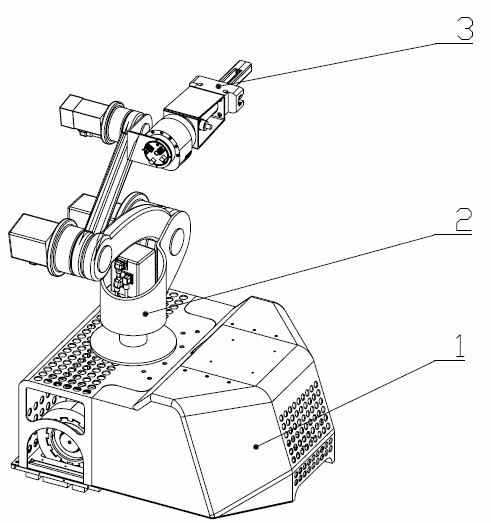

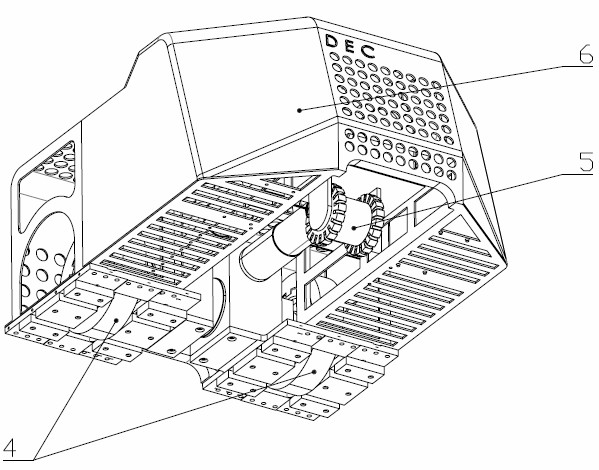

Differential motion driving magnetic adsorption type multifunctional wall climbing robot with small-folding-size mechanical arms

The invention belongs to the technical field of special robots and particularly relates to a differential motion driving magnetic adsorption type multifunctional wall climbing robot with small-folding-size mechanical arms, comprising a climbing mechanism and an operation mechanism, wherein the operation mechanism comprises multifunctional mechanical arms and tail end working modules; a base of each multifunctional mechanical arm is fixed on an adsorption type climbing mechanism; and each tail end working module is fixed at the tail end of each multifunctional mechanical arm. According to the invention, the small-folding-size mechanical arms are carried; with the adoption of a five-degree-of-freedom matching manner, the tail end of each arm can work in a working region at any position and any angle; and compared with the other mechanical arms with less degree-of-freedom, the movement of the multifunctional mechanical arms is more flexible. The small-folding-size mechanical arms refer to that the arm folding is more compact and the size of the folded arm is smaller according to explanation; and according to the shape represented on each arm, particularly a large arm adopts a curve design, so that other structures can be avoided when the arms are folded.

Owner:DONGFANG ELECTRIC CORP LTD

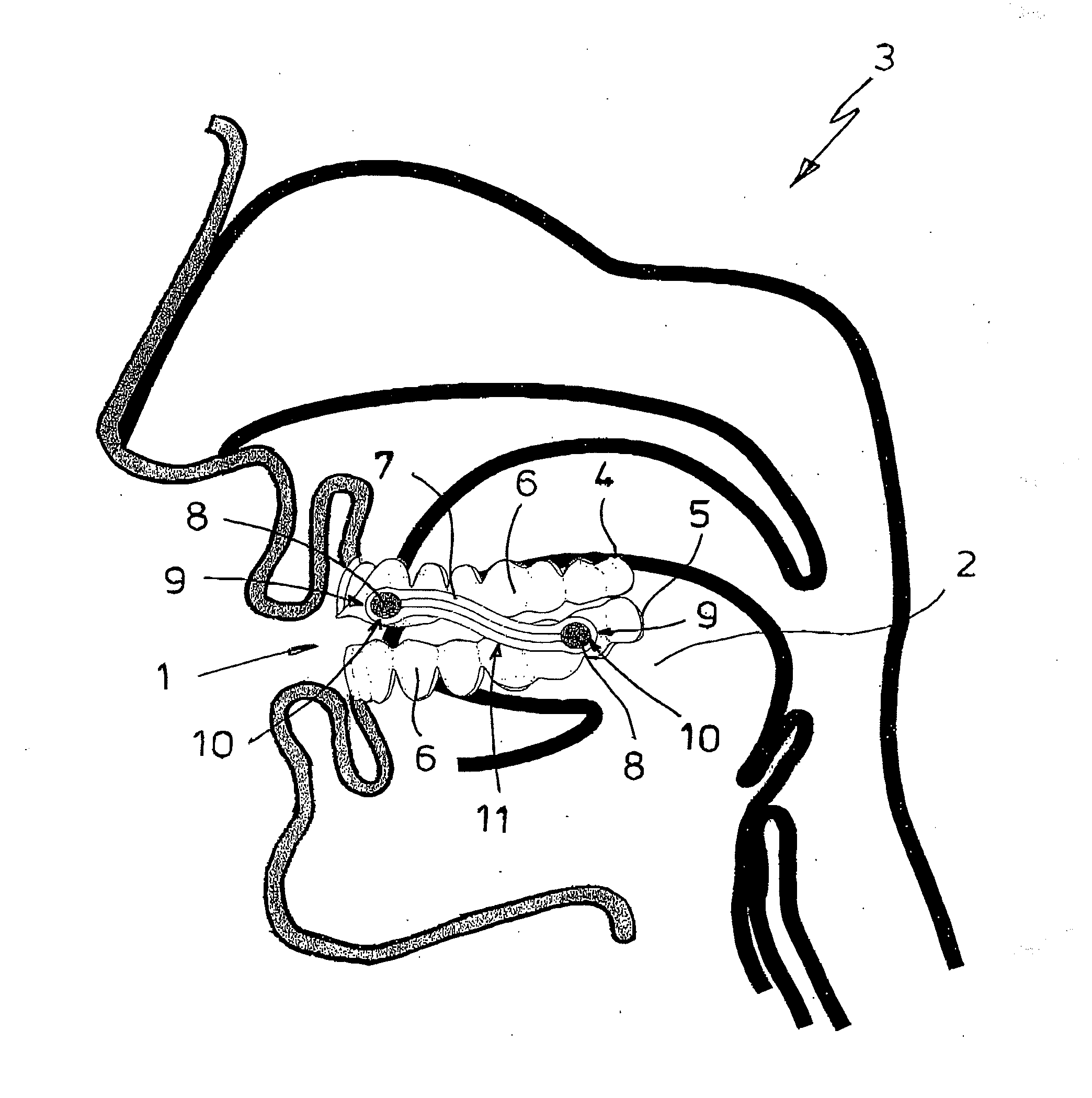

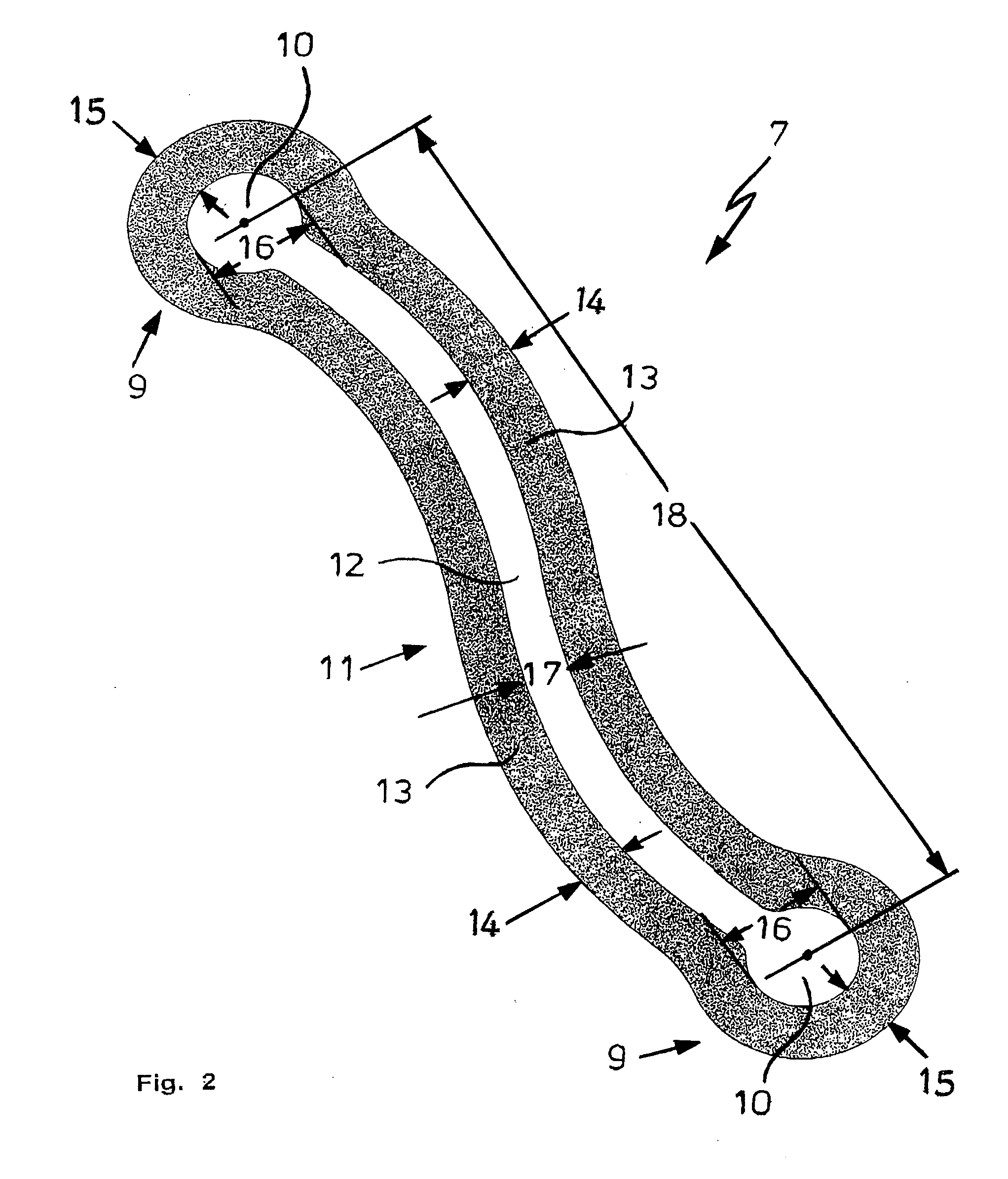

Anti-snoring device

ActiveUS20120073582A1Improve comfortReduce the impactSnoring preventionNon-surgical orthopedic devicesEngineeringCurve design

An intraoral anti-snoring device, for shifting the lower jaw forward in relation to the upper jaw, with an upper jaw bar and a lower jaw bar that are both U-shaped and are connected to each other in a hinge joint at their outer flanks facing away from each other via protrusion ties by means of fixing buttons. At each of the two end sections of the protrusion tie, a round hole is provided for accepting the fixing button. The invention proposes a curved design for the protrusion tie, specifically an S-shaped design, with the center section having a cross-sectional contour—at least in part—that permits a temporary change of the distance of the round holes relative to each other by means of an elastic deformation of the protrusion tie in the longitudinal and in transverse direction. Preferably, the center section has an elongated hole that extends from one round hole to the other round hole and has a width that is smaller than or equal to the diameter of the round hole. Due to the resulting longitudinal edge strips that are capable of spring action, the fixing button is able to avoid excessive pressure by moving into the elongated hole.

Owner:ERKODENT ERICH KOPP

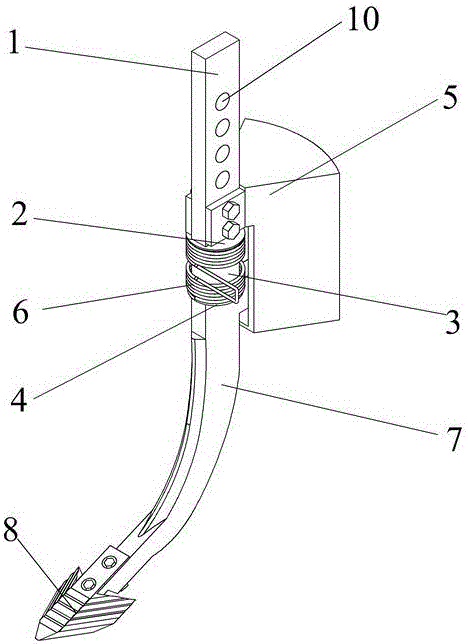

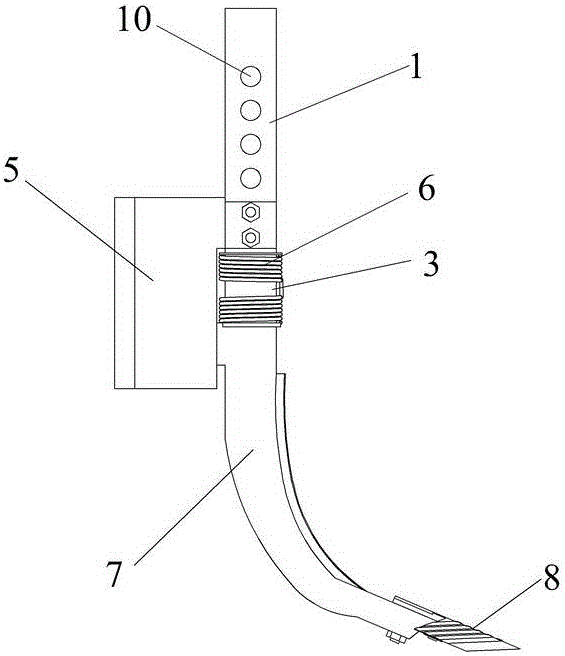

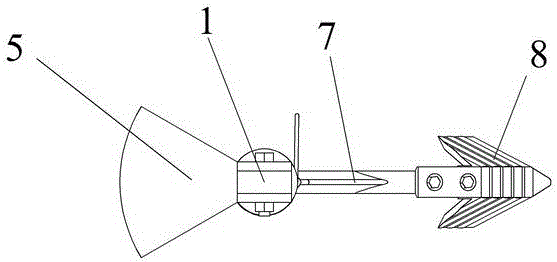

Subsoiler based on dynamic bionic principle

InactiveCN105874902AAchieve dynamic loosening effectImprove performance in soilPloughsEngineeringTorsion spring

The invention discloses a subsoiler based on a dynamic bionic principle. The subsoiler comprises a subsoiler mounting handle, a limiting device, a bidirectional torsion spring, a subsoiler handle, a subsoiler tip and a pulley, wherein the subsoiler mounting handle and the subsoiler handle are mounted through a bearing, so that the subsoiler handle can be rotated at the bottom of the soil; the pulley is mounted at the rear end of the subsoiler handle, is in contact with the limiting device and is used for supplying a support force along a heading direction and limiting the rotating angle; the bidirectional torsion spring is mounted at the external end of the bearing, so that the rotating resetting of the subsoiler is realized and the dynamic operation effect is achieved; the subsoiler is optimized through bionic curve design, so that the improvement of the soil-breaking property is ensured; the dynamic bionic principle is designed and the moving form of the whole subsoiler is similar to the forms of the animals, such as, earthworm, mole cricket, and the like, in the moving process, so that the dynamic bionic motion is realized.

Owner:JILIN UNIV

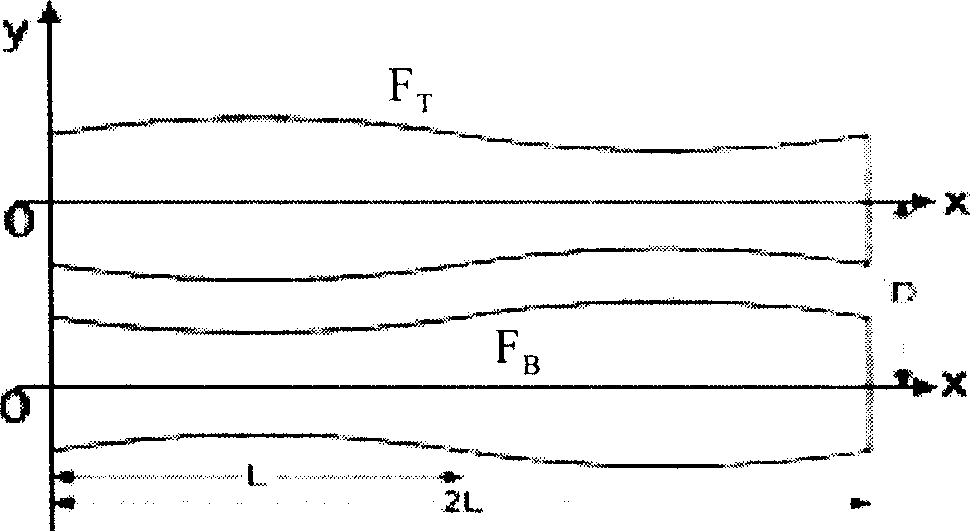

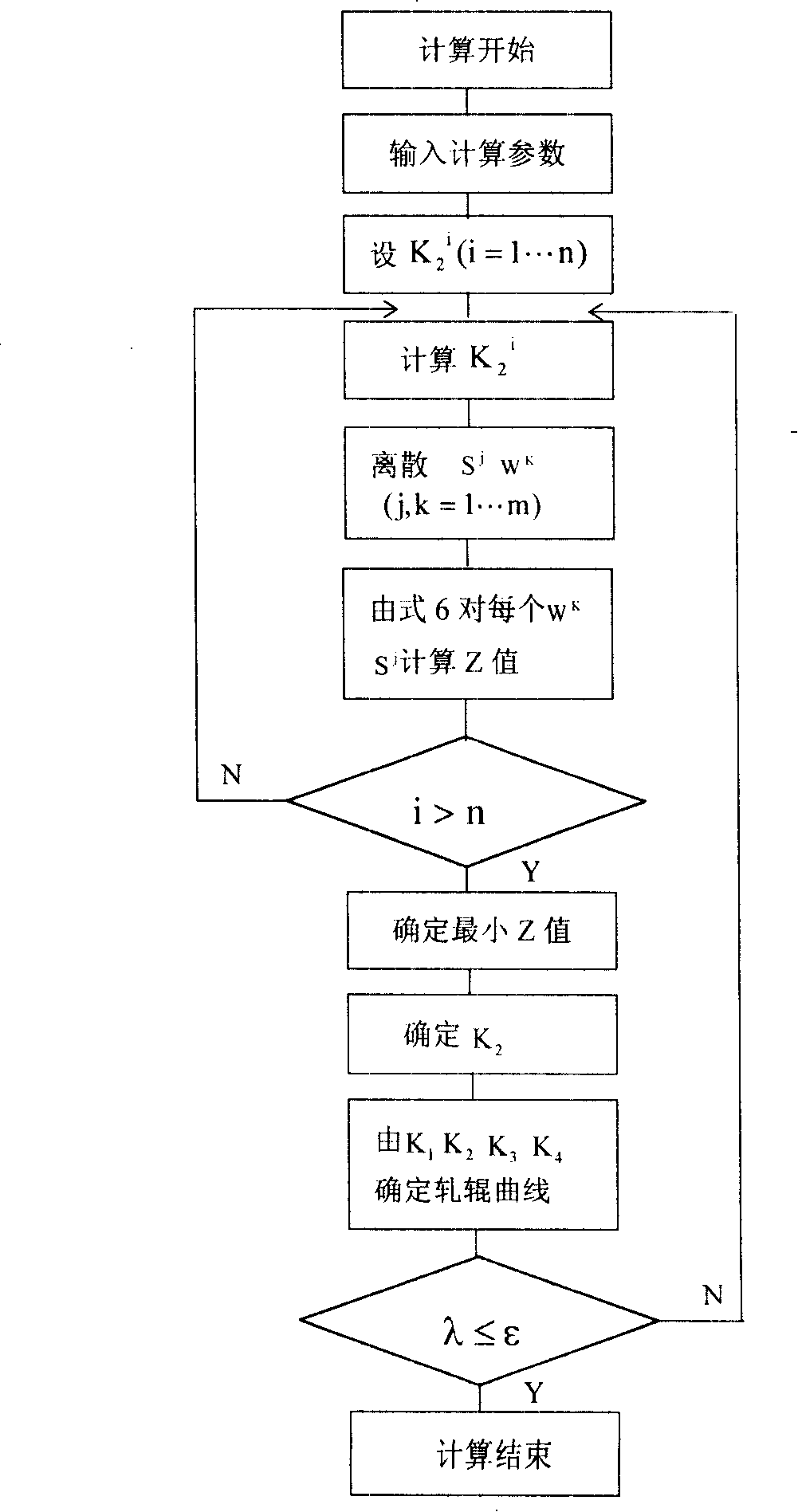

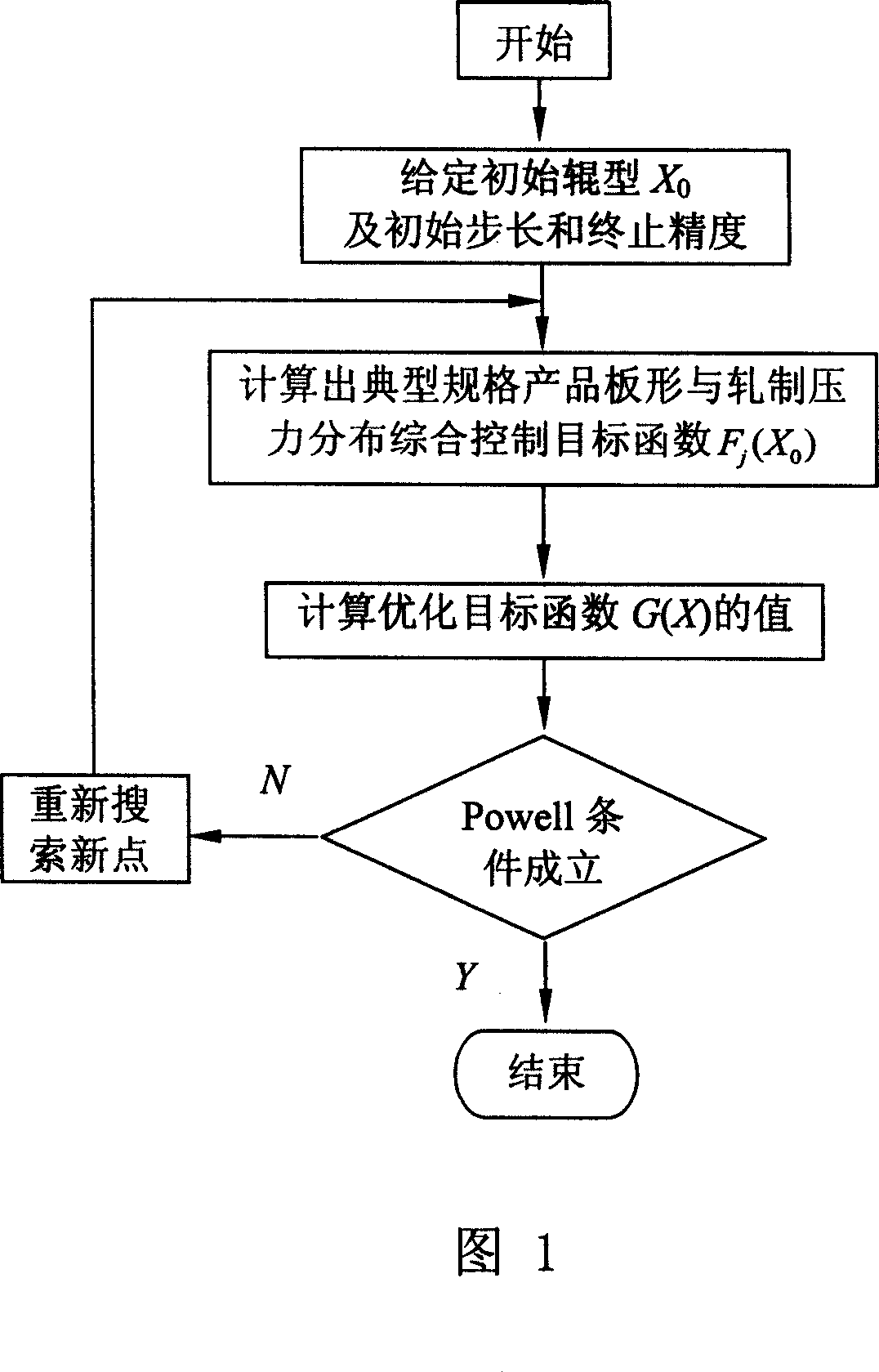

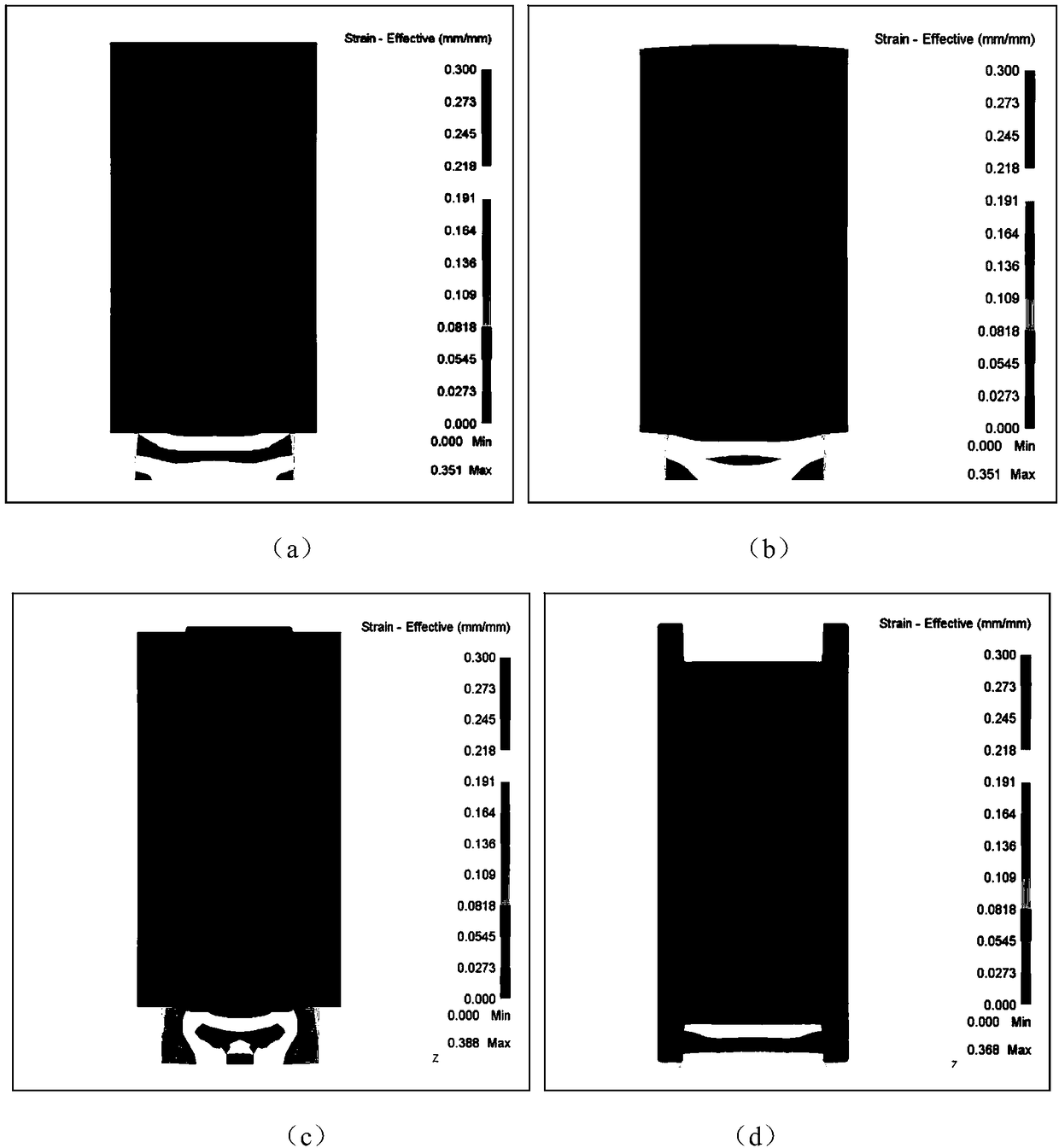

Roller type curve design method in thin narrow material smoothing and rolling process

InactiveCN1828616AGuaranteed mechanical performance indexMeet the shape quality requirementsSpecial data processing applicationsPerformance indexStrip steel

The provided method comprises: (a) collecting the parameters on machine and technique; (b) collecting the variety and standard range of strip steel; (c) setting the curve equation for work roller and support roller; (d) optimizing the curve parameters; (e) substituting the parameters into former equations to obtain the optimal equations. This invention ensures product performance index, and can be also used to the condition with broad-thick material without pressing.

