Round angle drum washing machine

A washing machine and drum technology, which can be used in other washing machines, washing devices, textiles and paper making, etc., and can solve problems such as poor washing results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Embodiments of the present invention will now be further described in conjunction with the accompanying drawings.

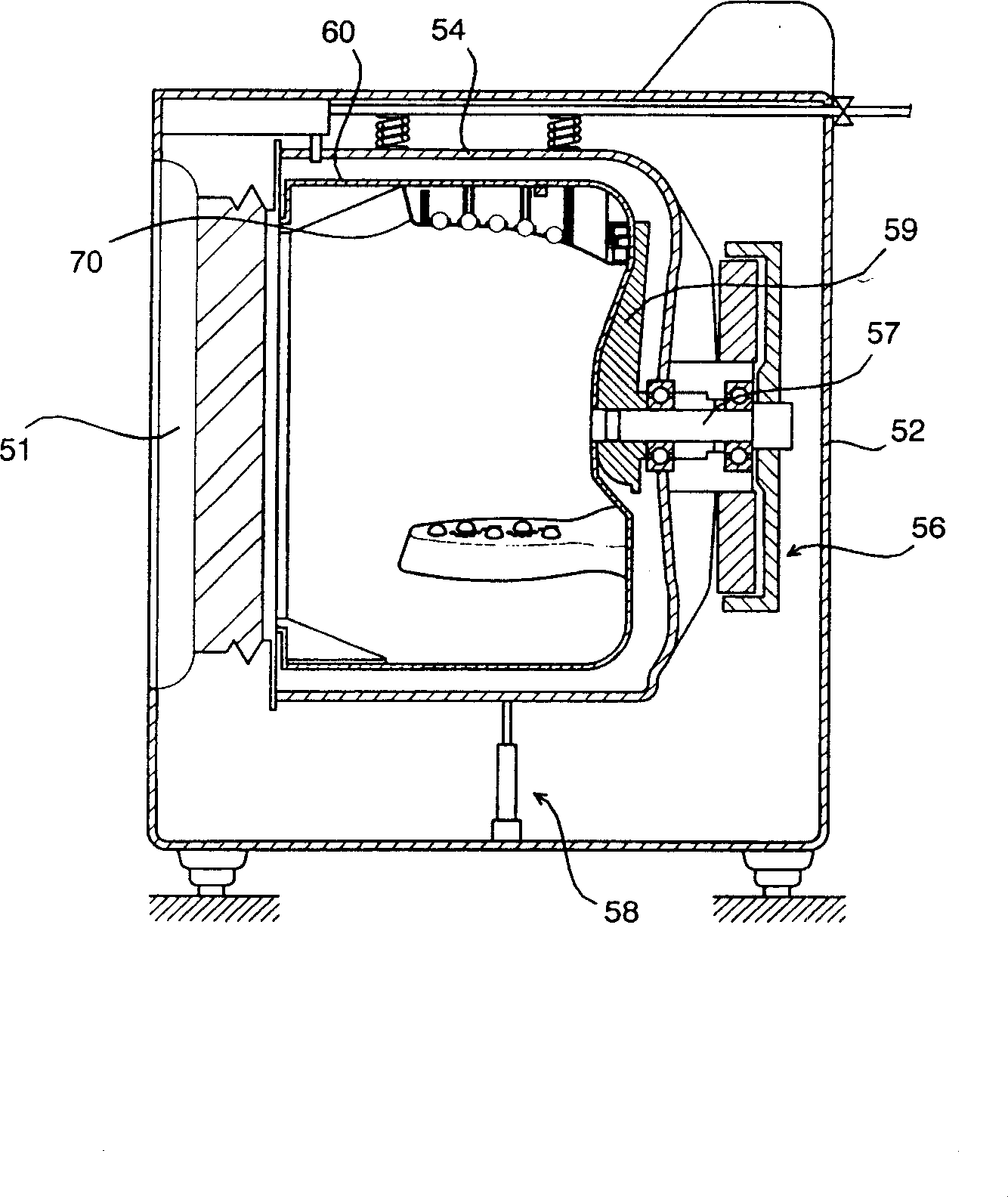

[0030] The drum washing machine that the present invention forms is as image 3 shown.