Owner:YANSHAN UNIV

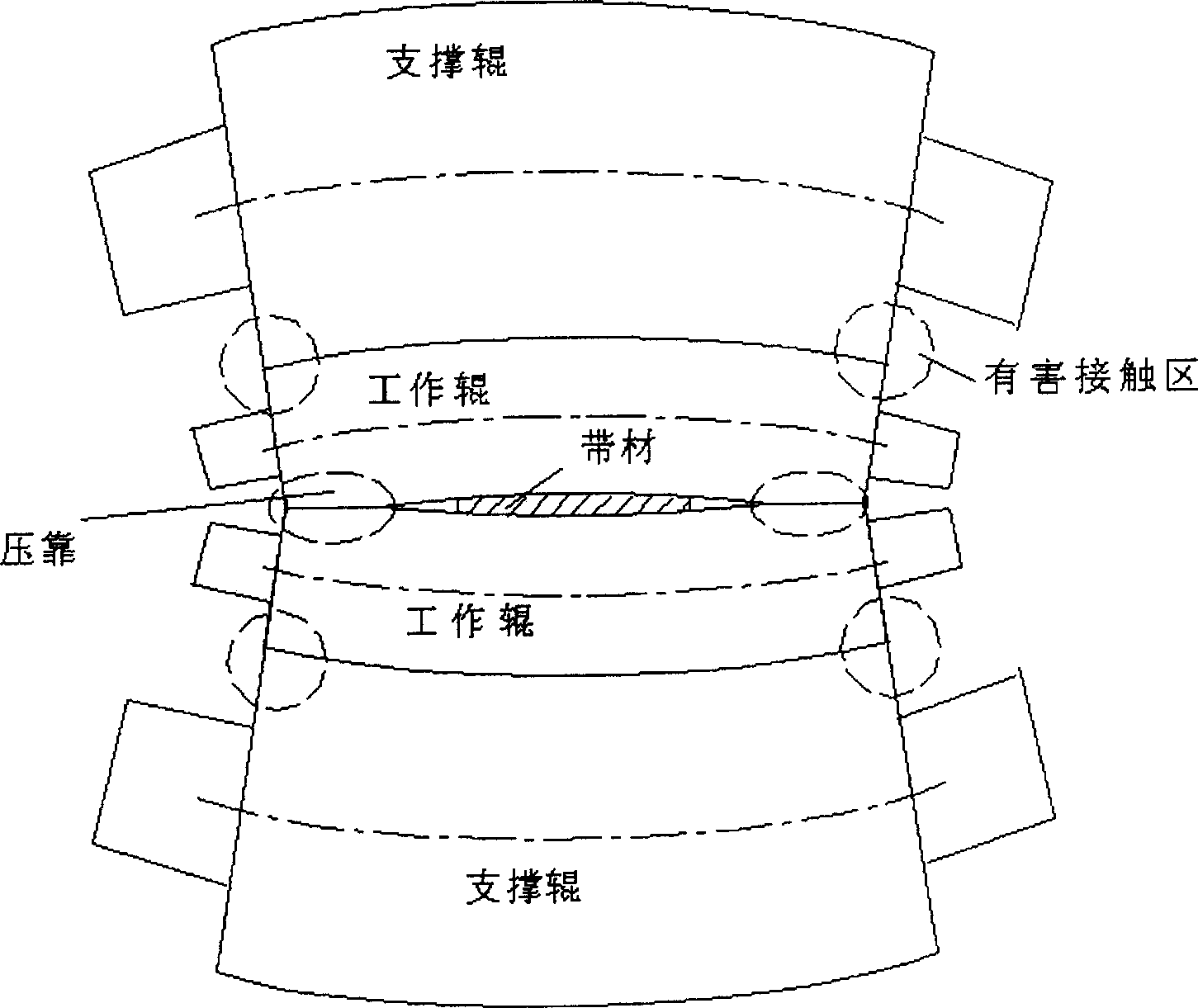

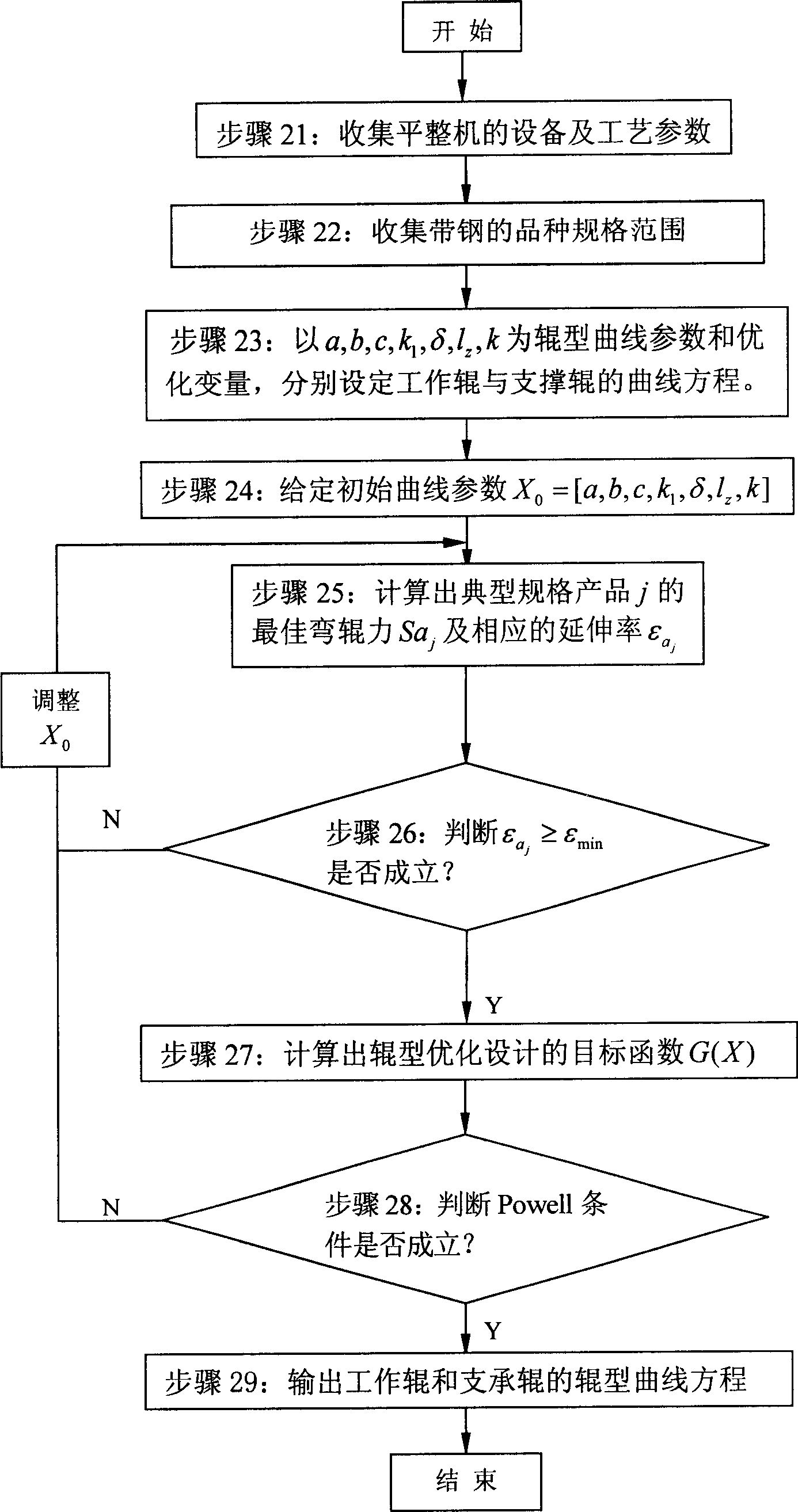

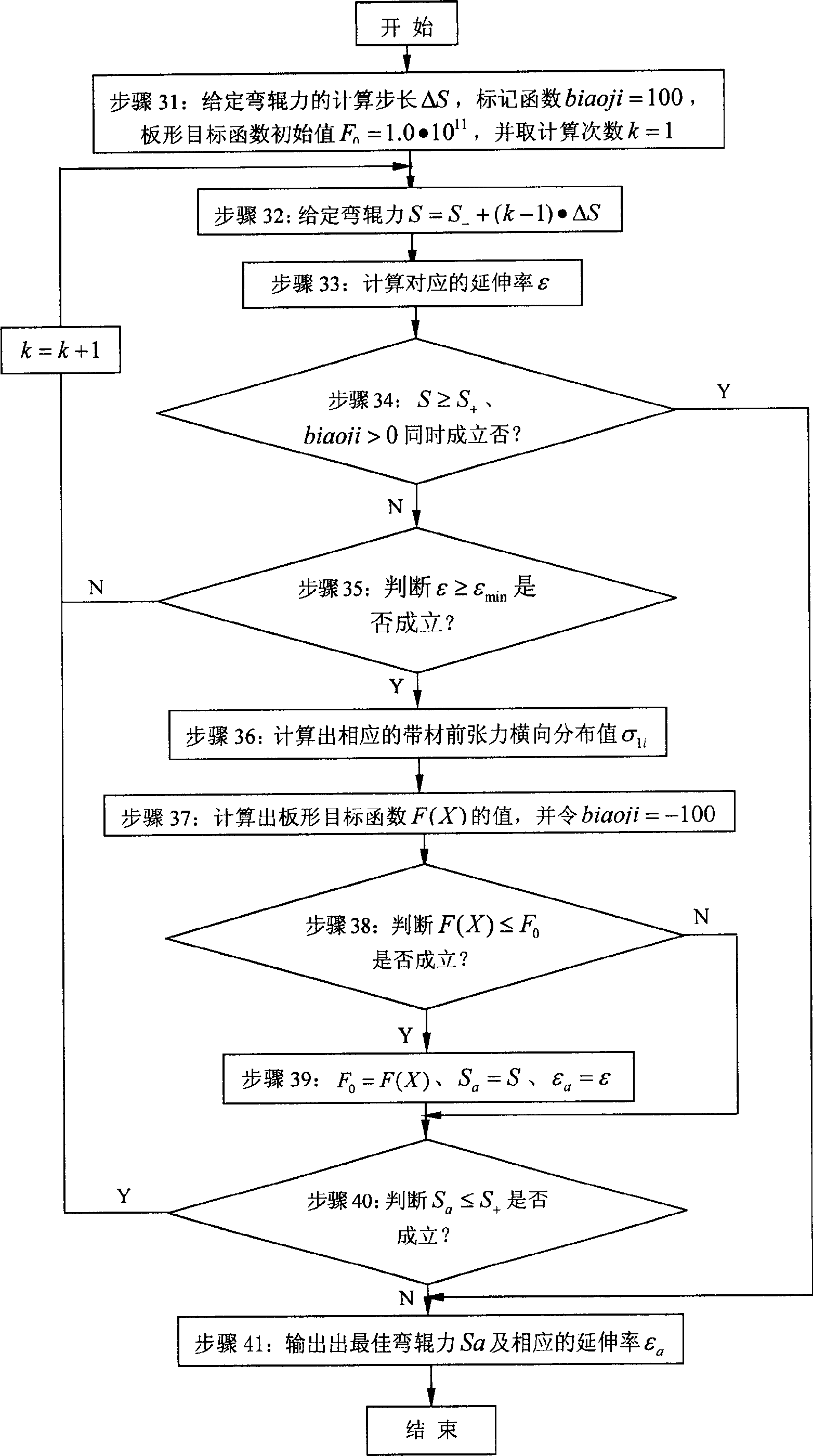

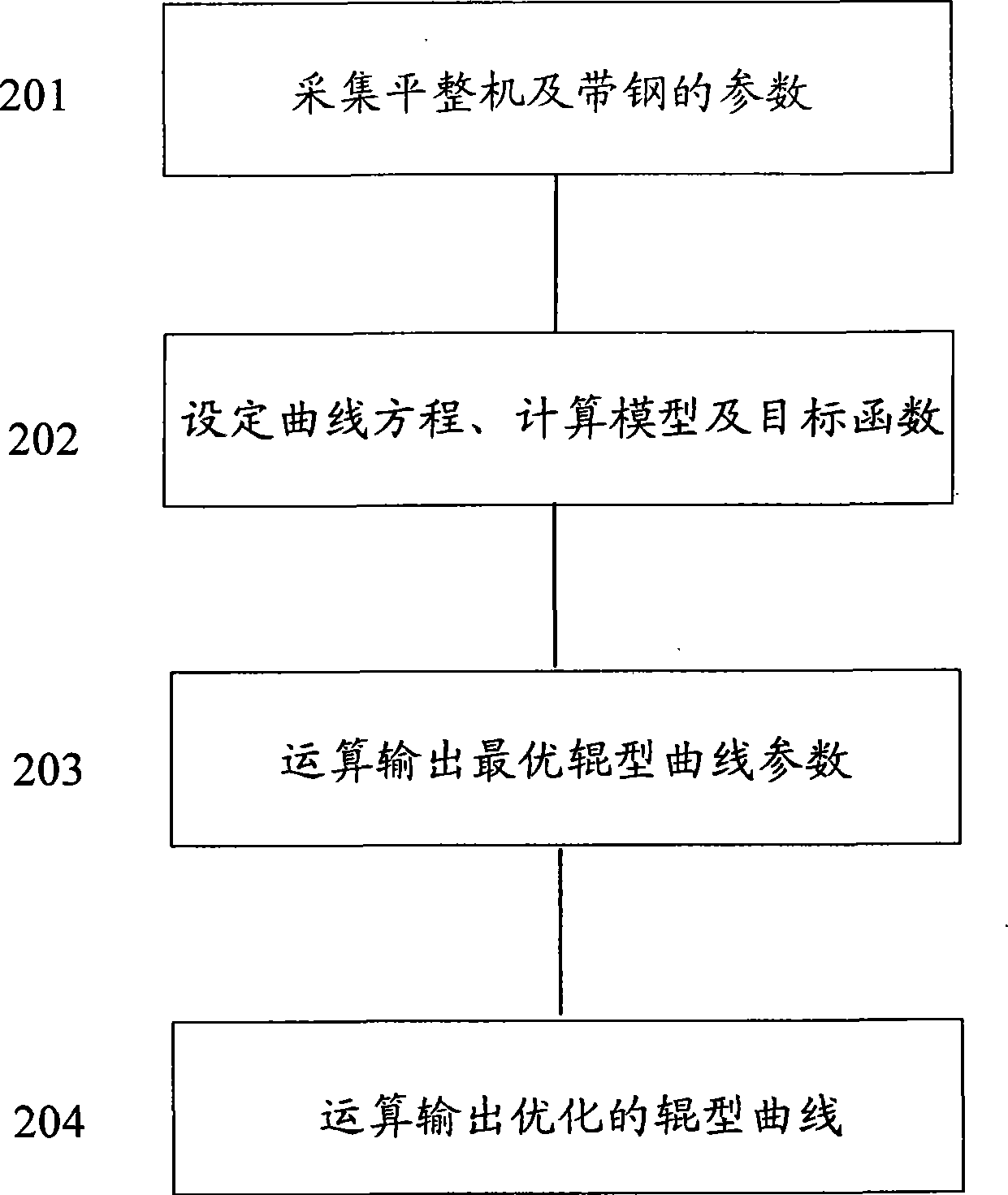

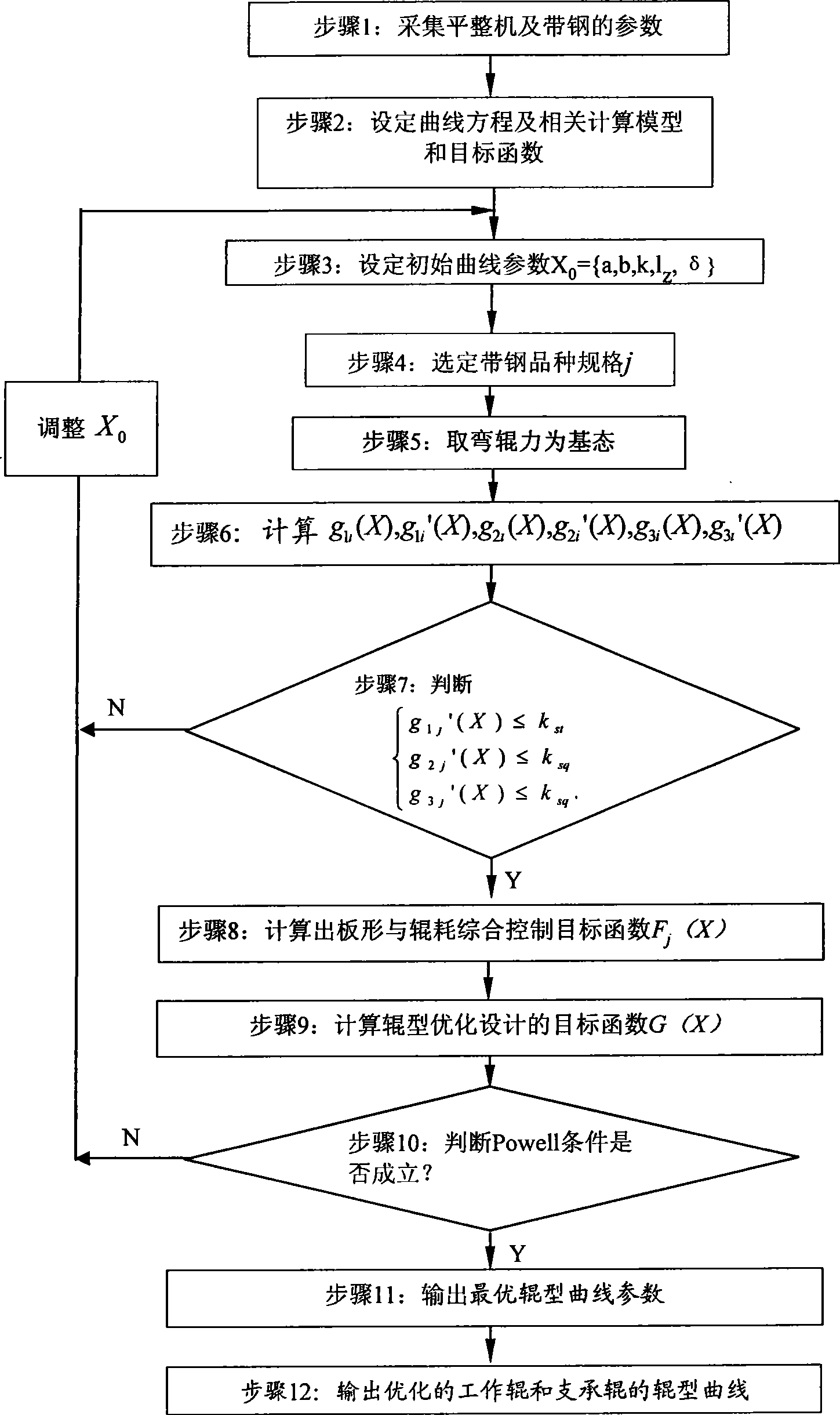

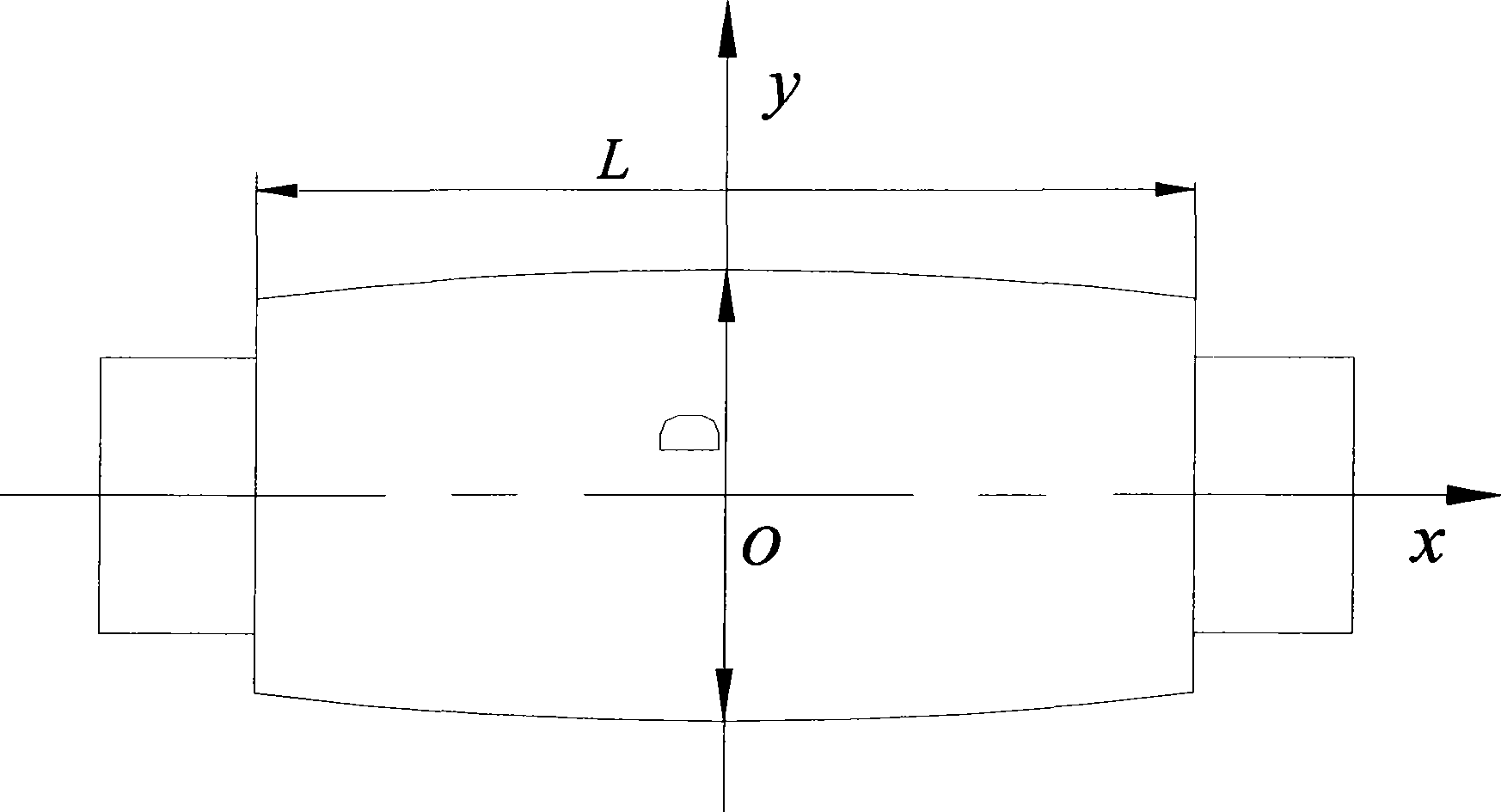

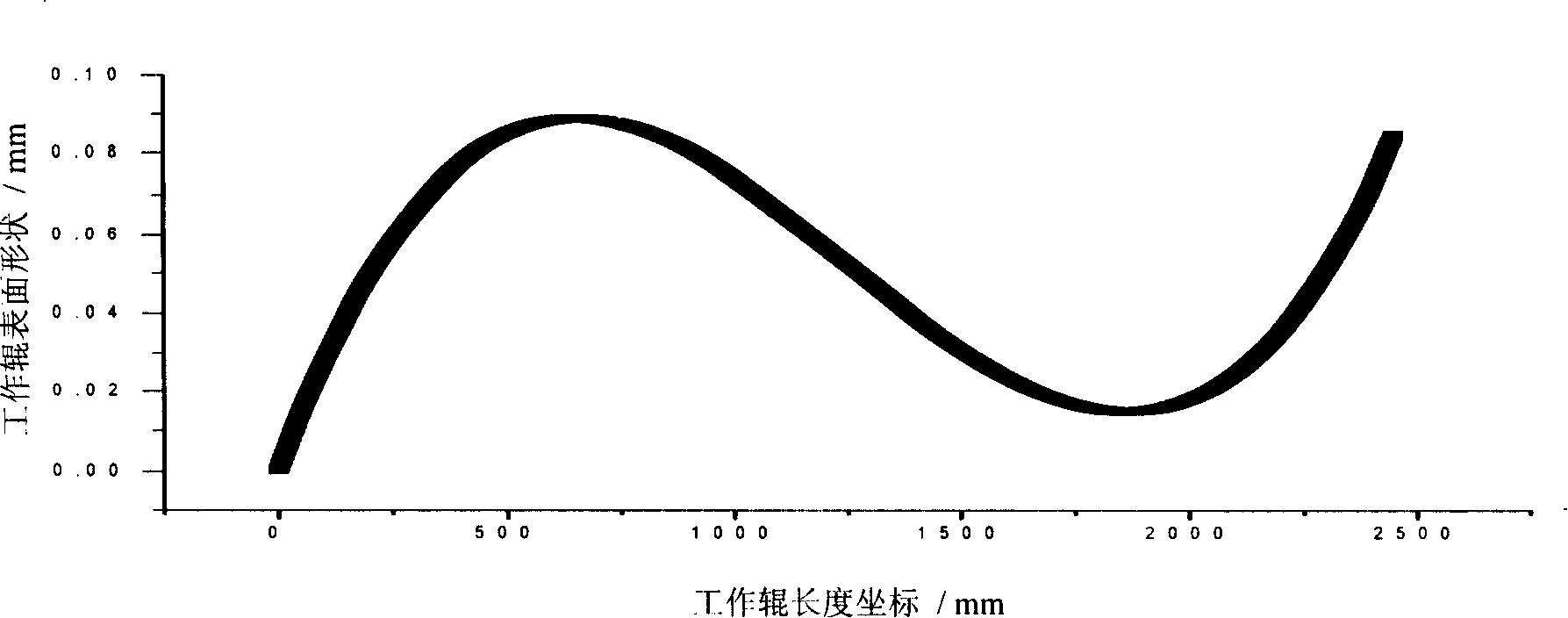

Roll-shaped curve design method of high-strength steel temper mill

ActiveCN101477579AImprove shape qualityReduce work roll consumptionSpecial data processing applicationsMathematical modelPeak value

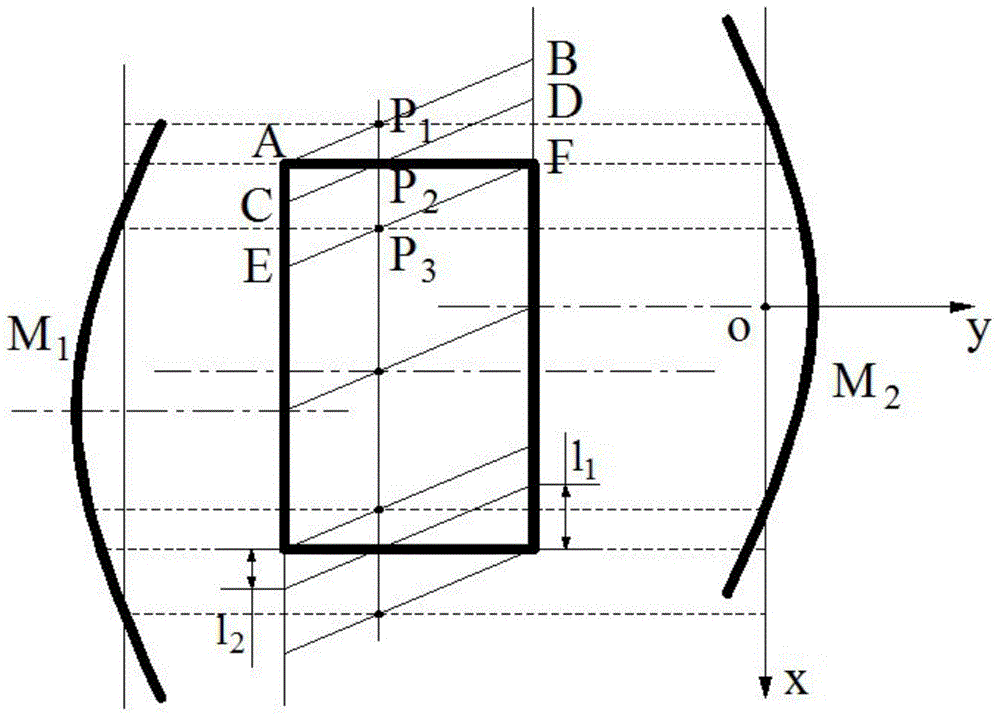

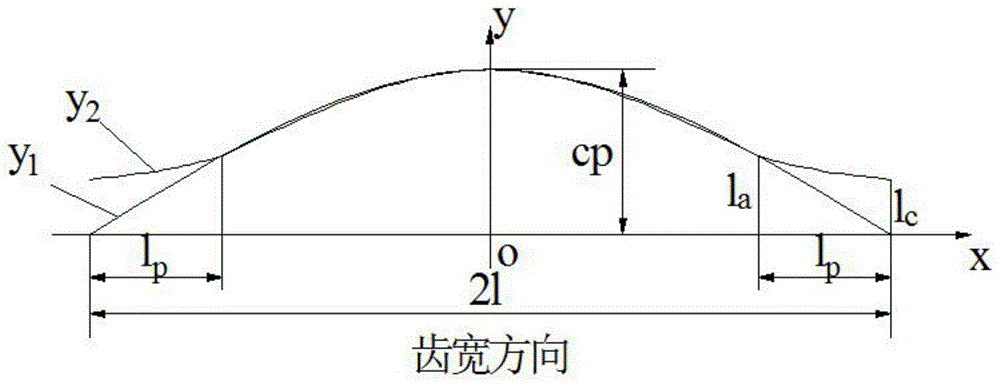

The invention discloses a method for designing a roller curve of a high-strength steel leveling machine, which comprises the following steps: collecting parameters of steel in the leveling machine, setting a curvilinear equation and a related computation model and an objective function, inputting the related parameters into the curvilinear equation, the computation module and the objective function, obtaining the optimal parameters of the roller curve, and further obtaining the optimal roller curve of a working roller and a supporting roller. The method for designing the roller curve is characterized in that all the front tension, the rolling pressure and the pressure among rollers are transversely and evenly distributed and adopted as the optimal objective function at the first time, and peak values of the front tension, the rolling pressure and the pressure among rollers are restrained at the same time, a set of new mathematical models optimally designed of the curve of the high-strength steel roller is established, and applicable roller curves of the working roller and the supporting roller are designed; therefore, the quality of the shape of a plate and a strip after leveling is greatly improved, the roller loss of the working roller is reduced, the phenomena of 'gnawing shoulders' and 'losing weight' of the supporting roller are eliminated, and the occurrence probability of accidental roller replacement is reduced to the maximum.

Owner:BAOSHAN IRON & STEEL CO LTD

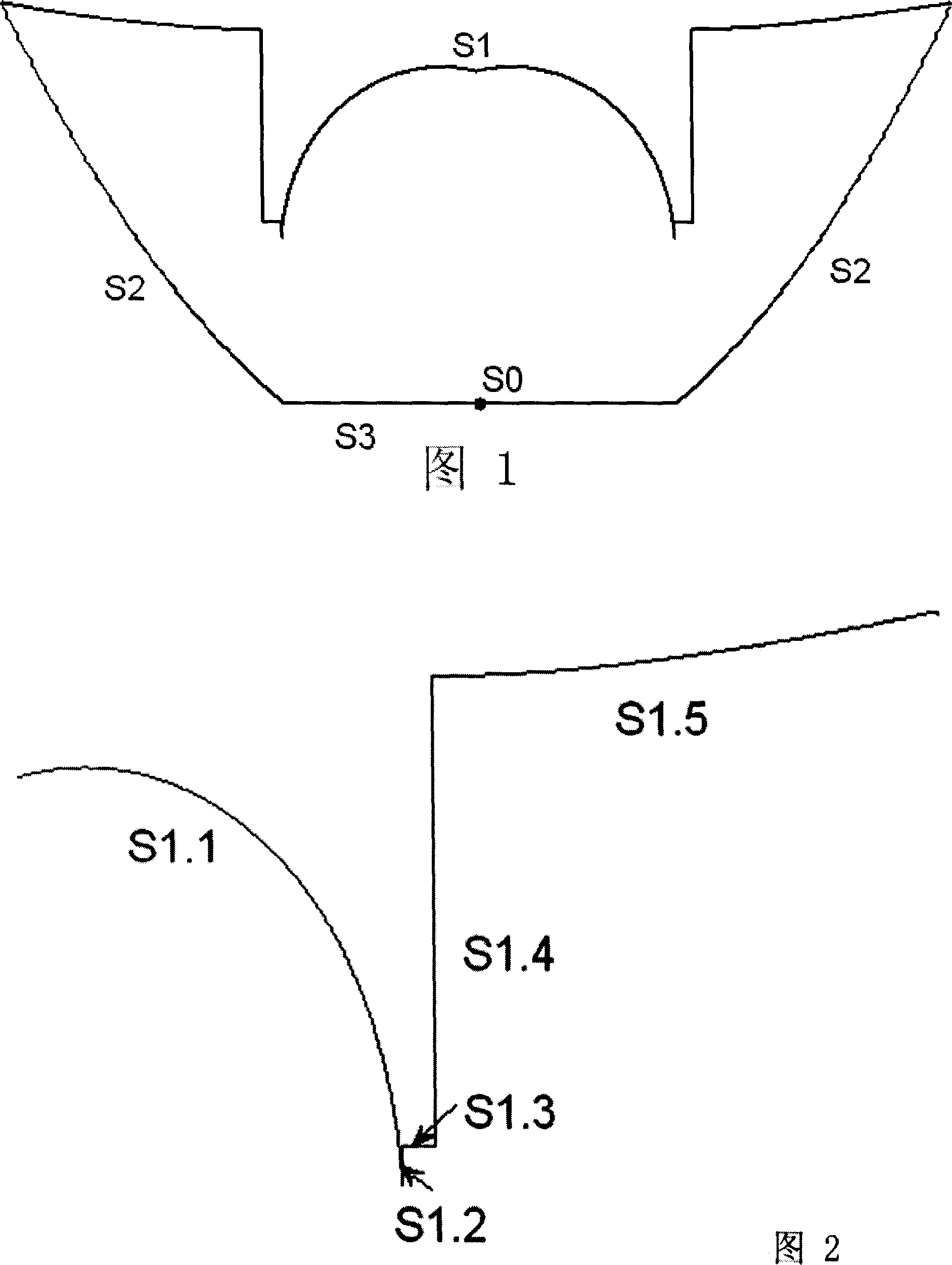

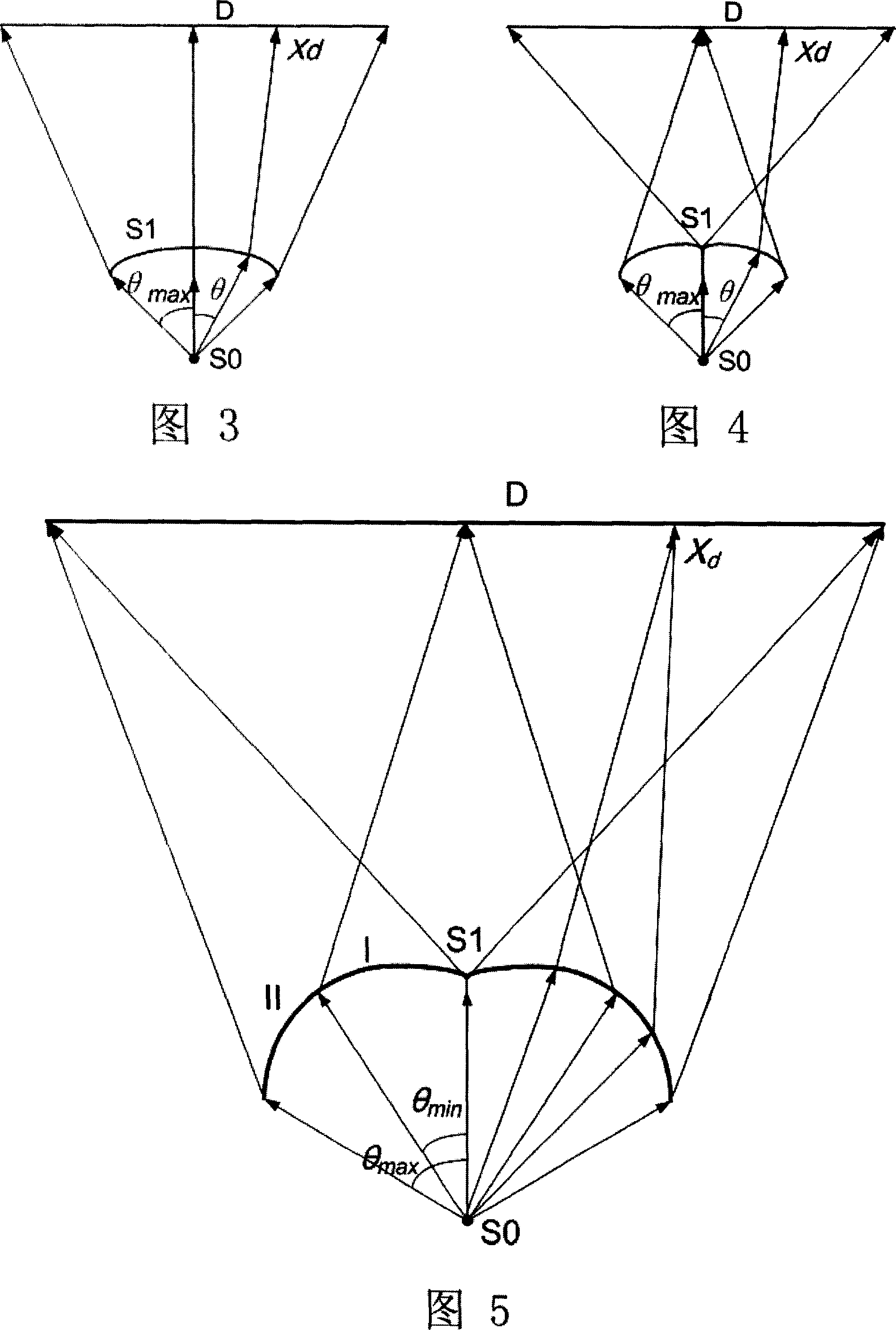

Refraction free curve design method for uniform lighting and its lens

A free curved design used on uniform illumination includes apply Lambert light source, using free curved surface to refract light beam, using side surface to reflect light within specific divergent angle and applying base surface. It is featured as reflecting light in diverging semi-angle being less than 45degree directly to illumination region and refracting light in diverging semi-angle of 45-90degree to illumination region after said light is reflected first.

Owner:ZHEJIANG UNIV

Method for designing axial modification curve for reducing gear surface distortion

ActiveCN104832623AReduces bite-in and bite-out shocksReduce shockPortable liftingGearing elementsGear grindingEngineering

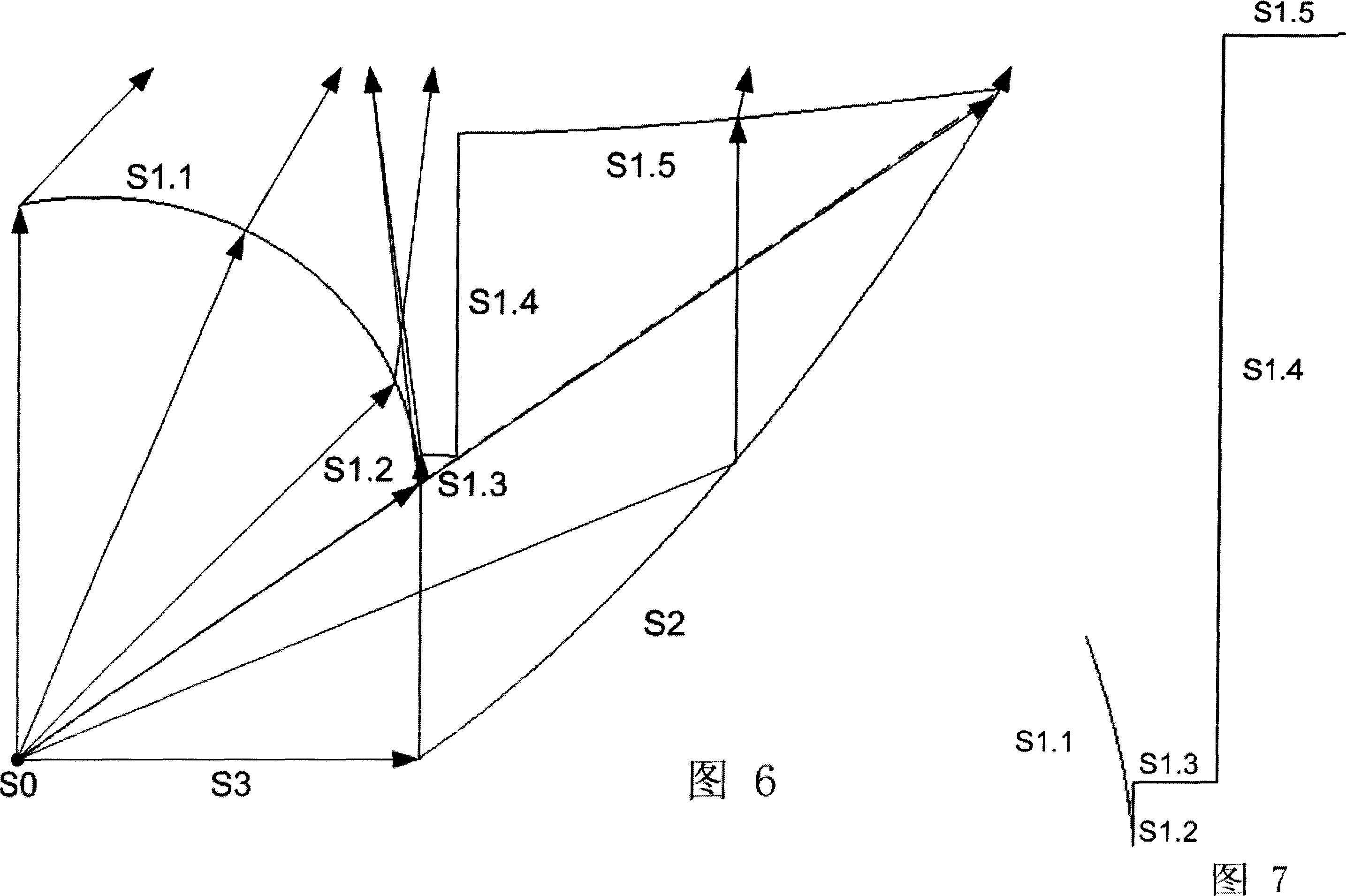

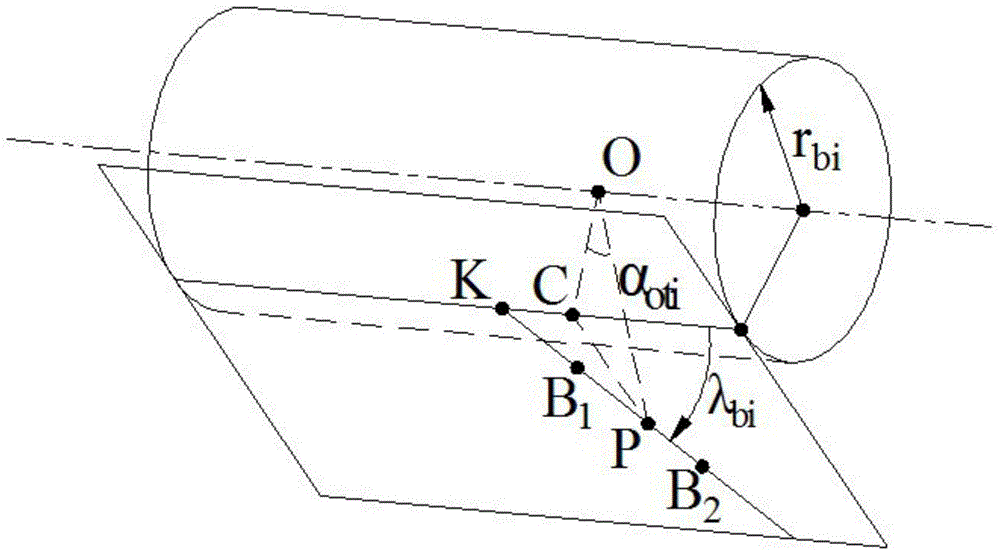

The invention belongs to the field of gear design and relates to a method for designing an axial modification curve for reducing gear surface distortion. The method for designing the axial modification curve for reducing gear surface distortion solves the problem of gear surface distortion during grinding of a bevel gear subjected to axial modification. Different from a traditional modification curve, the modification curve designed through the method can effectively weaken distortion at the two ends of the gear. The method comprises the steps that the distortion quantity of the left gear surface and the right surface of the gear is calculated according to the gear grinding technique and based on a standard parabola modification curve, then the curve is divided into three sections, and the scaling factor of each curve section and the drum-shaped size of each portion are adjusted.

Owner:CHONGQING UNIV

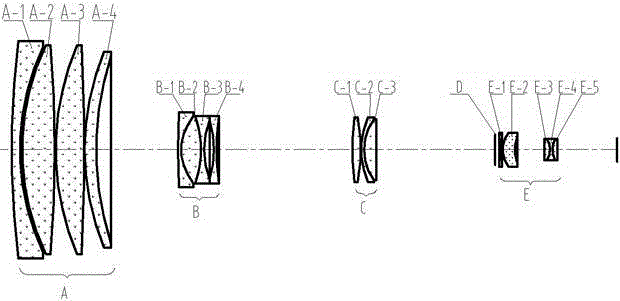

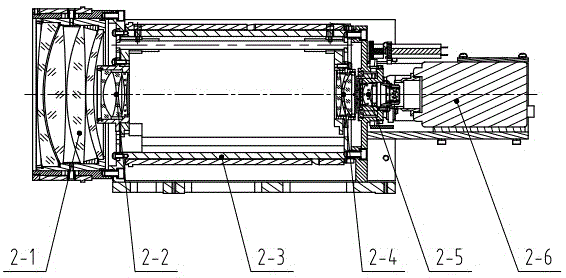

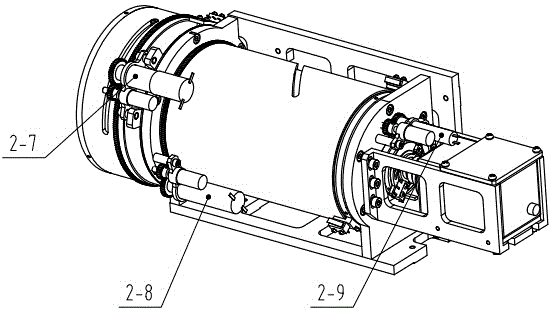

High-resolution large-field-of-view continuous zoom pick-up lens and control method thereof

ActiveCN105005137AImprove clarityWith focus control functionProjector focusing arrangementCamera focusing arrangementCamera lensHigh-definition video

The invention relates to the technical field of video shooting, and specifically relates to a high-resolution large-field-of-view continuous zoom pick-up lens and a control method thereof. The optical system of the lens is sequentially provided with a front fixed group A with positive focal power, a zoom group B with negative focal power, a compensation group C with positive focal power, a variable diaphragm assembly D, and a rear fixed group E with positive focal power along the incident direction of light. The lens is designed by using a mechanical compensation method and a steepest zoom cam curve design technology, has a focusing control function, a continuous zoom control function, an electric dimming function and an image output function, and can provide photoelectric signals for CCD or CMOS cameras with the target surface of 1'' in good weather and produce a high-definition video image. The lens has the advantages of long focal length, compact structure, high zoom ratio and the like, and has a larger observation field-of-view angle than an ordinary optical lens under the same focal length. The detection ability is improved significantly.

Owner:FUJIAN FORECAM OPTICS CO LTD

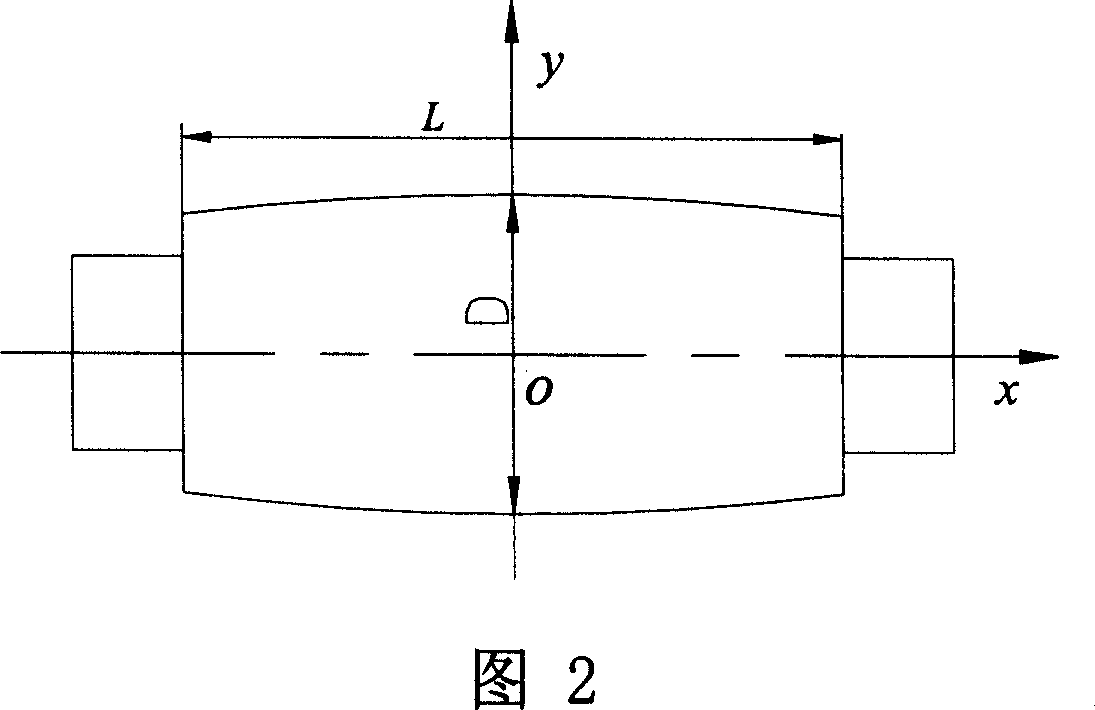

Four-high mill plate control work roll curve design method for strip rolling

InactiveCN101211372AReduce axial resistanceReduce grindingProgramme controlComputer controlWork rollStrip mill

The invention discloses a roll-shaped curve design method for work rollers in a four-roller rolling machine sheet profile control work for tape and sheet rolling treatment. The method is optimized to design in the premises of guaranteeing the equivalent convex that is necessary for tape steel sheet profile control effects, and meanwhile, with the constraint conditions of the wearing volume of rollers being the minimum and roller axial resistance being the minimum. With the help of the axial movement of the vertical work rolls in the roll shape, it is possible to continuously modify the equivalent convex of roll seams, so as to meet the requirements for controlling the shapes of sheets produced by rolling tape steel of different materials and sizes. It is shown in actual application that, utilization of the roll-shaped rollers can effectively control profile quality of different types and sizes of tape steel sheets, and meanwhile, lower the wearing cost in roller utilization process. Besides, since the axial resistance is lowered during the working process of the rollers, the invention can further increase the utilization period of the rollers and rolling machine mechanical devices.

Owner:ANGANG STEEL CO LTD

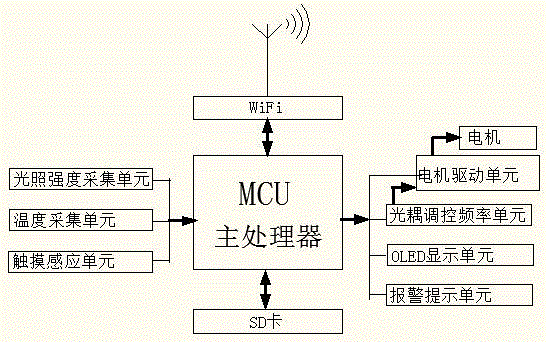

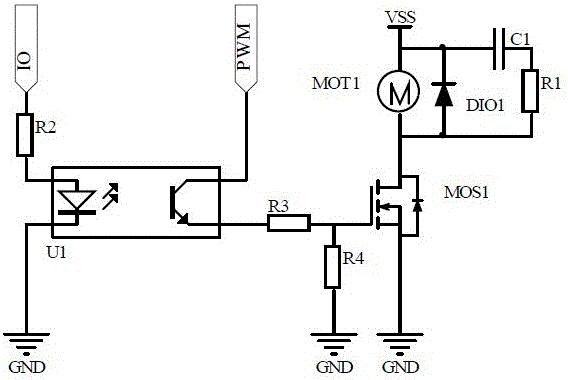

Automatic frequency adjustment fan and control method thereof

ActiveCN105065317AVarious working modesPump controlNon-positive displacement fluid enginesMicrocontrollerMotor speed

Provided are an automatic frequency adjustment fan and a control method thereof. A single chip microcomputer acquires and processes indoor temperature and illumination intensity and outputs the frequencies of duty ratios corresponding to the indoor temperature and the illumination intensity acquired at the moment to a collector electrode of an optical coupler by utilizing a PWM output function inside the single chip microcomputer, and one end of the collector electrode of the optical coupler is connected with a driving signal input end of a motor so as to achieve motor speed control. One lead pin of the single chip microcomputer is connected with a transmitting tube of the optical coupler, high and low levels corresponding to the indoor temperature and the illumination intensity acquired at the moment, the delay time of the high level and the delay time of the low level are output through the pin, and further adjustment and control of the stalling frequency of the motor are achieved. A user can set various parameters through client-side software of a mobile phone and a computer and design a sleep curve suitable for himself / herself, can upload the sleep curve designed by himself / herself to a client platform through cloud services and can download sleep curves shared by others through the client platform as well.

Owner:上海爱朴环保科技有限公司

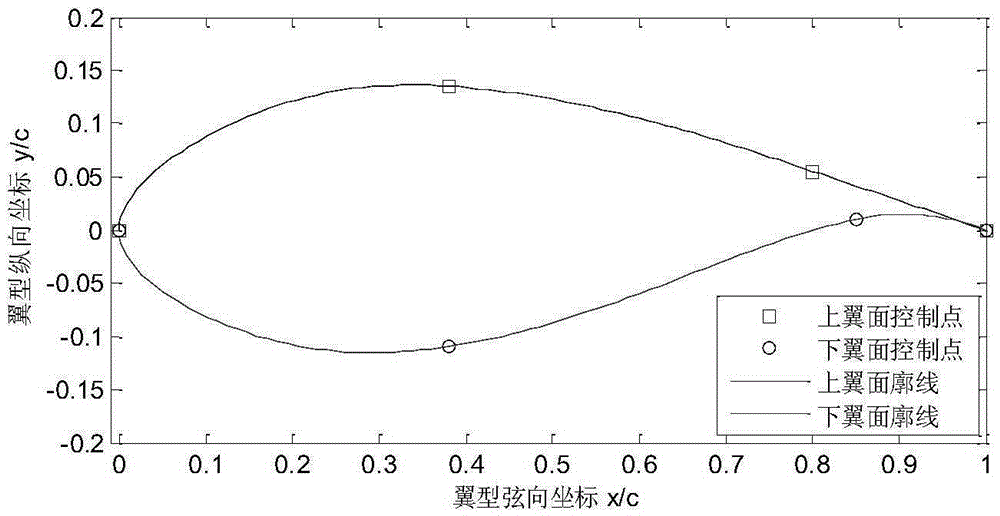

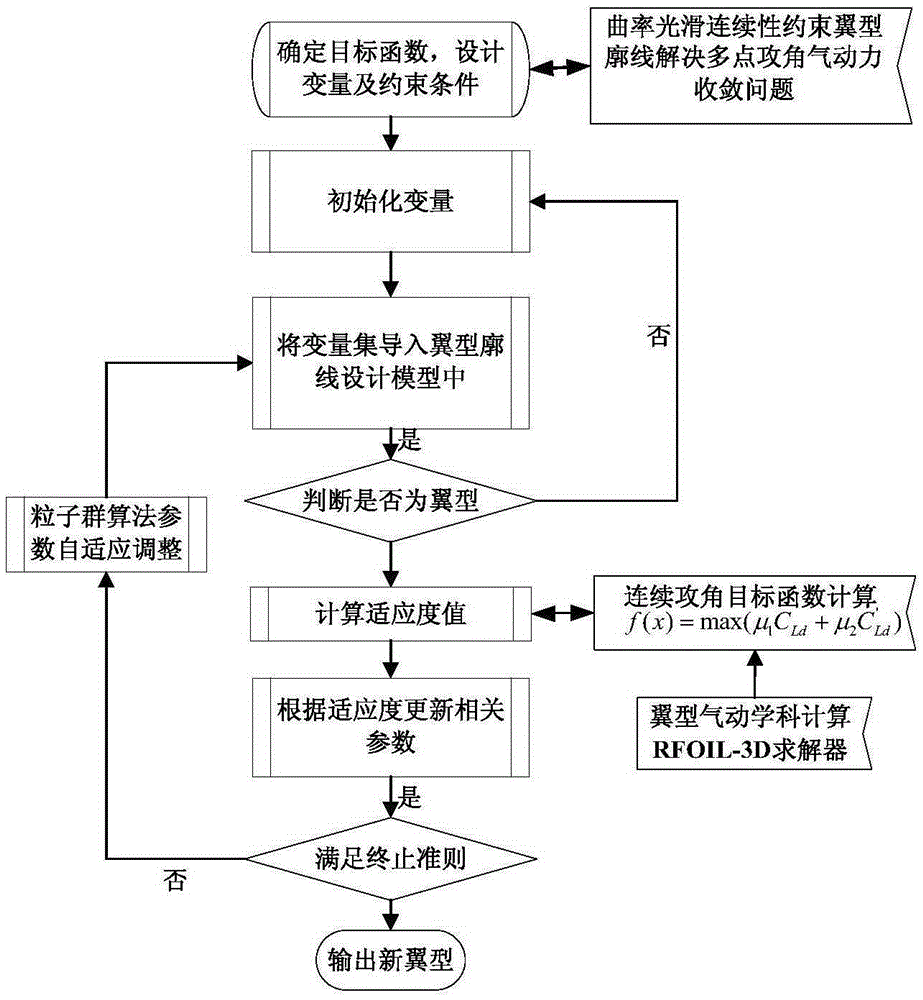

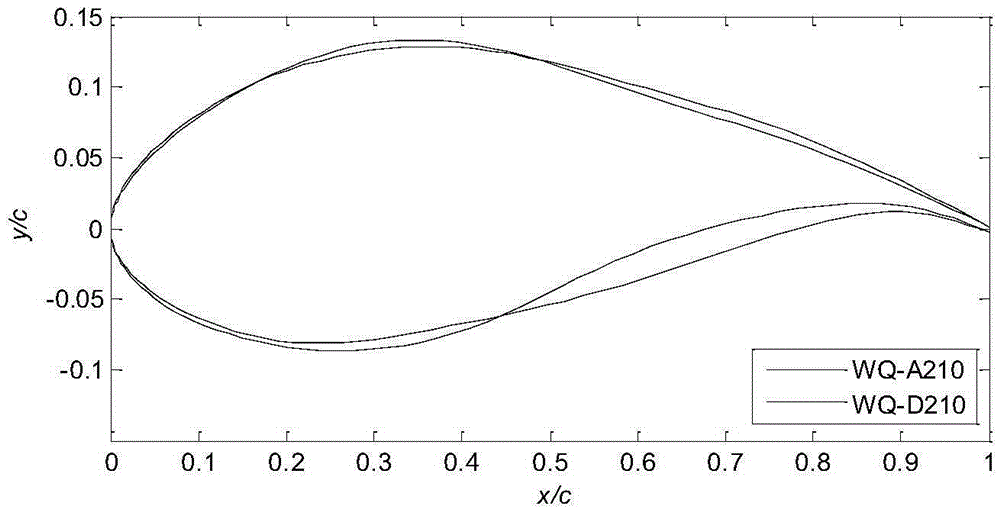

Wind turbine airfoil design method combining B spline with curvature smooth continuity

ActiveCN105404743ASolve the problem of non-convergence of aerodynamic forcesImprove aerodynamic performanceGeometric CADSpecial data processing applicationsTurbine bladeEconomic benefits

The present invention discloses a wind turbine airfoil design method combining a B spline with curvature smooth continuity, which considers the curvature smooth continuity of an airfoil profile surface and achieves airfoil profile control and parameter optimization under the condition of a multi-point design attack angle on the basis of establishing an airfoil B spline functional expression in the process of airfoil optimization design. According to the method provided by the present invention, in the continuously iterative optimization process of an airfoil, the characteristic of the curvature smooth continuity of the airfoil profile surface is constrained, so that the problem of no convergence of an aerodynamic force in the multi-point attack angle airfoil optimization design process can be well solved; the overall aerodynamic performance of the designed airfoil is significantly improved, so that the chord length of a blade is reduced, and a material required for the blade is lightened; due to the high overall aerodynamic performance, a wind turbine has a more wide applicable condition; and the method disclosed by the present invention can be popularized to design of wind turbine airfoils with various thicknesses, design of airplane airfoils and complete curve design of a turbine blade profile and the like, and has good societal value and economic benefits.

Owner:HUBEI UNIV OF TECH

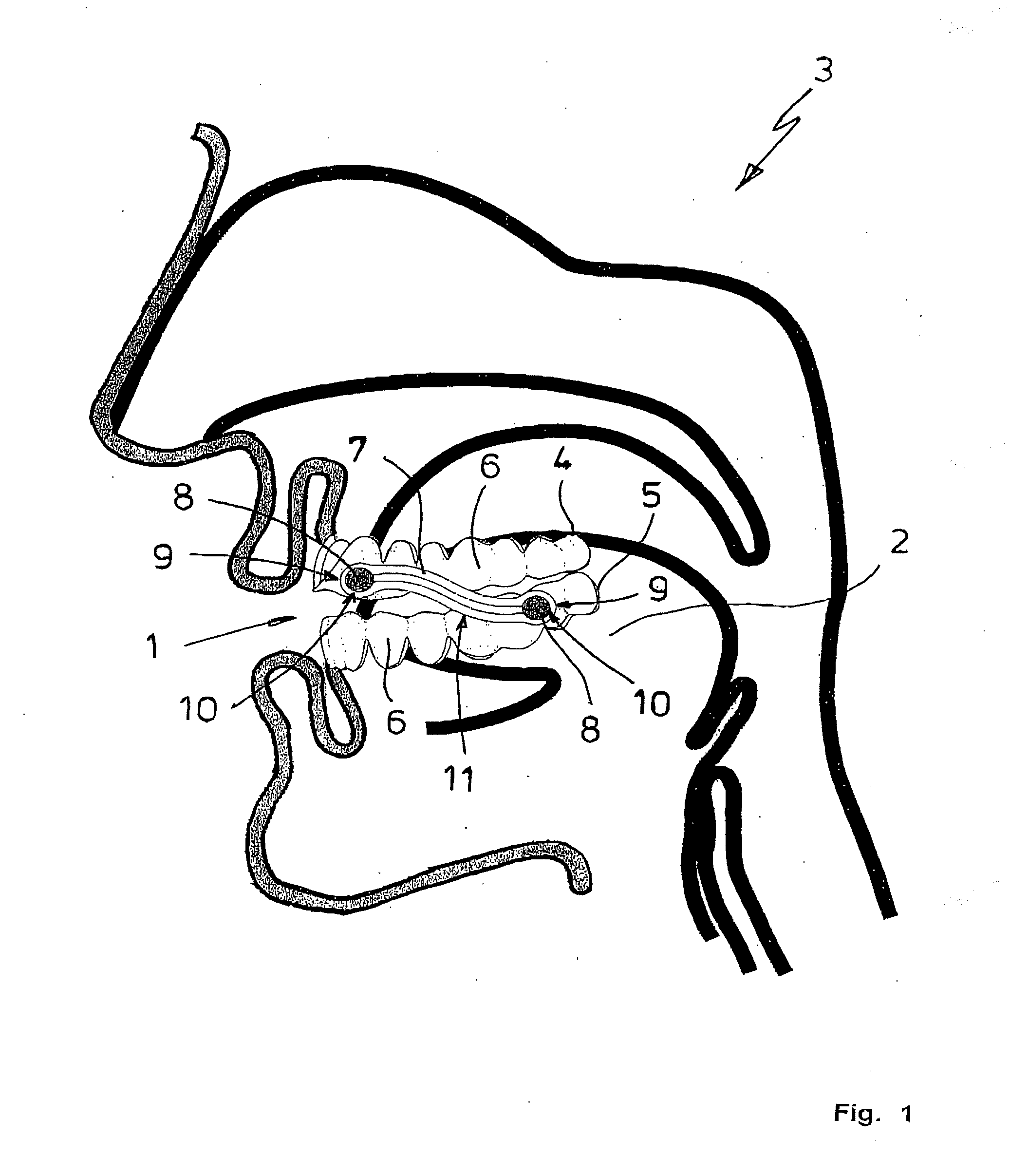

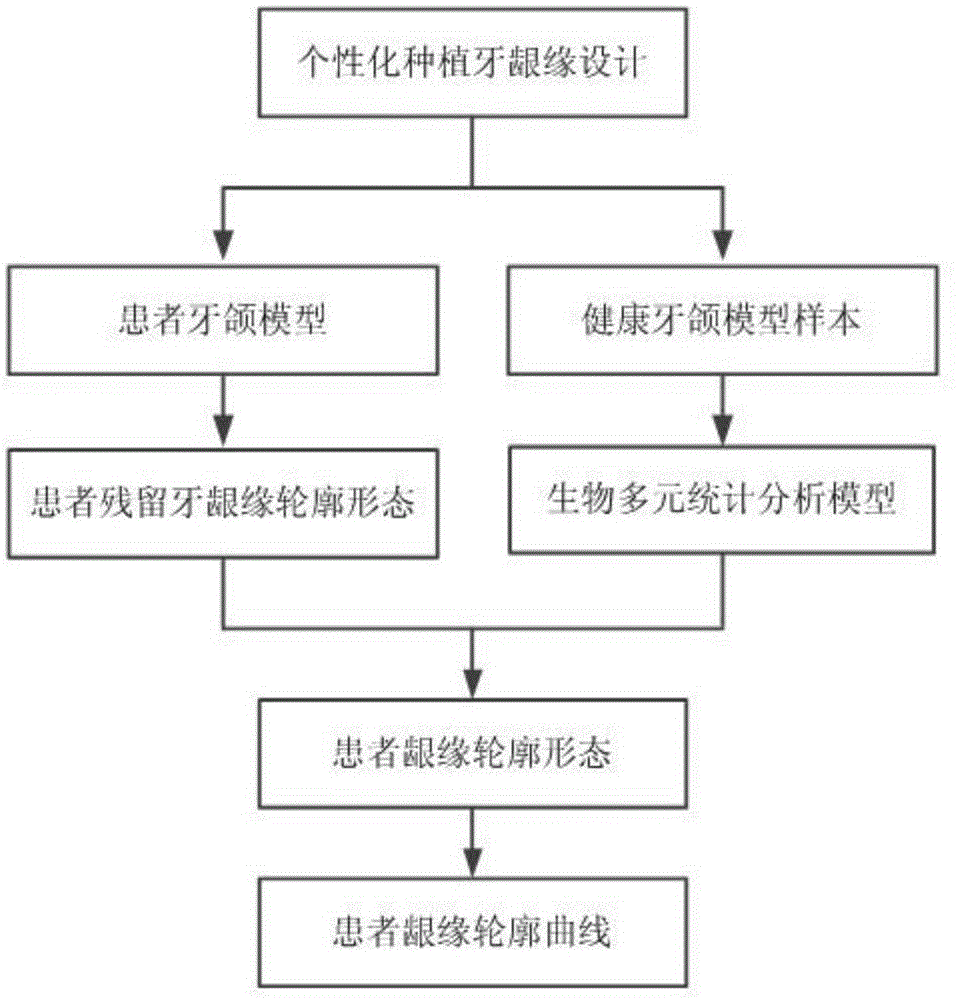

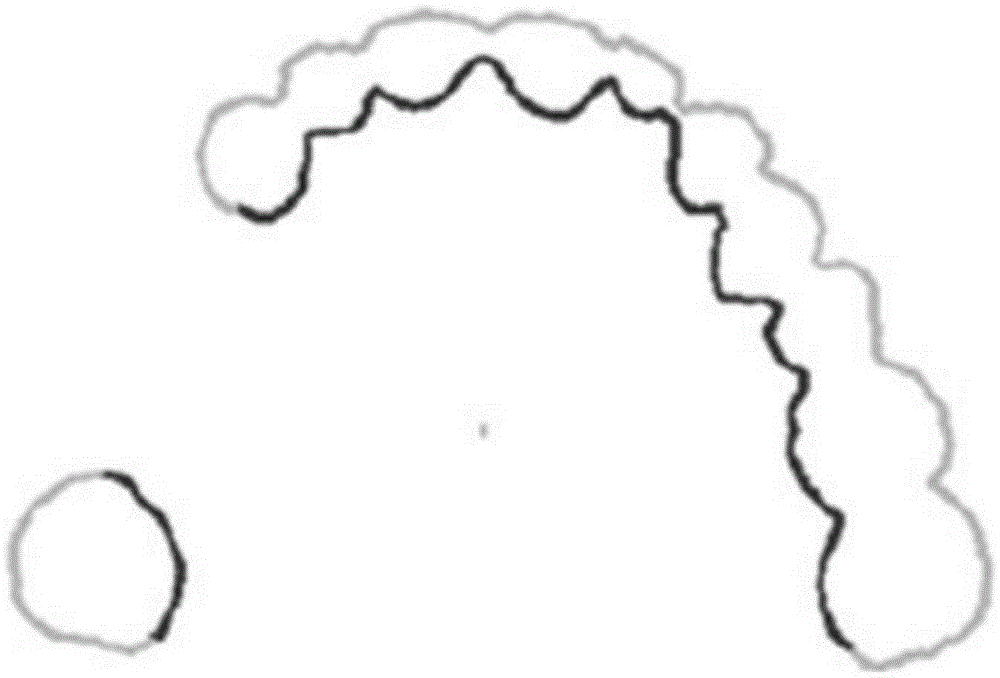

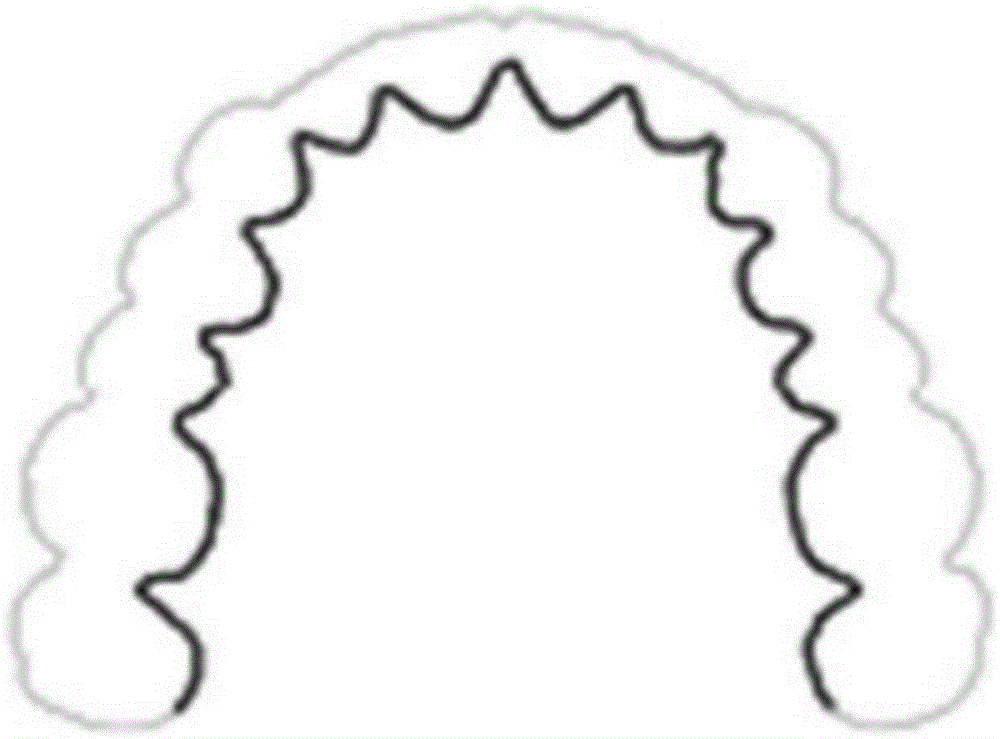

Gingival margin curve design method for personalized implant tooth

InactiveCN105389444AAutomatic and accurate refactoringGeometric CADSpecial data processing applicationsPersonalizationCellular automation

In order to overcome the defects of an existing gingival margin curve extraction mode, the present invention discloses a gingival margin curve design method for a personalized implant tooth. The gingival margin curve design method for the personalized implant tooth comprises the following steps of: a step 1 of respectively reconstructing gingival margin profiles of a residual tooth of a patient suffering from tooth missing and a three-dimensional dental model of a sample, extracting feature regions of gingival margin curves according to an obtained maximum principal curvature value, extracting gingival margin feature lines of the residual tooth of the patient suffering from tooth missing and the sample by utilizing a granular computing and cellular automaton combining method, then respectively fitting the gingival margin feature curves of the residual tooth of the patient suffering from tooth missing and the dental model of the sample, and finally, constructing a single gingival margin curve of the residual tooth of the patient suffering from tooth missing and the sample; a step 2 of constructing a gingival margin biological multivariate statistical analysis model of the sample; and a step 3 of designing a personalized gingival margin curve of a missed tooth of the patient. The method disclosed by the present invention aims to improve accuracy and efficiency of designing the implant tooth gingival margin curve, improve the repaired gingival margin profile form of the implant tooth, and improve a repair success rate of the personalized implant tooth.