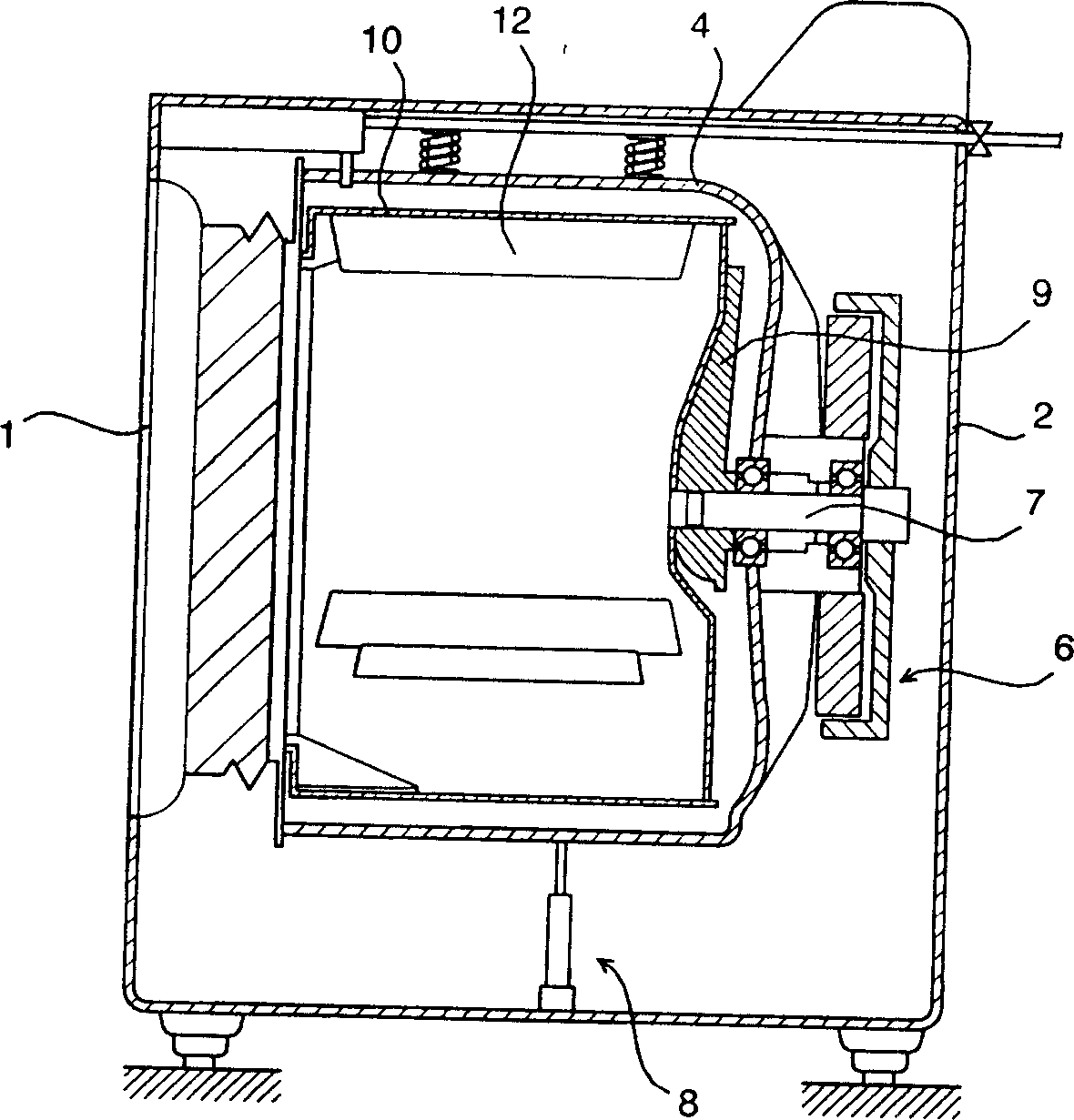

[0031] The washing machine of the present invention is that the opening (51) is arranged on the front of the cabinet (52), the water tank (54) is placed inside it, and the rotary shaft (57) is set in the water tank to put the washing and detergent in the drum (60 ), install the motor (56) behind the water cylinder (54) and be connected with the rotary shaft (57), in order to allow the water cylinder (54) and the inside of the cabinet (52) to leave a certain flow space on the inside of the cabinet and the water tank Load onto support bar (58) between outer wall.

[0032] The fork-shaped support (59) is connected with the rear end of the rotary shaft (57) of the motor (56), and operates around the rotary shaft (57) placed in the horizontal direction. Bottom side and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com