Owner:JIAXING UNIV

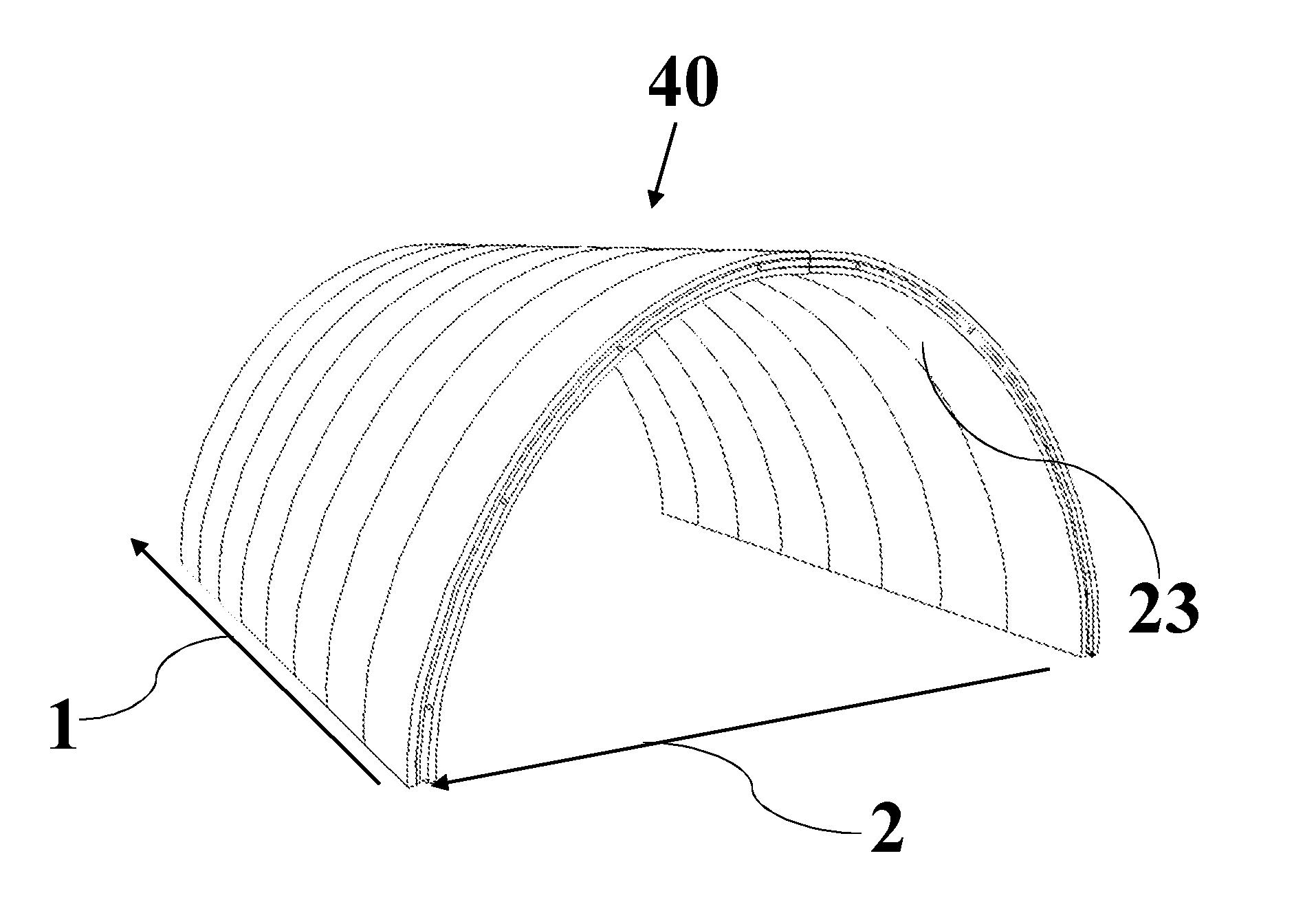

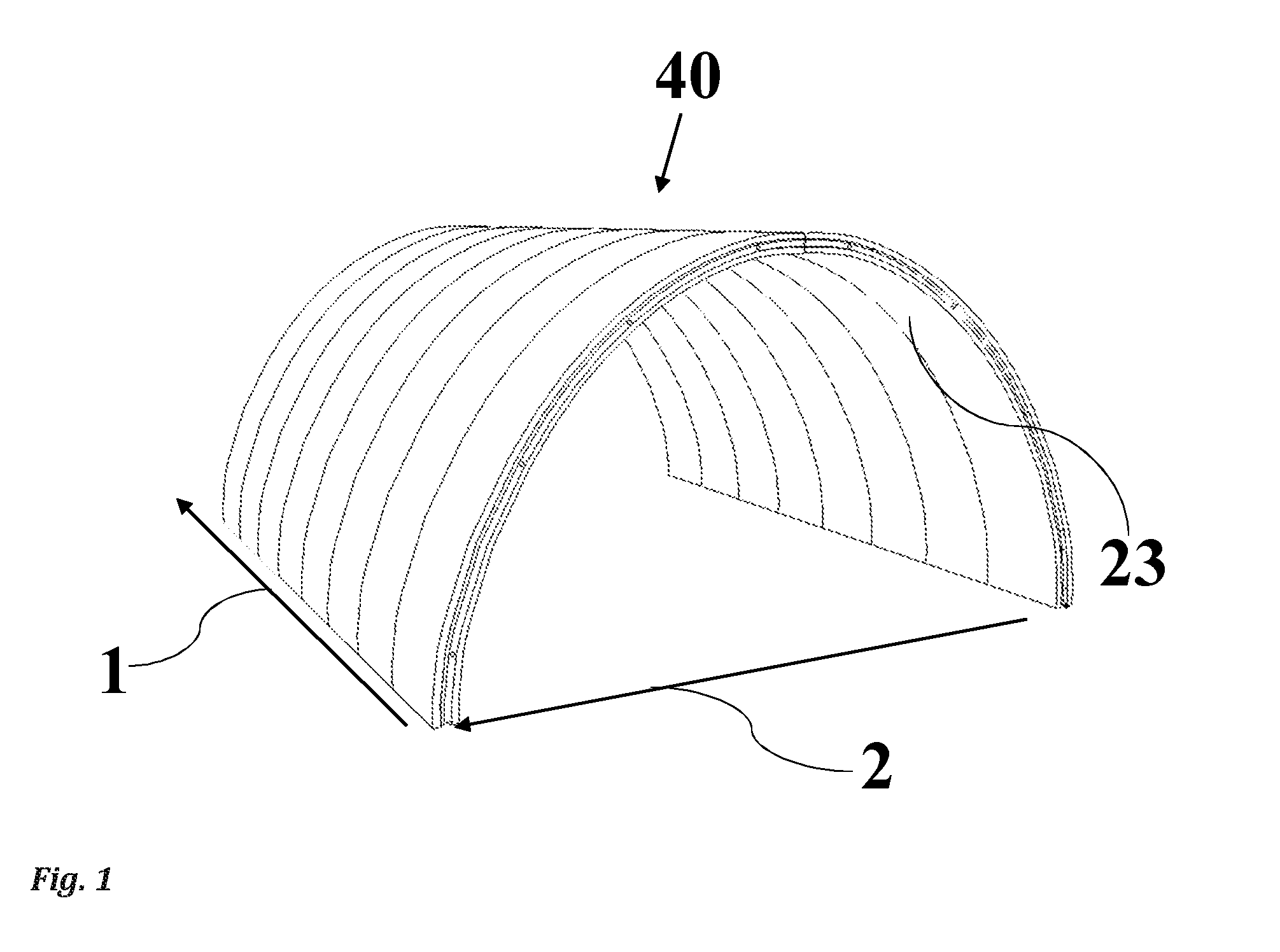

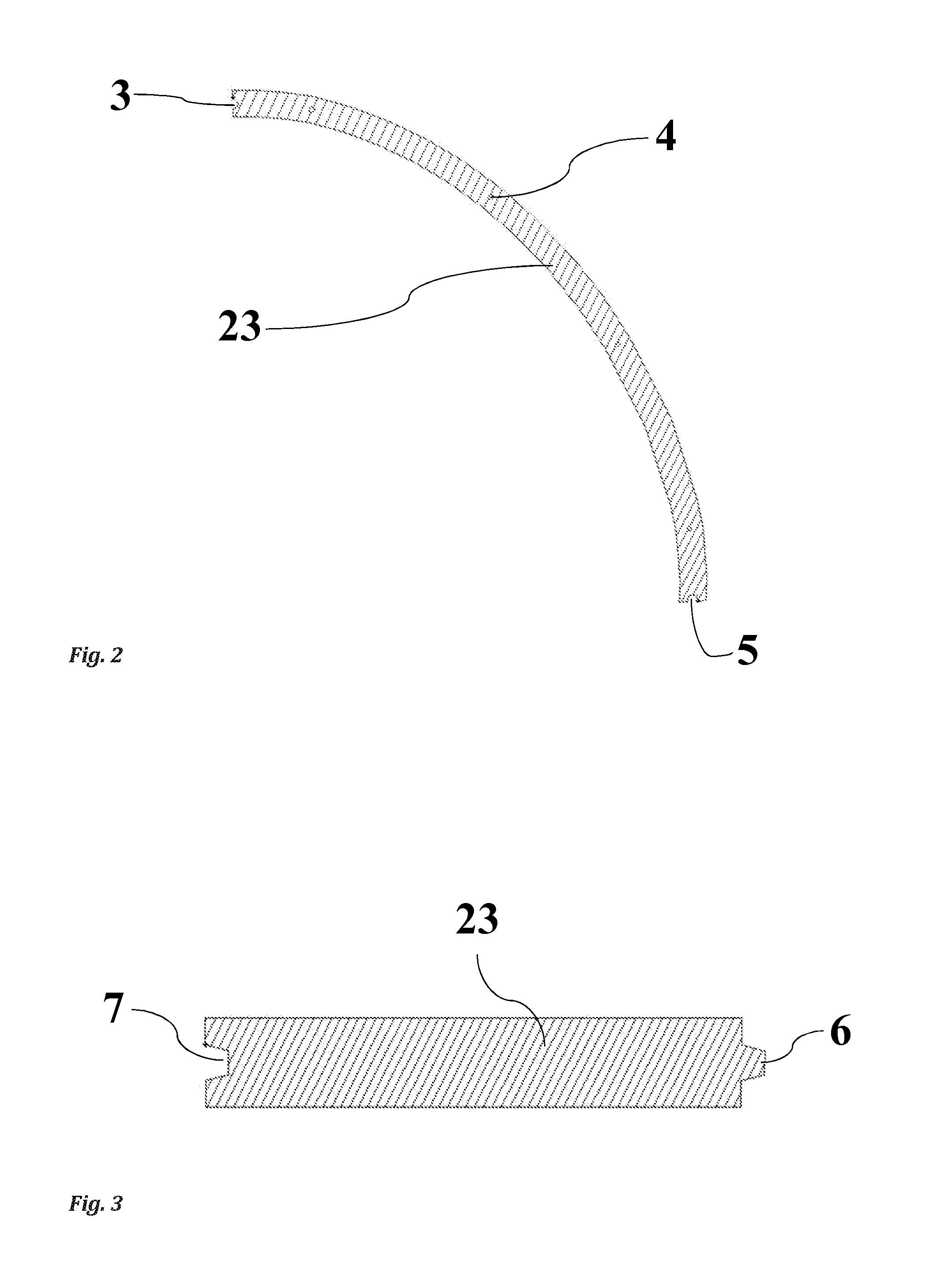

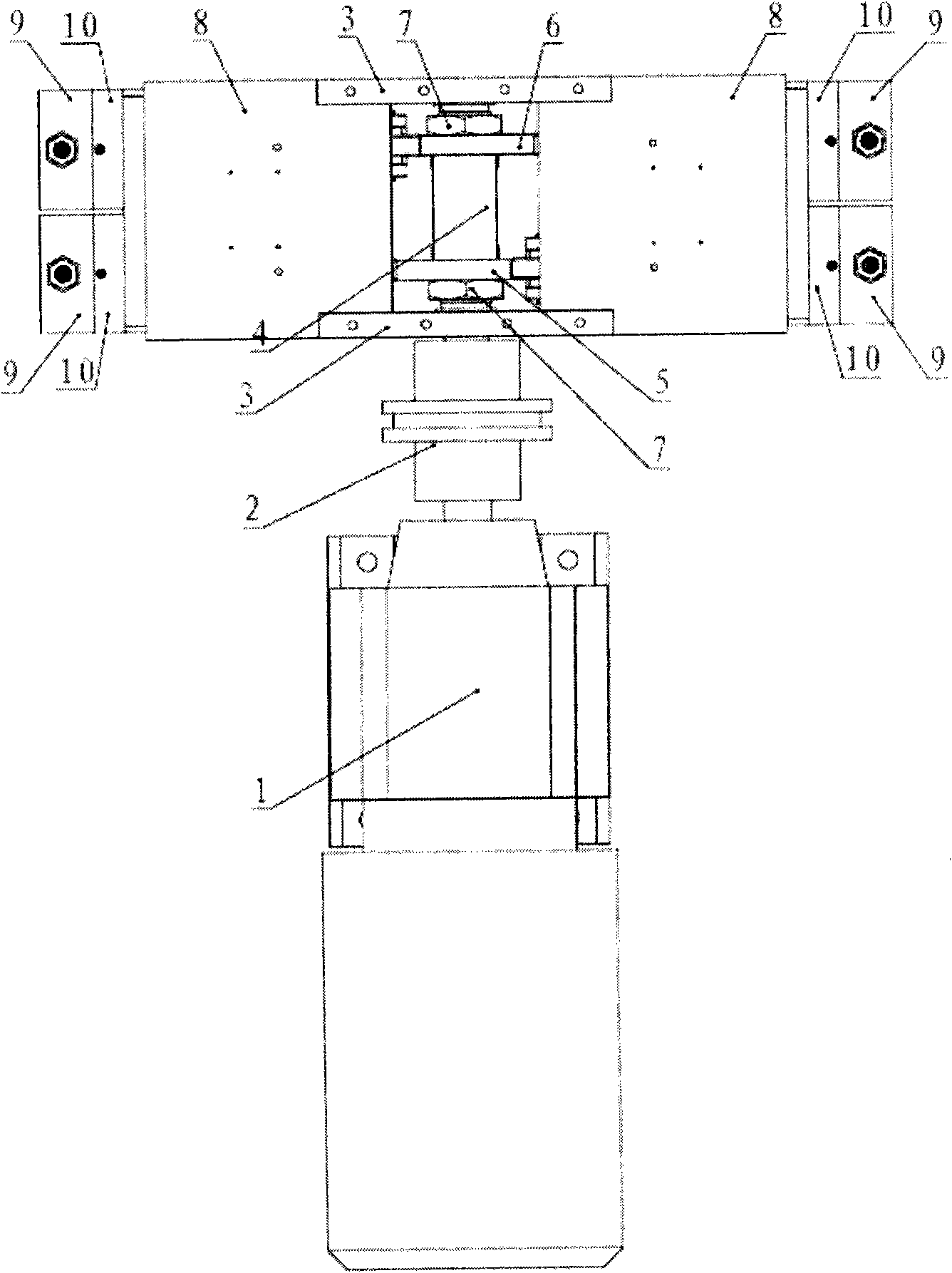

Construction-unit for immediate or permanent shelter

ActiveUS9371641B2Easy to transportEasy to handleConstruction materialArched structuresEllipseEngineering

A construction-unit (23) that is adapted for being combined with one more similar units (23) to constitute a self-carrying structure (40) to use for shelter or dwelling wherein each construction-unit (23) make up for both one sidewall and half a roof in one segment. A plurality of construction-units (23) are adapted for constructing a static functional self-carrying structure (40) where the shape has a curved design related to the mathematical expression The Hyperbolic Cosine or part of an Ellipse in the traverse direction and a linear design in the longitudinal direction when placed as a part of an assembled shelter (40).

Owner:EVERSHELTER APS

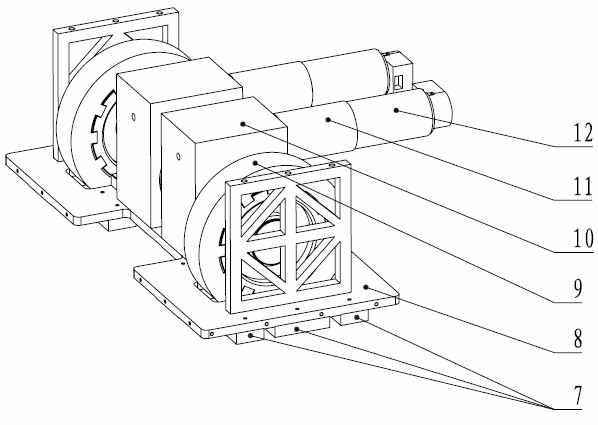

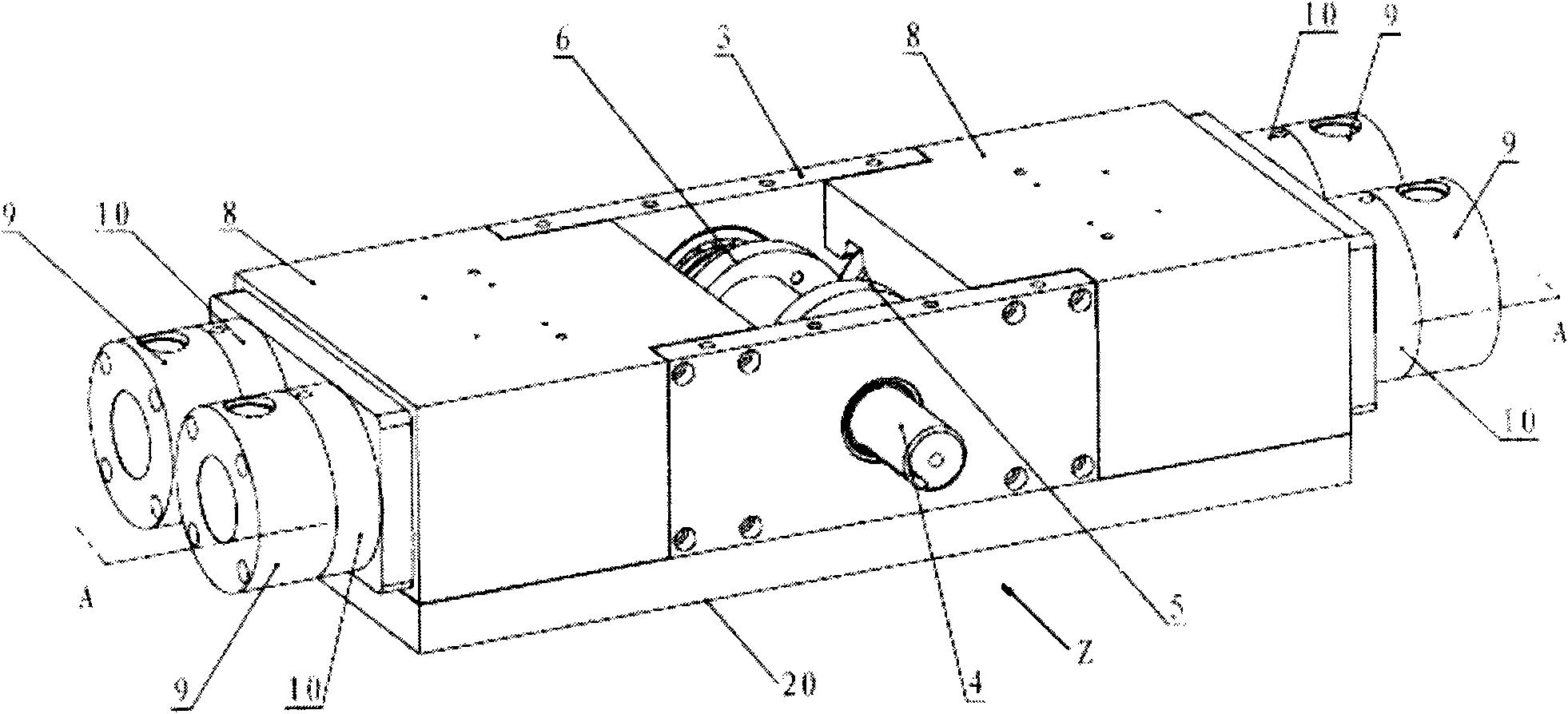

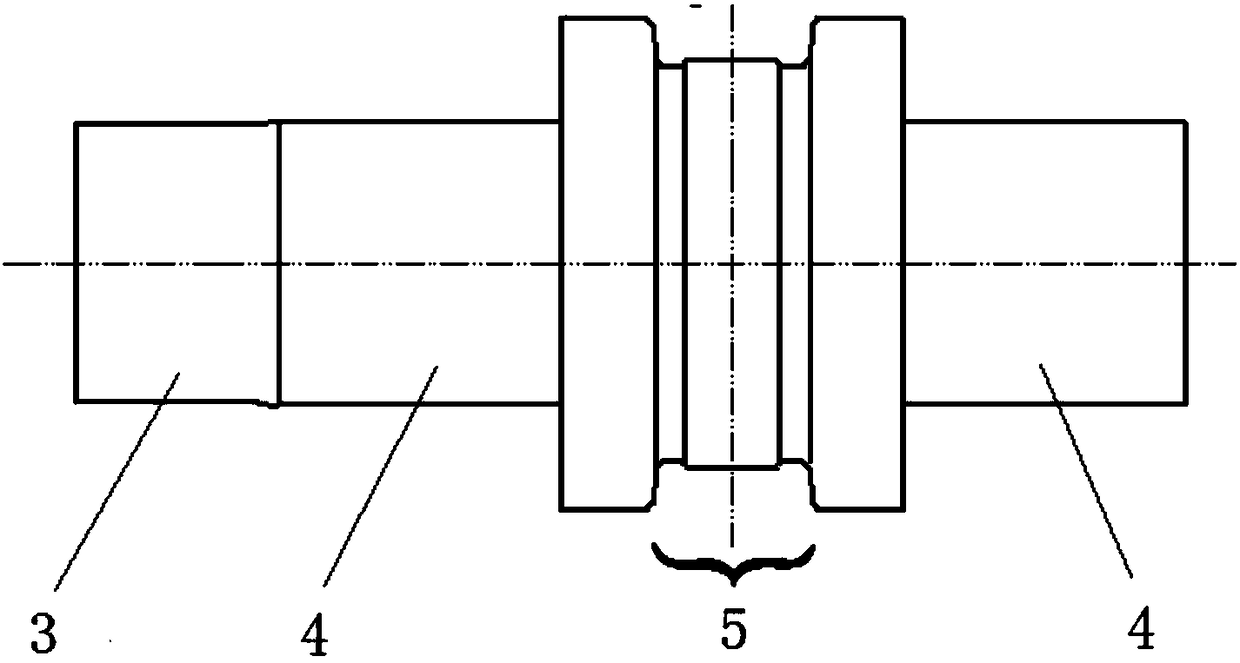

Plunger pump for preparing liquid chromatographic column

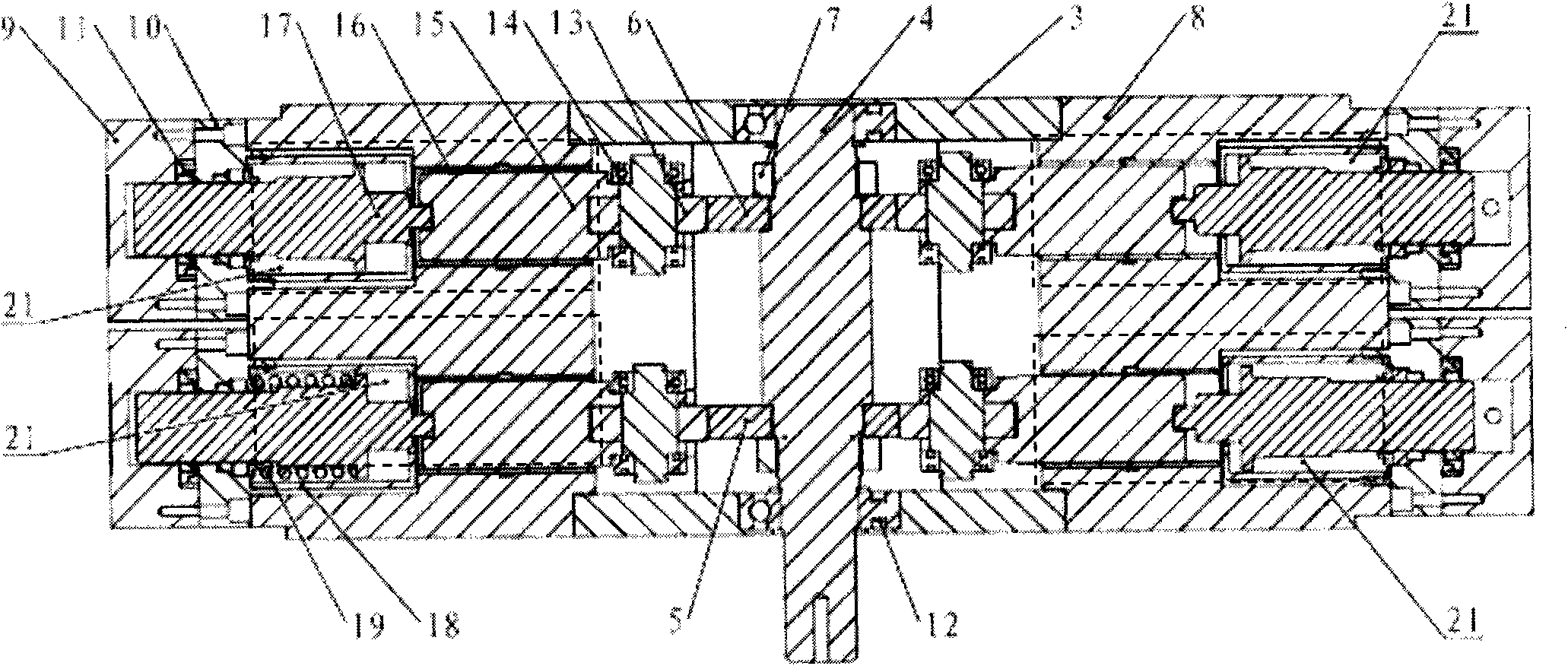

InactiveCN102094777APiston pumpsPositive-displacement liquid enginesReciprocating motionPhase angle difference

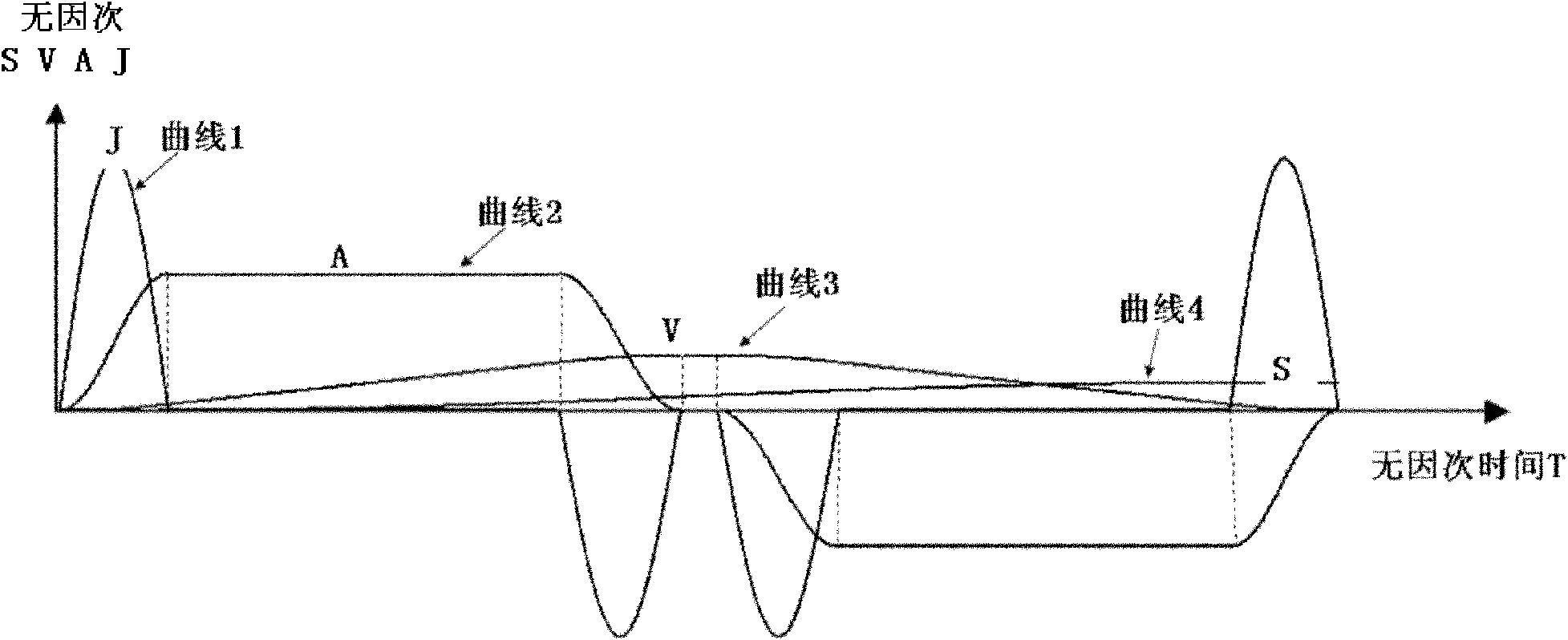

The invention provides a plunger pump for preparing a liquid chromatographic column. A master cam and a slave cam are arranged on a spindle; two pump casings are symmetrically arranged on the two sides of the spindle; four groups of pump heads and pump head seats with the same structure are arranged at the ends of the two pump casings; four groups of sliders with the same structure are arranged inside the two pump casings, and are matched with the master cam and the slave cam by cam bearings; and the spindle rotates to drive the master cam and the slave cam to drive the four groups of sliders to reciprocate. The working curves of the master cam and the slave cam are completely the same, the master cam and the slave cam have the same basic circle radius and the phase angle difference of 90 degrees. Due to the special working curve designs and the phase angles with the difference of 90 degrees of the master cam and the slave cam, the plungers of the four groups of sliders reciprocate in a mutually compensating mode, and the plunger pump can suck and discharge liquid stably and pulselessly.

Owner:北京清博华科技有限公司

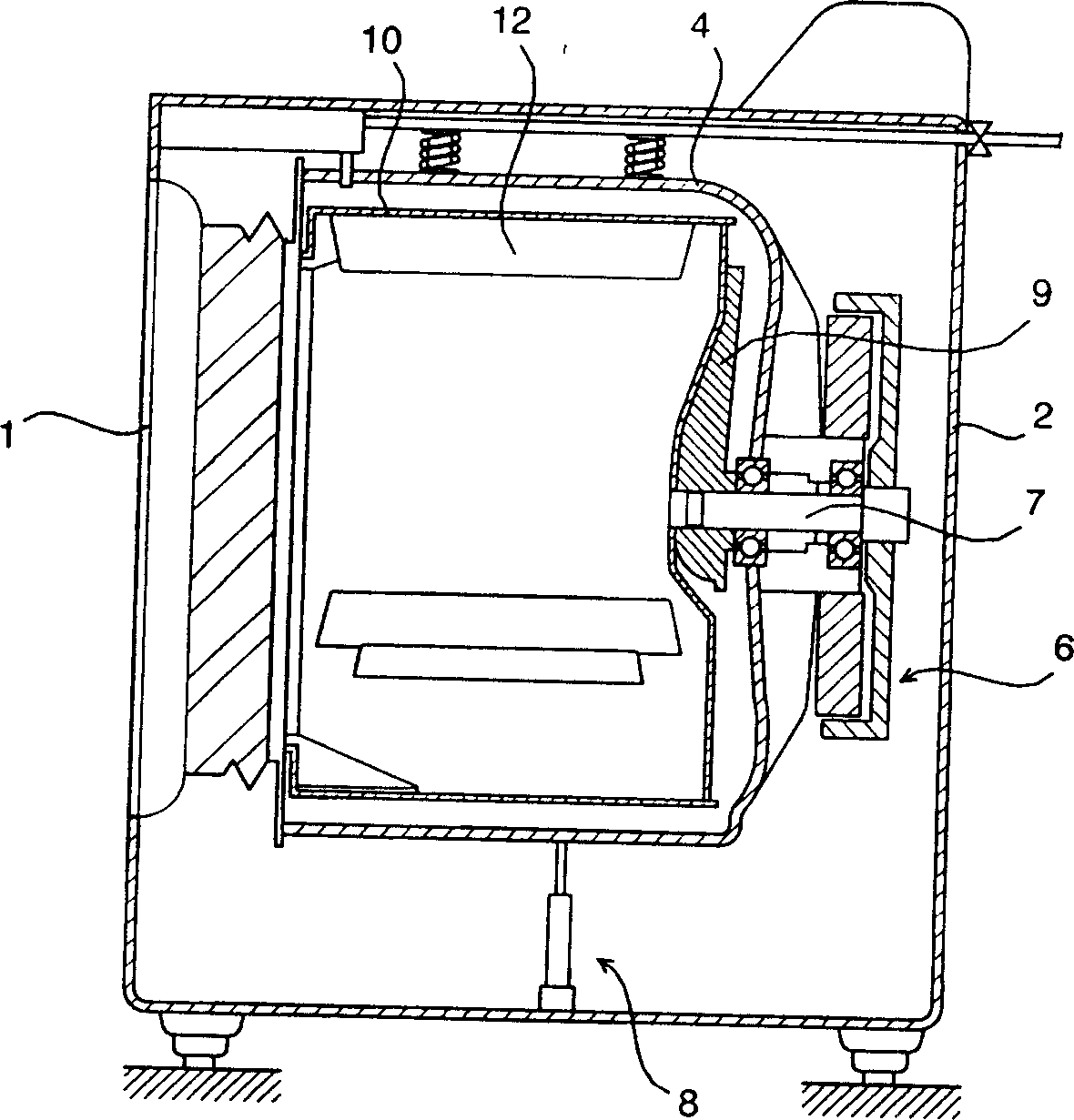

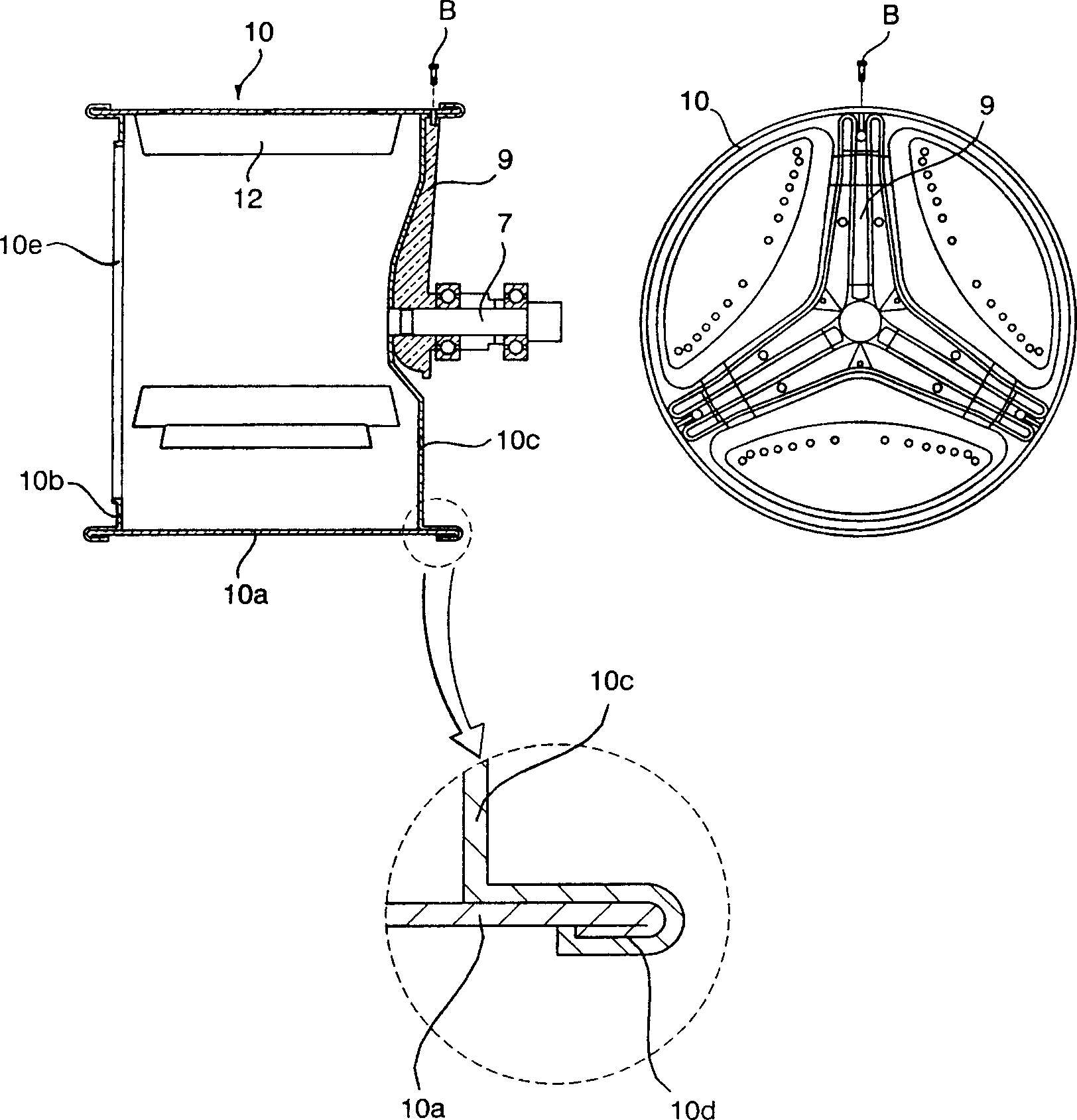

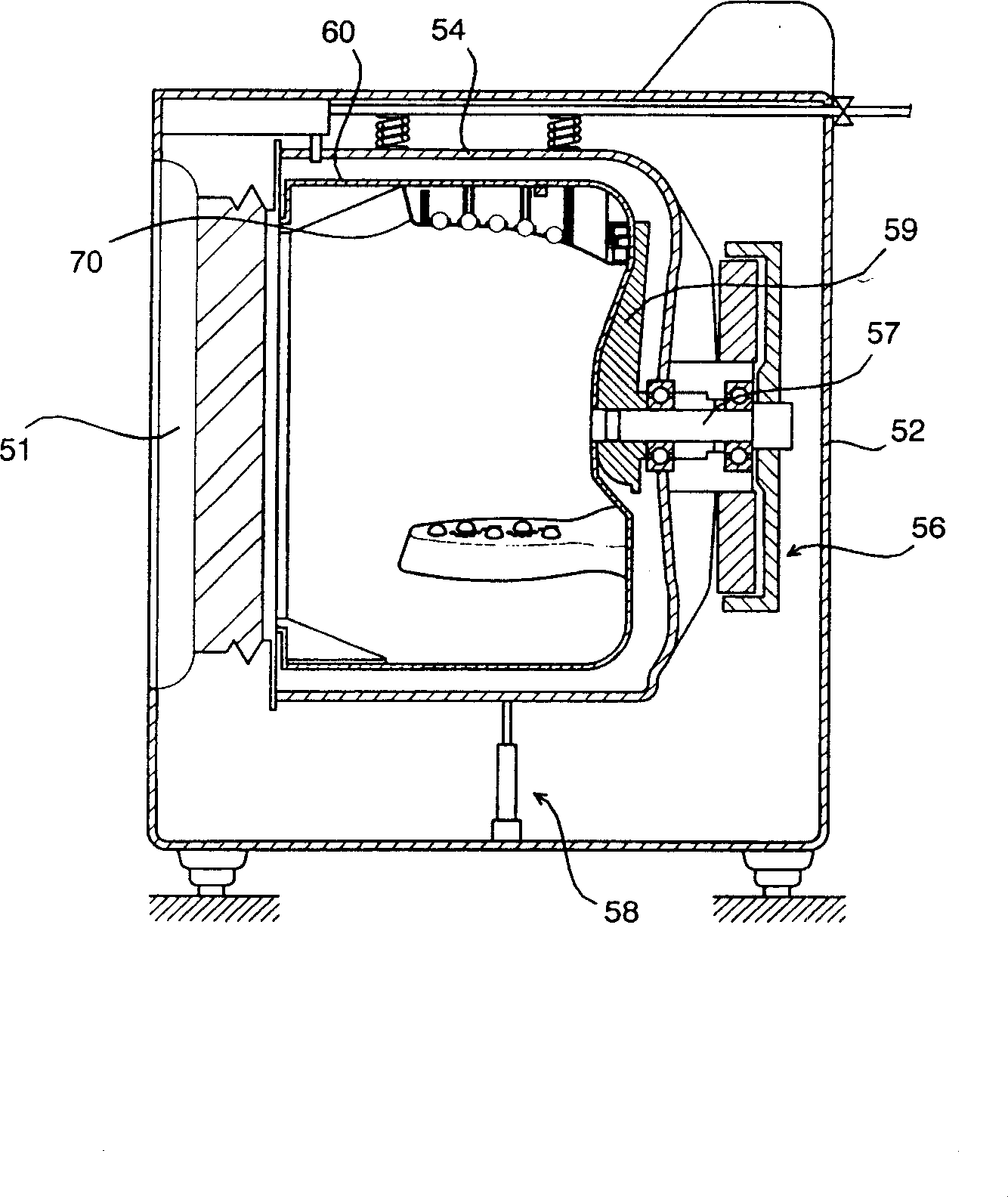

Round angle drum washing machine

InactiveCN1521314AImprove washing effectOther washing machinesTextiles and paperWater flowFresh water

The present invention relates to tumble washer with horizontal rotation shaft, and is especially the curve design of round drum corner, which avoids the washed clothing to retain in the corner and makes it flow gently for being washed. The tumble washer with the improved structure has lifter set inside the casing with forward mouth and rotation shaft set horizontally inside the water tank to filter the washing water into fresh water, and in the back outer wall of the drum, the lifter is connected to the rotation shaft of the motor to result in vertical mixed water flow. The present invention features the curved design of the drum corner to avoid retaining washed clothing in some place.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

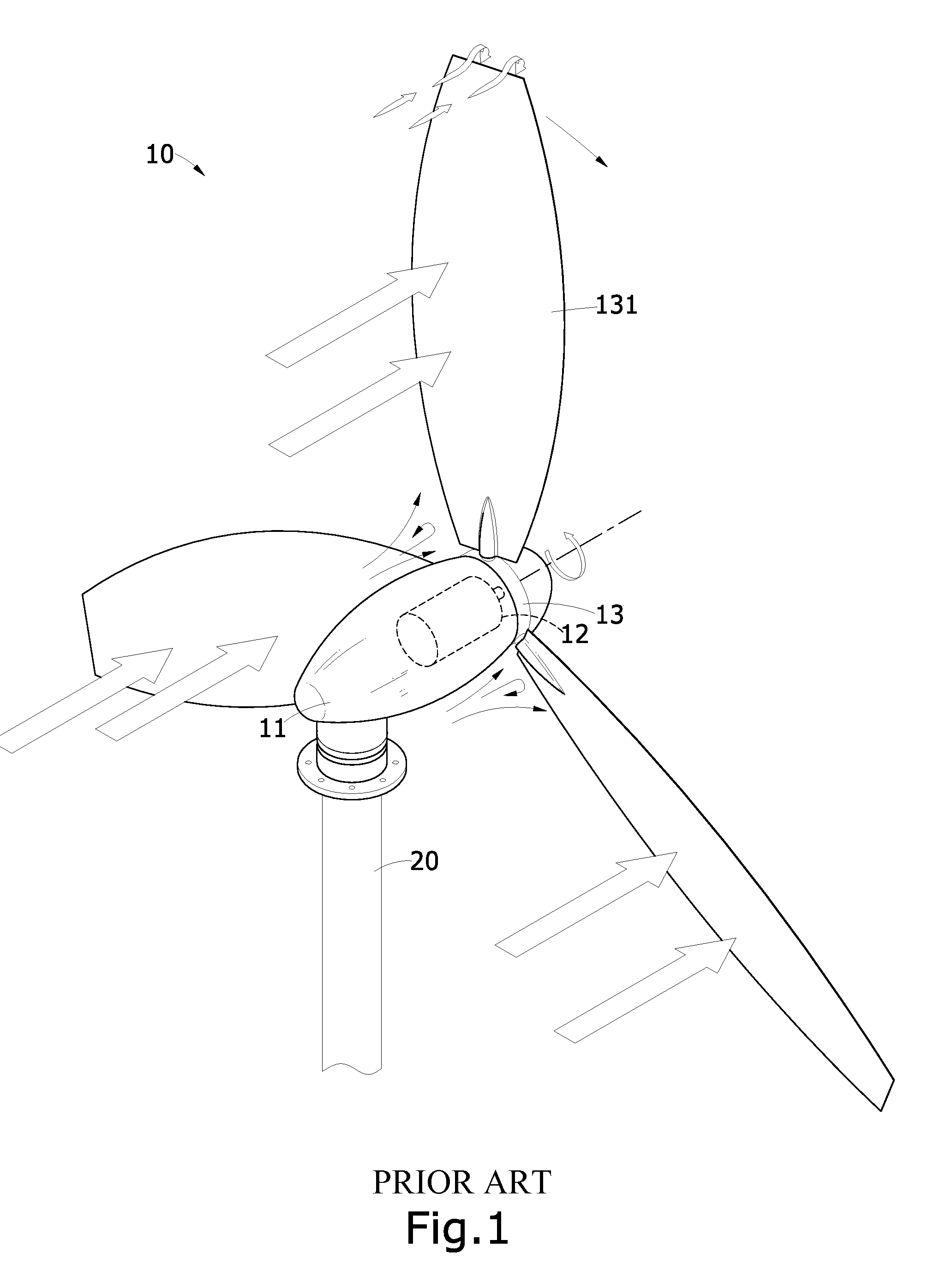

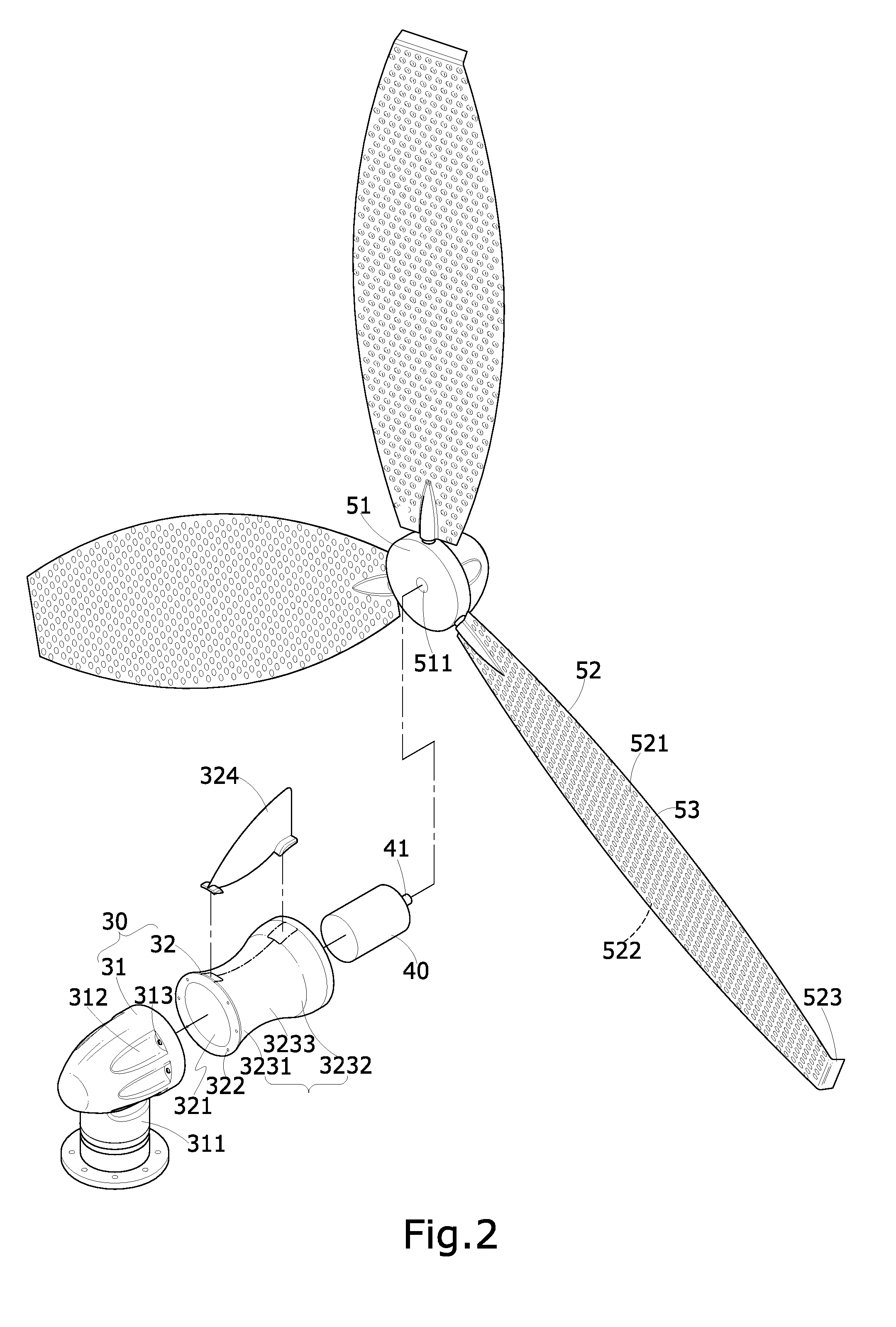

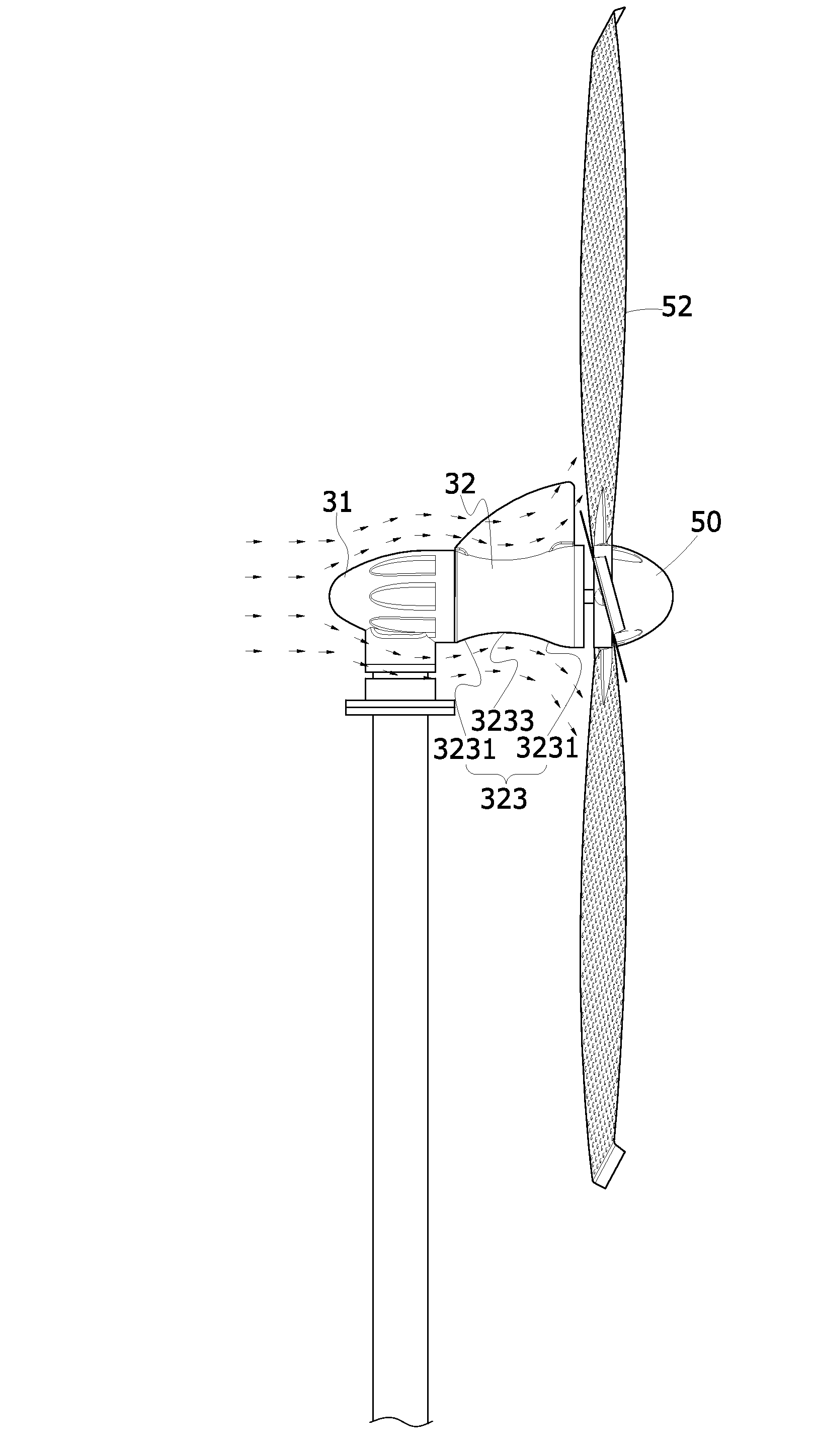

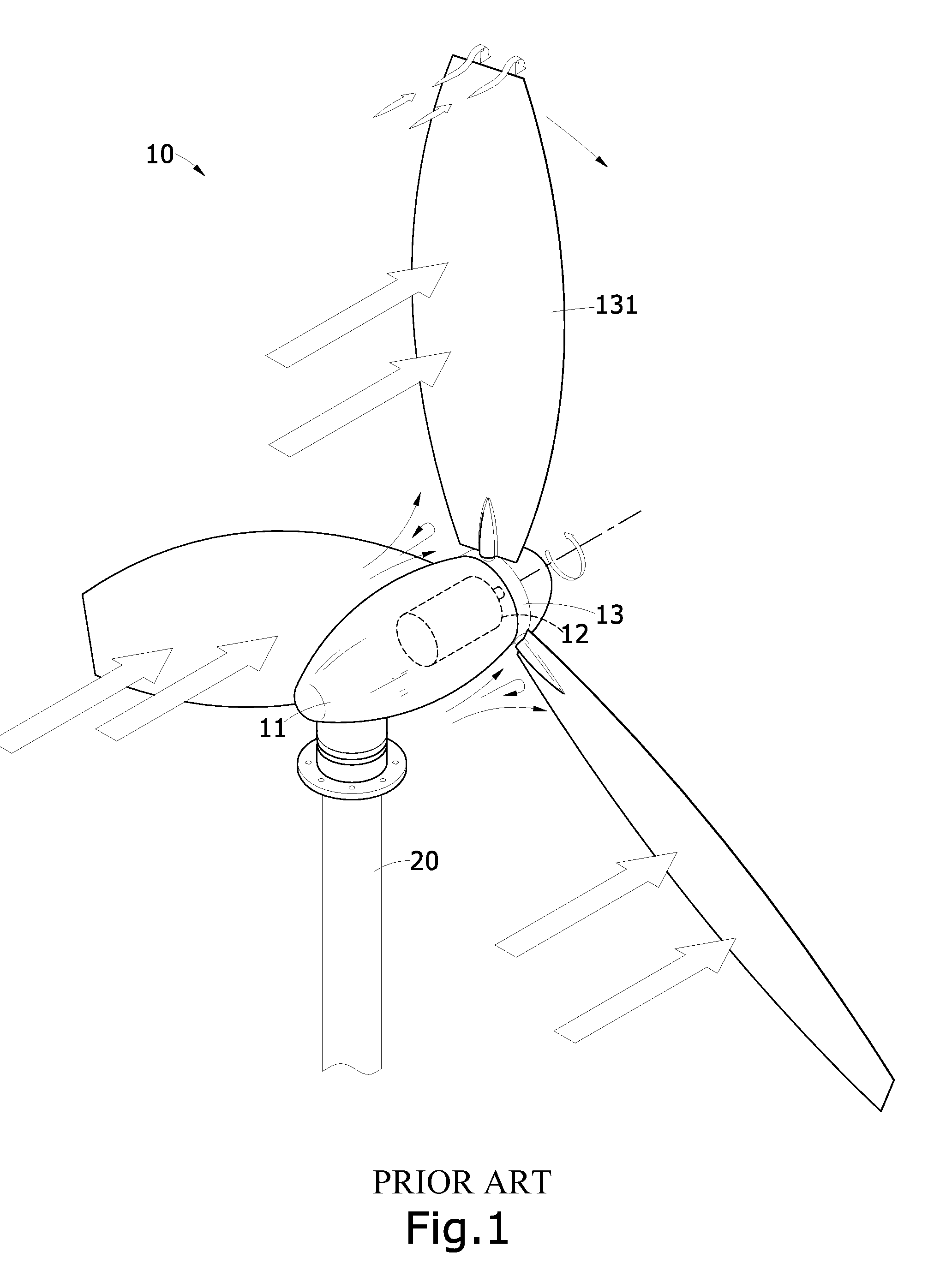

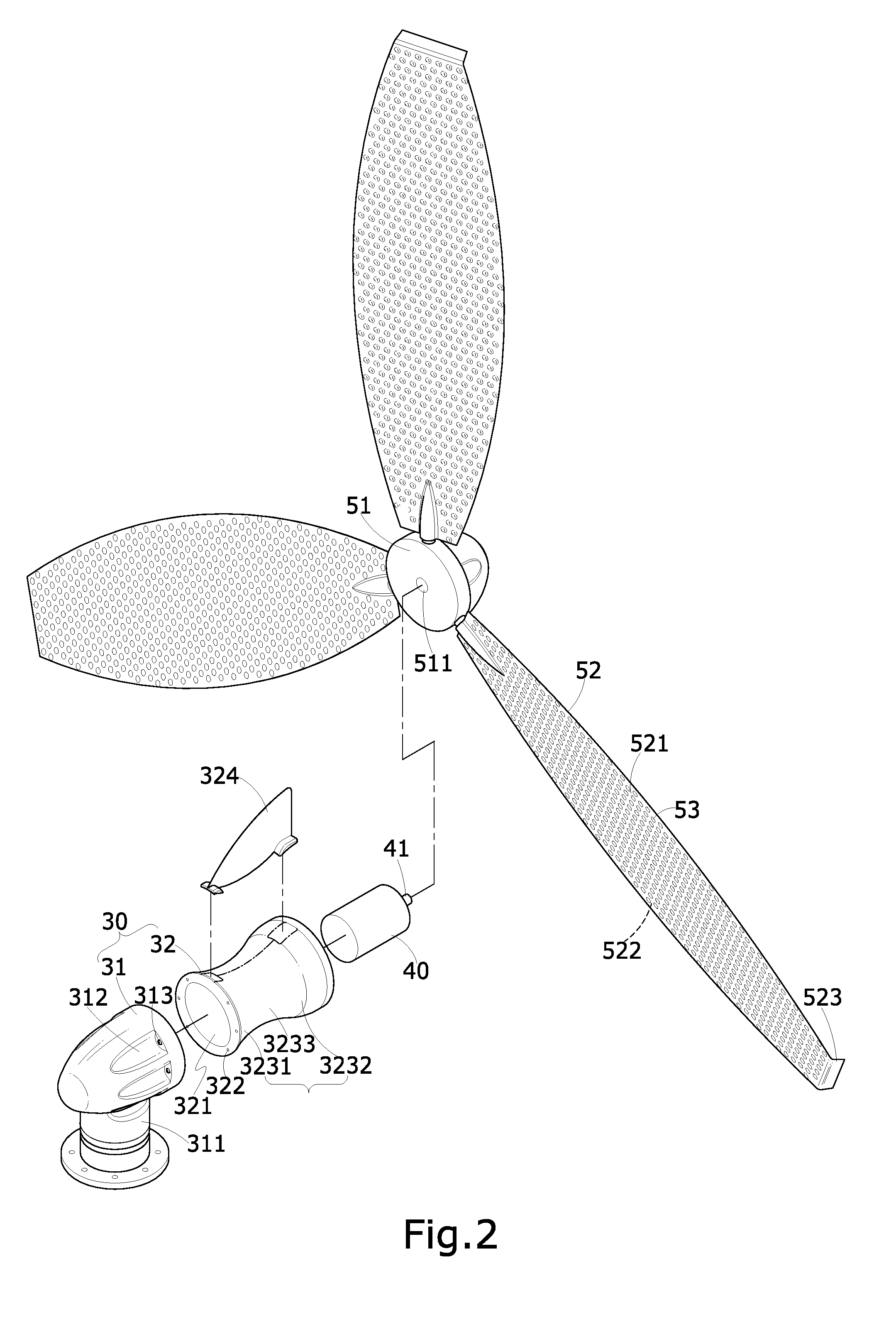

Wind turbine

InactiveUS20100301612A1Improve utilization efficiencyReduce turbulenceWind motor controlWind motor combinationsImpellerNacelle

A wind turbine includes a nacelle that houses a dynamo and a vane wheel coupled to an end of the dynamo. The nacelle is movably mounted to a post. The nacelle has a body forming a circumferentially extending curved slot that has a front portion forming a reducing section and a rear portion forming an expanding section. The vane wheel has a hub at a center thereof and including a plurality of blades radially extending therefrom. Each blade has an end forming a down wash. With the curved design of the nacelle body, the rising angle of airflow exiting the nacelle is improved and with the down wash, the occurrence of tip vortex is suppressed, whereby the utilization efficiency of wind energy in the wind generation operations is improved.

Owner:LEE JIA YUAN

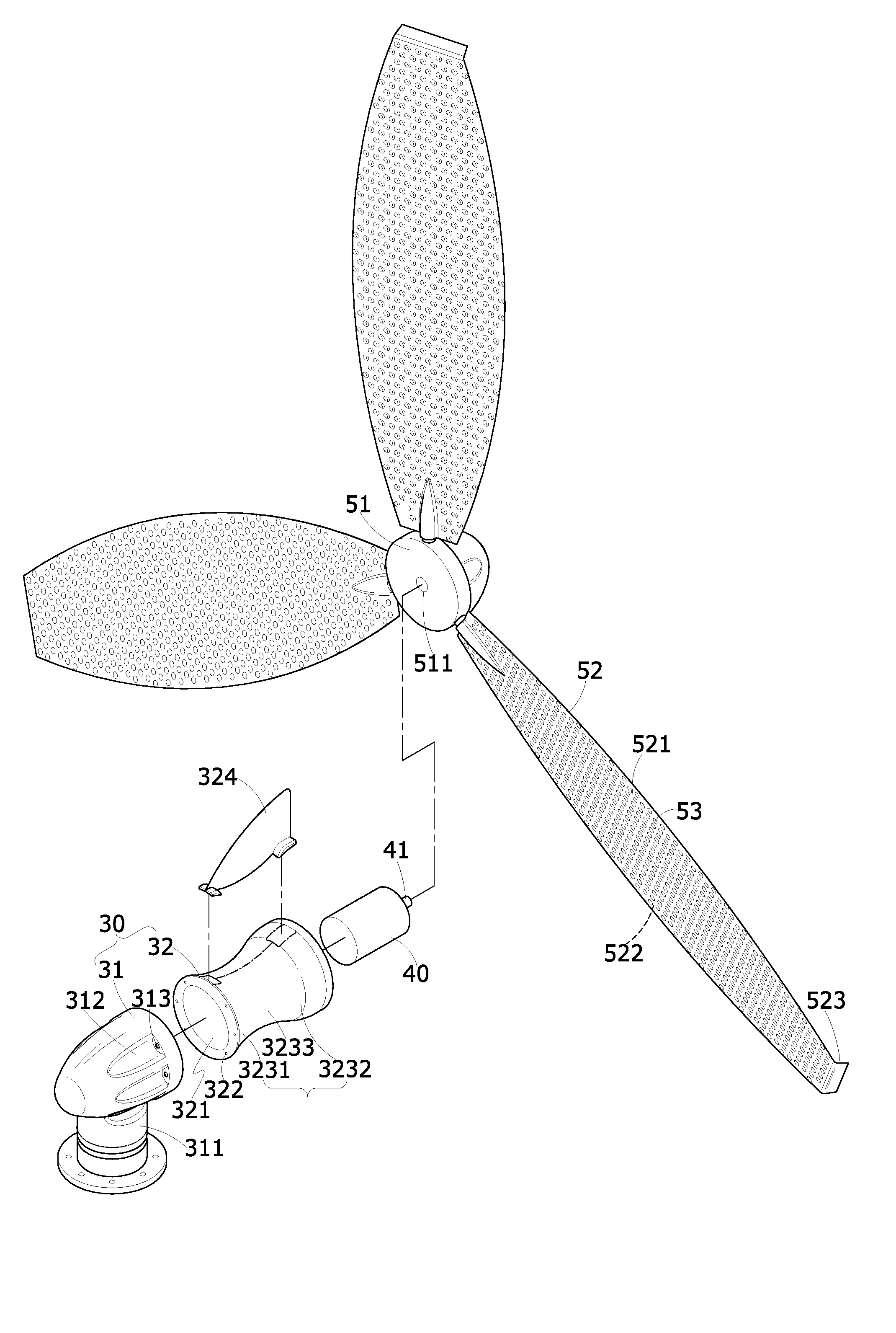

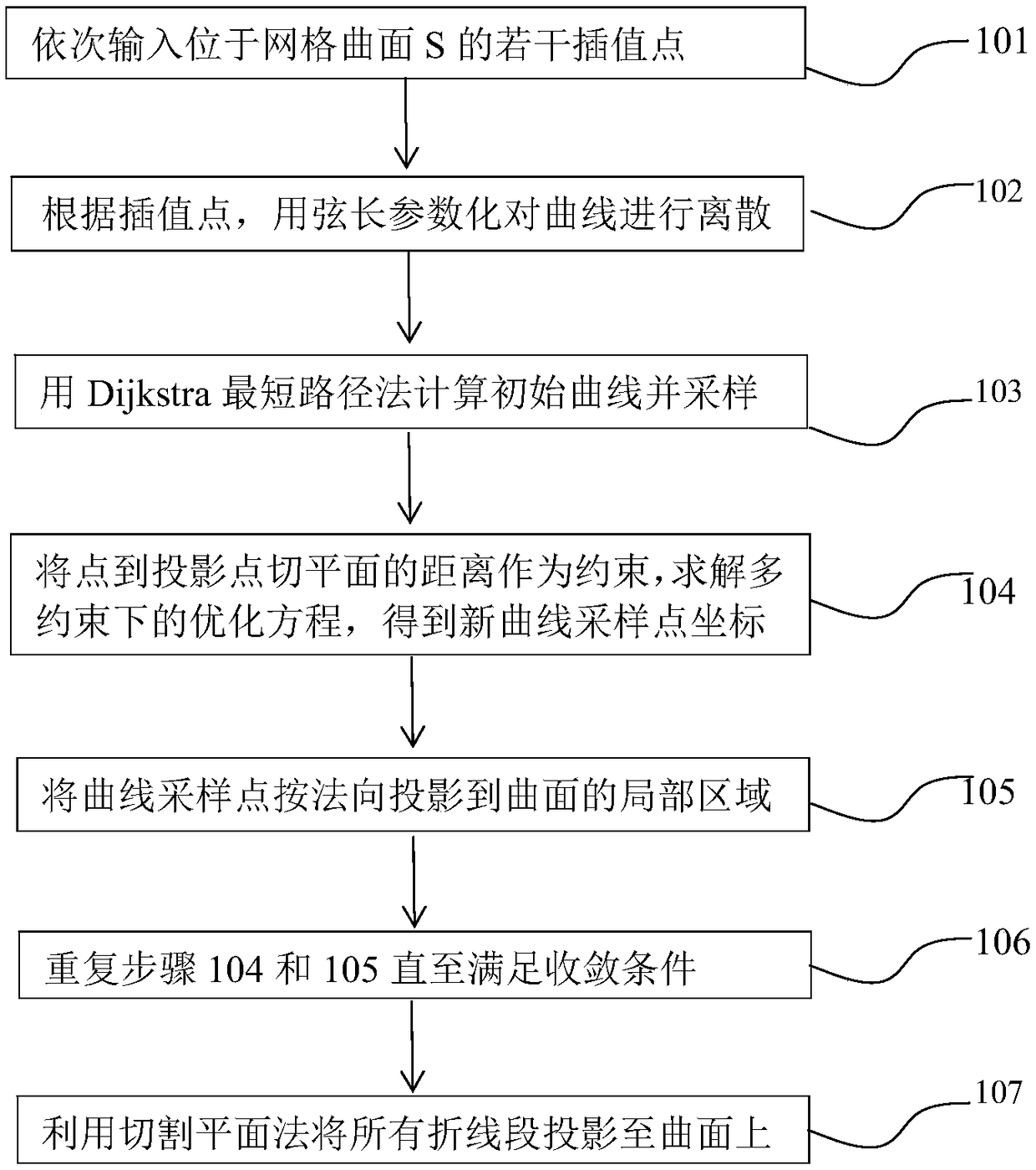

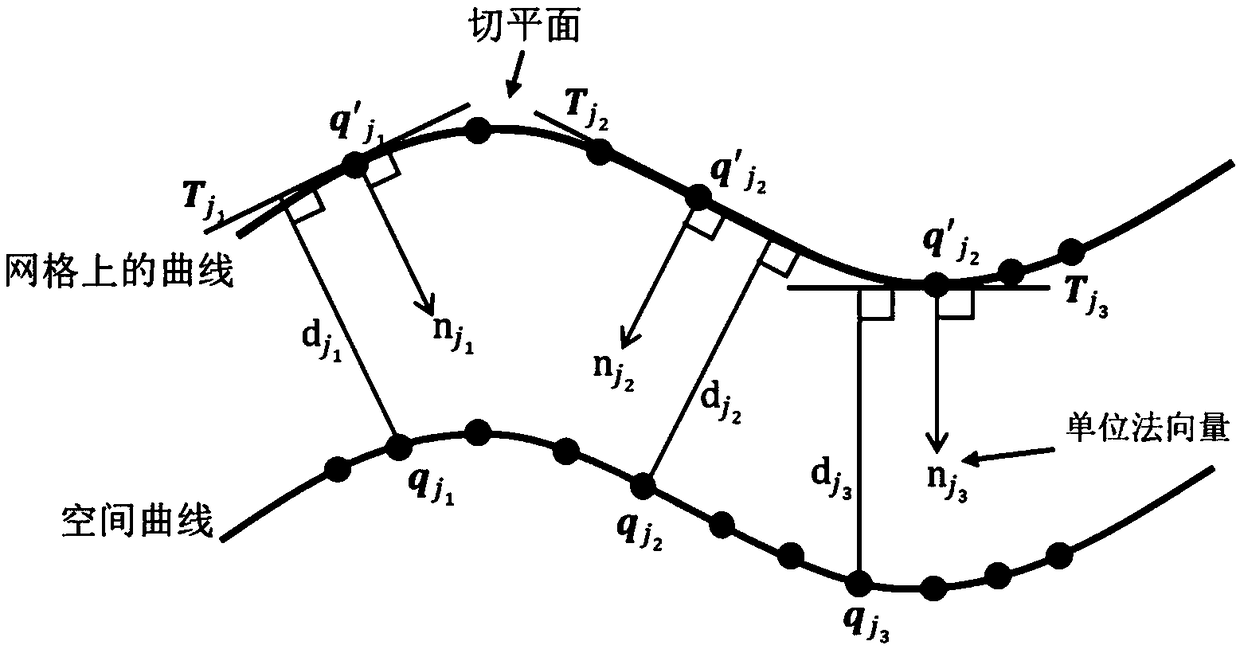

A mesh surface curve design method based on distance constraint

ActiveCN109360272AImprove efficiencyImprove robustness3D modellingDistance constraintsCutting-plane method

The invention discloses a mesh surface curve design method based on distance constraint. The designed curve passes through a given interpolation point and is smooth (in the sense of discreteness) andstrictly located on the mesh surface. The method transforms the complex manifold constraints into distance constraints and describes them as optimization problems together with smooth constraints andinterpolation constraints. The local surface is approximated by the tangent plane, and the distance constraint is relaxed to the distance from the point to the tangent plane. Because the points on thecurve used to calculate the distance are interdependent with their corresponding tangent points, a global-local iterative strategy is adopted and Gauss- Newton idea method is used to control its convergence behavior: in the whole stage, it is relaxed into a convex optimization problem by distance approximation to solve the iterative step size; In the local phase, a robust and efficient projectionmethod is used to map the optimized curves to the surface to update the tangent points. Finally, all the relaxed polygons are mapped to the mesh surface by using the cutting plane method. Compared with the existing methods, this method has many advantages in efficiency, robustness and application range.

Owner:ZHEJIANG SCI-TECH UNIV

Heat zincplating planisher roll shape curve design method

The invention relates to thermal zinc plating finisher curvature design method, which comprises a, collecting device parameter of finisher, and kind standards; b, selecting right standard, to fix the weight factor of each standard; c, designing the roller curvature formula and optimizing the curvature parameters; d, adding said parameter into roller curvature formula to obtain optimized formula. The invention uses pre-discharge tension stress and rolling pressure transverse distribution uniformity as target function, to optimize the working roller and support roller curvatures, to support the stability and uniformity of zinc layer.

Owner:BAOSHAN IRON & STEEL CO LTD +1

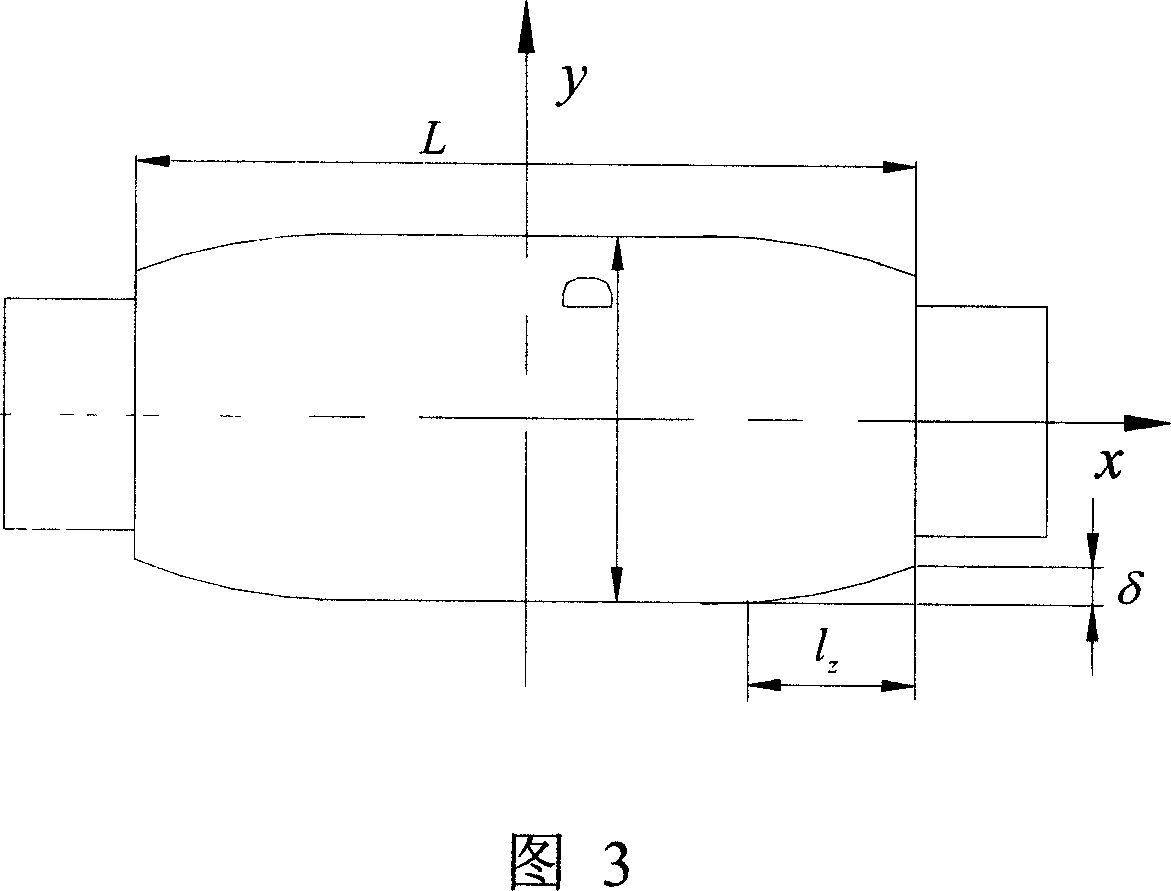

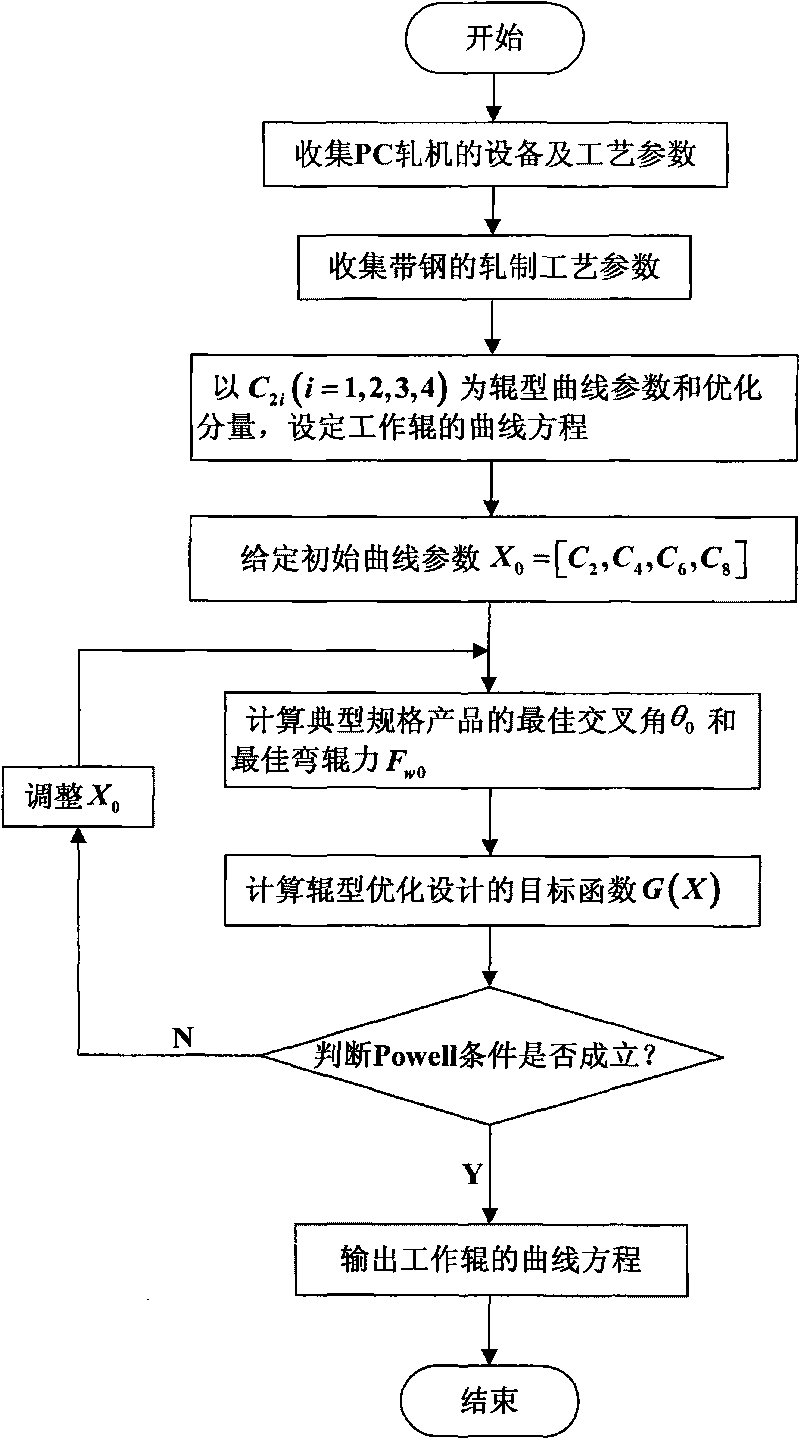

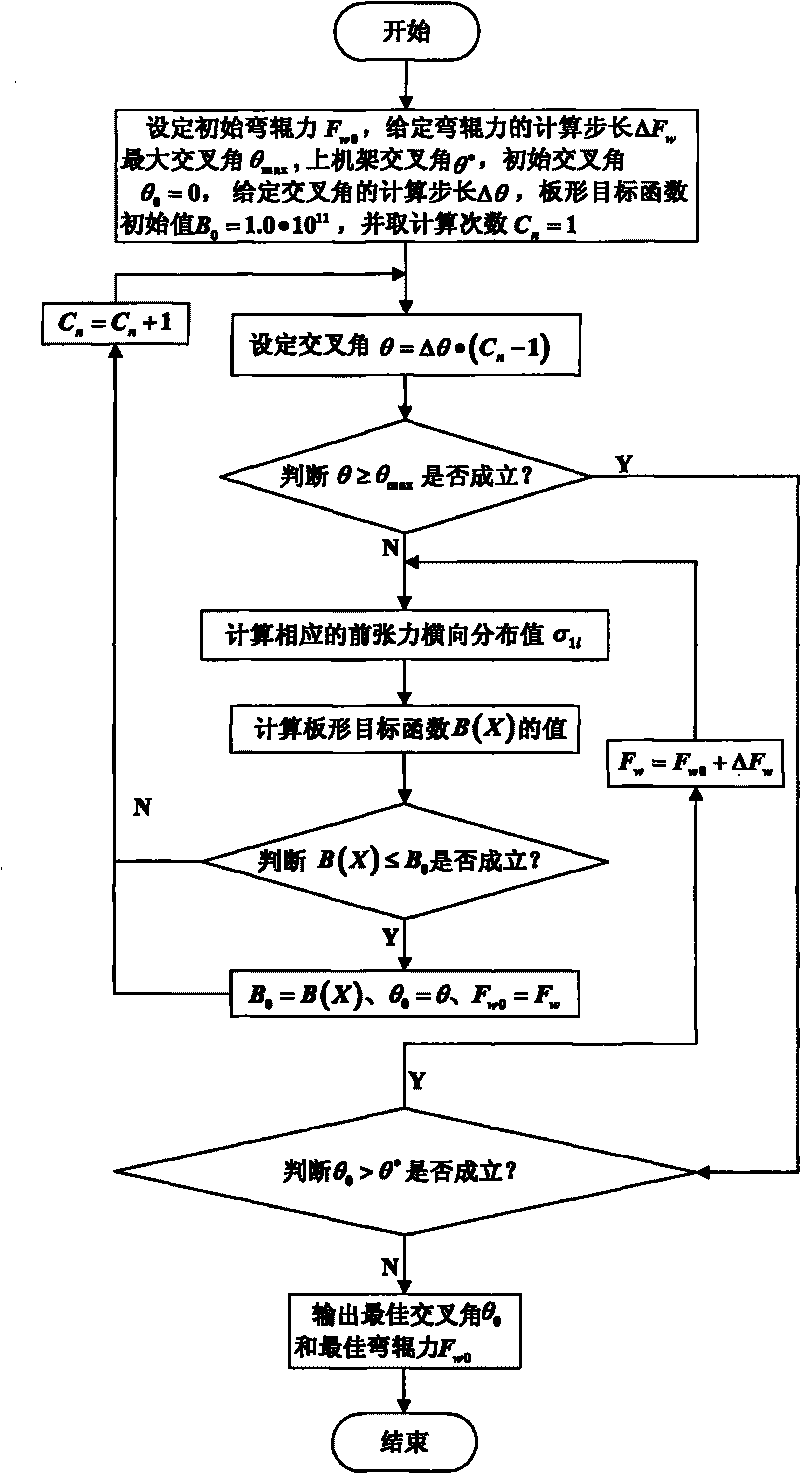

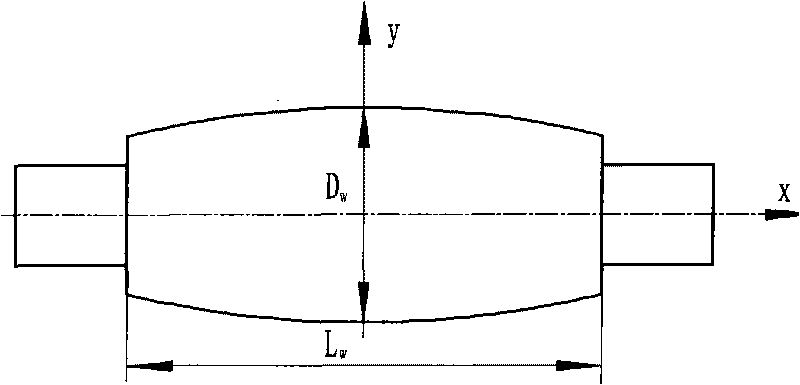

Crossing angle and roll bending force reduction based roll shape design method of work roll of PC rolling mill

InactiveCN101714177AImprove plate crown control abilityImprove stabilityRollsSpecial data processing applicationsWork rollStrip mill

The invention provides a crossing angle and roll bending force reduction based roll shape design method of a work roll of a PC rolling mill, aiming at the rolling characteristics of the PC rolling mill. The roll shape design method comprises the following steps of: (a) collecting equipment parameters and process parameters of the PC rolling mill; (b) collecting rolling process parameters of typical band steel; (c) setting a curve equation of the work roll; (d) optimally computing curve parameters of a roll shape; and (e) substituting the curve parameters of the roll shape into the roll shape curve equation of the work roll so as to obtain an optimized roll shape curve equation of the work roll. The invention enhances the stability of the PC rolling mill because a roll shape curve of the work roll reduces the crossing angle and the roll bending force, prolongs the service life of the work roll, enhances the convexity control capacity of the PC rolling mill, not only ensures the qualityrequirement of a profile shape, but also meets the requirement for industrial application precision, and can also be used for the roll shape curve design of the work roll of any rack according to actual field situation.

Owner:YANSHAN UNIV

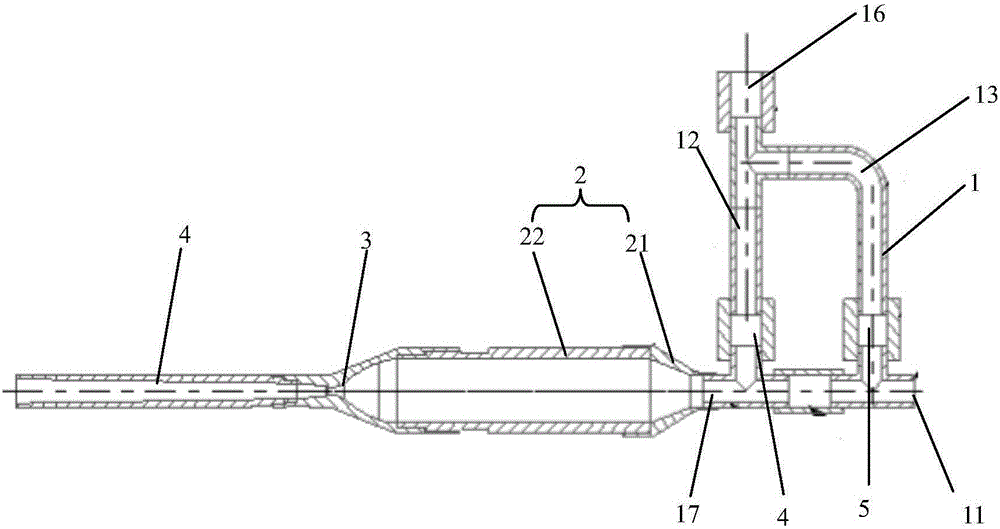

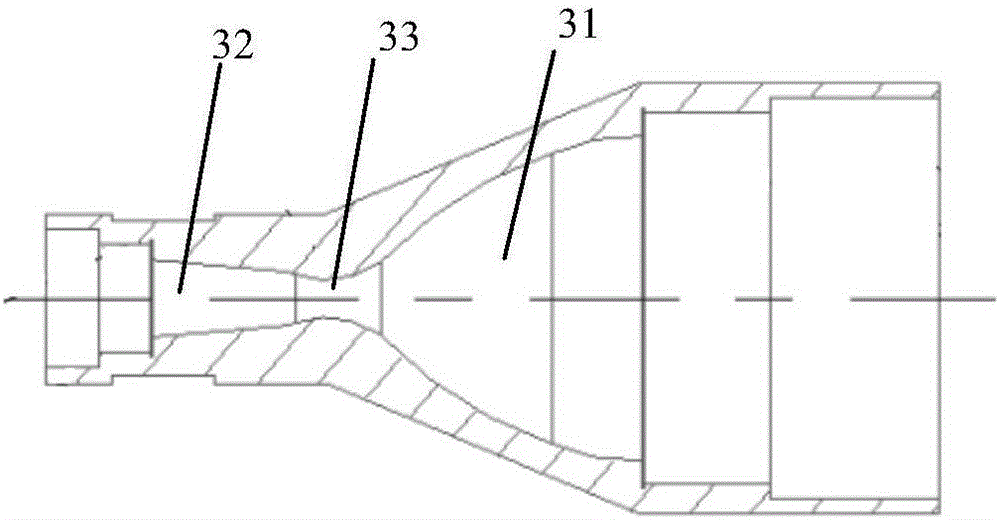

Supersonic sand blasting gun

ActiveCN106525627ASimple structureImprove qualityInvestigating abrasion/wear resistanceSand blastingEngineering

The invention discloses a supersonic sand blasting gun which comprises a laval tube, an expansion tube communicated with the laval tube and an acceleration tube communicated with the laval tube. A sand mulling tube uses a design method of air flow deceleration and sand acceleration to enable sand and air to be evenly mixed before passing through the laval tube; the acceleration tube uses a design method of a shaped surface with a small expansion angle, so that the sand can continuously obtain larger boost to further accelerate to the set supersonic velocity and further reduce the effect of on-way resistance to the air flow; the laval tube uses a curve design method, so that the abrasion of the sand to a throat is reduced, the high-quality air flow with zero axial velocity gradient can be obtained at an outlet of the laval tube, the sand can move along the axis as possible to reduce the collision between the sand and the tube wall, and the abrasion resistance of the spray gun can be improved fundamentally.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

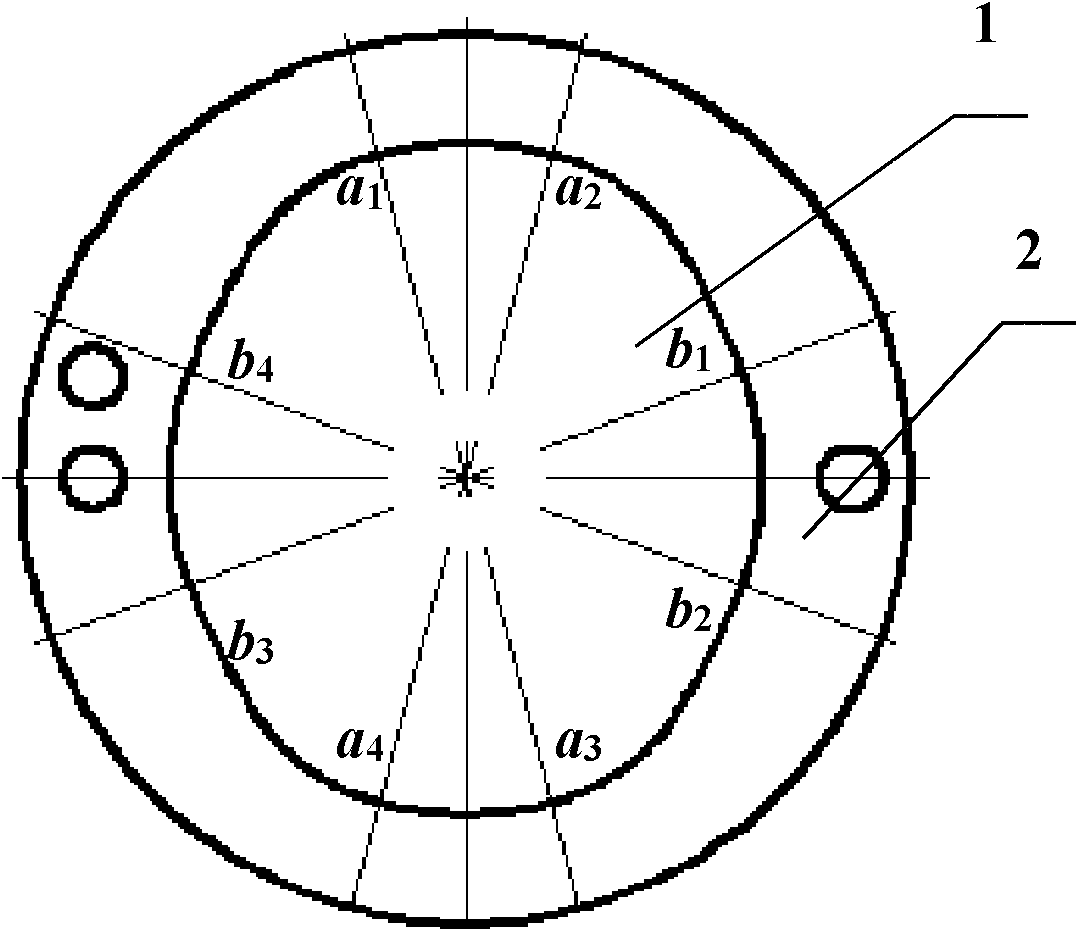

Stator of automobile power steering pump and method for designing stator curve

InactiveCN102094818AThere will be no change in the compression forceSatisfy the impactRotary piston pumpsRotary piston liquid enginesLow noiseEngineering

The invention discloses a stator of an automobile power steering pump and a method for designing a stator curve. The cross section of the outer surface of the stator is of a regular round structure; the circumferential curve of the cross section of the inner surface of the stator, namely the stator curve of the stator, consists of a big circular arc ala2, a big circular arc a3a4, a small circular arc b1b2, a small circular arc b3b4 and four sections of transition curves for connecting the four circular arcs; and the transition curves consist of simple harmonic trapezoidal subsection combined motion law curves. The designing method comprises optimization of optimized target function acceleration Am, simulation solution and final obtaining of the optimized simple harmonic trapezoidal subsection combined motion law curves. The stator curve designed with the method does not generate 'hard impact' or 'rigid impact', does not cause 'soft impact' or 'flexible impact' due to the abrupt change of the acceleration, meets the requirements of the stator curve on no vibration impact and low noise, effectively eliminates the steering noise in a cab, and prolongs the service life of the power steering pump.

Owner:DALIAN POLYTECHNIC UNIVERSITY

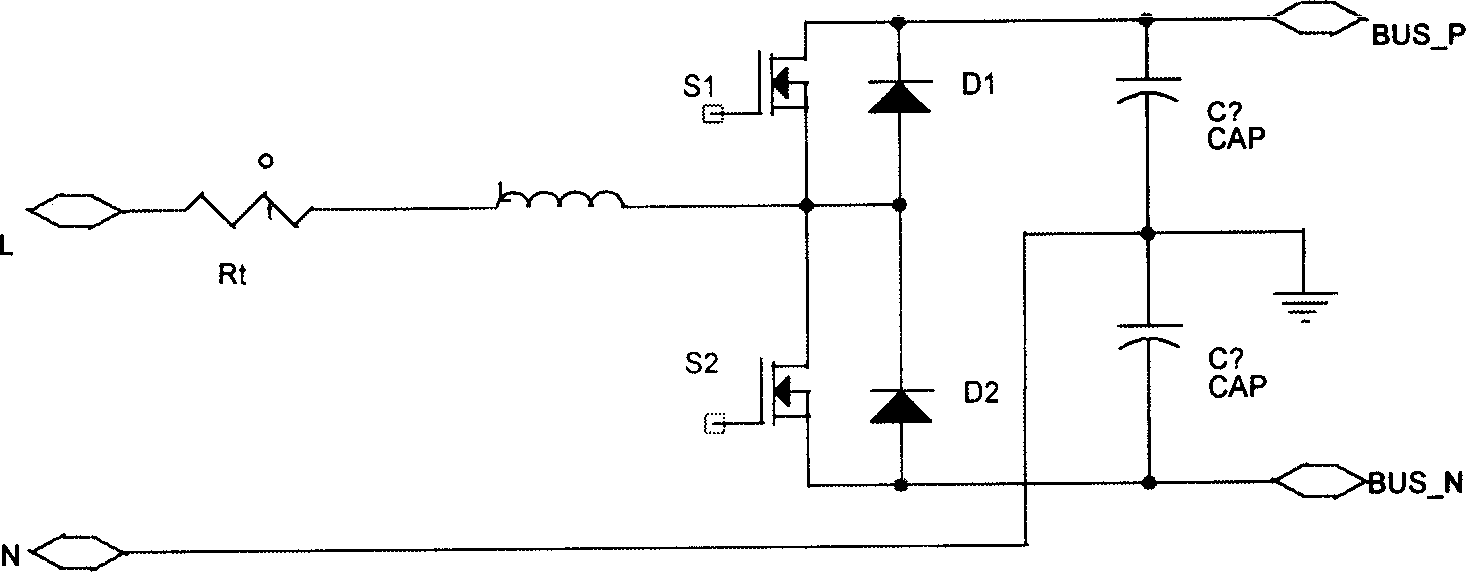

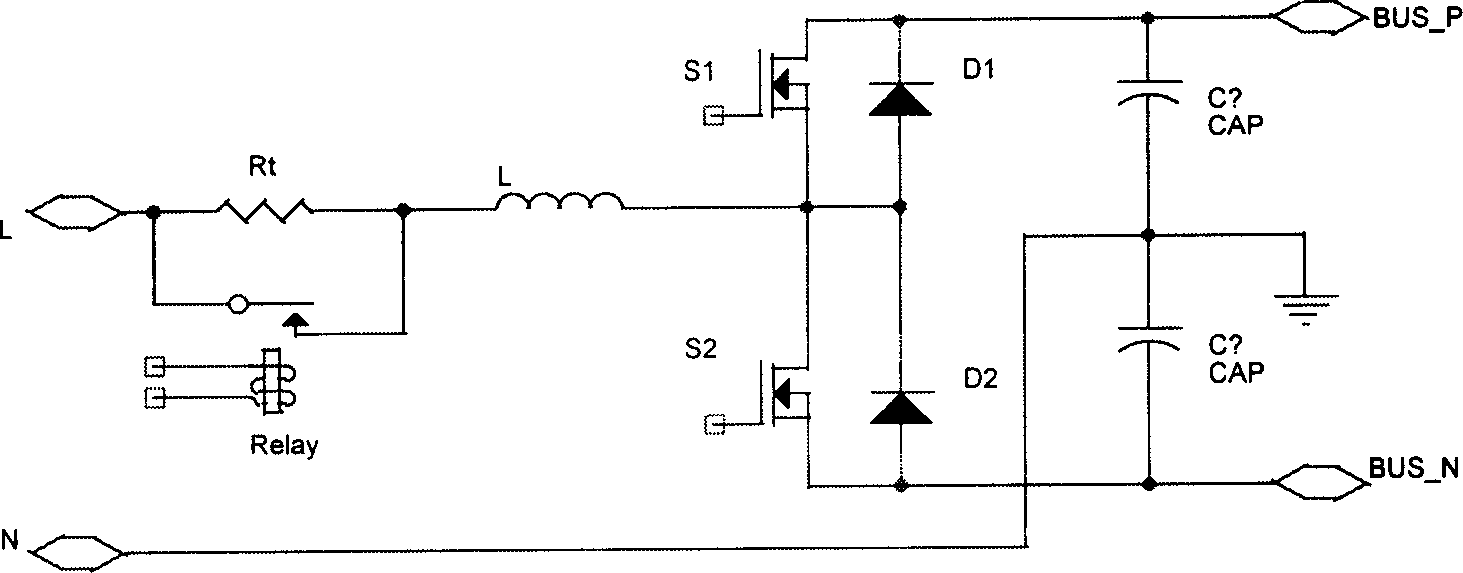

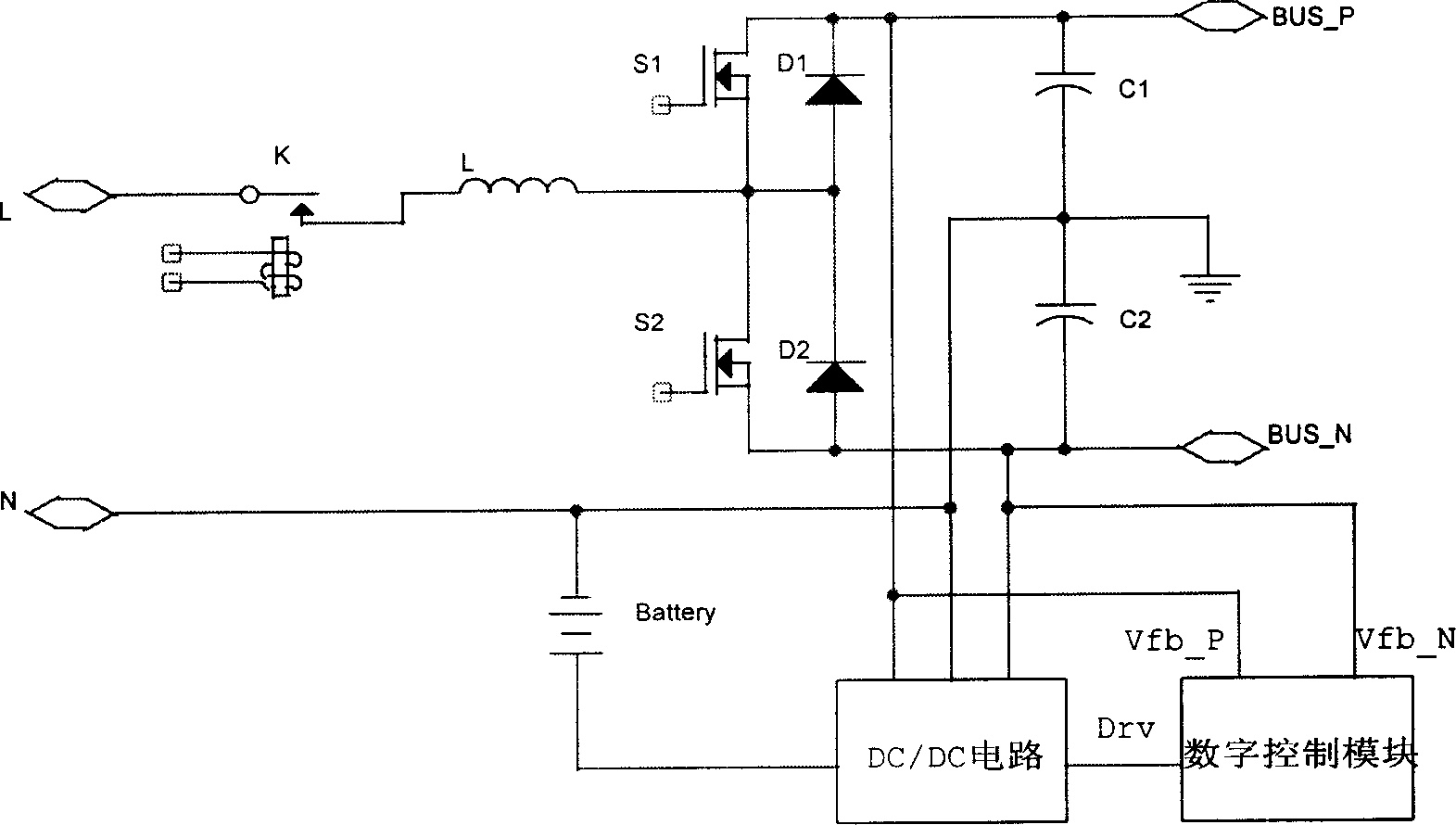

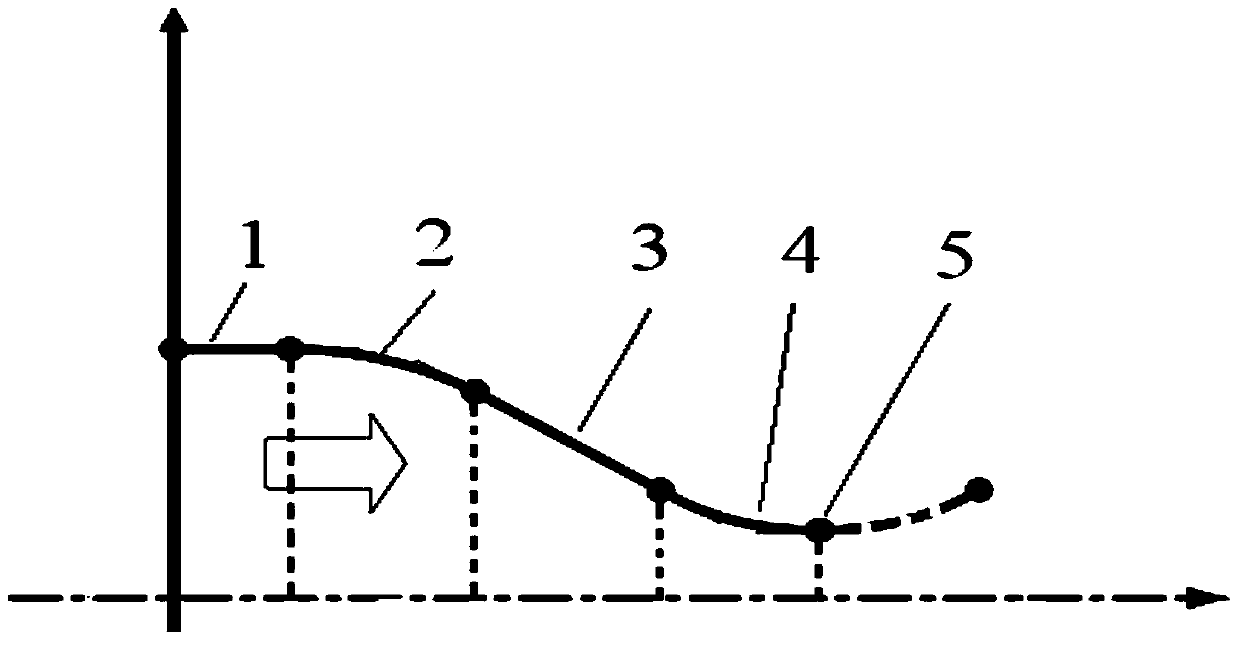

Bus voltage soft actuating method in uninterrupted power source and its device

InactiveCN1479427AReduce shockLow costBatteries circuit arrangementsElectric powerCapacitanceElectricity

Energy of battery through power inversion is transmitted to positive / negative bus line. In charging process, power inverted output voltage is detected as feedback value Controlling signal for driving power inversion circuit makes bus voltage change according to designed rule so as to make bus capacitance be charged according to soft starting rule. After charging is completed, electric power is input to power supply, entering normal working state. 'DC / DC circuit' and 'digital control module' are basic unit of digit controlled UPS without additional parts so as to lower cost and raise reliability. The digit controlled soft starting process can be based on soft starting curve designed smartly in order to reach satisfied soft starting feature and reduce impaction to bus capacitance. Moreover, the invention can test battery and DC / DC circuit.

Owner:LIANYUNGANG DAFA ENVIRONMENTAL PROTECTION TECH CO LTD

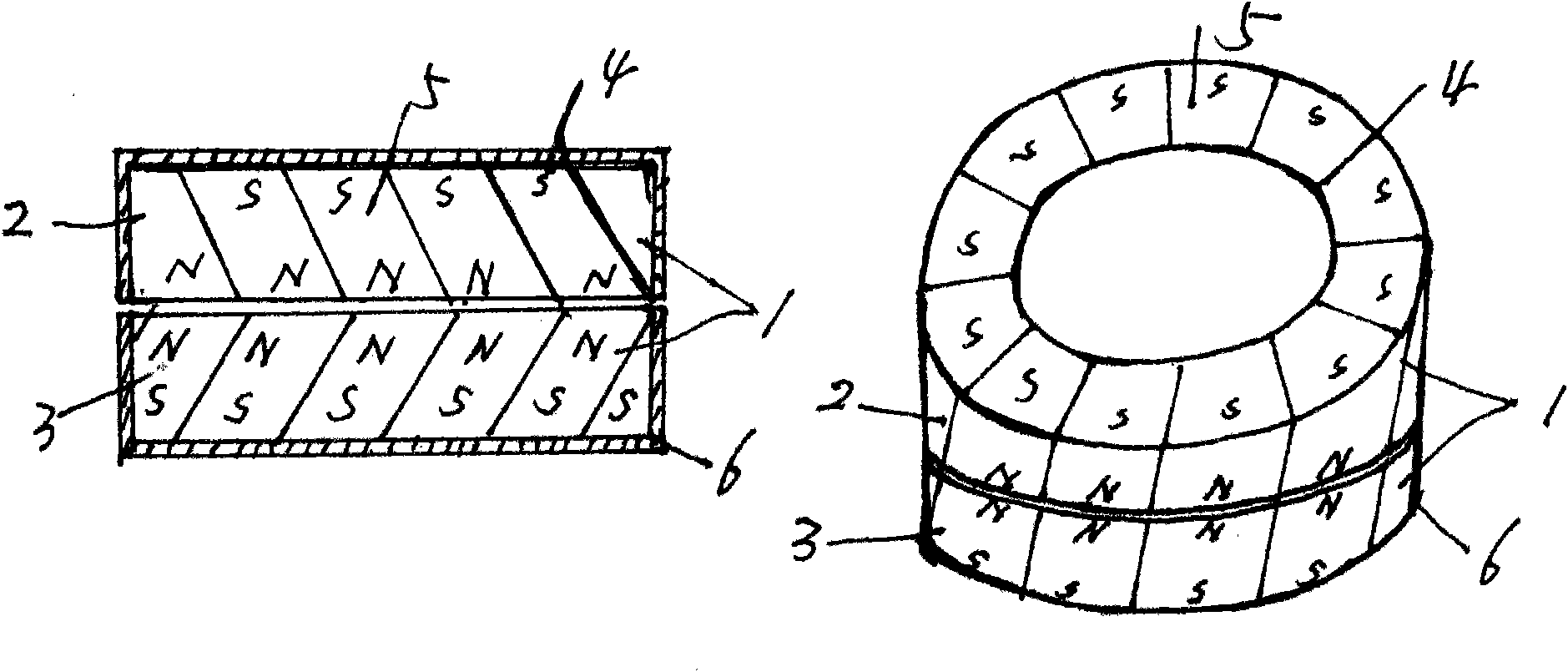

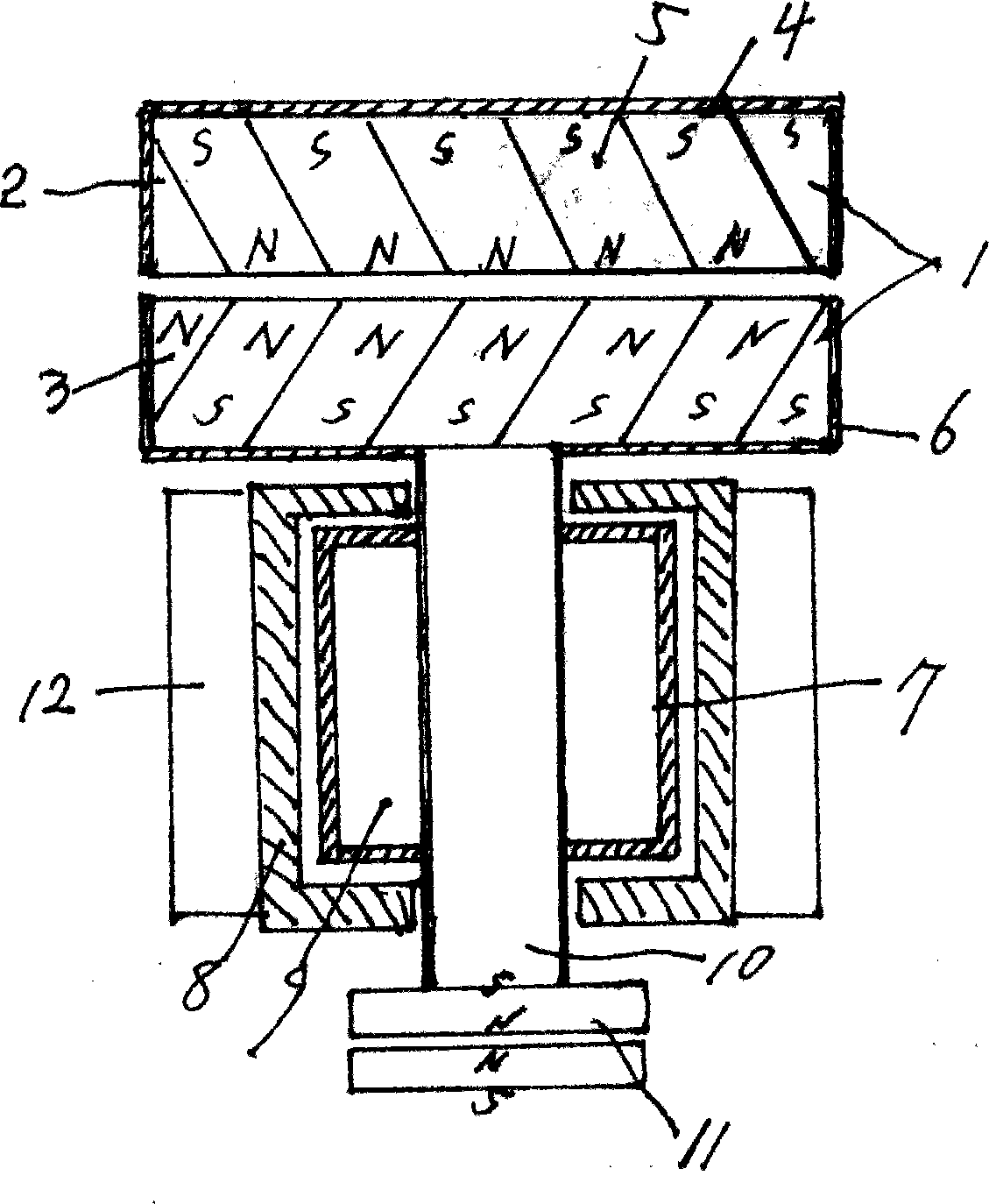

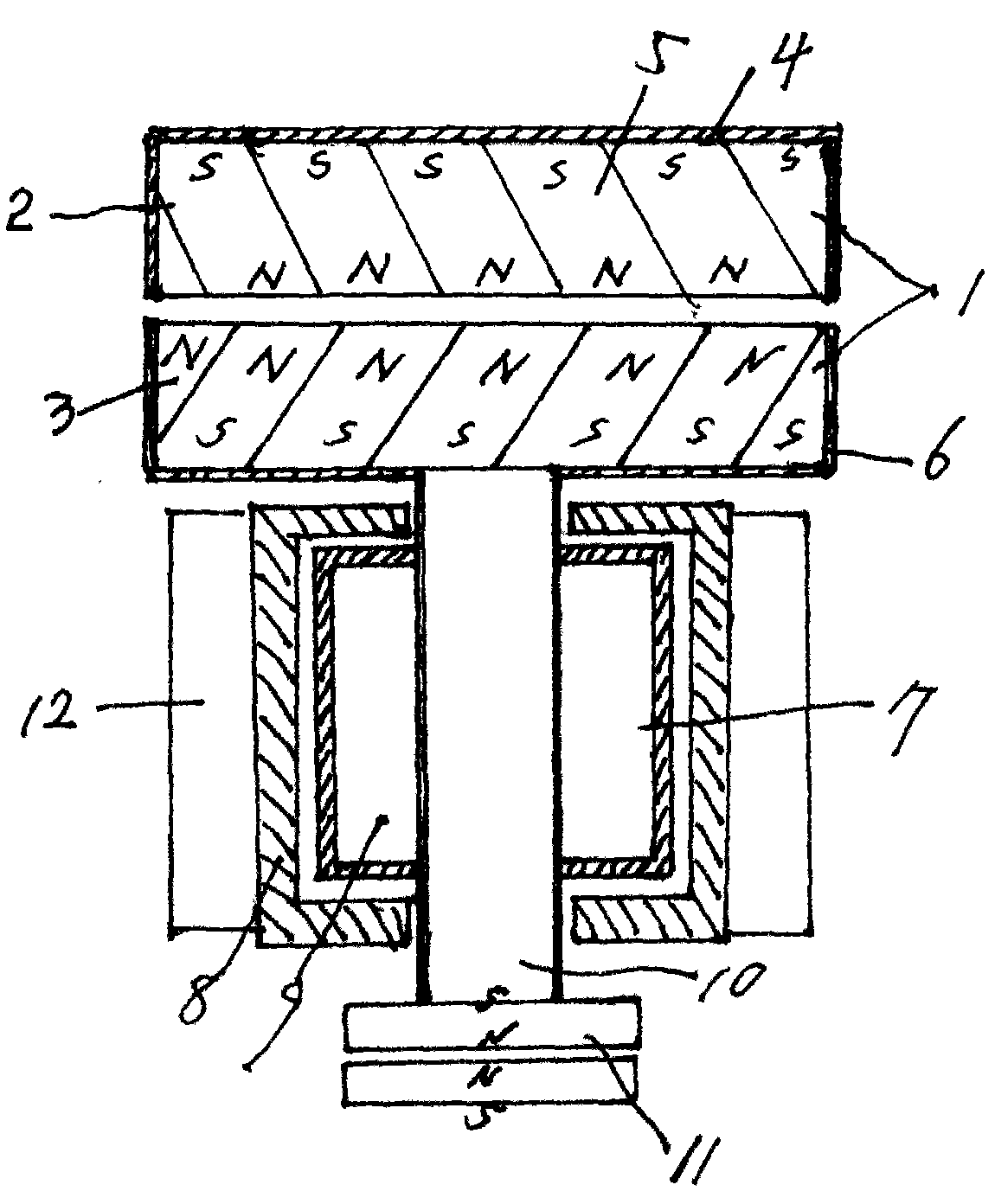

Permanent magnet power generator-motor

InactiveCN102111093AReduce consumptionReduce the number of configurationsGenerators/motorsForce linesPermanent magnet synchronous generator

The invention provides a permanent magnet power generator-motor. The permanent magnet power generator-motor consists of a magnetic power generator, a generator-motor integrated machine, a magnetic suspension booster and a superconducting cooling system. The permanent magnet power generator-motor overcomes the defects of complex design structure, single function, great magnetic eddy current interference, instable power output, over-high temperature and the like of various conventional magnetic power generators. By adopting a novel magnetic circuit power curve design and utilizing a like-pole repulsion principle and an included angle mechanical theory, magnetic force lines formed by the repulsion of like poles form a certain included angle so as to generate stable and orientated composite magnetic power output which can not only provide energy power for the generation of a generator, but also serve as a greater power source together with the generator (motor) to drive other sets of equipment to operate.

Owner:王文明

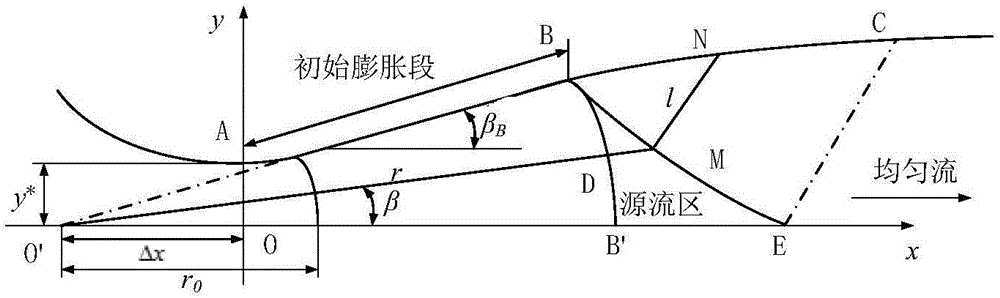

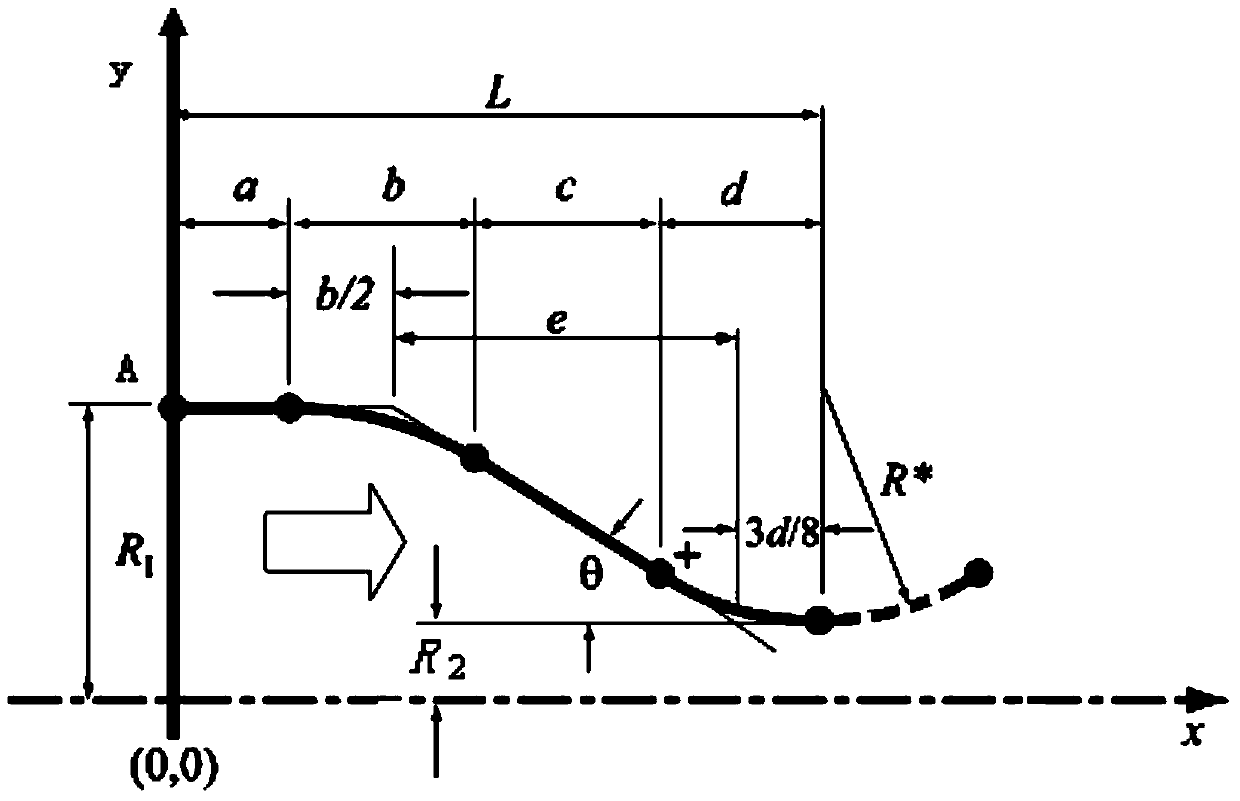

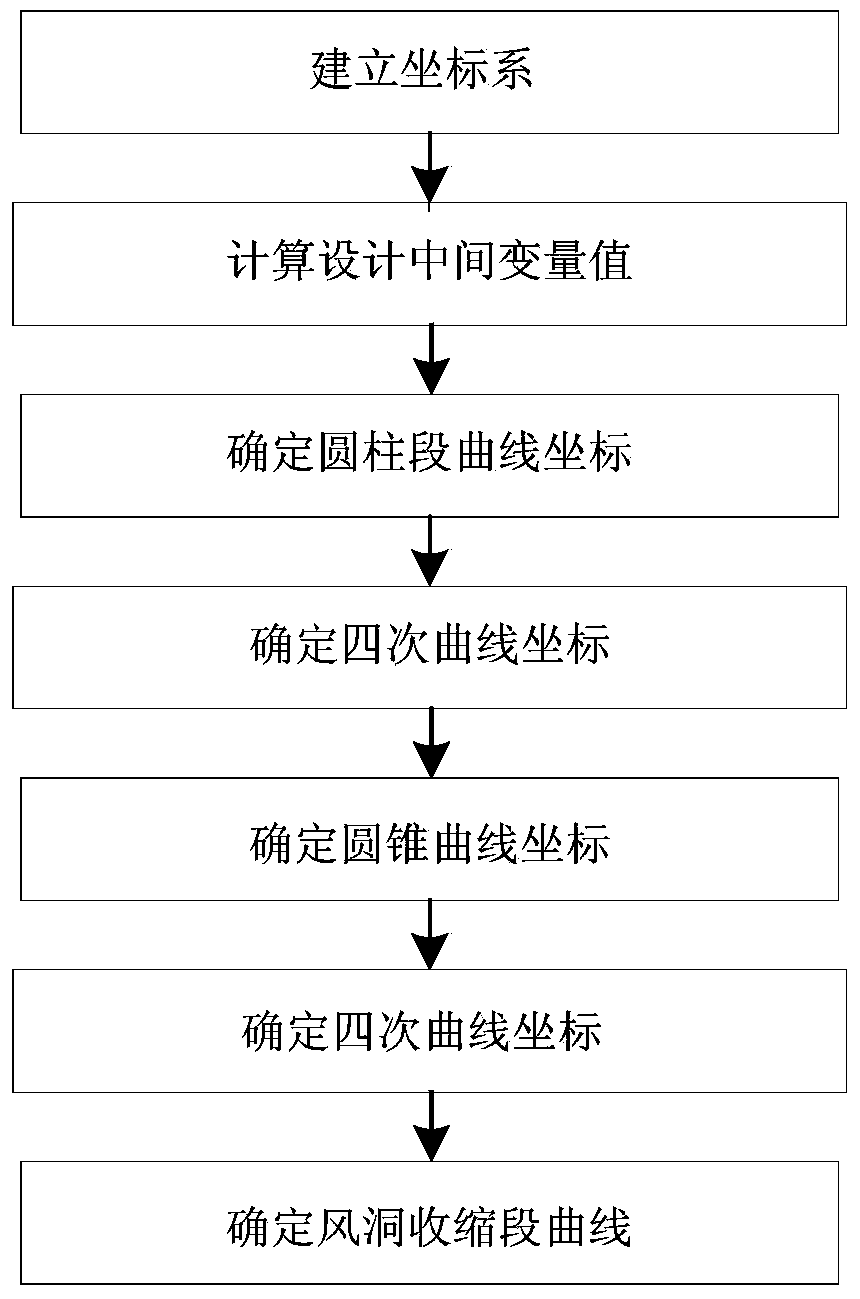

Method for confirming wind tunnel shrink section curve

InactiveCN103500265ANo overshootThe curvature of the curve is completely continuousAerodynamic testingSpecial data processing applicationsEngineeringSupersonic speed

The invention provides a method for confirming a wind tunnel shrink section curve. According to the method, once an inlet size, an outlet size, a shrink section length and a curvature radius of a shrink section outlet are given, a cylindrical curve, a first biquadratic curve, a conic curve and a second biquadratic curve are sequentially arranged from an inlet of the shrink section, and the shrink section curve is obtained. The shrink section curve designed in the method is suitable for a subsonic speed wind tunnel and a supersonic speed wind tunnel, the whole curve curvature is completely continuous, the curvature of the inlet and the curvature of an outlet are the same as the curvature of a front element and the curvature of a rear element, and perfect connection is achieved. The front of the curve cannot shrink abruptly, an overshoot phenomenon cannot occur to the outlet, and defects of an existing shrink curve are overcome. Air flows of the outlet are evenly distributed.

Owner:BEIJING AEROSPACE YISEN WIND TUNNEL ENG TECH

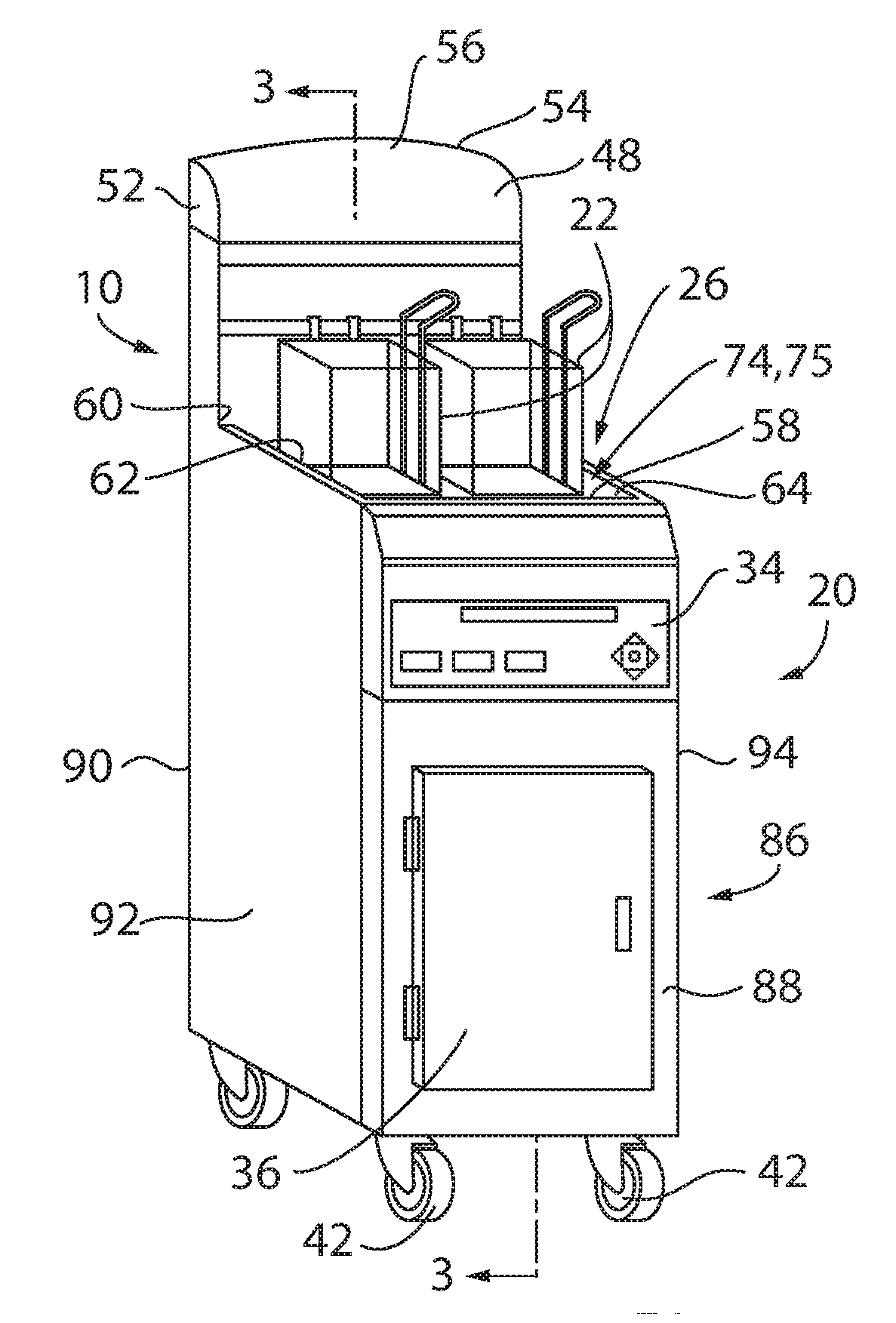

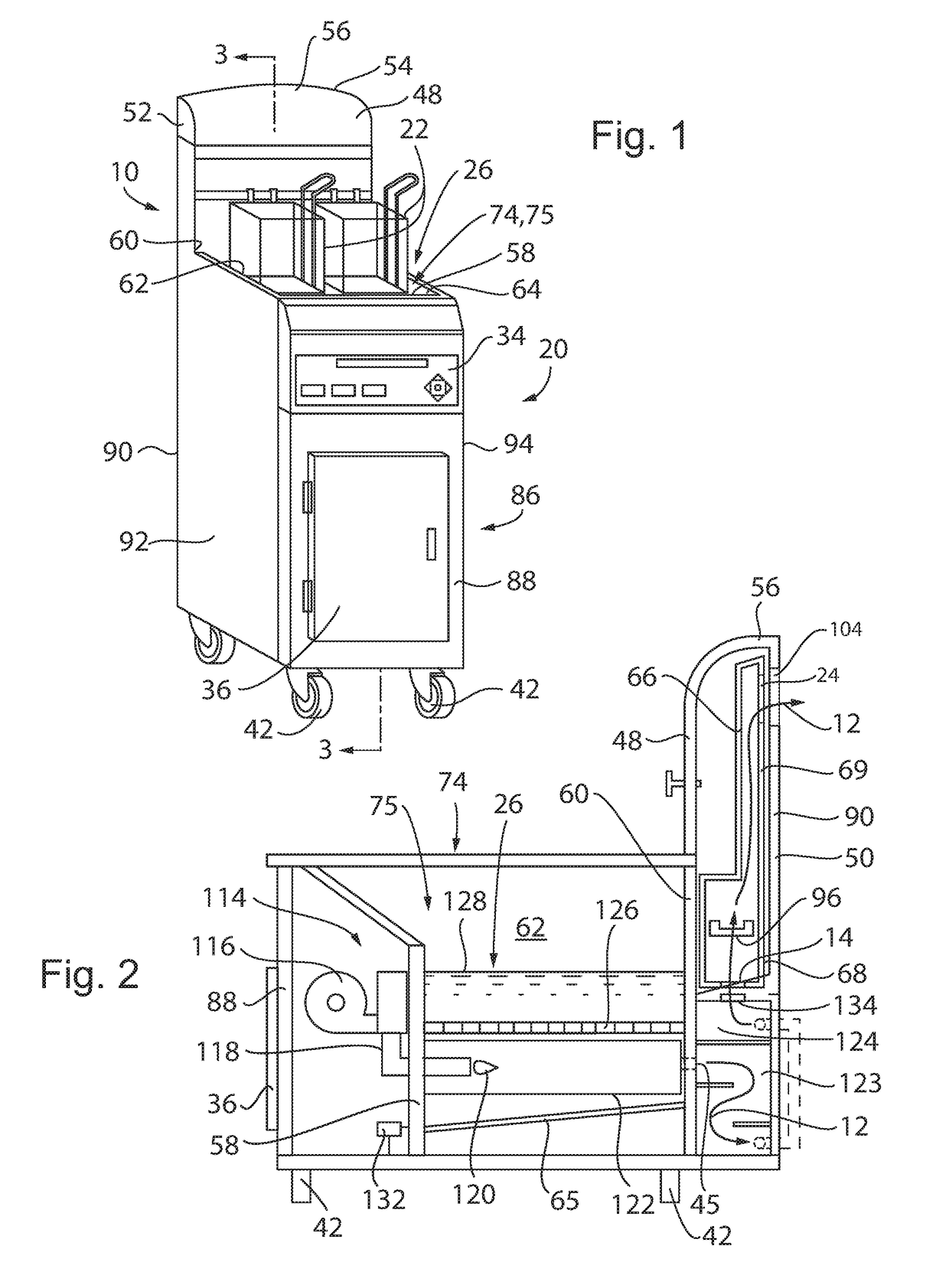

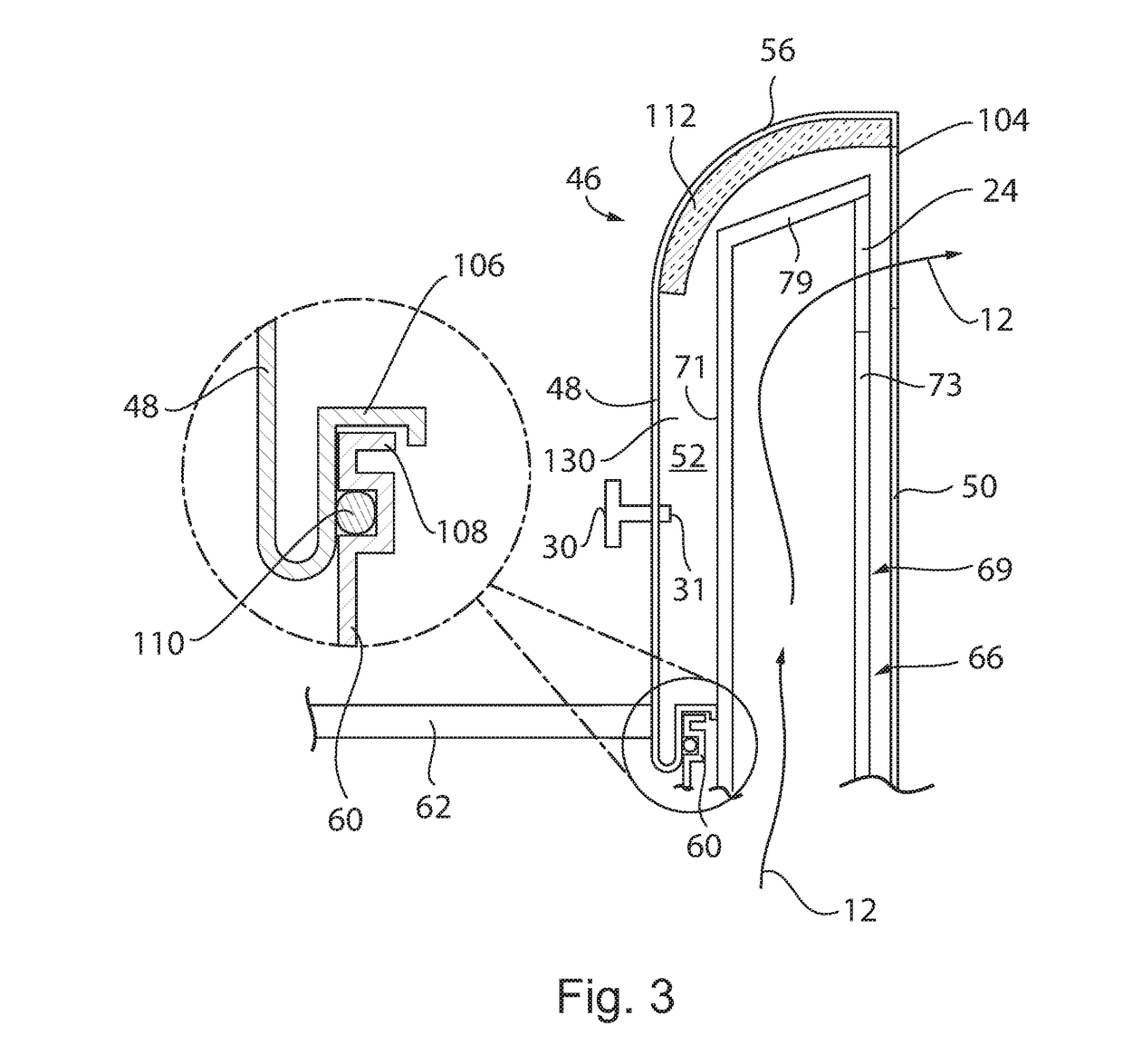

Flue Assembly and Splash Back Panel for a Cooking Appliance

ActiveUS20180289217A1Prevent “ baking-on ”Easy to cleanDomestic stoves or rangesLighting and heating apparatusForeign objectMechanical engineering

The present invention provides a deep fat fryer separating the flue from the splash back panel and with a flue opening directed not upwardly, but rearwardly from the flue. By arranging the flue opening on the rear wall, the opening is protected from grease fallback (e.g., dripping from an overhead exhaust hood) or other foreign objects falling into the opening. The splash back panel further provides a seamless curved design that is easy to clean and also insulated from the heat of the flue. A baffle installed within the flue allows the combustion products to mix, cool, and slow upon exiting the baffle opening and entering the atmosphere reducing the exit temperature and also reducing the heating of the splash back panel.

Owner:ALTO SHAAM

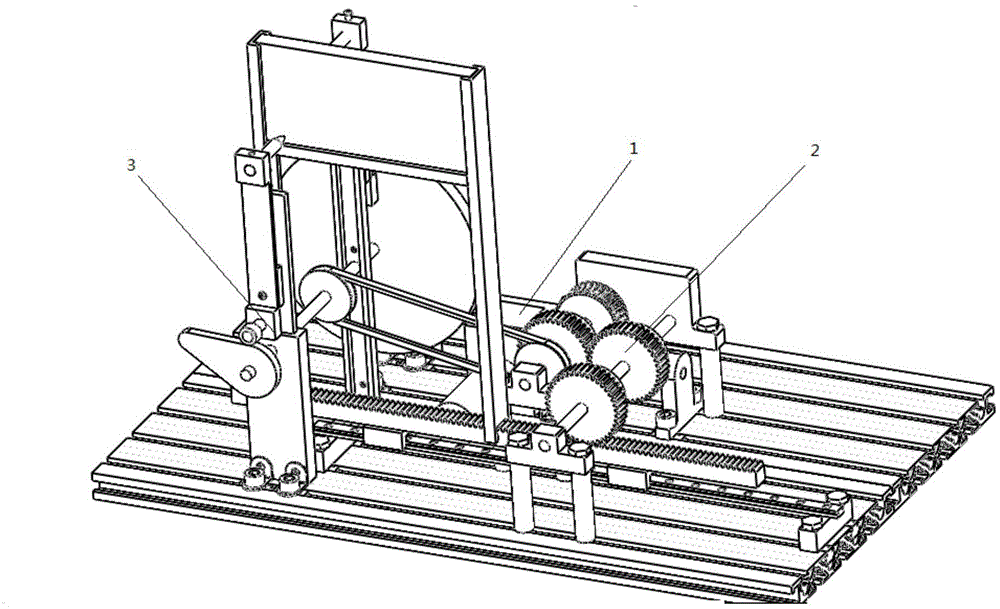

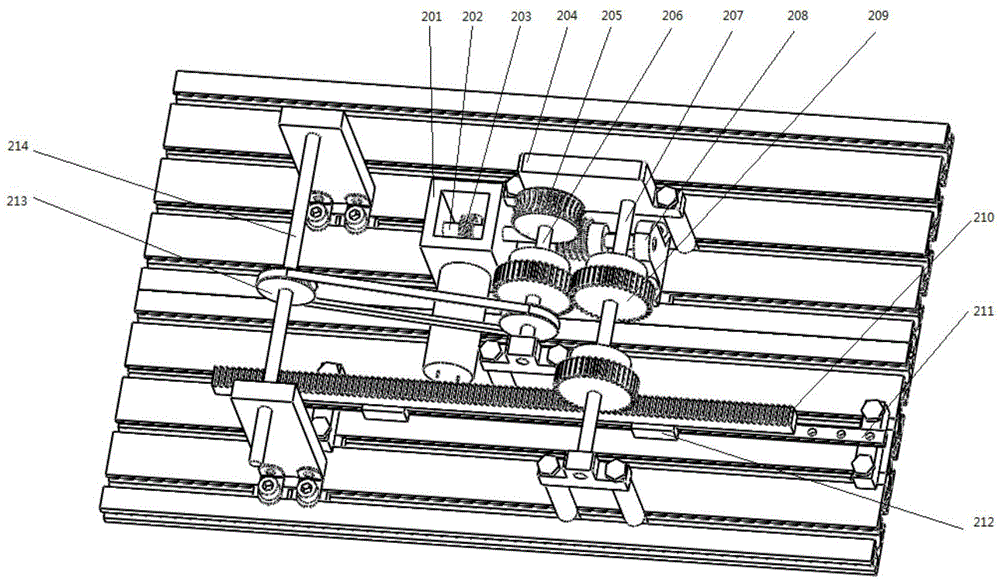

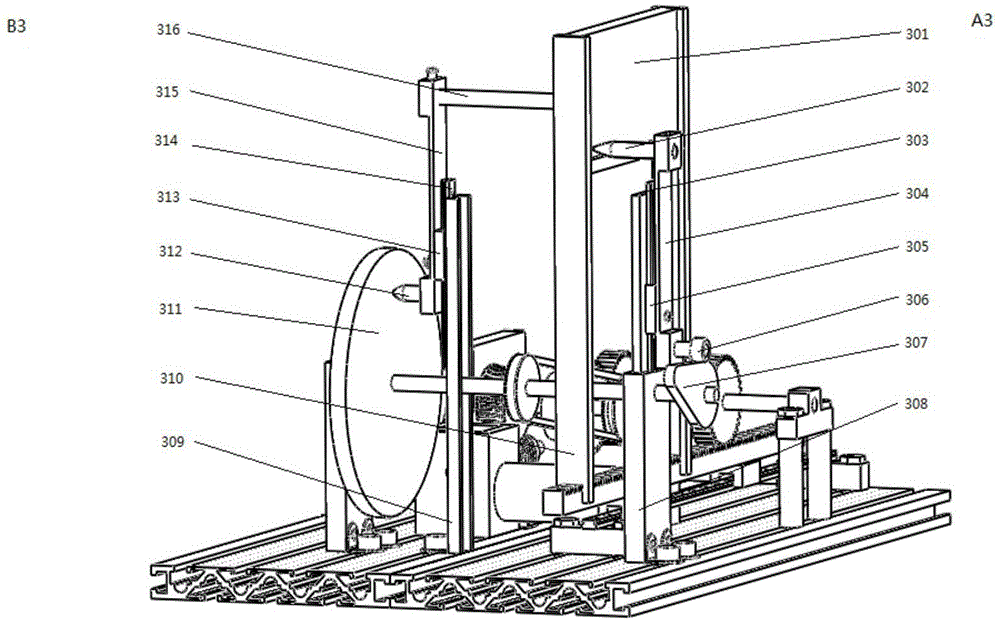

Cam mechanism contour design and driven part motion characteristic mapping platform

The invention is mainly applied to science and engineering mechanical principle teaching of colleges and universities, belongs to the technical field of cam applications, teaching apparatuses and the like and mainly solves the problems of teaching planarizartion and experiment singularization. A mapping platform comprises mechanical and electrical integration power input system, a power distribution system and an output cam mapping system. The output cam mapping system can be divided into a known cam mapping driven part characteristic curve module and a known driven part curve mapping cam module. The cam mechanism driven part basic laws, the plane cam contour curve design and the cam motion characteristic curve analysis are emphasized. The power distribution system is formed by worm transmission, gear transmission, belt drive and gear and rack transmission. A work cycle of the output end cam mapping system can complete two steps of driven part characteristic curve mapping and cam mapping. By means of the mapping platform, student can master basic theories, basic knowledge and basic skills of mechanical principles and have mechanical motion scheme determination and analysis and mechanism design capacities preliminarily.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Wind turbine

InactiveUS8033794B2Improve utilization efficiencyReduce resistancePropellersWind motor controlImpellerNacelle

Owner:LEE JIA YUAN

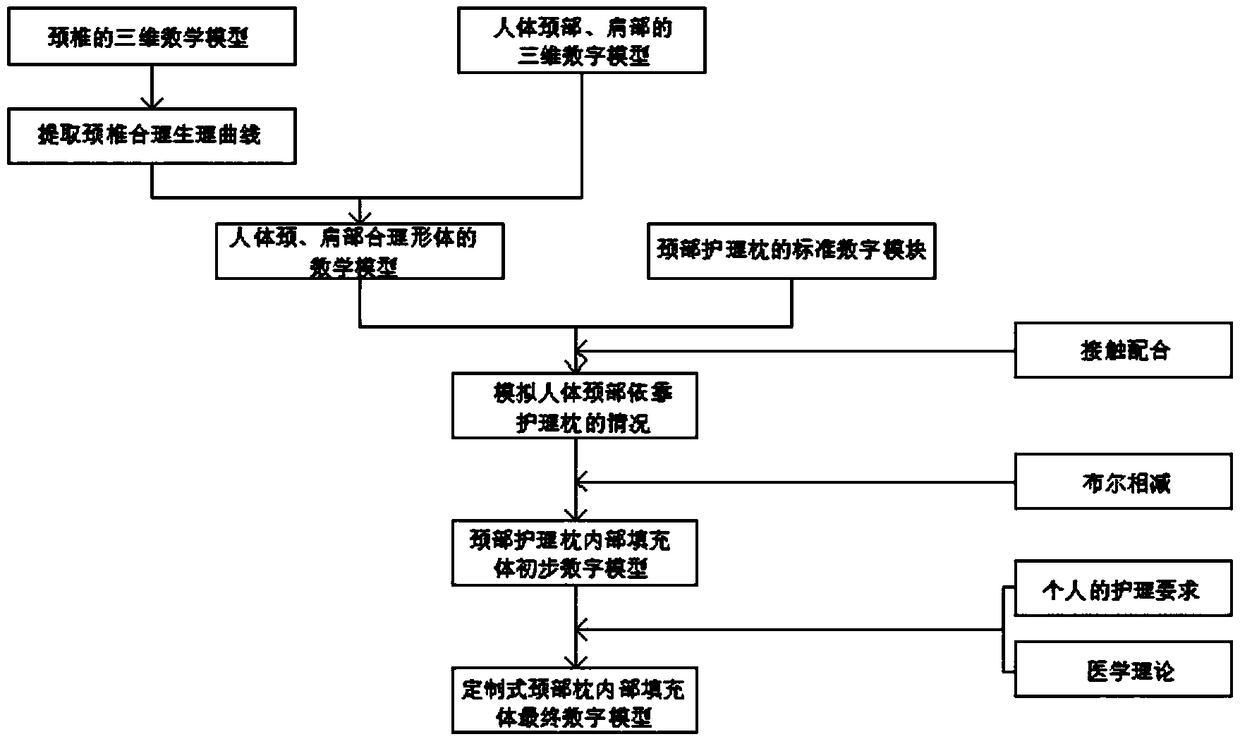

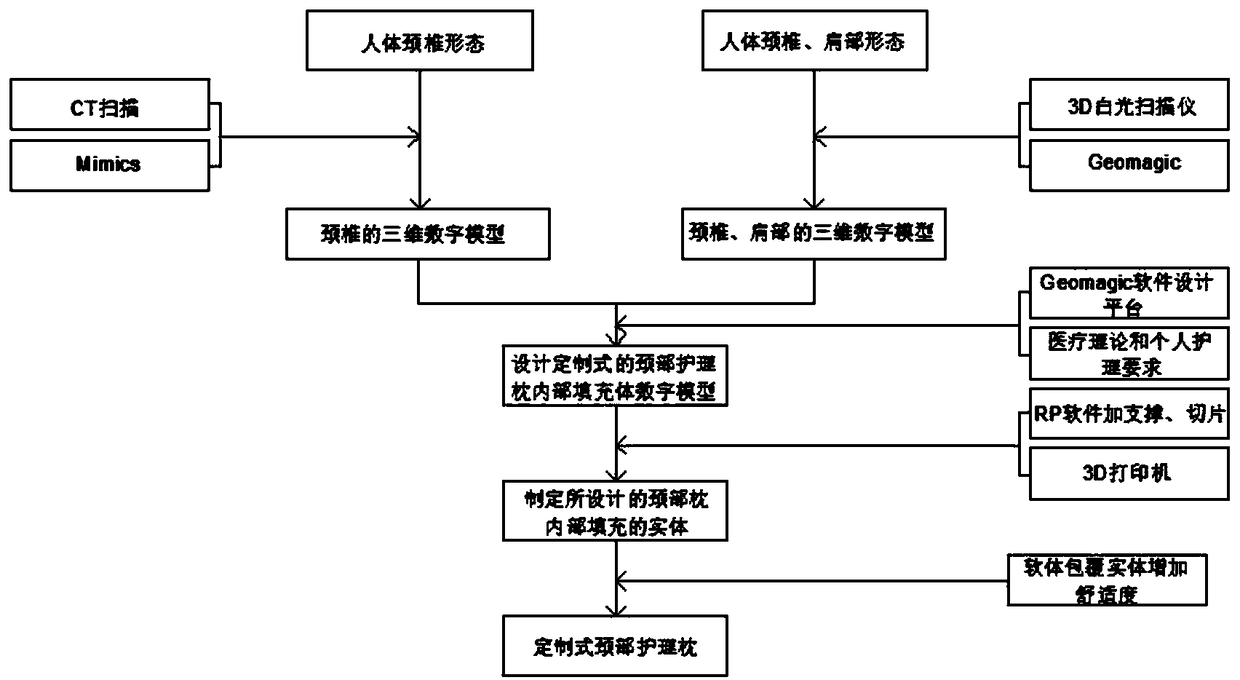

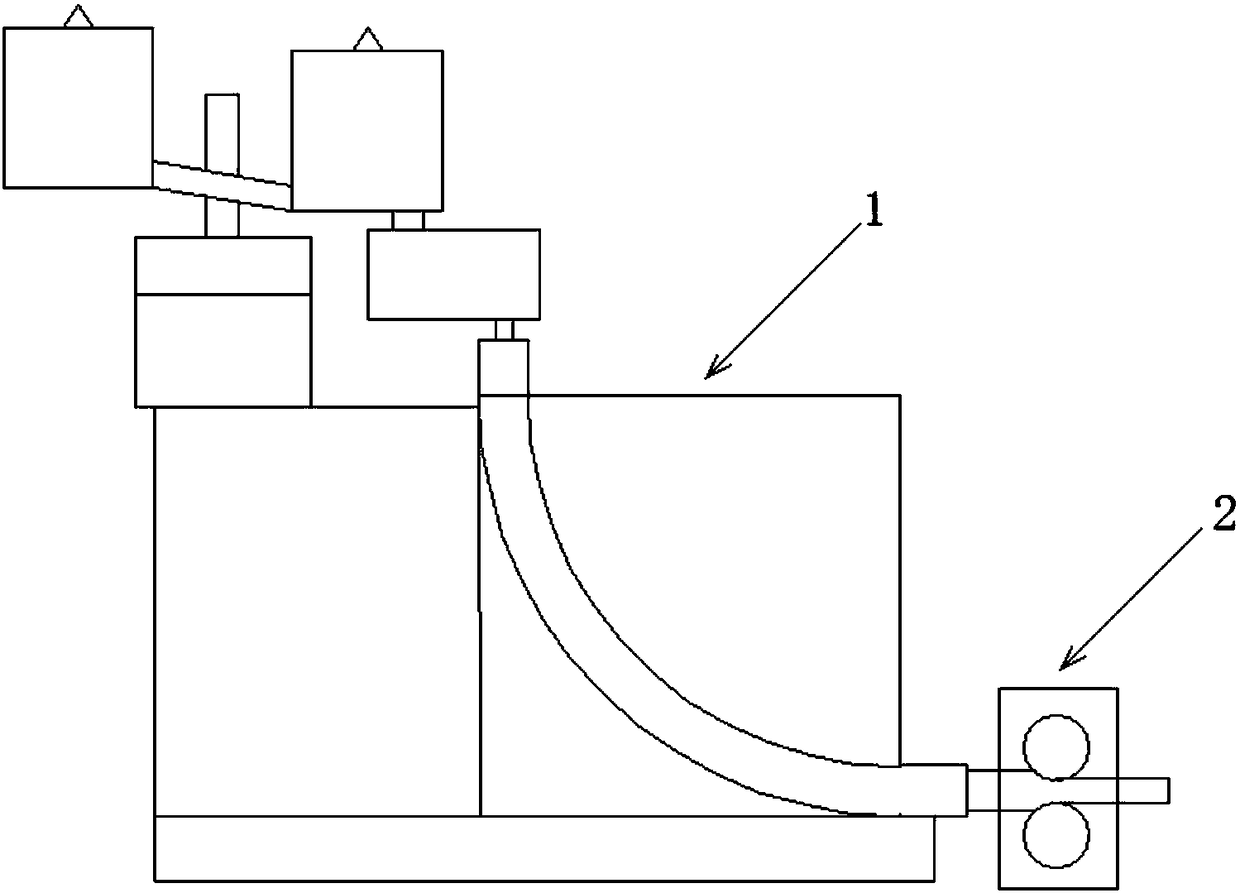

3D printing customized neck-protective pillow

InactiveCN108433475AReasonable designStable supportPillowsAdditive manufacturing apparatusPersonal careCurve shape

The invention discloses a 3D printing customized neck-protective pillow, which comprises a human body form, a three-dimensional digital model, an internal filling body digital model and a making solid. The 3D printing customized neck-protective pillow provided by the invention has the beneficial effects that neck and shoulder digital models, which are generated by the three-dimensional digital model, are subjected to curve design, so that the neck-protective pillow can closely fit to a neck; meanwhile, in combination with natural transition of curve shapes of shoulders, comfort is enhanced, ahead and cervical vertebra are effectively supported and the head is applied with supporting force; the inner filling body digital model, in accordance with common requirements on medical theory and personnel nursing, is reshaped accordance with a real and accurate basis; the making solid is made by conducting printing in accordance with an additional manufacturing technique; different neck-protective pillows can be printed out in accordance with the obtained different digital models, so that customization is achieved, and people's various requirements are satisfied; according to step 4, an inner filler solid, which is printed out, is covered by a soft body, so that comfort is enhanced and a neck-protective effect is improved; therefore, the neck-protective pillow is beneficial for healthof human body.

Owner:保定翰阳科技有限公司

Curve design of rolling mill work roller for high-temperature large-rolling-reduction technology of large square billet and rectangular billet

ActiveCN108067501AEasy to compressGood shrinkage and lamination effectRollsMetal rolling arrangementsLiquid coreHot Temperature

The invention relates to the field of continuous casting billet high-temperature large-rolling-reduction rolling mills, in particular to roll shape curve design of a rolling mill work roller for a high-temperature large-rolling-reduction technology of a large square billet and a rectangular billet. The roll shape curve design is particularly applied to the single-pass hot core or liquid core high-temperature large-rolling-reduction rolling process of the large square billet or the rectangular billet. The work roller achieves optimal combination of a flanged roller shape and a box type hole shape, and optimization design of the geometrical characteristics of the work roller is conducted through calculation. The flange width coefficient of a combined roller is 0.4-0.8, and the flange heightof the combined roller is 5-45 mm. The radius of a box type inner fillet of the combined roller is 10-40 mm, the inclination angle of the side wall of the combined roller is 90-120 degrees, and the diameter of the work roller is 500-1000 mm. After the work roller in a combined roller shape is applied to the high-temperature large-rolling-reduction rolling technology, the shrinkage cavity press fiteffect, in the thickness direction and the extension direction, of the flanged roller and the shrinkage cavity press fit effect, in the width direction, of the box type hole shape can be highlightedat the same time. In this way, the casting billet core deformation permeability and the central shrinkage cavity three-direction press fit effect in the single-pass high-temperature large-rolling-reduction rolling deformation can be improved to a greater extent.

Owner:NORTHEASTERN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com